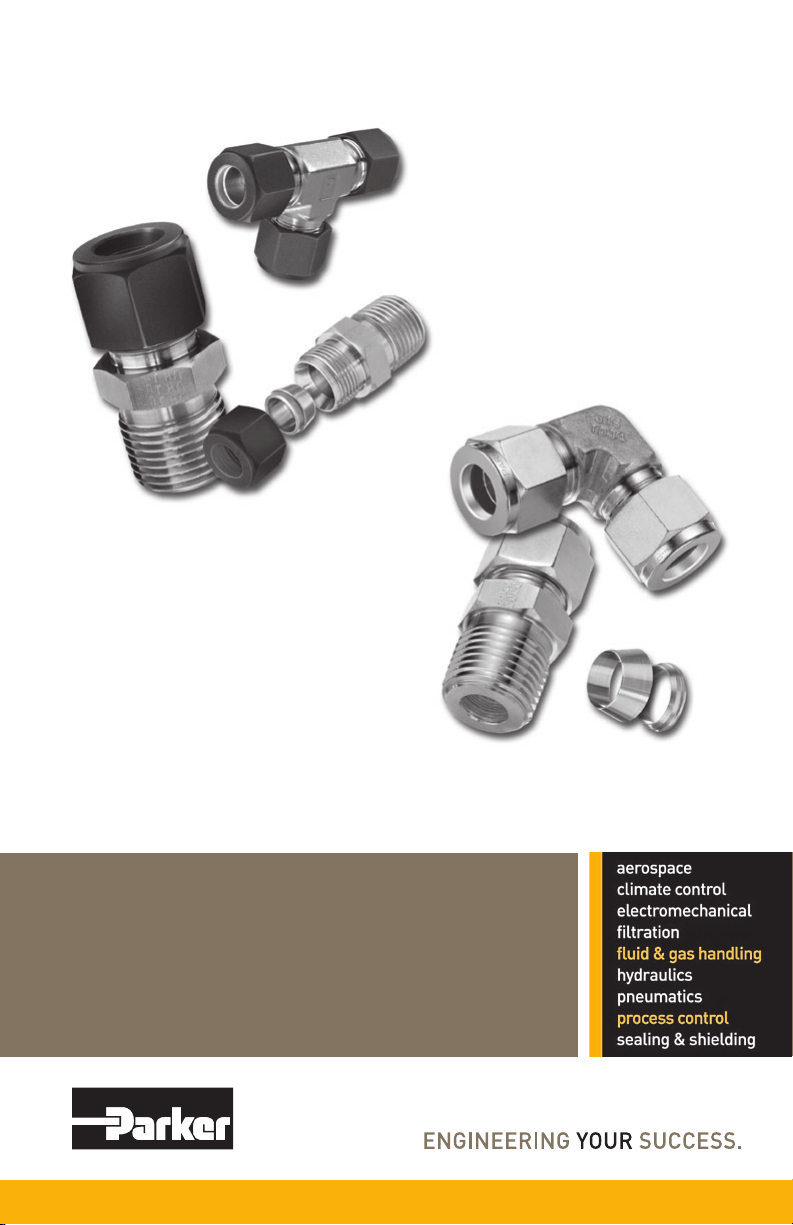

Parker Hannifin Instrument Tube Fitting Installation Manual

Instrument Tube Fitting

Installation Manual

Bulletin 4200-B4 May 2014

Table of Contents

Installation

Installation Valves Fittings Tubing

Tubing Fitting Installation

Tubing vs Pipe ............................................................ 1

Principles of Tube Line Fabrication

Instrument Tubing Selection Guide........................... 19

Tubing Preparation

(handling, cutting, deburring, cleaning)

Assembly & Remake

Parker IPD Ferrule Presetting Tool

MPI™ Assembly & Remake

MPI™ Preset Tools

MPI™ Tubing Selection

Dielectric Fittings

High Integrity Coupling Assembly

Installation of Weld Fittings

Analytical Tube Fittings

Heat Code Traceability

Parker Suparcase

Thread Identification

Thread and Tube End Size Charts

Pipe Data and Dimensions

............................. 3

.................... 29

................................................ 32

........................... 37

..................................... 41

................................................... 42

............................................ 44

...................................................... 48

............................ 49

....................................... 50

............................................. 56

............................................. 58

®

– Ferrule Hardening ................. 60

................................................. 63

........................... 69

....................................... 77

Bulletin 4200-B4

Offer of Sale

The items described in this document are hereby offered for sale by Parker-Hannifin Corporation, its subsidiaries or its

authorized distributors. This offer and its acceptance are governed by the provisions stated in the detailed “Offer of Sale”

elsewhere in this document or available at www.parker.com/ipdus.

© 2014 Parker Hannifin Corporation. All rights reserved.

ii

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Bulletin 4200-B4

Table of Contents

Parker Valves Overview

Needle Valves ........................................................... 79

Ball Valves

Check Valves

Metering Valves

................................................................ 85

............................................................ 93

...................................................... 105

Parker Fittings Overview

CPI™ / A-LOK® Fittings ........................................... 109

MPI Fittings

Pipe Fittings

Welded Fittings

............................................................. 110

............................................................ 111

....................................................... 112

Parker Tubing Overview ................................... 113

InstallationValvesFittingsTubing

WARNING – USER RESPONSIBILITY

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS DESCRIBED HEREIN OR

RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE.

This document and other information from Parker-Hannifin Corporation, its subsidiaries and authorized distributors

provide product or system options for further investigation by users having technical expertise.

The user, through its own analysis and testing, is solely responsible for making the final selection of the system and

components and assuring that all performance, endurance, maintenance, safety and warning requirements of the

application are met. The user must analyze all aspects of the application, follow applicable industry standards, and

follow the information concerning the product in the current product catalog and in any other materials provided from

Parker or its subsidiaries or authorized distributors.

To the extent that Parker or its subsidiaries or authorized distributors provide component or system options based upon

data or specifications provided by the user, the user is responsible for determining that such data and specifications

are suitable and sufficient for all applications and reasonably foreseeable uses of the components or systems.

NOTICE: The information contained within this publication is intended

for educational purposes only. Information contained within is not intended

for re-sale and may not be reproduced in whole or in part without the

express written consent of The Parker Hannifin Corporation.

iii

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Notes

Installation

Bulletin 4200-B4

iv

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Bulletin 4200-B4

Tubing vs. Pipe

Tubing vs. Pipe

Standard fluid line systems, whether for simple household use or for

the more exacting requirements of industry, were for many years

constructed from threaded pipe of assorted materials and were

assembled with various standard pipe fitting shapes, unions and

nipples. Such systems under high pressures were plagued with leakage

problems besides being cumbersome, inefficient and costly to assemble

and maintain. Therefore, the use of pipe in these systems has largely

been replaced by tubing because of the many advantages it offers.

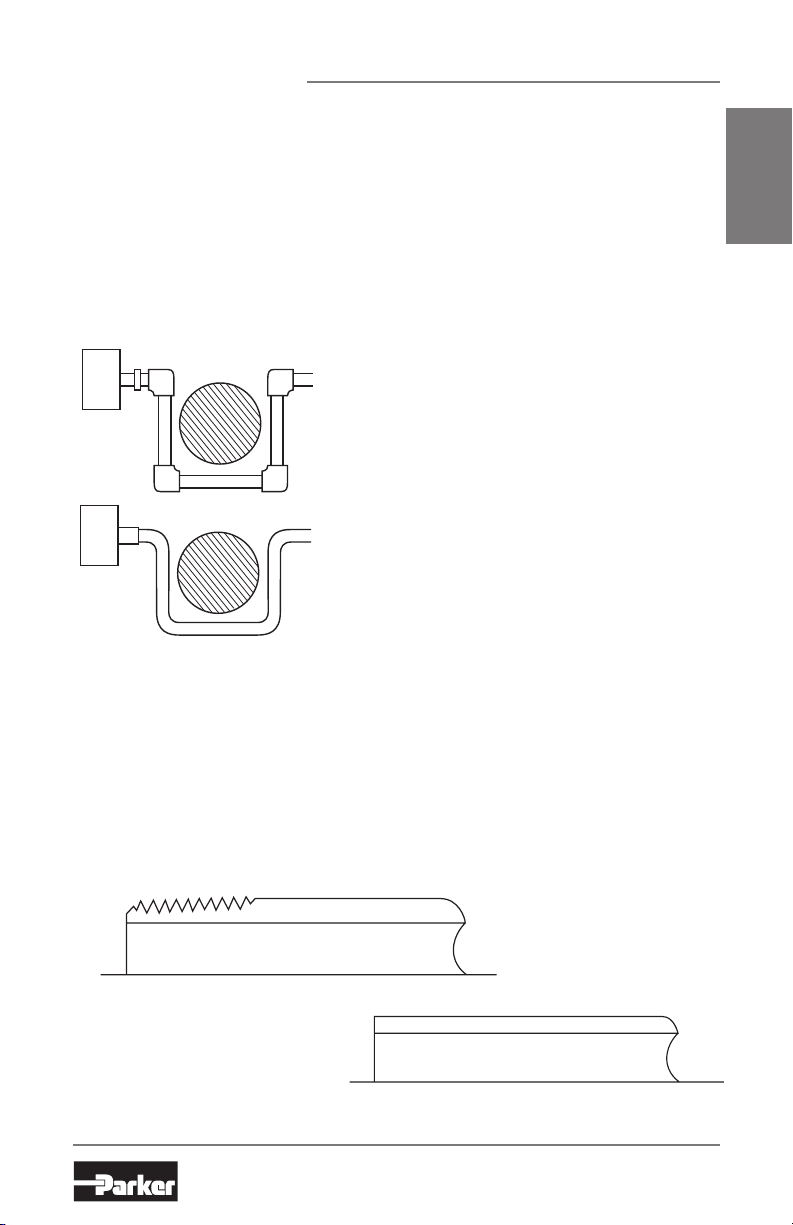

Old Method – Each connection is

threaded – requires numerous fittings

– system not flexible or easy to install

and service connections not smooth

inside – pockets obstruct flow.

Modern Method – Bendable tubing

needs fewer fittings – no threading

required – system light and compact

– easy to install and service – no

internal pockets or obstructions to

Figure 1 Tubing provides simplified,

free flow system.

free flow.

Installation

Major Advantages of Tubing vs. Pipe

1. Bending Quality – Tubing has strong but relatively thin walls; is easy

to bend. Tube fabrication is simple.

2. Greater Strength – Tubing is stronger. No weakened sections from

reduction of wall thickness by threading.

Pipe

Figure 2 With no threading necessary, tubing does not require extra wall

thickness

1

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Tubing

Tubing vs. Pipe

Installation

3. Less Turbulence – Smooth bends result in streamlined flow passage

Bulletin 4200-B4

and less pressure drop.

4. Economy of Space and Weight – With its better bending qualities and

a smaller outside diameter, tubing saves space and permits working

in close quarters. Tube fittings are smaller and also weigh less.

5. Flexibility – Tubing is less rigid, has less tendency to transmit

vibration from one connection to another.

6. Fewer Fittings – Tubing bends substitute for elbows. Fewer fittings

mean fewer joints, fewer leak paths.

7. Tighter Joints – Quality tube fittings, correctly assembled, give better

assurance of leak-free systems.

8. Better Appearance – Tubing permits smoother contours with fewer

fittings for a professional look to tubing systems.

9. Cleaner Fabrication – No sealing compounds on tube connections.

Again no threading; minimum chance of scale, metal chips, foreign

particles in system.

10. Easier Assembly and Disassembly – Every tube connection serves as

a union. Tube connections can be reassembled repeatedly with easy

wrench action.

11. Less Maintenance – Advantages of tubing and tube fittings add up to

dependable, trouble-free installations.

2

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Bulletin 4200-B4

Principles of Tube Line Fabrication

Principles of Tube Line Fabrication

1. Measure Exactly and Bend Accurately

Measuring exactly and bending accurately are the two most important rules which must be observed when fabricating a tube line.

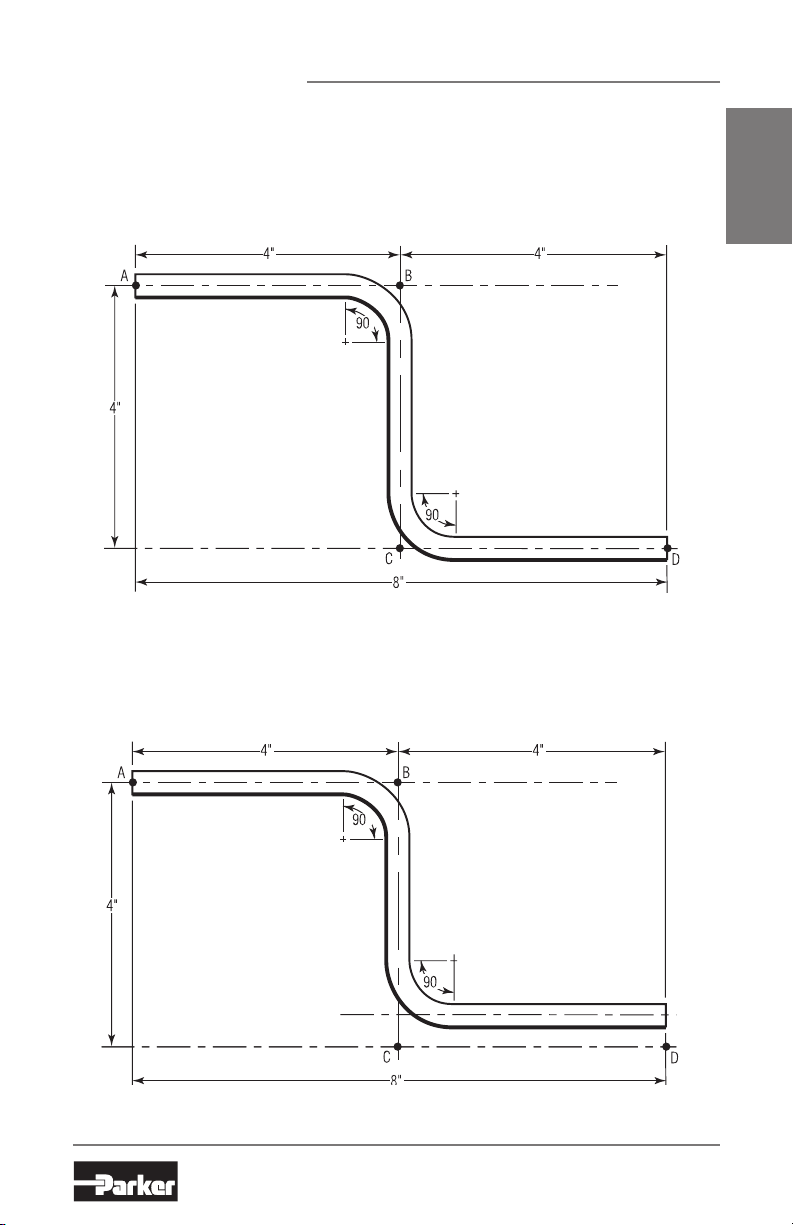

Figure 3 Accurate measurements coupled with exact angles may

result in a tube line that will fit at points (A-D).

Installation

Exact measurement is required to insure that you obtain the desired

distance between bends. If you do not measure exactly, the tube line

will not fit.

Figure 4 Measuring error on second leg (B-C) results in tube line that can

not fit at point (D).

3

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Principles of Tube Line Fabrication

Bulletin 4200-B4

Installation

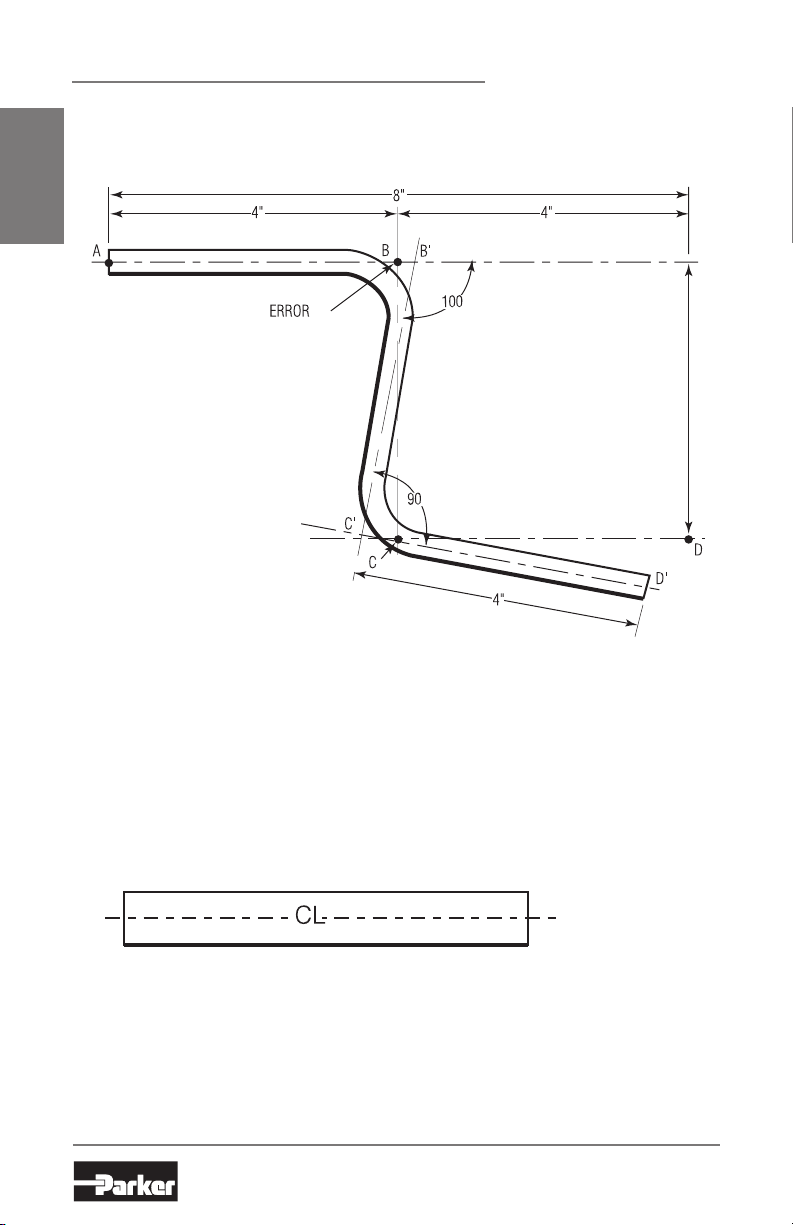

Accurate bending is necessary to achieve the exact angles required

for the tube line. If you do not bend accurately, the tube line will not fit

(Figure 5).

Figure 5

You must always measure exactly and bend accurately.

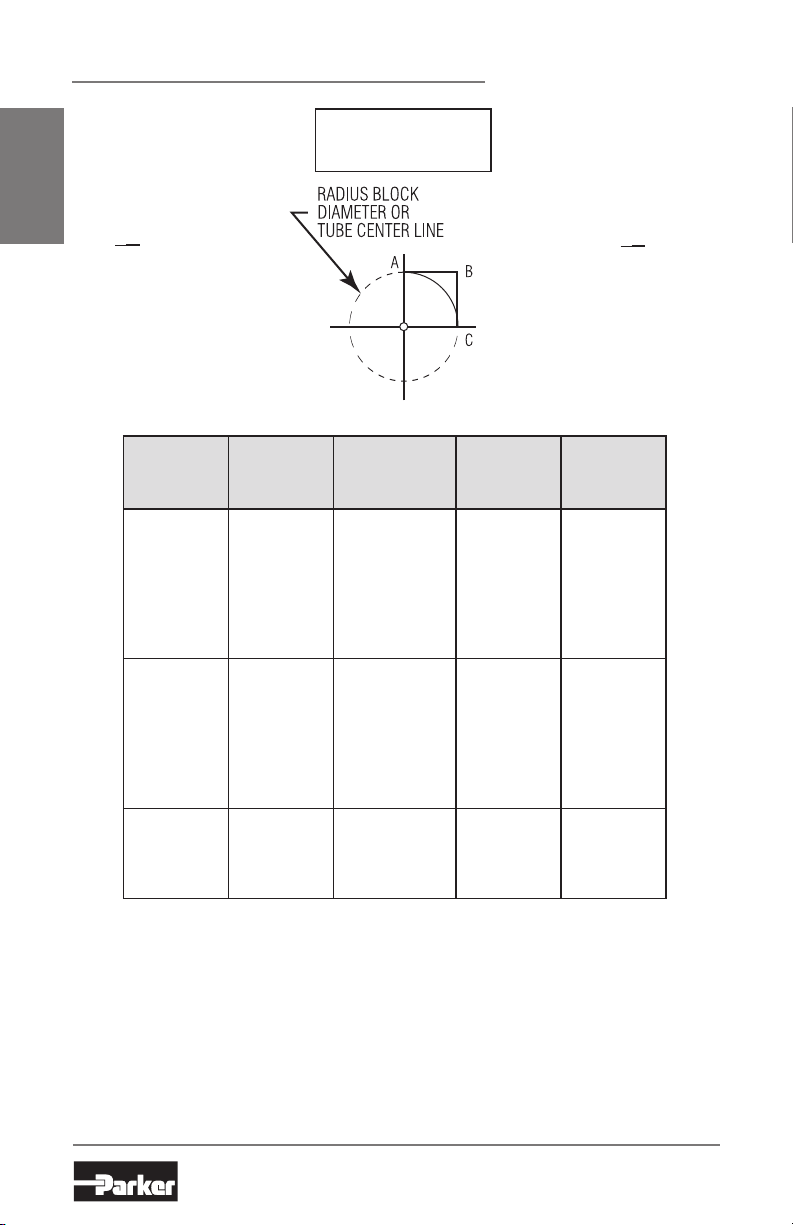

2. Tube Centerline Basis for Measurement

The centerline of the tube is the basis for all tube line measurement

(Figure 6). Always measure from the centerline except from the first

bend which is measured from the end of the tube. On most benders,

the edge of the radius block is at the centerline of the tube.

Figure 6

3. You Control Accuracy

Remember only you can control the accuracy of your work. Use

good, careful workmanship at all times.

4

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Bulletin 4200-B4

Principles of Tube Line Fabrication

Tube Bending Checklist

Follow this list to insure good results on each bend.

1. Measure and mark exactly. Insert tube in bender.

2. Always try to bend in the same direction! If you backbend, be sure

to compensate for gain or pickup. Remember, gain always occurs to

the right side of the tube radius block.

3. Clamp tubing securely in bender.

4. Check to make certain length mark is tangent to desired angle on

radius block or in line with the desired degree on the link member.

5. Bend accurately to the desired angle plus springback allowance.

6. Open bender, remove tube.

7. Double check bend angle with triangle.

8. Check measurement length with tape or ruler.

Keep Track of Changes of Plane

Benders bend in only one direction. Changes in plane are accomplished

by rotating the tubing in the bender. To insure that the tubing is correctly

placed for the desired change in plane, a reference mark on the tube is

very helpful.

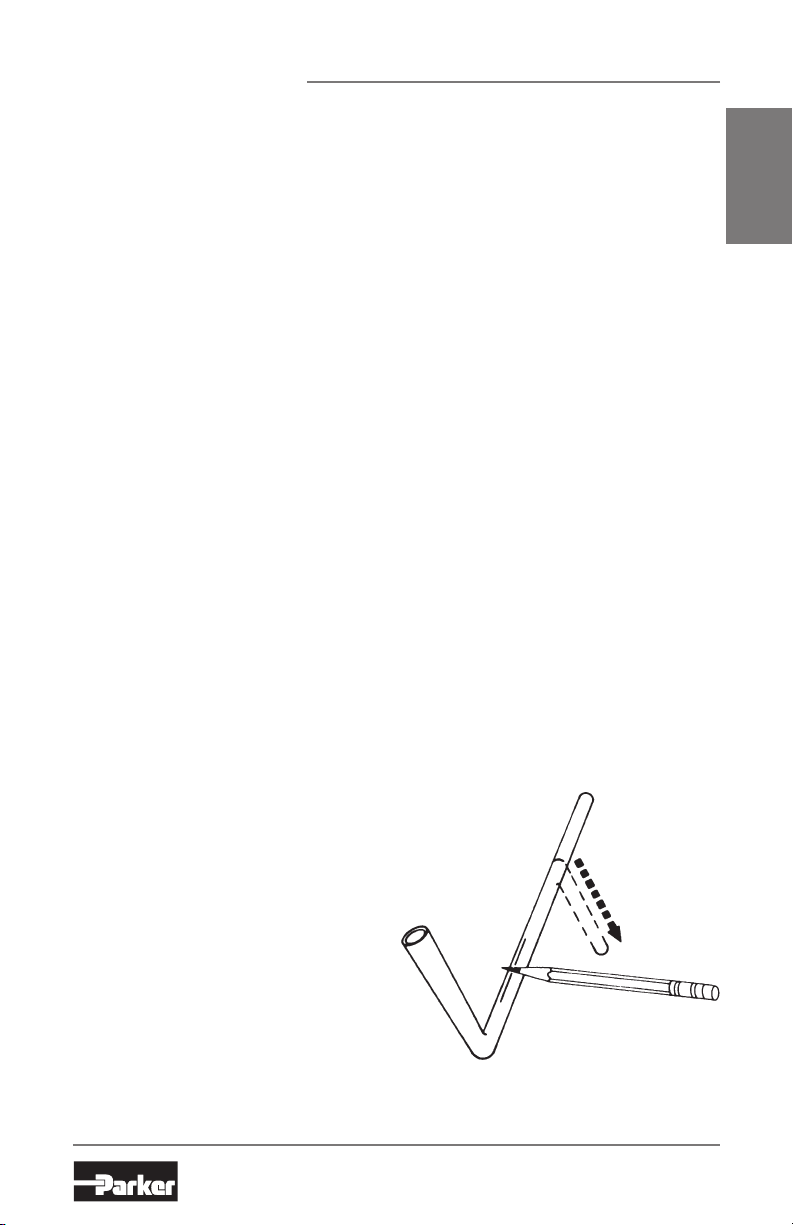

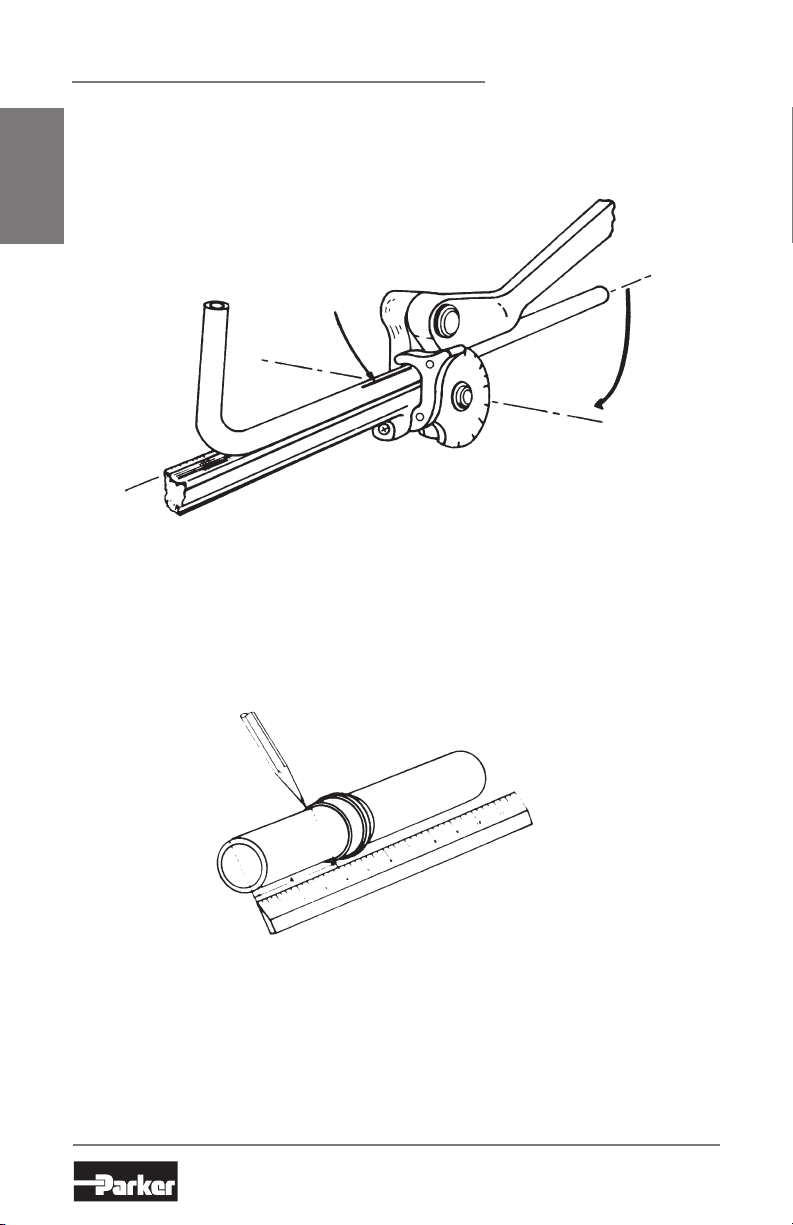

Bend Direction Mark

One method for keeping track of changes

in plane is to use a longitudinal or lengthwise bend direction mark (Figure 7).

Put the mark on the side opposite the

direction in which you wish to bend.

Installation

Figure 7

5

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Principles of Tube Line Fabrication

Installation

When you put the tube in the bender, center the mark face up in the

Bulletin 4200-B4

groove of the radius block (Figure 8). This will insure that you bend in

the correct direction. It also gives you a reference mark in case you must

leave your work unfinished.

Figure 8

Marking the Tube

Whenever you make a mark on tubing, use a sharp pencil. Use a ferrule

as a guide to make measurement marks all the way around the tube so

that the mark is always visible (Figure 9). Don’t use grease pencils or

crayons as these make too wide a line which can easily affect accuracy.

Figure 9

Measure and Mark

Never use a sharp tool to scratch marks onto tubing. Scratches create

points where corrosion or stress concentration can ruin or dangerously

weaken the tube.

6

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Bulletin 4200-B4

Principles of Tube Line Fabrication

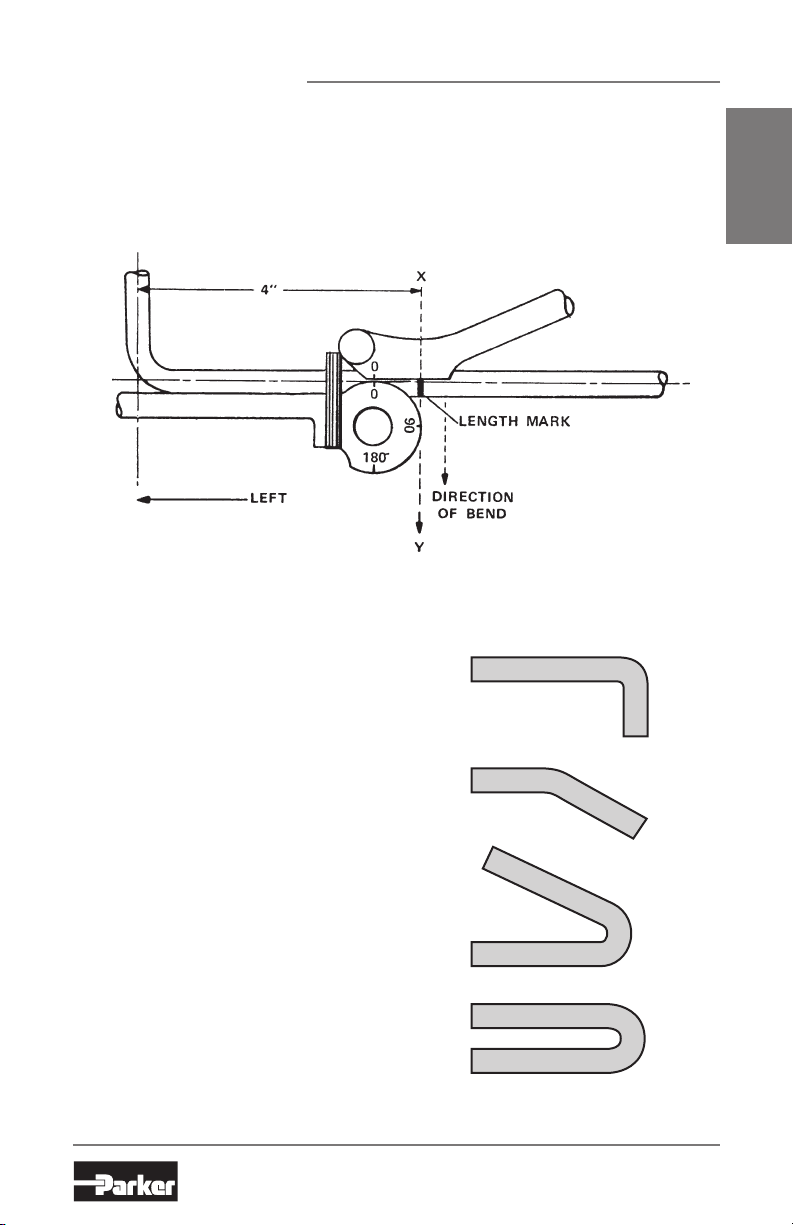

Rules for Positioning Tubing in Bender

A line which is tangent to the desired angle mark on the radius block

and which passes through the measurement mark at the centerline

of the tube, is used to control the distance between bend centerlines

(Figure 10).

Figure 10

Tube Positioning Rules

Installation

90° angles – Tangent flush with length

mark (refer to dotted line XY tangent to

radius block @ 90°, Figure 10).

Angles less than 90° – Tangent

intersects length mark at centerline.

Angles more than 90° – Position for a 90°

bend and continue on to desired angle,

i.e., 135°, 145° (i.e., length mark @ 90°

on link member).

Horseshoe or U-Bends – Measure first leg,

position for 90°, bend around to 180°.

7

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Principles of Tube Line Fabrication

Installation

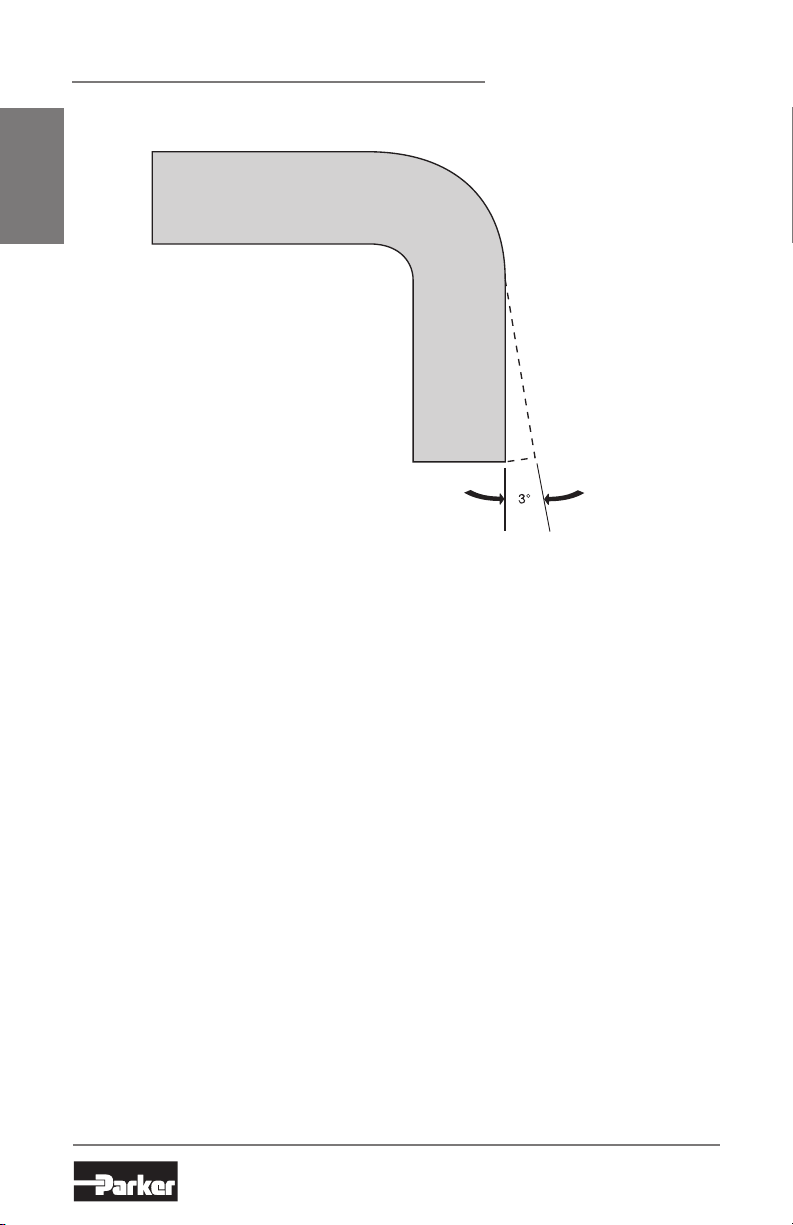

Springback 90° Bend

Figure 11

Rule of Thumb – Springback is approximately 3° for each

90° bend with stainless steel tubing.

Bulletin 4200-B4

Compensate for springback:

1. Test a piece of the material before you start fabricating a line to see

how much it springs back on a 90° bend.

2. Overbend by the amount of springback. For example, if the material

springs back 3° on a 90° bend, bend to 93° to secure a finished

90° bend, or to 46-1/2° to obtain finished 45° bend. This works

especially well with large heavy-wall tubing.

3. Remember, it is always better to underbend slightly. You can always

bend a little more if needed, but it’s almost impossible to remove or

straighten a bend, especially with large, heavy-wall tubing.

Remember – a tube bender bends – it cannot unbend.

8

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Bulletin 4200-B4

Principles of Tube Line Fabrication

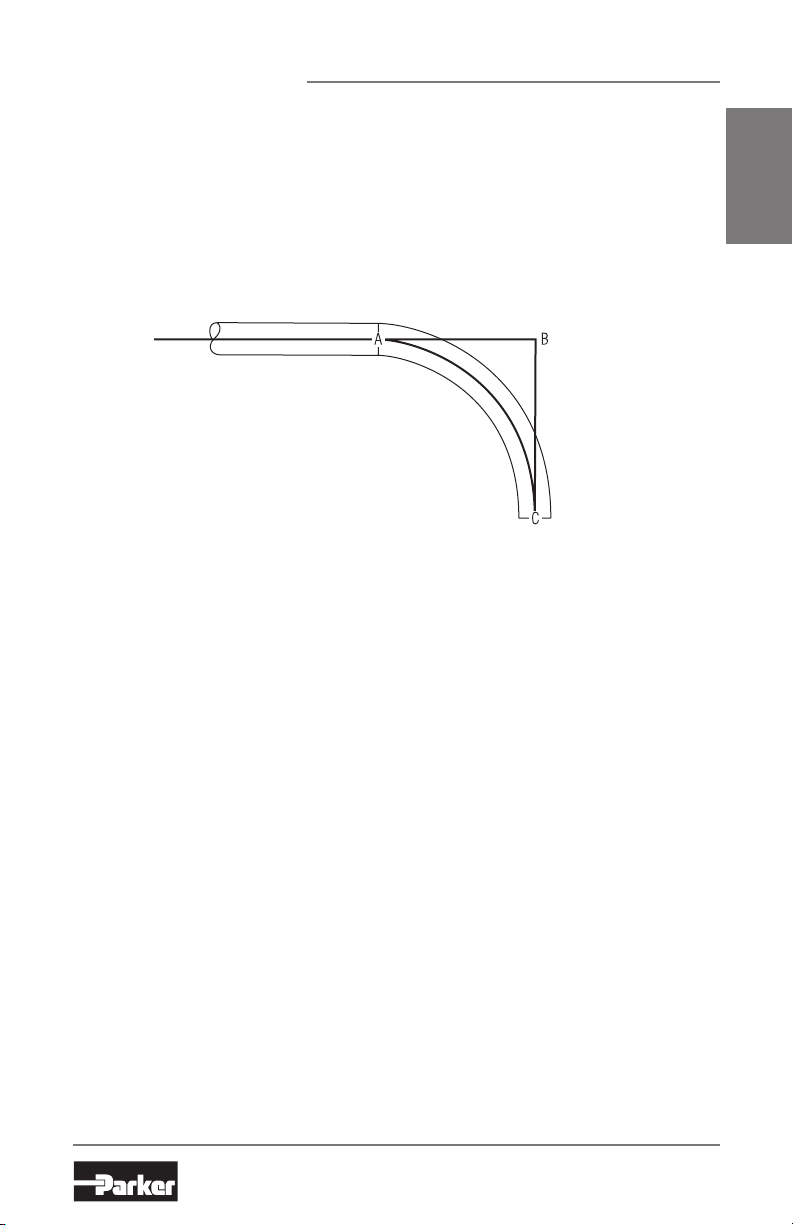

Tube Stretch or Pickup

When bent, tubing seems to stretch or pick up length. This is because

it takes a curved shortcut across the inside of the angle. A good “rule of

thumb” for most standard tubing materials and radius blocks is that the

tubing will stretch approximately one tube diameter for each 90° bend.

Triangle A-B-C – with Arc “A-C”

Figure 12

The arc “A-C” is shorter than the distance from “A” to “B”,

plus “B” to “C”.

Installation

Always try to bend in the same direction – away from the original starting end. If you reverse the direction of bending (bending towards instead

of away from the original starting end) you will “trap” the stretch. Thus, if

you unknowingly make a reverse bend of 90°, you will trap the gain, in

Table 1 (approximately one tube O.D.) and increase your length between

bends by that amount.

If bend direction for either 45° or 90° bend must be reversed, subtract

the “gain” amount listed in Table 1.

While our rule of thumb is approximately correct, the amount of stretch

is related to the diameter of the radius block used. Table 1 gives the

accurate increase in length that occurs with the most commonly used

sizes of radius blocks.

As long as you measure and bend with the tube inserted from the left,

and measure centerline, “pickup” will not affect your actual center-tocenter measurement.

9

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Principles of Tube Line Fabrication

Bulletin 4200-B4

Installation

Gain – 90° Bend

pR

2R 2

or

.429 R

Table 1

p = 3.1416

R= radius bender

Gain – 45° Bend

8284R 4

or

.043 R

Radius of

Bender

Tube Size

1/8 2 3/8 .16 .02

3/16 3 7/16 .19 .02

1/4 4 9/16 .24 .02

5/16 5 11/16 .30 .03

3/8 6 15/16 .40 .04

1/2 8 1-1/2 .64 .06

5/8 10 1-7/8 .80 .08

3/4 12 2-1/4 .97 .10

7/8 14 2-5/8 1.13 .11

1 16 3 1.29 .13

1-1/4 20 3-3/4 1.61 .16

1-1/2 24 4-1/2 1.93 .19

2 32 *8 3.43 .34

(in inches) Gain 90° Gain 45°

pR

10

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Bulletin 4200-B4

Principles of Tube Line Fabrication

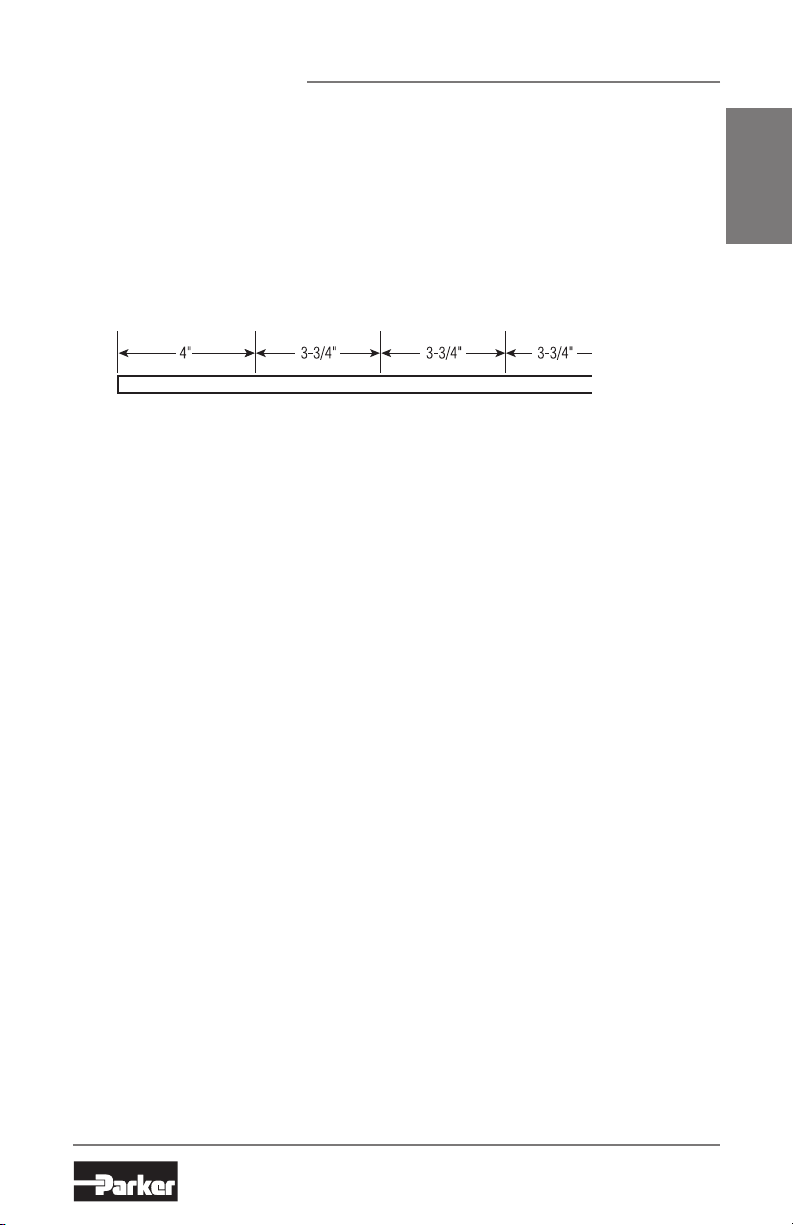

Pre-Measuring

You may pre-measure a series of bends. Measure the first bend from the

end of the tube, the correct length. Compensate for each bend after the

first by subtracting the amount of gain from your chart for each 90° of

bend to allow for stretch (Figure 13). Always custom measure for the last

bend.

Example of 1/4" Tubing

Figure 13

“Rule of Thumb” Method

Compensate each measurement after the first by subtracting the gain

listed in Table 1.

Best Way to Measure

For maximum accuracy, measure and bend exactly for each individual

bend in the tubing line. We recommend the practice of Measure and

Bend, Measure and Bend, etc.

Installation

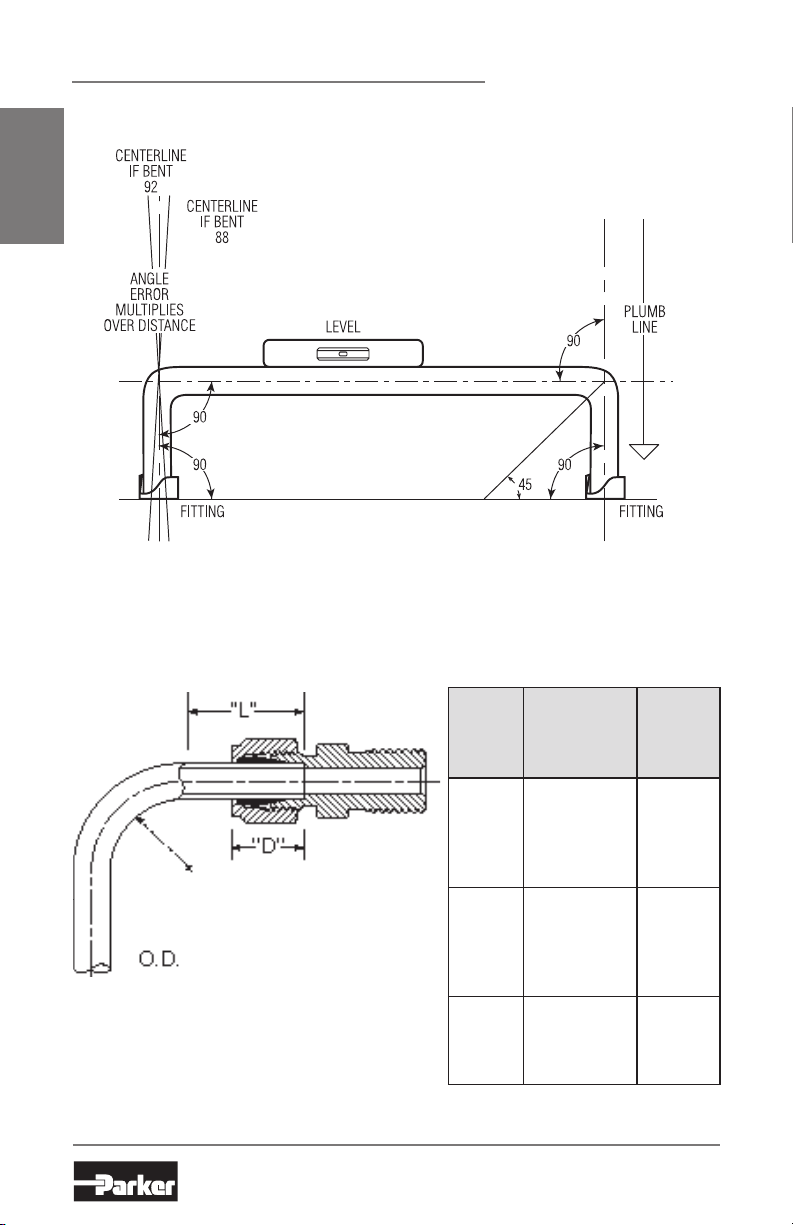

Characteristics of a Well-Made Tubing Circuit

In a well made tubing circuit or line, bends are accurate, measurement

exact. The run is plumb, square and level. Tube ends rest firmly in the

fittings and entry into the fittings is straight. Straight tube entry is very

important to insure that fittings are not under stress and can be

assembled without leaks (Figure 14).

Remember too, that length magnifies bend angles errors. If the leg

following the bend is fairly long, an error of 1° may result in the tube

line missing the desired point completely.

11

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Principles of Tube Line Fabrication

Installation

Properly Made Tube Circuit

Bulletin 4200-B4

Figure 14

Recommended Free Tubing Lengths

It is important to consider the length of tubing from the end in the fitting

body to the beginning of the bend.

Figure 15

Failure to allow for

this proper distance

can result in improper

connections, and

leaks.

12

L

Free Length

Tube

O.D.*

of Straight

Tubing*

1/16 0.50 0.38

1/8 0.70 0.52

3/16 0.75 0.56

1/4 0.80 0.61

5/16 0.88 0.66

3/8 0.94 0.69

1/2 1.19 0.94

5/8 1.25 0.98

3/4 1.25 0.98

7/8 1.31 1.05

1 1.50 1.22

1-1/4 1.94 1.61

1-1/2 2.41 1.96

2 3.25 2.65

Table 2

*All dimensions in inches.

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

D

Tube

Insertion

Depth*

Bulletin 4200-B4

Principles of Tube Line Fabrication

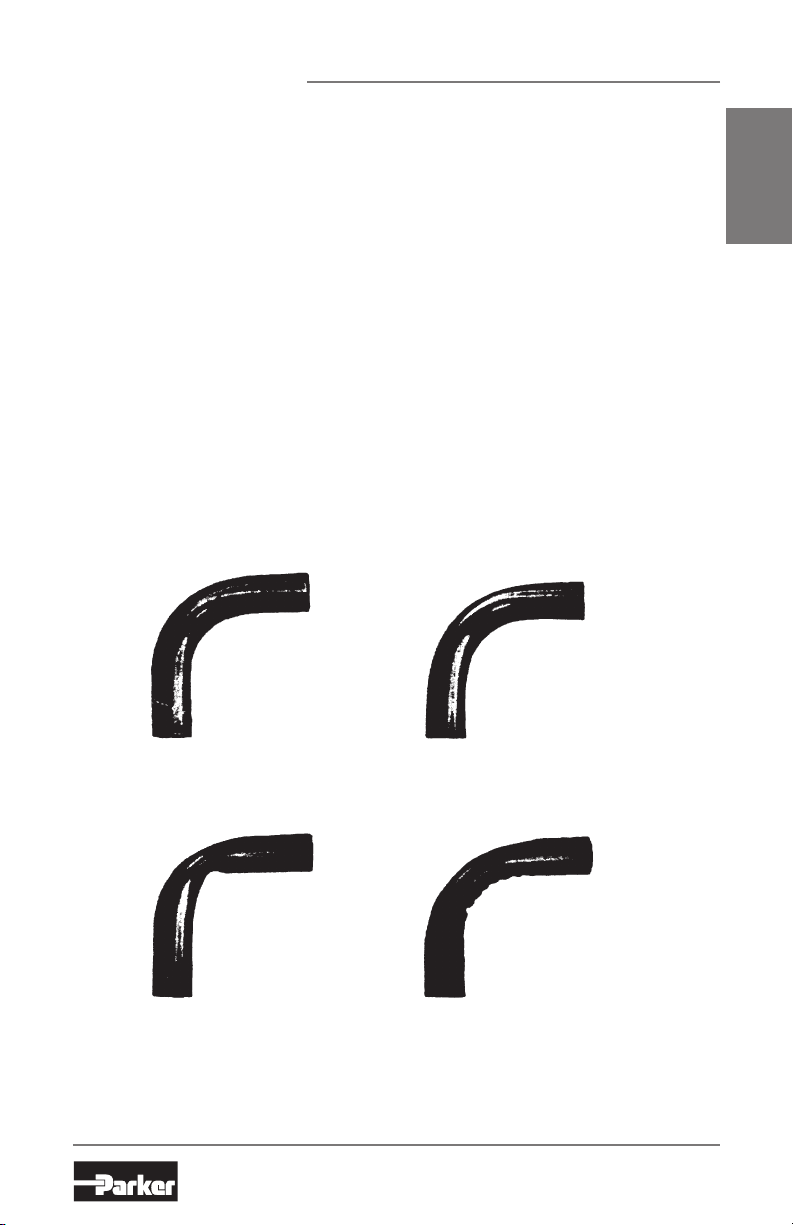

Common Causes of Imperfect Bends

Figure 16 shows an ideal bend. Bends with little or no flattening are

produced when correct equipment and methods are employed; when

proper consideration is given to co-relationship of the radius of the bend,

material wall thickness and hardness of the tube.

Figure 17 shows a flattened bend, caused by trying to bend too short a

radius, or bending smaller diameter tube in larger radius block.

Figure 18 shows a kinked and flattened bend, caused by the tube slipping

in the bender, or by using non-annealed tubing. Tubes must be firmly

clamped by clamp block to prevent slippage during bending process.

Figure 19 shows a wrinkled bend, sometimes produced when thin wall

tube is bent.

Breakage will sometimes occur when mandrel is too far forward in tube,

or when too short a radius is attempts with hard tube.

Installation

Figure 16 Good Bend Figure 17 Flattened Bend

Figure 18 Kinked Bend Figure 19 Wrinkled Bend

13

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Principles of Tube Line Fabrication

F

L

(A)

(B)

Installation

Offset Bends

Bulletin 4200-B4

To form a tube offset, it is obviously necessary to make two bends. With

these Parker hand tube benders, it is easy to make double 45° bends.

To make an offset bend simply follow the “Offset Bend Allowance” steps

below to determine the proper distance between the two 45° bends.

Here’s the procedure.

Figure 20

STEP 1 First, determine the total amount of offset required (dimension “F”

in the diagram).

STEP 2 Next, determine the angle of offset – 30° or 45°. The latter (45°)

is recommended because Parker hand benders are calibrated for 45°

bending.

STEP 3 Figure the length of the tube required to meet your offset requirements (“L” dimension) in the diagram.

For 30° bends multiply desired offset “F” x 2 = 30° offset dimension

“L”. For 45° bends multiply desired offset “F” x 1.414 = 45° offset

dimension “L”.

STEP 4 Determine where you want the offset bend of the tube to start;

and make a reference mark (A). Now measure off the “L” dimension

(determined in Step 3), starting from the reference mark and make a

second mark (B). You are now ready to make the bends.

STEP 5 Align mark (A) with reference mark 45° on bender shoe handle

(measurement end to the left) and proceed with first bend. Then align

(B) with 45° mark and make second bend in proper direction (measurement end to the left). Follow previous detailed instructions for making 45°

bends in one plane.

14

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Bulletin 4200-B4

Principles of Tube Line Fabrication

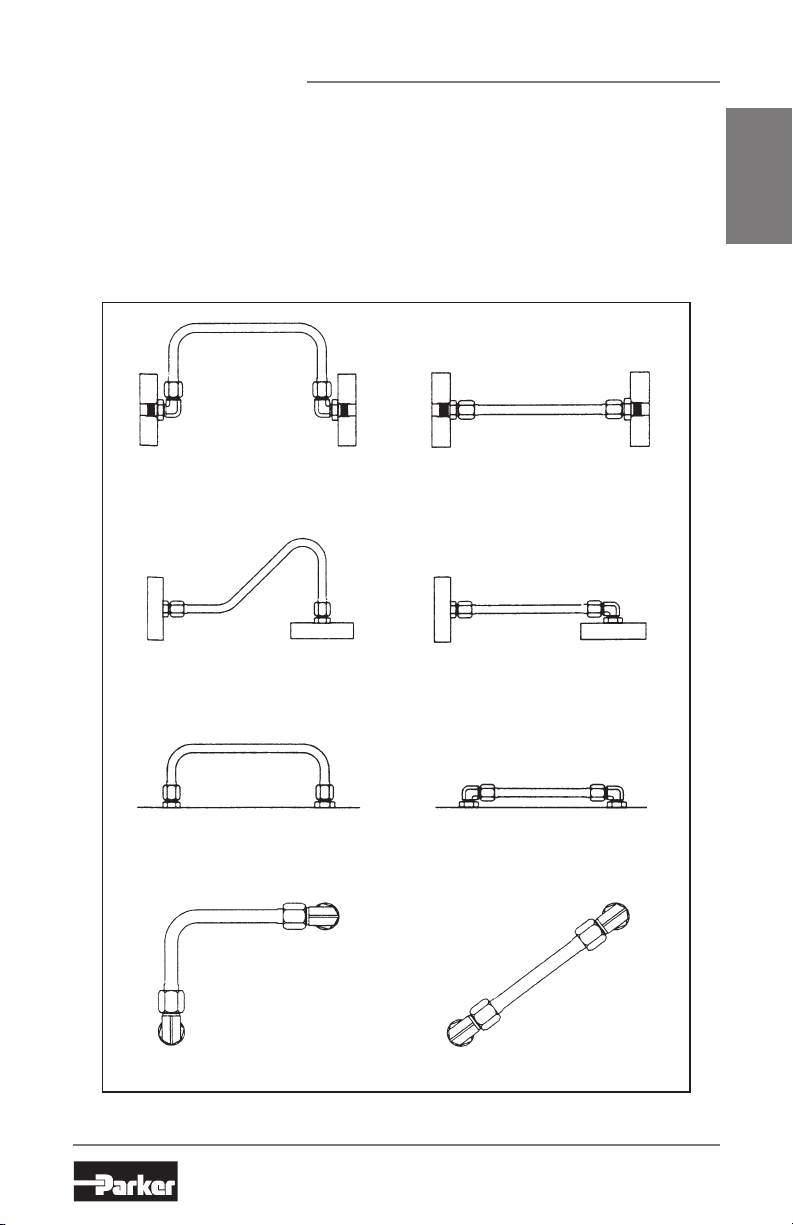

Routing of Bends

Routing of lines is probably the most difficult yet most significant of

these system design considerations. Proper routing involves getting a

connecting line from one point to another through the most logical path.

The most logical path should:

Avoid excessive strain on joints – A strained joint will eventually leak.

Correct Routing Incorrect Routing

Installation

Correct Routing Incorrect Routing

Correct Routing Incorrect Routing

Correct Routing Incorrect Routing

Figure 21

15

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Principles of Tube Line Fabrication

Installation

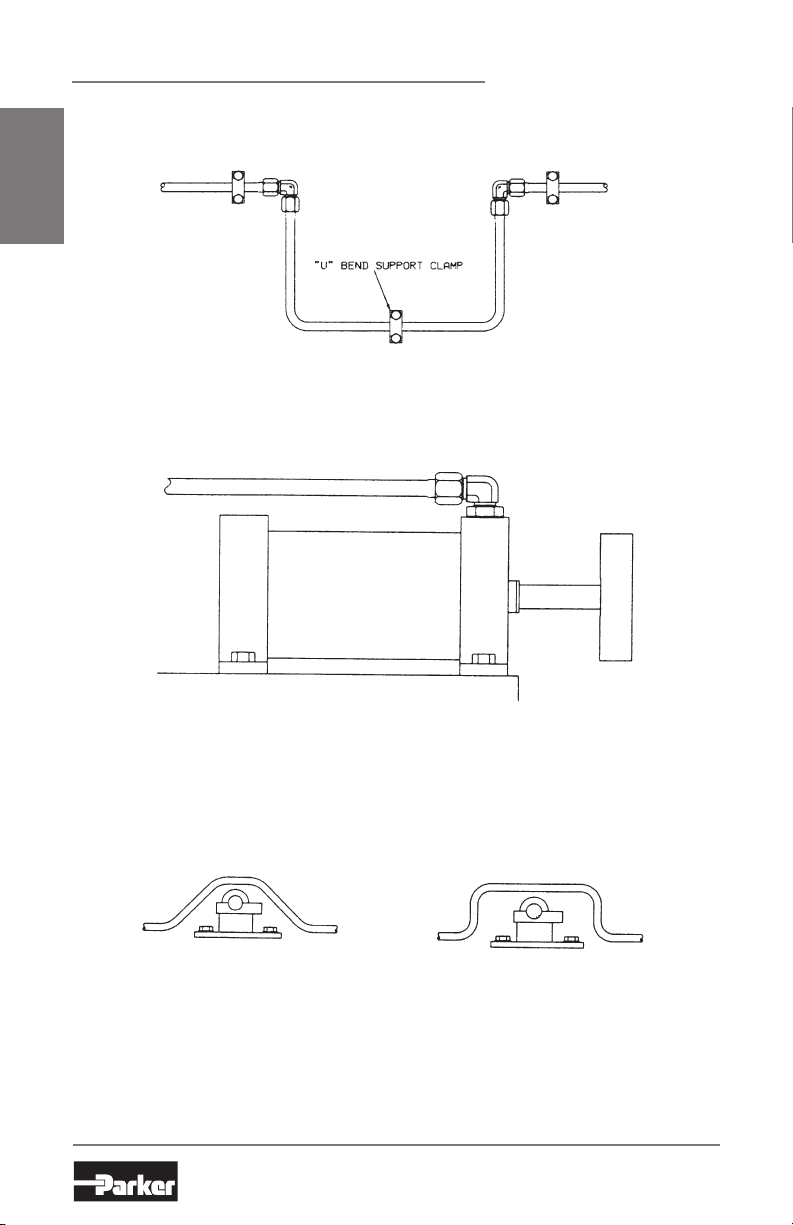

Allow for expansion and contraction – Use a “U” bend in long lines to allow

Bulletin 4200-B4

for expansion and contraction.

Figure 22 U-Bend Allowing for Expansion and Contraction

Allow for motion under load – Even some apparently rigid systems do

move under load.

Figure 23 Bent Tube Allowing for Motion Under Load

Get around obstructions without using excessive amount of 90° bends.

Pressure drop due to one 90° bend is greater than that due to two 45°

bends.

Correct Incorrect

Figure 24

16

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Bulletin 4200-B4

Principles of Tube Line Fabrication

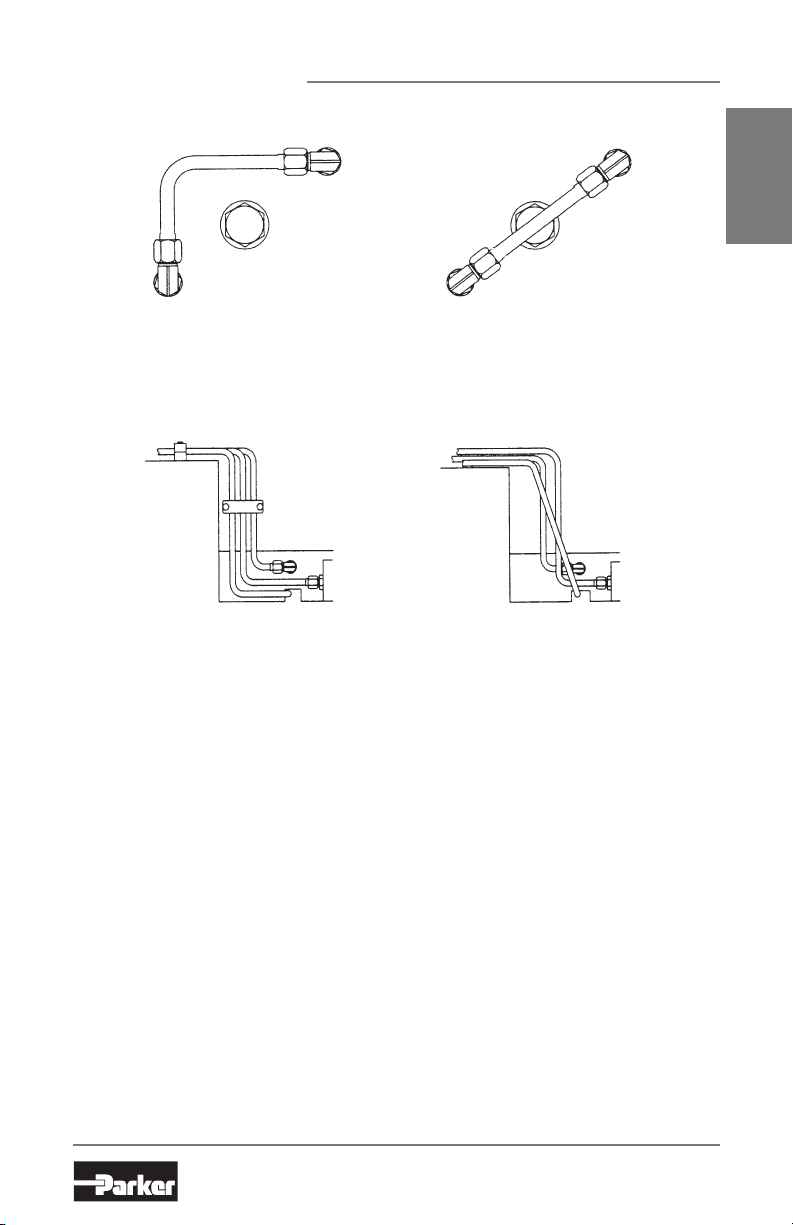

Keep tube lines away from components that require regular maintenance.

Correct Incorrect

Figure 25

Have a neat appearance and allow for easy troubleshooting, maintenance and

repair.

Installation

Correct

Figure 26

Incorrect

Tube Clamping

Once you’ve taken the time to make good bends and installed them,

it’s not enough to just let them lay suspended in mid-air. When tubing

is left unsupported, shock and vibration will cause the tubing to shake,

and in turn, cause the fitting to loosen and leak or even allow tube to fall

through fatigue.

Tube support and clamping is a necessary requirement in the fluid

power industry. Tubing can be clamped individually, in sets, and can also

be stacked. The most important part of any clamping system is having

enough clamps to attain the final result. That being, a well supported,

vibration and noise free system.

Also, most manufacturers specify SAE and JIC approved components on

their equipment. The best way to meet these specs concerning clamps

is to utilize a clamp that employs both an upper and lower unit made of

metal and a rubber split bushing which surrounds the tube or pipe and

fits on the inside of the clamping units.

17

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Principles of Tube Line Fabrication

Installation

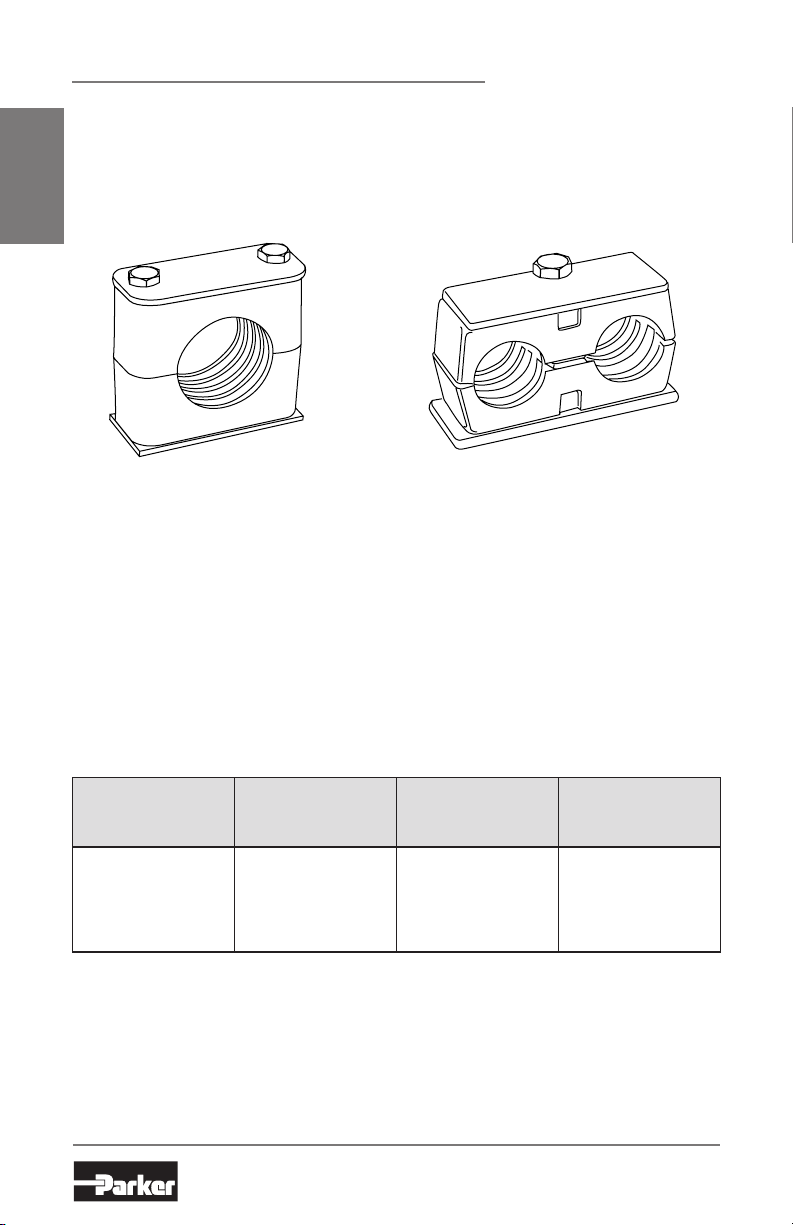

Parker Hannifin offers a tube clamp support system by the name of

Bulletin 4200-B4

“ParKlamp”. ParKlamp can clamp and support tube from 1/4" to 2" and

pipe or hose from 1/4" to 1-1/2". It comes standard in steel and uses a

rubber grommet around the tube for vibration dampening.

Standard Series –

for outside diameters from

1/4" to 2".

Clamp material: Polypropylene

Figure 27

Twin Series –

for equal or unequal outside

diameters from 1/4" to 2"

Clamp Material: Polypropylene

Below you will find a chart of recommended spacing between clamps.

We suggest you clamp as close to each bend of the tube as possible;

and you must clamp each side. This eliminates thrust in all directions.

For further information, please refer to Bulletin 4300, Industrial Tube

Fittings, Adapters and Equipment.

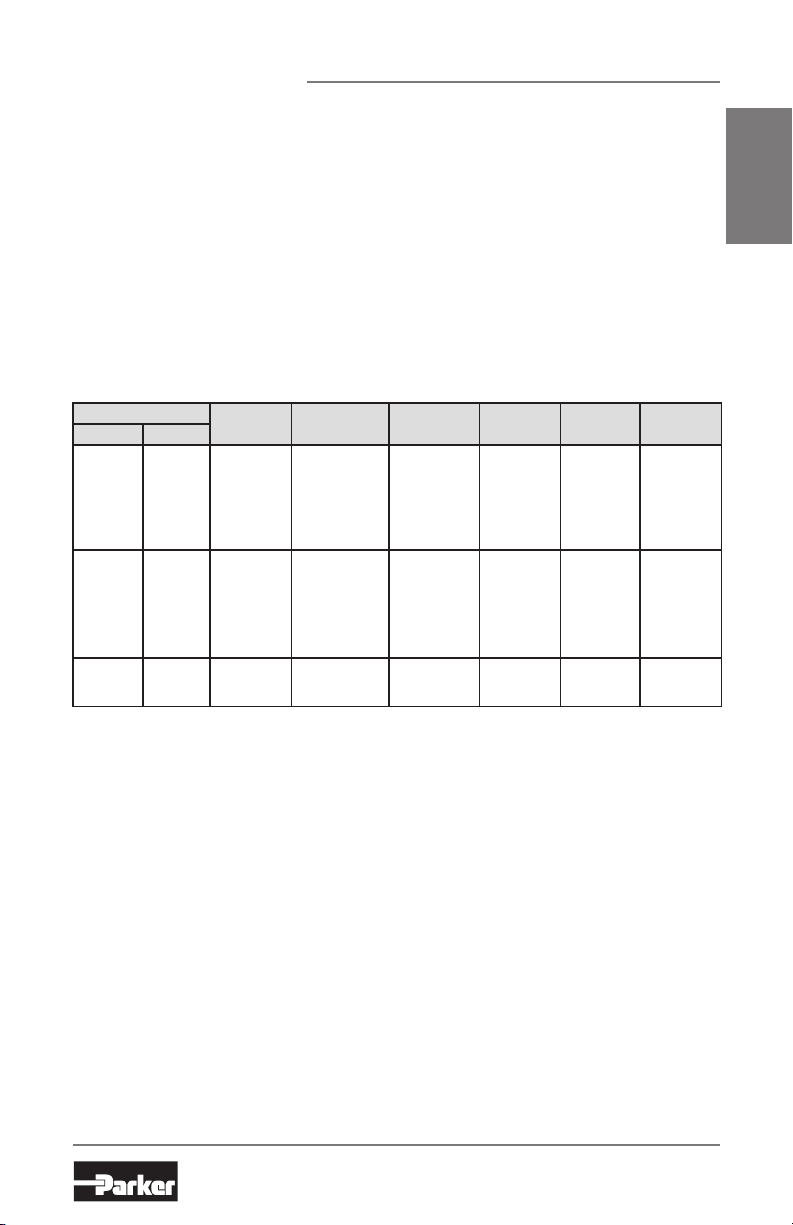

Equivalent

Tube

O.D.

1/4" – 1/2" 6 – 13 mm 3 ft. 0.9 m

3/8" – 7/8" 14 – 22 mm 4 ft. 1.2 m

1" 23 – 30 mm 5 ft. 1.5 m

1-1/4" & up 31 & up mm 7 ft. 2.1 m

Table 3

Tube

(mm)

Foot Spacing

Between

Supports

Spacing in

Meters

(Approx.)

18

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Bulletin 4200-B4

Instrument Tubing Selection Guide

Overview

1. Always Match Materials – I.E., Stainless steel tubing should be used

only with SS Fittings. The only exception to this rule is copper tubing

with brass fittings. Mixing materials can cause galvanic corrosion.

Galvanic Corrosion (Electrochemical)

All metals have a specific relative electrical potential. When

dissimilar metals come in contact in the presence of moisture

(electrolyte), a low energy electric flows from the metal having the

higher potential to the metal having the lower potential. The result

of this galvanic action is the corrosion of the metal with the higher

potential (more anodic). (See Galvanic Series Chart on page 20.)

2. Select proper tubing hardness – Remember Parker Instrumentation

Tube Fittings are designed to work within specific hardness ranges.

Rb 90 max. for S.S., Rb 80 recommended.

3. Select proper tubing wall thickness – Proper wall thickness is neces-

sary to accommodate accepted safety factors relative to desired

working pressures. For details on items 2 & 3 note “Instrumentation

Tubing Selection Guide” shown below and on the following pages.

Installation

4. Tubing surface finish – Always select tubing free of visible

drawmarks or surface scratches. If possible, cut off any undesirable

sections. These “deep” scratches can cause leaks when attempting

to seal low-density gases such as argon, nitrogen, or helium.

Instrument Tubing Selection Guide

Parker’s instrument tube fittings have been designed to work in a wide

variety of applications that demand the utmost in product performance.

Although Parker’s Instrument tube fittings have been engineered and

manufactured to consistently provide this level of reliability, no systems

integrity is complete without considering the critical link, tubing.

This booklet is intended to assist the designer to properly select and

order quality tubing.

Proper tube selection and installation, we believe, are key ingredients in

building leak-free reliable tubing systems.

19

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Instrument Tubing Selection Guide

+0.2 0 –0.2 –0.4 –0.6 –0.8 –1.0 –1.2

ZINC

–1.4 –1.6

LEAD

MAGNESIUM

BERYILIUM

ALUMINUM ALLOYS

CADMIUM

LOW ALLOY STEEL

AUSTENITIC NICKEL CAST IRON

ALUMINUM BRONZE

NAVAL BRASS, YELLOW BRASS, RED BRASS

TIN

COPPER

Pb-Sn SOLDER (50/60)

ADMIRALTY BRASS, ALUMINUM BRASS

MANGANESE BRONZE

SILICON BRONZE

MILD STEEL, CAST IRON

TIN BRONZE (G & M)

NICKEL SILVER

90-10 COPPER-NICKEL

80-20 COPPER-NICKEL

70-30 COPPER – NICKEL

NICKEL – ALUMINUM BRONZE

STAINLESS STEEL – TYPE 430

STAINLESS STEEL – TYPE 410, 416

SILVER BRAZE ALLOYS

NICKEL 200

SILVER

MONEL ALLOYS 400, K-500

STAINLESS STEEL – TYPES 316, 317

STAINLESS STEEL – TYPES 302, 304, 321, 347

INCONEL ALLOY 600

CARPENTER 20 Cb 3, HAYNES No. 20, CN-7M

INCOLOY ALLOY B

ILLIUM ALLOY B

TITANIUM

HASTELLOY ALLOY C

PLATINUM

GRAPHITE

Installation

Parker does not recommend the use of dissimilar metals when putting

together a tubing/ fitting connection system.

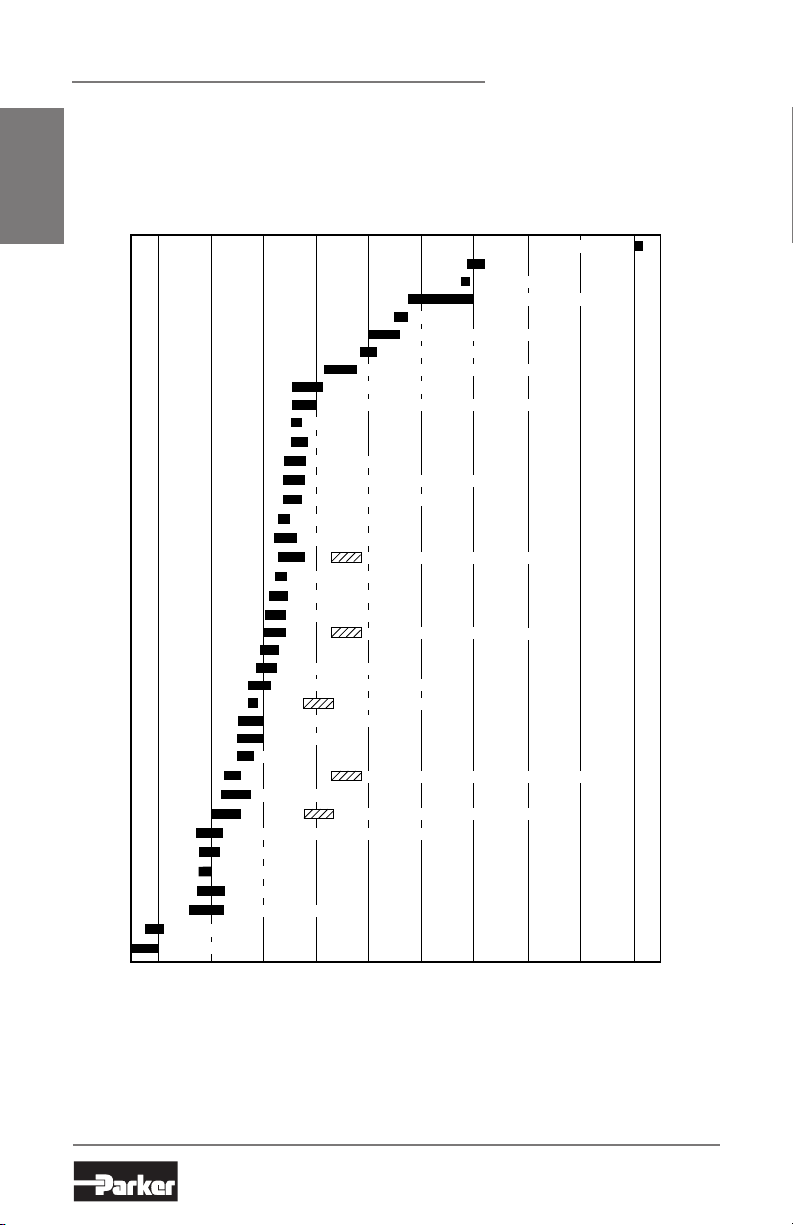

(Cathodic) Galvanic Series Chart (Anodic)

Bulletin 4200-B4

Above represents corrosion potentials of materials in flowing seawater at temperature

in the range 10°C – 26°C. The hatched symbols indicate potentials exhibited by stainless steels in pits or crevices.

Figure 28 Galvanic Series Chart

20

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Bulletin 4200-B4

Instrument Tubing Selection Guide

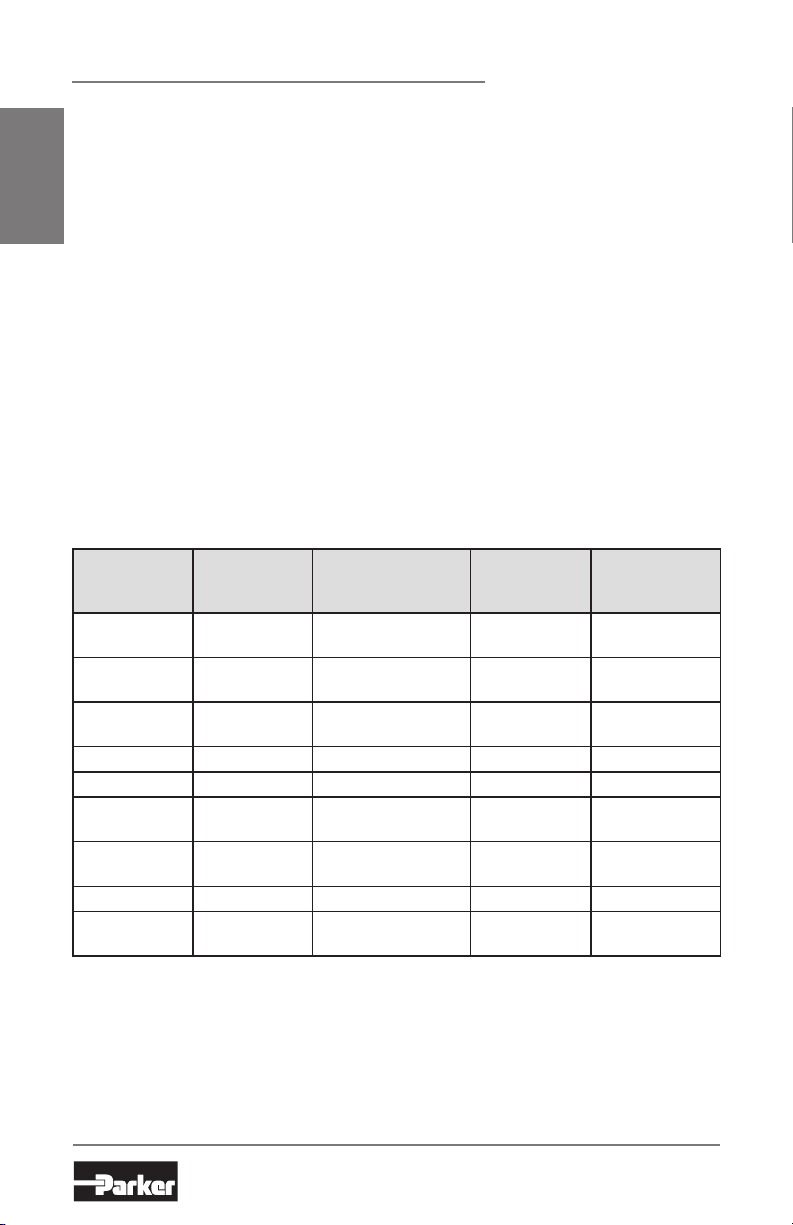

General Selection Criteria

The most important consideration in the selection of suitable tubing for

any application is the compatibility of the tubing material with the media

to be contained. Table 4 lists common materials and their associated

general application. Table 4 also lists the maximum and minimum

operating temperature for the various tubing materials.

In addition, Parker instrument fittings are designed to work on like

materials. Stainless steel fittings should be used only with stainless

steel tubing, aluminum fittings with aluminum tubing, etc. The practice

of mixing materials is strongly discouraged. The only exception is brass

fittings with copper tubing.

Dissimilar materials in contact may be susceptible to galvanic corrosion.

Further, different materials have different levels of hardness, and can

adversely affect the fittings ability to seal on the tubing.

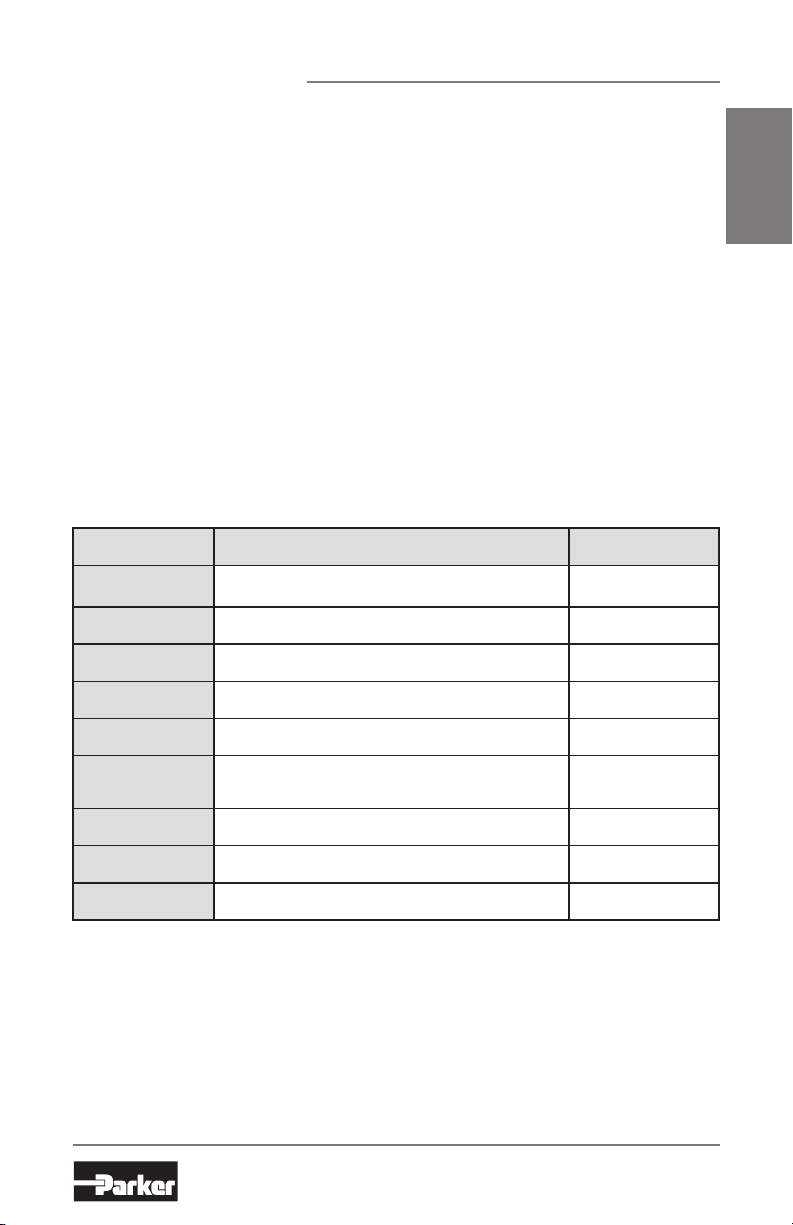

Table 4

Tubing

Material

Stainless Steel

(Type 316)

Carbon Steel

Copper

Aluminum

®

Monel

400

®

Hastelloy

Carpenter

Inconel

Titanium

C-276

®

20

®

Alloy 600

High pressure, high temperature, generally corrosive media -425°F to 1,200°F

High pressure, high temperature oil, air, some specialty

chemicals

Low temperature, low pressure water, oil, air -40°F to 400°F

Low temperature, low pressure water, oil, air, some

specialty chemicals

Recommended for sour gas applications well suited for

marine and general chemical processing applications

Excellent corrosion resistance to both oxidizing and

reducing media and excellent resistance to localized

corrosion attack

Applications requiring resistance to stress corrosion

cracking in extreme conditions

Recommended for high temperature applications with

generally corrosive media

Resistant to many natural environments such as sea water,

body fluids and salt solutions

1. For operating temperatures above 800°F (425°C), consideration should be given to media. 300

Series Stainless Steels are suspectible to carbide precipitation which may lead to intergranular

corrosion at elevated temperatures.

2. Consideration should be given to maximum temperature ratings if fittings and/or tubing are coated

or plated. All temperature ratings based on temperatures per ASME B31.3 Chemical Plant and

Petroleum Refinery Piping Code, 1999 Edition.

The information listed in Table 4 is general in scope. For specific applications, please contact Parker’s

Instrumentation Products Division, Product Engineering Department (256) 881-2040.

Note: Hastelloy

®

is a registered trademark of Haynes International. Inconel®, and Monel® are registered

trademarks of Special Metals Corporation. Carpenter® is a registered trademark of CRS Holdings Inc.

General

Application

Recommended

Temperature Range

(-255°C to 605°C)

-20°F to 800°F

(-29°C to 425°C)

(-40°C to 205°C)

-40°F to 400°F

(-40°C to 205°C)

-325°F to 800°F

(-198°C to 425°C)

-325°F to 1000°F

(-198°C to 535°C)

-325°F to 800°F

(-198°C to 425°C)

-205°F to 1200°F

(-130°C to 650°C)

-75°F to 600°F

(-59°C to 315°C)

1

2

Installation

21

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Instrument Tubing Selection Guide

Installation

Gas Service

Bulletin 4200-B4

Special care must be taken when selecting tubing for gas service. In

order to achieve a gas-tight seal, ferrules in instrument fittings must seal

any surface imperfections. This is accomplished by the ferrules penetrating the surface of the tubing. Penetration can only be achieved if the

tubing provides radial resistance and if the tubing material is softer than

the ferrules.

Thick walled tubing helps to provide resistance. Tables 5 through 10 indicate the minimum acceptable wall thickness for various materials in gas

service. The ratings in white indicate combination of diameter and wall

thickness which are suitable for gas service.

Acceptable tubing hardness for general application is listed in Table 12.

These values are the maximum allowed by ASTM. For gas service, better results can be obtained by using tubing well below this maximum

hardness. For example, a desirable hardness of 80 Rb is suitable for

stainless steel. The maximum allowed by ASTM is 90 Rb.

System Pressure

The system operating pressure is another important factor in determining the type, and more importantly, the size of tubing to be used. In

general, high pressure installations require strong materials such as

steel or stainless steel. Heavy walled softer tubing such as copper

may be used if chemical compatibility exists with the media. However,

the higher strength of steel or stainless steel permits the use of thinner

tubes without reducing the ultimate rating of the system. In any event,

tube fitting assemblies should never be pressurized beyond the recommended working pressure.

The following tables (5 through 10) list by material the maximum suggested working pressure of various tubing sizes. Acceptable tubing

diameters and wall thicknesses are those for which a rating is listed.

Combinations, which do not have a pressure rating, are not recommended for use with instrument fittings.

22

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Bulletin 4200-B4

Instrument Tubing Selection Guide

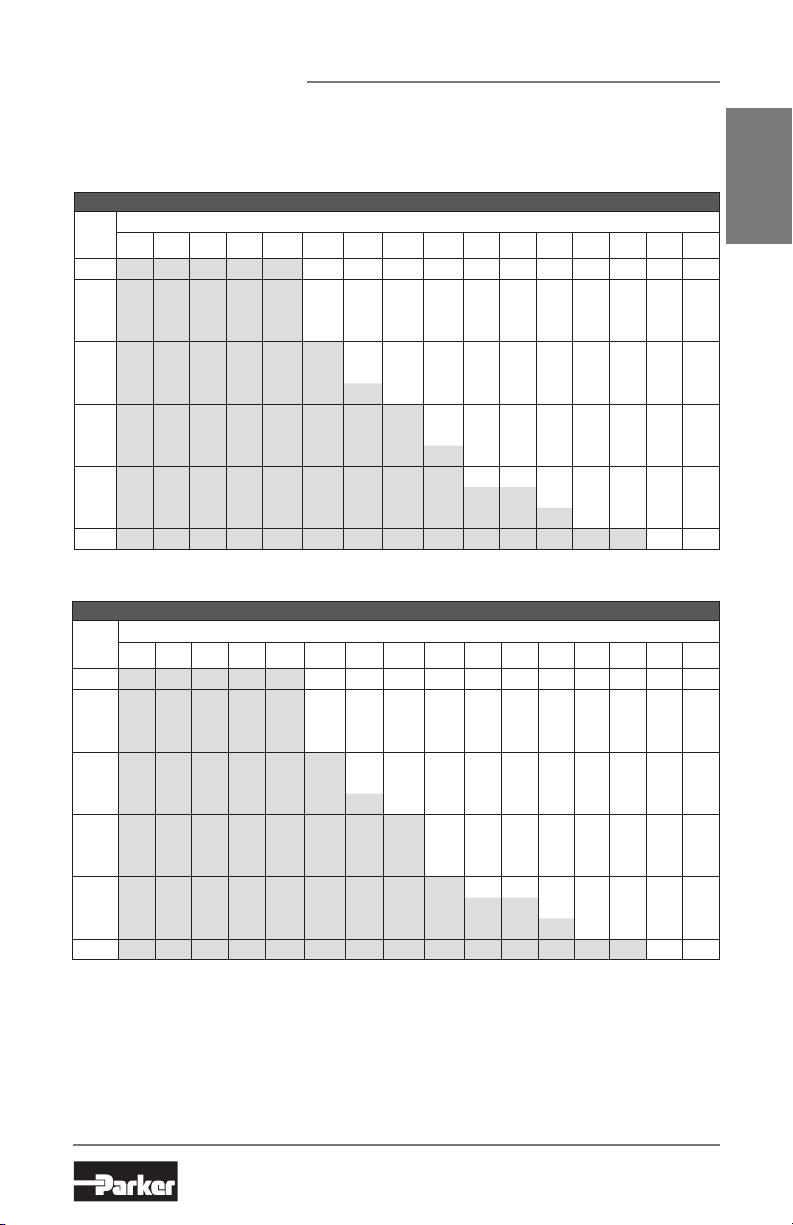

Maximum Allowable Working Pressure Tables

Ratings in gray not suitable for gas service.

Table 5*

Tube

O.D.

0.010 0.012 0.014 0.016 0.020 0.028 0.035 0.049 0.065 0.083 0.095 0.109 0.120 0.134 0.156 0.188

Size

1/16 5600 6900 8200 9500 12100 16800

1/8 8600 10900

3/16 5500 7000 10300

1/4 4000 5100 7500 10300

5/16 4100 5900 8100

3/8 3300 4800 6600

1/2 2600 3700 5100 6700

5/8 3000 4000 5200 6100

3/4 2400 3300 4300 5000 5800

7/8 2100 2800 3600 4200 4900

1 2400 3200 3700 4200 4700

1-1/4 2500 2900 3300 3700 4100 4900

1-1/2 2400 2700 3000 3400 4000 4500

2 2000 2200 2500 2900 3200

Table 6*

Tube

O.D.

0.010 0.012 0.014 0.016 0.020 0.028 0.035 0.049 0.065 0.083 0.095 0.109 0.120 0.134 0.156 0.188

Size

1/16 4800 5900 7000 8100 10300 14300

1/8 7300 9300

3/16 4700 6000 8700

1/4 3400 4400 6400 8700

5/16 3400 5000 6900

3/8 2800 4100 5600

1/2 2200 3200 4300 5700

5/8 2500 3400 4500 5200

3/4 2100 2800 3700 4200 4900

7/8 1800 2400 3100 3600 4200

1 2100 2700 3100 3600 4000

1-1/4 2100 2400 2800 3100 3500 4200

1-1/2 2000 2300 2600 2900 3400 4200

2 1700 1900 2100 2500 3000

*Notes for Tables 5 through 10:

• Allworkingpressureshavebeencalculatedusingthemaximumallowablestresslevelsinaccordance

with ASME/ANSI B31.3, Chemical Plant and Petroleum Refinery Piping or ASME/ANSI B31.1 Power

Piping.

• Allcalculationsarebasedonmaximumoutsidediameterandminimumwallthickness.

• Allworkingpressuresareatambient(72°F) temperature.

316 or 304 STAINLESS STEEL (Seamless)

Wall Thickness

316 or 304 STAINLESS STEEL (Welded)

Wall Thickness

Installation

Maximum Allowable Working Pressure Tables are continued on the following page.

23

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Instrument Tubing Selection Guide

Installation

Maximum Allowable Working Pressure Tables (cont'd)

Bulletin 4200-B4

Ratings in gray not suitable for gas service.

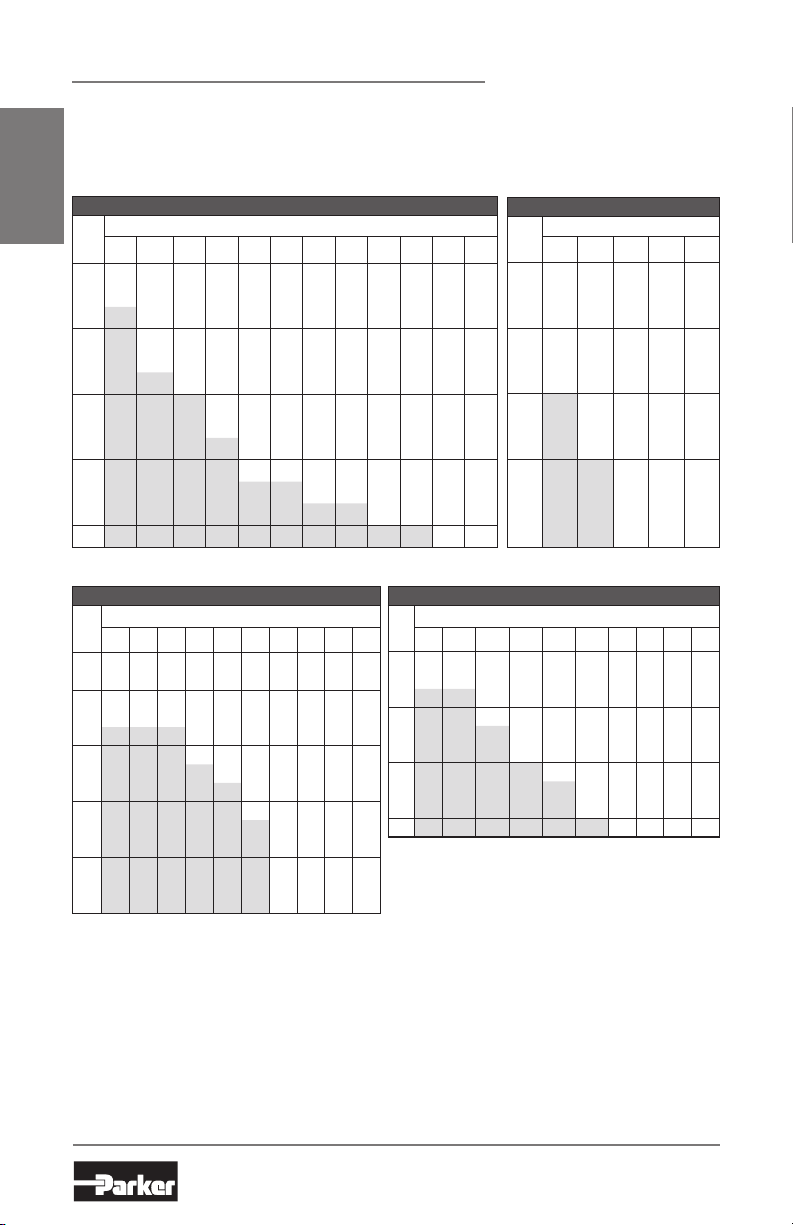

Table 7*

CARBON STEEL (Seamless)

Tube

O.D.

0.028 0.035 0.049 0.065 0.083 0.095 0.109 0.120 0.134 0.148 0.165 0.180

Size

1/8 8100 10300

3/16 5200 6700 9700

1/4 3800 4900 7100 9700

5/16 3800 5500 7700

3/8 3100 4500 6200

1/2 2300 3300 4500 6000

5/8 1800 2600 3500 4600 5400

3/4 2200 2900 3800 4400 5100

7/8 1800 2500 3200 3700 4300

1 1600 2100 2800 3200 3700 4100

1-1/4 1700 2200 2500 2900 3200 3700 3800

1-1/2 1800 2100 2400 2700 3000 3400 3800 4000

2 1600 1800 2000 2200 2500 2800 3000

Wall Thickness

Table 9*

ALUMINUM (Seamless)

Tube

O.D.

Size

1/8 8700

3/16 5600 8100

1/4 4100 5900

5/16 3200 4600

3/8 2600 3800

1/2 1900 2800 3800

5/8 1500 2200 2900

3/4 1800 2400 3200

7/8 1500 2100 2700

1 1300 1800 2300 2700

Wall Thickness

0.035 0.049 0.065 0.083 0.095

Table 8*

COPPER (Seamless)

Tube

O.D.

.010 .020 .028 .035 .049 .065 .083 .095 .109 .120

Size

1/16 1700 3800 5400

1/8 2800 3600

3/16 1800 2300 3500

1/4 1300 1700 2600 3500

5/16 1300 2000 2800

3/8 1100 1600 2300

1/2 800 1200 1600 2200

5/8 900 1300 1700 2000

3/4 800 1000 1400 1600 1900

7/8 600 900 1100 1300 1600

1 600 800 1000 1200 1400 1500

1-1/8 500 700 900 1000 1200 1300

1-1/4 800 900 1100 1200

1-1/2 650 750 850 950

Wall Thickness

Table 10*

Tube

O.D.

.010 .020 .028 .035 .049 .065 .083 .095 .109 .120

Size

1/16 5500 11800 16300

1/8 8100 10400

3/16 5100 6600 9600

1/4 3800 4800 7000 9600

5/16 3800 5500 7500

3/8 3100 4500 6100

1/2 2300 3300 4500 5900

5/8 2700 3700 4900 5600

3/4 2300 3100 4000 4600 5400

1 2300 2900 3400 3900 4400

MONEL 400 (Seamless)

Wall Thickness

*Notes for Tables 5 through 10:

• Allworkingpressureshavebeencalculatedusingthemaximumallowablestresslevelsinaccordance

with ASME/ANSI B31.3, Chemical Plant and Petroleum Refinery Piping or ASME/ANSI B31.1 Power

Piping.

• Allcalculationsarebasedonmaximumoutsidediameterandminimumwallthickness.

• Allworkingpressuresareatambient(72°F) temperature.

24

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Bulletin 4200-B4

Instrument Tubing Selection Guide

System Temperature

Operating temperature is another factor in determining the proper tubing

material. Copper and aluminum tubing are suitable for low temperature

media. Stainless steel and carbon steel tubing are suitable for higher

temperature media. Special alloys such as Alloy 600 are recommended

for extremely high temperatures (see Table 4). Table 11 lists derating

factors which should be applied to the working pressures listed in Tables

5 through 10 for elevated temperature conditions. Simply locate the correct factor in Table 11 and multiply this by the appropriate value in Tables

5 through 10 for elevated temperature working pressure.

Table 11 – Temperature Derating Factors

Temperature

Copper Aluminum

100 (38) 1.00 1.00 1.00 1.00 1.00 1.00

200 (93) .80 1.00 1.00 1.00 .96 .88

300 (149) .78 .81 1.00 1.00 .90 .82

400 (204) .50 .40 .97 .94 .86 .79

500 (260) .90 .88 .82 .79

600 (316) .85 .82 .77 .79

700 (371) .82 .80 .73 .79

800 (427) .80 .76 .59 .76

900 (486) .78 .73 .43

1000 (538) .77 .69

1100 (593) .62 .49

1200 (649) .37 .30

EXAMPLE: 1/2" x .49 wall seamless 316 stainless steel tubing has a working pressure of 3700 psi @

room temperature. If the system were to operate @ 800°F (425°C), a factor of 80% or (.80) would apply

(see Table 11 above) and the “at temperature” system pressure would be 3700 PSI x .80 = 2960 PSI.

316

SS

304

SS Steel

Monel

400°F (°C)

Installation

25

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Instrument Tubing Selection Guide

Installation

Tubing Ordering Guidelines

Bulletin 4200-B4

Tubing for use with Parker instrument fittings must be carefully ordered

to insure adequate quality for good performance. Each purchase order

must specify the material nominal outside diameter, and wall thickness. Ordering to ASTM specifications insures that the tubing will be

dimensionally, physically, and chemically within strict limits. Also, more

stringent requirements may be added by the user. All tubing should be

ordered free of scratches and suitable for bending.

A purchase order meeting the above criteria would read as follows:

“1/2 x .049 316 stainless steel, seamless, or welded and

redrawn per ASTM A-249. Fully annealed, 80 Rb or less.

Must be suitable for bending; surface scratches, and

imperfections (incomplete weld seams) are not permissible.”

Table 12 lists specific ordering information for each material.

Table 12

Material Type

Stainless Steel 304, 316, 316L

Copper K or L

Carbon Steel 1010

Aluminum Alloy 6061 ASTM B-210 T6 Temper 56 Rb

®

400 400 ASTM B-165 Fully Annealed 75 Rb

Monel

Hastelloy

C-276

Inconel® Alloy

600

Carpenter

Titanium

*B88 Copper Tube to be ordered non-engraved

Note: Hastelloy

trademarks of Special Metals Corporation. Carpenter

®

C-276 ASTM-B-622, B-626 Fully Annealed 90 Rb

600 ASTM B-167 Fully Annealed 90 Rb

®

20 20CB-3 ASTM B-468 Fully Annealed 90 Rb

Commercially

Pure Grade 2

®

is a registered trademark of Haynes International. Inconel®, and Monel® are registered

ASTM

Tubing Spec. Condition

ASTM-A-269, A-249,

A-213, A632

ASTM-B75 B68,

B88 (K or L)*

SAE-J524b, J525b

ASTM-A-179

ASTM B-338 Fully Annealed

®

is a registered trademark of CRS Holdings Inc.

Fully Annealed 90 Rb

Soft Annealed

Temper 0

Fully Annealed 72 Rb

Recommended

Hardness

60 Max.

Rockwell 15T

99 Rb 200

Brinell Typical

Max.

26

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Loading...

Loading...