Parker Hannifin Instrumentation PTFE Hose, Thermoplastic Tubing, Fittings and Accessorie User Manual

Page 1

Instrumentation PTFE

Hose, Thermoplastic

Tubing, Fittings and

Accessories

Catalog 4200-INST

November 2004

Page 2

GENERAL INFORMATION

Parker thermoplastic tubing,

fittings, and PTFE hose products

support instrumentation process

systems.

For critical applications that require accurate control

and dependable sample transport, Parker Hannifin is

the only manufacturer that can provide such an

extensive range of products to meet the challenge in

any process. With over 2,700 product lines, solving

instrumentation system needs is our goal.

PTFE Hose

Parflex® PTFE hose is manufactured with the highest

quality, high performance PTFE material available.

Parflex

tance, flexibility and temperature resistance. PTFE

hose is available in static-dissipated or heavy wall low

permeation constructions.

Hose assemblies can be quickly made to your specification with Parker 91N series fittings attached, tested

and delivered complete and ready to use to your site.

The most common end connections available include:

Thermoplastic Reinforced Hose

In addition to PTFE hose, Parker offers one of the

most extensive lines of thermoplastic hose available in

the market.

Parker thermoplastic hose offers long-term durability,

clean core tubes and the industry’s highest level of

abrasion resistant jackets available.

For the long-term life of a system, Parker thermoplastic hose outperform rubber hose 10:1.

Parker offers hoses for just about every application.

From our General Hydraulic Hose 520N series to our

Polyflex

applications to 20,400 PSI, Parker has a hose available to meet the most demanding system needs.

Thermoplastic Tubing and Fittings

When it comes to solving instrumentation needs,

Parker is unmatched in the market for available

thermoplastic tubing and fittings.

®

PTFE hose offer excellent chemical resis-

• A-LOK

®

Compression

• CPI™ Compression

• Tube Stub

• Male NPT

• And many others

®

2440N series designed for high-pressure

We stock most thermoplastic tubing materials,

such as:

• Nylon

• Polyethylene

• Polypropylene

• Polyurethane

• Vinyl

Our standard color is black, but many other colors are

also available.

As part of the complete system, Parker also has a full

line of fittings specifically designed for use with our

thermoplastic tubing, offering tight, sure, leak proof

seal.

Our TrueSeal

without the need for special tools. Our Fast & Tite

™

fittings offer quick field connections,

®

are the most complete line in the industry.

The Par-Barb series is engineered with a 4-barb

design that generates the maximum gripping and

sealing power available in a barb connection, when

used in conjunction with a hose clamp.

These fittings are offered in a wide range of materials

and temperatures such as:

TrueSeal

™

• Grey Acetal –20˚F to 180˚F

• White Polypropylene 0˚F to 225˚F

• Natural Kynar

Fast & Tite

™

0˚F to 275˚F

®

• Black /White Polypropylene 0˚F to 212˚F

• White Nylon –40˚F to 212˚F

Par-Barb

• Black Polyethylene –65˚F to 190˚F

• White Nylon –40˚F to 200˚F

KYNAR® is a registered trademark of Atochem North America, Inc.

Hose Crimping Equipment

Parker’s MiniKrimp™ crimper is a patent pending

design. At just about 35 pounds, the MiniKrimp is the

lightest and fastest low-cost, portable crimper on the

market. It provides a factory style hose assembly on

the job-site within seconds. The exclusive

Parkalign™ feature correctly positions the fitting every

time, while the unitized die train keeps die segments

in place.

The MiniKrimp is available with a number of options,

including air over hydraulic, hand pump, vice mount or

bench mount styles.

2

Parker Hannifin Corporation

Parflex Division

Ravenna, OH

Page 3

PTFE HOSE

How to order PTFE Hoses ................................. 4

919, 919B, 919J, 929, 929B ........................... 4-6

End fitting 91N series ......................................... 7

Thermoplastic Hose

How to order Thermoplastic Hoses.................... 8

520N, 540P, 540N, 518C, 580N .................... 8-10

End fittings 55 series ....................................... 10

Accessories...................................................... 10

Crimping Equipment

MiniKrimp, accessories and specifications ...... 11

Thermoplastic Tubing

Introduction design features............................. 12

Thermoplastic Tubing selection chart .............. 12

Tubing and part number selection chart .......... 13

INDEX

Thermoplastic Fittings

Introduction design features............................. 14

TrueSeal Fittings Charts .................................. 15

Fast & Tite Fittings Charts........................... 16-17

Par-Barb Charts ..........................................18-19

Polyflex Hose

Introduction ...................................................... 20

Polyflex Hose Chart ......................................... 20

How to order Polyflex Hoses............................ 21

FAILURE, IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS AND/OR SYSTEMS DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL

INJURY AND PROPERTY DAMAGE.

This document and other information from Parker Hannifin Corporation, its subsidiaries and authorized distributors provide product and/or system options for further investigation by users

having technical expertise. It is important that you analyze all aspects of your application and review the information concerning the product or system in the current product catalog. Due to

the variety of operating conditions and applications for these products or systems, the user, through its own analysis and testing, is solely responsible for making the final selection of the

products and systems and assuring that all performance, safety and warning requirements of the application are met.

The products described herein, including without limitation, product features, specifications, designs, availability and pricing, are subject to change by Parker Hannifin Corporation and its

subsidiaries at any time without notice.

WARNING

The items described in this document are hereby offered for sale by Parker Hannifin Corporation, its subsidiaries or its authorized distributors. This offer and its acceptance are governed by

the provisions stated in the “Offer of Sale” located in Catalog 4660.

© Copyright 2004, Parker Hannifin Corporation. All Rights Reserved.

Offer of Sale

3

Parker Hannifin Corporation

Parflex Division

Ravenna, OH

Page 4

PTFE HOSE

Introduction

Parker reinforced PTFE hose is manufactured with a high-performance PTFE core material. Our PTFE hose

provide fluid conveyance solutions for a wide range of applications across many markets. Parker PTFE hose

offer excellent chemical resistance and is virtually inert to all chemical. Many other benefits of Parker PTFE hose

include:

BENEFITS:

• Extreme high and low temperature range

• Low friction minimizes pressure drops and deposits

• Exceptional chemical resistance

How to Order

P 919 TU AL 08 08 08 C- 36

• Stainless steel braid reinforcement is cleaned to reduce hydrocarbon content

• High purity non-contaminating material for pure system applications

• Flexibility allows motion, vibration dampening and easier routing & installation

TYPE OF

CONNECTION

P=Permanent

Crimp

Other End Connections and styles available. See Parflex 4660 catalog at www.Parker.com for additional details.

Assemblies are to be measured extreme end to end. Exception:

1. Face seal type fittings shall be measured from sealing to face.

2. Where elbow fittings are used, measurement shall be to the centerline of the sealing surface of the elbow end.

3. “A-LOK®” and “CPI™” fittings are measured from tube stops.

HOSE

STYLE

919

919B

919J

929

929B

1ST END

CONNECTION

01 = Male NPT

03 = Male JIC 37°

06 = Female SAE (JIC) 37°

Swivel

AL = A-LOK

P6 = CPI

TU = Universal Tube Stub

HV = Male Vacuseal

VH = Female Vacuseal

™

Compression

(nut & ferrule)

2ND END

CONNECTION

®

Compression

1ST END

DASH SIZE

02=1/8"

04=1/4"

06=3/8"

08=1/2"

12=3/4"

16=1"

2ND END

DASH SIZE

HOSE I.D.

DASH SIZE

04=3/16"

06=5/16"

08=13/32"

12=5/8"

16=7/8"

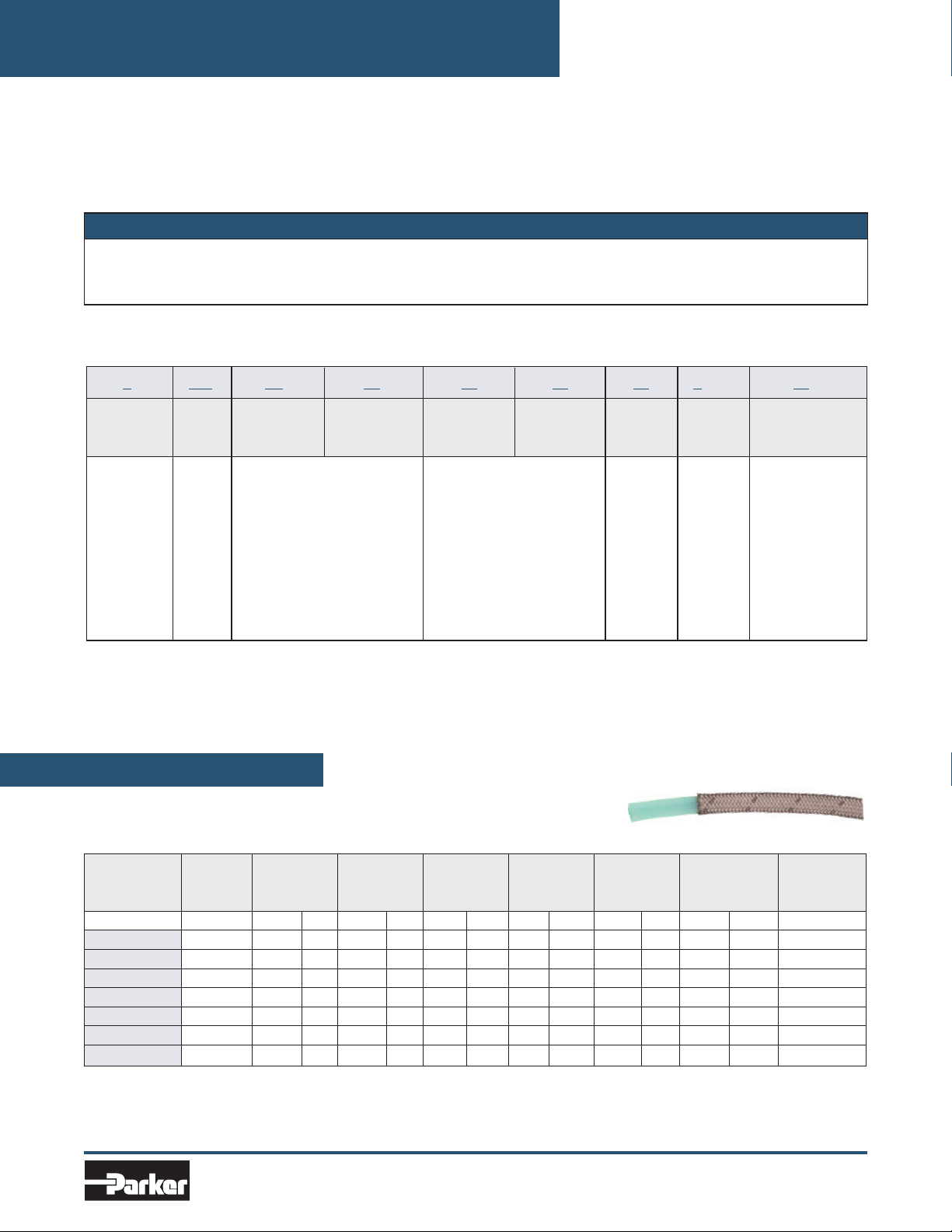

919 PTFE HOSE PTFE Hose

FITTING

MATERIAL

C=Stainless

OVERALL

ASSEMBLY

LENGTH (INCHES)

Overall length is

expressed in

inches measured

from extreme end

to end. Except

elbow fittings

which are

measured from

centerline or

the seat.

HOSE

SERIES -

DASH SIZE

919-4 28 3/16 5 5/16 8 .030 .762 3000 20.7 2.0 51 0.056 0.09 80C-T04N

919-5 28 1/4 6 3/8 10 .030 .762 3000 20.7 3.0 76 0.086 0.13 80C-T05N

919-6 28 5/16 8 7/16 11 .030 .762 2500 17.2 4.0 102 0.103 0.15 80C-T06N

919-8 28 13/32 10.5 17/32 14 .030 .762 2000 13.8 5.0 127 0.126 0.19 80C-T08N

919-10 28 1/2 12.5 5/8 16 .030 .762 1500 10.3 6.5 165 0.149 0.22 80C-T10N

919-12 12 5/18 16 3/4 19 .030 .762 1200 8.3 7.5 191 0.186 0.28 80C-T12N

919-16 14 7/8 22 1-1/32 26 .035 .889 1000 6.9 9.0 229 0.268 0.4 80C-T16N

Construction: Smooth bore natural PTFE core tube with a type 304 stainless steel braided wire reinforcement.

Typical applications: Instrumentation lines, analyzer sampling lines and for areas that require tight routing.

Temperature range: -100°F to +450°F (-73°C to +232°C)

VACUUM

RATING

INCHES/HG INCHES MM INCHES MM INCHES MM PSI MPA INCHES MM LBS/FT KG/M

HOSE I.D.

MAX.

HOSE O.D.

WALL

THICKNESS

4

MAXIMUM

WORKING

PRESSURE

MINIMUM

BEND

RADIUS

WEIGHT

Parker Hannifin Corporation

Parflex Division

Ravenna, OH

CRIMP DIE

PART NO.

Page 5

919B PTFE Hose Static-Dissipative Hose

PTFE HOSE

HOSE

SERIES -

DASH SIZE

919B-5 28 1/4 6 3/8 10 .030 .762 3000 20.7 3.0 76 0.086 0.13 80C-T05N

919B-6 28 5/16 8 7/16 11 .030 .762 2500 17.2 4.0 102 0.103 0.15 80C-T06N

919B-8 28 13/32 10.5 17/32 14 .030 .762 2000 13.8 5.0 127 0.126 0.19 80C-T08N

Construction: Smooth bore black PTFE core tube with a type 304 stainless steel braided wire reinforcement.

Typical applications: Static-Dissipative PTFE black core tube. Transfer line for most chemicals, hot oils, fuel lines, coolant and steam transfer. Compressed

air and gases. Adhesive dispensing, paints and coating materials.

Temperature range: -100°F to +450°F (-73°C to +232°C)

VACUUM

RATING

INCHES/HG INCHES MM INCHES MM INCHES MM PSI MPA INCHES MM LBS/FT KG/M

HOSE I.D.

MAX.

HOSE O.D.

WALL

THICKNESS

MAXIMUM

WORKING

PRESSURE

MINIMUM

BEND

RADIUS

WEIGHT

CRIMP DIE

PART NO.

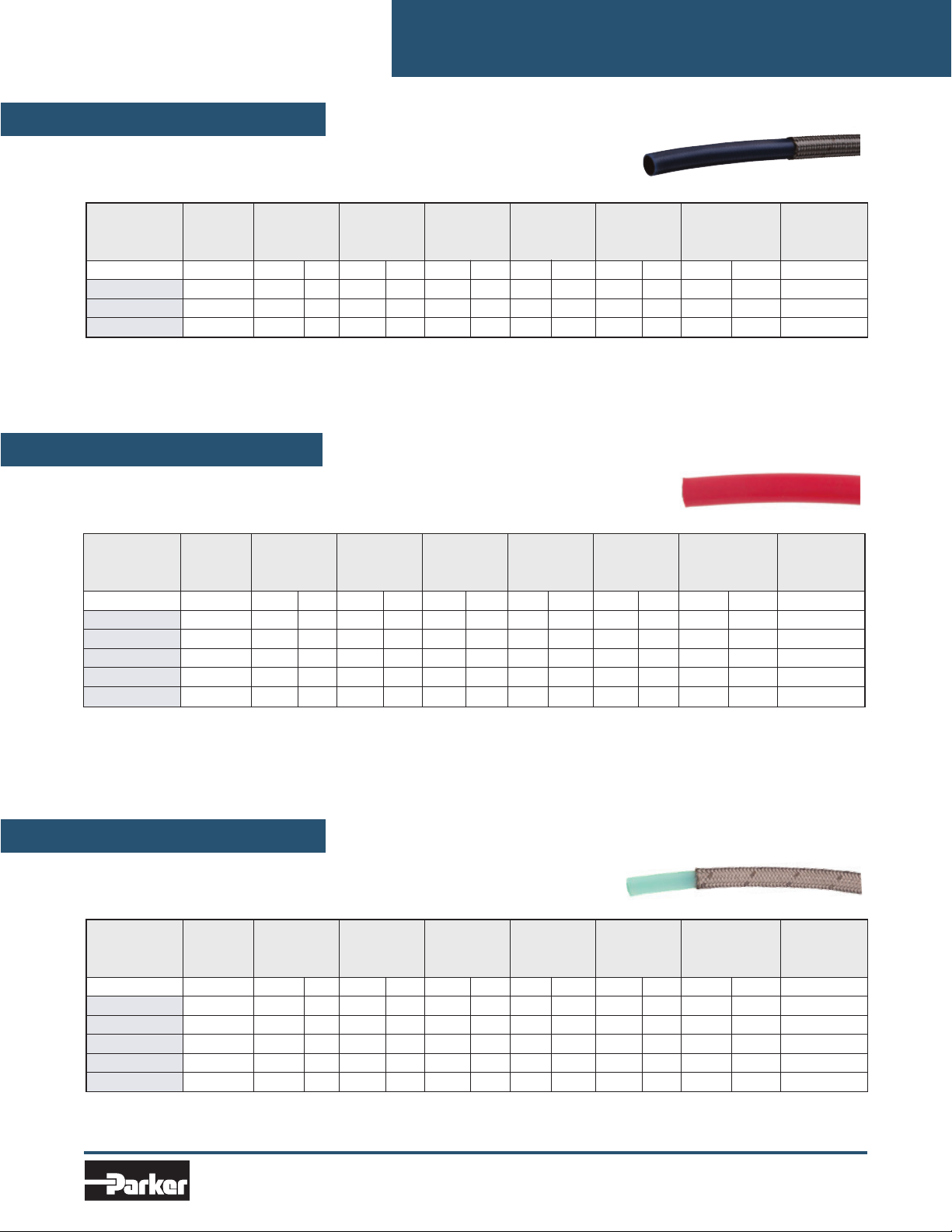

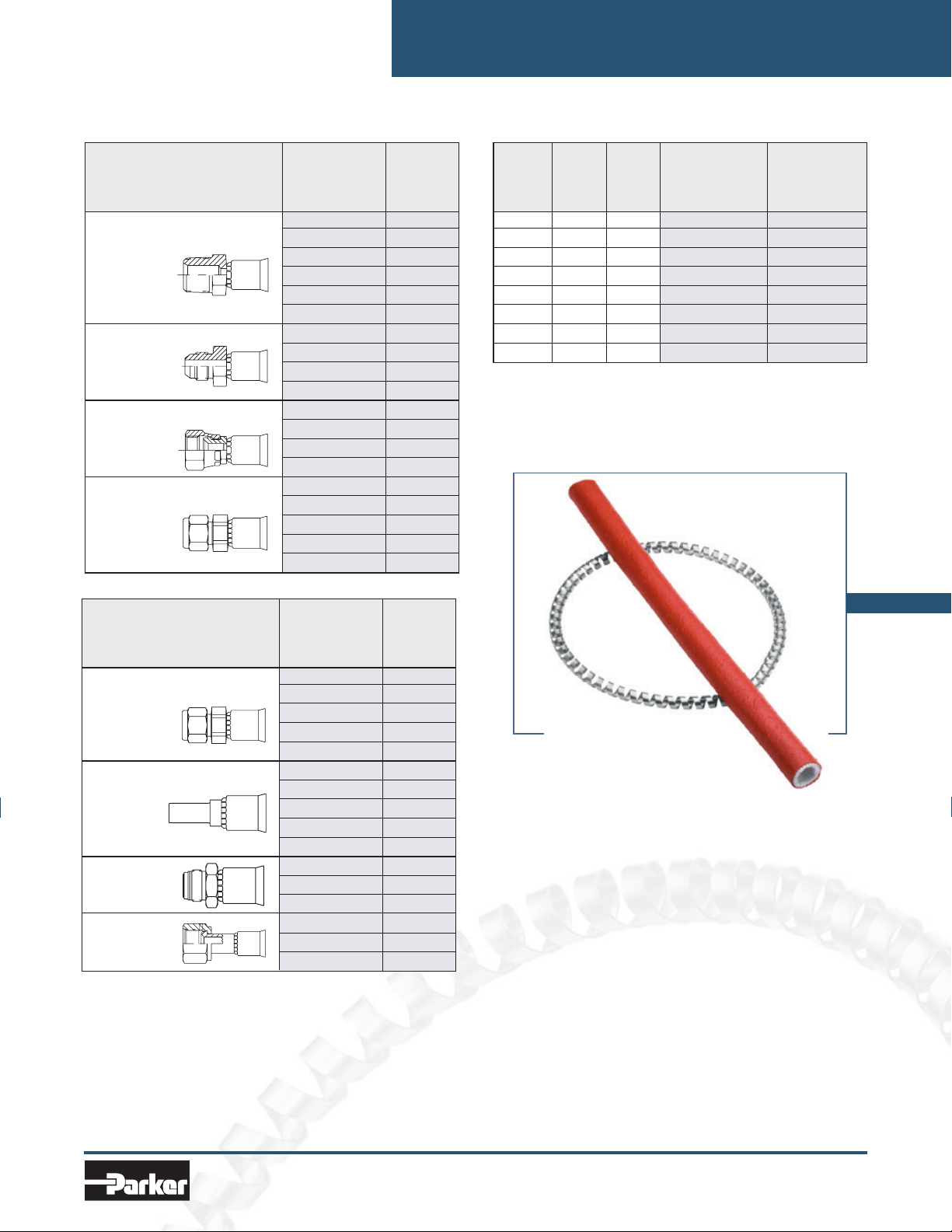

919J PTFE Hose Silicone Jacketed

PTFE Hose

HOSE

SERIES -

DASH SIZE

919J-4-Red 28 3/16 5 0.45 11 .030 .762 3000 20.7 2.0 51 0.124 0.19 80C-T04J

919J-6-Red 28 5/16 8 0.58 15 .030 .762 2500 17.2 4.0 102 0.165 0.25 80C-T06J

919J-8-Red 28 13/32 10.5 0.68 17 .030 .762 2000 13.8 5.0 127 0.202 0.3 80C-T08J

919J-10-Red 28 1/2 12.5 0.78 20 .030 .762 1500 10.3 6.5 165 0.236 0.35 80C-T10J

919J-12-Red 12 5/18 16 0.91 23 .030 .762 1200 8.3 7.5 191 0.291 0.43 80C-T12J

Construction: Smooth bore natural PTFE core tube with a type 304 stainless steel braided wire reinforcement and a red extruded silicone jacket.

Typical applications: Transfer lines for most chemicals, coolant lines, adhesive dispensing, compressed air and gases. Areas where a protective cover

is required to prevent contamination off of the braided hose. Areas where stainless wire needs protected from fraying. Silicone cover is red and rated for

temperatures 450¡F and is steam cleanable.

Temperature range: -100°F to +450°F (-73°C to +232°C)

VACUUM

RATING

INCHES/HG INCHES MM INCHES MM INCHES MM PSI MPA INCHES MM LBS/FT KG/M

HOSE I.D.

MAX.

HOSE O.D.

WALL

THICKNESS

MAXIMUM

WORKING

PRESSURE

MINIMUM

BEND

RADIUS

WEIGHT

CRIMP DIE

PART NO.

929 PTFE Hose Heavy Wall Low Permeation Hose

HOSE

SERIES -

DASH SIZE

929-4 28 3/16 5 5/16 8 .040 1.02 3000 20.7 2.0 51 0.06 0.09 80C-T04N

929-6 28 5/16 8 7/16 11 .040 1.02 2500 17.2 4.0 102 0.13 0.15 80C-T06N

929-8 28 13/32 10.5 9/16 14 .042 1.07 2000 13.8 5.0 127 0.126 0.19 80C-T08N

929-12 12 5/18 16 3/4 19 .048 1.22 1200 8.3 7.5 191 0.186 0.28 80C-T12N

929-16 14 7/8 22 1-1/8 26 .048 1.22 1250 6.9 9.0 229 0.268 0.4 80C-T16H

Construction: Smooth bore natural PTFE core tube with a type 304 stainless steel braided wire reinforcement.

Typical applications: Instrumentation lines, analyzer sampling lines and for areas that require tight routing.

Temperature range: -100°F to +450°F (-73°C to +232°C)

VACUUM

RATING

INCHES/HG INCHES MM INCHES MM INCHES MM PSI MPA INCHES MM LBS/FT KG/M

HOSE I.D.

MAX.

HOSE O.D.

WALL

THICKNESS

5

MAXIMUM

WORKING

PRESSURE

MINIMUM

BEND

RADIUS

WEIGHT

Parker Hannifin Corporation

Parflex Division

Ravenna, OH

CRIMP DIE

PART NO.

Page 6

PTFE HOSE

929B PTFE Hose Static Dissipative Heavy Wall

Low Permeation Hose

HOSE

SERIES -

DASH SIZE

929B-4 28 3/16 5 5/16 8 .040 1.02 3000 20.7 2.0 51 0.06 0.09 80C-T04N

929B-6 28 5/16 8 7/16 11 .040 1.02 2500 17.2 4.0 102 0.13 0.15 80C-T06N

929B-8 28 13/32 10.5 9/16 14 .042 1.07 2000 13.8 5.0 127 0.126 0.19 80C-T08N

929B-12 12 5/18 16 3/4 19 .048 1.22 1200 8.3 7.5 191 0.186 0.28 80C-T12N

929B-16 14 7/8 22 1-1/8 26 .048 1.22 1250 6.9 9.0 229 0.268 0.4 80C-T16N

Construction: Smooth bore black PTFE core tube with a type 304 stainless steel braided wire reinforcement.

Typical applications: Static-Dissipative PTFE black core tube. Transfer line for most chemicals, hot oils, fuel lines, coolant and steam transfer. Compressed

air and gases. Adhesive dispensing, paints and coating materials. Applications requiring enhanced permeation resistance.

Temperature range: -100°F to +450°F (-73°C to +232°C)

VACUUM

RATING

INCHES/HG INCHES MM INCHES MM INCHES MM PSI MPA INCHES MM LBS/FT KG/M

HOSE I.D.

MAX.

HOSE O.D.

WALL

THICKNESS

MAXIMUM

WORKING

PRESSURE

MINIMUM

BEND

RADIUS

WEIGHT

CRIMP DIE

PART NO.

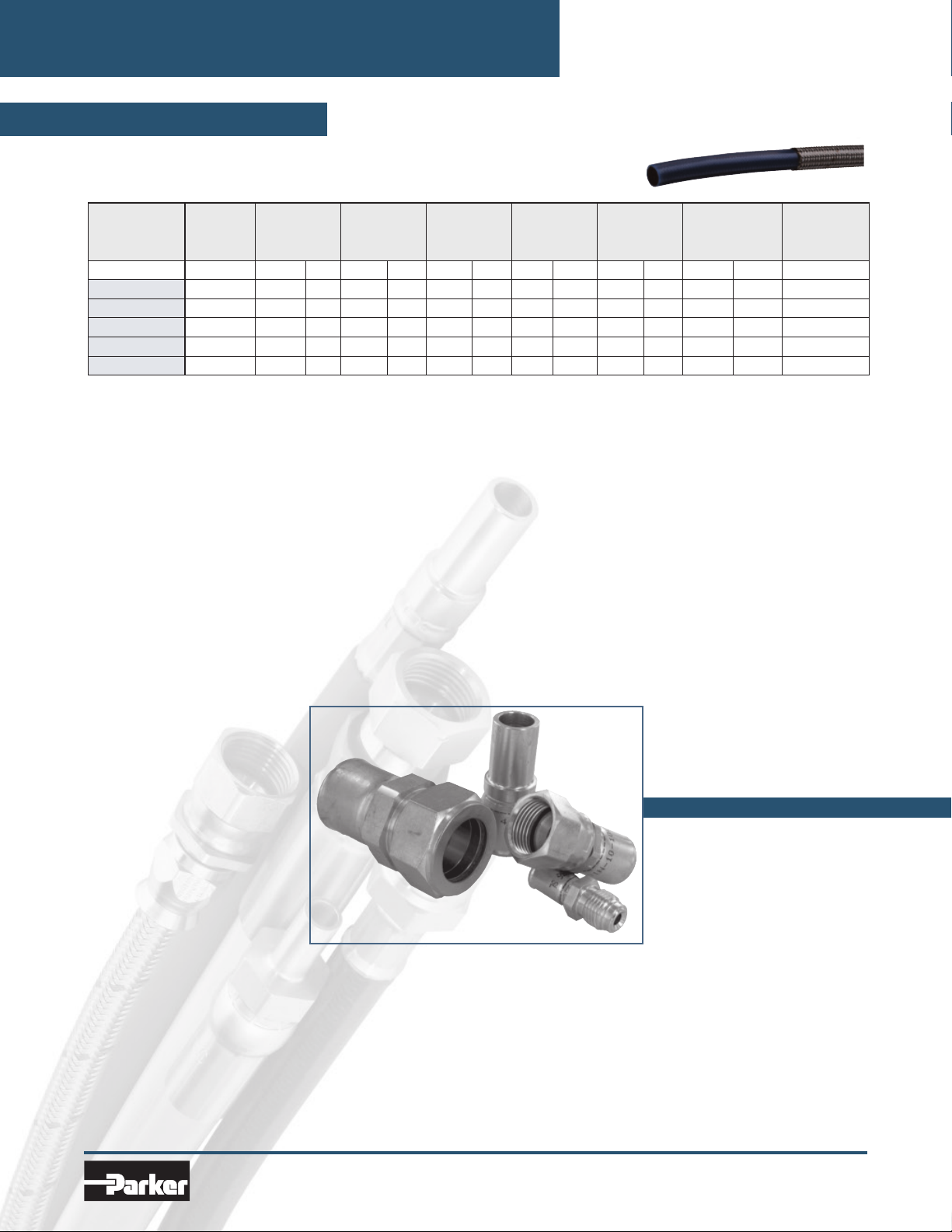

91N Series PTFE Fittings

6

Parker Hannifin Corporation

Parflex Division

Ravenna, OH

Page 7

PTFE HOSE

PTFE FITTINGS

END CONNECTION STYLE

(01) Male Taper Pipe Rigid

(03) Male (JIC) 37°

(06) Female (JIC) 37° Swivel

(AL) A-LOK® Compression

919/929 HOSE

STAINLESS

FITTING FITTING

DASH SIZE

NUMBER

10191N-4-4C -4

10191N-6-6C -6

10191N-8-8C -8

10191N-12-12C -12

10191N-16-16C -16

10191N-20-20C -20

10391N-4-4C -4

10391N-6-6C -6

10391N-8-8C -8

10391N-16-16C -16

10691N-4-4C -4

10691N-6-6C -6

10691N-16-16C -16

10691N-20-20C -20

1AL91N-4-4C -4

1AL91N-6-6C -6

1AL91N-8-8C -8

1AL91N-12-12C -12

1AL91N-16-16C -16

HOSE

PTFE ACCESSORIES

HOSE

919/929 -4 0.32 -

Other hose style accessories can be found by visiting www.Parker.com

DASH

SIZE

MAX.

O.D.

5 0.40 -

-6 0.46 - FS-F-8

8 0.56 2613-13CR FS-F-10

-10 0.66 2613-16CR FS-F-12

-12 0.79 2613-20CR FS-F-14

-16 1.05 2613-28CR FS-F-20

-20 1.32 2613-37CR FS-F-24

INTERNAL FLAT

SPRING

FIRE

SLEEVE

END CONNECTION STYLE

(P6) CPI™ Compression

(Nut & Ferrule)

(TU) Tube Stub

(HV) Male

VacuSeal

(VH) Female

VacuSeal

919/929 HOSE

STAINLESS

FITTING FITTING

DASH SIZE

NUMBER

1P691N-4-4C -4

1P691N-6-6C -6

1P691N-8-8C -8

1P691N-12-12C -12

1P691N-16-16C -16

1TU91N-4-4C -4

1TU91N-6-6C -6

1TU91N-8-8C -8

1TU91N-16-16C -16

1TU91N-20-20C -20

1HV91N-4-4C -4

1HV91N-6-6C -6

1HV91N-8-8C -8

1VH91N-4-4C -4

1VH91N-6-6C -6

1VH91N-8-8C -8

HOSE

Fire Sleeves & Flat Springs

7

Parker Hannifin Corporation

Parflex Division

Ravenna, OH

Page 8

THERMOPLASTIC HOSE

Introduction

Parflex reinforced thermoplastic hose has the industry’s highest level of abrasion resistance, outlasting rubber

hose in lab tests by as much as 10:1. Hoses are available in long lengths, reducing short hose lengths. Parflex

hoses are lighter in weight than comparably sized rubber hoses, in some cases up to 40% lighter. UV resistant

jacket, tight bend radius. Other benefits include:

BENEFITS:

• Long shelf life, thermoplastic hoses do not continuously cure.

• Easy to cut and couple.

• UV resistant

How to Order

520N TU AL 08 08 08 C - 36

• Low volumetric expansion, less energy loss and faster reaction times.

• Clean core tubes reduce the possible contamination of hydraulic systems

• Tight bend radius.

HOSE

STYLE

520N

540P

540N

518C

580N

How to order part derivation is applicabe to all hose assemblies in this catalog.

Ho

1ST END

CONNECTION

01 = Male NPT

03 = Male JIC 37°

06 = Female SAE (JIC) 37°

Swivel

AL = A-LOK

P6 = CPI

TU = Universal Tube Stub

™

Compression

(nut & ferrule)

2ND END

CONNECTION

®

Compression

1ST

CONNECTION

DASH SIZE

02=1/8"

04=1/4"

06=3/8"

08=1/2"

12=3/4"

16=1"

2ND

CONNECTION

DASH SIZE

HOSE I.D.

DASH SIZE

04=1/4"

06=3/8"

08=1/2"

12=3/4"

16=1"

FITTING

MATERIAL

C=Stainless

ASSEMBLY

LENGTH (INCHES)

Overall length is

expressed in

inches measured

from extreme end

to end. Except

elbow fittings

measured from

centerline or

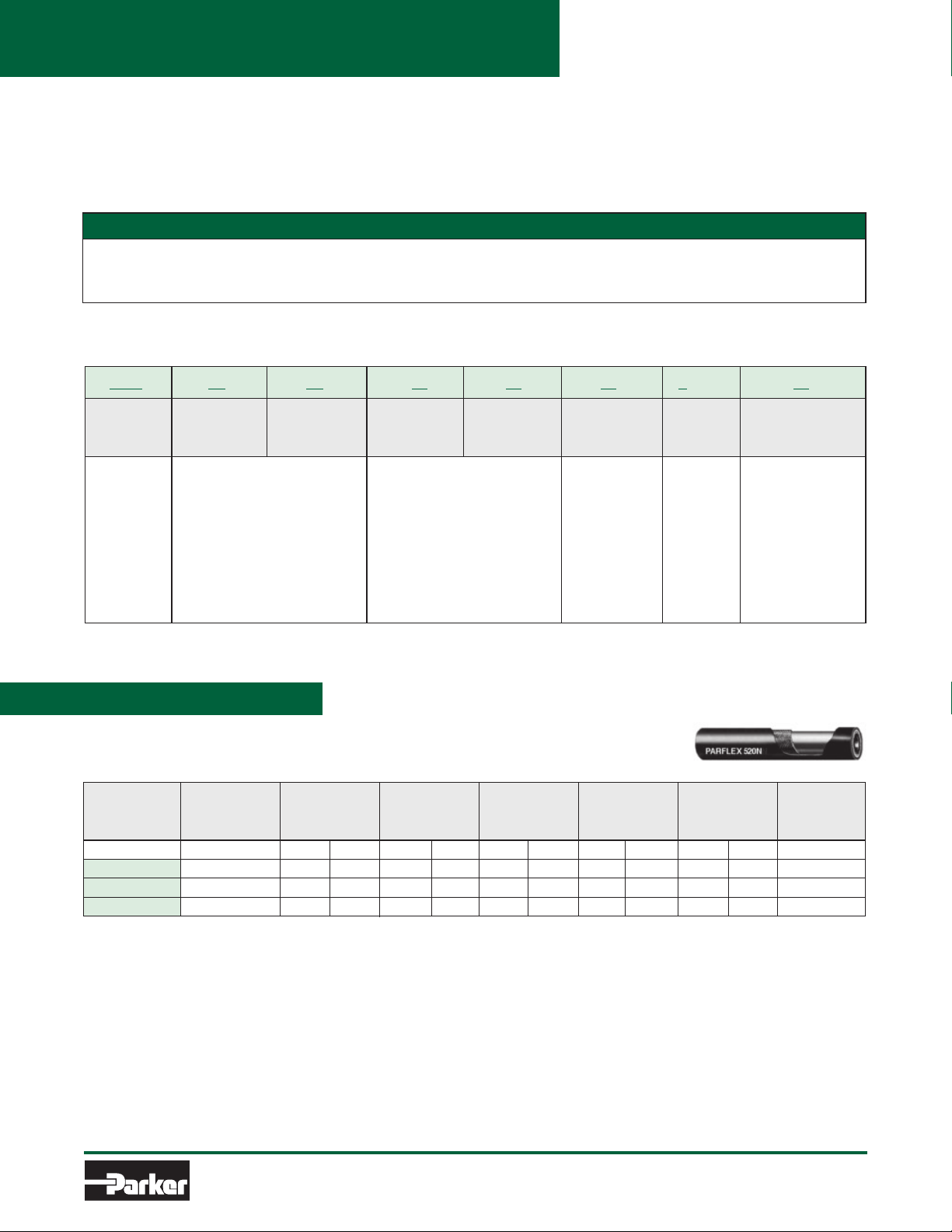

520N General Hydraulic Hose

HOSE

SERIES -

DASH SIZE

520N-4 28 1/4" 6 0.51 13 5000 34.5 2.0 51 0.06 0.09 80C-P04

520N-6 28 3/8" 10 0.65 16 4000 27.6 2.5 64 0.08 0.12 80C-P06

520N-8 28 1/2" 13 0.81 21 3500 24.1 4.0 102 0.13 0.19 80C-P08

Construction: Nylon Core Tube, Aramid Fiber Reinforcement, Black Perforated Urethane Jacket. Meets or exceeds SAE 100R8 performance.

Typical applications: Hydraulic and pneumatic circuits and systems. Ideal in hot water applications.

Temperature range: -40°F to +212°F (-40°C to +100°C)

Fittings: Use 55 series only.

VACUUM

RATING

INCHES/HG INCHES MM INCHES MM PSI MPA INCHES MM LBS/FT KG/M

HOSE I.D.

MAX.

HOSE O.D.

MAXIMUM

WORKING

PRESSURE

MINIMUM

BEND

RADIUS

WEIGHT

OVERALL

which are

the seat.

CRIMP DIE

PART NO.

For additional information about Parflex hose, including information about construction, typical applications and

installation, contact your authorized Parker Instrumentation Distributor.

8

Parker Hannifin Corporation

Parflex Division

Ravenna, OH

Page 9

PTFE 919 AND 929 HOSETHERMOPLASTIC HOSE

540P Specialty Water Hose

HOSE

SERIES -

DASH SIZE

540P-4 28 1/4" 6 0.50 13 2750 18.96 1-1/4 32 0.052 0.08 80C-P04

540P-6 28 3/8" 10 0.65 16 2250 15.51 2.0 51 0.086 0.13 80C-P06

540P-8 28 1/2" 13 0.81 21 2000 13.79 3.0 76 0.126 0.19 80C-P08

540P-12 28 3/4" 19 1.06 27 1250 8.62 6.0 152 0.17 0.25 80C-P12

Construction: Polyethylene Core Tube, Fiber Reinforcement, Aqua Perforated Urethane Jacket. Plasticizer free non-leaching core.

Typical applications: Potable water delivery to remote sites. Distilled and de-ionized water. Low moisture permeability.

Temperature range: -10°F to +150°F (-23°C to +66°C)

Fittings: Use 55 series only.

VACUUM

RATING

INCHES/HG INCHES MM INCHES MM PSI MPA INCHES MM LBS/FT KG/M

HOSE I.D.

MAX.

HOSE O.D.

MAXIMUM

WORKING

PRESSURE

MINIMUM

BEND

RADIUS

WEIGHT

CRIMP DIE

PART NO.

540N Medium Pressure Hose

HOSE

SERIES -

DASH SIZE

540N-4 28 1/4" 6 0.51 13 2750 18.96 1-1/2 38 0.057 0.09 80C-P04

540N-6 28 3/8" 10 0.65 16 2250 15.51 2.0 51 0.086 0.13 80C-P06

540N-8 28 1/2" 13 0.81 21 2000 13.79 3.0 76 0.126 0.19 80C-P08

Construction: Nylon Core Tube, Fiber Reinforcement, Black Core Hose with Urethane Jacket. Meets or exceeds SAE 100R7 performance.

Typical applications: Hydraulic and pneumatic circuits and systems, agriculture sprayers, urethane foam mixers, robotics, fire resistant fluid and hot water.

Temperature range: -40°F to +212°F (-40°C to +100°C)

Fittings: Use 55 series only.

VACUUM

RATING

INCHES/HG INCHES MM INCHES MM PSI MPA INCHES MM LBS/FT KG/M

HOSE I.D.

MAX.

HOSE O.D.

MAXIMUM

WORKING

PRESSURE

MINIMUM

BEND

RADIUS

WEIGHT

CRIMP DIE

PART NO.

518C Non-Conductive Hose

9

MAXIMUM

WORKING

PRESSURE

MINIMUM

BEND

RADIUS

WEIGHT

Parker Hannifin Corporation

Parflex Division

Ravenna, OH

CRIMP DIE

PART NO.

HOSE

SERIES -

DASH SIZE

518C-4 N/A 1/4" 6 0.47 12 2750 18.96 1-1/2 38 0.052 0.08 80C-P04J

518C-6 N/A 3/8" 10 0.63 16 2250 15.51 2.0 51 0.096 0.143 80C-P06

518C-8 N/A 1/2" 13 0.81 21 2250 15.51 3.0 76 0.148 0.221 80C-P08

Construction: Polyester Core Tube, Fiber Reinforcement, Orange Non-perforated Proprietary Jacket. Meets or exceeds SAE 100R7 performance.

Typical applications: Medium pressure hydraulic service where permanent hydraulic circuit exposure and contact with high voltage may be encountered.

Temperature range: -40°F to +212°F (-40°C to +100°C), limited to + 135F (57C) for synthetic hydraulic fluids and water-based fluids.

Fittings: Use 55 series only.

VACUUM

RATING

INCHES/HG INCHES MM INCHES MM PSI MPA INCHES MM LBS/FT KG/M

HOSE I.D.

MAX.

HOSE O.D.

Page 10

THERMOPLASTIC HOSES

580N High Pressure Hose

HOSE

SERIES -

DASH SIZE

580N-12 -40°F to +212°F 3/4" 19 1.16 30 2250 15.51 8.0 203 0.21 0.31 80C-P12H

580N-16 (-40°C to +100°C) 1" 25 1.48 37.6 2000 13.8 10.0 254 0.376 0.56 80C-P16H

Construction: Polymeric Core, Fiber Reinforcement, Black Perforated Urethane Jacket. Meets or exceeds SAE 100R8 performance.

Typical applications: Hydraulic and pneumatic circuits and systems. Replaces 100R2 rubber hose where greater flexibility, fluid compatibility and cover

durability is required. Lighter weight and smaller O.D. than 100R2 rubber hose.

Temperature range: -40°F to +212°F (-40°C to +100°C)

Fittings: Use 58 series only.

TEMPERATURE

HOSE I.D.

MAX.

HOSE O.D.

PERMANENT FITTINGS

END CONNECTION STYLE

(01) Male Taper Pipe Rigid

(03) Male (JIC) 37°

(06) Female (JIC) 37° Swivel

(AL) A-LOK® Compression

(P6) CPI™ Compression

(Nut & Ferrule)

THERMOPLASTIC

HOSE 55 SERIES

STAINLESS

FITTING

PART NUMBER

10155-4-4C -4

10155-6-6C -6

10155-6-6C -8

10155-12-12C -12

10355-4-4C -4

10355-6-6C -6

10355-8-8C -8

10355-12-12C -10

10655-4-4C -4

10655-6-6C -6

10655-8-8C -8

10655-12-12C -12

1AL55-4-4C -4

1AL55-6-6C -6

1AL55-8-8C -8

1P655-4-4C -4

1P655-6-6C -6

1P655-8-8C -8

HOSE

DASH

SIZE

MAXIMUM

WORKING

PRESSURE

MINIMUM

BEND

RADIUS

WEIGHT

CRIMP DIE

PART NO.

THERMOPLASTIC ACCESSORIES

HOSE STYLE

520N/540P/549/518C 55AG-4 55AG-6 55AG-8

580N 58AG-12 58AG-16

520N/540P/549/518C PV139-1 PV1611-1 PV2014-1

580N PV2420-1 PV3224-1

(AG) ARMOR GUARDS & (SP) SPRING

GUARDS - PART NUMBER PER HOSE

DASH SIZE

55SG-4 55SG-6 55SG-8

58SG-12 58SG-16

PVC GUARDS - PART NUMBER PER HOSE

DASH SIZE

-4 -6 -8

-12 16

(TU) Tube Stub

(TU) Tube Stub

1TU55-4-4C -4

1TU55-6-6C -6

1TU55-8-8C -8

58 Series

1TU58-12-12 -12

1TU58-16-16 -16

10

Parker Hannifin Corporation

Parflex Division

Ravenna, OH

Page 11

PTFE 919 AND 929 HOSECRIMPING EQUIPMENT

MINIKRIMP EQUIPMENT

DESCRIPTIONPART NUMBER

94C-080-PFD Minikrimp Base Unit

94C-001-PFD Minikrimp w/handpump

94C-002-PFD Minikrimp w/air/hydraulic

O15301 Handpump kit

O25411 Air/hydraulic kit

O15307 Upright Vice Mount

O15306 Upright Bench Mount

O15736 Side Vice Mount

94C-MKS MiniKrimp Stand

MiniKrimp Stand

MINIKRIMP SPECIFICATION

Approximate Size (with Pump) 7" wide, 5" deep, 15.5" high

Weight (w/o Die Set) 42 lbs. with hand pump

Rating 30 tons force @ 10,000 psi

maximum

Capability - 1" SAE 100R1 maximum

(steel & brass) - 1" SAE 100R2 maximum

91N series fittings - 1" SAE 100R16 maximum

Capability - 3/4" SAE 100R1 maximum

(stainless steel) - 3/4" SAE 100R2 maximum

91N series fittings - 3/4" SAE 100R16 maximum

Set Up Time 20 seconds

Full Cycle Time Approx. 20 seconds to 3

minutes.

Note: Cycle times vary

depending on hose, fitting,

operator, and crimping

environment.

Side Vice Mount

MiniKrimp with Handpump

and Stand

11

Upright Bench

Mount

Upright Vice

Mount

Handpump

Parker Hannifin Corporation

Parflex Division

Ravenna, OH

Page 12

THERMOPLASTIC TUBING

DESIGN FEATURES / STANDARDS

Polyethylene Tubing

• FDA, NSF Standard 51 and NSF Standard 61

compliant materials available.

• Meets ASTM D-1693

• Natural “E” Series is made of 100% virgin resin

material.

• Available in HD – High Density and FRPE – Flame

retardant plenum

Polypropylene

• Polypropylene tubing meets FDA, NSF Standard

51 for all food contact applications

• Polypropylene tubing exhibits excellent chemical

resistance to chlorinated water applications

• Polypropylene tubing is commonly used in outdoor

applications where UV light stabilization is required

Polyvinyl Chloride (PVC)

• PVC tubing is made from 100% virgin resin

material and meets all FDA specifications for

materials in contact with food and drugs

• PVC tubing is very flexible (70 Durometer) tubing

that is crystal clear and is Ideal for situations

where visible fluid flow is necessary (i.e. sight

gages for tank identification)

Nylon Tubing

• Flexible Nylon tubing use high grade resins for

strength and flexibility for routing in tight spaces

• Semi rigid high strength Nylon use high grade

resins without the addition of plasticizers for higher

pressure tubing applications

• Pure Air Tubing (PAT) is the tubing choice for pure

air systems (Semiconductor) due to its cleanliness

in addition to excellent chemical and UV light

resistance

Polyurethane

• Polyurethane tubing is a flexible, kink resistant and

abrasion resistant material commonly used in

pneumatic applications

• Polyurethane is available in multiple transparent

and opaque colors for system color coding

• Polyurethane is available in the following

durometers (measurement of material hardness):

• Low Durometer (85-most flexible, very soft)

• Medium Durometer (90-less flexible)

• High Durometer (>95-least flexible, highest

pressures)

THERMOPLASTIC TUBING SELECTION GUIDE

TEMPERATURE RATING

-80°F to 150°F

[-62°C to 66°C]

-40°F to 150°F

[-18°C to 65°C]

-80°F to 175°F

[-62°C to 79°C]

-40°F to 180°F

[-40°C to 82°C]

-65°F to 200°F

[-54°C to 93°C]

-40°F to 200°F

[-40°C to 93°C]

-60°F to 200°F

[-51°C to 93°C]

0

°F to 200°F

[-18°C to 93°C]

MATERIAL PRODUCT FAMILY SUGGESTED MARKETS AND APPLICATIONS

Potable water, chemical transfer, and low cost, low pressure

pneumatics, NSF-51 & 61

Pneumatic controls in HVAC/plenum space (UL 1820),

Dubl-Barb fitting from Parker Brass

Low pressure chemical requiring high clarity and flexibility

FDA 21CFR compliant.

Pneumatic controls requiring high flexibility, kink resistance

and movement

High pressure pneumatics requiring flexibility and kink

resistance, Robotics

Low pressure pneumatics requiring extreme flexibility and

kink resistance, pneumatic logic boards

Pneumatic and petroleum-based chemical transfer

High pressure pneumatic, lubrication, and Marine control

systems

Food contact and chemical transfer applications, chlorinated

water, NSF-51

Polyethylene

FRPE (Flame Resistant)

Clear Vinyl PV

Polyethylene

HDPE (High Density) Chemical transfer and low cost pneumatics

Urethane

Nylon

Polypropylene

E

PE Economical, low pressure pneumatics, NSF-51

U

HU

LU

N

PAT Pure air and gas distribution systems, Semiconductor

NR

PP

12

Parker Hannifin Corporation

Parflex Division

Ravenna, OH

Page 13

PLASTIC TUBING

THERMOPLASTIC TUBING

MATERIAL O.D. INCHES I.D. INCHES

Polyethylene

High Density HDPE 1/4" 0.170 0.040 1.10 300 250' HDPE-43-0250

Polyethylene 3/8" 0.251 0.062 2.50 300 250' HDPE-64-0250

Nylon

Polypropylene

Urethane

PRODUCT

FAMILY

E

PE

FRPE

N

PAT

NR

PP

U

HU

LU

1/4" 0.170 0.040 1.10 120 500' EB-43-0500

3/8" 0.251 0.062 2.50 125 500' EB-64-0500

1/2" 0.375 0.062 3.60 90 500' EB-86-0500

1/4" 0.170 0.040 1.10 100 1000' PE-4-040-BK-1000

3/8" 0.251 0.062 2.50 87 500' PE-6-062-BK-0500

1/2" 0.375 0.062 3.40 62 250' PE-8-062-BK-0250

1/4" 0.170 0.040 1.17 160 250' 1FRPE4-0250

3/8" 0.251 0.062 2.71 195 250' 1FRPE6-0250

1/2" 0.375 0.062 3.80 135 250' 1FRPE8-0250

1/4" 0.180 0.035 1.10 250 250' NB-4-035

3/8" 0.275 0.050 2.34 250 250' NB-6-050

1/2" 0.375 0.062 3.94 250 250' NB-8-062

1/4" 0.170 0.040 1.24 300 250' PAT4-BLK-250

3/8" 0.251 0.062 2.82 350 250' PAT6-BLK-250

1/2" 0.375 0.062 3.95 235 500' PAT8-BLK-500

1/4" 0.18 0.035 1.1 425 250' NBR-4-035

3/8" 0.279 0.048 2.2 425 250' NBR-6-048

1/2" 0.375 0.062 3.8 375 250' NBR-8-062

1/4" 0.17 0.040 1.01 300 500' PP-43-0500

3/8" 0.25 0.062 2.35 300 500' PP-64-0500

1/2" 0.375 0.062 3.28 225 250' PP-86-0250

1/4" 0.2 0.062 1.8 125 250' U-42-BLK-0250

3/8" 0.25 0.062 3 125 250' U-64-BLK-0250

1/2" 0.375 0.062 4.2 85 250' U-86-BLK-0250

1/4" 0.16 0.045 1.55 180 500' HU-4-BLK-0500

3/8" 0.25 0.062 3.27 180 500' HU-6-BLK-0500

1/2" 0.32 0.09 6.18 180 250' HU-8-BLK-0250

1/8" 0.062 0.031 0.44 145 100' LU-2-BLK-0100

1/4" 0.125 0.062 1.78 145 100' LU-4-BLK-0100

5/16" 0.187 0.062 2.38 100 100' LU-5-BLK-0100

WALL

INCHES

NET WEIGHT

PER 100FT

(IBS)

WORKING

PRESSURE

@ 73°F (PSI)

BOX

LENGTH

PART NUMBER

(ALL P/N’S REF.

BLACK TUBING)*

PLASTIC TUBING

MATERIAL O.D. INCHES I.D. INCHES

Clear Vinyl PV

PRODUCT

FAMILY

1/8" 0.062 0.031 0.48 35 100' PV21-1

1/6" 0.125 0.025 0.58 35 100' PV32-1

1/4" 0.125 0.062 2.52 65 100' PV42-1

3/8" 0.25 0.062 3.15 55 100' PV64-1

1/2" 0.375 0.062 4.41 45 100' PV86-1

5/8" 0.5 0.062 5.66 30 100' PV108-1

11/16" 0.5 0.094 8.94 40 100' PV118-1

3/4" 0.5 0.125 12.59 45 100' PV128-1

1" 0.75 0.125 17.62 35 100' PV1612-1

1-1/4" 0.75 0.25 40.28 55 50' PV2012-1

2-1/2" 2" 0.25 90.63 35 50' PV4032-1

WALL

INCHES

NET WEIGHT

PER 100FT

13

(IBS)

WORKING

PRESSURE

@ 73°F (PSI)

BOX

LENGTH

Parker Hannifin Corporation

Parflex Division

Ravenna, OH

PART NUMBER

CLEAR VINYL

Page 14

THERMOPLASTIC FITTINGS

TRUESEAL™ THERMOPLASTIC

PUSH-IN FITTINGS

The patented* TrueSeal™ push-to-connect thermoplastic fittings are lightweight, field attachable, and connect

to plastic tubing without the use of tools.

Features

• All components in TrueSeal™ fittings are

manufactured from FDA compliant materials

and are NSF-51 listed for contact with food.

• Gray acetal TrueSeal™ fittings meet NSF-61

requirements for drinking water (potable water)

system components.

• All-plastic body designs offer reduced weight,

eliminate rust, corrosion, and system

contamination in applications where metal

components cannot be tolerated.

• Collets are offered in either a patented all-plastic

design for use with flexible tubing or with a metal

grip edge made from 300 series stainless steel for

use on all tubing including copper.

• Extra deep tube seat in fitting body provides

support to reduce side-load leakage.

• Elastomer o-ring seal provides positive

compression on tubing O.D. in vacuum or

pressure applications.

• Removable collet design permits o-ring

replacement in the field. Collets are available in

colors for easy color-coding of systems.

• Tube stem adapters provide a wide range of tube-

to-port jump size potential and allow elbows and

tees to swivel for positive tube routing alignment.

Connections made with metal gripper collets may

require tube stems to be replaced upon

reconnection.

• Actual-working pressures will be lower at elevated

temperatures. Consult division.

• Meets pressure integrity tests of NSF-53 and

NSF-58

Assembly Instructions

Tube Sizes O.D. Tolerance Insertion Depth

O.D. TOLERANCE

5/32" +/-.005 9/16"

1/4" +/-.005 11/16"

5/16" +/-.005 13/16"

3/8" +/-.005 3/4"

1/2" +/-.005 7/8"

1. Cut tubing square and clean. (Use a Parker

plastic tube cutter, Part No. PTC.)

2. Mark from end of tube the length of insertion

(see table above).

3. Push tube into the fitting until it bottoms out.

4. To remove, depress collet and pull tubing out.

5. Use Parker TrueSealant™ (Part No. PTS) on

threads.

INSERTION DEPTHTUBE SIZE O.D.

Working Pressure

TrueSeal™ fittings are rated for the pressures listed

below or at 1/4 (one-fourth) of the rated burst pressure

of the tubing

FITTING SIZE

1/4" 300 150 300

5/16" 300

3/8" 300 150 300

1/2" 250 150

Temperature -20°F (-29°C) to 0°F (-18°C) to 0°F (-18°C) to

Range +180°F (85°C) +225°F (110°C) +275°F (135°C)

ACETAL

(PSI)

POLYPROPYLENE

(PSI)

KYNAR

(PSI)

®

These pressure ratings are based on tests conducted

with Series NR tubing at 73˚F.

These products are available from Brass Products Division

14

Parker Hannifin Corporation

Brass Products Division

Otsego, MI

Page 15

TRUESEAL™ FITTINGS

THERMOPLASTIC FITTINGS

TRUESEAL™ FITTINGS

(MC) Male Connector A4MC2-MG PP4MC2 F4MC2 1/4" 1/8"

(EU) Elbow Union A4EU4-MG PP4EU4 F4EU4 1/4" N/A

(MES) Male Elbow Swivel A4MES2-MG PP4MES2 F4MES2 1/4" 1/8"

(UC) Union Connector A4UC4-MG PP4UC4 F4UC4 1/4" N/A

GRAY ACETAL

(EPDM SEAL)

A4MC4-MG PP4MC4 F4MC4 1/4" 1/4"

A4MC6-MG PP4MC6 F4MC6 1/4" 3/8"

A6MC4-MG PP6MC4 F6MC4 3/8" 1/4"

A6MC6-MG PP6MC6 F6MC6 3/8" 3/8"

A8MC8-MG PP8MC8 N/A 1/2" 1/2"

A6EU4-MG PP6EU4 F6EU4 3/8" N/A

A6EU6-MG PP6EU6 F6EU6 3/8" N/A

A8EU8-MG PP8EU8 N/A 1/2" N/A

A4MES4-MG PP4MES4 F4MES4 1/4" 1/4"

A4MES6-MG PP4MES6 M4MES6 1/4" 3/8"

A6MES4-MG PP6MES4 F6MES4 3/8" 1/4"

A6MES6-MG PP6MES6 F6MES6 3/8" 3/8"

A8MES6-MG PP8MES6 N/A 1/2" 3/8"

A8MES8-MG PP8MES8 N/A 1/2" 1/2"

A6UC4-MG PP6UC4 F6UC4 3/8"-1/4" N/A

A6UC6-MG PP6UC6 F6UC6 3/8" N/A

A8UC6-MG PP8UC6 N/A 1/2"-3/8" N/A

A8UC8-MG PP8UC8 N/A 1/2" N/A

WHITE

POLYPROPYLENE

(EPDM SEAL)

NATURAL

KYNAR

VITON SEAL

NOMINAL

TUBE O.D.

(INCHES)

NPTF

THREAD SIZE

(INCHES)

TRUESEAL™ FITTINGS

(TMC) Tube Stem Adapter A4TMC2-MG PP4TMC2 F4TMC2 1/4" 1/8"

Tube Stem to Pipe A4TMC4-MG PP4TMC4 F4TMC4 1/4" 1/4"

(BU) Bulkhead Union A4BU4-MG PP4BU4 F4BU4 1/4" N/A

Tube-to-Tube A6BU4-MG PP6BU4 N/A 3/8"-1/4" N/A

(TEU) Tube Elbow Union TUBE O.D. STEM O.D.

Tube to Tube Stem A4TEU4-MG PP4TEU4 F4TEU4 1/4"-1/4" N/A

(ME) Male Elbow (Tube-to-Pipe) A4ME2-MG PP4ME2 F4ME2 1/4" 1/8"

(TPL) Plug FITTING SIZE

GRAY ACETAL

(EPDM SEAL)

A6TMC4-MG PP6TMC4 F6TMC4 3/8" 1/4"

A6TMC6-MG PP6TMC6 F6TMC6 3/8" 3/8"

A8TMC6-MG PP8TMC6 N/A 1/2" 3/8"

A8TMC8-MG PP8TMC8 N/A 1/2" 1/2"

A6BU6-MG PP6BU6 F6BU6 3/8" N/A

A8BU8-MG N/A N/A 1/2" N/A

A6TEU6-MG PP6TEU6 F6TEU6 3/8"-3/8" N/A

A8TEU8-MG PP8TEU8 N/A 1/2"-1/2" N/A

A4ME4-MG PP4ME4 F4ME4 1/4" 1/4"

A4ME6-MG PP4ME6 F4ME6 1/4" 3/8"

A6ME4-MG PP6ME4 F6ME4 3/8" 1/4"

A6ME6-MG PP6ME6 F6ME6 3/8" 3/8"

A4TPL PP4TPL F4TPL 1/4"

A6TPL PP6TPL F6TPL 3/8"

A8TPL PP8TPL N/A 1/2"

WHITE

POLYPROPYLENE

(EPDM SEAL)

NATURAL

KYNAR

VITON SEAL

NOMINAL

TUBE O.D.

(INCHES)

NPTF

THREAD SIZE

(INCHES)

These products are available from Brass Products Division

15

Parker Hannifin Corporation

Brass Products Division

Otsego, MI

Page 16

THERMOPLASTIC FITTINGS

FAST & TITE

®

THERMOPLASTIC FITTINGS

Fast & Tite® fittings are the most complete line of

plastic fittings for thermoplastic tubing in the industry.

Fast & Tite® thermoplastic tube fittings from Parker will

prove to be the answer to your tubing connector

needs. Patented Fast & Tite® fittings install in seconds

without tools and provide a tight, sure, leak proof seal

without clamps or adjustments. A unique 302 stainless

steel grab ring for tube retention, coupled with a Nitrile

O-Ring for positive seal, assures good tube connection with only hand tight assembly. A plastic grab ring

is also available upon special request. Vibration or

tube movement will not break the seal and cause

leakage.

Preassembled in either highly inert polypropylene, or

strong, durable nylon, Fast & Tite® fittings are the

answer to full flow thermoplastic tubing system

requirements.

When necessary, Fast & Tite® fittings can be disassembled by hand for fast system drainage. Fittings are

completely Field Attachable. Parts are easily replaced.

O-Rings are standard size and universally available.

(For applications requiring other than Nitrile O-Rings,

consult your Fast & Tite® distributor.)

Use Fast & Tite® fittings with Parker Parflex tubing or

other plastic, glass or metal tubing for low pressure or

vacuum lines up to the pressure limits shown below.

When using clear vinyl tubing or urethane tubing, it is

necessary to use a TS tube support. A tube support

can be used with any tubing for maximum holding

power where tensiling, vibration or pressure spikes

may occur.

Fast & Tite® fittings meet FDA and NSF-51 requirements for food contact.

Working Pressures

Air-Oil-Water Pressure in PSI

TUBE O.D.

1/4" 300 300 300

5/16" 300 300 300

3/8" 250 250 150

1/2" 200 200 150

5/8" 150 100 50

UP TO 75°F

76°F TO

125°F

126°F TO

175°F

Ratings are based on use with copper tubing, and in

all cases represent the maximum recommended

working pressure of the fitting only. Working pressures

(vs. temperatures) of other types of tubing may limit

the tube and fitting assembly to pressures lower than

shown above. Consult factory for recommendations

on applications other than shown above.

Temperature Range:

Black/White Polypropylene:

0˚F (-18˚C) to +212˚F (+100˚C)

White Nylon: -40˚F (-40˚C) to +200˚F (+93˚C)

Fast Assembly

Step 1. Cut the tube squarely and remove any burrs.

Step 2. Mark from end of tube the length of insertion.

If using a tube support, insert fully into tube

and then mark from end of tube support length

of insertion. (See table below)

TUBE O.D.

1/4" 5/8" 9/16"

5/16" 5/8" 9/16"

3/8" 13/16" 3/4"

1/2" 7/8" 13/16"

5/8" 1" 15/16"

INSERT LENGTH

WITH TUBE

SUPPORT

Step 3.

Loosen nut on fitting until three threads are visible.

Fittings for glass tubes must be disassembled and the

grab ring removed. If the fitting has been disassembled the components are to be placed in the

following order: Fitting body, o-ring, spacer, grab ring

and nut. Assemble the nut until three threads are

showing on the body before inserting tube.

Step 4.

Moisten end of the tube with water. Push the tube

Straight into fitting until it bottoms on the fitting’s

shoulder. Tighten nut by hand. Additional tightening

should not be necessary, but 1/4 additional turn may

be added if desired. Do not over tighten nut as the

threads will strip and the fitting will not function properly. A proper assembly will not show the insertion

mark extending beyond the nut. If the insertion mark

is visible, then steps 1 thru 4 must be repeated.

INSERT LENGTH

WITHOUT TUBE

SUPPORT

These products are available from Brass Products Division

16

Parker Hannifin Corporation

Brass Products Division

Otsego, MI

Page 17

FAST AND TITE FITTINGS

THERMOPLASTIC FITTINGS

FAST AND TITE FITTINGS

(MC) Male Connector W4MC2 P4MC2 N4MC2 1/4" 1/8"

Tube to Male Pipe W4MC4 P4MC4 N4MC4 1/4" 1/4"

(EU) Elbow Union W4EU4 P4EU4 N4EU4 1/4" N/A

Tube to Tube W6EU4 P6EU4 N6EU4 3/8"-1/4" N/A

(ME) Male Elbow W4ME2 P4ME2 N4ME2 1/4" 1/8"

Tube to Male Pipe W4ME4 P4ME4 N4ME4 1/4" 1/4"

(BU) Bulkhead Union W4BU4 P4BU4 N4BU4 1/4" N/A

Tube-to-Tube W6BU6 P6BU6 N6BU6 3/8" N/A

(UC) Union Connector W4UC4 P4UC4 N4UC4 1/4" N/A

Tube to Tube W6UC4 P6UC4 N6UC4 3/8"-1/4" N/A

WHITE

POLYPROPYLENE

W6MC4 P6MC4 N6MC4 3/8" 1/4"

W6MC6 P6MC6 N6MC6 3/8" 3/8"

W8MC6 P8MC6 N8MC6 1/2" 3/8"

W8MC8 P8MC8 N8MC8 1/2" 1/2"

W6EU6 P6EU6 N6EU6 3/8" N/A

W8EU6 P8EU6 N8EU6 1/2"-3/8" N/A

W4ME6 P4ME6 N4ME6 1/4" 3/8"

W6ME4 P6ME4 N6ME4 3/8" 1/4"

W6ME6 P6ME6 N6ME6 3/8" 3/8"

W6ME8 P6ME8 N6ME8 3/8" 1/2"

W8ME6 P8ME6 N8ME6 1/2" 3/8"

W8ME8 P8ME8 N8ME8 1/2" 1/2"

W8BU8 P8BU8 N8BU8 1/2" N/A

W6UC6 P6UC6 N6UC6 3/8" N/A

W8UC6 P8UC6 N8UC6 1/2"-3/8" N/A

W8UC8 P8UC8 N8UC8 1/2" N/A

BLACK

POLYPROPYLENE

WHITE

NYLON

NOMINAL

TUBE O.D.

(INCHES)

NPTF

THREAD SIZE

(INCHES)

FAST AND TITE FITTINGS

(FE) Female Elbow W4FE2 P4FE2 N4FE2 1/4" 1/8"

Tube to Female Pipe W4FE4 P4FE4 N4FE4 1/4" 1/4"

(FC) Female Connector W4FC2 P4FC2 N4FC2 1/4" 1/8"

Tube to Female Pipe W4FC4 P4FC4 N4FC4 1/4" 1/4"

(TU) Tee Union W4TU4 P4TU4 N4TU4 1/4" N/A

Tube to Tube W6TU6 P6TU6 N6TU6 3/8" N/A

WHITE

POLYPROPYLENE

W6FE4 P6FE4 N6FE4 3/8" 1/4"

W6FE6 P6FE6 N6FE6 3/8" 3/8"

W8FE8 P8FE8 N8FE8 1/2" 1/2"

W6FC4 P6FC4 N6FC4 3/8" 1/4"

W6FC6 P6FC6 N6FC6 3/8" 3/8"

W8FC6 P8FC6 N8FC6 1/2" 3/8"

W8FC8 P8FC8 N8FC8 1/2" 1/2"

W8TU8 P8TU8 N8TU8 1/2" N/A

BLACK

POLYPROPYLENE

WHITE

NYLON

NOMINAL

TUBE O.D.

(INCHES)

THREAD SIZE

These products are available from Brass Products Division

17

Parker Hannifin Corporation

Brass Products Division

Otsego, MI

NPTF

(INCHES)

Page 18

THERMOPLASTIC FITTINGS

Par-Barb Thermoplastic Fittings

Par-Barb fittings are precision injection molded

from high strength, chemically inert, thermoplastic

materials.

The specially engineered four-barb design generates

the maximum gripping and sealing power when

combined with a hose clamp. The unique barb design

requires the tube or hose to expand slightly to accept

the fitting, providing a positive seal on the barbs.

Par-Barb fittings are widely used with Parflex clear

vinyl tubing, urethane tubing and a variety of rubber

tubing and hose.

Par-Barb fittings meet FDA and NSF-51 specifications

for food contact.

Par-Barb is recommended in medical, pollution control,

food and beverage applications. Other uses include

irrigation, instrumentation, reverse osmosis and

deionized water systems.

Temperature range:

Black Polyethylene: -65˚F (-54˚C) to +190˚F (+88˚C.)

White Nylon: -40˚F (-40˚C) to +200˚F (+93˚C.)

Working Pressures:

Par-Barb fittings are generally used in systems where

pressures do not exceed 125 PSI. When used in

excess of 125 PSI, the customer in his particular

application should test Par-Barb fittings, in all sizes.

Ambient and fluid temperatures, type of fluid conveyed, hose or tubing used, clamping mechanism

employed and conditions of mechanical abuse, govern

operating pressures of Par-Barb fittings.

These products are available from Brass Products Division

18

Parker Hannifin Corporation

Brass Products Division

Otsego, MI

Page 19

PAR-BARB FITTINGS

THERMOPLASTIC FITTINGS

BLACK HIGH

PAR-BARB FITTINGS

DENSITY LINEAR

POLETHYLENE

(EUB) Elbow Union P4EUB4 N4EUB4 1/4" N/A

P6EUB6 N6EUB6 1/4" N/A

P8EUB6 N8EUB6 1/2"-3/8" N/A

P8EUB8 N8EUB8 1/2" N/A

(MTB) Tee Male Branch P4MTB2 N4MTB2 1/4" 1/8"

P4MTB4 N4MTB4 1/4" 1/4"

P4MTB6 N4MTB6 1/4" 3/8"

P6MTB4 N6MTB4 3/8" 1/4"

P6MTB6 N6MTB6 3/8" 3/8"

P6MTB8 N6MTB8 3/8" 1/2"

P8MTB6 N8MTB6 1/2" 3/8"

P8MTB8 N8MTB8 1/2" 1/2"

(HPL) Hex Head Pipe Plug P2HPL N2HNL N/A 1/8"

P4HPL N4HNL N/A 1/4"

P6HPL N6HNL N/A 3/8"

P8HPL N8HNL N/A 1/2"

(TUB) Tee Union TEE I.D. STEM I.D.

P2TUB2 N2TUB2 1/8" 1/8"

P4TUB4 N4TUB4 1/4" 1/4"

P6TUB4 N6TUB4 3/8" 1/4"

P6TUB6 N6TUB6 3/8" 3/8"

P6TUB8 N6TUB8 3/8" 1/2"

P8TUB6 N8TUB6 1/2" 3/8"

P8TUB8 N8TUB8 1/2" 1/2"

(MEB) Male Elbow Connector P4MEB2 N4MEB2 1/4" 1/8"

P4MEB4 N4MEB4 1/4" 1/4"

P4MEB6 N4MEB6 1/4" 3/8"

P6MEB4 N6MEB4 3/8" 1/4"

P6MEB8 N6MEB8 3/8" 1/2"

P8MEB4 N8MEB4 1/2" 1/4"

P8MEB6 N8MEB6 1/2" 3/8"

P8MEB8 N8MEB8 1/2" 1/2"

WHITE

NYLON

TUBE OR

HOSE I.D.

NPTF

THREAD SIZE

(INCHES)

(UCB) Union Connector P2UCB2 N2UCB2 1/8" 1/8"

P4UCB4 N4UCB4 1/4" 1/4"

P6UCB6 N6UCB6 3/8" 3/8"

P8UCB6 N8UCB6 1/2" 3/8"

P8UCB8 N8UCB8 1/2" 1/2"

(HPN) Hex Pipe Nipple P2HPN2 N2HNN2 1/8" 1/8"

P4HPN4 N4HNN4 1/4" 1/4"

P6HPN6 N6HNN6 3/8" 3/8"

P8HPN8 N8HNN8 1/2" 1/2"

(MCB) Male Connector P4MCB2 N4MCB2 1/4" 1/8"

P4MCB4 N4MCB4 1/4" 1/4"

P6MCB4 N6MCB4 3/8" 1/4"

P6MCB6 N6MCB6 3/8" 3/8"

P8MCB6 N8MCB6 1/2" 3/8"

P8MCB8 N8MCB8 1/2" 1/2"

These products are available from Brass Products Division

19

Parker Hannifin Corporation

Brass Products Division

Otsego, MI

Page 20

polyflex® HOSES

Introduction

polyflex

vast number of industrial and offshore applications. Styles shown on these pages are

compatible with Parker MPI™ Fittings and offer these benefits:

®

reinforced polymer hose is available in a wide variety of constructions, styles, and lengths to meet a

• Flexible with small outside diameter for tight routing • Chemical-resistant tube and cover

• Abrasion resistant polymer cover for longer life • Steel-reinforced styles resist kinks

TYPICAL APPLICATIONS:

• Offshore oil and gas platforms and satellites

• Replacement of hard tube lines

• Chemical injection lines

• Pressure testing

• Hydraulic controls

• Tank and process vessel cleaning

polyflex® Hose

PARKER

PART NO.

2020N-02V30 0.12 0.24 9,280 23,200 1.18 0.05

2240D-025V34 0.17 0.30 17,400 43,500 2.95 0.067

2245N-04V00 0.25 0.50 10,440 26,100 2.76 0.17

2245N-04V02 0.25 0.50 10,440 26,100 2.76 0.17

2245N-04V04 0.25 0.50 10,440 26,100 2.76 0.17

2380N-04V00 0.25 0.53 16,240 40,600 2.76 0.22

2380N-04V02 0.25 0.53 16,240 40,600 2.76 0.22

2380N-04V04 0.25 0.53 16,240 40,600 2.76 0.22

2380N-04V01 0.25 0.53 16,240 40,600 2.76 0.22

2380N-04V33 0.25 0.50 13,200 33,000 3.50 0.17

MIN.

I.D.

INCH INCH PSI PSI INCH LBS/FT

MAX.

O.D.

MAX.

WORKING

PRESSURE

MIN.

BURST

PRESSURE

MIN.

BEND

RADIUS

WEIGHT

2390N-06V13 0.4 0.70 10,300 25,810 3.00 0.28

2440N-08V37 0.5 0.88 20,400 51,000 7.87 0.63

2440N-08V71 0.5 0.88 20,400 51,000 7.87 0.63

2440N-12V37 0.81 1.19 14,500 37,500 10.00 0.93

2440N-12V71 0.81 1.19 14,500 37,500 10.00 0.93

Temperature range: -40o to +140oF (-40o to +60oC). Contact the factory for temperatures outside this range.

For additional information about

working pressure and installation, contact your authorized Parker Instrumentation Distributor or

polyflex®

hose, including information about construction, typical applications,

polyflex

(281) 530-5300.

20

Parker Hannifin Corporation

Parflex Division, polyflex

Stafford, TX

®

at

®

Page 21

polyflex® HOSES

How to Order Polyflex® Hose Assemblies

Example Hose Assembly Number: 2244NAYAY111108C10-600

2244N AY AY 11 11 08 C 10 - XXX

(A)

(B)

AB C F

This series

of numbers

will indicate

the hose

base number.

Examples:

2040N - 02

2040N - 04

2240D - 025

2245D - 03

2243D - 03

2390N - 04

2390N - 06

2390N - 08

2390N - 12

2440D - 025

2440D - 05

2440N - 08

2440N - 12

2640N - 08

2640N - 12

2740D - 03

2740D - 05

2840D - 03

These two letters will indicate

the STYLE of connection.

End 1 & End 2

01 = NPT Pipe, Male, Rigid

02 = NPT Pipe; Female Rigid

06 = JIC 37 degree.; Female Swivel

07 = NPSM Pipe; Female Swivel

60°

92 = BSP Pipe; Female Swivel

AY = Type M; Female Swivel 58°

YA = Type M; Male (adaptor ends)

C9 = Metric; Female, Swivel

24/O-Ring

D9 = BSP; Male, Rigid

Y1 = MP Nipple; Male, w/ GNut &

Collar

Y2 = MP Nipple; Male, wo/ GNut &

Collar

Y3 = HP Nipple; Male, w/ GNut &

Collar

Y4 = HP Nipple; Male, wo/ GNut &

Collar

Y5 = MP Flare; Male, Rigid

Y6 = HP Flare; Male, Rigid

5Y = MP Flare; Female

6Y = HP Flare; Female

(C) (D) (E) (F)

D

This part will contain a

dash followed by a one

or two digit number

indicating the end

connection size.

End 1 & End 2

UNF

1 = 1/4" - 28 UNF

2 = 5/16" - 24 UNF

3 = 3/8" - 24 UNF

4 = 7/16" - 20 UNF

5 = 1/2" - 20 UNF

6 = 9/16" - 18 UNF

7 = 5/8" - 18 UNF

8 = 3/4" - UNF

9 =

10 = 7/8" - 14 UNF

11 = 1" - 12 UNF

12 = 1 1/16" - 12 UNF

13 = 1 1/8" - 12 UNF

14 =

15 = 1 1/4" - 12 UNF

16 = 1 5/16" - 12 UNF

17 = 1 3/8" - 12 UNF

18 =

19 = 1 1/2" - 12 UNF

20 = 1 5/8" - 12 UNF

NPT

1 = 1/16-27

2 = 1/8-27

4 = 1/4-18

6 = 3/8-18

8 = 1/2-14

12 = 3/4-14

16 = 1-11 1/2

20 = 1 1/4-11 1/2

24 = 1 1/2-11 1/2

32 = 2-11 1/2

Medium and High

Pressure Tube

Male or female, sized

by nominal tube O.D.

04 = 1/4" tube

06 = 3/8" tube

09 = 9/16" tube

12 = 3/4" tube

16 = 1" tube

When

specifying

hose size,

indicate the

two digit code.

Hose

Dash Code

Size

01 01

015 1A

02 02

025 2B

03 03

04 04

05 05

06 06

08 08

10 10

12 12

16 16

20 20

24 24

32 32

E

Indicate the

fitting material.

S = Steel

B = Brass

C = Stainless

Steel

Indicate Length

in Inches

This series of

numbers will

indicate the hose

Variation Number.

Examples:

2040N - 02 V00

2020N - 02 V30

2240D - 025 V34

2245N - 16 V30

2245N - 20 V30

2244N - 025 V00

2244N - 08 V10

2380N - 04 V33

2380N - 04 V00

2380N - 05 V00

2440N - 08 V37

2440N - 12 V37

2440N - 16 V37

2640D - 025 V32

2640N - 12 V32

2740D - 03 V30

2740D - 05 V32

2840D - 03 V34

21

Parker Hannifin Corporation

Parflex Division, polyflex

Stafford, TX

®

Page 22

OFFER OF SALE

The items described in this document and other documents or descriptions provided by Parker Hannifin Corporation, its subsidiaries and its authorized distributors are hereby offered for sale at prices to be established by Parker Hannifin Corporation, its subsidiaries and its authorized distributors.

This offer and its acceptance by any customer ("Buyer") shall be governed by all of the following Terms and Conditions. Buyer’s order for any such

items, when communicated to Parker Hannifin Corporation, its subsidiary or an authorized distributor ("Seller") verbally or in writing, shall constitute

acceptance of this offer.

1. Terms and Conditions of Sale: All descriptions, quotations, proposals,

offers, acknowledgments, acceptances and sales of Seller’s products are

subject to and shall be governed exclusively by the terms and conditions

stated herein. Buyer’s acceptance of any offer to sell is limited to these terms

and conditions. Any terms or conditions in addition to, or inconsistent with

those stated herein, proposed by Buyer in any acceptance of an offer by

Seller, are hereby objected to. No such additional, different or inconsistent

terms and conditions shall become part of the contract between Buyer and

Seller unless expressly accepted in writing by Seller. Seller’s acceptance

of any offer to purchase by Buyer is expressly conditional upon Buyer’s

assent to all the terms and conditions stated herein, including any terms in

addition to, or inconsistent with those contained in Buyer’s offer, Acceptance

of Seller’s products shall in all events constitute such assent.

2. Payment: Payment shall be made by Buyer net 30 days from the date

of delivery of the items purchased hereunder. Amounts not timely paid

shall bear interest at the maximum rate permitted by law for each month

or portion thereof that the Buyer is late in making payment. Any claims by

Buyer for omissions or shortages in a shipment shall be waived unless Seller

receives notice thereof within 30 days after Buyer’s receipt of the shipment.

3. Delivery: Unless otherwise provided on the face hereof, delivery shall

be made F.O.B. Seller’s plant. Regardless of the method of delivery, however, risk of loss shall pass to Buyer upon Seller’s delivery to a carrier. Any

delivery dates shown are approximate only and Seller shall have no liability

for any delays in delivery.

4. Warranty: Seller warrants that items sold hereunder shall be free

from defects in material or workmanship. THIS WARRANTY COMPRISES

THE SOLE AND ENTIRE WARRANTY PERTAINING TO ITEMS PROVIDED HEREUNDER. SELLER MAKES NO OTHER WARRANTY,

GUARANTEE, OR REPRESENTATION OF ANY KIND WHATSOEVER.

ALL OTHER WARRANTIES, INCLUDING BUT NOT LIMITED TO, MERCHANTABILITYAND FITNESS FOR PURPOSE, WHETHER EXPRESS,

IMPLIED, OR ARISING BY OPERATION OF LAW, TRADE USAGE, OR

COURSE OF DEALING ARE HEREBY DISCLAIMED.

NOTWITHSTANDING THE FOREGOING, THERE ARE NO WARRANTIES WHATSOEVER ON ITEMS BUILT OR ACQUIRED WHOLLY OR

PARTIALLY, TO BUYER’S DESIGNS OR SPECIFICATIONS.

5. Limitation Of Remedy: SELLER’S LIABILITY ARISING FROM OR IN

ANY WAY CONNECTED WITH THE ITEMS SOLD OR THIS CONTRACT

SHALL BE LIMITED EXCLUSIVELY TO REPAIR OR REPLACEMENT

OF THE ITEMS SOLD, AT SELLER’S SOLE OPTION. IN NO EVENT

SHALL SELLER BE LIABLE FOR ANY INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES OF ANY KIND OR NATURE WHATSOEVER, INCLUDING BUT NOT LIMITED TO LOST PROFITS ARISING

FROM OR IN ANY WAY CONNECTED WITH THIS AGREEMENT OR

ITEMS SOLD HEREUNDER, WHETHER ALLEGED TO ARISE FROM

BREACH OF CONTRACT, EXPRESS OR IMPLIED WARRANTY, OR IN

TORT, INCLUDING WITHOUT LIMITATION, NEGLIGENCE, FAILURE

TO WARN OR STRICT LIABILITY.

6. Changes, Reschedules and Cancellations: Buyer may request to

modify the designs or specifications for the items sold hereunder as well

as the quantities and delivery dates thereof, or may request to cancel all

or part of this order, however, no such requested modification or cancellation

shall become part of the contract between Buyer and Seller unless accepted

by Seller in a written amendment to this Agreement. Acceptance of any

such requested modification or cancellation shall be at Seller’s discretion,

and shall be upon such terms and conditions as Seller may require.

7. Special Tooling: A tooling charge may be imposed for any special tooling, including without limitation, dies, fixtures, molds and patterns, acquired

to manufacture items sold pursuant to this contract. Such special tooling

shall be and remain Seller’s property notwithstanding payment of any

charges by Buyer. In no event will Buyer acquire any interest in apparatus

belonging to Seller which is utilized in the manufacture of the items sold

hereunder, even if such apparatus has been specially converted or adapted for such manufacture and not withstanding any charges paid by Buyer.

Unless otherwise agreed, Seller shall have the right to alter, discard or

otherwise dispose of any special tooling or other property in its sole discretion at any time.

8. Buyer’s Property: Any designs, tools, patterns, materials, drawings,

confidential information or equipment furnished by Buyer or any other

items which become Buyer’s property, may be considered obsolete and

may be destroyed by Seller after two (2) consecutive years have elapsed

without Buyer placing an order for the items which are manufactured using

such property, Seller shall not be responsible for any loss or damage to

such property while it is in Seller’s possession or control.

9. Taxes: Unless otherwise indicated on the face hereof, all prices and

charges are exclusive of excise, sales, use, property, occupational or like

taxes which may be imposed by any taxing authority upon the manufacture, sale or delivery of the items sold hereunder. If any such taxes must

be paid by Seller or if Seller is liable for the collection of such tax, the

amount thereof shall be in addition to the amounts for the items sold.

Buyer agrees to pay all such taxes or to reimburse Seller therefore upon

receipt of its invoice. If Buyer claims exemption from any sales, use or

other tax imposed by any taxing authority, Buyer shall save Seller harmless from and against any such tax, together with any interest or penalties

thereon which may be assessed if the items are held to be taxable.

10. Indemnity For Infringement of Intellectual Property Rights: Seller

shall have no liability for infringement of any patents, trademarks, copyrights, trade dress, trade secrets or similar rights except as provided in this

Part 10. Seller will defend and indemnify Buyer against allegations of

infringement of U.S. Patents, U.S. Trademarks, copyrights, trade dress and

trade secrets (hereinafter ‘Intellectual Property Rights’). Seller will defend

at its expense and will pay the cost of any settlement or damages awarded

in an action brought against Buyer based on an allegation that an item sold

pursuant to this contract infringes the Intellectual Property Rights of a third

party. Seller’s obligation to defend and indemnify Buyer is contingent on

Buyer notifying Seller within ten (10) days after Buyer becomes aware of

such allegations of infringement, and Seller having sole control over the

defense of any allegations or actions including all negotiations for settlement or compromise. If an item sold hereunder is subject to a claim that it

infringes the Intellectual Property Rights of a third party, Seller may, at its

sole expense and option, procure for Buyer the right to continue using said

item, replace or modify said item so as to make it noninfringing, or offer to

accept return of said item and return the purchase price less a reasonable

allowance for depreciation. Notwithstanding the foregoing, Seller shall

have no liability for claims of infringement based on information provided

by Buyer, or directed to items delivered hereunder for which the designs

are specified in whole or part by Buyer, or infringements resulting from the

modification, combination or use in a system of any item sold hereunder.

The foregoing provisions of this Part 10 shall constitute Seller’s sole and

exclusive liability and Buyer’s sole and exclusive remedy for infringement

of Intellectual Property Rights.

If a claim is based on information provided by Buyer or if the design for an

item delivered hereunder is specified in whole or in part by Buyer, Buyer

shall defend and indemnify Seller for all costs, expenses or judgments

resulting from any claim that such item infringes any patent, trademark,

copyright, trade dress, trade secret or any similar right.

11. Force Majeure: Seller does not assume the risk of and shall not be

liable for delay or failure to perform any of Seller’s obligations by reason of

circumstances beyond the reasonable control of Seller (hereinafter

‘Events of Force Majeure’). Events of Force Majeure shall include without

limitation, accidents, acts of God, strikes or labor disputes, acts, laws, rules

or regulations of any government or government agency, fires, floods,

delays or failures in delivery of carriers or suppliers, shortages of materials

and any other cause beyond Seller’s control.

12. Entire Agreement/Governing Law: The terms and conditions set

forth herein, together with any amendments, modifications and any different

terms or conditions expressly accepted by Seller in writing, shall constitute

the entire Agreement concerning the items sold, and there are no oral or

other representations or agreements which pertain thereto. This Agreement

shall be governed in all respects by the law of the State of Ohio. No actions

arising out of the sale of the items sold hereunder or this Agreement may

be brought by either party more than two (2) years after the cause of action

accrues.

11/98-P

22

Parker Hannifin Corporation

Parflex Division

Ravenna, OH

Page 23

Parker Hannifin Corporation

6035 Parkland Blvd.

Cleveland, Ohio 44124-4141

Telephone: (216) 896-3000

Fax: (216) 896-4000

www.parker.com

Parker Hannifin Corporation

About Parker Hannifin Corporation

Parker Hannifin is a leading global motion-control

company dedicated to delivering premier customer

service. A Fortune 500 corporation listed on the New

York Stock Exchange (PH), our components and

systems comprise over 1,400 product lines that

control motion in some 1,000 industrial and aerospace markets. Parker is the only manufacturer to

offer its customers a choice of hydraulic, pneumatic,

and electromechanical motion-control solutions. Our

Company has the largest distribution network in its

field, with over 7,500 distributors serving nearly

400,000 customers worldwide.

The Aerospace Group is

a leader in the development,

design, manufacture and

servicing of control systems

and components for aerospace

and related high-technology

markets, while achieving

growth through premier

customer service.

Parker’s Charter

To be a leading worldwide manufacturer of components and systems for the builders and users of

durable goods. More specifically, we will design,

market and manufacture products controlling

motion, flow and pressure. We will achieve

profitable growth through premier customer service.

Product Information

North American customers seeking product information, the location of a nearby distributor, or repair

services will receive prompt attention by calling the

Parker Product Information Center at our toll-free

number: 1-800-C-PARKER (1-800-272-7537). In

Europe, call 00800-C-PARKER-H (00800-2727-5374).

The Climate & Industrial

Controls Group designs,

manufactures and markets

system-control and fluidhandling components and

systems to refrigeration,

air-conditioning and industrial customers worldwide.

The Fluid Connectors

Group designs, manufactures

and markets rigid and flexible

connectors, and associated

products used in pneumatic

and fluid systems.

The Hydraulics Group

designs, produces and

markets a full spectrum of

hydraulic components and

systems to builders and

users of industrial and

mobile machinery and

equipment.

The Automation Group

is a leading supplier of pneumatic and electromechanical

components and systems

to automation customers

worldwide.

The Seal Group designs,

manufactures and distributes

industrial and commercial

sealing devices and related

products by providing

superior quality and total

customer satisfaction.

The Filtration Group

designs, manufactures and

markets quality filtration

and clarification products,

providing customers with

the best value, quality,

technical support, and global

availability.

The Instrumentation

Group is a global leader in

the design, manufacture and

distribution of high-quality

critical flow components for

worldwide process instrumentation, ultra-highpurity, medical and

analytical applications.

23

Parker Hannifin Corporation

Parflex Division

Ravenna, OH

Page 24

Parker Hannifin Corporation

Parflex Division

1300 N. Freedom Street

Ravenna, OH 44266-1212

USA

Phone: (330) 296-2871

Fax: (330) 296-1829

Parker Hannifin Corporation

Brass Products Division

300 Parker Drive

Ostego, MI 49078

USA

Phone: (269) 694-9411

Fax: (269) 694-4614

Catalog 4200-INST, 20M, WP, 11/04

Parker Hannifin Corporation

Parflex Division polyflex

®

Operation

12840 Sugar Ridge Boulevard

Stafford, TX 77477

USA

Phone: (281) 530-5300

Fax: (281) 530-5353

www.parker.com

Loading...

Loading...