Page 1

Automation

p/n 88-020389-01 A

Dynaserv G2 Drive

User Guide

Effective: March 1, 2002

Page 2

Introduction

Thank you very much for your purchase of the DD servo actuator DYNASERV. The DYNASERV is an outer rotor type

servo actuator that has achieved high torque, high speed, and high precision. It can be used in a wide range of

applications in the FA device-related fields, such as industrial robotics and indexing.

This technical manual explains the DYNASERV DM/SR series motors as well as its combinations with the DrvGII

drivers. Please refer to this technical manual thoroughly when you use the product.

Precautions for Using this Technical Manual

1. Please make sure that this manual is handed out to the end user.

2. Please read this manual thoroughly and understand the contents fully before proceeding to the operation of the

product.

3. Please note that the safety protection may be lost and the proper safety may not be guaranteed if the product is

not used according to the instructions described in this manual.

4. Always make sure that this manual is handy for the operator when using this product. If it is stained or lost, we

will distribute copies upon request, subject to charge.

5. This manual explains details of the features included in the product and does not guarantee to meet the specific

purpose of the customers.

6. No part of this manual may be reprinted or reproduced in any form without permission.

7. The information in this document is subject to change without notice.

8. The information contained in this document is believed to be accurate at the time of publication, but if you notice

any inaccuracies, errors, or omissions, please contact our sales or service staff.

-1-

Page 3

Regarding the safe usage of this device

! This product has been marked with and signs so that it can be used safely. Ignoring precautions and

prohibitions related to these signs and using this product in an incorrect way may cause danger to the life and body

of the operator. Always follow the precautions and observe the prohibitions explained below.

! Please make sure to understand the information given below completely before you start reading the technical

manual.

! Please keep the technical manual and this sheet handy while using the product. In addition, make sure that they are

handed out to the operator of the product.

!!!!

Warnings

!!!!

!!!!

Warnings

!!!! Warning about rotation:

The motor periphery part of this device rotates at a high speed. People and objects should not be placed within the

rotational radius when a load is attached to the motor.

!!!! Warning about electric shock:

Make sure to connect the device to ground to avoid electric shock.

Make sure to turn the power off when connecting cables to the driver part.

Make sure to turn the power off when removing the cover of the driver part while performing adjustment

operations, etc.

!!!! Fire and electric shock warning:

If any abnormalities such as abnormal noise, bad smell, or release of fumes that coming from the device are

detected while it is in operation, turn the power off immediately, pull out the power supply plug, and contact us.

If the device is dropped or given a strong impact, stop the operation immediately, turn the power off, and contact

us.

Do not operate at power supply voltages other than the one indicated on the device.

!!!! Fire and electric shock warning:

Avoid dropping or inserting metal shards or combustible materials, or allowing water to get into the opening parts

of the device (e.g., the clearance between the rotor and stator of the motor part, or the air vent of the driver part).

In such an eventuality, turn the power off immediately and contact us.

The cables coming out from the motor part or the bottom of the index part should not be forcibly bent, twisted,

pulled, heated, or placed under a heavy object.

Never try to remodel or repair the device by yourself.

-2-

Page 4

Precautions

! This product has been marked with and signs so that it can be used safely. Ignoring precautions and

prohibitions related to these signs and using this product in an incorrect way may cause danger to the life and body

of the operator. Always follow the precautions and observe the prohibitions explained below.

! Please make sure to understand the information given below completely before you start reading the technical

manual.

! Please keep the technical manual and this sheet handy while using the product. In addition, make sure that they are

handed out to the operator of the product.

! Make sure to read the technical manual before using the device.

Operational mistakes and faulty wiring may result in damages and failure of the device.

! Make sure to check the wiring once more before turning the power on.

Faulty wiring may result in fire, electric shock, or damage of the device.

! Confirm that the proper combination of motor and driver parts is used. Using the device with an incorrect

configuration may result in failure. (Be sure to confirm the model--MODEL--on the rating nameplates.)

! Make sure the conditions of temperature, humidity, dust, etc. are as specified for the installation and storage

environments.

! Do not block the air vent of the device. Keep the specified open space around the device as well. Poor ventilation

may cause overheating, leading to failure.

!!!!

!!!!

Precautions

!!!!

! Some of the motor parts are very heavy; please pay sufficient attention to this when carrying and installing the

parts. If the weight is more than 10kg (22.04 lbs), carrying or lifting tools should be used as much as possible.

! Both the motor and driver parts should be installed in the specified orientation.

! Keep the protection cover (transparent plastic plate) attached on the power supply terminal part of the driver. It is

provided to prevent inadvertent electric shock accidents.

-3-

Page 5

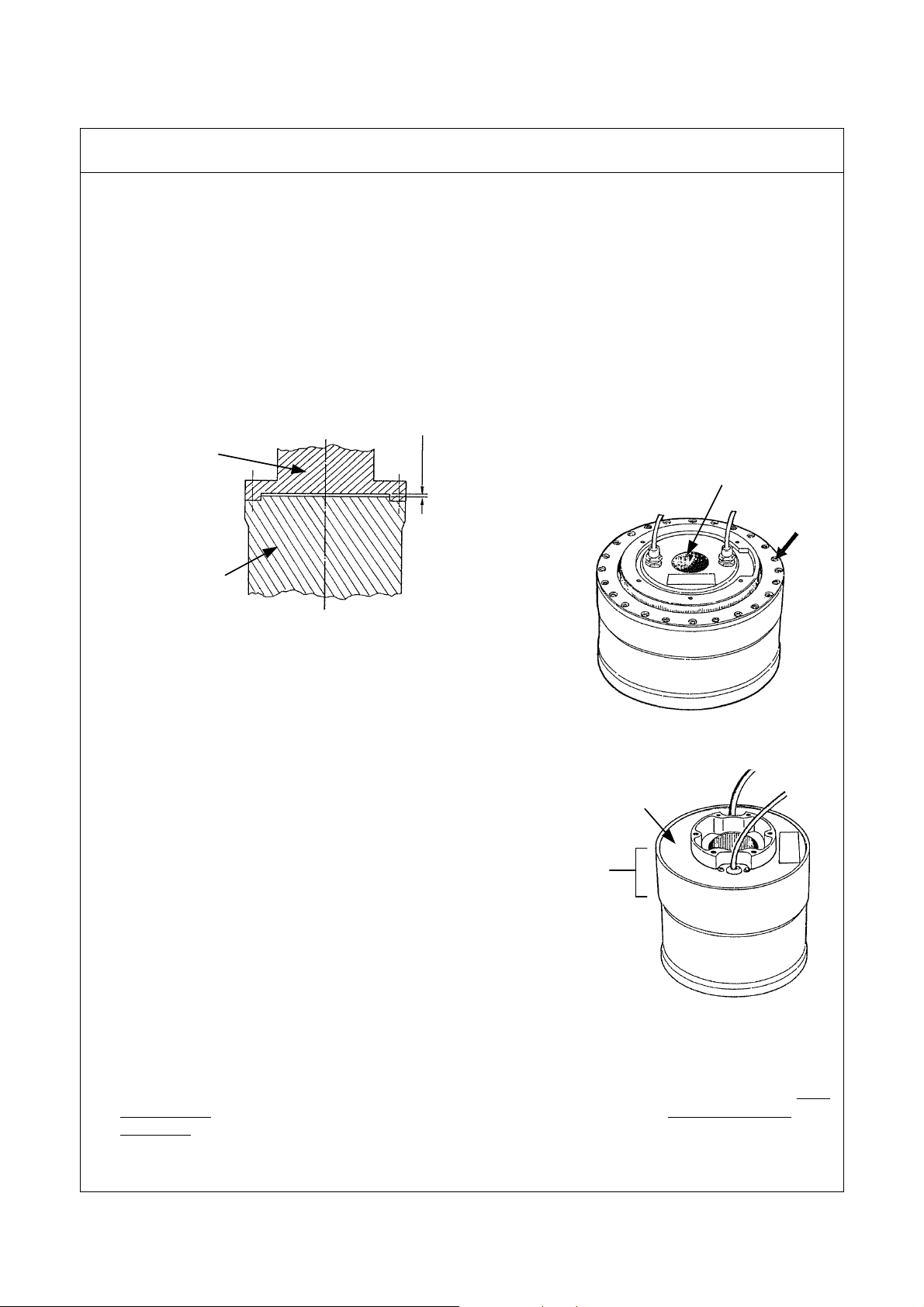

Handling Precautions

1. Do not install the motor in reverse direction in such a way that the rotor of the motor is fixed and the stator rotates.

2. Make sure to turn the power off before removing the side panel of the driver to set jumpers, etc. Touching the high

voltage part inside the driver is dangerous.

3. This motor rotates at a high speed and with a high torque. Take the rotation radius into consideration and pay

special attention to the prevention of any dangerous situations that may occur during the operation when a load is

attached to the motor.

4. Make sure to ground the ground terminal to earth.

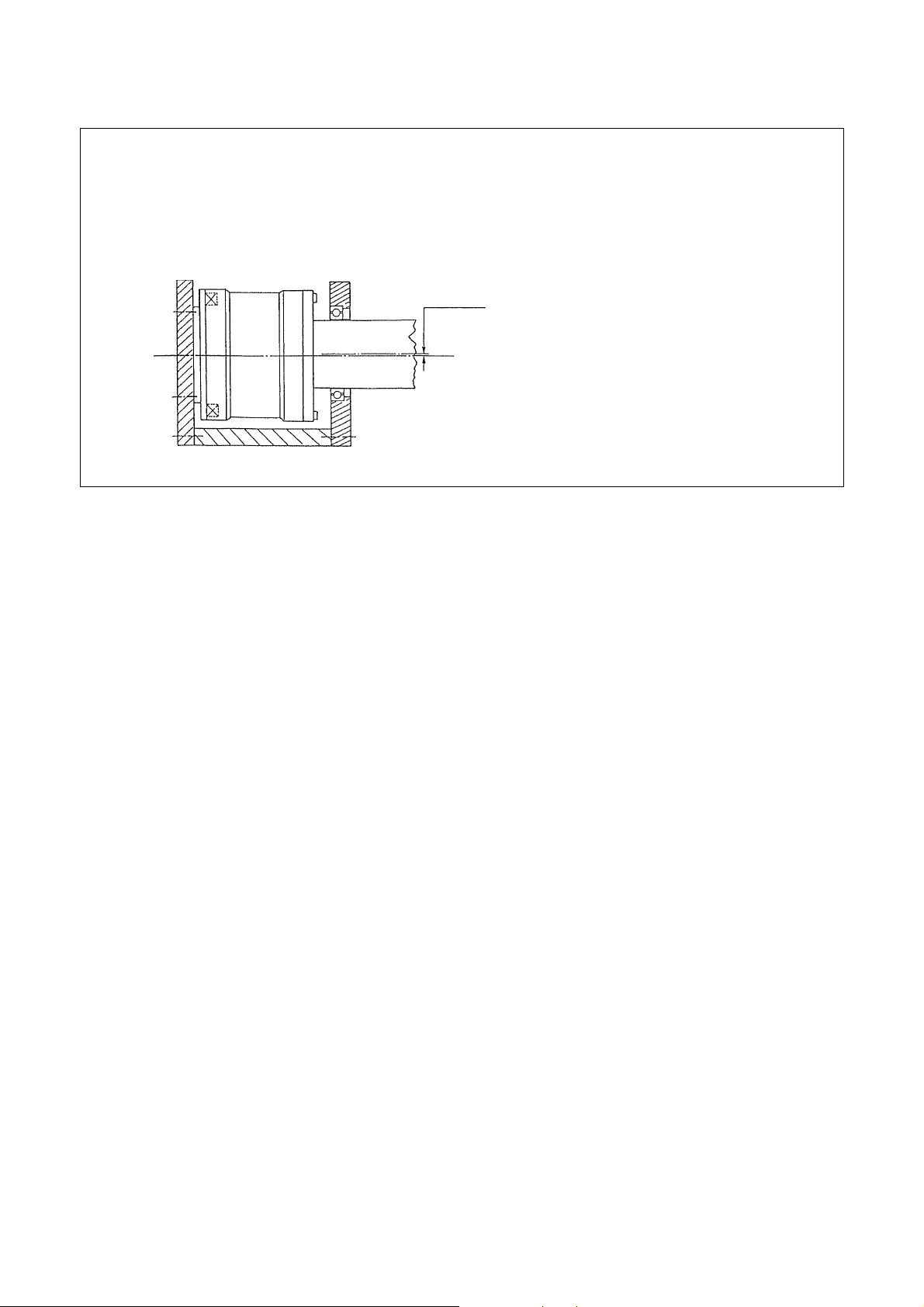

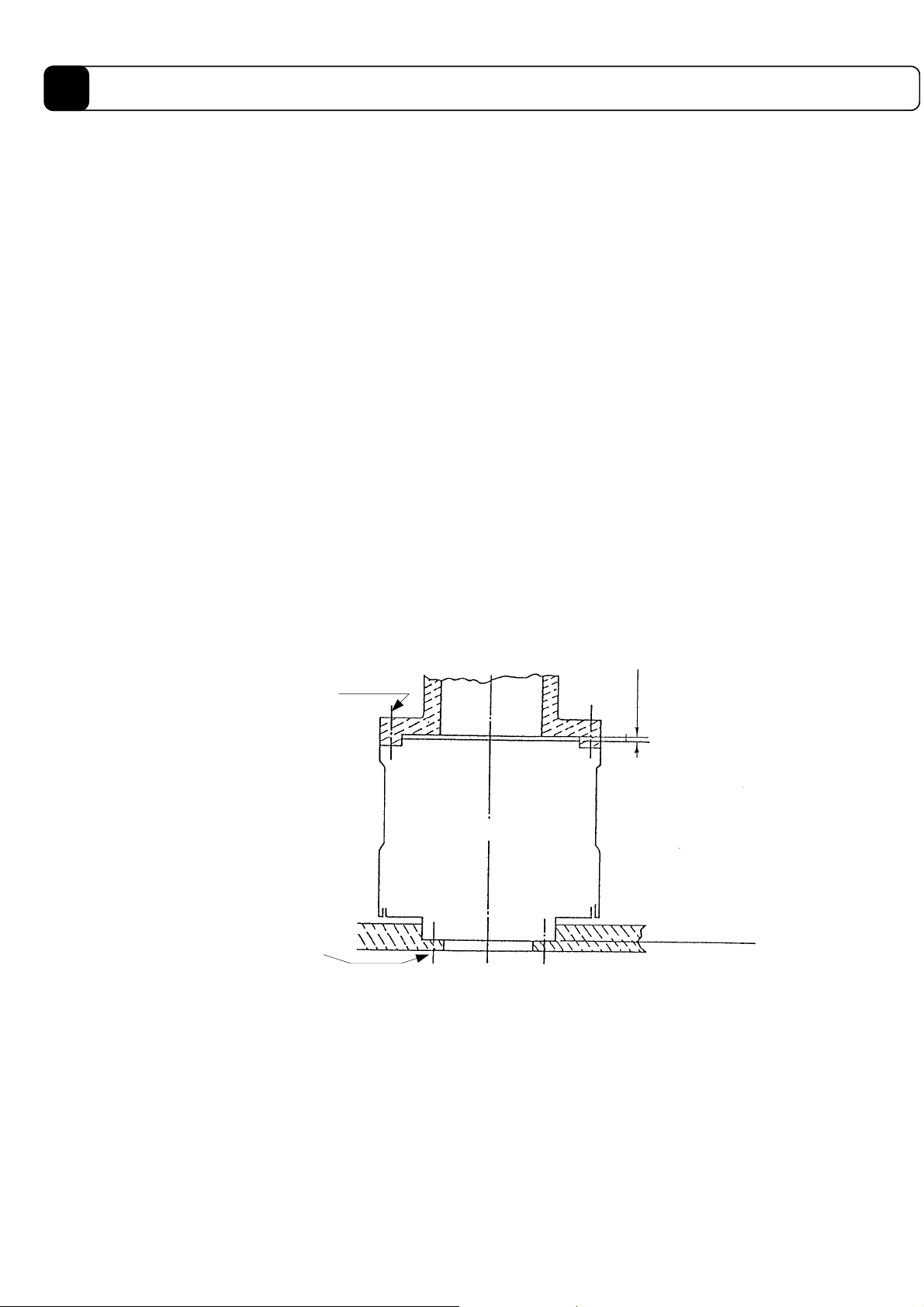

5. When attached a load to the rotor, make sure to keep a clearance of 1 mm or more between the load and the upper

surface of the motor in order to maintain the surface precision. Furthermore, never push or squeeze an object into

the shaft hole. (See the figure below.)

Attached part

1mm or more

Rotor

When feeding an object through the shaft

hole, make sure to secure a clearance of

at least 1mm on one side.

Shaft hole

6. Do not touch the bolts (indicated by the arrow) that fix the

bottom part of the rotor (see the figure to the right). If these bolts

are loosened or tightened, the commutation angle will become

inaccurate, which may result in uneven rotation (this applies only

to the DM series).

DM series motor

7. The motor surface is magnetized; do not place things that can be affected by magnetism close to it.

8. The motor part shown in the figure to the right includes a

magnetic resolver. Strong force, impacts, or magnetic fields

Bottom cap

should not be applied to the motor part (this applies only to the

DR series).

Magnetic

9. Make sure to use load attachment screws that are shorter than the

resolver

effective depth of the thread in the motor part. Depending on the

model, if a screw exceeds the effective thread depth, the function

may be impaired (this applies only to the DR series).

DR series motor

10. The motor is neither dust-, drip- nor water (oil)-proof; the motor should be installed in carefully chosen

environments.

11. If the motor will be oscillating or rotating at small angles (50° or less), it should be allowed to oscillate at an angle

of 90° or more for approximately 10 times (running-in operation) each time it has made 10,000 small-angle

oscillations in order to prevent poor lubrication of the bearing.

12. In order for the motor and driver to be compatible with each other, they must be of the same model.

-4-

Page 6

13. Never attempt to disassemble or remodel the motor and driver. If such service is necessary, please contact us. We

assume no responsibility for products that have been disassembled or remodeled without permission.

14. For the DYNASERV DR series motors, a coating has been applied on the load attachment surface of the upper

surface of the motor and the stator on the lower surface in order to prevent rust. When starting to use the product,

wipe off the coating completely with cloth or paper soaked in a petroleum or chlorine solvent before assembling. If

any of the coating remains, it may affect the mechanical precision.

Rust-proof

coated

surface

15. Do not place the motor on the floor and other surface in the manner shown in the figure below when carrying and

installing the DYNASERV. The cables are crushed by the motor’s own weight and the copper wires may be broken

inside the cables. If it cannot be avoided to place the motor in such a manner, a support bench should always be

placed so that the cables are lifted. Furthermore, if the cables need to be bent when installed in a device, etc., the

minimum bending radius should be 50 mm or more. The cables are not strong enough to live up to robot cable

specifications, so they should not be bent repeatedly.

An example of a DM series motor

An example of a DM series motor

The minimum

bending radius

should be

50mm or more.

The minimum

bending radius

should be

50mm or more.

-5-

Page 7

16. Do not perform a withstanding voltage test on this device. If such a test is performed without discretion, the

circuits may be damaged. If such test must be conducted, make sure to contact us.

17. When connecting the motor with a load, the centerlines of both cores should be aligned to a sufficient degree.

Please note that if the deviation between the two cores becomes 10 µm or more, the bearings inside the motor may

be damaged.

The core deviation should

be 10

mm or less.

µ

-6-

Page 8

Table of Contents

Introduction..........................................................................................................................1

Chapter 1 Overview of the Product 1-1

1.1 About the DYNASERV DM/DR Series ................................................................... 1-2

1.2 About the DrvGII Type Driver ................................................................................. 1-3

1.3 Product Configuration .............................................................................................. 1-4

1.4 Model Names and Codes .......................................................................................... 1-5

1.5 Name and Function of Each Part .............................................................................. 1-6

1.6 System Configuration Diagram .............................................................................. 1-10

Chapter 2 Installation 2-1

2.1 Installation of the Motor ........................................................................................... 2-2

2.2 Installation of the Driver........................................................................................... 2-3

Chapter 3 Connection and Wiring 3-1

3.1 Diagram of Overall Connection................................................................................ 3-2

3.2 Cable Specification List............................................................................................ 3-3

3.3 Connection between Motor and Driver .................................................................... 3-4

3.4 Wiring of Motor, AC Power Supply, and Ground Cable.......................................... 3-6

3.5 Wiring of Encoder Cable .......................................................................................... 3-8

3.6 Wiring of Controller Cable....................................................................................... 3-9

3.7 Wiring of Sensor Brake Terminal ........................................................................... 3-10

3.8 Wiring of Regenerative Alarm Contact <CNA>

(For 500W Level Drive Only) ................................................................................ 3-11

Chapter 4 Basic Settings for Operating the Motor 4-1

4.1 Procedure (Flowchart) .............................................................................................. 4-2

4.2 Preoperation check.................................................................................................... 4-3

4.3 Installing the PC Utility on the PC ........................................................................... 4-6

4.3.1 Procedure .......................................................................................................................................4-6

4.3.2 Startup............................................................................................................................................4-8

4.4 Preparation................................................................................................................ 4-9

4.4.1 Selecting Communication Port ......................................................................................................4-9

4.4.2 Selecting Channels.........................................................................................................................4-9

4.4.3 Displaying Communication Strings.............................................................................................4-10

4.4.4 Main Menu...................................................................................................................................4-11

4.5 Setting the Status to Servo ON ............................................................................... 4-12

4.6 Auto-tuning............................................................................................................. 4-14

4.7 Performing Homing Operation ............................................................................... 4-16

-i-

Page 9

4.8 Performing the Basic Settings of Pulse Commands ............................................... 4-18

4.8.1 About Position Command Pulse Input.........................................................................................4-18

4.8.2 Example of Operation..................................................................................................................4-19

Chapter 5 Functions 5-1

5.1 Parameters and Monitors .......................................................................................... 5-2

5.1.1 General Parameters........................................................................................................................5-2

5.1.2 Mechanical Setting Parameters......................................................................................................5-2

5.1.3 Monitors.........................................................................................................................................5-2

5.2 Operation Functions.................................................................................................. 5-3

5.2.1 Jog Move........................................................................................................................................5-3

5.2.2 Test Operation................................................................................................................................5-4

5.2.3 Auto-Tuning Operation ..................................................................................................................5-4

5.2.4 Homing Move................................................................................................................................5-5

5.2.5 Mechanical Setting Mode ..............................................................................................................5-9

5.3 Coordinate System.................................................................................................... 5-9

5.3.1 Coordinate System.........................................................................................................................5-9

5.3.2 Switching Position Command Pulse Weights ................................................................................5-9

5.4 Control System ....................................................................................................... 5-10

5.4.1 Velocity Control Part....................................................................................................................5-11

5.4.2 Position Control Part....................................................................................................................5-12

5.4.3 Feed Forward...............................................................................................................................5-12

5.4.4 Servo Stiffness Parameter ............................................................................................................5-13

5.5 Acceleration/Deceleration Function ....................................................................... 5-14

5.5.1 Velocity Override Function..........................................................................................................5-14

5.5.2 Velocity Profile ............................................................................................................................5-15

5.6 Other Functions ...................................................................................................... 5-17

5.6.1 Settling Wait, Position Settling Status, and Positioning Status ....................................................5-17

5.6.2 Velocity Monitor and Analog Monitor.........................................................................................5-18

5.6.3 Brake Signal.................................................................................................................................5-18

5.7 Special Parameter Processing ................................................................................. 5-19

5.7.1 Internal Generation of Parameter Initial Values ...........................................................................5-19

5.7.2 Limiting and Checking Maximum Velocity When Changing Simplified Scaling

Weighted Data and Maximum Velocity Parameters.....................................................................5-19

5.7.3 Auto Conversion and Clear Functions When Changing Simplified Scaling Weighted Data.......5-20

5.7.4 Limiting the Maximum Parameter Values ...................................................................................5-20

Chapter 6 Control Interfaces 6-1

6.1 Terminal Function..................................................................................................... 6-2

6.1.1 Connection, Setting, and I/O Mapping ..........................................................................................6-2

6.1.2 Explanation of Terminals ...............................................................................................................6-3

6.1.3 Electrical specifications .................................................................................................................6-4

6.1.4 I/O logic setting..............................................................................................................................6-5

6.2 Position Command Pulse Input ................................................................................ 6-6

6.3 Encoder Pulse Output ............................................................................................... 6-6

6.4 Operations................................................................................................................. 6-7

6.4.1 Starting an Operation.....................................................................................................................6-7

6.4.2 Aborting an Operation ...................................................................................................................6-7

6.4.3 Timing Charts ................................................................................................................................6-8

-ii-

Page 10

6.5 Other Inputs .............................................................................................................. 6-9

6.5.1 Pulse Weight Selection PLS_DIRECT ..........................................................................................6-9

6.5.2 Position Control Bandwidth Selection FN.....................................................................................6-9

6.5.3 Velocity Control Bandwidth Selection GAIN................................................................................6-9

6.5.4 Settling Width Selection POSW [1..0] ...........................................................................................6-9

6.5.5 Disable Position Control Integral Operation PACT .......................................................................6-9

6.5.6 Error reset (ERR_RESET).............................................................................................................6-9

6.5.7 Servo ON SERVO........................................................................................................................6-10

6.5.8 Current Limit Input ......................................................................................................................6-10

Chapter 7 RS232C Interfaces 7-1

7.1 Overview .................................................................................................................. 7-2

7.2 Connection and Setting ............................................................................................ 7-2

7.3 Communication Specifications ................................................................................ 7-4

7.4 @ Commands ........................................................................................................... 7-6

7.4.1 Start @3: Field 0 .........................................................................................................................7-6

7.4.2 Stop @2 ......................................................................................................................................7-6

7.4.3 Abort @1 ....................................................................................................................................7-6

7.4.4 Error reset @4.............................................................................................................................7-6

7.4.5 Homing offset position setting @10 ...........................................................................................7-7

7.4.6 Jog move command @11: Field 0...............................................................................................7-7

7.4.7 Other convenient commands..........................................................................................................7-7

7.5 Parameter Commands............................................................................................... 7-8

Chapter 8 DrvGII PC Utility 8-1

8.1 Overview .................................................................................................................. 8-2

8.1.1 Overview of the Operation Menu ..................................................................................................8-2

8.1.2 Overview of the Action Menu........................................................................................................8-2

8.1.3 Overview of the Data Management Menu .....................................................................................8-2

8.2 Installation ................................................................................................................ 8-3

8.2.1 Installation under Windows 95/98/98SE/Me/NT4.0/2000.............................................................8-3

8.2.2 Starting the PC Utility....................................................................................................................8-5

8.3 Preparation................................................................................................................ 8-6

8.3.1 Selecting a Communication Port....................................................................................................8-6

8.3.2 Selecting Channels.........................................................................................................................8-6

8.3.3 Displaying Communication Strings...............................................................................................8-7

8.3.4 Main Menu.....................................................................................................................................8-8

8.4 Operation Menu ........................................................................................................ 8-9

8.4.1 Terminal .........................................................................................................................................8-9

8.4.2 Servo Tuning................................................................................................................................8-14

8.4.3 Oscilloscope.................................................................................................................................8-16

8.5 Action Menu ........................................................................................................... 8-19

8.5.1 Homing ........................................................................................................................................8-20

8.5.2 Jog Move......................................................................................................................................8-22

8.5.3 Test Operation..............................................................................................................................8-23

8.6 Data Management Menus ....................................................................................... 8-24

8.6.1 Parameter Manager......................................................................................................................8-24

8.6.2 I/O Set..........................................................................................................................................8-27

8.6.3 Pulse Set.......................................................................................................................................8-30

-iii-

Page 11

Chapter 9 Operation Display Pendant ........................................................................... 9-1

9.1 Overview................................................................................................................... 9-2

9.2 Features and Part Names .......................................................................................... 9-2

9.3 Switching Displays ................................................................................................... 9-3

9.4 Terminal Mode Display ............................................................................................ 9-4

9.5 Parameter Monitor Display....................................................................................... 9-5

9.6 Parameter Settings Display....................................................................................... 9-6

9.7 I/O Monitor Display.................................................................................................. 9-7

9.8 Special Command Display........................................................................................ 9-8

Chapter 10 Maintenance and Inspection ....................................................................... 10-1

10.1 Maintenance and Inspection of the Motor Part....................................................... 10-2

10.2 Maintenance and Inspection of the Driver Part ...................................................... 10-2

10.3 Replacing the Battery for Memory Backup............................................................ 10-2

10.4 Backup and Restore Operations of Driver Memory Contents................................ 10-3

10.4.1 Backup Operation ........................................................................................................................10-3

10.4.2 Restore Operation ........................................................................................................................10-4

10.5 Motor Problems and Corrective Actions ................................................................ 10-5

Chapter 11 Specifications...............................................................................................11-1

11.1 Standard Specifications ...........................................................................................11-2

11.2 Torque - Speed Characteristics ................................................................................11-8

11.3 External Dimensions (Unit: mm).............................................................................11-9

11.4 Restrictive Conditions for the Frequency of

Repeated Operations (DR5000B Series Only) ......................................................11-13

-iv-

Page 12

Chapter 1

Overview of the Product

1.1 About the DYNASERV DM/DR Series

1.2 About the DrvGII Type Driver

1.3 Product Configuration

1.4 Model Names and Codes

1.5 Name and Function of Each Part

1.6 System Configuration Diagram

1-1

Page 13

1

Overveiw of the Product

1.1 About the DYNASERV DM/DR Series

The DYNASERV servo motor, is a high speed, high torque, and high precision outer rotor type direct drive motor.

The DM series motors are contained in an aluminum chassis and have a built-in optical encoder. There are four

models in the A series with output torques of 50 to 200N⋅m and five models in the B series with torques of 15 to

75N⋅m. The outside diameters are 264 mm for the A series and 160 mm for the B series. Each has a shaft hole of

58 mm and 25 mm in diameter at the center, respectively.

The outer shapes of the small-diameter and flat type DM series motors have successfully been made flatter and

smaller in diameter based on the basic performance of the conventional DM/SD series. An outer diameter of 116

mm and a height (thickness) of 45 mm, respectively, are achieved for the DM small-diameter type and the DM

flat type.

Both types are equipped with an optical encoder, which is characteristic of the DM series, and have the added

features of high resolution and high mechanical precision. They are actuators with excellent output-to-space

ratios and the best available option for servos for semi-conductor manufacturing devices, precision test devices,

etc. They can be used in various applications.

The DYNASERV DR series is a series of operational direct drive motors that was developed based on the fieldproven DM series to satisfy new demands. There are six A type models (50 to 400N⋅m) with an outer diameter

of 264 mm (10 inches), seven E type models (30 to 250N⋅m) with an outer diameter of 205 mm (8 inches), and

five B type models (8 to 60N⋅m) with an outer diameter of 150 mm (6 inches). In addition, there is a 5000B/E

type (consisting of five high-speed type models).

Moreover, in addition to the above standard models, several special type models are also available, such as lightweight types, types with flanges, types with brakes, and high mechanical precision installation surface types.

1-2

Page 14

1.2 About the DrvGII Type Driver

The DrvGII type driver is a digital servo driver with a RS232 communication, developed as the successor to the

conventional SD/SR/TM type driver. Not only have the functions been improved, but also the driver box volume

has been made smaller, and it can support the DYNASERV rotation type motors, as well as the LINEARSERV

series motors that are of the direct drive type.

The features include the following:

(1) The size of the driver is reduced to approximately half of the previous size (comparison within our

company).

(2) The internal resolution is increased by a factor of four for the DM series and a factor of two for the DR

series.

(3) It can now support most of the models of the DYNASERV and LINEARSERV series.

(4) A sophisticated utility is now available and an oscilloscope function has been included as well.

1

1-3

Page 15

1

Overveiw of the Product

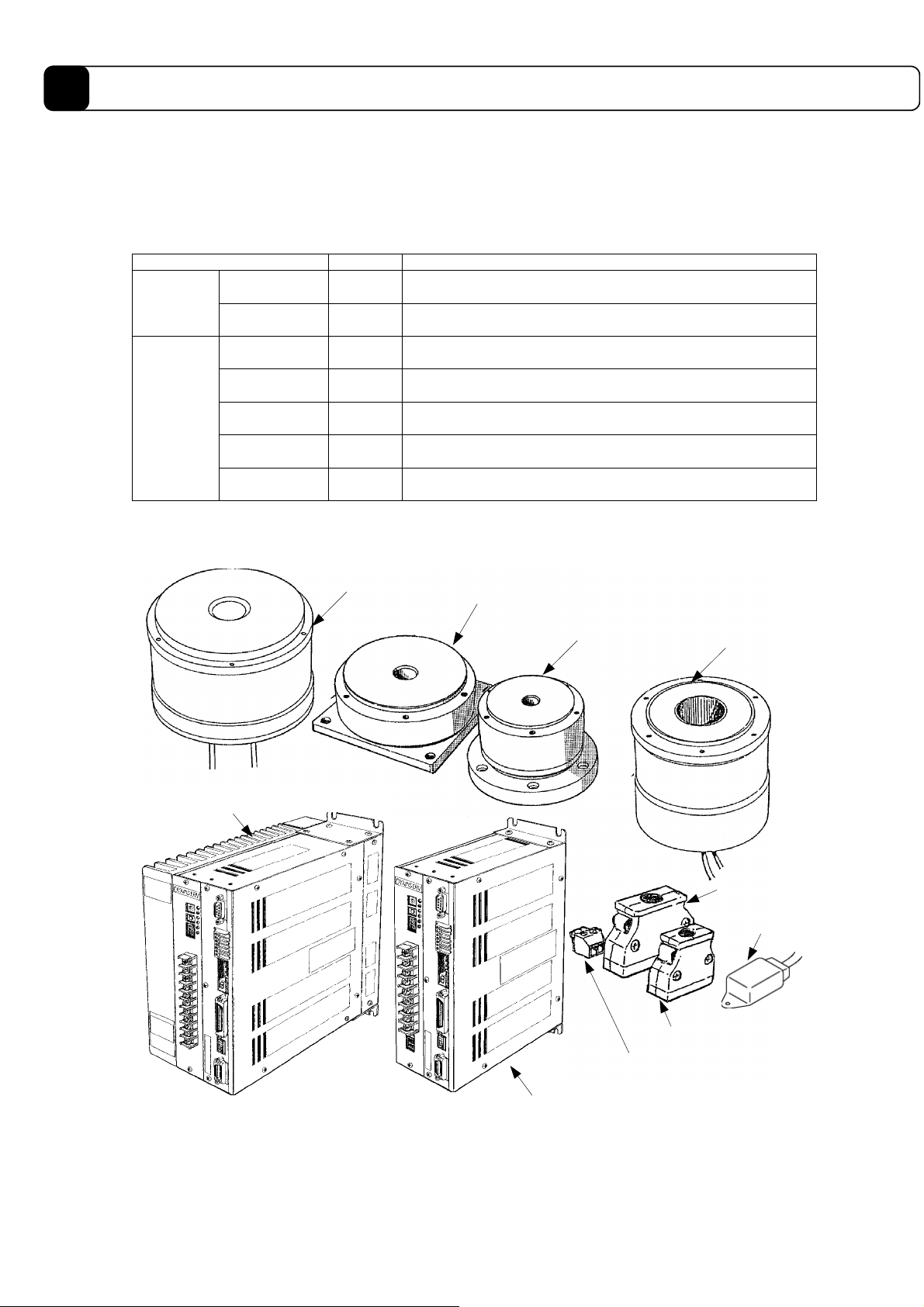

1.3 Product Configuration

The following shows the configuration of this product. Upon unpacking, please check the model name and code

of the product’s main unit, whether or not all the standard accessories are included, and also the quantity

supplied.

Part name Number Notes

Motor part 1

Main body

Driver part 1

Connector for

driver CN2

Connector for

driver CN4

Standard

accessory

* Supplied for drivers whose interface type is the I/O contact type.

** Supplied only for 500W level drivers with regenerative terminals

Connector for

driver CN5*

Terminal for

driver CNA**

Regenerative

resistor **

The external appearance varies depending on the model

name/code.

The external appearance varies depending on the model

name/code.

1

1

1 Made by Phoenix Contact MC1, 5/6-ST-3, 81

1 Made by Phoenix Contact MC1, 5/2-ST-5, 08

1

Made by Honda Tsushin Kogyo (connector) PCR-S20FS

(cover) PCR-LS20LA1

Made by Honda Tsushin Kogyo (connector) PCR-S50FS

(cover) PCR-LS50LA

80W 60Ω (for 100V) or 80W 200Ω (for 200V)

Driver part (2kW level)

With regenerative unit

Motor part/DM series

Motor part/DM1004B

Motor part/DM1004C Motor part/

DR series

Connector for CN4

Regenerative

terminal

Connecto for CN2

Connector for CNA

Driver part

(500W level)

Note: The exact shape varies depending on the model you ordered. Refer to the figure showing the outer

dimensions for more details.

1-4

Page 16

1.4 Model Names and Codes

There are restrictions on the combination of specifications. Please check with our sales staff before determining

the specification.

(1) Motor

!

Motor series name

(DM or DR)

!

Design version

(1: standard/5: high-speed)

!

Maximum output torque

(N-m, three-digit number)

!

Motor type/outer diameter (A:φ264/B:φ160/C:φ116/E:φ205)

!

Destination

(0: domestic)

!

Motor part special shape

(0: standard/B: light-weight/C: with flange/

D: with mechanical brake/F: with base)

!

Mechanical precision - only for models requiring mechanical precision.

Omitted if it is not required

(-1: mechanical precision of 5 mm or less/-2: mechanical precision of 10 mm or less/µm

-3: mechanical precision of 20 mm or less)

!

With compatibility function

□□□□□□□□□-□*

1

(2) Driver

□□□□□□□□□□-□□□_

!

Driver series name (UD for DM and UR for DR)

!

Motor type/

(four-digit number of the motor, one line of alphabet letters)

!

Box type/

(first digit 0: domestic standard/second digit A: 500W level without regenerative

terminal, B: 500W level with regenerative terminal, K: 2kW level with built-in

regenerative unit, L: 2kW level without regenerative unit)

!

Current/

(A: 5A-DM small-diameter/B: 6A-DM flat/C: 15A-DMB type, DRB type, DR5000B type /

D: 20A-DMA type, DRA type, DRE type, DR5000E type)

!

Voltage/1: 100V system, 2: 200V system

Interface/(first digit/S: pulse train position command,

!

!

Option/0: none, N: with notch filter

!

CE marking/no mark: no CE specification, *C: with CE mark specification*

Note: 1. Compatibility between the motor and driver is valid only between the same models.

second digit/A: contact I/O voltage 12 to 24V + position command input;

differential, B: contact I/O voltage 5V + position command input; differential)

This means that, for the standard models, the motor and driver are compatible only when the designations

of the five digits in motor type (DR""""") and driver type (UR"""""

) are the same.

2. Separate selection is required for the driver without 2 kW class regenerative unit.

1

1-5

Page 17

1

Overveiw of the Product

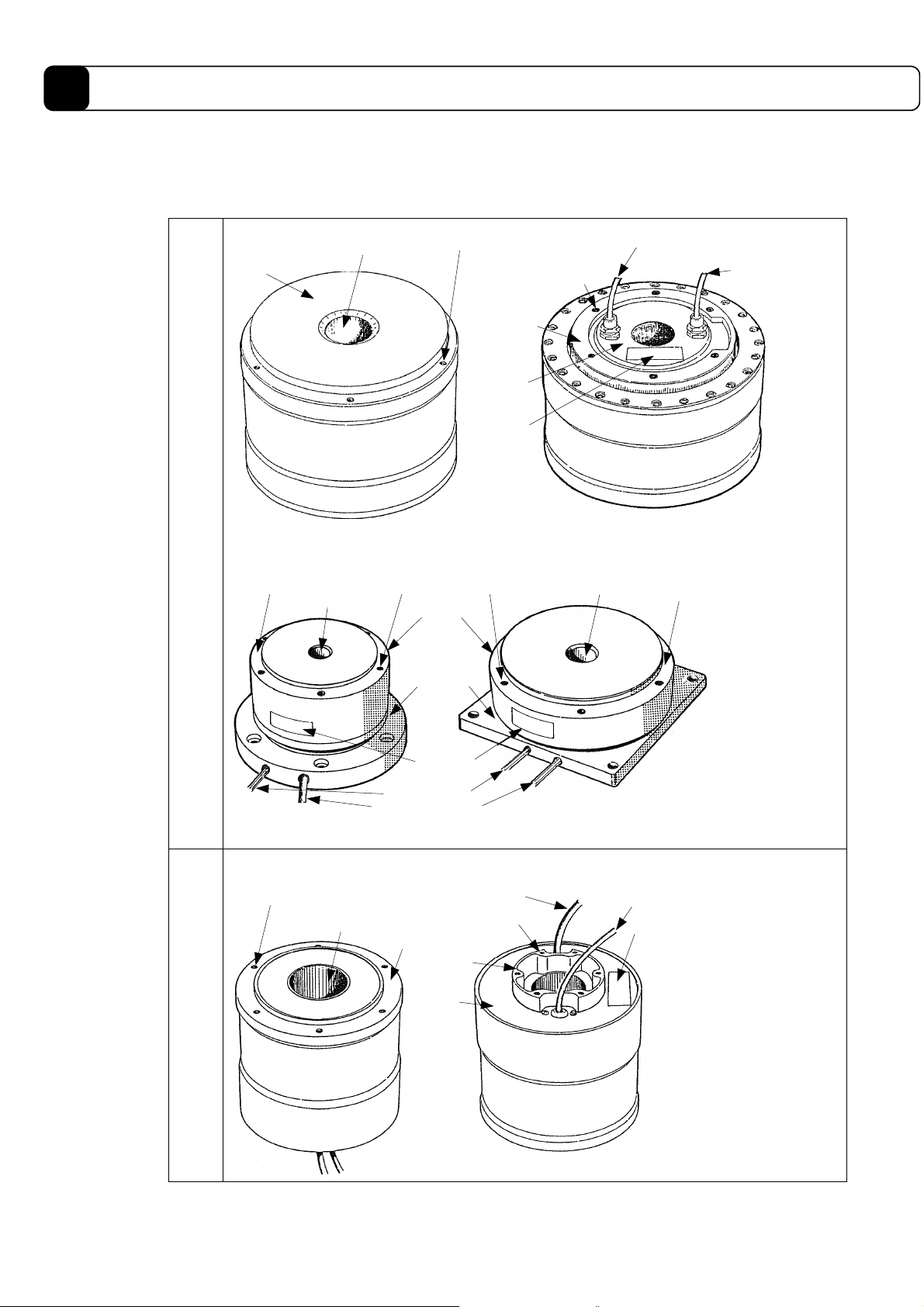

1.5 Name and Function of Each Part

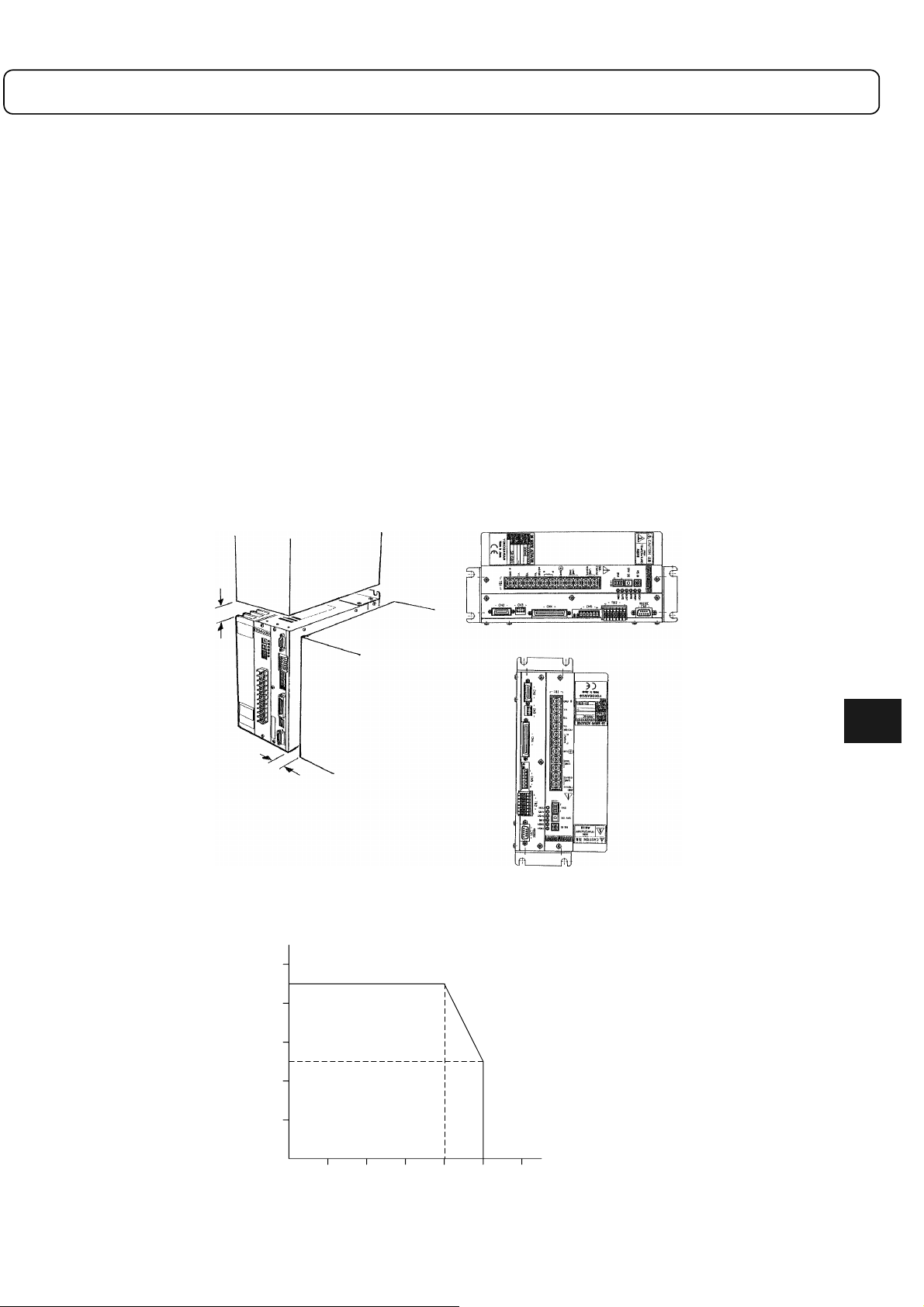

(1) Motor Part

DM

series

Rotor

Load installation

surface

Shaft hole

(Upper surface)

Shaft hole

Load installation screw

Bottom cap

nameplate

Load installation

screw

Rotor

Base part

(stator)

Stator installation

screw

Stator

Rating

Encoder cable

(Bottom surface)

Shaft hole

Motor cable

Load installation

surface

DR

series

(DM1004C)

Load installation screw

Shaft hole

Rating

nameplate

Motor cable

Encoder cable

Stator installation

Rotor

Stator

Bottom

cap

Motor cable

screw

(DM1004B)

Encoder cable

Rating

nameplate

1-6

Page 18

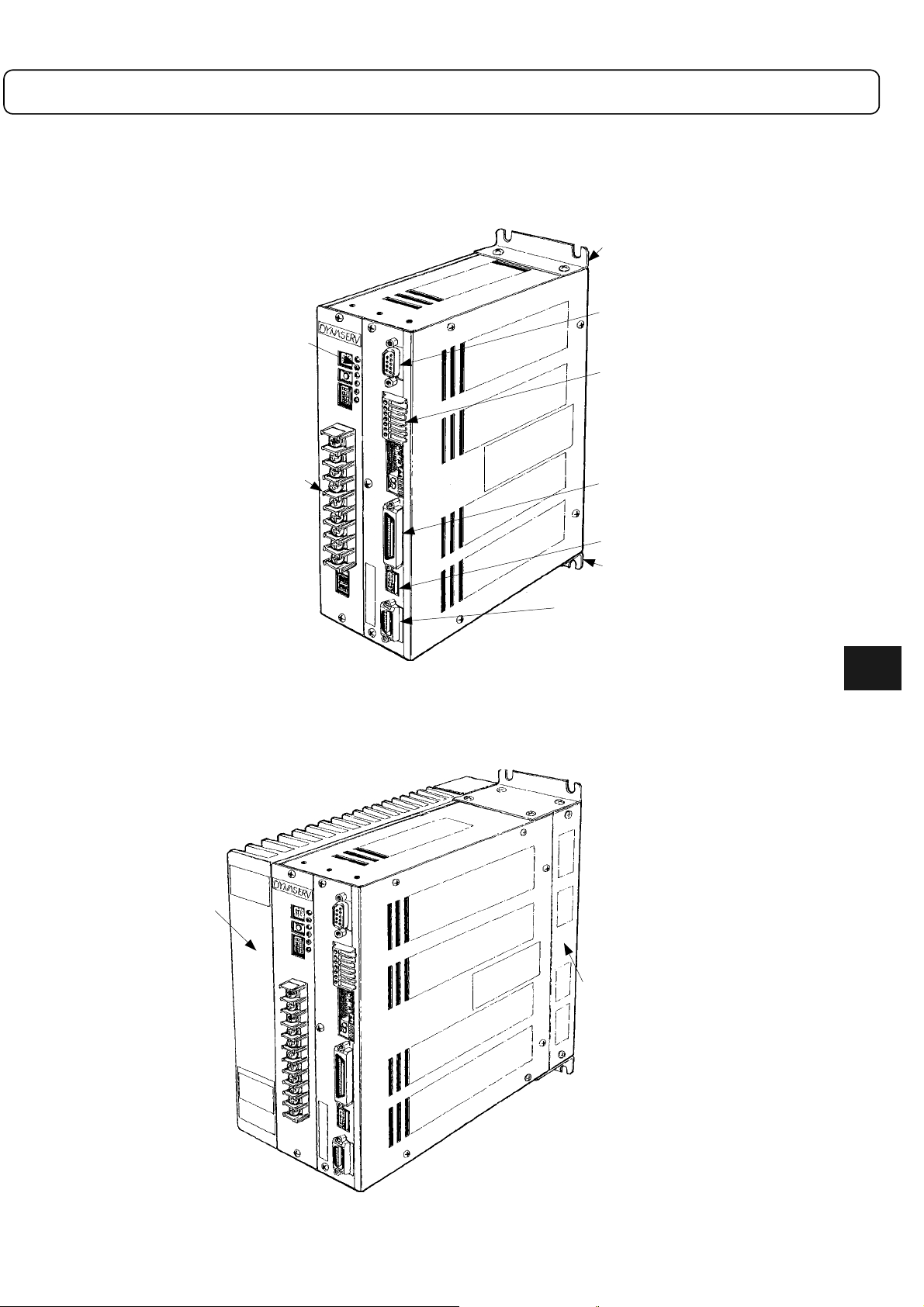

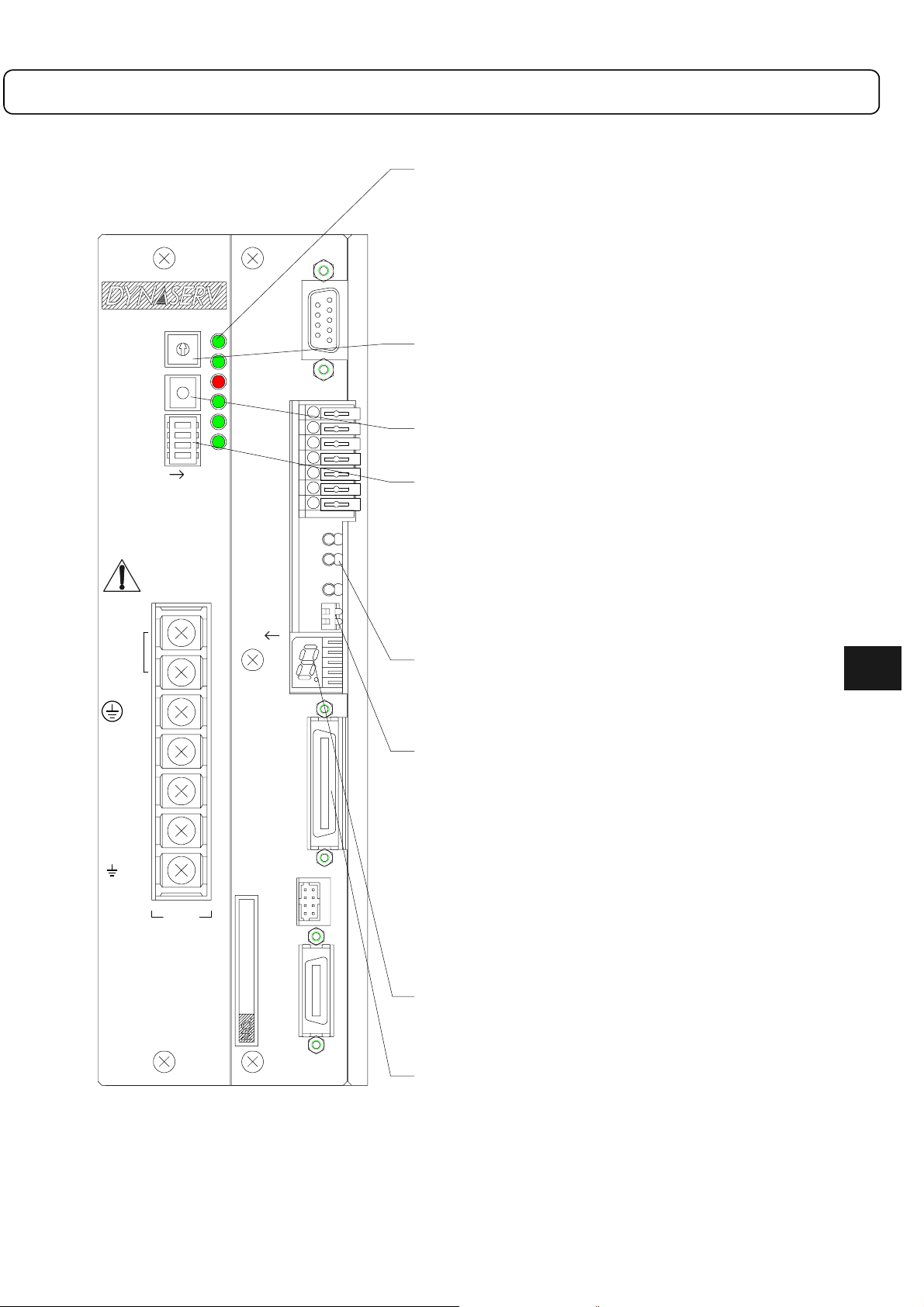

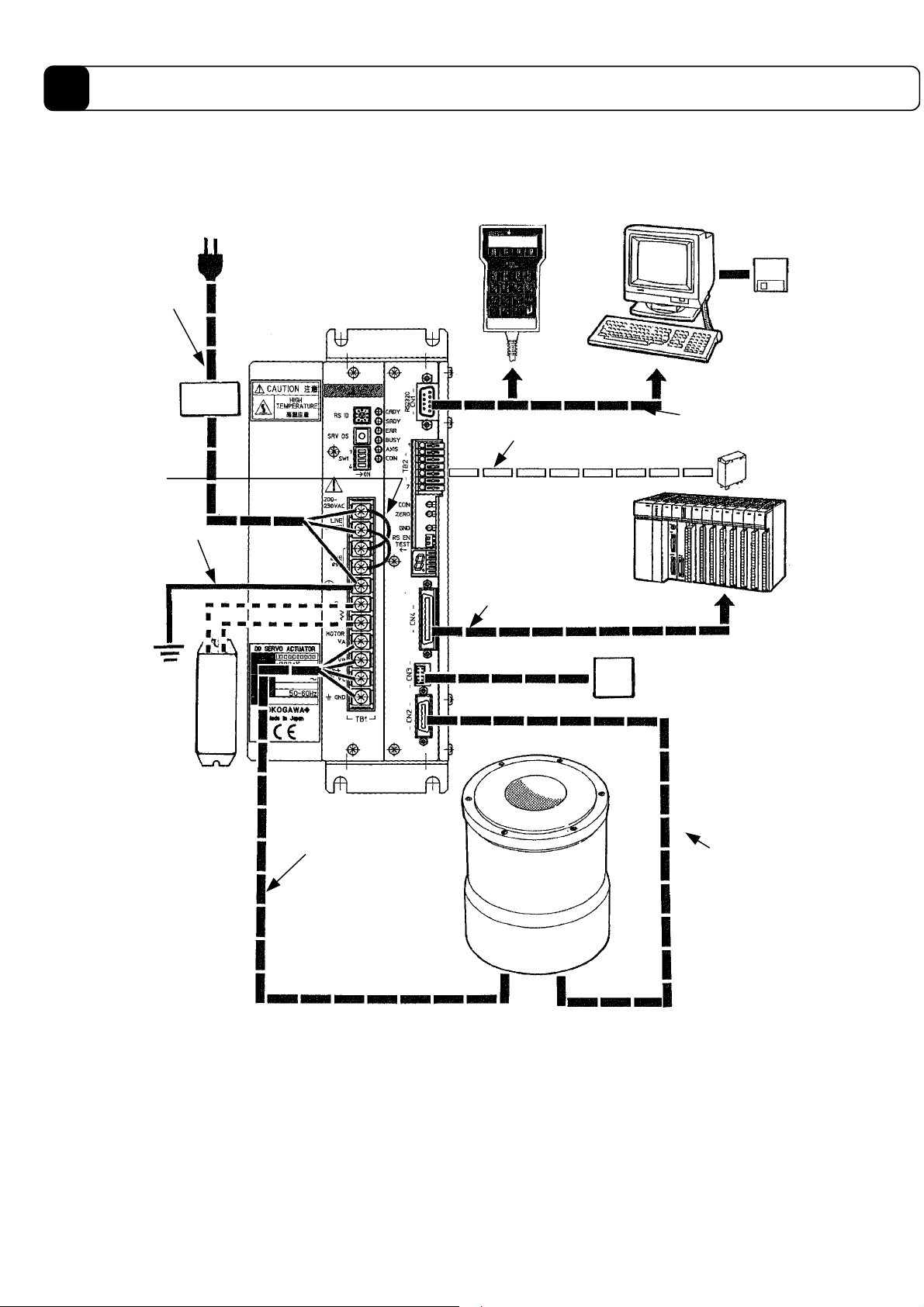

(2) Driver part

! 500W level

(A model with regenerative terminal is shown)

Setting switch

and status LED

display part

Mounting bracket

<CN1>RS232C

connnector

<TB2> Sensor brake

terminal

Connection of power

<TB1>

supply and motor cable

! 2kW level

(A model with a regenerative terminal is shown)

Heat sink

<CN4> Contact I/O connector 1

<CN3> Analog monitor connector

Mounting bracket

<CN2> Encoder resolver connector

1

1-7

Regenerative unit

Page 19

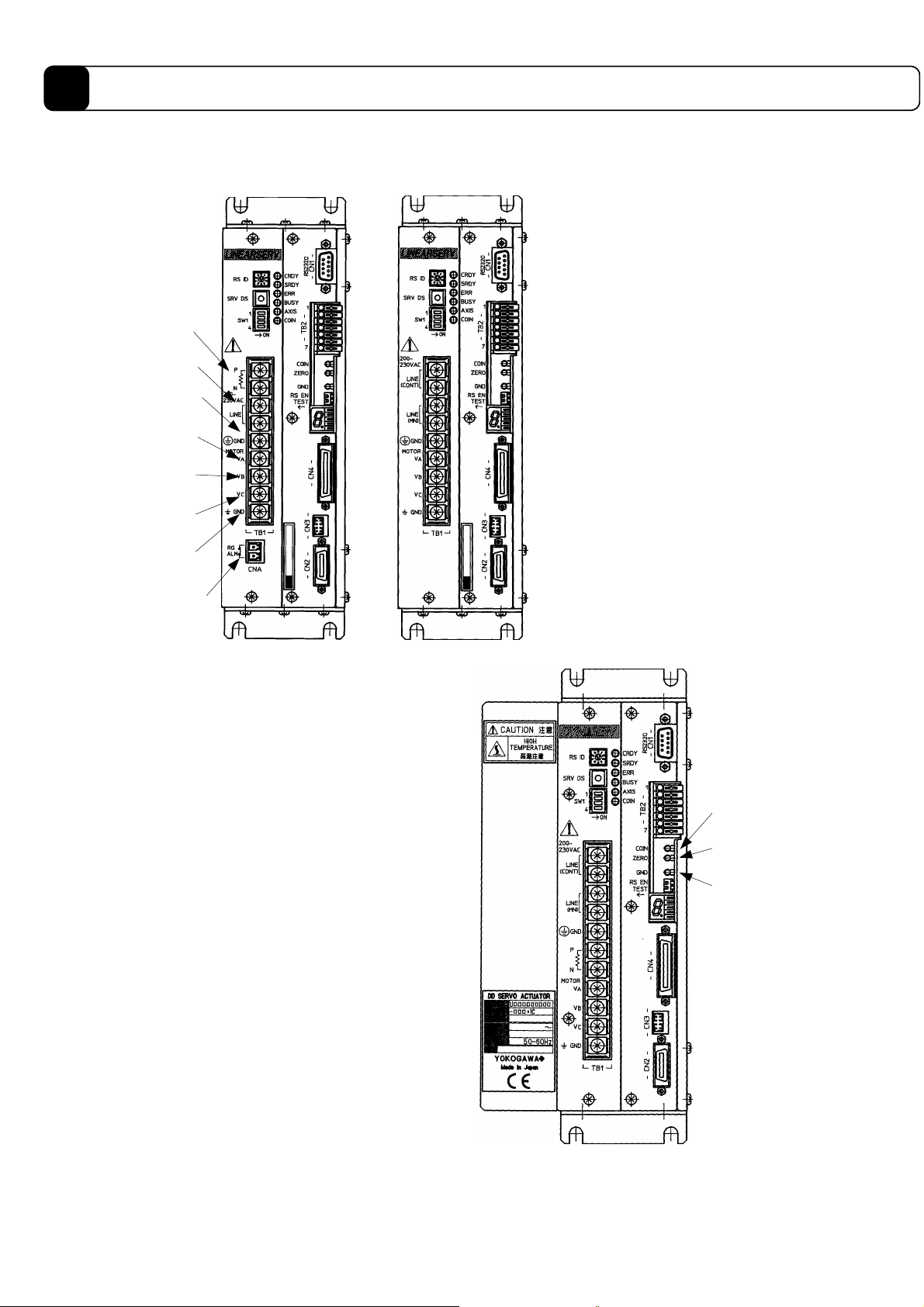

1

Overveiw of the Product

(3) Details of the Front Panel of the Driver

!

500W level

(with regenerative terminal)

Regenerative

terminal

Power supply

terminal

Power supply

ground terminal

Motor cable

phase A terminal

Motor cable

phase B terminal

Motor cable

phase C terminal

Motor cable

ground terminal

Regenerative error

<CNA>

connector

(without regenerative terminal)

!

500W level

!

2kW level

Signal ground

terminal

ZERO signal

terminal

Settling signal

terminal

Note: (1) All the items shown are of the contact I/O type.

(2) The power supply ground terminal and the motor cable ground terminal are connected within the driver

chassis.

1-8

Page 20

[Details of Setting Switches and Status Display LEDs]

Status display LEDs

CRDY CPU ready Indicates that the driver finished its initial

SRDY Servo ready

ERR Error status

BUSY Busy Indicates that the driver is currently

AXIS Axis is operating Indicates that the axis is currently operating

COIN Settling status Indicates that the axis is in its position

COIN

ZERO

GND

RS EN

TEST

RS232C

- CN1 -

1

- TB2 -

7

- CN4 -

- CN3 -

RS-ID Rotary switch

The communication method of the RS232C interface is set according

to the status of this switch when the power is turned on.

0 Single channel communication

1 to 9 Multi-channel communication. The value corresponds to

SRV-DS Servo disable switch

The servo is turned off for as long as this switch is pressed, regardless

of the command status of the RS232C interface and PLC interface.

SW1 Slide switch

When the power is turned on, the operation status of the driver is

determined by the status of these switches.

bit1 Reset all

bit2 Reserved

bit3 Reserved

bit4 Maintenance operation setting

Check terminal

COIN Settling Indicates that the axis is in its position settling

ZERO Zero signal status

GND Digital ground

PSW1 Piano switch

bit1 Test operation

bit2 RS-232C operation enable

RS ID

SRV DS

200230VAC

LINE

GND

MOTOR

V

V

V

GND

SW1

A

B

C

0

1

9

2

8

7

6

5

1

4

ON

CRDY

3

4

SRDY

ERR

BUSY

AXIS

COIN

TB1

processing and went into its normal status.

operating.

(dwell operation)

settling status.

the ID of the slave station.

If this bit is on when the power is turned on, all driver

information is reset to the default status at shipping.

If this bit is on when the power is turned on, the driver is set

in maintenance operation status. Normally, this bit should be

set to off.

status.

(LED display indicates the Zero signal status.)

Starts test operation when the lever is up.

Ends test operation when the lever is down.

Enables or disables the following

commands from the RS-232C interface

depending on the status when the power is

turned on.

Commands to be disabled: @1 Abort

@2 Stop

@3 Stop

@11 Jog

Lever up: Enable

Lever down: Disable

1

- CN2 -

Error display LED

Displays an error code when an error occurs.

When resetting: "0" (lit)

When operating: "." (flashing)

CN4 Controller interface connector

1-9

Page 21

1

Overveiw of the Product

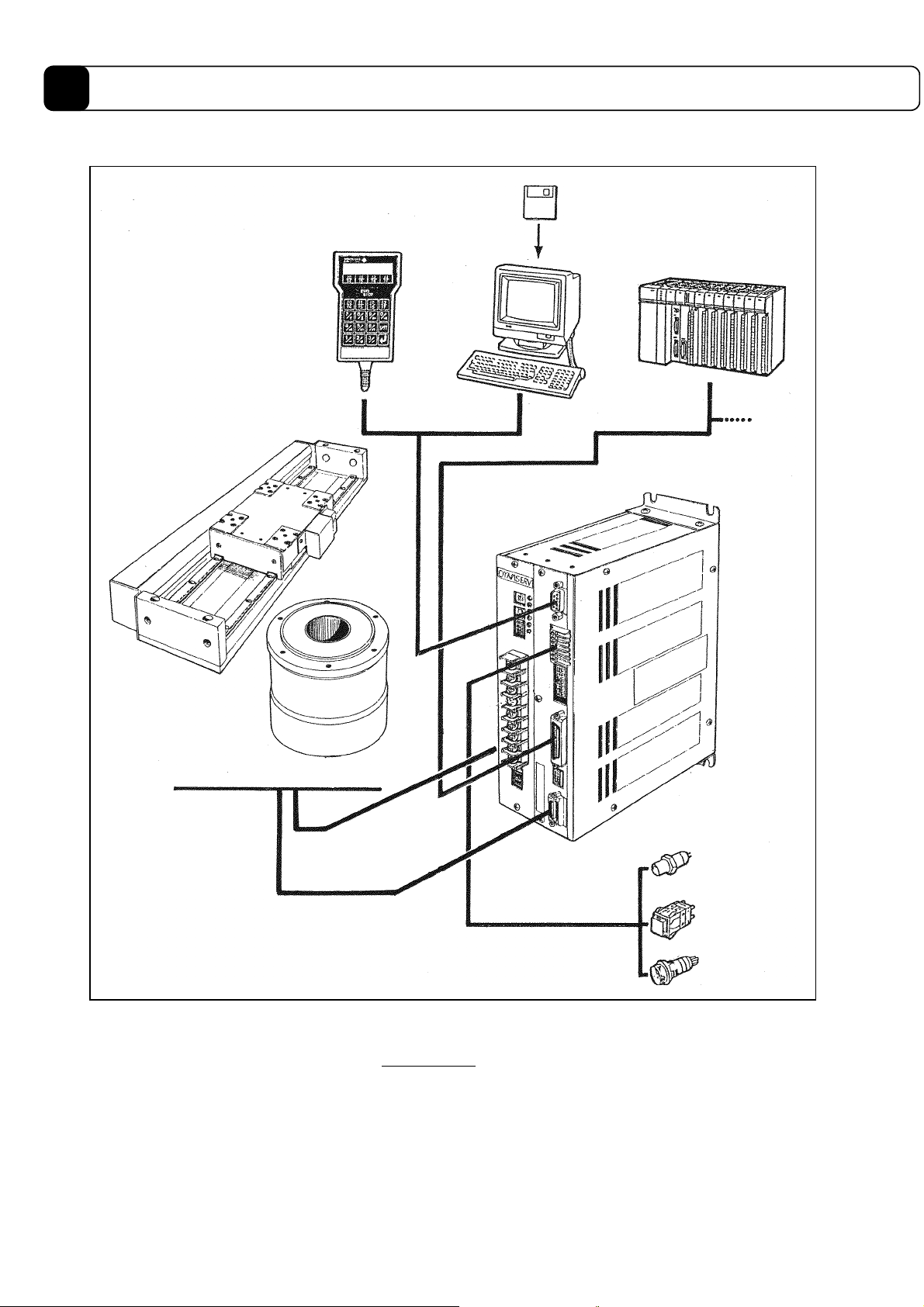

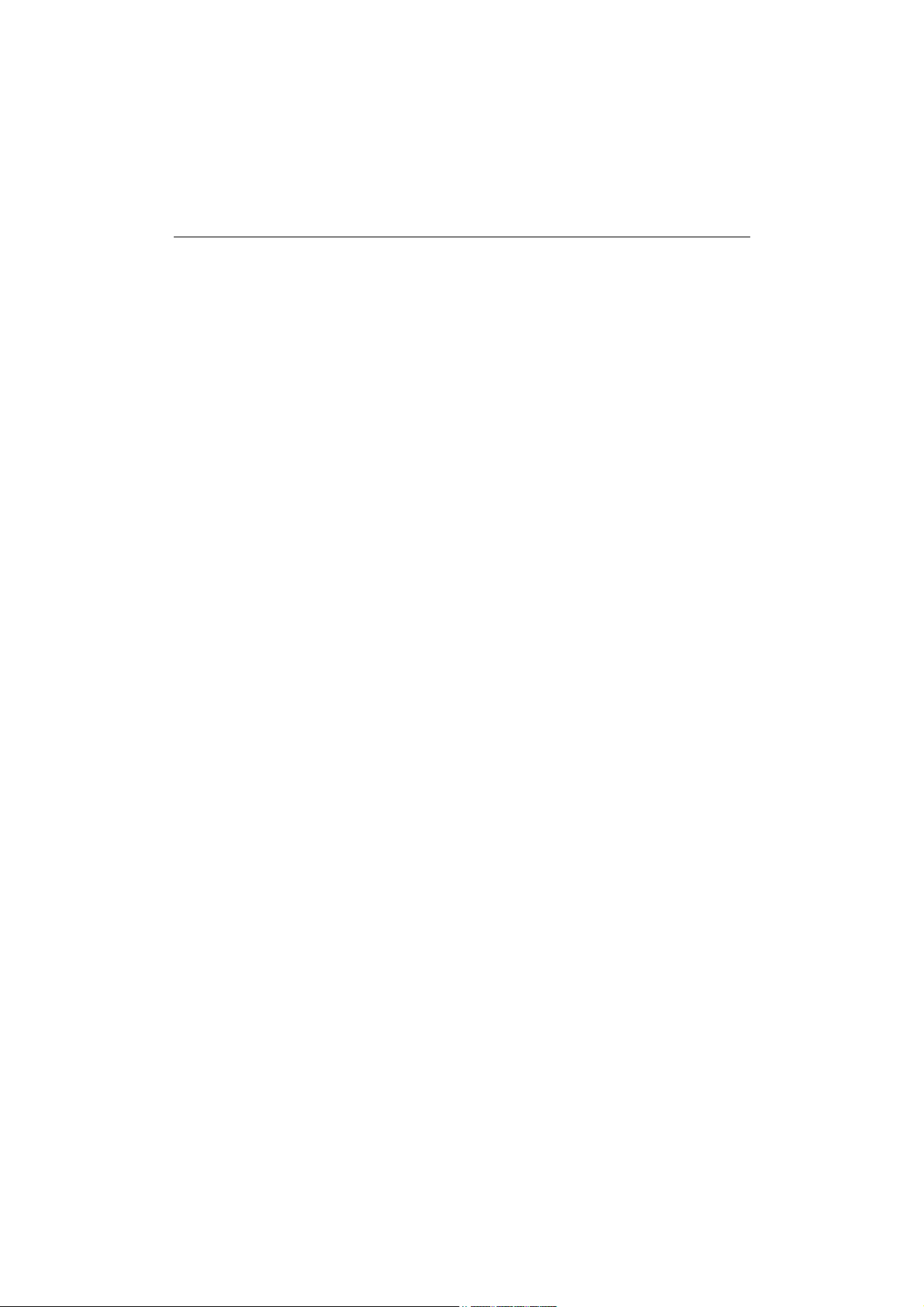

1.6 System Configuration Diagram

Operation display pendant

(PC)

LINEARSERV motor part

<LM series>

PC utility floppy disk

<Utility>

(PLC)

I/O monitor

board

DYNASERV motor part

<DM/DR series>

DrvGII type driver

(Home position

sensor)

(Over travel sensor)

(Over travel sensor)

Note: The allowable combinations between the DYNASERV motors and the DrvGII drivers are as follows.

(1) The 500W level driver can only be used with the DM1004B/1004C.

(2) All other DM and DR series should be used with the 2kW level driver. Note that they cannot be used

with the 500W level driver.

1-10

Page 22

Chapter 2

Installation

2.1 Installation of the Motor

2.2 Installation of the Driver

2-1

Page 23

2

Installation

When you receive the product, verify the model name and code of the product’s main unit, whether all the

standard accessories are included, and that the combination of a motor and a driver is correct before you begin

installation and wiring.

2.1 Installation of the Motor

The motor part can be installed and used in either a horizontal or a vertical position. However, if installed in a

wrong way or position, the life of the motor may be shortened or the motor may fail. Always follow the

instructions explained below.

(1) Installation Position

The motor part is designed based on the assumption that it is used indoors. Therefore, choose the location of

installation so that it satisfies the following conditions:

! It should be indoors and not in a place where it can be exposed to corrosive and/or volatile gases.

! The ambient air temperature should be from 0 to 45 °C.

! There should not be too much dust or particles, the ventilation should be good, and the humidity should

be low.

Note: The DYNASERV is not drip- or water (oil)-proof. If it is used in such an environment, a proper drip- or

water (oil)-proof cover should be applied.

(2) Mechanical Installation

! When installing a load on the rotor of the motor, make sure to secure a clearance of 1 mm or more

between the upper surface of the motor and the installed part in order to maintain the surface accuracy.

! The clamping torque of the screws used to install the rotor and stator of the motor should be equal to or

less than the value indicated below.

! The surface flatness where the motor is fixed should be 0.01 mm or less.

Rotor mounting screw

Clamping torque (maximum)

A/E type: 21N-m (210kgf-cm)

B type: 11N-m (110kgf-cm)

DM1004B/1004C: 2N-m (20kgf-cm)

Motor

Stator mounting screw

Clamping torque (maximum)

A/E type: 21N-m (210kgf-cm)

B type: 11N-m (110kgf-cm)

DM1004B/1004C: 2N-m (20kgf-cm)

1mm or more

Flatness of fixing

surface: 0.01mm

Note: When tightening the screws, make sure to apply a screw lock using Loctite 601 or equivalent product.

2-2

Page 24

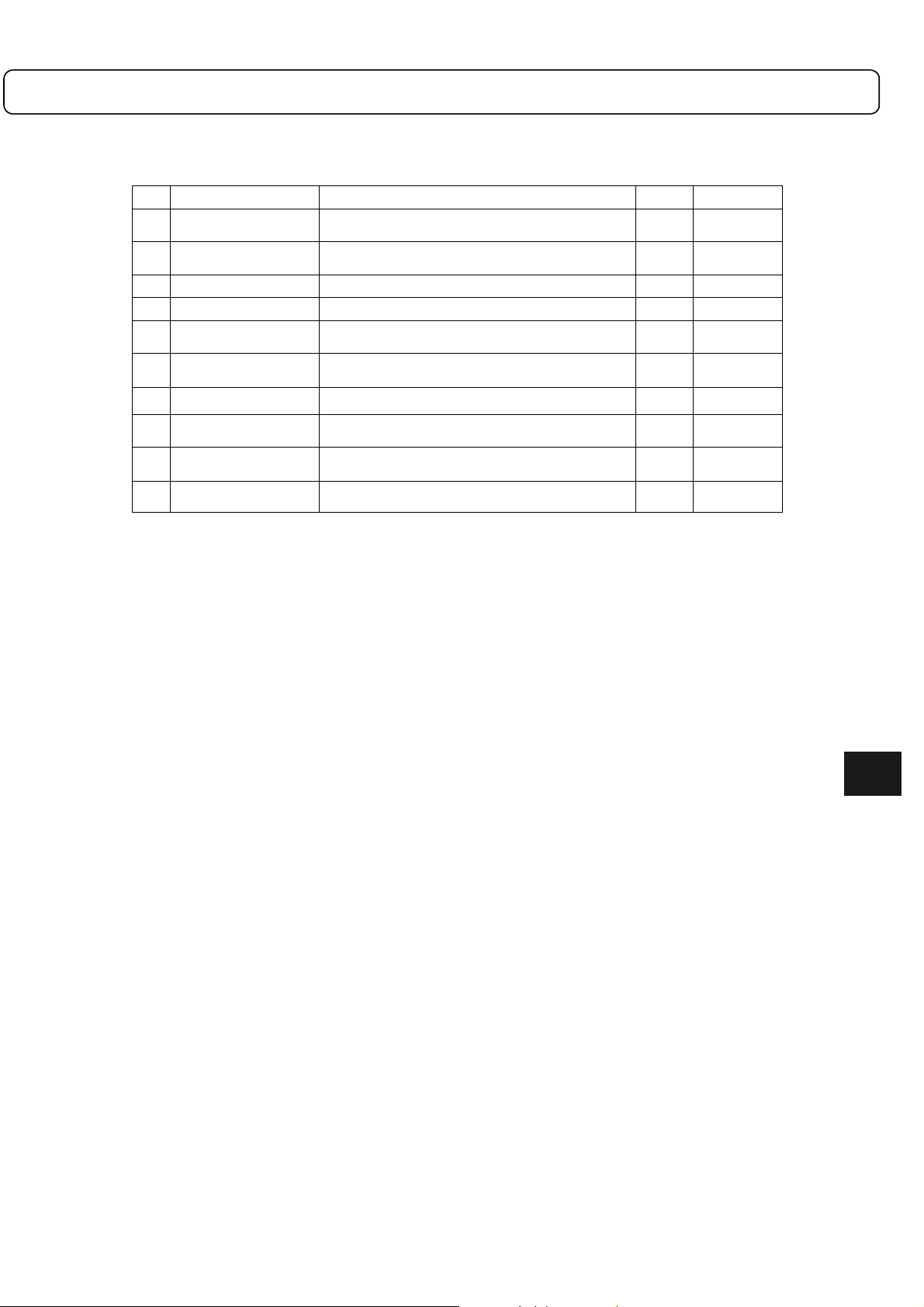

2.2 Installation of the Driver

e

The standard installation method for the driver is either to mount it on a rack or a wall.

(1) Installation Position

! If there is a heating source near by, the temperature should be prevented from increasing by installing a

shielding cover, etc.; the temperature around the driver should not exceed 50 °C (Note 1).

! If there is a source of vibration near by, the rack should be installed via a vibration absorption material.

! In addition to the above, it should be avoided to install the driver in surroundings that are high in

temperature and humidity, filled with dust, metal powder, corrosive gas, etc.

(2) Installation Method

! The standard way of installation is to install the driver on a rack, aligning the top and bottom with the

front panel in the front. Do not put the panel surface into a sideways position or upside down (see the

figure below).

! The driver box employs a natural air ventilation system. Make sure to secure space for ventilation above

and below (25 mm or more) and right and left (25 mm or more) (see the figure below).

! Make sure to use the installation holes (four places) of the upper and lower brackets at installation.

25 mm

Should not be installed in a

sideways position.

Should not b

25 mm

(Note: 1) 2 kW level drivers, but not other types, will have the current characteristics shown in the graph below as a

function of the ambient air temperature during operation. Therefore, it is recommended to use the driver in an

ambient air temperature of 40 °C or less in order to prolong its life.

Current derating curve

50%

45%

40%

30%

25%

20%

Square current duty

10%

installed

upside down.

2

0%

10℃ 20℃ 30℃0℃

Ambient air temperature during operation

40℃ 50℃ 60℃

2-3

Page 25

Chapter 3

Connection and Wiring

3.1 Diagram of Overall Connection

3.2 Cable Specification List

3.3 Connection between Motor and Driver

3.4 Wiring of Motor, AC Power Supply, and Ground Cable

3.5 Wiring of Encoder Cable

3.6 Wiring of Controller Cable

3.7 Wiring of Sensor Brake Terminal

3.8 Wiring of Regenerative Alarm Contact <CNA>

(For 500W Level Drive Only)

3-1

Page 26

3

Connection and Wiring

3.1 Diagram of Overall Connection

* Operation display pendant

(including 1.5 m cable)

[PM000AT]

PC

* PC Utility

1) * AC

power supply

cable

7) Jumper

cable

2) Ground cable

<DrvGII> type drive

The figure shows a 2kW level.

Line

*

filter

4) Sensor brake cable

Programmable controller

9) Controller cable

[CP4202G-ooo]

5) * RS232C communication

cable

[CP7675S-020 (for DOSV, 2m)]

[CP7577S-020 (for PC98, 2m)]

8) * Analog monitor card

(with cable connector)

[KC 601A

(Japanese)]

[KC 602A

(English)]

Sensor

* Regenerative resistance

(with lead wire)

3) * Motor cable

Motor part

(DM/DR series)

* Optional parts (see separate wiring section for motor and encoder cables.)

3-2

6) * Encoder cable

Page 27

3.2 Cable Specification List

Cable name Electric cable size Driver Current (A)

AC power supply

1)

cable

Ground cable (power

2)

supply)

3) Motor cable 2.0 mm2 or more, 30 m or less in length TB1

4) Sensor brake cable 0.3 to 0.75 mm

RS232C

5)

communication cable

Encoder resolver

6)

cable

7) Jumper cable 2.0 mm2 or more TB1

8) Analog monitor card

9) Controller cable

* 20A for the A (φ 264mm) and E (φ 205mm) types for both the DM and DR series

15A for the B (φ 160mm) type, and 10A for the DM1004B/1004C motors

2

2.0 mm

2.0 mm

or more, 30 m or less in length TB1

2

or more TB1

2

Dedicated cable is required. CN1

2

0.2mm

twisted pair, batch shielded cable, outer

diameter φ 14 mm or less, 10 m or less in length

Dedicated cable is required. [R7033YB] (cable

with connector)

0.2 to 0.5mm

2

, batch shielded cable, outer

diameter φ 9 mm or less, 3 m or less in length

TB2

CN2

CN3

CN4

*

*

*

Maximum

100 mA DC

*

Maximum

500 mA DC

3

3-3

Page 28

3

Connection and Wiring

3.3 Connection between Motor and Driver

Note: Shielding should be applied to each wire.

(1) DM Series (DM1004B/1004C) motors

Motor partDriver part

<TB1>

GND

V

A

V

B

V

C

Motor cable

Red

White

Black

Green

<CN2>

+10V/ 1

GND/12

θSIG0/3

GND/14

θSIG1/5

GND/16

ECLK+/ 7

ECLK-/18

Chassis ground

Red

Black

Blue

Blue and white

Brown

Brown and white

Orange

Orange and white

Encoder cable

(2) DM Series motors (models other than the above)

Shielded cable

Motor partDriver part

Red

White

Black

Green

Red

Black

Blue

Blue and white

Brown

Brown and white

Green

Green and white

Orange

Orange and white

<TB1>

GND

<CN2>

+10V/ 1

GND/12

θSIG0/3

GND/14

θSIG1/5

GND/16

ZERO+/ 9

ZERO-/19

ECLK+/ 4

ECLK-/13

Chassis ground

Motor cable

V

A

V

B

V

C

Shielded

cable

Encoder cable

Shielded twisted

pair cable

3-4

Page 29

(3) DR Series motors

<TB1>

GND

<CN2>

+S0/ 2

+S180/11

-S0/6

-S180/15

+C0/10

+C180/20

-C0/ 8

-C180/17

Chassis ground

VA

VB

VC

Motor cable

Motor partDriver part

Red

White

Black

Green

Encoder cable

Brown and white

Green and white

Brown

Green

Orange and white

Blue and white

Orange

Blue

Black

3

3-5

Page 30

3

Connection and Wiring

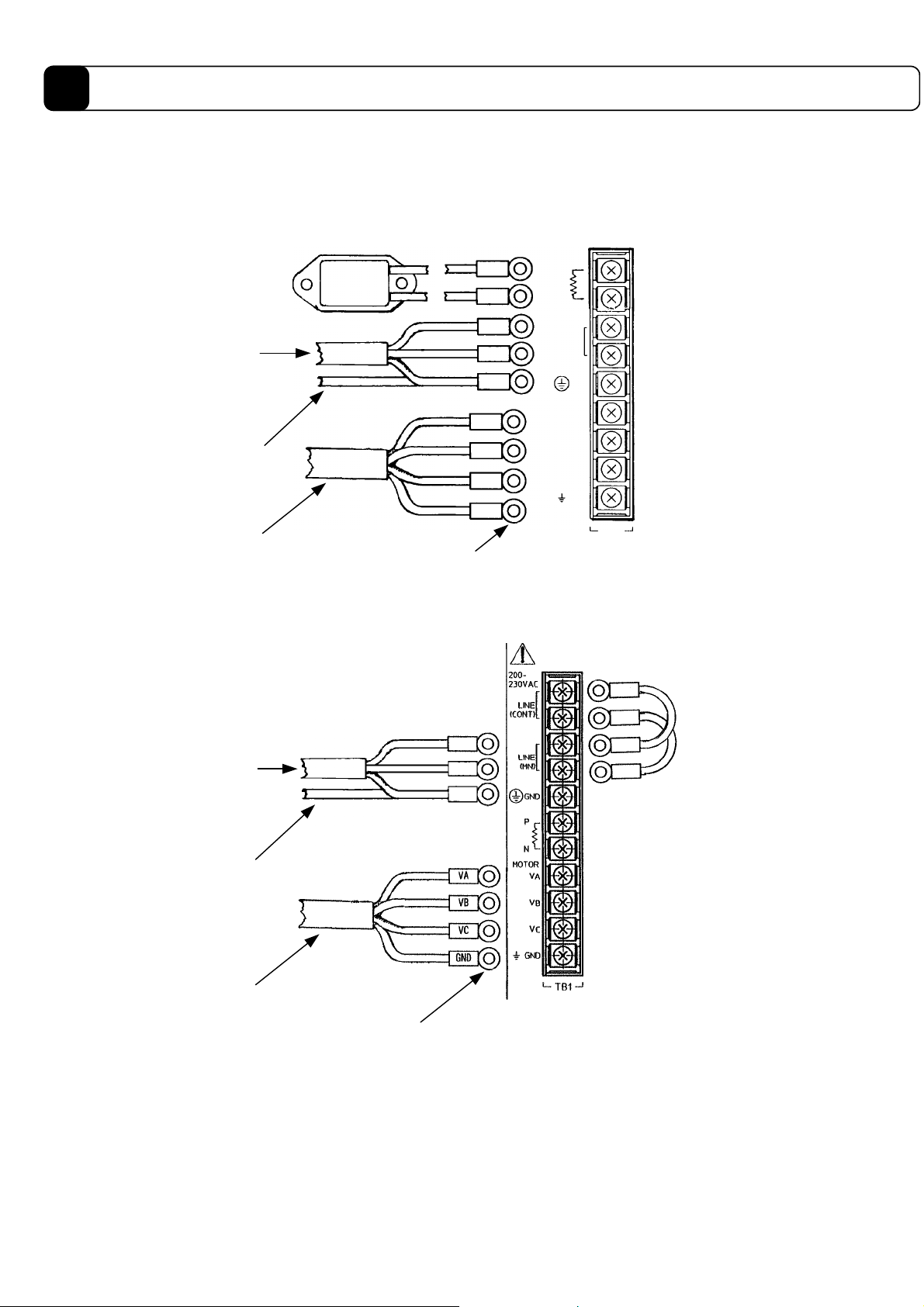

3.4 Wiring of Motor, AC Power Supply, and Ground Cable

(1) For the DM1004B/1004C motors (in connection with a 500W level driver)

* In the case shown, a regenerative resistance is required.

Regenerative

P

resistance*

AC power

supply cable

Ground cable

Motor cable

(Red)

(White)

(Black)

(Green)

Japan Solderless Terminal

type (N1.25-M4)

GND

V

V

V

GND

AC

AC

A

B

C

N

100115VAC

LINE

GND

MOTOR

V

A

V

B

V

C

GND

Driver side

(500W level)

TB1

(2) For other DM/DR series (other than above) (in connection with 2kW level driver)

Power supply

cable

Ground cable

Motor cable

Japan Solderless

Terminal type (N2-M4)

(Red)

(White)

(Black)

(Green)

AC

AC

GND

Jumper

cable

Driver side

(2KW level)

3-6

Page 31

Cable

AC power

supply cable

Motor cable

Specification

DM1004B/1004C Other DM/DR series

!

0.5 mm2 or more, 30 m or less in length

! Clamping torque of terminal: 12[kgf-cm

2

](1.18[N⋅m])

!

2.0 mm2 or more, 30 m or less in length

(terminal screw: M4x0.7)

! Power supply filter, recommended part: Tokin Corporation #LF-200 series

! 0.5 mm

!

Optional cable: CM6000C-

2

or more, 15 m or less in length ! 2.0 mm2 or more, 30 m or less in length

"""

! Optional cable: CM300M-""" or

CM0300R-"""

2

or more (use as thick cable as

Ground cable

!

0.5 mm2 or more (use as thick cable as possible)

!

2.0 mm

possible)

! Third grade ground (ground resistance 100Ω or less)

Jumper wire ! 2.0 mm2 or more

Regenerative

resistance*

For 100V: 80W 60Ω

For 200V: 80W 200Ω

* Only for models with regenerative resistance (500W level)

3

3-7

Page 32

3

Connection and Wiring

3.5 Wiring of Encoder Cable

(1) DM1004B/C motor

Pin #

Signal

name

1 + 10 V 11 - 1 + 10 V 11 - 1 - 11 +S180

2 - 12 GND 2 - 12 GND 2 +S0 12 3

θSIG 0

4 - 14 GND 4 ECLK+ 14 GND 4 - 14 5

θ SIG 1

6 - 16 GND 6 - 16 GND 6 -S0 16 7 ECLK+ 17 - 7 - 17 - 7 - 17 -C180

8 - 18 ECLK- 8 - 18 - 8 -C0 18 9 - 19 - 9 ZERO+ 19 ZERO- 9 - 19 -

10 - 20 - 10 - 20 - 10 +C0 20 +C180

Pin #

Chassis

ground

Signal

name

13 - 3

15 - 5

Shielded

cable

(other than the one described to the left)

Pin #

(2) DM series motor

Signal

name

θSIG 0

θSIG 1

Pin #

13 ECLK- 3 - 13 -

15 - 5 - 15 -S180

Chassis

ground

Signal

name

Shielded

cable

Pin #

(3) DR series motor

Signal

name

Pin #

Chassis

ground

Terminal for <CN2>

2011

Insertion

surface

Made by Honda Tsushin Kogyo

Connector: PCR-S2OF

Housing: PCR-LS20LA1

Chassis ground

(shielded cable)

1

1 32

10

Signal

name

FG

Shielded

cable

Soldering

surface

Electric wire

specification

11 1312

! 0.2 mm

less in length*

2

multiple-core twisted pair batch shielded cable, 30 m or

20

Optional cable

DM series motor

DM1004B/C

(other than the ones

described to the left)

CE7900C-""" CE7900M-""" CE7900R-"""

* Within 10 m only for small-diameter/flat types (DM1004B/C).

DR series motor

3-8

Page 33

3.6 Wiring of Controller Cable

<CN4> terminal

Pin # Signal name Pin # Signal name Pin # Signal name Pin # Signal name

1 COMP1 10 UA_OUT- 19 IN_ERR_RESET 28 IN_FN

2 COMN1 11 DB_OUT+ 20 IN_SERVO 29 IN_PLS_DIRECT

3 OUT_DRDY 12 DB_OUT- 21 IN_MODE_START 30 IN_PACT

4OUT_SRDY 13Z_OUT+ 22IN_ABORT 31 (NC)

5 OUT_BUSY 14 Z_OUT- 23 IN_MODE.0 32 (NC)

6 OUT_XOVL 15 PUA_IN+ 24 IN_MODE.1 33 CRNT_LMT_IN+

7 OUT_OVER 16 PUA_IN- 25 IN_POSW.0 34 CRNT_LMT_IN-

8 OUT_COIN 17 SDB_IN+ 26 IN_POSW.1 35 (NC)

9 UA_OUT+ 18 SDB_IN- 27 IN_GAIN 36 (NC)

Terminal for <CN4>

Made by Honda Tsushin Kogyo

Connector: PCR-S36FS

Housing: PCR-LS36LA

Chassis ground

(shielded cable)

Electric wire

specification

19 36

118

1 32

!

0.2 to 0.5 mm2 or more, multiple-core batch shielded cable, 3 m or

less in length

!

Optional cable: CP4202G-

Insertion surface

Soldering surface

18

36212019

"""

3

3-9

Page 34

3

Connection and Wiring

3.7 Wiring of Sensor Brake Terminal

Pin # Signal name

1COMP0

2XORG

3XOTD

4XOTU

5(NC)

6 XBRKP

7 XBRKN

1) Push down the lever with

a screwdriver.

Electric wire

specification

See the panel surface of the driver for the pin numbers.

<TB2> Made by Sato Parts (ML1900H)

2) Insert the wire deeply.

! 0.3 to 0.75 mm2, electric wire coating with 10 mm of the core

exposed at the tip

! If a twisted wire is used, the diameter of the strand should be

φ 0.18 or larger.

3) Push up the lever

(until you hear the click)

10mm

Example of sensor connection (sensor: EE-SX670 manufactured by Omron)

The recommended sensor logic is B contact.

Set the sensor to OFF when the light is shielded. The sensor described above will be set to OFF when the light is shielded

by the following result.

Signal

name

XORG

XOTD

XOTU

(NC)

XBRKP

XBRKN

Pin #

1COMP0

2

3

4

5

6

7

1

2

3

4

1

2

3

4

1

2

3

4

+

DC power

supply

-

Home position sensor

(-) Over travel

(+) Over travel

COMP0

XORG

XOTD

XOTU

[Electrical specifications]

Input specifications

Rated voltage

Rated input

current

Input

impedance

Operating voltage

(relative to COMP*)

Allowable

leakage current

470Ω

2.7kΩ

12~24VDC (±10%)

4.1 mA/point (at 12 VDC)

8.5 mA/point (at 24 VDC)

3.0kΩ

At OFF: 3.0 VDC or less

At ON: 9.0 VDC or more

OFF is guaranteed at 1.0

mA or less.

Vcc

100kΩ

PS2805

10kΩ

0.01μF

3-10

Page 35

3.8 Wiring of Regenerative Alarm Contact <CNA>

(For 500W Level Drive Only)

This driver (with regenerative terminal) is equipped with a regenerative circuit failure detection circuit. When

connecting the regenerative circuit, build a sequence circuit as shown in the figure below in order to prevent

burnout incidents.

Note: Build a sequence circuit so that it will turn off the power supply at alarm operation.

Driver

MC

LINE

<TB1>

MC

L

N

<CNA>

Made by Phoenix Contact

(plug: MC1, 5/2-ST-5, 08)

Direction of

insertion

ONOFF

MC

MC

Regenerative

<CNA>

Blade point of the driver used

Thickness 0.4mm, width 2.5mm

(clamping torque: 0.22 to 0.25 [N-m]

alarm

250 V AC 0.1 A

30 V DC 1 A

7 mm

3

3-11

Page 36

Chapter 4 Basic Settings for Operating

the Motor

This chapter describes "Basic Settings," which should be used as the

first step in understanding the "motor/driver/PC utility." The information

is provided progressively, focusing on motor tuning, homing operation,

and its setting method.

Make sure to perform the operations described in this chapter as a

preliminary step before commencing device production.

4.1 Procedure (Flowchart)

4.2 Preoperation check

4.3 Installing the PC Utility on the PC

4.3.1 Procedure

4.3.2 Startup

4.4 Preparation

4.4.1 Selecting Communication Port

4.4.2 Selecting Channels

4.4.3 Displaying Communication Strings

4.4.4 Main Menu

4.5 Setting the Status to Servo ON

4.6 Auto-tuning

4.7 Performing Homing Operation

4.8 Performing the Basic Settings of Pulse Commands

4.8.1 About Position Command Pulse Input

4.8.2 Example of Operation

4-1

Page 37

4

Basic Settings for Operating the Motor

4.1 Procedure (Flowchart)

In this section, we will operate the motor according to the procedure below.

START

Preoperation check

Install the PC utility.

Set the status to

"Servo ON."

Auto-tuning

Homing operation

Basic settings of

pulse commands

Check the installation of the motor, wiring etc.

Install the software PC utility on your PC.

Set the status of the motor to "Servo ON."

!

Operation using the PC utility (RS-232C).

Adjust the servo (gain adjustment).

!

Operation using the PC utility (RS-232C).

Perform homing operation.

!

The case where the home position proximity

sensor is input in the driver is explained.

Perform the basic settings required for pulse

input.

Operate (pulse input)

END

Perform the settings and pulse input required for

operation from the user's controller.

4-2

Page 38

4.2 Preoperation check

(1) Items to prepare

• Motor unit/driver/sensor/DC power supply

• PC utility (floppy disk)

• Level block for fixing the motor

• PC (with Windows 95/98/98SE/Me/NT4.0/2000 installed)

• Various cables

(2) Installation and Wiring

Positioning

controller

PC utility (software)

24V DC

power supply

(prepared by customers)

TB 2

DrvGII

type

TB 1

CN 2

driver

CN 1

CN 4

(prepared by customers)

7) RS232C cable

(dedicated)

CP7576(77)S-020

3) Power supply line

1) Level block

(prepared by customers)

6) Sensor wiring

(prepared bycustomers)

Motor part

(main body)

Sensor

Level block

4) Motor cable

CM0300M(R) -ooo

5) Encoder cable

CE7800M(R)-ooo

(3) Items to be checked Check

1) Is the main body fixed on the level block? "

2) Is the motor not interfering with peripherals? "

PC

4

3) Is the power supply line wired properly? (LINE, GND) "

4) Is the motor cable wired properly? (VA, VB, VC. GND) "

5) Is the encoder cable wired properly? "

6) Is the sensor wired properly? "

(Home position, OT sensor: driver (or positioning controller))

7) Is the RS232C cable wired properly? "

8) Is RS-232C operation enabled? "

(Is bit 2 of PSW1 is on?)

9) Is the wiring with the positioning controller done properly? "

(See a connection example on the following page.)

4-3

Page 39

4

Basic Settings for Operating the Motor

Controller

12 to 24 VDC

Photocoupler, contact, etc.

DrvGII (CN4) I/O 24V Specification

01

19

20

21

22

23

24

25

26

27

28

29

30

COMP1

IN_ERR_RESET

IN_SERVO

IN_MODE_START

IN_ABORT

IN_MODE.0

IN_MODE.1

IN_POSW.0

IN_POSW.1

IN_GAIN

IN_FN

IN_PLS_DIRECT

IN_PACT

2.7K

PS2805 or equivalent

Ω

470

Ω

Photocoupler,

contact, etc.

AM26LS31 or equivalent

AM26LS32 or equivalent

LMIT

12 to 24 VDC

+

-

+

-

+

-

+

-

+

-

03

04

05

06

07

08

02

15

16

17

18

09

10

11

12

13

14

33

34

OUT_DRDY

MA8330 or

equivalent

OUT_SRDY

OUT_BUSY

OUT_XOVL

OUT_OVER

OUT_COIN

COMN1

PUA_IN+

PUA_IN-

SDB_IN+

SDB_IN-

UA_OUT+

UA_OUT-

DB_OUT+

DB_OUT-

Z_OUT+

Z_OUT-

CRNT_LMT_IN+

CRNT_LMT_IN-

33

Ω

2AD1820A or

equivalent

91

MA8330 or equivalent

PS2805 or equivalent

TLP115A or equivalent

Ω

AM26LS31 or equivalent

+

-

+

-

+

-

200K

Ω

Ω

200K

-

+

Connect the shield with the shell of

the connector.

4-4

Page 40

Controller

5VDC

7407 or equivalent

DrvGII (CN4) I/O 5V Specification

01

19

COMP1

IN_ERR_RESET

Ω

470

Ω

1K

PS2805 or equivalent

74LS244 or

equivalent

20

21

22

23

24

25

26

27

28

29

30

5VDC

Ω

1K

03

04

IN_SERVO

IN_MODE_START

IN_ABORT

IN_MODE.0

IN_MODE.1

IN_POSW.0

IN_POSW.1

IN_GAIN

IN_FN

IN_PLS_DIRECT

IN_PACT

OUT_DRDY

MA8330 or

equivalent

OUT_SRDY

MA8330 or equivalent

2AD1820A or

equivalent

PS2805 or equivalent

AM26LS31 or equivalent

+

-

+

-

AM26LS32 or equivalent

+

-

+

-

+

-

LMIT

05

06

07

08

02

15

16

17

18

09

10

11

12

13

14

33

34

Connect the shield with the shell of

the connector.

OUT_BUSY

OUT_XOVL

OUT_OVER

OUT_COIN

COMN1

PUA_IN+

PUA_IN-

SDB_IN+

SDB_IN-

UA_OUT+

UA_OUT-

DB_OUT+

DB_OUT-

Z_OUT+

Z_OUT-

CRNT_LMT_IN+

CRNT_LMT_IN-

4

Ω

33

Ω

91

200K

200K

TLP115A or equivalent

AM26LS31 or equivalent

+

-

+

-

+

-

Ω

-

+

Ω

4-5

Page 41

4

Basic Settings for Operating the Motor

4.3 Installing the PC Utility on the PC

4.3.1 Procedure

Installation under Windows 95/98/98SE/Me/NT4.0/2000

The G2 PC utility (hereinafter referred to as the “PC utility”) runs on Windows 95, 98, 98SE, Me,

WindowsNT4.0 and 2000. It can be installed via “Add/Remove Programs” under the “Control Panel” in

Windows. If an older version of the PC utility is present, delete it first and then install the new version.

Display the “Properties of Adding/Removing Programs” dialog box and click “Set Up (1).” Then proceed

according to the instructions displayed on the screen. The PC utility setup program starts up.

Proceed with the setup according to the instructions on the screen. A dialog box for determining the directory in

which to install the PC utility appears (see Figure 4.3.1).

Figure 4.3.1 “Choose Destination Location” dialog box

Click “Browse” to display the “Select Directory” dialog box and select the desired drive and directory. Click

“Next” to display “Select Program Folder” (see Figure 4.3.2).

4-6

Page 42

Figure 4.3.2 “Select Program Folder” dialog box

Select a program folder and click “Next.” The installation begins. Follow the instructions on the screen and

change disks. When the setup is completed, the “Setup Complete” dialog box appear (see Figure 4.3.3).

4

Figure 4.3.3 “Setup Complete” dialog box

To start the program, select “Launch the program file” and click “Finish.” If you do not want to start the program,

just click “Finish.” If you are prompted to restart the computer, simply follow the message and restart it.

Note: Remove the floppy disk before restarting the computer.

4-7

Page 43

4

Basic Settings for Operating the Motor

4.3.2 Startup

1)To start the PC utility, click “Start,” “Program (P),” “YOKOGAWA_E” and then “DrvGII.”

Figure 4.3.4 “Startup”

2) An “Version Information” dialog box is displayed for several seconds and then the PC utility starts up.

Version of PC utility

Figure 4.3.5 “Version Information” dialog box

Figure 4.3.6 After starting up the PC utility

4-8

Page 44

4.4 Preparation

Connect the serial port of the PC with the serial port of the driver with a dedicated cable.

(Do not use any of commercially available cables. Since 5V power is being output from the driver as the power

supply for the operation display pendant, a breakdown may occur in the PC if such cable is used.)

4.4.1

Selecting Communication Port

When you start the PC utility, the “ComPortSelect” dialog box appears in the left side of the screen (see Figure

4.4.1). Change the setting according to the communication port of the connected PC.

Figure 4.4.1 “ComPortSelect” dialog box

Note: Settings made in the “ComPortSelect” dialog box are stored in a file. It is not necessary to make settings

from the next time you start the PC utility. Change the setting as necessary.

4.4.2 Selecting Channels

When you start the PC utility, the “Communication mode” dialog box appears in the upper left corner of the

screen (see Figure 4.4.2). If you are using one driver, select a single channel, and if you are using multiple

drivers, select multi-channel addresses. (See Chapter 6 for how to make setting on the driver side.)

Figure 4.4.2 “Communication mode” dialog box

Note: The settings made in the “Communication mode” dialog box are not stored. When the PC utility is started up,

a single channel is always set.

4

4-9

Page 45

4

Basic Settings for Operating the Motor

4.4.3 Displaying Communication Strings

When you start the PC utility, the “Communication string” dialog box appears in the upper right corner of the

screen. (See Figure 4.4.3.) Any strings that the PC utility sends to the driver as well as any strings received from

the driver are displayed regardless of the menu.

-> [String sent]

<- [String received]

Figure 4.4.3 “Communication string” dialog box

4-10

Page 46

4.4.4 Main Menu

When you start the PC utility, the “MainMenu” dialog box appears (see Figure 4.4.4). See the following chapters

for how to start the actual operation.

Figure 4.4.4 “MainMenu” dialog box

4-11

4

Page 47

4

Basic Settings for Operating the Motor

4.5 Setting the Status to Servo ON

The driver can be put into Servo On status through the following operation.

(1) Click the “I/O Config (I)” button in the “MainMenu” and then the “I/O config (L)” button.

Click the I/O Config (I)

button.

(2) Enable Servo ON. Click the checkmark of “1” under DI and then click the Set (S) button.

Set Servo ON (DI-1) to “no

check.” (Negative setting)

Click the I/O Config

(L) button.

!!!!

Caution

Set button

Make sure to click the “Set” button after finishing the setting (the status will become

Servo ON). Verify that the “S-RDY” LED on the front panel is turned on.

4-12

Page 48

(3) Reset the driver according to the message in the dialog box.

Click OK.

(4) Verify that the driver is reset and the “SRDY” LED on the front panel is turned on.

4-13

4

Page 49

4

Basic Settings for Operating the Motor

4.6 Auto-tuning

The auto-tuning can be performed according to the following procedure.

(1) Checking the rotation direction

Check the rotation direction (CW/CCW) of the motor.

CW CCW

Load

installation

surface

Look carefully from both sides of the load installation surface to check the CW/CCW

Caution

!!!!

(2) Click the “Servo Cntl (S)” button on the “MainMenu.”

movement. When started, the motor operates in the CCW direction. Take extra care to

ensure that there is no mechanical interference with the rotor, which is currently in the

stop position.

Click the Servo Cntl

button

4-14

Page 50

(3) Click Auto Tuning Start (tuning starts).

play

(4) Follow the message on the dialog box and click “OK” to start the auto-tuning operation.

Click the Auto Tuning

Start button

After the auto-tuning is

performed, the set values

!!!!

Caution

are dis

ed.

The rotor rotates a maximum of 30º (seven times of reciprocating operation) in the CW

direction. The operation width varies depending on the velocity rating of the motor.

Take extra care not to cause any mechanical interference around the rotor.

<How to calculate the operation width>

Operation width (degree) = motor velocity rating [rps] x 0.02 x 360

(5) Each parameter setting value is displayed and the auto-tuning is automatically terminated.

4

4-15

Page 51

4

Basic Settings for Operating the Motor

4.7 Performing Homing Operation

A homing operation can be performed according to the following procedure.

(1) Checking the rotation direction

Check the rotation direction (CW/CCW) of the motor.

Load

installation

surface

CW CCW

!!!!

Caution

(2) Check the setting of the homing direction through the PC utility.

Look carefully from both sides of the load installation surface to check the CW/CCW

movement. When started, the motor operates in the CCW direction. Take extra care to

ensure that there is no mechanical interference with the rotor.

Click “Drive” in the Main Menu, then “Homing.”

Click “Drive.”

Click “Homing.”

MainMenu DriveMenu

4-16

Page 52

(3) Set the “homing direction” in the “Homing” dialog box.

1) The current setting values are displayed in the

Setting value box by clicking grid “#20.”

The current setting values for the “homing

related” parameters are displayed.

3) Click the “Set” button.

2) Enter 1 in the Setting Value box.

Make sure to press the return key;

otherwise the entry is not made valid.

!!!!

Caution

The initial value that should be set depends on the homing direction. Enter “#20 = 1” if

the homing direction is CW and “#20 = 0” if it is CCW.

(4) Click the “Start” button to start the homing operation.

Click “Start.”

1) The homing operation finishes automatically after the operation is completed.

In the event of

• The homing operation does not finish, and

!!!!

Caution

2) If a homing abnormality message is displayed, follow the message to adjust the

• The motor does not stop even when the home position sensor is detected,

Click “Abort (A)” to stop the motor, then check “wiring” and “auto-tuning” again.

flag position using the limit value as a guideline. If an error occurs, press “ErrReset”

as well.

4

4-17

Page 53

4

Basic Settings for Operating the Motor

4.8 Performing the Basic Settings of Pulse Commands

4.8.1 About Position Command Pulse Input

Perform input (pulses) required for operation according to the explanation in Section 6.2, “Position Command

Pulse Input” in Chapter 6, “Controller Interface.” Prior to performing pulse input, be sure to perform required

settings according to the explanation in Section 6.1, “Terminal Function.”

The position command value instructed from the controller interface is given to the driver by any pair of the

(PLS, SIGN), (UP, DOWN) and (A, B) signals, which is then reflected in the command unit command value.

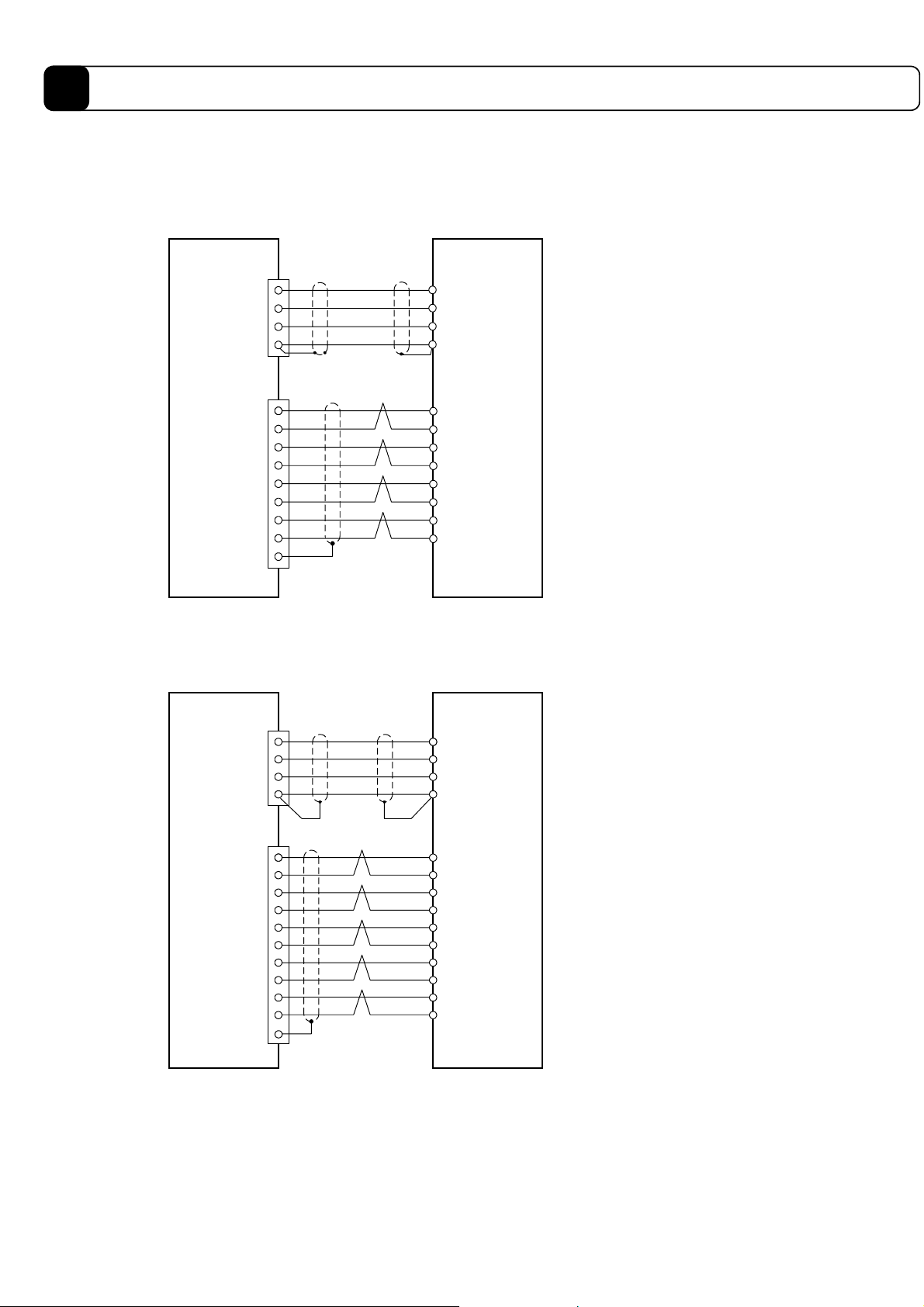

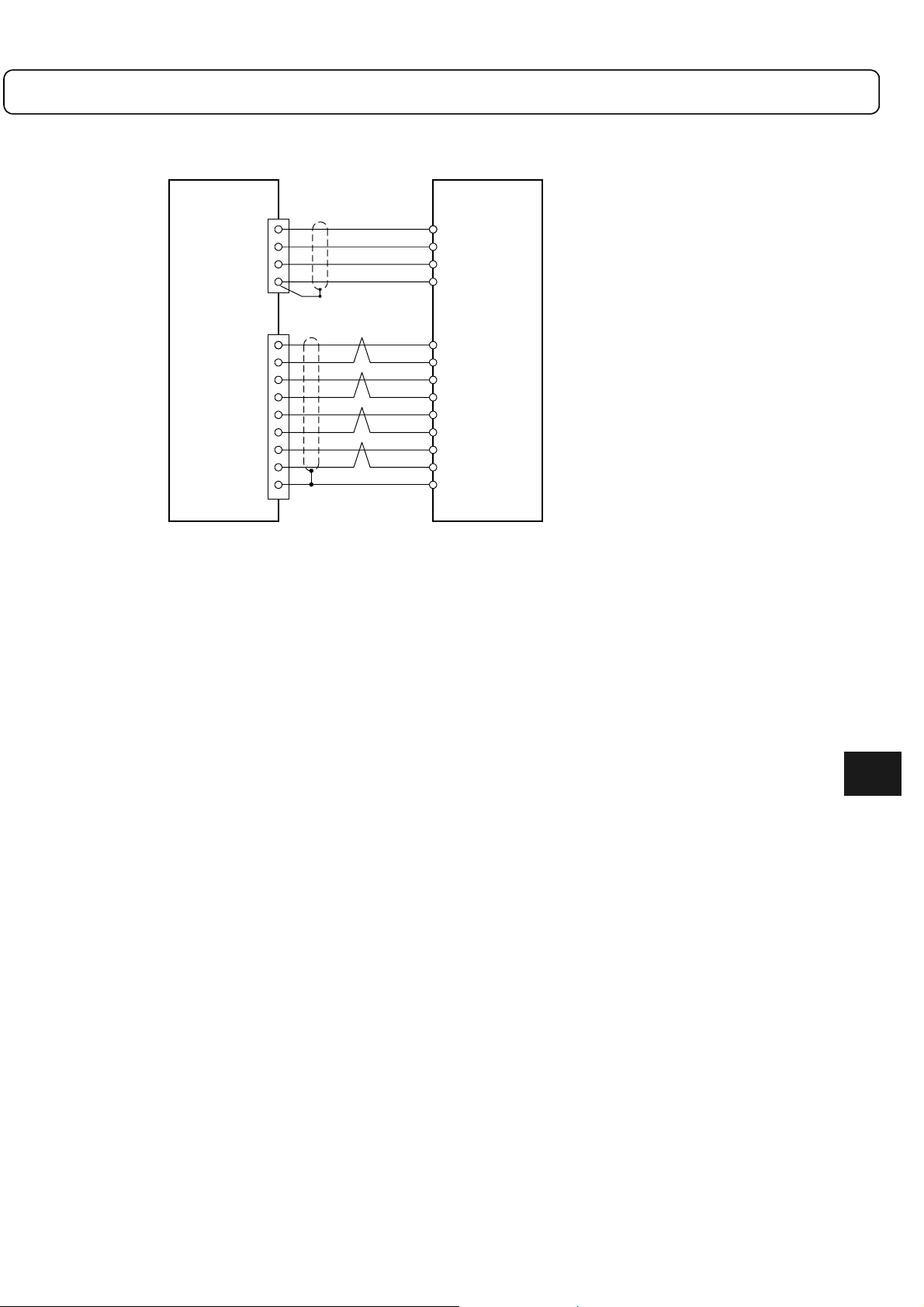

Which pair of the signals will be used to give a command is set with the #204 Command pulse type

parameter.

(PLS, SIGN) (UP, DOWN) (A, B)

+ direction - direction + direction - direction + direction - direction

PUA_IN

±

PLS

150ns min

UP

150ns min

A

SDB_IN

±

Caution

3µs min 3µs min

The signal should be H when active

(status for flowing current to the

driver photocoupler).