Page 1

Pneumati

c

Fittings & Tubing

Prestolok / Prestolok II,

P & DB Fittings,

Nylon & Polyethylene Tubing

Section Z

Prestolok / Prestolok II Fittings ................................. 2-9

P Fittings .............................................................. 10-17

DB Fittings ............................................................ 18-21

Polyethylene Tubing ..............................................22-23

Nylon Tubing ......................................................... 24-25

Tube Cutter ................................................................ 25

Burst Pressure Temperature Charts ..................... 26-27

Chemical Compatibility Guide (Brass).................. 28-29

Chemical Compatibility Guide (Thermoplastic) ......... 30

Z

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Page 2

Pneumati

c

Catalog 0600P-9/USA

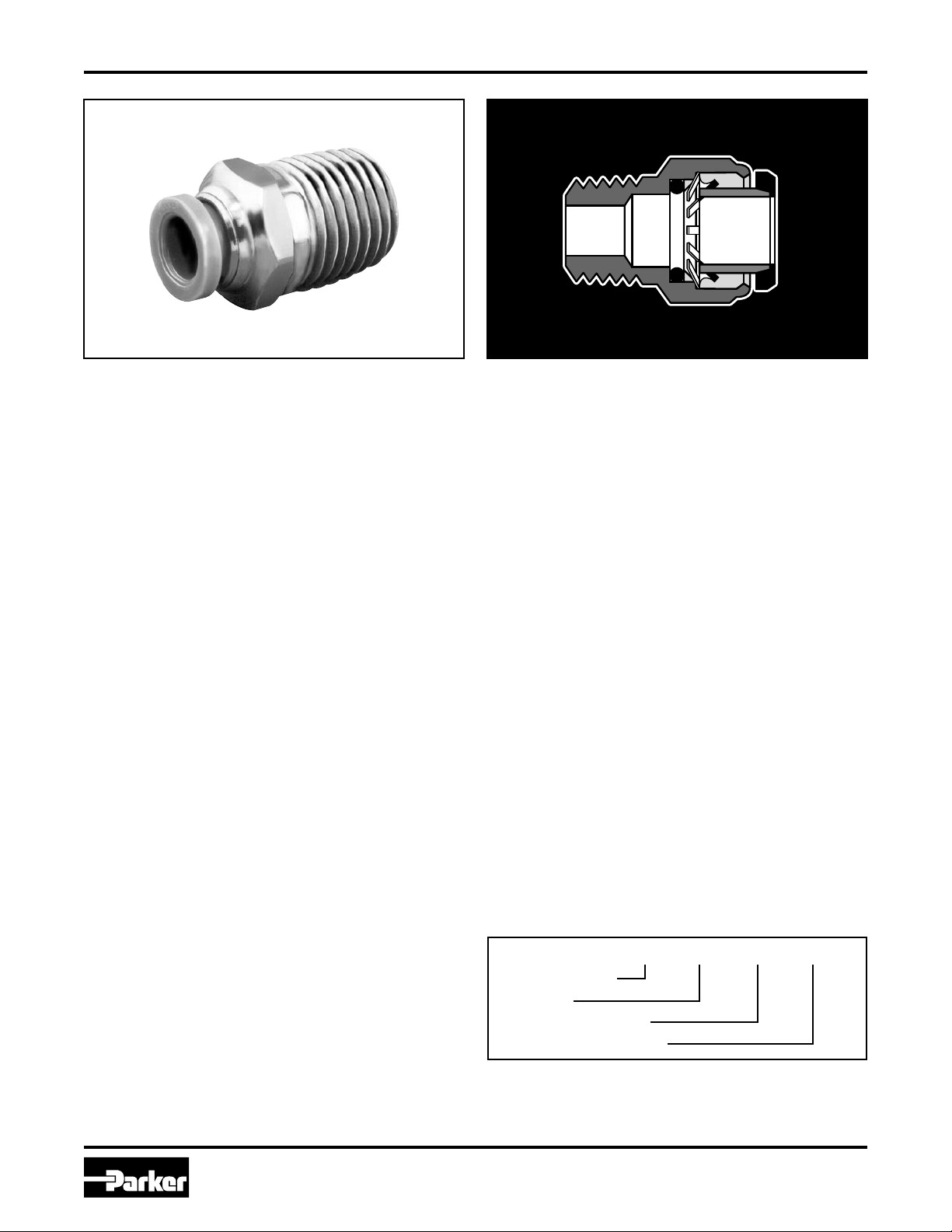

Basic Features

Fittings & Tubing Prestolok / Prestolok II Fittings

Advantages

Ready-to-use compact one-piece fitting for use with most

thermoplastic and copper tubing. This fitting is specially

designed for low pressure circuits where fast assembly,

disassembly and reassembly is impor tant. No special

tools are needed for assembly; just insert the tubing until it

bottoms. Prestolok/Prestolok II is designed to be used with

no tube support. Radial claws on the stainless steel grab

ring grip the tubing securely to provide retention. Brass Male

pipe threads come standard with a white acrylic sealant

pre-applied (“W” prefix) swivels are featured on all male

pipe threaded shapes for installation in tight places and for

precise positioning. Prestolok/Prestolok II should not be

used for live swivel applications. The outside diameter of the

tubing to be used with the fitting is marked on the release

button. The removable release button can be color coded for

ease of identification. Standard release button is green.

Materials

Prestolok Bodies: CA377, CA360, CA345

Prestolok II Bodies: Glass Filled Nylon

O-Ring: Nitrile (other compounds available on request)

Release Button: Polyacetal

Grab Ring: Stainless Steel

Applications

Use with Parker Parflex series “E” polyethylene tubing,

series “N” nylon tubing, series “U” polyurethane tubing or

copper tubing. Perfectly adapted for use in a large variety

of industries, Prestolok II was designed as an economical

alternative for pneumatic applications that do not require

the higher pressure capacity of the standard prestolok

fittings, consult the factory with any questions regarding

special product applications. All applications should be

carefully tested through the range of conditions which may

be encountered prior to use. For inch O.D. tubing

Working Pressure and

Temperature Ranges

Prestolok: Zero to 200°F at up to 300 PSI depending

on tubing being used.

Prestolok II: Zero to 150°F at up to 150 PSI depending

on tubing being used.

Vacuum applications are dependent upon temperature

and type of tubing used.

Assembly Instructions

1. Cut thermoplastic tubing squarely, using Parker Tube

Cutter PTC 001. Metal tubing should be cut squarely

and free of burrs. Be certain the port or mating part is

clean and free of debris.

2. Insert tubing into fitting until it bottoms. A slight twisting

motion will ease the insertion. Pull on tubing to verify

it is properly retained in the fitting.

3. To disassemble, simply push the release button

against the body and remove tubing.

Order

By part number and name.

Nomenclature

Part numbers are constructed from symbols that identify

the style and size of the fitting. The first series of numbers

and letters identify the style and type fitting. The second

series of numbers describe the size.

Example 69 PL –4 –2

Male Connector

Prestolok

1/4" (4/16) Tube O.D.

1/8" (2/16) Pipe Thread

Sizes

Tube sizes are determined by the number of sixteenths

of an inch in the tube O.D.

2

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Page 3

Pneumati

c

L

D

O.D.

Catalog 0600P-9/USA

L

2

1

D

O.D.

O.D.

L

D

D

L

B

C HEX

P

D

L

D

L

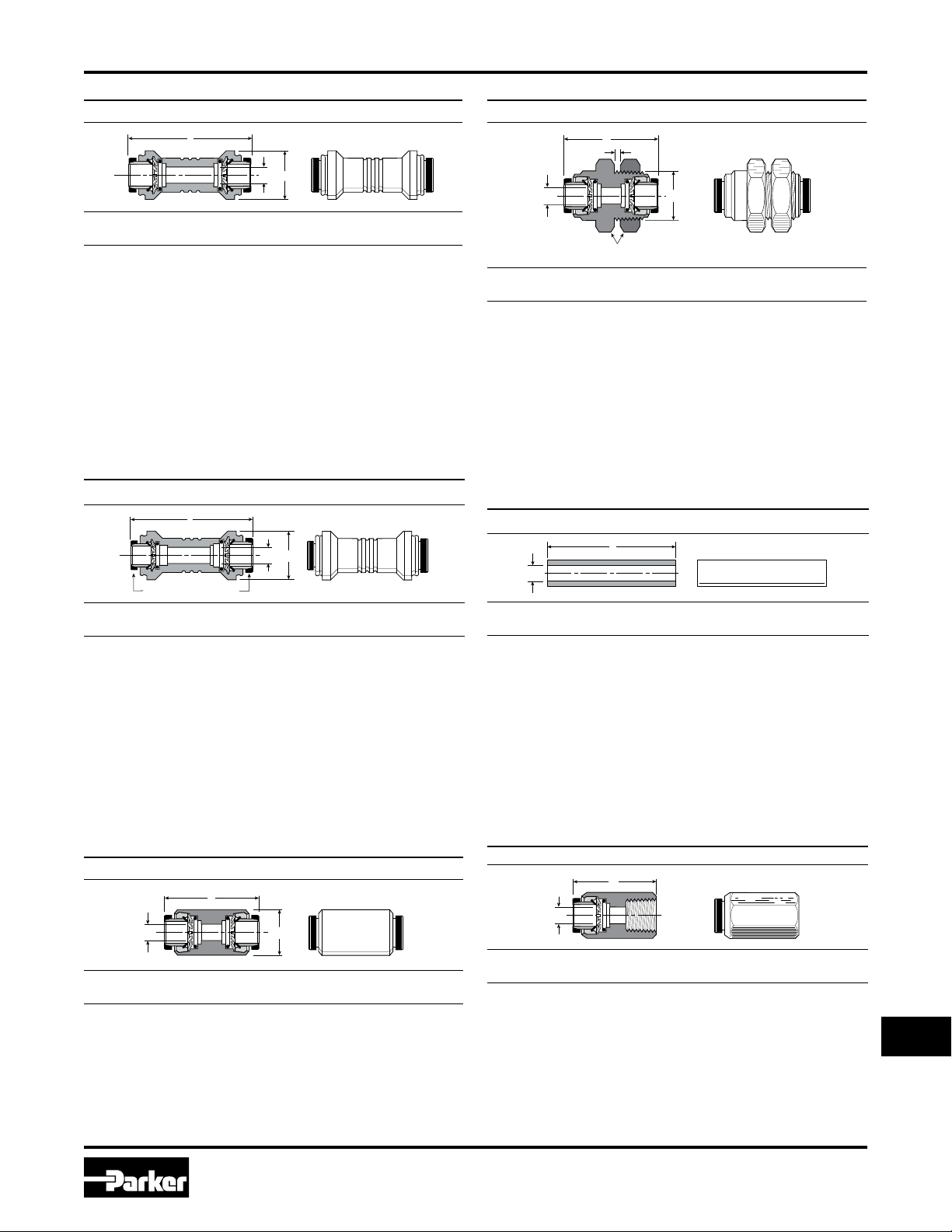

Part Numbers & Dimensions

Fittings & Tubing

Prestolok / Prestolok II Fittings

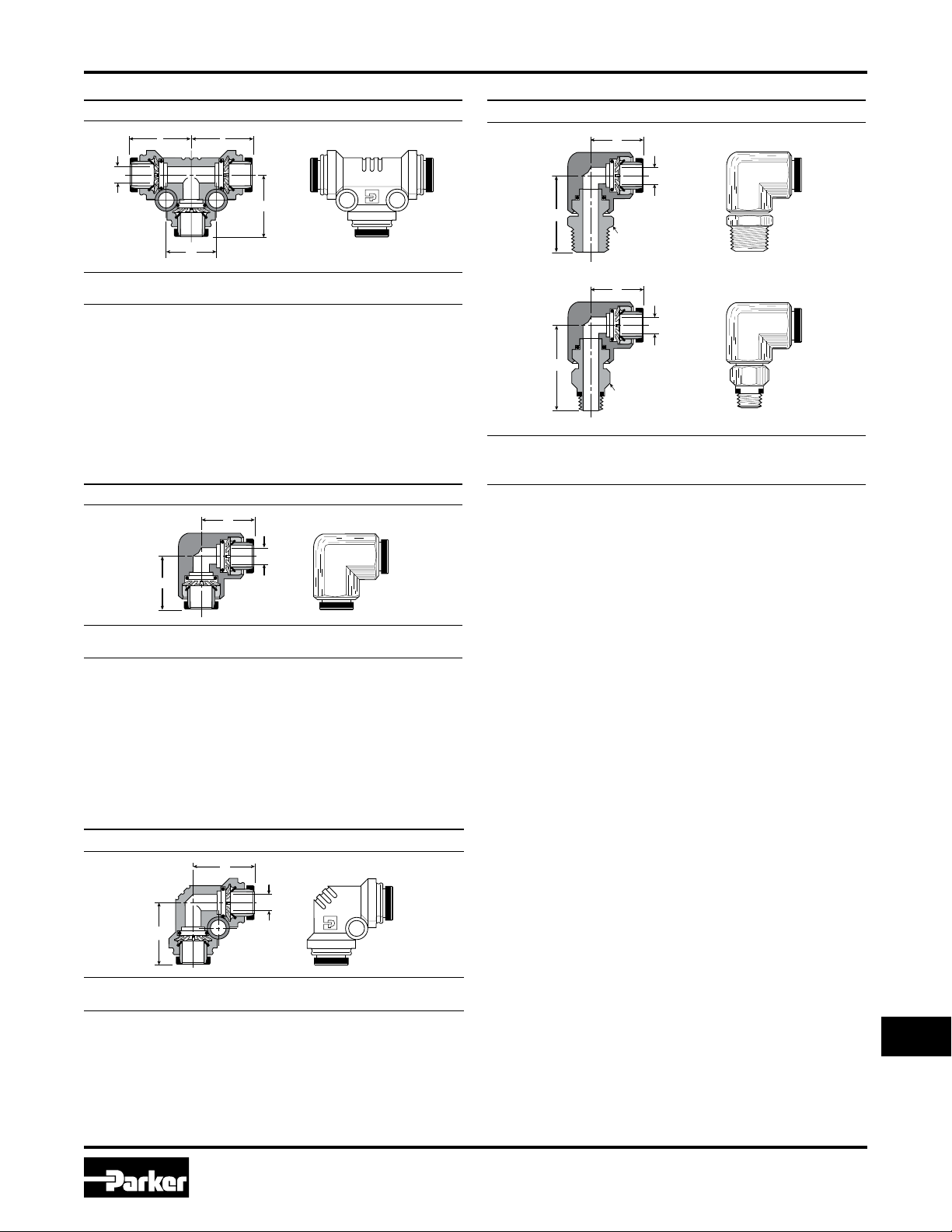

32PL Equal Union

Part

No.

32PL-2 1/8 0.51 1.32 0.09

32PL-5/32 5/32 0.51 1.32 0.12

32PL-3 3/16 0.59 1.37 0.16

32PL-4 1/4 0.59 1.37 0.19

32PL-5 5/16 0.67 1.49 0.25

32PL-6 3/8 0.83 1.76 0.31

Tube

Size O.D. L

Flow

Dia. D

32PL Unequal Union

62PLBH Bulkhead Union

Part

No.

62PLBH-2 1/8 7/16 9/16 0.39 1.44 0.094

62PLBH-5/32 5/32 7/16 9/16 0.39 1.44 0.125

62PLBH-4 1/4 9/16 11/16 0.29 1.51 0.188

62PLBH-5 5/16 5/8 3/4 0.60 1.68 0.250

62PLBH-6 3/8 3/4 7/8 0.54 1.68 0.312

62PLBH-8 1/2 7/8 1 0.66 2.07 0.375

Tube

Size B

C

HexPMax. L D

63PL Double Male Union Plastic Body

Part

No.

32PL-5/32-2 5/32 1/8 0.51 1.32 0.09

32PL-4-2 1/4 1/8 0.59 1.37 0.09

32PL-5-4 5/16 1/4 0.67 1.47 0.19

32PL-6-4 3/8 1/4 0.82 1.75 0.19

1 Tube

Size

2 Tube

Size O.D. L

62PL Union

Part

No.

62PL-2 1/8 0.406 1.44 0.094

62PL-3 3/16 0.437 1.35 0.156

62PL-5/32 5/32 0.406 1.49 0.125

62PL-4 1/4 0.500 1.51 0.188

62PL-5 5/16 0.562 1.68 0.250

62PL-6 3/8 0.625 1.68 0.312

62PL-8 1/2 0.750 1.86 0.375

Tube

Size O.D. L D

Flow

Dia. D

Part

No.

63PL-2 1/8 1.49 0.078

63PL-5/32 5/32 1.49 0.106

63PL-4 1/4 1.61 0.188

63PL-5 5/16 1.61 0.236

63PL-6 3/8 2.00 0.295

63PL-8 1/2 2.12 0.374

Tube

Size L D

66PL Female Connector

Part

No.

66PL-2-2 1/8 1/8 1.18 .094

66PL-3-2 3/16 1/8 1.16 .156

66PL-5/32-2 5/32 1/8 1.18 .125

66PL-5/32-4 5/32 1/4 1.39 .125

66PL-4-2 1/4 1/8 1.21 .188

66PL-4-4 1/4 1/4 1.42 .188

66PL-5-2 5/16 1/8 1.27 .250

66PL-5-4 5/16 1/4 1.47 .250

66PL-6-4 3/8 1/4 1.46 .312

66PL-6-6 3/8 3/8 1.51 .312

3

Tube

Size

Pipe Thread

(NPTF)

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

L D

Z

Page 4

Pneumati

c

Catalog 0600P-9/USA

D

L

C HEX

P

D

L

2

1

D

L

M

C HEX

D

L

M

C HEX

L

D

O.D.

D

L

L

L

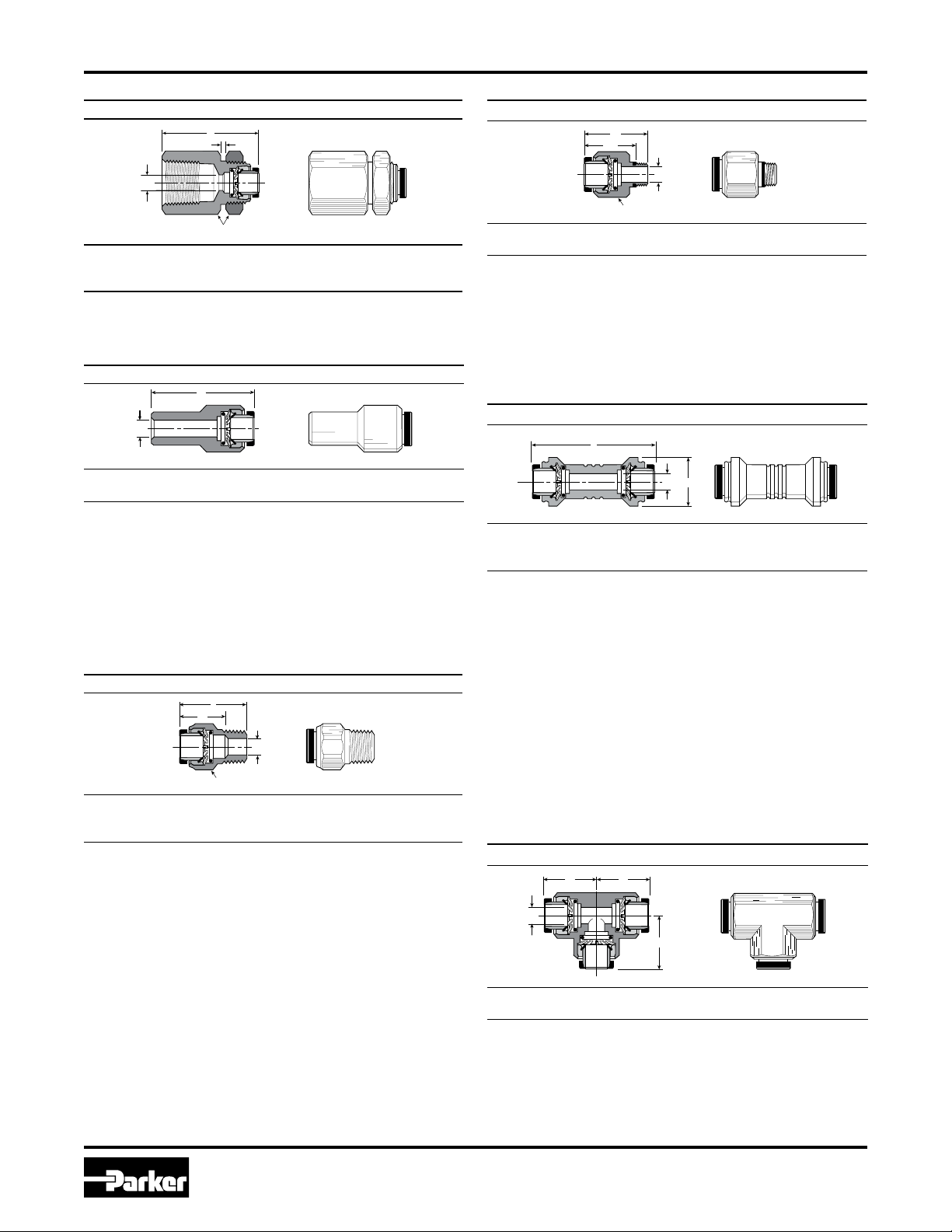

Part Numbers & Dimensions

Fittings & Tubing

Prestolok / Prestolok II Fittings

66PLBH Female Bulkhead

Part

No.

66PLBH-5/32-4

66PLBH-4-4 1/4 1/4 11/16 0.19 1.35 0.18 9/16

66PLBH-6-6 3/8 3/8 1 0.22 1.44 0.31 7/8

66PLBH-8-6 1/2 3/8 1 1/4 0.35 1.57 0.34 1

Pipe

Tube

Thread

Size

(NPTF) C HexP Max. L

5/32 1/4 11/16 0.24 1.38 0.13 1/2

Flow

Dia. DBulkhead

Hole Dia.

67PPL Tube End Reducer Plastic Body

Part

No.

67PPL-2-5/32

67PPL-2-4

67PPL-5/32-4 *

67PPL-5/32-5 *

67PPL-5/32-6 *

67PPL-4-5

67PPL-4-6

67PPL-4-8

67PPL-5-6 *

67PPL-6-8

* Parts supplied with black bodies and black release buttons

1 Tube

Size 2 Tube Size L D

1/8 5/32 1.48 0.078

1/8 1/4 1.48 0.078

5/32 1/4 1.48 0.118

5/32 5/16 1.41 0.118

5/32 3/8 1.63 0.118

1/4 5/16 1.52 0.177

1/4 3/8 1.64 0.177

1/4 1/2 1.72 0.177

5/16 3/8 1.79 0.236

3/8 1/2 1.92 0.295

W68PL Male Connector

68PL-X-10x32 Male connector

Part

No.

68PL-2-10X32

68PL-5/32-10X32

68PL-4-10X32

Tube

Thread

Size

(UNF)CHex L M D

1/8 10-32 3/8 0.93 0.68 0.094 0.094

5/32 10-32

1/4 10-32 1/2 1.00 0.71 0.094 0.094

13/32

0.95 0.69 0.094 0.094

Internal

Broach

PLHBF4-B BSPP Male Connector

Part

No.

3-1/8PLHBF4-B 3/16 1/8-28 11/16 0.96 0.156

3-1/4PLHBF4-B 3/16 1/4-19 3/4 0.97 0.156

4-1/8PLHBF4-B 1/4 1/8-28 11/16 1.13 0.188

4-1/4PLHBF4-B 1/4 1/4-19 3/4 1.13 0.188

4-3/8PLHBF4-B 1/4 3/8-19 7/8 1.13 0.188

6-1/4PLHBF4-B 3/8 1/4-19 3/4 1.26 0.256

6-3/8PLHBF4-B 3/8 3/8-19 7/8 1.26 0.312

6-1/2PLHBF4-B 3/8 1/2-14 1-1/16 1.26 0.312

8-3/8PLHBF4-B 1/2 3/8-19 7/8 1.41 0.452

8-1/2PLHBF4-B 1/2 1/2-14 1-1/16 1.37 0.452

Tube

Size

Pipe

Thread

(BSPP)CHex L D

Part

No.

W68PL-2-1 1/8 1/16 3/8 0.85 0.68 0.094

W68PL- 2-2 1/8 1/8 7/16 0.85 0.68 0.094

W68PL-2-4 1/8 1/4 9/16 1.10 0.68 0.094

W68PL-3-2 3/16 1/8 7/16 0.92 0.63 0.156

W68PL-3-4 3/16 1/4 9/16 1.10 0.64 0.156

W68PL-5/32-2 5/32 1/8 7/16 0.85 0.69 0.125

W68PL-5/32-4 5/32 1/4 9/16 1.10 0.69 0.125

W68PL-4-1 1/4 1/16 1/2 1.15 0.71 0.140

W68PL-4-2 1/4 1/8 1/2 0.97 0.71 0.188

W68PL-4-4 1/4 1/4 9/16 1.10 0.71 0.188

W68PL-4-6 1/4 3/8 3/4 1.14 0.71 0.188

W68PL-5-2 5/16 1/8 9/16 1.23 0.78 0.234

W68PL-5-4 5/16 1/4 9/16 1.11 0.78 0.250

W68PL-5-6 5/16 3/8 11/16 1.12 0.79 0.250

W68PL-6-2 3/8 1/8 11/16 1.26 0.78 0.234

W68PL-6-4 3/8 1/4 11/16 1.14 0.78 0.312

W68PL-6-6 3/8 3/8 11/16 1.09 0.79 0.312

W68PL-6-8 3/8 1/2 7/8 1.34 0.78 0.312

W68PL-8-4 1/2 1/4 13/16 1.52 0.87 0.344

W68PL-8-6 1/2 3/8 13/16 1.31 0.87 0.344

W68PL-8-8 1/2 1/2 7/8 1.43 0.87 0.375

Tube

Size

Pipe

Thread

(NPTF)CHex L M D

164PL Union Tee

Part

No.

164PL-2 1/8 0.78 0.094

164PL-3 3/16 0.79 0.156

164PL-5/32 5/32 0.81 0.125

164PL-4 1/4 0.94 0.188

164PL-5 5/16 0.99 0.250

164PL-6 3/8 1.04 0.312

164PL-8 1/2 1.17 0.375

4

Tube

Size L D

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Page 5

Pneumati

c

Catalog 0600P-9/USA

D

L

L

D

L

G

L

L

C HEX

D

L

N

D

L

L

C HEX

D

L

N

Part Numbers & Dimensions

Fittings & Tubing

Prestolok / Prestolok II Fittings

364PL Union Tee Composite Body

Part

No.

364PL-2 1/8 0.13 0.71 0.52 0.094

364PL-5/32 5/32 0.13 0.71 0.52 0.125

364PL-3 3/16 0.17 0.76 0.64 0.156

364PL-4 1/4 0.17 0.76 0.64 0.188

364PL-5 5/16 0.17 0.84 0.71 0.250

364PL-6 3/8 0.17 1.04 0.83 0.312

364PL-8 1/2 0.17 1.30 0.99 0.344

Tube

Mounting

Size

Hole Dia. L G D

165PL Union Elbow

Part

No.

165PL-2 1/8 0.77 0.094

165PL-5/32 5/32 0.79 0.125

165PL-4 1/4 0.86 0.188

165PL-5 5/16 0.97 0.250

165PL-6 3/8 1.03 0.312

165PL-8 1/2 1.17 0.375

Tube

Size L D

365PL Union Elbow Composite Body

W169PL Male Elbow Swivel 90°

169PL-X-10/32

Part

No.

W169PL-2-2

169PL-2-10X32

W169PL-2-4

W169PL-3-2

W169PL-5/32-2

W169PL-5/32-4

169PL-5/32-10X32

W169PL-4-2

W169PL-4-4

W169PL-4-6

169PL-4-10X32

W169PL-5-2

W169PL-5-4 5/16 1/4 9/16 0.99 1.60 0.234

W169PL-6-2 3/8 1/8 9/16 1.04 1.49 0.297

W169PL-6-4 3/8 1/4 9/16 1.04 1.66 0.297

W169PL-6-6 3/8 3/8 11/16 1.04 1.70 0.297

W169PL-6-8 3/8 1/2 7/8 1.04 1.89 0.297

W169PL-8-4 1/2 1/4 11/16 1.17 1.74 0.344

W169PL-8-6 1/2 3/8 3/4 1.17 1.77 0.375

W169PL-8-8 1/2 1/2 7/8 1.16 1.97 0.375

Tube

Size

3/16 1/8 7/16 0.79 1.16 0.156

5/32 1/8 7/16 0.80 1.24 0.109

5/32 1/4 9/16 0.81 1.42 0.109

5/32 10-32 3/8 0.81 1.04 0.094

5/16 1/8 1/2 0.99 1.42 0.234

Pipe

Thread

(NPTF)CHex L N D

1/8 1/8 7/16 0.78 1.22 0.094

1/8 10-32 3/8 0.78 1.02 0.094

1/8 1/4 9/16 0.78 1.40 0.094

1/4 1/8 7/16 0.86 1.13 0.172

1/4 1/4 9/16 0.86 1.31 0.172

1/4 3/8 11/16 0.86 1.35 0.172

1/4 10-32 7/16 0.86 0.94 0.094

Part

No. Tube Size

365PL-2 1/8 0.13 0.71 0.094

365PL-3 3/16 0.17 0.76 0.156

365PL-5/32 5/32 0.13 0.71 0.125

365PL-4 1/4 0.17 0.76 0.188

365PL-5 5/16 0.17 0.84 0.250

365PL-6 3/8 0.17 1.04 0.312

365PL-8 1/2 0.17 1.03 0.344

Mounting

Hole Dia. L D

Z

5

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Page 6

Pneumati

c

Catalog 0600P-9/USA

D

N

C HEX

L

C HEX

D

L

N

C HEX

D

L

N

C HEX

D

L

N

Part Numbers & Dimensions

Fittings & Tubing

Prestolok / Prestolok II Fittings

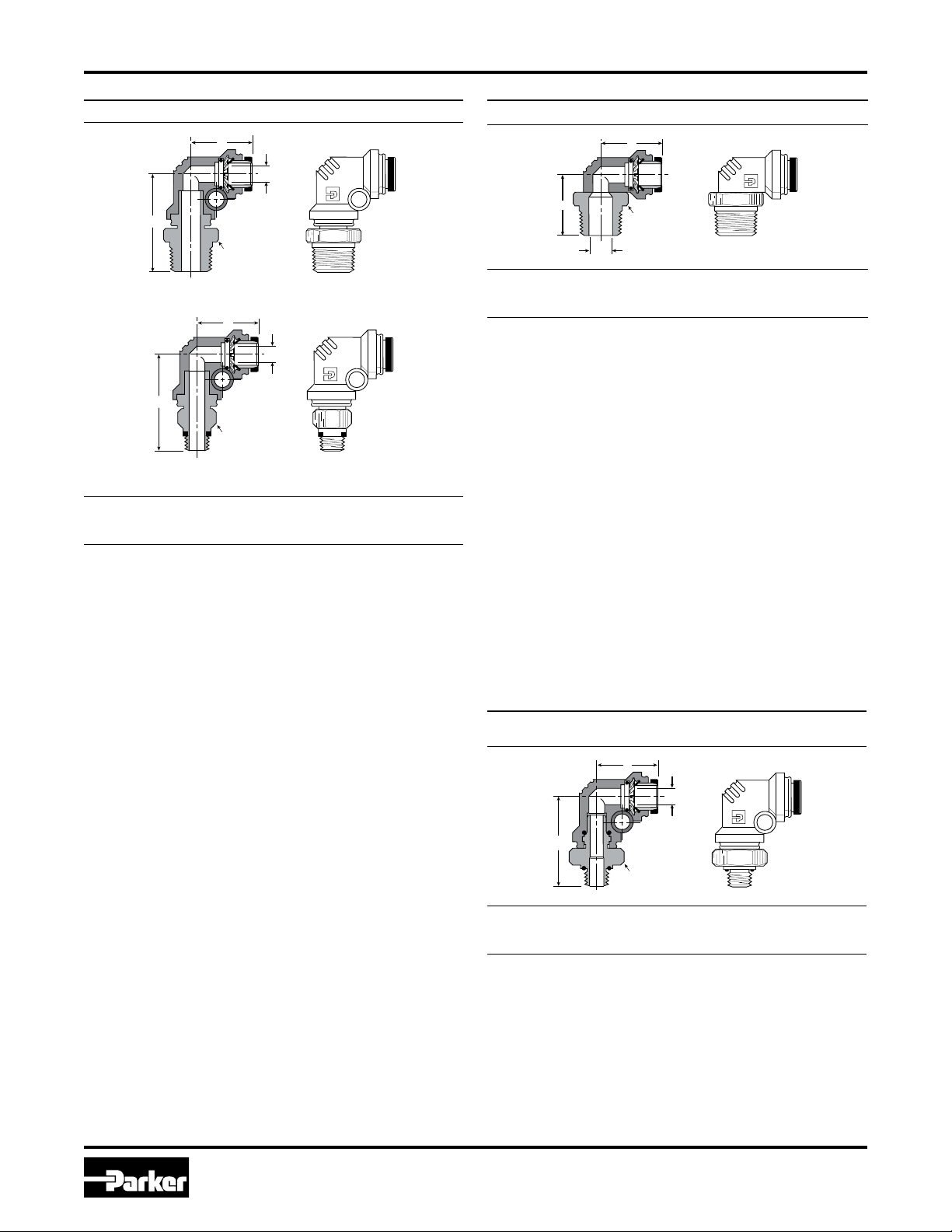

W369PL Male Elbow Swivel 90° Composite Body

369PL-X-10/32

Part

No.

W369PL-2-1 1/8 1/16 3/8 0.13 0.71 1.08 0.078

W369PL-2-2 1/8 1/8 7/16 0.13 0.71 1.14 0.078

369PL-2-10X32 1/8 10-32 3/8 0.13 0.71 0.94 0.078

W369PL-2-4 1/8 1/4 9/16 0.13 0.71 1.32 0.078

W369PL-3-2 3/16 1/8 7/16 0.17 0.76 1.20 0.147

W369PL-3-4 3/16 1/4 9/16 0.17 0.76 1.44 0.147

W369PL-5/32-2 5/32 1/8 7/16 0.13 0.74 1.14 0.094

W369PL-5/32-4 5/32 1/4 9/16 0.13 0.74 1.32 0.094

369PL-5/32-10X32

W369PL-4-1 1/4 1/16 7/16 0.17 0.76 1.20 0.094

W369PL-4-2 1/4 1/8 7/16 0.17 0.76 1.20 0.172

W369PL-4-4 1/4 1/4 9/16 0.17 0.77 1.38 0.172

W369PL-4-6 1/4 3/8 11/16 0.17 0.77 1.42 0.172

369PL-4-10X32 1/4 10-32 7/16 0.17 0.76 1.05 0.094

W369PL-5-2 5/16 1/8 1/2 0.17 0.84 1.23 0.234

W369PL-5-4 5/16 1/4 9/16 0.17 0.84 1.46 0.234

W369PL-6-2 3/8 1/8 9/16 0.17 1.04 1.48 0.234

W369PL-6-4 3/8 1/4 5/8 0.17 1.04 1.66 0.234

W369PL-6-6 3/8 3/8 11/16 0.17 1.04 1.66 0.297

W369PL-6-8 3/8 1/2 7/8 0.17 1.05 1.85 0.297

W369PL-8-4 1/2 1/4 3/4 0.17 1.03 1.80 0.314

W369PL-8-6 1/2 3/8 3/4 0.17 1.03 1.80 0.375

W369PL-8-8 1/2 1/2 7/8 0.17 1.03 1.99 0.375

Pipe

Tube

Thread

Size

(NPTF)CHex

5/32 10-32 3/8 0.13 0.74 0.94 0.094

Mounting

Hole Dia. L N D

W369PLC Compact Elbow

Part

No.

W369PLC-2-2 1/8 1/8 7/16 0.81 0.71 0.08

W369PLC-5/32-2 5/32 1/8 7/16 0.83 0.71 0.08

W369PLC-5/32-4 5/32 1/4 9/16 0.83 0.89 0.08

W369PLC-3-2 3/16 1/8 7/16 0.86 0.81 0.08

W369PLC-4-2 1/4 1/8 7/16 0.86 0.81 0.08

W369PLC-4-4 1/4 1/4 9/16 0.86 0.99 0.08

W369PLC-5-4 5/16 1/4 9/16 0.94 0.97 0.11

W369PLC-6-4 3/8 1/4 5/8 1.13 1.07 0.20

W369PLC-6-6 3/8 3/8 3/4 1.13 1.15 0.20

Tube

Pipe

Thread

Size

(NPTF)CHex L N

Flow

Dia. D

PLE2BF4-K BSPP Male Elbow Swivel

Composite Body

Part

No.

3-1/8PLE2BF4-K 3/16 1/8-28 11/16 0.17 0.76 1.17 0.147

3-1/4PLE2BF4-K 3/16 1/4-19 3/4 0.17 0.76 1.31 0.147

4-1/8PLE2BF4-K 1/4 1/8-28 11/16 0.17 0.76 1.06 0.180

4-1/4PLE2BF4-K 1/4 1/4-19 3/4 0.17 0.76 1.31 0.172

4-3/8PLE2BF4-K 1/4 3/8-19 7/8 0.17 0.76 1.31 0.182

6-1/4PLE2BF4-K 3/8 1/4-19 3/4 0.17 1.04 1.57 0.297

6-3/8PLE2BF4-K 3/8 3/8-19 7/8 0.17 1.04 1.68 0.297

6-1/2PLE2BF4-K 3/8 1/2-14 1-1/16 0.17 1.04 1.83 0.297

8-3/8PLE2BF4-K 1/2 3/8-19 7/8 0.17 1.03 1.63 0.406

8-1/2PLE2BF4-K 1/2 1/2-19 1-1/16 0.17 1.03 1.78 0.406

Tube

Size

Pipe

Thread

(BSPP)CHex

Mounting

Hole Dia. L N D

6

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Page 7

Pneumati

c

Catalog 0600P-9/USA

C HEX

D

L

N

D

L

N

D

D

C HEX

N

L

L

C HEX

D

L

N

Part Numbers & Dimensions

Fittings & Tubing

Prestolok / Prestolok II Fittings

W369PLX Male Elbow Swivel 90° Composite Body

Pipe

Tube

Part No.

W369PLX-2-2 1/8 1/8 7/16 0.13 0.73 1.74 0.080

W369PLX-2-4 1/8 1/4 9/16 0.13 0.73 1.74 0.080

W369PLX-3-2 3/16 1/8 7/16 0.17 0.76 1.88 0.150

W369PLX-3-4 3/16 1/4 9/16 0.17 0.76 1.88 0.150

W369PLX-3-6 3/16 3/8 11/16 0.17 0.76 1.88 0.150

W369PLX-4-2 1/4 1/8 7/16 0.17 0.76 1.88 0.170

W369PLX-4-4 1/4 1/4 9/16 0.17 0.76 1.88 0.170

W369PLX-4-6 1/4 3/8 11/16 0.17 0.76 1.88 0.170

369PLX-5/32-0 5/32 10-32 3/8 0.13 0.73 1.54 0.090

W369PLX-5/32-2

W369PLX-5/32-4

W369PLX-5-2 5/16 1/8 9/16 0.17 0.84 1.99 0.223

W369PLX-5-4 5/16 1/4 9/16 0.17 0.84 1.99 0.230

W369PLX-5-6 5/16 3/8 11/16 0.17 0.84 1.99 0.230

W369PLX-6-4 3/8 1/4 5/8 0.17 1.04 2.56 0.223

W369PLX-6-6 3/8 3/8 11/16 0.17 1.04 2.56 0.300

W369PLX-6-8 3/8 1/2 7/8 0.17 1.04 2.56 0.300

W369PLX-8-4 1/2 1/4 3/4 0.17 1.03 2.80 0.310

W369PLX-8-6 1/2 3/8 3/4 0.17 1.03 2.80 0.340

W369PLX-8-8 1/2 1/2 7/8 0.17 1.03 2.80 0.340

Thread

Size

(NPTF)CHex

5/32 1/8 7/16 0.13 0.73 1.54 0.090

5/32 1/4 9/16 0.13 0.73 1.54 0.090

Mounting

Hole Dia. L N D

370PL Female Elbow Swivel Composite Body

Part

No.

370PL-2-2 1/8 1/8 9/16 0.13 0.71 1.01 0.078

370PL-5/32-2 5/32 1/8 9/16 0.13 0.73 1.01 0.090

370PL-5/32-4 5/32 1/4 3/4 0.13 0.73 1.23 0.090

370PL-4-10x32 1/4 10x32 7/16 0.17 0.76 1.02 0.159

370PL-4-2 1/4 1/8 9/16 0.17 0.76 1.07 0.170

370PL-4-4 1/4 1/4 3/4 0.17 0.76 1.29 0.170

370PL-5-4 5/16 1/4 3/4 0.17 0.84 1.37 0.230

370PL-6-4 3/8 1/4 3/4 0.17 1.04 1.57 0.297

370PL-8-6 1/2 3/8 7/8 0.17 1.03 1.57 0.340

Tube

Size

Pipe

Thread

(NPTF)CHex

Mounting

Hole Dia. L N D

W169PLNS Male Elbow 90°

W171PL Male Run Tee Swivel

Part

No. Tube Size

W169PLNS-2-2 1/8 1/8 0.78 0.68 0.094

W169PLNS-5/32-2

W169PLNS-5/32-4

W169PLNS-4-2 1/4 1/8 0.86 0.68 0.188

W169PLNS-4-4 1/4 1/4 0.96 0.89 0.188

W169PLNS-5-2 5/16 1/8 0.98 0.78 0.234

W169PLNS-5-4 5/16 1/4 1.02 0.97 0.250

W169PLNS-6-4 3/8 1/4 1.04 0.97 0.312

W169PLNS-6-6 3/8 3/8 1.11 1.09 0.312

W169PLNS-6-8 3/8 1/2 1.20 1.26 0.312

W169PLNS-8-6 1/2 3/8 1.31 1.15 0.375

W169PLNS-8-8 1/2 1/2 1.31 1.31 0.375

5/32 1/8 0.81 0.68 0.125

5/32 1/4 0.81 0.89 0.125

Pipe

Thread

(NPTF) L N D

Part

No.

W171PL-2-2 1/8 1/8 7/16 0.78 1.22 0.078

W171PL-5/32-2 5/32 1/8 7/16 0.80 1.24 0.109

W171PL-4-2 1/4 1/8 7/16 0.96 1.29 0.188

W171PL-4-4 1/4 1/4 9/16 0.96 1.47 0.188

W171PL-5-2 5/16 1/8 1/2 0.99 1.42 0.234

W171PL-5-4 5/16 1/4 9/16 0.99 1.60 0.234

W171PL-6-4 3/8 1/4 9/16 1.04 1.66 0.297

W171PL-6-6 3/8 3/8 11/16 1.04 1.70 0.297

W171PL-8-6 1/2 3/8 3/4 1.19 1.79 0.375

W171PL-8-8 1/2 1/2 7/8 1.19 1.98 0.375

Tube

Size

7

Pipe

Thread

(NPTF)CHex L N D

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Z

Page 8

Pneumati

c

Catalog 0600P-9/USA

D

L

L

C HEX

N

D

L

G

L

C HEX

N

C HEX

N

D

L

G

L

D

L

G

L

C HEX

N

Part Numbers & Dimensions

Fittings & Tubing

Prestolok / Prestolok II Fittings

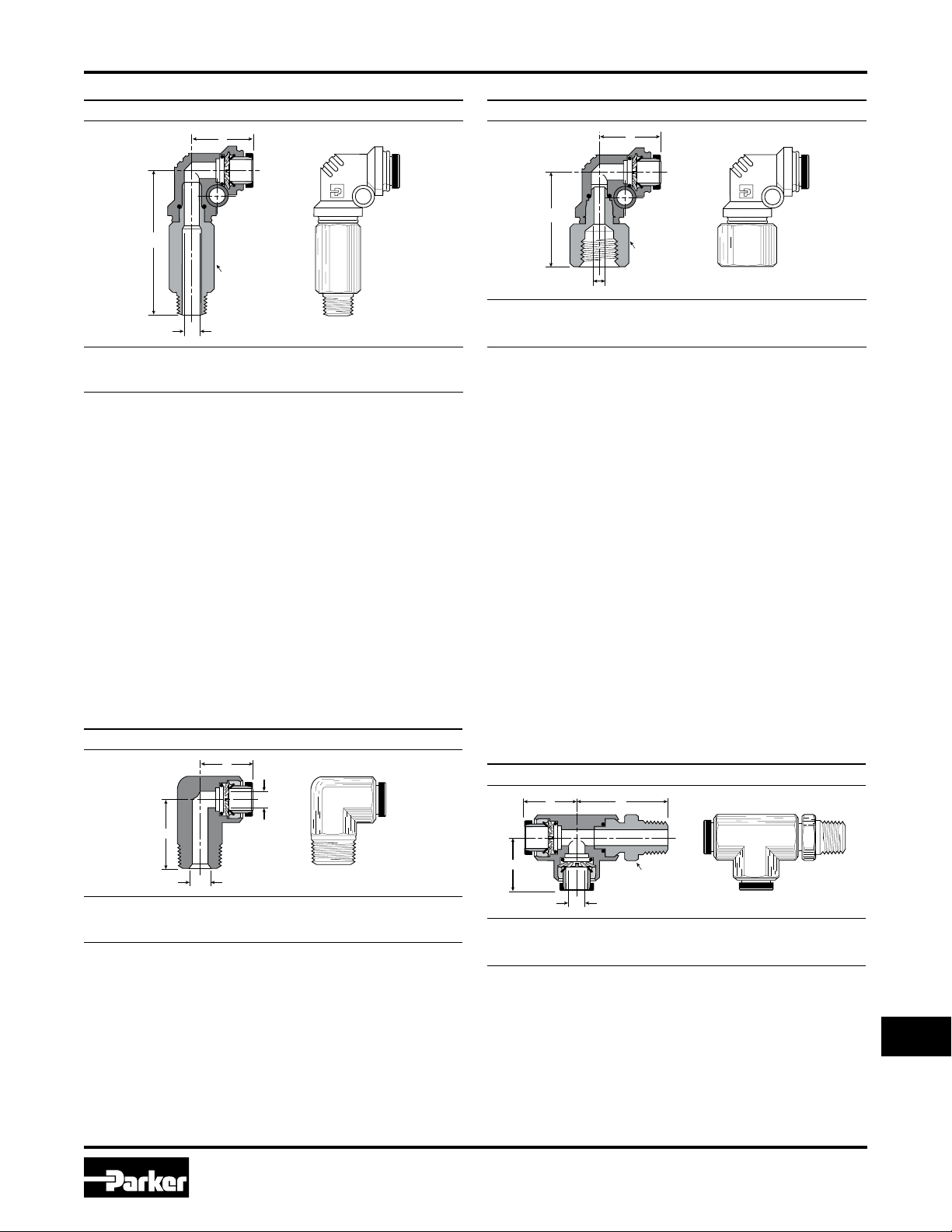

W371PL Male Run Tee Swivel Composite Body

Part

No.

Tube

Size

Thread

(NPTF)CHex

W371PL-2-1 1/8 1/16 3/8 0.13 0.71 1.08 0.52 0.078

W371PL-2-2 1/8 1/8 7/16 0.13 0.71 1.14 0.52 0.078

W371PL-2-4 1/8 1/4 9/16 0.13 0.71 1.32 0.52 0.080

371PL-2-10x32 1/8 10-32 3/8 0.13 0.71 0.94 0.52 0.078

W371PL-3-2 3/16 1/8 7/16 0.17 0.76 1.20 0.64 0.150

W371PL-3-4 3/16 1/4 9/16 0.17 0.76 1.40 0.64 0.147

W371PL-5/32-2 5/32 1/8 7/16 0.13 0.71 1.14 0.52 0.094

W371PL-5/32-4 5/32 1/4 9/16 0.13 0.71 1.14 0.52 0.094

371PL-5/32- 10x32 5/32 10-32 3/8 0.13 0.71 0.94 0.52 0.090

W371PL-4-1 1/4 1/16 7/16 0.17 0.76 1.20 0.64 0.094

Pipe

Mtg.

Hole

Dia. L N G D

W172PL Male Branch Tee Swivel

Part

Tube

No.

W172PL-2-2 1/8 1/8 7/16 0.78 1.22 0.078

W172PL-3-2 3/16 1/8 7/16 0.78 1.17 0.156

W172PL-5/32-2 5/32 1/8 7/16 0.80 1.24 0.109

W172PL-4-2 1/4 1/8 7/16 0.96 1.26 0.188

W172PL-4-4 1/4 1/4 9/16 0.96 1.44 0.188

W172PL-5-2 5/16 1/8 1/2 0.99 1.42 0.234

W172PL-5-4 5/16 1/4 9/16 0.99 1.60 0.234

W172PL-6-4 3/8 1/4 9/16 1.04 1.66 0.297

W172PL-6-6 3/8 3/8 11/16 1.04 1.70 0.297

W172PL-8-6 1/2 3/8 3/4 1.19 1.79 0.375

W172PL-8-8 1/2 1/2 7/8 1.19 1.98 0.375

Pipe

Thread

Size

(NPTF)CHex L N D

W371PL-4-2 1/4 1/8 7/16 0.17 0.76 1.20 0.64 0.170

W371PL-4-4 1/4 1/4 9/16 0.17 0.76 1.38 0.64 0.170

W372PL Male Branch Tee Swivel Composite Body

371PL-4-10x32 1/4 10-32 7/16 0.13 0.76 1.05 0.64 0.094

W371PL-4-6 1/4 3/8 11/16 0.17 0.76 1.42 0.64 0.170

W371PL-5-2 5/16 1/8 9/16 0.17 0.84 1.28 0.71 0.220

W371PL-5-4 5/16 1/4 9/16 0.17 0.84 1.46 0.71 0.234

W371PL-6-2 3/8 1/8 9/16 0.13 1.04 1.48 0.83 0.230

W371PL-6-4 3/8 1/4 5/8 0.17 1.04 1.66 0.83 0.297

W371PL-6-6 3/8 3/8 11/16 0.17 1.04 1.70 0.83 0.297

W371PL-6-8 3/8 1/2 7/8 0.13 1.04 1.85 0.83 0.300

W371PL-8-4 1/2 1/4 3/4 0.17 1.30 2.07 1.00 0.310

W371PL-8-6 1/2 3/8 3/4 0.17 1.30 1.68 1.00 0.344

W371PL-8-8 1/2 1/2 7/8 0.17 1.30 2.26 1.00 0.344

PLR2BF4-K BSPP Male Run Tee Swivel

Composite Body

Part

No.

W372PL-2-1 1/8 1/16 3/8 0.13 0.71 1.08 0.52 0.078

W372PL-2-2 1/8 1/8 7/16 0.13 0.71 1.14 0.52 0.078

W372PL-2-4 1/8 1/4 9/16 0.13 0.70 1.32 0.52 0.080

Tube

Size

Pipe

Thread

(NPTF)CHex

Mtg.

Hole

Dia. L N G D

372PL-2-10X32 1/8 10-32 3/8 0.13 0.70 0.94 0.52 0.080

W372PL-3-2 3/16 1/8 7/16 0.17 0.76 1.20 0.64 0.147

W372PL-3-4 3/16 1/4 9/16 0.17 0.76 1.40 0.64 0.147

W372PL-5/32-2 5/32 1/8 7/16 0.13 0.71 1.14 0.52 0.094

W372PL-5/32-4 5/32 1/4 9/16 0.13 0.68 1.32 0.52 0.090

372PL-5/32-10x32 5/32 10-32 3/8 0.13 0.70 0.94 0.52 0.090

W372PL-4-1 1/4 1/16 7/16 0.17 0.76 1.20 0.64 0.094

W372PL-4-2 1/4 1/8 7/16 0.17 0.76 1.20 0.64 0.170

W372PL-4-4 1/4 1/4 9/16 0.17 0.76 1.38 0.64 0.170

372PL-4-10x32 1/4 10-32 7/16 0.17 0.76 1.05 0.64 0.090

W372PL-4-6 1/4 3/8 11/16 0.17 0.76 1.42 0.64 0.170

W372PL-5-2 5/16 1/8 9/16 0.17 0.84 1.28 0.71 0.234

W372PL-5-4 5/16 1/4 9/16 0.17 0.84 1.23 0.71 0.234

W372PL-6-2 3/8 1/8 9/16 0.17 1.03 1.48 0.83 0.230

W372PL-6-4 3/8 1/4 5/8 0.17 1.04 1.66 0.83 0.297

W372PL-6-6 3/8 3/8 11/16 0.17 1.04 1.66 0.83 0.297

W372PL-6-8 3/8 1/2 7/8 0.17 1.03 1.85 0.83 0.300

W372PL-8-4 1/2 1/4 3/4 0.17 1.30 2.07 0.99 0.310

W372PL-8-6 1/2 3/8 3/4 0.17 1.30 2.07 0.99 0.344

W372PL-8-8 1/2 1/2 7/8 0.17 1.30 2.26 0.99 0.344

8

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Part

No.

Tube

Size

Pipe

Thread

(BSPP)CHex

Mtg.

Hole

Dia. L N G D

3-1/4PLR2BF4-K 3/16 1/4-19 3/4 0.17 0.76 1.31 0.64 0.150

4-1/8PLR2BF4-K 1/4 1/8-28 11/16 0.17 0.76 1.06 0.64 0.170

4-1/4PLR2BF4-K 1/4 1/4-19 3/4 0.17 0.76 1.31 0.64 0.170

6-1/4PLR2BF4-K 3/8 1/4-19 3/4 0.17 1.04 1.52 0.83 0.300

6-3/8PLR2BF4-K 3/8 3/8-19 7/8 0.17 1.04 1.68 0.83 0.300

8-3/8PLR2BF4-K 1/2 3/8-19 7/8 0.17 1.30 1.90 0.99 0.340

8-1/2PLR2BF4-K 1/2 1/2-19 1-1/16 0.17 1.30 2.05 0.99 0.340

Page 9

Pneumati

c

Catalog 0600P-9/USA

C HEX

N

D

L

G

L

L

C HEX

D

N

L

G

L

D

G

L

N

N1

D

G

L

NN

1

Part Numbers & Dimensions

Fittings & Tubing

Prestolok / Prestolok II Fittings

PLS2BF4-K BSPP Male Branch Tee Swivel

Composite Body

Part

No.

3-1/8PLS2BF4-K 3/16 1/8-28 11/16 0.17 0.76 1.05 0.64 0.150

3-1/4PLS2BF4-K 3/16 1/4-19 3/4 0.17 0.76 1.31 0.64 0.150

4-1/8PLS2BF4-K 1/4 1/8-28 11/16 0.17 0.76 1.06 0.64 0.180

4-1/4PLS2BF4-K 1/4 1/4-19 3/4 0.17 0.76 1.31 0.64 0.170

6-1/4PLS2BF4-K 3/8 1/4-19 3/4 0.17 1.04 1.57 0.83 0.300

6-3/8PLS2BF4-K 3/8 3/8-19 7/8 0.17 1.04 1.68 0.83 0.300

6-1/2PLS2BF4-K 3/8 1/2-14 1-1/16 0.17 1.04 1.83 0.83 0.300

8-3/8PLS2BF4-K 1/2 3/8-19 7/8 0.17 1.30 1.90 0.99 0.410

Tube

Size

Pipe

Thread

(BSPP)CHex

Mtg.

Hole

Dia. L N G D

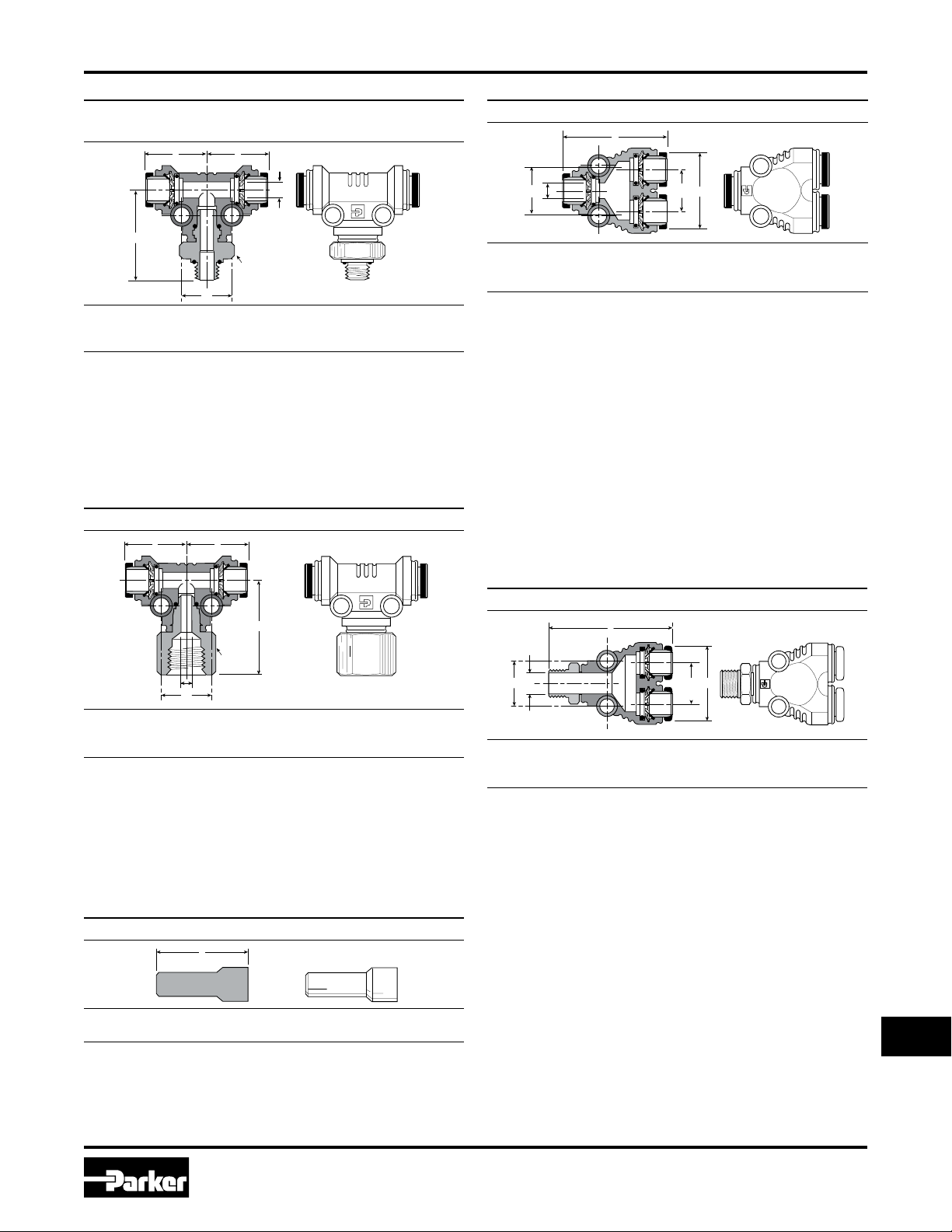

377PL Female Branch Tee Swivel Composite Body

362PL Union Y Connector Composite Body

Part

No.

362PL-2 1/8 0.13 1.38 0.92 0.41 0.57 0.130

362PL-5/32 5/32 0.13 1.36 0.92 0.41 0.57 0.160

362PL-3 3/16 0.17 1.49 1.13 0.54 0.67 0.200

362PL-4 1/4 0.17 1.49 1.13 0.53 0.67 0.260

362PL-5 5/16 0.17 1.49 1.21 0.54 0.72 0.320

362PL-6 3/8 0.17 1.88 1.54 0.71 0.76 0.380

Tube

Mtg.

Hole

Size

Dia. L N N1 G D

W368PL Union Y Male Connector Composite Body

Part

No.

377PL-2-2 1/8 1/8 9/16 0.17 0.70 1.01 0.52 0.080

377PL-5/32-2 5/32 1/8 9/16 0.13 0.70 1.01 0.52 0.090

377PL-5/32-4 5/32 1/4 3/4 0.13 0.70 1.23 0.52 0.090

377PL-4-2 1/4 1/8 9/16 0.17 0.76 1.07 0.64 0.170

377PL-4-4 1/4 1/4 3/4 0.17 0.76 1.29 0.64 0.170

377PL-5-4 5/16 1/4 3/4 0.17 0.84 1.37 0.72 0.230

377PL-6-4 3/8 1/4 3/4 0.17 1.04 1.57 0.83 0.300

377PL-8-6 1/2 3/8 7/8 0.17 1.30 1.84 0.99 0.410

Tube

Size

Pipe

Thread

(NPTF)CHex

639PL Plug

Part

No.

639PL-2 1/8 1.30

639PL-5/32 5/32 1.34

639PL-4 1/4 1.34

639PL-5 5/16 1.28

639PL-6 3/8 1.50

639PL-8 1/2 1.69

Tube

Size L

Mtg.

Hole

Dia. L N G D

Part

No.

W368PL-2-2 1/8 1/8 0.57 0.13 1.81 0.91 0.41 0.080

W368PL-2-4 1/8 1/4 0.57 0.13 1.98 0.91 0.41 0.080

368PL-5/32-10x32 5/32 10-32 0.57 0.13 1.60 0.92 0.41 0.090

W368PL-5/32-2 5/32 1/8 0.57 0.13 1.80 0.92 0.41 0.090

W368PL-5/32-4 5/32 1/4 0.57 0.13 1.98 0.92 0.41 0.090

368PL-3-10x32 3/16 10-32 0.67 0.17 1.77 1.13 0.54 0.094

W368PL-3-2 3/16 1/8 0.67 0.17 1.92 1.13 0.54 0.150

W368PL-3-4 3/16 1/4 0.67 0.17 2.16 1.13 0.54 0.150

W368PL-3-6 3/16 3/8 0.67 0.17 2.16 1.13 0.54 0.147

368PL-4-10x32 1/4 10-32 0.67 0.17 1.78 1.13 0.53 0.090

W368PL-4-2 1/4 1/8 0.67 0.17 1.93 1.13 0.53 0.172

W368PL-4-4 1/4 1/4 0.67 0.17 2.11 1.13 0.53 0.170

W368PL-4-6 1/4 3/8 0.67 0.17 2.15 1.13 0.53 0.170

W368PL-5-2 5/16 1/8 0.72 0.17 1.87 1.20 0.54 0.230

W368PL-5-4 5/16 1/4 0.72 0.17 2.10 1.20 0.54 0.230

W368PL-5-6 5/16 3/8 0.72 0.17 2.04 1.20 0.54 0.234

W368PL-6-4 3/8 1/4 0.76 0.17 2.50 1.53 0.71 0.300

W368PL-6-6 3/8 3/8 0.76 0.17 2.50 1.53 0.71 0.300

W368PL-6-8 3/8 1/2 0.76 0.17 2.69 1.53 0.71 0.300

Tube

Size

Pipe

Size G

9

Mtg.

Hole

Dia. L N N1 D

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Z

Page 10

Pneumati

c

Catalog 0600P-9/USA

Basic Features

Fittings & Tubing P Fittings

Advantages

A compact brass compression fitting designed to speed

any installation. Body, nut and sleeve are furnished

preassembled, ready for installation. An exclusive acetal

copolymer sleeve holds plastic tubing where it belongs,

even when the system pressure exceeds the tubing burst

point. P fitting sleeves have superior resilience to resist

creeping and stress caused from compression. The black

acetal copolymer sleeve also resists ultra-violet ray attack

and has excellent dimensional stability. P fitting nuts will

rotate around the sleeve as it tightens to prevent twisting

and weakening of the plastic tubing. P fittings can be

assembled and disassembled repeatedly.

Materials

Elbows and Tees: Brass Forgings: CA 377

Connectors, Unions, Nuts: CA 360, CA 345

Plastic Sleeves: Acetal Copolymer (Celcon®).

Applications

Use with Parker or other high-quality thermoplastic tubing

for pneumatic instrumentation circuits, lubricant and

coolant lines, and applications with other gases and liquids.

For use with soft metal tubing and nylon thermoplastic

tubing, use brass sleeve and nut assembly 61PB.

Working Pressure and

Temperature Ranges

Up to 150 PSI from 0° to + 150°F with thermoplastic tubing.

Up to 300 PSI from 0° to +175°F with soft metal tubing.

Assembly Instructions

Polyethylene, polypropylene and vinyl tubing:

1.

Cut tubing squarely - maximum of 15° angle allowable.

2. Check that port or mating part is clean and free of

debris.

3.

Insert tube end until it bottoms in the fitting and tighten

knurl / hex nut finger tight - plus one wrench turn.

Copper, aluminum and nylon tubing:

Brass sleeves are recommended. Insert tube until it

bottoms in the P fitting and tighten one wrench turn past

finger-tight.

Maximum allowable metal tube wall

thickness for use with P fittings:

1/8", 3/16", O.D. — no limitation, 1/4" O.D. — 0.035

5/16", 3/8", 1/2" O.D. — 0.049.

Nomenclature

Part numbers are constructed from symbols that identify

the style and size of the fitting. The first series of numbers

and letters identifies the style and type fitting. The second

series of numbers describes the size.

Example:

66 P -4 -2

Female Connector

(Tube to female pipe)

P Fitting

1/4" (4/16) Tube O.D.

1/8" (2/16) Pipe Thread

Sizes

Tube sizes are determined by the number of sixteenths

of an inch in the tube O.D.

10

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Page 11

Pneumati

c

Catalog 0600P-9/USA

L

A

L

A

D

L

D

C HEX

L

D

C HEX

L

D

C HEX

L

M

C HEX

D

L

M

1 2

C HEX

D

Part Numbers & Dimensions

Fittings & Tubing

P Fittings

59P Plastic Cap

Part

No.

59P-4 1/4 0.247 0.50

59P-5

59P-6 3/8 0.372 0.56

59P-8

Tube

Size A L

5/16 0.307 0.53

1/2 0.497 0.63

60P Acetal Plastic Sleeve

Part

No.

60P-4

60P-5

60P-6 3/8 0.465 0.381 0.367

60P-8

Tube

Size A D L

1/4 0.334 0.261 0.338

5/16 0.405 0.321 0.340

1/2 0.628 0.514 0.399

61PN Nut

Part

No.

61PN-2 1/8 5/16-24 3/8 0.34

61PN-3

61PN-4 1/4 3/8-24 7/16 0.38

61PN-5 5/16 7/16-24 1/2 0.34

61PN-6

61PN-8 1/2 11/16-20 3/4 0.44

Tube

Size

3/16 3/8-24 7/16 0.37

3/8 1/2-24 9/16 0.38

Straight

Thread C Hex L

62P Union

61P Nut and Sleeve Assembly

Part

No.

61P-2* 1/8 5/16-24 3/8 0.130 0.34

61P-3*

61P-4

61P-5 5/16 7/16-24 1/2 0.321 0.34

61P-6

61P-8 1/2 11/16-20 3/4 0.514 0.44

*Brass Sleeve

Tube

Size

3/16 3/8-24 7/16 0.192 0.37

1/4 3/8-24 7/16 0.261 0.38

3/8 1/2-24 9/16 0.380 0.38

Straight

ThreadCHex D L

Part

No.

62P-2*

62P-3* 3/16 3/8-24 3/8 1.16 0.73 0.125

62P-4

62P-5 5/16 7/16-24 7/16 1.16 0.96 0.144

62P-6 3/8 1/2-24 1/2 1.23 0.99 0.204

62P-8

*Brass Sleeve, No Tube Support

Tube

Straight

Size

ThreadCHex L M

1/8 5/16-24 5/16 1.08 0.64 0.094

1/4 3/8-24 3/8 1.17 0.96 0.125

1/2 11/16-20 11/16 1.47 1.24 0.323

Flow

Dia. D

61PB* Nut and Sleeve Assembly

62P Union Reducer

Part

No.

61PB-4

61PB-5 5/16 7/16-24 1/2 0.318 0.34

61PB-6

61PB-8 1/2 11/16-20 3/4 0.507 0.44

*Brass Sleeve

Tube

Size

1/4 3/8-24 7/16 0.255 0.38

3/8 1/2-24 9/16 0.382 0.38

Straight

ThreadCHex D L

1

2

Part

No.

62P-6-4 1/4 3/8 3/8-24 1/2-24 1/2 1.22 0.99 0.125

Tube

Size

Tube

Size

1

Straight

Thread

11

2

Straight

ThreadC Hex L M

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Z

Flow

Dia. D

Page 12

Pneumati

c

Catalog 0600P-9/USA

L

M

P

C HEX

D

L

M

P

C HEX

D

L

M

D

1

2

C HEX

L

M

D

C HEX

1 2

P

L

M

C HEX

D

L

M

D

C HEX

L

M

D

C HEX

Part Numbers & Dimensions

Fittings & Tubing

P Fittings

62PBH Bulkhead Union

Part

No.

62PBH-4

62PBH-5 5/16 7/16-24 5/8 0.38 1.71 1.52 7/16 0.144

62PBH-6 3/8 1/2-24 11/16 0.47 1.89 1.65 1/2 0.204

62PBH-8

Tube

Straight

Size

ThreadCHexPMax. L M

Bulkhead

Hole Dia.

Flow

Dia. D

1/4 3/8-24 9/16 0.38 1.75 1.53 3/8 0.125

1/2 11/16-20 7/8 0.63 2.28 2.05 11/16 0.323

62PCA Union (Tube to CA Fitting)

Part

No.

62PCA-4

Tube

Straight

Size

Thread

1/4 3/8-24 7/16-24 7/16 1.25 0.89 0.125

62PCA-5 5/16 7/16-24 1/2-24 1/2 1.30 0.92 0.144

1

62PCA-6

3/8 1/2-24 9/16-24 9/16 1.37 0.98 0.204

2

Straight

ThreadCHex L M

Flow

Dia. D

66P Female Connector

Part

No.

66P-2-2*

66P-3-2* 3/16 1/8 3/8-24 9/16 1.00 0.78 0.125

66P-3-4* 3/16 1/4 3/8-24 11/16 1.18 0.96 0.125

66P-4-2

66P-4-4 1/4 1/4 3/8-24 5/8 1.18 1.07 0.125

66P-5-2

66P-6-4 3/8 1/4 1/2-24 5/8 1.18 1.07 0.204

66P-8-6

*Brass Sleeve, No Tube Support

Tube

Size

Pipe

Thread

Straight

Thread CHex L M

Flow

Dia. D

1/8 1/8 5/16-24 9/16 0.97 0.75 0.094

1/4 1/8 3/8-24 1/2 0.97 0.86 0.125

5/16 1/8 7/16-24 1/2 0.97 0.86 0.144

1/2 3/8 11/16-20 13/16 1.31 1.20 0.323

68P Male Connector

62PCABH Bulkhead Union (Tube to CA Fitting)

Part

No.

62PCABH-4 1/4 3/8-24 7/16-24 9/16 0.38 1.81 1.45 3/8 0.125

62PCABH-6

Tube

Size

3/8 1/2-24 9/16-24 11/16 0.47 2.03 1.64 1/2 0.204

62PTBH Bulkhead Union (Straight Through)

Part

No.

62PTBH-4

62PTBH-5 5/16 7/16-24 5/8 0.31 1.19 0.93 7/16 0.323

62PTBH-6

Tube

Size

1/4 3/8-24 9/16 0.31 1.19 0.93 3/8 0.260

3/8 1/2-24 11/16 0.34 1.26 0.99 1/2 0.387

1

Straight

Thread

2

Straight

Thread CHex PMax. L M

Straight

ThreadCHexP Max. L M

Bulkhead

Hole

Dia.

Bulkhead

Hole Dia.

Flow

Dia.

D

Flow

Dia. D

68P-2-10 x 32

Part

No.

68P-2-1*

Tube

Pipe

Size

Thread

Straight

ThreadCHex L M

1/8 1/16 5/16-24 11/32 1.00 0.78 0.094

68P-2-2* 1/8 1/8 5/16-24 7/16 0.99 0.77 0.094

68P-3-1

3/16 1/16 3/8-24 7/16 1.09 0.84 0.094

68P-3-2* 3/16 1/8 3/8-24 7/16 1.06 0.84 0.125

68P-3-4*

3/16 1/4 3/8-24 9/16 1.25 1.03 0.125

68P-4-1 1/4 1/16 3/8-24 3/8 1.06 0.95 0.125

68P-4-2

1/4 1/8 3/8-24 7/16 1.06 0.95 0.125

68P-4-4 1/4 1/4 3/8-24 9/16 1.25 1.14 0.125

68P-4-6

1/4 3/8 3/8-24 11/16 1.28 1.17 0.125

68P-5-2 5/16 1/8 7/16-24 7/16 1.05 0.95 0.144

68P-5-4

5/16 1/4 7/16-24 9/16 1.24 1.14 0.144

68P-6-2 3/8 1/8 1/2-24 1/2 1.10 0.98 0.204

68P-6-4

3/8 1/4 1/2-24 9/16 1.29 1.17 0.204

68P-6-6 3/8 3/8 1/2-24 11/16 1.29 1.17 0.204

68P-8-4

1/2 1/4 11/16-20 11/16 1.46 1.29 0.320

68P-8-6 1/2 3/8 11/16-20 11/16 1.37 1.29 0.323

68P-2-10 x 32* 1/8 10-32 5/16-24 3/8 0.86 0.64 0.094

68P-4-10 x 32 1/4 10-32 3/8-24 3/8 0.86 0.75 0.094

*Brass Sleeve, No Tube Support

12

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Flow

Dia. D

Page 13

Pneumati

c

Catalog 0600P-9/USA

L

H

C HEX

D

L

P H

C HEX

D

H

C SQ

D

F

H

C SQ

D

F

H

C SQ

D

F

M

L

P H

F

C HEX

Part Numbers & Dimensions

Fittings & Tubing

P Fittings

391P Pipe Coupler Body (Chrome Plated)

Part

No.

391P-4-2

391P-4-4 1/4 1/4 9/16 0.73 1.29

391P-6-4

D

Insert

Dia.

1/4 1/8 1/2 0.91 1.29

3/8 1/4 5/8 0.85 1.41

Pipe

ThreadCHex H L

392P Bulkhead Coupler Body (Chrome Plated)

393PD Shut-off Type Insert (Chrome Plated)

393PD-4-4

393PD-6-6

Part

No.

393PD-4-4

393PD-6-6 3/8 3/8 1/2-24 1/2 1.45 0.187

Tube

Size

1/4 1/4 3/8-24 7/16 1.61 0.110

D

Insert

Dia.

Straight

ThreadCSquare H

Flow

Dia. F

Part

No.

392P-4-4

392P-6-6 3/8 3/8 11/16-24 13/16 0.93 0.37 2.01 11/16

D

Tube

Insert

Size

1/4 1/4 1/2-24 5/8 0.84 0.39 2.13 1/2

Straight

Dia.

ThreadCHexP Max. H L

Bulkhead

Hole Dia.

394P Single End Shut-off Bulkhead Quick Coupler

‡

(Chrome Plated)

393P Through Type Insert (Chrome Plated)

Bulk-

Part

No.

393P-4-4 1/4 1/4 3/8-24 7/16 1.12 0.125

393P-6-6

Tube

Size

3/8 3/8 1/2-24 1/2 1.34 0.203

D

Insert

Straight

Dia.

ThreadCSquare H

Flow

Dia. F

Part

No.

394P-4-4 1/4 1/2 - 24 5/8 0.84 0.39 3.28 2.13 1/2 0.125

394P-6-6

‡ Same as 392P-*-* and 393P-*-* Assembled.

13

Tube

Straight

Size

ThreadCHexPMax. H L M

3/8 11/16-24 13/16 0.93 0.37 3.41 2.01 11/16 0.203

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

head

Hole

Dia.

Flow

Dia. F

Z

Page 14

Pneumati

c

L

M

C HEX

F

Catalog 0600P-9/USA

M

L

P H

C HEX

F

F

M

L

P H

C HEX

L

M

C HEX

F

L

M

C HEX

F

L

L

L

M

M

M

D

Part Numbers & Dimensions

Fittings & Tubing

P Fittings

394PD Double End Shut-off Bulkhead

Quick Coupler‡ (Chrome Plated)

394PD-4-4

398PD Double End Shut-off Pipe Connector Quick Coupler

‡

(Chrome Plated)

394PD-4-X

394PD-6-4

394PD-6-6

Bulk-

head

Part

No.

394PD-4-4

Tube

Straight

Size

ThreadCHexP Max. H L M

1/4 1/2-24 5/8 0.84 0.39 3.77 2.13 1/2 0.125

Hole

Dia.

Flow

Dia.

394PD-6-6 3/8 11/16-24 13/16 0.93 0.47 3.48 2.01 11/16 0.204

‡ Same as 393PD-*-* and 392P-*-* Assembled.

Part

No.

398PD-4-2

398PD-4-4

398PD-6-4 3/8 1/4 1/2-24 5/8 3.10 1.43 0.204

F

‡ Same as 391P-*-* and 393PD-*-* Assembled.

Tube

Pipe

Size

Thread

Straight

ThreadCHex L M

1/4 1/8 3/8-24 1/2 2.93 1.31 0.125

1/4 1/4 3/8-24 9/16 2.93 1.32 0.125

Flow

Dia. F

164P-264P Union Tee

398P Single End Shut-off Pipe Connector Quick Coupler

Part No.

398P-4-2 1/4 1/8 3/8-24 1/2 2.45 1.32 0.125

398P-4-4

398P-6-4 3/8 1/4 1/2-24 5/8 2.80 1.46 0.203

‡ Same as 391P-*-* and 393P-*-* Assembled.

‡

(Chrome Plated)

Tube

Size

Pipe

Thread

Straight

Thread C Hex L M

Flow

Dia. F

1/4 1/4 3/8-24 9/16 2.45 1.32 0.125

Tube

Part No.

Straight

Size

Thread L M

164P-2* 1/8 5/16-24 0.83 0.61 0.094

264P-3*

3/16 3/8-24 0.83 0.61 0.125

164P-4 1/4 3/8-24 0.84 0.73 0.125

164P-5

5/16 7/16-24 0.83 0.73 0.144

164P-6 3/8 1/2-24 0.98 0.86 0.203

164P-8

*Brass Sleeve, No Tube Support

14

1/2 11/16-20 1.12 1.04 0.323

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Flow

Dia. D

Page 15

Pneumati

c

Catalog 0600P-9/USA

L

L

1

L

M

1

3

1 2

D

M

M

D

N

L

M

D

N

L

M

D

N

L

M

D

N

L

M

L

L

N

M

M

D

Part Numbers & Dimensions

Fittings & Tubing

P Fittings

164P Union Tee Combination Size

1

2

Part

No.

164P-6-4A

Tube

Tube

Size

Size

3/8 3/8 1/4 0.98 0.90 0.86 0.79 0.125

3

Tube

Size L L

1

169P-269P Male Elbow

M M

1

Flow

Dia. D

169PS Male Elbow Swivel

Part

No.

169PS-4-2

169PS-4-4

Tube

Pipe

Size

Straight

Thread

ThreadCHexEHex L M N

1/4 1/8 3/8-24 3/8 7/16 0.81 0.59 0.86 0.121

1/4 1/4 3/8-24 9/16 9/16 0.91 0.69 1.22 0.125

169PS-6-2 3/8 1/8 1/2-24 7/16 7/16 0.88 0.63 0.90 0.203

169PS-6-4 3/8 1/4 1/2-24 9/16 9/16 0.94 0.69 1.22 0.203

169PS-6-6

3/8 3/8 1/2-24 9/16 11/16 0.86 0.60 1.19 0.203

169PS-8-6 1/2 3/8 11/16-20 1/2 11/16 1.03 0.78 1.22 0.323

Flow

Dia.

D

170P Female Elbow

Part

No.

Tube

Size

169P-2-1 1/8 1/16 5/16-24 0.88 0.63 0.69 0.094

269P-2-2*

1/8 1/8 5/16-24 0.83 0.61 0.67 0.094

169P-3-1 3/16 1/16 3/8-24 0.88 0.63 0.69 0.094

169P-3-2*

3/16 1/8 3/8-24 0.83 0.61 0.69 0.125

169P-3-4* 3/16 1/4 3/8-24 0.85 0.63 0.94 0.125

169P-4-1

169P-4-2

1/4 1/16 3/8-24 0.92 0.58 0.67 0.130

1/4 1/8 3/8-24 0.84 0.73 0.75 0.121

169P-4-4 1/4 1/4 3/8-24 0.90 0.79 0.92 0.125

169P-4-6 1/4 3/8 3/8-24 0.93 0.84 1.08 0.125

169P-5-2

5/16 1/8 7/16-24 0.87 0.73 0.68 0.144

169P-6-2 3/8 1/8 1/2-24 0.93 0.81 0.73 0.203

169P-6-4

3/8 1/4 1/2-24 0.98 0.86 1.05 0.203

169P-6-6 3/8 3/8 1/2-24 0.98 0.86 1.08 0.203

169P-8-6

*Brass Sleeve, No Tube Support

1/2 3/8 11/16-20 1.12 1.04 1.13 0.323

169LP Long Male Elbow

Part

No.

Tube

Size

169LP-4-4 1/4 1/4 3/8-24 0.90 0.79 1.38 0.125

Pipe

Thread

Thread

Straight

Thread L M N

Pipe

Straight

Thread L M N

Flow

Dia. D

Flow

Dia. D

Part

No.

170P-2-2*

Tube

Pipe

Size

Thread

Straight

Thread L M N

1/8 1/8 5/16-24 0.91 0.69 0.56 0.094

170P-3-2* 3/16 1/8 3/8-24 0.91 0.69 0.56 0.125

170P-4-2

1/4 1/8 3/8-24 0.90 0.79 0.56 0.125

170P-4-4 1/4 1/4 3/8-24 1.00 0.89 0.69 0.125

170P-6-4

3/8 1/4 1/2-24 1.01 0.89 0.69 0.204

170P-8-6 1/2 3/8 11/16-20 1.19 1.11 1.13 0.323

*Brass Sleeve, No Tube Support

171P Male Run Tee

Part

No.

171P-2-2*

171P-3-2* 3/16 1/8 3/8-24 0.82 0.60 0.67 0.125

171P-4-2

171P-4-4 1/4 1/4 3/8-24 0.92 0.81 0.92 0.125

171P-5-2

171P-6-4 3/8 1/4 1/2-24 0.98 0.86 1.03 0.203

171P-8-6

*Brass Sleeve, No Tube Support

15

Tube

Pipe

Size

Thread

Straight

Thread L M N

1/8 1/8 5/16-24 0.82 0.60 0.67 0.094

1/4 1/8 3/8-24 0.84 0.73 0.72 0.125

5/16 1/8 7/16-24 0.83 0.73 0.72 0.144

1/2 3/8 11/16-20 1.12 1.04 1.13 0.323

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Flow

Dia. D

Flow

Dia. D

Z

Page 16

Pneumati

c

Catalog 0600P-9/USA

L

N

L

M M

D

L

N

L

M M

D

H

L

M N

H

H

L

M

Part Numbers & Dimensions

Fittings & Tubing

P Fittings

172P Male Branch Tee

Part

No.

172P-2-2* 1/8 1/8 5/16-24 0.82 0.60 0.67 0.094

172P-3-2* 3/16 1/8 3/8-24 0.82 0.60 0.67 0.125

172P-4-2

172P-4-4

172P-5-2 5/16 1/8 7/16-24 0.83 0.73 0.72 0.144

172P-6-2

172P-6-4 3/8 1/4 1/2-24 0.98 0.86 1.03 0.204

172P-8-6

*Brass Sleeve, No Tube Support

Tube

Pipe

Size

Thread

1/4 1/8 3/8-24 0.84 0.73 0.72 0.125

1/4 1/4 3/8-24 0.92 0.81 0.92 0.125

3/8 1/8 1/2-24 0.88 0.86 0.74 0.204

1/2 3/8 11/16-20 1.12 1.04 1.13 0.323

Straight

Thread L M N

Flow

Dia. D

177P Female Branch Tee

NV312P Angle Needle Valve

Part

No.

NV312P-4-2 1/4 1/8 1.06 1.70 1.50 0.63 0.68

NV312P-4-4

NV312P-6-4 3/8 1/4 1.06 2.00 1.75 0.74 0.86

Tube

Pipe

Size

Thread H L OpenL Closed M N

1/4 1/4 1.06 2.07 1.82 0.71 0.86

Part

No.

177P-4-2 1/4 1/8 3/8-24 0.92 0.81 0.88 0.125

177P-4-4

177P-4-6 1/4 3/8 3/8-24 1.03 0.92 1.13 0.125

Tube

Pipe

Size

Thread

1/4 1/4 3/8-24 0.92 0.81 1.03 0.125

Straight

Thread L M N

Flow

Dia. D

NV311P Needle Valve

Part

No.

NV311P-4-2 1/4 1/8 1.06 1.36 1.16 0.64 0.63

NV311P-4-4 1/4 1/4 1.06 1.38 1.18 0.64 0.72

NV311P-6-4

Tube

Pipe

Size

Thread H L OpenL Closed M N

3/8 1/4 1.06 1.38 1.18 0.64 0.72

16

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Page 17

Pneumati

c

Catalog 0600P-9/USA

Notes

Fittings & Tubing

P Fittings

Z

17

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Page 18

Pneumati

c

Catalog 0600P-9/USA

Basic Features

Fittings & Tubing DB Fittings

Advantages

Compact one piece, push-on barbed fitting for a quick,

economical way to connect polyethylene tubing. Extruded

from CA 360 or CA 345 brass rod.

Applications

Because of the many available variations in qualities of

polyethylene tubing DB fittings are recommended for

use with Parker polyethylene tubing (or an equal grade).

Parker tubing is highly resistant to environmental stress

cracking which is necessary for long life when coupled

with expansion fittings.

Working Pressure and

Temperature Ranges

In tube sizes 1/4 to 3/8 working pressures up to 150

psi are practical at temperatures ranging from -65° to

+90°F. On 1/2" tube size, working pressures to 100 psi

at temperatures ranging from -65° to +75°F.

Nomenclature

Part numbers are constructed from symbols that identify

the style and size of the fitting. The first series of numbers

and letters identifies the style and type fitting. The second

series of numbers describes the size.

Example:

231 -8 -6

Run Tee (tube

to male pipe)

1/2" (8/16) Tube O.D.

3/8" (6/16) Pipe Thread

Sizes

Tube sizes are determined by the number of sixteenths

of an inch in the tube O.D.

Assembly Instructions

Simply push tube over the two barbs — be sure tubing

is cut square.

18

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Page 19

Pneumati

c

Catalog 0600P-9/USA

L

M

C

L

M

D

L

M

D

L

M

D

P

C HEX

L

D

C HEX

L

D

C HEX

L

D

2

1

C HEX

L

C HEX

D

Part Numbers & Dimensions

Fittings & Tubing

DB Fittings

20 Plug

Part

No.

20-4 1/4 0.170 0.290 0.56 0.41

20-6 3/8 0.250 0.390 0.68 0.44

20-8 1/2 0.377 0.577 0.81 0.56

Tube

O.D.

Tube

I.D.

C

Dia. L M

22 Union

Part

No.

22-5/32

22-4 1/4x1/4 0.170x0.170 0.84 0.41 0.120

22-6

22-8 1/2x1/2 0.375x0.375 1.19 0.56 0.312

Tube

O.D.

5/32x5/32 0.096x0.096 0.59 0.28 0.062

3/8x3/8 0.250x0.250 0.94 0.44 0.187

Tube

I.D. L M

Flow

Dia. D

26 Female Connector

Part

No.

26-5/32-2

26-4-2 1/4 0.170 1/8 1/2 0.91 0.120

26-6-2

26-6-4 3/8 0.250 1/4 11/16 1.06 0.187

Tube

Tube

O.D.

5/32 0.096 1/8 1/2 0.79 0.062

3/8 0.250 1/8 1/2 0.93 0.187

Pipe

I.D.

ThreadCHex L

Flow

Dia. D

27 Male Connector

Part

No.

27-1*

27-2* 1/4 0.125 10-32 UNF 1/4 0.74 0.093

*For vinyl tubing only.

Tube

Tube

O.D.

1/8 0.062 10-32 UNF 1/4 0.61 0.052

I.D.

Pipe

ThreadCHex L

Flow

Dia. D

22 Union Reducer

Part

No.

22-4-5/32

22-4-6 1/4x3/8 0.170x0.250 0.88 0.44 0.120

22-4-8

22-6-8 3/8x1/2 0.250x0.375 1.06 0.56 0.187

Tube

O.D.

1/4x5/32 0.170x0.096 0.72 0.41 0.062

1/4x1/2 0.170x0.375 1.06 0.56 0.120

Tube

I.D. L M

22BH Bulkhead Union

Part

No.

22BH-4-4 1/4 0.170 5/16-24 7/16 0.219 1.38 0.78 0.120

22BH-6-6

Tube

O.D.

3/8 0.250 3/8-24 7/16 0.375 1.63 1.00 0.187

Tube

I.D.

Straight

ThreadCHexP Max. L M

Flow

Dia. D

Flow

Dia. D

28 Barb to Pipe Adapter

Part

No.

28-4-5/32-2 5/32 0.096 1/4 0.170 1/8 7/16 1.07 0.062

Tube

O.D. 1

Tube

I.D. 1

Tube

O.D. 2

Tube

Pipe

I.D. 2

Thread CHex F

28 Male Connector

Part

No.

28-5/32-2 5/32 0.096 1/8 7/16 0.84 0.062

28-4-1

28-4-2 1/4 0.170 1/8 7/16 0.97 0.120

28-4-4

28-6-2 3/8 0.250 1/8 7/16 1.00 0.187

28-6-4

28-8-4 1/2 0.375 1/4 9/16 1.25 0.312

28-8-6

28-8-8 1/2 0.375 1/2 7/8 1.44 0.312

19

Tube

O.D.

Tube

I.D.

1/4 0.170 1/16 11/32 0.93 0.120

1/4 0.170 1/4 9/16 1.09 0.120

3/8 0.250 1/4 9/16 1.13 0.187

1/2 0.375 3/8 11/16 1.28 0.312

Pipe

ThreadCHex L

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Flow

Dia. D

Flow

Dia. D

Z

Page 20

Pneumati

c

N

D

L

L

Catalog 0600P-9/USA

D

L

M

M

D

M

L

D

L

M

N

D

1

D

M

L

N

D

N

M

D

M

M

12

Part Numbers & Dimensions

Fittings & Tubing

DB Fittings

220 Adapter Tee

Part

No.

220-4-2 1/4 0.170 1/8 1.5 1.0 0.120

Tube

O.D.

Tube

Pipe

I.D.

Thread L M

Flow

Dia. D

224 Union Tee

225 Union Elbow

Part

No.

225-5/32

225-4-4 1/4 0.170 0.63 0.63 0.120

225-6-6 3/8 0.250 0.69 0.69 0.187

225-8-8

Tube

O.D.

5/32 0.096 0.50 0.50 0.062

1/2 0.375 0.81 0.81 0.312

Tube

I.D. L M

Flow Dia.

D

228 Gauge Tee

Part

No.

228-4-2

Tube

Tube

O.D.

1/4 0.170 1/8 1.91 0.66 0.44 0.120

Pipe

I.D.

Thread L M N

Flow

Dia. D

229 Male Elbow

Part

No.

224-5/32 5/32 0.096 1.000 0.50 0.062

224-4 1/4 0.170 1.250 0.63 0.120

224-6 3/8 0.250 1.375 0.69 0.187

224-8 1/2 0.375 1.625 0.81 0.312

224 Union Tee (Combination Sizes)

Tube

O.D.

Tube

I.D. L M

Flow

Dia. D

Part

No.

229-5/32-2

229-4-1

229-4-2 1/4 0.170 1/8 0.69 0.63 0.120

229-4-4

229-6-2 3/8 0.250 1/8 0.69 0.69 0.187

229-6-4

229-8-6 1/2 0.375 3/8 0.94 0.81 0.312

Tube

O.D.

5/32 0.096 1/8 0.56 0.63 0.062

Tube

1/4 0.170 1/16 0.62 0.60 0.120

1/4 0.170 1/4 0.72 0.72 0.120

3/8 0.250 1/4 0.75 0.75 0.187

Pipe

I.D.

Thread M N

Flow

Dia. D

229 Barb Adapter Elbow 90°

Flow

Part

No.

224-4-4-5/32 1/4x5/32 0.170x0.096 1.25 0.63 0.50 0.120 0.062

224-6-6-5/32 3/8x5/32 0.250x0.096 1.38 0.69 0.50 0.187 0.062

224-6-6-4

224-8-8-4 1/2x1/4 0.375x0.170 1.62 0.81 0.65 0.312 0.120

224-8-8-6

Tube

O.D.

3/8x1/4 0.250x0.170 1.38 0.69 0.62 0.187 0.120

1/2x3/8 0.375x0.250 1.62 0.81 0.69 0.312 0.187

Tube

I.D. L M N

Dia.

D

Flow

Dia.

D1

Part

No.

229-4-5/32-2 5/32 0.096 1/4 0.170 1/8 0.78 0.062

20

Tube

O.D. 1

Tube

I.D. 1

Tube

Tube

O.D. 2

I.D. 2

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Pipe

Thread M

Flow

Dia. D

Page 21

Pneumati

c

Catalog 0600P-9/USA

D

L

M

N

D

L

M

N

D

L

M

N

L

N

M

M

L

D

L

D

L

M

1

2

D

L

M

N

Part Numbers & Dimensions

Fittings & Tubing

DB Fittings

230 Female Elbow

Part

No.

230-4-2

230-6-4 3/8 0.250 1/4 1.12 0.78 0.63 0.187

Tube

Tube

O.D.

1/4 0.170 1/8 0.91 0.66 0.44 0.120

Pipe

I.D.

Thread L M N

Flow

Dia. D

231 Male Run Tee

233 Tee

Part

No.

233-4-4-4 1/4 0.170 1/4 0.73 0.53 0.74 0.120

233-6-6-4

Tube

Tube

O.D.

1/4 0.170 3/8 0.87 0.59 0.80 0.120

Comp.

I.D.

Tube L M N

Flow

Dia. D

237 Female Branch Tee

Part

No.

231-4-2

231-6-2 3/8 0.250 1/8 1.38 0.69 0.69 0.187

231-6-4

Tube

Tube

O.D.

1/4 0.170 1/8 1.28 0.66 0.69 0.120

3/8 0.250 1/4 1.44 0.75 0.75 0.187

Pipe

I.D.

Thread L M N

Flow

Dia. D

Part

No.

237-4-2

Tube

Tube

O.D.

1/4 0.170 1/8 1.34 0.67 0.49 0.120

Pipe

I.D.

Thread L M N

Flow

Dia. D

238 Solder Connector

Part

No.

238-4-4

Tube

O.D. 1

1/4 0.170 0.91 0.254 0.120

Tube

I.D. 2 L M

Flow Dia.

D

232 Male Branch Tee

20GT DB Tool*

Part

No.

232-4-1

232-4-2 1/4 0.170 1/8 1.38 0.69 0.66 0.120

232-6-2

232-6-4 3/8 0.250 1/4 1.50 0.75 0.75 0.187

Tube

Tube

O.D.

1/4 0.170 1/16 1.33 0.66 0.65 0.120

3/8 0.250 1/8 1.38 0.69 0.69 0.187

Pipe

I.D.

Thread L M N

Flow

Dia. D

Part

No.

20GT-4 1/4 1.00 0.245

*For ease in assembling polyethylene tubing onto DB Fittings.

21

Tube

O.D. L Thru Dia.

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Z

Page 22

Pneumati

c

Catalog 0600P-9/USA

Features & Part Numbers

Fittings & Tubing

Polyethylene Tubing

Advantages

Chemical resistant, flexible, low cost,

eight colors, five tube sizes and choice

of reel lengths.

Construction

Flexible polyethylene thermoplastic tubing

is extruded from high molecular weight

resin for increased dimensional stability,

uniformity and long-term strength. Its

resistan ce to envi ronmental str ess

cracking greatly exceeds that of ordinary

polyethylene tubing as measured by

ASTM D-1693, (10% IGEPAL).

Applications &

Approvals

Polyethylene tubing is available in

black as well as seven coding colors

as recommended by the Instrument

Society of America. Black (EB) tubing

contains an ultra-violet inhibitor which

is re c o m mended for use in sunlit

areas. Ingredients of natural and color

tubing (except black) listed below meet

FDA requirements for food contact

applications. All tubing conforms to

AST M D-12 4 8, Type I , Clas s A,

Category 4, Grade E5.

Temperature Range

Suggested operating temperature range

is -80°F to 150°F (-62°C to 66°C).

Fitting Recommendation

• Brass fittings

E Instrument Grade Tubing

Working

Reel

Part

Number Color O.D. I.D. Wall

E-43-0100 Natural 1/4 0.170 0.040 100 120 625 1 1.1

E-43-0500 Natural 1/4 0.170 0.040 500 120 625 1 1.1

E-43-1000

EB-43-0100 Black 1/4 0.170 0.040 100 120 625 1 1.1

EB-43-0500

EB-43-1000 Black 1/4 0.170 0.040 1000 120 625 1 1.1

E-43-R-0100

E-43-R-0500 Red 1/4 0.170 0.040 500 120 625 1 1.1

E-43-B-0100

E-43-B-0500

E-43-O-0500 Orange 1/4 0.170 0.040 500 120 625 1 1.1

E-43-Y-0500 Yellow 1/4 0.170 0.040 500 120 625 1 1.1

E-43-P-0500

E-43-G-0500 Green 1/4 0.170 0.040 500 120 625 1 1.1

E-53-0500

EB-53-0500 Black 5/16 0.187 0.062 500 145 800 1-1/8 2.1

E-64-0100

E-64-0500 Natural 3/8 0.250 0.062 500 125 675 1-1/4 2.5

EB-64-0100

EB-64-0500 Black 3/8 0.250 0.062 500 125 675 1-1/4 2.5

E-64-R-0500

E-64-B-0500 Blue 3/8 0.250 0.062 500 125 675 1-1/4 2.5

E-64-O-0500

E-64-Y-0500 Yellow 3/8 0.250 0.062 500 125 675 1-1/4 2.5

E-64-P-0500

E-64-G-0500 Green 3/8 0.250 0.062 500 125 675 1-1/4 2.5

E-86-0100

EB-86-0100 Black 1/2 0.375 0.062 100 90 425 2-1/2 3.6

E-108-0100

EB-108-0100 Black 5/8 0.500 0.062 Coil 70 325 4 4.6

Natural 1/4 0.170 0.040 1000 120 625 1 1.1

Black 1/4 0.170 0.040 500 120 625 1 1.1

Red 1/4 0.170 0.040 100 120 625 1 1.1

Blue 1/4 0.170 0.040 100 120 625 1 1.1

Blue 1/4 0.170 0.040 500 120 625 1 1.1

Purple 1/4 0.170 0.040 500 120 625 1 1.1

Natural 5/16 0.187 0.062 500 145 800 1-1/8 2.1

Natural 3/8 0.250 0.062 100 125 675 1-1/4 2.5

Black 3/8 0.250 0.062 100 125 675 1-1/4 2.5

Red 3/8 0.250 0.062 500 125 675 1-1/4 2.5

Orange 3/8 0.250 0.062 500 125 675 1-1/4 2.5

Purple 3/8 0.250 0.062 500 125 675 1-1/4 2.5

Natural 1/2 0.375 0.062 100 90 425 2-1/2 3.6

Natural 5/8 0.500 0.062 100 70 325 4 4.6

Length

Feet

Pressure

psi at

73°F

Min.

Burst

psi at

73°F

Bend

Radius

Inches

Min.

Weight

Per 100

Feet

Nomenclature

Part numbers are constructed from

symbols that identify the style and size

of the fitting. Letters identify style and

material. Numbers identify size in 1/16’s

of an inch.

Example:

E - 6 4 - Y - 0500

Polyethylene

3/8" (6/16) Tube O.D.

1/4" (4/16) Tube I.D.

Color, Yellow

Reel Footage

22

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Page 23

Pneumati

c

Catalog 0600P-9/USA

Features & Part Numbers

Construction &

Approvals

Fl a me r es i st a nt p ol y ethy len e is

manu factured from a distinctively

formulated compound which meets

the UL94 V-2 flame classification. It

also meets the flame spread, fuel

co n tr ibut ion an d sm o ke d ens ity

requirements of the ASTM E84-81a

tunnel test.

Applications

Parker series FRPE tubing is the

preferred product for pneumatic control

applications in the heating- ventilatingair conditioning-energy conservation

industry. It is also suitable for use

in petrochemical plants, petroleum

refineries, pulp and paper mills, mines,

steel mills and other industries where

protection against intermittent flame and

hot sparks is necessary.

Fittings & Tubing

Polyethylene Tubing

Temperature Range

Sug ges ted o pe r ati n g t e mpe rat u re r ang e is - 8 5° F to 1 50° F

(-65°C to +66°C).

Nomenclature

Order by tubing part number and name.

Example:

FR PE 4 — 0500

Flame Resistant

Polyethylene

1/4" (4/16) Tube O. D.

Reel Footage

FRPE Flame Resistant Tubing

Part

Number Color O.D. I.D. Wall

FRPE2.5-0500

FRPE4-0250

FRPE4-0500

FRPE4-1000

FRPE6-0250

FRPE6-0500

FRPE8-0250

Black 5/32 0.096 0.030 500 225 900 1/2 0.56

Black 1/4 0.170 0.040 250 160 650 3/4 1.24

Black 1/4 0.170 0.040 500 160 650 3/4 1.24

Black 1/4 0.170 0.040 1000 160 650 3/4 1.24

Black 3/8 0.250 0.062 250 195 780 1-1/2 2.90

Black 3/8 0.250 0.062 500 195 780 1-1/2 2.90

Black 1/2 0.375 0.062 250 135 540 1-3/4 4.05

Reel

Length

Feet

Working

Pressure

psi at

73°F

Min.

Burst

psi at

73°F

Min.

Bend

Radius

Inches

Weight

Per 100

Feet

Z

23

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Page 24

Pneumati

c

Catalog 0600P-9/USA

Features & Part Numbers

Advantages

Flexible nylon tubing is carefully made from

high-grade, abrasion-resistant, heat-and

light-stabilized nylon. Resistance to stresscracking greatly exceeds that of ordinary

nylon tubing. Extremely low level water

absorption.

Chemical-resistant nylon tubing has the

additional benefits of better flexibility, lighter

weight and resistance to flexural fatigue.

Colors

Available in natural (NN) and black (NB).

Black tubing is recommended for use outdoors and in sunlit areas.

Temperature Range

Operating temperatures, depending upon

conditions, are -65°F to 200°F (-54°C to

93°C) continuous.

Fitting Recommendations

• Brass fittings

Fittings & Tubing

Nylon Tubing – N

Nomenclature

Order by tubing part number and name.

Example:

N N — 2 — 016

Nylon

Color, Natural

1/8" (2/16) Tube O.D.

Wall Thickness in thousandths of an inch

N Flexible Tubing

*Min.

Nylon

Part No. Color

NN-2-016

NB-2-016

NN-2-031

NB-2-031

NN-2.5-025

NB-2.5-025

NN-3-025

NB-3-025

NN-3-046

NB-3-046

NN-4-035

NB-4-035

NN-4-040

NB-4-040 Black 1/4 0.170 0.040 1250 7/8 250

NN-4-062

NB-4-062

NN-5-040

NB-5-040

NN-6-050

NB-6-050

NN-6-093

NB-6-093

NN-8-062

NB-8-062

NN-8-124

NB-8-124

*Suggested working pressure is 1/4 of burst pressure.

Natural 1/8 0.093 0.016 1000 1/4 250

Black 1/8 0.093 0.016 1000 1/4 250

Natural 1/8 0.064 0.031 2000 1/4 250

Black 1/8 0.064 0.031 2000 1/4 250

Natural 5/32 0.106 0.025 1200 1/2 250

Black 5/32 0.106 0.025 1200 1/2 250

Natural 3/16 0.138 0.025 1000 5/8 250

Black 3/16 0.138 0.025 1000 5/8 250

Natural 3/16 0.096 0.046 2000 7/16 250

Black 3/16 0.096 0.046 2000 7/16 250

Natural 1/4 0.180 0.035 1000 7/8 250

Black 1/4 0.180 0.035 1000 7/8 250

Natural 1/4 0.170 0.040 1250 7/8 250

Natural 1/4 0.127 0.062 2000 1/2 250

Black 1/4 0.127 0.062 2000 1/2 250

Natural 5/16 0.233 0.040 1250 1-1/8 250

Black 5/16 0.233 0.049 1250 1-1/8 250

Natural 3/8 0.275 0.050 1250 1-1/8 250

Black 3/8 0.275 0.050 1250 1-1/8 250

Natural 3/8 0.190 0.093 2000 3/4 250

Black 3/8 0.190 0.093 2000 3/4 250

Natural 1/2 0.375 0.062 1000 1-1/4 250

Black 1/2 0.375 0.062 1000 1-1/4 250

Natural 1/2 0.253 0.124 2000 1 250

Black 1/2 0.253 0.124 2000 1 250

Nom.

Tube

O.D.

Nom.

Tube

I.D.

Average

Wall

Thick.

Burst

Pressure

at 73°F

psi

Min.

Bend

Radius

Inches

Length

Std.

Reel

Feet

24

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Page 25

Pneumati

c

Catalog 0600P-9/USA

Features & Part Numbers

Advantages

Series NR semi-rigid nylon tubing offers

better chemical resistance than series N,

good resistance to high ambient temperature and low moisture absortion. NR has a

high tensile strength which will give excellent coupling retention in high pressure,

temperature and vibration environments.

Construction

Parker series NR tubing is manufactured

from a semi-rigid nylon II material. The

tubing does not contain plasticizers.

Applications & Approvals

NR tubing is specified for machine tool

lubricating systems, marine control systems,

process lines for chemicals and oils and

other applications requiring a high quality

nylon tube.

Temperature Range

The recommended operating temperature

range for service at rated pressures with

compatible fluids is -60°F to 200°F (-51°C

to 93°C).

Fittings & Tubing

Nylon Tubing – NR

Fitting Recommendations

• Brass fittings

Nomenclature

Order by tubing part number and name.

Example:

N B R 2 016

Nylon

Color, Black

Rigid

1/8" (2/16) Tube O.D.

Wall Thickness in thousandths of an inch

NR Semi-rigid High Strength Tubing

*Min.

Nylon

Part No. Color

NNR-2-017 Natural 1/8 0.091 0.017 1700 1/2 500

NBR-2-017

NNR-2-026 Natural 1/8 0.073 0.026 2500 3/8 500

NBR-2-026

NNR-3-024 Natural 3/16 0.140 0.024 1700 3/4 500

NBR-3-024 Black 3/16 0.140 0.024 1700 3/4 500

NNR-3-039

NBR-3-039

NNR-4-035 Natural 1/4 0.180 0.035 1700 1 250

NBR-4-035

NNR-4-050 Natural 1/4 0.150 0.050 2500 7/8 250

NBR-4-050 Black 1/4 0.150 0.050 2500 7/8 250

NNR-5-040

NBR-5-040

NNR-6-048 Natural 3/8 0.279 0.048 1700 1-3/4 250

NBR-6-048 Black 3/8 0.279 0.048 1700 1-3/4 250

NNR-6-075

NBR-6-075 Black 3/8 0.225 0.075 2500 1-1/2 250

NNR-8-062

NBR-8-062 Black 1/2 0.376 0.062 1500 2-3/8 250

NNR-8-075

NBR-8-075 Black 1/2 0.350 0.075 2200 2-1/2 250

*Suggested working pressure is 1/4 of burst pressure.

Black 1/8 0.091 0.017 1700 1/2 500

Black 1/8 0.073 0.026 2500 3/8 500

Natural 3/16 0.110 0.039 2500 5/8 500

Black 3/16 0.110 0.039 2500 5/8 500

Black 1/4 0.180 0.035 1700 1 250

Natural 5/16 0.233 0.040 1700 1-1/2 250

Black 5/16 0.233 0.040 1700 1-1/2 250

Natural 3/8 0.225 0.075 2500 1-1/2 250

Natural 1/2 0.376 0.062 1500 2-3/8 250

Natural 1/2 0.350 0.075 2200 2-1/2 250

Nom.

Tube

O.D.

Nom.

Tube

I.D.

Average

Wall

Thick.

Burst

Pressure

at 73 °F

psi

Min

Bend

Radius

Inches

Length

Std.

Reel

Feet

PTC Plastic Tube Cutter

Part No. PTC

An easy to handle razor/edged tube cutter, closes

automatically, assuring clean and square cuts.

May be used with polyethylene, polypropylene, nylon and

other plastic tubing.

How To Use

Insert plastic tube to desired length, allow tube cutter to

close, then apply pressure until tube snaps off.

25

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Z

Page 26

Pneumati

c

Minimum

Burst

Pressure

(psig)

3.0

2.8

2.6

2.4

2.2

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

75 100 125 150 175 200

(NR-2-026)

(NR-3-039)

(NR-4-050)

(NR-6-075)

(NR-8-075)

Temperature (deg. F.)

Minimum

Burst Pressure

(psig)

(Thousands)

1.5

1.4

1.3

1.2

1.1

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

75 100 125 150 175 200

(N-4-040)

(N-2-016)

(N-2.5-025)

(N-3-025)

(N-4-035)

(N-5-040)

(N-6-050)

(N-8-062)

Temperature (deg. F.)

Minimum

Burst

Pressure

(psig)

2.0

1.9

1.8

1.7

1.6

1.5

1.4

1.3

1.2

1.1

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

75 100 125 150 175 200

(NR-2-017)

(NR-3-024)

(NR-4-035)

(NR-5-040)

(NR-6-048)

(NR-8-062)

Temperature (deg. F.)

Minimum

Burst Pressure

(psig)

(Thousands)

Nylon Semi-Rigid Tubing

NR Series (NNR, NBR)

1/8 thru 1/2 O.D. Inches

Nylon Flexible Tubing

N Series (NN, NB)

1/8 thru 1/2 O.D. Inches

Nylon Semi-Rigid Tubing

NR Series (NNR, NBR)

1/8 thru 1/2 O.D. Inches

2000

1800

1600

1400

1200

1000

800

600

400

200

0

75 100 125 150 175 200

Temperature (deg. F.)

Nylon Flexible Tubing

N Series

1/8 thru 1/2 O.D. Inches

Suggested working pressures are 1/4 of burst pressure at system operating temperature.

(N-2-031)

(N-3-046)

(N-4-062)

(N-6-093)

(N-8-124)

Catalog 0600P-9/USA

Technical Information

Fittings & Tubing

Burst Pressure / Temperature Charts

26

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Page 27

Pneumati

c

Catalog 0600P-9/USA

Polyethylene Tubing

Laboratory Grade E Series

1/4 thru 5/8 O.D.

900

800

700

600

500

400

300

200

100

75 100 125 150

(E-53)

(E-108)

Temperature (deg. F.)

Minimum

Burst

Pressure

900

800

700

600

500

400

300

200

100

0

75 100 125 150

(FRPE-2.5 x .030")

(FRPE-6 x .062")

(FRPE-3 x .030")

(FRPE-4 x .040")

(FRPE-8 x .062")

Temperature (deg. F.)

(E-86)

(E-64)

(E-43)

Minimum

Burst

Pressure

Polyethylene Tubing

Flame Resistant FRPE Series

5/32 thru 1/2 O.D.

Suggested working pressures are 1/4 of burst pressure at system operating temperature.

Technical Information

Fittings & Tubing

Burst Pressure / Temperature Charts

Z

27

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Page 28

Pneumati

c

Catalog 0600P-9/USA

Technical Information

Fittings & Tubing

Chemical Compatibility Guide - Brass Fittings

All Brass

Body Fittings Prestolok

(Except Prestolok) Fitting

Rating Rating

Acetic Acid 4 4

Acetic Anhydride 4 4

Acetone 1 4

Alum 4 4

Aluminum Chloride 4 4

Aluminum Sulfate 4 4

Ammonium Hydroxide 4 4

Ammonium Chloride 4 4

Ammonium Nitrate 4 4

Ammonium Sulfate 4 4

Amyl Acetate 2 4

Aniline 3 4

Aniline Dyes 3 4

Asphalt 1 2

Barium Chloride 4 4

Beer 2 4

Beet Sugar Syrups 2 2

Benzoic Acid 2 4

Black Liquor, Sulfate Process 4 4

Bleaching Powder, Wet 4 4

Borax 1 2

Bordeaux Mixture 2 2

Boric Acid 2 2

Bromine, Dry 1 4

Bromine, Moist 4 4

Butyric Acid 3 4

Calcium Bisulfite 4 4

Calcium Chloride 4 4

Calcium Hydroxide 2 2

Calcium Hypochlorite 4 4

Cane Sugar Syrups 2 2

Carbolic Acid 2 4

Carbon Dioxide, Dry 1 1

Carbon Dioxide, Moist 3 3

Carbon Disulfide 1 4

Carbon Tetrachloride, Moist 4 4

Castor Oil 1 1

Chlorine, Dry 1 4

Chlorine, Moist 4 4

Chloracetic Acid 4 4

Chloroform, Dry 1 4

All Brass

Body Fittings Prestolok

(Except Prestolok) Fitting

Rating Rating

Citric Acid 3 3

Coffee 1 4

Copper Chloride 4 4

Copper Sulfate 4 4

Corn Oil 2 2

Cottonseed Oil 2 2

Creosote 2 2

Crude Oil 3 3

Ethers 1 4

Ethyl Acetate 2 4

Ethyl Chloride 3 3

Ethylene Glycol 2 2

Ferric Chloride 4 4

Formaldehyde 3 3

Furfural 3 4

Gelatine 1 1

Glucose 1 1

Glycerine 1 1

Hydrobromic Acid 4 4

Hydrochloric Acid 4 4

Hydrocyanic Acid 4 4

Hydrofluoric Acid 4 4

Hydrofluosilicic Acid 4 4

Hydrogen Peroxide 3 4

Hydrogen Sulfide, Moist 3 4

Lacquers 1 4

Lacquer Solvents 1 4

Lactic Acid Cold 3 3

Lime 1 1

Lime-Sulfur 2 4

Linseed Oil 2 2

Magnesium Chloride 4 4

Magnesium Hydroxide 1 2

Magnesium Sulfate 3 3

Methyl Chloride, Dry 1 4

Milk 2 4

Nitric Acid 4 4

Nitrogen 1 1

Oleic Acid 3 3

Oxalic Acid 3 3

Palmitic Acid 3 3

1 — SATISFACTORY

2 — FAIR

3 — RECOMMEND TESTING

4 — UNSATISFACTORY

28

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatic

Page 29

Pneumati

c

Catalog 0600P-9/USA

Technical Information

Fittings & Tubing

Chemical Compatibility Guide - Brass Fittings

All Brass

Body Fittings Prestolok

(Except Prestolok) Fitting

Rating Rating

Phosphoric Acid 4 4

Potassium Chloride 4 4

Potassium Cyanide 4 4

Potassium Dichromate, Acid 4 4

Potassium Hydroxide 3 3

Potassium Sulfate 2 2

Sea Water 3 3

Soap Solutions 2 2

Sodium Bicarbonate 3 3

Sodium Bisulfate 4 4

Sodium Bisulfite 4 4

Sodium Carbonate 2 2

Sodium Chloride 4 4

Sodium Cyanide 4 4

Sodium Hydroxide 3 3

Sodium Hypochlorite 4 4

Sodium Nitrate 3 3

Sodium Peroxide 4 4

Sodium Phosphate 2 2

Sodium Silicate 2 2

All Brass

Body Fittings Prestolok

(Except Prestolok) Fitting

Rating Rating

Sodium Sulfite 4 4

Sodium Thiosulfate 2 2

Steam 3 4

Stearic Acid 3 3

Sulfur, Dry 1 4

Sulfur Chloride, Dry 1 4

Sulfur Dioxide, Dry 1 4

Sulfur Dioxide, Moist 4 4

Sulfur Trioxide, Dry 1 4

Sulfuric Acid 4 4

Sulfurous Acid 4 4

Tar 2 2

Tartaric Acid 3 3

Toluene 1 4

Trichloracetic Acid 4 4

Trichlorethylene, Dry 1 3

Trichlorethylene, Moist 3 3

Vinegar 4 4

Zinc Chloride 4 4

Zinc Sulfate 4 4

1 — SATISFACTORY

2 — FAIR

3 — RECOMMEND TESTING

4 — UNSATISFACTORY

This brass compatibility chart is a ready reference for

brass fittings with various media. It is intended as a guide

to chemical compatibility and has been compiled from