Parker Hannifin Instrumentation PTFE Hose, Thermoplastic Tubing, Fittings and Accessorie User Manual

Instrumentation PTFE

Hose, Thermoplastic

Tubing, Fittings and

Accessories

Catalog 4200-INST

November 2004

GENERAL INFORMATION

Parker thermoplastic tubing,

fittings, and PTFE hose products

support instrumentation process

systems.

For critical applications that require accurate control

and dependable sample transport, Parker Hannifin is

the only manufacturer that can provide such an

extensive range of products to meet the challenge in

any process. With over 2,700 product lines, solving

instrumentation system needs is our goal.

PTFE Hose

Parflex® PTFE hose is manufactured with the highest

quality, high performance PTFE material available.

Parflex

tance, flexibility and temperature resistance. PTFE

hose is available in static-dissipated or heavy wall low

permeation constructions.

Hose assemblies can be quickly made to your specification with Parker 91N series fittings attached, tested

and delivered complete and ready to use to your site.

The most common end connections available include:

Thermoplastic Reinforced Hose

In addition to PTFE hose, Parker offers one of the

most extensive lines of thermoplastic hose available in

the market.

Parker thermoplastic hose offers long-term durability,

clean core tubes and the industry’s highest level of

abrasion resistant jackets available.

For the long-term life of a system, Parker thermoplastic hose outperform rubber hose 10:1.

Parker offers hoses for just about every application.

From our General Hydraulic Hose 520N series to our

Polyflex

applications to 20,400 PSI, Parker has a hose available to meet the most demanding system needs.

Thermoplastic Tubing and Fittings

When it comes to solving instrumentation needs,

Parker is unmatched in the market for available

thermoplastic tubing and fittings.

®

PTFE hose offer excellent chemical resis-

• A-LOK

®

Compression

• CPI™ Compression

• Tube Stub

• Male NPT

• And many others

®

2440N series designed for high-pressure

We stock most thermoplastic tubing materials,

such as:

• Nylon

• Polyethylene

• Polypropylene

• Polyurethane

• Vinyl

Our standard color is black, but many other colors are

also available.

As part of the complete system, Parker also has a full

line of fittings specifically designed for use with our

thermoplastic tubing, offering tight, sure, leak proof

seal.

Our TrueSeal

without the need for special tools. Our Fast & Tite

™

fittings offer quick field connections,

®

are the most complete line in the industry.

The Par-Barb series is engineered with a 4-barb

design that generates the maximum gripping and

sealing power available in a barb connection, when

used in conjunction with a hose clamp.

These fittings are offered in a wide range of materials

and temperatures such as:

TrueSeal

™

• Grey Acetal –20˚F to 180˚F

• White Polypropylene 0˚F to 225˚F

• Natural Kynar

Fast & Tite

™

0˚F to 275˚F

®

• Black /White Polypropylene 0˚F to 212˚F

• White Nylon –40˚F to 212˚F

Par-Barb

• Black Polyethylene –65˚F to 190˚F

• White Nylon –40˚F to 200˚F

KYNAR® is a registered trademark of Atochem North America, Inc.

Hose Crimping Equipment

Parker’s MiniKrimp™ crimper is a patent pending

design. At just about 35 pounds, the MiniKrimp is the

lightest and fastest low-cost, portable crimper on the

market. It provides a factory style hose assembly on

the job-site within seconds. The exclusive

Parkalign™ feature correctly positions the fitting every

time, while the unitized die train keeps die segments

in place.

The MiniKrimp is available with a number of options,

including air over hydraulic, hand pump, vice mount or

bench mount styles.

2

Parker Hannifin Corporation

Parflex Division

Ravenna, OH

PTFE HOSE

How to order PTFE Hoses ................................. 4

919, 919B, 919J, 929, 929B ........................... 4-6

End fitting 91N series ......................................... 7

Thermoplastic Hose

How to order Thermoplastic Hoses.................... 8

520N, 540P, 540N, 518C, 580N .................... 8-10

End fittings 55 series ....................................... 10

Accessories...................................................... 10

Crimping Equipment

MiniKrimp, accessories and specifications ...... 11

Thermoplastic Tubing

Introduction design features............................. 12

Thermoplastic Tubing selection chart .............. 12

Tubing and part number selection chart .......... 13

INDEX

Thermoplastic Fittings

Introduction design features............................. 14

TrueSeal Fittings Charts .................................. 15

Fast & Tite Fittings Charts........................... 16-17

Par-Barb Charts ..........................................18-19

Polyflex Hose

Introduction ...................................................... 20

Polyflex Hose Chart ......................................... 20

How to order Polyflex Hoses............................ 21

FAILURE, IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS AND/OR SYSTEMS DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL

INJURY AND PROPERTY DAMAGE.

This document and other information from Parker Hannifin Corporation, its subsidiaries and authorized distributors provide product and/or system options for further investigation by users

having technical expertise. It is important that you analyze all aspects of your application and review the information concerning the product or system in the current product catalog. Due to

the variety of operating conditions and applications for these products or systems, the user, through its own analysis and testing, is solely responsible for making the final selection of the

products and systems and assuring that all performance, safety and warning requirements of the application are met.

The products described herein, including without limitation, product features, specifications, designs, availability and pricing, are subject to change by Parker Hannifin Corporation and its

subsidiaries at any time without notice.

WARNING

The items described in this document are hereby offered for sale by Parker Hannifin Corporation, its subsidiaries or its authorized distributors. This offer and its acceptance are governed by

the provisions stated in the “Offer of Sale” located in Catalog 4660.

© Copyright 2004, Parker Hannifin Corporation. All Rights Reserved.

Offer of Sale

3

Parker Hannifin Corporation

Parflex Division

Ravenna, OH

PTFE HOSE

Introduction

Parker reinforced PTFE hose is manufactured with a high-performance PTFE core material. Our PTFE hose

provide fluid conveyance solutions for a wide range of applications across many markets. Parker PTFE hose

offer excellent chemical resistance and is virtually inert to all chemical. Many other benefits of Parker PTFE hose

include:

BENEFITS:

• Extreme high and low temperature range

• Low friction minimizes pressure drops and deposits

• Exceptional chemical resistance

How to Order

P 919 TU AL 08 08 08 C- 36

• Stainless steel braid reinforcement is cleaned to reduce hydrocarbon content

• High purity non-contaminating material for pure system applications

• Flexibility allows motion, vibration dampening and easier routing & installation

TYPE OF

CONNECTION

P=Permanent

Crimp

Other End Connections and styles available. See Parflex 4660 catalog at www.Parker.com for additional details.

Assemblies are to be measured extreme end to end. Exception:

1. Face seal type fittings shall be measured from sealing to face.

2. Where elbow fittings are used, measurement shall be to the centerline of the sealing surface of the elbow end.

3. “A-LOK®” and “CPI™” fittings are measured from tube stops.

HOSE

STYLE

919

919B

919J

929

929B

1ST END

CONNECTION

01 = Male NPT

03 = Male JIC 37°

06 = Female SAE (JIC) 37°

Swivel

AL = A-LOK

P6 = CPI

TU = Universal Tube Stub

HV = Male Vacuseal

VH = Female Vacuseal

™

Compression

(nut & ferrule)

2ND END

CONNECTION

®

Compression

1ST END

DASH SIZE

02=1/8"

04=1/4"

06=3/8"

08=1/2"

12=3/4"

16=1"

2ND END

DASH SIZE

HOSE I.D.

DASH SIZE

04=3/16"

06=5/16"

08=13/32"

12=5/8"

16=7/8"

919 PTFE HOSE PTFE Hose

FITTING

MATERIAL

C=Stainless

OVERALL

ASSEMBLY

LENGTH (INCHES)

Overall length is

expressed in

inches measured

from extreme end

to end. Except

elbow fittings

which are

measured from

centerline or

the seat.

HOSE

SERIES -

DASH SIZE

919-4 28 3/16 5 5/16 8 .030 .762 3000 20.7 2.0 51 0.056 0.09 80C-T04N

919-5 28 1/4 6 3/8 10 .030 .762 3000 20.7 3.0 76 0.086 0.13 80C-T05N

919-6 28 5/16 8 7/16 11 .030 .762 2500 17.2 4.0 102 0.103 0.15 80C-T06N

919-8 28 13/32 10.5 17/32 14 .030 .762 2000 13.8 5.0 127 0.126 0.19 80C-T08N

919-10 28 1/2 12.5 5/8 16 .030 .762 1500 10.3 6.5 165 0.149 0.22 80C-T10N

919-12 12 5/18 16 3/4 19 .030 .762 1200 8.3 7.5 191 0.186 0.28 80C-T12N

919-16 14 7/8 22 1-1/32 26 .035 .889 1000 6.9 9.0 229 0.268 0.4 80C-T16N

Construction: Smooth bore natural PTFE core tube with a type 304 stainless steel braided wire reinforcement.

Typical applications: Instrumentation lines, analyzer sampling lines and for areas that require tight routing.

Temperature range: -100°F to +450°F (-73°C to +232°C)

VACUUM

RATING

INCHES/HG INCHES MM INCHES MM INCHES MM PSI MPA INCHES MM LBS/FT KG/M

HOSE I.D.

MAX.

HOSE O.D.

WALL

THICKNESS

4

MAXIMUM

WORKING

PRESSURE

MINIMUM

BEND

RADIUS

WEIGHT

Parker Hannifin Corporation

Parflex Division

Ravenna, OH

CRIMP DIE

PART NO.

919B PTFE Hose Static-Dissipative Hose

PTFE HOSE

HOSE

SERIES -

DASH SIZE

919B-5 28 1/4 6 3/8 10 .030 .762 3000 20.7 3.0 76 0.086 0.13 80C-T05N

919B-6 28 5/16 8 7/16 11 .030 .762 2500 17.2 4.0 102 0.103 0.15 80C-T06N

919B-8 28 13/32 10.5 17/32 14 .030 .762 2000 13.8 5.0 127 0.126 0.19 80C-T08N

Construction: Smooth bore black PTFE core tube with a type 304 stainless steel braided wire reinforcement.

Typical applications: Static-Dissipative PTFE black core tube. Transfer line for most chemicals, hot oils, fuel lines, coolant and steam transfer. Compressed

air and gases. Adhesive dispensing, paints and coating materials.

Temperature range: -100°F to +450°F (-73°C to +232°C)

VACUUM

RATING

INCHES/HG INCHES MM INCHES MM INCHES MM PSI MPA INCHES MM LBS/FT KG/M

HOSE I.D.

MAX.

HOSE O.D.

WALL

THICKNESS

MAXIMUM

WORKING

PRESSURE

MINIMUM

BEND

RADIUS

WEIGHT

CRIMP DIE

PART NO.

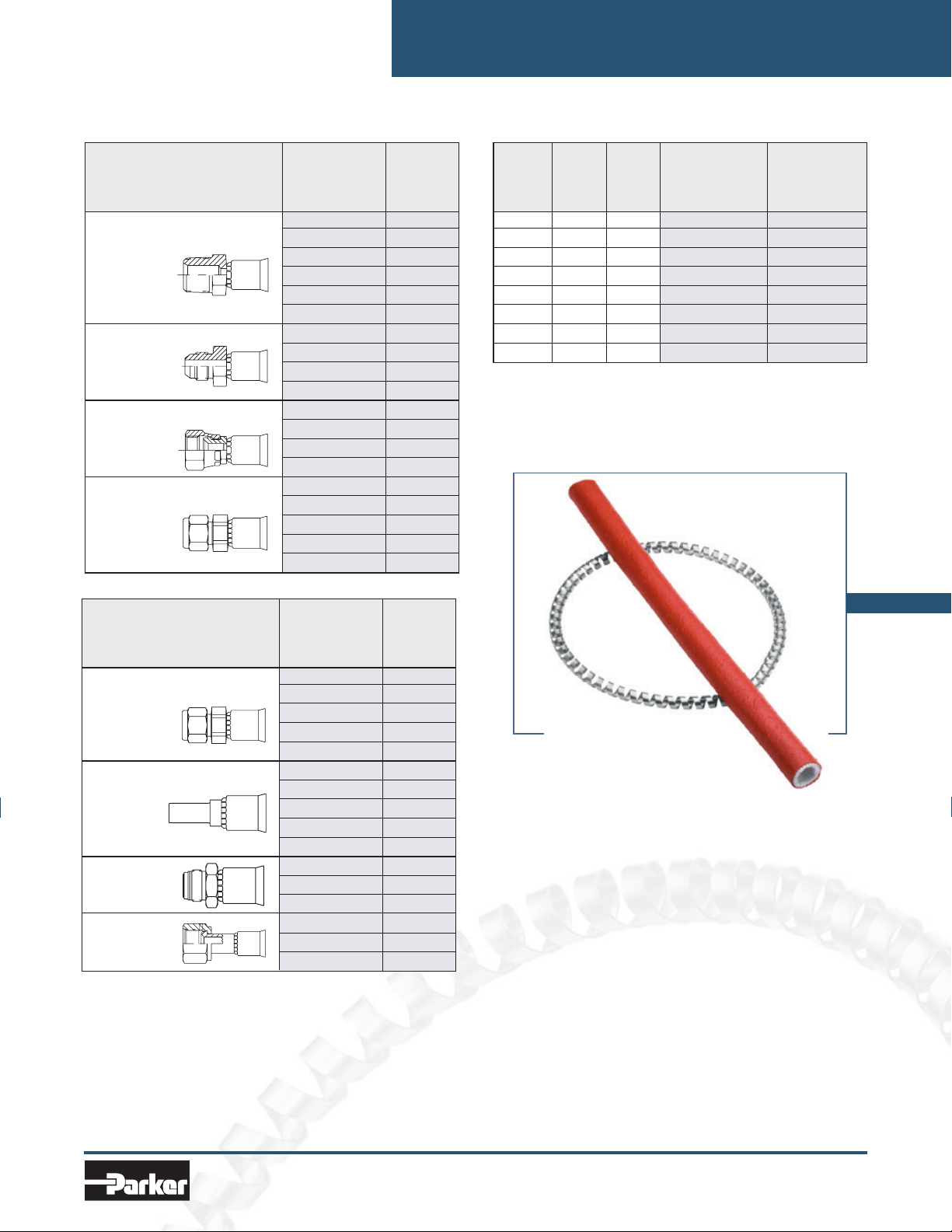

919J PTFE Hose Silicone Jacketed

PTFE Hose

HOSE

SERIES -

DASH SIZE

919J-4-Red 28 3/16 5 0.45 11 .030 .762 3000 20.7 2.0 51 0.124 0.19 80C-T04J

919J-6-Red 28 5/16 8 0.58 15 .030 .762 2500 17.2 4.0 102 0.165 0.25 80C-T06J

919J-8-Red 28 13/32 10.5 0.68 17 .030 .762 2000 13.8 5.0 127 0.202 0.3 80C-T08J

919J-10-Red 28 1/2 12.5 0.78 20 .030 .762 1500 10.3 6.5 165 0.236 0.35 80C-T10J

919J-12-Red 12 5/18 16 0.91 23 .030 .762 1200 8.3 7.5 191 0.291 0.43 80C-T12J

Construction: Smooth bore natural PTFE core tube with a type 304 stainless steel braided wire reinforcement and a red extruded silicone jacket.

Typical applications: Transfer lines for most chemicals, coolant lines, adhesive dispensing, compressed air and gases. Areas where a protective cover

is required to prevent contamination off of the braided hose. Areas where stainless wire needs protected from fraying. Silicone cover is red and rated for

temperatures 450¡F and is steam cleanable.

Temperature range: -100°F to +450°F (-73°C to +232°C)

VACUUM

RATING

INCHES/HG INCHES MM INCHES MM INCHES MM PSI MPA INCHES MM LBS/FT KG/M

HOSE I.D.

MAX.

HOSE O.D.

WALL

THICKNESS

MAXIMUM

WORKING

PRESSURE

MINIMUM

BEND

RADIUS

WEIGHT

CRIMP DIE

PART NO.

929 PTFE Hose Heavy Wall Low Permeation Hose

HOSE

SERIES -

DASH SIZE

929-4 28 3/16 5 5/16 8 .040 1.02 3000 20.7 2.0 51 0.06 0.09 80C-T04N

929-6 28 5/16 8 7/16 11 .040 1.02 2500 17.2 4.0 102 0.13 0.15 80C-T06N

929-8 28 13/32 10.5 9/16 14 .042 1.07 2000 13.8 5.0 127 0.126 0.19 80C-T08N

929-12 12 5/18 16 3/4 19 .048 1.22 1200 8.3 7.5 191 0.186 0.28 80C-T12N

929-16 14 7/8 22 1-1/8 26 .048 1.22 1250 6.9 9.0 229 0.268 0.4 80C-T16H

Construction: Smooth bore natural PTFE core tube with a type 304 stainless steel braided wire reinforcement.

Typical applications: Instrumentation lines, analyzer sampling lines and for areas that require tight routing.

Temperature range: -100°F to +450°F (-73°C to +232°C)

VACUUM

RATING

INCHES/HG INCHES MM INCHES MM INCHES MM PSI MPA INCHES MM LBS/FT KG/M

HOSE I.D.

MAX.

HOSE O.D.

WALL

THICKNESS

5

MAXIMUM

WORKING

PRESSURE

MINIMUM

BEND

RADIUS

WEIGHT

Parker Hannifin Corporation

Parflex Division

Ravenna, OH

CRIMP DIE

PART NO.

PTFE HOSE

929B PTFE Hose Static Dissipative Heavy Wall

Low Permeation Hose

HOSE

SERIES -

DASH SIZE

929B-4 28 3/16 5 5/16 8 .040 1.02 3000 20.7 2.0 51 0.06 0.09 80C-T04N

929B-6 28 5/16 8 7/16 11 .040 1.02 2500 17.2 4.0 102 0.13 0.15 80C-T06N

929B-8 28 13/32 10.5 9/16 14 .042 1.07 2000 13.8 5.0 127 0.126 0.19 80C-T08N

929B-12 12 5/18 16 3/4 19 .048 1.22 1200 8.3 7.5 191 0.186 0.28 80C-T12N

929B-16 14 7/8 22 1-1/8 26 .048 1.22 1250 6.9 9.0 229 0.268 0.4 80C-T16N

Construction: Smooth bore black PTFE core tube with a type 304 stainless steel braided wire reinforcement.

Typical applications: Static-Dissipative PTFE black core tube. Transfer line for most chemicals, hot oils, fuel lines, coolant and steam transfer. Compressed

air and gases. Adhesive dispensing, paints and coating materials. Applications requiring enhanced permeation resistance.

Temperature range: -100°F to +450°F (-73°C to +232°C)

VACUUM

RATING

INCHES/HG INCHES MM INCHES MM INCHES MM PSI MPA INCHES MM LBS/FT KG/M

HOSE I.D.

MAX.

HOSE O.D.

WALL

THICKNESS

MAXIMUM

WORKING

PRESSURE

MINIMUM

BEND

RADIUS

WEIGHT

CRIMP DIE

PART NO.

91N Series PTFE Fittings

6

Parker Hannifin Corporation

Parflex Division

Ravenna, OH

PTFE HOSE

PTFE FITTINGS

END CONNECTION STYLE

(01) Male Taper Pipe Rigid

(03) Male (JIC) 37°

(06) Female (JIC) 37° Swivel

(AL) A-LOK® Compression

919/929 HOSE

STAINLESS

FITTING FITTING

DASH SIZE

NUMBER

10191N-4-4C -4

10191N-6-6C -6

10191N-8-8C -8

10191N-12-12C -12

10191N-16-16C -16

10191N-20-20C -20

10391N-4-4C -4

10391N-6-6C -6

10391N-8-8C -8

10391N-16-16C -16

10691N-4-4C -4

10691N-6-6C -6

10691N-16-16C -16

10691N-20-20C -20

1AL91N-4-4C -4

1AL91N-6-6C -6

1AL91N-8-8C -8

1AL91N-12-12C -12

1AL91N-16-16C -16

HOSE

PTFE ACCESSORIES

HOSE

919/929 -4 0.32 -

Other hose style accessories can be found by visiting www.Parker.com

DASH

SIZE

MAX.

O.D.

5 0.40 -

-6 0.46 - FS-F-8

8 0.56 2613-13CR FS-F-10

-10 0.66 2613-16CR FS-F-12

-12 0.79 2613-20CR FS-F-14

-16 1.05 2613-28CR FS-F-20

-20 1.32 2613-37CR FS-F-24

INTERNAL FLAT

SPRING

FIRE

SLEEVE

END CONNECTION STYLE

(P6) CPI™ Compression

(Nut & Ferrule)

(TU) Tube Stub

(HV) Male

VacuSeal

(VH) Female

VacuSeal

919/929 HOSE

STAINLESS

FITTING FITTING

DASH SIZE

NUMBER

1P691N-4-4C -4

1P691N-6-6C -6

1P691N-8-8C -8

1P691N-12-12C -12

1P691N-16-16C -16

1TU91N-4-4C -4

1TU91N-6-6C -6

1TU91N-8-8C -8

1TU91N-16-16C -16

1TU91N-20-20C -20

1HV91N-4-4C -4

1HV91N-6-6C -6

1HV91N-8-8C -8

1VH91N-4-4C -4

1VH91N-6-6C -6

1VH91N-8-8C -8

HOSE

Fire Sleeves & Flat Springs

7

Parker Hannifin Corporation

Parflex Division

Ravenna, OH

THERMOPLASTIC HOSE

Introduction

Parflex reinforced thermoplastic hose has the industry’s highest level of abrasion resistance, outlasting rubber

hose in lab tests by as much as 10:1. Hoses are available in long lengths, reducing short hose lengths. Parflex

hoses are lighter in weight than comparably sized rubber hoses, in some cases up to 40% lighter. UV resistant

jacket, tight bend radius. Other benefits include:

BENEFITS:

• Long shelf life, thermoplastic hoses do not continuously cure.

• Easy to cut and couple.

• UV resistant

How to Order

520N TU AL 08 08 08 C - 36

• Low volumetric expansion, less energy loss and faster reaction times.

• Clean core tubes reduce the possible contamination of hydraulic systems

• Tight bend radius.

HOSE

STYLE

520N

540P

540N

518C

580N

How to order part derivation is applicabe to all hose assemblies in this catalog.

Ho

1ST END

CONNECTION

01 = Male NPT

03 = Male JIC 37°

06 = Female SAE (JIC) 37°

Swivel

AL = A-LOK

P6 = CPI

TU = Universal Tube Stub

™

Compression

(nut & ferrule)

2ND END

CONNECTION

®

Compression

1ST

CONNECTION

DASH SIZE

02=1/8"

04=1/4"

06=3/8"

08=1/2"

12=3/4"

16=1"

2ND

CONNECTION

DASH SIZE

HOSE I.D.

DASH SIZE

04=1/4"

06=3/8"

08=1/2"

12=3/4"

16=1"

FITTING

MATERIAL

C=Stainless

ASSEMBLY

LENGTH (INCHES)

Overall length is

expressed in

inches measured

from extreme end

to end. Except

elbow fittings

measured from

centerline or

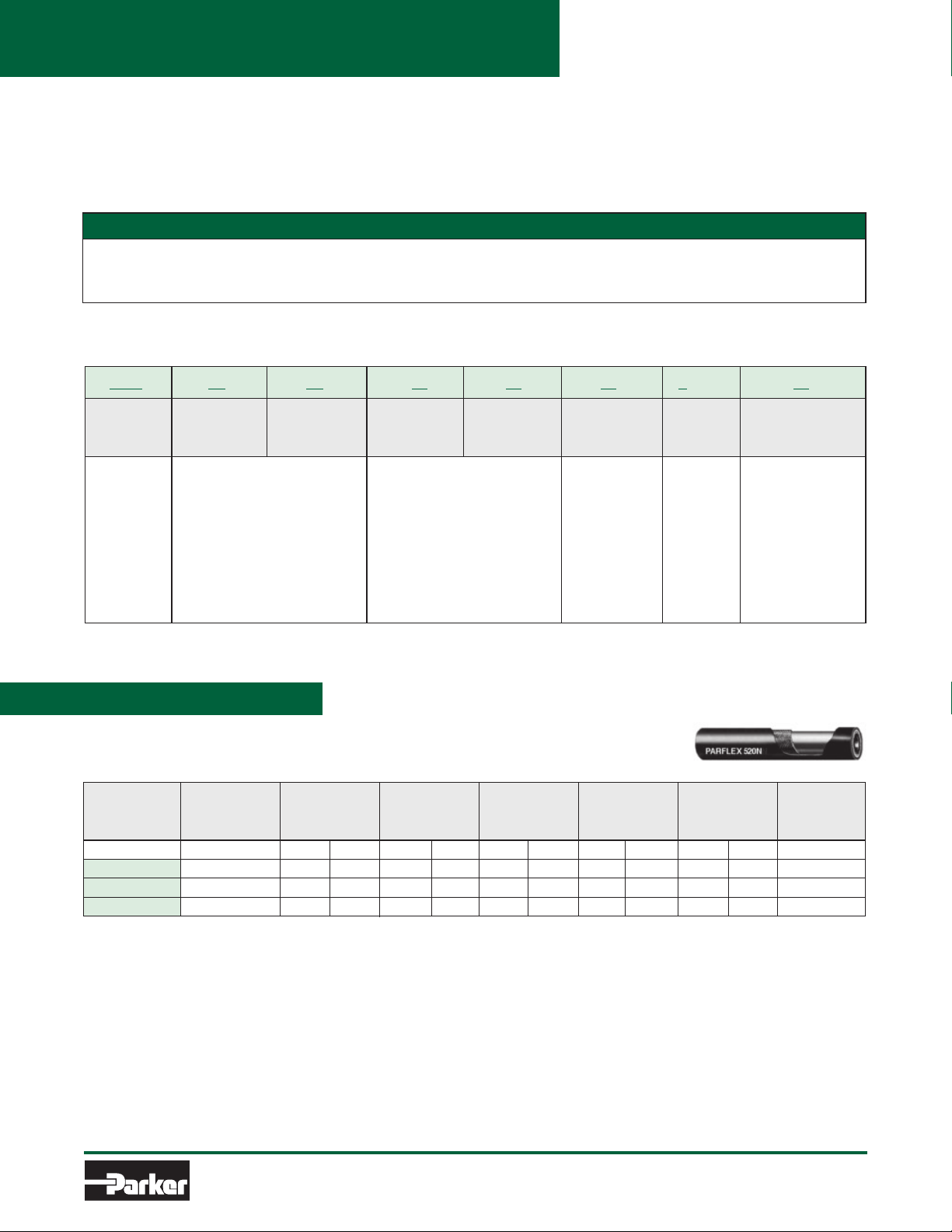

520N General Hydraulic Hose

HOSE

SERIES -

DASH SIZE

520N-4 28 1/4" 6 0.51 13 5000 34.5 2.0 51 0.06 0.09 80C-P04

520N-6 28 3/8" 10 0.65 16 4000 27.6 2.5 64 0.08 0.12 80C-P06

520N-8 28 1/2" 13 0.81 21 3500 24.1 4.0 102 0.13 0.19 80C-P08

Construction: Nylon Core Tube, Aramid Fiber Reinforcement, Black Perforated Urethane Jacket. Meets or exceeds SAE 100R8 performance.

Typical applications: Hydraulic and pneumatic circuits and systems. Ideal in hot water applications.

Temperature range: -40°F to +212°F (-40°C to +100°C)

Fittings: Use 55 series only.

VACUUM

RATING

INCHES/HG INCHES MM INCHES MM PSI MPA INCHES MM LBS/FT KG/M

HOSE I.D.

MAX.

HOSE O.D.

MAXIMUM

WORKING

PRESSURE

MINIMUM

BEND

RADIUS

WEIGHT

OVERALL

which are

the seat.

CRIMP DIE

PART NO.

For additional information about Parflex hose, including information about construction, typical applications and

installation, contact your authorized Parker Instrumentation Distributor.

8

Parker Hannifin Corporation

Parflex Division

Ravenna, OH

Loading...

Loading...