Parker Hannifin CPI/A-LOK Tube Fittings User Manual

CPI™ / A-LOK® Tube Fittings

Catalog 4230/4233 December 2009

Instrumentation Products Division

Catalog 4230/4233

Huntsville, Alabama, USA

Barnstaple, UK

WARNING – USER RESPONSIBILITY

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND

PROPERTY DAMAGE.

This document and other information from Parker-Hannifin Corporation, its subsidiaries and authorized distributors provide product or system options for further investigation by users

having technical expertise.

The user, through its own analysis and testing, is solely responsible for making the final selection of the system and components and assuring that all performance, endurance,

maintenance, safety and warning requirements of the application are met. The user must analyze all aspects of the application, follow applicable industry standards, and follow the

information concerning the product in the current product catalog and in any other materials provided from Parker or its subsidiaries or authorized distributors.

To the extent that Parker or its subsidiaries or authorized distributors provide component or system options based upon data or specifications provided by the user, the user is responsible

for determining that such data and specifications are suitable and sufficient for all applications and reasonably foreseeable uses of the components or systems.

Offer of Sale

The items described in this document are hereby offered for sale by Parker-Hannifin Corporation, its subsidiaries or its authorized distributors. This offer and its acceptance are governed by

the provisions stated in the detailed “Offer of Sale” elsewhere in this document or available at www.parker.com/ipdus.

© Copyright 2004, 2005, 2008 Parker Hannifin Corporation. All Rights Reserved.

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Catalog 4230/4233

CPI™ / A-LOK® Tube Fittings

Table of Contents

Introduction ...................................................................................................................... 2

Visual Index .....................................................................................................................4

Typical Raw Material Specifications ................................................................................6

Tube End Dimensional Data ...........................................................................................6

Nomenclature (How to Order) .........................................................................................7

®

CPI™ / A-LOK

Tube to Male Pipe Fittings ...............................................................................................9

Tube to Female Pipe Fittings ........................................................................................21

Tube to Tube Unions ......................................................................................................27

Port Connectors ............................................................................................................36

37° Flare (AN) to CPI™ / A-LOK

Options ................................................................................................... 8

®

Fittings .....................................................................48

Tube to O-Ring Seal Fittings ......................................................................................... 49

Tube to Welded Systems ..............................................................................................58

Analytical Fittings........................................................................................................... 62

Barbed Fittings ..............................................................................................................67

Components .................................................................................................................. 68

Assembly & Remake Instructions .................................................................................75

Gaugeability Instructions ............................................................................................... 75

Instrument Tubing Selection Guide ............................................................................... 76

Thread & Tube End Size Chart (USA) .......................................................................... 80

Offer of Sale ..................................................................................................................84

Parker Motion & Control Technologies .................................................. inside back cover

1

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

CPI™ / A-LOK® Tube Fittings

Catalog 4230/4233

Introduction

Parker CPI™ / A-LOK® Instrumentation Tube Fittings

are designed as leak-free connections for process,

power and instrumentation applications. These

single and two ferrule fittings are manufactured to

the highest quality standards and are available in a

broad range of sizes, materials and configurations.

Features

The Parker CPI™ / A-LOK® tube fitting has been

specifically designed for use on instrumentation,

process and control systems, analysers and

environmental equipment employed in chemical,

petroleum, power generating and pulp and paper

plants. CPI™ / A-LOK® fittings have also been used

extensively in other applications and industries

wherever high reliability and quality are required.

Materials

Parker CPI™ / A-LOK® fittings are available as standard in Heat Code Traceable, 316 stainless steel.

Other materials include steel, brass, aluminum,

nickel-copper, Hastelloy C®, Alloy 600, Titanium,

6Mo, Incoloy 625 and 825. Straight fittings are

machined from cold finished bar stock and shaped

bodies are machined from close grain forgings. The

raw materials used fully conform to the chemical

requirements listed in Specification Table 1 found on

page 6. For nuclear and other critical applications,

stainless steel CPI™ / A-LOK® fittings are readily

available with documented heat code traceability.

Pipe Fittings/Adapters

Parker CPI™ / A-LOK® tube fittings are available in

combination with a variety of ISO and ANSI pipe

thread configurations. For a full listing of these

fittings, see Catalog 4260.

Tubing

Parker CPI™ / A-LOK® tube fittings can be used

with a wide variety of tubing materials and a broad

range of tube wall thicknesses. CPI™ / A-LOK® seals

equally well on both thin wall and heavy wall tubing.

Tubing and fitting materials should be selected

to be compatible with the fluid media. Due to

thermal expansion characteristics and chemical

stability, the tubing should be of the same material as the fitting. (The exception is brass fittings

and copper tubing.)

Torque

Parker CPI™ / A-LOK® tube fittings do not twist the

tubing during installation. CPI™ / A-LOK® ferrule

designs assure that all make and remake motion

is transmitted axially to the tubing. Since no radial

movement of the tubing occurs, the tubing is not

stressed. The mechanical integrity of the tubing is

maintained.

No Distortion

In make-up, there is no undue force in an outward

direction to distort the fitting body or ferrules to

cause interference between the ferrules and nut.

This assures that the nut will back-off freely for

disassembly and permits a greater number of easy

remakes.

Sealing

Positive, reliable connections with Parker CPI™/

A-LOK® fittings have been qualified by exhaustive

tests and over four decades of experience in the

manufacture of quality tube fittings.

Nomenclature

Parker CPI™ / A-LOK® fitting part numbers are

constructed from symbols that identify the size

and style of the fitting and material used.

Assembly, Remake, Gaugeability

Proper assembly is the key component to a

leak-free system. CPI™ / A-LOK® tube fitting

assembly, remake and gaugeability instructions

are found on page 75 of this catalog.

Pressure Rating & Tubing Selection

For working pressures of CPI™ / A-LOK® tube

connections, please see pages 76 – 79 of this

catalog, the Instrument Tubing Selection Guide

(4200-TS) found in the Technical Section of

your Parker Instrumentation Products Process

Binder, or the Parker Instrument Tube Fitting

Installation Manual (Bulletin 4200-B4).

In cases where a male or female pipe thread is

the second end of a Parker CPI™ / A-LOK

such threads may be the pressure limiting factor

of the tubing system. Pressure ratings for Pipe

Ends are shown on page 79.

®

fitting,

2

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Catalog 4230/4233

CPI™ / A-LOK® Tube Fittings

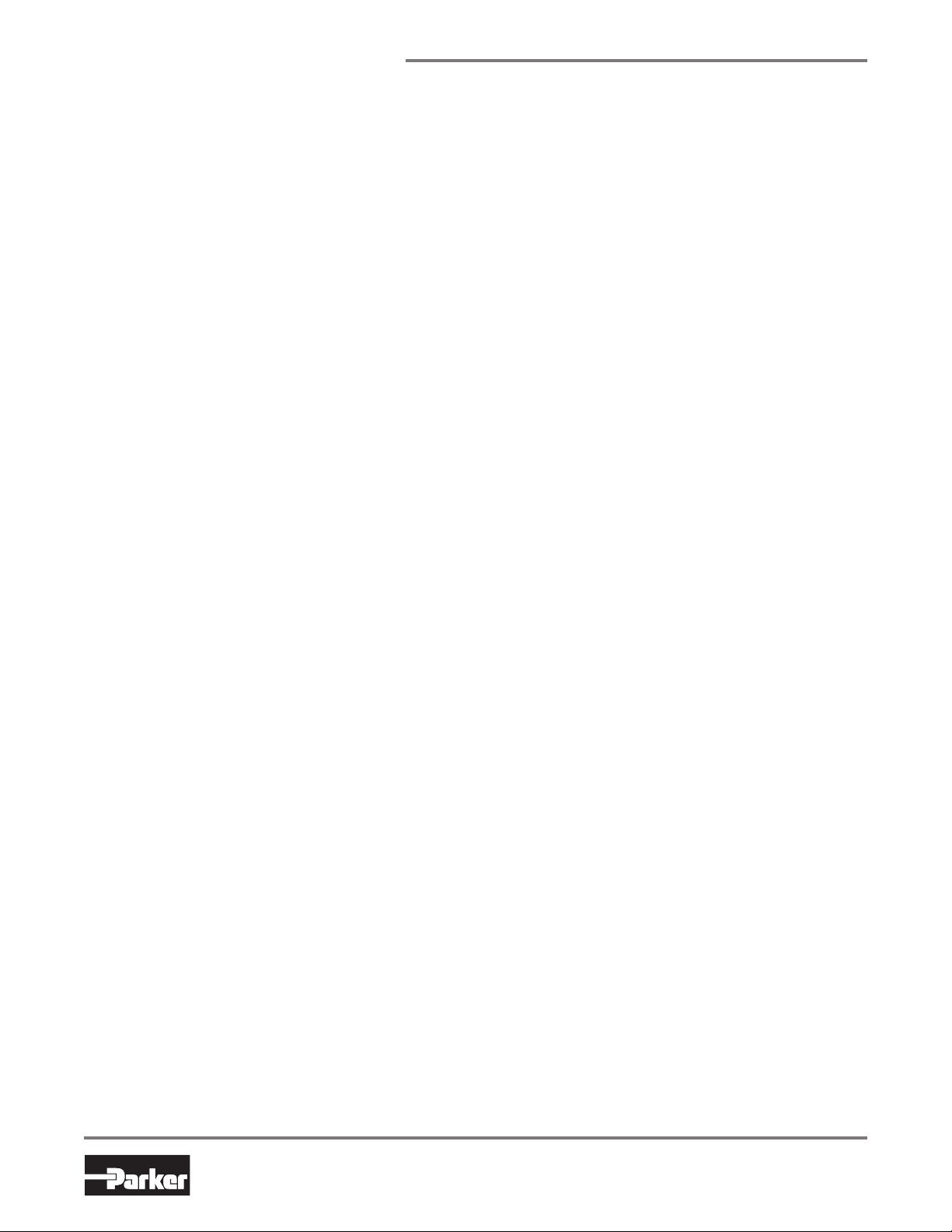

Parker CPI™ / A-LOK® fittings consists of precision engineered parts designed to provide secure leak-proof

joints capable of satisfying high pressure, vacuum and vibration applications.

Inch — CPI™

The Parker Suparcase®

ferrule provides a

strong mechancial

and anti-vibration

hold on the tube

Molybdenum disulfide

coated nut with fine

pitch threads ensure

no galling

Metric — CPI™

The Parker Suparcase

ferrule provides a

strong mechancial

and anti-vibration

hold on the tube

Molybdenum

disulfide coated

nut with fine pitch

threads ensure no

galling

®

Inch — A-LOK

Dynamic seal

by ferrule on

tube and body

Close tolerance

of nut and body

dimensions for

accurate tube

alignment

The Parker

Suparcase

ferrule provides a

strong mechanical

and anti-vibration

hold on the tube.

Parker’s high

quality, silver

plated nut ensures

no galling of body

threads

®

back

Metric — A-LOK

Metric identification

shoulder

Dynamic seal by

ferrule on tube and

body

Close tolerance

of nut and body

dimensions for

accurate tube

alignment

The Parker

Suparcase

ferrule provides a

strong mechanical

and anti-vibration

hold on the tube.

Parker’s high

quality, silver

plated nut ensures

no galling of body

threads

®

back

®

Pressure seal

by front ferrule

on tube and

body

Deep tube abutment

and close tolerance

of nut and body for

accurate tube alignment

®

Metric

identification

shoulder

Pressure

seal by front

ferrule on

tube and

body

Deep tube

abutment and

close tolerance

of nut and body

for accurate

tube alignment

Parker Instrumentation Tube Fittings are supplied complete and ready to use. The ferrule(s) swage onto the

tube as it moves down the body seat creating a pressure/vacuum-tight seal on both tube and body by the

interface pressure and surface finish of mating components. The Parker Suparcase® ferrule (back-ferrule only

on A-LOK®) creates a strong mechanical hold on the tube.

3

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

CPI™ / A-LOK® Tube Fittings

BSPP

BSP

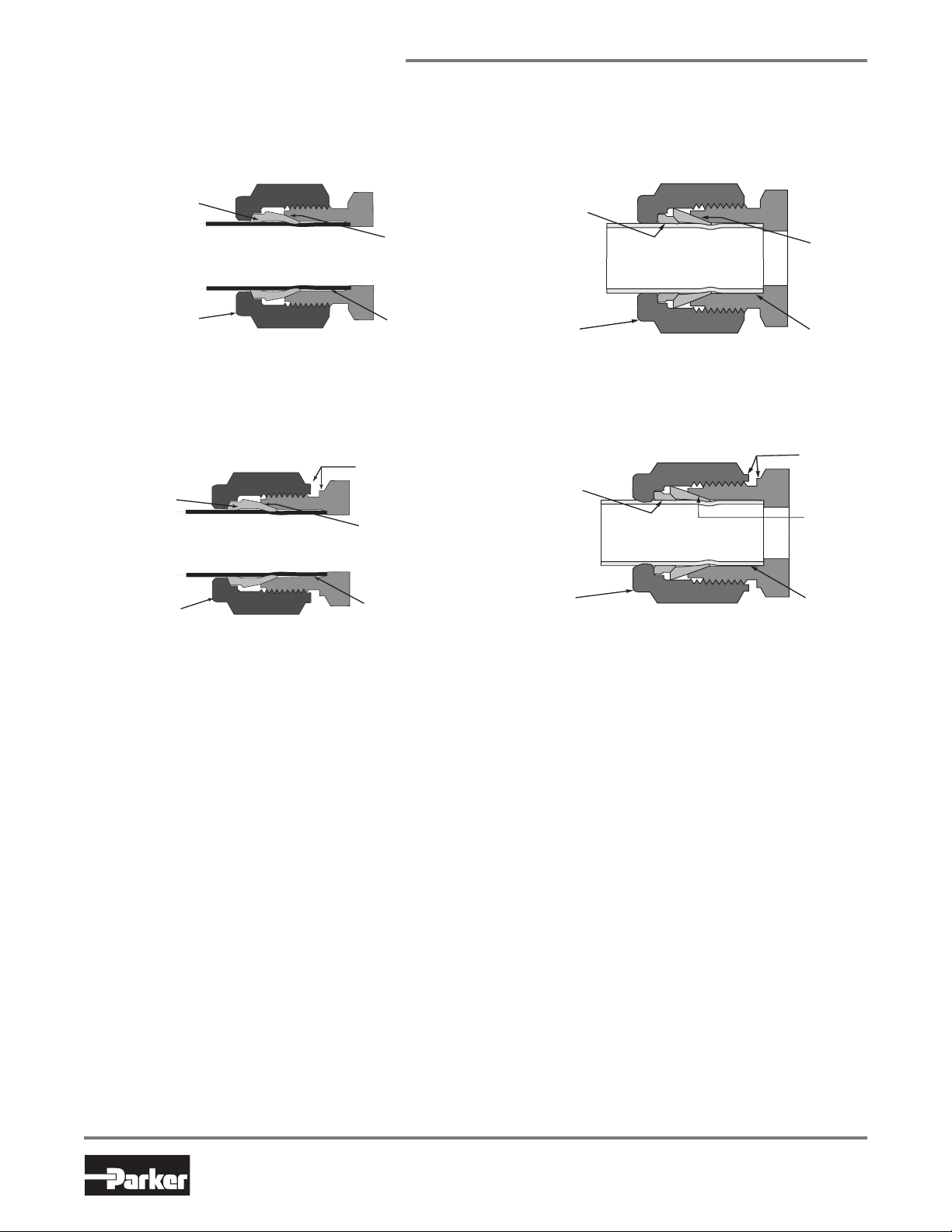

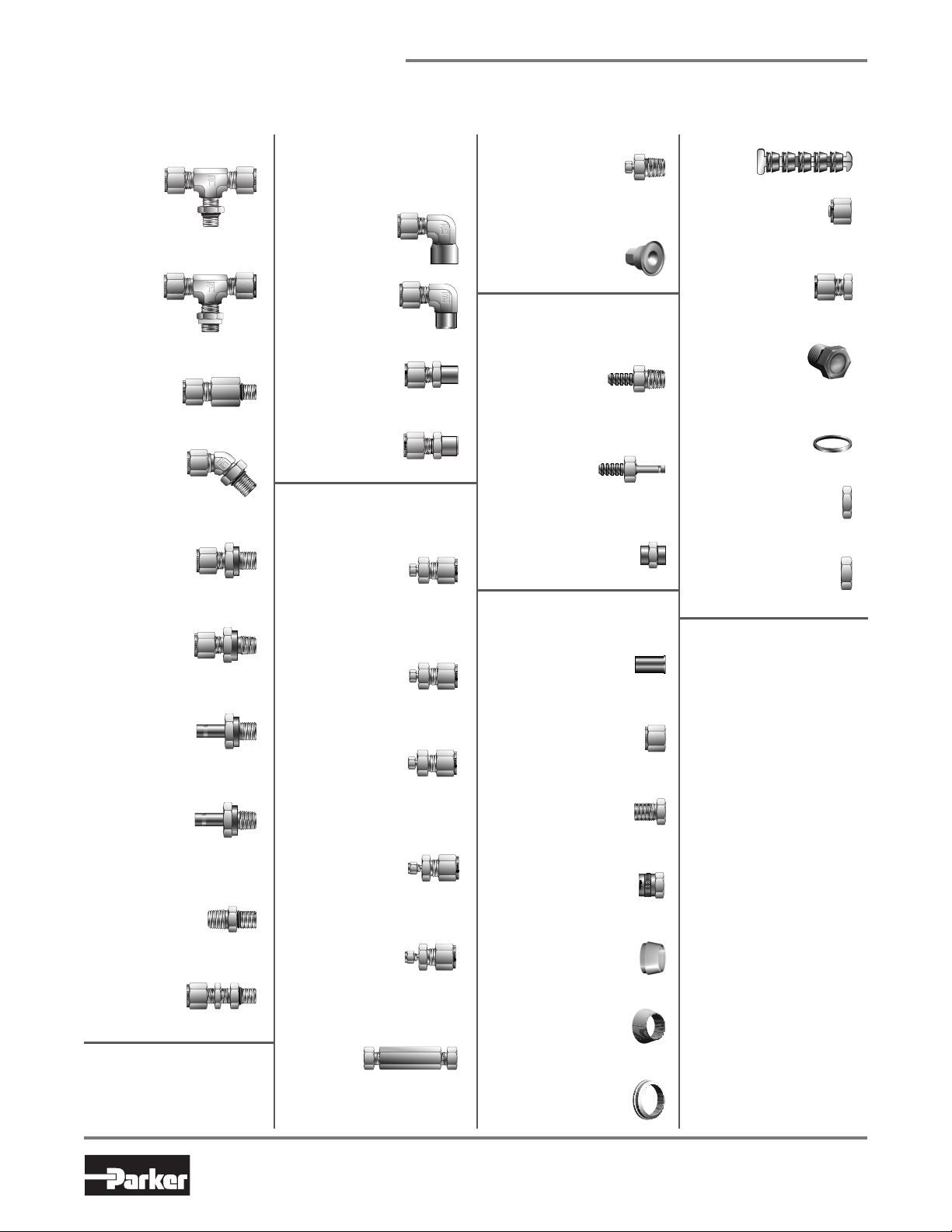

Visual Index

Tube to Male Pipe

Male Connector

FBZ, MSC

pages 9, 10,

11, 12, 13

Male Bulkhead Connector

FH2BZ, MBC

page 14

Thermocouple Connector

FH4BZ, MTC

page 15

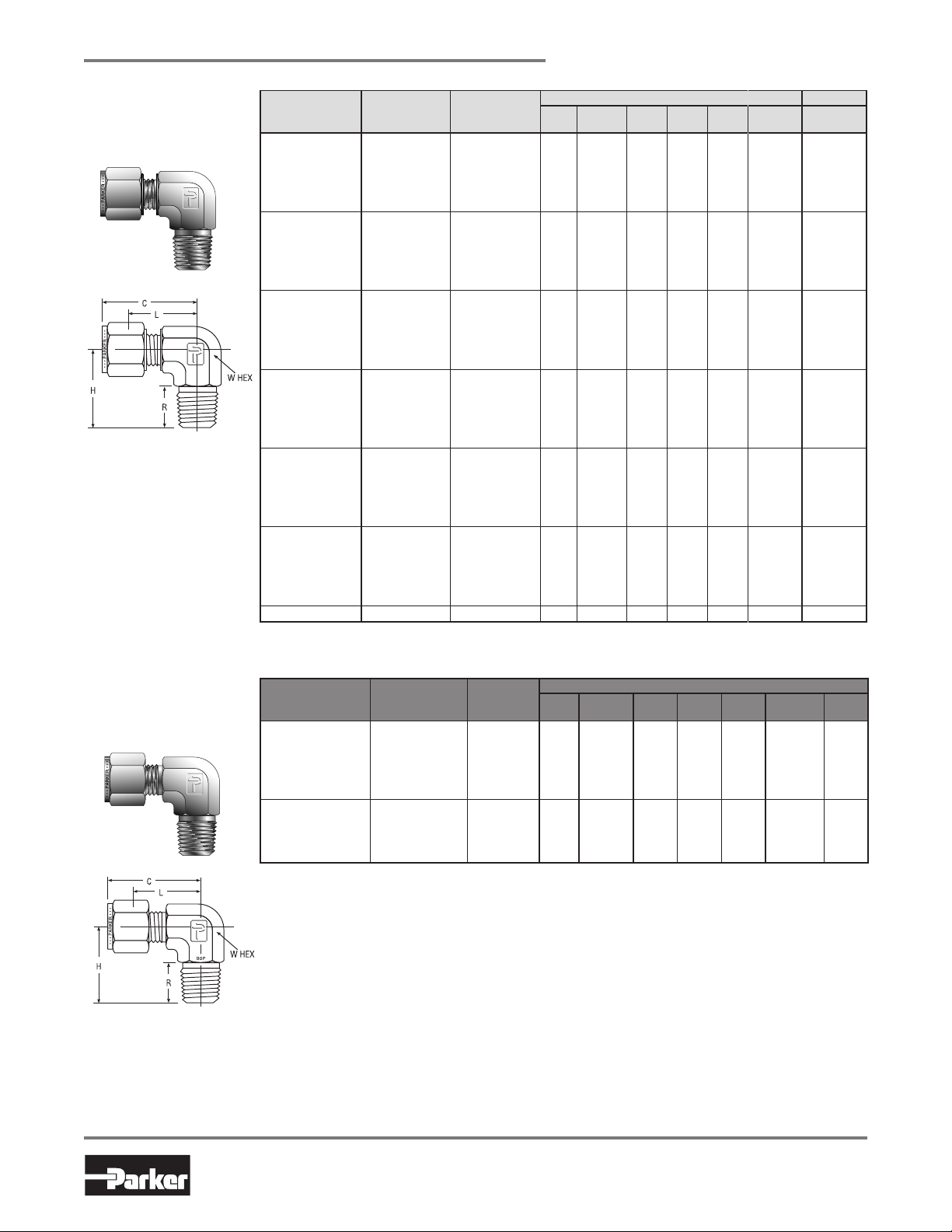

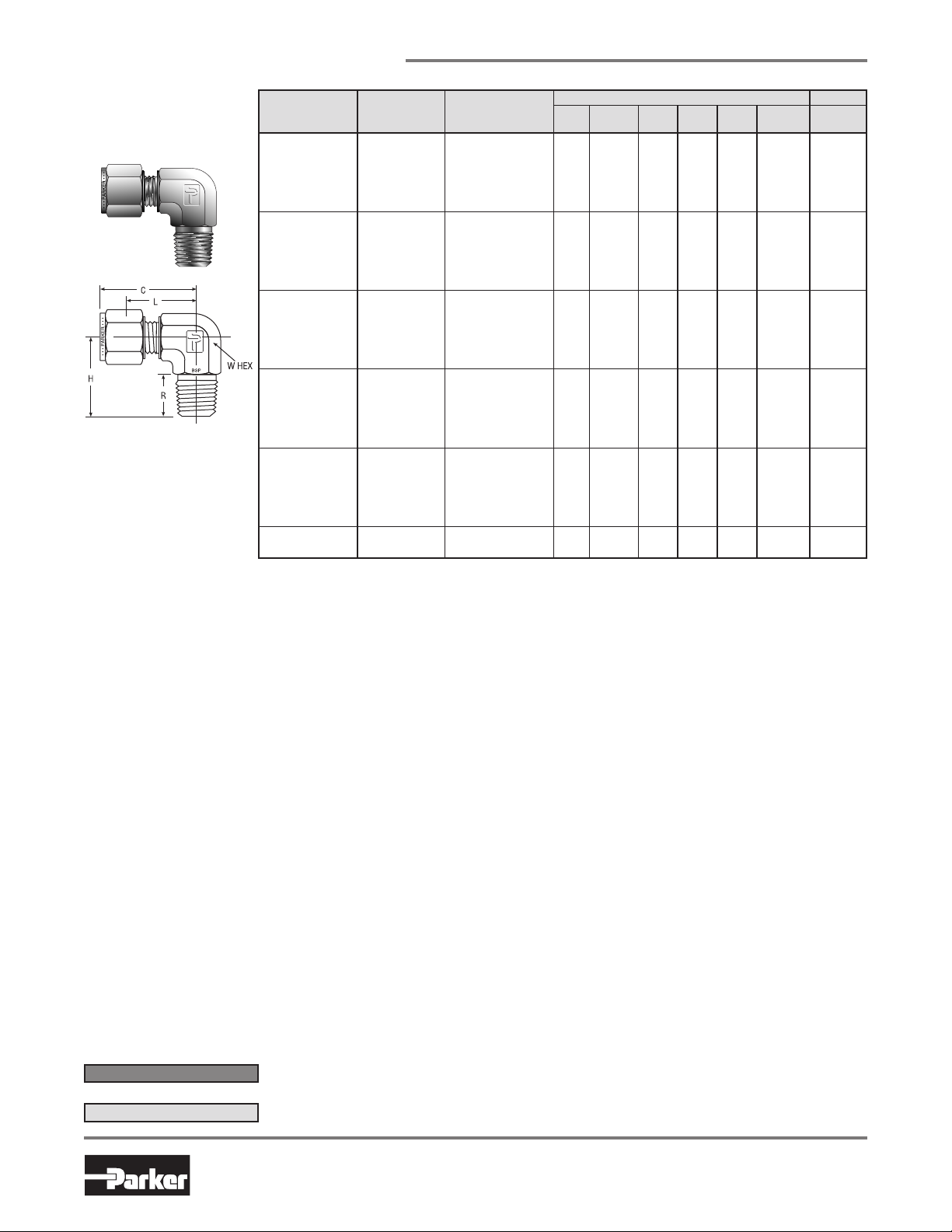

Male Elbow

CBZ, MSEL

pages 15, 16, 17

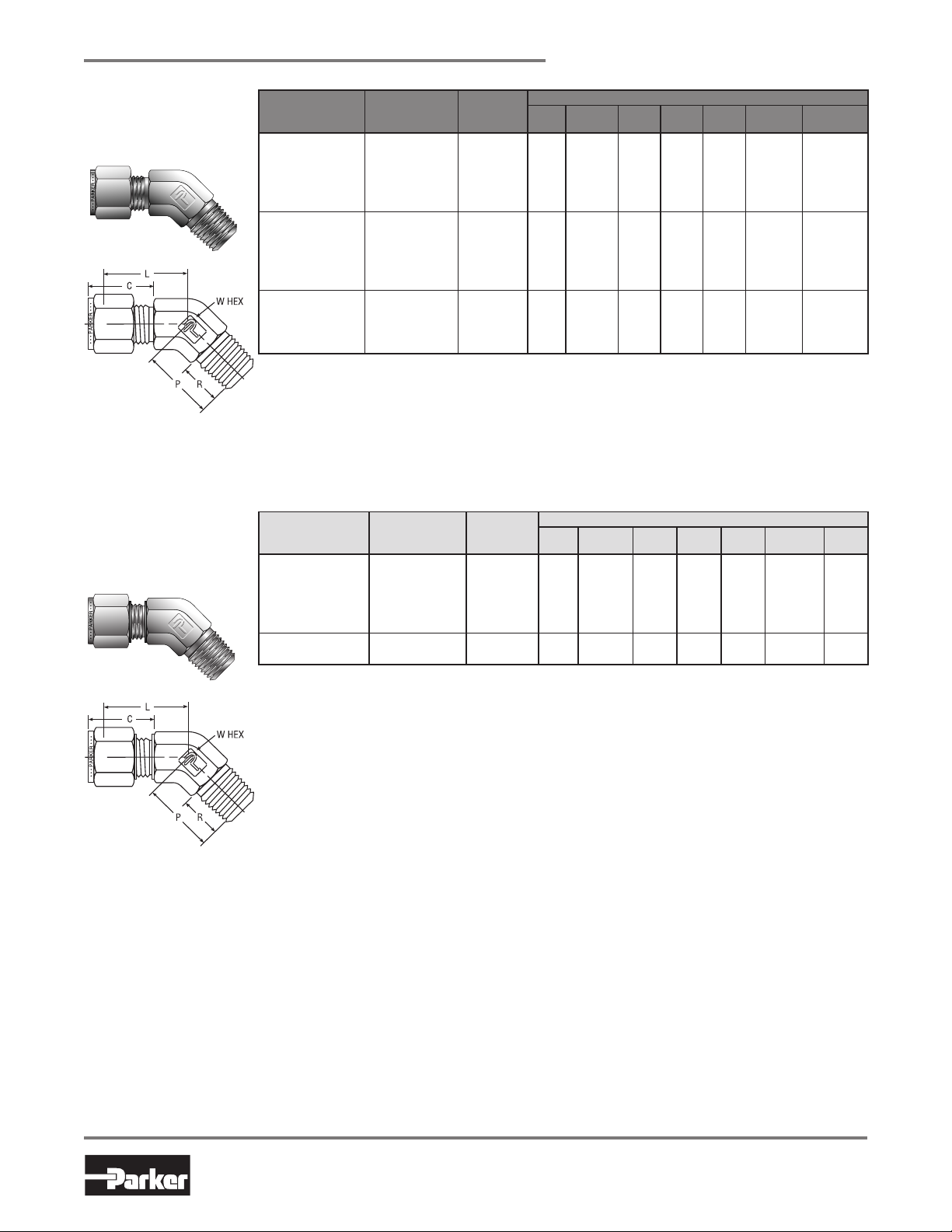

NPT Male 45° Elbow

VBZ, MVEL

page 18

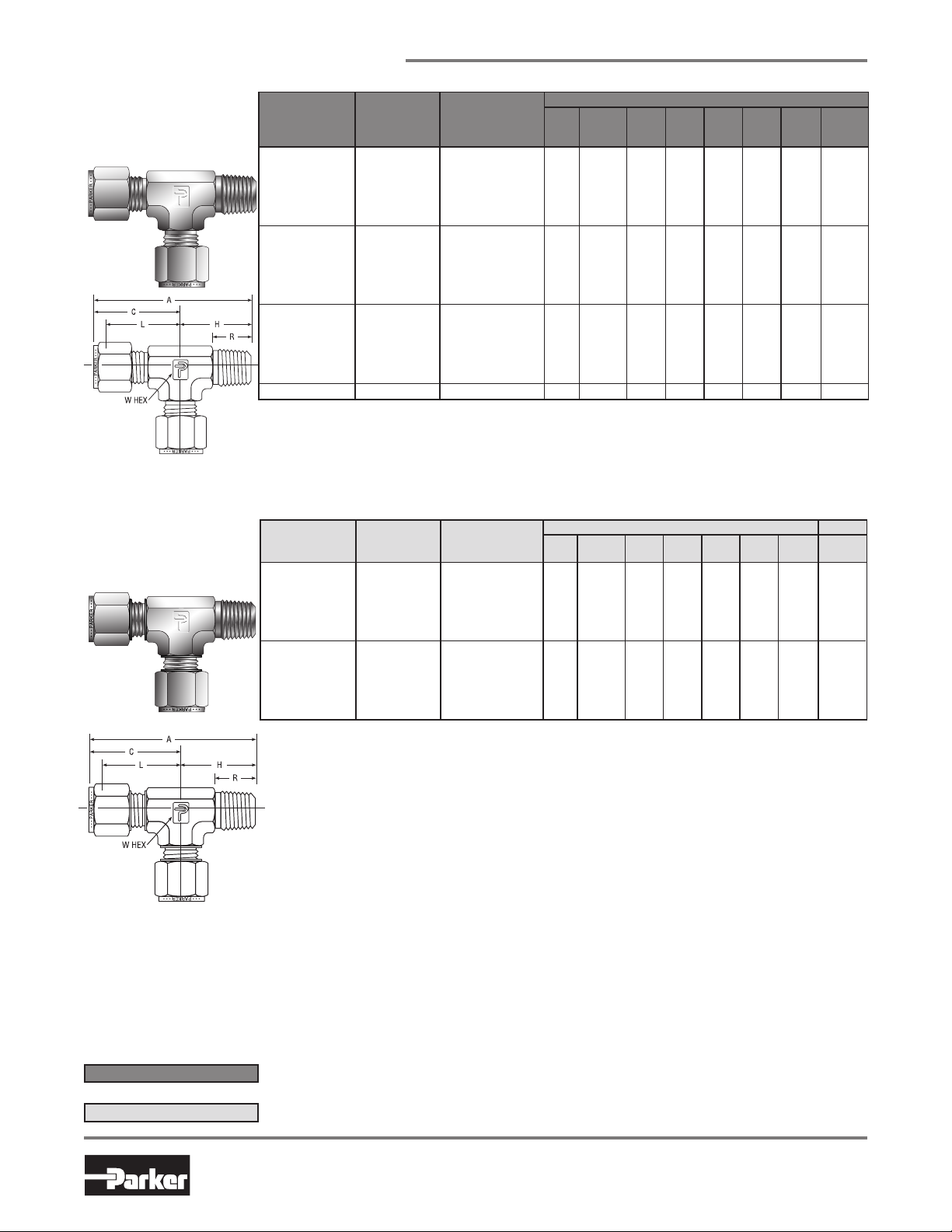

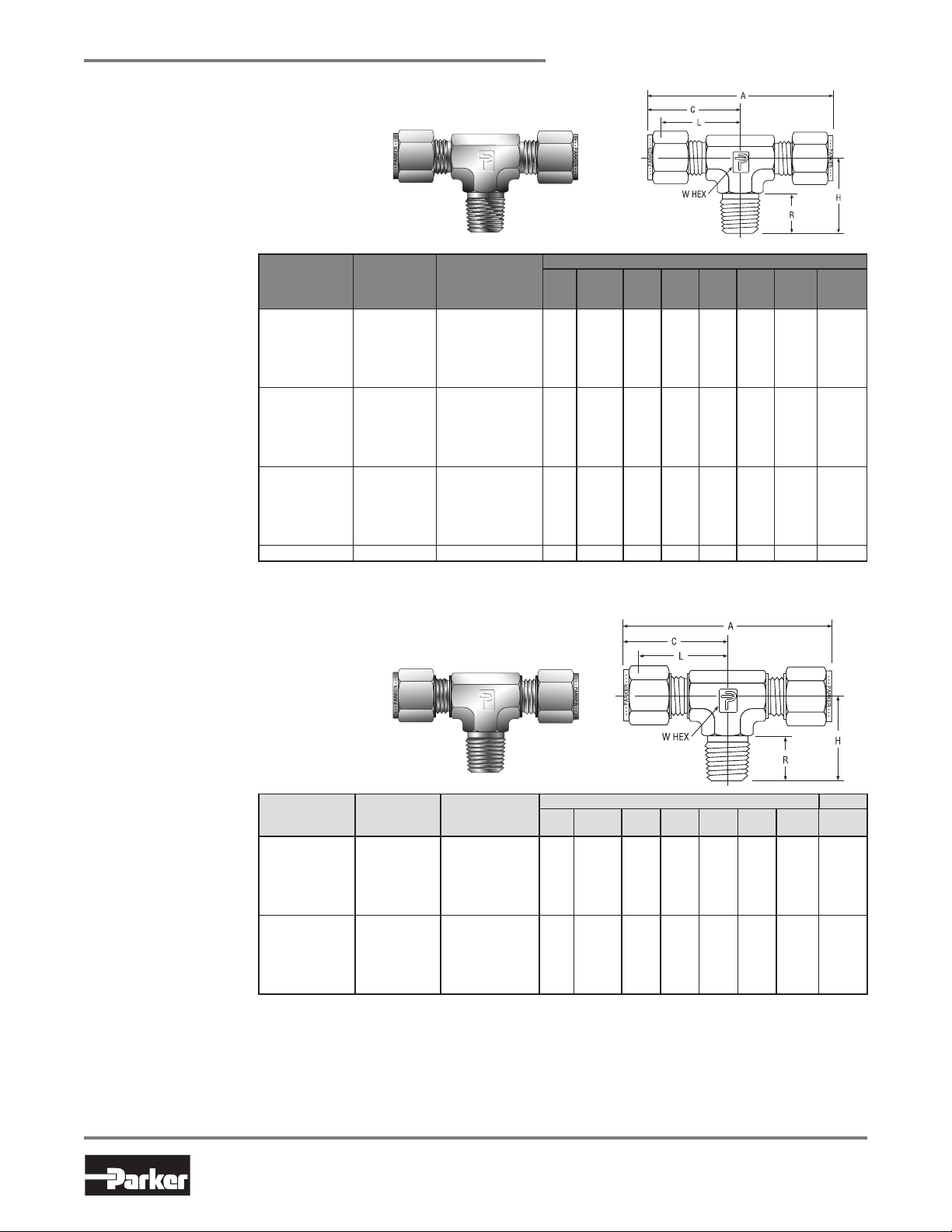

NPT Male Run Tee

RBZ, MRT

page 19

NPT Male Branch Tee

SBZ, MBT

page 20

Tube to Female Pipe

Female Connnector

GBZ, FSC

pages 21, 22

Female Bulkhead

Connector

GH2BZ, FBC

page 23

Gauge Connector

GBZ, FSC

pages 23, 24

Female Elbow

DBZ, FEL

page 24

Female Run Tee

MBZ, FRT

page 25

Female Branch Tee

OBZ, FBT

page 26

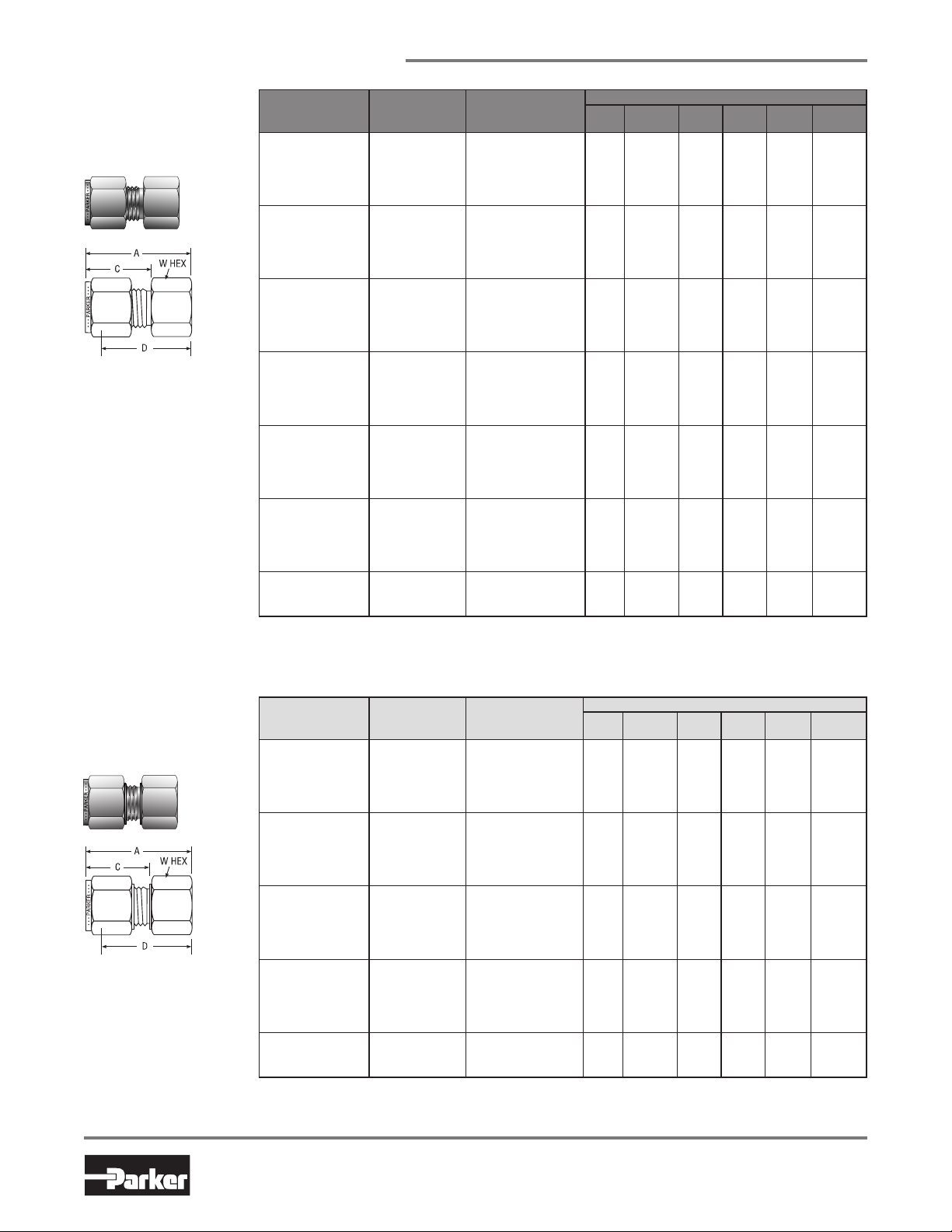

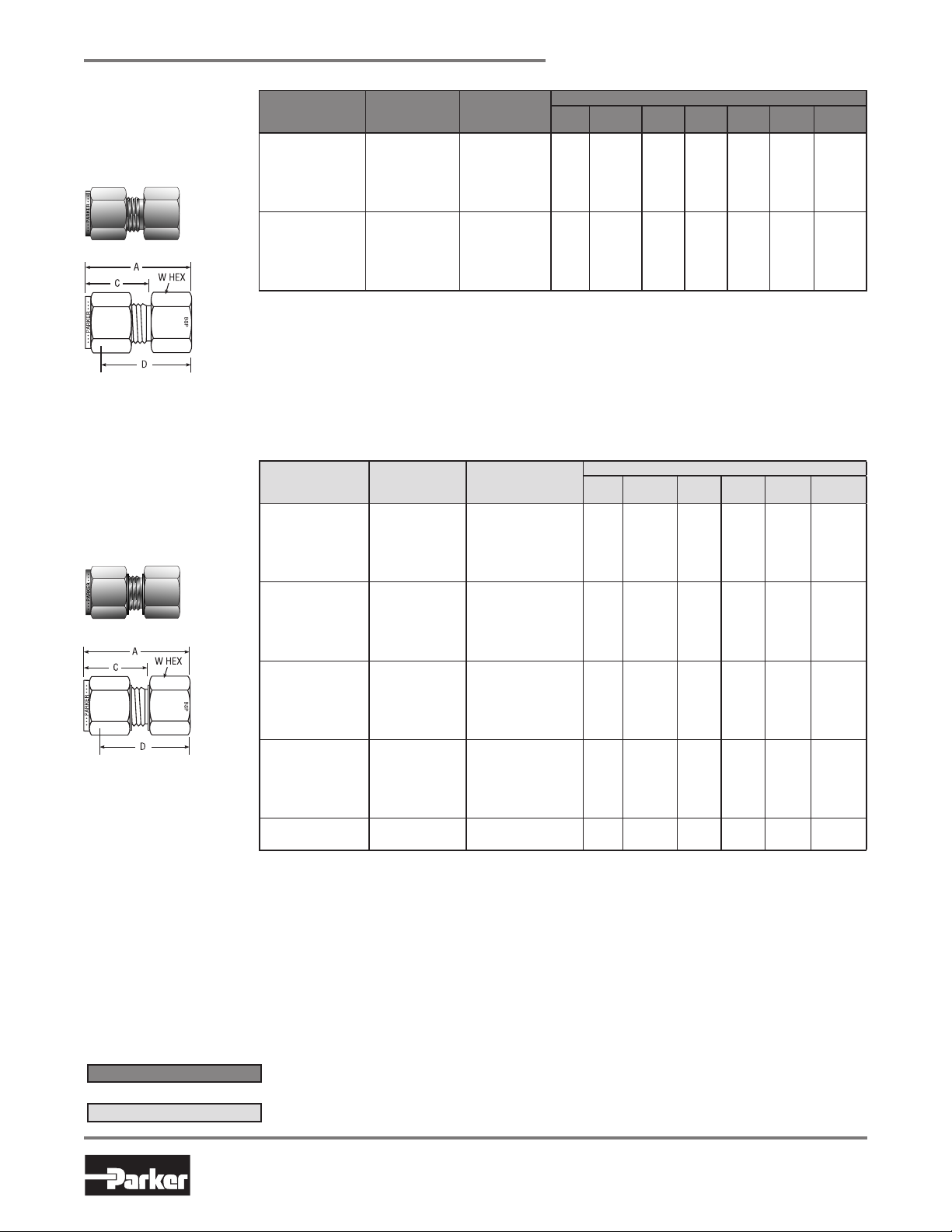

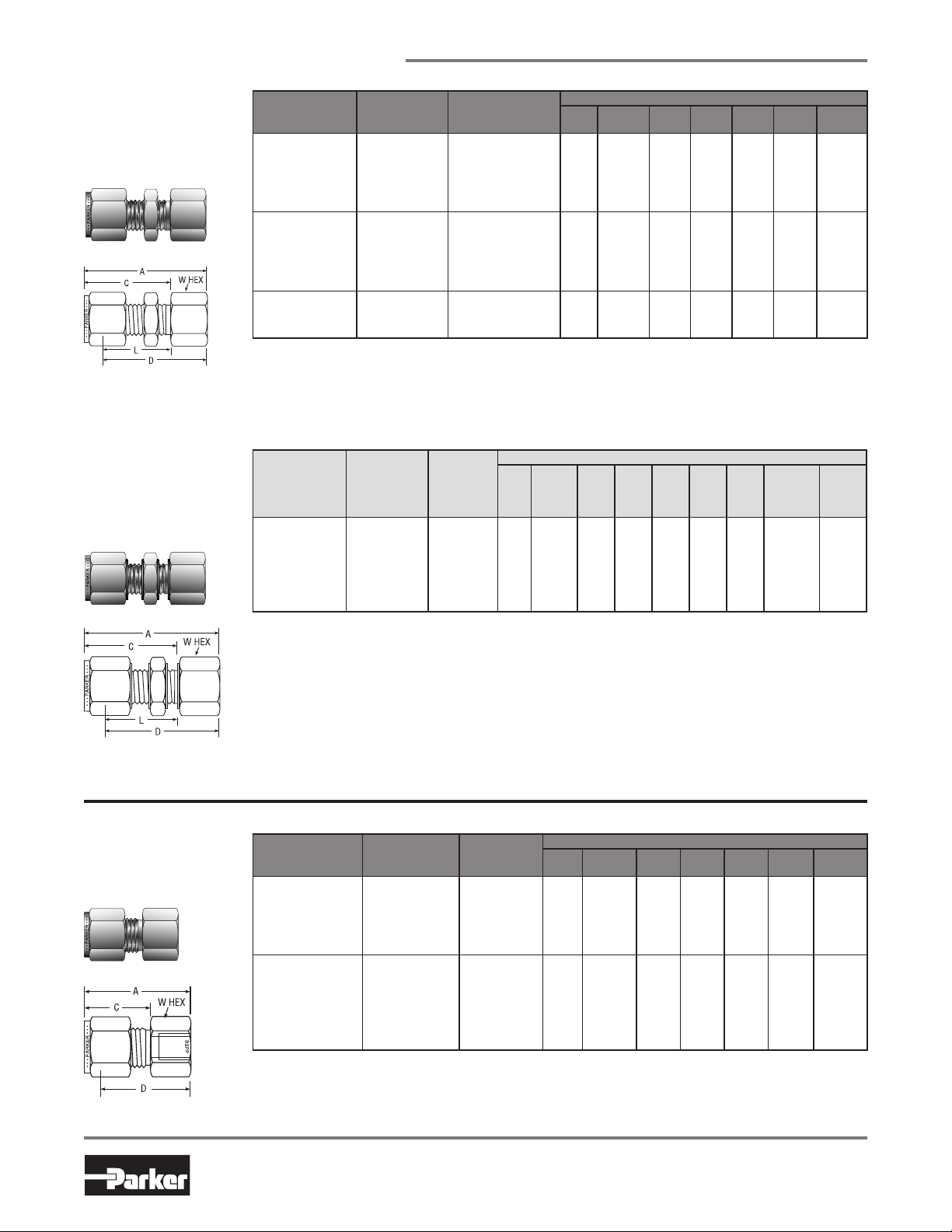

Tube to Tube Unions

Union

HBZ, SC

page 27

Conversion Union

HBZ, CU

page 28

Reducing Union

HBZ, RU

page 28

Bulkhead Union

WBZ, BC

page 29

Dielectric Union Adapter,

Dielectric Assembly

DEBTADELTA

page 30

Union Elbow

EBZ, EE, ELZ

pages 30, 31

Union Tee

JBZ, ET

page 32

Drop Size Tee

JBZ, JLZ

page 33

Union Cross

KBZ, ECR

page 34

Port Connectors

Tube End Reducer

TRBZ, TUR,

TUC

pages 35, 36, 37

Tube End Bulkhead

Adapter

T2H2BZ,

TUBC

page 38

Port Connector

ZPC, PC

page 38

Tube End Male Adapter

T2HF, MA

pages 39, 40,

41, 42

Tube End to SAE Straight

Thread Adapter

T2HOA, TUOHA

page 43

Tube End Female Adapter

T2HG, FA

pages 43, 44, 45

Push-Lok to Tube Adapter

P2T2, P2TU

page 45

Push-Lok to Male Adapter

P2HF

page 46

Push-Lok to CPI™/

®

A-LOK

P2BZ6, P2LZ6

page 46

Push-Lok to Port

Connector

ZPB2, ZPC2

page 46

Lapped Joint Tube

Adapters

LJFBZ, LJF

page 47

Catalog 4230/4233

DP Transmitter Calibration

Adapters

ZH2LX

page 47

37° Flare (AN) to

CPI™ / A-LOK

37° Flare (AN) to CPI™/

®

A-LOK

X6HBZ6, X6TU

page 48

37° Flare Connector to

CPI™ / A-LOK

XHBZ, XASC

page 48

37° Flare Bulkhead

Connector to CPI™/

®

A-LOK

XH2BZ,

XABC

page 48

®

®

Tube to O-Ring Seal

Male Connector SAE

Straight Thread

ZHBA, M1SC

page 50

Male SAE Straight Thread

Elbow

C5BZ, M5SEL

page 51

Male BSPP Straight

Thread Elbow

CBZ, MSEL

page 51

Male Run Tee SAE

Straight Thread

R5BZ,

M5RT

page 52

Male BSPP Run Tee

Straight Thread

RBZ, MRT

page 52

4

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Catalog 4230/4233

Visual Index

Male Branch Tee SAE

Straight Thread

S5BZ,

M5BT

page 53

Male BSPP Branch Tee

Straight Thread

SBZ, MBT

page 53

Long Male Connector SAE

Straight Thread

ZH3BA, ZH3LA

page 54

45° Positionable Male

Elbow

V5BZ, M5VEL

page 54

Male Connector to O-Ring

Straight Thread

ZHBA5, M2SC

page 55

Male Connector to O-Ring

Pipe Thread

ZHBF5, M3SC

page 55

Tube End to O-Ring

Straight Thread

T2HOA5, M2TU

page 56

Tube End to O-Ring Pipe

Thread

T2HOF5, M3TU

page 56

Pipe Thread to SAE

Straight Thread Adapter

FHOA

page 57

Bulkhead to Conversion

Adapter

AH2BZ, AH2LZ

page 57

Tube to Welded

Systems

Socket Weld Elbow

ZEBW, ZELW

page 59

Buttweld Elbow

ZEBW2, ZELW2

page 59

Socket Weld Connector

ZHBW, ZHLW

page 60

Buttweld Connector

ZHBW2, ZHLW2

page 60, 61

Analytical Fittings

Column End Fitting — Low

Internal Volume

with Frit

Z2HCZ7, Z2HLZ7

page 63

Column End Fitting — Low

Internal Volume

Z3HCZ7, Z3HLZ7

page 63

Column End Fitting — Low

Internal Volume

(without Frit)

ZHCZ7, ZHLZ7

page 64

Column End Fitting — with

Frit

Z2HCZ, Z2HLZ

page 64

Column End Fitting

(without Frit)

ZHCZ, ZHLZ

page 65

Union Connector — Low

Dead Volume

Z7HBZ7,

Z7HLZ7

page 65

CPI™ / A-LOK® Tube Fittings

Male Connector — Low

Dead Volume

FBZ7, FLZ7

page 66

Sanitary Flange Fitting

ZHBS, ZHLS

page 66

Barbed Fittings

Barbed Connector to

Male Pipe

B2HF

page 67

Barbed Connector to

Tube Adapter

B2HT2, B2TU

page 67

Hose Connector Sleeve

HCS

page 67

Components

Insert

TIZ

page 68

Tube Nut

BZ, NU

page 68, 69

Inverted Tube Nut

BZI

page 69

Knurled Nut

BZP

page 69

Ferrules

TZ

page 69

Front Ferrules

FF

page 70

Back Ferrules

BF

page 70

Ferrule Holder

page 70

Plug

FNZ, BLP

page 71

Cap

PNBZ, BLEN

page 71, 72

Vent Protector

MDF

page 72

Sealing Washers

Bonded Seal and Copper

page 73

Bulkhead Locknut

WLZ, WLN, BN

page 74

Accessory Locknut

L5NR

page 74

Reference Material

Assembly and Remake

Instructions

page 75

Gaugeability Instructions

page 75

Instrument Tubing

Selection Guide

pages 76 – 79

Pipe End Pressure

Ratings

page 79

Thread and Tube End

Size Charts (USA/

International)

pages 80 – 82

Offer of Sale

page 84

5

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

CPI™ / A-LOK® Tube Fittings

Table 1 – Typical Raw Material Specifications

BASIC

FITTING MATERIAL

Brass B CA-360

Stainless Steel (Type 316)

(1)

Steel S ASTM-A-108

Aluminum A 2017-T4 or 2024-T4

®

400 – Forgings

Monel

®

405 – Bar Stock

Monel

®

Hastelloy

Inconel

Carpenter

Titanium T ASTM-B-348 ASTM-B-381 ASTM-B-338

Inconel

Incoloy

C-276 HC ASTM-B-574

®

Alloy 600 IN ASTM B-166

®

20 SS20 ASTM-B-473 ASTM-B-462

®

Alloy 625 625 BS3076 NA16

®

Alloy 825 825

6MO 6MO UNS S31254

(1) If more specific information, including heat code traceability, is required, your Parker Hannifin CPI™ / A-LOK® distributor will provide details.

(2) If an “L” appears in the A-LOK

(3) Stainless steel CPI

NOTE: Hastelloy

Carpenter

®

is a registered trademark of CRS Holdings Inc.

™

/ A-LOK® tube fittings work reliably on both seamless and welded-redrawn, fully annealed type 304, 316 and 316L tubing.

®

is a registered trademark of Haynes International. Inconel®, Incoloy® and Monel® are registered trademarks of Special Metals Corporation.

MATERIAL

DESIGNATOR

BAR

STOCK FORGING

CA-377

A-LOK® = 316

CPI™ = SS

QQ-B 626 Alloy 360

ASTM-B16 Alloy 360

CA-345

ASTM-B-453 Alloy 345

(1)(2)

ASME-SA-479

Type 316-SS

BS970 316-S31

DIN 4401

QQ-B 626 Alloy 377

ASTM-B-124 Alloy 377

BS2872 CZ122

ASME-SA-182 316

BS970 316-S31

DIN 4401

ASTM A276 Type 316

ASTM-A-576 SAE J524b

QQ-S-637

ASTM-B211

QQ-A-225/5 or 6

M ASTM-B-164

QQ-N-281

BS3076 NA13

2014T (as fabricated)

ASTM-B-211

QQ-A-225/4

ASTM-B-164

QQ-N-281

BS3076 NA13

ASTM-B-574 ASTM-B-622

ASTMB575

ASTM-B-564 ASTM-B-163

ASME-SB-166

ASTM-B-472

BS3076 NA16

ASTMB425

UNS N08367

ASTM A479

®

fitting description, then the material designator will be “SS” (e.g., JLZ drop size tee).

ASTMB425

UNS S31254

UNS N08367

ASTM A 479

COMMON TUBING

SPECIFICATION

ASTM-B75

ASME-SB75

(TEMPER “O”)

ASME-SA-213

ASTM-A-213

ASTM-A-249

ASTM-A-269

MIL T-8504

MIL T-8506

SAE J525b

ASTM-A-179

303, 6061T6

ASTM-B-210

ASTM-B-165

ASTM-B-626

ASTM-B-468

ASTM-B-625

ASTM-B-444

ASTM-B-423

ASTM-B-829

ASTM-A-269

(3)

Catalog 4230/4233

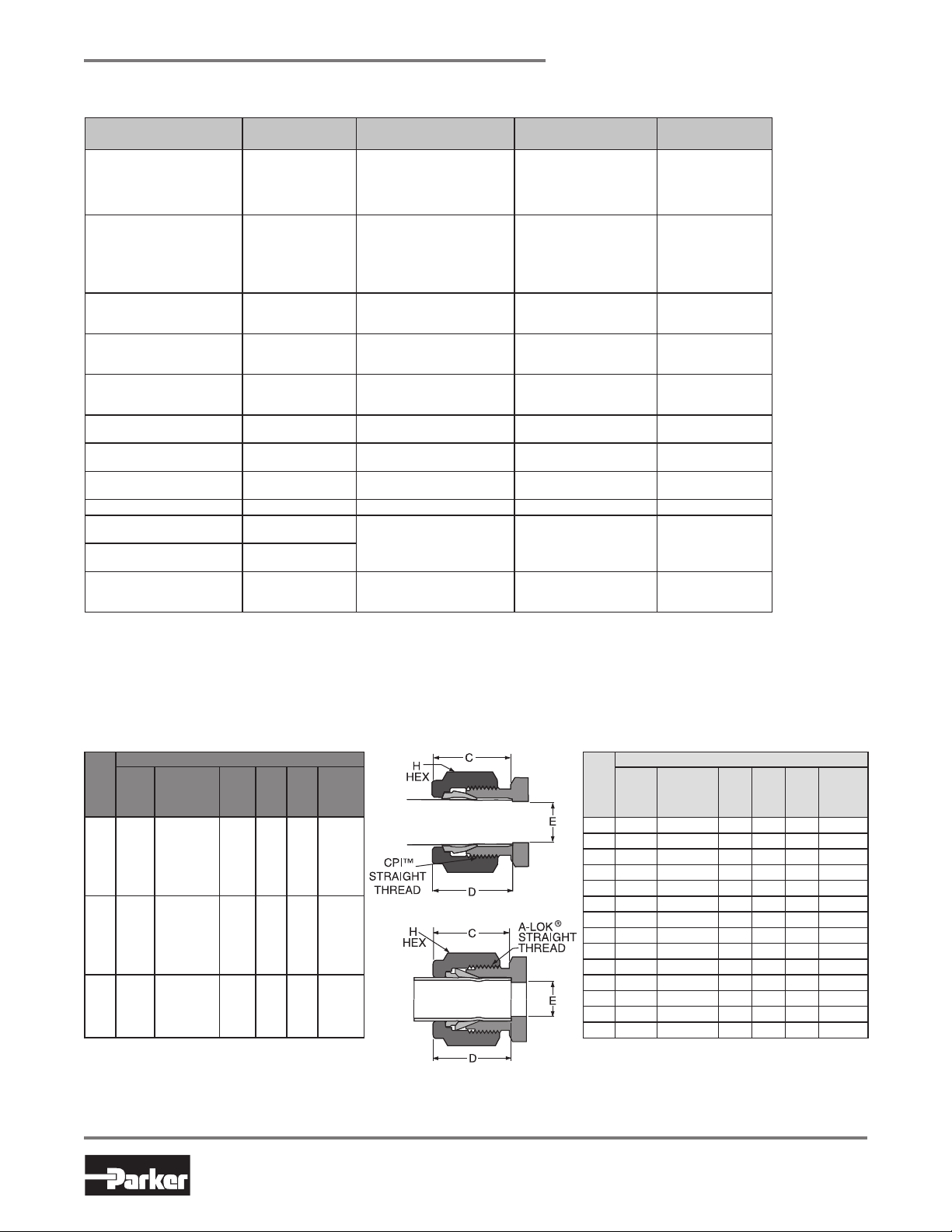

Tube End Dimensional Data

INCHES

SIZE

TUBE

NO.

1

2

3

4

5

6

8

10

12

14

16

20

24

32

NOTE: Dimensions C and D are shown in the finger-tight

position.

† Average Value

Dimensions for reference only, subject to change.

STRAIGHT

O.D.

THREAD †CH HEXE DIA.

1/16 10-32 .43 5/16 .052 .34

1/8 5/16-20 .60 7/16 .093 .50

3/16 3/8-20 .64 1/2 .125 .54

1/4 7/16-20 .70 9/16 .187 .60

5/16 1/2-20 .73 5/8 .250 .64

3/8 9/16-20 .76 11/16 .281 .67

1/2 3/4-20 .87 7/8 .406 .90

5/8 7/8-20 .87 1 .500 .96

3/4 1-20 .87 1-1/8 .625 .96

7/8 1-1/8-20 .87 1-1/4 .750 1.03

1 1-5/16-20 1.05 1-1/2 .875 1.24

1-1/4 1-5/8-20 1.52 1-7/8 1.09 1.61

1-1/2 1-15/16-20 1.77 2-1/4 1.34 1.96

2 2-5/8-20 2.47 2-3/4 1.81 2.65

†D

TUBE

INS.

DEPTH

MILLIMETERS

SIZE

TUBE

NO.

2

3

4

6

8

10

12

14

15

16

18

20

22

25

NOTE: Dimensions C and D are shown in the finger-tight

position.

† Average Value

Dimensions for reference only, subject to change.

6

STRAIGHT

O.D.

THREAD †CH HEXE DIA.

2mm 5/16-20 15,3 12,0 1,7 12,9

3mm 5/16-20 15,3 12,0 2,4 12,9

4mm 3/8-20 16,1 12,0 2,4 13,7

6mm 7/16-20 17,7 14,0 4,8 15,3

8mm 1/2-20 18,6 15,0 6,4 16,2

10mm 5/8-20 19,5 18,0 7,9 17,2

12mm 3/4-20 22,0 22,0 9,5 22,8

14mm 7/8-20 22,0 24,0 11,1 24,4

15mm 7/8-20 22,0 24,0 11,9 24,4

16mm 7/8-20 22,0 24,0 12,7 24,4

18mm 1-20 22,0 27,0 15,1 24,4

20mm 1-1/8-20 22,0 30,0 15,9 26,0

22mm 1-1/8-20 22,0 30,0 18,3 26,0

25mm 1-5/16-20 26,5 35,0 21,8 31,3

Parker Hannifin Corporation

Instrumentation Products Division

†D

TUBE

INS.

DEPTH

Huntsville, AL USA

http://www.parker.com/ipdus

Catalog 4230/4233

CPI™ / A-LOK® Tube Fittings

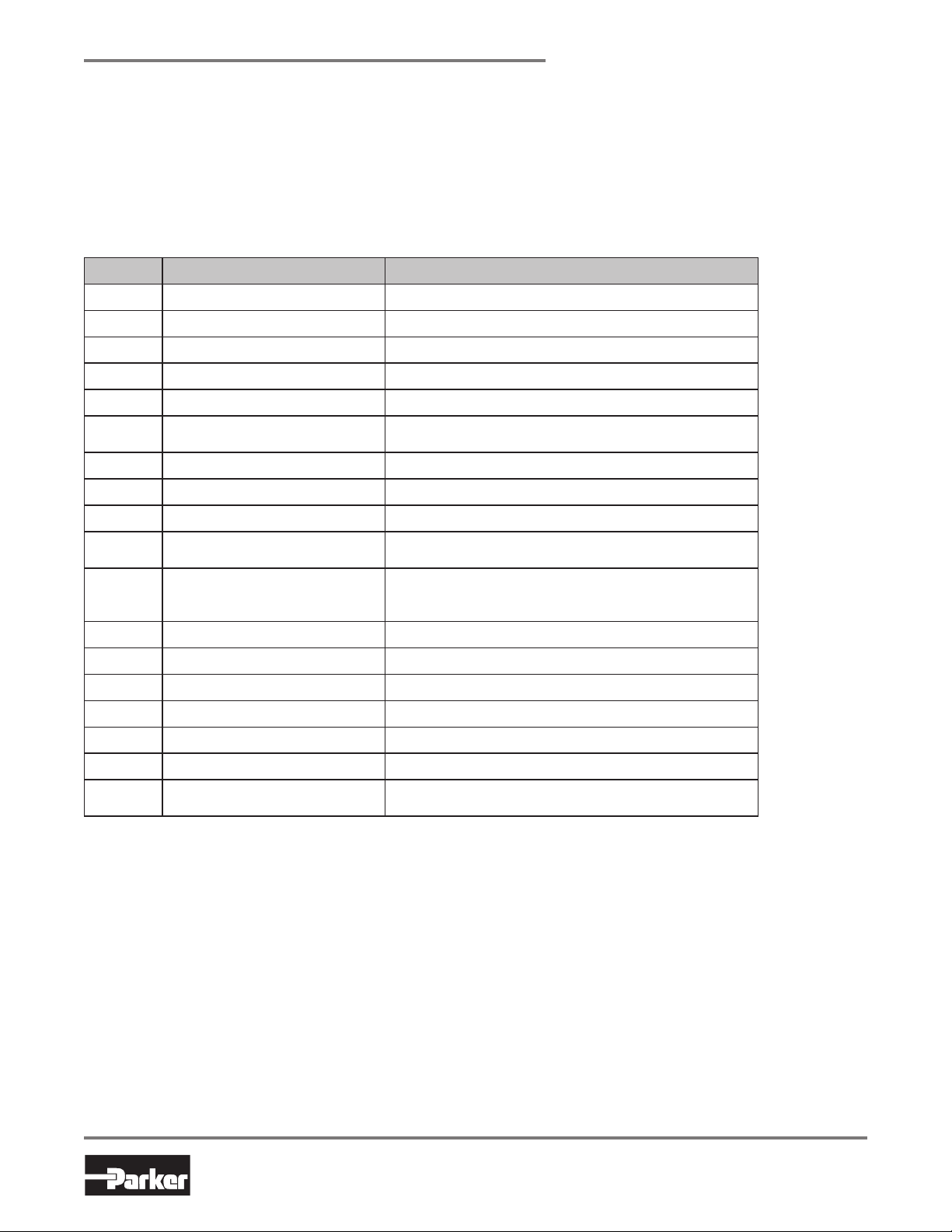

Nomenclature / How to Order

Parker CPI™ / A-LOK® tube fitting part numbers are constructed using alphanumeric characters to identify the size, style and

material of the fitting.

CPI™ Inch Parts

Port 1 Size

Designator

Example: 8 – 4 FBZ – SS

1/2" Tube O.D. – 1/4" Pipe Thread (blank – see Note 1 below) Male Connector – Stainless Steel – (blank)

Part Number as it is ordered (without options): 8-4 FBZ-SS. This part appears on page 9 and is a CPI™ NPT male connector.

– – –

Designator

Thread

Designator

Shape

Designator

A-LOK® Inch Parts

Port 1 Size

Designator

Example: 8 MSC 4 N – 316

1/2" Tube O.D. Male Connector 1/4" Pipe Thread NPT – Stainless Steel – (blank)

Part Number as it is ordered (without options): 8MSC4N-316. This part appears on page 9 and is an A-LOK® NPT male connector.

Designator

Port 2 Size

Designator

Thread

Designator

– –

CPI™ Metric Parts

Port 1 Size

Designator

Example: GBZ 12 – 1/4 K – SS

Female Connector 12mm – 1/4" BSP – Stainless Steel – (blank)

Part Number as it is ordered (without options): GBZ 12-1/4K-SS. This part appears on page 21 and is a CPI™ NPT female connector.

Port 2 Size

Designator

Thread

–

Size

Designator

A-LOK® Metric Parts

Port 1 Size

Designator

Example: M12 FSC 1/4 N – 316

12mm Female Connector 1/4" NPT – Stainless Steel – (blank)

Part Number as it is ordered (without options): M12FSC1/4N-316. This part appears on page 21 and is a A-LOK® NPT female connector.

Body Designator: A letter or combination of letters and numbers are used to designate the type of fitting. See the visual index on pages 4 – 5

for body designator.

Fractional Size: Tube and pipe thread sizes are designed by the number of sixteenths of an inch (1/2" tube = 8/16" = 8)

(1/4" pipe thread = 4/16" = 4).

Metric Size: Metric tube is designated in millimeters and prefixed “M” (i.e., 12mm tube – M12.) The pipe thread size is written as a fraction

(i.e., 1/4 NPT = 1/4).

All Straights & Elbows: Call out largest CPI™ / A-LOK

Fractional Tees & Crosses: For drop size tees – first size the run (1 to 2) and then branch (3). Example – the size

designator for a male run tee for 3/8" O.D. tube and 1/4" male pipe thread would be 6-4-6. For crosses – first size

the run (1 to 2) and then the branch (3 to 4). For tees with all ends the same, use the tube and size before and

after the style designator; i.e. 4-4-4 JBZ (CPI™), 4ET4 (A-LOK®).

Metric Tees & Crosses: For drop size tees – first size the run (1 to 2) and then branch (3). Example – the size

designator for a male run tee for 6mm tube and 1/4" male pipe thread would be 6-4-6. For crosses – first size the

run (1 to 2) and then the branch (3 to 4). For tees with all ends the same, use the tube end size after the style

designator; i.e. JBZ 4-4-4 JBZ (CPI™), ETM4 (A-LOK®).

Material: See Table 1 on the previous page for the material symbol.

Thread Types:

N = NPT

(1)

/ National Pipe Taper ANSI B1.20.1

K = BSP / ISO Taper BS21, ISO7/1

R = BSP / ISO Parallel BS2779, ISO 228/1+2, DIN 3852 FORM A

BR = BSP / ISO Parallel BS2779, ISO 228/1+2, DIN 3852 FORM B

M = Metric Thread ISO 6149-2

R-ED = BSPP / ISO Parallel BS2779, ISO 228/1+2, DIN 3852 with elastic sealing washer

GC = BSPP Gauge Connector B2779, ISO 228/1+2, DIN 3852

(1) N thread designator is only used for A-LOK® nomenclature.

(2) Form A requires the use of a bonded washer. See page 73 of this catalog.

(3) Form B (cutting face) may be used with or without a sealing washer.

(4) ED fittings are supplied with Nitrile sealing washers as standard. Fluorocarbon seals are available

upon request.

Special Fittings: Consult the factory. If there is any question as to the fitting desired, particularly for

special fitting configurations, it is suggested that a customer print be submitted.

Special Options: See the following page for available options.

Shape

Designator

Port 2 Size

Designator

®

tube end size first followed by the smaller CPI™ / A-LOK® tube end or pipe thread size.

Designator

– –

Material Port 2 Size

Material Shape

Material Thread

–

Material Thread

(2)

(3)

(see page 8)

Options

(see page 8)

–

See page 8

Options

See page 8

(4)

Options

Options

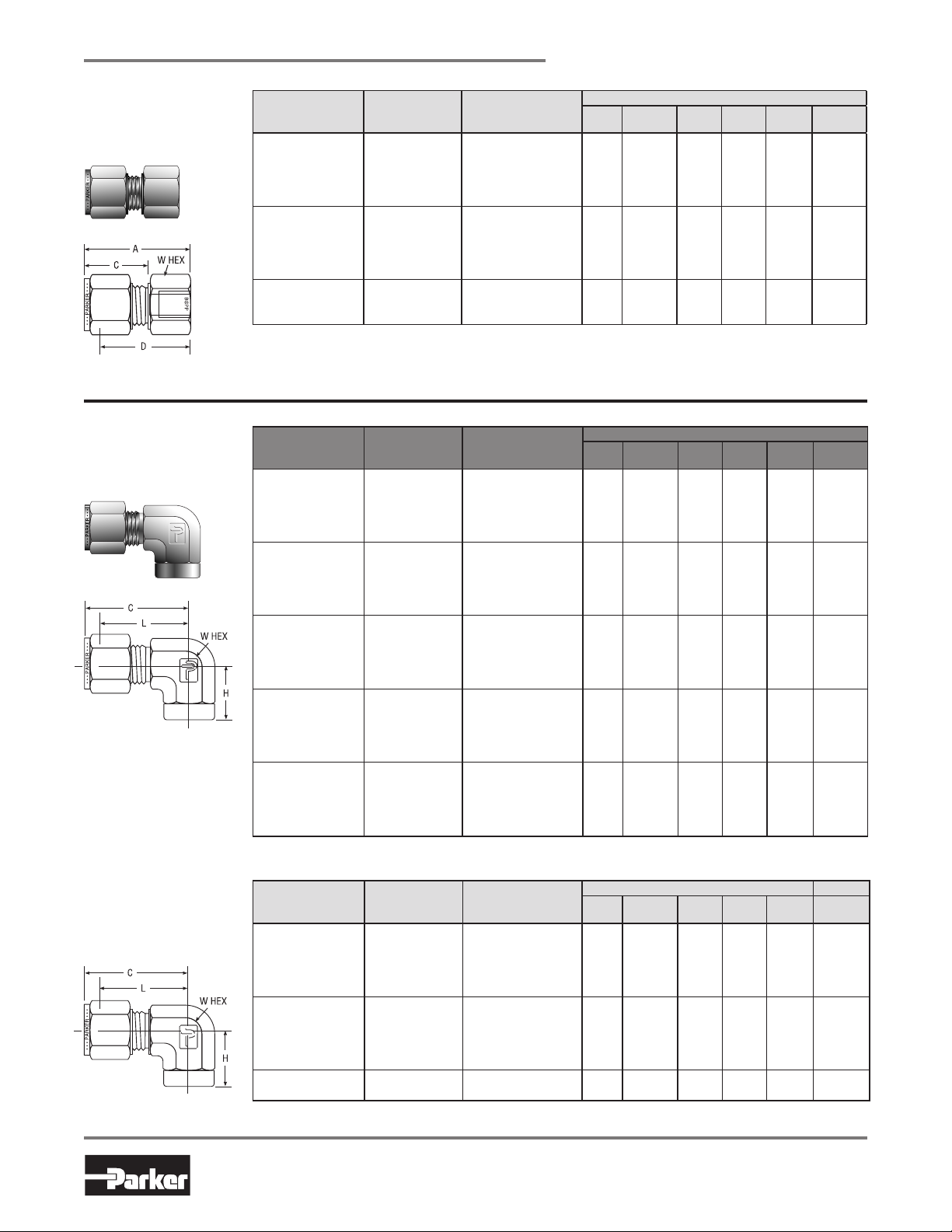

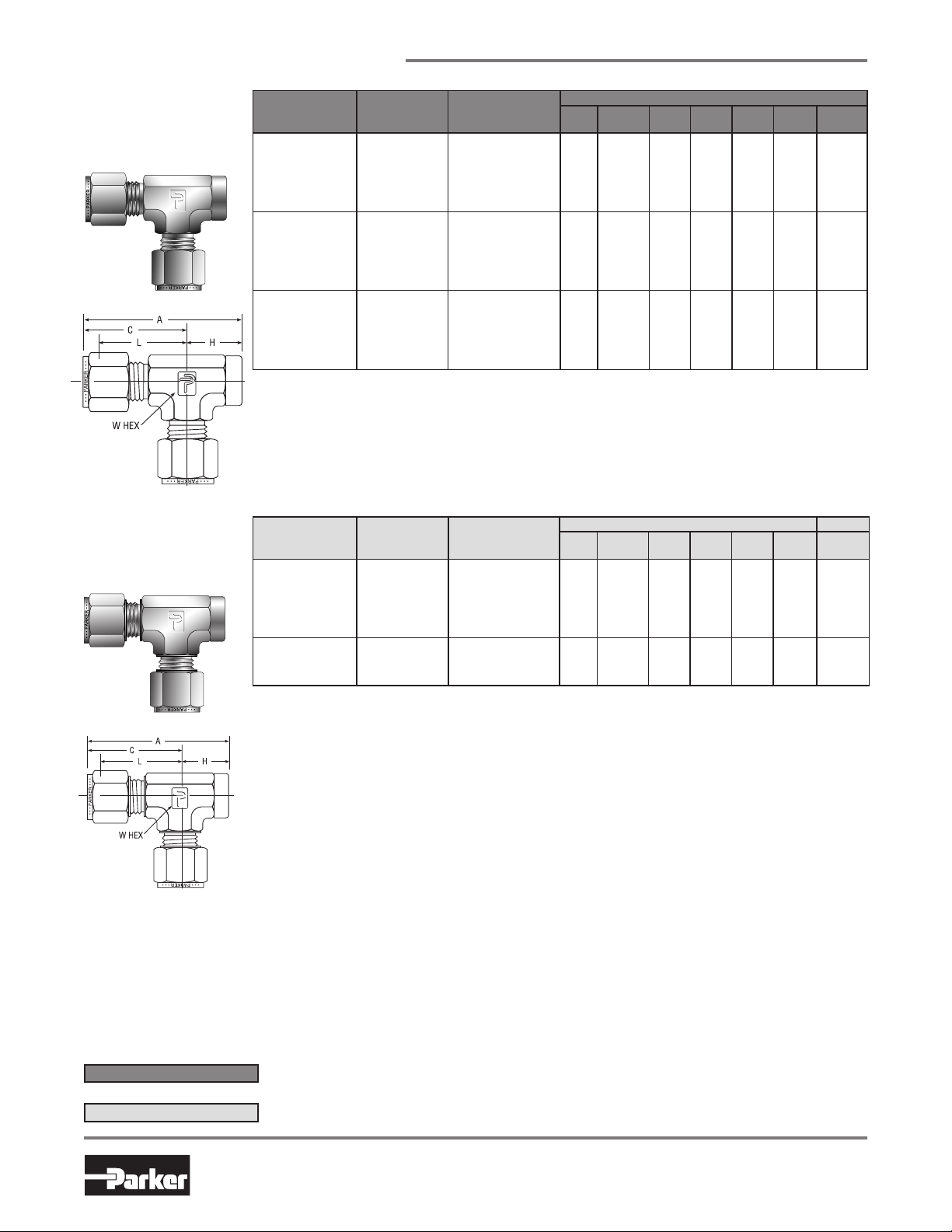

Color Coding

For easy reference, table

column headings are

color indicated as follows:

fractional

metric

7

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

CPI™ / A-LOK® Tube Fittings

Catalog 4230/4233

CPI™ / A-LOK® Options

Parker CPI™ / A-LOK® fittings may be ordered with the following options.

How to order

After the complete CPI™ / A-LOK® number simply add a "dash" then the suffix for the option.

The following example is an A-LOK® male connector for 1/2" OD tube and 1/4" male pipe that has been cleaned for oxygen

service. For additional options, please consult the factory.

8MSC4N-316-C

Suffix Option Additional Information

ZYF Assembled with nylon ferrule(s)

SPF Silver plated ferrule(s)

TF PTFE ferrule(s)

BP* Bulk packed * Indicates the quantity i.e BP50 for a fifty count package.

LWH Lock wire hole

BZP Knurled nut

C Silver plated nut Replaces moly coated nut (BZ).

MI Moly inside nut

CNQ Certified Nuclear Quality

C1 Grade A Cleaning

C3 Cleaned for oxygen service

CNG Compressed natural gas service Assembled with a specific o-ring compound.

NIC Nickel plated

CRM Chrome plated

VO Viton O-ring

NC NACE MRO175-2003

NACE NACE MRO175-2002

DFARS

Defense Acquisition Regulations

System

Replaces standard nut on CPI™/A-LOK

soft plastic tubing.

Special cleaning, assembly, inspection and packaging for

high purity applications.

Meets the requirements of ASTM G93-88; Standard

Practice for Cleaning Methods for Materials and Equipment

used in Oxygen-Enriched Environments.

All components and raw material must be of US origin or

from an approved country.

®

fittings for use on

8

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Catalog 4230/4233

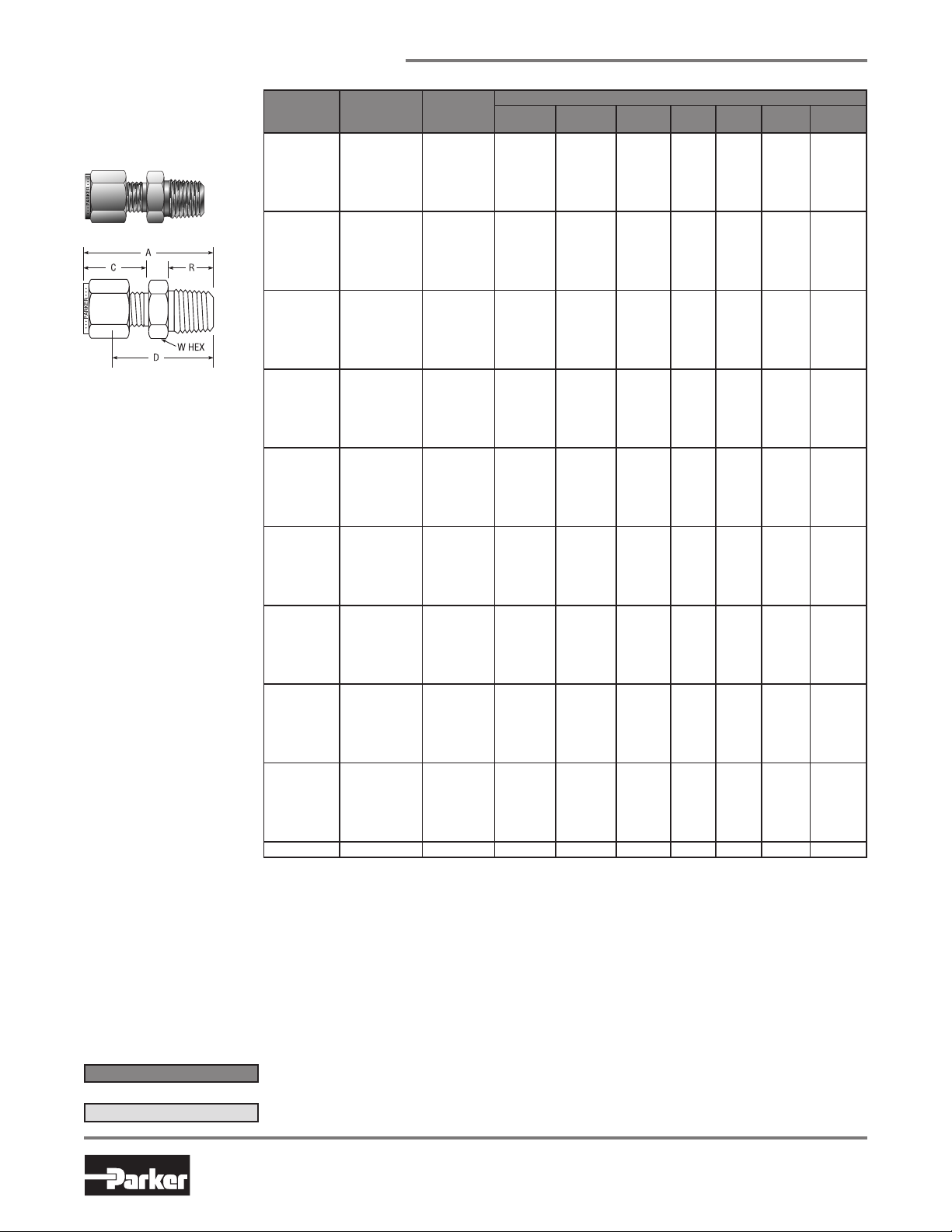

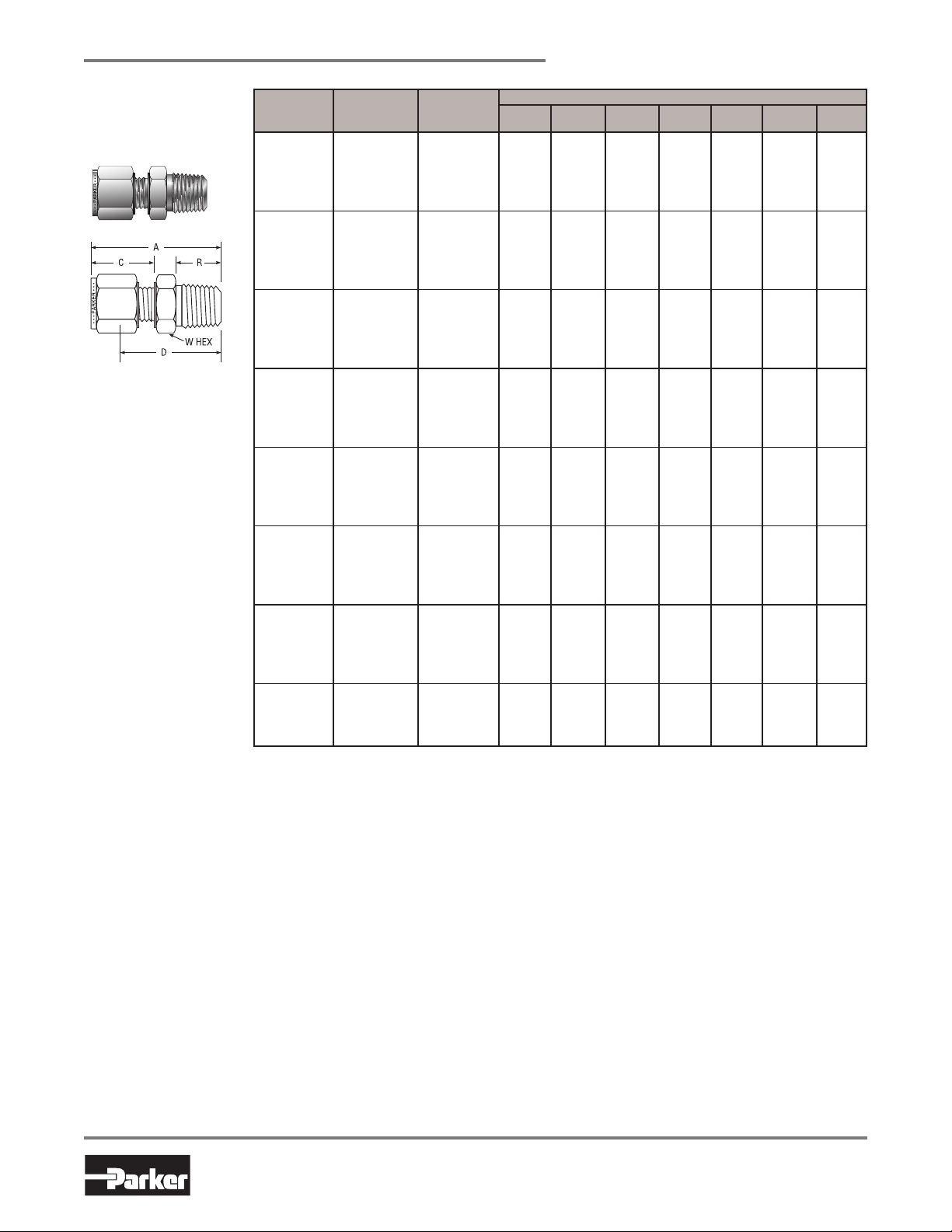

Tube to Male Pipe

NPT Male

Connector

For fractional tube

CPI™

PART NO.

1-1 FBZ 1MSC1N

1-2 FBZ 1MSC2N

1-4 FBZ 1MSC4N

2-1 FBZ 2MSC1N

2-2 FBZ 2MSC2N

2-4 FBZ 2MSC4N

2-6 FBZ 2MSC6N

2-8 FBZ 2MSC8N

3-1 FBZ 3MSC1N

3-2 FBZ 3MSC2N

3-4 FBZ 3MSC4N

4-1 FBZ 4MSC1N

4-2 FBZ 4MSC2N

4-4 FBZ 4MSC4N

4-6 FBZ 4MSC6N

4-8 FBZ 4MSC8N

4-12 FBZ 4MSC12N

5-2 FBZ 5MSC2N

5-4 FBZ 5MSC4N

5-6 FBZ 5MSC6N

5-8 FBZ 5MSC8N

6-2 FBZ 6MSC2N

6-4 FBZ 6MSC4N

6-6 FBZ 6MSC6N

6-8 FBZ 6MSC8N

6-12 FBZ 6MSC12N

8-2 FBZ 8MSC2N

8-4 FBZ 8MSC4N

8-6 FBZ 8MSC6N

8-8 FBZ 8MSC8N

8-12 FBZ 8MSC12N

8-16 FBZ 8MSC16N

10-6 FBZ 10MSC6N

10-8 FBZ 10MSC8N

10-12 FBZ 10MSC12N

12-8 FBZ 12MSC8N

12-12 FBZ 12MSC12N

12-16 FBZ 12MSC16N

14-12 FBZ 14MSC12N

14-16 FBZ 14MSC16N

16-8 FBZ 16MSC8N

16-12 FBZ 16MSC12N

16-16 FBZ 16MSC16N

20-20 FBZ 20MSC20N

24-24 FBZ 24MSC24N

32-32 FBZ 32MSC32N

NOTE: A and C dimensions are typical finger-tight. Dimensions for reference only, subject to change.

Sizes 20, 24, 32 require additional lubrication prior to assembly.

A-LOK®

PART NO.

INTER-

CHANGES

WITH

100-1-1 1/16 1/16 .93 .43 .78 .38 5/16

100-1-2 1/16 1/8 1.03 .43 .88 .38 7/16

100-1-4 1/16 1/4 1.23 .43 1.08 .56 9/16

200-1-1 1/8 1/16 1.17 .60 .91 .38 3/8

200-1-2 1/8 1/8 1.20 .60 .94 .38 7/16

200-1-4 1/8 1/4 1.40 .60 1.14 .56 9/16

200-1-6 1/8 3/8 1.42 .60 1.16 .56 11/16

200-1-8 1/8 1/2 1.67 .60 1.41 .75 7/8

300-1-1 3/16 1/16 1.23 .64 .97 .38 7/16

300-1-2 3/16 1/8 1.23 .64 .97 .38 7/16

300-1-4 3/16 1/4 1.43 .64 1.17 .56 9/16

400-1-1 1/4 1/16 1.29 .70 1.00 .38 1/2

400-1-2 1/4 1/8 1.29 .70 1.00 .38 1/2

400-1-4 1/4 1/4 1.49 .70 1.20 .56 9/16

400-1-6 1/4 3/8 1.51 .70 1.22 .56 11/16

400-1-8 1/4 1/2 1.76 .70 1.47 .75 7/8

400-1-12 1/4 3/4 1.82 .70 1.53 .75 1-1/16

500-1-2 5/16 1/8 1.34 .73 1.05 .38 9/16

500-1-4 5/16 1/4 1.52 .73 1.23 .56 9/16

500-1-6 5/16 3/8 1.55 .73 1.25 .56 11/16

500-1-8 5/16 1/2 1.79 .73 1.5 .75 7/8

600-1-2 3/8 1/8 1.38 .76 1.09 .38 5/8

600-1-4 3/8 1/4 1.57 .76 1.28 .56 5/8

600-1-6 3/8 3/8 1.57 .76 1.28 .56 11/16

600-1-8 3/8 1/2 1.82 .76 1.53 .75 7/8

600-1-12 3/8 3/4 1.88 .76 1.59 .75 1-1/16

810-1-2 1/2 1/8 1.53 .87 1.13 .38 13/16

810-1-4 1/2 1/4 1.71 .87 1.31 .56 13/16

810-1-6 1/2 3/8 1.71 .87 1.31 .56 13/16

810-1-8 1/2 1/2 1.93 .87 1.53 .75 7/8

810-1-12 1/2 3/4 1.99 .87 1.59 .75 1-1/16

810-1-16 1/2 1 2.28 .87 1.88 .94 1-3/8

1010-1-6 5/8 3/8 1.74 .87 1.34 .56 15/16

1010-1-8 5/8 1/2 1.93 .87 1.53 .75 15/16

1010-1-12 5/8 3/4 1.99 .87 1.59 .75 1-1/16

1210-1-8 3/4 1/2 1.99 .87 1.59 .75 1-1/16

1210-1-12 3/4 3/4 1.99 .87 1.59 .75 1-1/16

1210-1-16 3/4 1 2.28 .87

1410-1-12 7/8 3/4 1.99 .87 1.59 .75 1-3/16

1410-1-16 7/8 1 2.28 .87 1.88 .94 1-3/8

1610-1-8 1 1/2 2.27 1.05 1.78 .75 1-3/8

1610-1-12 1 3/4 2.27 1.05 1.78 .75 1-3/8

1610-1-16 1 1 2.46 1.05 1.97 .94 1-3/8

2010-1-20 1-1/4 1-1/4 3.03 1.52 2.17 .97 1-3/4

2410-1-24 1-1/2 1-1/2 3.50 1.77 2.44 1.00 2-1/8

3210-1-32 2 2 4.47 2.47 3.00 1.04 2-3/4

TUBE

O.D.

NPT PIPE

THREAD A C D R

INCHES

W

HEX

1.88 .94 1-3/8

Color Coding

For easy reference, table

column headings are color

indicated as follows:

fractional

metric

9

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

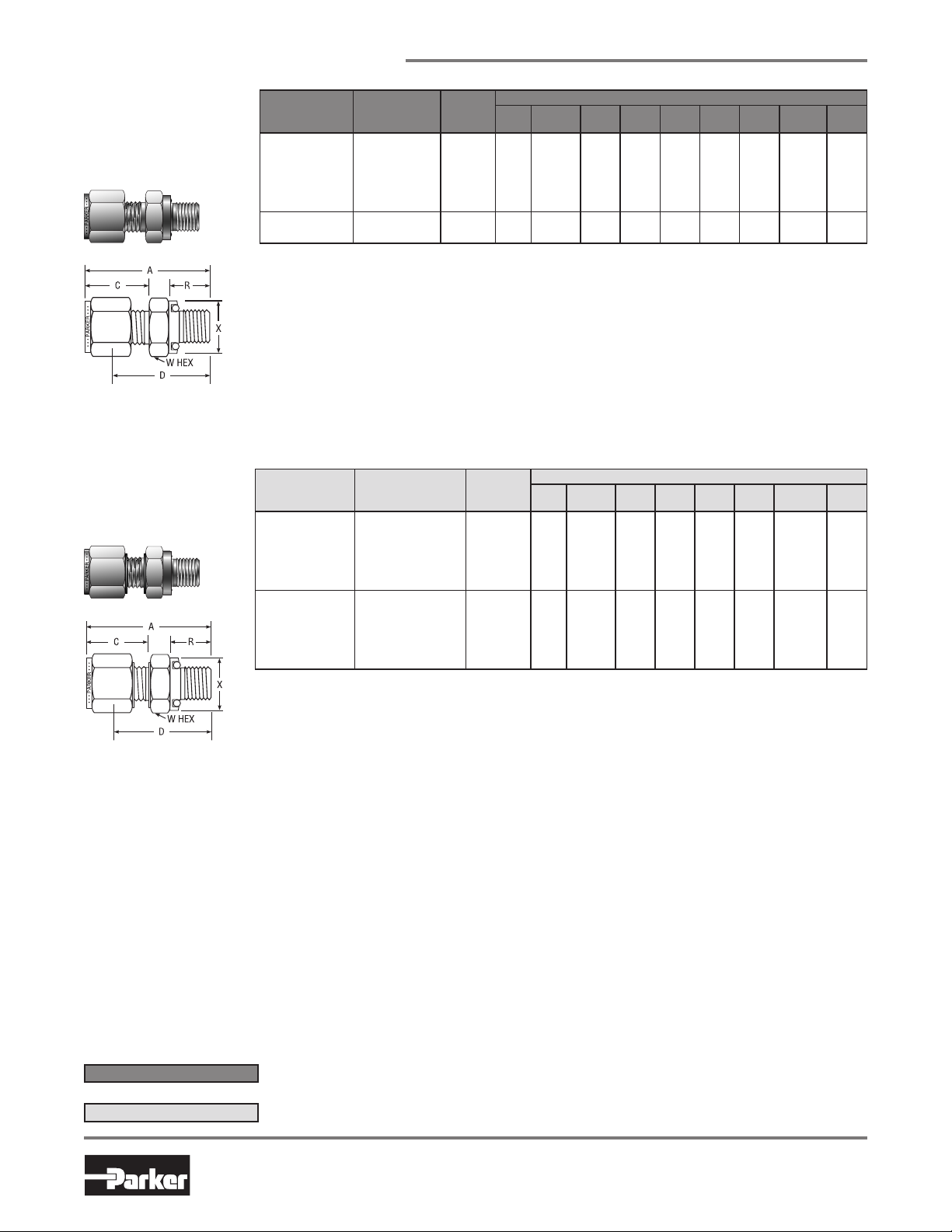

Tube to Male Pipe

Catalog 4230/4233

NPT Male

Connector

For metric tube

CPI™

PART NO.

FBZ 2-1/8 M2MSC1/8N

FBZ 3-1/8 M3MSC1/8N

FBZ 3-1/4 M3MSC1/4N

FBZ 4-1/8 M4MSC1/8N

FBZ 4-1/4 M4MSC1/4N

FBZ 6-1/8 M6MSC1/8N

FBZ 6-1/4 M6MSC1/4N

FBZ 6-3/8 M6MSC3/8N

FBZ 6-1/2 M6MSC1/2N

FBZ 8-1/8 M8MSC1/8N

FBZ 8-1/4 M8MSC1/4N

FBZ 8-3/8 M8MSC3/8N

FBZ 8-1/2 M8MSC1/2N

FBZ 10-1/8 M10MSC1/8N

FBZ 10-1/4 M10MSC1/4N

FBZ 10-3/8 M10MSC3/8N

FBZ 10-1/2 M10MSC1/2N

FBZ 10-3/4 M10MSC3/4N

FBZ 10-1 M10MSC1N

FBZ 12-1/4 M12MSC1/4N

FBZ 12-3/8 M12MSC3/8N

FBZ 12-1/2 M12MSC1/2N

FBZ 12-3/4 M12MSC3/4N

FBZ 14-1/4 M14MSC1/4N

FBZ 14-3/8 M14MSC3/8N

FBZ 14-1/2 M14MSC1/2N

FBZ 15-1/2 M15MSC1/2N

FBZ 16-3/8 M16MSC3/8N

FBZ 16-1/2 M16MSC1/2N

FBZ 16-3/4 M16MSC3/4N

FBZ 18-1/2 M18MSC1/2N

FBZ 18-3/4 M18MSC3/4N

FBZ 20-1/2 M20MSC1/2N

FBZ 20-3/4 M20MSC3/4N

FBZ 20-1 M20MSC1N

FBZ 22-3/4 M22MSC3/4N

FBZ 24-1/2 M25MSC1/2N

FBZ 25-3/4 M25MSC3/4N

FBZ 25-1 M25MSC1N

NOTE: A and C dimensions are typical finger-tight. Dimensions for reference only, subject to change.

A-LOK®

PART NO.

INTER-

CHANGES

WITH

2MO-1-2 2 1/8 29,7 15,3 23,1 9,5 12,0

3MO-1-2 3 1/8 29,7 15,3 23,1 9,5 12,0

3MO-1-4 3 1/4 35,3 15,3 28,7 14,3 14,0

4MO-1-2 4 1/8 31,2 16,1 24,6 9,5 12,0

4MO-1-4 4 1/4 36,3 16,1 29,7 14,3 14,0

6MO-1-2 6 1/8 32,9 17,7 25,4 9,5 14,0

6MO-1-4 6 1/4 38,1 17,7 30,6 14,3 14,0

6MO-1-6 6 3/8 38,5 17,7 31,0 14,3 18,0

6MO-1-8 6 1/2 44,8 17,7 37,3 19,1 22,0

8MO-1-2 8 1/8 34,2 18,6 26,7 9,5 15,0

8MO-1-4 8 1/4 38,8 18,6 31,3 14,3 15,0

8MO-1-6 8 3/8 39,3 18,6 31,8 14,3 18,0

8MO-1-8 8 1/2 45,6 18,6 38,1 19,1 22,0

10MO-1-2 10 1/8 36,1 19,5 28,6 9,5 18,0

10MO-1-4 10 1/4 40,9 19,5 33,3 14,3 18,0

10MO-1-6 10 3/8 40,9 19,5 33,3 14,3 18,0

10MO-1-8 10 1/2 47,5 19,5 38,9 19,1 22,0

10MO-1-12 10 3/4 46,4 19,5 38,9 19,1 27,0

10MO-1-16 10 1 55,0 19,5 47,5 23,8 35,0

12MO-1-4 12 1/4 43,4 22,0 33,3 14,3 22,0

12MO-1-6 12 3/8 43,4 22,0 33,3 14,3 22,0

12MO-1-8 12 1/2 49,0 22,0 38,9 19,1 22,0

12MO-1-12 12 3/4 50,5 22,0 40,4 19,1 27,0

14MO-1-4 14 1/4 44,2 22,0 34,1 14,3 24,0

14MO-1-6 14 3/8 44,2 22,0 34,1 14,3 24,0

14MO-1-8 14 1/2 49,0 22,0 38,9 19,1 24,0

15MO-1-8 15 1/2 49,0 22,0 38,9 19,1 24,0

16MO-1-6 16 3/8 44,1 22,0 34,01 14,3 24,0

16MO-1-8 16 1/2 49,0 22,0 38,9 19,1 24,0

16MO-1-12 16 3/4 50,5 22,0 40,5 19,1 27,0

18MO-1-8 18 1/2 50,6 22,0 40,5 19,1 27,0

18MO-1-12 18 3/4 50,6 22,0 40,5 19,1 27,0

20MO-1-8 20 1/2 50,6 22,0 42,2 19,1 30,0

20MO-1-12 20 3/4 52,3 22,0 42,2 19,1 30,0

20MO-1-16 20 1 57,7 22,0 47,6 23,8 35,0

22MO-1-12 22 3/4 52,3 22,0 42,2 19,1 35,0

25MO-1-8 25 1/2 57,5 26,5 45,3 19,1 35,0

25MO-1-12 25 3/4 57,5

25MO-1-16 25 1 62,3 26,5 50,0 23,8 35,0

TUBE

NPT PIPE

O.D.

THREAD A C D R

MILLIMETERS

W

HEX

26,5 45,2 19,1 35,0

10

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Catalog 4230/4233

BSP

BSP

Tube to Male Pipe

BSP Taper Male

Connector

For fractional tube

BSP Taper Male

Connector

For metric tube

Color Coding

For easy reference, table

column headings are color

indicated as follows:

fractional

CPI™

PART NO.

2-2K FBZ 2MSC2K

2-4K FBZ 2MSC4K

4-2K FBZ 4MSC2K

4-4K FBZ 4MSC4K

4-6K FBZ 4MSC6K

4-8K FBZ 4MSC8K

5-2K FBZ 5MSC2K

5-4K FBZ 5MSC4K

6-2K FBZ 6MSC2K

6-4K FBZ 6MSC4K

6-6K FBZ 6MSC6K

6-8K FBZ 6MSC8K

8-4K FBZ 8MSC4K

8-6K FBZ 8MSC6K

8-8K FBZ 8MSC8K

NOTE: A and C dimensions are typical finger-tight. Dimensions for reference only, subject to change.

CPI™

PART NO.

FBZ 2-1/8K M2MSC1/8K

FBZ 3-1/8K M3MSC1/8K

FBZ 3-1/4K M3MSC1/4K

FBZ 4-1/8K M4MSC1/8K

FBZ 4-1/4K M4MSC1/4K

FBZ 6-1/8K M6MSC1/8K

FBZ 6-1/4K M6MSC1/4K

FBZ 6-3/8K M6MSC3/8K

FBZ 6-1/2K M6MSC1/2K

FBZ 8-1/8K M8MSC1/8K

FBZ 8-1/4K M8MSC1/4K

FBZ 8-3/8K M8MSC3/8K

FBZ 8-1/2K M8MSC1/2K

FBZ 10-1/8K M10MSC1/8K

FBZ 10-1/4K M10MSC1/4K

FBZ 10-3/8K M10MSC3/8K

FBZ 10-1/2K M10MSC1/2K

FBZ 12-1/4K M12MSC1/4K

FBZ 12-3/8K M12MSC3/8K

FBZ 12-1/2K M12MSC1/2K

FBZ 12-3/4K M12MSC3/4K

FBZ 15-1/2K M15MSC1/2K

FBZ 16-3/8K M16MSC3/8K

FBZ 16-1/2K M16MSC1/2K

FBZ 16-3/4K M16MSC3/4K

FBZ 18-1/2K M18MSC1/2K

FBZ 18-3/4K M18MSC3/4K

FBZ 20-1/2K M20MSC1/2K

FBZ 20-3/4K M20MSC3/4K

FBZ 22-3/4K M22MSC3/4K

FBZ 25-3/4K M25MSC3/4K

FBZ 25-1K M25MSC1K

NOTE: A and C dimensions are typical finger-tight. Dimensions for reference only, subject to change.

A-LOK

PART NO.

PART NO.

®

A-LOK®

INTER-

CHANGES

WITH

200-1-2RT 1/8 1/8 1.20 .60 0.94 .38 7/16 .19

200-1-4RT 1/8 1/4 1.40 .60 1.14 .56 9/16 .19

400-1-2RT 1/4 1/8 1.30 .70 1.00 .38 1/2 .19

400-1-4RT 1/4 1/4 1.50 .70 1.20 .56 9/16 .19

400-1-6RT 1/4 3/8 1.52 .70 1.22 .56 11/16 .19

400-1-8RT 1/4 1/2 1.77 .70 1.47 .75 7/8 .19

500-1-2RT 5/16 1/8 1.34 .73 1.05 .38 9/16 .19

500-1-4RT 5/16 1/4 1.52 .73 1.23 .56 9/16 .19

600-1-2RT 3/8 1/8 1.39 .76 1.09 .38 5/8 .19

600-1-4RT 3/8 1/4 1.57 .76 1.28 .56 5/8 .28

600-1-6RT 3/8 3/8 1.57 .76 1.28 .56 11/16 .28

600-1-8RT 3/8 1/2 1.82 .76 1.53 .75 7/8 .28

810-1-4RT 1/2 1/4 1.69 .86 1.31 .56 13/16 .28

810-1-6RT 1/2 3/8 1.69 .86 1.31 .56 13/16 .38

810-1-8RT 1/2 1/2 1.91 .66 1.53 .75 7/8 .41

TUBE

O.D.

INTER-

CHANGES

WITH

2MO-1-2RT 2 1/8 29,7 15,3 23,1 9,5 12,0

3MO-1-2RT 3 1/8 29,7 15,3 23,1 9,7 12,0

3MO-1-4RT 3 1/4 35,3 15,3 28,7 14,2 14,0

4MO-1-2RT 4 1/8 31,2 16,1 24,6 9,7 12,0

4MO-1-4RT 4 1/4 36,3 16,1 29,7 14,2 14,0

6MO-1-2RT 6 1/8 32,9 17,7 25,4 9,7 14,0

6MO-1-4RT 6 1/4 40,0 17,7 30,5 14,2 14,0

6MO-1-6RT 6 3/8 38,5 17,7 31,0 14,2 18,0

6MO-1-8RT 6 1/2 45,6 17,7 38,1 19,1 22,0

8MO-1-2RT 8 1/8 33,9 18,6 26,4 9,5 15,0

8MO-1-4RT 8 1/4 38,7 18,6 31,2 14,2 15,0

8MO-1-6RT 8 3/8 39,3 18,6 31,8 14,2 18,0

8MO-1-8RT 8 1/2 45,6 18,6 38,1 19,1 22,0

10MO-1-2RT 10 1/8 36,2 19,5 28,6 9,5 18,0

10MO-1-4RT 10 1/4 40,9 19,5 33,3 14,2 18,0

10MO-1-6RT 10 3/8 40,9 19,5 33,3 14,2 18,0

10MO-1-8RT 10 1/2 46,5 19,5 38,9 19,1 22,0

12MO-1-4RT 12 1/4 43,4 22,0 33,3 14,2 22,0

12MO-1-6RT 12 3/8 43,4 22,0 33,3 14,2 22,0

12MO-1-8RT 12 1/2 49,0 22,0 38,9 19,1 22,0

12MO-1-12RT 12 3/4 49,5 22,0 40,4 19,1 27,0

15MO-1-8RT 15 1/2 49,0 22,0 38,9 19,1 24,0

16MO-1-6RT 16 3/8 44,2 22,0 34,1 14,2 24,0

16MO-1-8RT 16 1/2 49,0 22,0 38,9 19,1 24,0

16MO-1-12RT 16 3/4 49,5 22,0 40,5 19,1 27,0

18MO-1-8RT 18 1/2 50,6 22,0 40,4 19,1 27,0

18MO-1-12RT 18 3/4 50,6 22,0 40,4 19,1 27,0

20MO-1-8RT 20 1/2 52,3 22,0 42,2 19,1 30,0

20MO-1-12RT 20 3/4 52,3 22,0 42,2 19,1 30,0

22MO-1-12RT 22 3/4 52,3 22,0 42,2 19,1 30,0

25MO-1-12RT 25 3/4 57,5 26,5 45,2 19,1 35,0

25MO-1-16RT 25 1 62,3 26,5 50,0 23,9 35,0

BSPT

THREAD A C D R

TUBE

BSPT

O.D.

THREAD A C D R

INCHES

W

HEX BORE

MILLIMETERS

W

HEX

metric

11

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Tube to Male Pipe

BSPP

BSPP

Catalog 4230/4233

BSPP Male

Connector

For fractional tube

BSPP Male

Connector

For metric tube

CPI™

PART NO.

2-2R FBZ 2MSC2R

2-4R FBZ 2MSC4R

2-6R FBZ 2MSC6R

4-2R FBZ 4MSC2R

4-4R FBZ 4MSC4R

4-6R FBZ 4MSC6R

4-8R FBZ 4MSC8R

6-2R FBZ 6MSC2R

6-4R FBZ 6MSC4R

6-6R FBZ 6MSC6R

6-8R FBZ 6MSC8R

8-4R FBZ 8MSC4R

8-6R FBZ 8MSC6R

8-8R FBZ 8MSC8R

12-8R FBZ 12MSC8R

12-12R FBZ 12MSC12R

16-8R FBZ 16MSC8R

16-16R FBZ 16MSC16R

NOTE: A and C dimensions are typical finger-tight. Dimensions for reference only, subject to change.

Sealing washer must be used with BSPP end shown ISO228/1 (Form A). See page 73.

For Form B undercut change part number and add B before R. e.g. M6MSC1/4BR.

CPI™

PART NO.

FBZ 2-1/8R M2MSC1/8R

FBZ 3-1/8R M3MSC1/8R

FBZ 3-1/4R M3MSC1/4R

FBZ 6-1/8R M6MSC1/8R

FBZ 6-1/4R M6MSC1/4R

FBZ 6-3/8R M6MSC3/8R

FBZ 6-1/2R M6MSC1/2R

FBZ 8-1/8R M8MSC1/8R

FBZ 8-1/4R M8MSC1/4R

FBZ 8-3/8R M8MSC3/8R

FBZ 8-1/2R M8MSC1/2R

FBZ 10-1/4R M10MSC1/4R

FBZ 10-3/8R M10MSC3/8R

FBZ 10-1/2R M10MSC1/2R

FBZ 12-1/4R M12MSC1/4R

FBZ 12-3/8R M12MSC3/8R

FBZ 12-1/2R M12MSC1/2R

FBZ 12-3/4R M12MSC3/4R

FBZ 16-3/8R M16MSC3/8R

FBZ 16-1/2R M16MSC1/2R

FBZ 18-1/2R M18MSC1/2R

FBZ 18-3/4R M18MSC3/4R

FBZ 20-1/2R M20MSC1/2R

FBZ 20-3/4R M20MSC3/4R

FBZ 22-3/4R M22MSC3/4R

FBZ 25-3/4R M25MSC3/4R

FBZ 25-1R M25MSC1R

NOTE: A and C dimensions are typical finger-tight. Dimensions for reference only, subject to change.

Sealing washer must be used with BSPP end shown ISO228/1 (Form A). See page 73.

For Form B undercut, add a “B” before the “R.” e.g. M6MSC1/4BR.

A-LOK

PART NO.

A-LOK

PART NO.

®

INTER-

CHANGES

WITH

200-1-2RS 1/8 1/8 1.18 .60 0.92 .28 0.54 9/16 .16

200-1-4RS 1/8 1/4 1.27 .60 1.13 .44 0.70 3/4 .09

200-1-6RS 1/8 3/8 1.46 .60 1.17 .44 0.86 7/8 .28

400-1-2RS 1/4 1/8 1.28 .70 0.98 .28 0.54 9/16 .16

400-1-4RS 1/4 1/4 1.49 .70 1.19 .44 0.70 3/4 .19

400-1-6RS 1/4 3/8 1.55 .70 1.25 .44 0.86 7/8 .19

400-1-8RS 1/4 1/2 1.77 .70 1.47 .56 1.01 1-1/16 .19

600-1-2RS 3/8 1/8 1.35 .76 1.06 .28 0.54 5/8 .16

600-1-4RS 3/8 1/4 1.54 .76 1.25 .44 0.70 3/4 .25

600-1-6RS 3/8 3/8 1.57 .76 1.28 .44 0.86 7/8 .28

600-1-8RS 3/8 1/2 1.82 .76 1.53 .56 1.01 1-1/16 .28

810-1-4RS 1/2 1/4 1.66 .86 1.28 .44 0.70 13/16 .25

810-1-6RS 1/2 3/8 1.69 .86 1.31 .44 0.86 7/8 .31

810-1-8RS 1/2 1/2 1.91 .86 1.53 .56 1.01 1-1/16 .41

1210-1-8RS 3/4 1/2 1.93 .86 1.53 .56 1.01 1-1/16 .41

1210-1-12RS 3/4 3/4 2.07 .86 1.69 .63 1.25 1-3/8 .63

1610-1-8RS 1 1/2 2.21 1.04 1.72 .56 1.01 1-3/8 .41

1610-1-16RS 1 1 2.35 1.04 1.88 .72 1.52 1-5/8 .88

®

INTER-CHANGES

2MO-1-2RS 2 1/8 28,4 15,3 21,8 7,1 14,0 13,7

3MO-1-2RS

3MO-1-4RS

6MO-1-2RS

6MO-1-4RS

6MO-1-6RS

6MO-1-8RS

8MO-1-2RS 8 1/8 33,1 18,6 25,6 7,1 15,0 13,7

8MO-1-4RS

8MO-1-6RS

8MO-1-8RS

10MO-1-4RS

10MO-1-6RS

10MO-1-8RS

12MO-1-4RS

12MO-1-6RS

12MO-1-8RS

12MO-1-12RS

1

6MO-1-6RS 16 3/8 43,5 22,0 33,4 11,2 22,0 21,8

16MO-1-8RS 16 1/2 49,0 22,0 38,9 14,2 26,0 27,0

18MO-1-8RS 18 1/2 49,0 22,0 38,9 14,2 26,0 27,0

18MO-1-12RS 18 3/4 53,1 22,0 43,0 16,0 35,0 32,0

20MO-1-8RS 20 1/2 50,5 22,0 40,4 14,2 30,0 25,7

20MO-1-12RS 20 3/4 52,8 22,0 42,7 16,0 32,0 35,0

22MO-1-12RS 22 3/4 52,8 22,0 42,7 16,0 32,0 35,0

25MO-1-12RS 25 3/4 59,8 26,5 47,6 16,0 35,0 31,8

25MO-1-16RS 25 1 60,1 26,5 47,8 18,3 39,0 41,0

WITH

TUBE

BSPP

O.D.

THREAD A C D R XW HEX BORE

TUBE

BSPP

O.D.

THREAD A C D R XW HEX

3 1/8 30,0 15,3 23,4 7,1 13,7 14,0

3 1/4 35,3 15,3 28,7 11,2 17,8 19,0

6 1/8 32,5 17,7 25,0 7,1 13,7 14,0

6 1/4 37,7 17,7 30,2 11,2 17,8 19,0

6 3/8 39,0 17,7 31,5 11,2 21,8 22,0

6 1/2 45,6 17,7 38,1 14,2 25,7 27,0

8 1/4 38,5 18,6 31,0 11,2 17,8 19,0

8 3/8 39,8 18,6 32,3 11,2 21,8 22,0

8 1/2 45,6 18,6 38,1 14,2 25,7 27,0

10 1/4 39,4 19,5 31,8 11,2 17,8 19,0

10 3/8 40,6 19,5 33,0 11,2 21,8 22,0

10 1/2 46,5 19,5 38,9 14,2 25,7 27,0

12 1/4 42,6 22,0 32,5 11,2 17,8 22,0

12 3/8 43,1 22,0 33,0 11,2 21,8 22,0

12 1/2 49,0 22,0 38,9 14,2 25,7 27,0

12 3/4 52,8 22,0 42,7 16,0 31,8 35,0

INCHES

MILLIMETERS

12

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

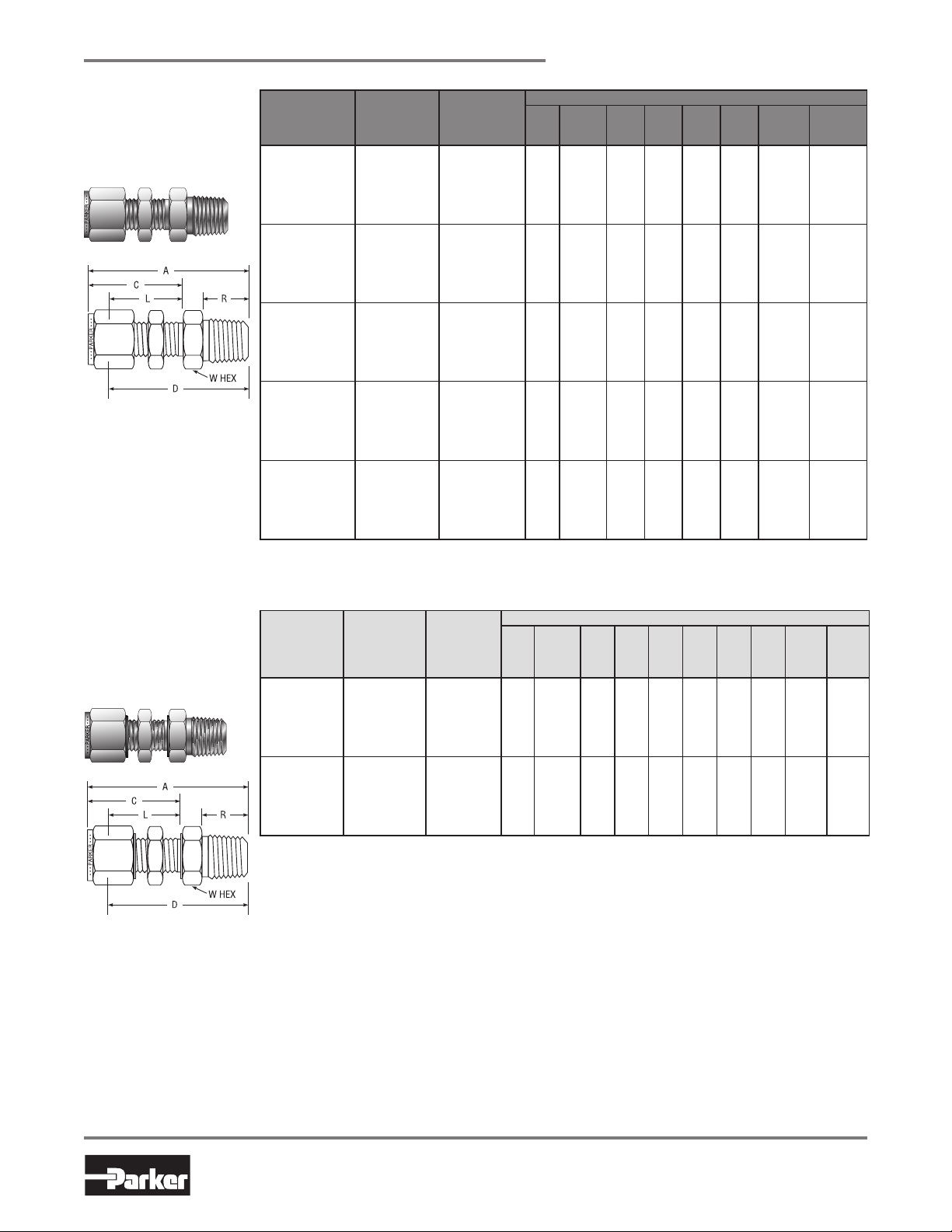

Catalog 4230/4233

Tube to Male Pipe

BSPP Male

Connector with

ED Seal

For fractional tube

Male Connector

with ED Seal

For metric tube

CPI™

PART NO.

4-4R-ED FBZ

4-8R-ED FBZ

6-6R-ED FBZ 6MSC6R-ED

8-4R-ED FBZ 8MSC4R-ED

8-6R-ED FBZ

8-8R-ED FBZ

12-12R-ED FBZ 12MSC12R-ED

NOTE: A and C dimensions are typical finger-tight. Dimensions for reference only, subject to change.

ED fittings are supplied with sealing washers in nitrile as standard, suitable for temperatures of between -35°C and +100°C

(-31°F to +212°F). Fluorocarbon seals are available upon request which are suitable for temperatures of between -25°C and

+120°C (-13°F to +248°F).

CPI™

PART NO.

FBZ6-1/8R-ED

FBZ6-1/4R-ED

FBZ6-3/8R-ED M6MSC3/8R-ED

FBZ6-1/2R-ED M6MSC1/2R-ED

FBZ10-1/4R-ED

FBZ10-3/8R-ED

FBZ10-1/2R-ED M10MSC1/2R-ED

FBZ12-1/4R-ED M12MSC1/4R-ED

FBZ12-3/8R-ED

FBZ12-1/2R-ED

NOTE: A and C dimensions are typical finger-tight. Dimensions for reference only, subject to change.

ED fittings are supplied with sealing washers in nitrile as standard, suitable for temperatures of between -35°C and +100°C

(-31°F to +212°F). Fluorocarbon seals are available upon request which are suitable for temperatures of between -25°C and

+120°C (-13°F to +248°F).

A-LOK®

PART NO.

4MSC4R-ED

4MSC8R-ED

8MSC6R-ED

8MSC8R-ED

A-LOK

PART NO.

M6MSC1/8R-ED

M6MSC1/4R-ED

M10MSC1/4R-ED

M10MSC3/8R-ED

M12MSC3/8R-ED

M12MSC1/2R-ED

INTER-

CHANGES

®

TUBE

WITH

– 1/4 1/4 1.48 .70 1.19 .47 .74 3/4 .19

– 1/4 1/2 1.76 .70 1.38 .55 1.04 1-1/16 .19

– 3/8 3/8 1.60 .76 1.31 .47 .86 7/8 .28

– 1/2 1/4 1.69 .86 1.31 .47 .74 13/16 .25

– 1/2 3/8 1.69 .86 1.31 .47 .86 7/8 .31

– 1/2 1/2 1.85 .86 1.47 .55 1.04 1-1/16 .41

– 3/4 3/4 1.98 .86 1.59 .63 1.25 1-5/16 .63

INTER-

CHANGES

WITH

– 6 1/8 32,5 17,7 25,0 7,9 13,7 14,0

– 6 1/4 38,2 17,7 30,7 11,9 18,8 19,0

– 6 3/8 39,5 17,7 32,0 11,9 21,8 22,0

– 6 1/2 44,5 17,7 37,0 14,0 26,4 27,0

– 10 1/4 40,0 19,5 32,3 11,9 18,8 19,0

– 10 3/8 41,1 19,5 38,1 11,9 21,8 22,0

– 10 1/2 46,0 19,5 38,4 14,0 26,4 27,0

– 12 1/4 43,1 22,0 33,0 11,9 18,8 22,0

– 12 3/8 43,6 22,0 33,5 11,9 21,8 22,0

– 12 1/2 48,5 22,0 38,4 14,0 26,4 27,0

BSPP

O.D.

THREAD A C D R X

TUBE

BSPP

O.D.

THREAD A C D R X

INCHES

W

HEX BORE

MILLIMETERS

W

HEX

Color Coding

For easy reference, table

column headings are color

indicated as follows:

fractional

metric

13

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Tube to Male Pipe

Catalog 4230/4233

NPT Male

Bulkhead

Connector

For fractional tube

CPI™

PART NO.

1-1 FH2BZ 1MBC1N

1-2 FH2BZ 1MBC2N

2-2 FH2BZ 2MBC2N

3-2 FH2BZ 3MBC2N

4-2 FH2BZ 4MBC2N

4-4 FH2BZ 4MBC4N

4-6 FH2BZ 4MBC6N

4-8 FH2BZ 4MBC8N

5-2 FH2BZ 5MBC2N

5-4 FH2BZ 5MBC4N

6-2 FH2BZ 6MBC2N

6-4 FH2BZ 6MBC4N

6-6 FH2BZ 6MBC6N

6-8 FH2BZ 6MBC8N

8-4 FH2BZ 8MBC4N

8-6 FH2BZ 8MBC6N

8-8 FH2BZ 8MBC8N

8-12 FH2BZ 8MBC12N

10-6 FH2BZ 10MBC6N

10-8 FH2BZ 10MBC8N

12-8 FH2BZ 12MBC8N

12-12 FH2BZ 12MBC12N

14-12 FH2BZ 14MBC12N

16-12 FH2BZ 16MBC12N

16-16 FH2BZ 16MBC16N

NOTE: A and C dimensions are typical finger-tight. Dimensions for reference only, subject to change.

For bulkhead hole drill size and maximum bulkhead thickness, see page 29, Part BC.

A-LOK®

PART NO.

INTER-

CHANGES

WITH

100-11-1 1/16 1/16 1.19 0.68 1.038 .53 .38 5/16

100-11-2 1/16 1/8 1.27 0.68 1.116 .53 .38 7/16

200-11-2 1/8 1/8 1.83 1.23 1.571 .97 .38 1/2

300-11-2 3/16 1/8 1.89 1.26 1.634 1.00 .38 9/16

400-11-2 1/4 1/8 1.95 1.31 1.655 1.02 .38 5/8

400-11-4 1/4 1/4 2.132 1.31 1.842 1.02 .56 5/8

400-11-6 1/4 3/8 2.162 1.31 1.872 1.02 .56 11/16

400-11-8 1/4 1/2 2.374 1.31 2.084 1.02 .75 7/8

500-11-2 5/16 1/8 2.08 1.42 1.779 1.12 .38 11/16

500-11-4 5/16 1/4 2.27 1.42 1.966 1.12 .56 11/16

600-11-2 3/8 1/8 2.08 1.44 1.788 1.15 .38 3/4

600-11-4 3/8 1/4 2.265 1.44 1.975 1.15 .56 3/4

600-11-6 3/8 3/8 2.265 1.44 1.975 1.15 .56 3/4

600-11-8 3/8 1/2 2.48 1.44 2.219 1.15 .75 7/8

810-11-4 1/2 1/4 2.494 1.65 2.094 1.25 .56 15/16

810-11-6 1/2 3/8 2.494 1.65 2.094 1.25 .56 15/16

810-11-8 1/2 1/2 2.712 1.65 2.312 1.25 .75 15/16

810-11-12 1/2 3/4 2.722 1.65 2.322 1.25 .75 1-1/8

1010-11-6 5/8 3/8 2.628 1.68 2.228 1.28 .56 1-1/16

1010-11-8 5/8 1/2 2.816 1.68 2.416 1.28 .75 1-1/16

1210-11-8 3/4 1/2 3.00 1.87 2.601 1.47 .75 1-3/16

1210-11-12 3/4 3/4 3.00 1.87 2.601 1.47 .75 1-3/16

1410-11-12 7/8 3/4 3.31 2.09 2.913 1.69 .75 1-3/8

1610-11-12 1 3/4 3.54 2.27 3.006 1.78 .75 1-5/8

1610-11-16 1 1 3.72 2.27 3.194 1.78 .94 1-5/8

NPT

TUBE

PIPE

O.D.

THREAD A C D L R

INCHES

W

HEX

NPT Male

Bulkhead

Connector

For metric tube

MILLIMETERS

CPI™

PART NO.

FH2BZ 6-1/8 M6MBC1/8N

FH2BZ 6-1/4 M6MBC1/4N

FH2BZ 8-1/8 M8MBC1/8N

FH2BZ 8-1/4 M8MBC1/4N

FH2BZ 10-1/4 M10MBC1/4N

FH2BZ 10-3/8 M10MBC3/8N

FH2BZ 10-1/2 M10MBC1/2N

FH2BZ 12-1/4 M12MBC1/4N

FH2BZ 12-3/8 M12MBC3/8N

FH2BZ 12-1/2 M12MBC1/2N

NOTE: A and C dimensions are typical finger-tight. Dimensions for reference only, subject to change.

A-LOK

PART NO.

®

INTER-

CHANGES

WITH

6MO-11-2 6 1/8 49,6 33,7 42,1 26,2 9,5 16,0 11,5 10,2

6MO-11-4 6 1/4 53,5 33,7 46,0 26,2 14,3 16,0 11,5 10,2

8MO-11-2 8 1/8 52,3 36,0 44,8 28,5 9,5 18,0 13,1 11,2

8MO-11-4 8 1/4 57,5 36,0 50,0 28,5 14,3 18,0 13,1 11,2

10MO-11-4 10 1/4 58,4 37,0 50,8 29,4 14,3 22,0 16,3 11,2

10MO-11-6 10 3/8 58,4 37,0 50,8 29,4 14,3 22,0 16,3 11,2

10MO-11-8 10 1/2 63,1 37,0 55,5 29,4 19,0 22,0 16,3 11,2

12MO-11-4 12 1/4 63,3 10,1 53,2 31,8 14,3 24,0 19,5 12,7

12MO-11-6 12 3/8 64,5 10,1 54,4 31,8 14,3 24,0 19,5 12,7

12MO-11-8 12 1/2 67,5 10,1 57,4 31,8 19,0 24,0 19,5 12,7

TUBE

NPT

O.D.

THREAD A C D L RW HEX

B’HEAD

HOLE

DRILL

SIZE

MAX.

B’HEAD

THICK.

14

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

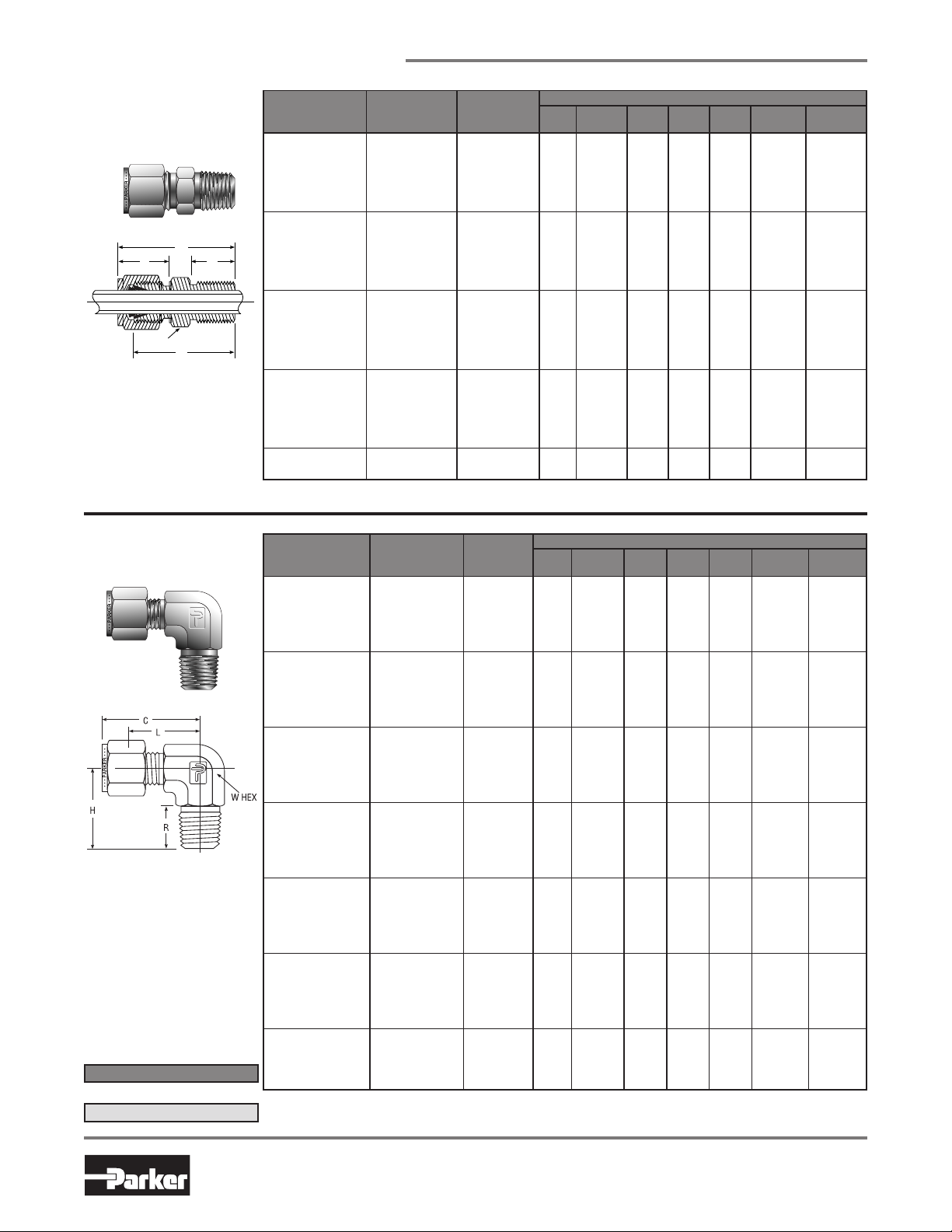

Catalog 4230/4233

A

C

R

D

W HEX

Tube to Male Pipe

Thermocouple

Connector

For fractional tube

NPT Male Elbow

For fractional tube

Color Coding

For easy reference, table

column headings are color

indicated as follows:

fractional

metric

CPI™

PART NO.

1-1 FH4BZ 1MTC1N

1-2 FH4BZ 1MTC2N

1-4 FH4BZ 1MTC4N

2-1 FH4BZ 2MTC1N

2-2 FH4BZ 2MTC2N

2-4 FH4BZ 2MTC4N

3-2 FH4BZ 3MTC2N

3-4 FH4BZ 3MTC4N

4-2 FH4BZ 4MTC2N

4-4 FH4BZ 4MTC4N

4-6 FH4BZ 4MTC6N

4-8 FH4BZ 4MTC8N

5-4 FH4BZ 5MTC4N

6-4 FH4BZ 6MTC4N

6-6 FH4BZ 6MTC6N

6-8 FH4BZ 6MTC8N

6-12 FH4BZ 6MTC12N

8-8 FH4BZ 8MTC8N

8-12 FH4BZ 8MTC12N

10-12 FH4BZ 10MTC12N

12-12 FH4BZ 12MTC12N

16-16 FH4BZ 16MTC16N

NOTE: A and C dimensions are typical finger-tight. Dimensions for reference only, subject to change.

CPI™

PART NO.

1-1 CBZ 1MSEL1N

1-2 CBZ 1MSEL2N

2-1 CBZ 2MSEL1N

2-2 CBZ 2MSEL2N

2-4 CBZ 2MSEL4N

3-2 CBZ 3MSEL2N

3-4 CBZ 3MSEL4N

4-1 CBZ 4MSEL1N

4-2 CBZ 4MSEL2N

4-4 CBZ 4MSEL4N

4-6 CBZ 4MSEL6N

4-8 CBZ 4MSEL8N

5-2 CBZ 5MSEL2N

5-4 CBZ 5MSEL4N

6-2 CBZ 6MSEL2N

6-4 CBZ 6MSEL4N

6-6 CBZ 6MSEL6N

6-8 CBZ 6MSEL8N

6-12 CBZ 6MSEL12N

8-4 CBZ 8MSEL4N

8-6 CBZ 8MSEL6N

8-8 CBZ 8MSEL8N

8-12 CBZ 8MSEL12N

10-6 CBZ 10MSEL6N

10-8 CBZ 10MSEL8N

10-12 CBZ 10MSEL12N

12-8 CBZ 12MSEL8N

12-12 CBZ 12MSEL12N

14-12 CBZ 14MSEL12N

16-12 CBZ 16MSEL12N

16-16 CBZ 16MSEL16N

20-20 CBZ 20MSEL20N

24-24 CBZ 24MSEL24N

32-32 CBZ 32MSEL32N

NOTE: C dimension is typical finger-tight. Dimensions for reference only, subject to change.

Sizes 20, 24 require additional lubrication prior to assembly.

A-LOK®

PART NO.

A-LOK®

PART NO.

INTER-

CHANGES

WITH

100-1-1BT 1/16 1/16 0.93 .43 0.78 .38 5/16

100-1-2BT 1/16 1/8 1.03 .43 0.88 .38 7/16

100-1-4BT 1/16 1/4 1.23 .43 1.08 .56 9/16

200-1-1BT 1/8 1/16 1.17 .60 0.91 .38 3/8

200-1-2BT 1/8 1/8 1.20 .60 0.94 .38 7/16

200-1-4BT 1/8 1/4 1.40 .60 1.14 .56 9/16

300-1-2BT 3/16 1/8 1.23 .64 0.97 .38 7/16

300-1-4BT 3/16 1/4 1.43 .64 1.17 .56 9/16

400-1-2BT 1/4 1/8 1.29 .70 1.00 .38 1/2

400-1-4BT 1/4 1/4 1.49 .70 1.20 .56 9/16

400-1-6BT 1/4 3/8 1.60 .70 1.22 .56 11/16

400-1-8BT 1/4 1/2 1.87 .70 1.47 .75 7/8

500-1-4BT 5/16 1/4 1.52 .73 1.22 .56 9/16

600-1-4BT 3/8 1/4 1.57 .76 1.28 .56 5/8

600-1-6BT 3/8 3/8 1.57 .76 1.28 .56 11/16

600-1-8BT 3/8 1/2 1.82 .76 1.53 .75 7/8

600-1-12BT 3/8 3/4 1.88 .76 1.59 .75 1-1/16

810-1-8BT 1/2 1/2 1.93 .87 1.53 .76 7/8

810-1-12BT 1/2 3/4 1.99 .87 1.59 .75 1-1/16

1010-1-12BT 5/8 3/4 1.99 .87 1.59 .75 1-1/16

1210-1-12BT 3/4 3/4 1.99 .87 1.59 .75 1-1/16

1610-1-16BT 1 1 2.46 1.05 1.97 .94 1-3/8

INTER-

CHANGES

WITH

100-2-1 1/16 1/16 .75 0.70 .60 .38 7/16

100-2-2 1/16 1/8 .75 0.70 .60 .38 7/16

200-2-1 1/8 1/16 .93 0.70 .67 .38 7/16

200-2-2 1/8 1/8 .93 0.70 .67 .38 7/16

200-2-4 1/8 1/4 .97 0.93 .72 .56 9/16

300-2-2 3/16 1/8 1.00 0.74 .74 .38 1/2

300-2-4 3/16 1/4 1.00 0.93 .74 .56 9/16

400-2-1 1/4 1/16 1.06 0.74 .77 .38 1/2

400-2-2 1/4 1/8 1.06 0.74 .77 .38 1/2

400-2-4 1/4 1/4 1.06 0.93 .77 .56 9/16

400-2-6 1/4 3/8 1.17 1.04 .88 .56 11/16

400-2-8 1/4 1/2 1.25 1.31 .96 .75 13/16

500-2-2 5/16 1/8 1.13 0.79 .84 .38 9/16

500-2-4 5/16 1/4 1.13 0.97 .84 .56 9/16

600-2-2 3/8 1/8 1.20 0.82 .91 .38 5/8

600-2-4 3/8 1/4 1.20 1.01 .91 .56 5/8

600-2-6 3/8 3/8 1.23 1.13 .97 .56 11/16

600-2-8 3/8 1/2 1.31 1.31 1.02 .75 13/16

600-2-12 3/8 3/4 1.46 1.46 1.17 .75 1-1/16

810-2-4 1/2 1/4 1.42 1.12 1.02 .56 13/16

810-2-6 1/2 3/8 1.42 1.12 1.02 .56 13/16

810-2-8 1/2 1/2 1.42 1.31 1.02 .75 13/16

810-2-12 1/2 3/4 1.57 1.46 1.17 .75 1-1/16

1010-2-6 5/8 3/8 1.50 1.20 1.10 .56 15/16

1010-2-8 5/8 1/2 1.50 1.39 1.10 .75 15/16

1010-2-12 5/8 3/4 1.57 1.46 1.17 .75 1-1/16

1210-2-8 3/4 1/2 1.57 1.46 1.17 .75 1-1/16

1210-2-12 3/4 3/4 1.57 1.46 1.17 .75 1-1/16

1410-2-12 7/8 3/4 1.76 1.65 1.36 .75 1-3/8

1610-2-12 1 3/4 1.93 1.65 1.45 .75 1-3/8

1610-2-16 1 1 1.93 1.84 1.45 .94 1-3/8

2010-2-20 1-1/4 1-1/4 2.61 1.88 1.75 .97 1-5/8

2410-2-24 1-1/2 1-1/2 3.06 2.38 2.00 1.00 1-7/8

3200-2-32 2 2 4.22 2.79 2.75 1.04 2-13/16

TUBE

NPT PIPE

O.D.

THREAD A C D R

TUBE

NPT PIPE

O.D.

THREAD C H L R

15

INCHES

W

HEX

INCHES

W

HEX

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Tube to Male Pipe

BSP

Catalog 4230/4233

NPT Male

Metric Elbow

For metric tube

CPI™

PART NO.

CBZ 3-1/8

CBZ 3-1/4

CBZ 4-1/8 M4MSEL1/8N

CBZ 4-1/4 M4MSEL1/4N

CBZ 6-1/8

CBZ 6-1/4

CBZ 6-3/8 M6MSEL3/8N

CBZ 6-1/2 M6MSEL1/2N

CBZ 8-1/8

CBZ 8-1/4

CBZ 8-3/8 M8MSEL3/8N

CBZ 8-1/2 M8MSEL1/2N

CBZ 10-1/8

CBZ 10-1/4

CBZ 10-3/8 M10MSEL3/8N

CBZ 10-1/2 M10MSEL1/2N

CBZ 12-1/4

CBZ 12-3/8

CBZ 12-1/2 M12MSEL1/2N

CBZ 12-3/4 M12MSEL3/4N

CBZ 15-1/2

CBZ 16-3/8

CBZ 16-1/2 M16MSEL1/2N

CBZ 16-3/4 M16MSEL3/4N

CBZ 18-1/2

CBZ 18-3/4

CBZ 20-1/2 M20MSEL1/2N

CBZ 20-3/4 M20MSEL3/4N

CBZ 22-3/4

CBZ 25-3/4 M25MSEL3/4N

CBZ 25-1 M25MSEL1N

NOTE: C dimension is typical finger-tight. Dimensions for reference only, subject to change.

M10MSEL1/8N

M10MSEL1/4N

M12MSEL1/4N

M12MSEL3/8N

M15MSEL1/2N

M16MSEL3/8N

M18MSEL1/2N

M18MSEL3/4N

M22MSEL3/4N

®

A-LOK

PART NO.

M3MSEL1/8N

M3MSEL1/4N

M6MSEL1/8N

M6MSEL1/4N

M8MSEL1/8N

M8MSEL1/4N

INTER-

CHANGES

WITH

3MO-2-2 3 1/8 23,6 17,8 17,0 9,7 7/16

3MO-2-4 3 1/4 24,6 23,4 18,0 14,2 1/2

4M0-2-2 4 1/8 25,4 18,8 19,2 9,7 1/2

4MO-2-4 4 1/4 26,2 25,4 19,6 14,2 1/2

6MO-2-2 6 1/8 27,0 18,8 19,6 9,7 1/2

6MO-2-4 6 1/4 27,0 23,4 19,6 14,2 1/2

6MO-2-6 6 3/8 29,8 26,2 22,4 14,2 11/16

6MO-2-8 6 1/2 31,8 33,0 24,4 19,0 13/16

8MO-2-2 8 1/8 28,8 19,8 21,3 9,7 9/16

8MO-2-4 8 1/4 28,8 24,4 21,3 14,2 9/16

8MO-2-6 8 3/8 30,6 26,2 23,1 14,2 11/16

8MO-2-8 8 1/2 32,7 33,0 25,2 19,1 13/16

10MO-2-8 10 1/8 31,5 21,6 23,9 9,7 11/16

10MO-2-4 10 1/4 31,5 26,2 23,9 14,2 11/16

10MO-2-6 10 3/8 31,5 26,2 23,9 14,2 11/16

10MO-2-8 10 1/2 33,5 33,0 25,9 19,0 13/16

12MO-2-4 12 1/4 36,0 28,2 25,9 14,2 13/16

12MO-2-6 12 3/8 36,0 28,2 25,9 14,2 13/16

12MO-2-8 12 1/2 36,0 33,0 25,9 19,0 13/16

12MO-2-12 12 3/4 39,8 36,8 29,7 19,0 1-1/16

15MO-2-8 15 1/2 38,0 35,1 27,9 19,0 15/16

16MO-2-6 16 3/8 38,0 30,2 27,9 14,2 15/16

16MO-2-8 16 1/2 38,0 35,1 27,9 19,0 15/16

16MO-2-12 16 3/4 39,8 36,8 29,7 19,0 1-1/16

18MO-2-8 18 1/2 39,8 36,8 29,7 19,0 1-1/16

18MO-2-12 18 3/4 39,8 36,8 29,7 19,0 1-1/16

20MO-2-8 20 1/2 44,6 41,7 34,5 19,0 1-3/8

20MO-2-12 20 3/4 44,6 41,7 34,5 19,0 1-3/8

22MO-2-12 22 3/4 44,6 41,7 34,5 19,0 1-3/8

25MO-2-12 25 3/4 49,1 41,7 36,8 19,0 1-3/8

25MO-2-16 25 1 49,1 46,5 36,8 23,9 1-3/8

TUBE

NPT

O.D.

THREAD C H L R

MILLIMETERS INCHES

W

HEX

BSP Taper

Male Elbow

For fractional tube

CPI™

PART NO.

4-2K CBZ 4MSEL2K

4-4K CBZ 4MSEL4K

4-6K CBZ 4MSEL6K

4-8K CBZ 4MSEL8K

5-4K CBZ 5MSEL4K

6-4K CBZ 6MSEL4K

6-6K CBZ 6MSEL6K

8-6K CBZ 8MSEL6K

8-8K CBZ 8MSEL8K

NOTE: C dimension is typical finger-tight. Dimensions for reference only, subject to change.

A-LOK®

PART NO.

INTER-

CHANGES

WITH

400-2-2RT 1/4 1/8 1.06 0.75 0.77 .38 1/2

400-2-4RT 1/4 1/4 1.06 0.94 0.77 .56 9/16

400-2-6RT 1/4 3/8 1.17 1.05 0.88 .56 11/16

400-2-8RT 1/4 1/2 1.25 1.32 0.96 .75 13/16

500-2-4RT 5/16 1/4 1.13 0.98 0.84 .38 9/16

600-2-4RT 3/8 1/4 1.20 1.02 0.91 .56 5/8

600-2-4RT 3/8 3/8 1.23 1.05 0.97 .56 11/16

810-2-6RT 1/2 3/8 1.42 1.13 1.02 .56 13/16

810-2-8RT 1/2 1/2 1.42 1.32 1.02 .75 13/16

TUBE

BSPT

O.D.

THREAD C H L R

INCHES

W

HEX

16

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Catalog 4230/4233

BSP

Tube to Male Pipe

BSP Taper Male

Elbow

For metric tube

CPI™

PART NO.

CBZ 3-1/8K M3MSEL1/8K

CBZ 3-1/4K M3MSEL1/4K

CBZ 4-1/8K M4MSEL1/8K

CBZ 4-1/4K M4MSEL1/4K

CBZ 6-1/8K M6MSEL1/8K

CBZ 6-1/4K M6MSEL1/4K

CBZ 6-3/8K M6MSEL3/8K

CBZ 6-1/2K M6MSEL1/2K

CBZ 8-1/8K M8MSEL1/8K

CBZ 8-1/4K M8MSEL1/4K

CBZ 8-3/8K M8MSEL3/8K

CBZ 8-1/2K M8MSEL1/2K

CBZ 10-1/8K M10MSEL1/8K

CBZ 10-1/4K M10MSEL1/4K

CBZ 10-3/8K M10MSEL3/8K

CBZ 10-1/2K M10MSEL1/2K

CBZ 12-1/4K M12MSEL1/4K

CBZ 12-3/8K M12MSEL3/8K

CBZ 12-1/2K M12MSEL1/2K

CBZ 12-3/4K M12MSEL3/4K

CBZ 16-3/8K M16MSEL3/8K

CBZ 16-1/2K M16MSEL1/2K

CBZ 18-1/2K M18MSEL1/2K

CBZ 18-3/4K M18MSEL3/4K

CBZ 20-3/4K M20MSEL3/4K

CBZ 25-3/4K M25MSEL3/4K

CBZ 25-1K M25MSEL1K

NOTE: C dimension is typical finger-tight. Dimensions for reference only, subject to change.

A-LOK

PART NO.

®

INTER-

CHANGES

WITH

3MO-2-2RT 3 1/8 23,6 17,8 17,0 9,7 7/16

3MO-2-4RT 3 1/4 24,6 23,4 18,0 14,2 1/2

4MO-2-2RT 4 1/8 25,4 18,8 18,8 9,7 1/2

4MO-2-4RT 4 1/4 24,6 23,4 18,8 14,2 1/2

6MO-2-2RT 6 1/8 27,0 18,8 19,6 9,7 1/2

6MO-2-4RT 6 1/4 27,0 23,4 19,6 14,2 1/2

6MO-2-6RT 6 3/8 29,8 26,2 22,4 14,2 11/16

6MO-2-8RT 6 1/2 31,8 33,0 24,4 19,0 13/16

8MO-2-2RT 8 1/8 28,8 19,8 21,3 9.7 9/16

8MO-2-4RT 8 1/4 28,8 24,4 21,3 14,2 9/16

8MO-2-6RT 8 3/8 30,6 26,2 23,1 14,2 11/16

8MO-2-8RT 8 1/2 32,7 33,0 25,2 19,1 13/16

10MO-2-2RT 10 1/8 31,5 21,6 23,9 9,7 11/16

10MO-2-4RT 10 1/4 31,5 26,2 23,9 14,2 11/16

10MO-2-6RT 10 3/8 31,5 26,2 23,9 14,2 11/16

10MO-2-8RT 10 1/2 33,5 33,0 25,9 19,0 13/16

12MO-2-4RT 12 1/4 36,0 28,2 25,9 14,2 13/16

12MO-2-6RT 12 3/8 36,0 28,2 25,9 14,2 13/16

12MO-2-8RT 12 1/2 36,0 33,0 25,9 19,0 13/16

12MO-2-12RT 12 3/4 39,8 36,8 29,7 19,1 1-1/16

16MO-2-6RT 16 3/8 38,0 30,2 27,9 14,2 15/16

16MO-2-8RT 16 1/2 38,0 35,1 27,9 19,0 15/16

18MO-2-8RT 18 1/2 39,8 36,8 29,7 19,0 1-1/16

18MO-2-12RT 18 3/4 39,8 36,8 29,7 19,0 1-1/16

20MO-2-12RT 20 3/4 44,6 41,7 34,5 19,0 1-3/8

25MO-2-12RT 25 3/4 49,0 41,7 36,8 19,1 1-3/8

25MO-2-16RT 25 1 49,1 46,5 36,8 23,9 1-3/8

TUBE

BSPT

O.D.

THREAD C H L R

MILLIMETERS INCHES

W

HEX

Color Coding

For easy reference, table

column headings are color

indicated as follows:

fractional

metric

17

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Tube to Male Pipe

Catalog 4230/4233

NPT Male

45° Elbow

For fractional tube

NPT Male

45° Elbow

For metric tube

CPI™

PART NO.

1-1 VBZ 1MVEL1N

2-2 VBZ 2MVEL2N

3-2 VBZ 3MVEL2N

4-2 VBZ 4MVEL2N

4-4 VBZ 4MVEL4N

5-2 VBZ 5MVEL2N

6-2 VBZ 6MVEL2N

6-4 VBZ 6MVEL4N

6-6 VBZ 6MVEL6N

8-6 VBZ 8MVEL6N

10-8 VBZ 10MVEL8N

12-12 VBZ 12MVEL12N

14-12 VBZ 14MVEL12N

16-16 VBZ 16MVEL16N

NOTE: C dimension is typical finger-tight. Dimensions for reference only, subject to change.

CPI™

PART NO.

VBZ 6-1/8 M6MVEL1/8N

VBZ 6-1/4 M6MVEL1/4N

VBZ 8-1/8 M8MVEL1/8N

VBZ 10-1/4 M10MVEL1/4N

VBZ 12-3/8 M12MVEL3/8N

VBZ 12-1/2 M12MVEL1/2N

VBZ 16-1/2 M16MVEL1/2N

NOTE: C dimension is typical finger-tight. Dimensions for reference only, subject to change.

A-LOK®

PART NO.

A-LOK®

PART NO.

INTER-

CHANGES

WITH

100-5-1 1/16 1/16 0.43 0.47 0.57 .38 7/16

200-5-2 1/8 1/8 0.60 0.53 0.57 .38 7/16

300-5-2 3/16 1/8 0.64 0.56 0.58 .38 7/16

400-5-2 1/4 1/8 0.70 0.66 0.66 .38 9/16

400-5-4 1/4 1/4 0.70 0.66 0.86 .56 9/16

500-5-2 5/16 1/8 0.73 0.66 0.66 .38 9/16

600-5-2 3/8 1/8 0.76 0.72 0.67 .38 9/16

600-5-4 3/8 1/4 0.76 0.72 0.86 .56 9/16

600-5-6 3/8 3/8 0.76 0.75 0.95 .56 3/4

810-5-6 1/2 3/8 0.87 0.75 0.95 .56 3/4

1010-5-8 5/8 1/2 0.87 0.84 1.20 .75 1-1/16

1210-5-12 3/4 3/4 0.87 0.84 1.20 .75 1-1/16

1410-5-8 7/8 3/4 0.87 1.36 1.27 .75 1-5/16

1610-5-8 1 1 1.05 1.19 1.14 .94 1-5/16

INTER-

CHANGES

TUBE

NPT PIPE

O.D.

THREAD C L P R

TUBE

WITH

– 6 1/8 17,7 16,0 16,8 9,5 14,0

– 6 1/4 17,7 16,0 21,8 14,3 14,0

– 8 1/8 18,6 16,8 16,8 9,5 14,0

– 10 1/4 19,5 19,0 24,1 14,3 19,0

– 12 3/8 22,0 19,0 24,1 14,3 19,0

– 12 1/2 22,0 20,6 29,7 19,0 22,0

– 16 1/2 22,0 20,6 29,7 19,0 22,0

NPT PIPE

O.D.

THREAD C L P R

INCHES

W

HEX

MILLIMETERS

W

HEX

18

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Catalog 4230/4233

Tube to Male Pipe

NPT Male

Run Tee

For fractional tube

NPT Male

Run Tee

For metric tube

CPI™

PART NO.

2-2-2 RBZ 2MRT2N

2-4-2 RBZ 2MRT4N

3-2-3 RBZ 3MRT2N

4-2-4 RBZ 4MRT2N

4-4-4 RBZ 4MRT4N

5-2-5 RBZ 5MRT2N

5-4-5 RBZ 5MRT4N

6-4-6 RBZ 6MRT4N

6-6-6 RBZ 6MRT6N

8-6-8 RBZ 8MRT6N

8-8-8 RBZ 8MRT8N

10-8-10 RBZ 10MRT8N

12-12-12 RBZ 12MRT12N

14-12-14 RBZ 14MRT12N

16-12-16 RBZ 16MRT12N

16-16-16 RBZ 16MRT16N

NOTE: A and C dimensions are typical finger-tight. Dimensions for reference only, subject to change.

CPI™

PART NO.

RBZ 6-1/8-6 M6MRT1/8N

RBZ 6-1/4-6 M6MRT1/4N

RBZ 8-1/8-8 M8MRT1/8N

RBZ 8-1/4-8 M8MRT1/4N

RBZ 10-1/4-10 M10MRT1/4N

RBZ 10-1/2-10 M10MRT1/2N

RBZ 12-1/4-12 M12MRT1/4N

RBZ 12-3/8-12 M12MRT3/8N

RBZ 12-1/2-12 M12MRT1/2N

RBZ 16-1-16 M16MRT1N

NOTE: A and C dimensions are typical finger-tight. Dimensions for reference only, subject to change.

A-LOK®

PART NO.

A-LOK®

PART NO.

INTER-

CHANGES

WITH

200-3-2TMT 1/8 1/8 1.63 0.93 0.71 0.66 .38 7/16

200-3-4TMT 1/8 1/4 1.89 0.97 0.93 0.70 .56 9/16

300-3-2TMT 3/16 1/8 1.66 0.96 0.70 0.70 .38 7/16

400-3-2TMT 1/4 1/8 1.80 1.06 0.74 0.77 .38 1/2

400-3-4TMT 1/4 1/4 1.98 1.06 0.93 0.77 .56 1/2

500-3-2TMT 5/16 1/8 1.99 1.17 0.82 0.88 .38 5/8

500-3-4TMT 5/16 1/4 2.18 1.17 1.01 0.88 .56 5/8

600-3-4TMT 3/8 1/4 2.20 1.20 1.01 0.91 .56 5/8

600-3-6TMT 3/8 3/8 2.42 1.31 1.12 1.02 .56 13/16

810-3-6TMT 1/2 3/8 2.53 1.42 1.12 1.02 .56 13/16

810-3-8TMT 1/2 1/2 2.72 1.42 1.31 1.02 .75 7/8

1010-3-8TMT 5/8 1/2 2.88 1.50 1.39 1.10 .75 15/16

1210-3-12TMT 3/4 3/4 3.02 1.57 1.46 1.17 .75 1-1/16

1410-3-12TMT 7/8 3/4 3.41 1.76 1.65 1.36 .75 1-3/8

1610-3-12TMT 1 3/4 3.59 1.94 1.65 1.45 .75 1-3/8

1610-3-16TMT 1 1 3.78 1.94 1.84 1.45 .94 1-3/8

INTER-

CHANGES

WITH

6MO-3-2TMT 6 1/8 45,8 27,0 18,0 19,6 9,7 1/2

6MO-3-4TMT 6 1/4 50,3 27,0 23,4 19,6 14,2 1/2

8MO-3-2TMT 8 1/8 50,7 29,9 20,8 22,4 9,7 5/8

8MO-3-4TMT 8 1/4 55,3 29,9 25,4 22,4 14,2 5/8

10MO-3-4TMT 10 1/4 61,7 33,5 28,2 25,9 14,2 13/16

10MO-3-8TMT 10 1/2 66,5 33,5 33,0 25,9 19,0 13/16

12MO-3-4TMT 12 1/4 64,2 36,0 28,2 25,9 14,2 13/16

12MO-3-6TMT 12 3/8 64,2 36,0 28,2 25,9 14,2 13/16

12MO-3-8TMT 12 1/2 69,0 36,0 33,0 25,9 19,0 13/16

16MO-3-16TMT 16 1 93,1 46,6 46,5 34,4 23,9 1-3/8

NPT

TUBE

PIPE

O.D.

THREAD A C H L R

TUBE

NPT

O.D.

THREAD A C H L R

INCHES

W

HEX

MILLIMETERS INCHES

W

HEX

Color Coding

For easy reference, table

column headings are color

indicated as follows:

fractional

metric

19

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Tube to Male Pipe

NPT Male

Branch Tee

For fractional tube

Catalog 4230/4233

NPT Male

Branch Tee

For metric tube

CPI™

PART NO.

2-2-2 SBZ 2MBT2N

2-2-4 SBZ 2MBT4N

3-3-2 SBZ 3MBT2N

4-4-2 SBZ 4MBT2N

4-4-4 SBZ 4MBT4N

5-5-2 SBZ 5MBT2N

5-5-4 SBZ 5MBT4N

6-6-4 SBZ 6MBT4N

6-6-6 SBZ 6MBT6N

8-8-6 SBZ 8MBT6N

8-8-8 SBZ 8MBT8N

10-10-8 SBZ 10MBT8N

12-12-12 SBZ 12MBT12N

14-14-12 SBZ 14MBT12N

16-16-12 SBZ 16MBT12N

16-16-16 SBZ 16MBT16N

NOTE: A and C dimensions are typical finger-tight. Dimensions for reference only, subject to change.

A-LOK®

PART NO.

INTER-

CHANGES

WITH

200-3-2TTM 1/8 1/8 1.84 0.92 0.70 0.66 .38 7/16

200-3-4TTM 1/8 1/4 1.96 0.98 0.93 0.72 .56 1/2

300-3-2TTM 3/16 1/8 2.00 1.00 0.74 0.74 .38 1/2

400-3-2TTM 1/4 1/8 2.12 1.06 0.74 0.77 .38 1/2

400-3-4TTM 1/4 1/4 2.12 1.07 0.93 0.77 .56 1/2

500-3-2TTM 5/16 1/8 2.34 1.17 0.82 0.88 .38 5/8

500-3-4TTM 5/16 1/4 2.34 1.17 1.01 0.88 .56 5/8

600-3-4TTM 3/8 1/4 2.40 1.20 1.01 0.91 .56 5/8

600-3-6TTM 3/8 3/8 2.62 1.31 1.12 1.02 .56 13/16

810-3-6TTM 1/2 3/8 2.84 1.42 1.12 1.02 .56 13/16

810-3-8TTM 1/2 1/2 2.86 1.43 1.31 1.03 .75 7/8

1010-3-8TTM 5/8 1/2 2.86 1.53 1.42 1.13 .75 1

1210-3-12TTM 3/4 3/4 3.14 1.57 1.46 1.17 .75 1-1/16

1410-3-12TTM 7/8 3/4 3.52 1.76 1.65 1.36 .75 1-3/8

1610-3-12TTM 1 3/4 3.88 1.94 1.65 1.45 .75 1-3/8

1610-3-16TTM 1 1 3.88 1.94 1.84 1.45 .94 1-3/8

NPT

TUBE

PIPE

O.D.

THREAD A C H L R

INCHES

W

HEX

CPI™

PART NO.

SBZ 6-6-1/8 M6MBT1/8N

SBZ 6-6-1/4 M6MBT1/4N

SBZ 8-8-1/8 M8MBT1/8N

SBZ 8-8-1/4 M8MBT1/4N

SBZ 10-10-1/4 M10MBT1/4N

SBZ 10-10-3/8 M10MBT3/8N

SBZ 12-12-1/4 M12MBT1/4N

SBZ 12-12-3/8 M12MBT3/8N

SBZ 12-12-1/2 M12MBT1/2N

SBZ 16-16-1/2 M16MBT1/2N

NOTE: A and C dimensions are typical finger-tight. Dimensions for reference only, subject to change.

A-LOK

PART NO.

®

INTER-

CHANGES

WITH

6MO-3TTM 6 1/8 53,9 27,0 18,8 19,6 9,7 1/2

6MO-3-4TTM 6 1/4 53,9 27,0 23,4 19,6 14,2 1/2

6MO-3-2TTM 8 1/8 59,7 29,9 20,8 22,4 9,7 5/8

8MO-3-4TTM 8 1/4 59,7 29,9 25,4 22,4 14,2 5/8

10MO-3-4TTM 10 1/4 67,0 33,5 28,2 25,9 14,2 13/16

10MO-3-6TTM 10 3/8 67,0 33,5 28,2 25,9 14,2 13/16

12MO-3-4TTM 12 1/4 72,0 36,0 28,2 25,9 14,2 13/16

12MO-3-6TTM 12 3/8 72,0 36,0 28,2 25,9 14,2 13/16

12MO-3-8TTM 12 1/2 72,0 36,0 33,0 25,9 19,0 13/16

16MO-3-8TTM 16 1/2 77,6 38,8 35,8 28,7 19,1 1

TUBE

NPT

O.D.

THREAD A C H L R

20

MILLIMETERS INCHES

W

HEX

Parker Hannifin Corporation

Instrumentation Products Division

Huntsville, AL USA

http://www.parker.com/ipdus

Catalog 4230/4233

Tube to Female Pipe

NPT Female

Connector

For fractional tube

CPI™

PART NO.

1-1 GBZ 1FSC1N

1-2 GBZ 1FSC2N

2-2 GBZ 2FSC2N

2-4 GBZ 2FSC4N

3-2 GBZ 3FSC2N

3-4 GBZ 3FSC4N

4-2 GBZ 4FSC2N

4-4 GBZ 4FSC4N

4-6 GBZ 4FSC6N

4-8 GBZ 4FSC8N

5-2 GBZ 5FSC2N

5-4 GBZ 5FSC4N

5-6 GBZ 5FSC6N

6-2 GBZ 6FSC2N

6-4 GBZ 6FSC4N

6-6 GBZ 6FSC6N

6-8 GBZ 6FSC8N

6-12 GBZ 6FSC12N

8-4 GBZ 8FSC4N

8-6 GBZ 8FSC6N

8-8 GBZ 8FSC8N

8-12 GBZ 8FSC12N

10-6 GBZ 10FSC6N

10-8 GBZ 10FSC8N

10-12 GBZ 10FSC12N

12-8 GBZ 12FSC8N

12-12 GBZ 12FSC12N

14-12 GBZ 14FSC12N

16-12 GBZ 16FSC12N

16-16 GBZ 16FSC16N

20-20 GBZ 20FSC20N

24-24 GBZ 24FSC24N

32-32 GBZ 32FSC32N

NOTE: A and C dimensions are typical finger-tight. Dimensions for reference only, subject to change.

Sizes 20, 24, 32 require additional lubrication prior to assembly.

A-LOK®

PART NO.

INTER-

CHANGES

WITH

100-7-1 1/16 1/16 0.93 0.43 0.78 7/16

100-7-2 1/16 1/8 0.95 0.43 0.81 9/16

200-7-2 1/8 1/8 1.14 0.60 0.88 9/16

200-7-4 1/8 1/4 1.32 0.60 1.06 3/4

300-7-2 3/16 1/8 1.17 0.64 0.91 9/16

300-7-4 3/16 1/4 1.35 0.64 1.09 3/4

400-7-2 1/4 1/8 1.23 0.70 0.94 9/16

400-7-4 1/4 1/4 1.42 0.70 1.13 3/4

400-7-6 1/4 3/8 1.48 0.70 1.19 7/8

400-7-8 1/4 1/2 1.67 0.70 1.38 1-1/16

500-7-2 5/16 1/8 1.27 0.73 0.97 9/16

500-7-4 5/16 1/4 1.46 0.73 1.16 3/4

500-7-6 5/16 3/8 1.51 0.73 1.22 7/8

600-7-2 3/8 1/8 1.29 0.76 1.00 5/8

600-7-4 3/8 1/4 1.48 0.76 1.19 3/4

600-7-6 3/8 3/8 1.54 0.76 1.25 7/8

600-7-8 3/8 1/2 1.73 0.76 1.44 1-1/16

600-7-12 3/8 3/4 1.85 0.76 1.56 1-1/4

810-7-4 1/2 1/4 1.59 0.87 1.19 13/16

810-7-6 1/2 3/8 1.65 0.87 1.25 7/8

810-7-8 1/2 1/2 1.84 0.87 1.44 1-1/16

810-7-12 1/2 3/4 1.96 0.87 1.56 1-1/4

1010-7-6 5/8 3/8 1.65 0.87 1.25 15/16

1010-7-8 5/8 1/2 1.84 0.87 1.44 1-1/16

1010-7-12 5/8 3/4 1.96 0.87 1.56 1-3/8

1210-7-8 3/4 1/2 1.84 0.87 1.44 1-1/16

1210-7-12 3/4 3/4 1.96 0.87 1.56 1-3/8

1410-7-12 7/8 3/4 1.96 0.87 1.56 1-3/8

1610-7-12 1 3/4 2.15 1.05 1.66 1-3/8

1610-7-16 1 1 2.46 1.05 1.97 1-5/8

2010-7-20 1-1/4 1-1/4 2.94 1.52 2.08 2

2410-7-24 1-1/2 1-1/2 3.28 1.77 2.22 2-3/8

3210-7-32 2 2 4.00 2.47 2.53 2-7/8

TUBE

NPT PIPE

O.D.

THREAD A C D

INCHES

W

HEX

NPT Female

Connector

For metric tube

CPI™

PART NO.

GBZ 3-1/8 M3FSC1/8N

GBZ 3-1/4 M3FSC1/4N

GBZ 4-1/8 M4FSC1/8N

GBZ 6-1/8 M6FSC1/8N

GBZ 6-1/4 M6FSC1/4N

GBZ 6-3/8 M6FSC3/8N

GBZ 6-1/2 M6FSC1/2N

GBZ 8-1/8 M8FSC1/8N

GBZ 8-1/4 M8FSC1/4N

GBZ 8-3/8 M8FSC3/8N

GBZ 10-1/4 M10FSC1/4N

GBZ 10-3/8 M10FSC3/8N

GBZ 10-1/2 M10FSC1/2N

GBZ 12-1/4 M12FSC1/4N

GBZ 12-3/8 M12FSC3/8N

GBZ 12-1/2 M12FSC1/2N

GBZ 16-3/8 M16FSC3/8N

GBZ 16-1/2 M16FSC1/2N

GBZ 20-1/2 M20FSC1/2N

GBZ 20-3/4 M20FSC3/4N

GBZ 22-3/4 M22FSC3/4N

GBC 25-3/4 M25FSC3/4N

GBC 25-1 M25FSC1N

Dimensions for reference only, subject to change.

A-LOK®

PART NO.

INTER-

CHANGES

WITH

3MO-7-2 3 1/8 28,8 15,3 22,2 14,0

3MO-7-4 3 1/4 33,6 15,3 27,0 19,0

4MO-7-2 4 1/8 29,6 16,1 23,0 14,0

6MO-7-2 6 1/8 31,3 17,7 23,8 14,0

6MO-7-4 6 1/4 36,1 17,7 28,6 19,0

6MO-7-6 6 3/8 37,7 17,7 30,2 22,0

6MO-7-8 6 1/2 42,5 17,7 35,0 27,0

8MO-7-2 8 1/8 32,1 18,6 24,6 14,0

8MO-7-4 8 1/4 36,9 18,6 29,4 19,0

8MO-7-6 8 3/8 38,5 18,6 31,0 22,0

10MO-7-4 10 1/4 37,8 19,5 30,2 19,0

10MO-7-6 10 3/8 39,4 19,5 31,8 22,0

10MO-7-8 10 1/2 44,1 19,5 36,5 27,0

12MO-7-4 12 1/4 41,9 22,0 31,8 22,0

12MO-7-6 12 3/8 41,9 22,0 31,8 22,0

12MO-7-8 12 1/2 46,6 22,0 36,5 27,0

16MO-7-6 16 3/8 41,9 22,0 31,8 27,0

16MO-7-8 16 1/2 46,9 22,0 36,5 27,0

20MO-7-8 20 1/2 47,9 22,0 37,8 30,0