Page 1

Go to

Table of

Contents

Ball and Plug Valves

Catalog 4121-BV July 2014

Page 2

Go to

Table of

Contents

Parker Hannifin Corporation

Instrumentation Products Division

Jacksonville, AL USA

http://www.parker.com/ipdus

Page 3

Catalog 4121-BV

Table of Contents

Description ............................................................................................................ Page

B Series Ball Valves, 6,000 psi Maximum*

................................................................. 2

Two-Way ................................................................................................................2

Three-Way ............................................................................................................. 4

Go to

Table of

Contents

B

PR Series Rotary Plug Valves, 3,000 psi Maximum*

MB Series Ball Valves, 3,000 psi Maximum*

............................................................ 16

...............................................12

Two-Way In-Line ..................................................................................................17

Two-Way Angle .................................................................................................... 18

Three-Way ........................................................................................................... 18

Four-Way .............................................................................................................20

Five-Way .............................................................................................................. 20

HB Series Ball Valves, 10,000 psi Maximum*

MPB Series Ball Valves, 20,000 psi Maximum*

.......................................................... 22

.......................................................28

Two-Way ..............................................................................................................28

Three-Way ........................................................................................................... 29

SWB Series Ball Valves, 2,500 psi Maximum*

Pneumatic Actuators

.................................................................................................38

......................................................... 32

61 Model .............................................................................................................. 39

62, 63, 64, 65, 66, 68, and 69 Models ................................................................. 39

90° Models (AC, AO and AD) ..............................................................................41

180° Models (ACX and ADX) ............................................................................... 42

Electric Actuators

...................................................................................................... 44

70 Series .............................................................................................................45

80 Series .............................................................................................................46

90 Series .............................................................................................................47

PR

MB

HB

MPB

SWB

Pneu

Act

Elec

Act

B12 Series Ball Valves, 4,000 psi Maximum*

Available End Connections

Offer of Sale

* Actual pressure rating will be determined by the valve configuration, such as body material, seat material, etc.

Contact the factory for more information.

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND

PROPERTY DAMAGE.

This document and other information from Parker-Hannifin Corporation, its subsidiaries and authorized distributors provide product or system options for further investigation by users

having technical expertise.

The user, through its own analysis and testing, is solely responsible for making the final selection of the system and components and assuring that all performance, endurance,

maintenance, safety and warning requirements of the application are met. The user must analyze all aspects of the application, follow applicable industry standards, and follow the

information concerning the product in the current product catalog and in any other materials provided from Parker or its subsidiaries or authorized distributors.

To the extent that Parker or its subsidiaries or authorized distributors provide component or system options based upon data or specifications provided by the user, the user is responsible

for determining that such data and specifications are suitable and sufficient for all applications and reasonably foreseeable uses of the components or systems.

The items described in this document are hereby offered for sale by Parker-Hannifin Corporation, its subsidiaries or its authorized distributors. This offer and its acceptance are governed by

the provisions stated in the detailed “Offer of Sale” elsewhere in this document or available at www.parker.com/ipdus.

© Copyright 2014 Parker Hannifin Corporation. All Rights Reserved.

...............................................................................................................55

......................................................................................54

WARNING – USER RESPONSIBILITY

........................................................... 52

Offer of Sale

1

Parker Hannifin Corporation

Instrumentation Products Division

Jacksonville, AL USA

http://www.parker.com/ipdus

B12

End

Conn

Page 4

Two-Way B Series Ball Valves

Catalog 4121-BV

Introduction

B

Parker manually, pneumatically, and electrically actuated two-way B Series Ball Valves provide quick 1/4 turn

on-off control of fluids utilized in process and instrumentation applications. A broad selection of valve body, seat,

and seal materials provide a wide range of pressures and temperatures at which the valve may be used.

Go to

Table of

Contents

Features

Free floating ball design provides seat wear

compensation.

Available in 316 stainless steel and brass

construction. Monel® Alloy 400 and Hastelloy®

C-276 construction available upon request.

Micro-finished ball provides a positive seal.

Straight through flow path for minimum

pressure drop.

Bi-directional flow.

Wide variety of US Customary and SI ports.

90° actuation.

Panel mountable.

Adjustable PTFE stem seal can be maintained

in-line.

Handle indicates flow direction.

Low operating torques.

Positive handle stops.

Color coded handles.

Optional pneumatic and electric actuation.

Optional live-loaded PTFE stem seals.

Optional non-adjustable O-ring stem seals.

Optional upstream and downstream drain

models.

Optional stainless steel and extended handles.

Specifications

Pressure Ratings:

Material CWP with PTFE Seats

316 Stainless Steel 6000 psig (414 bar)* 1500 psig (103 bar)

Brass 3000 psig (207 bar) 1500 psig (103 bar)

®

Monel

Alloy 400

B2 and B6:

B8:

Hastelloy

B2 and B6:

B8:

* B6 Series: 6000 psig rating or 4400 psig (303 bar) CWP

®

C-276

B8 Series: 6000 psig rating or 4000 psig (276 bar) CWP

Pressure Rating and Tubing Selection

For working pressures of A-LOK® and CPI™ tube connections,

please see the Instrument Tubing Selection Guide (Bulletin

4200-TS), found in the Technical Section of the Parker

Instrumentation Process Control Binder, or the Parker

Instrument Fitting Installation Manual (Bulletin 4200-B4).

For working pressures of valves with external or internal pipe

threads, please see Catalog 4260, Instrumentation Pipe Fittings.

3000 psig (207 bar)

2000 psig (138 bar)

4000 psig (276 bar)

3000 psig (207 bar)

1500 psig (103 bar)

1500 psig (103 bar)

1500 psig (103 bar)

1500 psig (103 bar)

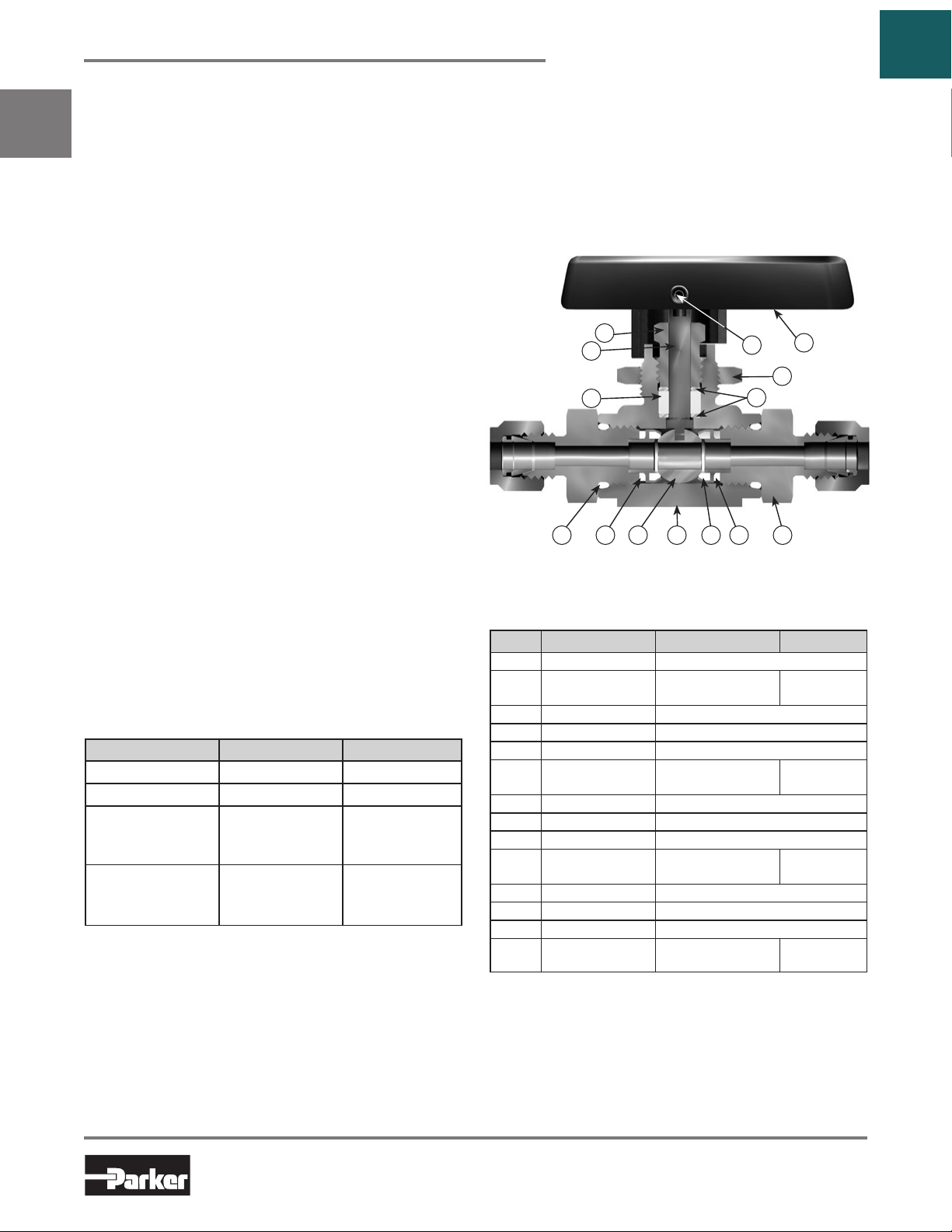

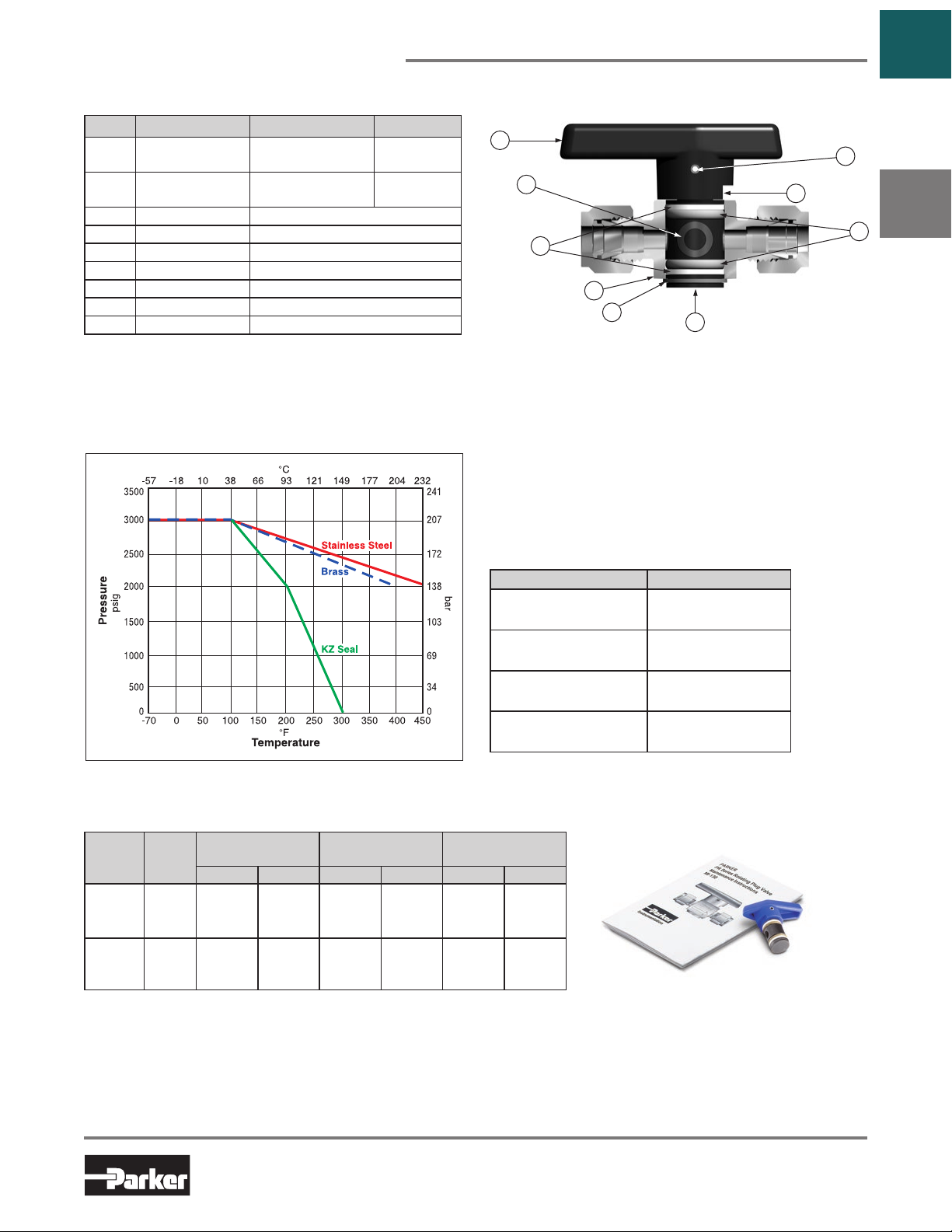

Materials of Construction

7

* 6A

* 6B

1 *

3 * 4 * 5 * 11 *

2B *

9

6C *

2A *

Model Shown: 6A-B6LJ-SSP

Materials of Construction

Item # Part Description Stainless Steel Brass

*1 Connector O-Ring PTFE**

*2A Seat Retainer

*2B Seat PTFE, PCTFE, PEEK

*3 Retainer Seal PTFE**

*4 Ball 316 Stainless Steel

*5 Body

*6A Stem ASTM A 276 Type 316

*6B Stem Seal PTFE**

*6C Stem Washer 316 Stainless Steel

7 Packing Nut

8 Handle Nylon 6/6

9 Handle Set Screw Stainless Steel

10 Panel Nut 316 Stainless Steel

*11 End Connector

* Wetted Parts.

** Optional stem seal and body seal materials are described in the How to

Order section.

Lubrication: Perfluorinated Polyether.

Hastelloy® is a registered trademark of Haynes International.

Monel® Alloy 400 is a registered trademark of Special Metals Corporation.

ASTM A 276

Type 316

ASTM A 351

Grade CF3M

ASTM A 479

Type 316

ASTM A 479

Type 316

8

10

ASTM B 16

Alloy C36000

ASTM B 283

Alloy C37700

ASTM B 453

Alloy C34000

ASTM B 16

Alloy C36000

2

Parker Hannifin Corporation

Instrumentation Products Division

Jacksonville, AL USA

http://www.parker.com/ipdus

Page 5

Catalog 4121-BV

Two-Way B Series Ball Valves

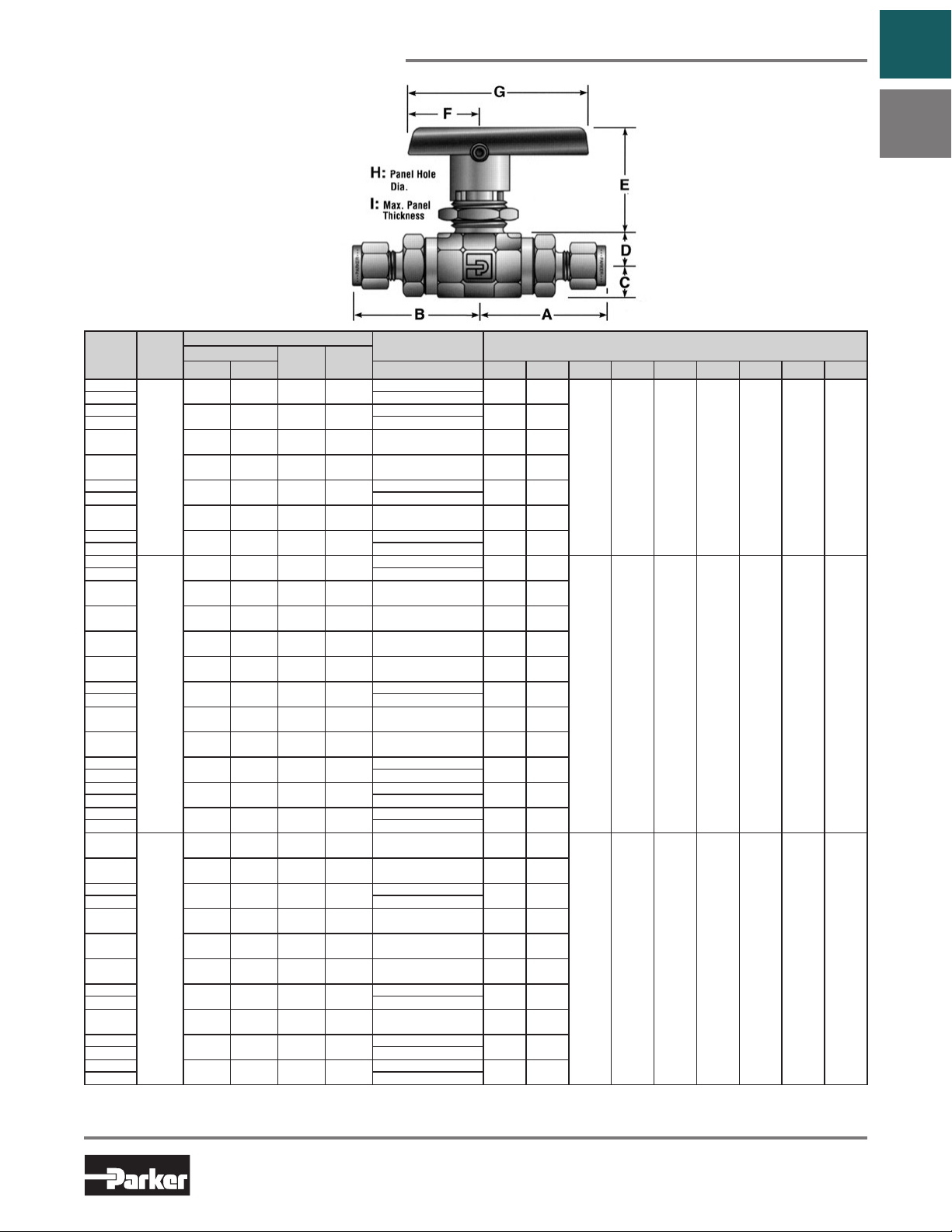

Dimensions & Flow Data

Flow Data

Port

Basic

Size

Part #

1A

1Z 1/16" CPI™

2A

2Z 1/8" CPI™

2F 0.165 4.2 0.93 0.43 1/8" Female NPT

2M 0.165 4.2 0.93 0.43 1/8" Male NPT

4A

4Z 1/4" CPI™

4M 0.165 4.2 0.93 0.43 1/4" Male NPT

M3A

M3Z 3mm CPI™

4A

4Z 1/4" CPI™

4F 0.250 6.4 2.34 0.29 1/4" Female NPT

4M 0.250 6.4 2.34 0.29 1/4" Male NPT

4Q 0.180 4.6 1.03 0.42 1/4" UltraSeal

4V 0.188 4.8 1.04 0.42 1/4" VacuSeal

6A

6Z 3/8" CPI™

6M 0.250 6.4 2.34 0.29 3/8" Male NPT

6Q 0.250 6.4 2.34 0.29 3/8" UltraSeal

M6A

M6Z 6mm CPI™

M8A

M8Z 8mm CPI™

M10A

M10Z 10mm CPI™

6F

8F 0.406 10.3 6.42 0.37 1/2" Female NPT

8A

8Z 1/2" CPI™

8M 0.406 10.3 6.42 0.37 1/2" Male NPT

8Q 0.375 9.5 5.57 0.37 1/2" UltraSeal

8V 0.406 10.3 6.42 0.37 1/2" VacuSeal

12A

12Z 3/4" CPI™

12F 0.406 10.3 6.42 0.37 3/4" Female NPT

M12A

M12Z 12mm CPI™

M16A

M16Z 16mm CPI™

0.052 1.3 0.06 0.45

0.093 2.4 0.21 0.47

B2L

0.165 4.2 0.93 0.43

0.086 2.2 0.18 0.44

0.187 4.7 1.04 0.42

B6L

0.250 6.4 2.34 0.29

0.187 4.7 1.04 0.42

0.250 6.4 2.34 0.42

0.250 6.4 2.34 0.42

0.406 10.3 6.42 0.37 3/8" Female NPT

0.406 10.3 6.42 0.37

B8L

0.406 10.3 6.42 0.37

0.375 9.5 5.57 0.37

0.406 10.3 6.42 0.37

Cv XT*Inch mm Port 1 Port 2 A† B† C D E F G H I

* Tested in accordance with ISA S75.02. Gas flow will be choked when P1- P2 / P1= xT.

† For CPI™ and A-LOK®, dimensions are measured with nuts in the finger tight position

End Connections

1/16" A-LOK

®

1/8" A-LOK

®

1/4" A-LOK

3mm A-LOK

®

1/4" A-LOK

®

3/8" A-LOK

6mm A-LOK

8mm A-LOK

10mm A-LOK

®

1/2" A-LOK

®

3/4" A-LOK

12mm A-LOK

16mm A-LOK

®

1.30

(33.0)

1.36

(34.5)

1.07

(27.2)

1.18

(30.0)

1.48

(37.6)

1.35

(34.3)

®

1.37

(34.8)

1.74

(44.2)

1.51

(38.4)

1.62

(41.1)

1.51

(38.4)

1.75

(44.5)

1.80

(45.7)

1.62

(41.1)

1.51

(38.4)

®

1.75

(44.5)

®

1.78

(45.2)

®

1.81

(46.0)

1.95

(49.5)

2.15

(54.6)

2.34

(59.4)

2.22

(56.4)

1.92

(48.8)

2.21

(56.1)

2.33

(59.2)

2.25

(57.1)

®

2.33

(59.2)

®

2.33

(59.2)

1.30

(33.0)

1.36

(34.5)

1.07

(27.2)

1.18

(30.0)

1.48

(37.6)

1.35

(34.3)

1.37

(34.8)

1.74

(44.2)

1.51

(38.4)

1.62

(41.1)

1.51

(38.4)

1.75

(44.5)

1.80

(45.7)

1.62

(41.1)

1.51

(38.4)

1.75

(44.5)

1.78

(45.2)

1.81

(46.0)

1.95

(49.5)

2.15

(54.6)

2.34

(59.4)

2.22

(56.4)

1.92

(48.8)

2.21

(56.1)

2.33

(59.2)

2.25

(57.1)

2.33

(59.2)

2.33

(59.2)

0.33

(8.4)

0.42

(10.7)

0.69

(17.5)

Model Shown:

4A-B6LJ-SSP

Dimensions

Inches (mm)Orifice

0.33

0.94

(8.4)

(23.9)

0.47

1.53

(11.9)

(38.9)

0.70

1.74

(17.8)

(44.2)

Dimensions in inches/millimeters are

for reference only, subject to change.

0.75

(19.1)

1.00

(25.4)

1.50

(38.1)

1.88

(47.8)

2.50

(63.5)

4.00

(101.6)

0.58

(14.7)

0.77

(19.6)

0.90

(22.9)

Go to

Table of

Contents

B

0.13

(3.3)

0.25

(6.4)

0.38

(9.7)

3

Parker Hannifin Corporation

Instrumentation Products Division

Jacksonville, AL USA

http://www.parker.com/ipdus

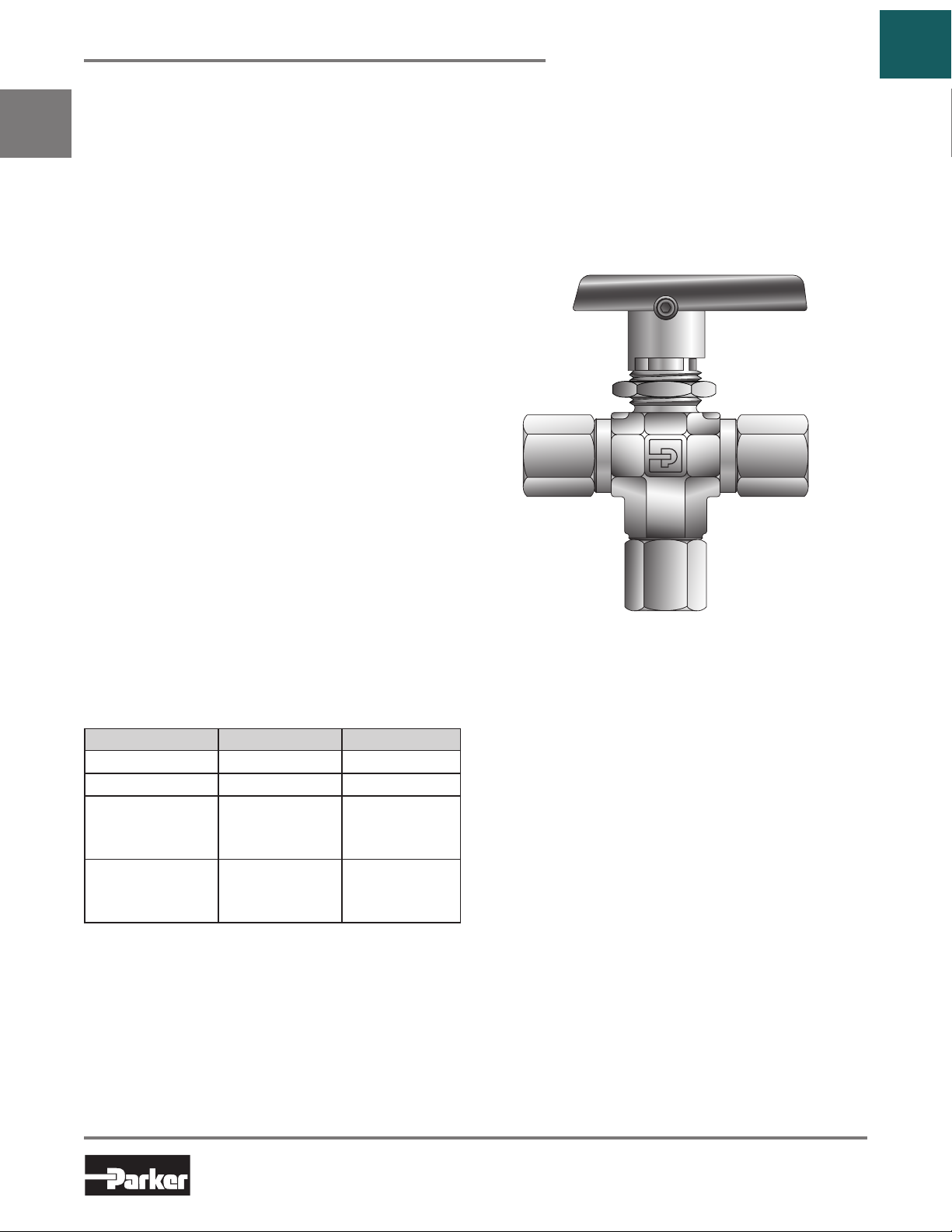

Page 6

Three-Way B Series Ball Valves

Catalog 4121-BV

Introduction

B

Parker manually, pneumatically, and electrically actuated three-way B Series Ball Valves may be used as diverting

or selecting valves for fluids utilized in process and instrumentation applications. The standard three-way diverter

valve is designed to accept media through the bottom port and direct it out of two outlet ports. When equipped

with spring-loaded seats, the three-way valve may be used as a selector valve, alternately accepting media from

either of two inlet sources (side ports) and directing it through a single outlet (bottom port).

Features

Available in 316 stainless steel and brass

construction. Monel® Alloy 400 and Hastelloy®

C-276 construction available for Diverter Valves

upon request.

Micro-finished ball provides a positive seal.

Wide variety of US Customary and SI ports.

180 degree actuation.

Panel mountable.

Adjustable PTFE stem seal can be maintained

in-line.

Handle indicates flow direction.

Low operating torques.

Positive handle stops.

Color coded handles.

Optional pneumatic and electric actuation.

Optional live-loaded PTFE stem seals.

Optional non-adjustable O-ring stem seals.

Optional stainless steel and extended handles.

Model Shown:

4F-B6XJ2-BP

Go to

Table of

Contents

Diverter Valve Specifications

Pressure Ratings with bottom port as inlet:

Material CWP with PTFE Seats

316 Stainless Steel 6000 psig (414 bar)* 1500 psig (103 bar)

Brass 3000 psig (207 bar) 1500 psig (103 bar)

®

Monel

Alloy 400

B2 and B6: 3000 psig (207 bar) 1500 psig (103 bar)

B8: 2000 psig (138 bar) 1500 psig (103 bar)

Hastelloy

B2 and B6: 4000 psig (276 bar) 1500 psig (103 bar)

B8: 3000 psig (207 bar) 1500 psig (103 bar)

* B6 Series: 6000 psig rating or 4400 psig (303 bar) CWP

Pressure Rating and Tubing Selection

For working pressures of A-LOK® and CPI™ tube connections,

Pressure Rating with side ports as inlet:

150 psig (10 bar)

®

C-276

B8 Series: 6000 psig rating or 4000 psig (276 bar) CWP

Selector Valve Specifications

(Spring Loaded – B6 and B8 models only)

Pressure Rating with bottom port as inlet:

316 Stainless Steel ................... 6000 psig (414 bar) CWP*

Brass ..........................................3000 psig (207 bar) CWP

Pressure Rating with side ports as inlet:

316 Stainless Steel and Brass ....3000 psig (207 bar) CWP

Pressure Rating and Tubing Selection

For working pressures of A-LOK® and CPI™ tube

connections, please see the Instrument Tubing Selection

Guide (Bulletin 4200-TS), found in the Technical Section

of the Parker Instrumentation Process Control Binder, or

the Parker Instrument Fitting Installation Manual (Bulletin

4200-B4).

For working pressures of valves with external or internal

pipe threads, please see Catalog 4260, Instrumentation Pipe

Fittings.

4

Parker Hannifin Corporation

Instrumentation Products Division

Jacksonville, AL USA

http://www.parker.com/ipdus

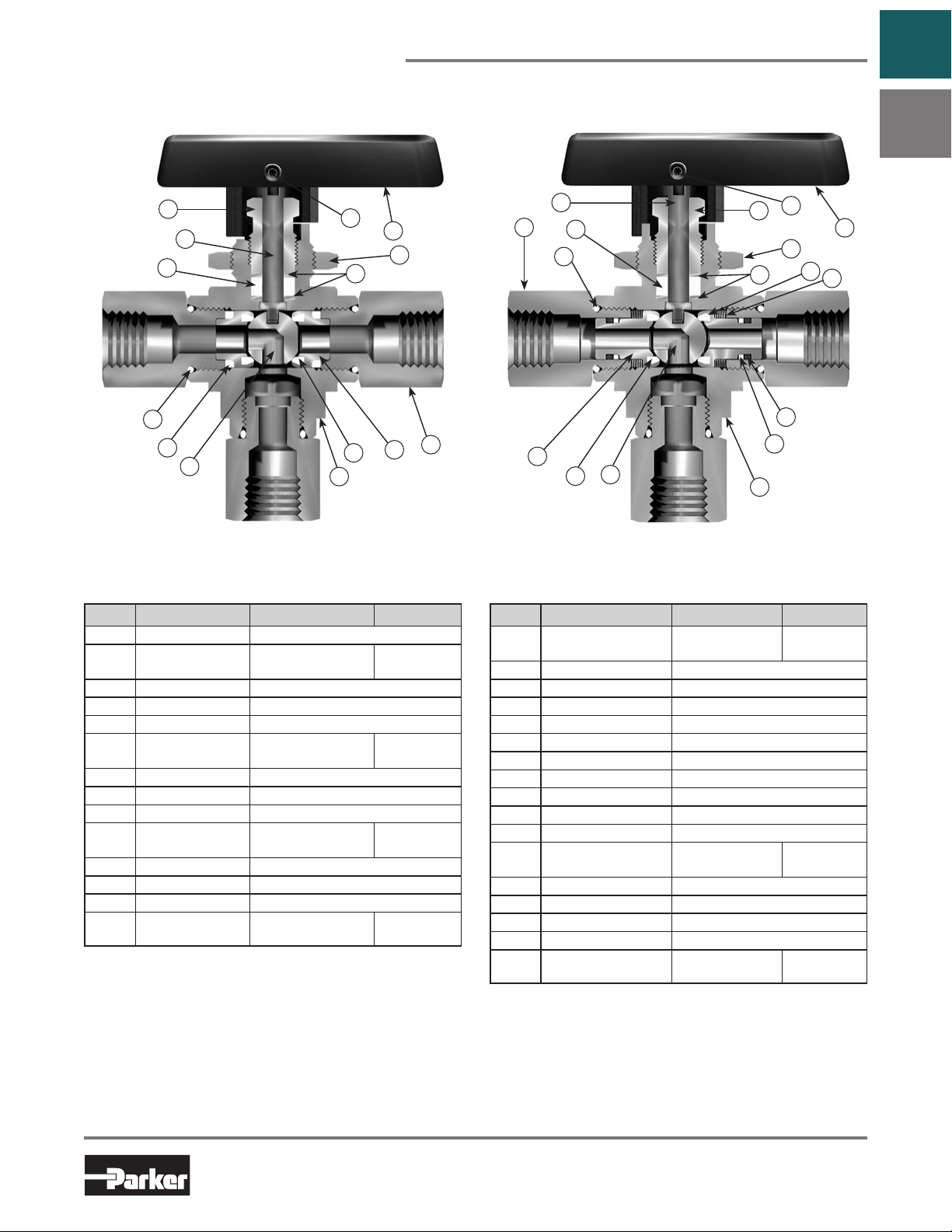

Page 7

Catalog 4121-BV

Three-Way B Series Ball Valves

Diverter Valve Selector Valve

Go to

Table of

Contents

B

7

6A *

6B *

1 *

3 *

4 *

5 *

9

6C *

2B *

8

10

2A *

11 *

Model Shown: 4F-B6XJ-SSP Model Shown: 4F-B6XS2-SSP

Materials of Construction

Item # Part Description Stainless Steel Brass

*1 Connector O-Ring PTFE**

*2A Seat Retainer

ASTM A 276

Type 316

*2B Seat PTFE, PCTFE, PEEK

*3 Retainer Seal PTFE**

*4 Ball 316 Stainless Steel

*5 Body

ASTM A 351

Grade CF3M

*6A Stem ASTM A 276 Type 316

*6B Stem Seal PTFE**

*6C Stem Washer 316 Stainless Steel

7 Packing Nut

ASTM A 479

Type 316

8 Handle Nylon 6/6

9 Handle Set Screw Stainless Steel

10 Panel Nut 316 Stainless Steel

*11 End Connector

* Wetted Parts.

** Optional stem seal and body seal materials are described in the How to

Order section.

Lubrication: Perfluorinated Polyether.

ASTM A 479

Type 316

ASTM B 16

Alloy C36000

ASTM B 283

Alloy C37700

ASTM B 453

Alloy C34000

ASTM B 16

Alloy C36000

15 *

3 *

9A *

7 *

9B *

2 *

14 *

10

9C *

1 *

6 *

13

11

8 *

4 *

12

5 *

Materials of Construction

Item # Part Description Stainless Steel Brass

1 Body

ASTM A 351

Grade CF3M

*2 Seat PTFE, PEEK

*3 Seat Retainer ASTM A 276 Type 316

4 Spring Stainless Steel

*5 Seat Retainer Washer 316 Stainless Steel

*6 Back-up Ring PTFE

*7 Connector O-Ring PTFE**

*8 Seat Retainer O-Ring Fluorocarbon Rubber**

*9A Stem ASTM A 276 Type 316

*9B Stem Seal PTFE*

*9C Stem Washer 316 Stainless Steel***

10 Packing Nut

ASTM A 479

Type 316

11 Panel Nut 316 Stainless Steel

12 Handle Nylon 6/6

13 Handle Set Screw Stainless Steel

*14 Ball 316 Stainless Steel

*15 End Connector

* Wetted Parts.

** Optional stem seal and body seal materials are described in the How to

Order section.

Lubrication: Perfluorinated Polyether.

***The lower stem washer material is PEEK for B8 Selector Valves.

Lubrication: Perfluorinated polyether.

ASTM A 479

Type 316

ASTM B 283

Alloy C37700

ASTM B 453

Alloy C34000

ASTM B 16

Alloy C36000

5

Parker Hannifin Corporation

Instrumentation Products Division

Jacksonville, AL USA

http://www.parker.com/ipdus

Page 8

Three-Way B Series Ball Valves

Dimensions & Flow Data

B

Model Shown:

4Z-B6XSPKR-V-SSP

Catalog 4121-BV

Go to

Table of

Contents

Flow Data

Port

Basic

Size

Part #

1A

1Z 1/16" CPI™

2A

2Z 1/8" CPI™

2F 0.165 4.2 0.63 0.59 1/8" Female NPT

2M 0.165 4.2 0.63 0.59 1/8" Male NPT

4A

4Z 1/4" CPI™

4M 0.165 4.2 0.63 0.59 1/4" Male NPT

M3A

M3Z 3mm CPI™

4A

4Z

4F 0.196 5.0 0.87 0.74 1/4" Female NPT

4M 0.196 5.0 0.87 0.74 1/4" Male NPT

4Q 0.180 4.6 0.68 0.67 1/4" UltraSeal

4V 0.188 4.8 0.70 0.69 1/4" VacuSeal

6A

6Z 3/8" CPI™

6M 0.196 5.0 0.87 0.74 3/8" Male NPT

6Q 0.196 5.0 0.87 0.74 3/8" UltraSeal

M6A

M6Z 6mm CPI™

M8A

M8Z 8mm CPI™

M10A

M10Z 10mm CPI™

6F

8A

8Z 1/2" CPI™

8F 0.406 10.3 3.62 0.64 1/2" Female NPT

8M 0.406 10.3 3.62 0.64 1/2" Male NPT

8Q 0.375 9.5 3.46 0.62 1/2" UltraSeal

8V 0.406 10.3 3.62 0.64 1/2" VacuSeal

12A

12Z 3/4" CPI™

12F 0.406 10.3 6.42 0.37 3/4" Female NPT

M12A

M12Z 12mm CPI™

M16A

M16Z 16mm CPI™

0.052 1.3 0.06 0.56

0.093 2.4 0.21 0.64

B2X

0.165 4.2 0.63 0.59

0.086 2.2 0.18 0.63

0.187 4.7 0.70 0.69

0.196 5.0 0.87 0.74

B6X

0.187 4.7 0.70 0.69

0.196 5.0 0.87 0.74

0.196 5.0 0.87 0.74

0.406 10.3 3.62 0.64 3/8" Female NPT

0.406 10.3 3.62 0.64

B8X

0.406 10.3 3.62 0.64

0.375 9.5 3.46 0.62

0.406 10.3 3.62 0.64

Cv X

*Inch mm

T

End Connections

Port 1 Port 2 Port 3 A† B† C D E F G H I

10mm A-LOK

12mm A-LOK

16mm A-LOK

1/16" A-LOK

1/8" A-LOK

1/4" A-LOK

3mm A-LOK

1/4" A-LOK

1/4" CPI™

3/8" A-LOK

6mm A-LOK

8mm A-LOK

1/2" A-LOK

3/4" A-LOK

®

®

®

®

®

®

®

®

®

®

®

®

®

1.30

(33.0)

1.36

(34.5)

1.07

(27.2)

1.18

(30.0)

1.48

(37.6)

1.35

(34.3)

1.37

(34.8)

1.74

(44.2)

1.51

(38.4)

1.62

(41.1)

1.51

(31.8)

1.75

(35.1)

1.80

(45.7)

1.62

(41.1)

1.52

(38.6)

1.75

(44.5)

1.78

(45.2)

1.81

(46.0)

1.95

(49.5)

2.34

(59.4)

2.15

(54.6)

2.22

(56.4)

1.93

(49.5)

2.21

(56.1)

2.33

(59.2)

2.25

(57.1)

2.33

(59.2)

2.33

(56.9)

1.30

(33.0)

1.36

(34.5)

1.07

(27.2)

1.18

(30.0)

1.48

(37.6)

1.35

(34.3)

1.37

(34.8)

1.74

(44.2)

1.51

(38.4)

1.62

(41.1)

1.51

(31.8)

1.75

(35.1)

1.80

(45.7)

1.62

(41.1)

1.52

(38.6)

1.75

(44.5)

1.78

(45.2)

1.81

(46.0)

1.95

(49.5)

2.34

(59.4)

2.15

(54.6)

2.22

(56.4)

1.93

(49.5)

2.21

(56.1)

2.33

(59.2)

2.25

(57.1)

2.33

(59.2)

2.33

(56.9)

* Tested in accordance with ISA S75.02. Gas flow will be choked when P1- P2 / P1= xT.

† For CPI™ and A-LOK®, dimensions are measured with nuts in the finger tight position

1.39

(35.3)

1.45

(36.8)

1.15

(29.2)

1.26

(32.0)

1.56

(39.6)

1.43

(36.3)

1.45

(36.8)

1.88

(47.8)

1.65

(41.9)

1.76

(44.7)

1.65

(33.8)

1.89

(37.1)

1.94

(49.3)

1.76

(44.7)

1.65

(41.9)

1.88

(47.8)

1.91

(48.5)

1.95

(49.5)

2.29

(58.2)

2.68

(68.1)

2.49

(63.2)

2.59

(65.8)

2.27

(57.7)

2.55

(65.0)

2.68

(68.1)

2.59

(65.8)

2.67

(67.8)

2.67

(65.5)

0.33

(8.4)

0.47

(11.9)

0.70

(17.8)

Dimensions

Inches (mm)Orifice

0.94

0.75

(19.1)

1.00

(25.4)

1.50

(38.1)

1.88

(47.8)

2.50

(63.5)

4.00

(101.6)

(23.9)

1.53

(38.9)

1.74

(44.2)

Dimensions in inches/millimeters are

for reference only, subject to change.

0.58

(14.7)

0.77

(19.6)

0.90

(22.9)

0.13

(3.3)

0.25

(6.4)

0.38

(9.7)

6

Parker Hannifin Corporation

Instrumentation Products Division

Jacksonville, AL USA

http://www.parker.com/ipdus

Page 9

Catalog 4121-BV

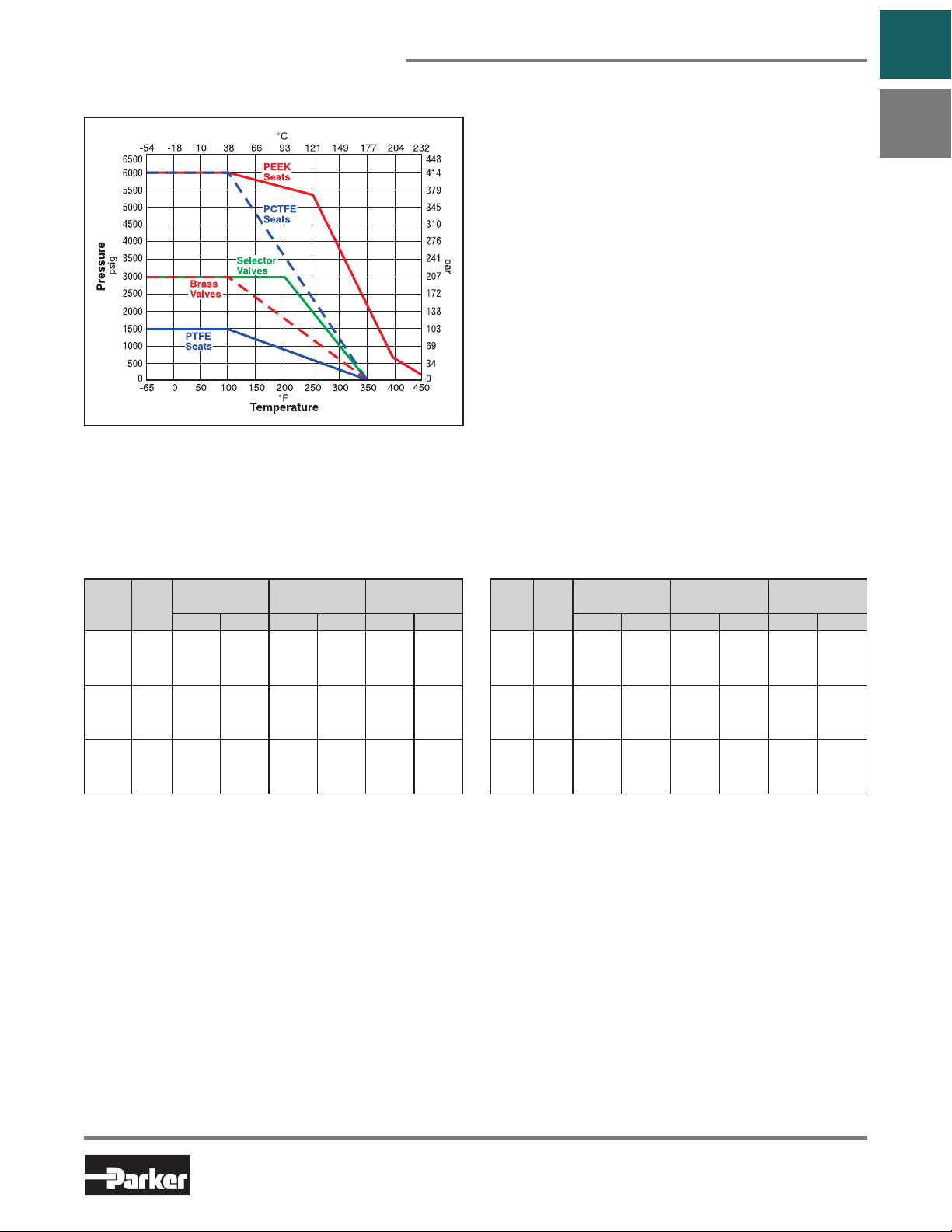

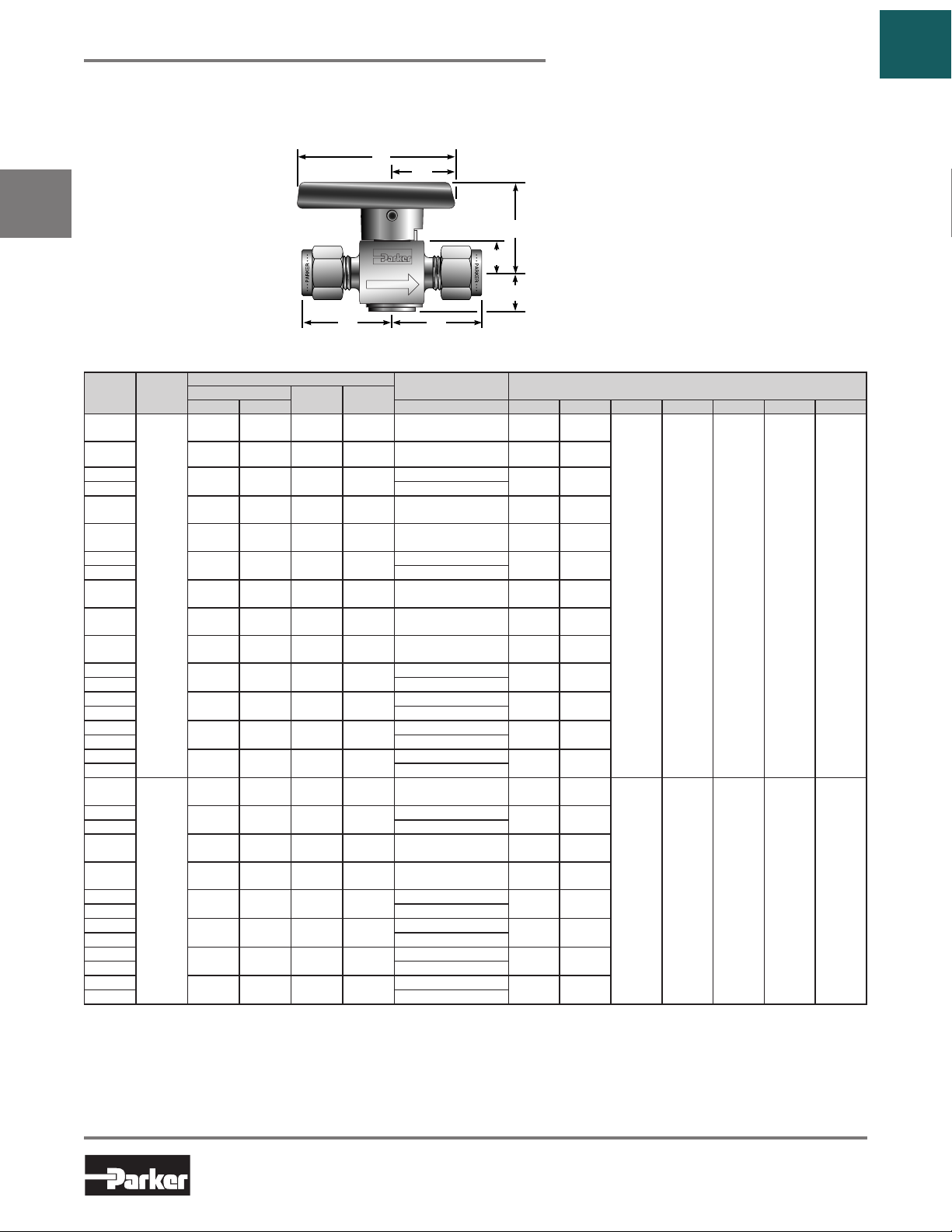

Pressure vs. Temperature

Note: To determine MPa, multiply bar by 0.1

B Series Ball Valves

Note: This Pressure versus Temperature chart

reflects the maximum temperature range of indicated

materials.

When combining seat and seal materials, the most

restrictive temperature rating of the seats or seals

becomes the limiting factor on valve temperature

range.

Elastomeric stem packing and seals are recommended

if the application subjects the valve to thermal cycling.

Please see pages 2 and 4 for maximum pressure ratings.

Temperature Ratings:

PTFE ................................... -65°F to 350°F (-54°C to 177°C)

................................. -65°F to 350°F (-54°C to 177°C)

PCTFE

PEEK

................................... -65°F to 450°F (-54°C to 232°C)

Nitrile Rubber....................... -40°F to 250°F (-40°C to 121°C)

Fluorocarbon Rubber ........... -15°F to 450°F (-26°C to 232°C)

Ethylene Propylene Rubber.... -65°F to 300°F (-54°C to 149°C)

Highly Fluorinated

Fluorocarbon Rubber ......... -15°F to 200°F (-26°C to 93°C)

Go to

Table of

Contents

B

Flow Calculations with 1000 psig (69 bar) Inlet Pressure

Two-Way Three-Way

Valve

Max.

Series

B2L 0.93

B6L 2.34

B8L 6.42

Pressure Drop

∆P

Cv

psig bar gpm m3/hr scfm m3/hr

10 0.7 2.9 0.7 92.4 156.2

50 3.5 6.6 1.5 200.3 338.3

100 6.9 9.3 2.1 272.0 458.9

10 0.7 7.4 1.7 231.7 391.5

50 3.5 16.5 3.8 494.2 834.7

100 6.9 23.4 5.3 657.0 1107.9

10 0.7 20.3 4.6 637.1 1076.8

50 3.5 45.4 10.3 1373.6 2320.3

100 6.9 64.2 14.6 1852.3 3124.8

Water

@ 60°F (16°C)

Air

@ 60°F (16°C)

Valve

Series

B2X 0.63

B6X 0.87

B8X 3.62

Pressure Drop

Max.

Cv

∆P

psig bar gpm m3/hr scfm m3/hr

10 0.7 2.0 0.5 62.7 106.0

50 3.5 4.5 1.0 137.1 231.7

100 6.9 6.3 1.4 188.4 317.9

10 0.7 2.8 0.6 86.7 146.6

50 3.5 6.2 1.4 190.5 321.8

100 6.9 8.7 2.0 263.2 444.4

10 0.7 11.5 2.6 360.6 609.5

50 3.5 25.6 5.9 789.7 1343.5

100 6.9 36.2 8.2 1087.4 1836.6

Water

@ 60°F (16°C)

Air

@ 60°F (16°C)

7

Parker Hannifin Corporation

Instrumentation Products Division

Jacksonville, AL USA

http://www.parker.com/ipdus

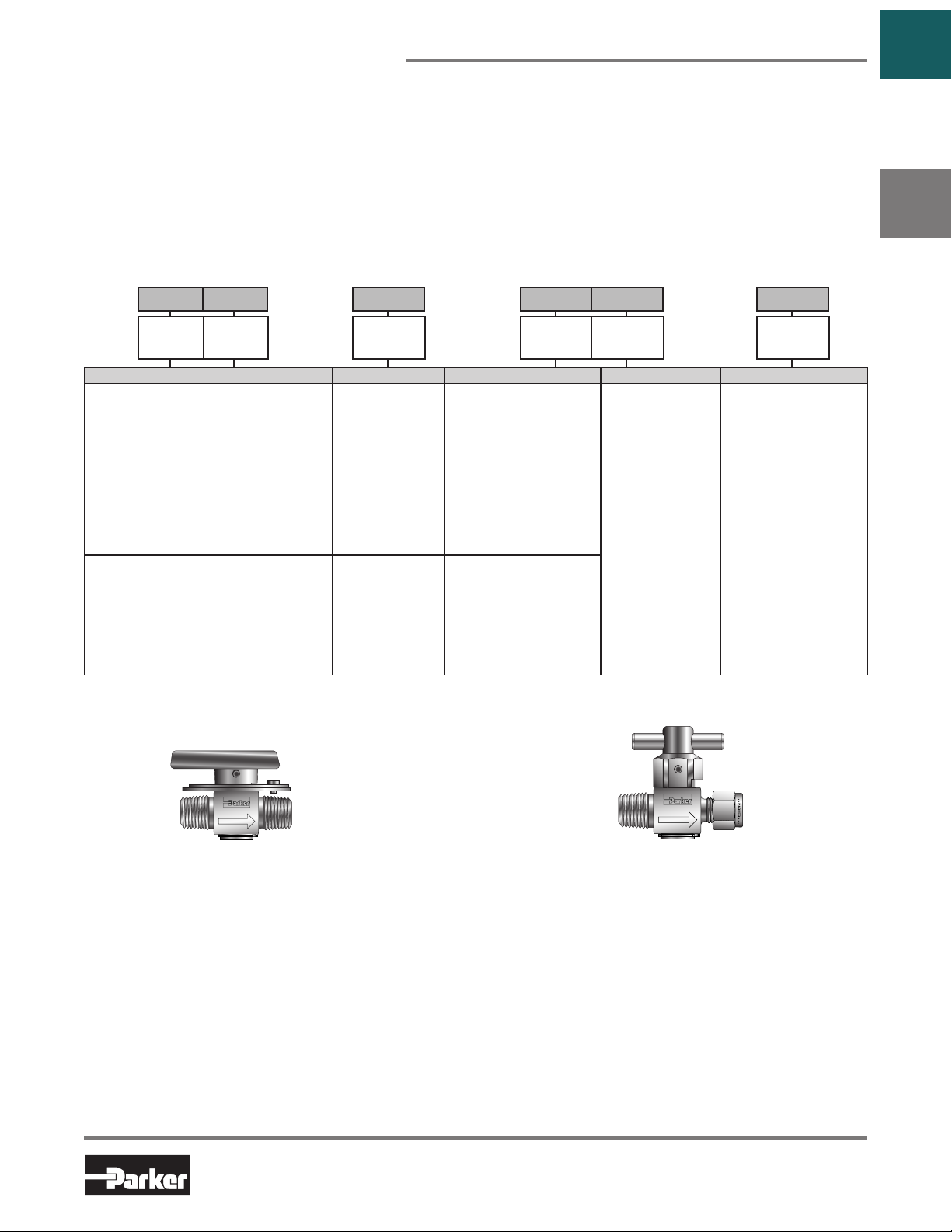

Page 10

B Series Ball Valves

Port 1

Port 2

Port 1

Port 2

Port 3

How to Order

B

Model Shown: 6A-B6LJ2-SSP

Catalog 4121-BV

Model Shown:

6A-B6XJ2-SSP

Go to

Table of

Contents

– –

Port 3Port 2Port 1

Ports 1, 2 and 3 Valve Series Seat Material Seal Material Body Material

1A

1/16" A-LOK

1Z 1/16" CPI™

2A 1/8" A-LOK®

2Z 1/8" CPI™

2F 1/8" Female NPT

2M 1/8" Male NPT

4A 1/4" A-LOK

4Z 1/4" CPI™

4M 1/4" Male NPT

M3A 3mm A-LOK

M3Z 3mm CPI™

4A

1/4" A-LOK

4Z 1/4" CPI™

4F 1/4" Female NPT

4M 1/4" Male NPT

4Q 1/4" UltraSeal

4V 1/4" VacuSeal

6A 3/8" A-LOK

6Z 3/8" CPI™

6M 3/8" Male NPT

6Q 3/8" UltraSeal

M6A 6mm A-LOK

M6Z 6mm CPI™

M8A 8mm A-LOK

M8Z 8mm CPI™

M10A 10mm A-LOK

M10Z 10mm CPI™

6F 3/8" Female NPT

8A 1/2" A-LOK

8Z 1/2" CPI™

8F 1/2" Female NPT

8M 1/2" Male NPT

8Q 1/2" UltraSeal

8V 1/2" VacuSeal

12Z 3/4" CPI™

12F 3/4" Female NPT

M12A 12mm A-LOK

M12Z 12mm CPI™

M16A 16mm A-LOK®

M16Z 16mm CPI™

See examples on page 9. See pages 10 and 11 for information about How to Order Options and Maintenance Kits.

®

®

®

®

®

®

®

®

®

Valve

Series

B2L

B2X

B6L

B6X

B8L

B8X

Seat

Material

J

PTFE

J2 PCTFE

J

PTFE

J2 PCTFE

S2 Spring-Loaded

PCTFE

PKR PTFE Lubricated

PEEK

SPKR Spring-Loaded

PTFE Lubricated

PEEK

J

PTFE

J2 PCTFE

S2 Spring-Loaded

PCTFE

PKR PTFE Lubricated

PEEK

SPKR Spring-Loaded

PTFE Lubricated

PEEK

Seal

Material

(Blank) PTFE

V Fluorocarbon Rubber

EPR Ethylene Propylene

Rubber

BN Nitrile Rubber

KZ Highly Fluorinated

Fluorocarbon Rubber

LT Live-Loaded PTFE

Packing with PTFE

Seals

VLT Live-Loaded PTFE

Packing with Fluoro

carbon Rubber Seals

EPRLT Live-Loaded PTFE

Packing with Ethylene

Propylene Rubber

Seals

BNLT Live-Loaded PTFE

Packing with Nitrile

Rubber Seals

KZLT Live-Loaded PTFE

Packing with Highly

Flourinated Fluoro carbon Rubber Seals

Notes:

1. Panel Mounting Nut supplied with each valve.

Various port combinations are available.

2. See How to order.

3. VacuSeal and UltraSeal are not available in

Brass.

4. 12F (3/4" Female NPT) not panel mountable.

–

SSP 316 Stainless Steel

BP Brass

MP Monel® Alloy 400

HCP Hastelloy® C-276

Body

Material

8

Parker Hannifin Corporation

Instrumentation Products Division

Jacksonville, AL USA

http://www.parker.com/ipdus

Page 11

Catalog 4121-BV

How to Order (Continued)

Examples: Two-Way Valves

Examples: Three-Way Diverter Valves

–

–

Examples: Three-Way Selector Valves

–

–

B Series Ball Valves

Go to

Table of

Contents

B

4Z

Port 1

Describes a B6L ball valve with a 1/4" CPI™ end connection for port 1 and a 1/4" female NPT end

connection for port 2, PTFE seats, PTFE stem and body seals, brass construction, with a panel mounting

nut.

8A

Port 1

Describes a B8L ball valve with a 1/2" A-LOK® end connections for ports 1 and 2, PTFE seats, Nitrile

rubber stem and body seals, stainless steel construction, with a panel mounting nut.

* Note: If ports 1 and 2 are the same, eliminate the port 2 designator.

M3A

Port 1

Describes a B2L ball valve with 3mm A-LOK® end connections for ports 1 and 2, PCTFE seats,

fluorocarbon rubber body seals, PCTFE packing, stainless steel construction, with a panel mounting nut.

* Note: If ports 1 and 2 are the same, eliminate the port 2 designator.

4Z

4F

Port 2

*

Port 2

*

Port 2

4Z

–

Valve Series

Valve Series

4F

B6L

Valve Series

B8L

B2L

B6X

J

Seat Material

J

Seat Material

J2

Seat Material

–– –

–– –

J2

–

Seal Material

BN

Seal Material

VLT

Seal Material

–

Body Material

V

BP

SSP

Body Material

SSP

Body Material

BP

Port 1

Describes a B6X ball valve with 1/4" CPI™ end connections for side ports 1 and 2, 1/4" female NPT end

connection for bottom port 3, PCTFE seats, fluorocarbon rubber stem and body seals, brass construction,

and a panel mounting nut.

2Z

Port 1

Port 2

*

Port 2

Port 3

*

Port 3

Valve Series

B2X

Valve Series

Seat Material

J

Seat Material

Seal Material

–

Seal Material

Body Material

SSP

Body Material

Describes a B2X ball valve with 1/8" CPI™ end connections for ports 1, 2, and 3, PTFE seats, PTFE

stem and body seals, stainless steel construction, and a panel mounting nut.

* Note: If ports 1, 2, and 3 are the same, eliminate the port 2 and port 3 designators.

4M

Port 1

Describes a B6X ball valve with 1/4" male NPT end connections for side ports 1 and 2, 1/4" female NPT

end connection for bottom port 3, spring-loaded PCTFE seats, ethylene propylene rubber stem and body

seals, stainless steel construction, and a panel mounting nut.

8A

Port 1

Describes a B8X ball valve with 1/2" A-LOK® end connections for ports 1, 2, and 3, spring-loaded PCTFE

seats, Nitrile rubber body seals, live loaded PTFE packing, stainless steel construction, and a panel

mounting nut.

* Note: If ports 1, 2, and 3 are the same, eliminate the port 2 and port 3 designators.

4M

Port 2

*

Port 2

4F

Port 3

*

Port 3

B6X

Valve Series

B8X

Valve Series

S2

Seat Material

S2

Seat Material

–

–

EPR

Seal Material

BNLT

Seal Material

SSP

Body Material

SSP

Body Material

9

Parker Hannifin Corporation

Instrumentation Products Division

Jacksonville, AL USA

http://www.parker.com/ipdus

Page 12

B Series Ball Valves

Options

B

Catalog 4121-BV

Go to

Table of

Contents

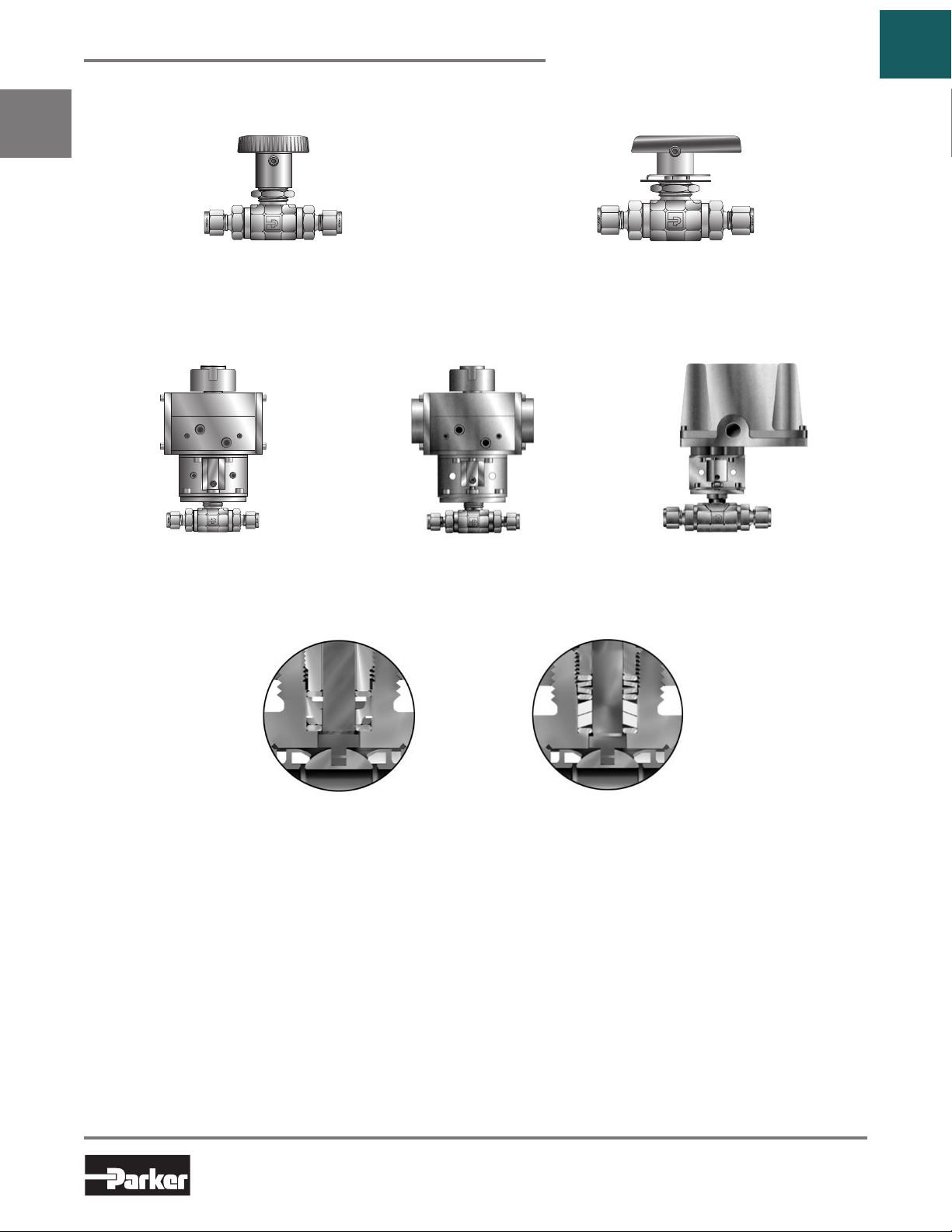

Round Handle

Actuator Options

Double Acting (61AD)

Pneumatic Actuator

Spring Returns (61AC & AO)

Pneumatic Actuator

Lock-Out Handle

70, 80 & 90 Series

Electric Actuator

Live-Loaded Stem SealsO-Ring Stem Seals

Two-Way Valve Upstream and Downstream Drain Options

For draining upstream or downstream media on two-way valves at pressures below 150 psig (10 bar), add the

suffix –VBU (Vented Ball Upstream) or –VBD (Vented Ball Downstream). Example: 4Z-B6LJ-SSP-VBU. This

option is also suitable to vent the ball cavity in vacuum applications. For pressures up to 3,000 psig (207 bar),

select S2 or SPKR spring-loaded seats and add the suffix –VBU (Vented Ball Upstream) or –VBD (Vented Ball

Downstream). Example: 4Z-B6LS2-SSP-VBU

Note: VBD and VBU are ball cavity vents only.

10

Parker Hannifin Corporation

Instrumentation Products Division

Jacksonville, AL USA

http://www.parker.com/ipdus

Page 13

Catalog 4121-BV

B Series Ball Valves

How to Order Options Examples

Lock-Out Devices: Add the suffix LD to the end of the part number to order directly on the valve. 4F-B6LJ2-BN-SSP-LD

For field installation, simply substitute the correct valve series number after LD. LD-B8L

Colored Lever Handles: Add the designator corresponding to the correct handle as a suffix to the part number

(black is standard). W = white, B = blue, G = green, R = red, Y

Colored Round Handles: Add the designator corresponding to the correct handle as a suffix to the part number.

S = Black, S-W = white, S-B = blue, S-G = green, S-R = red, S-Y = yellow. M6A-B6XPKR-SSP-S-G

NOTE: Round handles are not recommended for B8 valves with PEEK seats.

Metal Oval Handles: Add the designator corresponding to the correct handle as a suffix to the valve part number.

OVSS = stainless steel, SA

NOTE: Not available in size 2.

Stainless Steel Handles: Add the suffix -ST to the end of the part number (B6 and B8 only). 4F-B6LJ-SSP-ST

Pneumatic Actuators: For detailed actuator information, refer to the Pneumatic Actuators section of this catalog.

For factory assembly, add the actuator part number as the suffix to the valve part number. 2F-B2XJ2-V-SSP-61ACX-2

For field installation, specify the actuator desired. 61ACX-2

The appropriate mounting hardware may be obtained by adding the valve series and actuator size to the prefix MK-. MK-B2X-61

Electric Actuators: For detailed actuator information refer to the Electric Actuators section of this catalog.

For factory assembly, add the actuator part number as the suffix to the valve part number. 8A-B8LPKR-BN-SS-71A

For field installation, specify the actuator desired. 71A

The appropriate mounting hardware may be obtained by adding the valve series and actuator series to the prefix MK-. MK-B8L-70

Oxygen Cleaning: Add the suffix -C3 to the end of the part number to receive valves cleaned and asembled

for oxygen service in accordance with Parker Specification ES8003. 4A-B6LJ-EPR-SSP-C3

Electron Beam Welded End Connections: For tamper resistant valves, add the suffix -EBW to the end of the

part number of stainless steel valves to have end connections electron beam welded. M6A-B6LSPKR-V-SSP-EBW

Fillet Weld End Connections: For seal welded valves, add the suffix -FW to the end of the part number of the

stainless steel valves to have the end connections seal welded to the body. 8Z-B8LJ2-SSP-FW

Grounding Spring: To obtain B6 and B8 series valves with a grounding spring, add the suffix -SPG to the end

of the part number. 8A-B8LJ2-SSP-SPG

= oval aluminum. 8F-B8LPKR-SSP-OVSS

= yellow. M6A-B6XPKR-SSP-G

Go to

Table of

Contents

B

How to Order Maintenance Kits

Colored Round Handle Kits: Series-Handle-Color. (Example consists of a green handle and handle screw.) B6-RD-HANDLE-GREEN

NOTE: Stainless Steel kits not available in size 2.

Stainless Steel Handle Kits: Series-Handle-SS. (Example consists of a stainless steel handle and handle screw.) B8-HANDLE-SS

Colored Lever Handle Kits: Series-Handle-Color. (Example consists of a red handle and handle screw.) B6-HANDLE-RED

Two-way Valve Seal Kits:

PTFE Stem Seal Kits: Kit-Valve Series and Seat Material-Body Material. KIT-B2LJ-SS

(Consists of one PTFE stem seal, two stem seal washers, two encapsulated PTFE ball seats, two end connector

PTFE seals, one assembly mandrel, maintenance instructions.)

Elastomeric Stem Seal Kits: Kit-Valve Series and Seat Material-Elastomer Material-Body Material. KIT-B2LJ2-BN-SS

(Consists of two stem seal Nitrile rubber O-rings, two PTFE back-up rings, two stem seal washers, two encapsulated PCTFE ball seats,

two end connector Nitrile rubber O-ring seals, two seat retainer Nitrile rubber O-ring seals, stem glands and maintenance instructions.)

Diverter Valve Seal Kits:

PTFE Stem Seal Kits: Kit-Valve Series and Seat Material-Body Material. KIT-B6XPKR-SS

(Consists of one PTFE stem seal, two stem seal washers, two encapsulated PEEK ball seats, three end connector

PTFE seals, one assembly mandrel, maintenance instructions.)

Elastomeric Stem Seal Kits: Kit-Valve Series and Seat Material-Elastomer-Body Material. KIT-B6XJ-V-SS

(Consists of two stem seal fluorocarbon rubber O-rings, two PTFE back-up rings, two stem seal washers, two

encapsulated PTFE ball seats, three end connector fluorocarbon rubber O-ring seals, two seat retainer fluorocarbon

rubber O-ring seals, stem glands and maintenance instructions.)

Selector Valve Seal Kits:

PTFE Stem Seal Kits: Kit-Valve Series and Seat Material. KIT-B6XS2

(Consists of one PTFE stem seal, two stem seal washers, two encapsulated spring-loaded PCTFE ball seats, two

seat retainer fluorocarbon rubber O-rings, three end connector PTFE seals, one assembly mandrel, maintenance instructions.)

Elastomeric Stem Seal Kits: Kit-Valve Series and Seat Material-Elastomer. KIT-B6XSPKR-V

(Consists of two stem seal fluorocarbon rubber O-rings, two PTFE back-up rings, two stem seal washers, two

encapsulated spring-loaded PEEK ball seat assemblies, three end connector fluorocarbon O-ring seals, two seat

retainer fluorocarbon rubber O-rings, stem glands and maintenance instructions.)

Live-loaded Seal Kits:

Kit-Valve Series and Seat Material-Seal Material-Body Material. KIT-B6LJ2-BNLT-SS

(Consists of one live-loaded PTFE stem packing, two packing springs (B8 series valves have four springs), three packing washers, two PCTFE

encapsulated ball seats, two Nitrile rubber end connector O-ring seals, two Nitrile rubber seat retainer O-ring seals, maintenance instructions.)

11

Parker Hannifin Corporation

Instrumentation Products Division

Jacksonville, AL USA

http://www.parker.com/ipdus

Page 14

PR Series Rotary Plug Valves

Catalog 4121-BV

Introduction

Parker PR Series Plug Valves provide positive leak tight shut-off, high flow capacity, and quick quarter-turn

operation in a compact attractive package. The patented blow-out resistant seat design offers reliable sealing

technology at all operating pressures. In addition to on-off actuation, the plug design allows forward flow throttling.

A selection of valve seat and seal materials may be chosen for media compatibility and performance over a broad

PR

range of temperatures. The pressure balanced atmospheric seals are backed by PTFE rings to enhance their

performance and increase cycle life.

Features

Patented blow-out resistant seat design

Pressures up to 3,000 psig (207 bar) CWP

Quarter-turn operation

Reliable simple design

Straight-through flow

Stainless steel and brass construction

Nitrile, ethylene propylene, fluorocarbon, and highly

fluorinated fluorocarbon rubber seats and seals

Open

Go to

Table of

Contents

PTFE back-up rings on atmospheric seals

Low operating torque

Minimum pressure drop

Throttling capability

Positive handle stops

Color coded fracture resistant nylon handles with

directional flow indication

Easy to service

100% factory tested

Options include lock-out devices, downstream

venting, and both stainless steel and T-bar handles

Specifications

Pressure Ratings:

Normal Flow Direction: 3000 psig (207 bar) CWP

Reverse Flow Direction: 150 psig (10 bar)

Downstream Vent Option: 150 psig (10 bar)

Closed

Model Shown: 4A-PR4-VT-SS

U.S. Patent 5,234,193

12

Parker Hannifin Corporation

Instrumentation Products Division

Jacksonville, AL USA

http://www.parker.com/ipdus

Page 15

Catalog 4121-BV

Materials of Construction

Item # Part Description Stainless Steel Brass

1 Body

2 Plug*

3 Seat** Fluorocarbon Rubber

4 O-Ring Seals** Fluorocarbon Rubber

5 Back-up Rings PTFE

6 Handle Nylon 6/6

7 Handle Pin 316 Stainless Steel

8 Body Pin 316 Stainless Steel (not shown)

9 Retaining Ring 316 Stainless Steel

* Plugs are PTFE color coated – Stainless steel plugs are black;

Brass plugs are brown.

** Optional Seat and O-ring seal materials are available.

Lubrication: Perfluorinated polyether

ASTM A 479

Type 316

ASTM A 479

Type 316

ASTM B 16

Alloy C36000

ASTM B 16

Alloy C36000

Pressure vs. Temperature

PR Series Rotary Plug Valves

6

7

3

5

1

9

2

Model Shown: 4A-PR4-VT-SS

Note: This Pressure versus Temperature chart reflects the

maximum temperature range of indicated body materials.

The temperature rating of the elastomer seals become the

limiting factor on temperature range.

8

Go to

Table of

Contents

PR

4

Temperature Ratings

Material Temperature Rating

Nitrile Rubber

Fluorocarbon Rubber

Highly Fluorinated

Fluorocarbon Rubber

Ethylene Propylene

Rubber

Note: To determine MPa, multiply bar by 0.1

Flow Calculations with 1000 psig (69 bar) Inlet Pressure

Valve

Series

PR4 1.24

PR6 3.19

Max.

Cv

Water

Pressure Drop ∆P

psig bar gpm m3/hr scfm m3/hr

10 0.7 3.9 0.9 123.1 209.6

50 3.4 8.8 2.0 265.9 446.3

100 6.9 12.4 2.8 359.6 607.0

10 0.7 10.1 2.3 315.7 533.5

50 3.4 22.6 5.1 672.3 1128.2

100 6.9 31.9 7.2 891.6 1504.1

@ 60°F (16°C)

Air

@ 60°F (16°C)

-30°F to 225°F

(-34°C to 107°C)

-10°F to 450°F

(-23°C to 232°C)

-10°F to 300°F

(-23°C to 149°C)

-70°F to 275°F

(-57°C to 135°C)

Kits

Plug Kits – Specify the combination of valve series, seal material, plug material, and handle color (if applicable).

Example: KIT-PR4-VT-SS-Y. This kit consists of a PR4 stainless steel plug with fluorocarbon rubber seat and seal

elastomers, PTFE back-up rings, yellow handle, and handle pin.

Seal Kits – Specify the combination of valve series and seal material.

Example: KIT-PR4-BN. This kit consists of a PR4 Nitrile rubber seat and seal elastomers and PTFE back-up rings.

13

Parker Hannifin Corporation

Instrumentation Products Division

Jacksonville, AL USA

http://www.parker.com/ipdus

Page 16

PR Series Rotary Plug Valves

Flow Data / Dimensions

G

PR

A B

Catalog 4121-BV

Go to

Table of

Contents

F

E

D

C

Model Shown: 4A-PR4-VT-B

Port

Size

M3A

M3Z 3mm CPI™

M6A

M6Z 6mm CPI™

M8A

M8Z 8mm CPI™

M8A

M8Z 8mm CPI™

M10A

M10Z 10mm CPI™

M12A

M12Z 12mm CPI™

Basic

Part #

2F

2M 0.172 4.4 1.02 0.39 1/8" Male NPT

2A

2Z 1/8" CPI™

4F 0.193 4.9 1.24 0.39 1/4" Female NPT

4M 0.193 4.9 1.24 0.39 1/4" Male NPT

4A

4Z 1/4" CPI™

4Q 0.187 4.7 1.18 0.41 1/4" UltraSeal

4V 0.187 4.7 1.18 0.41 1/4" VacuSeal

6M 0.193 4.9 1.24 0.39 3/8" Male NPT

6A

6Z 3/8" CPI™

4F

6A

6Z 3/8" CPI™

8F 0.281 7.1 3.19 0.28 1/2" Female NPT

8M 0.281 7.1 3.19 0.28 1/2" Male NPT

8A

8Z 1/2" CPI™

PR4

PR6

0.193 4.9 1.24 0.39 1/8" Female NPT

0.093 2.4 0.22 0.48

0.187 4.7 1.18 0.41

0.193 4.9 1.24 0.39

0.086

0.188 4.8 1.18 0.41

0.193 4.9 1.24 0.48

0.281 7.1 3.19 0.28 1/4" Female NPT

0.281 7.1 3.19 0.28

0.281 7.1 3.19 0.28

0.250 6.4 2.84 0.29

0.281 7.1 3.19 0.28

0.281 7.1 3.19 0.28

Flow Data

Cv XT *Inch mm Port 1 Port 2 A† B† C D E F G

2.2 0.15 0.48

End Connections

®

1/8" A-LOK

®

1/4" A-LOK

®

3/8" A-LOK

3mm A-LOK

6mm A-LOK

8mm A-LOK

®

3/8" A-LOK

®

1/2" A-LOK

8mm A-LOK

10mm A-LOK

12mm A-LOK

0.89

(22.6)

0.77

®

®

®

®

®

®

(19.6)

1.00

(25.4)

1.05

(26.7)

0.96

(24.4)

1.09

(27.7)

0.85

(21.7)

1.02

(25.9)

0.94

(23.9)

1.14

(29.0)

0.98

(24.9)

1.08

(27.4)

1.11

(28.2)

1.19

(30.2)

1.33

(33.8)

1.44

(36.6)

1.32

(33.5)

1.44

(36.6)

1.30

(33.0)

1.34

(34.0)

1.47

(37.3)

* Tested in accordance with ISA S75.02. Gas flow will be choked when P1 - P2 / P1 = xT .

† For CPI™ and A-LOK®, dimensions are measured with nuts in the finger tight position.

0.89

(22.6)

0.77

(19.6)

1.00

(25.4)

1.05

(26.7)

0.96

(24.4)

1.09

(27.7)

0.85

(21.7)

1.02

(25.9)

0.94

(23.9)

1.14

(29.0)

0.98

(24.9)

1.08

(27.4)

1.11

(28.2)

1.19

(30.2)

1.33

(33.8)

1.44

(36.6)

1.32

(33.5)

1.44

(36.6)

1.30

(33.0)

1.34

(34.0)

1.47

(37.3)

0.46

(11.7)

0.67

(17.0)

Dimensions

Inches (mm)Orifice

0.38

(9.7)

0.56

(14.2)

1.07

(27.2)

1.49

(37.8)

0.75

(19.1)

0.99

(25.1)

Dimensions in inches/millimeters are

for reference only, subject to change.

1.88

(47.8)

2.40

(61.0)

14

Parker Hannifin Corporation

Instrumentation Products Division

Jacksonville, AL USA

http://www.parker.com/ipdus

Page 17

Catalog 4121-BV

PR Series Rotary Plug Valves

How to Order

The correct part number is easily derived from the following example and ordering chart. The six product

characteristics required are coded as shown in the chart.

* Note: If the inlet and outlet ports are the same, eliminate the outlet port designator.

The following example describes a PR Series rotary plug valve equipped with 1/4" CPI™ compression inlet and

outlet ports, Nitrile seals, PTFE back-up rings, and stainless steel construction.

Example:

4Z – PR4 – BNT – SS

–

– –

Go to

Table of

Contents

PR

Inlet

Port*

Inlet and Outlet Ports* Valve Series Seal Material Back-Up Rings Body Material

2A

1/8" A-LOK®

2Z 1/8" CPI™

2F 1/8" Female NPT

2M 1/8" Male NPT

4A 1/4" A-LOK

4Z 1/4" CPI™

4F 1/4" Female NPT

4M 1/4" Male NPT

4Q 1/4" UltraSeal

4V 1/4" VacuSeal

4F 1/4" Female NPT

6A 3/8" A-LOK

6Z 3/8" CPI™

8A 1/2" A-LOK

8Z 1/2" CPI™

8F 1/2" Female NPT

8M 1/2" Male NPT

* If the inlet and outlet ports are the same, eliminate the outlet port designator.

®

®

®

Outlet

Port*

6M 3/8" Male NPT

6A 3/8" A-LOK

6Z 3/8" CPI™

M3A 3mm A-LOK

M3Z 3mm CPI™

M6A 6mm A-LOK

M6Z 6mm CPI™

M8A 8mm A-LOK

M8Z 8mm CPI™

M8A 8mm A-LOK

M8Z 8mm CPI™

M10A 10mm A-LOK

M10Z 10mm CPI™

M12A 12mm A-LOK

M12Z 12mm CPI™

®

®

®

®

®

®

®

Valve

Series

PR4

PR6

V

Fluorocarbon Rubber

KZ Highly Fluorinated

Fluorocarbon Rubber

EPR Ethylene Propylene

Rubber

BN Nitrile Rubber

V

Fluorocarbon Rubber

EPR Ethylene Propylene

Rubber

BN Nitrile Rubber

Options

Seal

Material

Back-Up

Rings

T PTFE SS Stainless Steel

Body

Material

B Brass

Lock-Out Device T-Bar Handle

Used to lock the handle from accidental rotation in either the

opened or closed position. To order the device with the valve,

add the suffix –LD to the end of the part number.

Example and model shown: 4F-PR4-VT-B-LD.

To order the device separately, specify LD-PR4 or LD-PR6.

Downstream Venting – As the valve is positioned from opened to closed, downstream pressure is released to atmosphere

through a vent hole in the body and plug. The maximum recommended operating pressure for this option is 150 psig (10 bar).

To order, insert V after PR in the model number. Example: 4A-PRV4-VT-B

Colored Handles – Black is the standard color. Add the designator corresponding to the correct handle color as a suffix to

the part number: W – white, B – blue, G – green, R – red, Y – yellow. Example: M6A-PR4-BNT-SS-G

Stainless Steel Directional Handles – A stainless steel handle with the same design configuration as the standard nylon

handle is available for the PR4 series. Add the designator –ST as a suffix to the part number.

Example: 4Q-PR4-EPRT-SS-ST

An all metal bar stock design for higher strength and

durability. Consists of a stainless steel pin and aluminum

adapter. To order, add the suffix –T to the end of the part

number.

Example and model shown: 4M4A-PR4-EPRT-SS-T.

15

Parker Hannifin Corporation

Instrumentation Products Division

Jacksonville, AL USA

http://www.parker.com/ipdus

Page 18

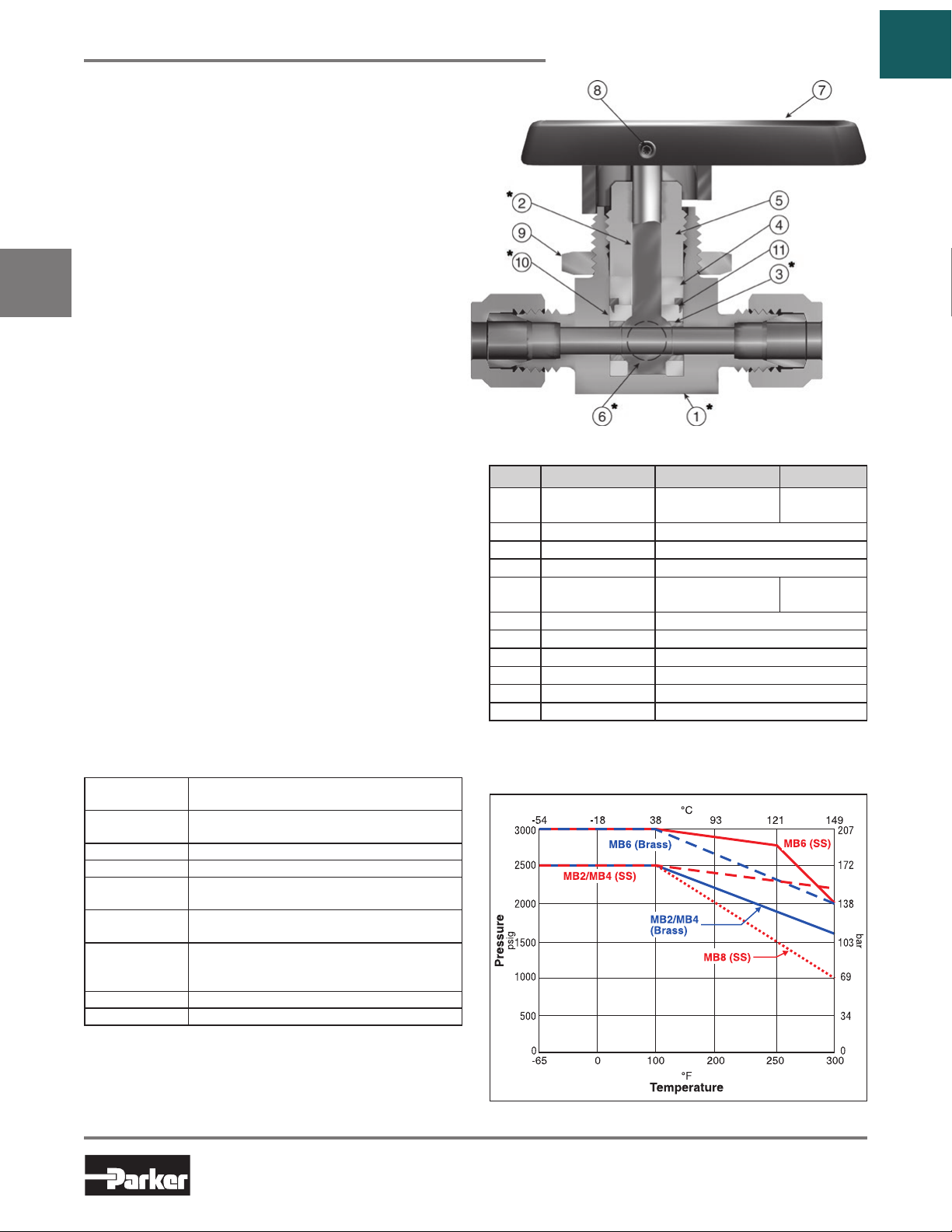

MB Series Ball Valves

Introduction

Parker MB Series Ball Valves, with their rugged

compact design, offer positive shut off or directional

control of fluids in process, power and instrumentation

applications. The unique one piece seat/packing

design insures excellent sealing characteristics while

accommo dating a superior temperature range and

cycle life.

These valves are available in two-way and three-way

MB

configurations, brass and stainless steel construction,

with a wide variety of port connections. Also, all ports

are suitable as inlets to full operating pressure of the

valve.

Features

One piece seat/packing design

Broad temperature range

Coated metal inserts

One piece stem/ball

Wide variety of US Customary and SI ports

Panel mountable to 1/4" thickness

Bi-directional flow

Handle indicates direction of flow

Full operating pressure at any port

Positive handle stops

Color coded handles

100% factory tested

Vent option

Manual, electric or pneumatic actuation

Leak-tight center-off position on three-way valves

Specifications

Pressure

Rating

Temperature

Rating

Orificer

C

V

Body

Materials

Body

Configurations

Port

Connections

Port Size

Seat/Packing

* Preset from factory to 1000 psig (69 bar) bubble tight service.

To achieve higher pressures packing nut must be tightened with

Packing Tool MB6X5. Additional details are in INI-243 Installation

Instructions. Packing in vented MB Series Ball Valves is factory

adjusted for the maximum valve pressure rating of 500 psig (34

bar).

3000 psig* (207 bar) CWP - MB6

2500 psig* (172 bar) CWP - MB2/MB4/MB8

-65°F to 300°F

(-54°C to 149°C)

.052" to .406" (1.3mm to 10.3mm)

.05 to 6.96

Stainless steel and brass

two-way (in-line and angle)

3-way, 4-way and 5-way

Tube compression (CPI™ / A-LOK

NPT (Male / Female)

BSP, VacuSeal and UltraSeal

1/16" to 3/4" and 3mm to 12mm

PFA-Perfluoroalkoxy

Catalog 4121-BV

Go to

Table of

Contents

Materials of Construction

Item # Part Description Stainless Steel Brass

1 Body

2 Stem ASTM A 276 Type 316

3 Hollow Insert 316 Stainless Steel

4 Packing Washer ASTM B 16 Alloy C36000

5 Packing Nut

6 Solid Insert 316 Stainless Steel

7 Handle Nylon 6/6

8 Set Screw Stainless Steel

9 Panel Nut 316 Stainless Steel**

*10 Seat/Packing Perfluoroalkoxy (PFA)

11 Packing Ring ASTM A 479 Type 316

* Wetted Parts **Nickel Plated Brass for MB8

Lubrication: Perfluorinated polyether

ASTM A 276

Type 316

ASTM A 479

Type 316

ASTM B 16

Alloy C36000

ASTM B 16

Alloy C36000

Pressure vs. Temperature

®

)

Note: To determine MPa, multiply bar by 0.1

16

Parker Hannifin Corporation

Instrumentation Products Division

Jacksonville, AL USA

http://www.parker.com/ipdus

Page 19

Catalog 4121-BV

H-Maximum Panel Thickness

I-Panel Hole Diameter

J-Body Width

Port

Two-Way In-Line MB Series Ball Valves

Two-Way In-Line Dimensions, Flow Data

Go to

Table of

Contents

G

F

Two-Way In-Line

Vented – In off position

the downstream port

vents to atmosphere

E

through a hole in the

side of the body.

D

2

K

B

Model shown: 4A-MB6LPFA-SSP

Port

Basic

Size

Part #

1Z

1A 1/16" A-LOK

2Z

2A 1/8" A-LOK

M3Z

M3A 3mm A-LOK

2F

4Z 1/4" CPI™

4A 1/4" A-LOK

M6Z 6mm CPI™

M6A 6mm A-LOK

2Z

2A 1/8" A-LOK

2F

4M 1/4" Male NPT

4Z 1/4" CPI™

4A 1/4" A-LOK

4F 1/4" Female NPT

4M4Z 1/4" Male NPT

4M4A 1/4" Male NPT

4V 1/4" VacuSeal

6Z 3/8" CPI™ 1.31 1.31

6A 3/8" A-LOK

M6Z 6mm CPI™ 1.19 1.19

M6A 6mm A-LOK

M8Z 8mm CPI™ 1.22 1.22

M8A 8mm A-LOK

8A

8Z 1/2" A-CPI™

8F 0.406 10.3 6.1 0.20 1/2" FNPT

12A

12Z 3/4" CPI

M12A

M12Z 12mm CPI™

* Tested in accordance with ISA S75.02. Gas flow will be choked when P1 - P

™

† For CPI

and A-LOK®, dimensions are measured with nuts in the finger tight position.

0.052 1.3 0.03 0.46

0.093 2.4 0.20 0.42

MB2L

0.086 2.2 0.17 0.43

MB4L 0.125 3.2 0.44 0.34

0.093 2.4 0.18 0.55

MB6L

0.187 4.7 1.02 0.53

0.406 10.3 10.7 0.16

MB8L

0.406 10.3 6.4 0.19

0.375 9.5 10.7 0.16

Flow Data

Cv X

*Inch mm Port 1 Port 2 A† B† D E F G H I J K

T

End Connections

1/16" CPI™

®

1/8" CPI™

®

3mm CPI™

®

1/8" Female NPT

®

®

1/8" CPI™

®

(27.7)

1/8" Female NPT

®

(30.2)

1/4" CPI™

1/4" A-LOK

®

(33.3) (33.3)

®

(30.2) (30.2)

®

(31.0) (31.0)

®

1/2" A-LOK

®

3/4" A-LOK

™

12mm A-LOK

®

/ P1 = xT .

2

0.84

(21.3)

1.00

(25.4)

1.00

(25.4)

0.81

(20.6)

1.12

(28.5)

1.12

(28.5)

1.09

(27.7)

1.00

(25.4)

1.00

(25.4)

1.19

(30.2)

1.03

(26.2)

1.00

®

(25.4)

1.03

(26.2)

1.94

(49.3)

1.56

(39.6)

1.94

(49.3)

1.96

(49.8)

H - Maximum Panel Thickness

I - Panel Hole Diameter

J - Body Width

VENTED STANDARD

ON

Port 1

OFF

A

Dimensions

Inches (mm)Orifice

0.84

(21.3)

1.00

0.34

1.31

1.88

0.75

0.25

0.58

(25.4)

1.00

(25.4)

0.81

(20.6)

1.12

(28.5)

1.12

(28.5)

1.09

1.00

(25.4)

1.00

(25.4)

1.19

1.03

(26.2)

1.19

(30.2)

1.03

(26.2)

1.94

(49.3)

1.56

(39.6)

1.94

(49.3)

1.96

(49.8)

(8.6)

0.34

(8.6)

0.44

(11.2)

0.69

(17.5)

(33.3)

1.31

(33.3)

1.56

(39.6)

2.39

(60.7)

(47.8)

1.88

(47.8)

2.37

(60.2)

4.50

(114.3)

(19.1)

(6.4)

0.75

0.25

(19.1)

(6.4)

0.88

0.25

(22.4)

(6.4)

1.50

0.38

(38.1)

(9.7)

Dimensions in inches/millimeters are

for reference only, subject to change.

(14.7)

0.58

(14.7)

0.77

(19.6)

1.50

(38.1)

0.58

(14.7)

0.58

(14.7)

0.80

(20.3)

1.50

(38.1)

(7.1)

(7.1)

(9.7)

(17.5)

MB

0.28

0.28

0.38

0.69

17

Parker Hannifin Corporation

Instrumentation Products Division

Jacksonville, AL USA

http://www.parker.com/ipdus

Page 20

Two-Way Angle / Three-Way MB Series Ball Valves

Port 1

Two-Way Angle and Three-Way Dimensions, Flow Data

Catalog 4121-BV

Go to

Table of

Contents

Two-Way Angle

G

MB

Port 2

C

B

Model shown:

F

D

VENTED STANDARD

ON

OFF

E

E

D

Port 2

4A-MB6APFA-SSP

Port

Basic

Size

Part #

1Z

1A 1/16" A-LOK

2Z

MB2A

MB2X

2A 1/8" A-LOK

M3Z

M3A 3mm A-LOK

2F

4Z 1/4" CPI™

MB4A

MB4X

4A 1/4" A-LOK

M6Z 6mm CPI™

M6A 6mm A-LOK

4Z

4A 1/4" A-LOK

4F 1/4" Female NPT

4V 1/4" VacuSeal

4Z4Z4M

MB6A

MB6X

4A4A4M 1/4" A-LOK

6Z 3/8" CPI™

6A 3/8" A-LOK

M6Z 6mm CPI™

M6A 6mm A-LOK

M8Z 8mm CPI™

M8A 8mm A-LOK

8A

8Z 1/2" A-CPI™

8F 0.406 10.3 5.0 0.33 1/2 “ Female NPT

MB8A

MB8X

12A

12Z 3/4" CPI™

M12A

M12Z 12mm CPI™

Flow Data

Cv X

0.052 1.3 0.02 0.58

0.093 2.4 0.18 0.48

0.086 2.2 0.15 0.47

0.125 3.2 0.34 0.45

0.187 4.7 0.70 0.58

0.406 10.3 5.4 0.36

0.406 10.3 4.9 0.39

0.375 9.5 5.6 0.37

*Inch mm Port 1 Port 2 Port 3 ‡ A† B† C C E F G H I J

T

1/4" CPI™ 1/4" CPI™ 1/4" Male NPT

* Tested in accordance with ISA S75.02. Gas flow will be choked when P1 - P2 / P1 = xT .

‡ Not applicable for the two-way Angle pattern.

† For CPI™ and A-LOK®, dimensions are measured with nuts in the finger tight position.

End Connections

1/16" CPI™

®

1/8" CPI™

®

3mm CPI™

®

1/8" Female NPT

®

®

1/4" CPI™ 1.19 1.19 1.15

®

(30.2) (30.2) (29.2)

®

1/4" A-LOK® 1/4" Male NPT

®

®

®

®

1/2" A-LOK

®

3/4" A-LOK

12mm A-LOK

®

Three-Way

G

Port 3

B

F

A

Model shown:

4A-MB6XPFA-SSP

0.84

0.84

(21.3)

1.00

(25.4)

1.00

(25.4)

0.81

(20.6)

1.12

(28.4)

1.12

(28.4)

1.19

(30.2)

1.31

(33.3)

1.19

(30.2)

1.22

(31.0)

1.75

(44.5)

1.56

(39.6)

1.75

(44.5)

1.75

(44.5)

0.81

(20.6)

0.97

(24.6)

0.97

(24.6)

0.81

(20.6)

1.12

(28.4)

1.12

(28.4)

1.03

(26.2)

1.23

(31.2)

1.15

(29.2)

1.18

(30.0)

1.75

(44.5)

1.56

(39.6)

1.75

(44.5)

1.75

(44.5)

(11.2)

(17.5)

(21.3)

1.00

(25.4)

1.00

(25.4)

0.81

(20.6)

1.12

(28.4)

1.12

(28.4)

1.03 1.03 1.03

(26.2) (26.2) (26.2)

1.03 1.03 1.03

(26.2) (26.2) (26.2)

1.19

(30.2)

1.31

(33.3)

1.19

(30.2)

1.22

(31.0)

1.75

(44.5)

1.56

(39.6)

1.75

(44.5)

1.75

(44.5)

H - Maximum Panel

Thickness

I - Panel Hole

Diameter

J - Body Width

VENTED STANDARD

Port 1

C

Dimensions

Inches (mm)Orifice

0.34

1.31

(33.3)

(33.3)

1.56

(39.6)

2.39

(60.7)

1.88

(47.8)

(47.8)

2.37

(60.2)

4.50

(114.3)

(19.1)

(19.1)

(22.4)

(38.1)

(8.6)

0.34 1.31 1.88 0.75 0.25 0.58 0.58

(8.6)

0.44

0.69

Dimensions in inches/millimeters are

for reference only, subject to change.

0.75

0.88

1.50

ON

CENTER

OFF

ON

0.25

(6.4)

(6.4)

0.25

(6.4)

0.38

(9.7)

0.58

(14.7)

(14.7)

0.77

(19.6)

1.50

(38.1)

0.58

(14.7)

(14.7)

0.80

(20.3)

1.50

(38.1)

18

Parker Hannifin Corporation

Instrumentation Products Division

Jacksonville, AL USA

http://www.parker.com/ipdus

Page 21

Catalog 4121-BV

MB Series Ball Valves

How to Order Two-Way In-Line, Two-Way Angle and Three-Way Patterns

The correct part number is easily derived from the following example and ordering chart. The six product

characteristics required are coded as shown in the chart.

The following example describes a MB Series, two-way, in-line pattern ball valve with 1/8" CPI™ compression end

connections for ports 1 and 2 Inline

Go to

Table of

Contents

Example:

2Z – MB2LPFA – SSP

– –

Port

1*

1Z

1/16" CPI™

1A 1/16" A-LOK®

2Z 1/8" CPI™

2A 1/8" A-LOK

2F 1/8" Female NPT

4Z 1/4" CPI™

4A 1/4" A-LOK

1/8" CPI™

2Z

2A 1/8" A-LOK®

2F 1/8" Female NPT

4Z 1/4" CPI™

4A 1/4" A-LOK

4F 1/4" Female NPT

4M 1/4" Male NPT

4V 1/4" VacuSeal

1/2" CPI™

8Z

8A 1/2" A-LOK

8F 1/2" Female NPT

* Valves with identical port connections for port 1 and port 2 require only one designator.

Port

2*

Ports

1, 2 and 3*

®

®

®

®

Port

3*

M3Z 3mm CPI™

M3A 3mm A-LOK

M6Z 6mm CPI™

M6A 6mm A-LOK®

6Z 3/8" CPI™

6A 3/8" A-LOK®

M6Z 6mm CPI™

M6A 6mm A-LOK®

M8Z 8mm CPI™

M8A 8mm A-LOK

12Z 3/4" CPI™

12A 3/4" A-LOK

M12Z 12mm CPI™

M12A 12mm A-LOK

®

®

®

Valve

Series

Valve

Series

MB2L

MB2A

MB2X

MB4L

MB4A

MB4X

MB6L

MB6A

MB6X

MB8A

MB8L

MB8X

®

Seat

Material

Seat

Material

PFA

Perfluoro

alkoxy

Body

Material

Body

Material

SSP Stainless Steel

(Stainless

Steel with

Stainless Steel

Panel Nut)

BP Brass (Brass

with Stainless

Steel Panel

Nut) (Only

available in

MB 2, 4, 6)

Lock-Out Device Option

MB

Oval Handle Option

Pneumatic Actuator

Option

How to Order Options (Two-Way, Angle, and Three-Way)

Lock-Out Devices – Add the suffix -LD to the end of the part number to order directly on the valve.

For field installation, simply substitute the correct valve series number in the following nomenclature: LD-valve series. Example: LD-MB6L

Colored Handles – Add the designator corresponding to the correct handle as a suffix to the part number:

R - red, Y - yellow. Example: 4Z-MB6LPFA-SSP-G

NOTE: Not offered in MB8 series.

Stainless Steel Handles – Add the suffix -ST to the part number.

Oval Handles – Add the suffix -S to the part number.

-S-color designator. Example: 6Z-MB6APFA-SSP-S-W

NOTE: MB6 series only.

Vented Valves – Add the designator V after the MB in the part number for the vent option.

Example: 2Z-MBV2XPFA-SSP.

Example: 6Z-MB6APFA-SSP-S. If requesting a colored oval handle, add the suffix

Example: 4F-MB6LPFA-SSP-ST (MB6 series only)

Example: 2F-MB4LPFA-SSP-LD.

W - white, B - blue, G - green,

Oxygen Cleaning – Add the suffix -C3 to the end of the part number to receive valves cleaned and assembled for oxygen service in

accordance with Parker Specification ES8003. Example: 4A-MB4LPFA-SSP-C3

Pneumatic Actuators – For detailed actuator information, refer to the Pneumatic Actuators section of this catalog. For factory assembly,

add the actuator part number as the suffix to the valve part number. Example: 4A-MB4LPFA-SSP-61AC-2. For field installation, specify the

actuator desired. Example: 61AC-2. The appropriate mounting hardware may be obtained by adding the valve series and actuator size to the

prefix MK-. Example: MK-MB4L-61

Electric Actuators – For detailed actuator information, refer to the Electric Actuators section of this catalog. For factory assembly, add the

actuator part number as the suffix to the valve part number. Example: M6A-MB6XPFA-SSP-71C. For field installation, specify the actuator

desired. Example: 71C. The appropriate mounting hardware may be obtained by adding the valve series and actuator series to the prefix MK-.

Example: MK-MB6X-70

19

Parker Hannifin Corporation

Instrumentation Products Division

Jacksonville, AL USA

http://www.parker.com/ipdus

Page 22

Four-Way and Five-Way MB Series Ball Valves

kness

kness

Dimensions, Flow Data

Catalog 4121-BV

Go to

Table of

Contents

Four-Way

G

MB

E

B

Port

Basic

Size

Part #

2A7

2Z7 1/8" Female CPI™

MB6X4 0.063 1.6 0.17 0.16

2F 1/8" Female NPT

2A7

2Z7 1/8" Inverted CPI™

MB6X5 0.063 1.6 0.17 0.16

2F 1/8" Female NPT

* Tested in accordance with ISA S75.02. Gas flow will be choked when P1 - P2 / P1 = xT .

† For CPI™ and A-LOK®, dimensions are measured with nuts in the finger tight position.

F

H - Maximum Panel Thic

I - Panel Hole Diameter

2

1

3

D

4

K

A

Flow Data

Cv XT*Inch mm Port 1 Port 2 A† B† D E F G H I K L

2

1

4

End Connections

1/8" Female A-LOK

1/8" Inverted A-LOK

3

®

®

0.97

(24.6)

0.78

(19.8)

0.97

(24.6)

0.78

(19.8)

Five-Way

G

E

L

B

0.97

(24.6)

0.44

1.57

(11.2)

0.44

(11.2)

(39.9)

1.57

(39.9)

0.78

(19.8)

0.97

(24.6)

0.78

(19.8)

F

A

Dimensions

Inches (mm)Orifice

2.37

(60.2)

2.37

(60.2)

H - Maximum Panel Thic

I - Panel Hole Diameter

D

K

0.88

0.25

0.77

(22.4)

(6.4)

0.88

0.25

(22.4)

(6.4)

Dimensions in inches/millimeters are

for reference only, subject to change.

(19.6)

0.77

(19.6)

0.44

(11.2)

0.44

(11.2)

0.97

(24.6)

0.88

(22.4)

How to Order Four-Way and Five-Way Patterns

The correct part number is easily derived from the following example and ordering chart. The four product

characteristics required are coded as shown in the chart.

The following example describes a MB-Series four-way pattern ball valve with 1/8" female CPI™ compression end

connections for all ports, PFA seat and packing, stainless steel body construction, and a panel mounting nut.

Example:

2Z7 – MB6X4PFA – SSP

– –

End

Connection

End Connection Valve Series Seat Material Body Material

2F

1/8" Female NPT

2Z7 1/8" CPI™

2A7 1/8" A-LOK

®

How to Order Options

Valve

Series

MB6X4

MB6X5

Colored Handles – Add the designator corresponding to the correct handle as a suffix to the part number:

R - red, Y - yellow. Example: 2F-MB6X4PFA-SSP-R

Stainless Steel Handles – Add the suffix -ST to the part number.

Seat

Material

PFA

Perfluoroalkoxy SSP Stainless Steel (Stainless Steel

with Stainless Steel Panel Nut)

Example: 2A7-MB6XPFA-SSP-ST

Body

Material

20

W - white, B - blue, G - green,

Parker Hannifin Corporation

Instrumentation Products Division

Jacksonville, AL USA

http://www.parker.com/ipdus

Page 23

Catalog 4121-BV

Notes

Go to

Table of

Contents

MB

21

Parker Hannifin Corporation

Instrumentation Products Division

Jacksonville, AL USA

http://www.parker.com/ipdus

Page 24

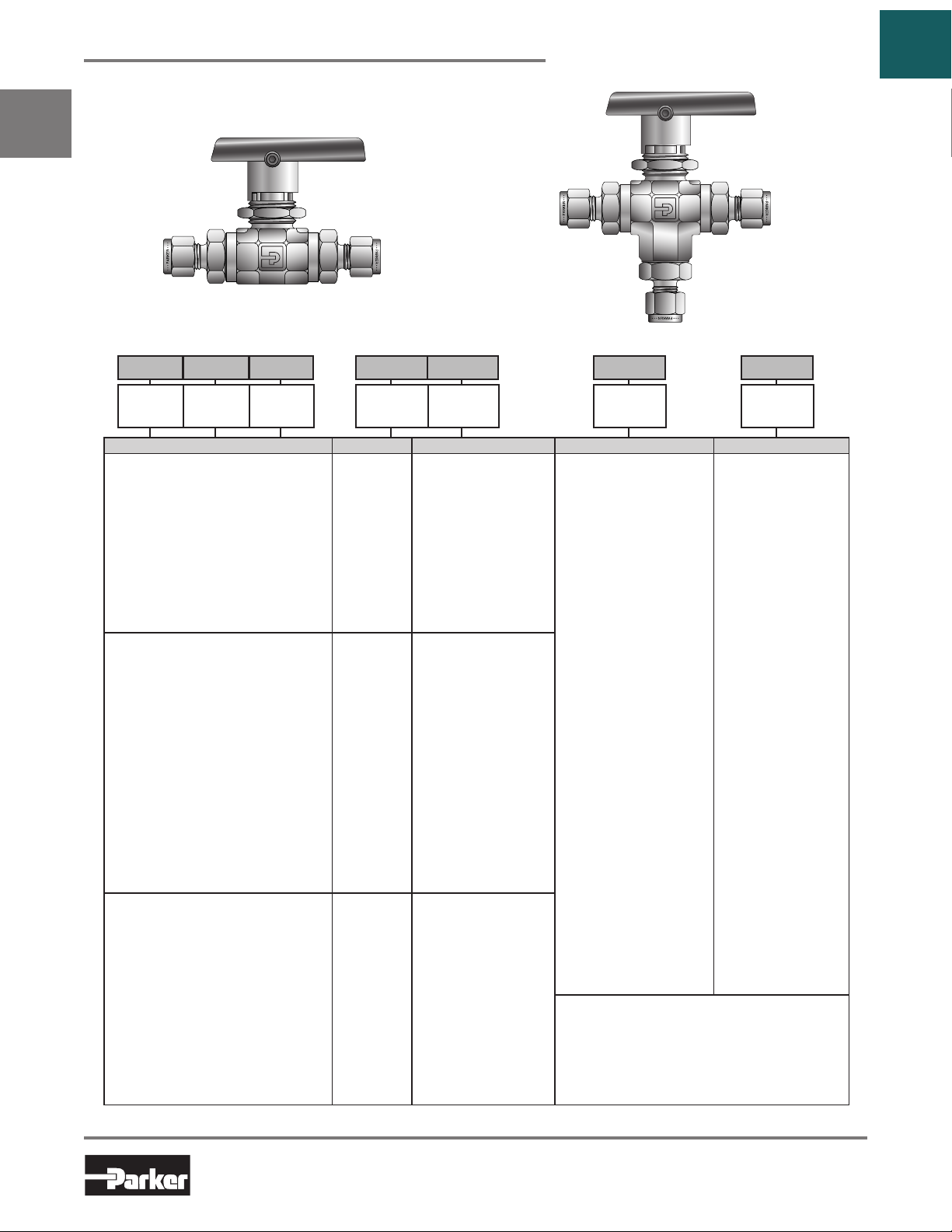

HB Series Ball Valves

Catalog 4121-BV

Introduction

Parker High Pressure HB4 Series Ball Valves provide reliable shut-off or switching functions. The upper and lower

trunnion bearings enhance the resistance of the trunnions against seizure, and increase the valve life in extreme

applications. The compact and rugged design employs spring-loaded seats for high cycle life and low operating

torques at pressures up to 10,000 psig (689 bar).

Go to

Table of

Contents

Features

PEEK trunnion bearings for longer cycle life

Two-way and three-way designs

Compact FNPT version for tight work areas

Blow-out resistant two-piece ball/stem

Full operating pressure at any port

HB

Low operating torque

Manual, electric or pneumatic actuation

Panel mountable to 3/8" (9.6mm) thickness

No packing to adjust

Color coded fracture resistant handles

Handle indicates direction of flow

Positive handle stops

Wide variety of US customary and SI ports

Top of stem marked to indicate flow direction

100% factory tested

Compact package

Heat code traceability

Specifications

Pressure

Rating

Temp. Rating

Body Materials

Body Config.

Port

Connections

Port Size

10,000 psig (689 bar) CWP with PEEK

(PKR) Seats

6,000 psig (414 bar) CWP with PCTFE (K)

Seats

-65˚F to 400˚F (-54˚C to 204˚C)

Stainless steel

Two-way and three-way

Tube compression (CPI™/A-LOK

Short and long female NPT

1/8" – 1/2" (6 mm to 12 mm)

Flow Data

Two-Way HB4L Three-Way HB4X

C

v

X

T

Orifice

Tested in accordance with ISA S75.02. Gas flow will be

choked when P1 - P2 / P1 = xT .

1.02 0.62

0.42 0.71

0.188"

(4.8mm)

(4.8mm)

0.188"

®

)

Two-Way HB4L Design

22

Three-Way HB4X Design

Parker Hannifin Corporation

Instrumentation Products Division

Jacksonville, AL USA

http://www.parker.com/ipdus

Page 25

Catalog 4121-BV

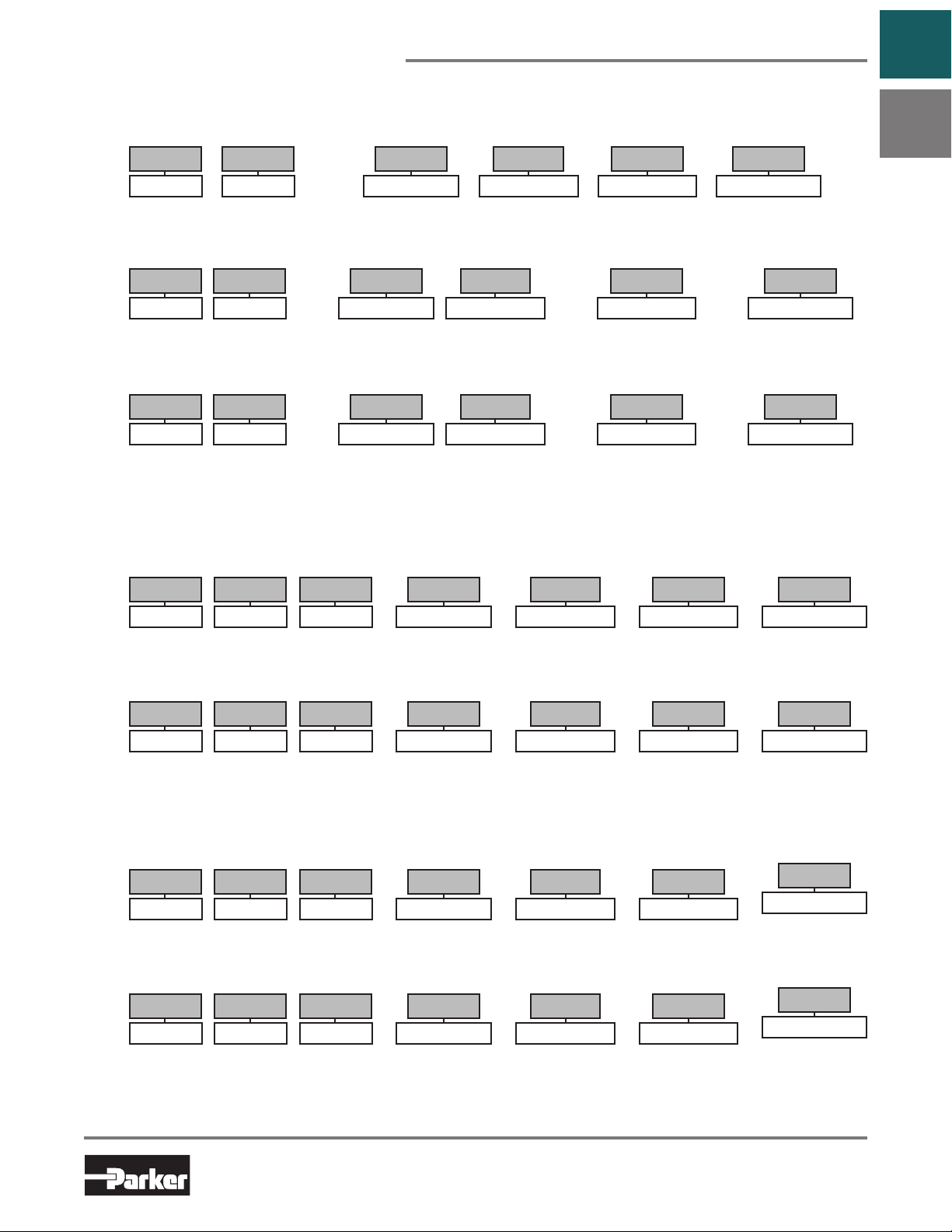

Pressure vs. Temperature

HB Series Ball Valves

Note: To determine MPa, multiply bar by 0.1

This pressure versus temperature chart reflects the

maximum temperature range of indicated materials.

When combining seat and seal materials, the most

restrictive temperature rating of the seats or seals

becomes the limiting factor on valve temperature

range.

Temperature Ratings:

Nitrile (Nitrile) Rubber 40°F to 250°F

(-40°C to 121°C)

Ethylene Propylene Rubber -65°F to 300°F

(-54°C to 149°C)

Fluorocarbon Rubber

-15°F to 400°F

(-26°C to 204°C)

Go to

Table of

Contents

HB

Flow Calculations,

Two-Way HB4L

Inlet

Pressure

psig bar psig bar gpm m3/hr scfm m3/hr

100 7

1000 69

3000 207

6000 414

10000 689

Pressure Drop

∆P

1 0.1 1.0 0.2 10.8 17.4

10 0.7 3.2 0.7 32.0 50.7

50 3.5 7.2 1.6 50.5 76.0

10 0.7 3.2 0.7 101.3 171.3

100 6.9 10.2 2.3 297.7 502.3

500 34.5 22.8 5.2 446.7 749.6

100 6.9 10.2 2.3 542.0 919.9

1000 69.0 32.3 7.3 1297.0 2198.9

1500 103.4 39.5 9.0 1327.2 2248.8

1000 69.0 32.3 7.3 2158.5 3662.7

2000 137.9 45.6 10.4 2188.5 4388.6

3000 206.8 55.9 12.7 2647.9 4486.8

1000 69.0 32.3 7.3 2954.3 5020.2

2000 137.9 45.6 10.4 3818.4 6487.0

3000 206.8 55.9 12.7 4236.2 7194.9

Water

@ 60°F (16°C)

Air

@ 60°F (16°C)

Flow Calculations,

Three-way HB4X

Inlet

Pressure

psig bar psig bar gpm m3/hr scfm m3/hr

100 7

1000 69

3000 207

6000 414

10000 689

Pressure Drop

∆P

1 0.1 0.6 0.1 6.6 10.6

10 0.7 2.0 0.4 20.0 31.9

50 3.5 4.4 1.0 37.1 57.4

10 0.7 2.0 0.4 61.8 104.4

100 6.9 6.2 1.4 187.2 316.1

500 34.5 13.9 3.1 337.4 567.7

100 6.9 6.2 1.4 333.1 565.4

1000 69.0 19.6 4.5 903.4 1532.8

1500 103.4 24.0 5.5 1004.4 1703.2

1000 69.0 19.6 4.5 1393.5 2365.2

2000 137.9 27.7 6.3 1803.8 3060.4

3000 206.8 34.0 7.7 2004.9 3399.8

1000 69.0 19.6 4.5 1858.9 3159.0

2000 137.9 27.7 6.3 2499.6 4247.2

3000 206.8 34.0 7.7 2903.0 4932.1

Water

@ 60°F (16°C)

Air

@ 60°F (16°C)

23

Parker Hannifin Corporation

Instrumentation Products Division