Page 1

aerospace

climate control

electromechanical

filtration

fluid & gas handling

hydraulics

pneumatics

process control

sealing & shielding

Accumulators and Receivers

Catalog C-1, May 2016

Page 2

Page 2 / Catalog C-1, Accumulators and Receivers

Table of Contents

Accumulators and Receivers

Typical Piping Diagram ......................................................3

Steel Suction Line Accumulators ..............................................4

Copper Vertical, Horizontal, and Stand-Pipe Accumulators - OEM only ............11

Steel Receivers............................................................13

Terms of Sale with Warranty Limitations ......................................16

⚠WARNING – USER RESPONSIBILITY

Failure or improper selection or improper use of the products described herein or related items can cause death, personal injury and property damage.

This document and other information from Parker Hannin Corporation, its subsidiaries and authorized distributors provide product or system options for further investigation

by users having technical expertise.

The user, through its own analysis and testing, is solely responsible for making the nal selection of the system and components and assuring that all performance, endurance,

maintenance, safety and warning requirements of the application are met. The user must analyze all aspects of the application, follow applicable industry standards, and follow

the information concerning the product in the current product catalog and in any other materials provided from Parker or its subsidiaries or authorized distributors.

To the extent that Parker or its subsidiaries or authorized distributors provide component or system options based upon data or specications provided by the user, the user

is responsible for determining that such data and specications are suitable and sufcient for all applications and reasonably foreseeable uses of the components or systems.

OFFER OF SALE

The items described in this document are hereby offered for sale by Parker Hannin Corporation, its subsidiaries or its authorized distributors. This offer and its acceptance are

governed by the provisions stated in the detailed “Offer of Sale” elsewhere in this document or available at www.parker.com.

Page 3

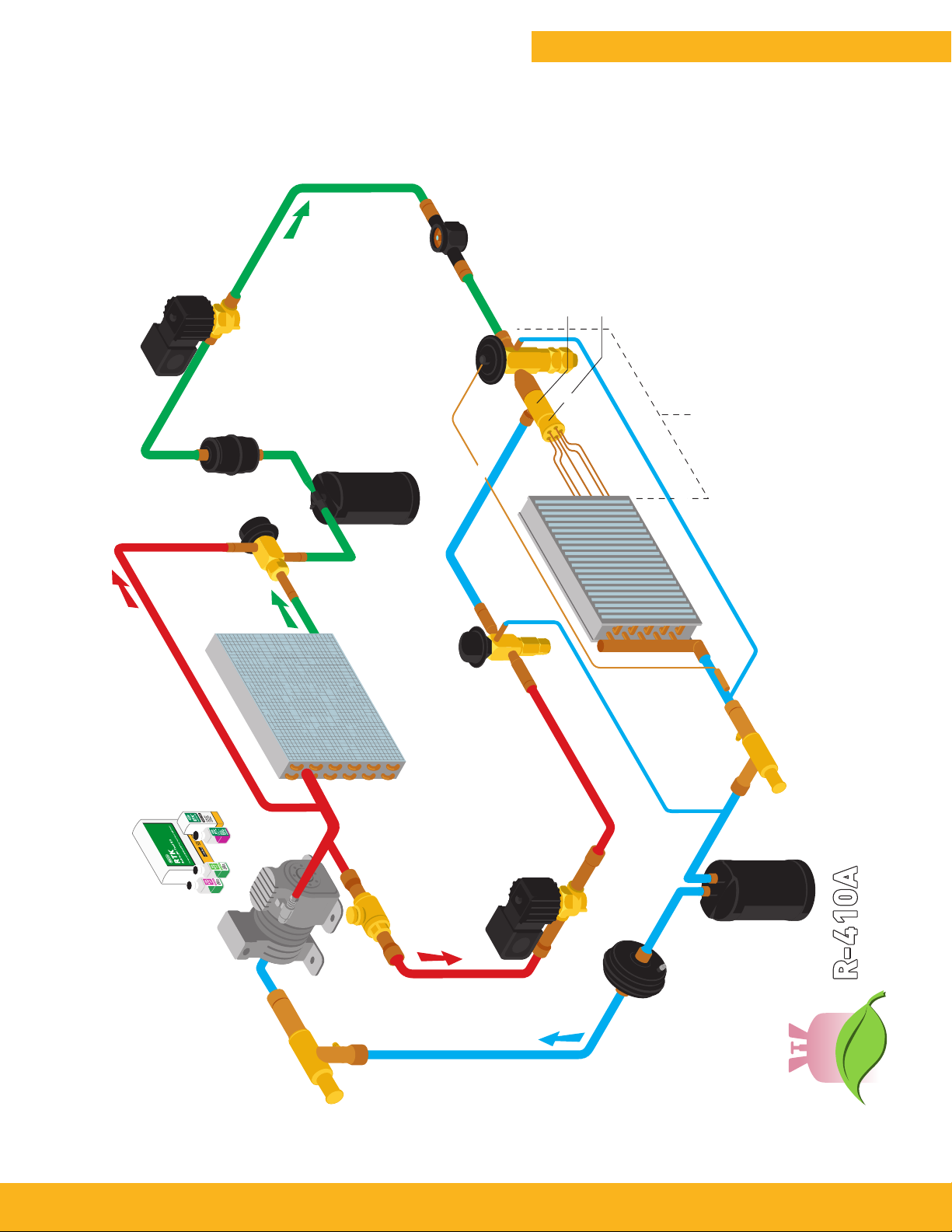

Typical Piping Diagram

Suction Line

Filter-Drier

Accumulator

*

Liquid Line

Solenoid

Valve

*

Liquid

*

Liquid Line

Filter-Drier

*

Receiver

Moisture &Liquid

Indicator

Liquid

Catalog C-1, Accumulators and Receivers / Page 3

Thermostatic

Expansion Valve

ASC Auxiliary

Side Connector

Refrigerant

Distributor

*

TEVs,

Assemblies

Saturated Liquid &

Vapor at TEV Outlet

Distributors, Tube

This schematic is for component location

only, not a typical piping recommendation.

LAC

Head

Pressure

Control

ETK/RTK

Acid Test Kit

Valve

*

Condensed

Liquid

Discharge Gas Bypassed

External Equalizer Connection

EVAPORATOR

*

HGBE

Discharge

Bypass

CONDENSER

Condenser Bypass Discharge Gas

*

EBV

Ball Valve

Valve

Hot Gas

Solenoid

*

ORIT

Evaporator Pressure

Regulating Valve

External Equalizer

Connection

Valve

*

COMPRESSOR

CROT

Crankcase

Pressure

Regulating

*

Valve

Suction Line

Models Available

*

Superheated Suction Gas

Page 4

Page 4 / Catalog C-1, Accumulators and Receivers

Steel Suction Line Accumulators

Design

The function of a suction line accumulator in a heat pump or refrigeration system

is to catch and hold any unused portion of

the system charge. The device must also

prevent liquid slugging of the compressor and excessive refrigerant dilution of

the compressor oil.

The accumulator must return refrigerant

and oil to the compressor at a sufficient

rate to maintain both system operating

efficiency and proper crankcase oil level.

To make sure these tasks are accomplished, system designers must consider

the following items:

■ A properly sized and protected oil re-

turn orifice is required to ensure positive oil (and refrigerant) return to the

compressor

■ The accumulator must have sufficient in-

ternal volume

■ The pressure drop across the accumula-

tor should be as low as possible

Oil return at a minimum flow rate is

controlled by the outlet U-tube size.

Refrigerant and oil will be returned to

the compressor by pressure drop across

the orifice metering area and the liquid

head above the orifice. Other design

requirements include safe working pressure, agency approvals and corrosion

resistance.

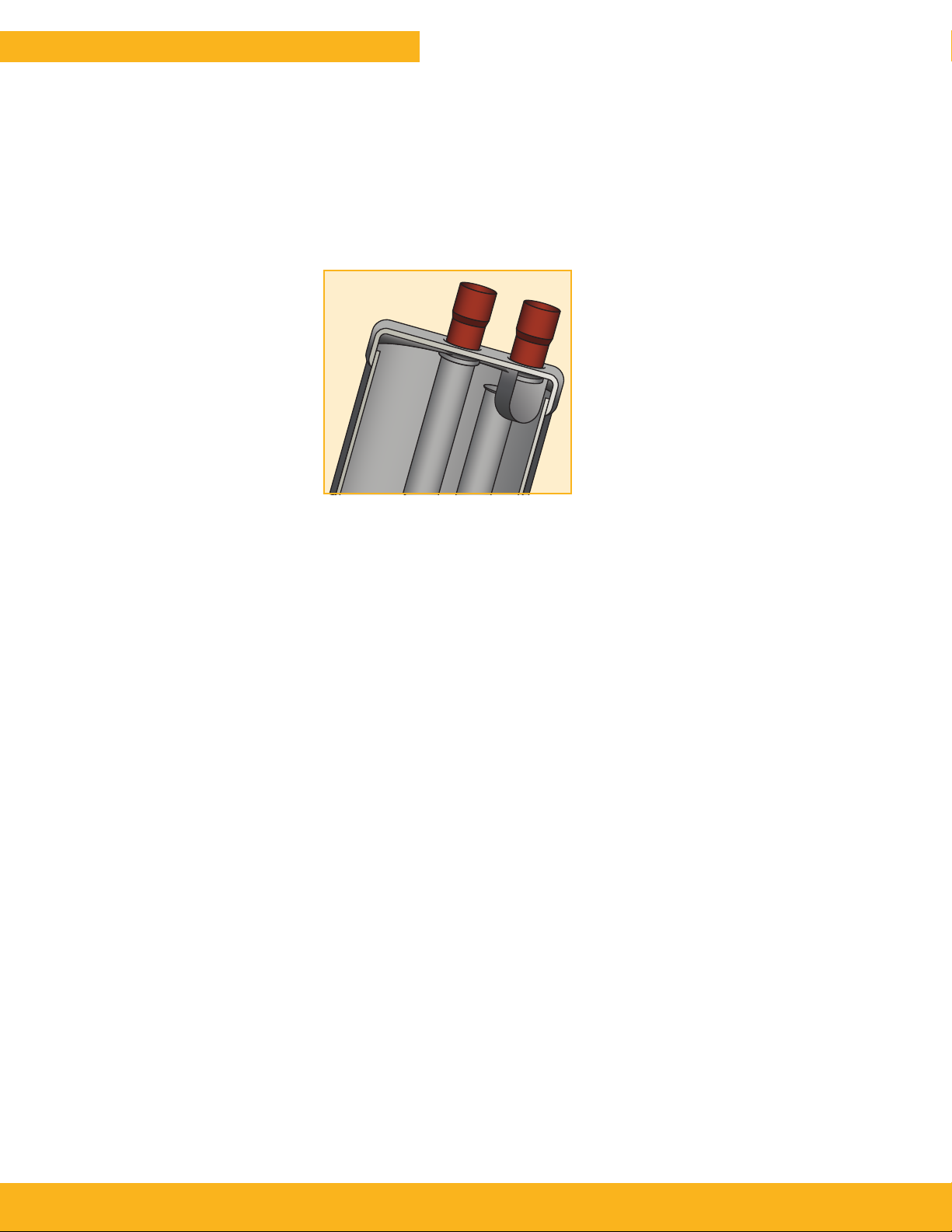

Figure 1 illustrates a typical accumulator with an inlet defector. The shape of

the deflector directs the inlet flow in a

slightly downward tangential direction.

The inlet to the U-tube is located behind

the inlet deflector to prevent liquid carryover and is bell-shaped to reduce the

sudden contraction loss of the highvelocity gas. The U-tube diameter is

selected to minimize pressure drop at

high flow rates yet provide adequate oil

return at low flow rates.

Other features include a 50 x 60 mesh

screen to protect the oil return orifice,

an anti-siphon hole and a fusible alloy

plug in the accumulator. The anti-siphon

hole located near the outlet of the U-tube

prevents liquid from siphoning into the

outlet tube and compressor during an offcycle. The fusible alloy plug is generally

a U.L. requirement since it is a safety

device to protect against excessive pressure in the event of a fire.

Figure 1

Typical accumulator with inlet deflector baffle.

Selection

Accumulator selection can be fine-tuned

for best performance. This involves the

sizing of the accumulator and the sizing

of the orifice. The controlling factor for

both types is the type of metering device

used in the system. In systems using a

fixed orifice, the accumulator holding

capacity should be about 70% of the

system charge. This provides adequate

holding capacity during operation with

blocked or fouled heat exchanger coils.

The resulting high discharge/low suction

pressure condition will result in more

liquid refrigerant in the accumulator. The

oil return orifice size should be small to

prevent excess liquid refrigerant being

returned to the compressor. For these

systems, a 0.040 inch (1.02 mm) diameter orifice is the recommended starting

point.

For systems with a thermostatic expan-

sion valve (TEV), the accumulator holding capacity should be approximately

50% of the system charge. At startup

and after defrost the bulb of the TEV is

warm. Until the valve regains control,

the accumulator plays a role in preventing liquid slugging of the compressor.

The accumulator must also contend with

off cycle refrigerant migration. At shut-

down, the accumulator is the coldest

component in the system. This results

in migration of liquid refrigerant to the

device. This type of system needs to

return the refrigerant to circulation more

quickly than the fixed orifice system.

For these systems, a 0.055 inch (1.4 mm)

diameter orifice allows quick return of

the liquid refrigerant. The recommended

sizes of the orifices can be further tested

for optimum results. Other size orifices

are possible to satisfy the characteristics

required by the system designer.

New Refrigerants

The introduction of alternative refrigerants and oils requires reviewing the

design of components within the system, including suction accumulators. As

previously stated, the accumulator is the

coldest component in the system. The

new refrigerants and oils may or may

not be fully miscible in the temperature

range the accumulator normally operates. The oil and refrigerant can separate

into oil rich and refrigerant rich layers

in the accumulator, with the refrigerant

rich layer at the bottom. The oil return

orifice would be located in the refrigerant rich layer.

The solution to this problem is to provide

active mixing of the layers in the accumulator. This is accomplished by the

shape and position of the inlet deflector

and outlet U-tube. The inlet flow stream

is directed tangentially into the liquid

layers in the bottom of the accumulator.

The resulting circulation of the liquid

past the off center U-tube forces a mixing of the oil and refrigerant layers.

Field Replacement

The accumulator should be changed

when a compressor is replaced. The

old accumulator may contain contaminants from the problem that caused the

compressor failure. There may also be

considerable oil remaining from the first

compressor if a gradual loss of refrigerant caused the failure. This amount

coupled with the oil in the replacement

compressor may create an oil overcharge

condition.

Page 5

Catalog C-1, Accumulators and Receivers / Page 5

Steel Suction Line Accumulators

U-Tube Style Accumulators – VA, PA and VPA Series

The U-tube accumulator design is a result of extensive laboratory testing of

various designs. It takes into account essential requirements such as safe holding

volume (relative to the system’s total charge), protected flow control for positive

refrigerant and oil return, and minimum pressure drop across the accumulator.

Parker offers standard accumulator models designed for application on heat pump and

refrigeration systems from 1/4 ton (.88 kW) through 28.5 tons (100.2 kW). Liquid

refrigerant holding requirements of suction accumulator may vary by application.

Features and Benefits

■ Solid copper connections (except where noted in the following tables)

■ U-tube design for maximum flow of refrigerant and minimum oil entrapment

■ Inlet flow deflector guides refrigerant toward wall for smooth tangential flow and gradual

expansion

■ Baffled U-tube entrance is positioned behind the inlet flow deflector to prevent unwanted

liquid refrigerant from entering and damaging compressor at all rated conditions

■ Metering orifice matched to system capacity which optimizes liquid refrigerant and oil

flow return back to compressor at all rated conditions

■ Protective screen and orifice assembly on U-tube protects against contaminants affecting

metering function

■ Minimum pressure drop and Maximum refrigerant flow

■ VA and VPA models are U.L. Listed for USA and Canada for 300 psig (20.7 bar) maximum

working pressure under SA5764-SKXY/SKXY7

■ PA models are U.L. Listed for USA and Canada for 355 psig (24.5 bar) maximum working

pressure under SA5764-SKXY/SKXY7

■ Powder coating surpasses 500 hour ASTM salt spray

■ Integral 430°F (221°C) fuse plugs on larger models

■ Compatible with CFC, HCFC and HFC refrigerants including R-22, R-134a, R-404A, R-407C,

R-410A, R-500, R-502 and R-507

Dimensions and Flow Data

Refer to pages 6 through 10 for dimension values and flow data.

Page 6

Page 6 / Catalog C-1, Accumulators and Receivers

Dimensions

IN

“VA” Series

“E”

OUT

“A”

“D”

“C”

“B”

“PA” and “VPA” Series

“E”

“D”

IN

OUT

“A”

“B”

“C”

Page 7

Dimensions

Catalog C-1, Accumulators and Receivers / Page 7

Catalog

Number

VA304S

Unit

Item

Number

Weight

lbs.

(KG)

1

470043 1.7 (0.8) 3 (76.0) 8-1/4 (210.0) 7-1/2 (191.0) 1/2 (12.7) 1-5/8 (41.0) 0.060 (1.5) 0.030 (0.85) 35 (1.02)

“A”

Diameter

Inches

(mm)

“B”

Overall Length

Inches

(mm)

“C””C”

Vessel Length

Inches

(mm)

“D”

Connection

Inches

(mm)

“E”

Fitting

Inches

(mm)

“F”

Oil Orifice

Inches

(mm)

Internal

Volume

Cu. Ft.

(liters)

Capacities

VA314S 470106 1.9 (0.9) 3 (76.0) 10-3/8 (264.0) 9-3/8 (238.0) 1/2 (12.7) 1-3/4 (44.0) 0.055 (1.4) 0.034 (0.96) 1.16 (39)

VA315S 470107 1.9 (0.9) 3 (76.0) 10-3/8 (264.0) 9-3/8 (238.0) 5/8 (15.9) 1-3/4 (44.0) 0.055 (1.4) 0.034 (0.96) 1.16 (39)

VA325S 470048 2.1 (1.0) 3 (76.0) 12-1/4 (311.0) 11-1/2 (292.0) 5/8 (15.9) 1-5/8 (41.0) 0.060 (1.5) 0.040 (1.13) 46 (1.36)

1

VA326S

470136 2.1 (1.0) 3 (76.0) 12-5/8 (321.0) 11-1/2 (292.0) 3/4 (19.1) 1-5/8 (41.0) 0.060 (1.5) 0.040 (1.13) 46 (1.36)

VA355S 470049 2.7 (1.2) 3 (76.0) 15-1/16 (383.0) 13-3/4 (349.0) 5/8 (15.9) 1-5/8 (41.0) 0.055 (1.4) 0.051 (1.44) 59 (1.74)

VA356S 470093 2.7 (1.2) 3 (76.0) 15-1/16 (383.0) 13-3/4 (349.0) 3/4 (19.1) 1-5/8 (41.0) 0.055 (1.4) 0.051 (1.44) 59 (1.74)

1

VA445SRD

VA446SRD

470051 4.3 (2.0) 4 (102.0) 10-3/4 (273.0) 9-15/16 (252.0) 5/8 (15.9) 2-1/2 (64.0) 0.035 (0.9) 0.072 (2.04) 83 (2.45)

1

470094 4.3 (2.0) 4 (102.0) 10-5/8 (270.0) 9-3/4 (248.0) 3/4 (19.1) 2-1/2 (64.0) 0.055 (1.4) 0.072 (2.04) 83 (2.45)

PA4065-9-5C 960119 4.3 (2.0) 4 (102.0) 9-5/8 (244.0) 8-1/2 (216.0) 5/8 (15.9) 1-3/4 (44.0) 0.055 (1.4) 0.061 (1.73) 70 (2.08)

PA4065-9-6C 960120 4.3 (2.0) 4 (102.0) 9-5/8 (244.0) 8-1/2 (216.0) 3/4 (19.1) 1-3/4 (44.0) 0.055 (1.4) 0.061 (1.73) 70 (2.08)

VA546SRD 470052 5.2 (2.4) 5 (127.0) 9-5/8 (244.0) 8-1/2 (216.0) 3/4 (19.1) 2-3/4 (70.0) 0.063 (1.6) 0.09 (2.55) 104 (3.07)

VA547SRD 470054 5.2 (2.4) 5 (127.0) 9-3/4 (248.0) 8-1/2 (216.0) 7/8 (22.2) 2-3/4 (70.0) 0.063 (1.6) 0.09 (2.55) 104 (3.07)

VA557SRD 470055 7.0 (3.2) 5 (127.0) 10-3/4 (273.0) 9-1/2 (241.0) 7/8 (22.2) 3.0 (76.0) 0.055 (1.4) 0.11 (3.11) 127 (3.75)

VA566SRD 470056 7.9 (3.6) 5 (127.0) 12-3/4 (324.0) 11-5/8 (295.0) 3/4 (19.1) 2-3/4 (70.0) 0.063 (1.6) 0.13 (3.68) 150 (4.43)

VA567SRD 470058 7.9 (3.6) 5 (127.0) 13 (330.0) 11-3/4 (298.0) 7/8 (22.2) 2-3/4 (70.0) 0.063 (1.6) 0.13 (3.68) 150 (4.43)

VA577SRD 470059 8.1 (3.7) 5 (127.0) 14-5/8 (371.0) 13-3/8 (340.0) 7/8 (22.2) 2-3/4 (70.0) 0.063 (1.6) 0.14 (3.96) 161 (4.77)

VA579SRD 470060 8.1 (3.7) 5 (127.0) 14-13/16 (376.0) 13-3/8 (340.0) 1-1/8 (28.6) 2-3/4 (70.0) 0.063 (1.6) 0.14 (3.96) 161 (4.77)

VPA5896SRD 470110 5.1 (2.3) 5 (127.0) 9-5/8 (244.0) 8-5/16 (211.0) 3/4 (19.1) 1-3/4 (44.0) 0.055 (1.4) 0.085 (2.41) 98 (2.90)

VPA5897SRD 470111 4.9 (2.2) 5 (127.0) 9-5/8 (244.0) 8-1/8 (206.0) 7/8 (22.2) 1-3/4 (44.0) 0.055 (1.4) 0.083 (2.35) 96 (2.83)

VPA58116SRD 470112 6.8 (3.1)

5 (127.0) 11-5/16 (287.0) 10 (254.0) 3/4 (19.1) 1-3/4 (44.0) 0.055 (1.4) 0.103 (2.91) 119 (3.51)

VPA58117SRD 470069 6.0 (2.7) 5 (127.0) 11-5/16 (287.0) 9-13/16 (249.0) 7/8 (22.2) 1-3/4 (44.0) 0.055 (1.4) 0.101 (2.86) 116 (3.44)

VPA58127SRD 470070 7.7 (3.5) 5 (127.0) 12-7/8 (327.0) 11-3/8 (289.0) 7/8 (22.2) 1-3/4 (44.0) 0.055 (1.4) 0.117 (3.31) 135 (3.99)

VPA58157SRD 470115 8.4 (3.8) 5 (127.0) 15-3/8 (391.0) 13-13/16 (351.0) 7/8 (22.2) 1-3/4 (44.0) 0.055 (1.4) 0.143 (4.05) 165 (4.88)

VPA58177SRD 470116 9.6 (4.4) 5 (127.0) 17-1/4 (438.0) 15-3/4 (400.0) 7/8 (22.2) 1-3/4 (44.0) 0.055 (1.4) 0.163 (4.61) 188 (5.56)

VA599SRD 470062 8.4 (3.8) 5 (127.0) 18-3/8 (467.0) 16-15/16 (430.0) 1-1/8 (28.6) 2-3/4 (70.0) 0.063 (1.6) 0.18 (5.09) 207 (6.14)

VA5911SRD 470061 8.4 (3.8) 5 (127.0) 18-7/16 (468.0) 16-15/16 (430.0) 1-3/8 (34.9) 2-3/4 (70.0) 0.063 (1.6) 0.18 (5.09) 207 (6.14)

VA6107SRD

VA6109SRD

1

470117 11.8 (5.4) 6 (152.0) 13-7/8 (352.0) 12-5/8 (321.0) 7/8 (22.2) 2-15/16 (75.0) 0.040 (1.0) 0.18 (5.09) 207 (6.14)

1

470118 11.8 (5.4) 6 (152.0) 14 (356.0) 12-5/8 (321.0) 1-1/8 (28.6) 2-15/16 (75.0) 0.040 (1.0) 0.18 (5.09) 207 (6.14)

VA6119SRD 470065 12.4 (5.6) 6 (152.0) 15-1/4 (387.0) 13-3/4 (349.0) 1-1/8 (28.6) 2-15/16 (75.0) 0.075 (1.9) 0.20 (5.66) 230 (6.82)

VA61111SRD

1

470063 12.4 (5.6) 6 (152.0) 15-1/4 (387.0) 13-3/4 (349.0) 1-3/8 (34.9) 2-15/16 (75.0) 0.060 (1.5) 0.20 (5.66) 230 (6.82)

VA61511SRD 470066 15.9 (7.2) 6 (152.0) 19-1/2 (495.0) 18 (457.0) 1-3/8 (34.9) 2-15/16 (75.0) 0.075 (1.9) 0.29 (8.21) 334 (9.89)

VA61613SRD

1

470068 16.3 (7.4) 6 (152.0) 21-7/8 (556.0) 20-1/4 (514.0) 1-5/8 (41.3) 2-15/16 (75.0) 0.060 (1.5) 0.30 (8.49) 346 (10.23)

Holding capacities stated for R-410A at 40°F (4°C).

Multiply holding capacity by 1.1 to obtain R-22 data at 40°F (4°C).

Multiply total system charge by 0.7 to obtain recommended maximum holding capacity for fixed orifice systems.

Multiply total system charge by 0.5 to obtain recommended maximum holding capacity for systems with TEVs.

Catalog numbers in bold font are available as standard wholesale offering.

1

These models have copper-plated steel connections. All other models have solid copper connections.

Holding

Ounces

(liters)

Page 8

Page 8 / Catalog C-1, Accumulators and Receivers

Flow Capacity

Catalog

Number

1

VA304S

VA314S 2.0 (7.0) 1.3 (4.6) 0.9 (3.1)

VA315S 3.0 (10.6) 2.0 (6.9) 1.3 (4.7)

VA325S 3.0 (10.6) 2.0 (6.9) 1.3 (4.7)

1

VA326S

VA355S 3.0 (10.6) 2.0 (6.9) 1.3 (4.7)

VA356S 4.0 (14.1) 2.6 (9.2) 1.8 (6.2)

1

VA445SRD

1

VA446SRD

PA4065-9-5C 3.0 (10.6) 2.4 (8.4) 1.9 (6.7)

PA4065-9-6C 3.0 (10.6) 2.5 (8.8) 2.0 (7.0)

VA546SRD 4.0 (14.1) 2.6 (9.2) 1.8 (6.2)

VA547SRD 7.3 (25.7) 4.8 (16.7) 3.2 (11.4)

VA557SRD 7.3 (25.7) 4.8 (16.7) 3.2 (11.4)

VA566SRD 4.0 (14.1) 2.6 (9.2) 1.8 (6.2)

VA567SRD 7.3 (25.7) 4.8 (16.7) 3.2 (11.4)

VA577SRD 7.3 (25.7) 4.8 (16.7) 3.2 (11.4)

VA579SRD

VPA5896SRD 4.0 (14.1) 2.6 (9.1) 1.8 (6.3)

VPA5897SRD 7.3 (25.7) 4.8 (16.7) 3.2 (11.4)

VPA58116SRD 7.5 (26.4) 5.0 (17.6) 3.4 (12.0)

VPA58117SRD 7.3 (25.7) 4.8 (16.9) 3.2 (11.3)

VPA58127SRD 6.3 (22.2) 4.5 (15.8) 3.0 (10.6)

VPA58157SRD 10.4 (36.6) 6.9 (24.3) 3.7 (13.0)

VPA58177SRD 11.2 (39.4) 7.4 (26.0) 4.9 (17.2)

VA599SRD 11.8 (41.5) 7.7 (27.0) 5.2 (18.4)

VA5911SRD 18.8 (66.1) 12.3 (43.1) 8.3 (29.3)

VA6107SRD

VA6109SRD

VA61111SRD

VA61511SRD 18.8 (66.1) 12.3 (43.1) 8.3 (29.3)

VA61613SRD

1

1

1

1

+40°F (+4°C) +20°F (-6°C) 0°F (-17°C)

2.0 (7.0) 1.3 (4.6) 0.9 (3.1)

4.0 (14.1) 2.6 (9.2) 1.8 (6.2)

3.0 (10.6) 2.0 (6.9) 1.3 (4.7)

4.0 (14.1) 2.6 (9.2) 1.8 (6.2)

11.8 (41.5) 7.7 (27.0) 5.2 (18.4)

7.3 (25.7) 4.8 (16.7) 3.2 (11.4)

11.8 (41.5) 7.7 (27.0) 5.2 (18.4)

18.8 (66.1) 12.3 (43.1) 8.3 (29.3)

28.5 (100.2) 18.6 (65.3) 12.6 (44.5)

Flow Capacity in Tons (kW)

Refrigerant 22

Factors For Other Ratings

Evaporator Temperature -20°F (-28°C) -40°F (-40°C)

X Factor 0.28 0.18

To find the capacity for -20°F (-28°C) and -40°F (-40°C) evaporator temperatures in tons, multiply the 40°F (4°C) evaporator

temperature by the X factor.

To find the minimum capacity in tons, multiply the 40°F (4°C)

rating by 0.15.

Maximum recommended tons based on pressure drop through

the accumulator equal to 1.0°F (-17°C) temperature drop.

Notes:

1. Minimum recommended tons should be no less than 15%

of recommended tons to ensure positive oil return.

2. All data based on actual tons and is not related to horsepower.

3. Minimum evaporator temperature: -40°F (4°C). Minimum

suction gas temperature through the accumulator: +10°F

(-12°C). For operating conditions not within the rating data,

please contact Parker before proceeding with installation.

Page 9

Flow Capacity

Catalog C-1, Accumulators and Receivers / Page 9

Catalog

Number

1

VA304S

VA314S 1.3 (4.5) 0.8 (2.9) 0.5 (1.9) 1.3 (4.5) 0.9 (3.0) 0.5 (1.8)

VA315S 1.9 (6.8) 1.2 (4.3) 0.8 (2.8) 1.9 (6.7) 1.3 (4.5) 0.8 (2.8)

VA325S 1.9 (6.8) 1.2 (4.3) 0.8 (2.8) 1.9 (6.7) 1.3 (4.5) 0.8 (2.8)

1

VA326S

VA355S 1.9 (6.8) 1.2 (4.3) 0.8 (2.8) 1.9 (6.7) 1.3 (4.5) 0.8 (2.8)

VA356S 2.6 (9.1) 1.6 (5.7) 1.1 (3.8) 2.5 (8.9) 1.7 (6.0) 1.0 (3.7)

VA445SRD

VA446SRD

PA4065-9-5C 2.2 (7.7) 1.8 (6.3) 1.6 (5.6) 2.5 (8.8) 1.6 (5.6) 1.4 (4.9)

PA4065-9-6C 2.2 (7.7) 1.9 (6.7) 1.7 (5.9) 2.5 (8.8) 1.7 (5.9) 1.5 (5.3)

VA546SRD 2.6 (9.1) 1.6 (5.7) 1.1 (3.8) 2.5 (8.9) 1.7 (6.0) 1.0 (3.7)

VA547SRD 4.7 (16.5) 3.0 (10.5) 2.0 (6.9) 4.6 (16.3) 3.1 (11.0) 1.9 (6.7)

VA557SRD 4.7 (16.5) 3.0 (10.5) 2.0 (6.9) 4.6 (16.3) 3.1 (11.0) 1.9 (6.7)

VA566SRD 2.6 (9.1) 1.6 (5.7) 1.1 (3.8) 2.5 (8.9) 1.7 (6.0) 1.0 (3.7)

VA567SRD 4.7 (16.5) 3.0 (10.5) 2.0 (6.9) 4.6 (16.3) 3.1 (11.0) 1.9 (6.7)

VA577SRD 4.7 (16.5) 3.0 (10.5) 2.0 (6.9) 4.6 (16.3) 3.1 (11.0) 1.9 (6.7)

VA579SRD 7.6 (26.7) 4.8 (16.9) 3.2 (11.1) 7.5 (26.4) 5.0 (17.7) 3.1 (10.9)

VPA5896SRD 2.6 (9.1) 1.6 (5.6) 1.1 (4.0) 2.5 (8.8) 1.7 (6.0) 1.0 (3.5)

VPA5897SRD 4.7 (16.5) 3.0 (10.5) 2.0 (6.9) 4.6 (16.3) 3.1 (11.0) 1.9 (6.7)

VPA58116SRD 4.7 (16.5) 3.0 (10.6) 2.0 (7.0) 4.6 (16.2) 3.1 (10.9) 1.9 (6.7)

VPA58117SRD 4.5 (15.8) 2.8 (9.8) 1.8 (6.3) 4.4 (15.5) 2.8 (9.8) 1.7 (6.0)

VPA58127SRD 4.6 (16.2) 2.9 (10.2) 1.9 (6.7) 4.5 (15.8) 2.9 (10.2) 1.8 (6.3)

VPA58157SRD 4.8 (16.9) 3.2 (11.3) 2.2 (7.7) 4.7 (16.5) 3.2 (11.3) 2.0 (7.0)

VPA58177SRD 6.6 (23.2) 4.8 (16.9) 3.2 (11.3) 7.5 (26.4) 5.0 (17.6) 3.1 (10.9)

VA599SRD 7.6 (26.7) 4.8 (16.9) 3.2 (11.1) 7.5 (26.4) 5.0 (17.7) 3.1 (10.9)

VA5911SRD 12.1 (42.6) 7.7 (27.0) 5.1 (17.8) 12.0 (42.1) 8.0 (28.2) 4.9 (17.3)

VA6107SRD

VA6109SRD

VA61111SRD

VA61511SRD 12.1 (42.6) 7.7 (27.0) 5.1 (17.8) 12.0 (42.1) 8.0 (28.2) 4.9 (17.3)

VA61613SRD

+40°F (+4°C) +20°F (-6°C) 0°F (-17°C) +40°F (+4°C) +20°F (-6°C) 0°F (-17°C)

1.3 (4.5) 0.8 (2.9) 0.5 (1.9) 1.3 (4.5) 0.9 (3.0) 0.5 (1.8)

2.6 (9.1) 1.6 (5.7) 1.1 (3.8) 2.5 (8.9) 1.7 (6.0) 1.0 (3.7)

1

1

1

1

1.9 (6.8) 1.2 (4.3) 0.8 (2.8) 1.9 (6.7) 1.3 (4.5) 0.8 (2.8)

2.6 (9.1) 1.6 (5.7) 1.1 (3.8) 2.5 (8.9) 1.7 (6.0) 1.0 (3.7)

4.7 (16.5) 3.0 (10.5) 2.0 (6.9) 4.6 (16.3) 3.1 (11.0) 1.9 (6.7)

7.6 (26.7) 4.8 (16.9) 3.2 (11.1) 7.5 (26.4) 5.0 (17.7) 3.1 (10.9)

1

12.1 (42.6) 7.7 (27.0) 5.1 (17.8) 12.0 (42.1) 8.0 (28.2) 4.9 (17.3)

1

18.4 (64.6) 11.6 (40.9) 7.7 (26.9) 18.1 (63.8) 12.2 (42.8) 7.5 (26.2)

Refrigerant 502 Refrigerant 134a

Flow Capacity in Tons (kW)

Factors For Other Ratings

Evaporator Temperature -20°F (-28°C) -40°F (-40°C)

X Factor 0.28 0.18

To find the capacity for -20°F (-28°C) and -40°F (-40°C) evaporator temperatures in tons, multiply the 40°F (4°C) evaporator

temperature by the X factor.

To find the minimum capacity in tons, multiply the 40°F (4°C)

rating by 0.15.

Maximum recommended tons based on pressure drop through

the accumulator equal to 1.0°F (-17°C) temperature drop.

Notes:

1. Minimum recommended tons should be no less than 15%

of recommended tons to ensure positive oil return.

2. All data based on actual tons and is not related to horsepower.

3. Minimum evaporator temperature: -40°F (4°C). Minimum

suction gas temperature through the accumulator: +10°F

(-12°C). For operating conditions not within the rating data,

please contact Parker before proceeding with installation.

Page 10

Page 10 / Catalog C-1, Accumulators and Receivers

Flow Capacity

Catalog

Number

1

VA304S

VA314S 1.9 (6.7) 1.2 (4.2) 0.8 (2.8) 1.4 (4.8) 0.8 (2.9) 0.6 (1.9)

VA315S 2.8 (10.0) 1.8 (6.4) 1.2 (4.2) 2.0 (7.2) 1.3 (4.4) 0.8 (2.9)

VA325S 2.8 (10.0) 1.8 (6.4) 1.2 (4.2) 2.0 (7.2) 1.3 (4.4) 0.8 (2.9)

1

VA326S

VA355S 2.8 (10.0) 1.8 (6.4) 1.2 (4.2) 2.0 (7.2) 1.3 (4.4) 0.8 (2.9)

VA356S 3.8 (13.4) 2.4 (8.5) 1.6 (5.6) 2.7 (9.6) 1.7 (5.9) 1.1 (3.9)

VA445SRD

VA446SRD

PA4065-9-5C 2.9 (10.2) 2.5 (8.8) 2.3 (8.0) 3.0 (10.6) 2.4 (8.4) 1.9 (6.7)

PA4065-9-6C 2.9 (10.2) 2.6 (9.1) 2.3 (8.0) 3.0 (10.6) 2.5 (8.8) 2.0 (7.0)

VA546SRD 3.8 (13.4) 2.4 (8.5) 1.6 (5.6) 2.7 (9.6) 1.7 (5.9) 1.1 (3.9)

VA547SRD 6.9 (24.4) 4.4 (15.5) 2.9 (10.3) 5.0 (17.5) 3.0 (10.7) 2.0 (7.1)

VA557SRD 6.9 (24.4) 4.4 (15.5) 2.9 (10.3) 5.0 (17.5) 3.0 (10.7) 2.0 (7.1)

VA566SRD 3.8 (13.4) 2.4 (8.5) 1.6 (5.6) 2.7 (9.6) 1.7 (5.9) 1.1 (3.9)

VA567SRD 6.9 (24.4) 4.4 (15.5) 2.9 (10.3) 5.0 (17.5) 3.0 (10.7) 2.0 (7.1)

VA577SRD 6.9 (24.4) 4.4 (15.5) 2.9 (10.3) 5.0 (17.5) 3.0 (10.7) 2.0 (7.1)

VA579SRD 11.2 (39.4) 7.1 (25.0) 4.7 (16.6) 8.1 (28.3) 4.9 (17.3) 3.3 (11.5)

VPA5896SRD 3.8 (13.4) 2.4 (8.4) 1.6 (5.6) 2.7 (9.5) 1.7 (6.0) 1.1 (3.9)

VPA5897SRD 6.9 (24.4) 4.4 (15.5) 2.9 (10.3) 5.0 (17.5) 3.0 (10.7) 2.0 (7.1)

VPA58116SRD 6.9 (24.3) 4.4 (15.5) 2.9 (10.2) 5.0 (17.6) 3.0 (10.6) 2.0 (7.0)

VPA58117SRD 6.5 (22.9) 4.2 (14.8) 2.5 (8.8) 4.7 (16.5) 2.8 (9.8) 1.8 (6.3)

VPA58127SRD 6.8 (23.9) 4.3 (15.1) 2.8 (9.8) 4.8 (16.9) 2.8 (9.8) 1.8 (6.3)

VPA58157SRD 7.0 (24.6) 4.6 (16.2) 3.2 (11.3) 5.2 (18.3) 3.2 (11.3) 2.2 (7.7)

VPA58177SRD 12.1 (42.6) 8.0 (28.1) 5.6 (19.7) 9.0 (31.7) 5.8 (20.4) 4.1 (14.4)

VA599SRD 11.2 (39.4) 7.1 (25.0) 4.7 (16.6) 8.1 (28.3) 4.9 (17.3) 3.3 (11.5)

VA5911SRD 17.8 (62.7) 11.3 (39.9) 7.5 (26.4) 12.8 (45.2) 7.8 (27.6) 5.2 (18.3)

VA6107SRD

VA6109SRD

VA61111SRD

VA61511SRD 17.8 (62.7) 11.3 (39.9) 7.5 (26.4) 12.8 (45.2) 7.8 (27.6) 5.2 (18.3)

VA61613SRD

+40°F (+4°C) +20°F (-6°C) 0°F (-17°C) +40°F (+4°C) +20°F (-6°C) 0°F (-17°C)

1.9 (6.7) 1.2 (4.2) 0.8 (2.8) 1.4 (4.8) 0.8 (2.9) 0.6 (1.9)

3.8 (13.4) 2.4 (8.5) 1.6 (5.6) 2.7 (9.6) 1.7 (5.9) 1.1 (3.9)

1

1

1

1

2.8 (10.0) 1.8 (6.4) 1.2 (4.2) 2.0 (7.2) 1.3 (4.4) 0.8 (2.9)

3.8 (13.4) 2.4 (8.5) 1.6 (5.6) 2.7 (9.6) 1.7 (5.9) 1.1 (3.9)

6.9 (24.4) 4.4 (15.5) 2.9 (10.3) 5.0 (17.5) 3.0 (10.7) 2.0 (7.1)

11.2 (39.4) 7.1 (25.0) 4.7 (16.6) 8.1 (28.3) 4.9 (17.3) 3.3 (11.5)

1

17.8 (62.7) 11.3 (39.9) 7.5 (26.4) 12.8 (45.2) 7.8 (27.6) 5.2 (18.3)

1

27.0 (95.1) 17.2 (60.4) 11.4 (40.1) 19.5 (68.4) 11.9 (41.8) 7.9 (27.7)

Refrigerant 407C Refrigerant 404A/507C

Flow Capacity in Tons (kW)

Factors For Other Ratings

Evaporator Temperature -20°F (-28°C) -40°F (-40°C)

X Factor 0.28 0.18

To find the capacity for -20°F (-28°C) and -40°F (-40°C) evaporator temperatures in tons, multiply the 40°F (4°C) evaporator

temperature by the X factor.

To find the minimum capacity in tons, multiply the 40°F (4°C)

rating by 0.15.

Maximum recommended tons based on pressure drop through

the accumulator equal to 1.0°F (-17°C) temperature drop.

Notes:

1. Minimum recommended tons should be no less than 15%

of recommended tons to ensure positive oil return.

2. All data based on actual tons and is not related to horsepower.

3. Minimum evaporator temperature: -40°F (4°C). Minimum

suction gas temperature through the accumulator: +10°F

(-12°C). For operating conditions not within the rating data,

please contact Parker before proceeding with installation.

Page 11

Catalog C-1, Accumulators and Receivers / Page 11

Copper Vertical, Horizontal and Stand-Pipe

Accumulators - OEM only

Parker's Vertical, Horizontal, and Stand-Pipe Copper Accumulators hold unused

system charge to prevent liquid slugging of the compressor and excessive refrigerant

dilution of the compressor oil.

Applications

■ Low temperature refrigeration and heat-pump applications

■ Residential air conditioning systems

Features and Benefits

■ Accumulators available in vertical (inlet and outlet on same end), horizontal (inlet and out-

let on opposite ends), and stand-pipe designs

■ Stand-pipe design can be made with or without an orifice to meter oil return to the compressor

■ Systems using a rotary compressor should use a stand-pipe accumulator including a

screened baffle and an oil-return orifice for maximum system performance

■ A wide variety of O.D. and volume sizes are designed to meet the unique requirements of

a system

■ Bifurcated ODF solder in a variety of sizes provide for easy installation

■ Copper Accumulator models are UL recognized for maximum working pressures listed under

SA5764-SKXY/SKXY7

1-1/8" Copper Accumulator

Maximum

Part

Number

032185-00 450 31.0 3/8 1/4 8.25 210 1.97 32.3 1.13 28.7

Rated

Pressure

PSIG bar Inlet (A) Outlet (B) Inches mm Cu. In. cm3Inches mm

Standard Nominal

Sizes (Inches)

Overall Length

(C)

Internal Volume Diameter (D)

1-3/16" Copper Accumulator

Maximum

Part

Number

056268-00 450 31.0 3/8 3/8 5 127 4.75 77.8 1.19 30.2

051639-03 450 31.0 3/8 3/8 6.5 165 4.75 77.8 1.19 30.2

056039-01 450 31.0 3/8 5/16 6.5 165 4.75 77.8 1.19 30.2

056039-02 450 31.0 5/16 5/16 6.5 165 4.75 77.8 1.19 30.2

Rated

Pressure

PSIG bar Inlet (A) Outlet (B) Inches mm Cu. In. cm3Inches mm

Standard Nominal

Sizes (Inches)

Overall Length

(C)

Internal Volume Diameter (D)

Dimensions

BA

C

1-3/8" Copper Accumulator

Maximum

Part

Number

057375-00

056380-01 450 31.0 3/8 3/8 6 152 6.86 112 1.38 35.1

Rated

Pressure

PSIG bar Inlet (A) Outlet (B) Inches mm Cu. In. cm3Inches mm

450 31.0

Standard Nominal

Sizes (Inches)

3/8 3/8 7.06 179 2.52 41.3 1.38 35.1

Overall Length

(C)

Internal Volume Diameter (D)

1-5/8" Copper Accumulator

Maximum

Part

Number

056238-01 450 31.0 5/16 1/4 4 102 5.41 88.7 1.63 41.4

056689-02 450 31.0 3/8 3/8 4 102 5.41 88.7 1.63 41.4

057337-00 450 31.0 1/2 1/2 5 127 7.29 119.5 1.63 41.4

058489-01 450 31.0 5/16 5/16 5 127 7.29 119.5 1.63 41.4

057995-00 450 31.0 3/8 3/8 5.5 140 2.59 42.4 1.63 41.4

056326-03 450 31.0 1/4 1/4 7 178 11.15 182.7 1.63 41.4

056472-01 450 31.0 3/8 3/8 8 203 12.902 211.4 1.63 41.4

056463-03 450 31.0 1/2 1/2 10 254 16.55 271.2 1.63 41.4

056463-02 450 31.0 3/8 3/8 10 254 16.55 271.2 1.63 41.4

Rated

Pressure

PSIG bar Inlet (A) Outlet (B) Inches mm Cu. In. cm3Inches mm

Standard Nominal

Sizes (Inches)

Overall Length

(C)

Internal Volume Diameter (D)

D

Page 12

Page 12 / Catalog C-1, Accumulators and Receivers

1-7/8" Copper Stand Pipe Accumulator

Maximum

Part

Number

071442-00 450 31.0 3/8 3/8 10.2 259 13.44 220.2 1.88 47.6

Rated

Pressure

PSIG bar Inlet (A) Outlet (B) Inches mm Cu. In. cm3Inches mm

Standard Nominal

Sizes (Inches)

Overall Length

(C)

Internal Volume

Diameter

(D)

2-1/4" Copper Stand Pipe Accumulator

Maximum

Part

Number

032236-00 450 31.0 1/2 0.616 8.19 208 12.63 207.0 2.25 57.2

Rated

Pressure

PSIG bar Inlet (A) Outlet (B) Inches mm Cu. In. cm3Inches mm

Standard Nominal

Sizes (Inches)

Overall Length

(C)

Internal Volume

Diameter

(D)

Dimensions

A

C

B

D

A

C

B

D

Page 13

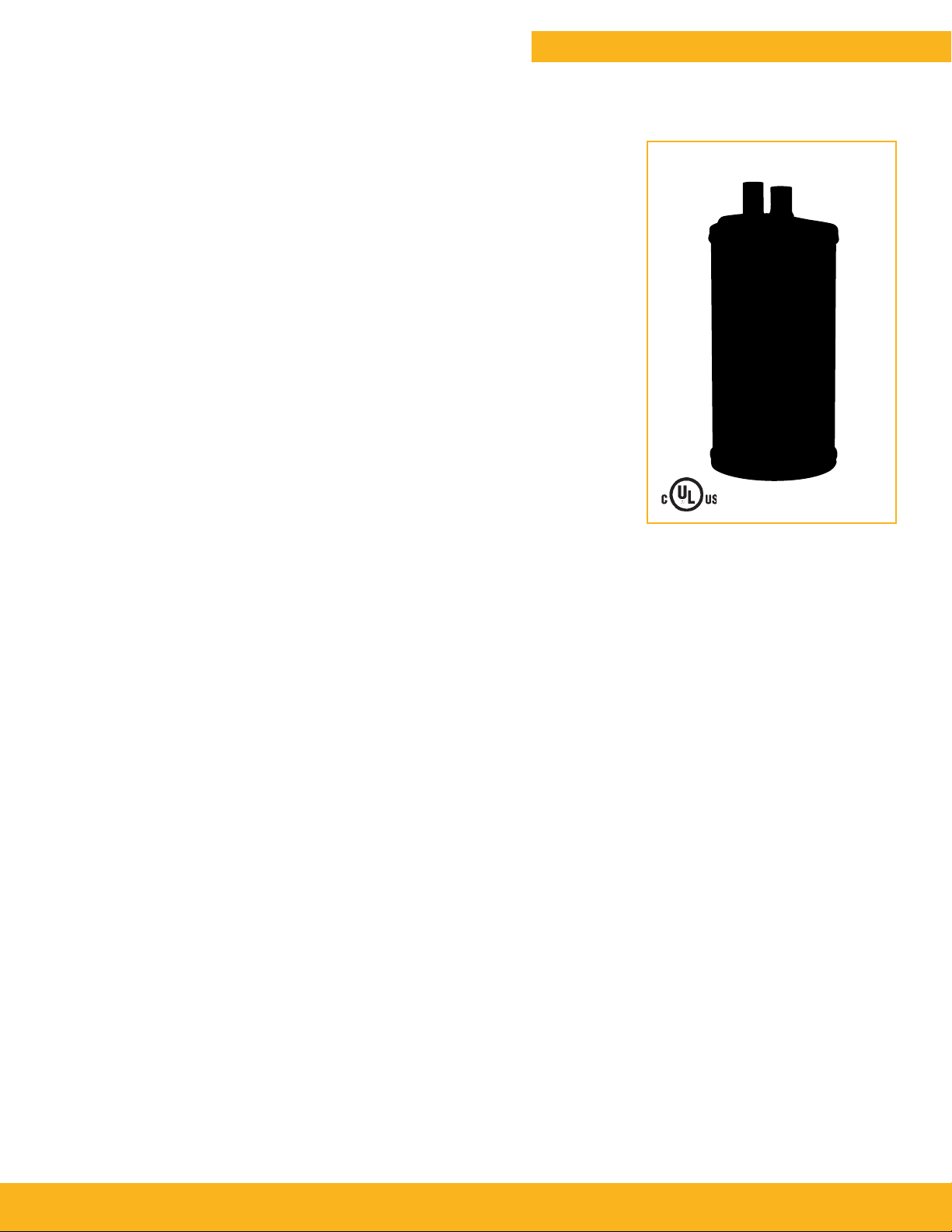

Steel Receivers

Catalog C-1, Accumulators and Receivers / Page 13

Design

The RT series receiver tanks are multifunctional in a refrigeration system. It

provides a reservoir for refrigerant during normal operation of a refrigeration

system, ensures availability of a reserve

quantity of refrigerant during periods of

high load demands and provides a place

to store the refrigerant charge during either automatic or service pump downs.

Receiver tank storage capacities are

based on 80% of the internal volume

of the tank when the temperature of the

refrigerant is 90°F (32°C) per ARI standard 495. Receiver selection should be

based on the vessels ability to hold 100%

of the total system refrigerant charge.

Four different styles of receiver connections are available: one with a sweat inlet and a rotolock outlet spud, one with

sweat by sweat connections, one with a

sweat inlet with a sweat outlet service

valve brazed onto the top closure and

one with a sweat inlet with a sweat outlet service valve brazed onto body tube.

Additionally, Parker offers vertical and

horizontal models to provide greater

flexibility in different applications.

Applications

Designed for installation in the liquid

line of any refrigeration or air conditioning application which requires a storage

vessel for liquid refrigerant either for

system pump downs or as a safeguard to

ensure that a solid column of liquid is in

the liquid line.

CAUTION: Do not exceed design pressure. Fasten receiver and piping securely

before use.

Features and Benefits

■ Available with 1/4” - 5/8” ODF sweat

solid copper connections

■ Vertical, horizontal and custom designed

models available

■ Models from 2-1/2” through 6” diameters

with maximum lengths of 35”

■ Vertical models are provided with

3 different types of connections

■ Horizontal models have sweat

connections

■ 500 psig (35 bar) maximum working

pressure

■ Compatible with CFC, HCFC, HFC

refrigerants, mineral oils, alkylbenzene

(AB), polyolester (POE) and polyalkylene

glycol (PAG) lubricants.

■ Integral 430°F (221°C) fuse plug in 5”

and 6” diameter models

■ Valve is shipped unassembled

■ PTFE gasket seal for valve

■ UL listed for USA and Canada under

SA5915-SOJV/SOJV7

■ Manufactured in ISO 9001/ISO 14001

registered facility

■ Valves can be brazed to the body or

connected via rotolock stub with

PTFE seal

■ Receivers available with or without

isolation valves

■ Powder coating surpasses 500 hour

ASTM salt spray

Page 14

Page 14 / Catalog C-1, Accumulators and Receivers

Dimensions

OUT

OUT

OUT

OUT

OUT

OUT

“A”

“A”

“C”

“C”

TYPE 1

Type 1

“B”

OUT

OUT

Type 4

TYPE 4

“B”

IN

IN

“A”

“C”

IN

“D”

TYPE 2

Type 2

IN

IN

“D” “D”

“B”

“D”

Type 5

TYPE 5

IN

OUT IN

OUT

“C” “C”

IN

“A”

“C”

OUT

OUT

TYPE 3

Type 3

“B”

Type 6

TYPE 6

IN

IN

“D”

IN

IN

“D”

“B”

“B”

Page 15

Dimensions

Catalog C-1, Accumulators and Receivers / Page 15

Type

Holding

Capacity

Catalog

Number

RT256V 469988 1/4 (6.0) Solder x 1/4 (6.0) Solder 6-3/4 (171) 2-1/2 (64) 5-7/8 (149) 2 (51) 29.4 (0.482) 1 1.1 (0.52)

RT306V-TS 470122 1/4 (6.0) Solder x 1/4 (6.0) Solder 6-3/4 (171) 3 (76) 5-7/8 (149) 2 (51) 43.2 (0.708) 1 1.6 (0.76)

RT306V-TR 469993 1/4 (6.0) Solder x 3/4 (19.0) Rotolock 6-3/4 (171) 3 (76) 5-7/8 (149) 2 (51) 43.2 (0.708) 2 1.6 (0.76)

RT308V-TR 469996 1/4 (6.0) Solder x 3/4 (19.0) Rotolock 8-3/8 (213) 3 (76) 7-1/2 (191) 2 (51) 51.9 (0.851) 2 1.9 (0.91)

RT308V-TS 470137 3/8 (10.0) Solder x 3/8 (10.0) Solder 8-3/8 (213) 3 (76) 7-1/2 (191) 2 (51) 51.9 (0.851) 1 1.9 (0.91)

RT312V-TS 470139 3/8 (10.0) Solder x 3/8 (10.0) Solder 14 (356) 3 (76) 13-1/8 (333) 2 (51) 82.9 (1.360) 1 3.1 (1.45)

RT3510V2S-KS 470123 3/8 (10.0) Solder x 1/4 (6.0) Valve 11-1/8 (283) 3-1/2 (89) 10 (254) 2 (51) 84.7 (1.389) 4 3.1

RT3510V2S 450220 3/8 (10.0) Solder x 1/4 (6.0) Solder — 3-1/2 (89) 10 (254) 2-1/2 (64) 84.7 (1.389) 5 3.1 (1.48)

RT3510V3S 469999 3/8 (10.0) Solder x 3/8 (10.0) Valve 11-1/8 (283) 3-1/2 (89) 10 (254) 2 (51) 84.7 (1.389) 4 3.1 (1.48)

RT3510V 470087 3/8 (10.0) Solder x 3/8 (10.0) Solder — 3-1/2 (89) 10 (254) 2-1/2 (64) 94.2 (1.545) 5 3.5 (1.65)

RT507V 470002 1/4 (6.0) Solder x 3/4 (19.0) Rotolock 8-5/8 (219) 5 (127) 7-3/4 (197) 2-1/2 (64) 136.5 (2.239) 3 5.1 (2.39)

RT508V3S 470000 3/8 (10.0) Solder x 3/8 (10.0) Valve — 5 (127) 8 (203) 2-1/2 (64) 126.6 (2.076) 6 4.7 (2.22)

RT510V3S 470124 3/8 (10.0) Solder x 3/8 (10.0) Valve 11-1/8 (283) 5 (127) 10 (254) 2-1/2 (64) 177.9 (2.918) 4/6 6.6 (3.12)

RT510V3S-KS 470004 3/8 (10.0) Solder x 3/8 (10.0) Valve — 5 (127) 10 (254) 2-1/2 (64) 177.9 (2.918) 5 6.6 (3.12)

RT512V 470010 3/8 (10.0) Solder x 3/4 (19.0) Rotolock 12-7/8 (327) 5 (127) 12 (305) 2-1/2 (64) 214.3 (3.515) 3 7.9 (3.76)

RT512V3S 470008 3/8 (10.0) Solder x

RT612V 470019 3/8 (10.0) Solder x 3/4 (19.0) Rotolock 12-7/8 (327) 6 (152) 12 (305) 2-1/2 (64) 298.9 (4.902) 3 11.1 (5.24)

RT612V3S-KS 470125 3/8 (10.0) Solder x 3/8 (10.0) Valve — 6 (152) 12 (305) 4 (102) 298.9 (4.902) 6 11.1 (5.24)

RT612V3S 470013 3/8 (10.0) Solder x 3/8 (10.0) Valve 13-1/8 (333) 6 (152) 12 (305) 2-1/2 (64) 298.9 (4.902) 4/5 11.1 (5.24)

RT612V4S 470089 3/8 (10.0) Solder x 1/2 (13.0) Valve 13-1/8 (333) 6 (152) 12 (305) 2-1/2 (64) 298.9 (4.902) 4 11.1 (5.24)

RT615V 470022 3/8 (10.0) Solder x 1 (25.0) Rotolock 15-7/8 (403) 6 (152) 15 (381) 2-1/2 (64) 376.7 (6.178) 3 13.9 (6.60)

RT616V3S-KS 470126 3/8 (10.0) Solder x 3/8 (10.0) Valve 17-1/8 (435) 6 (152) 16 (406) 2-1/2 (64) 416.4 (6.829) 4 15.4 (7.30)

RT616V3S 470024 3/8 (10.0) Solder x 3/8 (10.0) Solder — 6 (152) 16 (406) 2-1/2 (64) 416.4 (6.829) 5 15.4 (7.30)

RT616V4S 470025 3/8 (10.0) Solder x 1/2 (13.0) Valve 17-3/8 (441) 6 (152) 16 (406) 2-1/2 (64)

RT616V4S 470138 1/2 (13.0) Solder x 1/2 (13.0) Valve 17-3/8 (441) 6 (152) 16-1/8 (410) 2-1/2 (64) 418.4 (6.862) 4 15.5 (7.33)

RT617V4S 470026 1/2 (13.0) Solder x 1/2 (13.0) Valve — 6 (152) 17-1/8 (435) 3-3/4 (95) 480.4 (7.879) 6 17.8 (8.42)

RT618V4S-KS 470127 1/2 (13.0) Solder x 1/2 (13.0) Valve 19-3/8 (492) 6 (152) 18 (457) 2-1/2 (64) 470.0 (7.708) 4 17.4 (8.24)

RT619V 470033 1/2 (13.0) Solder x 1 (25.0) Rotolock 20 (508) 6 (152) 19 (483) 2-1/2 (64) 480.4 (7.879) 3 17.8 (8.42)

RT623V4S-KS 470128 1/2 (13.0) Solder x 1/2 (13.0) Valve 24-3/8 (619) 6 (152) 23 (584) 2-1/2 (64) 601.3 (9.861) 4 22.2 (10.54)

RT623V5S 470034 1/2 (13.0) Solder x 5/8 (16.0) Valve 24-3/8 (619) 6 (152) 23 (584) 2-1/2 (64) 601.3 (9.861) 4 22.2 (10.54)

RT627V4S 470036 1/2 (13.0) Solder x 1/2 (13.0) Valve — 6 (152) 27-1/8 (689) 3-3/4 (95) 709.1 (11.629) 6 26.2 (12.43)

RT630V5S 470038 5/8 (16.0) Solder x 5/8 (16.0) Solder — 6 (152) 30 (762) 5 (127) 784.3 (12.863) 6 29.0 (13.74)

RT634V4S

Select receiver with holding capacity equal to or greater than 90% of system charge.

Holding capacities stated for R-410A at 90°F (32°C).

Multiply holding capacity by 1.1 to obtain R-22 data at 90°F (32°C).

Catalog numbers in bold font are available as standard wholesale offering.

Item

470040 1/2 (13.0) Valve x 1/2 (13.0) Valve — 6 (152) 35 (876) 4-1/8 (105) 915.0 (15.006) 6 33.9 (16.03)

No.

Inches

(mm)

Fitting

Type

Inches

(mm)

3/4 (19.0) Rotolock 13-1/8 (333) 5 (127) 12 (305) 2-1/2 (64) 214.3 (3.515) 4 7.9 (3.76)

Fitting

Type

“A” “B” “C” “D” Cu. In. (liters) lbs. (liters)

Dimensions: Inches (mm) Internal Volume

416.4 (6.829) 4 15.4 (7.30)

(1.48)

Page 16

Page 16 / Catalog C-1, Accumulators and Receivers

OFFER OF SALE

The goods, services or work (referred to as the “Products”) offered by Parker-Hannifin Corporation, its subsidiaries, groups, divisions, and authorized distributors (“Seller”)

are offered for sale at prices indicated in the offer, or as may be established by Seller. The offer to sell the Products and acceptance of Seller’s offer by any customer (“Buyer”) is

contingent upon, and will be governed by all of the terms and conditions contained in this Offer of Sale. Buyer’s order for any Products specied in Buyer’s purchase document

or Seller’s offer, proposal or quote (“Quote”) attached to the purchase order, when communicated to Seller verbally, or in writing, shall constitute acceptance of this offer.

1. Terms and Conditions. Seller’s willingness to

offer Products for sale or accept an order for Products

is subject to the terms and conditions contained in

this Offer of Sale or any newer version of the same,

published by Seller electronically at www.parker.com/

saleterms/. Seller objects to any contrary or additional

terms or conditions of Buyer’s order or any other

document or other communication issued by Buyer.

2. Price; Payment. Prices stated on Seller’s Quote

are valid for thirty (30) days, except as explicitly

otherwise stated therein, and do not include any sales,

use, or other taxes or duties unless specically stated.

Seller reserves the right to modify prices to adjust for

any raw material price uctuations. Unless otherwise

specied by Seller, all prices are F.C.A. Seller’s facility

(INCOTERMS 2010). Payment is subject to credit approval and payment for all purchases is due thirty (30)

days from the date of invoice (or such date as may

be specied by Seller’s Credit Department). Unpaid

invoices beyond the specied payment date incur

interest at the rate of 1.5% per month or the maximum

allowable rate under applicable law.

3. Shipment; Delivery; Title and Risk of Loss. All

delivery dates are approximate. Seller is not responsible for damages resulting from any delay. Regardless

of the manner of shipment, delivery occurs and title

and risk of loss or damage pass to Buyer, upon

placement of the Products with the shipment carrier

at Seller’s facility. Unless otherwise stated, Seller

may exercise its judgment in choosing the carrier and

means of delivery. No deferment of shipment at Buyers’ request beyond the respective dates indicated will

be made except on terms that will indemnify, defend

and hold Seller harmless against all loss and additional

expense. Buyer shall be responsible for any additional

shipping charges incurred by Seller due to Buyer’s

acts or omissions.

4. Warranty. Seller warrants that the Products sold

hereunder shall be free from defects in material or

workmanship for a period of twelve (12) months from

the date of delivery or 2,000 hours of normal use,

whichever occurs rst. All prices are based upon the

exclusive limited warranty stated above, and upon the

following disclaimer: DISCLAIMER OF WARRANTY:

THIS WARRANTY IS THE SOLE AND ENTIRE WARRANTY PERTAINING TO PRODUCTS PROVIDED.

SELLER DISCLAIMS ALL OTHER WARRANTIES,

EXPRESS AND IMPLIED, INCLUDING DESIGN,

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

5. Claims; Commencement of Actions. Buyer shall

promptly inspect all Products upon receipt. No claims

for shortages will be allowed unless reported to the

Seller within ten (10) days of delivery. No other claims

against Seller will be allowed unless asserted in writing within thirty (30) days after delivery. Buyer shall

notify Seller of any alleged breach of warranty within

thirty (30) days after the date the defect is or should

have been discovered by Buyer. Any claim or action

against Seller based upon breach of contract or any

other theory, including tort, negligence, or otherwise

must be commenced within twelve (12) months from

the date of the alleged breach or other alleged event,

without regard to the date of discovery.

6. LIMITATION OF LIABILITY. IN THE EVENT OF

A BREACH OF WARRANTY, SELLER WILL, AT ITS

OPTION, REPAIR OR REPLACE A DEFECTIVE PRODUCT, OR REFUND THE PURCHASE PRICE WITHIN

A REASONABLE PERIOD OF TIME. IN NO EVENT

IS SELLER LIABLE FOR ANY SPECIAL, INDIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES

ARISING OUT OF, OR AS THE RESULT OF, THE

SALE, DELIVERY, NON-DELIVERY, SERVICING,

USE OR LOSS OF USE OF THE PRODUCTS OR

ANY PART THEREOF, OR FOR ANY CHARGES OR

EXPENSES OF ANY NATURE INCURRED WITHOUT

SELLER’S WRITTEN CONSENT, WHETHER BASED

IN CONTRACT, TORT OR OTHER LEGAL THEORY.

IN NO EVENT SHALL SELLER’S LIABILITY UNDER

ANY CLAIM MADE BY BUYER EXCEED THE PURCHASE PRICE OF THE PRODUCTS.

7. User Responsibility. The user, through its own

analysis and testing, is solely responsible for making

the nal selection of the system and Product and assuring that all performance, endurance, maintenance,

safety and warning requirements of the application

are met. The user must analyze all aspects of the

application and follow applicable industry standards

and Product information. If Seller provides Product

or system options based upon data or specications provided by the user, the user is responsible for

determining that such data and specications are suitable and sufcient for all applications and reasonably

foreseeable uses of the Products or systems.

8. Loss to Buyer’s Property. Any designs, tools,

patterns, materials, drawings, condential information

or equipment furnished by Buyer or any other items

which become Buyer’s property, will be considered

obsolete and may be destroyed by Seller after two (2)

consecutive years have elapsed without Buyer ordering

the items manufactured using such property. Seller

shall not be responsible for any loss or damage to such

property while it is in Seller’s possession or control.

9. Special Tooling. A tooling charge may be imposed

for any special tooling, including without limitation, dies, xtures, molds and patterns, acquired to

manufacture Products. Such special tooling shall be

and remain Seller’s property notwithstanding payment

of any charges by Buyer. In no event will Buyer acquire

any interest in apparatus belonging to Seller which

is utilized in the manufacture of the Products, even

if such apparatus has been specially converted or

adapted for such manufacture and notwithstanding

any charges paid by Buyer. Unless otherwise agreed,

Seller has the right to alter, discard or otherwise dispose of any special tooling or other property in its sole

discretion at any time.

10. Buyer’s Obligation; Rights of Seller. To secure

payment of all sums due or otherwise, Seller retains a

security interest in all Products delivered to Buyer and

this agreement is deemed to be a Security Agreement under the Uniform Commercial Code. Buyer

authorizes Seller as its attorney to execute and le on

Buyer’s behalf all documents Seller deems necessary

to perfect its security interest.

11. Improper Use and Indemnity. Buyer shall

indemnify, defend, and hold Seller harmless from any

losses, claims, liabilities, damages, lawsuits, judgments and costs (including attorney fees and defense

costs), whether for personal injury, property damage,

patent, trademark or copyright infringement or any

other claim, brought by or incurred by Buyer, Buyer’s

employees, or any other person, arising out of: (a)

improper selection, application, design, specication

or other misuse of Products purchased by Buyer from

Seller; (b) any act or omission, negligent or otherwise,

of Buyer; (c) Seller’s use of patterns, plans, drawings,

or specications furnished by Buyer to manufacture

Products; or (d) Buyer’s failure to comply with these

terms and conditions. Seller shall not indemnify Buyer

under any circumstance except as otherwise provided.

12. Cancellations and Changes. Buyer may not

cancel or modify or cancel any order for any reason,

except with Seller’s written consent and upon terms

that will indemnify, defend and hold Seller harmless

against all direct, incidental and consequential loss or

damage. Seller may change Product features, specications, designs and availability.

13. Limitation on Assignment. Buyer may not

assign its rights or obligations under this agreement

without the prior written consent of Seller.

14. Force Majeure. Seller does not assume the risk

and is not liable for delay or failure to perform any of

Seller’s obligations by reason of events or circumstances beyond its reasonable control (hereinafter

“Events of Force Majeure”). Events of Force Majeure

shall include without limitation: accidents, strikes or

labor disputes, acts of any government or government

agency, acts of nature, delays or failures in delivery

from carriers or suppliers, shortages of materials, or

any other cause beyond Seller’s reasonable control.

15. Waiver and Severability. Failure to enforce any

provision of this agreement will not invalidate that provision; nor will any such failure prejudice Seller’s right

to enforce that provision in the future. Invalidation of

any provision of this agreement by legislation or other

rule of law shall not invalidate any other provision

herein. The remaining provisions of this agreement will

remain in full force and effect.

16. Termination. Seller may terminate this agreement

for any reason and at any time by giving Buyer thirty

(30) days prior written notice. Seller may immediately

terminate this agreement, in writing, if Buyer: (a)

breaches any provision of this agreement (b) appoints

a trustee, receiver or custodian for all or any part of

Buyer’s property (c) les a petition for relief in bankruptcy on its own behalf, or one if led by a third party

(d) makes an assignment for the benet of creditors; or

(e) dissolves its business or liquidates all or a majority

of its assets.

17. Governing Law. This agreement and the sale and

delivery of all Products are deemed to have taken place

in, and shall be governed and construed in accordance

with, the laws of the State of Ohio, as applicable to

contracts executed and wholly performed therein and

without regard to conicts of laws principles. Buyer

irrevocably agrees and consents to the exclusive jurisdiction and venue of the courts of Cuyahoga County,

Ohio with respect to any dispute, controversy or claim

arising out of or relating to this agreement.

18. Indemnity for Infringement of Intellectual

Property Rights. Seller is not liable for infringement

of any patents, trademarks, copyrights, trade dress,

trade secrets or similar rights except as provided in

this Section. Seller will defend and indemnify Buyer

against allegations of infringement of U.S. patents, U.S.

trademarks, copyrights, trade dress and trade secrets

(“Intellectual Property Rights”). Seller will defend at

its expense and will pay the cost of any settlement or

damages awarded in an action brought against Buyer

based on an allegation that a Product sold pursuant

to this agreement infringes the Intellectual Property

Rights of a third party. Seller’s obligation to defend and

indemnify Buyer is contingent on Buyer notifying Seller

within ten (10) days after Buyer becomes aware of

such allegations of infringement, and Seller having sole

control over the defense of any allegations or actions

including all negotiations for settlement or compromise. If a Product is subject to a claim that it infringes

the Intellectual Property Rights of a third party, Seller

may, at its sole expense and option, procure for Buyer

the right to continue using the Product, replace or

modify the Product so as to make it noninfringing, or

offer to accept return of the Product and refund the

purchase price less a reasonable allowance for depreciation. Notwithstanding the foregoing, Seller is not

liable for claims of infringement based on information

provided by Buyer, or directed to Products delivered

hereunder for which the designs are specied in whole

or part by Buyer, or infringements resulting from the

modication, combination or use in a system of any

Product sold hereunder. The foregoing provisions

of this Section constitute Seller’s sole and exclusive

liability and Buyer’s sole and exclusive remedy for

infringement of Intellectual Property Rights.

19. Entire Agreement. This agreement contains the

entire agreement between the Buyer and Seller and

constitutes the nal, complete and exclusive expression of the terms of sale. All prior or contemporaneous

written or oral agreements or negotiations with respect

to the subject matter are herein merged. The terms

contained herein may not be modied unless in writing

and signed by an authorized representative of Seller.

20. Compliance with Laws. Buyer agrees to comply

with all applicable laws, regulations, and industry and

professional standards of care, including those of the

United Kingdom, the United States of America, and

the country or countries in which Buyer may operate,

including without limitation the U. K. Bribery Act,

the U.S. Foreign Corrupt Practices Act (“FCPA”), the

U.S. Anti-Kickback Act (“Anti-Kickback Act”) and the

U.S. Food Drug and Cosmetic Act (“FDCA”),each as

currently amended, and the rules and regulations promulgated by the U.S. Food and Drug Administration

(“FDA”), and agrees to indemnify and hold harmless

Seller from the consequences of any violation of such

provisions by Buyer, its employees or agents. Buyer

acknowledges that it is familiar with the provisions

of the U. K. Bribery Act, the FCPA, the FDA, and the

Anti-Kickback Act, and certies that Buyer will adhere

to the requirements thereof. In particular, Buyer

represents and agrees that Buyer will not make any

payment or give anything of value, directly or indirectly

to any governmental ofcial, any foreign political party

or ofcial thereof, any candidate for foreign political

ofce, or any commercial entity or person, for the purpose of inuencing such person to purchase Products

or otherwise benet the business of Seller.

Page 17

Parker Hannin Corporation

A/C & Refrigeration Aftermarket

206 Lange Drive, Washington, MO 63090 USA

phone 800 742 2681 • fax 800 241 2872

www.parker.com/coolparts

Catalog C-1 / 52016 © 2016 Parker Hannin Corporation

Loading...

Loading...