Page 1

p/n 88-020292-01 A

Automation

E-AC Drive

Hardware Installation

Guide

Effective: April 9, 2002

Page 2

User Information

!!

WARNING

E Series products are used to control electrical and mechanical

components of motion control systems. You should test your motion

system for safety under all potential conditions. Failure to do so can result

in damage to equipment and/or serious injury to personnel.

E Series products and the information in this user guide are the proprietary property of Parker Hannifin Corporation or its licensers, and may

not be copied, disclosed, or used for any purpose not expressly authorized by the owner thereof.

Since Parker Hannifin constantly strives to improve all of its products, we reserve the right to change this user guide and software and

hardware mentioned therein at any time without notice.

In no event will the provider of the equipment be liable for any incidental, consequential, or special damages of any kind or nature

whatsoever, including but not limited to lost profits arising from or in any way connected with the use of the equipment or this user guide.

© 2002 Parker Hannifin Corporation

All Rights Reserved

Technical Assistance

North America and Asia:

Compumotor Division of Parker Hannifin

5500 Business Park Drive

Rohnert Park, CA 94928

Telephone: (800) 358-9070 or (707) 584-7558

Fax: (707) 584-3793

FaxBack: (800) 936-6939 or (707) 586-8586

e-mail: tech_help@cmotor.com

Internet: http://www.compumotor.com

Automation

Contact your local automation technology center (ATC) or distributor, or ...

Europe (non-German speaking):

Parker Digiplan

21 Balena Close

Poole, Dorset

England BH17 7DX

Telephone: +44 (0)1202 69 9000

Fax: +44 (0)1202 69 5750

Germany, Austria, Switzerland:

HAUSER Elektronik GmbH

Postfach: 77607-1720

Robert-Bosch-Str. 22

D-77656 Offenburg

Telephone: +49 (0)781 509-0

Fax: +49 (0)781 509-176

Technical Support Email

tech_help@cmotor.com

Page 3

Table of Contents

Chapter 1 – Introduction................................................................................................................................ 5

E-AC Drive – Description .................................................................................................................... 6

E-AC Drive – Compatible Motors .........................................................................................................7

Chapter 2 – Installation.................................................................................................................................. 9

What You Should Have (ship kit) ........................................................................................................10

Precautions ....................................................................................................................................... 10

Installation Overview ......................................................................................................................... 10

Automatic Test ....................................................................................................................................12

Installation ......................................................................................................................................... 14

ELECT A MOTOR ......................................................................................................................14

1 – S

2 – CONNECT THE MOTOR TO THE DRIVE – WIRING...............................................................................18

3 – SET DIP SWITCHES .................................................................................................................. 20

4 – CONNECT A CONTROLLER – INPUTS & OUTPUTS .............................................................................22

5 – M

OUNT THE DRIVE .....................................................................................................................25

6 – MOUNT THE MOTOR ....................................................................................................................26

7 – CONNECT THE MOTOR TO THE LOAD – COUPLERS ...........................................................................28

8 – CONNECT AC POWER ................................................................................................................29

9 – TEST THE INSTALLATION ...............................................................................................................30

Chapter 3 – Troubleshooting........................................................................................................................31

Troubleshooting Basics ......................................................................................................................32

Diagnostic LEDs................................................................................................................................ 32

Protective Circuits ..............................................................................................................................32

OVERTEMPERATURE PROTECTION ........................................................................................................32

SHORT CIRCUIT PROTECTION .............................................................................................................33

Automatic Test ....................................................................................................................................33

Anti-Resonance Disable.....................................................................................................................33

Technical Support ..............................................................................................................................33

Product Return Procedure ................................................................................................................ 34

Appendix A – Using Non-Compumotor Motors .........................................................................................35

Appendix B – Regulatory Compliance: UL and CE....................................................................................41

Index.............................................................................................................................................................. 47

E-AC Drive Hardware Installation Guide

3

Page 4

4

E-AC Drive Hardware Installation Guide

Page 5

CHAPTER ONE

Introduction

1

• E-AC Drive Description

• Compumotor Products

E-AC Drive Hardware Installation Guide

IN THIS CHAPTER

Chapter 1 – Introduction

5

Page 6

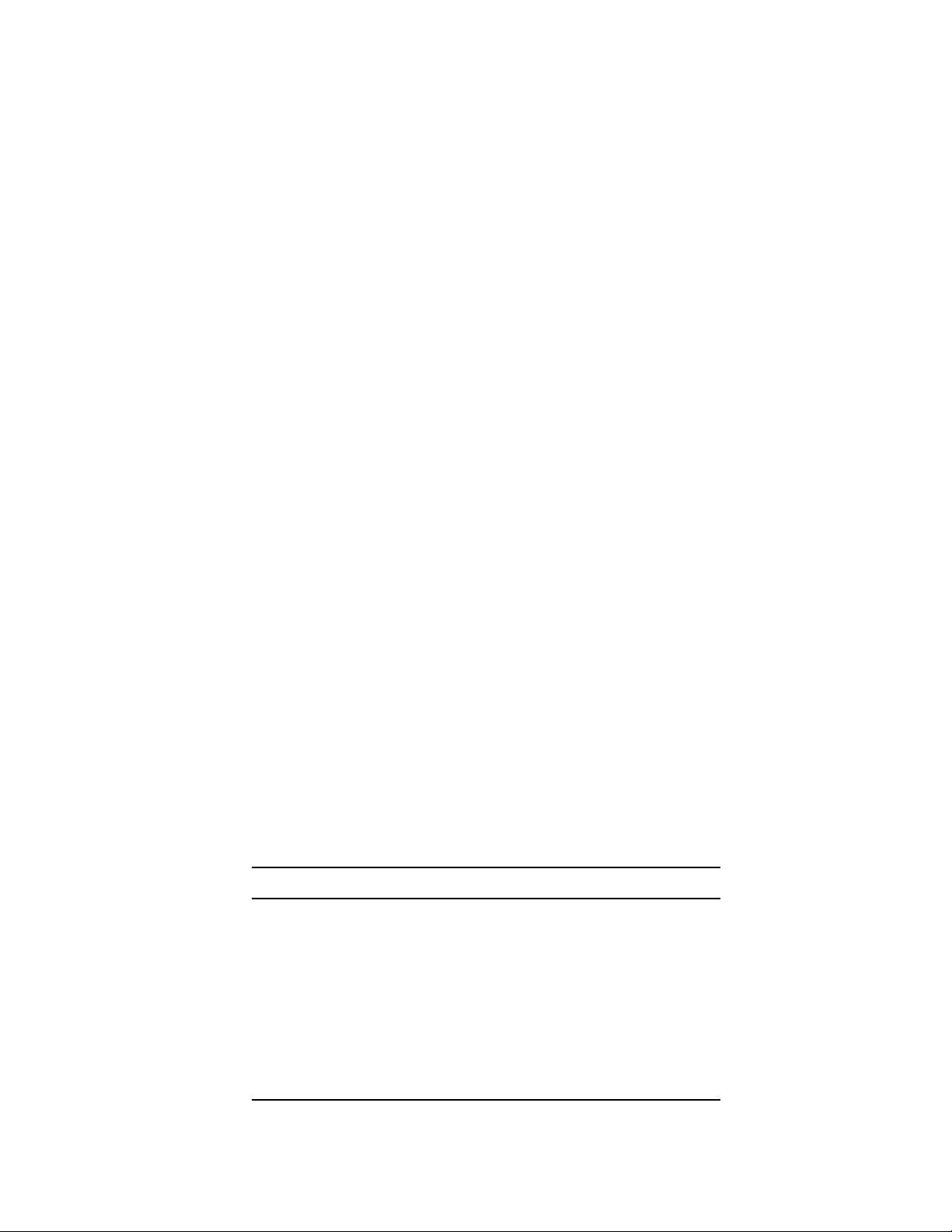

E-AC DRIVE – DESCRIPTION

C

r

e

or

or

C

s

p

ses

l

C

s

r

o

e

C

r

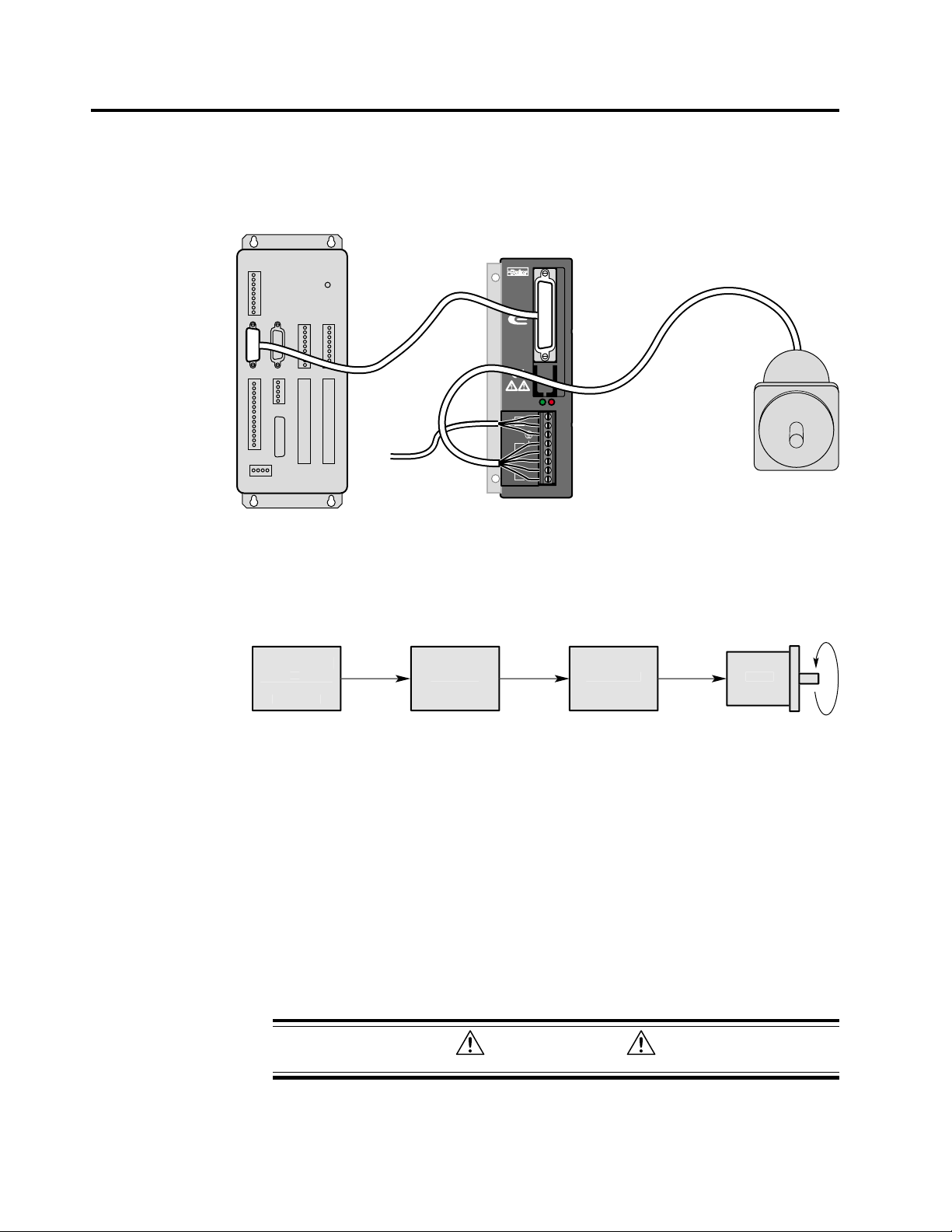

The E-AC Drive is a microstepping drive that runs two-phase step motors.

It operates directly from 120VAC power; no separate DC power supply or

transformer is required.

A typical system is shown below.

L1

N

A +

A -

MOTOR

B +

B -

Compumotor

DRIVE I/O

Motor

Controller

To AC

Power Source

SERIES

PWR/FLT

120V

E-AC Drive

System Components

The controller sends step and direction signals to the drive. For each step

pulse it receives, the drive will commutate the motor to increment rotor

position. This is shown in the next drawing.

Host Compute

r

Programmabl

ontrolle

High Leve

ommand

ontrolle

Pul

Ste

E-AC Driv

Mot

urrent

Mot

Block Diagram of E-AC Drive System

The host computer or programmable controller may or may not be necessary, depending upon the controller’s capabilities.

The motor can be wired in series or parallel; the amount of current the

drive sends to the motor is set by DIP switches.

DIP SWITCHES

DIP switches are located on top of the E-AC Drive, accessible through an

opening in the top of the cover. During the installation procedure, the

user sets these DIP switches to configure the drive for motor current,

resolution, waveform, and other functions.

CAUTION

Remove power before changing DIP switches

6

E-AC Drive Hardware Installation Guide Chapter 1 – Introduction

Page 7

INPUTS & OUTPUTS

All communications with the controller take place through the

E-AC Drive’s 25-pin D-connector. Available inputs and outputs are:

• Step Input

• Direction Input

• Shutdown Input

• Fault Output

• Reset Input

ANTI-RESONANCE

All step motors are subject to resonance, and to ringing after quick transient moves. The E-AC Drive has an anti-resonance circuit. This is a

general purpose damping circuit that provides aggressive and effective

damping. Anti-resonance can be disabled with a DIP switch.

E-AC DRIVE – COMPATIBLE MOTORS

Compumotor offers a wide range of motors that are compatible with the

E-AC Drive. See Chapter 2 – Installation for recommended motors.

COMPUMOTOR FAMILY OF PRODUCTS

The E-AC Drive is compatible with Compumotor’s broad range of

microstepper controllers (single-axis and multi-axis) and motion control

products.

E-AC Drive Hardware Installation Guide

Chapter 1 – Introduction

7

Page 8

8

E-AC Drive Hardware Installation Guide Chapter 1 – Introduction

Page 9

CHAPTER TWO

Installation

2

• Product Ship Kit

• Quick T est

• Motor Selection and Wiring

• Drive Configuration – DIP Switches and I/O

• Mounting the Drive and Motor; Attaching the Load

• Connecting AC Power

• Testing the Installation

E-AC Drive Hardware Installation Guide

IN THIS CHAPTER

Chapter 2 – Installation

9

Page 10

WHAT YOU SHOULD HAVE

Inspect your shipment carefully. You should have received one or more of

the following:

Part Part Number

E-AC Drive E-AC

E-AC Drive Quick Reference Guide 88-020290-01

You may have ordered a motor from one of the following families of

Compumotor motors:

OS Motors

VS Motors

PRECAUTIONS

To prevent injuries to personnel and damage to equipment, observe the

following guidelines:

• Never probe the drive. Hazardous voltages are present within the drive.

• Never open the drive. Opening the drive will void the warranty.

• Never increase the current setting to a value greater than that specified for

the motor you are using. Excessive current may cause motor overheating

and failure.

• Always remove AC power before changing or reconfiguring DIP switches.

(

SHIP KIT

)

INSTALLATION OVERVIEW

Topics in this chapter are arranged to lead you through the installation

process in a step–by–step manner. Complete each step before proceeding

to the next.

The order of topics in the installation procedure is:

• Quick Test

• Motor selection: specifications, speed/torque curves and dimensions

• Motor wiring—series vs. parallel

• DIP switch configuration

• Controller connections and 25 pin D-connector input/output schematic

• Drive mounting

• Motor mounting

• Connecting the load

• Connecting AC power

• Testing the installation

10

E-AC Drive Hardware Installation Guide Chapter 2 – Installation

Page 11

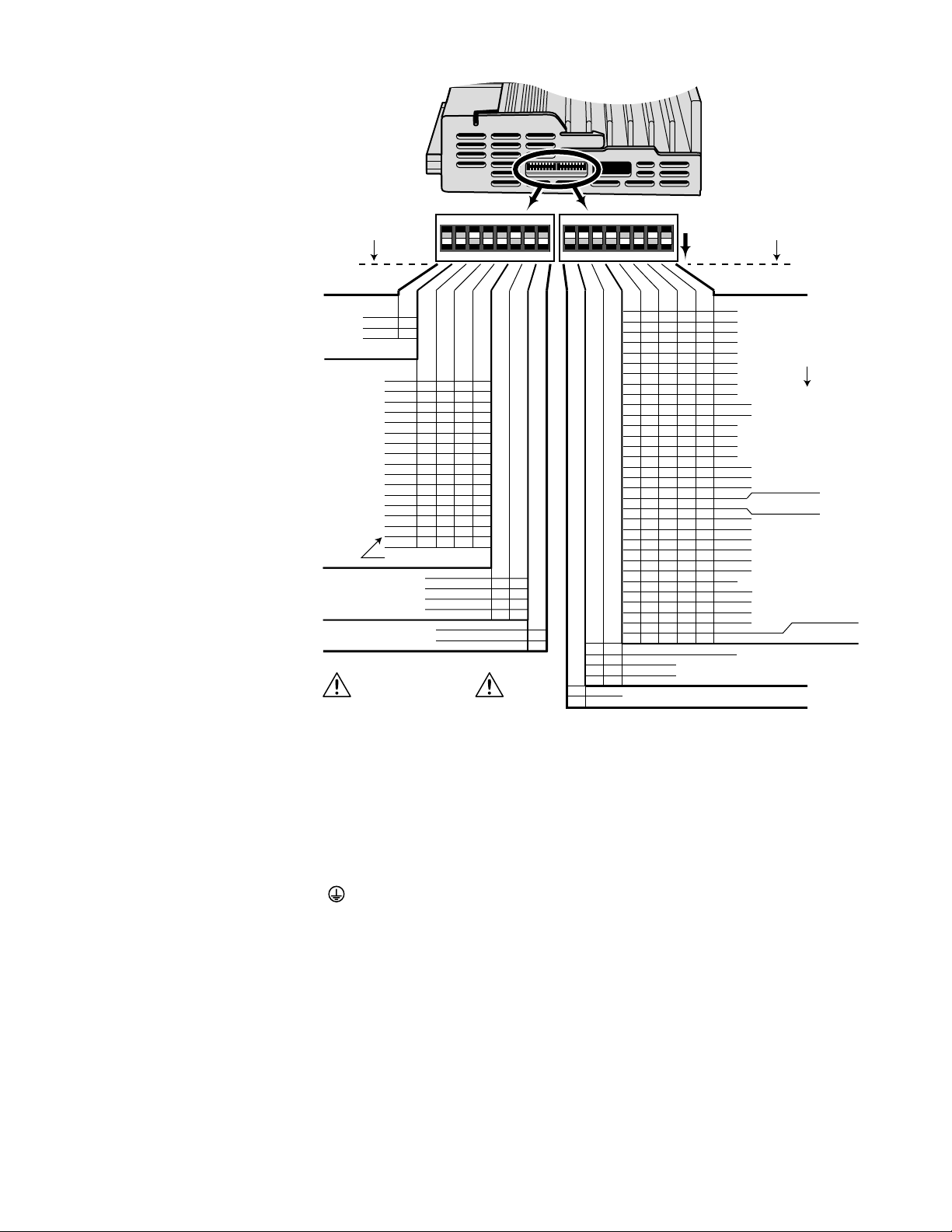

INSTALLATION PROCEDURE

11

23

21

17

16

15

14

RESET+

RESET

FLT C

FLT E

SD

SD +

DIR

DIR +

STEP

STEP +

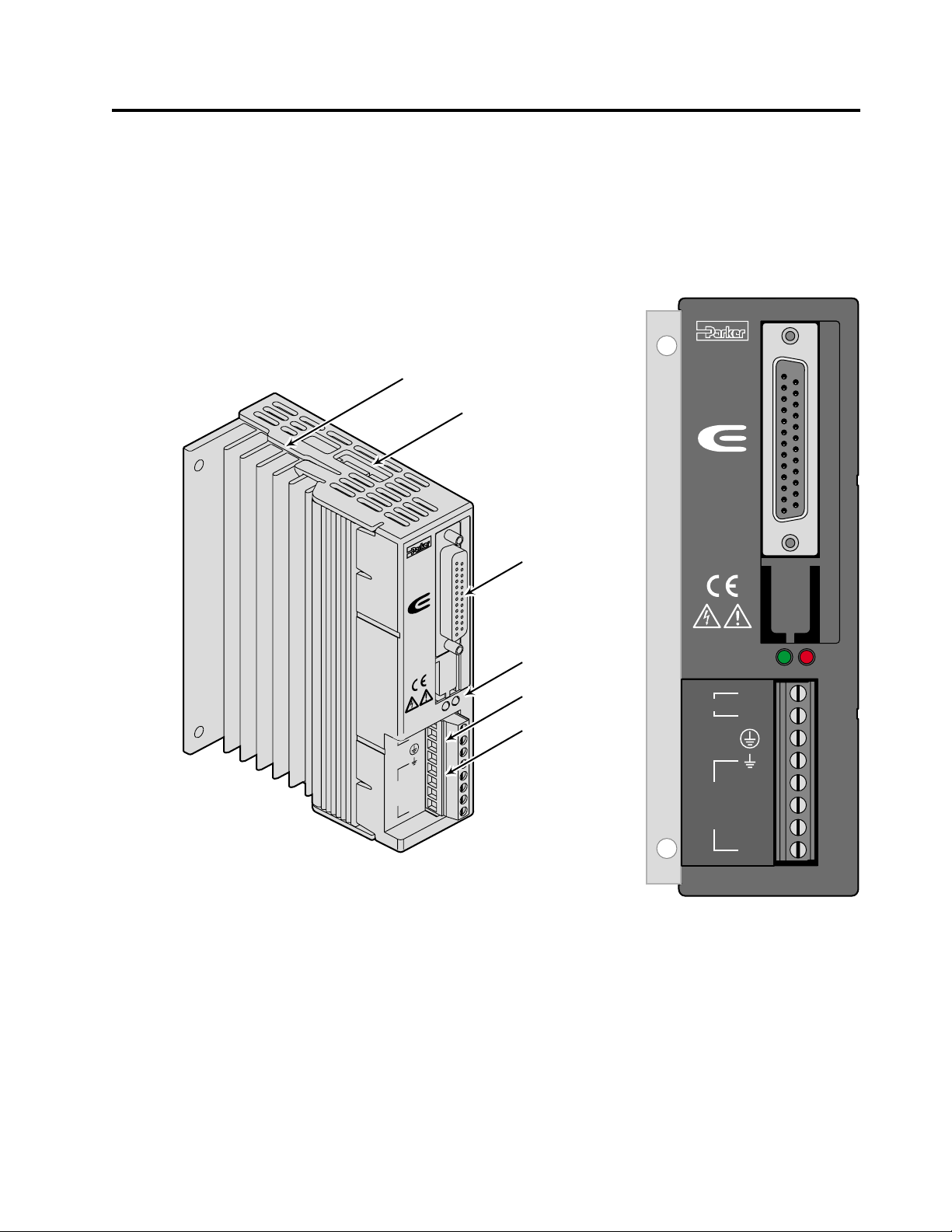

In the following installation procedure, we assume you are using a

Compumotor motor with your E-AC Drive. If you are using a nonCompumotor motor, consult Appendix A – Using Non-Compumotor Motors

for information you may need during the following installation steps.

The next drawing shows locations and names of the various connectors,

switches and LEDs that you will encounter during the installation procedure.

Heatsink

DIP Switches

RESET+

RESET

FLT C

FLT E

SD

–

SD +

DIR

–

DIR +

STEP

STEP +

11

–

23

9

21

17

16

15

2

–

14

1

SERIES

DRIVE I/ O

I/O Connections

SERIES

Status LEDs

AC Power

PWR/FLT

V

N

120

A +

A -

MOTOR

B +

B -

otor

m

pu

om

C

Motor Power

PWR/FLT

120V

A +

MOTOR

B +

L1

N

A -

B -

Compumotor

Component Locations

E-AC Drive Hardware Installation Guide

Chapter 2 – Installation

11

Page 12

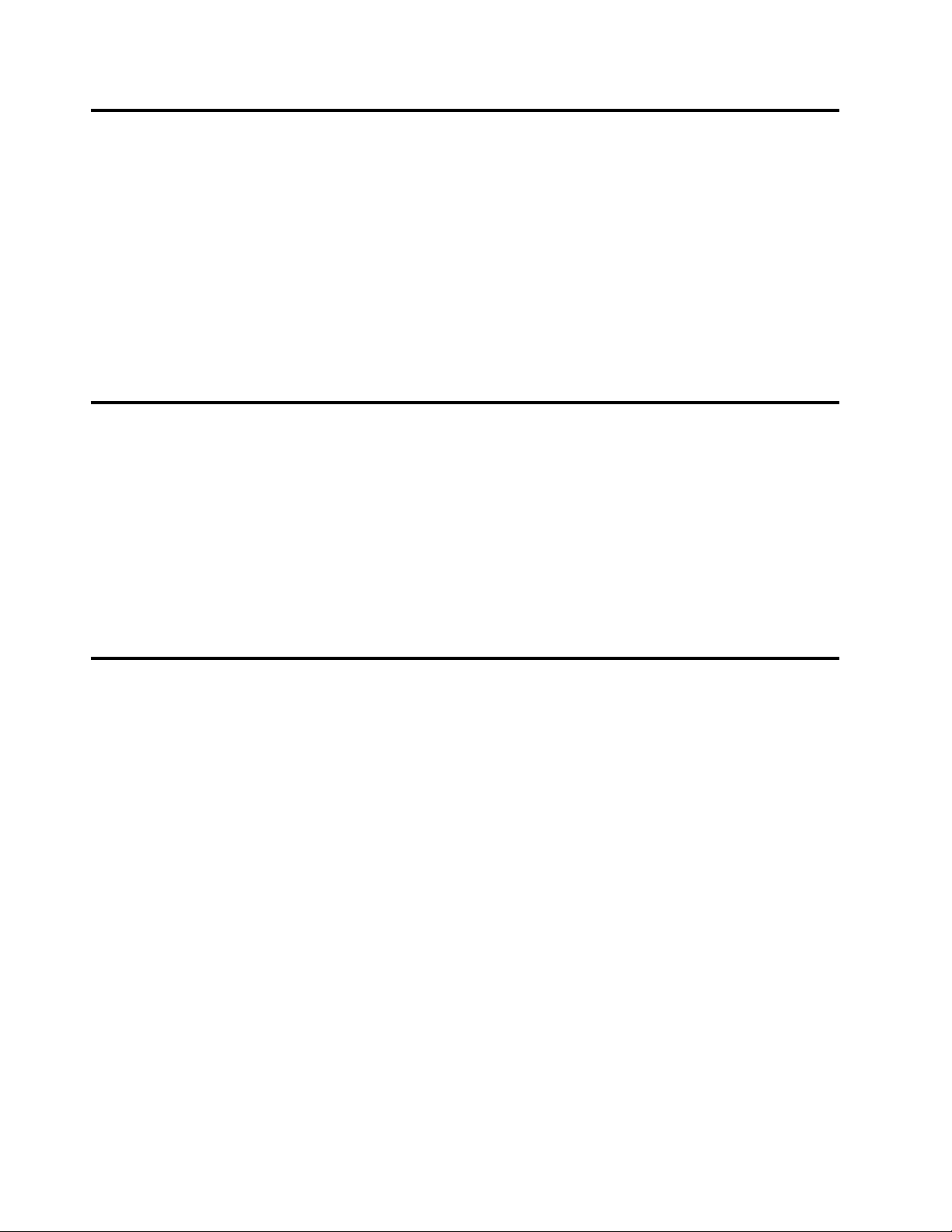

AUTOMATIC TEST

Follow this procedure to have your E-AC Drive perform its automatic test

function. Once you set DIP switches, connect the motor, and connect AC

power, the automatic test will begin—the motor shaft will turn at one

revolution per second in an alternating mode until you remove power.

This will verify that the drive, motor, and motor cable work properly as a

system.

Alternating

Shaft Rotation

Motor

Automatic Test Setup

This is a bench top procedure—as the drawing shows, you can perform it

before you connect a controller, mount the drive, or mount the motor. Full

installation instructions follow this Automatic Test section.

1. SET DIP SWITCHES FOR Motor Current

Two 8-position DIP switches are located on top of the E-AC Drive.

NOTE: if you are testing a drive that has already been configured for an

application, make note of the original DIP switch settings.

Set DIP switches SW2-#4 — SW2-#8 for the current for your motor,

according to the table. (For non-Compumotor motors, see Appendix A.)

To AC

Power Source

SERIES

PWR/FLT

L1

120V

N

A +

A -

MOTOR

B +

B -

Compumotor

E-AC Drive

DRIVE I/O

12

2. SET DIP SWITCHES FOR THE A utomatic Test Function

Set DIP switch SW1-#1 to the on position. This selects the automatic test

function.

3. CONNECT THE MOTOR

Connect your motor cable to the drive’s MOTOR terminals. Motor wiring

instructions are presented later in this chapter. (For non-Compumotor

motors, see Appendix A.) Always observe the following two warnings:

WARNING

POWER MUST BE OFF when you connect or disconnect the motor connector. Lethal

voltages are present on the screw terminals!

WARNING

You must ground the motor case. Large potentials can develop at the motor case that can

create a lethal shock hazard if the motor case is not grounded.

E-AC Drive Hardware Installation Guide Chapter 2 – Installation

Page 13

Default Position:

Drive ships from factory

with all DIP switches in

the OFF position.

Edge of

Circuit Board

Auto Test

1 rps for 2 revs in each

direction until disabled

Disabled

Enabled

1

off

on

Resolution

25,000

50,800

50,000

36,000

25,600

25,400

21,600

20,000

18,000

12,800

10,000

5,000

2,000

1,000

400

200

200 & 400 not affected by

waveform settings

Waveform

Auto Standby

Remove power before

changing DIP switches

SW1

12345678 12345678

4

2

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

Pure sine

-4% 3

-6% 3

-8% 3

5

3

off

off

off

off

off

off

off

off

on

off

off

on

on

off

off

on

off

off

on

off

on

on

off

on

off

on

off

off

on

off

off

on

on

off

on

on

on

on

off

on

on

off

on

on

on

on

on

on

76

off

rd

harmonic

rd

harmonic

rd

harmonic

Full Current

50% Current Reduction

on

off

off

on

off

on

on

8

off

on

1

off

on

off

on

off

on

Disabled

Enabled

SW2

off

54

off

off

off

off

off

off

off

off

on

on

on

on

on

on

on

on

off

off

off

off

off

off

off

off

on

on

on

on

on

on

on

on on

off

off

off

off

on

off

on

off

off

on

off

on

on

on

on

on

off

off

off

off

on

off

on

off

off

on

off

on

on

on

on

on

off

off

off

off

on

off

on

off

off

on

off

on

on

on

on

on

off

off

off

off

on

off

on

off

off

on

off

on

on

on

on

off

off

off

off

off

off

off

off

off

off

off

off

off

off

off

off

on

on

on

on

on

on

on

on

on

on

on

on

on

on

on

32

on

< 32 mH (all VS, OS motors)

off

32 – 64 mH

off

> 64 mH

on

> 64 mH

on

Edge of

Circuit Board

876

(amps)

Current

0.02

off

0.13

on

0.24

off

0.35

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

Select a setting based on

motor inductance (in mH).

Series = S

0.46

Parallel = P

0.58

0.69

0.80

0.91

1.03

VS12BS, VS13BS

1.14

1.25

1.36

1.48

1.59

1.70

OS2HBS

1.82

OS21BS

1.93

VS12BP, VS13BP

2.04

VS22BS, VS23BS

2.15

2.27

VS21BS

2.38

OS22BS

2.49

2.60

2.72

2.83

2.94

3.05

VS31BS

3.16

VS32BS

3.28

3.39

OS2HBP VS2xBP, VS3xBP

3.50

OS21BP, OS22BP

Gain

Anti-Resonance

NOTE: This drawing is duplicated in

4. CONNECT AC POWER

The E-AC Drive does not have an ON/OFF switch. When you connect

power, the automatic test will begin—the drive will turn on and the motor

will start turning. Therefore, before you apply power to the E-AC Drive:

• Properly secure the motor.

• Do not attach a load to the motor shaft.

To apply power, connect one end of your power cable to the drive’s 120V

and terminals. Connect the other end to a grounded 120VAC power

source. (Further instructions are presented later in this chapter.)

5. OBSERVE THE AUTOMATIC TEST

Your E-AC Drive should now be running in the automatic test mode.

• The motor shaft should rotate at approximately one revolution per second

(1 rps) in an alternating mode, until you remove power.

• LED Operation – observe the LEDs on the front panel:

6. STOP THE AUTOMATIC TEST

Disconnect power to stop the motor. Set DIP SW1-#1 to off. (Return DIP

switches of previously configured drives to original settings, if desired.)

E-AC Drive Hardware Installation Guide

Installation – Step 3: DIP Switches

PWR LED (power; green) should illuminate

FLT LED (fault; red) should be off

Chapter 2 – Installation

, later in this chapter.

13

Page 14

INSTALLATION

00

0

00

0

0

84

OS

e

q

(

)

(

)

OS

e

q

(

)

OS

e

(

)

0

3040

50

0

8

35

01020

3040

50

0

0

80

0

35

9

56

0

3040

50

8.56.70

01020

3040

50

200

0

1.05

1.40

8001000

5.607.01

e

)

(

)

e

)

q

(

)

(

)

e

)

(

)

e

)

q

(

)

(

)

e

q

(

)

e

e

q

(

)

(

)

00

300

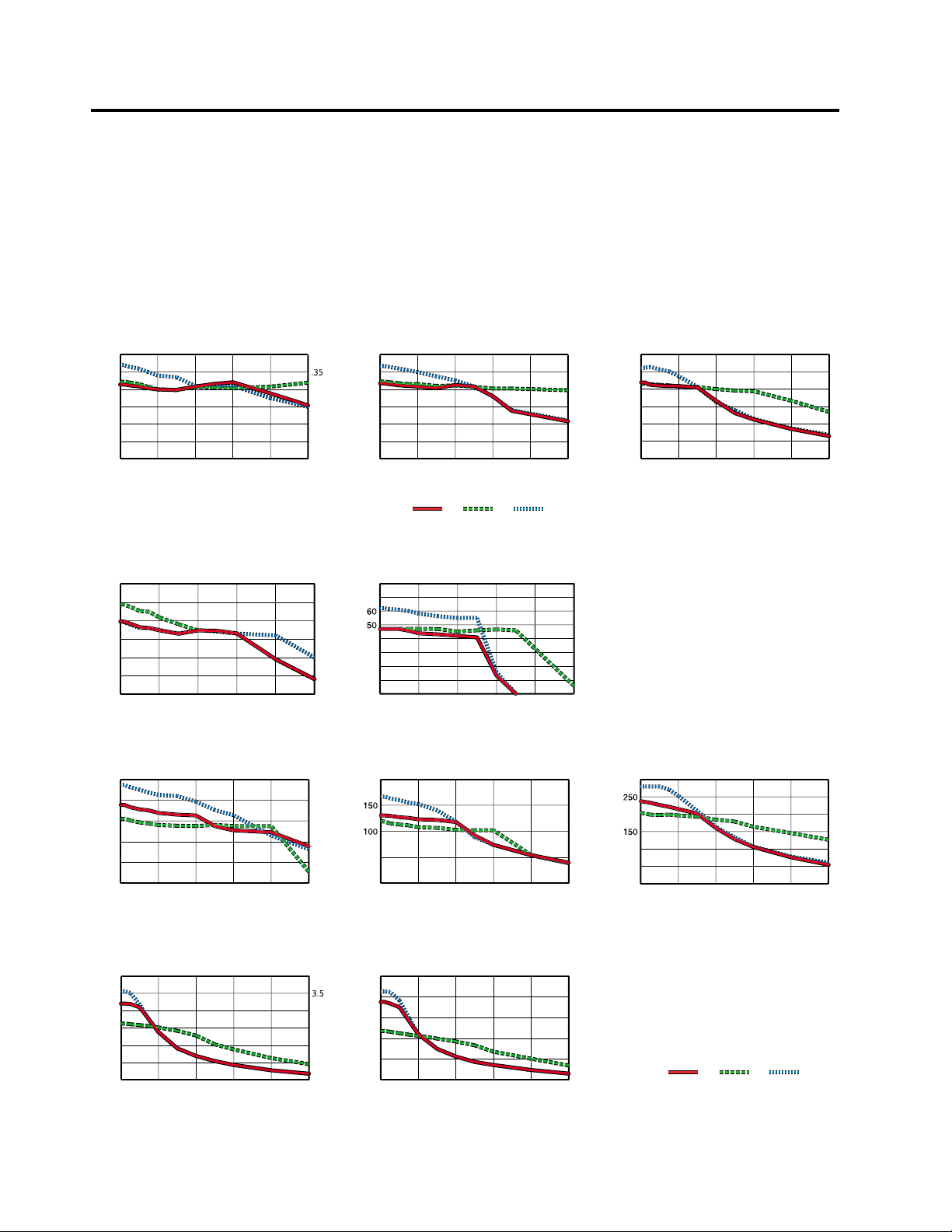

The procedures in the rest of this chapter will lead you through the steps

required to permanently install your E-AC Drive and motor.

1 – SELECT A MOTOR

Speed/Torque curves, specifications, and motor dimensions for

Compumotor motors are shown below.

SPEED/TORQUE CURVES

2HB/E-AC Driv

60

50

40

30

Torque (oz-in)

20

10

0

0 1020304050

Speed (RPS)

21B/E-AC Driv

12

Torque

.35

.28

.21

.14

.07

0

1

oz-in

80

Nm

ue

60

or

40

20

0

0 1020304050

Speed (RPS)

.

.7

.56

.42

.28

.14

0

24

Torque

2

oz-in

160

Nm

ue

120

or

80

40

0

0 1020304050

22B/E-AC Driv

Speed (RPS)

1.68

1.40

1.12

.84

.56

.28

0

Torque (Nm)

VS12B/E-AC Driv

60

50

40

30

Torque (oz-in)

20

10

0

0102

Speed (RPM

VS21B/E-AC Driv

100

80

60

40

Torque (oz-in)

20

0

0102

Speed (RPM

VS31B/E-AC Driv

600

500

400

300

Torque (oz-in)

200

100

0

0 1020304050

Speed (RPM)

.

.2

.21

.14

.07

.2

.14

0

3.5

2.8

2.1

1.4

.70

0

Series

Parallel

VS13B/E-AC Driv

7

Torque

oz-in

Nm

ue

40

or

30

20

10

Speed (RPM

VS22B/E-AC Driv

Torque

oz-in

Nm

ue

or

50

0

Speed (RPM

VS32B/E-AC Driv

Torque (Nm)

oz-in

600

ue

or

400

200

0

0 1020304050

Speed (RPM)

Full Step

.7

.35

0

4.20

2.80

1.40

0

.

.4

.

.28

.21

.14

.07

Torque

Nm

VS23B/E-AC Driv

Torque

oz-in

2

Nm

ue

or

100

50

0

0 1020304050

Speed (RPM)

Torque

Nm

Series

Parallel

Full Step

2.10

1.75

1.40

1.05

.70

.35

0

Torque (Nm)

14

E-AC Drive Hardware Installation Guide Chapter 2 – Installation

Page 15

MOTOR SPECIFICATIONS

OS Motors

Size 23 Frame

Parameters Units OS2HB OS21B OS22B

Static torque oz-in 61.35 126.5 238

Rotor inertia oz-in

Drive Current Series 1.76 (1.24) 1.88 (1.33) 2.38 (1.68)

(Apk)(Arms) Parallel 3.25 (2.48) 3.76 (2.66) 4.76 (3.36)

Phase Inductance Series 8.6 12 16.6

(mH) Parallel 2.2 3 4.2

Detent Tor que oz-in 2.5 4.0 7.0

Bearings

Information

Thrust Load lb 13 13 13

Radial Load lb 20 20 20

End Play in 0.001 0.001 0.001

(Reversing load (mm) (0.025) (0.025) (0.025)

equal to 1 lb)

Radial Play in 0.0008 0.0008 0.0008

(Per 0.5 lb load) (mm) (0.02) (0.02) (0.02)

Motor Weight lb 1 1.5 2.5

Certifications UL recognized Pending Pending Pending

(Nm) (0.43) (0.84) (1.68)

2

(kg-cm2) (0.07) (0.12) (0.25)

(N-m) (0.02) (0.03) (0.05)

(kg) (5.9) (5.9) (5.9)

(kg) (9.1) (9.1) (9.1)

(kg) (0.5) (0.7) (1.1)

CE (LVD) Yes Yes Yes

CE (EMC & LVD) No No No

0.39 0.66 1.39

VS Motors

Size 17 Frame Size 23 Frame Size 34 Frame

Parameters Units VS12B VS13B VS21B VS22B VS23B VS31B VS32B

Static torque oz-in 55.27 72.8 115.5 194.5 334.5 551.8 1269.67

Rotor inertia oz-in

Drive Current Series 1.00 (0.71) 1.01(0.71) 2.26 (1.6) 2.01 (1.42) 2.01 (1.42) 3.0 (2.12) 3.13 (2.21)

(Apk)(Arms) Parallel 2.00 (1.42) 2.02 (1.43) 4.52 (3.2) 4.02 (2.84) 4.02 (2.84) 6.0 (4.24) 6.26 (4.42)

Phase Inductance Series 12.8 11.2 5.0 12.0 15.4 15.8 25

(mH) Parallel (3.2) (2.8) (1.2) (3.0) (3.8) 4.0 6.25

Detent Tor que oz-in 2.5 4.0 7.0 8.8 18.0 27.0 50

Bearings

Information

Thrust Load lb 11.0 11.0 17.6 17.6 17.6 35.3 35.3

Radial Load lb 7.7 7.7 15.0 15.0 15.0 30.9 30.9

End Play in 0.003 0.003 0.003 0.003 0.003 0.0032 0.0032

(with 2.2 lbs axial (mm) (0.075) (0.075) (0.075) (0.075) (0.075) (0.080) (0.080)

load)

Radial Play (with in 0.001 0.001 0.001 0.001 0.001 0.0008 0.0008

1.1 lb radial load) (mm) (0.025) (0.025) (0.025) (0.025) (0.025) (0.020) (0.020)

Motor Weight lb 0.55 0.77 1.03 1.54 2.2 3.86 6.18

(Nm) (0.39) (0.51) (0.82) (1.37) (2.36) (3.90) (8.97)

2

2

(kg-cm

) (0.054) (0.068) (0.12) (0.3) (0.48) (1.4) (2.7)

(N-m) (0.02) (0.03) (0.05) (0.06) (0.13) (0.19) (0.35)

(kg) (5) (5) (8) (8) (8) (16) (16)

(kg) (3.5) (3.5) (6.8) (6.8) (6.8) (14) (14)

(kg) (0.25) (0.35) (0.47) (0.7) (1.0) (1.75) (2.8)

0.3 0.37 0.66 1.64 2.62 7.65 4.8

E-AC Drive Hardware Installation Guide

Chapter 2 – Installation

15

Page 16

MOTOR DIMENSIONS

Dimensions in inches (mm)

0.200 (5.08) dia (4)

(66.68) BC

on 2.625

1.86

2.25

(47.2)

(57.2)

1.502

(38.15)

1.498

(38.05)

Model

OS2HA, OS2HB

OS21A, OS21B

OS22A, OS22B

OS Motors – Frame Size 23 – Dimensions

45°

A

1.60 (40.7)

2.06 (52.4)

3.10 (78.8)

0.2500

0.2495

Shaft Dia

0.81(20.6)

(6.350)

(6.337)

B

2.44 (62.0)

2.90 (73.7)

3.94 (100.1)

Flexible boot

may be bent as

(5.08)

shown. Nominal

height 1.0 (25.4).

1.0

(25.4)

Ø 0.02500

.75 ± 0.04

Optional rear

shaft

0.25

C

(6.4)

0.20

0.055(1.40)

A

C

For flying leads (FLY) – 13.5 (343) min.

For 10 ft cable (L10) – 120.0 (3048)

+.0000

-.0005

1.06

(26.9)

2.44

(62.0)

2X 2–56 UNC–2B

.170 MIN.

ON A Ø 1.812 B.C.

.84

(21.34)

1.50

(38.1)

B

RE/RC Encoder (optional)

VS Motors – Frame Size 17 – Dimensions

16

E-AC Drive Hardware Installation Guide Chapter 2 – Installation

Page 17

VS Motors – Frame Size 23 – Dimensions

VS Motors – Frame Size 34 – Dimensions

E-AC Drive Hardware Installation Guide

Chapter 2 – Installation

17

Page 18

2 – CONNECT THE MOTOR TO THE DRIVE – WIRING

Most Compumotor motor windings—phase A and phase B—are bifilar

windings made from double-stranded copper wire. Each phase has two

half-windings, which can be wired together in series or parallel.

These two alternatives—series and parallel—produce different speed/

torque characteristics, affect the motor’s current rating, and alter the

motor’s operating temperature. They are explained below.

GROUND THE MOTOR CASE

The motor case must be grounded, for safety purposes. On pre-cabled

Compumotor motors, one end of the cable shield is permanently wired to

the motor case; you should connect the other end to on the drive’s

motor connector. Inside the drive, connects directly to the ground pin

on the AC power terminals.

PRECAUTIONS

Follow these precautions when you wire the motor connector.

1. Turn off power to the drive before connecting or disconnecting the motor

leads.

2. Verify that no wire whiskers short out motor connections.

3. Do not apply power to the drive when the motor is not connected.

4. Never connect anything other than the motor to the motor terminals.

5. After wiring the motor connector, perform the Automatic Test, to verify that

the connector is wired correctly.

CONNECTING THE MOTOR: SERIES WIRING

For series motor current, connect a Compumotor motor as shown in the

following diagram.

OS Motors;

VS Motors

Compumotor Motor

Phase A

Windings

PM

Phase B

Windings

Shield is internally connected

to the motor’s case

(flying lead):

Red/White

Yellow/White

Red

Yellow

Orange

Black

Orange/White

Black/White

Shield

Motor Connector – Wired for SERIES Motor Current

Be sure to insulate the center tap connections; these are the wires shown

joined together in the drawing above, but not connected to the drive.

The operating temperature of a motor connected in series will be lower

than that of a motor connected in parallel. Therefore, you should operate

your motor in series, if your application permits. Typically, series connections work well in high torque/low speed applications.

VS Motors

(with cable):

Yellow

Blue

Red

Black

White

Green

Orange

Brown

A +

A -

B +

B -

18

E-AC Drive Hardware Installation Guide Chapter 2 – Installation

Page 19

CONNECTING THE MOTOR: PARALLEL WIRING

For parallel motor current, connect a Compumotor motor as shown in the

following diagram.

Compumotor Motor

Phase A

Windings

PM

Phase B

Windings

Shield

VS Motors

(flying lead):

Red

Yellow/White

Red/White

Yellow

Orange

Black/White

Orange/White

Black

OS Motors;

VS Motors

(with cable):

Red

Blue

Yellow

Black

White

Brown

Orange

Green

Shield is internally

connected to the

motor’s case

A+

AB+

B-

Motor Connector – Wired for PARALLEL Motor Current

At higher speeds, a motor connected in parallel will produce more torque

than the same motor connected in series. However, the operating temperature of the motor in parallel will be much higher.

If you operate your motor in parallel, you must measure motor temperature under actual operating conditions. If the motor exceeds its maximum

case temperature, reduce the duty cycle, or use automatic standby to

reduce current at rest, or use forced air cooling to limit motor heating.

Compumotor motors have maximum case temperature of 100°C (212°F).

CAUTION

High current in parallel connected motors may cause motor overheating. You may need to

reduce the duty cycle to 50% to decrease motor temperature, or use automatic standby.

SERIES VERSUS PARALLEL – SUMMARY

The following list summarizes the points discussed above.

1. Examine the speed/torque curves for your motor.

2. Use series connection, if possible. (The motor will run cooler.)

3. Use parallel connection, if you need more torque than series connection

provides. (Typically, at higher speeds.)

4. Parallel connection will cause the motor to run hotter, so measure motor

temperature under operating conditions.

5. If necessary, reduce duty cycle, use automatic standby or use forced air

cooling to keep motor temperature within acceptable limits.

E-AC Drive Hardware Installation Guide

Chapter 2 – Installation

19

Page 20

3 – SET DIP SWITCHES

Two 8-position DIP switches are located on top of the E-AC Drive. Configure these DIP switches for your motor and application. The table below

summarizes switch settings.

Default Position:

Drive ships from factory

with all DIP switches in

the OFF position.

Edge of

Circuit Board

Auto Test

1 rps for 2 revs in each

direction until disabled

Disabled

Enabled

1

off

on

Resolution

25,000

50,800

50,000

36,000

25,600

25,400

21,600

20,000

18,000

12,800

10,000

5,000

2,000

1,000

400

200

200 & 400 not affected by

waveform settings

Waveform

Auto Standby

Remove power before

changing DIP switches

SW1

12345678 12345678

4

2

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

Pure sine

-4% 3

-6% 3

-8% 3

5

3

off

off

off

off

off

off

off

off

on

off

off

on

on

off

off

on

off

off

on

off

on

on

off

on

off

on

off

off

on

off

off

on

on

off

on

on

on

on

off

on

on

off

on

on

on

on

on

on

76

off

rd

harmonic

rd

harmonic

rd

harmonic

Full Current

50% Current Reduction

on

off

off

on

off

on

on

8

off

on

1

off

on

off

off

off

on

on

off

on

on

Disabled

Enabled

SW2

off

54

off

off

off

off

off

off

off

off

on

on

on

on

on

on

on

on

off

off

off

off

off

off

off

off

on

on

on

on

on

on

on

on on

off

off

off

off

on

off

on

off

off

on

off

on

on

on

on

on

off

off

off

off

on

off

on

off

off

on

off

on

on

on

on

on

off

off

off

off

on

off

on

off

off

on

off

on

on

on

on

on

off

off

off

off

on

off

on

off

off

on

off

on

on

on

on

off

off

off

off

off

off

off

off

off

off

off

off

off

off

off

off

on

on

on

on

on

on

on

on

on

on

on

on

on

on

on

32

on

< 32 mH (all VS, OS motors)

32 – 64 mH

> 64 mH

> 64 mH

Edge of

Circuit Board

876 (amps)

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

Current

0.02

0.13

0.24

0.35

0.46

0.58

0.69

0.80

0.91

1.03

1.14

1.25

1.36

1.48

1.59

1.70

1.82

1.93

2.04

2.15

2.27

2.38

2.49

2.60

2.72

2.83

2.94

3.05

3.16

3.28

3.39

3.50

Select a setting based on

motor inductance (in mH).

Series = S

Parallel = P

VS12BS, VS13BS

OS2HBS

OS21BS

VS12BP, VS13BP

VS22BS, VS23BS

VS21BS

OS22BS

VS31BS

VS32BS

OS2HBP VS2xBP, VS3xBP

OS21BP, OS22BP

Gain

Anti-Resonance

20

NOTE: This drawing is duplicated in

Quick Test

, earlier in this chapter.

DIP Switch Location and Settings

DEFAULT SETTINGS

The factory default position is off for all switches. For the drive to operate

correctly, you must set the DIP switches for your application.

MOTOR CURRENT

Set DIP switches SW2-#4 — SW2-#8 for motor current. Verify that your

connector wiring (series or parallel) and motor current rating match the

current you set with these five switches.

E-AC Drive Hardware Installation Guide Chapter 2 – Installation

Page 21

DRIVE RESOLUTION

Set DIP switches SW1-#2 — SW1-#5 for drive resolution. There are sixteen settings, which range from 200 to 50,800 steps per revolution. The

default setting is 25,000 steps per revolution.

Be sure to set your controller to the same resolution as your E-AC Drive.

If the controller resolution and drive resolution do not match, commanded

accelerations and velocities will not be properly scaled.

WAVEFORM

Set SW1-#6 and SW1-#7 to select a current waveform. There are four

choices: one is a pure sine wave; the other three reduce the current

waveform’s 3rd harmonic by 4%, 6%, or 8%. In most applications, the

default setting (both switches off = -4% 3rd harmonic) provides the best

performance.

AUTOMATIC TEST

DIP switch SW1-#1 enables or disables the Automatic Test function. For

more information, see the Automatic Test section earlier in this chapter.

AUTOMATIC STANDBY

SW1-#8 should be off if you do not use automatic standby. Turn this

switch on to use automatic standby.

The automatic standby function allows the motor to cool when it is not

moving. Automatic standby reduces motor current by 50% if the drive

does not receive a step pulse for one second. Full current is restored upon

the first step pulse that the drive receives. Be aware that reduced current

results in reduced holding torque.

If you use the position maintenance feature of 6K or 6000 Series controllers, we recommend that you do not use automatic standby.

ANTI-RESONANCE DISABLE

SW1-#1 should be on for the anti-resonance circuit to be enabled. Normally, you will want anti-resonance enabled; therefore, this switch should

be on. If you must disable anti-resonance, turn this switch off.

CURRENT LOOP GAIN

Set SW2-#2 and SW2-#3 according to your motor’s small-signal inductance, in millihenries. The table shows the small-signal inductance range

that corresponds to each of the four settings.

Small-signal inductance is the value read on an ordinary inductance

bridge or meter.

NOTE: These two switches should be off for all Compumotor VS and OS

motors, or for any motor whose inductance is less than 32 mH.

E-AC Drive Hardware Installation Guide

Chapter 2 – Installation

21

Page 22

4 – CONNECT A CONTROLLER – INPUTS & OUTPUTS

Connect your controller cable to the DRIVE I/O connector, a 25 pin Dconnector on the front of the drive. The cable that comes with Compumotor controllers is prewired for compatibility with the E-AC Drive—you

can plug the cable directly into the E-AC Drive’s DRIVE I/O connector.

SERIES

PWR/FLT

L1

120V

N

A +

A -

MOTOR

B +

B -

Compumotor

Controller

E-AC Drive

Connecting a Compumotor Controller

If you make your own cable, or use a non-Compumotor controller, consult the drawing below when you wire your cable and connector.

Step+

Step–

Direction+

Direction–

Shutdown+

Shutdown–

Fault– (E)

Fault+ (C)

Reset–

Reset+

1

2

14

3

15

4

16

5

17

6

18

7

19

8

20

9

21

10

22

11

23

12

24

13

25

243Ω

243Ω

681Ω

681Ω

E-AC Drive – Internal Connections

HCPL2631

HCPL2631

ILD213

ILD223

ILD213

DRIVE I/O

22

Drive I/O Connector

Descriptions of each function on the 25 pin D-connector follow.

STEP INPUT

For every step pulse it receives on its step input, the drive will commutate

the motor to increment rotor position. To send a step pulse to the drive,

apply a positive voltage to STEP+ with respect to STEP–. The drive registers the pulse on the rising edge.

E-AC Drive Hardware Installation Guide Chapter 2 – Installation

Page 23

The input is optically isolated. You can drive the input differentially, or

from a single-ended source.

Step input specifications are:

Input Current: 6.5 mA minimum

15 mA maximum

Input Voltage: 3.5V minimum (min. required for on or high signal)

5.2V maximum*

Step Pulse: 200 nanosecond minimum pulse width

200 nanosecond minimum off time

2 MHz maximum pulse rate

Optically Isolated: Yes

*As a custom product, Compumotor can modify drive for higher input voltage

DIRECTION INPUT

While a positive voltage is applied to DIRECTION+ with respect to DIRECTION–, the drive will commutate the motor in the clockwise (positive)

direction as it receives step pulses on its step input.

While zero voltage (or a negative voltage) is applied to DIRECTION+ with

respect to DIRECTION–, the drive will commutate the motor in the counterclockwise (negative) direction as it receives step pulses.

The input is optically isolated. You can drive the input differentially, or

from a single-ended source.

Direction input specifications are:

Input Current: 6.5 mA minimum

15 mA maximum

Input Voltage: 3.5V minimum (min. required for on or high signal)

5.2V maximum*

Optically Isolated: Yes

Direction Change: Direction input may change polarity coincident with

first step pulse.

*As a custom product, Compumotor can modify drive for higher input voltage

SHUTDOWN INPUT

You can use the shutdown input to shutdown, or disable, the E-AC Drive.

To activate shutdown, apply a positive voltage to SHUTDOWN+ with respect

to SHUTDOWN– when the motor is not moving. During shutdown, the drive

turns off current to the motor. The current stays off as long as the voltage

is maintained on the shutdown input.

When you remove the voltage on the input, shutdown ends. The drive

restores current to the motor, in the same phase relationship that existed

before shutdown was invoked.

The shutdown input may also be differentially driven. Specifications are:

Input Current: 2.5 mA minimum

30 mA maximum

Input Voltage: 3.5V minimum (min. required for on or high signal)

13V maximum

5V maximum reverse voltage

Active Level: While voltage is applied, current to motor is shut down.

When voltage is removed, normal operations resume.

Time: 250 nanosecond minimum width

Optically Isolated: Yes

E-AC Drive Hardware Installation Guide

Chapter 2 – Installation

23

Page 24

FAUL T OUTPUT

The E-AC Drive can signal, through its fault output, that it has detected a

fault. Internally, the terminals FAULT+ (C) and FAULT- (E) connect to the

open collector and open emitter, respectively, of an optically isolated

transistor. The transistor acts like a switch: it conducts when the drive is

functioning normally; it does not conduct when any of the following

conditions exist.

• No power is applied to the drive

• AC line voltage is too low (less than 95VAC)

• Drive temperature is higher than 55°C (131°F)

• Drive detects a short circuit in motor or motor cable

Fault output specifications are:

VCE: 30VDC

V

CESAT

Collector Current: 40 mA minimum

Dissipation: 40 mW maximum

Optically Isolated: Yes

: 1 VDC

RESET INPUT

The reset input provides a means for you to reset the E-AC Drive, without

actually cycling power. To activate the reset input, apply a positive voltage

to RESET+ with respect to RESET– when the motor is not moving. The reset

will not be complete until 0.7 seconds after the voltage is removed. A reset

has the same effect on the drive as cycling power:

• DIP switch settings are loaded into the drive for configuration.

• Existing faults are cleared.

• Current to the motor is turned off while voltage is applied to the reset input.

• After voltage is removed from the reset input, the drive’s soft start procedure

will ramp current up to the startup state. The motor will move to the nearest

pole position.

• After voltage is removed from the reset input, there will be a 0.7 second

delay before reset is complete, and normal operations can continue.

Reset input specifications are:

Input Current: 2.5 mA minimum

30 mA maximum

Input Voltage: 3.5V minimum (min. required for on or high signal)

13V maximum

5V maximum reverse voltage

Reset Voltage Pulse: 250 nanosecond minimum pulse width

Active Level: While voltage is applied, reset occurs.

When voltage is removed, normal operations resume.

Reset Delay: 0.7 second delay until reset is complete, after voltage is

removed from input.

Optically Isolated: Yes

24

E-AC Drive Hardware Installation Guide Chapter 2 – Installation

Page 25

5 – MOUNT THE DRIVE

Dimensions of the E-AC Drive are shown below.

4.34

(110.1)

4.10

(104.1)

0.43

(10.8)

0.18

(4.6)

1.89

(48.1)

1.59

(40.5)

Dimensions in inches (mm)

Dimensions – E-AC Drive

ENVIRONMENTAL CONSIDERATIONS

TEMPERATURE SPECIFICATIONS

Maximum Ambient Temperature: 50°C (122°F)

Minimum Ambient Temperature: 0°C(32°F)

Overtemperature Shutdown Fault: 55°C (131°F)

The E-AC Drive has an internal temperature sensor, located near the

heatsink. If the sensor reaches 55°C (131°F), it will trigger an overtemperature fault, and the drive will shut down.

5.35

(135.9)

2x clearance for

#8 or M4 mounting screws

4.500

(114.3)

SERIES

PWR/FLT

120V

MOTOR

Compumotor

DRIVE I/ O

L1

N

A +

A -

B +

B -

FAN COOLING

Operating the E-AC Drive in high ambient temperatures may require fan

cooling to keep the drive from shutting down due to an overtemperature

fault.

HUMIDITY

Keep the relative humidity below 95%, non-condensing.

LIQUIDS

Do not allow liquids or fluids to come into contact with the E-AC Drive or

its cables.

AIRBORNE CONTAMINANTS

Particulate contaminants, especially electrically conductive material such

E-AC Drive Hardware Installation Guide

Chapter 2 – Installation

25

Page 26

as metal shavings or grinding dust, can damage the E-AC Drive and

motor. Do not allow contaminants to come into contact with the drive or

motor.

PANEL LAYOUT

Follow these minimum spacing and clearance requirements when you

mount multiple E-AC Drives.

2.39

(60.7)

Minimum

1.00

(25.4)

Minimum

Clearance

Panel Layout Dimensions

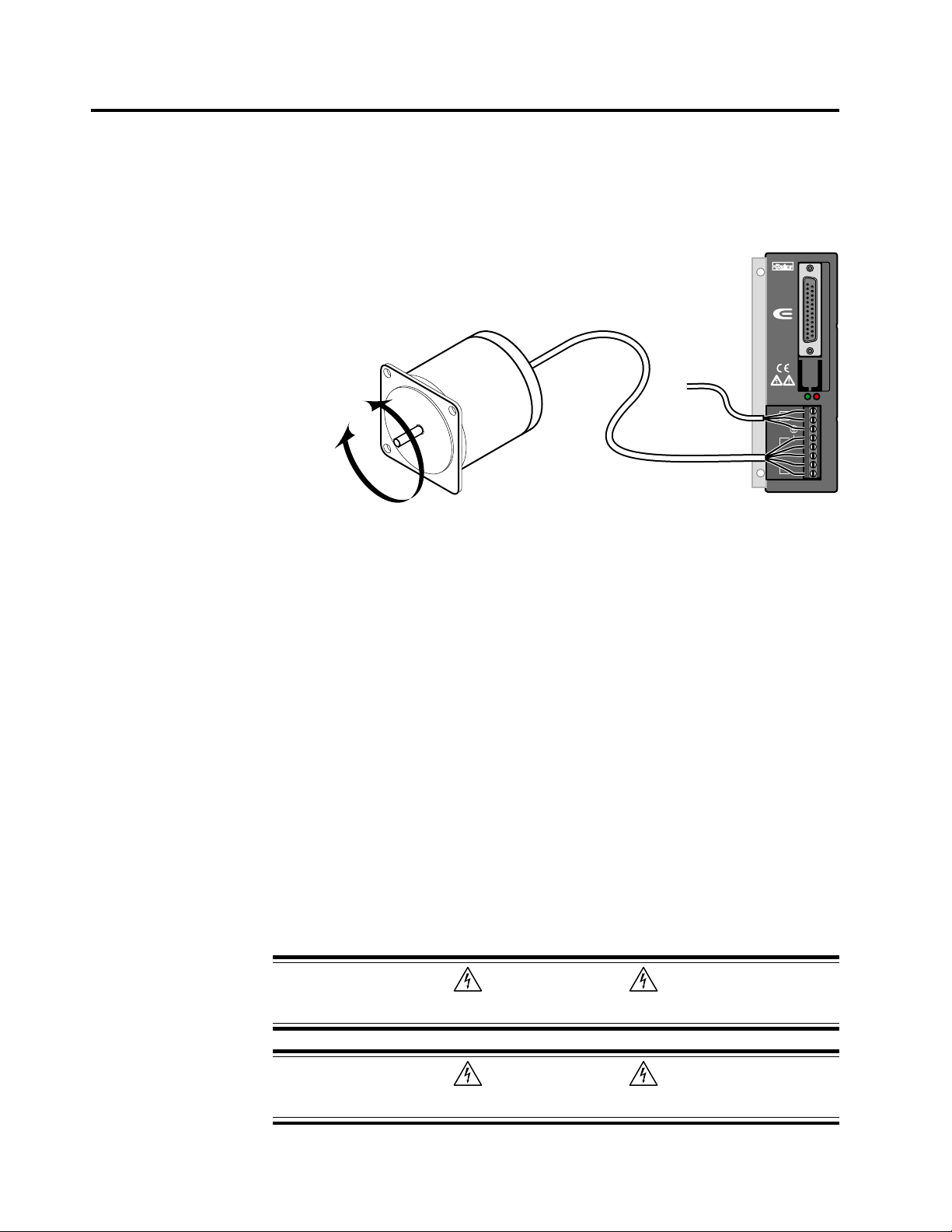

6 – MOUNT THE MOTOR

Use flange bolts to mount rotary step motors. The pilot, or centering flange

on the motor’s front face, should fit snugly in the pilot hole.

SERIES

120V

0.50

(12.7)

Minimum

Clearance

PWR/FLT

L1

N

A +

A -

MOTOR

B +

B -

Compumotor

DRIVE I/ O

SERIES

PWR/FLT

L1

120V

N

A +

A -

MOTOR

B +

B -

Compumotor

Dimensions in

inches (millimeters)

DRIVE I/ O

0.25

(6.4)

Minimum

Clearance

1.00

(25.4)

Minimum

Clearance

26

Do not use a foot-mount or cradle configuration, because the motor’s

torque is not evenly distributed around the motor case. When a foot

mount is used, for example, any radial load on the motor shaft is multiplied by a much longer lever arm.

Step Motors can produce very high torques and accelerations. If the

mounting is inadequate, this combination of high torque/high acceleration can shear shafts and mounting hardware. Because of shock and

vibration that high accelerations can produce, you may need heavier

hardware than for static loads of the same magnitude.

Under certain move profiles, the motor can produce low-frequency vibra-

E-AC Drive Hardware Installation Guide Chapter 2 – Installation

Page 27

tions in the mounting structure that can cause fatigue in structural

members. A mechanical engineer should check the machine design to

ensure that the mounting structure is adequate.

WARNING

Improper motor mounting can jeopardize personal safety, and

compromise system performance.

For Compumotor motor dimensions, see Select a Motor earlier in this

chapter.

MOTOR TEMPERATURE & COOLING

The motor’s face flange is used not only for mounting; it is also a heatsink.

Mount the face flange to a large thermal mass, such as a thick steel or

aluminum plate, which should be unpainted, clean, and flat. Heat will be

conducted from inside the motor, through the face flange, and dissipated

in the thermal mass. This is the best way to cool the motor. You can also

use a fan to blow air across the motor for increased cooling, if conduction

through the flange does not provide enough cooling.

MOTOR MODIFICATIONS

Modifying or machining the motor shaft will void the motor warranty.

Contact a Compumotor Applications Engineer (800-358-9070) about shaft

modifications as a custom product.

EXTENDING MOTOR CABLES

If you need to extend Compumotor motor cables beyond the standard

10 feet (3 m), consult the table below for recommended wire sizes. Cables

longer than 50 feet (15 m) may degrade system performance. Do not

extend cables beyond 200 feet (61 m).

Max. Current Less than 100 ft. (30 m) 100 – 200 ft. (30 – 60 m)

Motor Type (amps) Size: AWG mm

OS2HBS 1.70 22 0.34 20 0.50

OS2HBP 3.39 20 0.50 18 0.75

OS21BS 1.82 22 0.34 20 0.50

OS21BP 3.50 20 0.50 18 0.75

OS22BS 2.38 22 0.34 20 0.50

OS22BP 3.50 20 0.50 18 0.75

VS12BS 1.03 22 0.34 20 0.50

VS12BP 2.04 22 0.34 20 0.50

VS13BS 1.03 22 0.34 20 0.50

VS13BP 2.04 22 0.34 20 0.50

VS21BS 2.27 22 0.34 20 0.50

VS21BP 3.50 20 0.50 18 0.75

VS22BS 2.04 22 0.34 20 0.50

VS22BP 3.50 20 0.50 18 0.75

VS23BS 2.04 22 0.34 20 0.50

VS23BP 3.50 20 0.50 18 0.75

VS31BS 3.05 22 0.34 20 0.50

VS31BP 3.50 20 0.50 18 0.75

VS32BS 3.16 22 0.34 20 0.50

VS32BP 3.50 20 0.50 18 0.75

S: Series Configuration P: Parallel Configuration Rated current in wire sizes shown may result in a maximum

temperature rise of 10°C (18°F) above ambient.

2

AWG mm

2

E-AC Drive Hardware Installation Guide

Chapter 2 – Installation

27

Page 28

7 – CONNECT THE MOTOR TO THE LOAD – COUPLERS

Align the motor shaft and load as accurately as possible. In most applications, some misalignment is unavoidable, due to tolerance buildups in

components. However, excessive misalignment may degrade your system’s

performance. The three misalignment conditions, which can exist in any

combination, are illustrated and described below.

Aligned

Angular Misalignment

End Float

Parallel Misalignment

Combined Parallel & Angular Misalignment

Misalignment Condition

• Angular Misalignment: The center lines of two shafts intersect at an angle

other than zero degrees.

• Parallel Misalignment: The offset of two mating shaft center lines, although

the center lines remain parallel to each other.

• End Float: A change in the relative distance between the ends of two shafts.

The type of misalignment in your system will affect your choice of coupler.

SINGLE-FLEX COUPLING

Use a single-flex coupling when you have angular misalignment only.

Because a single-flex coupling is like a hinge, one and only one of the

shafts must be free to move in the radial direction without constraint. Do

not use a double-flex coupling in this situation: it will allow too much

freedom and the shaft will rotate eccentrically, which will cause large

vibrations and catastrophic failure. Do not use a single-flex coupling

with a parallel misalignment: this will bend the shafts, causing excessive bearing loads and premature failure.

DOUBLE-FLEX COUPLING

Use a double-flex coupling whenever two shafts are joined with parallel

misalignment, or a combination of angular and parallel misalignment (the

most common situation).

Single-flex and double-flex couplings may or may not accept end play,

depending on their design.

28

RIGID COUPLING

Rigid couplings are generally not recommended, because they cannot

compensate for any misalignment. They should be used only if the motor

or load is on some form of floating mounts that allow for alignment compensation. Rigid couplings can also be used when the load is supported

entirely by the motor’s bearings. A small mirror connected to a motor

shaft is an example of such an application.

COUPLING MANUFACTURERS

HUCO ROCOM CORP. HELI-CAL

70 Mitchell Blvd, Suite 201 5957 Engineer Drive P.O. Box1069

San Rafael, CA 94903 Huntington Beach, CA 92649 Santa Maria, CA 93456

(415) 492-0278 (714) 891-9922 (805) 928-3851

E-AC Drive Hardware Installation Guide Chapter 2 – Installation

Page 29

8 – CONNECT AC POWER

At this point in your installation procedure, you should have mounted

your drive and motor, coupled the motor to the load, and connected the

controller and motor cables to the drive.

The E-AC Drive does not have an on/off switch. When you apply power to

the drive, the drive will turn on. Therefore, before you apply power, verify

the following:

• Motor should be properly secured

• Motor cable should be connected to drive

• Drive should be properly mounted

• Controller cable should be connected to drive

• Controller cable should not be in close physical proximity to motor cable

APPLY POWER

To apply power, connect one end of your power cable to the drive’s L1, N

and

terminals.

95 – 132VAC,

50 – 60 Hz,

Single phase

L1

External Fuses:

N

Are not required for AC mains with

Line and Neutral designations.

For AC mains without Line and

Neutral designations:

1. Fuse both sides of the AC mains,

as shown at right.

2. Use 125VAC Time Delay, 10 amp,

type RK5 or better fuses.

95 – 132VAC

Fuses

L1

N

AC Input Connections

Connect the other end of your power cable to a grounded 120VAC power

source that meets the following specifications:

Specifications – AC Power Input

Input Power: 120VAC nominal

95VAC minimum

132VAC maximum

50 – 60 Hz

Inrush Current: 22.2 amps (peak) maximum

Fuses: No user serviceable fuses

Grounding: You must provide a proper AC power ground

Transformer: Not required for 120VAC operation; to size step-

down transformer, use Volt-Amp rating (see the

following table)

WARNING

The motor case and drive are grounded through the drive’s terminal.

You must provide a proper AC power ground for safety purposes.

E-AC Drive Hardware Installation Guide

Chapter 2 – Installation

29

Page 30

PEAK POWER RATINGS

The amount of power the E-AC Drive requires from your AC power source

depends upon the motor you use, whether you wire the motor in series or

parallel, and upon your specific application. The next table shows peak

power requirements. Power required for your application may be less.

Motor Type Current Cabinet Peak Motor Peak Shaft Peak Total Volt-Amp

OS2HBS 1.70 22.0 22 39 83 151

OS2HBP 3.39 32.0 76 82 190 314

OS21BS 1.82 24.0 30 65 119 205

OS21BP 3.50 55.0 86 129 270 432

OS22BS 2.38 18.0 41 87 146 247

OS22BP 3.50 29.0 93 161 283 451

VS12BS 1.02 17.0 29 32 78 141

VS12BP 2.04 24.0 87 33 144 266

VS13BS 1.02 18.0 25 38 81 147

VS13BP 2.04 39.0 93 32 164 280

VS21BS 2.27 18.0 60 100 178 300

VS21BP 3.50 37.0 105 137 279 438

VS22BS 2.04 13.0 46 93 152 258

VS22BP 3.50 36.0 95 149 280 452

VS23BS 2.04 14.0 39 113 166 281

VS23BP 3.50 24.0 99 202 325 531

VS31BS 3.05 19.0 45 135 199 339

VS32BS 3.16 22.0 57 121 200 334

S: Series Configuration P: Parallel Configuration

(Amps) Loss (W) Loss (W) Power (W) Power (W) Rating (VA)

9 – TEST THE INSTALLATION

System installation should be complete at this point. Perform the test

procedure below to verify that your system is functioning properly.

In the test procedure, you will command single revolution moves in the

clockwise and counterclockwise direction. If your mechanics do not

permit such moves, choose a move that allows you to easily verify correct

system response.

30

TEST PROCEDURE

1. Apply 120VAC power. The green LED labeled PWR should illuminate.

2. Command a slow move of one revolution in the clockwise direction. Verify

that the motor turns as commanded.

3. Command a slow move of one revolution in the counterclockwise direction.

Verify that the motor turns as commanded.

4. Test the shutdown input. With the motor stopped, activate the input. The

motor will have no torque when shutdown is activated. You should be able

to turn the motor manually (if your mechanics permit).

Successful completion of this procedure will verify that your controller

and motor are correctly connected to the E-AC Drive, and that the drive is

functioning properly.

If the test is unsuccessful, proceed to Chapter 3 Troubleshooting for

problem identification and solution procedures.

E-AC Drive Hardware Installation Guide Chapter 2 – Installation

Page 31

CHAPTER THREE

Troubleshooting

3

• Troubleshooting Basics

• Diagnostic LEDs

• Protective Circuits

• Automatic T est

• Anti-Resonance Disable

• Product Return Procedure

E-AC Drive Hardware Installation Guide

IN THIS CHAPTER

Chapter 3 – Troubleshooting

31

Page 32

TROUBLESHOOTING BASICS

When your system does not function properly (or as you expect it to

operate), the first thing that you must do is identify and isolate the problem. When you have accomplished this, you can effectively begin to

resolve the problem.

The first step is to isolate each system component and ensure that each

component functions properly when it is run independently. You may

have to dismantle your system and put it back together piece by piece to

detect the problem. If you have additional units available, you may want

to exchange them with existing components in your system to help identify the source of the problem.

Determine if the problem is mechanical, electrical, or software-related.

Can you repeat or re-create the problem? Random events may appear to

be related, but they are not necessarily contributing factors to your

problem.

You may be experiencing more than one problem. You must isolate and

solve one problem at a time. Log (document) all testing and problem

isolation procedures. You may need to review and consult these notes

later. This will also prevent you from duplicating your testing efforts.

Once you have isolated a problem, take the necessary steps to resolve it.

Refer to the problem solutions contained in this chapter.

DIAGNOSTIC LEDS

The E-AC Drive has two LEDs on its front panel. The following summary

of LED functions may help you isolate problems.

LED Name Color Function

PWR (POWER) Green Illuminates when AC power is applied

FLT (FAULT) Red Indicates short circuit in motor or cabling; or

PROTECTIVE CIRCUITS

The E-AC Drive has several protective circuits, some of which can indicate

fault conditions by illuminating one of the above LEDs.

OVERTEMPERATURE PROTECTION

To protect against damage from high temperatures, the E-AC Drive has an

internal temperature sensor. If the sensor reaches 55°C (131°F) it will

trigger an overtemperature fault. The red FAULT LED will illuminate, and

the drive will shut down. This is a latched fault. To restart the drive, first

allow it to cool, then cycle power or toggle the reset input.

Off if AC power is under voltage (<95VAC)

Drive overtemperature

32

E-AC Drive Hardware Installation Guide Chapter 3 – Troubleshooting

Page 33

SHORT CIRCUIT PROTECTION

The E-AC Drive has short circuit protection. When the drive detects a

short circuit in the motor or motor cabling, it illuminates the FAULT LED,

and stops producing motor current. This is a latched condition. To restart

the drive, first remove power to the drive; fix the short in the motor or

cable; then reapply power.

AUTOMATIC TEST

Often in diagnosing a problem, it is helpful to rule out possible causes. If

you disconnect the load and controller from the drive, four components

remain—the drive, motor, motor cable, and power cable.

You can then configure the drive to run the automatic test function. See

instructions near the beginning of Chapter 2 Installation. If the motor

turns as expected—in an alternating mode—then the drive, motor, and

cables are probably not the cause of the problem. The cause may lie with

the controller, software, mechanics, etc.

ANTI-RESONANCE DISABLE

If your mechanical system is highly resonant at precisely the wrong

frequency, anti-resonance might interpret the mechanical vibrations as

rotor position error. You would notice greater torque ripple, increased

audible noise, and possibly even stalling. To solve these problems, try

disabling anti-resonance (SW2-#1 off), and see if the problems improve.

TECHNICAL SUPPORT

If you cannot solve your system problems using this documentation,

contact your local Automation Technology Center (ATC) or distributor for

assistance. If you need to talk to our in-house application engineers,

contact Parker Compumotor’s Applications Department at (800) 358-

9070.

E-AC Drive Hardware Installation Guide

Chapter 3 – Troubleshooting

33

Page 34

PRODUCT RETURN PROCEDURE

If you must return your E-AC Drive for repairs, use the following steps:

1. Get the serial number and the model number of the defective unit,

and a purchase order number to cover repair costs in the event the

unit is determined to be out of warranty.

2. Before you return the unit, have someone from your organization

with a technical understanding of the E-AC Drive and its application

include answers to the following questions:

• What is the extent of the failure/reason for return?

• How long did the unit operate?

• Did any other items fail at the same time?

• What was happening when the unit failed (e.g., installing the unit,

cycling power, starting other equipment, etc.)?

• How was the unit configured (in detail)?

• What, if any, cables were modified and how?

• With what equipment is the unit interfaced?

• What was the application?

• What was the system environment (temperature, enclosure, spac-

ing, unit orientation, contaminants, etc.)?

• What upgrades, if any, are required (hardware, cables, etc.)?

3. In the USA, call your Automation Technology Center (ATC) for a

Return Material Authorization (RMA) number. Returned products

cannot be accepted without an RMA number. If you cannot obtain

an RMA number from your ATC, call Parker Compumotor’s Customer Service Department at (800) 722-2282.

Ship the unit to: Parker Hannifin Corporation

Compumotor Division

5500 Business Park Drive, Suite D

Rohnert Park, CA 94928

Attn: RMA # xxxxxxx

4. In the UK, call Parker Digiplan for a GRA (Goods Returned Authorization) number. Returned products cannot be accepted without a

GRA number. The phone number for Parker Digiplan Repair Department is 0202-690911. The phone number for Parker Digiplan Service/Applications Department is 0202-699000.

Ship the unit to: Parker Digiplan Ltd.,

21, Balena Close,

Poole, Dorset,

England. BH17 7DX

5. Elsewhere: Contact the distributor who supplied the equipment.

34

E-AC Drive Hardware Installation Guide Chapter 3 – Troubleshooting

Page 35

APPENDIX A

Using

Non-Compumotor

Motors

Α

• Wiring Configurations: 4-, 6- and 8-lead motors

• Terminal Connections: 4-, 6- and 8-lead motors

• Setting Motor Current: Series or Parallel

E-AC Drive Hardware Installation Guide

IN THIS APPENDIX

Unipolar or Bipolar

Appendix A – Non-Compumotor Motors

35

Page 36

USING NON-COMPUMOTOR MOTORS

We recommend that you use Compumotor motors with the E-AC Drive. If

you use a non-Compumotor motor, it must meet the following requirements:

• A minimum inductance of 2 mH, series or parallel, is required.

(Compumotor recommends a minimum inductance of 5 mH.)

• A minimum of 500VDC high-pot insulation rating from phase-to-phase and

phase-to-ground.

• The motor must be designed for use with a bipolar drive (no common center

tap).

• Motors with riveted rotors or stators are not recommended.

• Motors with solid rotors are not recommended.

• Test all motors carefully. Verify that the motor temperature in your applica-

tion is within the system limitations. The motor manufacturer’s maximum

allowable motor case temperature must not be exceeded. You should test the

motor over a 2-to-3 hour period. Motors tend to have a long thermal time

constant, but can still overheat, which results in motor damage.

Consult your motor vendor to verify that your motor meets the above specifications.

Consult your Automation Technology Center (ATC) if you have questions regarding the use

of a non-Compumotor motor with Compumotor equipment.

CAUTION

36

WIRING CONFIGURATIONS

Refer to the manufacturer’s motor specification document to determine

the motor’s wiring configuration. You can also determine the wiring

configuration with an ohmmeter using the procedures below (4-Lead

Motor, 6-Lead Motor, 8-Lead Motor). Once you determine the correct motor

wiring configuration, use the terminal connection diagram, shown at the

end of this section, that applies to your configuration.

4-LEAD MOTOR

1. Label one motor lead A+.

2. Connect one lead of an ohmmeter to the A+ lead and touch the other lead of

the ohmmeter to the three remaining motor leads until you find the lead

that creates continuity. Label this lead A–.

3. Label the two remaining leads B+ and B–. Verify that there is continuity

between the B+ and B– leads.

4. Proceed to the Terminal Connections section below.

6-LEAD MOTOR

1. Determine, with an ohmmeter, which three of the six motor leads are

common (one phase).

2. Label each one of these three motor leads A.

3. Using the ohmmeter, verify that the remaining three leads are common.

4. Label the remaining three leads B.

5. Set the ohmmeter range to the 100 ohm scale (approximately).

6. Connect the ohmmeter’s negative lead to one of the motor leads labeled A.

Alternately measure the resistance to the two remaining motor leads also

labeled A. The resistance measurements will reflect one of the following two

scenarios.

Scenario #1 — The resistance measurements to the two remaining motor

leads are virtually identical. Label the two remaining motor leads A+ and A–.

Label the motor lead connected to the negative lead of the ohmmeter

A CENTER TAP (this is the center tap lead for Phase A of the motor).

E-AC Drive Hardware Installation Guide Appendix A – Non-Compumotor Motors

Page 37

Scenario #2 — The resistance measurement to the second of the three

motor leads measures 50% of the resistance measurement to the third of

the three motor leads. Label the second motor lead A CENTER TAP (this is

the center tap lead for Phase A of the motor). Label the third motor lead A–.

Label the motor lead connected to the ohmmeter A+.

7. Repeat the procedure as outlined in step 6 for the three leads labeled B

(B CENTER TAP is the center tap lead for Phase B of the motor).

8. Proceed to the Terminal Connections section below.

8-LEAD MOTOR

Because of the complexity involved in phasing an 8-lead motor, you must

refer to the manufacturer’s motor specification document. Using the

manufacturer’s specifications, label the motor leads as shown in the next

drawing.

1

2

3

Phase A Windings

4

PM

21 43

Phase B Windings

8-Lead Motor – Labeling the Leads

You can configure the 8-lead motor in series or parallel.

Series Configuration Use the following procedure for series configura-

tions.

1. Connect A2 & A3 together and relabel this common point A CENTER TAP.

2. Connect B2 & B3 together and relabel this common point B CENTER TAP.

3. Relabel the A1 lead A+.

4. Relabel the A4 lead A–.

5. Relabel the B1 lead B+.

6. Relabel the B4 lead B–.

7. Proceed to the Terminal Connections section below.

Parallel Configuration Use the following procedure for parallel configurations.

1. Connect motor leads A1 & A3 together and relabel this common point A+.

2. Connect motor leads A2 & A4 together and relabel this common point A–.

3. Connect motor leads B1 & B3 together and relabel this common point B+.

4. Connect motor leads B2 & B4 together and relabel this common point B–.

5. Proceed to the Terminal Connections section below.

E-AC Drive Hardware Installation Guide

Appendix A – Non-Compumotor Motors

37

Page 38

TERMINAL CONNECTIONS

After you determine the motor’s wiring configuration, connect the motor

leads to the E-AC Drive’s MOTOR terminals according to the following

figure.

4-Lead Motor 6-Lead Motor

E-AC Drive

A +

A -

B +

B -

E-AC Drive

A +

A -

B +

B -

A+

A–

B+

B–

8-Lead Motor

Series

A1

A Center

Tap

B Center

Tap

A2

A3

A4

B1

B2

B3

B4

E-AC Drive

A +

A -

B +

B -

E-AC Drive

A +

A -

B +

B -

A+

A Center

Tap

B Center

Tap

A-CT

A–

B+

B-CT

B–

8-Lead Motor

Parallel

A1

A2

A3

A4

B1

B2

B3

B4

38

Non-Compumotor Motor Connections

WARNING

The E-AC Drive has no

Center Tap

terminals. You must insulate and

properly secure the ends of the motor’s center tap wires.

DIRECTION OF MOTOR ROTATION

The procedures above do not determine the direction of motor shaft

rotation. To find out which direction the shaft turns, you must power up

your system and command motion. If the shaft turns in the opposite

direction than you desire, exchange the motor leads connected to A+ and

A– to reverse the direction of rotation.

WARNING

Motor shaft rotation may be opposite than you expect. Do not connect a load to the shaft

E-AC Drive Hardware Installation Guide Appendix A – Non-Compumotor Motors

until you first determine the direction of shaft rotation.

Page 39

SETTING MOTOR CURRENT – NON-COMPUMOTOR MOTORS

To set motor current for a non-Compumotor motor, refer to the formulas

below that correspond to your motor (4-lead, 6-lead, 8-lead) and use the

current settings shown in the DIP switch table (in Chapter 2 Installation)

to set the motor’s current.

WARNING

Do not connect or disconnect the motor with the power on. Doing so will damage the

4-LEAD MOTORS

If you use a 4-lead motor, the manufacturer’s current specification will

translate directly to the values shown for current in the DIP switch table.

6-LEAD MOTORS

Manufacturers generally use either a bipolar rating or a unipolar rating

for motor current in 6-lead motors.

Bipolar Rating: If the manufacturer specifies the motor current as a

bipolar rating, you can use the DIP switch table’s current settings directly

to set motor current—no conversion is required.

Unipolar Rating: If the manufacturer specifies the motor current as a

unipolar rating:

contacts of the motor connector and may cause personal injury.

• Use the following formula to convert the unipolar current rating to the

correct bipolar rating:

Unipolar Current ∗ 0.707 = Bipolar Current

• Use the converted value and the DIP switch table’s current settings to set

the motor current.

8-LEAD MOTORS

Manufacturers generally use either a bipolar rating or a unipolar rating

for motor current in 8-lead motors.

Bipolar Rating: If the manufacturer specifies the motor current as a

bipolar series rating:

• If you wire the motor in series, use the DIP switch table’s current settings

directly.

• If you wire the motor in parallel, you must double the manufacturer’s rating

and then use the DIP switch table’s current settings to set the motor current.

Unipolar Rating: If the manufacturer specifies the motor current as a

unipolar rating:

• Use the following formula to convert the unipolar current rating to the

correct bipolar rating:

Unipolar Current ∗ 0.707 = Bipolar Current

• If you wire the motor in series, use the converted value and the DIP switch

table’s current settings to set the motor current.

• If you wire the motor in parallel, you must double the converted value and

use the DIP switch table’s current settings to set the motor current.

If you have questions about setting motor current, call Compumotor’s

Applications Engineering Department at the number shown inside the

front cover.

E-AC Drive Hardware Installation Guide

Appendix A – Non-Compumotor Motors

39

Page 40

40

E-AC Drive Hardware Installation Guide Appendix A – Non-Compumotor Motors

Page 41

APPENDIX B

Regulatory

Compliance:

UL and CE

B

IN THIS CHAPTER

• Installation Instructions

• Installation Guidelines

• System Installation Techniques

E-AC Drive Hardware Installation Guide Appendix B – Regulatory Compliance: UL and CE

41

Page 42

Regulatory Agencies