Page 1

Automation

Linear actuators

HLE with timing belt drive

HLEZ with rack-and-pinion drive

Catalogue: 192-510011N7

Version 7 / May 1999

Page 2

HLE – Linear actuators with timing belt drive

Automation

2

Parker Hannifin GmbH

Electromechanical Division

Page 3

HLE – Linear actuators with timing belt drive

g g

HLE linear actuators with timing belt drive

- for guiding, transporting and positioning -

Contents:

The HLE - a proven technology.............. 4

Construction of the HLE..........................5

Technical data..........................................6

Dimensional drawings.............................8

HLE 80......................................................8

HLE100...................................................10

HLE 150..................................................12

Idler unit.................................................14

Carriage with bar ..................................14

Order code .............................................15

HLEZ linear actuators with rack-and-

pinion drive.............................................17

Mechanical accessories........................ 25

Assembly angle plate...........................25

Clamping profile ...................................26

T-nuts and bolts....................................26

Link shaft bearing.................................27

External buffer stop..............................27

Cable carrier..........................................28

Longitudinal flange connection set....30

Attachment of position sensors ..........31

Tripping plate........................................32

Mechanical limit switch........................33

Electrical limit switch...........................33

Distribution box....................................34

Other accessories and software...........34

The dynamic linear unit Typical fields of application Proven technology

for gui ding, transporting and positioning, even over long distances,

offers:

i

High speeds in practical appli -

cations of up to 7 m/s

i

Up to 108 Nm permitted dr iv-

ing torque

i

Long travel distances, up to

20 m

i

High load capacity, horizontal

up to 1000 kg /, vertical up to

300 kg

i

Repeatability, up to ±0.05 mm

i

High mechanical effic iency of

95 %

i

Three prof ile sizes: HLE80,

HLE100 and HLE150, can be

combined in a modular system

i

Simple, rapid installation and

start-up

as part of advanced, cost-effec tive construction of m ac hines and

handling systems:

i

Materials handling

e.g. pal-

letization, feeding, withdrawal

i

Textile machinery building

e.g. cross-cutt ing, slit ting and

stacking, quilting, seam stitching

i

Process engi neering

e.g.

painting, coating, bonding

i

Warehouse technology

e.g.

picking, storage

i

Construction

e.g. f or mwork,

placing reinforcing steel

i

Clean room technology

e.g.

wafer transport, wafer coati ng

i

Machine tool building

e.g.

loading wit h workpiece, tool

changing

i

Testing technology

e.g.

guiding ul trasonic sensors

Subject to technical m odification. Data correct at time of printi ng 06/99

proven in numerous applications,

offers the fol lowing advantages:

i

Low-friction runnin

i

Low particle generation (clean

room suitability to class 10)

i

low wear

i

zero maintenance

i

quiet running

i

high efficiency and

i

long service life

High dynamic perfor mance

i

uaranteed:

due to low-mass, pl ay - free

wheels

Simplif ied inspection with long

i

inspection intervals.

Longitudinal groov es i ntegra-

i

ted on all sides of the profile

for mounting att ac hments or

for use as a cable duct

Tim ing belts can be repl aced

i

without dismantling load attachment plate.

Flex ible installation options

i

provided by longitudinal grooves in the load attachment

plate.

Automation

3

Parker Hannifin GmbH

Electromechanical Division

Page 4

HLE – Linear actuators with timing belt drive

The HLE - a proven technology

The universal one

The HLE linear actuator offers an appropriate solution for all motion tasks.

It is ideal for use as a single axis, or as

a component in a m ul tiple axis system.

It has been developed for rapid linear

movements over long stroke distances.

The HLE provides a simple machine

and system element and can be used

without the need for any specialised

knowledge. Installation and start ing up

only requires a small amount of effort

from the user. The HLE is supplied in

many different configurations with numerous options and many accessories.

The HLE drive principle

The HLE consists of an extruded, selfsupporting aluminium profile, inside

which a backlash-free wheeled carriage

is moved by a timing belt.

Our experience

You can have confidence in our experience and skill because over 6000 axes

are already in use throughout t he world

- be it in automatic textile equipment,

handling systems, packaging machines, automat ic painting and bi nding

equipment ...etc.

The HLE can be found in a wide range

of applications: in clean rooms, in the

food industry, production plants in the

chemical indust r y or i n the manufacture

of prefabricated concrete components.

We work together with a wide range of

different industrial sectors including t he

automobile industry, machine tool

manufactur ers, microelectronics m anufacturers - and hopefully soon with you

...

The steel cord tensile strands integrated into the belt provide the necessary stiffness and effectively prevent

belt streching.

Examples/applications

Mercedes Benz

i

supporting cockpit parts in the S-class

, Böblingen, Germany: wafer transport

IBM

i

in chip production

Bosch-Siemens Hausgeräte GmbH

i

Traunreut, Germany: ha ndling co okers

, Stuttgart, Germany: picking e l ectronic

SEL

i

components

Bitterfeld: palettising folding cartons

Bayer,

i

(flatpa ck box es) for pharmaceut icals

LT Engineering,

i

unit for small parts stores

, Steinfeld: handling roof tiles

Braas

i

Philips,

i

Weckenmann,

i

profiles in the concrete branch.

Special pulleys ensure play-free drive,

ensuring high repeatibility even with

long travel paths and high speeds.

, Sindelfingen, Germany:

,

Switzerland: shelf-picking

Holland: handling screen masks

Dormettingen: setting shell

Optional steel strip cover

A totally new steel strip cover concept

applies fully to the HLE-design. It re-

The T-grooves of the load attachment plate and the basic HLE profile are suitable for T-nuts in accordance with DIN508 and T-bolt in

accordance with DIN 787 (T-nuts

and bolts: refer to page 26)

Ma gnetic strips recessed in the

profile ensure that the steel belt is

fully sealed with the profile

Steel plate integrated in the carriage

plate serves as switching plate for

home & limit sensors.

Switches or sensors for the end

limit or for the machine zero point

can be integrated in the T-groove of

the HLE profile

liably protects the timing belt, wheels

and the bearing surface of the profile

Protectiv e caps ensure th at no dust

enters the in terior of the HLE

Plastic inlays serve as

bearing surface for steel

strip.

against dirt ( pr ot ecti on cl ass I P30) .

A spring-loaded felt insert reliably

keeps dirt away

The timing belt is attached to the carriage

with a clamping angle piece.

The belt can be changed without dismantling the flange plate.

Automation

4

Parker Hannifin GmbH

Electromechanical Division

Page 5

HLE – Linear actuators with timing belt drive

g

g

g

g

y

y

g

g

y

g

g

g sy

g

g

g

g

y g

y

g

g

y

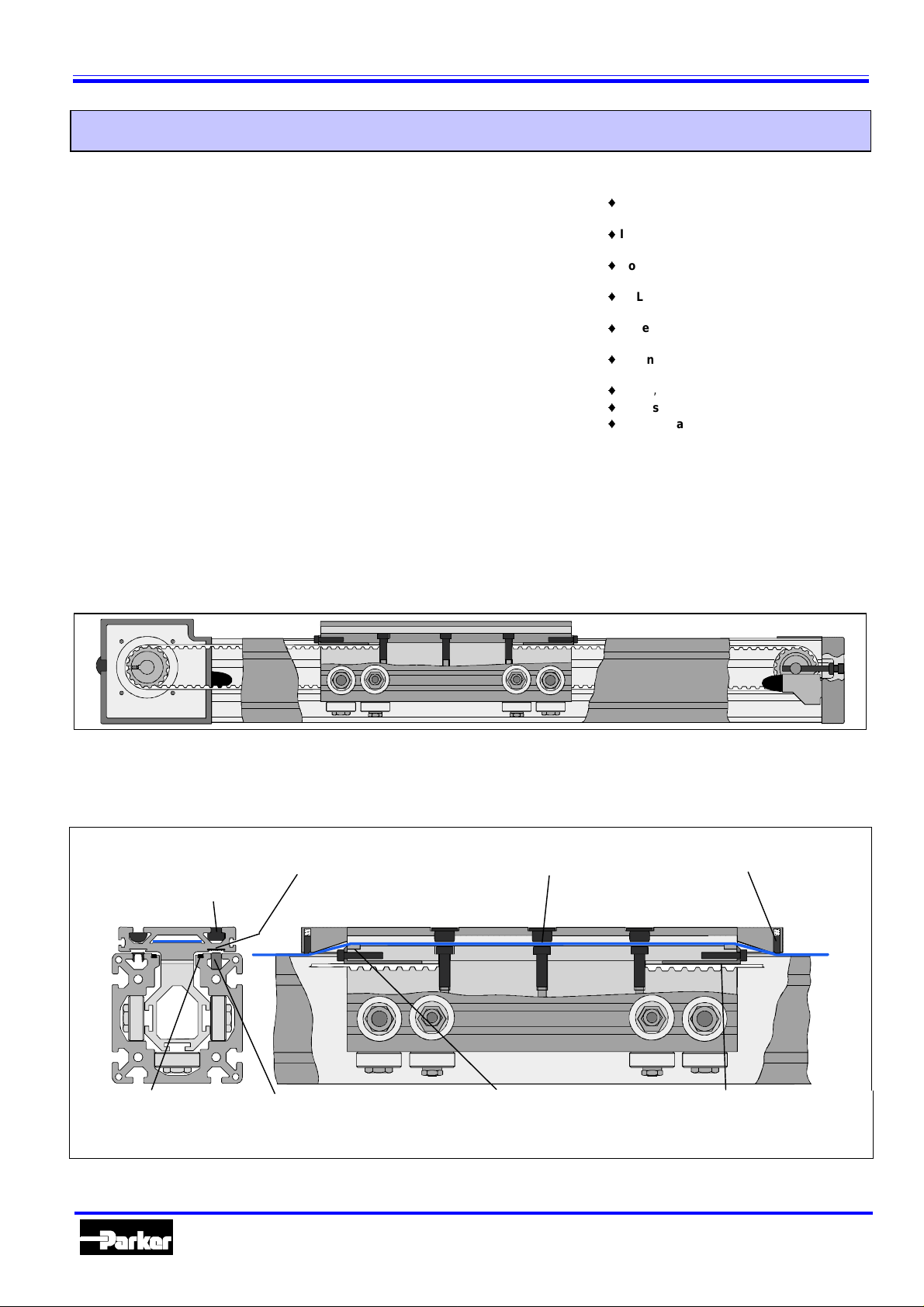

Construction of the HLE

4

1

59

7

6

The profile (1)

Light, compact and self-supporting alum inium

prof ile con stru ction. Available in t he fol lowin

cross-sections:

80x80 mm (HLE80)

100x100 mm (HLE100)

150x150 mm (HLE150)

All profi les feat ure a tot al of ei

clampin g grooves f or the attach ment of additional mechanical components and for the

connection of several HLE units. These

grooves also s erve as at tac hment and mou nting points for initiators and mechanical switches.

To

ether with the HAUSER cover profiles (8),

these can be used as cable ducts.

ht longitudinal

The carri age (2)

Light, rigid carriages with plastic rollers

moun t ed on roller bear i n

for pla

-free carriage settings on all sides.

Overall, this results in high mechanical efficienc

and virtually wear-free operation. The

carria

e can be supplied in two lengths, either

standard or extended.

We can also produce special carria

customised applications.

s and eccentric axles

es for

The tensioning station (3)

An easily maintained and assembly-friendly

tensioning station for setting the te nsio n required for the timing belt and its orientation

(parallelism of pulleys).

8

2

The d rive station (4)

Robust cast ca sing with standard flange. Man

earboxes can be directly flange-mou nted ( for

bore pattern, refe r t o dimensions).

On request, this can be supplied with the drive

shaft on the right, on the left or on both sides.

The timing belt (5)

The timing belt has no play and is reinforced

by in tegr al s teel wir es, th ereb y ens ur in g m aximum trave l spe eds and repeatability.

Clamping of timing belt (6)

The timing belt clamping angle guarantees a

secure connection between the timin

the carriage.

Th e cl ampi n

be rep laced with out t he load attac hmen t p late

havin g to be di smant led. T his means that attachments do not normally need to be remove d.

st em all ows t he t imi ng belt to

The l oad attachment plate (7)

The longitudinal grooves integrated on

i

the top of the plate offer many options for

the assembly of attachments.

belt and

3

When used in conjunction with the

clampin

simple incorporation in a multi-axis system.

Sim pl e and ad j us t abl e att ac h men t of oper -

i

atin

lon

the underside of the plate.

Hei

i

the s teel str ip cover is att ached at a later

date.

Special designs are also available on request.

The optional drive motor (9)

Parker servo motor with res olver and an approp riate pl anetar

drive for dynamic and accurate applications.

W hen used together with the COMPAX compact servo controller, the HLE becomes a

complete, read

sin

le and multi-axis travel and continuous

path controls.

The V2A version (option V)

Minimum particle emissions and high levels of

resistance to water and various cleanin

agents make th e V2A vers ion th e num ber one

ch oice for use in clean r ooms or the food industry.

Th e st eel c om pon en ts ar e mad e of V 2A m aterial and the rollers and pulle

fitted w ith corrosion-resistant bearings.

profile (page 26) this allows for

cams or switch lugs by means of

itudinal grooves on the sides and on

ht and bolt points are unaffected when

earbox f orm an optimum

-to- run aut omation system for

mountings are

Automation

5

Parker Hannifin GmbH

Electromechanical Division

Page 6

HLE – Linear actuators with timing belt drive

Technical data

HLE size 80 100 150

Unit

Standard

Steel strip

cover

Standard

Weight and moment of inertia

Weight of basi c unit without strok e

HLE with standard carriage S kg 7.1 7.9 11.5 12.7 28.6 31.2

HLE with extended carriage E kg 8.4 9.9 14.6 15.8 35.9 38.5

Weight of standar d c ar r iage +

load attachment plat e S

Weight of extended carriage +

load attachment plat e E

Weight per meter of additional length kg/m 6.4 6.4 9.9 10.0 21.0 21.1

Moment of inertia related t o the drive shaft

Standard carriage S kgcm

Extended car riage E kgcm

kg 1.5 1.7 2.5 2.8 6.7 7.3

kg 2.5 2.8 4.1 4.4 10.9 11.5

2

2

18.1 20.3 22.3 24.6 114.0 123.3

27.5 29.7 34.1 36.4 174.4 183.6

Steel strip

cover

Standard

Steel strip

cover

Travel paths and speeds

Maximum tr avel speed

Maximum acceleration

Maximum tr avel path, standard

carriage S/T2 with one profile bar

Maximum tr avel path, extended

carriage E/F2 with one profile bar

1

1

m/s 5.0 5.0 5.0

2

m/s

10.0 10.0 10.0

mm 5350 5260 6300 6210 9150 9060

mm 5200 5110 6150 6060 9000 8910

Geometrical data

Cross-section mm x mm 80 x 80 100 x 100 150 x 150

Moment of inertia I

Moment of inertia I

Moment of inertia I

x cm

y cm

t cm

Modulus of elasticit y N/mm2 0.72*10

4 152 383 1940

4 177 431 2147

4 24 117 391

5

Pulley data, torques and forces

Travel distance per r evolution mm/rev 190 170 240

Pulley diameter mm 60.479 54.113 76.394

Nominal drive torque Nm 17.5 15.7 51.4

Maximum drive t or que

Nominal belt traction (effective load) N 580 580 1350

Max. belt traction3 (effective load) N 1058 1478 2827

Repeatability

Please contact HAUSER in t he event of t he f ollowing deviations f r om the standard techni cal data:

1

Travel speeds over 5m/s and acceleration over 10m/s2.

2

Longitudinal f lange connection possible for longer travel distances. This does lead to li mitati ons wi t h r egard to: maximum

permitted load, dr i v e torque, speed, acceleration and repeatability (refer to page 30)

3

Increased timing belt t ension required.

4

Repeatability up to ± 0.05 mm

4

3

Nm 32 40 108

mm ±0.2 ±0.2 ±0.2

Technical data, issued 06/99, safety factor taken into co nsideration S=1. Data a pplies for a temperature range of betw een -10°C and +40°C

Parker Hannifin GmbH

Electromechanical Division

Automation

6

Page 7

HLE – Linear actuators with timing belt drive

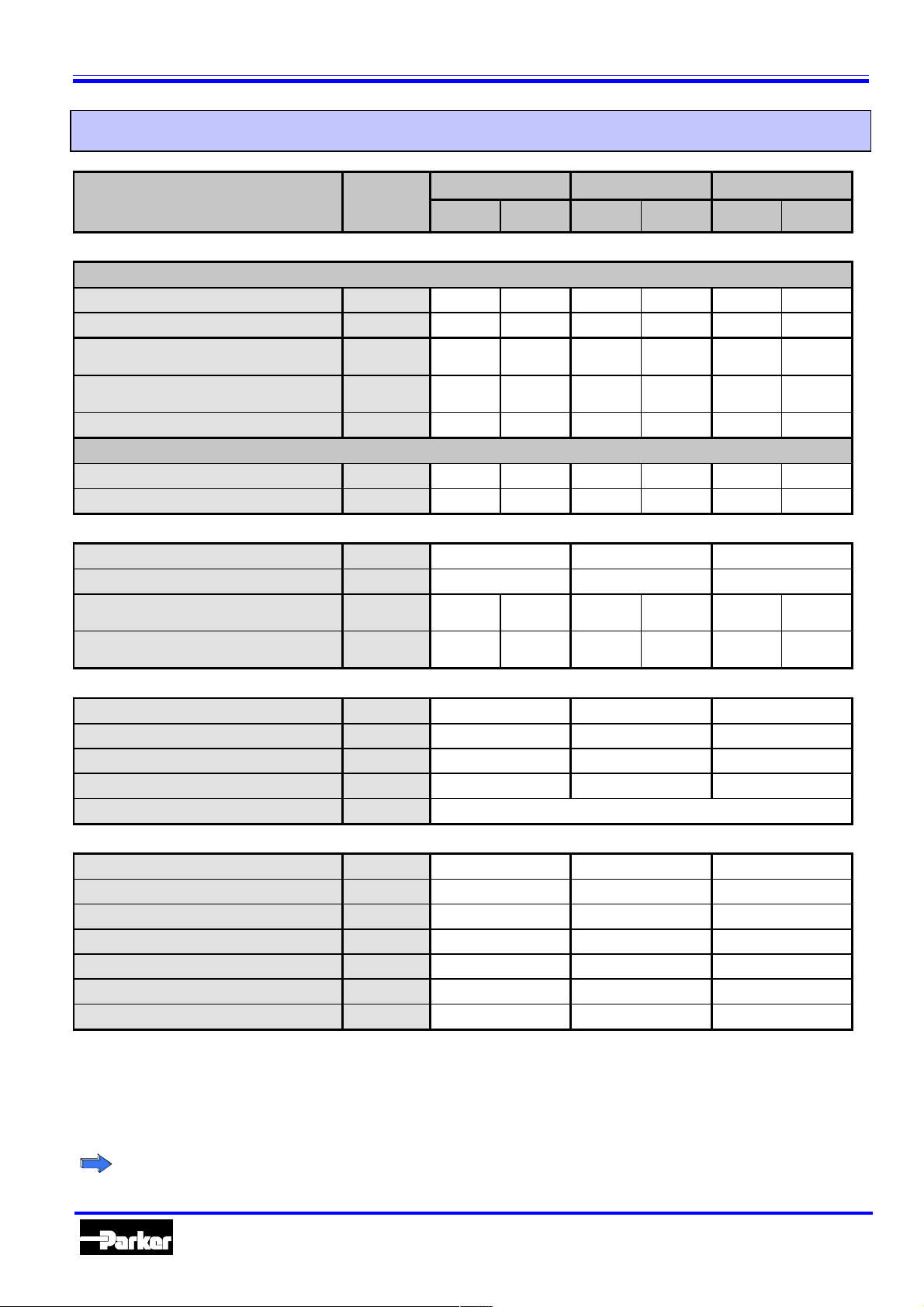

Mz

Fz

Fx

Mx

Fy

My

Fx [N] (load-be aring capac ity of timing belt)

3000

2500

2000

1500

1000

500

Fy [N]

1800

1600

1400

1200

1000

800

600

400

200

Fz [N]

3500

3000

2500

2000

1500

1000

500

HLE150c

HLE100c

HLE80c

0

012345

HLE150c

HLE100c

HLE80c

0

012345

HLE150c

HLE100c

HLE80c

0

012345

v [m/s]

v [m/s]

v [m/s]

The forces and torques the carriage and the timi ng belt are

capable of transferring ar e speed-dependent.

The curves shown in the graphs apply to a standard carr i age

(S/T).

Wi th the extended carriage (E/F), all the values apart from

Fx (load-bearing capacity of timing belt) can be doubled if

the load is applied equally to both hal ves of the carr iage or

distribut ed unifor mly along it s enti r e length.

The curves show the maximum load-bearing capacity of a

carriage in one direction of for ce or torque. If several loads

are applied in different directions, the values given by the

curves

must be derated

, i.e. the load or speed should be

reduced if necessary.

For precise carriage dimensioni ng, our software "DimAxes"

is available (Refer to "Other accessories and software", page

34).

Mx [Nm]

250

200

HLE150c

150

100

HLE100c

50

HLE80c

0

012345

My [Nm]

450

400

HLE150c

350

300

250

HLE100c

200

150

HLE80c

100

50

0

012345

Mz [Nm]

250

HLE150c

200

150

HLE100c

100

50

HLE80c

0

012345

v [m/s]

v [m/s]

v [m/s]

Automation

7

Parker Hannifin GmbH

Electromechanical Division

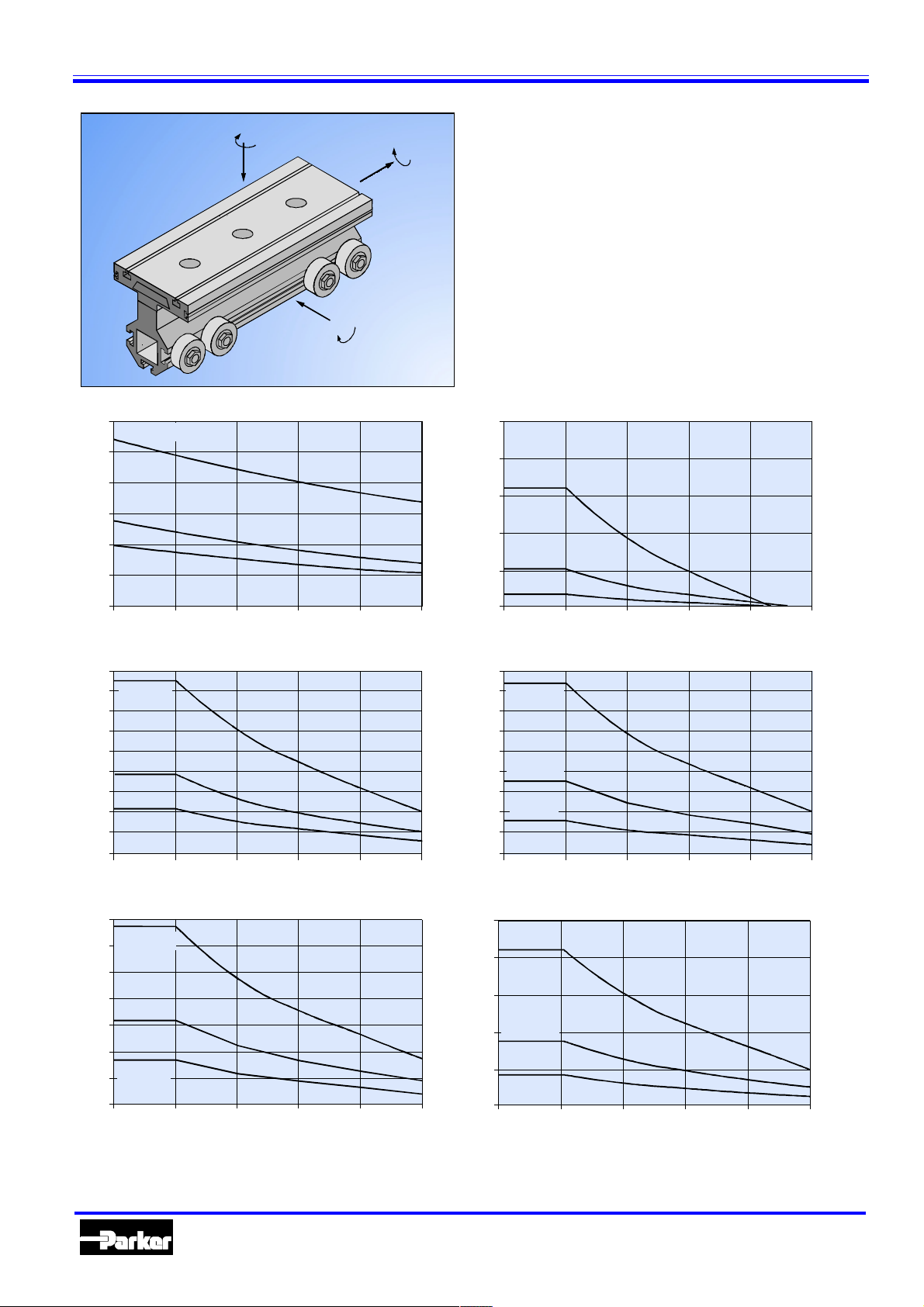

Page 8

HLE – Linear actuators with timing belt drive

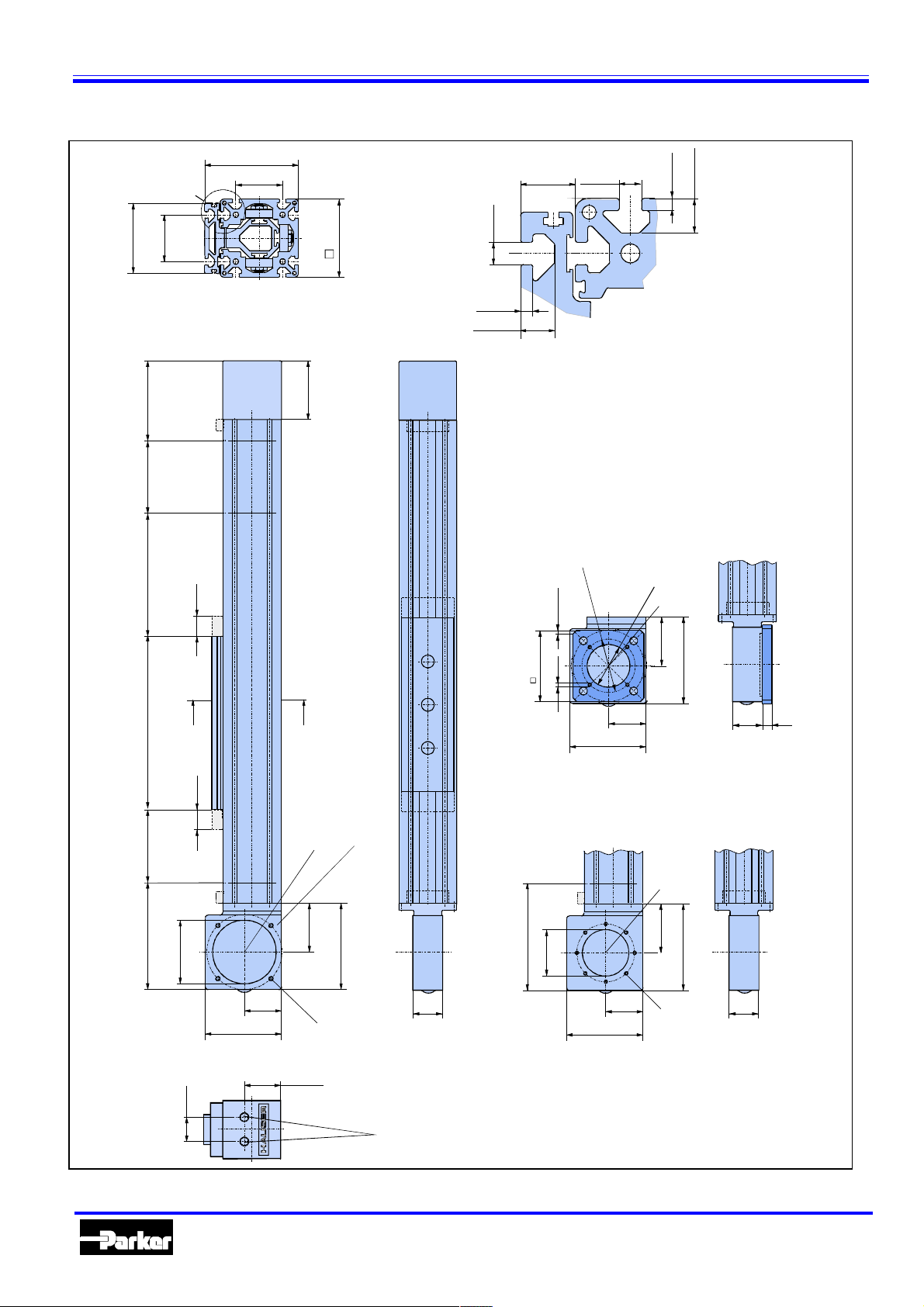

Dimensional drawings

HLE 80 single axis

Section A-A enlarged

stroke

+0,2

+0,3

4,5

12,5

Slots compatible with

DIN508 T-nuts

DIN787 T-bolts

70

20

8,1

+0,3

100

Detail X

+0,3

4,5

12,5

8,1

+0,3

+0,2

±0,3

X

±0,3

40

80

40

106

130 (175)

125

travel

Safety

7

±0,1

H

Pulley for drive shaft Ø16

Key complying with

DIN 6885 T1, type A

Ø60

(35)

Ø75

5x45°

Dimensions in () apply in combination with

steel strip cover. Pa rts indicated in broken lines:

Steel strip cover option. Casing projecti on at drive

and tensioning sta t ion approx . 1mm.

70

100

120

M5

gearbox flange A

50

40

A

gearbox flange Q

Pulley for drive shaft Ø20

+0,2

70

120

50

4xM6 Pitch

circle Ø100

H7

164 (209)

110

gearbox flange R

A

250 standard carriage

400 extended carriage

125

144 (189)

(35)

travel

Safety

H7

80

100

+0,2

100

122

50

61

Pulley for drive shaft Ø25

80

50

10

Key complying with

DIN 6885 T1, type A

140

52

4xM8 Pitch

circle Ø130

34

Timing belt

tensioning screws

Automation

8

Parker Hannifin GmbH

Electromechanical Division

Page 9

HLE – Linear actuators with timing belt drive

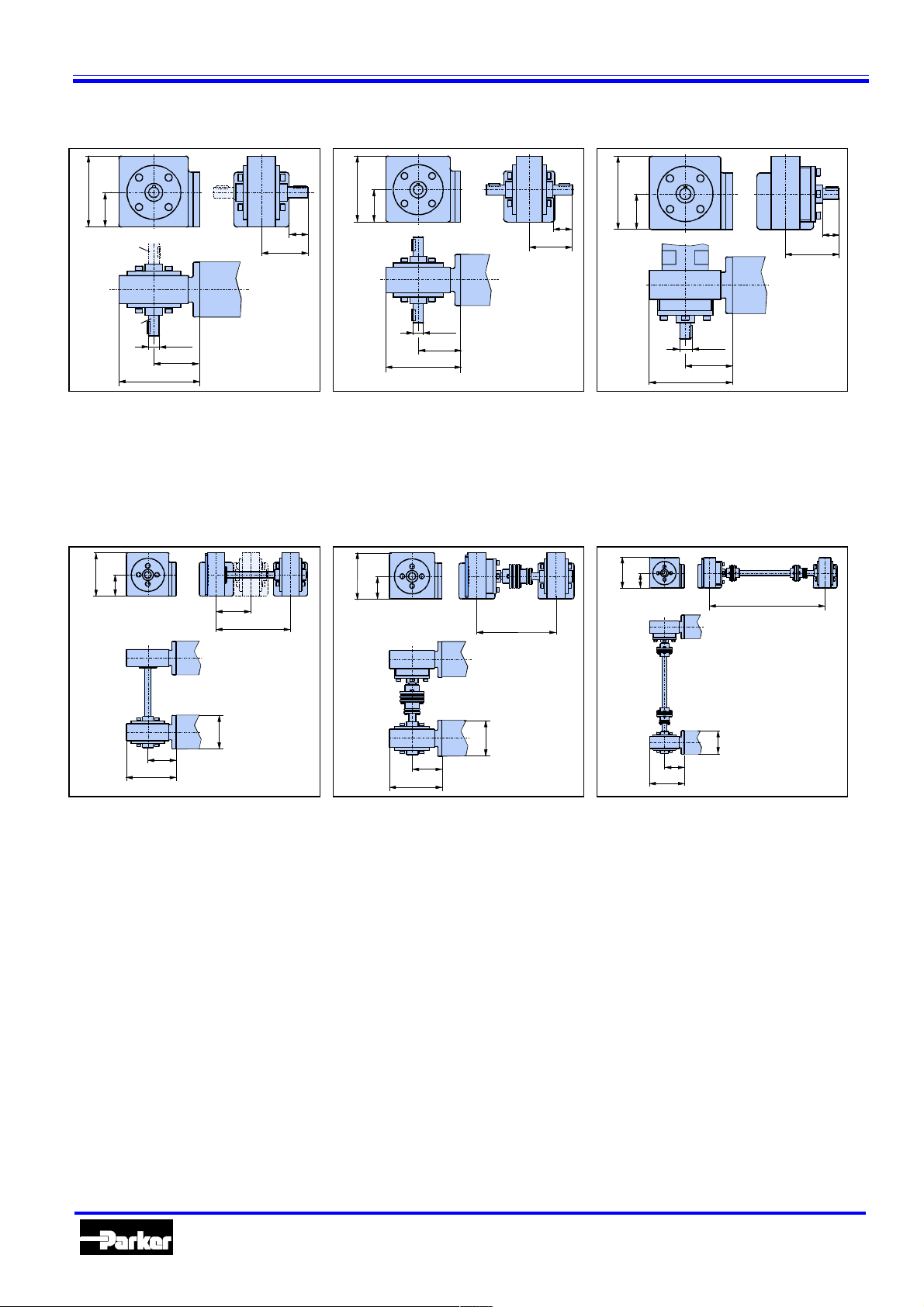

HLE80 drive housing with drive shafts

100

50

SR

SL

20

h9

70

120

SL: shaft on left

40

87

100

50

20

h6

70

120

SB: shafts on both sides RL:gearbox on right and

SR: shaft on right

HLE 80 dual axis with gearbox flange Q

100

50

80

215

100

50

215 < A < 500

87

40

100

50

120

70

20

h8

29

96

shaft on left

LR: gearbox on left and shaft

on right

100

50

A > 500

80

70

120

Centre distance A between 80215 mm

Centre distance A between

215-500 mm

70

120

HLE 80 dual axis with gearbox flange R

122

61

80

215

80

80

140

Centre distance A between 80215 mm

122

61

80

140

Centre distance A between

215-500 mm

80

A > 215

80

80

70

120

Centre distance A greater than

500 mm

122

61

80

140

A > 500

80

Centre distance A greater than

500 mm

Automation

9

Parker Hannifin GmbH

Electromechanical Division

Page 10

HLE – Linear actuators with timing belt drive

HLE100 single axis

Section A-A enlarged

90

120

60

±0,3

20

8,1

+0,3

X

+0,3

±0,3

60

100

8,1

,2

0

+

+0,3

4,5

12,5

Detail X

+0,3

4,5

+

0

,2

12,5

102

126(171)

Slots compati ble with

DIN 508 T-nuts

DIN 787 T-bolts

125174(219)

travel

Safety

Dimensions in () apply in combination with

steel strip cover. Parts indicated in broken lines:

Steel strip cover option. Casing projection at drive

and tensioning station approx. 1mm.

stroke

(35)

±0,1

Ø75

Ø60

H7

Pulley for drive shaft Ø16

Key complying with

DIN 6885 T1, type A

85

100

M5 5x45°

A

A

gearbox flange A

64,4

150

52 12

132

300 standard carriage

450 extended carriage

(35)

gearbox flange R

Pulley for drive shaft Ø25

85

±0,2

Key complying with DIN 6885 T1, type A

Pulley for drive shaft Ø20

Key complying with

DIN 6885 T1, type A

85

150

gearbox flange Q

52 52

H7

80

174(219)

150

64,4

132

4xM8 Pitch

circle Ø130

8xM6 Pitch

circle Ø100

125

travel

Safety

H7

110

64,4

132

63,4

+0,2

43

Automation

Timing belt

tensioning screw

10

Parker Hannifin GmbH

Electromechanical Division

Page 11

HLE – Linear actuators with timing belt drive

HLE100 drive housing with drive shafts

132

64,4

SR

SL

20

h9

85

150

SL: shaft on left

40

87

132

64,4

20

h6

85

150

SB: shaft on both sides RL:gearbox on right and

SR: shaft on right

HLE 100 dual axis with gearbox flanges Q and R

132

64,4

100

225

132

64,4

225<A<500

87

40

132

64,4

20

h8

85

150

40

87

shaft on left

LR: gearbox on left and shaft

on right

132

64,4

A > 500

85

100

150

Centre distance A between

100-225 mm

100

85

150

Centre distance A between

225-500 mm

85

150

100

Centre distance A greater than

500 mm

Automation

11

Parker Hannifin GmbH

Electromechanical Division

Page 12

HLE – Linear actuators with timing belt drive

HLE 150 single axis

175

25

10,1

8

Section A-A enlarged

±0,3

X

±0,3

140

90

110

146(191)

125

travel

Safety

90

150

Detail X

+0,5

+0,5

10,1

8

+0,5

8

+0,5

8

Slots compatible with

DIN508 T-nuts

DIN787 T-bolts

stroke

350 standard carriage

125

234(279)

(35)

A

500 extended carriage

(35)

travel

Safety

H7

110

104

187

A

Pulley for drive shaft Ø25

Key complying with DIN 6885 T1, type A

gearbox flange R

Dimensions in () apply in combination with

steel strip cover. Parts indicated in broken lines:

Steel strip cover option. Casing projection at drive

and tensioning sta t ion approx . 1mm.

115

198

60

4xM8

TK Ø130

54

Automation

102

Timing belt

tensioning screws

12

Parker Hannifin GmbH

Electromechanical Division

Page 13

HLE – Linear actuators with timing belt drive

HLE150 drive housing with drive shafts

187

104

SR

SL

30

h9

115

150

SL: shaft on left

56

108

187

104

30

h9

115

198

SB: shaft on both sides RL:gearbox on right and

SR: shaft on right

HLE 150 – dual axis with gearbox flange R

186

186

104

150

260

104

260 < A < 500

108

56

187

104

45

123

30

h9

115

198

shaft on left

LR: gearbox on left and shaft

on right

186

104

A > 500

150

115

198

Centre distance A between

150-260 mm

150

115

198

Centre distance A between

260-500 mm

150

115

198

Centre distance A greater than

500 mm

Automation

13

Parker Hannifin GmbH

Electromechanical Division

Page 14

HLE – Linear actuators with timing belt drive

Idler unit

10

125

Safety

travel

Carriage length

(35)

stroke

A

(35)

125

Safety

travel

L2L1

10

Section A-A

The HLE is also available as

a non-driven, idler unit. In this

case it acts as a guide only.

The profile cross-section and

carriage dimensions correspond to those for the driven

axes.

Please take di mensions L1

A

Dimensions in ( ) apply in combination with steel strip cover

and L2 from the following table:

HLE80 HLE100 HLE150

Dimensions

Unit

L1 L2 L1 L2 L1 L2

Standard mm 34 34 34 34 46 46

Steel strip cover mm 79 79 79 79 91 91

Carriage with bar

(type T or F without load attachment plate)

When or dering an HLE without load attachm ent plate, t he bar is used as a replacement for the belt c lamp. T he

threads in the car r iage are accessible thr ough holes in the bar for mounting your own attachments. Diagrams show

the location of tapped holes for load attachment.

HLE80 / HLE100 st andard carriage ( T) HLE80 / HLE100 ext ended carriage ( F)

1

L

1

2

L

L

2

Ø9 (3x)

L

2

L

3

L

3

L

2

L

L

L

HLE Unit L L1 L2 HLE Unit L L1 L2 L3

80 T mm 250 75 50 80 F mm 400 75 75 50

100 T mm 300 95 55 100 F mm 450 95 75 55

HLE150

Standard carriage(T) / extended carriage (F)

1

L

2

L

3

L

L

2

Ø14 (4x)

HLE80 / HLE100 /HLE150

B

thread.

12T

4

L

HLE Unit L L1 L2 L3 HLE Unit B T Thread

150 T mm 350 75 70 60 80 mm 15 20 M8

150 F mm 500 105 100 90 100 mm 25 20 M8

150 mm 30 25 M12

Ø9 (5x)

Automation

14

Parker Hannifin GmbH

Electromechanical Division

Page 15

Order code

HLE – Linear actuators with timing belt drive

HLE linear actuator

Drive system

Timing belt drive B

Idler unit N

Model / size

80 (Dimensional drawing o n pa ge 8) 0 8 0

100 (Dimensional drawing o n pa ge 10) 1 0 0

150 (Dimensional drawing o n pa ge 12) 1 5 0

Carriage

Standard carriage with load attachment plate S

Standard carriage w ith bar T

Extend ed carriage with load attachment plate E

Extended ca rria ge with bar F

Special carriage with load attachment plate (on request) C

Specia l carriag e with bar (on request) D

Extras (e .g . two or m ore carriages) X

Guide system

Plastic sheathed wheels P

Stroke

Specify desired stroke (in mm) n n n n n

Drive options

Shaft on left (Dimensional drawings: refer to pages 9, 11, 13) S L

Shaft on right (Dimensional drawings: refer to pa ges 9, 11, 13) S R

Shaft on both sides (Dimensional drawings: refer to pages 9, 11, 13) S B

Without drive – prepared for drive to be fitted on left N L

Without drive – prepared for drive to be fitted on right N R

Gearbox on left D L

Gearbox on right D R

Gearbox on left and shaft on right (Dimensional dra wings: refer to pages 9, 11, 13) L R

Gearbox on right and shaft on left (Dimensional dra wings: refer to pages 9, 11, 13) R L

Without drive – idler unit (Dimensional drawing: refer to page 14) N N

Extras (others, e.g. central drive with dual axes) (on request) X X

Gearbox flange

Flange suitable for Stöber planetary gears P3 A

Flange suitable for Stöber planetary gears P4 B

Flange suitable for Stöber planetary gears P5 C

Flange suitable for Stöber planetary gears P7 D

Flange suitable for Stöber planetary gears P4, compatible with PL90 Q

Flange suitable for Stöber planetary gears P5, compatible with PL115 R

Without drive housing – idler unit N

Extras (others, n ot stand ard) (on request) X

Centre distance with dual axes

Specify desired centre distance (in mm) n n n n n

Specify for single axis or idler unit 0 0 0 0 0

Steel strip cover

Without ste el strip cov er N

With steel st rip cover (protection class IP30) C

Material version

Standard – version N

Corrosion-resistant v ersion (V2A) V

Linear encoder

Without linear encoder (standard) N

With linear encoder L

(refer to figures on page 16)

(refer to page 4)

LE P

(from centre of axis to centre of axi s)

Automation

15

Parker Hannifin GmbH

Electromechanical Division

Page 16

HLE – Linear actuators with timing belt drive

Drive options

SL SR SB NL NR DL DL

(dual ax is)

DR DR

(dual ax is)

A=

LR RL NN

Automation

16

Parker Hannifin GmbH

Electromechanical Division

Page 17

HLEZ – linear actuators with rack-and-pinion drive

HLEZ linear actuators with rack-and-pinion drive

- for long travel paths with high rigidity and accuracy

Contents:

The HLEZ - a combined technology......18

Construction of the HLEZ.......................19

Technical data..........................................20

Dimensional drawings............................22

HLEZ100..................................................22

HLEZ150..................................................22

Gearbox fitting - examples .....................23

HLEZ150 with planetary gearbox P5....23

HLEZ150 with worm gearbox................23

Order code ...............................................24

Mechanical accessories .........................25

Assembly angle plate ............................25

Clamping profile.....................................26

T-nuts and bolts.....................................26

Link shaft bearing..................................27

External buffer stop...............................27

Cable carrier...........................................28

Longitudinal flange connection set .....30

Attachment of position sensors ...........31

Tripping plate .........................................32

Mechanical limit switch.........................33

Electrical limit switch.............................33

Distribution box......................................34

Other accessories and software............34

The "endless" linear unit Typical fields of application The combined technology

for gui ding, transporting and positioning over l ong str ok es, offer s:

Long travel distances, up t o

i

50 m

High speeds in practical appli -

i

cations, up to 5 m/s

High levels of load capacity ,

i

horizontally up to 1000 kg /

vertically up to 300 kg

Up to 64 Nm permitted dr ive

i

torque

Repeatability, up to ±0.05 mm

i

Sever al carriages possible on

i

one linear unit

Two profile sizes: HLEZ100

i

and HLEZ150

Simple, rapid installation and

i

start-up

as part of advanced, cost-effec tive construction of m ac hines and

handling systems:

Materials handling

i

e.g. pal-

letiz ation, feeding, removal

Textile machinery building

i

e.g. cross-cutt ing, slit ting and

stacking, quilting, seam stitching

Process engi neering

i

e.g.

painting, coating, bonding

Storage technology

i

e.g.

comm issioning, inventory

Construction technology:

i

e.g. peeling, layi ng r einforcement of concrete

Clean room technology

i

e.g.

wafer transport, wafer coati ng

Machine tool building

i

e.g.

workpiece loading, tool changing

Testing technology

i

e.g.

guiding ul trasonic sensors

of the linear actuat or and r ac k offers the following advantages:

High dynamic response, even

i

over long travel distances, due

to:

the short timing belt, regard-

i

less of travel length

the lightweight carriage

i

the backlash-free drive

i

High positi onal accuracy, r e-

i

gardless of stroke length

Option of several carriages per

i

linear unit, mak ing over lapping

strokes along a single axis possible

Easy servicing at long intervals

i

Grooves running in the profil es

i

on all sides to enable mounti ng

of the HLEZ to a supporting

structure, fitt ing attachments or

as cable ducts

Grooves in the load attachment

i

plate for fl exible installat ion

Automation

17

Parker Hannifin GmbH

Electromechanical Division

Page 18

HLEZ – li n ear actuators with rack-and-pinion drive

The HLEZ - a combined technology

The new design

Taking the HLE linear units as its

base, a new rack-and-pini on dr ive

system has been designed for the

HLE100 and HLE150.

The system which is especially

suitable for long travel distances

and high speeds, opens up a

whole range of new application

options. The pat ented rack principle permits "endless" travel whil st

maint aining high acc ur ac y. At the

same time the dynamic characteristics of the system are out standing.

When r equired several carriages

can be positioned on a si ngle unit

independently of each another. In

combination with other HA US E R

mechanic al components, this allows the constructi on of effici ent

and cost-effective gantry and

automation systems.

Our experience

You can hav e c onfidence in our

experienc e and skill because over

6000 linear axes are already in

use throughout the world –

whether it be i n automatic texti le

equipment , handling system s,

packaging m achines, automatic

painting and binding equipment,

etc....

The HLEZ is found across a broad

applicat ion area - in clean rooms,

in the food industry, in chemic al

production plants and in the production of precast concrete c omponents.

We work together with a wide

range of sector s i nc luding the

automobi le industry, machine tool

manuf ac turers, mi c roelectroni cs

manuf ac turers - and hopeful ly

soon with you ...

Examples/applications

, Waldkirc h: sensor testing

Sick

i

equipment

Desarrollo

i

bots for transporting glass fibre

coils

Springs

i

Weckenmann

i

wide-area gantry robots for the

precast-concret e industry

AZO

i

equipment

EEW

i

milling centre

Telecom

i

phone accessory order picking

system

LT Engineering,

i

shelf-picking unit for small

parts stores

Allied Signal

i

bags

Weber-Haus

i

sawing cut-outs for the mounting of distribution boxes and

socket outlets

, Spain: gantry ro-

, USA: sewing textiles

, Dormet tingen:

, Osterburken: marshalling

, Schönberg: high-speed

, Switzerland: tele-

Switzerland:

, USA: sewing air -

, Linx : boring and

HLEZ drive principle

The HLEZ drive offers all the advant ages of a rack drive, but without the usual drawbacks. The

short timing belt ( whi c h is independent of t r avel lenght) reduces

belt stretching to an absolute minimum.

The lateral defl ec tion roller pretensions the system and thereby r emoves backlash. Hold-down rol lers ensure that sufficient teeth always remain in mesh. The combination of plastic t iming belts and

an aluminium rac k - and-pinion is a

safe

and clean drive which requires no

lubrication.

All of t his offers the following

advantages:

high constant rigidity r egard-

i

less of the travel or posi tion

Very long travel distances

i

achievable

high levels of ac c ur ac y

i

high speeds are possible

i

smooth, l ow-noise running

i

no lubrication necessary

i

any installation position possi-

i

ble

Automation

18

Parker Hannifin GmbH

Electromechanical Division

Page 19

HLEZ – linear actuators with rack-and-pinion drive

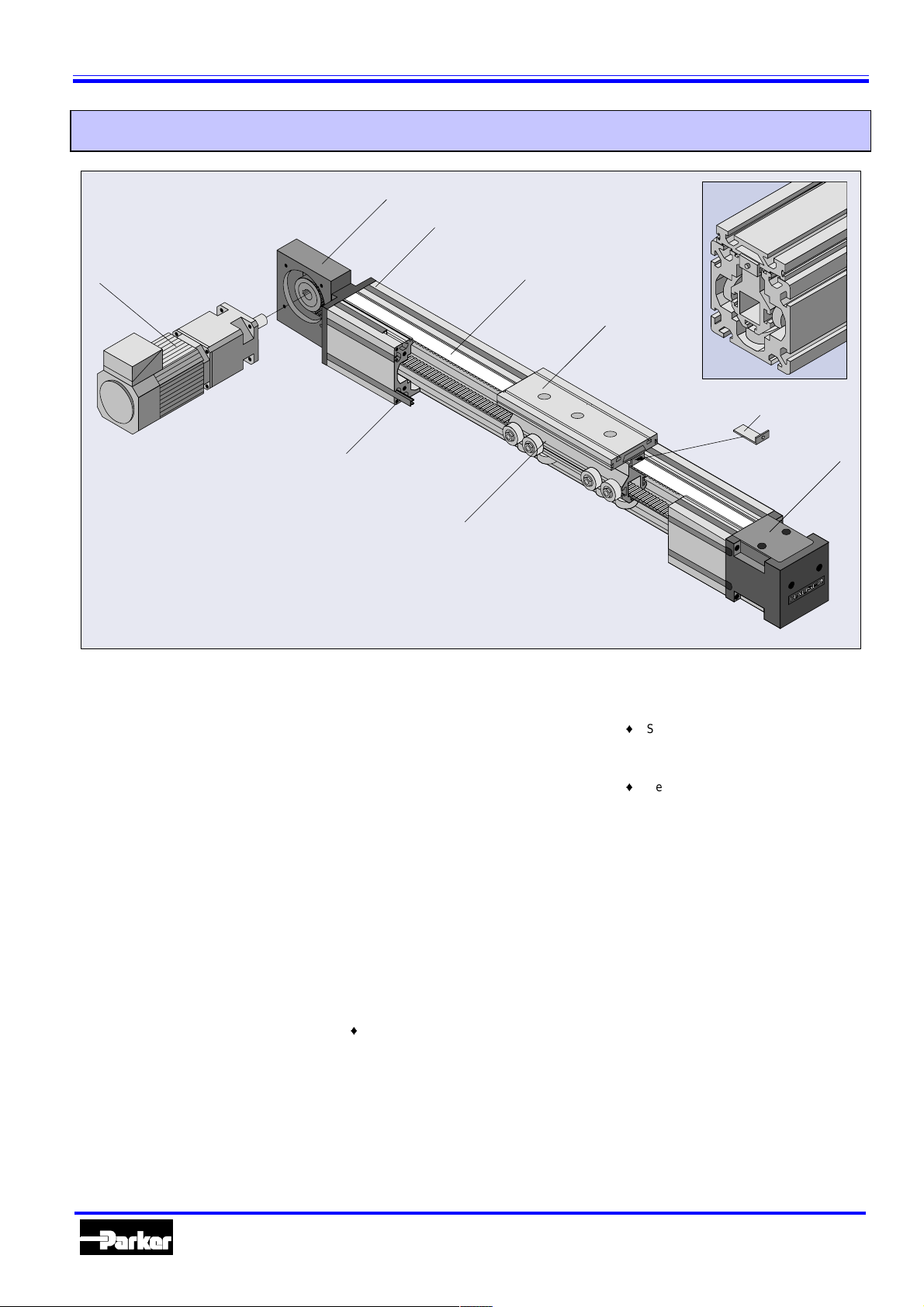

Construction of the HLEZ

2

5

3

4

The profile (1)

Light, com pact and self-supporti ng

aluminium profile construction.

Available in the following crosssections:

100x100 mm (HL EZ100)

150x150 mm (HL EZ150)

All profiles have a total of seven

grooves along their length for

clamping further mechanical components and for joining several

HLEZ and HLE units. These

grooves also serve as attachment

and mounting points for sensors

and mechanic al switches.

Together with the cover profiles

(2), these can be used as cable

ducts.

The carriage (3)

Lightweight, rigid carriage with

plastic wheels mounted on roll er

bearings (4) and eccent r ic axl es for

playf r ee carriage settings on all

sides.

7

6

1

Ov erall , this result s in high m echanical ef ficiency and v irtually wearfree operat ion. The carriage can be

supplied in two lengths eit her standard or extended.

We can also produce special carriages for c ustomised appli c ations.

The load attachment plate (5)

The longitudinal grooves integrated

on the top of the plate off er many

options for the assem bly of at tachments. When used together with

the clam pi ng prof i l es (ref er t o page

26) this allows simple incorporation

in a multi-axis system.

Simple and adjustable attachment

of operating cam s or switch lugs is

provided by longitudinal grooves

on the sides and on the underside

of the plate.

Special designs are also available

on request.

The drive module (6)

Compact drive module, can optionally be supplied fitted on either

side of the load attachment plate.

For a descript ion of the dri ve pri nciple, refer to page 18.

The optional Parker servo motor

(7) with resolver and an appropriate planetary gearbox forms an

optimum drive for dynamic and

accurate applications.

When used together with the

COMPAX compact servo-controller, the HLE becom es a complet e,

ready-to-run aut om ati on system f or

single and multi-axis travel and

continuous path controls.

Automation

19

Parker Hannifin GmbH

Electromechanical Division

Page 20

HLEZ – li n ear actuators with rack-and-pinion drive

Technical data

HLEZ size Unit HLEZ100 HLEZ150

Weight and moment of inertia

Weight of basi c unit without strok e

HLEZ with standard car r iage kg 22 53

HLEZ with ex tended carriage kg 26 61

Weight of standar d c ar r iage with

load attachment plat e and dr ive

module

Weight of extended carriage with

load attachment plat e and dr ive module

Weight per meter additi onal length

(guide profile + r ac k )

Moment of inertia of drive shaf t*1 (allowing for carriage with load attac hment plat e and dr ive module)

Standard carriage S kgcm

Extended car riage E kgcm

kg 11.3 25.7

kg 13.3 29.7

kg/m 11.3 23.9

2

2

33.3 325

37.9 363.4

Travel, speed and efficiency

Maximum speed m/s 5.0 5.0

Maximum stroke, standard carriage

S/T2 with one profile bar

Maximum stroke, extended carr iage

E/F2 with one profile bar

Max. str ok e with longitudinal load

attachm ent connection(s)

*3

mm

mm

mm

6102 8888

5952 8738

50000

Efficiency %85

Geometry of guide profile

Cross-section mm x mm 100 x 100 150 x 150

Moment of inertia I

Moment of inertia I

Moment of inertia I

x cm

y cm

t cm

Modulus of elasticit y N/mm

4 383 1940

4 431 2147

4 117 391

2

0.72*10

5

Pulley data, torques and forces

Travel distance per r evolution mm/rev 100 200

Diamet er of pulley (DA) mm 31.83 63.66

Number of teeth on pulley 20 20

Tim ing belt pi tch mm 5 10

Maximum drive t or que Nm 16 64

Feed forc e N 1000 2000

Repeatability

*4

mm ± 0.05

Please refer any departures f r om these technical st andar ds t o HAUSER.

*1: Additional inertia moment caused by effective load: J

*2: Longitudinal load attachment conne ction is a vailable for greater travel pa ths (refer to page 30).

*3: The travel distance is unlimited as far as the linear actuator is concerned - it is only dependent on the power supply to drive unit.

*4: Applies to the linear a ctuator with drive modul e, withou t drive.

Technical data issued 06/99, safety factor taken into co nside ration S=1. Data applies to a temperature range of between -10°C and +40°C

eff_load

= m

eff_load

Automation

2

x ¼ D

(Motor and gearbox weight are added to form the effective load)

A

20

Parker Hannifin GmbH

Electromechanical Division

Page 21

HLEZ – linear actuators with rack-and-pinion drive

Mz

Fz

(Load-bearing capacity of rack and pinion drive)

Fx [N]

3000

2500

2000

HLEZ150

1500

1000

HLEZ100

500

Fy

My

Fx

Mx

The force and torque ratings of the carriage ar e speed-dependent. The curves shown in the graphs apply to a standard carriage (S/T).

Wi th the extended carriage (E/F), all the values apart from

Fx (load-bearing capacity of rack and pinion drive) can be

doubled if the load is applied equally to both hal ves of the

carriage or distributed uniforml y al ong its entire length.

The curves show the maximum load-bearing capacity of a

carriage in one direction of for ce or torque. If several loads

are applied from dif ferent directions, the values stat ed in the

curves

must be derated

, i.e. the load or speed should be

reduced if necessary.

For precise carriage dimensioni ng, our software "DimAxes"

is available - calculation is identical to the corresponding

HLE size (refer to "Other accessories and software", page

34).

Mx [Nm]

250

200

HLEZ150

150

100

HLEZ100

50

0

012345

Fy [N]

1800

1600

HLEZ150

1400

1200

1000

HLEZ100

800

600

400

200

0

012345

Fz [N]

3500

HLEZ150

3000

2500

2000

HLEZ100

1500

1000

500

v [m/s]

v [m/s]

0

012345

My [Nm]

450

400

HLEZ150

350

300

250

HLEZ100

200

150

100

50

0

012345

Mz [Nm]

250

HLEZ150

200

150

HLEZ100

100

50

v [m/s]

v [m/s]

0

012345

v [m/s]

Automation

0

012345

21

Parker Hannifin GmbH

Electromechanical Division

v [m/s]

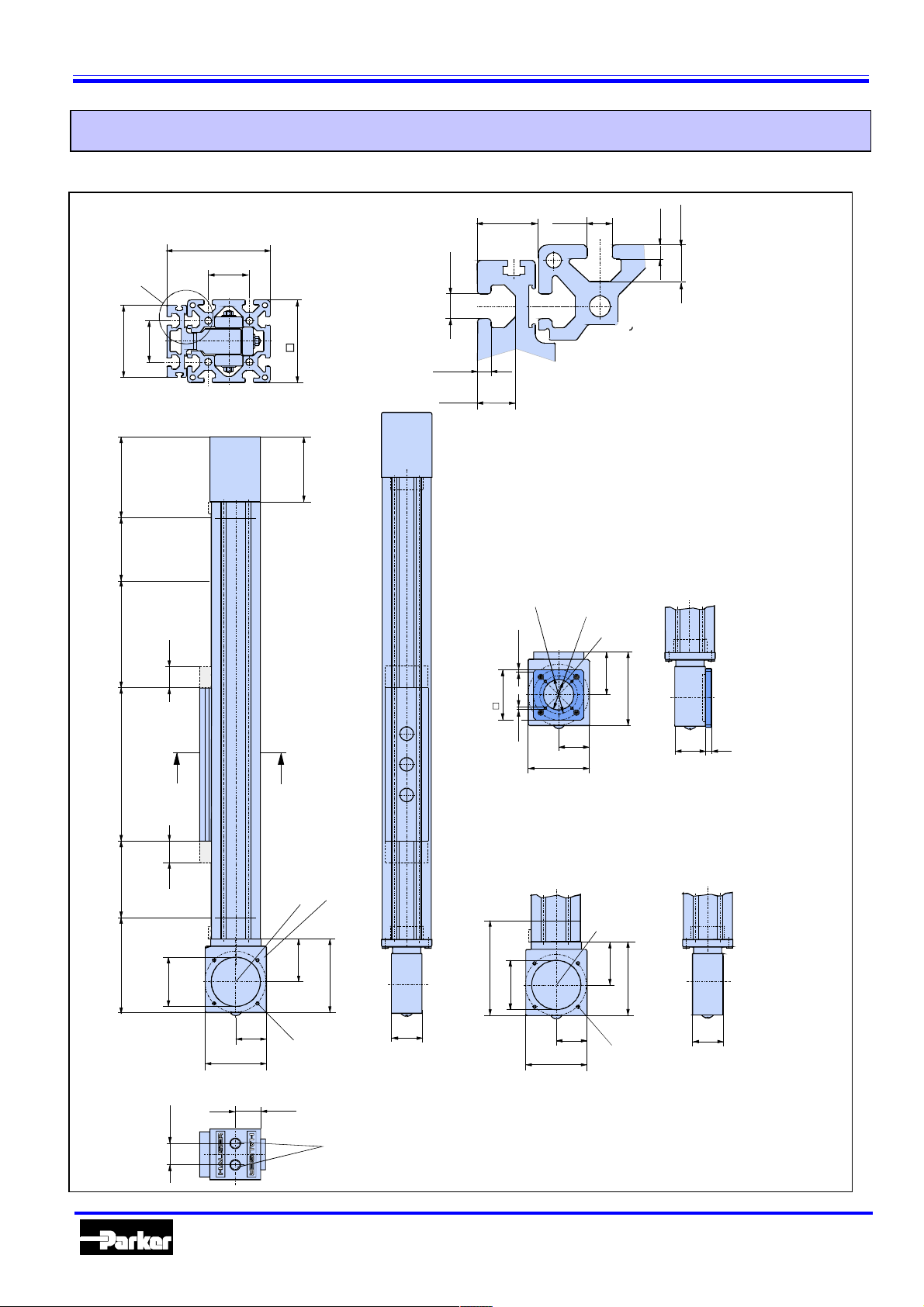

Page 22

HLEZ – li n ear actuators with rack-and-pinion drive

Dimensional drawings

HLEZ100

10

34

125

SW*

Stroke

300S

450E

A

600S

750E

37,4

225,2

190

85

60

45°

M6x10

60

125

SW*

34

Y

B

10

135,25

X

19

35,25

60±0,3

Section A-A

90

60

37,5

76

A

S: standard carriage

E: extend ed carriage

SW*= Safety travel

Detail Y

+0,3

8,1

4,5

+0,5

12,5

+0,2

Detail X

8,1

+0,3

4,5

+0,3

+0,2

12,5

HLEZ150

46

SW* SW*

10

Stroke125

350 S

500 E

A

46

790 S

940 E

45

348

300

142

100

°

Ø 45h6

B

100

Section B-B

153,75

47,5

2

30

10

Ø 16k6

139

130

110

38,75

176,5

12,5

Section A-A

125

M8x11

120

46

B

10

X

24

50,5

140

90

65

138

S = standard carriage

E = extended ca rriage

SW* = Safety travel

Automation

+0,5

4,5

A

10,1

+0,3

Detail Y

12,5

Key A 10x8x70

DIN 6885 Bl. 1

Detail X

10,1

+0,2

200,5

90±0,3

70

80h6

+0,5

+0,3

+0,5

4,5

12,5

h6

Ø 80

Ø 70

22

B

Detail Z

80

82

Y

47,5

4

Ø38k6

223

Z

Parker Hannifin GmbH

Electromechanical Division

150

Section B-B

148

126

156

4

11

183

45

288

Page 23

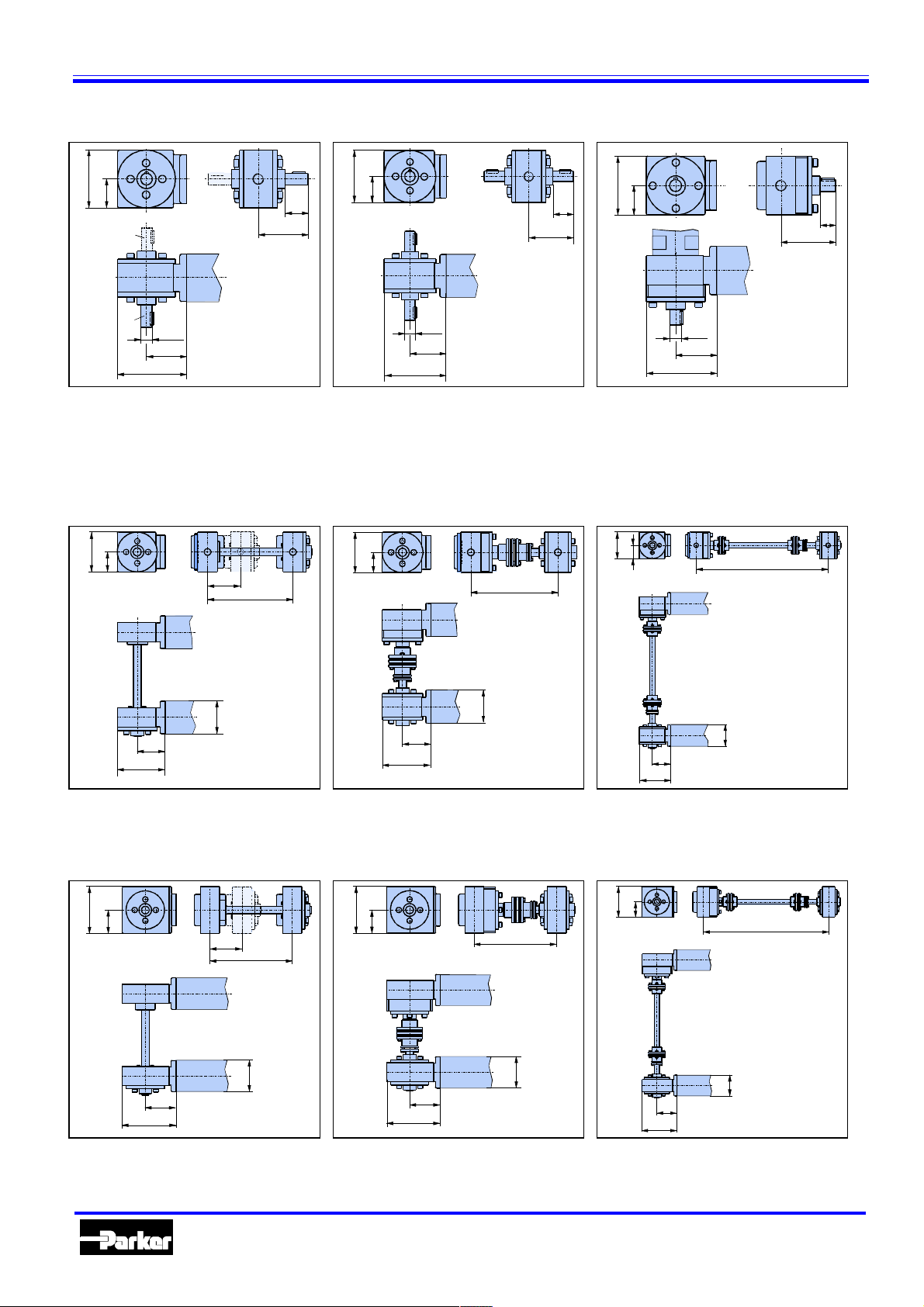

HLEZ – linear actuators with rack-and-pinion drive

Gearbox fitting - examples

HLEZ150 with planetary gearbox P5 (PL115 or PLE120-compatible type)

7,5

115

164

91

28

B

*1: Ratio range can be supplied; *2: gearbox P5 compati bl e with PL115, can be supplied as from August 1999.

L

1-stage 2-stage 1-stage 2-stage 3-stage

114x114 114 x 114 Ø 120 Ø 120 Ø 120

B

L

1

*

i

99 139 146 173 200

3-10 15-100 3-8 9-64 60-512

P5*

2

PLE120

HLEZ150 with worm gearbox 52.314.06

345

Ø 160

164

110

140

75

63

208

Automation

120

88

28

23

91

180

Gear ratios available: i = 5 - 80

Parker Hannifin GmbH

Electromechanical Division

Page 24

HLEZ – li n ear actuators with rack-and-pinion drive

Order code

HLEZ linear unit

Drive system

Rack-and-pinion drive Z

Model / size

100 (Dimensional drawing, page 22) 1 0 0

150 (Dimensional drawing, page 22) 1 5 0

Carriage

Standard carriage with load attachment plate S

Standard carriage w ith bar T

Extend ed carriage with load attachment plate E

Extended ca rria ge with bar F

Special carriage with load attachment plate (on request) C

Specia l carriag e with bar (on request) D

Extras (e .g . 2 or more carriages) X

Guide system

Plastic sheathed wheels P

Stroke

Specify desired stroke (in mm) n n n n n

Drive options

Shaft on left S L

Shaft on right S R

Gearbox on left D L

Gearbox on right D R

Extra (other drive versions) X X

Gearbox flange

Flange suitable for worm gearbox 52.314.06 L

Flange suitable for planetary gearbox P5 (PL115 or PLE120 compatible type) R

Extras (others, n ot stand ard) (on request) X

Centre distance with dual axes

Specify for single axis or idler unit 0 0 0 0 0

Specify desired centre distance (in mm) – no standard – only on request! n n n n n

Steel strip cover

Witho ut steel strip cover (stand ard) N

Material - version

Standard – version N

Linear encoder

Without linear encoder (standard) N

(for definition of on right/on left: see figure below)

LEZ P NNN

(from centre of axis to centre of axi s)

Automation

Indication right / left: looking from

flange plate to the drive module

right left

drive

24

Parker Hannifin GmbH

Electromechanical Division

Page 25

Accessories for HLE and HLEZ

Mechanical accessories

Assembly angle plate

The assembly angle plate is used to connect an HLE or HLEZ

x

to another linear actuat or

x

to the subf r ame (a HAUSER profile can be used as the support)

x

to other machine components

This is available in various sizes, with equal or unequal legs, both with through-holes.

Assembly angle plate with equal legs

B1

LA1

D

SD

HLE80 + HLE100/

HLEZ100

BO

SD

HLE150/

HLEZ150

LA1

A1

B2

D

A2

LA2

B2

Model / size Type A1 A2 BO B1 B2 D LA1 LA2 SD Art. no.

HLE80 MW 70/70

HLE100 / HLEZ100 MW 90/90

HLE150 / HLEZ150 MW 140/140

20 30 Ø 9 68 70 10 40 30 10 500-000503

20 30 Ø 9 88 90 10 60 50 10 500-000512

30 40 Ø 11 138 140 15 90 80 12 500- 000523

Assembly angle plate with unequal legs

D

B3

A5

A4

D

B2

LA1

A3

A2

A1

SD

BO

SD

B1

LA1

Model / size Type A1 A2 A3 A4 A5 BO B1 B2 B3 D LA1 SD Art. no.

HLE80 MW 70/150

HLE100 / HLEZ100 MW 90/190

HLE150 / HLEZ150 MW 140/290

Automation

20 30 60 100 140 Ø 9 68 70 150 10 40 10 500-000504

20 30 80 120 180 Ø 9 88 90 190 10 60 10 500-000513

30 40 120 180 270 Ø11 138 140 290 15 90 12 500-000524

25

Parker Hannifin GmbH

Electromechanical Division

Page 26

Accessories for HLE and HLEZ

Clamping profile

The clamping profile is used in conjunction with t he standard load attachment plat e to rapi dly install and fasten various combinations of HAUSER linear units. Two clamping profi les are required to fasten an HLE or HLEZ to a load attachment plate. The

following table shows the profiles required for the various axis combinations:

bottom

top

HLE80

HLE100 / HLEZ100

HLE150 / HLEZ150

KP70cM6

KP90cM6

KP140c2

HLE80 HLE100 / HLE Z100 HLE150 / HLEZ150

(Art.no.: 500-000904)

(Art.no.: 500-000905)

(Art.no.: 500-000903)

A2

LA1

L

KP90cM6

KP140c2

B

A1

--- ---

(Art.no.: 500-000905)

(Art.no. 500-000903)

T

ØD2

ØD1

B1

D

KP140c1

---

(Art. no.500-000902)

Model / size Type A1 A2 B B1 D D1 D2 L LA1 T Art. no.

0.2

HLE80 KP70cM6

HLE100 / HLEZ100 KP90cM6

HLE150 / HLEZ150 KP140c1

HLE150 / HLEZ150 KP140c2

15 10 30 20 20 Ø 11 Ø 6.6 70 40±

15 10 30 20 20 Ø 11 Ø 6.6 90 60±

25 12 40 25 30 Ø 15 Ø 9 140 90±

25 10 30 20 20 Ø 15 Ø 9 140 90±

7 500-000904

0.2

7 500-000905

0.1

9 500-000902

0.1

9 500-000903

T-nuts and bolts

The T-nuts and bolts are used to fasten any element into the T-grooves of the profil e and to t he upper side of the flange plate.

e

e1

e

e1

k

l

d

k

h1

d

a

Model / size Designation a d e e1 1h k l Art. no.

HLE80+100 / HLEZ100 Bolt DIN787 M8x8x25 -- M8 13 13 -- 6 25 131-700001

HLE80+100 / HLEZ100 Bolt DIN787 M8x8x32 -- M8 13 13 -- 6 32 131-700002

HLE80+100 / HLEZ100 Bolt DIN787 M8x8x40 -- M8 13 13 -- 6 40 131-700003

HLE150 / HLEZ150 Bolt DIN787 M10x10x25 -- M10 15 15 -- 6 25 131-700007

HLE150 / HLEZ150 Bolt DIN787 M10x10x32 -- M10 15 15 -- 6 32 131-700008

HLE150 / HLEZ150 Bolt DIN787 M10x10x40 -- M10 15 15 -- 6 40 131-700009

HLE150 / HLEZ150 Bolt DIN787 M10x10x63 -- M10 15 15 -- 6 63 131-700011

HLE80+100 / HLEZ100 Nut DIN508 M6x8 8 M6 13 13 10 6 -- 131-700103

HLE150 / HLEZ150 Nut DIN508 M8x10 10 M8 15 15 12 6 -- 131-700104

HLE80+100 / HLEZ100 Long nut* HWN313 ZN M6x8 8 M6 13 26 10 6 -- 131-700140

HLE150 / HLEZ150 Long nut* HWN313 ZN M8x10 10 M8 15 30 12 6 -- 131-700141

HLE80+100 / HLEZ100 Nut ITEM St M6 without drawing 400-000033

HLE150 / HLEZ150 Nut HWN314 ZN M8x10 Rhombus form for installation at late r date 131-700155

* When using a combination of t wo l inear axes over the clamping prof ile, we recommend that long nuts are used

Automation

26

Parker Hannifin GmbH

Electromechanical Division

Page 27

Accessories for HLE and HLEZ

Link shaft bearing for HLE dual axes

The link shaft bearing is used to support the linking shaft of a HLE dual axis when there is a large centre distance. This bearing must be used if the critical speed is exceeded with the dual-axis linki ng shaf t (refer to diagram on t he left).

L [mm]

3500

L

3000

2500

2000

1500

1000

500

0

0 250 500 750 1000 1250 1500 1750 2000

H

HLE150

HLE80/

HLE100

M

W

K1

n [min

K

A

C

v [m/s]

5

4

3

2

HLE150

n

1

-1

0

]

0 250 500 750 1000 1250 1500 1750 2000

d

B

HLE80

HLE100

v

n [min

-1

]

Model / size Type A B C d H K K1 M W Art . no.

HLE80 / HLE100 PASE20

HLE150 PASE30

33.3 32 14.5 Ø 20 64 11 8 97 130 416- 000120

42.9 40 17 Ø 30 82 14 8 118 158 416-000160

External buffer stop

The exter nal buffer stop is fitted to t he gr ooves of t he HLE /HLEZ prof ile and is fully adjustable.

L

LA

BPL

PA

only HLE150/

HLEZ150

Model / size Type B D d1 d2 L LA PA PL t

HLE80 EAP80

HLE100 / HLEZ100 EAP100

HLE150 / HLEZ150 EAP150

30 20 Ø 6.6 Ø 11 80 40 60 24 6.8 510–001185

30 20 Ø 6.6 Ø11 90 60 40 24 6.8 510-001285

30 20 Ø 9 Ø 15 140 90 90 24 9 510-001385

D

t

d1

d2

Art. no.

attachment material)

(including

Automation

27

Parker Hannifin GmbH

Electromechanical Division

Page 28

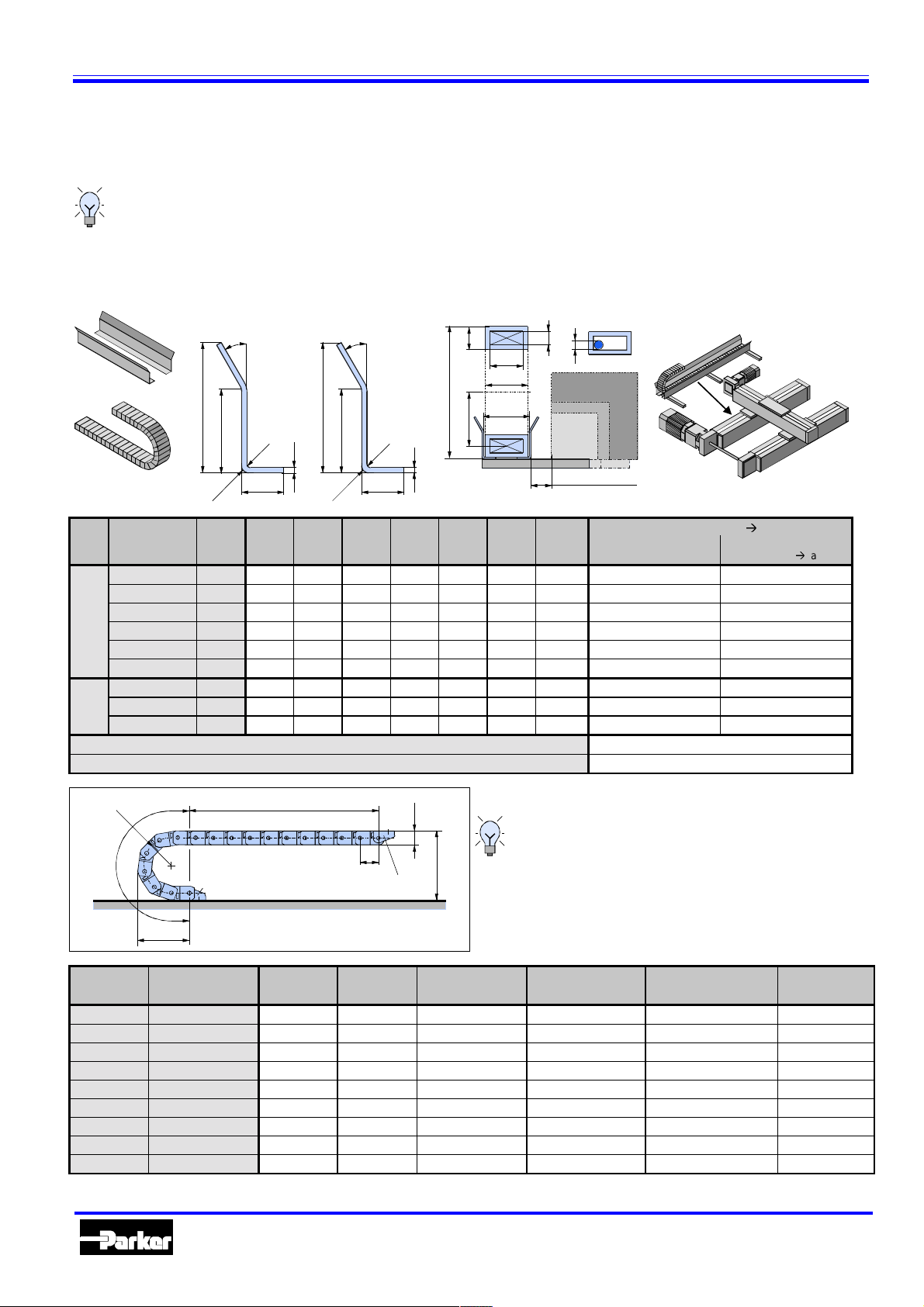

Accessories for HLE and HLEZ

g

Cable carrier

A cable carrier is needed when making power connections to movi ng elements. The cable carrier chain consi s t s of glass fibre

reinforced polyami de, and the support pr ofile is made of aluminium.

The process for fully determing t he dimensions of a cable carrier is very compl ex. The examples listed below represent

simple applications, but more data will normally be required when the situation is less straightforward.

descriptions only apply to power supplies arranged horizontally, which l ie above a support profil e and whic h

are within the li mits specifi ed in the technical data

. If the applicat ion you are running is more demanding, please

contact us.

Dimensions of support profile and cable carrier cha in

The following

0.320.20 37

0.320.42 37

0.450.21 52

with

0.450.21 94

KSP1

0.450.41 94

0.450.61 150

0.625.25 200

0.625.45 200

with

KSP2

0.625.45 300

KSP1

KSP2

KSP 1

30°

73

48

R2

3

24

R4

Type CR A B C D E F

13 24 29 103 25 19 11 100-906000 100-906100

24 35 40 103 25 19 16 100-905800 100-906110

38 54 59 147 40 24 22 100-905900 100-906090

38 54 59 231 40 24 22 100-906200 100-906090

58 74 79 231 40 24 22 100-906300 100-906095

78 94 99 343 40 24 22 100-906310 100-906350

65 93 98 459 62 42 31 100-906505 100-906506

108 136 141 459 62 42 31 100-906510 100-906506

108 136 141 659 62 42 31 100-906530 100-906506

Small cable support profile (specify length required, equal to travel lenght) 400-010120

Large cable suppo rt pro file (specify length re quired, equal to travel lenght) 400-010121

KSP 2

30°

135

107,1

R4

4

60

R6

E

D

KR

F

A

B

C

d

HLE150

HLEZ150

HLE(Z)100

HLE80

customized

d

max.

(For lengths

Art. no.

Cable carrier chain

page 30)

Æ

2 x connection angle

(for dimensions

page 29)

Æ

KR

B

L

Ü

B

Bending radius Pitch Height Curve length Curve protrusion Connection height Own chain

Type KR

0.320.20 37

0.320.42 37

0.450.21 52

0.450.21 94

0.450.41 94

0.450.61 150

0.625.25 200

0.625.45 200

0.625.45 300

Automation

Fix point

LS/2

Drivin

t h

32 25 181 82 99 0.32

32 25 181 82 99 0.39

45 40 254 117 144 0.75

45 40 386 159 228 0.75

45 40 386 159 228 0.85

45 40 562 215 340 0.92

62.5 62 754 290 456 1.35

62.5 62 754 290 456 1.50

62.5 62 1068 390 656 1.50

G

h

t

G

plate

H

L

28

Dimensional drawings of connection points

(fi x point and driving plate):

Page 29

B

Ü

B

(= 2KR+hg)

H

min

Parker Hannifin GmbH

Electromechanical Division

weight kg/m

Page 29

Dimensional drawings of connection points

Type 0320. xx Type 0450.xx Type 0625. xx

Accessories for HLE and HLEZ

L

K

connection

Standard fix poi nt

L

K

connection

Standard driver

Technical data

Type

40

7

26

40

26

maximum

acceleration

[m/s2]

2

16

2

16

6

A+9

A-16

6

A+9

A-13

arrangement with per-

mitted deflectio n

maximum

stroke

[mm]

3

50 (l1)

7

18,5

15 7,5

35

3

50 (l1)

7

23

15 7,5

35

Self supporting arrangement Self supporting

maximum stroke

[mm]

L

K

A: see dimensions

of cable carrier chain

L

K

A: see dimensions

of cable carrier

chain

maximum speed

[m/s]

7

L

K

9

L

K

maximum speed

[m/s]

63

55

30

35

2

25

94

118

1,5

12,5

10

2

70

25

9

55

30

35

100

1,5

12,5

10

maximum

acceleration

123

[m/s2]

0.320

0.450

0.625

2400 10 10 3500 2.5 1

3000 10 10 4400 2.5 1

5000 8 10 6000 3 1

Guidelines for using cable carriers

Use only electrical cables which are suitable for use in cable carriers. Hose lines should be highly flexible and should

only extend slightly under pressure. Weight should be distr ibuted across the cable track as evenly as possible. Cables

must not be twist ed when routed in the cable carrier and should be routed next to one another and as loosely as possible.

<d

d

electric line

1,1 d

d

hose flat cable

d

1,2 d

d

1,1 d

h

1,1h

Avoid laying several lines on top of each other and laying lines of different diam eters directly next to one another. If mul t i ple layers must be used, separating strips

should be inserted between each layer – should such circumstances arise, please

contact HAUSER.

If there is no alternative to rout ing several lines beside each other without sub-divisions, the clearance height within the carrier m ust be less than li ne diameter.

This is the only way of preventing the cables from twisting.

The supply cables must be able to move freely in the cable carrier – they must

never be fastened or bundled together. Separating strips must al ways be inserted

between flat cables routed in multiple layers.

Recommended di mensions of the space re qui r ed:

with round cables: approx. 10% of the li ne diameter

with flat cables: for each, approx. 10% of the cable width and cable thickness

with hose lines: approx. 20% of the hose diameter

Automation

29

Parker Hannifin GmbH

Electromechanical Division

Page 30

Accessories for HLE and HLEZ

Highly flexible, thin l ines with a low bending strength should be loosely gathered together and routed in order in a protective

hose. When selecting the size of the protective hose, ensure that its area is considerably greater than the sum of t he indi vi dual

cross-sectional areas. As a guide, allow appr oximately 10 % of the diameter of each line as clearance.

Load diagrams

Maximum suspended length vs. additional load Maximum length with permitted deflection vs. additional load

L

S

L

D

additio nal load q

in kg/m

5

0.625

4

3

0.450

2

0.320

1

L

S

L

f

z

additional load q

in kg/m

0.625

5

4

0.450

3

2

1

KR 52 94 150

0.320

z

KR 200 300

KR

0

0123

02

46

suspended length

in m

L

f

stroke L

in m

S

0

0123

0

246

Length with

deflection L

4

Stroke L

8

in m

S

D

in m

Determining the chain length

Suspended chain Chain with permitted deflection

rounded to a multiple of 32 mm

6

/

.

/

%

/

0.320:

rounded to a multiple of 45 mm

0.450:

0.625: rounded to a multiple of 62.5 mm

6

.5/

.

/

%

/

rounded to a multiple of 32 mm

0.320:

rounded to a multiple of 45 mm

0.450:

0.625: rounded to a multiple of 62.5 mm

Longitudinal flange connection set (option V)

Longitudinal f lange plates make it possible to m ove more than the standard avail able stroke. A fl ange connection is al ways

necessary if the maximum travel pat h is exceeded (refer to Technical data, pages 6 and 20). Pr ofil e sections should norm al ly

be split equally, with the separation point cl ose to a fixing point. The bearing dist ance should generally be between 1.0m and

1.5m. I f a l ongitudi nal f lange connection is used to extend the travel distance, the load data must be reduced as shown in the

table below. An HLE with a longitudinal flange connection should only be install ed with the profile aperture in t he top or t he

bottom.

Unit HLE80 HLE100 HLE150 HLEZ100 HLEZ150

maximum permitted load N 0.5 x Fx

Speed m/s < 1 < 1 < 1

Acceleration m/s

Repeatability mm > ±0.5 > ±0.5 > ±0.5

*1. Fx-HLE: refer to p age 7;

2

*1

< 1 < 1 < 1

0.5 x Fx

*1

A

0.5 x Fx

*1

unchanged

Section A-A

FB

A

FL

FD

Model / size Type FL FB FD HB

HLE80 LVS80 300 70 15 80

HLE100 / HLEZ100 LVS100 400 90 15 100

HLE150 / HLEZ150 LVS150 500 130 15 150

Parker Hannifin GmbH

Electromechanical Division

Automation

30

HB

Page 31

Accessories for HLE and HLEZ

Attachment of position sensors and electr onic accessories

Attachment variants for position sensors

Tripping plates, switches and distribution box are attached as standard on the sam e si de as the motor.

The limit switches are fitt ed ensuring that they are ac tivated direct ly before t he st ar t of the standard

safety tr avel ( 125 mm). Unless agreed otherwise, the actuator will be supplied with positi on switches

attached using attachment variant 1 or 2. The tripping plates, swit c hes and di str ibutor sockets are described on page 32.

Variant 1: HL E with 3 integrated proximity swi t ches (standard f or HLE with load attach ment plate)

This sensor attachment is made as standard at the factory. This variant is only possible in the HLEZ, or the HLE c ar r iage

version with bar (T/F/D) and in the corrosion-resistant V2A version (V), if switch lugs are fitted by the customer.

Optional steel strip cover (C) Distribution box

a

=

150

=

b

switch

lug

Schematic drawing

Limit stop Switch lugs Machine origin Limit stop

Standard - HLE HLE with steel strip cover

HLE80 HLE100 HLE150 HLE80 HLE100 HLE150

Dimensions Unit S E S E S E S E S E S E

a

b

mm 187 262 212 287 249 324 232 307 257 332 294 369

mm 171 246 196 271 221 296 216 291 241 316 266 341

Variant 2: HL E or HLEZ wi t h 3 external pro ximity switches

This sensor attachment is made as standard at the factor y for the HLEZ and the HLE ver si ons with bar (T/F/D) and

in the corrosion-resistant V2A version (V).

HLE HLEZ Optional steel strip

cove r (only for HLE)

c

125

Standard safety travel Machine origin Standard safety travel Distribution box

Limit

stop

Drive module

HLEZ

Limit stop HLEZ HLE

d

125

Standard - HLE HLE with steel strip cover HLEZ

HLE80 HLE100 HLE150 HLE80 HLE100 HLE150 HLEZ100 HLEZ150

Dimensions Unit S/T E/F S/T E/F S/T E/F S/T E/F S/T E/F S/T E/F S/T E/F S/T E/F

c

d

The tripping plate is loosely attached in the carriage version with bar (T/F).

mm 223 298 248 323 285 360 268 343 293 368 330 405 248 323 285 360

mm 235 310 260 335 297 372 280 355 305 380 342 417 560 635 737 812

Parker Hannifin GmbH

Electromechanical Division

Automation

31

Page 32

Accessories for HLE and HLEZ

Variant 3: HL E with 2 mechanical end switches and one proximi t y switch

HLE HLEZ Optional steel strip

cove r (only for HLE)

e

Limit

stop

Drive module

HLEZ

Limit stop HLEZ HLE

f

125

Standard safety travel Machine origin Standard safety travel Distribution box

125

Standard - HLE HLE with steel strip cover HLEZ

HLE80 HLE100 HLE150 HLE80 HLE100 HLE150 HLEZ100 HLEZ150

Dimensions Unit S/T E/F S/T E/F S/T E/F S/T E/F S/T E/F S/T E/F S/T E/F S/T E/F

e

f

mm 204 279 229 304 266 341 249 324 274 349 311 386 229 304 266 341

mm 255 330 280 355 317 392 300 375 325 400 362 437 580 655 757 832

The tripping plate is l oosely att ached in t he carri age version with bar ( T/ F) .

Variant 4: HL E with 1 mechanical end switch and 1 proximity switch, bo t h attached to t he moving carriage

This is the preferred variant for robot syst em s if the connections to the switches come via the cable carrier. The tripping pl ates

must be assembled in a m anner which ensures that the mechanical swi t ch i s act uat ed immediately before the start of the

safety travel.

HLE HLEZ Optional steel strip

cove r (only for HLE)

g

125

Standard safety travel Machine origin Standard safety travel

Limit

stop

Drive module

HLEZ

Limit stop HLEZ HLE

h

125

Standard - HLE HLE with steel strip cover HLEZ

HLE80 HLE100 HLE150 HLE80 HLE100 HLE150 HLEZ100 HLEZ150

Dimensions Unit S/T E/F S/T E/F S/T E/F S/T E/F S/T E/F S/T E/F S/T E/F S/T E/F

g

h

mm 270 345 295 370 332 407 315 390 340 415 377 452 295 370 332 407

mm 287 362 312 387 349 424 332 407 357 432 394 469 603 678 780 855

The initiator and t he limit switch ar e loosely att ached in the carri age version with bar ( T/ F).

Tripping plate

Ø4,5

15

Automation

7,5

7

Ø6,5

60

80

90

150

32

2

15

The tripping plate i s suit able for all

standard load attachment plates. It is

°

mounted at the side of the flange

plate using cheese-head screws and

square nuts.

23

25

Parker Hannifin GmbH

Electromechanical Division

Page 33

Accessories for HLE and HLEZ

Mechanical limit switch

The switching but ton complies with DIN EN 50047. The contacts satisfy the safety requirements in ac c or danc e

with EN 60947-5-1 by virt ue of for c ed opening (positively dr iven) .

60

4,4

20

60

51

35

51

85

100

Electrical limit switch

There are two variants of inductive prox imity sensors:

Integrated sensors: These are installed i n a T groove on the upper side of t he pr ofile (standard with flange plate)

External sensors: These are attached to the outside of t he profile (and are used for carr iage ver si on with bar

T/F or for the corrosi on-resistant version V)

The sensors are either activated by a trippi ng plate fastened to the side of the flange plate (ext er nal sensors) or by

a switch lug att ac hed to the underside of the flange plate (integr ated sensors – can only be used for the HLE).

max. 6 5

30

5

Integrat ed sensors:

H

L

LA

B

G

A

S

LED

Model / size A B G H L LA S

HLE80 / HLE100

HLE150

128M4124034 8

128M412524610

Technical data DC electrical data

Switching distance

Switch hysteresis

Repeatability

Ambient te mperature

Type of protection

Cable length

1.8-2.2 m m

3 - 15 %

± 3 %

-25°C - +70°C

IP67

6 m

Connection diagram

bn

bk

bu

Voltage range

Supply current

Maximum switching

current

Voltage drop

Max. swit chi ng f r equency

Connection cables

1

normally closed

2

A

3

PNP-

contact

load

switch

lug

10 - 30 V DC

< 10 mA

150 mA when T = 25°C

< 3.5 V at a switch current of

150 mA

1 kHz

3 x 0.14 mm

2

Automation

33

Parker Hannifin GmbH

Electromechanical Division

Page 34

Accessories for HLE and HLEZ

External sensors:

70

Switching distance

Switch hysteresis

Repeatability

Temperature dr i ft

Ambient te mperature

Type of protection

Cable length

59

26

50

40

Technical data DC electrical data

2mm / 4mm ± 10%

> 1% ...<

0.01 mm

-25°C - +70°C

< 10 %

IP67

6 m

21

6

15

4,4

12

15%

20

5

Connection diagram

bn

bk

bu

Rated voltage

Voltage range

Supply current

Maximum load current

Residual voltage

Max. swit chi ng f r equency

Connection cables

1

normally closed

2

A

3

PNP-

contact

load

24 V DC

10...35 V DC

< 15 mA

300 mA

< 2.5 V DC

2 kHz

3 x 0.25 mm

2

Distribution box

15

20

15

2929

19

20

29

82

22

20

5

80

15

29

20

assembly plate

20

A distri bution box with 2.5 m of c able is attached as standard. If

a different cable length is required, please specify when ordering.

Other accessories and software

DimAxes:

Dimensioning software f or the

HAUSER li near axes (Art. no.: 840-

014400) - for PCs as of Windows

Version 3.xx.

Belt tension measuring device

RSM:

For accurat ely setting the timing belt

tension (Art .no.: 037-000200).

DimAxes

s

e

x

A

im

D

Ini limit

stop 1

normally

closed

contact

Ini machine

origin

normally

closed

contact

Ini limit

stop 2

normally

closed

contact

X3/9

+24V

brown

Sig. E1

black

GND

blue

+24V

brown

Sig. MN

black

GND

blue

+24V

brown

Sig. E2

black

GND

blue

X3/8

X3/7

X2/6

X2/5

X2/4

X1/3

X1/2

X1/1

X4/12

X4/15

X4/14

X4/13

X4/10

distribution

box

+24V

brown

Sig. E1

yellow

Sig. MN

green

Sig. E2

white

GND

blue

DXF/MI f iles on CD-RO M :

CAD fi les of the HLE units. Modular

system for all commonly used CAD

systems

Manual f or using the DXF/MI files

with CD-ROM, Art.nos.:

German: 890-070001

English: 892- 070001

controller

Automation

34

Parker Hannifin GmbH

Electromechanical Division

Page 35

Accessories for HLE and HLEZ

Automation

35

Parker Hannifin GmbH

Electromechanical Division

Page 36

Automation Group

Automation

Parker Hannifin GmbH

Hauser - Elektromechanik

Robert-Bosch-Str. 22

D-77656 Offenburg, Germany

Tel.:+49 (0)781 509-0

Fax:+49 (0)781 509-176

Website: www.parker-emd.com

e-mail: vertrieb@parker-emd.com

Parker Hannifin plc

Electromechanical Division - Digiplan

21 Balena Close

Poole, Dorset. BH17 7DX UK

Tel.:+44 (0)1202 69 9000

Fax:+44 (0)1202 69 5750

Website: www.parker-emd.com

e-mail: sales@parker-emd.com

Loading...

Loading...