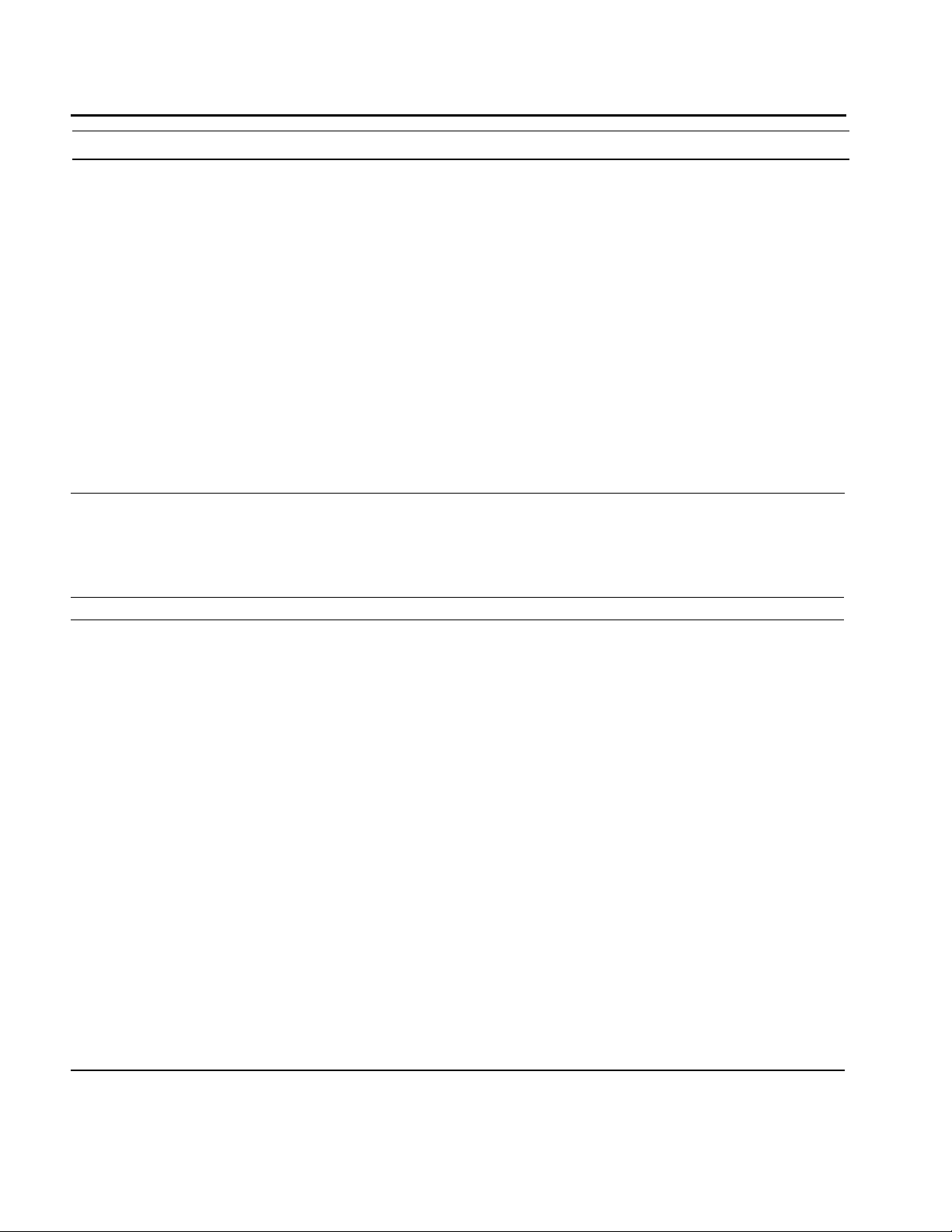

parker ZETA6xxx Installation Guide

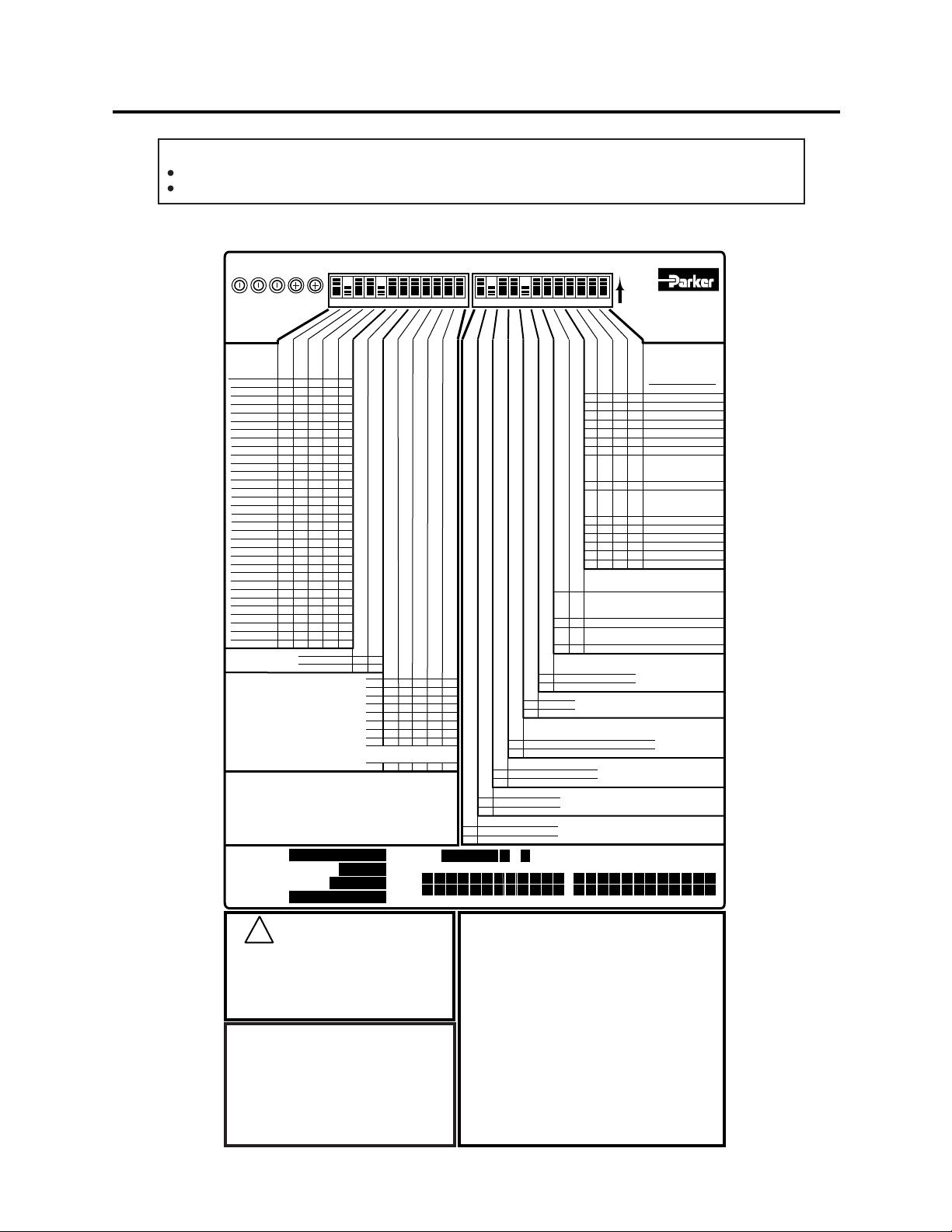

ZETA6xxx Indexer/Drive

MOTOR

INTERLOCK

A+

AEARTH

B+

BINTERLOCK

POWER

STEP

OVER TEMP

MOTOR FAULT

ZETA

Rx

Tx

GND

SHLD

+5V

GND

Rx

Tx

SHLD

Rx+

RxTx+

TxGND

SHLD

GND

ZZ+

BB+

AA+

+5V

GND

HOM

NEG

POS

TRG-A

TRG-B

OUT-A

GND

P-CUT

+5V

OUT-P

IN-P

AUX-P

V_I/O

Installation Guide

x

R

x

T

D

N

COM 1 COM 2 ENCODER LIMITS I/O

+

G

D

x

L

R

H

-

S

x

R

V

5

+

+

x

D

T

N

-

G

x

T

x

D

R

N

A

G

PROGRAMMABLE I/O

x

T

L

H

S

L

H

S

D

N

G

-

Z

+

Z

-

B

+

B

-

A

+

A

V

5

+

D

N

G

M

O

H

G

E

N

S

O

P

G

R

T

G

R

T

T

U

O

D

N

G

U

C

-

P

V

5

+

T

U

O

P

-

IN

X

U

A

I/O

_

V

D

D

A

B

A

T

P

P

-

T

E

Z

R

E

W

O

P

P

P

M

E

T

E

T

L

T

S

U

R

A

E

F

V

R

O

O

T

O

K

M

C

O

L

R

E

T

MOTOR

IN

+

A

-

A

H

T

R

A

E

+

B

K

C

-

O

B

L

R

E

T

IN

Compumotor Division

Compumotor

Parker Hannifin Corporation

p/n 88-017277-01A October 1998

User Information

! !

WARNING

6000 Series products are used to control electrical and mechanical

components of motion control systems. You should test your motion

system for safety under all potential conditions. Failure to do so can result

in damage to equipment and/or serious injury to personnel.

6000 Series products and the information in this user guide are the proprietary property of Parker Hannifin Corporation or its licensers, and

may not be copied, disclosed, or used for any purpose not expressly authorized by the owner thereof.

Since Parker Hannifin constantly strives to improve all of its products, we reserve the right to change this user guide and software and

hardware mentioned therein at any time without notice.

In no event will the provider of the equipment be liable for any incidental, consequential, or special damages of any kind or nature

whatsoever, including but not limited to lost profits arising from or in any way connected with the use of the equipment or this user guide.

© 1998, Parker Hannifin Corporation

All Rights Reserved

Motion Architect is a registered trademark of Parker Hannifin Corporation.

Motion Builder, CompuCAM and DDE6000 are trademarks of Parker Hannifin Corporation.

Microsoft and MS-DOS are registered trademarks, and Windows, DDE and NetDDE are trademarks of Microsoft Corporation.

Motion Toolbox is a trademark of Snider Consultants, Inc.

LabVIEW is a registered trademark of National Instruments Corporation.

Technical Assistance

North America and Asia:

Compumotor Division of Parker Hannifin

5500 Business Park Drive

Rohnert Park, CA 94928

Telephone: (800) 358-9070 or (707) 584-7558

Fax: (707) 584-3793

FaxBack: (800) 936-6939 or (707) 586-8586

BBS: (707) 584-4059

e-mail: tech_help@cmotor.com

Internet: http://www.compumotor.com

Automation

Contact your local automation technology center (ATC) or distributor, or ...

Europe

Parker Digiplan

21 Balena Close

Poole, Dorset

England BH17 7DX

Telephone: +44 (0)1202 69 9000

Fax: +44 (0)1202 69 5750

(non-German speaking)

:

Germany, Austria, Switzerland:

HAUSER Elektronik GmbH

Postfach: 77607-1720

Robert-Bosch-Str. 22

D-77656 Offenburg

Telephone: +49 (0)781 509-0

Fax: +49 (0)781 509-176

ABOUT

THIS

GUIDE

Chapter 1. Installation

What You Should Have (ship kit).................................................2

Before You Begin........................................................................3

Recommended Installation Process ....................................3

Electrical Noise Guidelines..................................................3

General Specifications.................................................................4

Pre-installation Adjustments........................................................7

DIP Switch Settings.............................................................7

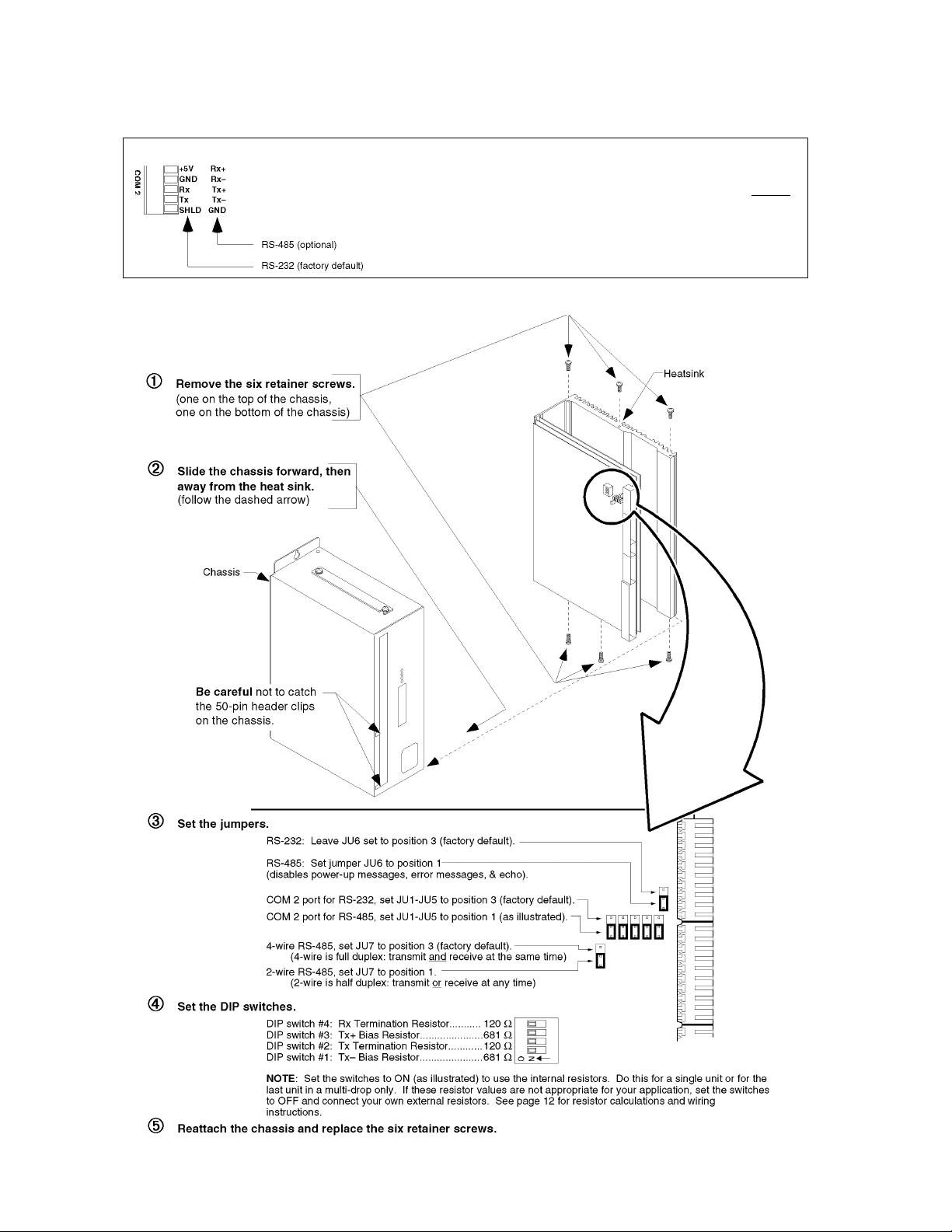

Changing the COM 2 Connector from RS-232 to RS-485....8

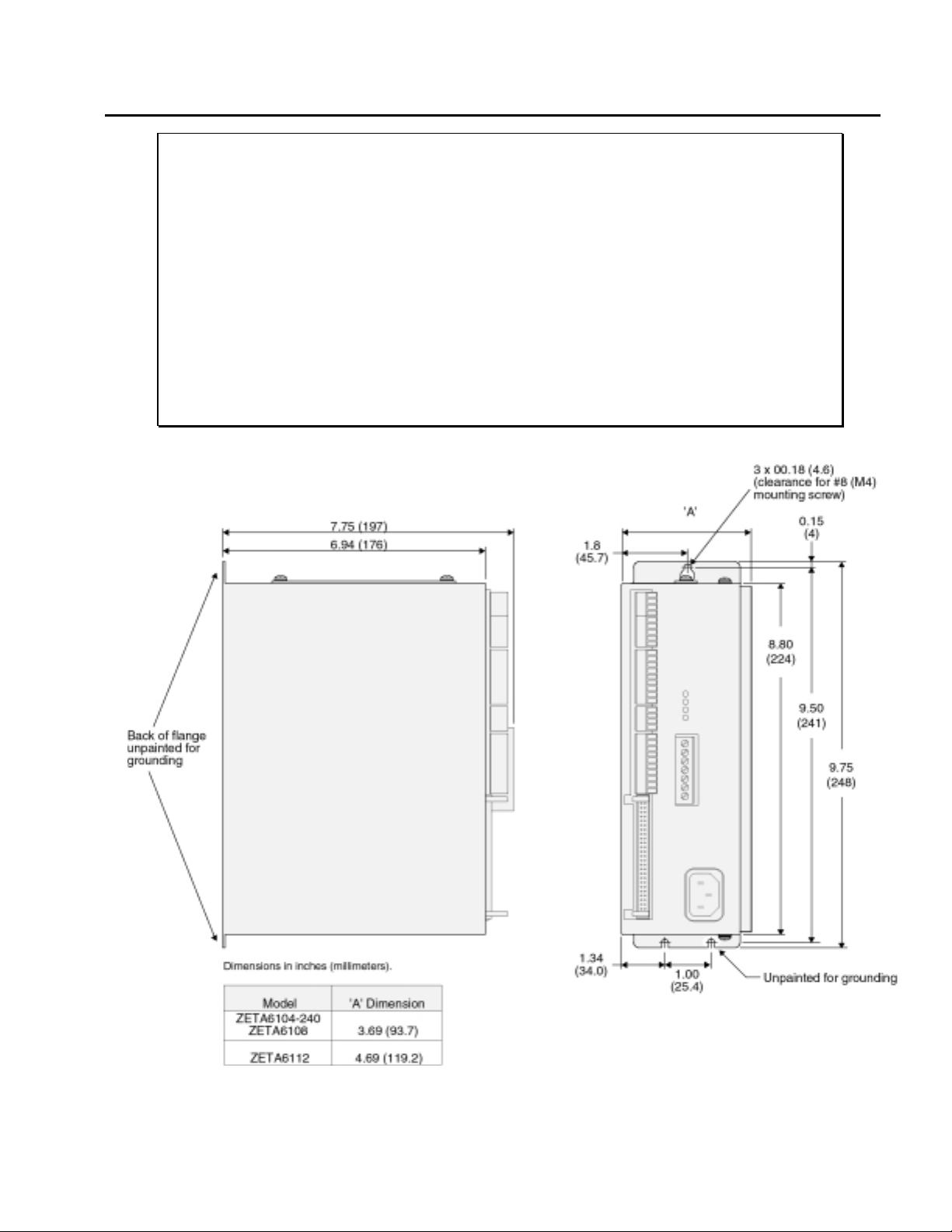

Mounting the ZETA6xxx...............................................................9

Electrical Connections...............................................................11

Grounding System.............................................................11

Pulse Cut-Off (P-CUT) — Emergency Stop Switch............11

Serial Communication .......................................................12

Motor (OS/RS/TS motors only)..........................................13

End-of-Travel and Home Limit Inputs ................................17

Encoder.............................................................................18

Trigger Inputs....................................................................19

General-Purpose Programmable Inputs & Outputs............20

RP240 Remote Operator Panel.........................................25

Input Power.......................................................................25

Lengthening I/O Cables.....................................................26

Testing the Installation...............................................................27

Matching the Motor to the ZETA6xxx (OPTIONAL)....................30

Mounting & Coupling the Motor .................................................33

Mounting the Motor............................................................33

Coupling the Motor ............................................................35

Optimizing System Performance (OPTIONAL)..........................36

Configuring Active Damping..............................................36

Configuring Electronic Viscosity (EV) ................................38

Record Your System’s Configuration.........................................40

Recommended Set-up Program Elements........................40

What’s Next?.............................................................................42

Program Your Motion Control Functions............................42

Chapter 2. Troubleshooting

Troubleshooting Basics.............................................................46

Reducing Electrical Noise..................................................46

Diagnostic LEDs................................................................46

Test Options......................................................................46

Technical Support .............................................................47

Common Problems & Solutions.................................................48

Troubleshooting Serial Communication Problems.....................50

Product Return Procedure.........................................................52

Appendix A

Appendix B

Appendix C

Appendix D

Appendix E

Index

(Resonance, Ringing & Damping) ......................53

(Using Non-Compumotor Motors).......................57

(LVD Installation Instructions).............................61

(EMC Installation Guidelines).............................63

(R or T Series Motor with C10 Cable Kit) ...........69

.......................................................................................71

Purpose of This Guide

This document is designed to help you install and troubleshoot your ZETA6xxx hardware

system. Programming related issues are covered in the 6000 Series Programmer’s Guide and

the 6000 Series Software Reference.

The nomenclature "ZETA6xxx" is used in this documentation to indicate the higher power

versions of the ZETA6000 Indexer Drive, the ZETA6104-240, the ZETA6108 and the

ZETA6112. Any information that refers to the ZETA6xxx is applicable to all three higher power

versions.

In older versions of the 6000 Software & Programmers Guides as well as the older versions

of the Motion Architect software, references are made to the ZETA6104 or "6104". These

references are equally applicable to the higher power versions of the ZETA6xxx series.

What You Should Know

To install and troubleshoot the ZETA6xxx, you should have a fundamental understanding of:

• Electronics concepts, such as voltage, current, switches.

• Mechanical motion control concepts, such as inertia, torque, velocity, distance, force.

• Serial communication and terminal emulator experience: RS-232C and/or RS-485.

"ZETA6xxx" Nomenclature

Related Publications

• 6000 Series Software Reference, Parker Hannifin Corporation, Compumotor Division;

part number 88-012966-01

• 6000 Series Programmer’s Guide, Parker Hannifin Corporation, Compumotor Division;

part number 88-014540-01

• Current Parker Compumotor Motion Control Catalog

• Schram, Peter (editor). The National Electric Code Handbook (Third Edition). Quincy,

MA: National Fire Protection Association

Online Manuals

LVD and EMC

Installation

Guidelines

This manual (in Acrobat PDF format) is available from our web site: h

The ZETA6xxx is in compliance with the Low Voltage Directive (72/23/EEC) and the CE

Marking Directive (93/68/EEC) of the European Community.

When installed according to the procedures in the main body of this installation guide, the

ZETA6xxx may not necessarily comply with the Low Voltage Directive (LVD). To install

the ZETA6xxx so that it is LVD compliant, refer to supplemental installation instructions

provided in Appendix C. If you do not follow these instructions, the protection of the

ZETA6xxx may be impaired.

The ZETA6xxx is sold as a complex component to professional assemblers. As a

component, it is not required to be compliant with Electromagnetic Compatibility Directive

89/336/EEC. However, Appendix D provides guidelines on how to install the ZETA6xxx in

a manner most likely to minimize the ZETA6xxx’s emissions and to maximize the

ZETA6xxx’s immunity to externally generated electromagnetic interference.

ttp://www.compumotor.com

ZETA6xxx Installation Guide

ii

ζ

CHAPTER ONE

Installation

IN THIS CHAPTER

• Product ship kit list

• Things to consider before you install the ZETA6xxx

• General specifications table

• Optional pre-installation alterations

- DIP switch settings – motor current, device address, autobaud feature

- Changing the COM 2 port from RS-232C to RS-485

• Mounting the ZETA6xxx

• Connecting all electrical components (includes specifications)

• Testing the installation

• Matching the motor to the ZETA6xxx

• Motor mounting and coupling guidelines

• Using the damping features to optimize performance

• Preparing for what to do next

To install the ZETA6xxx so that it is LVD compliant, refer to the supplemental

instructions in Appendix C. Appendix D provides guidelines on how to install the

ZETA6xxx in a manner most likely to minimize the ZETA6xxx’s emissions and to

maximize the ZETA6xxx’s immunity to externally generated electromagnetic

interference.

What You Should Have (ship kit)

Part Part Number

ZETA6108 standard product (with ship kit)………………………………………..…………………………………ZETA6108

OR

ZETA6112 standard product (with ship kit)………………………………………………………………………….ZETA6112

OR

ZETA6104-240 standard product (with ship kit)…………………………………………………………………….ZETA6104-240

Ship kit:

This user guide

(ZETA6xxx Indexer/Drive Installation Guide) …….………………………………………………………..88-017277-01

6000 Series Software Reference .…………………………………………………………………………..88-012966-01

6000 Series Programmer's Guide ………………………………………………… ……………………….88-014540-01

Motion Architect disks: Disk 1 …………………………………………………………………………….95-013070-01

Disk 2…………………………………………………………………………….95-013070-02

Driver & Samples……………………………………………………………….95-016324-01

Wire jumpers: Qty 3………………………………………………………………………………………..44-015142-01

Qty 1……………………………………………………………………………………….44-015741-01

Quick-reference magnet

(located on the side of the ZETA6xxx chassis)…………………………………………………………….87-017473-01

Motor connector……………………………………………………………………………………………….43-008755-01

120VAC power cord…………………………………………………………………………………………..44-014768-01

(ZETA6108 and ZETA6112 versions only)

240 VAC power connector……………………………………………………………………………….…..43-011905-01

(ZETA6104-240 version only)

If an item is missing, call the factory (see phone numbers on inside front cover).

You may have also ordered some of the following accessories:

Part Part Number

* O Series Motor (CE/LVD Marked) OS2HB (170 VDC winding) OS21B OS22B* R Series Motor (CE/LVD Marked) RS31B (170 VDC winding) RS32B RS33B RS42B RE42B* T Series Motor (CE/LVD Marked) TS31B (170 VDC winding) TS32B-

TS33B TS41B TS42B-

TS43B** R Series Motor (CE/LVD Marked) RS31C (340 VDC winding) RS32C-

RS33C-

RS42C-

RE42C-

RS43CCable Kit for LVD/EMC Motor Installation (10') (compatible with R & T series motors) C10

C10H***

EMC Kit for LVD/EMC Installation ZETA EMC SHIPKIT

24V input/output module VM24

50-pin header-to-screw terminal breakout board VM50

Operator interface RP240

Operator interface (NEMA 4 rated) RP240-NEMA 4

nnnnn

nnnnn

nnnnn

nnnnn

nnnnn

nnnnn

nnnnn

nnnnn

nnnnn

nnnnn

nnnnn

nnnnn

nnnnn

nnnnn

nnnnn

nnnnn

nnnnn

nnnnn

nnnnn

nnnnn

DDE server for 6000 series DDE 6000

LabVIEW library of VI's for Motion Control Motion Toolbox

Graphical icon-based programming software Motion Builder

* These motors are recommended for use with the ZETA6108, ZETA6112 and the ZETA6104-240 operating at 120 VAC.

** These motors are recommended for use with the ZETA6104-240 operating at 240 VAC.

***The C10H (to be released soon) is recommended for use with applications rated for more than 10 amps of current in the motor.

: See the Compumotor catalog for more information on accessories.

NOTE

ZETA6xxx Installation Guide

2

ζ

Before You Begin

The ZETA6xxx is used to control your system’s electrical and mechanical components.

Therefore, you should test your system for safety under all potential conditions. Failure to do

so can result in damage to equipment and/or serious injury to personnel.

Always remove power to the ZETA6xxx before:

• Connecting any electrical device (e.g., motor, encoder, inputs, outputs, etc.)

• Adjusting the DIP switches, jumpers, or other internal components

Recommended Installation Process

This chapter is

organized sequentially

to best approximate a

typical installation

process.

1. Review the general specifications

2. Perform configuration/adjustments (if necessary)

3. Mount the ZETA6xxx

4. Connect all electrical system components

5. Test the installation

6. Match the motor to the ZETA6xxx — optional

7. Mount the motor and couple the load

8. Optimize performance (using the ZETA6xxx’s damping features) — optional

9. Record the system configuration (record on the information label and/or in a set-up

program)

10. Program your motion control functions. Programming instructions are provided in the

6000 Series Programmer’s Guide and the 6000 Series Software Reference. We

recommend using the programming tools provided in Motion Architect for Windows

(found in your ship kit). You can also benefit from an optional iconic programming

interface called Motion Builder (sold separately).

WARNINGS

Electrical Noise Guidelines

• Do not route high-voltage wires and low-level signals in the same conduit.

• Ensure that all components are properly grounded.

• Ensure that all wiring is properly shielded.

• Noise suppression guidelines for I/O cables are provided on page 26.

• Appendix D (page 63) provides guidelines on how to install the ZETA6xxx in a manner

most likely to minimize the ZETA6xxx’s emissions and to maximize the ZETA6xxx’s

immunity to externally generated electromagnetic interference.

Chapter 1. Installation

3

General Specifications

Parameter Specification

Power

AC input...........................................................95-132VAC, 50/60Hz, single-phase (95-264VAC for ZETA6104-240)

Status LEDs/fault detection..............................Refer to

Environmental

Operating Temperature ...................................32 to 113°F (0 to 45°C)

Storage Temperature....................................... -22 to 185°F (-30 to 85°C)

Humidity...........................................................0 to 95% non-condensing

Performance

Position Range & Stepping Accuracy...............Position range: ±2,147,483,648 steps; Stepping accuracy: ±0 steps from preset total

Velocity Range, Accuracy, & Repeatability ...... Range: 1-2,000,000 steps/sec; Accuracy: ±0.02% of maximum rate;

Acceleration Range..........................................1-24,999,975 steps/sec

Motion Algorithm Update Rate.........................2 ms

Serial Communication

Connection Options ......................................... RS-232C, 3-wire; RS-485 (default is 4-wire; for 2-wire move JU7 to position 1);

Maximum units in daisy-chain or multi-drop.....99 (use DIP switch or

Communication Parameters ............................ 9600 baud (range is 19200-1200—see

Inputs

HOM, POS, NEG, TRG-A, TRG-B, P-CUT

.............Powered by voltage applied to

Encoder...........................................................Differential comparator accepts two-phase quadrature incremental encoders with

16 General-Purpose Programmable ...............HCMOS compatible* with internal 6.8 KΩ pull-ups to

Outputs

9 Programmable (includes

) ...................Open collector output with 4.7 KΩ pull-ups. Can be pulled up by connecting

OUT-A

+5V Output ......................................................Internally supplied +5VDC.

*

HCMOS-compatible switching voltage levels

TTL-compatible switching voltage levels

(refer to page 25 for peak power requirements, based on the motor you are using)

Diagnostic LEDs

Repeatability: ±0.02% of set rate

on page 46

2

RS-485 requires internal jumper and DIP switch configuration (see page 8).

Change internal jumpers JU1-JU6 to position 1 to select RS-485 communication

command to set individual addresses for each unit)

ADDR

AutoBaud

, page 7), 8 data bits, 1 stop bit, no

parity; RS-232: Full duplex; RS-485: Half duplex (change jumper JU6 to position 1)

All inputs are optically isolated from the microprocessor (not from the other inputs).

terminal (switching levels: ≤1/3 of

low, ≥2/3 of

voltage = high).

V_I/O

Internal 6.8 KΩ pull-ups to

terminal or an external 5-24V supply) to source current or connect

current;

can handle 0-24V with max. current of 50mA. Voltage range for these

AUX-P

V_I/O

V_I/O

terminal—connect

AUX-P

can handle 5-24V with max. current of 100mA.

to power source (

AUX-P

AUX-P

inputs is 0-24V.

differential (recommended) or single-ended outputs.

Maximum voltage = 5VDC. Switching levels (TTL-compatible): Low ≤ 0.4V,

High ≥2.4V.

Maximum frequency = 1.6 MHz. Minimum time between transitions = 625 ns.

terminal—connect

power source (

to

to sink current;

GND

P

pin #49 or an external 5-24V supply) to source current or connect

+5V

can handle 0-24V with max. current of 100 mA. Voltage

IN-P

IN-P

range = 0-24V.

All outputs are optically isolated from the microprocessor (not from the other outputs).

power source (

terminal or an external 5-24V supply);

+5V

can handle 0-24V with

OUT-P

max. current of 50mA. Outputs will sink up to 300mA or source up to 5mA at 524VDC.

8 general-purpose outputs on the

Programmable I/O

connector,

OUT-A

connector.

terminals are available on the

+5V

COM2, ENCODER

connectors. Load limit (total load for all I/O connections) is 0.5A.

: Low ≤ 1.00V, High ≥ 3.25V.

: Low ≤ 0.4V, High ≥ 2.4V.

V_I/O

on the

voltage =

+5V

to

GND

IN-P

OUT-P

I/O

to sink

to

to

and

IN-

I/O

ZETA6xxx Installation Guide

4

ζ

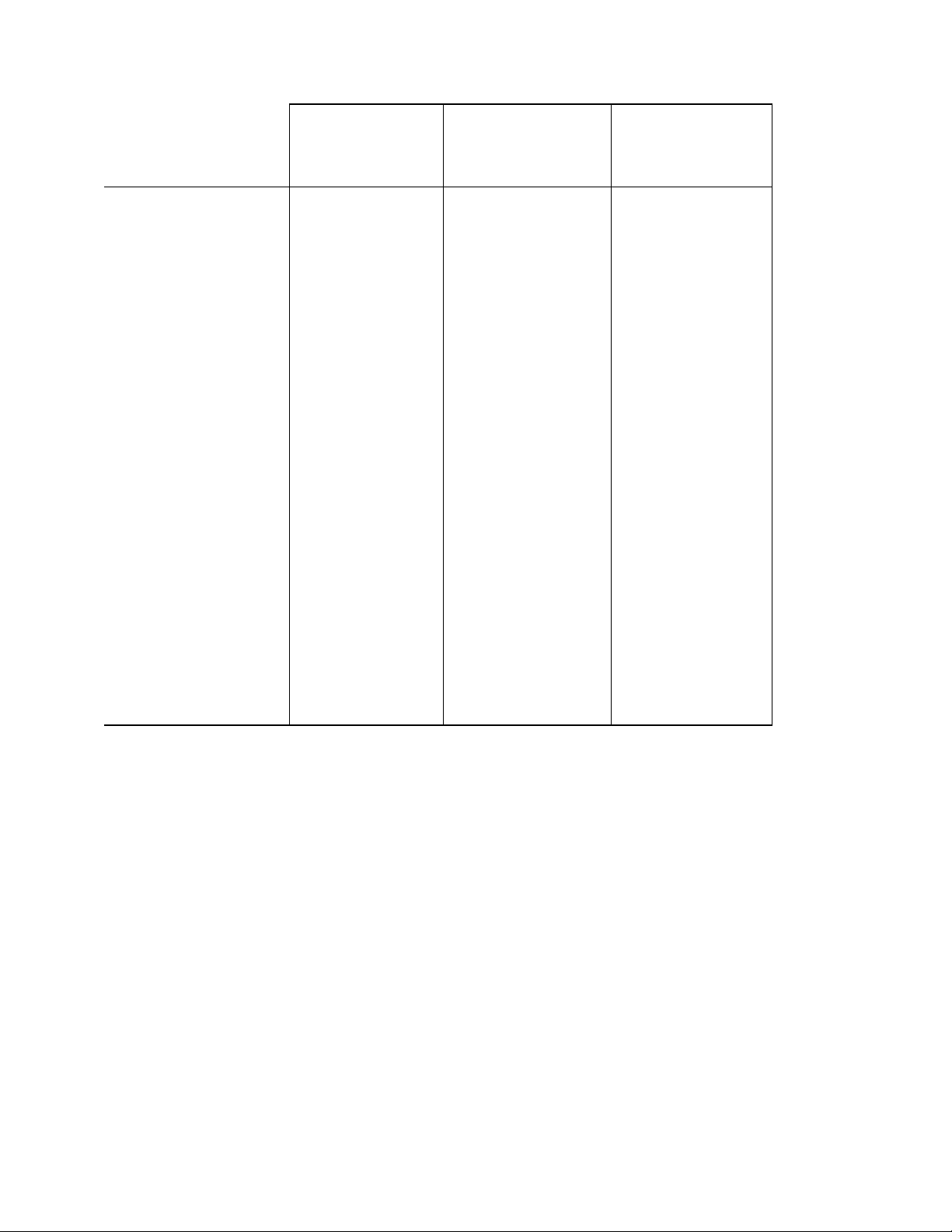

Motor Specifications

Parameters

Size 23 O Motors Size 34 R Motors Size 42 R Motors

(170 VDC winding) (170 VDC winding) (170 VDC winding)

OS2HB OS21B OS22B RS31B RS32B RS33B RS42B RE42B

Static Torque**

Rotor Inertia

oz-in

(N-m)

2

oz-in

(kg-cm2)

Drive Current (Apk)(Arms)**

Series

Parallel

Phase Inductance (mH)***

Series

Parallel

Drive Bus Voltage (VDC)

Detent Torque

oz-in

(Nm)

Bearings Information

&

lb

(kg)

lb

(kg)

in

(mm)

in

(mm)

lb

(kg)

EMC)*

Thrust load

Radial load

End play

equal to 1 lb)

(Reversing load

Radial play

(Per 0.5 lb load)

Motor Weight

(Motor+Cable+Connector)

Certifications

UL Rec.

CE (LVD)

CE (LVD

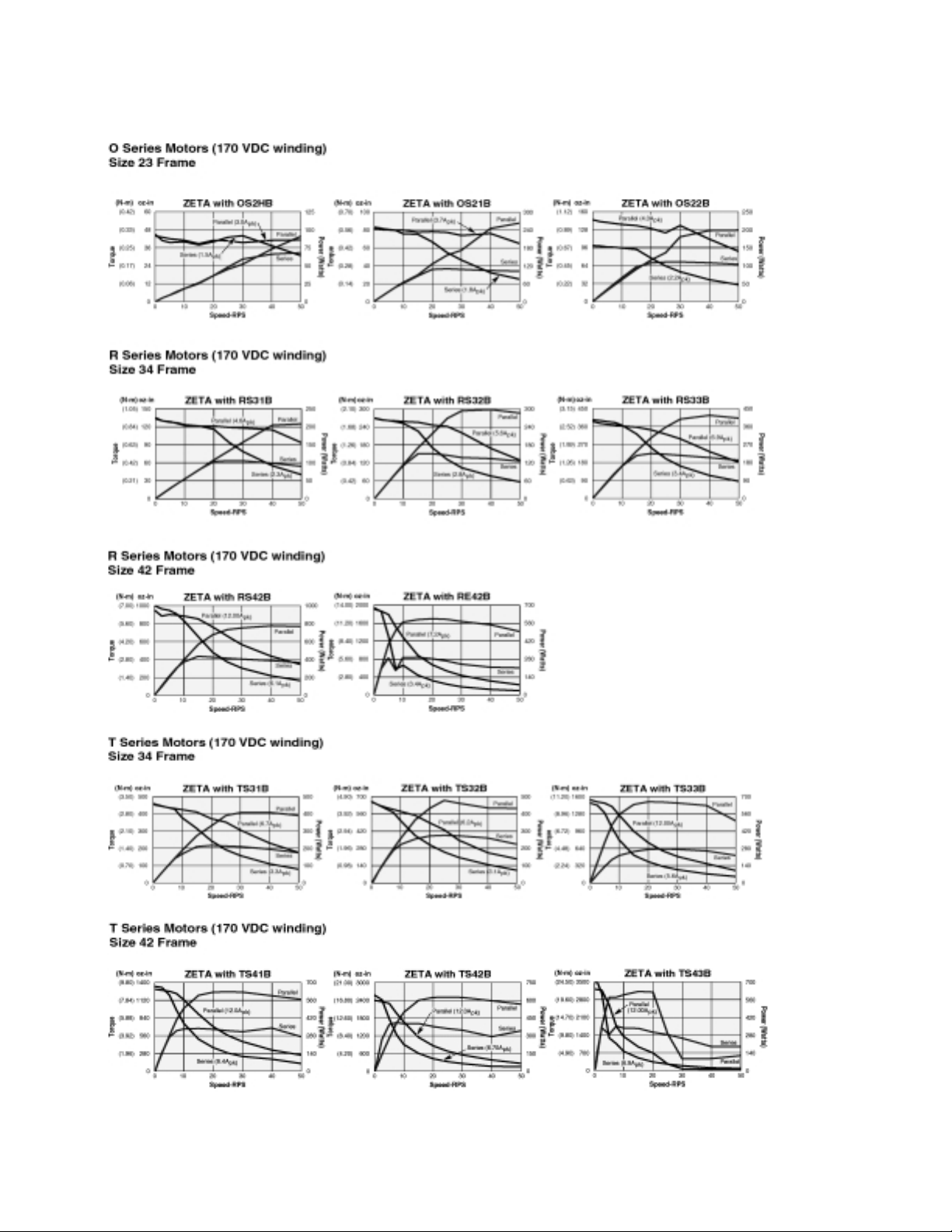

Speed/Torque Curves

Dimensions

43

(0.30)

0.39

(0.07)

1.5 (1.0)

3.0 (2.1)

8.6

2.2

170 170 170 170 170 170 170 170

2.5

(0.02)

13

(5.9)

20

(9.1)

0.001

(0.025)

0.0008

(0.02)

1

(0.5)

Pending

Yes

No

82

(0.58)

0.66

(0.12)

1.8 (1.3)

4.0 (2.8)

12

3

4.0

(0.03)

13

(5.9)

20

(9.1)

0.001

(0.025)

0.0008

(0.02)

1.5

(0.7)

Pending

Yes

No

------ Refer to page 15 ------ ------ Refer to page 15 ------ -- Refer to page 15 ------

------ Refer to page 33 ------ ------ Refer to page 34 ------ -- Refer to page 34 ------

155

(1.09)

1.39

(0.25)

2.2 (1.5)

4.0 (2.8)

16.6

4.2

7.0

(0.05)

13

(5.9)

20

(9.1)

0.001

(0.025)

0.0008

(0.02)

2.5

(1.1)

Pending

Yes

No

133

(0.93)

3.02

(0.55)

2.3 (1.6)

4.6 (3.3)

9.4

2.4

8.8

(0.06)

180

(81.6)

35

(15.9)

0.001

(0.025)

0.0008

(0.02)

3.2

(1.5)

Yes

Yes

*

267

(1.87)

6.56

(1.20)

2.8 (2.0)

5.6 (4.0)

11.6

2.9

18.0

(0.13)

180

(81.6)

35

(15.9)

0.001

(0.025)

0.0008

(0.02)

5.3

(2.4)

Yes

Yes

*

392

(2.74)

9.65

(1.77)

3.4 (2.4)

6.9 (4.9)

9.6

2.4

27.0

(0.19)

180

(81.6)

35

(15.9)

0.001

(0.025)

0.0008

(0.02)

7.6

(3.5)

Yes

Yes

*

985

(6.90)

61.76

(11.30)

6.1 (4.3)

12.0 (8.5)

8.2

2.1

41.7

(0.35)

400

(182)

140

(63.6)

0.001

(0.025)

0.0008

(0.02)

18.2

(8.3)

Yes

Yes

*

1907

(13.35)

61.76

(11.30)

3.4 (2.4)

7.2 (5.1)

42.6

10.7

81.0

(0.57)

400

(182)

140

(63.6)

0.001

(0.025)

0.0008

(0.02)

18.2

(8.3)

Yes

Yes

*

*EMC is a system compliance. To comply with EMC and low-noise (C15PR22/EN55022 Class B or FCC Class B

emissions) standards, the following items are required:

•

ZETA4-240, ZETA8, or ZETA12 Drive

•

CE(LVD) motor for LVD. Compumotor recommends a terminal board (NPS) motor construction for easier

EMC installation

•

C10 motor accessory (LVD/EMC cable kit)

•

ZETA EMC Kit

**Values shown in speed-torque curves

***Small signal values

Chapter 1. Installation

5

Motor Specifications

Parameters

Size 34 T Series Size 42 T Series Size 34 R Series Size 42 R Series

(170 VDC winding) (170 VDC winding) (340 VDC winding) (340 VDC winding)

TS31B TS32B TS33B TS41B TS42B TS43B RS31C RS32C RS33C RS42C RE42C RS43C

Static Torque**

Rotor Inertia

oz-in

(N-m)

2

oz-in

(kg-cm2)

Drive Current (Apk)(Arms)**

Series

Parallel

Phase Inductance (mH)***

Series

Parallel

Drive Bus Voltage (VDC)

Detent Torque

oz-in

(Nm)

Bearings Information

Thrust load

Radial load

End play

equal to 1 lb)

(Reversing load

Radial play

(Per 0.5 lb load)

Motor Weight

(Motor+Cable+Connector)

Certifications

UL Rec.

CE (LVD)

CE (LVD

lb

(kg)

lb

(kg)

in

(mm)

in

(mm)

lb

(kg)

&

EMC)*

455

(3.19)

7.80

(1.43)

3.3 (2.3)

6.7 (4.7)

10.3

2.6

170 170 170 170 170 170 340 340 340 340 340 340

18

(0.13)

305

(139)

65

(30)

0.001

(0.025)

0.0008

(0.020)

5.0

(2.3)

Yes

Yes

*

647

(4.53)

14.67

(2.68)

3.1 (2.2)

6.2 (4.4)

10.3

2.6

36

(0.25)

305

(139)

65

(30)

0.001

(0.025)

0.0008

(0.020)

8.4

(3.8)

Yes

Yes

*

1525

(10.68)

21.89

(4.01)

5.6 (4.0)

12.0 (8.5)

13.6

3.4

54

(0.38)

305

(139)

110

(50)

0.001

(0.025)

0.0008

(0.020)

11.9

(5.4)

Yes

Yes

*

1332

(9.32)

30.22

(5.53)

6.4 (4.5)

12.0 (8.5)

15.8

3.9

42

(0.30)

404

(184)

125

(57)

0.001

(0.025)

0.0008

(0.020)

11.0

(5.0)

Yes

Yes

*

2515

(17.61)

59.68

(10.92)

6.7 (4.7)

12.0 (8.5)

22.0

5.5

84

(0.59)

404

(184)

110

(50)

0.001

(0.025)

0.0008

(0.020)

18.4

(8.4)

Yes

Yes

*

3479

(24.35)

88.51

(16.20)

6.9 (4.9)

12.0 (8.5)

30.7

7.7

106

(0.75)

404

(184)

110

(50)

0.001

(0.025)

0.0008

(0.020)

25.7

(11.7)

Yes

Yes

*

171

(1.21)

3.20

(0.59)

2.2 (1.6)

4.0 (2.8)

17.4

4.4

8.8

0.062

180

(81.6)

35

(15.9)

0.001

(0.025)

0.0008

(0.02)

3.2

(1.5)

Yes

Yes

*

292

(2.06)

6.56

(1.20)

2.8 (2.0)

4.0 (2.8)

26.2

6.6

18.0

0.130

180

(81.6)

35

(15.9)

0.001

(0.025)

0.0008

(0.02)

5.3

(2.4)

Yes

Yes

*

532

(3.76)

9.65

(1.77)

3.5 (2.5)

4.0 (2.8)

23.3

5.8

27.0

0.190

180

(81.6)

35

(15.9)

0.001

(0.025)

0.0008

(0.02)

7.6

(3.5)

Yes

Yes

*

1,266

(8.94)

61.76

(11.30)

3.2 (2.3)

4.0 (2.8)

65.4

16.4

50.0

(0.350)

400

(182)

140

(63.6)

0.001

(0.025)

0.0008

(0.02)

18.2

(8.3)

Yes

Yes

*

1,959

(13.8)

61.76

(11.30)

3.4 (2.4)

4.0 (2.8)

55.6

13.9

81.0

(0.570)

400

(182)

140

(63.6)

0.001

(0.025)

0.0008

(0.02)

18.2

(8.3)

Yes

Yes

*

1,671

(11.8)

92.64

(16.95)

4.0 (2.8)

4.0 (2.8)

42.9

10.7

71.0

(0.500)

400

(182)

140

(63.6)

0.001

(0.025)

0.0008

(0.02)

25.7

(11.7)

Yes

Yes

*

Speed/Torque Curves

Dimensions

------ Refer to page 15 ------ ------ Refer to page 15 ------ ------ Refer to page 16 ------ ------ Refer to page 16 ------

------ Refer to page 34 ------ ------ Refer to page 35 ------ ------ Refer to page 34 ------ ------ Refer to page 34 ------

*EMC is a system compliance. To comply with EMC and low-noise (C15PR22/EN55022 Class B or FCC Class B

emissions) standards, the following items are required:

•

ZETA4-240, ZETA8, or ZETA12 Drive

•

CE(LVD) motor for LVD. Compumotor recommends a terminal board (NPS) motor construction for easier

EMC installation

•

C10 motor accessory (LVD/EMC cable kit)

•

ZETA EMC Kit

**Values shown in speed-torque curves

***Small signal values

ZETA6xxx Installation Guide

6

ζ

Pre-installation Adjustments

Factory Settings May Be Sufficient (if so, skip this section):

Device address is set to zero (if daisy-chaining you can automatically establish with the ADDR command).

Serial communication method is RS-232C.

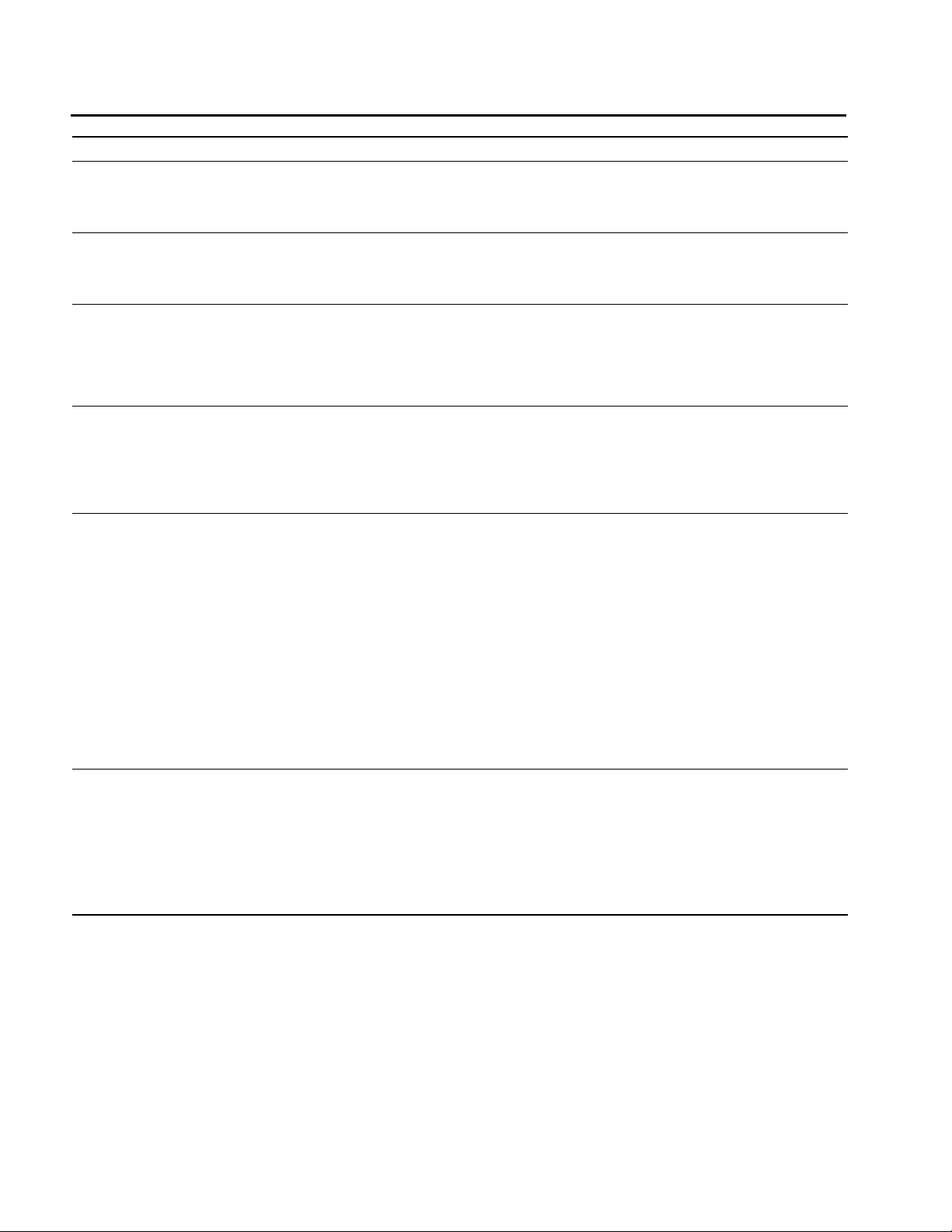

DIP Switch Settings

S W1 S W2

1234 567891 01112 12345 6789101 112

A. D.

Vi sc o.

Ph as e B

Ph as e A

Off se t

Off se t

1

Z-1 2

0.1 2

off off off

0.3 9

off off onoff off

0.7 7

off on offoff off

1.1 6

off on onoff off

1.5 5

off off offoff on

1.9 4

off off onoff on

2.3 2

off on offoff on

2.7 1

off on onoff on

3.1 0

off off offon off

3.4 8

off off onon off

3.8 7

off on offon off

4.2 6

off on onon off

4.6 5

off off offon on

5.0 3

off off onon on

5.4 2

off on offon on

5.8 1

off on onon on

6.1 9

on off offoff off

6.5 8

on off onoff off

6.9 7

on on offoff off

7.3 5

on on onoff off

7.7 4

on off offoff on

8.1 3

on off onoff on

8.5 2

on on offoff on

8.9 0

on on onoff on

9.2 9

on off offon off

9.6 8

on off onon off

10. 06

on on offon off

10. 45

on on onon o ff

10. 84

on off offon on

11. 23

on off onon on

11. 61

on on offon on

12. 00

on on onon o n

!

E lec tr.

4 5

2 3

off off

6

enable d

default Ð disa bled

default Ð 0

off

offonoff

31

C AUT ION

7

98 10 11

off off off

off off

1

off off onoff off

2

off on offoff off

3

off on onoff off

4

off off offoff on

5

off off onoff on

6

off on offoff on

7

off on onoff on

(B inary Weighted)

on on onon o n

Motor Size

OFF

Ph as e

B ala nce

C urrent

(amps pk)

Z-2 40

Z-8

0.1 4

0.1 2

0.2 6

0.2 6

0.3 9

0.5 2

0.5 1

0.7 7

0.6 4

1.0 3

0.7 6

1.2 9

0.8 9

1.5 5

1.0 1

1.8 1

1.1 4

2.0 6

1.2 6

2.3 2

1.3 8

2.5 8

1.5 1

2.8 4

1.6 3

3.1 0

1.7 6

3.3 5

1.8 8

3.6 1

2.0 1

3.8 7

2.1 4

4.1 3

2.2 6

4.3 9

2.3 8

4.6 5

2.5 1

4.9 0

2.6 3

5.1 6

2.7 6

5.4 2

2.8 8

5.6 8

3.0 1

5.9 4

3.1 3

6.1 9

3.2 6

6.4 5

3.3 8

6.7 1

3.5 0

6.9 7

3.6 3

7.2 3

3.7 5

7.4 8

3.8 8

7.7 4

4.0 0

8.0 0

AUT OB AUD

ADDR E S S

T IP: The ADDR c ommand

allows you to automatically

es tablish a ddres ses for multiple

units in a c hain or multidrop

(ADDR addres s ove rrides the

DIP s witch s etting)

LE D functions:

P OW E R 120 VAC power is applied.

S T E P F lashe s gre en with e ach s tep puls e.

O VE R T E MP Ma x. drive temp limit ex ceede d.

MO TO R F AUL T S hort circuit in motor or ca ble, or

INT E R LOC K jumper is dis connected or

too long.

Axis Name

WF Setting (DWAVEF)

EV Setting (DELVIS)

AD Setting

Do not s et s witches S W1-6 thru S W 1-11

to ON a t the same time. This invoke s a

factory tes t mode in which the ZE TA6xxx

executes a motion s equence upon power

up.e xecutes

Automatic Ad dres s ing :

If y ou are connecting multiple units, you

ca n use the A DDR command to e stablis h

a unique address for each unit. T he

ADDR comma nd overrides the DIP switch

setting. For details, refer to the 6 000

S eries S oftware Reference or the 6000

S eries P rogrammer's G uide.

off

ZE TA 6000

z

C ompumotor

9 1211

10

off

off

off

off

off

off

off

off

on

off

on

off

on

off

on

off

off

on

off

on

off

on

off

on

on

on

on

on

on

on

on

on

Inductanc e

7 8

R ange (mH)

20. 08 & grea ter

off

off

off

10. 31Ð20 .07

on

on

5 .03Ð 10.3 0

off

on

les s than 5.0 2

on

12

off

on

2

Anti-res . E na bled

off

Anti-res . D isable d

on

1

Full Curre nt

off

50% C urrent S tandby

on

ON

1 2 3 4 5 6 7 8 9 10 11 12 1 2 3 4 5 6 7 8 9 10 11 1 2

T he defa ult ba ud rate os 9 600. As an alternative, you c an use

this proc edure to a utomatically ma tch your termina l's s peed of

120 0, 2 400, 4800 , 9 600 o r 1920 0 baud.

6

les s than 20 k g-cm

off

greater than 20 kg-cm

on

5

off

S tandard

on

R educed

4

S tandard ( sys tem inertia < 20 kg-cm2)

off

R educed (sy stem ine rtia > 20 kg-cm2)

on

3

R eso nant F req. < 80 H z

R eso nant F req. > 80 H z

S P

C urrent-Lo op G ain

Anti-R esona nc e G ai n

Anti-R es. D is able

Autom atic S tan dby

DIP Switch Settings

1. S et switch 6 to on and s witch 7 to off.

2. Co nnect the Z E TA6 xxx to the terminal.

3. Powe r up the termina l.

4. Cy cle powe r to the Z ET A6x xx a nd immediatly pre ss the

spa ceba r se veral times .

5. The ZE T A6xxx should send a me ss age with the baud ra te

on the first line of the res ponse . I f no baud ra te mes sa ge is

displa yed, verify s teps 1-3 a nd repe at step 4.

6. Cha nge s witches 6 & 7 to off.

7. Cy cle powe r to the Z ET A6x xx. This stores the baud rate in

non-vola tile me mory.

NO TE : Autobaud works only on the ZE TA 6xxx's

se rial port.

Torque R ange

N -m

20.26Ð20.72

off

off

20.73Ð21.41

off

on

21.42Ð22.33

on

off

22.34Ð23.47

on

on

21.48Ð22.12

off

off

22.13Ð23.60

off

on

23.61Ð27.06

on

off

27.07Ð14.83

on

on

23.18Ð24.94

off

off

24.95Ð27.77

off

on

on

off

27.78Ð16.24

on

on

16.25Ð35.31

off

off

25.65Ð28.12

off

on

28.13Ð14.12

on

off

14.13Ð28.95

on

on

28.96Ð60.02

Induc tanc e

S ys tem Inertia

2

2

Anti-R es. P ha s e

AutoB aud

S tatic

Torq ue

o z-in

236Ð100

2101Ð200

2201Ð330

2331Ð492

2210Ð300

2301Ð510

2511Ð1000

1001Ð2100

2450Ð700

2700Ð1100

1101Ð2300

2301Ð5000

2800Ð1150

1151Ð2000

2001Ð4100

4101Ð8500

C OM 1

Chapter 1. Installation 7

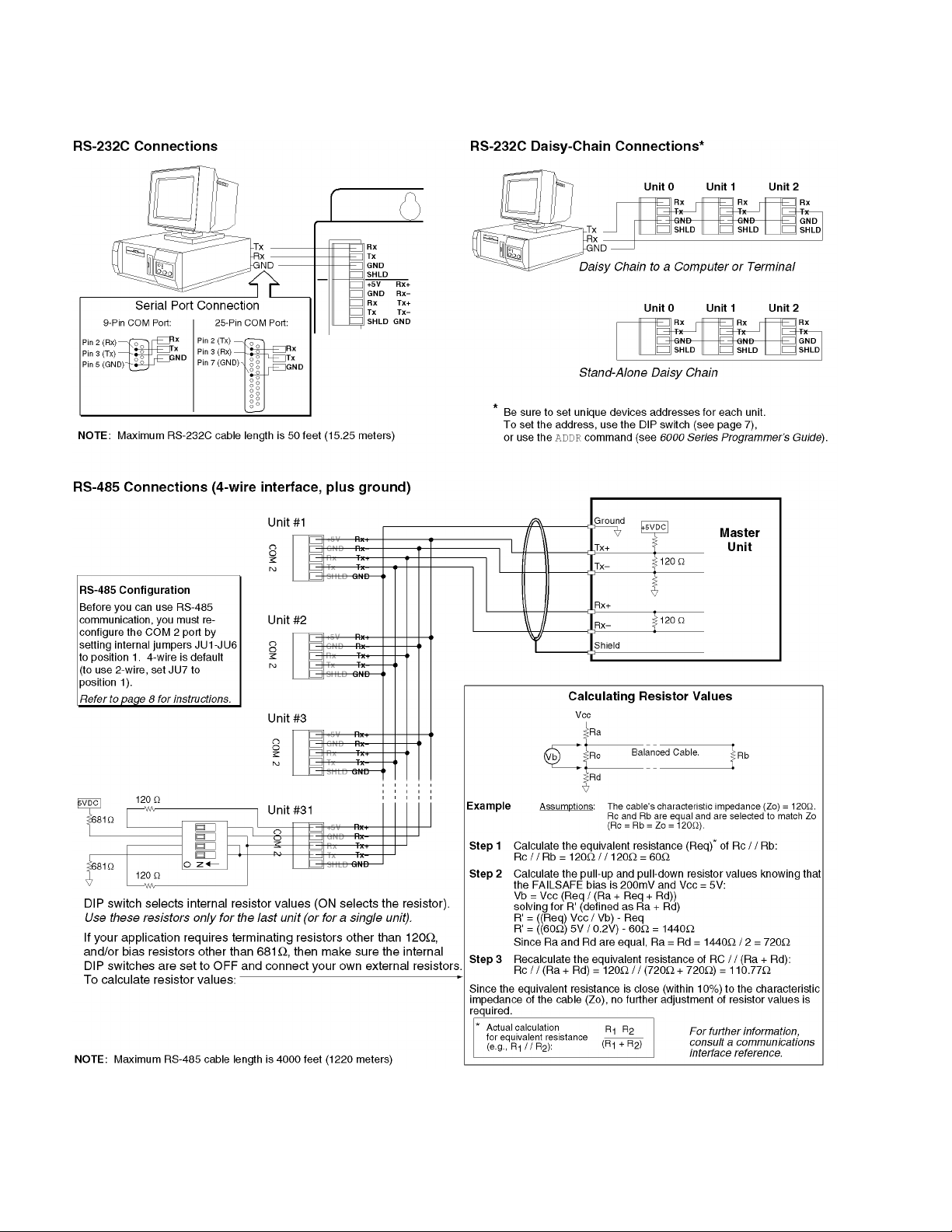

Changing the COM 2 Connector from RS-232 to RS-485

RS-232C Users

The ZETA6xxx’s

communication (use the left-hand pin descriptions). If you do not

need to use RS-485 communication, you may ignore this section

and proceed to the Mounting instructions.

port is factory configured for RS-232C

COM 2

ZETA6xxx Installation Guide

8

ζ

Mounting the ZETA6xxx

Check the list below to make sure you have performed all the necessary configuration tasks that require

accessing internal components (DIP switches, potentiometers, and jumpers). You may, however, be able to

adjust DIP switches and pots after mounting, if you allow access to the top of the ZETA6xxx chassis.

•

Select motor current (DIP switches)

settings. If you ordered an O, R or T series motor, see pages 5 and 6 for the correct drive current rating for your

particular motor.

•

Select device address (DIP switches)

or an RS-485 multi-drop, use the factory setting. If you need to change this setting, refer to page 7 for instructions.

•

Select serial communication method (jumpers & DIP switches)

the ZETA6xxx, use the factory settings. If you need to change these settings (i.e., for RS-485), refer to page 8 for

instructions.

• Be aware that if you exercise the motor matching procedures on page 30, you will need to access the potentiometers

at the top of the ZETA6xxx chassis. (The motor matching procedures are placed after the Electrical Connections

section of this manual because the process requires that you first understand how to connect the motor, serial

communication, and AC power.)

Before you mount the ZETA6xxx

. Set your motor current appropriately. See page 7 for current level DIP switch

. If you are not connecting multiple ZETA6xxx units in an RS-232C daisy chain

. If you are using RS-232C to communicate with

Chapter 1. Installation

9

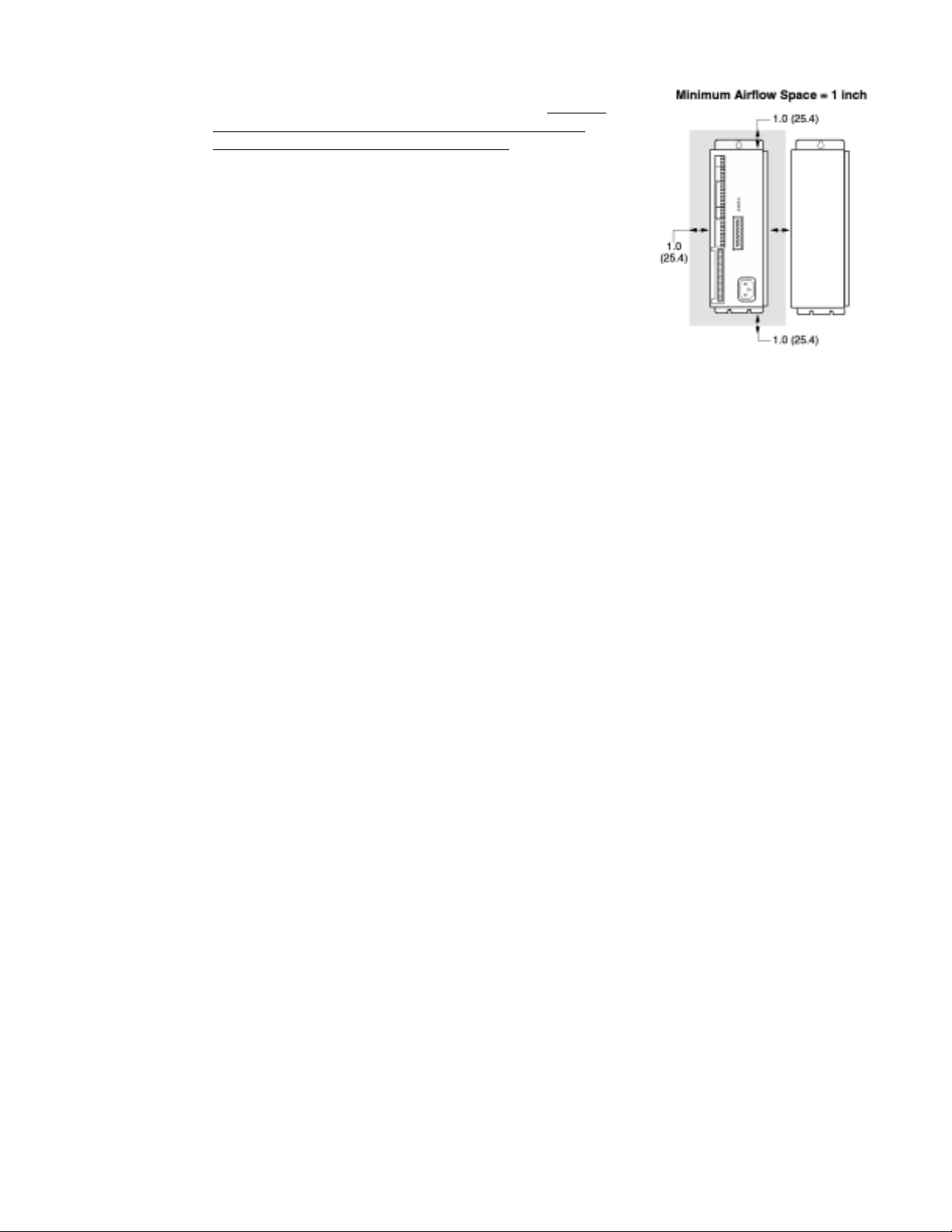

Environmental

Considerations

Temperature. Operate the ZETA6xxx in ambient

temperatures between 32°F (0°C) and 113°F (45°C). Provide a

minimum of 1 inch (25.4 mm) of unrestricted air-flow space

around the ZETA6xxx chassis (see illustration). The

ZETA6xxx will shut itself down if its internal sensor reaches

122°F (50°C).

Humidity. Keep below 95%, non-condensing.

Airborne Contaminants, Liquids. Particulate contaminants,

especially electrically conductive material, such as metal

shavings and grinding dust, can damage the ZETA6xxx and the

Zeta motor. Do not allow liquids or fluids to come in contact

with the ZETA6xxx or its cables.

ZETA6xxx Installation Guide

10

ζ

Electrical Connections

To install the ZETA6xxx so that it is LVD compliant, refer also to the supplemental

instructions in Appendix C. Appendix D provides guidelines on how to install the

ZETA6xxx in a manner most likely to minimize the ZETA6xxx’s emissions and to

maxim ize the ZETA6xxx’s immunity to externally generated electromagnetic

interference.

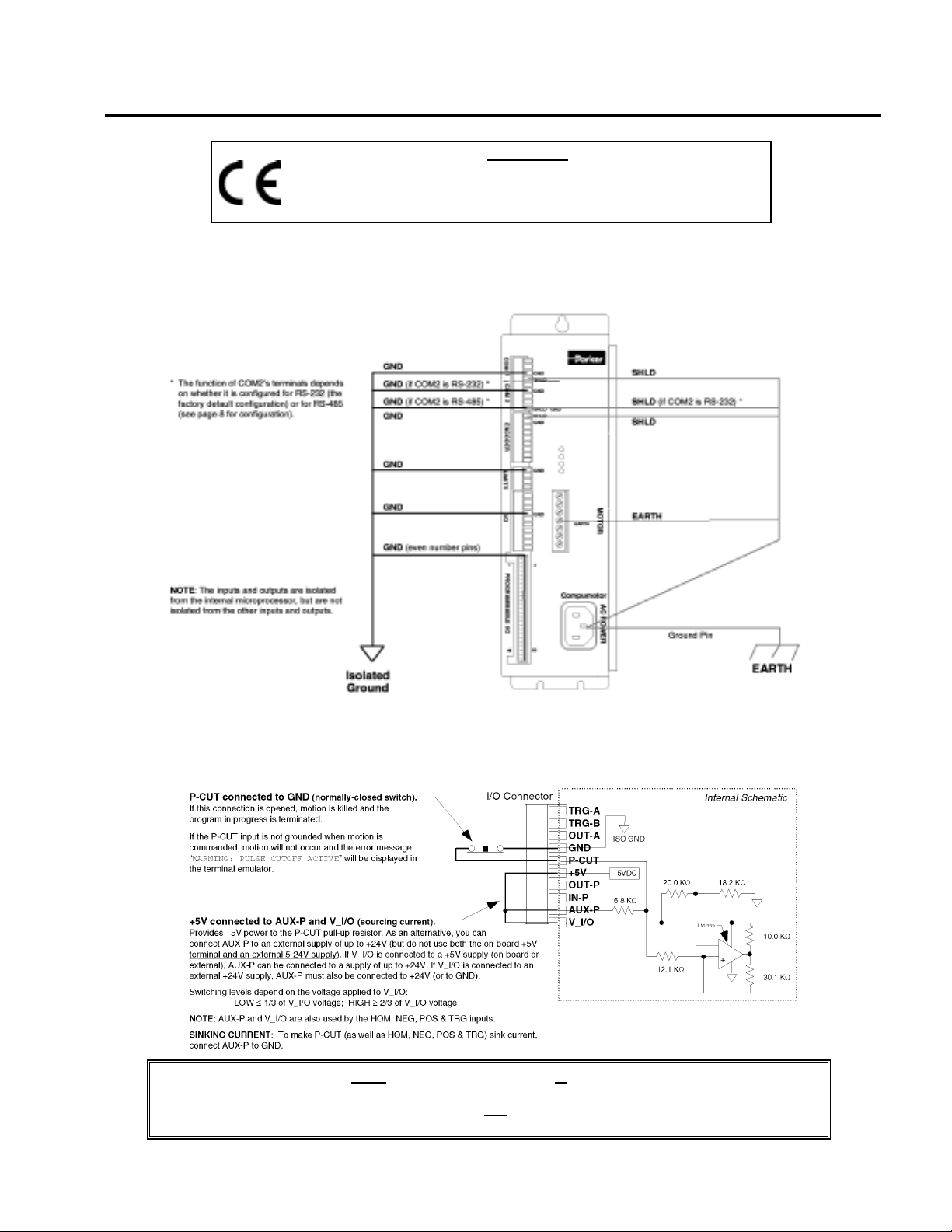

Grounding System

Pulse Cut-Off (P-CUT) Emergency Stop Switch

:

CAUTION

You must select either the on-board

pull-up resistor (for the

AUX-P

Connecting

(The same rule applies to the

AUX-P

to the

P-CUT, HOM, NEG, POS, TRG-A

terminal and an external supply will

+5V

IN-P

terminal or an external power supply to power the

+5V

and

terminals, see page 20.)

OUT-P

, and

damage the ZETA6xxx

inputs).

TRG-B

Chapter 1. Installation

.

11

Serial Communications

ZETA6xxx Installation Guide

12

ζ

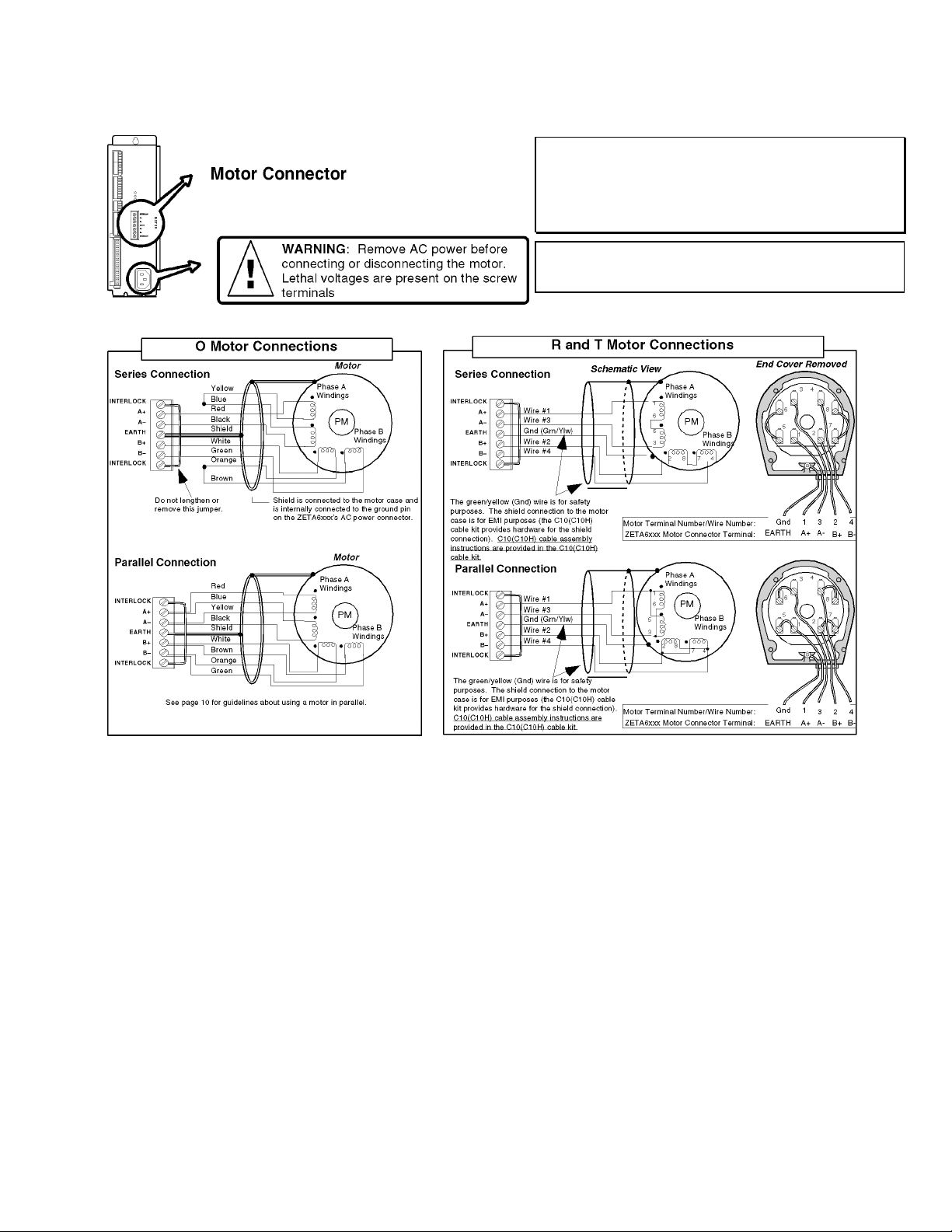

Motor (O, R and T motors only)

Specifications – see page 5.

Speed/Torque curves – see pages 15-16.

Considerations for series & parallel wiring − see pages 15-16.

Current settings – see page 7. Dimensions – see pages 33-35.

Cable extension – see table on following page.

If you intend to use a non-Compumotor motor, refer to Appendix

B for connection instructions and current selection.

OS, RS and TS Motors

Non-Compumotor Motors

Auto Current Standy Mode

: Reduces motor current by 50% when step pulses from the ZETA6xxx have stopped for one

second (

See page 11 for details.

CAUTION

: torque is also reduced). Full current is restored upon the first step pulse.

Chapter 1. Installation

13

Extending OS and RS Motor Cables

-L10, -S10 & -P10 motors are shipped with 10 ft (3 m) cables;

-FLY motor is shipped with 1 ft (0.3 m) flying leads.

-NPS motor does not include cable/leads; 10-foot: use 18 AW G (0.75 mm

current levels below 10 amps and 16 AWG (1.5 mm

LVD COMPLIANCE: Maximum DC resistance between the ZETA6xxx’s “EARTH”

terminal (“protective conductor terminal”) and motor body must not exceed 0.1Ω.

(This criteria must be taken into consideration when sizing cross-section (gage)

for extended cable lengths.) See Appendix C for more LVD information.

NON-LVD: Maximum extended length is 200 ft (61 m), but cables longer than 50

feet (15 m) may degrade performance. See table below for guidelines:

Max. Current < 100 ft (30 m) 100-200 ft (30-60 m)

Motor Type (amps) AWG mm

OS2HB(S) 1.51 22 0.34 20 0.50

OS2HB(P) 3.01 22 0.34 20 0.50

OS21B(S) 1.88 22 0.34 20 0.50

OS21B(P) 3.75 20 0.50 18 0.75

OS22B(S) 2.14 22 0.34 20 0.50

OS22B(P) 4.00 20 0.50 18 0.75

RS31B(S) 2.32 20 0.50 18 0.75

RS31B(P) 4.65 18 0.75 16 1.50

RS32B(S) 3.10 20 0.50 18 0.75

RS32B(P) 5.81 18 0.75 14 2.50

RS33B(S) 3.48 18 0.75 16 1.50

RS33B(P) 6.97 16 1.50 14 2.50

RS42B(S) 6.19 16 1.50 14 2.50

RS42B(P) 12.00 14 2.50 12 4.00

RE42B(S) 3.48 18 0.75 16 1.50

RE42B(P) 7.35 16 1.50 14 2.50

TS31B(S) 3.48 18 0.75 16 1.50

TS31B(P) 6.97 16 1.50 14 2.50

TS32B(S) 3.10 20 0.50 18 0.75

TS32B(P) 6.19 16 1.50 14 2.50

TS33B(S) 5.81 18 0.75 14 2.50

TS33B(P) 12.00 14 2.50 12 4.00

TS41B(S) 6.58 16 1.50 14 2.50

TS41B(P) 12.00 14 2.50 12 4.00

TS42B(S) 6.97 16 1.50 14 2.50

TS42B(P) 12.00 14 2.50 12 4.00

TS43B(S) 6.97 16 1.50 14 2.50

TS43B(P) 12.00 14 2.50 12 4.00

RS31C(S) 2.26 20 0.50 18 0.75

RS31C(P) 4.00 18 0.75 16 1.50

RS32C(S) 2.88 20 0.50 18 0.75

RS32C(P) 4.00 18 0.75 16 1.50

RS33C(S) 3.50 18 0.75 16 1.50

RS33C(P) 4.00 18 0.75 16 1.50

RS42C(S) 3.26 20 0.50 18 0.75

RS42C(P) 4.00 18 0.75 16 1.50

RE42C(S) 3.38 20 0.50 18 0.75

RE42C(P) 4.00 18 0.75 16 1.50

RS43C(S) 4.00 18 0.75 16 1.50

RS43C(P) 4.00 18 0.75 16 1.50

2)

for up to 12 amps..

2

AWG mm

2

2

) wire for

(S) = Series Configuration (P) = Parallel Configuration

: Rated current in wire sizes shown may result in a maximum temperature rise of 18°F (10°C) above ambient.

NOTE

CAUTION: Cables longer than 50 feet (15m) may degrade performance.

ZETA6xxx Installation Guide

14

ζ

Selecting Series or Parallel Motor Wiring

Chapter 1. Installation

15

ZETA6xxx Installation Guide

ζ

16

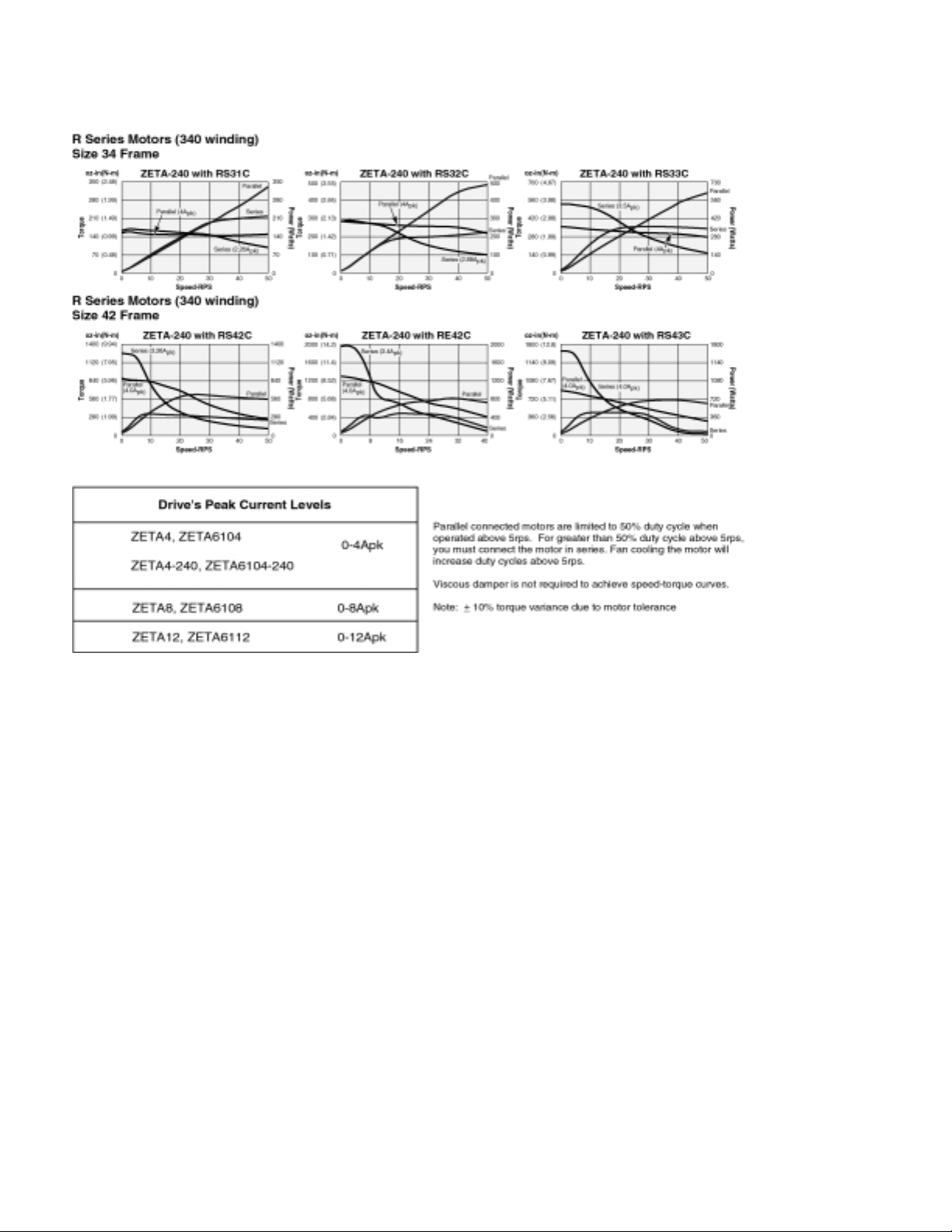

End-of-Travel and Home Limit Inputs

NOTES

• CAUTION: Use either the on-board

the

pull-up resistor (using both will damage the ZETA6xxx).

AUX-P

• Motion will not occur until you do one of the following:

- Install end-of-travel (

POS

&

- Disable the limits with the

coupled).

- Change the active level of the limits with the

• Refer to the Basic Operation Setup chapter in the 6000 Series Programmer’s Guide for

in-depth discussions about using end-of-travel limits and homing.

CONNECTIONS & INTERNAL SCHEMATICS

LHØ

terminal or an external power supply to power

+5V

) limit switches.

NEG

command (recommended only if load is not

LHLVL

command.

PIN OUTS & SPECIFICATIONS

Name In/Out Description Specification for all limit inputs

GND

HOM

NEG

POS

—

IN

IN

IN

Isolated ground.

Home limit input.

Negative-direction

end-of-travel limit

input.

Positive-direction endof-travel limit input.

(4-pin LIMITS Connector)

• Powered by voltage applied to V_I/O terminal (switching levels: Low ≤1/3 of V_I/O voltage,

High ≥2/3 of V_I/O voltage). V_I/O can handle 5-24V with max. current of 100mA. Internal

6.8 KΩ pull-ups to AUX-P terminal—connect AUX-P to power source (+5V terminal or an

external 5-24V supply) to source current, or connect AUX-P to GND to sink current; AUX-P

can handle 0-24V with max. current of 50mA. Voltage range for these inputs is 0-24V.

• Active level for HOM is set with

• Active level for POS & NEG is set with

(default is active low, requires n.o. switch).

HOMLVL

(default is active low, requires n.c. switch).

LHLVL

Chapter 1. Installation

17

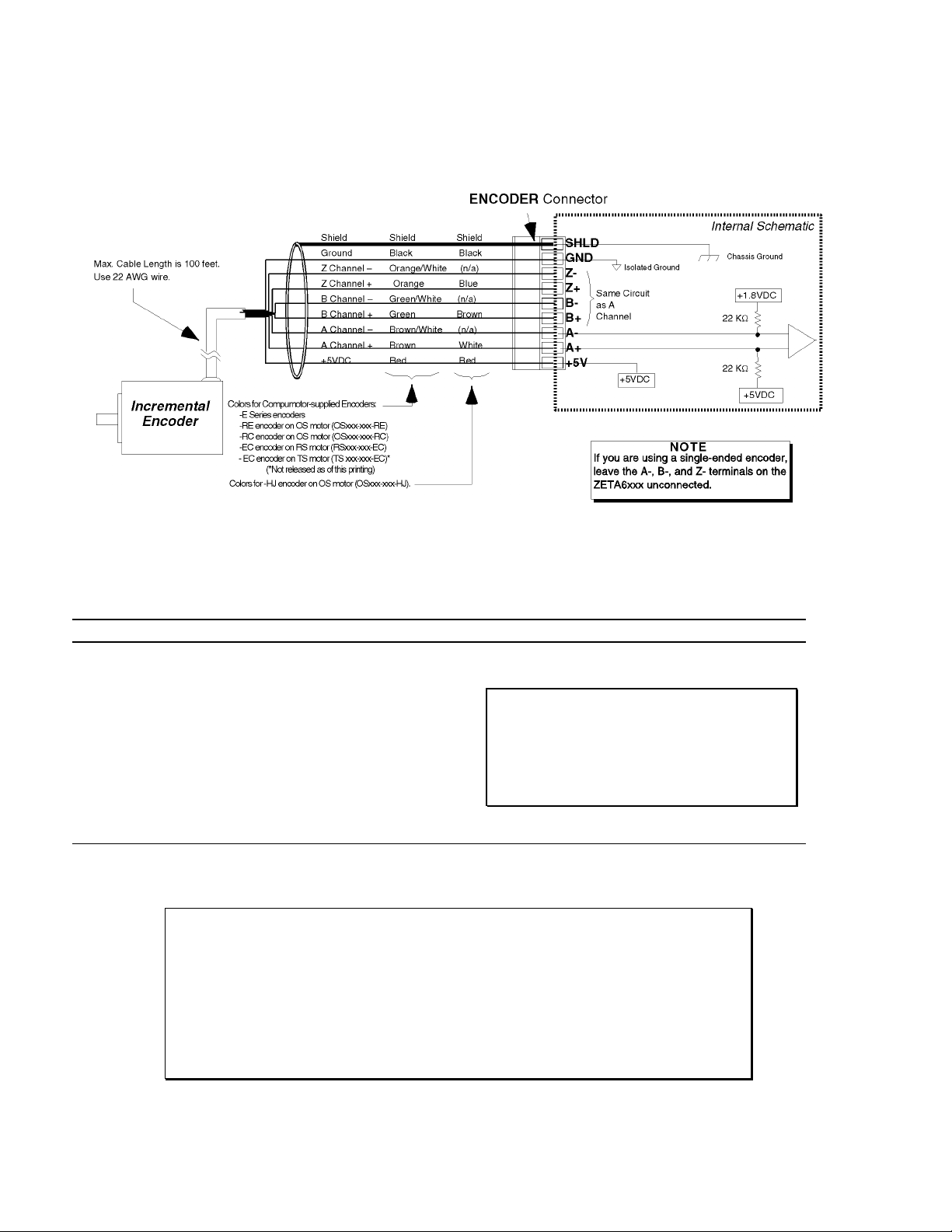

Encoder

CONNECTIONS & INTERNAL SCHEMATICS

PIN OUTS & SPECIFICATIONS

Pin Name In/Out Description

SHLD

GND

Z–

Z+

B–

B+

A–

A+

+5V

-----

----IN

IN

IN

IN

IN

IN

OUT

Shield—Internally connected to chassis ground

(earth).

Isolated logic ground.

Z– Channel signal input.

Z+ Channel signal input.

B– Channel quadrature signal input.

B+ Channel quadrature signal input.

A– Channel quadrature signal input.

A+ Channel quadrature signal input.

+5VDC output to power the encoder.

• Use incremental encoders with two-phase quadrature output. An index or

is optional.

output

• It must be a 5V (< 200mA) encoder to use the ZETA6xxx’s

be separately powered with TTL-compatible (low ≤ 0.4V, high ≥ 2.4V) or open-collector

outputs.

• The decoded quadrature resolution should be less than the motor resolution by a factor of

four to take advantage of the ZETA6xxx’s position maintenance capability.

(9-pin ENCODER Connector)

Specification for all encoder inputs

Differential comparator accepts two-phase quadrature

incremental encoders with differential (recommended)

or single-ended outputs. Max. frequency is 1.6 MHz.

Minimum time between transitions is 625 ns.

TTL-compatible voltage levels: Low ≤ 0.4V,

High

2.4V. Maximum input voltage is 5VDC.

≥

Requirements for Non-Compumotor Encoders

Differential outputs are recommended.

output. Otherwise, it must

+5V

Z channel

ZETA6xxx Installation Guide

ζ

18

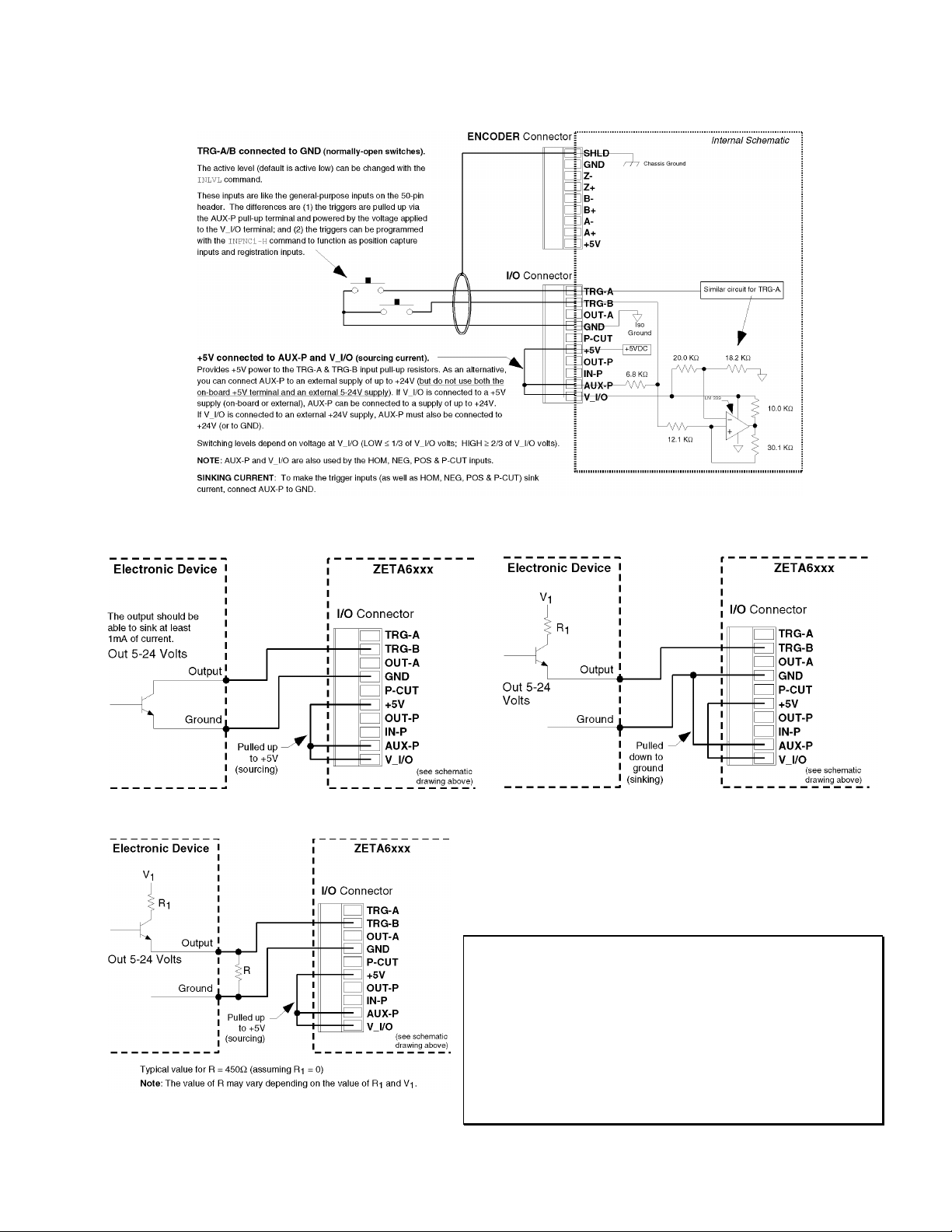

Trigger Inputs

Connection to a Sinking Output Device Connection to a Sourcing Output Device

Connection to a Combination of Sinking & Sourcing Outputs

If you will be connecting to a combination of sourcing and sinking outputs,

connect

each individual input connected to a sourcing output, wire an external

resistor between the ZETA6xxx’s trigger input terminal and ground (see

illustration). The resistor provides a path for current to flow from the device

when the output is active.

Connecting to a sinking output?

low with the

Connecting to a sourcing output?

high with the

Thus, when the output is active, the

(indicates that the input is active), regardless of the type of output that is

connected.

For details on setting the active level and checking the input status refer

to the

Software Reference

AUX-P

INLVL

to

INLVL

INLVL

and

to accommodate sinking output devices. Then for

+5-24V

PROGRAMMING TIP

command (Ø = active low,

command (1 = active high).

command descriptions in the

TIN

.

Set the trigger input’s active level to

Set the trigger input’s active level to

TIN

default setting

status command will report a “1”

).

6000 Series

Chapter 1. Installation

19

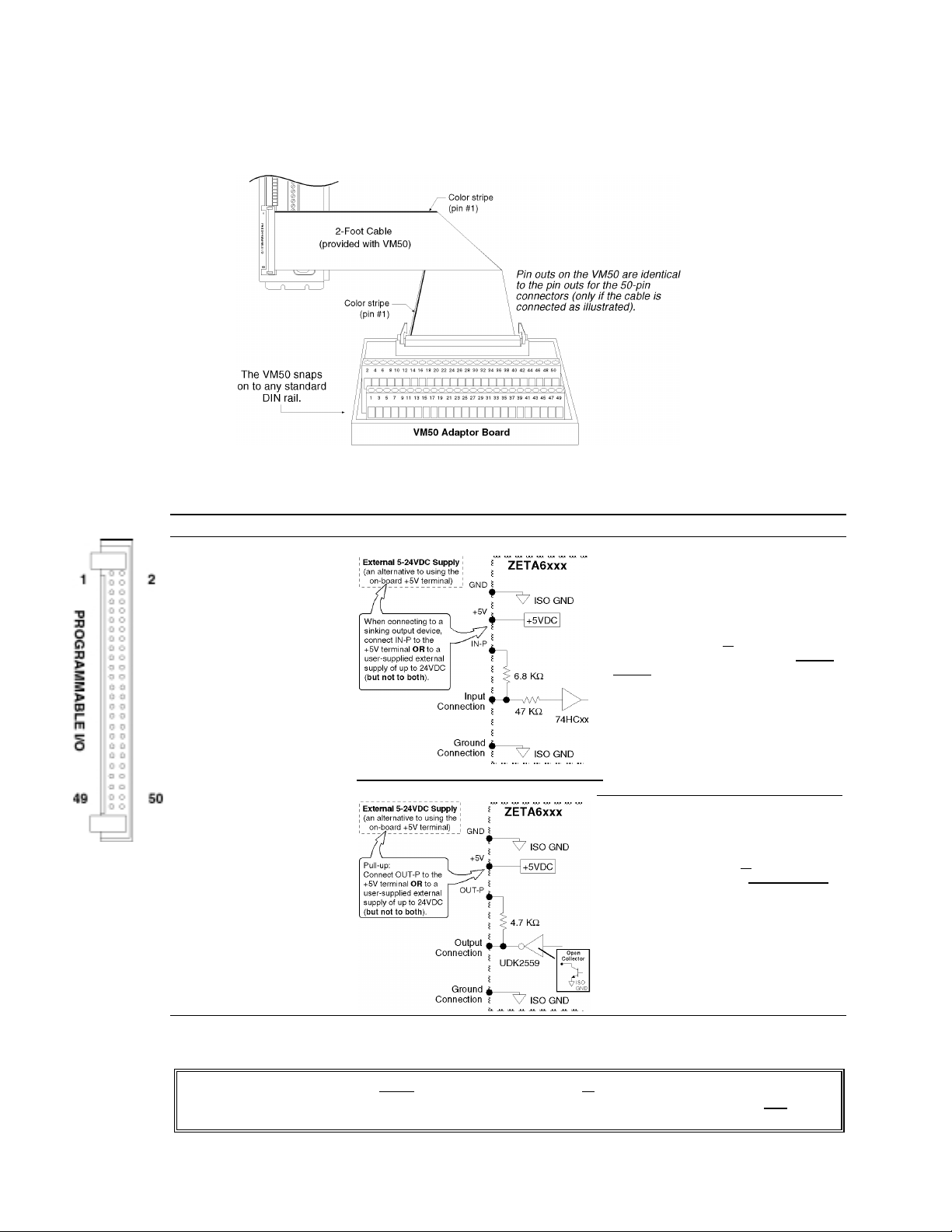

General-Purpose Programmable Inputs & Outputs

VM50 ADAPTOR

— for screw-terminal connections

PIN OUTS & SPECIFICATIONS

Pin Function Internal Schematics Specifications

(MSB of inputs)

(MSB of outputs)

(LSB of outputs)

(LSB of inputs)

50-pin plug is

compatible with

OPTO-22™

signal

conditioning

equipment.

1 Input #16

3 Input #15

5 Input #14

7 Input #13

9 Input #12

11 Input #11

13 Input #10

15 Input #9

17 Output #8

19 Output #7

21 Output #6

23 Output #5

25 Input #8

27 Input #7

29 Input #6

31 Input #5

33 Output #4

35 Output #3

37 Output #2

39 Output #1

41 Input #4

43 Input #3

45 Input #2

47 Input #1

49 +5VDC

Inputs

Outputs (including OUT-A)

Inputs

HCMOS-compatible voltage levels

(low ≤ 1.00V, high ≥ 3.25V).

Voltage range = 0-24V.

Sourcing Current: On the

connect

external 5-24VDC power supply (but not

to both).

Sinking Current: On the

connect

STATUS: Check with

Active level: Default is active low, but

can be changed to active high with the

INLVL

Outputs (including OUT-A)

Open collector output.

Pull-up connection on

Connect

5-24VDC power supply (but not to both).

Outputs will sink up to 300mA or source

up to 5mA at 5-24VDC.

STATUS: Check with

Active level: Default is active low, but

can be changed to active high with the

OUTLVL

to

IN-P

to

IN-P

command.

to

OUT-P

command.

or connect

+5V

.

GND

+5V

connector,

I/O

IN-P

connector,

I/O

or

TIN

INFNC

connector:

I/O

, or to an external

or

TOUT

OUTFNC

to an

.

.

NOTE:

All even-numbered pins are connected to a common logic ground (DC ground) — see drawing on page 11.

LSB = least significant bit; MSB = most significant bit

CAUTION

ZETA6xxx Installation Guide

ζ

20

:

You must select either the on-board

and

IN-P

external supply will

pull-up resistors. Connecting

OUT-P

damage the ZETA6xxx

terminal or an external power supply to power the

+5V

or

IN-P

(The same rule applies to the AUX-P terminal.)

.

OUT-P

to the

terminal and an

+5V

Loading...

Loading...