Parker ETH080, ETH050, ETH, ETH032 Mounting Instructions

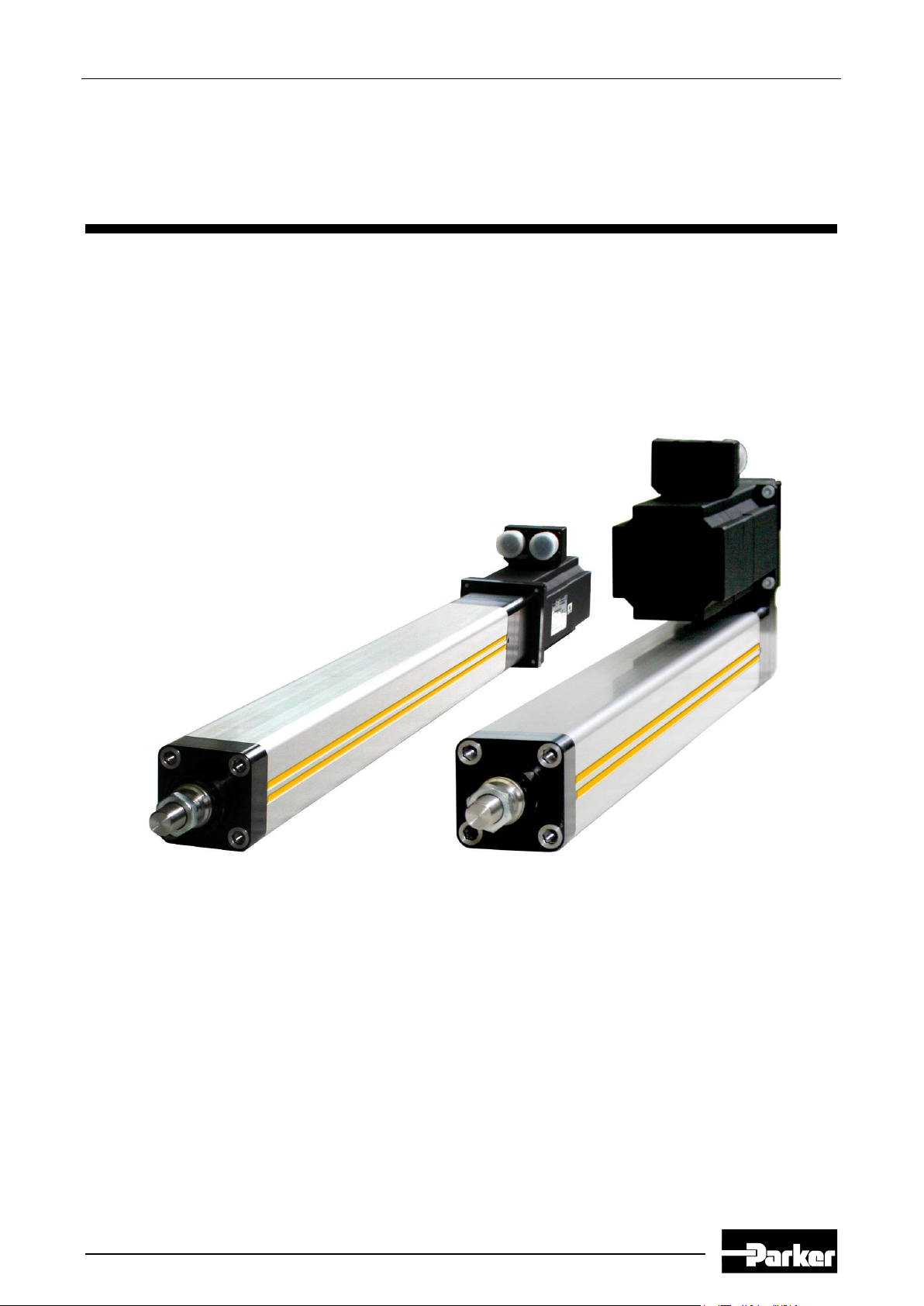

ETH - ElektrozylinderElectromechanical

Cylinders

Electromechanical Automation

Technical Changes Reserved 21.11.18 07:42192-550002N2 ETH Mounting instructions March 2011September 2012

Data shown complies with known technical data when printed.

Mounting instructions

ETH Manual - Installation, Commissioning, Maintenance and Repair

ETH - Electro Cylinder

Parker High Force Electro Thrust

Cylinder

192-550002N2.EMN ETH Mounting instructions

Revision: B November 21,2018

Introduction

ETH- Electromechanical Cylinders

2 192-550002N2 ETH Mounting instructions March 2011

Production site:

Parker Hannifin GmbH

Electromechanical Automation Europe [EME]

Robert-Bosch-Strasse 22

77656 Offenburg (Germany)

Tel.: + 49 (0781) 509-0

Fax: + 49 (0781) 509-98176

Internet: www.parker-eme.com http://www.parker-eme.com

E-mail: sales.automation@parker.com mailto:sales.automation@parker.com

Parker Hannifin Electromechanical

Automation Division/ Daedal

1140 Sandy Hill Road

Irwin, PA 15642

Tel.: (724) 861 – 8200

(800) 245 – 6903

Fax: (724) 861 - 3330

Internet: www.parkermotion.com

E-mail: ddlcat@parker.com

Headquarters:

Parker Hannifin S.p.A • SSD SBC • Electromechanical Automation • Via Gounod, 1

I-20092 Cinisello Balsamo (MI), Italy

Tel.: +39 (0)2 66012459 • Fax: +39 (0)2 66012808

E-mail: sales.automation@parker.com mailto:sales.sbc@parker.com •

Internet: www.parker-eme.com http://www.parker-eme.com

Parker Hannifin PLC • Electromechanical Automation • Arena Business Centre

Holy Rood Close • Poole, Dorset BH17 7FJ UK

Tel.: +44 (0)1202 606300 • Fax: +44 (0)1202 606301

E-mail: sales.automation@parker.com mailto:sales.automation@parker.com •

Internet: www.parker-eme.com http://www.parker-eme.com

Worldwide sales

http://divapps.parker.com/divapps/eme/EME/Contact_sites/Sales%20Channel_Par

ker-EME.pdf

nonwarranty clause

We checked the contents of this publication for compliance with the associated

hard and software. We can, however, not exclude discrepancies and do therefore

not accept any liability for the exact compliance. The information in this publication

is regularly checked, necessary corrections will be part of the subsequent

publications.

Further information:

Our product on the Internet: http://www.parker-eme.com/eth or

http://www.parkermotion.com

Italy:

England:

Parker EME/EMN

Introduction

192-550002N2 ETH Mounting instructions March 2011 3

Content Assembly Instructions

1. Introduction.................................................................................................................. 6

1.1 Device assignment ............................................................................................ 6

1.2 Type specification plate .................................................................................... 6

1.3 Mounting explanation ........................................................................................ 7

1.4 Safety instructions ............................................................................................ 8

1.4.1. General hazards ................................................................................................. 8

1.4.2. Intended use ....................................................................................................... 8

1.4.3. Identifying Residual Dangers and Hazardous Areas ..................................... 8

1.4.4. Working safely ................................................................................................... 9

1.4.5. Safety Instructions for the Company Using the System ............................... 9

1.4.6. Safety Instructions for Operating Personnel ................................................ 10

1.5 Packaging, storage, transport ........................................................................ 10

1.5.1. Special notes on transport ............................................................................. 11

1.6 Warranty conditions ........................................................................................ 12

1.7 Conditions of utilization .................................................................................. 12

2. Set-up ......................................................................................................................... 14

2.1 Mounting .......................................................................................................... 14

2.1.1. Mounting with mounting threads on the cylinder ........................................ 14

2.1.2. Mounting with mounting accessories ........................................................... 14

2.1.2.1 Screw tightening torques for the mounting of the ETH cylinder by the

customer. .......................................................................................................... 15

2.1.2.2 Accessory mounting – bearing block ................................................................ 16

2.1.3. Mounting notes ................................................................................................ 16

2.1.3.1 Side Load.......................................................................................................... 16

2.1.3.2 Mounting of the payload ................................................................................... 16

2.2 Electric installation .......................................................................................... 17

2.2.1. Sensors ............................................................................................................. 17

2.2.2. Sensor mounting ............................................................................................. 17

2.2.3. Direction of the motor during extension of the cylinder ............................. 17

2.2.4. Setting the end limits ...................................................................................... 18

2.3 Motor and feedback mounting ........................................................................ 19

2.3.1. Motor / gearbox mounting with inline motor configuration ........................ 20

2.3.2. Motor / gearbox mounting with parallel motor configuration ..................... 21

2.3.2.1 Re-apply toothed belt pre-tension (reinsert the same toothed belt) .................. 22

2.3.2.2 Resetting the toothed belt pre-tension (new toothed belt) ................................ 23

2.4 Exchanging the toothed belt ........................................................................... 24

2.5 Belt / belt tensions ........................................................................................... 24

2.6 North American Inline Coupling Placement Guide ........................................ 25

2.7 North American Parallel Pulley Placement Guide ......................................... 26

3. Maintenance ............................................................................................................... 27

3.1 Lubricating intervals and amount of lubricant .............................................. 27

3.2 Greasing via central lubrication port (standard) ........................................... 28

3.3 Relubrication via central lubrication port (option) ........................................ 28

4. Repair ......................................................................................................................... 29

Introduction

ETH- Electromechanical Cylinders

Introduction

ETH -

ElektrozylinderElectromechanical

Cylinders

4 192-550002N2 ETH Mounting instructions March 2011

5. Index ................................ ................................................................ ........................... 30

6. Further information ................................................................................................... 31

7. Revisions ................................................................................................................... 31

Parker EME/EMN

Introduction

192-550002N2 ETH Mounting instructions March 2011 5

Contents of catalog section:

Electro Cylinder ETH Series

ETH Product Description................................................................................ 3

Product Design............................................................................................... 5

Technical Data................................................................................................ 6

Step by Step Selection Process...................................................................... 7

Calculating Required Axial Force................................................................... 8

Calculation of axial forces: 8

Selection of the Size and Screw Lead............................................................. 9

Required maximum axial force 9

Required maximum velocity 9

Required maximum acceleration 9

Service life.................................................................................................... 10

Calculation........................................................................................................ 10

Diagrams........................................................................................................... 11

Permissible Axial Thrust Forces.................................................................. 12

Diagrams........................................................................................................... 12

Stroke, Usable Stroke and Safety Travel...................................................... 14

Calculation........................................................................................................ 14

Diagram ............................................................................................................ 14

Relubrication................................................................................................ 15

Dimensions................................................................................................... 16

Motor Mounting Options............................................................................... 17

Motor and Gearbox Selection....................................................................... 18

Mounting Methods........................................................................................ 19

Standard............................................................................................................ 19

Center Trunnion Mounting................................................................................ 19

Rear Eye Mounting............................................................................................ 19

Rear Clevis........................................................................................................ 20

Rear Plate......................................................................................................... 21

Front Plate ........................................................................................................ 21

Front and Rear Plate......................................................................................... 21

Foot Mounting................................................................................................... 22

Mounting Flanges.............................................................................................. 22

Cylinder Rod Version.................................................................................... 23

External Thread................................................................................................ 23

Internal Thread................................................................................................. 23

Rod Clevis......................................................................................................... 24

Spherical Rod Eye............................................................................................. 24

Alignment Coupler ............................................................................................ 25

Outrigger Bearing............................................................................................. 26

Accessories .................................................................................................. 28

Force Sensors ................................................................................................... 28

Initiators / Limit Switches................................................................................. 32

DriveTrain Selection.................................................................................... 33

Example for Dimensioning with Predefined Drive Trains.................................. 33

Predefined Motion Packagesfor ETH032.......................................................... 34

Predefined Motion Packagesfor ETH050.......................................................... 36

Predefined Motion Packagesfor ETH080.......................................................... 38

Order code.................................................................................................... 40

Introduction

6 192-550002N2 ETH Mounting instructions March 2011

1.1 Device assignment

This manual is valid for the following devices:

Electro cylinder for motors and gearboxes:

◆ ETH032

◆ ETH050

◆ ETH080

1.2 Type specification plate

Type specification plate (example)

In this chapter you can read about:

Device assignment ............................................................................................................ 6

Type specification plate ..................................................................................................... 6

Mounting explanation ........................................................................................................ 7

Safety instructions ............................................................................................................. 8

Packaging, storage, transport ......................................................................................... 10

Warranty conditions ........................................................................................................ 12

Conditions of utilization ................................................................................................... 12

1. Introduction

ETH050M05A1K1A 1199999901A

ETH050M05A1K1AFMN0300A

Parker Hannifin EMN

1140 Sandy Hill Rd.

Irwin, PA 15642

724-861-8200

800-245– 6903

Parker Hannifin GmbH

Electromechanical Automation

Robert-Bosch-Straße 22

D-77656 Offenburg

Tel.+49(0)781 509-0

Serial number: 285950-0001

Type: ETH050M05A1K1AFMN0200A

Order confirmation No.: 21015463

Date: 02.11.2010

Made in Germany

Parker EME/ EMN

Introduction

192-550002N2 ETH Mounting instructions March 2011 7

1.3 Mounting explanation

Introduction

Error! Use the Home tab to apply Überschrift 1 to the text that you

want to appear here.

ETH - Elektrozylinder

8 192-550002N2 ETH Mounting instructions March 2011

1.4 Safety instructions

1.4.1. General hazards

General Hazards on Non-Compliance with the Safety Instructions

The subsystem has been designed in accordance with state-of-the-art technical

developments and is operationally reliable. If it is not operated by qualified, or at least

trained personnel, or if it is operated improperly or not in accordance with the operating

instructions, the unit may bear the risk of hazards.

Electronic, moving and rotating components can

◆ Danger for life and limb of the operator or third persons and / or

◆ cause material damage

If the linear actuator is installed in a machine plant, the safety requirements noted in the

operating instructions for that machine must be combined with those described in this

manual.

1.4.2. Intended use

The linear actuator has a number of uses including:

Positioning, transporting, feeding, removing, pallet handling, loading, unloading, processing

and manipulating as well as testing work pieces or tools.

Since the component can be used in a very wide range of applications, the user is

responsible for its use in specific applications.

Please make sure that the mounting of parts or tools will not pose a threat to persons or

cause damages to any parts or devices. This also applies, for example, to the case of a

broken toothed belt (if existing).

The linear actuator must only be used in areas that are not accessible to persons during

operation.

If the linear actuator is used in areas accessible to people, it must be installed in such a

manner that no one can be endangered during operation.

1.4.3. Identifying Residual Dangers and Hazardous Areas

If there are still residual dangers present to persons or property from the linear actuator in

spite of operating it in a safe manner, the user must make reference to these residual

dangers through signs and written rules requiring appropriate procedures.

The following safety signal words are used:

Danger!

Indicates that an imminent hazardous situation may lead to death or serious bodily harm if

not prevented using appropriate safety measures.

Warning!

Indicates a potentially hazardous situation which, if not avoided using appropriate safety

measures, could result in serious or minor injury.

Caution!

Indicates a potentially hazardous situation which, if not avoided using appropriate safety

measures, may result in minor injury or material damage.

Hint

Provides important information about the product, how to handle the product or about the

part of the manual to which particular attention must be paid.

Parker EME/ EMN

Introduction

192-550002N2 ETH Mounting instructions March 2011 9

1.4.4. Working safely

Heed the Instructions

The information (such as instructions and notes) contained in this manual must be heeded

for all work involved in installing, commissioning, setting up, operating, changing operating

conditions and modes, servicing, inspecting and repairing the unit.

The manual must be available close to the linear module during the performance of all

tasks.

It is impermissible to operate the liner module if it is not in perfectly functional condition.

Operating personnel

The following jobs must only be performed by appropriately trained and authorized

personnel:

◆ Installation and set-up tasks on the linear actuator

◆ Attaching safety limit switches (initiators)

◆ Connecting the drive and testing the motion direction

Instructions for Special Hazards

The linear module must be fixed or supported in accordance with the indications in this

manual.

The operator must ensure that operation of the linear module does not cause any danger.

If the linear module moves in hazardous areas, these areas can be safeguarded with safety

transmitter switches.

1.4.5. Safety Instructions for the Company Using the System

Supervisors must also become familiar with the entire chapter entitled "Safety" and

handling required on the linear actuator.

Supervisors must ensure that installation and operating personnel have read and

understand the chapter entitled "Safety" and the description of how to work with the

machine, and that they observe the instructions.

The manual must be available close to the linear module during the performance of all

tasks.

It is impermissible to operate the liner module if it is not in perfectly functional condition.

Depending on the application, the operating company must provide for a suitable

separating safety fence. Access to the motion range during operation must be prevented.

The user must make sure that the work area is protected by appropriate safety devices.

Introduction

Error! Use the Home tab to apply Überschrift 1 to the text that you

want to appear here.

ETH - Elektrozylinder

10 192-550002N2 ETH Mounting instructions March 2011

1.4.6. Safety Instructions for Operating Personnel

Any work step that has a negative effect on the operating safety of the linear motor module

must be omitted.

Operating and supervisory personnel are required to check the linear actuator or machine

at least once per shift for externally visible damage or defects. Changes that have occurred

(including the operating behavior) that could have a negative effect on the operating safety

must be reported immediately.

Components and accessories are designed especially for this product. When purchasing

spare and wearing parts, use only original Parker parts. We note here explicitly that we are

unable to check or release spare parts or accessories that were not provided by us.

Installing and/or using such products may cause negative changes in the required design

properties in some circumstances, which in turn could negatively affect the active and/or

passive operating safety of the product.

The manufacturer is unable to accept any liability for damage caused by using non-original

parts and accessories.

Safety and protection devices are strictly NOT to be removed or bypassed or set out of

order.

Applicable requirements and national accident prevention regulations must always be

observed when installing and operating our linear motor module.

1.5 Packaging, storage, transport

First check

◆ Check the packaging for damages.

◆ Remove the packaging.

Do not discard the packaging; it is strongly recommended to use the original packaging

material for return deliveries.

◆ Depending on the storage location, metal surfaces may have a temperature of 0 °C or

below. Please provide appropriate worker protection (e.g. protective gloves).

◆ Please ensure that the consignment does correspond to your order.

◆ Check the product for damages. Do never use a device which seems damaged.

◆ Please read the installation manual carefully before installing or commissioning the device.

Packaging material

The packaging material is inflammable, if it is disposed of improperly by

burning, lethal fumes may develop.

Transport

Make sure to transport the linear module always in a safe manner and with the aid of

suitable lifting equipment (Means of transport).

Storage

The linear module must be stored evenly and without any mechanical load.

The stated storage temperature must be adhered to.

Disposal

We recommend disposing of the respective materials in accordance with the respectively

valid environmental laws. The following table states the materials suitable for recycling and

the materials which have to be disposed of separately.

Material

suitable for

recycling

Disposal

Metal

yes

no

Plastic materials

yes

no

Loading...

Loading...