Paragon Ceramic Kiln

Instruction & Service Manual

You are about to enter the

magical world of custom-fired

ceramics. To safely find your

way around and to master your

kiln, read this manual. Save for

future reference.

The First

Firing—

Seepage29

INTRODUCTION

Thank you for purchasing a Paragon kiln. We are confident that the kiln will give you many years of relaxation and

creative enjoyment. Before using yourkiln,readthe manuals that came withit. They will save you manyhours as you

learn about your kiln. The more you know about your kiln, the more you will enjoy it and the longer it will last.

This manual does not cover the digital controller or the Kiln Sitter and switches. They are

covered in a separate manual included in your instruction packet.

In the instruction packet for your kiln, you should find a copy of “Safe Installation of the Electric Kiln,” “Firebrick

Maintenance,” and a manual that covers your kiln’s control system. Please contact the factory if you do not have

copies. You can also find them at www.paragonweb.com. Select “Support” and then “Instruction Manuals” from

the drop menu. The manuals are listed alphabetically.

At www.paragonweb.com select “Products,” then “Books & DVDs” from the drop menu. The books we recom

mend will enhance your kiln experience. You can also email or phone us with questions. We are glad to help.

At www.paragonweb.com you will find online videos for many of the procedures shown in this manual. As you read

each section, you can go online to watch an actual demonstration on your computer.

Even though your Paragon kiln may be designed to shut off automatically, check the kiln

before the expected shut-off time. The warranty on your kiln does not cover damage from

overfiring, regardless of the circumstances. It is the operator’s responsibility to make sure the

kiln turns off when the firing is completed. Never leave your kiln unattended near the end of

the firing.

Check your new kiln frequently during the first few firings and note the color change

inside the kiln. After awhile you can learn to estimate, with considerable accuracy, when

the kiln is about to shut off just by observing the color.

We are accustomed to using products that stay new looking for years—cars, furniture,

cameras. But kilns are different. The high temperatures theyreach generate tremendous

stresses. Since the insulating firebricks expand and contract with each firing, hairline

cracks will appear in the bricks while the kiln is cold—even in a new kiln. Do not be concerned with these. They are normal. The cracks close tightly when the heated bricks

expand. The cracks function as expansion jointsand will not affect the firing. Though the

insulating firebrick is fragile enough to carve with a fingernail, it is a miracle of physics

and when properly maintained can survive for many years.

Do not beconcerned withthe light thatappears around the edge ofthe lid ordoor. As long as thelid/door is closedall

the way, there is little heat loss. Discolored paint is also inevitable and doesn’t affect firing results.

Please do not be concerned

with theline of lightthat appears

around the lid. It is normal.

-

Do not be concerned with the clicking sound that the kiln makes during operation. Digital kilns contain relays,

which send powerto the elements. Therelays click as theycycle on and off to maintainthe correct temperature.And

the infinite switches of manual kilns make a clicking noise too. You will also hear the

elements hum. This is only the sound of element coils vibratingin theirbrick grooves.

Once you become familiar with these sounds, you may find them a reassuring indica

tion that the kiln is firing normally.

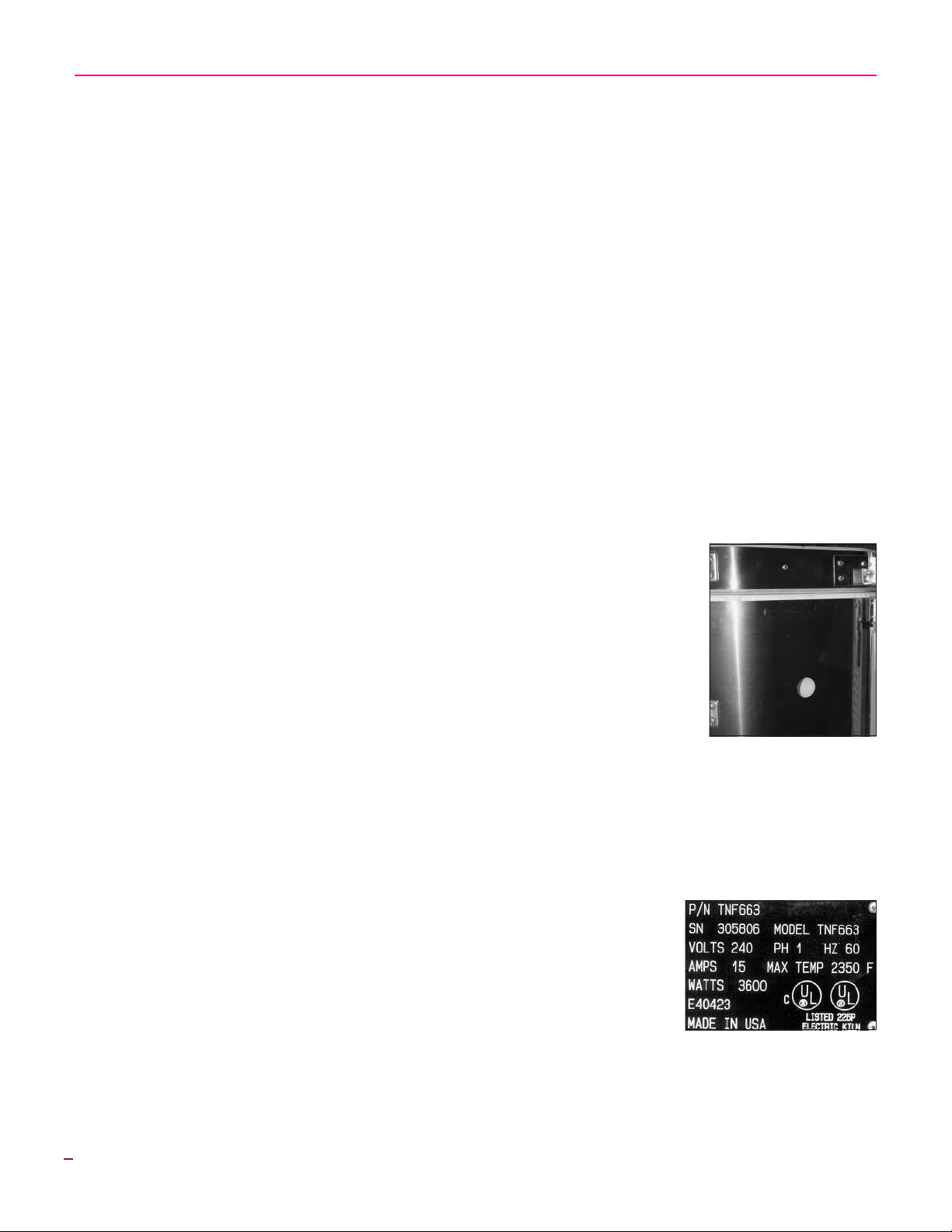

If you call us about your kiln, please have the model number, part number (P/N), and

voltagefromthekiln’selectricaldataplatehandy.(Theplateisonthesideofthe

switch box.) Write that information here for quick reference:

P/N____________________ SN______________ Model______________ Volts____________

Thank you again for purchasing a Paragon kiln. We wish you many years of relaxation and creative enjoyment with

your new purchase! You will find that owning a kiln will give you the freedom to experiment with new ideas and to

fire any time you want. Owning a kiln will take your ceramic skills to a new and exciting level.

2 Monitor the kiln during operation!

©2008, by Paragon Industries, L.P. IM-104/11-08

-

CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . 2

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Important Safety Rules . . . . . . . . . . . . . . . . 4

Setting Up. . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Setting Up The Stand . . . . . . . . . . . . . . . . . . . . . 6

Attach the Lock-In Lid Support. . . . . . . . . . . . . . 6

Where to Locate Your Kiln . . . . . . . . . . . . . . . . . 6

Seating the Elements . . . . . . . . . . . . . . . . . . . . . 7

Cleaning the Kiln. . . . . . . . . . . . . . . . . . . . . . . . . 8

The Electric Circuit . . . . . . . . . . . . . . . . . . . 8

Electrical Shutoff . . . . . . . . . . . . . . . . . . . . . . . . . 8

Circuit Breaker Panel . . . . . . . . . . . . . . . . . . . . . 8

Circuit Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Voltage Affects Firing Time. . . . . . . . . . . . . . . . . 9

Check the Electrical Installation . . . . . . . . . . . . . 9

Preparing The Kiln . . . . . . . . . . . . . . . . . . . . 9

Kiln Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Monthly Kiln Maintenance . . . . . . . . . . . . . . . . 10

Pyrometric Cones . . . . . . . . . . . . . . . . . . . 11

Cone Numbers . . . . . . . . . . . . . . . . . . . . . . . . . 11

Heat Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Using Cones . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pyrometric Cone Charts . . . . . . . . . . . . . . . 12, 13

How to Position Cones on the Shelf . . . . . . . . 14

Using Cones in Digital Kilns . . . . . . . . . . . . . . . 15

The Bending of the Cone . . . . . . . . . . . . . . . . . 15

Firing Accessories. . . . . . . . . . . . . . . . . . . 16

Preparing To Fire The Kiln . . . . . . . . . . . . 17

Vacuuming the Kiln. . . . . . . . . . . . . . . . . . . . . . 17

Drying Greenware. . . . . . . . . . . . . . . . . . . . . . . 18

Shelf Preparation . . . . . . . . . . . . . . . . . . . . . . . 19

Loading The Kiln . . . . . . . . . . . . . . . . . . . . 21

How to Store Kiln Furniture . . . . . . . . . . . . . . . 21

Guidelines for Loading the Kiln . . . . . . . . . . . . 21

Distances Inside the Kiln . . . . . . . . . . . . . . . . . 22

Glazed Ware . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Heat Distribution Inside the Kiln . . . . . . . . . . . . 23

How to Position Posts. . . . . . . . . . . . . . . . . . . . 24

Bead Rods . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Firing Large Ware Across Half Shelves . . . . . . 24

Tile Holders. . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Firing The Kiln . . . . . . . . . . . . . . . . . . . . . . 25

The Stages of Firing . . . . . . . . . . . . . . . . . . . . . 25

When to Speed Up the Firing . . . . . . . . . . . . . . 25

Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

The Basics of Firing . . . . . . . . . . . . . . . . . . . . . 28

The First Firing in Your New Kiln . . . . . . . . . . . 29

Loading and Firing Low-Fire Greenware . . . . . 30

Loading and Firing Low-Fire Glaze . . . . . . . . . 30

Loading and Firing Overglaze . . . . . . . . . . . . . 31

Loading and Firing Ceramic and Glass Decals 32

Loading and Firing Porcelain Greenware . . . . 32

Loading and Firing Porcelain Glaze . . . . . . . . . 33

Loading and Firing Stoneware

Greenware or Glaze . . . . . . . . . . . . . . . . . . . . . 33

Imperfections. . . . . . . . . . . . . . . . . . . . . . . 34

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Bisque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Glaze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Underglaze . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Overglaze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Porcelain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Kiln Maintenance . . . . . . . . . . . . . . . . . . . . 36

Note: Whenever you turnoff the circuitbreaker

to your kiln, tape the breaker box door shut

and leave a note saying, “WORKING ON

KILN. BREAKER OFF.”

How to Open the Switch Box . . . . . . . . . . . . . . 36

Preventive Maintenance

Inside the Switch Box . . . . . . . . . . . . . . . . . . . . 37

Element Maintenance . . . . . . . . . . . . . . . . . . . . 37

Firebrick Maintenance . . . . . . . . . . . . . . . . . . . 43

Tightening the Lid Band . . . . . . . . . . . . . . . . . . 45

Adding a Steel Base Plate . . . . . . . . . . . . . . . . 45

Replacing the Steel Base Plate and

Turning Over the Bottom . . . . . . . . . . . . . . . . . 45

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Index . . . . . . . . . . . . . . . . . . . . . . Back Cover

“Pottery, as you know, is frustrating. But we

could not fully enjoysuccess if wedid notexperi

ence failure. The whole experience is pro

found.”

—Steve Burtt

-

-

Fire only in a well ventilated area! 3

SAFETY

IMPORTANT

Read each page of this manual in detail

before you install or operate your kiln.

Warranty does not cover damage

caused by failure to follow instructions.

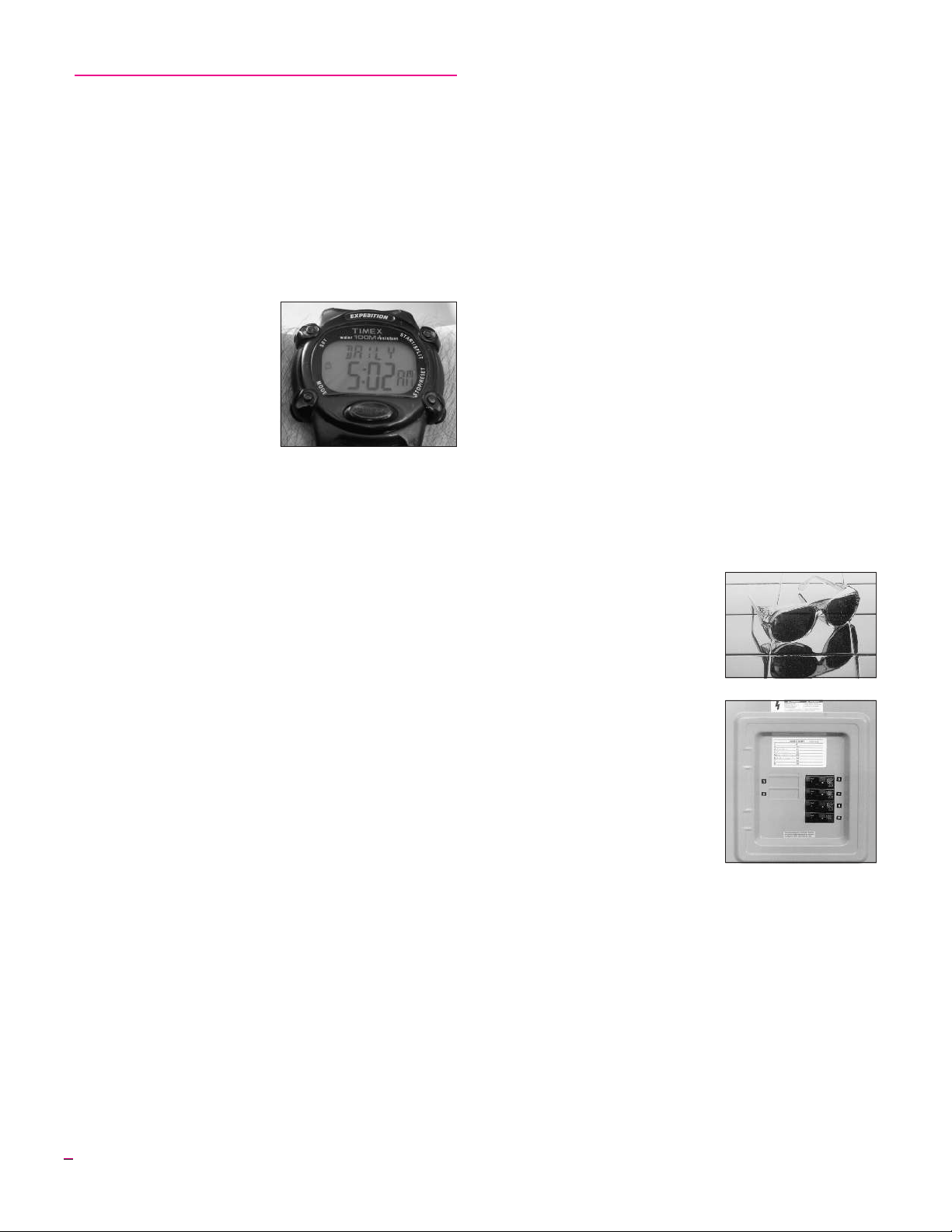

Note: Experienced kiln operators keep a small

timer with them as a reminder that the kiln is fir

ing. You could set the

alarm on a digital wrist

watch for the estimated

firing time less 20 min

utes. When the alarm

sounds, go to the firing

room to check the kiln.

Do not leavethe kiln un

attended, especially

near the estimated

shutoff time.

FOOD-SAFE GLAZES

Some glazes may not be designed for

surfaces that will be in contact with food

or drink. When you make food or drink

containers, select a glaze that has been

formulated, tested, and labeled as

approved for surfaces that will be in

contact with food or drink. Follow the

glaze manufacturer's instructions

exactly, without any variations. Have

custom glazes tested for food safety by a

lab such as Alfred Analytical Laboratory.

You can learn more about glaze safety in

Mastering Cone 6 Glazes, by John

Hesselberth and Ron Roy.

Insurance Companies

If your insurance company ever inspects your kiln

room, tell the inspector that you follow the safety and in

stallation guidelinesshown next. What insurance compa

nies want to see:

■

Fire extinguishers and smoke detectors.

■

An electrical shut-off near the kiln (not needed for 120

volt models).

■

You have removed combustibles from the kiln room.

■

A licensed electrician installed the circuit.

-

Important Safety Rules

Following these safety pointers will add little extra

time to your daily routine. There is little danger of serious

burn from accidental contact if you exercise the same

caution you would use with an electric iron.

●

Place the kiln on the stand recommended by Para

gon. When a kiln is safety tested, the lab fires the kiln

on the stand designed for it. Cinder blocks or bricks

can inhibit the flow of air under the kiln. They can

also change the kiln’s heating characteristics.

●

Place the kiln on a non-combustible surface.

●

Do not install closer than 12" from any wall or com

bustible surface.

●

Fire only in a well ventilated, covered, and protected

area.

●

Do not open the lid until kiln has cooled to room

temperature and all switches are off.

●

Dangerous voltage: do not touch the heating ele

ments with anything.

●

Disconnect kiln before servicing.

●

Do not leave kiln unattended while firing. Do not

leave a kiln turned onat your

studio while you are at home

sleeping.

●

Wear firing safety glasses

when looking intoa hot kiln.

●

Unplug the kiln, or turn off

the electrical shut-off box or

circuit breaker when the

kiln is not in use, especially

if you are concerned that

someone could turn it on

while you are away.

●

-

-

Keep the kiln lid or door

closed when thekiln is not in

use. This keeps dust out of

the kiln. Also, should some

one turn onthe kiln whileyou are away, the closed lid

will keep the heat safely inside the firing chamber.

●

Never place anything on the kiln lid, even when the

kiln is idle. If people become accustomed to placing

papers and otherobjects onthe kiln,they may forget

and do that while the kiln is firing.

-

-

-

“Centering the clay has a way of putting me

into that altered state where time doesn’t hap

pen.”

—Millie Carpenter

4 Monitor the kiln during operation!

●

Remove all tripping hazards from around the kiln.

Keep the kiln’s supply cord out of traffic areas.

-

●

Do not let the cord touch the side of the kiln; it be

comes hot enough to damage the cord.

●

Avoid using extension cords.

-

●

Wear gloves when you

load and unload your

kiln. The gloves should

be thick enough to pro

tect you from glaze

shards and bits of pyro

metric cones that have

stuck to shelves, sharp

edges of broken ware,

and sharp stilt marks on

the bottom of glazed

ware. Razor-sharp glaze

fragments can be so

small that they are difficult to see.

never feel hot. Make sure the plug is pushed all the

way into the receptacle.

●

Never place extra insulation around the kiln in an at

tempt to conserve energy. The extra insulation can

cause the switch box wiring to over-heat and the

steel case to warp.

●

Do not wearloose-fitting clothing around a hotkiln.

●

Remove flammable materials from the kiln room. If

you fire a kiln in the garage, park your car outside.

Remove the lawn mower, gasoline, and other flam

mable materials. Keep packing materials such as

shredded newspapers out of the kiln room.

-

-

●

Do not remove the ware from the kiln until the kiln

has cooled to room temperature. It is possible for

thermal shock to break hot ceramic pieces. The

sharp edges of broken ware can injure hands.

●

After firing glazed ware in your kiln, examine the

shelves for glaze particles. Sharp slivers of glaze

stuck to the shelf can cut hands. Before rubbing a

hand over a shelf, be sure the shelf is free of glaze

shards.

●

Fire only approved materials purchased from a

knowledgeable supplier. Do not fire marbles, pieces

of concrete, rocks, and other objects. Rapid heating

to high temperature can cause violent reactions in

many materials.

●

Avoid firing toxicmaterials such asmoth balls inside

the kiln. Moth balls create toxic fumes inside a kiln

and can even explode.

●

Never fire tempered glass inside a kiln. It could explode.

●

Greenware, which is unfired

clay, must be bone dry be

fore firing. Moist greenware

can explode inside the kiln,

damaging the ware and the

kiln. Place a piece of

greenware against the inside

of your wrist. If it feels cool,

it is too wet to fire.

●

Do not fire cracked shelves. They can break during

firing, damaging the ware inside the kiln.

●

Store kiln shelves in a dry area.Moist shelves can ex

plode inside a kiln.

●

If you smell burning plastic, turn the kiln off. Exam

ine the wall outlet and supply cord for signs of burn

ing.

●

As the kiln fires, it is a good habit to place your hand

on the kiln’s power cordto check the temperature. It

is okay if the cord is slightly warm, but it should

●

Keep unsupervised children away.

●

Keep a Class C fire extinguisher and a smoke alarm

in the kiln room. Mount the extinguisher near the

door to the room.

●

Do not breathe brick dust, kiln wash, or kiln repair

cement. Prolonged exposure may cause lung injury.

Vacuum the kiln with a HEPA filtered vacuum

cleaner or a central vacuum that takes the dust outside.

●

Only vitrified ware should be used in a microwave

oven. (Vitrified clay has been fired to a point where

the particles becomeglass-like and nolonger absorb

water.) Non-vitrified clay such as earthenware is

generally not suitable for microwave use, because

the clay absorbs water. The water in the pores of the

clay can expand rapidly enough in a microwave to

cause the ware to crack or even explode. Ware that

has been decorated with metallic glazes should not

be used in a microwave oven.

●

Whenever you turn off the circuit breaker to your

kiln, tape the breaker box door shut and leave a note

saying, “WORKING ON KILN. BREAKER OFF.”

How to Avoid an Over-Fire

Suggestions by Mel Jacobson, Potter

1 Useanalarmclock.Iusetheoldwind-up

kindwithaloudringer.Setitforacertain

time, and make sure you follow the ring.

Place a small battery-operated oven timer in

your pocket if you need extra reminders.

-

-

-

2 Get a large bulldog clip and paint KILN in

red. Clip it to your jacket, or hang it from a

doorknob. Or place a sign where you hang

your apron: KILN ON.

3 When I was a high school teacher, I had the

janitor turnoff the master breaker to the kiln

every night at 8. No kiln would ever be on

past 7, ever, anyway.

Fire only in a well ventilated area! 5

SETTING UP

Setting Up The Stand

Operate your Paragon kiln only on the stand provided.

(Sometimes people buy used kilns that are missing the

original stand and place the kiln on cinder blocks or

bricks. This is not a good idea,because bricksmay inhibit

the flow of air under the kiln. Cinder blocks could also

change the kiln’s heating characteristics.)

We recommend that you wear tight-fitting gloves such

as mechanic’s gloves while assembling the stand.

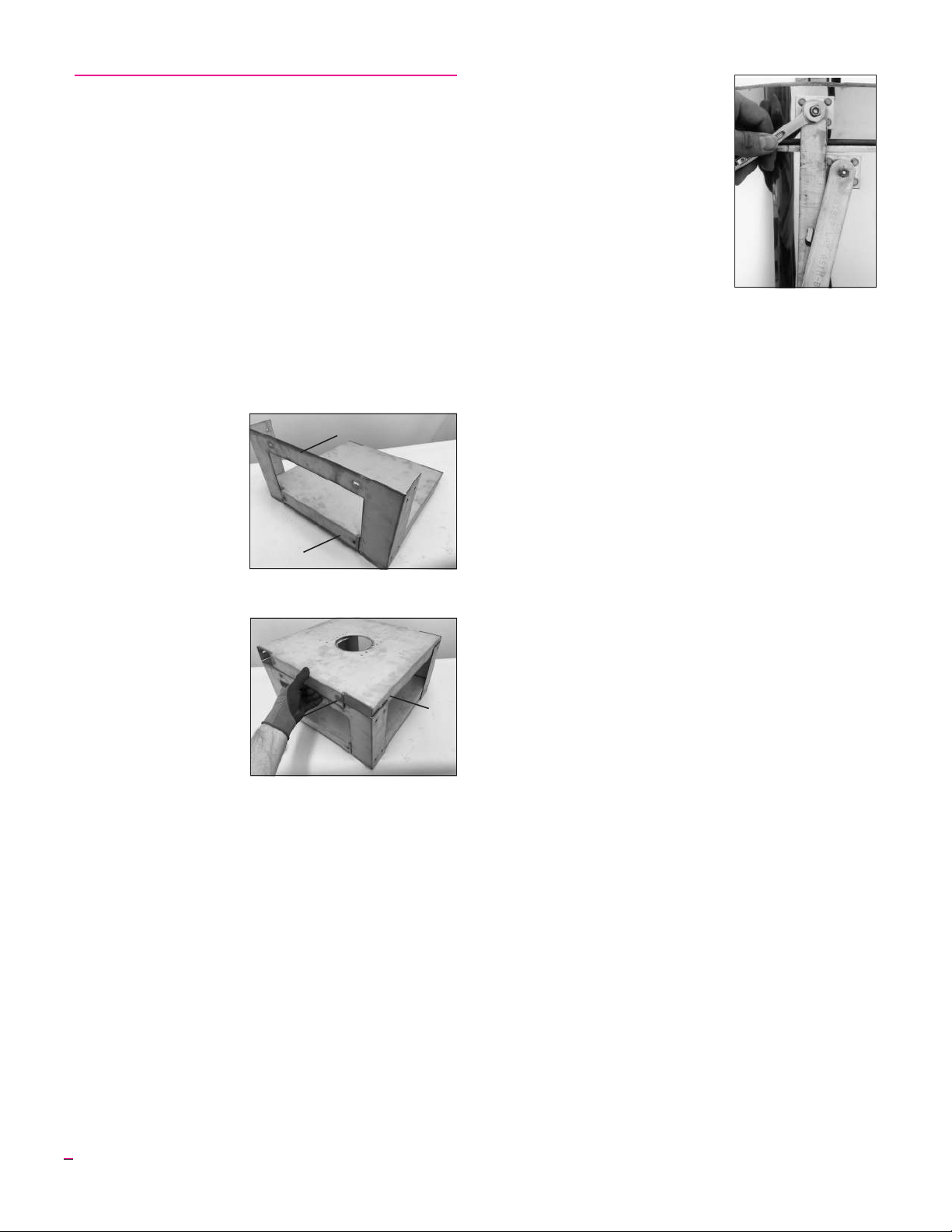

You will find 2 shelves, 2 side frames, and a bag of nuts

and screws in the stand kit. The shelf with the hole in the

center is a top shelf. The solid shelf goes on the bottom.

Thesideframeshavebottommountingholesforcasters.

1 Insert a short tab

from the solid

shelf into a side

frame. The tab

goes on the out

side of the side

frame.

2 Repeat Step 1 for

the other side

frame.

3 Lay the top shelf

(the one with the

hole in the center)

over the side

frames. The short

tabs goon the outside of the side

frames. The long

tabs go on the in

side of the side

frames.

4 Insert the screws

and nuts.

5 Install the casters. You can leave off the casters if

you want to make the stand shorter.

Caution: You MUST lock the casters before

placing the kiln on the stand.

-

Short

tab goes

on outside.

The short bent tab goes on the outside

of the side frames.

-

Short

tabs go

outside.

The long bent tabs go on the inside of

the side frames. The short bent tabs go

on the outside.

Install the Orton Vent Cup

Skip this stepif your kilndoes not have an OrtonVent.

1 Attach the hose to the vent cup with the clamp

that came with the Orton Vent.

2 Slide the ventcup up insidethe standand into the

flange supports in the top shelf. Rotate the vent

cup a littleas you slide it into the flange supports.

3 Place the gasket that came with the vent over the

vent cup.

Side frame

Long

tabs go

inside.

Attach the

Lock-In Lid

Support

Models with the lid support:

Connect the lid support to the

studonthesideofthekiln.

Tighten the lock nut until it is

snug.

Where to

Locate Your Kiln

In addition to these guidelines, please see “Safe Instal

lation of the Electric Kiln,” a separate publication

shipped with your kiln.

■

Plan your firing area near a present electrical outlet or

where a new circuit can easily be installed.

■

Place your kiln in a well-ventilated, covered, and pro

tected area such as the garage, basement, storage

building, utility or ceramic hobby room.

Caution: The fumes from ware fired in a kiln can

corrode metal and etch windows. If you are installing your kiln in a living area such as the basement or in the garage, it should be vented with a

motorized vent. Please see “Safe Installation of

the Electric Kiln.”

Q Is it okay toplace thekiln on a covered porch or

in a carport?

A Yes. As long as the kiln is protected from the

weather,itcanbeinstalledinaroofed-inarea

withopensidessuchasacarport.Butespecially

in humid areas, the kiln may rust faster than it

would inside an enclosed building.

■

Do NOTstore gasoline, paint, or other flammable liq

uids in the kiln room.

■

Never allow the room temperature of your firing room

to exceed 100 - 110°F. (Room temperature is the tem

perature measured three or more feet away from the

kiln.) If necessary, use a fan to move the heat away

from the kiln’s switch box.

■

Electrical components such as switches, the digital

controller, relays, and wiring lastlonger when theystay

cool. The easiest way to lower the temperature of a

kiln’s switch box is to blow air into the side louvers

with a fan. It doesnot need to be alarge fan; one with 4"

- 8" diameter blades on low speed is effective. The air

shouldgoinonesideoftheswitchboxandoutthelou

vers of the other side. Do not allow air to blow into the

kiln through the peepholes or lid.

-

-

-

-

-

6 Monitor the kiln during operation!

Lower the switch box temperature with air movement. This is especially

useful during hot summers.

■

Provide a minimum of 12” clearance between the kiln

and the closest wall.

■

Never place the kiln near curtains or other combusti

ble materials such as art room supplies.

■

Position the kiln stand on a level surface that will not

be damaged by heat. We recommend a cement floor.

However, a sheet of protective material may be used

under the stand. Consult your hardware or building

supply store for a recommendation.

■

Avoid placing the kiln stand on rubbertile, linoleum or

any surface that might tend to mar or discolor when

heated.

■

Place the kiln in an area where it can be easily loaded

and unloaded yet out of the way when not in use. For

convenience in moving the kiln when not in use, consider the reinforced, deluxe stand with casters.

■

Keep unsupervised childrenaway from the firing area.

■

Do not allow the kiln’s power supply cord to contact

thesideofthekiln.Thiscouldburnthecord.Before

each firing, check all around the kiln to make sure

nothing is touching the kiln case.

Cold Weather

It is okay to store and firethe kiln in an unheatedbuild

ing during winter. But before operating, raise the tem

perature of the kiln’s switch box to at least 32°F (0°C)

with a space heater.

Q What is the difference in the cost to fire a kiln

in a warm room compared to firing in a cold

room?

A Room temperature has almost no effect on the

electrical cost of firing a kiln. However, if your

kiln is under a carport that has open sides, pro

tect the kiln from wind. Air blowing against the

case can raise the electrical cost slightly. If you

use a fan to lower the temperature of the switch

box, position the fan so that the air blows into the

-

switch box louvers but not onto the firing cham

ber case.

Installing the Kiln in an

Institutional Setting

Sometimes maintenance employees are not familiar

with kilns. For this reason you might want to place a sign

on top of the kiln when the kiln is not in use:

Do not stand on the kiln.

Do not move the kiln.

Do not place anything on top.

(Reminder: Remove any signs from your kiln before

you fire it.)

Place a signon the door of thekiln room: Kilnis Firing.

Every year hold a short kiln orientation session for the

maintenance staff. You could also send the same infor

mation by e-mail to the school principal and the mainte

nance department. Explain the following:

-

1 The kiln is fragile.

2 During operation, the kiln makes a clicking noise.

This is normal.

3 If you use a temperature alarm on your digital kiln,

explain the beeping noise. Otherwise it will

frighten students and maintenance people because they will assume that something is wrong.

Seating the Elements

Shipping may dislodge the elements of your kiln.

Please performthe kitchen knife test to make sure the elements are seated in their grooves.

Kitchen Knife Test

Caution: Always unplug the kiln before touching

an element with anything.

Caution: Touch only a cold element, never a hot

one, with a plastic object such as a comb. Plastic

will melt on and ruin a hot element.

Press the ele

ments into their

-

grooves by running a

-

blunt kitchen knife,

plastic comb, orsimi

lar blunt object com

pletely around each

groove. Do this be

fore the first firing,

because it may not be

evident to the eye

whether the coil is in

its groove.

Note: Don’t force the element into the groove

corners. If the element won’tfit easily, lengthenit

with automotive snap-ring pliers (available from

auto parts stores). Stretch the space between the

-

-

-

-

-

-

-

Fire only in a well ventilated area! 7

Expanding coils with automotive

snap-ring pliers.

As shown here, new elements do

not lie flat in a curved groove.

coils just a little where

the element fits into

the wall brick corners.

It should then easily

seat into the corners.

If the element doesn’t

lie flat in the bottom of its

groove, you needn’t be

concerned as long as the

element fits all the way

back into each corner and

doesn’t bulge outside the

groove. In fact, elements

will not lie flat in their ter

minal bricks (right behind

switch box).

Before the kiln is fired,

the elements are mallea

ble; there is no danger of

breaking the elements

when you bend them. After

firing, however, the ele

mentsbecomebrittleand

must be reheated if they

bulge out of the groove.

See “Reseating a Bulging

Element,” page 38.

THE ELECTRIC CIRCUIT

Please have only a qualified electrician install your kiln

circuitincompliancewithlocalcodes.Ifyouplantouse

an existing circuit, have a qualified electrician check the

circuit and compare the wire and breaker sizes with those

shownintheParagoncatalogandwebsite.Thecircuit

must never be used by other appliances while the kiln is

firing.

-

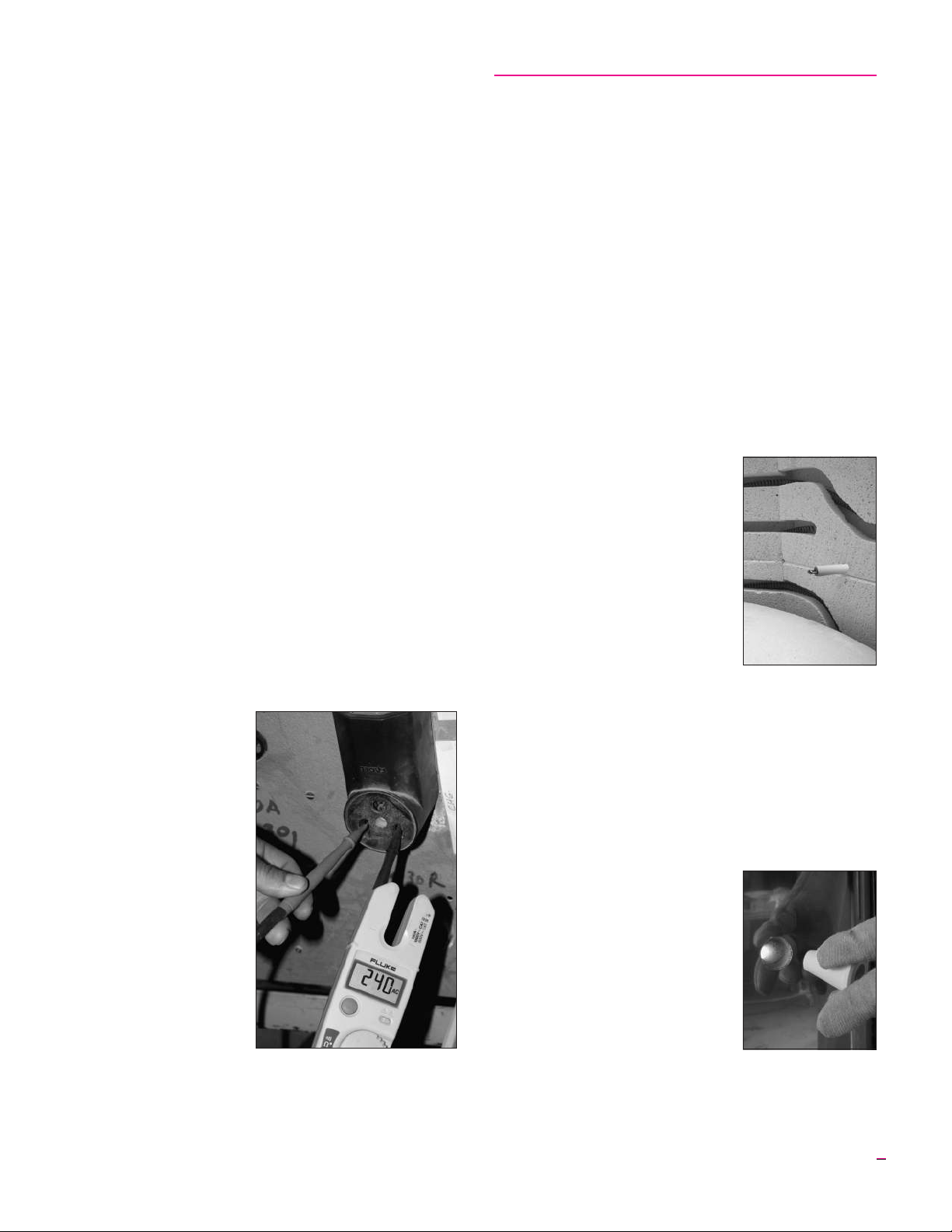

Electrical Shutoff

We recommend an electrical

shutoff box near the kiln in addi

tion to having a circuit breaker at

the electrical panel. The shutoff

box is a must for direct-wired

kilns, which can’t be unplugged

to disconnect the power. We rec

ommend disconnecting the

power when the kiln is not in use.

If you unplug the kiln frequently,

the spring tension on the wall outlet may eventually

weaken. The shutoff box disconnects the power without

having to unplug the kiln.

-

-

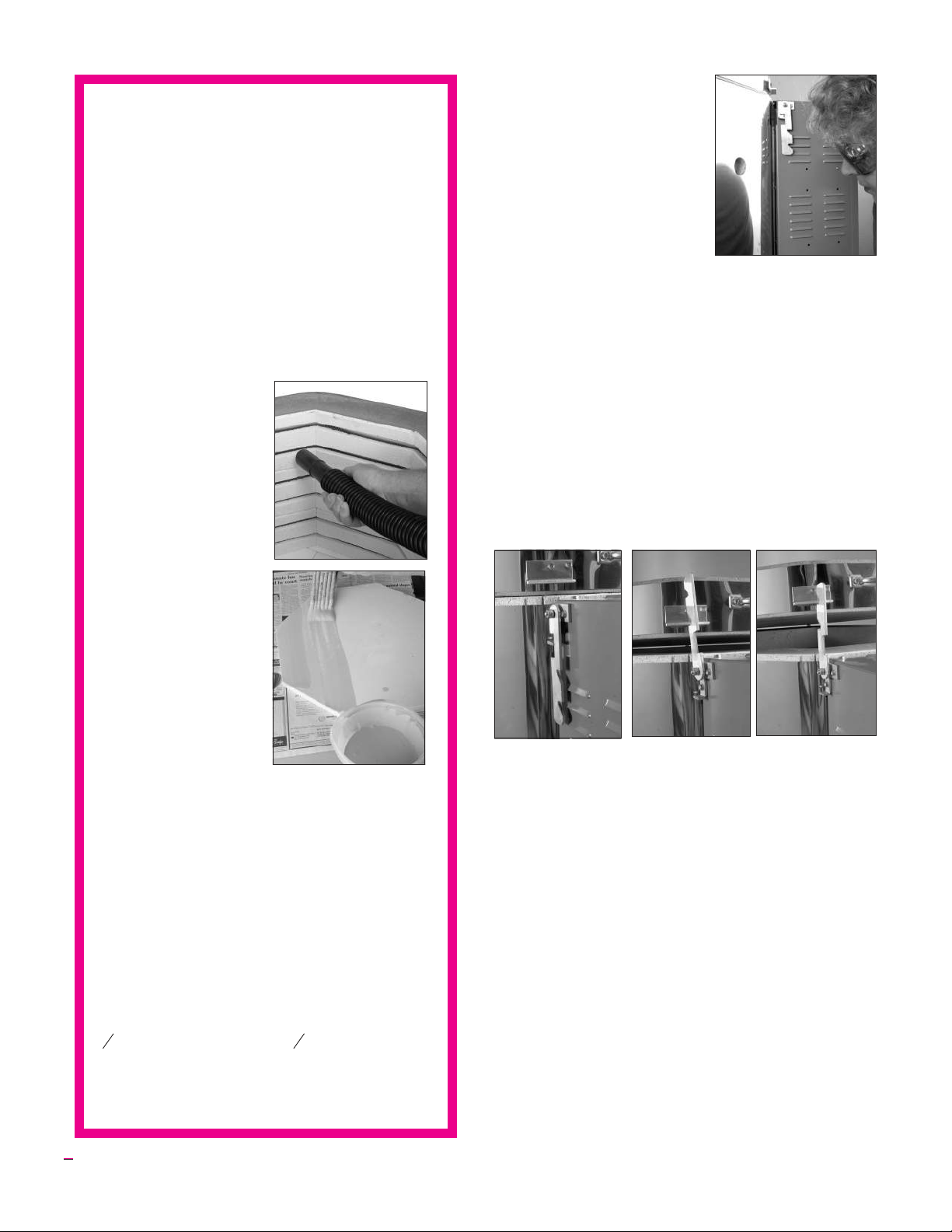

Cleaning the Kiln

Cleanyourkilnbefore

firing. Use a a vacuum

cleaner (preferably with a

soft brush nozzle) to remove brick dust from inside the kiln, especially

from the grooves. A damp

cloth or damp sponge may

also be usedto gently wipe

dust from the sidewalls

and brick bottom. Clean

the kiln again whenever

you notice dust inside.

Note: Vacuum the kiln with a HEPA filtered vac

uum cleaner or a central vacuum that takes the

dust outside. Keep the vacuum hose away from

the controller on digital kilns.

“What is it about that meditative quiet when

kids are working with clay? I teach 3rd, 4th and

5th graders in a very poor neighborhood, and

even the toughest 5th grader will let down his

‘cool and tough’ act for clay.”

—Grace Sheese

-

Note: The shutoff box is not needed for 120 volt

kilns.

Circuit Breaker Panel

Install the kiln within 25' of the fuse or circuit breaker

panel. For every additional 50' from the panel, increase

the circuit wire size by one gauge.

But do not place the kiln right in front of the electrical

panel. Keep the panel at least 3' - 4' away. Otherwise, the

breakers may trip more easily on a hot day. This is be

cause a circuit breaker is triggered by heat, and a nearby

kiln can raise the temperature of the electrical panel.

Note: Do not use the circuit breaker to discon

nect the kiln. Frequently switching the circuit

breaker will weaken it. Instead, use a shutoff box

located near the kiln.

-

Circuit Wire

Useacircuitwiresizelargeenoughforthewallrecep

tacle amperage, even if the kiln amperage is less than the

wall receptacle amperage.

WARNING: Changing the cord plug on

Paragon kilns mayvoid your warranty.

Trying to save money on the circuit installation by us

ing a smaller diameter wire is not cost effective, because

the thinner wire generates more heat than the thicker

-

-

-

8 Monitor the kiln during operation!

wire. The heat means wasted electricity and sometimes

slightly lower voltage.

Use copper wire. Do notallow an electrician to usealu

minum wire on your new circuit. Aluminum terminals

corrode worse than copper and require greater installa

tion care. Avoid using extension cords.

The Paragon kiln catalog and website show recom

mended breaker and wire sizes for the circuit. (These

recommendations assume that the circuit is dedicated,

which means that it powers only the kiln and no other

appliance.) Local codes supersede our catalog recom

mendations.

You may already have a heavy-amperage circuit conve

niently located where you will keep your kiln. But do not

assume that the circuit is the correct size. Clothes dryer

circuits are too small for most studio kilns. Even if you

have the correct wall outlet,you shouldverify that the wire

and breaker sizes are also correct.

Voltage Affects Firing Time

Voltage fluctuation can vary the firing time for a given

pyrometric cone from as little as one half to more than

twice the average time. If the voltage is too low, the kiln

will never reach full temperature. This can be corrected

only by having the utility company adjust the voltage.

(However, 208 volts cannot be adjusted to 240 volts, and

vice versa.)

Check the Electrical

Installation

Check the receptacle voltage with a voltmeter before

plugging in your kiln. Measure between the two slots

where the flat blades on

the plug are inserted.

Only a qualified person

should perform this test,

because improper use of

a voltmeter can result in

shock to the user.

Verify that the safety

grounding wire is prop

erly connected in accor

dance with the National

Electric Code (or equiv

alent for your country).

Thiscanbeprovenonly

by visual inspection of

the receptacle wiring.

Sometimes circuits have

been installed by home

owners with limited

electrical experience.

-

-

-

-

Checking the voltage of a wall outlet in

the Paragon factory.

PREPARING

-

THE KILN

-

Kiln Features

-

Kiln Firebricks

Premium, hand-selected insulating refractory bricks

are lightweight, porous, and precision cut tofit tightly and

store heat in the walls, bottom, and lid. The form-fitted

jacket snugly holds the bricks together. Because the fire

bricks store heatso efficiently,the cost ofelectricity to fire

the kiln is surprisingly low. Kiln brick is extremely fragile

and will chip easily; always handle your kiln and its brick

with care. Never let a shelf bump against the firebrick.

Firebrick damage is not covered by warranty.

Note: Allow only trusted people to load and un

load your kiln. Beginners may not understand

that the firebricks are fragile.

The temperature required for

ceramics is well above the melting

pointofmostmetals,andtremendous stressesare generated during

the firing. The insulating firebricks expand and contract with

each firing. In time, cracks will appear in the brick while the kiln is

cold. This is normal and will notaffect your kiln’s operation.

Heating Elements

The heating elements in your Paragon kiln are heavy

duty for long life. All high temperature, heavy duty elements are quite brittle after being heated to a high tem

perature and will break if bent while cold. By heating to a

dull red glow with a propane torch, an element may be

bent safely.

Never allowglaze, glass, silica sand, kiln wash, or other

foreign materials to touch the elements since they will

destroy the element when the kiln is fired.

Peepholes

Large peepholes (view ports),

tapered for a wide view without

heat loss, are used for observing

theprogressofyourfiringsoyou

can see when the pyrometric cones

bend. Use at least one large cone

on the shelf during every fir

ing—even in a digital kiln. With

venting as their secondary func

tion, peepholes allow oxygen to be

drawn into the kiln’s chamber and serve as anescape pas

sage for smoke and water vapor.

When looking through the peepholes, always wear fir

ing safety glasses, which areavailable from Paragon.They

-

-

-

-

-

-

-

Fire only in a well ventilated area! 9

Monthly Kiln

Maintenance

1 Make sure the kiln is centered on the stand

and that the stand is stable. Check the area

around the kiln and remove flammable ma

terials that have accumulated.

2 Vacuum the kiln with the soft brushnozzle of

avacuum.(Youcanuseahardplasticnozzle

as long as you don’t touch the bricks with it.)

Remember to vacuum the brick grooves. If

you have difficulty removing debris inside

the grooves,use anarrow wand-typevacuum

cleaner nozzle being careful not to scrape

the brick walls. (See

page 17.)

3 Vacuum around and

under the kiln: floor,

shelves, and walls.

This keeps the kiln

interior cleaner and

adds life to the option vent motor.

protect your eyes from the

bright glareof the firing cham

ber and make it easier to see

the cones at high tempera

tures.

Peephole plugs are used to

stop air from entering the kiln,

-

not to prevent heat loss. It is

beneficial to have some air en

tering the kiln at all times, so it

is not necessary that the plugs

fit tightly.

Wear firing safety glasses

when looking through a peep

hole into a hot kiln.

-

You can leave the peephole

plugs out for some firings. This improves oxygenation in

side the kiln. However, this may cause cold spots in the

kiln, especiallyif there are air drafts in your firing room. If

you leave the peephole plugs out, keep ware at least 3"

from the peephole. If your ware develops problems from

cool air drafts, such as a glazed piece with a crazed spot,

insert the peephole plugs after the kiln reaches 1000°F

(537°C), or about half way through the firing. If you use a

motorized downdraft Orton Master Vent, keep peephole

plugs inserted and the lid closed all the way for the entire

firing.

Prop-R-Vent

4 Check the kiln wash

on shelves and kiln

bottom for cracks

and bare spots in the

coating. Remove any

glaze drips. Reapply

kiln wash if needed.

(See page 19.)

5 Check the power

cord and outlet for

heat damage. Has

the cord touched

the side of the kiln during firing? This will

damage the cord insulation. Replace the

cordsetorwalloutletthatshowssignsofheat

damage.

6 Make sure elements are not bulging out of

the grooves. Repair if necessary. (See page

38.)

7 Kiln Downdraft Vent: Check the vent duct

for leaks. (See page 26.)

8 Digital kilns: Make sure the thermocouple

extends far enough into kiln:

¼" diameter thermocouple: 1" into the kiln

1

" diameter thermocouple:

8

5

" into the kiln

8

Leave the lid closed if

you have a motorized

downdraft vent.

The Prop-R-Ventin the

first position.

The Prop-R-Vent in the

extended position.

Ceramic pieces release gases and water vapor during

firing. Venting allows these gases to escape. Paragon’s fall

away Prop-R-Vent is installed on the switch box of most

top-loading kilns. The prop supports the lid in an open

position during the venting period. The Prop-R-Vent

vents the lid in two stages.

To close the lid after venting, lift the lid handle an inch

to let the Prop-R-Vent fall. Lower the lid gently; warranty

does not cover damage to the kiln or the ware due to a

dropped lid. For lusters and overglazes, engage the

Prop-R-Vent in its second position for additional venting.

Do not rush the cooling of your kiln with the

Prop-R-Vent. This can damage your ware.

Do not drop the lid. Some people touch the lid handle

for the first time to lower the lid from venting and drop

the lid because the handle is hot. Use a heat-resistant

glove or a lid lifter (sold by Paragon) to lower the lid.

10 Monitor the kiln during operation!

Full-Formed Steel

Base

The galvanized steel base

under the brick bottom

strengthens the kiln. It cov

ers the entire bottom from

edge to edge.

The Lid Support

Your kiln

has either the

lock-in lid

support or

the LiteLid

spring coun

ter-balance.

Please do not

let unat

tended chil

-

dren raise the

lid. Do not let the lid drop. It is

fragile and mustbe lowered gently.

Keep the kiln lid closed when

the kiln is not in use. This keeps

Do not exert downward

pressure on the lid until

the lock-in lid support is

completely disengaged.

dust out of the kiln. Also, should

someoneturnonthekilnwhileyouareaway,theclosed

lid will keep the heat safely inside the firing chamber.

The LiteLid Support

1 Begin raising the lidusing

the center lid handle.

When the lid feels

weightless, hold a side lid

handle with your other

hand to guide the lid the

rest of the way up.

2 Donotletgoofthesidelid

handle until the lid

The LiteLid spring can pinch fin

gers. Please keep unattended

children away from the kiln.

reaches its fully opened

position. Otherwise the

lid could slam upward,

damaging the firebricks

near the hinge. (Please

note: This type of damage

is not covered by war

-

ranty.)

3 Stay clear of the lid when

raising or lowering. This

is to prevent injury should

Do not let go of the side lid han

dle until the lid reaches its fully

opened position.

the lid drop.

Dust-Free Refractory Coating

The dark coating on the lid, the top rim of firebricks,

and in the peepholes reduces dust and hardens the fire

brick surface for longer life. Though it will lighten after

the first firing, the coating will last for several years.

PYROMETRIC CONES

Ceramists of early

times judged when the fir

ing was completed by the

color of the kiln interior

and the length of firing. In

1886, a German ceramist

named Seger made clay

cones that bent when the

A selection of self-supporting

cones. See the cone charts on

pages 12 and 13 for a list of cone

colors.

could see the cones bend and knew when to turn off the

kiln. His cones took the guesswork out of firing.

Today westill use Seger’s cones. They are called pyro

metric cones and are small pyramids of clay and mineral

oxide that soften and bend when exposed to heat. They

indicate when your ware has fired to maturity. When consulting your dealer with a glaze problem, you should have

abentconefromthatfiring.Theconewillhelptrouble

shoot the problem. The cone lets you compare one firing

to the next. Cones are manufactured by the Orton Ceramic Foundation andare available fromyour distributor.

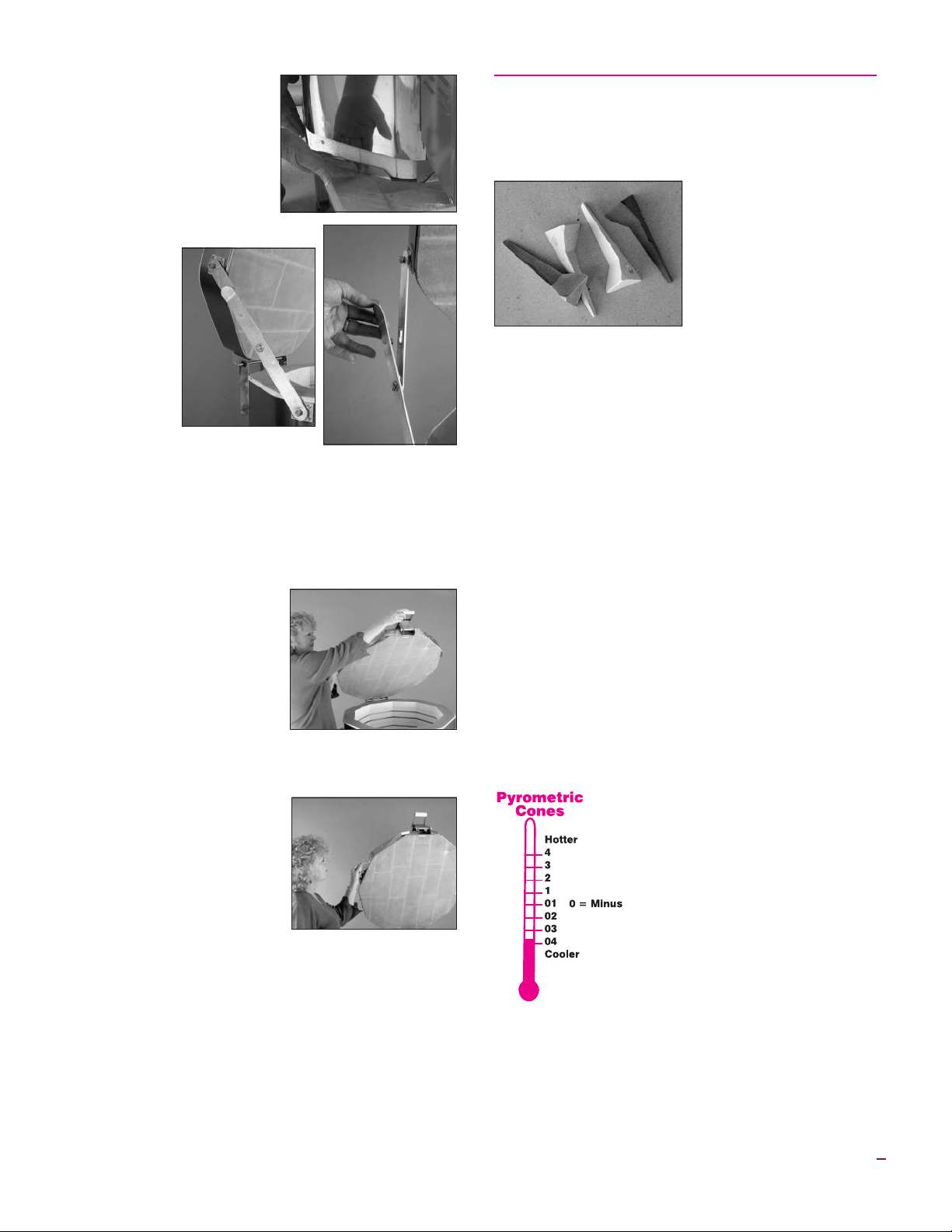

Cone Numbers

The most confusing thing about cones is the way they

are numbered. They are easier to understand when you

know the reason behind the numbers. Pyrometric cones

are numbered from 022 through 01 and 1 through 10.

Cone 022 matures at the lowest temperature, and 10 ma

-

tures at the highest.

Seger numberedhis original cones from 1 to 20, with 1

being the lowest temperature.

Later, cones of even lower temper

atures thancone 1 were needed. To

avoid changing all the cone num

bers, thenew numbers started with

“0” and went from 01 to 022, with

higher numbers getting progres

sively cooler.

-

place the “0” with a minus sign.

Numbers without the “0” are posi

tive. The higher the positive num

ber, the higher the temperature.

Numbers with the “0” (or a minus sign) are negative.

The higher the negative number, the lower the tempera

ture.Withthisinmind,youcanquicklyseethatcone5is

hotter than 05.

Note: Store boxes of cones in numerical order

from lowest to highest temperature so that you

ceramic ware received the

proper heat work. He posi

tioned the cones on a shelf

inside the kiln. By looking

through a peephole, he

To avoid confusion, mentally re

-

-

-

-

-

-

-

-

-

-

-

Fire only in a well ventilated area! 11

will be less likely to inadvertently pick up the

wrong box.

The number is stamped on the base of the cone. The

cone number for each material is usually stated on the la

bel by the clay or glaze manufacturer. Your supplier can

also give you the cone number.

Heat Work

Cones are rated by temperature. But it is more accu

rate to think of themas measuring heatwork, not temper

ature alone. Heat work is the combined effect of time,

temperature, and the atmosphere inside the kiln. All

thesefactorsaffectthematurityofyourwareandnotjust

temperature. For instance, firing to a lower temperature

for a longer time will produce the same maturity as firing

to a higher temperature for a shorter time. The “Tem

perature Equivalents” chart (next column) shows that a

self-supporting 05 cone requires a temperature of1911°F

to bend to 6 o’clock, yet when fired slower, it will bend at

1870°F.

During the last 100 - 200 degrees of firing, the firing

rate affects the bending temperature of a pyrometric

cone. The faster the rate, the higher the temperature

whentheconebends.Butthefiringspeedbeforethelast

100 - 200 degrees has no influence on the final temperature of the pyrometric cone. The exception is an extremely fast firing that bloats the cone.

Consult your supplier for therecommended firing rate

of yourclays andglazes. Thethicker theclay, theslower it

should be fired. Firing clay is like making cookies in an

oven. Heat the cookies fast, and they will be brown on the

outside but still gooey on the inside. Heat the cookies

slowly, and they will be brown all the way through.

Using Cones

Place the cones on a kiln shelf with the ware. As the

cones heat and bend, they form a glassy material that will

stick to a bare shelf. Therefore, apply kiln wash to the

shelvestopreventsticking.Donotapplykilnwashtothe

cones.(Seepage19forkilnwash.)Theconesslant8de

grees from vertical and bend in the direction of the slant.

They will not bend accurately if they are slanted at the

wrong angle. Position a cone so it will not touch nearby

ware as it bends.

Large cones come in ei

ther standard or self-sup

porting. Standard large

cones must be mounted in a

clay or wire plaque with 2" of

the cone exposed above the

cone holder. Or you can

mount largecones ina patof

clay. The clay should be dry

before firing. To speed dry

ing, make indentions in the

clay with the end of a small

-

-

-

Standard large cones in clay cone

packs.

°F Temperature Equivalents For Orton

Self-Supporting Pyrometric Cones

-

-

-

-

-

Cone Self-Supporting Cones Pre-Fire

Number Color

Heated at: 27° F 108° F 270° F

Per Hour* Per Hour* Per Hour*

022 — 1087 1094 Green

021 — 1112 1143 Fuschia

020 — 1159 1180 Orange

019 1213 1252 1283 Yellow

018 1267 1319 1353 White

017 1301 1360 1405 Pink

016 1368 1422 1465 Light Blue

015 1382 1456 1504 Violet

014 1395 1485 1540 Gray

013 1485 1539 1582 Green

012 1549 1582 1620 Fuschia

011 1575 1607 1641 Orange

010 1636 1657 1679 Dark Red

09 1665 1688 1706 Dark Red

08 1692 1728 1753 Dark Red

07 1764 1789 1809 Dark Red

06 1798 1828 1855 Dark Red

05 1/2 1839 1859 1877 Dark Red

05 1870 1888 1911 Dark Red

04 1915 1945 1971 Dark Red

03 1960 1987 2019 Dark Red

02 1972 2016 2052 Dark Red

01 1999 2046 2080 Dark Red

1 2028 2079 2109 Dark Red

2 2034 2088 2127 Dark Red

3 2039 2106 2138 Dark Red

4 2086 2124 2161 Gray

5 2118 2167 2205 Green

5 1/2 2133 2197 2237 White

6 2165 2232 2269 Fuchsia

7 2194 2262 2295 Orange

8 2212 2280 2320 Yellow

9 2235 2300 2336 White

10 2284 2345 2381 Pink

*Rate of temperature increase during last 90 120 minutes of firing. Tables by courtesy of the Ed

ward Orton, Jr. Ceramic Foundation.

Cone

-

12 Monitor the kiln during operation!

°C Temperature Equivalents

For Orton Self-Supporting

Pyrometric Cones

Cone Self-Supporting Cones Pre-Fire

Number Color

Heated at: 15° C 60° C 150° C

Per Hour* Per Hour* Per Hour*

022 — 586 590 Green

021 — 600 617 Fuschia

020 — 626 638 Orange

019 656 678 695 Yellow

018 686 715 734 White

017 705 738 763 Pink

016 742 772 796 Light Blue

015 750 791 818 Violet

014 757 807 838 Gray

013 807 837 861 Green

012 843 861 882 Fuschia

011 857 875 894 Orange

010 891 903 915 Dark Red

09 907 920 930 Dark Red

08 922 942 956 Dark Red

07 962 976 987 Dark Red

06 981 998 1013 Dark Red

05 1/2 1004 1015 1025 Dark Red

05 1021 1031 1044 Dark Red

04 1046 1063 1077 Dark Red

03 1071 1086 1104 Dark Red

02 1078 1102 1122 Dark Red

01 1093 1119 1138 Dark Red

1 1109 1137 1154 Dark Red

2 1112 1142 1164 Dark Red

3 1115 1152 1170 Dark Red

4 1141 1162 1183 Gray

5 1159 1186 1207 Green

5 1/2 1167 1203 1225 White

6 1185 1222 1243 Fuchsia

7 1201 1239 1257 Orange

8 1211 1249 1271 Yellow

9 1224 1260 1280 White

10 1251 1285 1305 Pink

*Rate of temperature increase during last 90 120 minutes of firing. Tables by courtesy of the Ed

ward Orton, Jr. Ceramic Foundation.

brushhandleaftertheconeisinserted.Self-supporting

cones stand upright without holders. We recommend

self-supporting cones; they are easier and faster to use

than standard large cones.

Handle cones carefully. They are fragile because they

are unfired clay. If dropped, they may develop cracks that

could affect their performance. Age and normal humidity

do not affect the accuracy of cones. Even if a box of cones

is 20 years old, you can still

use them. However, do not

use them ifthey become wet.

Standard pyrometric

cones come in two lengths: 1

1

" and 2 ½". The small cone

8

is used in the Kiln Sitter and

the large cone is used on the

kiln shelf.

Note: The Kiln Sitter is

a mechanical shut-off

device that is triggered

by the bending of a

smallcone.Digitalcon

trollers do not use the

-

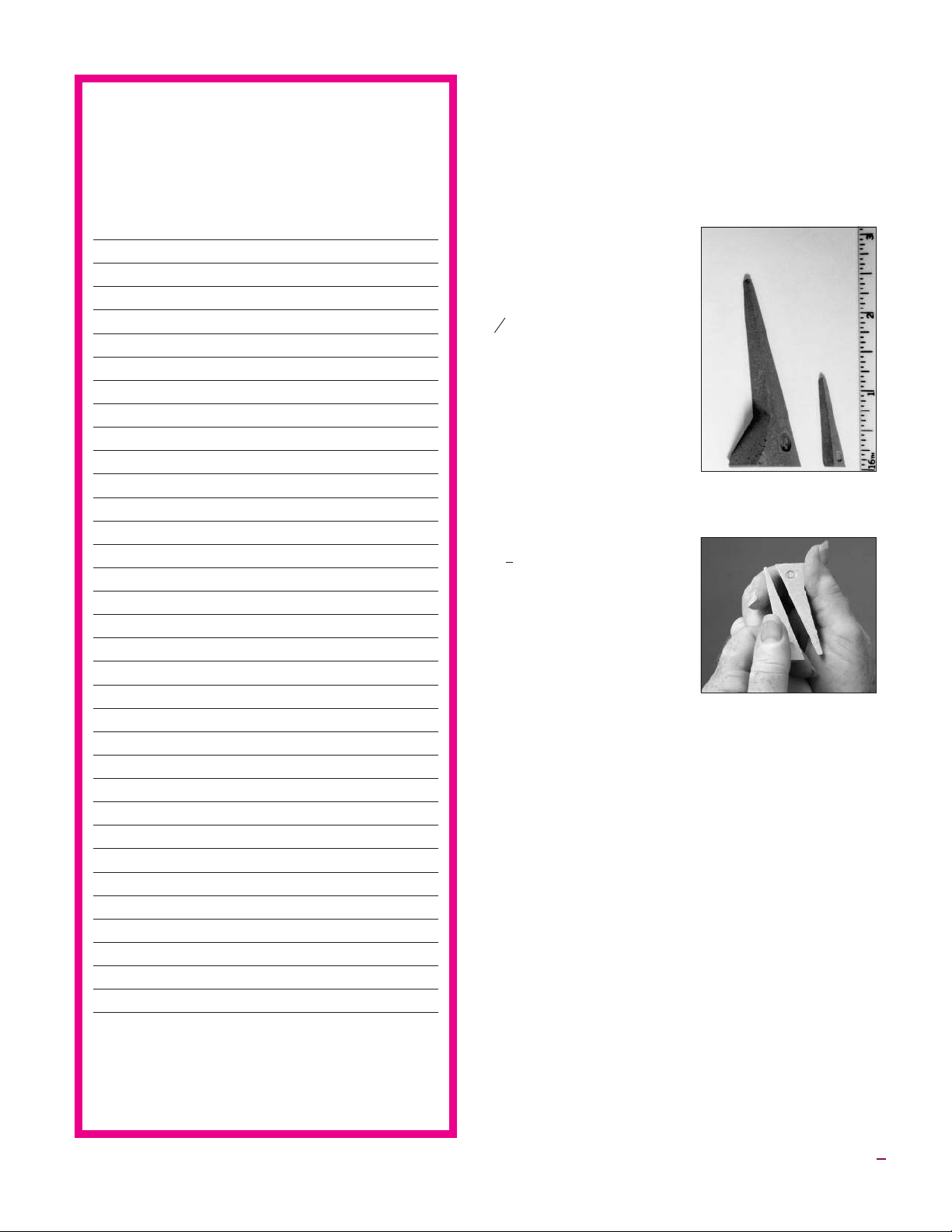

A self-supporting cone next to a

small Kiln Sitter cone.

small Kiln Sitter cone.

Self-supporting conesare

3

2

" long. They are packaged

8

as sets of double cones so

that they will be less fragile

in shipping. You will need to

separate the cones. Hold the

large section of the cones

with the thumb and forefinger of each hand and twist.

They will snap apart.

Check the accuracy of

Separate the cones with thumb

pressure.

yourKilnSitterordigital

controller by placing cones on the shelf. Mount behind

each peephole a large cone of the same number you are

firing to. This is the firing cone. Next to the firing cone

placealargeconeofthenextlowertemperature;thisis

the guard cone. For example, if you are firing to cone 05,

place large cones 05 and 06 on the shelf behind the peep

holes. We recommend at least one large shelf cone in ev

-

-

ery firing.

Place large cones on the shelf at least 3" away from a

peephole. This is to avoid cool air drafts.

Always use Paragon firing safety glasses when looking

into the peepholes. These glasses are specially coated to

filter out the infra-red and ultra-violet light inside a kiln.

They also protect your eyes from heat and reduce glare,

making the pyrometric cones easier to see.

-

Fire only in a well ventilated area! 13

How to Position Cones

mit placing a shelf at peephole level, use a post to

raise the cones.

on the Shelf

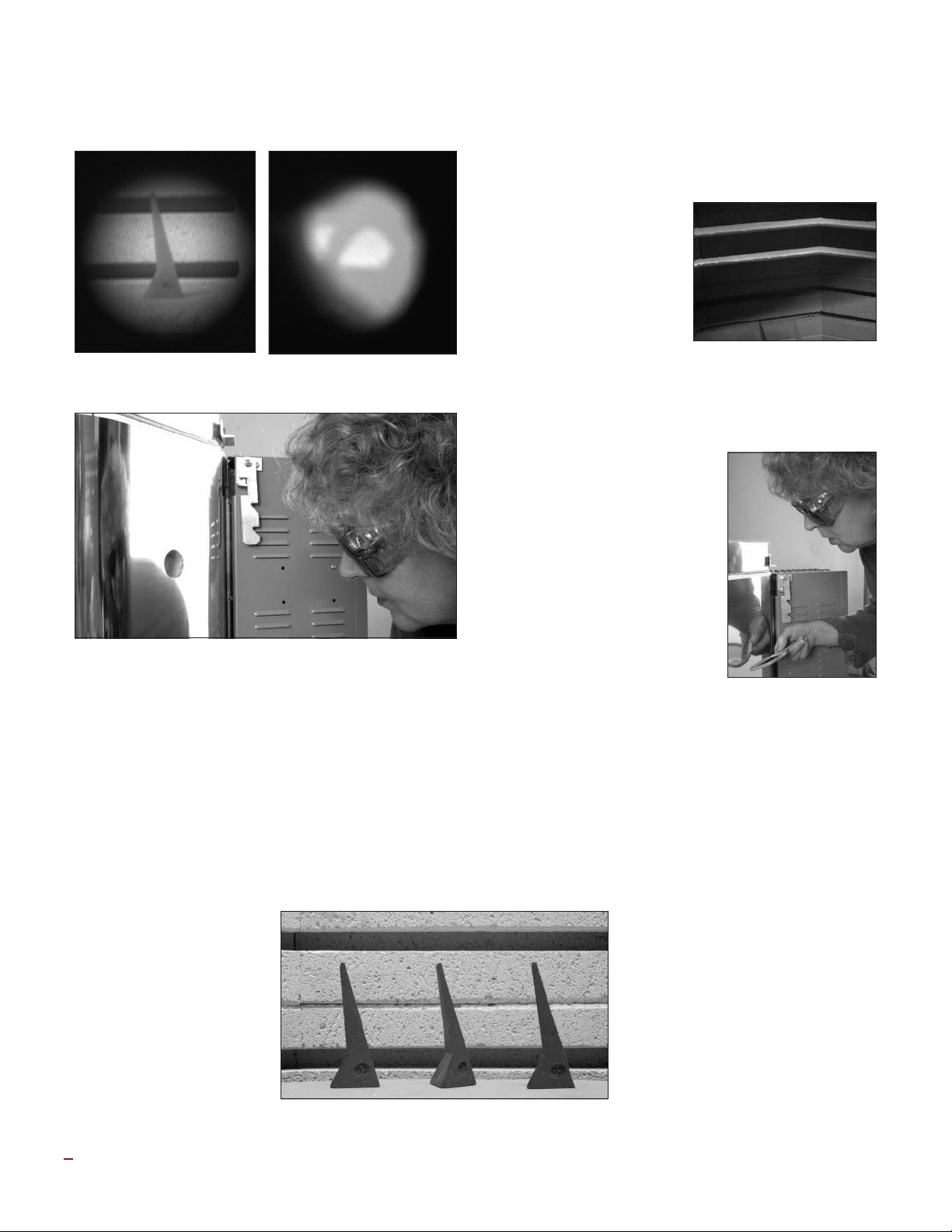

A cone seen through a peephole

while the kiln is at room tempera

ture.

A same cone silhouetted by a heat

-

ing element at cone 7—2262°F

(1239°C).

4 The element thatsilhouettes the cones should be

level with the lower part of the cone. If the ele

ment is in line with the upper part of the cone,

the cone willdisappear from view when itbends.

Note: The center ele

ments in some kiln

models do not glow

brightly even at high

temperatures. In this

case, position the wit

ness cones level with a

top or bottom element.

-

The element must

glow brightly to silhou

The top and bottom elements glow

brighter than thecenterelementsin

-

some kilns.

ette the cones.

5 If you use the three-cone system, always have the

higher temperature cone

onthesamesideinevery

firing. Otherwise you can

lose track of which cone is

which.

6 Wear kiln firing safety

glasses when viewing the

cones through the peephole.

Wear firing safety glasses when viewing a witness cone.

Position the witness cones so that you can see them

through a peephole during firing. If the kiln takes longer

than usual to fire, you may wonder if something has gone

wrong and the kiln is over-firing. But by seeing the cones,

you will know how the firing is actually progressing.

If you follow these guidelines,you shouldbe able to see

the cones even at cone 10:

1 Place the cones8" - 12" away from a peephole.Po

sitioning them closer makes them difficult tosee

and may also subject them to cool air drafts.

Note: Keep cones at least 2" from an element.

2 Have enough space

around the cones to

keep them from

touching a piece of

ware when they bend.

3 Position cones so that

when viewed from the

peephole, they are sil

houetted by an ele

-

ment on the opposite

kiln wall. If the size of

your ware doesn’t per

Line up the heating element with the lower part of the cones.

-

Note: You may find it easier

to see the cones by holding a

small mirror at a 45° angle in

front of the peephole. You

will still need firing safety

glasses.

Caution: Some ceramists blow into the peephole

to momentarily darken the cone so they can see it

better. Please do not do this. This can blow brick

dust onto the ware and is a safety hazard. Cool air

also changes the temperature at which the cone

bends.

Caution: Some ceramists coat the witness cones

with red iron oxide to make them easier to see.

Avoid this. It changes the temperature at which

theconebends.

“Working in my small studio

keepsmesaneandhappy.Ifor

get about everythingelse and am

grateful to do what I do.”

—Heidrun Schmid

-

14 Monitor the kiln during operation!

The Bending

Q When a kiln is taking longer thanusual tocom

plete a firing, how do you know whether some

thing has gonewrong and the kiln isover-firing?

-

-

of the Cone

You can watch the cones as they bend. If you

want to slow down the bending for greater con

trol, add a digital temperature hold near the end

of the firing. (See the separate controller man

ual.)

The large standard and self-supporting wit

ness cones have reached maturity when the tip

bends to the 6 o’clock position.

Large standard cone: The tip should bend

straight down until it just begins to touch the

cone holder.

Self-supporting cone: The self-supporting

cone should bend downward until the tip is even

with the top of the base. The tip should be about

½" above the shelf surface. If the self-supporting

cone tip touches the shelf, the cone is over-fired

by a few degrees of temperature.

Self-supporting cones: Left, over-fired or “puddled”; Center,

fired to maturity; Right, under-fired.

UsingConesin

A You should place pyrometric witness cones on

the shelf so that you can see them through a

-

-

-

peephole.

Here’s another way to

help prevent an over-fire:

Learn to estimate kiln tem

perature by the color of

light showing around the

lid and peepholes. That

way, you can tell at a glance

if all is well with your kiln

when you check it.

Q Is it okay to use old

cones?

A Yes. Age does not af

fect the cones.

Q Do you need to look

at witness cones during a firing or only after

the kiln has cooled?

A Position the cones so that you can see them

through a peephole. Form the habit of looking at

the cones near the expected shutoff time especially if thefiring is taking longer thanexpected.

-

The light around the edge of the lid

-

and inside the peephole changes

color as the kiln gets hotter. You

can learn to estimate temperature

by the color of that light.

“My grandmother, who has taught china

painting for 60 years,coached me duringmy first

firing. I treasure the memory of that moment of

my life with her.”

—Darcy Giesseman

Digital Kilns

Although the digital controllers do not need cones to

operate, we recommend them anyway. Place at least one

self-supporting cone on a shelf behind a peephole in ev

ery firing.

If the bending of the witness cones varies slightly from

firing to firing, you need not be concerned. Slight varia

tions in the bending of the cone are normal and may be

due to the location of the cones on the shelf, the distance

of the cones from ceramic ware, and even variations in

cones from box to box. This normal variation will have no

effect on your ware.

If your digital kiln shutsoff before the large coneon the

shelf bends and you’re there when it happens, program

the controller to a higher temperature or add a hold. (See

the separate digital controller manual for your kiln.)

Then turn the kiln back on.

“When I couldn’t get my first little half pound

ball of clay to center, my teacher kneeled down

beside my wheel, waited for me to stop, and said,

-

‘Hey, it’s just mud. Don’t let it control you. You

control it.’ When I have a problem, especially

-

with centering, I just zone out with my hands in

position on the clay, relax my shoulders, and tell

myself, ‘It’s just mud.’ And the clay obeys.”

—Sheron Roberts

“I love the impossibility of ceramics. Just

when I think I’ve got it figured out, something

bursts my bubble once again. It keeps me hum

ble. It keeps me interested, challenged, en

thralled.”

—Kelley Webb Randel

Fire only in a well ventilated area! 15

-

-