Page 1

ESPRIT

LISTED

728/738

Installation Manual

P R DOX

SECURITY SYSTEMS

IM728-738 960716-0000

VERSION 2.20

Page 2

Requirements and guidelines for U.L. INSTALLATIONS

I

UL listed in accordance with standard UL1023 (Household Burglar - Alarm System

Units), standard UL985 (Household Fire Warning Units) and UL1635 (Digital Alarm

Communicator System Units).

UL has only evaluated the 718, 728L, 728, 728 EXPRESS, 738, 738 EXPRESS and

748 for compatibility with the Ademco model 685, FBI model CP220FB, SUR-GUARD

SG-MLR2-D6 and Silent Knight model 9000.

Some operational features are not permitted in UL installations. To respect the standards for household applications, the installer should follow these guidelines when configuring the system.

1. ALL components of the system should be UL listed for the intended application.

2. If the installation is a FIRE ALARM application, refer to NFPA Standard 74 for details

on locating smoke detectors. There must be at least one UL-Listed Indoor Fire Alarm

Warning Signaling Appliance.

IM728-738

3. For U.L. Burglar Applications:

Maximum entry time = 45 seconds

Maximum exit time = 60 seconds

Minimum bell cutoff time = 4 minutes

4. Models 629, 633, 639, are not UL listed.

5. The upload/download software should not be used on UL listed systems.

Requirements and Guidelines for AUSTEL INSTALLATIONS

Austel-approved installations: use a transformer approved by the State Electricity

mission, such as "Dyen" PA series 15VAC 22VA. With this transformer, do not exceed

com-

the

following maximum currents: - maximum Auxiliary current (including keypads): 300mA

- maximum Bell current :600mA

Requirements and Guidelines for ULC INSTALLATIONS

When the system controls a fire alarm system, wiring method must correspond to

section 32 of the Canadian Electrical Code.

Page 3

TABLE OF CONTENTS

REQUIREMENTS/GUIDELINES FOR UL, ULC AND AUSTELINSTALLATIONS . I

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

ABOUT THIS MANUAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ABOUT PARADOX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

FEATURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Reliability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Total compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

User-Friendly Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

False Alarm Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Flexible System Partitioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

High-Speed Preprogrammed Communication. . . . . . . . . . . . . . . . . . . 4

Event Buffer and “Real Time Clock”. . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Programmable Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Espload Upload/Download Software. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Advanced Technology Zoning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Alarm Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Inputs and Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Event Buffer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operating Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Digital Communicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Espload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Accessory Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Keypads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Current Consumption. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

BASIC INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

LOCATION AND MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

EARTH GROUND. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

AC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

PROGRAMMABLE OUTPUTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

BELL/SIREN OUTPUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

AUXILIARY POWER TERMINALS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

KEYPAD CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

ZONE INPUT TERMINALS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Loop configurations and zone connections . . . . . . . . . . . . . . . . . . . . . 8-9

TAMPER/WIRE FAULT DEFINITIONS AND OPTIONS . . . . . . . . . . . . . . . . . 9-10

FIRE CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

TELEPHONE LINE CONNECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

POWERING-UP THE UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Panel Programming Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Battery Hook-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Battery Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

INSTALLER PROGRAMMING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-23

ESPLOAD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

KEYPAD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

PROGRAMMABLE FEATURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Hexa programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

Panel answer options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Panel Identifier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PC Password. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installer Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Intellizone Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Streamlined section programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

IM728 -738

1

Page 4

TABLE OF CONTENTS (continued)

Telephone and Account Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Computer telephone number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Central station telephone numbers . . . . . . . . . . . . . . . . . . . . . . . 13

System account codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Reporting Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-14

Arming codes/disarming codes. . . . . . . . . . . . . . . . . . . . . . . . . . 13

Zone alarm codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Zone restore codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Trouble codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Trouble restore codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Special codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Communicator Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-15

Programmable Output (PGM) Types. . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Typical PGM Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

System Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-20

Feature select programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Code priority. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

TLM options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-17

Arming using PS1 keyswitch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Call back. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Auto arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Touch tone options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Partitioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Silent alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-18

Dialing pulse rates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Reporting options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Bell squawk. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Auto zone shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Automatic event buffer transmission. . . . . . . . . . . . . . . . . . . . . . 19

Enable keypad panic signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Keypad panic options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

"One key" arming enable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

User/access code length. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Tamper/wire fault definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Beep on exit delay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Zone restore transmission. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Zones with EOL resistors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Always report disarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Exclude power failure from trouble display . . . . . . . . . . . . . . . . . 20

“Associated zone” deactivation . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Arming Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-21

Auto arm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

No tamper bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Advanced Technology Zoning (ATZ) . . . . . . . . . . . . . . . . . . . . . . 20

Audible trouble warning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

20 sec. delay before alarm transmission. . . . . . . . . . . . . . . . . . . 20

Keypad zone supervision. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Zone Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Intellizone definition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Silent/audible. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

24 hour - fire/regular. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Instant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Follow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

IM728 -738

2

Page 5

TABLE OF CONTENTS (continued)

Delay 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Bypass-enabled. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

System assignment .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Special Timing Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-23

3 digit decimal value programming. . . . . . . . . . . . . . . . . . . . . . . . 22

"No movement" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

"Late to close". . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Auto arming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Operational note regarding special timing functions. . . . . . . . . 22-23

Auto arm/report options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Installer Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Power down reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

USER/KEYPAD FUNCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-29

SYSTEM ARMING/DISARMING OPTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . 24-25

Regular System Arming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Force (Away) Arming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Stay Arming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Fast “Regular” Arming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Fast "Stay" Arming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Double "Stay" Arming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Fast Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

System Disarming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Alarm Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

SYSTEM PARTITIONING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-26

Partitioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Arming/Disarming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Keyswitch/push button arming/disarming (PS1) . . . . . . . . . . . . . 26

ZONE BYPASSING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Bypass Recall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

CHIME ZONES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

KEYPAD (PANIC) ALARMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

TROUBLE DISPLAY/MONITORING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-28

No battery/low battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Power failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Bell disconnect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Maximum bell current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Maximum auxiliary current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Communicator report failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Timer loss. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Tamper/zone wiring failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Telephone line monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Fire trouble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

PROGRAMMING MASTER AND USER CODES . . . . . . . . . . . . . . . . . . . . . . 28

KEY ACCESS PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

IM728 -738

WARRANTY STATEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

PROGRAMMING INFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-31

FCC COMPLIANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

INDUSTRY CANADA ATTACHMENT LIMITATION NOTICE. . . . . . . . . . . 33

INDEX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3

Page 6

IM728-738

Thank you for placing your trust in the

user-friendly control panels designed to meet all of your technological, performance and security requirements.

We hope that the important features of the

uploadable event buffer and high-speed pre-programmed communicator formats, will simplify your task of

supplying quality security service to your customers.

Esprit 728

Esprit 728

and

Esprit 738

control panels. You've chosen sophisticated,

and

Esprit 738

, which include a 120-event, PC-

ABOUT THIS MANUAL

This installation manual has been created to provide you with the information you will need to understand

panel operation, features and functions. It expands on the directions found in the

Even if you are familiar with other security control panels, we recommend that you read this manual at least

once to familiarize yourself with panel features. Please refer to the index for a complete list of manual contents.

"Programming Guide”

.

ABOUT PsRsDOX

We do our best to develop technologically-advanced products. If you have any comments or suggestions, or if you require additional technical assistance, please contact your local distributor. Every effort

has been made to ensure that your distributor's staff has received complete training from Paradox

Security Systems so that you receive prompt and effective service.

FEATURES

Reliability

The superior capabilities of the 728 and 738 are driven by cutting edge hardware. Use of the most powerful RISC processors on the market, with built-in “Analog to Digital” converters and SMD Technology,

means these control panels require 30-40% less components than any previous generations.

Total Compatibility

All programming, comprehensive system features, and upload/download software of Esprit panels are

identical. This total compatibility significantly reduces the time required to conduct training, programming

and system upgrades. There’s just one set of procedures for all Esprit panels.

User-friendly Operation

The reduced number of steps required to program Esprit panels via a keypad speeds up installation. Enduser access to most system functions calls for just one touch of the keypad. A “streamlined programming”

feature further simplifies the programming process, by saving data automatically and leading the installer

through the programming addresses without the need to enter them manually.

False Alarm Prevention

Important advances have been made in Esprit control panel technology which guarantee exceptional levels of

false alarm protection. A full range of high tech features dramatically reduce the frequency of false alarms.

These easy to use tools include “Intellizone” definition, “Auto Zone Shutdown”, “Beep On Exit Delay” and “20

Second Delay before Alarm Transmission”.

Flexible System Partitioning

Each control panel can be used to monitor two distinct security systems. Partitioning provides a practical

and flexible solution to situations where combined systems are a necessity. User-friendly Esprit partitioning does it all with just one access code. Protected area zones can be defined as belonging to System

“A”, System “B”, both systems (dual area), or given no system assignment (common area).

High-Speed Preprogrammed Communication

Esprit panels can slash set-up and reporting time by transmitting preprogrammed and high-speed communicator formats.

Event Buffer and “Real Time Clock”

Incorporation of a real time clock permits the creation of a 120 event, PC uploadable buffer with time and

date. Two automatic arming options are made possible by the inclusion of the "real time" clock. Auto

arming can be programmed to take place at a specific time, or following a set time period without any

zone activity (auto arm and/or report only).

4

Page 7

Programmable Outputs

Almost any control panel status situation may be used to activate the Esprit’s programmable outputs.

Once a panel status mode is selected for a PGM to follow, the polarity and duration of the output may

also be programmed. 18 supplementary programmable outputs are available with the SRI18 module,

which connects to the panel’s serial output.

Espload Upload/Download Software

Espload upload/download software revolutionizes control panel supervision by offering powerful panel

programming, modification, real-time monitoring and data management tools. It functions with most

Hayes-compatible modems, requires only 45 seconds to transmit a full upload or download, and is

extremely simple to learn and operate. The upload/download software is not permitted on UL installations.

Advanced Technology Zoning

Advanced Technology Zoning was developed to permit connection of 2 zones and a tamper on a single

pair of wires, as well as providing wire fault recognition. ATZ simplifies the task of meeting the zone

reguirements of any installation and, at the same time, reduces installation costs.

Alarm Relay (optional-738)

Single pole, double throw dry contacts rated at 5 amps that follow the local alarm (bell/siren) output.

IM728-738

SPECIFICATIONS

Inputs and Outputs:

Maximum Zones: Varies according to control panel/keypad combination.

639/640 LCD keypads: (See "Keypad Connections", page 8.)

728: 10 zones (4 onboard zones + 4 ATZ zones + 2 keypad zones)

738: 14 zones (6 onboard zones + 6 ATZ zones + 2 keypad zones)

616/626/633 LED keypads: (See "Keypad Connections", page 8.)

728: 9 zones(4 onboard zones+ 4 ATZzones + 1 keypad zone) - using 1 keypad.

728: 10 zones (4 onboard zones + 4 ATZ zones + 2 keypad zones) - using 2 keypads.

738: 13 zones(6 onboard zones+ 6 ATZ zones+ 1 keypad zone) - using 1 keypad.

738: 14 zones (6 onboard zones + 6 ATZ zones + 2 keypad zones) - using 2 keypads.

Zone Configuration: N.C. (no resistors), EOL (1 resistor), “Advanced Technology Zoning” and

wire/tamper recognition using.

2 resistors per zone. (Zone configuration programmed at address 208)

Battery Charger: 360mA with active Battery test.

Aux power: 400 mA, Fuseless electronic shutdown at 1A, Automatic restore

Bell Out: 1A, Fuseless electronic shutdown at 3A, Automatic restore

AC input: 16.5 Vac, 40VA, 50 - 60Hz

PGM outputs: More than 1000 options to follow

2 operation modes: Timed (1 sec.-2 hrs.) or following predetermined condition.

N.C. or N.O to ground, 50 mA Max.

Can also be remote-controlled by PC using Espload.

Event Buffer:

120 event buffer with time and date.

Operating Modes:

17 User codes (2 Master codes) 4 or 6 digit codes.

Partitioning to System “A”, System “B”, both systems (dual area), or no system assignment (common area).

Regular, “Stay” (at Home) arming, Force “Away” arming

Fast “One key Full Arm”, “One key Stay Arm” and “One key Exit”.

Key Switch Arm/Disarm ("stay" or "regular" mode).

PS1 bedside remote.

3 keypad-activated panic alarms.

Real Time Clock for "list of events", auto arming and test reports.

Auto arm on “time” or “no zone activity delay time”.

5

Page 8

Digital Communicator:

Compatible with most worldwide telecommunication standards.

Reporting formats:

Pulse: Ademco slow (10BPS), Silent Knight fast, Sescoa (20 BPS) Radionics,

Radionics with parity (40 BPS), 1400Hz - 1800Hz (10 BPS)

DTMF: Contact ID, Ademco Express, “No handshake” DTMF format.(Pager)

True Dial tone detection and telephone line monitoring.

Fully up/downloadable with PC.

Regular, Split and Double reporting modes.

“Delay before alarm transmission” option.

Espload

Upload/download PC software.

Provides full up/download within 45 seconds.

Permits creation of unlimited number of account and panel default files.

Powerful "monitoring" mode supervises all panel activity.

"Scheduler" activates panel features at preprogrammed intervals.

"Batch" mode carries out tasks following panel call.

Accessory Modules:

SRI 18:

708DV:

18 PGM outputs,

DVACS communicator (Canada only),

708:

Secondary Digital Dialer (UL listed)

Esprint:

Parallel printer interface (not UL listed).

IM728-738

Keypads:

616, 626, 629 and 633 (LED) keypads. 639 and 640 (LCD) keypads, PS1 bedside remote. (For UL systems use only 616, 626, 640 or PS1.)

Current Consumption:

(measured with battery connected, without AC and with 1KW resistor on bell and 1KW resistor on zones.)

738

control panel

728

control panel

616/626 LED keypads: 15mA DCTypical PS1 bedside remote: 15mA DCTypical

629 access control keypad: 30mA DCTypical SRI-18: 50mA

639/640 LCD keypads: 20mA DCTypical

:

:

25mA

45mA DCMaximum

DC

25mA

DC

30mA DCMaximum 20mA DCMaximum

DC

55mA

Maximum

633 LED keypad: 15mA DCTypical

35mA DCMaximum

DC

Typical

LOCATION AND MOUNTING

Remove the printed circuit board, mounting hardware and keypad from the packaging inside the panel

box. Press the four white nylon mounting studs into cabinet from the back before mounting the

cabinet. Before mounting circuit board on the back of the cabinet, pull all cables into cabinet and prepare

them for connection.

Select a control panel installation site that is not easily accessible to intruders. Leave at least 2” around

the panel box to permit adequate ventilation/heat dissipation. Installation location should be dry, close to

an AC source, ground connection and a telephone line connection.

6

Page 9

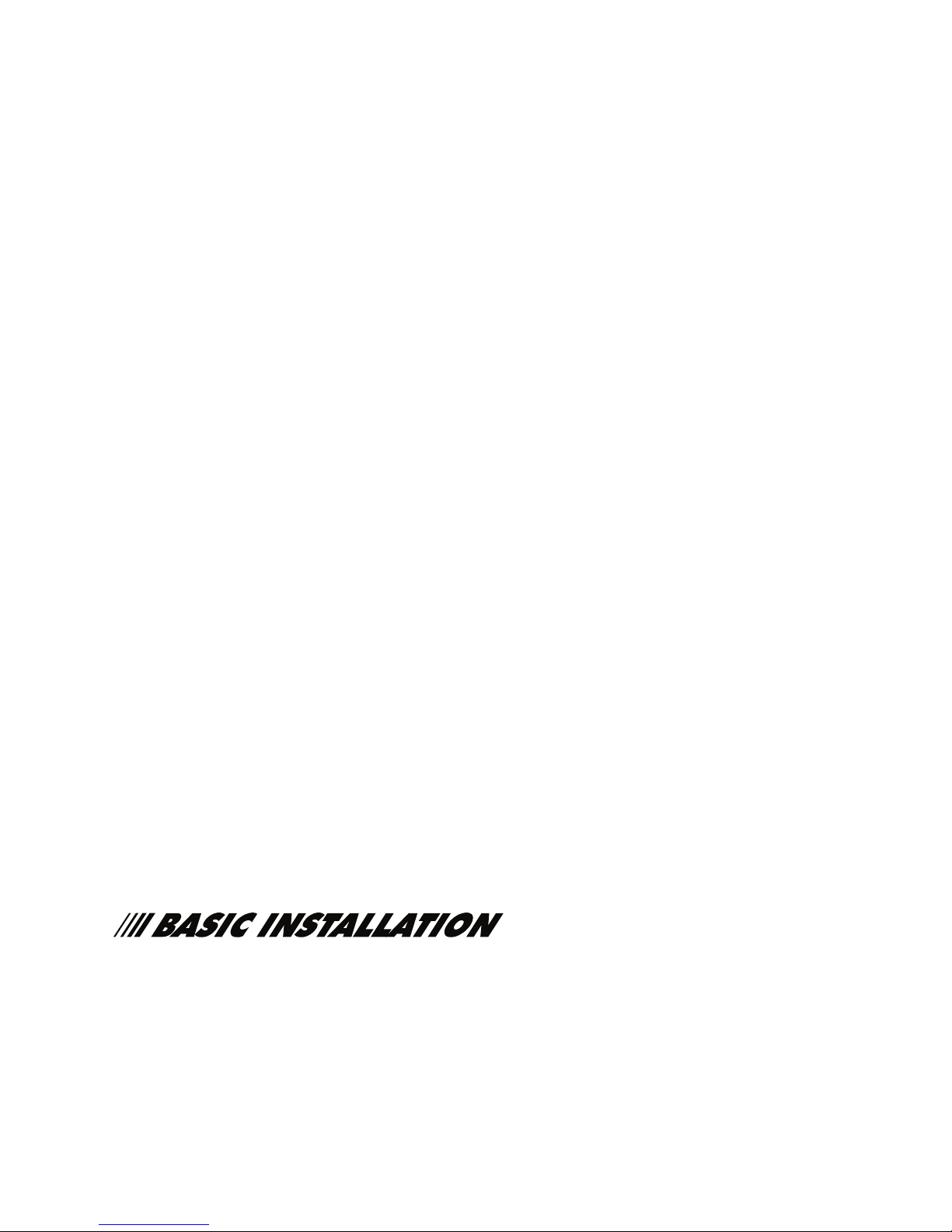

EARTH GROUND

The earth terminal should be connected to the cabinet and

ground

ing rod as per local electrical codes.

AC

Use a 16.5VAC (50-60 Hz) transformer with a minimum 40VA rating to pro

trolled outlets to power the transformer. UL listed systems require

K12 model T16V40 transformer, ULC listed systems require Frost

model FTC 1637 transformer. Warning: Do not con

former until all wiring is completed.

vide sufficient AC power. Do

not utilize any switch-con-

nect trans-

PROGRAMMABLE OUTPUTS

If programmable outputs are to be used, they should ideally

be connected through external relays, as these outputs

should not drive more than 50mA. A relay should be used in

cases where more than 50mA is required. (UL tested for

30mA only.)

IM728-738

Example: To program PGM1 to open/close an automat

garage door when keys [3] and [6] are pressed at the same

time:

Address 195: [6] (1st digit)

Address 196: [5] [8]

Address 198: [1] [1]

Address 254: [10] [10] [1]

ic

BELL/SIREN OUTPUT

Bells or other warning devices requiring a steady voltage output during

alarms, are powered by the Bell+/ Bell- terminals. The bell output is microprocessor-controlled and will automatically shut down if current exceeds 3

amps. The processor will allow current to resume as soon as another

alarm is triggered. The correct polarity connections should be made when

hooking up sirens (speakers with built-in siren drivers). “Bell+” terminal is

the connection for the positive lead. “Bell-” terminal is the connection for

the negative lead. The bell output supplies 12V upon alarm. It can support

two 20-watt or two 30-watt sirens. (Above 1A, battery supplies current.)

AUXILIARY POWER TERMINALS

Motion detectors and any security devices requiring 12VDC voltage can be powered by the auxiliary

power supply. A maximum of 400mA 12VDC is available 250mA 12VDC for 24hrs standby for UL/ULC

installations is available from the AUX+ and AUX- terminals. For each additional keypad or PS1 module,

the auxiliary supply must be reduced by the corresponding keypad current consumption value. (See

"Current Consumption”, page 6). The auxiliary supply is microprocessor-protected against current overload and automatically shuts down if current exceeds 1 amp. Auxiliary power will resume after battery test

takes place (within 1 - 60 seconds).

7

Page 10

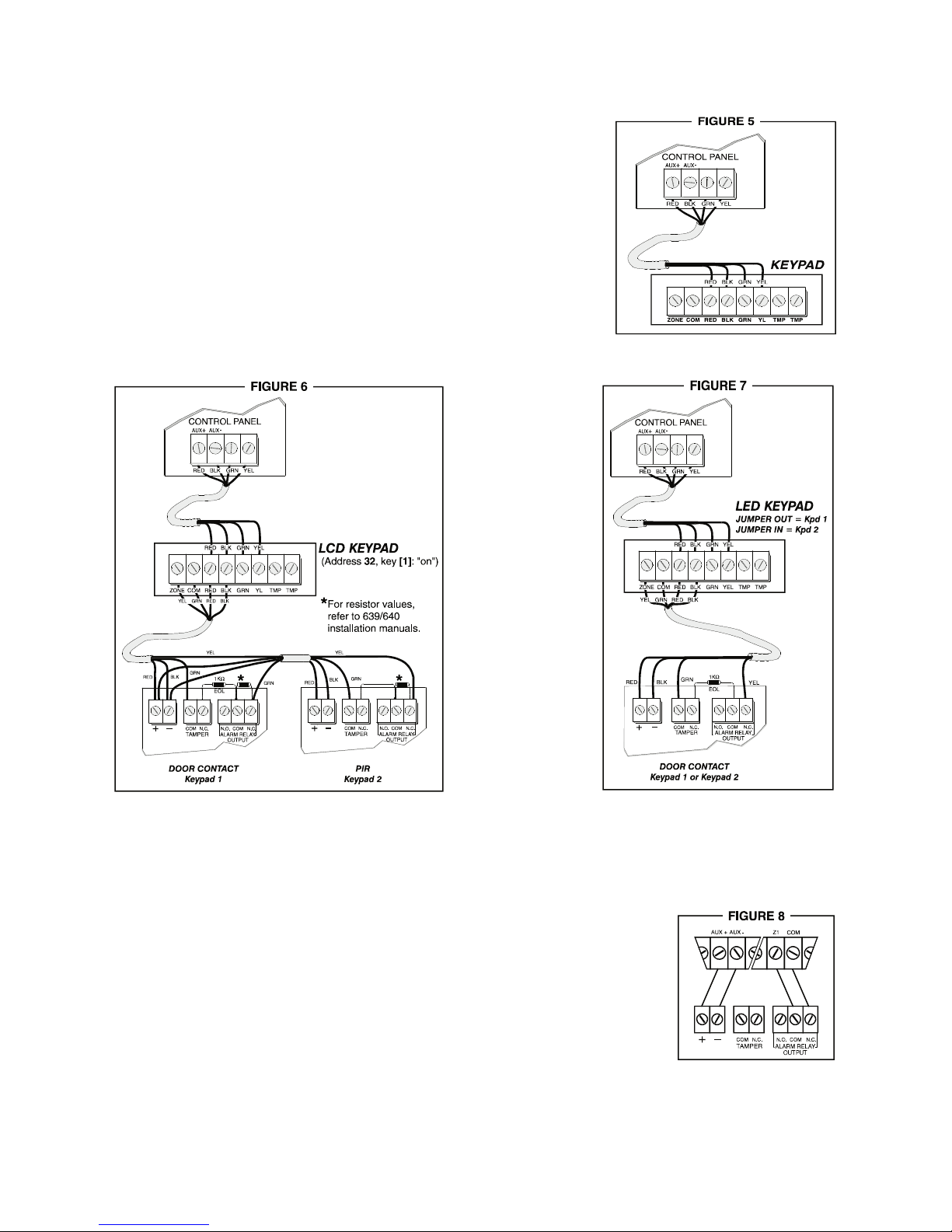

KEYPAD CONNECTIONS

Panel/keypad connection:

The four keypad connections labeled "red", "black", "green" and

"yellow" should be connected to the cor

on the control panel PC board.

Keypad zone connection:

The two connections labeled "zone" and "com" are used to connect a

zone to the keypad. Up to 5 keypads may be connected to the control

panel but only two (2) keypad zones (Keypad 1 and Keypad 2) can

be active at any one time. Examples of keypad zone connection

pos

sibilities (depending on type of keypad used) are shown below:

639/640 LCD keypads 616/626/633 LED keypads

responding colour terminals

728 (no ATZ):

Kpd 1 = Zone 5

Kpd 2 = Zone 6

IM728-738

728 (with ATZ):

Kpd 1 = Zone 9

Kpd 2 = Zone 10

738 (no ATZ):

Kpd 1 = Zone 7

Kpd 2 = Zone 8

738 (with ATZ):

Kpd 1 = Zone 13

Kpd 2 = Zone 14

To disable the keypad zone (when keypad zone supervision is deactivated), you must connect a 1KW

resistor across the two connections labeled “zone” and “com” on the keypad. (On the 616 keypad, connect the blue wire “zone” to the black wire “com” and remove the EOL jumper 2.)

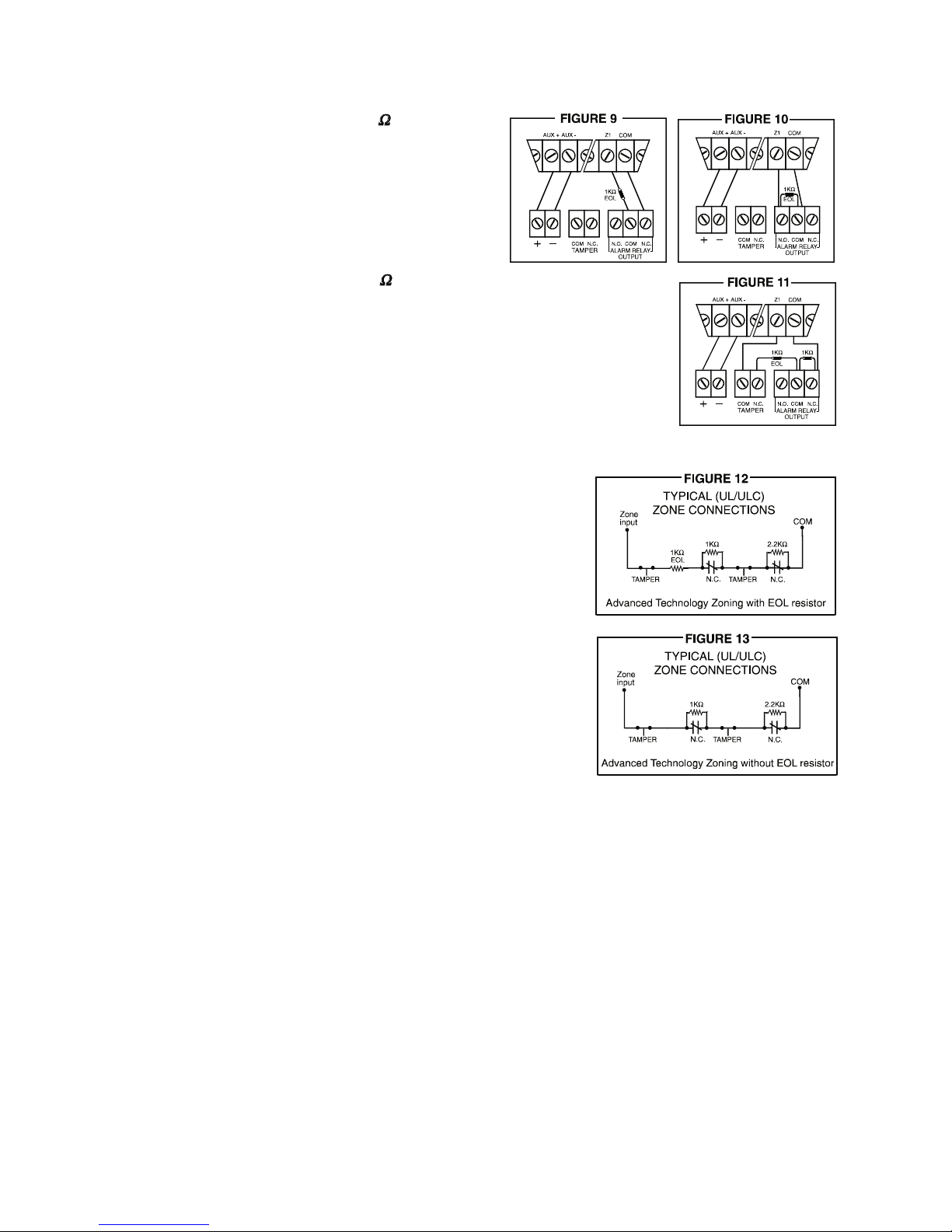

ZONE INPUT TERMINALS

Loop Configurations and Zone Connections

The system hardware will recognize the following conditions for each zone:

SINGLE ZONE connection without EOL resistor (N.C. contacts)

address 208, key [MEM] = "on"

key [10] = "off" (default)

key [11] = "off" (default)

Note: Keypad zones always use a 1KW EOL resistor.

8

Page 11

SINGLE ZONE connection with a 1KWEOL resistor

(N.C. and N.O. contacts)

address 208, key [MEM] = "off" (default)

key [10] = "off" (default)

key [11] = "off" (default)

SINGLE ZONE connection with a 1KWEOL resistor, tamper recognition

(N.C. contacts)

address 208, key [MEM] = "off"

key [10] =

key [11] =

Tamper fault transmits separate code.

See "Tamper/wire Fault Definitions

and Options"

IM728-738

ADVANCED TECHNOLOGY ZONE connection, 2 zones with zone resistors, 1 EOL resistor (

1KOHM)

tamper (open) recognition, wire fault (short circuit) recognition (N.C. contacts)

address 208, key [MEM] = "off"

key [10] =

key [11] =

address 210, key [8] = "on"

Each zone transmits a separate alarm code.

Tamper/wire fault transmits a separate alarm code, indicated by fast

flashing zone light on keypad, and displayed in

See "Tamper/wire Fault Definitions

and Options"

Espload.

ADVANCED TECHNOLOGY ZONE connection, 1 zone resistor

(without EOL), tamper recognition (N.C. contacts)

address 208, key [MEM] = "on"

key [10] =

key [11] =

address 210, key [8] = "on"

Tamper fault transmits separate code.

See "Tamper/wire Fault Definitions

and Options"

TAMPER/WIRE FAULT DEFINITIONS AND OPTIONS

When using 2 zone resistors, the panel offers four possible definitions for tamper/wiring recognition,

independent of zone definition.

"Tamper/wire” disabled (Address 208, Key [10] "off", Key [11] "off")

Tamper/wiring failure recognition is disabled.

"Trouble" enabled (Address 208, Key [10] "off", Key [11] "on")

Tamper/wiring failure will generate an alarm, when armed. A trouble report code will be sent to the central

when disarmed.

"Silent alarm" enabled (Address 208, Key [10] "on", Key [11] "off")

Tamper/wiring failure will generate a silent alarm (no siren) when the system is disarmed. Alarm and

trouble report codes will be sent to the central.

"Audible alarm" enabled (Address 208, Key [10] "on", Key [11] "on")

Tamper/wiring failure will generate an audible alarm (siren). Alarm and trouble report codes will be sent

to the central.

9

Page 12

Exception: When the zone definition is "24 hour", the tamper definition follows the audible/silent

alarm arm definition of the "24 hour" zone.

Tamper recognition addresses:

Tamper report and restoration codes should be programmed at addresses 191 and 180.

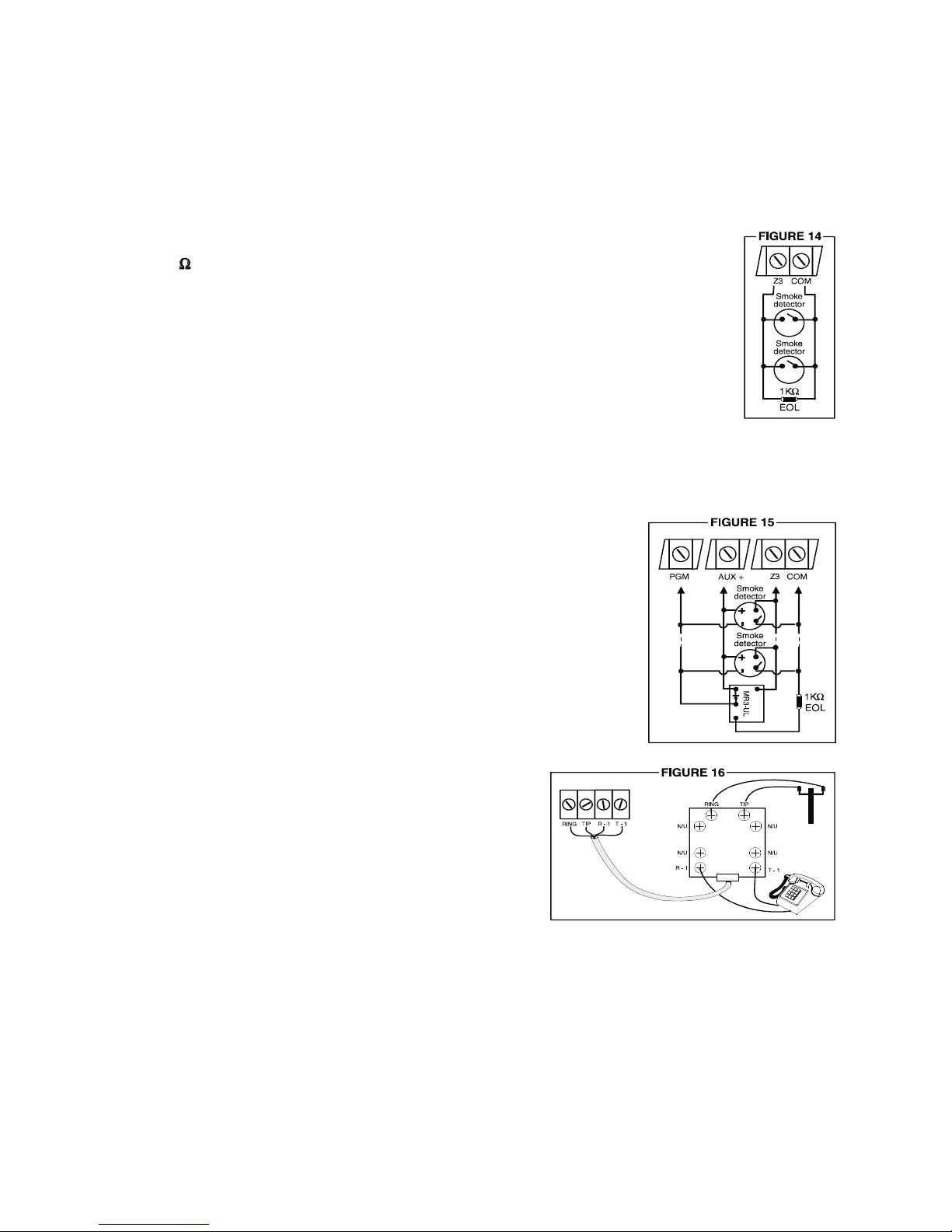

FIRE CIRCUIT

The fire zone (enabled by defining zone 3 as "24 hour') should always be connected

with a 1KWEOL resistor (PN201100200-PRT on UL systems). If there is a line short

in the fire zone, a fire alarm will be generated. If the line is "open", a "fire loop" trouble

report will be sent to the central and trouble indicator [11] will illuminate on the keypad.

For UL/ULC installations, a 4 wire, latching, smoke detector (UL - Falcon Model 5454,

ULC - BRK Model 2412) must be used. To supervise power supply, an “end of line”

relay (Model MR3) is installed. This relay’s contacts will cause a FIRE TROUBLE in

the event the power is interrupted.

To reset (unlatch) smoke detectors after an alarm, power to detectors must momentarily be interrupted. To do so, connect the negative (-) side of smoke detector power

to PGM1. PGM1 should then be programmed “Timed N.C.” (normally closed), programmed to “open” when any two keys on the keypad are pressed simultaneously.

IM728-738

Example:

To program PGM1 to conduct smoke detector reset when

[CLEAR] and [ENTER] are pressed at the same time.

Address 195 = [BYP] (in the first digit)

Address 196 = [5] [10]

Address 198 = [2ND] [6]

Address 254 = [10] [10] [4]

TELEPHONE LINE CONNECTION

Connect the incoming telephone company wires into

"TIP" and "RING". Wires should then be run from "T1" and

"R1" to the installation's phone system.

POWERING UP THE UNIT

When keypads are installed far from the control panel, a keypad should be temporarily connected close

to the panel to conduct "power-up" testing. Connect the transformer. After 5 seconds, begin testing the

unit. Enter random commands on the keypad. It should "beep" in response to these commands. Open a

zone to ensure that keypad and panel are responding to signals. If the keypad does not respond and

indicator lights do not illuminate, check for AC voltage at the “AC” terminals. If 16VAC is flowing, then

keypad wiring should be verified. Also check for a short between "black" and "red” keypad wires.

10

Page 13

Panel Programming Methods

To conduct panel programming, use the keypad or initiate communication with Espload (see page 11).

Use of

programming. For Keypad Programming instruction, refer to "Programming Guide".

Espload

is highly recommended, as it greatly reduces the potential for data entry errors during

Battery Hook-Up (required on UL/ULC installations)

Use a 12VDC 7AH rechargeable acid/lead or gel cell battery. Connect

"red" battery lead to positive battery terminal, and "black" battery lead to

negative battery terminal. Reversed connections will blow the battery

fuse. Battery should not be connected until AC panel connections have

been made. After connecting battery [TRBL] key should illuminate.

Pressing [TRBL] causes key [8] to illuminate (trouble indicator for "timer

loss"). (See "Trouble Display Monitoring" section, page 27-28.)

Warning: Do not connect battery until all wiring is completed.

Battery Test

The panel verifies battery connection every 60 seconds. If the battery is not connected, trouble indicator

key [1] illuminates. If battery is connected, a 4 second test of battery under load is conducted. Test failure causes trouble indicator key [1] to illuminate, indicating that battery capacity is insufficient. When the

panel runs on battery power, with or without AC, if battery voltage drops to 10.5 volts, trouble indicator

key [1] will illuminate. (If programmed, a trouble report code will also be sent to the central station.) At 8.5

volts all outputs are closed.

IM728-738

ESPLOAD

Esprit control panels can be remotely programmed with Espload upload/download software, or on site

using Espload and a ADP-1 adapter. Advanced Espload software can carry out a full upload or download

in just 45 seconds, and provides many powerful features, including a comprehensive "monitoring" mode

to oversee all panel activity, a "scheduler" to initiate preprogrammed tasks at set intervals, and a "batch"

mode to carry out preprogrammed tasks following a call from the panel. There is no limit to the number of

account files or panel defaults that can be created, and thousands of programming combinations can be

assigned to PGM outputs using Espload. Espload can be converted to the language of your choice, and

individualized help menus can also be generated. Contact your local Paradox Distributor for your free

copy of Espload software.

KEYPAD

To program Esprit panels via the keypad, first complete the programming work sheets and follow the programming procedures outlined in the "Programming Guide".

PROGRAMMABLE FEATURES

Hexa Programming:

All digits from 0 to F are valid. Programming values are programmed into memory locations from address

000 to 007.

1) Press [ENTER] + installer code 4) Enter 2 digit data.

2) [ENTER] will flash (programming mode) 5) To erase, press [CLEAR]. To save press

3) Enter 3 digit memory address (000-007) 6) Go to step 3 for next address.

To exit programming mode, press [CLEAR].

[ENTER].

11

Page 14

Panel Answer Options: (Address 000) DIRECT ADDRESS

Intelli

zone

The first digit entered disables the “Answering Machine Override” (key [2ND] or key [1]), or determines

the period of time between first and second call.

The second digit entered determines the number of rings required before the panel will answer. If

[2ND][2ND] is entered, the panel will not answer. (Default value is [2ND] [8].)

Panel Identifier: (Addresses 001, 002) DIRECT ADDRESS

This four digit code identifies the control panel to the PC before uploading can be initiated. Each pair of

code digits has its own memory address. There is no default code. Any hexa digits from 00 - FF can be

entered. Program first 2 digits in address 001 and second 2 digits in 002.

Related features: "Panel Answer Options"

000

"Call back"

206, [4]

IM728-738

PC Password: (Addresses 003, 004) DIRECT ADDRESS

This four digit download password identifies the PC to the panel, prior to beginning the programming

download process. Program the first 2 digits in address 003 and the second 2 digits in 004.

Installer Code: (Addresses 005, 006, 007) DIRECT ADDRESS

(Use only numeric keys from [1] to [10] to enter installer code. Key [10] = 0.)

The default installer code contains 6 digits. Default code for the 728 is 282828, and for the 738 is

383838. (Codes can also be programmed to contain 4 digits, address 208, [9] "on".) Create a new

installer code by entering the values of 1st and 2nd digit at address 005, 3rd and 4th digit at address 006,

and 5th and 6th digit at address 007.

The installer code has access to all programming addresses, except 008-058. It does not provide access

to arming/disarming or user code programming. It can be used to modify itself.

Related features: "Installer lock"

The first digit determines the period of time in which two intellizone detections must take place, or in

which an intellizone must remain open, in order for an alarm to be communicated.

First digit: (factory default [3])

[1] = 16 sec. [5] = 80 sec. [9] = 144 sec. [BYP] = 208 sec.

[2] = 32 sec. [6] = 96 sec. [10] = 160 sec. [MEM] = 224 sec.

[3] = 48 sec. [7] = 112 sec. [11] = 176 sec. [TRBL] = 240 sec.

[4] = 64 sec. [8] = 128 sec. [12] = 192 sec. [2ND] = 256 sec.

Delay: (Address 059) DIRECT ADDRESS

255

"User/access code length"

208, [9]

Streamlined Section Programming:

To begin programming:

Press [ENTER] + installer code + [2] [7]. ([ENTER] and [2ND] keys will flash.)

Enter 2 digit section for programming (00 - 34). ([ENTER] key is "steady" and [2ND] key is "off".)

Enter 8 digits to program the section. Keypad will beep, to show section has been programmed.

Data is saved and the next section is advanced to automatically for programming.

To select a specific section, press [CLEAR] or [ENTER]. ([ENTER] and [2ND] keys will flash.)

Enter 2 digit section (00-34). ([ENTER] key is "steady" and [2ND] key is "off".)

To exit programming mode, press [CLEAR].

12

Page 15

IM728-738

Telephone and Account Numbers

Three telephone numbers can be programmed: a PC telephone number and two central station numbers.

Each number can contain a maximum of 16 digits. Special instructions can be entered in the telephone

numbers using the following keys:

[10] = the number "0" [BYP] = switch from pulse to tone while dialing

[11] =

[12] = # [TRBL] = end of number

If only one central station telephone number is available, the same telephone number must be programmed for telephone number 1 and 2. A separate "communicator reporting" format can be selected for

each central station telephone number at address 194.

*

Computer telephone number: (Addresses 060-067) SECTION 00 - 01

The PC download telephone number is dialed in three situations. It is dialed when communication with

PC is initiated from the keypad. It is the automatic "call back" number, when the "call back" feature is

enabled (206, [4] "on"). If the event buffer is ready to report, and "automatic event buffer transmission"

feature is enabled (208, [2ND] "on"), this number will be dialed in order to download the event list.

Related features: "Panel Identifier"

Central station telephone number 1 (Addresses 068-075) SECTION 02 - 03

Central station telephone number 2 (Addresses 076-083) SECTION 04 - 05

The panel can communicate with two central station numbers. Each of the numbers can be assigned a

separate reporting format.

Related features: "Communicator Formats"

Espload note: Upon alarm, upload/download in progress will be interrupted and the panel will dial the central.

[MEM] = pause 4 seconds

001 - 002 "

PC password"

194

"Reporting options"

003 - 004

206, [11] and [12]

"Call back"

206, [4]

System account codes (system "A"/"B") (Addresses 084-087) SECTION 06

All report codes are

zone(s) in a partitioned system. If partitioning is deactivated, the same value should be pro-

grammed for both account numbers. To program account codes for System "A" and "B", press

[

ENTER

] + installer code + [2] [7] + [10] [6]. The first four digits entered after this sequence correspond

to the System "A" account code, and the last four

preceded by a system account code to ensure correct identification of active

digits to the System "B" account code.

Reporting Codes: (Addresses 088-193) SECTION 07- 33

The panel can report information regarding system and "protected area" status to the central monitoring

station, when reporting is activated at address 206. All data to be communicated should be assigned a 2digit hexa reporting code, consisting of numbers from 0-15. Examples of two digit hexa code combinations are [6] [BYP] and [9] [TRBL]. Written in hexa notation, these codes are [6] [D] and [9] [F].

Using the keypad for hexa digit entry, keys [10], [11], [12], [BYP], [MEM] and [TRBL] correspond to hexa

digits A, B, C, D, E and F, respectively.

The [2ND] key's value is "skip" (empty). It is ignored by the panel, so to avoid reporting a specific condition

to the central, enter [2ND][2ND] after the report address for that condition. Also, when programming 3 digit

account codes and 1 digit alarm codes (3-1 reporting), use [2ND] in lieu of the first digit.

All report codes are assigned to a system account, whether or not partitioning is activated. Arm/disarm

reports are assigned to System "A" when partitioning is "off", or to the system account to which they

belong, based on code priority assignment, when partitioning is activated.

Trouble and special report codes are always assigned to System "A".

Arming codes/disarming codes: (Addresses 088-119) SECTION 07- 14

System access codes can be programmed to generate hexa report codes that communicate the identity

of the user arming/disarming the control panel to the central monitoring station. Each user code can be

assigned an arm/disarm report code. (

at addresses 188/189 - see “Special codes”, page 14.)

Espload

and the master code can be assigned a report code

13

Page 16

Zone alarm codes: (Addresses 120-143) SECTION 15- 20

Alarm report codes programmed will be sent to the monitoring station, identifying the zones that are generating alarms.

Zone restore codes: (Addresses 144-167) SECTION 21- 26

Zone restoration codes programmed will be sent to the monitoring station, identifying zones returning to

normal status after alarms.

Trouble codes: (Addresses 168-175) SECTION 27- 28

8 trouble status codes can be reported to the central, if programmed: max. auxiliary current, bell

disconnect/max. bell current, battery disconnected/low voltage, power failure, program change (indicates that

someone has initiated "installer" or Espload programming), timer loss, fire loop trouble, and test report.

(See "Trouble Display/Monitoring", page 27-28, for a list of trouble conditions displayed on the keypad.)

Trouble restore codes: (Addresses 176-183) SECTION 29-30

If trouble conditions occur and are reported, once normal status is re-established, a "restoration" code

can be transmitted to the central to indicate that the "trouble" situation has been rectified. Note: All

Tamper/Wire Faults must be restored before a restoration code is transmitted.

Special codes: (Addresses 184-193) SECTION 31- 33

These codes are assigned to report 10 special status conditions.

IM728-738

Panic 1

Panic 2

Panic 3

Partial arming

Auto/Espload Arm

Arm with master code

No movement/

late to close

Tamper report

Disarm with Espload

Disarm with

master code

Panic alarm will be reported to the central if keys [1] and [3] are pressed for 2 seconds.

Panic alarm will be reported to the central if keys [4] and [6] are pressed for 2 seconds.

Panic alarm will be reported to the central if keys [7] and [9] are pressed for 2 seconds.

Will be reported to the central if the control panel is armed while any zones are

bypassed or when the system is force armed.

Will be reported to the central when Espload is used to arm the control panel or

when the system arms itself automatically (on “no movement” or at a specified time.)

Will be reported to the central when the master code is used to arm control panel.

Will be reported to the central when there is no movement in the protected area for

a designated time period, or if the system has not been armed by the required time.

The hexa digit entered for this report code will replace the first digit of all zone alarm

report codes when tamper "trouble" occurs. This identifies zone location of the tamper "trouble" to the central (auto-generated codes).

Will be reported to the central when Espload is used to disarm the control panel.

Will be reported to the central when master code is used to disarm control panel.

Communicator Formats (Address 194)

Ademco contact ID (all codes reported) (key [10])

All report codes are preprogrammed in this DTMF reporting format. There is no need to program values for

addresses 088-193 if both central station numbers use this format. Contact ID event codes are listed below:

14

Page 17

IM728-738

Ademco contact ID

Select certain report codes to be reported by entering any value other than [2ND][2ND] at the required

addresses. The preprogrammed Contact ID report code for that event will then be reported. Default value

of all addresses is [2ND][2ND].

(selected codes reported)

(key [9])

Ademco express (key [8])

This high speed reporting format communicates events in 2 seconds.

DTMF - no handshake ([TRBL] key)

This format can be utilized in reporting situations where a central station receiver is not connected to the

telephone number. It's useful for personal reporting where a "handshake" is not required. (In "double

reporting" mode, first central station number can be connected to a receiver, while second can be used

for personal reporting using "no handshake" format. The panel will make two attempts to call the "no

handshake" number.)

Standard pulse formats

Ademco slow, Silent Knight, Sescoa, and Radionics are programmable with keys [2ND] to [7].

Programmable Output (

Regular N.O. Solid state switch conducts to negative (*50mA) upon an event or events, and returns to its

original state (N.O) once the conditions that triggered it have terminated.

Regular N.C. Solid state switch opens circuits from ground upon an event or events and returns to its

original state (N.C.) once the conditions that triggered it have terminated.

PGM

) Types (Address 195) SECTION 33

Timed N.O. Solid state switch conducts to negative (*50mA) upon an event or events and remains acti-

vated for the amount of time programmed at address 254.

Timed N.C. Solid state switch opens circuits from ground upon an event(s) and remains activated for

the amount of time programmed at address 254.

"OR" logic

"AND" logic Causes the programmable output command to occur when all selected events from a spec-

"EQUAL" logic Causes the programmable output command to occur when all events from a specified

Causes the programmable output command to occur when one or more selected events

from a specified group of events takes place (example: key [1]OR[2] is pressed on keypad.)

ified group of events take place (example: key [1] AND key [2] are pressed.)

group of events take place (example: key [1] and [2] are pressed but [3], [4], [5], [6], [2ND]

and [TRBL] are not pressed.)

*UL tested for 30mA only.

15

Page 18

Typical PGM (Programmable Output) Programming

IM728-738

FUNCTION DESCRIPTION TYPE HEXA PROG.

Ground start Pulse Provides 3 sec. pulse before 5 5/2 [2ND]/8

**

(Timed N.O.) communication attempt.

Push key [1] and [2] Provides output when keys [1] 1 5/8 [2

(Regular N.O.) and [2] are pressed simultaneously.

System armed Output removed when system 9 2/B [2

(Regular N.C.) armed.

Strobe output Provides latching output on 1 2/C [2

(Regular N.O.) alarm, until disarmed.

Fail to communicate Provides output upon fail to 5 2/6 [2

(Timed N.O.) communicate for

2nd telephone line relay Provides output after one failed [2

(Regular N.O.) communication attempt.

Kiss off Provides

(Timed N.O.) received at monitoring station.

Time output Provides

(Timed N.O.) at 8PM.

*

*

2 minutes.

*

*

3 sec. output after signal 5 7/D [2ND]/8

3 sec. output every day 6 2/3 1/4

Address Address

196/197 198/199

ND]/6

ND]/8

ND]/2

ND]/4

ND] 7/A [2ND]/E

*Times must be programmed at address 254.

**Not permitted on UL listed systems

Note:

For other PGM operations, i.e. home automation, programmable controller, false alarm reduction,

etc., use

programming options are needed, fax your requests to Paradox Technical Support at 514-491-2313.)

Espload

software to provide programming codes (over 1000 options available). (If other

System Options (Default = "off" for addresses 200-242)

Feature select programming

"ON”/"OFF" status of the key lights determines feature selection.

In programming mode, enter 3 digit memory address (200 to 242).

To save entries, press [ENTER]. To exit programming mode press [CLEAR].

Code priority (Addresses 200 to 204)

Keys [1] to [12] represent the corresponding code number. Key [1] represents user code 1, [2] = 2, [3] =

3, etc. [

If partitioning is disabled (Address 206, key [8] "off")

If partitioning is enabled (Address 206, key [8] "on")

(See also page 26.)

TLM options (Address 206, key [2ND] and key [1])

The system verifies the existence of a telephone line every 4 seconds. After successful tests, the dialer

LED (green light) flashes briefly on control panel. If the test fails, LED illuminates 4 seconds "on", then 4 seconds "off". TLM trouble will be activated when less than 3 volts are detected in 4 consecutive

Note:

BYP

] = user code 13, [

MEM

] = user code 14, [

TRBL

] = user code 15, and key [2ND] = user code 16.

Address 200: Lighted keys indicate which user codes can activate "stay" arming.

Address 202: Lighted keys indicate which user codes can activate force "away” arming.

Address 204: Lighted keys indicate which user codes can "bypass" zones.

Address 200: Lighted keys indicate which user codes are assigned to System "A".

Address 202: Lighted keys indicate which user codes are assigned to System "B".

Address 204: Lighted keys indicate which user codes can "bypass" zones.

When the dialer detects a telephone ring, the TLM flashing stops for 1 minute.

tests.

16

Page 19

There are three options for TLM use.

(1) Line test failure can generate a trouble indication.

(2) Line test failure can generate a trouble indication and an

alarm if the system is armed.

(3) Line test failure will cause silent or panic zones to switch

to audible mode.

(default)

Arming using PS1 or keyswitch (Address 206, key [2] and key [3])

The PS1 bedside remote arming module or keyswitch can be used to stay arm, full arm, or disarm the

system. The PS1 keyswitch is enabled at address 206, key [3].

Key [2] "off": PS1 or keyswitch "regular" arms system.

Key [2] "on": PS1 or keyswitch "stay" arms system.*

*Note: If partitioning is enabled (address 206, key [8] "on"), PS1 arms system "A" only. Use of PS1 is not

recommended for partitioned systems.

Call back (Address 206, key [4])

For extra security, the panel can be programmed to call the PC back when communication is attempted

by the PC. The panel will first answer the call, then Espload and the panel will verify identification codes.

The panel will then hang up and call the PC back and establish communication. Espload automatically

goes into the “wait for call mode” ready to answer when the panel calls back. The identification codes are

verified again before allowing access to the panel.

Related features: “Computer telephone number” 060-067.

IM728-738

Auto arm

On Time: (Address 206, key [5])

The panel may be programmed to arm at the same time every day. Program both the hour and minute

(addresses 245, 246) for arming. (This will also be the "auto test report" time, if enabled.) A late closing

code may be programmed (address 190).

Related features:“Auto arm”

No Movement: (Address 206, key [6])

If zone activity is not detected for a programmed period (address 253) while disarmed, the panel can auto

arm and/or send a "no movement" report (address 190).

210, [2]

“Auto/Espload Arm”

Refer also to "No movement" p. 22

188

"Auto arming"

p.22

.

.

Touch tone options (Address 206, key [7])

Tone (key [7] = "on") or pulse dialing can be programmed. If "pulse" is chosen for a central station phone

number, "tone" dialing can be programmed for the other number. [BYP] ("switch from pulse to tone")

should be entered in the second phone number during programming.

Partitioning (Address 206, key [8])

Partitioning is activated, (key [8] "on"). The panel's

zones)

can be divided into two systems. (See “System Partitioning”, page 25.)

fully programmable zones (plus 2 remote keypad

Silent alarm (Address 206, key [9])

Key [9] "off":

Silent zones/panics generate only a silent alarm.

panic zones will not cause an audible alarm, however, the keypad "armed" light will flash and the alarm

condition will remain until a valid user code is entered.

Zones defined as "silent" at address 216 and keypad

Key [9] "on":

Silent zones/panics generate only a report (The red keypad LED does not flash, and there is no need

to "reset" the silent alarm.)

Silent delay zones generate an entry delay beep, and a report at the end of the entry delay.

Zone restore is always reported upon zone closure.

17

Page 20

Memory display and auto zone shutdown are always active for silent zones (when enabled at

address 206, key [TRBL].)

Silent alarms can be monitored by a PGM output. (Silent flag is cleared on report or disarm.)

On split reporting, silent zones/panic are reported to Telephone #1.

The Contact ID report for all zones is "burglary".

Dialing pulse rates (Address 206, key [10])

This selection reflects the ratio between pulse time and "quiet" time. Select Pulse Europe for a 1:2 ratio

(Key [10] = "off"), Pulse USA for 1:1.5. (Key [10] = "on")

Reporting options

Regular reporting

To activate central station reporting, the feature must be enabled and all required reporting codes, except

when using “Ademco contact ID (all codes reported)”, must be assigned a value other than [2ND][2ND].

To establish communication, the communicator takes the telephone line and waits for a dial tone. If a dial

tone is identified, the communicator will dial the first central station telephone number. If a connection is

made, system report will take place and the communicator will hang up upon completion. If for any reason, communication is interrupted, the communicator will dial the 2nd central telephone line and report

only the events that were not reported during the interrupted attempt.

During a communication attempt, the communicator waits for a dial tone for up to 8 seconds. Even if a

dial tone is not found, the communicator will dial the central station.*** After 60 seconds, if communication has not been established, the dialer will hang up, wait 5 seconds and try the second number. This

sequence will be repeated 8 times, switching back and forth between the 1stand 2ndnumber. (Regular

reporting dialing procedure: 1,2,1,2,1,2,1,2, "communicator report failure".)

***This feature is useful for PBX systems, which do not provide a dial tone. You can program the dialing

sequence required to get a line on a PBX system, and this sequence will be added before the central

station number. If there is a time delay between dialing and getting a line, this can be programmed

into the dialing sequence using the [MEM] ("pause") key.

(Address 206, key [11] and key [12])

IM728-738

After 8 unsuccessful attempts, the redial sequence ends and "communicator report failure" will appear in the

keypad’s trouble display (key [7] "on"). When the next reportable event occurs, (even if it is not programmed

to report to the central), the communicator will again try to establish communication. If successful, all events

stored in the event buffer that have not yet been reported will be communicated to the central.

Split reporting

All "system" reports (i.e. trouble reports, arm/disarm reports, etc.) are sent to Telephone #2, until an alarm is

generated. Following alarm generation, all activity, including alarm and restoration reports, is sent to Telephone

#1 until the system is disarmed. When there is an alarm, any ongoing communication (upload/download or

reporting to Telephone #2) will immediately be stopped and the panel will dial Telephone #1.

"System" reports dialing procedure: (2,2,2,2,2,2,2,2, "communicator report failure")

Alarm reports dialing procedure: (1,1,1,1,1,1,1,1, "communicator report failure")

Double reporting

The panel will transmit all reports to both programmed telephone numbers. If, after 8 attempts using either

number, communication is not established, "communicator report failure" will be displayed by key [7].

Double reporting dialing procedure: (1,1,1,1,1,1,1,1, "communicator report failure")

(2,2,2,2,2,2,2,2, "communicator report failure")

Note:

To stop communication attempts until the next reportable event, press [ENTER] + installer code + [STAY].

(Address 206, key [11] "on", key [12] "off")

(Address 206, key [11] "on", key [12] "on")

Bell squawk (Address 206, key [MEM])

Bell/siren will emit a 0.5 second “squawk” once upon arming, and twice upon disarming.

(Key [MEM] "on" = enabled)

18

Page 21

IM728-738

Auto zone shutdown

Key [TRBL] "on" = zones that initiate 4 consecutive alarms during the same armed period will be auto-

matically bypassed. (Zones must be bypass-enabled at address 236.) After a zone

has been bypassed, the panel can send a "partial arming" report to the central (if

programmed to do so at address 187).

Note: Once auto zone shutdown has been enabled, it will either be activated after 4 "zone closure"

restoration reports or 4 "bell cut-off" restoration reports, depending on which type of alarm restoration code has been activated at address 208, key [BYP].

(Address 206, key [TRBL] "on")

Automatic event buffer transmission (Address 208, key [2ND])

Key [2ND] "on" = system will dial the computer telephone number programmed in Section 00 and 01

(addresses 060-067) to upload the contents of the event buffer to the PC. (Espload must be in "wait for

call" mode.) The system will make two attempts to call the PC when the event buffer reaches 50%

capacity. If communication is established, the system will then proceed to report the contents of the event

buffer to the PC. Should transmission be interrupted before the complete contents of the buffer can be

transmitted, or if after two attempts, communication is not established, the system will wait until the event

buffer is full, before attempt to communicate with the central again.

If communication is established, the system will then proceed to report the contents of the event buffer to

the PC. If after two attempts, communication is not established, each subsequent new event will erase

the oldest event in the buffer, until the event buffer once again reaches 50% capacity.

Enable keypad panic signals (Address 208)

Key [1] "on" = Panic 1 (keys [1] and [3]) enabled

Key [2] "on" = Panic 2 (keys [4] and [6]) enabled

Key [3] "on" = Panic 3 (keys [7] and [9]) enabled

Keypad panic options (Address 208)

Key [4] "off" = Panic 1 silent Key [5] "off" = Panic 2 silent Key [6] "off" = Panic 3 silent

Key [4] "on" = Panic 1 audible Key [5] "on" = Panic 2 audible Key [6] "on" = Panic 3 fire

Silent operation

When panic keys [1] and [3], OR [4] and [6], OR [7] and [9] are pushed simultaneously for 2 seconds, a

single confirmation beep is sounded, codes programmed at addresses 184, 185, and 186 are transmitted

and the alarm latches, flashing the keypad "armed" light until reset by a user code.

Audible operation

When panic keys are pushed in addition to alarm codes being transmitted, the alarm output (bell/siren)

will activate until reset by a user code or until the bell cut-off time (address 250) expires.

Fire operation

Same as audible operation except that bell/siren output will be pulsed (intermittent "on"/"off").

"One key" arming enable (Address 208)

Key [7] "on" = Pushing key [10] for 2 seconds "full" arms system.

Key [8] "on" = Pushing key [11] for 2 seconds "stay" arms system.

User/access code length (Address 208)

Key [9] "off" = 6 digit user/access codes and installer code.

Key [9] "on" = 4 digit user/access codes and installer code.

Tamper/wire fault definitions (Address 208)

Note: If key [10] and key [11] are both "off", this means that tamper and wire faults will not be recog-

nized. See "Loop configuration and zone connections" page 8-9, "Tamper/Wire Fault Definition

and Options", page 9, and "Tamper/wire Fault Definition table" in the "Programming Guide".

19

Page 22

Beep on exit delay (Address 208)

Key [12] "on" = the keypad will sound on exit delay (except when in “stay” arming). Frequency of inter-

mittent beeps increases during the last 10 seconds of the exit delay period.

Zone restore transmission (Address 208)

Key [

BYP

] "off" = If zone is closed, restoration code will be transmitted after "bell cut-off".

Key [BYP] "on" = Restoration code transmitted as soon as zone is closed.

Silent zones are always restored as soon as they are closed.

Zones with EOL resistors (Address 208, key [MEM])

See "Loop configuration and zone connections" pages 8-9.

Always report disarm (Address 208)

Key [TRBL] "off" = always reports disarm codes.

Key [TRBL] "on" = reports disarm code only after alarm.

Exclude power failure from trouble display (Address 210, key [2ND])

Key ="on": Power failure will not make the [TRBL] key flash.

This trouble condition may still be viewed after pressing [TRBL].

IM728-738

“Associated zone” deactivation: (Address 210, key [1])

Key = “on”: Disables burglar alarm zone associated with fire zone. Wire fault on the fire zone (fire trou-

ble) will not cause an alarm on the associated burglar zone.

Panel Fire Zone Associated zone

728 3 4 (ATZ)

738 3 9 (ATZ)

Arming Options

Auto arm (Address 210, Key [2])

Key ="off ": When system auto arms (on time or "no movement"), "regular" arming will take place (if all

zones are closed).

Key ="on": When system auto arms (on time or “no movement”), "STAY" arming will take place (if all

zones are closed). If zone partitioning is programmed (address 206, key [8]), System “A” will

arm. (See also "Auto arming" p 22.)

No tamper bypass (Address 210, key [6])

Key ="off": Device tamper will not follow zone bypass.

Key ="on": Device tamper will follow zone bypass.

Advanced Technology Zoning (ATZ) (Address 210, key [8])

Key = “on” Permits the use of two zone resistors per zone input. Each zone can transmit a separate

alarm that can each transmit its own alarm.

Key = “off” Single zone per zone input.

Audible trouble warning (Address 210, Key [9])

Key ="on":

Trouble conditions cause intermittent audible trouble warning on keypad. To silence, push [

20 sec. delay before alarm transmission

Key ="on": The first time an alarm is generated, there will be a twenty (20) second delay before reporting

begins. During the waiting period, system disarm will cancel all pending reports.

(Address 210, Key [10])

20

TRBL

].

Page 23

Keypad zone supervision

Intelli

zone

Keypad 1 zone supervision (Kpd 1) Keypad 2 zone supervision (Kpd 2)

(Address 210, key [11]) (Address 210,

“ON” = enabled “OFF” = disabled “ON” = enabled “OFF” = disabled

Keypad zone supervision allows the system to verify the presence of a keypad and its keypad zone(s).

When enabled, only two keypad zones (one configured as keypad 1, and one configured as keypad 2)

can be used at one time. Any other keypad zone terminals must be shorted.

If using a 616, 626, or 633 LED keypad with software version 3.9 or earlier, OR a PS1 version 1.1, OR a

639/640 keypad with its keypad zone supervision feature disabled (address 32, key [3] “off”), or if the keypad zone is not used:

• KEYPAD ZONE SUPERVISION FEATURE MUST BE “OFF”.

If using a 616, 626, or 633 LED keypad with software version 4.0 onward, OR a PS1 version 2.0 onward,

OR a 639/640 LCD keypad with its keypad zone supervision enabled (address 32, key [3] “on”):

• KEYPAD ZONE SUPERVISION FEATURE MUST BE “ON”.

key [12])

IM728-738

Related features: Keypad connections.

728 (no ATZ): Kpd 1 = Zone 5 Kpd 2 = Zone 6 738 (no ATZ): Kpd 1 = Zone 7 Kpd 2 = Zone 8

728 (with ATZ): Kpd 1 = Zone 9 Kpd 2 = Zone 10 738 (with ATZ): Kpd 1 = Zone 13 Kpd 2 = Zone 14

p.8

Zone Definition (Addresses 212-242)

Zone definition is assigned during "feature selection" programming. Turning zone key "on" or "off" at

addresses 212-242 assigns a particular definition to the zone. (See Programming Work Sheets.)

Key “ON”: An alarm will be generated and communicated following any two detections in zones

assigned this definition, whether the two detections stem from a single intellizone or any two separate

intellizones - as long as the two detections take place within a designated time frame. An alarm will also

be generated and communicated if an intellizone stays “open” for the total length of the designated “intellizone” delay. The "intellizone" delay, which determines the period of time (between 16-256 seconds) in

which two detections must take place or an intellizone must remain open, is programmed at address 059.

"Intellizone" definition is disregarded while the panel is in audible alarm.

Key "OFF": An alarm is generated as soon as the zone is opened. This feature should be disabled on UL

listed systems.

Silent/audible (Addresses 216, 218)

Silent zones (keys "on") report alarms without triggering bells/sirens. (Reminder: fire zone is never silent.)

Audible zones (keys "off") will trigger a bell or siren upon alarm generation.

definition (Addresses 212, 214)

24 hour - fire/regular (Addresses 220, 222)

"24 hour" zones (keys "on") generate alarms whenever the zone is detected, even if the system is not

armed. Zone 3 becomes a fire zone when defined "24 hour". The fire zone should always be connected

with a 1KWEOL resistor. If there is a line short in the fire zone, a fire alarm will be generated. If the line is

"open", a fire trouble report (if assigned at address 182) will be sent to the central, and trouble indicator

[11] and fire zone key [3] will flash on the keypad. Alarms in a fire zone generate an intermittent output

signal, regardless of system arming status.

Instant (Addresses 224, 226)

"Instant" zones (key "on") will immediately generate an alarm when detected while the system is armed.

There is no entry delay.

Follow (Addresses 228, 230)

"Follow" zones (key "on") are "instant" zones that switch to "delay" definition during entry delay.

21

Page 24

Delay 2 (Addresses 232, 234)

One of two different zone delays (delay 1 & delay 2) can be assigned to each zone. Zones activated at this

address are assigned "Delay 2" definition. The length of zone entry delays is programmed at addresses

249. Any zones that are not activated at addresses 220-232 are assigned "Delay 1" zone definition.

Note: When more than one zone definition is selected, zone definition priority is assigned in this

order: (1) 24 hr., (2) instant, (3) follow, (4) delay 2 and (5) delay 1.

248-

Bypass-enabled (Addresses 236, 238)

"Bypass-enabled" zones (keys "on") are zones that can be bypassed during "manual bypass" arming and

auto zone shutdown. The fire zone cannot be bypassed.

Note: If a zone should not be bypassed, turn "off" its corresponding zone key.

System assignment (Addresses 240, 242)

Refer to "System Partitioning", page 25)

Related programming: "Partitioning

206, [8]

."

Special Timing Functions

3 Digit Decimal Value Programming

Decimal programming is used to program addresses 244 to 255. Values entered must contain 3 digits.

Decimal value programming:

1) Press [ENTER] + installer code. ([ENTER] key will flash.)

2) Enter 3 digit address (244 to 255).

3) Enter 3 digit DECIMAL value.

4) To erase, press [CLEAR]. To save, press [ENTER].

5) Repeat from step 2 onward for next address. To exit programming mode press [CLEAR].

IM728-738

“No movement”

If a time is programmed at address 253, and a report code is entered at address 190 (SECTION 32), the panel

will send a report to the central, when there is no movement in the protected area for a designated time period.

"Late to close"

If the system is not armed by a specified time (addresses 245, 246) the code programmed at address

190 (SECTION 32) will be transmitted.

Auto arming

The panel can be programmed to automatically arm itself every day in two ways: at the same time programmed for the auto test report (addresses 245, 246) and/or once the "no movement" delay has

elapsed (address 253). To program "auto arming", go to address 206 and enable key [5] (auto arm on

time), and/or key [6] (auto arm on "no movement"). All zones must be closed in order for the system to

auto arm. If panel fails to auto arm, only the "no movement/late to close" report will be transmitted. The

"auto arm" report is programmed at address 188 (SECTION 32).

Operational note regarding special timing functions

The time programmed at addresses 245, 246 can be used to:

• Specify the time of day for the Test Report (code programmed at address 175 (SECTION 28).

• Transmit the Late to Close/No Movement code (address 190 (SECTION 32) if the system is not armed

by a specified time.

•

Auto-arm the system and if programmed, transmit the arming code at address 188 (SECTION 32)

after transmitting the Late to Close/No Movement code (as above).

The amount of time programmed at address 253 (Max = 63.75 hours) can be used to;

• Transmit the Late to Close/No Movement code, address 190 (SECTION 32), if there is no move

the protected area while the system is disarmed.

•

Auto-arm the system and if programmed, transmit the arming code at address 188 (SECTION 32)

after transmitting the Late to Close/No Movement code (as above).

ment in

22

Page 25

The "late to close/no movement" code programmed at address 190 (SECTION 32) will be transmitted;

•

at the time programmed at addresses 245 and 246 if the system is not armed (Late to Close).

•

after the time programmed at address 253 expires (No Movement).

The amount of time programmed at address 254 (Max = 127 minutes) can be used to:

•

designate the length of time a programmable output (PGM) will remain active following a specified

event.

Auto arm/report options

1) Report the code programmed at address 175 after the number of days programmed at address 244.

(To disable, program 000 at address 244.)

2) Send a "late to close" code programmed at address 190.

3) Auto arm the system (on time) if enabled at address 206, key [5].

IM728-738

Exit delay

Range 001 to 255 seconds (

factory default 060 seconds)