Page 1

889 WEIGHT STACK OPTION

CLASS H

PART # 7305301

REV . A

USER’S GUIDE

1

WARNING:

Read and follow all directions

for each step to insure proper

assembly of this product.

Version: 889108

Revision: 06/19/02

Page 2

j

TABLE OF CONTENTS

Safety Statement.............2

General Notes..................3

Tools Required................3

Parts List.........................4

Assembly Instructions......4-13

General Maintenance........14

W arranty Statement..........15

Product Services..............16

Insert-Registration Card

IMPORTANT SAFETY INFORMATION

THERE IS A RISK ASSUMED BY INDIVIDUALS WHO USE THIS TYPE OF

EQUIPMENT. TO MINIMIZE RISK FOLLOW THESE RULES!

1. Before using, read all the warnings and instructions

on the use of this machine. Use only for intended

exercise. DO NOT modify the machine.

2. Obtain a medical exam before beginning any

exercise program.

3. Keep body and clothing free of all moving objects.

4. Inspect the machine before use. DO NOT use it if it

appears damaged. DO NOT attempt to fix a broken or

ammed machine. Notify your authorized ParaBody

dealer before use and have repairs made by an

authorized service technician.

6. Never pin the weights or prop plate into an elevated

position. DO NOT use the machine if found in this

condition. DO NOT attempt to fix. Notify your

authorized ParaBody dealer.

7. Inspect cables and their connections before using

machine. Pay particular attention to the cable ends.

DO NOT attempt to fix. Notify your authorized

ParaBody dealer before use and have repairs made by

an authorized service technician.

8. Make sure all spring loaded pull pins are fully

engaged in the adjustment position and fully tighten

thumbscrew before use.

5. Be certain that weight pin is completely inserted.

Use only the pin provided by the manufacturer. If

unsure, call your authorized ParaBody dealer.

9. Children must not be allowed near this machine.

Supervise teenagers.

.

NOTE: In a continual effort to improve our products, specifications are subject to change

2001 Life Fitness, a division of Brunswick Corporation. All rights reserved.

©

ParaBody is a trademark of Brunswick Corporation

www.parabody.com

2

Page 3

IMPORTANT NOTES

Please note:

* Thank you for purchasing the ParaBody 889 Weight Stack Option. Please read these

instructions thoroughly and keep them for future reference. This product must be assembled

on a flat, level surface to assure its proper function.

* This product must be assembled on a flat, level surface to assure its proper function. DO NOT

securely tighten any frame connections until the entire frame has been assembled, unless

otherwise stated.

T ools Required for Assembly

* 3/4” wrench

* 9/16” wrench

* Ratchet with 3/4” and 9/16” sockets

* 5/32” Allen wrench

* Adjustable wrench

* T ape measure

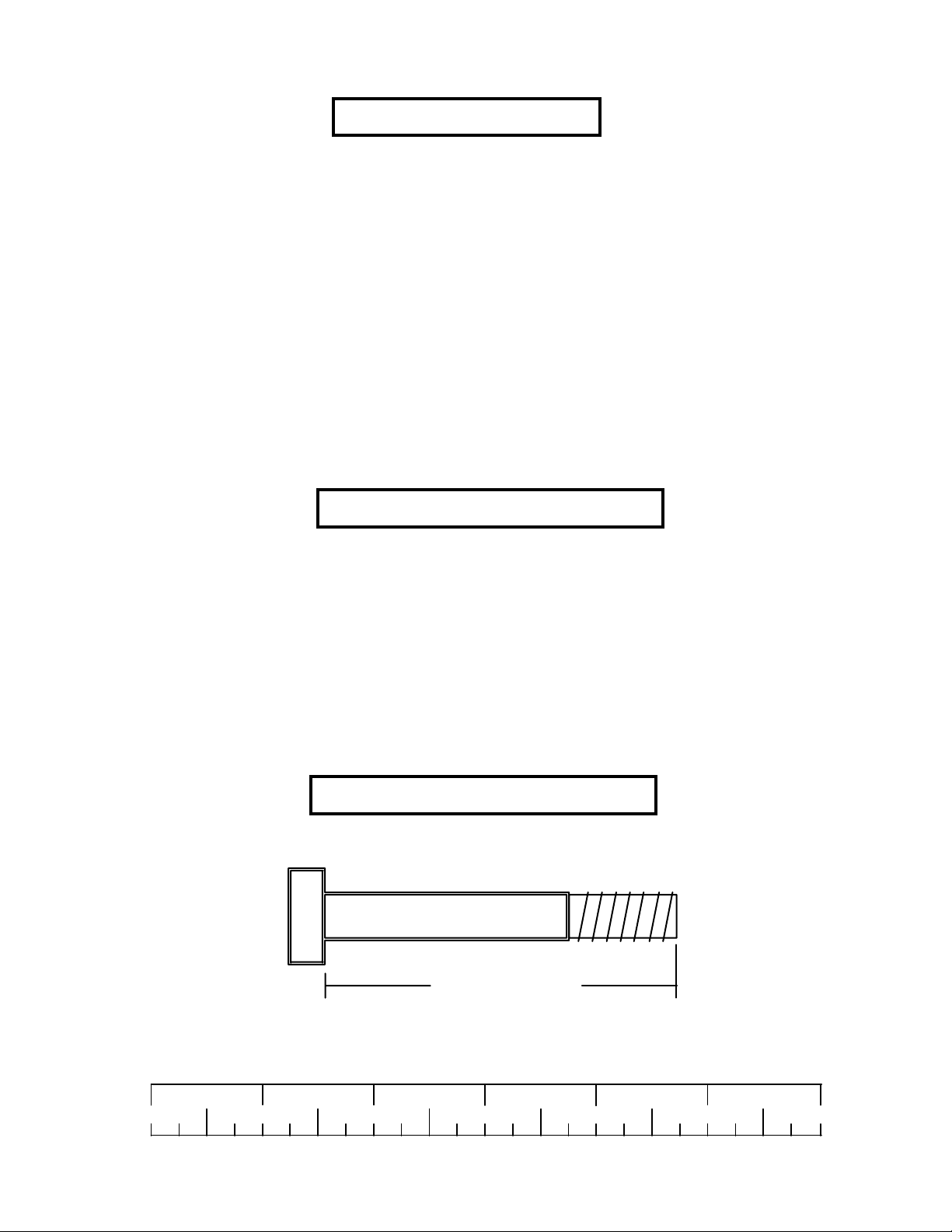

Bolt Length Ruler

NOTE: BOL T LENGTH IS MEASURED FROM THE UNDERSIDE OF THE HEAD OF THE BOLT.

BOLT LENGTH

BOL T LENGTH RULER:

1/2 1/2 1/2 1/2 1/2 1/2

0

1

2

345

3

6

Page 4

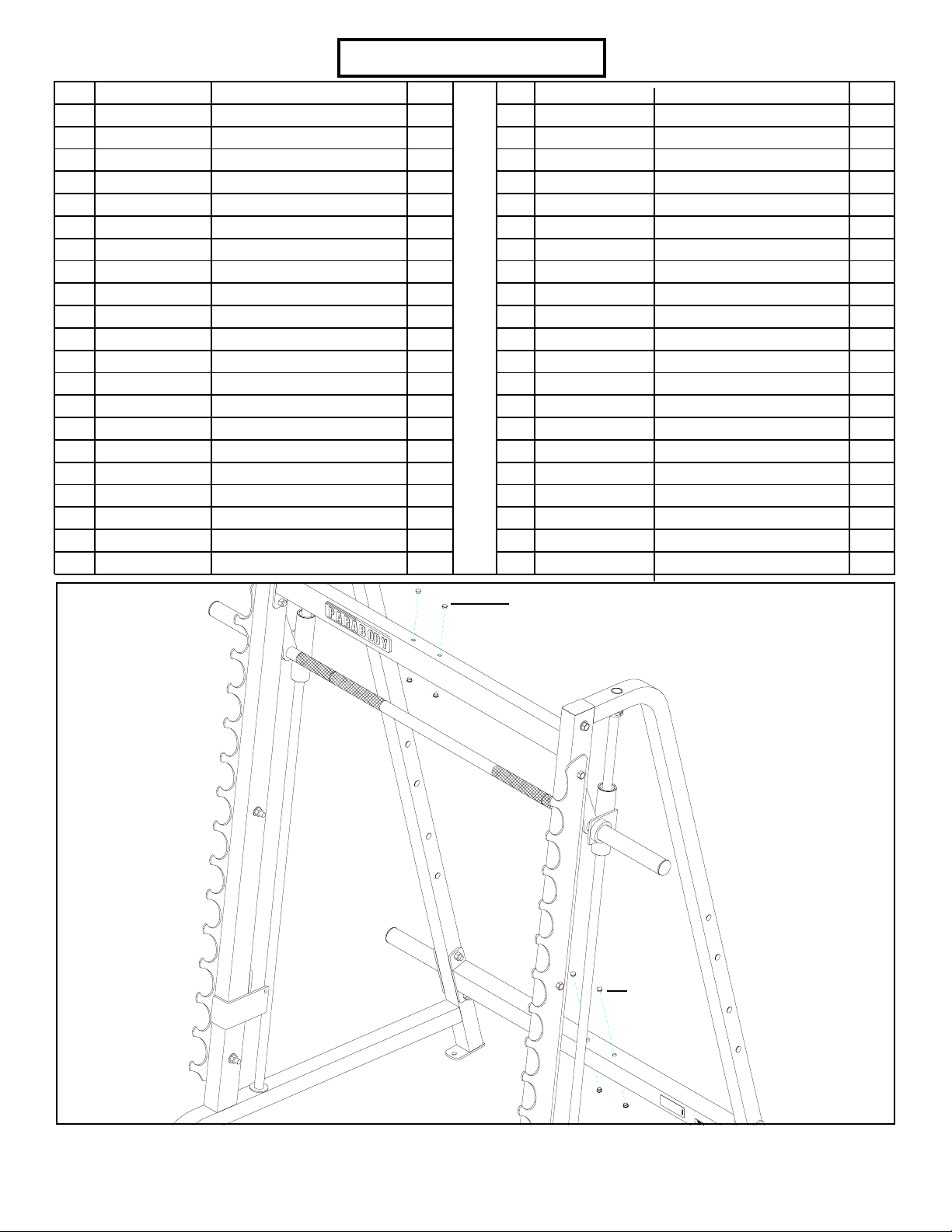

PARTS LIST

KEY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

PART #

LEA6814309

LEA6800610

LEA6814009

LEA6813709

LEA6801110

LEA6816501

LEA6274410

LEA6725310

LEA3116201

LEA3116101

LEA6832801

LEA6671002

LEA6692601

LEA3103102

LEA3103302

LEA6405201

LEA6972201

LEA6177001

LEA3119301

LEA6236701

LEA6412001

DESCRIPTION

UPRIGHT

ADJ FOOT SUPPOR T

ST ACK BASE

TOP BOOM

LA T BAR SUPPOR T

76” GUIDE ROD

LOW ROW BAR

LA T BAR

3-1/2” PULLEY

4-1/2” PULLEY

124” CABLE

115-3/4” CABLE

3 X 2” END CAP

1 X 8” GRIP

13/16” SHAFT COLLAR

2” SQ. END CAP

WEIGHT ST ACK SELCT PIN

2-1/2 X 5-1/2” NON-SKID STP

2-1/2” ROUND END CAP

1-3/4” SQ. END CAP

SPRING PIN ASSEMBL Y

QTY

1

1

1

1

1

2

1

1

5

1

1

1

2

4

2

4

1

2

2

1

1

KEY

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

PART #

LEA3203301

LEA6542402

LEA6416601

LEA7292501

LEA3108002

LEA6595201

LEA7308601

LEA3235502

LEA3114403

LEA3114702

LEA3235211

LEA6480301

LEA3103801

LEA3235208

LEA7292801

LEA6075906

LEA3235216

DESCRIPTION

VINYL CAP

3/16 X 1-3/4 X 5-1/4” PL TE

3/4 X 1-1/2” GLIDE

WEIGHT PLA TE

WEIGHT ST ACK CUSHION

GUIDE ROD BUSHING

WEIGHT ST ACK LBLS (1-26)

3/8” LOW HT LOCK NUT

3/8” W ASHER

3/8” LOCK NUT

3/8 X 2-3/4” BOL T

3/8” FLANGE SP ACER

5/16” SNAP HOOK

3/8 X 2” BOL T

HEAD PLA TE ASSEMBL Y

12 LINK CHAIN

3/8 X 4” BOL T

QTY

2

2

1

20

2

2

1

3

14

10

7

8

3

2

1

1

4

7/16” CAP PLUG

7/16” CAP

PLUG

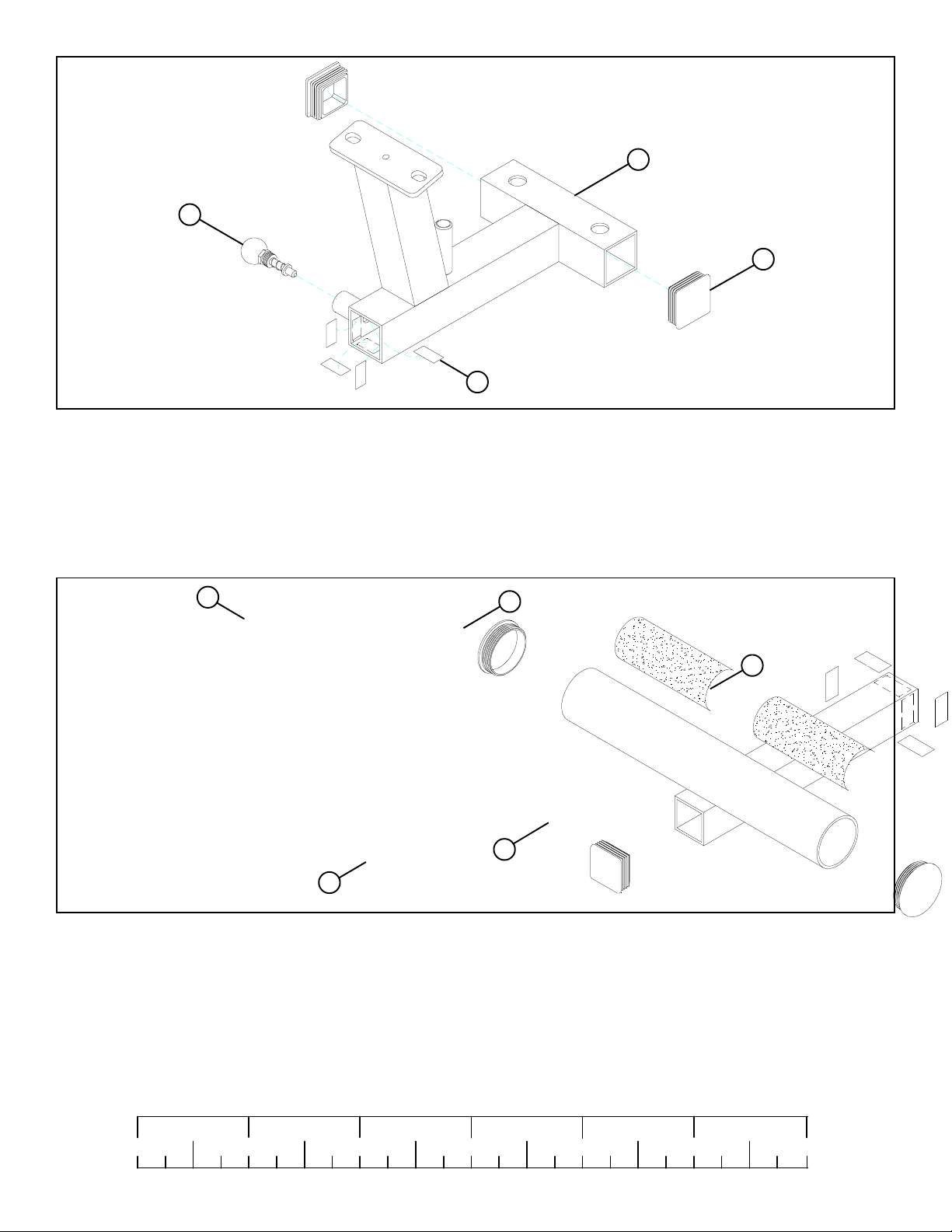

FIGURE 1

STEP 1:

• Remove four 7/16” CAP PLUGS from the UPPER & LOWER CROSS SUPPOR TS on the 888 SMITH MACHINE as shown in FIGURE 1.

4

Page 5

3

21

16

FIGURE 2

24

STEP 2:

• Insert two 2” END CAP (16) into the ends of the ST ACK BASE (3) as shown in FIGURE 2.

• Attach four 3/4 X 1-1/2” GLIDES (24) to the inside of the tube on the STACK BASE (3) as shown in FIGURE 2 using the

following steps:

• Thoroughly clean all surfaces where the 3/4 X 1-1/2” GLIDES (24) are to be attached.

• Remove the 3/4 X 1-1/2” GLIDES (24) from the paper backing and firmly apply them to all shown surfaces.

• SECUREL Y assemble one SPRING PIN ASSEMBLY (21) to the spring pin barrel on the STACK BASE (3). See FIGURE 2.

19

18

24

2

20

FIGURE 3

STEP 3:

• Insert two 2-1/2” ROUND END CAPS (19) into the ends of the ADJ. FOOT SUPPORT (2) as shown in FIGURE 3.

• Insert one 1-3/4” END CAP (20) into the end of the ADJ. FOOT SUPPOR T (2) as shown in FIGURE 3.

• Apply two 2-1/2 X 5-1/2” NON-SKID STRIPS (18) to the ADJ. FOOT SUPPORT (2) as shown in FIGURE 3.

• Attach four 3/4 X 1-1/2” GLIDES (24) to the outside of the ADJ FOOT SUPPORT (2) as shown in FIGURE 3 using the

following steps:

• Thoroughly clean all surfaces where the 3/4 X 1-1/2” GLIDES (24) are to be attached.

• Remove the 3/4 X 1-1/2” GLIDES (24) from the paper backing and firmly apply them to all shown surfaces.

1/2 1/2 1/2 1/2 1/2 1/2

0

1

2

345

5

6

Page 6

UPRIGHT FRAME

3/8 X 4” 38

30

1

LOWER CROSS SUPPORT

3

2

FIGURE 4

21

3/8”

LOW HEIGHT

LOCK NUT

30

29

STEP 4:

• NOTE: It may be necessary to loosen the 1/2 X 3-1/4” BOL TS of the LOWER CROSS SUPPORT connecting to the UPRIGHT

FRAME before beginning STEP 4.

• SECUREL Y assemble the ST ACK BASE (3) and the UPRIGHT (1) to the LOWER CROSS SUPPOR T using two 3/8 X 4” BOL TS (38),

four 3/8” W ASHERS (30), and two 3/8” LOW HEIGHT LOCK NUTS (29). See FIGURE 4.

• Pull back on the SPRING PIN (21) and CAREFULLY insert the ADJ. FOOT SUPPORT (2) into the ST ACK BASE (3) as shown in

FIGURE 4.

6

Page 7

STEP 5:

• Insert two GUIDE RODS (6) into the ST ACK

BASE (3) as shown in FIGURE 5. Lubricate

the GUIDE RODS (6) with a silicon or teflon

spray that is available at most hardware stores.

HEAD PLA TE

ASSEMBL Y

36

25

28

15

6

• Slide two WEIGHT STACK CUSHIONS

(26) down over the GUIDE RODS (6). See

FIGURE 5.

• Using EXTREME CARE slide twenty

WEIGHT PLATES (25) down over the GUIDE

RODS (6) with the key-hole facing as shown

in FIGURE 5.

• Carefully Slide the HEAD PLA TE ASSEMBLY

(36) down over the GUIDE RODS (6) onto the

weight stack as shown in FIGURE 5.

• Slide two 13/16” SHAFT COLLARS (15)

over the GUIDE RODS (6) as shown in

FIGURE 5.

• Apply one set of WEIGHT ST ACK LABELS 1-26 (28) to each WEIGHT PLATE (25) as

shown in FIGURE 5.

26

3

FIGURE 5

1/2 1/2 1/2 1/2 1/2 1/2

0

1

2

345

7

6

Page 8

FIGURE 6

UPRIGHT

16

4

31

30

27

31

13

13

1

UPPER CROSS

SUPPORT

30

38 3/8 X 4”

15

32 3/8 X 2-3/4”

6

STEP 6:

• NOTE: It may be necessary to loosen the 1/2 X 3-1/4” BOL TS of the UPPER CROSS SUPPORT connecting the UPRIGHT

FRAME before beginning STEP 6.

• Insert two GUIDE ROD BUSHINGS (27) into the TOP BOOM (4) as shown in FIGURE 6.

• Insert two 3 X 2” END CAPS (13) into the ends of the TOP BOOM (4). See FIGURE 6.

• Insert two 2” SQ. END CAPS (16) into the ends of the TOP BOOM (4). See FIGURE 6.

• Place T OP BOOM (4) over the GUIDE RODS (6) and LOOSELY assemble the TOP BOOM (4) to the UPRIGHT (1) using one 3/8 X 2-

3/4” BOLT (32) and one 3/8” LOCK NUT (31) as shown in FIGURE 6

• LOOSEL Y assemble the T OP BOOM (4) to the UPPER CROSS SUPPOR T using two 3/8 X 4” BOLTS (38), four 3/8” W ASHERS (30)

and two 3/8” LOCK NUTS (31). See FIGURE 6.

• Slide the 13/16” SHAFT COLLARS (15) to the top of the GUIDE RODS (6) and SECURELY tighten the SHAFT COLLAR (15) set

screws. See FIGURE 6.

• SECURELY tighten all connections made up to this point.

8

Page 9

FIGURE 7

3/8” LOW HEIGHT 29

4

5

22

32 3/8 X 2-3/4

STEP 7:

• SECURELY assemble the LA T BAR SUPPOR T (5) to the TOP BOOM (4) using one 3/8 X 2-3/4” (32) and one 3/8” LOW HEIGHT LOCK

NUT (29). See FIGURE 7.

• Slide two VINYL CAPS (22) over the LAT BAR SUPPORT (5) as shown in FIGURE 7.

FIGURE 8

4

Make sure CABLE

is routed over bolt!

31

33

9

3/8 X 2-3/4” 32

12

STEP 8:

• Route the 115-3/4” CABLE (12) through the TOP BOOM (4) as shown in FIGURE 8. (NOTE: It may be necessary to remove

the 3/8 X 2-3/4” BOLT to ensure CABLE is routed over the TOP of the BOLT.)

• SECUREL Y assemble three 3-1/2” PULLEYS (9) into the slots of the TOP BOOM (4) using three 3/8 X 2-3/4” BOL TS (32), six 3/8” FLANGE

SPACERS (33), and three 3/8” LOCK NUTS (31) as shown in FIGURE 8. (NOTE: Make sure the cable is routed over all the

pulleys.)

• SECURELY retighten the removed 3/8 X 2-3/4” BOL T from the above step.

1/2 1/2 1/2 1/2 1/2 1/2

0

1

2

345

9

6

Page 10

FIGURE 9

4

31

9

23

12

36

17

30

35 3/8 X 2”

!IMPORT ANT!

SECUREL Y

TIGHTEN

JAM NUT

STEP 9:

• Slide ring of WEIGHT STACK SELECT OR PIN (17) over top of HEAD PLATE ASSEMBLY (36)

• Screw the threaded end of the CABLE (12) approximately 3/4” into the end of the HEAD PLATE ASSEMBLY (36) and tighten

jam nut securely. See FIGURE 9.

• Place one 3-1/2” PULLEY (9) into the loop of the CABLE (12) below the second and third PULLEY of the TOP BOOM (4) as shown

in FIGURE 9.

• LOOSEL Y assemble two 3/16 X 1-3/4 X 5-1/4” PLA TES (23) to each side of the 3-1/2” PULLEY (9) using one 3/8 X 2” BOL T (35),

two 3/8” WASHERS (30), and one 3/8” LOCK NUT (31). See FIGURE 9.

10

Page 11

1

31

10

11

33

33

30

32 3/8 X 2-3/4”

FIGURE 10

STEP 10:

• Route the threaded end of the 124” CABLE (11) through the slot of the UPRIGHT (1) then SECURELY assemble one 4-1/2” PULLEY

(10) to the UPRIGHT (1) using two 3/8 X 2-3/4” BOL TS (32), two 3/8” FLANGE SP ACERS (33), two 3/8” WASHERS (30), and two 3/8”

LOCK NUTS (31). (NOTE: The CABLE (11) should be routed between the pulley and the retaining bolt as shown in FIG-

URE 10.)

11

Page 12

31

23

9

30

11

35 3/8 X 2”

SECUREL Y

TIGHTEN

JAM NUT!

3

FIGURE 11

STEP 11:

• Loop the 124” CABLE (11) around one 3-1/2” PULLEY (9) as shown in FIGURE 11.

• LOOSEL Y assemble the 3-1/2” PULLEY (9) to the 3/16 X 1-3/4 X 5-1/4” PLA TES (23) using one 3/8 X 2” BOL T (35), two 3/8” W ASHERS

(30), and one 3/8” LOCK NUT (31). See FIGURE 11.

• SECURELY thread the end of the 124” CABLE (11) 3/4 of the way into into the threaded housing on the STACK BASE (3) and

SECUREL Y tighten jam nut.

• SECUREL Y tighten the two 3/8 X 2” BOL TS (35) of the 3/16 X 1-3/4 X 5-1/4” PLATES (23).

12

Page 13

14

11

34

8

34

34

37

7

14

36

12

FIGURE 12

STEP 12:

• Slide two 1 X 8” GRIPS (14) on the LOW ROW BAR (7) and two 1 X 8” GRIPS (14) on the LAT BAR (8) as shown in FIGURE 12.

• Attach the LAT BAR (8) to the ball end of the upper CABLE (12) using one 5/16” SNAP HOOK (34) as shown in FIGURE 12.

• Attach the LOW ROW BAR (7) to the ball end of the lower CABLE (11) using one 12-LINK CHAIN (37) and two 5/16” SNAP

HOOKS (34) as shown in FIGURE 12.

• If the HEAD PLA TE (36) does not sit on top of the first WEIGHT PLA TE (40), push the head plate down, insert the SELECTOR PIN (17)

and perform several repetitions on the machine. This will relax the cable system and prevent the HEAD PLATE (36) from lifting up.

• If after completing the previous step the HEAD PLATE (36) still does not sit on top of the first WEIGHT PLATE (40) or if there is

excess slack in the cable system, adjust the threaded end of the CABLE accordingly and retighten the jam nut.

Thank you for purchasing the Parabody 889 WEIGHT STACK OPTION. If unsure of proper use of equipment, call your local Parabody distributor or call the Parabody customer service department at (800) 328-9714.

13

Page 14

MAINTENANCE

Please note:

* We recommend cleaning your product (pads and frame) on a regular basis, using warm soapy

water . Touch-up paint can be purchased from your ParaBody customer service representative

at (800) 328-9714.

* Inspect equipment daily . Tighten all loose connections are replace worn parts immediately.

Failure to do so may result in serious injury

* Lubricate guide rods with a teflon based (or equivalent) lubricant on a regular basis

* PLEASE RECORD THE INFORMATION REQUESTED BELOW. IN THE EVENT

YOU MAY NEED SER VICE YOU WILL BE ASKED FOR THIS INFORMATION.

REMEMBER TO FILL OUT YOUR WARRANTY REGISTRATION CARD AND

MAIL BACK.

MODEL #________________________

SERIAL #_________________________

DATE OF PURCHASE: _____________

DEALERS NAME: _________________

DEALERS PHONE #_______________

SERIAL NUMBER LOCATION

Thank you for purchasing the ParaBody 889 W eight Stack Option.

14

Page 15

LIMITED W ARRANTY

ParaBody extends the following LIMITED WARRANTY to the original owner of the ParaBody products. The Warranty terms apply to IN HOME USE ONL Y.

1. LIMITED WARRANTY ON FRAME AND WELDS. If the frame of the ParaBody product or a weld should crack or break, it will be repaired

or replaced by ParaBody. Terms: Lifetime – for so long as the Customer owns the ParaBody product.

2. LIMITED WARRANTY ON P ARTS. If the following part s are defective in material or workmanship, ParaBody will supply replacement parts:

all bolts, nuts, washers, bearings, bushings, pulleys, thumbscrews, collars, cable retaining clips, adjustable pre-stretch slides, roller pad

shafts, allen head bolts, weight selector pin, weight stack shaft, set screws, protector caps, adjustment chain, cotter pin, plunger , spring

and knob. Terms: Lifetime – for so long as the Customer owns the ParaBody product.

3. LIMITED WARRANTY ON CABLES AND UPHOLSTERY. If the coated cables or upholstery are defective in material or workmanship,

ParaBody will repair or replace them, at its option. Terms: Three (3) years.

4. CONDITIONS AND EXCEPTIONS. Any product misuse, abuse or alteration, any attempt to repair by a person other than an authorized

ParaBody Service Center, any improper assembly, accident, or any other condition resulting from occurrences beyond the control of

ParaBody will void this Limited Warranty .

5. REPLACEMENT AND REPAIR EXPENSES. ParaBody will provide only replacement parts or repair under this warranty. The Owner is

responsible for all other costs. Such costs may include, but are not limited to: a. labor charges for service, removal, repair or reinstallation

of the ParaBody product or any component part; b. shipping, delivery, handling and administrative charges for returning part s to ParaBody;

and c. all necessary or incidental costs related to installation of the replacement parts.

6. SHIPPING . If shipping by the Owners is deemed necessary (in sole discretion of ParaBody), parts should be shipped in their original carton

or equivalent packaging, fully insured with shipping charges prepaid. ParaBody will not assume any responsibility for any loss or damage

incurred in shipping.

7. CLAIM PROCEDURES. If service on your ParaBody product is required during the warranty period, please contact our Customer Service

Department at 1-800-328-9714 for instructions regarding returning or replacing parts. Please have available the following information: (i) the

dealer’s name; (ii) the date of purchase; (iii) the serial # (s) of your product (the serial number location is called out on the final assembly

drawing included with your assembly instruction); (iv) a description of the nature of the problem.

8. OWNER’S RIGHT . This Limited W arranty gives you specific legal rights. Y ou may also have other rights, which vary depending on local law .

9. LIMITATION OF IMPLIED W ARRANTIES. All implied warranties, except to the extent prohibited by applicable law , shall have no greater

duration than the warranty period set forth above. There are no warranties which extend beyond the description in this Limited Warranty .

Because local laws do not allow limitations on how long an implied warranty lasts, the above limitations may not apply to you.

10. DISCLAIMER. No other express warranty has been made or will be made on behalf of ParaBody with respect to any ParaBody product or

the operation, repair or replacement of any ParaBody product. ParaBody shall not be responsible for injury , loss of use of the ParaBody

product, inconvenience, loss or damage to personal property, whether direct or indirect, and incidental or consequential damages, so the

above limitation or exclusion may not apply to you.

NOTES:

15

Page 16

LIFE FITNESS

14150 Sunfish Lake Blvd. Ramsey Minnesota, 55303 U.S.A.

T el: 763.323.4500 Fax: 763.323.4797

800.328.9714 (T oll-free within the U.S. and Canada)

www.parabody.com

INTERNATIONAL OFFICES

Life FitnessAtlantic BV

Atlantic Headquarters

Bijdorpplein 25-31

2992 LB Barendrecht

The Netherlands

Phone: (180) 646 666

Fax: (180) 646 703

Life Fitness EUROPE GmbH

Siemensstrasse 3

85716 Unterschleissheim

Germany

Phone: (089) 31 77 51-0

Fax: (089) 31 77 51 99

Life Fitness Italia S.R.L.

V ia Elvas 92

39042 Bressanone

Italy

Phone: 39 (472) 835-470

Fax: 39 (472) 833-150

Life Fitness (UK) Ltd.

Queen Adelaide

Ely , Cambs CB7 4UB

United Kingdom

Phone CSS: (01353) 665507

Fax CSS: (01353) 666719

Life Fitness Benelux N.V.

Bijdorpplein 25-31

2992 LB Barendrecht

The Netherlands

Phone: 31 (180) 64 66 69

Fax: 31 (180) 64 66 99

Life Fitness Japan

8/F , Nippon Brunswick Building

5-27-7 Sendagaya

Shibuya-Ku, T okyo 151-0051

Japan

Phone: 81 (3) 3359-4309

Fax: 81 (3) 3359-4307

Life Fitness Asia Pacific Limited

Room 2610, Miramar T ower

132 Nathan Road, T simshatsui

Kowloon, Hong Kong

Phone: (852) 2891-6677

Fax: (852) 2575-6001

16

Life Fitness Do Brazil

Al. Rio Negro, 433-Predio 2-Sala 2

3

º andar (Confab)

Aplhaville-Barueri-Sao Paulo

CEP: 06454-904

Brazil

Phone: 55 (11)7295-2217

Fax: 55 (11) 7295-2218

Loading...

Loading...