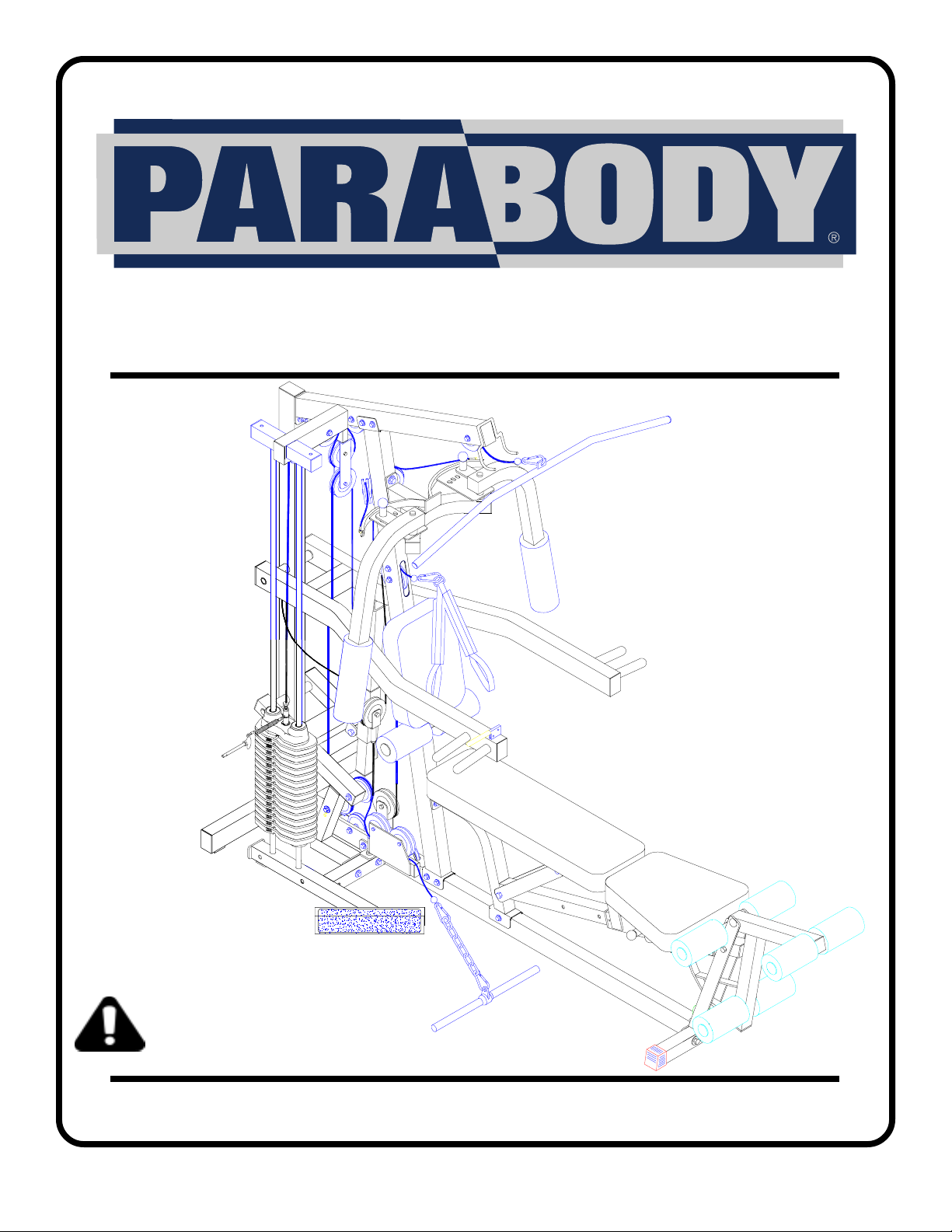

ParaBody 440 User Manual

440 GYM SYSTEM

WARNING:

Read and follow all directions

for each step to insure proper

assembly of this product.

CLASS H

PART # 7031801

REV . E

USER’S GUIDE

1

Version: 440101

Revision: 07/10/01

j

TABLE OF CONTENTS

Safety Statement.............2

General Notes..................3

Tools Required................3

Gym Layout.....................4

Parts list..........................5

Assembly Instructions.....6-30

General Maintenance.......31

W arranty Statement..........32

Product Services..............33

Insert-Registration Card

IMPORTANT SAFETY INFORMATION

THERE IS A RISK ASSUMED BY INDIVIDUALS WHO USE THIS TYPE OF

EQUIPMENT. TO MINIMIZE RISK FOLLOW THESE RULES!

1. Before using, read all the warnings and instructions

on the use of this machine. Use only for intended

exercise. DO NOT modify the machine.

2. Obtain a medical exam before beginning any

exercise program.

3. Keep body and clothing free of all moving objects.

4. Inspect the machine before use. DO NOT use it if it

appears damaged. DO NOT attempt to fix a broken or

ammed machine. Notify your authorized ParaBody

dealer before use and have repairs made by an

authorized service technician.

6. Never pin the weights or prop plate into an elevated

position. DO NOT use the machine if found in this

condition. DO NOT attempt to fix. Notify your

authorized ParaBody dealer.

7. Inspect cables and their connections before using

machine. Pay particular attention to the cable ends.

DO NOT attempt to fix. Notify your authorized

ParaBody dealer before use and have repairs made by

an authorized service technician.

8. Make sure all spring loaded pull pins are fully

engaged in the adjustment position and fully tighten

thumbscrew before use.

5. Be certain that weight pin is completely inserted.

Use only the pin provided by the manufacturer. If

unsure, call your authorized ParaBody dealer.

9. Children must not be allowed near this machine.

Supervise teenagers.

.

NOTE: In a continual effort to improve our products, specifications are subject to change

2001 LifeFitness, a division of Brunswick Corporation. All rights reserved.

©

ParaBody is a trademark of Brunswick Corporation

www.parabody.com

2

IMPORTANT NOTES

Please note:

* Thank you for purchasing the ParaBody 440 Gym System. Please read these

instructions thoroughly and keep them for future reference.

* This product must be assembled on a flat, level surface to assure its proper function. DO NOT

securely tighten any frame connections until the entire frame has been assembled, unless

otherwise stated.

T ools Required for Assembly

* Rubber mallet or hammer

* 3/4” wrench

* 9/16” wrench

* Ratchet with 3/4” and 9/16” sockets

* 5/32” Allen wrench

* Adjustable wrench

* T ape measure

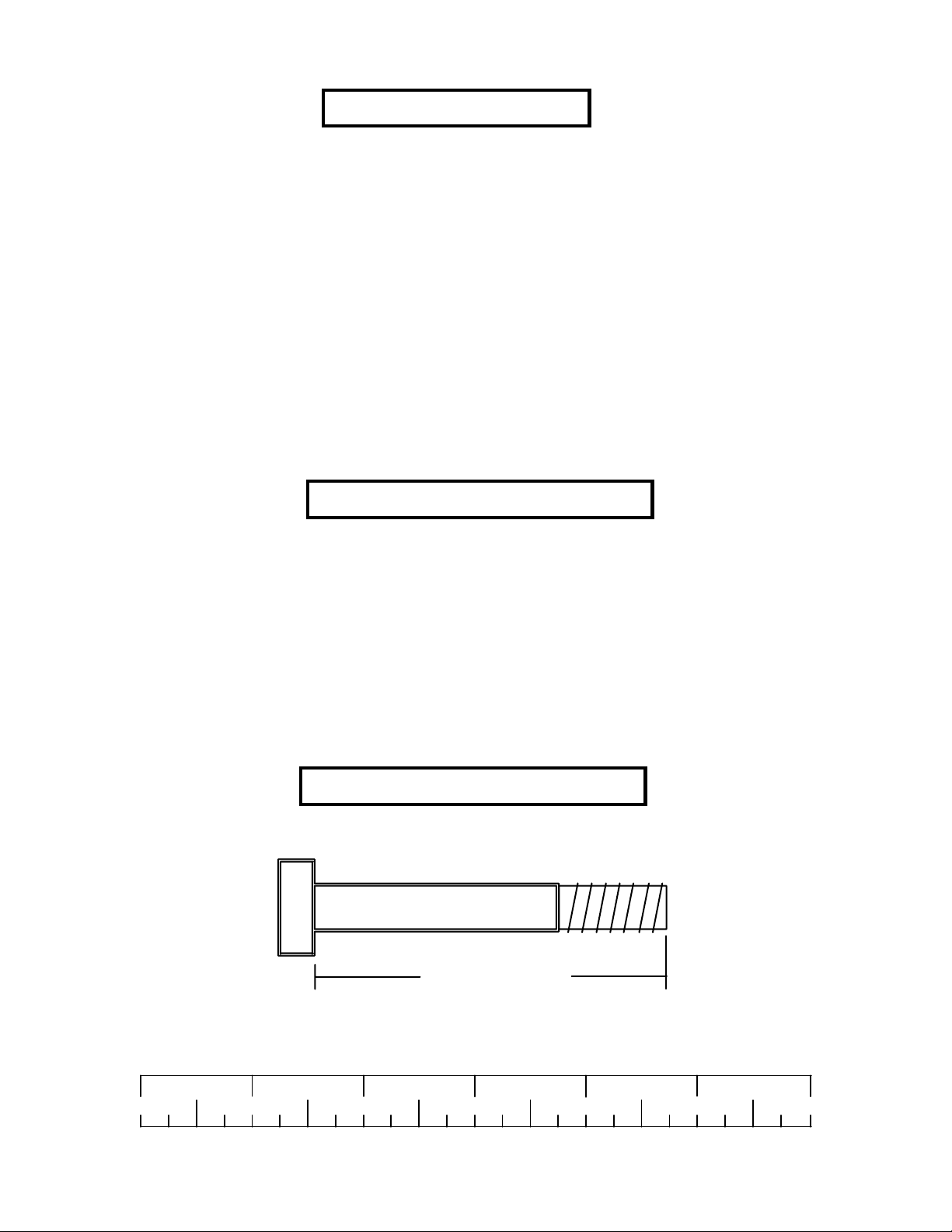

Bolt Length Ruler

NOTE: BOL T LENGTH IS MEASURED FROM THE UNDERSIDE OF THE HEAD OF THE BOLT.

BOLT LENGTH

BOL T LENGTH RULER:

1/2 1/2 1/2 1/2 1/2 1/2

0

1

2

345

3

6

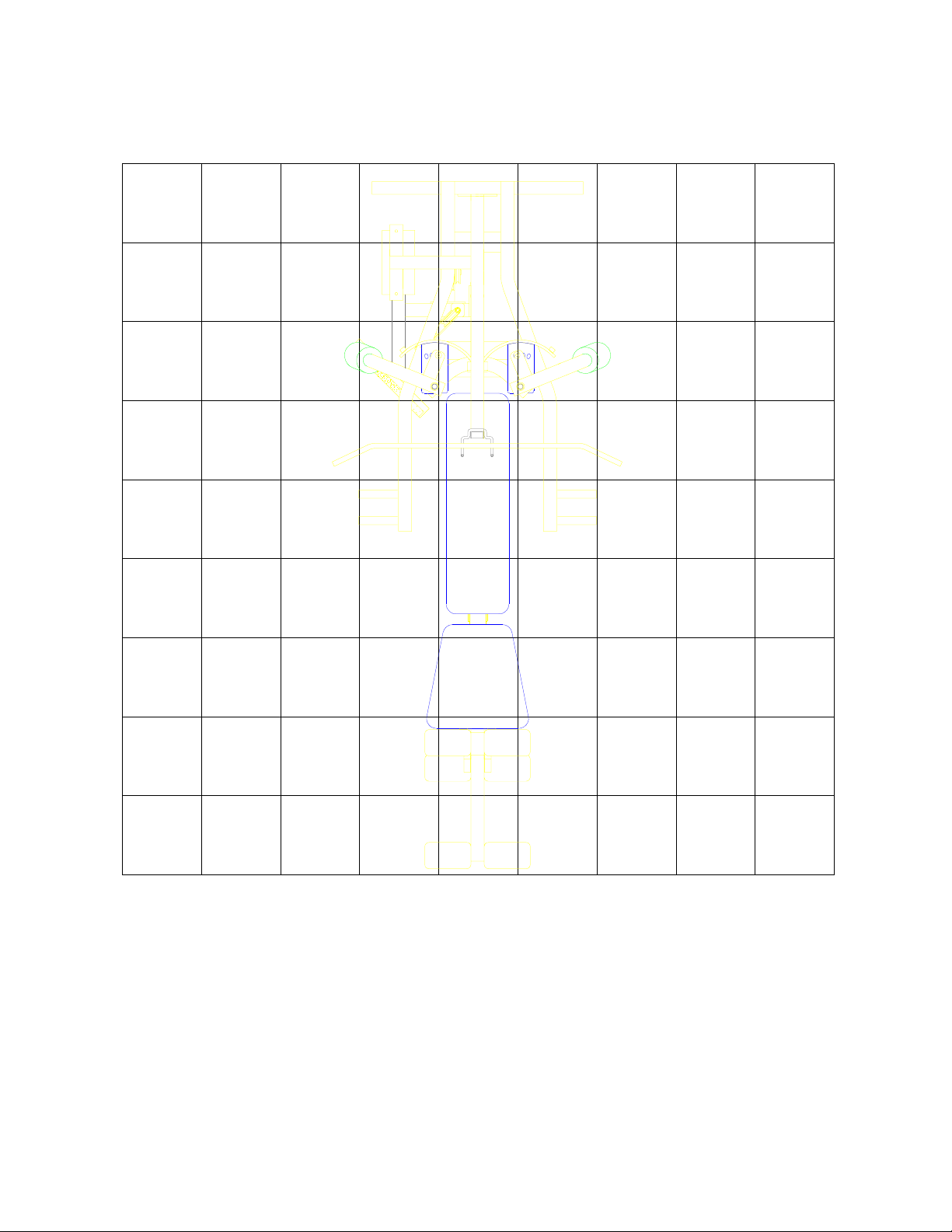

1’

2’

3’

4’

5’

1’

2’ 3’

4’

5’ 6’ 7’ 8’

9’

6’

7’

8’

9’

1 Square = 1’ X 1’

4

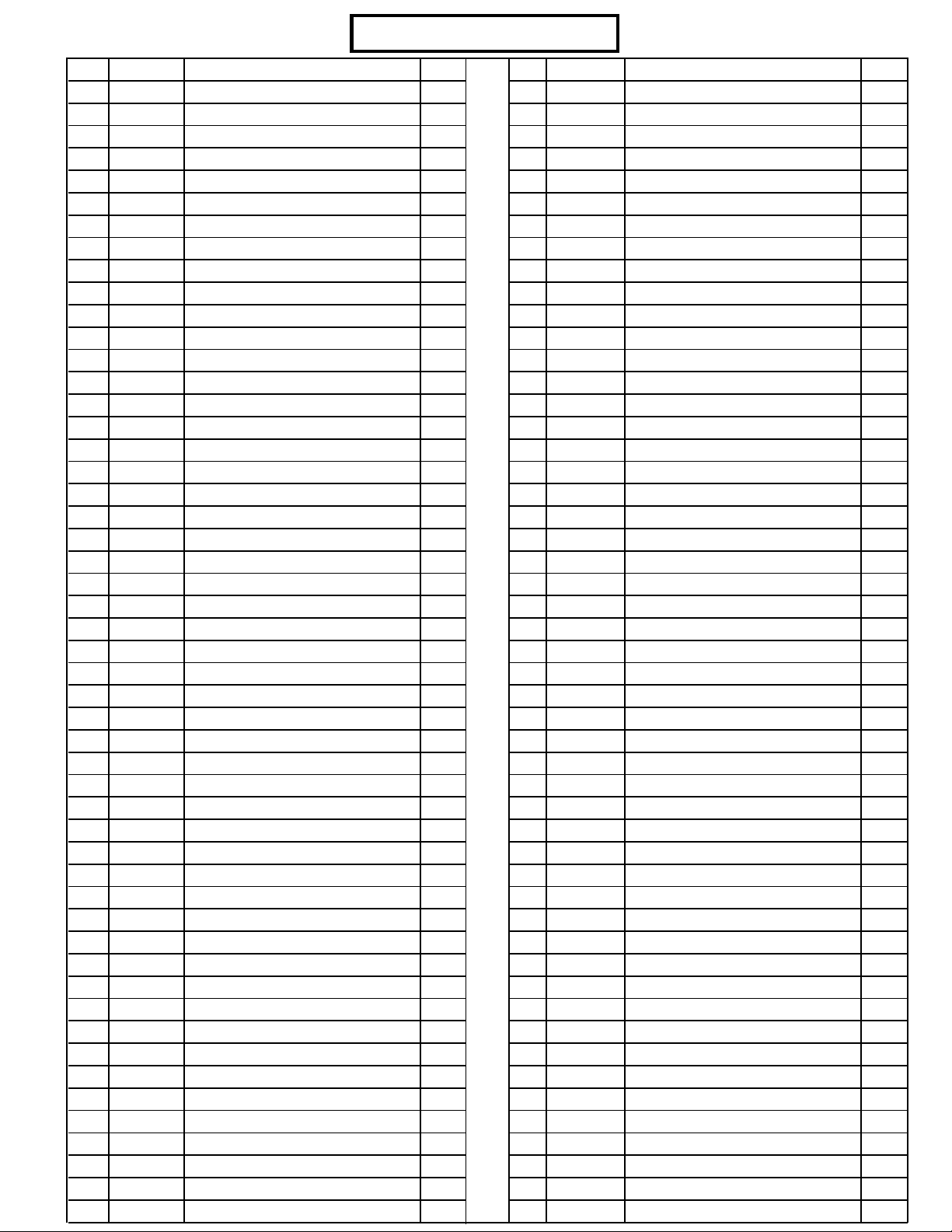

PARTS LIST

KEY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

PART #

6875108

6688202

6687308

6832308

6686802

6679508

6688008

6687508

6687902

6873408

7033508

6686908

6680202

6832902

6874808

6689408

6688108

6681902

6539808

6539708

6530208

6594702

6633902

6529702

6540202

6654321

6597421

6681521

6690901

6125101

6194601

6176201

6523401

7012102

3102909

3102924

3102933

3102922

3102904

3102905

3102906

3102910

3102943

3102917

3102937

3221702

3102949

3102802

3102801

3102804

3102501

DESCRIPTION

FRAME SUPPORT

WOLFF SLEEVE

WEIGHT ST ACK BASE

LEG CURL/EXTENSION

PULLEY BRACKET

ADJUSTMENT SLIDE

TOP BOOM

PRESS ARM

PRESS ARM LEVER

BASE

FRONT UPRIGHT

LEVER STOP

RECEIVING TUBE

BACK P AD SUPPOR T

LEG SUPPORT

REAR UPRIGHT

BEARING HOUSING

PLATE, 1/4 X 2 X 16-1/2”

PEC ARM RIGHT

PEC ARM LEFT

CENTER PULLEY BRACKET

FLOA TING PULLEY

SWIVEL PULLEY BRACKET

PEC CAM

LA T BAR

33-1/2 X 9-1/2” BACK SEAT PAD

15-1/2 X 10-1/2” PEC SEAT PAD

15-3/4 X 15-1/2” LEG SEAT PAD

3/4 DIA X 1 1” SHAFT

3/4 OD X 16” TUBE

4 X 7” ROLLER PAD

PEC DEC ROLLER P A D

3/4 X 72-3/8” GUIDE ROD

WEIGHT ST ACK SP ACER

3/8 X 1” BOLT

3/8 X 1-3/4” BOLT

3/8 X 2” BOLT

3/8 X 2-3/4” BOLT

3/8 X 3” BOLT

3/8 X 3-3/4" BOLT

3/8 X 4" BOL T

1/2 X 3" BOL T

1/2 X 3-1/2" BOLT

1/2 X 4" BOL T

1/2 X 4-1/2" BOLT

3/4” E-RING

1/2 X 5-1/2” BOLT

3/8” LOCK NUT

1/2” LOCK NUT

1/2” LOW HT . NYLOCK NUT

3/8” WASHER

QTY

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

2

1

2

1

1

1

1

2

3

8

2

2

2

4

5

4

10

6

2

4

10

3

2

2

1

2

29

10

8

31

KEY

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

PART #

3102502

3102503

3109602

6686301

6075906

6972201

6533501

6321202

3119201

3226301

3117901

3114407

3118401

3106803

6480301

6020601

6019701

3104901

6416601

6412001

3103801

3105401

6939202

6692601

6405201

6236701

6406401

3116201

7095701

6953702

6375801

6389701

6409101

3116001

6270501

6140701

3108002

3117401

6873801

6687201

7032301

6535601

6978101

6145801

6382301

6866601

6866801

6122702

6427101

DESCRIPTION

1/2” WASHER

3/4” WASHER

P AL NUT

1/2” DIA U-PIN

CHAIN

WEIGHT ST ACK PIN

CABLE RET AINING CLIP

CONTROL LEVER

8-32 X 3/16” SCREW

3/8” JOINT CONNECTOR CAP

E-RING

#10 FLA T WASHER

4” VINYL CAP

5/16” SET SCREW

3/8” FLANGE SP ACER

1/2” FLANGE BEARING

3/4” THRUST BEARING

3/4” FLANGE BEARING

1-3/4 X 3/4” PARAGLIDE

SPRING PIN ASSEMBLY

5/16” DIA SNAP LINK

ST ARLOCK COLLAR

WEIGHT PLATE

3 X 2” END CAP

2” SQ. END CAP

1-3/4” SQ END CAP

HINGE T AB

3-1/2” PULLEY

WEIGHT ST ACK SHAFT

HEAD PLA TE

STRAP AB CRUNCH

LOW ROW BAR

STRAP ANKLE

1-1/4” BUMPER RUBBER

4 X 14” NON-SKID

1 X 1” GLIDE

WEIGHT ST ACK CUSHION

CAP PLUG

227-5/8” LEG EXT. CABLE

73” AB CABLE

101-1/2” LAT CABLE

77-5/8” PEC DEC CABLE

WEIGHT ST ACK LABELS

THUMBSCREW

WEIGHT PLATE BUSHING 10CT

BOL T COVER CAP

BOL T COVER WASHER

3/8” X 1/2” SPACER

KEYHOLE CLEVIS

QTY

14

2

1

1

1

1

5

1

2

2

1

2

1

4

14

6

2

8

1

3

4

10

15

2

2

1

2

19

1

1

1

1

1

1

1

4

2

2

1

1

1

1

1

1

3

2

2

2

1

49

16

69

52

1/2 X 3” 42

66

3/8 X 2-3/4” 38

79

48

66

10

90

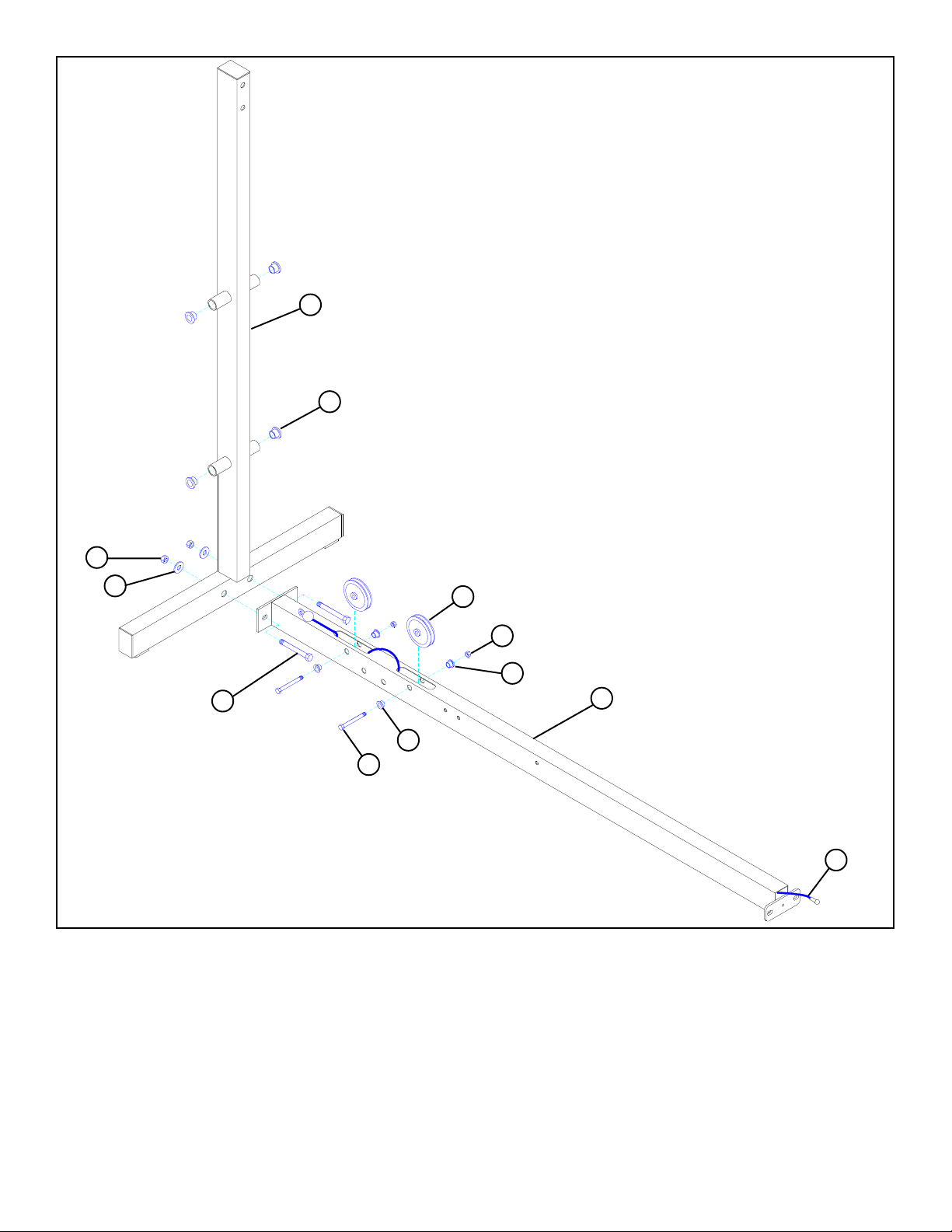

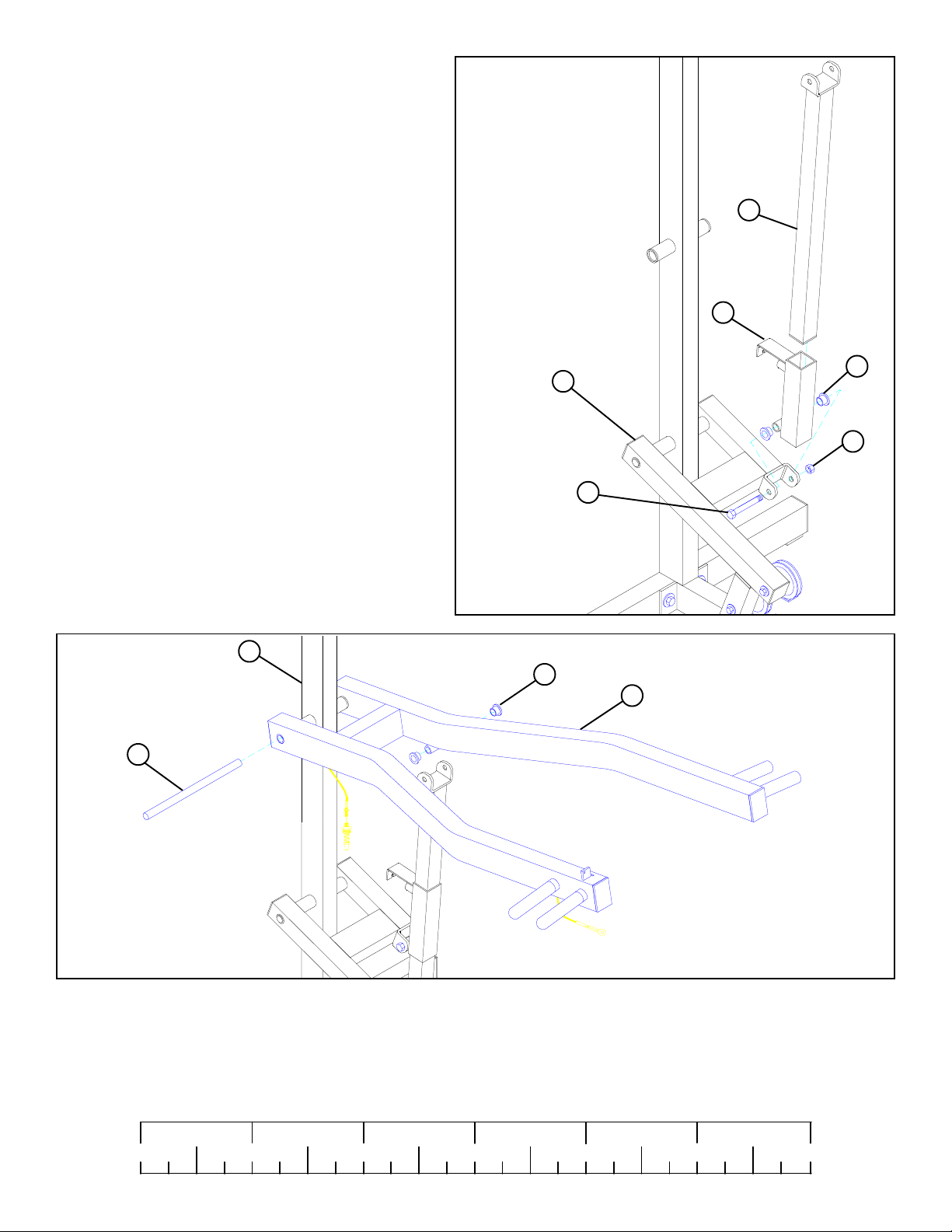

FIGURE 1

STEP 1

• Securely assemble REAR UPRIGHT (16 ) to BASE (10) using two 1/2 X 3" BOLTS (42), two 1/2" WASHERS (52), and two

1/2" LOCKNUTS (49).

• Slide LEG EXT . CABLE ASSEMBLY (90) through openings in BASE (10) as shown in FIGURE 1.

• Securely assemble two 3-1/2" PULLEYS (79) into BASE (10) using two 3/8 X 2-3/4" BOLTS (38), four 3/8" FLANGE

SPACERS (66), and two 3/8" LOCKNUTS (48). (NOTE: Make sure LEG EXT. CABLE ASSEMBLY (90) is routed under

PULLEYS and BOL TS.)

• Slide LEG EXT . CABLE ASSEMBLY (90) through the opening in the end of the BASE (10) as shown in FIGURE 1.

• Insert four 3/4" FLANGE BEARINGS (69) into tubes on REAR UPRIGHT (16) as shown in FIGURE 1

6

3/8 X 3-3/4” 40

51

12

79

58

48

51

50 1/2” LOW HEIGHT

49

3

1/2 1/2 1/2 1/2

0

52

23

42 1/2 X 3”

1

86

2

34

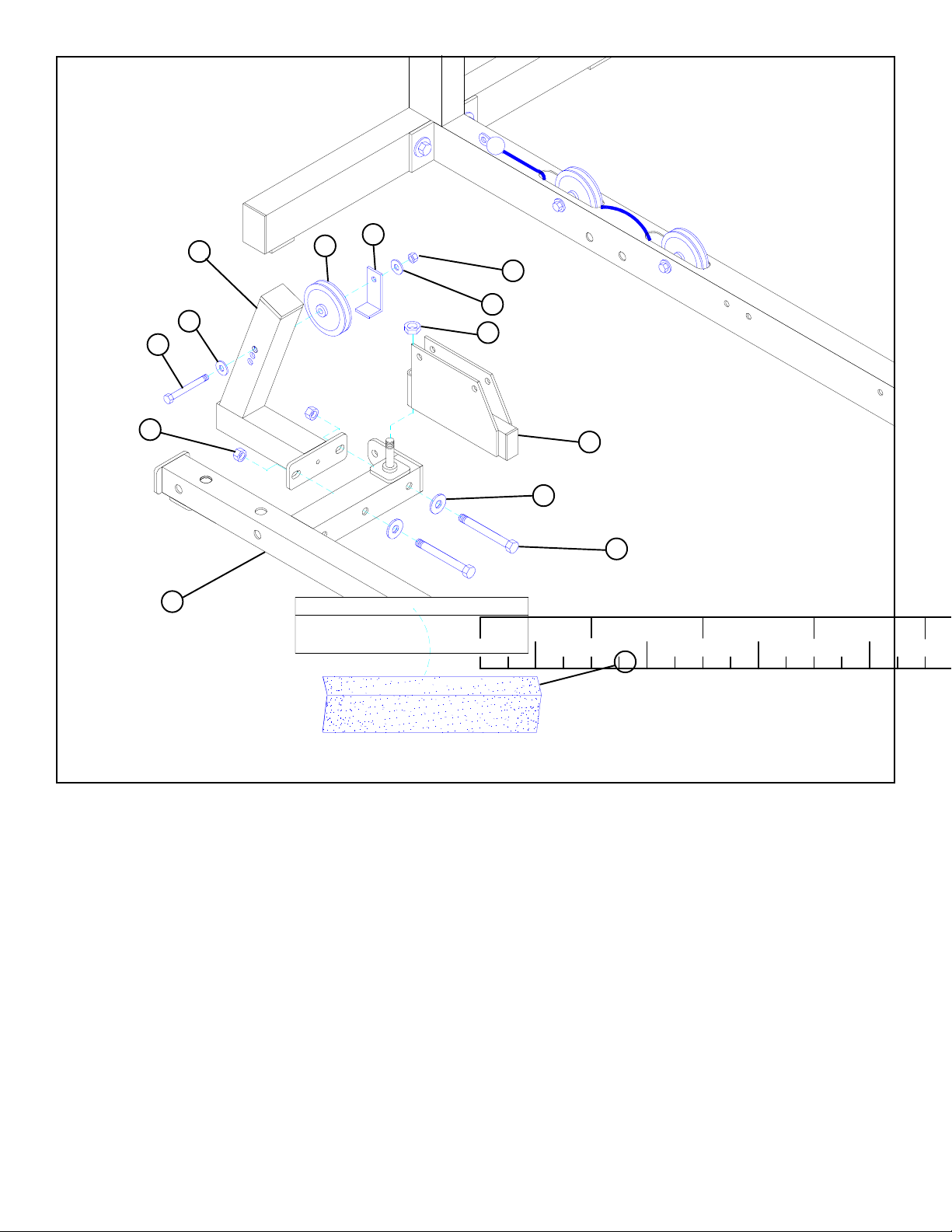

FIGURE 2

STEP 2

• Securely assemble one 3-1/2" PULLEY (79) to the top hole of the LEVER STOP (12) using one 3/8 X 3-3/4" BOLT (40), two 3/8"

WASHERS (51), one 2-3/8" RETAINING CLIP (58), and one 3/8" LOCKNUT (48). The extra holes in the LEVER STOP (12) are

to be used for cable adjustment.

• Securely attach LEVER STOP (12) to WEIGHT STACK BASE (3) using two 1/2 X 3" BOLTS (42), two 1/2" WASHERS (52),

and two 1/2" LOCKNUTS (49).

• Attach SWIVEL PULLEY BRACKET (23) to the WEIGHT STACK BASE (3) using one 1/2" LOW HEIGHT LOCKNUT

(50). (NOTE: Securely tighten, then back nut off 1/4 turn to allow the SWIVEL PULLEY BRACKET (23) to rotate freely.)

• Center 4 X 14" NON SKID STRIP (86) on WEIGHT STACK BASE (3) as shown in FIGURE 2.

7

29

3/8 X 3-3/4” 40

49

16

51

9

79

48

51

58

42 1/2 X 3”

52

10

86

3

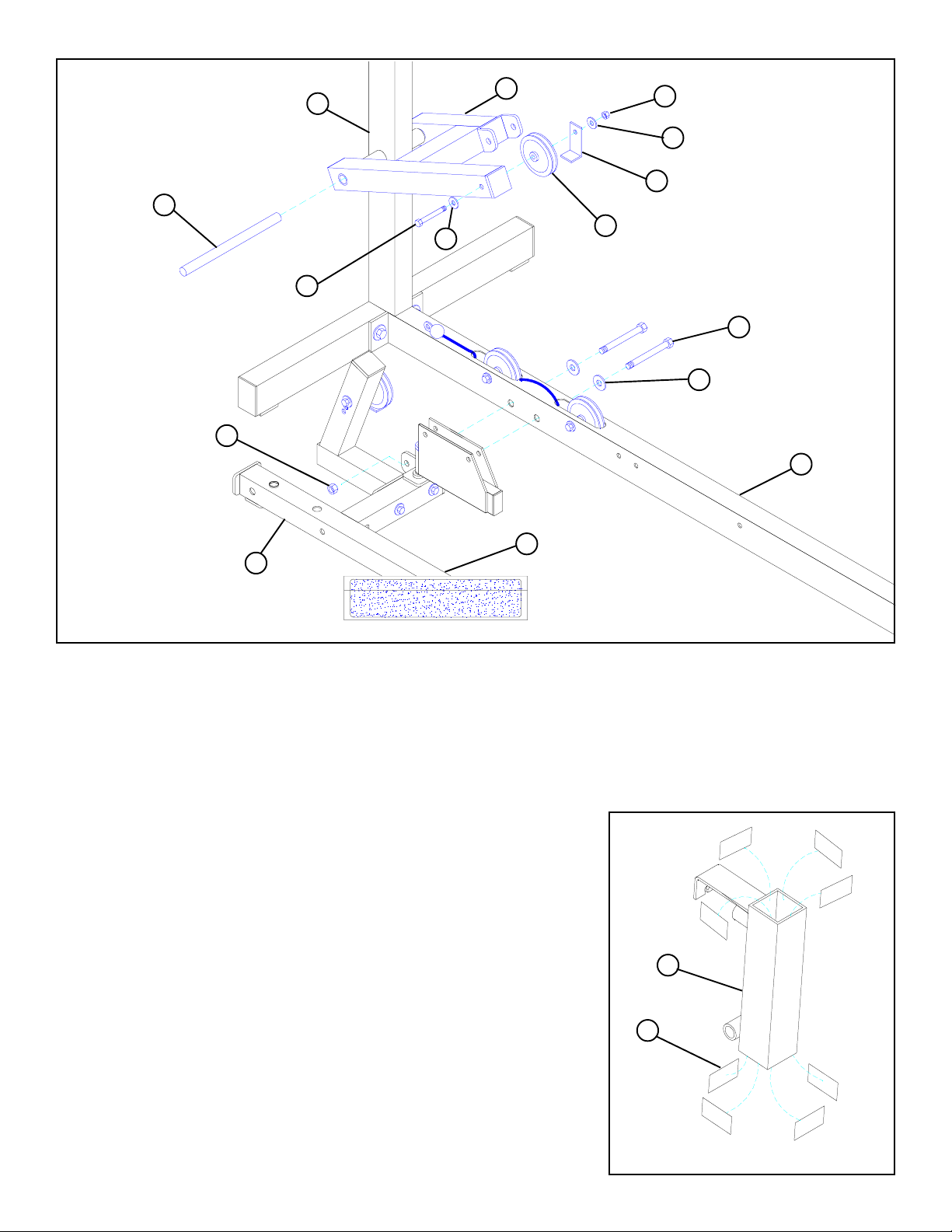

FIGURE 3

STEP 3

• Securely attach WEIGHT STACK BASE (3) to BASE (10) using two 1/2 X 3" BOLTS (42), two 1/2" WASHERS (52), and

one 1/2" LOCKNUT (49).

• Slide one 3/4 DIA X 11" SHAFT (29) through PRESS ARM LEVER (9) & tube on REAR UPRIGHT (16). See FIGURE 3.

• Securely assemble one 3-1/2" PULLEY (79) to PRESS ARM LEVER (9) using one 3/8 X 3-3/4" BOLT (40), two 3/8"

WASHERS (51), one 2-3/8" RETAINING CLIP (58), and one 3/8" LOCKNUT (48).

STEP 4

• Apply eight 1-3/4 x 3/4" PARAGLIDES (70) to the INSIDE of RECEIVING

TUBE (13) as shown in FIGURE 4. (NOTE: Throughly clean the inside

surface before attaching PARAGLIDES.)

13

70

FIGURE 4

8

STEP 5

• Insert two 1/2" FLANGE BEARINGS (67) into

RECEIVING TUBE (13).

• Attach RECEIVING TUBE (13) to PRESS ARM LEVER

(9) using one 1/2 X 3-1/2" BOL T (43), and one 1/2" LOW

HEIGHT LOCKNUT (50). (NOTE: Securely tighten,

then back nut off 1/4 turn to allow the RECEIVING

TUBE (13) to rotate freely.)

6

• Insert the ADJUSTMENT TUBE (6) into the

RECEIVING TUBE (13) as shown in FIGURE 5.

16

29

9

1/2 X 3-1/2” 43

FIGURE 5

67

13

67

50

1/2”

LOW

HEIGHT

8

FIGURE 6

STEP 6

• Slide one 3/4 DIA X 11" SHAFT (29) through PRESS ARM (8) & tube on REAR UPRIGHT (16). See FIGURE 6.

• Insert two 1/2" FLANGE BEARINGS (67) into PRESS ARM (8).

1/2 1/2 1/2 1/2 1/2 1/2

0

1

2

345

9

6

8

43 1/2 X 3-1/2”

6

50

1/2” LOW

HEIGHT

STEP 7

• Attach ADJUSTMENT SLIDE (6) to PRESS ARM (8)

using one 1/2 X 3-1/2" BOL T (43), and one 1/2" LOW

HEIGHT LOCKNUT (50). (NOTE: Securely

tighten, then back nut off 1/4 turn to allow the

PRESS ARM (8) to rotate freely.)

FIGURE 7

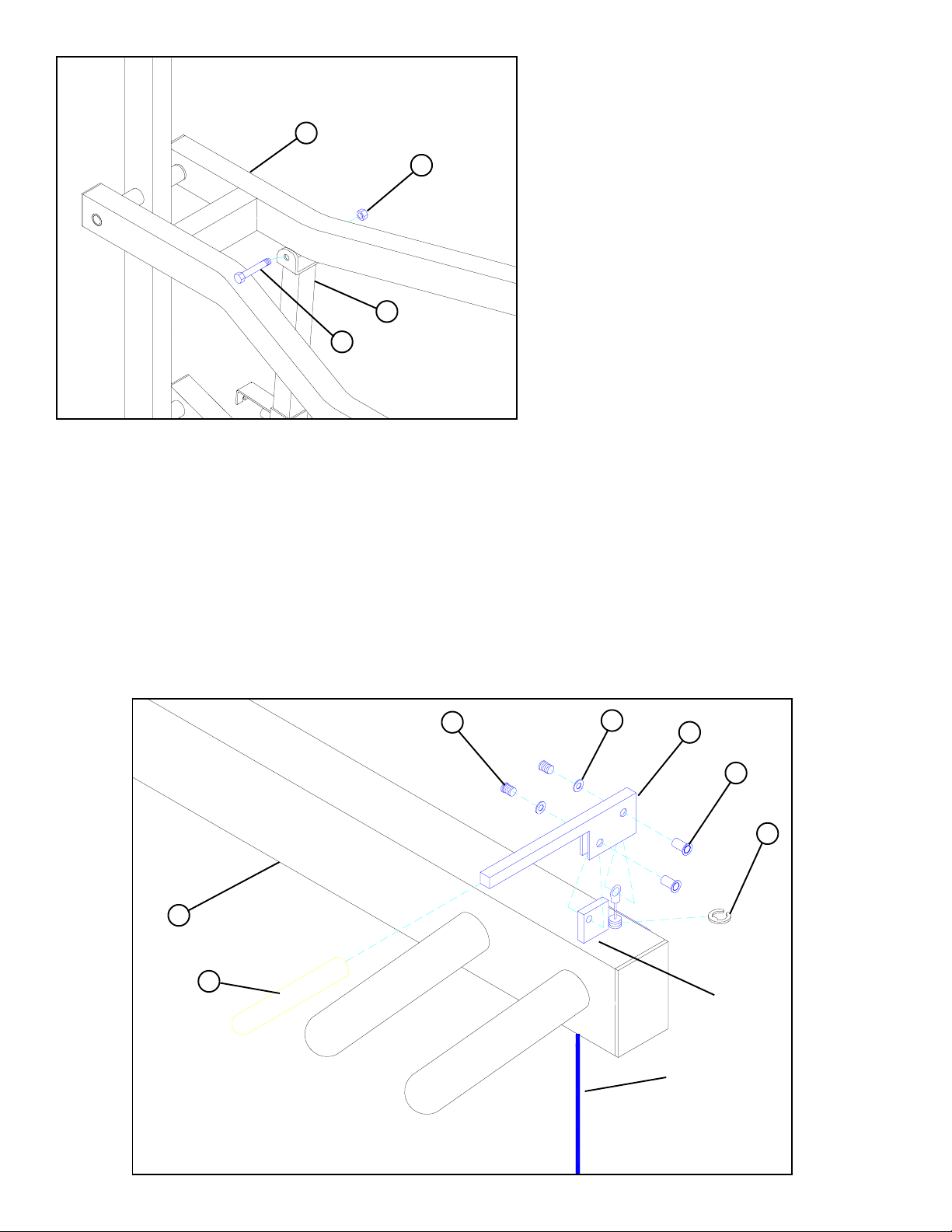

STEP 8

• Insert the PUSH/PULL CABLE through the bottom of the PRESS ARM (8) up to the CONTROL LEVER (59) and hold in place

with one E-RING (62) as shown in FIGURE 8.

• Securely assemble the PUSH/PULL CABLE to the CONTROL LEVER (59) using one 3/8 IN. JOINT CONNECTOR CAP (61),

one #10 FLAT WASHER (63), and one 8-32 X 3/16 IN. SCREW (60) as shown in FIGURE 8.

• Slide one 4” VINYL SLEEVE (64) over the CONTROL LEVER (59). Then SECURELY assemble the CONTROL LEVER (59) to

the TAB on the PRESS ARM (8) using one 3/8” JOINT CONNECTOR CAP (61), one #10 FLAT WASHER (63), and one 8-32 X

3/16 IN. SCREW (60) as shown in FIGURE 8.

60

8

64

63

59

61

62

TAB

FIGURE 8

PUSH/PULL

CABLE

10

Loading...

Loading...