Page 1

425101 HOME GYM

ASSEMBLY INSTRUCTIONS

TItANK YOU

FORPURCHASING THE 4~5T01 HOME G~t. PLEASE SAVE TI-IESE ASSEMBLY INSTRUCTIONS

FOR YOUR PERSONAL REFERENCE, AND ADDITIONAL SERVICE INFORmaTION.

***IMPORTANT***

’

THE #2~10! HO:~,~E GY,~ MUST BE ASSEMBLED ON A FLAT, LEVEL SURFACE TO ASSURE ITS PROPER.

FUNCTION.

PARABODY INC. STRONGLY RECOMMENDS THAT THIS PRODUCT BE ASSEMBLED BY TWO PERSONS TO

AVOID POSSIBLE INJURY.

KEEP ALL FRAME CONNECTIONS LOOSE, UNTIL INSTRUCTED IN THE ASSEMBLY STEP SEQLrENCES TO

SECURELY TIGHTEN. "

IF YOU EXPERIENCE ANY PROBLEM WITH THE ASSEMBLY OF THIS PRODUCT, PLEASE CONTACT YOUR

DEAL~ OR YOUR PARABODY CUSTOMER SERVICE REPRESENTATIVE AT: 1-800-328-97.I4

TOOLS REQUIRED: RATCHET, 3/4 SOCKET or WRENCH, 9/16 SOCKET or WR£.NCH, 7/’.16 SOCKET or

WRENCH, ADJUSTABLE WRENCH: PHILLIPS SCREWDRIVEl~ 5/32 ALLEN WRENCH, 7/32 ALLEN WRENCH,

LEVEL, and RUBBEt¢. MALLET or HAMMER-

07P...~96

1

Page 2

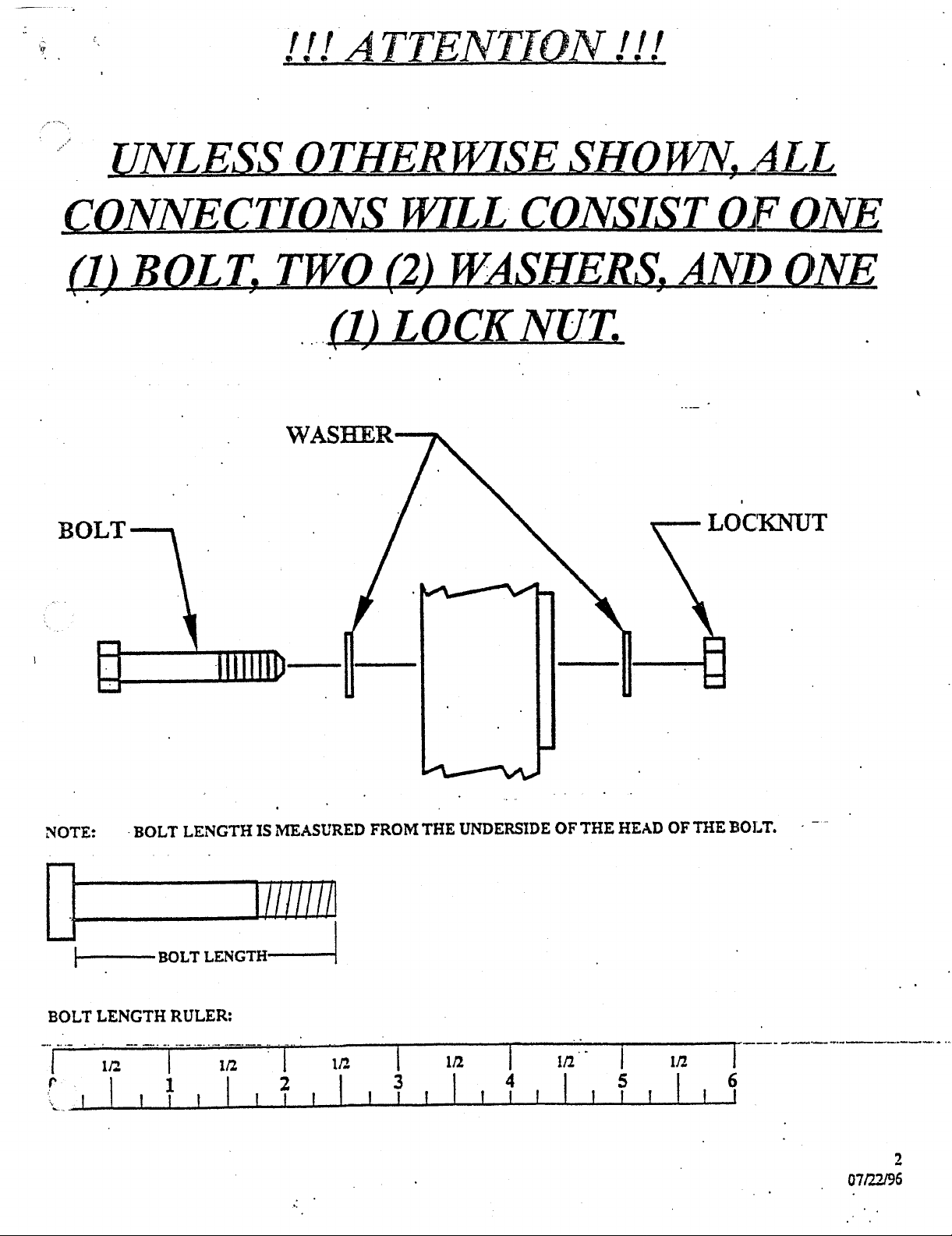

! ! ! A TTENTtON ! ! !

........ _U_NL ES_S__Q£HE~ ~ L L

_C_Q_NNE TI, N,

WAS

BOLT

L ’N, I, T F__._O_N_~

LOCKNUT

NOTE: - BOLT LENGTH I$ MEASURED FROM THE UNDERSIDE OF THE HEAD OF THE BOI.,T. - ....

[

BOLT LENGTH RULER:

BOLT LENGTH ~

Page 3

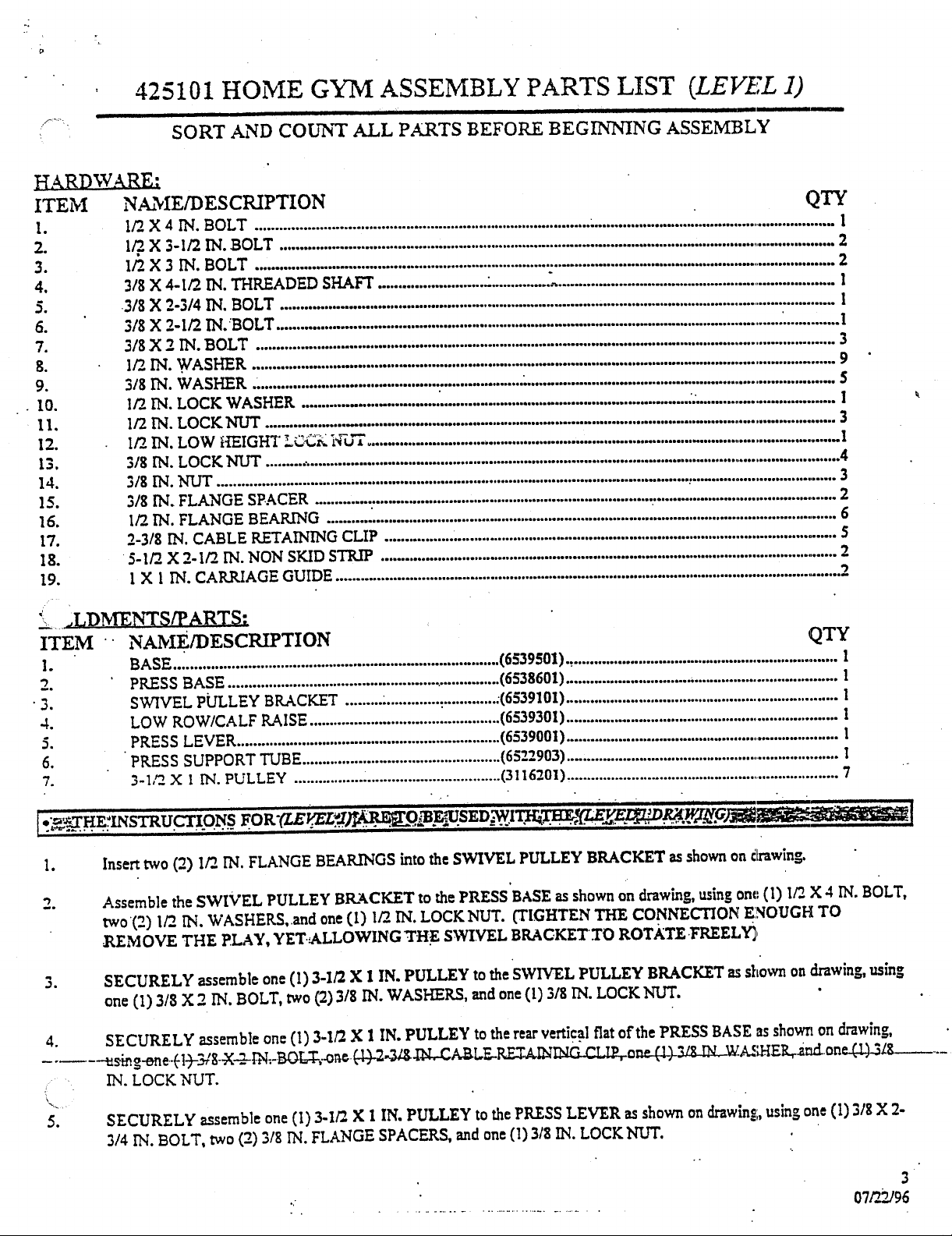

425101 HOME GYM ASSEMBLY PARTS LIST (LEVEL 1)

SORT AND CODq~"r ALL PARTS BEFORE BEGIIN-NING ASSEMBLY

HARDWARE:

ITEM

1.

2.

4.

6.

7.

g.

9.

. 10.

11.

12.

13.

14.

15.

16.

17.

I8.

19. I X I IN. CAP.R/AGE GUIDE ...............................................................................................................................

NAME/DESCRIPTION

I/2 X 4 IN. BOLT ...................................................................................

1/2 X 3-I/2 IN.BOLT .

I~ X 3 IN. BOLT ........................................................................ .: .......................................................................

.3/8 X 4-t/2 IN. THREADED SHAFT ..........................

¯ 3/8 X 2-.3/4 IN. BOLT ...........................................................................................................................................

.3/8 X 2-I/2 IN/BOLT .............................................................................................................................

.3/8 X 2 IN. BOLT .................................................................................................................................................

1/2 IN. WASHER ................................................................................................................................................

.3/8 IN. WASHER, ........................................... ... ....................

I/2 IN. LOCK WASHER

1/2 IN. LOCKNUT .............................................................................................................................................

1/2 IN. LOW ~IEIGHT ~-~,~. r~u ¯ .....................................................................................................................

.3/8 IN. LOCK NUT ...............................................................................................................................................

318 IN. NUT .............................................................................................

.3/8 IN. FLANGE SPACER ...................................................................................

I/2 IN. FLANGE BEAKING

2-318 IN. CABLE IL~TAINING CLIP .................

5-I/2 X 2-I/2 IN. NON SKID STR/P ..................................................................................................................

’

-- .......................................................................................

; ...............................................................................................

; .............................................................

’

-. ..............................................

QTY

.. 2

: .............

l

2

1

l

1

9

1

I

4

3

2.

6

5

". ’.LDMENTS/PARTS:

ITEM NAME/DESCRIPTION

BASE..I .............................................................................

PRESS BASE ...................................................................

SWIVEL PULLEY BRACKET .........

4.

5.

6.

7.

1.

3.

LOW ROW/CALF RAISE ...............................................

PRESS LEVER .................................................................

¯

PRESS SUPPORT TUBE .................................................

3-1,~ X 1 IN. PULLEY .................

Insert two (2) 1/2 IN. FLANGE BEARINGS into the SWIVEL PULLEY BRACKET as shown on drawing.

Assemble the SWIVEL PULLEY BRACKET to the PRESS BASE as shown on drawing, using ore: (I) I~ X 4 IN. BOLT,

two(2) I/2 IN. WASHERS, and one (I) I/2 IN. LOCKNUT. frIGHTEN THE CONNECTION ENOUGH

.REMOVE THE PLAY, YET-ALLOWING THE SWIVEL BRACKET.TO ROTATE.FREELY~

SECURELY assemble one (1) 3-1/2 X 1 IN. PULLEY to the SWIVEL PULLEY BRACKET as shown on drawing, using

one (1) 3/8 X 2 IN. BOLT, two (2) 3/8 IN. WASHERS, and one (1) 3/8 IN. LOCK NUT.

SECURELY assemble one (I) 3-I/2 X I IN. PULLEY to the rear vertic.al flat ofthe PRESS BASE as shown on drawing,

:isi~g-e,ae..(-1-)-3Cg-X-2-2 t:N~-BOL-T-,-on~ (!) 2,.2#.g.IN,-~ABLE-R,E-T~I~I~one (!) 3/~ _.rN..W.A£HER,-.and-.one (!)

IN. LOCK NUT.

(6539S01)., ..................................................................

(6538601) ...............................

~ .............: .............

: .................................

:(6539101) ....................................................................

(6539301) ....................................................................

(~$39001) .....................................................................

QTY

~ ....................................

"’~’~ 03

(6~..9) .....................................................................

(3116201) ....................................................................

1

1

1

1

!

7

...

SECURELY assemble one (I) 3-I/2 X I IN. PULLEY to the PRESS LEVER as shown on drawha~;, using one (I) 318

3/4 IN. BOLT, two (2) 3/8 IN. FLANGE SPACERS, and one (1)3/8 IN. LOCK

07D/2/96

Page 4

,Attach two (2) 1 X I IN. CARRIAGE GuIDEs to the underside of the PRESS LEVER,as shown in (DETAIL

Q

I1.

12.

13.

14.

insert two (2) I~ IN. FLANGE BEAR$NGS into the PRESS LEVER as shown on drawing.

Assemble the PRESS LEVER to the PRESS BASE as shown on drawing, using one (1) 1:2_ X 3-1/’2- IN. BOLT, two (2)

IN. WASHERS, and one (I) I~ IN. LOCK NUT. frIGHTEN THE CONNECTION ENOUGH TO REMOVE THE

PLAY, YET ALLOWING THE PRESS LEVER TO ROTATE FILEELY)

Insert two (2) 1/2, IN. FLANGE BEARINGS into the PRESS SUPPORT TUBE as shown on drawin!~.

Assemble the PRESS SUPPORT TUBE to the PRESS BASE as shown on drawing, using one (1) I/2 X 3-I/2 IN. BOLT,

two (.2) 1/2 IN, WASHERS, and one (I) I/2 IN. LOCK NUT. frIGHTEN THE CONNEC’rlON EI~IOUGH

REblOVE THE PLAY, YET ALLOWING THE PRESS SUPPORT TUBE TO ROTATE FREELY)

A~’tach two (2) :5-.I/2 X 2-1/2..IN. NON SKID,STRIPS to the.LOW ROW/CALF RAISE approximately where-shown

drawing.

SECURELY assemble the LOW Row/CALF RAISE to the PRESS BASE using two ~) b2 X 3 lq,l. BOLTS, three

I/2 IN. WASHERS, and one (I) 1/2 IN. LOW HEIGHT LOCK NUT.

SECURELY assemble one (I) 3-1~ X 1 IN, PULLE~’~ re tbe..r-gnt flat of the BASE as shown on &awing, using one (1)

3/g X 2 IN. BOLT, one (1) CABLE RETAINING CLIP, one (1) 31g IN. WASHER, and one (I) 3/1| IN. LOCK

SECURELY assemble two (2) 3,1/2 X I IN. PULLEYS to the middle fiat of the BASE as shown in ,~ETAIL B), using

one (I) 3/8 X 4-1~ IN. THREADED STUD, two (2) CABLE RETAINING CLIPS, and two (2) 3/8.2~.

o

15.

I--IAR~WARE:

ITEM

1.

2.

3.

4.

5.

6.

7,

g.

9.

I0.

I1.

12.

13.

SECURELY assemble one (1) 3-1/2 X 1 IN. PULLEYS to the rear flat of the BASE as shown on dr~twing, using one (1)

3/8 X 2-I~ IN. BOLT, one (1) 2-3/8 IN. CABLE RETAINING CLIP, one (1) 3/8 IN. WASHER, and one (1) 3/8 [N. ,~U77..

NA.ME/DESCRIPTION QTY

3/$ X 2 IN. BOLT ................................................................................................ : ............................: ....................

~/8 X ~-~/4 IN. BOLT ..........................................................................................................................................

3/8 X 3 IN. BOLT .....................................................................

I/2 X 3-1/4 IN. BOLT ............................................................................................................................................

3/8 IN. WASHER ...............................................................................................................................................

1~ IN. WASHER ...................................................................................................................................................

3/8 IN. LOCK.NUT

I/2 IN. LOCK N, UT .................................................................................................................................................

318 IN. SPKINGPIN A:SSEMBL~/" .......................................................................................................................

9/16 MUSHKOQM CAP .......................................................................................................................................

THUMBSCREW ...................................................................................................................................................

3/8 IN. FLANGE SPACER .....................................................................................................................................

2-7I$ IN. CABLE RETAINING CLIP .....................................................................................................................

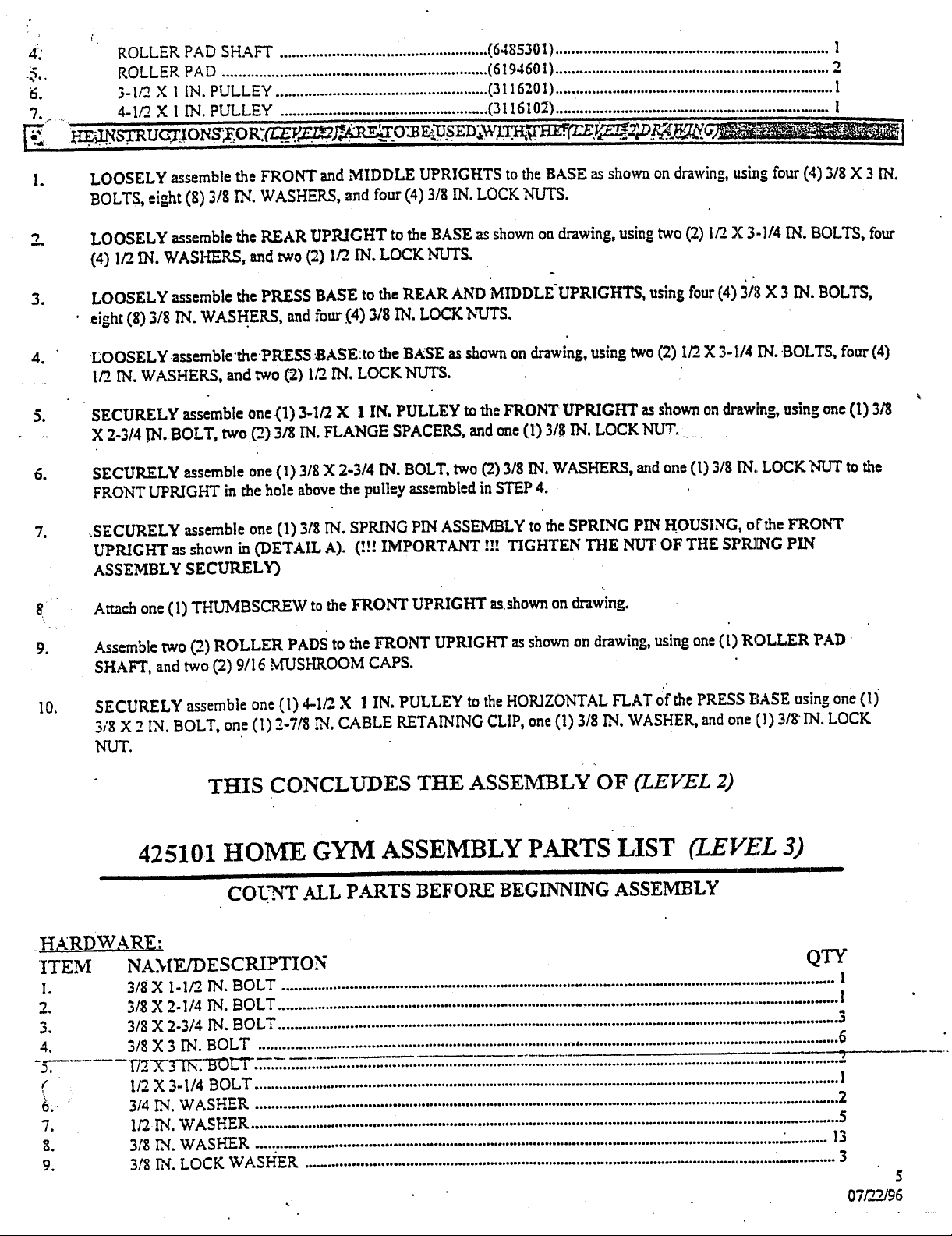

THIS CONCLUDES THE ASSEMBLY OF (LEVEL 1)

425101 HOME GYM ASSEMBLY PARTS LIST (LEVEL 2)

COUNT A1.L PARTS BEFORE BEGINNING ASSEMBLY

~ ..........................................................................

" 11

I

2

$

4

19

8

4

1

2

1

.29

I

WELDMENT$/PARTS: ""

,.:~EM NAM.E/DESCRIPTION

",~..

2.

3. FR.ONT UPRIGHT ..........................................................

REAR UPRIGHT ............................................................

MIDDLE UPRIGHT .......................................................

(6538501) .................................................................... I

(6~30303) ....................................................................

(6540001) .....................................................................

QTY"

I

Page 5

~:’ ROLLE~. PAD SHAFT ..............................

-5..

~. 3-l/2 X ! iN. PULLEY ....................................................

?. .......

ROLLER PAD .................................................................

4-I~ X I IN. PULLEY ...................................................

LOOSELY assemble the FRONT and MIDDLE UPRIGHTS to the BASE as shown on drawing, using four (4) 31g X 2 IN.

BOLTS¯ eight (8) 3/8 IN. WASHERS, and four (4) 3/8 IN. LOCK NUTS.

LOOSELY assembl~ the REAR UPRIGHT to the BASE as shown on drawing, using two (2) I~ 3.1/4 IN. BOLTS, four

(4) l~ I"N. WASHER.S, and two (2) I/2. IN. LOCK NUTS.

LOOSELY assemble th~ PRESS BASE to the REAR AND MIDDLE’UPRIGHTS, using four (4) ~/g X 3 IN. BOL’I~,

.eight (g) 3/8 IN. WASHEP,.S, and four .(4) 3/g IN. LOCK NUTS.

i~OOSELY.assemblethePRESS :BASE:tothe BASE as shown on drawing, using two (2) IP- X 3-I/4 IN..BOLTS¯ four (4)

I/2. rN. WASHERS, and two (2) l~ IN. LOCK NUTS.

SECURELY assemble one (I) 3-I/2 X 1 IN. PULLEY to the FRONT UPRIGHT as shown on drawing, using one (I)

X 2-314 IN. BOLT, two (2) 31g IN. FLANGE SPACERS, and one (I) 31.g IN. LOCK NUT, .........

SECURELY assemble one (I) 31g X 2-3/4 IN. BOLT, two (2) 318 IN. WASHERS, and one (I) 318 IN.. LOCK NUT

FRONT UPRIGHT in the hole above the pullsy assembled in STEP 4.

i ....................(6435301) ....................................................................

(6194601) ....................................................................

(3116201) .....................................................................

(311610~) ...... ..............................................................

l

2

!

1

.SECURELY assemble one (I) 318 IN. SPRING PIN ASSEMBLY to the SPRING PIN HOUSING, of’the FRONT

UPRIGHT as shown in (DETAIL A). (Ill IMPORTANT !!! TIGHTEN THE NUT OF THE SPR]ING

ASSEMBLY SECURELY)

A~tach one (I) THUMBSCREW to the FRONT UPRIGHT as.shown on drawing.

o

10.

Assemble two (2) ROLLER PADS to the FRONT UPRIGHT as shown on drawing, using one (I) ROLLER

SHAFT, and two (2) 9/I 6 M’USHROOM CAPS.

SECURELY assemble one (I) 4-I/2 X I IN. PULLEY to the HORIZONTAL FLAT o’f the PRESS BASE using one (1)

.~/$ X 2 IN. BOLT, one (I) 2-7/8 IN. CABLE RETAINING CLIP, one (1) 3/8 IN. WASHER, and one (1) .3/~ IN.

NUT.

THIS CONCLUDES THE ASSElVIBLY OF (LEVEL 2)

425101 HOME GYM ASSEMBLY PARTS LIST (LEVEL

COL".’NT ALL PARTS BEFORE BEGIN’NING ASSEMBLY

.H,~RDWARE:

ITEM

2.

.% .~/I~ X 2-2/4 IN. BOLT .............................................................................................................................................

~. 3/~ X 3 IN. BOLT

~. T~ ~’X’~"-~.’BOLT, ...................................................................................................................................................

( I~ X 3-114 BOLT ...................................................................................................................................................

6~, ’

7. I/2 IN. WASHER ....................................................................................................................................................

8. 3/~ IN. WASHER

9.

NAME/DESCRIPTION

~/8 X l-1/2 IN. BOLT ...........................................................................................................................................I.

.~/~ X 2-I/4 IN. BOLT ...........................................

314 IN. WASHER ....................................................................................................................................................

3/8 IN. LOCK WAS~ER

’ .................................................................................................

... ....................................................6

QTY"

1

5

"

Page 6

~0.

1I.

12.

I3.

16.

17.

18.

19.

20.

21.

2.3.

I~ IN. LOCK WASHER .......................................................................................................................................

.3/8 IN. LOCK NUT .............................................................................................................................................

I~ IN. LOW HEIGHT LOCK NUT ......................................................................................................................

WEIGHT STACK SELECTOR PiN" ....................................................................................................................

GUIDE ROD PIN ................................................................................................................................................

j. ...................................................

.3/8 IN. FLANGE SPACER .....................................................................

, .......

WEIGHT PLATE BUSHING .........................................................................: ..................................................

WEIGHT STACK CUSHION ...............................................................................................................................

9/I 6 MUSHROOM CAP., ...............................................: .................................................... ................................

I~ IN. FLANGE BEARING ................; ...................................................................................................; .............

.3/8 IN. SPRING PIN ASSEMBLY .........................................................................................................................

I’-I/4 IN. SQ. RUBBER BUMPER ...............................................: .........................................................................

PARAGLIDB STRIP .....................................................: ...............~. ......................................................................

PLASTIC .WASHER ...............................................................................................................................................

I

g

2

I

2

6

.30

2

4

2

I

I

16

2

WELDMENTS/PARTS:

ITEM NAME/DESCRIPTION

QTY

I. .TOP BOOM ..............................................

2. GUIDE ROD ...................................................................(6~.3401) ....................................................................

3.

. .w~!~H’r ST,ACK SPACER ...........................................

4. WEIGHt" PLATE ............................................................

5.

WEIGHT STACK SFL~.FT ............... ; ..............................

"’9

(6375903) ...................................................................

(6,14501) .................................

~ ................................

(6,66001) ....................................................................

2

"~

15

I

6. HEAD PLATE .......... ~’ ...........................................(622300I) ...................................

7.

WEIGHT STACK LABELS ........................................... (6189501) ..................................................... ; ..............

l

8. 3-I~ X I IN. PULLEY ................................................... (3116201) .................................................................... .3

9.

4-I~ X 1 IN. PULLEY .. .................................................. (3116102) ....................................... ~ ............................

l

10. PAD, 13-1/2, X 10-1/2. ...................................................... (6457301) .......... : ..........................................................1

I 1. ROLLER PAD .................................................................. (6194601) .....................................................................

)"

"

ROLLER PAD SHAFT ....................................................(6.485301) .....................................................................2

ADJUSTABLE ROLLER PAD SLEEVE ........................ (6.16702) .....................................................................I

I-~. PEC SEAT ..................... , ..................................................(6539901) .....................................................................

13. LEG CURL/EXTENSION ............................................... (6540101): .......... : .........................................................

4

I

I

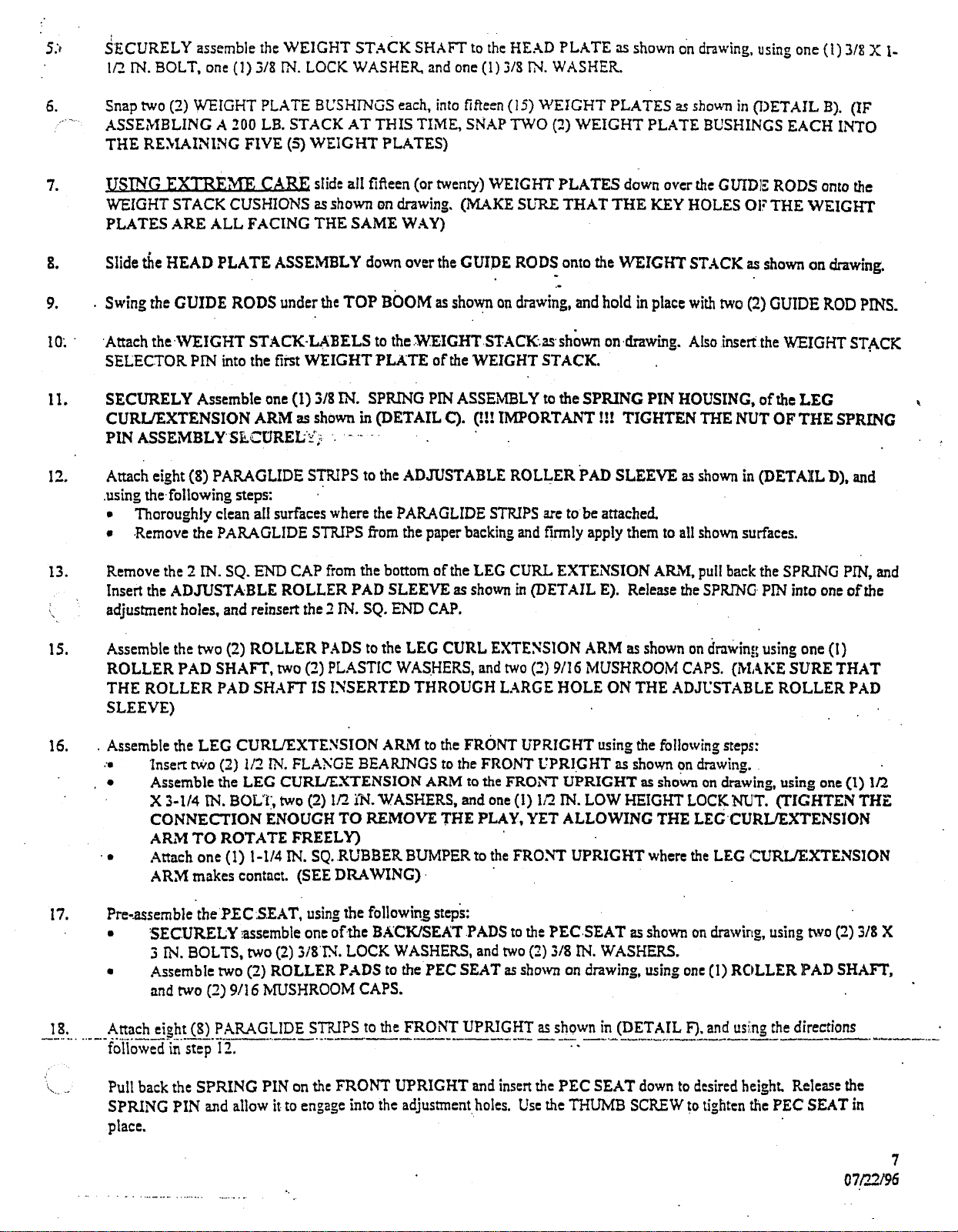

[, :-..’THE INSTRUCTIONS F O R" (LEI/T, L i’~)’.’AR.E’.-~ BE:IJSED WlTH.THE. (ZF, I/ ~’r..~..DRA .W .L~. .G ) ~~

I. LOOSELY Itssemble three (.3) 3-1/2, X I IN. PULLEYS, one (1) 4-I/2, X 1 IN. PULLEY to the inside ofthe TOP

as shown in (DETAIL A), using three (.3) 3/8 X 2-3/4 IN. BOLTS, one (1) 318 X 2-II4 IN. BOLT, six (6) 3/8 IN.

SPACERS, two (2) 318 IN. WASHERS, and four (4) 3/8 IN. LOCK NIYI’S.

2. _.LOOSELY resemble the TOP BOOM to the top ofthe REAR. MIDDLE, and FRONT UPRIGHTS as shown on oh-awing,

using.four (~) 3/8 X 3 IN. BOLTS, two (2) I~ X 3 IN. BOLTS, eigh.t (8) 3/8 IN. WASHERS, three (3) I/’2. IN.

one (I) I/2 IN. LOCK WASHER, four (4) 3/8 IN. LOCK NUTS, and one (I) I~ IN. LOW HEIGHT ]LOCK

3.

Insert the GUIDE RODS into the BASE as shown on drawing. (NOTE: LUBRICATE GUIDE RODS WITH

¯ SILICON OR TEFLON SPRAY THAT’ISAVAILABLE .ATIMOST HARDWARE STORES)

NOTE: THETWO (2) WEIGHT STACK SPACERS, AND THE TWO (2) 3/4 IN. WASHERS IN STEP 5 ARE TO BE

WHEN ASSEMBLING A 150 LB. STACK. IF ASSEMBLING A 200 LB. STACK AT THIS TIME PLEASE

DISCARD THESE ITEMS.

6. Slide t~o (2) WEIGHT STACK SPACERS, two 3/4 IN. WASHERS, and two (2) WEIGHT STACK CUSHIONS

...........(-’RADIUS EDGE FACING UP)

~ :’E: THE WEIGHT STACK SHAFF hN STEP 6 IS TO BE USED WHEN ASSEMBLING A I50 LB. STACK. IF

......"ASSEMBLING A 200 LB. STACK AT THIS TIME PLEASE DISCARD THIS ITEM AND REPLACE WITH THE

WEIGHT STACK SHAFT USED IN THE (50 LB. ADD-ON KIT 359101).

07/2.2/96

Page 7

SECURELY assemble the WEIGHT sTACK SHAFT to the HEAD PLATE as shown on drawing, using one (I) 3/2 X

1~ IN. BOLT, one (1) 3/8 IN. LOCK WASHER, and one (I) 3/8 IN. WASHER.

Snap two (2) W3~IGHT PLATE BUSHINGS each, into fiReen (}5) WEICHT PLATES shown in (DETAIL B).(IF

ASSEMBLING A 200 LB. STACK AT THIS TIME, SNAP TWO (2) WEIGHT PLATE BUSHINGS EACH INTO

THE RE.~tAINING FIVE (S) WEIGHT PLATES)

USING EXTRE~TE CARE slide all fifteen (or twenty) WEIGHT PLATES down over the CUIDIE RODS onto the

WEIGHT STACK CUSHIONS as shown on drawing. (MAKE SURE THAT THE KEY HOLES OF THE WEIGHT

PLATES ARE ALL FACING THE SAME WAY)

Slide t~e HEAD PLATE ASSEMBLY down over the GUIDE RODS onto the WEIGHT STACK as shown on drawing.

Swing th~ GUIDE RODS under the TOP BOOM as shown on drawing, and hold in place with two (2) GUIDE ROD PINS.

¯

Auach the-WEIGHT STACK-LABELS to the ..W.EIGHTSTACK:as shown on.drawing. Also .insertthe WEIGHT STACK

SELECTOR PIN into the first WEIGHT PLATTE of the WEIGHT STACK.

II.

12.

13.

15.

16.

SECURELY Assemble one (I) ~/8 IN. SPRING PIN ASSEMBLY to the SPRING PIN HOUSING, of the LEG

CURL/~XTENSION ARM as shown in (DETAIL C). (Ill IMPORTANT !!! TIGHTEN THE NUT OF THE SPRING

PIN ASSEMBLYSECUREL@.

Attach eight (8) PAKAGLIDE STRIPS to the AD.IUSTABLE ROLLER PAD SLEEVE as shown in (DETAIL D),

.using the. following steps:

¯

Thoroughly clean all surfaces where the PARAGLIDE STR/PS are robe attached.

~

.Remove the PAKAGLIDE STRIPS from the paper backing and firmly apply them to all showa surfaces.

Remove the 2 IN. SQ. END CAP from the bottom of the LEG CURL EXTENSION AR~,I, pull back the SPRING PIN, and

Insert the ADJUSTABLE ROLLER PAD SLEEVE as shown in (DETAIL E). Release the SPKI’NG, PIN into one of the

adjustment holes, and reinsert the 2 IN. SQ, END CAP.

Assemble the two (2) ROLLER PADS to the LEG CURL EXTENSION ARM as shown on drawing using one (I)

ROLLER PAD SHAFT, two (2) PLASTIC WASHERS, and two (2) 9/I 6 MUSHROOM CAPS. (MAKE SURE

THE ROLLER PAD SHAFT IS INSERTED THROUGH LARGE HOLE ON THE ADJUSTABLE ROLLER PAD

SLEEVE)

¯ Assemble the LEG CURI./EXTENSION ARM to the FRONT UPRIGHT using the following s~eps:

¯ ". Insert twO (2) 1/2 IN. FLANGE BEARINGS to the FRONT UPRIGHT as shown n drawing..

¯

Assemble the LEG CURL/EXTENSION ARM to the FRONT UPRIGHT as shoum on drawing, using one (I) I/2

X 3-I14 IN. BOLT, two (2) I/2 TN. 3k’ASHERS, and one (1) I}2 IN. LOW I-I~IGI-IT LOCK NUT. (TIGHTEN

CONNECTION ENOUGH TO REMOVE THE PLAY, YET ALLOWING THE LEG CURL/EXTENSiON

ARM TO ROTATE FREELY)

¯ * Attach one (1) 1-1/4 IN. SO..RUBBER BUMPER to the FRON’r UPRIGHT whcr~ the LEG CURL/EXTENSION

ARM makes contact. (SEE DRAWING).

17.

__I_3.: ....... .A.~.n.~c/~ht (8) PAP,.AGLIDE STR.IPS to the FRONT UPRIGHT as shown in (DETAIL F), and usilng the directions

’, ......

Pre-.assemble thePEC SEAT, using the following step’s:

¯

:SECURELY ~assemble one of.the BACK/SEAT .PADS to the PEG.SEAT as shown on drawing, using two (2) 318

3 IN. BOLTS, two (2) 3/8I"N. LOCK WASHERS, and two (2) 3/8 IN. WASHERS.

Assemble two (2) ROLLER PADS to thePEG SEAT as shown on drawing, using one (I) ROLLER PAD SHAFT,

and two (2) 9/I 6 MUSHROOM CAPS.

followed ~n step I2. "

Pull back the SPRING PIN on the FRONT UPRIGHT and insert the PEG SEAT down to desired height. Release the

SPRING PIN and allow it. to engage into the adjustment.holes. Use the THUMB SCREW ~o tighten the PEG SEAT in

place.

Page 8

THIS CONCLUDES TIIE ASSEMBLY OF (ZEFEL

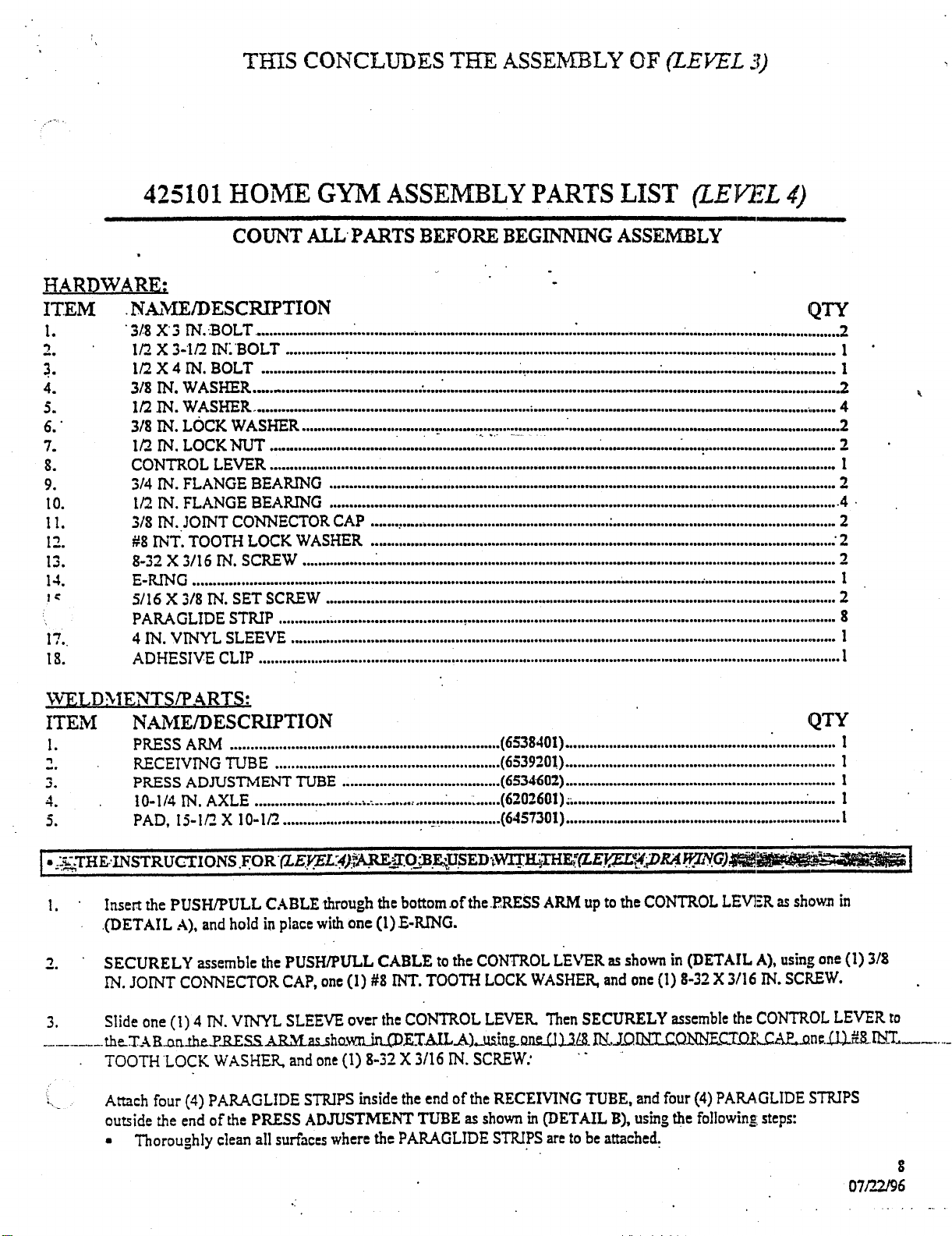

425101 HOME GYM ASSEMBLY PARTS LIST

COUNT ALL PARTS BEFORE BEGINNI!NG ASSEMBLY

HARDWARE:

ITEM .NAME/DESCRIPTION QTY

7.

$.

9.

I0.

11.

12.

13.

14.

¯ 318 X’3 IN..BOLT .........................

I/2 X 3-’I/2 IN~ ’BOLT ................................................................................................................... ~ ......................1

1/2 X 4 IN. BOLT ................................................................ ~: .................................". ......................~ ....., ..............1

318 IN. WASHER ......................................... ~...~. ...................................................................................................2

1/2 IN. WASHER .....................................................................

3/8 IN. LOCK WASHER ..................................................................

1/2_ IN. LOCKNUT

CONTROL LEVER

3/4 IN. FLANGE BEARING

I/2 IN. FLANGE BEARING ................................................................................................ ................................

3/8 l’N. JOINT CONNECTOR CAP ............................................................

#8 INT. TOOTH LOCK WASHER ....................................................................................................................

8-32 X 3/16 IN. SCREW

E-KING ...........................................................................................................

5/16 X 3/8 IN. SET SCREW ................................................................................................................................

PARAGLIDE STRIP ............. ~ ................................, .............................................................................................

4 IN. VINYL SLEEVE .........................................................................................................................................

ADHESIVE CLIP ................................ ’ ...............

~ .....................................................

" "

’

’

~ .................................................................................................

:. .........................~. ......................................

; ............................................................................4

2 ...................................................................2

" ,

: ........................................................2

"

,1

: 2

2

2

2

4

2

2

8

1

1

WELDMENTS/PARTS:

ITEM

I. PRESS ARM ...................................................................

2. RECEIVING TUBE ........................................................

3. PRESS ADJUSTMENT TUBE .......................................

"4. I0-I/4 IN. AXLE ...............................................~ ......~ ......(62{]~-601);: ....................." .....................................

5.

I.

2. SECURELY assemble the PUSH/PULL CABLE to the CONTROL LEVER as shown in (DETAIL A), using one (1)

NAME/DESCRIPTION QTY

(6538401) ...................................................

(6539201) .................................................................... 1

(6534602) ....................................................................

PAD, IS-ira. X 10-1/2 ........

Inse~t the PUSH/PULL CABLE through the bottom .oftheRRESS ARM up to the CONTROL LEV~-’R as shown in

.(DETAIL A), and hold in pla~e with one (1)E-RING.

IN. JOINT CONNECTOR CAP, one (I) #8 INT. TOOTH LOCK WASHER, and one (1) 8-32 X 3/16 IN. SCREW.

Slide one (I) IN. VI NYL SLEEVE over th e CONTROL LEVER. Then SECURELY assemble th e CONTROL LEVER to

the_TA.R.at~.tha/~ EfiSARM..~s~ho.wm_ia.(DETAIL_K)Ja~u~omwd,/l/iS_ lh[,JD[hEL~OBlq!CZD~’,..CKP.~n~..CD,.~-.I’ST ........

TOOTH LOCK WASHER, and one (I) 8-32 X 3/16 IN. SCREW.’

Attach four (4) PAPA.GLIDE STRIPS inside the end of the RECEIVING TUBE, and four (4) PAPA.GLIDE STRIPS

ou~ide the end of the PRESS ADJUSTMENT TUBE as shown in (DETAIL B), using the followin@ steps:

¯

Thoroughly clean all surfaces where the PARAGLIDE STRIPS are to be attached.

~ ............................

,: ...............

(6457301) .....................................................................

." ................

.’ .......

I

I

I

1

07P_2~6

Page 9

’ ~* Remove the PAPA.GLIDE ST/UPS from the paper backing and firmly apply them tO all shown surfaces.

,Carefully slide the PRESS ADJUSTMENT TUBE into the RECEIVING TUBE. (MAKE SURE"],’HE SPRING PIN

BARREL ON THE RECEIVING TUBE IS ON THE SAME SIDE AS THE HOLES IN THE PF~SS ADJUSTM~IlNT

TUBE)

Insert two (2) 1/2- IN. FLANGE BEARINGS into the PRESS LEVER as shown on drawing.

Assemble the PRESS ADJUSTMENT TUBE to the PRESS LEVER as shown on drawing, using one (1) 1/2 X

BOLT, two (2) 1/2 IN. WASHERS, and one (1) I/2 IN. LOCK NUT. (TIGHTEN THE CONNEL-i’ION ENOUGH

TO .REMOVE THE PLAY, YET ALLOWING THE RECEIVING TUBE TO ROTATE FREELY)

Insert two (2) .3/4 IN. FLANGE BEAP,.INGS into the PRESS ARM ~s shown on the drawing.

¯ ’. Hold the PRESS ARM between the. REAR and ~MIDDLE UPRIGHTS as shown in on drawing, and’sIide the I0-I/4 IN.

AXLEthrough the MIDDLE UPRIGHT,th~ PRESS.A~RM,:and.througfi the COLLAR on.the REAR UPRIGHT. To

SECURE the AXLE in place, insert two (2) 3116 X 3/8 IN. SET SCREWS, into the COLLARS on the UPRIGHTS and

tighten it down onto the AXLE. (SEE DETAIL C)

10.

I1.

12.

Insert two (2) I~ IN. FLANGE BEARINGS into the RECEIVING TUBE as shown on drawing.

Assemble the RECEIVING TUBE to the PRESS ARM as shown on drawing, ~tsing one (1) I/2 X 3.-I/2 IN. BOLT, two

1/2 IN. WASHER.S, and one (I) 1;2 IN. LOCK NUT. (TIGHTEN THE CONNECTION ENOUGIt TO REMOVE

PLAY,.YET ALLOWING THE PRESS ARM TO ROTATE FREELY)

Assemble the PUSH/PULL CABLE to the SPRING PIN HOUSING and to the L-BRACKET on fl~e RECEIVING

TUBE as shown in (DETAIL D), using the f’ollowing steps:

¯

¯

¯

¯

¯

¯ Use the extra thread on the end of.the CABLE’to adjust out slack, ( !!! DO NOT ADJUST OUT TO FAR 1!!

¯

"SECURELY tighten all loose frame cormectiot~s made to this point. (!!! IMPORTANT !!! TO ASSUR~ PROPER "

.:~FUNCTION OF THE 425, THE LOOSE FRAME CONNECTIONS MUST BE TIGHTENED IN THE FOLLOWING

ORDER) Tighten the:

¯ REAR UPRIGHT to the BASE and to the TOP BOOM.

¯ PRESS BASE to the REAR and MIDDLE UPRIGHTS.

¯ PRESS BASE to the BASE.

.= MIDDLE UPRIGHTto the BASE’and to the .TOPBOOM.

¯ FRONT. UPRIGHT to the.BASE.

Thread the first I/4-2~i IN. NUT to the bottom of the threaded end of’the CABLE. Allow

other I/4-28 IN. NUT to hang loose on the exposed CABLE .until the SPRING PIN ASSEMBLY is attached.

Securely assemble the SPRING PIN ASSEMBLY to the SPRING PIN BARREL. (!:! IMPORTANT !!!

TIGHTEN THE NUT OF THE SPRING PIN ASSEMBLY SECURELY)

Swing the PRESS ARM up until the SPRING PIN of’the PUSH/PULL CABLE engages in one of the

adjustment holes.

Thread the second I/4-25 IN. NUT onto the threaded end of the CABLE, and cinch the two (2) 114-2~ .IN.

around the fiat.

ALWAYS ALLOW SPRING PIN ASSEMBLY TO FULLY ENGAGE)

Attach one (1) ADHESIVE CLIP to the RECEIVING TUBE and snap the CABLE into it.

14.

NOTE: DO NOT TIGHTEN THE FRONT UPRIGHT TO THE TOP BOOM AT THIS TIME,

SECURELY assemble the other BACK/SEAT PAD to the FRONT UPRIGHT as shown on drawing, using two (2) 3/~

.3 IN. BOLTS, two (2) 3/8 IN. LOCK WASHERS, and two (2) 3/g IN. WASHERS.

THIS CONCLUDES THE ASSEMBLY OF (LEVEL 4)

9

07/22/96

Page 10

425101 HOME GYM ASSEMBLY PARTS LIST (LEVEL S)

COUNT ALL PARTS BEFORE BEGINNING ASSEMBLY

ITEM

1. 3/8 x 2 IN. BOLT

2.

3.

4. I’/2 X 3-I~ IN. BOLT. .............................................................................................................................................

5.

6.

7. .3/.8 IN. LOCK.WASHER ..........................................................................................

8. ,3/4. IN. THRUST,WASHER ..............

9.

I0.

I I. I/2-IN. FLANGE BEARING .............................

12. 3/4 IN. FLANGE BEARING ...............................................................................................................................

13. 2-3/8 IN. CABLE RETAINING CLIP ..................................................................................................................

14;

15.

16. 1/2 IN. SPRING PIN ASSEMBLY ..............................................

17.

18.

19. 1 X 1 IN. CARRIAGE GUIDE ..............................................................................................................................

20.

2 I. 3 IN. WHEEL

"~’~ 3/8 X’ I/4 IN. SPACER .........................................................................................................................................

NA~ME/I)ESCRIPTION QTY"

2

3/8 X 2-3/4 IN. BOLT ............................................................................................... ; ...........................................

318 X 3 IN. BOLT ..............................

3]8 IN. WASHER, ................................................................................................................................................

1/22. IN. WASHER .......

3/8 IN. LOCK NUT .................................................................................................................................................

I/2 IN. LOCKNUT ..................................................................................................

,~,

" ’" """ "" "" "t;

:,~, ~ ~~ ~ ....................................................................................................................................................

3/g IN. SPRING PIN ASSEMBLY .......................... 2 ............................................................................................3

THUMBSCREW .............

PARAGLIDE STRIP ...............................................................................................................................................

2 IN. PULLEY .............

- ..................................................."- ......................................................................................6

’ ...........................................4

~." ............................................

~ ....................". ...............................................................................

: ..............................................

2 ...........................................................................................................................................

’

2 ........................................................................................1

: .............................................

: .....

: ........................................

2 .........................................................................1

:£.i ................2

4

3

2

3

2

4

2

~-~ . ..

2

: 2

V,~ELDMENTS/P ARTS:

ITEM. NAME/DESCRIPTION QTY

2. ADJUSTABLE PRESS SEAT ................: .......................

3.

4. CENTER PULLEY BRACKET ......................................

~. BEARING HOUSING ......................................................

6.

7, RIGHT PEC ARM .......................................................

8. BACK PAD .............................................................

9. SEAT PAD ......................................................................

10."

l I. 4 X. 12 IN. ROLLER PADS . ............................................

I. Pre-assemble the PRESS BACK SUPPORT using the following s~eps:

"

PEC CAM ................................................

LEFT PEC ARM ............................................................. (6ff~97__O!)~ ...................................................................

3-1".2 X I IN. PULLEY .......................................... ~ .........

¯ Attach eight (8) PARAGLIDE STRIPS to the PRESS BACK SUPPORT as shown in

(DETAIL A), using tht following steps:

¯ Thoroughly clean all surfaces where the PARAGLIDE STRIPS are to be attached.

¯

¯ SECURELY assemble one (I) 3/g IN. SPRI’NG PIN ASSEMBLY to the SPRING PLN HOUSING, of~h¢

¯ SECURELY assemble ~o (2) 3 IN. WHEELS to the PRESS BACK SUPPORT as shown on i drawing, using

Remove the PA~t.-~-CID-E-STPd’PS

PRESS BACK SUPPORT as shown in (DETAIL B). (!!! IMPORTANT !!! TIGHTEN ’THE NUT OF

SPRING PIN ASSEMBLY SECURELY)

two (2) 3/8 X 2-3/4 IN. BOLTS, two (2) 3/8 IN. WASHERS,. and two ~) 3/8 X 1/4 IN. SPACERS. (IF

-fff~-the

: ...........

: ...........

(6538901) ..............................................

(6~2~702) .....................................................................

(6~30203) .....................................................................

(6~9601)..., ................................................................. I

L..(6529801) .....................................................................

’. ........(6433701) ................... , ............................

(64~3~01) .....................................................................

(3116201) .....................................................................

(61"~6,01)" ......................................................................

Pap’elr’b~ffd" ~-u"miY apply them to aii-~ii~n si~/aces.

-.J.~ ..............1

1

I

1

10

07.~2/96

Page 11

WHEELS DO NOT ROTATE FREELY AFTER THE BOLTS ARE TIGHT, REMOVE WASHERS.)

SECURELY assemble ~he SEAT PAD to the ADJUSTABLE PRESS SEAT as shown on/rzwing, using two (2) 3;8 X

314 IN. BOLTS, two (2) 318 IN. LOCK WASHERS, and two (2) 318 IN. WASHERS.

Pull back the SPRING PrN on the PRESS BACK SUPPORT and.slide the ADJUSTABLE PRESS SEAT into the

RECEIVING W’ELL. Engage the SPRING PIN into one of the adjustment holes. Secure the ADJUSTABLE PRESS SEAT

in place with one (1) THUMBSCREW.

SECURELY assemble the BACK PAD t6 the PRESS BACK SUPPORT as shown on drawing, using two (2) 3/8 X 3 IN.

BOLTS, two (2) 3/~ IN. LOCK WASHERS, and two (2) 3/8 IN. WASHERS.

Insert two (2) I/2 IN. FLANGE BEARINGS into the PRESS SUPPORT TUBE as shown on drawing.

"..SECURELY"assemble.the PRESSBACK SUPPDRT to the.PRESS suPPORT TU.BE,~s shown in drawing;using one (I)

I~.X3~I/’2 IN. :BOLT/:two" (2) I/2IN.~W.ASHERS,.~m~d one (I)I/2 IN~.LOCK NUT. (~IGHTEN THE CONNECTION

ENOUGH TO.REMOVE’THE :PLAY,~/ET.ALLOWING THEPRESS BACK SUPPORT..TO ]ROTATE FREELY)

SECURELY assemble one (I) ID_ I~ SPRING PIN.ASSEMBLY to the SPRING PIN HOUSING, of the PRESS

SUPPORT TUBE Rs shown in (DETAIL E). (!!! IMPORTANT !!! TIGHTEN THE NUT Oi~ .THE SPRING

ASSEMBLY SECUILI’. LY) "~ ...................... -’

SECURELY assemble, the BEARING HOUSING and the CENTER PULLEY BRACKET to the ]FRONT UPRIGHT ~s

shown.on drawing, using two(2) 1/2 X 3-1/2IN. BOLTS, four (4) I/2 IN. WASHERS, and two (2) 1/2 IN. LOCK

(THE CONNECTOR PLATES ON THE BEARING HOUSING AND THE CENTER PULLEY BRACKET HAVE

SLOTTED HOLES. SHIFT THE BEARING HOUSING DOWN AND THE CENTER PULLEY BRACKET UP AS

FAR AS POSSIBLE)

¯

o

ll. Insert the LEFT and RIGHT PEC DEC ARMS through the 3/4 IN. FLANGE BEARINGS in the BEARING HOUSING

12.

14. SECURELY assemble two (2) 3/8 IN. SPRING PIN ASSEMBLIES to the SPRING PIN BARRELS, ofthe PEC CAMS

15.

Assemble two (2) 3/4 IN. THRUST WASHERS and two (2) PEC CAMS to the LEFT and RIGHT :FEC ARMS, as shown

¯

on drawing.

Insert four (4) .3/4 IN. FLANGE BEARINGS into the BUSHINGS of the BEARING HOUSING, as shown on drawing.

on their respective sides as shown on drawing, and SECURE ~hem in place with two (2) 3/4 I.D. STAR LOCK COLLARS.

¯

..Attach two (2) 1 X 1 IN. CARKIAGE GUIDES to the ANGLE on the BEARING HOUSING where the PEC CAMS

,make contact with the ANGLE.

.Slide t~,.o (2) 4 X 12 ROLLER PADS onto the LEFT and RIGHT PE’C.D~.C ’ARMS, umirthe ROLLER PAD is FLUSH

,~ith the bottom of.the ARMS. (IF A LUBRICANT-IS REQUIRED, COAT THE INSIDE OF THE ROLLER PAD

"WITH RUBBING ALCOHOL ALSO, ROTATING THE PAD WHILEP.USHING UP WILL HELP TO EASE

’ASSEMBLY)

sho,h’n in (DETAIL B). (!!! IMPORTANT !!! TIGHTEN THE NUTOF THE SPRING PIN ASSEMBLY SECURELY)

LOOSELY’asscmble.two (2) 3-I~ X 1 IN..P.ULLEYS and two (2) 2-3/,~ IN, CABLE RETAINING CLIPS to the CENTER

PULLEY BRACKET as shown in (DETAIL D), using two (2) 3/8 X 2 IN. BOLTS, two (2) 3/$ IN. WASHERS, and

(2) 3/8 IN~ LOCK NUTS. (NOTE: THIS CONNECTION WILL BE TIGHTENED AFTER THE CABLE HAS BEEN

ROUTED)

.... place with three (.3) I/4.IN. CAP NUTS.

THIS CONCLUDES THE ASSEMBLY OF (LEVEL

425101 HOME GYM ASSEMBLY PARTS LIST .(LEVEL’6)

II

07~6

Page 12

COUNT ALL PARTS BEFORE BEGINNING ASSEMBLY

ITEM NA~[E/DESCRIPTION

""’",

.,..

.3. KEYHOLE CLEVIS ............................................................................................................................................

4.

~,VELDMENTS/PARTS:

ITEM

1. D-P.ING ........................................................................

2.

3. .LAT CABLE ....................................................................

4. ,,MULTI-PKESS ,CABLE ...................................................

* ~T.H.E~ .S~rRU C’T.I O N..S.~FO R (/,,E.. V~J,, "6) ,~RF~To ~BE,.USED

1. To assemble the D-RING CABLE, follow the cable routing diagram shown in (DETAIL A), and use.the following steps:

I/4 IN. WASHER

I!,1-28 IN. NUT ....................................................................................................................................................

SNAP LINK ............................................................................................................................

NAME/DESCRIPTION

:..(6540301) ........................ , ........................., ................

D-RING CABLE ...: ....................................................... :.(656890"I).~ ..................................................................

(6535901) ....................................................................

(653600.1.) .................................................: .................

¯

SECURELY’ assemble the D-RING CABLE to the WEIGHT STACK SHAFT of the HEAD PLATE as.shown on

drawing.

¯

Route the CABLE up and over the two (2) PULLEYS in the LAT BOOM abbve the WEIGHT STACK.

(REMOVE PULLEYS FOR EASE OF INSTALLATION)

¯

LOOSELY assemble the D-RING to the D-RING CABLE as shown on drawing, using one (I) 1/4 IN. WASHER,

and two (2) 1/4-28 IN. NUTS. (LOCATE 1/4-28 NUTS HALF WAY UP ON THE THREADS OF THE D-RING

CABLE. DO NOT TIGHTEN NUTS AT THIS TIME)

SECURELY Tighten the two (2) PULLEY connections from the SECOND STEP.

*

-.

" "-". ...................

. .............................

QTY

1

2

2

2

QTY

1

i

!

I

2 To. assemblethe LAT CABLE, follow the cable routing diagram on drawing, and use the following st~.’ps:

¯ . Attach one (I) SNAP LINK to the ball end of the LAT CABLE.

¯

Remove the two bolts in the FRONT UPRIGHT and TOP BOOM connection.

.. Route the LAT CABLE as shown on drawing and in (DETAIL B). (REMOVE PULLEYS FOR EASE

INSTALLATION)

¯

Run the LAT CABLE through the hole ofthe D-RING as shown in (DETAIL B) and attach one (I) KEYHOLE

CLEVIS to the end of the LAT CABLE.

,*

¯ ..’to assemble the MULTI-PRESS CABLE, follow the cable routing diagram shown .in drawing and use the following steps:

Replace and SECURELY tighten the two (2) PULLEY and two (2) BOLT comiections from the previous steps.

(IMPORTANT: NL-kKE SURE THE LAT CABLE RUNS OVER THE TOP OF THE BOLTS IN THE TOP

BOOM !!!)

¯

Attach one .(I) SNAP LINK to the ball end of the MULTI-PRESS CABLE.

¯

Run the MULTI-PRESS CABLE through the hole of the D-RING as shown in (DETAIL B) a6d attach one (I)

KEYHOLE CLEVIS to the end of the MULTI-PRESS CABLE.

THIS CONCLUDES .THE.ASSEM.BLY-OF (LEVEL 6)

425101 HOME GYM ASSEMBLY PARTS LIST (LEVEL 7)

COUNT ALL PARTS BEFORE BEGINNING ASSEMBLY

Page 13

iTEM

I.

4.

5.

6.

7.

g.

9.

10.

,VCELDMENTS/PARTS:

ITEM

I.

2.

3.

5.

NAME/D ESCtLIPTION

3/8 x l IN. BOLT ........................................................................

318 X 2 IN. BOLT ............................... : .......................... .....................................................................................I

S/g X 2-I/4 IN. BOLT .......................................................................................................................................

1/4 IN. WASHER. ..................................................................................................

3/8 IN. WASHER. ................................

1/4-2g IN. NUT ..................................

3/8 IN. LOCK NUT ............................................................................................................................................

SNAP LINK ....................................................................................................................................................... I

I~EYHOLE CLEVIS ....................................................

PULLEY BRACKET ....................................................................

NAME/DESCRIPTION QTY

3-1/2 x 1 IN. PULLEY ...................................................

PEC DEC CABLE ...........................................................

AB CABLE ......................................................................

LEG CABLE ..........................................................

5-I14 IN, PLATES ....

~ .....................................................................1

~..~ .........................................

,.., ...........................................................................................................

- ............................................................................................................~.. 2

:. ...................................................................

(31i6201) ....................................................................

(653S601) ................................................................... : I

(653S801) ............ -.; .....................................................1

.. ........(6569001) .................

; .....................................................(6013703) ...................................

~ ............~ ..............................

QTY

2

2

4

1

.; ...............................

3

I

2

FOmaZrZ~~~:AR~.~O..~E.~trSE~..wr_7ni.~. z

I .-. . To a~scmble the PEC DEC CABLE, follow ~c cable routing dia~ on d~wing, ~d use ~e following steps:

¯

Assemble each end of the PEC DEC CABLE to ~e ~EC CAMS.

- Dmp~ ~e CABLE over ~e P~LEYS on ~c CENTER PULLEY B~C~T. ~HIS WILL FO~I A LOOP IN

THE CENTER OE THE CABLE)

~

Positiqn .the CABLE RETAINING CLIPS in a 45 DEGREE position over the P~LEYS and the CABLES, ~d

*

tighmn the two (2) PULLEY connections SECURELY.

To assemble the AB CABLE, follow the cable routing diagram on drawing, and use the following steps:

¯ Attach one (1) SNAP LINK to the ball end of the AB CABLE.

¯

Insert the threaded end of the AB CABLE between the top of the AB PULLEY and the BOLT in the FRONT

UPRIGHT.

-’ LOOSELY assemble the PULLEY BRACKETto the AB CABLE as shown in drawing Osing two (2) I/4 IN.

WASHERS, and two (2) 1/4~28 .IN. NUTS. (LOCATE PULLEY.BRACKET HALFWAY UP ON

THREADS OF THE AB CABLE. DO NOT TIGHTEN N"UTS AT THIS TIME)

Make’a loop with the AB CA/IL~" and"-t~aCti’~he PULLEY BRACKET to the PEC CABLE Using one (I) 3-I/2. X

¯ ’

IN. PULLEY, one (I) 3/8 X 2 IN. BOLT, two (2) 3/g.iN. WASHERS, and one (1) 3/g IN. LOCK

LOOSELY assemble two (2) 5-l/# IN. PLATES and two (2) 3-1~ X I IN. PULLEYS to the AB CABLE using t~o (2)

X 2-1/4 IN. BOLTS, four (~) 3/8 IN. WASHERS, and two (2) 3/8 IN. LOCK NUTS.

SECURELY attachthe LEG:CABLE to the~LEG.CURI~EXT using one (I) 318 X I IN. BOLT, two (2).3/g IN.

.WASHERS, and one (I) 3/8’.IN.. LOCKNUT. ..

!

Route the LEG CABLE as shown in drawing.

Run the LEG CABLE through the hole¯ of the D-RING as shown in (DETAIL A) and attach one (I) KEYHOLE CLEVIS

the end of the LEG CABLE. ..

THIS CONCLUDES THE ASSEMBLY OF (LEVEL, 7)

425101 HOME GYM ASSEMBLY PARTS LIST (LEVEL .8)

13

Page 14

CO .UNT ALL PARTS BEFORE BEGINNING ASSEMBLY

Y~EM

2.

3."

4.

.~ELDMENTS/PARTS:

ITEM

I.

2.

3.

¯ 4.

5.

5.

7.

¯ NA~ESCRIPTION

318 X ! IN. BLFFFON HEAD CAP SCKEW ........................................................................................................

3/8 IN. LOCK ~ ..............................................................................................................................................3

~AP L~ ...........................................................................................................................................................

S~L ..............................................

SHOCK CO~S .................................................................................................................................................... 3

NAME/DESCRIPTION QTY

LAT BAR. .........................................

LOWROW BAR ............................................................. (6389701) .................................................................... 1

CHAIN .............................................................................

AB STRAP ............

ANKLE STRAP ......................... ~ .....................................(6409101) ..................................................................... I

FRONT SHROUD ............................................................

" ’ " REAk- s~~.b0D’:: ...........................

: ..........................................................(6375801) .....................................................................

: ..................................................................................................................

: ............................:.(6540201) ....................................................................

(6075906) .....................................................................

., ..............................................

: ................................

(653330I) ....................

(65.33401) ............................................................

QTY

8

l

~

1

1

l

: .......1

I ~KE~INSTRU.CTI.O~S iFOR(LE.~.L’..g);,ARE..T:O~BE:U.sED’~%~I..TH~_TI~.7(LE.F, ELfS:~

I. Attach ~ree (3) SHOCK CORDS to the KEYHOLE CLEVIS on the end of each CABLE ~ shown in (DETAIL A).

2. Route the SHOCK CORDS up and around the pre-.determined 2 IN. PULLEYS above the D.IRING and down to the BASE.

: Attach three (3) SWIVELS to the end of the S~OCK CORDS. Slip the end of the SWIVELS for the LEG CABLE ~md the

- LAT CABLE over the THREADED SHAFT on the BASE, and slip the end of the SWIVEL for the M:UTLI-PRESS

CABLE over the BOLT on the BASE a~ shown in drawing.

4. SECURELY attach three (3) 3/8 IN. LOCK NUTS to the THREADED SHAFT and ~he BOLT from the previous step.

SECURELY tighten any loose BOLT connections made to this point:

SECURELY attach the FRONT and the REAR SHROUD to the BASE and the TOP BOOM using eight (8) 3/8 X I IN.

BUTTON HEAD CAP SCREWS,

Attach the LAT BAR to the SNAP LINK on the end of the LAT CABLE as shown on drawing.

$. Attach the CHAIN to the SNAP LINK on the end of the MULTI-PRESS CABLE as shown on drawing.

9. A~tach the A.B STRAP to the SNAP LINK on the end of the AB.CABLE as shown on drawing.

Attadh one (I) SNAP LiNK.to:thedesired.link on the:CHAIN,.and-attach either the LOW ROWBAF,.or.the ANKLE

STRAP to the SNAP LINK.

THIS CONCLUDES TIlE ASSEMBLY OF (LEVEL 8)

AND THE ASSEMIBLY OF THE PAR.ABODY 425 HOME GYM.

14

Page 15

Page 16

,DETAIL A

,DETAIL E

,DETAIL D.

~

~ PARAE, ODY, INC.

)

Page 17

’ i

Page 18

DETAIL E!

SEE D~’~,,AIL ,,B

c

ETA! L ,,A,

Page 19

DETAIL B

DETAIL F

WEIGNT STACK

.GUIDE RODS

WEIGHT PLATI

LEVEL 3

Page 20

Page 21

L_AT BAR

CRUNCH

¯

¯

Page 22

¯

%

Page 23

SHOWN

---

’~

FRONT OF MACH(N

f L~ CURL/EXT~SlON

/~ CRUNCH

t

.~IP# D-~D.

I

I

I

Page 24

!

I

I

!

I

t

\

~

PARABODY, INc.

42.9101

Page 25

Page 26

PARABODY, INC.

~,..,

~Y IN~"T; ~1

I~=’Y, ~I~NII, i~:~:~A- _

Page 27

DETAIL

Page 28

~_~L PARABODY, INC.R.~,~’Y.

Page 29

,RECEIVING

.SEE DETAIL

LEVEL

Page 30

DETAIL~

DETAIL C

I

1

I

I I I

I I

--.__~ PARAt3ODY, INC.

Loading...

Loading...