Page 1

Operating

Instructions

indoor Panning

WV-7220D

^

•’ a . ’>■ -V *

/ ^ {f S i ^ '

V. ■’ ,‘ti -i ^ ^ i . '■ « '

• / ii-. / > > ....-'li,/ « /' ,

Panasonic

Before attempting to conr^ect or operate this product, please read tf>ese instructions complete^.

«•

Page 2

CONTENTS

INTRODUCTION .................................................................................................................................................................................................................1

PRECAUTIONS ...................................................................................................................................................................................................................1

MAJOR OPERATING CONTROLS AND THEIR FUNCTIONS ...........................................................................................................................................2

APPLICABLE CAMERAS, LENSES AND HOUSINGS ..................................................................................................................................................... 3

PRECAUTIONS ON INSTALLATION ..................................................................................................................................................................................4

INSTALLATIONS ..................................................................................................................................................................................................................4

TYPICAL SYSTEM CONNECTIONS ...................................................................................................................................................................................5

CONNECTIONS ...................................................................................................................................................................................................................5

ADJUSTMENTS ...................................................................................................................................................................................................................7

OUTLINE DRAWING ........................................................................................................................................................................................................... 7

SPECIFICATIONS ................................................................................................................................................................................................................0

STANDARD ACCESSORIES ...............................................................................................................................................................................................8

OPTIONAL ACCESSORIES ................................................................................................................................................................................................8

INTRODUCTION__________________________________________________

The WV-7220D Indoor Panning with WV-CU254 System Controller and WV-RC100 Indoor Receiver allows to operate the

automatic remote control of camera panning. The panning unit can be ceiling mounted or bracket mounted to any flat surface. The

camera can be panned an angle from 20° to 320° at a speed of 6.8°/sec.

This unit allows to operate the Manual Panning, Auto Panning or Random Pannig using with the system controller WV-CU254 and

the indoor receiver WV-RC100.

PRECAUTIONS___________________________________________________

1. Do not attempt to disassemble this unit. There are

no user serviceable parts inside. Refer servicing to

qualified service personnel.

2. Use this unit within its rating.

(a) Designed for indoor use.

Ambient temperature: 14°F - 122°F (—10°C +50°C)

(b) Avoid using this unit when humidity is above 90'/^

3. Do not use this unit in the place which has a high

percentage steam or oil.

CAUTION

niSK OF ELECTRIC SHOCK

A

CAUTION:

TO REDUCE THE RISK OF ELECTRIC SHOCK, DO

NOT REMOVE COVER (OR BACK). NO USERSERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

A

SA 1965

SA 1966

00 NOT OPEN

The lightning flash with arrowhead

symbol, within an equilateral triangle,

is intended to alert the user to the

presence of uninsulated "dangerous

voltage" within the product's

enclosure that may be of sufficient

magnitude to constitute a risk of elec

tric shock to persons.

The exclamation point within an

equilateral triangle is intended to alert

the user to the presence of important

operating and maintenance (servicing)

instructions in the literature accompa

nying the appliance.

4.5.Select a flat location which can support the entire

weight (panning head, camera, camera housing).

The input power source must be 24Vi20'^ ~ 26.4V)

AC 60 Hz for WV-7220D. (Supplied by Indoor Receiver

WV-RC100)

Use only a low voltage camera (24V AC).

Every necessory procedures with regard to install this

product should be made by qualified Service Personnel

or System Installers.

.................................................................................................................For U.S.A

Warning:

This equipment generates and uses radio frequency

energy and if not installed and used properly, i.e., in

strict accordance with the instruction manual, may

cause harmful interference to radio communications.

It has been tested and found to comply with the limits

for a Class A computing device pursuant to Subpart

J of Part 15 of FCC Rules, which are designed to pro

vide reasonable protection against such interference

when operated in a commercial environment.

.......................................................................................................... For CANADA

This digital apparatus does not exceed the Class A

limits for radio noise emissions from digital apparatus

set out in the Radio Interference Regulations of the

Canadian Department of Communications.

The serial number of this product may be found on

the bottom of the unit.

You should note the serial number of this unit in the

space provided and retain this book as a permanent

record of your purchase to aid identification in the

event of theft.

Model No._____________________________________

Serial No.

_____________________________________

WARNING:

TO PREVENT FIRE OR SHOCK HAZARD, DO NOT EXPOSE THIS APPLIANCE TO RAIN OR MOISTURE.

- 1 -

Page 3

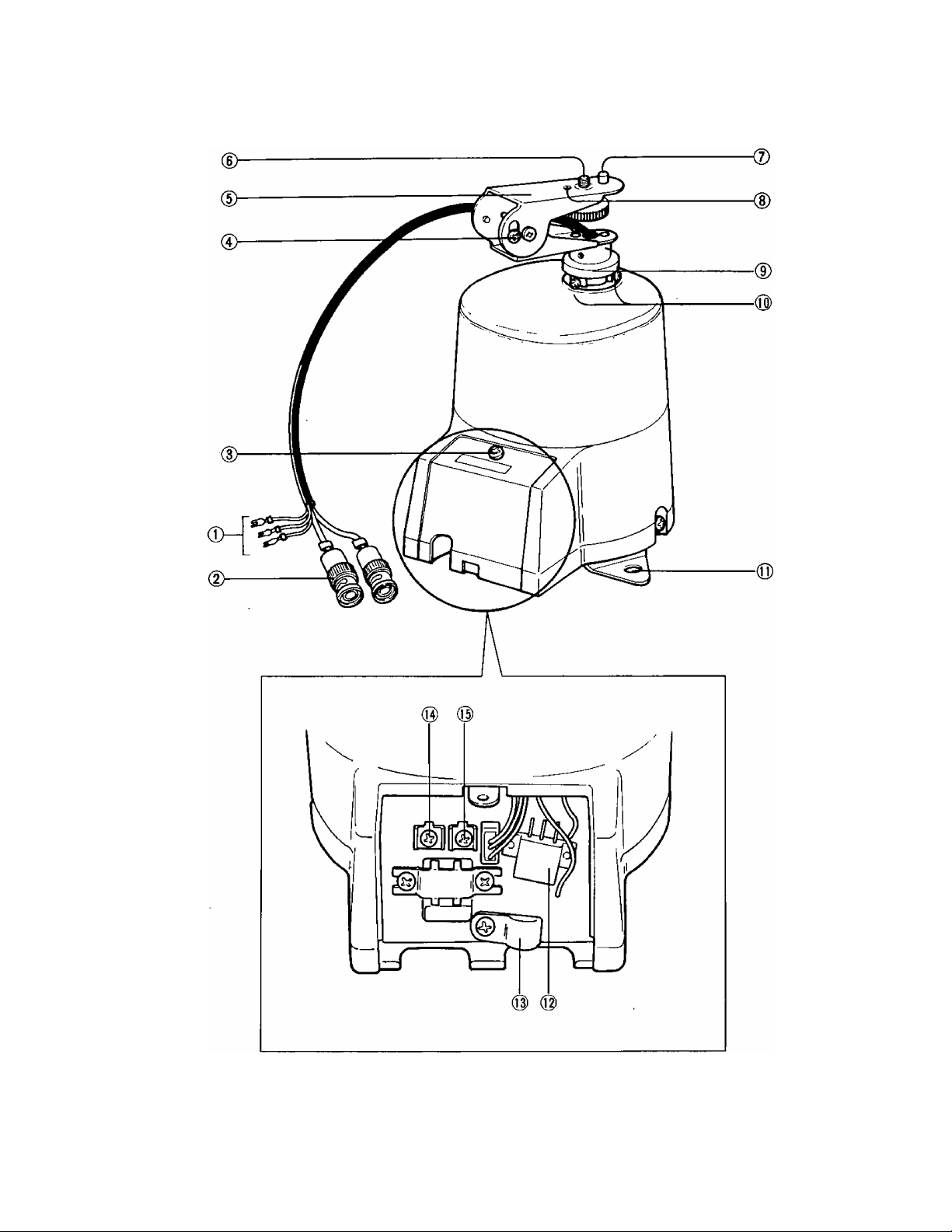

MAJOR OPERATING CONTROLS AND THEIR FUNCTIONS

-2-

Page 4

(1) Camera Power Cable

Indicate 1 — Power Supply 1

Indicate 2 — Power Supply 2

Indicate G — Camera Ground

(2) Camera Cables

BNC Type Connectors

Indicate V — Video

Indicate S — Ext Sync.

(3) Cover Locking Screw

(4) Tilting Angle Adjusting Screw

Adjustable tilting angle 0° - 45°.

(5) Camera Mounting Plate

(6) Camera Mounting Screw

Standard photographic pan head screw (U-1/4*).

(7) Camera Guide Screw

(8) Camera Guide Hole

(9) Panning Angle Indicator

(10) Panning Angle Limit Adjusting Screw

Adjustable panning angle.

20° - 320°.

(11) Mounting Plate

(12) Control Connector (6 Pins)

5 4

6

3 2

(13) Cable Clamp

Clamp for connector cable

(14) Video Terminal Board (VIDEO)

This terminal is connected with the video input of the

Receiver WV-RC100,

(15) Ext. Sync Terminal Board (EXT SYNC)

This terminal is connected with the external sync

generator.

1

LEFT

RIGHT

AUTO

CAMERA

AC Connector

Ground

APPLICABLE CAMERAS, LENSES AND HOUSINGS

O Possible

X Impossible

<Panasonic Lens Only>

-3-

Page 5

PRECAUTIONS ON INSTALLATION

This panning unit Model WV-7220D is designed for

indoor use. Avoid mounting it outdoors under the eaves

or any other place where rain or moisture could be

problem.

If the panning unit is mounted upside down, as shown

below, the image on monitor TV will also be upside

down. Therefore, remove the camera mounting plate

from the top of the camera and attach it to the bottom

of the camera

INSTALLATION

CAUTION:

The following installation should be made by qualified

service personnel or system installers.

1. Make holes which align to those on the Mounting Plate

and mount on the panning head.

(a) Plot the three points for making holes

A camera with various lenses and a camera housing

(Model WV-7110 and 7120D) can be used. Select a

location where the total weight is sufficiently support

and firmly fix the units onto plywood, gypsum board,

plaster board or concrete, install the panning unit

before mounting the camera on it.

Mount on flat surface - flat ceiling or mounting bracket

Model WV-7030.

Avoid a location which is susceptible to vibration, such

as close to a motor or ventilation fan.

(1) Mount the camera using with Camera Mounting

Screw.

Use rear side of the camera mounting screw hole

for better weight balance. Proper weight balance

will put less strain on the gears in the motorized

head.

(2) Adjust the tilt angle with Tilt Angle Adjusting Screw.

Set the focus ring at the proper distance.

(3)

Tilting angle

(b) Make three preliminary holes.

(c) Mount the Mounting Plate to the base with it's

three screws on the base.

2. Mount the panning head.

4. When mount the panning unit upside down and camera

is aimed downward, remove the Camera Guide Screw

to the Camera Guide Hole. If needed, change the

direction of the Camera Plate.

3. Mount the low voltage camera (24V AC} with fixed focal

lens on the Camera Plate.

CAUTION: After changing the camera plate direction,

replace these spacers.

-4-

Page 6

TYPICAL SYSTEM CONNECTIONS

Indoor Receiver

WV-RC100

-----

System Controller

WV-CU254

SE53 EB““““

V

Coax, Cable

<0

HE

Coax. Cable

EEj'b □ ó

AC 120V 60Hz

Monitor

Pre-wired cable f

WV-CA51 AC24V60HZ

CONNECTIONS

CAUTIONS:

• The following connections should be made by qualified

service personnel or system installers.

• Make all connections with the power turned OFF.

• Avoid shorting the terminals, as this may blow a fuse.

• If the installation is to be upside-down, the Pan

Left-Right directions will be reversed. This must be

considered when the wiring is done.

In this case, replace 1 and 2 pin of CN1. If the

pre-wired cable WV-CA51 is used, replace them using

with MOLEX brand tool 57031 -6000.

A. Video and Ext. Sync Terminal Board

1. Wiring precautions;

• Do not bend coaxial cable into a curve whose

radius is smaller than 10 times diameter.

• Never staple the cable - not even with circular

staples.

• Never crush or pinch the cable.

All these will charge the impedance of the cable and

cause poor picture quality.

2. Use the following conditions cable.

Impedance;

Diameter: <¡>8 mm or less

Example: RG - 59/U (BELDEN 9259}

U i t:

]

AC 120V 60Hz

B. In case of using the Connection Cable (WV-CA51);

The appearance and cord length is shown in the drawing.

The parts name of WV-CA51 is shown in the following.

No.

1 17 wires cable

2 14P housing

3

12P housing

4 10P housing

5 6P housing

6

Contact

7

BNC connector

Parts name

WV-CA51

8 Contraction tube

Clamp

Coaxial cable

-5-

Page 7

C. In case of using the accessory connectors

(MX555706):

3. After clamping the contacts, push them into the proper

holes in the connector housing until they snap in place.

3 2 1

CN-1

CN Pin No.

WV-7220D

CN1-1

CN1-2

CN1-3

CN1-4

CN1-5

CN1-6

Copper wire gauge fWG No.

(UL1007, UL1015}

The atx>ve length indicated are approximate.

Usage of Terminal

LEFT

RIGHT

AUTO PAN

24V AC CAMERA

AC COMMON

GND

Impedance

at 68®F (20°C)

(ii/km)

#24 77.9 ft

#22 50.4 ft

#20 32.3 H

#18

19.9

Power Source

24 V AC

24V AC Common

Cable

length

55

m

m

m

ft

m

14

90

25

140

40

220

60

How to assemble the connector:

1. Strip back the cable jacket approx. 0.1 inch (3 mm) and

separate the individual conductors.

2. Prepare the individual conductors for clamping. If

clamping, use MOLEX brand tool part number

57027-5000 (for UL-Style Cable UL1015) or

57026-5000 (for UL-Style cable UL1007).

Up

wire

t

Contact

CAUTION:

Shrinking the cable-entry seal is a one-time procedure.

DO NOT shrink the cable-entry seal until it has been

ascertained that the unit is functioning.

D. Connect with TV camera

Camera Power Cable

Connect the connectors to the 24 V AC Power Terminal

Strip of the low-voltage camera according to the diagram.

Camera Cable

Connect the Camera Cable to the video output connector

of the low-voltage camera.

CAMERA

Turn on the Power ON/OFF Switch of the TV camera.

Connect the Power Cord of the Indoor Receiver

WV-RC100 to the 24V AC camera

3.

Turn on the Power ON/OFF Switch of the indoor

receiver.

CAUTION:

• CONNECT THIS TO A 24V AC CLASS 2 POWER

SUPPLY ONLY.

Caution: To prevent fire or shock hazard,

the UL listed wire VW-1, style 1007

should be used for the cable for 24V

AC Input Terminals.

Contact ^

Up

Approx. 0.1

-1

■ Wire

Insert the wire until A position

clamp the contacts.

an“

-6-

Page 8

ADJUSTMENTS

CAUTION:

The following adjustment should be made by qualified

service personnel or system installers.

1. Adjust the panning angle limits.

(a) Determing the right - limit and left - limit angle.

(b) Move the Right - limit Angle and Left - limit Angle

Adjusting Screws to the appropriate position on to

2. Adjust the tilting angle with Tilting Angle Adjusting

3. Adjusting the focus and iris of the camera.

CAUTION:

the Panning Angle Indicator.

Screws,

It is impossible to set the panning angle passing the

rear side.

Max. 320°

Rear

OUTLINE DRAWING

-7-

Page 9

SPECIFICATIONS

System controller:

Indoor receiver;

Mountable housing:

Bracket:

Power source:

Power consumption:

Panning;

Panning angle:

Tilting speed:

Load weight:

Operating ambient temperature:

Operating ambient humidity:

Dimensions:

Weight:

WV-CU254 (Optional)

WV-RC100 (Optional)

WV-7120D, WV-7110 (Optional)

WV-7030 (Optional)

24V AC from the indoor receiver WV-RClOO

Approx. 15W Max.

• Automatic, Manual or Random (Selectable)

20® - 320® (Adjustable)

Approx. 6.B®/sec

Approx. 11 lbs. (5 kg)

14®F - 122®F(-10®C - +50®C)

Less than 90'/.

Approx. 5-7/l6"(W) x 7-1/4’(H) x 7-7/16'(D)

(140(W) X 186(H) x 190(D) mm]

Approx. 7 lbs. (2.5 kg)

• REMARK:

This unit allows to operate the Manual Pannimg, Auto Panning or Random Panning using with the system controller WV-CU254

and the indoor receiver WV-RC100.

STANDARD ACCESSORIES

Connector

[Part No.: MX5557P06]

.............................................................

OPTIONAL ACCESSORIES

Pre-wired Cable

.............................................................

Ipc.

WV-CA51

-8-

Page 10

Panasonic

Communications & Systems Company

Panasonic Communications & Systems Company

Division of Matsushita Electric Corporation of America

CLOSED CIRCUIT VIDEO EQUIPMENT DIVISION

HEADQUARTERS

SO Meadowland Parkway Secaucus New Jersey 07094

EASTERN ZONE

50 Maaddwiand Parkway Secaucus NJ 07094 (201) 348-7620

CENTRAL ZONE

425 E Algonquin Read Arlirroton Hts IL 60005(708)981-4826

SOUTHERN ZONE

Dallas Region 4500 Amon Carter Blvd Ft Worth TX 76155(817)685-1117

Atlanta Region 1854 Shackleford Ct Suite 115. Norcross GA 30093 (404) 925-6841

WESTERN ZONE

Seattle Region 1200 Westlake Ave N Suite 508 Seattle WA 98109 (206) 285-8883

Los Angeles Region 6550 Katella Ave Cypress CA 90630 (714) 373-7275

MATSUSHITA ELECTRIC OF CANADA LIMITED

5770 Ambler Drive Mississauga Ontario Canada L4W 2X3(416)624-5010

PANASONIC SALES COMPANY

DIVISION OF MATSUSHITA ELECTRIC OF PUERTO RICO, INC

San Gabriel Industrial Park 65th Infantry Ave KM 9 5 Carolina Puerto Rico 00630(809)750*4300

N1189-0

YVW8QA2022AN Printed m Japan

®13

Loading...

Loading...