Page 1

U-72MF2U9

U-96MF2U9

U-120MF2U9

U-144MF2U9

U-72MF2U94

U-96MF2U94

Order No. SBPAC1509017CE

3WAY VRF System

U-120MF2U94

U-144MF2U94

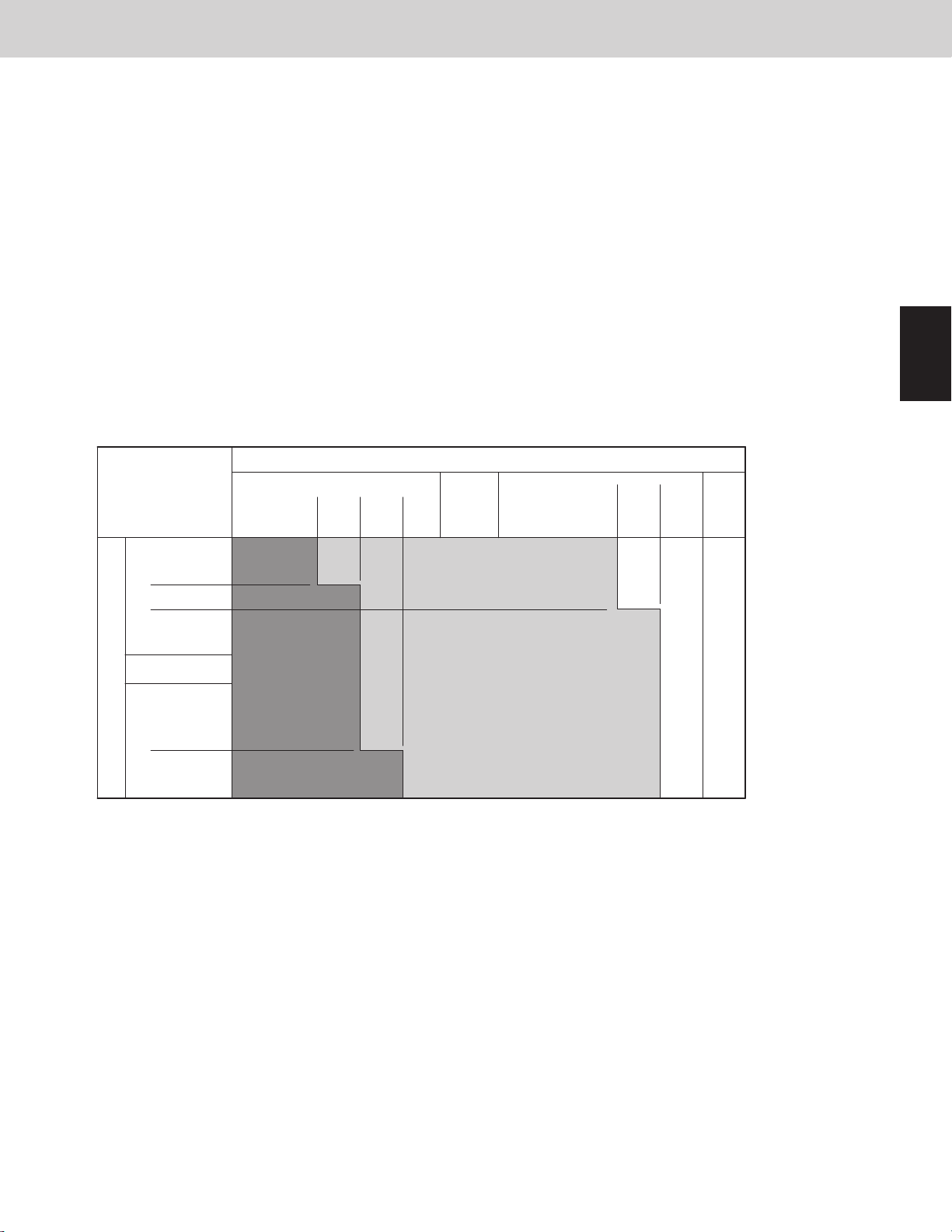

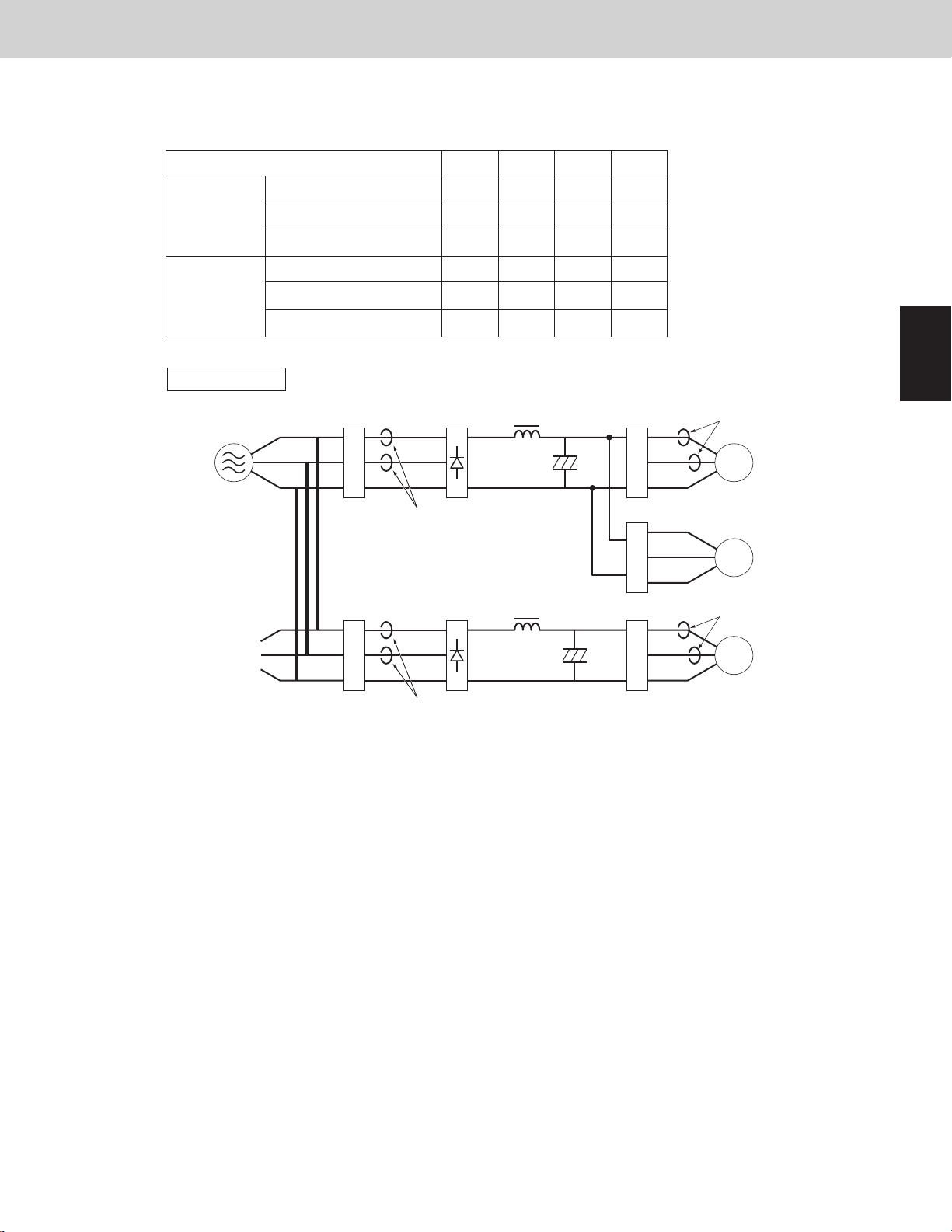

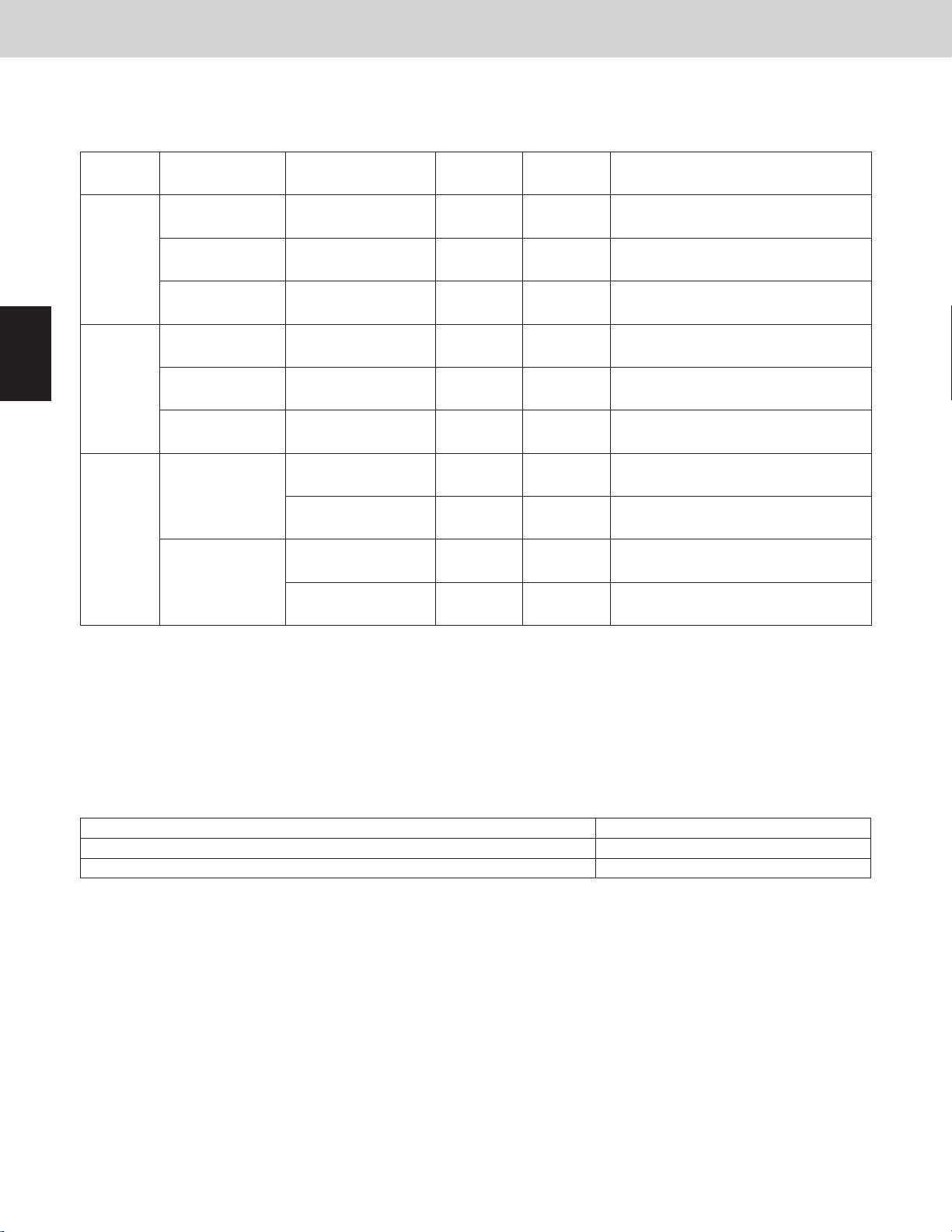

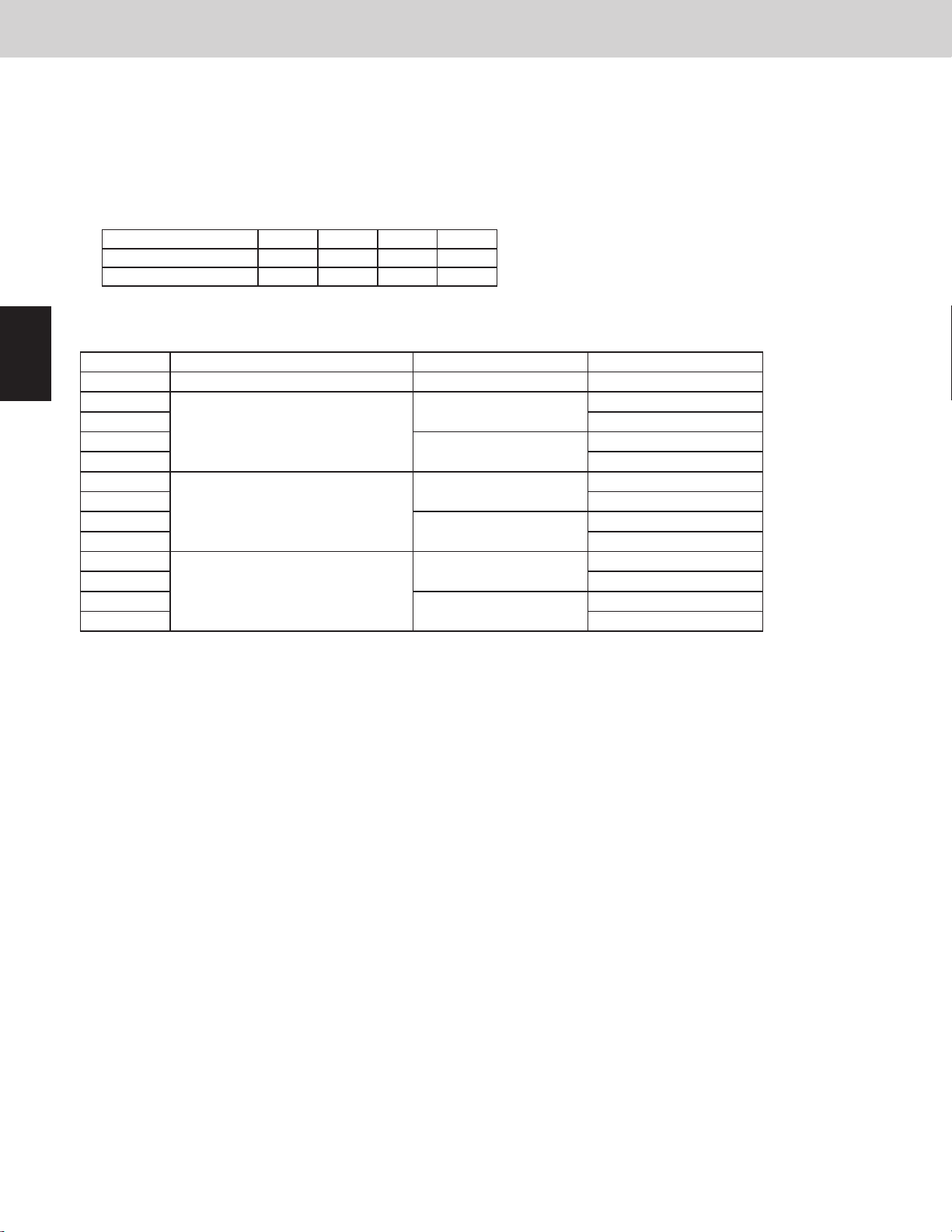

Model No.

Outdoor Unit

Outdoor Unit TypeType

MF2 3WAY VRF System

To be connecting Indoor Units

Indoor Units

Indoor Unit TypeType

U2 4-Way Cassette 36"x36"

4-Way Cassette 24"x24"

Y2

D1

1-Way Cassette

Concealed Duct

F2

-Medium Static

Concealed Duct

M2

-Low Static

Concealed Duct

E1

-High Static

T2

Ceiling

K2

Wall Mounted

P1

Floor Standing

R1

Concealed Floor Standing

S-07MD1U6

S-07MF2U6

S-07MM2U6

S-07MK2U6

S-07MP1U6

S-07MR1U6

Nominal Capacity

72 96 120 144

U-72MF2U9

U-72MF2U94

7 9 12 15 18 24 36 48 54

S-12MU2U6S-09MU2U6S-07MU2U6

S-09MY2U6S-07MY2U6

S-09MD1U6

S-09MF2U6

S-09MM2U6

S-09MK2U6

S-09MP1U6

S-09MR1U6

S-12MY2U6

S-12MD1U6

S-12MF2U6

S-12MM2U6

S-12MT2U6

S-12MK2U6

S-12MP1U6

S-12MR1U6

U-96MF2U9 U-120MF2U9 U-144MF2U9

U-96MF2U94 U-120MF2U94 U-144MF2U94

Nominal Capacity

S-15MF2U6

S-15MM2U6

S-15MP1U6

S-15MR1U6

S-18MY2U6

S-18MF2U6

S-18MM2U6

S-18MT2U6

S-18MK2U6

S-18MP1U6

S-18MR1U6

S-24MU2U6

S-24MF2U6

S-24MT2U6

S-24MK2U6

S-24MP1U6

S-24MR1U6

S-36MU2U6

S-36MF2U6

S-36ME1U6

S-48MF2U6 S-54MF2U6

S-48ME1U6

85464849346003

This air conditioner uses the refrigerant R410A.

REFERENCE NO.

SM830246-03

Page 2

•Donotleakrefrigerantwhilepipingworkforan

installationorre-installation,andwhilerepairing

refrigerationparts.

Handleliquidrefrigerantcarefullyasitmaycause

frostbite.

When Servicing

•TurnthepowerOFFatthemainpowerbox(mains)

beforeopeningtheunittocheckorrepairelectrical

partsandwiring.

•Keepyourfingersandclothingawayfromanymoving

parts.

•Cleanupthesiteafteryounish,rememberingto

checkthatnometalscrapsorbitsofwiringhavebeen

leftinsidetheunit.

WARNING

•Thisproductmustnotbemodiedor

disassembledunderanycircumstances.

Modiedordisassembledunitmaycausere,

electricshockorinjury.

•Donotcleaninsidetheindoorandoutdoor

unitsbyusers.Engageauthorizeddealeror

specialistforcleaning.

•Incaseofmalfunctionofthisappliance,do

notrepairbyyourself.Contacttothesales

dealerorservicedealerforarepair.

CAUTION

•Donottouchtheairinletorthesharp

aluminumfinsoftheoutdoorunit.Yo u

maygetinjured.

• Ventilateanyenclosedareaswheninstallingor

testingtherefrigerationsystem.Leaked

refrigerantgas,oncontactwithfireorheat,can

producedangerouslytoxicgas.

• Conrmafterinstallationthatnorefrigerantgas

isleaking.Ifthegascomesincontactwitha

burningstove,gaswaterheater,electricroom

heaterorotherheatsource,itcancausethe

generationoftoxicgas.

Others

CAUTION

•Donotsitorstepontheunit,youmay

falldownaccidentally.

•Donottouchtheairinletorthesharp

aluminumfinsoftheoutdoorunit.

Yo u maygetinjured.

•DonotstickanyobjectintotheFA N

CASE.

Yo u maybeinjuredandtheunitmay

bedamaged.

Check of Density Limit

The room in which the air conditioner is to be

installed requires a design that in the event of

refrigerant gas leaking out, its density will not exceed

a set limit.

Therefrigerant(R410A),whichisusedintheair

conditioner,issafe,withoutthetoxicityorcombustibilityof

ammonia,andisnotrestrictedbylawsimposedtoprotect

theozonelayer.However,sinceitcontainsmorethanair,

itposestheriskofsuffocationifitsdensityshouldrise

excessively.Suffocationfromleakageofrefrigerantis

almostnon-existent.Withtherecentincreaseinthe

numberofhighdensitybuildings,however,theinstallation

ofmultiairconditionersystemsisontheincrease

becauseoftheneedforeffectiveuseofoorspace,

individualcontrol,energyconservationbycurtailingheat

andcarryingpower,etc.

Mostimportantly,themultiairconditionersystemisable

toreplenishalargeamountofrefrigerantcomparedto

conventionalindividualairconditioners.

Ifasingleunitofthemultiairconditionersystemistobe

installedinasmallroom,selectasuitablemodeland

installationproceduresothatiftherefrigerant

accidentallyleaksout,itsdensitydoesnotreachthelimit

(andintheeventofanemergency,measurescanbe

madebeforeinjurycanoccur).

ASHRAEandtheInternationalMechanicalCodeofthe

ICCaswellasCSAprovideguidanceanddefine

safeguardsrelatedtotheuseofrefrigerants,allofwhich

defineaRefrigerantConcentrationLevel(RCL)of 400 oz

(11.3kg)per1,000ft3(28.3m

3

)for

R410Arefrigerant.

Foradditionalguidanceandprecautionsrelatedto

refrigerantsafety,pleaserefertothefollowingdocuments:

InternationalMechanicalCode2012(IMC-2012)

(ormorerecentlyrevised)

ASHRAE15

ASHRAE34

IMPORTANT!

Please Read Before Starting

This air conditioning system meets strict safety and

operating standards. As the installer or service person, it is

an important part of your job to install or service the

system so it operates safely and efficiently.

For safe installation and trouble-free operation, you

must:

Carefully read this instruction booklet before beginning.

Follow each installation or repair step exactly as shown.

This air conditioner shall be installed in accordance with

National Wiring Regulations.

Pay close attention to all warning and caution notices

given in this manual.

WARNING

CAUTION

If Necessary, Get Help

These instructions are all you need for most installation

sites and maintenance conditions. If you require help for a

special problem, contact our sales/service outlet or your

certified dealer for additional instructions.

In Case of Improper Installation

The manufacturer shall in no way be responsible for

improper installation or maintenance service, including

failure to follow the instructions in this document.

SPECIAL PRECAUTIONS

• Do not supply power to the unit until all wiring and tubing

are completed or reconnected and checked.

• Highly dangerous electrical voltages are used in this system.

Carefully refer to the wiring diagram and these instructions

when wiring. Improper connections and inadequate

grounding can cause accidental injury or death.

• Ground the unit following local electrical codes.

• Connect all wiring tightly. Loose wiring may cause over-

heating at connection points and a possible fire hazard.

• To prevent possible hazards from insulation failure,

the unit must be grounded.

• This equipment is strongly recommended to be installed

with Earth Leakage Circuit Breaker (ELCB) or Residual

Current Device (RCD). Otherwise, it may cause electrical

shock and fire in case of equipment breakdown or

insulation breakdown.

WARNING

ELECTRICAL SHOCK CAN CAUSE

SEVERE PERSONAL INJURY OR DEATH.

ONLY A QUALIFIED, EXPERIENCED

ELECTRICIAN SHOULD ATTEMPT TO

WIRE THIS SYSTEM.

This symbol refers to a hazard or

unsafe practice which can result

in severe personal injury or death.

This symbol refers to a hazard or

unsafe practice which can result

in personal injury or product or

property damage.

When Wiring

When Transporting

Be careful when picking up and moving the indoor and

outdoor units. Get a partner to help, and bend your knees

when lifting to reduce strain on your back. Sharp edges or

thin aluminum fins on the air conditioner can cut your

fingers.

When Installing…

Select an installation location which is rigid and strong

enough to support or hold the unit, and select a location for

easy maintenance.

…In a Room

Properly insulate any tubing run inside a room to prevent

“sweating” that can cause dripping and water damage to

walls and floors.

…In Moist or Uneven Locations

Use a raised concrete pad or concrete blocks to provide a

solid, level foundation for the outdoor unit. This prevents

water damage and abnormal vibration.

…In an Area with High Winds

Securely anchor the outdoor unit down with bolts and a

metal frame. Provide a suitable air baffle.

…In a Snowy Area (for Heat Pump-type Systems)

Install the outdoor unit on a raised platform that is higher

than drifting snow. Provide snow vents.

When Connecting Refrigerant Tubing

• Pay particular attention to refrigerant leakages.

• Ventilate the room immediately, in the event that is

refrigerant gas leaks during the installation. Be careful not

to allow contact of the refrigerant gas with a flame as this

will cause the generation of toxic gas.

• Keep all tubing runs as short as possible.

• Apply refrigerant lubricant to the matching surfaces of the

flare and union tubes before connecting them, then tighten

the nut with a torque wrench for a leak-free connection.

• Check carefully for leaks before starting the test run.

i

CAUTION

Keep the fire alarm and the air

outlet at least 5 ft. (1.5 m) away

from the unit.

WARNING

• When performing piping work, do not mix air

except for specified refrigerant (R410A) in

refrigeration cycle. It causes capacity down, and

risk of explosion and injury due to high tension

inside the refrigerant cycle.

• If the refrigerant comes in contact with a flame,

it produces a toxic gas.

• Do not add or replace refrigerant other than

specified type. It may cause product damage,

burst and injury, etc.

Page 3

•Donotleakrefrigerantwhilepipingworkforan

installationorre-installation,andwhilerepairing

refrigerationparts.

Handleliquidrefrigerantcarefullyasitmaycause

frostbite.

When Servicing

•TurnthepowerOFFatthemainpowerbox(mains)

beforeopeningtheunittocheckorrepairelectrical

partsandwiring.

•Keepyourfingersandclothingawayfromanymoving

parts.

•Cleanupthesiteafteryounish,rememberingto

checkthatnometalscrapsorbitsofwiringhavebeen

leftinsidetheunit.

CAUTION

•Donottouchtheairinletorthesharp

aluminumfinsoftheoutdoorunit.Yo u

maygetinjured.

• Ventilateanyenclosedareaswheninstallingor

testingtherefrigerationsystem.Leaked

refrigerantgas,oncontactwithfireorheat,can

producedangerouslytoxicgas.

• Conrmafterinstallationthatnorefrigerantgas

isleaking.Ifthegascomesincontactwitha

burningstove,gaswaterheater,electricroom

heaterorotherheatsource,itcancausethe

generationoftoxicgas.

WARNING

•Thisproductmustnotbemodiedor

disassembledunderanycircumstances.

Modiedordisassembledunitmaycausere,

electricshockorinjury.

•Donotcleaninsidetheindoorandoutdoor

unitsbyusers.Engageauthorizeddealeror

specialistforcleaning.

•Incaseofmalfunctionofthisappliance,do

notrepairbyyourself.Contacttothesales

dealerorservicedealerforarepair.

Check of Density Limit

The room in which the air conditioner is to be

installed requires a design that in the event of

refrigerant gas leaking out, its density will not exceed

a set limit.

Therefrigerant(R410A),whichisusedintheair

conditioner,issafe,withoutthetoxicityorcombustibilityof

ammonia,andisnotrestrictedbylawsimposedtoprotect

theozonelayer.However,sinceitcontainsmorethanair,

itposestheriskofsuffocationifitsdensityshouldrise

excessively.Suffocationfromleakageofrefrigerantis

almostnon-existent.Withtherecentincreaseinthe

numberofhighdensitybuildings,however,theinstallation

ofmultiairconditionersystemsisontheincrease

becauseoftheneedforeffectiveuseofoorspace,

individualcontrol,energyconservationbycurtailingheat

andcarryingpower,etc.

Mostimportantly,themultiairconditionersystemisable

toreplenishalargeamountofrefrigerantcomparedto

conventionalindividualairconditioners.

Others

CAUTION

•Donotsitorstepontheunit,youmay

falldownaccidentally.

•Donottouchtheairinletorthesharp

aluminumfinsoftheoutdoorunit.

Yo u maygetinjured.

•DonotstickanyobjectintotheFA N

CASE.

Yo u maybeinjuredandtheunitmay

bedamaged.

Ifasingleunitofthemultiairconditionersystemistobe

installedinasmallroom,selectasuitablemodeland

installationproceduresothatiftherefrigerant

accidentallyleaksout,itsdensitydoesnotreachthelimit

(andintheeventofanemergency,measurescanbe

madebeforeinjurycanoccur).

ASHRAEandtheInternationalMechanicalCodeofthe

ICCaswellasCSAprovideguidanceanddefine

safeguardsrelatedtotheuseofrefrigerants,allofwhich

defineaRefrigerantConcentrationLevel(RCL)of 400 oz

(11.3kg)per1,000ft3(28.3m

Foradditionalguidanceandprecautionsrelatedto

refrigerantsafety,pleaserefertothefollowingdocuments:

InternationalMechanicalCode2012(IMC-2012)

(ormorerecentlyrevised)

ASHRAE15

ASHRAE34

3

)for

R410Arefrigerant.

ii

Page 4

3-2. Use R410A exclusive cylinder only.

Single-outlet valve

with the cylinder standing on end as

shown.

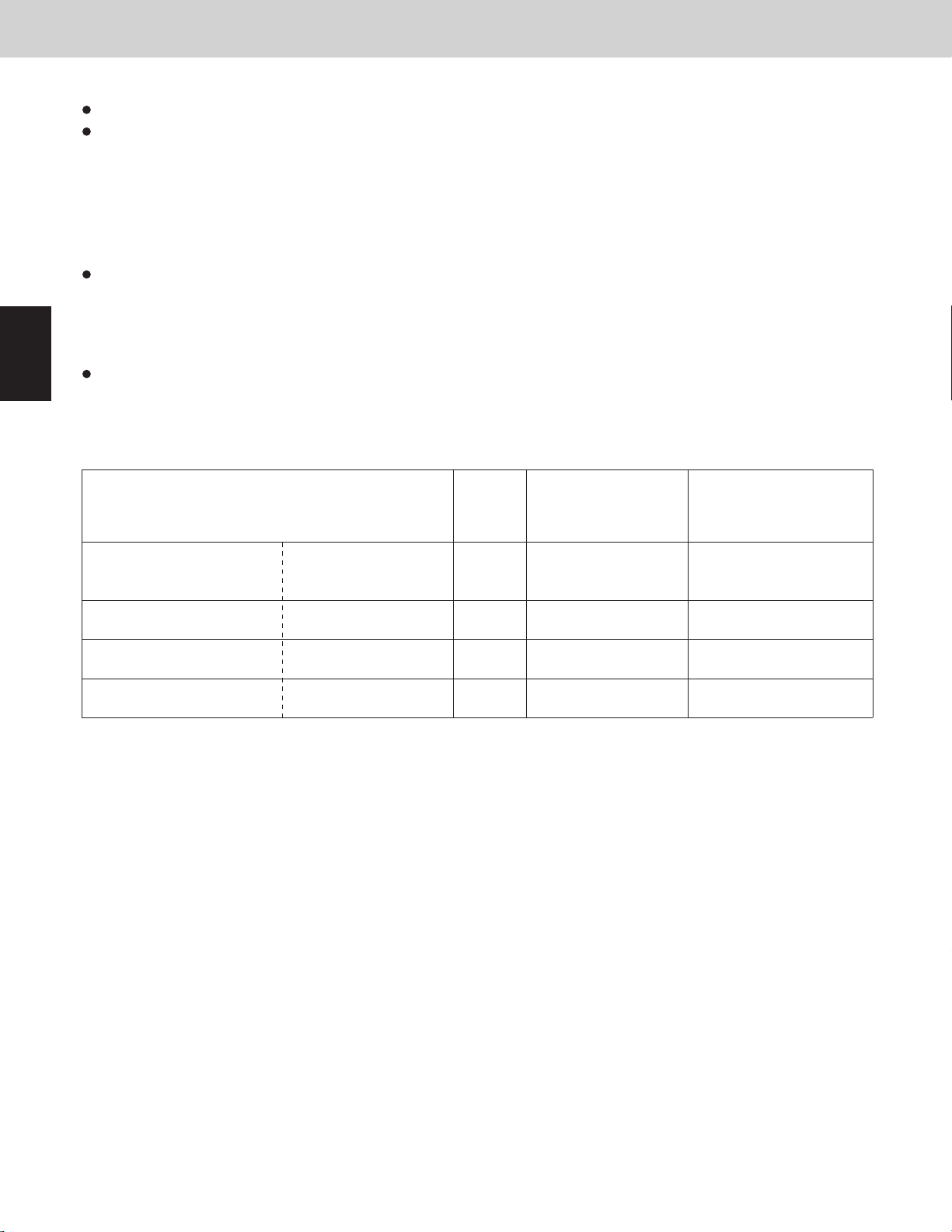

New refrigerant R410A cannot be used for

earlier models

1. Compressor specifications are different.

some of the materials used for compressor parts are

different.

2. Existing tubing cannot be used (especially R22).

Completely cleaning out residual refrigerating

3. Refrigerating machine oil differs (R22).

Since R22 refrigerating machine oil is mineral oil, it

does not dissolve in R410A. Therefore, refrigerating

machine oil discharged from the compressor can

cause compressor damage.

R22 refrigerating machine oil Mineral oil (Suniso oil)

R407C refrigerating machine oil Synthetic fluid (ether oil)

R410A refrigerating machine oil Synthetic fluid (ether oil)

Valve

Precautions for Installation Using New Refrigerant

1. Care regarding tubing

1-1. Process tubing

l

Material: Use clean, dry, free of oil, refrigeration grade, seamless, phosphorous deoxidized copper tube rated for

R410A only. Wall thickness shall comply with the applicable legislation. The minimal wall thickness must be in

accordance with the table below.

l

Tubing size: Be sure to use the sizes indicated in the table below.

l

Use a tube cutter when cutting the tubing, and be sure to remove any flash. This also applies to distribution joints

(optional).

l

When bending tubing, use a bending radius that is 4 times the outer diameter of the tubing or larger.

Use sufficient care in handling the tubing. Seal the tubing ends with caps or tape to

CAUTION

prevent dirt, moisture, or other foreign substances from entering.

These substances can result in system malfunction.

Outer diameter Wall thickness Outer diameter Wall thickness

5/8" (15.88) 0.040 (1.016) 1-5/8" (41.28) 0.060 (1.524)

3/4" (19.05) 0.042 (1.0668) Unit: in. (mm)

Material: O Material: O

1/4" (6.35) 0.025 (0.635) 7/8" (22.22) 0.045 (1.143)

3/8" (9.52) 0.030 (0.762) 1-1/8" (28.58) 0.050 (1.27)

1/2" (12.7) 0.035 (0.889) 1-3/8" (34.92) 0.055 (1.397)

1-2. Prevent impurities including water, dust and oxide from entering the tubing. Impurities can cause R410A

refrigerant deterioration and compressor defects. Due to the features of the refrigerant and refrigerating machine

oil, the prevention of water and other impurities becomes more important than ever.

2. Be sure to recharge the refrigerant only in liquid form.

2-1. Since R410A is a non-azeotrope, recharging the refrigerant in gas form can lower performance and cause defects

in the unit.

2-2. Since refrigerant composition changes and performance decreases when gas leaks, collect the remaining

refrigerant and recharge the required total amount of new refrigerant after fixing the leak.

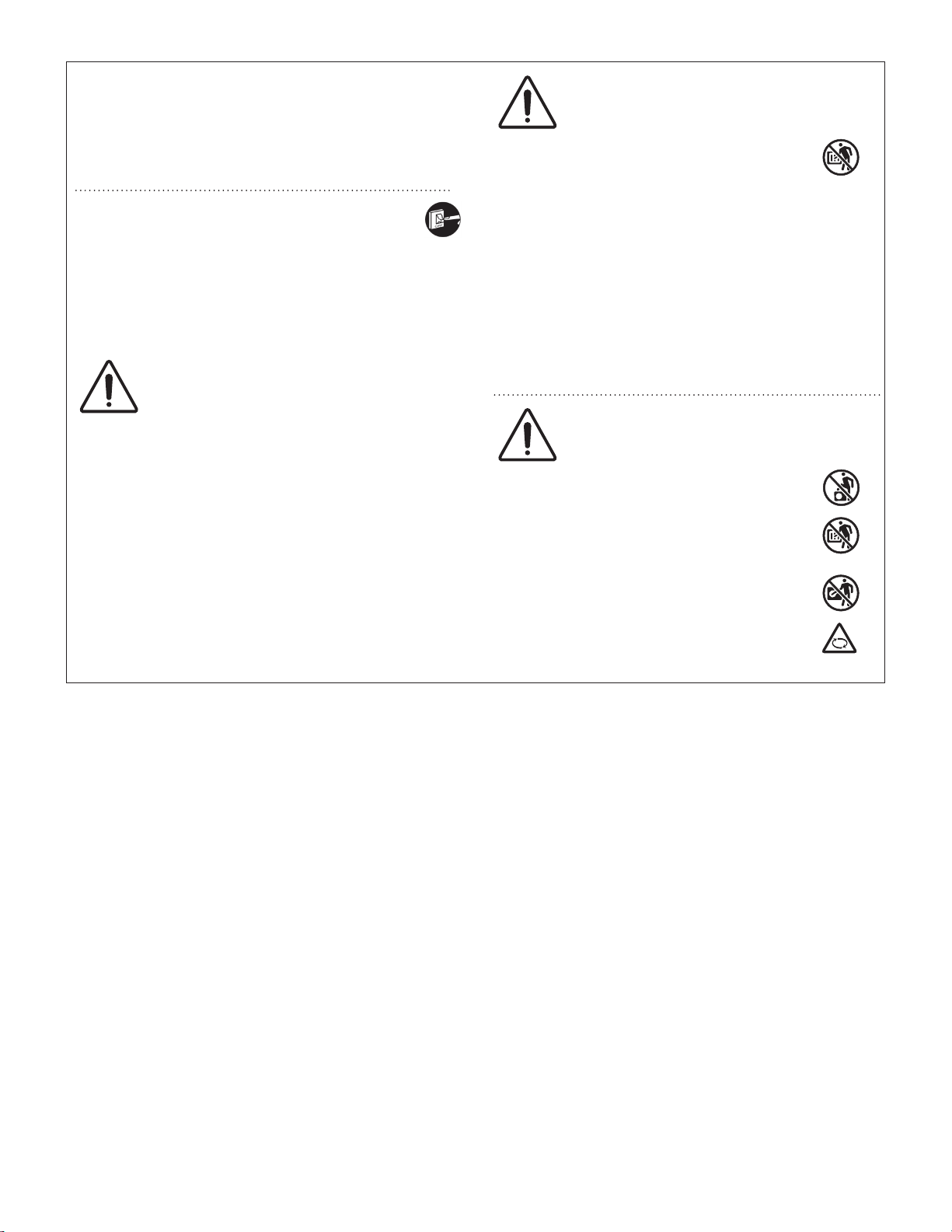

3. Different tools required

3-1. Tool specifications have been changed due to the characteristics of R410A.

Some tools for R22- and R407C-type refrigerant systems cannot be used.

Item

Manifold gauge Yes No

Charge hose Yes No To resist higher pressure, material must be changed.

Vacuum pump Yes Yes

Leak detector Yes No

Flaring oil Yes No

* Using tools for R22 and R407C and new tools for R410A together can cause defects.

tools?

New

R407C tools

compatible

with R410A?

Remarks

Types of refrigerant, refrigerating machine oil, and

pressure gauge are different.

Use a conventional vacuum pump if it is equipped with

a check valve. If it has no check valve, purchase and

attach a vacuum pump adapter.

Leak detectors for CFC and HCFC that react to chlorine

do not function because R410A contains no chlorine.

Leak detector for HFC134a can be used for R410A.

For systems that use R22, apply mineral oil (Suniso

oil) to the flare nuts on the tubing to prevent refrigerant

leakage. For machines that use R407C or R410A, apply

synthetic oil (ether oil) to the flare nuts.

Manifold gauge

Vacuum pump

Outlet

Inlet

iii

Page 5

3-2. Use R410A exclusive cylinder only.

New refrigerant R410A cannot be used for

earlier models

1. Compressor specifications are different.

some of the materials used for compressor parts are

different.

Valve

Single-outlet valve

with the cylinder standing on end as

shown.

2. Existing tubing cannot be used (especially R22).

Completely cleaning out residual refrigerating

3. Refrigerating machine oil differs (R22).

Since R22 refrigerating machine oil is mineral oil, it

does not dissolve in R410A. Therefore, refrigerating

machine oil discharged from the compressor can

cause compressor damage.

R22 refrigerating machine oil Mineral oil (Suniso oil)

R407C refrigerating machine oil Synthetic fluid (ether oil)

R410A refrigerating machine oil Synthetic fluid (ether oil)

iv

Page 6

—

CONTENTS

—

Section 1: CONTROL FUNCTIONS .......................................... 1-1

1. Introduction .............................................................1-2

2. Selecting Outdoor Unit for Operation .......................................... 1-3

3. Compressor Control .......................................................1-5

4. Output of PCB ..........................................................1-14

5. Outdoor Fan Control .....................................................1-20

6. Outdoor Unit CCU (command controller unit) Control ............................1-24

7. Tube Refrigerant Recovery Control ..........................................1-28

8. Oil Control .............................................................1-30

9. Defrost Control ..........................................................1-33

10. Discharge Tube Accumulated Refrigerant Recovery Control ....................... 1-39

11. Upper Current Limitation Mode (Demand control) ............................... 1-40

12. Backup Operation ....................................................... 1-42

13. Other Functions .........................................................1-46

14. Detailed Settings in EEPROM of Outdoor Unit .................................1-48

15. Outdoor Unit Control PCB .................................................1-50

Section 2: OUTDOOR UNIT REPAIR PROCEDURES ........................... 2-1

1. Removing Panels ......................................................... 2-2

2. Discharging Compressor Oil ................................................ 2-4

3. Backup Operation ........................................................ 2-7

4. Recovering Refrigerant .................................................... 2-9

5. Checking for Leakage After Repair .......................................... 2-14

6. Evacuating System ...................................................... 2-15

7. Charging Compressor Oil ................................................. 2-16

8. Pumping Out Refrigerant from Outdoot Unit ................................... 2-22

9. Compressor ........................................................... 2-26

10. Replacing Peripheral Parts of Fusible Plug .................................... 2-36

11. High and Low Pressure Sensors ............................................ 2-37

Section 3: OUTDOOR UNIT MAINTENANCE REMOTE CONTROLLER ............. 3-1

1. Overview ...............................................................3-2

2. Functions ...............................................................3-3

3. Ordinary Display Controls and Functions ...................................... 3-4

4. Monitoring Operations .....................................................3-9

5. Outdoor Unit Alarm History Monitor .......................................... 3-11

6. Mode Settings ..........................................................3-12

Section 4: REMOTE CONTROLLER FUNCTIONS ............................. 4-1

1. Simple Settings Function ................................................... 4-2

2. Detailed Settings Function .................................................. 4-8

3. Remote Controller Servicing Functions ....................................... 4-28

v

Page 7

Section 5: TROUBLE DIAGNOSIS .......................................... 5-1

1. Contents of Remote Controller Switch Alarm Display .............................5-2

2. Outdoor Unit Control Panel LED Display .......................................5-4

3. 3WAY Alarm Codes .......................................................5-5

4. Blinking Inspection Display on the Remote Controller ............................5-30

5. Inspection and Characteristics of Parts .......................................5-31

6. Test Pin ...............................................................5-35

7. Symptom: Thermostat in OFF continues or cycles OFF & ON too frequently ..........5-36

Section 6: TEST RUN .................................................... 6-1

1. Preparing for Test Run ..................................................... 6-2

2. Test Run Procedure ....................................................... 6-3

3. Main Outdoor Unit PCB Setting ..............................................6-4

4. Function Switches on P. C. Board ............................................6-7

5. Auto Address Setting ......................................................6-8

6. Setting Test Run Remote Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

7. Caution for Pump Down ................................................... 6-17

8. Self-Diagnosis Function Table and Contents of Alarm Display ..................... 6-17

vi

Page 8

– MEMO –

vii

Page 9

3WAY VRF SYSTEM

2WAY VRF SYSTEM

Control Functions

Contents

Contents

Introduction .....................................................................................................................

1. 1-2

Selecting Outdoor Unit for Operation ...........................................................................

2.

Compressor Control .......................................................................................................

3.

Output of PCB ...............................................................................................................

4.

Outdoor Fan Control .....................................................................................................

5.

Outdoor Unit CCU (command controller unit) Control ..............................................

6.

1. CONTROL FUNCTIONS

Control Functions

1-3

1-5

1-14

1-20

1-24

7. Tube Refrigerant Recovery Control .............................................................................

Oil Control ......................................................................................................................

8.

Defrost Control ..............................................................................................................

9.

Discharge Tube Accumulated Refrigerant Recovery Control ...................................

10.

Upper Current Limitation Mode (Demand control) .....................................................

11.

Backup Operation .........................................................................................................

12.

Other Functions ............................................................................................................

13.

Detailed Settings in EEPROM of Outdoor Unit ...........................................................

14.

Outdoor Unit Control PCB ............................................................................................

15.

1-28

1-30

1-33

1-39

1-40

1-42

1-46

1-48

1-50

1

2

3

4

5

1 - 1

6

7

8

9

Page 10

1

2WAY VRF SYSTEM

Control Functions

1. Introduction

2. Selecting Outdoor Unit for Operation

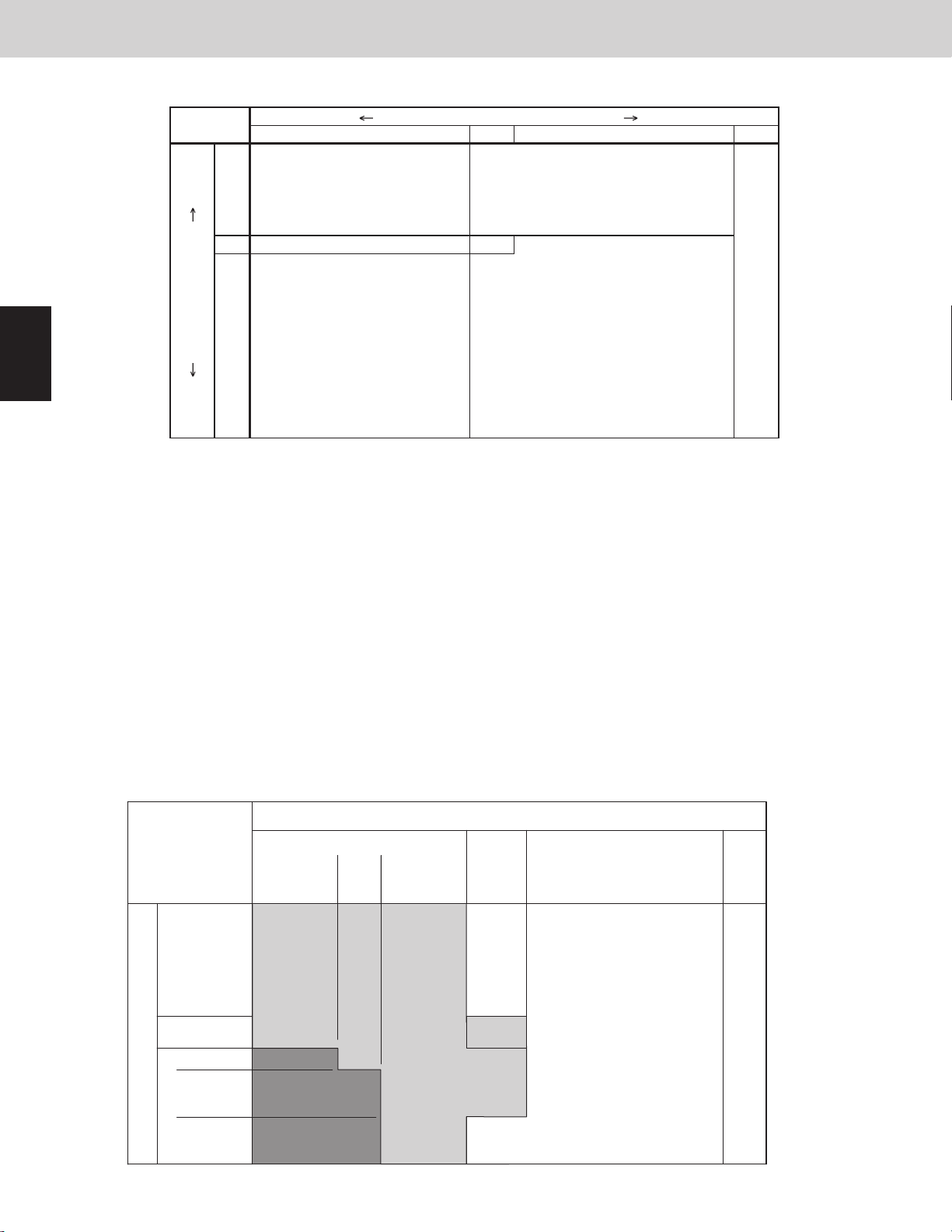

2-1. Outdoor Unit Operating Rules

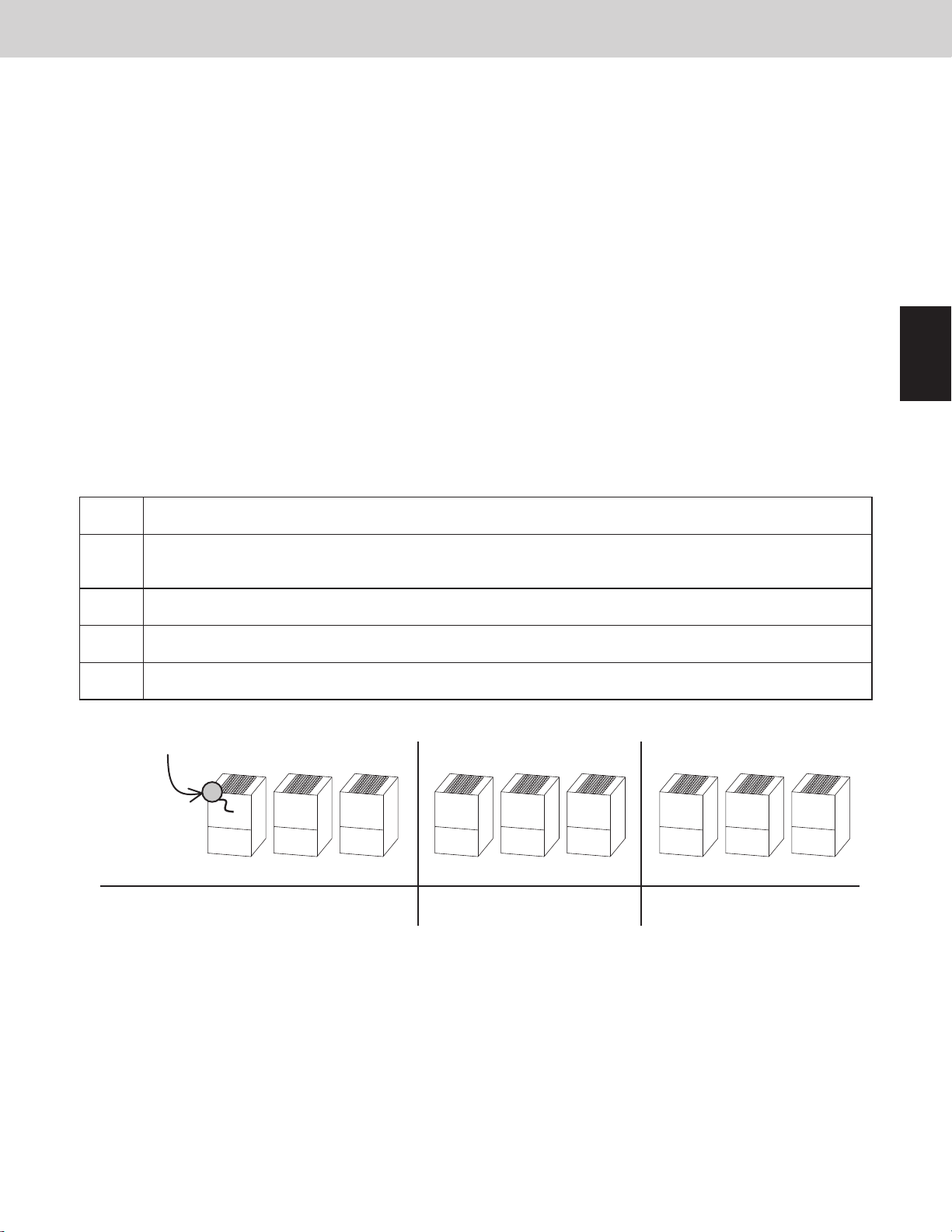

As a result of setting the main outdoor and sub outdoor units due to the O/U.ADD setting, the order of priority for

the outdoor units is determined in small values of O/U.ADD sequence. Because in this system all outdoor units

contain an inverter compressor, ordinarily there is no absolute order of priority for compressor operation.

2-2. Delayed Start of Outdoor Units

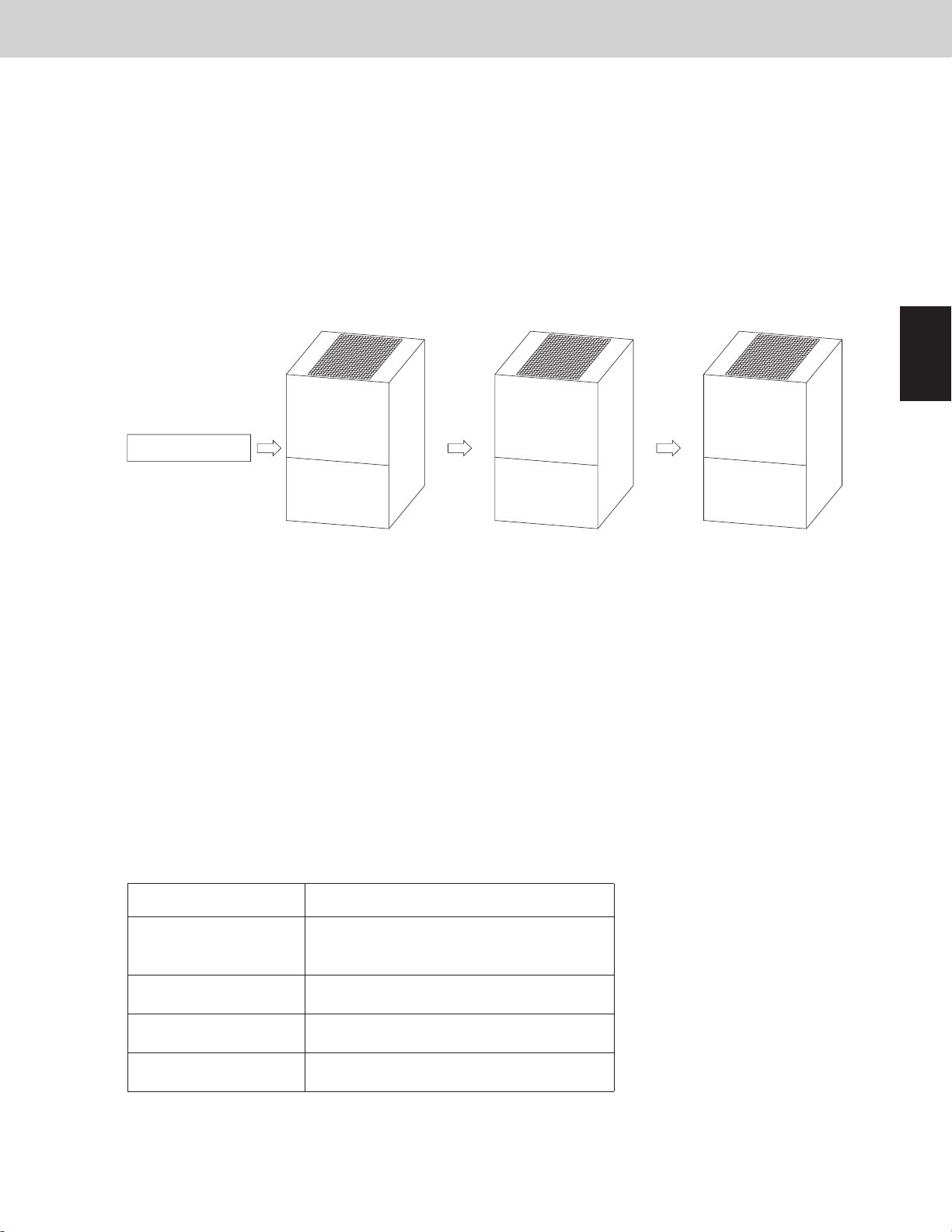

2-2-1. Delayed start of outdoor unit in the same system

If it is necessary to operate the compressors simultaneously at multiple outdoor units, each outdoor unit will

start in order of unit No. every one second, beginning with unit No. 1.

*

Operation starts

Main outdoor unit Sub outdoor unit Sub outdoor unit

O/U.ADD = 1 O/U.ADD = 2 O/U.ADD = 3

Starts after 1 second Starts after 2 seconds Starts after 3 seconds

This is in order to reduce the load on the power supply equipment.

2-2-2. Delayed start for each system

When systems are linked with one communication cable and multiple systems are required to operate

simultaneously by the central control device, all main outdoor units will begin operating simultaneously.

In this situation, the load of the power supply equipment increases temporarily.

To prevent the overload, the start timing of each system can be delayed.

In order to enable this delay time, it must be set in the EEPROM for each system (Main outdoor unit).

Those systems (Main outdoor units) where this setting has been made will start after a delay according to

their system addresses.

To activate this delay start function, it is necessary to set it to EEPROM on main outdoor PCB.

EEPROM setting in main outdoor unit

CODE: 3E

2WAY VRF SYSTEM

Control Functions

Delay timeSetting No.

0

(factory preset mode)

No delay start for each system

1 (System address × 1 × 8) seconds delay

2 (System address × 2 × 8) seconds delay

3 (System address × 3 × 8) seconds delay

3WAY VRF SYSTEM

1. Introduction

The MF2U series outdoor units for USA is a system that allows multiple outdoor units to be connected.

All the outdoor units do not utilize the sub units that were used in earlier systems.

The O/U.ADD of outdoor unit PCB where the unit is set to “1” becomes the main unit and activates

as the CCU (command controller unit) functions that controls the entire system.

PCB Setting of Outdoor Unit

In order to determine the outdoor unit to be the main or sub unit, it is necessary to make settings at each PCB.

Main outdoor unit

The outdoor unit where the O/U.ADD is set to “1” activates the CCU (command controller unit) functions that

controls the entire system. This outdoor unit is the main outdoor unit.

* For the main outdoor unit, perform all the settings in the table (PCB setting of outdoor unit) below.

Sub outdoor unit

The outdoor unit where the unit No. is set to other than “1” is a sub outdoor unit.

* The system will not operate if outdoor units have been set other than unit No. “1”.

Control Functions

2

3

4

5

6

PCB Setting of Outdoor Unit

Factory

O/U.ADD [SW5] 11Outdoor units address

R.C.ADD [SW1, SW2] 1 Not necessarySystem 1 ~ 30System address

NO.OF I/U [SW3, SW4] 1 Not necessarySystem 1 ~ 52 unitsNo. of indoor units

NO.OF O/U 1 Not necessarySystem 1 ~ 3 unitsNo. of outdoor units[SW6]

* This system can be exteded to connect a maximum of 3 outdoor units.

preset

mode

Main outdoor unit

On-site setting

Sub outdoor unit

On-site setting

Setting other than 1

(Duplication prohibited)

7

8

9

1 - 2

Page 11

3WAY VRF SYSTEM

2. Selecting Outdoor Unit for Operation

2WAY VRF SYSTEM

Control Functions

2. Selecting Outdoor Unit for Operation

2-1. Outdoor Unit Operating Rules

As a result of setting the main outdoor and sub outdoor units due to the O/U.ADD setting, the order of priority for

the outdoor units is determined in small values of O/U.ADD sequence. Because in this system all outdoor units

contain an inverter compressor, ordinarily there is no absolute order of priority for compressor operation.

2-2. Delayed Start of Outdoor Units

2-2-1. Delayed start of outdoor unit in the same system

If it is necessary to operate the compressors simultaneously at multiple outdoor units, each outdoor unit will

start in order of unit No. every one second, beginning with unit No. 1.

*

This is in order to reduce the load on the power supply equipment.

Control Functions

1

Operation starts

Main outdoor unit Sub outdoor unit Sub outdoor unit

O/U.ADD = 1 O/U.ADD = 2 O/U.ADD = 3

Starts after 1 second Starts after 2 seconds Starts after 3 seconds

2-2-2. Delayed start for each system

When systems are linked with one communication cable and multiple systems are required to operate

simultaneously by the central control device, all main outdoor units will begin operating simultaneously.

In this situation, the load of the power supply equipment increases temporarily.

To prevent the overload, the start timing of each system can be delayed.

In order to enable this delay time, it must be set in the EEPROM for each system (Main outdoor unit).

Those systems (Main outdoor units) where this setting has been made will start after a delay according to

their system addresses.

To activate this delay start function, it is necessary to set it to EEPROM on main outdoor PCB.

EEPROM setting in main outdoor unit

CODE: 3E

2

3

4

5

6

Delay timeSetting No.

0

(factory preset mode)

1 (System address × 1 × 8) seconds delay

2 (System address × 2 × 8) seconds delay

3 (System address × 3 × 8) seconds delay

No delay start for each system

1 - 3

7

8

9

Page 12

2. Selecting Outdoor Unit for Operation

3. Compressor Control

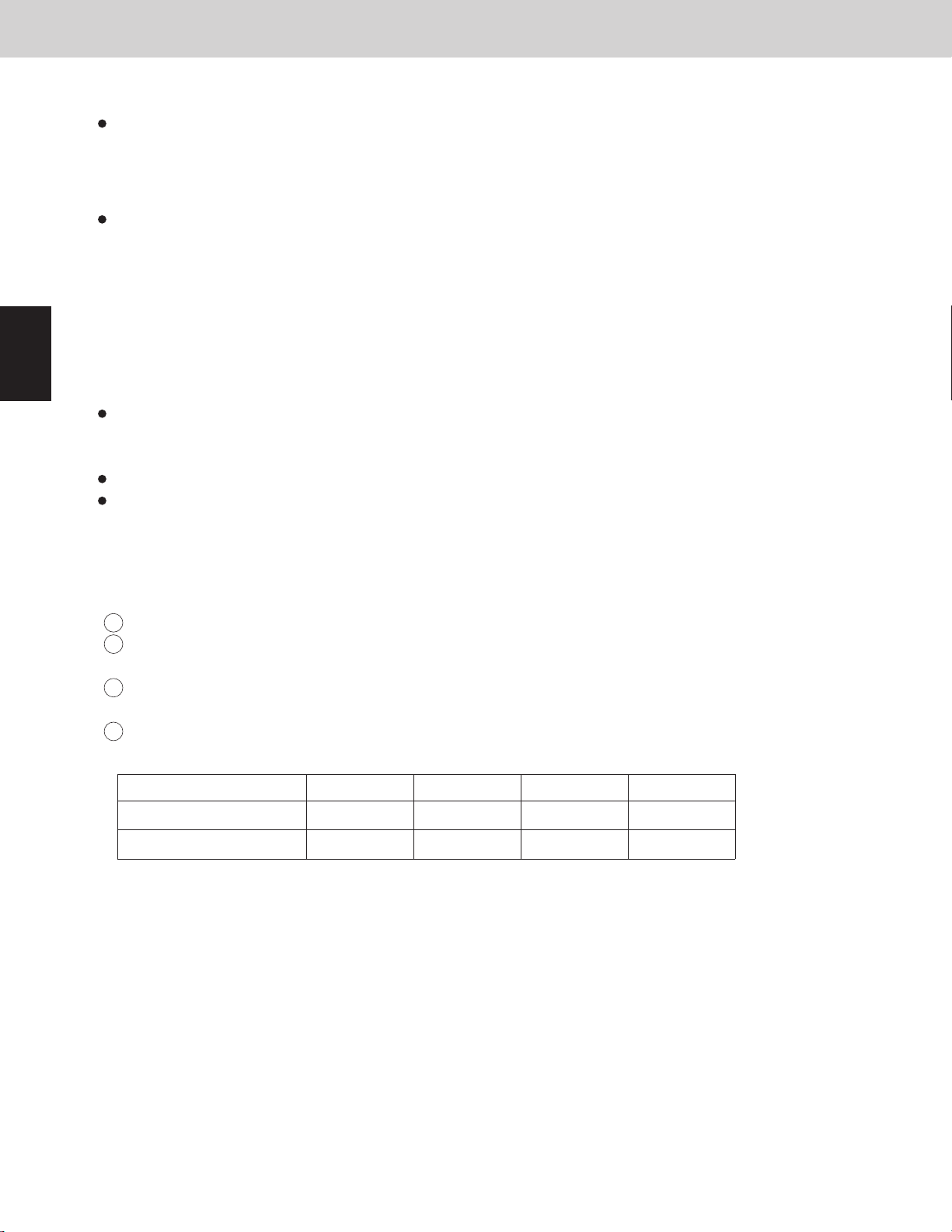

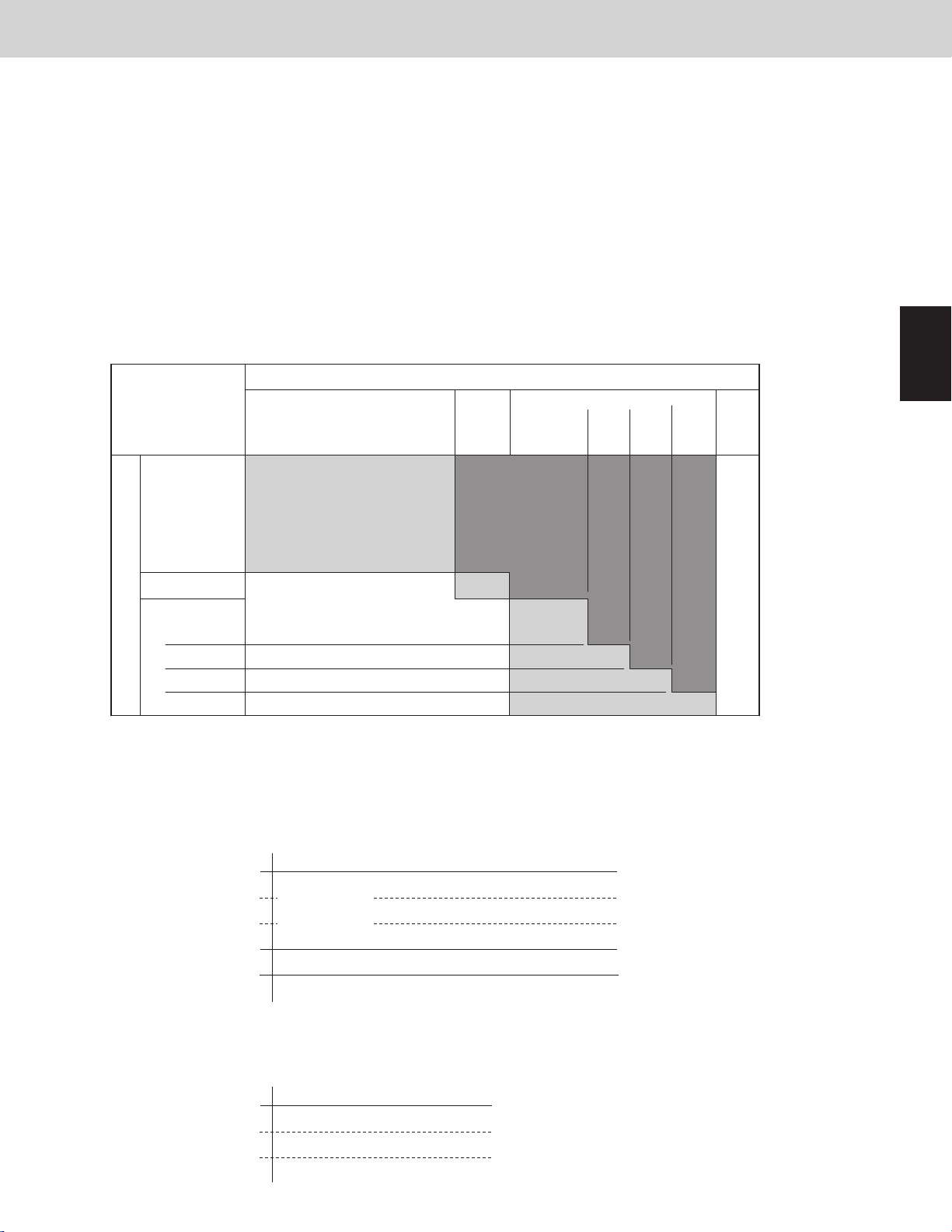

3-1. Compressors Mounted in the Outdoor Units

3-2. Compressor Selection Rules

Placement of compressor seen from the top

3-2-1. Priority order of compressors

A.

A

B

C

D

Decide first priority order of compressor in each outdoor unit.

B. Priority order of compressor trip counter = 0 is higher than that of compressor trip counter = 1.

C. Inverter compressor: Shorter operating time > Longer operating time

D. Compressor that “outdoor unit small address”

installed in outdoor unit

Compressor that “outdoor unit large address”

installed in outdoor unit

First priority order of inverter compressor in each outdoor unit > Other inverter compressor

Compressor trip counter =0 > Compressor trip counter =1

Shorter operating time > Longer operating time

“Outdoor unit small address”

installed in outdoor unit

“Outdoor unit large address”

installed in outdoor unit

>

>

*1

*1 Select first priority order of compressor in each outdoor unit by following method.

The compressor that has no trip counter, shorter operating time and smaller number of compressor will be

taken first priority.

First priority order of inverter compressor in each outdoor unit > Other inverter compressor

2WAY VRF SYSTEM

Control Functions

Type 120, 144

2nd compressor

1st compressor

Front side

Compressor trip counter =0 > Compressor trip counter =1

Shorter operating time > Longer operating time

1st compressor > 2nd compressor

Priority order flow of all compressors

Priority order flow of each outdoor unit

Type 72, 96

Front side

1st compressor

2-3. Outdoor Unit Stop Rules

2-3-1. Stopping of all outdoor units

When all outdoor units must stop, the units stop at the same time.

2-3-2. Stopping of individual outdoor units according to load of air-conditioning

● All cooling mode

3WAY VRF SYSTEM

Control Functions

1

2

3

4

Outdoor air temperature ≥ 113°F (45°C): All outdoor units will be operated. However, there is the outdoor unit

which has the stopped compressor according to load of air-conditioning.

69.8°F (21°C) < outdoor air temperature < 113°F (45°C): the outdoor unit which has the compressor with the

shortest amount of operating time continues to run and rest of the outdoor units may be stopped according to

load air-conditioning.

The outdoor unit which has any compressors without operation may be stopped.

Outdoor air temperature ≤ 69.8°F (21°C): The outdoor unit which has the compressor with the shortest

amount of operating time continues to run and rest of the outdoor units may be stopped according to load airconditioning.

There is the outdoor unit which has only the operating compressor or uses only the heat exchanger with the

stopped compressor according to some conditions.

● All heating mode

The outdoor unit which has the compressor with the shortest amount of operating time continues to run and rest

of the outdoor units may be stopped according to load air-conditioning.

● Mixed cooling/heating

The outdoor unit which has the compressor with the shortest amount of operating time continues to run and rest

of the outdoor units may be stopped according to load air-conditioning.

There is the outdoor unit which has only the operating compressor or uses only the heat exchanger with the

compressor stopped according to some conditions.

5

6

7

8

9

1 - 4

Page 13

3. Compressor Control

3. Compressor Control

2WAY VRF SYSTEM

Control Functions

3-1. Compressors Mounted in the Outdoor Units

Placement of compressor seen from the top

Type 72, 96

3WAY VRF SYSTEM

Control Functions

Type 120, 144

1st compressor

Front side

3-2. Compressor Selection Rules

3-2-1. Priority order of compressors

A.

Decide first priority order of compressor in each outdoor unit.

The compressor that has no trip counter, shorter operating time and smaller number of compressor will be

taken first priority.

First priority order of inverter compressor in each outdoor unit > Other inverter compressor

B. Priority order of compressor trip counter = 0 is higher than that of compressor trip counter = 1.

C. Inverter compressor: Shorter operating time > Longer operating time

D. Compressor that “outdoor unit small address”

installed in outdoor unit

A

First priority order of inverter compressor in each outdoor unit > Other inverter compressor

B

Compressor trip counter =0 > Compressor trip counter =1

2nd compressor

Front side

Compressor that “outdoor unit large address”

>

installed in outdoor unit

Priority order flow of all compressors

1st compressor

*1

1

2

3

C

D

*1 Select first priority order of compressor in each outdoor unit by following method.

“Outdoor unit small address”

Shorter operating time > Longer operating time

“Outdoor unit large address”

installed in outdoor unit

Priority order flow of each outdoor unit

Compressor trip counter =0 > Compressor trip counter =1

Shorter operating time > Longer operating time

1st compressor > 2nd compressor

>

installed in outdoor unit

4

5

6

7

8

1 - 5

9

Page 14

1

2WAY VRF SYSTEM

Control Functions

3. Compressor Control

2

3WAY VRF SYSTEM

3. Compressor Control

Control Functions

3-2-2. Operating compressors

When heat exchanger of the outdoor unit is condenser (All cooling mode or mixed cooling/heating)

The compressor with higher priority order starts according to the priority order described on the compressor

selection rules.

Outdoor air temperature<50°F (10°C): More than one compressor among all outdoor units will be operated.

When heat exchanger of the outdoor unit is evaporator (All cooling mode or mixed cooling/heating)

At least, one inverter compressor operates when the system starts.

The other compressors operate according to the priority order described on the compressor selection rules.

3-2-3. Stopping compressors

The compressor with lower priority order starts according to the priority order described on the compressor

selection rules.

3-3. Operation When Starting 2 Compressors Mounted in Outdoor Unit

When necessary capacity gradually increases and one more inverter compressor is additionally started under

the present operating compressor, reduce the compressor frequency to 25Hz temporarily and then start an

additional compressor.

The operation noted above is performed when 1st compressor or 2nd compressor is additionally started.

If necessary capacity is initially higher and two compressors are started simultaneously, the operation noted

above is not performed and both of them are regarded as the target frequency.

3

4

5

6

7

3-4. Operating Frequency Range of Inverter Compressor

The inverter compressor can operate within the range in the table below.

1

When the high pressure is over 435psi (3.0MPa), the upper limit frequency is 90Hz.

If the high pressure is over 450psi (3.1MPa) and the minimum frequency operation is in progress, the system

2

is stopped. (P25: Pre-trip)

If the low pressure is over 213psi (1.47MPa) during operation of the inverter compressor, the system is stopped.

3

(P27: Pre-trip)

If 2 inverter compressors are simultaneously operating in the same outdoor unit, the frequency of 1st

4

compressor becomes 5Hz lower than that of 2nd compressor.

Type of outdoor unit

Minimum frequency (Hz)

Maximum frequency (Hz) 80

The frequency range in the table above is subject to change without notice.*

3-5. Forced Stopping of Compressor

Once a compressor stops, it will not start for a period of 3 minutes (3-minute forced OFF).

However, this does not apply when the compressor was forced to stop as the result of a special control operation.

(start control, defrost control, refrigerant oil recovery control, etc.)

72 96 120 144

15 15 15

100

15

80

80

8

9

1 - 6

Page 15

3WAY VRF SYSTEM

3. Compressor Control

3-6. Capacity Control (Roadmap control)

1 The capacity control by the compressors is performed according to the pressure sensor attached to the outdoor

unit and temperature thermistor attached to the indoor / outdoor unit heat exchanger.

* With roadmap control, the pressure detected by the pressure sensor is converted to saturation temperature

before it is used by microcomputer. This converted temperature is called “pressure sensor temperature”.

2 This control is performed every 30 seconds.

3 Required level of each indoor unit

Required level of indoor unit is calculated by difference between preset temperature in remote controller and

intake temperature of indoor unit (TA), difference between preset discharge air temperature in EEPROM on

indoor unit PCB and discharge air temperature of indoor unit (TF).

Required level has “0” to “30” phases. This level becomes “31” at the test run.

The target temperature of indoor unit heat exchanger is decided according to the maximum required level.

* Target temperature of all indoor units heat exchanger is same value because all indoor units are connected

with the same pressure piping.

4 Denition of evaporation temperature and condensation temperature

● Evaporation temperature (Te):

Shows the lowest temperature among the temperature sensors (E1 or E3) when the indoor unit heat exchanger

is functioning as an evaporator.

* When operating in mixed cooling/heating mode and the outdoor units are mixed evaporators, the outdoor unit

heat exchanger temperature is not recognized as “Te”.

● Condensation temperature (Tc):

Shows the highest temperature among the high-pressure saturated temperature in the system and indoor unit

heat exchanger’s liquid tube temperature (E1) with the thermostat ON.

Control Functions

1

2

3-6-1. Evaporation temperature adjustment by roadmap control

The cooling capacity is adjusted with this control. It prevents freezing of the indoor unit's heat exchanger and the

dew to the outside panel of the indoor unit. The capacity is adjusted according to the following gure.

Evaporation temperature area

deg

Compressor capacity increase possible

43.0 (6.1)

42.8 (6.0)

37.4 (3.0)

37.2 (2.9)

* The evaporation temperature area changes depending on the maximum required level of each indoor unit as

shown above.

* Area C is regarded as area B for 6 minutes after compressor starts.

* When the system operates in a minimum capacity, the system will continue operating for at least 6 minutes if the

evaporation temperature area is area C.

* The evaporation temperature is not adjusted while specially controlling defrosting and the oil recovery, etc.

* The evaporation temperature is not adjusted when there are one or more indoor units that select the test run.

If one or more indoor units are selected into test run, the system doesn't stop in all states except alarm appearing.

* The test run will nish automatically in about one hour.

Compressor capacity

increase prohibited

Compressor capacity decrease

60.8 (16.0)

55.4 (13.0)

Area A

Area B

Area C

51.8 (11.0)

46.4 (8.0)

0

Max. required level

15

unit: °F (°C)

42.8 (6.0)

37.4 (3.0)

30

3

4

5

6

7

8

1 - 7

9

Page 16

1

2

3

4

3WAY VRF SYSTEM

3. Compressor Control

3-6-2. Condensation temperature adjustment by roadmap control

The area B target temperature is different due to cooling, heating and mixed cooling/heating operation.

Target lower temperature

(Tc_tgt_min)

Cooling 127.4°F (53.0°C) 131.0°F (55.0°C)

Heating 118.4°F (48.0°C) 123.8°F (51.0°C)

Mixed cooling/heating 118.4°F (48.0°C) 123.8°F (51.0°C)

Cooling mode

1

The purpose of this control at cooling

is to prevent abnormal high-pressure.

・Standard setting (at the shipment)

°F (°C) °F (°C)

PX=136.4

(58.0)

136.2

(57.9)

131.2

(55.1)

131.0

(55.0)

127.4

(53.0)

127.2

(52.9)

Thermostat

OFF

Compressor

capacity

decrease

Compressor

capacity

increase

prohibited

Compressor

capacity

increase

possible

Area D

Area C

Area B

Area A

Heating mode and mixed cooling/heating mode

2

Heating capacity is adjusted with this control.

It also prevents abnormal high-pressure simultaneously.

The capacity is controlled in the following diagram.

PX=136.4

(58.0)

136.2

(57.9)

124.0

(51.1)

123.8

(51.0)

118.4

(48.0)

118.2

(47.9)

Target upper temperature

(Tc_tgt_max)

Thermostat

OFF

Compressor

capacity

decrease

Compressor

capacity

increase

prohibited

Compressor

capacity

increase

possible

Area D

Area C

Area B

Area A

95.0

(35.0)

109.4

(43.0)

Control Functions

104.9

(40.5)

°F (°C)

123.8

(51.0)

118.4

(48.0)

5

6

7

8

91.4

(33.0)

15 300

Max. required level

* PX is usually xed to 136.4°F (58°C). If the high pressure goes up rapidly after the compressor starts, the

system experiences urgent stop. The next time the system will start with lower PX.

* In the area B, the compressor capacity changes depending on the refrigerant condition.

* When the system operates in a minimum capacity, the system will continue operating for at least 6 minutes

if the condensation temperature area is area C.

* The condensation temperature is not adjusted when there are one or more indoor units that select the test run.

Limit pressure adjustment function

Operation pressure is able to be adjusted for existing old piping.

If area shift function is set, values below shift.

EEPROM setting in main outdoor unit

CODE : 4B

Setting No. Limited pressure PX °F (°C) Cooling mode

Tc_tgt_min Tc_tgt_max Tc_tgt_min Tc_tgt_max

0 478.5psi (3.3MPa) 126.5 (52.5) 116.6 (47.0) 120.2 (49.0) 116.6 (47.0) 118.4 (48.0)

1 No use - - - - 2 551.1psi (3.8MPa) 136.4 (58.0) 127.4 (53.0) 131.0 (55.0) 118.4 (48.0) 123.8 (51.0)

3 No use - - - - -

Heating mode and mixed

cooling/heating mode

9

1 - 8

Page 17

3WAY VRF SYSTEM

3. Compressor Control

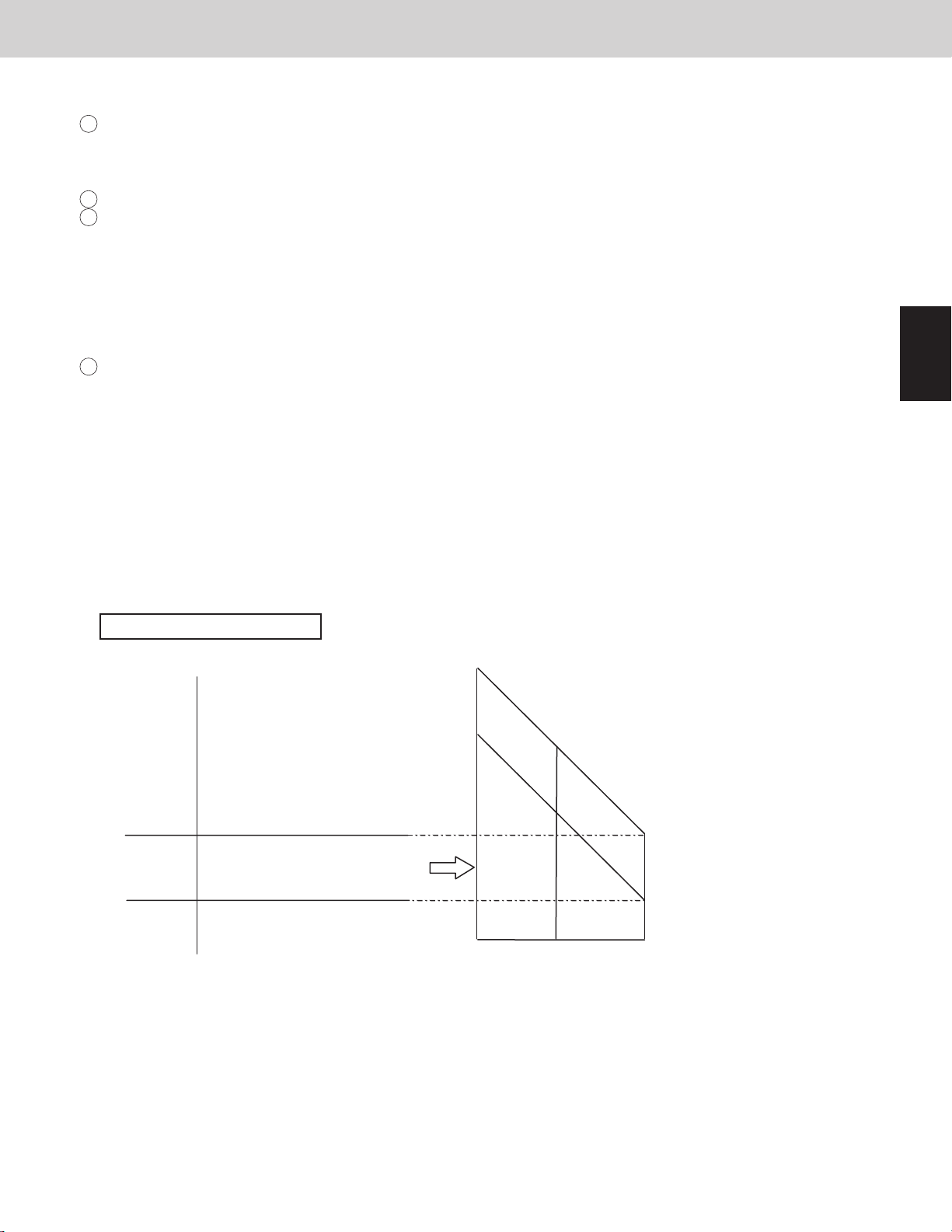

3-6-3. Cooling operation with low ambient temperature

When operating in cooling mode with the ambient temperature less than 69.8°F (21°C), the unit is set in low

ambient temperature cooling mode.

During low ambient temperature cooling mode, the heat exchanger capacity control is performed in addition to the

compressor capacity control. The target condensation temperature (Tc_tgt) is controlled between 73.4°F ~ 77°F

(23°C ~ 25°C).

Thereof, the heat exchanger may sometimes be used by half even if the operation is cooling in all indoor units.

(1) Capacity changes of compressor

Similar to control normal cooling operation

(2) Capacity changes of heat exchanger

* Condensation temperature (Tc) is high

The outdoor heat exchanger capacity is increased, increasing the system condensation capacity and lowering the

condensation temperature (Tc).

* Condensation temperature (Tc) is low

The outdoor heat exchanger capacity is decreased, decreasing the system condensation capacity and raising the

condensation temperature (Tc).

Outdoor Unit Heat Exchanger Control Table

Low ← Condensation Temp. [Tc] → High

A C

B D

Control Functions

1

2

91.4°F

87.8°F

(31°C)

83.3°F

(28.5°C)

57.2°F (14°C)

A

51.8°F (11°C)

42.8°F (6°C)

B

37.4°F (3°C)

C

26.6°F (-3°C)

Low←Evaporation Temp. [ Te ]→High

3-6-4. Control of condensation temperature and evaporation temperature during mixed cooling/heating operation

During mixed cooling/heating operation, the control maintains a heat balance with a target evaporation temperature

(Te) for the cooling mode indoor units of 37.4°F ~ 42.8°F (3°C ~ 6°C) and a target condensation temperature (Tc)

for the heating mode indoor units of 118.4°F ~ 123.8°F (48°C ~ 51°C).

Heat balance control is performed by varying the compressor capacity and heat discharge (heat intake) of the heat

exchanger.

(1) Increasing/decreasing the compressor capacity

* When evaporation temperature (Te) is high and condensation temperature (Tc) is low.

This occurs when both the cooling capacity (heat intake) and the heating capacity (heat discharge) are low.

The compressor capacity and the circulation ow of refrigerant are increased in order to lower the evaporation

temperature (Te) and raise the condensation temperature (Tc).

* When evaporation temperature (Te) is low and condensation temperature (Tc) is high

This occurs when both the cooling capacity (heat intake) and the heating capacity (heat discharge) are high.

The compressor capacity and the circulation ow of refrigerant are decreased in order to raise the evaporation

temperature (Te) and lower the condensation temperature (Tc).

* Under conditions other than those listed above, the capacity of the outdoor unit heat exchanger is adjusted.

In some cases the heat exchanger capacity may also be adjusted at the same time when the compressor capacity

is varied.

89.6°F

(32°C)

(33°C)

95°F

1 - 9

(35°C)

100.58°F

100.4°F

(38°C)

(38.1°C)

101.48°F

UPDOWN STAY

136.4°F

(38.6°C)

(58°C)

Compressor stop

3

4

5

6

7

8

9

Page 18

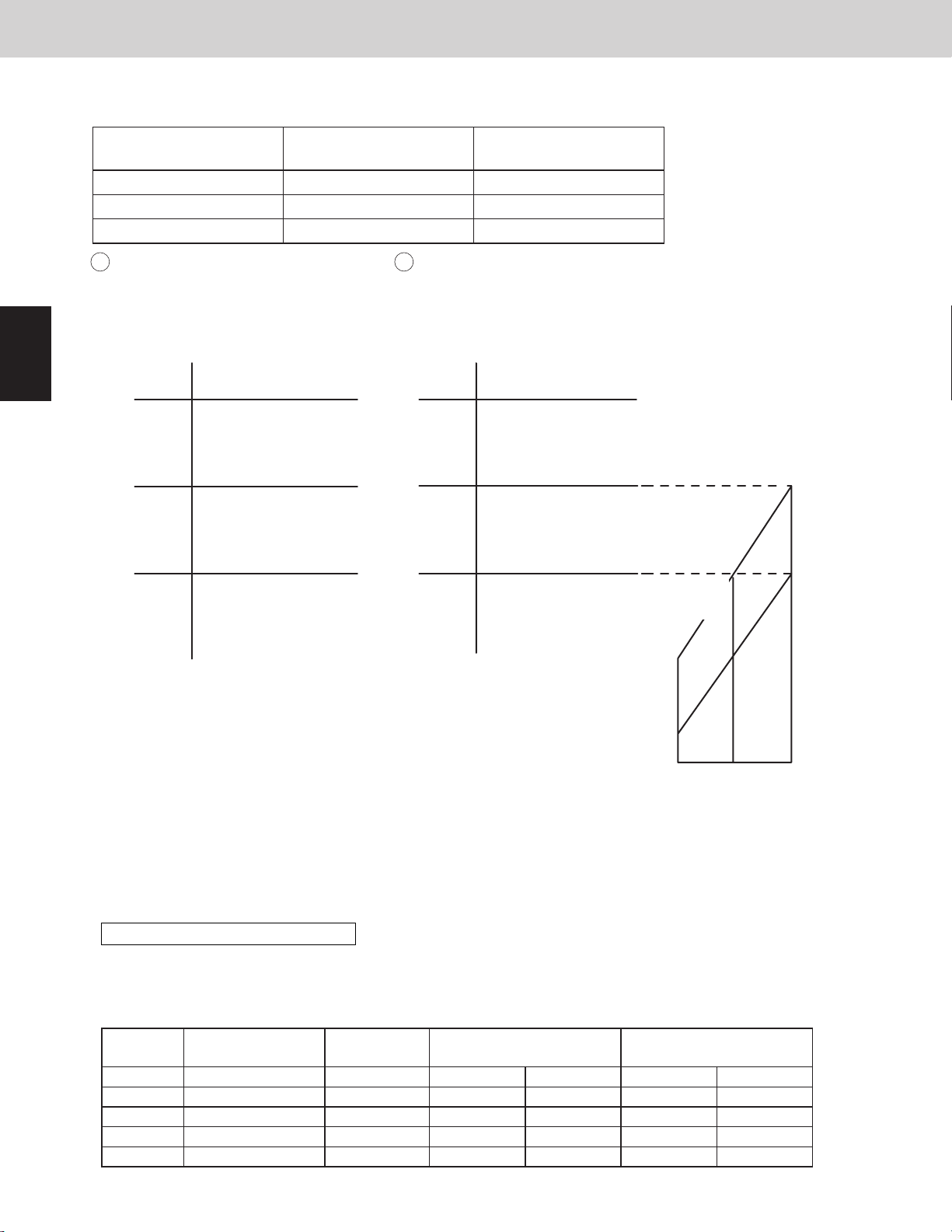

Compressor Control Table

ABCD

3. Compressor Control

Low Condensation Temp. [Tc] High

3WAY VRF SYSTEM

Control Functions

1

2

3

4

A

B

C not_UP

Low Evaporation Temp. [Te] High

Evaporation temperature (Te) and condensation temperature (Tc) areas A, B, C and D are the same as for

evaporation temperature control and condensation temperature control.

(2) Increasing/decreasing the heat exchanger capacity (when the outdoor unit heat exchanger is functioning as a

condenser)

• Primarily when both the evaporation temperature (Te) and condensation temperature (Tc) are high

This occurs when the cooling capacity (heat intake) is low and the heating capacity (heat discharge) is high.

The outdoor heat exchanger capacity is increased, increasing the system condensation capacity and lowering

the condensation temperature (Tc). The amount of heat discharge at the outdoor unit heat exchanger is

increased, increasing the heat intake at the cooling mode indoor units and lowering the evaporation

temperature (Te).

• Primarily when both the evaporation temperature (Te) and condensation temperature (Tc) are low

This occurs when the cooling capacity (heat intake) is high and the heating capacity (heat discharge) is low.

The outdoor heat exchanger capacity is decreased, decreasing the system condensation capacity and raising

the condensation temperature (Tc). The amount of heat discharge at the outdoor unit heat exchanger is

decreased, decreasing the heat intake at the cooling mode indoor units and raising the evaporation

temperature (Te).

UP

slow_UP Target

not_UP

STOP

DOWN

5

6

Outdoor Unit Heat Exchanger Control Table (when the outdoor unit heat exchanger is functioning as a

condenser)

A

7

42.8°F (6°C)

B

37.4°F (3°C)

8

C

26.6°F (-3°C)

Low←Evaporation Temp. [ Te ]→High

9

32°F (0°C)

Low ← Condensation Temp. [Tc] → High

A C

110.3°F

(43.5°C)

114.8°F

(46°C)

STAY

DOWN

B D

123.8°F

(51°C)

118.4°F

(48°C)

UP

Target

1 - 10

136.4°F

(58°C)

Compressor stop

Page 19

3WAY VRF SYSTEM

3. Compressor Control

(3) Increasing/decreasing the heat exchanger capacity (when the outdoor unit heat exchanger is functioning as an

evaporator)

• Primarily when both the evaporation temperature (Te) and condensation temperature (Tc) are low

This occurs when the cooling capacity (heat intake) is high and the heating capacity (heat discharge) is low.

The outdoor heat exchanger capacity is increased, increasing the system evaporation capacity and raising

the evaporation temperature (Te). The amount of heat intake at the outdoor unit heat exchanger is increased,

increasing the heat discharge at the heating mode indoor units and raising the condensation temperature (Tc).

• Primarily when both the evaporation temperature (Te) and condensation temperature (Tc) are high

This occurs when the cooling capacity (heat intake) is low and the heating capacity (heat discharge) is high.

The outdoor heat exchanger capacity is decreased, decreasing the system evaporation capacity and lowering

the evaporation temperature (Te). The amount of heat intake at the outdoor unit heat exchanger is

decreased, decreasing the heat discharge at the heating mode indoor units and lowering the condensation

temperature (Tc).

Outdoor Heat Exchanger Control Table (when the outdoor heat exchanger is functioning as an evaporator)

Low ← Condensation Temp. [Tc] → High

A C

B D

127.4°F

(53°C)

129.2°F

(54°C)

130.1°F

118.4°F

(48°C)

123.8°F

(51°C)

(54.5°C)

Control Functions

136.4°F

(58°C)

1

2

A

42.8°F (6°C)

B

37.4°F (3°C)

STAY

UP

30.2°F (-1°C)

C

26.6°F (-3°C)

24.8°F (-4°C)

Low←Evaporation Temp. [ Te ]→High

DOWN

Target

STA Y

Compressor stop

3-7. Protection Control

3-7-1. Compressor discharge temperature protection

The compressor capacity is controlled according to the table below.

*Discharge temperature that is used for this control is the highest temperature among all compressors.

Discharge temp.

°F (°C)

222.8

(106)

221.0 (105)

219.2 (104)

217.4 (103)

213.8 (101)

3-7-2. Abnormal low pressure protection

The compressor capacity is controlled according to the table below.

Low pressure

psi (MPa)

36.3 (0.25)

29.0 (0.20)

24.7 (0.17)

Stop

If this temperature is detected at regular intervals, alarm appears.

Compressor

capacity

decrease

Compressor capacity increase prohibited

Compressor capacity increase possible

No restriction

Capacity goes up slowly

Capacity increase prohibited

Capacity goes down

Capacity goes down 2.0 hp

Capacity goes down 1.0 hp

Capacity goes down 0.5 hp

1 - 11

hp = horsepower

3

4

5

6

7

8

9

Page 20

2WAY VRF SYSTEM

Control Functions

3. Compressor Control

2WAY VRF SYSTEM

Control Functions

3. Compressor Control

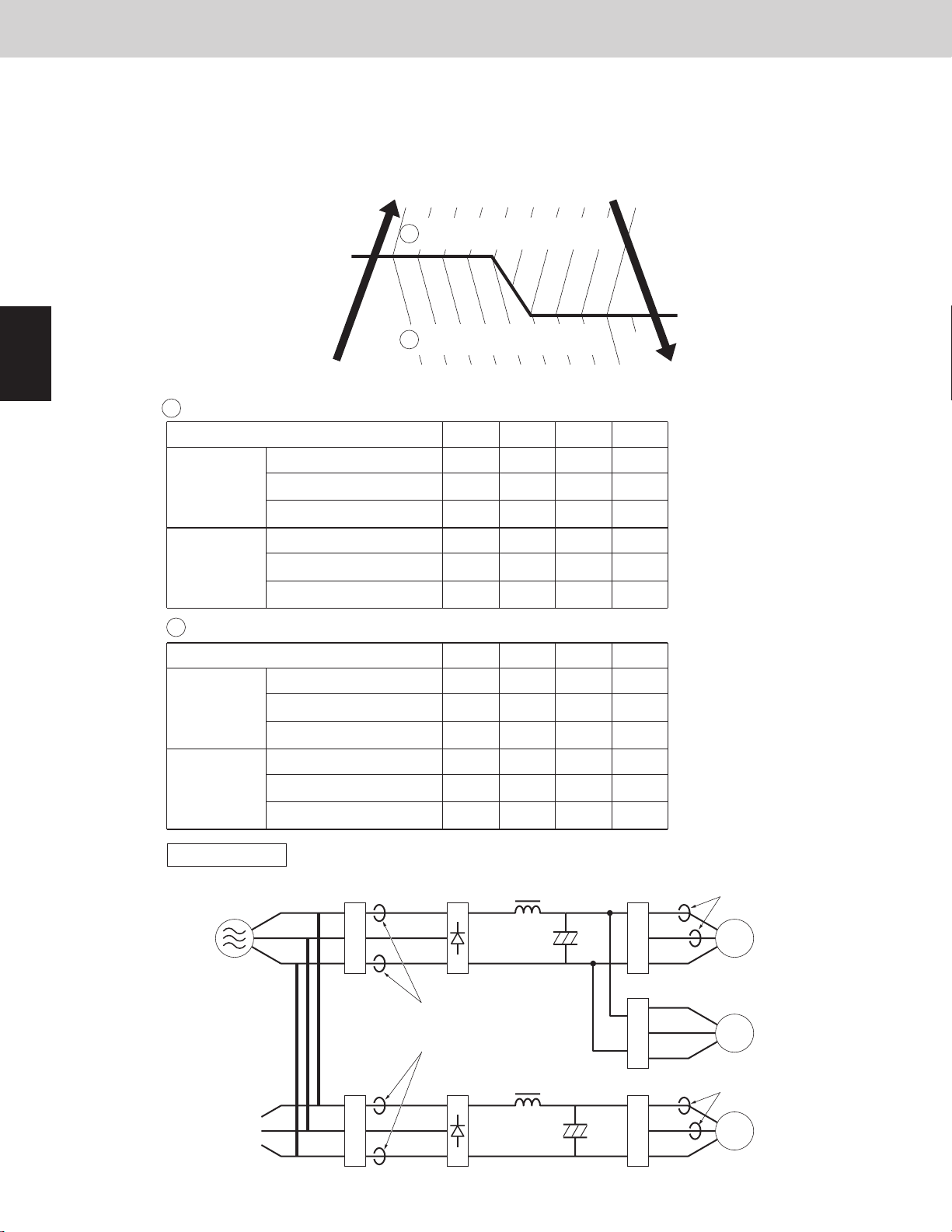

Inverter layout

Noise

filter

R

S

T

U

V

W

U

V

W

U

V

W

R

S

T

Power

supply

Primary CT1

Primary CT2

Secondary CT1

Secondary CT2

Diode

bridge

IPM (CM)

1st compressor

Fan motor

U-72MF2U94 / U-96MF2U94 / U-120MF2U94 / U-144MF2U94

Use the same values of 1st compressor and 2nd compressor.

unit: Ampere

Current limit 1

Maximum current 1 H

Primary

Maximum current 1 L 15.5

19.5 19.5 19.5 19.5

72 96 120 144

15.5

16.5

15.5

16.5 16.5 16.5

15.5

Current limit 2

Maximum current 2 H

Secondary

Maximum current 2 L 13.1

16.6 23.0 16.6 16.6

19.5

14.1

13.1

14.1 20.5 14.1

13.1

Type of outdoor unit

Noise

filter

Diode

bridge

IPM (CM)

IPM (FN)

2nd compressor

3. Compressor Control

3-7-3. Current protection

This restriction protects the compressor and controls the compressor electric current simultaneously.

The current limitation value changes to “normal status” and “overload status” according to the outdoor

temperature.

The primary and secondary current values of 1st compressor and 2nd compressor are measured.

3WAY VRF SYSTEM

Control Functions

1

2

3

4

Outdoor temperature

U-72MF2U9 / U-96MF2U9 / U-120MF2U9 / U-144MF2U9

A Normal status: Use the same values of 1st compressor and 2nd compressor.

Primary

Secondary

Overload status: Use the same values of 1st compressor and 2nd compressor.

B

114.8°F (46°C)

Type of outdoor unit

Type of outdoor unit

Current limit 1

Maximum current 1 H

Maximum current 1 L24

Current limit 2

Maximum current 2 H

Maximum current 2 L24

Current limit 1

B

A

Current table <Overload>

Current table <Normal>

72 96 120 144

30 43 30 30

25 38 22.5

30 44 30 30

25 40 25

72 96 120 144

30 43 30 30

37

39

22.5

21.5

25

24

21.5

24

Outdoor temperature

109.4°F (43°C)

unit: Ampere

unit: Ampere

5

6

7

8

Primary

Secondary

Inverter layout

Power

supply

R

S

T

Maximum current 1 H

Maximum current 1 L24

Current limit 2

Maximum current 2 H

Maximum current 2 L24

R

S

T

Noise

Noise

filter

Primary CT1

Primary CT2

filter

25 38 21

30 44 30 30

25 40 23

Diode

bridge

Diode

bridge

37

39

21

20

23

22

20

22

IPM (CM)

U

V

W

IPM (FN)

U

V

W

IPM (CM)

U

V

W

Secondary CT1

1st compressor

Fan motor

Secondary CT2

2nd compressor

9

1 - 12

Page 21

2WAY VRF SYSTEM

Control Functions

3. Compressor Control

3. Compressor Control

U-72MF2U94 / U-96MF2U94 / U-120MF2U94 / U-144MF2U94

Use the same values of 1st compressor and 2nd compressor.

Type of outdoor unit

Current limit 1

72 96 120 144

19.5 19.5 19.5 19.5

3WAY VRF SYSTEM

Control Functions

unit: Ampere

Primary

Secondary

Inverter layout

Power

supply

R

S

T

Maximum current 1 H

Maximum current 1 L 15.5

Current limit 2

Maximum current 2 H

Maximum current 2 L 13.1

Noise

filter

R

S

T

Primary CT1

Noise

filter

16.5 16.5 16.5

16.6 23.0 16.6 16.6

14.1 20.5 14.1

Diode

bridge

Diode

bridge

15.5

19.5

16.5

15.5

14.1

13.1

15.5

13.1

IPM (CM)

U

V

W

IPM (FN)

U

V

W

IPM (CM)

U

V

W

Secondary CT1

1st compressor

Fan motor

Secondary CT2

2nd compressor

1

2

3

4

Primary CT2

5

6

7

8

1 - 13

9

Page 22

1

2

4. Output of PCB

Item Indication on PCB

Solenoid valve

Expansion valve

Crankcase heater

3WAY VRF SYSTEM

Control Functions

Discharge valve 1 DCV1

Discharge valve 2 DCV2

Suction valve 1 SCV1

Suction valve 2 SCV2

Heat exchanger pressure balance valve 1 PBV1

Heat exchanger pressure balance valve 2 PBV2

Save valve SAVE

Refrigerant control valve RCV

Refrigerant balance valve RBV

Oil recovery valve ORVR

By-pass valve BPV

Accumulator valve ACV

2

O

valve O2

MOV for heat exchanger 1 MOV1

MOV for heat exchanger 2 MOV2

SC circuit expansion valve MOV4

Crankcase heater control 1 CH1

Crankcase heater control 2 CH2

3

4

5

6

7

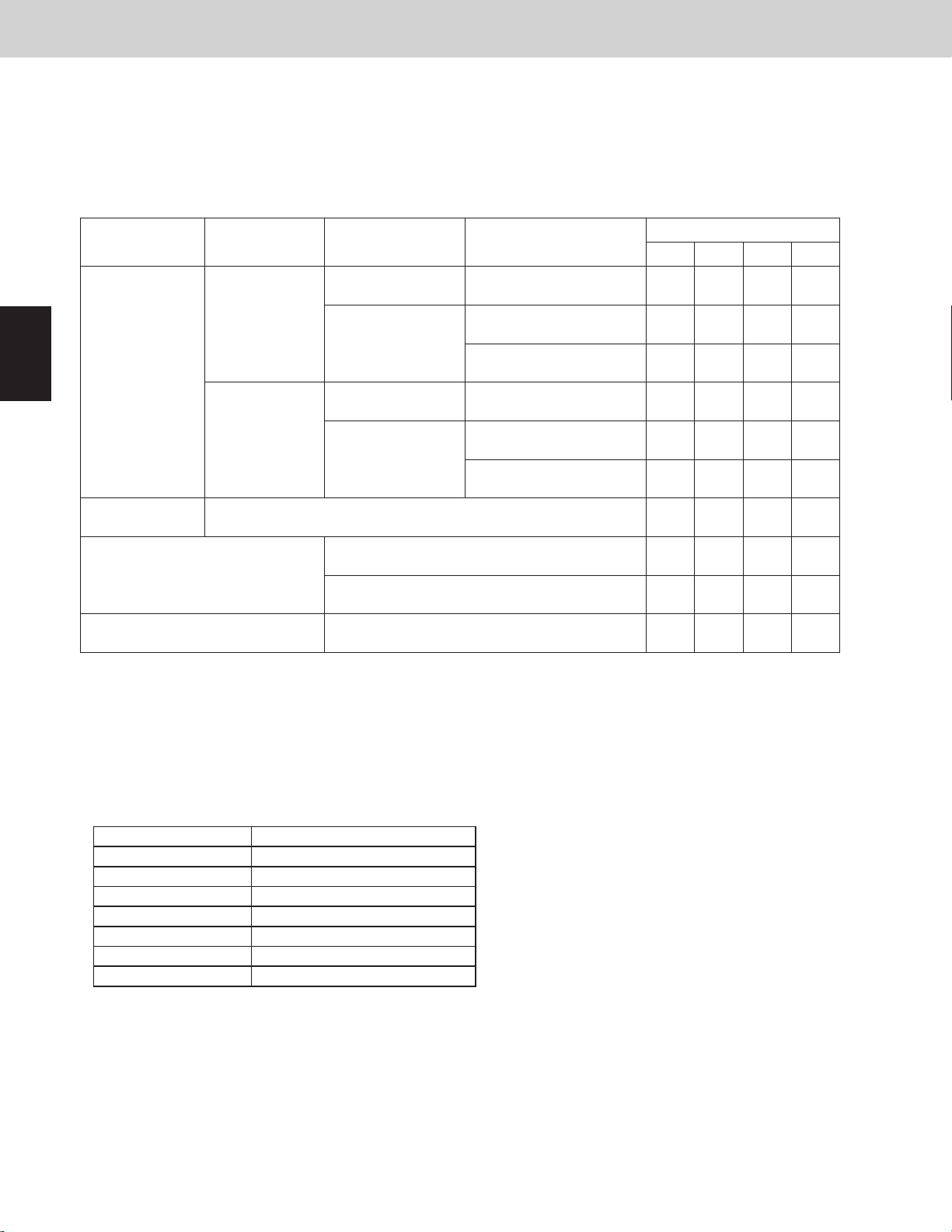

4-1. [DCV, SCV, PBV]

Turn DCV, SCV and PBV to ON/OFF.

Change the outdoor unit heat exchanger mode and/or control the heat exchanger capacity.

See the basic operation listed below.

All

cooling

mode

All

heating

mode

Mixed

cooling/

heating

mode

Status of

heat exchanger

Normal Condenser ON ON OFF OFF OFF OFF

Low ambient

temperature

System stopped

Other outdoor *2

units operating

Heat exchanger

[condenser] of

outdoor unit

Heat exchanger

[evaporator] of

outdoor unit

Condenser ON/OFF ON OFF OFF OFF OFF

Stop OFF OFF OFF OFF OFF OFF

Evaporator ON ON ON ON ON ON

*1

Stop OFF OFF OFF OFF OFF OFF

Stop ON ON ON ON ON ON

Condenser ON/OFF ON OFF OFF OFF OFF

Stop OFF OFF OFF OFF OFF OFF

Evaporator ON/OFF ON ON/OFF ON ON/OFF ON

Stop OFF OFF OFF OFF OFF OFF

DCV1

*3

DCV2 SCV1

*3

SCV2 PBV1

*3

PBV2

8

9

*1 The system which is stopped in heating mode shows the status of all outdoor units stopped.

*2 When other outdoor units are operating in heating mode, the outdoor unit in stop mode is holding the pulse

at 0 pulses of MOV1 and MOV2 in a situation in which the heat exchanger is evaporator.

*3 DCV1, SCV1 and PBV1 turn ON/OFF respectively due to the capacity control of the heat exchanger.

1 - 14

Page 23

3WAY VRF SYSTEM

4. Output of PCB

4-2. Save Valve [SAVE]

● This valve turns ON for 5 seconds before the inverter compressor starts.

After the inverter compressor starts, the valve turns ON for 10 seconds. Then it turns OFF.

● This valve turns ON for 30 seconds after the outdoor unit stops. Then it turns OFF.

● This valve turns ON when high pressure sensor detects 496psi (3.42MPa) to prevent abnormal pressure.

This valve turns OFF when the high pressure goes down below 481.5psi (3.32MPa).

● This valve might turn ON when the system capacity is excessive although the inverter compressor operates at

Min. frequency.

● This valve turns ON in the following status :

(Compressor discharge temperature - High pressure saturation temperature) < 9deg F (5deg C)

● Under control of Tube Refrigerant Recovery Control

● Under control of heat exchanger select mode

● This valve turns ON when low pressure sensor goes down 24.7psi (0.17MPa) to prevent abnormal pressure.

This valve turns OFF when low pressure sensor increase 29psi (0.20MPa) or over.

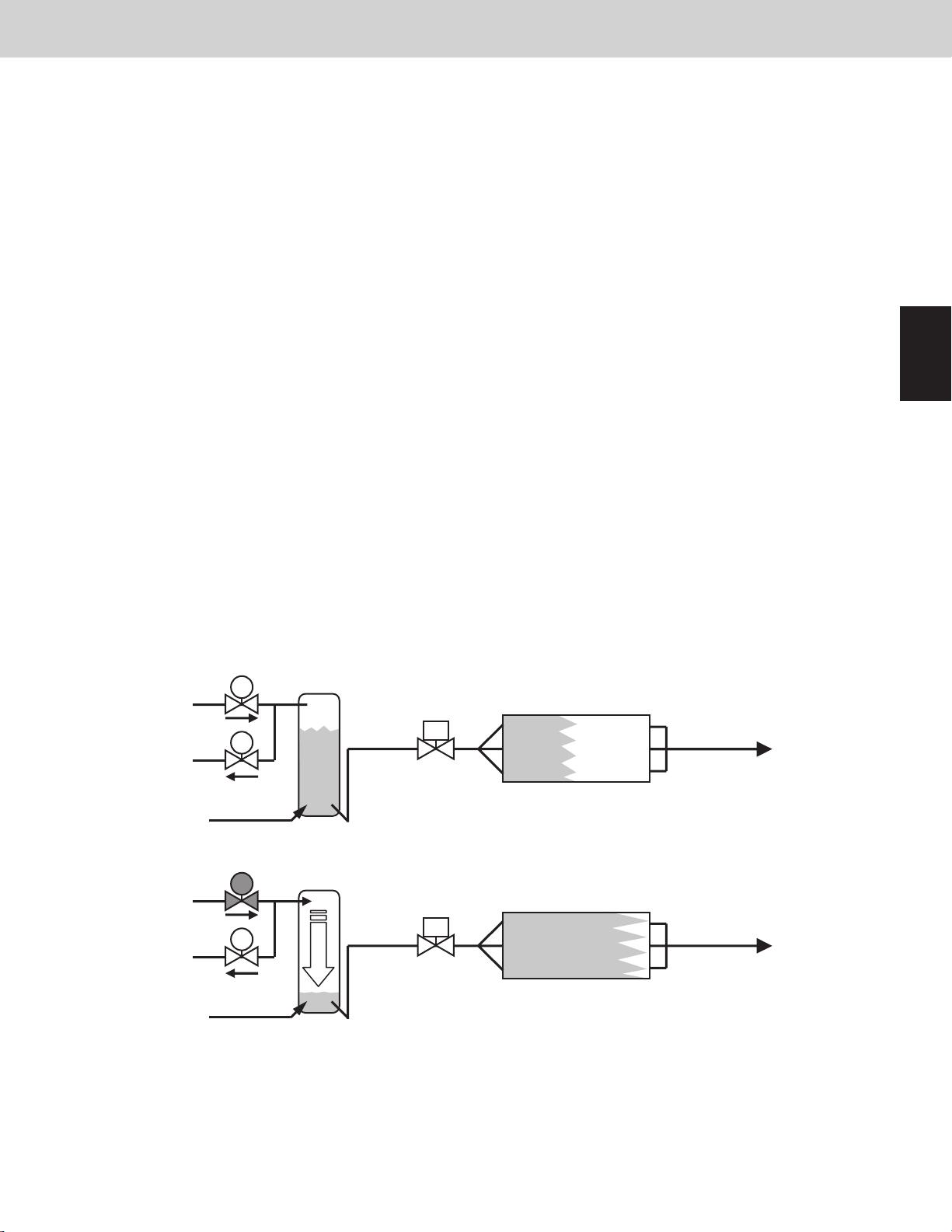

4-3. Refrigerant Control Valve [RCV]

The main purpose of this valve is to detect the ow of refrigerant (refrigerant volume) on the indoor unit when the

outdoor unit heat exchanger is functioning as a condenser. When the valve determines that there are signs of a low

refrigerant level, refrigerant is supplied from the receiver tank to the system.

● This valve turns ON when the evaporator is refrigerant shortage.

The heat exchanger of indoor unit is evaporator in cooling operation.

The heat exchanger of outdoor unit is evaporator in heating operation.

● This valve turns OFF when the excessive refrigerant is in the condenser.

The heat exchanger of indoor unit is condenser in heating operation.

The heat exchanger of outdoor unit is condenser in cooling operation.

● This valve turns OFF when the outdoor unit is stopped.

● This valve turns ON at stopped outdoor units when the heat exchanger at another outdoor unit is functioning as a

condenser.

Control Functions

1

2

3

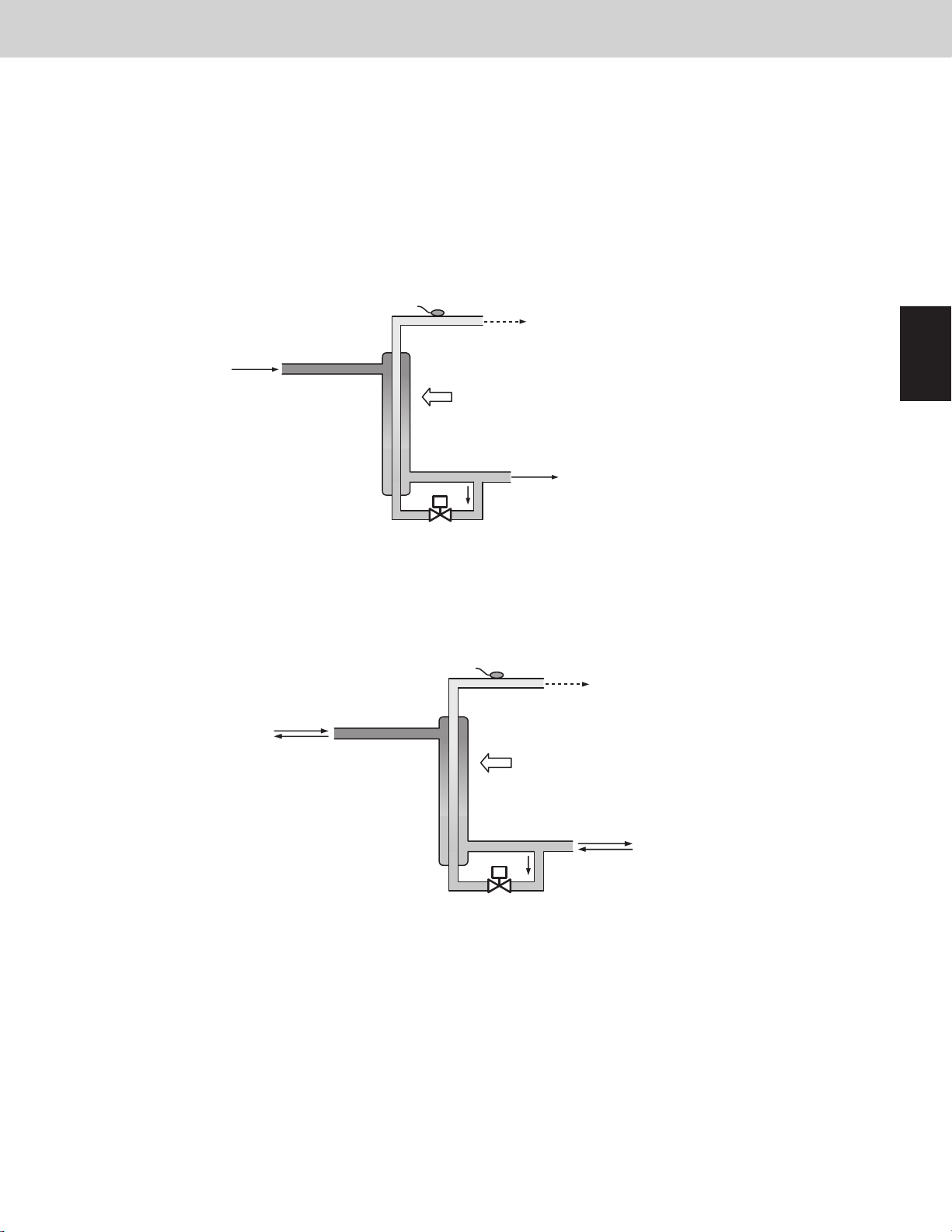

HP

LP

HP

LP

RCV

RBV

RCV

RBV

Evaporator

Two-phase

flow

Refrigerant shortage in evaporator

Receiver tank holds refrigerant

ON

Evaporator

Two-phase flow

Sufficient refrigerant is supplied to evaporator

High pressure from RCV pushes the liquid refrigerant out of the receiver tank

4

5

6

7

8

1 - 15

9

Page 24

1

2

3WAY VRF SYSTEM

4. Output of PCB

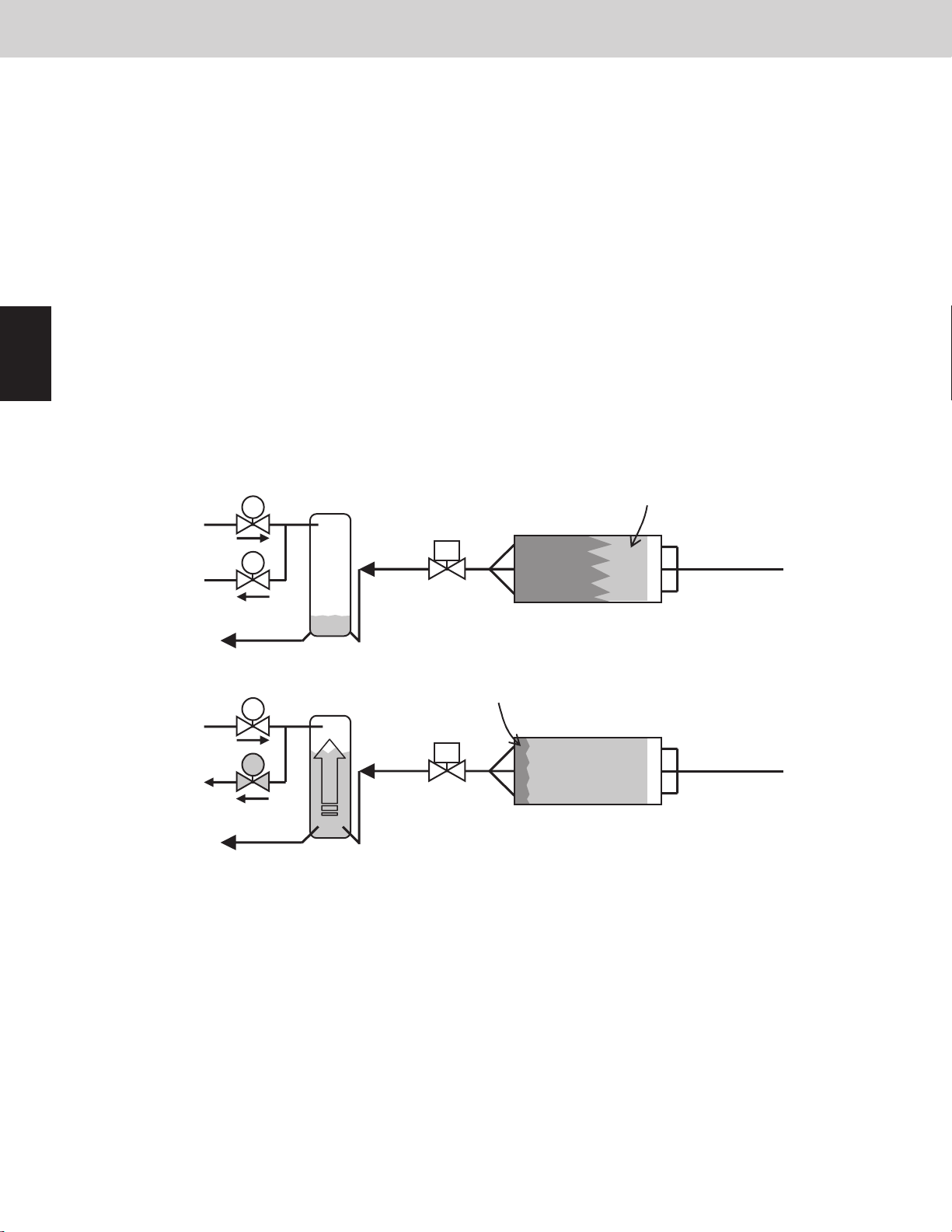

4-4. Refrigerant Balance Valve [RBV]

The main purpose of this valve is to detect the ow of refrigerant (refrigerant volume) on the indoor unit when the

outdoor unit heat exchanger is functioning as an evaporator.

When the valve determines that there are signs of excess refrigerant, refrigerant is recovered at the receiver tank.

This valve is ON during heating operation and when the outdoor unit heat exchanger is functioning as an

evaporator during mixed heating/cooling operation. It also turns ON in order to recover refrigerant at the outdoor

unit after heating operation is stopped.

* This valve is never ON at the same time as the RCV.

● This valve turns ON for 20 seconds after the system stops at heating mode, and then turns OFF.

● This valve turns ON once after the system starts at heating mode.

● This valve turns OFF when an abnormal drop in compressor discharge gas temperature is detected.

● This valve turns OFF when liquid back to the compressor is occurring.

Judgment of liquid back:

Detected suction temperature is lower than low-pressure sensor temperature.

Difference between high-pressure sensor temperature and discharge temperature of compressor is small.

(less than 9deg F (5deg C))

* After the valve turns from ON to OFF, it will not turn ON again for 15 minutes.

● This valve turns ON when low pressure sensor decreases 24.7psi (0.17MPa) at stopped system.

This valve turns OFF when low pressure sensor increases 29psi (0.20MPa).

Two-phase flow

HP

RCV

Condenser

Control Functions

3

4

5

6

7

8

RBV

LP

Receiver tank holds small amount of refrigerant

Liquid flow

RCV

HP

RBV

LP

ON

Refrigerant gas in the top of receiver tank is pulled into low pressure side.

4-5. Oil Recovery Valve [ORVR]

This valve is for recovering oil from the oil separator of its own outdoor unit or balance tube to the compressor of

its own outdoor unit.

● This valve turns ON when the oil level of the compressor is “0” or “1”.

In this situation, system performs Self oil recovery control, Inter-outdoor unit oil recovery control, or system oil

recovery control.

● This valve turns ON for 2 minutes after the compressor starts.

● This valve is always OFF when outdoor unit is stopped.

* For oil level of compressor, see “Oil Control” section.

Liquid

flow

Over charge condition

Condenser

Two-phase flow

Adequate condition

9

1 - 16

Page 25

3WAY VRF SYSTEM

4. Output of PCB

4-6. By-Pass Valve [BPV]

This valve is for pushing the oil in the balance piping into other outdoor unit.

● This valve turns ON when the oil level of compressor is “2” or “1” in its own outdoor unit and the oil level of

compressor is “0” in other outdoor unit.

* This valve turns ON for 10 seconds and turns OFF for 20 seconds. This operation is repeated while oil is

supplied to others.

* For more information on oil level of compressor, see “Oil Control” section.

4-7. Accumulator Valve [ACV]

The purpose of this valve is to recover oil and refrigerant from the accumulator to the compressor.

● This valve turns OFF when the compressor operation just started.

● This valve turns ON when the compressor is warmed up.

● This valve turns ON while the oil recovery among the systems and defrost control are in progress.

● This valve turns ON while the MOV4 is operating.

Control Functions

1

4-8. O2 Valve [O2*]

This valve works when the outdoor unit receives signal of the refrigerant leakage from the indoor unit.

The indoor unit that transmits the signal of the refrigerant leakage gives “P14”alarm.

To activate this function, it is necessary to set it to EEPROM on the main outdoor PCB and indoor PCB.

EEPROM setting in main noutdoor unit

CODE: C1

Setting No.

0 This function invalid (factory preset mode)

1

2

EEPROM setting in indoor unit

CODE: 0B

Setting No.

0 Function of EXCT plug short-circuit

1 Indoor unit gives “P14”alarm and transmits the refrigerant leakage signal.

4-9. MOV for Heat Exchanger [MOV1, MOV2]

4-9-1. Type of expansion valves

This valve is turned OFF when the system is normal.

This valve is turned ON when the outdoor unit receives signal from the indoor unit.

This valve is turned ON when the system is normal.

This valve is turned OFF when the outdoor unit receives signal from the indoor unit.

MOV1 For upper side heat exchanger

MOV2 For lower side heat exchanger

*O2 valve is the eld supply parts.

2

3

4

5

6

4-9-2. Power Initialization

If no indoor units have started (even once) after the power supply to the outdoor unit, the MOV for heat exchanger

holds the pulse at 480 pulses.

1 - 17

7

8

9

Page 26

3WAY VRF SYSTEM

4. Output of PCB

4-9-3. Expansion valves for heat exchanger control

The conguration of the heat exchangers is different depending on the capacity of the outdoor unit.

Operation of electronic control valves during normal unit operation

All

cooling

mode

Status of

heat exchanger

Normal Condenser 480 480 Maximum ow control

Low ambient

temperature

Condenser 0 ~ 480 0 ~ 480 Heat exchanger capacity control

Stop 0 0 Refrigerant shut-off

MOV1 MOV2 Remarks

Control Functions

1

2

3

4

5

6

Evaporator 12 ~ 480 12 ~ 480 SH control

All

heating

mode

Mixed

cooling/

heating

mode

When operating in all cooling or all heating mode, the heat exchangers of which the compressors are driving in the

outdoor units are used.

However, when operating in cooling mode with low ambient temperature, the number of pieces for using the heat

exchanger is changed according to the operating condition of indoor units and the status of outdoor units.

When operating in mixed cooling/heating mode, the condition and the number of pieces for using the heat

exchanger are changed according to the operating condition of indoor units and the status of outdoor units.

The heat exchanger is selected in turn from the outdoor unit 2nd heat exchanger as the shortest operating time of

the inverter compressor.

SH control is controlled so that the difference of temperature between the liquid tube temperature and gas tube

temperature should be set within the range as shown below.

Mixed cooling/heating mode (Heat exchanger [evaporator] of outdoor unit) 3.6deg F ~ 9deg F (2deg C ~ 5deg C)

System stopped Stop 0 0 Refrigerant shut-off

Other outdoor

units operating

Heat exchanger

[condenser] of

outdoor unit

Heat exchanger

[evaporator] of

outdoor unit

Stop 0 0 Refrigerant shut-off

Condenser 0 ~ 480 0 ~ 480 Heat exchanger capacity control

Stop 0 0 Refrigerant shut-off

Evaporator 12 ~ 480 12 ~ 480 SH control

Stop 0 0 Refrigerant shut-off

Outdoor unit Capacity Target value of SH control

All heating mode -1.8deg F ~ 9deg F (-1deg C ~ 5deg C)

7

8

9

1 - 18

Page 27

3WAY VRF SYSTEM

4. Output of PCB

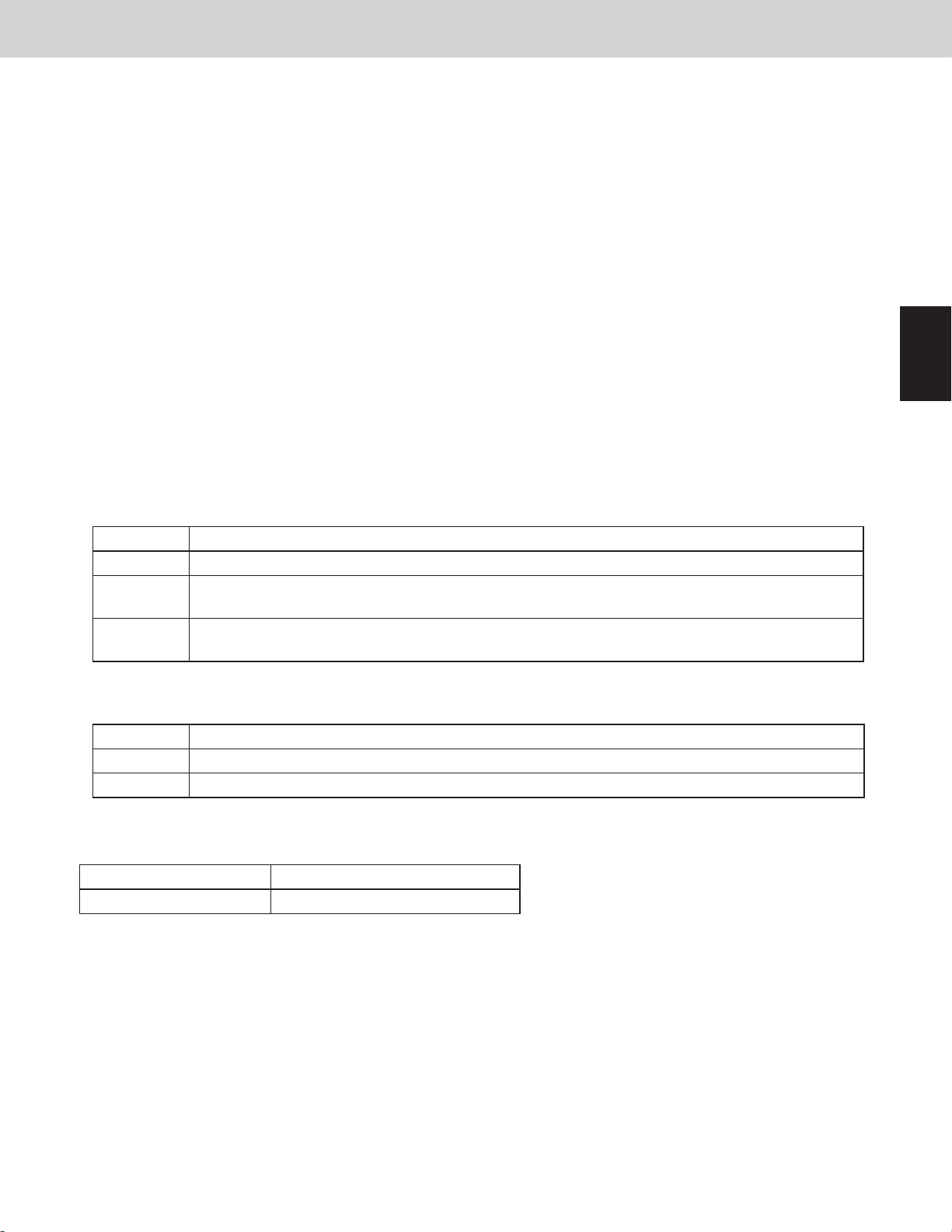

4-10. SC Circuit Expansion Valve [MOV4]

4-10-1. SC control (Cooling mode only)

During cooling operation, the liquid refrigerant which condenses at the outdoor unit heat exchanger ows into

the receiver tank, and SC (sub-cooling) approaches 32°F (0°C). When SC is small and the length of the tubing

connecting the indoor and outdoor units is long, the refrigerant ow in the indoor unit will be reduced signicantly.

To prevent this trouble from occurring, MOV4 operates so as to increase supercooling in the double tube coil near

the outlet of the outdoor unit.

In addition, MOV4 controls refrigerant ow volume so that it will not ow back to the compressor in the liquid state.

SH in suction that is difference between the SCG temperature and low pressure sensor temperature is adjusted to

5.4deg F ~ 9deg F (3deg C ~ 5deg C).

SCG

Gas returns to

accumulator

Control Functions

Liquid

(SC=0deg)

(SH control)

4-10-2. Discharge temperature control of compressor

When the discharge temperature increases to 194°F (90°C) or more, MOV4 opens to 100 pulses to cool down the

compressor. MOV4 operates according to the state of the discharge temperature between 20 - 480 pulses. This

operation takes priority over SC control.

Liquid

Refrigerant on the inner side evaporates,

cooling the liquid refrigerant on the outer side.

Liquid

(Large SC)

MOV4

SCG

Does not fully evaporate,

resulting in liquid backup.

Liquid returns to

accumulator

1

2

3

4

5

Liquid

MOV4

(Discharge temperature control of compressor.)

This operation is continued until discharge temperature decreases to 176°F (80°C) or less.

4-10-3. Discharge temperature and high pressure control in outdoor unit cycle defrost control

When outdoor unit cycle defrost control operates, MOV4 opens to 200 pulses or over.

4-11. Crankcase Heater Control [CH1, CH2]

When the compressor stops, the crankcase heater of its own compressor is turned ON in the following conditions.

● When the discharge temperature ≤ the outdoor air temperature + 27deg F (+15deg C)

● When the outdoor air temperature ≤ 68°F (20°C)

● When the compressor stops and 30 minutes later.

1 - 19

6

7

8

9

Page 28

3WAY VRF SYSTEM

5. Outdoor Fan Control

5-1. Fan Mode

These outdoor units utilize a DC fan motor that can be controlled in a maximum of 15 steps (15 modes).

However, fan modes 14 and 15 can only be used if high static pressure mode has been set.

* For information concerning EEPROM settings, refer to the eld application functions.

The following table shows the maximum and minimum fan mode and fan forced mode for each unit.

Status of

heat exchanger

Condenser 13 11 12 12

Type of outdoor unit

72 96 120 144

Control Functions

1

2

3

4

5

6

7

Standard

Evaporator

Maximum value

Condenser 15 15 12 12

High static

pressure mode

setting

Minimum value * 1 1 1 1

Fan forced mode

Silent mode Silent mode 9 9 10 10

* For the sake of protecting temperature of the electrical parts, the minimum values of the fan mode may

sometimes increase in accordance with the ambient temperature or the amount of secondary current.

5-1-1. High static pressure mode

The outdoor unit allows a high static pressure changing the settings.

The maximum permissible static pressure is 0.01psi (80Pa).

EEPROM setting in each outdoor unit

CODE : 8F

Setting No.

0 Invalid (factory preset mode)

1 High static pressure mode

2 Never use

3 Never use

4 Never use

5 Never use

6 Never use

However, maximum fan mode is upper limit.

Evaporator

Control for fan crack prevention 9 9 7 7