Panasonic U-5ML5DPQ, U-5ML5XPQ, U-4ML5DPQ, U-6ML5XPQ, U-6ML5DPQ Installation Manual

...

INSTALLATION MANUAL

URBAN MULTI AIR CONDITIONER

U-4ML5DPQ

U-5ML5DPQ

U-6ML5DPQ

U-4ML5XPQ

U-5ML5XPQ

U-6ML5XPQ

Installation manual

Urban Multi air conditioner

Installationsanleitung

Urban Multi Klimaanlage

Manuel d'installation

Unité extérieure Urban Multi

Montagehandleiding

Urban Multi airconditioner

Manual de instalación

Acondicionador de aire Urban Multi

Manuale d'installazione

Climatizzatore Urban Multi

∂Á¯ÂÈÚ›‰ÈÔ ÂÁηٿÛÙ·Û˘

KПИМ·ЩИЫЩИОfi Urban Multi

Manual de instalação

Ar condicionado Urban Multi

English

Deutsch

Français

Nederlands

Español

Italiano

EППЛУИО¿

Portugues

D2D2

L1

L2

B1

B2

D2D2

L1

L2

3

1

1

1

4

D2D2

D2

CC

L2

L2

AA

D2D2

D2

CC

L2

L2

AA

2

2

3

500

≥1

1

≥1000

≥1000

≥1000

6

≥1500

≥1500

4

5

≥1500

3

2

(mm)

2 3

B2

B2

EE

L1

L1

HH

B1B1B1

D1D1D1

B2B2B2

EE

L1

L1

HH

B1

B1

D1D1D1

L2>H

L2<H

L2>H

L2<H

≥100

≥150 ≥150

L2>H

L2<H

L1≤H

H<L1

L2≤H

H<L2

≥200 ≥1000

L2>H

L2<H

L1≤H

H<L1

L2≤H

H<L2

B

1

3

C

2

≥100

≥100

≥100

≤500

≥100

≥100

≥250

≤500

≥100

≥200

≥300≥200

≥300

≤500

≥300

≥250

≥300

≥300 ≤500

≥250

≥300

≥100

≥150

≥1000

L1≤H

L2≤H

L1≤H

L2≤H

A

2

≥500

≥500

≥500

≥500

≥750

≥1000

≥1000

≥1000

≥1000

≥1000

≥1500

≥1000

≥1250

≥1500

≤500 ≥1000

≤500

≥1000

≥1000

≥1000

≤500

≥1000

≤500

≥1000

≥1000

≥1000

≤500 ≥1000

0<L1≤1/2 H

1

/2 H<L1≤H

0<L2≤1/2 H

1

/2 H<L2≤H

0<L2≤1/2 H

1

/2 H<L2≤H

0<L1≤1/2 H

1

/2 H<L1≤H

0<L2≤1/2 H

1

/2 H<L2≤H

3

1

3

3

1+2

3

4

5

321

78

44

5 611

5

6

1

4

7

9

3

2

56

13

6

8

10

12

B

9

10

A

C

7

D

1111

1

7

U-4ML5DPQ U-4ML5XPQ

U-5ML5DPQ U-5ML5XPQ

U-6ML5DPQ U-6ML5XPQ

Urban Multi air conditioner

Installation manual

ONTENTS

C

1. Safety considerations.................................................................1

2. Introduction ................................................................................ 2

2.1. Combination ................................................................................... 2

2.2. Standard supplied accessories ......................................................2

2.3. Optional accessories...................................................................... 2

2.4. Technical and electrical specifications ........................................... 2

3. Before installation ......................................................................3

3.1. Precautions for R410A ................................................................... 3

3.2. Installation ...................................................................................... 3

3.3. Handling ......................................................................................... 3

4. Selecting installation site............................................................3

5. Precautions on installation.........................................................4

5.1. Installation method for prevention of falling over ............................ 4

5.2. Method for removing transportation stay ........................................ 4

5.3. Method for installing drain piping....................................................4

6. Installation servicing space........................................................5

7. Refrigerant pipe size and allowable pipe length.........................5

7.1. Selection of piping material............................................................ 6

8. Precautions on refrigerant piping...............................................6

8.1. Cautions for brazing ....................................................................... 6

8.2. Cautions for flare connection..........................................................6

9. Refrigerant piping.......................................................................7

9.1. Preventing foreign objects from entering........................................7

9.2. Cautions for handling stop valve .................................................... 7

9.3. How to use the stop valve .............................................................. 8

9.4. Cautions for handling the valve cover............................................. 8

9.5. Cautions for handling service port.................................................. 8

9.6. Precautions when connecting field piping and

regarding insulation........................................................................8

9.7. Leak test and vacuum drying .......................................................10

10. Additional refrigerant charge.................................................... 10

10.1. Important information regarding the refrigerant used...................10

10.2. 3 procedures for adding refrigerant..............................................11

11. Electrical wiring work ...............................................................13

11.1. Internal wiring – Parts table.......................................................... 13

11.2. Precautions on electrical wiring work ........................................... 14

11.3. Connection example of total system wiring..................................14

11.4. Connecting power wire and transmission wires ........................... 15

11.5. Power circuit and cable requirements .......................................... 15

12. Before operation ......................................................................17

12.1. Service precautions...................................................................... 17

12.2. Checks before initial start-up........................................................ 17

12.3. Field setting..................................................................................17

12.4. Test operation............................................................................... 19

12.5. Checks in normal operation.......................................................... 20

12.6. Temperature adjustment operation confirmation.......................... 20

13. Service mode operation...........................................................21

14. Caution for refrigerant leaks.....................................................21

14.1. Introduction................................................................................... 21

14.2. Maximum concentration level....................................................... 21

14.3. Procedure for checking maximum concentration ......................... 21

15. Disposal requirements ............................................................. 22

age

P

READ THESE INSTRUCTIONS CAREFULLY BEFORE

INSTALLATION. KEEP THIS MANUAL IN A HANDY

PLACE FOR FUTURE REFERENCE.

IMPROPER INSTALLATION OR ATTACHMENT OF

EQUIPMENT OR ACCESSORIES COULD RESULT IN

ELECTRIC SHOCK, SHORT-CIRCUIT, LEAKS, FIRE OR

OTHER DAMAGE TO THE EQUIPMENT. BE SURE ONLY

TO USE ACCESSORIES MADE BY PANASONIC WHICH

ARE SPECIFICALLY DESIGNED FOR USE WITH THE

EQUIPMENT AND HAVE THEM INSTALLED BY A

PROFESSIONAL.

PANASONIC EQUIPMENT IS DESIGNED FOR

COMFORT APPLICATIONS. FOR USE IN OTHER

APPLICATIONS, PLEASE CONTACT YOUR LOCAL

PANASONIC DEALER.

IF UNSURE OF INSTALLATION PROCEDURES OR USE,

ALWAYS CONTACT YOUR DEALER FOR ADVICE AND

INFORMATION.

THIS AIR CONDITIONER COMES UNDER THE TERM

"APPLIANCES NOT ACCESSIBLE TO THE GENERAL

PUBLIC".

1. S

AFETY CONSIDERATIONS

The precautions listed here are divided into the following two types.

Both cover very important topics, so be sure to follow them carefully.

WARNING

If the warning is not observed, it may cause serious casualties.

CAUTION

If the caution is not observed, it may cause injury or damage to the

equipment.

Warning

■

Ask your dealer or qualified personnel to carry out installation

work. Do not install the machine by yourself.

Improper installation may result in water leakage, electric shocks

or fire.

■

Perform installation work in accordance with this installation

manual.

Improper installation may lead to water leakage, electric shocks

or fire.

■

When a unit is installed in a small room, it is necessary to take

measures so that the leaked refrigerant amount does not exceed

the limit even if it leaks. As for the measures to prevent the leak

from not exceeding the limit, please consult with your distributor.

If the leaked amount exceeds the limit, it may cause an oxygen

deficiency accident.

■

Be sure to use only the specified accessories and parts for

installation work.

Failure to use the specified parts may result in water leakage,

electric shocks, fire, or the unit falling.

■

Install the air conditioner on a foundation that can withstand its

weight.

Insufficient strength may result in the fall of equipment and

causing injury.

■

Carry out the specified installation work in consideration of strong

winds, typhoons, or earthquakes.

Improper installation work may result in accidents due to fall of

equipment.

U-4~6ML5DPQ + U-4~6ML5XPQ

Urban Multi air conditioner

4PW40731-1

Installation manual

1

■

Make certain that all electrical work is carried out by qualified

personnel according to the local laws and regulations and this

installation manual, using a separate circuit.

Insufficient capacity of the power supply circuit or improper

electrical construction may lead to electric shocks or fire.

■

Make sure that all wiring is secure, using the specified wires and

ensuring that external forces do not act on the terminal

connections or wires.

Incomplete connection or fixing may cause a fire.

■

When wiring between the indoor and outdoor units, and wiring

the power supply, form the wires so that the frontside panel can

be securely fastened.

If the frontside panel is not in place, the terminals may overheat

and electric shocks or a fire may be caused.

■

If refrigerant gas leaks during installation work, ventilate the

area immediately.

To xic gas may be produced if refrigerant gas comes into contact

with fire.

■

After completing the installation work, check to make sure that

there is no leakage of refrigerant gas.

To xic gas may be produced if refrigerant gas leaks into the room

and comes into contact with a source of fire, such as a fan

heater, stove or cooker.

■

Before touching electric terminal parts, turn off power switch.

Caution

■

Ground the air conditioner.

Grounding resistance should be according to national

regulations

Do not connect the earth wire to gas or water pipes,

lightning conductor or telephone earth wire.

Incomplete grounding may cause electric shocks.

■

Gas pipe.

Ignition or explosion may occur if the gas leaks.

■

Water pipe.

Hard vinyl tubes are not effective grounds.

■

Lightning conductor or telephone ground wire.

Electric potential may rise abnormally if struck by a lightning

bolt.

■

Be sure to install an earth leakage breaker.

Failure to install an earth leakage breaker may cause electric

shocks or fire.

■

Install drain piping according to this installation manual to

ensure good drainage, and insulate the pipe to prevent

condensation.

Improper drain piping may cause water leakage, and make the

furniture get wet.

■

Install the indoor and outdoor units, power wire and connecting

wire at least 1 meter away from televisions or radios to prevent

image interference or noise.

(Depending on the radio waves, a distance of 1 meter may not

be sufficient to eliminate the noise.)

■

Do not rinse the outdoor unit.

This may cause electric shocks or fire.

■

Do not install the air conditioner in places such as the following:

■

Where there is mist of mineral oil, oil spray or vapour for

example a kitchen.

Plastic parts may deteriorate, and cause them to fall out or

water to leak.

■

Where corrosive gas, such as sulfurous acid gas, is

produced.

Corrosion of copper pipes or soldered parts may cause the

refrigerant to leak.

■

Where there is machinery which emits electromagnetic

waves.

Electromagnetic waves may disturb the control system, and

cause malfunction of the equipment.

■

Where flammable gases may leak, where carbon fiber or

ignitable dust is suspended in the air or where volatile

flammables, such as thinner or gasoline, are handled.

Such gases may cause a fire.

■

Where the air contains high levels of salt such as that near

the ocean.

■

Where voltage fluctuates a lot, such as that in factories.

■

In vehicles or vessels.

■

Where acidic or alkaline vapour is present.

■

Do not allow a child to mount on the outdoor unit or avoid

placing any object on the unit.

Falling or tumbling may result in injury.

■

Do not touch any refrigerant which has leaked out of refrigerant

piping connections.

This may result in frostbite.

NTRODUCTION

2. I

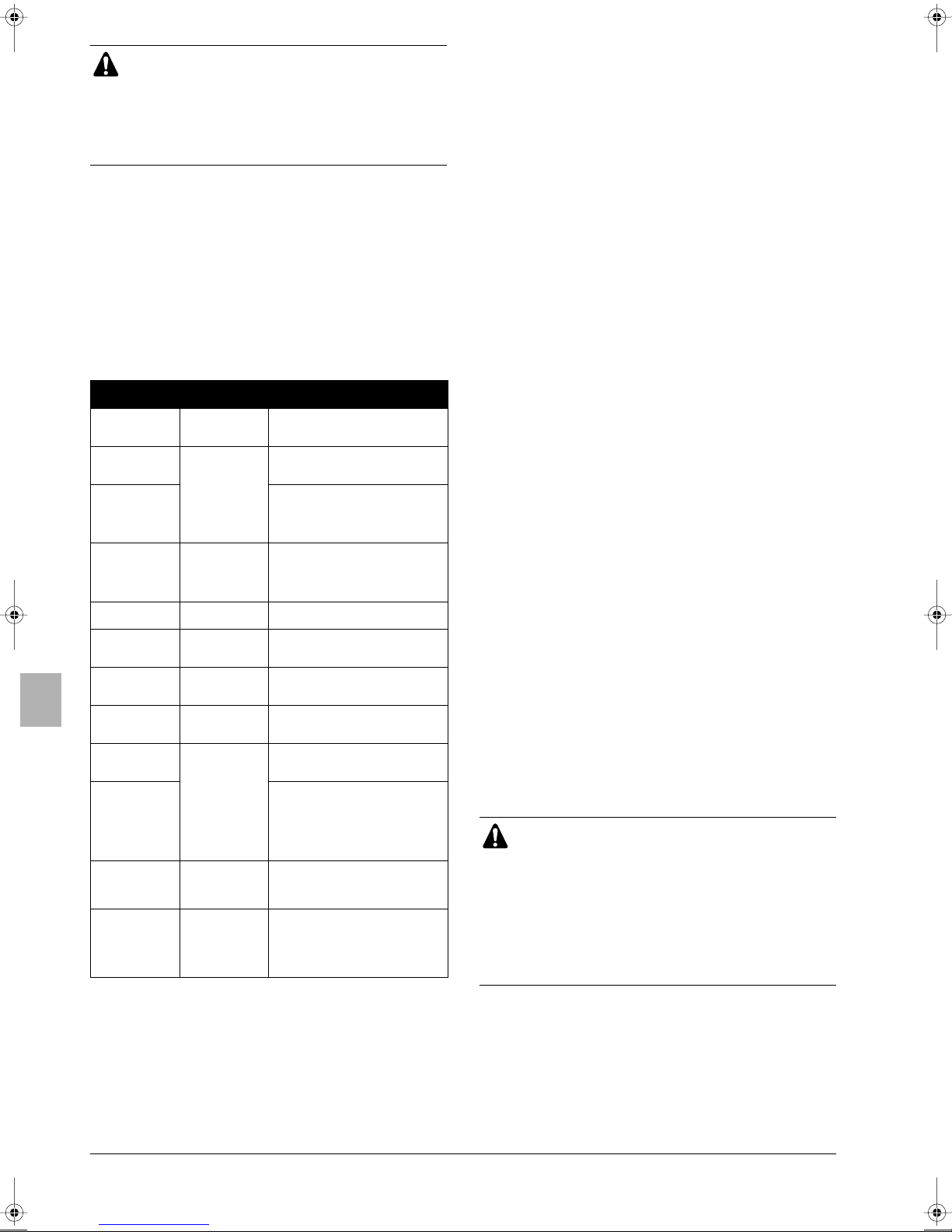

2.1. Combination

The indoor units can be installed in the following range.

■

Always use appropriate indoor units compatible with R410A.

To learn which models of indoor units are compatible with

R410A, refer to the product catalogs.

■

Total capacity/number of indoor units

Outdoor unit

U-4ML5 50~130 6

U-5ML5 62.5~162.5 8

U-6ML5 70~182 9

Total capacity of

indoor units

Total number of

indoor units

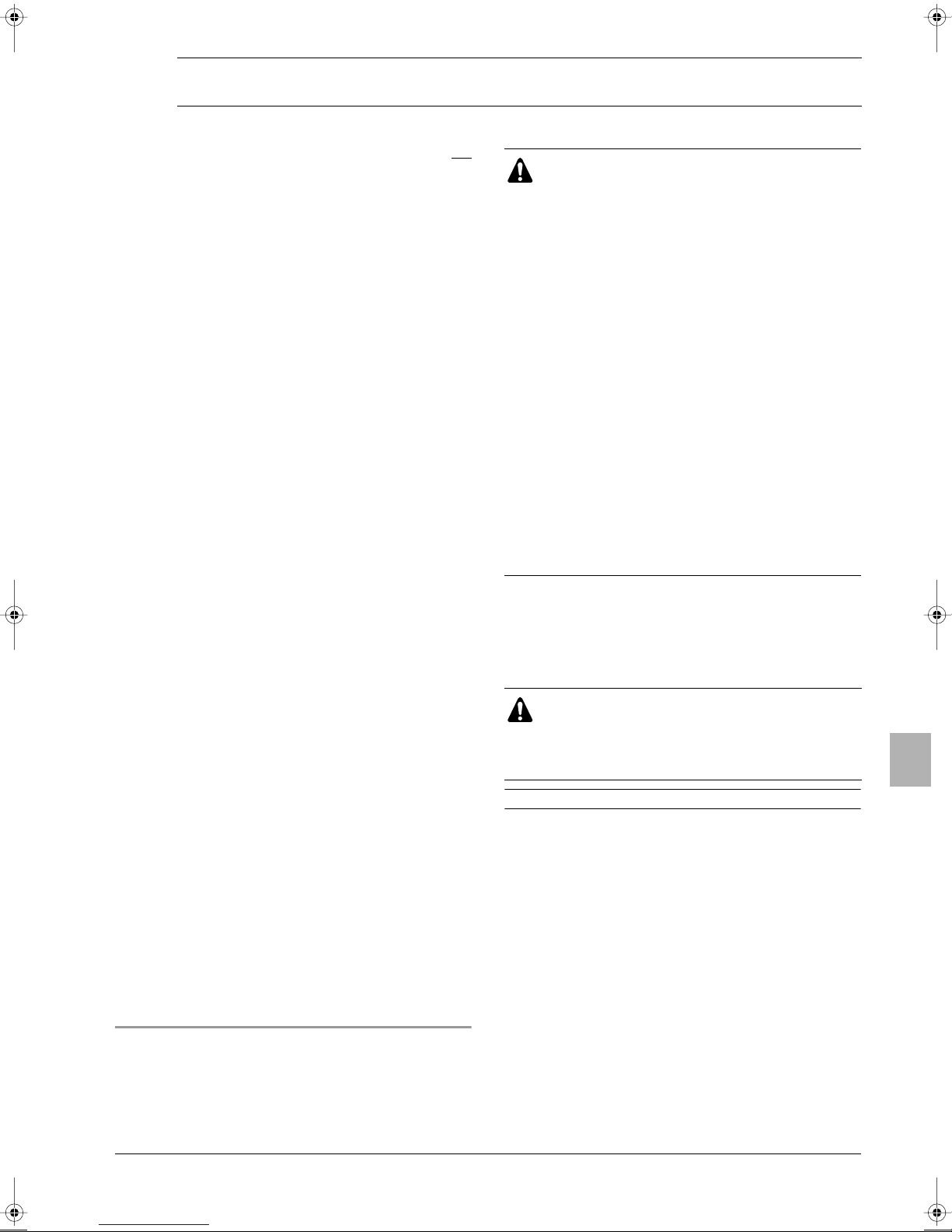

2.2. Standard supplied accessories

(*)

Gas line piping (1)

Gas line piping (2)(*)

Gas line piping (3)(*)

Installation manual

Operation manual

(*) Only for U-6ML5.

+ copper gasket

Location of accessories: refer to figure 1.

1

Accessories

1

1

1

1

1

+

2.3. Optional accessories

To install the above outdoor units, the following optional parts are

also required.

■

Refrigerant branching kit (for R410A only: Always use an

appropriate kit dedicated for your system.)

Refnet header

CZ-P29HK12Q CZ-P20BK12Q

Refnet joint

To select an optimum refrigerant branching kit, refer to "Refrigerant

branch kit selection" on page 9.

2.4. Technical and electrical specifications

Refer to the Engineering Data Book for the complete list of

specifications.

Installation manual

2

U-4~6ML5DPQ + U-4~6ML5XPQ

Urban Multi air conditioner

4PW40731-1

3. B

EFORE INSTALLATION

Since design pressure is 4.0 MPa or 40 bar, pipes of larger

wall thickness may be required. Refer to paragraph

"7.1. Selection of piping material" on page 6.

3.1. Precautions for R410A

■

The refrigerant requires strict cautions for keeping the system

clean, dry and tight.

- Clean and dry

Foreign materials (including mineral oils or moisture) should be

prevented from getting mixed into the system.

- Tight

Read "8. Precautions on refrigerant piping" on page 6 carefully

and follow these procedures correctly.

■

Since R410A is a mixed refrigerant, the required additional

refrigerant must be charged in its liquid state. (If the refrigerant

is in state of gas, its composition changes and the system will

not work properly).

■

The connected indoor units must be indoor units designed

exclusively for R410A.

3.2. Installation

■

For installation of the indoor unit(s), refer to the indoor unit

installation manual.

■

Never operate the air conditioner with the discharge pipe

thermistor (R2T), suction pipe thermistor (R3T) and pressure

sensors (S1NPH, S1NPL) removed. Such operation may burn

out the compressor.

■

Be sure to confirm the model name and the serial no. of the

outer (front) plates when attaching/detaching the plates to avoid

mistakes.

■

When closing the service panels, take care that the tightening

torque does not exceed 4.1 N•m.

1

Select an installation site where the following conditions are

satisfied and that meets with your customer's approval.

- Places which are well-ventilated.

- Places where the unit does not bother next-door neighbours.

- Safe places which can withstand the unit's weight and

vibration and where the unit can be installed level.

- Places where there is no possibility of flammable gas or

product leak.

- Places where servicing space can be well ensured.

- Places where the indoor and outdoor units' piping and wiring

lengths come within the allowable ranges.

- Places where water leaking from the unit cannot cause

damage to the location (e.g. in case of a blocked drain pipe).

- Places where the rain can be avoided as much as possible.

2

When installing the unit in a place exposed to strong wind, pay

special attention to the following.

Strong winds of 5 m/sec or more blowing against the outdoor

unit's air outlet causes short circuit (suction of discharge air),

and this may have the following consequences:

- Deterioration of the operational capacity.

-Frequent frost acceleration in heating operation.

- Disruption of operation due to rise of high pressure.

- When a strong wind blows continuously on the face of the

unit, the fan can start rotating very fast until it breaks.

Refer to the figures for installation of this unit in a place where

the wind direction can be foreseen.

■

Tu rn the air outlet side toward the building's wall, fence or

screen.

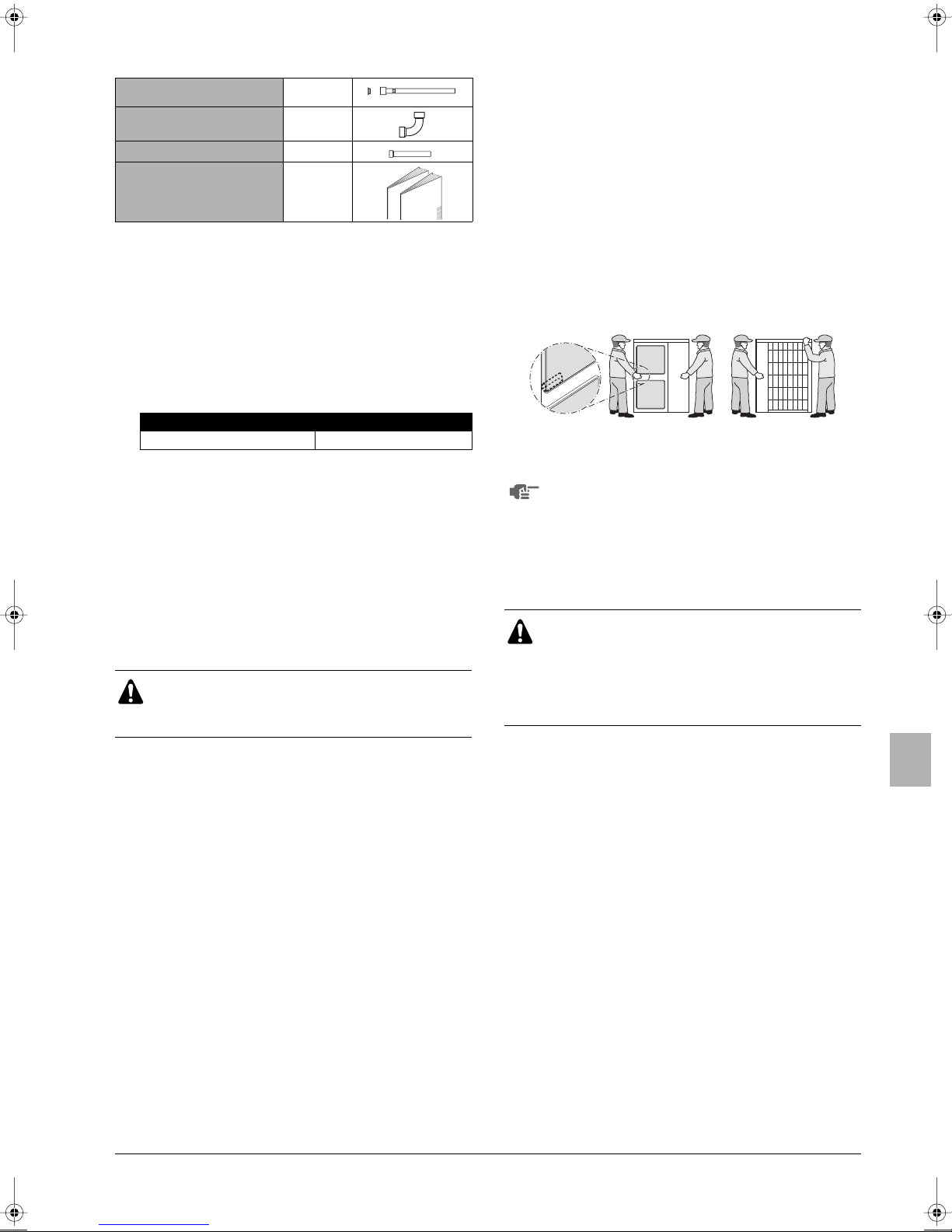

3.3. Handling

As shown in the figure, bring the unit slowly by grabbing the left and

right grips.

Place your hands on the corner instead of holding the suction inlet in

the side of the casing, otherwise the casing could be deformed.

Ta ke care not to let hands or objects come in contact with

rear fins.

4. S

This is a class A product. In a domestic environment this product may

cause radio interference in which case the user may be required to

take adequate measures.

ELECTING INSTALLATION SITE

■

Make sure to provide for adequate measures in order

to prevent that the outdoor unit be used as a shelter

by small animals.

■

Small animals making contact with electrical parts can

cause malfunctions, smoke or fire. Please instruct the

customer to keep the area around the unit clean.

Make sure there is enough room to do the installation

■

Set the outlet side at a right angle to the direction of the wind.

Strong wind

Blown air Strong wind

3

Prepare a water drainage channel around the foundation, to

drain waste water from around the unit.

4

If the water drainage of the unit is not easy, please build up the

unit on a foundation of concrete blocks, etc. (the height of the

foundation should be maximum 150 mm).

5

If you install the unit on a frame, please install a waterproof plate

within 150 mm of the underside of the unit in order to prevent the

invasion of water from the lower direction.

6

When installing the unit in a place frequently exposed to snow,

pay special attention to the following:

- Elevate the foundation as high as possible.

- Construct a large canopy (field supply).

- Remove the rear suction grille to prevent snow from

accumulating on the rear fins.

U-4~6ML5DPQ + U-4~6ML5XPQ

Urban Multi air conditioner

4PW40731-1

Installation manual

3

7

The outdoor unit may short circuit depending on its environment,

so use the louvers (field supply).

8

If you install the unit on a building frame,

please install a waterproof plate (within

150 mm of the underside of the unit) or

use a drain plug kit (option) in order to

avoid the drain water dripping.

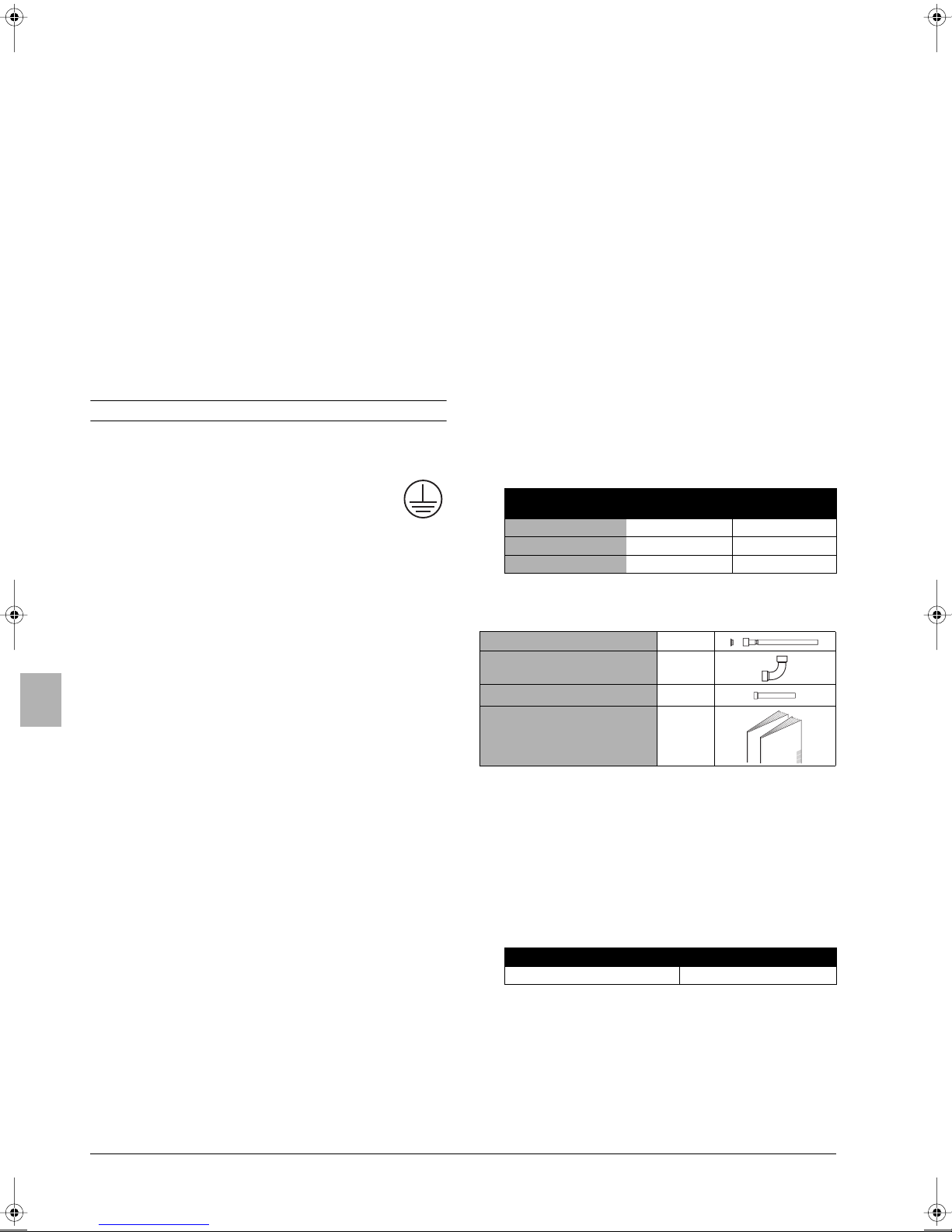

5.1. Installation method for prevention of falling over

If it is necessary to prevent the unit from falling over, install as shown

in the figure.

■

prepare all 4 wires as indicated in the drawing

■

unscrew the top plate at the 4 locations indicated A and B

■

put the screws through the nooses and screw them back tight

The equipment described in this manual may cause

electronic noise generated from radio-frequency energy.

The equipment complies to specifications that are

designed to provide reasonable protection against such

interference. However, there is no guarantee that

interference will not occur in a particular installation.

It is therefore recommended to install the equipment and

electric wires keeping proper distances away from stereo

equipment, personal computers, etc... (See figure 2)

1 Personal computer or radio

2 Fuse

3 Earth leakage breaker

4 Remote controller

5 Cool/heat selector

6 Indoor unit

In extreme circumstances you should keep distances of

3 m or more and use conduit tubes for power and

transmission lines.

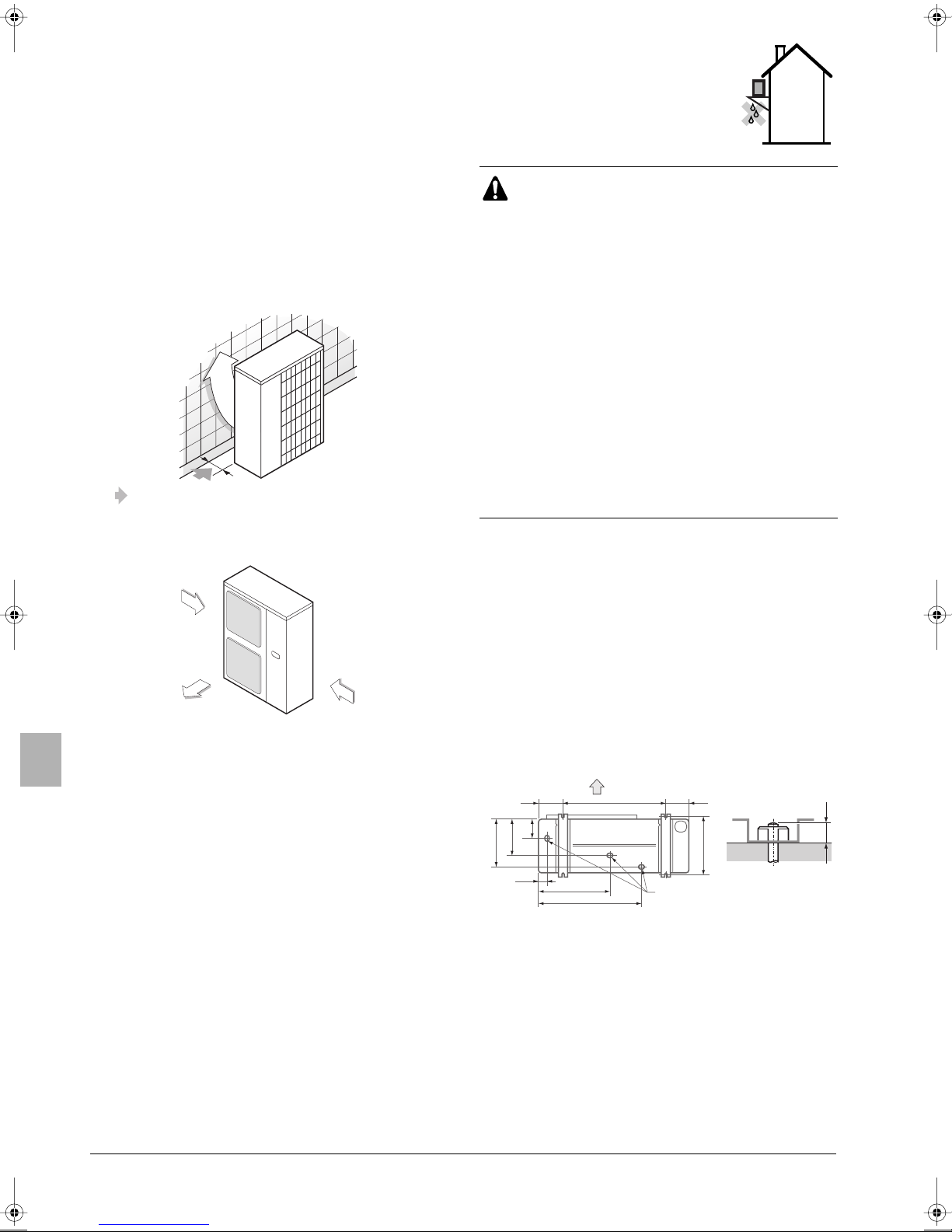

5. P

■

RECAUTIONS ON INSTALLATION

Check the strength and level of the installation ground so that

the unit will not cause any operating vibration or noise after

installation.

■

In accordance with the foundation drawing in the figure, fix the

unit securely by means of the foundation bolts. (Prepare four

sets of M12 foundation bolts, nuts and washers each which are

available on the market.)

■

It is best to screw in the foundation bolts until their length are

20 mm from the foundation surface.

A

140620

350

(345-355)

C

289

219

45

A

B

C

140

117

421

612

Discharge side

Bottom view (mm)

Drain hole

B

AA

B

C

A

location of the 2 fixation holes on the front side of the unit

B

location of the 2 fixation holes on the rear side of the unit

C

wires: field supply

5.2. Method for removing transportation stay

The yellow transportation stay installed over the compressor leg for

protecting the unit during transport must be removed. Proceed as

shown in figure 3 and described below.

A

Compressor

B

Fixing nut

C

Tr ansportation stay

1

Slightly loosen the fixing nut (B).

2

Remove the transportation stay (C) as shown in figure 3.

3

Tighten the fixing nut (B) again.

CAUTION

If the unit is operated with the transportation stay attached,

abnormal vibration or noise may be generated.

5.3. Method for installing drain piping

Depending on installation site, it may be required to install drain plug

for drainage (option kit).

In cold areas, do not use a drain hose with the outdoor unit.

Otherwise, drain water may freeze, impairing the heating

20

performance.

1

See figure below for installation of the drain plug.

Installation manual

4

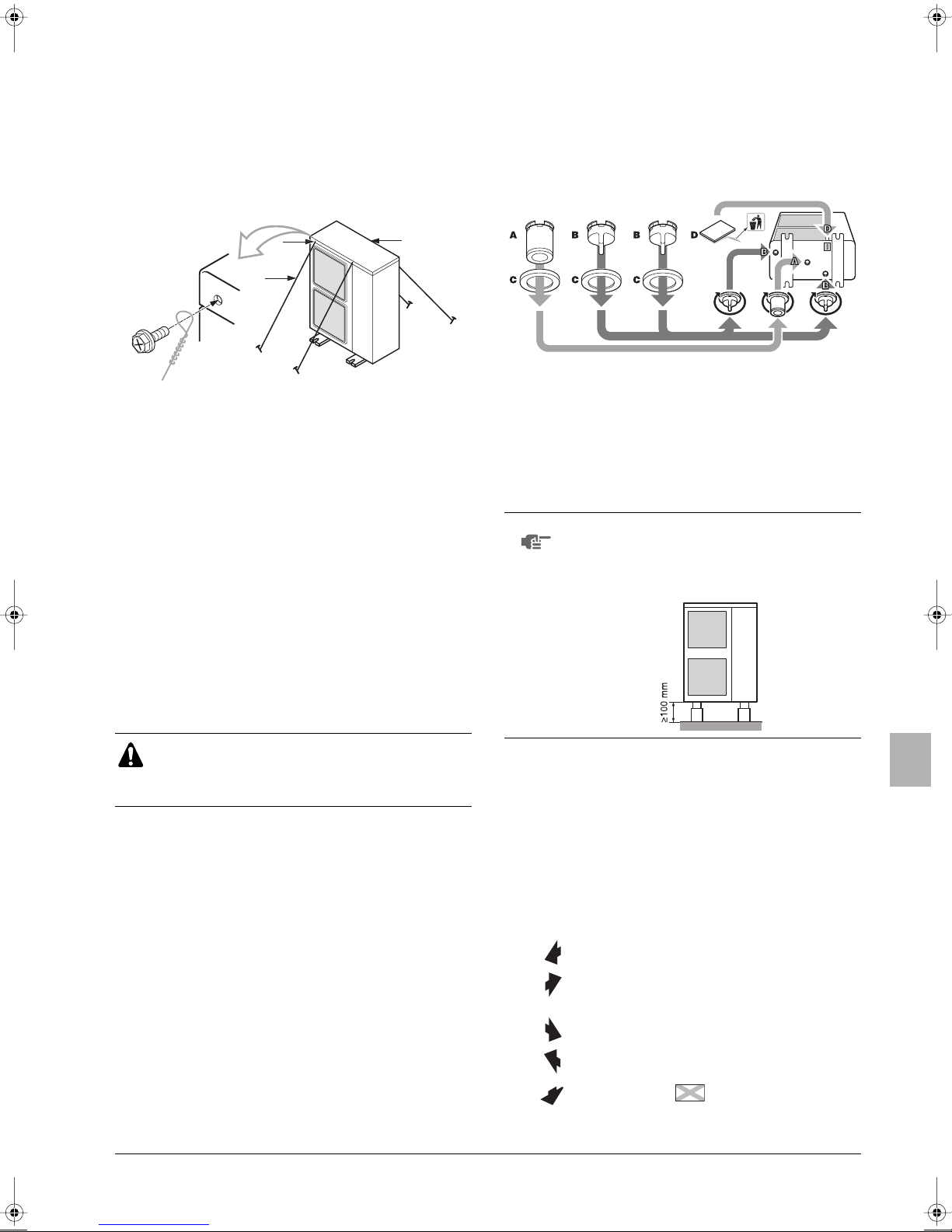

A

Drain socket

B

Drain cap

C

Drain receiver

D

Insulation tape

2

Connect a field supplied vinyl hose (internal diameter of 25 mm)

to the drain socket (A).

If the hose is too long and hangs down, fix it carefully to prevent

kinks.

U-4~6ML5DPQ + U-4~6ML5XPQ

Urban Multi air conditioner

4PW40731-1

NOTE

000

000

00

000

If drain holes of the outdoor unit are covered by a

mounting base or by floor surface, raise the unit in

order to provide a free space of more than 100 mm

under the outdoor unit.

NSTALLATION SERVICING SPACE

6. I

■

The connection piping outlet direction in the installation shown in

figure 4 is frontward or downward. The unit of numeric values is

mm.

■

When routing the piping backward, secure space of ≥250 mm on

the right side of the unit.

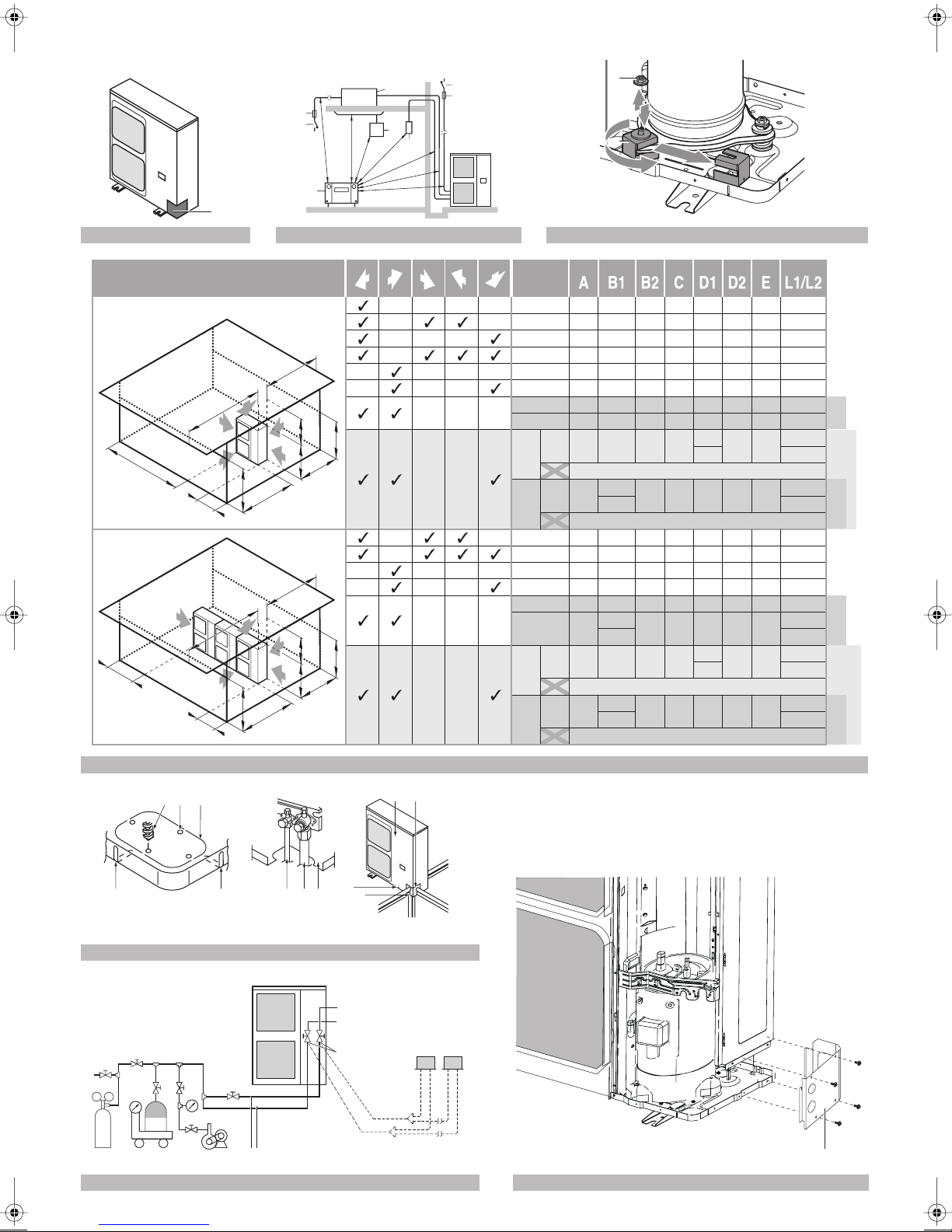

(A) In case of non-stacked installation (See figure 4)

Suction side obstacle

Discharge side obstacle

Left side obstacle

Right side obstacle

Top side obstacle

1 In these cases, close the

bottom of the installation

frame to prevent the

discharged air from

being bypassed

2 In these cases, only 2

units can be installed.

3 In these cases, no

restriction of height L1.

This situation is not

allowed

(C) In case of multiple-row installation (for roof top use, etc.)

1.

In case of installing one unit per row.

≥100

≥2

≥2

≥1

2.

In case of installing multiple units (2 units or more) in lateral

connection per row.

L

A

≥3000

H

≥600

≥1500

Relation of dimensions between H, A and L is shown in the table

below.

L A

L≤H

H<L Installation impossible

0<L≤1/2H 250

1/2H<L≤H 300

Obstacle is present

✓

(B) In case of stacked installation

1.

In case obstacles exist in front of the outlet side.

2.

In case obstacles exist in front of the air inlet.

NOTE

■ Do not stack more than one unit.

■ About 100 mm is required as the dimension

for laying the upper outdoor unit's drain pipe.

■ Get the portion A sealed so that air from the

outlet does not bypass.

7. R

EFRIGERANT PIPE SIZE AND ALLOWABLE

PIPE LENGTH

All field piping must be installed by a licensed refrigeration

technician and must comply with relevant local and

national regulations.

A

100

≥1

A

100

≥300

To persons in charge of piping work:

■ Be sure to open the stop valve after piping installing

and vacuuming is complete. (Running the system with

the valve closed may break the compressor.)

■ It is forbidden to discharge refrigerant into the

atmosphere. Collect the refrigerant in accordance

with the freon collection and destruction law.

■ Do not use flux when brazing the refrigerant piping.

For brazing, use phosphor copper brazing filler metal

(BCuP) which does not require a flux.

(If a chlorine flux is used, the piping will corrode, and if

the flux contains fluoride, it will cause the coolant oil to

deteriorate, adversely affecting the coolant piping

system.

U-4~6ML5DPQ + U-4~6ML5XPQ

Urban Multi air conditioner

4PW40731-1

Installation manual

5

7.1. Selection of piping material

■ Foreign materials inside pipes (including oils for fabrication)

must be ≤30 mg/10 m.

■ Construction material: phosphoric acid deoxidized seamless

copper for refrigerant.

■ Temper grade: use piping with temper grade in function of the

pipe diameter as listed in table below.

■ The pipe thickness of the refrigerant piping should comply with

relevant local and national regulations. The minimal pipe

thickness for R410A piping must be in accordance with the table

below.

Temper grade of piping

Pipe Ø

6.4 / 9.5 / 12.7 O 0.80

15.9 O 1

19.1 1/2H 1

O = Annealed

1/2H = Half hard

material

■ Make sure to use the particular branches of piping that have

been selected.

■ In case the required pipe sizes (inch sizes) are not available, it is

also allowed to use other diameters (mm sizes), taken the

following into account:

■ select the pipe size nearest to the required size.

■ use the suitable adapters for the change-over from inch to

mm pipes (field supply).

Minimal thickness t

(mm)

■ Always use the supplied copper gasket when connecting the

gas pipe supplied with the unit. See "9. Refrigerant piping" on

page 7.

8.1. Cautions for brazing

■ Be sure to carry out a nitrogen blow when brazing.

Brazing without carrying out nitrogen replacement or releasing

nitrogen into the piping will create large quantities of oxidized

film on the inside of the pipes, adversely affecting valves and

compressors in the refrigerating system and preventing normal

operation.

■ When brazing while inserting nitrogen into the piping, nitrogen

must be set to 0.02 MPa with a pressure-reducing valve (=just

enough so that it can be felt on the skin).

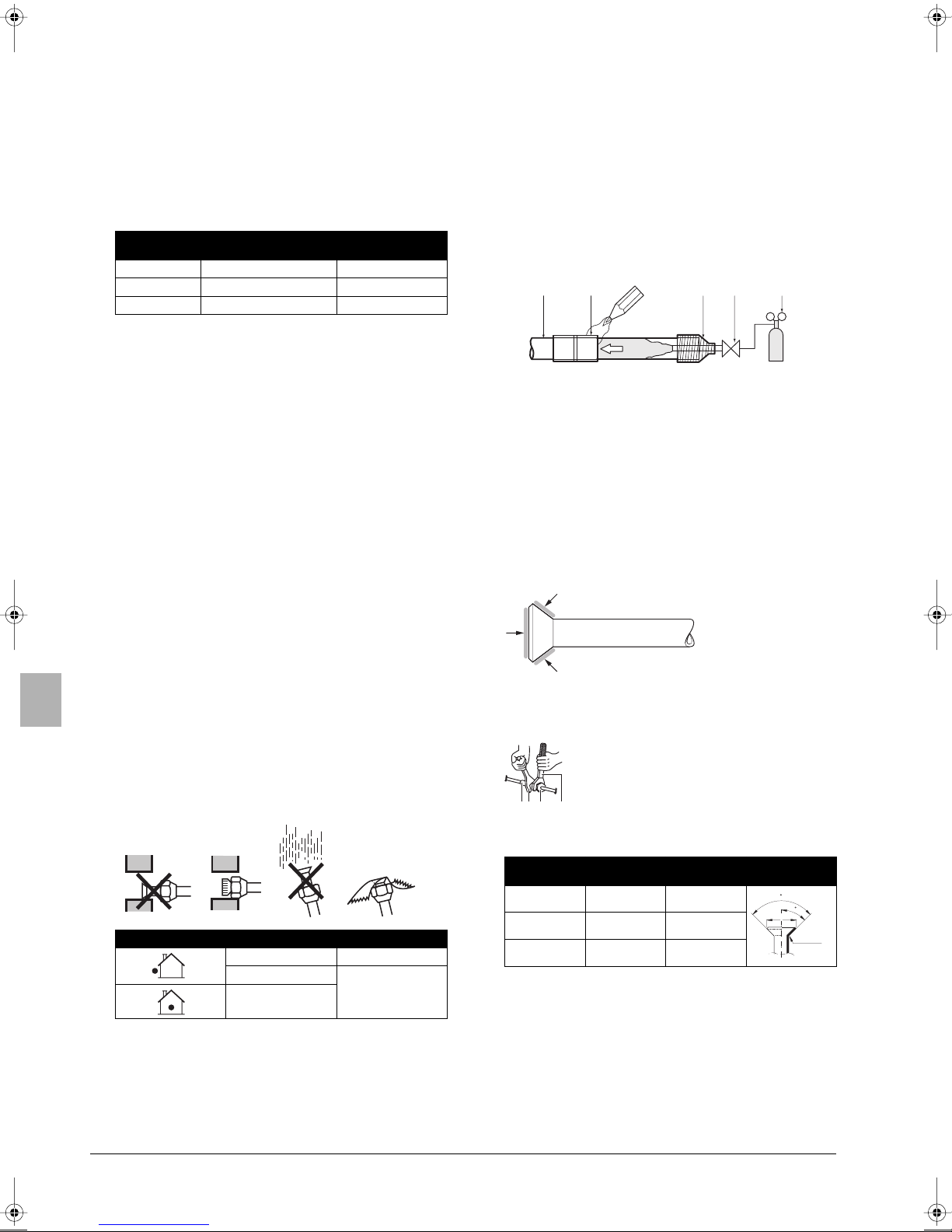

12 345

6

1 Refrigerant piping

2 Part to be brazed

3 Taping

4 Hands valve

5 Pressure-reducing valve

6 Nitrogen

6

8. PRECAUTIONS ON REFRIGERANT PIPING

■ Do not allow anything other than the designated refrigerant to

get mixed into the freezing cycle, such as air, etc. If any

refrigerant gas leaks while working on the unit, ventilate the

room thoroughly right away.

■ Use R410A only when adding refrigerant

Installation tools:

Make sure to use installation tools (gauge manifold charge hose,

etc.) that are exclusively used for R410A installations to withstand

the pressure and to prevent foreign materials (e.g. mineral oils

and moisture) from mixing into the system.

Vacuum pump:

Use a 2-stage vacuum pump with a non-return valve

Make sure the pump oil does not flow oppositely into the system

while the pump is not working.

Use a vacuum pump which can evacuate to –100.7 kPa (5 Torr,

–755 mm Hg).

■ In order to prevent dirt, liquid or dust from entering the piping,

cure the piping with a pinch or taping.

Installation period Protection method

More than a month Pinch the pipe

Less than a month

Regardless of the

period

Pinch or tape the

pipe

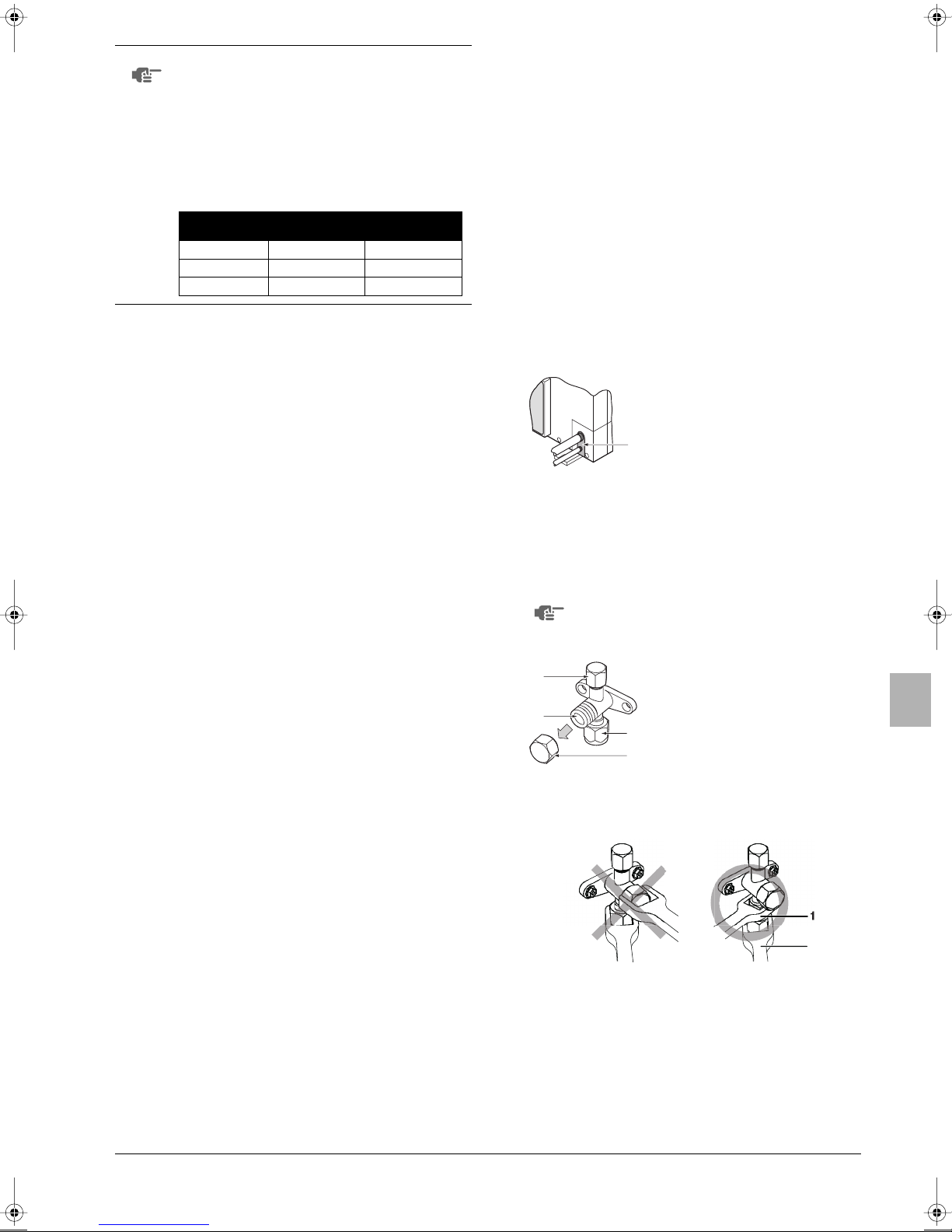

8.2. Cautions for flare connection

■ See the following table for flare part machining dimensions.

■ When connecting the flare nuts, apply refrigerant ether or ester

oil to the inside and outside of the flares and turn them three or

four times at first.

■ When loosening a flare nut, always use two wrenches in

combination. When connecting the piping, always use a spanner

and torque wrench in combination to tighten the flare nut.

1 Piping union

2 Spanner

3 Flare nut

12 3 4

■ See the following table for tightening torque.

(Applying too much torque may cause the flares to crack.)

Pipe size

Ø9.5 32.7~39.9 12.8~13.2

Ø15.9 61.8~75.4 19.3~19.7

Ø19.1 97.2~118.6 12.3~23.7

■ After all the piping has been connected, use nitrogen to perform

a gas leak check.

4 Torque wrench

Tightening

torque (N•m)

A (mm) Flare shape

±2

90

45

±2

A

R=0.4~0.8

Great caution is needed when passing copper tubes through

walls.

■ For handling of stop valves, refer to "9.3. How to use the stop

valve" on page 8.

■ Only use the flare nuts included with the unit. Using different

flare nuts may cause the refrigerant to leak.

Installation manual

6

U-4~6ML5DPQ + U-4~6ML5XPQ

Urban Multi air conditioner

4PW40731-1

NOTE

You must use a torque wrench but if you are obliged to

install the unit without a torque wrench, you may follow

the installation method mentioned below.

After the work is finished, make sure to check that

there is no gas leak.

When you keep on tightening the flare nut with a

spanner, there is a point where the tightening torque

suddenly increases. From that position, further tighten

the flare nut within the angle shown below:

Further tightening

Pipe size

Ø9.5 (3/8") 60~90° ±200 mm

Ø15.9 (5/8") 30~60° ±300 mm

Ø19.1 (5/8") 20~35° ±450 mm

angle

Recommended

arm length of tool

9. REFRIGERANT PIPING

■ Field pipes can be installed in four directions.

Figure - Field pipes in four directions (See figure 5)

1 Drill

2 Center area around knockout hole

3 Knockout hole

4 Slit

5 Connecting pipe liquid (field supply)

6 Bottom frame

7 Front plate

8 Pipe outlet plate

9 Screw front plate

10 Pipe outlet plate screw

11 Connecting pipe gas (field supply, except U-6ML5)

A Forward

B Backward

C Sideways

D Downward

When connecting the piping in the lateral direction (on the rear),

remove the piping cover (rear) in reference to figure 7.

1 Piping cover (rear)

■ To install the connecting pipe to the unit in a downward direction,

make a knockout hole by penetrating the center area around the

knockout hole using a Ø6 mm drill. (See figure 5).

■ Cutting out the two slits makes it possible to install as shown in

figure 5.

(Use a metal saw to cut out the slits.)

■ After knocking out the knock-out, it is recommended to apply

repair paint to the edge and the surrounding end surfaces to

prevent rusting.

For U-6ML5 only

The size of the gas side stop valve is Ø15.9 while the inter-unit piping

is Ø19.1. Use the standard supplied accessory piping to make the

connection. See figure 15.

A Front connection

B Rear connection

C Side connection

D Bottom connection

1 Gas line piping + copper gasket supplied with the unit (make sure

to always use the copper gasket).

2 Gas line piping supplied with the unit

3 Gas piping (field supply)

4 Cut to the appropriate length.

5 Gas line piping supplied with the unit

9.1. Preventing foreign objects from entering

Plug the pipe through-holes with putty or insulating material (field

supply) to stop up all gaps, as shown in the figure.

1

1 Putty or insulating material (field

supply)

Insects or small animals entering the outdoor unit may cause a short

circuit in the electrical box.

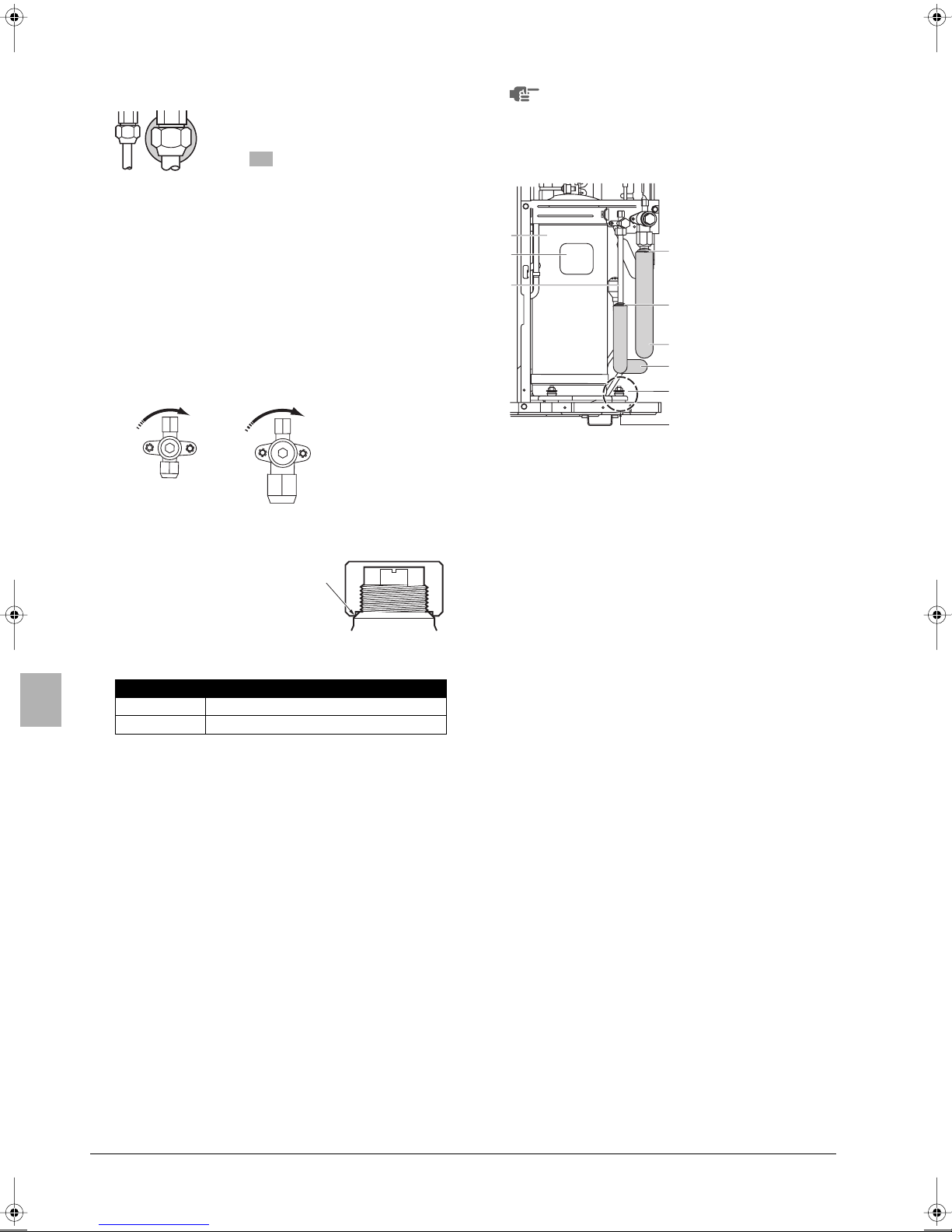

9.2. Cautions for handling stop valve

■ The stop valves for indoor-outdoor connecting piping are closed

at shipment from the factory.

Make sure to keep the valve open during operation.

The names of parts of the stop valve are shown in the figure.

1

2

3

4

■ Since the side boards may be deformed if only a torque wrench

is used when loosening or tightening flare nuts, always lock the

stop valve with a wrench and then use a torque wrench.

Do not place wrenches on the valve cover.

1 Service port

2 Stop valve

3 Field piping connection

4 Valve cover

U-4~6ML5DPQ + U-4~6ML5XPQ

Urban Multi air conditioner

4PW40731-1

1 Spanner

2 Torque wrench

Do not apply force on the valve cover, this may result in a

refrigerant leak.

Installation manual

7

■ For cooling operation under low ambient temperature or any

other operation under low pressure, apply silicon pad or similar

to prevent freezing of the gas stop valve flare nut (see figure).

Freezing of the flare nut may cause refrigerant leak.

Silicon sealing pad

(Make sure there is no gap)

9.3. How to use the stop valve

Use hexagonal wrenches 4 mm and 6 mm.

■ Opening the valve

1. Place the hex wrench on the valve bar and turn counter-

clockwise.

2. Stop when the valve bar no longer turns. It is now open.

■ Closing the valve

1. Place the hex wrench on the valve bar and turn clockwise.

2. Stop when the valve bar no longer turns. It is now closed.

Closing direction

Liquid side Gas side

■ Be sure to insulate the liquid and gas-side field piping and the

refrigerant branch kit.

Any exposed piping may cause condensation or burns

if touched.

(The highest temperature that the gas-side piping can reach is

around 120°C, so be sure to use insulating material which is

very resistant.)

1

2

3

4

1 Compressor

2 Te r minal cover

3 Indoor and outdoor

4

4 Corking, etc.

5

5 Insulation material

5

6 Bolts

6

A Be careful with pipe,

A

field piping

(field supply)

bolt and outer panel

connections

9.4. Cautions for handling the valve cover

■ The valve cover is sealed where

indicated by the arrow.

Ta ke care not to damage it.

■ After operating the valve, be sure to tighten the valve cover

properly.

Tightening torque

Liquid pipe 13.5~16.5 N•m

Gas pipe 22.5~27.5 N•m

■ Check for refrigerant leakage after tightening the cap.

9.5. Cautions for handling service port

After the work, tighten the valve cover in place.

Tightening torque: 11.5~13.9 N•m

9.6. Precautions when connecting field piping and

regarding insulation

■ Be careful not to let the indoor and outdoor branch piping come

into contact with the compressor terminal cover.

If the liquid-side piping insulation might come into contact with it,

adjust the height as shown in the figure below. Also, make sure

the field piping does not touch the bolts or outer panels of the

compressor.

■ When the outdoor unit is installed above the indoor unit the

following can occur:

The condensated water on the stop valve can move to the

indoor unit. To avoid this, please cover the stop valve with

sealing material.

■ If the temperature is higher than 30°C and the humidity is higher

than RH 80%, then the thickness of the sealing materials should

be at least 20 mm in order to avoid condensation on the surface

of the sealing.

Installation manual

8

U-4~6ML5DPQ + U-4~6ML5XPQ

Urban Multi air conditioner

4PW40731-1

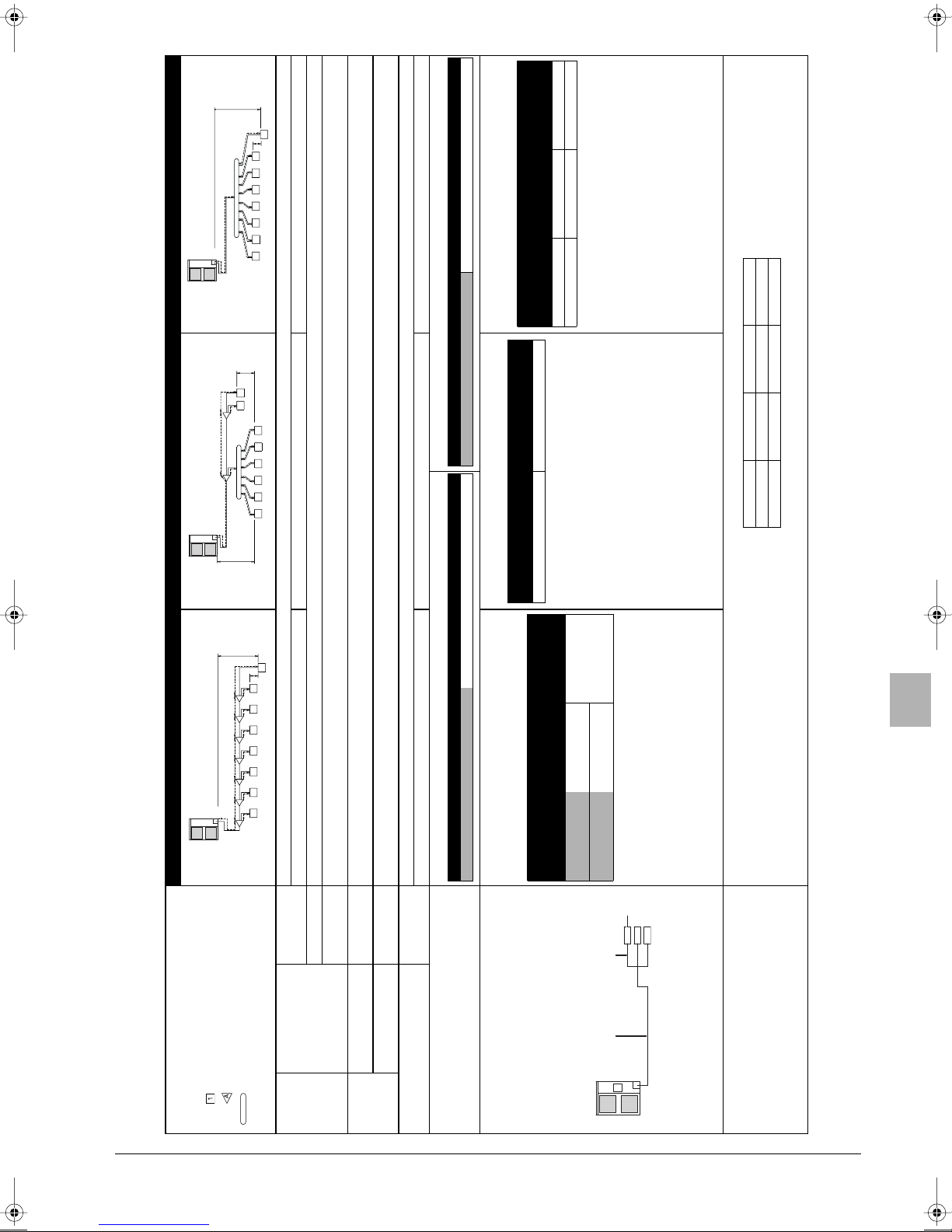

H1

Outdoor unit

capacity type

Piping size (outer diameter x minimum

thickness)

Gas pipe Liquid pipe

U-4+5ML5 Ø15.9x1.0

(Ø19.1x1.0)

Ø9.5x0.8

U-6ML5 Ø19.1x1.0

(Ø22.2x1.0)

8

H2

hi

g

f

cde

a

1234567

b

H2

k

78

j

B

h

i

g

A

b

123456

cde f

a

H1

Piping size

Gas pipe Liquid pipe

(outer diameter x minimum thickness)

Indoor capacity

index

20+25+32+40+50 Ø12.7x0.8 Ø6.4x0.8

Gas pipe Liquid pipe

Ø15.9x1.0 Ø9.5x0.8

63+80+100+125 Ø15.9x1.0 Ø9.5x0.8

connection size of indoor unit.

• Pipe size for direct connection to indoor unit must be the same as the

C. Piping between refrigerant branch kit and indoor unit

Outdoor unit capacity type Refrigerant branch kit name

U-4~6ML5 CZ-P29HK12Q

Piping size (outer diameter x minimum thickness)

• Use the pipe size from the following table.

B. Piping between refrigerant branch kits

a: Ø9.5x30 m d: Ø9.5x13 m g: Ø6.4x10 m j: Ø6.4x10 m

Example for refrigerant branch using line branch pipe and header branch pipe

x0.022

b: Ø9.5x10 m e: Ø6.4x10 m h: Ø6.4x20 m k: Ø6.4x9 m

c: Ø9.5x10 m f: Ø6.4x10 m i: Ø9.5x10 m

)

R=[73 x 0.054] + [69 x 0.022] = 5.46 ⇒ 5.5 kg

p

H1

8

H2

g

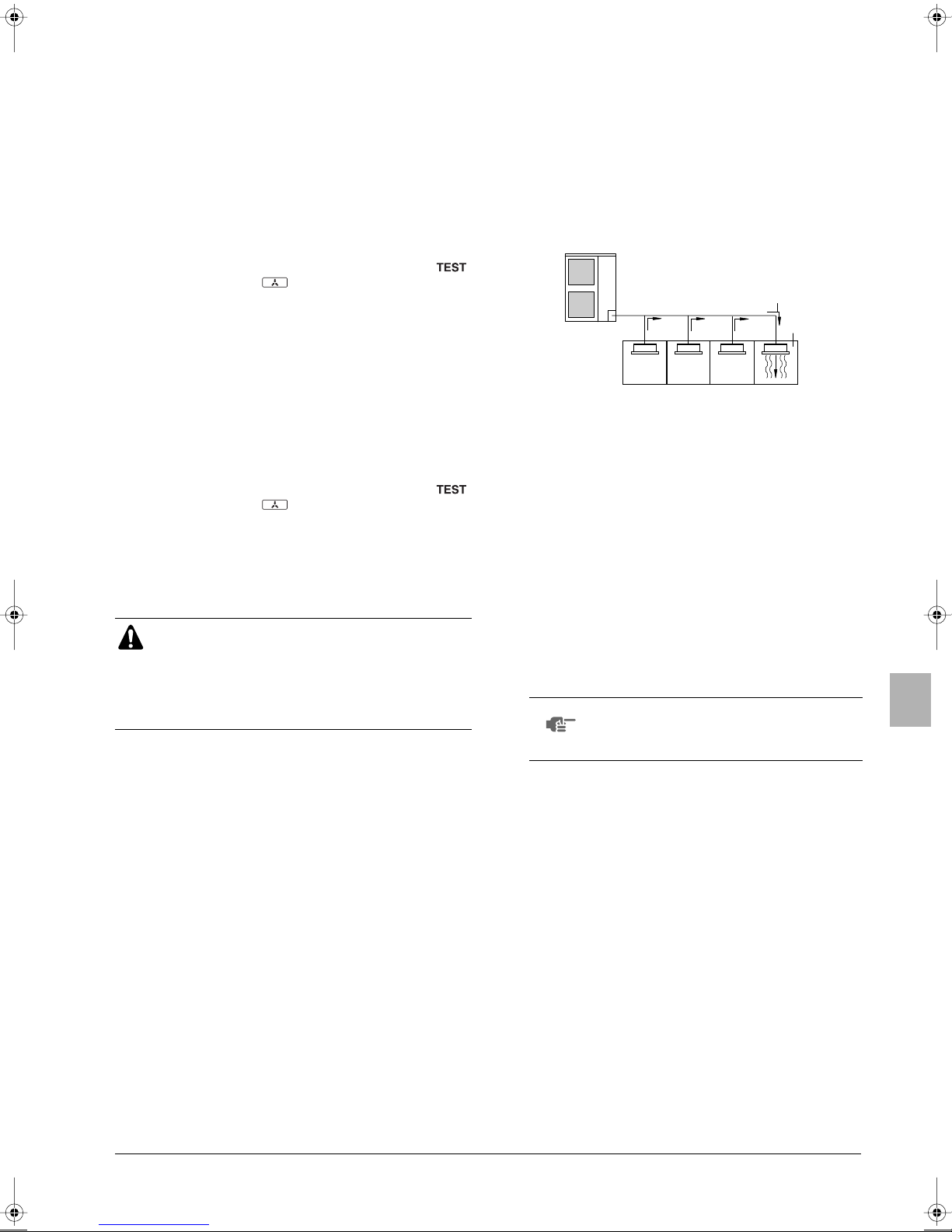

Branch with line branch pipe Branch with line branch pipe and header branch pipe Branch with header branch pipe

Example of connection

(Connection of 8 indoor units Heat pump system)

ABCDEFG

ab c d e f

indoor unit

line branch pipe

1234567

hi j k l mn

header branch pipe

Pipe length between outdoor and indoor units ≤150 m

[Example] unit 8: a+b+c+d+e+f+g+p≤150 m [Example] unit 6: a+b+h≤150 m, unit 8: a+i+k≤150 m [Example] unit 8: a+i≤150 m

Actual pipe length

Equivalent length Equivalent pipe length between outdoor and indoor units ≤175 m (Assume equivalent pipe length of line branch pipe to be 0.5 m and of the header branch pipe to be 1.0 m. (for calculation purposes))

Total extension

Between outdoor and

indoor units

Maximum

allowable

length

Total piping length from outdoor unit to all indoor units between 10 m and 300 m

length

Difference in height between outdoor and indoor units (H1)≤50 m (≤40 m if outdoor unit is located in a lower position).

Difference in height between adjacent indoor units (H2)≤15 m

Pipe length from first refrigerant branch kit (either line branch pipe or header branch pipe) to indoor unit ≤40 m

Difference in

height

Difference in

height

Between outdoor and

indoor units

Between indoor and indoor

units

Allowable

height

Outdoor unit capacity type Refrigerant branch kit name

U-4~6ML5 CZ-P20BK12Q

[Example] unit 8: b+c+d+e+f+g+p≤40 m [Example] unit 6: b+h≤40 m, unit 8: i+k≤40 m [Example] unit 8: i≤40 m

Use the following line branch pipe Use the following header branch pipe

Allowable length after the branch Actual pipe length

Refrigerant branch kit selection

• Match to the size of the connection piping on the outdoor unit.

A. Piping between outdoor unit and refrigerant branch kit

Refrigerant branch kits can only be used with R410A.

Pipe size selection

Caution on selecting connection pipes

If the overall equivalent piping length is ≥90 m, be sure to

Outdoor unit connection piping size

1 2

enlarge the pipe diameter of the gas-side main piping. If the

recommended pipe size is not available, stick to the original

pipe diameter (which may result in a small capacity decrease).

[Gas side]

U-4+5ML5: Ø15.9➝Ø19.1

U-6ML5: Ø19.1➝Ø22.2

3

Total length (m) of liquid

Total length (m) of liquid

1 Main pipe (enlarge)

2 First refrigerant branch kit

3 Indoor unit

How to calculate the additional refrigerant to be charged

Additional refrigerant to be charged R (kg)

piping size at Ø6.4

(

x0.054+

)

piping size at Ø9.5

(

R=

R should be rounded off in units of 0.1 kg

U-4~6ML5DPQ + U-4~6ML5XPQ

Urban Multi air conditioner

4PW40731-1

Installation manual

9

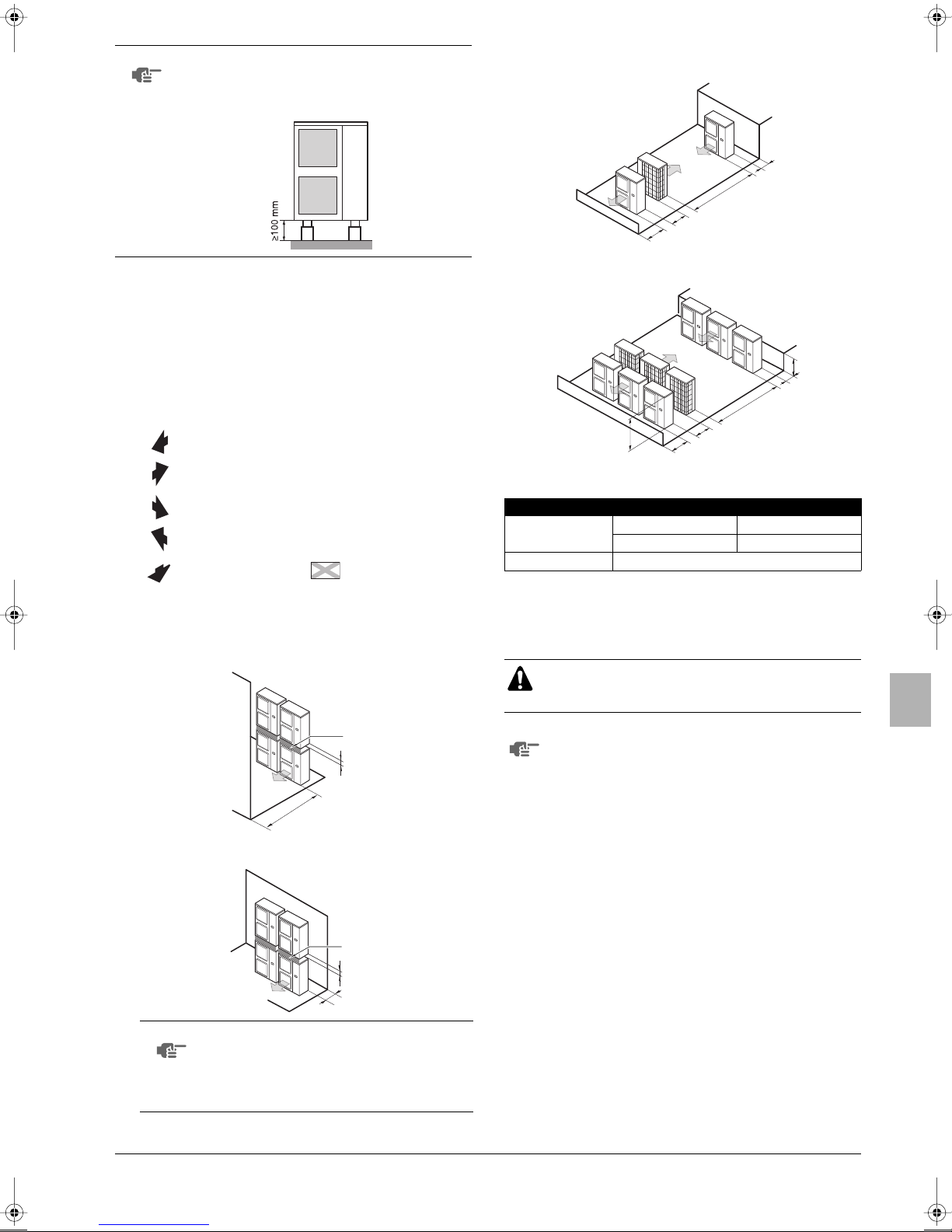

9.7. Leak test and vacuum drying

The units were checked for leaks by the manufacturer.

See figure 6 and refer to "Additional refrigerant charge" on page 10

for nomenclature of the parts in figure 6.

• Confirm that the gas and liquid line stop valves are firmly closed

before pressure test or vacuuming.

• Make sure that valve A is completely open.

Air tight test and vacuum drying

■ Air tight test: Make sure to use nitrogen gas. (For the service

port position, refer to "9.2. Cautions for handling stop valve" on

page 7.

■ Pressurize the liquid and gas pipes to 4.0 MPa (40 bar) (do not

pressurize more than 4.0 MPa (40 bar)). If the pressure does not

drop within 24 hours, the system passes the test. If the pressure

drops, check where the nitrogen leaks from.

■ Vacuum drying: Use a vacuum pump which can evacuate to

–100.7 kPa (5 Torr, –755 mm Hg)

1. Evacuate the system from the liquid and gas pipes by using a

vacuum pump for more than 2 hours and bring the system to

–100.7 kPa. After keeping the system under that condition for

more than 1 hour, check if the vacuum gauge rises or not. If it

rises, the system may either contain moisture inside or have

leaks.

2. Following should be executed if there is a possibility of moisture

remaining inside the pipe (if piping work is carried out during the

raining season or over a long period of time, rainwater may enter

the pipe during work).

After evacuating the system for 2 hours, pressurize the system to

0.05 MPa (vacuum break) with nitrogen gas and evacuate the

system again using the vacuum pump for 1 hour to –100.7 kPa

(vacuum drying). If the system cannot be evacuated to –100.7 kPa

within 2 hours, repeat the operation of vacuum break and vacuum

drying.

Then, after leaving the system in vacuum for 1 hour, confirm that

the vacuum gauge does not rise.

4 Siphon system

5 Measuring instrument

6 Vacuum pomp

7 Valve A

8 Gas line stop valve

9 Outdoor unit

10 Liquid line stop valve

11 Indoor unit

12 Stop valve service port

13 Charge hose

To avoid compressor breakdown. Do not charge the refrigerant

more than the specified amount.

■ This outdoor unit is factory charged with refrigerant and

depending on pipe sizes and pipe lengths some systems require

additional charging of refrigerant. See "How to calculate the

additional refrigerant to be charged" on page 9.

■ In case re-charge is required, refer to the nameplate of the unit.

The nameplate states the type of refrigerant and necessary

amount.

Precautions when adding R410A

Be sure to charge the specified amount of refrigerant in liquid state to

the liquid pipe.

Since this refrigerant is a mixed refrigerant, adding it in gas form may

cause the refrigerant composition to change, preventing normal

operation.

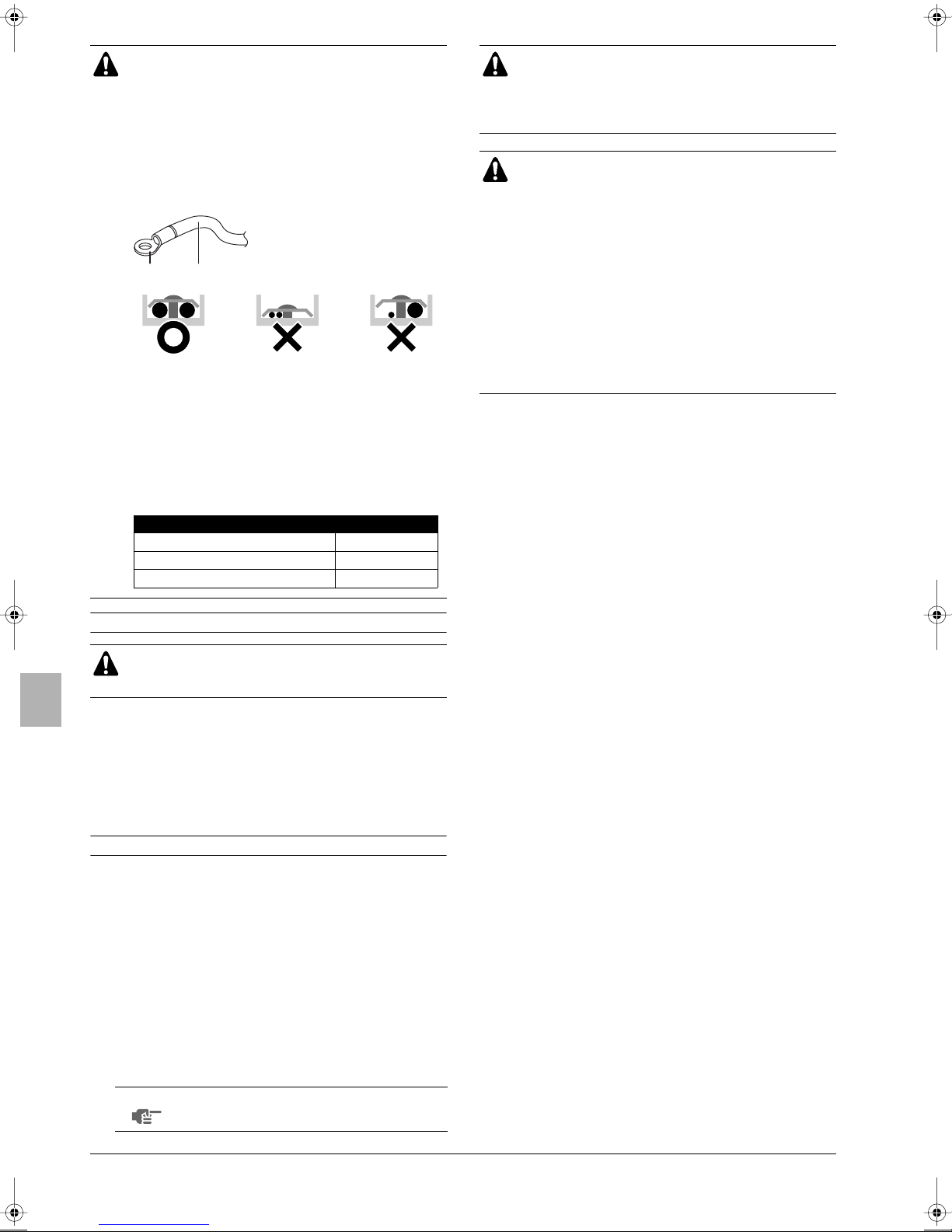

■ Before charging, check whether the refrigerant cylinder is

equipped with a siphon tube or not.

Charge the liquid

refrigerant with the cylinder

in upright position.

Charge the liquid

refrigerant with the cylinder

in up-side-down position.

10. ADDITIONAL REFRIGERANT CHARGE

■ Refrigerant cannot be charged until field wiring has

been completed.

■ Refrigerant may only be charged after performing the

leak test and the vacuum drying (see above).

■ When charging a system, care shall be taken that its

maximum permissible charge is never exceeded, in

view of the danger of liquid hammer.

■ Charging with an unsuitable substance may cause

explosions and accidents, so always ensure that the

appropriate refrigerant (R410A) is charged.

■ Refrigerant containers shall be opened slowly.

■ Always use protective gloves and protect your eyes

when charging refrigerant.

■ When performing service on the unit requiring the

refrigerant system to be opened, refrigerant must be

evacuated according to local regulations.

■ Do not use the automatic refrigerant charging function

while working on the indoor units.

When using the automatic refrigerant charging

function, the indoor units operate automatically as

well as the outdoor unit.

■ When the power is on, please close the front

panel when leaving the unit.

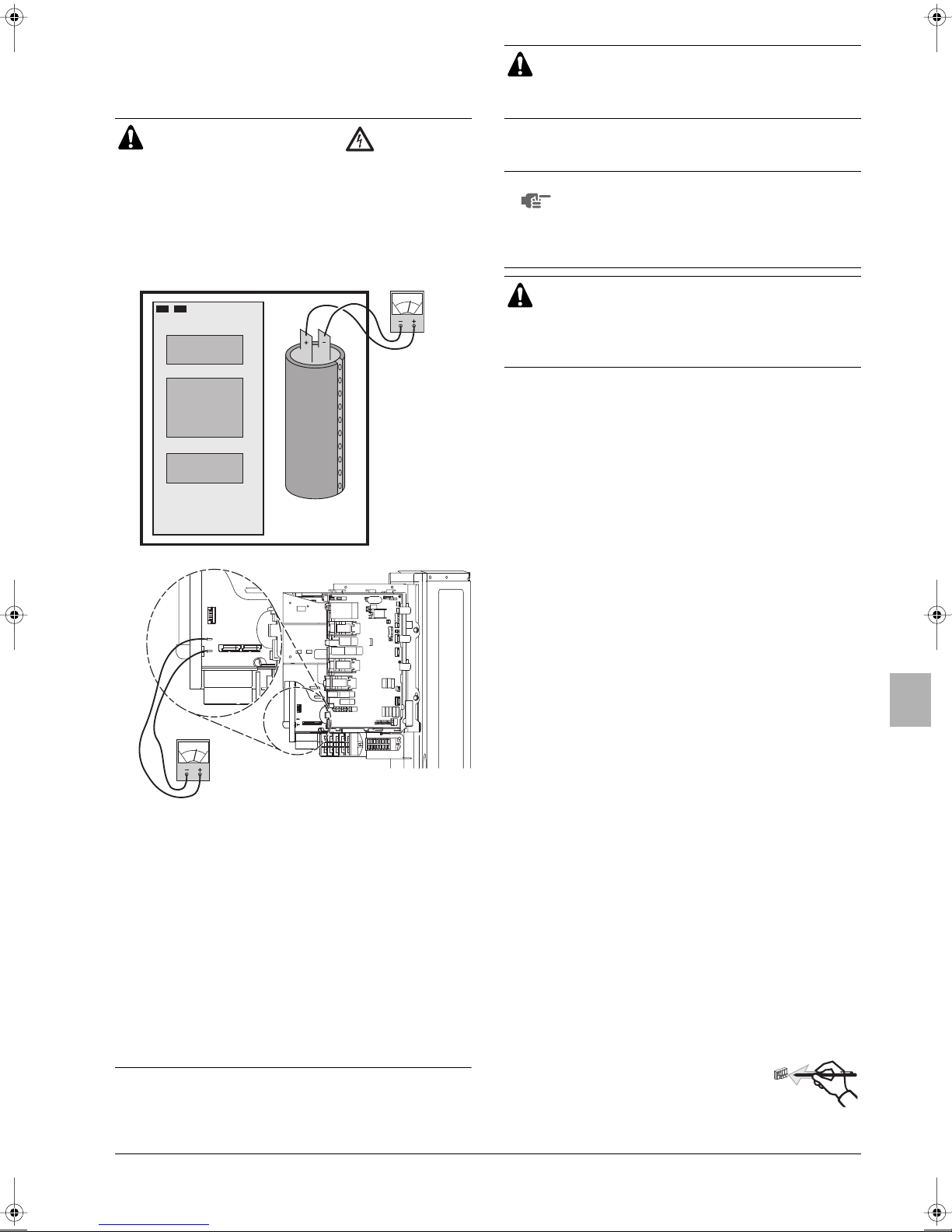

See figure 6.

1 Pressure reducing valve

2 Nitrogen

3 Tank

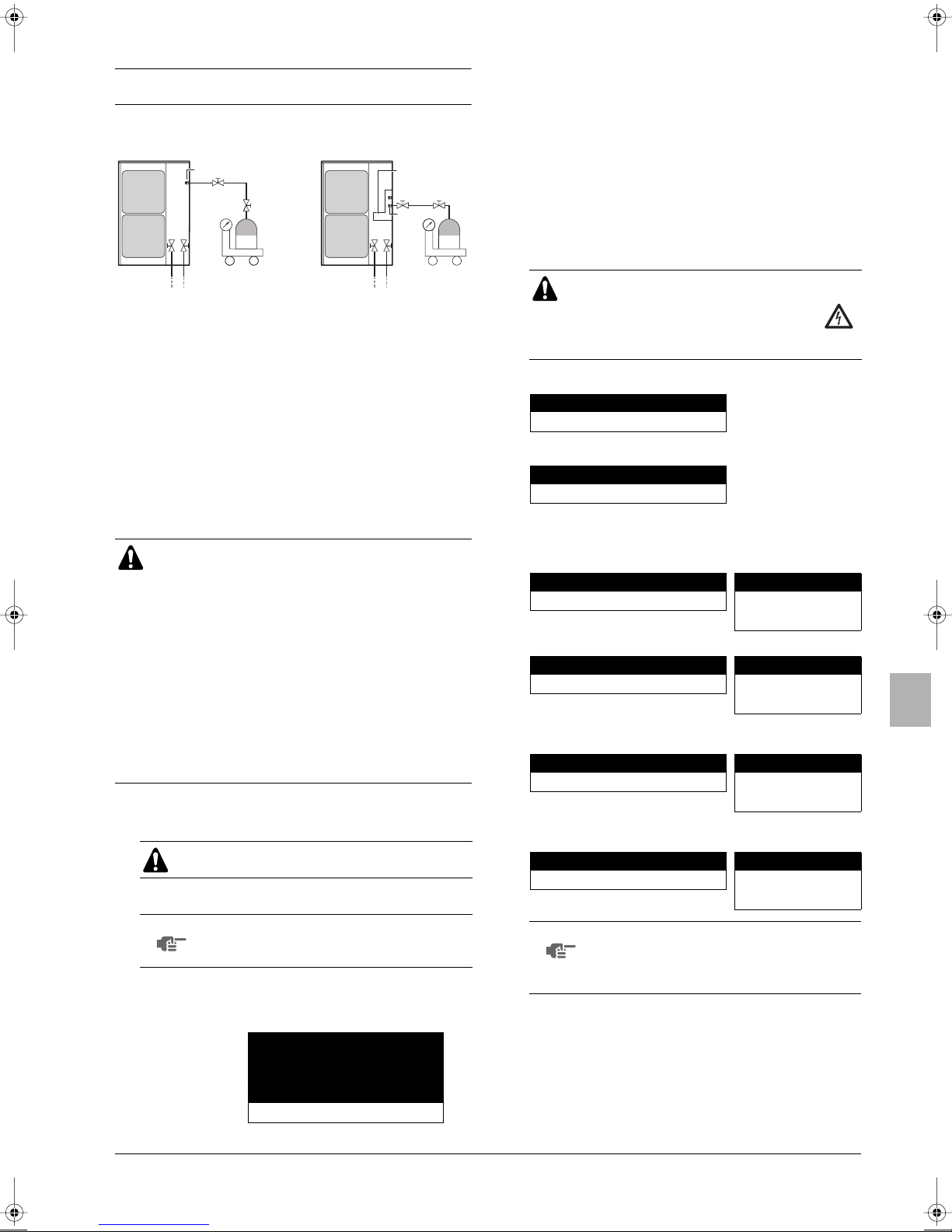

10.1. Important information regarding the refrigerant

used

This product contains fluorinated greenhouse gases covered by the

Kyoto Protocol. Do not vent gases into the atmosphere.

Refrigerant type: R410A

(1)

GWP

value: 1975

(1)

GWP = global warming potential

Please fill in with indelible ink,

■➀ the factory refrigerant charge of the product,

■➁ the additional refrigerant amount charged in the field and

■➀+➁ the total refrigerant charge

on the refrigerant charge label supplied with the product.

The filled out label must be adhered in the proximity of the product

charging port (e.g. onto the inside of the service cover).

1 factory refrigerant charge

4

of the product:

see unit name plate

1

2 additional refrigerant

amount charged in the

2

field

3 total refrigerant charge

3

4 Contains fluorinated

5

6

greenhouse gases

covered by the Kyoto

Protocol

5 outdoor unit

6 refrigerant cylinder and

manifold for charging

Installation manual

10

U-4~6ML5DPQ + U-4~6ML5XPQ

Urban Multi air conditioner

4PW40731-1

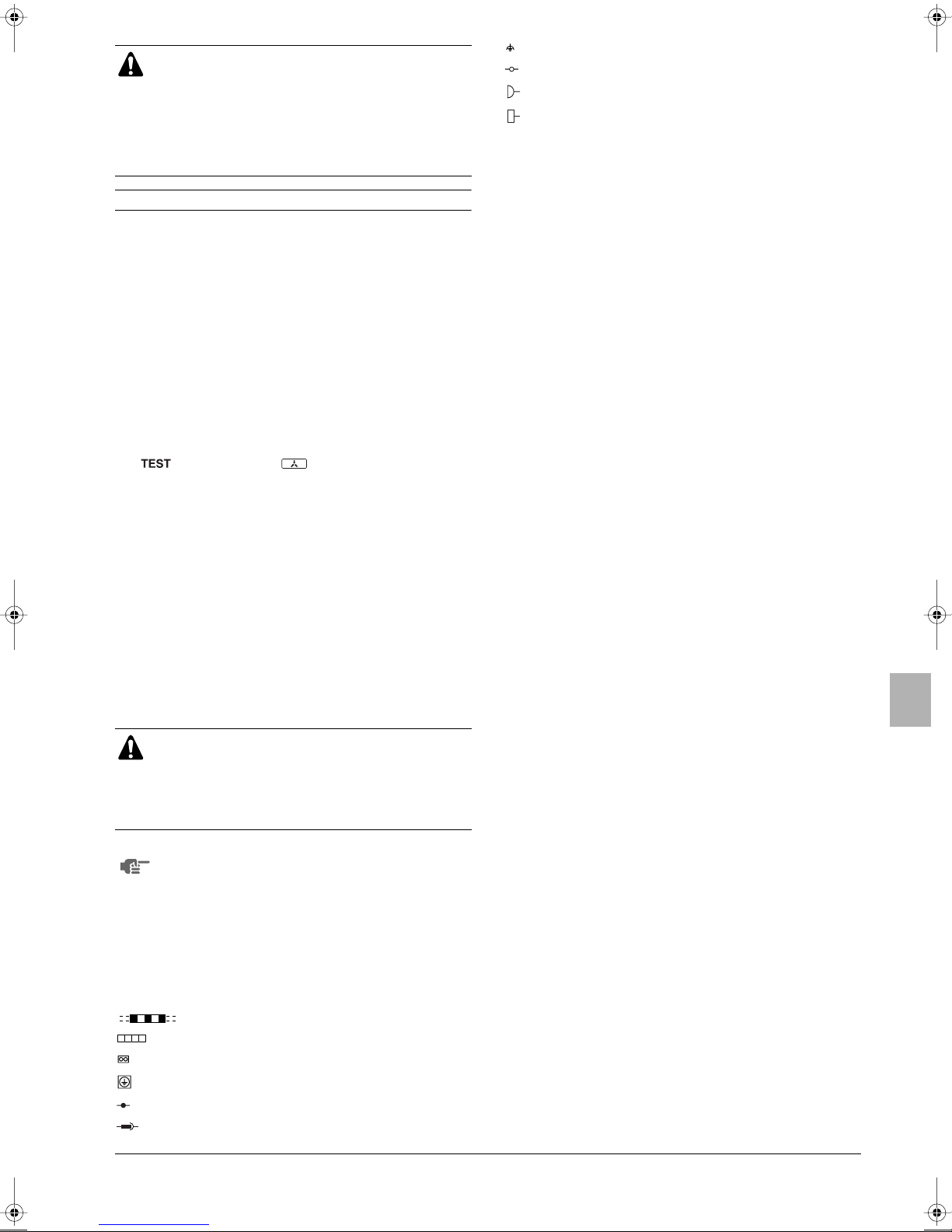

10.2. 3 procedures for adding refrigerant

Procedure 1: Adding refrigerant by using the automatic

refrigerant charging function (recommended)

How to connect the tank?

DPQ XPQ

5

4

12

6

7

3

1 Liquid line stop valve

2 Gas line stop valve

3 To indoor unit

4 Service port for adding refrigerant

5 Valve A

6 R410A tank

7 Measuring instrument

8 Pipe fixing plate

When the refrigerant tank is connected and the specified operation is

performed, the appropriate amount of refrigerant will be charged into

the system. After charging, the system will stop automatically. The

refrigerant must be charged according to the procedure described

below.

CAUTION

■ Make sure to turn ON the power 6 hours before

starting the operation. This is necessary to warm the

crankcase by the electric heater.

■ Automatic charging is able to charge 6 kg/hour

refrigerant at an outside temperature of 0°C to 24 kg/

hour refrigerant at an outside temperature of 35°C.

The charging time depends on the amount of charged

refrigerant and on the outside temperature.

■ Automatic refrigerant charging is NOT possible if the

following restrictions are exceeded:

■ Outside temperature: 0°C DB~43°C DB

■ Indoor temperature: 0°C DB~32°C DB

■ Indoor unit connection capacity: 50%~130%

Automatic refrigerant charging procedure

1 Open the liquid and gas side stop valves completely.

Note that valve A must be closed!

2 Turn on the power of the outdoor unit and indoor units.

12

3

8

5

4

6

7

Led state

Throughout the manual the state of the leds is indicated as

follows:

x

OFF

w

ON

c

blinking

❃

ON or OFF

If H2P is lit up, check the type of error based on the error code in

the remote controller and correct the error in accordance with

"12.4. Test operation" on page 19.

4 Automatically charge the refrigerant according to the procedure

described below.

WARNING

Do not touch anything else than the pushbuttons (BS1~5) on the PCB when making

the settings. These settings must be done

with the power on

4.1 Press once.

BS4 TEST

H1P H2P H3P H4P H5P H6P H7P

wwwwwww

4.2 Press for 5 seconds. The unit will start running.

BS4 TEST

H1P H2P H3P H4P H5P H6P H7P

xcxxx

❃❃

If the led display below appears, the automatic refrigerant

charging restriction has been exceeded. Additional refrigerant

must be charged by calculating the additional refrigerant

charging amount.

H1P H2P H3P H4P H5P H6P H7P Description of error

wcccw x x

Inappropriate outdoor

temperature

or

H1P H2P H3P H4P H5P H6P H7P Description of error

wccc x w x

Inappropriate indoor

temperature

If the led display below appears, check the indoor unit

connection capacity.

H1P H2P H3P H4P H5P H6P H7P Description of error

wcccc x w

Inappropriate indoor unit

connection capacity

If the led display below appears, the liquid and gas side stop

valves may be closed.

H1P H2P H3P H4P H5P H6P H7P Description of error

wx

❃❃❃❃❃

Stop valve is closed

NOTE

When an indoor unit is connected to the

refrigerant system and the indoor unit is turned

off, automatic charging will fail.

3 Make sure that the led on the PCB on the outdoor unit are as

shown in the table below. This indicates that the system is

operating normally.

MODE

TEST/HWL

H1P H2P H3P H4P H5P H6P H7P

xxwxxxx

U-4~6ML5DPQ + U-4~6ML5XPQ

Urban Multi air conditioner

4PW40731-1

IND

MASTER

SLAVE

L.N.O.P.

DEMAND

NOTE

If you want to repeat the automatic refrigerant

charging operation from step 4.2, fully open the

liquid and gas side stop valves and press the

BS1 MODE

button once.

4.3 When the led indication becomes as shown in the table below in

about 15 to 30 minutes after start of operation, open valve A at

once to start charging of the refrigerant.

Immediately after starting charging of the refrigerant by opening

valve A, press once. When is not pressed

BS4 TEST BS4 TEST

within 10 minutes after the led indication is shown, charging is

stopped.

Installation manual

11

H1P H2P H3P H4P H5P H6P H7P Code on remote controller

ccc xwxw

PA

4.4 The led indication becomes as shown in the table below during

automatic refrigerant charging.

During automatic refrigerant charging, the remote controller

indicates (test operation) and (external control).

H1P H2P H3P H4P H5P H6P H7P

wc

NOTE

❃❃❃❃❃

If the led display below appears, the refrigerant

tank is empty. Replace the refrigerant tank, open

valve A and re-charge.

H1P H2P H3P H4P H5P H6P H7P Code on remote controller

wcc x xwx

PA

The led indication becomes as shown in the table below when

automatic refrigerant charging is about to end. Prepare to close

the valve on the refrigerant tank.

H1P H2P H3P H4P H5P H6P H7P Code on remote controller

cccwwww

PE

After correcting the problem, press button once and

BS1 MODE

perform automatic refrigerant charging again starting from

step 4.2.

Case 4: Failure

Error code on remote

H1P H2P H3P H4P H5P H6P H7P

xwwxxxx

(*) An error in the system interrupted the operation of the unit. Check the

error by using the error code displayed on the remote controller. For an

explanation of the error codes, see "Error codes on the remote controller"

on page 20 and solve the problem.

After correcting the problem, press button once and

BS1 MODE

controller

See footnote

(*)

perform automatic refrigerant charging again starting from

step 4.2.

5 When charging is complete, determine the weight of refrigerant

that was added and fill in the amount in the "Additional

refrigerant charge label" attached to service precautions plate

on the unit.

6 After adding the refrigerant, do not forget to close the lid of the

service port. The tightening torque for the lid is 11.5~13.9 N•m.

NOTE

It is possible that the code PE is not shown on the

remote controller but this does not indicate a

malfunction. The led indication can immediately

shift to the situation as shown in "Case 1:

Charging complete" on page 12.

4.5 When the led indication becomes as shown in the table below,

quickly close valve A and follow instructions as described below.

CAUTION

■ When adding refrigerant is done or when

pausing, close the valve on the refrigerant tank

immediately.

More refrigerant might be charged by any

remaining pressure after the machine is stopped.

■ The outdoor fan may keep rotating a little bit

more, but this does not indicate a malfunction.

Case 1: Charging complete

H1P H2P H3P H4P H5P H6P H7P Code on remote controller

wccwwww

Charging of the refrigerant is complete. Press

P9

BS1 MODE

button once and go to step 5.

Case 2: Recharging operation

H1P H2P H3P H4P H5P H6P H7P Code on remote controller

wcc x www

Press button once and perform automatic

BS1 MODE

P8

refrigerant charging again starting from Step 4.2.

Case 3: Charging interrupted

H1P H2P H3P H4P H5P H6P H7P Code on remote controller

wcc xxxw

P2

Something is preventing normal operation:

■ Is the gas side stop valve completely open?

■ Are the valve on the refrigerant tank and valve A open?

Check if the button was pressed within 10

BS4 TEST

minutes after the valves were opened.

■ Is the indoor unit air intake vent or outlet vent blocked?

1

DPQ XPQ

2

3

1 Service port for adding refrigerant

2 Liquid line stop valve

3 Gas line stop valve

4 Pipe fixing plate

Procedure 2: Charging while the outdoor unit is at a standstill

See figure 6.

1 Determine the weight of refrigerant to be charged additionally

referring to the item "Additional refrigerant charge" in "How to

calculate the additional refrigerant to be charged" on page 9 and

fill in the amount in the "Additional refrigerant charge label"

attached to the unit.

2 After the vacuum drying is finished, open valve A and charge the

additional refrigerant in its liquid state through the service port

on the liquid stop valve taking into account following instructions:

-Turn on the power of the outdoor unit and indoor units.

- Check that gas and liquid stop valves are closed.

- Stop the compressor and charge the specified weight of

refrigerant.

4

2

3

Installation manual

12

U-4~6ML5DPQ + U-4~6ML5XPQ

Urban Multi air conditioner

4PW40731-1

■ To avoid compressor breakdown. Do not charge the

refrigerant more than the specified amount.

■ If the total refrigerant cannot be charged while the

outdoor unit is at a standstill, it is possible to charge

the refrigerant by operating the outdoor unit using the

refrigerant charge function (refer to "Setting mode 2"

on page 18) and follow "Procedure 3: Charging while

the outdoor unit is operating" on page 13.

Procedure 3: Charging while the outdoor unit is operating

See the figure in "How to connect the tank?" on page 11.

1 Completely open the gas side stop valve and liquid side stop

valve. Valve A must be left fully closed.

2 Close the front panel and turn on the power to all indoor units

and the outdoor unit.

3 Open valve A immediately after starting of the compressor.

4 Charge the additional refrigerant in its liquid state through the

service port of the liquid line stop valve.

5 While the unit is at a standstill and under setting mode 2 (refer to

Checks before initial start-up, "Setting the mode" on page 18),

set the required function A (additional refrigerant charging

operation) to (ON). Then operation starts. The blinking H2P

led indicates test operation and the remote controller indicates

6 When the specified amount of refrigerant is charged, push the

BS3 RETURN

■ The operation automatically stops within 30 minutes.

■ If the refrigerant charge cannot be finished within 30 minutes,

repeat step 5.

■ If the operation stops immediately after restart, there is a

possibility that the system is overcharged.

The refrigerant cannot be charged more than this amount.

7 After the refrigerant charge hose is removed, make sure to close

valve A.

ON

(test operation) and (external control).

button. Then operation stops.

11. ELECTRICAL WIRING WORK

■ All wiring must be performed by an authorized

electrician.

■ All field supplied components and all electric

construction should comply with the applicable local

and national codes.

To persons in charge of electrical wiring work:

Do not operate the unit until the refrigerant piping is

complete. (Running it before the piping is ready will break

the compressor.)

11.1. Internal wiring – Parts table

L............................. Live

N............................ Neutral

........... Field wiring

.................... Terminal strip

......................... Connector

......................... Protective earth (screw)

.......................... Connection

....................... Relay connector

...........................Functional earthing

...........................Terminal

..........................Movable connector

..........................Fixed connector

BLU........................Blue

BRN .......................Brown

GRN.......................Green

RED .......................Red

WHT....................... White

YLW ....................... Yellow

ORG....................... Orange

BLK ........................ Black

A1P ........................ Printed circuit board (main)

A2P ........................ Printed circuit board (inverter)

A3P ................ * .....Printed circuit board (noise filter)

A4P ................ * .....Printed circuit board (C/H selector)

BS1~BS5 ............... Push button switch (mode, set, return, test,

reset)

C1~C3....................Capacitor

C4 ..................* .....Capacitor

DS1........................DIP switch

E1HC .....................Crankcase heater

F1U, F4U .......* .....Fuse (T 6.3 A/250 V)

F1U (A1P)......# .....Fuse (T 6.3 A/250 V)

F3U (A1P)......# .....Fuse (T 6.3 A/250 V)

F4U (A1P)......# .....Fuse (T 6.3 A/250 V)

F6U ................ * .....Fuse (T 5.0 A/250 V)

FINTH ............* .....Thermistor (fin)

H1P~H8P...............Light emitting diode (service monitor orange)

Prepare, test: blinking

H2P........................Malfunction detection: light up

HAP................ * ..... Light emitting diode (service monitor green)

HAP (A1P) .....# .....Light emitting diode (service monitor green)

HAP (A2P) .....# .....Light emitting diode (service monitor green)

K1M................ * ..... Magnetic contactor (M1C)

K1M (A1P) .....# .....Magnetic contactor

K1R........................Magnetic relay (Y1S)

K2R........................Magnetic relay (Y2S)

K3R........................Magnetic relay (Y3S)

K4R........................Magnetic relay (E1HC)

K5R........................Magnetic relay

K6R................# .....Magnetic relay

L1R ........................Reactor

M1C .......................Motor (compressor)

M1F........................ Motor (fan) (upper)

M2F........................ Motor (fan) (lower)

PS .......................... Switching power supply

Q1DI.......................Field earth leakage breaker (300 mA)

R1 ..................* .....Resistor (current limiting)

R1 (A1P) ........# ..... Resistor

R1 (A2P) ........# ..... Resistor

R2 ..................* .....Resistor (current sensor)

R2 (A2P) ........# ..... Resistor

R1T ........................ Thermistor (air)

U-4~6ML5DPQ + U-4~6ML5XPQ

Urban Multi air conditioner

4PW40731-1

Installation manual

13

R2T ................* ......Thermistor (discharge)

R2T ............... #......Thermistor (M1C discharge)

R3T ........................Thermistor (suction 1)

R4T ................* ......Thermistor (heat exchanger)

R4T ............... #......Thermistor (subcool)

R5T ........................Thermistor (suction 2)

R6T ................* ......Thermistor (subcooling heat exchanger)

R6T ............... #......Thermistor (heat exchanger)

R7T ................* ......Thermistor (liquid pipe)

R7T ............... #......Thermistor (liquid pipe 1)

R8T ........................Thermistor (liquid pipe 2)

R9T ............... #......Thermistor (power module)

S1NPH ...................Pressure sensor (high)

S1NPL....................Pressure sensor (low)

S1PH......................Pressure switch (high)

V1R ........................Power module

V2R, V3R ...............Diode module

V1T.................*......IGBT (Insulated Gate Bipolar Transistor)

X1M........................Terminal strip (power supply)

X1M................*......Terminal strip (C/H selector) (A4P)

X2M................*......Terminal strip (control)

X2M............... #......Terminal strip (control) (cool/heat selector)

Y1E ........................Electronic expansion valve (main)

Y3E ........................Electronic expansion valve (subcool)

Y1S ........................Solenoid valve (4 way valve)

Y2S ........................Solenoid valve (hot gas)

Y3S ........................Solenoid valve (unload circuit)

Z1C~Z8C........*......Noise filter (ferrite core)

Z1C~Z4C....... #......Noise filter (ferrite core)

Z1F~Z4F ........*......Noise filter

Z1F................ #......Noise filter (with surge absorber)

Z2F................ #......Noise filter

Cool/heat selector

S1S ........................Selector switch (fan/cool – heat)

S2S ........................Selector switch (cool – heat)

11.2. Precautions on electrical wiring work

■ Before obtaining access to terminal devices, all supply circuits

must be interrupted.

■ Use only copper wires.

■ Do not turn on the main switch until all the wiring is completed.

Make sure that the main switch has a contact separation of at

least 3 mm in all poles.

■ Never squeeze bundled cables into a unit.

■ Secure the electrical wiring with clamping material as shown in

figure 9 so that it does not come in contact with the piping,

particularly on the high-pressure side.

Make sure no external pressure is applied to the terminal

connectors.

■ When installing the earth leakage breaker make sure that it is

compatible with the inverter (resistant to high frequency

electrical noise) to avoid unnecessary opening of the earth

leakage breaker.

■ As this unit is equipped with an inverter, installing a phase

advancing capacitor not only will deteriorate power factor

improvement effect, but also may cause capacitor abnormal

heating accident due to high-frequency waves. Therefore, never

install a phase advancing capacitor.

■ Follow the "electrical wiring diagram" when carrying out any

electrical wiring.

■ Always ground wires. (In accordance with national regulations of

the pertinent country.)

■ Do not connect the ground wire to gas pipes, sewage pipes,

lightning rods, or telephone ground wires.

• Combustion gas pipes: can explode or catch fire if there is a gas

leak.

•Sewage pipes: no grounding effect is possible if hard plastic

piping is used.

•Telephone ground wires and lightning rods: dangerous when

struck by lightning due to abnormal rise in electrical potential in

the grounding.

■ This unit uses an inverter, and therefore generates noise, which

will have to be reduced to avoid interfering with other devices.

The outer casing of the product may take on an electrical charge

due to leaked electrical current, which will have to be discharged

with the grounding.

■ XPQ: Make sure to connect power supply cables in normal

phase. If connected in reverse phase, the remote controller of

the indoor unit indicates "U1" and the equipment cannot operate.

Change any two of the three power supply cables (L1, L2, L3) to

correct phase.

Connector of option adaptor

X37A ......................Connector (option adaptor power supply)

*..............................For U-4~6ML5DPQ only

# .............................For U-4~6ML5XPQ only

Notes

1 This wiring diagram only applies to the outdoor unit.

4 When using the option adaptor, refer to the installation manual.

5 Refer to the wiring diagram sticker (on the back of the front

plate) for instructions on how to use BS1~BS5 and DS1-1,

DS1-2 switches.

6 Do not operate the unit by short-circuiting protection device

S1PH.

8 Refer to the installation manual for connection wiring to indoor-

outdoor transmission F1-F2.

9 When using the central control system, connect outdoor-

outdoor transmission F1-F2.

Installation manual

14

11.3. Connection example of total system wiring

(See figure 8)

1 Power

2 Earth leakage breaker

3 Branch switch overcurrent breaker (fuse)

4 Ground

5 Remote controller

U-4~6ML5DPQ + U-4~6ML5XPQ

Urban Multi air conditioner

4PW40731-1

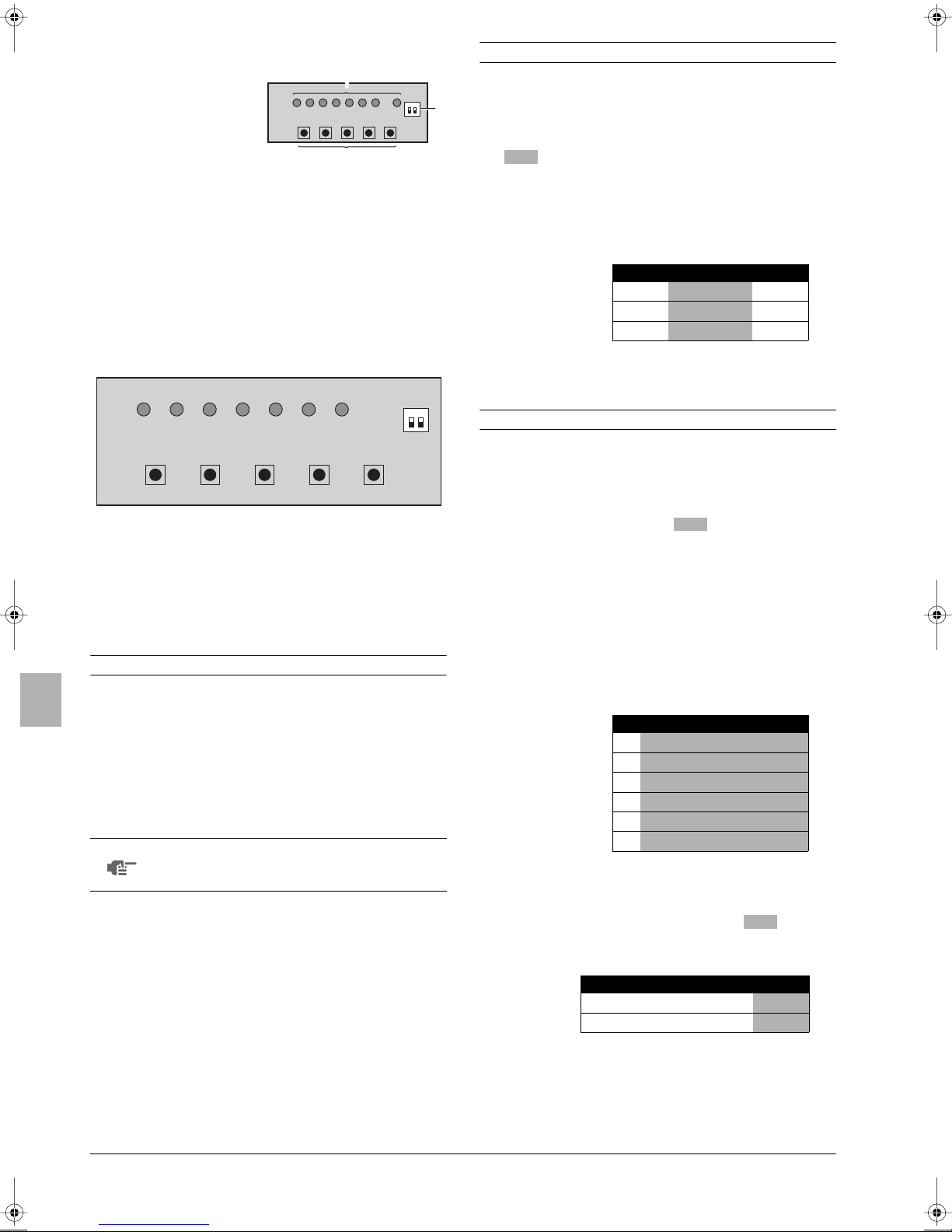

11.4. Connecting power wire and transmission wires

■ Let the power wire (including ground wire) go through the power

outlet port on either the front, side or back of the outdoor unit.

■ Let the transmission wires go through the cable outlet port, pipe

outlet port or knock out hole on either the front, side or back of

the outdoor unit. (See figure 9).

A Rear direction

B Lateral direction

C Front direction

1 Power terminal block (X1M)

2 Control wiring between units

3 Power cable with ground wire. (Keep proper distance between

power cable and control wiring).

4 Clamp (field supply)

5 Stop valve mounting plate

6 Power cable

7 Ground cable (yellow/green)

8 Fix the control wiring with the clamp

9 Control terminal block (X2M)

11.5. Power circuit and cable requirements

A power circuit (see table below) must be provided for connection of

the unit. This circuit must be protected with the required safety

devices, i.e. a main switch, a slow blow fuse on each phase and an

earth leakage breaker.

U-4~6ML5DPQ U-4~6ML5XPQ

Phase and

frequency

Voltage 220-240 V 380-415 V

Recommended

field fuse

Minimum circuit

amps (MCA)

Tr ansmission line

section

Wire type

(*)

(†)

(*) Stated values are maximum values (see electrical data of combination with

indoor units for exact values).

(†) Only in protected pipes, use H07RN-F when protected pipes are not used.

1 N~50 Hz 3 N~50 Hz

32 A 16 A

27 13.5

0.75~1.25 mm

H05VV

2

Precautions when knocking out knockout holes

■ To punch a knock hole, hit on it with a hammer.

■ After knocking out the holes, we recommend you paint the

edges and areas around the edges using the repair paint to

prevent rusting.

■ When passing electrical wiring through the knock holes, remove

any burrs from the knock holes and wrap the wiring with

protective tape to prevent damage.

■ If there is any possibility that small animals enter the system

through the knock holes, plug the holes with packing materials

(to be prepared on-site).

2

1

1 Knockout hole

2 Burr

3 Packing materials

3

■ Use a power wire pipe for the power wiring.

■ Outside the unit, make sure the low voltage electric

wiring (i.e. for the remote control, between units, etc.)

and the high voltage electric wiring do not pass near

each other, keeping them at least 50 mm apart.

Proximity may cause electrical interference,

malfunctions, and breakage.

■ Be sure to connect the power wiring to the power

wiring terminal block and secure it as described under

"11.4. Connecting power wire and transmission wires"

on page 15.

■ Inter-unit wiring should be secured as described in

"11.4. Connecting power wire and transmission wires"

on page 15.

• Secure the wiring with clamps so that it does not touch

the piping.

• Make sure the wiring and the electric box lid do not

stick up above the structure, and close the cover

firmly.

NOTE

■ Select the power supply cable in accordance with

relevant local and national regulations.

■ Wire size must comply with the applicable local

and national code.

■ Specifications for local wiring power cord and

branch wiring are in compliance with IEC60245.

■ In connecting the power cable to the power terminal block,

securely clamp the cable as shown in figure 9.

After finishing the electric work, confirm that each electric

part and terminal inside the electric parts box is connected

securely.

U-4~6ML5DPQ + U-4~6ML5XPQ

Urban Multi air conditioner

4PW40731-1

Installation manual

15

Precautions when laying power wiring

Use round pressure terminals for connections to the power

terminal block.

When none are available, follow the instructions below.

■ Do not connect wiring of different thicknesses to the

power terminal block. (Slack in the power wiring may

cause abnormal heat.)

■ When connecting wiring which is the same thickness,

do as shown in the figure below.

1 Round pressure terminal

2 Power wire

12

■ For wiring, use the designated power wire and

connect firmly, then secure to prevent outside

pressure being exerted on the terminal board.

■ Use an appropriate screwdriver for tightening the

terminal screws. A screwdriver with a small head will

strip the head and make proper tightening impossible.

■ Over-tightening the terminal screws may break them.

■ See the table below for tightening torque for the

terminal screws.

Tightening torque (N•m)

M5 (Power terminal block/ground wire) 2.39~2.92

M4 (Shielded ground) 1.18~1.44

M3.5 (Control wiring block) 0.79~0.97

Field line connection: Control wiring and cool/heat selection

For low-noise operation or demand operation, it is

necessary to get the optional 'External control adaptor for

outdoor unit' (DTA104A61/62).

For details, see the installation manual attached to the

adaptor.

■ Be sure to follow the limits below. If the unit-to-unit

cables are beyond these limits, it may result in

malfunction of transmission.

Maximum wiring length: 300 m

Total wiring length: 600 m

Maximum No. of branches: 9

■ Up to 9 branches are possible for unit-to unit cabling.

No branching is allowed after branching. (See

figure 13).

1 Branch

2 Subbranching

■ Never connect the power supply to unit-to-unit cabling

terminal block. Otherwise the entire system may

break down.

■ The wiring from the indoor units must be connected to the F1/F2

(In-Out) terminals on the PC board in the outdoor unit.

■ After installing the interconnecting wires inside the unit, wrap

them along with the on-site refrigerant pipes using finishing

tape, as shown in figure 14.

1 Liquid pipe

2 Gas pipe

3 Interconnecting wiring

4 Insulator

5 Finishing tape

For the above wiring, always use vinyl cords with 0.75 to 1.25 mm

sheath or cables (2-core wires). (3-core wire cables are allowable for

the cooler/heater changeover remote controller only.)

2

If an excessive force is applied while connecting a cable to

the terminal block on the PC board, the PC board may be

damaged.

See figure 10.

1 Cool/heat selector

2 Outdoor unit PC board

3 Ta ke care of the polarity

4 Use the conductor of sheathed wire (2 wire) (no polarity)

5 Te r minal board (field supply)

Setting the cool/heat operation

1 Performing cool/heat setting with the remote controller

connected to the indoor unit.