Page 1

ORDER NO. ITD0804012CE

DVI-D Terminal Board

Model No. TY-FB11DD

TY-FB11DDC

B34 Canada: D10

© 2008 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and distribution is a violation of law.

Page 2

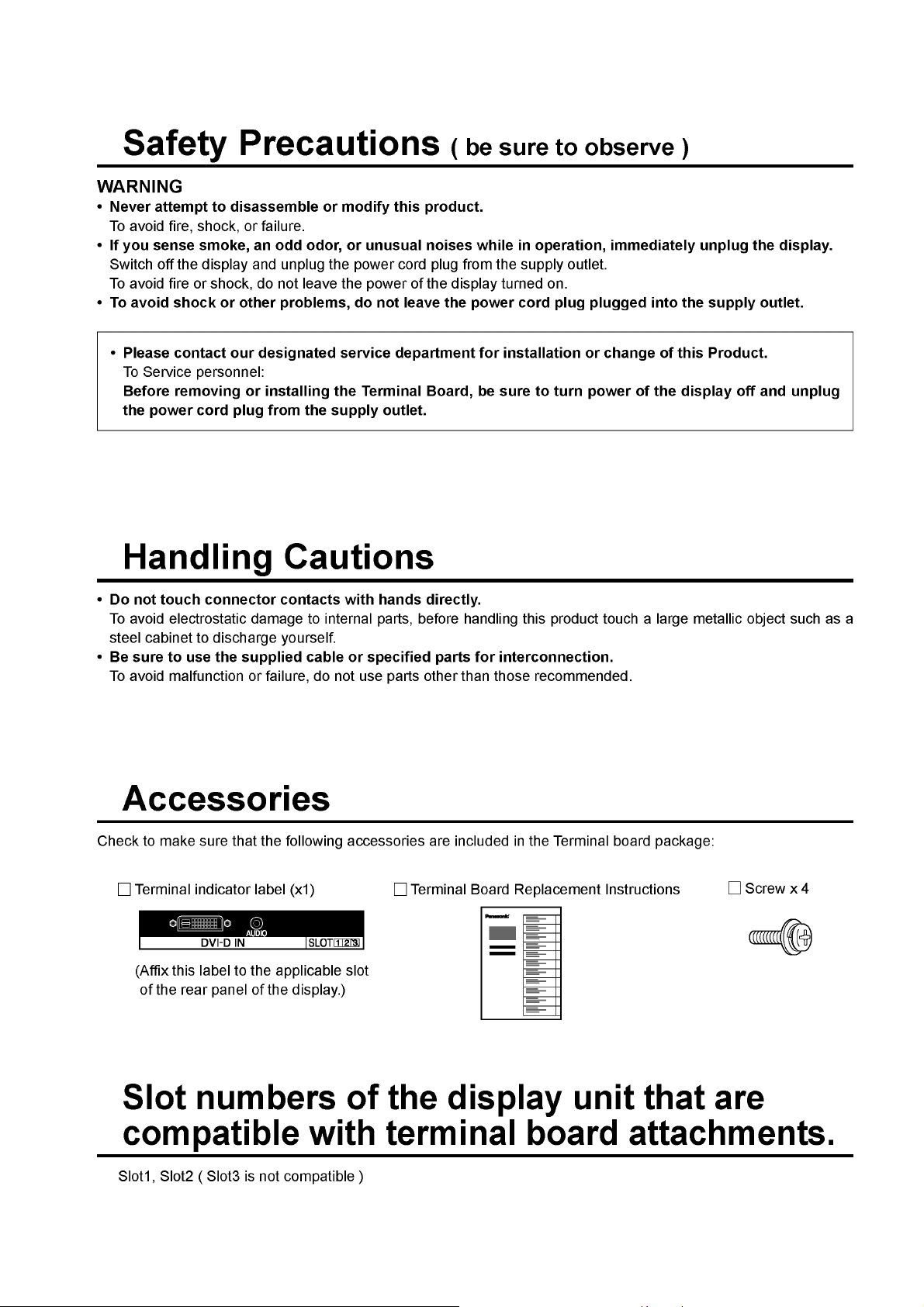

1 Safety Precautions

1.1. General Guidelines

1. When conducting repairs and servicing, do not attempt to modify the equipment, its parts or its materials.

2. When wiring units (with cables, flexible cables or lead wires) are supplied as repair parts and only one wire or some of the

wires have been broken or disconnected, do not attempt to repair or re-wire the units. Replace the entire wiring unit instead.

3. When conducting repairs and servicing, do not twist the Faston connectors but plug them straight in or unplug them straight

out.

4. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

5. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

6. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

1.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the

two prongs on the plug.

2. Measure the resistance value, with an ohmmeter,

between the jumpered AC plug and each exposed metallic cabinet part on the equipment such as screwheads,

connectors, control shafts, etc. When the exposed metallic part has a return path to the chassis, the reading

should be between 1Mohm and 5.2Mohm.

When the exposed metal does not have a return path to

the chassis, the reading must be .

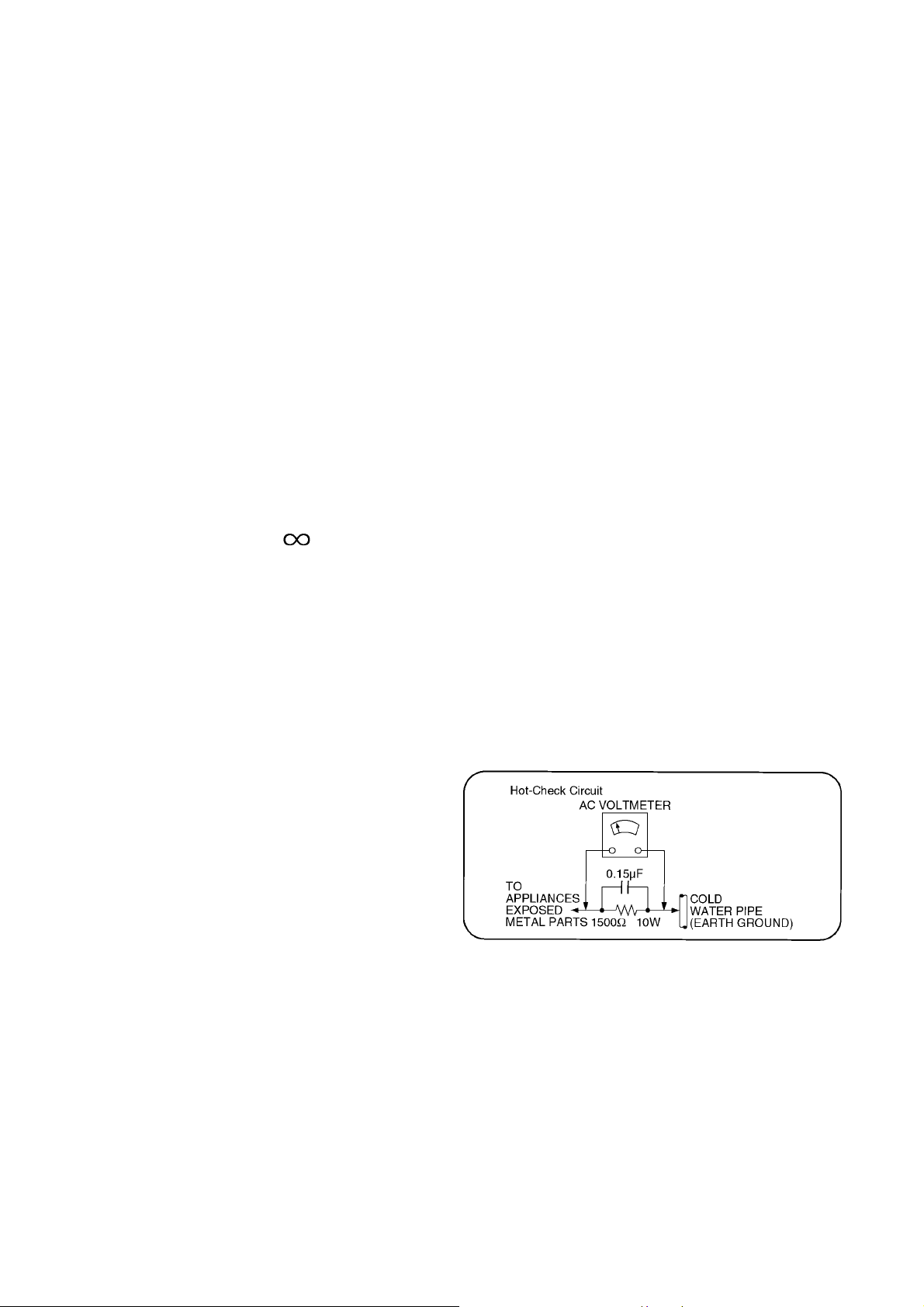

1.1.2. Leakage Current Hot Check (See Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer for this check.

2. Connect a 1.5kohm, 10 watts resistor, in parallel with a

0.15μF capacitors, between each exposed metallic part

on the set and a good earth ground such as a water pipe,

as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of

the above measurements.

6. The potential at any point should not exceed 0.75 volts

RMS. A leakage current tester (Simpson Model 229 or

equivalent) may be used to make the hot checks, leakage

current must not exceed 1/2 milliamp. In case a measurement is outside of the limits specified, there is a possibility of a shock hazard, and the equipment should be

repaired and rechecked before it is returned to the customer.

Figure 1

2

Page 3

2 Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor [chip] components. The following techniques should be used to help reduce the incidence of component damage

caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as [anti-static (ESD protected)] can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise ham less motion such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient

to damage an ES device).

3

Page 4

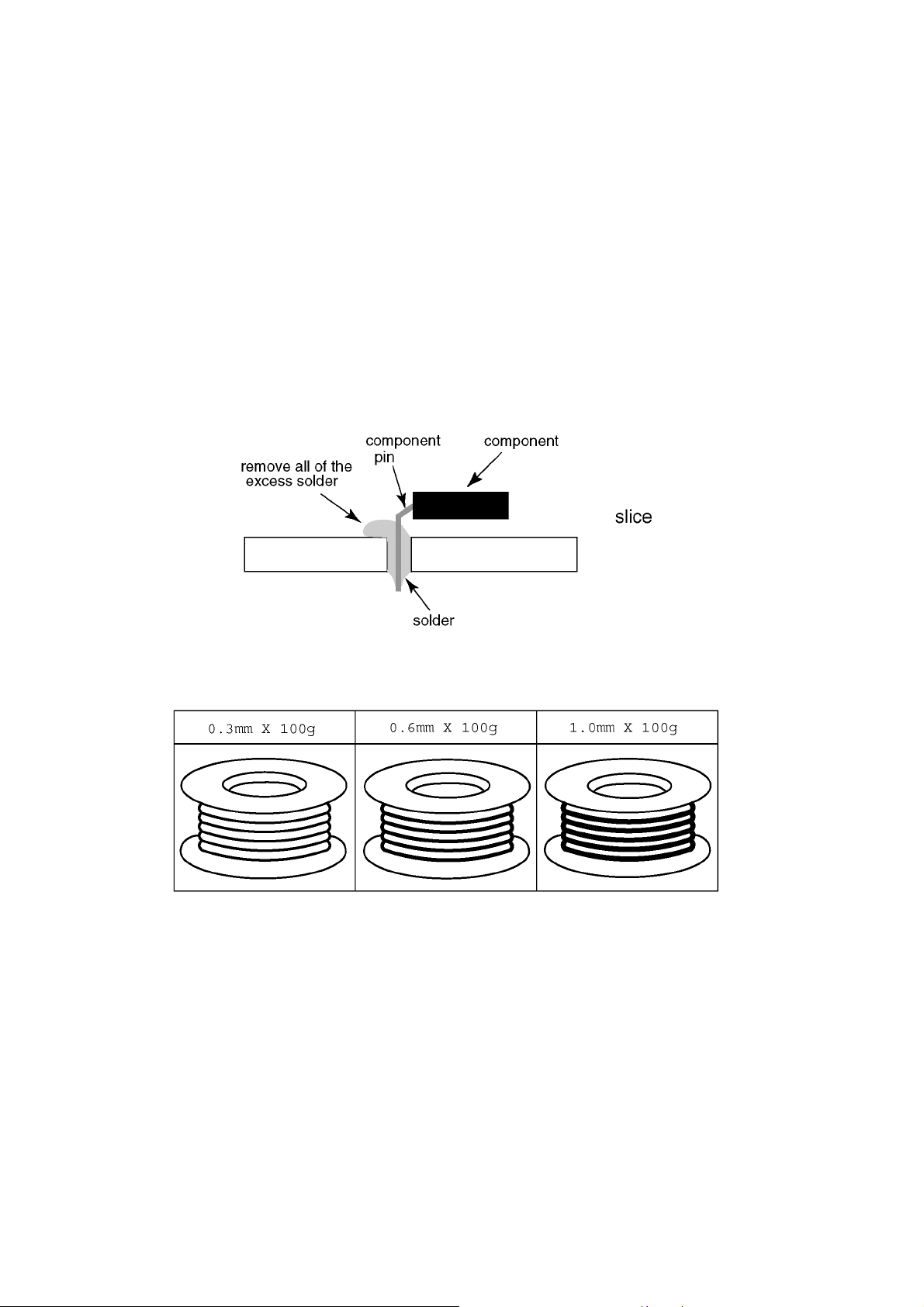

2.2. About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair work, we’d

suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol PbF stamped on the back of PCB.

Caution

• Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30~40 °C) higher. Please

use a high temperature soldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

• Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before applying Pb solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

• After applying PbF solder to double layered boards, please check the component side for excess solder which may flow onto the

opposite side. (see figure below)

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin, silver, copper) solder. However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used.

4

Page 5

3 Specifications

Term in als Video Input DVI-D 24 Pin × 1

Content Protection Compatible with HDCP 1.1

compliance with DVI Revision 1.0

Audio Input Stereo mini jack (M3) × 1

0.5 Vrms

5

Page 6

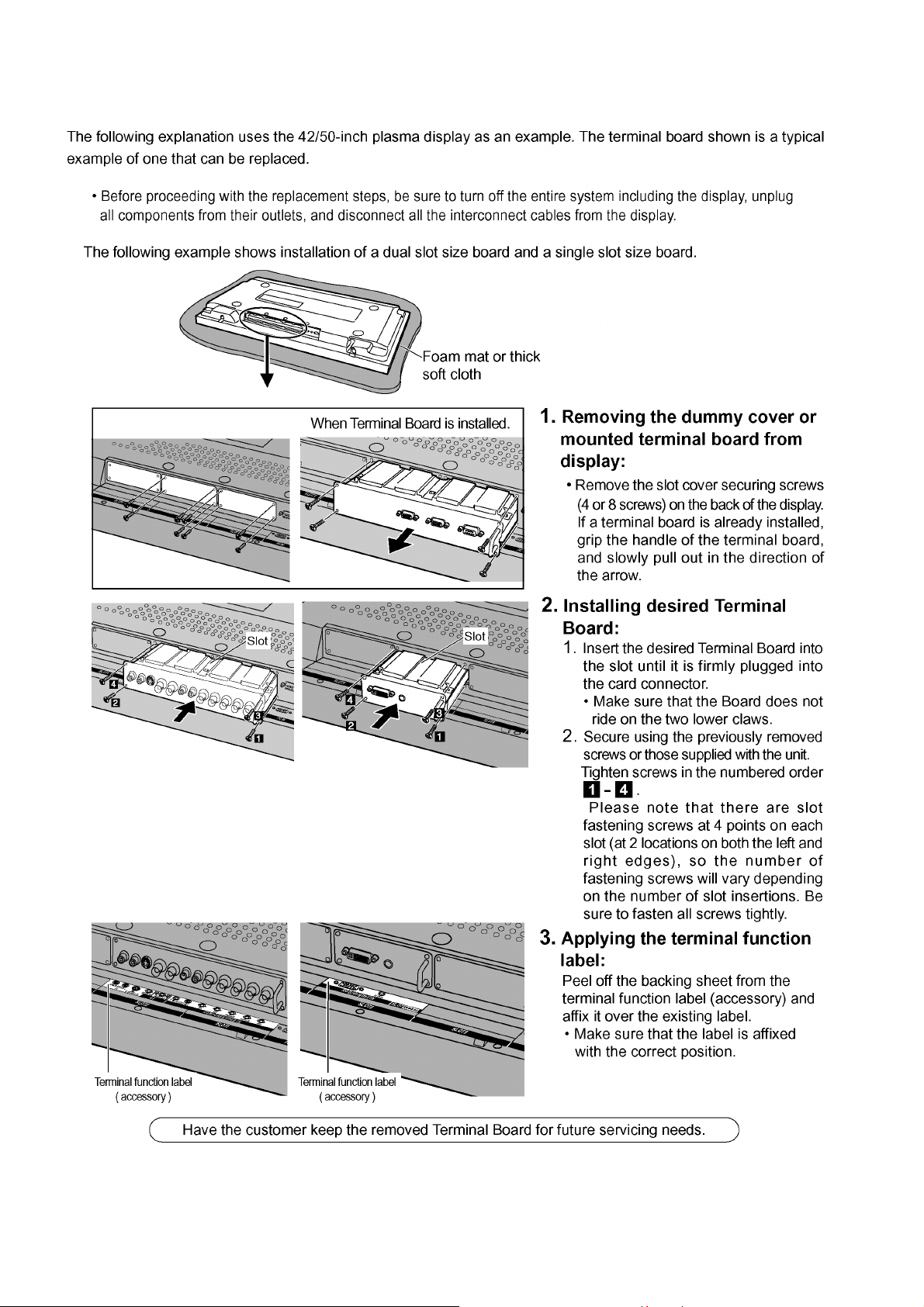

4 Installation Instructions

6

Page 7

5 Operating Instructions

7

Page 8

8

Page 9

6 Service Fixture & Tools

Note:

Extension cable kit for Slot Board is supplied as service fixtures and tools.

(Part No. TZSC07040)

9

Page 10

7 Disassembly and Assembly Instructions

7.1. Remove the HDE Board

1. Remove the screws ( ×2 ) and then remove the HDE

terminal fixed metal.

2. Remove the screws( ×4 ) and then remove the Shield

case A/B and HDE Board.

10

Page 11

8 Block Diagram

8.1. HDE-Board Block Diagram

A

JK3302

DVI AUDIO IN

R

L

FOR

FACTORY

USED

H2

Q3302

Q3303

B

D3025

FOR

FACTORY

USED

JK3301

C

DVI IN

HPS

TMDS_CDDCD

GND

TMDS_C+

DDCC

+5V

TMDS_G

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

TMDS_G

TMDS_G

TMDS_G

TMDS_D2+

TMDS_D1+

TMDS_D0+

TMDS_D2TMDS_D1TMDS_D0-

H4

8

16

24

7

15

23

6

14

22

5

13

21

4

12

20

3

11

19

2

10

18

1

9

17

DVI_CN_SDA/SCL

EDID_WP

D3011

D

DVI_CN_SDA

DVI_CN_SCL

TMDS_RX2+

TMDS_RX1+

TMDS_RX0+

TMDS_RX2TMDS_RX1TMDS_RX0-

AUDIO_R

AUDIO_L

+5V

SDA/SCL

Q3304

IC3303

LEVEL SHIFT

5V<->3.3V

VCC

B

IC3301

EEPROM

SDA

SCL WC

TMDS_RXC-

TMDS_RXC+

TMDS RX0

Q3301

DVI_5V_DET

OE2

VCC

A

Q3305

-RX2

IC3307

DVI I/F RECEIVER

VCC(+1.8V)

VCC(+3.3V)

DSCL1/DSA1

R1PWR5V

CSDA/CSCL

IC3312

RESET

VCC

VOUT

DVI_IIC

PLL

LATCH

IC3308

+1.8V

DATA RECOVERY

SYNCHRONIZATION

X3301

3

OUT4VDD

1OE2

GND

IC3310

GENX MPU

NRST RESET

SDA0

SCL0

VCC(+3.3V)

DVI_5V_DET

HPD

AND

XTAL IN

N_FHD

SDA2

SCL2

SDA1

SCL1

OSCXO

OSCXI

TMDS

DECODER

IC3314

CONFIG ROM

DATA

ASD

VCC

DCLK

EPCS_DATA

EPCS_ASD

EPCD_DCLK

RGB

OUTPUT

RESET

GENX_COMTROL_IIC

X3302

10MHz

R0-R7

G0-G7

B0-B7

HSYNC,VSYNC,DOCK

TVLOAD_IIC

IC3341

R0-R7

G0-G7

B0-B7

H,V,CK

CLK7(27MHz)

NRST

FPGA

VCC(+3.3V)

VCC(+1.2V)

SDA/SCL

IC3320

LEVEL SHIFT

5V<->3.3V

A

O_CLK

CLK4

VCC

S2

S1

B

EVEN_R0-R7

EVEN_G0-G7

EVEN_B0-B7

H,V,CLK

ODD_R0-R7

ODD_G0-G7

ODD_B0-B7

SLOT_IIC

XIN

CKOUT

FREQ0

FREQ1

IC3342

+1.2V

IC3343

CPG

VCC(+3.3V)

SLOT_IIC

+3.3V

VCC(+3.3V)

R0-R7

G0-G7

B0-B7

H,V,CK

R0-R7

G0-G7

B0-B7

IC3346

LVDS TX

SDA/

SCL

TA1 -TE1

TA2

IC3319

EEPROM

IC3345

+3.3V

VCC

WR

-TE2

TCK1

PA3301

TO

SLOT1,SLOT2

H1

A26

AUDIO_OUT_L

A28

AUDIO_OUT_R

A19

+5V

B19

+5V

B39

PLUG DET

A21

+9V

B21

+9V

B38

+15V

B37

+15V

A22

STB+5V

LVDS_TX4+

A3

LVDS_TX4-

A2

B3

LVDS_TX0+

LVDS_TX0-

B2

A10

LVDS_TX7+

A9

LVDS_TX7-

A5 LVDS_TX5+

LVDS_TX5-A4

LVDS_TX1+

B6

LVDS_TX1-

B5

B12

LVDS_TXC+

B11

LVDS_TXC-

LVDS_TX6+

A8

A7 LVDS_TX6-

A13

LVDS_TX8+

A12

LVDS_TX8-

B9

LVDS_TX2+

B8

LVDS_TX2-

A15

LVDS_TX9+

A14

LVDS_TX9-

B15

LVDS_TX3+

B14

LVDS_TX3-

A23

HD/FHD DET

B25

IIC_SCL

B24

IIC_SDA

B23

SRQ

FOR

FACTORY

USED

H3

TA1+

TA1-

TB1+

TB1-

TC1+

TC1-

TD1+

TD1-

TE1+

TE1-

AUDIO_L

AUDIO_R

+15V

TCK1+

TCK1-

TA2+

TA2-

TB2+

TB2-

TC2+

TC2-

TD2+

TD2-

TE2+

TE2-

+9V

STB+5V

+5V

E

TY-FB11DD/C

HDE-Board Block Diagram

TY-FB11DD/C

HDE-Board Block Diagram

1

25

3

4

876

11

Page 12

9 Schematic Diagram

9.1. Schematic Diagram Note

12

Page 13

9.2. HDE-Board (1/3) Schematic Diagram

L3357

J0JHC0000075

C3416

C3421

6.3V

16V

0.1u

10u

7

C3372

10V

1u

6

VSYNC

HSYNC

DE

L3325

C3420

6.3V

10u

R3578

R3577

3.3k

FPGA_RST

J0JHC0000075

C3423

16V

0.1u

DVI_RST

C3389

C3388

R3452

50V

18p

10MHz

85

86

P2487P2588P2689P27

IVDD

IC3310

MNZSFD7GDE1

GENX MPU

H0J100500030

R3453

820

82

83

VSS

OSCXO84OSCXI

TVRP845

50V

15p

X3302

C3390

16V

C3393

0.1u

16V

C3392

0.1u

10V

1u

C3394

10V

1u

74

75

79

80

VDD

N.C.76N.C.77N.C.78IVDD

N.C.81RONA

VPPEX

P66/SBI2

P65/SBO2

P76/CEC0

R3459

100

R3511

47k

10k

R3464

66

67

68

65

63

P3069P3170P3271P3372P3473P35

62

61

N.C.

60

N.C.

59

P17

58

P16

57

N.C.

P15

56

P14

P72/SDA164P73/SCL1

55

P13

54

P12

53

P11

52

P10

51

VSS

50

IVDD

49

P23

48

P22

47

P21

46

P20

45

P50/RMIN/IRQ0

44

N.C.

43

N.C.

42

N.C.

41

N.C.

40

P71/SCL0

39

P70/SDA0

P60/SBO0A34P61/SBT0A35P62/SBI0A

38

P07/IRQ8

VDD

IVDD

P46

R3502 0

10k

R3454

47k

R3503

GENX_NBOOT

P06/IRQ7

P05/IRQ6

R3540

47k

GenX-EEP_WP

37

36

33

31

32

30

C3395

10V

1u

R3509 47k

R3507 47k

C3396

16V

0.1u

22

R350022R3499

R3494

R3493 10k

22

R3465

22

R3481

10k

R3505

47k

R3504

10k

C3397

16V

R3479

47k

10k

R3466

22

R3495

R3467

22

TVLOAD_SCL

TVLOAD_SDA

HPD

R3501

100

DVI_5V_DET

0.1u

DVI_INT

10k

R3461

DVI_SCL

DVI_SDA

R3451

R3450

C3385

C3384

10V

16V

0.1u

10u

0

4.7k

R3544

4.7k

R3545

R3441

R3449

C3386

16V

0.1u

R3506

R3508

GENX_NBOOT

100

47k

47k

47k

GENX_NBOOT

1k

33

100

97

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

47k

R3448

C3387

10V

1u

90

92

93

94

95

96

NRST

NBOOT

P64/SBI191P63/SBO1

TRCST

NTEST

TRCD0

SCLOCK

SDATA

TRCD1

TRCD2

TRCD3

EXTRG098EXTRG199TRCCLK

P90

P91

VSS

IVDD

P92

P93

P80/ADIN0

P81/ADIN1

P82/ADIN2

P83/ADIN3

P84/ADIN4

P85/ADIN5

P86/ADIN6

P87/ADIN7

P74/SDA2/CECAVL1B

P75/SCL2/CECAVL1A

P36

P37

PC0

PC1

P40/TMIO0/SYSCLK

P47

P41/TMIO1

P42/TMIO2

PB0

P43/TMIO3

PB1

P44/TMIO45P00/TMIO56P017P028P03/SBT0B9P04/SBO0B10P51/IRQ211P52/IRQ312PB213PB314PB415PB516PB617PB718P53/IRQ419P54/IRQ520PA721PA622PA523VSS24PA425PA326PA227PA1/IRQ128PA029P45

1

2

3

4

47k

R3573

R3571 47k

R3572 47k

FPGA_CLK

B0

B1

B2

B3

B4

B5

B6

B7

G0

G1

G2

G3

G4

G5

G6

G7

DOCK

R0

R1

R2

R3

R4

R5

R6

R7

GENX_CTRL_SDA

GENX_CTRL_SCL

C3417

6.3V

10u

L3328

C3357

C3358

C3359

C3360

C3361

C3362

C3356

10V

1u

J0JHC0000034

0.1u

0.1u

0.1u

0.1u

0.1u

0.1u

C3363

6.3V

2.2u

C3364

50V

470p

J0JHC0000034

J0JHC0000034

R3404

C3414

6.3V

10u

IC3308

C0DBFFD00003

MAIN 1.8V

1

Vin

Vo

2

NC

sub

3

GND

45

CONT

Cn

L3312

L3314

R3496 22

R3492 22

R3491 82

EXB2HV820JV

EXB2HV820JV

EXB2HV820JV

10

R3410

R3406

R3407

/PLUG_DET

5V

C3313

1u

1

/OE1

2

A1

3

B2

45

GND

IC3303

C0JBAZ002269

5V<=>3.3V

FOR

FACTORY

USE

1

2

3

4

10V

R3350

10k

8

Vcc

TP3317

7

/OE2

6

B1

R3357

33

A2

R3356

33

3.3VTMDS

L3368

TMDS_RXC-

TMDS_RXC+

TMDS_RX0-

TMDS_RX0+

L3310

J0JHC0000034

TMDS_RX1-

TMDS_RX1+

J0JHC0000034

C3497

6.3V

10u

TMDS_RX2-

TMDS_RX2+

C3328

16V

0.1u

C3329

10V

1u

C3320

1u

10V

C3321

1u

10V

C3322

1u

10V

C3323

1u

10V

C3318

10V1u

C3319

C3324

0.1u

16V

1u

10V

C3325

1u

10V

C3326

1u

10V

C3327

1u

10V

A

DVI_CN_SCL

DVI_CN_SDA

R3349

TP3347

10k

R3346

33

R3345

33

TVRP844

IC3301

C3EBDC000067

EDID EEPROM

1

E0

B

C

2

E1

3

E2

4

VSS

JK3301

K1FB124B0025

DVI I N

-

HPS

TMDS_C-

DDCD

GND

TMDS_C+

DDCC

+5V

TMDS_G

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

TMDS_G

TMDS_G

TMDS_G

TMDS_D2+

TMDS_D1+

TMDS_D0+

TMDS_D2-

TMDS_D1-

TMDS_D0-

VCC

WC

SCL

SDA

8

16

24

7

15

23

6

14

22

5

13

21

4

12

20

3

11

19

2

10

18

1

9

17

D3309

MAZ30560ML

R3022

10k

R3023

R3024

4.7k

D3001

EZAEG2A50AX

C3488

16V

0.1u

C3426

16V

0.1u

D3004

EZAEG2A50AX

4.7k

R3025

56

R3026

56

D3002

EZAEG2A50AX

L3364

J0JHC0000034

D3003

EZAEG2A50AX

D3011

B0HCMM000014

D3307

MAZ30560ML

8

7

6

5

D3025

B0HCMM000014

D3310

MAZ30560ML

5V

H4

DVI_CN_SCL

DVI_CN_SCL

DVI_CN_SDA

DVI_CN_SDA

TMDS_RXC-

DVI_CN_SDA

TMDS_RXC+

DVI_CN_SCL

D3311

MAZ30560ML

TMDS_RX2+

TMDS_RX1+

TMDS_RX0+

TMDS_RX2-

TMDS_RX1-

TMDS_RX0-

D

D3005

EZAEG2A50AX

D3009

EZAEG2A50AX

D3006

EZAEG2A50AX

D3010

EZAEG2A50AX

D3008

EZAEG2A50AX

EZAEG2A50AX

HPD

DVI_5V_DET

R3431

10k

5V

R3518

1k

D3308

Q3304

R3463

R3462

39

2SD0601ASL

10k

C3494

16V

0.1u

R3469

10k

C3495

16V

0.1u

Q3301

2SD0601ASL

D3007

EZAEG2A50AX

E

22

R3470

DVI_SCL

Q3305

2SK122800L

R3510

4.7k

R3512

4.7k

R3377

10k

C3335

0.01u

25V

R3374

10k

C3333

25V

0.01u

C3330

16V

0.1u

C3498

16V

0.1u

35

36

37

38

39

R0XC+

40

AGND

41

AVCC

42

R0X0-

43

R0X0+

44

AGND

45

AVCC

46

R0X1-

47

R0X1+

48

AGND

49

AVCC

50

R0X2-

51

R0X2+

52

AGND

53

TMDSPGND

54

PVCC1

55

RSVD_A

56

AVCC

57

R1XC-

58

R1XC+

59

AGND

60

AVCC

61

R1X0-

62

R1X0+

63

AGND

64

AVCC

65

R1X1-

66

R1X1+

67

AGND

68

AVCC

69

70

74

73

0.1u

C3331

16V

DVI_SDA

SGD

C3340

16V

0.1u

C3336

16V

4.7k

4.7k

R3364

R3365

33

34

R1PWR5V

AVCC

R0XC-

R1X2-71R1X2+72AGND

IOVCC77MUTEOUT78SPDIF79CVCC1880CGND81NC82NC83NC84SD085WS86SCK87NC88MCLKOUT89IOVCC90IOGND91CGND92CVCC1893NC94AUDPVCC1895AUDPGND96XTALOUT97XTALIN98XTALVCC99REGVCC

75

76

0.1u

C3332

16V

0.1u

22

22

C3341

16V

0.1u

R3380

R3381

0.1u

C3337

16V

22

24

25

27

29

CGND

CSDA28CSCL

IOGND26IOVCC

DSDA130DSCL131DSDA032DSCL0

R0PWR5V

CVCC18

CGND

PVCC0

CGND

CVCC18

IOGND

0.1u

C3334

16V

CVCC1823CVCC18

IC3307

C1AB00002848

DVI I/F RECEIVER

C3338

CGND

C3339

J0JHC0000075

MAIN1.8V

C3354

C3346

C3344

16V

0.1u

10u

6.3V

0.1u

16V

L3311

C3353

16V

16V

0.1u

0.1u

10NC11NC12NC13NC14NC15

17NC18NC19NC20NC21

IOGND16IOVCC

EVNODD

VSYNC

HSYNC

Pad

Thermal

IOGND

CLK48B

CGND

RSVDL

100NC101

0.1u

0.1u

0.1u

C3351

C3345

C3342

16V

R3394

16V

16V

C3349

16V

0.1u

DVI_CLK

27MHz

10

R3401

R3408

10

2

GND3OUT

X3301

H1A2705B0032

VDD

OE

1

4

C3476

16V

0.1u

C3355

16V

6.3V

0.1u

10u

1DE2

3

4

6NC7NC8NC9

144

143

IOGND5IOVCC

142

Q3

141

16V

Q4

140

CVCC18

139

CGND

Q2

Q1

Q0

138

Q5

137

Q6

136

16V

IOGND

135

IOVCC

134

Q7

133

Q8

132

Q9

131

Q10

130

16V

Q11

129

CVCC18

128

CGND

127

Q12

126

Q13

125

Q14

124

16V

Q15

123

IOVCC

122

ODCK

121

IOGND

120

Q16

119

Q17

118

Q18

117

Q19

116

16V

CGND

IOVCC

Q23

Q22

115

CVCC18

114

Q20

113

Q21

112

111

110

RESET

SCDT

INT

CVCC18

109

102

103

104

22

R3399

1.8k

DVI_RST

DVI_INT

16V

105

106

107

108

4.7k

R3398

1

2

3

4

N_FHD

F

TY-FB11DD/C

HDE-Board (1/3) Schematic Diagram

!

HDE-BOARD TXNHDE10UNT (1/3)

13

FPGA_PWD

GENX_NBOOT

LVDS_PWD

TY-FB11DD/C

5

6

HDE-Board (1/3) Schematic Diagram

74312

956 8

Page 14

9.3. HDE-Board (2/3) Schematic Diagram

1

2

C3422

6.3V

10u

FOR

FACTO RY

USE

DCLK

GND

CONF_DONE

VCC(TRGT)

nCONFIG

nCE

DATAOUT

nCS

ASDI

GND

J0JHC0000075

C3425

16V

0.1u

R3488

10k

L3327

R3517 47

1

XIN

XIN

XOUT

2

XOUT

VSS

3

VSS

SEL

4

SEL

IC3343

C0ZBZ0001561

IC3341

C1ZBZ0003575

ALTERA CYCLONE2 (BGA)

FPGA_CLK

CPG

FREQ1

FREQ0

CKOUT

!

HDE-BOARD TXNHDE10UNT (2/3)

3

IC3342

C0DBEHG00006

PLL 1.8V

FREQ1

8

FREQ0

7

VDD

6

VDD

R3651

10

CKOUT

5

GND

IC3341 D3 IO

IC3341 D7 IO

IC3341 D8 IO

IC3341 D9 IO

IC3341 D10 IO

IC3341 E3 IO

IC3341 E4 IO

IC3341 E5 IO

IC3341 E6 IO

IC3341 E13 IO

IC3341 F5 IO

IC3341 F6 IO

IC3341 F7 IO

IC3341 F8 IO

IC3341 F9 IO

IC3341 F10 IO

IC3341 G4 IO

IC3341 G6 IO

IC3341 G7 IO

IC3341 G10 IO

IC3341 G11 IO

IC3341 G12 IO

IC3341 G13 IO

IC3341 H6 IO

IC3341 H11 IO

IC3341 H12 IO

IC3341 H13 IO

IC3341 J4 IO

IC3341 J6 IO

IC3341 J11 IO

IC3341 J12 IO

10k

R3641

R3400

IC3341 K4 IO

IC3341 K5 IO

IC3341 K6 IO

IC3341 K7 IO

IC3341 K10 IO

IC3341 K13 IO

IC3341 L4 IO

IC3341 L7 IO

IC3341 L8 IO

IC3341 L9 IO

IC3341 L10 IO

IC3341 L11 IO

IC3341 L12 IO

IC3341 L14 IO

IC3341 M3 IO

IC3341 M4 IO

IC3341 M11 IO

IC3341 M12 IO

IC3341 M14 IO

IC3341 N16 IO

IC3341 N3 IO

IC3341 N4 IO

IC3341 N6 IO

IC3341 N7 IO

IC3341 N8 IO

IC3341 N9 IO

IC3341 N10 IO

IC3341 N11 IO

IC3341 N12 IO

C3400

50V

1000p

10k

3.3VAnalog

C3399

0.1u

10k

R3644

CLK Pin

TEST_Pin

16V

SEL

R3482

R3484

R3485

R3486

R3515

R3519

L3322

J0JHC0000075

C3455

6.3V

10u

IC3341 K15 IO

IC3341 K16 IO

IC3341 L15 IO

IC3341 L16 IO

IC3341 H2 CLK0

IC3341 H1 CLK1

IC3341 J2 CLK2

IC3341 J1 CLK3

IC3341 H16 CLK4

IC3341 H15 CLK5

IC3341 J15 CLK6

IC3341 J16 CLK7

10k

IC3341 F3 IO

10k

IC3341 F13 IO

10k

IC3341 E14 IO

10k

IC3341 M1 IO

10k

IC3341 M15 IO

10k

IC3341 M16 IO

IC3341 N14 IO

IC3341 N15 IO

IC3341 P2 IO

IC3341 P3 IO

IC3341 P4 IO

IC3341 P5 IO

IC3341 P6 IO

IC3341 P11 IO

IC3341 P12 IO

IC3341 P13 IO

IC3341 P14 IO

IC3341 P15 IO

IC3341 P16 IO

C3460

16V

0.1u

S0

O_CLK

S2

S1

TP3360

L3329

J0JHC0000075

+

C3407

C3408

C3406

16V

0.1u

C3403

16V

4V

6.3V

0.01u

100u

10u

POWER BLOCK(1.2V/3.3V/GND)

L3370

J0JHC0000075

C3480

6.3V

10u

J0JHC0000075

C3526

C3527

50V

50V

1000p

1000p

C3520

C3521

16V

16V

0.1u

0.1u

L3358

C3410

C3411

6.3V

10u

C3542

16V

0.1u

(FIN)

GND(FIN)

OUT5ADJ

4

R3439

33k

R3438

20k

C3415

C3405

16V

10V

0.1u

1u

CTL2Vcc

1

R3433

10k

L3326

J0JHC0000075

C3418

C3404

C3424

6.3V

10V

16V

10u

1u

0.1u

LVDS_OUT

1.2V

C3522

50V

50V

1000p

1000p

C3449

C3450

16V

16V

0.1u

0.1u

3.3VFPGA

C3412

C3541

6.3V

16V

0.1u

10u

C3546

C3547

16V

0.1u

C3538

C3537

16V

0.1u

C3531

C3532

16V

0.1u

C3446

50V

50V

50V

50V

1000p

1000p

1000p

C3445

C3443

C3444

16V

16V

16V

0.1u

0.1u

0.1u

L3343

J0JHC0000075

C3442

6.3V

10u

L3344

J0JHC0000075

C3440

6.3V

10u

C3540

C3539

16V

16V

16V

0.1u

0.1u

0.1u

C3545

C3544

16V

16V

16V

0.1u

0.1u

0.1u

C3534

C3536

16V

16V

16V

0.1u

0.1u

0.1u

C3529

C3530

16V

16V

16V

0.1u

0.1u

0.1u

IC3341 J7 VCCINT

1000p

IC3341 H10 VCCINT

IC3341 H7 VCCINT

IC3341 G9 VCCINT

IC3341 F11 VCCD_PLL2

IC3341 L6 VCCD_PLL1

C3427

16V

0.1u

IC3341 N5 GND_PLL1

IC3341 L5 GND_PLL1

IC3341 F12 GND_PLL2

IC3341 D12 GND_PLL2

1.2V(PLL)

IC3341

M5 VCCA_PLL1

C3434

C3441

50V

16V

1000p

0.1u

IC3341 M6 GNDA_PLL1

1.2V(PLL)

IC3341 E12 VCCA_PLL2

C3439

C3431

50V

16V

0.1u

1000p

IC3341 E11 GNDA_PLL2

3.3V(I/O)

IC3341 R1 VCCIO1

IC3341 G3 VCCIO1

C3535

16V

IC3341 K3 VCCIO1

0.1u

IC3341 B1 VCCIO1

IC3341 A2 VCCIO2

IC3341 A15 VCCIO2

IC3341 C10 VCCIO2

C3543

16V

IC3341 C7 VCCIO2

0.1u

IC3341 E10 VCCIO2

IC3341 E7 VCCIO2

IC3341 K14 VCCIO3

IC3341 R16 VCCIO3

IC3341 G14 VCCIO3

C3533

16V

IC3341 B16 VCCIO3

0.1u

IC3341 M10 VCCIO4

IC3341 M7 VCCIO4

IC3341

P7 VCCIO4

IC3341 P10 VCCIO4

C3528

16V

IC3341 T2 VCCIO4

0.1u

IC3341 T15 VCCIO4

GND

IC3341

A1 GND

IC3341 B2 GND

IC3341 A16 GNDIC3341

IC3341 E8 GND

IC3341 E9 GND

IC3341 B15 GND

IC3341 C8 GND

IC3341 C9 GND

IC3341 G8 GND

IC3341 H3 GND

IC3341 H8 GND

IC3341 H9 GND

IC3341 H14 GND

IC3341 J3 GND

IC3341 J8 GND

IC3341 J9 GND

IC3341 J14 GND

IC3341 K9 GND

IC3341 M8 GND

IC3341 M9 GND

IC3341 P8 GND

IC3341 P9 GND

IC3341 R2 GND

IC3341 T1 GND

IC3341 R15 GND

IC3341 T16 GND

IC3341 K8 VCCINT

IC3341 J10 VCCINT

C3432

C3447

C3448

C3523

GENX_CTRL_SDA

GENX_CTRL_SCL

S/D_SEL

N_FHD

IC3341E2IO

IC3341E1IO

IC3341D2IO

EXB2HV820JV

IC3341D1IO

IC3341C2IO

IC3341C1IO

IC3341C4IO

IC3341D4IO

IC3341C5IO

IC3341D5IO

IC3341C6IO

EXB2HV820JV

IC3341D6IO

IC3341A3IO

IC3341A4IO

IC3341B4IO

IC3341A5IO

IC3341B5IO

IC3341A6IO

IC3341B6IO

EXB2HV820JV

IC3341A7IO

IC3341B7IO

IC3341A8IO

IC3341B8IO

IC3341A9IO

IC3341B9IO

IC3341A10IO

IC3341B10IO

EXB2HV820JV

IC3341A11IO

IC3341B11IO

IC3341A12IO

IC3341B12IO

IC3341A13IO

IC3341B13IO

IC3341A14IO

IC3341B14IO

EXB2HV820JV

IC3341D11IO

IC3341C11IO

IC3341C12IOIC3341 K11 IO

IC3341D13IO

IC3341C13IO

IC3341D14IO

IC3341C14IO

R3418

IC3341C16IO

R3422

IC3341C15IO

EXB2HV820JV

IC3341D16IO

IC3341D15IO

IC3341E16IO

IC3341E15IO

IC3341F16IO

IC3341F15IO

IC3341G16IO

IC3341G15IO

R3427

R3428

R3429

R3423

R3424

R3425

R3411

R3417

R3426

R3476 0

R3477 0

R3483

82

82

56

82

82

33

LVDS_BE3

LVDS_GO2

LVDS_CLKIN1

LVDS_DE1

LVDS_VSYNC1

LVDS_HSYNC1

LVDS_BE7

LVDS_BE6

LVDS_BE5

LVDS_BE4

LVDS_BO1

LVDS_BE1

LVDS_BE0

LVDS_BO0

LVDS_GO1

LVDS_GO0

LVDS_RO1

LVDS_RO0

LVDS_BO3

LVDS_GE1

LVDS_GE0

LVDS_BO2

LVDS_GO7

LVDS_GO6

LVDS_GO5

LVDS_GO4

LVDS_GO3

LVDS_RE1

LVDS_RE0

LVDS_BO7

LVDS_BO6

LVDS_BO5

LVDS_BO4

LVDS_GE2

LVDS_RE7

LVDS_RO7

LVDS_RO6

LVDS_BE2

LVDS_GE7

LVDS_RE6

LVDS_RE5

LVDS_RE4

LVDS_RE3

LVDS_RE2

LVDS_RO5

LVDS_RO4

LVDS_GE6

LVDS_GE5

LVDS_RO3

LVDS_RO2

LVDS_GE4

LVDS_GE3

IC3341 L2 IO

IC3341 K1 IO

IC3341 F14 IO

IC3341 L3 IO

3.3VCONFIG

IC3314

C1ZBZ0003631

CONFIG ROM

1

nCS

2

DATA

3

VCC

4

GND

TVRP843

R3650

47

R3478

47

C3402

10V

1u

IC3312

C0EBE0000066

RESET

C3398

16V

0.1u

5

Vcc4Vout

SUB

1NC2

GND

3

R3473

470

open collector

RESET 2.8V

3

EPCS_DATA

EPCS_NCS

8

VCC

7

VCC

R3649

47

6

DCLK

EPCS_ASD

5

ASDI

R3489

C3413

10k

16V

0.1u

EPCS_DCLK

C3419

6.3V

10u

R3490

10k

H2

1

2

3

4

5

6

7

8

9

10

4

3.3VFPGA

R3475

10k

nCSO

ASDO

FPGA_PWD

FPGA_RST

IC3341N13IO

IC3341B3IO

IC3341M13nSTATUS

IC3341J5nCONFIG

IC3341F4IO

IC3341H4DCLK

IC3341F1DATA0

IC3341C3IO

IC3341G5nCE

IC3341L13CONF_DONE

IC3341H5TDI

IC3341F2TCK

IC3341G1TMS

IC3341G2TDO

IC3341K12MSEL1

IC3341J13MSEL0

TMDS_RX => FPGA

IC3341 M2 IO

IC3341 N1 IO

IC3341 N2 IO

IC3341 P1 IO

IC3341 T3 IO

IC3341 R3 IO

IC3341 T4 IO

IC3341 R4 IO

IC3341 T5 IO

IC3341 R5 IO

IC3341 T6 IO

IC3341 R6 IO

IC3341 T7 IO

IC3341 R7 IO

IC3341 T8 IO

IC3341 R8 IO

IC3341 T9 IO

IC3341 R9 IO

IC3341 T10 IO

IC3341 R10 IO

IC3341 T11 IO

IC3341 R11 IO

IC3341 T12 IO

IC3341 R12 IO

IC3341 T13 IO

IC3341 R13 IO

IC3341 T14 IO

IC3341 R14 IO

GENX

GENX

R3474

10k

R3487

10k

R3521 1k

R3647 1k

R3646 1k

1k

R3471

1k

R3472

DP_CLK

IC3341 L1 IO

K2 IO

NCONFIG

EPCS_DCLK

EPCS_DATA

EPCS_ASD

FPGA_PWD

FPGA_RST

INIT_DONE

DEV_CLR

VSYNC

HSYNC

DE

B0

B1

B2

B3

B4

B5

B6

B7

G0

G1

G2

G3

G4

G5

G6

G7

DOCK

R0

R1

R2

R3

R4

R5

R6

R7

5

11

12

13

6

TY-FB11DD/C

HDE-Board (2/3) Schematic Diagram

12 1410 11 16 181513 17

14

TY-FB11DD/C

HDE-Board (2/3) Schematic Diagram

14

Page 15

9.4. HDE-Board (3/3) Schematic Diagram

11

12

!

HDE-BOARD TXNHDE10UNT (3/3)

13

L3361

J0JHC0000034

LVDS_BO5

LVDS_BO6

LVDS_BO7

LVDS_RE0

LVDS_RE1

LVDS_GO3

LVDS_GO4

LVDS_GO5

LVDS_GO6

LVDS_GO7

LVDS_BO2

C3465

16V

0.1u

LVDS_GE0

LVDS_GE1

LVDS_BO3

LVDS_RO0

LVDS_RO1

LVDS_GO0

LVDS_GO1

LVDS_BO0

C3466

16V

0.1u

LVDS_BE0

LVDS_BE1

LVDS_BO1

14

TY-FB11DD/C

HDE-Board (3/3) Schematic Diagram

DCDC 15.7V => 3.3V

TP3362

R3421

0

AUDIO

JK3302

K2HC103B0105

DVI AUDIO IN

LVDS_BO4

LVDS_GE2

LVDS_RE7

C3493

6.3V

10u

107

108

106

109

110

111

112

B19/TE11

113

VCC

114

GND

115

R20/TE12

116

R21/TE13

117

R22/TE14

118

R23/TE15

119

R24/TE16

120

R25/TA20

121

R26/TA21

122

R27/TA22

123

R28/TA23

124

R29/TA24

125

VCC

126

GND

127

G20/TA25

128

G21/TA26

129

G22/TB20

130

G23/TB21

131

G24/TB22

132

G25/TB23

133

G26/TB24

134

G27/TB25

135

G28/TB26

136

G29/TC20

137

VCC

138

GND

139

B20/TC21

140

B21/TC22

141

B22/TC23

142

143

144

1

2

3

LVDS_BE4

LVDS_BE5

C3451

LVDS_GE5

L3360

G1C330MA0363

+

C3401

4V

10V

68u

10u

D3301

B0JCPE000004D3303

C3489

16V

1u

R3436

R3446

R3440

33k

100

100

C3490

16V

1u

LVDS_RO3

C3463

16V

0.1u

82

84

VCC83GND

R16/TA1685R17/TB1086R18/TB1187R19/TB1288G10/TB1389G11/TB1490G12/TB1591G13/TB1692G14/TC10

PGND

PVCC

PGND

PGND

PVCC

PGND

R3430

R3458

10k

LVDS_PWD

S/D_SEL

D3302

LVDS_RE4

LVDS_RE3

16V

B0BC6R600005

R3435

180k

R3445

180k

LVDS_RE2

LVDS_RO5

C3459

16V

0.1u

93

95

VCC94GND

G15/TC1196G16/TC1297G17/TC1398G18/TC1499G19/TC15

IC3346

C0ZBZ0001568

LVDS TX

LVDS_CLKIN1

LVDS_GO2

LVDS_BE3

L3366

EXC3BB221H

L3367

EXC3BB221H

LVDS_RO4

LVDS_GE6

R3413

0

R3412

26.1k

R3415

B0BC4R700007

10k

R

L

LVDS_RO7

LVDS_RO6

LVDS_RE6

LVDS_RE5

LVDS_BE2

LVDS_GE7

C3464

16V

0.1u

100

101

102

103

104

105

VCC

GND

B10/TC16

B11/TD10

B12/TD11

B13/TD12

B14/TD13

B15/TD14

B16/TD15

N/C

B17/TD16

B18/TE10

B23/TC24

B24/TC25

B25/TC26

B26/TD20

B27/TD21

VCC

GND5B28/TD226B29/TD237HSYNC1/TD248VSYNC1/TD259DE1/TD2610HSYNC2/TE2011VSYNC2/TE2112DE2/TE2213VCC14GND15CLKIN116CLKIN217CONT11/TE2318CONT12/TE2419CONT21/TE2520CONT22/TE2621R/F22RS23MODE324MAP25MODE126MODE027MODE228ASYNC29N/C30/PDWN31PRBS32Reserved33N/C

4

C3467

0.1u

LVDS_DE1

LVDS_VSYNC1

LVDS_HSYNC1

LVDS_BE6

LVDS_BE7

LVDS_RO2

10k

C3438

25V

0.01u

R3447

LVDS_GE4

LGND38TE2+39TE2-

R3437

R3442

R3455

15k

100

15k

R3456

33k

LVDS_GE3

76

R10/TA1077R11/TA1178R12/TA1279R13/TA1380R14/TA1481R15/TA15

TA1+71TA1-72LGND

R3420

4.7

R3443

100

R3457

74

75

TB1-

TB1+

LVCC

LGND

TC1-

TC1+

TCLK1-

TCLK1+

LVCC

LGND

TD1-

TD1+

TE1-

TE1+

LVCC

LGND

TA2-

TA2+

TB2-

TB2+

LVCC

LGND

TC2-

TC2+

TCLK2-

TCLK2+

LVCC

LGND

TD2-

TD2+

34

35

IC3345

C0DBAYY00183

AVR 3.3V

1

BS

2

VIN

3

SW

4

GND

Q3302

2SD0601ASL

R3444

100

1k

Q3303

2SD0601ASL

R3460

100

1k

TP3363

L3363

J0JHC0000034

C3478

6.3V

10u

C3430

16V

0.1u

C3429

50V

1000p

73

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

37

36

C3468

C3428

50V

1000p

J0JHC0000034

16V

0.1u

TP3361

PA3301

K5H4022A0023

C3409

C3454

R3402

25V

25V

100k

10u

0.1u

8

SS

C3436

25V

0.1u

7

EN

6

COMP

5

FB

L3369

J0JHC0000034

+

C3491

C3492

50V

16V

0.01u

47u

L3362

C3483

6.3V

10u

LVDS_TA1-

LVDS_TA1+

LVDS_TB1-

LVDS_TB1+

C3456

50V

1000p

C3457

16V

0.1u

C3461

50V

1000p

C3462

16V

0.1u

C3469

50V

1000p

C3470

16V

0.1u

C3471

50V

1000p

C3472

16V

0.1u

C3477

50V

1000p

C3487

16V

0.1u

AUDIO_R

AUDIO_L

LVDS_TC1-

LVDS_TC1+

LVDS_TCLK1-

LVDS_TCLK1+

9V

LVDS_TD1-

LVDS_TD1+

LVDS_TE1-

LVDS_TE1+

LVDS_TA1-

LVDS_TA1+

LVDS_TB1-

LVDS_TB1+

LVDS_TA2-

LVDS_TA2+

LVDS_TB2-

LVDS_TB2+

LVDS_TC2-

LVDS_TC2+

C3435

3900p

R3403

27k

LVDS_TC1-

LVDS_TC1+

LVDS_TCLK1-

LVDS_TCLK1+

LVDS_TD2-

LVDS_TD2+

50V

LVDS_TD1-

LVDS_TD1+

LVDS_TE1-

LVDS_TE1+

LVDS_TE2-

LVDS_TE2+

B0BC4R700007

LVDS_TA2-

LVDS_TA2+

LVDS_TC2-

LVDS_TC2+

D3304

LVDS_TB2-

LVDS_TB2+

LVDS_TD2-

LVDS_TD2+

LVDS_TE2-

LVDS_TE2+

FL3314

J0MAB0000169

1

2

3

4

FL3315

J0MAB0000169

1

2

3

4

FL3316

J0MAB0000169

1

2

3

4

FL3317

J0MAB0000169

1

2

3

4

FL3318

J0MAB0000169

1

2

3

4

FL3319

J0MAB0000169

1

2

3

4

LVDS_TXA2-

LVDS_TXA2+

LVDS_TXC2-

LVDS_TXC2+

LVDS_TXB2-

LVDS_TXB2+

LVDS_TXD2-

LVDS_TXD2+

LVDS_TXE2-

LVDS_TXE2+

LVDS_TXCLK1-

LVDS_TXCLK1+

LVDS_TXD1-

LVDS_TXD1+

LVDS_TXE1-

LVDS_TXE1+

LVDS_TXC1-

LVDS_TXC1+

LVDS_TXA1-

LVDS_TXA1+

LVDS_TXB1-

LVDS_TXB1+

5VSTB

10k

B40

A40

B39

A39

B38

A38

B37

A37

B36

A36

B35

A35

B34

A34

B33

A33

B32

A32

B31

A31

B30

A30

B29

A29

B28

A28

B27

A27

B26

A26

B25

A25

B24

A24

B23

A23

B22

A22

B21

A21

B20

A20

B19

A19

B18

A18

B17

A17

B16

A16

B15

A15

B14

A14

B13

A13

B12

A12

B11

A11

B10

A10

B9

A9

B8

A8

B7

A7

B6

A6

B5

A5

B4

A4

B3

A3

B2

A2

B1

A1

TO SLOT

H1

C3482

10V

R3552

1u

10k

R3550

22

R3551

22

R3547

33

R3548

33

FOR

FACTORY

USE

(CONFIG ROM)

(EDID EEPROM)

SLOT_SCL

SLOT_SDA

SLOT_SRQ

5V

5V

+

C3485

C3486

16V

16V

0.1u

47u

R3553

10k

H3

1

2

3

4

5

6

7

8

9

SLOT_SCL

SLOT_SDA

H_WP

SLOT_SCL

SLOT_SDA

5VSTB

SLOT_SRQ

TVLOAD_SCL

TVLOAD_SDA

SLOT_SCL

SLOT_SDA

H_WP

GENX_NBOOT

R3546

AUDIO_R

AUDIO_L

+

C3474

C3479

16V

16V

0.1u

47u

C3475

16V

0.1u

TVRP842

IC3319

C3EBGC000055

CONFIG ROM

1

NC

2

NC

3

A2

4

GND

100

R3653

0

R3549

8

VCC

7

WP

6

SCL

5

SDA

LVDS_TXB1+

LVDS_TXA1+

LVDS_TXB1-

LVDS_TXA1-

LVDS_TXCLK1+

LVDS_TXCLK1-

LVDS_TXC1+

LVDS_TXC1-

LVDS_TXE1+

LVDS_TXE1-

LVDS_TXD1+

LVDS_TXD1-

LVDS_TXC2+

LVDS_TXC2-

LVDS_TXA2+

LVDS_TXA2-

LVDS_TXD2+

LVDS_TXD2-

LVDS_TXB2+

LVDS_TXB2-

5VSTB

/PLUG_DET

9V

LVDS_TXE2+

LVDS_TXE2-

5VSTB

9V

EEPROM

IC3320

C0JBAZ002269

5V<=>3.3V

5V

C3473

1u

10V

N_FHD

GENX_CTRL_SDA

GENX_CTRL_SCL

8

7

6

R3543

33

R3542

33

1

/OE1

Vcc

2

/OE2

A1

3

B2

B1

45

A2

GND

TY-FB11DD/C

HDE-Board (3/3) Schematic Diagram

20 2724 262319 21 2522

15

Page 16

10 Printed Circuit Board

10.1. HDE-Board

24

16

8

TP3347

14

TP3362

3.3V

IC3345

Parts Location

HDE-BOARD (COMPONENT SIDE)

IC TRANSISTOR

IC3301 F-3

IC3307 G-4

IC3310 G-2

IC3314 H-4

IC3319 G-2

IC3320 H-2

IC3341 G-3

IC3342 H-3

IC3343 F-3

IC3345 E-2

JK3301

Q3304

5

8

TEST

+

8

5

14

TP3361

TP3317

IC3343

58

H4IC3301

4

1

15.7V

X3301

72

73

108

109

14

TP3331

B2

B1

A2

A1

Q3301 H-1

Q3302 H-4

Q3303 H-4

Q3304 F-4

17

9

1

JK3302

37

36

1

144

IC3341

A

1

TP3326

5VSTB 9V

5V

H1

IC3307

4

IC3319

TP3327

TP3360

5

TP3363

S3301 S3302

1.2V

1

8

TEST POINT

GND

1

IC3310

32

TP3317 F-4

TP3326 G-2

TP3327 G-2

TP3331 G-2

TP3347 F-4

TP3360 G-3

TP3361 F-2

TP3362 F-3

TP3363 G-5

Q3303

P b F

8

1

IC3314

5

128

1

IC3342

1

IC3320

8

5

4

33

B40

B39

11

H10

212

1

Q3302

1

5

4

H2

10

19

H3

97

96

65

64

A40

Q3301

A39

R E V E R S EF O RO R D E RN O.

S E E

HDE

1

TNPA4532

Parts Location

HDE-BOARD (FOIL SIDE)

IC TRANSISTOR

6

IC3303 D-4

IC3308 B-4

IC3312 B-3

IC3346 C-2

HDE-BOARD (FOIL SIDE)

5

4

TXNHDE10UNT

IC3312

1

3

45

57

IC3308

Q3305 B-4

PbF

14

Q3305

JK3302

HDE-BOARD (COMPONENT SIDE)

TXNHDE10UNT

24

16

17

9

1

JK3301

5

IC3303

14

8

8

3

123

144

1

2

36

37

B40

B39

A40

1

A39

HDE

H1

NO.

1

109

108

IC3346

73

72

B2

B1

A2

A1

ORDER

TNPA4532

TY-FB11DD/C

HDE-BOARD TXNHDE10UNT

ABCDE FGH I

TY-FB11DD/C

HDE-BOARD TXNHDE10UNT

16

Page 17

11 Exploded View and Replacement Parts List

11.1. Exploded View and Mechanical Replacement Parts List

11.1.1. Exploded View

17

Page 18

11.1.2. Mechanical Replacement Parts List

18

Page 19

Safety

Ref.

No.

1 TPCB13167 CARTON BOX 1 TY-FB11DD

1 TPCB13168 CARTON BOX 1 TY-FB11DDC

2 TPDF1103 CUSHION 1

3 TPEH135 PROTECT COVER 1

4 TBMU700 TERMINAL SHEET 1 TY-FB11DD

4 TBMU786 TERMINAL SHEET 1 TY-FB11DDC

5 TQZH461-1 INSTRUCTION SHEET (SLOT) 1 TY-FB11DD

5 TQZH886 INSTRUCTION SHEET (SLOT) 1 TY-FB11DDC

6 TQZH988 INSTRUCTION SHEET 1 TY-FB11DD

6 TQZH989 INSTRUCTION SHEET 1 TY-FB11DDC

7 XZBT6506 POLY BAG 1

8 THEL0239 SCREW 4

9 TQE6691 POLY BAG 1

Part No.

THEA068N SCREW 2

THEL027N SCREW 4

Part Name & Description Q'ty Remarks

19

Page 20

11.2. Electrical Replacement Parts List

11.2.1. Replacement Parts List Notes

20

Page 21

11.2.2. Electrical Replacement Parts List

Safety Ref. No. Part No. Part Name &

C3313 F1H1A1050032 C 10UF, 50V 1

C3318 F1H1A1050032 C 10UF, 50V 1

C3319 F1G1C104A077 C 0.10UF, K, 16V 1

C3320-27 F1H1A1050032 C 10UF, 50V 8

C3328 F1G1C104A077 C 0.10UF, K, 16V 1

C3329 F1H1A1050032 C 10UF, 50V 1

C3330-32 F1G1C104A077 C 0.10UF, K, 16V 3

C3333 F1G1E1030005 C 0.01UF, Z, 25V 1

C3334 F1G1C104A077 C 0.10UF, K, 16V 1

C3335 F1G1E1030005 C 0.01UF, Z, 25V 1

C3336,37 F1G1C104A077 C 0.10UF, K, 16V 2

C3338 F1J0J1060004 C 0.010UF, K,

C3339-42 F1G1C104A077 C 0.10UF, K, 16V 4

C3344-46 F1G1C104A077 C 0.10UF, K, 16V 3

C3349 F1G1C104A077 C 0.10UF, K, 16V 1

C3351 F1G1C104A077 C 0.10UF, K, 16V 1

C3353,54 F1G1C104A077 C 0.10UF, K, 16V 2

C3355 F1J0J1060004 C 0.010UF, K,

C3356 F1H1A1050032 C 10UF, 50V 1

C3357-62 F1G1C104A077 C 0.10UF, K, 16V 6

C3363 F1H0J2250008 C 2.2UF, K, 16V 1

C3364 F1H1H471A792 C 470UF, 50V 1

C3372 F1H1A1050032 C 10UF, 50V 1

C3384 F1J1A106A043 C 0.010UF, K,

C3385,86 F1G1C104A077 C 0.10UF, K, 16V 2

C3387 F1H1A1050032 C 10UF, 50V 1

C3388 ECJ1VC1H180J C 18PF, J, 50V 1

C3389 ECJ1VC1H150J C 15PF, J, 50V 1

C3390 F1G1C104A077 C 0.10UF, K, 16V 1

C3392 F1H1A1050032 C 10UF, 50V 1

C3393 F1G1C104A077 C 0.10UF, K, 16V 1

C3394,95 F1H1A1050032 C 10UF, 50V 2

C3396-99 F1G1C104A077 C 0.10UF, K, 16V 4

C3400 F1G1H1020008 C 1000UF, 50V 1

C3401 ECJ3YB1A106M C 10UF, M,6.3V 1

C3402 F1H1A1050032 C 10UF, 50V 1

C3403 F1J0J1060004 C 0.010UF, K,

C3404,05 F1H1A1050032 C 10UF, 50V 2

C3406 F2G0G101A007 E 100UF 6.3V 1

C3407 F1G1C1030008 C 0.010UF, K,

C3408 F1G1C104A077 C 0.10UF, K, 16V 1

C3409 ECJ3YB1E106M C 10 UF, K, 25V 1

C3410,11 F1J0J1060004 C 0.010UF, K,

C3412,13 F1G1C104A077 C 0.10UF, K, 16V 2

C3414 F1J0J1060004 C 0.010UF, K,

C3415 F1G1C104A077 C 0.10UF, K, 16V 1

C3416-20 F1J0J1060004 C 0.010UF, K,

C3421 F1G1C104A077 C 0.10UF, K, 16V 1

C3422 F1J0J1060004 C 0.010UF, K,

C3423-28 F1G1C104A077 C 0.10UF, K, 16V 6

C3429 F1G1H1020008 C 1000UF, 50V 1

C3430,31 F1G1C104A077 C 0.10UF, K, 16V 2

C3432 F1G1H1020008 C 1000UF, 50V 1

C3434 F1G1H1020008 C 1000UF, 50V 1

C3435 F1H1H392A970 C 3900PF, K, 50V 1

C3436 F1H1E104A129 C 0.1UF, 25V 1

C3438 F1G1E103A123 C 0.010UF, K,

C3439 F1G1H1020008 C 1000UF, 50V 1

C3440 F1J0J1060004 C 0.010UF, K,

C3441 F1G1C104A077 C 0.10UF, K, 16V 1

Description

16V

16V

10V

16V

16V

16V

16V

16V

16V

16V

16V

Pcs Remarks

1

1

1

1

1

2

1

5

1

1

1

Safety Ref. No. Part No. Part Name &

C3442 F1J0J1060004 C 0.010UF, K,

C3443-45 F1G1C104A077 C 0.10UF, K, 16V 3

C3446-48 F1G1H1020008 C 1000UF, 50V 3

C3449,50 F1G1C104A077 C 0.10UF, K, 16V 2

C3451 ECGRL0G680ER C 68PF, J, 4V 1

C3454 F1H1E104A129 C 0.1UF, 25V 1

C3455 F1J0J1060004 C 0.010UF, K,

C3456 F1G1H1020008 C 1000UF, 50V 1

C3457 F1G1C104A077 C 0.10UF, K, 16V 1

C3459,60 F1G1C104A077 C 0.10UF, K, 16V 2

C3461 F1G1H1020008 C 1000UF, 50V 1

C3462-67 F1G1C104A077 C 0.10UF, K, 16V 6

C3468,69 F1G1H1020008 C 1000UF, 50V 2

C3470 F1G1C104A077 C 0.10UF, K, 16V 1

C3471 F1G1H1020008 C 1000UF, 50V 1

C3472 F1G1C104A077 C 0.10UF, K, 16V 1

C3473 F1H1A1050032 C 10UF, 50V 1

C3474-76 F1G1C104A077 C 0.10UF, K, 16V 3

C3477 F1G1H1020008 C 1000UF, 50V 1

C3478 F1J0J1060004 C 0.010UF, K,

C3479 F2G1C470A022 E 47UF, 16V 1

C3480 F1J0J1060004 C 0.010UF, K,

C3482 F1H1A1050032 C 10UF, 50V 1

C3483 F1J0J1060004 C 0.010UF, K,

C3485 F1G1C104A077 C 0.10UF, K, 16V 1

C3486 F2G1C470A022 E 47UF, 16V 1

C3487,88 F1G1C104A077 C 0.10UF, K, 16V 2

C3489,90 ECJ2XF1C105Z C 1.0UF, Z, 16V 2

C3491 F2G1C470A022 E 47UF, 16V 1

C3492 ECJ1VF1H103Z C 0.010UF, Z,

C3493 F1J0J1060004 C 0.010UF, K,

C3494,95 F1G1C104A077 C 0.10UF, K, 16V 2

C3497 F1J0J1060004 C 0.010UF, K,

C3498 F1G1C104A077 C 0.10UF, K, 16V 1

C3520,21 F1G1C104A077 C 0.10UF, K, 16V 2

C3522,23 F1G1H1020008 C 1000UF, 50V 2

C3526,27 F1G1H1020008 C 1000UF, 50V 2

C3528-47 F1G1C104A077 C 0.10UF, K, 16V 20

D3001-10 EZAEG2A50AX DIODE 10

D3011 B0HCMM000014 DIODE 1

D3025 B0HCMM000014 DIODE 1

D3301 B0JCPE000004 DIODE 1

D3302 B0BC6R600005 ZENER DIODE 1

D3303,04 B0BC4R700007 ZENER DIODE 2

D3307 MA3056MTX ZENER DIODE 1

D3308 EZAEG2A50AX DIODE 1

D3309-11 MA3056MTX ZENER DIODE 3

FL3314-19 J0MAB0000169 LC FILTER 6

H1 K1KA80B00037 80P CONNECTOR 1

H2 K1KA10AA0715 10P CONNECTOR 1

H3 K1KA09AA0714 9P CONNECTOR 1

H4 K1KA04AA0714 4P CONNECTOR 1

IC3301 TVRP844 IC 1

IC3303 C0JBAZ002269 IC 1

IC3307 C1AB00002848 IC 1

IC3308 C0DBFFD00003 IC 1

IC3310 TVRP845 IC 1

IC3312 C0EBE0000066 IC 1

IC3314 TVRP843 IC 1

IC3319 TVRP842 IC 1

IC3320 C0JBAZ002269 IC 1

Description

16V

16V

16V

16V

16V

50V

16V

16V

Pcs Remarks

1

1

1

1

1

1

1

1

21

Page 22

Safety Ref. No. Part No. Part Name &

IC3341 C1ZBZ0003463 IC 1

IC3342 C0DBEHG00006 IC 1

IC3343 C0ZBZ0001561 IC 1

IC3345 C0DBAYY00183 IC 1

IC3346 C0ZBZ0001568 IC 1

JK3301 K1FB124B0025 CONNECTOR 1

JK3302 K2HC103B0105 JACK 1

L3310 J0JHC0000034 CHIP INDUCTOR 1

L3311 J0JHC0000075 CHIP INDUCTOR 1

L3312 J0JHC0000034 CHIP INDUCTOR 1

L3314 J0JHC0000034 CHIP INDUCTOR 1

L3322 J0JHC0000075 CHIP INDUCTOR 1

L3325-27 J0JHC0000075 CHIP INDUCTOR 3

L3328 J0JHC0000034 CHIP INDUCTOR 1

L3329 J0JHC0000075 CHIP INDUCTOR 1

L3343,44 J0JHC0000075 CHIP INDUCTOR 2

L3357,58 J0JHC0000075 CHIP INDUCTOR 2

L3360 G1C330MA0363 INDUCTION COIL 1

L3361-64 J0JHC0000034 CHIP INDUCTOR 4

L3366,67 EXC3BB221H BEAD CHOKE 2

L3368,69 J0JHC0000034 CHIP INDUCTOR 2

L3370 J0JHC0000075 CHIP INDUCTOR 1

PA3301 K5H4022A0023 FUSE 1

Q3301-04 2SD0601ASL TRANSISTOR 4

Q3305 2SK1228 FET 1

R3022 D0GB103JA057 M 10K OHM J 1/

R3023,24 ERJ3GEYJ472 M 4.7KOHM,J,1/

R3025,26 ERJ3GEYJ560 M 56 OHM,J,1/16W 2

R3345,46 ERJ3GEYJ330 M 33 OHM,J,1/16W 2

R3349,50 D0GB103JA057 M 10K OHM J 1/

R3356,57 ERJ3GEYJ330 M 33 OHM,J,1/16W 2

R3364,65 ERJ3GEYJ472 M 4.7KOHM,J,1/

R3374 D0GB103JA057 M 10K OHM J 1/

R3377 D0GB103JA057 M 10K OHM J 1/

R3380,81 ERJ3GEYJ220 M 22 OHM,J,1/16W 2

R3394 D0GB182JA057 M 1.8KOHM J 1/

R3398 ERJ3GEYJ472 M 4.7KOHM,J,1/

R3399 ERJ3GEYJ220 M 22 OHM,J,1/16W 1

R3400 D0GB103JA057 M 10K OHM J 1/

R3401 ERJ3GEYJ100 M 10 OHM,J,1/16W 1

R3402 D0GB104JA041 M 100KOHM J 1/

R3403 ERJ3GEYJ273 M 27KOHM,J,1/16W 1

R3404 ERJ3GEYJ100 M 10 OHM,J,1/16W 1

R3406,07 EXB2HV820JV RESISTOR ARRAY 2

R3408 ERJ3GEYJ100 M 10 OHM,J,1/16W 1

R3410,11 EXB2HV820JV RESISTOR ARRAY 2

R3412 D1BB2612A055 M26.1KOHM, 1/10W 1

R3413 ERJ3GEY0R00 M 0 OHM, 1/16W 1

R3415 D1BB1002A055 M 10KOHM, 1/10W 1

R3417 EXB2HV820JV RESISTOR ARRAY 1

R3418 ERJ3GEYJ820 M 82 OHM,J,1/16W 1

R3420 ERJ3GEYJ4R7 M 4.7HM,J,1/16W 1

R3421 D0GDR00Z0002 M 0 OHM, 1/10W 1

R3422 ERJ3GEYJ820 M 82 OHM,J,1/16W 1

R3423-26 EXB2HV820JV RESISTOR ARRAY 4

R3427,28 ERJ3GEYJ820 M 82 OHM,J,1/16W 2

R3429 ERJ3GEYJ560 M 56 OHM,J,1/16W 1

R3430,31 D0GB103JA057 M 10K OHM J 1/

Description

16W

16W

16W

16W

16W

16W

16W

16W

16W

16W

16W

Pcs Remarks

1

2

2

2

1

1

1

1

1

1

2

Safety Ref. No. Part No. Part Name &

R3433 D0GB103JA057 M 10K OHM J 1/

R3435 D0GB184JA057 M 180KOHM J 1/

R3436 ERJ3GEYJ101 M 100 OHM,J,1/

R3437 ERJ3GEYD153V M 15KOHM,J,1/16W 1

R3438 ERJ3EKF2002 M 20KOHM, 1/16W 1

R3439 ERJ3EKF3302 M 33KOHM, 1/16W 1

R3440 ERJ3GEYJ333 M 33KOHM,J,1/16W 1

R3441,42 ERJ3GEYJ101 M 100 OHM,J,1/

R3443 D0GB102JA057 M 1KOHM,J,1/16W 1

R3444 ERJ3GEYJ101 M 100 OHM,J,1/

R3445 D0GB184JA057 M 180KOHM J 1/

R3446 ERJ3GEYJ101 M 100 OHM,J,1/

R3447 ERJ3GEYD153V M 15KOHM,J,1/16W 1

R3448,49 D0GB473JA057 M 47KOHM,J,1/16W 2

R3450 ERJ3GEYJ101 M 100 OHM,J,1/

R3451 ERJ3GEYJ330 M 33 OHM,J,1/16W 1

R3452 D0GB102JA057 M 1KOHM,J,1/16W 1

R3453 ERJ3GEYJ821 M820 OHM,J,1/16W 1

R3454 D0GB103JA057 M 10K OHM J 1/

R3455 ERJ3GEYJ333 M 33KOHM,J,1/16W 1

R3456 ERJ3GEYJ101 M 100 OHM,J,1/

R3457 D0GB102JA057 M 1KOHM,J,1/16W 1

R3458 D0GB103JA057 M 10K OHM J 1/

R3459,60 ERJ3GEYJ101 M 100 OHM,J,1/

R3461,62 D0GB103JA057 M 10K OHM J 1/

R3463 ERJ3GEYJ390 M 39 OHM,J,1/16W 1

R3464-67 ERJ3GEYJ220 M 22 OHM,J,1/16W 4

R3469 D0GB103JA057 M 10K OHM J 1/

R3470 ERJ3GEYJ220 M 22 OHM,J,1/16W 1

R3471,72 D0GB102JA057 M 1KOHM,J,1/16W 2

R3473 ERJ3GEYJ471 M 470 OHM,J,1/

R3474,75 D0GB103JA057 M 10K OHM J 1/

R3476,77 ERJ3GEY0R00 M 0 OHM, 1/16W 2

R3478 ERJ3GEYJ470 M 47 OHM,J,1/16W 1

R3479 D0GB473JA057 M 47KOHM,J,1/16W 1

R3481,82 D0GB103JA057 M 10K OHM J 1/

R3483 ERJ3GEYJ330 M 33 OHM,J,1/16W 1

R3484-90 D0GB103JA057 M 10K OHM J 1/

R3491 ERJ3GEYJ820 M 82 OHM,J,1/16W 1

R3492 ERJ3GEYJ220 M 22 OHM,J,1/16W 1

R3493-95 D0GB103JA057 M 10K OHM J 1/

R3496 ERJ3GEYJ220 M 22 OHM,J,1/16W 1

R3499,00 ERJ3GEYJ220 M 22 OHM,J,1/16W 2

R3501 ERJ3GEYJ101 M 100 OHM,J,1/

R3502 ERJ3GEY0R00 M 0 OHM, 1/16W 1

R3503 D0GB473JA057 M 47KOHM,J,1/16W 1

R3504 D0GB103JA057 M 10K OHM J 1/

R3505-09 D0GB473JA057 M 47KOHM,J,1/16W 5

R3510 ERJ3GEYJ472 M 4.7KOHM,J,1/

R3511 D0GB473JA057 M 47KOHM,J,1/16W 1

R3512 ERJ3GEYJ472 M 4.7KOHM,J,1/

R3515 D0GB103JA057 M 10K OHM J 1/

R3517 ERJ3GEYJ470 M 47 OHM,J,1/16W 1

R3518 D0GB102JA057 M 1KOHM,J,1/16W 1

Description

16W

16W

16W

16W

16W

16W

16W

16W

16W

16W

16W

16W

16W

16W

16W

16W

16W

16W

16W

16W

16W

16W

16W

16W

Pcs Remarks

1

1

1

2

1

1

1

1

1

1

1

2

2

1

1

2

2

7

3

1

1

1

1

1

22

Page 23

Safety Ref. No. Part No. Part Name &

R3519 D0GB103JA057 M 10K OHM J 1/

R3521 D0GB102JA057 M 1KOHM,J,1/16W 1

R3540 D0GB473JA057 M 47KOHM,J,1/16W 1

R3542,43 ERJ3GEYJ330 M 33 OHM,J,1/16W 2

R3544,45 ERJ3GEYJ472 M 4.7KOHM,J,1/

R3546 ERJ3GEYJ101 M 100 OHM,J,1/

R3547,48 ERJ3GEYJ330 M 33 OHM,J,1/16W 2

R3549 D0GB103JA057 M 10K OHM J 1/

R3550,51 ERJ3GEYJ220 M 22 OHM,J,1/16W 2

R3552,53 D0GB103JA057 M 10K OHM J 1/

R3571-73 D0GB473JA057 M 47KOHM,J,1/16W 3

R3577 ERJ3GEYJ332 M 3.3KOHM,J,1/

R3578 ERJ3GEY0R00 M 0 OHM, 1/16W 1

R3641 D0GB103JA057 M 10K OHM J 1/

R3644 D0GB103JA057 M 10K OHM J 1/

R3646,47 D0GB102JA057 M 1KOHM,J,1/16W 2

R3649,50 ERJ3GEYJ470 M 47 OHM,J,1/16W 2

R3651 ERJ3GEYJ100 M 10 OHM,J,1/16W 1

R3653 ERJ3GEY0R00 M 0 OHM, 1/16W 1

Description

16W

16W

16W

16W

16W

16W

16W

16W

Pcs Remarks

1

2

1

1

2

1

1

1

TXNHDE10UNT HDE PWB BLOCK

X3301 H1A2705B0032 CRYSTAL 1

X3302 H0J100500030 CRYSTAL 1

ASSY

1

23

Loading...

Loading...