Page 1

ORDER NO. ITD0207025C2

Scart/Component Terminal Board

TY-42TM5T

TY-37TM5T

© 2002 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

TY-42TM5T / TY-37TM5T

CONTENTS

1 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

2 About lead free solder (PbF)

3 Conductor Views

3.1. HT-Board (TY-37/42TM5T)

4 Block and Schematic Diagrams

4.1. Schematic Diagram Notes

Page Page

4.2. HT-Board (TY-37/42TM5T) Block Diagrams

3

4

5

5

7

7

4.3. HT-Board (1 of 2) (TY-37/42TM5T) Schematic Diagrams

4.4. HT-Board (2 of 2) (TY-37/42TM5T) Schematic Diagrams

5 Replacement Parts List

5.1. Replacement Parts List Notes

5.2. Replacement Parts List

10

11

11

12

8

9

2

Page 3

TY-42TM5T / TY-37TM5T

1 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1.Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2.After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as alminum

foil, to prevent electrostatic charge buildup or exposure of the assembly.

3.Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4.Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5.Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6.Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, alminum foil or comparable

conductive material).

7.Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8.Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise hamless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to

damage an ES device).

3

Page 4

TY-42TM5T / TY-37TM5T

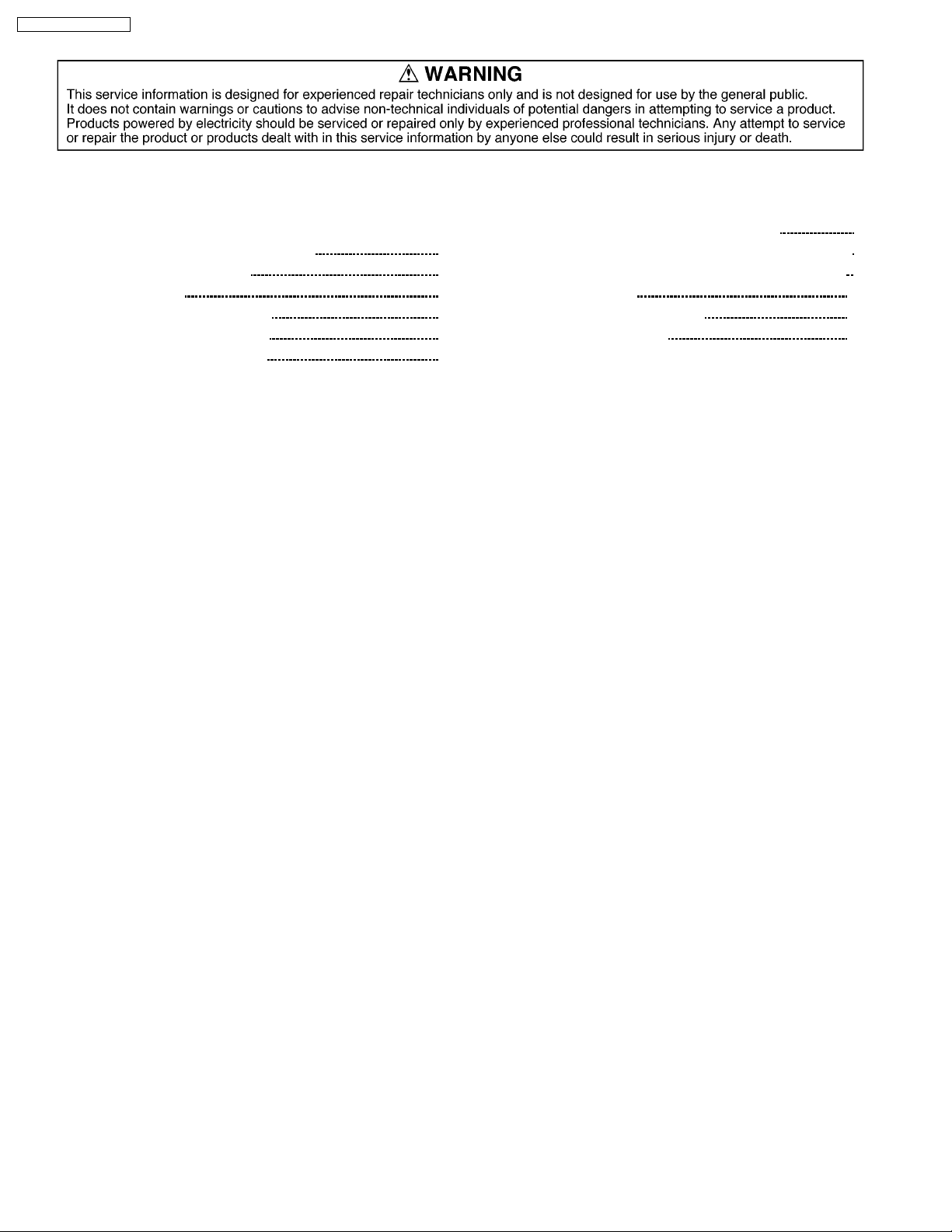

2 About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair work, we’d

suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol

Caution

·Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 ーF (30~40ーC) higher.

Please use a high temperature soldering iron and set it to 700 ± 20 ーF (370 ± 10 ーC).

·Pb free solder will tend to splash when heated too high (about 1100 ーF or600ーC).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before applying Pb

solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

·After applying PbF solder to double layered boards, please check the component side for excess solder which may flow onto

the opposite side. (see figure below)

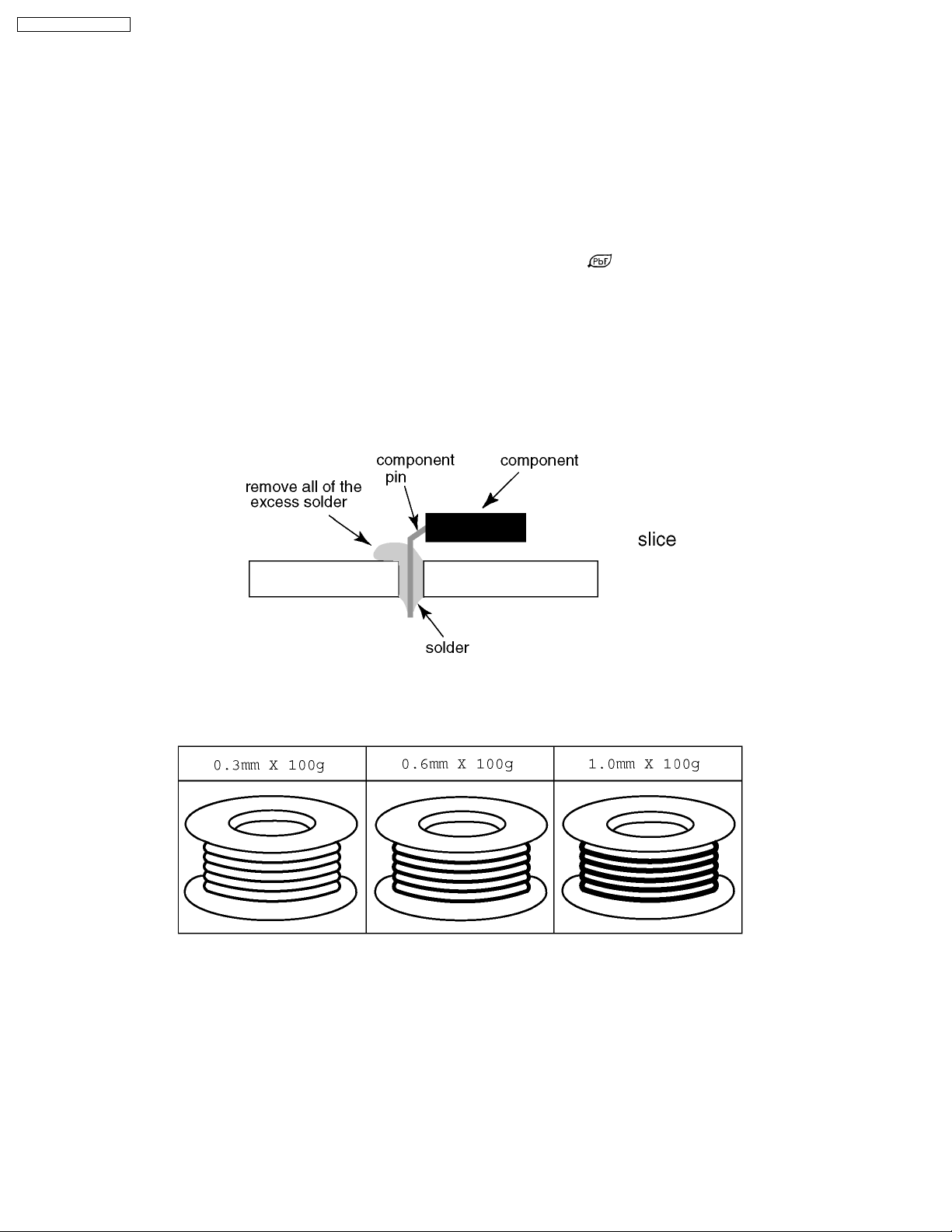

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin, silver, copper) solder.

However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used.

stamped on the back of PCB.

4

Page 5

3 Conductor Views

3.1. HT-Board (TY-37/42TM5T)

HT-BOARD (FOIL SIDE)

6

TXNHT10MKS (FOR TY-42TM5T)

TXNHT10NJS (FOR TY-37TM5T)

TY-42TM5T / TY-37TM5T

A24

A25 A1

B24

B25

5

R4607

C4603

C4604

C4608

C4607

C4606

C4605

R4608

H1

C4609

C4610

C3703

C3318

C4612

C4611

C3709

A2

A1

B2

B1

C3733

JS3305

C3317

JS3301

A20

A19

B20

B19

H2

A2

B2

B1

JS3311

HT

4

R3311

R3312

R3316

R3313

4

R3314

R3309

R3310

R3308

C3316

85

IC3699

1

C3718

C3724

C3732

C3705

C3741

R3729

C3731

C3708

R3716

C3734

C3706

C3702

C3716

C3715

C3714

C3725

C3727

C3726

3

1

SEE REVERSE FOR ORDER NO.

R3528

JS3312

R3433

R3562R3570

JS3309

R3434

R3561

TNPA2552

AV2

R

L

JK3103JK3104

BR

GR

AV1

R3529

R3502

R3501

21

20

R3530

2

JS3307

1

2

JS3308

R3304

R3303

R3503

C3302

JK3102

1

TY-42TM5T HT-BOARD TXNHT10MKS

TY-37TM5T HT-BOARD TXNHT10NJS

TY-42TM5T HT-BOARD TXNHT10MKS

TY-37TM5T HT-BOARD TXNHT10NJS

ABCDEFGH I

5

Page 6

TY-42TM5T / TY-37TM5T

6

HT-BOARD (COMPONENT SIDE)

TXNHT10MKS (FOR TY-42TM5T)

TXNHT10NJS (FOR TY-37TM5T)

C3319

JS3313

JS3314

R3320

JS3310

R3319

A2

A1

B2

R3315

B1

R3321

5

TS3301 TS3302

HD

VD

TNPA2552

R3537

ORDER

NO.

4

1

HT

3

PbF

R3462

R3464

2

GR

R3534

C3510

Q3501

C3507

IC3501

R3526

R3532

C3511

Q3502

R3523

R3520

R3517

C3508

C3505

IC3502 IC3503

R3514

C3554

R3563

4

5

3

1

Q3461

R3463

R3465

R3466

C3461

R3461

JK3103

B

Q3504

R3522

R3559

R3519

B

IC3551

R3557

C3551

R3516

C3504

R3513

NP

R3535

C3512

C3509

R3554

R3538

Q3503

L3583

C

R3553

C3581

R3564

Q3505

R3524

R3521

C3553

R3555

NP

R3518

C3506

R3515

5

13

R3556

C3584

R3551

A20

H2

A19

B20

B19

C3308

C3310

L3702

A

C3710

R3712

R3560

C3558

IC3552

R3571

5

4

1

R3566

R3567

R3568

R3558

NP

C3552

C3586

L3582

R3552

C3583

C3582

AV2

RL R

R3715

L3581

C3717

R3569

C3557

C3723

4

3

R3565

C3305

R3318

C3721

R3317

C3585

NP

C3701

IC3553

L3424

C3707

L3304

C3720

Q3422

R3430

C3424

C3728

R3427

JK3104

C3713

R3714

R3453

R3432

R3428

C3430

C3428

C3432

JS3306

C3712

C3722

R3424

C3313

C3729

R3422

R3423

Q3421

R3429

L3703

C3711

R3713

R3425

C3431

A1

B1

C3730

R3431

A2

B2

R3426

C3422

C3742

R3711

C3719

R3721

R3717

C3740

C3426

L3422

JS3303

X3701

65

80

C3739

R3452

C3704

R3451

NPNP

R3421

R3444

64

1

C3738

IC3441

R3447

R4612

R4611

L3701

C3322

C3429

Q3442

R3445

C3737

C3444

C3443

C3743

C3321

C3445

IC3701

C3736

L3442

IC4601

R3709

C3735

5

1

R3710

C3745

C3744

R3441

56

1

18

1

R3525

Q3441

R3705

R3727

4

3

R3449

R3442

H1

R3413

R3450

R3703

R3704

R3707

R3724

R3531

R3446

R3414

R3723

C

R3443

R3706

R3722

LC3501

R3448

R3504

C3442

Q3701

R3702

A24

R3708

41

R3725

1

3

R3510

24

C3746

R3701

3

A25

B25B24

R4605

25

4

R3728

TS3501

10

5

4

C4602

C4618

29

C4617

28

R4604

C4616

40

C3314

R3307

R3306

C3304

1

L3303

IC3702

5

R3540

18

1

9

5

1

3

R3505

R3511

C3501

C3502

NP

C3441

L3441

21

20

L4603

L4602

C4614C4615

L4601

C3303

C4613

L3305

1

8

R3305

IC3305

8

C3312

C3307

14

R4557

R3718

R3719

R3720

LC3502

10

1

4

3

R3507

B

R3506

C3503

NP

JK3102

AV1

L3301

C3315

5

4

TS3502

9

R3512

NP

L3302

R3541

1

C3311

16

9

5

18

A

R3509

R3508

C3320

IC3699

R3527

C3306

C3309

R3533

Q3402

C3412

JS3302

R3404

1

8

R3412

L3404

LC3503

R3536

R3407

C3408

R3410

C3410

R3408

R3402

R3539

C3404

NP

Q3506

Q3401

C3411

R3403

L3402

H0

R3542

10

TS3503

9

JS3304

R3411

R3405

R3406

R3409

C3406

R3401

NP

C3409

C3402

1

2

Parts Location

IC

IC3305 E-4

IC3501 E-2

IC3502 D-2

IC3503 D-2

IC3551 B-3

IC3552 B-3

IC3553 C-3

IC3699 E-3

IC3701 D-4

IC3702 D-3

IC4601 D-5

HT-BOARD (COMPONENT SIDE)

TRANSISTOR

Q3401 E-2

Q3402 E-2

Q3421 C-3

Q3422 C-3

Q3441 D-2

Q3442 C-2

Q3461 A-2

Q3501 D-2

Q3502 D-2

Q3503 E-2

Q3504 D-2

Q3505 E-2

Q3506 E-2

TP

TS3301 B-5

TS3302 B-5

TS3501 D-3

TS3502 E-3

TS3503 F-3

1

TY-42TM5T HT-BOARD TXNHT10MKS

TY-37TM5T HT-BOARD TXNHT10NJS

TY-42TM5T HT-BOARD TXNHT10MKS

TY-37TM5T HT-BOARD TXNHT10NJS

ABCDEFGH I

6

Page 7

4 Block and Schematic Diagrams

4.1. Schematic Diagram Notes

Important Safety Notice

Components identified by mark have special characteristics important for safety.

When replacing any of these components, use only manufacture's specified parts.

Notes:

1. Resistor

All resistors are cabon 1/4W resistor, unless marked as follows:

Unit of resistance is OHM [W] (K=1,000, M=1,000,000).

: Nonflammable : Metal Oxide

: Solid : Metal Film

: Wire Wound : Fuse:

2. Capacitor

All capacitors are ceramic 50V capacitor, unless marked as follows:

Unit of capacitance is mF, unless otherwise noted.

: Temperature Compensation : Electrolytic

: Polyester : Bipolar

M

m T

: Metalized Polyester : Dipped Tantalum

: Polypropylene : Z-Type

3. Coil

Unit of inductance is mF, unless otherwise noted.

4. Test Point

: Test Point position

5. Earth Symbol

: Chassis Earth (Cold) : Line Earth (Hot)

6. Voltage Measurement

Voltage is measured by a DC voltmeter.

Conditions of the measurement are the following:

Power Source ................................................... AC 120V, 50/60Hz

Receiving Signal ............................................... Colour Bar signal (RF)

All customer's controls ...................................... Maximum positions

7. Number in red circle indicates waveform nember.

(See waveform pattern table.)

8. When arrow mark ( ) is found, connection is easily found from the direction of arrow

NP

+

-

Z

(North America model)/AC220-240V,

50/60Hz (Except North America)

TY-42TM5T / TY-37TM5T

Remarks:

1. The Power Circuit contains a circuit area which uses a separate power supply to isolate the

earth connection.

The circuit is de fined by HOT and COLD indications in the schematic diagram. Take the

follwing precautions.

All circuits, except the Power Circuit, are cold.

Precautions

a. Do not touch the hot part or the hot and cold parts at the same time or you may

be shocked.

b. Do not short- circuit the hot and cold circuits or a fu se may blow and parts may

break.

c. Do not connect a n instrument, such as an oscilloscope, to th e hot and cold

circuits simulta neously or a fuse may blow.

Connect the earth of instruments to the earth connection of the circuit being

measured.

d. Make sure to disconnect the pow er plug before removing the chassis.

2. Following diodes are interchangeable.

MA150- MA162 (Replacement part)

9. Indicates the major signal flow. : Video Audio

10. This schematic diagram is the latest at the time of printing and subject to change without

notice.

TY-37TM5T/TY-42TM5T

Schematic Diagram Notes

TY-37TM5T/TY-42TM5T

Schematic Diagram Notes

7

Page 8

TY-42TM5T / TY-37TM5T

4.2. HT-Board (TY-37/42TM5T) Block Diagrams

TY-37TM5T/TY-42TM5T HT-Board Block Diagrams TY-37TM5T/TY-42TM5T HT-Board Block Diagrams

8

Page 9

4.3. HT-Board (1 of 2) (TY-37/42TM5T) Schematic Diagrams

TY-42TM5T / TY-37TM5T

TY-37TM5T/TY-42TM5T HT-Board(1of2)Schematic Diagrams TY-37TM5T/TY-42TM5T HT-Board(1of2)Schematic Diagrams

9

Page 10

TY-42TM5T / TY-37TM5T

4.4. HT-Board (2 of 2) (TY-37/42TM5T) Schematic Diagrams

TY-37TM5T/TY-42TM5T HT-Board(2of2)Schematic Diagrams TY-37TM5T/TY-42TM5T HT-Board(2of2)Schematic Diagrams

10

Page 11

5 Replacement Parts List

5.1. Replacement Parts List Notes

TY-42TM5T / TY-37TM5T

11

Page 12

TY-42TM5T / TY-37TM5T

5.2. Replacement Parts List

Ref.

No.

C3302 ECJ1XC1H101J C 100PF, J, 50V 1

C3303-05ECJ1XF1C104Z C 0.1UF, Z, 16V 3

C3306 EEVHB1C101P E 100UF, 16V 1

C3307 EEVHB0J101 E 100UF, 6.3V 1 EEVHB0J101P

C3308 EEVHB1C470 E 47UF, 16V 1

C3309 EEVHB1C101P E 100UF, 16V 1

C3310 EEVHB1C470 E 47UF, 16V 1

C3311-14ECJ1XF1C104Z C 0.1UF, Z, 16V 4

C3315 ECJ2VF1C105Z C 1UF, Z, 16V 1

C3316 TCUY0J685MBM C 6.8UF, 6.3V 1 F1K0J685A003

C3317-21ECJ2VF1C104Z C 0.1UF, Z, 16V 5

C3322 EEVHB1C470 E 47UF, 16V 1

C3402 ECJ1XC1H561J C 560PF, J, 50V 1

C3404 ECJ1XC1H561J C 560PF, J, 50V 1

C3406 ECJ1XC1H561J C 560PF, J, 50V 1

C3408 ECJ1XC1H561J C 560PF, J, 50V 1

C3409,10EEVHP1C100R E 10UF, 16V 2

C3411,12ECJ2VF1C105Z C 1UF, Z, 16V 2

C3422 ECJ1XC1H561J C 560PF, J, 50V 1

C3424 ECJ1XC1H561J C 560PF, J, 50V 1

C3426 ECJ1XC1H561J C 560PF, J, 50V 1

C3428 ECJ1XC1H561J C 560PF, J, 50V 1

C3429,30EEVHP1C100R E 10UF, 16V 2

C3431,32ECJ2VF1C105Z C 1UF, Z, 16V 2

C3441,42ECJ2XB1E104K C 0.1UF, K, 25V 2

C3443 EEVHB1C470 E 47UF, 16V 1

C3444 ECJ2VF1H103Z C 0.01UF, Z, 50V 1

C3445 ECJ2VF1C104Z C 0.1UF, Z, 16V 1

C3461 EEVHB1C470 E 47UF, 16V 1

C3501-03EEVHP0J470 E 47UF, 6.3V 3

C3504-09ECJ2VF1C104Z C 0.1UF, Z, 16V 6

C3510-12ECJ2VF1H103Z C 0.01UF, Z, 50V 3

C3551,52EEVHP0J470 E 47UF, 6.3V 2

Part No. Part Name &

Description

Pcs Remarks

Ref.

No.

C3733 ECJ2VF1H104Z C0.1UF,Z,50V 1

C3734 ECJ2VF1H683Z C 0.068UF, Z, 50V 1

C3738-40ECJ2XF1H224Z C 0.22UF, Z, 50V 3 ECJ2VF1H224Z

C3741 ECJ2XB1E104K C0.1UF,K,25V 1

C3743 ECJ2XC1H391J C390PF,J,50V 1

C3744 ECJ2XB1H152K C 1500PF, K, 50V 1

C3745 ECJ2XF1H224Z C 0.22UF, Z, 50V 1 ECJ2VF1H224Z

C3746 ECJ2VF1C104Z C0.1UF,Z,16V 1

C4603 ECJ1XB1H102K C 1000UF, Z, 50V 1

C4604 ECJ1XB1C104K C0.1UF,Z,16V 1

C4605 ECJ1XB1H102K C 1000UF, Z, 50V 1

C4606 ECJ1XB1C104K C0.1UF,Z,16V 1

C4607 ECJ1XB1H102K C 1000UF, Z, 50V 1

C4608 ECJ1XB1C104K C0.1UF,Z,16V 1

C4609 ECJ1XB1H102K C 1000UF, Z, 50V 1

C4610 ECJ1XB1C104K C0.1UF,Z,16V 1

C4611 ECJ1XB1H102K C 1000UF, Z, 50V 1

C4612 ECJ1XB1C104K C0.1UF,Z,16V 1

C4613-15EEVHB1C470 E 47UF, 16V 3

C4616-18ECJ1XB1C104K C0.1UF,Z,16V 3

H0 TJSF12608 8P CONNECTOR 1 K1KA08A00138

H1 K1KB50B00030 50P CONNECTOR 1

H2 K1KB40B00015 40P CONNECTOR 1

IC3305 JLC1562BF MOS IC (MICON LSI) 1 C0JBAZ001265

IC3501-03C0ABGB000001 IC 3

IC3551-53C0ABGB000001 IC 3

IC3699 TVRJ760 IC 1

IC3701 C1AB00001345 IC 1

IC3702 PST9142NR IC (LOGIC) 1 C0EBH0000095

IC4601 C0ZBZ0000684 IC 1

JK3102 K1FB121B0009 CONNECTOER 1

JK3103 K2HA306B0049 JACK 1

JK3104 K2HA204B0097 JACK 1

JS3301-14ERJ3GEY0R00 M 0 OHM, 1/16W 14

Part No. Part Name &

Description

Pcs Remarks

C3553,54ECJ2VF1C104Z C 0.1UF, Z, 16V 2

C3557 EEVHP0J470 E 47UF, 6.3V 1

C3558 ECJ2VF1C104Z C 0.1UF, Z, 16V 1

C3702 ECJ2XB1H473K C 0.047UF, K, 50V 1

C3703 ECJ2XC1H030C C 3PF, C, 50V 1

C3704 EEVHB1C100 E 10UF, 16V 1

C3705 ECJ2VF1H683Z C 0.068UF, Z, 50V 1

C3706 ECJ2XB1H152K C 1500PF, K, 50V 1

C3708 ECJ2VF1H104Z C 0.1UF, Z, 50V 1

C3709 ECJ2XC1H030C C 3PF, C, 50V 1

C3711 ECJ2XB1H473K C 0.047UF, K, 50V 1

C3713 EEVHB0J470 E 47UF, 6.3V 1

C3714 ECJ2XC1H391J C 390PF, J, 50V 1

C3715 ECJ2XB1H152K C 1500PF, K, 50V 1

C3716 ECJ2XF1H224Z C 0.22UF, Z, 50V 1 ECJ2VF1H224Z

C3718 ECJ2VF1H683Z C 0.068UF, Z, 50V 1

C3719 ECJ2XC1H102K C 1000PF, K, 50V 1

C3722 ECUV1C684KBM C 0.68UF, Z, 50V 1 ECJ3VB1C684K

C3724 ECJ2VF1H683Z C 0.068UF, Z, 50V 1

C3725 ECJ2XC1H391J C 390PF, J, 50V 1

C3726 ECJ2XB1H152K C 1500PF, K, 50V 1

C3727 ECJ2XF1H224Z C 0.22UF, Z, 50V 1 ECJ2VF1H224Z

C3728,29EEVHB1C470 E 47UF, 16V 2

C3730,31ECJ2XB1H473K C 0.047UF, K, 50V 2

C3732 ECJ2XB1H152K C 1500PF, K, 50V 1

L3302-04ELKE103FA NOISE FILTER 3

L3305 G1C100KA0008 INDUCTOR COIL 1

L3402 ELJNA1R5JF INDUCTION COIL 1

L3404 ELJNA1R5JF INDUCTION COIL 1

L3422 ELJNA1R5JF INDUCTION COIL 1

L3424 ELJNA1R5JF INDUCTION COIL 1

L3441 TLK20LFA223M EMI FILTER 1 J0HABB000003

L3442 TLK20LFA224M EMI FILTER 1 J0HABB000004

L3701 ELKE103FA NOISE FILTER 1

L3703 ELKE103FA NOISE FILTER 1

L4601-03ELKE103FA NOISE FILTER 3

LC3501-03TAX10079 FILTER 3 J0E7904B0002

Q3401,022SD601A TRANSISTOR 2 2SD0601A

Q3421,222SD601A TRANSISTOR 2 2SD0601A

Q3441,422SD601A TRANSISTOR 2 2SD0601A

Q3461 2SD601A TRANSISTOR 1 2SD0601A

Q3501-032SD601A TRANSISTOR 3 2SD0601A

Q3504-062SB709A TRANSISTOR 3 2SB0709A

12

Page 13

Ref.

No.

R3303 ERJ6ENF1802 M 18KOHM, 1/10W 1

R3304 ERJ6ENF9101 M 9.1KOHM, 1/10W 1

R3308 ERJ3GEYJ103 M 10KOHM,J,1/16W 1

R3309,10ERJ3GEYJ220 M 22 OHM,J,1/16W 2

R3311 ERJ3GEYJ103 M 10KOHM,J,1/16W 1

R3314 ERJ3GEYJ103 M 10KOHM,J,1/16W 1

R3315 ERJ6GEY0R00 M 0 OHM,J,1/10W 1

R3317,18TAJAAH0101JV M 100 OHM,J,1/16W 2 D0GB101JA006

R3320,21ERJ6GEY0R00 M 0 OHM,J,1/10W 2

R3401,02ERJ6GEYJ561 M 560 OHM,J,1/10W 2

R3403,04ERJ6GEYJ333 M 33KOHM,J,1/10W 2

R3405 ERJ6GEYJ153 M 15KOHM,J,1/10W 1

R3406 ERJ6GEYJ333 M 33KOHM,J,1/10W 1

R3407 ERJ6GEYJ153 M 15KOHM,J,1/10W 1

R3408 ERJ6GEYJ333 M 33KOHM,J,1/10W 1

R3409,10ERJ6GEYJ101 M 100 OHM,J,1/10W 2

R3411,12ERJ6GEYJ102 M 1KOHM,J,1/10W 2

R3421,22ERJ6GEYJ561 M 560 OHM,J,1/10W 2

R3423,24ERJ6GEYJ333 M 33KOHM,J,1/10W 2

R3425 ERJ6GEYJ153 M 15KOHM,J,1/10W 1

R3426 ERJ6GEYJ333 M 33KOHM,J,1/10W 1

R3427 ERJ6GEYJ153 M 15KOHM,J,1/10W 1

R3428 ERJ6GEYJ333 M 33KOHM,J,1/10W 1

R3429,30ERJ6GEYJ101 M 100 OHM,J,1/10W 2

R3431,32ERJ6GEYJ102 M 1KOHM,J,1/10W 2

R3441 ERJ6ENF75R0 M 75 OHM, 1/10W 1

R3442 ERJ3GEYJ153 M 15KOHM,J,1/16W 1

R3443 ERJ3GEYJ333 M 33KOHM,J,1/16W 1

R3444 ERJ3GEYJ123 M 12KOHM,J,1/16W 1

R3445 ERJ3GEYJ682 M 6.8KOHM,J,1/16W 1

R3446,47TAJAAH0101JV M 100 OHM,J,1/16W 2 D0GB101JA006

R3448,49ERJ3GEYJ102 M 1KOHM,J,1/16W 2

R3453 TAJAAH0101JV M 100 OHM,J,1/16W 1 D0GB101JA006

R3461 ERJ3GEYJ102 M 1KOHM,J,1/16W 1

R3462 ERJ3GEYJ123 M 12KOHM,J,1/16W 1

R3463 ERJ3GEYJ682 M 6.8KOHM,J,1/16W 1

R3464 TAJAAH0101JV M 100 OHM,J,1/16W 1 D0GB101JA006

R3465 ERJ3GEYJ102 M 1KOHM,J,1/16W 1

R3466 TAJAAH0101JV M 100 OHM,J,1/16W 1 D0GB101JA006

R3501-03ERJ6ENF75R0 M 75 OHM, 1/10W 3

R3504 ERJ6GEYJ103 M 10KOHM,J,1/10W 1

R3505 ERJ6GEYJ332 M 3.3KOHM,J,1/10W 1

R3506 ERJ6GEYJ103 M 10KOHM,J,1/10W 1

R3507 ERJ6GEYJ332 M 3.3KOHM,J,1/10W 1

R3508 ERJ6GEYJ103 M 10KOHM,J,1/10W 1

R3509 ERJ6GEYJ332 M 3.3KOHM,J,1/10W 1

R3510-12ERJ6GEYJ220 M 22 OHM,J,1/10W 3

Part No. Part Name &

Description

Pcs Remarks

TY-42TM5T / TY-37TM5T

Ref.

No.

R3537-39ERJ6GEYJ331 M 330 OHM,J,1/10W 3

R3540-42ERJ6GEYJ471 M 470 OHM,J,1/10W 3

R3551,52ERJ6ENF75R0 M 75 OHM, 1/10W 2

R3553 ERJ6GEYJ103 M 10KOHM,J,1/10W 1

R3554 ERJ6GEYJ332 M 3.3KOHM,J,1/10W 1

R3555 ERJ6GEYJ103 M 10KOHM,J,1/10W 1

R3556 ERJ6GEYJ332 M 3.3KOHM,J,1/10W 1

R3557,58ERJ6GEYJ220 M 22 OHM,J,1/10W 2

R3561,62ERJ6GEY0R00 M 0 OHM,J,1/10W 2

R3563,64ERJ6GEYJ271 M 270 OHM,J,1/10W 2

R3565 ERJ6ENF75R0 M 75 OHM, 1/10W 1

R3566 ERJ6GEYJ103 M 10KOHM,J,1/10W 1

R3567 ERJ6GEYJ332 M 3.3KOHM,J,1/10W 1

R3568 ERJ6GEYJ220 M 22 OHM,J,1/10W 1

R3570 ERJ6GEY0R00 M 0 OHM,J,1/10W 1

R3571 ERJ6GEYJ271 M 270 OHM,J,1/10W 1

R3708,09TAJAAH0101JV M 100 OHM,J,1/16W 2 D0GB101JA006

R3711 TAJAAH0101JV M 100 OHM,J,1/16W 1 D0GB101JA006

R3713 ERJ3GEYJ103 M 10KOHM,J,1/16W 1

R3714 TAJAAH0101JV M 100 OHM,J,1/16W 1 D0GB101JA006

R3716 ERJ3GEY0R00 M 0 OHM, 1/16W 1

R3718 ERJ3GEYJ330 M 33 OHM,J,1/16W 1

R3721 ERJ6ENF75R0 M 75 OHM, 1/10W 1

R3722-24TAJAAH0101JV M 100 OHM,J,1/16W 3 D0GB101JA006

R3725 ERJ3GEYJ103 M 10KOHM,J,1/16W 1

R3727 ERJ3GEYJ101 M 100 OHM,J,1/16W 1 D0GB101JA002

R3728 ERJ3GEYJ103 M 10KOHM,J,1/16W 1

R4557 ERJ3GEYJ102 M 1KOHM,J,1/16W 1

R4604,05ERJ3GEYJ330 M 33 OHM,J,1/16W 2

R4607 ERJ3GEYJ103 M 10KOHM,J,1/16W 1

R4608 ERJ3GEYJ472 M 4.7KOHM,J,1/16W 1

R4611,12EXB38V472J RESISTOR ARRAY 2

RTL TXNHT10MKS CIRCUIT BOARD HT 1 TY-42TM5T

RTL TXNHT10NJS CIRCUIT BOARD HT 1 TY-37TM5T

X3701 H0J202500003 CRYSTAL 1

Part No. Part Name &

XTV3+10J SCREW 4

XYN3+F8 SCREW 4

K2RD093E0001 RGB21P/RCA PLAG 1

TPCB13111 CARTON BOX 1 TY-42TM5T

TPCB13113 CARTON BOX 1 TY-37TM5T

TPDF0726 PARTITION 1

TPEH161 AIR MAT 1

TQBC0499 INSTRUCTION BOOK 1

TQBC7062 INSTRUCTION SEET 1

XZBT6506 POLY BAG 1

THEL023Z SCREW 4

TQE6691 POLY BAG 1

Description

MISCELLANEOUS

Pcs Remarks

R3513-15ERJ6ENF4301 M 4.3KOHM, 1/10W 3

R3516-18ERJ6ENF5621 M5.62KOHM, 1/10W 3

R3519-21ERJ6GEYJ331 M 330 OHM,J,1/10W 3

R3522-24ERJ6GEYJ122 M 1.2KOHM,J,1/10W 3

R3525-27ERJ6ENF2210 M 221 OHM, 1/10W 3

R3528-30ERJ6GEYJ152 M 1.5KOHM,J,1/10W 3

R3534-36ERJ6ENF2210 M 221 OHM, 1/10W 3

13

Loading...

Loading...