Panasonic TX-W28R4DP Service Manual

TX-W28R4DP Service Manual

Safety

Specifications

Parts List

Service

Information

Adjustments

Self Check

Service Hints

Mechanical

View

Disassembly

Location of

Controls

Waveforms

Block Diagrams

Schematic Diagrams

PCB Views

Service Support

Service and repair of

this product is

supported by

Panasonic's LUCI

interface.

This interface provides a

link between the TV and

a standard PC to allow a

number of diagnostic

and control functions to

be performed.

For more details contact

your local Panasonic

company.

BACK

EXIT

Audio

Control

Dolby

C - PCB

K - PCB

Video

BACK

Y - PCB

BACK

Power supply

E - PCB

M - PCB

C - Schematic

H - Schematic

M - Schematic

Y - Schematic

E - Schematic

K - Schematic

P - Schematic

BACK

SPECIFICATIONS

ORDER No. SM-98059

Colour Television

TX-W28R4DP

EURO4 Chassis

Power Source: 220-240V AC, 50Hz

Power Consumption: 135W

Aerial Impedance: 75Ω unbalanced, Coaxial Type

Stand-by Power

Consumption: 1,8W

Receiving System: PAL I, PAL 525/60

M.NTSC

NTSC (AV only)

Receiving Channels: UHF E21-E69

Intermediate Frequency:

Video 39,5MHz

Audio 33,5MHz, 32,95MHz

Colour 35,07MHz

Video/Audio

Terminals:

AV1 IN Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 10kΩ

RGB (21 pin)

AV1 OUT Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 1kΩ

AV2 IN Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 10kΩ

S-Video IN Y: 1V p-p 75Ω

(21 pin) C: 0.3V p-p 75Ω

AV2 OUT Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 1kΩ

Selectable Output (21 pin)

Dolby Surround Out 5 x Dolby Surround Out RCA

(Rear)

External Speaker

connections 2 x Surround

1 x External Centre

High Voltage: 30,5kV ±1kV

Picture Tube: W66EHK51X35 66cm

Audio Output: Front Left/Right 2 x 20W

(Music Power) External Centre 20W

3D Sub-Woofer 26W

Surround 2 x 15W

8Ω Impedance

Headphones: 8Ω Impedance

3,5 mm

Accessories

supplied : Remote Control

2 x R6 (UM3) Batteries

TS-400DP Video cabinet / Speaker pack

Dimensions:

Height: 518 mm

Width: 760 mm

Depth: 496,8 mm

Net weight: 38kg

Specifications are subject to change without notice.

Weights and dimensions shown are approximate.

NOTE: This Service Manual should be used in conjunction with

the EURO4 Technical Guide.

AV3 IN S-Video IN Y: 1V p-p 75Ω

(4-pin) C: 0,3V p-p 75Ω

Audio(RCAx2) 500mV rms10kΩ

Video (RCAx1) 1V p-p 75Ω

Panasonic CS ( U.K. ) Ltd.

WILLOUGHBY ROAD,

BRACKNELL,

BERKS.,

RG12 8FT.

CONTENTS

SAFETY PRECAUTIONS..........................................................................................................................................................2

SERVICE HINTS.......................................................................................................................................................................3

SERVICE POSITION.................................................................................................................................................................4

ADJUSTMENT PROCEDURE...................................................................................................................................................5

ADJUSTMENT PROCEDURE AND SELF-CHECK ..................................................................................................................6

WAVEFORM PATTERN TABLE...............................................................................................................................................7

ALIGNMENT SETTINGS...........................................................................................................................................................8

BLOCK DIAGRAMS..................................................................................................................................................................9

PARTS LOCATION.................................................................................................................................................................14

REPLACEMENT PARTS LIST................................................................................................................................................15

SCHEMATIC DIAGRAMS.......................................................................................................................................................27

CONDUCTOR VIEWS.............................................................................................................................................................32

SAFETY PRECAUTIONS

GENERAL GUIDE LINES

1. It is advisable to insert an isolation transformer in the

AC supply before servicing a hot chassis.

2. When servicing, observe the original lead dress in the

high voltage circuits. If a short circuit is found, replace

all parts that have been overheated or damaged by

the short circuit.

3. After servicing, see that all the protective devices

such as insulation barriers, insulation papers, shields

and isolation R-C combinations are correctly

installed.

4. When the receiver is not being used for a long period

of time, unplug the power cord from the AC outlet.

5. Potentials as high as 31,5kV are present when this

receiver is in operation. Operation of the receiver

without the rear cover involves the danger of a shock

hazard from the receiver power supply. Servicing

should not be attempted by anyone who is not

familiar with the precautions necessary when working

on high voltage equipment. Always discharge the

anode of the tube.

6. After servicing make the following leakage current

checks to prevent the customer from being exposed

to shock hazard.

LEAKAGE CURRENT COLD CHECK

1. Unplug the AC cord and connect a jumper between

the two prongs of the plug.

2. Turn on the receiver’s power switch.

3. Measure the resistance value with an ohmmeter,

between the jumpered AC plug and each exposed

metallic cabinet part on the receiver, such as screw

heads, aerials, connectors, control shafts etc. When

the exposed metallic part has a return path to the

chassis, the reading should be between 4M ohm and

20M ohm. When the exposed metal does not have a

return path to the chassis, the reading must be

infinite.

LEAKAGE CURRENT HOT CHECK

1. Plug the AC cord directly into the AC outlet. Do not

use an isolation transformer for this check.

2. Connect a 2kΩ 10W resistor in series with an

exposed metallic part on the receiver and an earth,

such as a water pipe.

3. Use an AC voltmeter with high impedance to

measure the potential across the resistor.

4. Check each exposed metallic part and check the

voltage at each point.

5. Reverse the AC plug at the outlet and repeat each of

the above measurements.

6. The potential at any point should not exceed

1,4 Vrms. In case a measurement is outside the limits

specified, there is a possibility of a shock hazard, and

the receiver should be repaired and rechecked before

it is returned to the customer.

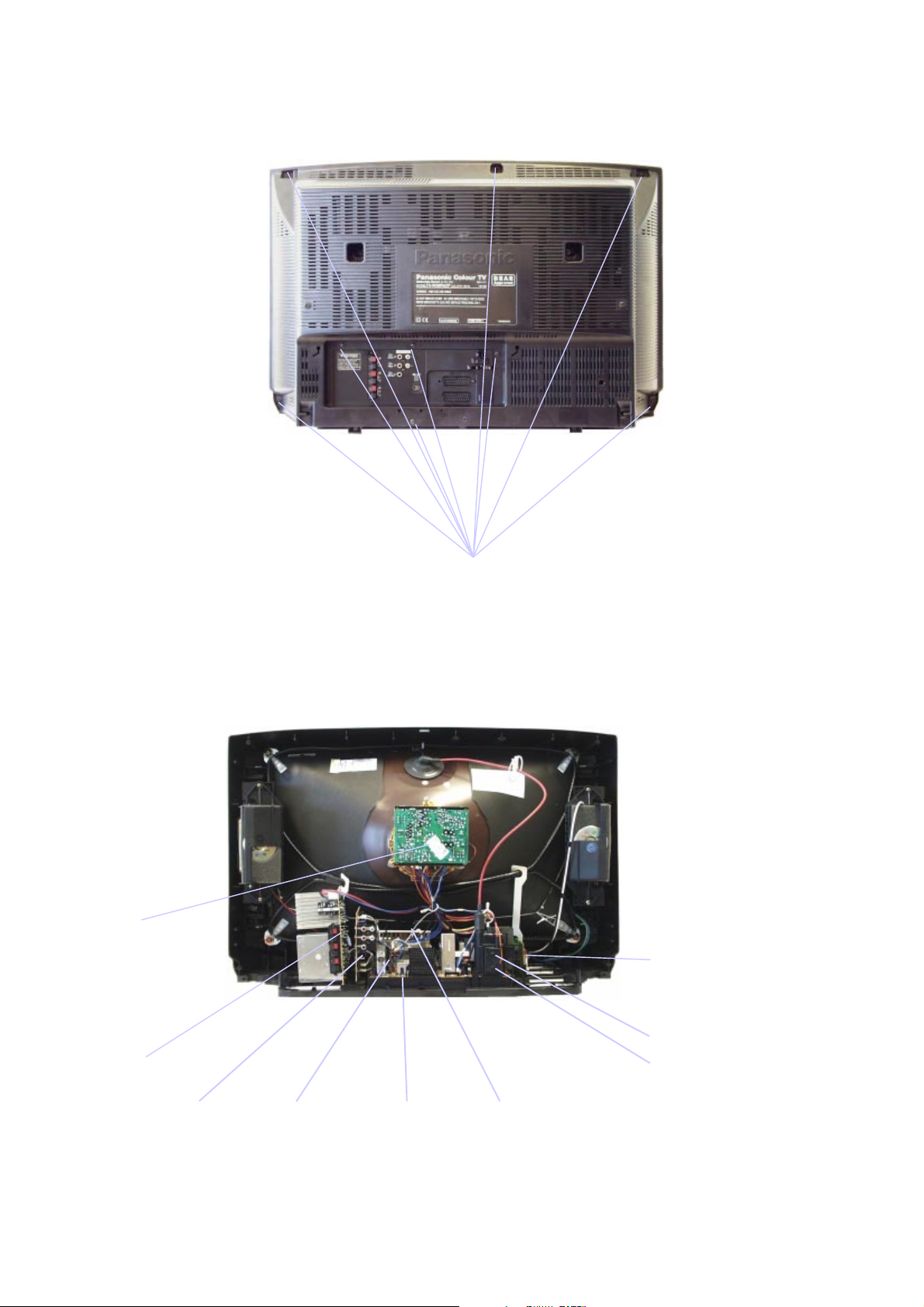

HOT CHECK CIRCUIT

A.C. VOLTMETER

2kΩ 10 Watts

TO INSTRUMENT’S EXPOSED

METALLIC PARTS

Fig. 1.

X-RADIATION WARNING

1. The potential sources of X-Radiation in TV sets are

the high voltage section and the picture tube.

2. When using a picture tube test jig for service, ensure

that the jig is capable of handling 30,5kV without

causing X-Radiation.

NOTE: It is important to use an accurate periodically

calibrated high voltage meter.

1. Set the brightness to minimum.

2. Measure the high voltage. The meter should

indicate :- 30,5kV ± 1kV. If the meter indication is out

of tolerance, immediate service and correction is

required to prevent the possibility of premature

component failure.

3. To prevent any X-Radiation possibility, it is essential

to use the specified tube.

WATER PIPE

(EARTH)

2

SERVICE HINTS

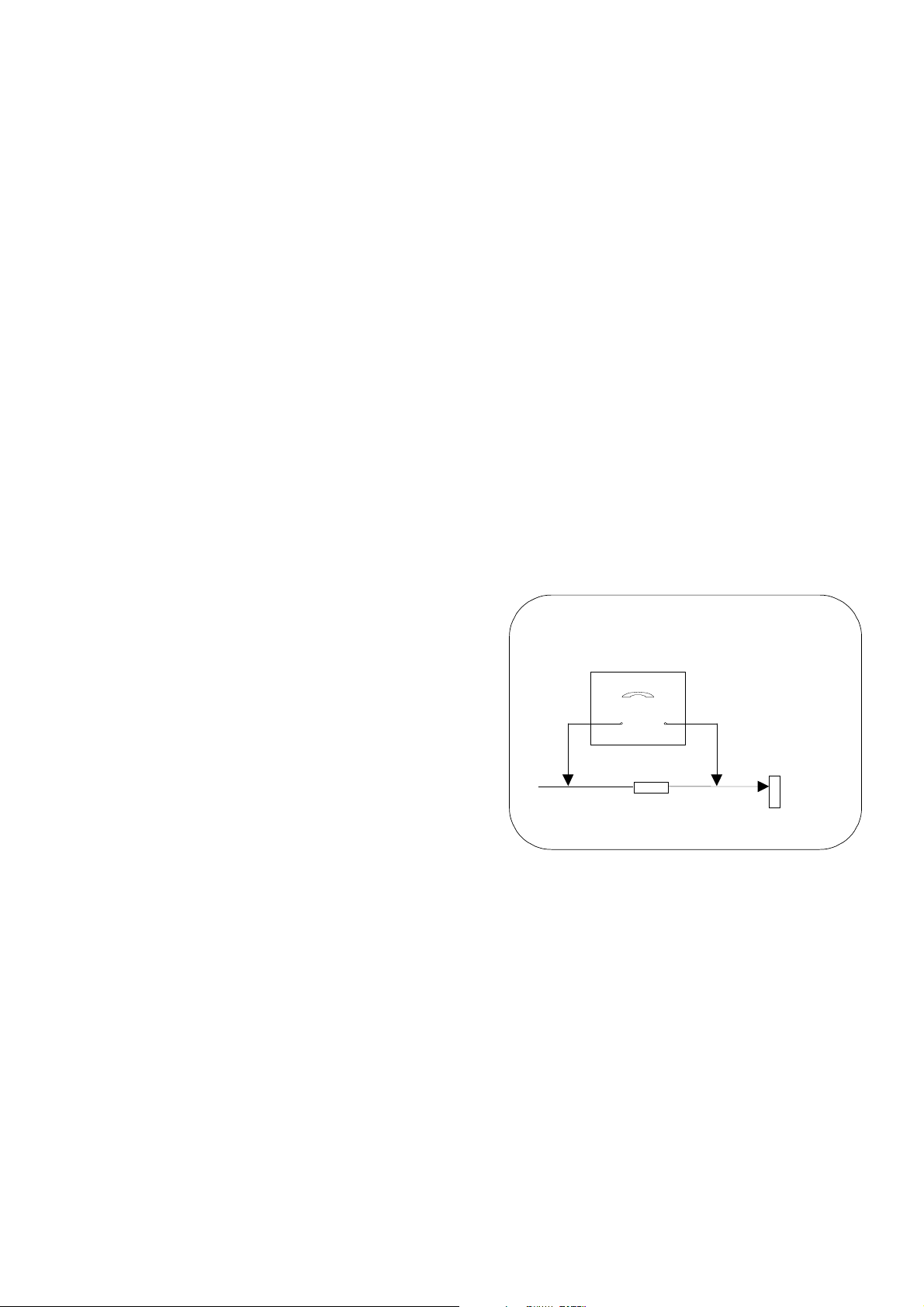

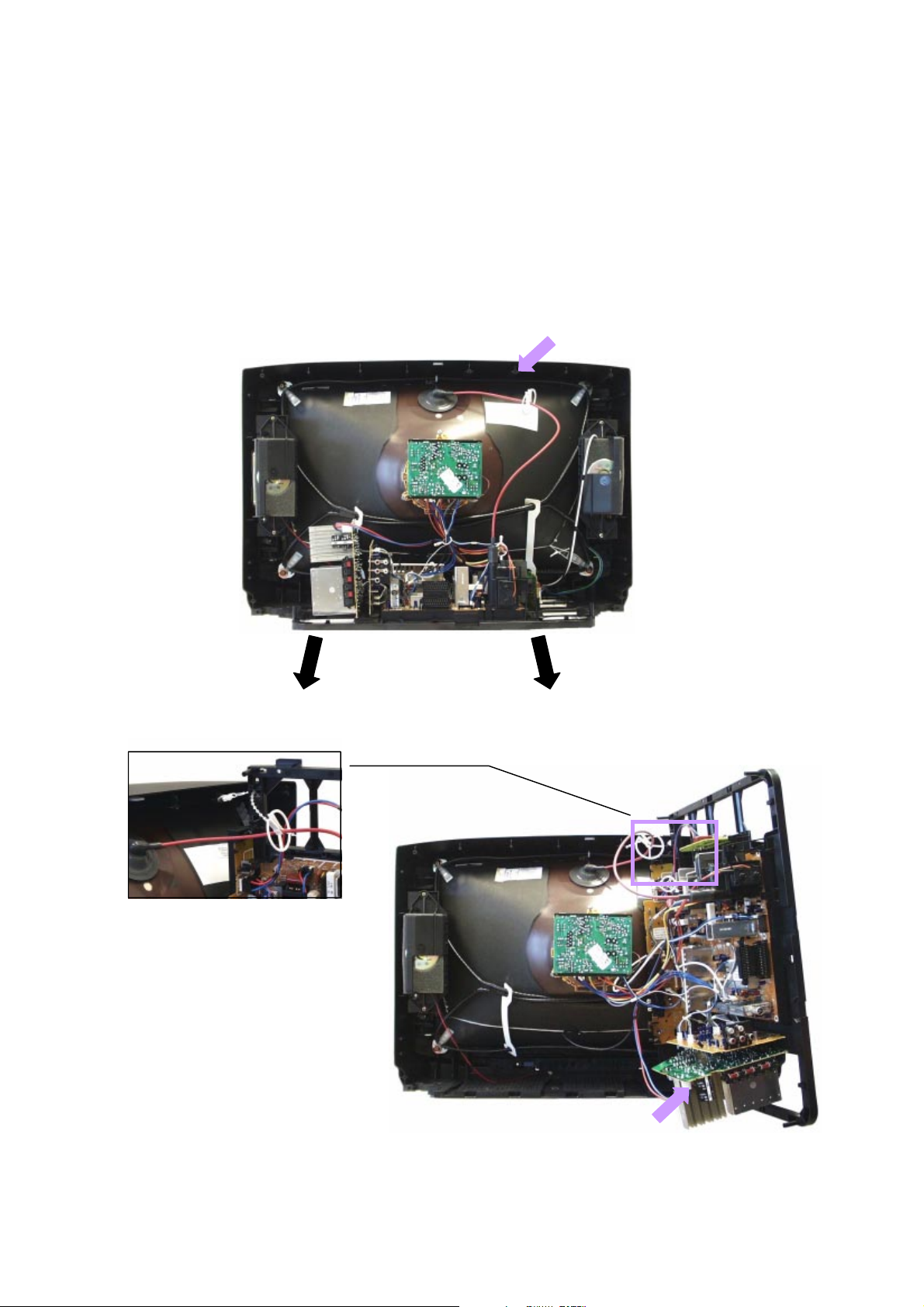

How to remove the rear cover

1. Remove the 9 screws as shown in Fig.2.

LOCATION OF CONTROLS

Y - Board

SCREWS

Fig.2.

P - Board

C - Board

K - Board

H - Board

Focus

Screen

E - Board M - Board

Fig.3.

3

HOW TO MOVE THE CHASSIS INTO SERVICE POSITION

(B)

(A)

1. Remove the bead clamper from the mains lead and affix, using back cover screw, into top right-hand cabinet rib (A),

shown in Fig.4.

2. Hold and lift the rear of the E-PCB chassis and gently pull the chassis toward you, as shown in Fig.4.

3. Release the respective wiring clips and rotate the chassis vertically through 90°, anti-clockwise.

4. Locate the base of the chassis frame into the hole (B), shown in Fig.6.

5. Clip the chassis frame onto the bead clamper, shown in Fig.5.

6. After servicing replace the bead clamper and ensure all wiring is returned to its original position before returning the

receiver to the customer.

Fig.5.

Fig.4.

Fig.6.

4

ADJUSTMENT PROCEDURE

The remote control is used for entering and storing adjustments, with the exception of Cut-off adjustments, which must

always be done prior to service adjustment. Perform adjustments in accordance with screen display. The display on the

screen also specifies the software version as well as the approx. setting values. The adjustment sequence for the service

mode is indicated below.

1. Set the Bass to maximum position, set the Treble to

minimum position, press the F button followed by the

volume down button on the customer controls at the

front of the TV and at the same time press the

"INDEX" button on the remote control, this will place

the TV into the Service Mode.

2. Press the RED / GREEN buttons to step up / down

through the functions.

NOTE: This TV also has the option of using a Memory Pack which enables you to copy the preset TV channels into the

Memory Pack and then download them onto this or any other EURO-4 TV set.

3. Press the YELLOW / BLUE buttons to alter the

function values.

4. Press the STR button after each adjustment has

been made to store the required values.

5. To exit the Service Mode, turn the TV off at the power

button.

TV to Memory Pack process

1. Plug the memory pack into the AV1 21 pin terminal at

the back of the TV and switch the TV on.

2. Enter Service Mode as explained above.

The screen will show :-

Program

External>>TV

3. Press the BLUE button on the remote control.

The screen will show :-

Program

TV>>External

4. Press the STR button on the TV.

The screen will show :-

Please Wait

5. All the tuning information stored inside the TV will

now be transferred to the Memory Pack. This process

will take 2-3 minutes to complete and when finished

the screen will show :-

Complete

Memory Pack to TV process

1. Plug the memory pack into the AV1 21 pin terminal at

the back of the TV and switch the TV on.

2. Enter Service Mode as explained above.

The screen will show :-

Program

External>>TV

3. Press the STR button on the TV.

The screen will show :-

Please Wait

4. All the tuning information stored inside the Memory

Pack will now be transferred to the TV. This process

will take 2-3 minutes to complete and when finished

the screen will show :-

Complete

5. The tuning information from the Memory Pack has

now been copied into the TV.

6. To exit the Service Mode turn the TV off at the power

button.

7. The process has now been completed and the

Memory Pack can now be removed.

ERRORS

If an error occurs while using the Memory Pack the TV will detect this and the screen will show :-

Error !!

Error !!

If this happens then press the "N" button and repeat the process that was being used. If the errors continue to occur then

check the connectors between the TV and the memory pack and check the 9V battery inside the memory pack.

5

ADJUSTMENT PROCEDURE

Item / Preparation Adjustments

+B SET-UP

1. Receive a Greyscale signal.

2. Set the controls :Brightness Minimum

Contrast Minimum

Volume Minimum

CUT OFF / Ug2 Test

1. Receive a Greyscale signal.

2. Degauss the tube externally.

3. Set the TV into Service Mode 1.

4. Select Cut off mode.

1. Set the +B voltage up as follows:Adjust R811 so that B2 shows 148V±1V.

2. Confirm the following voltages.

B9 5 ± 0,25V B10 5 ± 0,25V

B5 12 ± 0,5V B11 33 ± 1,5V

B4 16 ± 1V B7 8 ± 0,5V

B12 26 ± 1V B8 5,5 ± 0,5V

B3 41 ± 1,5V B13 15 ± 1V

B1 200± 10V B14 -15 ± 1V

To adjust Cutoff connect an oscilloscope to the Blue

cathode, adjust "cutoff" value using the "Yellow" and "Blue"

buttons until the black level is 160V±5V press "STR" to store

the value. Remove the oscilloscope.

Select Ug2 adjustment and adjust the screen VR until the

display shows "O.K."

FACTORY SETTINGS

To return customer settings to factory settings and clear owner ID of all information input by the customer, enter Self-Check

mode. Press the down (-/v) button on the customer controls at the front of the TV set, at the same time pressing the STATUS

button on the remote control. To exit Self Check, switch off the TV set at the power button.

NOTE: Self Check should only be used when refurbishing the TV set and not during normal repair work.

VDP O.K.

TUN O.K.

E2 O.K.

PCB O.K.

Cab O.K.

Sum

Factory use only

MSP O.K.

OPTION 1 00

OPTION 2 01

OPTION 3 02

OPTION 4 09

OPTION 5 B1

OPTION 6 A9

Self Check is also used to automatically check the bus lines and hexadecimal code of the TV set. If the CCU ports have

been checked and found to be incorrect or not located then " - - " will appear in place of "O.K.". For more in-depth TV

diagnostics use the LUCI interface as listed below.

Service Aids

To aid in the service of our current chassis there are a number of Service Aids which have been made available.

• LUCI interface kit (Linked Utility Computer Interface)

Part number: TZS6EZ002

This contains interface and cables for connecting TV service connector and a PC as well as diagnostic software. As new

models are introduced upgrade software will become available.

• VICI (Visual Interactive Computer Information)

These C.D.'s contain multimedia documentation providing quick access to service information.

Part No. TZS7EZ006 & TZS7EZ005

1. Service Manuals

2. Instruction Books

3. Technical Information

• TASMIN (Technically Advanced System for Multimedia Interactive Notes)

As well as providing a first step towards more interactive training this product also achieves quick access to Technical

Information.

6

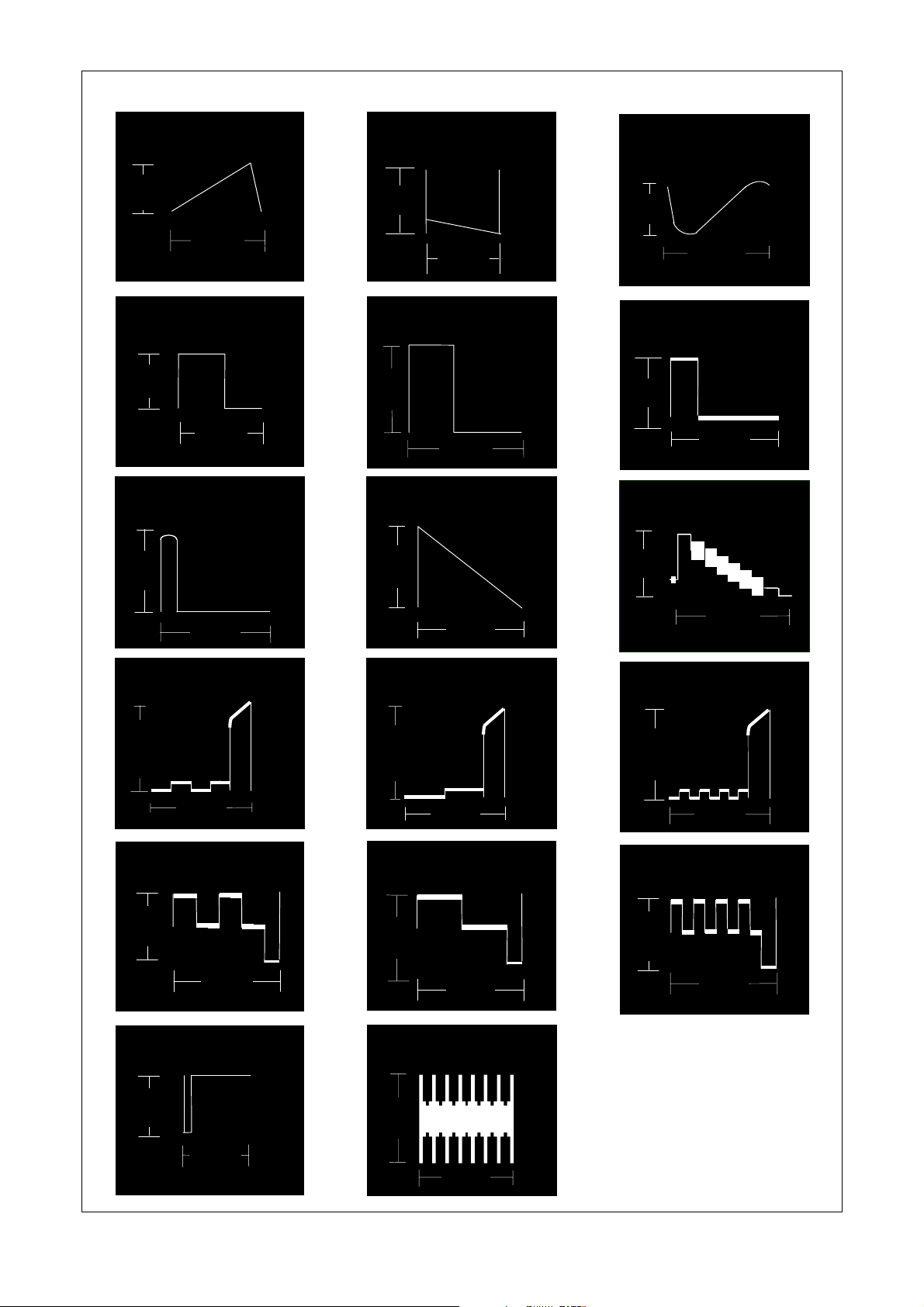

Vert Out

IC601 Pin 31

WAVEFORM PATTERN TABLE

Vert Drive

IC451 Pin 2

VFLB

IC451 Pin 3

0.7V

H - Out

IC601 Pin 50

3V

HFLB

IC601 Pin 13

6.2V

20mS

64µS

64µS

57V

H - Out

IC701 Pin 5

30mV

HFLB

IC701 Pin 8

1.5V

20mS

64µS

64µS

1V

20mS

H - Pulse

Base Q503

2V

64µS

Video Out

IC601 Pin 59

2V

64µS

R - Out

IC601 Pin 37

275mV

R - Out

E8 Pin 5

4.6V

SCL

IC1201 Pin 3

3.7V

64µS

64µS

G - Out

IC601 Pin 38

275mV

G - Out

E8 Pin 3

4.4V

SVM Out

IC601 Pin 34

88mV

64µS

64µS

B - Out

IC601 Pin 39

275mV

64µS

B - Out

E8 Pin 4

4.6V

64µS

13µS

64µS

7

ALIGNMENT SETTINGS

(The figures below are nominal and used for representative purposes only.)

Alignment Function Settings / Special features

Horizontal Position

Vertical Position

Horizontal Amplitude

Vert. Amplitude

EW-amplitude

EW-amplitude

Trapezium-comp

Trapezium-comp

H-Pos

061

V-Pos

005

H-Amp

055

V-Amp

054

E/W-Amp1

-128

E/W-Amp2

006

Trapez-1

047

Trapez-2

-128

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Vertical Linearity

Vertical Symmetry

DVCO

Cut-off DC

Ug2 Test

Highlight

Lowlight

Sub-Brightness

V-Lin

006

V-Sym

002

DVCO

-005

Cut-off

0171

Ug2

055

O.K.

High 0902 0777 0864

Low 0117 0132 0112

Sub-Brightness

255

Optimum setting.

Optimum setting.

Receive a PAL Colour Bar Pattern. For

DVCO alignment press "Blue" button, wait

until the colours are changing slowly and

press "STR".

To adjust Cutoff connect an oscilloscope to

the blue cathode, adjust "cutoff" value

using the "Yellow" and "Blue" buttons until

the black level is 160V±5V press "STR" to

store the value. Remove the oscilloscope.

Select Ug2 adjustment and adjust the

screen VR until the display shows "O.K."

Black Level

160V±5V

GND

Optimum setting.

Optimum setting.

8

,Q

Q352Q35

,Q

&

Q35

9

Y

C

AV1

9LGHR2XW

%OXH

*UHHQ

5HG

9LGHR

AV2

9LGHR

$9

2XW

9LGHR

E - BOARD

Q105

Q3001

Q104

61 V IN 1

43 B IN

42 G IN

41 R IN

62 VIN 2

63 VIN 3

60 C IN

VIN 4

64

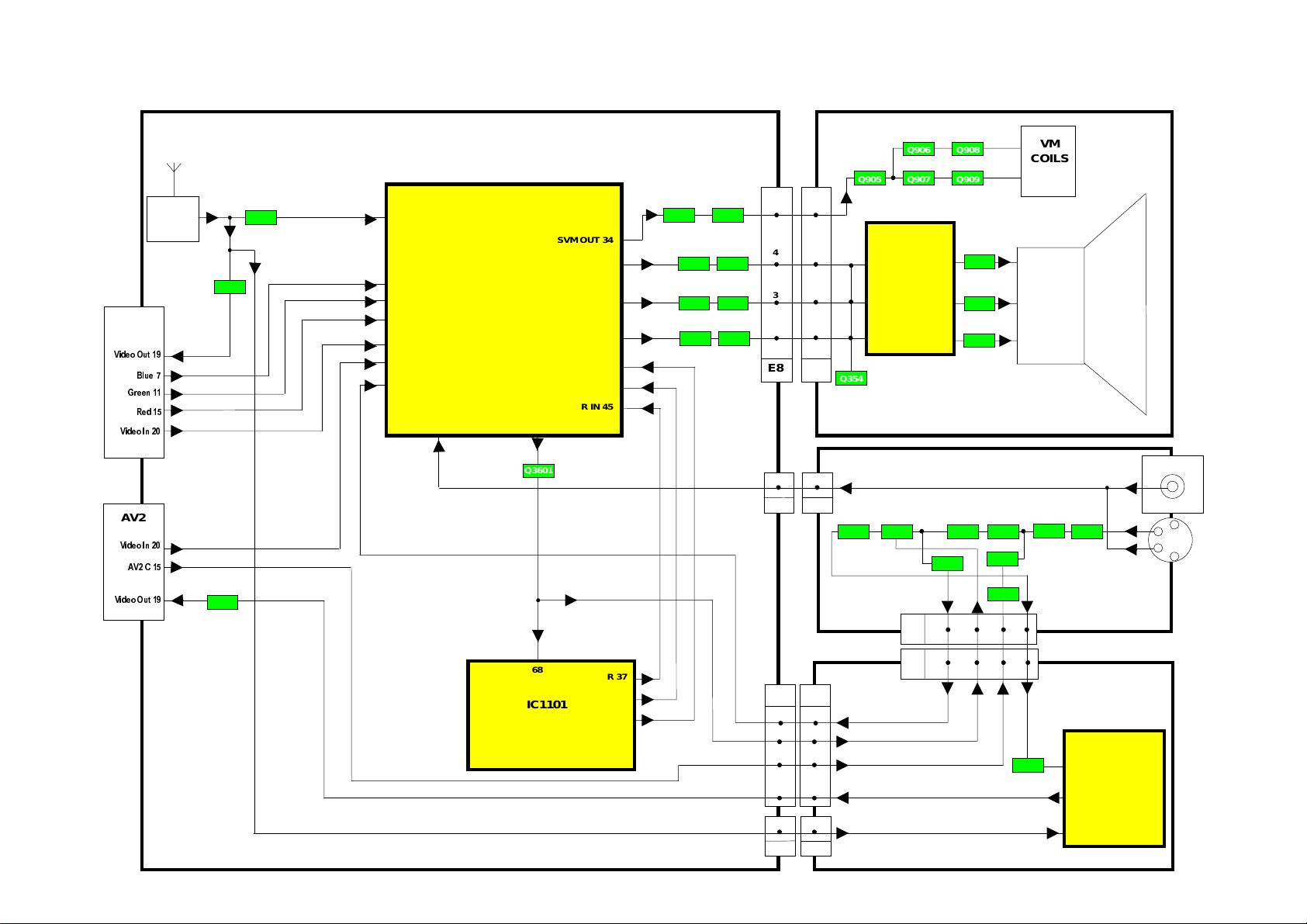

VIDEO BLOCK DIAGRAM

IC601

VIDEO

PROCESSOR

VIDEO OUT

59

Q3601

SVM OUT 34

B OUT 39

G OUT 38

R OUT 37

B IN 47

G IN 46

R IN 45

Q950 Q951

Q303

Q304

Q301

Q302

7

7

4

4

3

3

5

5

E8

Y2

66

M2

E17

Y - BOARD

Q905 Q907 Q909

IC351

3

RGB

OUTPUT

2

1

4

M - BOARD

7

8

9

Q3207

Q908Q906

Q353

VM

COILS

CRT

1

AV3

Q3204

Q3205Q3206Q3208Q3209

Q3202

Q3201

Q3203

68

CVBS

IC1101

MICRO

PROCESSOR

R 37

G 38

B 39

M3

H2

H - BOARD

E158H1

2 2

4 4

6 6

8

1 1

2 6

6

4

82

4 8

IC3401

Q3402

8

VIDEO

SWITCHING

6

3

H3E61

E - BOARD

AUDIO BLOCK DIAGRAM

M - BOARD

M4

1

K7

DACA_R

DACA_L

10

K3

I2S_DA_IN_2

I2S_DA_IN_1

I2S_DA_OUT

I2S_DA_WS

I2S_DA_CL

E22

3

1

E12

TUNER

Q101

Q102

Q2304

Q2302

IC2101

AUDIO

PROCESSOR

47 ANA_IN1+

21 DACA_R

22 DACA_L

DACM_R 24

DACM_L 25

SC3_IN_L 37

SC3_IN_R 38

Q2102

Q2103

Q252

Q251

5 R

2 L

IC251

AUDIO

OUTPUT

R 7

L 11

E16A M1

1 1

2 2

10 10

8 8

M5

3

AV3

6 R

7 R

3 R

HEADPHONE

5 L

4 L

2 L

L

R

E17 M2

1

3

M6 K8

SC1_OUT_R 30

SC1_IN_R 42

SC1_OUT_L 31

3

4

5

6

7

18 I2S_DA_IN_2

12 I2S_DA_IN_1

11 I2S_DA_OUT

10 I2S_DA_WS

9 I2S_DA_CL

SC1_IN_L 41

SC2_OUT_R 27

SC2_IN_R 40

SC2_OUT_L 28

SC2_IN_L 39

1 R OUT

2 R IN

3 L OUT

6 L IN

AV1

1 R OUT

2 R IN

3 L OUT

6 L IN

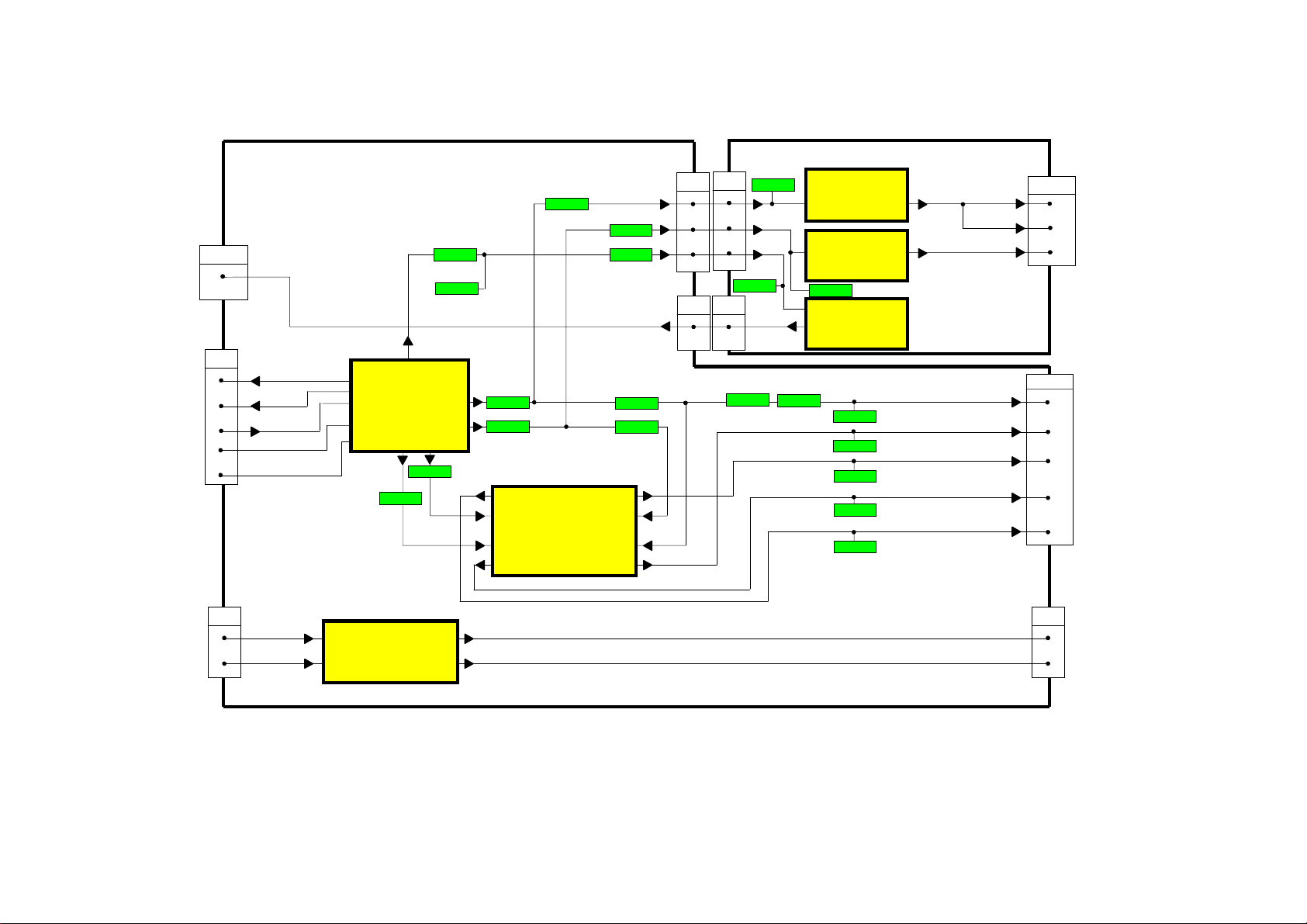

DOLBY BLOCK DIAGRAM

11

Woofer

E12 K3

I2S_DA_OUT_2

I2S_DA_OUT_1

I2S_DA_IN

I2S_WS

I2S_CL

JK2402

3

4

5

6

7

K - BOARD

27

19

IC2401

11

12

DOLBY

PROCESSOR

10

9

21

Q2409

Q2410

Q2423

Centre

Woofer

Q2426 Q2428

Q2427

Q2403

24

25

Q2401

22

1

3

5

7

IC2402

OPERATIONAL

AMPLIFIER

Surround

Q2425

Q2404

Q2402

14

12

10

8

K5

K6

C - BOARD

C2

Q2705

1

1

3

3

5

5

Q2703

C5

1

1

IC2704

AUDIO

1

AMPLIFIER

IC2703

1

AUDIO

AMPLIFIER

Q2704

IC2702

1

AUDIO

4

AMPLIFIER

JK2702

4

4

Surround L

Surround R

Centre

JK2401

Q2405

Q2406

Q2419

Surround R

Surround L

Q2418

Centre Out

Q2417

Right Front

Q2421

Left Front

Q2420

E22 K7

Audio Left

Audio Right

K8 M6

1

3

HEADPHONE

AMPLIFIER

5

IC2404

13

7

Headphone Left

1

Headphone Right

3

Loading...

Loading...