Panasonic TH-L32X50Z Schematic

ORDER NO. MTV1201007CE

Model No. TH-L32X50Z

Chassis: KM16

Destination: NEW ZEALAND

LCD TV

TABLE OF CONTENTS

1 Safety Precautions ----------------------------------------------- 3

1.1. General Guidelines---------------------------------------- 3

1.1.1. Leakage Current Cold Check ---------------------- 3

1.1.2. Leakage Current Hot Check (See Figure

1.) --------------------------------------------------------- 3

2 Warning-------------------------------------------------------------- 4

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatically Sensitive (ES) Devices---------- 4

2.2. About lead free solder (PbF)---------------------------- 5

3 Service Navigation ----------------------------------------------- 6

3.1. Service Hint ------------------------------------------------- 6

4 Specifications ----------------------------------------------------- 7

5 Service Mode ------------------------------------------------------ 8

5.1. How to enter into Service Mode ----------------------- 8

5.1.1. Contents of adjustment mode --------------------- 8

5.1.2. How to exit---------------------------------------------- 8

5.2. SRV-TOOL -------------------------------------------------- 9

5.2.1. How to access ----------------------------------------- 9

5.2.2. Display of SOS History ------------------------------ 9

5.2.3. POWER ON TIME/COUNT ------------------------ 9

PAG E PAG E

5.2.4. Exit -------------------------------------------------------- 9

5.2.5. Self Check Mode ------------------------------------ 10

5.2.6. Hotel Mode Adjustment ---------------------------- 10

5.2.7. Hotel Mode-------------------------------------------- 10

6 Troubleshooting Guide --------------------------------------- 11

6.1. Check of the IIC bus lines------------------------------ 11

6.1.1. How to access --------------------------------------- 11

6.1.2. Exit ------------------------------------------------------ 11

6.1.3. Screen display --------------------------------------- 11

6.2. Power LED Blinking timing chart --------------------- 12

6.3. No Power--------------------------------------------------- 12

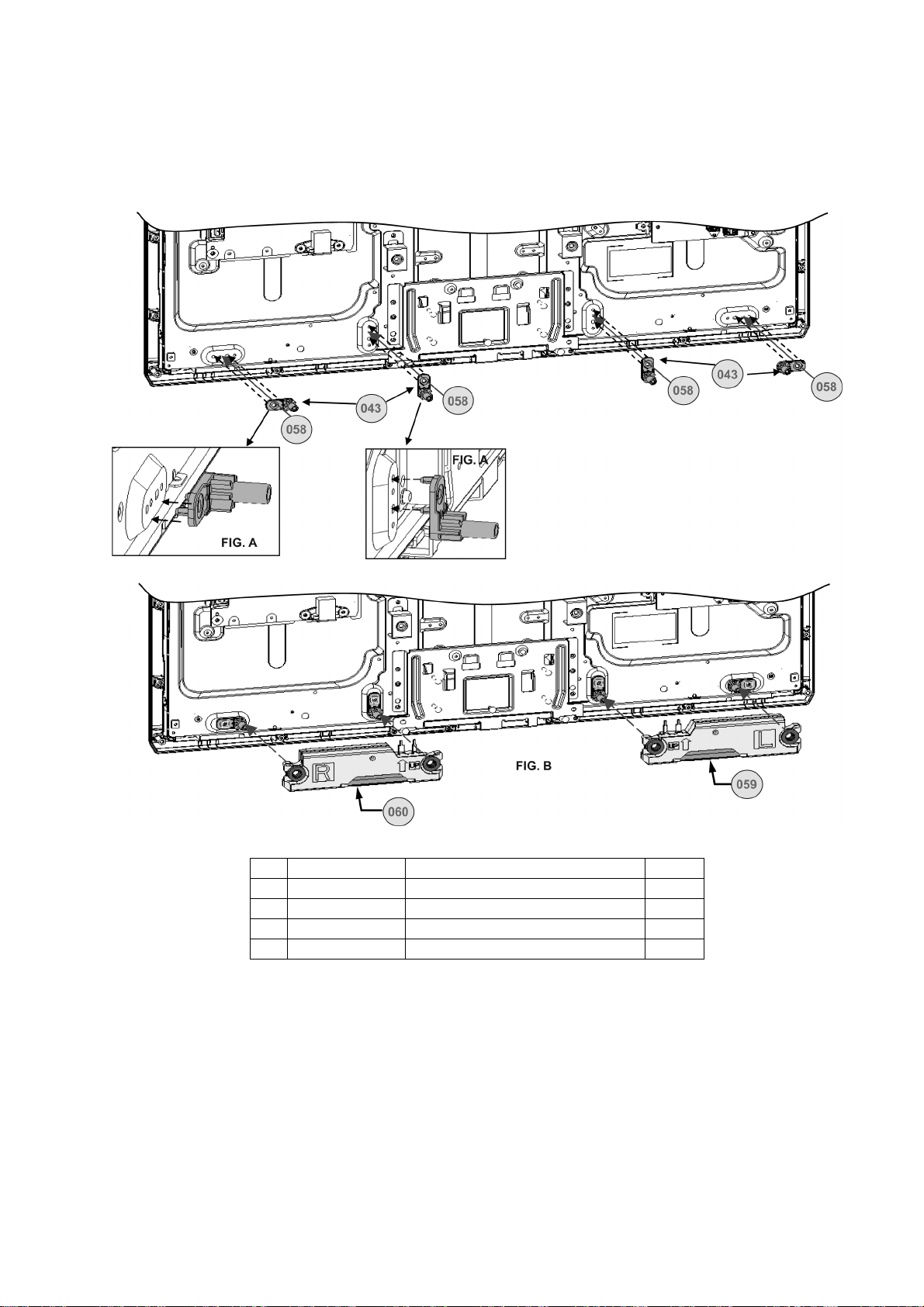

7 Disassembly and Assembly Instructions--------------- 13

7.1. SP Bracket------------------------------------------------- 13

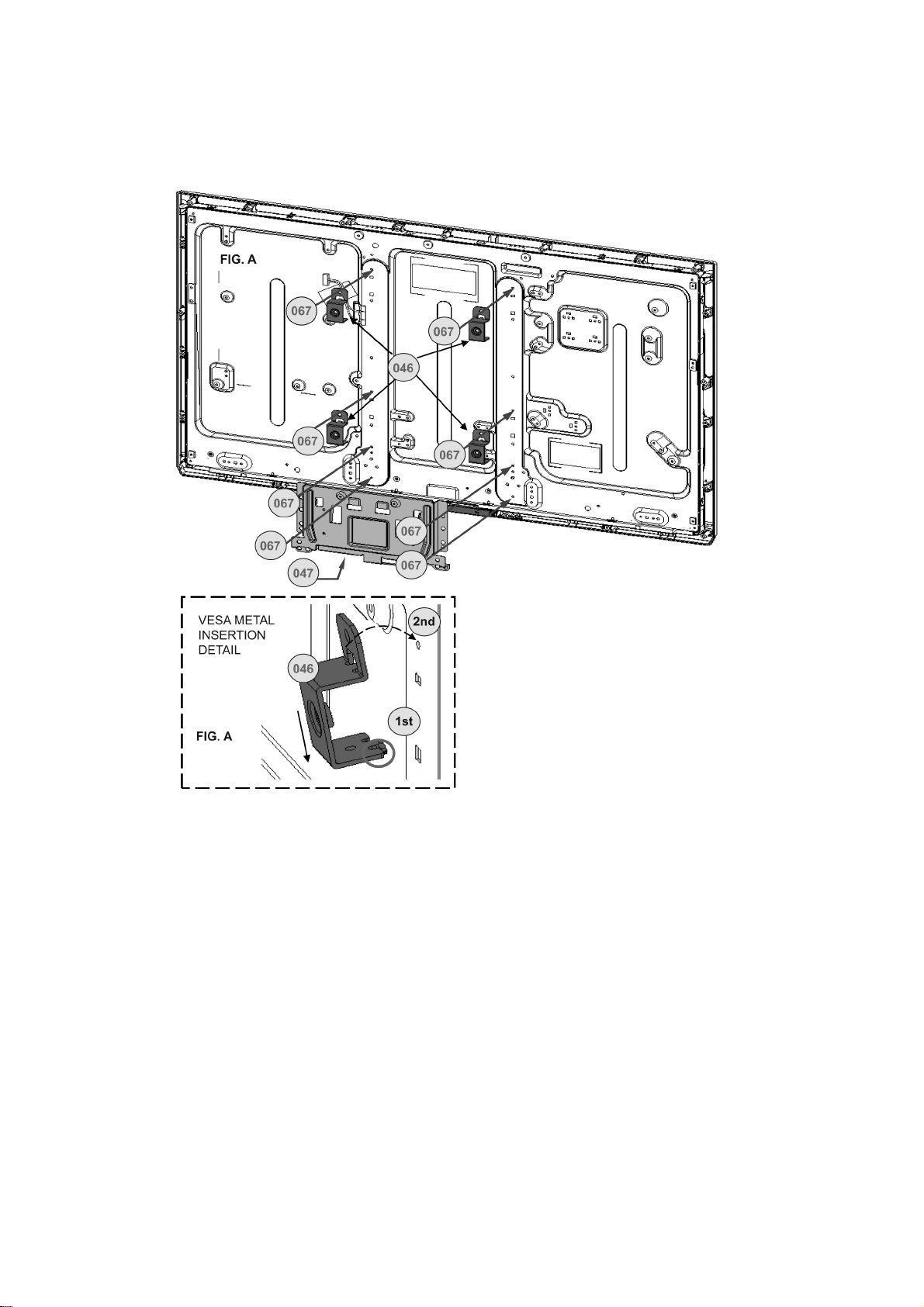

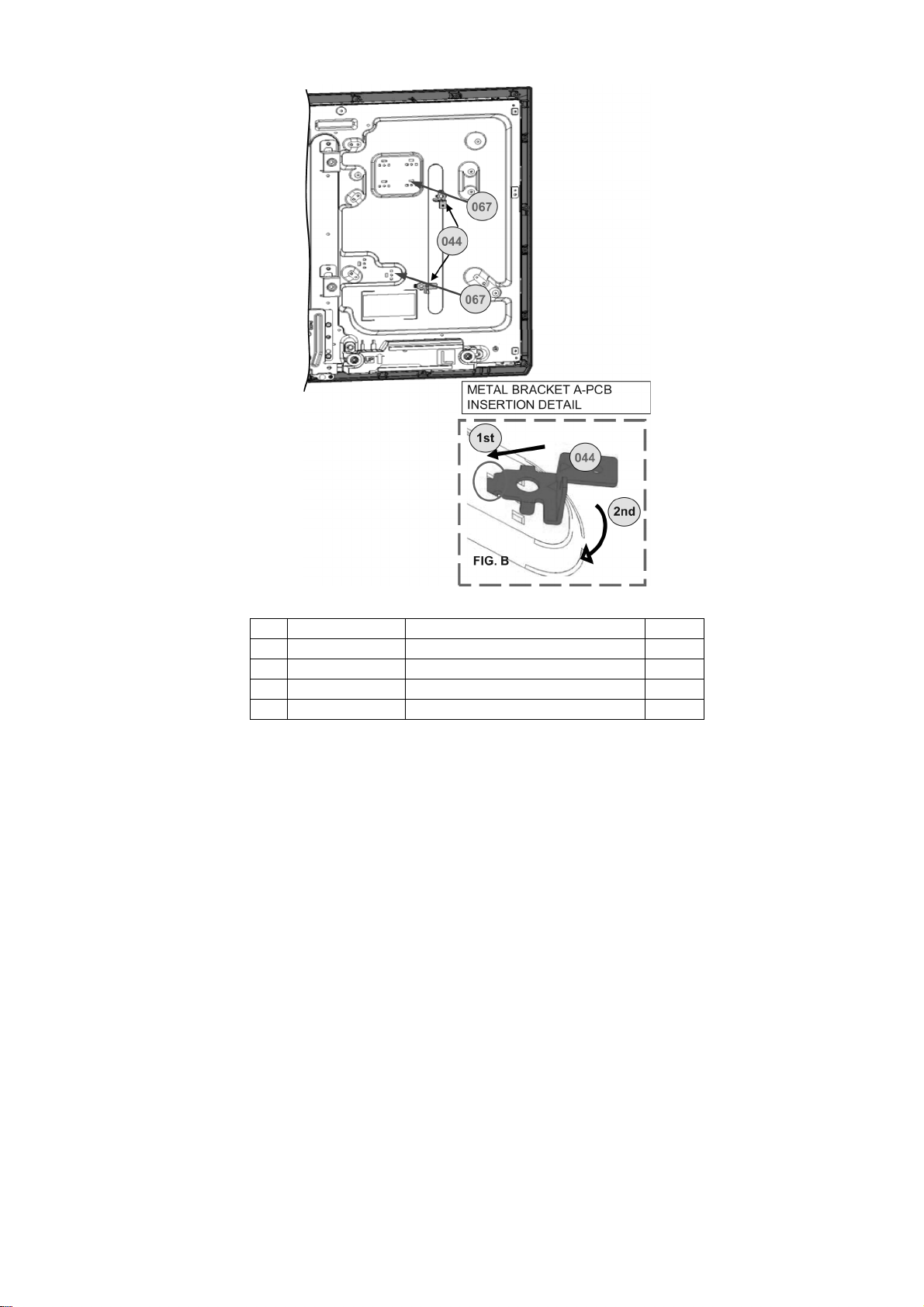

7.2. Vesa Metal Assembly ----------------------------------- 14

7.3. LCD Panel Fixing & Handling Method -------------- 16

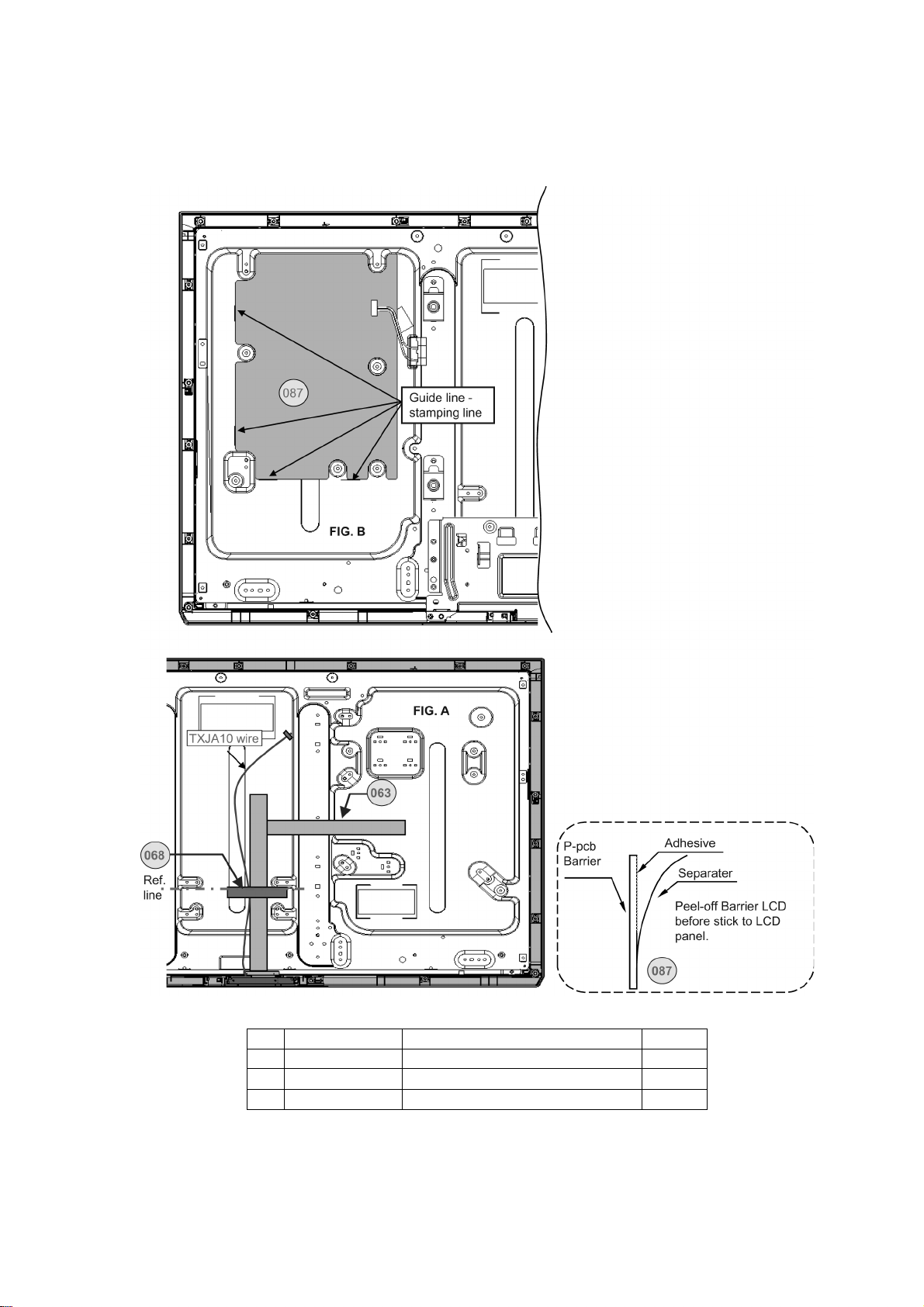

7.4. Barrier LCD ----------------------------------------------- 17

7.5. LED Panel Assembly------------------------------------ 18

7.6. Back Cover Screw --------------------------------------- 19

7.7. P-Print Assy ----------------------------------------------- 20

7.8. Bottom Cover --------------------------------------------- 22

© Panasonic Corporation 2012. Unauthorized

copying and distribution is a violation of law.

TH-L32X50Z

7.9. Stand MTG & Pedestal MTG-------------------------- 23

8 Measurements and Adjustments -------------------------- 24

8.1. Voltage chart of A-board-------------------------------- 24

8.2. Voltage chart of P-board-------------------------------- 24

9 Block Diagram --------------------------------------------------- 25

9.1. Main Block Diagram ------------------------------------- 25

10 Wiring Connection Diagram --------------------------------- 26

10.1. Wire Dressing --------------------------------------------- 26

11 Schematic Diagram--------------------------------------------- 27

11.1. Schematic Diagram Notes ----------------------------- 27

11.2. A Board ----------------------------------------------------- 28

11.2.1. A Board - Sheet : 002 (1 / 2)---------------------- 28

11.2.2. A Board - Sheet : 002 (2 / 2)---------------------- 29

11.2.3. A Board - Sheet : 003 (1 / 5)---------------------- 30

11.2.4. A Board - Sheet : 003 (2 / 5)---------------------- 31

11.2.5. A Board - Sheet : 003 (3 / 5)---------------------- 32

11.2.6. A Board - Sheet : 003 (4 / 5)---------------------- 33

11.2.7. A Board - Sheet : 003 (5 / 5)---------------------- 34

11.2.8. A Board - Sheet : 004 (1 / 2)---------------------- 35

11.2.9. A Board - Sheet : 004 (2 / 2)---------------------- 36

11.2.10. A Board - Sheet : 005 (1 / 2)----------------------37

11.2.11. A Board - Sheet : 005 (2 / 2)---------------------- 38

11.2.12. A Board - Sheet : 008 (1 / 1)----------------------39

11.2.13. A Board - Sheet : 009 (1 / 2)----------------------40

11.2.14. A Board - Sheet : 009 (2 / 2)----------------------41

11.2.15. A Board - Sheet : 010 (1 / 1)----------------------42

11.2.16. A Board - Sheet : 100 (1 / 3)----------------------43

11.2.17. A Board - Sheet : 100 (2 / 3)----------------------44

11.2.18. A Board - Sheet : 100 (3 / 3)----------------------45

11.2.19. A Board - Sheet : 101 (1 / 4)----------------------46

11.2.20. A Board - Sheet : 101 (2 / 4)----------------------47

11.2.21. A Board - Sheet : 101 (3 / 4)----------------------48

11.2.22. A Board - Sheet : 101 (4 / 4)----------------------49

11.2.23. A Board - Sheet : 300 (1 / 1)----------------------50

11.2.24. A Board - Sheet : 301 (1 / 3)----------------------51

11.2.25. A Board - Sheet : 301 (2 / 3)----------------------52

11.2.26. A Board - Sheet : 301 (3 / 3)----------------------53

11.2.27. A Board - Sheet : 302 (1 / 1)----------------------54

11.2.28. A Board - Sheet : 700 (1 / 2)----------------------55

11.2.29. A Board - Sheet : 700 (2 / 2)----------------------56

11.2.30. A Board - Sheet : 701 (1 / 2)----------------------57

11.2.31. A Board - Sheet : 701 (2 / 2)----------------------58

11.2.32. A Board - Sheet : 702 (1/ 1) ---------------------- 59

11.2.33. A Board - Sheet : 703 (1 / 1)----------------------60

11.2.34. A Board - Sheet : 704 (1 / 1)----------------------61

11.2.35. A Board - Sheet : 708 (1 / 1)----------------------62

11.3. K Board ----------------------------------------------------- 63

11.3.1. K Board (1 / 2)---------------------------------------- 63

11.3.2. K Board (2 / 2)---------------------------------------- 64

11.4. P Board ----------------------------------------------------- 65

11.4.1. P Board (1 / 4)---------------------------------------- 65

11.4.2. P Board (2 / 4)---------------------------------------- 66

11.4.3. P Board (3 / 4)---------------------------------------- 67

11.4.4. P Board (4 / 4)---------------------------------------- 68

12 Printed Circuit Board ------------------------------------------ 69

12.1. A-BOARD -------------------------------------------------- 69

12.2. K-BOARD -------------------------------------------------- 71

12.3. P-BOARD -------------------------------------------------- 72

13 Exploded View and Replacement Parts List -----------74

13.1. Exploded View and Mechanical Replacement

Parts List --------------------------------------------------- 74

13.2. Electrical Replacement Parts List ------------------- 74

13.2.1. Replacement Parts List Notes ------------------- 74

13.2.2. Electrical Replacement Parts List--------------- 75

2

TH-L32X50Z

1 Safety Precautions

1.1. General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

4. When conducting repairs and servicing, do not attempt to modify the equipment, its parts or its materials.

5. When wiring units (with cables, flexible cables or lead wires) are supplied as repair parts and only one wire or some of the

wires have been broken or disconnected, do not attempt to repair or re-wire the units. Replace the entire wiring unit instead.

6. When conducting repairs and servicing, do not twist the Faston connectors but plug them straight in or unplug them straight

out.

1.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the

two prongs on the plug.

2. Measure the resistance value, with an ohmmeter,

between the jumpered AC plug and each exposed

metallic cabinet part on the equipment such as

screwheads, connectors, control shafts, etc. When the

exposed metallic part has a return path to the chassis, the

reading should be 100 Mohm and over.

When the exposed metal does not have a return path to

the chassis, the reading must be .

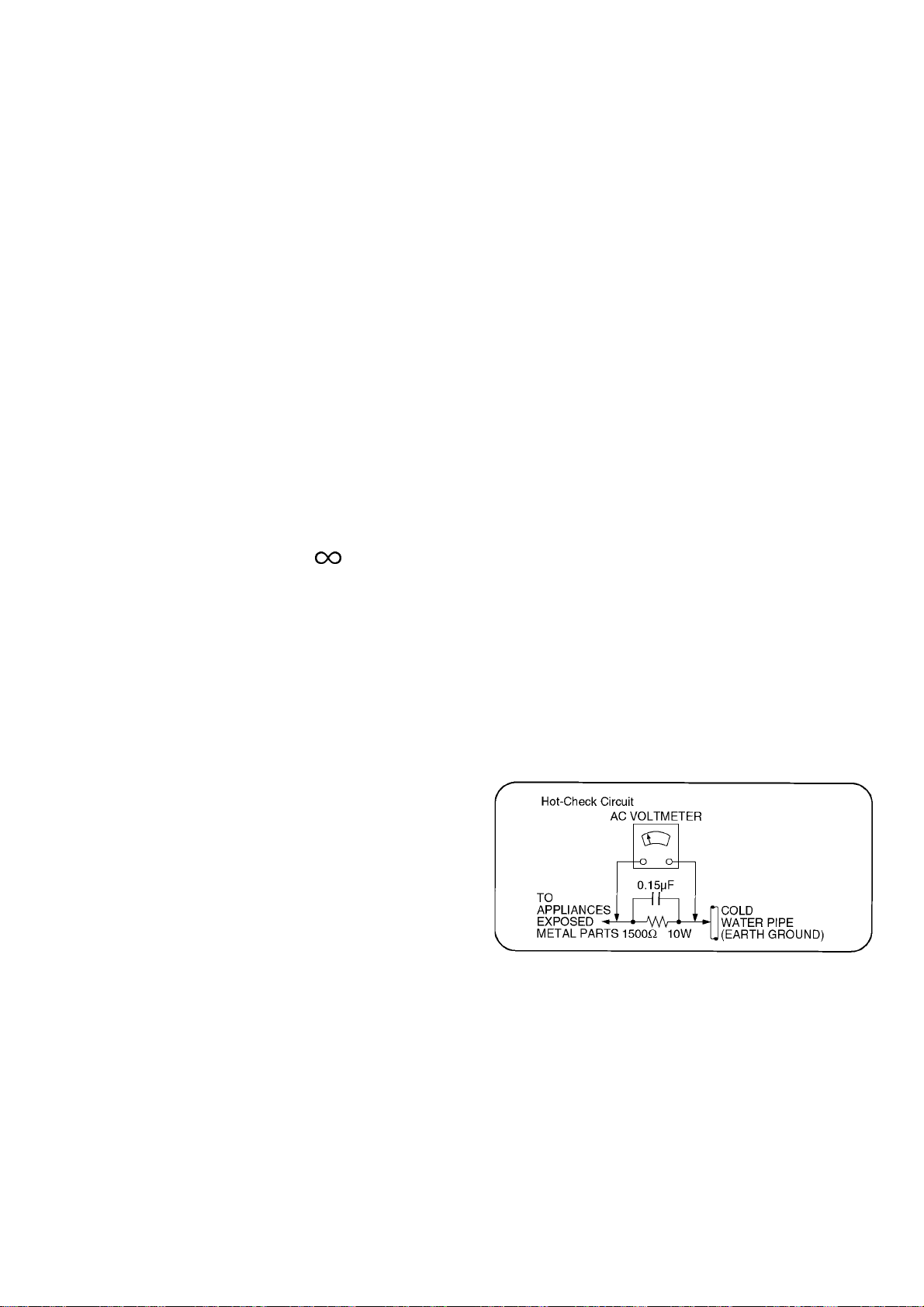

1.1.2. Leakage Current Hot Check (See

Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer for this check.

2. Connect a 1.5kohm, 10 watts resistor, in parallel with a

0.15μF capacitors, between each exposed metallic part

on the set and a good earth ground such as a water pipe,

as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more

sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of

the above measurements.

6. The potential at any point should not exceed 0.75 volts

RMS. A leakage current tester (Simpson Model 229 or

equivalent) may be used to make the hot checks, leakage

current must not exceed 1/2 milliamp. In case a

measurement is outside of the limits specified, there is a

possibility of a shock hazard, and the equipment should

be repaired and rechecked before it is returned to the

customer.

Figure 1

3

TH-L32X50Z

2Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatically

Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor [chip] components. The following techniques should be used to help reduce the incidence of component damage

caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as [anti-static (ESD protected)] can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or

comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise ham less motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD)

sufficient to damage an ES device).

4

TH-L32X50Z

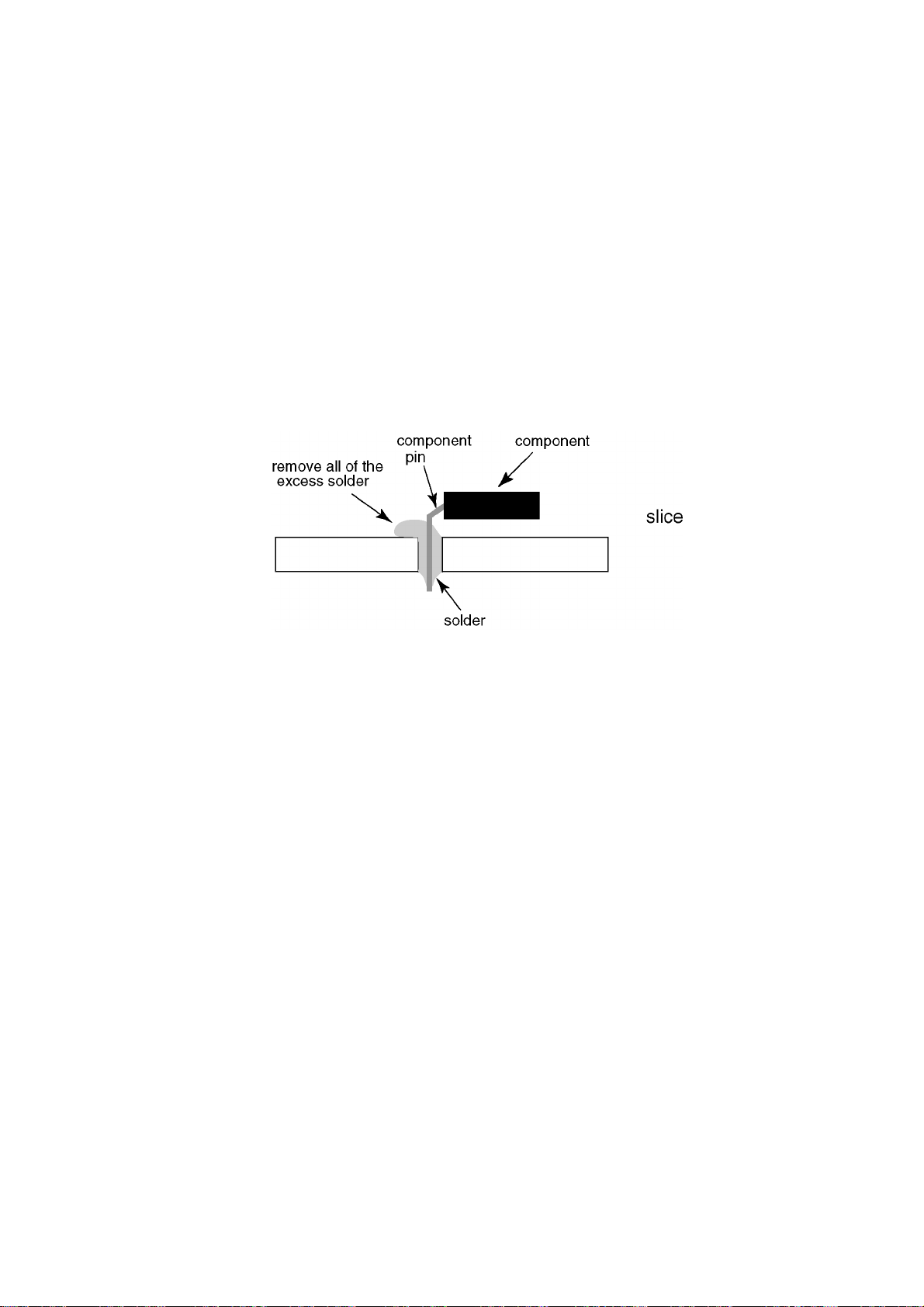

2.2. About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair work, we’d

suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol PbF stamped on the back of PCB.

Caution

• Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30~40 °C) higher. Please

use a high temperature soldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

• Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before applying Pb

solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

• After applying PbF solder to double layered boards, please check the component side for excess solder which may flow onto the

opposite side. (see figure below)

5

TH-L32X50Z

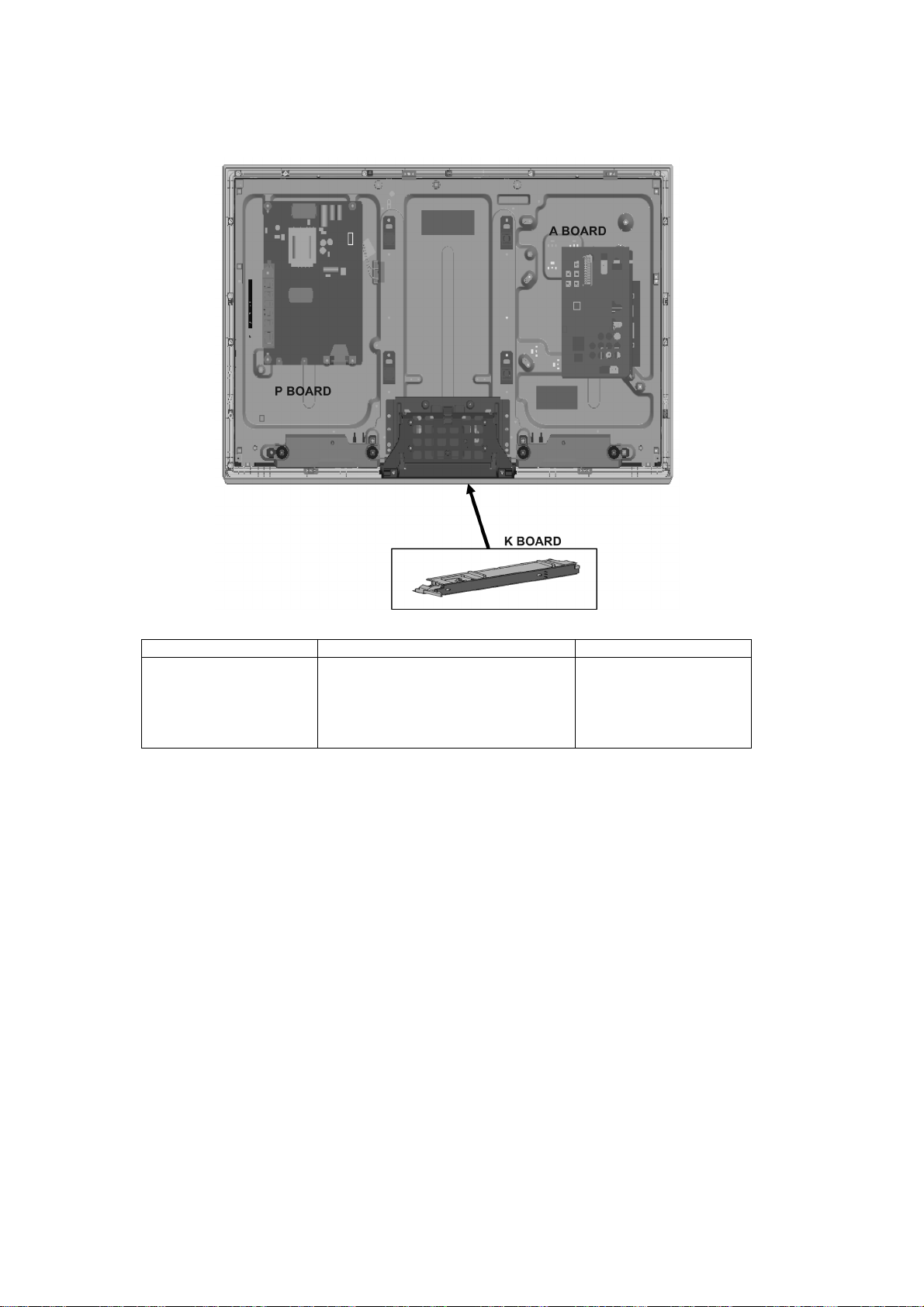

3 Service Navigation

3.1. Service Hint

Board Name Main Device Remarks

A BOARD AVSW, TUN, OFDM, P-SLD2, EEP Repairable

P BOARD Power Supply Repairable

K BOARD Remote, LED, Luminunce Sensor Repairable

6

4 Specifications

Power

Power rating AC 220-240 V, 50 / 60 Hz 0.55 A

Normal (Home) mode 70 W

Standby condition 0.25 W

Display panel

Panel system LED LCD panel

Visible screen size (diagonal) 82 cm / 32 inches

Number of pixels 1,049,080 (1,366 (W) × 768 (H))

Dimensions (W × H × D) 761 mm × 517 mm × 230 mm (With Pedestal)

761 mm × 463 mm × 53 mm (TV only)

Mass 10.0 kg Net (With Pedestal)

8.0 kg Net (TV only)

Sound

Speaker (75 mm × 22 mm) × 2, 8 Ω

Audio Output 20 W (10 W + 10 W)

Headphones M3 (3.5 mm) stereo mini Jack × 1

Receiving systems / Band name PAL B, G Reception of Off air broadcasts

Digital TV

PAL 60 Hz Playback of NTSC tape from some PAL Video recorders (VCR)

M.NTSC Playback from M.NTSC Video recorders (VCR)

NTSC Playback from NTSC Video recorders (VCR)

Aerial - Rear VHF / UHF

Operating Conditions Temperature : 0°C - 35°C

Humidity : 20 % - 80 % RH (non-condensing)

Connection Terminals

AV1 IN AUDIO L-R RCA PIN Type × 2 0.5 V [rms]

COMPONENT Y 1.0 V [p-p] (including synchronization)

VIDEO RCA PIN Type × 1 1.0 V[p-p] (75 Ω)

AV2 IN AUDIO L - R RCA PIN Type × 2 0.5 V[rms]

VIDEO RCA PIN Type × 1 1.0 V[p-p] (75 Ω)

AUDIO OUT AUDIO L -R RCA PIN Type × 2 0.5 V[rms] (high impedance)

HDMI 1 / 2 / 3 input TYPE A Connectors

• This TV supports ‘HDAVI Control 5’ function.

PC HIGH-DENSITY D-SUB 15 PIN

R, G, B: 0.7 V[p-p] (75 Ω)

HD, VD: TTL Level 2.0 - 5.0 V[p-p] (high impedance)

• Applicable input signals:

VGA, SVGA, WVGA, XGA

SXGA, WXGA .....(compressed)

Horizontal scanning frequency 31 - 69 kHz

Vertical scanning frequency 59 - 86 Hz

Card slot SD Card slot × 1

ETHERNET 10BASE-T / 100BASE-TX

USB 1 / 2 USB 2.0 TYPE A Connectors DC 5 V, Max, 500 mA

DIGITAL AUDIO OUT PCM / Dolby Digital / DTS, Fibre optic

Note

• Design and Specifications are subject to change without notice. Mass and Dimensions shown are approximate.

7 MHz VHF / UHF (Australia) free-to-air TV broadcast reception

P

B/CB, PR/CR

± 0.35 V [p-p]

TH-L32X50Z

7

TH-L32X50Z

5 Service Mode

5.1. How to enter into Service Mode

While pressing [VOLUME ( - )] button of the main unit, press [INFO] button of the remote control three times within 2 seconds.

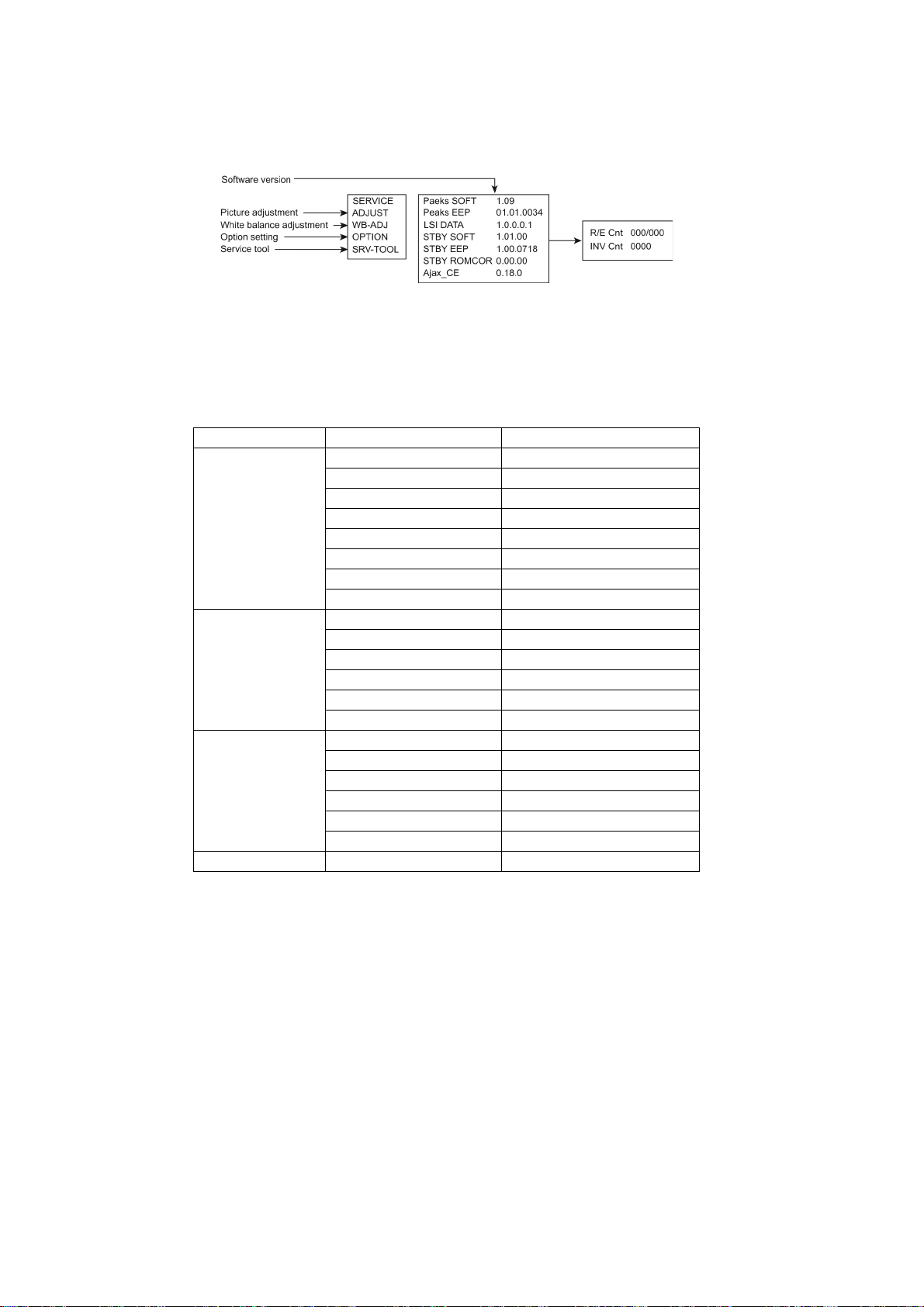

5.1.1. Contents of adjustment mode

• Value is shown as a hexadecimal number.

• Preset value differs depending on models.

• After entering the adjustment mode, take note of the value in each item before starting adjustment.

Main item Sub item Sample Data

ADJUST CONTRAST 000

COLOR 59

TINT FE

SUB-BRT 800

BACKLGT 20D

B-Y-G 40

R-Y-A 0

VCOM 189

WB-ADJ R-GAIN 75

G-GAIN 80

B-GAIN 65

R-CENT 80

G-CENT 80

B-CENT 9B

OPTION Boot ROM

STBY-SET 00

EMERGENCY ON

CLK MODE 00

CLOCK FC7

EDID-CLK HIGH

SRV-TOOL 00

5.1.2. How to exit

Switch off the power with the [POWER] button on the main unit or the [POWER] button on the remote control.

8

TH-L32X50Z

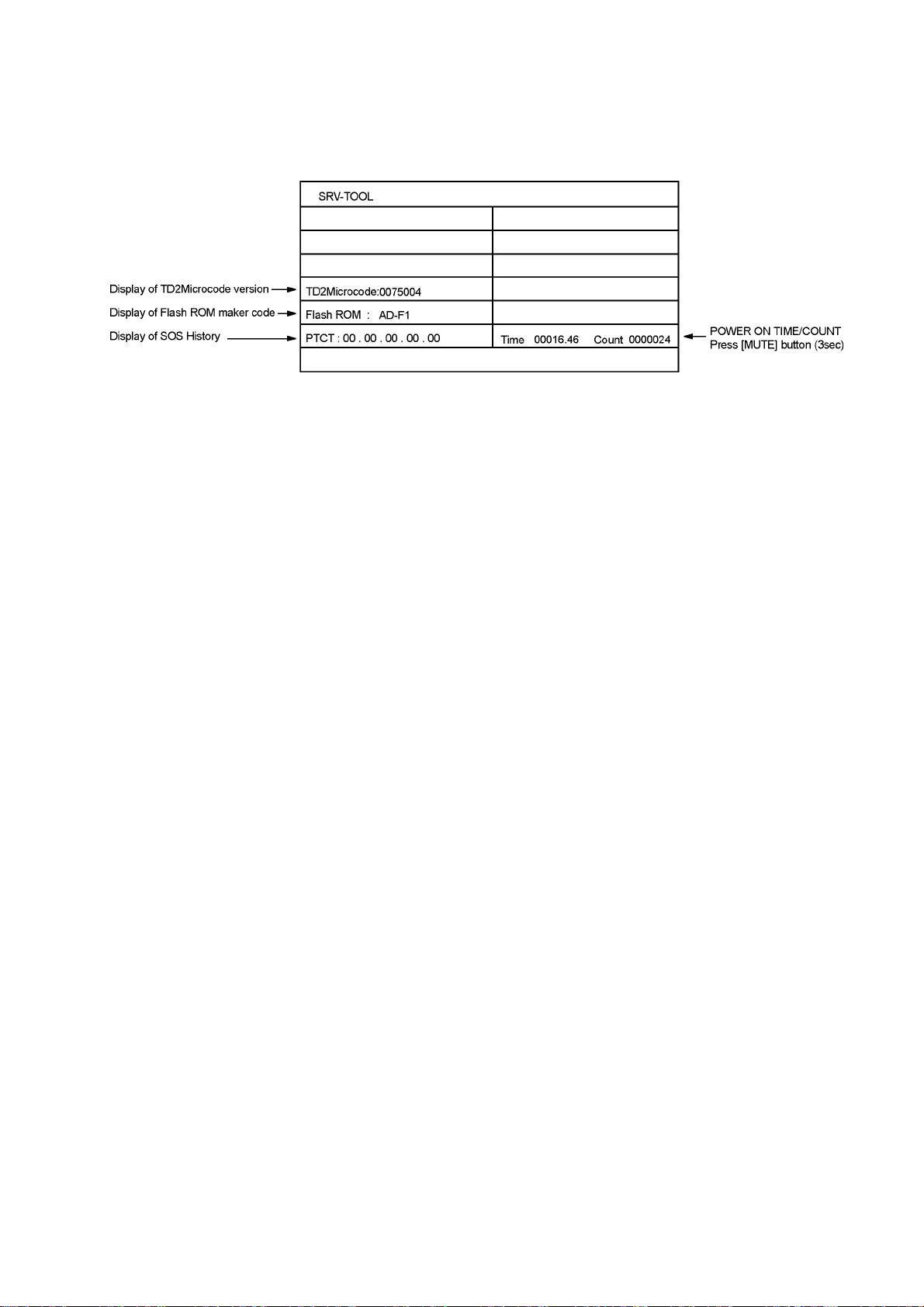

5.2. SRV-TOOL

5.2.1. How to access

1. Select [SRV-TOOL] in Service Mode.

2. Press [OK] button on the remote control.

5.2.2. Display of SOS History

SOS History (Number of LED blinking ) indication.

From left side; Last SOS, before Last, three occurrence before, 2nd occurrence after shipment, 1st occurrence after shipment.

This indication except 2nd and 1st occurrence after shipment will be cleared by [Self-check indication and forced to factory

shipment setting].

5.2.3. POWER ON TIME/COUNT

Note : To display TIME/COUNT menu, highlight position, then press MUTE for 3sec.

Time : Cumulative power on time, indicated hour : minute by decimal

Count : Number of ON times by decimal

Note : This indication will not be cleared by either of the self-checks or any other command.

5.2.4. Exit

1. Disconnect the AC cord from wall outlet.

9

TH-L32X50Z

5.2.5. Self Check Mode

1. Press the ‘MENU’ button (on the remote control) and the ‘VOL DOWN’ button on the LCD panel.

2. Press ON/OFF button on the panel to Exit.

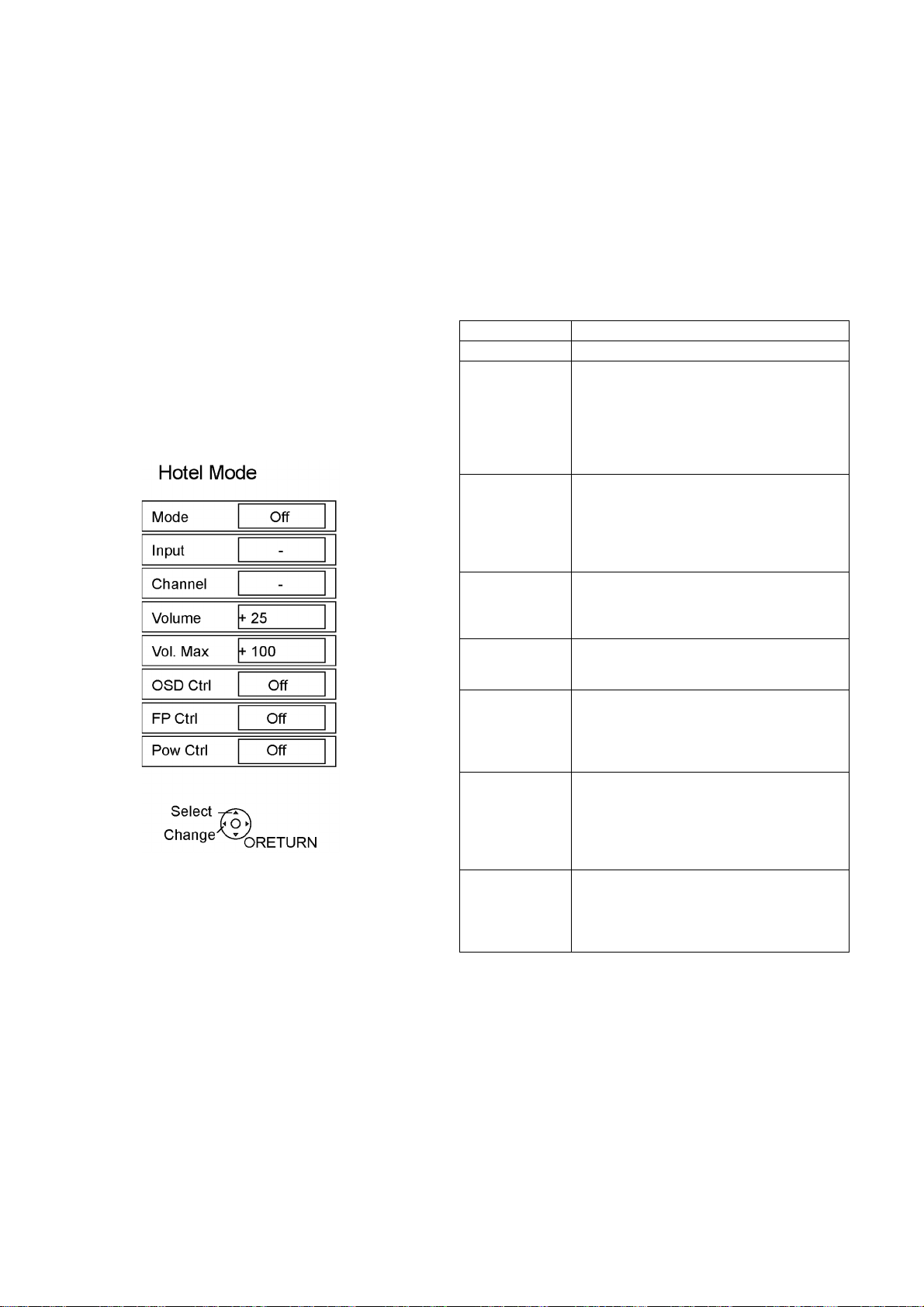

5.2.6. Hotel Mode Adjustment

1. Press the ‘VOLUME DOWN’ button on the TV panel and simultaneously press the AV button on the remote control 3 times to

enter Hotel Mode.

2. Set Hotel mode ‘on/off’, then press ‘EXIT’ to come out.

5.2.7. Hotel Mode

1. Purpose

Restrict a function for hotels.

2. Access command to the Hotel mode setup menu.

In order to display the Hotel mode setup menu, please

enter the following command (within 2 second).

[TV] : Vol [Down] + [REMOTE] : INPUT (3 times).

Then, the Hotel mode setup menu is displayed.

3. To exit the Hotel mode setup menu

Disconnect AC power cord from wall outlet.

4. Explain the Hotel mode setup menu

Item Function

Mode Select hotel mode off/on

Input Select input signal modes.

Set the input, when each time power is switched

on.

Selection :

-/RF/HDMI1/HDMI2/HDMI3/Component/

Video/PC

• Off: give priority to a last memory.

Channel Select channel when input signal is RF.

Set the channel, each time power is switched

on.

Selection :

Any channel number or [-].

[-] means the channel when turns off.

Volume Adjust the volume when each time power is

switched on.

Range :

0 to 100

Vol. Max Adjust maximum volume.

Range :

0 to 100

OSD Ctrl Restrict the OSD.

Selection :

OFF/PATTERN1

• OFF: No restriction

• PATTERN1: restriction

FP Ctrl Select front key conditions.

Selection :

OFF/PATTERN1/ALL

• OFF: altogether valid.

• PATTERN1: only input key is valid.

• ALL: altogether invalid.

Pow Ctrl Select POWER-ON/OFF condition when AC

power cord is disconnected and then connected.

OFF: The same condition when AC power

cord is disconnected.

ON: Forced power ON condition.

10

TH-L32X50Z

6 Troubleshooting Guide

Use the self-check function to test the unit.

1. Checking the IIC bus lines

2. Power LED Blinking timing

6.1. Check of the IIC bus lines

6.1.1. How to access

Self-check indication only:

Produce TV reception screen, and while pressing [VOLUME ( - )] button on the main unit, press [OK] button on the remote control

for more than 3 seconds.

Self-check indication and forced to factory shipment setting:

Produce TV reception screen, and while pressing [VOLUME ( - )] button on the main unit, press [MENU] button on the remote

control for more than 3 seconds.

6.1.2. Exit

Disconnect the AC cord from wall outlet.

6.1.3. Screen display

11

TH-L32X50Z

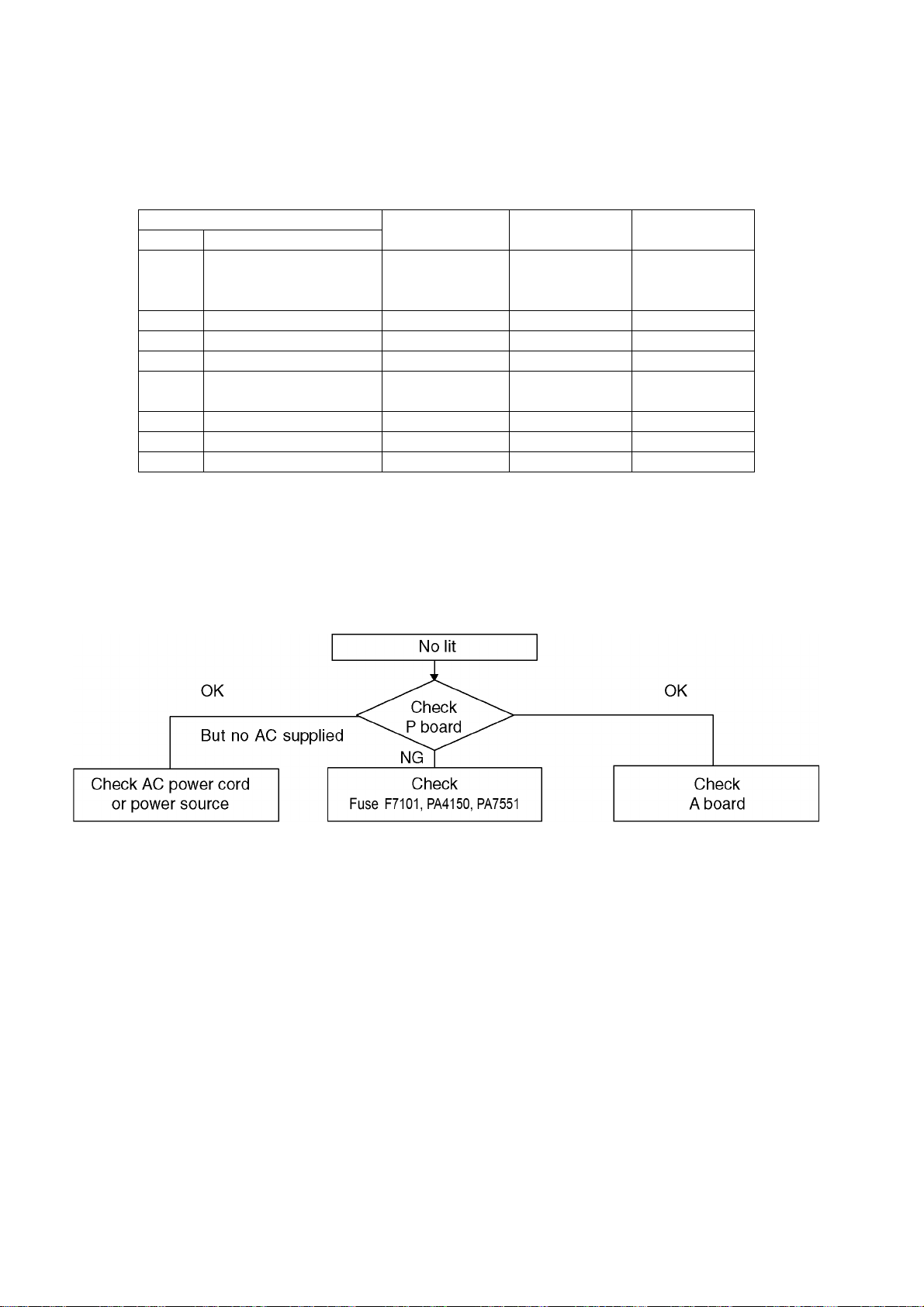

6.2. Power LED Blinking timing chart

1. Subject

Information of LED Flashing timing chart.

2. Contents

When an abnormality occurs, the protection circuit will operate and reset the unit to stand by mode. During this time, the

defective block can be identified by the number of blinking times of the Power LED on the front panel of the unit as follow:

LCD

Times SOS

1 BackLight_SOS 0 × 0461

3 SOS(Tuner_SOS) 0 × 045B A-Board

4 SUB12V_SENSE_SOS 0 × 045A A-Board

7 SUB3.3V_SENSE_SOS 0 × 0459 A-Board

9 SOUND_SOS 0 × 045D

12 BackEnd(sLD)_SOS 0 × 0466 A-Board

13 EMERGENCY_SOS communication error A-Board

14 IROM_SOS Error of STM micon A-Board

Remark

6.3. No Power

First check point

There are following 2 states of No Power indication by power LED.

1. No lit

2. Red is lit then turns red blinking a few seconds later. (See 6.2.)

EEPROM ADR

address

PCB NAME

A-Board

P-Board

LCD Panel

A-Board

P-Board

12

7 Disassembly and Assembly Instructions

7.1. SP Bracket

1. Fix Sp. Bracket to LCD panel with screw (Fig. A).

2. Fix Speaker Unit (L&R) to Sp. Bracket (Fig. B).

TH-L32X50Z

No Item Description Qty

043 TKX5ZA02301 SP BRACKET 4 PC

058 XYN3+F8FJ SCREW 4 PC

059 L0EYAA000006 SPEAKER UNIT L 1 PC

060 L0EYAA000007 SPEAKER UNIT R 1 PC

13

TH-L32X50Z

7.2. Vesa Metal Assembly

1. Fix Vesa Metal to LCD panel (Fig. A).

2. Fix Metal Bracket A-PCB to LCD panel (Fig. B).

3. Fix metal bracket bottom by screw.

14

TH-L32X50Z

No Item Description Qty

046 TKZ5ZX5008 VESA METAL 4 PC

044 TKZ4GG5014 METAL_BRACKET-A_PCB 2 PC

047 TKZ5ZX5010 METAL BRACKET BOTTOM 1 PC

067 THEJ036J SCREW 10 PC

15

TH-L32X50Z

7.3. LCD Panel Fixing & Handling Method

1. Place down the cabinet as shown below.

2. Fix LCD panel into the cabinet by taking below precautions.

Other general precautions

1. Do not press panel surface to avoid blue spot on the panel display.

2. Do not use hard cloth or rub the surface too hard. This may cause scratches on the surface.

3. Take care not to subject the TV’s surface to water or detergent. Any liquid (including pets urine) if enters the product could

lead to TV failure.

4. Take care not to subject the surface to insect repellent, solvent, thiner or other voiltile substances. This may degrade surface

quality or cause peeling of the paint.

5. The surface of the display panel is specially treated and may be easily damaged. Take care not to tap or scratch with your

fingernail or other hard objects.

16

7.4. Barrier LCD

1. Fix LVDS Cable to bottom LCD panel (Fig. A).

2. Stick LVDS cable & A10~K10 wire with pet tape (Fig. A).

3. Stick barrier LCD to LCD Panel (Fig. B).

TH-L32X50Z

No Item Description Qty

063 TSCKF0010005 LVDS CABLE 1 PC

068 T4FP1505J PET TAPE 0.1 MT

087 TMK4GX087 BARRIER LCD 1 PC

17

TH-L32X50Z

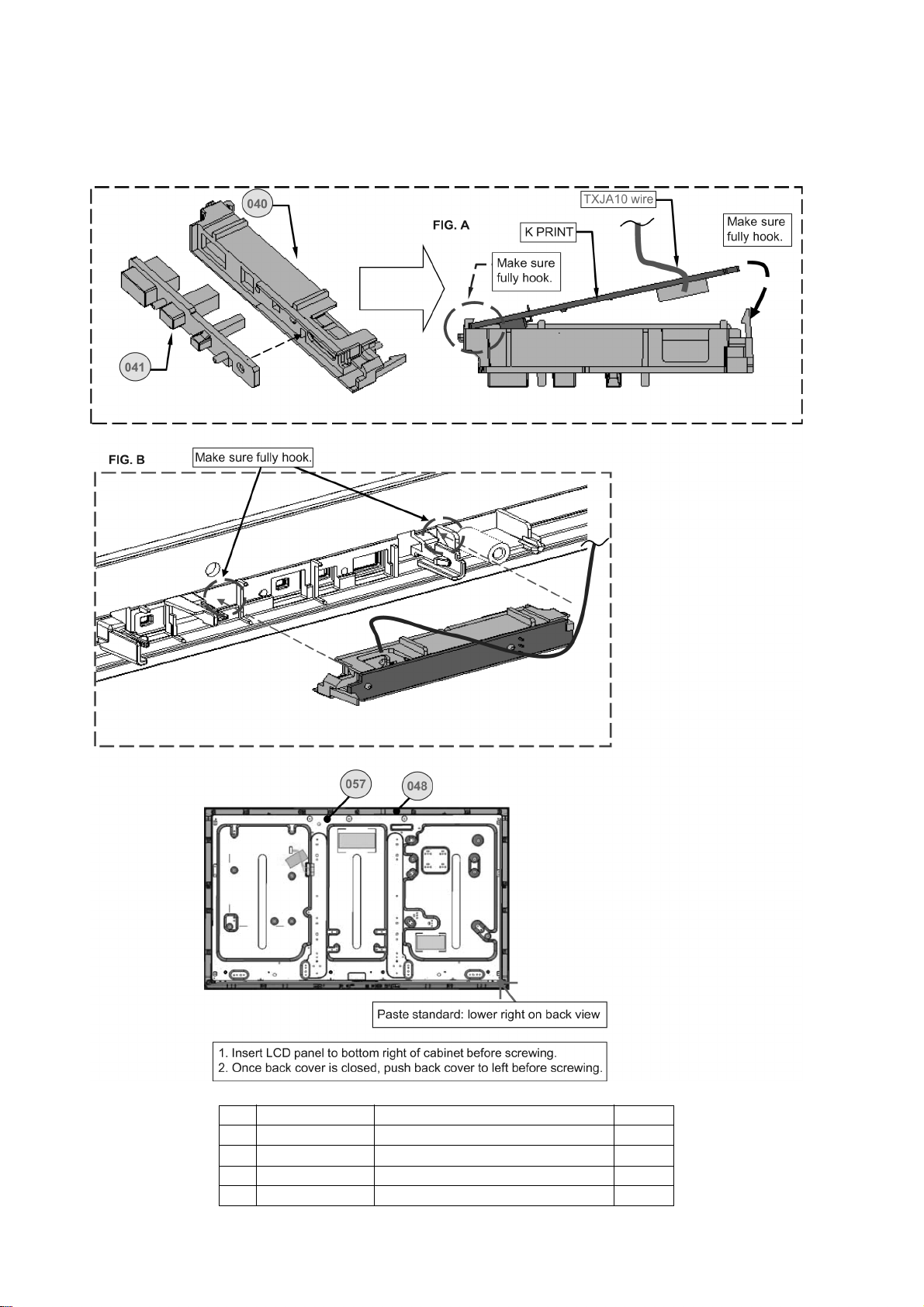

7.5. LED Panel Assembly

1. Prepare LED panel Assy (Fig. A).

2. Fix LED panel assy to Cabinet complete assy (Fig. B).

3. Fix LCD panel to Cabinet assy (Fig. C).

No Item Description Qty

041 TKK5ZC50201 LED PANEL 1 PC

040 TKK5ZC50141 LED PANEL BRACKET 1 PC

057 VVX32H125G00 LCD PANEL 1 PC

048 TTY4GA0261 CABINET COMPLETE ASS’Y 1 PC

18

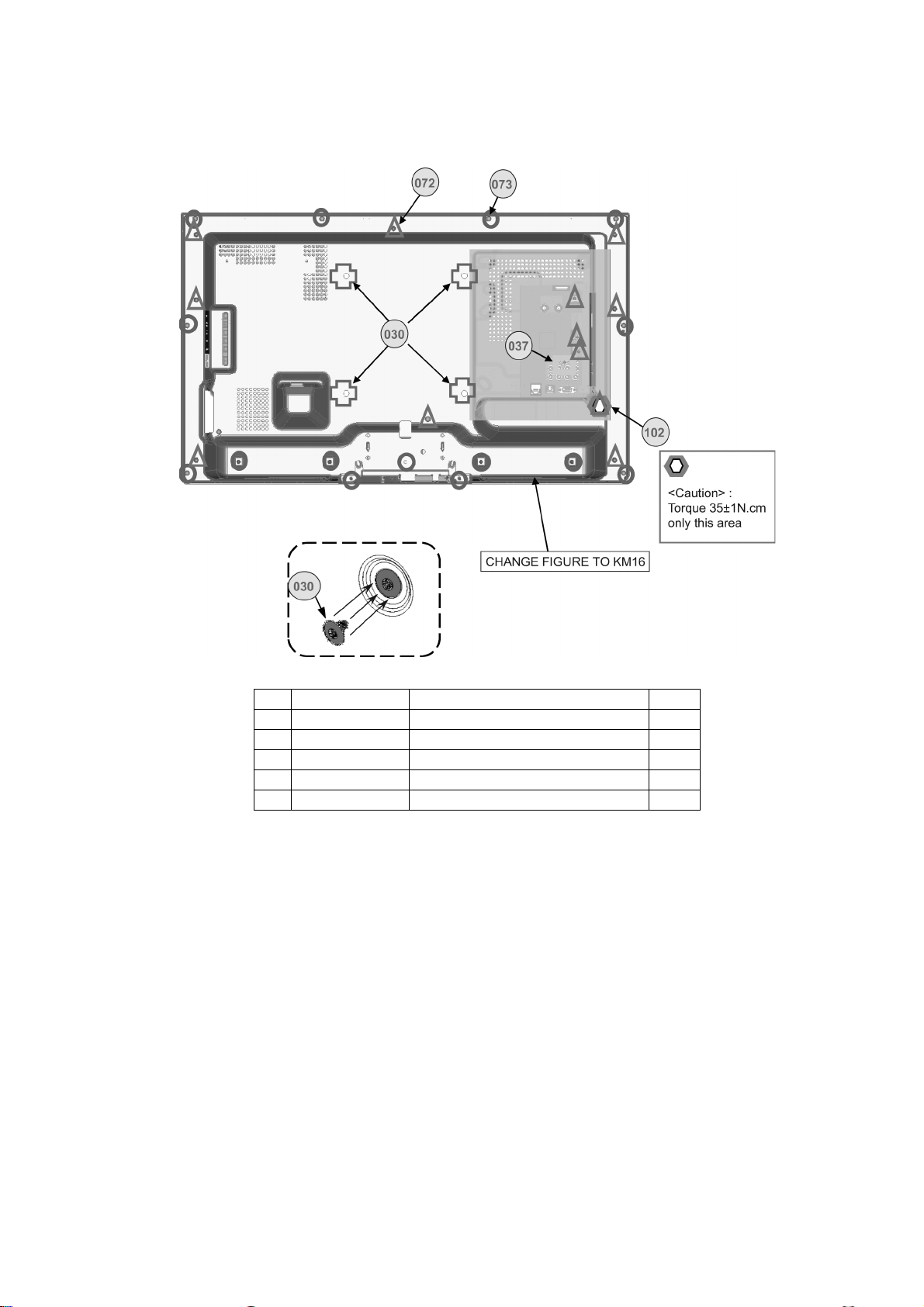

7.6. Back Cover Screw

1. Fix screw to Back Cover.

2. Install M6 cap to Back Cover.

TH-L32X50Z

No Item Description Qty

073 THTD030J SCREW 15

072 THEC1509 SCREW 12

037 XTV3+8GFJK SCREW(AV1) 1

030 TKKL5521 M6_CAP 4

102 TMK4GX113 WASHER 1

19

TH-L32X50Z

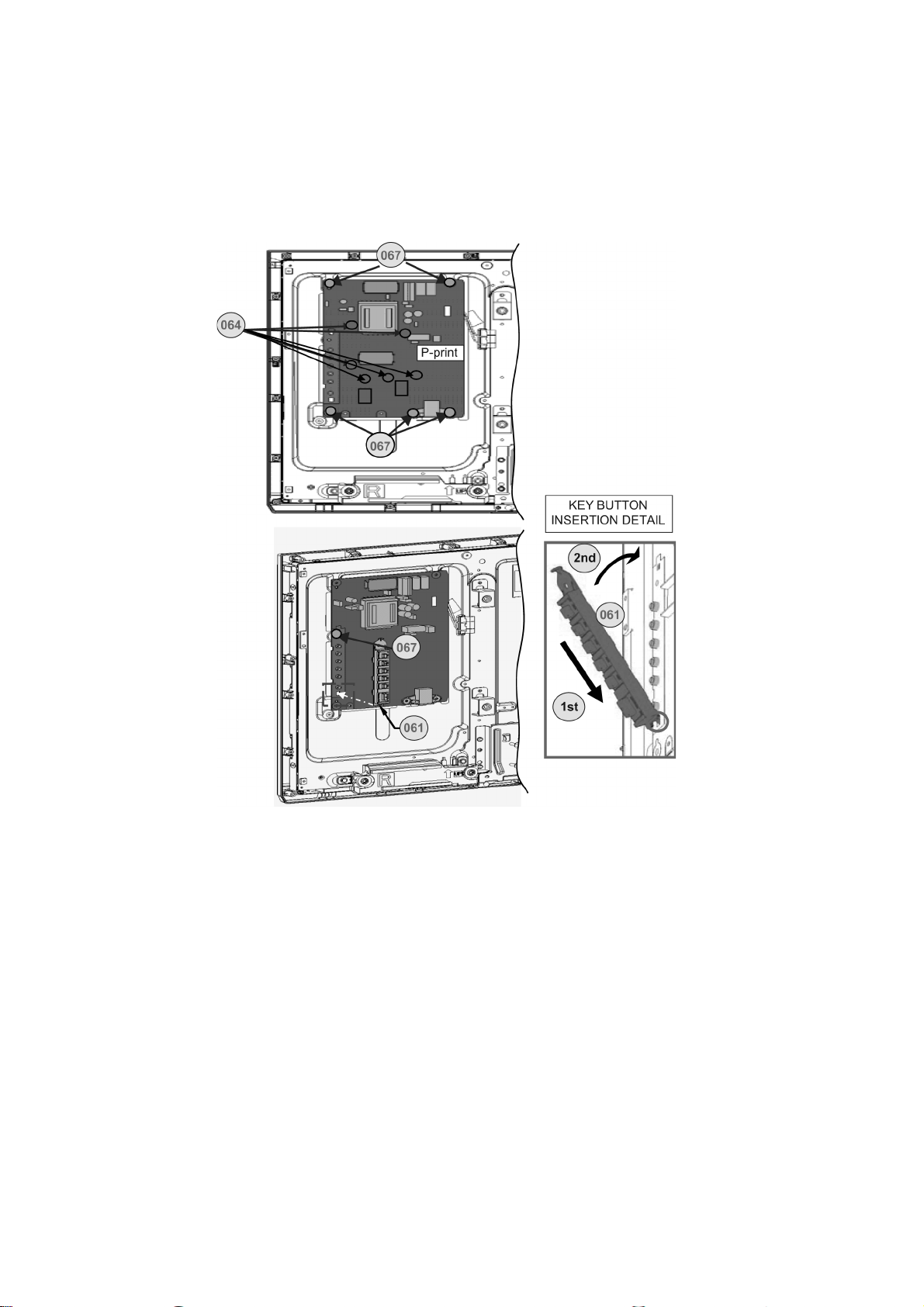

7.7. P-Print Assy

1. Fixing P-print to LCD panel.

2. Fix Spacer(P-pcb - 6 pcs) & Key Button to P-print.

3. Fix thermal pad to heat sink, peel-off sepatator behind heat sink and stick to LCD panel.

4. Fixing A-print to LCD panel.

5. Fixing Metal AV Bracket Side to A-print.

6. Fix above part with screw.

20

TH-L32X50Z

No Item Description Qty

064 TMME399 SPEACER (P-PCB) 6 PC

061 TBX5ZA00301 KEY BUTTON 1 PC

045 TKZ5ZF50162 METAL AV BRACKET SIDE 1 PC

067 THEJ036J SCREW 10 PC

062 TUC5ZJ50041 HEATSINK 1 PC

069 TMKK481 THERMAL PAD 1 PC

21

TH-L32X50Z

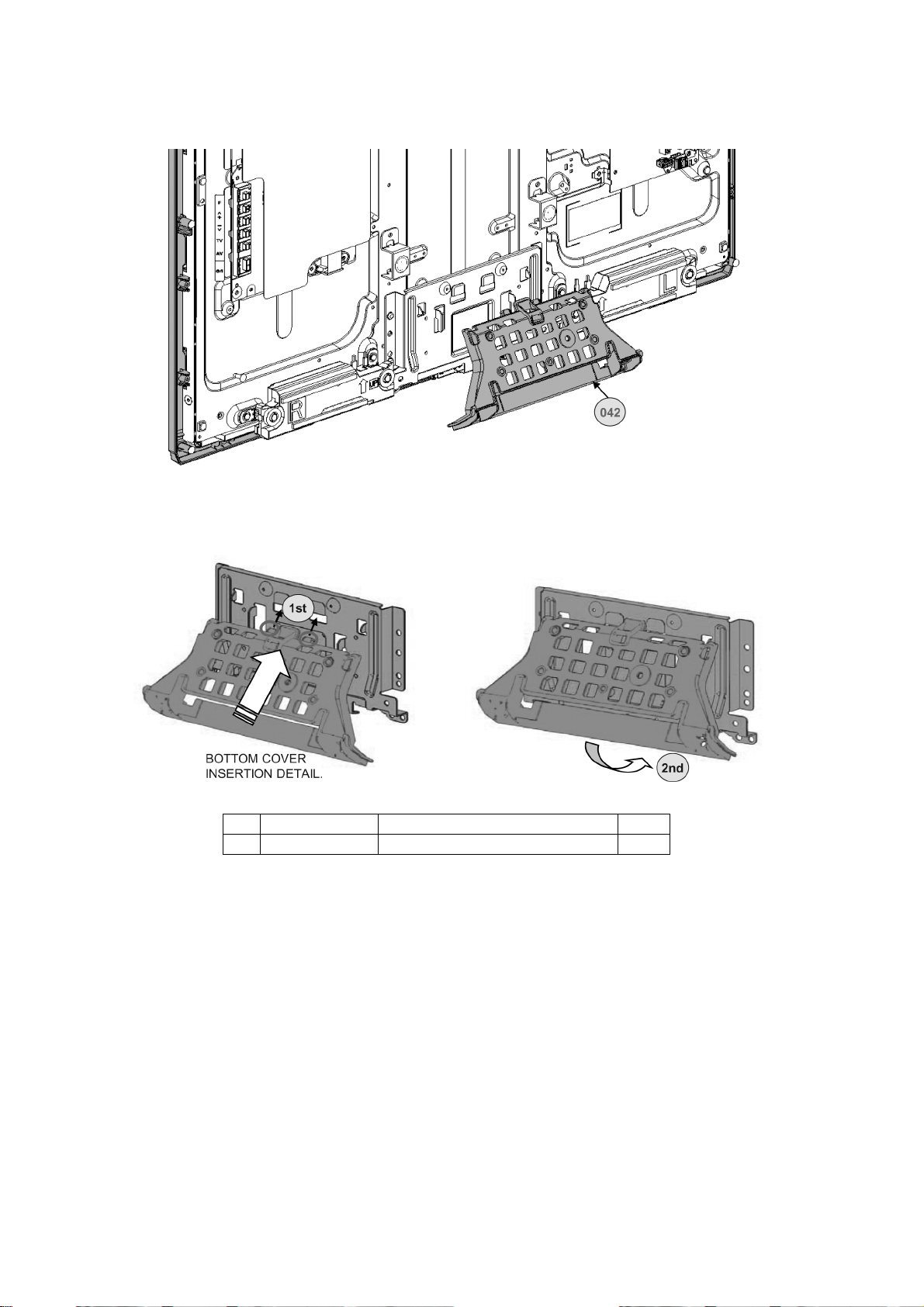

7.8. Bottom Cover

Fix Bottom Cover to Metal Bracket bottom.

No Item Description Qty

042 TKP5ZA13801 BOTTOM COVER 1 PC

22

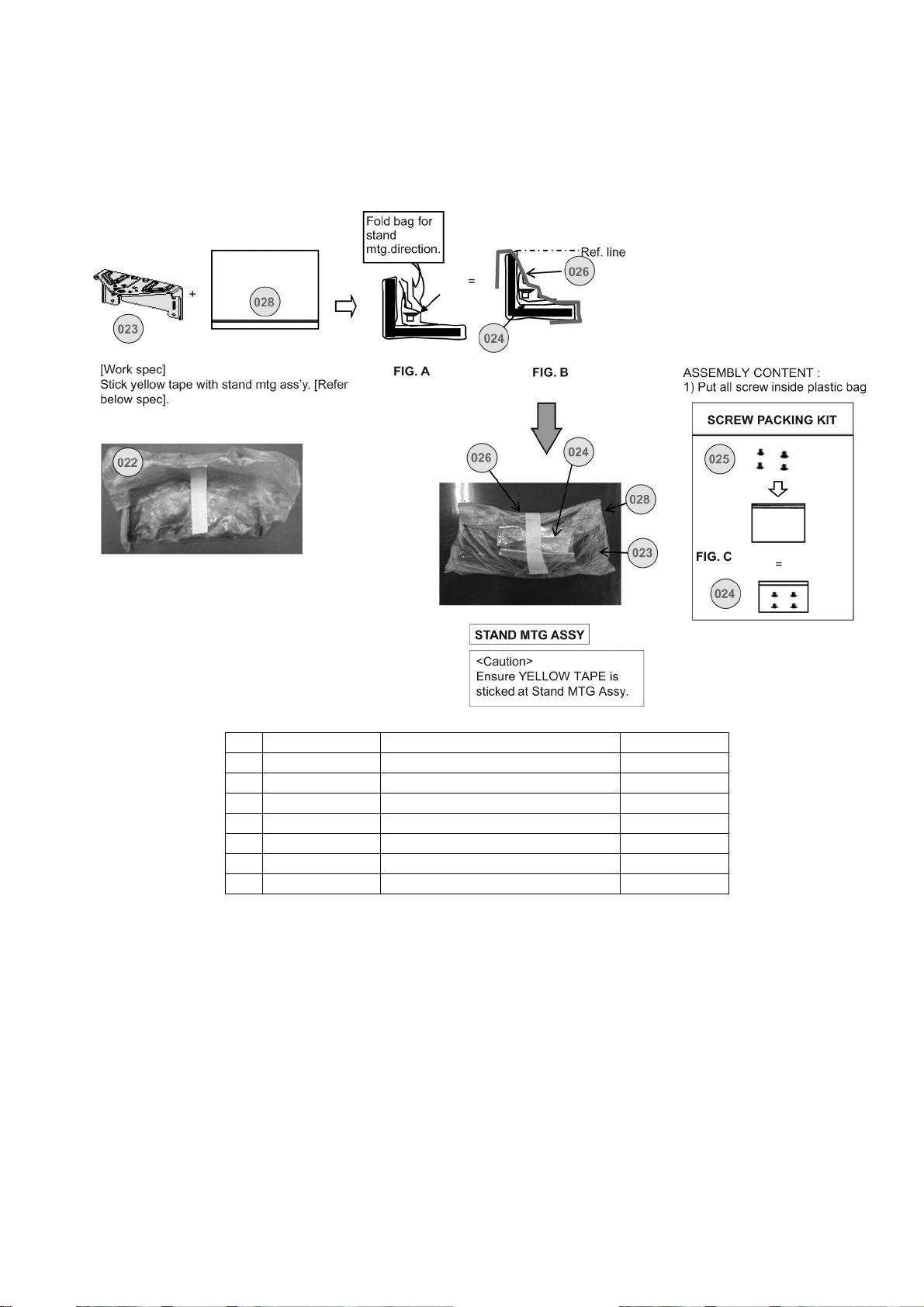

7.9. Stand MTG & Pedestal MTG

1. Prepare screw packing kit (Fig. C).

2. Insert Stand Mtg into bag.

3. Fold bag and put screw packing kit as shown (Fig. A).

4. Stick with Yellow Tape (Fig. B).

TH-L32X50Z

No Item Description Qty

022 TBL5ZX03761 STAND MTG ASSY 1 PC

023 TBL5ZA32151 STAND MOUNT 1 PC

026 T5E4G62400 PAPER TAPE 0.16 MT

027 TQF4GA175 BARCODE LABEL 1 PC

028 TPE4GH072 BAG 1 PC

024 TXFPE03NJUU SCREW PACKING KIT 1 PC

025 XSS5+16FJK SCREW 4 PC

23

TH-L32X50Z

8 Measurements and Adjustments

8.1. Voltage chart of A-board

Set A-Board to a dummy set and check the satisfaction with the specified voltage as following table.

Power Supply Name Measurement Point Specification (V)

SUB1.8V TP8700 1.74 - 1.90

SUB1.2V TP8100 1.18 - 1.32

SUB3.3V TP8701 3.19 - 3.46

SUB5V TP8702 4.95 - 5.25

STB5V TP5400 4.9 - 5.1

SUB1.5V TP8101 1.4 - 1.6

8.2. Voltage chart of P-board

Set IP-Board to a dummy set and check the satisfaction with the specified voltage as following table.

VOLTAGE TEST POINT

5.8V TP7507 6.2 ± 0.5 V 5.6 ± 0.3 V

15.6V TP7508 15.6 ± 0.8 V -

40V TP7501 40 ± 4V -

Operate STBY

Specification

24

S5/ S3.3

CPU BUS

XECS1

XEAS

XNMIRQ

XIRQ1

XERE

S5

CI POWER ON >

DATA

ADR

CTRL

LED Information

REMOCON

Reciever

ILLUMINANCE

Sensor

SD_LED_ON >

RMIN >

AI_SENSOR >

Flont Panel

G_LED_ON >

R_LED_ON

>

S12/S5

STB5/5VS

S9

REG

S9

(SD-Data-VCC)

S3.3

NAND

ED[7:0]

Support

Card

< DTV_XRST

XEAS

ECLK

ESZ1

XEWE1

ERXW

ESZ0

XEDK

BOOTSWAP

(XRST)

S3.3

Buffer

5V TS

CI

Power

Circuit

CI

_

POWER

_

ON >

< CI_OCP

ED[15:0]

EA[7:0],EA[24]

ERXW

ED[7:0]

CI_DA[7:0]

< PCDOE

5V TS

CI

>

RS-232C

Control Serial

RIMOCON

THRU OUT

For System VIErA Model

STB3.3

RS-232C IF

ICL3223EIVZ-T

STM-Serial

DMD_IIC0

< AGCI

S5/ S3.3/ S1.8

Low-IF

SCL

SD

A

IF_AGC

IFD_OUT1

IFD_OUT2

S12

< TV_SOS

AMP/HP MUTE

MONITOROUT MUTE

Analog

ASIC

AN34043A

OVP

SOS

Safety

Circuit

< MON_MUTE

< SP_HP_MUTE

STB3.3V/1.2V_REG

STB5V Reset IC (STM)

S9V_REG

S12V Reset IC (Peaks)

Audio MUTE

OCP/OVP/TV-SOS

HP_MUTE,EXT_MUTE

UHS-I_REG

TV_SOS

PWM

3.3/1.8

UHS-1

REG

S9

-

REG

< (SDVOLC)

PWM >

XNFCE,XNFWPNFCLE,NFAL

E

XNFWE,XNFRENANDRYBY

ED[15:0]

NAND-IF

EA[15:1]

< PCDOE

PCOE

PCWE

PCIORD

PCIOWR

PCRESET

PCCE1

HSBCLKOUT

HSSYNCOUT

HSVALOUT

HSDOUT[0:7]

HS0BCLKIN

HS0SYNCIN

HS0VALIN

HS0DIN[0:7]

PCWAIT

PCCD1

PCCD2

PCREADY

CI-IF

TS-INTS-OUT

Analog AV Input

S9/S5

㻴㻰㻛㼂㻰㻛㻲㻮㻷

㻹㼁㼀㻱

P

IIC

A-Chip VDD

Analog AV Input

SIFIN

FEAIN

HS1BCLKIN

HS1SYNCIN

HS1VALIN

HS1DIN[0:7]

DMD

P-IIC2 (For DMD only)

ADC

DTV Decoder

SIF Decoder

VIF Decoder

IIC

DMD-IIC0

DMD-IIC1

Trans Port Decoder CPUBUS NAND-IF

Cross Stream Switch

SCART-RGB

PC

7

7&21

LCD

PANEL

Driver

Ctrl

mini-LVDS 135MHz 2pair

(LPL),LPR,(POLL),POLR

CPV,GDATA1,GDATA2

(LD)

Back Light

INVERTER

or

LED Driver

BL_ON >

BL_SOS <

PWM

(ADIM)

S3.3

TEMP

SENSOR

P-IIC

S9

INV-LED

For EEFL

PANEL_LED_ON >

DVB-T

Video_OUT (CVBS)

D/A TUNER

SIF_OUT

Video_OUT

SIF_OUT

Reset

< FE_XRST

Peaks

DCDC

S1.2

S1.5

S1.8 S3.3

STB3.3

STB1.2

STB_XRST

DCDC_EN

DTV_XRST >

SW_OFF_DET >

XRST POWER_DET

iPod CVBS,L/R

CVBS

RGB /YPbPr /CVBS /YC

HS,VS

Audio OUT L/R

Monitor OUT L/R

Monitor Out L/R

Audio Input

Video Input

Monitor Out CVBS

AV-SW

R2A11014AFT

Head Phone L/R

P

-

IIC

Main Audio L/R

R1, G1, B1, V1

LIN1_R, LIN1_L

LO1_R, LO1_L

HP1_R, HP1_L

SCART TV-OUT L/R LO2_R, LO2_L

VDAC1

SCART Out L/R

(Audio L/R)

Scart Out CVBS

A-SW

(Thru)

ADC

DAC

IPR INS

DSP

V-SW

(Thru)

ADC

DAC

Analog Video

Processor

Video

Format

Processor

ea

k

s

sLD2

Head

Phone

V

R

L

Y

Pb

Pr

R

L

R

L

SCART-RGB

Side

/9'67[

PL

QL

/9'6

7

[

S1.5

DDR

LCD

Driver

EEP

2k

S12

P-IIC

T-CON

DCDC

P-IIC

GAMMA

DAC

AVDD_ENB >

PANEL_VCC_ON >

LCD_EEP_WP >

P-IIC

REV_DAC_ENB >

Panasonic

iPod Dock

P-UART

.

3

iPod

Authentication

Coprocessor

MFI341S2161

IPOD_CP_XRST

P-IIC

STB6

IPod

Power

Circuit

5V

IPOD_PWR_ON <

XIPOD_DET >

XIPOD_ACC_PWR >

< IPOD CTL SW

ExIO

STM-IIC

STB3.3

IPOD_PWR_SOS >

S12

Illumination

Illumination

LED

Circuit

SP_LED_ON <

SOUND_VCC/ S3

PWM

AMP

TAS5709PHPR

MCLK

LRCLK

SCLK

SDIN

P-IIC

< DTV_XRST

For sLD2 2AMP

I2S

SW

A-Chip

A-D Chip

Internal BUS

USB

S5

USB

Power SW

USB0VBUS >

< USB0OC

S5

S5

USB

USB1VBUS >

<USB1OC

USB Memory

EEP

EU,Russia

CI+: 32k

DLNA1 5 64k

DDR3+

x16

1G

DDR3+

x16

1G

''5,)[

__

SOUND_VCC

PWM

AMP

?

PWM0LP

PWM0LN

PWM0RP

PWM0RN

SP_LED_DIM <

AMP

PWM

SPDIF

SW

IIC

IIC

25MHz

S3.3

ETHER

S3.3

PHY

KSZ8041

0,,,)

COL,CRS,RXCLK

RXD0,RXD1,RXD2,RXD3

RXDV,RXER,TXCLK

TXD0,TXD1,TXD2,TXD3

TXEN,MDC,MDIO,MDIO_INTL

PHYRSTL,WAKEUP,WUC

USB

Power SW

<

USB1OC

S5

86%

,

)

D-Chip

STB3.3

EEP

16k

STM

EEP_WP >

For STM

S3.3

EEP

EEPROM_WP

P-IIC

For Peaks

DLNA1

.

5

:

64k

ASIA,Lathin

DLNA1.5: 32k

ELSE: 16k

Optical OUT

OPT

DDC0 > STM, Peaks

HPD0 < STM

HDMI 5V DET0> STM

HDMI1

S3.3

ARC Buffer-SW

ARC_OFF <

Rx0

IECOUT

HDMI

Rx

MUX

x3

CLK

GEN

STB3.3

STB1.2

-

IIC

Serial

STM-Serial0

STM-Serial1

24.576MHz

STM-D Chip

Communication Register

ETHER_XRST <

6',)

SDXC

S5

SD Reg

SD_PWR_ON >

< SD_COIN_DET

S3.3

ExFAT: yes

High Speed: no

UHS-I : no

SD-Data-VCC

SDCLK,SDCMD,SDVOLC,

SDDAT[3:0],SDCD,SDWP

<KEY1

CONTROL PANEL KEY

IIC

P-IIC0

P-IIC1

(P-IIC2)

P-IIC3

Serial

P-Serial0

P-Serial1

P-UART0

P-UART2

DMD IIC

DMD_IIC0DMD_IIC

1

XOR

DDC2 > STM, Peaks

HDMI

_

5V

_

DET0> STM

DDC1 > STM, Peaks

HPD1 < STM

HDMI_5V_DET1 > STM

HDMI2

HPD2 < STM

HDMI_5V_DET2 > STM

HDMI3

Rx1

Rx3

9 Block Diagram

9.1. Main Block Diagram

TH-L32X50Z

25

TH-L32X50Z

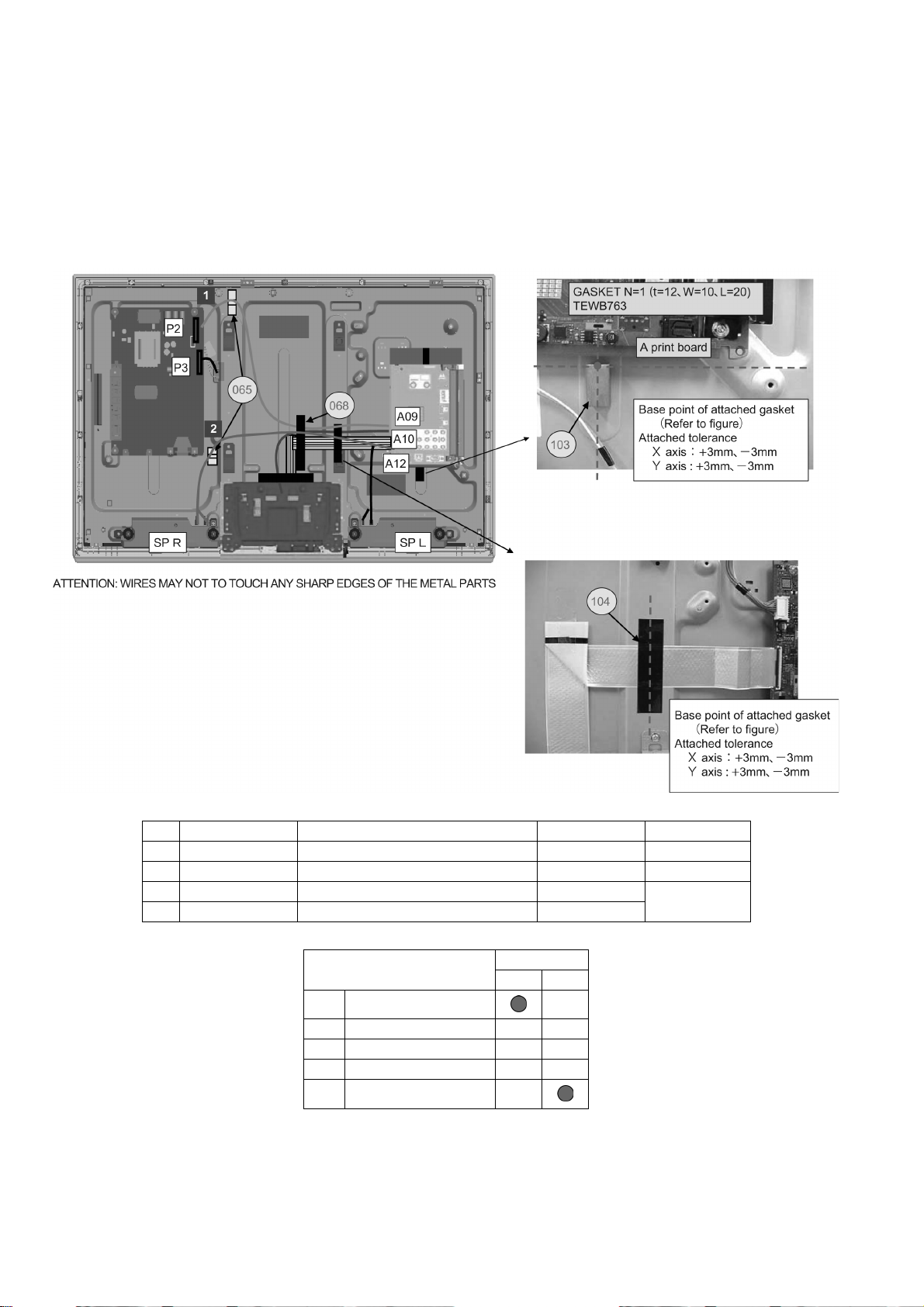

10 Wiring Connection Diagram

10.1. Wire Dressing

1. Fix clamper (2 pcs).

2. Wiring No 1~ No 2.

3. Stick gaasket (1).

4. Install PET tape (1).

5. Install AL PET tape (1)

No Item Description Qty Remarks

065 TMME268 CLAMPER(LCD2) 2 PC

068 T4FP1505J PET TAPE 0.1 PC

103 TEWB763 GASKET 1 PC

104 TEW4GF007 AL/PET TAPE 1 PC

Wire

No.1 P2 - A09

No.2 P3

No.3 A10 - KA10

No.4 A12 - SP(L)

No.5 A12 - SP(R)

Clamper

12

TH-L32X50A/H/Z

26

Loading...

Loading...