Panasonic TH-42PX75U Service manual

High Definition Plasma Television

A

A

V

A

A

A

A

GP10DHU Chassis

Specifications

PowerSource

PowerConsumption

Maximum 387 W

Standby condition 0.2 W

Plasma Displaypanel

Drive method

Aspect Ratio 16 : 9

Contrast Ratio (max) 10000 : 1

isible screen size

(W × H × Diagonal)

(No. of pixels)

Sound

Audio Output 20 W [10 W + 10 W] (10 % THD)

Channel Capability (Digital/Analog) VHF/UHF: 2 - 69, CATV: 1 - 135

Operating Conditions Temperature: 32 °F - 104 °F (0 °C - 40 °C)

Connection Terminals

INPUT 1-2 VIDEO: RCA PIN Type × 1 1.0 V [p-p] (75 ohm)

COMPONENTVIDEO

INPUT 1-2

HDMI 1-2 AUDIO IN TYPE A Connector×2

Card slot SD CARD slot × 1

AVPROG. OUT VIDEO: RCA PIN Type × 1 1.0 V [p-p] (75 ohm)

C 120 V, 60 Hz

C type

106 cm

36.3 ” × 20.4 ” × 41.6 ” (920 mm × 518 mm × 1,056 mm)

786,432 (1,024 (W) × 768 (H)) [3,072 × 768 dots]

Humidity: 20 % - 80 % RH (non-condensing)

S-VIDEO: Mini DIN 4-pin Y: 1.0 V [p-p] (75 ohm) C: 0.286 V [p-p] (75 ohm)

UDIO L-R: RCA PIN Type × 2 0.5 V [rms]

Y: 1.0 V [p-p] (including synchronization)

PB,PR: ± 0.35 V [p-p]

UDIO L-R: RCA PIN Type × 2 0.5 V [rms]

UDIO L-R: RCA PIN Type × 2 0.5 V [rms]

UDIO L-R: RCA PIN Type × 2 0.5 V [rms]

ORDER NO.MTNC070202CE

B34 Canada: B07

© 2007 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

TH-42PX75U

DIGITAL AUDIO OUT PCM/DolbyDigital, FiberOptic

FEATURES 3D Y/C FILTER

CLOSED CAPTION V-Chip

Photo Viewer HDAVI Control 2

Dimensions (W × H × D)

Including pedestal 40.2 ” × 28.6 ” × 13.0 ” (1,020 mm × 725 mm × 330 mm)

TV Set only 40.2 ” × 26.8 ” × 3.8 ” (1,020 mm × 680 mm × 97 mm)

Weight

Including pedestal 75.0 lb. (34 kg)

TV Set only 59.6 lb. (27 kg)

Note:

·

· Design and Specifications are subject to change without notice. Weight and Dimensions shown are approximate.

· ·

CONTENTS

Page Page

1 Applicable signals 4

2 Safety Precautions

2.1. General Guidelines

3 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

4 About lead free solder (PbF)

5 Service Hint

6 Plasma panel replacement method

6.1. Remove the rear cover

6.2. Remove the rear terminal cover

6.3. Remove the P-Board

6.4. Remove the Tuner unit

6.5. Remove the A-Board

6.6. Remove the D-Board

6.7. Remove the SU-Board

6.8. Remove the SD-Board

6.9. Remove the SC-Board

6.10. Remove the SS-Board

6.11. Remove the C1-Board

6.12. Remove the C2-Board

6.13. Remove the front bracket and the front shield case cover

6.14. Remove the GS-Board

6.15. Remove the speaker L, R

6.16. Remove the stand brackets

6.17. Remove the S-Board

6.18. Remove the K-Board

6.19. Remove the Plasma panel section from the Cabinet assy

(glass)

6.20. Replace the plasma panel (finished)

7 Caution statement

7.1. Caution statement.

8 Location of Lead Wiring

10

10

10

10

11

11

11

11

11

12

12

12

12

13

14

15

15

16

5

5

6

7

8

9

9

9

9

9

9

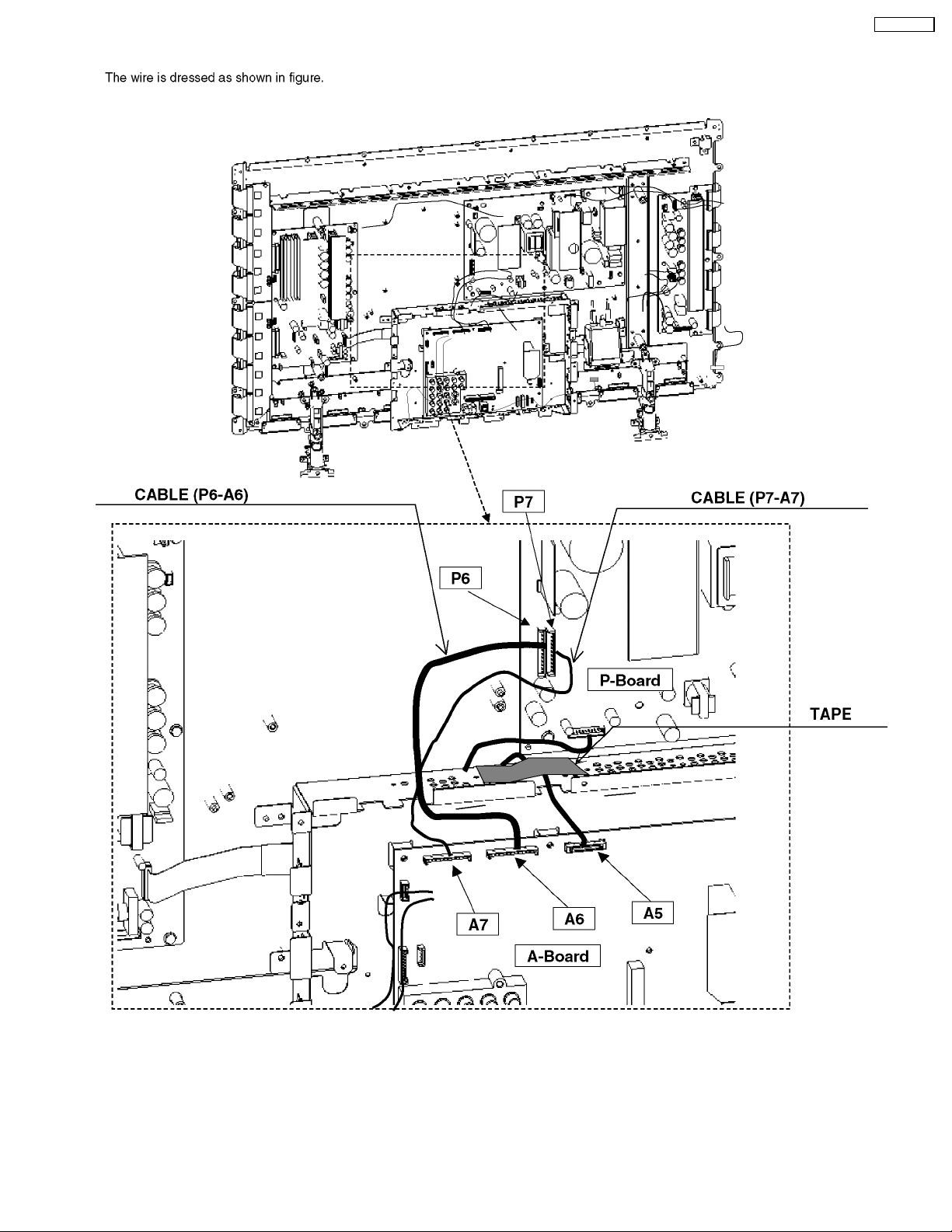

8.1. Lead of Wiring (1)

8.2. Lead of Wiring (2)

8.3. Lead of Wiring (3)

8.4. Lead of Wiring (4)

8.5. Lead of Wiring (5)

9 Self-check Function

9.1. Check of the IIC bus lines

9.2. Power LED Blinking timing chart

9.3. No Power

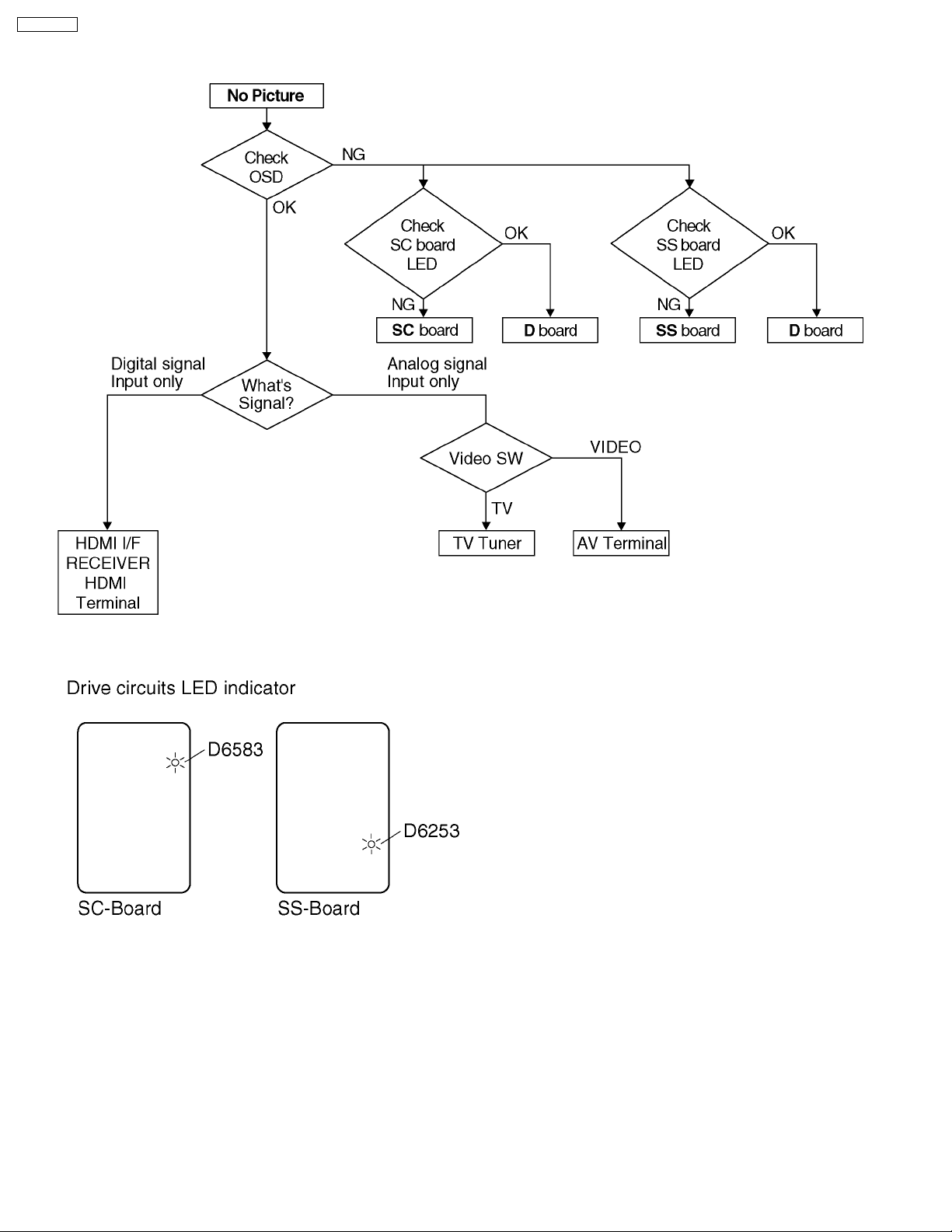

9.4. No Picture

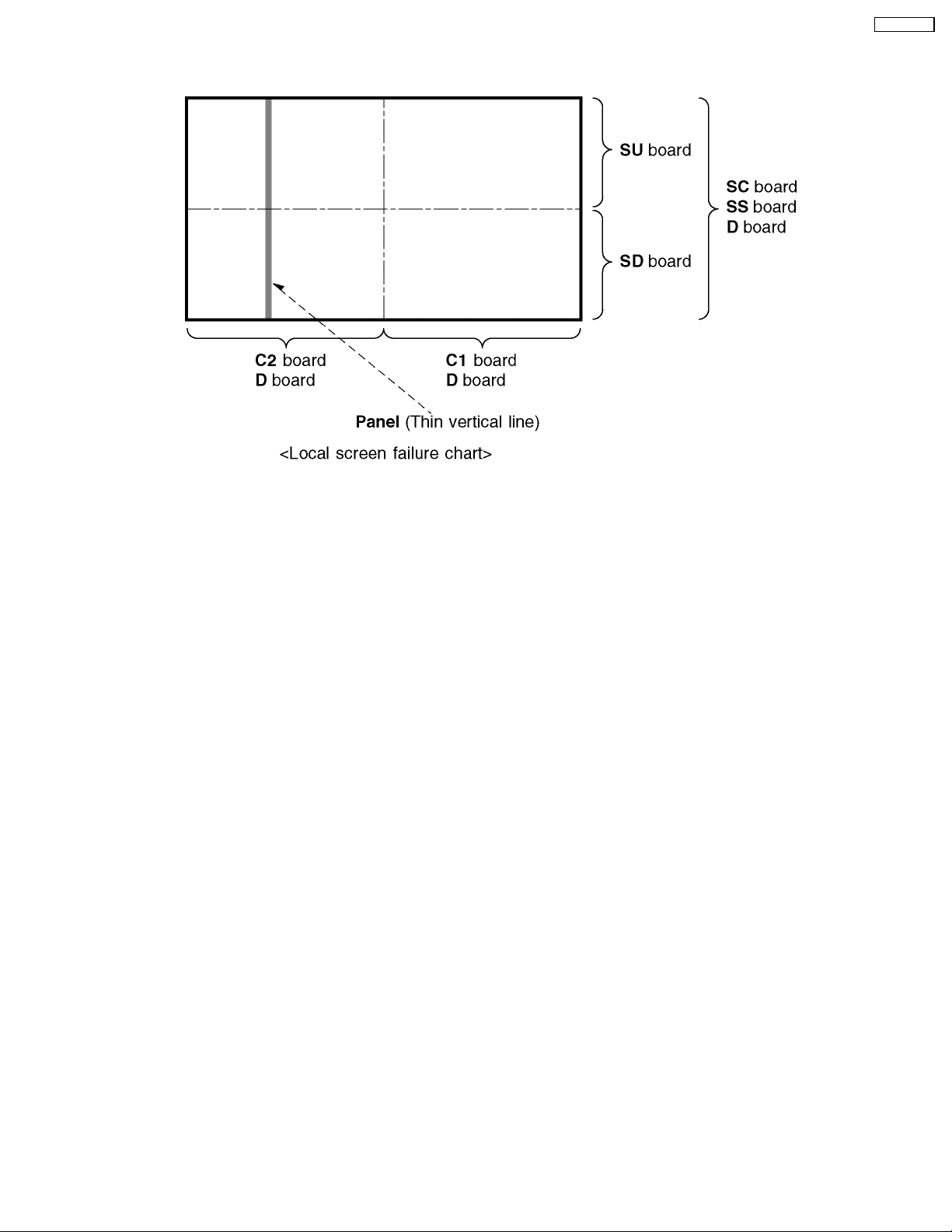

9.5. Local screen failure

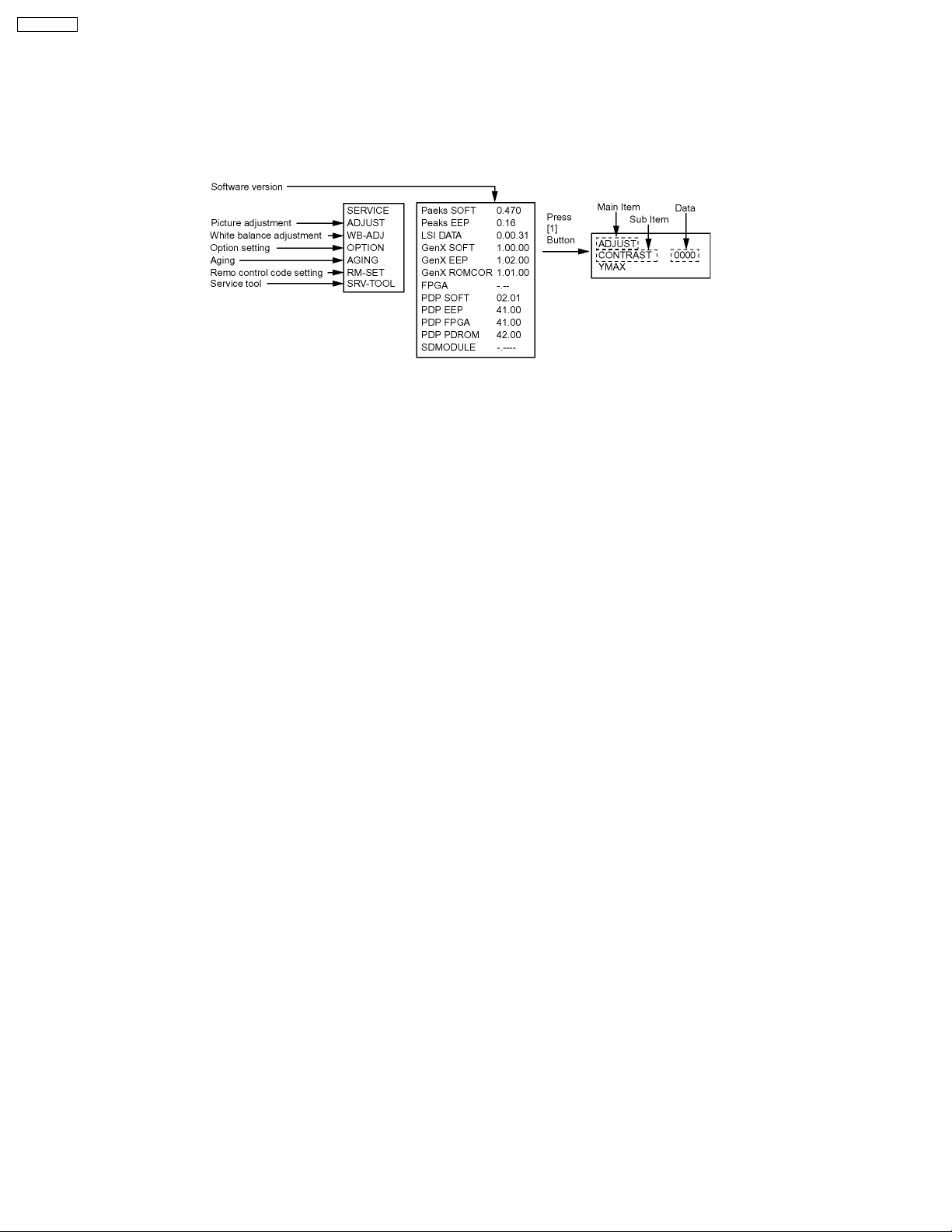

10 Service Mode

10.1. How to enter into Service Mode

10.2. Service tool mode

11 Adjustment Procedure

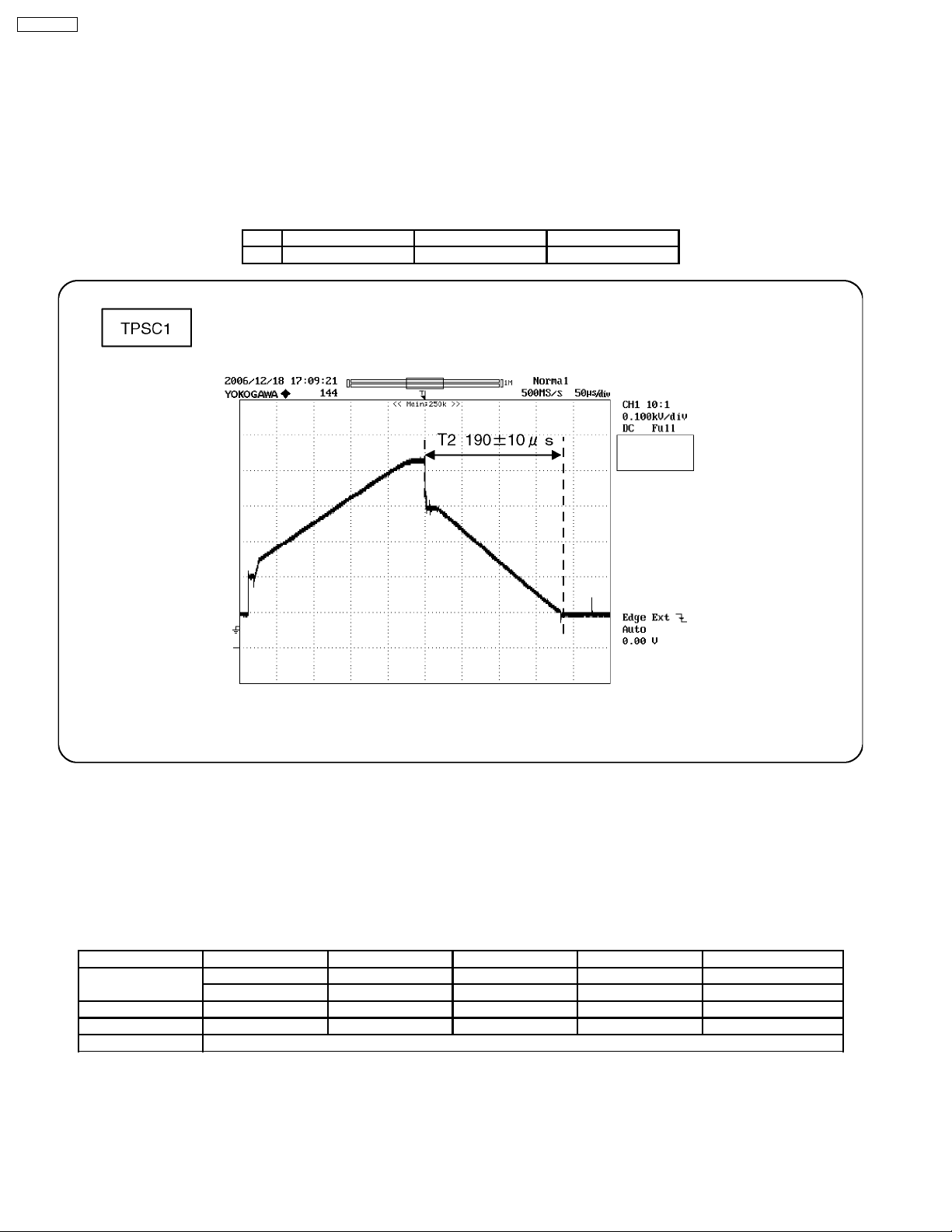

11.1. Driver Set-up

11.2. Initialization Pulse Adjust

11.3. P.C.B. (Printed Circuit Board) exchange

11.4. Adjustment Volume Location

11.5. Test Point Location

12 Adjustment

12.1. White balance adjustment

13 Hotel mode

14 Conductor Views

14.1. P-Board

14.2. GS, K and S-Board

14.3. A-Board

14.4. D-Board

14.5. C1-Board

14.6. C2-Board

14.7. SC-Board

14.8. SU-Board

14.9. SD-Board

16

17

18

19

20

21

21

22

23

24

25

26

26

28

29

29

30

30

31

31

32

32

34

35

35

38

39

42

44

45

46

49

50

2

14.10. SS-Board 51

15 Sche matic and Block Diagr am

15.1. Schematic Diagram Note

15.2. Main Block Diagram

15.3. P-Board Block Diagram

15.4. P-Board (1 of 6) Schematic Diagram

15.5. P-Board (2 of 6) Schematic Diagram

15.6. P-Board (3 of 6) Schematic Diagram

15.7. P-Board (4 of 6) Schematic Diagram

15.8. P-Board (5 of 6) Schematic Diagram

15.9. P-Board (6 of 6) Schematic Diagram

15.10. GS, K and S-Board Block and Schematic Diagram

15.11. A-Board (1 of 5) Block Diagram

15.12. A-Board (2 of 5) Block Diagram

15.13. A-Board (3 of 5) Block Diagram

15.14. A-Board (4 of 5) Block Diagram

15.15. A-Board (5 of 5) Block Diagram

15.16. A-Board (1 of 12) Schematic Diagram

15.17. A-Board (2 of 12) Schematic Diagram

15.18. A-Board (3 of 12) Schematic Diagram

15.19. A-Board (4 of 12) Schematic Diagram

15.20. A-Board (5 of 12) Schematic Diagram

15.21. A-Board (6 of 12) Schematic Diagram

15.22. A-Board (7 of 12) Schematic Diagram

15.23. A-Board (8 of 12) Schematic Diagram

15.24. A-Board (9 of 12) Schematic Diagram

15.25. A-Board (10 of 12) Schematic Diagram

15.26. A-Board (11 of 12) Schematic Diagram

15.27. A-Board (12 of 12) Schematic Diagram

15.28. D-Board Block Diagram

15.29. D-Board (1 of 6) Schematic Diagram

53

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

15.30. D-Board (2 of 6) Schematic Diagram

15.31. D-Board (3 of 6) Schematic Diagram

15.32. D-Board (4 of 6) Schematic Diagram

15.33. D-Board (5 of 6) Schematic Diagram

15.34. D-Board (6 of 6) Schematic Diagram

15.35. C1 and C2-Board Block Diagram

15.36. C1-Board (1 of 2) Schematic Diagram

15.37. C1-Board (2 of 2) Schematic Diagram

15.38. C2-Board (1 of 2) Schematic Diagram

15.39. C2-Board (2 of 2) Schematic Diagram

15.40. SC, SU and SD-Board Block Diagram

15.41. SC-Board (1 of 2) Schematic Diagram

15.42. SC-Board (2 of 2) Schematic Diagram

15.43. SU-Board (1 of 2) Schematic Diagram

15.44. SU-Board (2 of 2) Schematic Diagram

15.45. SD-Board (1 of 2) Schematic Diagram

15.46. SD-Board (2 of 2) Schematic Diagram

15.47. SS-Board Block Diagram

15.48. SS-Board (1 of 2) Schematic Diagram

15.49. SS-Board (2 of 2) Schematic Diagram

16 Explo ded Views & Replacement Parts List

16.1. Exploded Views

16.2. Packing Exploded Views (Accessories box)

16.3. Packing Exploded Views (Stand)

16.4. Replacement Parts List Notes

16.5. Mechanical Replacement Parts List (PDP TV)

16.6. Mechanical Replacement Parts List (Stand)

16.7. Electrical Replacement Parts List

80

TH-42PX75U

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

103

103

104

105

106

107

108

109

3

TH-42PX75U

1 Applicable signals

4

TH-42PX75U

2 Safety Precautions

2.1. General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

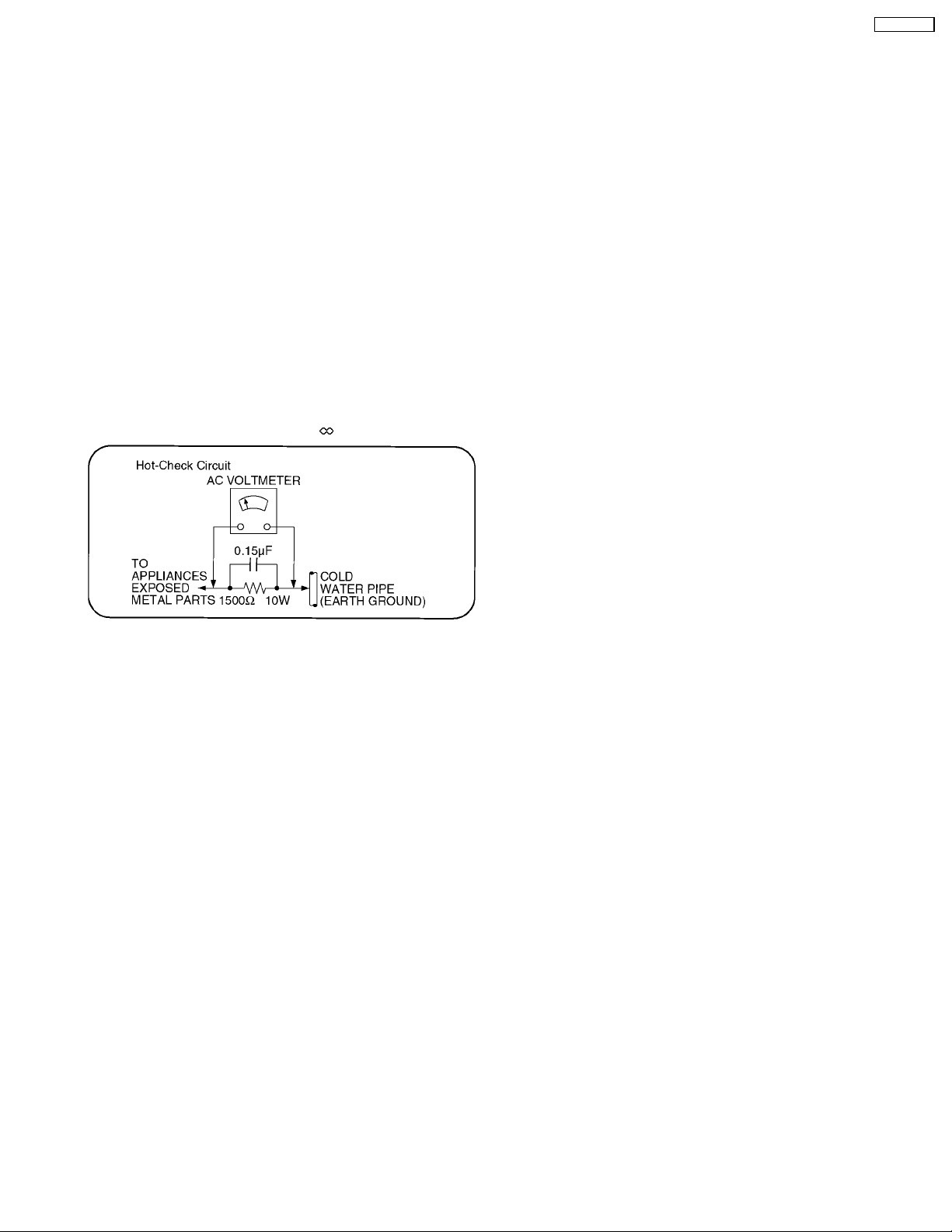

2.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two

prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between

the jumpered AC plug and each exposed metallic cabinet

part on the equipment such as screwheads, connectors,

control shafts, etc. When the exposed metallic part has a

return path to the chassis, the reading should be between

1Mohm and 5.2Mohm.

When the exposed metal does not have a return path to

the chassis, the reading must be

Figure 1

.

2.1.2. Leakage Current Hot Check (See

Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use an

isolation transformer for this check.

2. Connect a 1.5kohm, 10 watts resistor, in parallel with a

0.15µF capacitors, between each exposed metallic part on

the set and a good earth ground such as a water pipe, as

shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more

sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverse the ACplugintheACoutlet and repeat eachof the

above measurements.

6. The potential at any point should not exceed 0.75 volts

RMS. A leakage current tester (Simpson Model 229 or

equivalent) may be used to make the hot checks, leakage

current must not exceed 1/2 milliamp. In case a

measurement is outside of the limits specified, there is a

possibility of a shock hazard, and the equipment should be

repaired and rechecked before it is returned to the

customer.

5

TH-42PX75U

3 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable

conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ESdevices.(Otherwiseham less motion suchasthebrushing

together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to

damage an ES device).

6

TH-42PX75U

4 About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

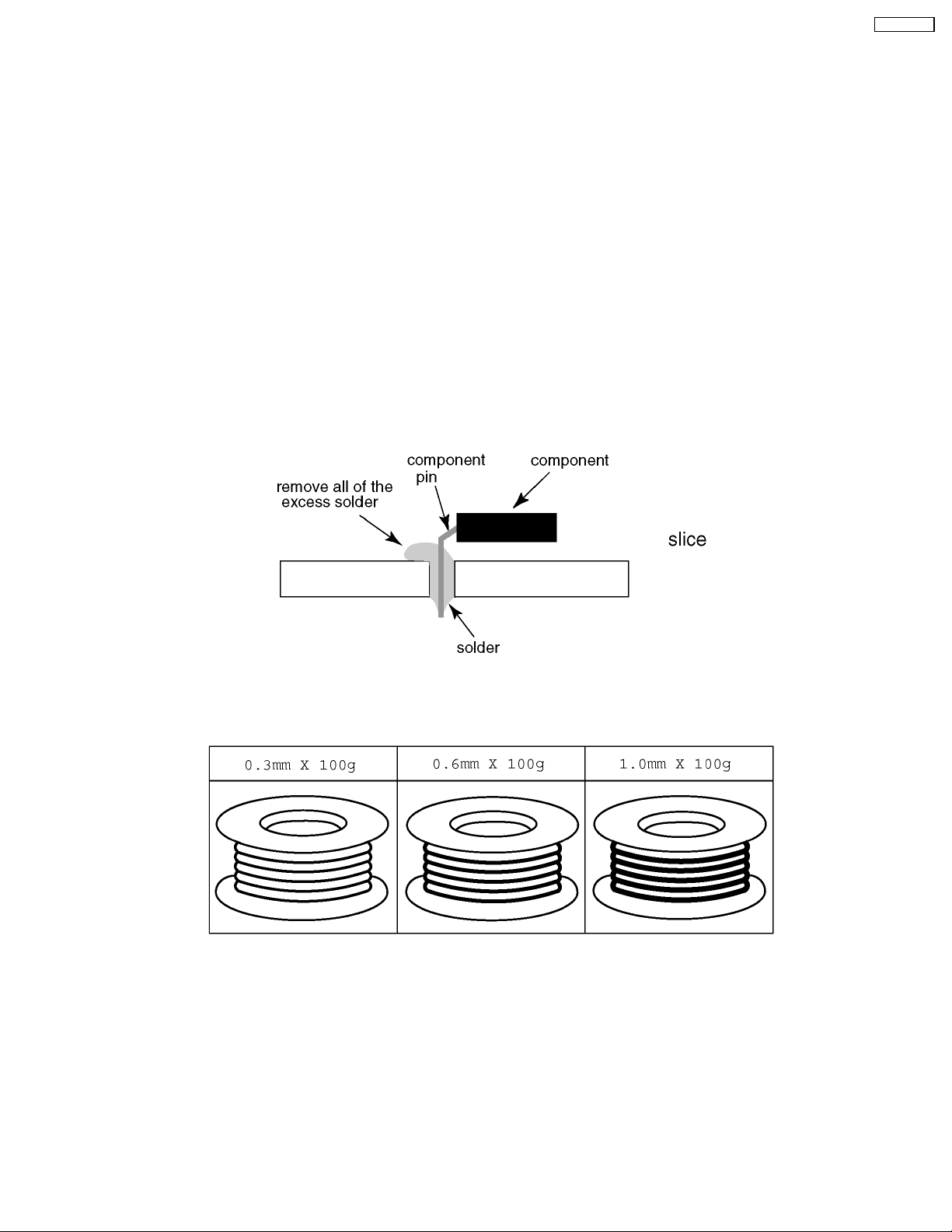

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair work, we’d

suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol PbF stamped on the back of PCB.

Caution

·

· Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30~40 °C) higher.

· ·

Please use a high temperature soldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

·

· Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

· ·

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before applying Pb

solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

·

· After applying PbF solder to double layered boards, please check the component side for excess solder which may flow onto

· ·

the opposite side. (see figure below)

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin, silver, copper) solder.

However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used.

7

TH-42PX75U

5 Service Hint

Remove the Rear Cover

Board Name Function Board Name Function

P Power Supply D Format Converter, Plasma AI, Sub-Field Processor

A DC-DC Converter

Speaker out, Sound Processor

AV Terminal, AV Switch

Digital Signal Processor, Microcomputer, HDMI

Interface

Peaks Lite 2

K Remote receiver, Power LED SS Sustain Drive

S Power Switch GS SD Card Slot, Key Switch

C1 Data Driver (Lower Right)

C2 Data Driver (Lower Left)

SC Scan Drive

SU Scan out (Upper)

SD Scan out (Lower)

8

6 Plasma panel replacement method

TH-42PX75U

6.1. Remove the rear cover

1. See Service Hint (Section 5)

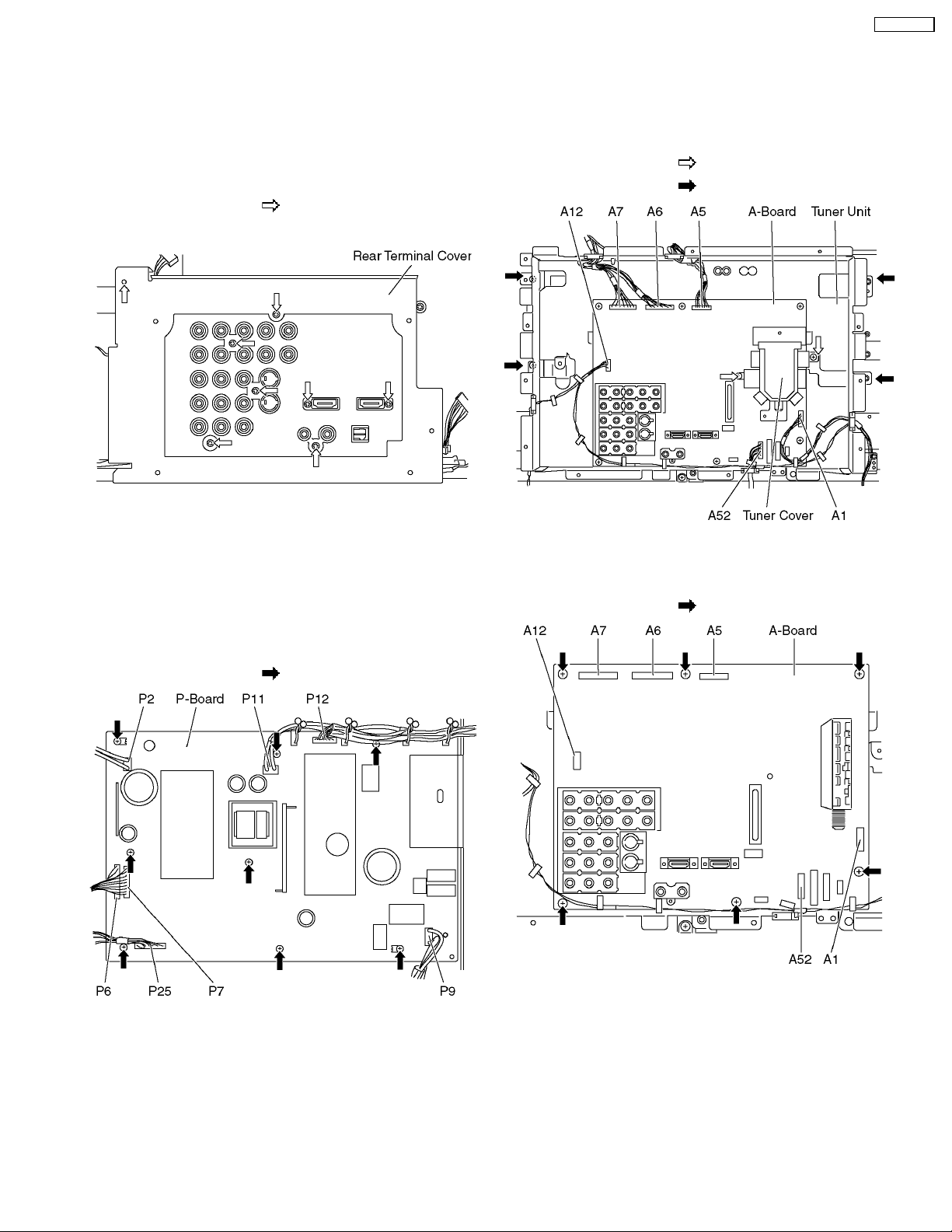

6.2. Remove the rear terminal

cover

1. Remove the screws (×8 ).

2. Remove the rear terminal cover.

6.3. Remove the P-Board

6.4. Remove the Tuner unit

1. Unlock the cable clampers to free the cable.

2. Disconnect the connectors (A1, A5, A6, A7, A12 and A52).

3. Remove the screws (×2

4. Remove the screws (×4

) and remove the tuner cover.

) and remove the tuner unit.

Caution:

To remove P.C.B. wait 1 minute after power was off for

discharge from electrolysis capacitors.

1. Unlock the cable clampers to free the cable.

2. Disconnect the connectors (P2, P6, P7, P9, P11, P12 and

P25).

3. Remove the screws (×8

) and remove the P-Board.

6.5. Remove the A-Board

1. Remove the tuner unit. (See section 6.4.)

2. Remove the screws (×6

) and remove the A-Board.

9

TH-42PX75U

6.6. Remove the D-Board

6.8. Remove the SD-Board

1. Remove the tuner unit. (See section 6.4.)

2. Disconnect the connectors (D5 and D25).

3. Disconnect the flexible cables (D20, D31 and D32).

4. Remove the screws (×4

) and remove the D-Board.

1. Remove the screws (×2 ).

2. Remove the flexible cables (SD1, SD2, SD3 and SD4)

connected to the SD-Board and remove the bridge

connector (SC46-SD46).

3. Slide the SD-Board to the left to disconnect from a

connector (SC42-SD42) on the SC-Board and remove the

SD-Board.

6.7. Remove the SU-Board

1. Remove the screws (×2 ).

2. Remove the flexible cables (SU1, SU2, SU3 and SU4)

connected to the SU-Board and remove the bridge

connector (SC45-SU45).

3. Slide the SU-Board to the left to disconnect from a

connector (SC41-SU41) on the SC-Board and remove the

SU-Board.

6.9. Remove the SC-Board

1. Remove the SU-Board and SD-Board. (See section 6.7.

and 6.8.)

2. Unlock the cable clampers to free the cable.

3. Disconnect the connector (SC2).

4. Disconnect the flexible cable (SC20).

5. Remove the screws (×6

) and remove the SC-Board.

10

6.10. Remove the SS-Board

TH-42PX75U

6.12. Remove the C2-Board

1. Disconnect the connectors (SS11, SS12 and SS23).

2. Disconnect the flexible cables (SS53A, SS54A, SS55A and

SS56A).

3. Remove the screws (×6

) and remove the SS-Board.

1. Remove the tuner unit. (See section 6.4.)

2. Unlock the cable clampers to free the cable.

3. Remove the flexible cables holder fastening screws (×8

).

4. Disconnect the flexible cables (CB5, CB6, CB7 and CB8).

5. Disconnect the flexible cables (C20 and C21).

6. Disconnect the connector (C23).

7. Remove the screws (×4

) and remove the C2-Board.

6.13. Remove the front bracket and

the front shield case cover

1. Disconnect the connector (A52). (See section 6.4.)

2. Remove the screws (×4

and the front shield case cover.

) and remove the front bracket

6.11. Remove the C1-Board

1. Remove the tuner unit. (See section 6.4.)

2. Unlock the cable clampers to free the cable.

3. Remove the flexible cables holder fastening screws (×8

).

4. Disconnect the flexible cables (CB1, CB2, CB3 and CB4).

5. Disconnect the flexible cables (C10 and C11).

6. Remove the screws (×4

) and remove the C1-Board.

6.14. Remove the GS-Board

1. Remove the front bracket and the front shield case cover.

(See section 6.13.)

2. Remove the screws (×2

top and the control button.

3. Remove the screws (×2 ) and disconnect the connector

(GS52).

4. Remove the GS-Board.

) and remove the front shield

11

TH-42PX75U

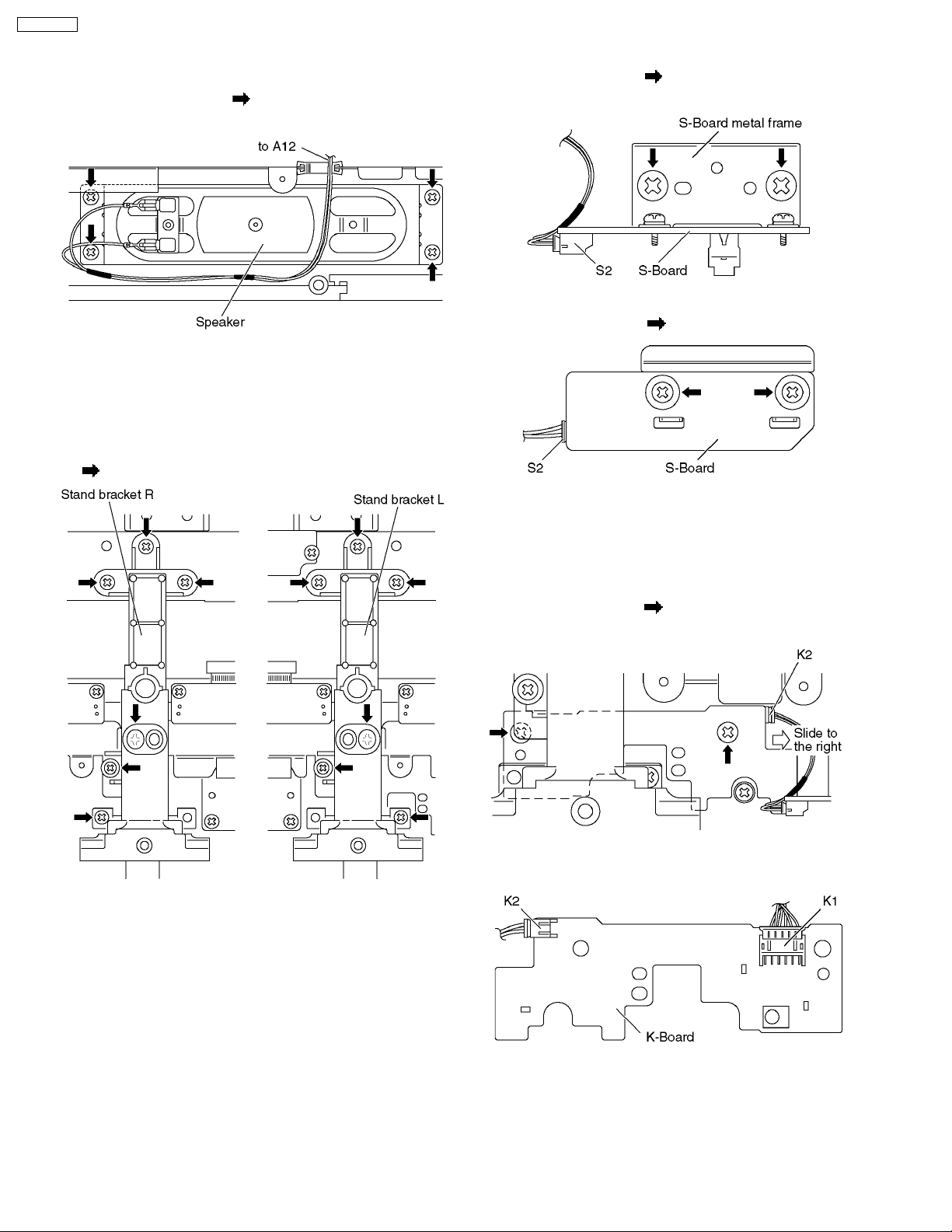

6.15. Remove the speaker L, R

6.17. Remove the S-Board

1. Disconnect the connector (A12). (See section 6.4.)

2. Remove the screws (×4

L, R.

each) and remove the speaker

6.16. Remove the stand brackets

1. Remove the plasma panel section from the servicing stand

and lay on a flat surface such as a table (covered) with the

plasma panel surface facing downward.

2. Remove the stand brackets (left, right)fastening screws (×6

each) and remove the stand brackets (left, right).

1. Remove the screws (×2 ) and remove the S-Board metal

frame.

2. Disconnect the connector (S2).

3. Remove the screws (×2

) and remove the S-Board.

6.18. Remove the K-Board

1. Remove the S-Board. (See section 6.17.)

2. Unlock the cable clampers to free the cable.

3. Disconnect the connectors (A1). (See section 6.4.)

4. Remove the screws (×2

the K-Board.

5. Disconnect the connectors (K1 and K2) and remove the KBoard.

) and slide to the right to remove

12

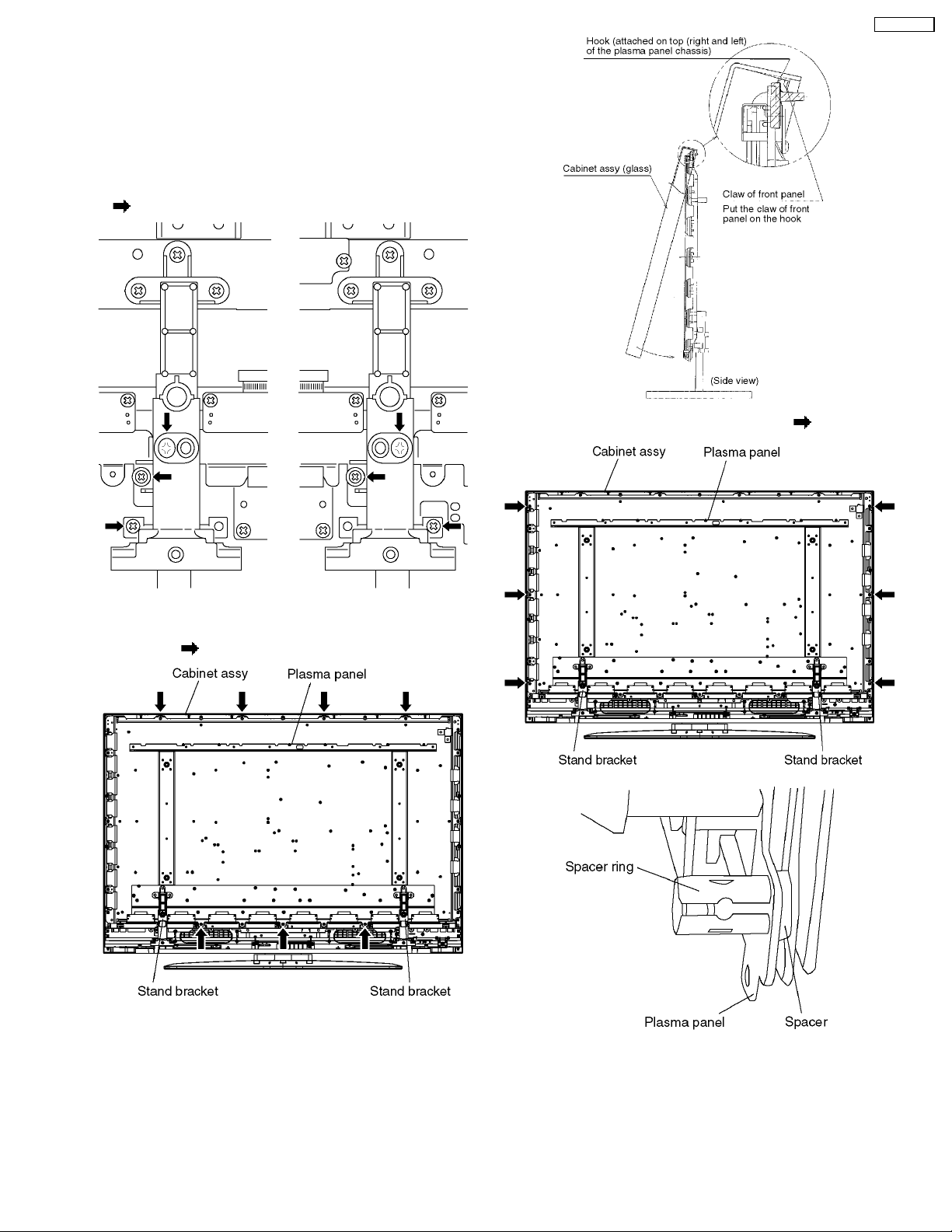

6.19. Remove the Plasma panel

section from the Cabinet assy

(glass)

1. Remove the plasma panel section from the servicing stand

and lay on a flat surface such as a table (covered) with the

plasma panel surface facing downward.

2. Remove the stand brackets (left, right)fastening screws (×3

each).

TH-42PX75U

6. Remove the spacers and spacer rings (×6 ).

3. Replace the servicing stand and stand the set.

4. Remove the cabinet assy and the plasma panel fastening

screws (×7

5. For leaving the plasma panel from the cabinet assy, pull the

bottom of the front frame forward, lift, and remove.

).

13

TH-42PX75U

6.20. Replace the plasma panel

(finished)

1. Place the new plasma panel (finished) on the flat surface of

the table (covered by a soft cloth), with the plasma panel

surface facing downward.

2. Attach the C1-Board and the C2-Board, connect the flexible

cables (×16) from the Plasma panel to the C1-Board and

the C2-Board, and fit the flexible cable holders.

3. Attach the Hooks (left, right) and fit the stand brackets (L,

R) to the new plasma panel.

4. Place the plasma panel section on the servicing stand.

5. Attach the cabinet assy and each P.C.Board and so on, to

the new plasma panel.

*When fitting the front frame, be careful to allow any

debris, dust or handling residue to remain between the

front glass and plasma panel.

14

7 Caution statement

7.1. Caution statement.

Caution:

Please confirm that all flexible cables are assembled correctly.

Also make sure that they are locked in the connectors.

Verify by giving the flexible cables a very slight pull.

TH-42PX75U

15

TH-42PX75U

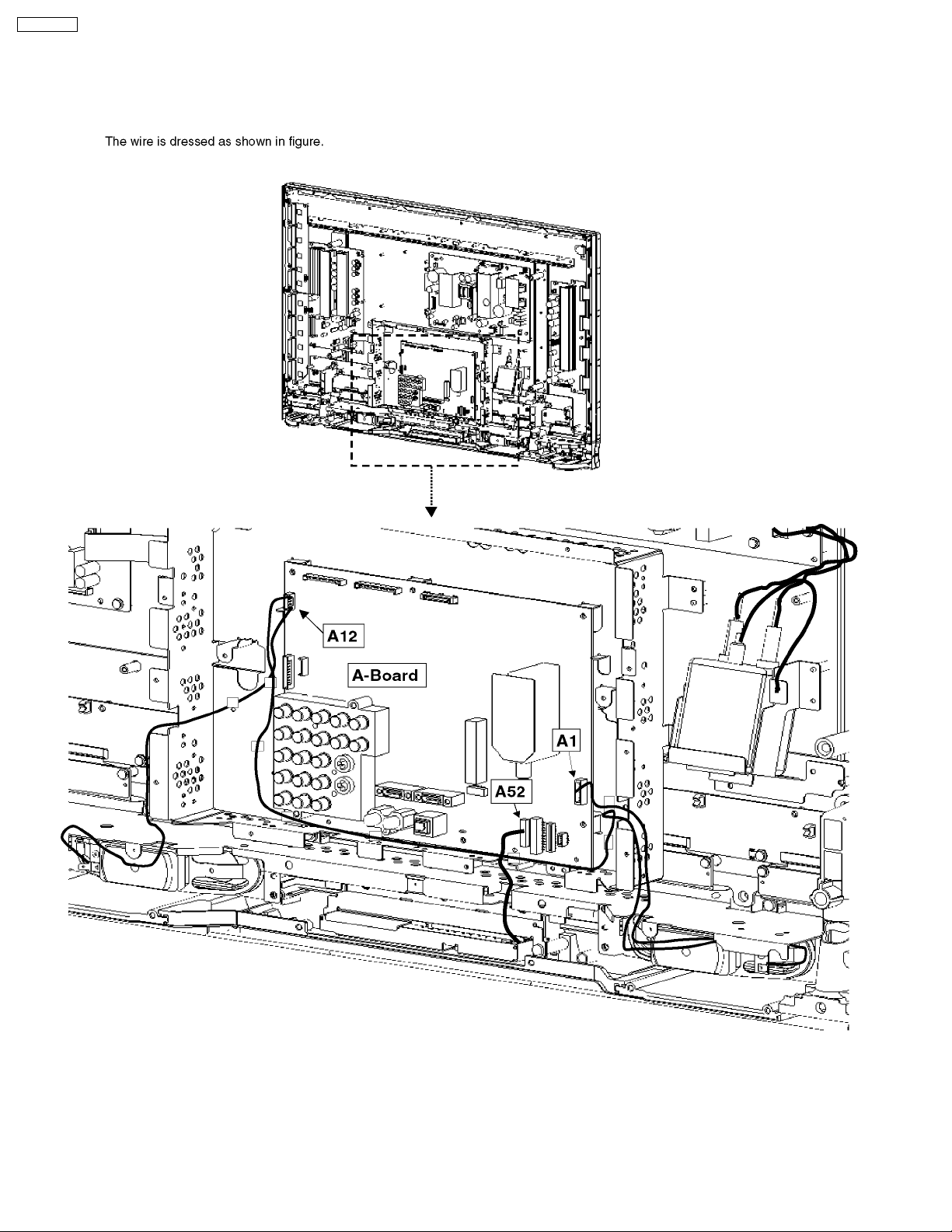

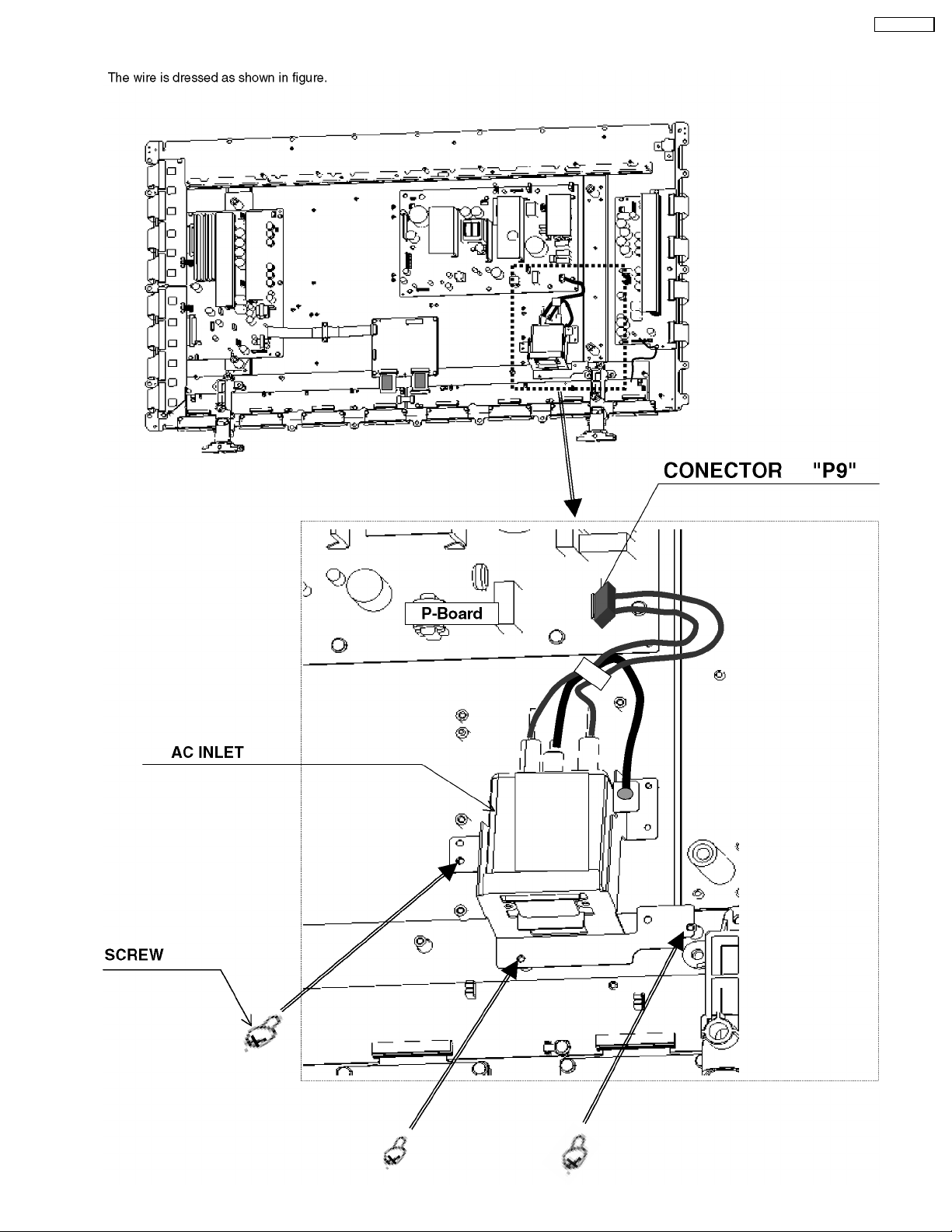

8 Location of Lead Wiring

8.1. Lead of Wiring (1)

16

8.2. Lead of Wiring (2)

TH-42PX75U

17

TH-42PX75U

8.3. Lead of Wiring (3)

18

8.4. Lead of Wiring (4)

TH-42PX75U

19

TH-42PX75U

8.5. Lead of Wiring (5)

20

TH-42PX75U

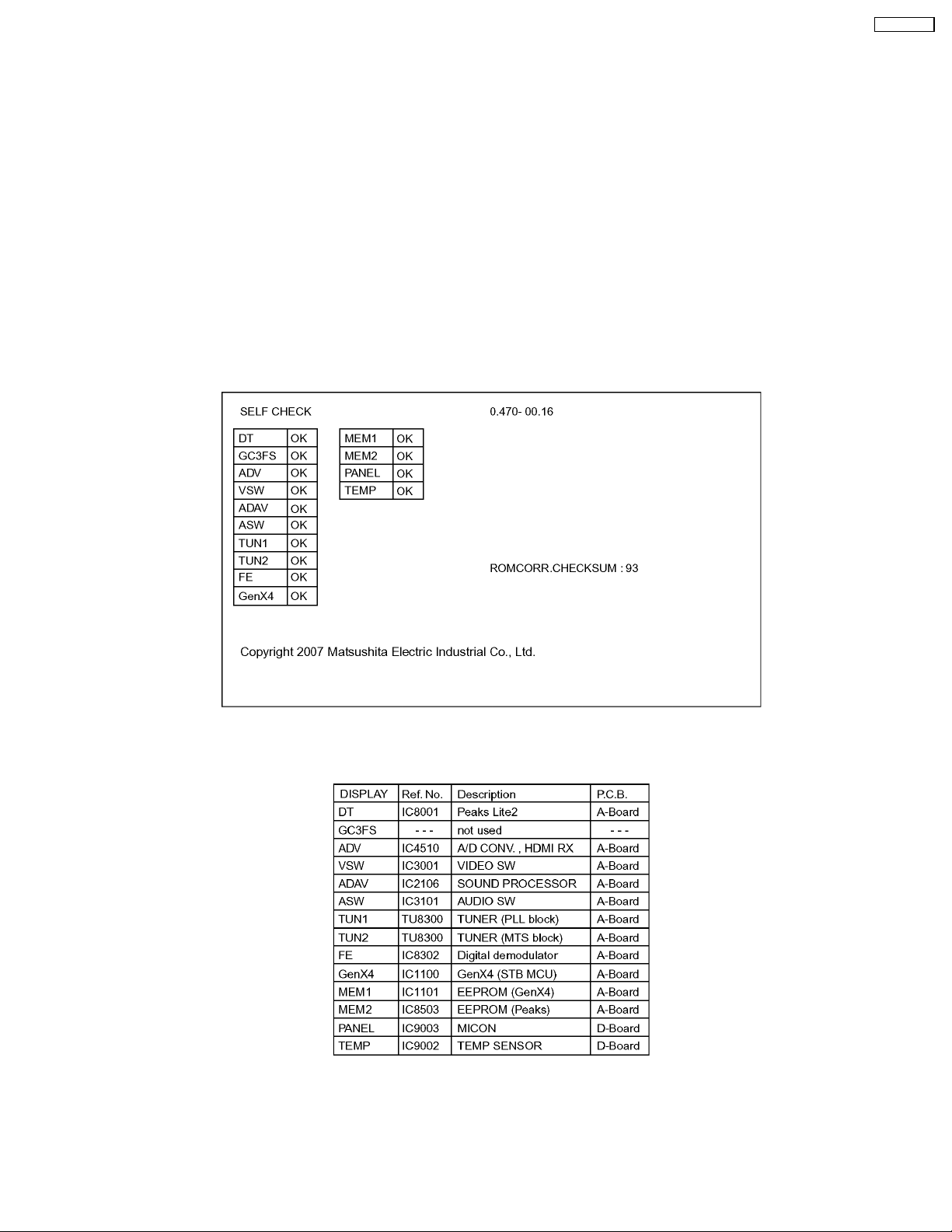

9 Self-check Function

Use the self-check function to test the unit.

1. Checking the IIC bus lines

2. Power LED Blinking timing

9.1. Check of the IIC bus lines

9.1.1. How to access

Self-check indication only:

Produce TV reception screen, and while pressing [VOLUME ( - )] button on the main unit, press [OK] button on the remote control

for more than 3 seconds.

Self-check indication and forced to factory shipment setting:

Produce TV reception screen, and while pressing [VOLUME ( - )] button on the main unit, press [MENU] button on the remote

control for more than 3 seconds.

9.1.2. Screen display

9.1.3. Check Point

Confirm the following parts if NG was displayed.

9.1.4. Exit

Disconnect the AC cord from wall outlet.

21

TH-42PX75U

9.2. Power LED Blinking timing chart

1. Subject

Information of LED Flashing timing chart.

2. Contents

When an abnormality has occurred the unit, the protection circuit operates and reset to the stand by mode. At this time, the

defective block can be identified by the number of blinks of the Power LED on the front panel of the unit.

22

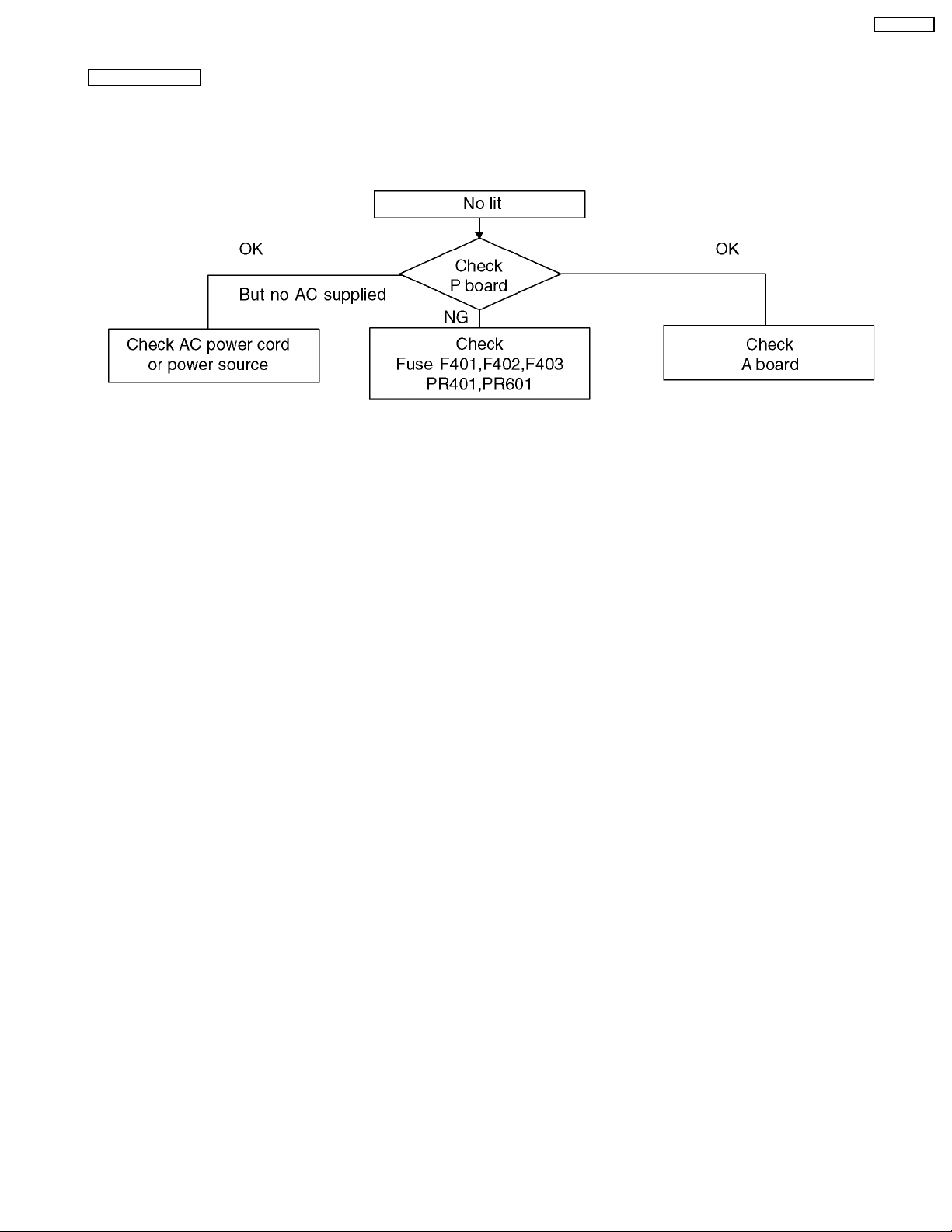

9.3. No Power

First check point

There are following 2 states of No Power indication by power LED.

1. No lit

2. Red is lit then turns red blinking a few seconds later. (See 9.2.)

TH-42PX75U

23

TH-42PX75U

9.4. No Picture

24

9.5. Local screen failure

Plasma display may have local area failure on the screen. Fig-1 is the possible defect P.C.B. for each local area.

TH-42PX75U

Fig-1

25

TH-42PX75U

10 Service Mode

10.1. How to enter into Service Mode

While pressing [VOLUME ( - )] button of the main unit, press [RECALL] button of the remote control three times within 3

seconds.

10.1.1. Key command

“1” button...Main items Selection in forward direction

“2” button...Main items Selection in reverse direction

“3” button...Sub items Selection in forward direction

“4” button...Sub items Selection in reverse direction

“VOL” button...Value of sub items change in forward direction ( + ), in reverse direction ( - )

26

10.1.2. Contents of adjustment mode

·

· Value is shown as a hexadecimal number.

· ·

·

· Preset value differs depending on models.

· ·

·

· After entering the adjustment mode, take note of the value in each item before starting adjustment.

· ·

Main item Sub item Sample Data Remark

ADJUST CONTRAST 000

COLOR 49

TINT FE

SUB-BRT 808

WB-ADJ R-CUT 80

G-CUT 80

B-CUT 80

R-DRV F6

G-DRV E2

B-DRV FC

ALL-CUT 80

ALL-DRV FC

OPTION BOOT ROM Factory Preset.

STBY-SET 00

Emergency OFF

CLK MODE 00

CLOCK 000

AGING RGBW

COUNT

ALL WHITE

ALL RED

ALL GREEN

ALL BLUE

ON/OFF

RAMP WHITE

RAMP RED

RAMP GREEN

RAMP BLUE

1% WINDOW

COLOR BAR

A-ZONE B-ZONE/4 TRIO

SCROLL

WHITE FLAME

RM-SET CODE A Fixed.

SRV-TOOL - See Next.

TH-42PX75U

10.1.3. How to exit

Switch off the power with the [POWER] button on the main unit or the [POWER] button on the remote control.

27

TH-42PX75U

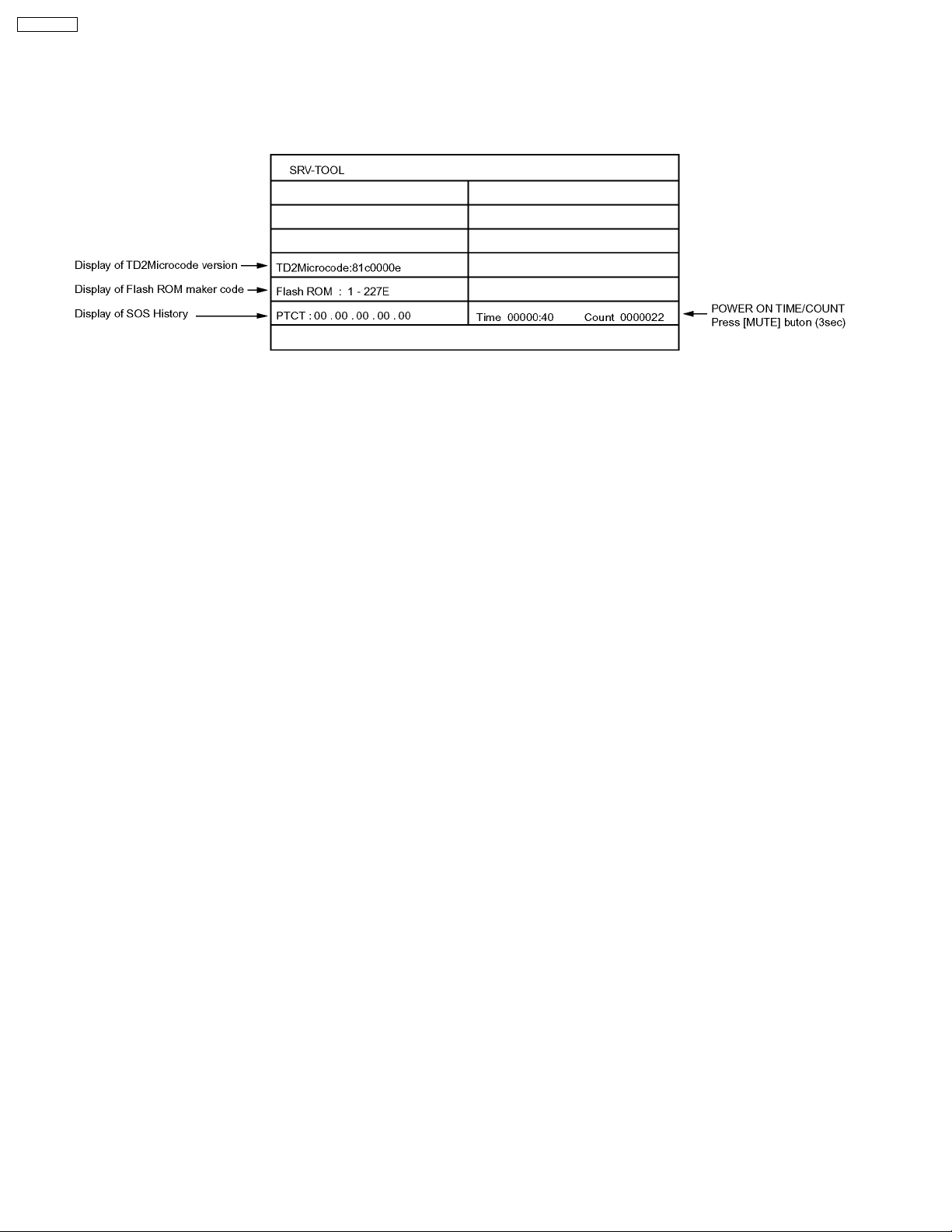

10.2. Service tool mode

10.2.1. How to access

1. Select “SRV-TOOL” in Service Mode.

2. Press [OK] button on the remote control.

10.2.2. Display of SOS History

SOS History (Number of LED blinking) indication.

From left side; Last SOS, before Last, three occurrence before, 2nd occurrence after shipment, 1st occurrence after shipment.

This indication will be cleared by “Self-check indication and forced to factory shipment setting”.

10.2.3. POWER ON TIME/COUNT Note: To display TIME/COUNT menu, highlight position, then press MUTE for (3sec).

Time : Cumulative power on time, indicated hour : minute by decimal

Count : Number of On times by decimal

Note : This indication will not be cleared by either of the self-checks or any other command.

10.2.4. Exit

1. Disconnect the AC cord from wall outlet.

28

11 Adjustment Proce dure

TH-42PX75U

11.1. Driver Set-up

11.1.1. Item / Preparation

1. Input a white signal to plasma video input.

2. Set the picture controls as follows.

Picture menu: Vivid

Normal: Set

Aspect: Full

Caution

1. First perform Vsus adjustment.

2. Confirmation of Vscn voltage should be performed after

confirmation of Vad adjustment.

When Vad=-105V, Voltage of Vscn is 40V ±4V.

11.1.2. Adjustments

Adjust driver section voltages referring the panel data on the

panel data label.

Check or adjust the following voltages with the multimeter.

Name Test Point Voltage Volume Remarks

Vsus TPVSUS

(SS)

Ve TPVE (SS) Ve ± 1V VR6000 (SS) *

Vset TPVSET

(SC)

Vad TPVAD (SC) -105V ± 1V VR6600

Vscn TPVSCN

(SC)

Vda TPVDA (SS) 75V ± 1V, -2V Fixed

PFC C446(+)(-) 396.0V±0.5V R443 (P)

*See the Panel label.

Vsus ± 2V R628 (P) *

330V ± 7V Fixed

(SC)

Vad+145V ±4VFixed

29

TH-42PX75U

11.2. Initialization Pulse Adjust

1. Input the White signal to plasma video input.

2. Set the picture controls as follows.

Picture menu : Vivid

Normal : Set

Aspect : Full

3. Connect Oscilloscope to TPSC1 (SC).

Check and adjust that the stand down pulse(T2) period are each within specification.

T2 TPSC1 (SC) VR6602 (SC) 190 ± 10µ Sec

Test point Volume Level

11.3. P.C.B. (Printed Circuit Board) exchange

11.3.1. Caution

1. To remove P.C.B. , wait 1 minute after power was off for discharge from electrolysis capacitors.

11.3.2. Quick adjustment after P.C.B. exchange

Adjust the following voltages with the multimeter.

P.C.B. Name Test Point Voltage Volume Remarks

P Board Vsus TPVSUS (SS) Vsus ± 2V R628 (P) *

PFC C446 (+) (-) 396.0V ± 0.5V R443 (P)

SC Board Vad TPVAD (SC) -105V ± 1V VR6600 (SC)

SS Board Ve TPVE (SS) Ve ± 1V VR6000 (SS) *

D, DG Board White balance and Sub brightness for NTSC, PAL, HD, PC and 625i signals

*See the Panel label.

Caution:

Absolutely do not reduce Vsus below Ve not to damage the P.C.B.

30

Loading...

Loading...