Panasonic TH37PE30B Schematic

ORDER NO. EXP0403007C2

Digital Progressi ve Plasma Television

TH-37PE30B

TH-42PE30B

GP6DE Chassis

Specifications

Power Source 220 V -240 V 50 Hz /60 Hz A.C.

Power Consumption

Normal use 253 W (TH-37PE30B), 323 W (TH-42PE30B)

Standby 1.8 W (TV only), 15.0 W (TV + DVB system set to record Timer programmes)

Power-OFF 1.0 W

Plasma Display panel

Drive method AC type

Aspect Ratio 16:9

Contrast Ratio 4000:1

Screen size (No.of pixels) 37-inch (TH-37PE30B)

818 mm (W) × 461 mm (H) × 939 mm (diagonal)

42-inch (TH-42PE30B)

920 mm (W) × 518 mm (H) × 1,056 mm (diagonal)

408,960 (852 (W) × 480 (H)) [2,556 × 480 dots ]

Sound

Speaker Woofer 80 mm × 2, Tweeter 16 mm × 73 mm × 8

Audio Output 26W[8W+8W,5W+5W]((10%THD)

Headphone M3 (3.5 mm) Jack × 1

Applicable signals

Colour System NTSC, PAL, PAL60, SECAM, Modified NTSC

Scanning format 525 (480) /60i 60p, 625 (575) /50i 50p

PC signals VGA display

VGA

SVGA, XGA, SXGA, UXGA ..... (compressed)

Horizontal scanning frequency 15 - 110 kHz

Vertical scanning frequency 48 - 120 Hz

Receiving Systems/Band namePAL I

UHF E21 - 68.

© 2004 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

TH-37PE30B / TH-42PE30B

OUTPUT

AUDIO OUT AUDIO L-R (RCA Pin Type × 2) 0.5 Vrms

INPUT

AV3-Front VIDEO (RCA Pin Type × 2) 1.0 Vp-p (75 9)

AV4C-Rear Y 1.0 Vp-p (including synchronization)

PC (HIGH-DENSITY D-SUB 15PIN) R, G, B/ 0.7 Vp-p (75 9)

Others SD Card slot × 1, PC Card slot × 1

INPUT/OUTPUT

AV1-Rear 21 Pin terminal (Audio/Video in, TV out, RGB in)

AV2-Rear 21 Pin terminal (Audio/Video in, Audio/Video out, S-Video in, Q-Link)

AV4-Rear 21 Pin terminal (Audio/Video in, Audio/Video out, S-Video in, RGB in, Q-Link)

ANT-Rear UHF / VHF

Operating Conditions Temperature :0 ° - 40 °C

Accessories Supplied

Operating Instructions TQBC0719-1

Mains Lead K2CT3DH00017

Remote Control Transmitter EUR7635010

Batteries 2×R6Size

Clamper TMME206 × 2

Ferrite core Large size × 2, Small size × 5

Dimensions ( W × H × D ) 1,040 mm × 697 mm × 139 mm (TH-37PE30B)

Mass (Weight) 34.5 kg (TH-37PE30B)

PAL 525/60 Playback of NTSC tape from some PAL Video recorders (VCR)

DVB Digital terrestrial services via UHF aerial input.

M.NTSC Playback from M.NTSC Video recorders (VCR)

NTSC (AV INPUT ONLY) Playback from NTSC Video recorders (VCR)

S-VIDEO (MINI DIN 4-pin) Y: 1.0 Vp-p (75 9 ) C:0.286 Vp-p (75 9)

AUDIO L-R (RCA Pin Type × 2) 0.5 Vrms

PB/P

R

Humidity :20 % - 80 %RH (non-condensing)

1,140 mm × 757 mm × 139 mm (TH-42PE30B)

41.0 kg (TH-42PE30B)

±0.35 Vp-p

HD, VD / 1.0 - 5.0 Vp-p (high impedance)

Notes:

·

· Design and specifications are subject to change without notice.Mass and dimensions shown are approximate.

· ·

·

· This equipment complies with the EMC standards listed below.

· ·

EN55013,EN61000-3-2,EN61000-3-3,EN55020.

CONTENTS

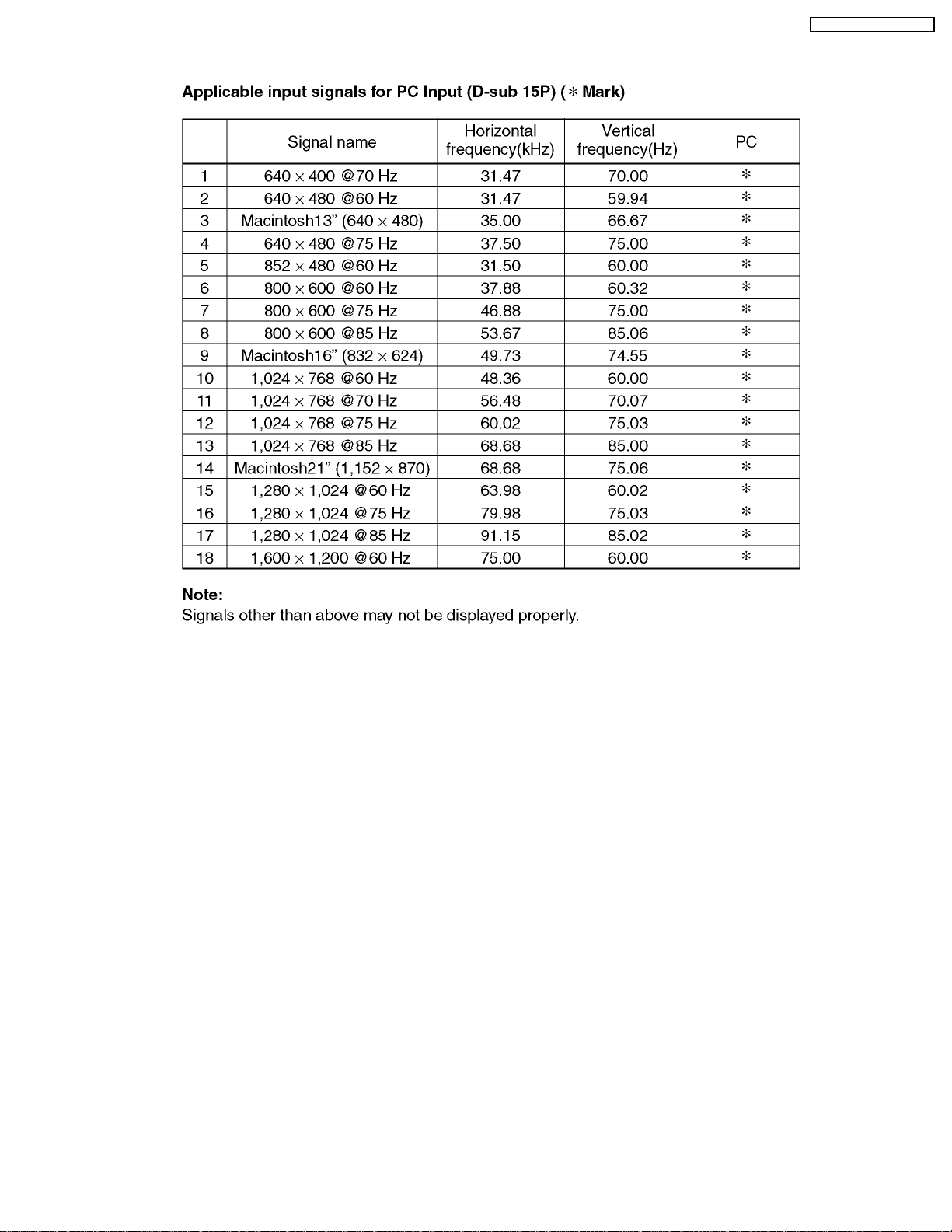

1 Applicable signals 5

2 Safety Precautions

2.1. General Guidelines

2.2. Touch-Current Check

3 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

4 About lead free solder (PbF)

Page Page

5 Service Hint

6

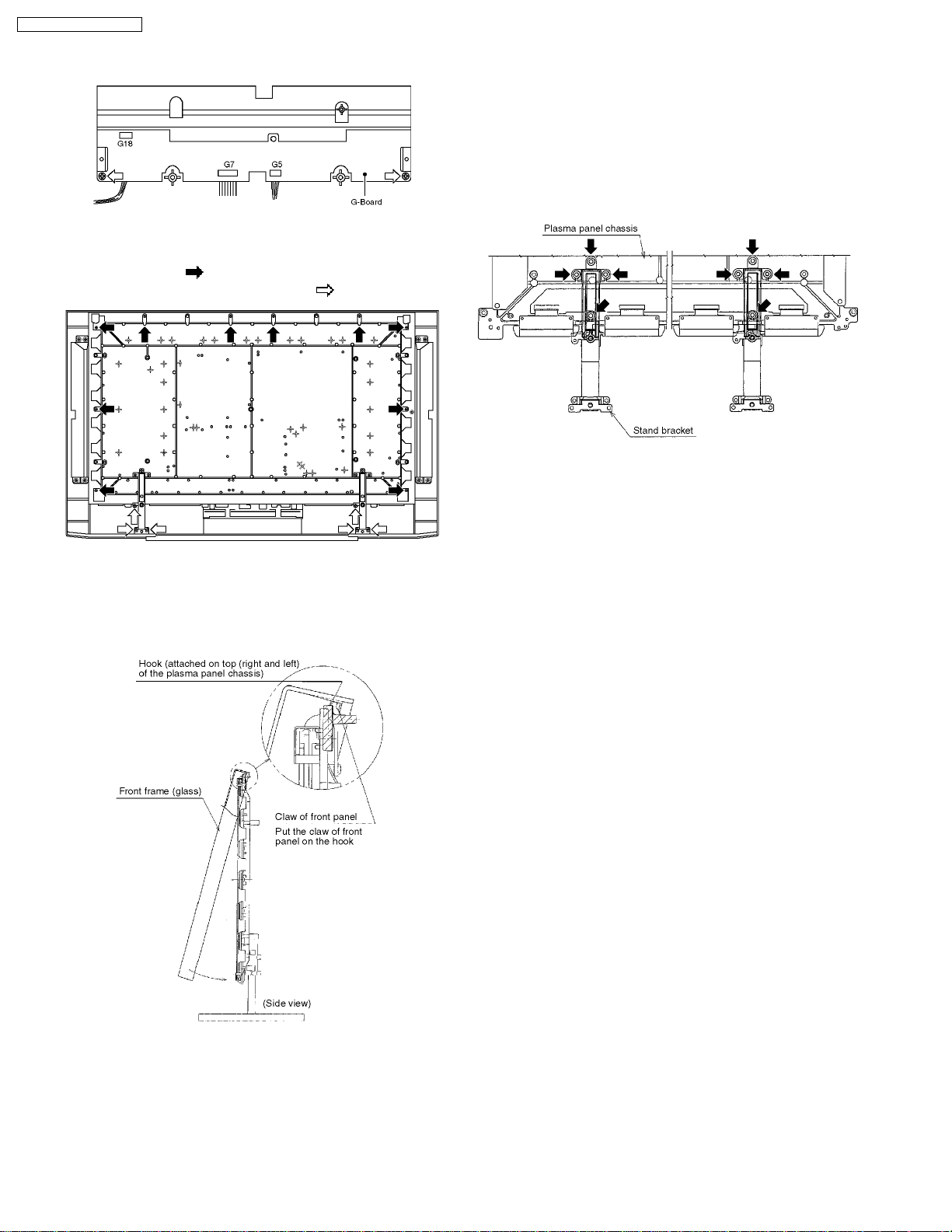

6 P.C.Board and Plasma panel replacement method

7 Location of Lead Wiring

6

6

7

8

7.1. Lead of Wiring (1)

7.2. Lead of wiring (2)

7.3. Lead of wiring (3)

7.4. Lead of wiring (4)

10

15

15

16

17

18

2

9

7.5. Lead of wiring (5) 18

7.6. Lead of wiring (7)

8SelfCheck

8.1. Power LED Blinking timing chart

8.2. No Power

8.3. No Picture

8.4. Local screen failure

9 Service Mode Function

9.1. How to enter SERVICE 1

9.2. How to enter SERVICE 2

9.3. Option Description

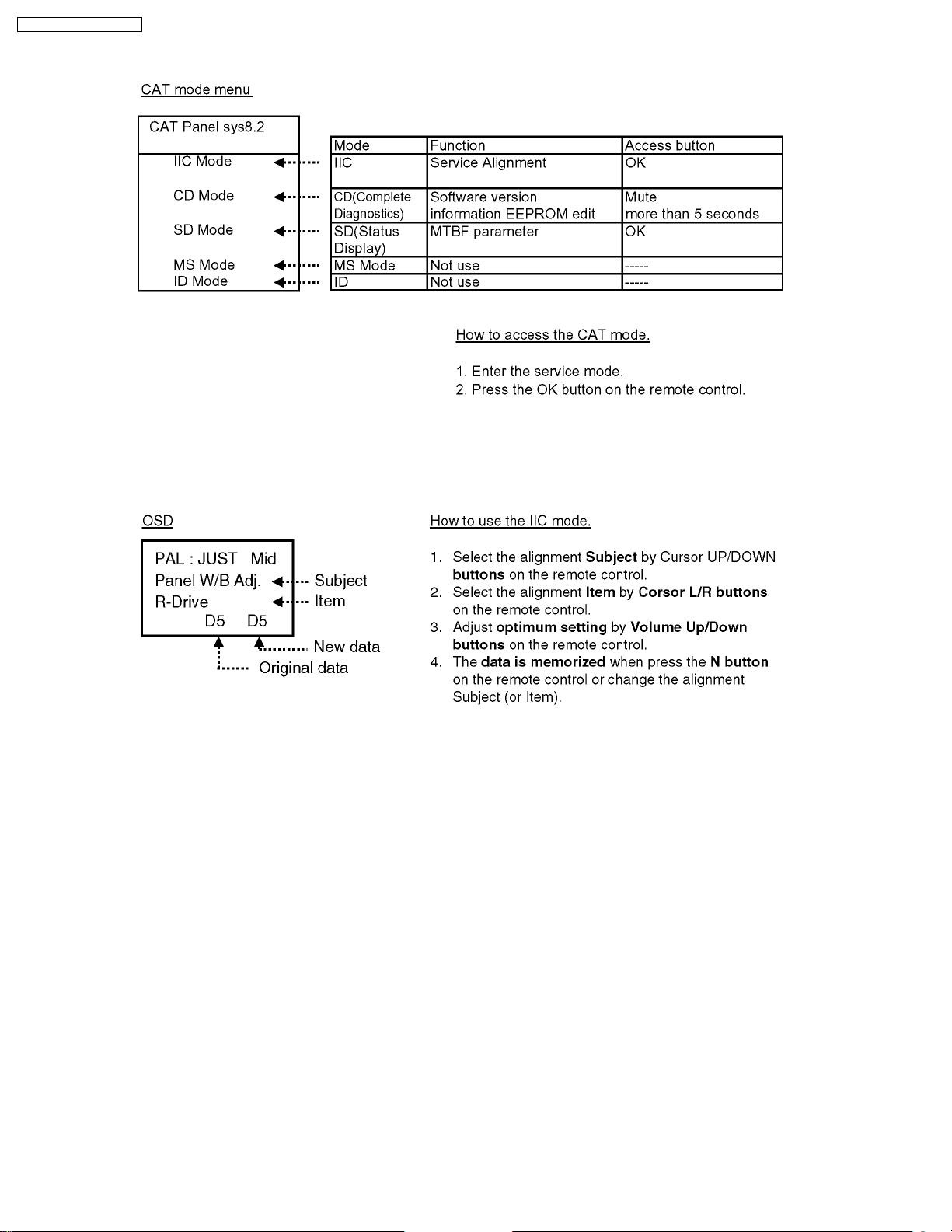

10 CAT (Computer Aided Test) mode

10.1. IIC mode

10.2. CD mode

10.3. SD mode

10.4. IIC mode structure (following items value is sample data.)

11 Adjustment Procedure

11.1. +B Set-up

11.2. Driver Set-up

11.3. Initialization Pulse Adjust

11.4. P.C.B. (Printed Circuit Board) exchange

11.5. Adjustment Volume Location

11.6. Test Point Location

12 Alignment

12.1. Pedestal setting

12.2. PAL panel white balance

12.3. PC panel white balance

12.4. Sub brightness setting

12.5. ABL Level

13 Hotel mode

14 Conductor Views

14.1. PF-Board

14.2. P-Board

14.3. PA-Board

14.4. D-Board

14.5. DG-Board

14.6. H and T-Board

14.7. C1-Board (For TH-37PE30B)

14.8. C1-Board (For TH-42PE30B)

14.9. C2-Board (For TH-37PE30B)

14.10. C2-Board (For TH-42PE30B)

14.11. SC-Board

14.12. SU-Board (For TH-37PE30B)

14.13. SU-Board (For TH-42PE30B)

14.14. SD-Board (For TH-37PE30B)

14.15. SD-Board (For TH-42PE30B)

14.16. SS-Board

14.17. SS2, SS3, SS4 and SS5-Board

14.18. K and S-Board

14.19. G-Board

14.20. JG-Board

14.21. XV-Board

15 Block and Schematic Diagr ams

19

20

21

22

23

23

24

24

24

26

28

28

29

29

30

31

31

31

32

33

33

33

34

34

35

36

37

37

38

39

39

41

43

45

47

49

51

52

53

54

55

58

59

60

61

62

64

65

66

67

69

71

TH-37PE30B / TH-42PE30B

15.1. Schematic Diagram Notes

15.2. Main Block Diagram

15.3. PF-Board Block Diagram

15.4. PF-Board Schematic Diagram

15.5. P-Board Block Diagram

15.6. P-Board Schematic Diagram

15.7. PA-Board Block Diagram

15.8. PA-Board (1 of 2) Schematic Diagram

15.9. PA-Board (2 of 2) Schematic Diagram

15.10. H and T-Board Block Diagram

15.11. H-Board (1 of 2) Schematic Diagram

15.12. H-Board (2 of 2) and T-Board Schematic Diagram

15.13. DG-Board (1 of 2) Block Diagram

15.14. DG-Board (2 of 2) Block Diagram

15.15. DG-Board (1 of 9) Schematic Diagram

15.16. DG-Board (2 of 9) Schematic Diagram

15.17. DG-Board (3 of 9) Schematic Diagram

15.18. DG-Board (4 of 9) Schematic Diagram

15.19. DG-Board (5 of 9) Schematic Diagram

15.20. DG-Board (6 of 9) Schematic Diagram

15.21. DG-Board (7 of 9) Schematic Diagram

15.22. DG-Board (8 of 9) Schematic Diagram

15.23. DG-Board (9 of 9) Schematic Diagram

15.24. D-Board Block Diagram

15.25. D-Board (1 of 12) Schematic Diagram

15.26. D-Board (2 of 12) Schematic Diagram

15.27. D-Board (3 of 12) Schematic Diagram

15.28. D-Board (4 of 12) Schematic Diagram

15.29. D-Board (5 of 12) Schematic Diagram

15.30. D-Board (6 of 12) Schematic Diagram

15.31. D-Board (7 of 12) Schematic Diagram

15.32. D-Board (8 of 12) Schematic Diagram

15.33. D-Board (9 of 12) Schematic Diagram

15.34. D-Board (10 of 12) Schematic Diagram

15.35. D-Board (11 of 12) Schematic Diagram

15.36. D-Board (12 of 12) Schematic Diagram

15.37. C1, C2, G and K-Board Block Diagram

15.38. C1-Board Schematic Diagram (TH-37PE30B)

15.39. C1-Board Schematic Diagram (TH-42PE30B)

15.40. C2-Board (1 of 2) Schematic Diagram (TH-37PE30B)

15.41. C2-Board (2 of 2) Schematic Diagram (TH-37PE30B)

15.42. C2-Board Schematic Diagram (TH-42PE30B)

15.43. G-Board Schematic Diagram

15.44. K-Board Schematic Diagram

15.45. SC-Board Block Diagram

15.46. SC-Board (1 of 3) Schematic Diagram

15.47. SC-Board (2 of 3) Schematic Diagram

15.48. SC-Board (3 of 3) Schematic Diagram

15.49. SU-Board Block Diagram

15.50. SU-Board Schematic Diagram (TH-37PE30B)

15.51. SU-Board Schematic Diagram (TH-42PE30B)

15.52. SD-Board Block Diagram

15.53. SD-Board Schematic Diagram (TH-37PE30B)

15.54. SD-Board Schematic Diagram (TH-42PE30B)

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

3

TH-37PE30B / TH-42PE30B

15.55. SS, S, SS2, SS3, SS4 and SS5-Board Block Diagram 125

15.56. SS-Board (1 of 2) and S-Board Schematic Diagram

15.57. SS-Board (2 of 2) SS2, SS3, SS4 and SS5-Board

Schematic Diagram

15.58. JG-Board Block Diagram

15.59. JG-Board (1 of 2) Schematic Diagram

15.60. JG-Board (2 of 2) Schematic Diagram

15.61. XV-Board Block Diagram

126

127

128

129

130

131

15.62. XV-Board (1 of 5) Schematic Diagram

15.63. XV-Board (2 of 5) Schematic Diagram

15.64. XV-Board (3 of 5) Schematic Diagram

15.65. XV-Board (4 of 5) Schematic Diagram

15.66. XV-Board (5 of 5) Schematic Diagram

16 Parts Location

17 Packing Exploded Views

132

133

134

135

136

137

138

4

1 Applicable signals

TH-37PE30B / TH-42PE30B

5

TH-37PE30B / TH-42PE30B

2 Safety Precautions

2.1. General Guidelines

1.When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2.After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3.After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

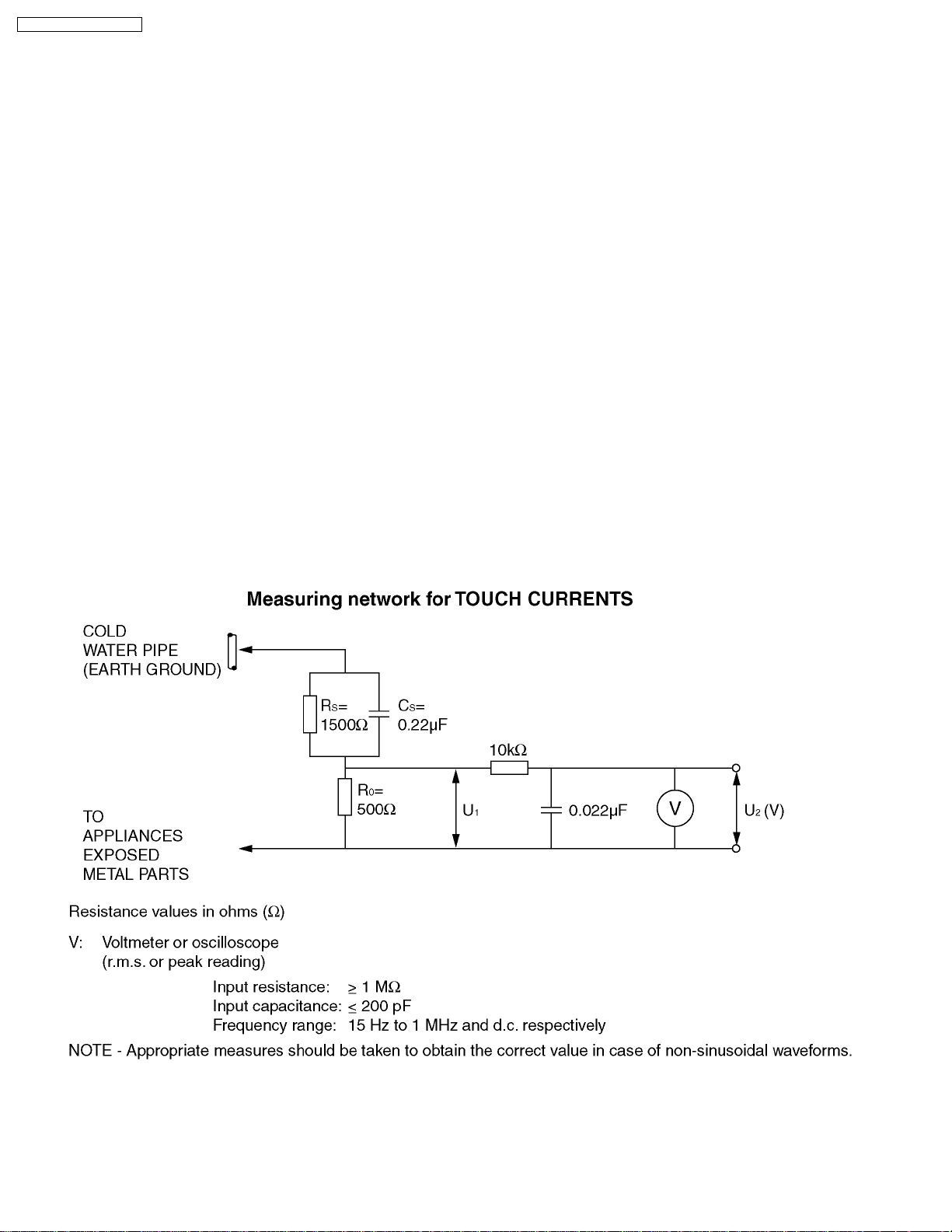

2.2. Touch-Current Check

1.Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2.Connect a measuring network for touch currents between each exposed metallic part on the set and a good earth ground such

as a water pipe, as shown in Figure 1.

3.Use Leakage Current Tester (Simpson 228 or equivalent) to measure the potential across the measuring network.

4.Check each exposed metallic part, and measure the voltage at each point.

5.Reserve the AC plug in the AC outlet and repeat each of the above measure.

6.The potential at any point (TOUGH CURRENT) expressed as voltage U

For a. c.: U

For d. c.: U

= 35 V (peak) and U2= 0.35 V (peak);

1

=1.0V,

1

Note:

The limit value of U

= 0.35 V (peak) for a. c. and U1= 1.0 V for d. c. correspond to the values 0.7 mA (peak) a. c. and 2.0

2

mA d. c.

The limit value U

= 35 V (peak) for a. c. correspond to the value 70 mA (peak) a. c. for frequencies greater than 100 kHz.

1

7.In case a measurement is out of the limits specified, there is a possibility of a shock hazard, and the equipment should be

repaired and rechecked before it is returned to the customer.

and U2, does not exceed the following values:

1

Figure 1

6

TH-37PE30B / TH-42PE30B

3 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1.Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2.After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as alminum

foil, to prevent electrostatic charge buildup or exposure of the assembly.

3.Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4.Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5.Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6.Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, alminum foil or comparable

conductive material).

7.Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8.Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise hamless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to

damage an ES device).

7

TH-37PE30B / TH-42PE30B

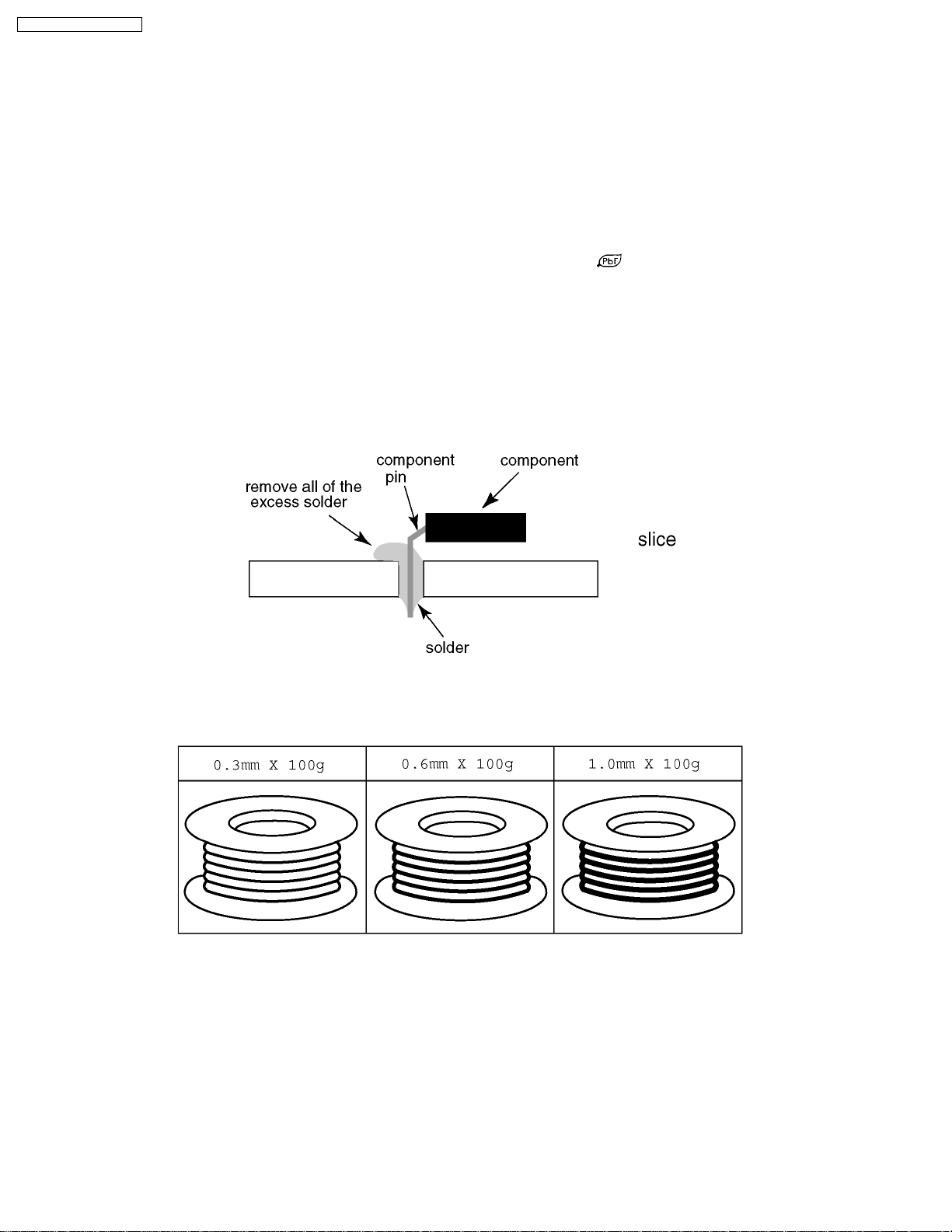

4 About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair work, we’d

suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol

Caution

·

· Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30~40 °C) higher.

· ·

Please use a high temperature soldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

·

· Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

· ·

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before applying Pb

solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

·

· After applying PbF solder to double layered boards, please check the component side for excess solder which may flow onto

· ·

the opposite side. (see figure below)

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin, silver, copper) solder.

However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used.

stamped on the back of PCB.

8

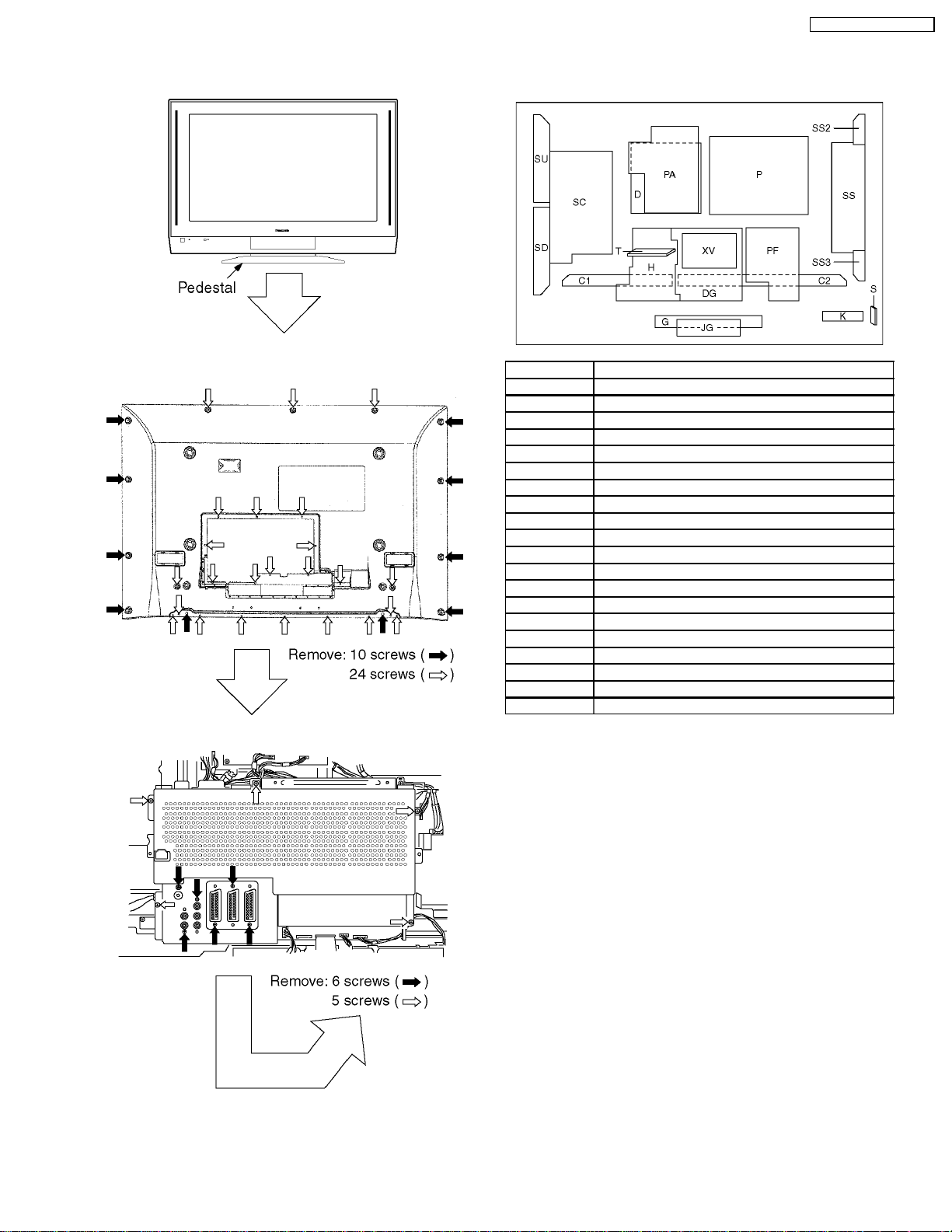

5 Service Hint

TH-37PE30B / TH-42PE30B

Stand the unit used for pedestal.

Remove the Rear Cover.

Service position.

Board Name Function

C1 DATA DRIVER (RIGHT)

C2 DATA DRIVER (LEFT)

D DIGTAL SIGNAL PROCESS

DG DIGTAL CORE, MICOM

G FRONT TERMINAL, SWITCH

H REAR TERMINAL

JG SD CARD/PC CARD, JPEG I/F D/A

K LED, REMOTE, POWER SWITCH

P POWER SUPPLY

PA DC/DC, AUDIO

PF LINE FILTER

S POWER SWITCH

SC SCAN DRIVE

SD SCAN OUT (DOWN)

SS SUSTAIN DRIVE

SS2 SUSTAIN CONNECTION (UP)

SS3 SUSTAIN CONNECTION (DOWN)

SU SCAN OUT (UP)

T TUNER

XV DVB TUNER

Remove the AV Connector Cover.

9

TH-37PE30B / TH-42PE30B

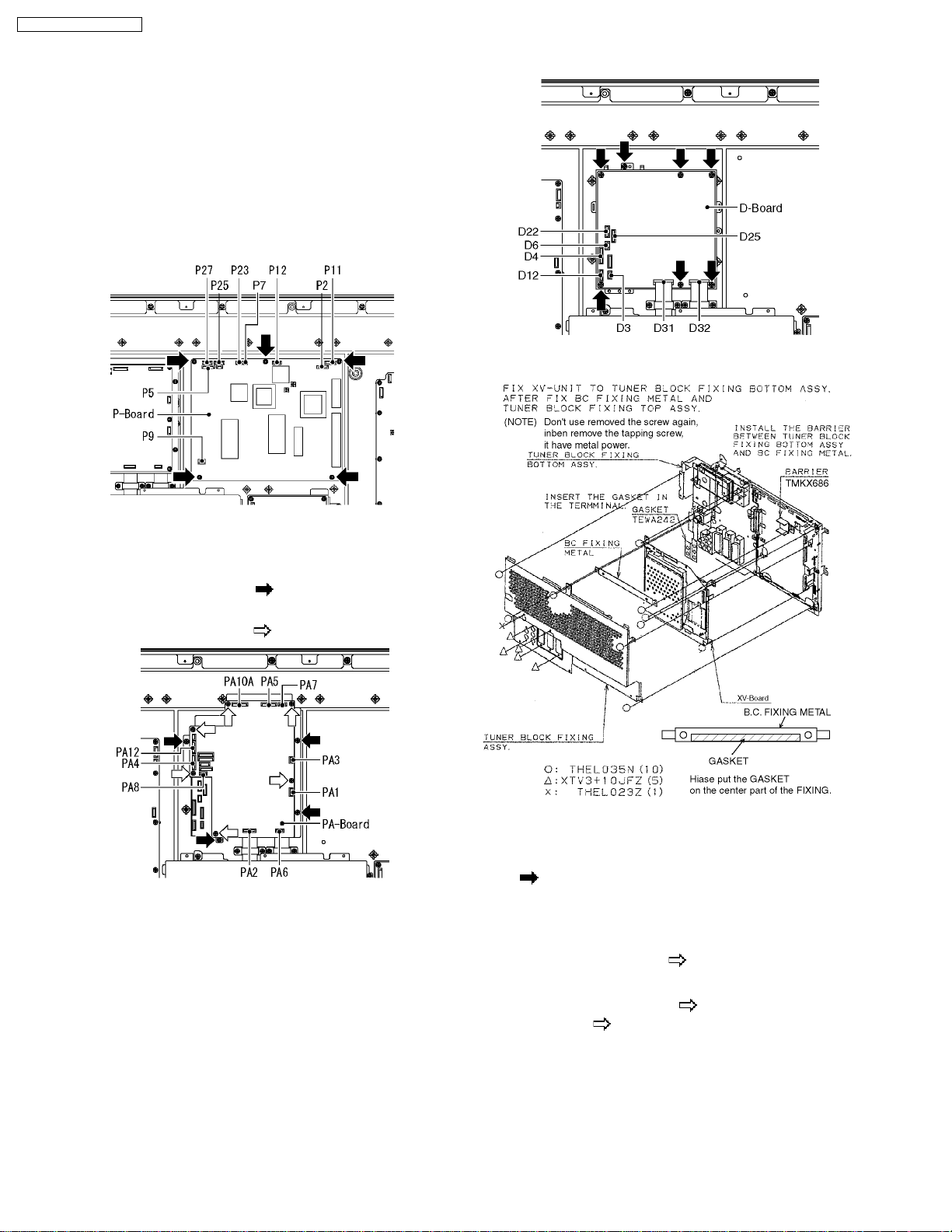

6 P.C.Board and Plasma panel replacement method

n

n To replace the plasma panel (finished), place the unit on

nn

the servicing stand, remove the front frame (finished), and

replace the panel, being careful not to scratch the plasma

panel surface.

1.Remove the rear cover and the AV connector cover.

2.Remove the P-Board.

a.Remove the couplers (P2, P5, P7, P9, P11, P12, P23,

P25, P27).

b.Remove the screws (×5) and remove the P-Board.

5.Remove the XV-Board.

3.Remove the PA-Board.

a.Remove the couplers (PA1, PA2, PA3, PA4, PA5, PA6,

PA7, PA8, PA10A, PA12).

b.Remove the screws (×4

with the PA-Board Bracket.

c.Remove the screws (×6

4.Remove the D-Board.

a.Disconnect the couplers (D3, D4, D6, D12, D22, D25)

and the flexible cables (D31, D32).

b.Remove the screws (×7) and remove the D-Board with

the bracket.

) and remove the PA-Board

) and remove the PA-Board.

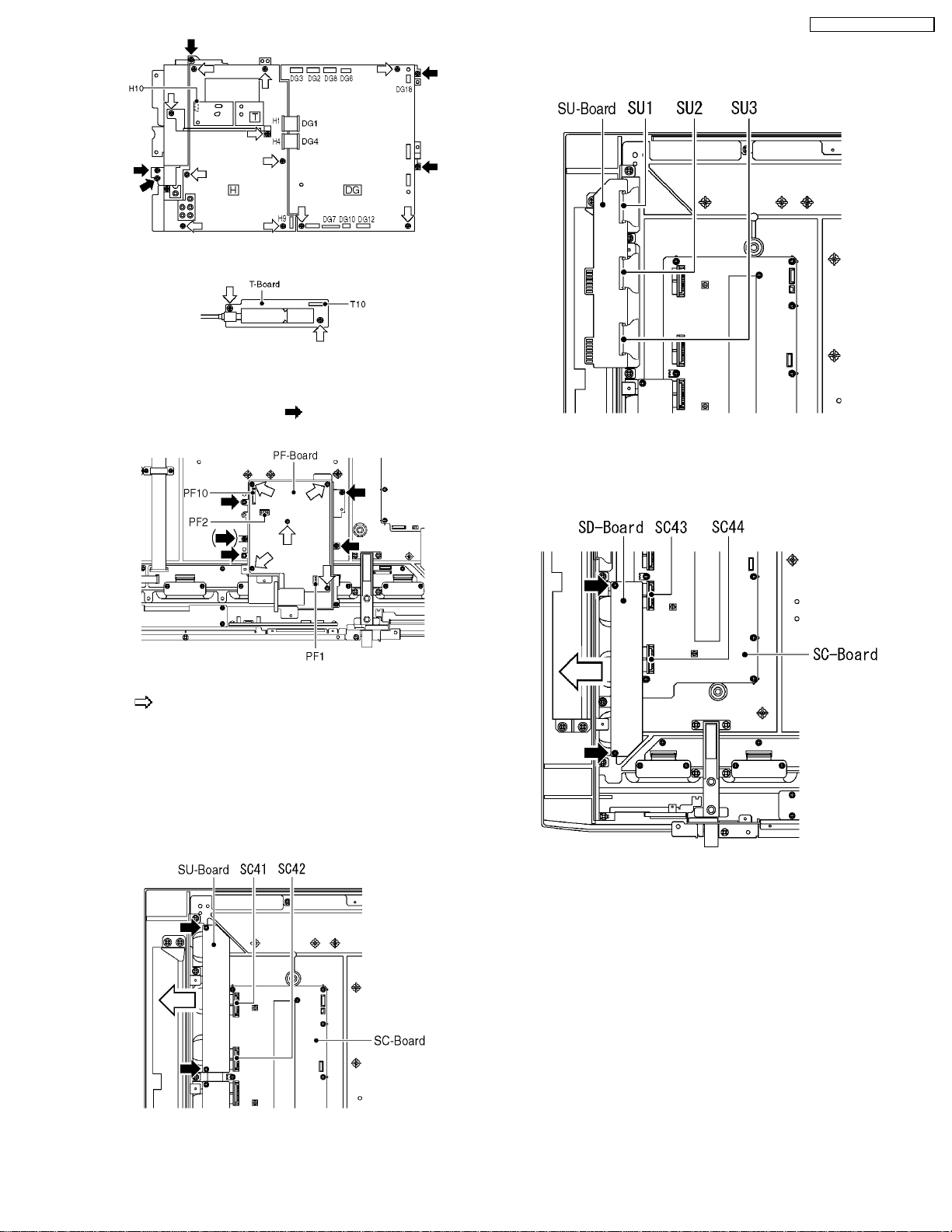

6.Remove the DG-Board, the H-Board and the T-Board.

a.Remove the couplers (DG2, DG3, DG6, DG8, DG10,

DG12, H9), a flexible cable (DG7), and the screws ( ×5

).

b.Remove the DG-Board, the H-Board and the T-Board

with the bracket.

c.Remove the bridge connectors (DG1-H1, DG4-H4) and

remove the screws (×3

d.Remove the DG-Board.

e.Remove the screws (×6

screws (×2

f.Remove the coupler (H10) and the antenna cable,

remove the T-Board with the T-Board bracket.

g.Remove the H-Board.

) on the T-Board bracket.

) on the DG-Board.

) on the H-Board and the

10

h.Remove the screws (×2) and remove the T-Board.

7.Remove the PF-Board.

a.Remove the couplers (PF2, PF10).

b.Remove the screws (×5

), and remove the PF-Board

with the Bracket.

TH-37PE30B / TH-42PE30B

c.Remove the flexible cables (SU1, SU2, SU3) connected

to the SU-Board, and remove the SU-Board.

9.Remove the SD-Board.

a.Remove the screws (×2).

b.Slide the SD-Board to the left and disconnect from the

couplers (SC43, SC44) on the SC-Board.

c.Remove the coupler (PF1) and remove the screws (×5

).

d.Remove the PF-Board.

8.Remove the SU-Board.

a.Remove the screws (×2).

b.Slide the SU-Board to the left and disconnect from the

couplers (SC41, SC42) on the SC-Board.

11

TH-37PE30B / TH-42PE30B

c.Remove the flexible cables (SD1, SD2, SD3) connected

to the SD-Board, and remove the SD-Board.

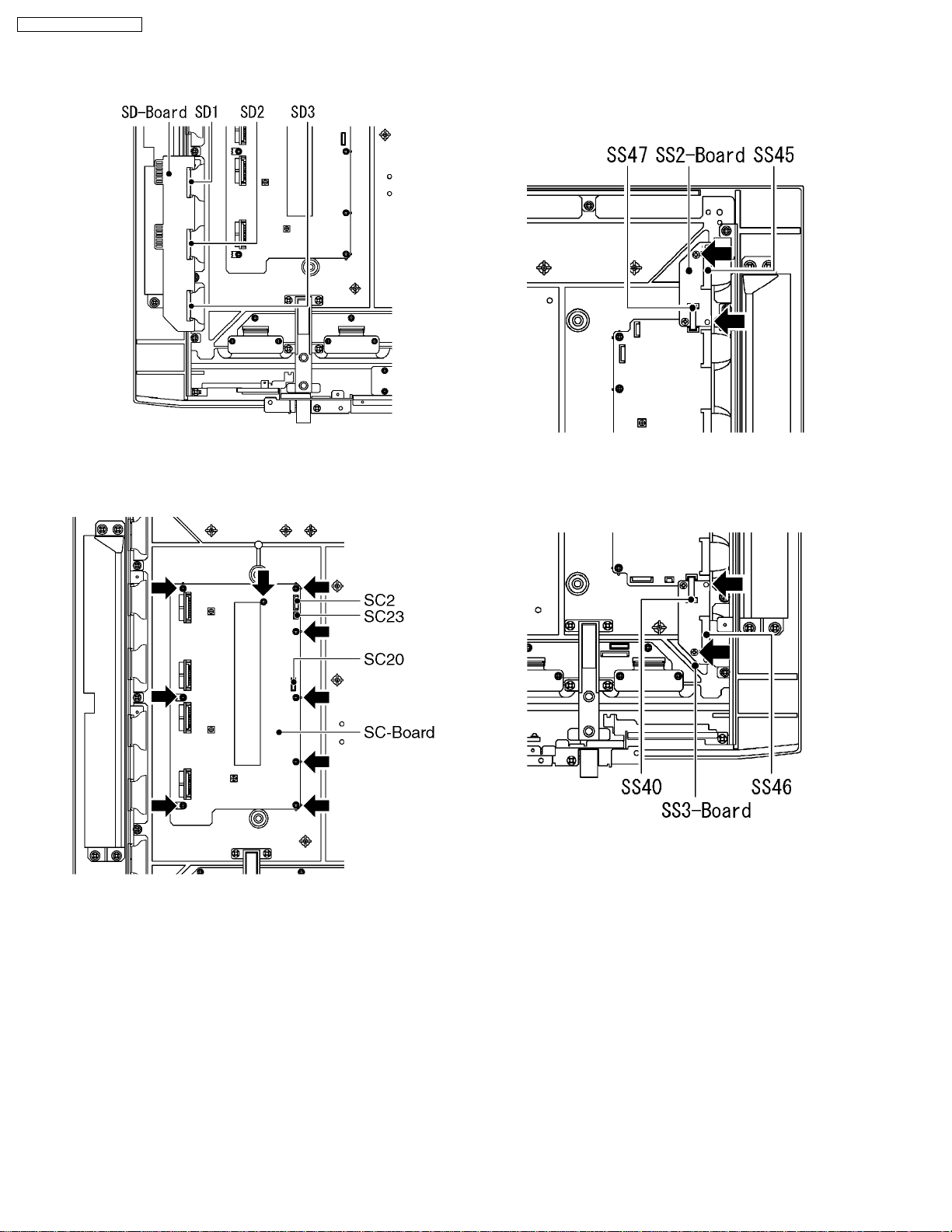

10.Remove the SC-Board.

a.Remove the couplers (SC2, SC20, SC23), the screws

(×9) and remove the SC-Board.

11.Remove the SS2-Board.

a.Remove the coupler (SS47), and remove the flexible

cable (SS45).

b.Remove the screws (×2), and remove the SS2-Board.

12.Remove the SS3-Board.

a.Remove the coupler (SS40) and the flexible cable

(SS46).

b.Remove the screws (×2), and remove the SS3-Board.

12

13.Remove the SS-Board.

a.Remove the couplers (SS11, SS12, SS23, SS34), and

remove the flexible cables (SS40, SS47) on the SS3Board and SS2-Board.

b.Remove the flexible cables (SS41, SS42, SS43, SS44).

c.Remove the screws (×6), and remove the SS-Board.

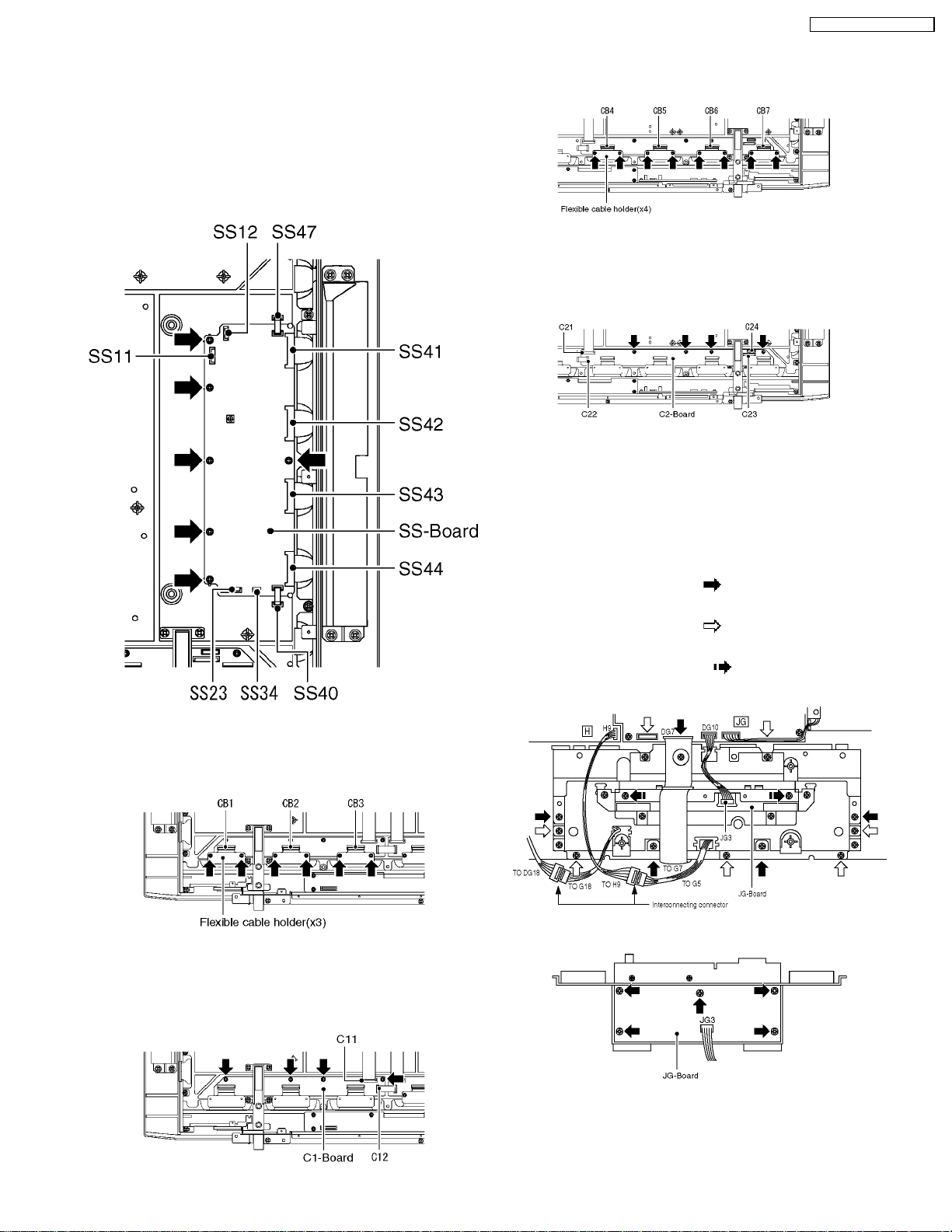

TH-37PE30B / TH-42PE30B

15.Remove the C2-Board.

a.Remove the flexible cable holder fastening screws (×8),

and remove the flexible cables (CB4, CB5, CB6, CB7).

b.Remove the couplers (C23, C24), a flexible cable (C21)

and release the speaker cables from the clamper on the

C2-Board.

c.Remove the screws (×4), and remove the C2-Board.

16.Remove the JG-Board and G-Board.

a.Remove the screws (×7) fixing the woofer speakers, the

interconnecting couplers (×4, to woofer and tweeter)

and remove the woofer speakers (right and left).

b.Disconnect a coupler (DG10), a flexible cable (DG7)

and the couplers of interconnecting connector (from

DG18 to G18 and H9 to G5).

c.Remove the screws (×5

) and remove the JG-Board

and G-Board with the Bracket.

d.Remove the screws (×7

) and remove the JG-Board

with Bracket.

e.Remove the screws (×2

) and remove the Shield

case of JG-Board.

14.Remove the C1-Board.

a.Remove the flexible cable holder fastening screws (×6)

and remove the flexible cables (CB1, CB2, CB3).

b.Remove the flexible cables (C11, C12) release the

speaker cables from the clampers (×2) on the C1Board.

c.Remove the screws (×4), and remove the C1-Board.

f.Remove the screws (×5) and remove the JG-Board.

13

TH-37PE30B / TH-42PE30B

g.Remove the screws (×2) and remove the G-Board.

17.Remove the Front frame (glass).

a.Remove the front frame and the plasma panel fastening

screws (×10

stand braket fastening screws(×6

), and remove the front frame and the

).

b.Release all cables from the clamper on the bracket of

the front frame.

c.For leaving the the plasma panel from the front frame,

pull the bottom of the front frame forward, lift, and

remove.

18.Remove stand brackets.

a.Remove the plasma panel section from the servicing

stand and lay on a surface such as a table (covered),

with the plasma panel surface facing downward.

Spread a soft cloth or similar on the table for protection,

so the panel surface is not scratched.

b.Remove the stand bracket (left, right) fastening screws

(×4 each) and remove the stand brackets (left, right).

19.Replace the plasma panel (finished).

a.Place the new plasma panel (finished) on the flat

surface of the table (covered by a soft cloth), with the

plasma panel surface facing downward.

b.Fit the stand brackets (left, right) to the new plasma

panel.

c.Place the plasma panel section on the servicing stand.

d.Attach the front frame and the each P.C.Board and so

on, to the new plasma panel.

* When fitting the front frame, be careful not to allow

any debris, dust or handling residues to remain

between the front glass and plasma panel.

14

7 Location of Lead Wiring

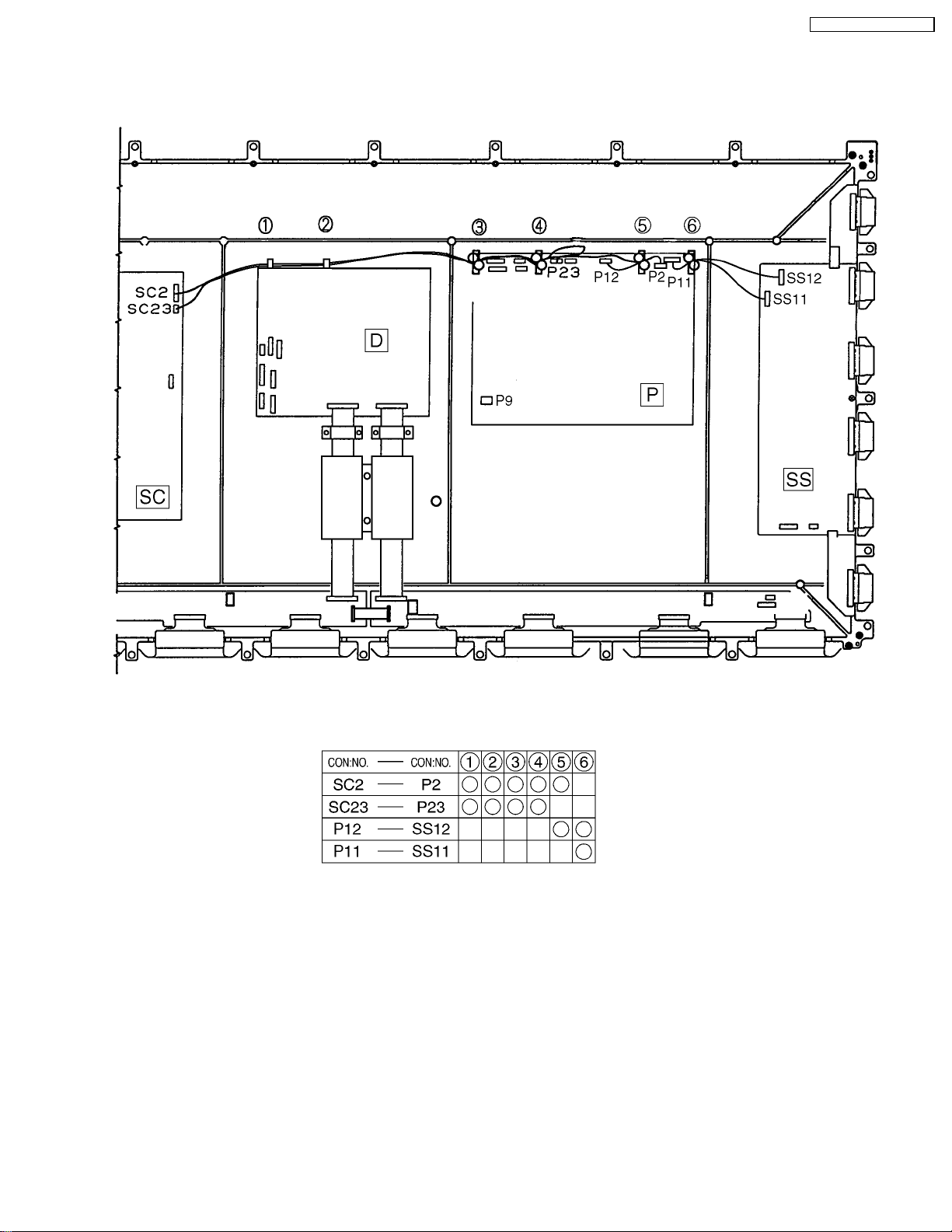

7.1. Lead of Wiring (1)

TH-37PE30B / TH-42PE30B

15

TH-37PE30B / TH-42PE30B

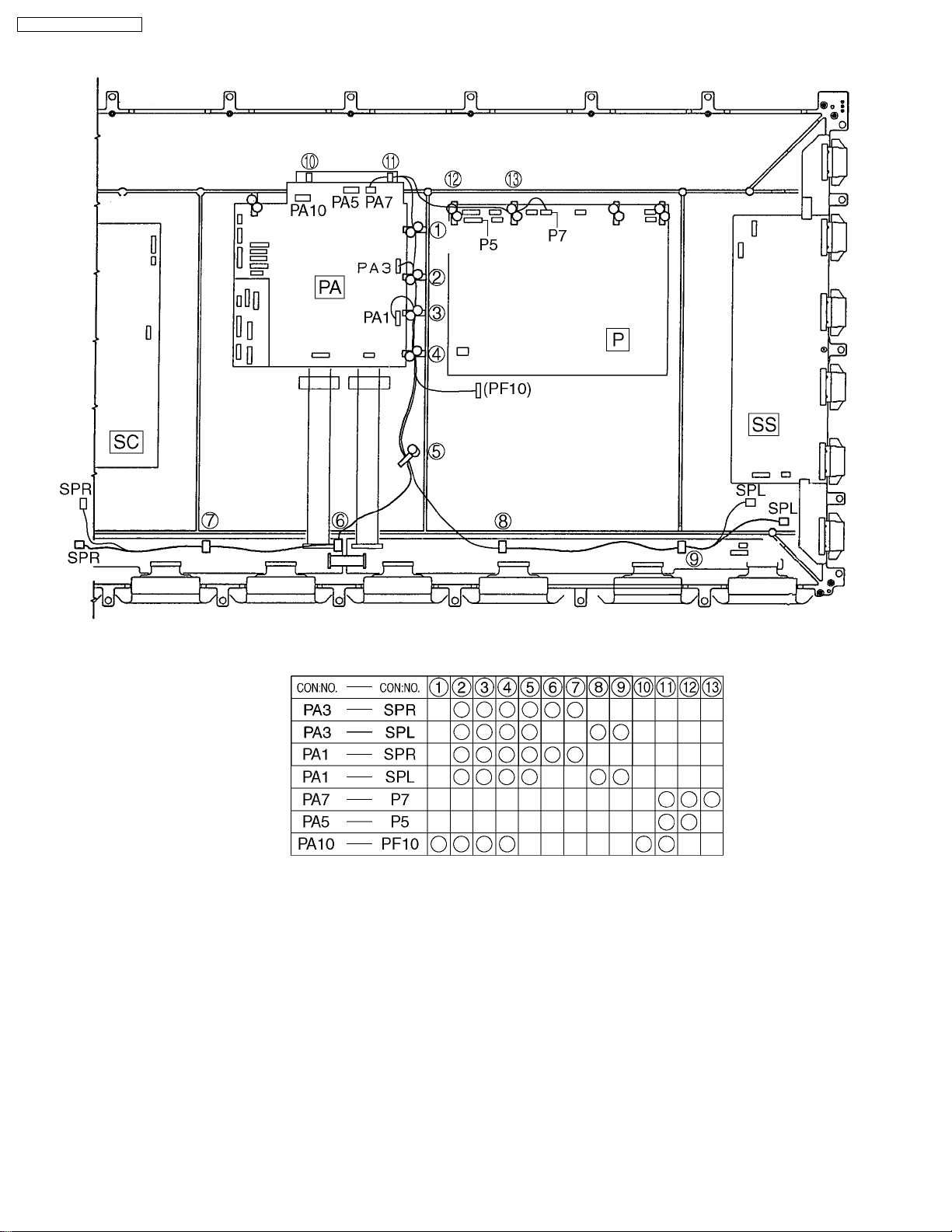

7.2. Lead of wiring (2)

16

7.3. Lead of wiring (3)

TH-37PE30B / TH-42PE30B

17

TH-37PE30B / TH-42PE30B

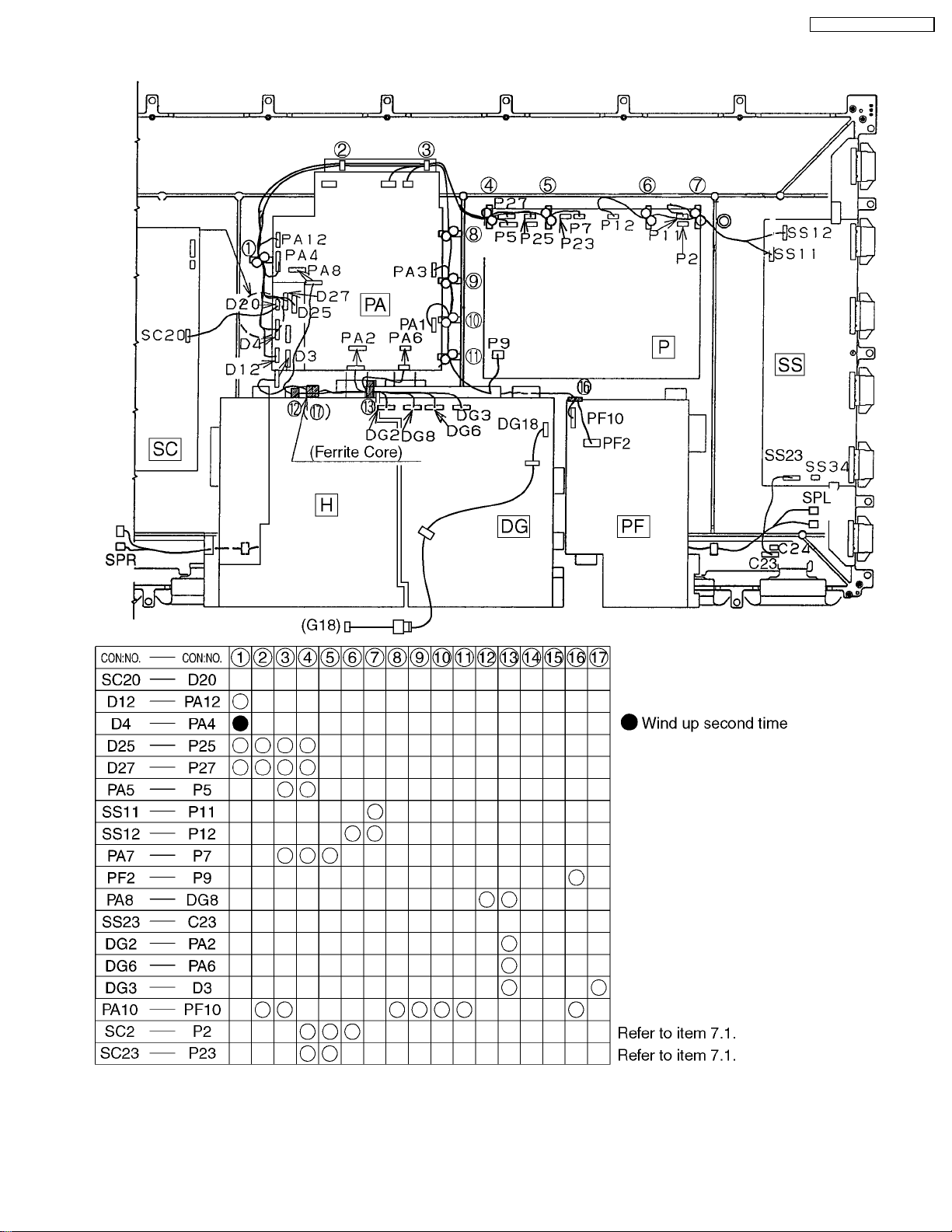

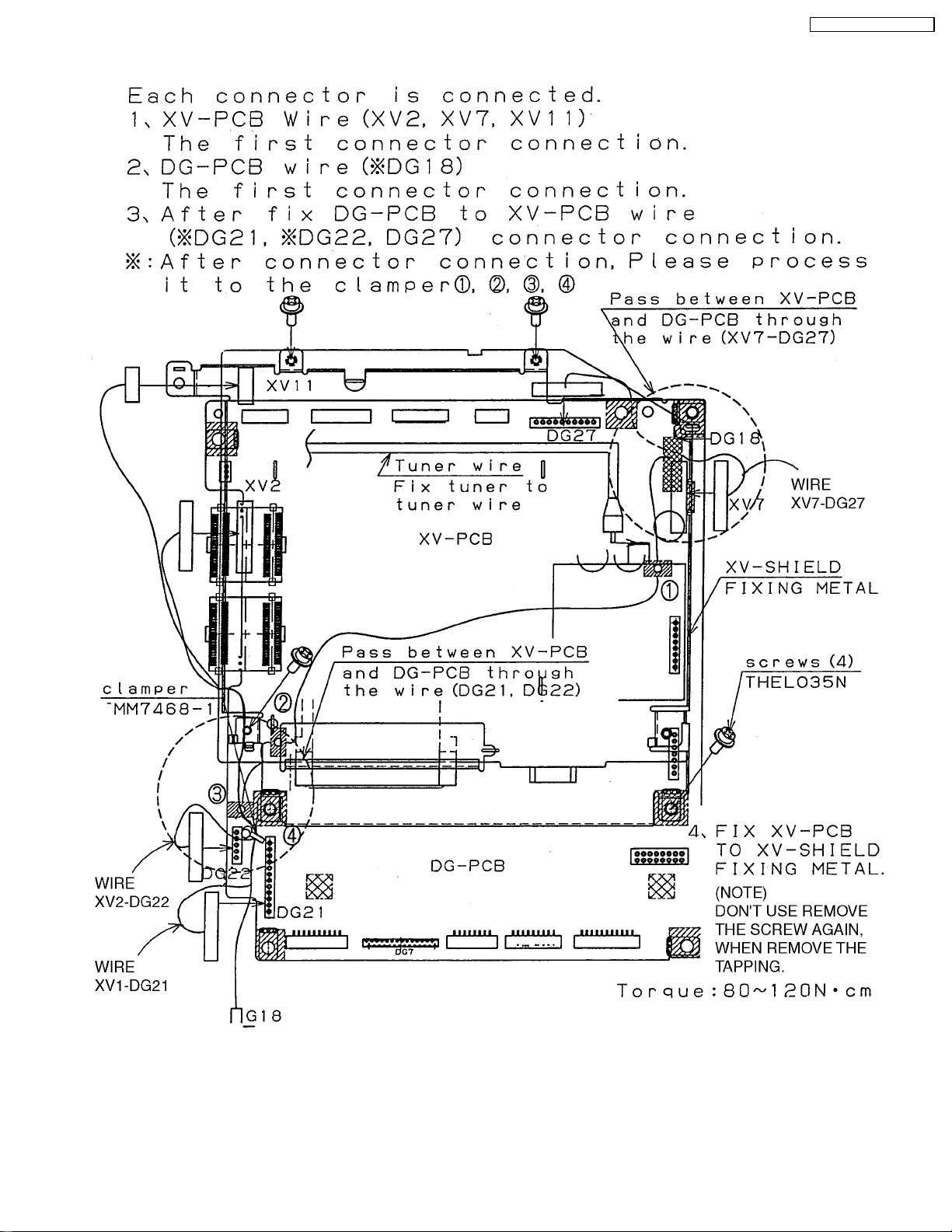

7.4. Lead of wiring (4)

7.5. Lead of wiring (5)

18

7.6. Lead of wiring (7)

TH-37PE30B / TH-42PE30B

19

TH-37PE30B / TH-42PE30B

8SelfCheck

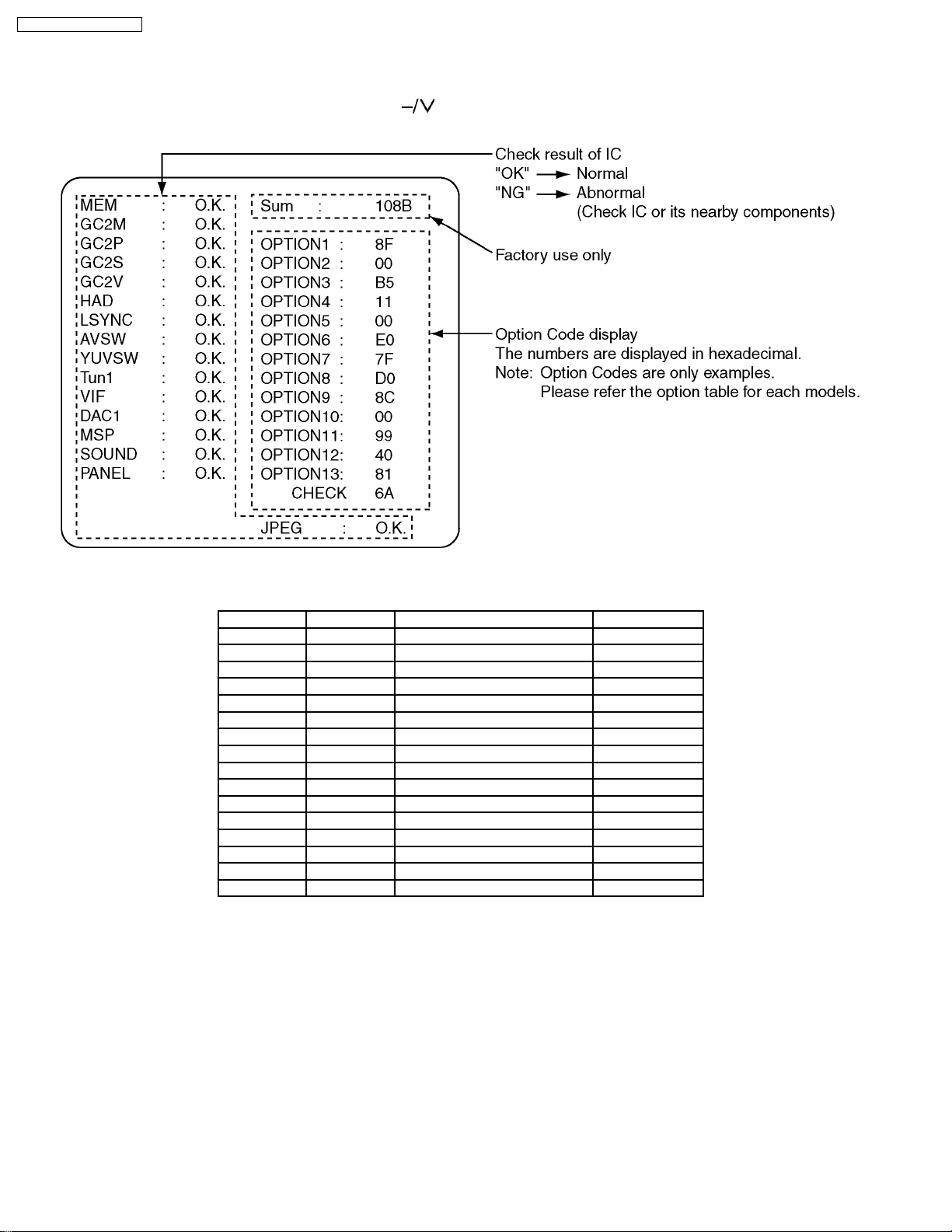

1.Self-Check is used to automatically check the bus lines and hexadecimal code of the TV set.

2.To get into the Self -Check mode press the Down (

time pressing the Status button on the remote control, and the screen will show :

) button on the customer controls at the front of the set, at the same

If the CCU ports have been ked and found to be incorrect or not located then “--” will appear in place of “O.K.”.

Display Ref.No Description P.C.B.

MEM IC1008 EEPROM DG-BOARD

GC2M IC1301 GROBAL CORE MAIN DG-BOARD

GC2P IC1304 GROBAL CORE SUB DG-BOARD

GC2S IC1302 GROBAL CORE 3D Comb DG-BOARD

GC2V IC1350 GROBAL CORE V Scalar DG-BOARD

HAD IC1851 HD-AD CONVERTER DG-BOARD

LSYNC IC2652 SYNC PROCESSOR H-BOARD

AVSW IC3200 AV switch H-BOARD

YUVSW IC1270 YUV switch DG-BOARD

Tun1 TNR001 TUNER 1 TU-BOARD

VIF --- --- --DAC1 IC3003 Ext. DAC DG-BOARD

MSP IC2002 Multi Sound Processor H-BOARD

SOUND IC2401 AUDIO AMP PA-BOARD

PANEL --- PANEL --JPEG IC60 JPEG I/F PG-BOARD

20

TH-37PE30B / TH-42PE30B

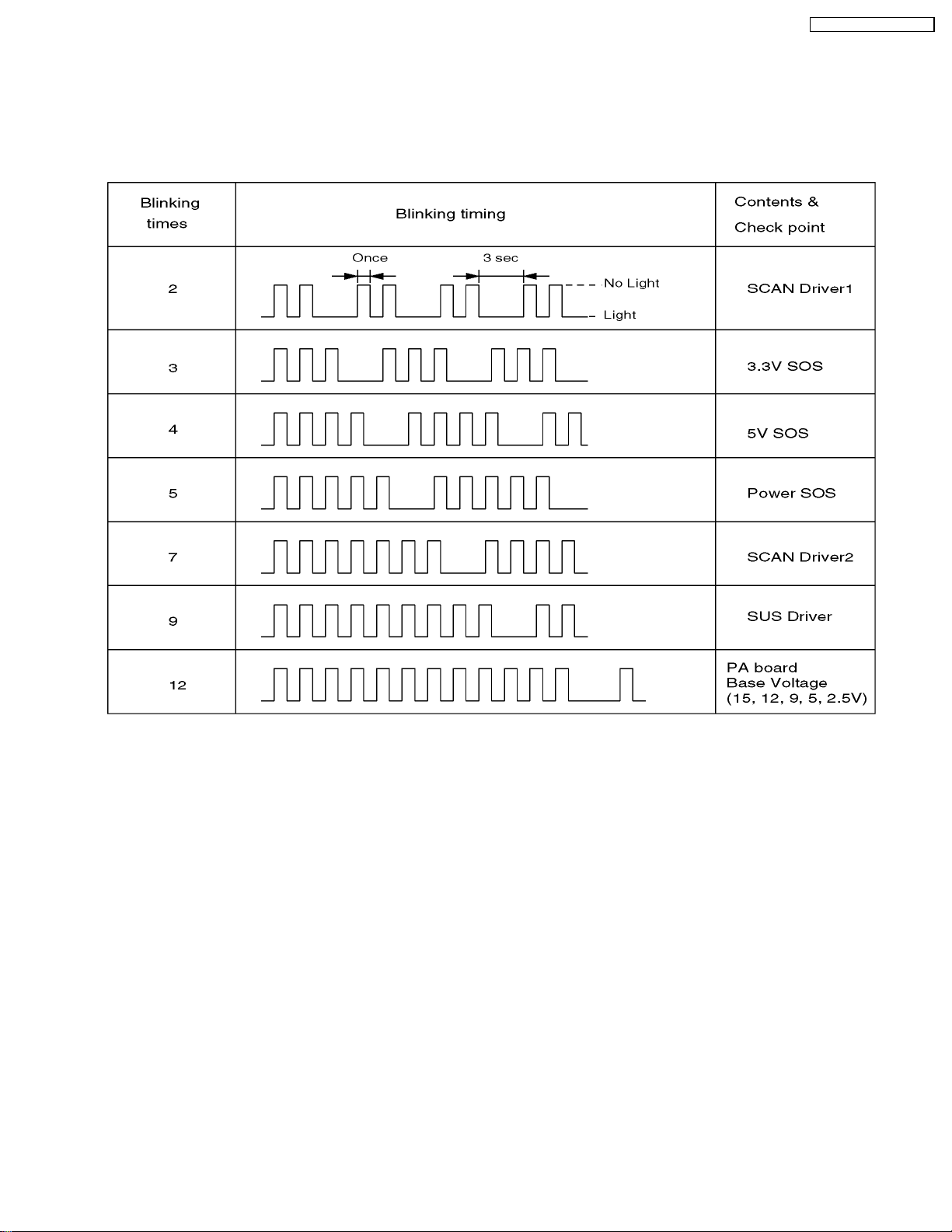

8.1. Power LED Blinking timing chart

1.Subject

Information of LED Flashing timing chart.

2.Contents

When an abnormality has occurred on the unit, the protection circuit operates and reset to the stand by mode. At this time, the

defective block can be identified by the number of blinkes of the Power LED on the front panel of the unit.

21

TH-37PE30B / TH-42PE30B

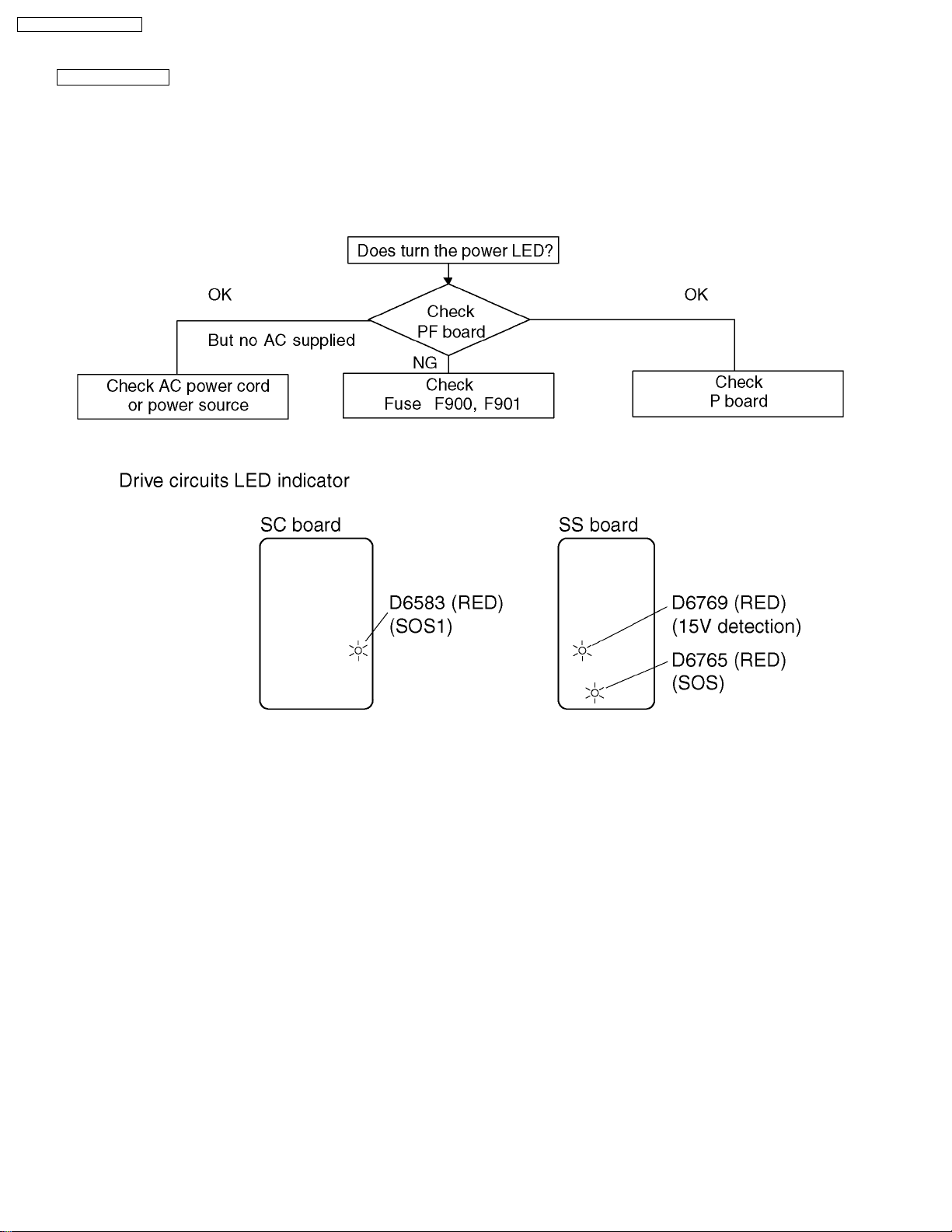

8.2. No Power

First check point

There are following 3 states of No Power indication by power LED.

1.No lit

2.Green is lit then turns red blinking a few seconds later.

3.Only red is lit.

1.No lit

22

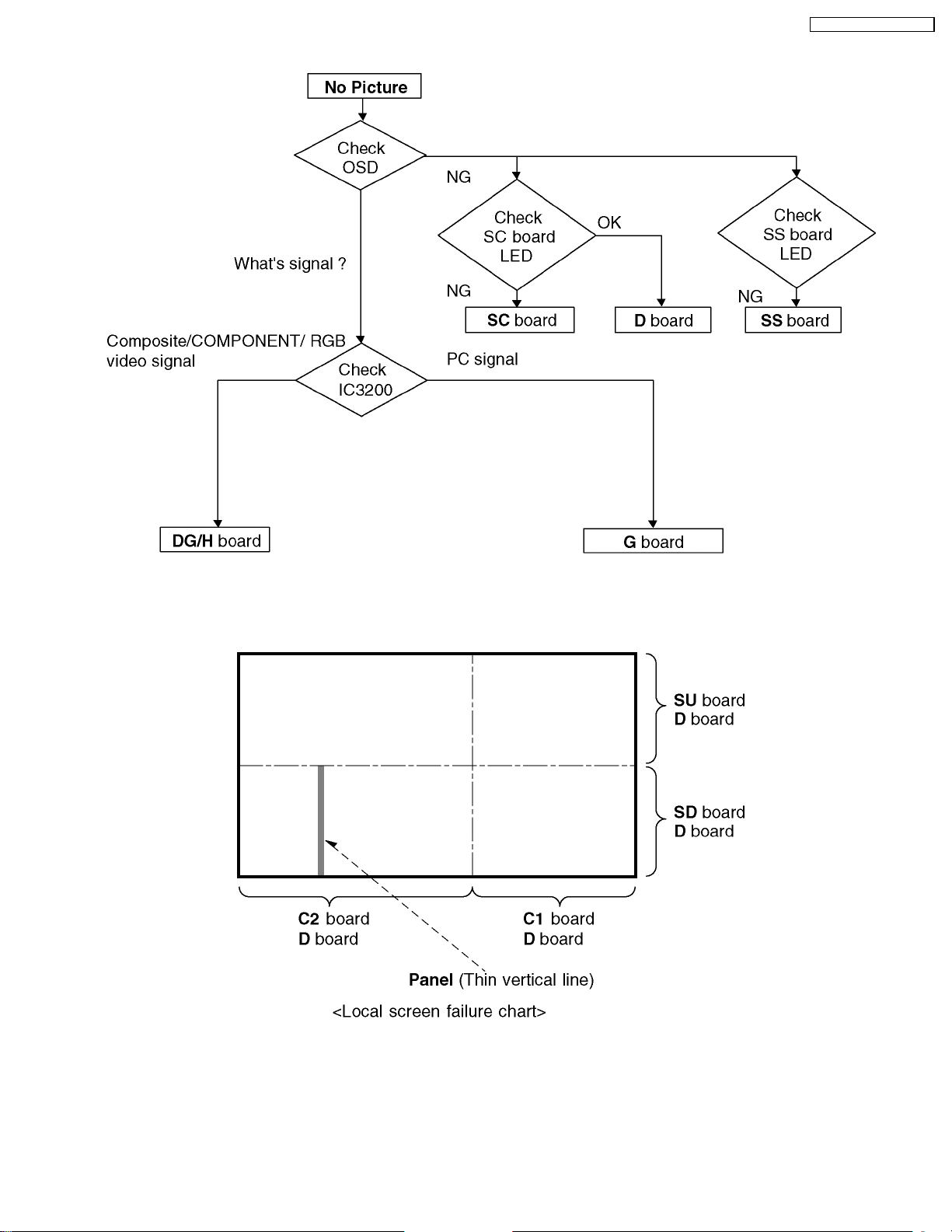

8.3. No Picture

TH-37PE30B / TH-42PE30B

8.4. Local screen failure

Plasma display may have local area failure on the screen. Fig - 1 is the possible defect P.C.Board for each local area.

Fig - 1

23

TH-37PE30B / TH-42PE30B

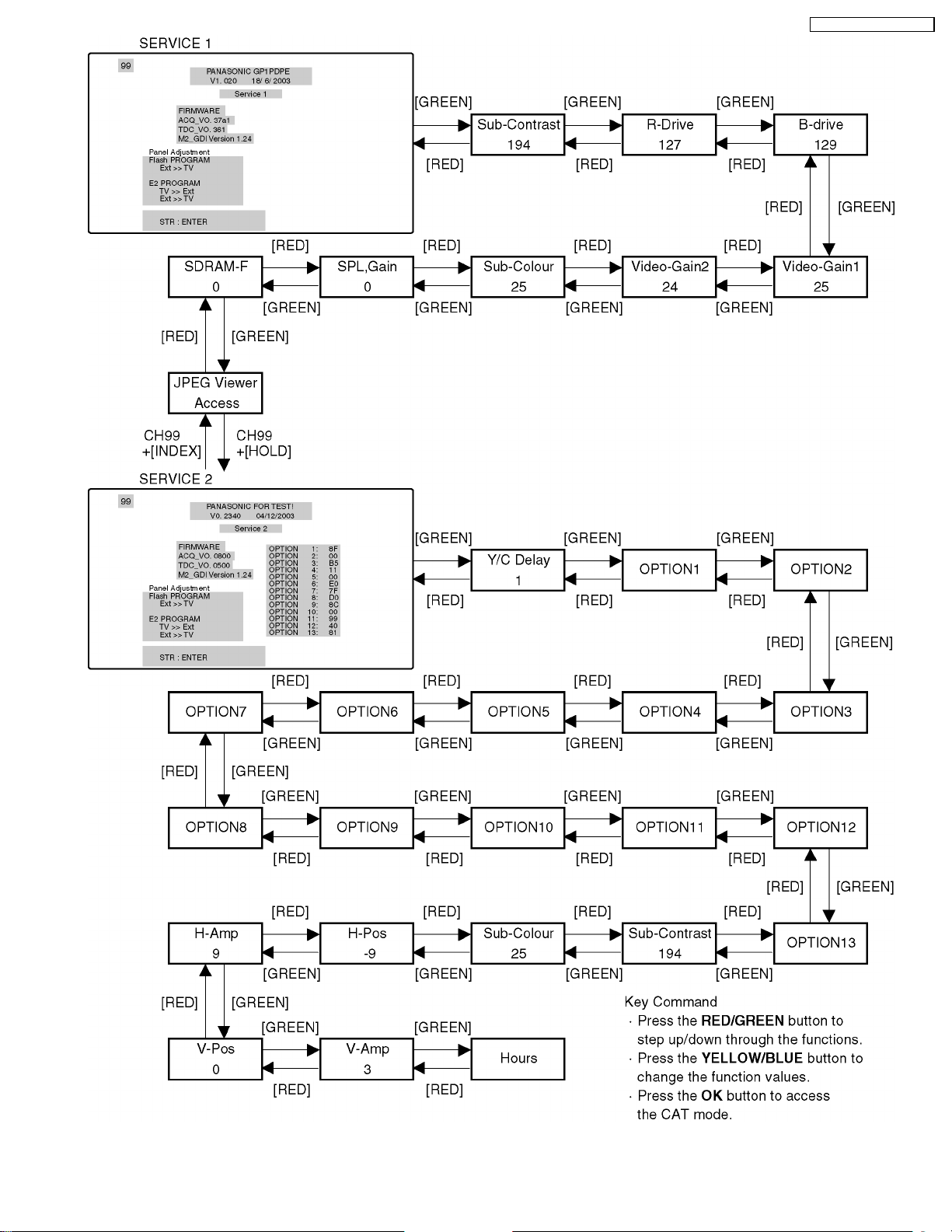

9 Service Mode Function

MPU controls the functions switching for each IICs through IIC bus in this chassis. The following setting and adjustment can be

adjusted by remote control in Service Mode.

9.1. How to enter SERVICE 1

1.In sound menu, set BASS to MAXIMUM, and set TREBLE to MINIMUM.

2.Simultaneously press INDEX button on remote control and DOWN button [

9.2. How to enter SERVICE 2

1.Set the channel to CH99.

2.Select the JPEG Viewer.

3.Press HOLD button on remote control.

Note:

To exit to Service mode, press N or Power button on remote control.

]ontheTVset.

24

TH-37PE30B / TH-42PE30B

25

TH-37PE30B / TH-42PE30B

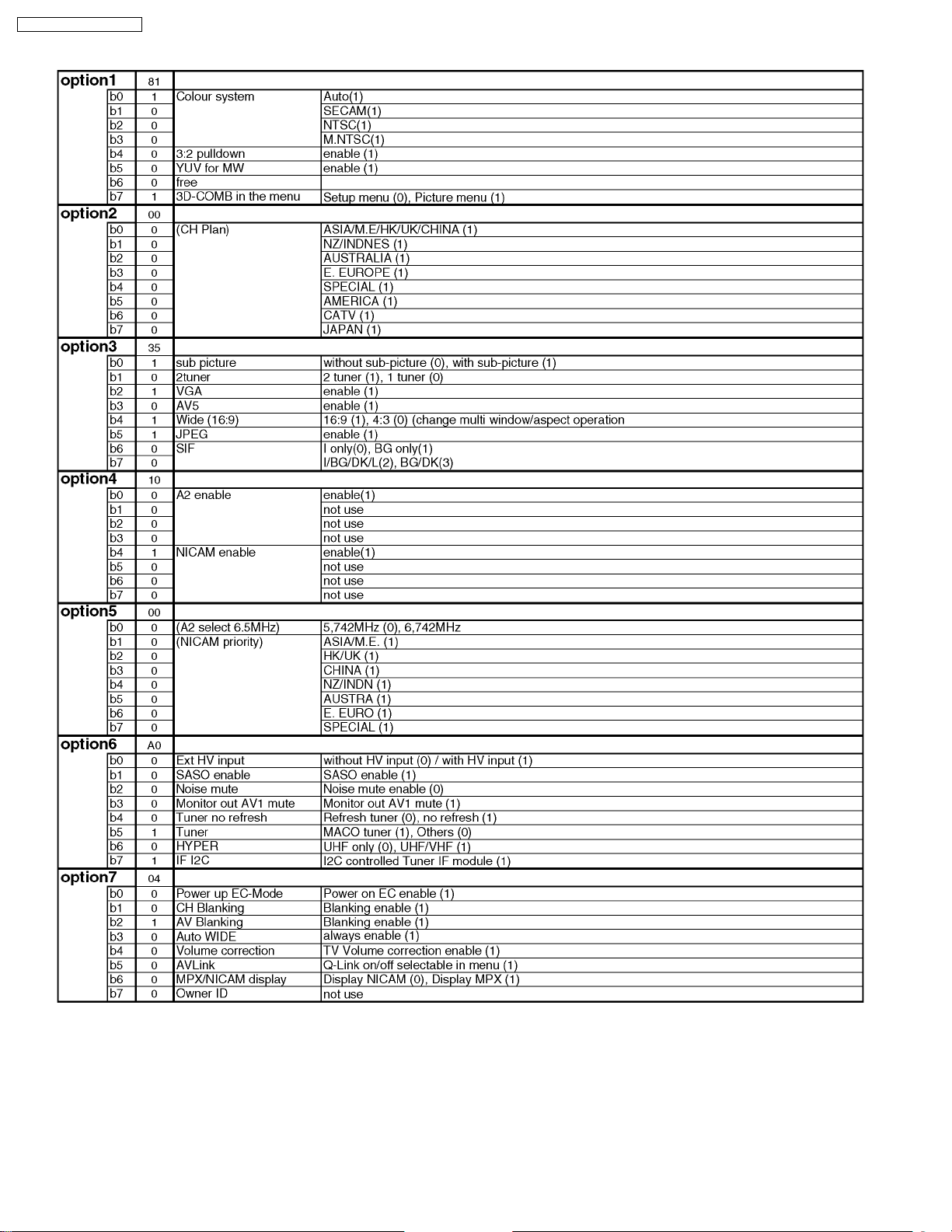

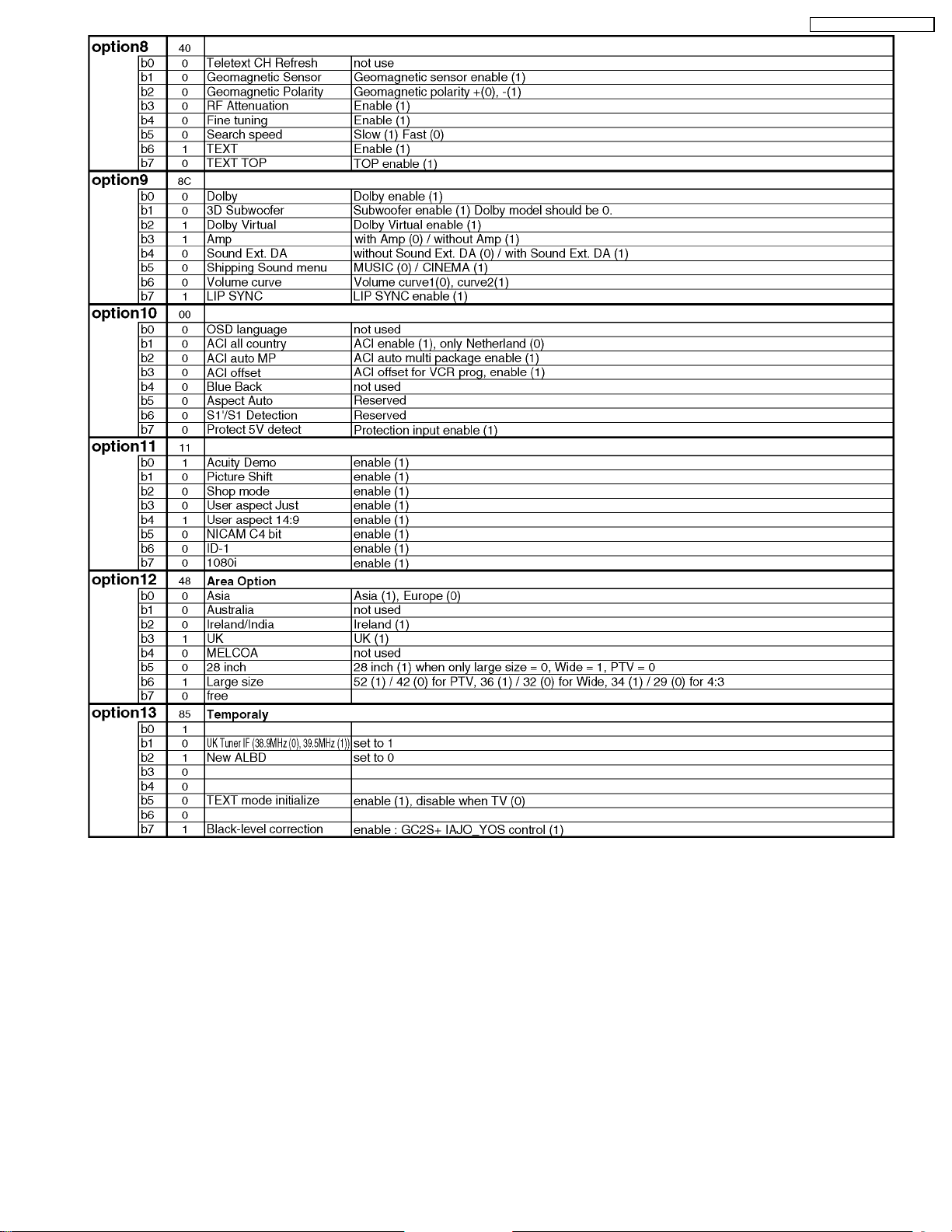

9.3. Option Description

26

TH-37PE30B / TH-42PE30B

27

TH-37PE30B / TH-42PE30B

10 CAT (Computer Aided Test) mode

10.1. IIC mode

Select the IIC mode by Up/Down (Channel) button on the remote control at the front page of CAT mode then press the OK button

on the remote control.

Subject and item are mentioned on IIC mode structure.

(Refer to item 10.4.)

To exit the IIC mode, press the MENU button on the remote control.

28

TH-37PE30B / TH-42PE30B

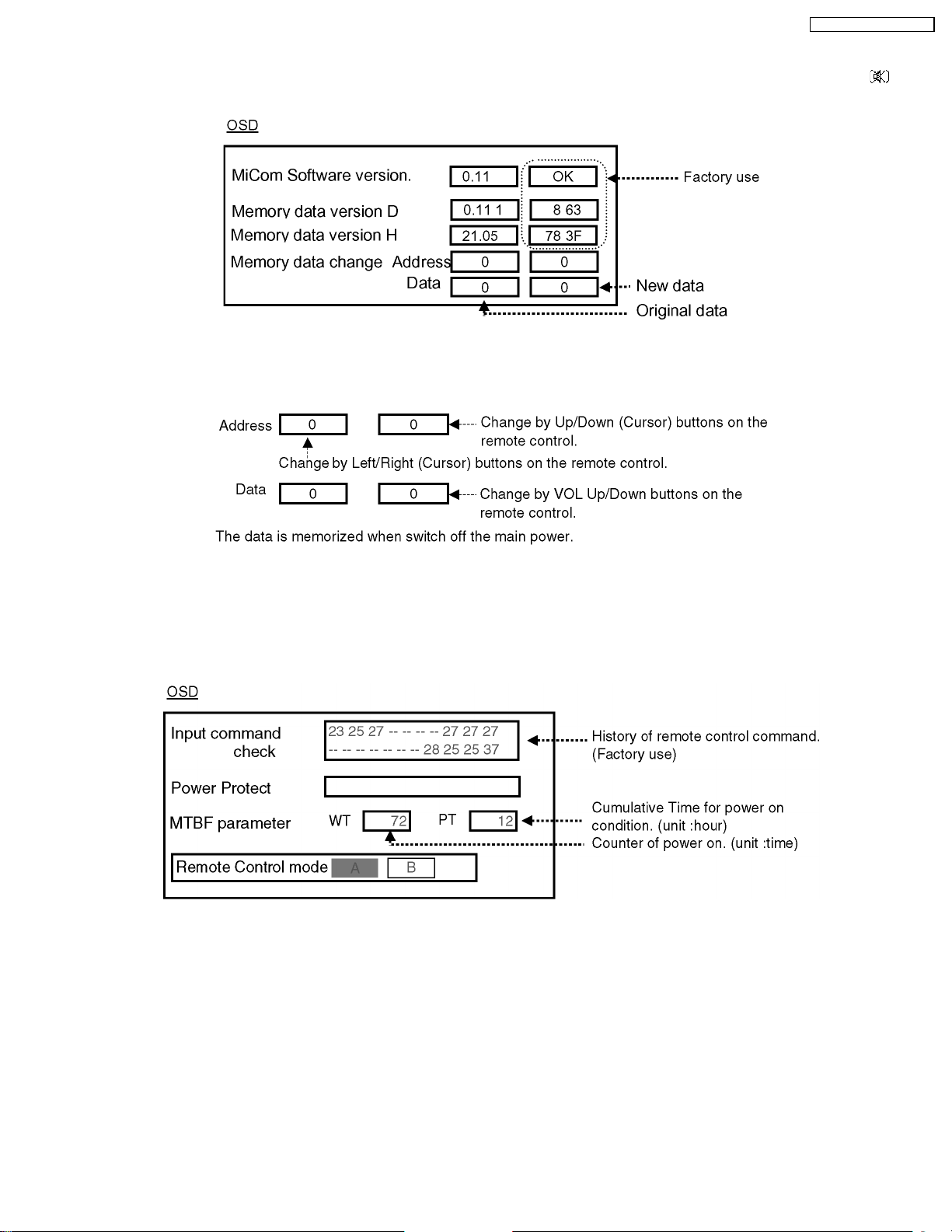

10.2. CD mode

Select the CD mode by Up/Down (Channel) button on the remote control at the front page of CAT mode then press the Mute

button on the remote control more than 5 sec.

Micom software version (IC1007), this version can be upgrade by replace of new version IC

Memory data change

To exit the CD mode, press the MENU button on the remote control.

10.3. SD mode

Select the SD mode by Up/Down (Channel) button on the remote control at the front page of CAT mode then press the OK

button on the remote control.

To exit the SD mode, press the MENU button on the remote control.

29

TH-37PE30B / TH-42PE30B

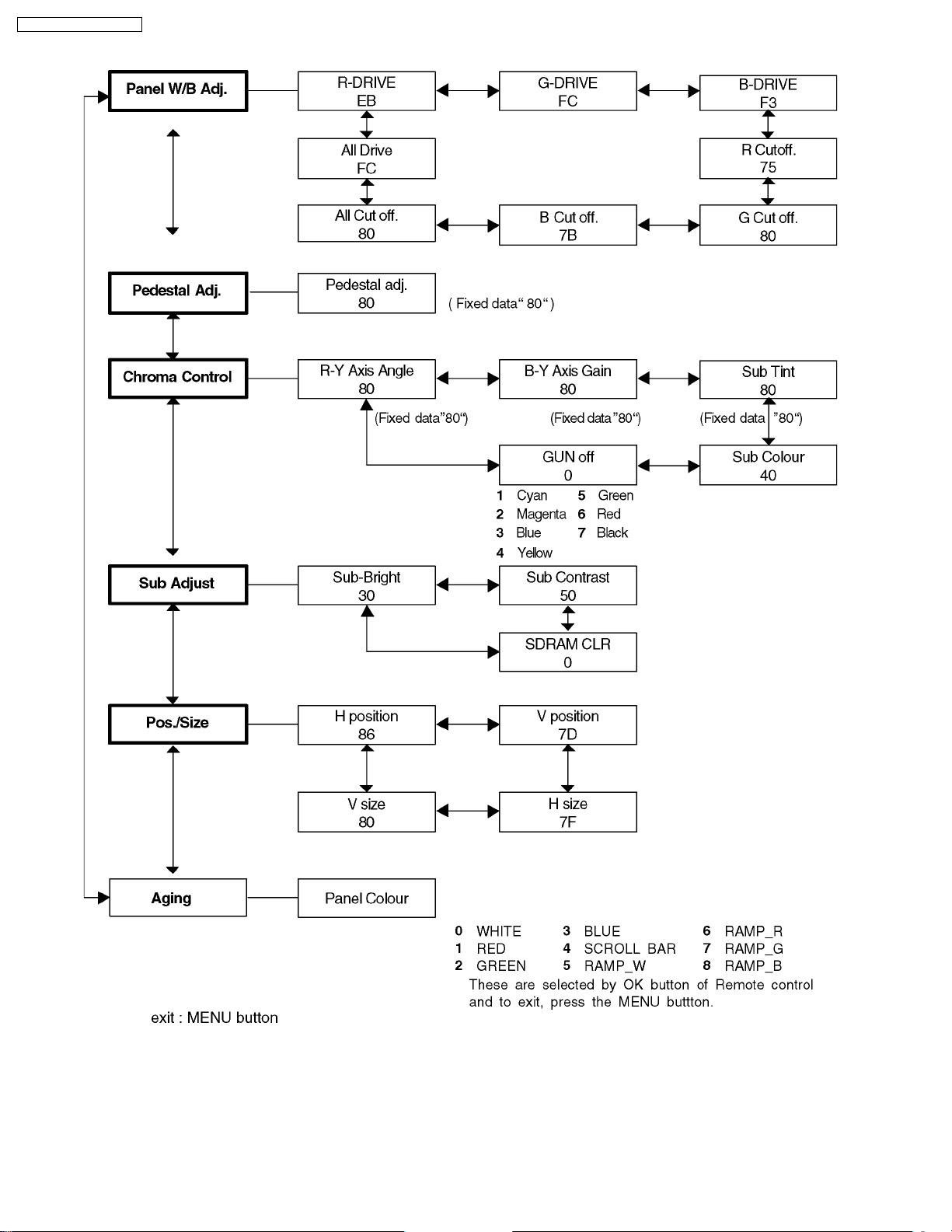

10.4. IIC mode structure (following items value is sample data.)

30

Loading...

Loading...