Page 1

FILE NO

SERVICE MANUAL

LED TV

TC-L39EM6X

1

Page 2

CONTENTS

1. Safety precautions .................................................................................................

2. Alignment instructions and method of software upgrading.....................................

3. Working principle analysis of the unit ...................................................................

4. Specifications.......................................................................................................13

5. Block diagram ......................................................................................................

6. IC block diagram..................................................................................................

7. Wiring diagram ...................................................................................................

8. Troubleshooting guide..........................................................................................

9. Schematic diagram ..............................................................................................33

10. APPENDIX-A: Assembly list

APPENDIX-B: Exploded View

11. Disassembly and Assembly Instructions

3

5

12

14

17

24

29

2

Page 3

Attention:

please read the following points carefully.

Safety precautions

This service manual is only for service personnel to take reference with. Before

servicing

1. Instructions

Be sure to switch off the power supply before replacing or welding any components or

inserting/plugging

process!):

a) Do not touch here and there by hand at will;

b) Be sure to use anti static electric iron;

c) It’s a must for the welder to wear anti static gloves.

Please refer to the detailed list before replacing components that have special safety requirements.

not change the specs and type at will.

Do

in

connection wire Anti static measures to be taken (throughout the entire production

2. Points for attention in servicing of LED

2.1 Screens are different from one model to another and therefore not interchangeable. Be sure to

Use the screen of the original model for replacement.

2.2 The operation voltage of LED screen is

protecting

right

yourself and the machine when testing the system in the course of normal operation or

after the power is switched off. Please do not touch the circuit or the metal part of the module

high voltage. Be

sure to take proper measures in

That is in operation mode. Relevant operation is possible only one minute after the power is switched

off.

2.3 Do not use any adapter that is not identical with the TV set. Otherwise it will cause fire or damage

to the set.

2.4 Never operate the set or do any installation work in bad environment such as wet bathroom,

laundry,

Otherwise

2.5 If any foreign substance such as water, liquid, metal slices or other matters happens to fall into the

module, be sure to cut the power off immediately and do not move anything on the module lest it should

cause fire or electric shock due to contact with the high voltage or short circuit.

2.6 Should there be smoke, abnormal smell or sound from the module, please shut the power off at

once.

power

2.7 Do not pull out or plug in the connection wire when the module is in operation or just after the

power

circuit.

2.8 When operating or installing LED please don’t subject the LED components to bending, twisting or

extrusion, collision lest mishap should result.

2.9 As most of the circuitry in LED TV set is composed of CMOS integrated circuits, it’s necessary to

pay attention to anti statics. Before servicing LED TV make sure to take anti static measure and

ensure

kitchen, or nearby fire source, heating equipment and devices or exposure to sunlight etc.

bad effect will result.

Likewise, if the screen is not working after the power is on or in the course of operation, the

must be cut off immediately and no more operation is allowed under the same condition.

is

off because in this case relatively high voltage still remains in the capacitor of the driving

Please wait at least one minute before the pulling out or plugging in the connection wire.

full grounding for all the parts that have to be grounded.

2.10 There are lots of connection wires between parts behind the LED screen. When servicing or

moving

would

If the connection wires, connections or components fixed by the thermo tropic glue need to disengage

when service, please soak the thermo tropic glue into the alcohol and then pull them out in case of

damage.

the set please take care not to touch or scratch them. Once they are damaged the screen

be

unable to work and no way to get it repaired.

3

Page 4

2.11 Special care must be taken in transporting or handling it. Exquisite shock vibration may lead to

breakage

before

2.12 For the storage make sure to put it in a place where the environment can be controlled so as to

prevent

prolonged

place.

of

screen glass or damage to driving circuit. Therefore it must be packed in a strong case

the transportation or handling.

the temperature and humidity from exceeding the limits as specified in the manual. For

storage, it is necessary to house it in an anti-moisture bag and put them altogether in one

The ambient conditions are tabulated as follows:

Temperature

Scope for operation

0

~ + 35

oC

Humidity

2.13

Display of a fixed picture for a long time may result in appearance of picture residue on the

as

screen,

of LED screen. This phenomenon doesn’t represent failure. This “ghost shadow” may remain

in the picture for a period of time (several minutes). But when operating it please avoid displaying still

picture in high brightness for a long time.

commonly called “ghost shadow”. The extent of the residual picture varies with the maker

Scope for storage

Scope for operation

Scope for storage

-20 ~

+ 60oC

20% ~

10% ~ 90%

80

%

3. Points for attention during installation

3.1 The front panel of LED screen is of glass. When installing it please make sure to put it in place.

3.2 For service or installation it’s necessary to use specified screw lest it should damage the screen.

3.3 Be sure to take anti dust measures. Any foreign substance that happens to fall down between the

screen and the glass will affect the receiving and viewing effect

3.4 When dismantling or mounting the protective partition plate that is used for anti vibration and

insulation

3.5 Be sure to protect the cabinet from damage or scratch during service, dismantling or mounting.

please take care to keep it in intactness so as to avoid hidden trouble.

4

Page 5

2. Alignment instructions

(1) Test equipment

VG-859 (YPbPr, VGA, HDMI signal generator)

FLUKE 54200(TV signal generator)

CA310

(white balancer)

(2) Power test

Connect main board, power board and IR board according the wiring diagram, connect

the power and press power key (Remote controller or Keypad) button to turn on the TV.

a) Test the pin voltage of P802/power board , the data is shown in table1:

Table1

voltage data of P802

For 39”

P802 Pin1,2 Pin3,4 Pin5,6,7 Pin8,9 Pin10,11

Voltage GND 11.4V~12.6V GND 11.4V~12.6V 4.75V~5.25V

For 39”

Pin12 Pin13 Pin 14 Pin15 Pin16

On:2.5V~5.25V

Off: 0~0.5V

Normal: 2.0~5V

Abnormal :0~0.5V

On:2.5V~5.25V

Off: 0~0.5V

Duty 5%~100% NC

5

Page 6

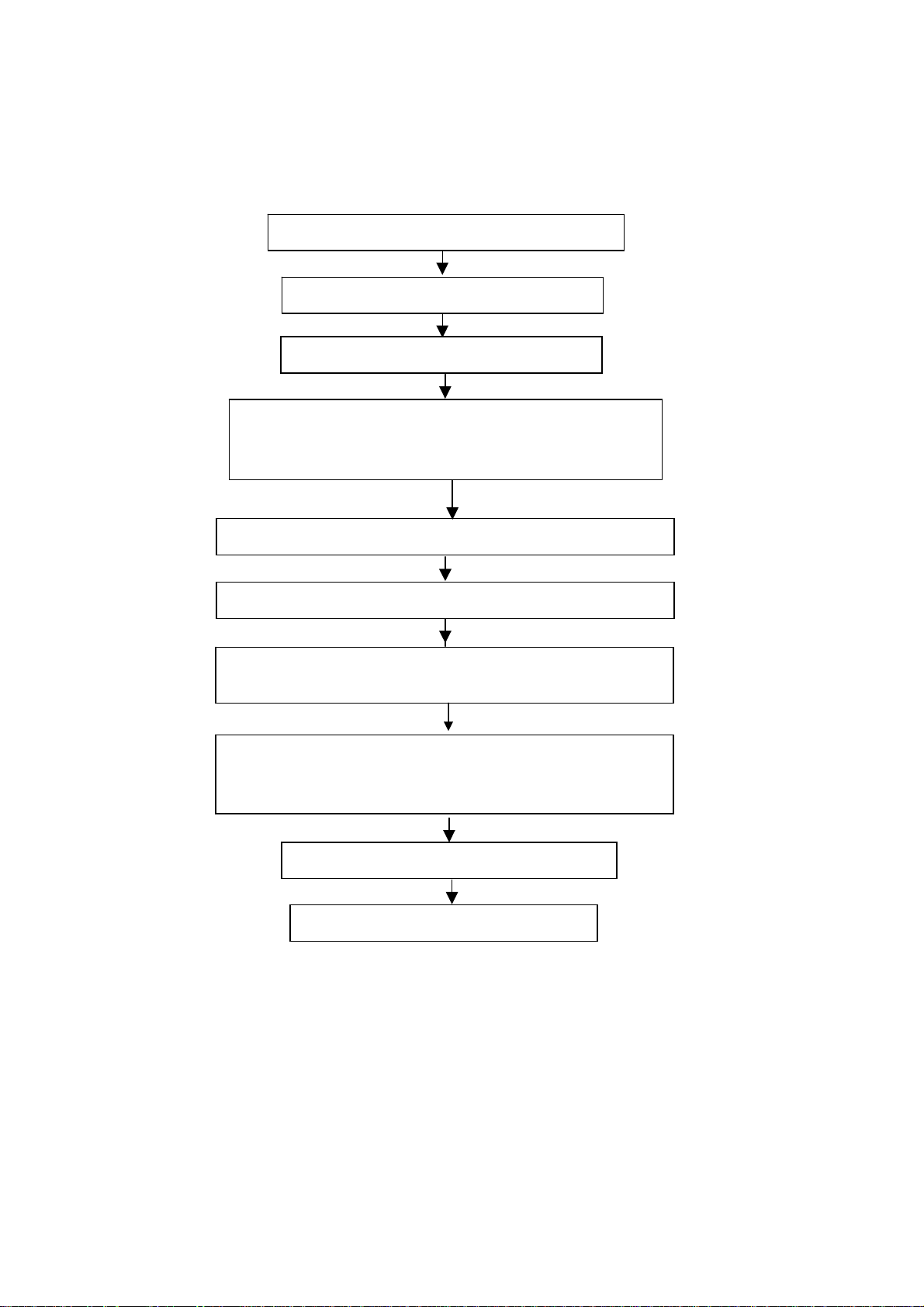

(3) Alignment flow-chart

The alignment flow-chart is shown as fig-1

Connect to the center signal source and check each

Function of TV (station leaking, analog control, etc.)

Check the output of speaker.

Check if EDID, HDCP KEY, FLASH are written

Combined test for general assembly

Auto Gamma adjustment

Input AV signal and check the function

Input HD signal and check the function of YPbPr

Input USB signal and check if the display is normal, check

the function (analog control), horizontal/vertical center, etc.

Input HDMI signal and check if the display is normal, check

the function (analog control), horizontal/vertical center, etc.

Checking SPDIF will output the signal on Amplifier.

Preset ex-factory

Check the accessories and packing

Fig-1 adjustment flow-chart

6

Page 7

(4) Adjustment instruction

At any input source then press the “←”, “EXIT” and “OK” (using RC within 1 sec) to enter factory mode

During Factory menu, if “EXIT” key is pushed, system will exit factory mode.

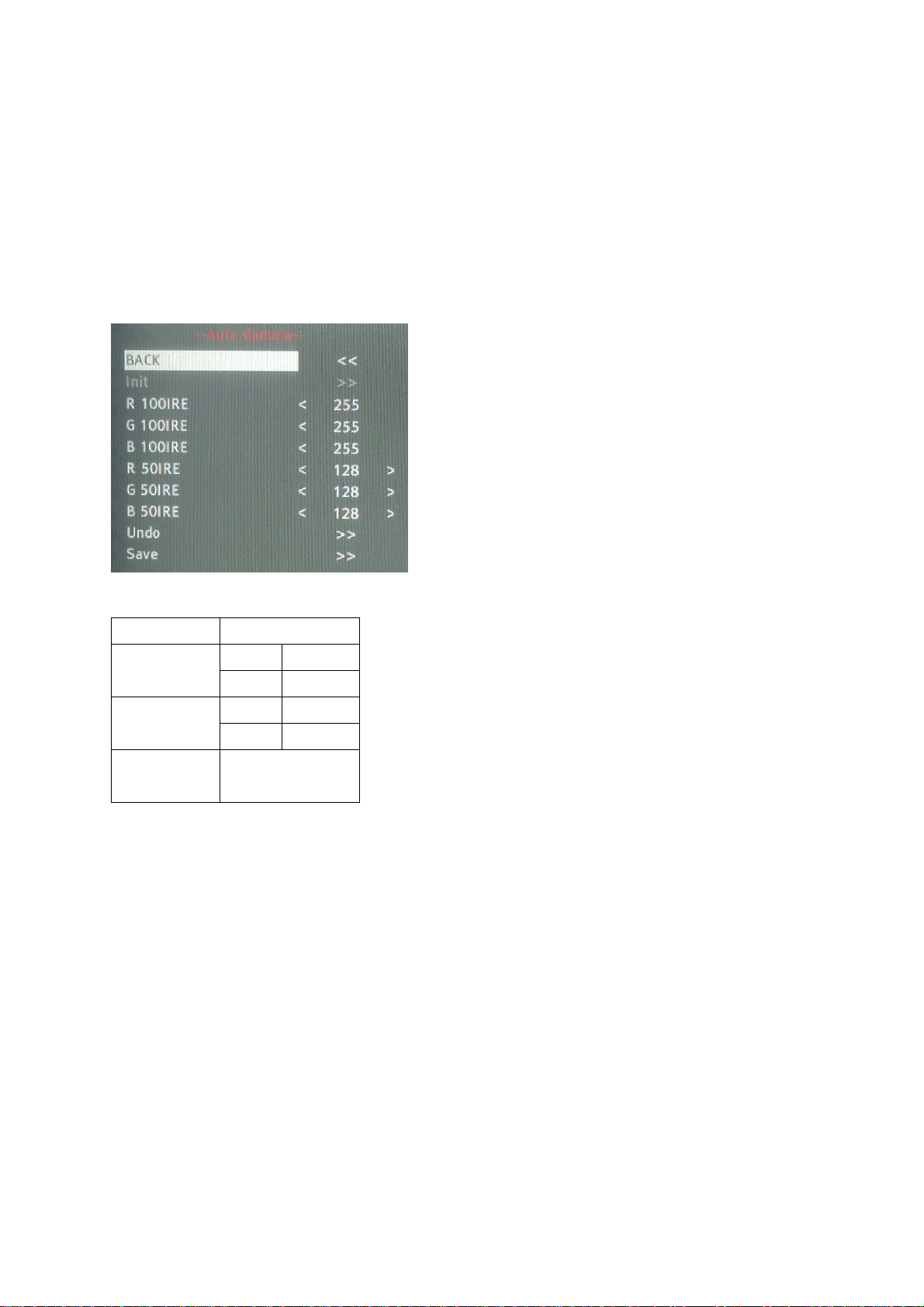

4-1. Auto Gamma Adjustment & Check

4-2.1. Set into factory mode then choose Auto Gamma Adjust,

4-2.2. Press "2" "3" "2" "4" in turn within 1sec to enter the item, and push Init will self-generate gray pattern

for adjusting.

4-2.3. Following the Cool spec as bellow.

Color Cool

x

100IRE 0.2662

50IRE 0.2658

y

Adjust

Tolerance

100IRE 0.2667

50IRE 0.2654

±0.005

(1) Adjust 100IRE

First, Decrease G to meet y spec(0.2667).

Second, Decrease R to meet x spec(0.2662).

(2) Adjust 50IRE

First, Decrease G to meet y spec(0.2654).

Second, Decrease R to meet x spec(0.2658).

Note: Do not adjust the B GAIN on both 100IRE and 50IRE.

When match the spec, pressing “Save” then exit the adjustment page.

(3) When match the spec, pressing right key in "Save" position then exit the adjustment page.

4-2.4. Exit Factory Mode:

After finish Gamma adjust press [EXIT] to exit factory mode.

7

Page 8

(5) Items of Factory menu

When in any source, press the “Left -> Exit -> Enter” key of remote control can enter into factory mode.

During Factory menu, only “EXIT” key is pushed, system will exit factory mode.

Press up and down key can move high light item from Model Change -> Color Temp. Adjust -> Auto Gamma

Adjust -> Timer Clear -> Preset Channel -> Full Power -> ADC Calibration -> Shipping reset -> Bypass Gamma ->

UART Enable -> I2C -> Boot Loader Upgrade -> V-Com Adjust -> SG Pattern.

Push “Enter” key can enter high light item function. (Press left and right can adjust value)

Display Model version, Release Date, firmware version and released date on the bottom.

1)Model ID

Press up or down key can select high light item function

Press enter or right key to enter the item.

It's only used for FW engineer.

2)Color Temp. Adjust

Press up or down key can select high light item function

Press enter or right key to enter the item.

It's only used for PQ engineer.

3)Auto Gamma Adjust

Press up or down key can select high light item function

Press enter or right key to enter the item.

It's only used for PQ engineer.

4)Timer Clear

Reset the timer which records hours of LED panel burn in

This item will have a check dialog “yes or no” to do or not.

- Time in factory mode: Time function shall be displayed automatically. Saving the total time of system

power on (LED turn on), and count the time automatically. The timer is continuous and saved (per 10

minutes) forever, unless it will be reset by doing “Timer Clear”.

5)Preset channel

Load preset channel for production line.

6)Full Power

This is for power consumption testing.

To measure the maximum power consumption of TV set, we adjust the value of following items to

maximum.

- Video: Contrast maximum value, Brightness maximum value, Backlight maximum value.

- Audio: Volume maximum value, Bass default value, Treble default value.

Press enter key to turn on Full Power and OSD stay display until press enter key to recover from Full

Power.

8

Page 9

7)ADC Calibration

ADC Calibration function is reserved for calibration by hand (PQ engineer only).

8)Shipping reset

Reset all settings of OSD menu to default value.

Reset settings: Channel table, Model table (H/V Position, Clock, Phase), Source dependent setting

(Contrast, Brightness etc.), Common setting (Volume, Language etc.), Parental Control (Rating,

Password etc), Closed Caption.

9)Bypass Gamma

For factory test value of gamma.

10)UART Enable

Enable to communicate with Auto-Alignment system.

11)I2C

Enable to communicate with Eeprom burn-in tool.

12)Boot Loader Upgrade

For firmware downgrade used.

13)V-Com Adjust

It's reserved for BMS function.

14)SG Pattern

Aging is for factory burn in and PTN ID provides each pattern for tester using.

(6) Performance check

6-1 TV function

Connect RF to the center signal source, enter Channel menu → auto tuning, check if there are channels be

skipped, check if the picture and speaker are normal.

6-2 AV terminals

Input Video signal, check if the picture and sound are normal.

6-3 YPbPr terminal

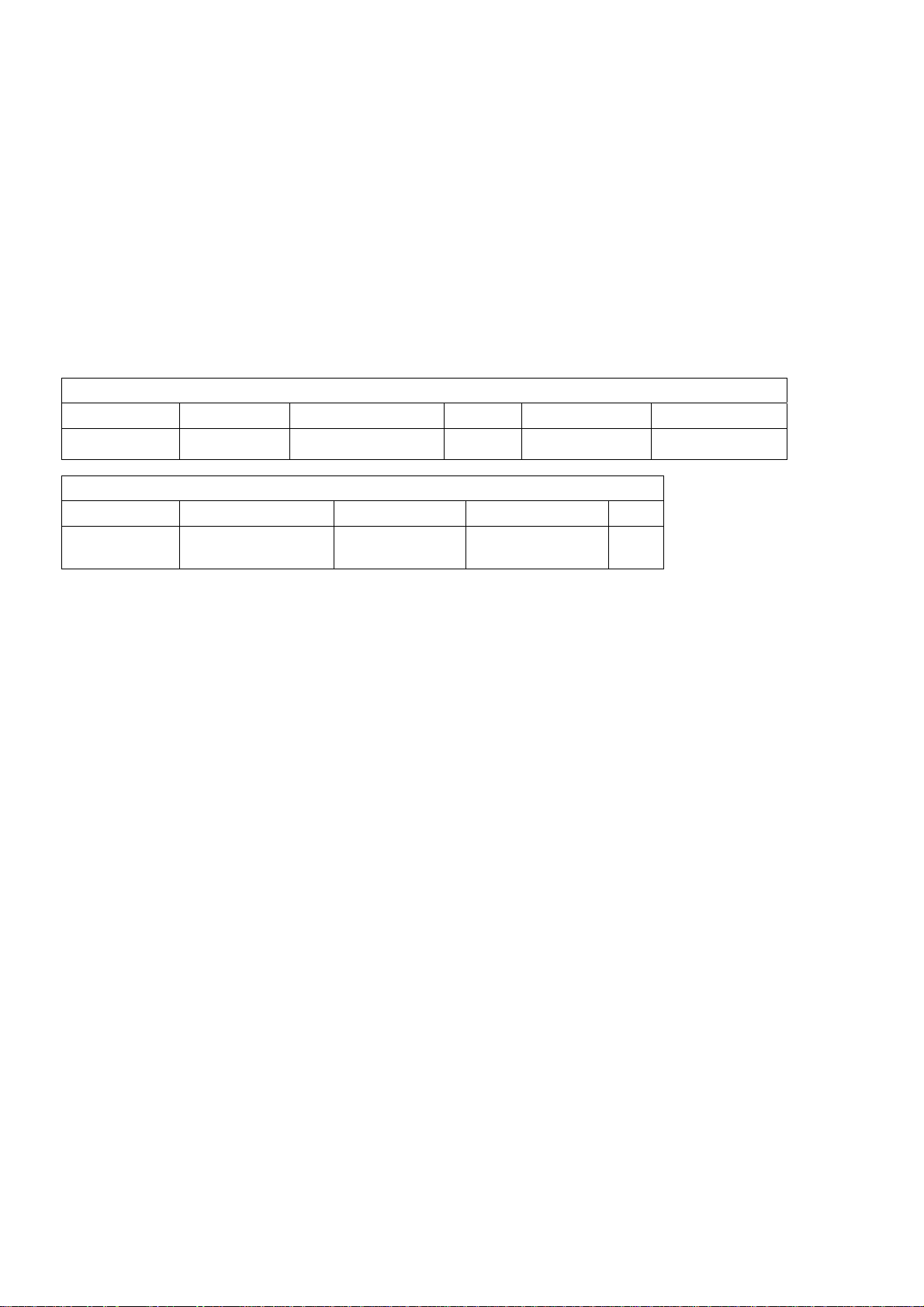

Input YUV signal (VG859 signal generator), separately input the YUV signals listed in table4 and check if the

display and sound are normal at any situation (power on, channel switch and format convert, etc.)

Table4

YUV signal format

FREQ PERIOD

SYNC

POLARITY

PIXEL

CLOCK

Display

SYNC

WIDTH

BACK

PORCH

MODE

LINE(kHz)

FRAME

(Hz)

LINE (pixel)

FIELD

(lines)

LINE

FIELD

(MHz)

LINE (pixel)

FRAME

(lines)

LINE (pixel)

FRAME

(lines)

LINE (pixel)

FRAME

(lines)

15.734 1716 Negitive 27 1440 124 114

59.94Hz 720x480i

59.94Hz 720x480P

60Hz 1280x720P

60Hz 1920X1080i

60Hz 1920X1080P

59.94 525 Negitive 480 3 15

31,469 858 Negitive 27 720 62 60

59.94 525 Negitive 480 6 30

45 1650 Positive 74.25 1280 40 220

60 750 Positive 720 5 20

33.75 2200 Positive 74.25 1920 44 148

60 1125 Positive 1080 5 15

67.5 2200 Positive 148.5 1920 44 148

60 1125 Positive 1080 5 36

9

Page 10

6-4 HDMI terminal

Input HDMI signal (VG859 signal generator), separately input the signals listed in table6 and check the display and

sound (32 KHz, 44.1 KHz, 48 KHz) at any situation (power on, channel switch and format convert, etc.)

HDMI signal format

SYNC

POLARITY

PIXEL

CLOCK

Display

SYNC

WIDTH

BACK

PORCH

HDMI

1/2/

DVI

Timing

Table

Table6

FREQ FREQ PERIOD

MODE

640x480

800x600

1024x768

1280x768 (1280cvt)

1280x768

1280x1024

1360x768

1366x768

1920x1080

59.94Hz 1440x480i

59.94Hz 720x480P

60Hz 1280x720P

60Hz 1920X1080i

24Hz 1920x1080P

30Hz 1920x1080P

60Hz 1920X1080P

LINE(kHz)

FRAME(Hz)

31.47 800 Negitive 25.175 640 96 48

LINE (pixel)

FIELD(lines)

LINE

FIELD

(MHz)

LINE (pixel)

FRAME

(lines)

LINE (pixel)

FRAME

(lines)

LINE (pixel)

FRAME

(lines)

59.94 525 Negitive 480 2 33

37.88 1056 Positive 40 800 128 88

60.32 628 Positive 600 4 23

48.36 1344 Negitive 65 1024 136 160

60 806 Negitive 768 6 29

47.4 1440 Positive 68.25 1280 32 80

59.99 790 Negitive 768 7 12

47.78 1664 Negitive 79.5 1280 128 192

59.87 798 Positive 768 7 20

63.98 1688 Positive 108 1280 112 248

60.02 1066 Positive 1024 3 38

47.71 1792 Positive 85.5 1360 112 256

60.02 795 Positive 768 6 18

47.71 1792 Positive 85.5 1366 112 256

59.79 795 Positive 768 6 18

67.5 2200 Positive 148.5 1920 44 148

60 1125 Positive 1080 5 36

15.73 1716 Negitive 27 1440 124 114

59.94 262.5 Negitive 480 3 15

31.47 858 Negitive 27 720 62 60

59.94 525 Negitive 480 6 30

45 1650 Positive 74.25 1280 40 220

60 750 Positive 720 5 20

33.75 2200 Positive 74.25 1920 44 148

60 562.5 Positive 1080 5 15

27 2750 Positive 74.25 1920 44 148

24 1125 Positive 1080 5 36

33.75 2200 Positive 74.25 1920 44 148

30 1125 Positive 1080 5 36

67.5 2200 Positive 148.5 1920 44 148

60 1125 Positive 1080 5 36

10

Page 11

6-5 other functions check

a) Check the sleep timer, picture/sound mode, OSD, stereo and analog TV Teletext, etc.

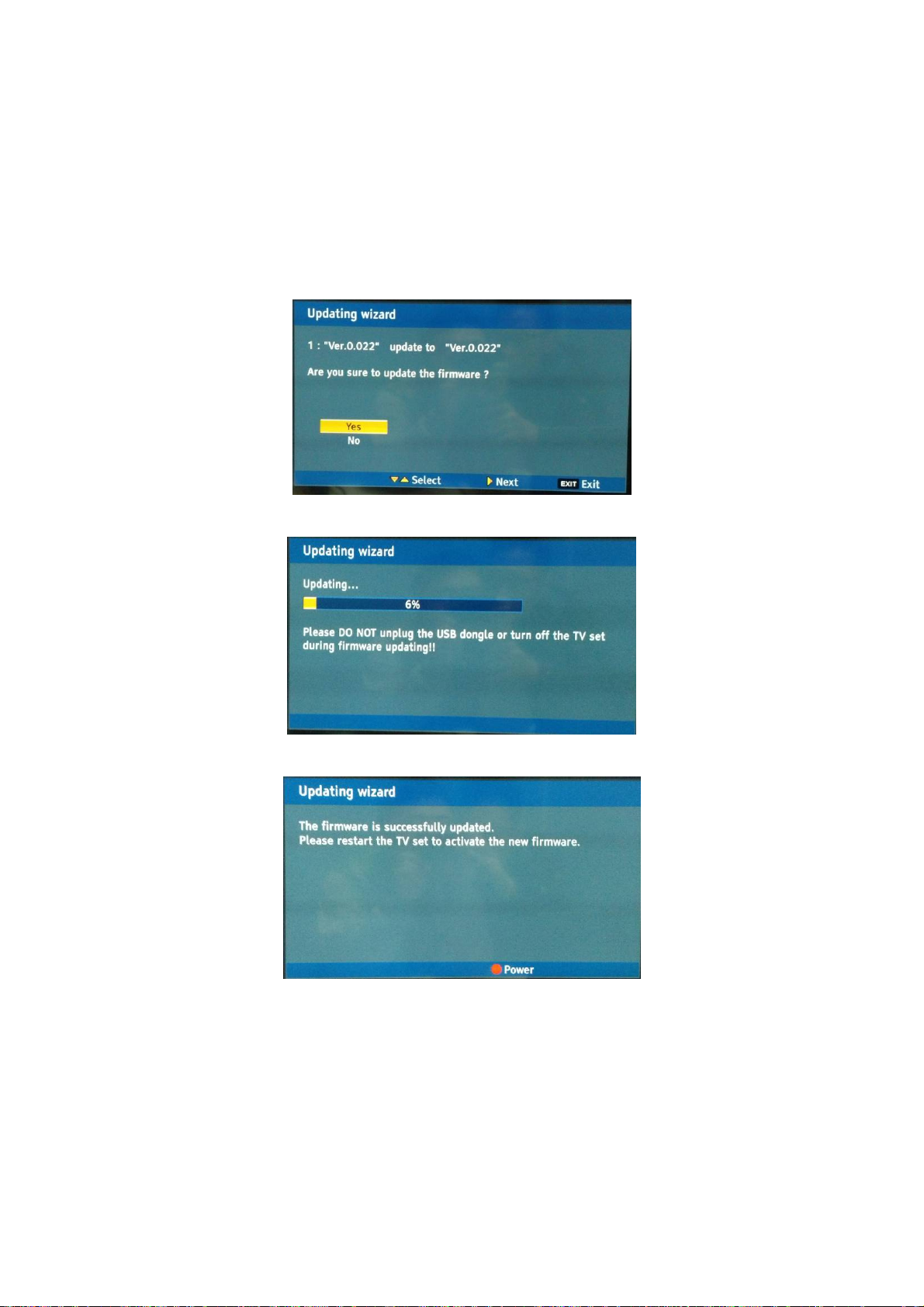

(7) Firmware update process

(1) Plug the USB with the firmware file named upgrade_2013_NA_60.pkg

(2) If system detect upgrade_2013_NA_60.pkg, USB upgrade message would appear automatically.

(3) Press Up key to select Yes, and then press OK key to start the upgrading.

(4) Upgrading is starting, please wait for the progress finish.

(5) When the progress completed, please follow the instruction to remove USB and restart Power off

then on.

11

Page 12

Working principle analysis of the unit

1.

NTSC

Antenna sig nal will be send to tuner TDST-H021F,

output standard video signal TV-CVBS, and sound SIF signal

signals flow:

the n Tun er wil l be

.

demodulating and

TV-CVBS will send to the master control IC MT5385 to video decode, de-interlace and scaler, then

output

The

volume

digital amplifier TAS5707.

2. Composite/Component signal flow

LVDS level drive for panel display.

sound IF (SIF) will be fed into MT5385, after demodulating, pre-amplifying, bass adjusting and

control, the sound signal

will b e tr ansform into di gital I2S sign al

and sent to

Composite signal an d Compo nent signal will be fed to MT5385 to perform video decode, deinterlace

Audio signal from Composite/Component

and scaler, then output LVDS drive level for panel display.

terminal

adjust and volume control, the sound signal will

to digital amplifier TAS5707.

3. HDMI signal flow

via matched resistance is fed to MT5385 to bass

be transform into digital I2S signal

and sent

Two HDMI video signals are directly fed to the master control IC MT5385 to digital decode, image

scale, then output LVDS drive level for panel display. HDMI audio signal via decoder built-in

adjust and volume control, the sound signal will

bass

sent to digital amplifier TAS5707.

be transform into digital I2S signal

MT5385

4. USB signal flow

USB signal via USB connector sent to

MT5385, then output

image scale, then send to LVDS level drive for panel display.

Sound signal of USB signal

volume control, the sound signal will

amplifier TAS5707.

5. SPDIF signal flow

The master control IC MT5385 will transfer digital sound signal out by format Dobly Digital or PCM.

MT53 85 and its

R/G/B of 24 bit to back end module to Video decode,

A/D conversion to

YPbPr

output

for

de-interlace and

via

matched resistance

be transform into digital I2S signal

and

sent to MT5385 to bass adjust and

and sent to digital

to

and

12

Page 13

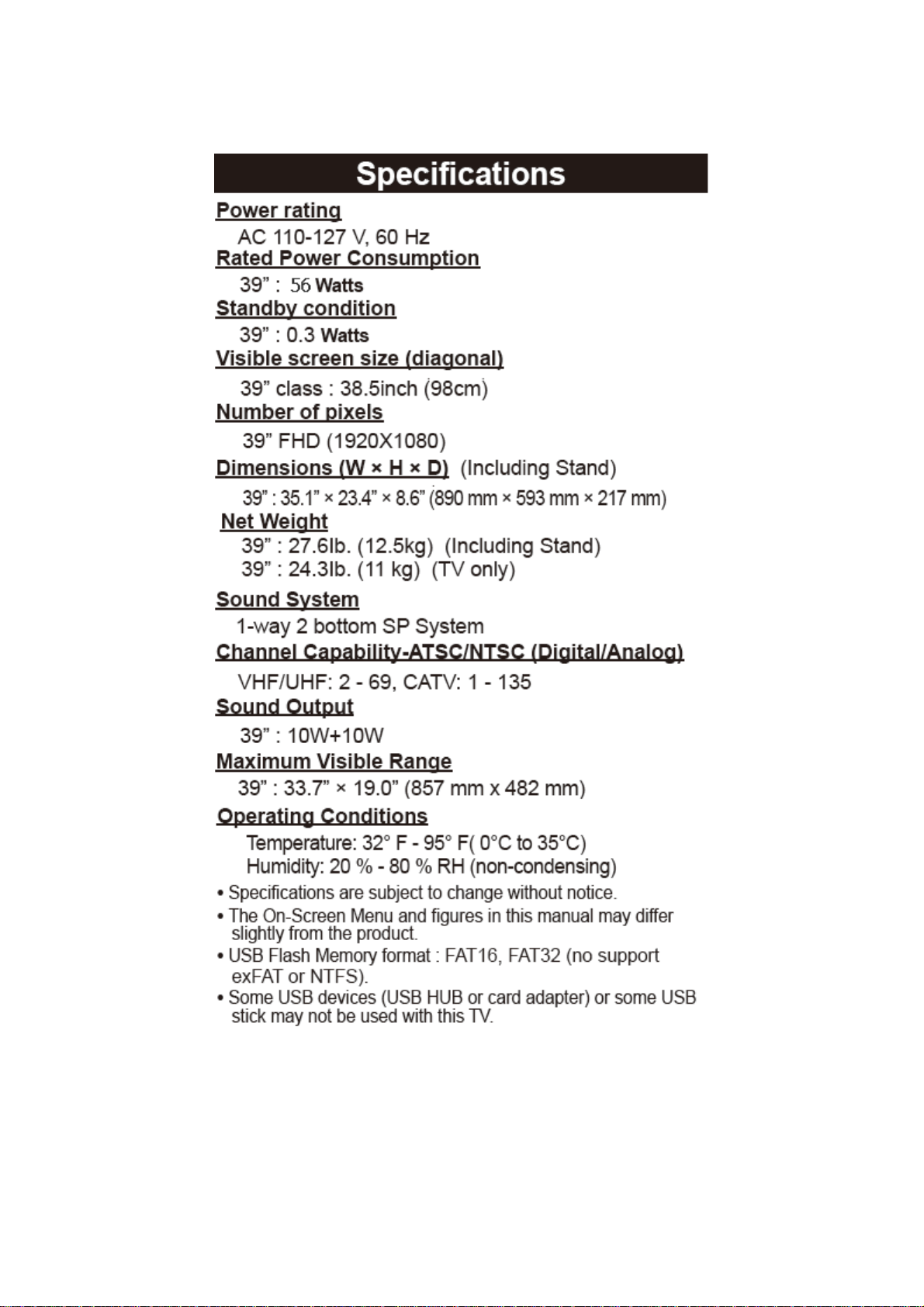

4. Specifications

13

Page 14

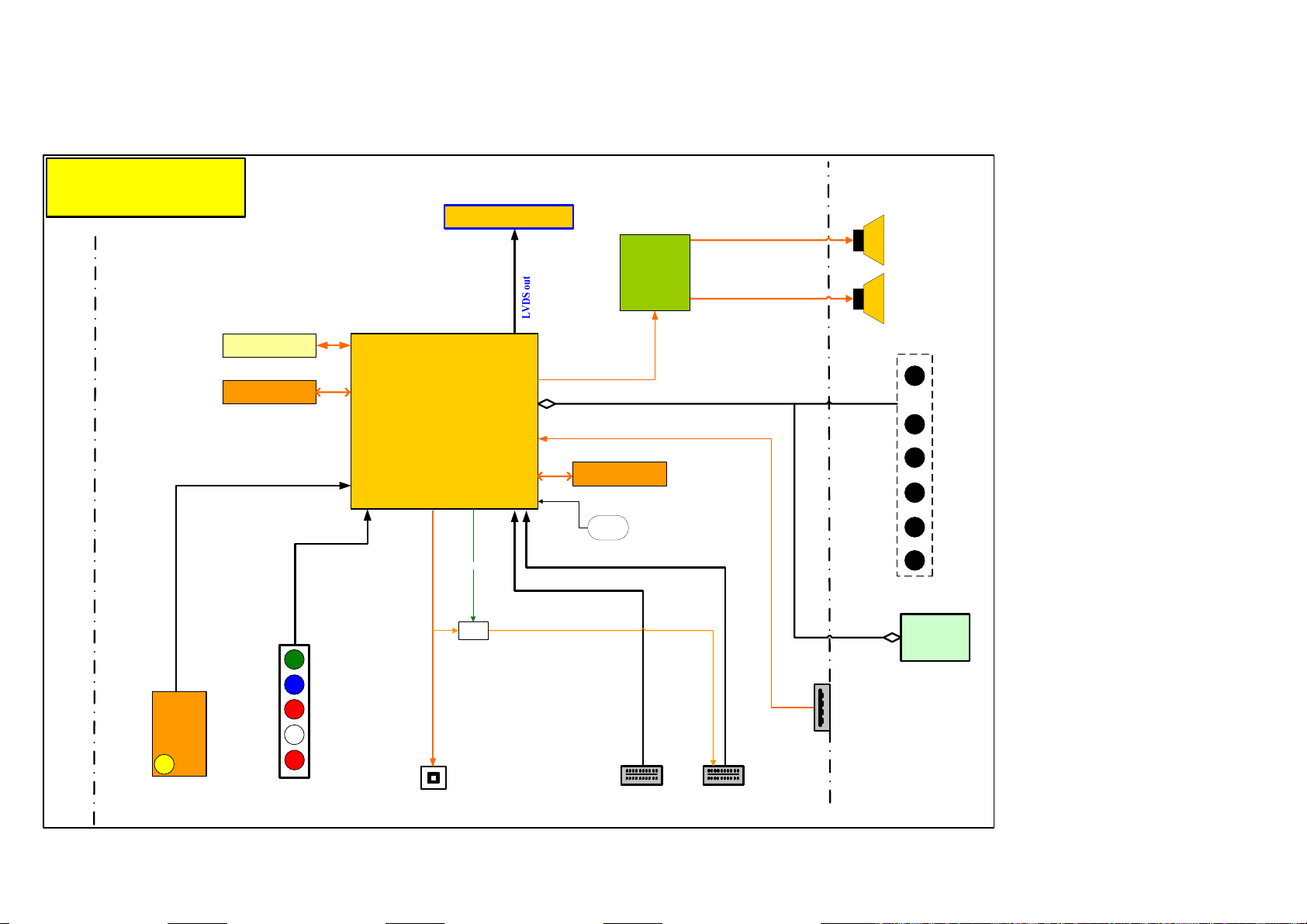

5-1 Block Diagram

EE:

SPE39T 39” Block Diagram

A70 60Hz Models by

MTK MT5835 Platform

H5TQ1G63DFR-PBC

MX25L12845EMI-10G

IF +/-

Tuner

LG

TDSTH021F

5-1 Block Diagram

ANT /

CABLE

Power board:FSP

DDR3 1G-1600

Flash 16MB

CVBS/Y Pb Pr

& Audio R/L

Y

Pb

Pr

L

R

COLOR STREAM HD

& COMPOSITE IN

& Audio R/L in

WXGA :2x10

Full-HD :2x20

Panel out

R_out

Audio

AMP

TAS5707

Audio I2S output

L_out

DTV system IC

MTK

MT5385

S/PDIF

Enable

ARC

Buffer

EEPROM 64KB

24C32

Crystal

27MHz

IR

SPE39T 39” Block Diagram

SPDIF

OUT

HDMI 1

14

HDMI 2

USB

Keypad

IR / LED-R

Board

Page 15

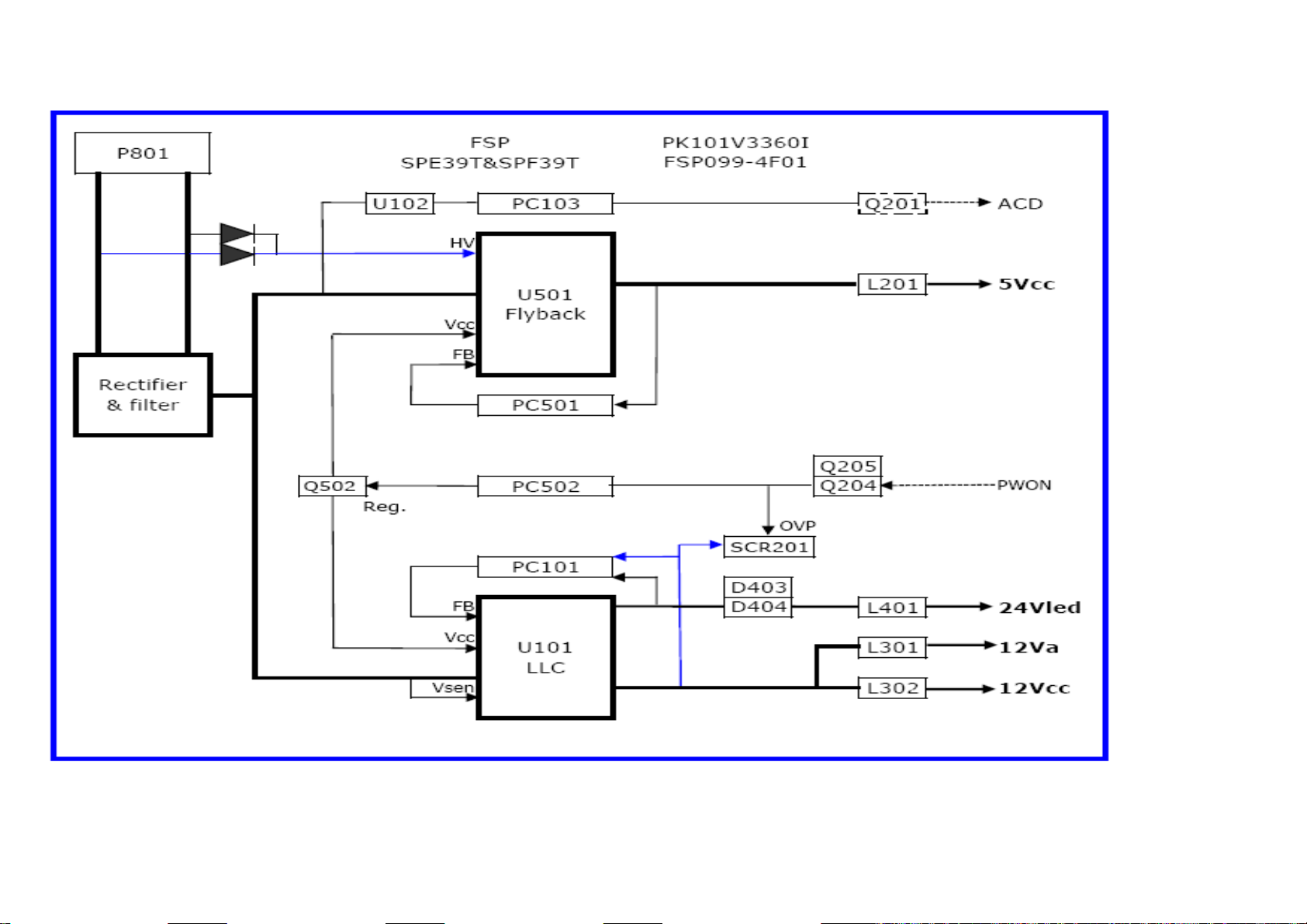

Power Board: FSP

15

Page 16

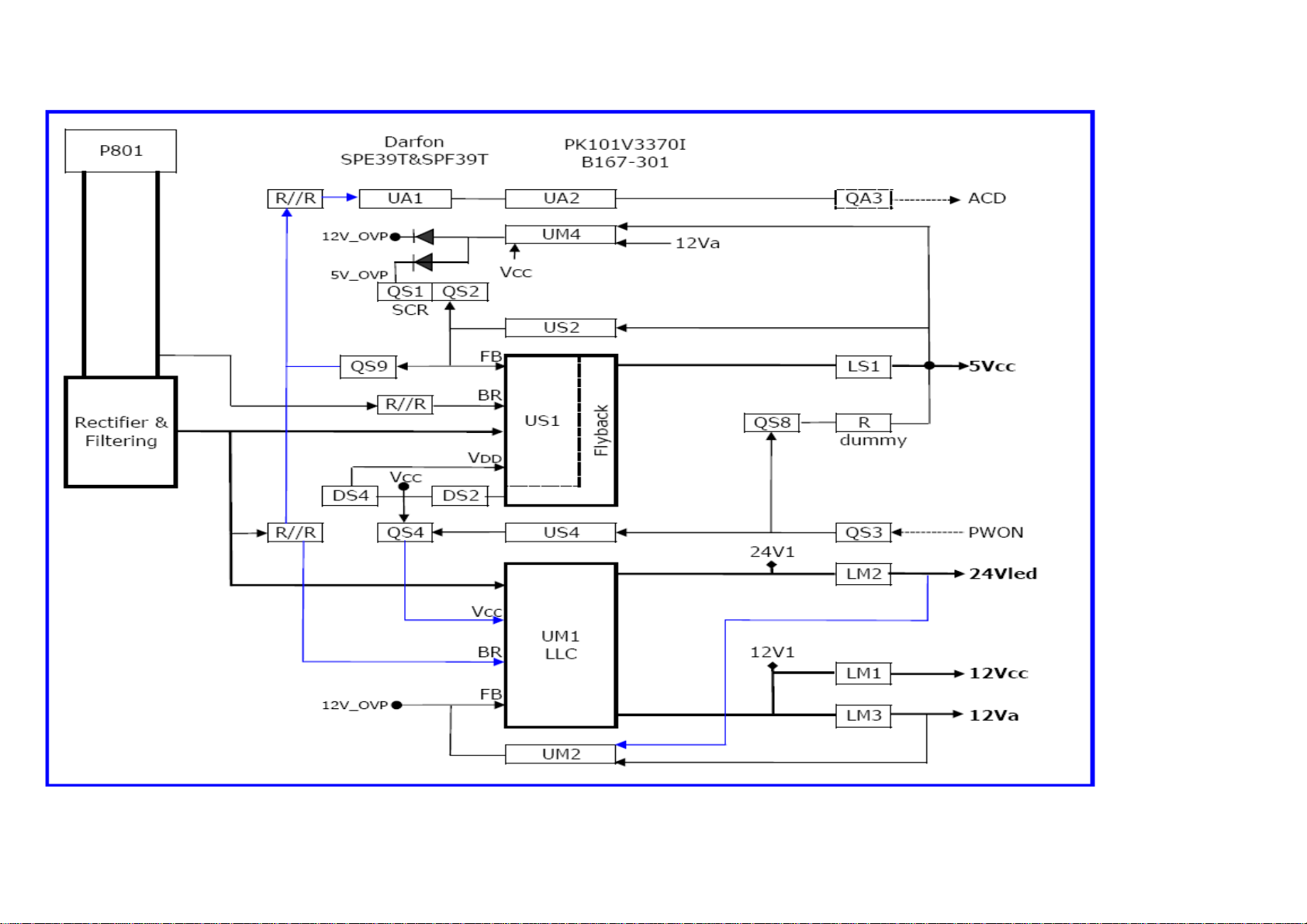

Power Board: DARFON

16

Page 17

IC block diagram

1. MT5385

GENERAL FEATURE LIST

Host CPU

ARM11 single core 700MHz

Floating Point Unit

16K I-Cache and 16K D-Cache for ARM11 core

128K L2 Cache

Boot ROM

Boot from serial flash, NAND flash

Supports security boot

JTAG ICE interface

Watch Dog timers

General Copy Protection Unit

Supports CPPM/CPRM

Supports AES with 128/192/256 bit key

Supports AACS

Supports DES/3DES

Supports SHA-1/224/256

Supports MD5

Supports CSS

Supports RC4

Random number generator

MPEG1 Decoder

MPEG2 Decoder

MPEG MP@ML, MP@HL

Supports de-blocking filter

Full-HD 30P dual decoder

MPEG4 Decoder (option)

ASP@L5

Full-HD 30P dual decoder

H.264 (MPEG4.10 / AVC) HD Decoder (option)

MP@L4.0, HP@L4.0, constrained BP@L3 video standard

Full-HD 30P dual decoder

VC-1 (SMPTE421M) Decoder (option)

MP@HL, AP@L3

WMV9 decoder MP@HL

Full-HD 30P dual decoder

DivX (XviD) Decoder (option)

17

Page 18

DIVX3 / DIVX4 / DIVX5 / DIVX6 / DIVX HD

Full-HD 30P dual decoder

AVS Decoder (option)

Jizhun profile @Level 6.2 (supports 4:2:0 format)

Full-HD 30P dual decoder

RMVB Decoder (option)

RealVideo8/9/10

Full-HD 30P dual decoder

VP6 Decoder (option)

VP8 Decoder (option)

Supports 3D side-by-side Full-HD contents

Full-HD 30P dual decoder

MVC

H.264 stereo high profile Full-HD 60fps

Still Image decoding

JPEG decoder (base-line or progressive), hardware accelerator

BMP/PNG/JIF decoder

De-mosquito engine

For all AV inputs

2D Graphics

Supports multiple color modes

Point, horizontal/vertical line primitive drawings

Rectangle fill and gradient fill functions

Bitblt with transparent options

Alpha blending and optional pre-multiplied alpha composition Bitblt

Stretch Bitblt

YCbCr to RGB color space conversion

Supports index to direct mode bitblt

Image Resizer

Supports 16bpp/32bpp direct color format

Supports 420/422 video format

Supports 420/422/444 JPEG format

Arbitrary ratio vertical/horizontal scaling of video, from 1/128X to 128X

Simple DMA

Supports MMU in OSD mode

OSD Plane

Three linking list OSDs with multiple color mode and all of them have

up-scaler

Supports stereo OSD

18

Page 19

Video Plane

Supports video freeze and over scan

Flesh tone management

Gamma correction

Color Transient Improvement (CTI)

2D Peaking

Saturation/hue adjustment

Brightness and contrast adjustment

Black and White level extender

Adaptive Luma management

Automatic detect video, film and mixed-mode source

3:2/2:2 pull down source detection

Supports FHD motion-adaptive de-interlace

Supports excellent low angle image processing

Brilliant boundary shaping for moving object

Advanced non-linear panorama scaling

Programmable zoom viewer

Progressive scan output

Supports alpha blending for OSD on video plane

Dithering processing for flat panel display

Frame rate conversion

Supports FHD panel and VGA dot-to-dot

Supports PIP/POP, (dual de-interlace, one HD and one SD)

OD (option)

Supports 60Hz Full-HD and WXGA panel over drive

TCON (option)

Flexible timing control with programmable timing

Horizontal timing control

Vertical timing control

Multi-line timing control

Multi-frame timing control

Supports gate power modulation timing

Supports command-based timing

Supports POL inversion every 30 seconds

Supports 1/2/4/8 frame inversion, 1-line inversion, 2-line inversion,

and could up to 255-line dot inversion

Local Dimming

Block division: up to 800 total blocks, up to 100 horizontal blocks

Supports 50K ~ 50M SPI clock rate

LVDS

19

Page 20

Supports 6/8/10-bit one-link, 6/8/10-bit dual-link LVDS transmitter

Built-in spread spectrum for EMI performance

Programmable panel timing output

Mini-LVDS

Dual port 8-bit 6 pairs mini-LVDS output

CVBS In

On-chip 54 MHz 10-bit video ADC

Supports PAL (B,G,D,H,M,N,I,Nc), NTSC, NTSC-4.43, SECAM

NTSC/PAL supports 3D/2D comb filter

Built-in motion-adaptive 3D Noise Reduction

VBI data slicer for CC/TT decoding

Supports 1 S-Video

Supports 2 1-channel CVBS

Supports SCART connector

VGA In

Supports VGA input up to UXGA 162 MHz

Supports full VESA standards

Component Video In

Supports 2 component video inputs

Supports 480i / 480p / 576i / 576p / 720p / 1080i / 1080p

Audio ADC

Supports 3 pair L/R input

Audio digital input

Supports 1 bit (2 channel) I

2

S audio input

HDMI Receiver

Two channel HDMI1.4a

Maximum data rate can be up to 3.3 GHz

Audio return channel

EIA/CEA-861 B

CEC

Video bypass

ATV bypass

CVBS Monitor (any AV or S-video input)

TV audio demodulator

Supports BTSC / EIA-J / A2 / NICAM / PAL FM / SECAM world-wide

formats

Standard automatic detection

20

Page 21

Stereo demodulation, SAP demodulation

Mode selection (Main/SAP/Stereo)

Audio DAC

Supports 2-pair audio DACs

DRAM Controller

16-bit DDR2/DDR3 interface

Supports DDR2 1066Mhz, DDR3 1333Mhz

Supports 512Mb or 1Gb or 2Gb DDR2 and DDR3 DRAM device

Supports DDR2-1066/DDR3-1333/DDR3-1600 device

Audio DSP

Supports AC-3 (Dolby Digital) decoding (ATSC) and E-AC3 (Dolby

Digital Plus) decoding (option)

MPEG-1 layer I/II decoding

Supports WMA / HE-AAC (option)

Support Dolby DDCO, and MS10 (option)

Dolby Prologic II (option)

Audio output: 5.1ch + 2ch (down mix) + 2ch(bypass)

Pink noise and white noise generator

Equalizer

Bass management

3D surround processing with virtual surround

Audio and video lip synchronization

Supports bass/treble

Automatic volume control

Supports 5-bit (10-channel) main audio I

2

S output interface, each of these channels is up to 24-bit resolution

S/PDIF interface

Supports SPDIF in bypass

SPDIF out

Analog TV IF Demodulator

Supports world-wide analog TV standard

Accept direct IF and low IF

Full digital AGC control and carrier recovery

Embedded SAW filter and IF Amplifier. Cost effective TV front-end

structure and no more cost on:

External analog SAW filters (Video/Audio)

External analog IF demodulator

External peripheral circuit on CVBS signal data path

External SAW filter and IF VGA on tuner

21

Page 22

Digital TV (ATSC / Open-Cable) Demodulator

Compliant with ATSC digital television standard

Supports SCTE DVS-031 and ITU J.83 Annex B digital CATV standard

Accept direct IF (44 MHz or 43.75 MHz) and low IF (5.38 MHz)

NTSC interference rejection capability

Meet all ATSC/A74 requirements

Excellent adjacent and co-channel rejection capability

Dual digital AGC controls for IF and RF, respectively

Full-digital frequency offset recovery with wide acquis ition

range 500KHz for ATSC and 250 kHz for CATV

reception

EIA/CEA-909 antenna interface, both mode A and mode B are

supported

Embedded SAW filter and IF Amplifier. Cost effective TV front-end

structure and no more cost on:

External analog IF demodulator

External SAW filter and IF VGA on tuner

Peripherals

Seven basic serial interfaces: one is for the tuner, three are the masters

for general purpose and two of them can

be active in stan dby mode, one is the slav e for VGA DDC, the

other two extra slave serial interfaces used for

HDMI EDID data

Five PWMs, two of them can be active in standby mode

IR receiver

Real-time clock and watchdog controller

Built-in 2-link USB2.0/1.1, both of them support external hub with 16

endpoints.

Built-in uP for standby mode

Supports SDIO interface

Supports smart card interface

Supports two serial flash or one serial and one NAND flash

Supports 2-input low-speed ADC

Supports boundary scan (JTAG)

IC Outline

LQFP Package 216 pins with E-pad

3.3V/1.2V and 1.8V for DDR2 or 1.5V for DDR3

22

Page 23

2. TI TAS5707

20-W STEREO DIGITAL AUDIO POWER AMPLIFIER WITH EQ AND DRC

23

Page 24

7-1 BLOCK

SPE39T 39-inch Wiring Diagram

24

Page 25

7-2 Wiring Connection

CMI panel

Main board to Panel Main board to Speaker

SPE39T SPE39T

DC02L00720I DC02A00160I

500 mm

Panel side Main board CN1 Main board CN4 Speaker

PKS24020P51 LVDS cable JWT A2006H00-2X20P JWT A2001WR2-4P Color Right

1 NC NC 1 SPK_OUTL+ Red P3 Speaker +

2 NC NC 2 SPK_OUTL- Black P2 Speaker -

3 NC NC Left

4 NC NC 3 SPK_OUTR- Green P5 Speaker -

5 NC NC 4 SPK_OUTR+ White P4 Speaker +

6 NC NC

7 SELLVDS Yellow 28 LVDS_SEL

8 NC NC Main board to IR board/ Key

9 NC NC SPE39T

10 NC NC DC02V04170I

11 GND NC IR:500 mm & Key:900mm

12 ORX0- White 40 TX_AO0N IR board CN1 Main board CN3

L:280 & R:480 mm

13 ORX0+ Black 39 TX_AO0P JWT A2001WR2-11P Color JWT A2001WR2-5P

14 ORX1- White 38 TX_AO1N 1 VCC3V3_STB Red 1 VCC5_0_STB

15 ORX1+ Brown 37 TX_AO1P 2 IRR White 2 IRR

25

Page 26

16 ORX2- White 36 TX_AO2N 3 GND Black 3 GND

17 ORX2+ Red 35 TX_AO2P 4 LED_G Orange 4 LEDG

18 GND Black 15 GND NC 5 LEDR

19 OCLK- White 34 TX_AOCKN NC 6 Light_S_C

20 OCLK+ Orange 33 TX_AOCKP NC 7 Light_S_D

21 GND Black 16 GND 1 GND Black 8 GND

22 ORX3+ White 32 TX_AO3N 2 Power Red 9 Power Key

23 ORX3- Yellow 31 TX_AO3P 3 SAR0 Orange 10 SAR0

24 NC NC 4 SAR1 Yellow 11 SAR1

25 NC NC

26 NC NC

27 NC NC

28 ERX0- White 12 TX_AE0N

29 ERX0+ Black 11 TX_AE0P

30 ERX1- White 1 TX_AE1N

31 ERX1+ Brown 9 TX_AE1P

32 ERX2- White 8 TX_AE2N

33 ERX2+ Red 7 TX_AE2P

34 GND Black 17 GND

35 ECLK- White 6 TX_AECKN

36 ECLK+ Orange 5 TX_AECKP

37 NC Black 18 GND

38 ERX3- White 4 TX_AE3N

39 ERX3+ Yellow 3 TX_AE3P

26

Page 27

40 NC NC

41 NC NC

42 GND NC

43 GND NC

44 GND Black 25 GND

45 GND Black 26 GND

46 GND Black 27 GND

47 NC NC

48 VCC Red 19 LVDS_PWR

49 VCC Red 20 LVDS_PWR

50 VCC Red 21 LVDS_PWR

51 VCC Red 22 LVDS_PWR

27 28

Page 28

Main board to Power board:

Page 29

8 . T rouble shooting

1. Fault clearance

Before calling your dealer or service center for assistance, check the matters below once again.

(1) Make sure you have connected LED TV to your equipment as described in the section

“ CONNECTING LED TV”.

(2) Check cable connection. Verify that all external equipment and power cord are properly

connected.

(3) Verify that all power is switched on.

(4) If LED TV still does not produce an image, re-start the external equipment.

(5) If the image still does not appear, unplug LED TV from the external equipment and check the

external equipment. The problem may be with your graphics controller rather than with LED TV.

(When you reconnect LED TV, remember to turn the external equipment and TV off before you

power up LED TV. Power the equipment back on in order of LED TV and external equipment.)

(6) If the problem still exists, check the following chart.

Problem Try these Solutions

NO POWER

Remote

Control does

not work

No image

No sound

There are tiny

black points

and/or bright

point on the TV

Abnormal

color of image

Plug this LED TV into the AC outlet.

Press POWER button on side control or on Remote Control to turn on LED TV.

Check POWER Indicator. If this indicator blank, this TV has getting trouble.

Check the batteries.

Make sure nothing is between the Remote Receiver and the Remote Control.

Make sure you are not too far from LED TV when using Remote Control.

Maximum operating range is 5m.

Is direct sunlight or strong artificial light shining on LED TV‘s Infrared Remote

Receiver? Eliminate the light by closing curtains, pointing the light in a different

direction, etc.

Check the connection between the external equipment and LED TV.

When turning LED TV on, it takes within 7 seconds (ATV mode) to display the

image.

Check the system that you select is corresponding with the external equipment

or the video equipment.

Make sure the temperature is not out of the Operating Temperature (0°C ~

40°C).

Turn off power, then turn on again, re-start LED TV.

Check Audio cable connection from Audio input source.

Adjust the Sound System.

Press VOLUME (+) button.

Press MUTE button.

Dark or bright points of light (red, green, or blue) may appear on the screen.

This is a characteristic of the LED panel, not a malfunction of the LED TV.

LED panel is produced with very high accuracy technology. There is 99.99% or

more dot pixel, but there is also 0.01 % or less of dot pixel lack or dot pixel that

is constantly lighted. This is not defect.

Regarding LED panel characteristic, it may occur picture remain (look like a

mirror) when the screen is changed if it displays same screen for a long time.

Changing the picture or turn-off the power supply may recover.

Stripe pattern (more, interference stripes) may show up on the screen depends

on the reflected picture.

Adjust the value of color.

Select different color system.

29

Page 30

2. Troubleshooting guide

The flow chart shown below will help you to troubleshoot your Televison set with it doesn’t display

normally. Each procedure offers a simple way to check for system errors. Before starting, ensure

that there is a signal in and that the Televison is turned on.

2-1 Power LED no light

30

Page 31

2-2 Has audio but no video out

2-3 Has video but no audio out step 1

31

Page 32

2-4

Has video but no audio out step 2

32

Page 33

9.SCHEMATIC DIAGRAM

--ELECTRON

Page 34

PCB1

PCB1

5

4

3

2

1

MT5385 Power Tree

(12V) AMP_VCC

D D

+12V

5V_SW

+5VSB

VTV-L32616 REV:1

VTV-L32616 REV:1

FW1

FW1

FIRMWARE

FIRMWARE

FW L32616

FW L32616

E1

E1

C C

EMIcover-50x68mm/NC

EMIcover-50x68mm/NC

B B

FB20

Q15

LMBT3904LT1G

FB22 (LVDS_PWR_EN)

(NC)

(Option)

U1

AX3518ESA

POWER_EN

U2

AX1007E33A

SOT-223

Q2

LMBT3904LT1G

VCCK

SOP8-T5

SOT-23B

FB1 FB2

FB3

SOT-23B

For AMP

FB4

Q1

DMP2160U

U14

DMG4435SSS

(1.2V)

VCCK

(About 3.2A)

(3.3V)

3V3SB

SOT-23GDS

SOP8

LVDS_PWR

FB21

R39

R41

FB5

AVDD33_XTAL_STB

AVDD33_REG_STB

(5V)

5V_SW

For Panel

FB17 +5V_USB0

For USB

U3

AX1117ADA

TO-252

+5V_USB0 => About 500mA

(3.295V) (3.295V)

DVDD3V3FB6

U5

AVDD3V3

R8

R9

(Option)(NC)

FB7 AVDD1V2

AX1007E12A

SOT-223

R21 AVDD33_MEMPLL

R29 AVDD33_DEMOD

R24 AVDD3V3_HDMI1

FB10

(1.2V)

AVDD12_RGBR30

R31

AVDD12_DEMOD

AVDD1V2_HDMI1R28

AVDD33_PLLGPR39

ADAC_3V3R15

AVDD33_DACR20

FB11 AVDD33_AADC

U4

AX1117ADA

TO-252

U13

FB19

AX1117AD33A

TO-252

A A

FB9FB8 DDRV

(3.3V)

+3.3V_TUNER

(1.5V)

For DDR3 Power

FB18 +3.3V_TUNER_1

For Tuner

(About 330mA)

COMPAL OPT OELECTRONICS CO., LTD

COMPAL OPT OELECTRONICS CO., LTD

COMPAL OPT OELECTRONICS CO., LTD

Title

Title

Title

SCHEMATIC,M/B VTV-L32616

SCHEMATIC,M/B VTV-L32616

SCHEMATIC,M/B VTV-L32616

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

Date: Sheet

Date: Sheet

5

4

3

2

Date: Sheet

XXXXXX

XXXXXX

XXXXXX

1

1

1

1

of

of

of

1 11Tuesday, November 27, 2012

1 11Tuesday, November 27, 2012

1 11Tuesday, November 27, 2012

Page 35

5

4

3

2

1

Buck Conve rter 4A

+5VSB

FB1

FB1

CLS UPB201212T-121Y-N 5A

CLS UPB201212T-121Y-N 5A

D D

ELNA SE100uF/16V

ELNA SE100uF/16V

POWER_EN11

L1

L1

SCD0403T-2R2M 2. 2uH/3.8A

REF

7

LX

4

FB

2

SCD0403T-2R2M 2. 2uH/3.8A

C2 15pF/50V/0402C2 15pF/50V/0402

RA

R3 332K/1%R3 332K/1%

R4 634K/1%R4 634K/1%

RB

C7

C7

0.1uF/10V/0402

0.1uF/10V/0402

U1 AX3518ESAU1 AX3518ESA

8

R1

10/1%R110/1%

C3

C3

+

+

C4

C4

0.1uF/10V/0402

0.1uF/10V/0402

C6

C6

0.1uF/10V/0402

0.1uF/10V/0402

R2

10/1%R210/1%

R6

100K/1%R6100K/1%

VIN

1

VCC

5

EN

PGND

GND

THEM_PAD

6

3

9

FB2

FB2

CLS UPB201212T-121Y-N 5A

CLS UPB201212T-121Y-N 5A

C5

C5

22uF/6.3V/0805

22uF/6.3V/0805

Vout=0.8Vx (1+RA/RB)

(1.2V)

VCCK

C1

C1

0.1uF/10V/0402

0.1uF/10V/0402

+3.3V_Standby power (3V3SB)

U2

+5VSB

FB3

FB3

CLS UPB201212T-121Y-N 5A

CLS UPB201212T-121Y-N 5A

10uF/16V/0805

10uF/16V/0805

C8

C8

+

+

U2

AX1007E33A

AX1007E33A

VIN3VOUT

C9

C9

0.1uF/10V/0402

0.1uF/10V/0402

VOUT

GND/ADJ

1

C13

C13

10uF/6.3V/NC

10uF/6.3V/NC

100mA

FB4

2

4

R5

249/1%/NCR5249/1%/NC

RA

RB

R70R7

0

C10

C10

+

+

ELNA SE100uF/16V/NC

ELNA SE100uF/16V/NC

FB4

CLS UPB201212T-121Y-N 5A

CLS UPB201212T-121Y-N 5A

C11

C11

C12

C12

4.7uF/6.3V

4.7uF/6.3V

0.1uF/10V/0402

0.1uF/10V/0402

3V3SB

+5V_Nomal power (5V_SW)

+5VSB

C C

R10

B

R10

47K/1%

47K/1%

C

Q2

Q2

E

LMBT3904LT1G

LMBT3904LT1G

VCCK

Strapping mode :Must

default Pull low.

POWER_EN :

High => 1.2V_SW POWER ON

Low => 1.2V_SW POWER OFF

R12

R12

100K/1%

100K/1%

0.1uF/10V/0402/N C

0.1uF/10V/0402/N C

C24

C24

1uF/6.3V/0402

1uF/6.3V/0402

C14

C14

U16

U16

1

S1

2

S2

3

S3

G4D1

DMG4435SSS/NC

DMG4435SSS/NC

G

3/1 ,3/2 Modify

Q1

Q1

DMP2160U

DMP2160U

8

D4

7

D3

6

D2

5

DS

+

+

ELNA SE100uF/16V

ELNA SE100uF/16V

CLS UPB201212T-121Y-N 5A

CLS UPB201212T-121Y-N 5A

C17

C17

C15

C15

0.1uF/10V/0402

0.1uF/10V/0402

FB5

FB5

5V_SW

C16

C16

4.7uF/16V/0805

4.7uF/16V/0805

+3.3V_Digital power (DVDD3V3)

400mA

5V_SW

FB6

FB6

CLS UPB201212T-121Y-N 5A

CLS UPB201212T-121Y-N 5A

10uF/16V/0805

10uF/16V/0805

C20

C20

+

+

U3

U3

AX1117ADA

AX1117ADA

C18

C18

0.1uF/10V/0402

0.1uF/10V/0402

VIN3VOUT

ADJ / GND

1

C23

C23

10uF/6.3V/NC

10uF/6.3V/NC

(3.295V)

DVDD3V3 AVDD3V3

2

R11

R11

110/1%

110/1%

RA

C21

C21

+

+

R13

R13

RB

180/1%

180/1%

ELNA SE100uF/16V/NC

ELNA SE100uF/16V/NC

R8 0/1%/0805R8 0/1% / 0805

R9 0/1%/0805/N CR9 0/1%/0805/N C

C22

C22

C19

C19

10uF/10V/0805

10uF/10V/0805

0.1uF/10V/0402

0.1uF/10V/0402

VO=1.25Vx(1+RB/RA)+IadjxR2

B B

FB10

FB10

(1.2V)

100mA

AVDD1V2

+1.5V_DDR3 power (DDRV)

U4

U4

AX1117ADA

5V_SW

FB8

FB8

CLS UPB201212T-121Y-N 5A

CLS UPB201212T-121Y-N 5A

10uF/16V/0805

10uF/16V/0805

C27

C27

+

+

AX1117ADA

C25

C25

0.1uF/10V/0402

0.1uF/10V/0402

VIN3VOUT

ADJ / GND

1

C35

C35

10uF/6.3V/NC

10uF/6.3V/NC

(1.5V)

DDRV

FB9

2

R14

R14

110/1%

110/1%

RA

R16

R16

RB

22/1%

22/1%

FB9

CLS UPB201212T-121Y-N 5A

CLS UPB201212T-121Y-N 5A

C26

C26

C28

C28

10uF/10V/0805

10uF/10V/0805

0.1uF/10V/0402

0.1uF/10V/0402

C29

C29

+

+

ELNA SE100uF/16V/NC

ELNA SE100uF/16V/NC

+3.3V_Analog power (ADAC_3V3) +1.2V_Analog power (AVDD1V2)

U5

U5

AX1007E12A

AX1007E12A

VIN3VOUT

C32

C32

0.1uF/10V/0402

0.1uF/10V/0402

VOUT

GND/ADJ

1

1/31 Delete

(3.295V)

AVDD3V3

ADAC_3V3

R15 0/1%/0805R15 0/1%/0805

C30

C30

1uF/16V

1uF/16V

AVDD3V3

FB7

FB7

CLS UPB201212T-121Y-N 5A

CLS UPB201212T-121Y-N 5A

10uF/16V/0805

10uF/16V/0805

C31

C31

+

+

2/20 Modify

2

4

4.7uF/6.3V

4.7uF/6.3V

C33

C33

CLS UPB201212T-121Y-N 5A

CLS UPB201212T-121Y-N 5A

C34

C34

0.1uF/10V/0402

0.1uF/10V/0402

A A

VO=1.25Vx(1+RB/RA)+IadjxRB

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

Title

Title

Title

SCHEMATIC,M/B VTV-L32616

SCHEMATIC,M/B VTV-L32616

SCHEMATIC,M/B VTV-L32616

Size Document Num ber Rev

Size Document Num ber Rev

Size Document Num ber Rev

Date: Sheet

Date: Sheet

5

4

3

2

Date: Sheet

XXXXXX

XXXXXX

XXXXXX

2 11Tuesday, November 27, 2012

2 11Tuesday, November 27, 2012

1

2 11Tuesday, November 27, 2012

1

1

1

of

of

of

Page 36

5

AVDD 3V3

C37

C37

0.1uF/10V/0402

C78

C78

AVDD 3V3

E-Fuse

(Pin108)

VCCK

VCCK

C67

C67

0.1uF/10V/0402

0.1uF/10V/0402

C68

C68

0.1uF/10V/0402

0.1uF/10V/0402

C70

C70

0.1uF/10V/0402

0.1uF/10V/0402

0.1uF/10V/0402

0.1uF/10V/0402

0.1uF/10V/0402

C42

C42

0.1uF/10V/0402

0.1uF/10V/0402

C46

C46

0.1uF/10V/0402

0.1uF/10V/0402

PSRC_WR

TX_AE4P

TX_AE4N

TX_AE3P

TX_AE3N

TX_AECKP

TX_AECKN

TX_AE2P

TX_AE2N

TX_AE1P

TX_AE1N

TX_AE0P

TX_AE0N

TX_AO4P

TX_AO4N

TX_AO3P

TX_AO3N

TX_AOC KP

TX_AOC KN

TX_AO2P

TX_AO2N

TX_AO1P

TX_AO1N

TX_AO0P

TX_AO0N

AVDD33_MEMPLL

1_CKE

1_A10

1_BA1

1_A4

1_A1

1_A6

1_A8

1_A11

1_A12

1_RAS#

1_CAS#

DDRV

1_WE#

1_A0

1_A13

1_A9

1_RST#

1_A7

1_A2

1_A5

1_A3

1_BA2

1_BA0

1_CS#

1_ODT

RDQ4

RVREF

C79

C79

C71

C71

1uF/6.3V/0402

1uF/6.3V/0402

0.1uF/10V/0402

0.1uF/10V/0402

5

0.1uF/10V/0402

0.1uF/10V/0402

C80

C80

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

C72

C72

AVDD 1V2

DVDD3V3

SCL_TUNER

SDA_TUNER

ARC_SELECT

PACLE

UART_Det

LVDS_PWR _EN

104

105

106

107

108

103

102

GPIO2

AVDD12_LVDSA

RDQ2

RDQ6

165

164

163

RDQ6

RDQ2

DDRV

1uF/6.3V/0402

1uF/6.3V/0402

101

GPIO0

GPIO1

PAALE

POWE_

VCC3IO

VCC2IO

RDQ9

RDQ13

RDQ11

RDQ0

168

170

169

167

166

RDQ13

RDQ9

DDRV

RDQ11

RDQ0

C74

C74

U6

U6

AE4P

AE4N

AE3P

AE3N

AECKP

AECKN

AE2P

AE2N

AE1P

AE1N

AE0P

AE0N

AVDD33_ LVD SA

AO4P

AO4N

AO3P

AO3N

AOCKP

AOCKN

AO2P

AO2N

AO1P

AO1N

AO0P

AO0N

VCCK

VCCK

AVDD33_MEMPLL

RCKE

RA10

RBA1

RA4

RA1

RA6

RA8

RA11

RA12

RRAS_

RCAS_

VCC2IO

RWE_

RA0

RA13

RA9

RRESET_

RA7

RA2

RA5

RA3

RBA2

RBA0

RCS_

RODT

RDQ4

C73

C73

0.1uF/10V/0402

0.1uF/10V/0402

Core Pow er ( Close to Main chip )

C81

C81

+

+

PXE100uF/16V/NC

PXE100uF/16V/NC

AVDD 1V2

AVDD 3V3

D D

R27

R27

4.7K/1%/0402

4.7K/1%/0402

C C

B B

A A

DDRV

R36

R36

1K/1%/0402

1K/1%/0402

R38

R38

1K/1%/0402

1K/1%/0402

DDRV

C69

C69

10uF/10V /0805

10uF/10V /0805

3.3V IO Power ( Close to Mainch ip)

DVDD3V3 VCCK

1uF/6.3V/0402

1uF/6.3V/0402

100/0402

100/0402

POOE#

POCE0#

CP_C

100

99

98

PACLE

PARB_

POOE_

POCE0_

RDQ15

VCC2IO

RDQM1

VCCK

174

171

172

173

RDQ15

RDQM1

VCCK

C75

C75

0.1uF/10V/0402

0.1uF/10V/0402

4.7uF/6.3V

4.7uF/6.3V

Add R99

reserve for

LED flash

LED_G

when AC-ON

R99

R99

R23

R23

100/0402/NC

100/0402/NC

PDD7

PDD2

PDD6

PDD4

PDD5

PDD797PDD696PDD595PDD494PDD393PDD292PDD191PDD0

RVREF

RDQS0

RDQS0_

VCC2IO

RCLK0

RCLK0_

175

176

177

179

178

RCLK0

RCLK0#

RDQS0

RDQS0#

RVREF

DDRV

(Pin18) (Pin40)(Pin79) (Pin104)

C82

C82

0.1uF/10V/0402

0.1uF/10V/0402

PDD1

RDQM0

180

RDQM0

C83

C83

4

AOSD ATA0_ 1 AOSD ATA0

R19

R19

33/0402

33/0402

AMP_MC KAMP_MCK_1

R22

R22

33/0402

AC Drop_DET

R104

R104

100/0402

100/0402

VCCK

SCL_SYSTEM

SDA_SYSTEM

PSRC_WR

SYS EE_WP

PANEL SLET

BL_DIMMING

PDD0

BL_ON/OFF

90

89

88

87

85

84

83

82

81

80

86

VCCK

GPIO3

POCE1_

FSRC_WR

SCL_SYSTEM

DEMOD_TSVAL

DEMOD_TSCLK

DEMOD_TSSYNC

DEMOD_TSDATA0

MT5385

MT5385

33/0402

C45

C45

22pF/50V /0402

22pF/50V /0402

DVDD3V3

79

SDA_SYSTEM

VCCK

IFAGC

R25 0/0402/NCR25 0/0402/NC

R26 0/0402/NCR26 0/0402/NC

SPDIF_OUT

AMP_MCK_1

AMP_LRCLK_1

AOSDATA0_1

AMP_BCK_1

78

77

75

74

73

72

71

68

70

76

VCCK

AOBCK

IF_AGC

VCC3IO

RF_AGC

AOLRCK

AOMCLK

ASPDIFO0

AOSDATA0

DEMOD_RST

AR1_ADAC69AR0_ADAC

AL1_ADAC67AL0_ADAC

YPbPr _R_In0

YPbPr _L_In0

AVDD33_AADC

AVDD33_DAC

63

62

66

61

57

59

60

58

64

65

AVSS33_DAC

AVDD33_DAC

AIN2_L_AADC

AIN1_L_AADC

AIN0_L_AADC

AIN2_R_AADC

AIN1_R_AADC

AIN0_R_AADC

AVDD33_AADC

R18

R18

33/0402

33/0402

AMP_LRCLKAMP_LRCLK_1

C39

C39

22pF/50V /0402

22pF/50V /0402

VMID_ AADC

C47

C47

1uF/6.3V/0402

1uF/6.3V/0402

AVDD33_XTAL_STB

55

56

VMID_AADC

AVDD33_XTAL_STB

AVSS33_DEMO D

AVDD33_ DEM OD

ADCINN_DEMOD

ADCINP_DEM OD

AVSS12_DEMO D

AVDD12_ DEM OD

CVBS0P

AVDD33_ CVBS

AVSS33_CVBS

AVDD33_PLLGP

VDACX_OUT

AVDD33_ VDAC

AVSS12_RGB

AVDD12_RGB

AVDD33_ VGA_ ST B

AVDD10_LDO

ORESET_

ADIN0_SRV

ADIN1_SRV

OPWRSB

VGA_SDA

VGA_SCL

OPCTRL2

OPCTRL1

OPCTRL0

VCC3IO _STB

HDMI_0_HPD

HDMI_0_SDA

HDMI_0_SCL

HDMI_1_HPD

HDMI_1_SDA

HDMI_1_SCL

HDMI_CEC

XTALO

VCCK

HSYNC

VSYNC

VCCK

XTALI

SY

SC

PRP

PBP

COM

YP

SOY

RP

COM

GP

SOG

BP

OIRI

U0TX

U0RX

R17

R17

33/0402

33/0402

AMP_BCKAMP_BCK_1

C38

C38

22pF/50V /0402

22pF/50V /0402

C48

C48

0.1uF/10V/0402

0.1uF/10V/0402

EPAD_GND

VCCK

RDQ5

RDQ3

RDQ10

RDQ12

RDQS1

RDQS1_

RDQ8

RDQ14

VCC2IO

RDQ1

RDQ7

VCC2IO

184

181

182

185

183

RDQS1

RDQ12

RDQS1#RDQS 1#

DDRV

VCCK

USB_DM

USB_DP

AVDD33_USB

AVDD33_HDMI _1_RX

HDMI_0_RX_CB

HDMI_0_RX_C

HDMI_0_RX_0B

HDMI_0_RX_0

HDMI_0_RX_1B

HDMI_0_RX_1

HDMI_0_RX_2B

HDMI_0_RX_2

HDMI_1_RX_CB

HDMI_1_RX_C

HDMI_1_RX_0B

HDMI_1_RX_0

HDMI_1_RX_1B

HDMI_1_RX_1

HDMI_1_RX_2B

HDMI_1_RX_2

REXT

198

192

190

186

187

189

188

191

193

196

197

195

199

200

201

202

203

204

205

206

207

194

REXTREXT

RDQ1

USB_DM0

USB_DP0

RDQ3

RDQ5

RDQ7

RDQ14

RDQ10

RDQ8

R3724K/1%/0402 R3724K/1%/0402

AVDD3V3_HDMI1

VCCK

DDRV

VCCK

AVDD3V3

(Pin70) (Pin87) (Pin134) (Pin135) (Pin135) (Pin173) (Pin193) (Pin198)

C84

C84

C85

C85

1uF/6.3V/0402

1uF/6.3V/0402

0.1uF/10V/0402

0.1uF/10V/0402

4

208

RX0_0B

RX0_CB

RX0_C

RX0_0

RX0_1

RX0_2B

RX0_2

RX0_1B

RX1_CB

0.1uF/10V/0402

0.1uF/10V/0402

AVDD12_HDMI _1_RX

209

210

211

212

213

214

215

216

RX1_0B

RX1_2

RX1_2B

RX1_C

RX1_0

RX1_1

RX1_1B

AVDD1V2_HDMI1

AVDD 3V3

R39

R39

(Pin41)

0/0402

0/0402

C76

C76

0.1uF/10V/0402

0.1uF/10V/0402

C88

C88

C87

C87

0.1uF/10V/0402

0.1uF/10V/0402

C89

C89

0.1uF/10V/0402

0.1uF/10V/0402

54

OXTALO

53

OXTALI

52

51

AVDD33_DEMOD

50

FAT_IN-

49

FAT_IN+

48

47

AVDD12_DEMOD

46

CVBS0P

45

44

43

42

41

AVDD33_PLLGP

40

39

38

37

36

AVDD12_RGB

35

PR0P

34

PB0P

33

COM0

32

Y0P

31

SOY0

30

29

28

27

26

25

24

23

AVDD33_REG_STB

22

AVDD10_LDO

21

ORESET#

20

ADIN0

19

SAR0

18

17

OPWRSB

16

OIRI

15

U0TX

14

U0RX

13

12

11

Power Key

10

AMP_MU TE

9

8

7

HDMI_HPD0

6

HDMI_SDA0

5

HDMI_SCL0

4

HDMI_HPD1

3

HDMI_SDA1

2

HDMI_SCL1

1

HDMI_CEC

217

AVDD33_PLLGP

C77

C77

10nF/50V /0402

10nF/50V /0402

Near to IC

0.1uF/10V/0402

0.1uF/10V/0402

3

C36

C36

22pF/50V /0402

22pF/50V /0402

R32 0/0402/NCR32 0/0402/NC

(OPCTRL1)

C90

C90

3

AVDD 3V3

VCCK

AVDD 3V3

VCCK

R35 0/0402/NCR35 0/0402/NC

3V3SB

C91

C91

0.1uF/10V/0402

0.1uF/10V/0402

C63

C63

4.7uF/6.3V

4.7uF/6.3V

C92

C92

0.1uF/10V/0402

0.1uF/10V/0402

LED_ROPCTRL0

GPIO

BL_ON/OFF

LVDS_PWR_EN

AC Drop_DE T

AMP_MU TE

LED_G

LED_R

SYS EE_WP

PANEL SLET

LIGHT_S_C

LIGHT_S_D

System IO

OPWRSB

ORESET#

OXTALI

OXTALO

OIRI

U0TX

U0RX

SDA_SYSTEM

SCL_SYSTEM

BL_ON/OFF 11

LVDS_PWR_EN 11

AC Drop_DE T 11

(OPCTRL1)

AMP_MU TE 4,5

LED_G 11

LED_R 11

SYS EE_WP 4

PANEL SLET 7

LIGHT_S_C 11

LIGHT_S_D 11

OPWRSB 11

ORESET# 4

OXTALI 4

OXTALO 4

OIRI 11

U0TX 4,6

U0RX 4,6

SDA_SYSTEM 4,5,7

SCL_SYSTEM 4,5,7

Add R73 & R102 if change

ACD pin to OPCTRL0

R103 100/0402/NCR103 100/0402/NC

2

Analog Normal Power

AVDD 3V3

AVDD 3V3

AVDD 1V2

AVDD 1V2

AVDD 3V3

AVDD 3V3

R21

R21

0/0402

0/0402

R24

R24

0/0402

0/0402

R28

R28

0/0402

0/0402

R30

R30

0/0402

0/0402

3V3SB

3V3SB

3V3SB

3V3SB

AC Drop_DE TOPCTRL0

AVDD3V3_HDMI1

AVDD1V2_HDMI1

AVDD12_RGB

R33

R33

0/0402

0/0402

R34

R34

0/0402

0/0402

HDMI

HDMI_CEC

RX0_2

RX0_2B

RX0_1

RX0_1B

RX0_0

RX0_0B

RX0_C

RX0_CB

RX1_2

RX1_2B

RX1_1

RX1_1B

RX1_0

RX1_0B

RX1_C

RX1_CB

HDMI_SDA0

HDMI_SCL0

HDMI_HPD0

HDMI_S DA1

HDMI_SCL1

HDMI_HP D1

SPK

AMP_MC K

AMP _LRCLK

AMP_BCK

AOSD ATA0

R102

R102

47K/1%/0402/NC

47K/1%/0402/NC

(Pin136)

AVDD33_MEMPLL

C43

C43

10nF/50V /0402

10nF/50V /0402

(Pin199)

C51

C51

0.1uF/10V/0402

0.1uF/10V/0402

(Pin216)

C52

C52

0.1uF/10V/0402

0.1uF/10V/0402

(Pin36)

C54

C54

0.1uF/10V/0402

0.1uF/10V/0402

(Pin43)

C56

C56

0.1uF/10V/0402

0.1uF/10V/0402

(Pin38)

C59

C59

0.1uF/10V/0402

0.1uF/10V/0402

Standby Power

AVDD33_XTAL_STB

+

+

C62

C62

10uF/6.3V/NC

10uF/6.3V/NC

AVDD33_REG_STB

HDMI_CEC 9

RX0_2 9

RX0_2B 9

RX0_1 9

RX0_1B 9

RX0_0 9

RX0_0B 9

RX0_C 9

RX0_CB 9

RX1_2 9

RX1_2B 9

RX1_1 9

RX1_1B 9

RX1_0 9

RX1_0B 9

RX1_C 9

RX1_CB 9

HDMI_SCL0 9

HDMI_HPD0 9

HDMI_S DA1 9

HDMI_SCL1 9

HDMI_HPD1 9

AMP_MC K 5

AMP_LRCLK 5

AMP_BCK 5

AOSD ATA0 5

2

C44

C44

0.1uF/10V/0402

0.1uF/10V/0402

(Pin55)

C64

C64

0.1uF/10V/0402

0.1uF/10V/0402

(Pin23)

C65

C65

0.1uF/10V/0402

0.1uF/10V/0402

(Pin8)

C66

C66

0.1uF/10V/0402

0.1uF/10V/0402

ADAC _3V3

R20

R20

0/0402

0/0402

ADAC _3V3

C49

C49

4.7uF/6.3V

4.7uF/6.3V

For improve Audio AADC

performance

AVDD 3V3

R29

R29

0/0402

0/0402

AVDD 1V2

R31

R31

0/0402

0/0402

AVDD 3V3

AVDD 3V3

DRAM

Tuner and Dem od TS I/F

SPDIF Out

Key

ADIN0

LIGHT_S_C

LIGHT_S_D

(Pin65)

AVDD 33_ DAC

+

+

C41

C41

10uF/10V

10uF/10V

(Pin57)

FB11

FB11

SBK160808T-800Y 0.4A

SBK160808T-800Y 0.4A

C50

C50

0.1uF/10V/0402

0.1uF/10V/0402

AVDD33_DEMOD

AVDD12_DEMOD

C58

C58

1uF/6.3V/0402/NC

1uF/6.3V/0402/NC

C60

C60

0.1uF/10V/0402/NC

0.1uF/10V/0402/NC

RDQ0

RDQ1

RDQ2

RDQ3

RDQ4

RDQ5

RDQ6

RDQ7

RDQ8

RDQ9

RDQ10

RDQ11

RDQ12

RDQ13

RDQ14

RDQ15

RDQS1

RDQS1#

RDQS0

RDQS0#

RDQM1

RDQM0

1_A0

1_A1

1_A2

1_A3

1_A4

1_A5

1_A6

1_A7

1_A8

1_A9

1_A10

1_A11

1_A12

1_A13

RCLK0

RCLK0#

1_WE#

1_ODT

1_CAS#

1_RAS#

1_CKE

1_CS#

1_RST#

1_BA0

1_BA1

1_BA2

IFAGC

SPDIF_OUT

SAR0

Power Key

SDA_TUNER

SCL_TUNER

R73 0/0402R73 0/0402

R40 0/0402/NCR40 0/0402/NC

R41 10/0402R41 10/0402

R42 10/0402R42 10/0402

R67 10/1%/0402R67 10/1%/0402

1

C40

C40

10nF/50V /0402

10nF/50V /0402

AVDD 33_ AADC

(Pin51)

C53

C53

0.1uF/10V/0402

0.1uF/10V/0402

(Pin195)

C55

C55

0.1uF/10V/0402

0.1uF/10V/0402

(Pin121)

C57

C57

0.1uF/10V/0402

0.1uF/10V/0402

(Pin106)

C61

C61

0.1uF/10V/0402

0.1uF/10V/0402

RDQ0 8

RDQ1 8

RDQ2 8

RDQ3 8

RDQ4 8

RDQ5 8

RDQ6 8

RDQ7 8

RDQ8 8

RDQ9 8

RDQ10 8

RDQ11 8

RDQ12 8

RDQ13 8

RDQ14 8

RDQ15 8

RDQS1 8

RDQS1# 8

RDQS0 8

RDQS0# 8

RDQM1 8

RDQM0 8

1_A0 8

1_A1 8

1_A2 8

1_A3 8

1_A4 8

1_A5 8

1_A6 8

1_A7 8

1_A8 8

1_A9 8

1_A10 8

1_A11 8

1_A12 8

1_A13 8

RCLK0 8

RCLK0# 8

1_WE# 8

1_ODT 8

1_CAS# 8

1_RAS# 8

1_CKE 8

1_CS# 8

1_RST# 8

1_BA0 8

1_BA1 8

1_BA2 8HDMI_SDA0 9

IFAGC 10

SPDIF_OUT 6,9

SAR0 11

Power Key 11

SCL_TUNER 10

Title

Title

Title

Size Docum ent Number Rev

Size Docum ent Number Rev

Size Docum ent Number Rev

Date: Sheet

Date: Sheet

Date: Sheet

YPbPr 0

SOY0

Y0P

COM0

PB0P

PR0P

Demod IF

FAT_INFAT_IN+

CVBS

CVBS0P

LVDS out

TX_AE0P

TX_AE0N

TX_AE1P

TX_AE1N

TX_AE2P

TX_AE2N

TX_AECKP

TX_AECKN

TX_AE3P

TX_AE3N

TX_AE4P

TX_AE4N

TX_AO0P

TX_AO0N

TX_AO1P

TX_AO1N

TX_AO2P

TX_AO2N

TX_AOC KP

TX_AOC KN

TX_AO3P

TX_AO3N

TX_AO4P

TX_AO4N

BL_DIMMING

USB

USB_DM0

USB_DP0

SOY0 6

Y0P 6

COM0 6

PB0P 6

PR0P 6

FAT_IN- 10

FAT_IN+ 10

CVBS0P 6

TX_AE0P 7

TX_AE0N 7

TX_AE1P 7

TX_AE1N 7

TX_AE2P 7

TX_AE2N 7

TX_AECKP 7

TX_AECKN 7

TX_AE3P 7

TX_AE3N 7

TX_AE4P 7

TX_AE4N 7

TX_AO0P 7

TX_AO0N 7

TX_AO1P 7

TX_AO1N 7

TX_AO2P 7

TX_AO2N 7

TX_AOC KP 7

TX_AOC KN 7

TX_AO3P 7

TX_AO3N 7

TX_AO4P 7

TX_AO4N 7

BL_DIMMING 11

USB_DM0 7

USB_DP0 7

NAND/Nor Flash

PACLE

POCE0#

POOE#

PDD7

PDD6

PDD5

AUDIO ADC IN

YPbPr_R_In0

YPbPr_L_In0

SDA_TUNER 10

SAR1 11

LIGHT_S_C

SCL_SYSTEM

SDA_SYSTEM

BL_ERRPDD2

BL_ERR 11

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

SCHEMATIC,M/B VTV-L32616

SCHEMATIC,M/B VTV-L32616

SCHEMATIC,M/B VTV-L32616

UART_Det

ARC_SELECT

CP_C

PDD1

PDD0

XXXXXX

XXXXXX

XXXXXX

1

PACLE 4

POCE0# 4

POOE# 4

PDD7 4

PDD6 4

PDD5 7

UART_Det 4

ARC_SELECT 9

CP_C 6

TP15TP15

TP16TP16

YPbPr_R_In0 6

YPbPr_L_In0 6

of

of

of

3 11Tuesday, November 27, 2012

3 11Tuesday, November 27, 2012

3 11Tuesday, November 27, 2012

1

1

1

Page 37

5

DVDD3V3

D D

POCE0#3

PDD73

POCE0#

PDD7

R44

R44

4.7K/1%/0402

4.7K/1%/0402

DVDD3V3

C94

C94

0.1uF/10V/0402

0.1uF/10V/0402

SPI FLASH

U7

U7

1

NC/SIO3

2

VCC

3

NC

4

PO2

5

PO1

6

PO0

7

CS#

SO/SIO1/PO78WP#/SIO2

MX25L12845EM 1-10G SOP16

MX25L12845EM 1-10G SOP16

27MHz CRYSTAL

Y1

Y1

27MHz/20pF/30ppm/S/2P

27MHz/20pF/30ppm/S/2P

OXTALI

C C

C96

C96

27pF/50V/0402

27pF/50V/0402

SCLK

SI/SIO0

PO6

PO5

PO4

PO3

GND

R81 0/0402R81 0/0402

C97

C97

27pF/50V/0402

27pF/50V/0402

4

DVDD3V3

R45

R43

R43

4.7K/1%/0402

4.7K/1%/0402

16

POOE#

15

PDD6

14

13

12

11

10

9

WP#

C93

C93

0.1uF/10V/0402

0.1uF/10V/0402

R45

4.7K/1%/0402

4.7K/1%/0402

POOE# 3

PDD6 3

RESET Circuit

OXTALO

OXTALO 3OXTALI3

POCE0#

PDD7

WP#

3

U17

U17

1

CS#

2

DOUT

3

WP#/VPP

4

VSS

MX25L6406EM 2I-12G/NC

MX25L6406EM 2I-12G/NC

3V3SB

(Low reset)

U8

U8

3

VCC

1

GND

AX6901ERA

AX6901ERA

HOLD#

POR

POR

/RESET

VCC

CLK

DIN

8

DVDD3V3

7

R140 10K/0402/NCR140 10K/0402/NC

6

5

2

J1

J1

1

2

HDR_1X2_H2031_P2_SW/NC

HDR_1X2_H2031_P2_SW/NC

POOE#

PDD6

R47

R47

100K/1%/0402/NC

100K/1%/0402/NC

3V3SB

R46

R46

1K/1%/0402

1K/1%/0402

ORESET#

C95

C95

10nF/50V/0402

10nF/50V/0402

2

1

ORESET# 3

STRAPPING (Default : Serial boot)

UART0

U0RX

U0RX3,6

U0TX3,6

8/31 Reserve UART_Detect

B B

UART_Det3

R53 100/1%/0402R53 100/1%/0402

U0TX

R54 100/1%/0402R54 100/1%/0402

R82 100/1%/0402R82 100/1%/0402

For ESD

4.7K/1%/0402

4.7K/1%/0402

3V3SB

R87

R87

R51

R51

4.7K/1%/0402/NC

4.7K/1%/0402/NC

3V3SB 3V3SB

12

R52

R52

4.7K/1%/0402

4.7K/1%/0402

12

J2

J2

1

2

3

4

JWT A2001WV2-4P

JWT A2001WV2-4P

A2001WV2-4P-6T2-F2

A2001WV2-4P-6T2-F2

DVDD3V3

R49 10K/1%/NCR49 10K/1%/NC

(OPCTRL1)

AMP_ MUTE

PACLE

R48 10K/1%R48 10K/1%

R50 10K/1%R50 10K/1%

PACLE 3

AMP_ MUTE3,5

(Place on TOP_Layer)

SESD0402P1BN-0450-090/NC

SESD0402P1BN-0450-090/NC

SESD0402P1BN-0450-090/NC

SESD0402P1BN-0450-090/NC

VD2

VD2

VD1

VD1

SYS EE_WP

SYSTEM EEPROM

J3

J3

SCL_SYSTEM

SDA_SYSTEM

A A

5

4

1

2

3

JWT A2001WV2-3P

JWT A2001WV2-3P

A2001WV2-3P-6T2-F2

A2001WV2-3P-6T2-F2

R58

R58

4.7K/1%/0402/NC

4.7K/1%/0402/NC

SCL_SYSTEM3,5,7

SDA_SYSTEM3,5,7

U5 depend on customer request.

If yes,ne ed one mo re GPIO to co ntrol pin 7 of U5

3

R56

R56

4.7K/1%/0402

4.7K/1%/0402

R55

R55

4.7K/1%/0402

4.7K/1%/0402

DVDD3V3

R57

R57

4.7K/1%/0402

4.7K/1%/0402

SYS EE_WP

SCL_SYSTEM

SDA_SYSTEM

DVDD3V3DVDD3V3DVDD3V3

I2C AD DRESS " A0"

U9

U9

8

VCC

7

WP

6

SCL

5

SDA

BR24T64FJ-WGE2

BR24T64FJ-WGE2

64K bit

E0

E1

E2

GND

2

SYS EE_WP 3

1

2

3

4

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

Title

Title

Title

SCHEMATIC,M/B VTV-L32616

SCHEMATIC,M/B VTV-L32616

SCHEMATIC,M/B VTV-L32616

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

Date: Sheet

Date: Sheet

Date: Sheet

XXXXXX

XXXXXX

XXXXXX

1

of

of

of

4 11Tuesday, November 27, 2012

4 11Tuesday, November 27, 2012

4 11Tuesday, November 27, 2012

1

1

1

Page 38

5

DVDD3V3

FB12

FB12

PBY160808T-300Y 3A

PBY160808T-300Y 3A

D D

C C

AMP_MUTE3,4

AMP_MUTE

Low : Enable

High : D isab le

DVDD

R71

R71

4.7K/1%

4.7K/1%

R79

R79

10K/0402/NC

10K/0402/NC

C98

C98

0.1uF/50V

0.1uF/50V

C99

C99

10uF/10V/0805

10uF/10V/0805

AMP_PDN

C100

C100

0.1uF/50V

0.1uF/50V

AMP_PDN

High : Enable

Low : Disable

C102

C102

C101

C101

0.1uF/50V

0.1uF/50V

10uF/10V/0805

10uF/10V/0805

AMP_MCK3

AMP_PDN

AMP_LRCLK3

AMP_BCK3

AOSDATA03

AMP_PDN AMP_RST

Delay 100ms

B B

4

R64 10/0402R64 10/0402

R66

R66

10K/1%

10K/1%

R68 10/0402R68 10/0402

R69 10/0402R69 10/0402

R70 10/0402R70 10/0402

R74 100K/1%R74 100K/1%

0.1uF/10V/0402

0.1uF/10V/0402

C105

C105

10uF/10V/0805

10uF/10V/0805

AMP_SDA

AMP_SCL

R75

R75

1K/1%

1K/1%

C137

C137

C106

C106

0.1uF/50V

0.1uF/50V

DVDD

R65 18.2K/1%R65 18.2K/1%

C121

C121

1uF/50V/0805

1uF/50V/0805

DVDD

3

AMP_VCC

R60 470R60 470

10

11

PLL_FLTP

PLL_FLTM

DVDD27DVSS

28

C132

C132

10uF/10V/0805

10uF/10V/0805

R61 470R61 470

C108 47nF/16VC108 47nF/16V

C112

C112

4.7nF/50V

4.7nF/50V

R62 22.1K/1%R62 22.1K/1%

7NC8

9

AVSS

U10

U10

TAS5707

TAS5707

TH_PD

GND29AGND30VREG31GVDD_OUT32BST_D33PVDD_D34PVDD_D

51

C128 0.1uF/50VC128 0.1uF/50V

C113

C113

2.2uF/16V/0805/NC

2.2uF/16V/0805/NC

C114 1uF/50V/0805C114 1uF/50V/0805

C115 33nF/50VC115 33nF/50V

3

4

5

6

OC_ADJ

BST_A

SSTIMER

GVDD_OUT

PGND_AB

PGND_AB

PVDD_B

PVDD_B

PVDD_C

PVDD_C

PGND_CD

PGND_CD

PVDD_A2PVDD_A

OUT_B

BST_B

BST_C

OUT_C

0.1uF/50V

0.1uF/50V

1uF/50V/0805

1uF/50V/0805

1

C117

C117

C116

C116

OUT_A

48

47

46

45

44

C125 33nF/50VC125 33nF/50V

43

42

C122 33nF/50VC122 33nF/50V

41

AMP_VCC

40

39

38

37

C127 1uF/50V/0805C127 1uF/50V/0805

C126 0.1uF/50VC126 0.1uF/50V

OUT_D

35

36

AMP_VCC

C129 1uF/50V/0805C129 1uF/50V/0805

C130 33nF/50VC130 33nF/50V

0.1uF/50V

0.1uF/50V

1uF/50V/0805

1uF/50V/0805

C139

C139

C138

C138

C107 47nF/16VC107 47nF/16V

C111

C111

4.7nF/50V

4.7nF/50V

12

13

14

15

16

17

18

19

20

21

22

23

24

AVDD

/FAULT

MCLK

OSC_RES

DVSSO

VR_DIG

/PDN

LRCLK

SCLK

SDIN

SDA

SCL

VR_ANA

/RESET25STEST

26

C131

C131

0.1uF/50V

0.1uF/50V

2

L2

L2

SMTDR75-150K 15uH/2A

SMTDR75-150K 15uH/2A

0.47uF/50V/0805/NC

0.47uF/50V/0805/NC

L3

L3

SMTDR75-150K 15uH/2A

SMTDR75-150K 15uH/2A

AMP_VCC

C124

C124

C123

C123

1uF/50V/0805/NC

1uF/50V/0805/NC

0.1uF/50V/NC

0.1uF/50V/NC

L4

L4

SMTDR75-150K 15uH/2A

SMTDR75-150K 15uH/2A

0.47uF/50V/0805/NC

0.47uF/50V/0805/NC

L5

L5

SMTDR75-150K 15uH/2A

SMTDR75-150K 15uH/2A

C103

C103

C133

C133

R59

R59

3.3/1206/NC

C109

C109

0.1uF/50V/NC

0.1uF/50V/NC

C119

C119

0.1uF/50V/NC

0.1uF/50V/NC

C135

C135

0.1uF/50V/NC

0.1uF/50V/NC

C141

C141

0.1uF/50V/NC

0.1uF/50V/NC

3.3/1206/NC

C110

C110

10nF/50V/NC

10nF/50V/NC

R63

R63

3.3/1206/NC

3.3/1206/NC

C120

C120

10nF/50V/NC

10nF/50V/NC

R76

R76

3.3/1206/NC

3.3/1206/NC

C136

C136

10nF/50V/NC

10nF/50V/NC

R77

R77

3.3/1206/NC

3.3/1206/NC

C142

C142

10nF/50V/NC

10nF/50V/NC

C104

C104

0.68uF/25V

0.68uF/25V

C118

C118

0.68uF/25V

0.68uF/25V

AD mode : (1) Mount :C131 ,C141 ;C159 ,C163

;C134

(2) Mount :C121 ;C158 ;C134

BD mode : (1) Mount :C131 ,C141 ;C159

,C163

C134

C134

0.68uF/25V

0.68uF/25V

C140

C140

0.68uF/25V

0.68uF/25V

1

SPK_OUTL+ 11

SPK_OUTL- 11

SPK_OUTR+ 11

SPK_OUTR- 11

SDA_SYSTEM3,4,7

SCL_SYSTEM3,4,7

A A

SCL_SYSTEM

5

R78 10/0402R78 10/0402

R80 10/0402R80 10/0402

AMP_SDASDA_SYSTEM

AMP_SCL

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

Title

Title

Title

SCHEMATIC,M/B VTV-L32616

SCHEMATIC,M/B VTV-L32616

SCHEMATIC,M/B VTV-L32616

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

Date: Sheet

Date: Sheet

4

3

2

Date: Sheet

XXXXXX

XXXXXX

XXXXXX

1

5 11Tuesday, December 11, 2012

5 11Tuesday, December 11, 2012

5 11Tuesday, December 11, 2012

1

1

1

of

of

of

Page 39

5

4

3

2

1

OPT SPDIF outComponent input A/V input

R123

R123

47/1%/0402

IO4

12

C371

C371

10pF/50V/NC

10pF/50V/NC

12

C369

C369

10pF/50V/NC

10pF/50V/NC

IO4

6

GND

7

GND

YUQIU/OPTICAL_V

YUQIU/OPTICAL_V

FB15

FB15

PBY160808T-300Y 3A

PBY160808T-300Y 3A

FB14

FB14

PBY160808T-300Y 3A

PBY160808T-300Y 3A

VCC

GND

IN

12

12

1

FB16

FB16

2

PBY160808T-300Y 3A

PBY160808T-300Y 3A

3

R144

R144

1 2

47K/1%/0402

47K/1%/0402

C224

C224

10pF/50V/NC

10pF/50V/NC

C315

C315

10pF/50V/NC

10pF/50V/NC

B

2/1 Modify

5V_SW

5V_SW

C

E

LMBT3906LQ4LMBT3906L

LMBT3904LQ5LMBT3904L

Q5

Q4

C171

C171

0.1uF/10V/0402

0.1uF/10V/0402

CBE

IO1

Close to IC Close to CONN.

R83

D D

C C

B B

CVBS0P3

PB0P3

PR0P3

SOY03

Y0P3

COM03

YBRL_IN0

YBRR_IN0

CVBS0P

SOY0

Y0P

COM0

C143

C143

47nF/16V/0402

47nF/16V/0402

C145

C145

1.5nF/50V/0402

1.5nF/50V/0402

C147

C147

10nF/50V/0402

10nF/50V/0402

C149

C149

10nF/50V/0402

10nF/50V/0402

C150

C150

10nF/50V/0402

10nF/50V/0402

PR0P Pr_HD

C153

C153

10nF/50V/0402

10nF/50V/0402

C151 10uF/6.3VC151 10uF/6.3V

C154 10uF/6.3VC154 10uF/6.3V

R83

100/1%/0402

100/1%/0402

100/1%/0402

100/1%/0402

100/1%/0402

100/1%/0402

R91

R91

100/1%/0402

100/1%/0402

R95

R95

100/1%/0402

100/1%/0402

Close to ICClose to CONN.

R85

R85

R89

R89

10pF/50V/0402

10pF/50V/0402

10pF/50V/0402

10pF/50V/0402

10pF/50V/0402

10pF/50V/0402

0/0402

0/0402

C152

C152

C155

C155

R84

R84

10/1%/0402

10/1%/0402

18/1%/0402

R94

R94

56/1%/0402

56/1%/0402

R98

R98

56/1%/0402

56/1%/0402

YPbPr_L_In0

YPbPr_R_In0

18/1%/0402

R88

R88

56/1%/0402

56/1%/0402

C148

C148

R90

R90

R9330K/1%/0402 R9330K/1%/0402

R9730K/1%/0402 R9730K/1%/0402

R86

R86

R92

R92

18/1%/0402

18/1%/0402

R96

R96

18/1%/0402

18/1%/0402

Y-V_IN

Pb_HDPB0P