Panasonic TC-14RM12L P, TC-20RM12LP, TC-20RA12LP Service Manual

Order DCS - DEZ2006 - 035 - LA

Service Manual

Color Television

TC-14RM12LP

TC-14RM12LP

TC-20RM12LP

TC-20RM12LP

TC-20RA12LP

TC-20RA12LP

Chassi GP41

Specifications

Television

Power Source

Antenna Input Jack

Color Systems

Tuning System

Channel Capability

Picture Tube

Audio Output

Video Input Jack

Dimension (WxHxD)

Weight

•

•

•

TC-14RM12LP

TC-14RM12LP.

110/220V AC 50/60Hz

Automatic Switch

75Ω VHF/UHF/CATV

PAL-M/NTSC/PAL-N

F.S.T

2~13 (VHF)

14~69 (UHF)

1~125 (CA TV)

33Cm

8W PMPO

1 (rear)

370x352x372mm

9,6Kg

TC-20RM12LP

TC-20RM12LP.

110/220V AC 50/60Hz

Automatic Switch

75Ω VHF/UHF/CATV

PAL-M/NTSC/PAL-N

F.S.T

2~13 (VHF)

14~69 (UHF)

1~125 (CA TV)

48Cm

13W PMPO

1 (rear)

514x468x461mm

17Kg

TC-20RA12LP

TC-20RA12LP.

110/220V AC 50/60Hz

Automatic Switch

75Ω VHF/UHF/CATV

PAL-M/NTSC/PAL-N

F.S.T

2~13 (VHF)

14~69 (UHF)

1~125 (CA TV)

48Cm

13W PMPO

1 (rear) + 1 (front)

514x468x461mm

17Kg

REMOTE CONTROL TRANSMITER:

Model: EUR7717070

Power source: 3V (2 AA type batteries)

Infrared Length: 9500 Å (angstron)

SUPPLIED ACCESSORIES:

• 1 Remote Control Transmitter

• 1 300Ω/75Ω Adaptor Ballum

• 2 “AA” type batteries

• 1 internal antenna

Specifications are subject to change without prior notice.

Mass and dimensions shown are aproximated.

© 2006 Panasonic do Brasil Limitada

CS Division

Technical Support

TC-14RM12LP/TC-14RM12LP(.)/ TC-20RA12LP/TC-20RA12LP(.)/TC-20RM12LP/TC-20RM12LP(.)

Important Safety Notice

Special components are used in this television set which are important for safety. These parts are identified on the schematic

diagram by the symbol . It is essential that these critical parts are replaced with the manufacturer’s specified replacement

parts to prevent X-ray radiation, shock, fire or other hazards. Do not modify the original design without manufacturer’s permission.

!

Contents

ABOUT LEAD FREE SOLDER (PBF) ........................................................ 3

SUGGESTED PBF SOLDER .................................................................... 3

HOW TO RECOGNIZE THAT PB FREE SOLDER IS USED ......................... 3

OPERA TING INSTRUCTIONS ................................................................... 4

IC601 PINOUT ......................................................................................... 5

IC601 PINOUT ......................................................................................... 6

IC VOLTAGE TABLES ............................................................................. 6

IC601 BLOCK DIAGRAM ........................................................................ 7

GP41 CHASSIS FEATURE SUMMAR Y .................................................... 8

SERVICE HINTS ...................................................................................... 9

FACTORY MODE ADJUSTMENT (TC-14RM12LP , LP• / TC-20RM12LP , LP

/TC-20RA12LP, LP•) .............................................................................. 9

HOW TO OPERATE THE CONTROLS IN THE SERVICE MODE 1 .............. 10

HOW TO OPERATE THE CONTROLS IN THE SERVICE MODE 2 .............. 10

HOW TO OPERATE THE CONTROLS IN THE SERVICE MODE 3 .............. 10

HOW TO ACCESS THE MEMORY MAPS (TC-14RM12LP, LP• /

TC-20RM12LP, LP• / TC-20RA12LP, LP• ............................................. 11

TABLE A0 ............................................................................................. 11

TABLE A2 ............................................................................................. 11

TABLE A4 ............................................................................................. 12

TABLE A6 ............................................................................................. 12

TABLE A8 ............................................................................................. 13

TABLE AA ............................................................................................. 13

TABLE AC ............................................................................................. 14

TABLE AE ............................................................................................. 14

ADJUSTMENTS ....................................................................................... 15

ADJUSTMENTS ................................................................................... 16

ADJUSTMENTS ....................................................................................... 17

ADJUSTMENTS ....................................................................................... 18

ADJUSTMENTS ....................................................................................... 19

SCHEMATICS DIAGRAMS ....................................................................... 20

CRT P.C.B. .............................................................................................. 20

MAIN P .C.B. SCHEMA TIC DIAGRAM ...................................................... 21

MAIN P .C.B. CIRCUIT LA YOUT ............................................................... 22

SIGNAL WA VEFORM .............................................................................. 23

EXPLODED VIEW .................................................................................... 26

REPLACEMENT MECHANICAL PARTS LIST .......................................... 27

REPLACEMENT ELECTRICAL P ARTS LIST ............................................ 28

General Guidelines

An Isolation Transformer should always be used during the servicing

of a receiver whose chassis is not isolated from the AC power line.

Use a transformer of adequate power rating as this protects the

technician from accidents resulting in personal injury from electrical

shocks. It will also protect the Receiver from being damaged by

accidental shorting that may occur during servicing.

When servicing, observe the original lead dress, especially in the high

voltage circuit. Replace all damaged parts (also parts that show signs

of overheating.)

Always Replace Protective Devices, such as fishpaper, isolation

resistors and capacitors, and shields after servicing the Receiver. Use

•

only manufacturer’s recommended rating for fuses, circuit breakers,

etc.

High potentials are present when this Receiver is operating. Operation

of the Receiver without the rear cover introduces danger from electrical

shock. Servicing should not be performed by anyone who is not

thoroughly familiar with the necessary precautions when servicing

high-voltage equipment.

Extreme care should be practiced when Handling the Picture Tube.

Rough handling may cause it to implode due to atmospheric pressure

(14.7 lbs per sq. in). Do not sick or scratch the glass or subject it to any

undue pressure. When handling, use safety goggles and heavy gloves

for protection. Discharge the picture tube by shorting the anode to

chassis ground (not to the cabinet or to other mounting hardware).

When discharging, connect cold ground (i.e. dag ground lead) to the

anode with a well insulated wire or use a grounding probe.

Avoid prolonged exposure at close range to unshielded areas of the

picture tube to prevent exposure to X-ray radiation.

The Test Picture Tube used for servicing the chassis at the bench

should incorporate safety glass and magnetic shielding. The safety

glass provides shielding for the tube viewing area against X-ray radiation

as well as implosion. The magnetic shield limits X-ray radiation around

the bell of the picture tube in addition to restricting magnetic effects.

When using a picture tube test jig for service, ensure that the jig is

capable of handling 31kV without causing X-ray radiation.

Before returning a serviced receiver to the owner, the service technician

must thoroughly test the unit to ensure that is completely safe to operate.

Do not use a line isolation transformer when testing.

- 2 -

!

Warning !

It is essential that these critical parts are replaced

with the manufacturer’s specified replacement parts

to prevent X-ray radiation, shock, fire or other hazards.

TC-14RM12LP/TC-14RM12LP(.)/ TC-20RA12LP/TC-20RA12LP(.)/TC-20RM12LP/TC-20RM12LP(.)

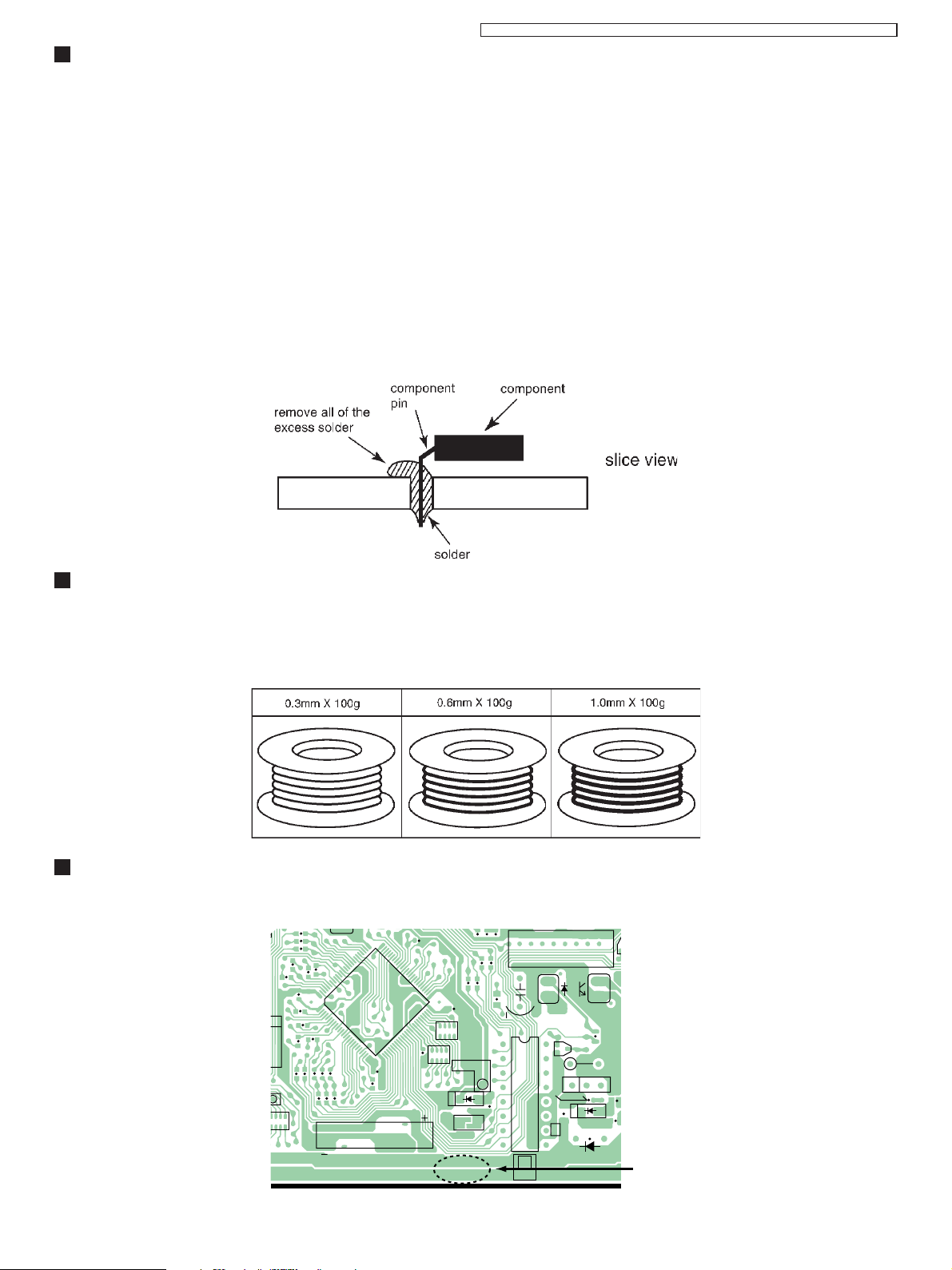

ABOUT LEAD FREE SOLDER (PbF)

Note:

In the information below, Pb, the symbol for lead in the periodic table of elements, will refer to standard solder or solder that

contains lead.

We will use PbF solder when discussing the lead free solder used in our manufacturing process which is made from Tin (Sn),

Silver, (Ag), and Copper, (Cu).

This model, and others like it, manufactured using lead free solder will have PbF stamped on the PCB. For service and repair

work we suggest using the same type of solder although, with some precautions, standard Pb solder can also be used.

Caution

• PbF solder has a melting point that is 50° ~ 70° F, (30° ~ 40°C) higher than Pb solder. Please use a soldering iron with

temperature control and adjust it to 700° ± 20° F, (370° ± 10°C).In case of using high temperature soldering iron, please be

careful not to heat too long.

• PbF solder will tend to splash if it is heated much higher than its melting point, approximately 1100°F, (600°C).

• If you must use Pb solder on a PCB manufactured using PbF solder, remove as much of the original PbF solder as possible

and be sure that any remaining is melted prior to applying the Pb solder.

• When applying PbF solder to double layered boards, please check the component side for excess which may flow onto the

opposite side (See figure, below).

SUGGESTED PbF SOLDER

There are several types of PbF solder available commercially. While this product is manufactured using Tin, Silver, and Copper,

(Sn+Ag+Cu), you can also use Tin and Copper, (Sn+Cu), or Tin, Zinc, and Bismuth, (Sn+Zn+Bi). Please check the manufac

turer’s specific instructions for the melting points of their products and any precautions for using their product with other

materials.

The following lead free (PbF) solder wire sizes are recommended for service of this product: 0.3mm, 0.6mm and 1.0mm.

HOW TO RECOGNIZE THAT PB FREE SOLDER IS USED

P.C.Boards marked as “PbF” use Pb Free solder. (See the figure below.) Pb Free is not used the Power Supply Board of this

unit.

(Example : Digital Board)

L624

L625

L626

L660

L661

L658

L659

100

C694

L653

L655

L657

L654

L656

1

L642

R768

L605

H

RA602

PFUP1330YA PbF

R767

R769

L606

L604

Q609

75

76

IC605

2625

C666

L643

BAT600

R70

C738

51

50

C667

RA609

D602

C668

RA610

C672

C731

L620

L619

L618

+3.3V/BAT

J600

C717

L621

R723

L630

1

R708

8

C728

IC610

+24V

CN612

16

9

Q613

E

R736

F605

25

18

R613R610

R611

R737

E

Q620

D608

C726

D607

Marked

DIGITAL BOARD COMPONENT VIEW

- 3 -

TC-14RM12LP/TC-14RM12LP(.)/ TC-20RA12LP/TC-20RA12LP(.)/TC-20RM12LP/TC-20RM12LP(.)

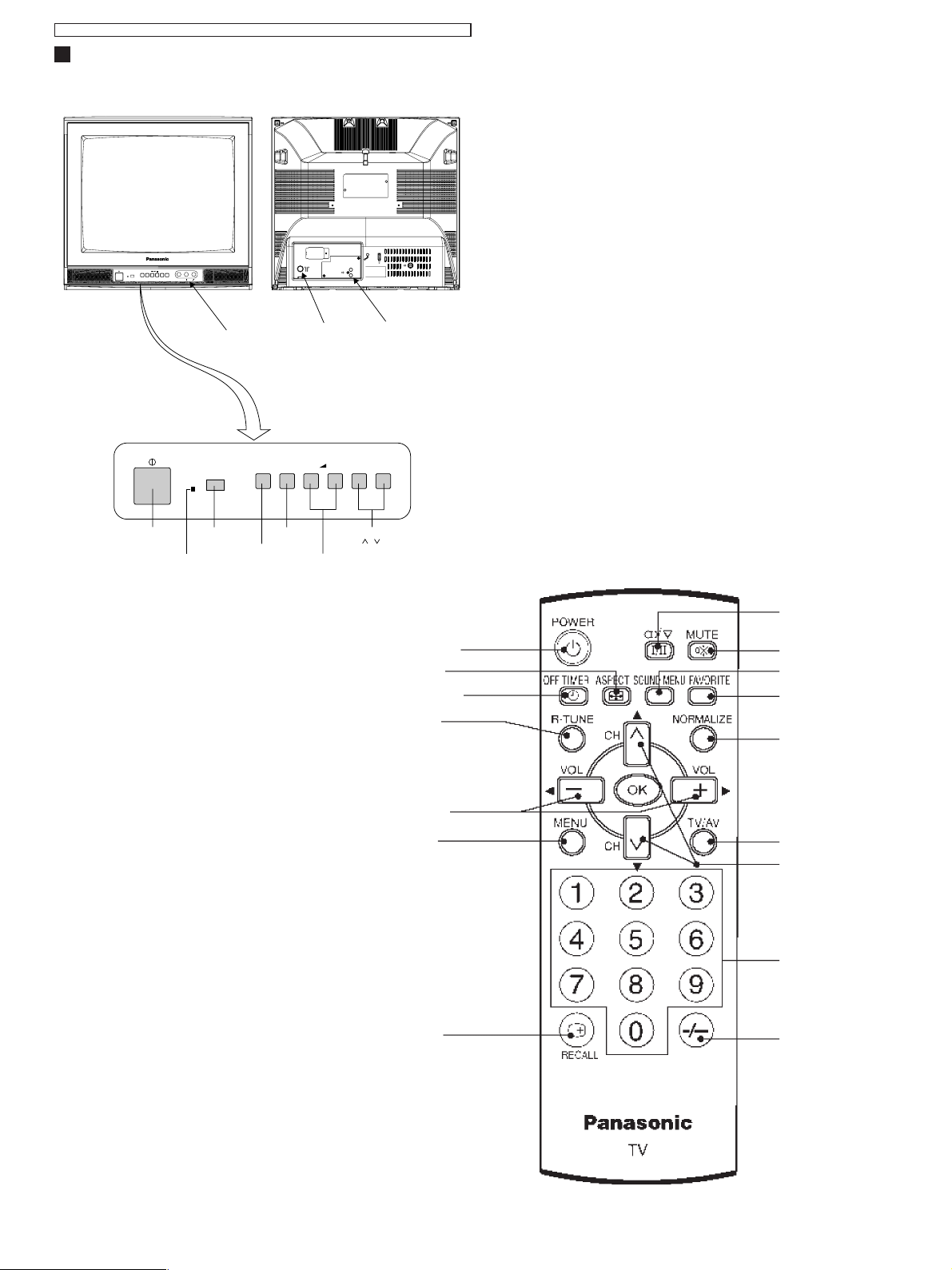

OPERATING INSTRUCTIONS

Front V ie w

Power

switch

(ON/STAND BY)

VIDEO

AUDIO

Remote control

Indication light

Only for

TC-20RA12LP/LP.

MENU TV/AV

sensor

MENU button

Rear View

TV/AV button

Antenna

input jack

–+

Volume buttons

(–) (+)

AV IN

VIDEO

AUDIO

Audio/Video

input jack

Channel buttons

( ) ( )

REMOTE CONTROL

POWER

ASPECT

OFF TIMER

R- TUNE

VOLUME

MENU

RECALL

ESTEREO / SAP

MUTE

SOUND MENU

]

FAVORITE

NORMALIZE

TV / AV

CHANNELS

SELECTION AND

MENU

NAVIGATION

CHANNELS

KEYBOARD FOR

DIRECT

SELECTION

TWO DIGITS

NUMBER

PROGRAM

SELECTION

]

- 4 -

]

FUNCTION UNABLE TO THIS MODEL

TC-14RM12LP/TC-14RM12LP(.)/ TC-20RA12LP/TC-20RA12LP(.)/TC-20RM12LP/TC-20RM12LP(.)

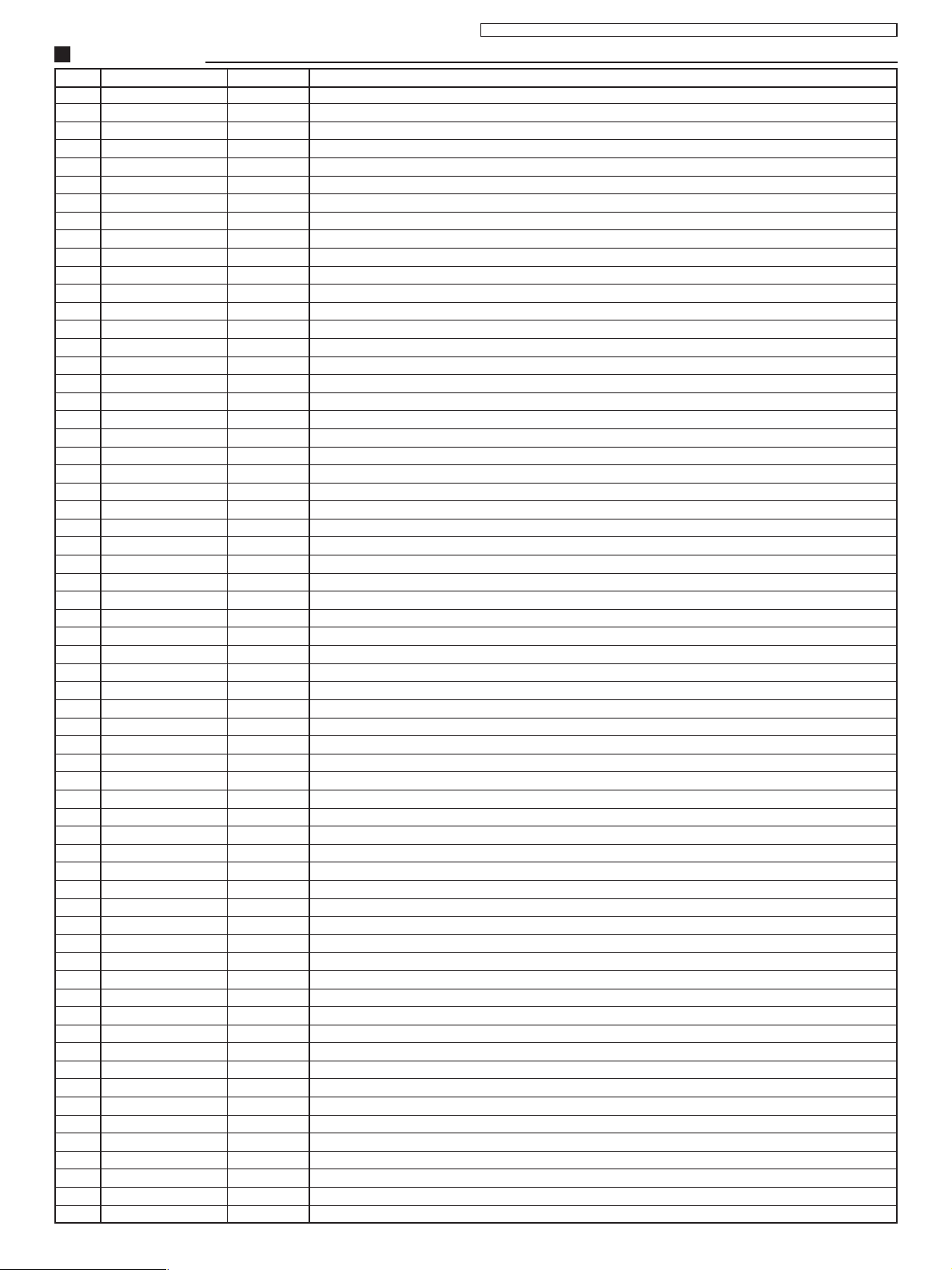

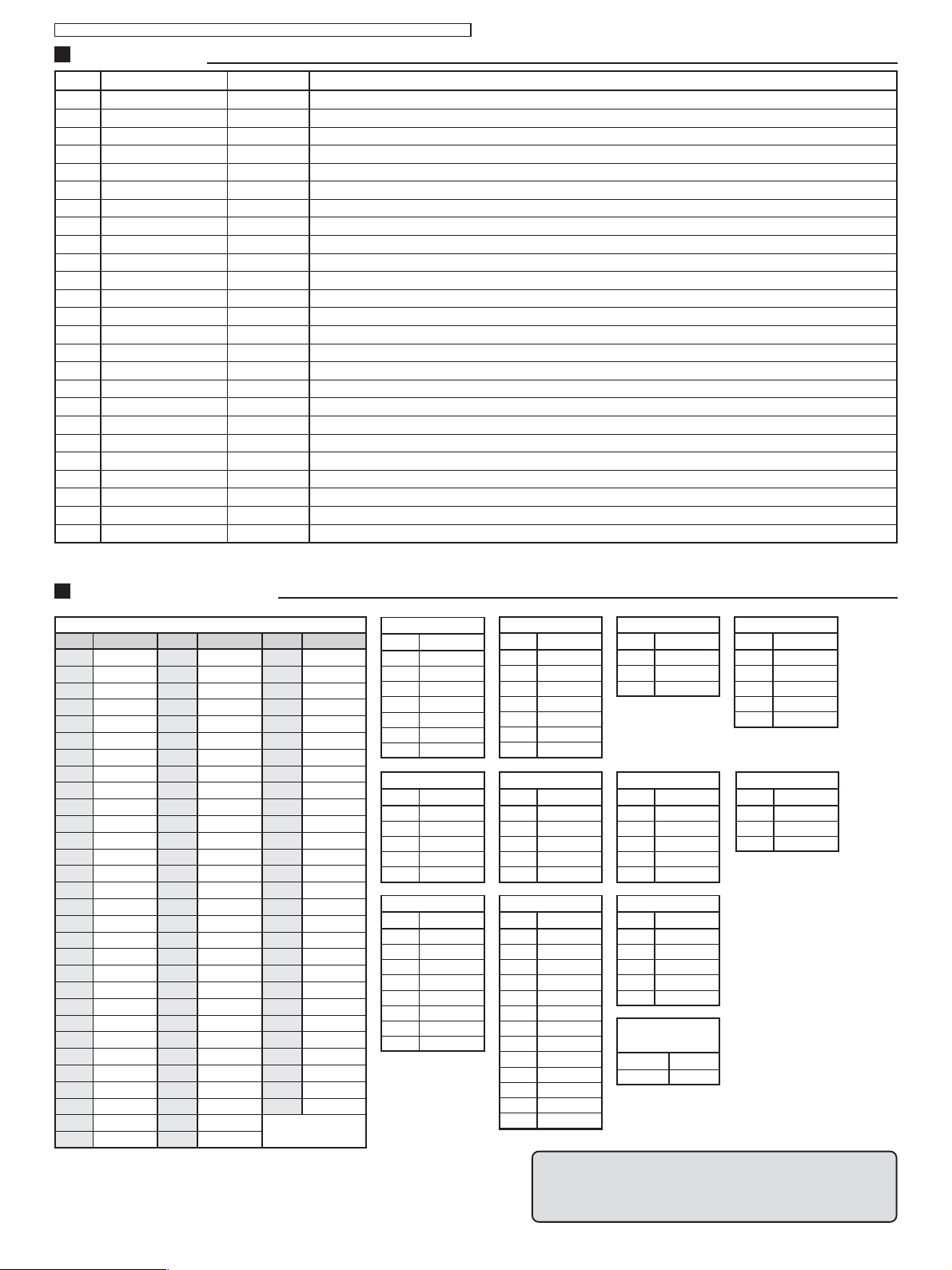

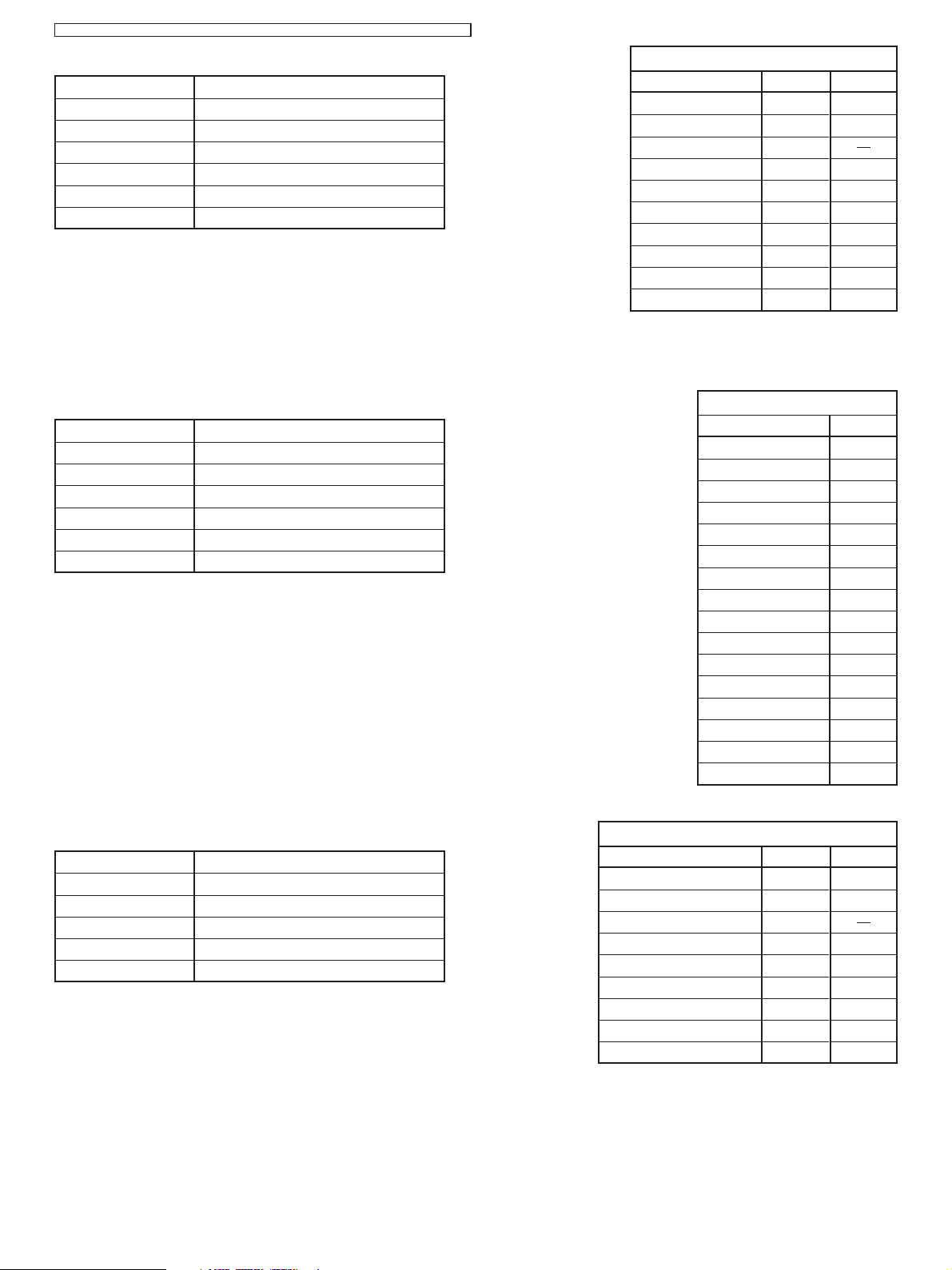

IC601 PINOUT

Pin

1 GND SUPPLY Ground Platform

2 VSUP8.0AU SUPPLY Supply Voltage Analog Audio, 8.0 V

3 VREFAU Reference Voltage, Audio

4 SPEAKERL OUT Analog Loudspeaker Output, Left

5 SPEAKERR OUT Analog Loudspeaker Output, Right

6 AOUT1L OUT Analog Audio 1 Output, Left

7 AOUT1R OUT Analog Audio 1 Output, Right

8 AIN3L / AOUT2L IN / OUT Analog Audio 3 Input, Left

9 AIN3R / AOUT2R IN / OUT Analog Audio 3 Input, Right

10 AIN2L IN Analog Audio 2 Input, Left

11 AIN2R IN Analog Audio 2 Input, Right

12 AIN1L IN Analog Audio 1 Input, Left

13 AIN1R / SIF IN/OUT Analog Audio 1 Input, Right

14 T AG C OUT Tuner AGC Output

15 VREFIF Reference Voltage, IF ADC

16 IFIN- IN Differential IF Input

17 IFIN+ IN Differential IF Input

18 RESETQ IN/OUT Reset Input/Output

19 VSUP5.0FE SUPPLY Supply Voltage Analog IF Front-end, 5.0 V

20 VSUP5.0IF SUPPLY Supply Voltage IF ADC, 5.0 V

21 VSUP3.3DIG SUPPLY Supply Voltage Digital Core, 3.3 V

22 GND SUPPLY Ground Platform

23 GND SUPPLY Ground Platform

24 VSUP1.8DIG SUPPLY Supply Voltage Digital Core, 1.8 V

25 XTAL1 IN Analog Crystal Input

26 XTAL2 OUT Analog Crystal Output

27 P22 IN/OUT Port 2, Bit 2 Input/Output

28 P23 IN/OUT Port 2, Bit 3 Input/Output

29 VIN11 IN Analog Video 11 Input

30 VIN10 IN Analog Video 10 Input

31 VIN9 IN Analog Video 9 Input

32 VIN8 IN Analog Video 8 Input

33 VIN7 IN Analog Video 7 Input

34 VIN6 IN Analog Video 6 Input

35 VIN5 IN Analog Video 5 Input

36 VIN4 IN Analog Video 4 Input

37 VIN3 IN Analog Video 3 Input

38 VIN2 IN Analog Video 2 Input

39 VIN1 IN Analog Video 1 Input

40 VOUT1 OUT Analog Video 1 Output

41 VOUT2 OUT Analog Video 2 Output

42 VOUT3 OUT Analog Video 3 Output

43 VSUP1.8FE SUPPLY Supply Voltage Analog Video Front-end, 1.8 V

44 GND SUPPLY Ground Platform

45 GND SUPPLY Ground Platform

46 VSUP3.3FE SUPPLY Supply Voltage Analog Video Front-end, 3.3 V

47 P10 IN/OUT Port 1, Bit 0 Input/Output

48 P11 IN/OUT Port 1, Bit 1 Input/Output

49 P12 IN/OUT Port 1, Bit 2 Input/Output

50 P13 IN/OUT Port 1, Bit 3 Input/Output

51 P14 IN/OUT Port 1, Bit 4 Input/Output

52 P15 IN/OUT Port 1, Bit 5 Input/Output

53 P16 IN/OUT Port 1, Bit 6 Input/Output

54 P17 IN/OUT Port 1, Bit 7 Input/Output

55 P20 IN/OUT Port 2, Bit 0 Input/Output

56 P21 IN/OUT Port 2, Bit 1 Input/Output

57 SCL IN/OUT I2C Bus Clock Input/Output

58 SDA IN/OUT I2C Bus Data Input/Output

59 VPROT IN Vertical Protection Input

60 HOUT OUT Horizontal Drive Output

61 HFLB IN Horizontal Flyback Input

62 SAFETY IN Safety Input

63 GNDDAC SUPPLY Ground Video DACs

Nome Tipo

Description

- 5 -

TC-14RM12LP/TC-14RM12LP(.)/ TC-20RA12LP/TC-20RA12LP(.)/TC-20RM12LP/TC-20RM12LP(.)

IC601 PINOUT

Pin Nome Tipo

64 VSUP3.3DAC SUPPLY Supply Voltage Video DACs, 3.3 V

65 VSUP3.3IO SUPPLY Supply Voltage I/O Ports, 3.3 V

66 GND SUPPLY Ground Platform

67 GND SUPPLY Ground Platform

68 VSUP3.3BE SUPPLY Supply Voltage Analog Video Back-end, 3.3 V

69 XREF Reference Current for RGB DACs

70 VRD Reference Voltage for RGB DACs

71 BOUT OUT Analog Blue Output

72 GOUT OUT Analog Green Output

73 ROUT OUT Analog Red Output

74 SVMOUT OUT Scan Velocity Modulation Output

75 BIN IN Analog Blue Input, Back-end

76 GIN IN Analog Green Input, Back-end

77 RIN IN Analog Red Input, Back-end

78 FBIN IN Fast Blank Input, Back-end

79 GNDM IN Reference Ground for Sense ADC

80 SENSE IN Sense ADC Input

81 RSW1 OUT Range Switch 1 Output

82 RSW2 OUT Range Switch 2 Output

83 EW OUT Vertical Parabola Output

84 VERT- OUT Differential Vertical Sawtooth Output

85 VERT+ OUT Differential Vertical Sawtooth Output

86 TEST / SUBW IN / OUT Test Input, reserved for Test Subwoofer Output

87 VSUP5.0BE SUPPLY Supply Voltage Analog Video Back-end, 5.0 V

88 GND SUPPLY Ground Platform

Description

IC VOLTAGE TABLES

Pin Voltage

1 0V

2 8,4V

3 3,7V

4 3,5V

5 3,6V

6 3,8V

7 7,4V

8 0V

9 0V

10 3,8V

11 0V

12 3,8V

13 0V

14 4,3V

15 2,5V

16 2,5V

17 2,4V

18 3,3V

19 5,2V

20 5,2V

21 3,3V

22 0V

23 0V

24 1,7V

25 1,8V

26 1,8V

27 3,3V

28 3,28V

29 0V

30 0V

IC601

Pin Voltage

31 0V

32 0V

33 0,9V

34 0V

35 0V

36 0V

37 0V

38 0V

39 0V

40 0,9V

41 1,0V

42 1,6V

43 1,9V

44 0V

45 0V

46 3,3V

47 3,3V

48 0V

49 3,2V

50 0V

51 3,3V

52 0V

53 3,3V

54 2,2V

55 0V

56 0V

57 1,5V

58 1,8V

59 0,3V

60 1,4V

Pin Voltage

61 0,4V

62 0V

63 0V

64 3,3V

65 3,3V

66 0V

67 0V

68 3,3V

69 1,2V

70 1,2V

71 4,7V

72 4,7V

73 4,7V

74 5,2V

75 0V

76 0V

77 0V

78 0V

79 0V

80 0,1V

81 0V

82 0V

83 0V

84 1,6V

85 1,3V

86 0V

87 5,2V

88 0V

IC451

Pin Voltage

1 0,4V

2 13,9V

3 -12,51V

4 -13,8V

50V

6 14,3V

7 0,4V

IC857

Pin Voltage

1 1,2V

20V

3 4,8V

4 5,2V

5 3,3V

IC1101

Pin Voltage

10V

20V

30V

40V

52V

6 1,7V

70V

8 3,3V

IC801

Pin Volta ge

1 183V

2NC

3 0,17V

4 22,4V

54V

6 1,6V

7 0,2V

IC871

Pin Voltage

1 3,9V

2 5,1V

30V

4 3,3V

5 1,3V

IC2301

Pin Voltage

1 10,5V

2 0,7V

30V

40V

5 5,2V

60V

7 10,9V

8 5,1V

9 5,1V

10 0V

11 0V

12 0,3V

13 0,7V

IC802

Pin Volta ge

1 142V

28V

30V

IC875

Pin Volta ge

1 1,3V

20V

3 3,1V

4 3,4V

5 1,8V

XF101

Pin Volta ge

1 0,2V

20V

30V

4 2,5V

5 2,5V

TEST

POINTS

TPA11

10V

TPA16

142V

IC851

Pin Volta ge

1 3,3V

2 8,6V

30V

4 5,1V

5 1,3V

IC605

Pin Volta ge

1 3,26V

20V

3 3,26V

- 6 -

All voltage measurements were made in POWER

ON mode, with 127V 60Hz power source and Color

Bars Video Pattern.

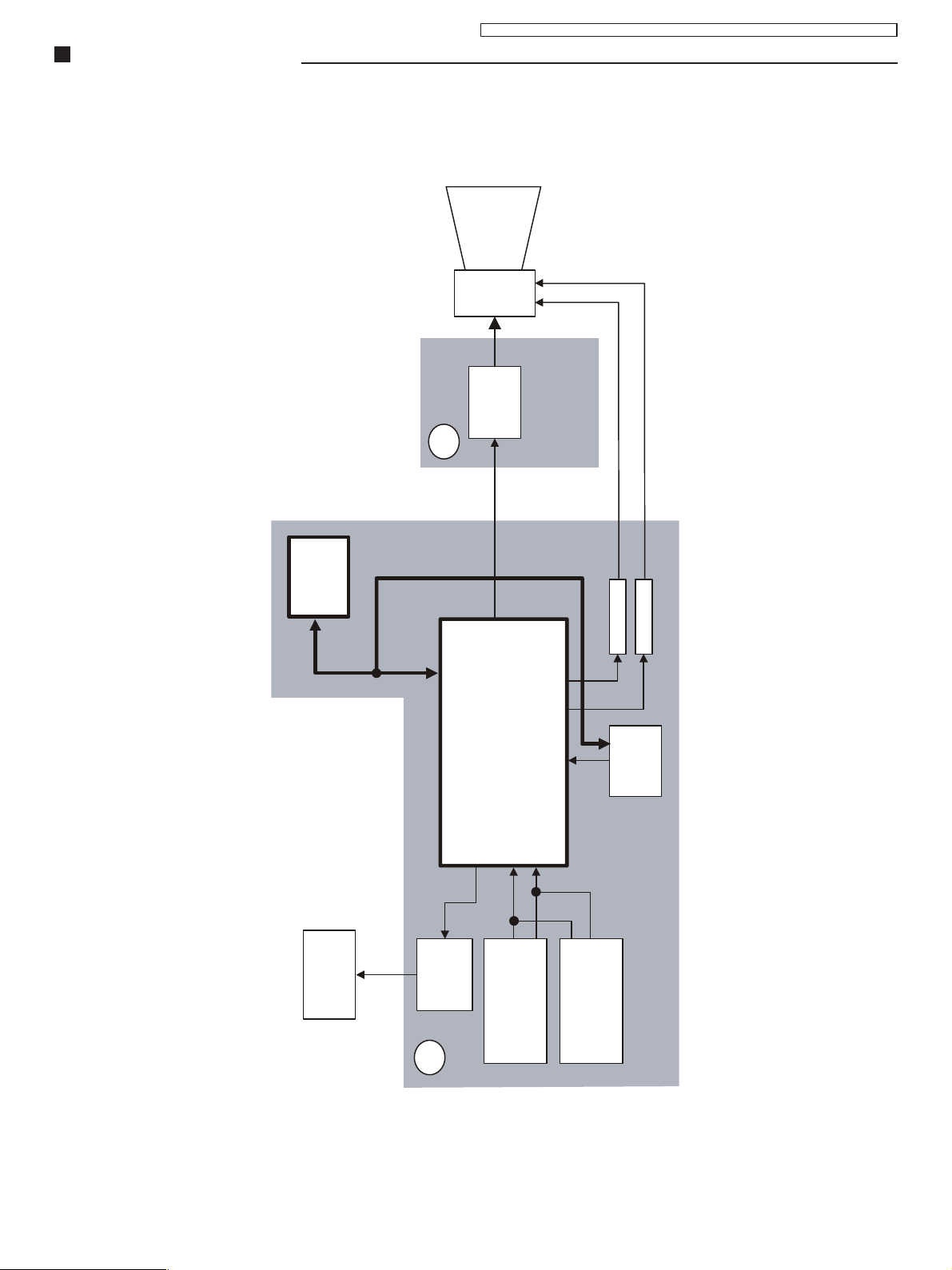

IC601 BLOCK DIAGRAM

TC-14RM12LP/TC-14RM12LP(.)/ TC-20RA12LP/TC-20RA12LP(.)/TC-20RM12LP/TC-20RM12LP(.)

CRT

coil

defl.

CRT

DRIVE

L

IC1101

EEPROM

RGB

SCL SDA

R/G/B

VCT-IF

CVBS OUT

OUT

AUDIO

AMP

IC2301

SPEAKER

AUDIO

A

REAR INPUTS

IC601

V_IN

AV1 : V/L/R

VM

V

H

IF

_IN

A

MON_OUT

FRONT INPUTS

AV2 : V/L/R

V OUT

H OUT

TUNER

- 7 -

TC-14RM12LP/TC-14RM12LP(.)/ TC-20RA12LP/TC-20RA12LP(.)/TC-20RM12LP/TC-20RM12LP(.)

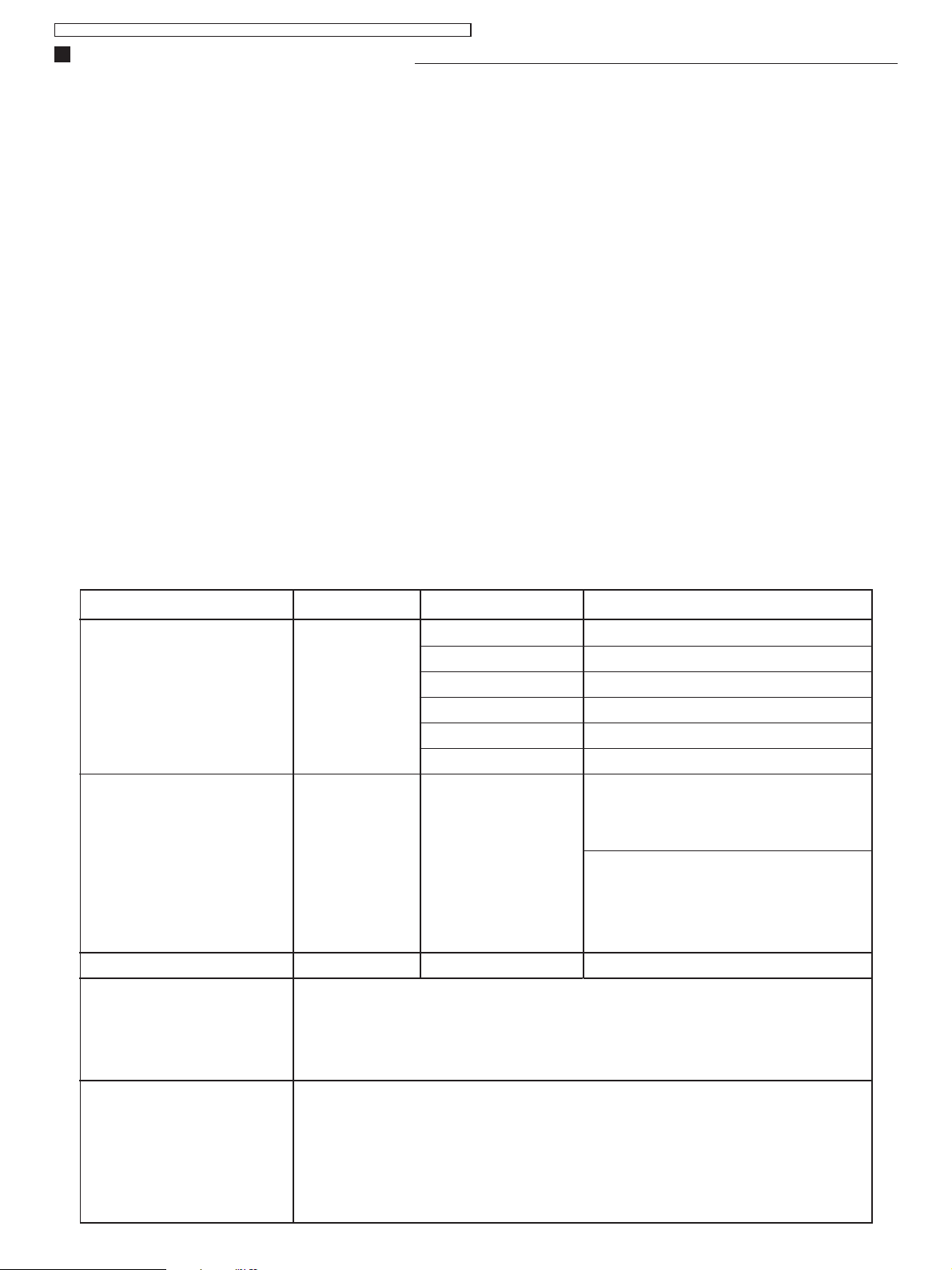

GP41 CHASSIS FEATURE SUMMARY

CHASSIS : GP41

MODEL : TC-14RM12LP, TC-14RM12LP•, TC-20RM12LP,

TC-20RM12LP•, TC-20RA12LP e TC-20RA12LP

•

SYSTEM : 3 systems (P AL-M/P AL-N/NTSC) (P AL-M 50Hz)

POWER SOURCE : AC automatic power switching 127/220V , 50/60Hz

MEMORY : 125 positions

TV TUNING RANGE : 181 channels

OSD LINGUAGE : Espanish, Portuguese and English

AUDIO : Mono

VERTICAL MAGNETIC FELD : -0.1 Gauss ±0.03 (BRASIL)

+0.36 Gauss ± 0.03 (P ANALAT)

COLOR TEMPERATURE : (High Light) x= 0.275±0.01, y=0.284 ±0.01, Y=150 (nit))

(Low Light) x= 0.273±0.01, y=0.283 ±0.01, Y=7.0 (nit)

REFERENCE VOLTAGE

CONTENTS REFERENCE TEST POINT

+B VOLTAGE

SOUND CONFIRMATION

SUB-CONTRAST

MEMORY DATA

14”

002

008

021

OPTION 1 = 36, OPTION 2 = 00, OPTION 3 = 00, OPTION 4 = 01,

OPTION 5 = 00, OPTION 6 = 10, OPTION 7 = 02, OPTION 8 = 87,

OPTION 9 = 90, OPTION 10 = A1, OPTION 11 = 00, OPTION 12 = 00,

OPTION 13 = 00, OPTION 14 = 08, OPTION 15 = 0F

TPA15

TPA16

TPA17

TPA18

TPA19

TPA20

ANODO

DO CRT

TPL5

SPECIFICATIONS

3.35±0.2 (V)

141.0 ±2.0 (V)

8.2 ±0.3 (V)

1.9 ±0.2 (V)

5.2±0.2 (V)

175±15 (V)

TC-14RM12L / TC-14RM12LP.

24.5 +0.7 (Kv)

24.5 -1.5 (kV)

TC-20RM12LP / TC-20RM12LP.

TC-20RA12LP / TC-20RA12LP.

26.5 +0.7 (Kv)

26.5 -1.5 (kV)

2.1±0.2 (VO-p)

MEMORY DATA

20”

OPTION 1 = 36, OPTION 2 = 00, OPTION 3 = 00, OPTION 4 = 01,

OPTION 5 = 00, OPTION 6 = 10, OPTION 7 = 02

OPTION 8 (TC-20RM12LP, TC-20RM12LP.) = 87

OPTION 8 (TC-20RA12LP, TC-20RA12LP.) = 07

OPTION 9 = 90, OPTION 10 = A1, OPTION 11 = 00, OPTION 12 = 00,

OPTION 13 = 00, OPTION 14 = 08, OPTION 15 = 0F

- 8 -

TC-14RM12LP/TC-14RM12LP(.)/ TC-20RA12LP/TC-20RA12LP(.)/TC-20RM12LP/TC-20RM12LP(.)

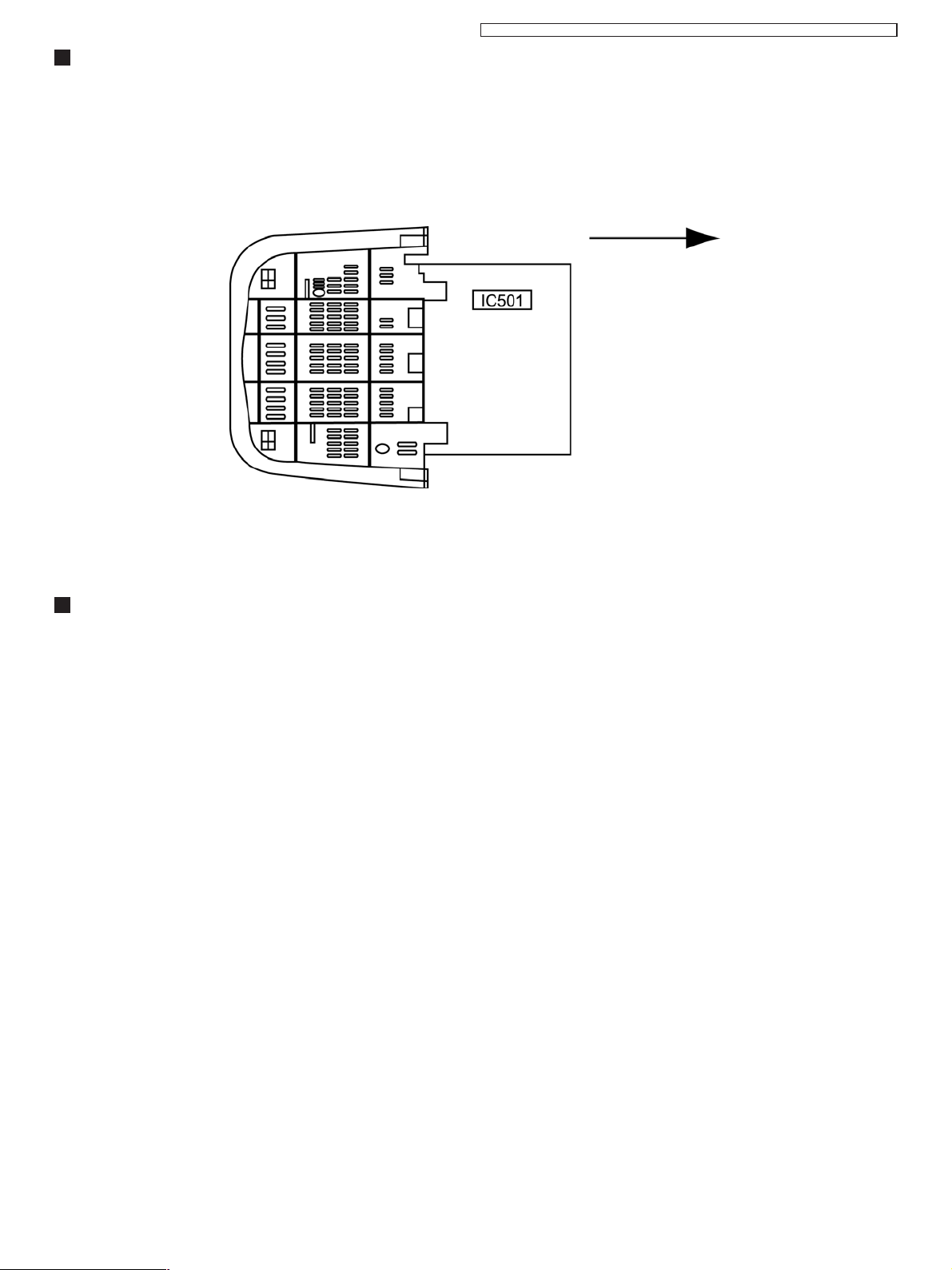

SERVICE HINTS

SERVICE POSITION FOR E-BOARD

1. Remove the back cover.

2. Stand the TV set as shown in Fig. 2.

3. Remove the A-Board from the TV set by pulling the main board out as shown in Figure 2.

Pull out this way

Main Board

Fig. 2

FACTORY MODE ADJUSTMENT (TC-14RM12LP, LP• / TC-20RM12LP, LP• /TC-20RA12LP, LP•)

HOW TO ENTER IN THE GP41 SERVICE MODE:

TO ENTER IN THE SERVICE MODE 1:

à

1. Adjust “OFF TIMER” to 30 minutes.

Press simultaneously “VOLUME (–)” on the front panel and “RECALL” on the remote control to enter “SERVICE MODE-1”.

TO ENTER IN THE SERVICE MODE 2:

à

1. Enter in the “SERVICE MODE 1”.

2. Press the “1” channel key to enter “SERVICE MODE 2”.

TO ENTER IN THE SERVICE MODE 3:

à

1. Enter in the “SERVICE MODE 2”.

2. Press the “1” channel key to enter “SERVICE MODE 3”.

Note: Always, finishing the adjustments, press the “NORMAL” key or the “POWER” key in the remote control to exit the

service mode and return to TV normal way .

- 9 -

TC-14RM12LP/TC-14RM12LP(.)/ TC-20RA12LP/TC-20RA12LP(.)/TC-20RM12LP/TC-20RM12LP(.)

How to operate the controls in the SERVICE MODE 1

à

Key 3 / 4 Previous / next item

Key 8 / 9 Adjusts bright (user) (–/+)

UP/DOWN Channel Up / Channel Down

Volume + Increment of selected item

Volume – Decrement of selected item

OK Store / saves selected item

Normal Exit the service mode

Obs: The vertical and horizontal deflection adjustments, in the SERVICE

MODE 1, was made in 50Hz power source frequency.

How to operate the controls in the SERVICE MODE 2

à

Key 3 / 4 Previous / next item

Key 8 / 9 Select bit 0–7 option

UP/DOWN Channel Up / Channel Down

Volume + Increment of selected item

Volume – Decrement of selected item

OK Store / saves selected item

Normal Exit the service mode

SERVICE MODE 1

ITEM

H-POS

V-POS

H-AMP

V-AMP

DVCO

R High

B High

R Low

B Low

SubBrightness

SERVICE MODE 2 - 14” / 20”

Y/C DELAY

OPTION 1

OPTION 2

OPTION 3

OPTION 4

OPTION 5

OPTION 6

OPTION 7

OPTION 8

OPTION 9

OPTION 10

OPTION 1 1

OPTION 12

OPTION 13

OPTION 14

OPTION 15

ITEM

14”

-17

-44

8

-40

63

0343

0397

0282

0229

-8

20”

-19

-42

-1

63

0354

0394

0255

0211

16

VALOR

-1

36

00

00

01

00

10

02

87

90

B1

00

00

00

08

0F

How to operate the controls in the SERVICE MODE 3

à

Key 3 / 4 Previous / next item

UP/DOWN Channel Up / Channel Down

Volume + Increment of selected item

Volume – Decrement of selected item

OK Store / saves selected item

Normal Exit the service mode

Note: Always, finishing the adjustments, press the “NORMAL” key or the “POWER” key in the remote control to leave

the service mode and return to TV normal way .

- 10 -

H-POS 60Hz Offs

V-POS 60Hz Offs

H-AMP 60Hz Offs

V-AMP 60Hz Of fs

V-LIN

V-SYM

ANGLE

BOW

VZOOM

SERVICE MODE 3

ITEM

14”

-17

8

-1

15

-8

28

-2

2

255

20”

-15

10

14

-1 1

21

-3

0

255

TC-14RM12LP/TC-14RM12LP(.)/ TC-20RA12LP/TC-20RA12LP(.)/TC-20RM12LP/TC-20RM12LP(.)

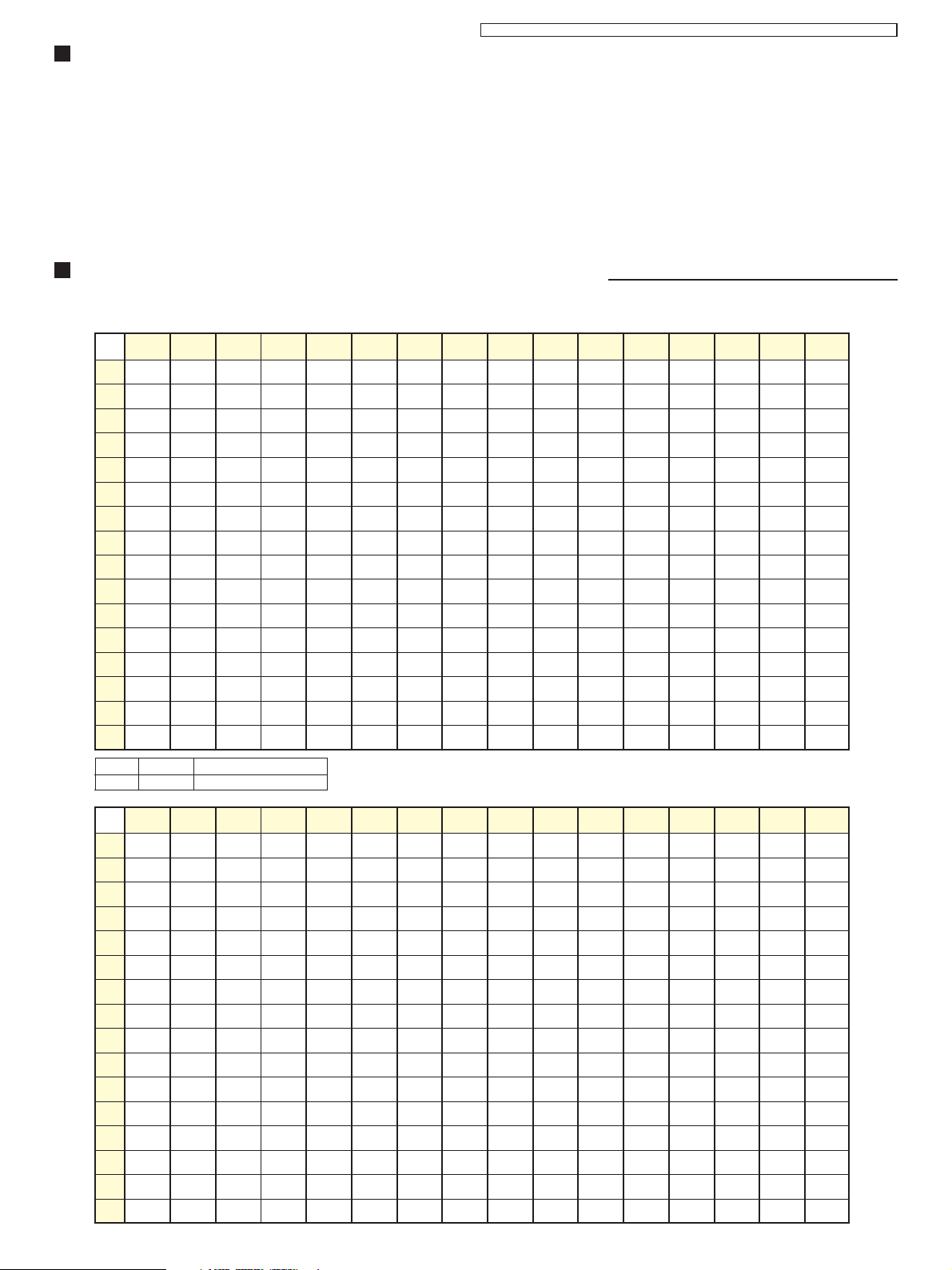

HOW TO ACCESS THE MEMOR Y MAPS (TC-14RM12LP, LP• / TC-20RM12LP, LP• / TC-20RA12LP, LP

1. Select SET UP – SYNTONY – ANTENNA – CABLE

2. Select the channel 99

3. Enter in the SERVICE MODE 2.

4. press “RECALL” in the remote control.

5. “MEMORY EDIT” appears in the screen.

6. Use the "1" or "2" key to move the cursor in the

horizontal direction and the "3" or "4" key to move the

7. The “

time.

8. The bytes are adjusted one by one through the

“VOLUME +” and “VOLUME–” keys.

9. Press the “OK” key to store each adjusted byte.

10. Press the “NORMAL” or “POWER” key to exit the

“MEMORY EDIT MODE”.

cursor in the vertical direction.

TC-14RM12LP, LP• / TC-20RM12LP, LP• /TC-20RA12LP, LP

∧∧

∧

∧∧

” and “

∨∨

∨

∨∨

” channel key changes the page one by

•

TABLE A0

COLUMN

COLUMN COLUMN COLUMN COLUMN COLUMN COLUMN COLUMN COLUMN COLUMN COLUMN COLUMN COLUMN COLUMN COLUMN COLUMN

+0 +1 +2 +3 +4 +5 +6 +7 +8 +9 +A +B +C +D +E +F

LINE

000 C9 23 00 00 04 00 00 00 00 00 00 00 00 00 00 46

LINE

010 36 00 00 01 00 10 02 * 90 B1 00 00 00 08 0F 00

LINE

020 80 00 06 00 81 00 06 00 82 00 06 00 83 00 06 00

LINE

030 84 00 06 00 85 00 06 00 86 00 06 00 87 00 06 00

LINE

040 88 10 06 00 89 00 06 00 8A 10 06 00 8B 00 06 00

LINE

050 8C 00 06 00 8D 00 06 00 8E 00 06 00 8F 00 06 00

LINE

060 90 00 06 00 91 10 06 01 92 00 06 00 93 10 06 00

LINE

070 94 00 06 00 95 00 06 00 96 00 06 00 97 00 06 00

LINE

080 98 00 06 00 99 00 06 00 9A 00 06 00 9B 00 06 00

LINE

090 9C 10 06 00 9D 00 06 00 9E 00 06 00 9F 00 06 00

LINE

0A0 A0 00 06 00 A1 00 06 00 A2 00 06 00 A3 10 06 00

LINE

0B0 A4 00 06 00 A5 00 06 00 A6 00 06 00 A7 00 06 00

LINE

0C0 A8 00 06 00 A9 00 06 00 AA 00 06 00 AB 00 06 00

LINE

0D0 AC 00 06 00 A D 00 06 00 AE 00 06 00 AF 00 06 00

LINE

0E0 B0 00 06 00 B1 00 06 00 B2 00 06 00 B3 00 06 00

LINE

0F0 B4 00 06 00 B5 00 06 00 B6 00 06 00 B7 00 06 00

Others87TC-20RA12LP/LP.

017

COLUMN COLUMN COLUMN COLUMN COLUMN COLUMN COLUMN COLUMN COLUMN COLUMN COLUMN COLUMN COLUMN COLUMN COLUMN COLUMN

+0 +1 +2 +3 +4 +5 +6 +7 +8 +9 +A +B +C +D +E +F

LINE

100 B8 00 06 00 B9 00 06 00 BA 00 06 00 BB 00 06 00

LINE

110 BC 00 06 00 BD 00 06 00 BE 00 06 00 BF 00 06 00

LINE

120 C0 00 06 00 C1 00 06 00 C2 00 06 00 C3 00 06 00

LINE

130 C4 00 06 00 C5 00 06 00 C6 00 06 00 C7 00 06 00

LINE

140 C8 00 06 00 C9 00 06 00 CA 00 06 00 CB 00 06 00

LINE

150 CC 00 06 00 CD 00 06 00 CE 00 06 00 CF 00 06 00

LINE

160 D0 00 06 00 D1 00 06 00 D2 00 06 00 D3 00 06 00

LINE

170 D4 00 06 00 D5 00 06 00 D6 00 06 00 D7 00 06 00

LINE

180 08 00 06 00 D9 00 06 00 D A 00 06 00 DB 00 06 00

LINE

190 DC 00 06 00 DD 00 06 00 DE 00 06 00 DF 00 06 00

LINE

1A0 E0 00 06 00 E1 00 06 00 EZ 00 06 00 E3 00 06 00

LINE

1B0 E4 00 06 00 E5 00 06 00 E6 00 06 00 E7 00 06 00

LINE

1C0 E8 00 06 00 E9 00 06 00 EA 00 06 00 EB 00 06 00

LINE

1D0 EC 00 06 00 ED 00 06 00 EE 00 06 00 EF 00 06 00

LINE

1E0 F0 00 06 00 F1 00 06 00 FZ 00 06 00 F3 00 06 00

LINE

1F0 F4 00 06 00 F5 00 06 00 F6 00 06 00 F7 00 06 00

07

TABLE A2

- 11 -

•

Loading...

Loading...