Panasonic SLCT-350-EE, SLCT-350-EB, SLCT-350-EG, SLCT-350-GN Service manual

o

/

A

Portable CD Player

SL-CT350EB

SL-CT350EE

SL-CT350EG

SL-CT350GN

Colours

(S)..................Silver Type

ORDER No.AD050200 5C8

Specification

●●●●Audi

Sampling frequency: 44.1 kHz

No. ofchannels: 2 (left and right, stereo)

Headphone outputlevel: M3, RMS max.6mW+6mW

16Ω

(adjustable)

Frequencyresponse: 20 Hz to 20,000 Hz

(+0.5dB to -7dB)

●●●●Pickup

Lightsource: Semiconductor laser

Wavelength: 780 nm

●●●●General

Power supply:

DC input; DC 4.5V

AC adaptor input; EB:AC220V-240V 50/60Hz

EG/EE:AC220V-230V 50/60Hz

GN:AC230V-240V 50Hz

Using AC adaptor; 0.8W

Recharging; 3.0W

Playtime:

Using on a flat stable surface at 25°C°, EQ is off, Hold is on,Antiskip is on POS 1.

Play times are in hours and approximate.

Recharging time:

· The playtime maybe less depending on the operating conditions.

· Play time will be considerably reduced when playing CD-RW.

Dimensions (WxHxD): 136.7x21.5x136.7mm

Mass: 180g (with batteries)

bout 3.5 to 4.5 hours

157g (without batteries)

© 2005 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

SL-CT350EB / SL-CT350EE / SL-CT350EG / SL-CT350GN

Operational temperature range: 0°C-40°C

Rechargeable temperature range: 5°C-40°C

Note:

Specifications are subject to change without notice.

Mss and dimensions are approximate.

Note on CD-R and CD-RW:

This unit can playCD-DA format audio CD-R and CD-RW that have

been finalized* upon completion of recording. it may not be able to

play some CD-R or CD-RW due to the condition of the recording.

*Finalizingisaprocess that enables CD-R/CD-RW players to play

audio CD-R and CD-RW.

CONTENTS

Page Page

1 Precaution of Laser Diode 2

2 Accessories

3 Handling Precautions for Traverse Deck

3.1. Handling the traverse deck (optical pickup)

3.2. Caution when replacing traverse deck

3.3. Grounding for electrostatic breakdown prevention

4 Operation Checks and Component Replacement Procedures

4.1. Checking for the P.C.B. ass 馳

4.2. Replacement for the CD lid unit, retainer plate and open

spring

4.3. Replacement for the LCD, button A, button B and multi

button SW unit

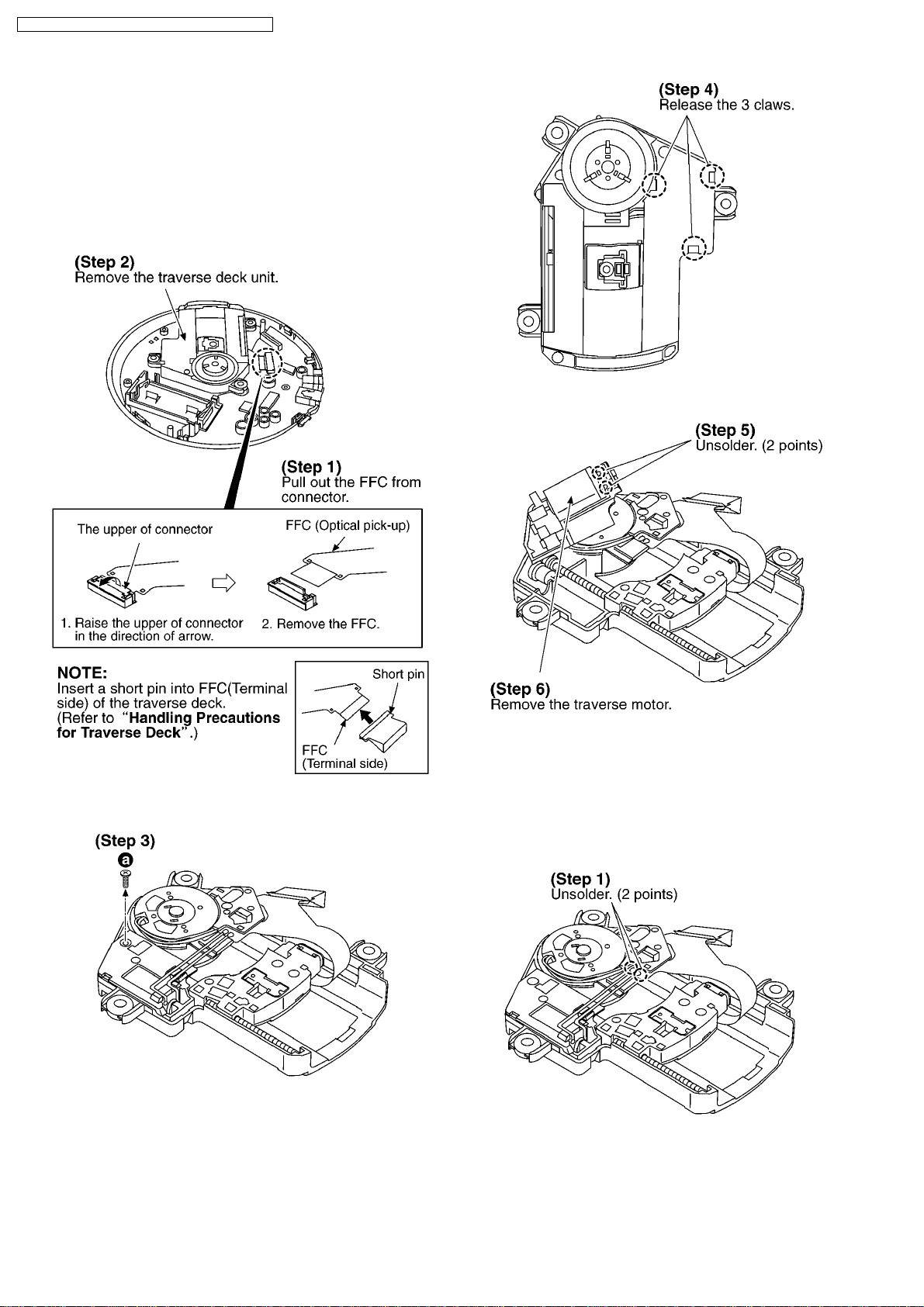

4.4. Replacement for the traverse motor

4.5. Replacement for the optical pick-up

4.6. Replacement for the rest switch

5 Checking the Operation Problems on the Traverse Deck

(Optical Pickup)

6 Automatic Adjustment Results Display Function (Self-check

Function)

6.1. How to display automatic adjustment results

10

10

12

13

14

14

3

4

4

4

4

6

6

8

9

6.2. Display of automatic adjustment results (self-check

function)

7 Display of Self-Diagnostic Function

8 Type Illustration of ICエs, Transistors and Diodes

9 Schematic Diagram Notes

10 Schematic Diagram

11 Printed Circuit Board and Wiring Connection Diagram

12 Block Diagram

13 Terminal Function of ICs

13.1. IC101(AN22003A-NF): Servo Amplifier

13.2. IC301(C2BBFD000574): System Control / LCD Drive

13.3. IC501(MN6627881SE): Servo Processor, Digital Signal

Processor, Digital Filter & D/A Converter

14 Replacement Parts List

15 Cabinet Parts Location

16 Traverse Parts Location

17 Packaging

17.1. SL-CT350EB

17.2. SL-CT350EE/EG/GN

14

15

15

16

17

21

23

25

25

25

26

27

29

30

31

31

32

1 Precaution of Laser Diode

CAUTION:

This unit utilizes a class 1 laser. Invisible laser radiation is emitted from the pickup lens when the unit is turned on:

1. Do not look directly into the pickup lens.

2. Do not use optical instruments to look at the pickup lens.

3. Do not adjust the preset variable resistor on the optical pickup.

4. Do not disassemble the optical pickup unit.

5. If the optical pickup is replaced, use the manufactures specified replacement pickup only.

6. Use of control or adjustments or performance of procedures other than those specified herin may result in hazardous

radiation exposure.

CAUTION:

This product utilizes a liser diode with the unit turned “on”, invisible laser radiation is emitted from the pickup lens.

Wave length: 780nm

Maximum output wadiation power from pickup: 100 µW/VDE

Laserradiationfromthepickuplens is safety level, but be sure the followings:

1. Do not disassemble the optical pickup unit, since radiation from exposed laser diode is dangerous.

2

SL-CT350EB / SL-CT350EE / SL-CT350EG / SL-CT350GN

2. Do not adjust the variable resistor on the pickup unit. It was already adjusted.

3. Do not look at the focus lens using optical instruments.

4. Recommend not to look at pickup lens for a long time.

ACHTUNG:

Dieses Produkt enthalt eine Laserdiode. Im eingeschalteten Zustand Wird unsichtbare Leserstrahlung von der Lasereinheit

abgestrahlt.

Wellenlage: 780nm

Maximale Strahlungsleistung der Lasereinheit: 100 µW/VDE

Die StrahlungasderLasereinheitistungefahrlich, wenn folgende Punkte beachtet werden:

1. Die Lasereinheit nicht zeriegen, de die Strahlung an der freigelegten Laserdiode gefahrlich ist.

2. Denwerkseitig Justierten Einstellregler der Lasereinhit nicht verstellen.

3. Nicht mit optischen Instrumenten in die Fokussierlines blicken.

4. Nicht uber langere Zeit in die Fokussierlines blicken.

2 Accessories

· Stereo earphones..................................................1 pc.

(L0BAB0000185)

· AC adaptor...............................................................1 pc.

(EB: RFEA435B-S)

(EE, EG: RFEA431E-S)

(GN: RFEA436A-S)

EE/GN only

· External battery case..............................................1 pc.

(RFA2666-H)

3

SL-CT350EB / SL-CT350EE / SL-CT350EG / SL-CT350GN

3 Handling Precautions for Traverse Deck

The laser diode in the traverse deck (optical pickup) may break

down due to potential difference caused by static electricity of

clothes or human body.

So, be careful of electrostatic breakdown during repair of the

traverse deck (optical pickup).

3.1. Handling the traverse deck (optical pickup)

1. The traverse deck (optical pickup) is an extremely highprecision construction and must not be subjected to impact,

excessive vibration, or other types of rough handling.

2. To protect the laser diode against electrostatic breakdown,

be sure that the short land A and B of the flexible board

(FFC board) should be short-circuit by solder before pulling

out the FFC. Then inserting a short pin or similar object

intothetipoftheflexible board.

(Refer to Fig. 1 )

3. Handle the flexible circuit boards with care; excessive force

could cause them to be broken.

4. Do not turn the pre-set variable resistor (for adjustment of

the laser power); it has been adjusted at the factory.

(as shown in Fig. 1 )

3.2. Caution when replacing traverse deck

The new traverse deck short-circuits by the short pin, the foil

(C) and short lands to protect the laser diode against

electrostatic breakdown. Be sure to replace to new one

following procedures.

1. Remove the short pin from the FFC, and then connect it to

the connector.

2. Cut the foil (C). (Refer to Fig. 1 ) (Take care not to make

contact with cutting point each other.)

3. Unsolder the short lands. (Refer to Fig. 1 )

3.3. Grounding for electrostatic breakdown prevention

1. Human body grounding

Use the anti-static wrist strap to discharge the static

electricity from your body. (as shown in Fig. 2 )

2. Work table grounding

Put a conductive material (sheet) or steel sheet on the area

where the optical pickup is placed, and fround the sheet.

(as shown in Fig. 3 )

Caution

The static electricity of your clothes will not be grounded

through the wrist strap.

So, take care not to let your clothes touch the traverse deck

(optical pickup).

Fig. 1

Fig. 2

4

Fig. 3

SL-CT350EB / SL-CT350EE / SL-CT350EG / SL-CT350GN

5

SL-CT350EB / SL-CT350EE / SL-CT350EG / SL-CT350GN

4 Operation Checks and Component Replacement

Procedures

· This section describes procedures for checking the

operation of the major printed circuit boards and

replacing the main components.

· For reassembly after operation checks or replacement,

reverse the respective procedures. Special reassembly

procedures are described only when required.

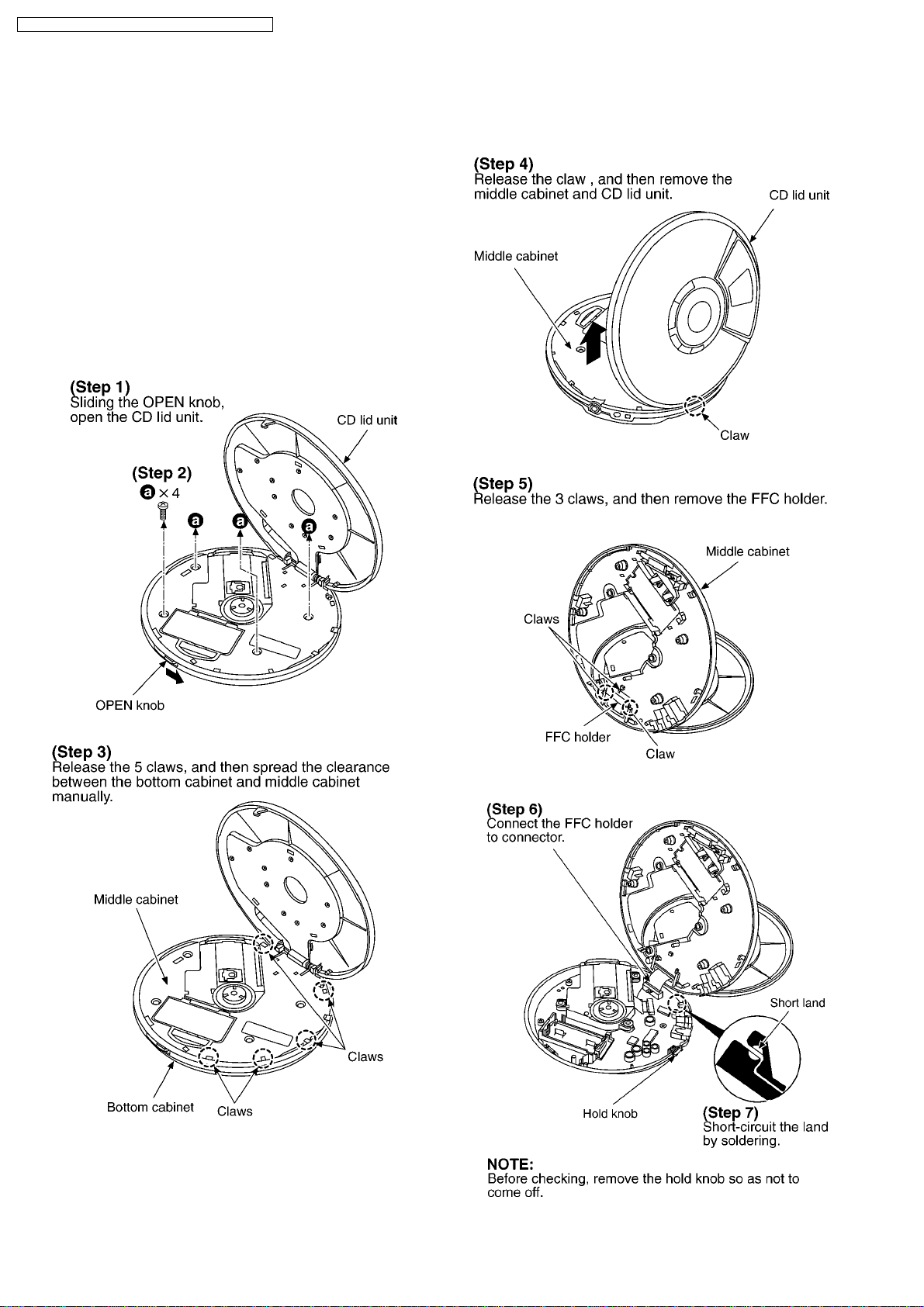

4.1. Checking for the P.C.B. ass’y

4.1.1. Checking for the P.C.B. ass’y

(A side)

6

SL-CT350EB / SL-CT350EE / SL-CT350EG / SL-CT350GN

4.1.2. Checking for the P.C.B. ass’y

(B side)

· Follow the (Step1)-(Step7) of item 4.1.1.

· Check the P.C.B. ass’y (A side) as shown below.

· Check the P.C.B. ass’y (B side) as shown below.

7

SL-CT350EB / SL-CT350EE / SL-CT350EG / SL-CT350GN

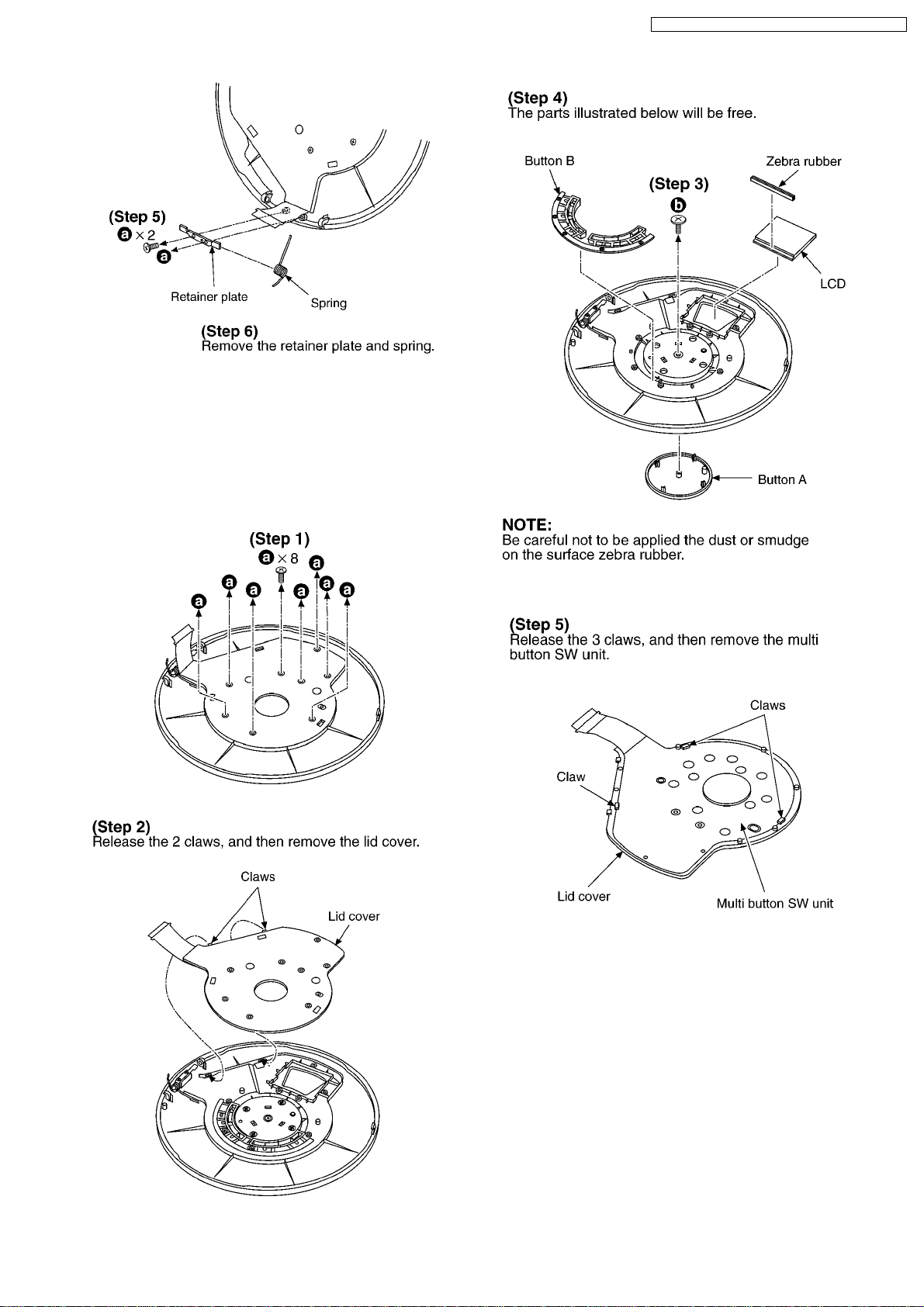

4.2. Replacement for the CD lid

unit, retainer plate and open

spring

· Follow the (Step1)-(Step5) of item 4.1.1.

8

4.3. Replacement for the LCD,

button A, button B and multi

button SW unit

SL-CT350EB / SL-CT350EE / SL-CT350EG / SL-CT350GN

· Follow the (Step1)-(Step5) of item 4.1.1.

· Follow the (Step1)-(Step4) of item 4.2.

9

SL-CT350EB / SL-CT350EE / SL-CT350EG / SL-CT350GN

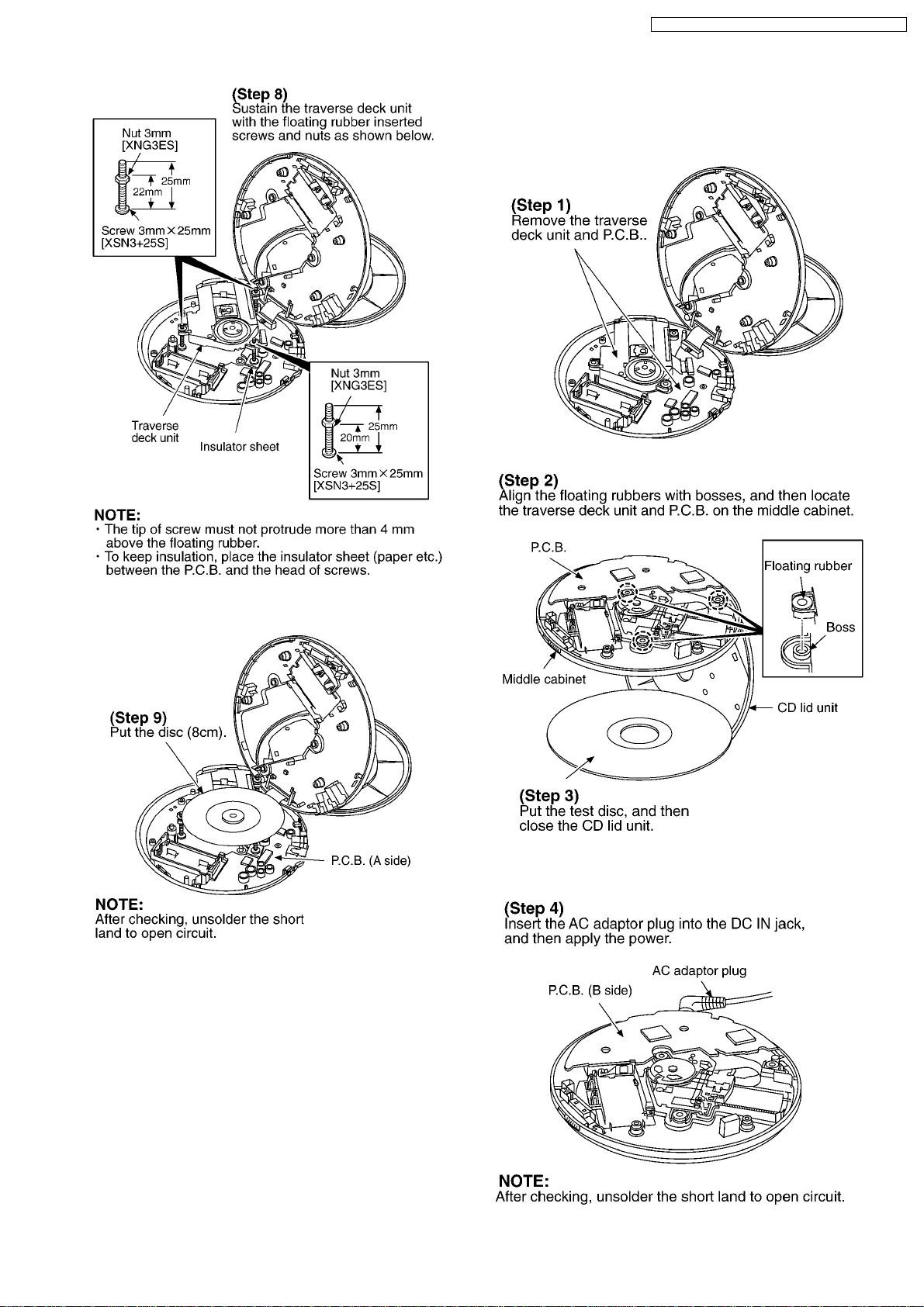

4.4. Replacement for the traverse

motor

· Follow the (Step1)-(Step4) of item 4.1.1.

NOTE:

Be sure to confirm the item 3 “Handling Precautions for

Traverse Deck” before removing the traverse deck unit.

4.5. Replacement for the optical

pick-up

· Follow the (Step1)-(Step4) of item 4.1.1.

· Follow the (Step1)-(Step3) of item 4.4.

10

Loading...

Loading...