Panasonic SF-C14EX-01 Installation Manual

INSTRUCTION MANUAL

Sensor Option

Application Expansion Unit for SF4B Series

SF-C14EX-01

CME-SFC14EX No.2146-00

Thank you very much for using SUNX products. Please read this Instruction Manual

carefully and thoroughly for the correct and optimum use of this product. Kindly keep

this manual in a convenient place for quick reference.

1

SAFETY PRECAUTIONS

٨

Use this device as per its specifications. Do not modify this product since its

functions and capabilities may not be maintained and it may malfunction.

٨

Use of this product under the following conditions or environment is not presupposed. Please consult us if there is no other choice but to use this product in such

an environment.

1)2)Operating this product under conditions or in an environment not described in this manual.

Using this product in the following fields: nuclear power control, railroad, aircraft,

automobiles, combustion facilities, medical systems, aerospace development, etc.

٨

When this product is to be used for enforcing protection of a person from

any danger occurring around an operating machine, the user should satisfy the

regulations established by national or regional security committees (Occupational

Safety and Health Administration: OSHA, the European Standardization Committee, etc.). Contact the appropreate organization(s) for details.

٨

When using this product together with particular machines, follow the respective safety regulations

in regard to appropriate usage, mounting (installation), operation and maintenance. Users, including the installer and operator, are responsible for making sure that this product is properly applied.

Install suitable protection equipment as a countermeasure for failure, damage, or

٨

malfunction of this product.

Before using this product, check whether the product performs properly with the

٨

functions and capabilities as per the design specifications.

Treat this product as industrial waste upon disposal.

٨

2

CAUTIONS

٨

Machine designer, installer, employer and operator

The machine designer, installer, employer and operator are solely

responsible to ensure that all applicable legal requirements relating to

the installation and the use in any application are satisfied.

Whether this product functions as intended and systems including

this product comply with safety regulations depend on the appropriateness of the application, installation and operation. The machine designer,

installer, employer and operator are solely responsible for these items.

Engineer

٨

The engineer would be a person who is appropriately educated, has

widespread knowledge and experience, and can solve various problems which may arise during work, such as a machine designer, or a

person in charge of installation or operation, etc.

Operator

٨

The operator should read this instruction manual thoroughly, under-

stand its contents, and perform operations following the procedures

described in this manual for the correct operation of this product.

In case this product does not perform properly, the operator should re-

port this to the person in charge and stop machine operation immediately. The machine must not be operated until correct performance of

this product has been confirmed.

Environment

٨

Do not use a mobile phone or a radio phone near this product.

WARNING

٨

٨

٨

Do not install this product in the following environments.

1) Areas with high humidity where condensation is likely to occur

2) Areas exposed to corrosive or explosive gases

3)

Areas exposed to vibration or shock of levels higher than that specified

4) Areas exposed to contact with water

5) Areas exposed to excessive steam or dust

Equipment in which this device is installed

٨

Do not install this product with a machine whose operation cannot

be stopped immediately in the middle of an operation cycle by emergency stop equipment.

This product starts performance 2 seconds after power ON. The con-

trol system must start to function in accordance with this timing.

Wiring

٨

Be sure to carry out the wiring while the power is OFF.

All electrical wiring should conform to the regional electrical regula-

tions and laws. The wiring should be done by engineer(s) having special electrical knowledge.

Do not run the sensor cable together with high-voltage lines or pow-

er lines or put them together in the same raceway.

Maintenance

٨

Periodical inspection of this product must be performed by an engi-

neer having special knowledge.

٨

Others

Never modify this product.

When connecting this product to a product other than the connectable input device, the

system does not conform to the control category 4 basd on ISO 13849-1(EN 954-1).

Connect this product to the same power supply which the light curtain uses.

Wrong wiring will damage the product.

Notes: 1)

٨

Verify that the supply voltage variation is within the rating. Note that if a voltage exceeding the rated

range is applied, or if an AC power supply is directly connected, the unit may get burnt or damaged.

The DC power supply unit must satisfy the conditions given below:

٨

1) Power supply unit authorized in the region where this device is to be used.

Power supply unit conforming to EMC Directive and Low-voltage Directive

2)

(In case CE conformity is required.)

3) Power supply unit conforming to the Low-voltage Directive and with an output

of 100VA or less.

4)

The frame ground (F.G.) terminal must be connected to ground when using a

commercially available switching regulator.

5)

Power supply unit with an output holding time of 20ms or more.

6)

Use an isolation transformer for the DC power supply unit.

7)

If surges are likely to occur, take countermeasures such as connecting a

surge absorber to the origin of the surge.

8)

Power supply unit corresponding to CLASS 2 (In case UL / cUL conformity is required.)

<Additional information>

As provided in IEC 60536 (CLASS: Protection against Electric Shook), this power supply should require no ground earth and satisfy the insulation distance by double insulation or reinforced insulation.

If the power supply conforms to Low-voltage Directive and has an output of

100VA or less, it can be used as a suitable product.

٨

This product is not dust-proof / splash proof. Be sure to put this product into a

control box having IP54 construction.

Avoid dust, dirt, and steam.

٨

Take care that the product does not come in direct contact with water, oil, grease,

٨

or organic solvents, such as, thinner, etc.

The seal as shown in the drawing on the right is

٨

stuck to the engagement point of unit. If the seal is

peeled off or broken, this equipment will not be

certified as 'Safety equipment' and will not be covered by our guarantee.

٨

Note that this equipment is applicable only in the control circuit grounded in accordance with IEC 60204-1 and JIS B 9960-1, or in the control circuit in which the

insulation monitor unit (ground fault detection unit) is included.

٨

This unit is suitable for indoor use only.

3

OUTLINE

٨ This is the application expansion unit which can control three different safety

outputs in combination with the light curtain SF4B series.

It exhibits the following features:

1)

Either PNP or NPN output can be selected with the slide switch.

It can be connected to the light curtain using the exclusive 8-core connection cable with connectors.

2)

A detachable spring gauge terminal is employed.

3)

The three auxiliary outputs (muting output, override output and lamp break out-

4)

put) and the auxiliary output of the light curtain SF4B series are incorporated.

The interference prevention wiring among the light curtains SF4B series is possible. Maximumly

5)

three sets in series / parallel mixed connection can be configured with the interference prevention system. The total no. of beam channels in series / parallel mixed connection is 192 max

4

SPECIFICATIONS

Designation Application expansion unit for SF4B series

Connectable light curtain

Applicable standard IEC 61496-1, UL 61496-1, EN 61496-1, JIS B 9704-1

Control category Applicable to Category 4 based on ISO 13849-1EN 954-1

Supply voltage 24V DCr10%ޓRipple P-P10% or less

Current consumption

Safety output

Safety output 1

Safety output 2

Safety output 3

Auxiliary output

Auxiliary output 1

Auxiliary output 2

Auxiliary output 3

Auxiliary output 4

Muting indicator output Applicable muting indicator: 24V DC, 3.6 to 30W (per unit)

Ambient temperature

Ambient humidity 30 to 85% RH, Storage: 30 to 95% RH

Connection terminal Detachable spring gauge terminal

Material Enclosure: ABS

Weight 250g approx.

Model No.Item SF-C14EX-01

0.2A or less (Excluding light curtain and other external connecting device)

PNP / NPN open-collector transistor 3

<When PNP output is selected>

Maximum source current: 200mA

Applied voltage: same as supply voltage

(between the safety output and +V)

Residual voltage: 2V or less

(at 200mA source current)

<Safety output 1>

ON when the light curtain is in light receiving condition, OFF when the light curtain is in light blocked condition (Note 1)

Operation mode

(Output operation)

Protection circuit

(Short-circuit protection)

Response time

Operation mode

(Output operation)

Protection circuit

(Short-circuit protection)

Protection circuit

(Short-circuit protection)

Both safety output 1 and 2 are OFF when the emergency stop is valid regardless of whether

the light curtain is in the light receiving or light blocked condition.

2)

The auto-reset cannot be used with safety output 3.

3)

The auxiliary output incorporated in the SF4B is output.

<Safety output 2>

ON when the light curtain is in light receiving condition or the muting function is valid

OFF when the light curtain is in light blocked condition and the muting function is invalid (Note 1)

<Safety output 3>

ON when the emergency stop is invalid, OFF when the emergency stop is valid

OFF response: 14ms or less (including the response time of the light curtain)

ON response: 90ms or less (auto-reset) / 140ms or less (manual reset) (Note 2)

PNP / NPN open-collector transistor3

<When PNP output is selected>

Maximum source current: 60mA

Applied voltage: same as supply voltage

(between the auxiliary output and +V)

Residual voltage: 2V or less

(at 60mA source current)

<Auxiliary output 1>

ON when the muting function is invalid, OFF when the muting function is valid

<Auxiliary output 2>

ON when the override function is invalid, OFF when the override function is valid

<Auxiliary output 3>

ON when the muting indicator is normal, OFF when the muting indicator is error

<Auxiliary output 4>

ON when the light curtain is in light blocked condition, OFF when the light curtain is in light receiving condition (Note 3)

-10 to +55 (No dew condensation or icing allowed), Storage: -25 to +70

SF4B series

<When NPN output is selected>

Maximum sink current: 200mA

Applied voltage: same as supply voltage

(between the safety output and 0V)

Residual voltage: 2V or less

Incorporated

Incorporated

Incorporated

(at 200mA sink current)

<When NPN output is selected>

Maximum sink current: 60mA

Applied voltage: same as supply voltage

(between the auxiliary output and 0V)

Residual voltage: 2V or less

(at 60mA sink current)

.

5

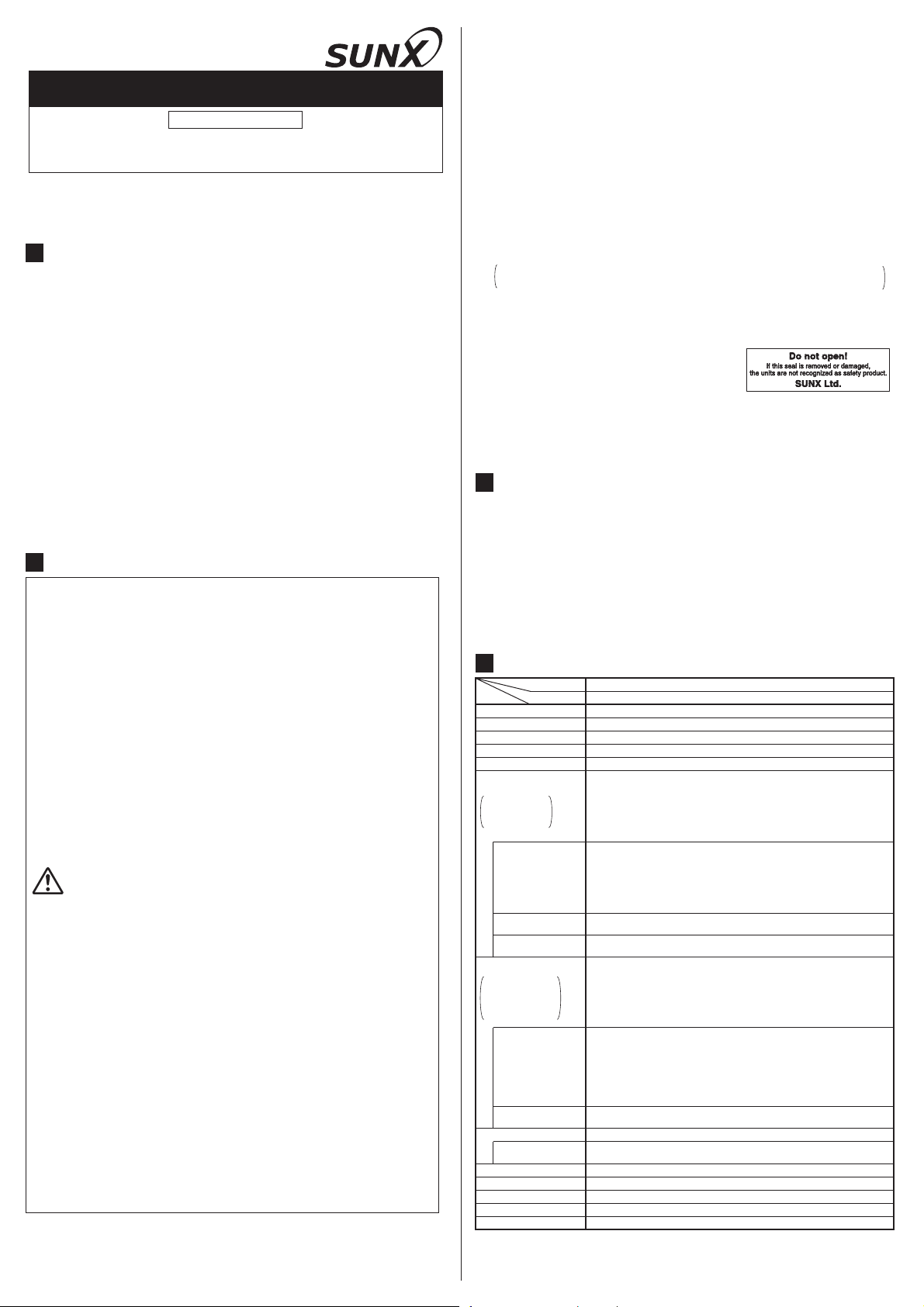

FUNCTIONAL DESCRIPTION

Ԙ Emitter side connector

Ԙ

ԙ

Ԛ

ԛ

Ԝ

ԝ

Ԟ

ԟ

Ԡ

Ԣ

ԣ

Ԥ

ԥ

Ԧ

ԧ

Ԩ

6

Terminal No. Terminal No.

ԙ Receiver side connector

Ԛ Digital indicator (Red)

ԛ

Power indicator (Ui) (Green)

Ԝ Test input indicator

(TEST) (Yellow)

ԝ Muting sensor 1

indicator (MU1) (Orange)

Ԟ Muting sensor 2

indicator (MU2) (Orange)

ԟ

Safety output 1 indicator (OUT1) (Green)

Ԡ

Safety output 2 indicator (OUT2) (Green)

ԡ

Safety output 3 indicator (OUT3) (Green)

Emitter side connector

Receiver side connector

Digital indicator (Red)

Power indicator (Ui) (Green)

Test input indicator (TEST) (Yellow)

Muting sensor 1

Muting sensor 2

Safety output 1 indicator (OUT1) (Green)

Safety output 2 indicator (OUT2) (Green)

Safety output 3 indicator (OUT3) (Green)

Output polarity selection switch

Auxiliary output 1

Auxiliary output 2

Auxiliary output 3

Interlock 1 indicator (INTER LOCK1) (Yellow)

Interlock 2 indicator (INTER LOCK2) (Yellow)

Interlock 3 indicator (INTER LOCK3) (Yellow)

Description FunctionNo.

indicator (MU1) (Orange)

indicator (MU2) (Orange)

indicator (AUX1) (Orange)

indicator (AUX2) (Orange)

indicator (AUX3) (Orange)

The emitter of SF4B series is connected.

The receiver of SF4B series is connected.

Blinks when an error occurs.

Lights up when power is supplied.

Lights up when the test input is valid.

Lights up when muting sensor 1 is ON.

Lights up when muting sensor 2 is ON.

Lights up when safety output 1 is ON.

Lights up when safety output 2 is ON.

Lights up when safety output 3 is ON.ԡ

PNP (Minus earthing) or NPN (Plus earthing)

can be selected.

Lights up when auxiliary output 1 is ON.

Lights up when auxiliary output 2 is ON.

Lights up when auxiliary output 3 is ON.

Lights up when interlock 1 is ON.

Lights up when interlock 2 is ON.

Lights up when interlock 3 is ON.

TERMINAL ARRANGEMENT

14

Safety output 1ޓReceiving light /

light blocked output of the light curtain

24

34

Safety output 2ޓLight curtain output

including the muting function

44

54

Safety output 3

Emergency stop output

64

S3

Muting sensor input 1

(PNP output type)

S3

S3+, S3-: Power supply, S3: Sensor output

S3

S4

Muting sensor input 1

(NPN output type)

S4

S4S4Power supplyS4: Sensor output

S4

T1

Test input terminal

Open: Test mode, Short-circuit: Normal operation

T2

O1

Override input terminal

Open: Invalid, Short-circuit: Valid

O2

L1

Muting indicator output 1

L1

L2

Muting indicator output 2

L2

24V DCA1

0VA2

Function Function

S11

S12

S21

S22

X11

X12

X13

X21

X22

X23

X31

X32

AUX4

IE

IE

IR

IR

Ԣ Output polarity selection

switch

ԣ Auxiliary output 1

indicator (AUX1) (Orange)

Ԥ Auxiliary output 2

indicator (AUX2) (Orange)

ԥ Auxiliary output 3

indicator (AUX3) (Orange)

Ԧ Interlock 1 indicator

(INTER LOCK1) (Yellow)

ԧ Interlock 2 indicator

(INTER LOCK2) (Yellow)

Ԩ Interlock 3 indicator

(INTER LOCK3) (Yellow)

Emergency stop contact input

2 NC input

Between S11 to S12

Between S21 to S22

Safety output 1 reset input

X11 to X12: Manual reset

X11 to X13: Auto-reset

Safety output 2 reset input

X21 to X22: Manual reset

X21 to X23: Auto-reset

Safety output 3 reset input

X31 to X32: Manual reset

Auxiliary output 1 Muting outputAUX1

Auxiliary output 2 Override outputAUX2

Auxiliary output 3 Lamp break outputAUX3

Auxiliary output 4ޓLight curtain auxiliary output

Interference prevention terminal Emission +

Interference prevention terminal Emission Interference prevention terminal Receipt +

Interference prevention terminal Receipt -

7

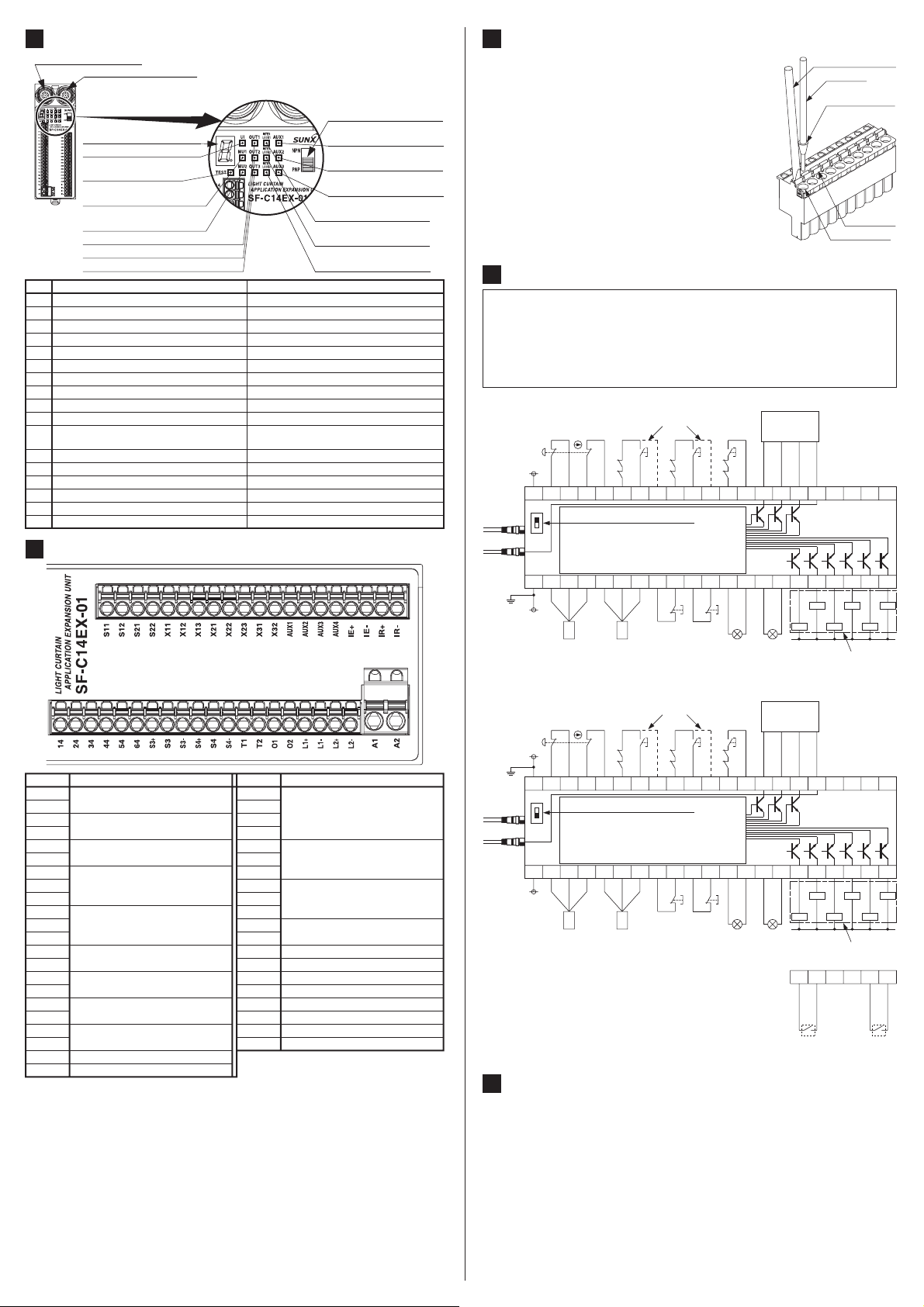

MOUNTING TERMINAL BLOCK

٨

When connecting to the terminal block with a ferrule

(sleeve) (please arrange separately), insert a solid wire

or twisted wire with a ferrule (sleeve) into the hole, as

shown in the figure at the right. The wire is locked when

it is properly inserted. However, do not to pull the wire

with exces

٨

When connecting the twisted wire (lead wire) without a

sive force, as this can cause a cable break.

Flat-head screwdreiver

Lead wire

Ferrule (sleeve)

terminal

(Please arrange separately)

ferrule (sleeve), insert the wire to the innermost of the

connecting hole while pressing the release button.

٨

When releasing the solid wire or the twisted wire (lead

wire), pull the wire while pressing the release button.

٨

The following solid wire and twisted wire (lead wire) are

recommended.

Power supply line side: 0.2 to 2.5mm2 (AWG 24 to 12)

Release button

Lead wire inlet

Signal line side: 0.2 to 1.5mm2(AWG 24 to 16)

8

WIRING

When this product is connected to the light curtain, be sure to use the following

٨

connecting cable.

SFB-CB05-EX (Cable length 0.5m), SFB-CB5-EX (Cable length 5m)

SFB-CB10

٨

The following cables are recommended for power supply and signal line.

Power supply cable:0.2 to 2.5mm

Signal line cable: 0.2 to 1.5mm

-EX(Cable length

10m)

2

AWG 24 to 12

2

(AWG 24 to 16)

<Wiring for PNP output (Manual reset)>

(*2)

Emergency

stop switch

+24V DC

A1

S11 S21 X11S22 X12 X22 X23

PNP

Receiver side

connector

NPN

Emitter side

connector

A2

S3+S3-S4S4+S4

F. G

0V

(*1) (*1)

Muting sensor 1

(PNP output type)

<Wiring for NPN output (

(*2)

Emergency

stop switch

+24V DC

F. G

A1

S11 S21 X11S22 X12 X22 X23

PNP

Receiver side

connector

NPN

Emitter side

connector

A2

S3+S3-S4S4+S4

0V

(*1) (*1)

Muting sensor 1

(PNP output type)

*1:

If the NO (Normally Open) contact switch is used as a

Wiring in auto-reset setting (broken line)

KA

KB

Output polarity selection switch

Control circuit

S3

㧗V

OUT0V㧗V

-

OUT

0V

Test

Muting sensor 2

(NPN output type)

input

Manual reset)

Wiring in auto-reset setting (broken line)

KA

KB

Output polarity selection switch

Control circuit

S3

㧗V

OUT0V㧗V

-

OUT

0V

Test

Muting sensor 2

(NPN output type)

input

KC

KD

X21X13S12

O1 O2

Override

input

Muting indicator

output 1

3.6 to 30W

KC

KD

X21X13S12

O1 O2

Override

input

Muting indicator

output 1

3.6 to 30W

X31

L1

>

X31

L1

muting sensor, wire it as shown in the figure right.

*2:

If the emergency stop switch is not used, short-circuit

between the terminals S11 to S12 and S21 to S22

directly.

*3:

KA to KF are relays with forcibly guided contacts or

magnet contactors.

9

SHORT-CIRCUIT PROTECTION

٨

The power supply unit of this equipment uses the electronic fuse which does not

require any replacement.

٨

When the electronic fuse trips, turn off the power supply and eliminate the cause

for the overcurrent. The reset the fuse and turn the power back on.

٨

The electronic fuse is not meant to be used for equipment that is operated continuously. Note that the specification may not be satisfied by continuous operation.

PLC etc.

KE

KF

AUX2AUX1

X32 IE+IE-IR-IR

+

KE

KF

X32 IE+IE-IR-IR

+

AUX3 AUX4

-

L2-L2+L1

14 24T2T1

Muting indicator

output 2

3.6 to 30W

PLC etc.

AUX2AUX1

AUX3 AUX4

-

L2-L2+L1

14 24T2T1

Muting indicator

output 2

3.6 to 30W

S3+S3-S4S4+S4

34 44 6454

(*3)

34 44 6454

(*3)

S3

+

KFKDKB

KEKCKA

0V

+

KFKDKB

KEKCKA

24V

-

Loading...

Loading...