Panasonic SF-C13 Installation Manual

INSTRUCTION MANUAL

Sensor Option

Safety Control Unit for Light Curtain

SF-C13

Thank you very much for using SUNX products. Please read this Instruction

Manual carefully and thoroughly for the correct and optimum use of this product.

Kindly keep this manual in a convenient place for quick reference.

1

OUTLINE

٨ The SF-C13 is an exclusive control unit for SUNX light curtain conforming to

European / North American safety standards.

This product is conforming to up to the control category 4 specified in EN 954-1.

2

SPECIFICATIONS

Item

Connectable input device

Rated operation

voltage / current

Contact material / contacts

Contact resistance

(Initial value)

Electrical lifetime

Rated operation

voltage / current

Semiconductor auxiliary

output (AUX terminal)

Fuse

Response time

(Drop-out delay)

Excess voltage category

Indicators

Trailing edge switching function

Polarity selection function

Environmental resistance

Notes: 1)2)The lifetime of the switch of relay depends on type of the load, frequency of switching or

Model No.

IEC 61496-1, UL 61496-1, JIS B 9704-1Applicable standard

24V DCr10% Ripple P-P 10% or lessSupply voltage

30V DC/4A, 230V AC/4A, Resistance load (the contact protection for

inductive load), Minute current: 10mA or more (CV24V DC)

AgSnO, Self cleaning, positively driven

10,000,000 times or more (switching frequency 180 times/min.) (Note 1)Mechanical lifetime

(switching frequency 20 times/min. at 230V AC/3A, resistive load) (Note 1)

Safety relay contact (NC contact)1 (interlocked to safety output)Auxiliary output

24V DC/2A, Minute current: 10mA or more (at 24V DC)

PNP open-collector transistor

Maximum source current: 60mA

Applied voltage: same as supply voltage

Residual voltage: 2.3V or less (at 60mA source current)

Leak current: 2mA or less

Built-in electronic fuse, Breaking current: 0.5A or more, reset by power supply stop

80ms or less / 90ms or less (Auto reset / Manual reset)Pick-up delay

Green LED (Lights up when power is supplied)Power

Green LED (lights up when the safety output is 'close')Safety output

Fault

Ambient temperature

Vibration resistance

Pollution degree

environment etc.

For details, refer to ' TROUBLESHOOTING'.

Yellow LED (lights up when the safety output is 'open'Interlock

Yellow LED (blinks when an error occurs) (Note 2)

Incorporated (selectable either plus or minus grounding by wiring process)

Plus grounding: For NPN input type light curtain

Minus grounding: For PNP input type light curtain

-10 to +55(No dew condensation or icing allowed), Storage: -25 to +70

No malfunction when tested with 10 to 55Hz frequency, 0.35mm

amplitude in X, Y and Z directions for twenty times each

9

30 to 85% RH, Storage: 30 to 95% RHAmbient humidity

Light curtains manufactured by SUNX

100mA or less (without light curtain)Current consumption

AC-15, DC-13 (IEC 60947-5-1)Application category

Enclosure: IP40, Terminal: IP20Protection

SF-C13

NO contact3Safety output

4A (slow-blow)Fuse

100mǡ or less

100,000 times or more

2A (slow-blow)Fuse

(between semiconductor auxiliary output and +V)

Dark-ONOutput operation

10ms or less

Υ

Incorporated

2

Spring gauge terminalConnection terminal

Enclosure: ABSMaterial

200g approx.Weight

5

SHORT-CIRCUIT PROTECTION

٨

The power supply unit of this equipment adopts the electronic fuse which do

not require any replacement.

٨

When the electronic fuse is operated, turn off the power supply, and remove

the cause of overcurrent before restarting the power supply for resetting.

The electronic fuse is not suitable to use in which the equipment is operated

٨

continuously or daily. Note that operating the equipment continuously may

not be unable to satisfy the specifications.

6

CAUTIONS

٨

In case this unit is connected to a product other than the connectable input

devices, this unit doesn't meet the control category 4 specified in EN 954-1.

Connect this product and the light curtain to a common power supply.

٨

Make sure that the power is off while wiring.

٨

Take care that wrong wiring will damage the product.

٨

Verify that the supply voltage variation is within the rating. Take care that if a

٨

voltage exceeding the rated range is applied, or if an AC power supply is directly connected, the unit may get burnt or damaged.

The DC power supply unit must satisfy the conditions given below:

٨

1) Power supply unit authorized in the region where this device is to be used.

2) Power supply unit conforming to EMC Directive and Low-voltage Directive

(In case CE conformity is required.)

3) Power supply unit conforming to the Low-voltage Directive and with an output of 100VA or less.

4)

The frame ground (F.G.) terminal must be connected to ground when using

a commercially available switching regulator.

5) Power supply unit with an output holding time of 20ms or more.

6) Use an isolation transformer for the DC power supply unit.

7) In case a surge is generated, take countermeasures such as connecting a

surge absorber to the origin of the surge.

8)

Power supply unit corresponding to CLASS 2 (In case C-UL conformity is required.)

<Additional information>

As provided in IEC 60536 (CLASS: Protection against Electric Shook), this

power supply should require no ground earth and satisfy the insulation distance called double insulation or reinforced insulation.

In case the power supply conforms to Low-voltage Directive and has an

output of 100VA or less, it can be used as a suitable product.

Do not run the wires together with high-voltage lines or power lines or put

٨

them in the same raceway. This can cause malfunction due to induction.

Avoid dust, dirt, and steam.

٨

Take care that the product does not come in direct contact with water, oil,

٨

grease, or organic solvents, such as, thinner, etc.

The seal as shown in the drawing on the right is

٨

stuck to the engagement point of unit. When the

seal is peeled off or broken, this equipment will

not be certified as 'Safety equipment' and will not be covered by our guarantee.

٨

Note that this equipment is applicable only in the control circuit grounded in

accordance with IEC 60204-1 and JIS B 9960-1, or in the control circuit in

which the insulation monitor unit (ground fault detection unit) is arranged.

This unit is suitable for indoor use only.

٨

7

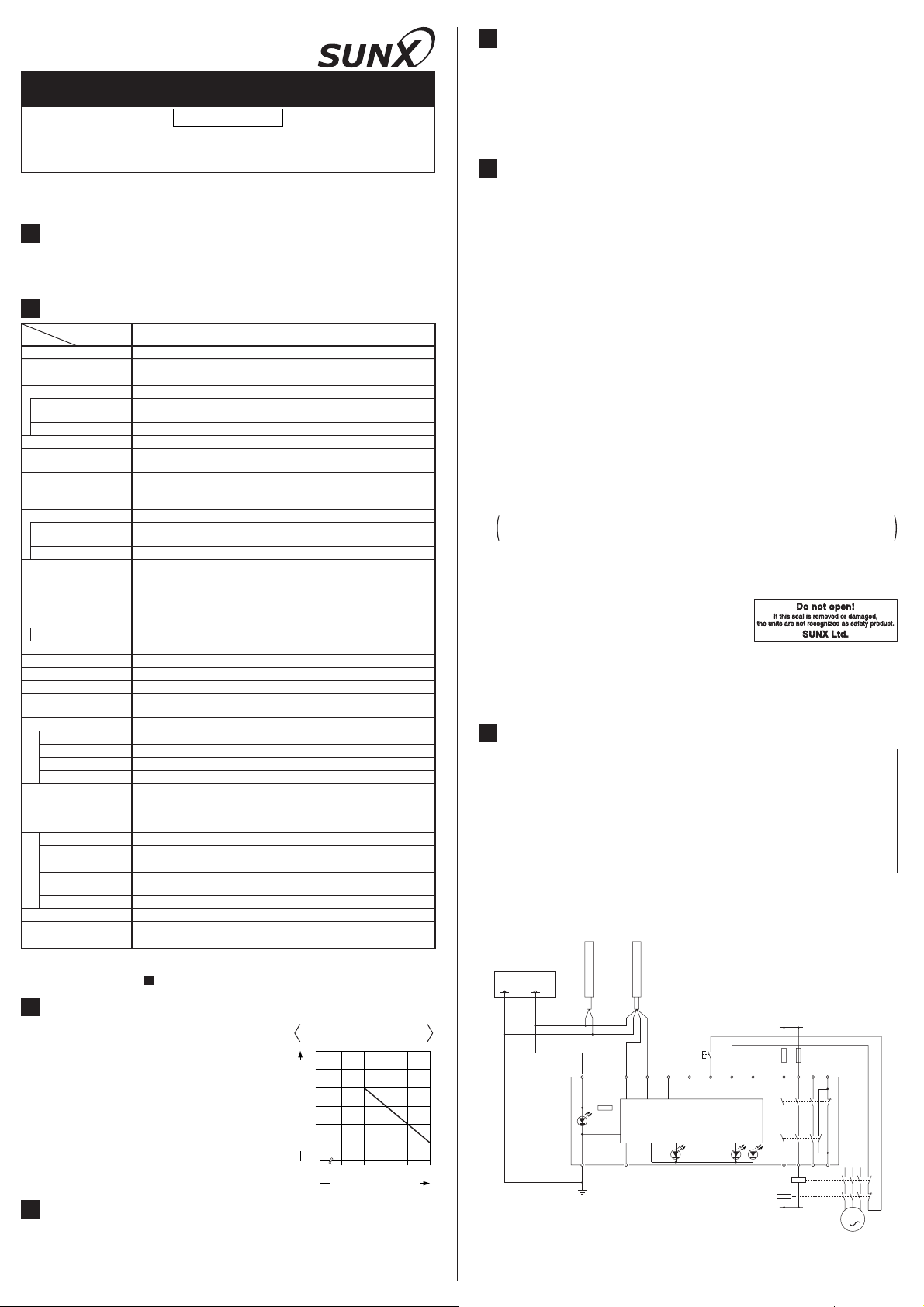

I/O CIRCUIT DIAGRAM

٨

The following cables are recommended for power supply / output line and

signal line.

Solid wire: Ǿ0.4 to Ǿ1.2mm (AWG 26 to 16)

Twisted wire: 0.3 to 1.25mm2(AWG 22 to 16)

Standard stripped wire length: 11mm

For wiring the light curtain, refer to the instruction manual enclosed with the

٨

light curtain.

When connecting a product other than this product with the light curtain,

٨

arrange a terminal block separately.

<Wiring for the minus grounding (PNP setting)>

٨ The figure shown below is the case that this product is connected to a type 4

PNP output type light curtain. Connect the control output OSSD 1 and OSSD

2 of the light curtain to S1 and S2 respectively.

Emitter Receiver

Power supply

0V 24V DC

3

INSTALLATION POSITION/DIRECTION/METHOD

٨

Use the 35mm width DIN rail to install the unit.

٨

The installation position/direction is not

basically limited.

Please fix this product with the optional DIN rail

٨

stopper (MS-DIN-E) after installing the product

on to the 35mm width DIN rail.

If two, or more, units are placed side by side,

٨

make sure to space them at least 5mm apart. In

case they are mounted close to each other,

lower the rated operation current of the safety

output depending on the ambient temperature,

refering the right graph.

4

FUNCTIONS

Derating for mounting the

units close to each other

6

5

4

3

2

1

Rated operation current (A)

0

35 40 45 50 55

Ambient temperature ()

ŪTrailing edge switching function

This function is to accept the input when the reset switch is pressed (contact

'close') and then released (contact 'open') at the manual start setting.

An unexpected start-up due to the welded reset switch can be avoided.

+V +V0V

0V

OSSD1

A1

F

Ui

A2 AUX

F.G.

KA, KB: Magnet contactor

OSSD2

RESET

X1 X2 X3S1 S4S2 S3

SF-C13 CONTROL-LOGIC

OUT

INTERLOCK

L1

FUSE 1 FUSE 2

13 23 33 41

K1

K2

FAULT

14 24 34 42

KB

KA

N

M

3

٨ In case of connecting a type 2 PNP output type light curtain, connect the

control output (OSSD) to S1, and also put a jumper between S2 and S3.

<Wiring for the plus grounding (NPN setting)>

٨ The figure shown below is the case that this product is connected to a type 4

NPN output type light curtain. Connect the control output OSSD 1 and OSSD

2 of the light curtain to S4 and S2 respectively.

Emitter Receiver

Power supply

0V 24V DC

8

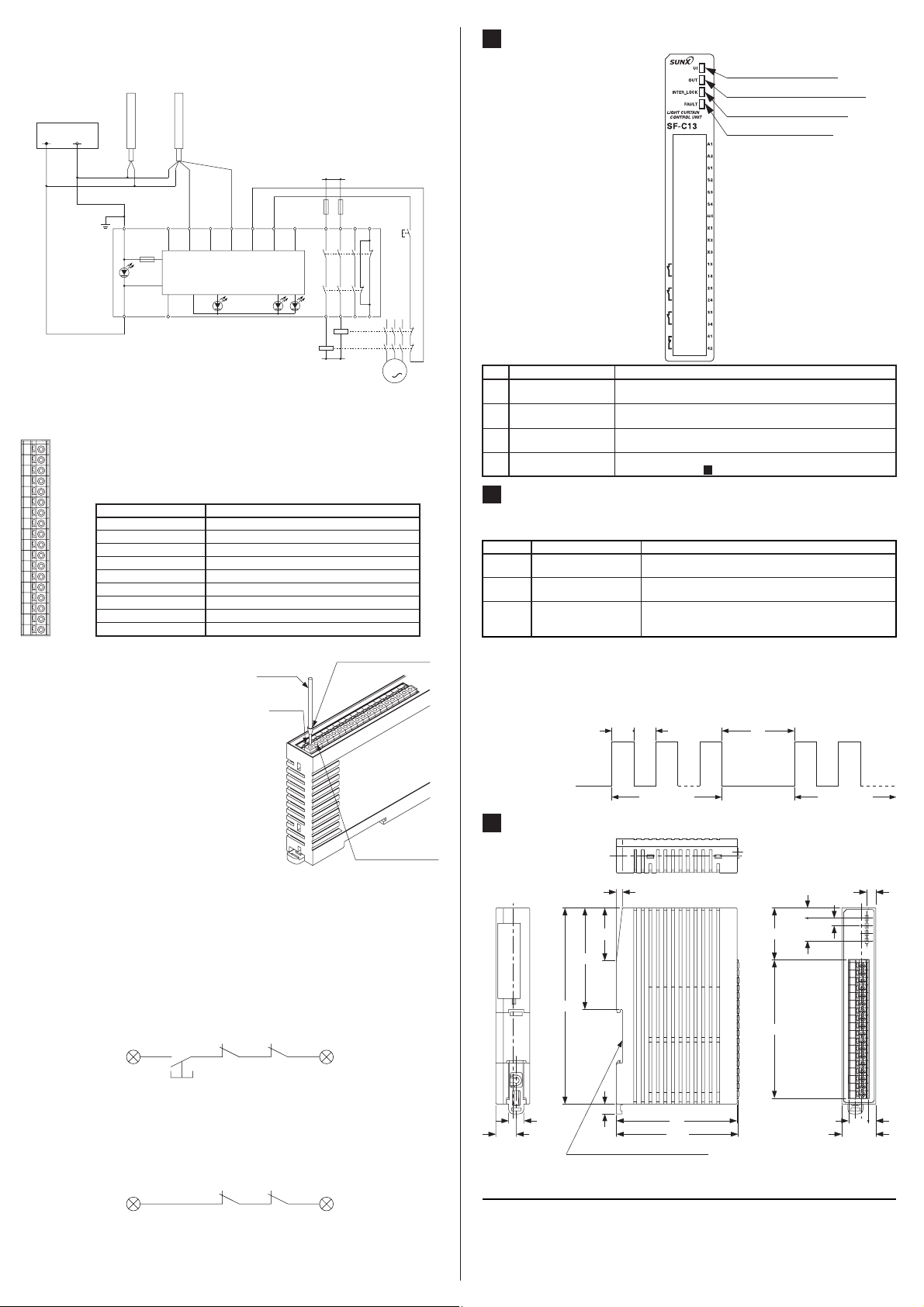

FUNCTIONAL DESCRIPTION

Ԙ Power indicator (Green)

ԙ Safety output indicator (Green)

Ԛ Interlock indicator (Yellow)

ԛ Fault indicator (Yellow)

+V +V0V

0V

OSSD2

A1

F.G.

F

Ui

A2 AUX

KA, KB: Magnet contactor

SF-C13 CONTROL-LOGIC

OUT

OSSD1

X1 X2 X3S1 S4S2 S3

INTERLOCK

L1

FUSE 1 FUSE 2

13 23 33 41

K1

K2

FAULT

14 24 34 42

KB

KA

N

RESET

M

3

٨ In case of connecting a type 2 NPN output type light curtain, connect the

control output (OSSD) to S4, and also put a jumper between S2 and S3.

٨ Terminal arrangement diagram

A1

A2

S1

S2

S3

S4

AUX

X1

X2

X3

13

14

23

24

33

34

41

42

When connecting to the terminal, insert

the solid wire or the twisted wire with a

ferrule (sleeve) terminal as shown in the

figure right (please arrange separately) to

the innermost of the connecting hole.

The wire is locked when it is properly in-

Terminal No. Description

A1

A2

S1 to S4 Light curtain control output (OSSD) input terminal

AUX Semiconductor auxiliary output

X1 Reset output terminal

X2 Reset input terminal (manual)

X3 Reset input terminal (automatic)

13-14, 23-24, 33-34 Safety output (NO contact 3)

41-42 Auxiliary output (NC contact 1)

24V DC

0V

Lead wire

Release

button

Ferrule (sleeve)

terminal

(Please arrange separately)

serted. However, do not to pull the wire

with excessive force, as this can cause a

cable break.

When connecting the twisted wire (lead

wire), without a ferrule (sleeve) terminal,

insert the wire to the innermost of the

connecting hole while pressing the release button.

When releasing the solid wire or the

twisted wire (lead wire), pull the wire

while pressing the release button.

The following solid wire and twisted wire

Solid wire or twisted

wire (lead wire) inlet

(lead wire) are recommended.

Solid wire: Ǿ0.4 to Ǿ1.2mm (AWG 26 to 16)

Twisted wire (lead wire): 0.3 to 1.25mm

2

(AWG 22 to 16)

Standard stripped wire length: 11mm

<Manual reset>

In case of the manual reset, configure the back check circuit between X1 and

X2. If KA and KB aren't needed to check, short-circuit KA and KB.

Do not connect anything to X3.

The control unit operates by the trailing operation of the external reset button.

Two, or more, units cannot be controlled by an external reset button. Prepare

the external reset button for unit by unit.

X1

RESET

KA KB

X2

<Auto reset>

In case of the auto reset, configure the back check circuit between X1 and

X3. If KA and KB aren't needed to check, short-circuit between X1 and X3.

Do not connect anything to X2.

Avoid auto-reset of the system after emergency stop by using the other

control circuit.(IEC/EN 60204-1 part 9.2.5.4.2 and 10.8.3)

X1

KA KB

X3

No.

Ԙ

ԙ

Ԛ

ԛ

9

Description Function

Power indicator

(Ui) (Green)

Safety output indicator

(OUT) (Green)

Interlock indicator

(INTER_LOCK) (Yellow)

Fault indicator

(FAULT) (Yellow)

Lights up when the power is supplied.

Lights up when the safety output is 'close'.

Lights up when the safety output is 'open'.

Blinks when an error occurs.

For details, refer to ' TROUBLESHOOTING'.

TROUBLESHOOTING

9

٨ The number of times the fault indicator (yellow) blinks indicates the type of

error state, as follows.

Blinking Description of error Cause/Measure

2 times

Internal relay contact is weld

3 times Reset mode error

Influence of noise /

4 times

power supply or internal

or more

circuit failure

٨

Make sure that this product and the light curtain a re connected to the

The contact was weld due to the lifetime of the relay.

Replace this product by new one.

Wiring of the terminal X1, X2 or X3 is not correct.

Check if the wiring has been correctly done.

Check the noise environment.

Check the wiring, power supply voltage and voltage

capacity.

common power supply.

٨

When the sensor doesn't operate properly even if the measures described

above are taken, contact our office.

The blinking cycle of the fault indicator (yellow) is as follows. Check the

٨

number of times the indicator blinks after 2 sec. of the indicator 'off' period.

Lights up

Blinking cycle of

fault indicator

Turns off

10

DIMENSIONS (Unit: mm)

67.3

130

10

13.5

Suitable for 35mm width DIN rail

No. of blinks No. of blinks

4

35

6.5

SUNX Limited

80

80.8

2s0.3s 0.3s

6.75

35㧩15

34.5

91.6

http://www.sunx.co.jp/

5

22.5

Head Office

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

Phone: +81-(0)568-33-7211 FAX: +81-(0)568-33-2631

Overseas Sales Dept.

Phone: +81-(0)568-33-7861 FAX: +81-(0)568-33-8591

PRINTED IN JAPAN

6

513

Loading...

Loading...