Page 1

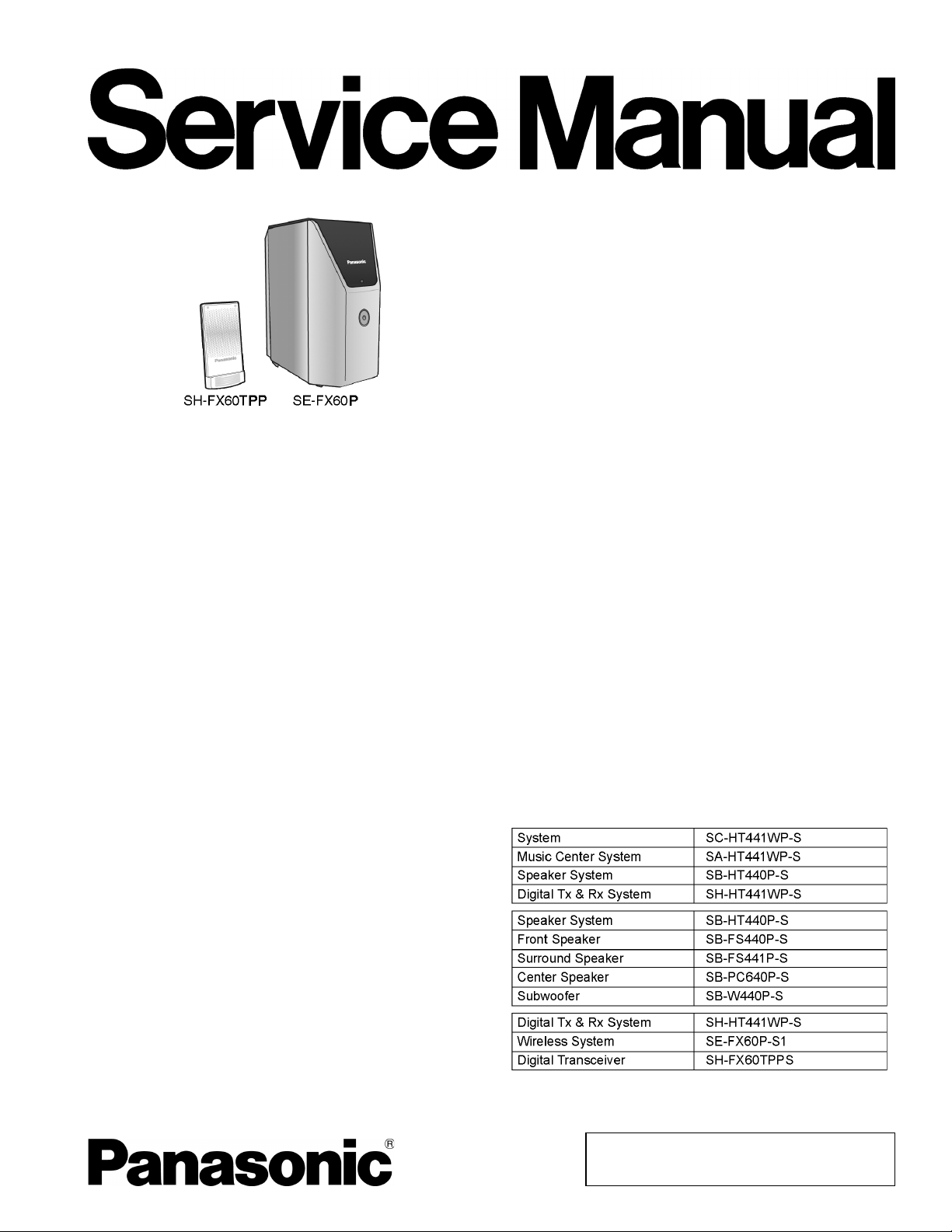

Wireless System and Digital Transceiver

Specification

n AMPLIFIER SECTION

RMS output power stereo mode

Surround Ch (both ch driven) 65 W per channel (4Ω), 1 kHz, 10

%THD

Total RMS stereo mode power 130 W

FTC output power stereo mode

Surround Ch (both ch driven) 40 W per channel (4Ω), 20 Hz-20

kHz, 1 % THD

Total FTC stereo mode power 80 W

n RF SECTION

Wireless module

Frequency range 2.402 to 2.480 GHz

RF output power 19 dBm (Max)

RF output impedance 50 Ω

Music Port (Rear)

Sensitivity 100 mV

Input impedance 4.7 kΩ

Terminal Stereo, 3.5 mm (1/8”) jack

ORDER NO. MD0607248CE

A6

SH-HT441WP

SH-FX60TPP

SE-FX60P

Colour

(S)..........Silver Type (For SH-HT441WP & SH-

FX60TPP only)

(S1)..........Silver Type (For SE-FX60P only)

Digital transceiver (SH-FX60TPP) 0.03 kg (0.07 lbs)

Wireless system (SE-FX60P) 0.7kg(1.5lbs)

Operating temperature range +5°Cto+35°C(+41°Fto+

95°F)

Operating humidity range 5 % to 90 % RH (no condensation)

Power consumption in standby mode

Transmit mode (SH-FX60TPP) 0.5 W

Receive mode (SE-FX60P) 1.2 W

n System : SC-HT441WP-S

Music Center : SA-HT441W P-S

Front Speaker : SB-FS440P-S

Surround Speaker : SB-FS441P-S

Center Speaker : SB-PC640P-S

Subwoofer : SB-W 440P-S

Digital Tx & Rx System : SH-

HT441W P-S

n GENERAL

Power supply AC 120 V, 60Hz

Power consumption

Digital transceiver (SH-FX60TPP) 0.85 W

Wireless system (SE-FX60P) 30 W

Dimensions (W x H x D)

Digital transceiver (SH-FX60TPP) 97 mm x 47.5 mm x 8.5 mm

(3-13/16” x 1-7/8” x 11/32”)

Wireless system (SE-FX60P) 89 mm x 189 mm x 180 mm

(3-1/2” x 7-7/16” x 7-3/32”)

Mass

© 2006 Matsushita Electric Industrial Co. Ltd.. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

SH-HT441WP

Power supply:

Notes:

1. Specifications are subject to change without notice.

Mass and dimensions are approximate

2. Total harmonic distortion is measured by a digital spectrum

analyzer

This model uses Switching Mode Power Supply (SMPS) Module for

powering the receiver unit. It is replaceable as an assembly unit.

CONTENTS

Page Page

1 Safety Precautions

1.1. GENERAL GUIDELINES

1.2. Before Repair and Adjustment (Digital Receiver SE-

FX60P)

1.3. Protection Circuitry

1.4. Caution for fuse replacement

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

3 Service caution based on legal restrictions

3.1. General description about Lead Free Solder (PbF)

4 Accessories

5 Using of Digital Receiver Unit

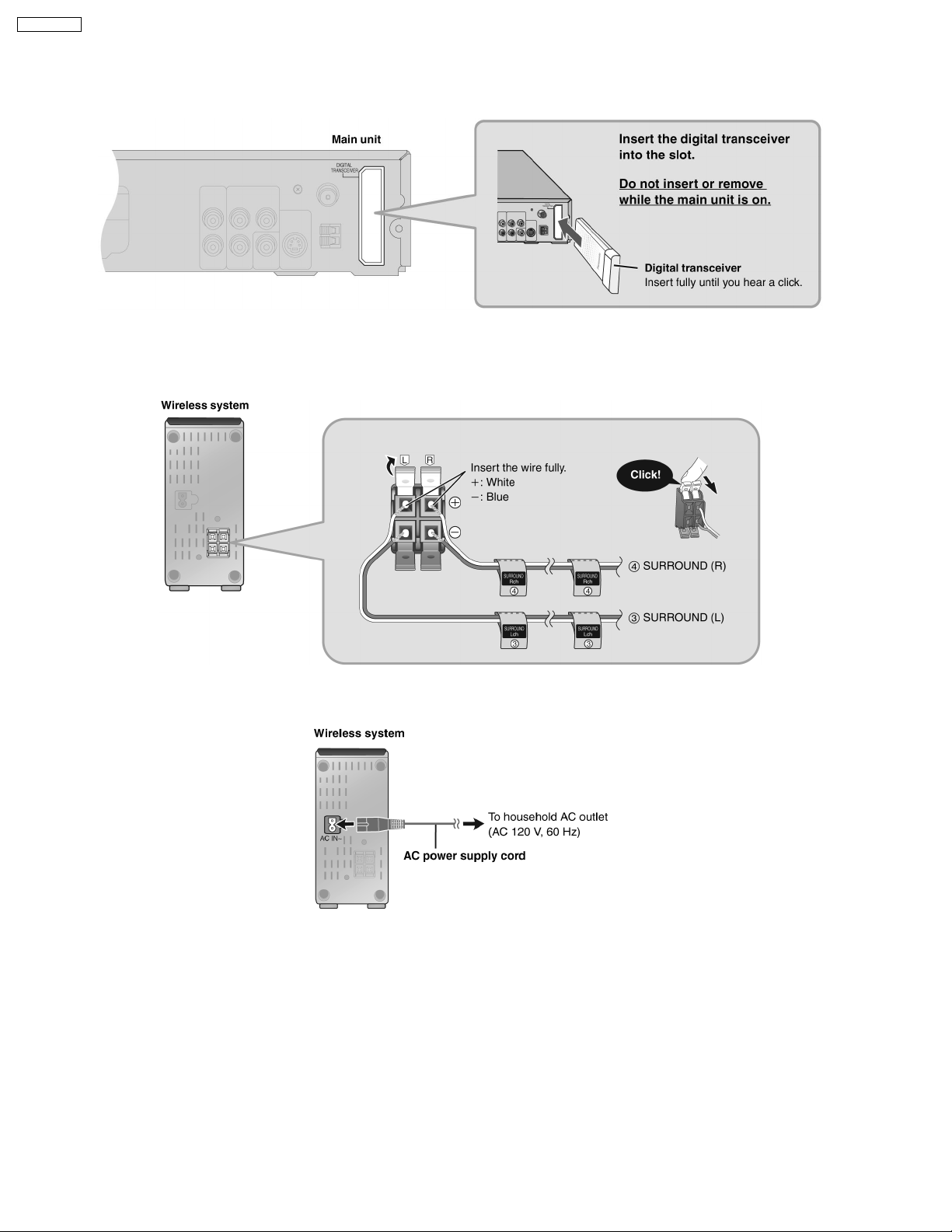

5.1. Connecting the digital transceiver (SH-FX60TPP)

5.2. Connecting the surround speaker cables to the wireless

system (SE-FX60P)

5.3. AC Power Cord connection (SE-FX60P)

5.4. Making the wireless link (SE-FX60P)

6 Technical Information (Wireless Surround)

6.1. RF Wireless Audio Transceiver

6.2. Detail Block Diagram (Receiver module)

6.3. Class-D Amplifier

7 Assembling and Disassembling

7.1. Note

7.2. Disassembly flow chart (For SE-FX60P)

7.3. Main Parts Location Diagram

7.4. Disassembly of Wireless System (SE-FX60P)

7.5. Disassembly of Digital Transceiver (SH-FX60TPP)

8 Service Positions

8.1. Checking of Led and Receiver Module P.C.B.

8.2. Checking of Digital Amp and SMPS Module Unit

9 Service Hint

9.1. Use of Service Jig (RFKZFX50PP-S)

9.2. Procedures for testing of link between digital transmitter &

receiver

3

3

3

4

4

5

6

6

7

8

8

8

8

9

10

10

11

15

18

18

19

19

20

25

28

28

29

30

30

31

9.3. Troubleshooting Guide for Wireless Surround Speaker 33

10 Service parts replacement

10.1. Replacement of P.C.B.

10.2. Replacement of Transmitter Assembly

10.3. ID Location

10.4. Digital Transceiver Card Service Assembly

(RFKVHT441WPS)

11 Voltage Measurement

11.1. DIGITAL AMP P.C.B.

11.2. LED P.C.B.

12 Wiring Connection Diagram

13 Block Diagram

13.1. DIGITAL AMP MODULE BLOCK

13.2. RECEIVER MODULE BLOCK

13.3. TRANSIMITTER MODULE BLOCK

14 Notes of Schematic Diagram

15 Schematic Diagram

15.1. DIGITAL AMP CIRCUIT and LED CIRCUIT

15.2. RECEIVER MODULE CIRCUIT

15.3. TRANSMITTER MODULE CIRCUIT

16 Printed Circuit Board Diagram

16.1. DIGITAL AMP P.C.B and LED P.C.B

16.2. RECEIVER MODULE P.C.B and TRANSMITTER

MODULE P.C.B

17 Illustration of IC's, Transistors and Diodes

18 Terminal Functions of Integrated Circuits

18.1. IC12 (M9Z000000013): IC RF

19 Exploded Views

19.1. Cabinet Parts Location

19.2. Packaging

19.3. Main Unit Packaging

20 Replacement Parts List

20.1. Parts List (SE-FX60P)

20.2. Parts List (SH-FX60TPP)

35

35

35

36

37

38

38

38

39

41

41

42

43

45

47

47

48

50

53

53

54

55

56

56

57

57

58

59

60

60

63

2

Page 3

SH-HT441WP

1 Safety Precautions

1.1. GENERAL GUIDELINES

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

(This “Safety Precaution” is applied only in U.S.A.)

1. Before servicing, unplug the power cord to prevent an electric shock.

2. When replacing parts, use only manufacturer’s recommended components for safety.

3. Check the condition of the power cord. Replace if wear or damage is evident.

4. After servicing, be sure to restore the lead dress, insulation barriers, insulation papers, shields, etc.

5. Before returning the serviced equipment to the customer, be sure to make the following insulation resistance test to prevent the

customer from being exposed to a shock hazard.

1.1.1. LEAKAGE CURRENT COLD CHECK

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between the jumpered AC plug and each exposed metallic cabinet part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MΩ and 5.2Ω.

When the exposed metal does not have a return path to the chassis, the reading must be

.

Figure. 1

1.1.2. LEAKAGE CURRENT HOT CHECK (See Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF capacitors, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent) may

be used to make the hot checks, leakage current must not exceed 1/2 milliamp. In case a measurement is outside of the limits

specified, there is a possibility of a shock hazard, and the equipment should be repaired and rechecked before it is returned to

the customer.

1.2. Before Repair and Adjustment (Digital Receiver SE-FX60P)

This model uses switching mode power supply (SMPS) module to provide the necessary voltages for the receiver (SE-FX60P)

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

Current consum ption at AC 120V, 60Hz in NO SIGNAL mode (at volume minimum) should be ~150 mA.

3

Page 4

SH-HT441WP

1.3. Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

· No sound is heard when the power is turned on.

· Stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

“shorted”, or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outline s below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

1.4. Caution for fuse replacement

Substituted service part no. for fuse: K5D312BNA005

4

Page 5

SH-HT441WP

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor “chip” components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equiped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potent ial shock reasons prior to applyin g power to the unit under test.

2. After removing an electrical assembly equiped with ES devices, place the assembly on a conductive surface such as aluminium

foil, to prevent electrostatic charge build up or exposu re of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsold er ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminium foil or

comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installe d.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD)

sufficient to damage an ES device).

5

Page 6

SH-HT441WP

3 Service caution based on legal restrictions

3.1. General description about Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86°F) more than that

of the normal solder.

Definition of PCB Lead Free Solder being used

The letter of “PbF” is printed either foil side or components side on the PCB using the lead free solder.

(See right figure)

Service caution for repair work using Lead Free Solder (PbF)

· The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the PCB using the lead free solder.)

· To put lead free solder, it should be well molten and mixed with the original lead free solder.

· Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

· Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt

the lead free solder.

· Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30

degrees C (662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

· The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01K-----------(0.3mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

Note

* Ingredient: Tin (Sn), 96.5%, Silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

6

Page 7

4 Accessories

Note : Refer to Packing Materials & Accessories Parts List (Section 20) for the part number.

AC Power Cord

SH-HT441WP

7

Page 8

SH-HT441WP

5 Using of Digital Receiver Unit

5.1. Connecting the digital transceiver (SH-FX60TPP)

5.2. Connecting the surround speaker cables to the wireless system (SEFX60P)

5.3. AC Power Cord connection (SE-FX60P)

8

Page 9

5.4. Making the wireless link (SE-FX60P)

SH-HT441WP

9

Page 10

SH-HT441WP

6 Technical Information (Wireless Surround)

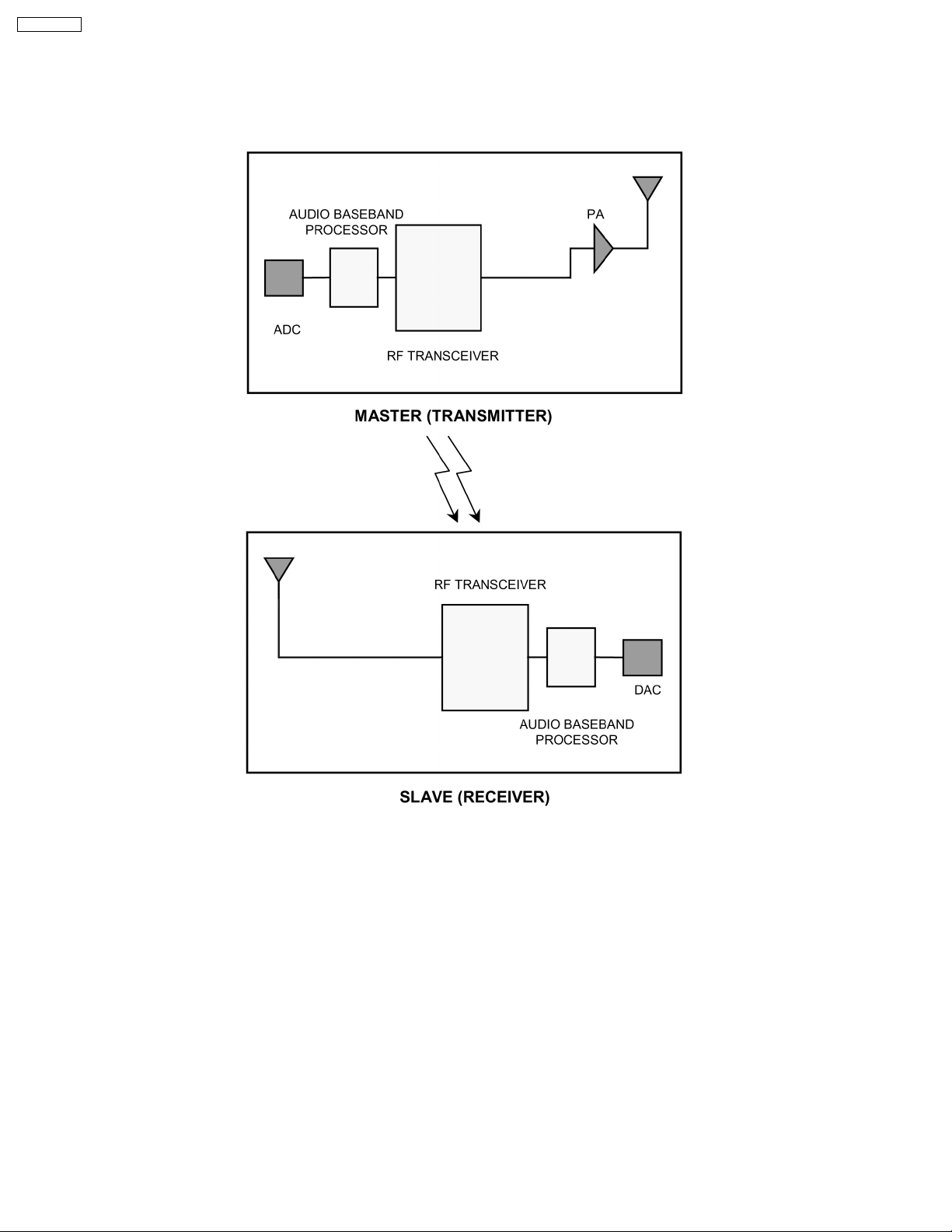

6.1. RF Wireless Audio Transceiver

6.1.1. Block Diagram

6.1.2. Definition

1. ADC : Analog -to-Digital Converter

2. Transceiver : Transmitter-Receiver Device

3. PA : Power Amplifier

4. DAC : Digital-to-Analog Converter

6.1.3. Features

· Crystal Clear CD Quality Stereo Sound

· Highly Robust Forward Error Correction

· 44.1KHz / 48KHz sampling frequency

· Adaptive Frequency Hoppin g System

· Range (open space) : 100m

· Low power consum ption

· SNR (for left / right channel analog interface) : 80 dB

· THD : 0.2%

· Compact : 40mm x 80mm

10

Page 11

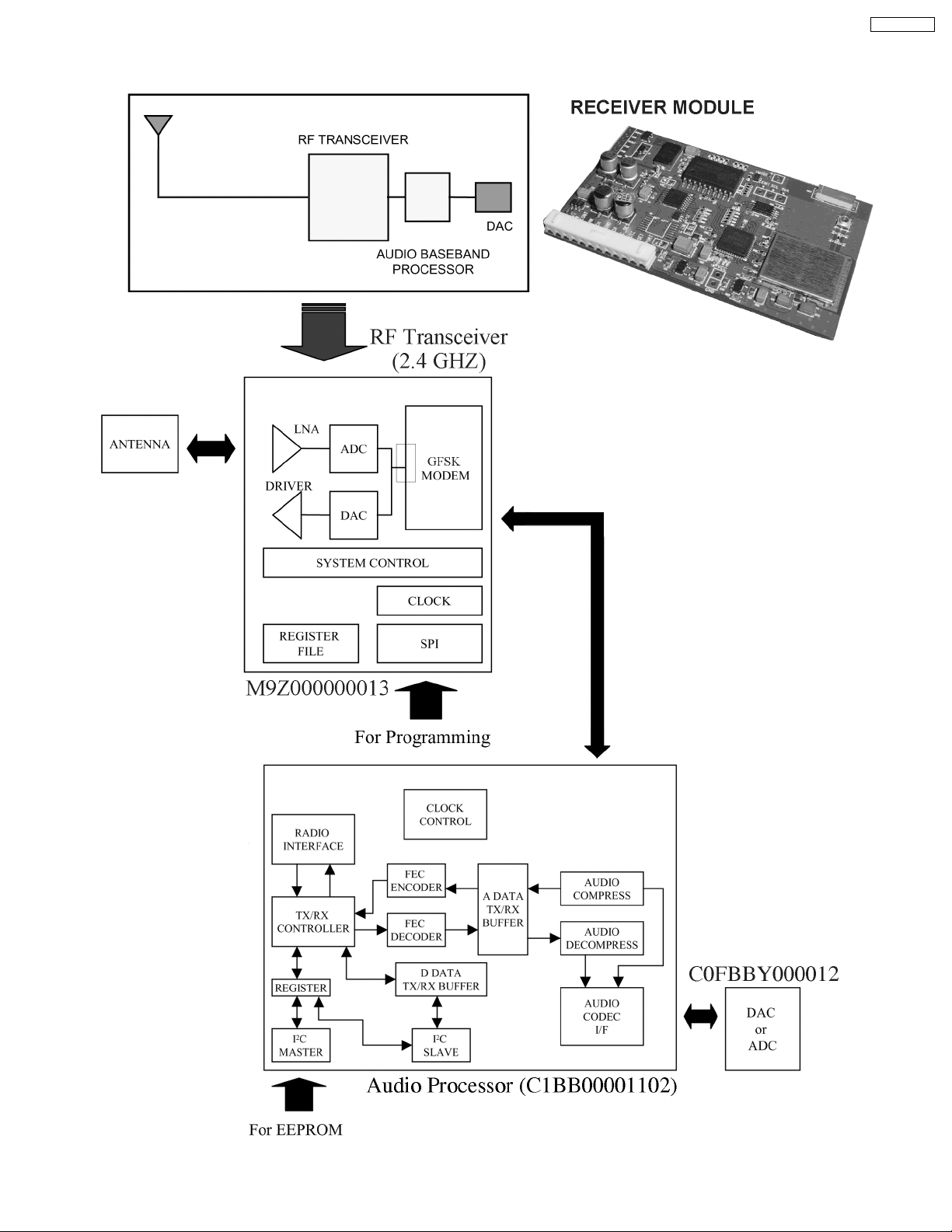

6.2. Detail Block Diagram (Receiver module)

SH-HT441WP

11

Page 12

SH-HT441WP

6.2.1. Operation

RF signal transmission and reception:

During the receive process, the radio signal is taken from a pair of balanc ed RF I/O pins that feed into the low noise amplifier (LNA).

Direct I/Q down conversion and on-chip filtering send the processed I/Q data to the analog-to-digital converter before processing

by the GFSK (Gaussian Frequency Shift Keying) demodulator. Within the demodulator, data detection and timing recovery circuits

convert the data for transfer to an external device. The transmit process operates in a similar fashion in reverse order.

The transmitted signal is GFSK (Gaussian Frequency Shift Keying) modulated data that is amplified on the chip to yield a radiated

output of 0dBm. A power control signal for an external amplifier is provided.

The audio baseband processor (C1BB00001102) is a digital audio processor IC encompassing apt-XTM audio

compress/decompress algorithm for wireless transmission of crystal-clear CD quality audio data.

For digital transmission the analog audio signals are sampled at 48kHz and converted to 1.536Mbps digital data through an

external 16-bit stereo audio codec. The digitized data are apt-XTM 4:1 compressed to 384Kbps stream data for efficient

transmission. Redundancy bits for forward error correction (FEC), synchronization flags, and control signals for time-division

duplexing (TDD) are appended to form data frames for error-free transmission.

In the receiver(Slave), synchronization flags and control data are first detected from the input stream. FEC decoder corrects any

errors that may have been introduced during the transmission and produces error-free compressed audio data. The compressed

audio is decompressed into 16-bit stereo PCM audio data through digital signal processing blocks. External audio codec converts

the PCM data to 2-channel (left and right) analog audio signals.

The Tx/Rx controller is in charge of several functions such as radio channel setup, frequency hopping for interference reduction and

generation of control signal for TDD and external RF chip.

In audio mode, the transmitter(Master) can send additional 16Kbps digital data simultaneously with stereo audio data.

How much time delay to transmit audio in wireless?

Audio compression and decompression requires about 3ms. Total time delay can be calculated as follows: Total delay time = audio

compression time + transmitter operating time + receiver operating time + audio decompression time. Total delay time is

approximately 12.2ms.

What is the power consumption?

The 2.4GHz RF module consumes about 45mA (max 65mA) for the transmitter and 55mA (max 71mA) for the receiver. The

EEPROM consumes about 1mA while the baseband IC consumes about 20mA.The total power consumption is 66mA (max 86mA)

for the transmitter and 76mA (max 92mA) for the receiver.

How does the system handle interference from other 2.4GHz RF devices?

12

Page 13

SH-HT441WP

It adopts Adaptive Frequency Hoppin g Spread Spectrum (AHSS) technology to avoid interference.

How does the system handle interference from other 2.4GHz RF devices?

The system supports 3 types of Spread Spectrum. These are

1. FHSS - Frequency Hopping Spread Spectrum

2. AHSS - Adaptive Frequency Hopping Spread Spectrum

3. Fixed Chann el Mode

FHSS refers to the conventional 79 channels (or 23 dependent on the country) hopping of Bluetooth. Devices using such hopping

method receives a lot of interference from other devices that use 2.4GHz range frequency such as WLAN and other Bluetooth

devices. FHSS, being built to avoid interfering with other devices, rather interferes a lot with devices that has high output power

using 2.4GHz frequency range and with other FHSS devices.During initialization, system scans 79 channels (or 23) and selects the

clear, non-interfered and reliable channel and starts the communication between master and slave. During the channel link, the

channel becomes unreliable and the error detection from FEC block exceeds the preset error threshold value, the system executes

scanning, as in initialization, and reselects new clear and reliable channel.

FHSS and AHSS can be selected by setting appropriate parameters on the EEPROM IC.

In Fixed Channel mode, 4 frequency levels can be selected (2.410GHz, 2.430GHz, 2.450GHz and 2.470GHz)

Spectrum distribution characteristic of 2.4GHz RF signal

13

Page 14

SH-HT441WP

Spectrum distribution characteristic of 2.4GHz RF signal

How can Master or Slave setting be selected? By software or hardware?

It can be selected by external control pin.

How long does it take to transmit single packet?

To establish communication channel properly, hopping frequency and Syncword of each packet should be determined by Device

ID(Identification). Device ID is unique value of each device, master and slaves. Only master and slaves with same Device ID can

communicate each other. Device ID can be set manually in case selected master and slaves do not communicate together. This

procedure is *Device ID set*. Device ID set procedure occurs when master and slave devices boot simultaneously with ID_SET=1.

In this procedure, the slave can figure out the Device ID of the master and store it in external EEPROM.When ID_SET is

established, S5G3000 performs ID send/scan to send Device ID of master to slave before general page operation. In normal mode,

communication is accomplished by going into page state directly without ID send/scan.

How can the Master and Slave units be paired to prevent mix-up?

It takes 2.5ms.

14

Page 15

SH-HT441WP

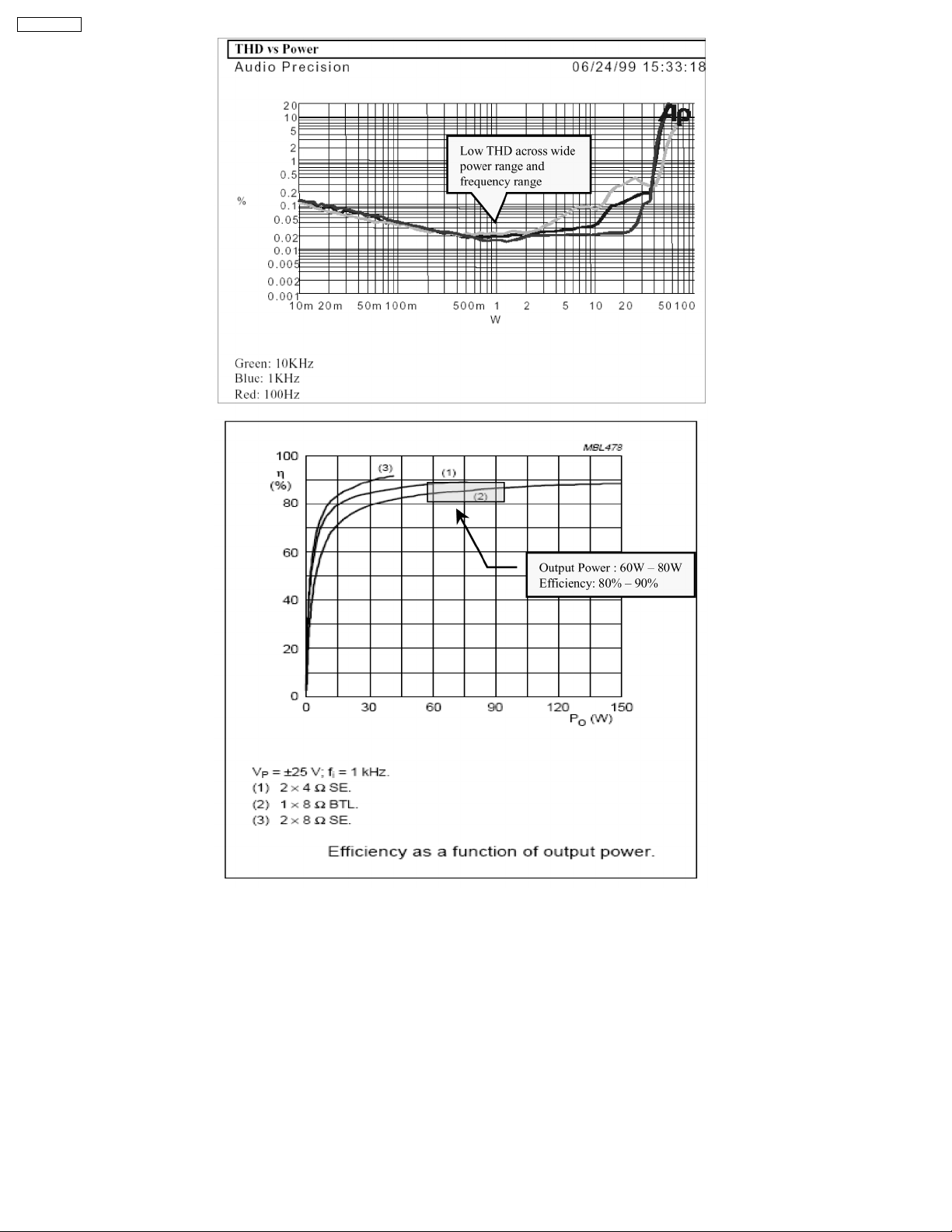

6.3. Class-D Amplifier

6.3.1. How are digital amplifiers different?

A digital amplifier incorporates a switching output stage that operates according to a principle known as pulse width modulation

(PWM). In contrast to the low-frequency control signal used in a conventional analog amplifier output stage, the switching output

stage of a digital amplifier is controlled by a high-frequency digital signal. The high-frequency digital signal is a PWM signal, in

which the music is modulated into a fixed-frequency carrier signal. In a digital amplifier, the modulation process is based on a digital

pulse code modula ted (PCM) representation of the music signal (or other signal that needs amplification) from a CD player, a DVD

player, or some other device.

BLOCK DIAGRAM OF TYPICAL ANALOG INPUT CLASS-D AMPLIFIER

6.3.2. What are the advantages of digital amplification technology?

· High power efficiency, i.e., smaller heat sinks and/or no fan required

· Compact (reduced PCB area)

· Low weight (reduced transformer size)

· Good sound quality (low signal distortion/THD)

6.3.3. Why is the digital amplifier so efficient?

A class-D amplifier is one in which the output transistors are operated as switches. When a transistor is off, the current through it

is zero. When it is on, the voltage across it is small, ideally zero. In each case, the power dissipation is very low.

6.3.4. Does the “D” in class-D mean DIGITAL?

No. This is not correct because the operation of the class-D amplifier is based on analog principles. There is no digital coding of

the signal. Before the advent of the class-D amplifier, the standard classes were class-A, class-AB, class-B, and class-C. The “D”

is simply the next letter in the alphabet after “C.” Indeed, the earliest work on class-D amplifiers involved vacuum tubes and can

be traced to the early 1950s.

15

Page 16

SH-HT441WP

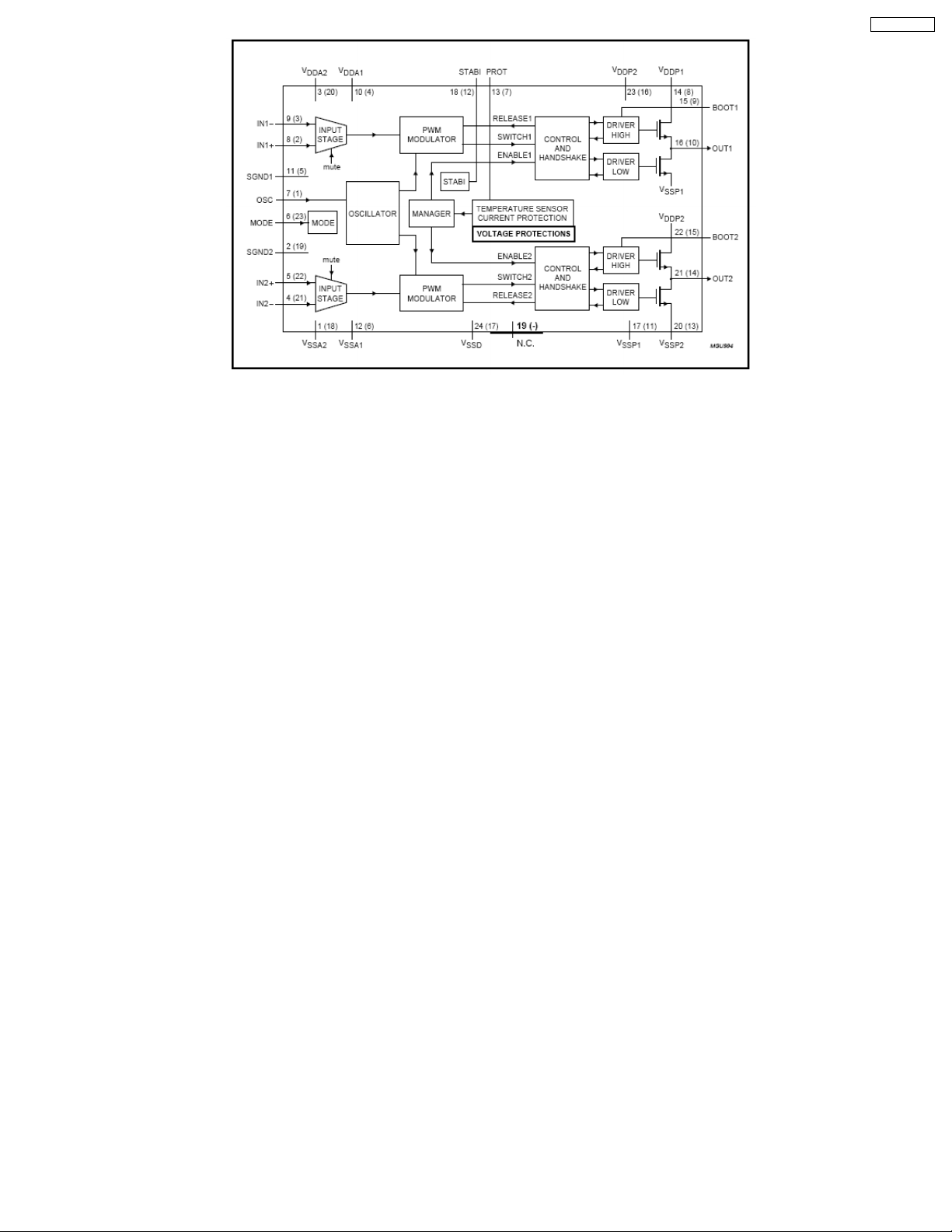

6.3.5. Actual Class-D amplifier IC information

Part number: C1AA0 0000755 (TDA8920BJ)

Block diagram:

16

Page 17

SH-HT441WP

Soldering Information

If the temperature of the soldering iron bit is less than 300 °C it may remain in contact for up to 10 seconds. If the bit temperature

is between 300 and 400 °C, contact may be up to 5 seconds.

17

Page 18

SH-HT441WP

7 Assembling and Disassembling

7.1. Note

“ATTENTION SERVICER”

Some chassis components may be have sharp edges. Be careful when disassembling and servicing.

1. This section describes procedures for checking the operation of the major printed circuit boards and replacing the main

components.

2. For reassembly after operation checks or replacement, reverse the respective procedures.

Special reassembly procedures are described only when required.

3. Select items from the following index when checks or replacement are required.

Below is the list of disassembly sections

· Disasse mbly of Front Panel

· Disasse mbly of Front Panel Ornament

· Disasse mbly of Led P.C.B

· Disasse mbly of Power Light Chip

· Disasse mbly of Music Port Lighting Unit

· Disasse mbly of Receiver Module P.C.B

· Disasse mbly of Digital Amp P.C.B

· Disasse mbly of Digital Amp IC

· Disasse mbly of SMPS Module Unit

· Disasse mbly of Digital Transceiver (SH-FX60TPP)

7.1.1. SMPS Module Unit Replacement

1. This model uses SMPS Module unit to provide the necessary supply voltages for the receiver unit (SE-FX60).

2. It is advisable to replace the SMPS Module Unit if upon detecting of non-working conditions. Do not attempt to repair or replace

its components on board.

3. Non-working conditions include:

· No output voltage (±30V, ±5V) at pin 2,3,7,8,9, of H1000/W1 respectively.

· Broken fuse part (compatible substitute fuse part : K5D312BNA005).

18

Page 19

SH-HT441WP

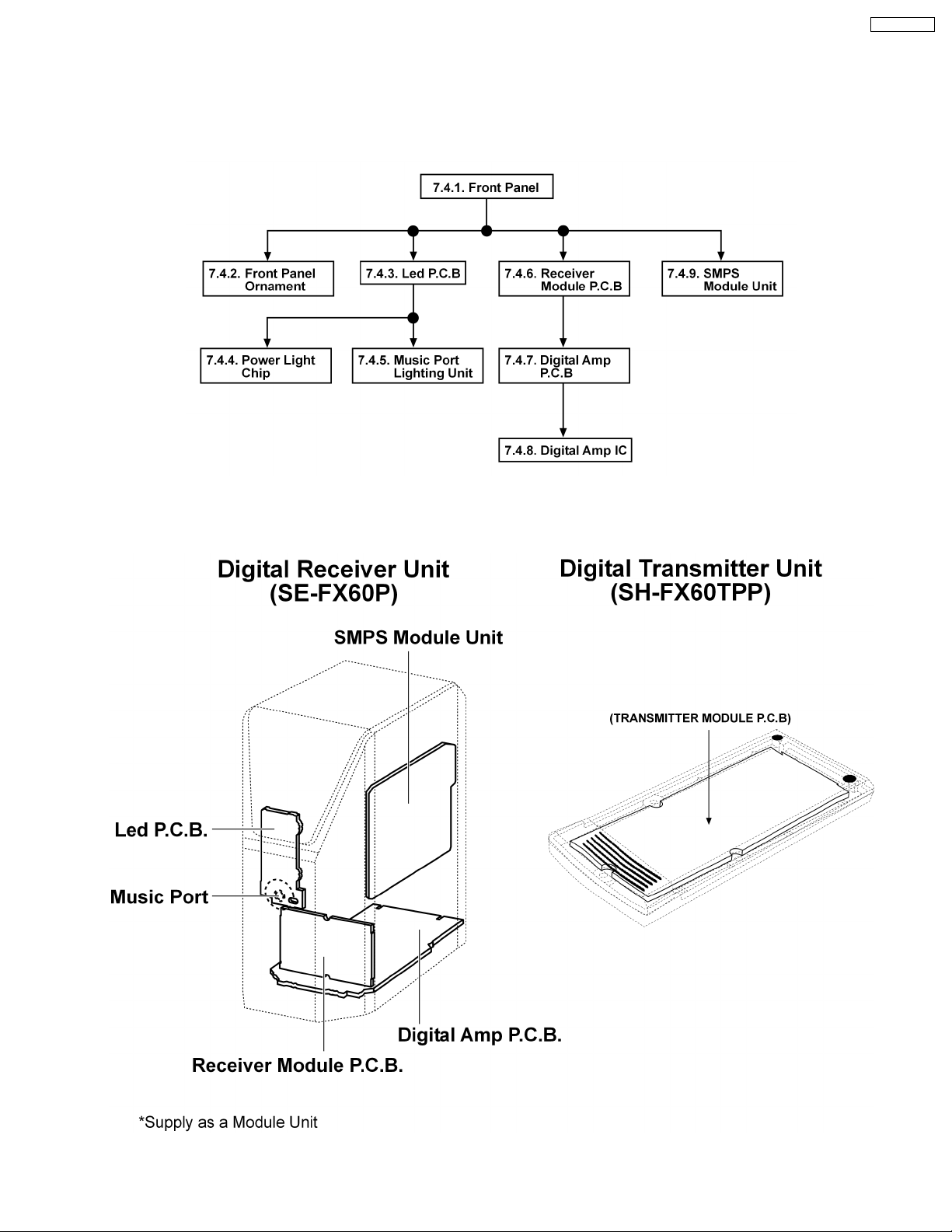

7.2. Disassembly flow chart (For SE-FX60P)

The following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the

servicing. For the digital receiver unit only.

To assemble the unit, reverse the steps shown in the chart below.

7.3. Main Parts Location Diagram

19

Page 20

SH-HT441WP

7.4. Disassembly of Wireless

System (SE-FX60P)

7.4.1. Disassembly of Front Panel

Step 1 : Remove 6 screws.

7.4.2. Disassembly of Front Panel

Ornament

· Follow the (Step 1) - (Step 3) of item 7.4.1.

Step 1 : Detach the catches as arrow shown.

Step 2 : Detach flat cable (CN1002).

Step 3 : Remove front panel.

Step 2 : Remove front panel ornament as arrow shown.

7.4.3. Disassembly of Led P.C.B

· Follow the (Step 1) - (Step 3) of item 7.4.1.

20

Page 21

Step 1 : Remove 3 screws.

SH-HT441WP

Step 1 : Detach power light chip from front panel assembly.

7.4.5. Disassembly of Music Port

Lighting Unit

· Follow the (Step 1) - (Step 3) of item 7.4.1.

· Follow the (Step 1) - (Step 2) of item 7.4.3.

Step 2 : Detach Led P.C.B from the front panel assembly.

7.4.4. Disassembly of Power Light Chip

· Follow the (Step 1) - (Step 3) of item 7.4.1.

· Follow the (Step 1) - (Step 2) of item 7.4.3.

Step 1 : Detach the catches of music port lighting unit from Led

P.C.B.

21

Page 22

SH-HT441WP

Step 2 : Remove music port lighting unit as arrow shown.

7.4.6. Disassembly of Receiver Module

P.C.B

· Follow the (Step 1) - (Step 3) of item 7.4.1.

Step 2 : Detach the flat cable from the ribs of back cabinet

assembly.

Step 3 : Detach connector CN1003 and remove Receiver

Module P.C.B.

Note: Ensure during assembly, the flat cable must be

properly dressed in between the 2 supporting ribs.

Step 1 : Push in the Speaker Jack (JK1002) as arrow shown.

Note: Take note of the 2 catches on the inside of the back

cabinet assembly.

When pushing up the Speak er Jack (JK1002), be careful

not to break the catches and do not apply too much

pressure on them.

22

Page 23

Step 4 : Desolder 4 points on the receiver shield plate as

shown.

SH-HT441WP

Step 6 : Desolder 4 points on the transmitter shield plate as

shown.

Step 5 : Detach Rx shield plate as arrow shown.

Step 7 : Detach transmitter shield plate as arrow shown.

7.4.7. Disassembly of Digital Amp P.C.B

· Follow the (Step 1) - (Step 3) of item 7.4.1.

· Follow the (Step 1) - (Step 2) of item 7.4.6.

23

Page 24

SH-HT441WP

Step 1 : Detach flat cable (CN2) .

Step 2 : Remove Digital Amp P.C.B as arrow shown.

Step 2 : De-solder and remove IC1500.

7.4.8. Disassembly of Digital Amp IC

· Follow the (Step 1) - (Step 3) of item 7.4.1.

· Follow the (Step 1) - (Step 2) of item 7.4.6.

· Follow the (Step 1) - (Step 2) of item 7.4.7.

Step 3 : Detach IC1500 from heat sink unit.

Step 1 : Remove heat sink clip as arrow shown.

Step 4 : Detach IC Insurator A from heat sink unit.

7.4.9. Disassembly of SMPS Module Unit

· Follow the (Step 1) - (Step 3) of item 7.4.1.

24

Page 25

Step 1 : Detach flat cable (CN2).

Step 2 : Remove SMPS Module as arrow shown.

SH-HT441WP

Step 2 : Remove bottom casing as arrow shown.

7.5. Disassembly of Digital

Transceiver (SH-FX60TPP)

Step 1 : Remove 4 screws.

Step 3 : Remove Transmitter Module P.C.B as arrow shown.

25

Page 26

SH-HT441WP

Step 4 : Desold er 4 points from Transmitter Module P.C.B.

Step 6 : Desold er 4 points from Transmitter Module P.C.B.

Step 5 : Remove Tx shield plate as arrow shown.

Step 7 : Remove Rx shield plate as arrow shown.

· Assembly of Digital Transceiver (SH-FX60TPP)

26

Page 27

Step 1 : Fix side-A ends of bottom casing and top casing

together.

Step 2 : Fit bottom casing and top casing together from side-A

to side-B.

SH-HT441WP

27

Page 28

SH-HT441WP

8 Service Positions

Note: For description of the disassembly procedures, see the Section 7.

8.1. Checking of Led and Receiver Module P.C.B.

28

Page 29

8.2. Checking of Digital Amp and SMPS Module Unit

SH-HT441WP

29

Page 30

SH-HT441WP

9 Service Hint

9.1. Use of Service Jig (RFKZFX50PP-S)

The service jig (Part No. RFKZFX50PP-S) is used for the purpose of testing the link between the digital transmitter and receiver

unit.It is available to see either the digital transmitter & receiver or Home Theater unit has cause of no connection to the

wirelesslink.

Below is the block diagram for the connection of the service jig:-

30

Page 31

SH-HT441WP

9.2. Procedures for testing of link between digital transmitter & receiver

Below is the list of steps to be carry out for the testing of the link between the digital transmitter & the receiver unit: -

Step 1 : Insert the digital transmitter unit into the service jig. (Part No. RFKZFX50PP-S)

Step 2 : Connect the 5V from the DC power source to the service jig as indicated by the jumper “5V”. Ensure that the DC power

source is connected properly.

Step 3 : Connect the Audio Signals (L & R) to the service jig as indicated by the jumpers (Left & Right) respectively from an audio

source.

Step 4 : Power on the digital Transmitter unit via the 5V DC power source.

Step 5 : Power on the digital receiver unit via AC power source by pressing the Power on/off button.

Ensure that the light indicator at the receiver unit is turn on. (Refer to the diagram below for the location of the Power on/off button)

31

Page 32

SH-HT441WP

Step 6 : Ensure that the Green LED (Digital Transmitter) is light-up. If it does not light up, there is no established link between them.

(No communication is established between the digital transmitter & receiver unit). It could be due the below possible causes:

1. The digital transmitter unit is not fully inserted into the slot of the service jig. (Note: The wireless link indicator light will be

flashing if the digital transmitter unit is not fully inserted into the slot.

2. The 5V DC power supply to the service jig is not connected properly or it is connected loosely.

3. The digital transmitter or the receiver unit is not operating properly due to power supply not connected properly. (Refer to

section 9.3.1 for troubleshooting procedures for the receiver module P.C.B.)

Step 7 : Ensure that the audio input into the digital transmitter can be heard from the speaker at the digital receiver unit. If there

is no audio output at the speaker, check and confirm the connection of speakers at the rear of the receiver unit. (Refer to section

9.3.3 for the troubleshooting procedures for checking of power Amp IC).

32

Page 33

9.3. Troubleshooting Guide for Wireless Surround Speaker

9.3.1. Troubleshooting for digital receiver unit (SE-FX60P)

Problem Phenomenon Possible Causes

No Audio Output (At surround

speaker)

1. No wireless connection between the main unit and

the digital receiver unit (SE-FX60).

1. Transmitter card is not inserted properly in

the main unit.

SH-HT441WP

Intermittent Audio output (At surround

speaker)

Note: When using Home Theater unit SU-RX57

The wireless option LED of the unit will not light up if

the wireless connection link is not established. If the

wireless option LED lights up, it means the wireless link

connection is established.

When using Home Theater unit SH-HT805W-S

FL Display on main unit will not show "W" if the wireless

connection link is not established. If FL displays shows

"W", it means the wireless link connection is

established.

Wireless link connection is established with FL display

showing "W"

2. No AC input power to the digital receiver

unit (SE-FX60) or AC cord faulty.

3. Shorted/Open circuit at speaker jack.

4. SMPS module unit or the digital amp P.C.B

is not working properly (For more

information, refer to section 9.2 on the

troubleshooting of the digital amp circuit.)

5. Transmitter card is not working properly due

to faulty parts within.

6. No +5V supply voltage to the transmitter

card due to failure within Home Theater

unit. (Refer to the troubleshooting for Home

Theater unit)

1. Transmitted signal interrupted by nearby

operating devices.

2. Loose speaker wire connection SMPS

module unit or the digital amp P.C.B is not

working properly (For more information,

refer to following section on the

troubleshooting of the digital amp circuit.)

Special Note: The digital transceiver and the receiver module P.C.B should be replaced using the transmitter assembly

(RFKVHFX60PPS) if it is found in not working condition.

9.3.2. Troubleshooting for digital amp circuit (Step By Step guide)

Below is the step by step guide on the troubleshooting of the digital amp circuit (When there is no audio output): -

Procedures Checking points Checking components

Step 1 Check open/short circuit connection at speaker jack JK1002, L1601-L1603 (Replace parts when

Step 2 1. Check regulated supply voltage +27V (pin 4, 8, 16

& 20)

2. Check regulated supply voltage -27V (pin 6, 11, 13

& 18)

Regulated supply to digital amp IC from SMPS module

unit.

determine NG)

Digital amp IC, IC1500

1. If no supply voltages to IC1500, go to Step

3.

2. If there is regulated voltage supply to

IC1500, go to Step 4.

33

Page 34

SH-HT441WP

Procedures Checking points Checking components

Step 3 Check for supply voltage +30V (pin 1 & 2) / -30V (pin 6

& 7) & +5V (pin 8)

Step 4 Check for supply voltage at pin 4 (+VCC) & 8 (-Vcc) Op-amp IC, IC1501If there is supply voltages to

Step 5 Check voltage regulator circuit Q1000, Q1002, Q1010 & Q1011If parts NG,

Step 6 1. Check for output audio signal at pin 10 & 14

2. Check for input audio signal at pin 3 & 22

No supply voltages (from SMPS module unit to

Digital amp P.C.B), check the following: -

1. Wire cable (W1) at H1000 (Digital amp

P.C.B)

2. F1 (blown fuse),

3. SMPS module unit (Faulty parts with burnt

mark etc)

4. AC Inlet Jack (SMPS module unit).

If there is supply from SMPS module unit, go to

Step 4

Special note: SMPS module should be replaced

if determined NG.

IC1501, proceed to Step 6If no supply voltages

to IC1501, proceed to Step 5

replaced.

Digital amp IC, IC1500

If there is input signal but no generated output

signal from IC1500 (all supply voltages is

present), replaced IC1500.

If there is no input audio signal, go to Step 7 for

checking on the Op-amp output.

Step 7 1. Check for output audio signal at pin 1 & 7

2. Check for input audio signal at pin 2 & 6

Step 8 Check input audio signal at pin 5 & 7 (CN1003) If no input signal, check following:

Step 9 (For music port input only) Check input signal at pin 6 & 8 (CN1002) If no input signal, check following:

Op-amp IC, IC1501

If there is input signal but no output signal from

IC1501, (all supply voltages is present),

replaced IC1501.

If there is no input signal, go to Step 8

1. FFC cable NG

2. FFC cable not connected properly

3. Receiver module P.C.B NG (parts NG Baseband IC, RF antenna etc)

4. No signal received by Receiver module due

to no transmission from the digital

transmitter.

5. No supply to receiver module. (Check pin 8

at H1000 from SMPS module)

1. If wire cable is not connected properly or

NG.

2. Music port jack abnormal (shorted).

(SMPS stands for switching mode power supply)

Special Note: The SMPS module unit is supplied as service parts and should be replaced as a unit if it is in not working condition.

34

Page 35

SH-HT441WP

10 Service parts replacement

10.1. Replacement of P.C.B.

Part No Part Name & Descriptions Applied models Remarks

RFKBHFX60PPS Module Kit Assembly SH-HT441WP-S [M]

Table 1

· Both Transmitter module P.C.B and Receiver Module P.C.B. should be replaced together using above Module Kit unit when you

find fault of IC5 within at the service operation.

· If ID codes of IC5 located on the back of both Transmitter and Receiver P.C.B. are not correspondent, wireless link will not be

established.

· The Module Kit unit is designed for the paired kit of the transmitter & receiver module P.C.B. with the same ID code.

10.2. Replacement of Transmitter Assembly

[In case of replacement of a new Transmitter by necessity, i.e, its loss.]

Applied models Digital system Transmitter Receiver

- SH-HT441WP-S SH-FX60TPPS SE-FX60P-S1

Table 2

· Both Transmitter Module P.C.B and Receiver Module P.C.B. should be replaced together using above Module Kit unit.

· If ID codes of IC5 located on the back of both Transmitter and Receiver P.C.B. are not correspondent, wireless link will not be

established as P.C.B.

· The Module Kit unit is designed for the paired kit of the transmitter & receiver module P.C.B. with the same ID code.

RFKVHFX60PPS Transmitter Assembly

Failure to do so may lead to the disabled of receiver unit due to ID codes mismatched hence no function of wireless surround.

35

Page 36

SH-HT441WP

10.3. ID Location

10.3.1. Transmitter Module P.C.B.

10.3.2. Receiver Module P.C.B.

36

Page 37

10.4. Digital Transceiver Card Service Assembly (RFKVHT441WPS)

If the digital transceiver card is lost, the Module kit assembly can be used for as service parts replacement.

The following steps needed to be performed together using main unit when replacing with new digital transceiver kit.

10.4.1. ID SET

1. Remove Back Cabinet Assembly.

2. Remove DAMP P.C.B & SMPS module unit.

3. Connect a wire to Pin 10 of Receiver Module P.C.B.

4. Power Up the digital receiver unit (SE-FX60).

5. Insert the transceiver into main unit.

6. Press “Surround Music” for main unit until the wireless LED lights up & FL displays “W”.

7. Short the wire on Receiver Module P.C.B to GROUND (Pin 2).

SH-HT441WP

37

Page 38

11 Voltage Measurement

Note:

· Indicated voltage values are the standard values for the unit measured by the DC electronic circuit tester (high-impedance)

with the chassis taken as standard.

Therefore, there may exist some errors in the voltage values, depending on the internal impedance of the DC circuit tester.

· Circuit voltage and waveform described herein shall be regarded as reference information when probing defect point

because it may differ from actual measuring value due to difference of Measuring instrument and its measuring condition

and product itself.

11.1. DIGITAL AMP P.C.B.

DIGITAL AMP P.C.B.

Ref No.

MODE 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

POWER ON -28.3 0 0 29.4 0 -28.3 -27..3 29.4 0 0 -28.4 -28.2 -28.3 -0.1 0 29.9 -28.4 -28.7 0 29.4

STANDBY -28.6 0 0 29.1 0 -28.7 -27.7 29.1 0 -0.6 -28.7 -28.5 -28.6 -27.5 -24.5 29.1 -28.7 -28.7 0 29.1

Ref No.

MODE 21 22 23

POWER ON 0 0 0

STANDBY 0 0 0

Ref No.

MODE 1 2 3 4 5 6 7 8

POWER ON 0 0 0 -0.3 0 0 0 -0.3

STANDBY 0 0 0 0 0 0 0 0

Ref No.

MODE E C B E C B E C B E C B E C B

POWER ON -0.4 -0.7 -0.7 0 -0.8 -0.4 -0.4 0 0 5 0 5 0 5.1 0

STANDBY -0.4 -0.7 -0.7 0 -0.7 -0.7 -0.4 0 0 5 0 6.7 0 7.2 0

Ref No.

MODE E C B E C B E C B E C B E C B

POWER ON 0 0 2.4 29.1 0 28.1 0 28.1 0 0 -27.5 0 -28.4 -0.7 -27.7

STANDBY 0 0 2.4 28.7 0 28 0 27.9 0 0 -27.8 0 -28.6 -0.7 -28

Ref No.

MODE E C B

POWER ON 0 3.3 0

STANDBY -0.6 1.3 0

Q1000 Q1001 Q1002 Q1003

Q1006 Q1008 Q1009 Q1010 Q1011

Q1013

IC1500

IC1500

IC1501

Q1004

11.2. LED P.C.B.

Ref No.

MODE E C B

POWER ON 0 4.8 0

STANDBY 0 5.9 0

Q1007

LED P.C.B.

38

Page 39

12 Wiring Connection Diagram

CN1002

1 . . . . . . . . . 9

1 . . . . . . . . . . . 12

CN1003

B

LED P.C.B

SH-HT441WP

SOLDER SIDE

H1000/W1

9

.

.

.

.

.

.

.

.

1

SOLDER SIDE

TO SMPS MODULE UNIT

A

DIGITAL AMP P.C.B

JK1002

SURROUND

SPEAKER

H1001/W2

1

.

.

.

.

.

.

.

.

9

MUSIC

JK1001

PbF

PORT

TO MAIN UNIT

11 . . . . . . . . . . . . . 1

J1

PbF

SOLDER SIDE

(SIDE A)

12 . . . . . . . . . . .1

CN2

C

RECEIVER MODULE P.C.B

SOLDER SIDE

PbF

D

TRANSMITTER MODULE P.C.B

PbF

39

Page 40

SH-HT441WP

40

Page 41

13 Block Diagram

13.1. DIGITAL AMP MODULE BLOCK

IC1500

C1AA00000755

DIGITAL AMP

SH-HT441WP

JK1001

MUSIC PORT

TO RECIVER

MODULE BLOCK

A

AUDIOLEFT

(AUDIORIGHT)

3(22) 10(14) 9(15)23

TO SWITCH MODE

POWER SUPPLY

UNIT

B

-30V

+30V

TEMP.TRIG

IN1-(IN2+)

VSSR1

VSSR2

STBY

VSSA1

1311 6 1 812 168420

VSSA2

B

VDDP1

B

VDDP2

B

Q1003

SWITCH

VDDA1

VDDA2

MODE

Q1006

MUTE

SWITCH

L1601,

L1602,

L1603

OUT1(OUT2)

FILTER

BOOT1(BOOT2)

JK1002

SURROUND LEFT( RIGHT)

SPEAKER

PCONT

MUTE

DC_DETECT

Q1004

PCONT

SWITCH

D1004~D1007

MUSIC PORT LED

B

D1003

Q1007

LED

SWITCH

B

SIGNAL LINES

: MAIN SIGNAL LINE

( ) Indicates Pin No. of Right Channel Note : Signal Lines are applicable to the Left Channel only.

Q1012,

Q1013

PCONT

SWITCH

41

Page 42

SH-HT441WP

DIGITAL AMP MODULE

13.2. RECEIVER MODULE BLOCK

AN1

CHIP

ANTENNA

BPF1

RF BANDPASS FILTER

J0E2457B0011

X2

H0J320500012

B

B

B

5

6,7,26,

28,30,32

15,18

25

24

IC6

C0DBZGC00067

Rfc

VCC

VCC

XTAL_P

XTAL_N

1

FILTER

31

C1BB00001029

Rf1

RF_IN

SW1

RF SPDT

FROM

CN1

RF SWITCH

K1QZA1AD0012

A

IC13

C0DBZGC00067

3.3V REGULATOR 3.3V REGULATOR

V2

V1

46

B

B

54

VC1

3

33

Rf2

FILTER

IC12

M9Z000000013

RF IC

IC7

C0DBZGC00067 C0DBZGC00067

3.3V REGULATOR 3.3V REGULATOR

6

PA1

OUT

C1CB00002396

POWER AMP

VRA

2

IC8

B B

VC0

RF_OUT

HOP_STROBE

SPI_SS

CD_TXEN

RX_TX_DATA

BB_CLK

SPI_TXD

SPI_CLK

SPI_RXD

RESET_N

ENABLE_RM

3

IN

IC11

FILTER

47

EPEAN

48

ELNA_CTRL

29

RF_

23

22

21

19

16

14

13

12

11

9

12

HOPSTB

5

RF_SEN

11

RF_TXON

8

RF_RXD

6

BB_CLK

3

RF_SIN

2

RF_SCLK

7

RF_SOUT

RF_

1

BCLKEN

46

CONNECT

30

ID_SET

XFILTER

38

IC4

C1BB00001102

BASEBAND IC

AMCLK/CS

ABCK/RE

ALRCK/WE

13 14 15 16

ADATA/ED7

26 1

EINT I1

SDA

SCL

RST

SCL

SDA

28

27

31

H0J600400025

27

28

9

10

8

2

X1

3

B

FILTER

FILTER

15(16)

10 12 11 8

LRCK

3(2)

AINL

(AINR)

AOUTL

(AOUTR)

SCLK

IC1

C0FBBY000012

CODEC IC

MCLK

SDT0

9

SDT1

13

/PWAD

14

/PWDA

C0JBAS000232

LOGIC IC

4

19

P2.4

P2.5

P2.3

IC10

C2BBYY000152

8 BIT CONTROLLER

XIN

XOUT

P0.5

14

5

SDA

6

SCL

IC5

7

RFKBHFX60PPS

WP

EEPROM

8

VCC

Z

P0.1

2,3,4

4

3

1

A

B1

B2

2

VCC

4

/RST

18

P0.1

11

P2.6

16

P0.3

15

P0.4

13

P0.6

6

P2.1

7

P2.2

5

P2.0

IC2

C0JBAC000232

LOGIC IC

B

IC9

1

C1BB00001071

POWER ON RESET

2

3

DC_DET

B

PCONT

MPORT_DET

PWR_OFF

MUTE

B

5

6

S

VCC

STATIC-SENSITIVE PART

LINK

ID_SET

AUDIO_L(AUDIO_R)

42

Page 43

13.3. TRANSIMITTER MODULE BLOCK

AN1

CHIP

ANTENNA

BPF1

RF BANDPASS FILTER

J0E2457B0011

X2

H0J320500012

B

B

B

5

6,7,26,

28,30,32

15,18

25

24

IC6

C0DBZGC00067

Rfc

VCC

VCC

XTAL_P

XTAL_N

1

FILTER

31

C1BB00001029

Rf1

RF_IN

SW1

RF SPDT

V2

46

V1

B

FROM

MAIN UNIT

A

CN1

RF SWITCH

K1QZA1AD0012

IC13

C0DBZGC00067

3.3V REGULATOR 3.3V REGULATOR

B

54

VC1

3

33

Rf2

FILTER

IC12

M9Z000000013

RF IC

IC7

C0DBZGC00067

3.3V REGULATOR

Q1,Q2

MUTING

B

SWITCH

PA1

6

OUT

C1CB00002396

POWER AMP

VRA

2

B

RF_OUT

SPI_SS

CD_TXEN

BB_CLK

SPI_TXD

SPI_CLK

SPI_RXD

RESET_N

3

IN

FILTER

29

23

22

21

19

16

14

13

12

11

9

VC0

HOP_STROBE

RX_TX_DATA

ENABLE_RM

IC8

C0DBZGC02588

BUFFER IC

24

SH-HT441WP

IC11

26 1

EINT I1

47

EPEAN

48

ELNA_CTRL

28

SDA

27

SCL

RF_

12

HOPSTB

5

RF_SEN

11

RF_TXON

8

RF_RXD

6

BB_CLK

3

RF_SIN

2

RF_SCLK

7

RF_SOUT

RF_

1

BCLKEN

46

CONNECT

30

ID_SET

XFILTER

38

IC4

C1BB00001102

BASEBAND IC

AMCLK/CS

ABCK/RE

ALRCK/WE

13 14 15 16

ADATA/ED7

RST

SCL

SDA

31

H0J600400025

27

28

B

FILTER

FILTER

15(16)

10 12 11 8

LRCK

3(2)

AINL

(AINR)

AOUTL

(AOUTR)

SCLK

IC1

C0FBBY000012

CODEC IC

MCLK

SDT0

9

SDT1

13

/PWAD

14

/PWDA

9

10

8

2

X1

3

B

C0JBAS000232

LOGIC IC

4

19

P2.4

P2.5

P2.3

IC10

C2BBYY000152

8 BIT CONTROLLER

XIN

XOUT

P0.5

14

5

SDA

6

SCL

IC5

7

RFKBHFX60PPS

WP

EEPROM

8

VCC

Z

P0.1

2,3,4

4

3

1

A

B1

B2

2

VCC

4

/RST

18

P0.1

11

P2.6

16

P0.3

15

P0.4

13

P0.6

6

P2.1

7

P2.2

5

P2.0

IC2

C0JBAC000232

LOGIC IC

B

IC9

1

C1BB00001071

POWER ON RESET

2

3

DC_DET

B

PCONT

MPORT_DET

PWR_OFF

MUTE

B

5

6

S

VCC

STATIC-SENSITIVE PART

MUTE_MCU

DWL_STATE

LINK

LINK

ID_SET

AUDIO_L(AUDIO_R)

43

Page 44

SH-HT441WP

44

Page 45

14 Notes of Schematic Diagram

(All schematic diagrams may be modified at any time with the

development of the new technology)

Note:

· Importance safety notice :

Components identified by

characteristics important for safety & special anti-static

handling. Furthermore, special parts which have purposes

of fire-retardant (resistors), high-quality sound (capacitors),

low-noise (resistors), etc. are used. When replacing any of

components, be sure to use only manufacturer´s specified

parts shown in the parts list.

mark have special

SH-HT441WP

Special Note :

· This model uses Switching Mode Power Supply (SMPS) for

providing necessary voltages.

· There is no schematic drawings included in this document

for the SMPS Module.

· It is advisable to replace the SMPS module as an assembly

unit.

· Substitute service part no for fuse (in SMPS) is

K5D312BNA005 (Manufacturer : Little fuse) 250V at 3.15A.

45

Page 46

SH-HT441WP

46

Page 47

15 Schematic Diagram

15.1. DIGITAL AMP CIRCUIT and LED CIRCUIT

SCHEMATIC DIAGRAM - 1

SH-HT441WP

LED CIRCUIT

W1001

0

W1004

+5V GND

7

6

1

W1006 0

2

3

4

5

0

W1009 0

W1002 0

JK1001

MUSIC PORT

W1008

0

W1005

C1004

0

W1007

220P

0

C1005

220P

R1009

470

R1010

470

R1023

47K

R1022

47K

DIGITALAMP CIRCUIT

FOR SH-FX60 ONLY

W1108 0

W1106 0

FOR P/PC ONLY

: +B SIGNAL LINE: -B SIGNAL LINE : MAIN SIGNALLINE

R1017 0

D1003

330

R1014

POWER_OFF

LINK

1

2

1

2

LINK

POWER_OFF

B3AAA0000583

R1019 100

R1015 100

R1024 100

R1025 100

R1013

D1005

0

W1111 0

L1000

J0JBC0000019

MPORT_IN

AUDIO RIGHT

AUDIO GND

AUDIO LEFT

+5V

+5V GND

PCONT

8

5

6

7

8

5

6

7

+5V

AUDIO GND

AUDIO LEFT

AUDIO RIGHT

0

W1112

C1704 16V10

4

3

4

3

PCONT

+5V GND

9

H1001/

W2

CN1002 CN1003

9

MPORT_IN

C1703 16V10

W1003

0

D1006

B1GBCFJJ0051

D1004

Q1007

LED SWITCH

D1004, D1005, D1006, D1007

B3ABA0000483

MUSIC PORT LED

D1007

W1110 0

TO

RECEIVER MODULE CIRCUIT (CN2)

ON SCHEMATIC DIAGRAM - 2

8

6

7

AUDIO GND

DC_DETECT

AUDIO RIGHT

4

5

3

LINK

PCONT

AUDIO LEFT

1

2

5V

+5V GND

10 91112

MPORT_IN

POWER_OFF

MUTE

C1701

6.3V820

TO

SMPS MODULE

UNIT

H1000/

W1

+5V

9

-30V

8

-30V

7

+5V GND

6

PGND

5

PGND

4

+30V

3

+30V

2

TEMP.TRIG

1

R1011

AGND

47K

AGND

C1533

0.1

R1008

47K

C1530

35V47

C1532

0.1

AGND

C1531

35V47

AGND

R1503

0

R1501

0

J0JKB0000020

R1502

L1503

R1603

0

R1601

0

0

W1114

C1502

35V470

L1502

J0JKB0000020

0

AGND

AGND

AGND

C1501

35V470

R1612

5.6K

R1611

5.6K

R1512

5.6K

R1511

5.6K

PGND

C1606

0.47

C1607

0.47

C1506

0.47

C1507

0.47

R1513

22K

C1520 220P

C1519 220P

C1620 220P

C1619 220P

R1602

0

AGND

C1511

0.1

R1514

10

R1614

10

OSC

IN1+

IN1-

VDDA1

SGND1

VSSA1

PROT

C1512

220P

0.1

C1617

AGND

VDDP1

C1624

C1616

0.015

0.1

2

45

3

1

C1608

330P

R1519

10

C1522

100V47

R1520

10

6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

C1618

C1621

0.1

0.1

AGND

C1526

0.22

C1AA00000755

DIGITALAMP

BOOT1

OUT1

AGND

IC1500

VSSP1

STAB1

0.1

C1513

0.1

C1614

C1514

AGND

132

L1601

ETQA15A150T

0.1

4

VSSP2

OUT2

C1516

0.015

C1615

0.68

AGND

C1515

0.68

C1524

0.1

BOOT2

C1517

AGND

0.1

R1623

5.6K

R1622

5.6K

VDDP2

PROT

C1610

0.1

R1615

22

R1515

22

C1510

0.1

VSSA2

C1518

0.1

C1626

SGND2

C1521

0.1

AGND

0.22

1

2

G0B9R5K00001

1

2

G0B9R5K00001

VDDA2

L1602

L1603

IN2-

C1508

330P

4

3

4

3

IN2+

MODE

C1604

16V10

R1624

5.6K

R1618

5.6K

B1GBCFJJ0051

R1604

4.7K

AGND

Q1004

B1GBCFJJ0051

PCONT SWTICH

Q1006

MUTE SWITCH

C1803

AGND

C1802

Q1003

B1ADCE000012

PCONT SWITCH

R1616

4.7K

AGND

AGND

0.015

0.015

R1521

4.7K

RIGHT

AGND

AGND

LEFT

3

1

2

4

JK1002

B1AACF000117

22K

R1621

C1627

AGND AGND

R1619

R1620

120K

120K

SURROUND

SPEAKERS

Q1012

DC DET SWITCH

Q1012

6.3V100

AGND

Q1013

AGND

Q1013

B1AACF000117

DC DET SWITCH

SE-FX60P DIGITAL AMP/LED CIRCUIT

47

Page 48

SH-HT441WP

15.2. RECEIVER MODULE CIRCUIT

SCHEMATIC DIAGRAM - 2

TO

DIGITAL AMP

CIRCUIT

(CN1003) ON

SCHEMATIC

DIAGRAM - 1

CN2

RECEIVER MODULE CIRCUIT

ANT1

CHIP ANTENNA

VCC

1

GND

2

PCONT

3

LINK

4

AUDIO_L

5

GND

6

AUDIO_R

7

DC_DET

8

MUTE

9

IDSET

10

MPORT_DET

11

PWR_OFF

12

C62

G1C1N1ZA0068

13

20

22

11

10

1

LNA_CTRL

PA_CTRL

8

7

9

4

3

2

SWITCH CONNECTOR

1

2

3

L8

2P

C62

4

12

C80

0.1

C79

0.1

K1QZA1AD0012

IN

OUT

GND GND

IN

CN1

3

C58

8.2P

C71

8.2P

OUT

C65

8.2P

6

GND

5

GND

4

BPF1

J0E2457B0011

BANDPASS FILTER

C91

2.2P

L90

G1C1N0ZA0068

4

5

6

EINT

19

: +B SIGNAL LINE : MAIN SIGNAL LINE

G1C22NJA0048

L7

12

C63

2.2P

SW1

C1BB00001029

RF SPDT

V2

Rfc

V1

15

IC11

C0JBAS000232

LOGIC IC

I1

1

GND

2

I0

3

S

VCC

L4

C1CB00002396

VC1

5

OUT

6

7

GND

Rf2

3

2

G

1

Rf1

R47

10K

6

5

4

Z

PA1

POWER AMP

3.3VMCU

C40

C90

1.5P

0.1

INT0

VC0

VRA

VCT

R48

100

IN

C72

8.2P

L3

6.8

C41

C42

10V10

0.1

L5

G1C10NJA0048

4

3

2

1

C59

0

C66

56P

VCC

VIN GND STBY NC VOUT

1

C27

16V1

R34 680P

C57

0.1

C56

8.2P

L10

ECJ0EC1H220J

C0DBZGC00067

3.3V REGULATOR

G1C3N9ZA0068

G1C2N2ZA0068

IC6

2345

C29

10V10

L11

L12

L13

G1C3N3ZA0068

C28

2.2

G1C10NJA0048

C68

3.3VRF

LD0_CTRL

10V10

L9

0.1

C30

16V1

C43

C44

0.1

H0J320500019

C55

0.1

C60

0.1

C69

0.1

VCC

VIN GND STBY NC VOUT

1

C49

15P

3.3VRF

C45

0.1

X2

C50

15P

XTAL_N

XTAL_P

25

VCC

26

27

VTUNE

28

VCC

M9Z000000013

RF_OUT

29

30

VCC

31

RF_IN

32

VCC

IDAC

1

C73

C74

0.1

L14

G1C18NJA0048

IC7

C0DBZGC00067

3.3V REGULATOR

2345

C33

10V10

222324

21

SPI_SS

HOP_STROBE

IC12

RF IC

VREFP_CAP

VREFN_CAP

234

0.1

19

20

CD_TXEN

VBB_READY

VCC_OUT

VBATT_ANA

5

6

C75

0.1

C32

2.2

1.8VD

18

17

VBB_OUT

VBATT_DIG

BB_CLK

RX_TX_DATA

VDD_IO

SPI_TXD

SPI_CLK

SPI_RXD

RESET_N

TX_RX_SW

ENABLE_RM

VCC

VCC

CHG_

PUMP

7

8

C76

0.1

3.3VD

LD0_CTRL

R51

30K

C78

390P

C51

R49

10K

C54

0.1

0.1

RF_

1

3.3VD

C25

10

11

12

0.1

BCLKEN

RF_SCLK

2

RF_SIN

3

VDDIO1

4

RF_SEN

5

BB_CLK

6

RF_SOUT

7

RF_RXD

8

RF_TXD

9

VSSIO1

RF_TXON

RF_

HOPSTB

R15 100

16

15

14

13

12

11

10

9

C77

47P

C31

16V1

R50

10K

C70

0.1

3.3VRF

VCC

C0DBZGC00067

VIN GND STBY NC VOUT

1

3.3V REGULATOR

2345

IC8

C35

10V10

R19 100

C34

2.2

3.3VMCU

LINK

PA_CTRL

LNA_CTRL

C81

0.1

C19

0.1

R12

4.7K

EPAEN

VSSINT2

VDDINT2

CONNECT

ELNA_CTRL

ABCK/RE

ALRCK/WE

13 14 15 16 17 18 19 20 21

R22 51

R24 51

R26 51

LRCK

BCLK

MCLK

3.3VD

R16 10K

R17 4.7K

R18 4.7K

BOOT_DIS

IDSET_DONE

IC4

C1BB00001102

BASEBAND IC

VDDINT1

MUTE/ED6

APWD/ED5

AMCLK/CS

ADATA/ED7

C26

R28 51

0.1

ADATA

1.8VD

C24

0.1

39

404142434445464748

AVSS

TMODE

VSSINT1

APIO4/ED4

22

WP

C17

2200P

38

37

IREF

AVDD

XFILTER

DVSS

DVDD

AXOUT

VSSIO2

ID_SET

VDDIO2

APIO0/

APIO3/ED3

APIO2/ED2

APIO1/ED1

23

24

SCL

SDA

RFKBHFX60PPS

8

VCC

7

WP

6

SCL

SDA

5

R11

10K

C20

0.1

36

35

34

AXIN

33

32

RST

31

30

29

SDA

28

SCL

27

EINT

26

25

ED0

R23 10K

R25 10K

R27 10K

R29 10K

R30 10K

IC5

EEPROM

C18

0.1

3.3VD

SCL

GND

1.8VD

C22

C21

10V10

0.1

BB_CLK

C23

0.1

ID_SET

EINT

R13 10K

R21 4.7K

3.3VD

SDA

DWM_NRST

R14

10K

1

NC

2

NC

3

NC

4

STATIC SENSITIVE PART

R31

R33

R31,R33

J0JCC0000166

48

SE-FX60P RECEIVER MODULE CIRCUIT

1/2

Page 49

SCHEMATIC DIAGRAM - 3

SH-HT441WP

RECEIVER MODULE CIRCUIT

C5

50V4.7

R53 0

R55 0

3.3VA

C8

50V4.7

R3 1K

R8 1K

C12 10

C13

0.1

C0FBBY000012

VCOM

1

AINR

2

AINL

3

VSS

4

VDD

5

DEM0

6

DEM1

7

SDT0

8

C0JBAS000232

B2

1

GND VCC

2

B1

3

IC1

CODEC IC

IC2

LOGIC IC

AOUTR

AOUTL

/PWDA

PWAD

SCLK

MCLK

LRCK

SDTI

S

A

6

5

4

C1 25V4.7

16

C6 25V4.7 R4 1K

15

14

13

12

11

10

9

: +B SIGNAL LINE

AUDIO_R

AUDIO_L

5

6

R1 1K

C11

0.1

PWDA

PWAD

BCLK

MCLK

10P

: MAIN SIGNAL LINE

LRCK

R6

10K

R7

10K

C9

MUX_CTRL

3.3VD

ADATA

MUX_CTRL

PWDA

PWAD

DWM_NRST

SCL

SDA

3.3VMCU

C1BB00001071

3

R52 10K

D1

B0JCAE000001

X1

H0J600400025

C38

15P

12

14 18

C39

15P

17

IC9

RESET IC

VOUT

1

R42 0

R43 100

R44 100

VSSVIN

2

IC10

C2BBYY000152

8 BIT CONTROLLER

VSS

1

2

XIN

3

XOUT

4

/RST

P2.0

5

P2.1

6

7

P2.2

P2.3

8

P2.4

9

P2.5

10

VDD

P0.0

P0.1

P0.2

P0.3

P0.4

P0.5

P0.6

P0.7

P2.6

VCC

AVCC

L15

100

IC13

C0DBZGC00067

3.3V REGULATOR

VIN GND EN Byp Vout

2345

1

C2

6.3V47

20

19

18

17

16

15

14

13

12

11

16 21

C4

0.1

C37

10V10

C3

6.3V47

C36

3.3VA

LDO_CTRL

0.1

R58 0

R46 10K

R45 10K

LD0_CTRL

PCONT

49

R57

0

PCONT

MPORT_DET

PWR_OFFWPMUTE

LD0_CTRL

TMODE

DC_DET

INT0

3.3VMCU

R40 10K

SE-FX60P RECEIVER MODULE CIRCUIT

2/2

R36 10K

R37 10K

R38 10K

R39 10K

Page 50

SH-HT441WP

15.3. TRANSMITTER MODULE CIRCUIT

SCHEMATIC DIAGRAM - 4

TO

MAIN UNIT

(CN2003)

1

2

3

4

5

6

7

8

9

10

11

J1

TRANSMITTER MODULE CIRCUIT

CN1

ANT1

CHIPANTENNA

ID_SET

AUDIO_L

GND

AUDIO_R

MUTE

GND

LINK

GND

VCC

MS_SEL

HOP_CHANGE

L8

3P

LNA_CTRL

PA_CTRL

9

4

5V

K1QZA1AD0012

SWITCH CONNECTOR

1

IN

2

OUT

3

GND GND

C62

G1C1N0ZA0068

C62

4

IN

1

C80

0.1

C79

0.1

5

GND

GND

3

BAND PASS FILTER

OUT

2

C65

8.2P

C58

8.2P

C71

8.2P

6

5

4

BPF1

J0E2457B0011

C91

2.2P

EINT

18

14

19 12

L90

G1C1N0ZA0068

L90

SW1

C1BB00001029

RF SPDT

V2

4

Rfc

5

6

V1

IC11

C0JBAS000232

LOGIC IC

I1

1

GND

2

3

I0

: +B SIGNAL LINE

L4

G1C22NJA0048

L7

12

C1CB00002396

5

VC1

6

OUT

7

GND

Rf2

3

2

G

1

Rf1

3.3VD

R46

10K

S

6

VCC

5

R43 100

4

Z

C40

PA1

POWER AMP

C63

2.2P

0.1

VC0

IN

VRA

VCT

C90

1.5P

C72

8.2P

INT0

C83

6.3V150P

4

3

2

1

: MAIN SIGNAL LINE

G1C10NJA0048

C59

0

C66

56P

VCC

2

10

C0DBZGC00067

3.3V REGULATOR

VIN GND STBY NC VOUT

1

C29

6.3V150

C41

C42

10V10

0.1

L5

C57

0.1

C56

8.2P

L10

22P

L11

G1C3N9ZA0068

L12

G1C2N2ZA0068

G1C3N3ZA0068

IC6

2345

C32

10V22

C31

2.2

L13

3.3VRF

L3

6.8

C43

10V10

L9

G1C10NJA0048

C68

0.1

C44

0.1

H0J320500019

C55

0.1

C60

0.1

C69

0.1

VCC

VIN GND STBY NC VOUT

1

C30

6.3V150

3.3VRF

C45

0.1

C49

12P

X2

C50

15P

XTAL_N

XTAL_P

25

VCC

26

27

VTUNE

28

VCC

M9Z000000013

RF_OUT

29

30

VCC

31

RF_IN

32

VCC

IDAC

1

C73

C74

0.1

0.1

L14

G1C18NJA0048

IC7

C0DBZGC00067

3.3V REGULATOR

2345

C34

10V10

222324

20

21

SPI_SS

CD_TXEN

HOP_STROBE

IC12

RF IC

VREFP_CAP

VREFN_CAP

VCC_OUT

5

234

C75

0.1

C33

2.2

19

18

17

VBATT_DIG

VBB_READY

RX_TX_DATA

ENABLE_RM

VBATT_ANA

VCC

VCC

6

7

C76

2.7P

3.3VD

1.8VD

VBB_OUT

BB_CLK

VDD_IO

SPI_TXD

SPI_CLK

SPI_RXD

RESET_N

TX_RX_SW

CHG_

PUMP

8

R49

30K

C78

390P

C51

PA_CTRL

LNA_CTRL

IDSET_DONE

R11

1K

C19

2200P

EPAEN

VSSINT2

CONNECT

ELNA_CTRL

IDSET_DONE

C1BB00001102

BASEBAND IC

ABCK/RE

ALRCK/WE

AMCLK/CS

ADATA/ED7

MUTE/ED6

R26 51

R28 51

R30 51

BCLK

MCLK

ADATA

3.3VD

C26

0.1

R15 10K

R16 4.7K

R17 4.7K

C21

0.1

VDDINT2

IC4

APWD/ED5

1.8VD

R12

4.7K

404142434445464748

AVSS

TMODE

BOOT_DIS

VDDINT1

VSSINT1

APIO4/ED4

C28

0.1

WP

39

38

IREF

APIO3/ED3

22

23

SCL

SDA

37

AVDD

XFILTER

APIO2/ED2

APIO1/ED1

24

8

7

6

5

R47

10K

C54

0.1

0.1

RF_

1

C27

BCLKEN

RF_SCLK

2

RF_SIN

3

VDDIO1

4

RF_SEN

5

BB_CLK

6

RF_SOUT

7

RF_RXD

8

RF_TXD

9

VSSIO1

10

RF_TXON

11

RF_

12

HOPSTB

0.1

3.3VD

13 14 15 16 17 18 19 20 21

R24 51

LRCK

R18 100

16

15

14

13

12

11

10

9

C77

47P

R48

10K

C70

0.1

3.3VRF

R19 100

C20

0.1

C22

0.1

DVSS

36

DVDD

35

AXOUT

34

AXIN

33

VSSIO2

32

RST

31

30

ID_SET

VDDIO2

29

SDA

28

SCL

27

EINT

26

APIO0/

25

ED0

R22 10K

R23 10K

R25 10K

R27 10K

R29 10K

SCL

3.3VD

IC5

RFKBHFX60PPS

EEPROM

VCC

TEST

SCL

SDA

NC

GND

1.8VD

C24

C23

10V10

0.1

BB_CLK

C25

0.1

ID_SET

EINT

R21 4.7K

R13 10K

SDA

DWM_NRST

3.3VD

R14

10K

1

2

NC

3

NC

4

8

STATIC SENSITIVE PART

R31

R35

R34 680P

R31,R35

J0JCC0000166

50

SH-FX60TPP TRANSMITTER MODULE CIRCUIT

1/2

Page 51

SCHEMATIC DIAGRAM - 5

SH-HT441WP

TRANSMITTER MODULE CIRCUIT

C12 16V2.2

C13

1K

3.3VA

AVCC

R51

47K

R53

47K

R50

1.8K

R52

1.8K

VCC

L15

56

R3 1K

C5 16V4.7

R8

C8 16V4.7

IC13

C0DBZGC00067

3.3V REGULATOR

VIN GND EN Byp Vout

2345

1

0.1

IC1

C0FBBY000012

CODEC IC

VCOM

1

AINR

2

AINL

3

VSS

4

VDD

5

DEM0

6

DEM1

7

SDT0

8

C0JBAS000232

B2

1

GND VCC

2

B1

3

AOUTR

AOUTL

/PWDA

PWAD

IC2

LOGIC IC

3.3VA

LDO_CTRL

SCLK

MCLK

LRCK

SDTI

S

A

16

15

14

13

12

11

10

9

6

5

4

: +B SIGNAL LINE

C1 10V22

C6 10V22

R1 1K

R4 1K

C11

0.1

6

AUDIO_R

7

AUDIO_L

: MAIN SIGNAL LINE

BCLK

MCLK

PWDA

PWAD

LRCK

10K

R7

C9

10P

MUX_CTRL

R6

10K

3.3VD

ADATA

MUX_CTRL

PWDA

PWAD

DWN_NRST

SCL

SDA

3.3VD

R54 10K

X1

H0J600400025

C38

15P

17 13

IC9

C1BB00001071

RESET IC

VOUT

1

C39

15P

B0JCAE000001

1116

R44 100

R45 100

VSSVIN

R42 0

D1

3

2

IC10

C2BBYY000152

8 BIT CONTROLLER

VSS

1

2

XIN

3

XOUT

4

/RST

P2.0

5

P2.1

6

7

P2.2

P2.3

8

P2.4

9

P2.5

10

VDD

P0.0

P0.1

P0.2

P0.3

P0.4

P0.5

P0.6

P0.7

P2.6

20

19

18

17

16

15

14

13

12

11

R37 10K

R38 10K

2

20 15

1

R39 10K

R40 10K

IC8

C0JBAZ002588

BUFFER IC

NC IN A GND OUT Y VCC

2345

1

DMW_STATE

C35

30P

C37

10V10

3.3VD

C36

0.1

R56 0

LINK

3

C2

6.3V47

C4

0.1

C3

6.3V47

3.3VD

HOP_CHANGEWPIDSET_DONE

INT0

TMODE

MS_SEL

3.3VD

MUTE

R33

10K

3.3VD

Q1,Q2

UNR521400L

MUTING SWITCH

Q1

Q2

SH-FX60TPP TRANSMITTER MODULE CIRCUIT

2/2

51

Page 52

SH-HT441WP

52

Page 53

16 Printed Circuit Board Diagram

16.1. DIGITAL AMP P.C.B and LED P.C.B

SH-HT441WP

1

2

3

4

5

6

7

8

ABCDEFG

A B

DIGITAL AMP P.C.B (REPX0525F) LED P.C.B (REPX0525F)

W1237

W1233

W1224

W1215

W1216

1

4

L1603

C1701

L1503

W1102

IC1500

C1511

W1211

R

1615

C1610

R1623

W1111

C1530

R1513

2

3

CN1003

123456789101112

W1236

H1000/W1

TO SMPS UNIT

9

8

7

6

5

4

3

2

1

C1533

C1532

L1502

C1502

C1501

CN1002

W1234

W1235

W1228

W1110

R1614

C1620

C1617

W1210

W1203

W1229

R1611

R1612

C1624

3

C1607

C1616

W1207

W1204

W1232

W1231

R1602

C1606

C1513

C1514

W1223

C1524

C1614

C1703

C1531

W1222

C1512

C1526

1

C1608

2

4365871091211141316151817201922

C1621

C1619

R1520

C1618

C1522

L1601

4

C1803

2345678

W1225

W1238

W1239

R1011

R1008

W1112

W1226

W1220

R1601

W1221

W1214

C1506

W1101

C1626

C1516

2

R1514

C1520

C1519

W1019

1

21 23

C1508

C1517

C1518

HEATSINK

R1519

W1202

C1704

R1512

C1507

R1511

C1521

L1602

Q1012

R1603

R1502

R1503

R1616

C

R1604

C

Q1006

C1510

R1622

1

4

91

B

C

E

R1501

W1114

E

Q1004

B

E

B

Q1003

R1618

R1624

R1521

C

B

C1515

C1615

W1106

...P/PC

1619

R

R1620

R1621

Q1013

W1219

W1218

W1217

W1213

W1212

W1214

E

W1209

R1515

2

3

W1108

C1627

C1604

W1103

...FX60

H1001/W2

BCE

D1006

JK1001

PbF

R1017

1

2

3

R1013

4

5

R1009

6

7

8

9

W1008

W1009

R1019

0486A-3

0486A-3

L1000

R1022

D1005

1

3

D1003

R1010

5

W1007

R1023

6

4

R1025

C1005

W1004

7

2

W1005

D1004

R1015

R1014

Q1007

E

C

C1004

W1001

W1002

W1006

W1003

HI J KL MNO P

R1024

B

D1007

MUSIC

PORT

9

4

L+

JK1002

C1802

2

L-

3

R+

SURROUND

SPEAKER

1

R-