Panasonic SBAK-250-PL Service manual

Specifications

Type 2 way, 2 speaker system (Bass reflex)

Speaker(s)

Woofer 16 cm cone type

Tweeter 6 cm cone type

Impedance 3 Ω

Input power (IEC) 115 W (Max)

Output sound pressure level 82 dB/W (1.0 m)

Cross over frequency 2kHz

Frequency range 34 Hz to 30 kHz (-16 dB)

ORDER NO. MD0704055CE

Speaker System

SB-AK250PL

Colour

(S)...Silver Type

41 Hz to 25 kHz (-10 dB)

Dimensions (W X H X D) 219 X 330 X 196 mm

Mass 2.6 kg

Notes:

1. Specifications are subject to change without notice. Mass and

dimensions are approximate.

2. Total harmonic distortion is measured by the digital spectrum

analyzer.

CONTENTS

Page Page

1 System Combination

1.1. System Breakdown

2 Assembling and Disassembling

2.1. Caution

2.2. Disassembly Procedures

2.3. Disassembly Flow Chart

2.4. Disassembly of Rear cabinet assembly

2

2

3

3

3

3

4

2.5. Disassembly of Woofer

2.6. Disassembly of Tweeter

3 Connection of the Speaker Cables

4 Exploded Views

4.1. Cabinet Parts Location

4.2. Packaging

5 Replacement Parts List

© 2007 Matsushita Electric Industrial Co. Ltd.. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

5

5

6

7

7

8

9

SB-AK250PL

1 System Combination

1.1. System Breakdown

Note:

The tables below show the breakdown for speaker combinations used in main unit system.

1.1.1. For SB-AK250PL-S

2

2 Assembling and Disassembling

2.1. Caution

“Attention Servicer”

Some chassis components may have sharp edges.

Be careful when disassembly and servicing.

1. This section describes procedure for checking the operation of replacing the main components.

2. For reassembly after operation checks or replacement, reverse the respective procedures.

3. Select items from the following index when checks or replacement are required.

4. Refer to the Part No.on the page of “Parts Location and Replacement Parts List” (Section 5) if necessary.

SB-AK250PL

2.2. Disassembly Procedures

· Disassembly of Rear cabine t assembly

· Disassembly of Woofer

· Disassembly of Tweeter

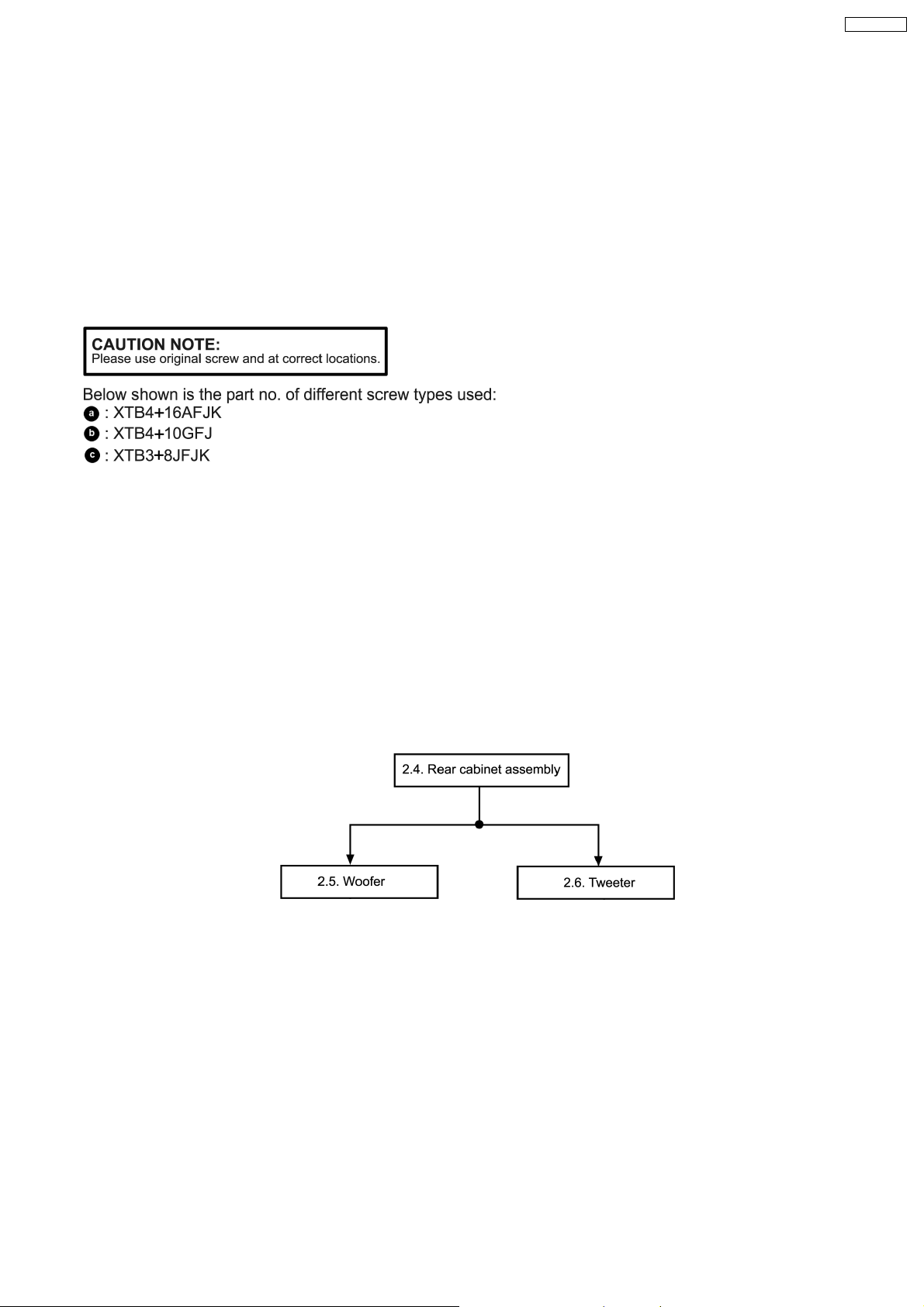

2.3. Disassembly Flow Chart

The following chart is the procedure for disassembly the casing and inside parts for internal inspection when carrying out the

servicing.

To assemble the unit, reverse the steps shown in the chart as below.

3

Loading...

Loading...