Panasonic SAVK-650-EE Service manual

A

A

A

DVD Stereo System

SA-VK650EE

Colour

(S)... Silver Type

ORDER NO. MD0604119C3

Notes: This model’s DVD/CD mechanism changer unit is CRS1D. Please refer to the original Service

Manual (Order No. MD0603065A3) for this mechanism.

Specifications

n AMPLIFIER SECTION

RMS Output Power Stereo mode:

Front CH (both ch driven)

95 W per channel (4 Ω), 1 kHz, 10% THD

Subwoofer Ch 95 W (4 Ω), 100 Hz, 10% THD

Total RMS Stereo mode power 285 W

n FM/AM TUNER, TERMINALS SECTION

Preset station FM 15 stations

AM 15 stations

Frequency Modulation (FM)

Frequency range 87.50 to 108.00 MHz (50 kHz

step)

Sensitivity 4.0 µV (IHF)

S/N 26dB 2.2 µV

ntenna terminals 75 Ω (unbalanced)

mplitude Modulation (AM)

Frequency range 522 to 1629 kHz (9 kHz step)

M Sensitivity S/N 20dB at 999 kHz

560 µV/m

Digital audio output

Coaxial digital output Pin jack

Phone jack

Terminal Stereo, 3.5 mm jack

Mic jack

Sensitivity 0.7 mV, 600 Ω

Terminal Mono, 6.3 mm jack (2 system)

Music Port Jack (Front)

Sensitivity 100 mV, 4.7 kΩ

Terminal Stereo, 3.5 mm jack

n CASSETTE DECK SECTION

Track system 4 Tracks, 2 Channels

Heads

Record/playback Solid permalloy head

Erasure Double gap ferrite head

Motor DC servo motor

Recording system AC bias 100 kHz

Erasing system AC erase 100 kHz

Tape speed 4.8 cm/sec

Overall frequency response (+3, -6 dB) at DECK OUT

Normal 35 Hz to 14 kHz

S/N ratio 50 dB (A-WTD)

Wow and flutter 0.18 % (WRMS)

Fast forward and rewind time Approx. 120 seconds with

C-60 cassette tape

n DISC SECTION

Disc played [8 cm or 12 cm]

(1) DVD (DVD-Video, DivX )

(2) DVD-RAM (DVD-VR, JPEG , MP3 , MPEG4 , DivX )

*6,*7

*4,*7

*2,*7

*5,*7

*6,*7

© 2006 Matsushita Electric Industrial Co. Ltd.. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

A

SA-VK650EE

(3) DVD-R (DVD-Video, DVD-VR, JPEG , MP3 , MPEG4 ,

* 6,*7

DivX

)

*4,*7

*2,*7

*5,*7

(4) DVD-R DL (DVD-Video, DVD-VR)

(5) DVD-RW (DVD-Video, DVD-VR, JPEG , MP3 , MPEG4 ,

* 6,*7

DivX

)

*4,*7

*2,*7

*5,*7

(6) +R/ +RW (Video)

(7) +R DL (Video)

*1

(8) CD,CD-R/RW [CD-DA, Video CD, SVCD , MP3 , WMA ,

JPEG

* 4,*7

, MPEG4

* 5,*7

, DivX

* 6,*7

, HighMAT Level 2 (Audio and

*2,*7

*3,*7

Image)]

*1

Conforming to IEC62107

*2

MPEG-1 Layer 3, MPEG-2 Layer 3

*3

Windows Media Audio Ver 9.0 L3

Not compatible with Multiple Bit Rate (MBR)

*4

Exif Ver 2.1 JPEG Baseline files

Picture resolution: between 160 x 120 and 6144 x 4096 pixels (Sub

sampling is 4:0:0, 4:2:0, 4:2:2 or 4:4:4). Extremely long and narrow

pictures may not be displayed.

*5

MPEG4 data recorded with the Panasonic SD multi cameras or

DVD video recorders. Conforming to SD VIDEO specifications (ASF

standard)/ MPEG4 (Simple Profile) video system/ G.726 audio

system.

*6

Plays all versions of DivX video (including DivX 6) with standard

® ®

playback of DivX®media files. Certified to the DixV®Home Theater

Profile. GMC (Global Motion Compensation) is not supported.

*7

The total combined maximum number of recognizable audio,

picture and video contents and groups: 4000 audio, picture and video

contents and 400 groups.

Pick up

Wavelength

CD 785 nm

DVD 662 nm

Laser Power

CD CLASS 1M

DVD CLASS 1

udio output (Disc)

Number of channels (FL, FR) 2 ch (stereo)

n VIDEO SECTION

Video system PAL625/50, PAL525/60, NTSC

Composite video output

Output level 1Vp-p(75Ω)

Terminal Pin jack (1 system)

S-video output

Y output level 1Vp-p(75Ω)

C output level 0.3 Vp-p (75 Ω)(PAL)

0.286 Vp-p (75 Ω )(NTSC)

Terminal S terminal (1 system)

Component video output

[NTSC : 480p/480i, PAL : 576p/576i]

Y output level 1Vp-p(75Ω)

PBoutput level 0.7 Vp-p (75 Ω)

PRoutput level 0.7 Vp-p (75 Ω )

Terminal

Pin jack (Y: green, PB:blue,PR:red)(1system)

n GENERAL

Power supply AC 230 V, 50 Hz

Power consumption 105 W

Power consumption in standby mode:

0.9 W (approx.)

Dimensions (W x H x D) 250 mm x 330 mm x 333.6 mm

Mass 7.5 kg

Operating temperatur e range +5 to +35°C

Operating humidity range 5 to 90% RH (no condensation)

n SYSTEM

SC-VK650(EE) Music Center: SA-VK650 (EE)

Speaker: SB-VK650 (EE)

Subwoofer: SB-WVK650 (EE)

For information on speaker system, please refer to the original

Service Manual (Order No. MD0605169C3) for SB-VK650EE-S and

(Order No. MD0605170C3) for SB-WVK650EE-S.

2

Notes:

1. Specifications are subject to change without notice. Mass and

dimensions are approximate.

2. Total harmonic distortion is measured by the digital spectrum

analyzer.

SA-VK650EE

3

SA-VK650EE

CONTENTS

Page Page

1 Safety Precautions 6

1.1. General Guidelines

1.2. Before Repair and Adjustment

1.3. Protection Circuitry

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

3 Handling Precautions for Traverse Unit

3.1. Handling Optical Pickup

3.2. Replacing Precautions for Optical Pickup Unit

3.3. Grounding for Preventing Electrostatic Destruction

4 Precaution of Laser Diode

5 Warning

5.1. Service caution based on legal restrictions

6 Accessories

7 Operation Procedures

7.1. Main Unit Operation Control

7.2. Remote Control Operation Control

7.3. Disc Information

7.4. DivX VOD Content

8 New Features

8.1. CRS1D Mechanism Overview

8.2. Music Port

9 About HighMAT

9.1. What 痴 HighMAT?

9.2. Why take advantage of HighMAT?

9.3. Benefits of HighMAT?

10 Self diagnosis and special mode setting

10.1. Service Mode Summary Table

10.2. Service Mode Table 1

10.3. Special Mode Table 2

11 Assembling and Disassembling

11.1. Caution

11.2. Disassembly flow chart

11.3. Main Parts Location

11.4. Disassembly of Top Cabinet

11.5. Disassembly of Rear Panel

11.6. Disassembly of CD/DVD Changer Unit (CRS1D)

11.7. Disassembly of Main P.C.B.

11.8. Disassembly of Transformer P.C.B.

11.9. Disassembly of Power P.C.B.

11.10. Disassembly of Front Panel Unit

11.11. Disassembly for Panel P.C.B. , Mic P.C.B. & Tact Switch

P.C.B.

11.12. Disassembly of Deck mechanism unit

11.13. Disassembly of Deck P.C.B.

10

10

11

12

12

13

14

16

17

17

19

20

20

20

21

24

24

24

31

39

39

40

41

42

42

42

44

44

45

46

47

48

48

6

6

6

7

8

8

8

8

9

11.14. Disassembly of Traverse Unit

11.15. Disassembly of Optical Pickup unit (CD/DVD mechanism)

11.16. Disassembly of Deck Mechanism

11.17. Replacement for cassette lid

11.18. Rectification for tape jam problem

12 Service Fixture and Tools

13 Service Positions

13.1. Checking and Repairing of Main P.C.B.

13.2. Checking and Repairing of Transformer P.C.B.

13.3. Checking and Repairing of Panel, Deck & Deck

Mechanism P.C.B.

13.4. Checking and Repairing of Power P.C.B.

14 Adjustment Procedures

14.1. Cassette Deck Section

14.2. Tuner Section

14.3. Alignment Points

15 Voltage and Waveform Chart

15.1. DVD Module P.C.B.

15.2. Main P.C.B.

15.3. Panel P.C.B. & Power P.C.B. & Transformer P.C.B.

15.4. Deck P.C.B. & Deck Mechanism P.C.B. & Mic P.C.B. &

Tuner P.C.B.

15.5. Waveform Chart

16 Wiring Connection Diagram

17 Block Diagram

18 Notes of Schematic Diagrams

19 Schematic Diagram

19.1. Optical Pickup Unit Circuit

19.2. (A) DVD Module Circuit

19.3. (B) Main (Tuner) Circuit

19.4. (B) Main Circuit

19.5. (C) Panel Circuit & (D) Tact Switch Cirucit

19.6. (E) Transformer Circuit

19.7. (G) Power Circuit

19.8. (H) Deck Circuit & (I) Deck Mechanism Circuit

20 Printed Circuit Board

20.1. (A) DVD Module P.C.B. (Side: A & B )

20.2. (B) Main P.C.B.

20.3. (C) Panel P.C.B.

20.4. (D) Tact Switch P.C.B., (F) Mic P.C.B., (H) Deck P.C.B. ,

(I) Deck Mechanism P.C.B. & (J) Tuner P.C.B.

20.5. (E) Transformer P.C.B.

20.6. (G) Power P.C.B.

21 Basic Troubleshooting Guide

48

50

52

56

56

57

58

58

58

59

60

61

61

62

63

64

64

66

68

69

70

73

75

81

83

83

84

88

89

94

96

97

100

101

102

103

104

105

106

107

109

4

SA-VK650EE

21.1. Basic Troubleshooting Guide for Traverse Unit (DVD

Module P.C.B.)

22 Illustration of ICs, Transistors and Diodes

23 Terminal Function of IC

23.1. IC2801 (C2CBYY000267) System Microprocessor

24 Exploded Views

109

110

111

111

113

24.1. Cabinet Parts Location

24.2. Cassette Mechanism Unit Parts Location (RAA3413-1S)

24.3. Packaging

25 Replacement Parts List

113

115

116

117

5

SA-VK650EE

1 Safety Precautions

1.1. General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following leakage current checks to prevent the customer from being expose d to shock hazards.

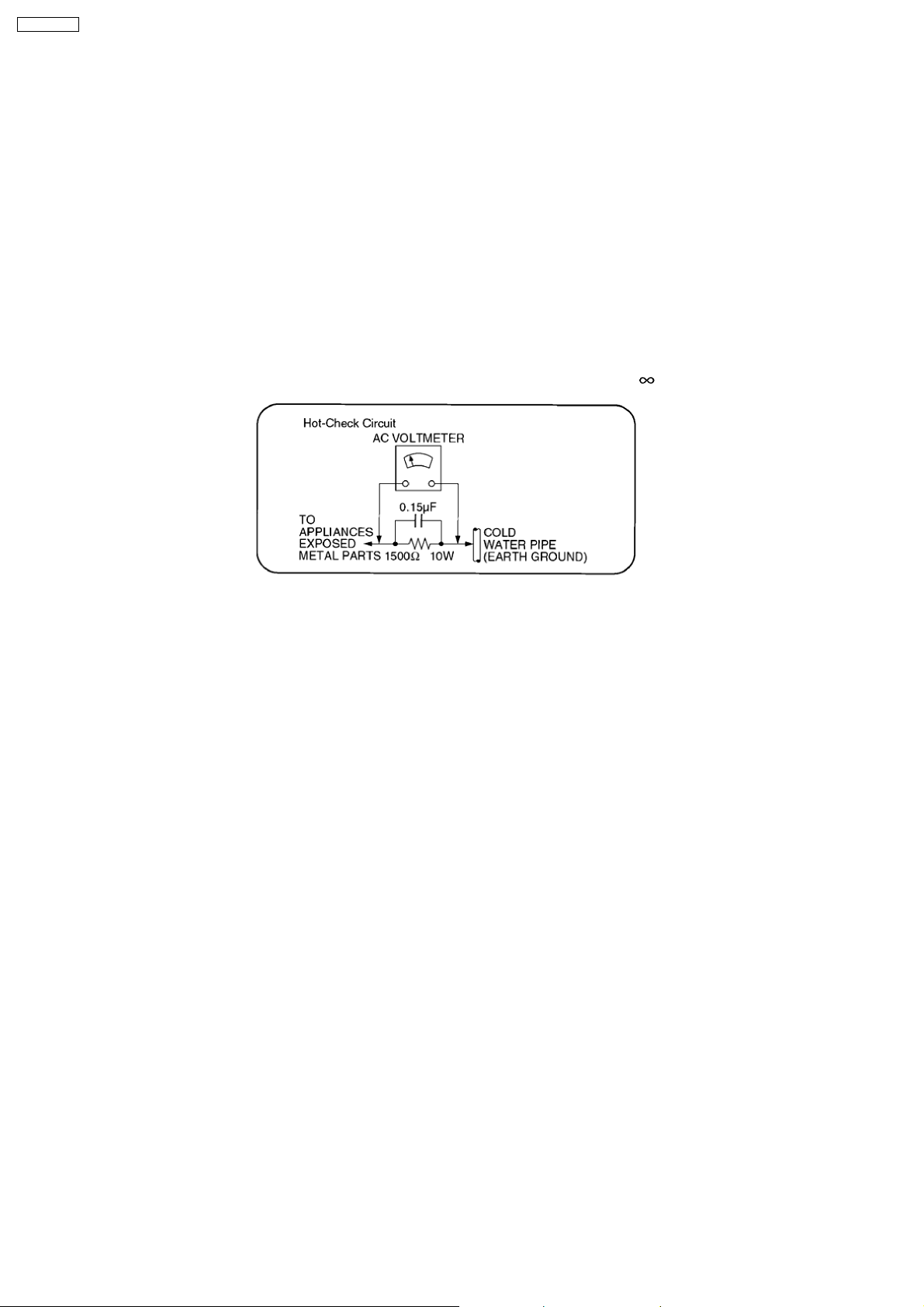

1.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between the jumpered AC plug and each exposed metallic cabinet part on

the equipment such as screwheads, connectors, control shafts, etc. When the expose d metallic part has a return path to the

chassis, the reading should be between 1MΩ and 5.2MΩ .

When the exposed metal does not have a return path to the chassis, the reading must be

.

Figure 1

1.1.2. Leakage Current Hot Check

(See Figure 1)

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF capacitor, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent) may

be used to make the hot checks, leakage current must not exceed 1/2 milliamp. In case a measurement is out of the limits

specified, there is a possibility of a shock hazard, and the equipment should be repaired and rechecked before it is returned to

the customer.

1.2. Before Repair and Adjustment

Disconnect AC power, discharge Power Supply Capacitors C2550 , C2556 , C5101, C5104, C5165 , C5166, C5171, C5172 , C5950

and C5966 through a 10Ω, 5W resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

Current consum ption at AC 230V, 50Hz in NO SIGNAL (vol. min, at CD mode) should be ~200mA.

1.3. Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

· No sound is heard when the power is turned on.

· Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

“shorted”, or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

6

SA-VK650EE

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note :

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconducto r (solid state) devices can be damaged easily by electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor “chip” components. The following techniques should be used to help reduce the inciden ce of component damage

caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potent ial shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminium foil, to prevent electrostatic charge build up or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder remover device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminium foil or

comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize body motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to

damage an ES device).

7

SA-VK650EE

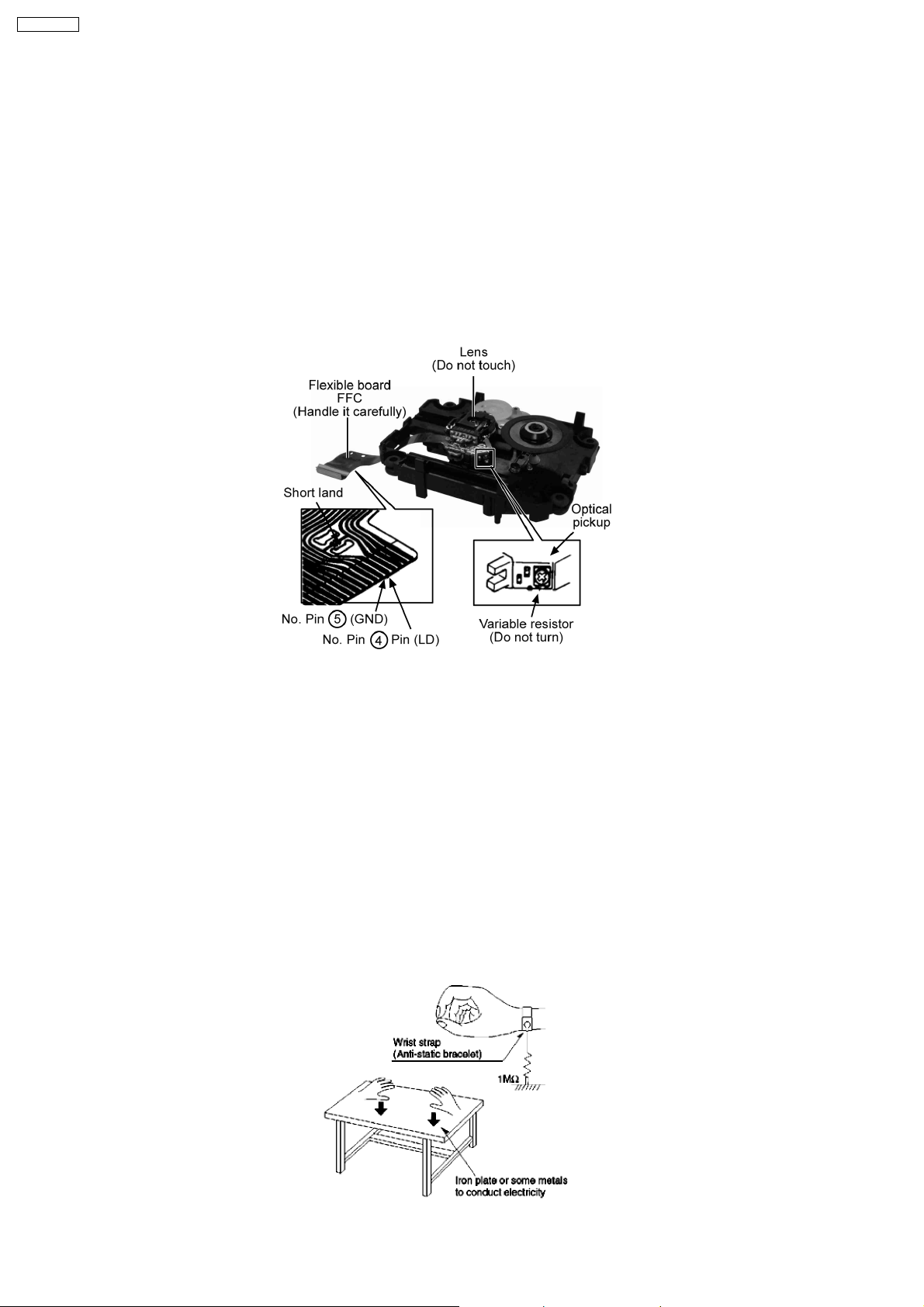

3 Handling Precautions for Traverse Unit

The laser diode used inside optical pickup could be destroyed due to static electricity as a potential difference is caused by

electrostatic load discharged from clothes or human body. Handling the parts carefully to avoid electrostatic destruction during

repair.

3.1. Handling Optical Pickup

1. Do not impact on optical pickup as the unit structurally uses an extremely precise technology.

2. Short-circuit the flexible cable of optical pickup remove from the circuit board using a short-circuit pin or clip in order to prevent

laser diode from electrostatic destruction (Refer to Fig. 3.1 and Fig. 3.2)

3. Do not handle flexible cables forcibly as this may cause snapping. Handle the parts carefully (Refer to Fig. 3.1)

4. A new optical pickup is equipped with an anti-static flexible cable. After replacing and connecting to the flexible board, cut the

anti-static flexible cable. (Refer to Fig. 3.1)

Fig 3.1

3.2. Replacing Precautions for Optical Pickup Unit

CD/DVD Optical Pickup

The optical pickup by which part supply was carried out attaches the short clip to the flexible board for laser diode electrostatic

discharge damage prevention. Please remove the short clip and be sure to check that the short land is open, before connecting.

(Please remove solder, when the short land short-circuits.)

3.3. Grounding for Preventing Electrostatic Destruction

1. Human body grounding

Use the anti-static wrist strap to discharge the static electricity accumulated in your body. (Refer to Fig. 3.2)

2. Work place grounding

Place a conductive material (conductive sheet) or ironboard where optical pickup is placed. (Refer to Fig. 3.2)

Note :

Keep your clothes away from optical pickup as wrist strap does not release the static electricity charged in clothes.

Fig. 3.2

8

SA-VK650EE

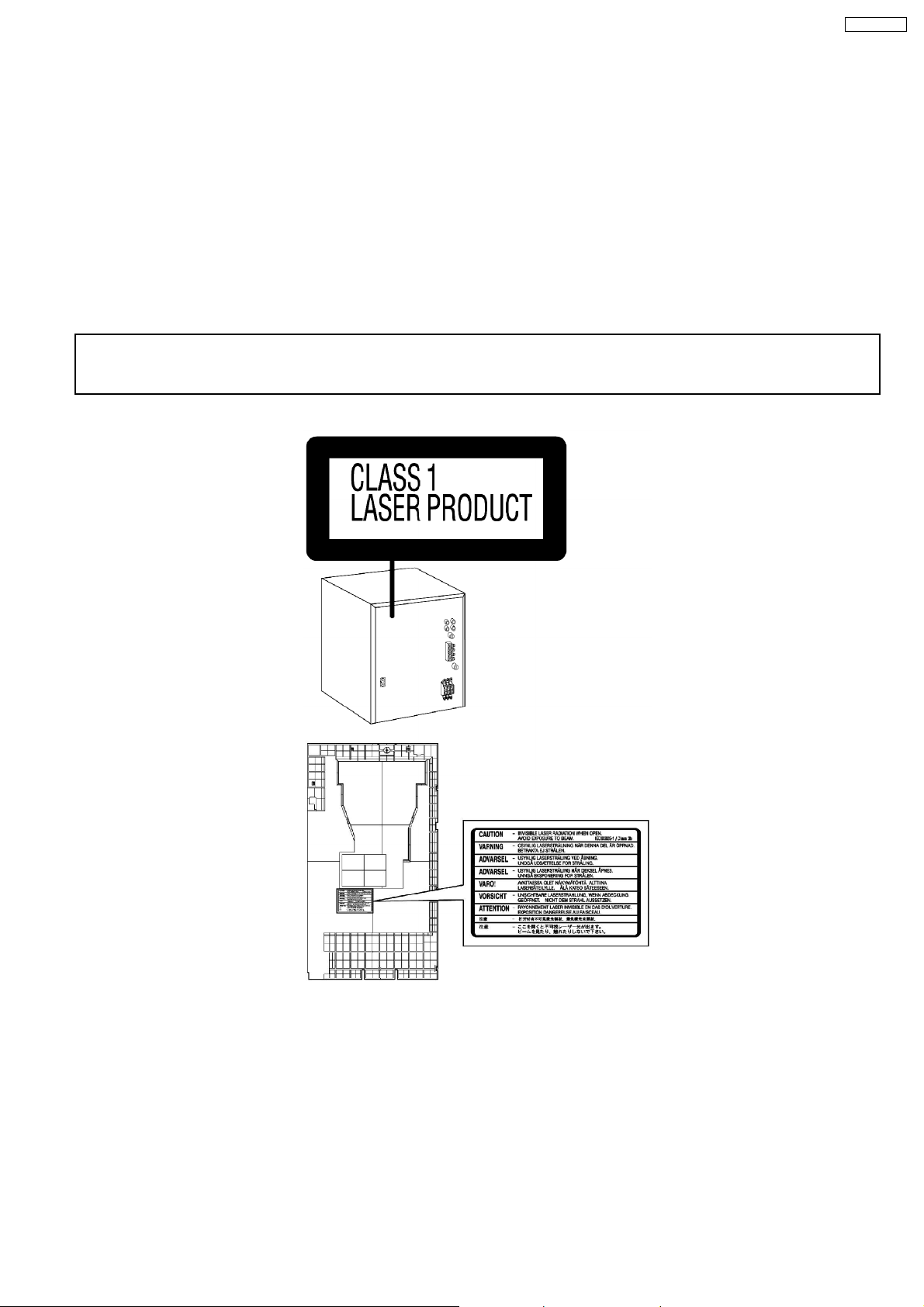

4 Precaution of Laser Diode

Caution :

This product utilizes a laser diode with the unit turned "ON", invisible laser radiation is emitted from the pick up lens.

Wavelength : 785 nm(CD)/662 nm(DVD)

Maximum output radiation power from pick up : 100 µW/VDE

Laser radiation from pick up unit is safety level, but be sure the followings:

1. Do not disassemble the optical pick up unit, since radiation from exposed laser diode is dangerous.

2. Do not adjust the variable resistor on the pick up unit. It was already adjusted.

3. Do not look at the focus lens using optical instruments.

4. Recommend not to look at pick up lens for a long time.

CAUTION!

THIS PRODUCT UTILIZES A LASER.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE SPECIFIED HEREIN MAY RESULT

IN HAZARDOUS RADIATION EXPOSURE.

n Use of Caution Labels

9

SA-VK650EE

5 Warning

5.1. Service caution based on legal restrictions

5.1.1. General description about Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86°F) more than that

of the normal solder.

Definition of PCB Lead Free Solder being used

The letter of “PbF” is printed either foil side or components side on the PCB using the lead free solder.

(See right figure)

Service caution for repair work using Lead Free Solder (PbF)

· The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the PCB using the lead free solder.)

· To put lead free solder, it should be well molten and mixed with the original lead free solder.

· Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

· Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt

the lead free solder.

· Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30

degrees C (662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

· The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01K-----------(0.3mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

Note

* Ingredient: Tin (Sn), 96.5%, Silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

10

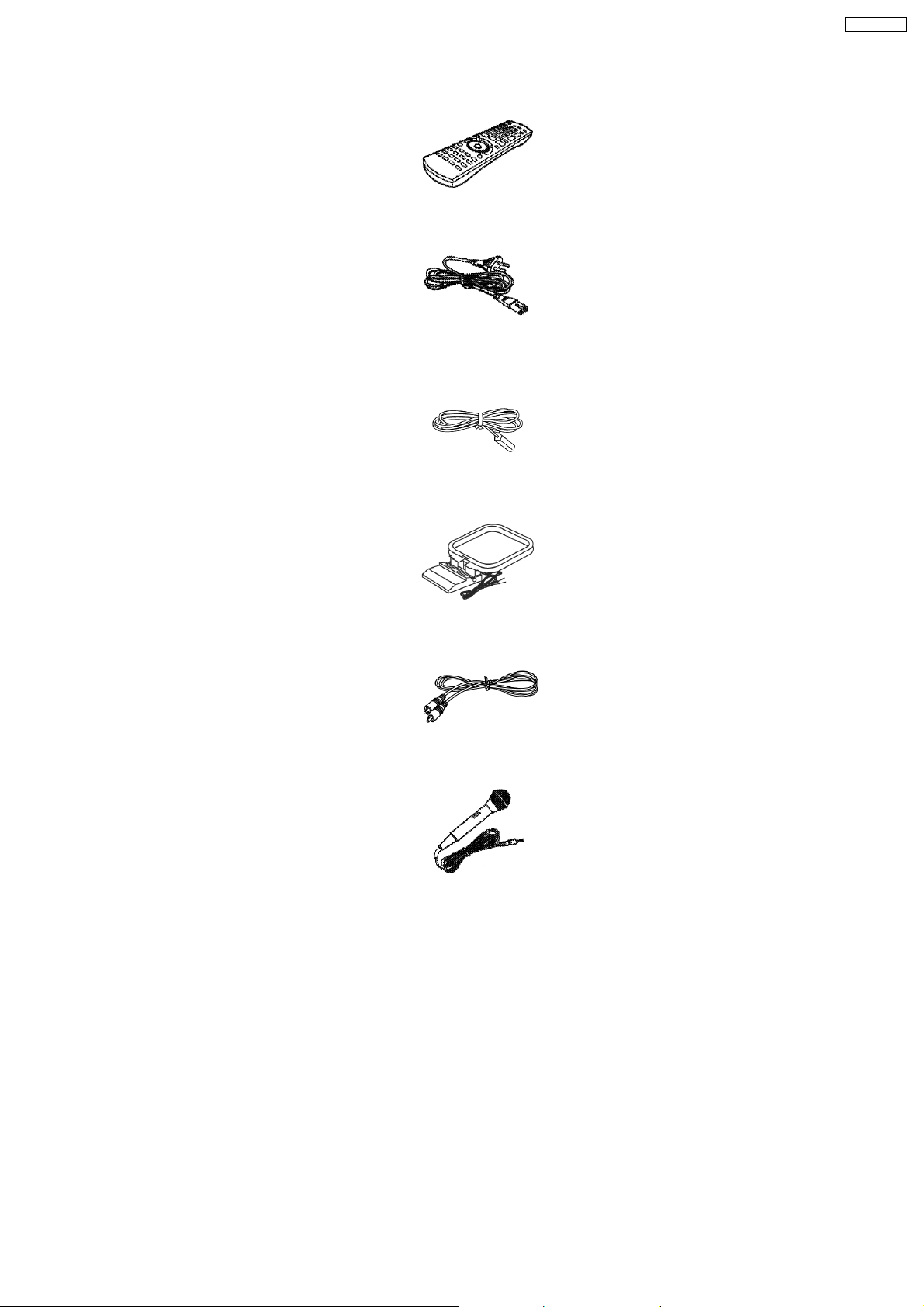

6 Accessories

SA-VK650EE

Remote control

AC power supply

cord

FM indoor antenna

AM loop antenna

Video cable

Mic

11

SA-VK650EE

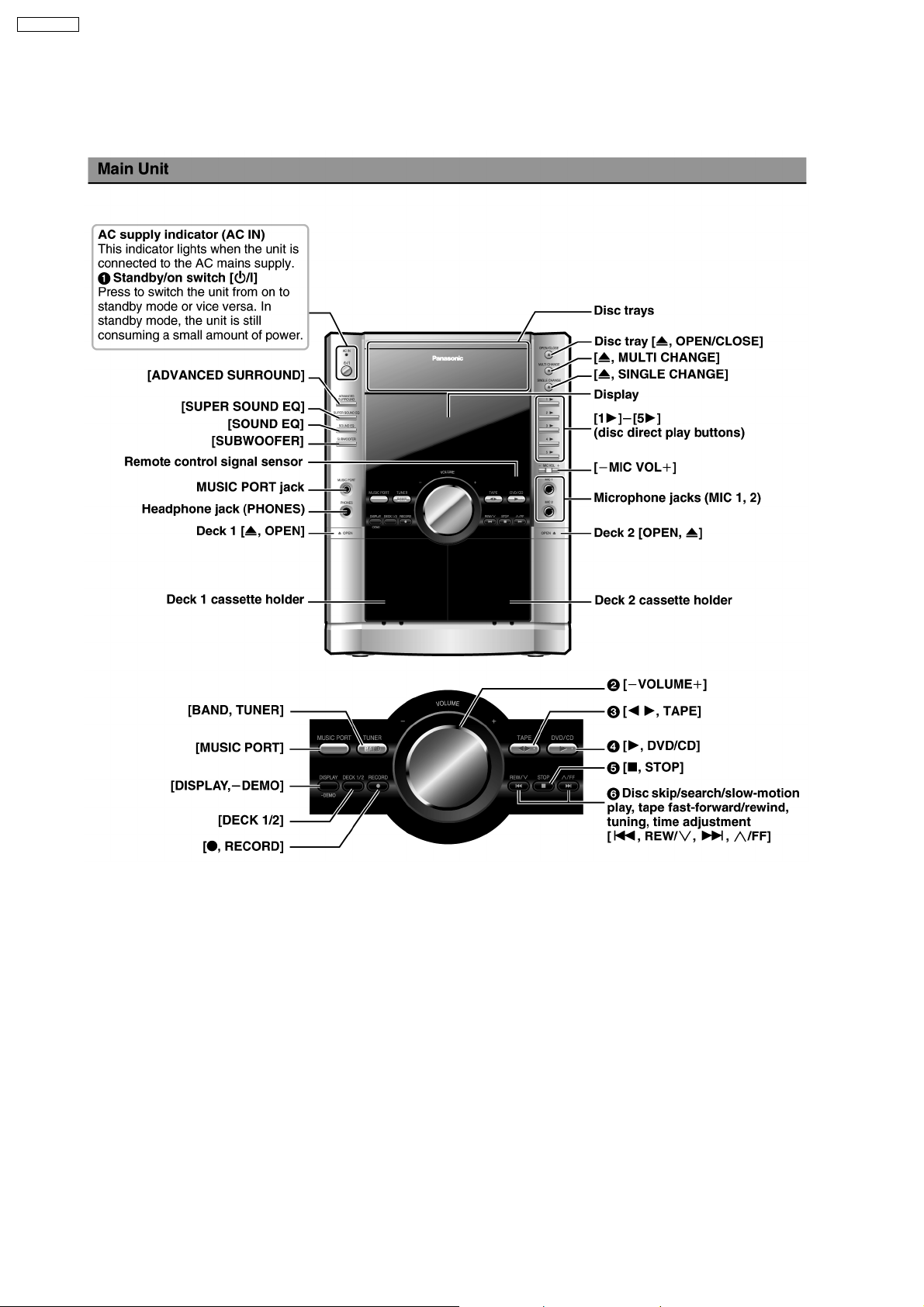

7 Operation Procedures

7.1. Main Unit Operation Control

12

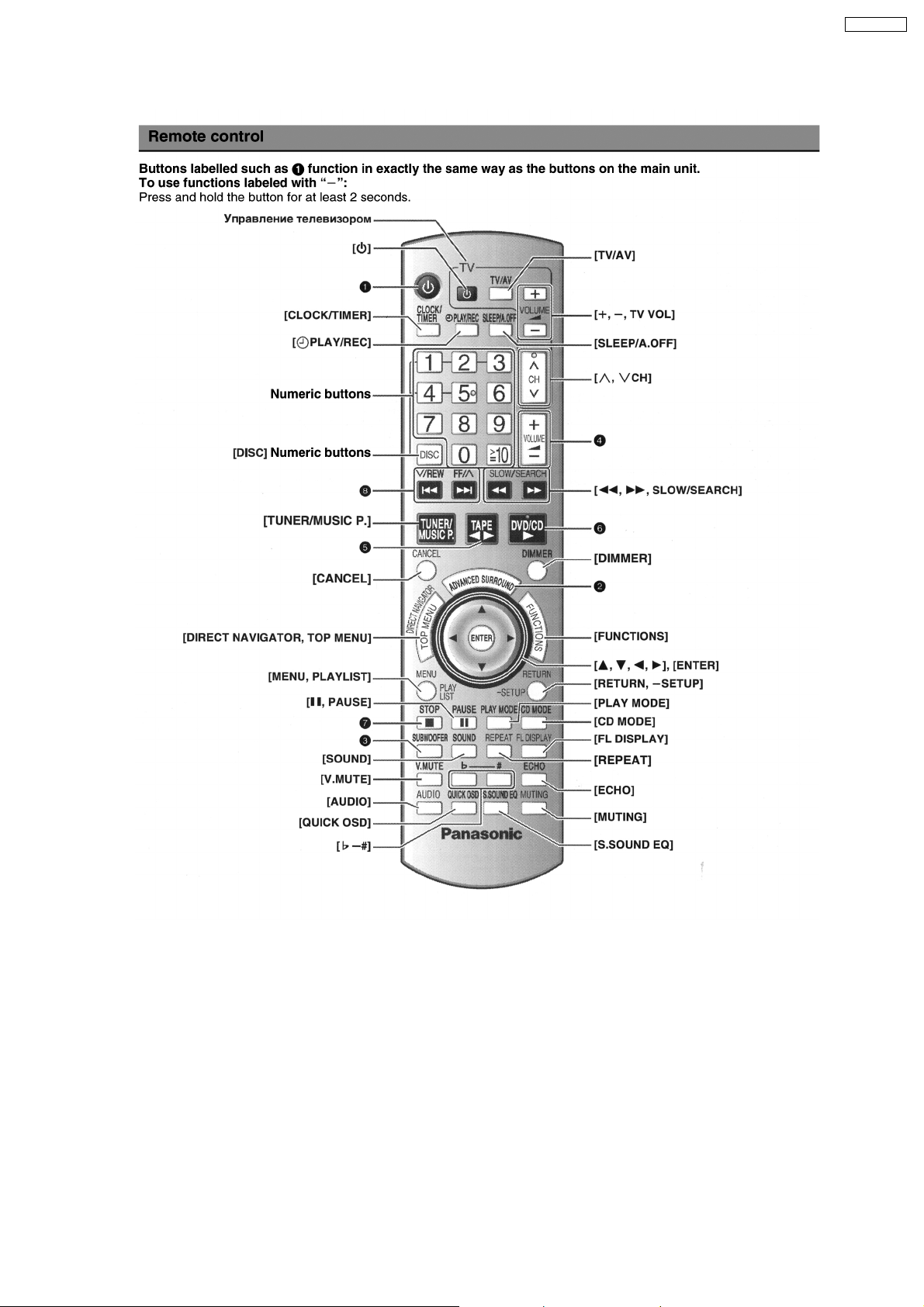

7.2. Remote Control Operation Control

SA-VK650EE

13

SA-VK650EE

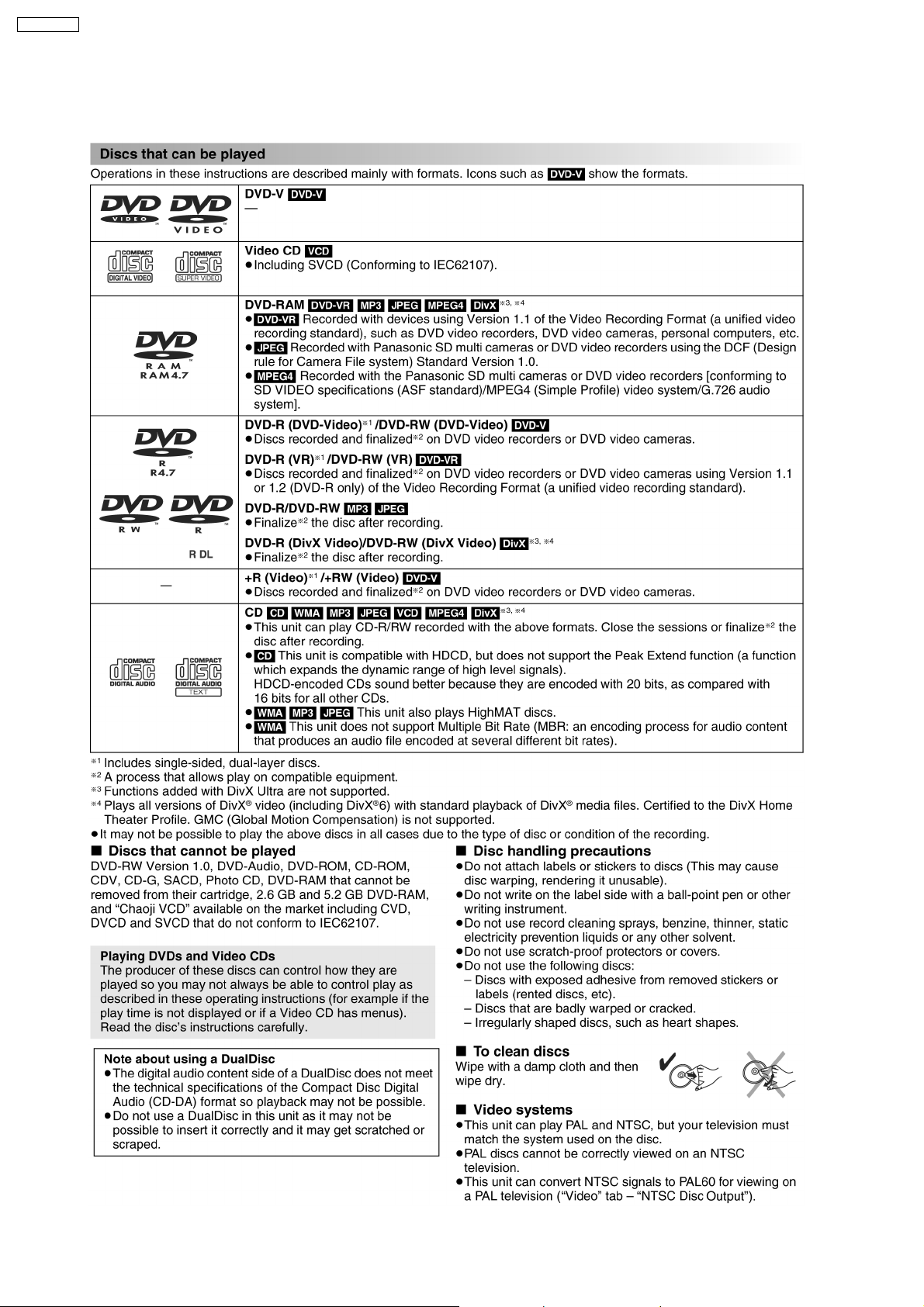

7.3. Disc Information

7.3.1. Disc Playability

14

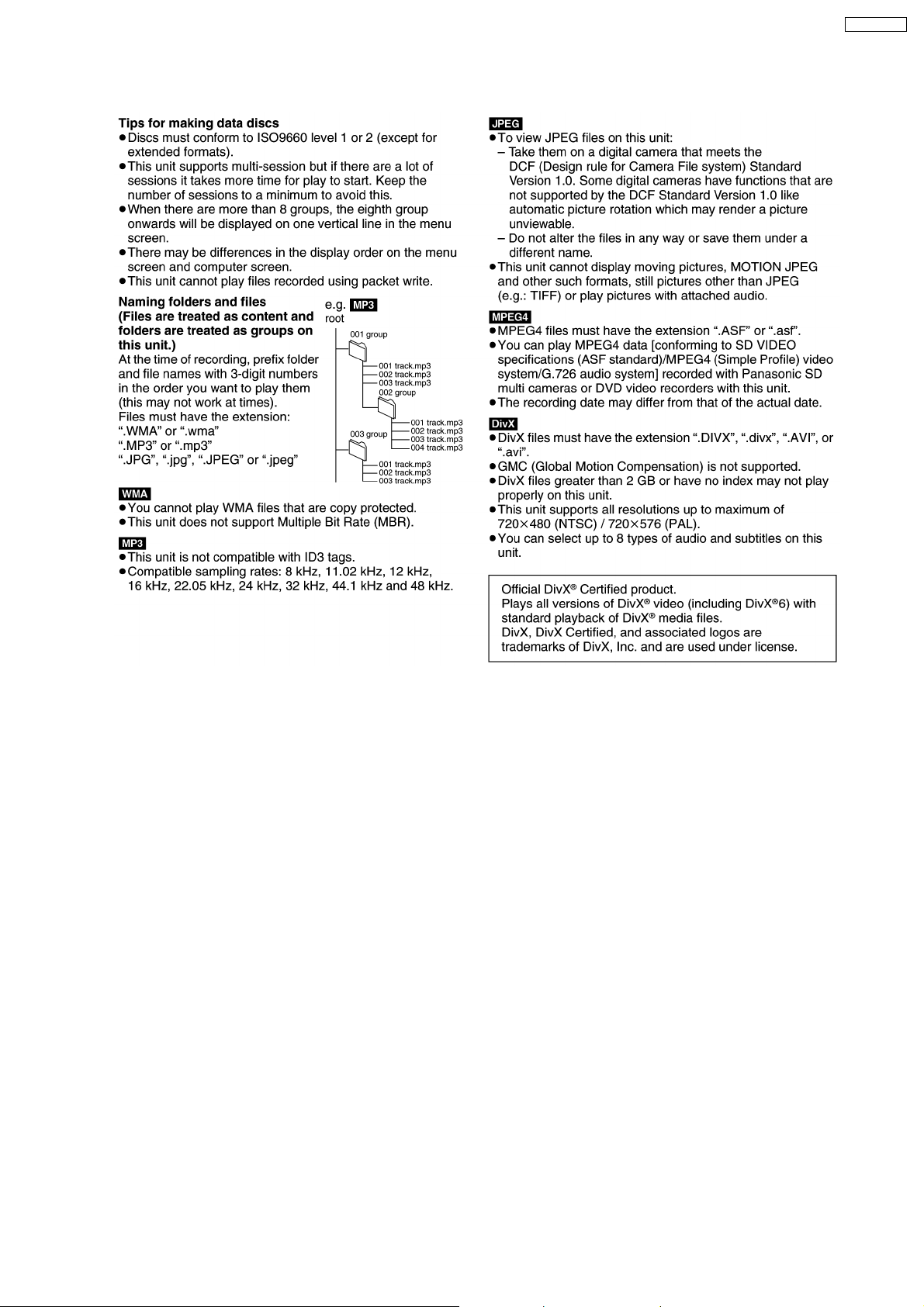

7.3.2. To Play MP3/WMA and still pictures (JPEG/tiff)

SA-VK650EE

15

SA-VK650EE

7.4. DivX VOD Content

16

8 New Features

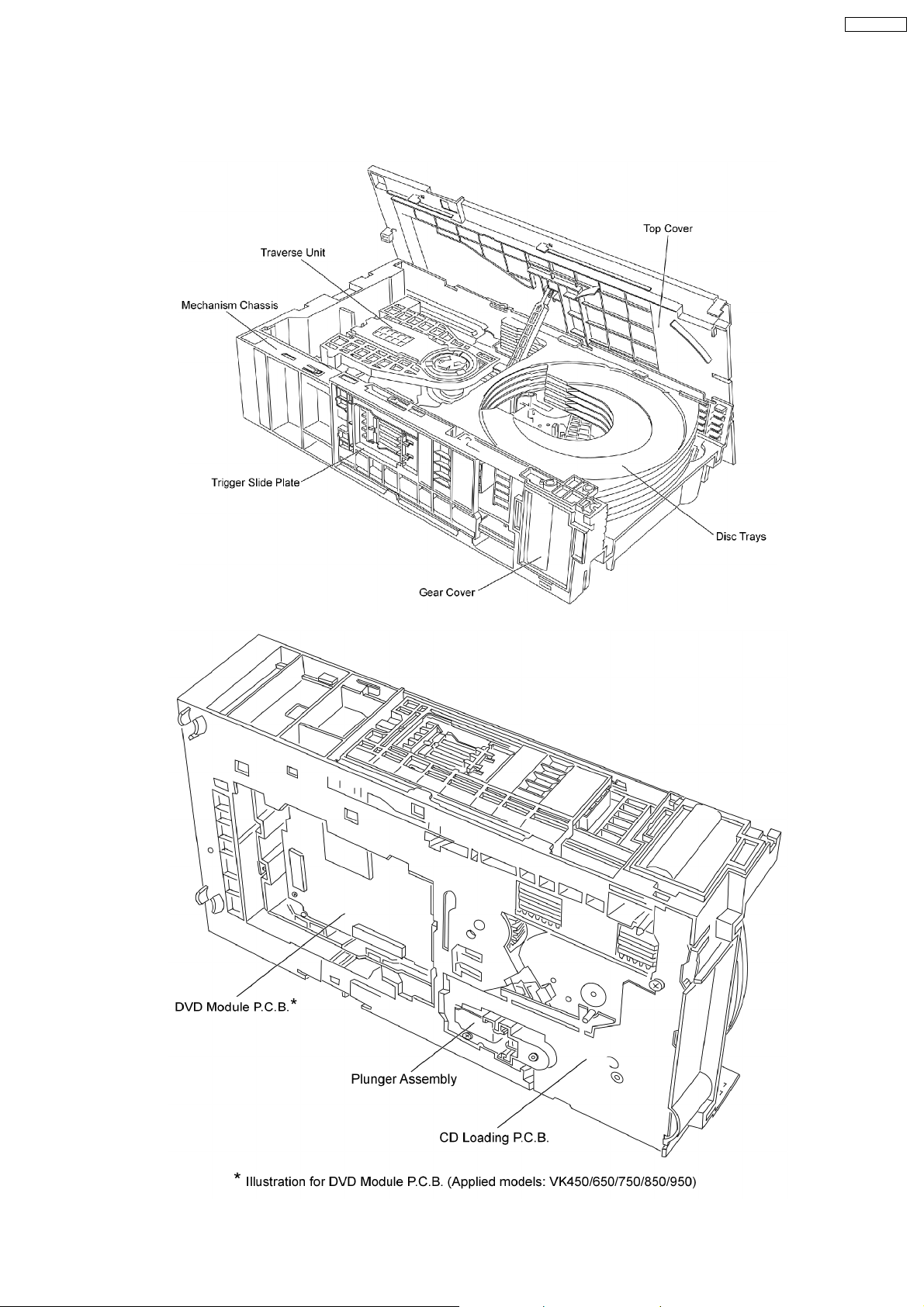

8.1. CRS1D Mechanism Overview

SA-VK650EE

17

SA-VK650EE

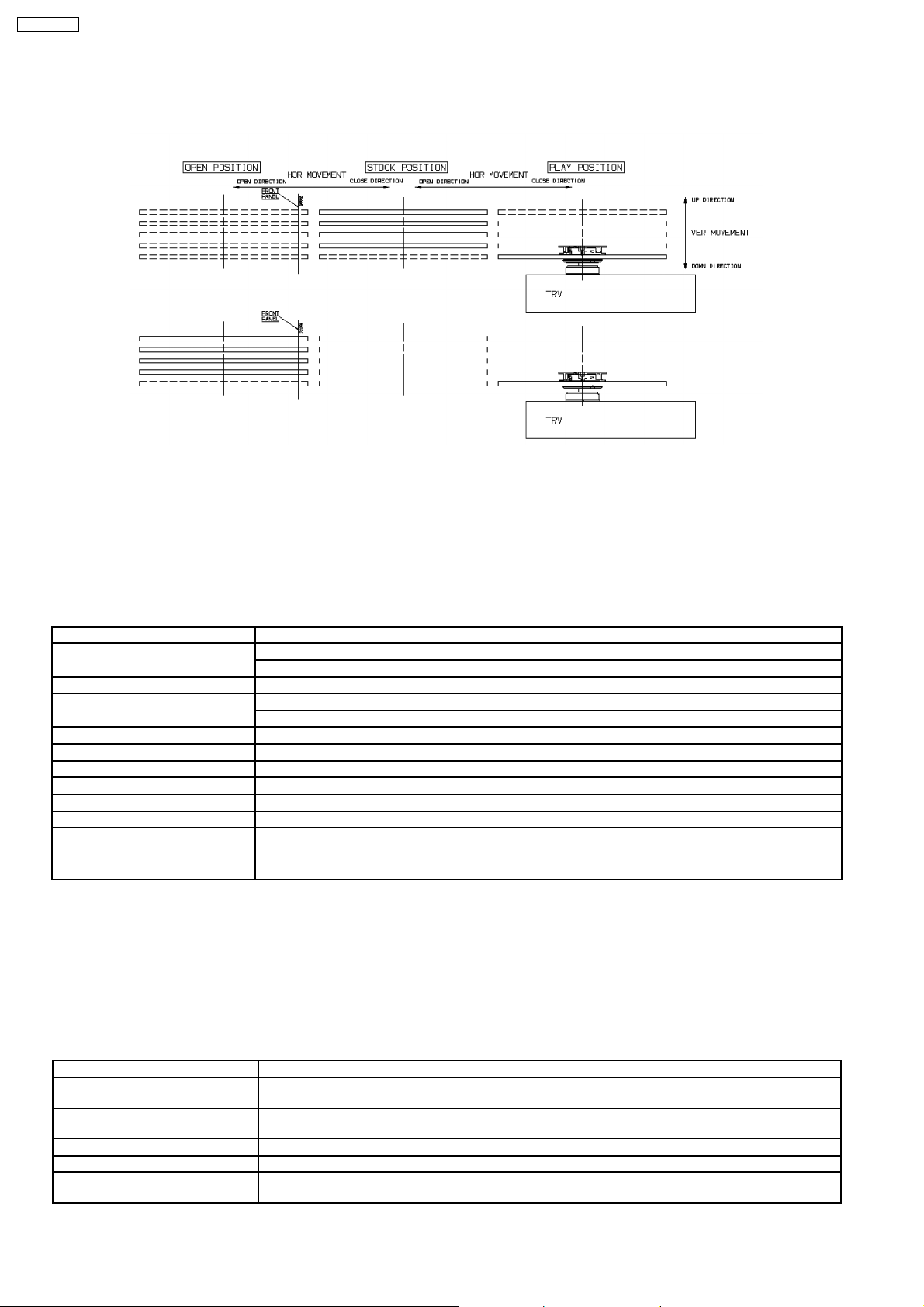

8.1.1. General Feature

· This is a five disc changer mechanism for CD/DVD. The outline figure is shown below.

· The mechanism has "CHANGE WHILE PLAY" function. It open other trays for disc exchanging while one tray is at PLAY

position performing recording or reproducing.

· The mechanism can quickly change all trays with "CHANGE ALL" function. All trays can be move to OPEN position with one

operation.

· There is no sensor to indicate presence of disc on any tray.

8.1.2. Hardware composition

· Below is the hardware components of the mechanism

Name Function

Open Switch (OPEN-SW) The switch is used to detect normal tray opening

The switch is used for detect tray being manually push/trigger when full open

Home Switch (HOME-SW) Is used to detect cam gear home position

Close Sensor (CLOSE-SENSOR) Used for normal single tray closing

Used to detect cam gear rotate to Play Driving position

Play Switch (PLAY-SW) Detect TRV clamping complete position

Stocking Switch (STOCK-SW) Detect tray completely transfer for play position to stocking position

UD Sensor (UD-SENSOR) Detect TRV vertical movement position

Top Switch (TOP-SW) Detect a default position of TRV vertical movement position

Driver IC To drive Motor

Motor Main driving source for changer

Plunger Switching the driving source from motor to:

1. Tray open/close

2. Drive tray to play/stock position and TRV vertical movement

8.1.3. Mechanism Operation

· This mechanism has the following state:

1. Driving of a tray to open/close

2. Up/down operation of a traverse performs a state changes of tray.

By using the plunger to lift/release of a switching gear, and the cam gear to lift/release the function gear the motor can be link

to several gear trains to perform various operations.

· The functions that can be perform in this mechanism are described as below:

Condition Explanation

Open current playing tray The state to change current playing disc. All tray will be open at once and current tray at PLAY position

Open All The state where all trays being driven to OPEN position. The disc can be taken in or out from tray to tray

Stock The state where the trays are stored in STOCK position

Play The state where one of the tray 5 trays is being driven to PLAY position and clamped by traverse unit

Play & Open Tray-* The state where one of the tray is in playing position performing recording or reproducing, other trays can

will be expose.

by close tray one by one from top to bottom.

be used (OPEN position) for disc exchanging without stopping the recording or reproducing process.

18

Condition Explanation

Change The state when one of the opened tray being driven from OPEN position to STOCK position and other

opened trays remain still at OPEN position.

Close All The state where all open trays will being driven from OPEN position to STOCK position, one by one from

top to bottom

Note: * represent tray number (from 1 ~ 5)

8.1.4. New CD/DVD Mechanism (CRS1D)

Note:

This service manual does not contain the following information for the mention CD/DVD Mechanism drive:

· Schematic Diagram, Block Diagram and P.C.B. layout of CD/DVD Loading P.C.B.

· Part List for individual parts of the mechanism.

· Explode d View and Parts List for individual parts of the CD/DVD Mechanism drive.

Please refer to the original service manual (Order No. MD0603065A3) for the CD/DVD Mechanism Drive CRS1D .

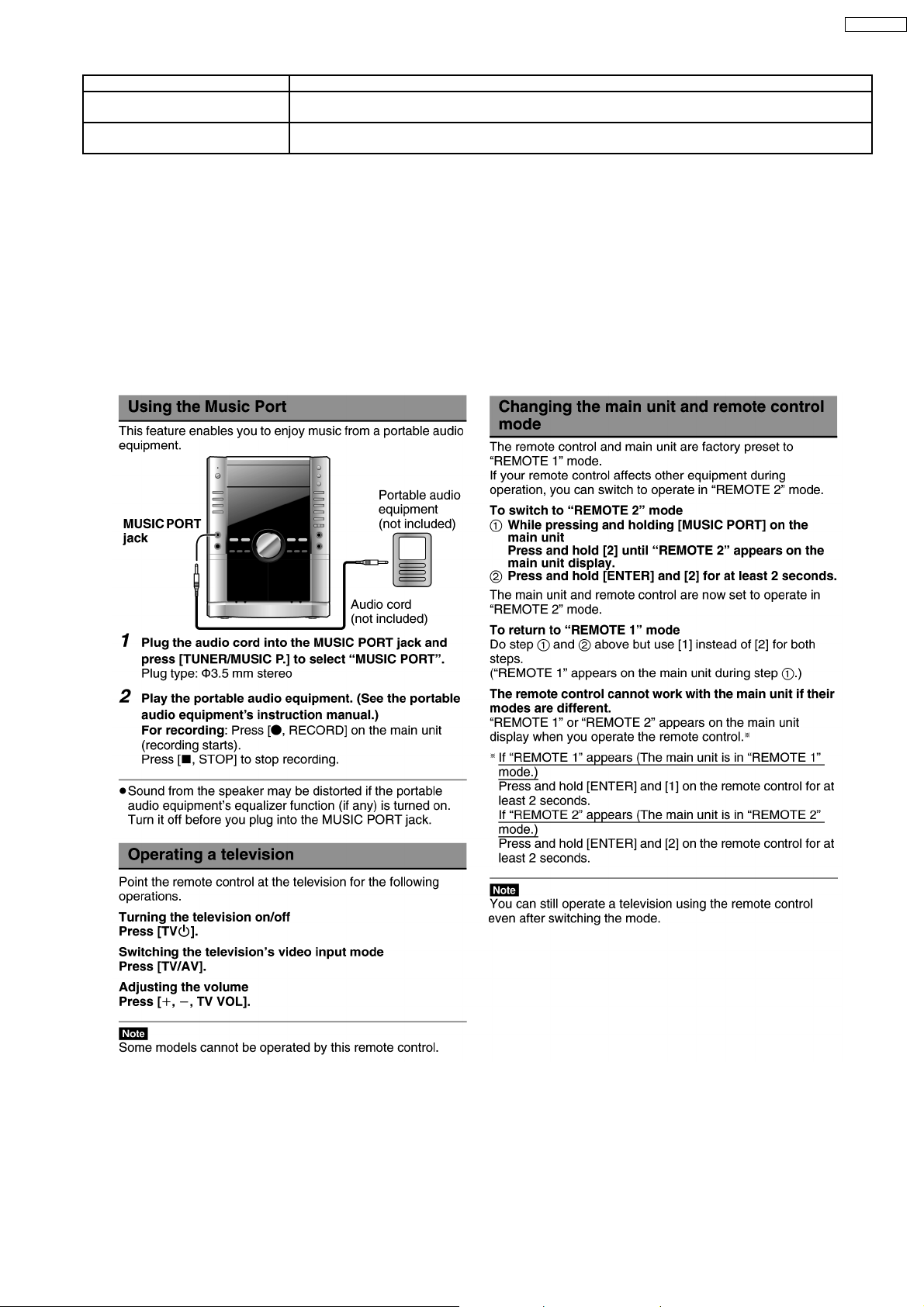

8.2. Music Port

SA-VK650EE

With reference to page 29 of the operating instruction manual.

19

SA-VK650EE

9 About HighMAT

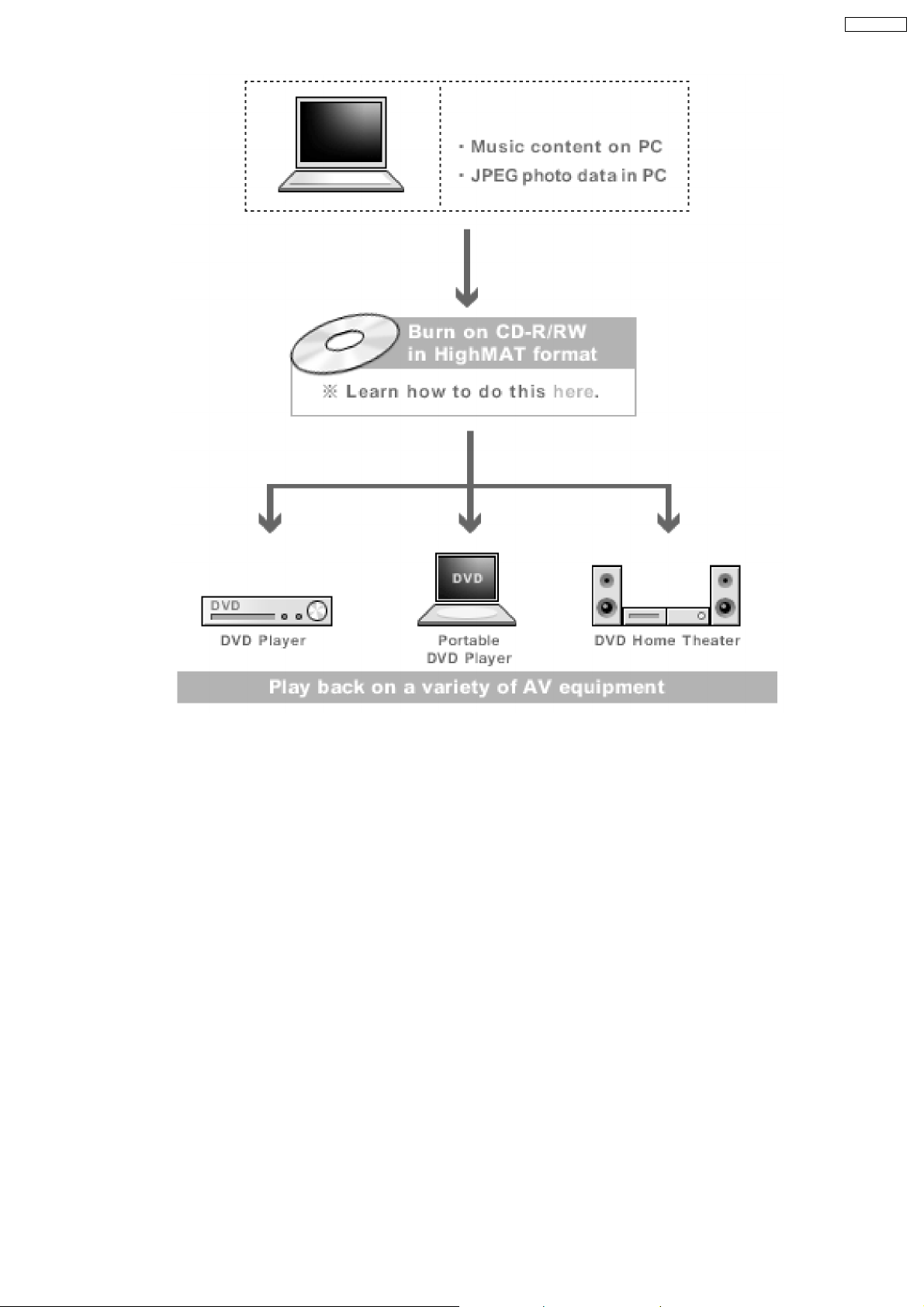

9.1. What’s HighMAT?

Consumers worldwide are using PCs to create their own collections of music, photos and even video by burning them onto CDs.

But how these collections can be experienced across different devices can be confusing to navigate, time consuming to access for

a DVD player, and be incomplete in terms of music information available to the customer.

HighMAT offers a solution to this growing consumer problem. HighMAT dramatically improves the digital media experience on

consumer electronic devices by delivering a simple, standardized approach that allows consumers who have created personal

collections of digital music, photography and video on their PC to:

>> Create a HighMAT CD or DVD which can be easily played back on consumer electronics devices such as CD and DVD players ,

and car stereos.

>> Move digital media files (using recordable media such as CD-R and CD-RW) between the PC and various playba ck devices

such as CD and DVD players.

A new standard for creating personal media on consumer electronic devices, HighMAT enable easier and more seamless

interoperability between Windows PCs and devices designed for your living room, or the car.

9.2. Why take advantage of HighMAT?

A Problem Defined:Toda y, when consumers create their own digital audio, video or photo collections on CD-R or other physical

formats, there are numerous, inconsistent ways that devices read the data. For the consumer, the playback experience can be

confusing:

20

SA-VK650EE

A Solution Created: HighMAT delivers a better digital media access experience by creating a standard approach for PCs to

structure digital media on various physical formats and for playback devices to read the data.

9.3. Benefits of HighMAT?

Conventional HighMAT

Even though DVD player is CD-R/RW compatible, the inconsistent ways

that various DVD players can read the music or photos files often leads

to a confusing and inconsistant playback experince.

HighMAT compatible products play content back with consistent

interface. This includes products which are JPEG compatible products

without HighMAT support.

21

SA-VK650EE

22

SA-VK650EE

HighMAT is now available for CD Burning and in Leading DVD PlayersHighMAT is a new technology that is now available in leading

software and consumer electronic devices to dramatically improve the digital media experience when you create homemade

CDsHighMAT delivers a simple, standardized way for PC software and consumer electronics devices to talk to each other and work

better together.

When you create your homemade CDs with software that supports HighMAT CD burning, and then play them back on a DVD

player that supports HighMAT, you get better, easier navigation. You get folders you can access with a single click of your DVD

player´s remote control. You can view important information about your music like full song names, artist titles, album names and

genre. And you can get faster startup on your home entertainment device.

To enjoy the benefits of HighMAT, all you need is software that supports HighMAT for CD burning of music or photos, as well as

a home entertainment device like a DVD player that supports HighMAT for playback. Always look for the HighMAT logo on your

software or home entertainment device to ensure it supports the HighMAT experience.

23

SA-VK650EE

10 Self diagnosis and special mode setting

This unit is equipped with functions for checking and inspecting namely: Self-Diagnostic and Test Mode.

10.1. Service Mode Summary Table

The service modes can be activated by pressing various button combination on the player and remote control unit.

Below is the summary of major checking:

Player buttons Remote control unit buttons Application Note

STOP 0 Error code display (Refer to the section,

5 Jitter checking (Refer to the section

6 Region display and mode (Refer to the section

7 Micro-processor firmware version check

FUNCTIONS DVD laser drive current check

3 CD laser drive current check

DVD/CD laser drive current check

Initialization of the player (factory setting is restored.)

Used after replacement of micro-computer, FLASH ROM IC,

EEPROM and HDMI module.

8 Region and Firmware version display

ENTER DVD Module Reset (During initialisation)

“10.2.2 DVD Self

Diagnostic Function-Error

Code”).

“10.2.1 Service Mode

Table 1 for more

information”).

“10.2.1 Service Mode

Table 1 for more

information”).

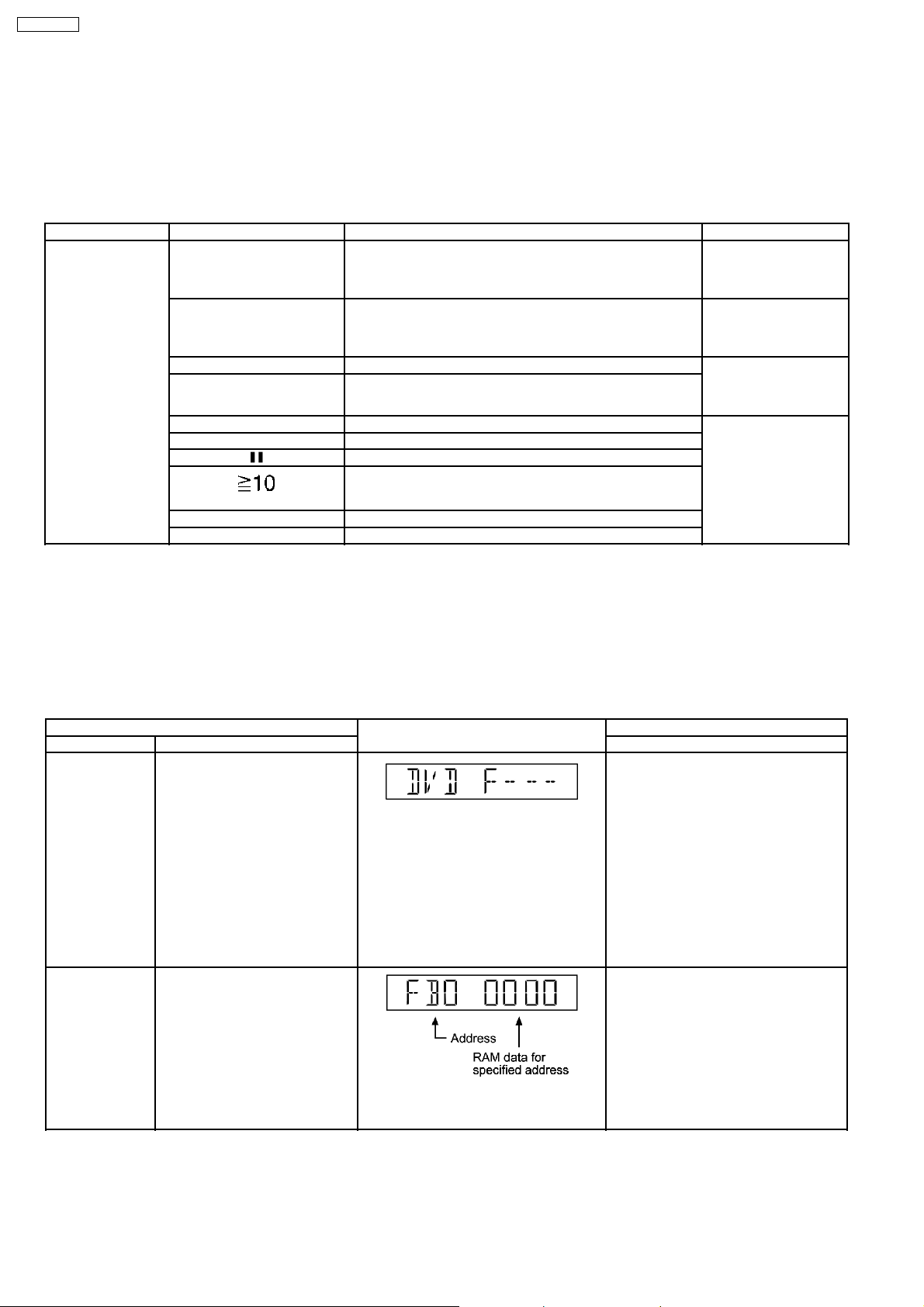

10.2. Service Mode Table 1

By pressing various button combin ations on the player and remote control unit can activate the various service modes for checking.

Special Note:

Due to the limitations of the no. characters that can be shown on FL Display, the “FL Display” button on the remote control unit

is used to show the following page. (Display 1 / Display 2).

10.2.1. Service Mode Table 1

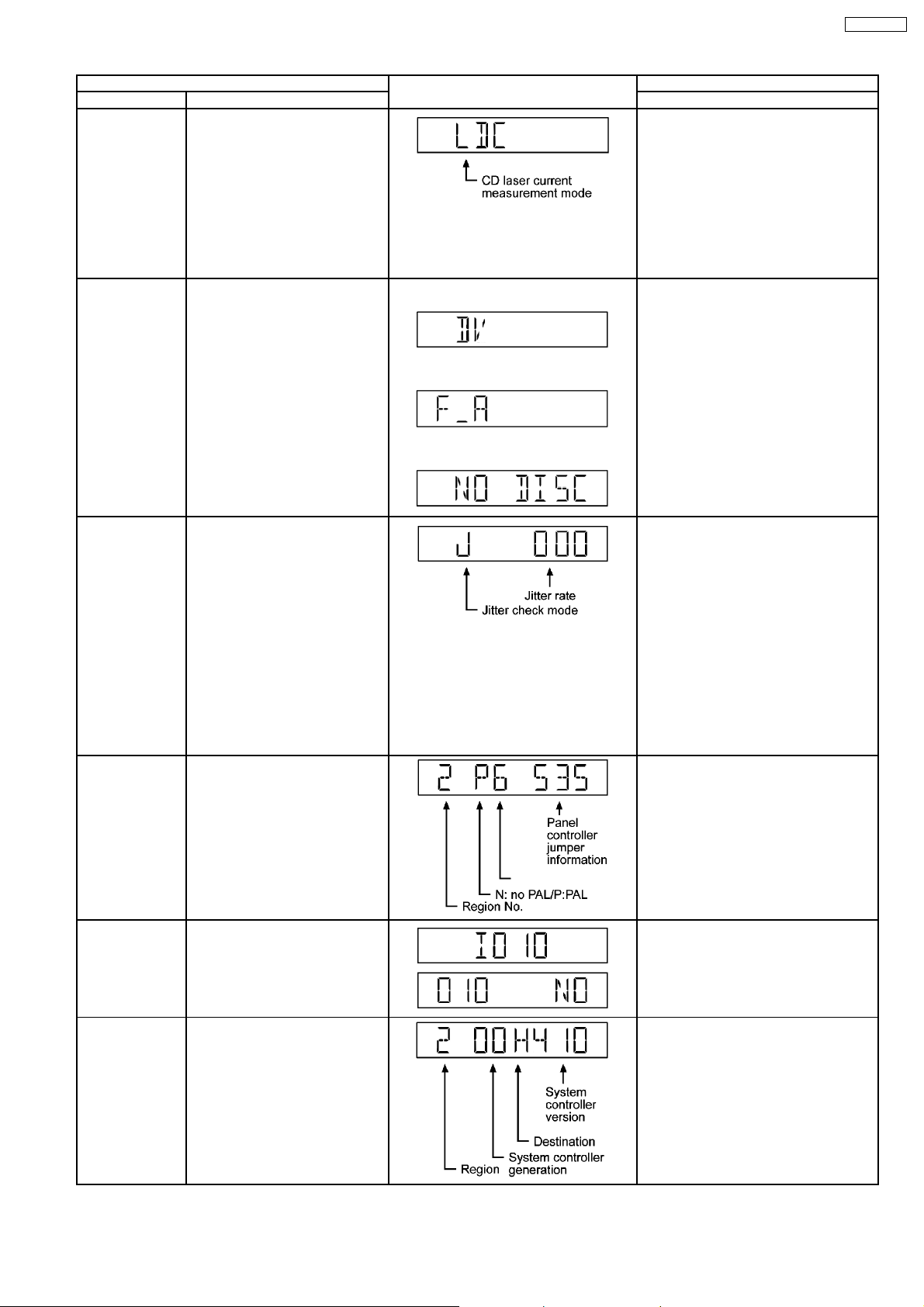

Item FL Display Key Operation

Mode Name Description Remote Control Key

Error code check Error code check.

ADSC internal

RAM data check

The latest error code stored in the

EEPROM IC is displayed.

ADSC internal RAM data check.

ADSC internal RAM data is read

out and displayed.

Error code (play_err) is expressed in the

following convention.

Error code = 0 x DAXX is expressed: DVDnn

UXX

Error code = 0 x DBXX is expressed: →

DVDnn HXX

Error code = 0 x DXXX is expressed: →

DVDnn FXXX

Error code = 0 x 0000 is expressed: →

DVDnn F--* “xx” denotes the error code →

In STOP (no disc) mode, press STOP

button on the player, and “0” button on the

remote control unit. *With pointing of cursor

up and down on display.

Cancelled automatically 5 seconds later.

To exit, press [POWER] button on main

unit or remote control.

In STOP (no disc) mode, press STOP

button on the player, and “1” & “2” button

on the remote control unit.

Press STOP or PLAY button.

The value is shown in hexadecimal notation.

The above example shows the data in

ADSC address OFAh is 6901h.

24

Item FL Display Key Operation

Mode Name Description Remote Control Key

CD laser drive

current

measurement

CD laser drive current

measurement.

CD laser drive current measured

and the result is displayed together

with the initial value stored in the

EEPROM IC.

In STOP (no disc) mode, press STOP

button on the player, and “3” button on the

remote control unit.

Cancelled automatically 5 seconds later.

Press “FL Display” button on remote

control unit for next page (FL Display).

After the measurement, CD laser

emission is kept on. It is turned off

when POWER key is switched off.

(It is also turned off when POWER

button on the player is switched

off.)

Device Name Display the device name. 1.

The value denotes the current in decimal

notation.

The above example shows the initial current

is 25mA and the measured value is 22mA.

In STOP (no disc) mode, press STOP

button on the player, and “4” button on the

remote control unit. *With pointing of cursor

up and down on display.

Cancelled automatically 5 seconds later.

2.

To exit, press [POWER] button on main

unit or remote control.

3.

SA-VK650EE

Jitter check Jitter check.

Jitter rate is measured and

displayed.

Measurement is repeatedly done in

the cycle of one second. Read

error counter starts from zero upon

In STOP (no disc) mode, press STOP

button on the player, and “5” button on the

remote control unit.

Press STOP or OPEN button to exit.

Press “FL DISPLAY” button on remote

control unit for next page (FL Display).

mode setting. When target block

data failed to be read out, the

counter advances by one

increment. When the failure is

caused by minor error, it may be

corrected when retired to enable

Jitter rate is shown in decimal notation to

one place of decimal.

Focus drive value is shown in hexadecimal

notation.

successful reading. In this case,

the counter advances by one.

When the error persists even after

retry, the counter may jump by two

or more.

Region display Region display & mode In STOP (no disc) mode, press STOP

button on the player, and “6” button on the

remote control unit.

Cancelled automatically 5 seconds later.

Micro- processor

firmware version

display &

EEPROM

checksum display.

Micro-processor firmware version

display & EEPROM checksum

display.

In STOP (no disc) mode, press STOP

button on the player, and “7” button on the

remote control unit.

Cancelled automatically 5 seconds later.

Press “FL Display” button on remote

control unit for next page. (FL Display)

DVD module

firmware version

display

DVD module firmware version

display is on the FL Display.

In STOP (no disc) mode, press STOP

button on the player, and “8” button on the

remote control unit.

Cancelled automatically 5 seconds later.

25

SA-VK650EE

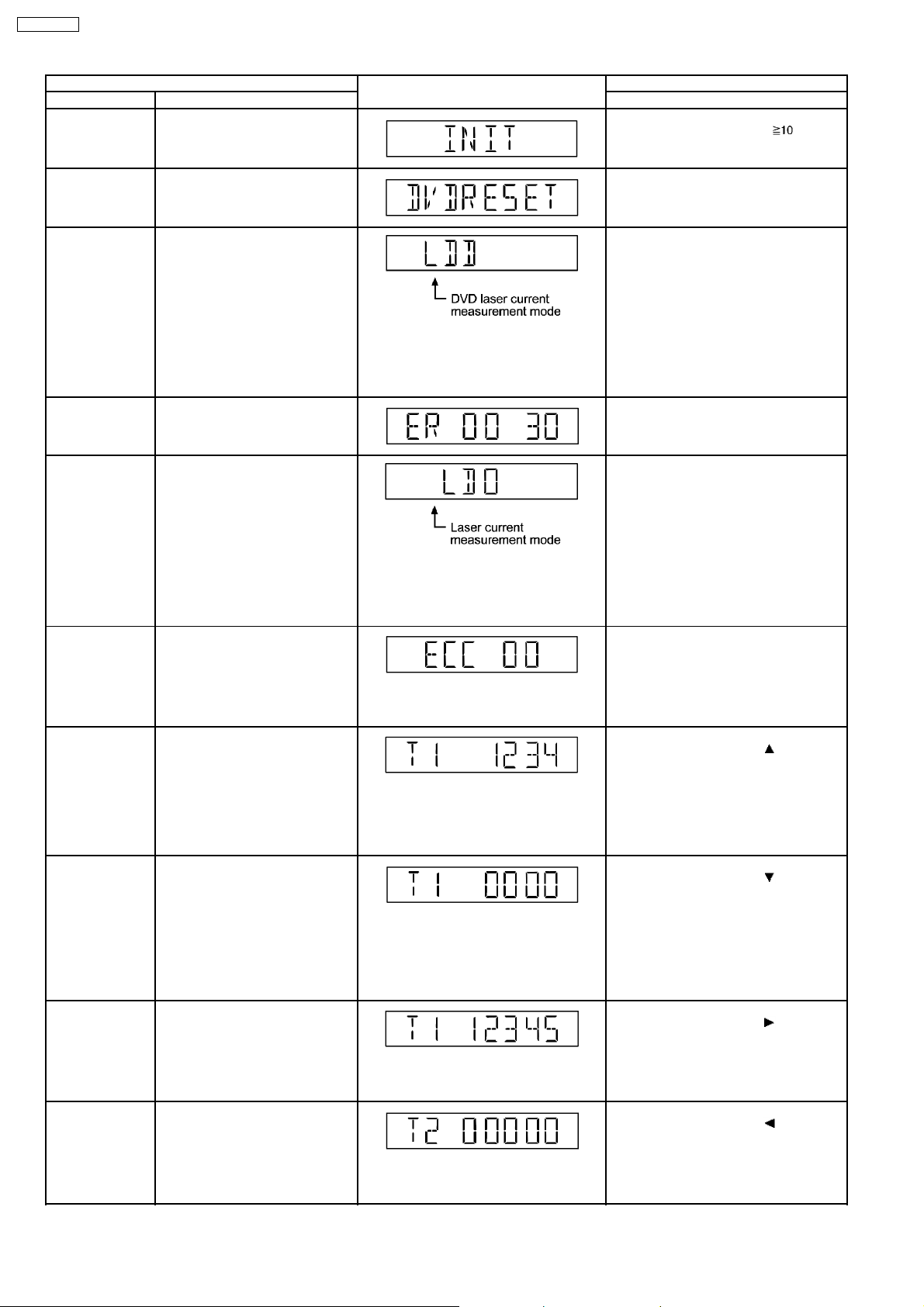

Item FL Display Key Operation

Mode Name Description Remote Control Key

Initialization Initialization.

User settings are cancelled and

player is initialized to factory

In STOP (no disc) mode, press STOP

button on the player, and

on the remote control unit.

setting.

DVD Module

Reset

DVD laser drive

current

measurement

Communication error display

Initial setting of

laser drive current

To reset DVD Module.(In

initialisation)

When the FLASH ROM IC or DVD

Module is replaced.

DVD laser drive current

measurement.

DVD laser drive current is

measured and the result is

displayed together with the initial

value stored in the EEPROM IC.

After the measurement, DVD laser

emission is kept on. It is turned off

when POWER key is switched off.

(It is also turned off when POWER

button on the player is switched

off.)

Displays frequency of

communication errors between

system control IC and mechanism

control IC during DVD module.

Initial setting of laser drive current.

Initial current value for each of

DVD laser and CD laser is

separately saved in the EEPROM

IC.

In initialisation, press and hold STOP

button on the player followed by “Enter”

button on the remote control.

Cancelled automatically 5 seconds later.

In STOP (no disc) mode, press STOP

button on the player, and FUNCTIONS

button on the remote control unit.

Cancelled automatically 5 seconds later.

Press “FL Display” button on remote

control unit for next page (FL Display) on

values of DVD drive current.

The value denotes the current in decimal

notation.

The above example shows the initial current

is 20mA and the measured value is 20mA.

In STOP (no disc) mode, press STOP

button on the player, and “MENU” button

on the remote control unit.

Cancelled automatically 5 seconds later.

In STOP (no disc) mode, press STOP

button on the player, and PAUSE button on

the remote control unit.

Cancelled automatically 5 seconds later.

Press “FL Display” button on remote

control unit for next page (FL Display) on

values of laser drive current.

The value denotes the current in decimal

notation. The above example shows the

initial current 20mA and 23mA for DVD laser

and CD laser respectively when the laser is

switched on.

ECC error display ECC decode error display. In STOP (no disc) mode, press STOP

button on the player, and TOP MENU

button on the remote control unit.

Cancelled automatically 5 seconds later.

Press “FL Display” button on remote

control unit for next page (FL Display) on

values of laser drive current.

Time 1 check Timer 1 check.

Laser operation time.

Press “FL Display” button for next

page of FL Display (to show CD

laser time).

Shown to the left is laser time, and to the

right laser time.

Time is shown in 4 digits of decimal notation

In STOP (no disc) mode, press STOP

button on the player, and “

the remote control unit.

Cancelled automatically 5 seconds later.

Press “FL Display” button on remote

control unit for next page (FL Display) on

values of laser drive current.

in a unit of 10 hours.

“0000” will follow “9999”.

Timer 1 reset Timer 1 reset.

Laser operation timer of both DVD

laser and CD laser is reset all at

once.

While display Timer 1 data, press STOP

button on the player, and “

the remote control unit.

Cancelled automatically 5 seconds later.

T1_0000/0000 (display1/display2)

Shown to the left is laser time and to the

right is laser time.

Time is shown in 4 digits of decimal notation

in a unit of 10 hours.

It cleared to ‘0000/0000’ upon reset.

Timer 2 check Timer 2 check.

Spindle motor operation timer.

Press “FL Display” button for next

page of FL Display.

In STOP (no disc) mode, press STOP

button on the player, and “

the remote control unit.

Cancelled automatically 5 seconds later.

Time is shown in 5 digits of decimal notation

in a unit of 10 hours.

“0000” will follow “9999”.

Timer 2 reset Timer 2 reset.

Spindle motor operation timer.

While display Timer 2 data, press STOP

button on the player, and “

the remote control unit.

Cancelled automatically 5 seconds later.

Time is shown in 5 digits of decimal notation

in a unit of 10 hours.

It cleared to ‘0000’ upon reset.

button

” button on

“ button on

“ button on

“ button on

26

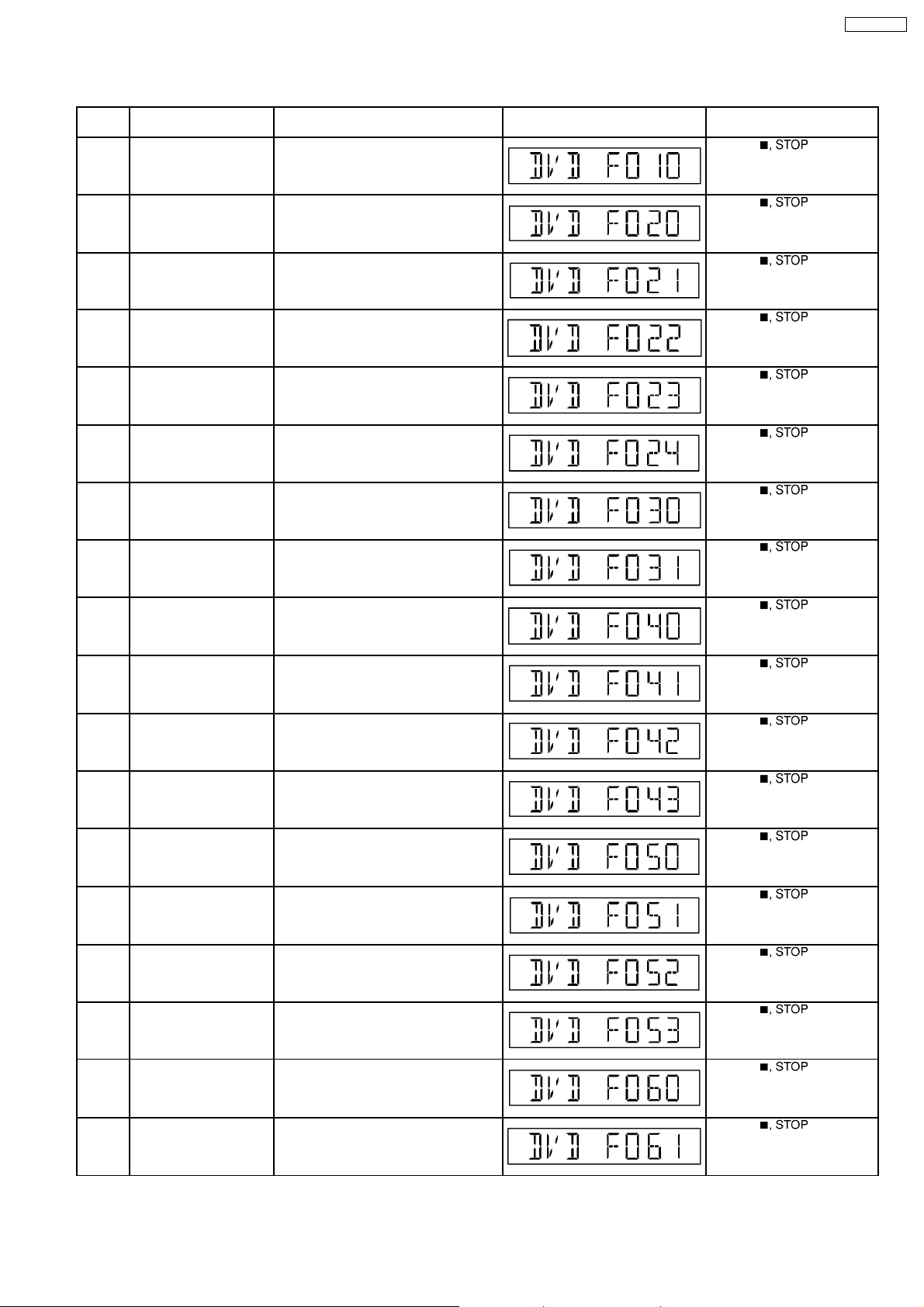

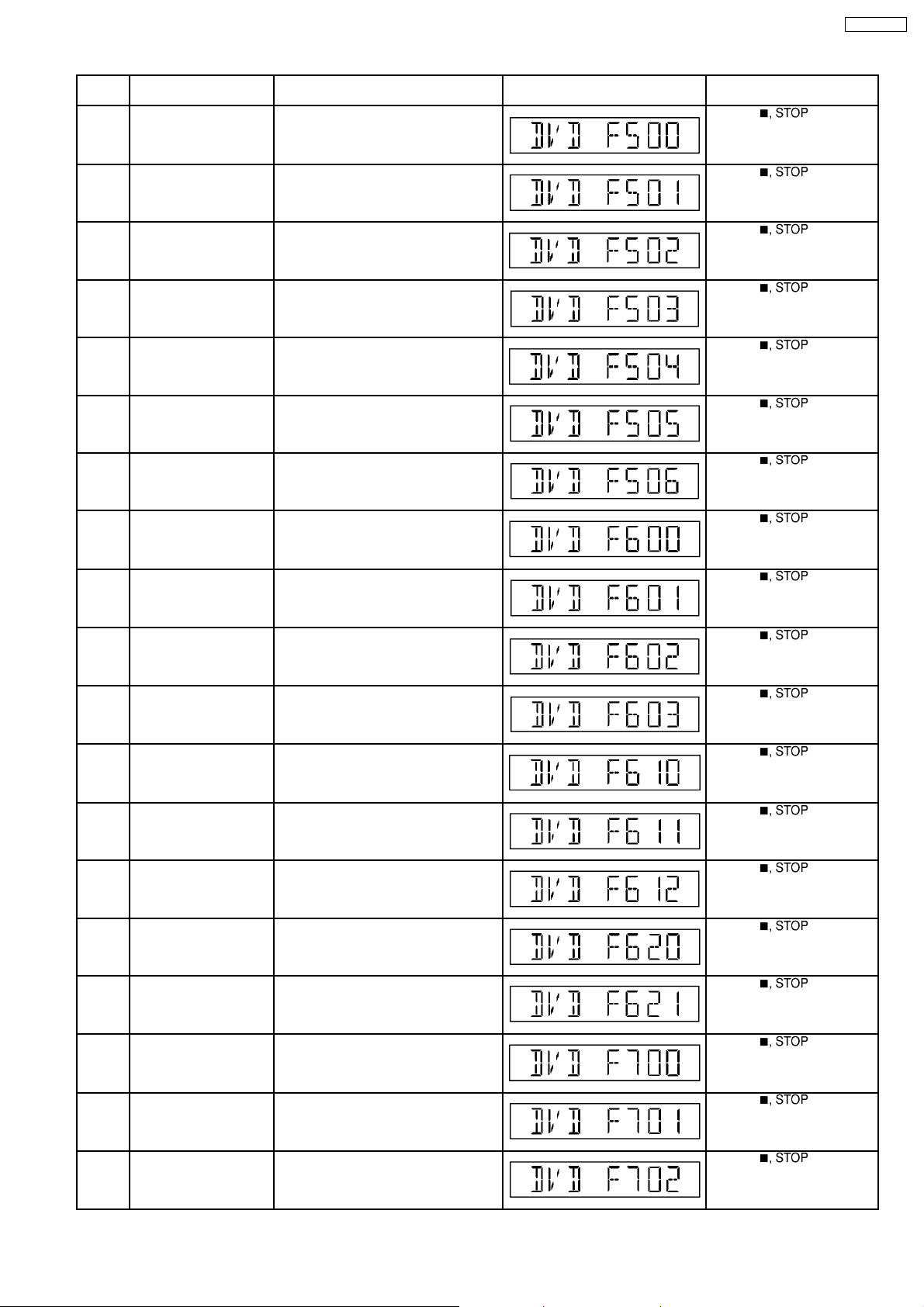

10.2.2. DVD Self-Diagnostic Function Error Code

SA-VK650EE

Error

Code

F010 DVD Media disk A specification value is size from the

F020 DVD Media disk There is no TT_SRPT. (RLBN is 0). Press [ ] on main

F021 DVD Media disk The number of TT_SRP is 0. Press [ ] on main

F022 DVD Media disk A specification value. It is size from the

F023 DVD Media disk VTSN or in agreement with VTS_TTN.

F024 DVD Media disk A specification value. It is size from

F030 DVD Media disk The number of TTU_SRP is 0. Press [ ] on main

F031 DVD Media disk A specification value. It is size from the

Diagnosis Contents Description of error Automatic FL Display Remarks

PARENTAL LOCK value of the

appointed country.

number of TT_SRP.

There is no SRP.

TT_SRP. PTT_Ns

number of TTU_SRP.

Press [ ] on main

unit for next error.

unit for next error.

unit for next error.

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

unit for next error.

Press [ ] on main

unit for next error.

F040 DVD Media disk The number of SRP1 is 0. Press [ ] on main

F041 DVD Media disk The number of PGCI_SRP is 0. Press [ ] on main

F042 DVD Media disk A specification value. It is size from the

number of PGCI_SRP.

F043 DVD Media disk It is in agreement with Menu ID. There is

no PGCI_SRP.

F050 DVD Media disk The number of TMAP_SRP is 0. Press [ ] on main

F051 DVD Media disk A specification value. It is size from the

number of TMAP_SRP.

F052 DVD Media disk Specification TMAP_SA is 0. Press [ ] on main

F053 DVD Media disk The number of MAP_EN is 0. Press [ ] on main

unit for next error.

unit for next error.

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

unit for next error.

Press [ ] on main

unit for next error.

unit for next error.

unit for next error.

F060 DVD Media disk Although C_POSIT exists, it is in PGC.

There is no PGMAP.

F061 DVD Media disk Although C_POSIT exists, it is in PGC.

There is no PGMAP.

27

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

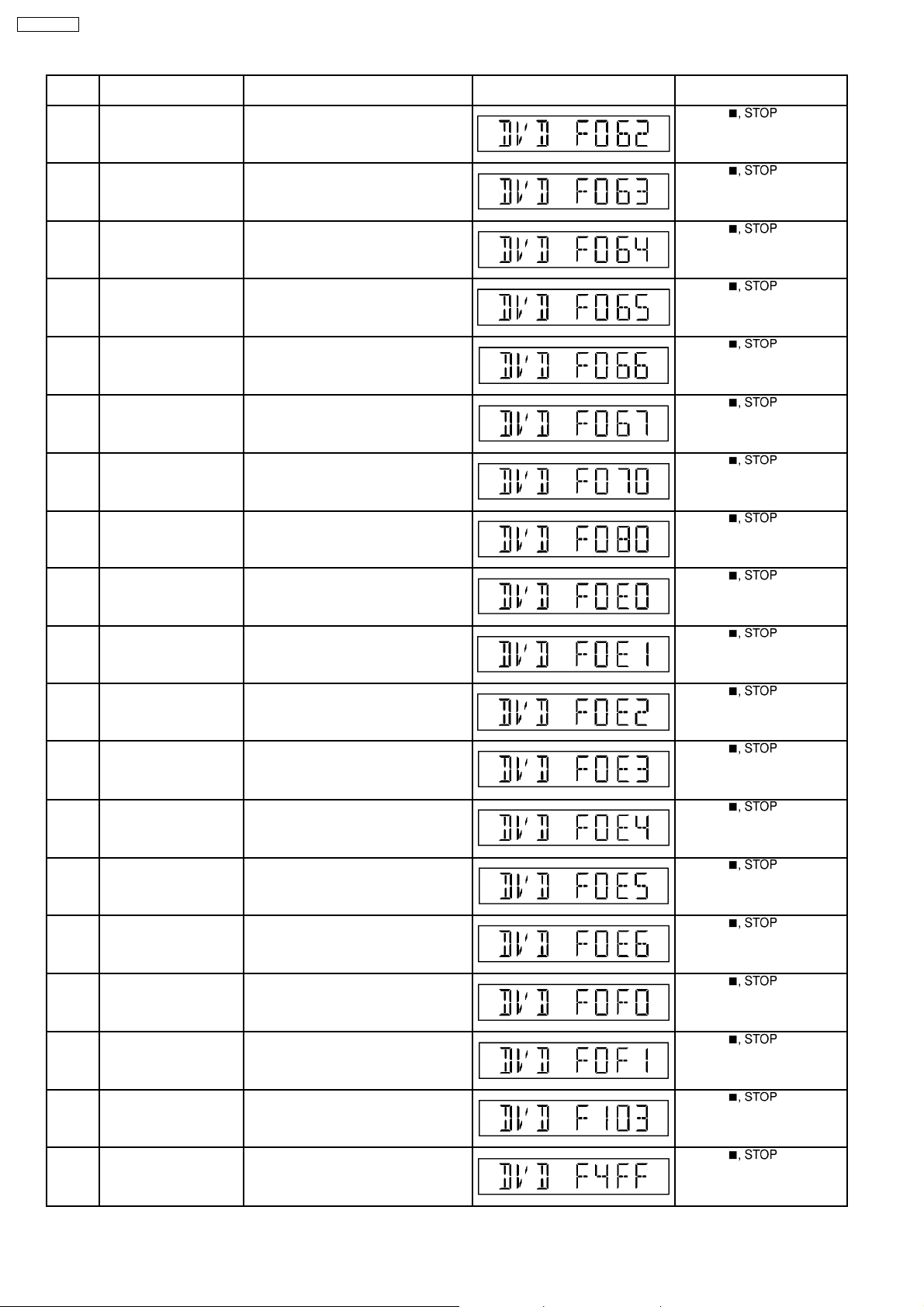

SA-VK650EE

Error

Diagnosis Contents Description of error Automatic FL Display Remarks

Code

F062 DVD Media disk A specification value inside of PGC. It is

size from the number of PGes.

F063 DVD Media disk Although C_POSIT exists, it is in PGC.

There is no C_PBIT.

F064 DVD Media disk Although C_POSIT exists, it is in PGC.

The number of PGes is 0.

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

F065 DVD Media disk Specification A cell number is 0.‘ Press [ ] on main

unit for next error.

F066 DVD Media disk A specification value inside of PGC. It is

size from the number of Cell(s).

Press [ ] on main

unit for next error.

F067 DVD Media disk A blocked cell is present. Press [ ] on main

unit for next error.

F070 DVD Media disk There is no NV_PACK data. Press [ ] on main

unit for next error.

F080 DVD Media disk Under reference. There is no Cell

number.

Press [ ] on main

unit for next error.

F0E0 DVD Media disk For [used as a DFD object] a user guide.

A PGC control file < impossible.

F0E1 DVD Media disk DFD main microcomputer. Compatibility

with a DFD type < download is

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

impossible.

F0E2 DVD Media disk DFD download start. PGC reproduction

error.

F0E3 DVD Media disk Waiting for the completion of DFD

download. PGC reproduction error.

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

F0E4 DVD Media disk At the time of DFD download AVDEC. Press [ ] on main

unit for next error.

F0E5 DVD Media disk It is the farm file lead error at the time of

DFD download.

F0E6 DVD Media disk DFD alteration check error of the read

firmware.

F0F0 DVD Media disk There is no farm file used as a DFD

object and it is downloading needlessly.

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

F0F1 DVD Media disk The firware which is in agreement with

DFD download conditions <

unnecessary.

F103 Illegal highlight Position Big possibility of disc specification

violation during highlight display

F4FF Force initialize failure

Timeout when force initialization fails Press [ ] on main

(time out)

28

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

unit for next error.

SA-VK650EE

Error

Diagnosis Contents Description of error Automatic FL Display Remarks

Code

F500 DSC error DSC (IC8251) stops in the occurrence of

servo error (startup, focus error, etc.)

F501 DSC not Ready error DSC-system computer communication

error (Communication failure caused by

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

idling of DSC)

F502 DSC Time out error Similar as F500 Press [ ] on main

unit for next error.

F503 DSC communication

Failure

Communication error (result error

occurred although communication

Press [ ] on main

unit for next error.

command was sent)

F504 Abnormal adjusting DSC

data slice offset

Press [ ] on main

unit for next error.

F505 DSC Attention error Similar as F500 Press [ ] on main

unit for next error.

F506 Invalid media Disc is flipped over, TOC unreadable,

incompatible disc media

F600 Access failure to

management information

caused by demodulation

Operation stopped because navigation

data is not accessible caused by the

demodulation defect

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

error

F601 Indeterminate sector ID

requested

Operation stopped caused by the

request to access abnormal ID data

Press [ ] on main

unit for next error.

F602 Access failure to LEAD-

IN caused by

LEAD IN data unreadable Press [ ] on main

unit for next error.

demodulation error

F603 Access failure to

KEYDET caused by

Access failure to CSS data of disc Press [ ] on main

unit for next error.

demodulation error

F610 ODC abnormality No permission for command execution Press [ ] on main

unit for next error.

F611 No CRC OK for a

specific time (CD)

F612 No CRC OK for a

specific time (DVD)

F620 Laser safeguard: high

temperature condition

F621 Laser safeguard: circuit

failure condition

Access failure to seek address in CD

series

Press [ ] on main

unit for next error.

Access failure to ID data in DVD series Press [ ] on main

unit for next error.

High temperature of the laser guide unit

(OPU unit)

Circuitry failure of the laser guide unit

(OPU unit)

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

F700 MBX overflow When replying message to disc manager Press [ ] on main

unit for next error.

F701 Message command

does not end

F702 Message command

changes

Next message is sent before replying to

disc manager

Message is changed before it is sent as

a reply to disc manager

29

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

SA-VK650EE

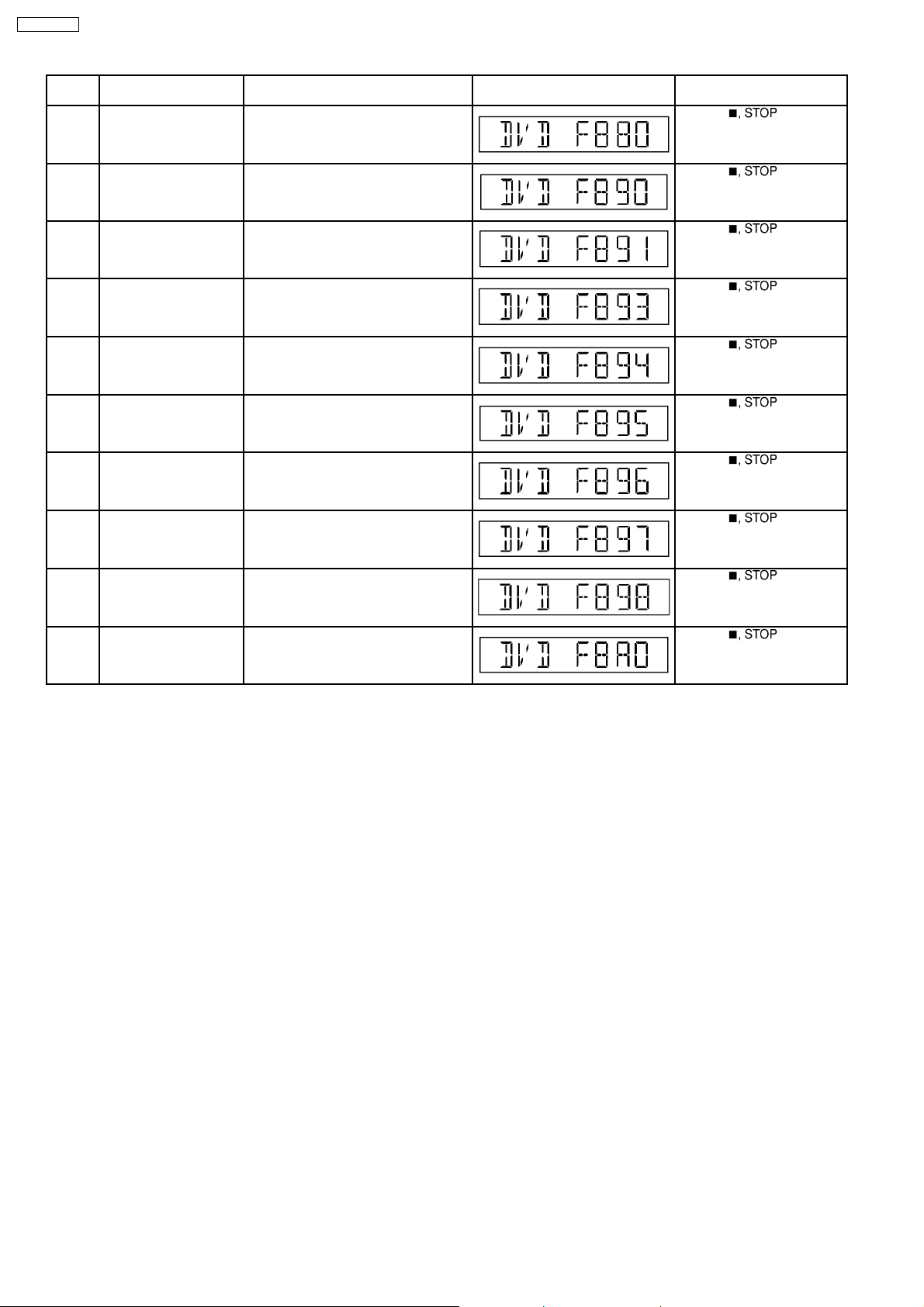

Error

Code

F880 Task number is not

F890 Sending message when

F891 Message couldn’t be

F893 FLASH ROM IC problem FLASH ROM IC installed is not operating

F894 EEPROM abnormality EEPROM IC installed is not operating in

F895 Region setting

F896 No existence model Firm version agreement check for factory

F897 Initialize is not

Diagnosis Contents Description of error Automatic FL Display Remarks

appropriate

message is being sent to

AV task

sent to AV task

abnormality

completed

Message coming from a non-existing

task

Sending message to AV task Press [ ] on main

Begin sending message to AV task Press [ ] on main

properly (Neccessary replacement of

FLASH ROM IC) or firmware problem

normal condition (EEPROM contains

neccessary data)

Firm version agreement check for factory

preset setting failure prevention. Check

region setting & re-initialize

preset setting failure prevention

Initialize completion check for factory

preset setting failure prevention

Press [ ] on main

unit for next error.

unit for next error.

unit for next error.

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

F898 Disagreement of

hardware and software

F8A0 Message command is

not appropriate

Unsuitable combination of AV

DECORDER, SDRAM and FLASH ROM

(firmware)

Begin sending message to AV task Press [ ] on main

Press [ ] on main

unit for next error.

unit for next error.

Note:

An error code will be canceled if a power supply is turned OFF.

*1: CPPM is the copy guard function beforehand written in the disk for protection of copyrights.

10.2.3. Optical Pickup Breakdown Diagnosis

This unit is equipped with the optical pickup self-diagnosis function and the tilt adjustment check function. Follow the procedure

described below during repair in order to perform self-diagnosis and tilt adjustment effectiv ely. Especially when “NO DISC” is

displayed, be sure to apply the self-diagnosis function before replacing with an optical pickup. Replac ement of optical pickup

generally requires when the present value of laser drive exceeds 45 (DVD) or 45 (CD).

Note:

Start diagnosis within three minutes after turning on the power (as diagnosis fails when the unit becomes warm).

30

Loading...

Loading...