A

ORDER NO.MD0607244CE

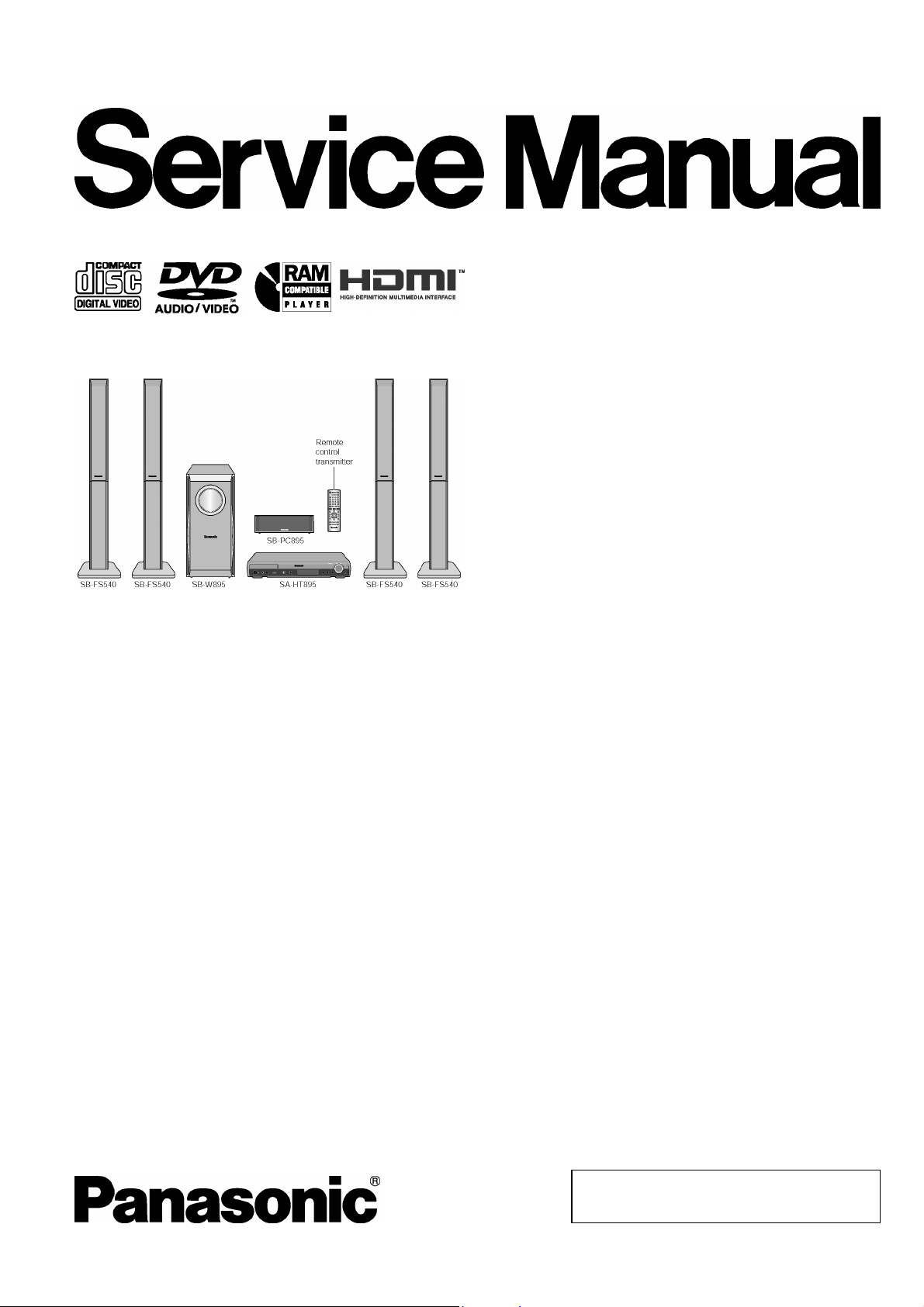

DVD Home Theater Sound System

SA-HT895EE

Colour

(S).......................Silver Type

Specifications

lGeneral

Power Source:

Power consumption:

Dimensions (W×H×D): 430×60×354 mm

Mass: 3.35kg

lAmplifier section

RMS Output Power: Dolby Digital Mode

lTotal RMS Dolby Digital

mode Power:

At 1kHz and total harmonic of 10%

lFront: 100 W/ Channel (3Ω)

lCenter: 225 W/ Channel (6Ω)

lSurround: 100 W/ Channel (3Ω)

At 100Hz and total harmonic of 10%

lActive subwoofers: 225 W/ Channel (6Ω)

DIN Output Power: Dolby Digital Mode:

lTotal DIN Dolby Digital mode Power:

At 1kHz and total harmonic of 1%

lFront: 75 W/ Channel (3Ω)

lCenter: 75 W/ Channel (6Ω)

C 230V, 50Hz

115 W

850 W

440 W

lSurround: 70 W/ Channel (3Ω )

At 100Hz and total harmonic of 1%

lSubwoofer: 75 W/ Channel (6Ω)

lPreset Memory: FM 15 stations

AM/MW 15 stations

lFrequency Modulation (FM)

Frequency Range: 87.50-108.00MHz

(50kHz step)

Sensitivity: 2.5µV (IHF)

S/N 26dB 2.2µV

Antenna terminals: 75Ω (unbalanced)

lAmplitude Modulation (AM/MW)

Frequency Range: 522-1629kHz (9kHz step)

AM Sensitivity S/N 20dB at

999kHz:

lPhone jack:

Terminal: Stereo 3.5 mm jack

lMic jack:

Sensitivity: 0.7mV (1.2kΩ)

Terminal: Mono 6.3 mm jack (1 system)

lMusic Port (Front):

560µV/m

© 2006 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

V

Y

Y

SA-HT895EE

Sensitivity: 100mV (15kΩ)

Terminal: Stereo 3.5 mm jack

lDisc section

Discs played (8 cm or 12 cm):

(1) DVD [DVD-Video, DVD-Audio, DivX(*1,2)]

(2) DVD-RAM [DVD-VR, MP3(*2,6), JPEG(*2,3), MPEG4(*2,4),

DivX(*1,2)]

(3) DVD-R [DVD-Video, DVD-VR, MP3(*2,6), JPEG(*2,3),

MPEG4(*2,4), DivX(*1,2)]

(4) DVD-R DL [DVD-Video, DVD-VR]

(5) DVD-RW [DVD-Video, DVD-VR, MP3(*2,6), JPEG(*2,3),

MPEG4(*2,4), DivX(*1,2)]

(6) +R/+RW [Video]

(7) +R DL [Video]

(8) CD, CD-R/RW [CD-DA, Video CD, SVCD(*5), MP3(*2,6),

WMA(*2,7), JPEG(*2,3), MPEG4(*2,4), DivX (*1,2), HighMAT

Level 2 (Audio and Image)]

*1 Plays all versions of DivX® video (including DivX®6) with

standard playback of DivX® media files. Certified to the DivX

Home Theater Profile.

lGMC (Global Motion Compensation) is not supported.

*2 The total combined maximum number of recognizable audio,

picture and video contents and groups: 4000 audio, picture

and video contents and 400 groups.

*3 Exif Ver 2.1 JPEG Baseline files

lPicture resolution: between 160 x 120 and 6144 x 4096

pixels (Sub sampling is 4:0:0, 4:2:0, 4:2:2, 4:4:4). Extremely

long and narrow pictures may not be displayed.

*4 MPEG4 data recorded with Panasonic SD multi cameras or

DVD video recorders.

lConforming to SD VIDEO specifications (ASF standard)/

MPEG4 (Simple Profile) video system/G.726 audio system.

*5 Conforming to IEC62107

*6 MPEG-1 Layer 3, MPEG-2 Layer 3

*7 Windows Media Audio Ver.9.0 L3

lNot compatible with Multiple Bit Rate (MBR)

Pick up:

Wavelength:

lCD: 785nm

lDVD: 662nm

Laser power:

lCD: CLASS 1M

lDVD: CLASS 1

Audio output (DISC):

Number of channels: 5.1 ch (FL, FR, C, SL, SR,

SW)

Audio performance:

Frequency response:

DVD (linear audio): 4 Hz-22 kHz (48 kHz sampling)

4 Hz-44 kHz (96 kHz sampling)

DVD-Audio: 4 Hz-88 kHz (192 kHz

sampling)

CD-Audio: 4 Hz-20 kHz

S/N ratio:

CD-Audio: 105 dB

Dynamic range:

DVD (linear audio): 95 dB

CD-Audio: 95 dB

Total harmonic distortion:

CD-Audio: 0.005 %

lVideo section

ideo system:

Signal system: PAL 625/50, PAL 525/60,

NTSC

Composite video output:

Output level: 1 Vp-p (75 Ω )

Terminal: Pin jack (1 system)

S-video output:

output level: 1 Vp-p (75 Ω)

C output level:

PAL; 0.3Vp-p (75Ω)

NTSC; 0.286 Vp-p (75 Ω)

Terminal S terminal (1 system)

Component video output (NTSC: 480p/480i, PAL: 576p/576i):

output level:

1 Vp-p (75 Ω )

PBoutput level: 0.7 Vp-p (75 Ω )

PRoutput level:

Terminal:

0.7 Vp-p (75 Ω )

Pin jack (Y: green, PB: blue,

P

: red) (1 system)

R

HDMI AV output:

Terminal: 19-pin type A connector

HDMI Ver.1.2a (EDID Ver.1.3)

Power consumption in standby mode:

approx 0.5W

Note:

1. Specifications are subject to change without notice.

Mass and dimensions are approximate.

2. Total harmonic distortion is measured by the digital spectrum

analyzer.

Solder:

This model uses lead free solder (PbF).

Mechanism:

This model uses DL2SU (Single tray) mechanism.

Refer to the original service manual for *1, *2, *3, *4.

2

SA-HT895EE

CONTENTS

Page Page

1 Safety Precautions 5

1.1. GENERAL GUIDELINES

1.2. Before Repair and Adjustment

1.3. Protection Circuitry

2 Prevention of Electro Static Discharge (ESD) to

5

5

5

Electrostatically Sensitive (ES) Devices

3 Precaution of Laser Diode

4 About Lead Free Solder (PbF)

4.1. Service caution based on legal restrictions

3

6

7

8

8

SA-HT895EE

5 Handling Precautions for Traverse Unit 9

5.1. Cautions to Be Taken in Handling the Optical Pickup Unit

5.2. Grounding for electrostatic breakdown prevention

6 Accessories

7 Operation Procedures

7.1. Remote Control Key Buttons Operations

7.2. Main Unit Key Buttons Operations

7.3. Use of HDAVI Control

7.4. Using of Music Port

7.5. Disc Information

7.6. About DivX VOD Content

8 New Features

8.1. About HDMI

9 Self-Diagnosis and special mode setting

9.1. Service Mode Summary Table

9.2. Service Mode Table

9.3. DVD Self Diagnostic Function-Error Code

9.4. Sales Demonstration Lock Function

9.5. Service Precautions

10 Assembling and Disassembling

10.1. Disassembly Flow Chart

10.2. Main Components and P.C.B. Locations

10.3. Disassembly of Top Cabinet

11

12

12

13

14

15

16

18

19

19

21

21

21

26

28

29

30

31

32

33

10.4. Disassembly of the DVD Lid (When taking out disc

manually)

10.5. Disassembly of Front Panel Assembly

33

34

10.6. Disassembly of Music Port P.C.B, Mic P.C.B., FL P.C.B.

& Top Button P.C.B.

10.7. Disassembly of DVD Mechanism Unit

10.8. Disassembly of Relay P.C.B.

10.9. Disassembly of Rear panel

10.10. Disassembly of HDMI Module P.C.B.

10.11. Disassembly of Scart P.C.B.

34

35

35

35

36

36

10.12. Disassembly of Main P.C.B., AC-Inlet P.C.B. & Tuner

Extent P.C.B.

10.13. Disassembly of Digital Amp IC (IC5000)

10.14. Disassembly of Digital Amp IC (IC5400)

10.15. Disassembly of Regulator Diodes & Transistor

10.16. Disassembly of Switch Regulator IC (IC5701)

11 Service Position

11.1. Servicing position of the HDMI Module P.C.B.

11.2. Servicing position of the Main P.C.B.

12 Assembly and disassembly of Mechanism Unit

12.1. Disassembly Procedure

13 Measurements and Adjustments

36

36

37

37

38

39

39

39

40

40

46

13.1. Service Tools and Equipment

9

9

13.2. Important points in adjustment

13.3. Storing and handling of test discs

13.4. Optical adjustment

14 Abbreviati ons

15 Voltage and Waveform Chart

15.1. HDMI Module P.C.B.

15.2. Main P.C.B.

15.3. FL P.C.B., Scart P.C.B., Mic P.C.B. & Tray Loading P.C.B.

15.4. Waveform Chart

16 Illustration of IC's, Transistors and Diodes

17 Wiring Connection Diagram

18 Block Diagram

19 Schematic Diagram Notes

20 Schematic Diagram

20.1. (A) Optical Pickup Unit & HDMI Module Circuit

20.2. (B) Main Circuit

20.3. (C) Power & AC-inlet Circuit

20.4. (D) FL, Mic, Music Port, Top Button, Tuner Extent, Tray

Loading, Relay & Scart Circuit

21 Printed Circuit Board

21.1. (A) HDMI Module P.C.B.

21.2. (B) Main/Power P.C.B.

21.3. (C) Tuner extent, AC-inlet, Tray Loading, FL, Music port &

Top button P.C.B.

21.4. (D) Scart, Mic & Relay P.C.B.

22 Basic Troubleshooting Guide

22.1. Basic Troubleshooting Guide for Traverse Unit (HDMI

Module P.C.B)

22.2. Basic Troubleshooting Guide for HDMI AV output

23 Overall Block (HT895)

23.1. HT895 DVD Unit Block

23.2. HT895 Block (Analog Signal : DVD 5.1ch Play Back

Mode)

23.3. HT895 Block (Analog Signal : 2ch Analog Input Mode)

23.4. HT895 Power Supply Block

23.5. HT895 Power Block (SMPS)

24 Terminal Function of ICs

24.1. IC2018 (C2CBYY000292): Micro-processor IC

25 Exploded Views

25.1. Cabinet Parts Location

25.2. Packaging

26 Replacement Parts List

26.1. Component Parts List

46

46

46

47

48

50

50

52

54

55

57

59

61

69

71

71

78

83

87

91

91

92

93

94

95

95

96

97

98

99

100

101

102

103

103

104

104

106

107

108

4

SA-HT895EE

1 Safety Precautions

1.1. GENERAL GUIDELINES

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, carry out the following leakage current checks to prevent the customer from being exposed to shock hazards.

1.1.1. LEAKAGE CURRENT COLD CHECK

1. Unplug the AC cord and connec t a jumper between the two prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between the jumpered AC plug and each exposed metallic cabine t part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MΩ and 5.2MΩ.

When the exposed metal does not have a return path to the chassis, the reading must be

.

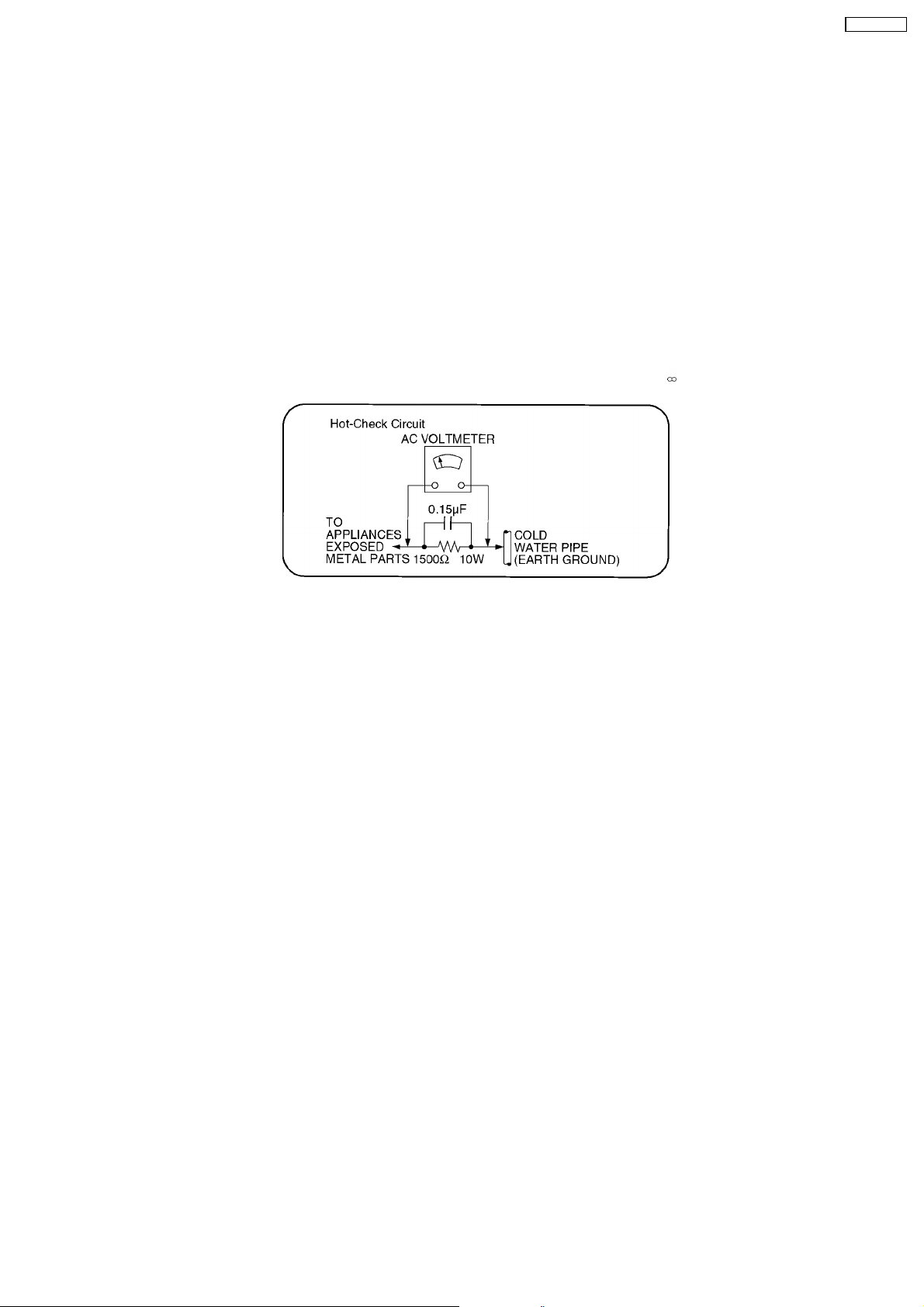

Figure 1

1.1.2. LEAKAGE CURRENT HOT CHECK (See Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF capacitors, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each expose d metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent) may

be used to make the hot checks, leakage current must not exceed 1/2 milliamp. In case a measurement is outside of the limits

specified, there is a possibility of a shock hazard, and the equipment should be repaired and rechecked before it is returned to

the customer.

1.2. Before Repair and Adjustment

Disconnect AC power, discharge Power Supply Capacitors C5701 , C5706 , C5714 , C5736, C5737 through a 10 Ω, 10 W resistor

to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

Current consum ption at AC 230 V, 50 Hz in NO SIGNAL mode (at volume minimum) should be ~ 600 mA.

1.3. Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

· No sound is heard when the power is turned on.

· Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

“shorted”, or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

5

SA-HT895EE

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touchin g a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD protected)" can

generate electrical charge sufficie nt to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable

conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD)

sufficient to damage an ES device).

6

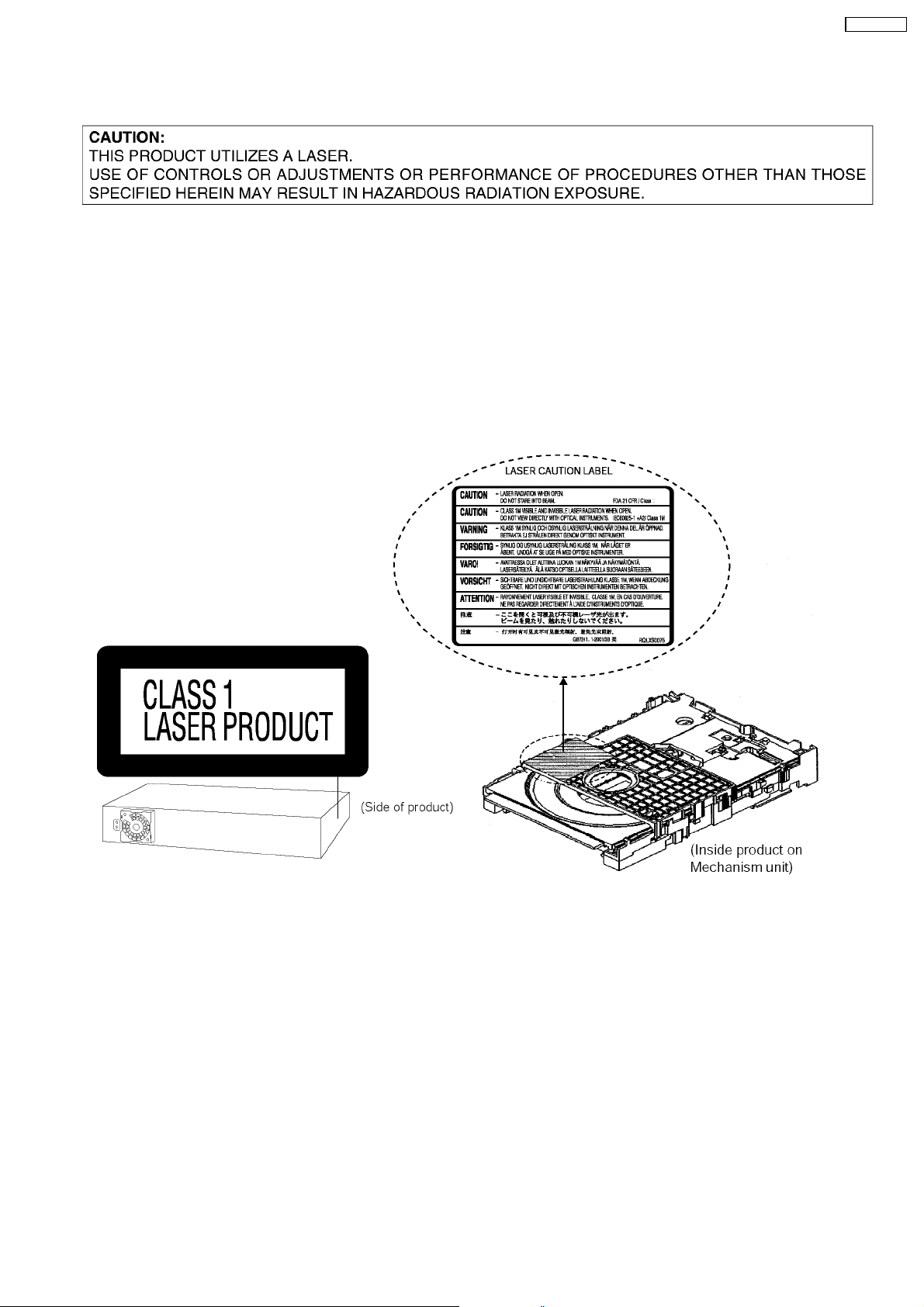

3 Precaution of Laser Diode

CAUTION :

This product utilizers a class 1 laser. Invisible laser radiation is emitted from the optical pick up lens.

When the unit is turned on:

Wavelength : 662nm/785nm

Maximum output radiation power from pick up : 100µW/VDE

Laser radiation from pick up unit is safety level, but be sure the followings:

1. Do not disassemble the optical pick up unit, since radiation from expose d laser diode is dangerous.

2. Do not adjust the variable resistor on the pick up unit. It was already adjusted.

3. Do not look at the focus lens using optical instruments.

4. Recommend not to look at pick up lens for a long time.

SA-HT895EE

7

SA-HT895EE

4 About Lead Free Solder (PbF)

4.1. Service caution based on legal restrictions

4.1.1. General description about Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86°F) more than that

of the normal solder.

Definition of PCB Lead Free Solder being used

The letter of “PbF” is printed either foil side or components side on the PCB using the lead free solder.

(See right figure)

Service caution for repair work using Lead Free Solder (PbF)

· The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the PCB using the lead free solder.)

· To put lead free solder, it should be well molten and mixed with the original lead free solder.

· Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

· Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt

the lead free solder.

· Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30

degrees C (662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

· The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01K-----------(0.3mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

Note

* Ingredient: tin (Sn), 96.5%, silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

8

SA-HT895EE

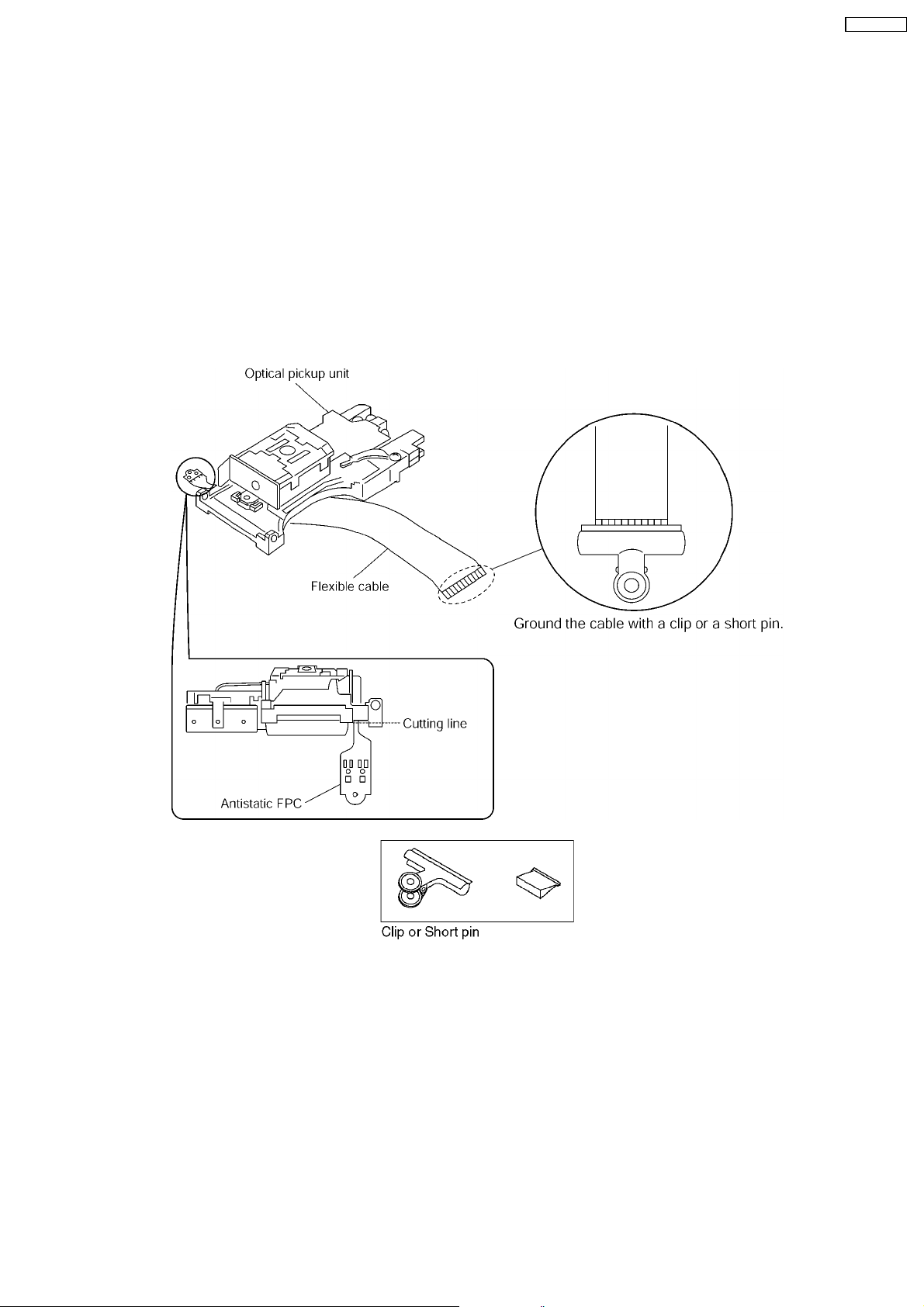

5 Handling Precautions for Traverse Unit

The laser diode in the optical pickup unit may break down due to static electricity of clothes or human body. Special care must be

taken avoid caution to electrostatic breakdown when servicing and handlin g the laser diode.

5.1. Cautions to Be Taken in Handling the Optical Pickup Unit

The laser diode in the optical pickup unit may be damaged due to electrostatic discharge generating from clothes or human body.

Special care must be taken avoid caution to electrostatic discharge damage when servicing the laser diode.

1. Do not give a considerable shock to the optical pickup unit as it has an extremely high-precise structure.

2. To prevent the laser diode from the electrostatic discharge damage, the flexible cable of the optical pickup unit removed should

be short-circuited with a short pin or a clip.

3. The flexible cable may be cut off if an excessive force is applied to it. Use caution when handling the flexible cable.

4. The antistatic FPC is connected to the new optical pickup unit. After replacing the optical pickup unit and connecting the flexible

cable, cut off the antistatic FPC.

5.2. Grounding for electrostatic breakdown prevention

Some devices such as the DVD player use the optical pickup (laser diode) and the optical pickup will be damaged by static

electricity in the working environment. Proceed servicing works under the working environment where grounding works is

completed.

5.2.1. Worktable grounding

1. Put a conductive material (sheet) or iron sheet on the area where the optical pickup is placed, and ground the sheet.

5.2.2. Human body grounding

1. Use the anti-static wrist strap to discharge the static electricity form your body.

9

SA-HT895EE

10

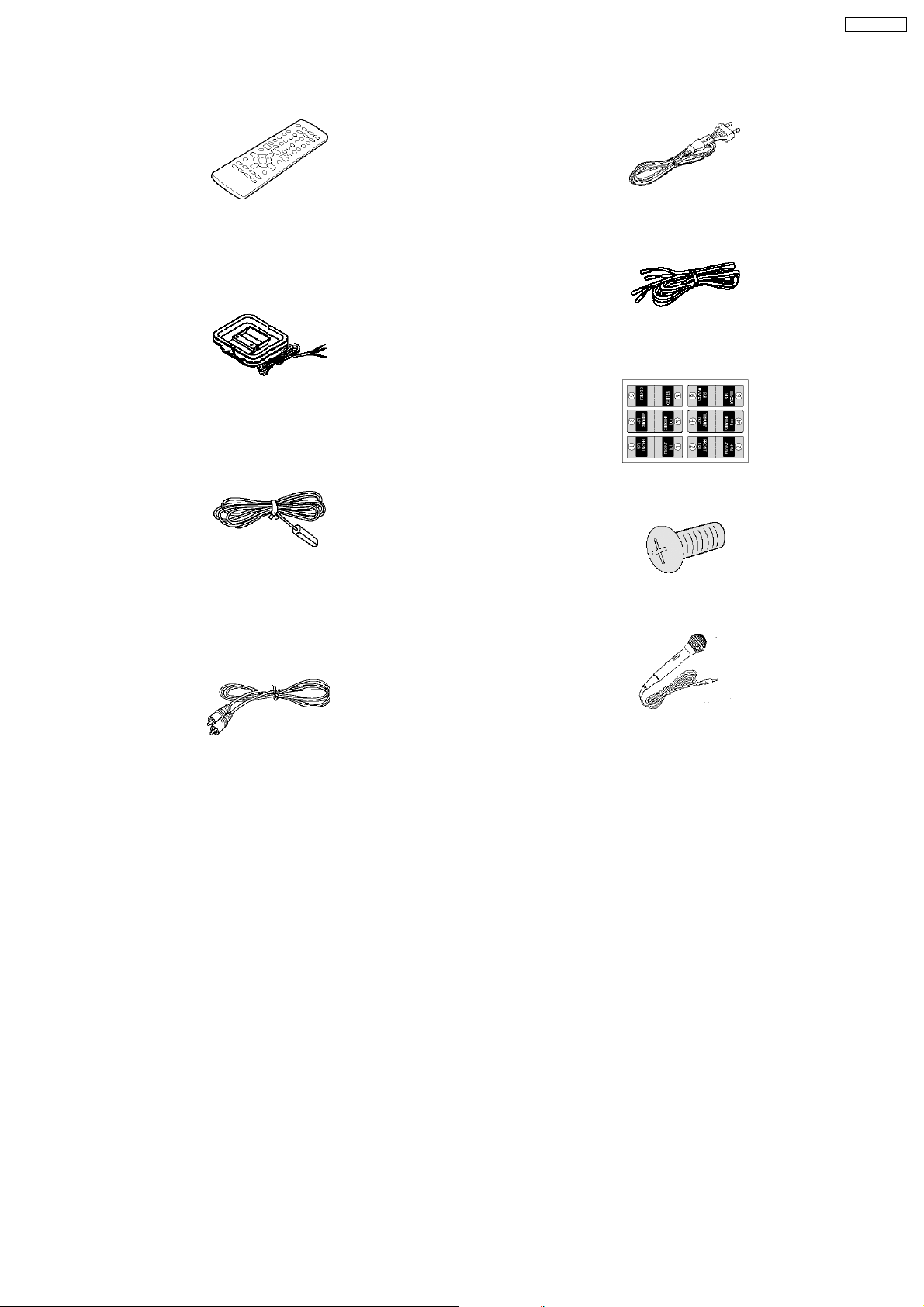

6 Accessories

SA-HT895EE

Remote control

AM loop antenna

FM antenna

AC cord

Speaker cord

Speaker label

Screw

Video cable

Mic

11

SA-HT895EE

7 Operation Procedures

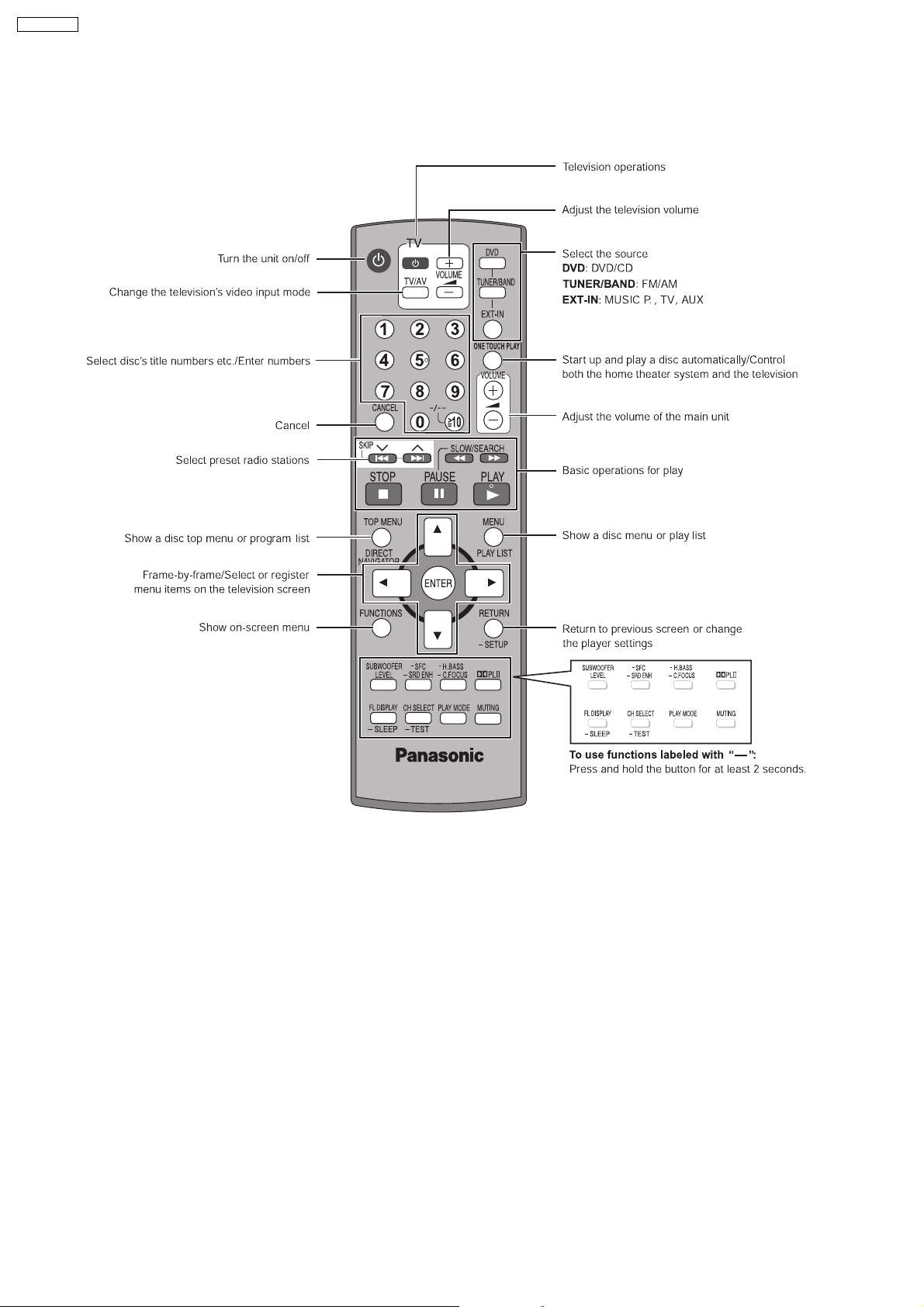

7.1. Remote Control Key Buttons Operations

12

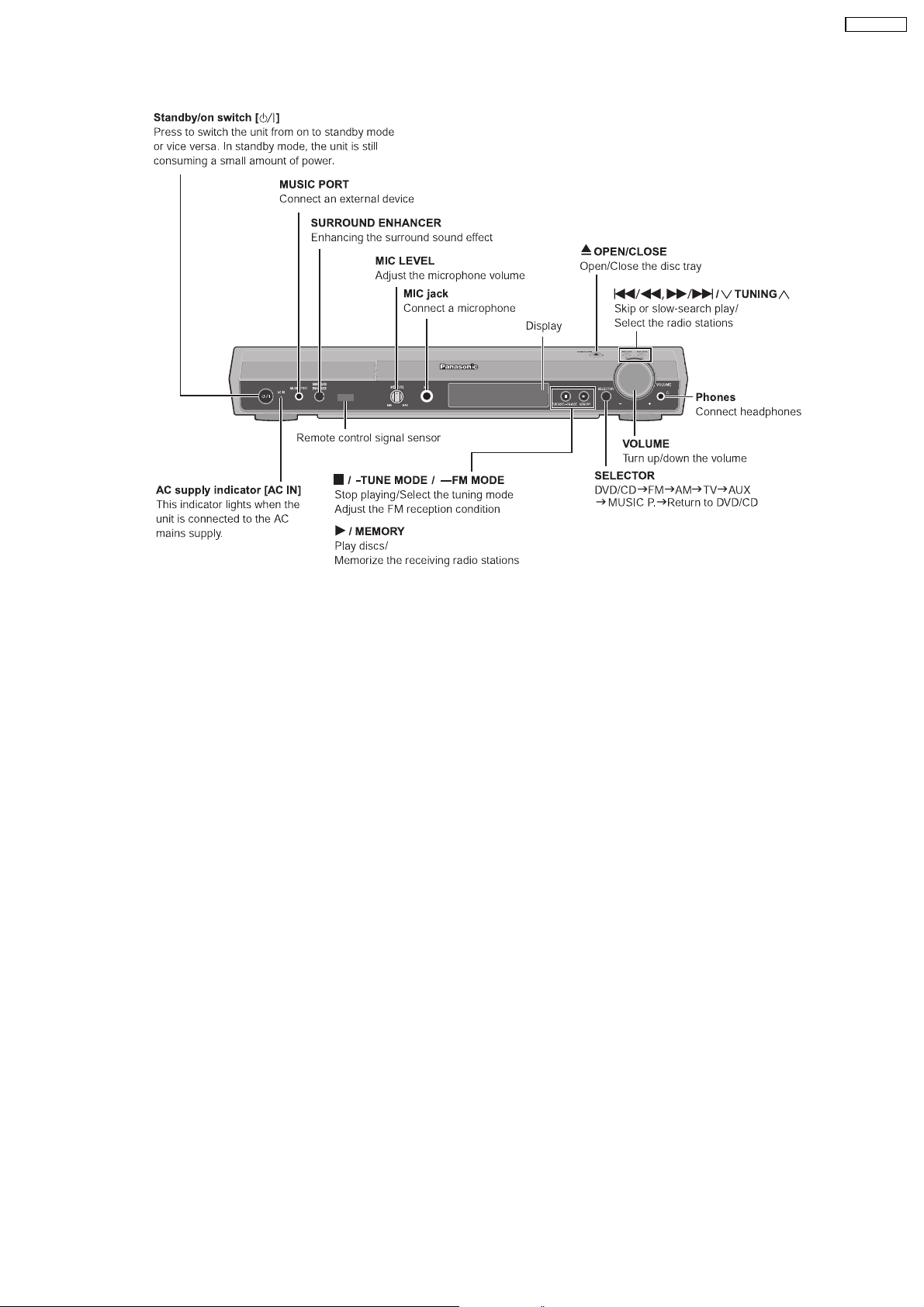

7.2. Main Unit Key Buttons Operations

SA-HT895EE

13

SA-HT895EE

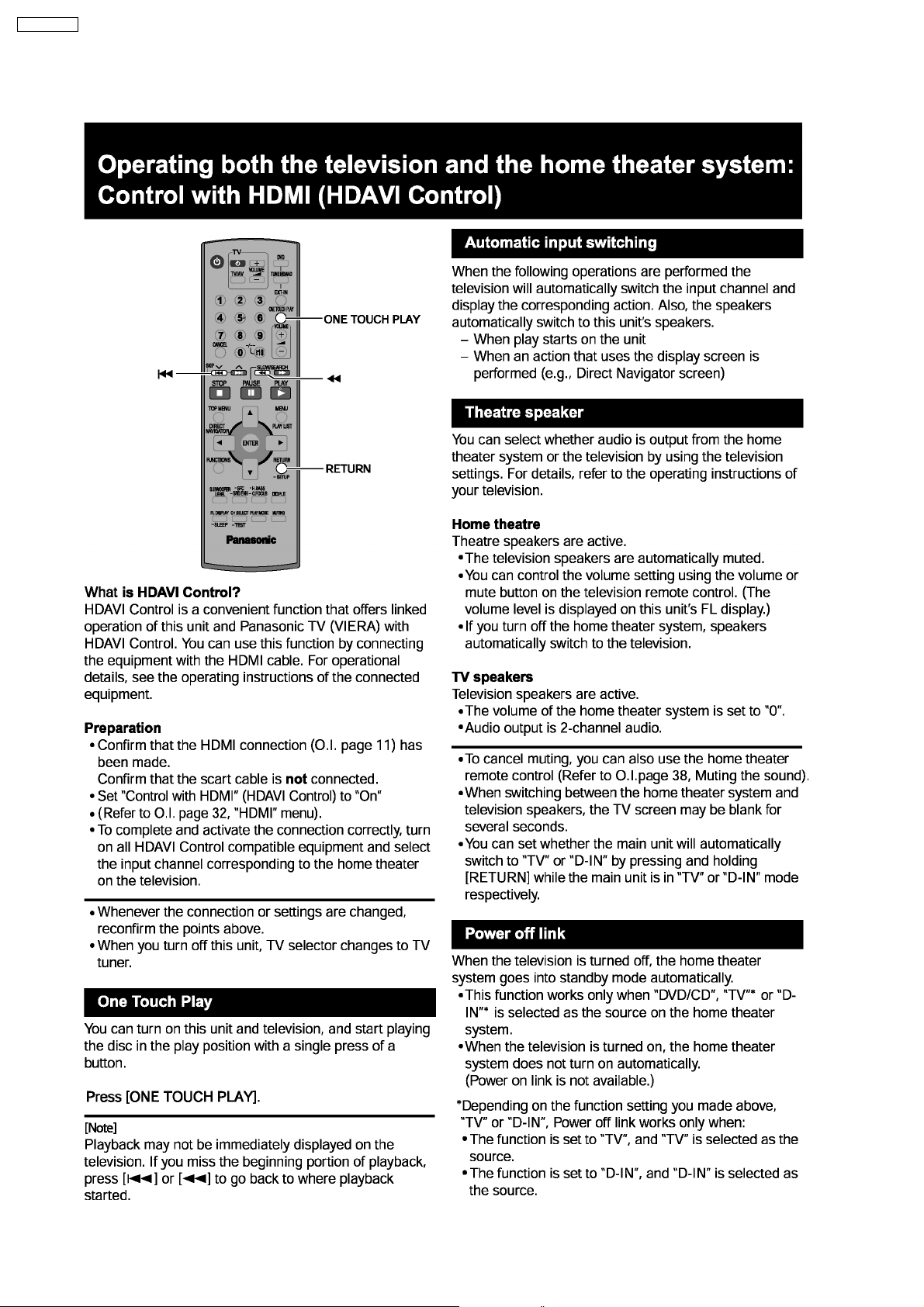

7.3. Use of HDAVI Control

14

7.4. Using of Music Port

SA-HT895EE

15

SA-HT895EE

7.5. Disc Information

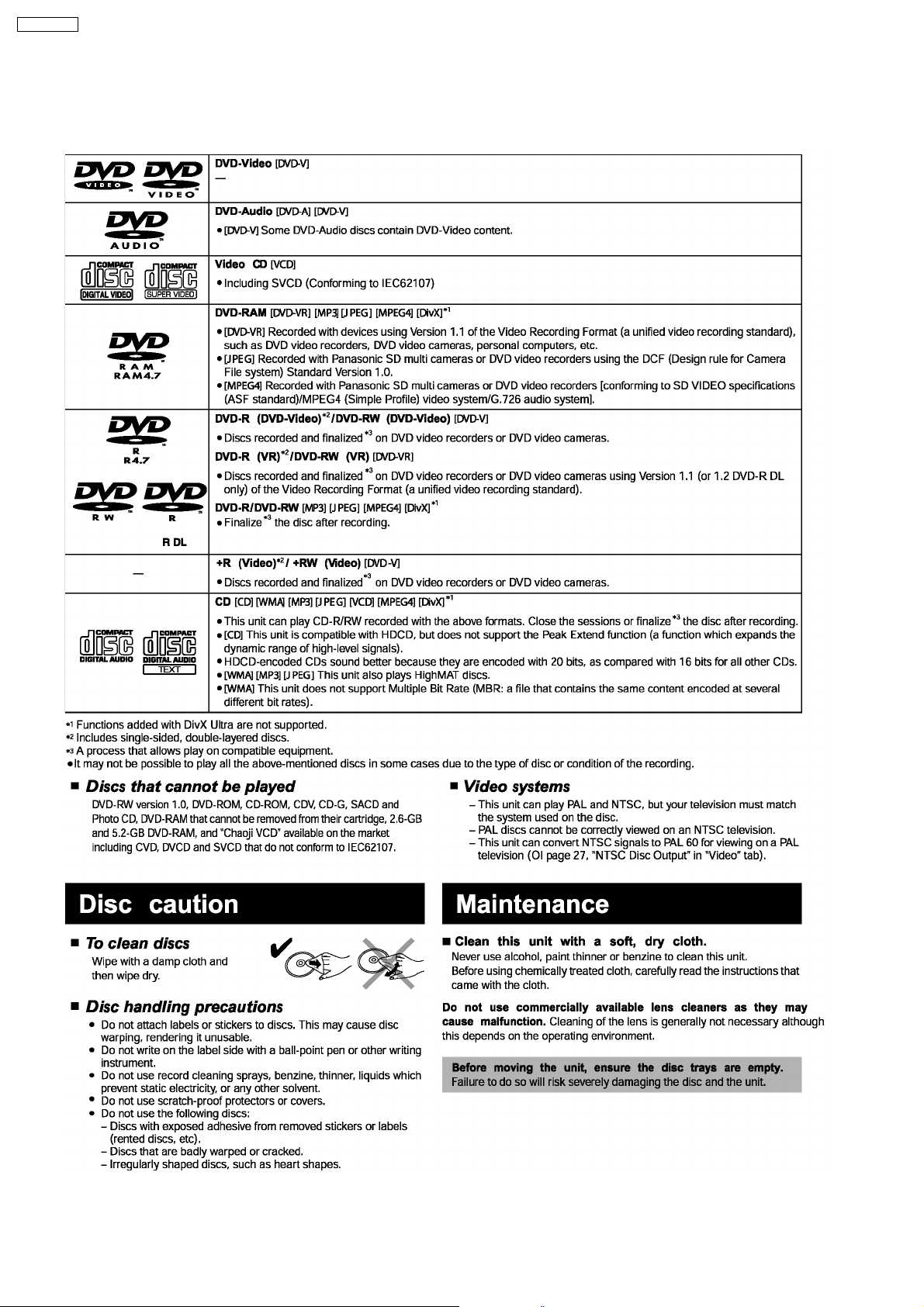

7.5.1. Disc Playability (Media)

16

7.5.2. File Extension Type Support (WMA/MP3/JPEG/MPEG4/DivX)

SA-HT895EE

17

SA-HT895EE

7.6. About DivX VOD Content

18

8 New Features

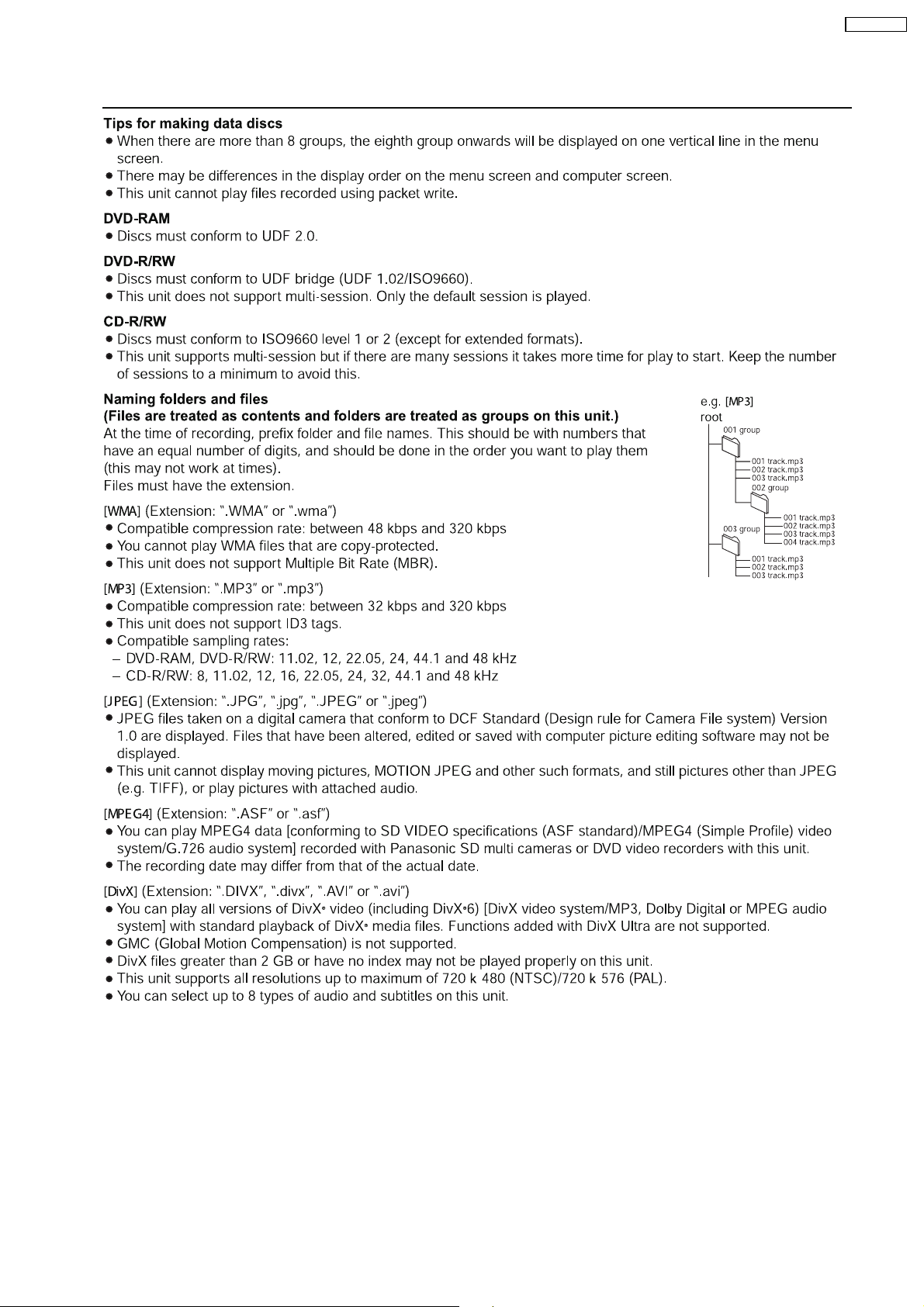

8.1. About HDMI

8.1.1. What is HDMI?

SA-HT895EE

8.1.2. Advanced Digital Pictures

19

SA-HT895EE

8.1.3. Advanced Digital Sound

8.1.4. Easy to Use

8.1.5. HDMI Compatible Products

20

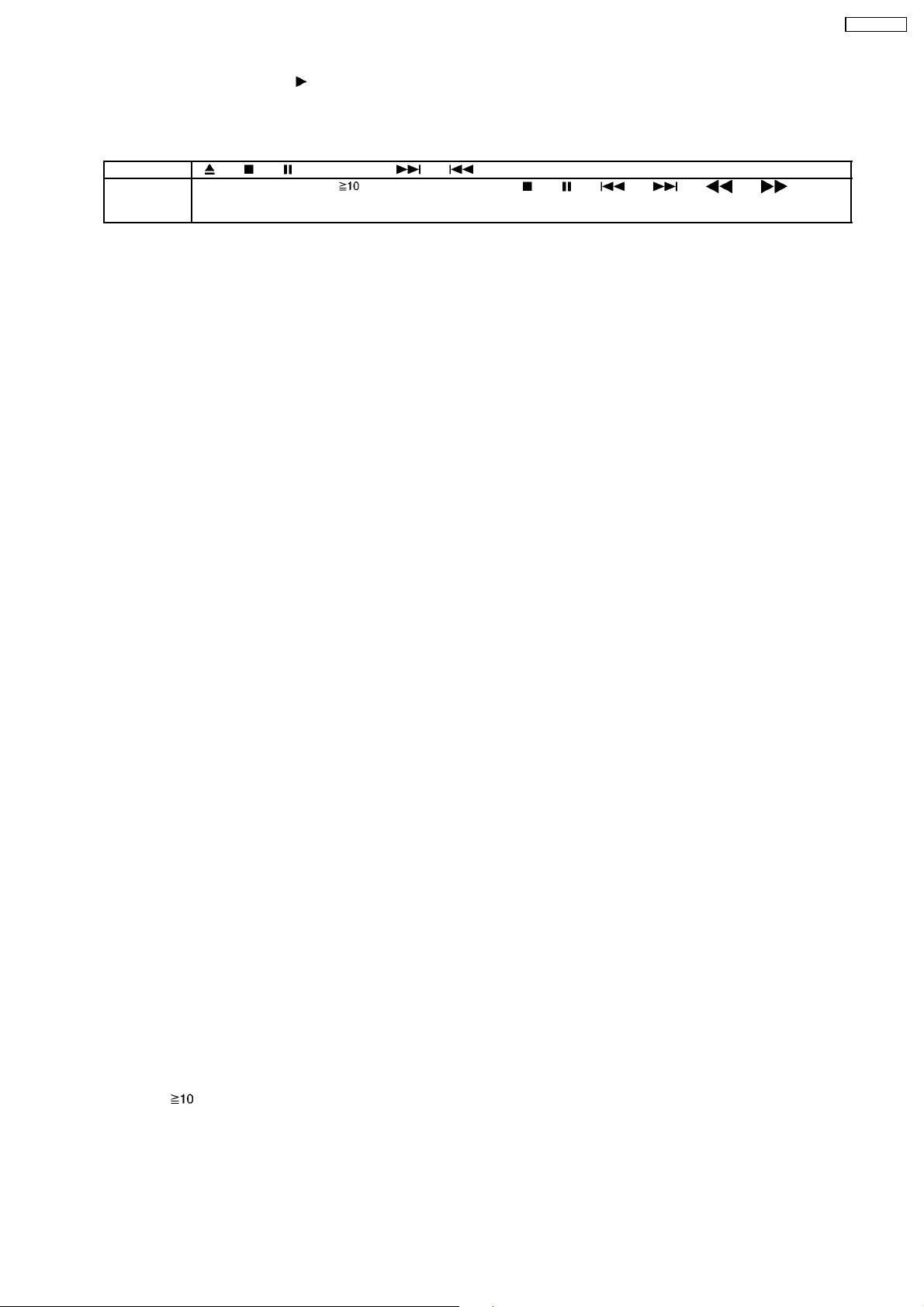

9 Self-Diagnosis and special mode setting

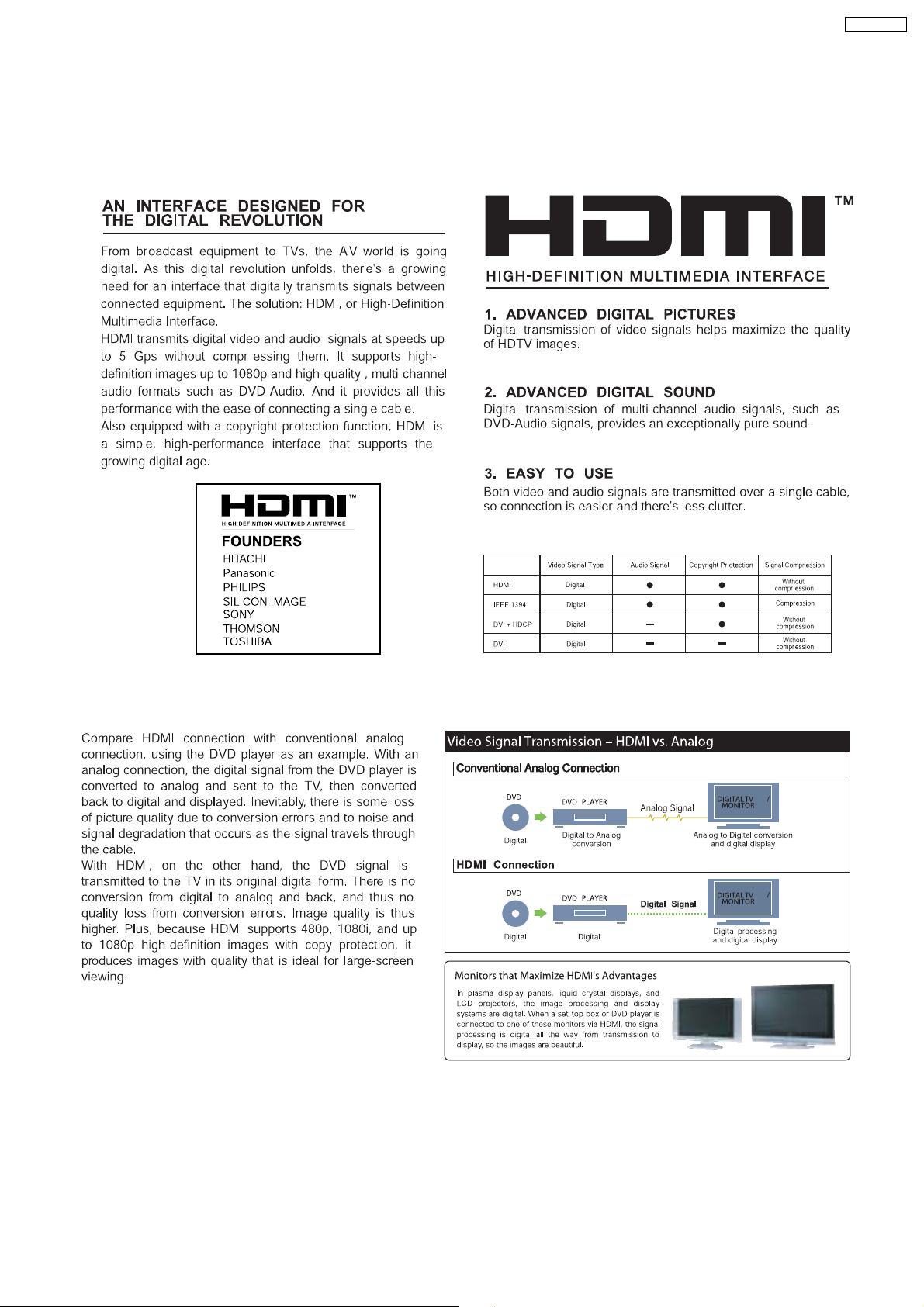

9.1. Service Mode Summary Table

The service modes can be activated by pressing various button combination on the player and remote control unit.

Below is the summary of major checking:

Player buttons Remote control unit buttons Application Note

STOP 0 Error code check (Refer to the section

1 ADSC internal RAM data check

3 CD laser drive current check

5 Jitter checking

FUNCTIONS DVD laser drive current check

PAUSE Initial setting of laser drive current.

6 Region display and mode (Refer to the section

7 Micro-processor firmware version check

8 HDMI module firmware version check.

Initialization of the player (factory setting is restored.)

Used after replacement of micro-computer, FLASH ROM IC,

EEPROM and HDMI module.

MENU Communication error display

ENTER DVD Module reset

Timer 1 check (Refer to the section

Timer 1 reset

Timer 2 check

Timer 2 reset

PAUSE Writing of laser drive current value after replacement of optical

pickup (Do use this function only when optical pickup is

replaced.)

“9.2.1. Service Mode

Table 1” for more

information).

“9.2.2. Service Mode

Table 2” for more

information).

“9.2.3. Service Mode

Table 3“ for more

information).

(Refer to the section

“9.2.4. Optical Pick-up

Self-Diagnosis” for more

information).

SA-HT895EE

9.2. Service Mode Table

By pressing various button combin ations on the player and remote control unit can activate the various service modes for checking.

Special Note:

Due to the limitations of the no. characters that can be shown on FL Display, the “FL Display” button on the remote control uni

is used to show the following page. (Display 1/Display 2).

21

SA-HT895EE

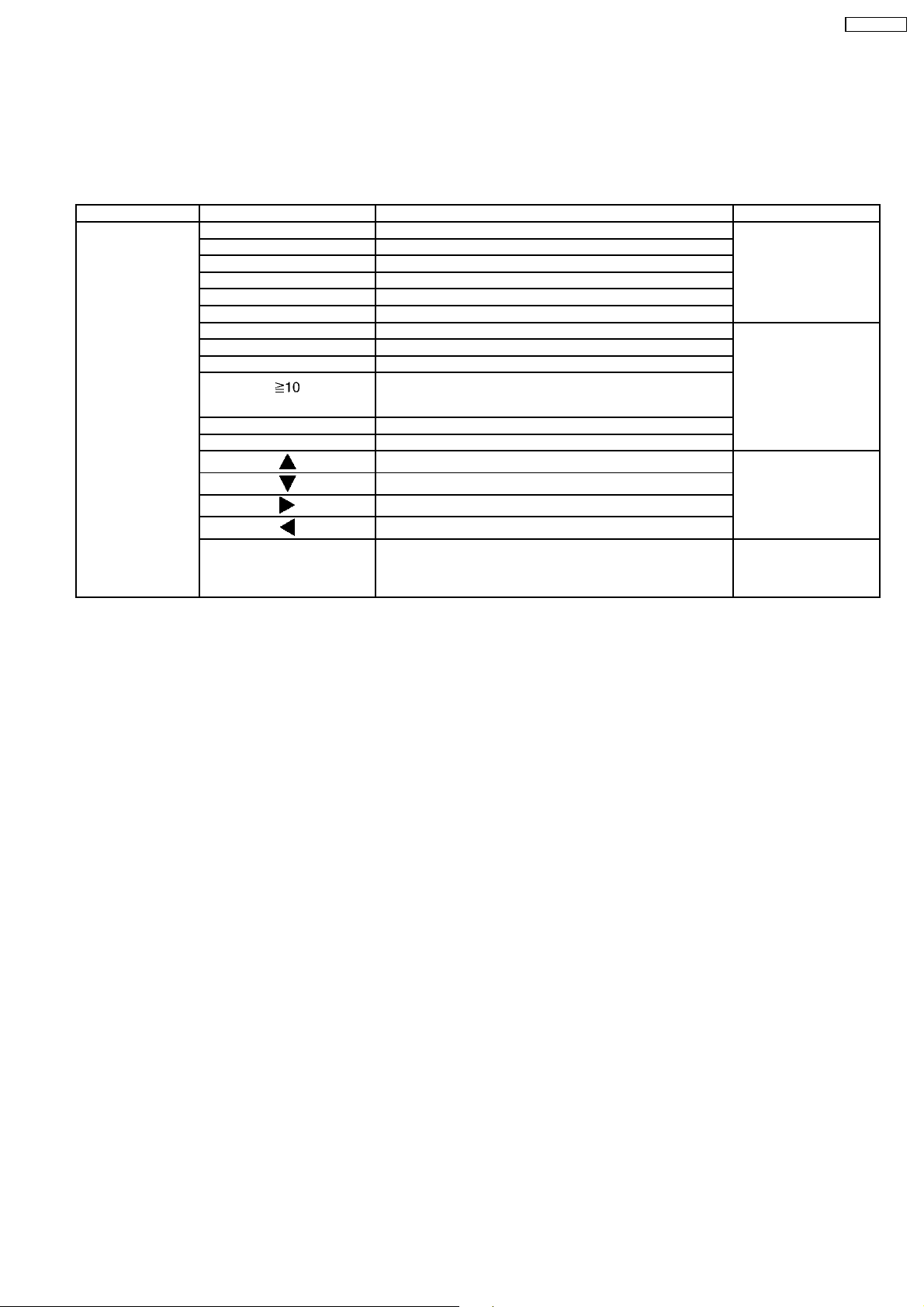

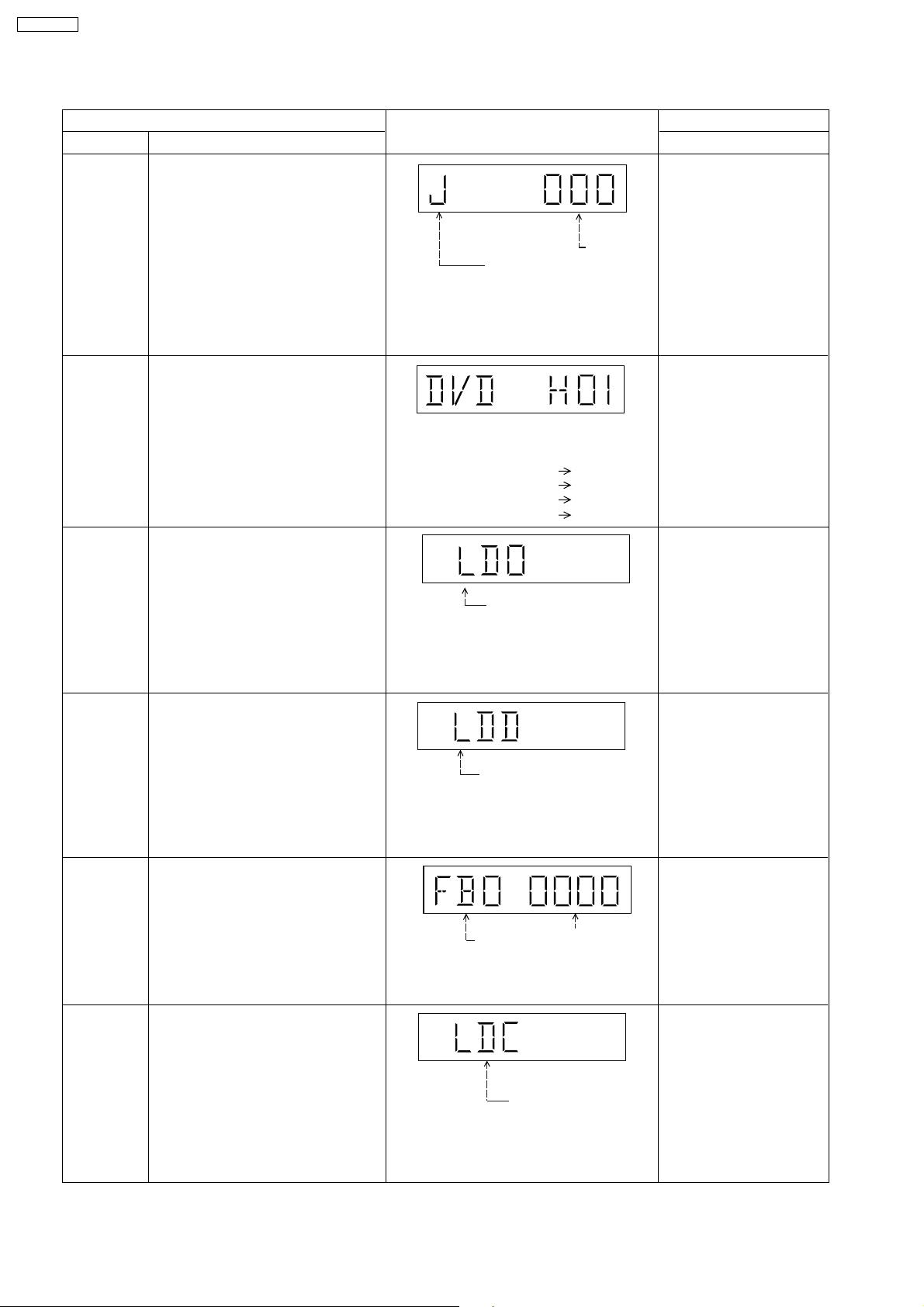

9.2.1. Service Mode Table 1

Mode Name

Jitter check

Error code

check

Initial setting

of laser drive

current

DVD laser

drive current

measurement

ADSC internal

RAM data

check

CD laser drive

current

measurement

Item

Description

Jitter check

Jitter rate is measured and displayed.

Measurement is repeatedly done in

the cycle of one second. Read error

counter starts from zero upon mode

setting. When target block data failed

to be read out, the counter advances

by one increment. When the failure is

caused by minor error, it may be

corrected when retried to enable

successful reading. In this case, the

counter advances by one. When the

error persists even after retry, the

counter may jump by two or more.

Error code check

The latest error code stored in the

EEPROM IC is displayed.

Initial setting of laser drive current.

Initial current value for each of DVD

laser and CD laser is separately saved

in the EEPROM IC.

DVD laser drive current measurement

·DVD laser drive current is measured

and the result is displayed together

with the initial value stored in the

EEPROM IC.

After the measurement, DVD laser

emission is kept on. It is turned off

when POWER key is switched off. (It

is also turned off when POWER button

on the player is switched off.)

ADSC internal RAM data check

·ADSC internal RAM data is read out

and displayed.

CD laser drive current measurement

CD laser drive current is measured

and the result is displayed together

with the initial value stored in the

EEPROM IC.

After the measurement, CD laser

emission is kept on. It is turned off

when POWER key is switched off. (It

is also turned off when POWER button

on the player is switched off.)

FL Display

Jitter rate

Jitter check mode

Jitter rate is shown in decimal notation to

one place of decimal.

Focus drive value is shown in hexadecimal

notation.

Error code (play_err) is expressed in the

following convention.

Error code = 0 x DAXX is expressed: DVDnn UXX

Error code = 0 x DBXX is expressed: DVDnn HXX

Error code = 0 x DXXX is expressed: DVDnn FXXX

Error code = 0 x 0000 is expressed: DVDnn F--* "xx" denotes the error code

Laser current measurement

mode

The value denotes the current in decimal

notation. The above example shows the

initial current is 34mA and 28mA for DVD

laser and CD laser respectively when the

laser is switched on.

DVD laser current

measurement mode

The value denotes the current in decimal

notation.

The above example shows the initial current

is 34mA and the measured value is 32mA.

Address

The value is shown in hexadecimal

notation. The above example shows the

data in ADSC address OFAh is 6901h.

The value denotes the current in decimal

notation.

The above example shows the initial current

is 28mA and the measured value is 26mA.

RAM data for

specified address

CD laser current

measurement mode

Key Operation

Front Key

In STOP (no disc) mode,

press STOP button on the

player, and "5" button on

the remote control unit.

Press STOP or OPEN

button to exit.

Press "FL Display" on

remote control unit for next

page (FL Display).

In STOP (no disc) mode,

press STOP button on the

player, and "0" button on the

remote control unit. * With

pointing of cursor up and

down on display.

Cancelled automatically

5 seconds later.

To exit, press [POWER]

button on main unit or

remote control.

In STOP (no disc) mode,

press STOP button on the

player, and PAUSE button

on the remote control unit.

Cancelled automatically

5 seconds later.

Press "FL Display" on

remote control unit for next

page (FL Display) on values

of laser drive current.

In STOP (no disc) mode,

press STOP button on the

player, and FUNCTIONS

button on the remote

control unit.

Cancelled automatically

5 seconds later.

Press "FL Display" on

remote control unit for next

page (FL Display) on values

of dvd drive current.

In STOP (no disc) mode,

press STOP button on the

player, and "1" button on

the remote control unit.

Press STOP or PLAY

button.

In STOP (no disc) mode,

press STOP button on the

player, and "3" button on

the remote control unit.

Cancelled automatically

5 seconds later.

Press "FL Display" on

remote control unit for next

page. (FL Display)

22

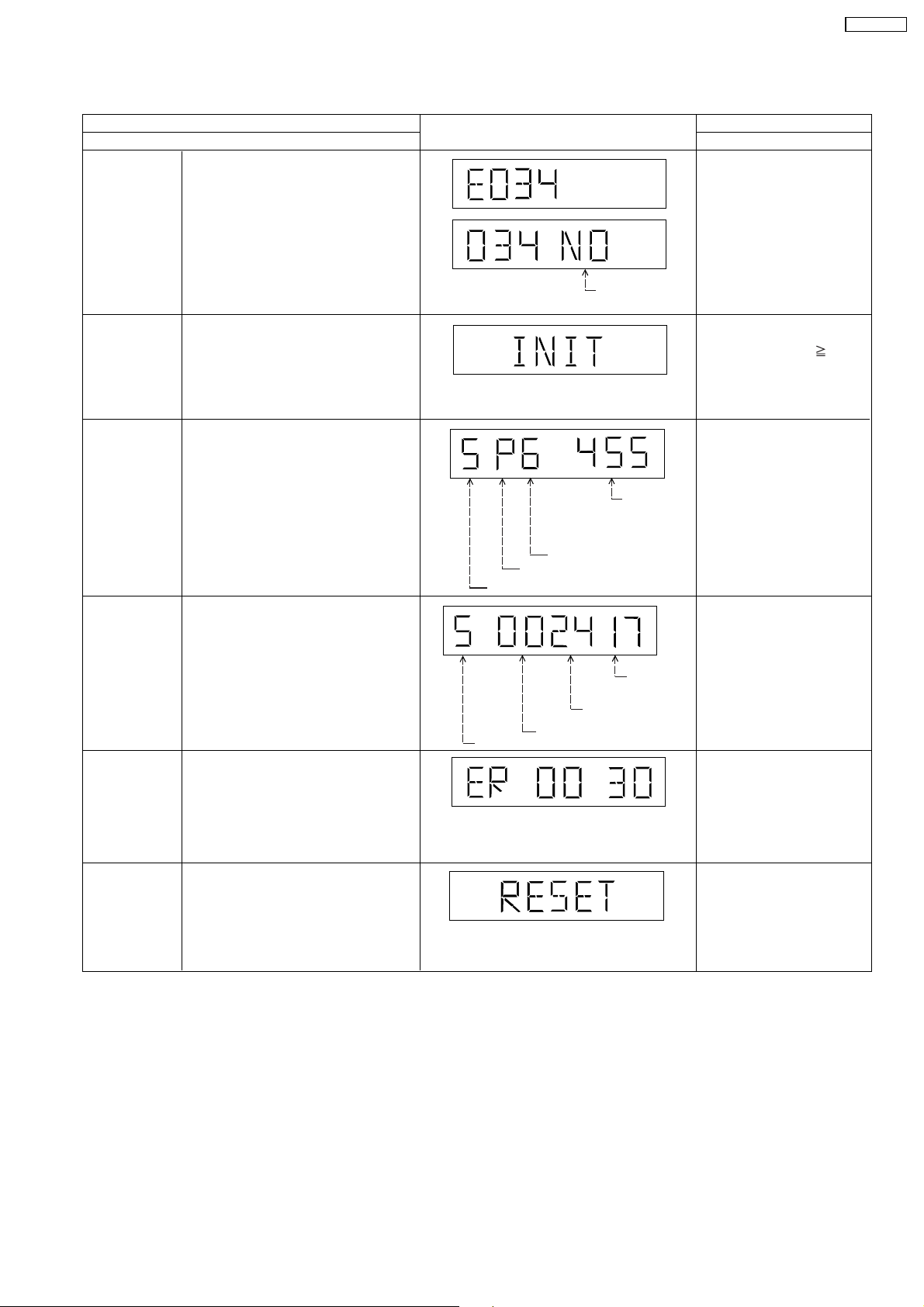

9.2.2. Service Mode Table 2

SA-HT895EE

Micro-processor

firmware version

display &

EEPROM

checksum

display.

Initialization

Region display

DVD module

firmware

version display

Communication

error display

DVD Module

Reset

Item

DescriptionMode Name

Micro-processor firmware version

display & EEPROM checksum display.

EEPROM checksum is only available

due to existence of EEPROM IC.

(NO: NO EEPROM IC)

If EEPROM IC is present, the checksum

value will be displayed. It displays as

"NG" if the EEPROM IC installed is not

working properly.

Initialization

User settings are cancelled and player

is initialized to factory setting.

Region display & mode

DVD module firmware version is

displayed on the FL Display.

The firmware version can be updated

using recovery disc.

Displays frequency of communication

errors between system control IC and

mechanism control IC during DVD

module.

To reset DVD Module.

This process is used when the DVD

module or flash ROM IC is replaced

with a new one.

N: noPAL / P: PAL

Region No.

Region

FL Display

Existence of

EEPROM

N: NTSC / 6: PAL60

Destination

System controller

generation

Panel

controller

jumper

information

System

controller

version

Key Operation

Front Key

In STOP (no disc)

mode, press STOP button

on the player, and "7"

button on the remote

control unit.

Cancelled automatically

5 seconds later.

Press "FL Display" button on

remote control unit for next

page. (FL Display)

In STOP (no disc)

mode, press STOP button

on the player , and

button on the remote

control unit.

Cancelled automatically

5 seconds later.

In STOP (no disc)

mode, press STOP button

on the player, and "6"

button on the remote

control unit.

Cancelled automatically

5 seconds later.

In STOP (no disc)

mode, press STOP button

on the player, and "8"

button on the remote

control unit.

Cancelled automatically

5 seconds later.

In STOP (no disc)

mode, press STOP button

on the player, and "MENU"

button on the remote

control unit.

Cancelled automatically

5 seconds later.

While in initialization

mode, press & hold STOP

button on player, follow by

"ENTER" button on the

remote control unit.

Cancelled automatically

5 seconds later.

10

23

SA-HT895EE

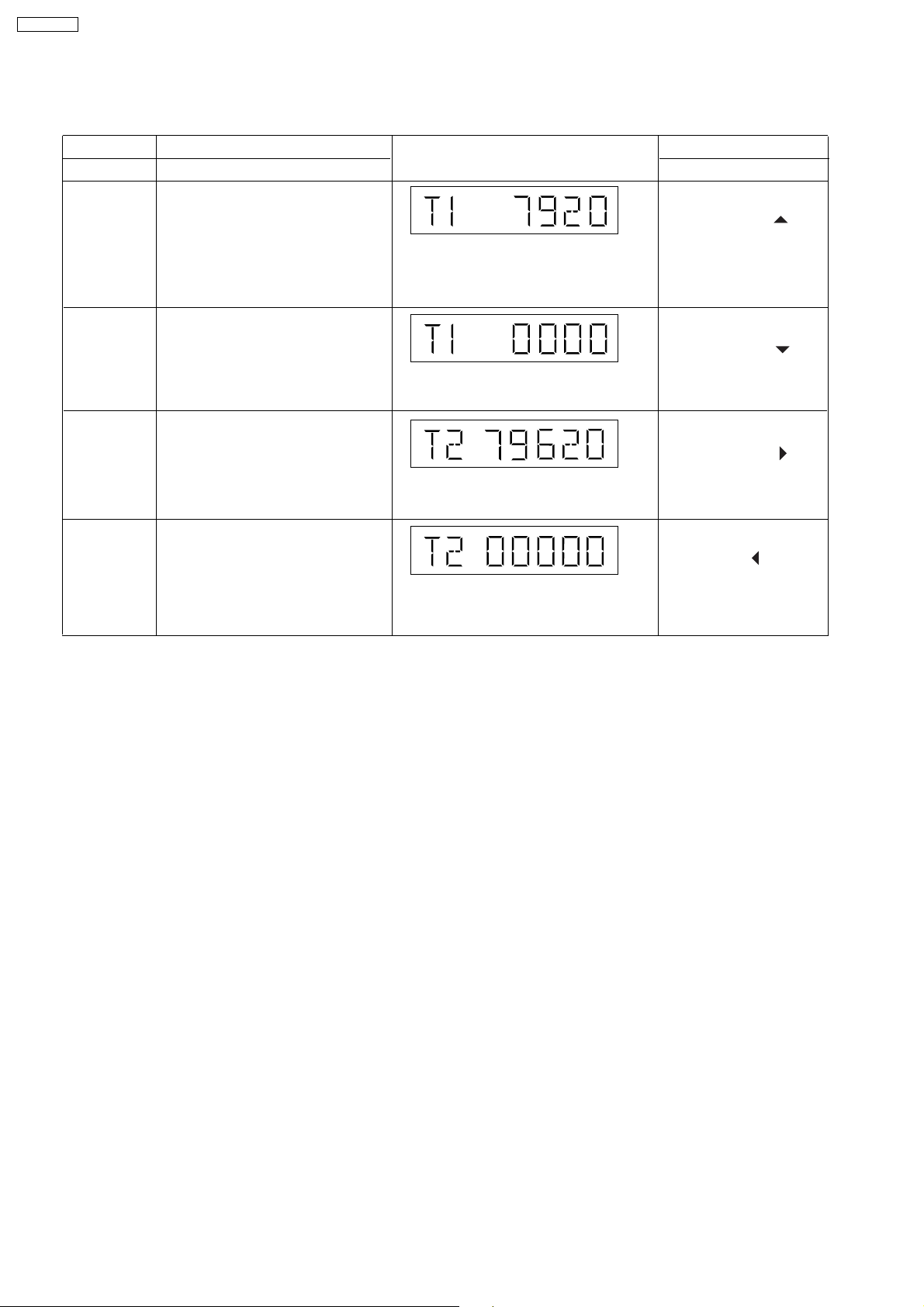

9.2.3. Service Mode Table 3

Mode Name

Timer 1 check

Timer 1 reset

Timer 2 check

Timer 2 reset

Item

Description

Timer 1 check

Laser operation timer is measured

separately for DVD laser and CD laser.

Press "FL Display" button for next

page of FL Display

Timer 1 reset

Laser operation timer of both DVD

laser and CD laser is reset all at once.

Press "FL Display" button for next

page of FL Display

Timer 2 check

Spindle motor operation timer

Press "FL Display" button for next

page of FL Display

Timer 2 reset

Spindle motor operation timer

Press "FL Display" button for next

page of FL Display

FL Display

Shown to the left is DVD laser time, and to

the right is CD laser time.

Time is shown in 4 digits of decimal notation

in a unit of 10 hours.

"0000" will follow "9999".

Shown to the left is DVD laser time, and to

the right is CD laser time.

It will clear to "0000" upon reset.

Time is shown in 5 digits of decimal notation in

a unit of 10 hours.

"00000" will follow "99999".

Time is shown in 5 digits of decimal notation in

a unit of 10 hours.

It will be cleared to "00000" upon activating

this.

Key Operation

Front Key

In STOP (no disc)

mode, press STOP button

on the player, and " "

button on the remote

control unit.

Cancelled automatically

5 seconds later.

While displaying Timer 1

data, press STOP button

on the player, and " "

button on the remote

control unit.

Cancelled automatically

5 seconds later.

In STOP (no disc)

mode, press STOP button

on the player, and " "

button on the remote

control unit.

Cancelled automatically

5 seconds later.

While displaying Timer 2

data, press STOP button on

the player, and " " button

on the remote control unit.

Cancelled automatically

5 seconds later.

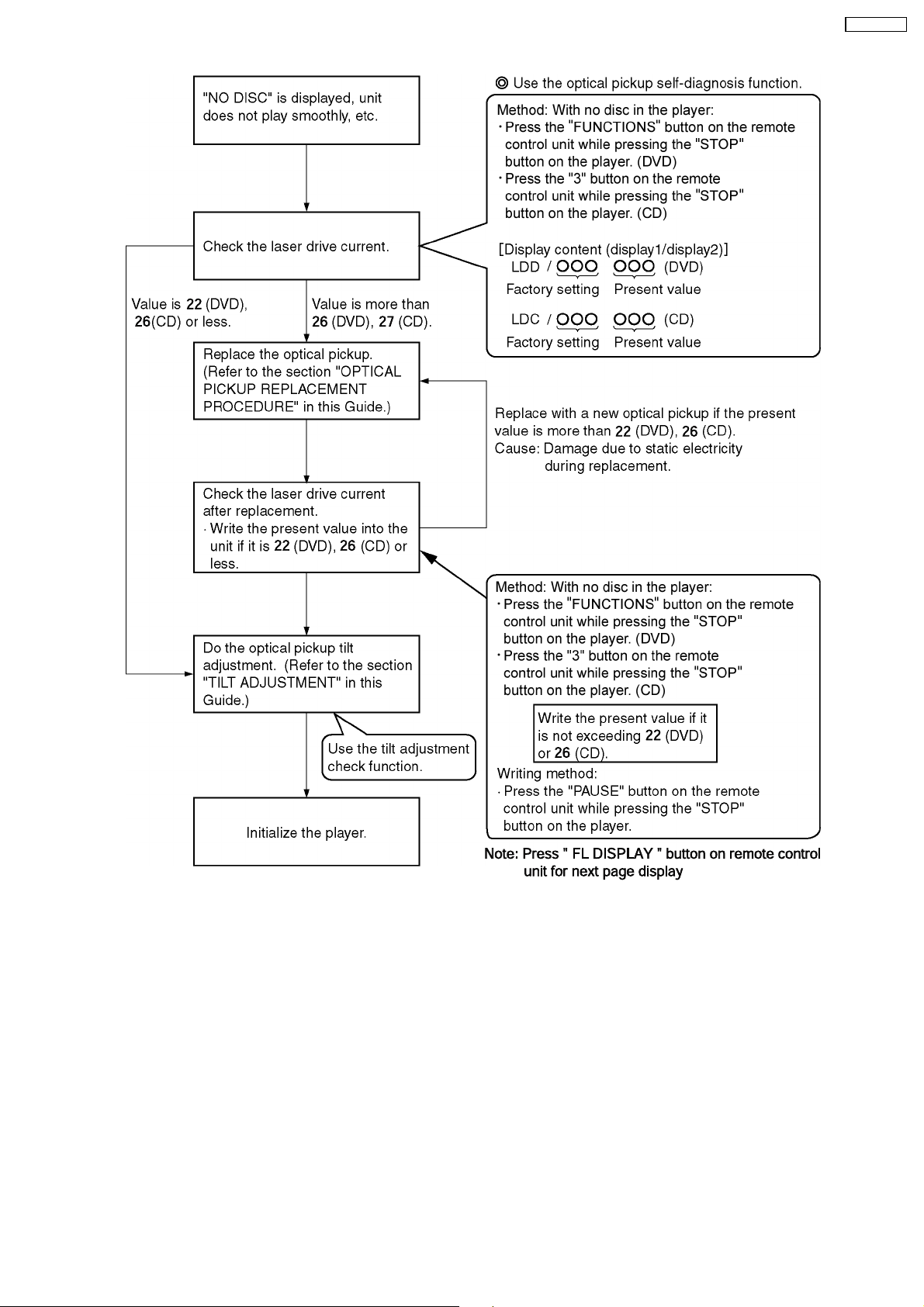

9.2.4. Optical Pick-up Self-Diagnosis

The optical pickup self-diagnosis function and tilt adjustment check function have been included in this unit. When repairing, use

the following procedure for effective self-diagnosis and tilt adjustment. Be sure to use the self-diagnosis function before replacing

the optical pickup when "NO DISC" is displayed. As a guideline, you should replace the optical pickup when the value of the laser

drive current is more than 55.

Note:

Press the power button to turn on the power, and check the value within three minutes before the unit warms up. (Otherwise,

the result will be incorrect.)

24

SA-HT895EE

25

SA-HT895EE

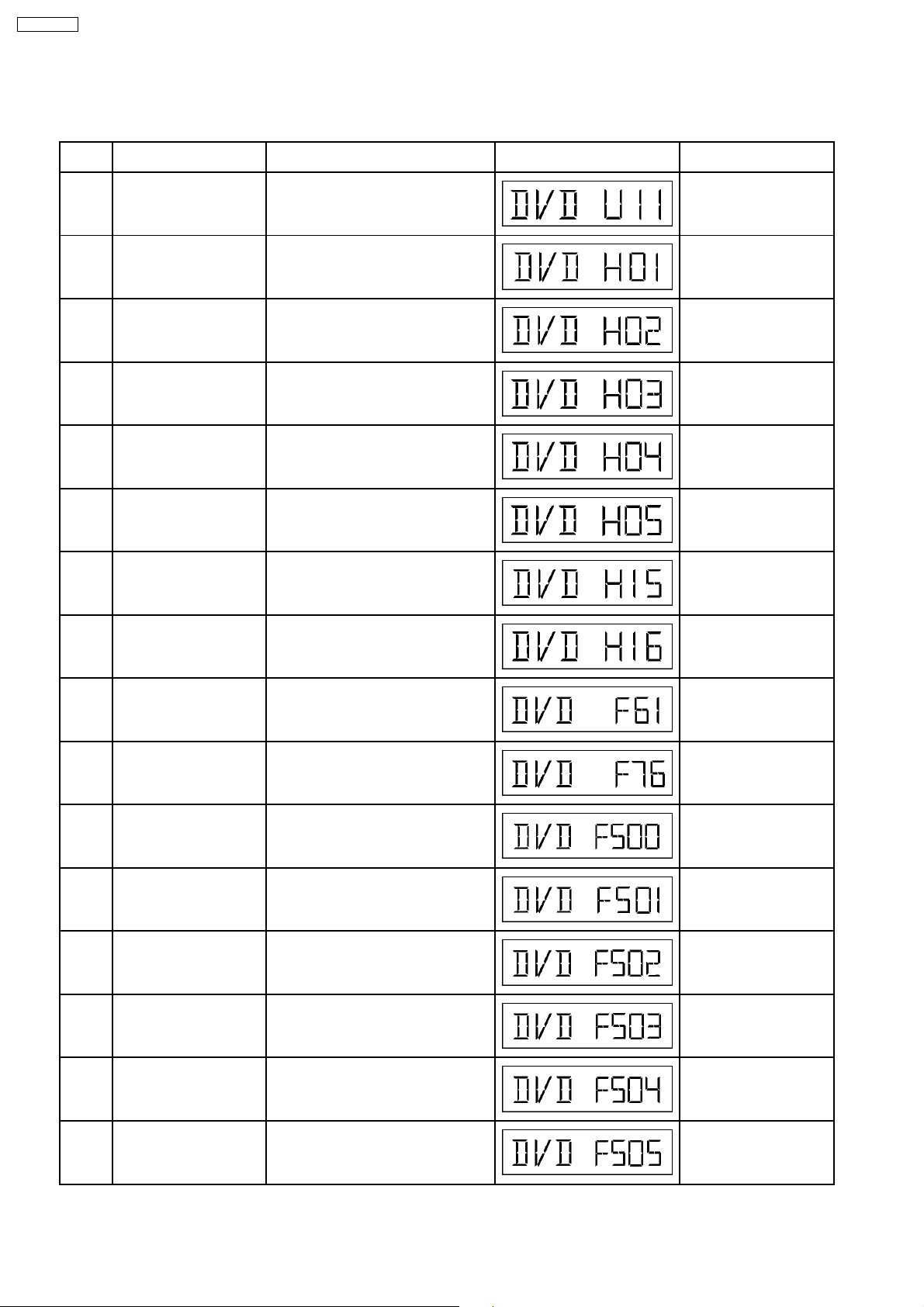

9.3. DVD Self Diagnostic Function-Error Code

9.3.1. Error Code Table 1

Error

Code

U11 Focus servo error Focus coil NG (OPU unit abnormal) Press [ n STOP] on main

H01 Tray loading error /

H02 Spindle servo error, DSC

H03 Traverse motor error (Traverse motor, IC8251) Press [ n STOP] on main

H04 Tracking servo error Tracking coil NG (OPU unit abmormal) Press [ n STOP] on main

H05 Seek timeout error Timeout of unit when seeking time is

H15 Disc tray open detection

Diagnosis Contents Description of error Automatic FL Display Remarks

unit for next error.

abnormality

disc motor error

switch (S9001) failure

The tray is not able to open Press [ n STOP] on main

(Spindle servo, DSC (IC8251) Spindle

motor, CLV servo error)

reached

The disc tray cannot be opened: it closes

spontaneously

unit for next error

Press [ n STOP] on main

unit for next error

unit for next error

unit for next error

Press [ n STOP] on main

unit for next error

Press [ n STOP] on main

unit for next error

H16 Disc tray close detection

switch (S9001) failure

F61 Power digital amp IC op &

DC output voltage

abnormal.

F76 Power digital amp IC op &

DC output voltage

abnormal.

F500 DSC error DSC (IC8251) stops in the occurrence of

F501 DSC not Ready error DSC-system computer communication

F502 DSC Time out error Similar as F500 Press [ n STOP] on main

F503 DSC communication

Failure

F504 Abnormal adjusting DSC

data slice offset

The disc tray cannot be closed: it opens

spontaneously

Upon power-on PCONT=High,

DCDET=Low.

Speaker connection could be problem

Speaker Jack shorted or amp circuit Press [ n STOP] on main

servo error (startup, focus error, etc.)

error (Communication failure caused by

idling of DSC)

Communication error (result error

occurred although communication

command was sent)

Press [ n STOP] on main

unit for next error

Press [ n STOP] on main

unit for next error

unit for next error

Press [ n STOP] on main

unit for next error

Press [ n STOP] on main

unit for next error

unit for next error

Press [ n STOP] on main

unit for next error

Press [ n STOP] on main

unit for next error

F505 DSC Attention error Similar as F500 Press [ n STOP] on main

unit for next error

26

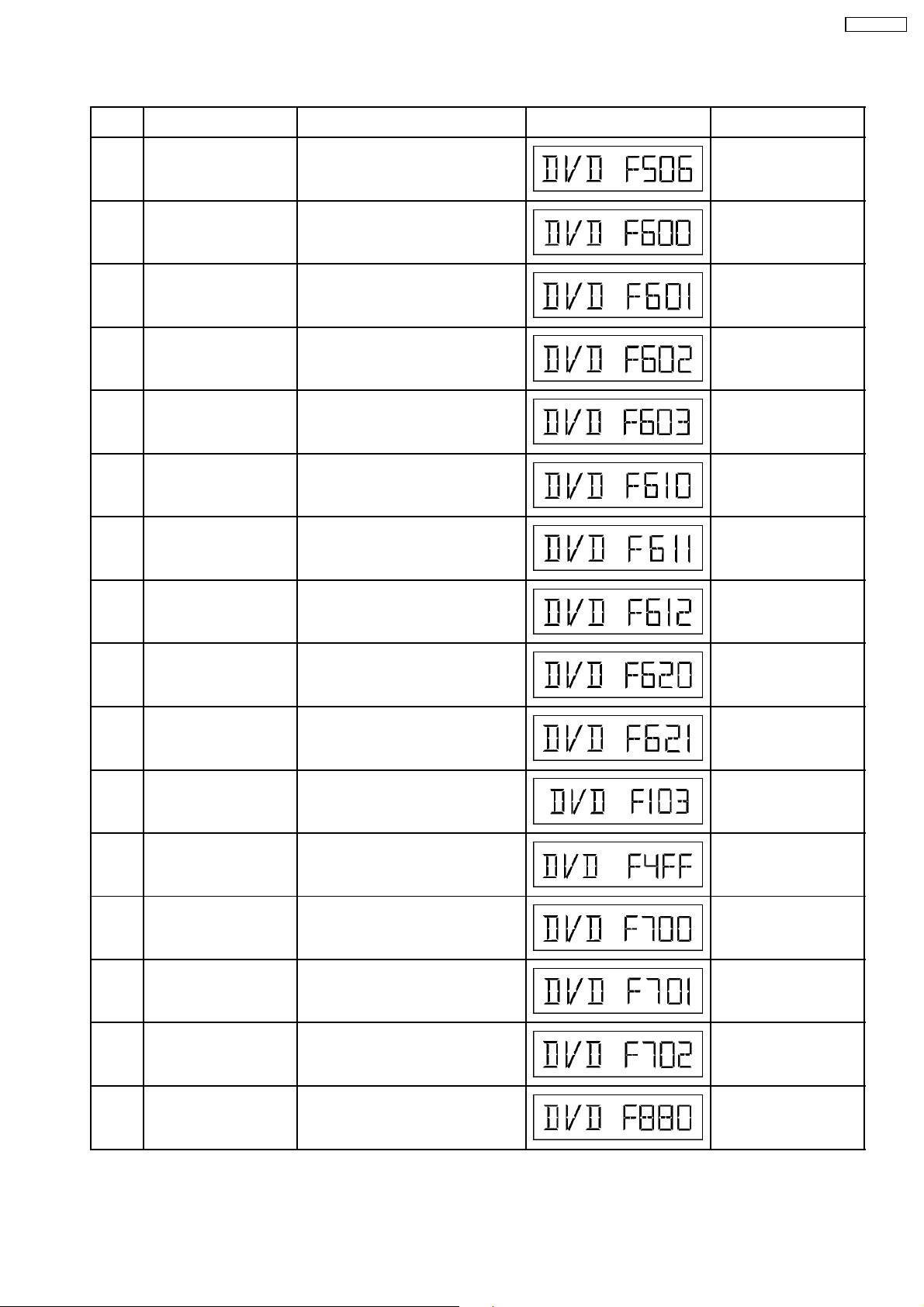

9.3.2. Error Code Table 2

SA-HT895EE

Error

Code

F506 Invalid media Disc is flipped over, TOC unreadable,

F600 Access failure to

F601 Indeterminate sector ID

F602 Access failure to LEAD-IN

F603 Access failure to KEYDET

F610 ODC abnormality No permission for command execution Press [ n STOP] on main

F611 No CRC OK for a specific

Diagnosis Contents Description of error Automatic FL Display Remarks

Press [ n STOP] on main

unit for next error

Press [ n STOP] on main

unit for next error

Press [ n STOP] on main

unit for next error

unit for next error

unit for next error

unit for next error

Press [ n STOP] on main

unit for next error

management information

caused by demodulation

error

requested

caused by demodulation

error

caused by demodulation

error

time (CD)

incompatible disc media

Operation stopped because navigation

data is not accessible caused by the

demodulation defect

Operation stopped caused by the

request to access abnormal ID data

LEAD IN data unreadable Press [ n STOP] on main

Access failure to CSS data of disc Press [ n STOP] on main

Access failure to seek address in CD

series

F612 No CRC OK for a specific

time (DVD)

F620 Laser safeguard: high

temperature condition

F621 Laser safeguard: circuit

failure condition

F103 Illegal highlight Position Big possibility of disc specification

F4FF Force initialize failure (time

out)

F700 MBX overflow When replying message to disc manager Press [ n STOP] on main

F701 Message command does

not end

F702 Message command

changes

Access failure to ID data in DVD series Press [ n STOP] on main

High temperature of the laser guide unit

(OPU unit)

Circuitry failure of the laser guide unit

(OPU unit)

violation during highlight display

Timeout when force initialization fails Press [ n STOP] on main

Next message is sent before replying to

disc manager

Message is changed before it is sent as

a reply to disc manager

unit for next error

Press [ n STOP] on main

unit for next error

Press [ n STOP] on main

unit for next error

Press [ n STOP] on main

unit for next error

unit for next error

unit for next error

Press [ n STOP] on main

unit for next error

Press [ n STOP] on main

unit for next error

F880 Task number is not

appropriate

Message coming from a non-existing

task

27

Press [ n STOP] on main

unit for next error

SA-HT895EE

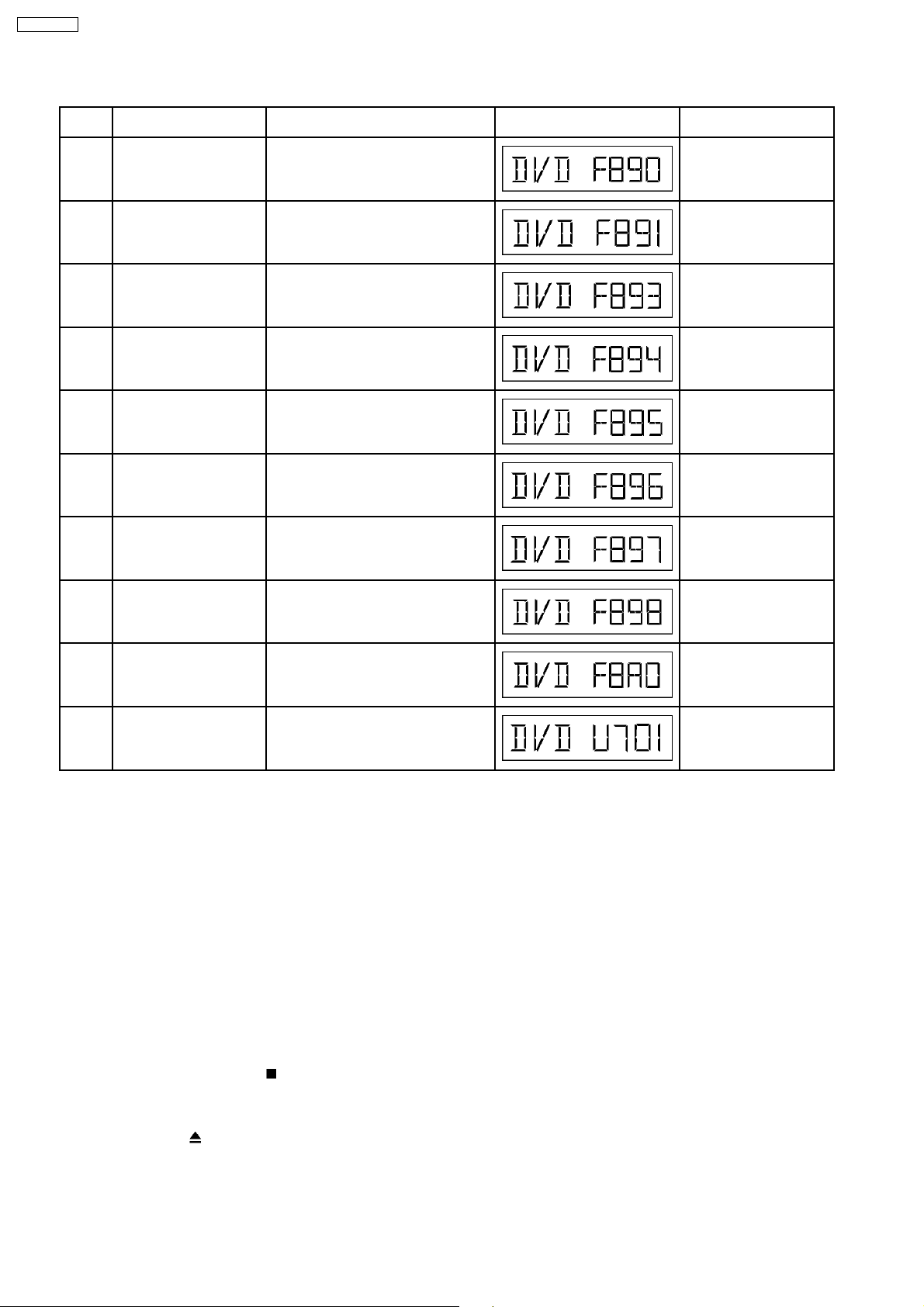

9.3.3. Error Code Table 3

Error

Code

F890 Sending message when

F891 Message couldn’t be sent

F893 FLASH ROM IC problem FLASH ROM IC installed is not operating

F894 EEPROM abnormality EEPROM IC installed is not operating in

F895 Region setting abnormality Firm version agreement check for factory

F896 No existence model Firm version agreement check for factory

F897 Initialize is not completed Initialize completion check for factory

Diagnosis Contents Description of error Automatic FL Display Remarks

Sending message to AV task Press [ n STOP] on main

message is being sent to

AV task

Begin sending message to AV task Press [ n STOP] on main

to AV task

properly (Neccessary replacement of

FLASH ROM IC) or firmware problem

normal condition (EEPROM contains

neccessary data)

preset setting failure prevention. Check

region setting & re-initialize

preset setting failure prevention

preset setting failure prevention

unit for next error

unit for next error

Press [ n STOP] on main

unit for next error

Press [ n STOP] on main

unit for next error

Press [ n STOP] on main

unit for next error

Press [ n STOP] on main

unit for next error

Press [ n STOP] on main

unit for next error

F898 Disagreement of hardware

and software

F8A0 Message command is not

appropriate

U701 HDMI compatibility The connected equipment is not HDMI-

Unsuitable combination of AV

DECORDER, SDRAM and FLASH ROM

(firmware)

Begin sending message to AV task Press [ n STOP] on main

compatible, HDMI cable is damaged.

Press [ n STOP] on main

unit for next error

unit for next error

Press [ n STOP] on main

unit for next error

Note:

An error code will be canceled if a power supply is turned OFF.

*1: CPPM is the copy guard function beforehand written in the disk for protection of copyrights.

*2: CEC is the consumer electronic control used for high-level user control of HDMI-connected devices.

*3: HDCP is the specification developed to control digital audio & video contents transmission for DVI or HDMI connections.

9.4. Sales Demonstration Lock Function

This function prevents discs from being lost when the unit is used for sales demon strations by disabling the disc eject function.

"LOCKED" is display ed on the unit, and ordinary operation is disabled.

9.4.1. Setting

· Prohibiting removal of disc

1. Select the DVD/CD function.

2. Press and hold down the

“___LOCKED_” appears when the function is activated.)

Note:

OPEN/CLOSE

, DISC CHECK and DISC CHANGE buttons are invalid and the player displays “___LOCKED_” while

the lock function mode is entered.

· Prohibiting operation of selector and disk

1. Select the DVD/CD function.

button and the power button on the player for at least three seconds. (The message,

28

SA-HT895EE

2. Press and hold down the button and the power button on the player for at least three seconds. (The message,

“___LOCKED_” appears when the function is activated.)

Note:

The following buttons are invalid and the player displays “___LOCKED_” while the lock function mode is entered.

Player , , , SELECTOR, , , VOLUME KNOB, DISC CHECK, DISC CHANGE, DISC1-DISC5

Remote

controller unit

SLEEP, REPEAT, 0~9, , RETURN, TOP MENU, , , , , , ,

POSITION MEMORY, TUNER/BAND, D.MIX, CH SELECT/ TEST, SET UP/ MUTING, DISPLAY, GROUP, TV, VCR/

AUX, QUICK REPLAY, SUBTITLE, FL DISPLAY, CH & VOLUME

9.4.2. Cancellation

The lock can be cancelled by the same procedure as used in setting. ("UNLOCK" is display ed on cancellation. Disconnecting the

power cable from power outlet does not cancel the lock.)

9.5. Service Precautions

9.5.1. Recovery after the DVD player is repaired

· W hen the FLASH ROM IC or HDMI module P.C.B. is replaced, carry out the recovery processing to optimize the drive.

Playback the recovery disk to process the recovery automatically.

· Recovery disc (Product number: RFKZD03R005) [SPG]

· Performing recovery process

1. Load the recovery disc on to the player and run it.

2. Recovery is performed automatically . When it is finished, a message appears on the screen.

3. Remove the recovery disc.

4. Turn off the power.

5. Initialize the player.

9.5.2. Firmware version-up of the DVD player

· The firmware of the DVD player may be updated to improve the quality including operability and playability to the substandard

discs.processing to optimize the drive.

The recovery disc contains firmware for update d purpose.

· After version-up, recovery processing is executed automatically.

· Part number of the recovery disc for version-up will be noticed when it is supplied.

· Updating firmware

1. Load the recovery disc on to the player and run it.

2. Firmware version of the player is automatically checked. Appropriate message appears whenever necessary.

3. Using remote controller´s cursor key, select whether version updating is to be done or not. (Selection of Yes/No)

4. a. If Yes is selected, version updating is performed.

b. If No is selected, only recovery is performed.

5. a. When updating is finished, remove the disc according to the message appearing on the screen.

b. Remove the disc according to the message appearing on the screen.

6. Turn off the power.

Note:

If the AC power supply is shut out during version-up due to a power failure, the version-up is improperly carried out.

In such a case, replace the FLASH ROM IC and carry out the version-up again.

9.5.3. HDMI Module Reset

· W hen after replacing FLASH ROM IC or the HDMI Module P.C.B., FL displays error code “ DVD F897”. This means the unit

is not initialized properly and the following process needs to be carry out.

· Procedures:

1. Press

2. FL display show “INIT”

3. While still pressing “STOP” button on main unit, press “ENTER” on remote control.

4. FL will display “RESET” before FL display will change to TOC reading again.

5. Power off unit. Unplug the AC cord.

6. Power on the unit. It should be no problem. If problem persist check on the HDMI module P.C.B. or FLASH ROM IC.

on remote control while pressing “STOP” button on main unit.

29

SA-HT895EE

10 Assembling and Disassembling

“ATTENTION SERVICER”

Be careful when disassembling and servicing.

Some chassis components may have sharp edges.

Special Note:

1. This section describes the disassembly procedures for all the major printed circuit boards and main components.

2. Before the disassembly process was carried out, do take special note that all safety precautions are to be carried out.

(Ensure that no AC power supply is connected during disassembling.)

3. For assembly after operation checks or replacement, reverse the respective procedures.

Special reassembly procedures are described only when required.

4. The Switch Regulator IC may have high temperature after prolonged use.

Use caution when removing the top cabinet and avoid touching heat sinks located in the unit.

5. Select items from the following index when checks or replacement are required.

· Disassembly of Top Cabinet

· Disassembly of DVD Lid (When taking out disc manually)

· Disassembly of Front Panel

· Disassembly of Music Port P.C.B., Mic P.C.B., FL P.C.B. & Top Button P.C.B.

· Disassembly of Mechanism Unit

· Disassembly of DVD Module P.C.B.

· Disassembly of Rear panel

· Disassembly of Relay P.C.B.

· Disassembly of HDMI Module P.C.B.

· Disassembly of Scart P.C.B.

· Disassembly of Main P.C.B., AC-Inlet P.C.B. & Tuner Extent P.C.B.

· Disassembly of Digital Amp IC (IC5000)

· Disassembly of Digital Amp IC (IC5400)

· Disassembly of Regulator Diodes & Transistor

· Disassembly of Switch Regulator IC (IC5701)

30

Loading...

Loading...