Panasonic SADK-20-GN Service manual

ORDER NO. MD0206154C3

DVD Stereo System

SA-DK20GN

Colour

(S)... Silver Type

TAPE SECTION :

SPECIFICATIONS

AR2 MECHANISM SERIES

Specifications

1

AMPLIFIER SECTION

RMS power output

10% THD, both channels driven

75 Hz

Subwoofer

150 W (4 )

1 kHz

Front

Center

Surround

45 W per ch (6 )

70 W (8 )

40 W per ch (8 )

Total power in stereo mode

(Front and Subwoofer)

240 W

Total power in Home Theater mode

390 W

Input sensitivity

AUX

250 mV

Input Impedance

AUX

10 k

FM TUNER SECTION

Frequency range

87.50 - 108.00 MHz (50

kHz steps)

Sensitivity

S/N 26 dB

1.8 V (IHF)

1.5 V

Antenna terminal(s) 75 (unbalanced)

AM TUNER SECTION

Frequency range

522 - 1629 kHz (9 kHz

steps)

Sensitivity

S/N 20 dB (at 999 kHz)

500 V/m

CASSETTE DECK

SECTION

Track system

4 track, 2 channel

Heads

Record/playback

Erasure

Motor

Recording system

Erasing system

Tape speed

Solid permalloy head

Double gap ferrite head

DC servo motor

AC bias 100 kHz

AC erase 100 kHz

4.8 cm/s (1 7/8 ips)

Overall frequency response (+3 dB, -6 dB at DECK

OUT)

NORMAL (TYPE I)

HIGH (TYPE II)

S/N ratio

35 Hz - 14 kHz

35 Hz - 14 kHz

50 dB (A weighted)

2

Wow and flutter

Fast forward and rewind

Approx. 120 seconds with

0.18 % (WRMS)

time

C-60 cassette tape

Disc SECTION

Disc

DVD-Video

8 cm/12 cm single-sided, single-layer

8 cm/12 cm single-sided, double-layer

8 cm/12 cm double-sided, double-layer

(One layer per side)

Video CD/CD 8 cm/12 cm (CD-R/RW)

Video

Signal system NTSC/PAL

(depending on disc

format)

Output level

Composite video 1 Vp-p (75 )

S-Video Y 1 Vp-p (75 )

S-Video C 0.300 Vp-p (75 )(PAL)

0.286 Vp-p (75 )(NTSC)

Audio

Sampling frequency

CD

DVD

Decoding

Wow and flutter

D/A converter

16/20/24 bit linear

Below measurable limit

Delta-sigma DAC)

44.1 kHz

48kHz/96 kHz

Pick up

Beam source

Semiconductor Laser

Wavelength

DVD 658 nm

VCD/CD 790 nm

GENERAL

Power supply

Power consumption

AC 230 - 240 V, 50Hz

186 W

Power consumption in standby mode

0.6 W

Dimensions (W x H x D)

Mass

215.4 X 315 X 350 mm

8.1 kg

SYSTEM

SC-DK20(GN) Music Center: SA-

DK20(GN)

3

Front Speaker: SB-

Surround & Centre Speaker: SB-PT93(P1)

Sub woofer: SB-W20(P)

Notes:

1. Specifications are subject to change without notice. Mass and

dimensions are aproximate.

2. Total harmonic distortion is measured by the digital spectrum analyzer.

1

1. Before Repair and Adjustment

DK20(P)

Disconnect AC power, discharge Power Supply Capacitors C566~C569, C782 and

C591 through a 10 , 5W resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as

this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid

overcurrent.

Current consumption at AC 240V, 50Hz in NO SIGNAL mode should be ~350mA

respectively.

2. Protection Circuitry

The protection circuitry may have operated if either of the following conditions

are noticed:

- No sound is heard when the power is turned on.

- Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the

positive and negative speaker connection wires are

“shorted”, or if speaker systems with an impedance less than the indicated rated

impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

4

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note :

When the protection circuitry functions, the unit will not operate unless the

power is first turned off and then on again.

3. Accessories

Remote Control Transmitter

FM indoor antenna

5

AC mains lead

AM Loop antenna

Video cable

6

4. Handling Precaution for Traverse Deck (Optical

Pickup)

The laser diode in the traverse unit (optical pickup) may break down due to static

electricity of clothes or human body.

Use due caution to electrostatic breakdown when servicing and handling the

laser diode.

4.1. Grounding for electrostatic breakdown prevention

Some devices such as the DVD player use the optical pickup (laser diode) and

the optical pickup will be damaged by static electricity in the working

environment. Proceed servicing works under the working environment where

grounding works is completed.

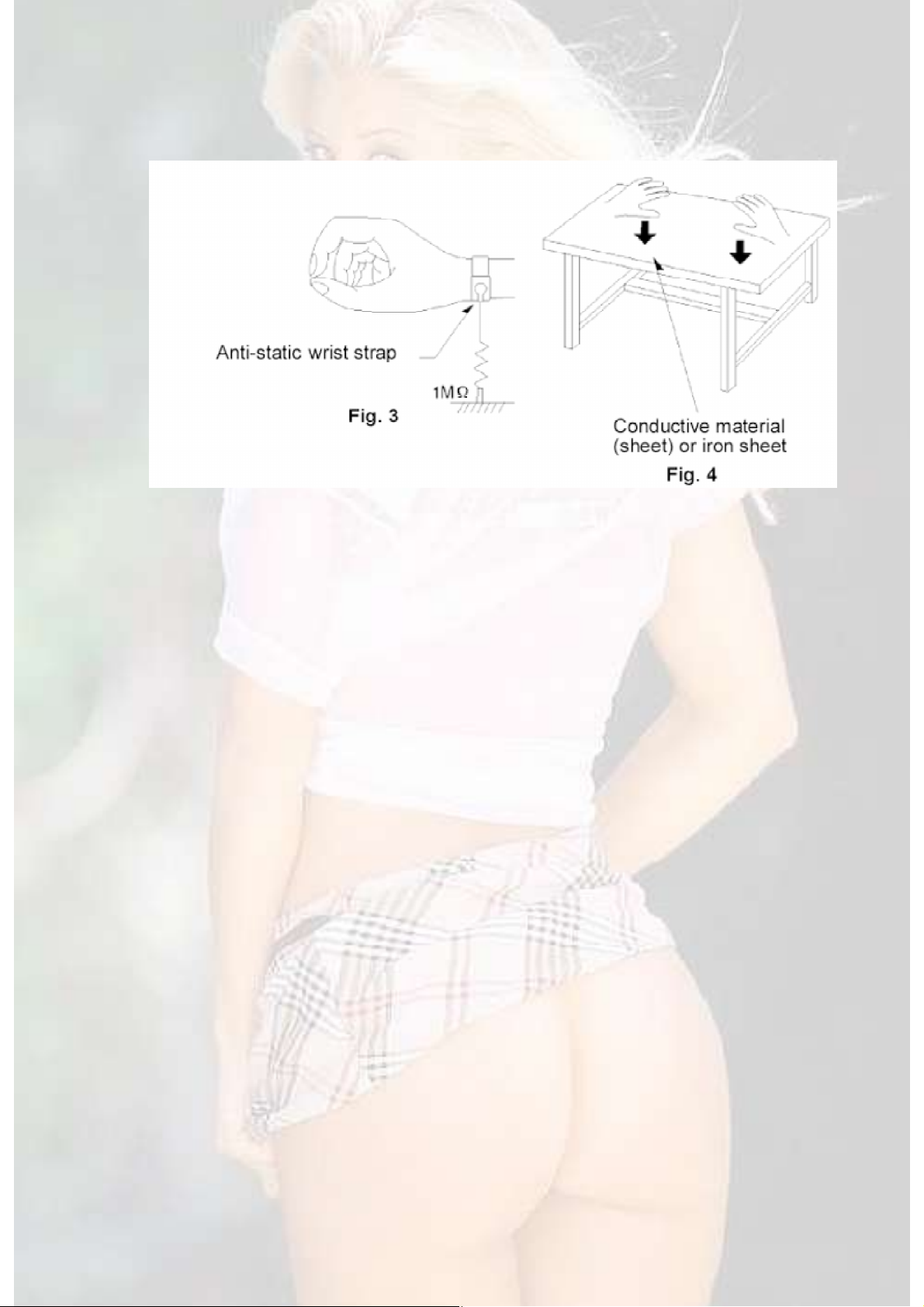

4.1.1. Workable grounding

1. Put a conductive materials (sheet) or iron sheet on the area where the optical

pickup is placed, and ground the sheet.

4.1.2. Human body grounding

1. Use the anti-static wrist strap to discharge the static electricity from your body.

7

4.1.3. Handling of optical pickup

1. To keep the good quality of the optical pickup maintenance parts during

transportation and before installatio,. the both ends of the laser diode are

short-circuited. After replacing the parts with new ones, remove the short

circuit according to the correct procedure. (See this Technical Guide.)

2. Do not use a tester to check the laser diode for the optical pickup. Failure to

do so will damage the laser diode due to the power supply in the tester.

4.2. Handling Precautions for Traverse Unit (Optical Pickup)

1. Do not give a considerable shock to the traverse unit (optical pickup) as it has

an extremely high-precise structure.

2. When replacing the optical pickup, install the flexible cable and cut its short

land with a nipper. See the optical pickup replacement procedure in this

Technical Guide. Before replacing the traverse unit, remove the short pin for

preventingstatic electricity and install a new unit. Connect the connector as

short times as possible.

3. The flexible cable may be cut off if an excessive force is applied to it. Use

caution when handling the cable.

4. The half-fixed resistor for laser power adjustment cannot be adjusted. Do not

turn the resistor.

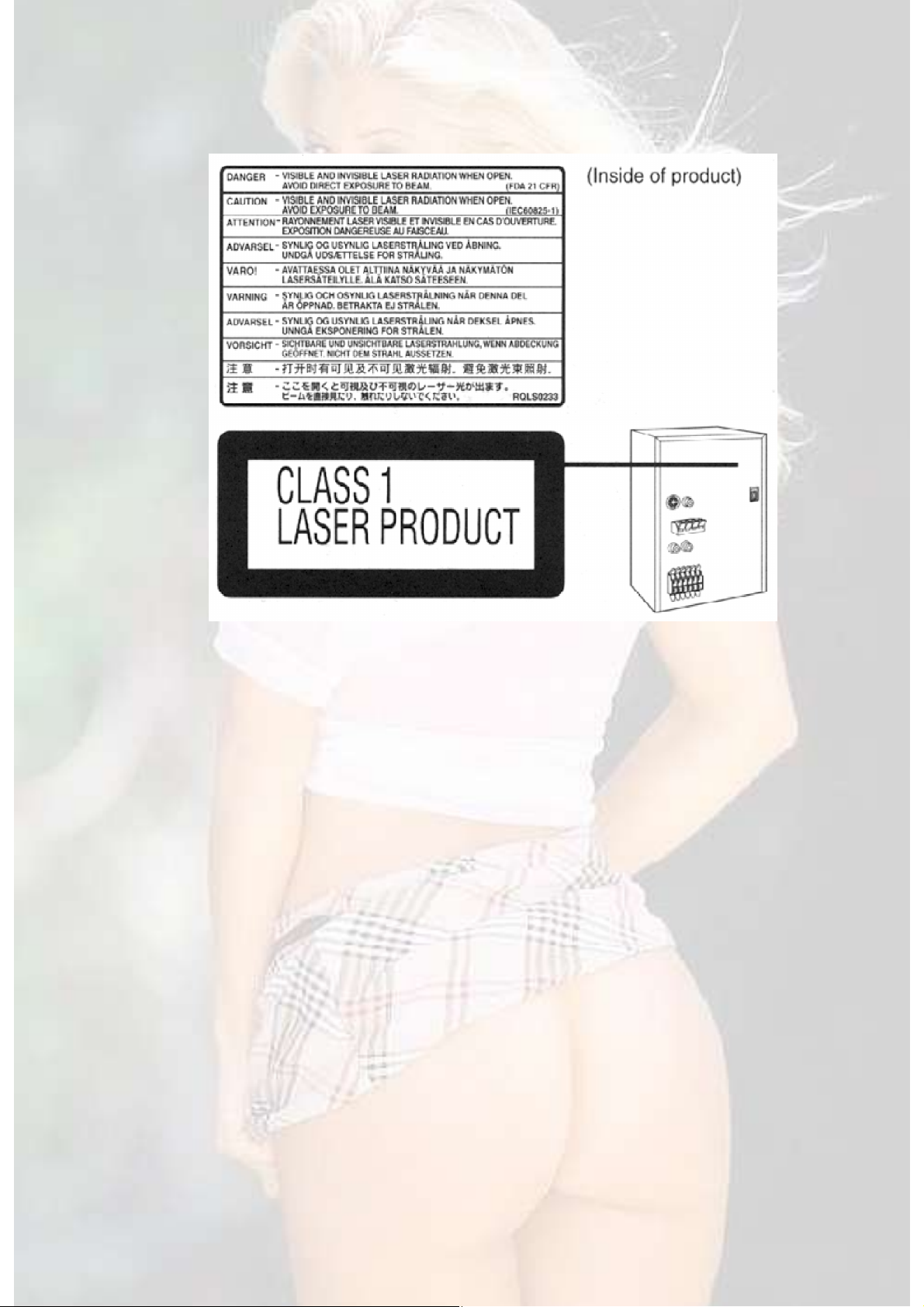

5. Precaution of Laser Diode

8

Caution :

This product utilizes a laser diode with the unit turned "ON", invisible laser

radiation is emitted from the pick up lens.

Wavelength : 780 nm

Maximum output radiation power from pick up : 100 W/VDE

Laser radiation from pick up unit is safety level, but be sure the followings:

1. Do not disassemble the optical pick up unit, since radiation from exposed

laser diode is dangerous.

2. Do not adjust the variable resistor on the pick up unit. It was already adjusted.

3. Do not look at the focus lens using optical instruments.

4. Recommend not to look at pick up lens for a long time.

ACHTUNG :

Dieses Produkt enthält eine Laserdiode. Im eingeschalteten Zustand wird

unsichtbare Laserstrahlung von der Lasereinheit abgestrahlt.

Wellenlänge : 780nm

Maximale Strahlungsleistung der Lasereinheit :100 W/VDE

Die Strahlung an der Lasereinheit ist ungefährlich, wenn folgende Punkte

beachtet werden:

1. Die Lasereinheit nicht zerlegen, da die Strahlung an der freigelegten

Laserdiode gefährlich ist.

2. Den werkseitig justierten Einstellregler der Lasereinhit nicht verstellen.

3. Nicht mit optischen Instrumenten in die Fokussierlinse blicken.

4. Nicht über längere Zeit in die Fokussierlinse blicken.

ADVARSEL :

I dette a apparat anvendes laser.

PRODUCT UTILIZES A LASER.

OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE

HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

Use of Caution Labels

9

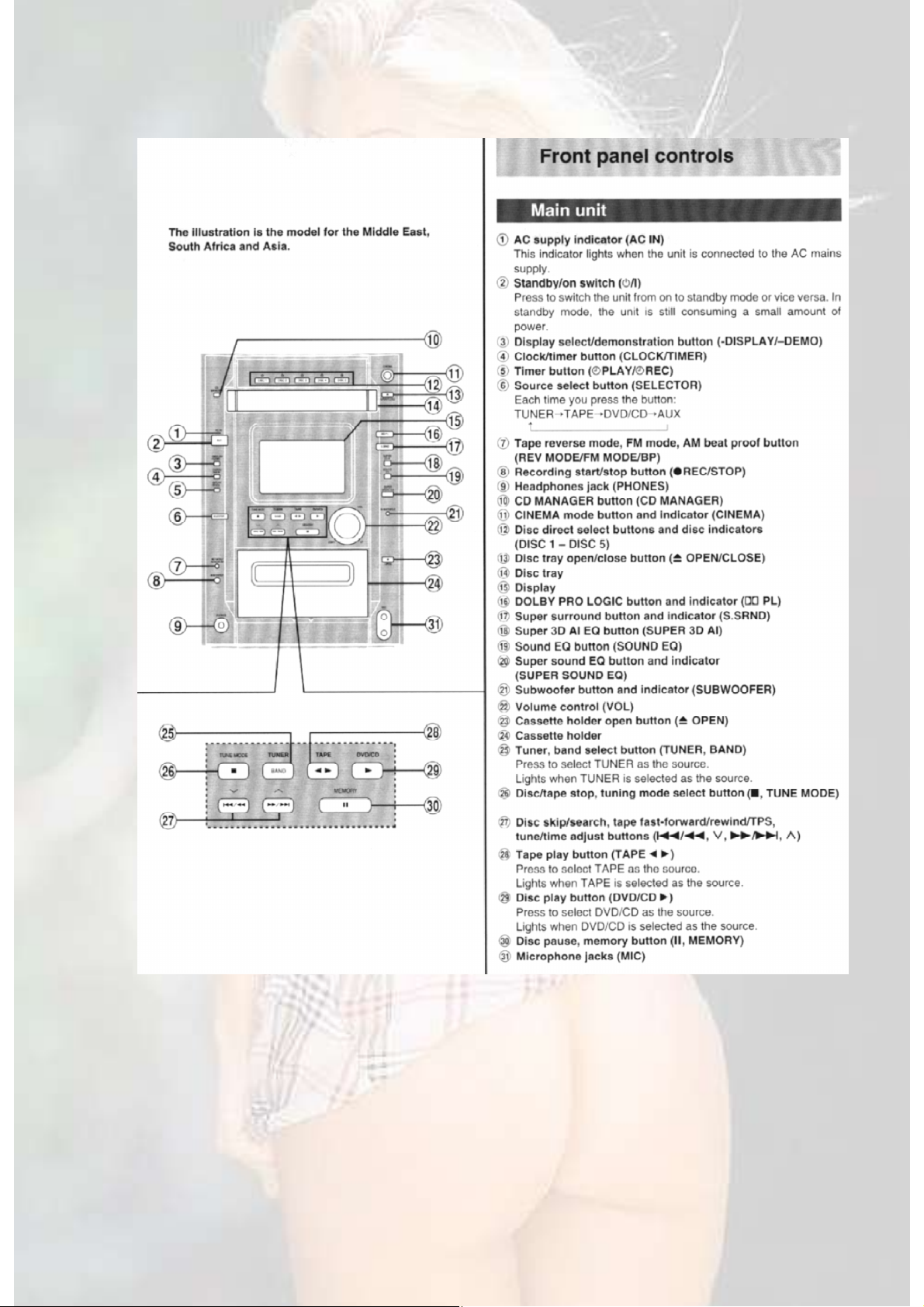

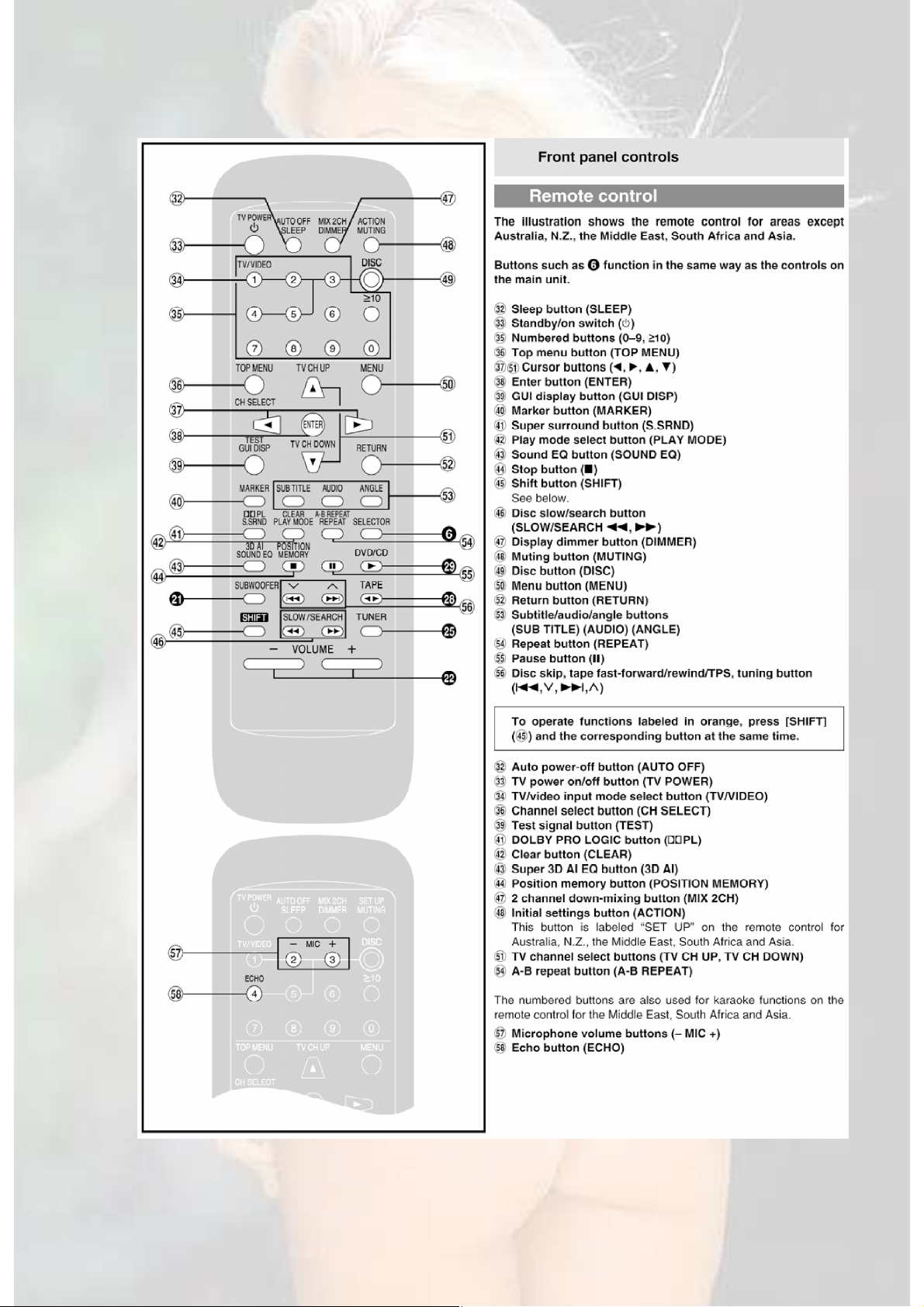

6. Operation Procedures

101112

7. Self-Diagnostic Function

continuous

10]

PAUSE]

commands

input

7.1. Outline

- Self-Diagnosis of error conditions on user equipment according to conditions

set by the head office.

- Occurance of an error condition and results of operations that occured after

entering self-diagnostic mode are displayed via the front (FL) display panel.

7.1.1. Outline of Functions

Complex

Operation

/CD Main unit

[STOP]Main unit

[>>]

/CD Main unit

[STOP]Remote

Control [0]

Main unit

[STOP]Other

Remote Control

button

Main unit

[STOP]Main unit

[>>]

/CD Main unit

[STOP]Main unit

[>>]

Front Panel Display

(Mode-in)

Y_ _ _ _ _ _ _ _ _ _ _ _ _ [OPEN/CLOSE] Changer mechanism operation;

Button check display All buttons Button check, blink all front

T_ _ _ _ _ _ _ _ _ _ _ _ _ _ [PAUSE] Display analog device (AD)

Next Operation Test Content

-Diagnostic code acquisition

[STOP] Single

press

[STOP] Long

press

Remote

Control [5]

None Display DVD module self-

Display self-diagnostic code

Clear recorded content of error

conditions

Changer mechanism

operation test

diagnostic(Display error code)

Remote control [5] [6] [7] [9] [>=

[0].[>=10] [ENTER] [

[DISPLAY] etc.Special

for DVD module

display panel lights

value [ FF FF FF FF FF ]Front

display panel (from left) [AN0]

[AN1] [AN2] [AN3] [AN4]

Cautions:

Self-diagnostics displayed via the [STOP] key display all recorded selfdiagnostic codes.

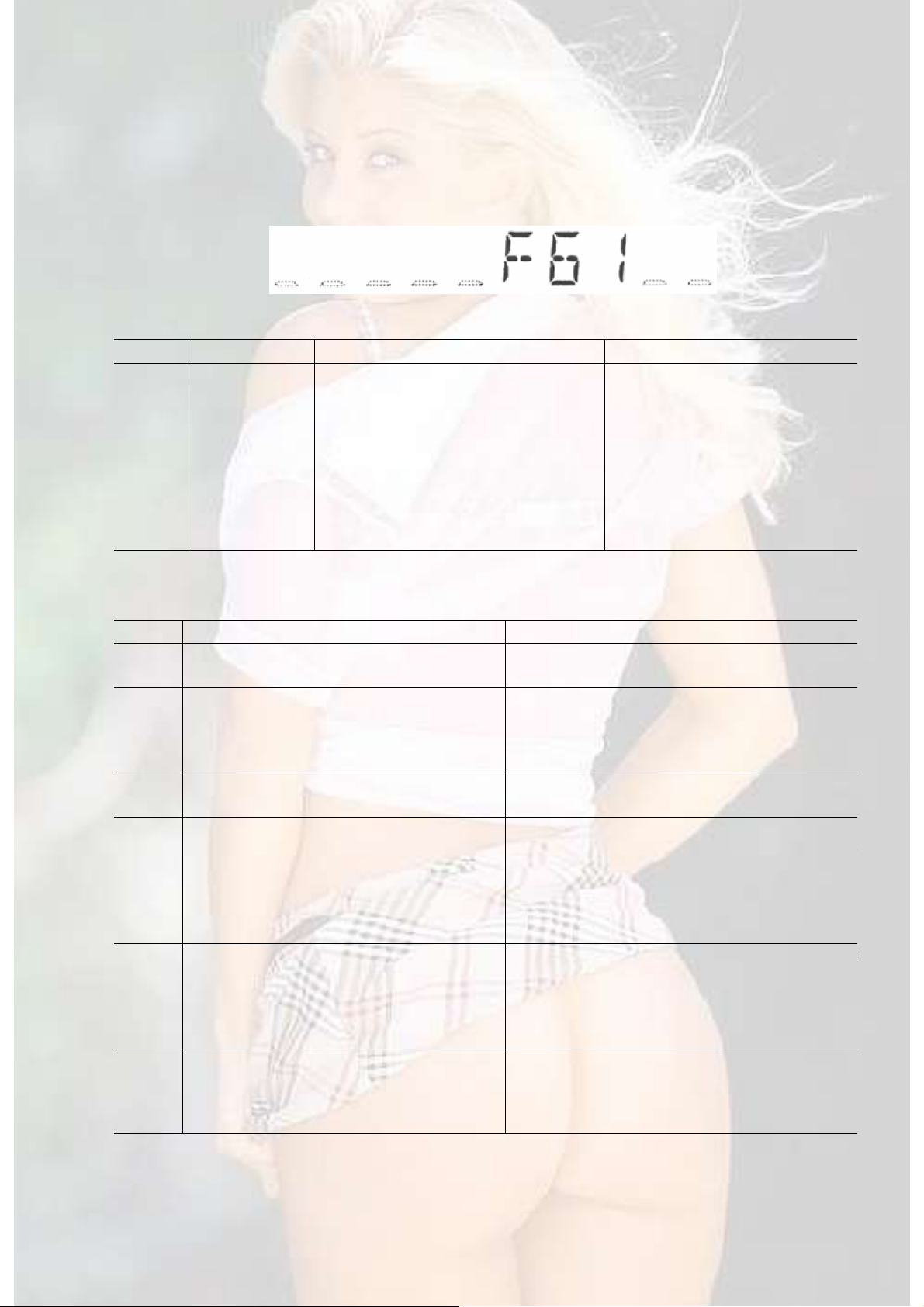

7.2. Self-Diagnostic Mode Settings and Display

13

1. Power-source related

to

F61

there

the

item

content

self

following

to

* Example display

* Self-Diagnostic Codes

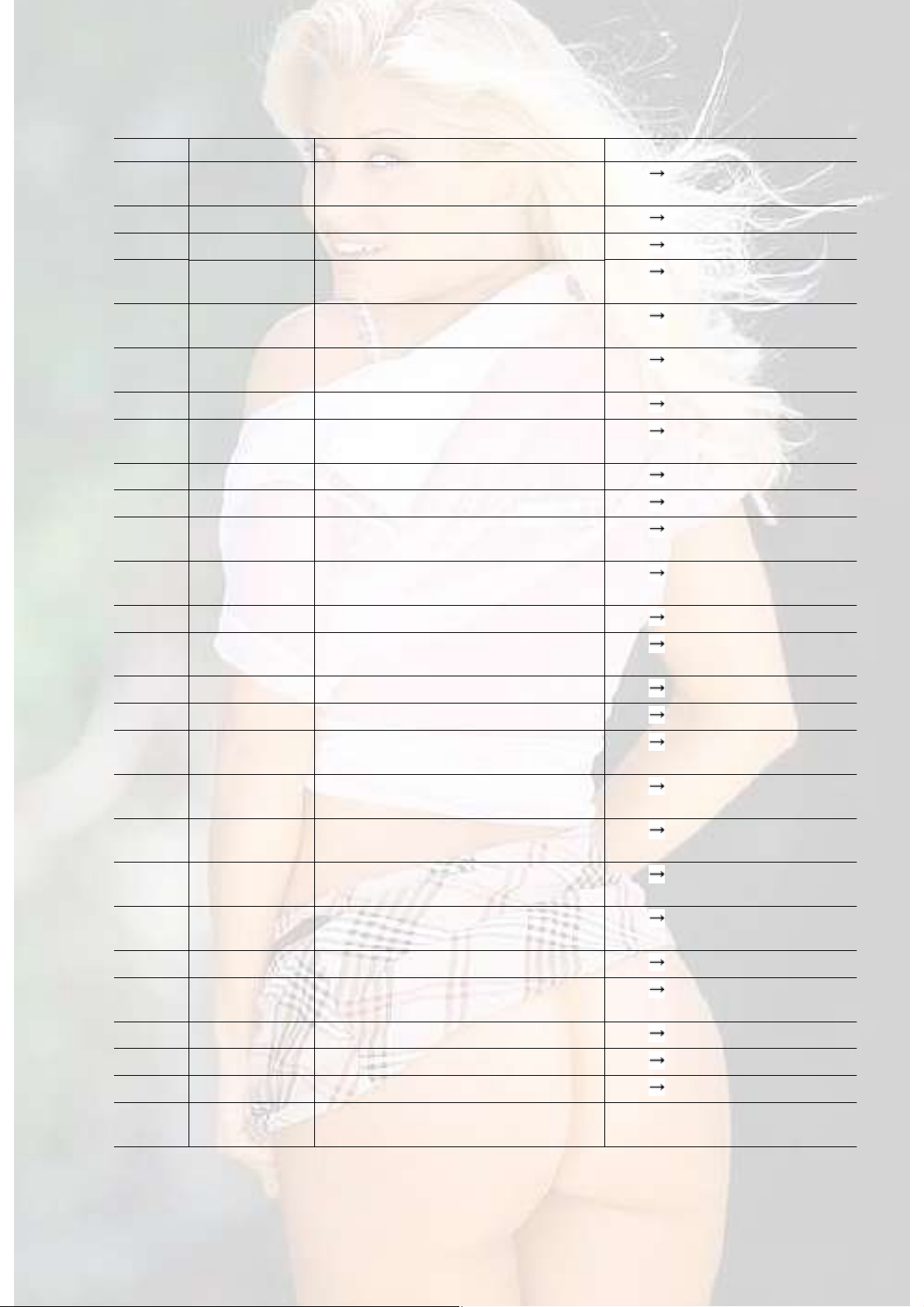

No. Error Display Error Item Detection Method

F61 Power Amp output error or power

supply circuit error

When DCDET is L during normal

operation do not POWER OFF

normally, immediately set PCNT

“GOODBYE” display and display

error.Do not start demonstrations

while error F61 is being

displayed.Record content of error

occurance and display content in

error detection mode.

2. CD/DVD Changer Mechanism (CR20)

Step Operating Procedure Micro-controller operation, processing, etc.

Switch the SELECTOR to CD/DVD, close

tray without disk

Press the [FF] button while holding down

the [STOP] button for two seconds or

Self-diagnostic mode will not be entered if

a disk in the tray.

more. Self-diagnostic mode is entered

when the [STOP] button is released.

[T ] is displayed by the front display (FL)

panel when entering self-diagnostic mode.

Press the [OPEN/CLOSE] button. Operations below wil be continued. While

operations are in progress buttons relating to

micro-controller will be ignored.

1. Change disc 1 and open the tray.

2. Close the tray 1 second after opening.

3. Initialize the mechanism.

4. Insert disc 5 in the play position and quit.

Confirm recorded error content by

pressing the [STOP] button while stopped

in the self-diagnostic mode and displaying

the results of the error check.

Each time the [STOP] button is pressed error

codes are displayed in sequence on the front

display panel Example of a DVD module

display: [_DVD_H05_ _]Example of a normal

diagnostic code display: [T_ _ _H02_ _]

Clear recorded error content by pressing

the [STOP] button for 5 seconds or more

while stopped in the self-diagnostic mode.

Recorded error content is cleared and the

is shown on the front display panel:[CLEAR] is

displayed for one second followed by a return

[T_ _ _ _ _ _ _]

14

Step Operating Procedure Micro-controller operation, processing, etc.

normal

and

Cancel self-diagnostic mode by pressing

the [POWER] button.

Power is turned off. At the next power on

operation will resume.

* If an error occurs while checking the RAM during a micro-controller reset all

recorded error detection content will be cleared while initializing the RAM.

* By skipping step 4 of the above procedure and moving directly to step 6 it is

possible to just display the self-diagnostic codes.

* Example display

* Self-Diagnostic Codes

No. Error Display Error Item Detection Method

H15 OPEN SW error If there is a failsafe for a SW error that occurs

during normal operation it will be recorded

displayed in self-diagnostic mode.

H16 CLOSE SW error SW errors will be detected even in error

detection mode.

H16 UP SW error

H17 DOWN SW error

H27 POSITION SW error

F28 DISC mount error

F29 DISC unmount error

* While stopped in conditions 3 or higher above it is possible to start a CR20

continuous test. Described in detail seperately.

3. Analog Device (AD) input value display

* Pressing the [PAUSE] button on the main unit after having entered selfdiagnostic mode through SELECTOR [DVD/CD] will show the analog device

conversion input value on the front display panel.

* Each time the button is pressed the value will be read again and the display

refreshed.

* Front display Panel:

15

AD Input Usage

AN 0 Key 1 input : Key input 1

AN 1 Key 2 input : Key input 2

AN 2 Key 3 input : Key input 3

AN 3 MK_IN1 : DECK input 1

AN 4 MK_IN2 : DECK input 2

- Exit the Analog Device input value display mode by cutting off the AC

power source and next time could start the device.

4. DVD/CD module

Step Operating Procedure Micro-controller operation, processing, etc.

Set the SELECTOR to CD/DVD

While pressing the [STOP] button on the

main unit press [0] button on the remote

control

See the “DVD/CD/ Changer Control” section of

“Error Display” for a detailed explanation.

* Since error detection for the DVD/CD module occurs in the system

component and is sent through the mechanism component codes are

received and displayed at the operating console.

* Since self-diagnostic codes for the DVD/CD module duplicate prior audio

codes the self-diagnostic codes are displayed prefixed by “DVD”.

* Self-Diagnostic Codes

16

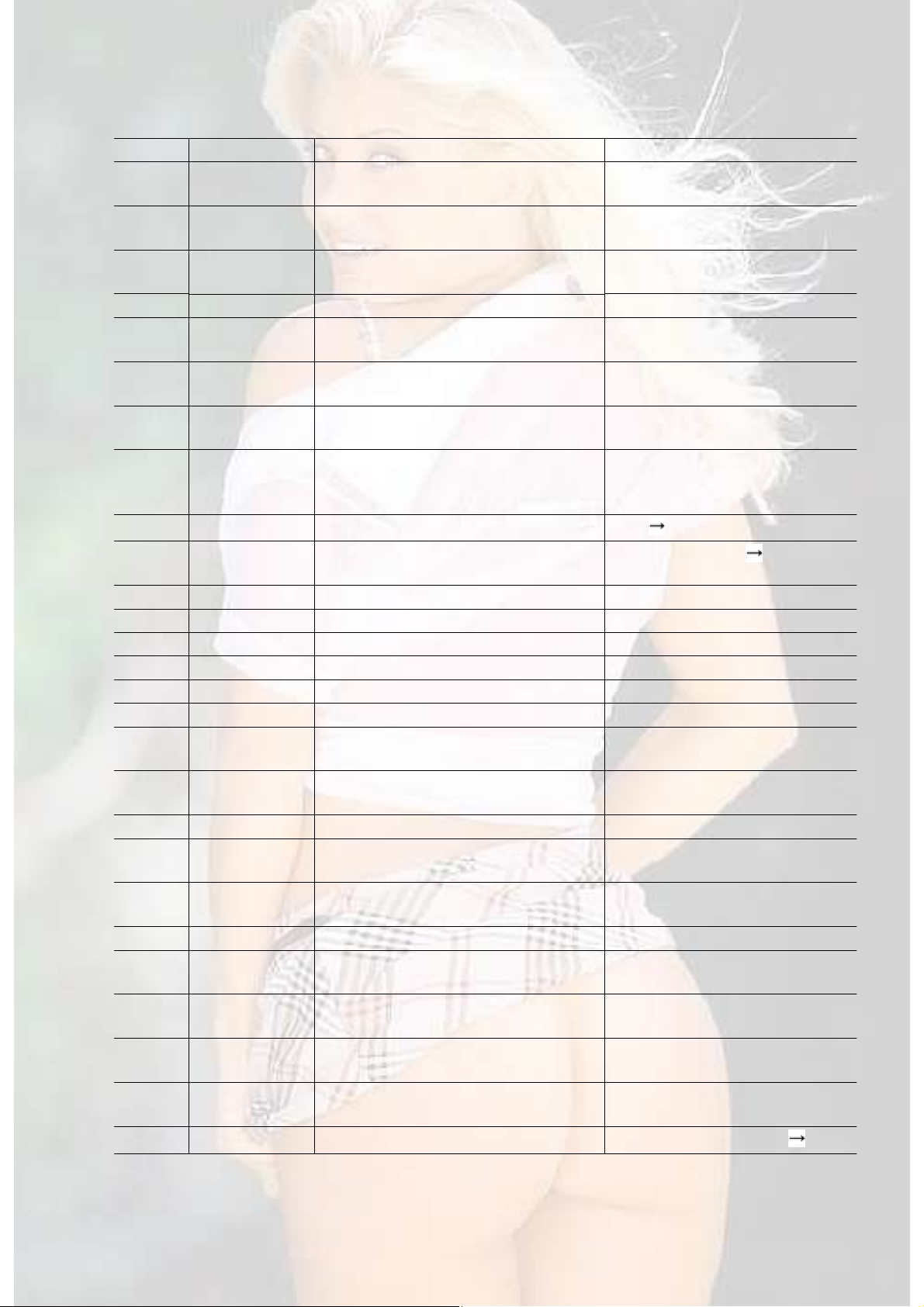

No. Error Display Error Explanation Cause (IC number, etc.)

F010 Specified value is larger than the

Disk IC7001

specified parental value.

F020 No TT_SRPT (RLBN is 0)

F021 TT_SRP number is 0

F022 Specified value is larger than the

Disk IC7001

Disk IC7001

Disk IC7001

TT_SRP number

F023 No matching SRP for VTSN or

Disk IC7001

VTS_TTN

F024 Specified value is larger than

Disk IC7001

TT_SRP.PTT_Ns

F030 TTU_SRP number is 0

F031 Specified value is larger than

Disk IC7001

Disk IC7001

TTU_SRP number

F040 SRP1 number is 0

F041 PGCI_SRP number is 0

F042 Specified value is larger than the

Disk IC7001

Disk IC7001

Disk IC7001

PGCI_SRP number

F043 No matching PGCI_SRP for this Menu

Disk IC7001

ID

F050 TMAP_SRP number is 0

F051 Specified value is larger than the

Disk IC7001

Disk IC7001

TMAP_SRP number

F052 Specified TMAP_SA is 0

F053 MAP_EN number is 0

F060 C_POSIT exists, but there is no

Disk IC7001

Disk IC7001

Disk IC7001

PGMAP in the PGC

F061 C_POSIT exists, but the PG number in

Disk IC7001

the PGC is 0

F062 Specified value is larger than the PG

Disk IC7001

number in the PGC

F063 C_POSIT exists, but there is no

Disk IC7001

C_PBIT in the PGC

F064 C_POSIT exists, but the PG number in

Disk IC7001

the PGC is 0

F065 Specified Cell number is 0

F066 Specified value is larger than the Cell

Disk IC7001

Disk IC7001

number in the PGC

F067 Must be a block array

F070 Is not NV_PCK data

FOB0 No Cell number for current search

Disk IC7001

Disk IC7001

Disk IC7001

F0E0 No user guide PGC control file for

DFD, cannot resolve

17

No. Error Display Error Explanation Cause (IC number, etc.)

IC6201

F0E1 DFD main micro-controller type not

compatible, cannot download

F0E2 DFD download start; PGC playback

error

F0E3 Waiting for DFD download completion;

PGC playback error

F0E4 AVDEC during DFD download

F0E5 Firmware file read error during DFD

download

F0E6 Interpolation check error in read-in

DFD firmware

F0F0 No firmware file for DFD; download

unnecessary

F0F1 No firmware matching the DFD

download parameters; download

unnecessary

F103 Illegal Highlight Position

F4FF No ACK when requesting forced

Disk IC7001

Panel Component IC6001

initialization of panel component

F500 DSC Error IC2001

F501 DSC Not Ready Error IC2001

F502 DSC Time Out Error IC2001

F503 DSC Communication Failure IC2001

F504 Error adjusting DSC data slice offset IC2001

F505 DSC Attention Error IC2001

F506 Can’t determine media type (invalid

IC2001

media type)

F600 Can’t access administrative data due

IC7001

to demodulation error

F601 Undefined sector ID requested IC7001

F602 Can’t access LEAD_IN data due to

IC7001

demodulation error

F603 Can’t access KEY_DET due to

IC7001

demodulation error

F610 Can’t control ODC IC7001

F611 No CRCOK within the set time period

IC7001

(CD related)

F612 No CRCOK within the set time period

IC7001

(DVD related)

F620 Laser safeguard: high temperature

condition

F621 Laser safeguard: circuit failure

condition

F700 MBX Overflow

System component bug

18

No. Error Display Error Explanation Cause (IC number, etc.)

IC6201

IC6201

IC6201

IC6201

IC6201

IC6201

number,etc.)

F701 Message Command Not Complete

Error

F702 Message Command Changed

F880 Task number not relevant

F890 Attempted to send message while

sending to an AV task (mailbox

overflow, etc.)

F891 Couldn’t send message to AV task

(mailbox overflow, etc.)

F8A0 Message command is not relevant

F893 Flash ROM is interpolated IC6302

F894 EEPROM is not normal IC6303

No. Error Display Error Explanation Cause (IC

U11 Focus servo error

H01 Tray loading error

H02

H03 Traverse motor error

H04 Tracking server error

H05 SEEK timeout error

Spindle server error

DSC disc motor error

6626 CLVS FAILURE

System component bug

System component bug

System component bug

System component bug

System component bug

System component bug

7.3. Additional Functions

7.3.1. Tray Lock Function

- There are two tray lock functions

- Power on through the SELECTOR /DVD/CD. While holding down the [CD STOP]

button on the main unit press the [POWER] button on the main unit or the

remote control. Lock Mode A will be entered, [_ _ _ _LOCKED_ _] will be

displayed for 3 seconds, and the current disc will begin playing.

- Lock Mode A will disable the button below while turning the power on or off.

[OPEN/CLOSE]

- When locked in Lock Mode A pressing the [POWER] button on the main unit or

the remote control while holding down the [CD STOP] button on the main unit

will display [_ _UNLOCKED_ _] and unlock the unit.

19

- Power on through the SELECTOR DVD/CD. While holding down the [CD PLAY]

button on the main unit press the [POWER] button on the main unit or the

remote control. Lock Mode B will be entered, [_ _ _LOCKED_ _] will be

displayed for 3 seconds, and the current disc will begin playing.

- In Lock Mode B the button below, mainly selector and disc operation related

items, will be disabled.

Main Unit: [DISC 1] ~ [DISC 5] [OPEN/CLOSE] [DISPLAY/DEMO] [CLOCK/

TIMER] [T.PLAY/REC] [SELECTOR] [STOP] [TUNER/BAND] [TAPE < >] [I<</<<]

[>>/>>I] [PAUSE] [TAPE EJECT] [REV MODE] [REC/STOP]

Remote Control: [SLEEP] [AUTO OFF] [DIMMER] [MIX 2ch] [MUTING] [0] ~ [9] [>

=10] [DISC]

[RETURN] [DISPLAY] [TEST] [CH SELECT] [TUNER/BAND] [TAPE < >]

[SELECTOR] [REPEAT]

[MARKER] [STOP] [PAUSE] [I<<] [>>I] [<<] [>>]

[KARAOKE ON/OFF] [KARAOKE DISP] [KARAOKE MODE] [ONE TOUCH]

[ECHO]

[KEYCON b] [KEYCON #] [MIC -] [MIC +] [SETUP]

While playing it is not necessary to re-disable buttons disabled under Lock

Mode B.

Also, button related to sound quality are not disabled. The buttons below are

not disabled.

Main Unit: [POWER] [CD MANAGER] [AMAZING] [DVD/CD] [CINEMA] [DPL]

[SSS]

Remote Control: [POWER] [SET UP] [PLAY MODE] [CLEAR] [EQ] [3D AI]

[SUPER W] [VOL -] [VOL +]

[DVD/CD >] [MENU] [TOP MENU] [<] [>] [^] [v] [ENTER]

[SUB TITLE] [AUDIO] [ANGLE]

- When locked in Lock Mode B pressing the [POWER] button on the main unit or

the remote control while holding down the [CD PLAY] button on the main unit

will unlock the unit after displaying [_ _UNLOCKED_ _] for 3 seconds.

- Tray lock is canceled when AC power is cut.

- Tray lock A and B functions are exclusive operations. The first one enabled will

have priority.

- When a disabled button is pressed while in lock mode [_ _ _LOCKED_ _] will

be displayed for 3 seconds on the front display panel.

- Lock mode will be cancelled when a loading error occurs with the CR20.

(If the [OPEN/CLOSE] button were disabled when the tray is opened by a TAKE

OUT DISC error recovery would be impossible)

20

7.3.2. Special Commands for the DVD Module

from

the

and

the

and

- When the SELECTOR is set to DVD/CD the commands for the operations

below will be sent to the mechanism component micro-controller.

- The mechanism component micro-controller relays these commands without

alteration to the DVD module.

- THe DVD module sends data resulting from commands to the mechanism

component, where they are then relayed to the operating console.

- Data received from the DVD module by the operating console is displayed by

the right 10 digits.

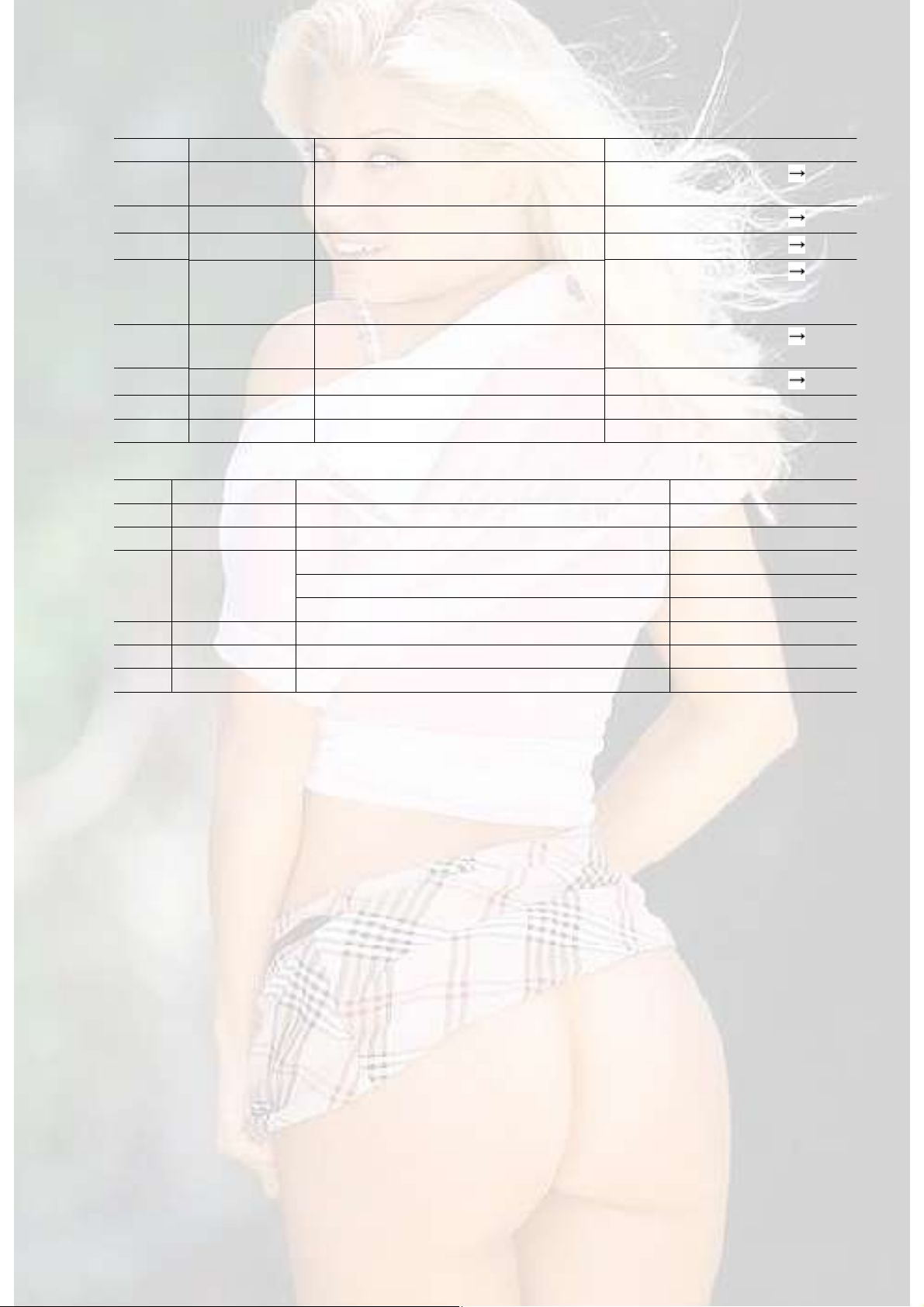

- Command Table

Special

Operation

Display

test

Command Operation/Display Release/Remarks

B5

B6

B7

Main Unit [STOP] + Remote Control [5]

xxx: jitter measurement (DEC)

[xxx_yyy_zz] yyy:read error counter (DEC)

zz: focus drive measurement (HEX)

Test string from DVD MODULE :[J_xxx_yyy_zz]

Main Unit [STOP] + Remote Control [6]

w: region number

[_ _w_xy_zzz] x: N noPAL P PAL

y: N NTSC 6 PAL60

zzz: panel component jumper data

Text string from DVD MODULE: [_ _w_xy_zzz]

Main Unit [STOP] = Remote Control [7]

s: panel component mode type

[srrrxxyzzz] rrr: panel component release

number

[_ _ _xxyzzz] x: generation of system

component (45)

y: system component model type

zzz: system component release number

Text string from DVD MODULE: [srrr_ _xxyzzz]

srrr will be blank with mini-components

Send STOP command

operating console

5 seconds after activation

text string from the DVD

MODULE dissappears

display is automatically

turned off.

5 seconds after activation

text string from the DVD

MODULE dissappears

display is automatically

turned off.

21

Special

the

and

tray

from

the

from

the

from

the

on

the

Operation

Code BA +

Current

laser

value)

Laser C3

RAM

A

RAM

B

pick

users)

Command Operation/Display Release/Remarks

request

record

number

Main Unit [STOP] + Remote Control [0]

[__DVD_Fxxx] xxx: error number

[__DVD_Uxxx]

[__DVD_Hxxx]

5 seconds after activation

text string from the DVD

MODULE dissappears

display is automatically

turned off.

C2

Main Unit [STOP] + Remote Control [PAUSE]

[DO_034_028] 034: DVD current measurement

(mA) (DEC)

028: CD current measurement (mA) (DEC)

Text string from DVD MODULE: [LDO_034_028]

C4

Main Unit [STOP] + Remote Control [DISPLAY]

034: saved in EEPROM

[DD_034_032] initial current mearement (mA)

(DEC)

032: present current measurement (mA) (DEC)

Text string from DVD MODULE: [LDD_034_032]

Main Unit [STOP] + Remote Control [1]

[A_0FA_6901] 0FA: address (HEX)

6901: RAM value of display address (HEX)

Laser lighting remains on

until POWER OFF of the

opens.

STOP command is sent

the operating console to

DVD MODULE

C5

Main Unit [STOP] + Remote Control [2]

[A_0FA_6901] 0FA: address (HEX)

6901: RAM value of display address (HEX)

STOP command is sent

the operating console to

DVD MODULE

C6

Main Unit [STOP] + Remote Control [9]

[FK_109_101] 109: maximum value of

calculated value (DEC)

101 : ratio of maximum value to minimum value

[FK_ER_9101] ER: display error occurance

STOP command is sent

the operating console to

DVD MODULE

9101: ADSC command error code

BC+

Model Table

+ 0 x 00

Main Unit [STOP] + Remote Control [>=10]

[INITIALIZED] display on the operating

console for 2 seconds.

When display clears the user initialization

commands is output the system component.

When the [INITIALIZED]

front panel dissappears

operation is complete.

GUI is INITIALIZE.

Returns user settings to factory values.

22

Special

be

RESET

display

temporarily

be

is

display

the

after

the

Operation

Reset

design

set

industrial

Name B1+

Time B1+

Command Operation/Display Release/Remarks

BC+

Model Table

+ 0 x 3C

While [INITIALIZED] is being displayed from

the user initialization operation press [STOP]

on the main unit and [ENTER] on the remote

control.

[_DVD_RESET] is displayed on the operating

console and the all reset command is output

instead of the user initialization command.

Returns user settings to factory values.

Panel component jumpers are referenced, and

If NO DISC or ---READ can

confirmed after DVD

displayed on the front

panel the operation is

completed.

No GUI. All items

dissappear.

the appropriate model number’s initialization

values are written to the EEPROM and global

region.

Laser times and spindle times are not

initialized.

F1

Receipt of remote control code [B0 00 F1].

Also, Main Unit [STOP] + Remote Control

[1DDF]

[_ALL_SET] (display text string from system

component).

Returns user settings to factory values.

Panel component jumpers are referenced, and

the appropriate model number’s initialization

values are written to the EEPROM and the

global region.

Laser times and spinlde times are also

If NO DISC or ---READ can

confirmed after ALL SET

displayed on the front

panel the operation is

completed.

ALL SET is displayed on

front displaye panel the

operation is completed.

GUI is ALL SET.

initialized.

0 x 13

Main Unit [STOP] + Remote Control [4]

[FEP_??????] [SRV_??????] [ODC_??????]

[Av_??????] [SYS_??????]

Display cycles every 3

seconds. Display

automatically turns off

the last device name is

displayed.

0 x 14

Main Unit [STOP] + Remote Control [^]

1234 : DVD laser use time

[_1234_5678] 5678: CD laser use time

10 hour units displayed in 4 digits

Text string from DVD MODULE: [T1_1234_5678]

5 seconds after activation

text string from the DVD

MODULE dissappear and

display is automatically

turned off.

23

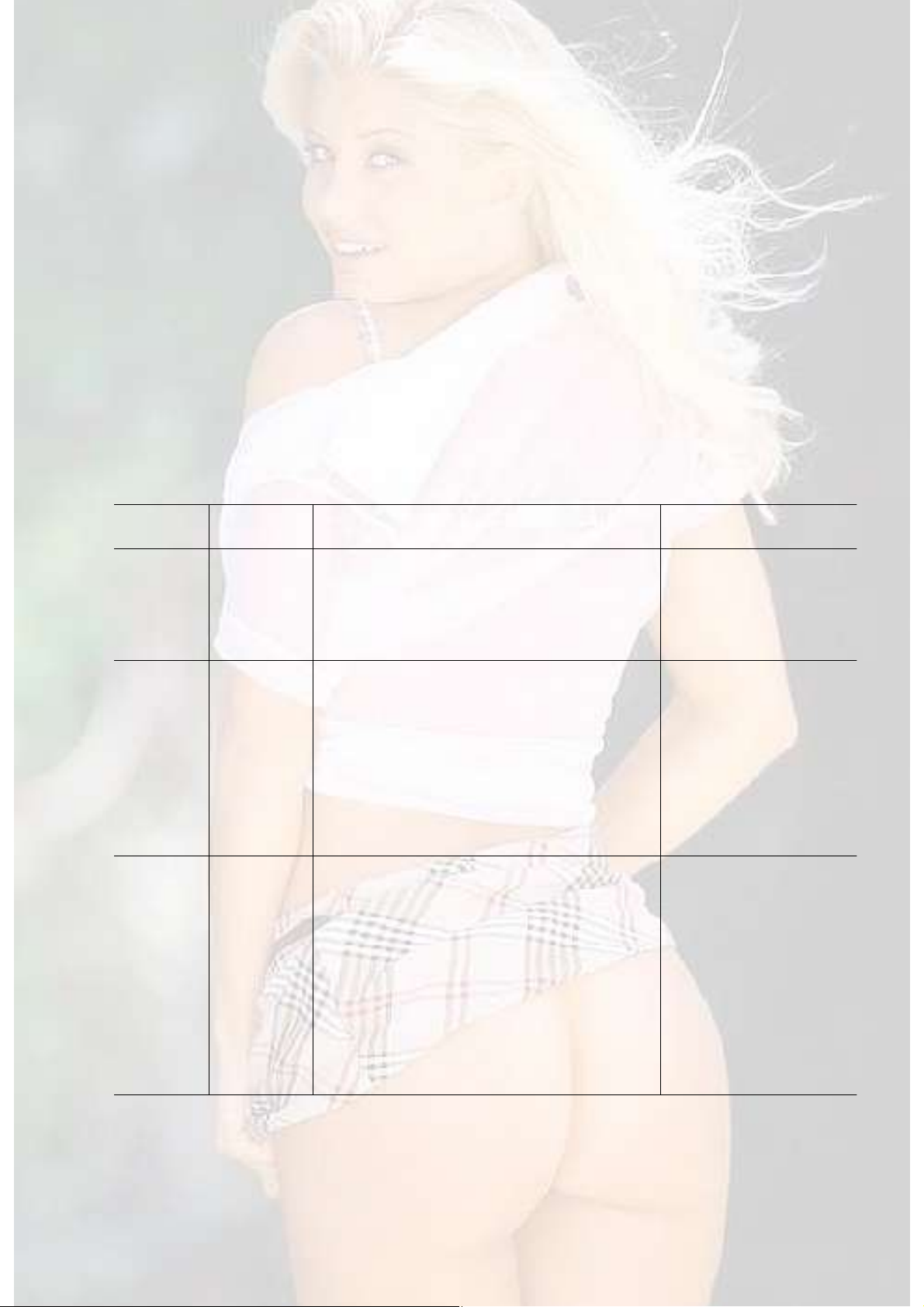

Special

the

the

the

until

opens.

the

Operation

Laser

Use

Use B1 +

Spindle

Time

Laser

and BF +

Command Operation/Display Release/Remarks

B2 +

0 x 14

0 x 15

B2 +

0 x 15

B1 +

0 x 92

0 x 92

While use time is being displayed press

Main Unit [STOP] + Remote Control [V]

[_0000_0000]

DVD and CD are both reset at the same time.

Main Unit [STOP] + Remote Control [>]

[___T2_1234] 1234: 10 hour units displayed in

4 digits

Text string from DVD MODULE: [T2_1234_____]

While use time is being displayed press

Main Unit [STOP] + Remote Control [<]

[___T2_0000]

Main Unit [STOP] + Remote Control [3]

028: initial current value

[DC_028_026] stored in EEPROM (mA)

026: Present current value (mA)

Text string from DVD MODULE: [LDG_028_026]

Main Unit [STOP] + Remote Control [8]

r: region number

[__r__xyzzz] x: generation of system

component

y: system component model type

zzz: system component model type

Text string from DVD MODULE: [____r__xyzzz]

5 seconds after activation

text string from the DVD

MODULE dissappear and

display is automatically

turned off.

5 seconds after activation

text string from the DVD

MODULE dissappear and

display is automatically

turned off.

5 seconds after activation

text string from the DVD

MODULE dissappear and

display is automatically

turned off.

Laser lighting continues

POWER OFF or the tray

5 seconds after activation

text string from the DVD

MODULE dissappear and

display is automatically

turned off.

7.3.3. Jitter Offset Correction

- The jitter offset correction function below is necessary for D5, but is not

necessary for D8.

- While displaying K objects,certain remote control operations correct the offset

of the DVD MODULE jitter value.

- When the DVD module firmware rewriting connector is inserted K objects will

24

be displayed [KC 00 0000].

- Key codes of input from the remote control’s ten key while displaying K

objects are relayed to the system component by the operating console.

- Inputting [2] [0] from the remote control returns a 14 hex value from the

system component. The value is converted from hex dec and displayed as

[KC 20 0000].

- Continuously pressing the [PLAY] button returns the offset result as a text

string from the system component, which is displayed as [KC 20 0002].

- The DVD Module has functions that support buttons other than [2] [0] [PLAY],

so when K objects are being displayed key codes are as below.

[0] [1] [2] [3] [4] [5] [6] [7] [8] [9] [>=10] [PLAY]

7.4. Pseudo ROM Correction

7.4.1. Outline

- Since the Mitsubishi M3819 series micro-controller is capable of making

programs operate in RAM the pseudo ROM corrections below are possible.

- Program the process calling the modifying sub-routine in advance.

- Program the process to read-out the program from the EEPROM into RAM in

advance.

- Processes previous to the read-out cannot be modified.

- In pseudo ROM corrections defective processses cannot be completely

bypassed.

7.4.2. EERPOM Flag Indicator Interpretation

- Regardless of the EEPROM flag indicator CS/CLK/DATA is output and the

DATA read-in process occurs.

Accordingly, even if there is no EEPROM hardware processing at the terminal

is necessary.

- If the data read-out below is valid then an EEPROM will be determined to be

present, and the modifying program will be read-out.

- When the MASK ROM file name (8 character ASCII code, 8 bytes) and the

EEPROM file name match.

25

- When the modifying points flag indicator data (8 points, 1 byte) written at two

places on the EEPROM match.

7.4.3. CHECK SUM Display

- In order to confirm that the EEPROM is loaded, the operations below display

the CHECK SUMs for the Operating Console, mechanism component, and DSP

micro-controller EEPROMs.

- Receiving [1DDF or 1CDF] when in Process Check Mode with Process Check

Mode-in [1DDF or 1 CDF] will display the operating console’s version and

EEPROM CHECK SUM.

- If [1DDF or 1CDF] are received while the operating console’s version and

EEPROM CHECK SUM are being displayed the mechanism component’s

version and EEPROM CHECK SUM are displayed.

- If [1DDF or 1CDF] are received while the mechanism component’s version and

EEPROM CHECK SUM are being displayed the DSP micro-controller’s version

and EEPROM CHECK SUM are displayed.

- If a valid remote control code is received while the CHECK SUM is being

displayed the CHECK SUM display will be erased to confirm with that

operation and display.

26

- When the result of referencing the EEPROM is a differing file name [NO] will be

displayed, just as when no EEPROM is present.

7.4.4. Insertion Points for ROM Correction Processing

- Processing read-outs from EEPROM

- RCaccE2PrSUB: Insert after port or control register setting (AC check).

It is also necessary for the EEPROM’s power supply to be in power-off (AC

positive).

- Processing Modifying Program Calls

- RCtimerinsSUB: Insert at the end of the timer interrupt.

- RCschedulerSUB: Insert in the OS scheduler.

- RCinitialSUB: Insert after initialization, immediately before jumping to the main

process.

- RCstandbySUB: Insert immediately before the power failure process STP

command.

- RCimagetskSUB: Insert immediately before branching to individual image

processing.

- RCdisptskSUB: Insert immediately before processing the data settings for the

display RAM.

- Rcreserve0SUB: Insert in the transmission process to the CD mechanism

component.

- Rcreserve1SUB: Insert in the transmission process to the DSP control micro-

controller.

- Data inside the EPROM (Required RAM capacity)

- EEPROM flag indicator determination data: 10 bytes

- Modifying Program’s starting address: 16 bytes

- Modifying Program: remaining bytes

8. Disassembly and Main Component Replacement

Procedures

27

“ATTENTION SERVICER”

Some chassis components may have sharp edges.

Be careful when disassembling and servicing.

1. This section describes procedures for checking the operation of the major

printed circuit boards and replacing the main components.

2. For reassembly after operation checks or replacement, reverse the respective

procedures.

Special reassembly procedures are described only when required.

3. Select items from the following index when checks or replacement are

required.

Warning:

This product uses a laser diode. Refer to caution statement Precaution of Laser

Diode.

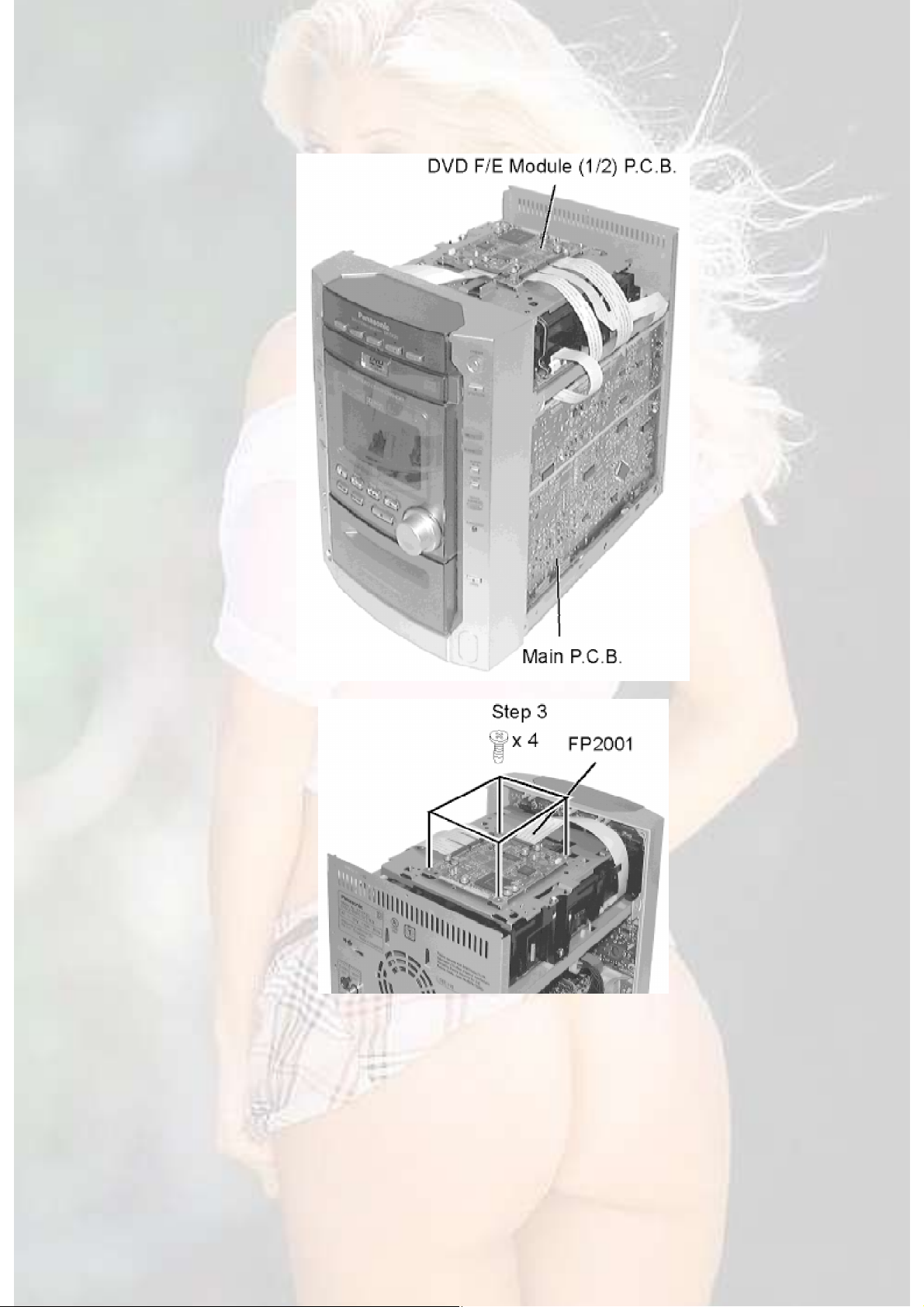

8.1. Checking for the Main and DVD F/E Module (1/2) and (2/

2) P.C.B.

28

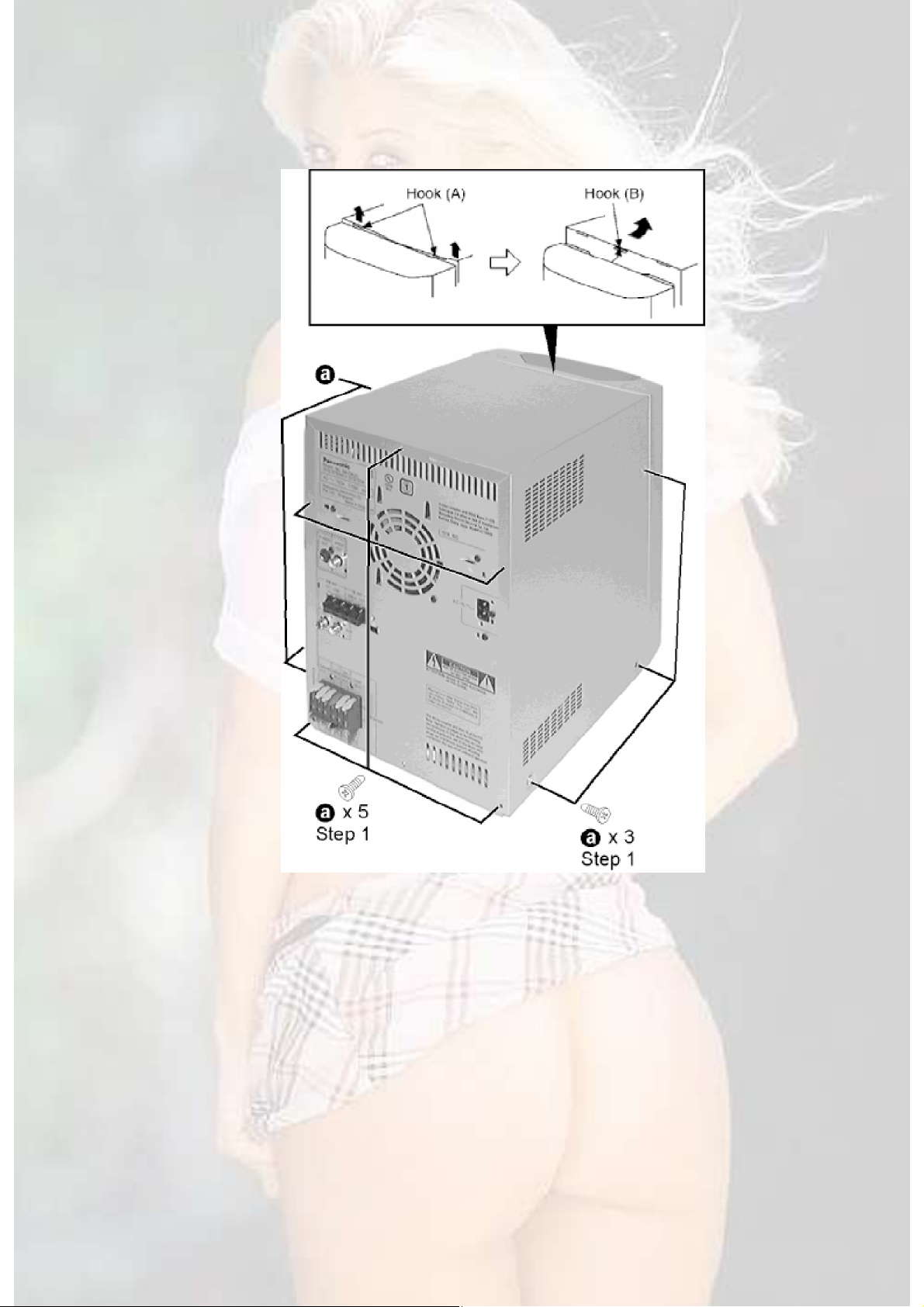

Step 1 Remove 3 screws each both side and 5 screws at rear panel.

Step 2 Lift up the both sides cabinet ass’y to release the hook (A). Then pull the

cabinet ass’y toward the rear and release the hook (B) to remove the cabinet

ass’y.

NOTE: When installing the cabinet ass’y, take care not to damage the front

cabinet ass’y from hook (B).

- Check the Main P.C.B. and DVD F/E Module (1/2) P.C.B..

29

Step 3 Remove 4 screws.

Step 4 Remove 4 connectors.

Step 5 Pull out 4 FFCs.

30

Loading...

Loading...