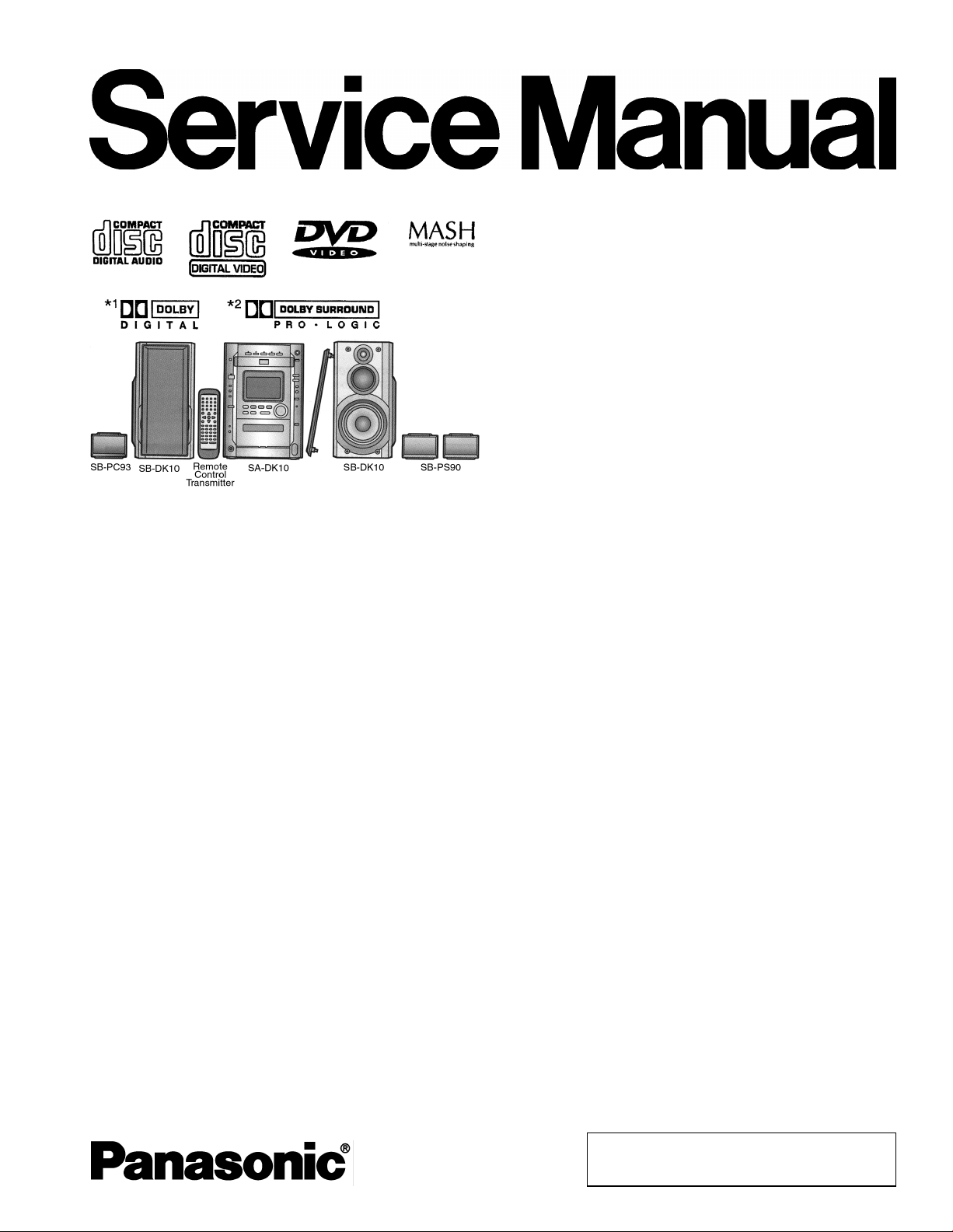

Panasonic SADK-10 Service manual

ORDER NO. MD010508 7C1

DVD Stereo System

SA-DK10

Colour

(S)... Silver Type

Area

(P)... U.S.A.

(PC)... Canada

TAPE SECTION :

AR2 MECHANISM SERIES

CD SECTION :

RAE0152Z-3 TRAVERSE DECK SERIES

A6

Specifications

■ AMPLIFIER SECTION

Stereo mode power output

THD 10% Total harmonic distortion

LF 75 Hz 65 W per channel (8 Ω)

HF 1 kHz 30 W per channel (6 Ω)

Total stereo mode power

LF 55Hz - 100 Hz 65 W per channel (8 Ω)

HF 100Hz - 15 kHz 28 W per channel (6 Ω)

Power output in Home Theater mode

THD 10%, both channels driven

Front

LF 75 Hz 65 W per channel (8 Ω)

HF 1 kHz 30 W per channel (6 Ω)

Center 1 kHz 40 W (8 Ω)

Surround 1 kHz 35 W per channel (8 Ω)

Total power output 300 W

Input sensitivity

AUX 250 mV

Input Impedance

AUX 10 kΩ

■ FM TUNER SECTION

Frequency range 87.9 - 107.9 MHz (200 kHz steps)

87.5 - 108.0 MHz (100 kHz steps)

Sensitivity 1.8 µV (IHF)

S/N 26 dB 1.5 µV

Antenna terminal(s) 75 Ω (unbalanced)

■ AM TUNER SECTION

Frequency range 520 - 1710 kHz (10 kHz steps)

Sensitivity

S/N 20 dB (at 1000 kHz) 500 µV/m

■ CASSETTE DECK SECTION

Track system 4 track, 2 channel

Heads

Record/playback Solid permalloy head

Erasure Double gap ferrite head

Motor DC servo motor

Recording system AC bias 100 kHz

Erasing system AC erase 100 kHz

Tape speed 4.8 cm/s (1 7/8 ips)

Frequency response (+3 dB, -6 dB at DECK OUT)

NORMAL (TYPE I) 35 Hz - 14 kHz

HIGH (TYPE II) 35 Hz - 14 kHz

S/N 50 dB (A weighted)

Wow and flutter 0.18 % (WRMS)

Fast forward and rewind time Approx. 120 seconds with

C-60 cassette tape

■ Disc SECTION

Disc

DVD-Video

© 2001 Matsushita Electronics (S) Pte. Ltd. All rights

reserved. Unauthorized copying and distribution is a

violation of law.

SA-DK10

8 cm/12 cm single sided, single layer

8 cm/12 cm single sided, double layer

8 cm/12 cm double sided, double layer

(One layer per side)

Video CD/CD 8 cm/12 cm

Video

Signal system NTSC

Output level

Composite video 1Vp-p(75Ω)

S-Video Y 1Vp-p(75Ω)

S-Video C 0.286 Vp-p (75 Ω/NTSC)

Audio

Sampling frequency

CD 44.1 kHz

DVD 48kHz/96 kHz

Decoding 16/20/24 bit linear

Wow and flutter Below measurable limit

D/A converter Delta-sigma DAC)

Pick up

Beam source Semiconductor Laser

Wavelength

DVD 658 nm

VCD/CD 790 nm

■ GENERAL

Power supply AC 120 V, 60Hz

Power consumption 161 W

Power consumption in standby mode

161 W

Dimensions (W x H x D) 215.4 X 315 X 350 mm

8 1/2” x 12 13/32” x 13 25/32”

Mass (7.8 kg) 17.2 lb

■ SYSTEM

SC-DK10(P) Music Center: SA-DK10(P)

Front Speaker: SB-DK10(P)

Surround Speaker: SB-PS90(P)

Center Speaker: SB-PC93(P)

SC-DK10(PC) Music Center: SA-DK10(PC)

Front Speaker: SB-DK10(P)

Surround Speaker: SB-PS90(P)

Center Speaker: SB-PC93(P)

Notes:

1. Specifications are subject to change without notice. Mass and

dimensions are aproximate.

2. Total harmonic distortion is measured by the digital spectrum

analyzer.

CONTENTS

Page Page

1 Safety Precaution

2 Before Repair and Adjustment

3 Protection Circuitry

4 Accessories

5 Handling Precautions For Traverse Deck

6 Precaution of Laser Diode

7 Operation Procedures

8 Disassembly and Main Component Replacement Procedures

3

9 Measurements and Adjustments

3

10 Illustration of ICs, Transistors and Diodes

11 Terminal Function of IC’s

3

4

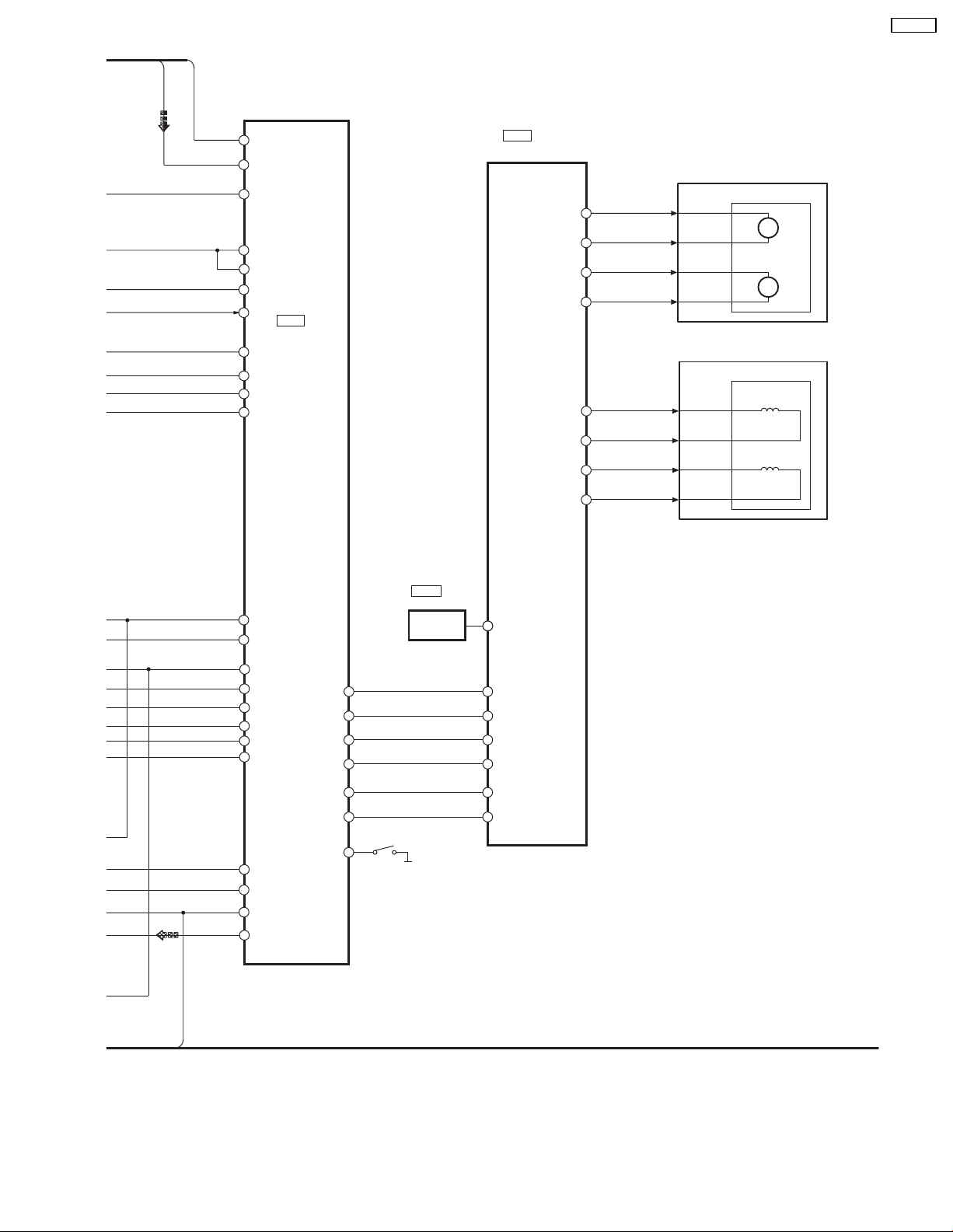

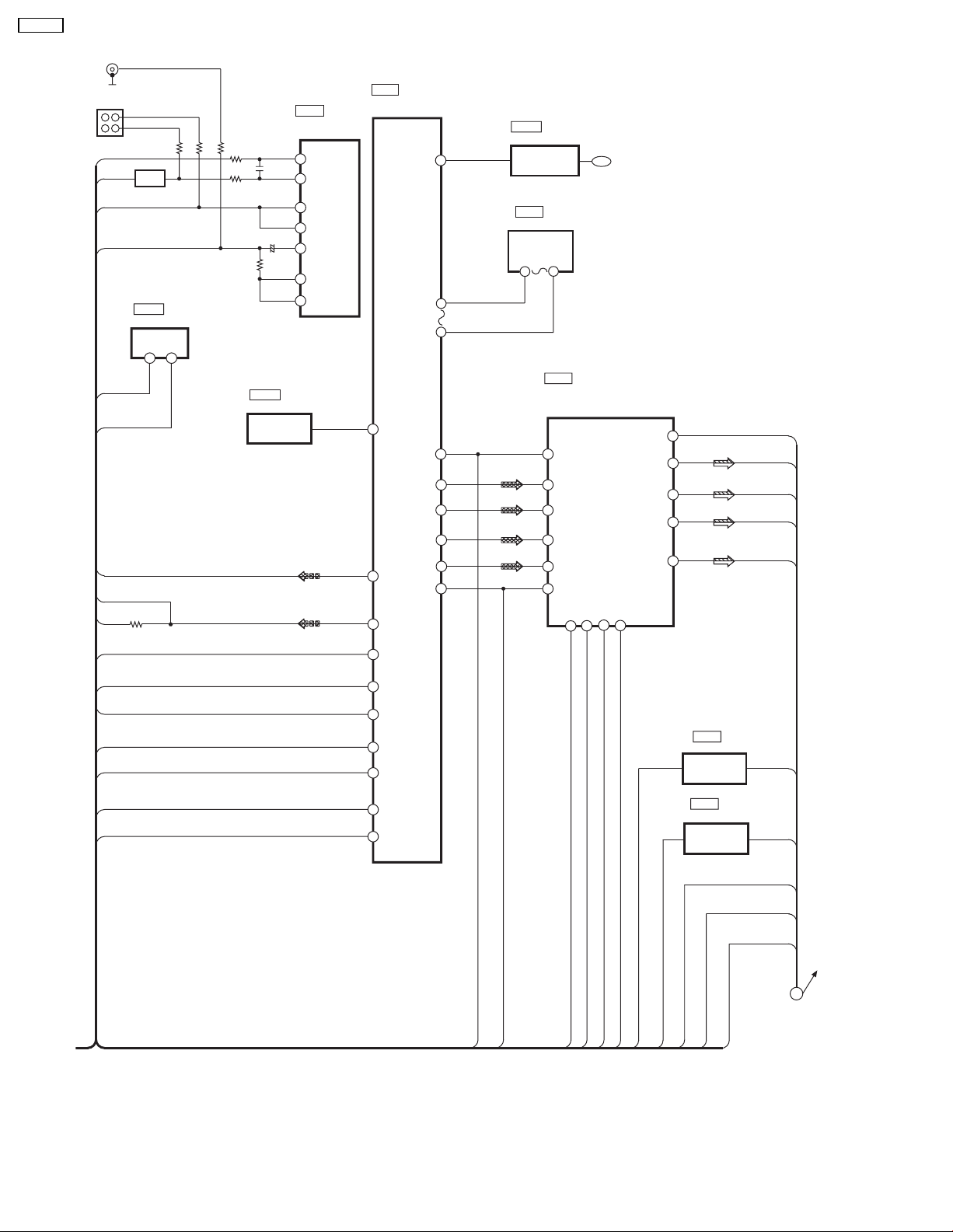

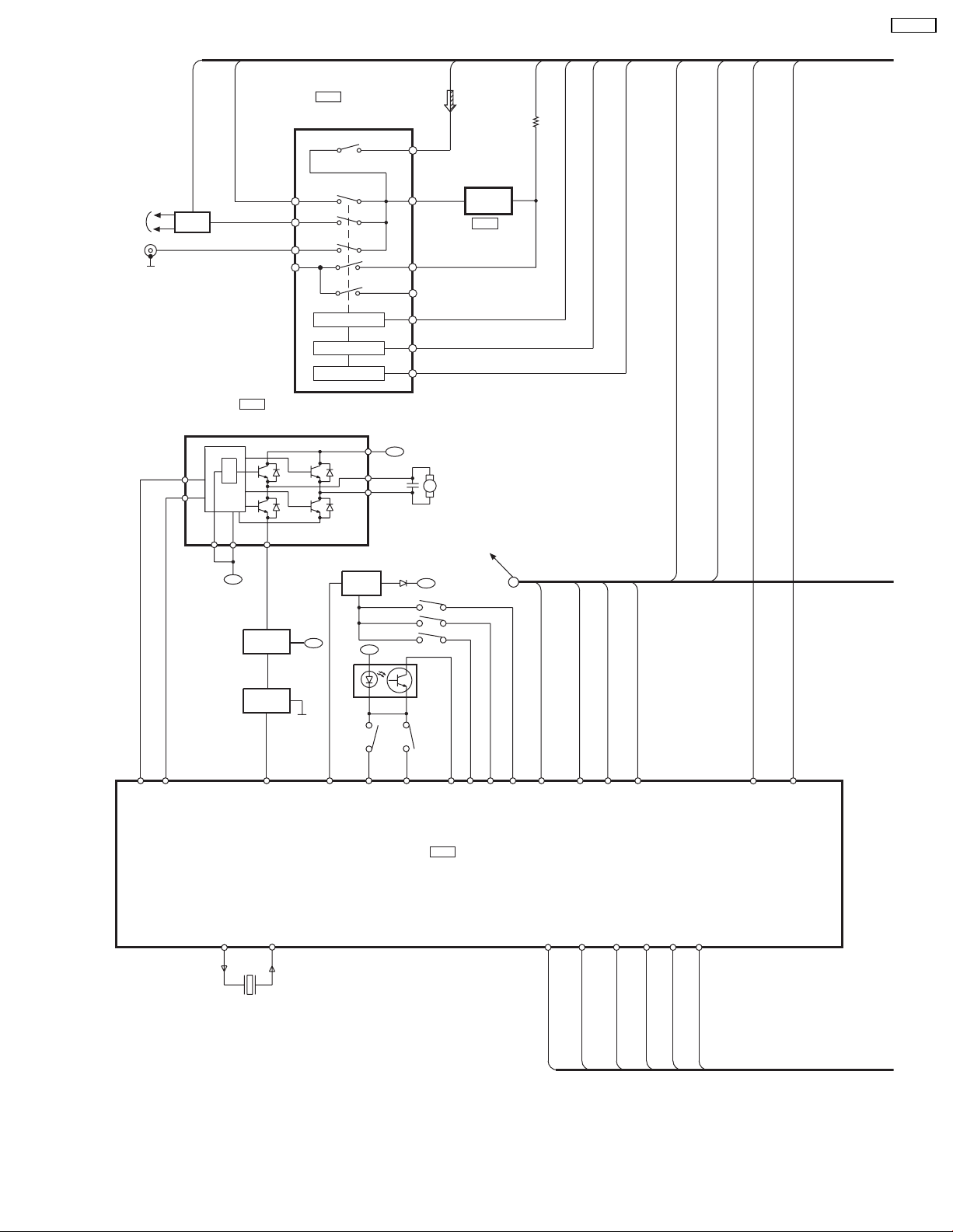

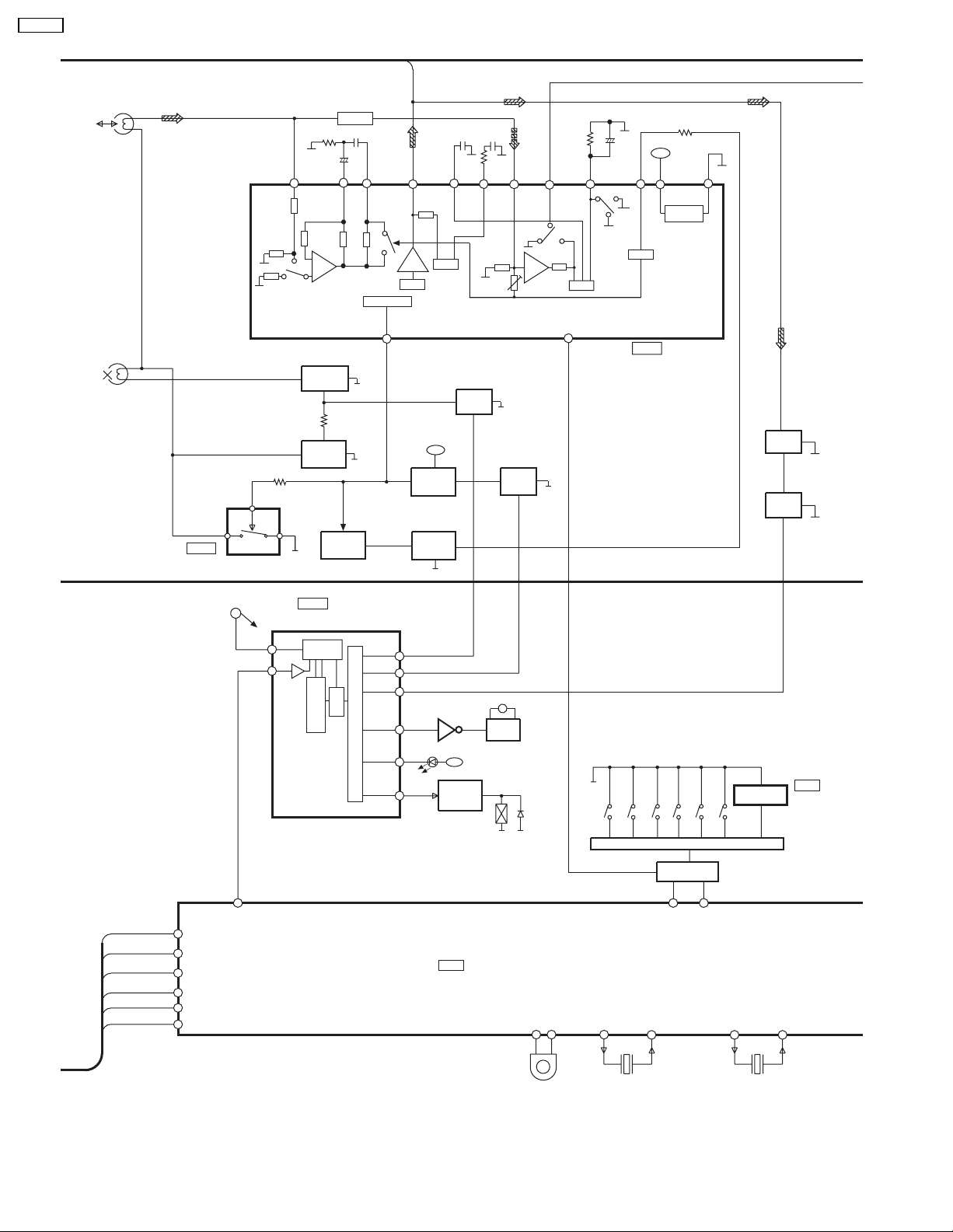

12 Block Diagram

5

13 Schematic Diagram

14 Printed Circuit Board

6

7

15 Wiring Connection Diagram

16 Parts Location and Replacement Parts List

9

22

24

25

26

35

68

81

83

2

1 Safety Precaution

(This “Safety Precaution” is applied only in U.S.A.)

1. Before servicing, unplug the power cord to prevent an electric shock.

2. When replacing parts, use only manufacturer’s recommended components for safety.

3. Check the condition of the power cord. Replace if wear or damage is evident.

4. After servicing, be sure to restore the lead dress, insulation barriers, insulation papers, shields, etc.

5. Before returning the serviced equipment to the customer, be sure to make the following insulation resistance test to

prevent the customer from being exposed to a shock hazard.

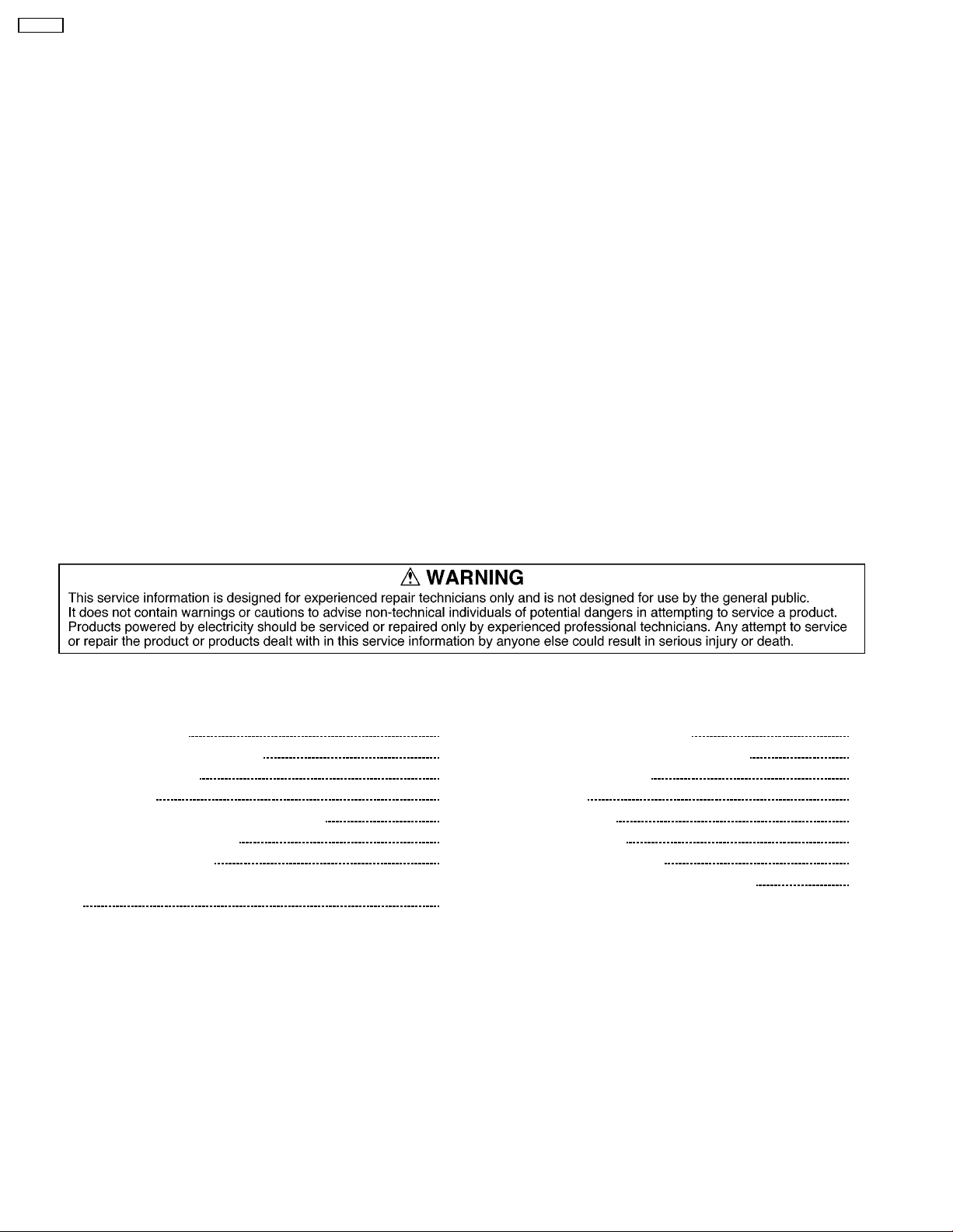

1.1. Insulation Resistance Test

1. Unplug the power cord and short the two prongs of the plug with a jumper wire.

2. Turn on the power switch.

3. Measure the resistance value with ohmmeter between the jumper AC plug and each exposed metal cabinet part, such as

screwheads, antenna, control shafts, handle brackets, etc.

Equipment with antenna terminals should read between 3 MΩ and 5.2 MΩ to all exposed parts*.(Fig.1)

Equipment without antenna terminals should read approximately infinity to all exposed parts.(Fig.2)

*Note: Some exposed parts may be isolated from the chassis by design. These will read infinity.

4. If the measurement is outside the specified limits, there is a possibility of a shock hazard. The equipment should be repaired

and rechecked before it is returned to the customer.

SA-DK10

2 Before Repair and Adjustment

Disconnect AC power, discharge Power Supply Capacitors C566~C569, C782 and C591 through a 10Ω, 5W resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

Current consumption at AC 120V, 60 Hz in NO SIGNAL mode should be ~650mA.

3 Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

• No sound is heard when the power is turned on.

• Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

“shorted”, or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note :

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

3

SA-DK10

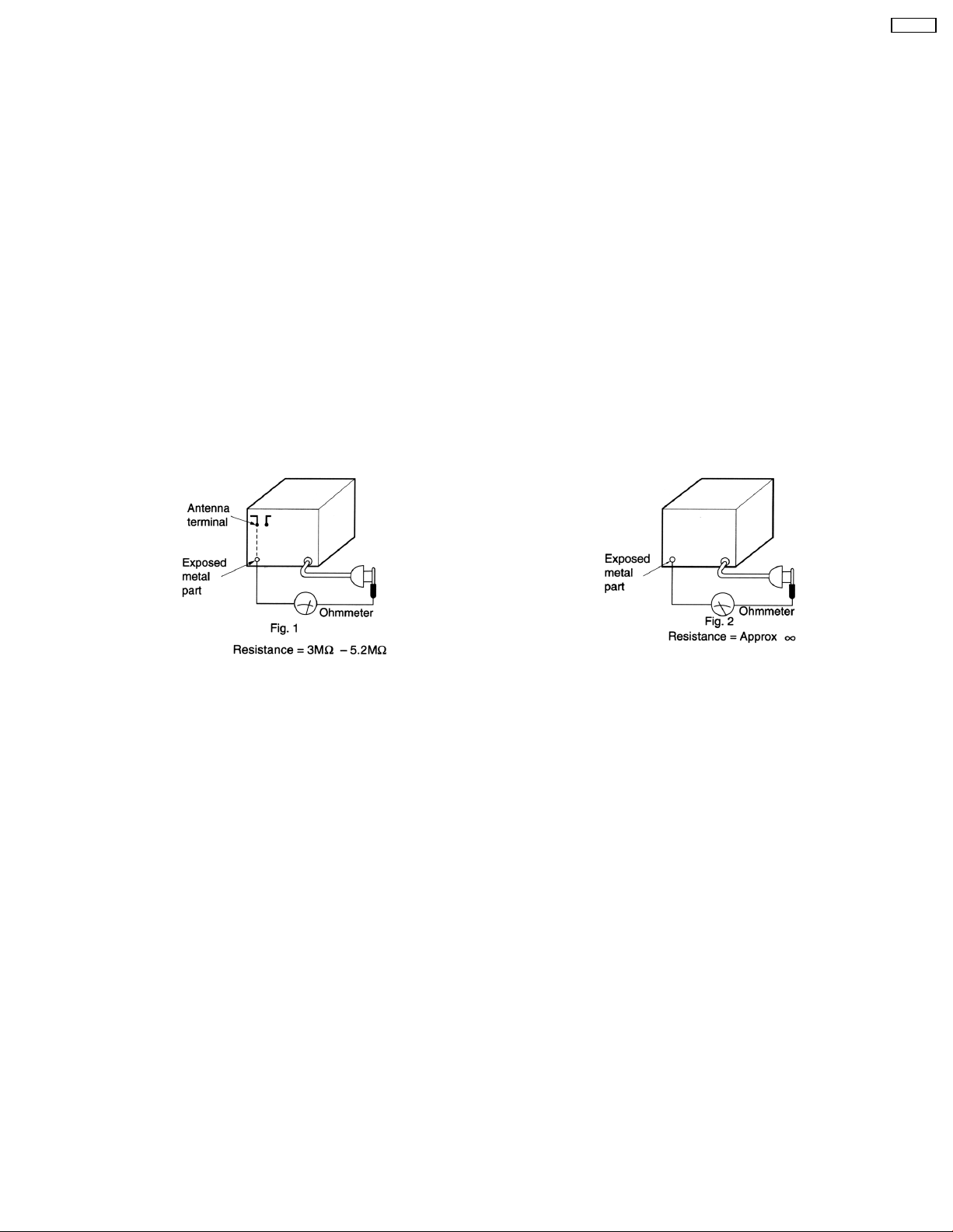

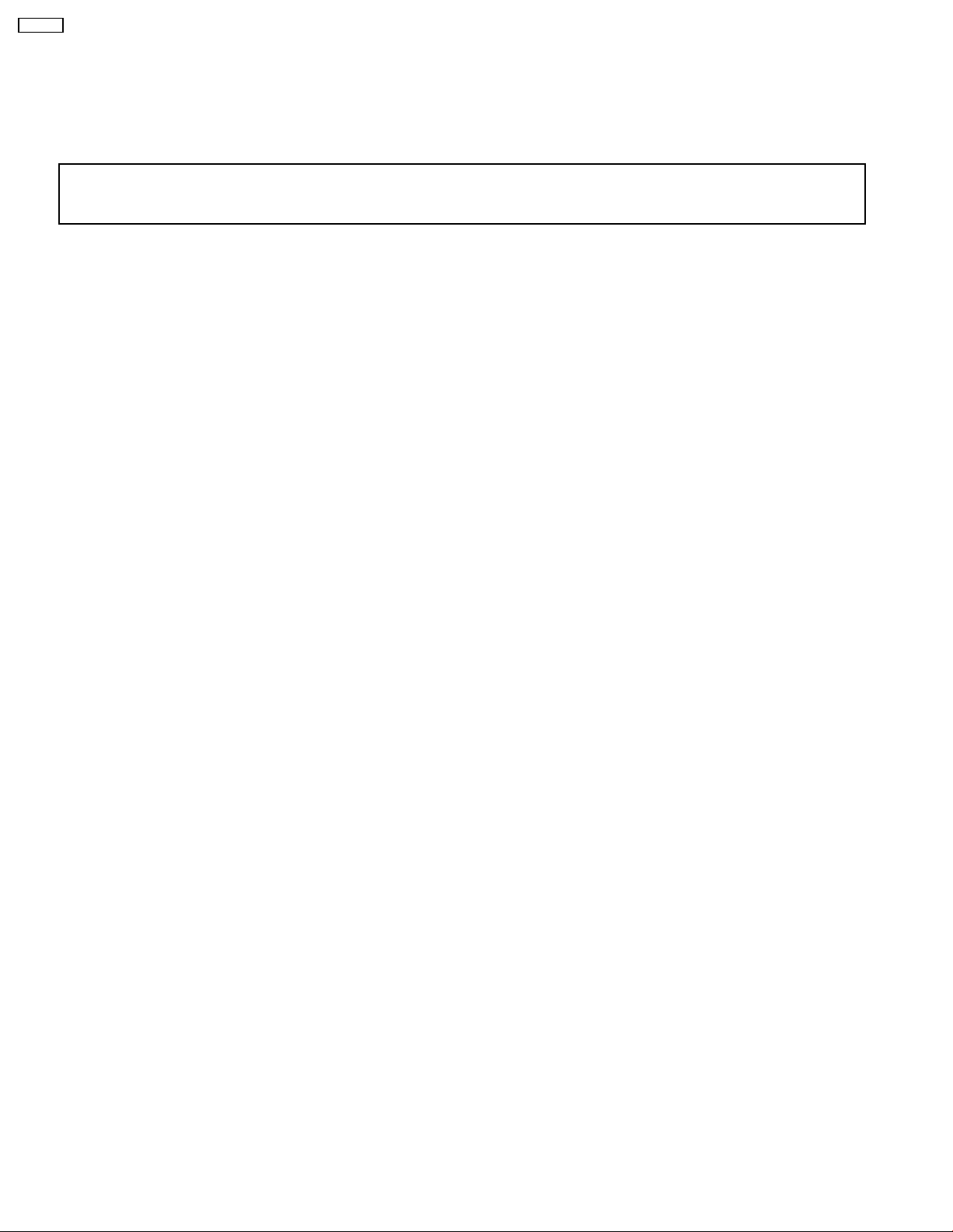

4 Accessories

Remote Control

Transmitter

FM indoor antenna

AC mains lead

AM Loop antenna

Video cable

4

5 Handling Precautions For Traverse Deck

SA-DK10

The laser diode in the traverse deck (optical pickup) may break

down due to potential difference caused by static electricity of

clothes or human body.

So, be careful of electrostatic breakdown during repair of the

traverse deck (optical pickup).

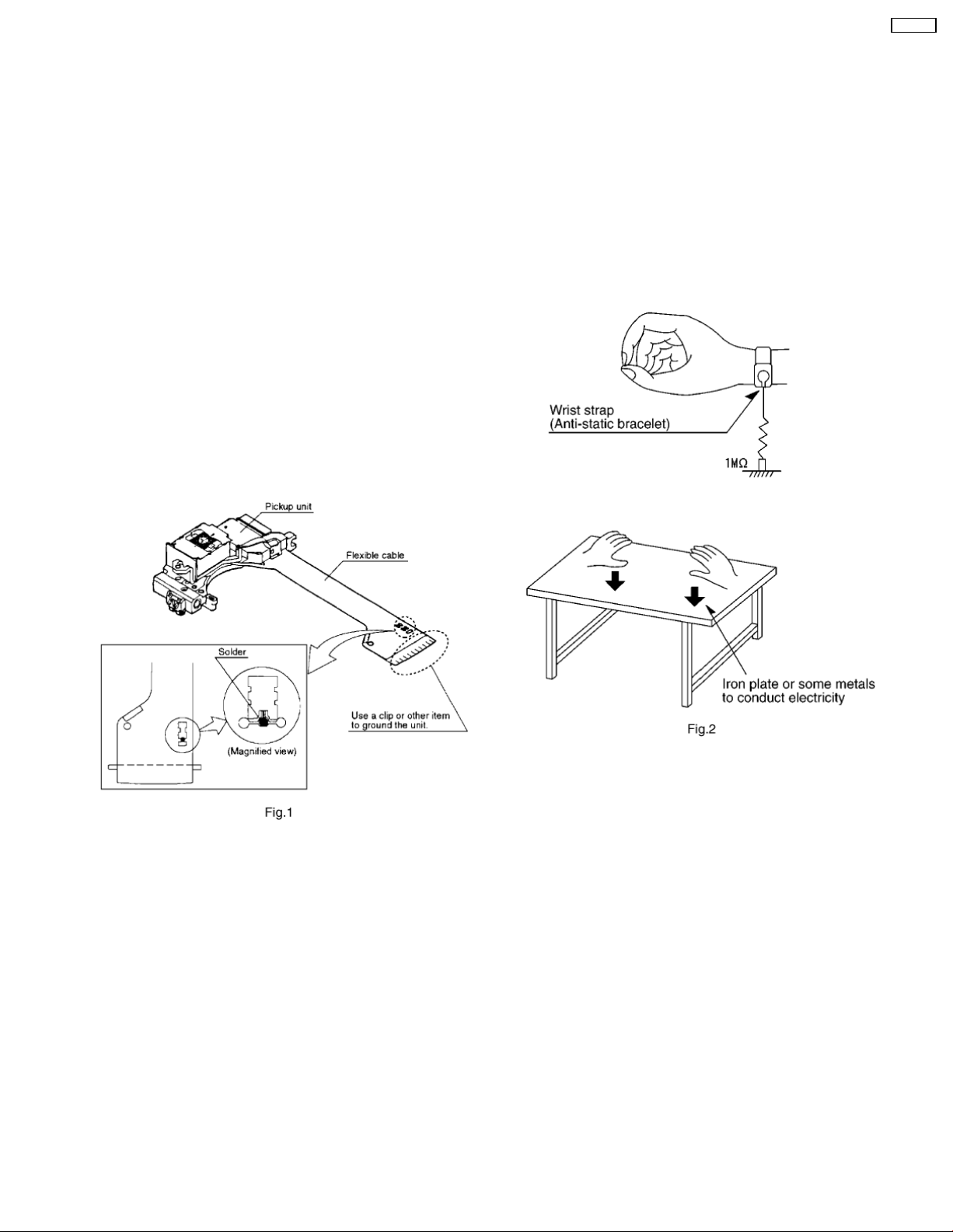

5.1. Handling the Traverse Deck

(Optical pickup)

1. The traverse deck (optical pickup) is an extremely

highprecsion construction and must not be subjected to

impact, excessive vibration, or other types of rough

handling.

2. In order to prevent static electricity damage to the laser

diode, use a short pin or similar tool to short the optical

pickup’s flexible circuit boards after they have been

disconnected from the main circuit board.

3. Handle the flexible circuit boards with care; excessive force

could cause them to be broken.

4. Do not turn the pre-set variable resistor (for adjustment of

the laser power); it has been adjusted at the factory. (as

shown in Fig. 1)

5.2. Grounding for electrostatic

breakdown prevention

1. Human body grounding

Use the anti-static wrist strap to discharge the static

electricity from your body.

2. Work table grounding

Put a conductive material (sheet) or steel sheet on the area

where the optical pickup is placed, and ground the sheet.

(sa shown in Fig. 2)

3.

Caution :

The static electricity of your clothes will not be grounded

through the wrist strap. So, take care not to let your clothes

touch the traverse deck (optical pickup).

5.3. Caution when Replacing the

Traverse Deck

The traverse deck has a short point shorted with solder protect

the laer diode against electrostatics breakdown. Be sure to

remove the solder from the short point before making

connections.

5

SA-DK10

6 Precaution of Laser Diode

CAUTION:

This product utilizes a laser diode with th unit turned “ON”,

invisible laser radiation is emitted from the pick up lens.

CAUTION!

THIS PRODUCT UTILIZES A LASER.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE SPECIFIED HEREIN MAY RESULT

IN HAZARDOUS RADIATION EXPOSURE.

1. Do not disassembly the pick up unit, since radioation from

exposed laser diode is dangerous.

2. Do not adjust the variable resistor on the pickup unit. It was

already adjusted.

3. Do not lock at the focus lens using optical instrument.

4. Recommend not to lock up lens for long time.

6

7 Operation Procedures

SA-DK10

7

SA-DK10

8

8 Disassembly and Main Component Replacement

Procedures

SA-DK10

“ATTENTION SERVICER”

Some chassis components may have sharp edges.

Be careful when disassembling and servicing.

1. This section describes procedures for checking the operation of the major printed circuit boards and replacing the

main components.

2. For reassembly after operation checks or replacement, reverse the respective procedures.

Special reassembly procedures are described only when required.

3. Select items from the following index when checks or replacement are required.

Contents

• Checking Procedure For Each Major P.C.B.

1. Checking of the Main, Panel, Deck and Power P.C.B.

2. Checking for the DVD F/E Module P.C.B.

3. Disassembly for the DVD Changer Unit.

• Main Component Replacement Procedures

1. Replacement of the Traverse Deck.

2. Replacement of the Power Amplifier IC.

• Disassembly and assembly of the Traverse Unit

• Disassembly and assembly of the Disc Tray

Warning:

This product uses a laser diode. Refer to caution statement Precaution of Laser Diode.

9

SA-DK10

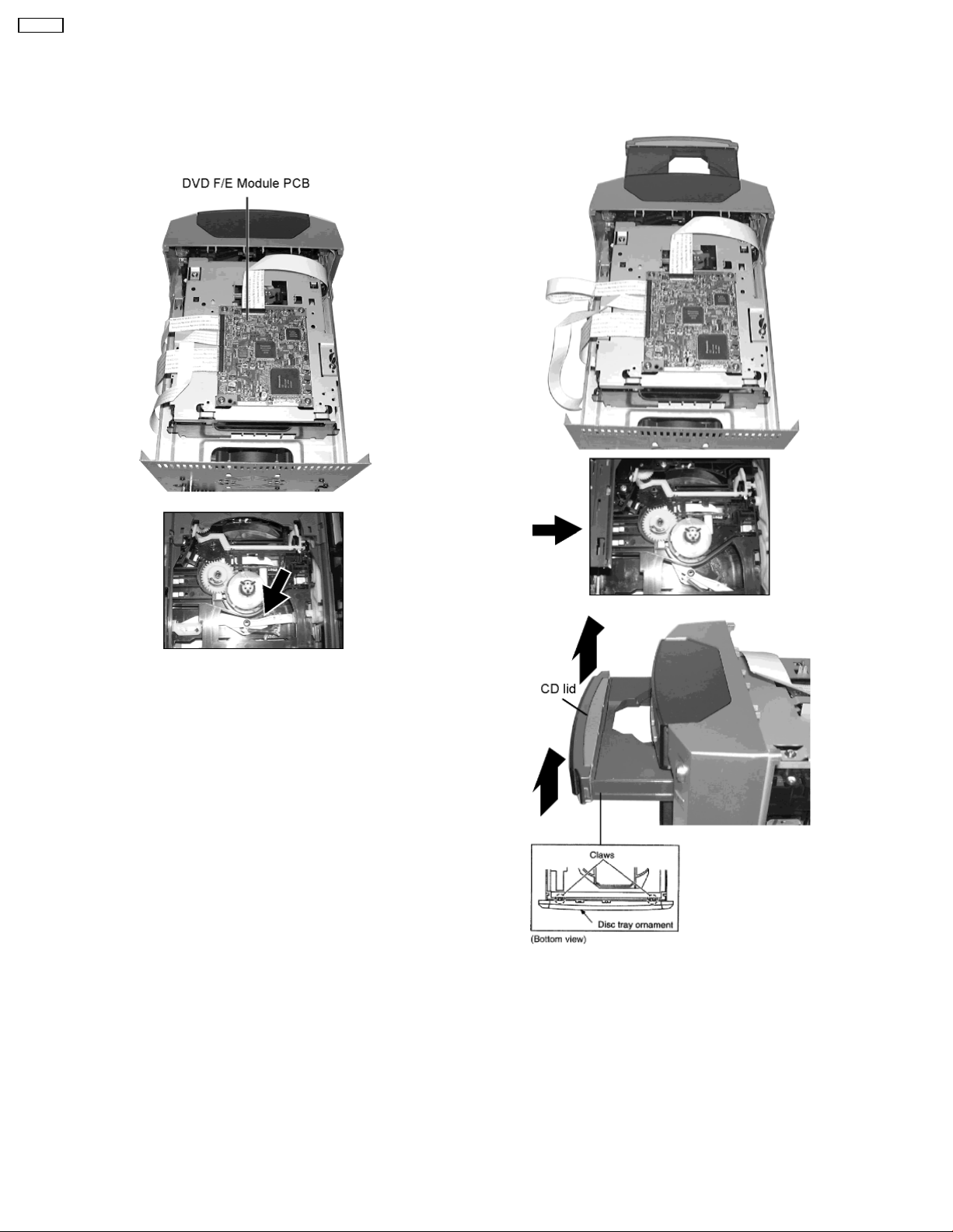

8.1. Disassembly Procedure for each major P.C.B. Checking

8.1.1. Checking of the DVD Servo, Main, Transformer, Panel and Deck P.C.B.

Step 1 Remove the top cabinet.

Step 2 Push lever in the direction of arrow.

Step 3 Pull out the CD tray as shown. Release the 2 claws and

remove the CD lid. Push back the CD tray after the CD lid has

been removed.

10

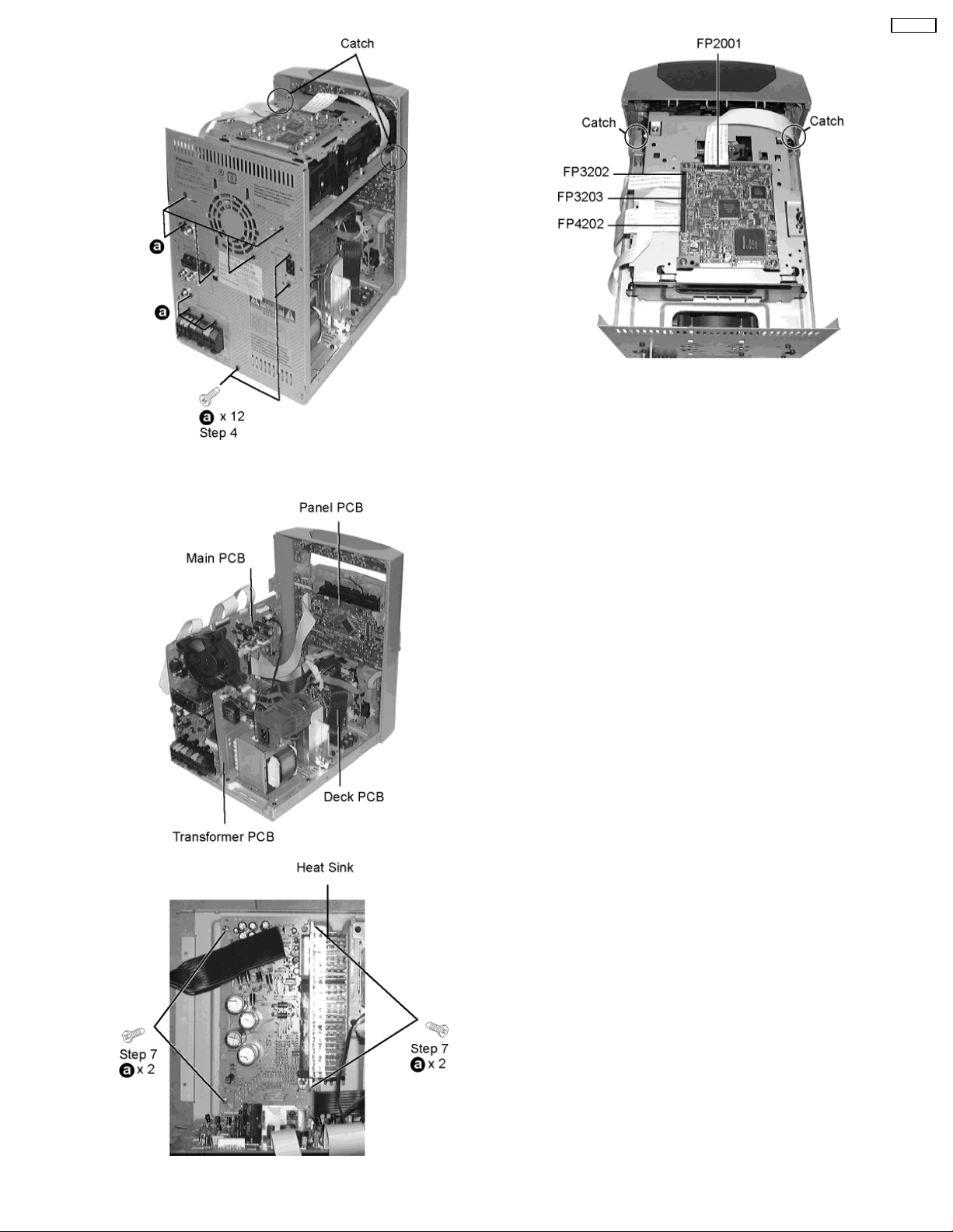

Step 4 Remove 12 screws and catches both side.

• Checking for Panel P.C.B., Main P.C.B. and Deck P.C.B..

SA-DK10

Step 5 Remove the wires at FP2001, FP3202, FP3203, and

FP4202.

Step 6 Release the wire from catch, remove the CD changer

base together with the CD changer.

11

SA-DK10

• Checking for Power P.C.B.

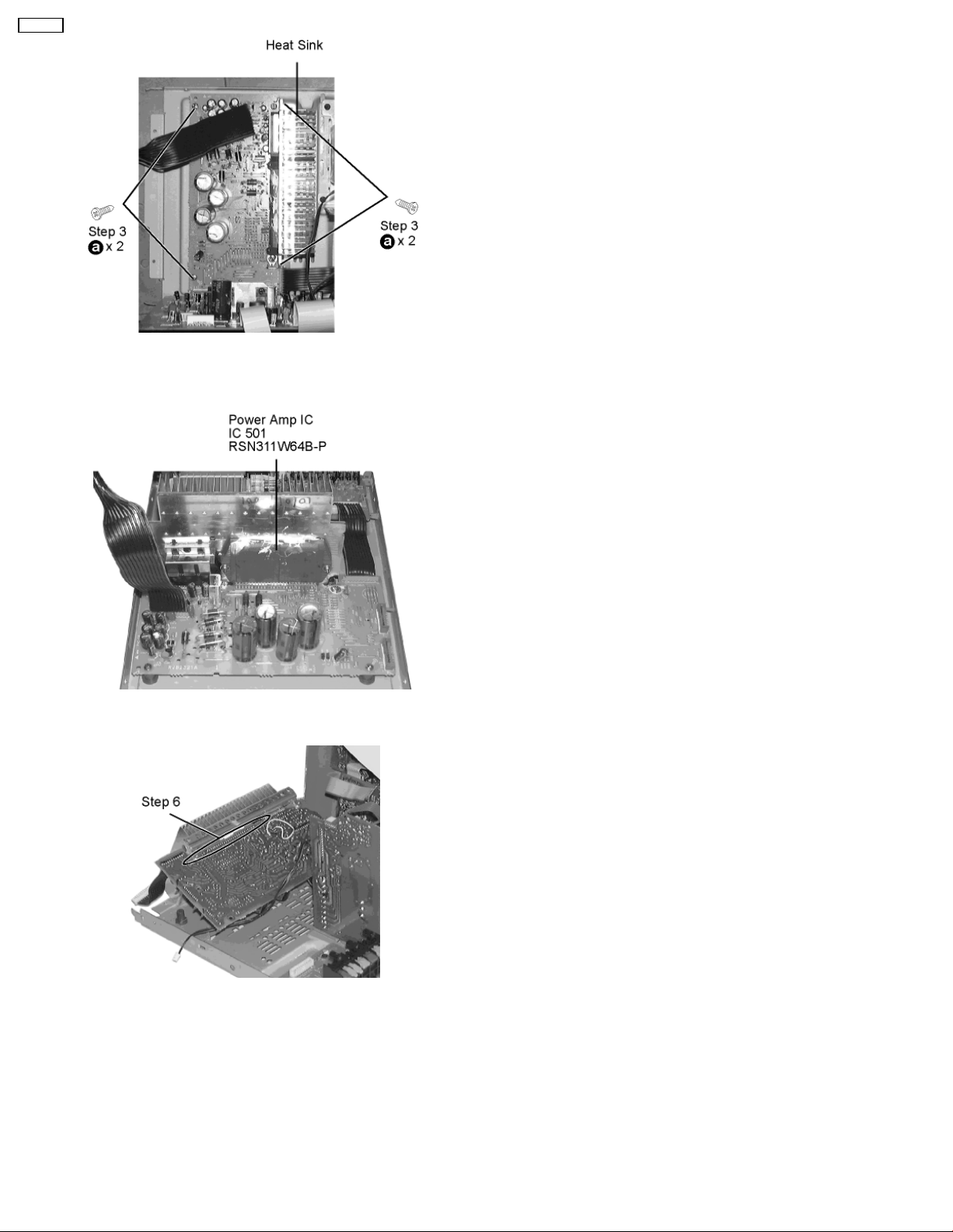

• Replacement of the Power Amplifier IC and Regulator

Transistor.

Step 1 Follow the procedures in “Checking procedure for each

major P.C.B.

Step 2 Remove the wires at CN302, CN303 and H603A/W603

and pull out the Main P.C.B..

Step 3 Remove 4 screws fixed to the Power Amplifier IC and

Transistor Holders.

Step 4 Unsolder the terminals of Power Amp IC and replace

the component.

12

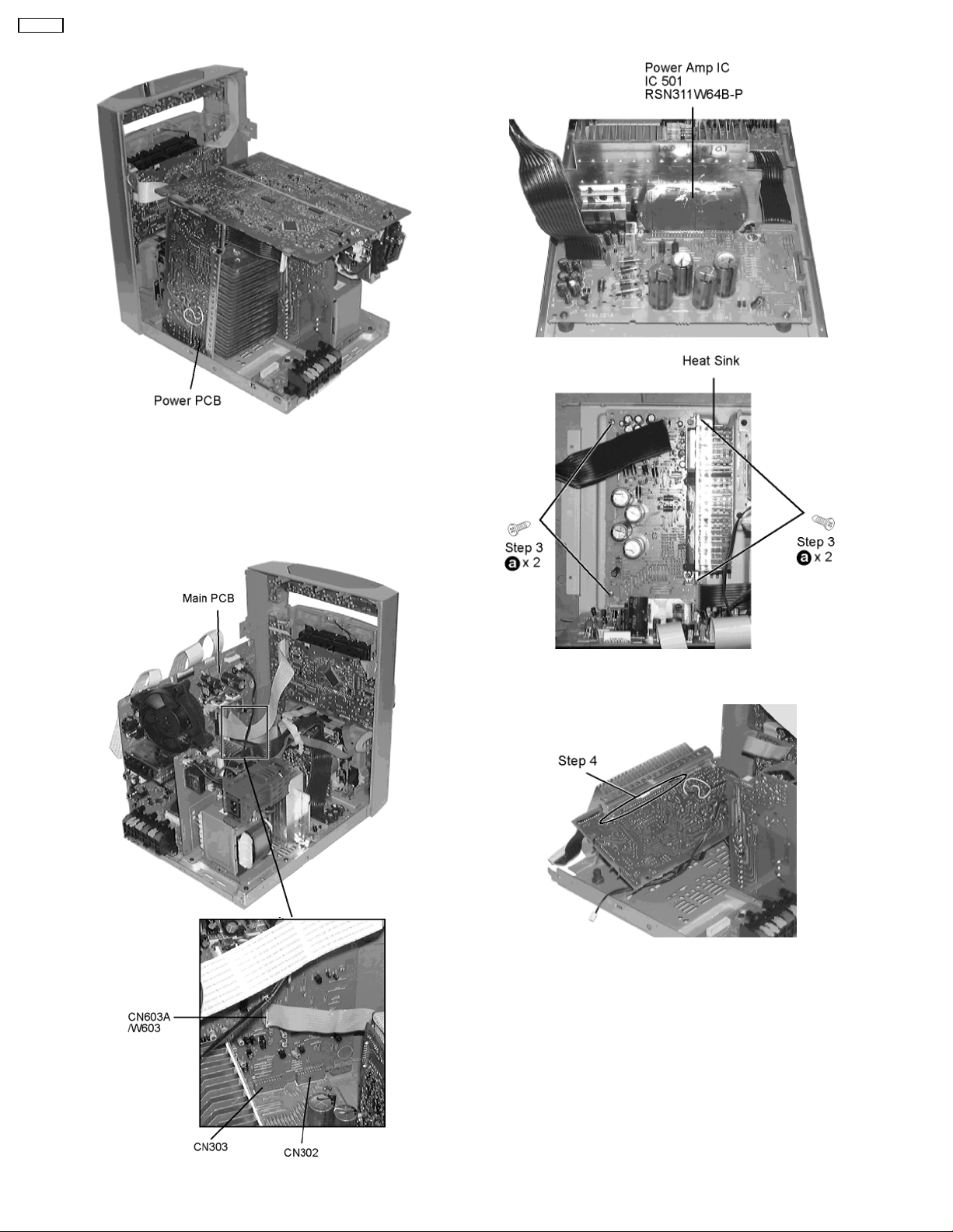

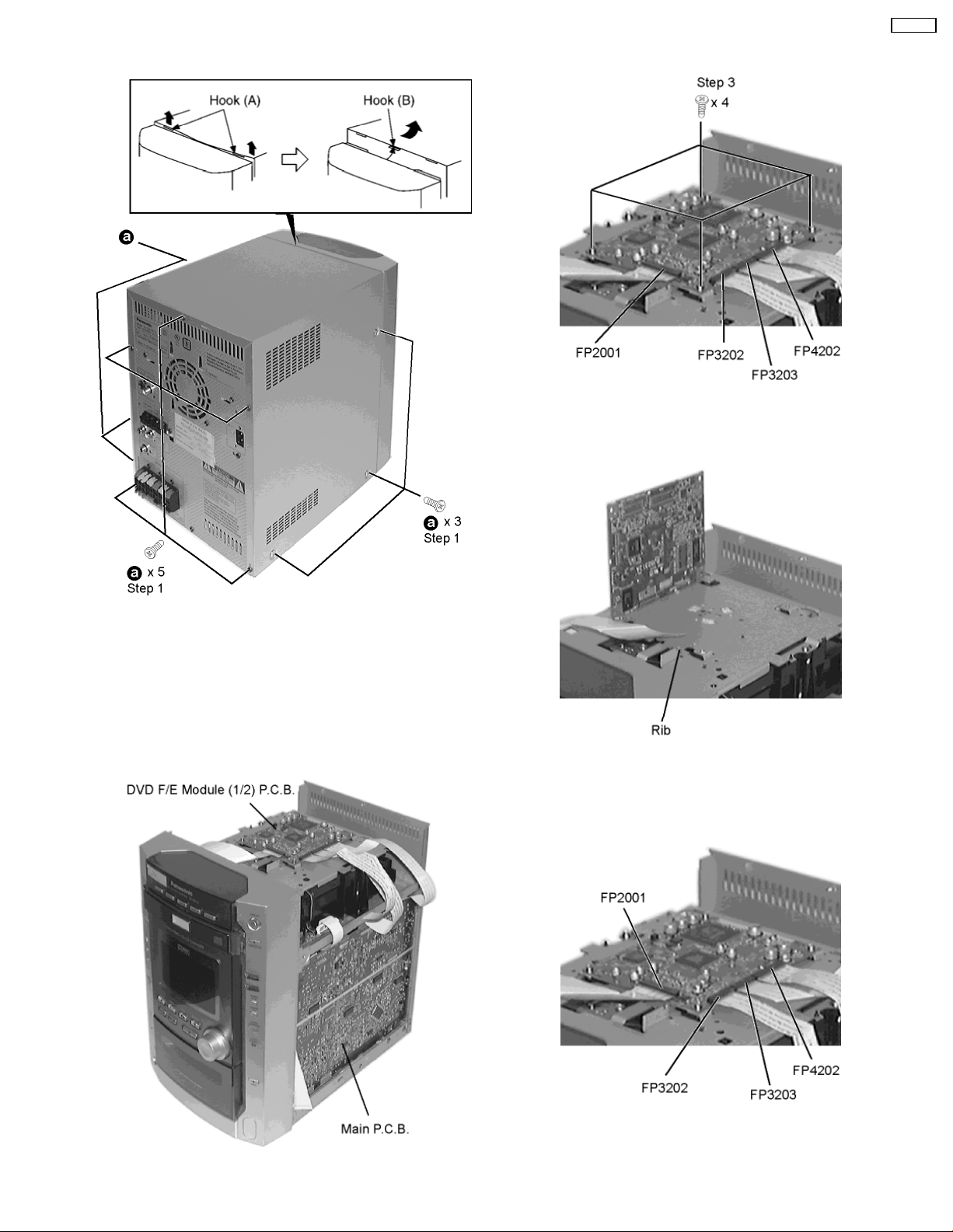

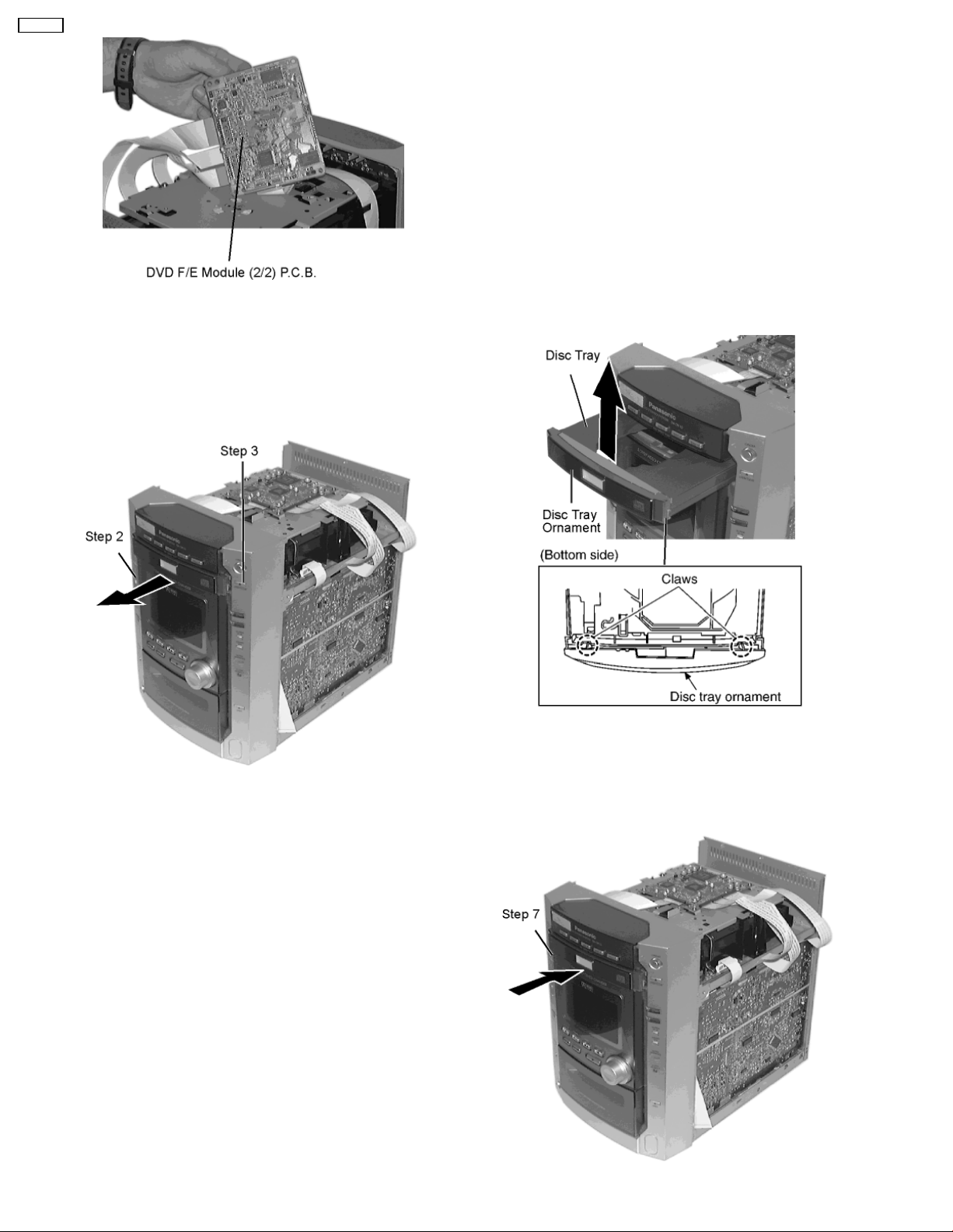

8.2. Checking for the Main and DVD F/E Module (1/2) P.C.B.

Step 3 Remove 4 screws.

Step 4 Remove 4 connectors.

Step 5 Pull out 4 FFCs.

SA-DK10

Step 1 Remove 3 screws each both side and 5 screws at rear

panel.

Step 2 Lift up the both sides cabinet ass’y to release the hook

(A). Then pull the cabinet ass’y toward the rear and release the

hook (B) to remove the cabinet ass’y.

NOTE: When installing the cabinet ass’y, take care not to

damage the front cabinet ass’y from hook (B).

• Check the Main P.C.B. and DVD F/E Module (1/2) P.C.B..

Step 6 Raise the DVD Module P.C.B..

• Checking the DVD F/E Module (2/2) P.C.B. as shown

below.

Step 7 Disconnect the FFCs to the connector.

Step 8 Lift up DVD F/E Module (2/2) P.C.B. as shown.

13

SA-DK10

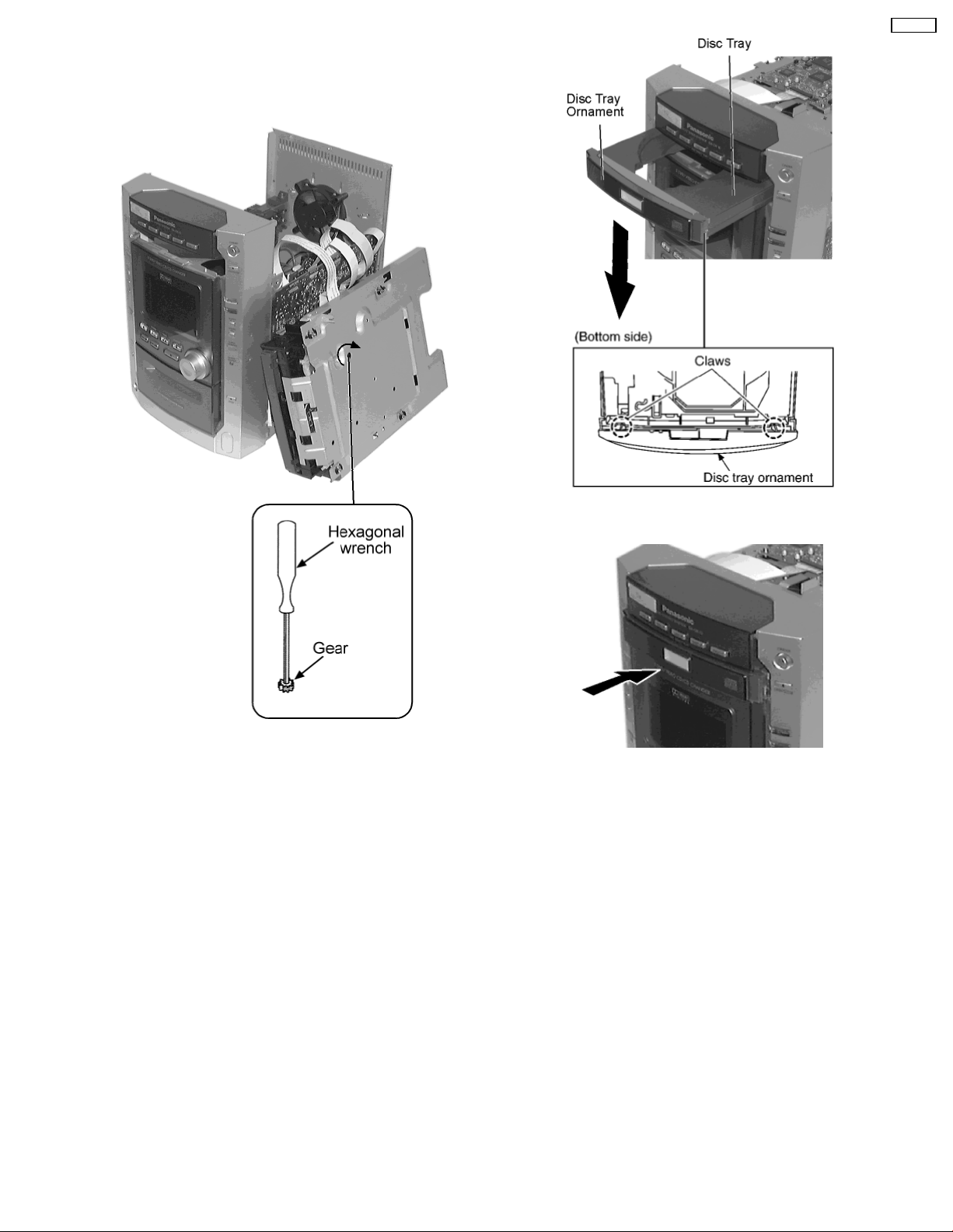

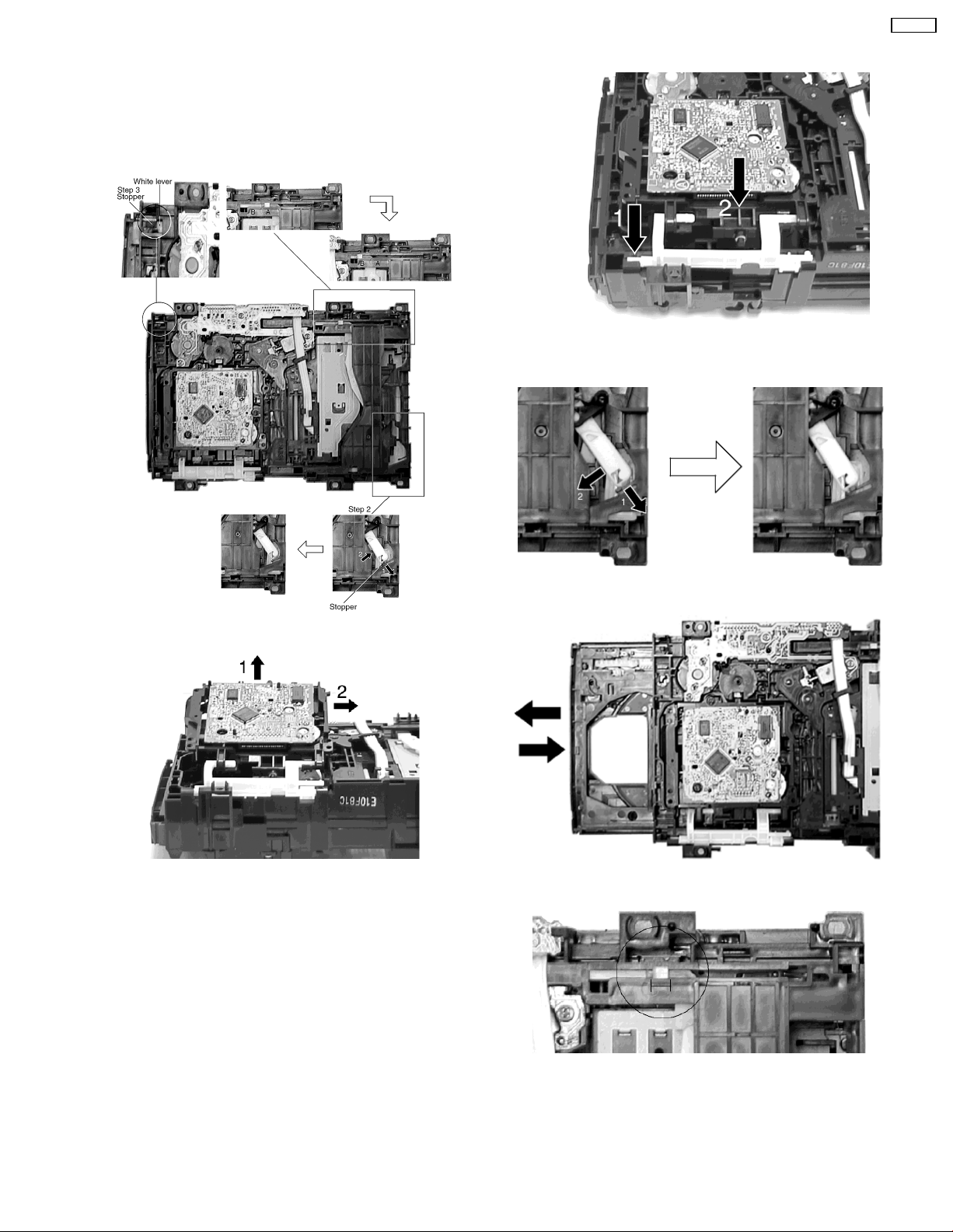

8.3. Disassembly for DVD/CD changer unit

8.3.1. Disassembly for the disc tray

ornament

• Follow the (Step 1) - (Step 3) of item 8.1

When opening the disc tray automatically

Step 1

Step 2

Step 3

open automatically. (If the other buttons would be push, disc

tray would be open.)

Connect the power.

Push the button and the power turns ON.

Push the open/close button, so the disc tray will be

Step 4

Step 5

ornament.

Step 6

Step 7

Disconnect the power.

Connect the power again.

Push the button and the power turns ON.

Release the 2 claws, and then remove the disc tray

14

Step 8 Push the open/close button1, so the disc tray will be

close.

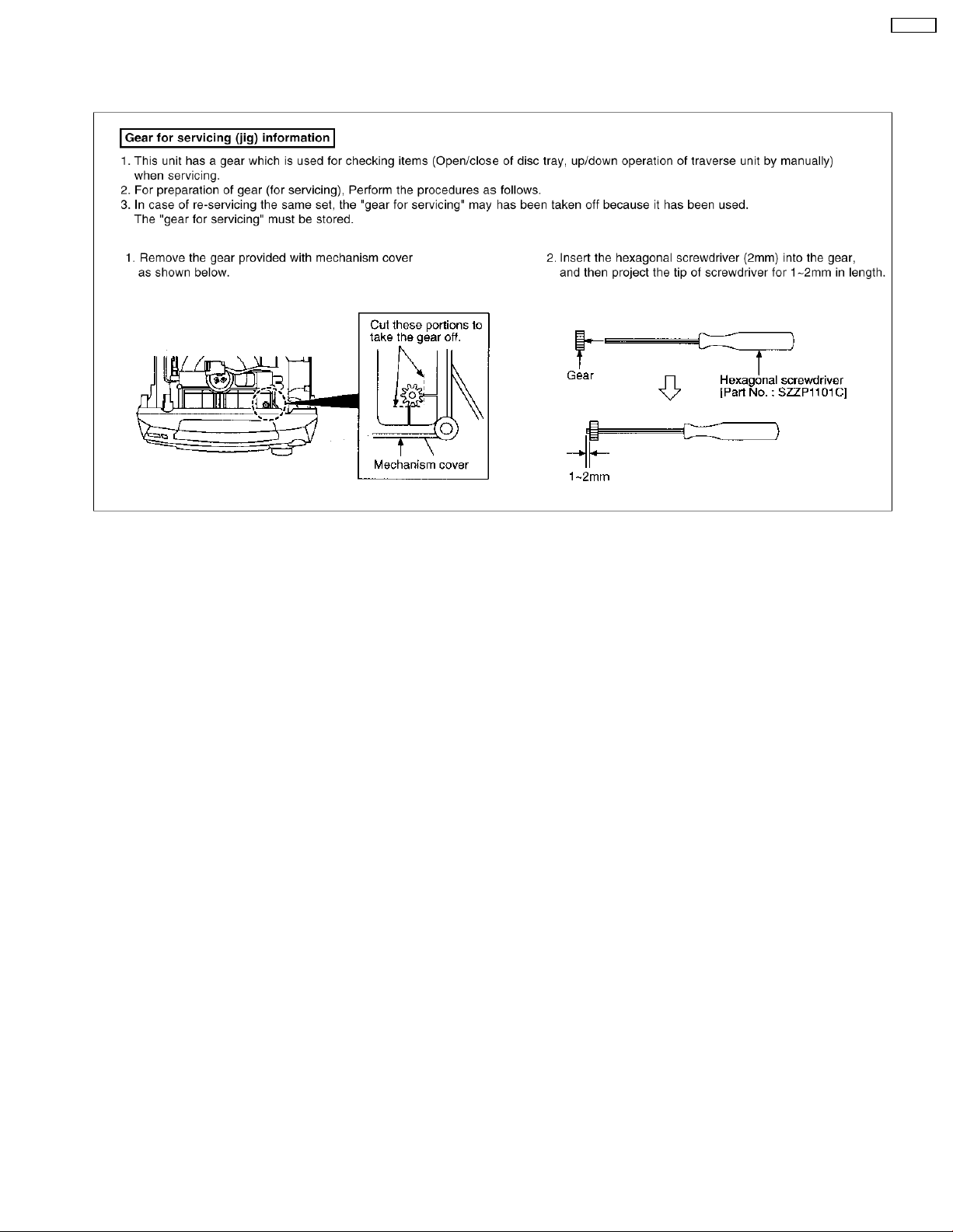

When opening the disc tray manually

Step 1 Off the unit.

SA-DK10

Step 2 Insert the gear for servicing into the bottom hole of

mechanism unit cover, and then rotate the hexagonal wrench

clockwise so the disc tray will be open.

Step 3 Release 2 claws, and then remove the disc tray

ornament.

Step 4 Push the disc tray.

15

SA-DK10

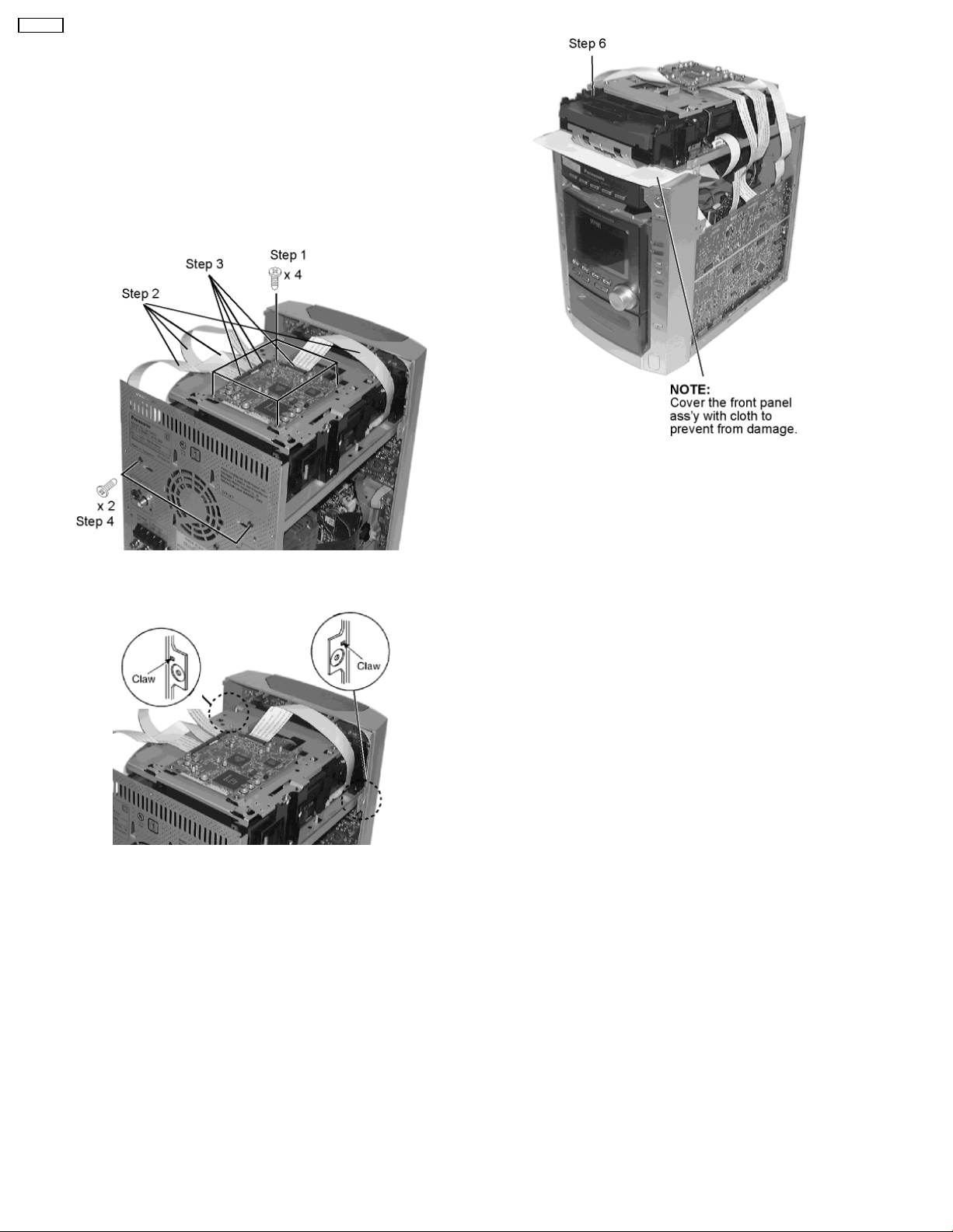

8.3.2. Disassembly for the DVD/CD

changer unit.

• Follow the (Step 1) - (Step 3) of item 8.1

• Follow the disassembly instruction for the disc tray

ornament .

Step 1

Step 2

Step 3

Step 4

Remove 4 screws.

Pull out 4 FFCs.

Remove 4 connectors.

Remove 2 screws at rear panel.

The preparation of checking procedures in operational

condition is completed.

Step 5

DVD changer unit.

Step 6

changer unit on the unit.

Release the claws of both ends, and then lift up the

Remove the DVD/CD changer and place the DVD/CD

16

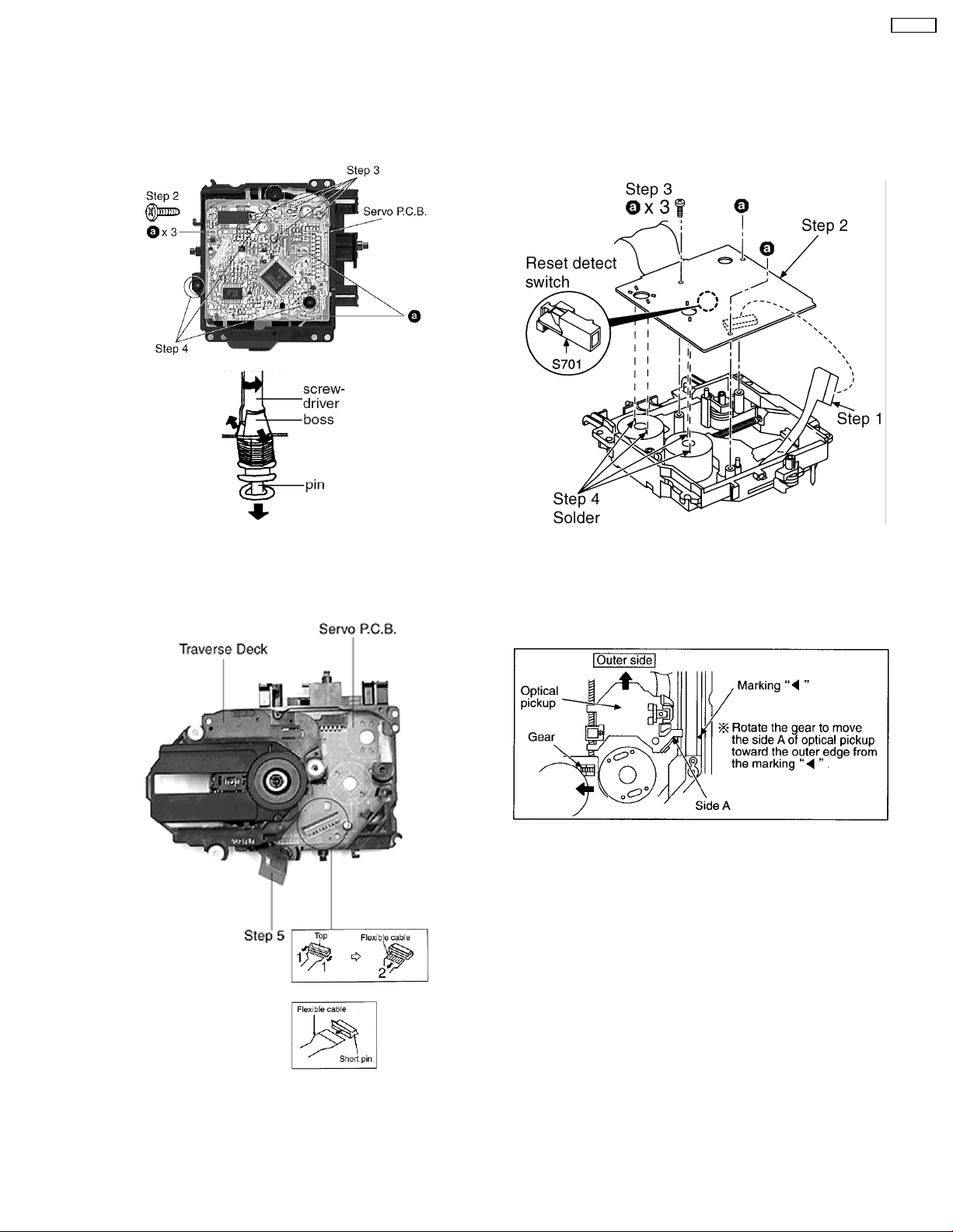

8.4. Main Component Replacement Procedures

SA-DK10

1. Replacement of the Traverse Deck

Step 1 Follow the procedures in ‘Disassembly of the Traverse

Unit’ ( Step 1 - Step 4 )

Insert a short pin into the flexible cable for traverse unit.

• Installation of the CD servo P.C.B. after replacement

Step 1 Connect the FFC board.

Step 2 Install the CD servo P.C.B. in the traverse deck

assembly.

Step 3 Desolder the 4 legs of the 2 motors and pull out the

Servo P.C.B.

Step 4 Widen the 3 bosses with a flat screwdriver and pull out

the 3 pins. Then remove the Traverse Deck.

Note:

Before installing the CD servo P.C.B., move the optical pickup

towards the outer edge from the marking (black triangle).

[Otherwise, the reset detect switch (S701) mounted on the CD

servo P.C.B. may be damaged.]

2. Replacement of the Power Amplifier IC

Step 1 Follow the procedures in ‘Checking Procedure for each

major P.C.B.’ ( Step 1 - Step 4 ).

Step 5 Remove the flexible cable CN 701.

• Removal of the flexible cable. Push the top of the connector

in the direction of the arrow 1, and then pull out the flexible

cable in the direction of the arrow 2.

Note:

17

SA-DK10

Step 2 Remove the wires at CN302, CN303 and CN304 and

pull out the Main P.C.B.

Step 3 Remove 4 screws fixed to the Power Amplifier IC.

Step 4 Unsolder the terminals of Power Amp IC and replace

the respective component.

18

8.5. Disassembly and assembly of the Traverse Unit

Step 1 Push the lever from position A to B.

Step 2 Pull the stopper (black) in the direction of arrow 1 and

push the lever in the direction of arrow 2.

Step 3 Push the stpeer (black) down until the white lever eject

out.

Step 3 Pull the stopper in the direction of arrow 1 and release

the lever in the direction of arrow 2 as shown.

SA-DK10

Step 4 Lift up the traverse unit and slide out the unit as shown.

• Replacement of Traverse Unit

Step 1 Place the traverse unit as shown.

Step 2 Press in the lever shaft in the direction of arrow 1 as

shown and push the traverse unit into the position in the

direction of arrow 2.

Step 4 Pull out the tray half way and push it back fully.

Step 5 Push the lever to the initial position indicated ‘I---I’.

19

SA-DK10

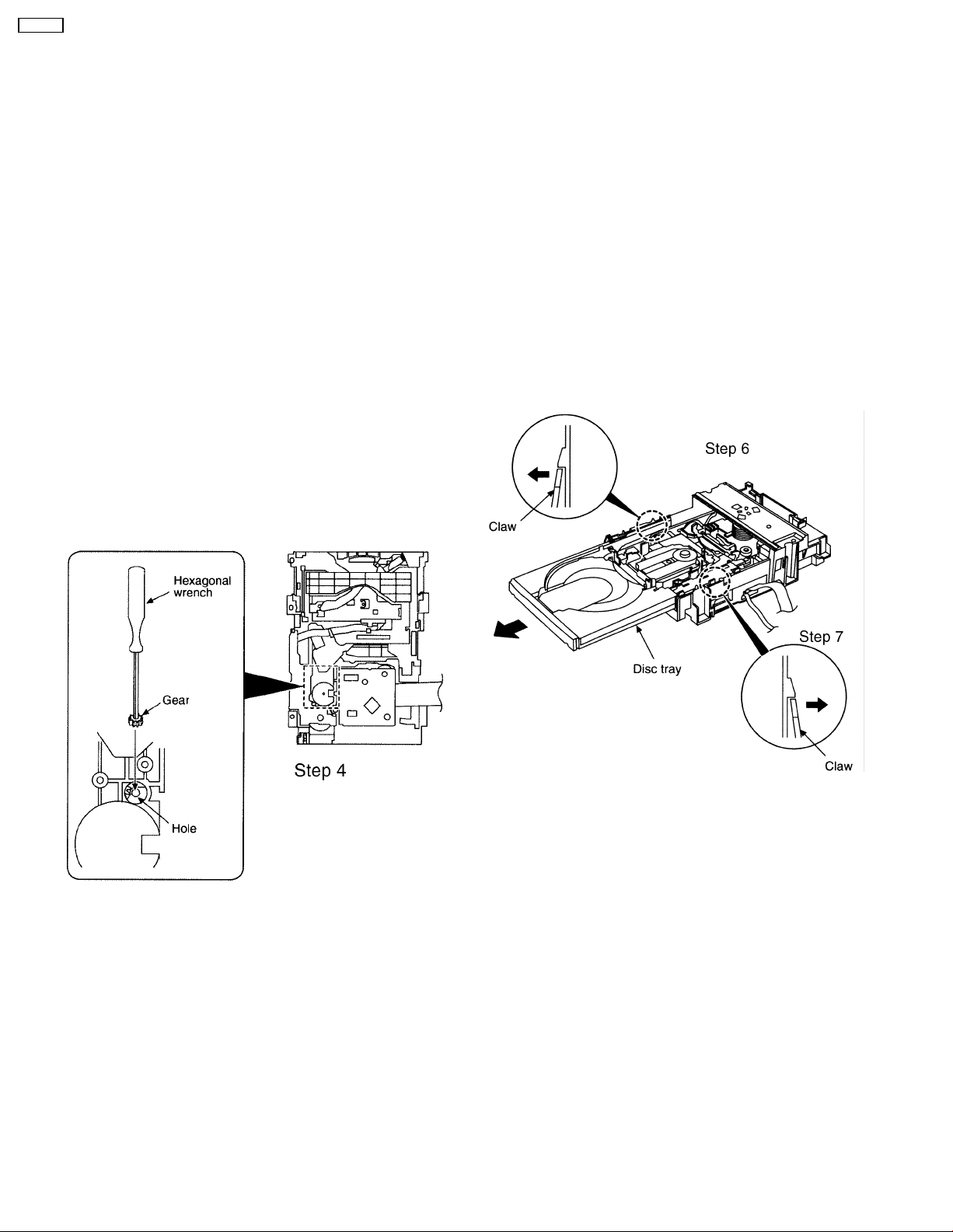

8.6. Disassembly and assembly of the Disc Tray

Step 5 Rotate the hexagonal wrench in the direction of arrow

(clockwise), and then open the disc tray fully.

Step 2 With lifting the claw in the direction of arrow 1, draw the

clamp SW P.C.B. in the direction of arrow 2.

Step 3 Remove the mechanism cover.

Step 4 Insert the gear with hexagonal wrench into the hole.

Step 6 Upset the CD changer unit again.

Step 7 Release both the claws, and then draw the disc tray.

20

SA-DK10

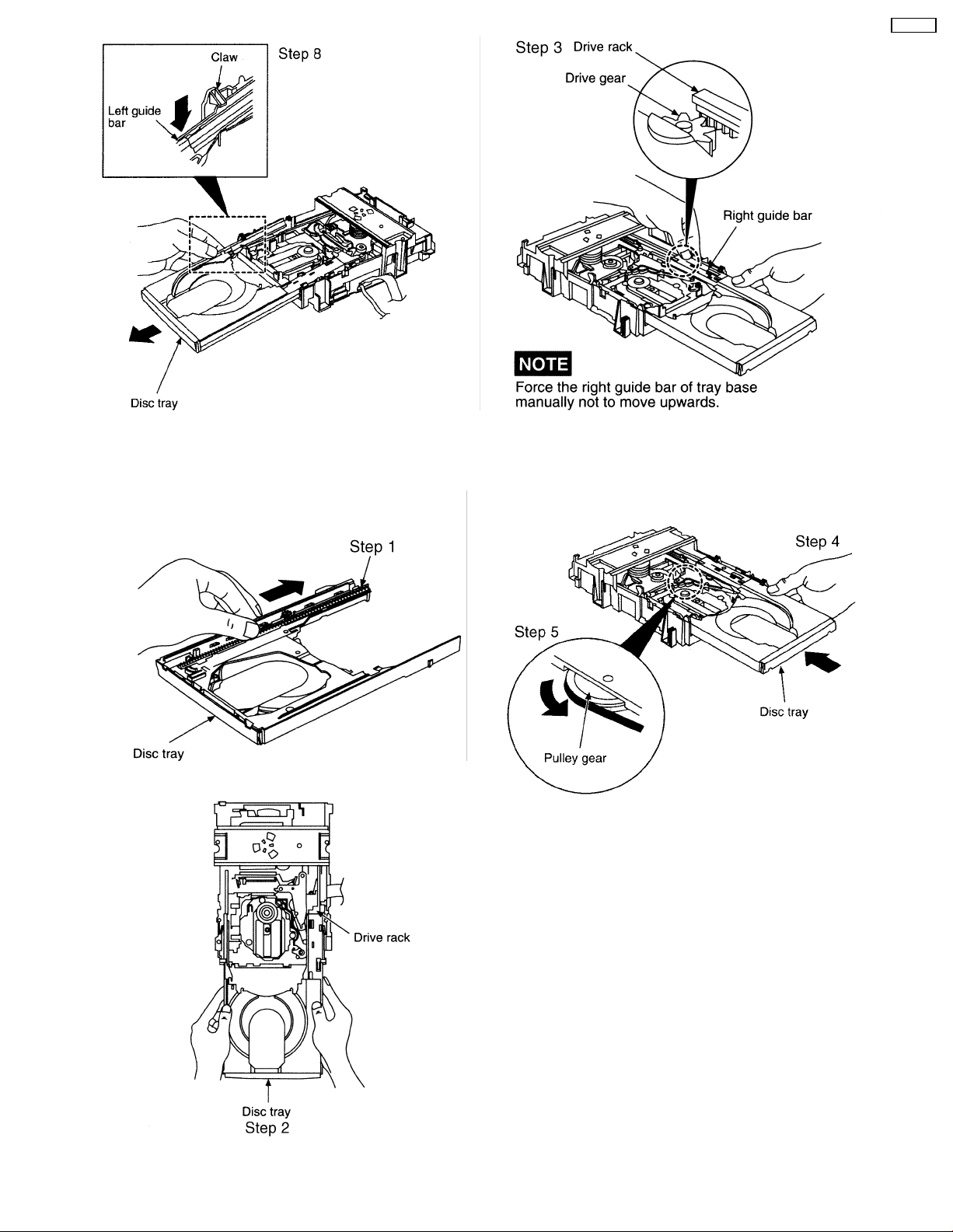

Step 8 With forcing the left guide bar manually because the left

guide bar interfers with claw, draw the disc tray.

• Installation of the disc tray after replacement

Step 1 Slide the drive rack fully in the direction of arrow.

Step 3 Align the drive rack with the driver gear.

Step 4 Holding the disc tray manually, rotate the pulley gear in

the direction of arrow.

Step 5 Rotate the gear 5 or 6 times manually, and then push

the disc tray.

Step 2 Holding the drive rack not to move, install the disc tray.

21

SA-DK10

9 Measurements and Adjustments

9.1. Cassette Deck Section

• Measurement Condition

− Reverse-mode selector switch:

− Tape edit: NORMAL

− Record timer: OFF

− Make sure head, capstan and press roller are clean.

− Judgeable room temperature 20 ± 5 °C (68 ± 9°F)

• Measuring instrument

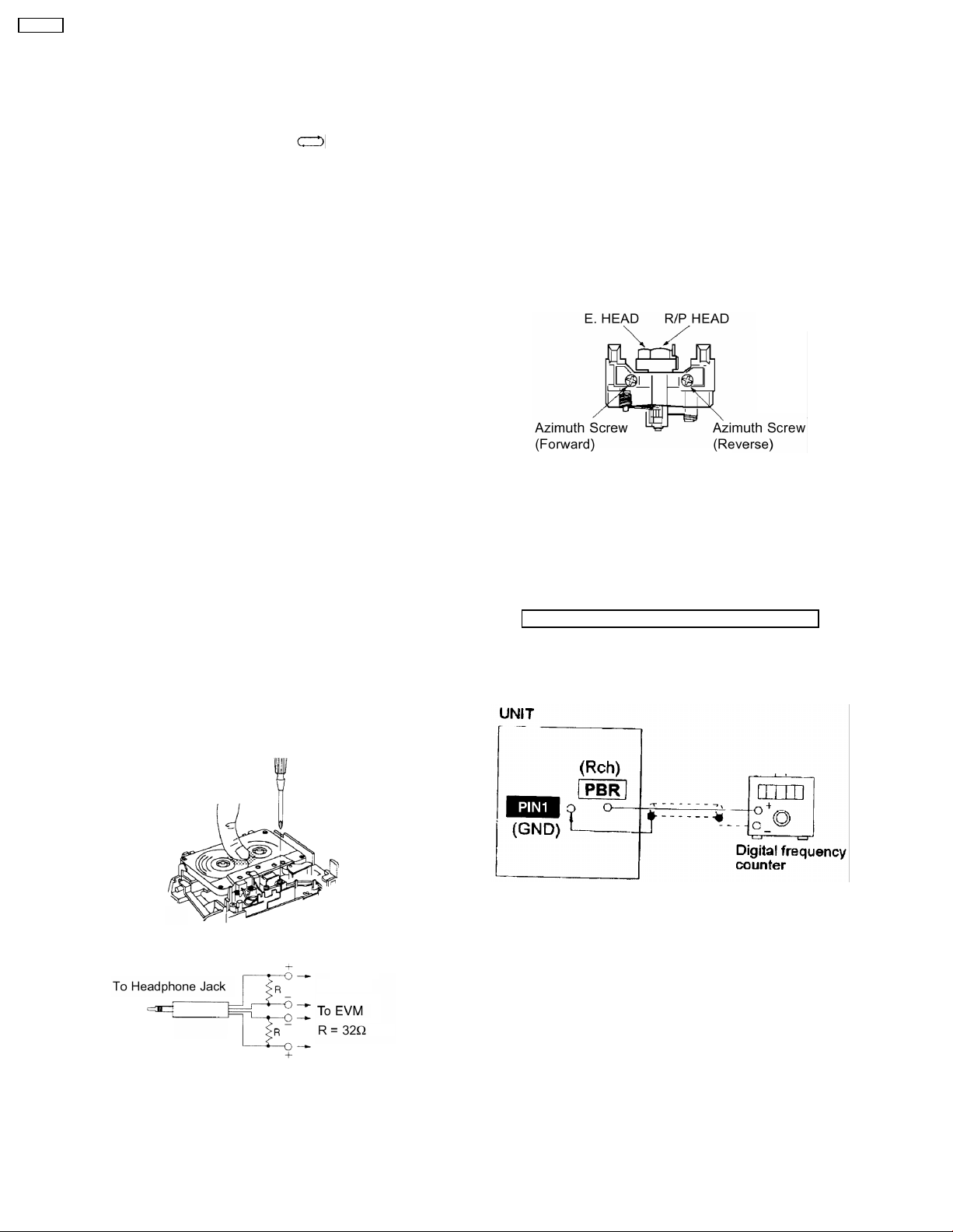

9.1.1. Head Azimuth Adjustment

Note :

If you wish to readjust the head azimuth, be sure to adjust with

adhering the casette tape closely to the mechanism by pushing

the cebter of cassette tape with your finger. (Shown in Fig. 1)

1. Connect the measuring instrument as shown in Fig. 2.

2. Replace azimuth screws for both forward and reverse

direction after removing the screw-locking bond left on the

head base.

3. Playback the azimuth adjustment portion(8kHz, -20dB) of

test tape(QZZCFM). Adjust the azimuth adjusting screw

until the outputs of the L/Rch are maximized. (Refer to Fig.

3)

Make sure that the difference in the peak level between the

left and right channels does not exceed 5dB.

4. Perform the same adjustment in reverse playback mode.

Check of the level difference forward and reverse

directions

5. Playback the playback gain adjustment portion(315Hz,

0dB) of test tape(QZZCFM). Check if level difference

between forward and reverse direction is within 1.5dB.

6. After the adjustment, apply screwlock to the azimuth

adjusting screw.

− EVM (Electronic Volmeter)

− Digital quency counter

• Test Tape

− Head azimuth adjustment (8 kHz, -20 dB); QZZCFM

− Tape speed gain adjustment (3 kHz, -10 dB);

QZZCWAT

− Playback gain adjustment (315 Hz, 0 dB); QZZCFM

− CrO2 tape, QZZCRX

Fig. 3

9.1.2. Tape Speed Adjustment (Deck 1/2)

1. Set the tape edit button to “NORMAL” position.

2. Insert the test tape (QZZCWAT) to DECK and playback

(FWD side) the middle portion of it.

3. Adjust Motor VR for the output value shown below.

Adjustment target: 2940~3060 Hz (NORMALspeed)

4. After alignment, assure that the output frequency of the

DECK REV is within ±60 Hz respectively of the value of the

output frequency of DECK FWD.

Fig. 1

Fig. 2

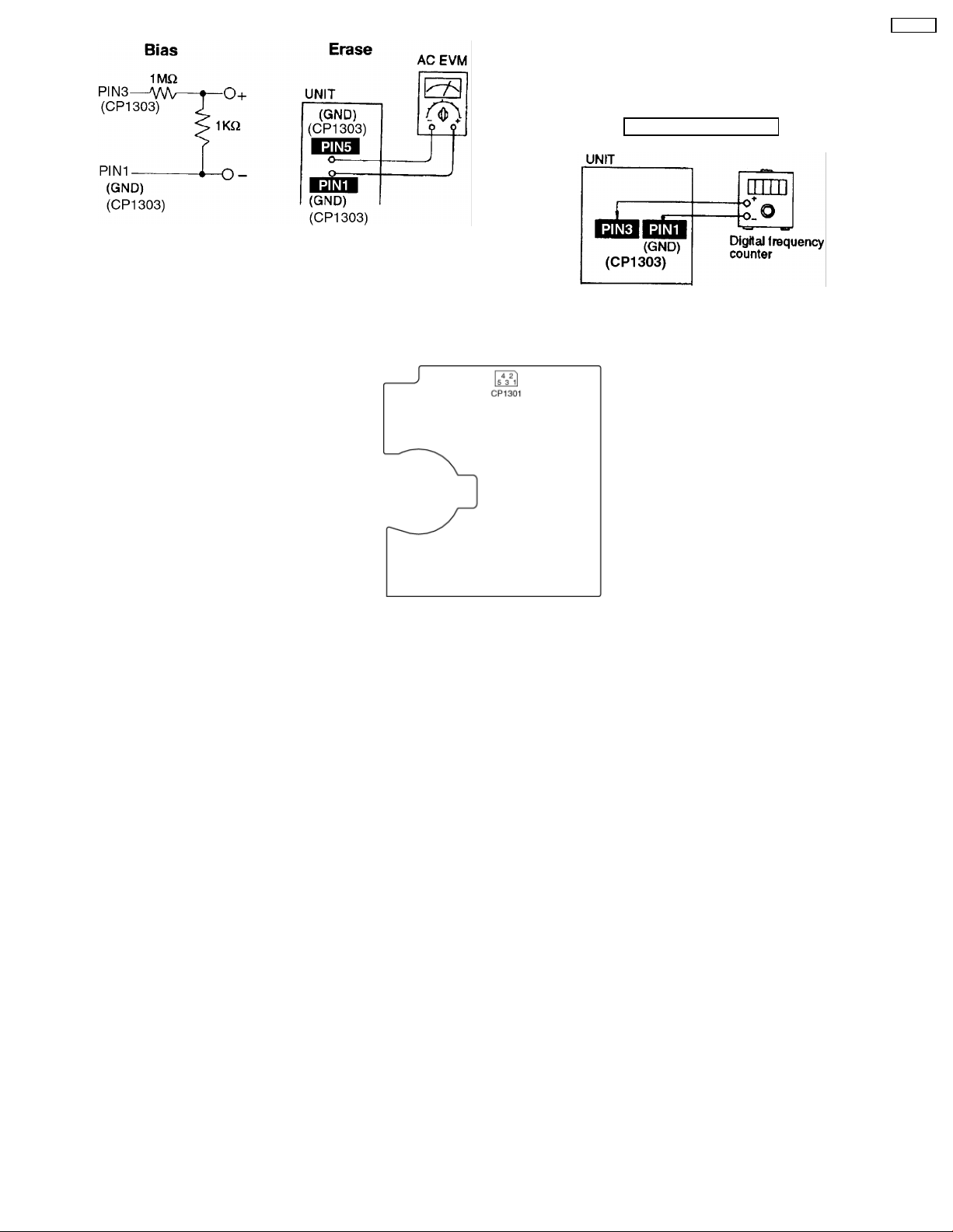

9.1.3. Bias and Erase Voltage Check

1. Set the unit “AUX” position.

2. Insert the Normal blank tape (QZZCRA) into DECK and the

unit to “REC” mode (use “● REC/PAUSE” key).

3. Measure and make sure that the output is within the

standard value.

4. Insert the Cr02 tape(QZZCRX).

5. Repeat steps 2 and 3.

Bias voltage 16 ± 4mV (Normal)

26 ± 5mV (Cr02)

Erase voltage for Deck 2 more than 80mV (Normal)

more than 90mV (Cr02)

22

9.1.4. Bias Frequency check

1. Set the unit to “AUX” position.

9.2. Alignment Points

Cassette Deck Section

SA-DK10

2. Insert the Normal blank tape (QZZCRA) into DECK 2 and

set the unit to “REC” mode (● use “REC/PAUSE” key).

3. Check so that the output frequency is within the standard

value.

Standard Value: 86 ±8 kHz

23

SA-DK10

10 Illustration of ICs, Transistors and Diodes

BU2090AF-E2 (16P)

M62457AFPE1 (16P)

M62456FPE1 (24P)

NJU7313AMT2 (30P)

M5218AFPE3 (8P)

BU4053BCF-E2 (14P)

M5228FPE1 (14P)

PQ1CZ31H2ZP

PQ018EZ01ZP

M62444FPE1

KM416S1DTG8T (60P)

C2BBFD000307 (42P)

C2BBFD000308 (42P)

C0CBCBD00002 (6P)

C1AB00001393 (16P)

C1DB00000582 (16P)

M5218AP

5

8

4

1

C0CBCBE00001 C3EBEC000024

2SC3940AQSTA

E

E

C

C

B

B

IMX9T110

B

B

C

E

C

Cathode

2SB1115-T1

B

2SB621ARSTA

2SD965RTA

KTA12710YTA

E

E

C

E

C

B

UDZSTE175R1B

UDZSTE177R5B

Ca

Anode

A

1SS355TE17

1SS380TE-17

Cathode

Anode

A

UDZSTE179R1B

DAP202KT146

DA204KT146

Cathode

Ca

Anode

Cathode

No.1

BA7755A

1

5

2SB1417PQTA

B

C

E

A

Anode

1D3E

RL1N4003N02

1N5402BM21

Cathode

A

Anode

SLR325MCT31W

Anode

Cathode

A

Ca

MN677533MP (208P)

MN103S13BGA (144P)

MN67706EC (100P)

AN8708FHK

MN102H60GFA (100P)

C0JBAA000001

PST596JNR

RFKFRV45C040

2SD2144STA

KRA102MTA

KRC102MTA

KTC3199GRTA

RVTDTC143EST

2SC2784FTA

Cathode

MTZJ30BTA

MTZJ4R7BTA

MTZJ6R8ATA

Ca

MTZJ16ATA

MTZJ9R1CTA

MA728TX

Ca

Anode

A

SELS5923C

Anode

A

Ca

Cathode

Cathode

C2BBGF000280 (100P)

C2HBZC000011 (80P)

C0FBBK000021 (48P)

KTC2026

KTA1046YU

KTA1046YTA

RSN311W64A-P

1

..................

2SA1037AKSTX

2SC2412KT96R

2SD2144K1

DTA114EKA146

DTA143XKA146

DTC114YKA146

MA165TA

MA700ATA

MA729TX

RVD1SS133TA

KRC103STA

MA111TX

Cathode

Ca

Anode

A

LNJ201LPQJA

Anode

A

Cathode

Ca

LM2940T5M

I

G

No.1

TA7291P

1

10

0N2180RLC1

4

1

3

2

4

1

26

2

3

O

AN7326K

C0GBG0000020

28

22

1

7

21

8

14

STK470-050A

1

14

15

DTC143XKA146

DTC114EKA146

C

DTC144TKA146

UN5212TX

UN2121-TX

KRC103STA

B

E

RK306LFU1

Ca

A

Anode

SFPB-72V

Anode

A

Ca

Cathode

Cathode

Ca

A

Anode

MA8047MTX

Anode

Ca

Cathode

Cathode

Ca

A

24

11 Terminal Function of IC’s

SA-DK10

11.1. IC601 (C2BBGF000280 )

System Microprocessor

Pin No.

1 SER5 I/O Searal 5 output (PLL/DSP DA)

2 MK_IN2 I/O Mech condition input 2

3 MK_IN1 I/O Mech condition input 1

4 KEY 3 I/O Key 3 input

5 KEY 2 I/O Key 2 input

6 KEY 1 I/O Key 1 input

7 JOG1B I/O JOG 1 input B Main Volume

8 JOG1A I/O JOG 1 input A Main Volume

9 SP_IN I/O Speana input

10 SP_A I/O Speana control output A

11 AP_B I/O Speana control output B

12 SP_C I/O Speana control output C

13 N.C. I/O No use

14 N.C. I/O No use

15 N.C. I/O No use

16 SER9 I/O Searal 9 output (Echo LA)

17 VSS - Ground

18 RESET I RESET input (Active L)

19 XCOUT I/O 32.768 kHz sub clock

20 XCIN I/O 32.768 kHz sub clock

21 VSS - Ground (0V)

22 XIN I 4.00 MHz main clock

23 XOUT O 4.00 MHz main clock

24 VCC - Power supply (+5V)

25 MBP1 I/O MPU beat proof output 1

26 MBP2 I/O MPU beat proof output 2

27 PCONT/PCNTI/O PCNT output

Mark I/O Function

(TPS/PHOTO)

(HALF/MODE/R_INHF/R_INHR)

Pin No.

98 VREF - Reference for A-D

99 SER7 I/O Searal 7 output (PLL CE)

100 SER6 I/O Searal 6 output (PLL/DSP CK)

Mark I/O Function

28 N.C. I/O No use

29 DCDET I/O DCDET input

30 SER4 I/O Searal 4 output (ROM CS)

31 RMT I/O Remoco input

32 SYNC I/O AC failure detect input

33 SER3 I/O Searal 3 output (Exp2 CK/ROM

34 SER2 I/O Searal 2 output (Exp1CK/ROM

35 SER1 I/O Searal 1 output (EXP1/2 DA)

36 DSPRST I/) DSP reset output

37 DSPACK I/O DSP ACK input

38 SENSE I/O DSP sense input

39 MIC SW I/O MIC output sw

40 PHONE I/O Phone output sw

41 D0/ST I/O Tuner D0/ST input

42 SDIN I/O Tuner signal DET input

43 REGION

IN/REG_IN

44-55 AND12-

1/REG12-1

56-88 SEG1-33 I/O Segment drive output (Anode

89 VEE - Power supply (-30V)

90 MECHSI I/O Mecha control data input

91 MECHSO I/O Mecha control data output

92 MECHCK I/O Mecha control clock input

93 MECHRQ I/O Mecha con request output

94 MECHCS I/O Mecha control CS input

95 MECRST I/O Mechcon reset output

96 SER8 I/O Searal 8 output (DSP LA)

97 AVSS - Analog ground (0V)

CK)

DA)

I/O Region input

I/O Grid drive output (Digit drive

output)

drive output)

25

SA-DK10

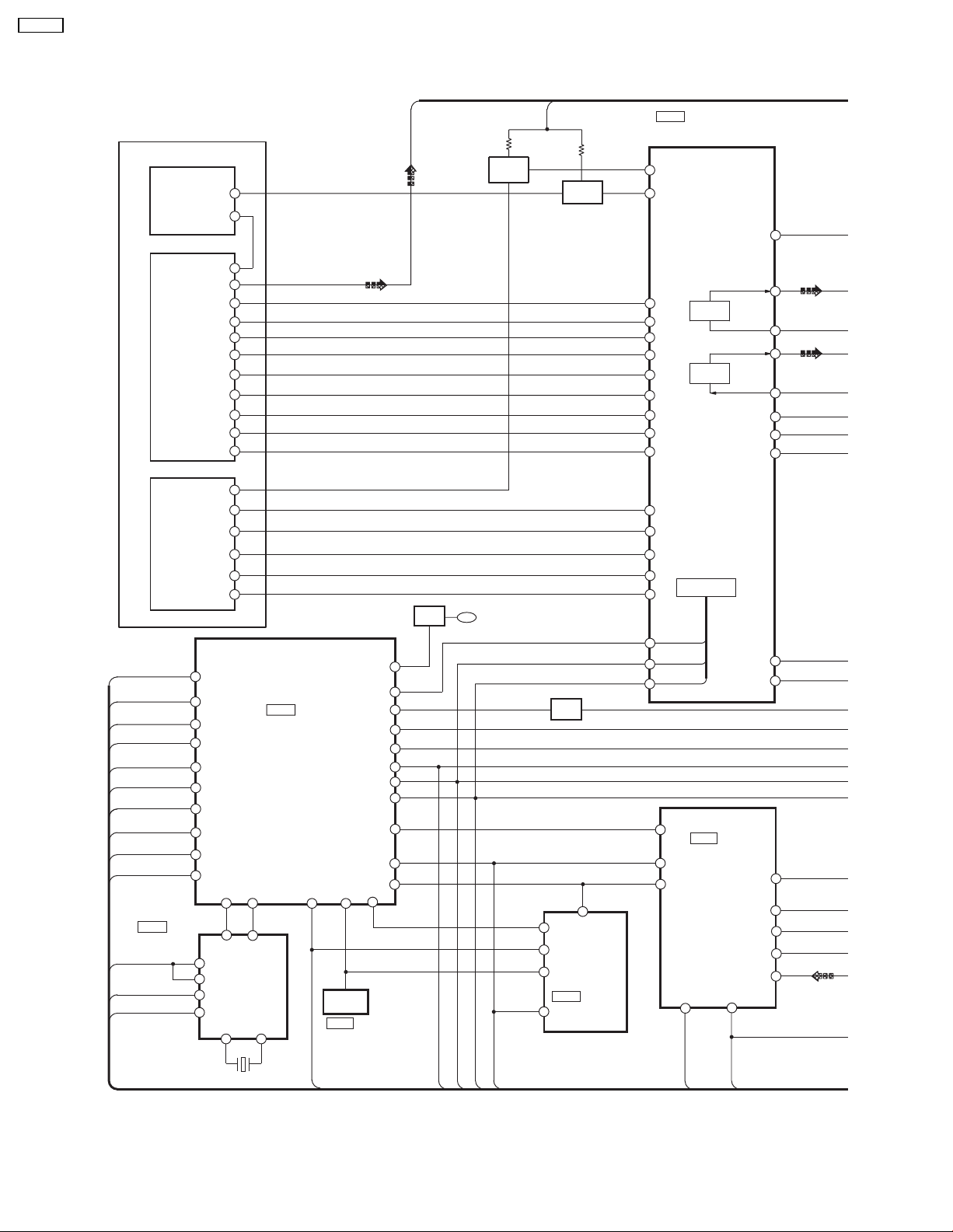

12 Block Diagram

OPTICAL PICKUP UNIT

HIGH FREQUENCY

DVD MODULATOR

CD MODULATOR

AMUTE

SDATA

SCLOCK

CMD

STATUS

DSPCLK

YDET

YVDL

STBDAC2

B

IC6501

C1DB00000582

CLOCK

CLK27M

EXTCLK

CLK16M

MODULATOR

64

AN2

56

SBO 4

53

SBT4

51

SBI3

52

SBO3

50

P82

63

AN1

49

DAC1

68

LCAS

7,18,78

3

4

10

13

LD-OUT

CLK27

CLK64

76BIS

CLK16

LD-IN

LD

SW

T2

T1

Mon

F2

F1

RFN

RFP

T4

T3

LD

F2

F

E

F1

Mon

AN323OSCI

65

14 15

FSEL

XTO

2

5

15

14

5

4

8

13

12

11

10

7

6

11

10

8

6

4

2

IC6201

MN102H60GFA

CPU

CLK33

XTI

78

93~100

NRST

82

8,41,42

RESET

IC6301

PST596JNR

VREF+

AN6,AN5

SBI1

SBT1

SBO1

TILTP

Q5215

QR5251

SWITCH

+B

80

47

AN7

79

PA4

46,45

76

PA0

71

70

72

1,6,13

2,3,

14~16,

26~33,

84~91

35~40,77

CD

SUPPLY

SWITCH

30,32,34,36,

39,41,43,45

16,17,26

6~8,11,

18~25,28,

29,31,33,

35,38,40,

42,44

LPCO1

Q5211

QR6301

RESET

SWITCH

1~5,

37,38,

40~48

12

XRESET

IC6302

RFKFRV45C040

4M FLASH ROM

LD

SUPPLY

SWITCH B

IC5201

AN8707FHK

FRONT END PROCESSOR

5

LPDO2

3

LPDO1

44

VIN2

43

VIN1

2

LPC1

41

VIN8

40

VIN7

33

RFINN

32

RFINP

46

VIN4

45

VIN3

38

VIN5

47

VIN9

48

VIN10

39

VIN8

4

LPC2

9

SEN

10

SCK

11

STDIO

32,57,58

30,31,45~55,

59,60,62,63,

68~70,72~74

26,37,

38,40~43

1,3,6,9,12,

14,17,20,24,

131,137,143

TRACKING

BALANCE

FOCUS

BALANCE

INTERFACE

IC7001

MN103S13BGA

CPU

85

NRST

FLTCP,

FLTON

TBAL

FBAL

RFENV

TESTSG

BDO

OFTR

BLKCK

ODCI1

26,27

TE

13

7

FE

20

6

36

21

FS

31

16

15

80

BD0

81,82,88,

90~92,

95~98,

109~111

97

100

112~115

X6501

SBI1

SBT1

SBO1

B1

C

NRST

D

26

TILTP

SA-DK10

LPCO1

97

AD6

54

TILTP

8,9

ARF,NARF

2

AD1

34

TRCRS

43

TBAL

3

AD0

IC2001

MN67706EC

44

100

50

DSC

FBAL

A03

1

A02

TSTSG

IC2501

C0GBG0000020

MOTOR DRIVE

VO3-

VO3+

VO4-

VO4+

VO2+

VO2-

VO1+

VO1-

STEPPING MOTOR UNIT

18

17

16

15

STEPPING MOTOR

-

M2501

M

+

-

M2502

M

+

OPTICAL PICK UP UNIT

ACTUATOR

FOCUS

12

11

14

13

ACT F+

ACT F-

ACT T+

ACT T-

COIL

TRACKING

COIL

CLK16M

85,86

61~63,

65~71,

76,83

77~80

49

47

84

87

90

88

89

83

48

BDO

OFTR

XRESET

ENS,ENC

CPUIRQ

CPUDTOUT

CPUCLK

CPUDTIN

TX

SYSCLK

DAT3~DAT0

TRSDRV

DA1,DA0

SPDRV

TILTIN

TILT

DTRD

IC6251

C0CBCBE00001

8

VIDEO

51

5,6

52

99

A04

56

55

SW2501

59

VCC

26

TRIN

3,2

VIN2,VIN1

23

VIN3

8

OPOUT

27

MUTE3

9

MUTE1

27

SA-DK10

K1

VIDEO OUT

JK701

VIDEO OUT

G

Y

C

CDET

WIDE1

CR/R

Y

SCLOCK

SDATA

CR/R

Y

YDET

YVDL

C

QR3301

AMP

IC6303

C3EBEC000024

EEPROM

6

5

15

12

11

10

2

+

5

6

IC3091

C0CBCD00002

REGULATOR

IC3301

C1AB00001393

VIDEO BUFFER

C-IN

C-OUT

CV-OUT

CV-SAG

Y-IN

Y-SAG

Y-OUT

118,123,

128,133

35~38,40~43,

45~47,49~51,

54~57,59,31

IC3001

MN677533MP

AV DECORDER

VCOUT

AOUT1,AOUT2

129

VCOUT

134

VYOUT

131

VREFY

LVDD

EXTCK

AOUT0

LRCK

SRCK

X HINT

174

1~10

110

92

93~94

89

90

158~208

IC3051

PQ018EZ01ZP

REGULATOR

IC3061

KM416S1DTG8T

SDRAM

IC4211

C0FBBK000021

6CH AUDIO

D/A CONVERTER

38

45

46,47

41

40

3712

SCLK1

DIN1

DIN2,DIN3

LRCIN

BCK IN

RSTB

33

MDO

+B

48

ZFLG1

12(11)

VOUT3

(VOUT4)

10

VOUT5

9

VOUT6

VOUT1

14(13)

(VOUT2)

ML

MC

MDI

36

35

34

ZFLAG

SL

CNT

SW

FL

CDET

D

B

B1

CLK27M

70~73,

75~78,

80~83

27,32,

33,

60~69

60~63,

65~67,

69

119

VBOUT

IC6222

C0JBAA000001

INVERTER

IC6221

99

CLK27

C0JBAA000001

INVERTER

STATUS

DSPCLK

AMUTE

CMD

WIDE1

TO MAIN

UNIT

D

EXTCLK

NRST

SBI1

SBO1

SBT1

STBDAC2

STATUS

DSPCLK

AMUTE

CMD

WIDE1

28

SER7

PBL(R)

IC201

NJU7313AMT2

SELECTOR

3(29)

MXL

LIN(R)

DATA

SA-DK10

ST

CK

AMUTE

ZFLAG

MUTE

PWCONT

FROM IC601

JK201

AUX1

TUNER

5

6

4(28)

5(24)

2(30)

9

Level shift

Latch circuit

Shift register

IC1

TA7291P

MOTOR DRIVE

Vs

REG

IN1

IN2

Vref

Vcc

GND

147

+B

Q451

SWITCH

OUT1

OUT2

Q1

POWER

SUPPLY

CONTROL

+B

+B

6(26)

7(24)

8

17

DATA

16

CK

14

ST

8

-B

2

10

M

+B

RM1

M5218AFPE3

SW2

SW1

SW3

OP

AMP

IC202

TO DVD UNIT

ZFLAG

D

CMD

DSPCLK

STATUS

AMUTE

WIDE1

33 32

CW

CCW

Q452

PLUNGER

SUPPLY

CONTROL

XOUT

20 19

X451

SW5

SW4

26

PLG

XIN

34 28

HALF

39

27 5

SW4

SW5

PSTN

IC451

C2BBFD000307

MECHA-CONTROL

31 30

SW3

SW1

29

SW2

35

DVD_CLK

DATA011DATA1

DATA0

36

DVD_CMD

12

DATA1

14

37

WIDE 1

DVD_STAT

B_CLK10B_CS9B_REQ8REST

B_CLK

B_CS

B_REQ

4

MUTE

PWCONT

18

REST

29

SA-DK10

PBL(R)

P.B. HEAD

FILTER

R/P HEAD

4

2

IC1000

BA7755A

ANALOG SWITCH

22(1)

+

+

21(2) 20(3) 19(4) 18 17 16 15 14 13 12 10

ALC

REC

PB LIN(R)

3

Q1317

BEAT PROOF

LEVEL

SWITCH

Q1313

SWITCH

Q1309,

Q1310,

Q1312

PB L NF(R)

SWITCH

PB L EQ(R)

SWITCHING

PB/REC

9

PB LOUT(R)

MUTE

SW

TPS GAIN

ALC LOW CUT

TPS

Q1305

SWITCH

+B

Q1304

SWITCH

(REC:H)

Q1308

SWITCH

(CR02:HIGH)

RECLIN(R)

Q1303

SWITCH

L OUT(R)

REC AMP (L)

ALC

TPS OUT

6

+B

VCC

RIPPLE

REJECTION

NOR/CRO SW

LOGIC

IC1001

AN7326K

P/B REC AMP

RF

Q1101

(Q1201)

MUTING

SWITCH

Q1302

DECK

MUTING

CONTROL

REST

B_REQ

B_CS

B_CLK

DATA1

DATA0

95

93

94

92

91

90

MECHARST

MECHRQ

MECHCS

MECHCK

MECHSQ

MECHSI

2

DATA

CLK

3

IC603

BU2090AF-E2

I/O EXPANDER 2

CONTROL

CIRCUIT

LATCH

REGISTER

12-BIT SHIFT

OUTPUT BUFFER

BP

15

14

REC_H

DMT

13

MRT_L

12

5~8

PL_L

11

C2BBGF000280

Q1314

+B

Q1315

SWITCH

MICRO-CONTROLLER

IC601

MOTOR

M

SWITCH

Q1316

SOLENOID

D1302

7

JOG1B

8

JOG1A

CR02

S1303

S1302

METAL

XCOUT

19 20

S1304

RECINH_L

Q1306,Q1307

XCIN

S1305

MODE

INTERFACE

SWITCH

2

MK_IN2

S1306

RECINH_R

3

HALF

S1307

MK_IN1

23 22

PHOTO

INTERRUPTOR

Z1001

XOUT

IC971

ON2180RLC1

(DECK 1)

XIN

A

33

SER3

30

VR601

JOG VOL

X601

X602

Loading...

Loading...