Panasonic SABT-200-P, SABT-200-PC Service manual

PSG0904006CE

A6

Blu-ray Disc Home Theater Sound System

Model No. SA-BT200P

SA-BT200PC

Vol.1

Product Color: (K)...Black Type

Notes: These model’s BD Drive/Digital P.C.B.

Module are - RFKNBT200P (For P);

- RFKNBT200PC (For PC).

Caution:

Pairing of BD Drive and Digital P.C.B. as “BD Drive/Digital P.C.B. Kit Assembly” have to be replaced

together . If the eithe r BD Drive o r Digit al P.C.B. is changed, BD Drive unit has to be re-a ligned. Because the

alignment data for BD Drive Unit is stored in Digital P.C.B.

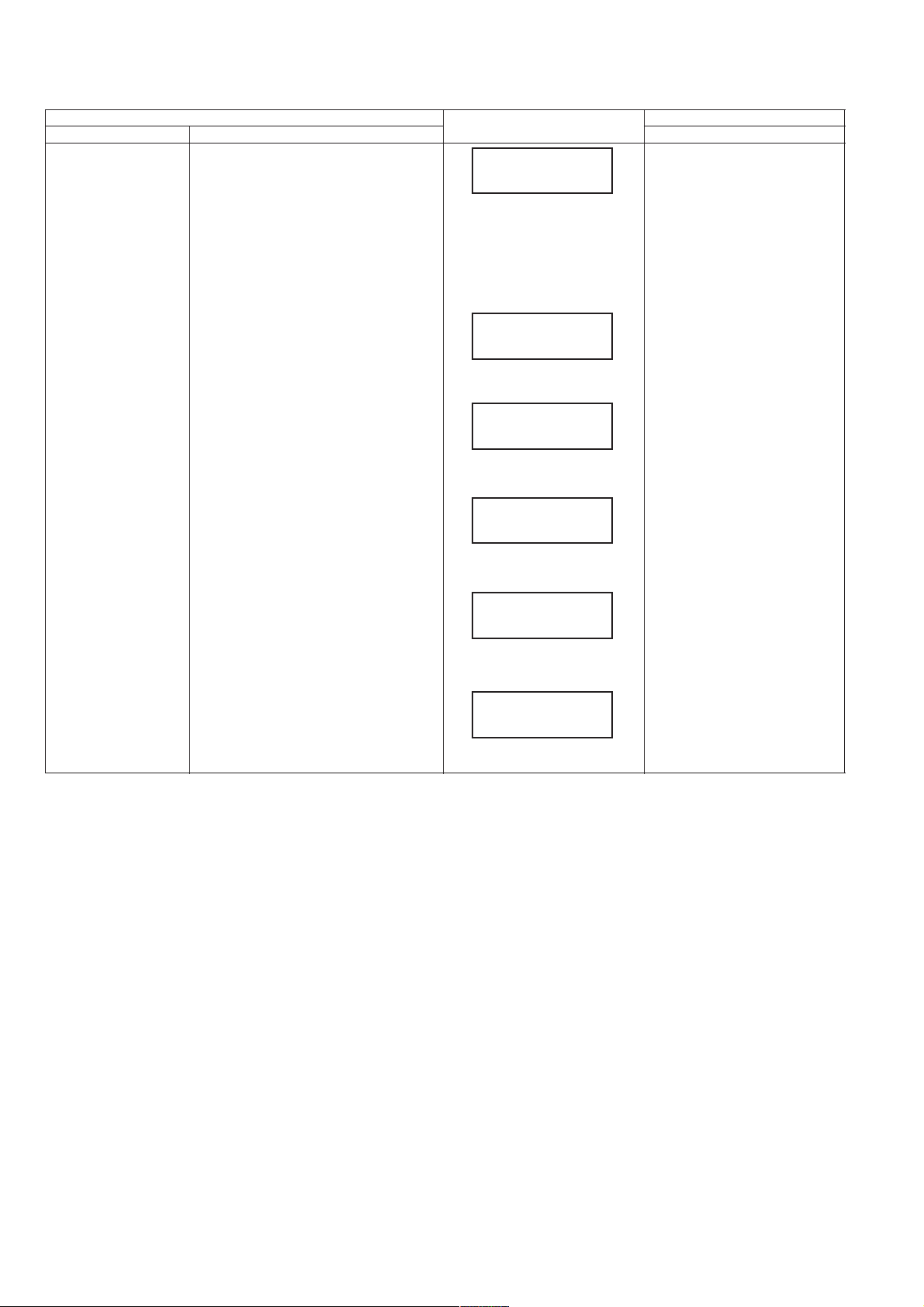

TABLE OF CONTENTS

PAGE PAGE

1 Safety Precautions----------------------------------------------- 3

1.1. GENERAL GUIDELINES-------------------------------- 3

1.2. Before Repair and Adjustment--------------------------3

1.3. Protection Circuitry ----------------------------------------4

© Panasonic Corporation 2009. All rights reserved.

Unauthorized copying and distribution is a violation

of law.

1.4. Safety Parts Information----------------------------------5

2Warning--------------------------------------------------------------6

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatic Sensitive (ES) Devices---------------6

2.2. Precaution of Laser Diode-------------------------------7

2.3. Service caution based on Legal restrictions---------8

2.4. Handling Precautions for Traverse Unit--------------9

3 Service Navigation----------------------------------------------11

3.1. Service Information---------------------------- --------- -11

4 Specifications---------------------------------------------------- 12

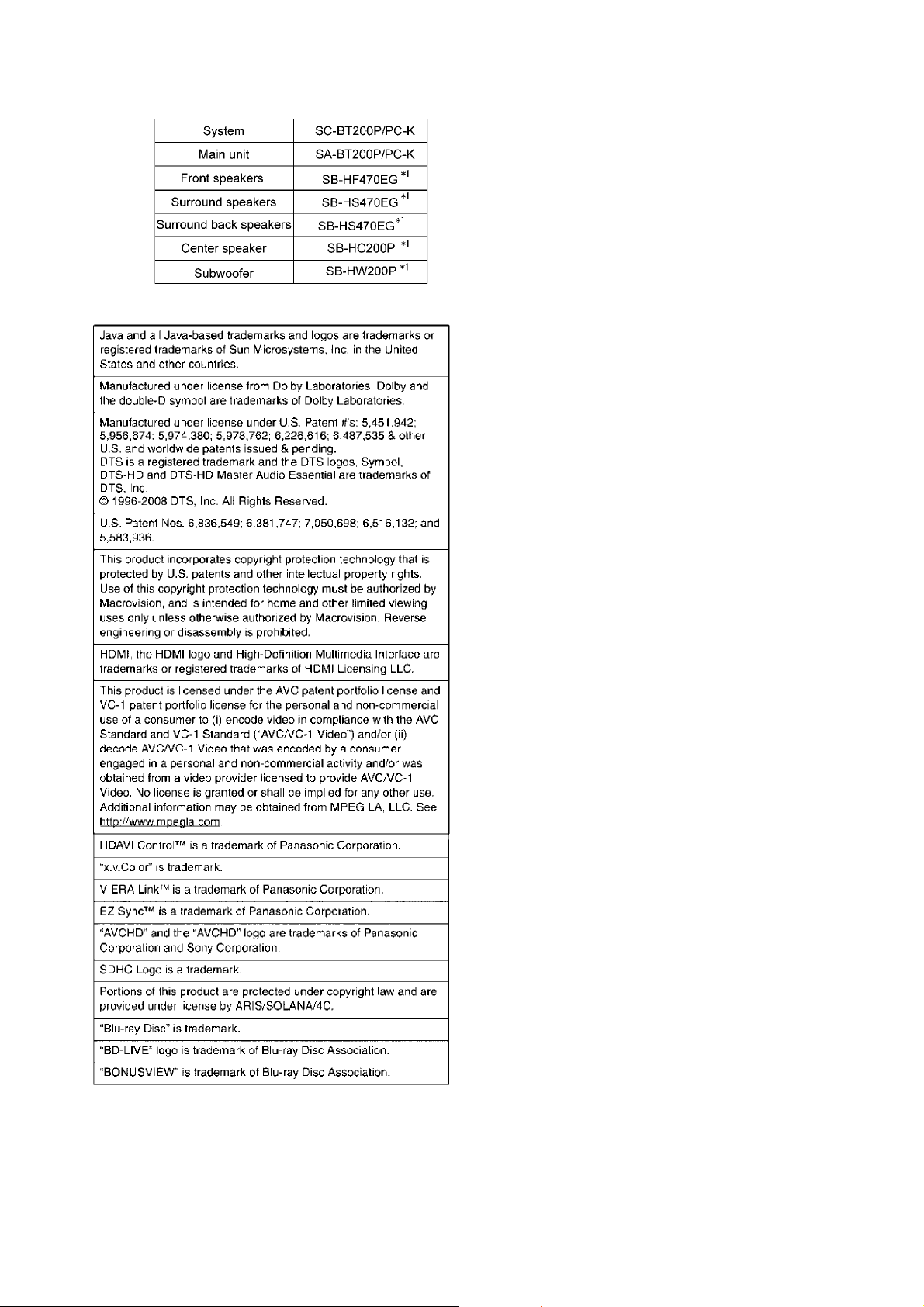

5 Location of Controls and Components------------------14

5.1. Remote Control Key Button Operations------------14

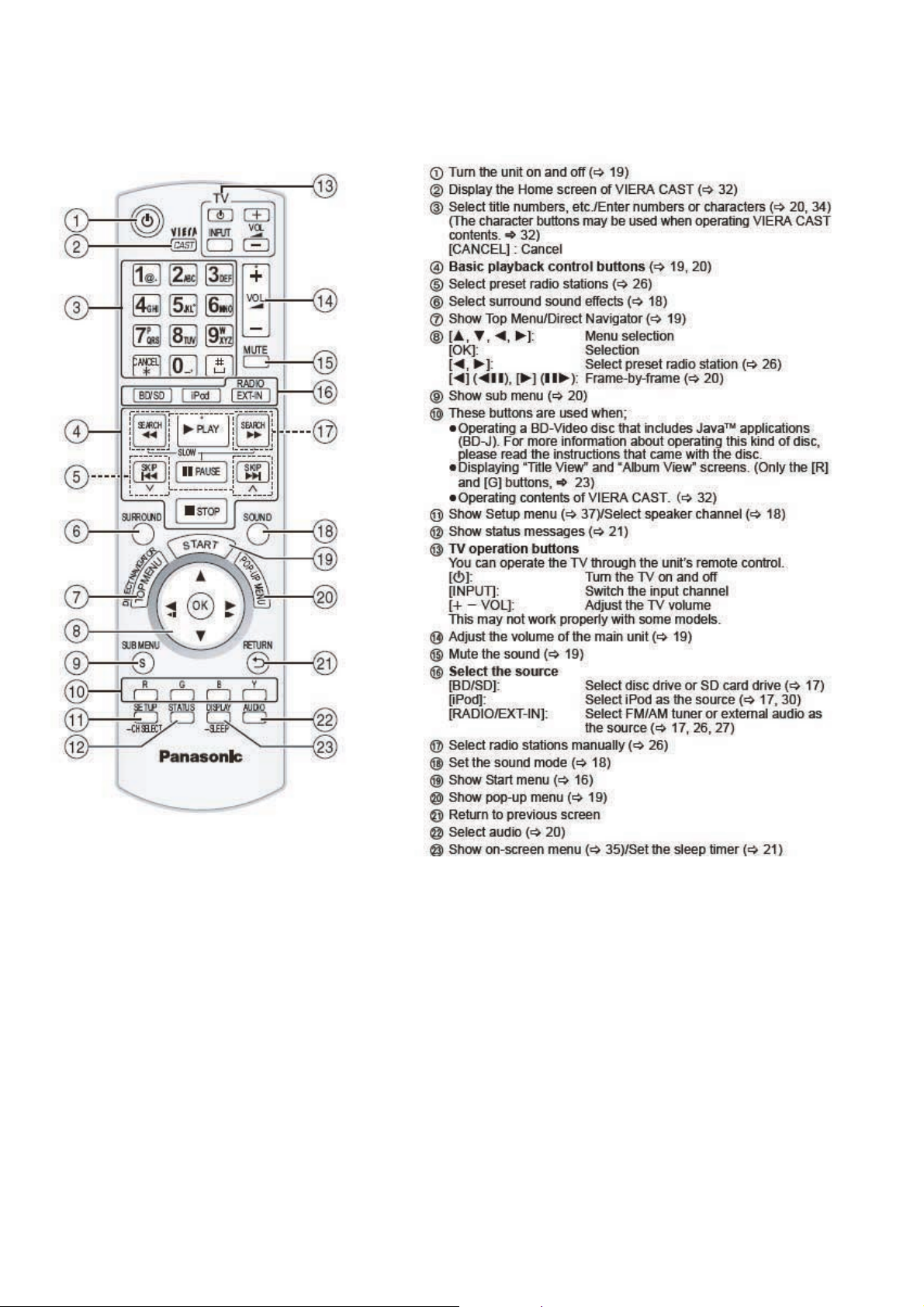

5.2. Main Unit Key Button Operations --------------------15

5.3. Using BD-LIVE or BONUSVIEW in BD-Video ----16

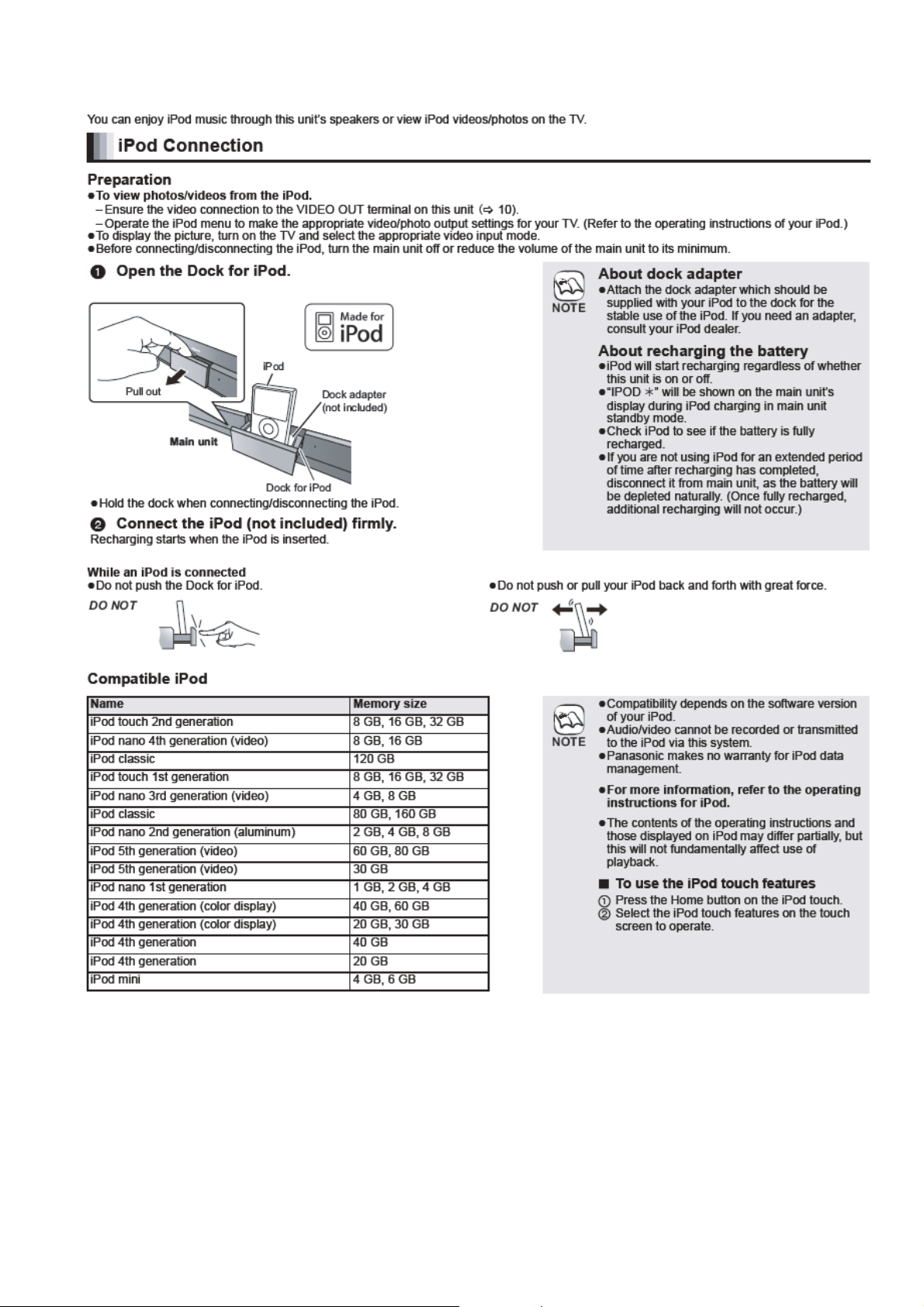

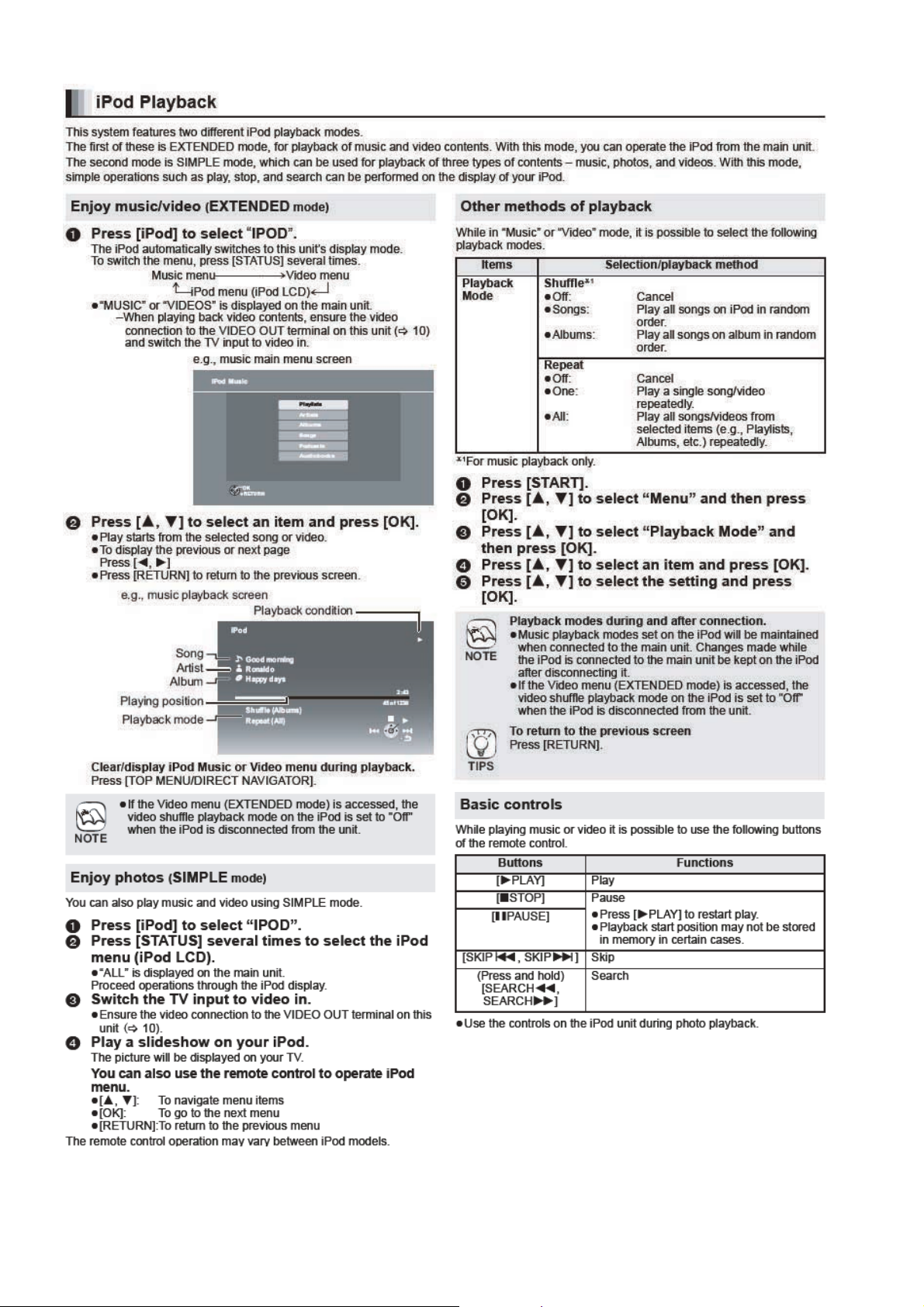

5.4. Using of iPod----------------------------------------------17

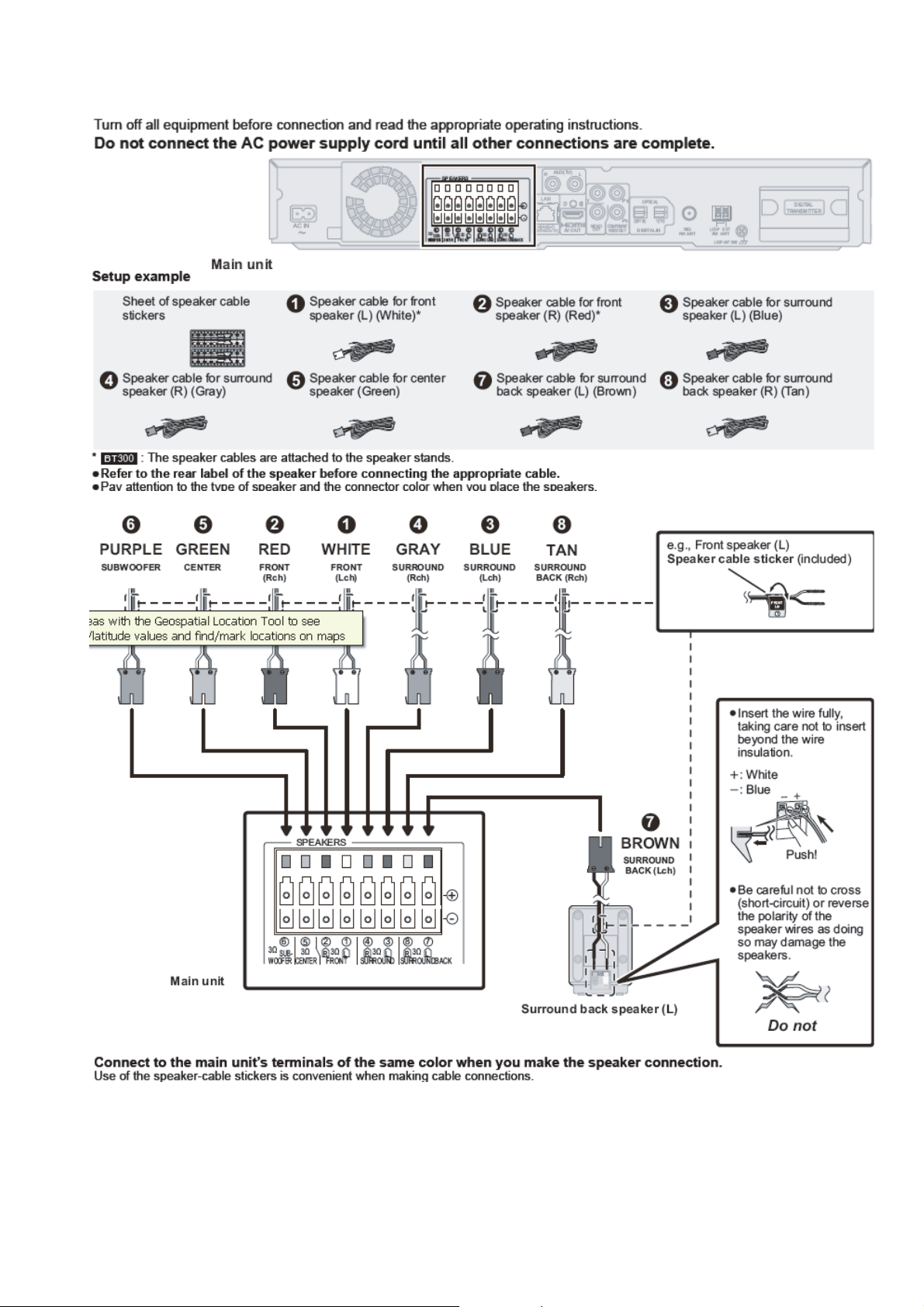

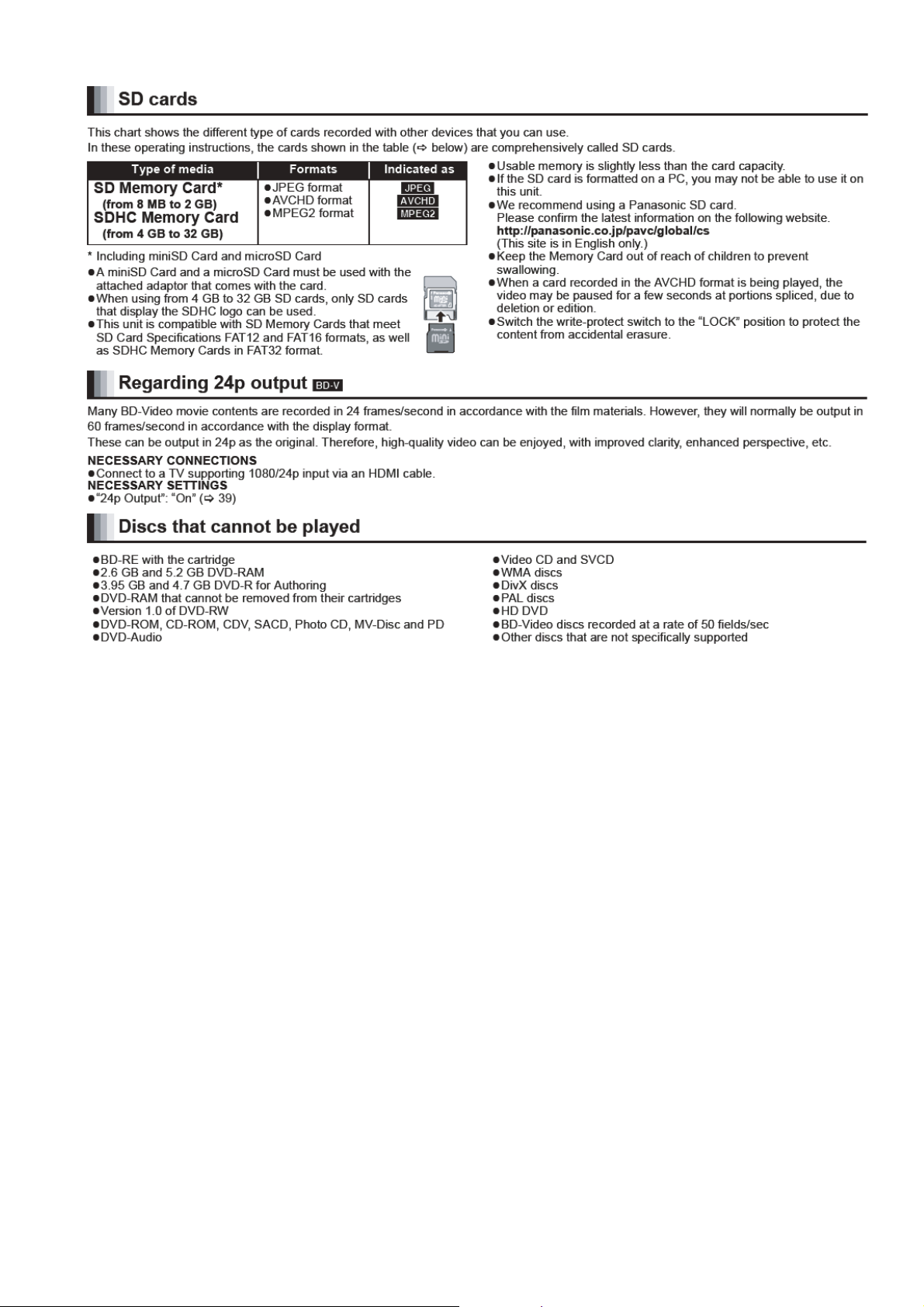

5.5. Speaker Connections -----------------------------------19

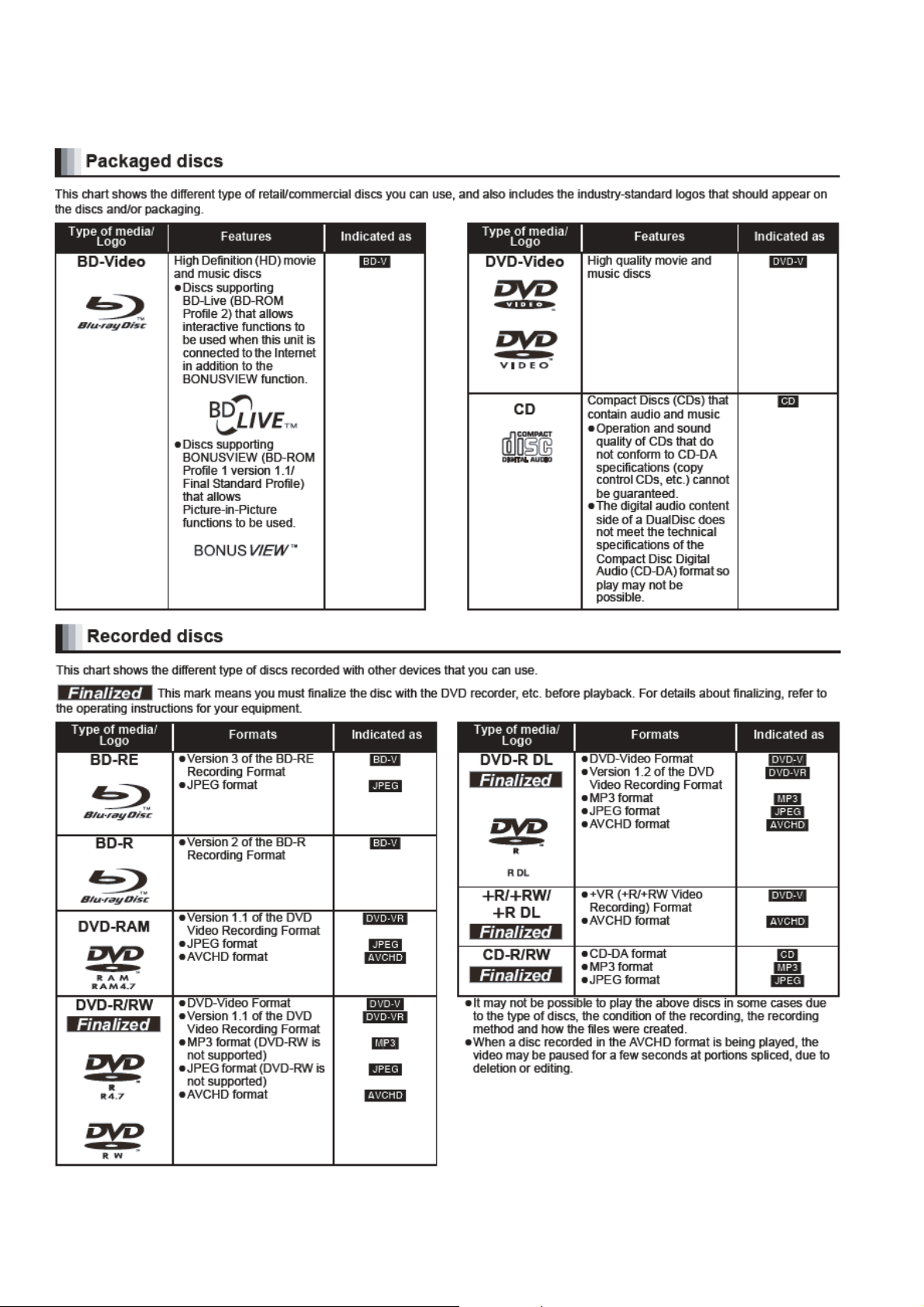

5.6. Disc and SD Card Information------------------------20

5.7. About MP3/JPEG files ----------------------------------22

6 Operating Instructions----------------------------------------23

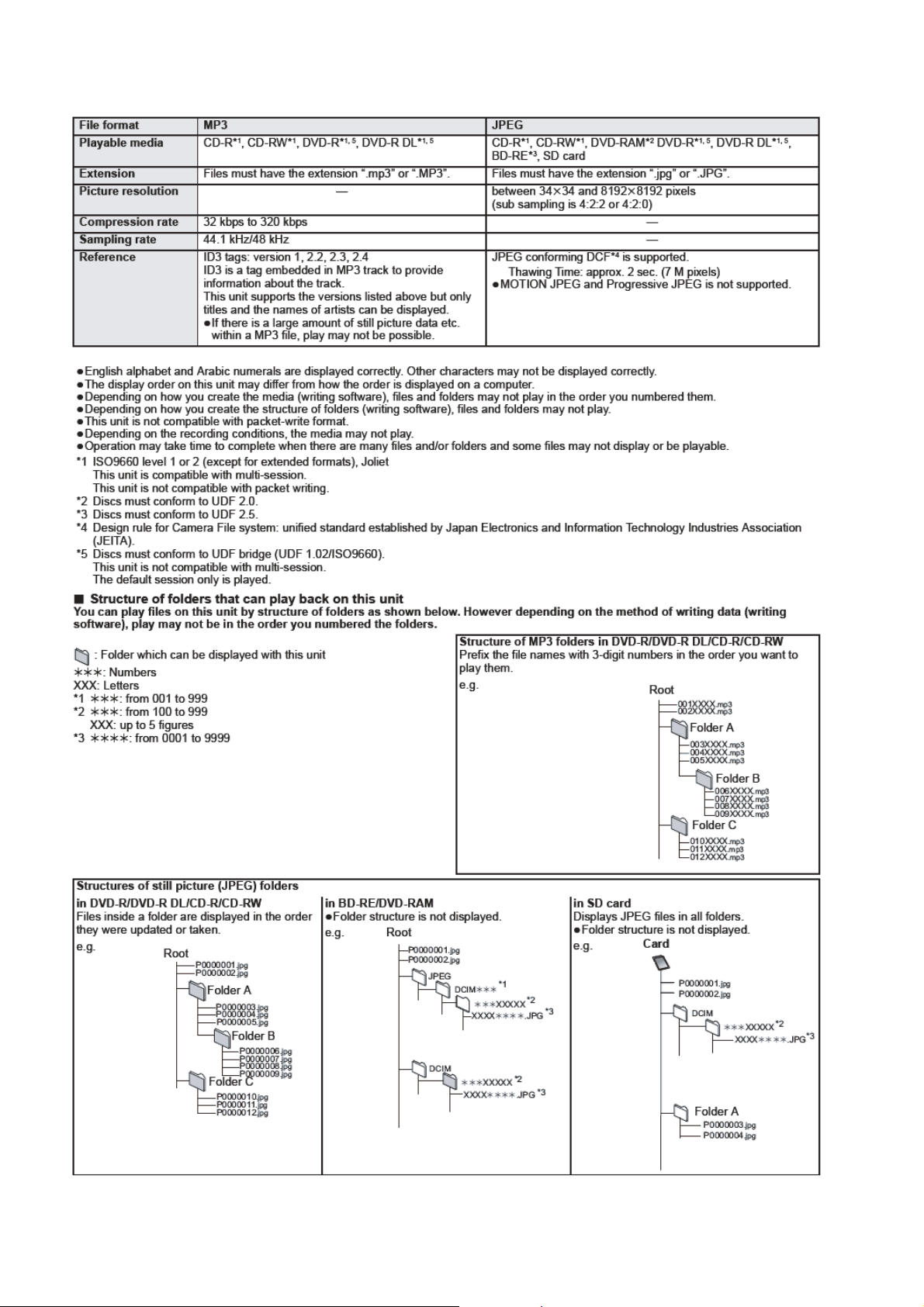

6.1. Taking out the Disc from BD/DVD Drive Unit

when Disc cannot be ejected by OPEN/

CLOSE button---------------------------------------------23

7 Self-Diagnosis and Special Mode Setting --------------24

7.1. Service Mode Summary Table------------------------24

7.2. Special Mode Setting------------------------------------27

7.3. Service Mode at glance --------------------------------29

7.4. Service Mode T able (Wireless - e.g. SH-FX70)--- 34

8 Service Fixture & Tools---------------------------------------36

8.1. Service Tools and Equipment-------------------------36

9 Disassembly and Assembly Instructions---------------37

9.1. Disassembly Flow Chart--------------------------------38

9.2. Main Components and P.C.B. Locations----------- 39

9.3. Disassembly of Top Cabinet---------------------------40

9.4. Disassembly of Rear Panel----------------------------40

9.5. Disassembly of Front Panel Assembly -------------41

9.6. Disassembly of Panel & Power Button P.C.B. ---42

9.7. Disassembly of Setup Mic P.C.B. --------------------43

9.8. Disassembly of SD P.C.B. -----------------------------44

9.9. Disassembly of Tray Lid--------------------------------44

9.10. Disassembly of iPod P.C.B.----------------------------45

9.11. Disassembly of BD Drive Unit ------------------------46

9.12. Disassembly of Main P.C.B.---------------------------47

9.13. Disassembly of Digital P.C.B. -------------------------48

9.14. Disassembly of D-Amp P.C.B. ------------------------49

9.15. Replacement of Audio Amplifier Driver IC

(IC8001) ----------------------------------------------------50

9.16. Replacement of Audio Amplifier Driver IC

(IC8002) ----------------------------------------------------51

9.17. Replacement of Regulator Transistor (Q8026)---53

9.18. Disassembly of AC Inlet P.C.B.-----------------------53

9.19. Disassembly of SMPS P.C.B.-------------------------54

9.20. Replacement of Switching Regulator IC

(IC5701) ----------------------------------------------------55

9.21. Replacement of Rectifier Diode (D5702)-----------55

9.22. Replacement of Regulator Diode (D5801)---------57

9.23. Replacement of Regulator Diode (D5802)---------57

9.24. Replacement of Regulator Diode (D5803)---------58

9.25. Disassembly of Wireless Adapter P.C.B.----------59

9.26. Disassembly of Tuner P.C.B.--------------------------60

10 Service Position-------------------------------------------------61

10.1. Checking & Servicing of Main P.C.B.----------------61

10.2. Checking & Servicing of SMPS P.C.B.------------- 62

10.3. Checking & Servicing of Digital P.C.B. ------------- 63

10.4. Checking and Servicing of D-Amp P.C.B.--------- 65

11 Voltage & Waveform Chart ---------------------------------- 67

11.1. Digital P.C.B. (1/5)--------------------------------------- 67

11.2. Digital P.C.B. (2/5)--------------------------------------- 68

11.3. Digital P.C.B. (3/5)--------------------------------------- 69

11.4. Digital P.C.B. (4/5)--------------------------------------- 70

11.5. Digital P.C.B. (5/5)--------------------------------------- 71

1 1 .6. Main P.C.B. (1/5)----------------------------------------- 72

1 1 .7. Main P.C.B. (2/5)----------------------------------------- 73

1 1 .8. Main P.C.B. (3/5)----------------------------------------- 74

1 1 .9. Main P.C.B. (4/5)----------------------------------------- 75

1 1.10. Main P.C.B. (5/5)----------------------------------------- 76

11.11. Panel P.C.B. ---------------------------------------------- 76

11.12. D-Amp P.C.B. (1/2)-------------------------------------- 77

11.13. D-Amp P.C.B. (2/2)-------------------------------------- 78

11.14. Setup Mic P.C.B. ---------------------------------------- 78

11 .15. SMPS P.C.B. --------------------------------------------- 79

1 1.16. Waveform Table------------------------------------------ 80

12 Illustration of ICs, Transistor and Diode---------------- 81

13 Block Diagram--------------------------------------------------- 83

13.1. Digital (1/2)------------------------------------------------ 83

13.2. Digital (2/2)------------------------------------------------ 84

13.3. IC Terminal Digital Chart (1/2)------------------------ 85

13.4. IC Terminal Digital Chart (2/2)------------------------ 86

13.5. Digital (Audio IO)----------------------------------------- 87

13.6. Digital (Video Out)--------------------------------------- 88

13.7. Digital P.C.B Regulator--------------------------------- 89

13.8. System Control------------------------------------------- 90

13.9. Audio-------------------------------------------------------- 91

13.10. D-Amp------------------------------------------------------ 92

13.11. SMPS------------------------------------------------------- 93

14 Wiring Connection Diagram -------------------------------- 94

15 Schematic Diagram Notes----------------------------------- 95

16 Schematic Diagram-------------------------------------------- 97

16.1. Digital Circuit---------------------------------------------- 97

16.2. Main Circuit-----------------------------------------------119

16.3. Panel Circuit ---------------------------------------------127

16.4. Tuner, Power Button & Setup Mic Circuit---------128

16.5. SD, iPod & Wireless Adapter Circuit---------------129

16.6. D-Amp Circuit--------------------------------------------130

16.7. SMPS Circuit---------------------------------------------136

16.8. AC Inlet Circuit ------------------------------------------138

17 Printed Circuit Board-----------------------------------------139

17.1. Digital P.C.B.---------------------------------------------139

17.2. Main P.C.B.-----------------------------------------------141

17.3. Tuner, Panel, Power Button, Setup Mic & SD

P.C.B.------------------------------------------------------143

17.4. iPod, Wireless Adapter & AC Inlet P.C.B. --------144

17.5. D-Amp P.C.B.--------------------------------------------145

17.6. SMPS P.C.B.---------------------------------------------147

18 Terminal Function of ICs------------------------------------149

18.1. IC6001(C0HBB0000057): IC FL Driver-----------149

19 Exploded View and Replacement Parts List----------151

19.1. Exploded View and Mechanical replacement

Part List ---------------------------------------------------151

19.2. Electrical Replacement Part List--------------------157

2

1 Safety Precautions

1.1. GENERAL GUIDELINES

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, carry out the following leakage current checks to prevent the customer from being exposed to shock hazards.

1.1.1. LEAKAGE CURRENT COLD CHECK

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between the jumpered AC plug and each exposed metallic cabinet part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MΩ and 5.2MΩ.

When the exposed metal does not have a return path to the chassis, the reading must be

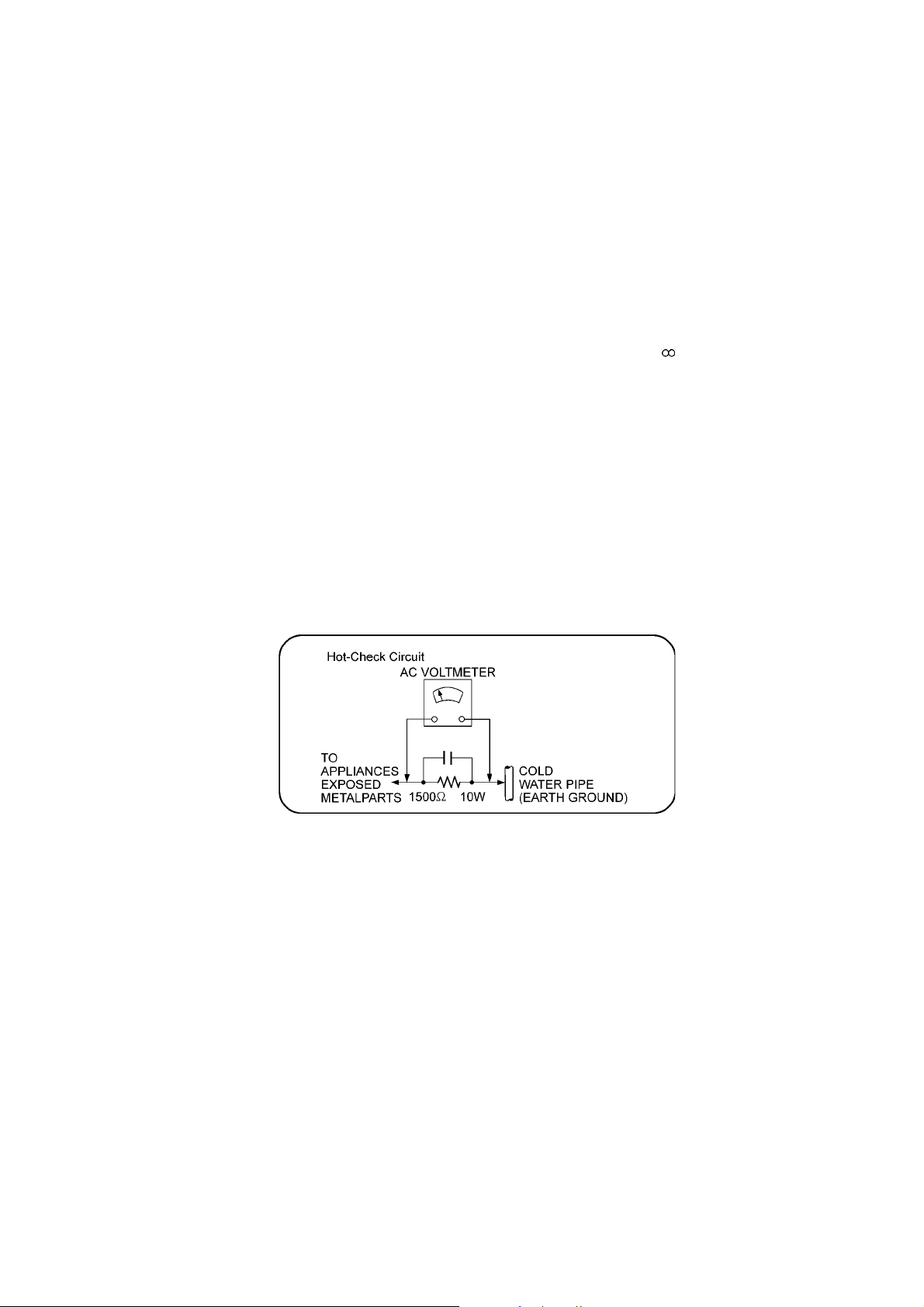

1.1.2. LEAKAGE CURRENT HOT CHECK

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF capacitors, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equiva lent)

may be used to make the hot checks, leakage current must not exceed 1/2 milliamp. In case a measurement is outside of the

limits specified, there is a possibility of a shock hazard, and the equipment should be repaired and rechecked before it is

returned to the customer.

Figure 1

1.2. Before Repair and Adjustment

Disconnect AC power to discharge unit AC Capacitors as such (C5700, C5701, C5702, C5703 , C5704, C5705, C 5706) through a

10 Ω, 10 W resistor to ground.

Caution:

DO NOT SHORT-CIR CUIT DIRECTLY (with a screwdriver bl ade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

Current consumption at AC 120 V, 60 Hz in NO SIGNAL mode volume minimal should be ~ 900 mA.

3

1.2.1. Caution for fuse replacement

1.3. Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

• No sound is heard when the power is turned on.

• Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

“shorted”, or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

4

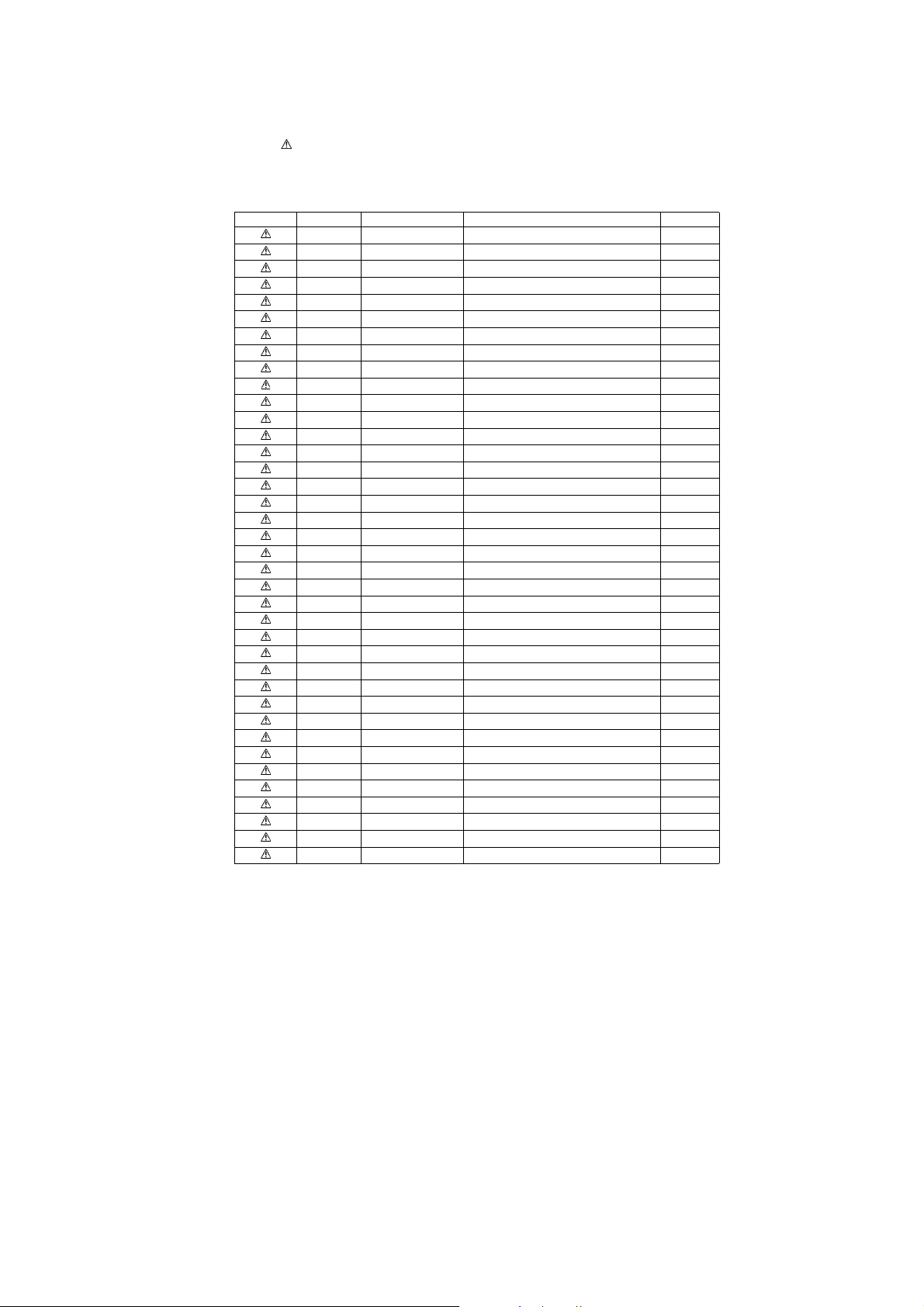

1.4. Safety Parts Information

Safety Parts List:

There are special components used in this equipment which are important for safety.

These parts are marked by ( ) in the Schematic Diagrams & Replacement Parts List. It is essential that these critical parts

should be replaced with manufacturer’s specified parts to prevent shock, fire or other hazards. Do not modify the original design

without permission of manufacturer.

Safety Ref. No. Part No. Part Name & Description Remarks

25 RGR0392A-A1 REAR PANEL P

25 RGR0392A-B2 REAR PANEL PC

41 RKMX0141-1K2 TOP CABINET

69 RFKNBT200P BD DRIVE/DIGITAL P.C.B ASS'Y (RTL) P

69 RFKNBT200PC BD DRIVE/DIGITAL P.C.B ASS'Y (RTL) PC

75 REE1510 RED WIRE (AC INLET-SMPS)

76 REE1511 BLACK WIRE (AC INLET-SMPS)

A2 K2CB2CB00021 AC CORD

A3 RQT9371-P O/I BOOK (En)

A3 RQT9372-C O/I BOOK (Cf) PC

PCB9 REP4505A SMPS P.C.B (RTL)

PCB10 REP4505A AC INLET P.C.B (RTL)

DZ5701 ERZV10V511CS ZNR

L5701 ELF15N035AN LINE FILTER

L5702 ELF21N024A LINE FILTER

L5703 ELF22V035B LINE FILTER

T5701 ETS42BM1EGAC MAIN TRANSFORMER

T5751 ETS19AB2A6AG BACKUP TRANSFORMER

T7001 G4D1A0000117 SWITCHING TRANSFORMER

PC5702 B3PBA0000402 PHOTO COUPLER

PC5720 B3PBA0000402 PHOTO COUPLER

PC5799 B3PBA0000402 PHOTO COUPLER

RY701 K6B1AEA00003 RELAY

F1 K5D802APA008 FUSE

F2 K5G162B00016 FUSE

IP7001 K5H7512A0010 FUSE PROTECTOR

IP55004 K5H252Z00003 FUSE PROTECTOR

IP55005 K5H202Z00005 FUSE PROTECTOR

IP58301 ERBSE3R00U FUSE PROTECTOR

TH5702 D4CAA2R20001 THERMISTOR

P5701 K2AB2B000011 AC INLET

C5700 F1BAF1020020 1000pF

C5701 ECQU2A104MLC 0.1uF

C5702 ECQU2A104MLC 0.1uF

C5703 ECQU2A104MLC 0.1uF

C5704 F1BAF1020020 1000pF

C5705 F1BAF1020020 1000pF

C5706 F1BAF1020020 1000pF

5

2Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatic Sensitive

(ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor “chip” components. The following techniques should be used to help reduce the incid ence of component damage

caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a cond uctive surface su ch as a luminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution:

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) suf-

ficient to damage an ES device).

6

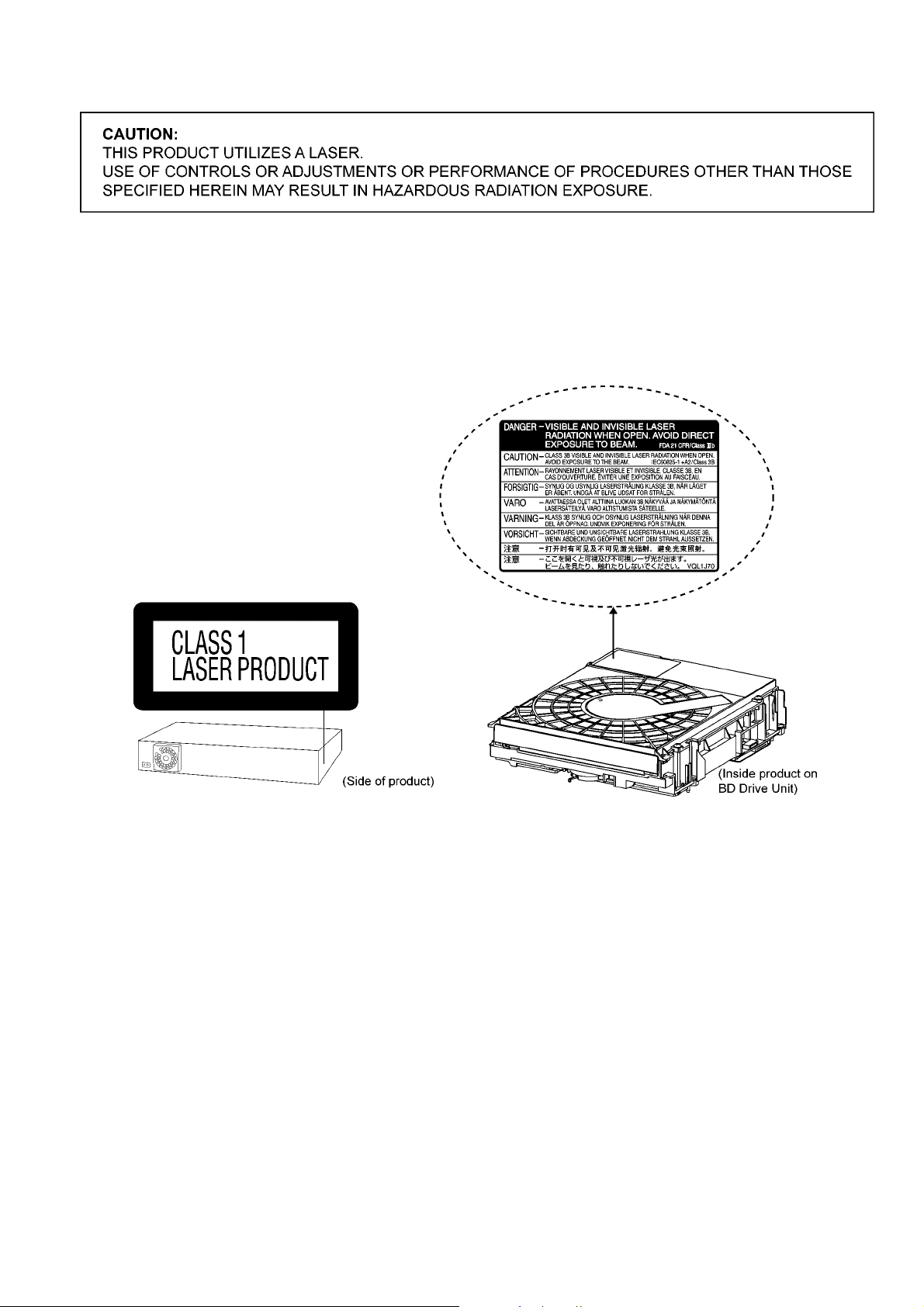

2.2. Precaution of Laser Diode

Caution:

This product utilizes a laser diode with the unit turned “on”, invisible laser radiation is emitted from the pickup lens.

Maximum output radiation power from pickup: 100 µW/VDE

Laser radiation from the pickup unit is safety level, but be sure the followings:

1. Do not disassemble the pickup unit, since radiation from exposed laser diode is dangerous.

2. Do not adjust the variable resistor on the pickup unit. It was already adjusted.

3. Do not look at the focus lens using optical instruments.

4. Recommend not to look at pickup lens for a long time.

7

2.3. Service caution based on Legal restrictions

2.3.1. General description about Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards us ed for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86°F) more than that

of the normal solder.

Definition of PCB Lead Free Solder being used

The letter of “PbF” is printed either foil side or components side on the PCB using the lead free solder.

(See right figure)

Service caution for repair work using Lead Free Solder (PbF)

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the PCB using the lead free solder.)

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

• Since the melting point of the lead free solder is higher th an that of the normal lead solder, it takes the longer time to melt the

lead free solder.

• Use the soldering iron (more than 70W) equi pped with th e temperature contro l after setting the temp erature at 350±30 degrees

C (662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

• The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01K-----------(0.3mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

Note

* Ingredient: tin (Sn), 96.5%, silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

8

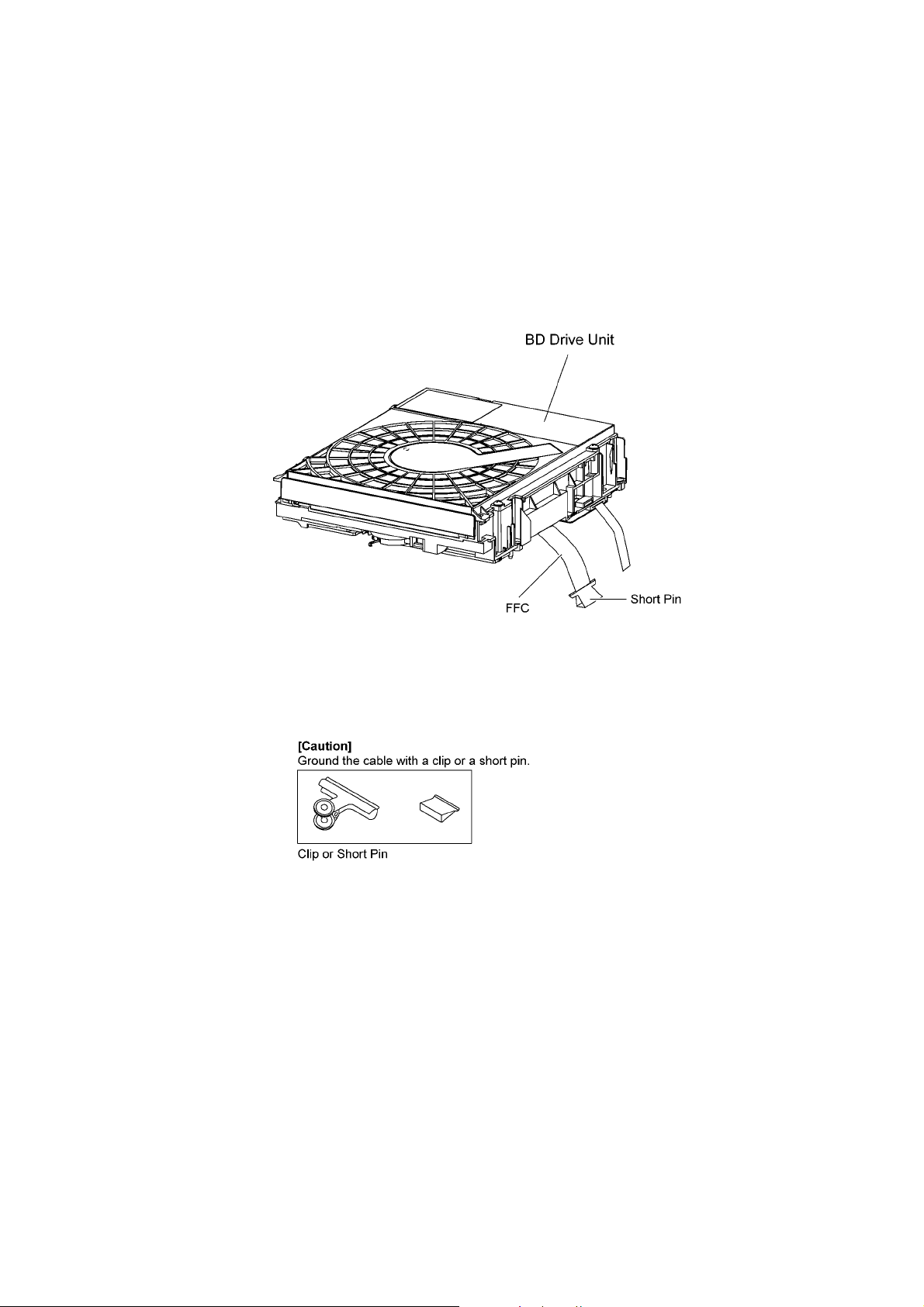

2.4. Handling Precautions for Traverse Unit

The laser diode in the optical pickup unit may break down du e to static electricity of clothes or human body. Special care must be

taken avoid caution to electrostatic breakdown when servicing and handling the laser diode in the traverse unit.

2.4.1. Cautions to Be Taken in Handling the Optical Pickup Unit

The laser diode in the optical pickup unit ma y be damaged due to electrostatic discharge genera ting from clothes or human body.

Special care must be taken avoid caution to electrostatic discharge damage when servicing the laser diode.

1. Do not give a considerable shock to the optical pickup unit as it has an extremely high-precise structure.

2. To prevent the laser diode from the electrostatic discharge damage , the flexible cable of the optical pickup unit removed

should be short-circuited with a short pin or a clip.

3. The flexible cable may be cut off if an excessive force is applied to it. Use caution when handling the flexible cable.

4. The antistatic FPC is connected to the new optical pickup unit. After replacing the optical pickup unit and connecting the flexible cable, cut off the antistatic FPC.

Figure 1

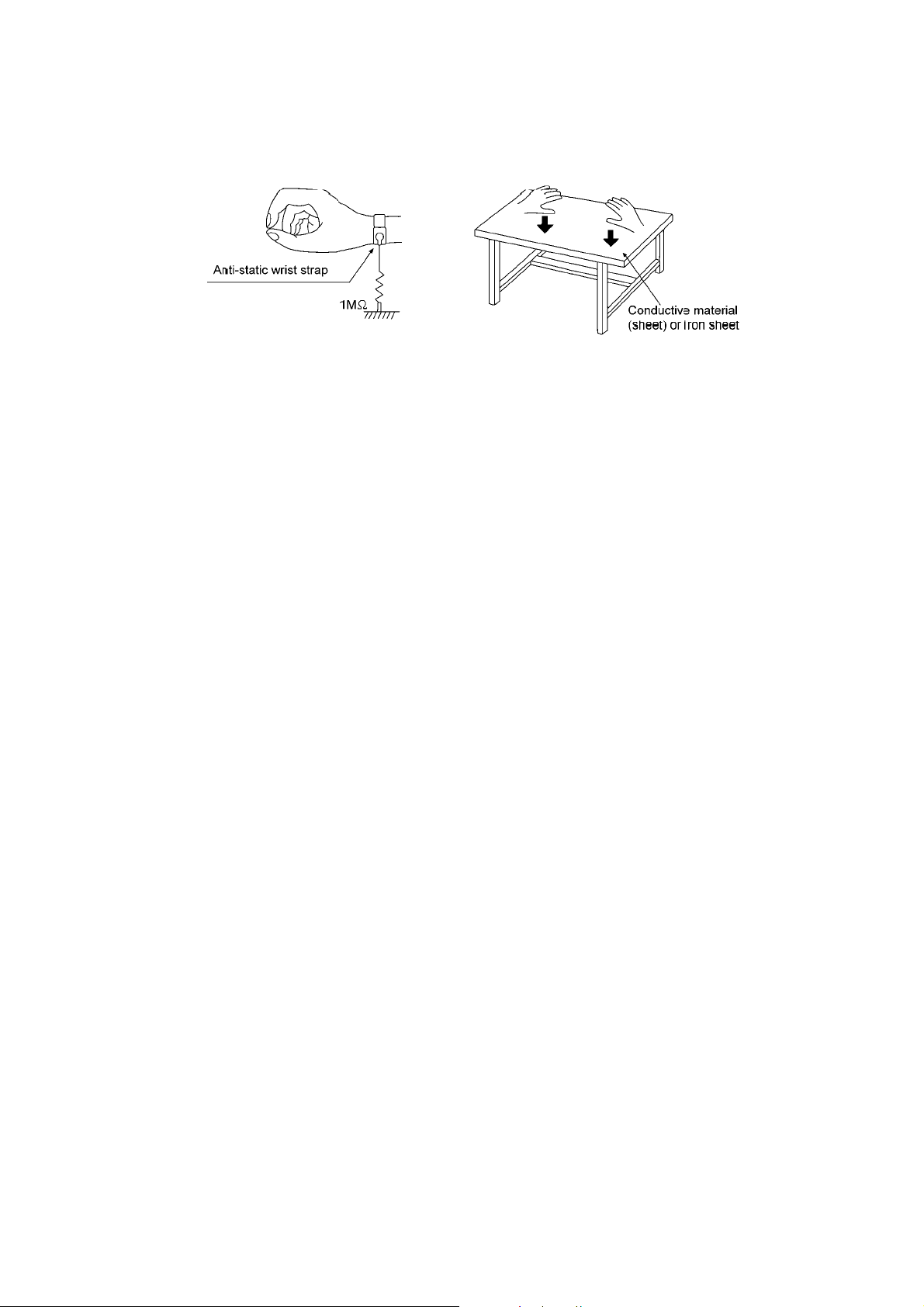

2.4.2. Grounding for electrostatic breakdown prevention

Some devices such as the DVD player use the optical pickup (laser diode) and the optical pickup will be damaged by static electricity in the working environment. Proceed servicing works under the working environment where grounding works is completed.

2.4.2.1. Worktable grounding

1. Put a conductive material (sheet) or iron sheet on the area where the optical pickup is placed, and ground the sheet.

9

2.4.2.2. Human body grounding

1. Use the anti-static wrist strap to discharge the static electricity form your body.

Figure 2

10

3 Service Navigation

3.1. Service Information

This service manual contains technical information which will allow service personnel’s to understand and service this model.

Please place orders using the parts list and not the drawing reference numbers.

If the circuit is changed or modified, this information will be followed by supplement service manual to be filed with the orig inal service manual.

• BD Drive Digital P.C.B Assembly:

1) This service manual does not contain the following information, because of the impossibility of servicing at

component level.

- Exploded View and Parts List for individual parts of BD/DVD drive.

2) The following category are recycle module part. Please send them to Central Repair Center.

- BD Drive/Digital P.C.B. Assembly (BT200P: RFKNBT200P)

(BT200PC: RFKNBT200PC)

• Micro-processor & EEPROM IC:

1) The following components are assembled part (with download firmware or device keys).

- Micro-processor IC, IC100 (BT200P: RFKWMBT200P)

(BT200PC: RFKWMBT200PC)

- EEPROM IC, IC105 (BT200P: RFKWMBT200P)

(BT200PC: RFKWMBT200PC)

• Speaker system

1) For information, please refer to original service manual,

- SB-BT200P (Order No. PSG0904007CE).

• Wireless system

1) This model supports wireless surround (SH-FX70PP).

2) For more information of wireless system, please refer to the original Service Manual, SH-FX70PP (Order No. PSG0901011CE).

11

4 Specifications

Main unit SA-BT200P/PC

O

OGENERAL

OO

Power supply: AC 120 V, 60 Hz

iPod Connector: DC OUT 5V 500mA Max

Power consumption: 120 W

Power consumption in standby mode:

approx. 0.2 W

Dimensions (W××××H××××D): 430 mm×63 mm×327 mm

(16 15/16”X2 31/64”X12 59/64”)

Mass: Approx 3.7 kg (8.2lbs)

Operating temperature range: 0 °C to +40 °C

(+37 °F to +104 °F)

Operating humidity range: 35 % to 80 % RH

(no condensation)

O

OAMPLIFIER SECTION

OO

RMS Output Power: 1000 W

Front Ch:

125 W per channel (3 Ω), 1 kHz, 10% THD

Surround Ch:

125 W per channel (3 Ω), 1 kHz, 10% THD

Surround Back Ch:

125 W per channel (3 Ω), 1 kHz, 10% THD

Center Ch:

125 W per channel (3 Ω), 1 kHz, 10% THD

Subwoofer Ch:

125 W per channel (3 Ω), 100 Hz, 10% THD

FTC Output Power: 520 W

Front Ch:

65 W per channel (3 Ω), 120Hz to 20 kHz, 1% THD

Surround Ch:

65 W per channel (3 Ω), 120Hz to 20 kHz, 1% THD

Surround Back Ch:

65 W per channel (3 Ω), 120Hz to 20 kHz, 1% THD

Center Ch:

65 W per channel (3 Ω), 120Hz to 20 kHz, 1% THD

Subwoofer Ch:

65 W per channel (3 Ω), 45Hz to 120 Hz, 1% THD

Audio input

AUX x1

Digital audio input

Optical digital input: x2

Sampling frequency: 32 kHz, 44.1 kHz, 48 kHz

Audio Format: PCM, Dolby Digital

O

OFM/AM TUNER SECTION

OO

Frequency Modulation (FM)

Frequency range:

87.9 MHz - 107.9 MHz (200-kHz step)

87.5-108.0 MHz (100-kHz step)

Antenna terminals: 75 Ω (unbalanced)

Amplitude Modulation (AM)

Frequency range:

520 kHz - 1710 kHz (10-kHz step)

ONETWORK SECTION

Ethernet

10BASE-T/100BASE-TX (1 system)

O

ODISC SECTION

OO

Playable disc:

BD-Video:BD-ROM Version 2

BD-RE: Version 3 (Single Layer, Dual Layer), JPEG

BD-R: Version 2 (Single Layer, Dual Layer)

DVD-RAM:

DVD Video Recording format, AVCHD format

DVD-R/DVD-R DL:

*7

*8

, JPEG

*5

*2

DVD Video format

*2,8

format

, JPEG*5, MP3

, DVD-Video Recording format*2, AVCHD

DVD-RW:

DVD Video format

*2,8

format

*2

, DVD-Video Recording format*2, AVCHD

+R/+RW/+R DL:

Video

21

, AVCHD format

*2,8

DVD-Video:

DVD-Video format

CD-Audio:

CD-DA

CD-R/CD-RW:

*6

CD-DA, JPEG

, MP3

Optical Pick up System with 2 lenses

Wavelength (BD/DVD/CD): 405/662/782 nm

LASER Specification:

Class 1 LASER Product

Wavelength (BD/DVD/CD): 405/662/782 nm

Laser power:

No hazardous radiation is emitted with the safety protection

OSD CARD SECTION

SD card slot: Connector (1 system)

SD card:

*3

SD Memory Card

*4

:JPEG*5, AVCHD format*8, MPEG2

FAT32

formatted FAT12, FAT16,

-Usable capacity will be less (SD Card)

*2

Finalizing is necessary

*3

Include SDHC card

Include miniSD cards (need a miniSD Adaptor)

Include microSD cards (need a microSD Adaptor)

*4

Does not support long file name

*5

The total combined maximum number of recognizable picture

contents and folder: 300 picture contents and 300 folders.

*6

The total combined maximum number of recognizable picture

contents and folder: 999 picture contents and 99 folders.

*7

The total combined maximum number of recognizable picture

contents and folder: 9999 picture contents and 300 folders.

*8

AVCHD format V1.0

O

OVIDEO SECTION

OO

Signal system: NTSC

Video output

Output level: 1 Vp-p (75 Ω)

Output connector: Pin jack (1 system)

(1080i/720p/480p/480i)

Component video output

Y output level: 1 Vp-p (75 Ω)

output level: 0.7 Vp-p (75 Ω)

P

B

P

output level: 0.7 Vp-p (75 Ω)

R

Output connector: Pin Jack (Y: green, P

P

: Red) (1 system)

R

: blue,

B

HDMI AV output

Output format:

480p (525p)/1080i (1125i)/720p (750p)/1080p(1125p)

Output connector: Type A (19 pin)

TM

:

HDMI

(Deep Color, x.v.Color

TM

, High Bit rate Audio)

HDAVI Control:

This unit supports “HDAVI Control 4” function.

Note:

1. Specifications are subject to change without notice.

Mass and dimensions are approximate.

2. Total harmonic distortion is measured by the digital spectrum

analyzer.

Solder:

This model uses lead free solder (PbF).

12

Wireless Features:

This Model supports wireless surround (e.g:SH-FX70)

Refer to their respective original service manuals for *1.

13

5 Location of Controls and Components

5.1. Remote Control Key Button Operations

14

5.2. Main Unit Key Button Operations

15

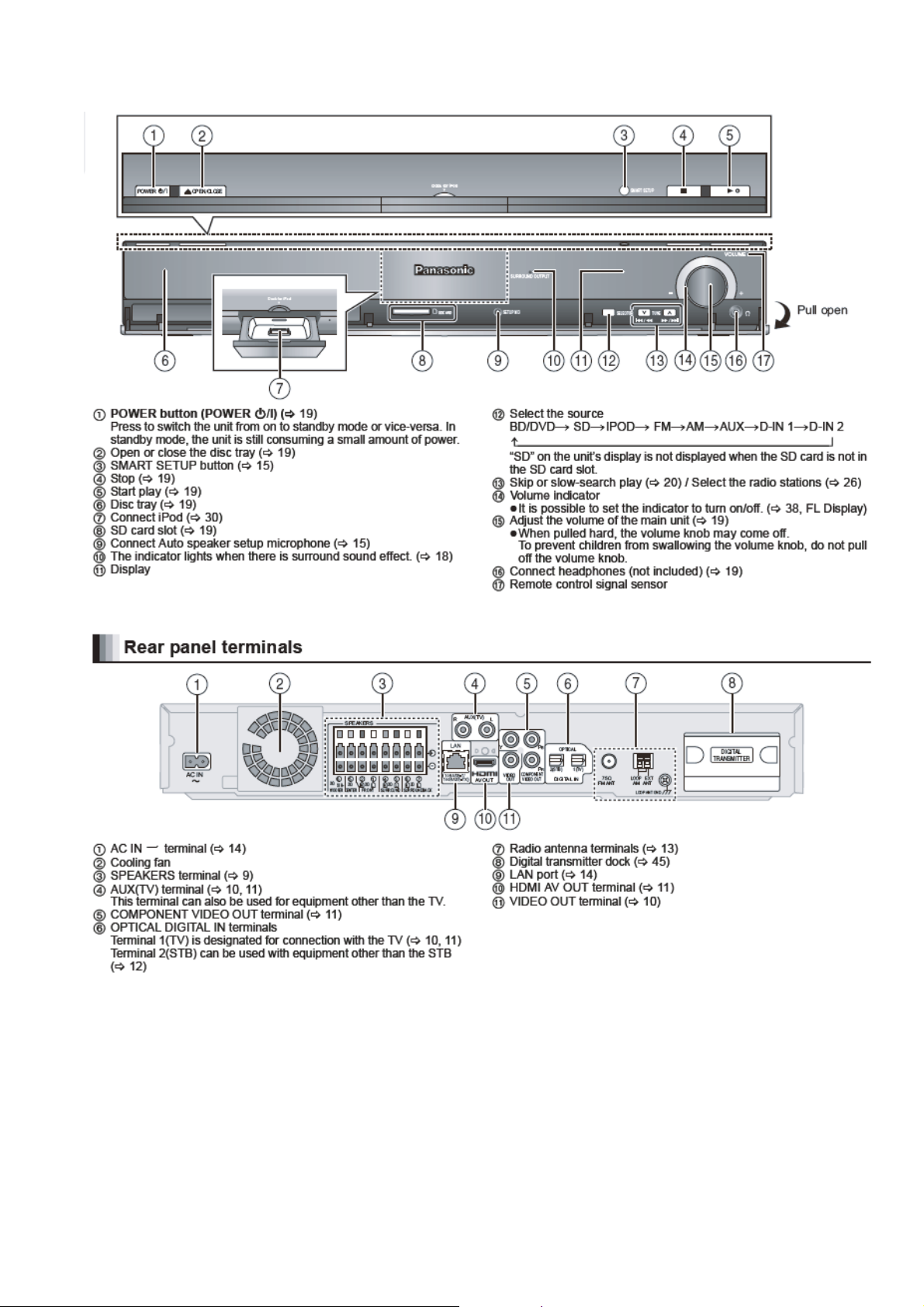

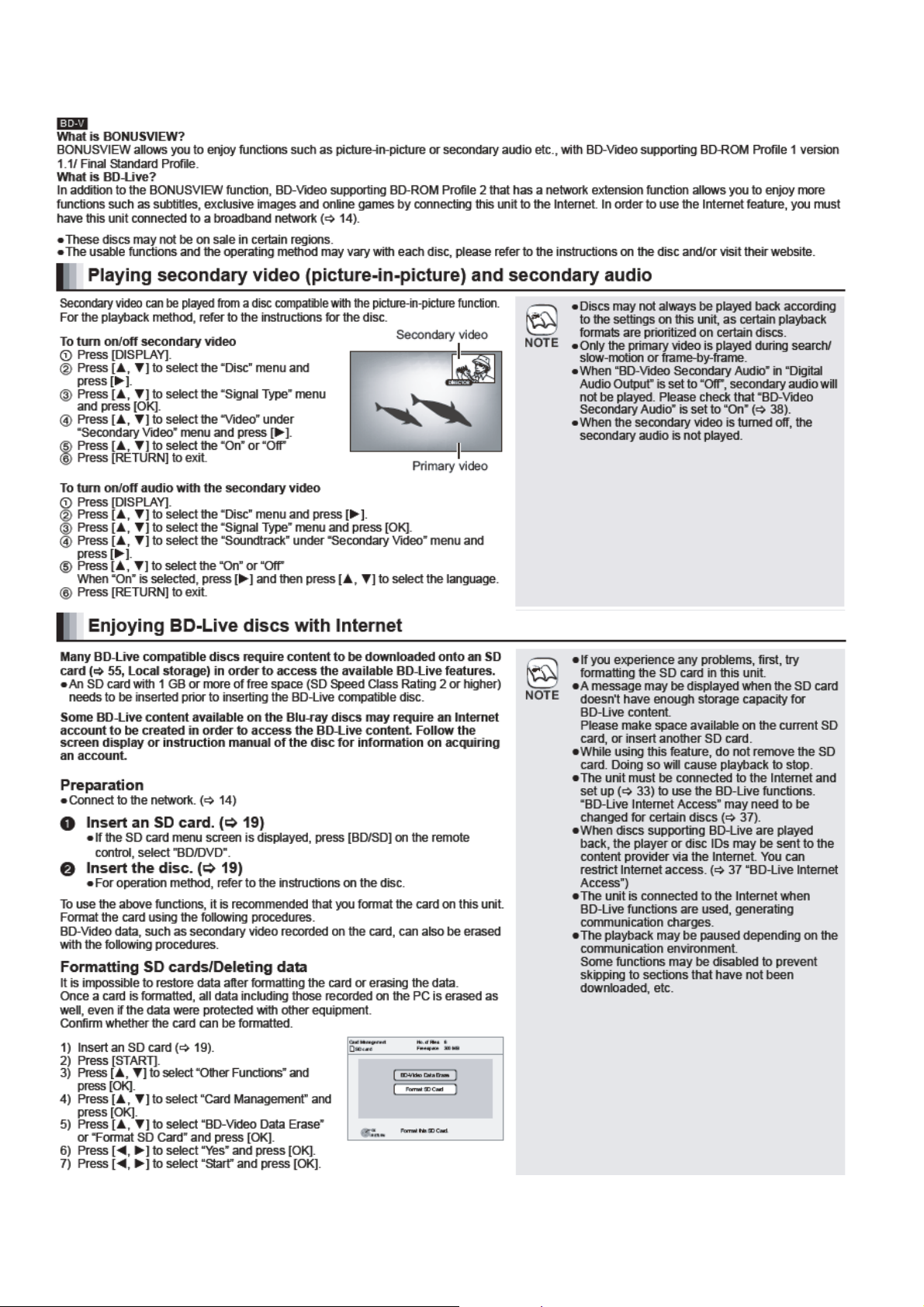

5.3. Using BD-LIVE or BONUSVIEW in BD-Video

16

5.4. Using the iPod

17

18

5.5. Speaker Connections

19

5.6. Disc and SD Card Information

5.6.1. Disc Playability (Media)

20

21

5.7. About MP3/JPEG files

22

6 Operating Instructions

6.1. Taking out the Disc from BD/DVD Drive Unit when Disc cannot be

ejected by OPEN/CLOSE button

6.1.1. Forcible Disc Eject

6.1.1.1. When the power can be turned off.

1. Turn off the power and press [SKIP FWD] and [OPEN/CLOSE] keys on the front panel simultaneously for 5 seconds.

6.1.1.2. When the power can not be turned off.

1. Press [POWER] key on the front panel for over 10 seconds to turn off the power forcibly, and press [SKIP FWD] a nd [OPEN/

CLOSE] key on the front panel simultaneously for 5 seconds.

6.1.2. When the Forcible Disc Eject can not be done.

1. Turn off the power and pull out AC cord.

2. Remove the Top Cover.

3. Insert Eject Pin (JZJ0484) into the hole on the bottom of BD/DVD Drive and slide the Eject Pin in the direction of the arrow to

eject tray slightly.

23

7 Self-Diagnosis and Special Mode Setting

7.1. Service Mode Summary Table

Self-Diagnosis Function provides information for error to service personnel by Self-Diagnosis Display when any error has occurred.

U**, H** and F** are stored in my memory and held.

• You can check latest error code by transmitting [0] [1] of Remote Control in Service Mode.

Automatic Display on FL will be cancelled when the power is turned off or AC input i s turned off during self-diagnosis display is

ON.

24

7.1.1. Error Code Table 1

Error Code Diagnosis contents Description Monitor Display Automatic FL display

U30 Remote control code error Display appears when main unit and remote

U59 Abnormal inner temperature

U71 HDMI incompatible error

U72 HDMI connection error

U73 HDMI connection error

F99 Hang-up Displayed when communication error has

H19 Inoperative fan motor When inoperative fan motor is detected after

F00 No error information Initial setting for error code in memory

F34 Initialization error when main

F58 Drive hardware error When drive unit error is detected, the event is

UNSUPPORT

NO READ Disc read error *A disc is flawed or dirty.

HARD

ERR

detected

(HDCP incompatible)

(communication error)

(authentication error)

microprocessor is started up

for program recording

Unsupported disc error *An unsupported format disc was played,

Drive error The drive detected a hard error. DVD drive error. Display for 5 seconds.

controller codes are not matched.

Display appears when the drive temperature

exceeds 70 C.

The power is turned off forcibly.

For 30 minutes after this, all key entries are

disabled. (Fan motor operates at the highest

speed for the first 5 minutes. For the remaining 25 minutes, fan motor is also stopped.)

The event is saved in memory as well.

Display this error when the equipment (compatible with DVI such as TV, amplifier etc.)

connected to the unit by HDMI is incompatible

with HDCP.

*HDCP=High-bandwidth Digital Content Protection

This error is displayed when there are any

communication problems with the unit and the

equipments (TV, amplifier etc.) connected to

the unit by HDMI. (or when there is a problem

with the HDMI cable)

when authentication error occurs while the

equipments (TV, amplifier etc.) are connected

by HDMI. (or when there is a problem with the

HDMI cable)

occurred between Main microprocessor

and Timer micropro

powered on, the power is turned off

automatically.

The event is saved in memory.

(Error code Initialization is possible with error

code initialization and main unit initialization.)

When initialization error is detected after

starting up main microprocessor

turned

is off

The event is saved in memory.

saved in memory.

although the drive starts normally.

*The data format is not supported, although

the media type is supported.

*Exceptionally in case of the disc is dirty.

*A poor quality failed to start.

*The track information could not be read.

cessor (IC7501).

the

automatically.

No display

No display

No display

No display

No display

No display

No display No display

No display No display

No display No display

power

No display No display

This disc is

incompatible.

Cannot rea d.

Please check the

disc.

SET *

* is remote controller code of the

main unit.

Display for 5 seconds.

U59

U59 is displayed for 30 minutes.

U71

U72

U72 display disappears when

error has been solved by Power

OFF/ON of connecting equipment

or by inserting/removing of HDMI

cable.

U73

U73 display disappears when

error has been solved by Power

OFF/ON of connecting equipment

or by inserting/removing of HDMI

cable.

F99

Displayed is left until the [POWER]

key is pressed.

UNSUPPORT

NOREAD

HARD ERR

The character indication flows

sideways.

25

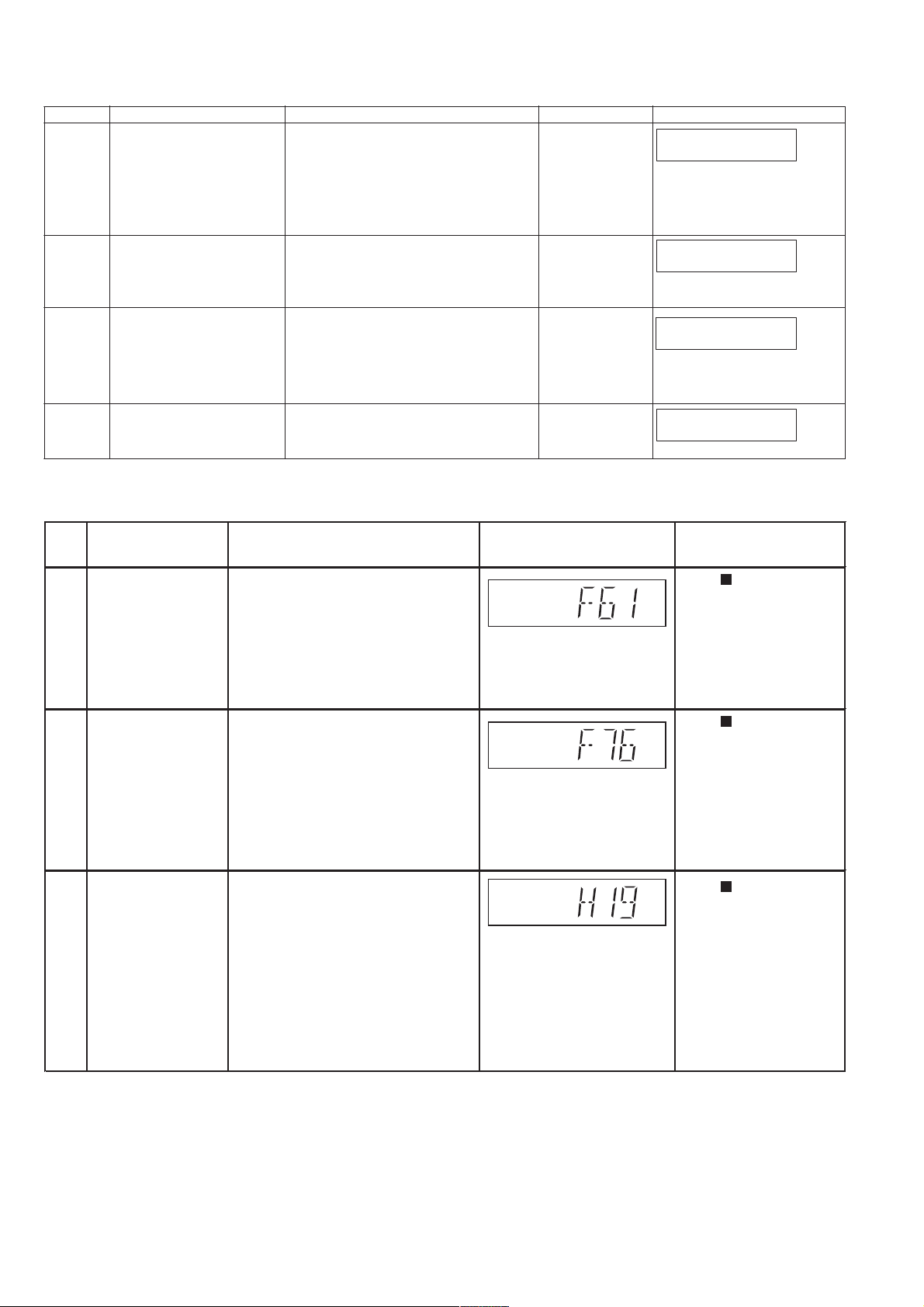

7.1.2. Error Code Table 2

Error Code Diagnosis contents Description Monitor Display Automatic FL display

SELF

CHECK

PLEASE

WAIT

UNFORMAT

Restoration operation Since the power cord fell out during a power

failure or operation, it is under restoration

operation.

*It will OK, if a display disappears automatically. If a display does not disappear, there is

the possibility that defective Digital P.C.B. /

DVD drive.

Unit is in termination process Unit is in termination process now.

BYE is displayed and power will be turned off.

Unformatted disc error You have inserted an unformatted DVD-RAM

or DVD-RW that is unformatted or recorded

on other equipment.

No display

No display

The disc is not

formatted properly.

SELF CHECK

PLEASE WAIT

The character indication flows

sideways.

UNFORMAT

No PLAY When there is a viewing restric-

tion on a BD-Video or DVDVideo.

Rating password is set. No display

No PLAY

7.1.3. Power Supply & Digital Amplifier Error Code Table

Error

Code

F61 The abnormalities In normal operation, when DCDET2 goes Press [ STOP] on main

F76F76

Diagnosis Contents Description of error Automatic FL Display Remarks

in an output or power to "L" (Low) (Not during POWER OFF unit for next error.

supply circuit of condition), F61 appears on FLDisplay

POWER AMP for 1 second and PCONT goes to

"L" (Low).This is due to speaker output

has DC voltage or fan is not working.

Abnormality in the

output voltage of detected "L" (Low) for two consecutive unit for next error.

stabilized power times, F76 is displayed on FL for

supply 1 second and after that PCONT will be

In normal operation when DCDET1 is

turned to "L" (Low). This is due to any of

the DC voltages (+9V, +7V, -7V, +5V,

+5.3V etc.) C22 not available.

Press [ STOP] on main

H19

Fan Module

Fan Module is not operating properly

Press [ STOP] on main

unit for next error.

26

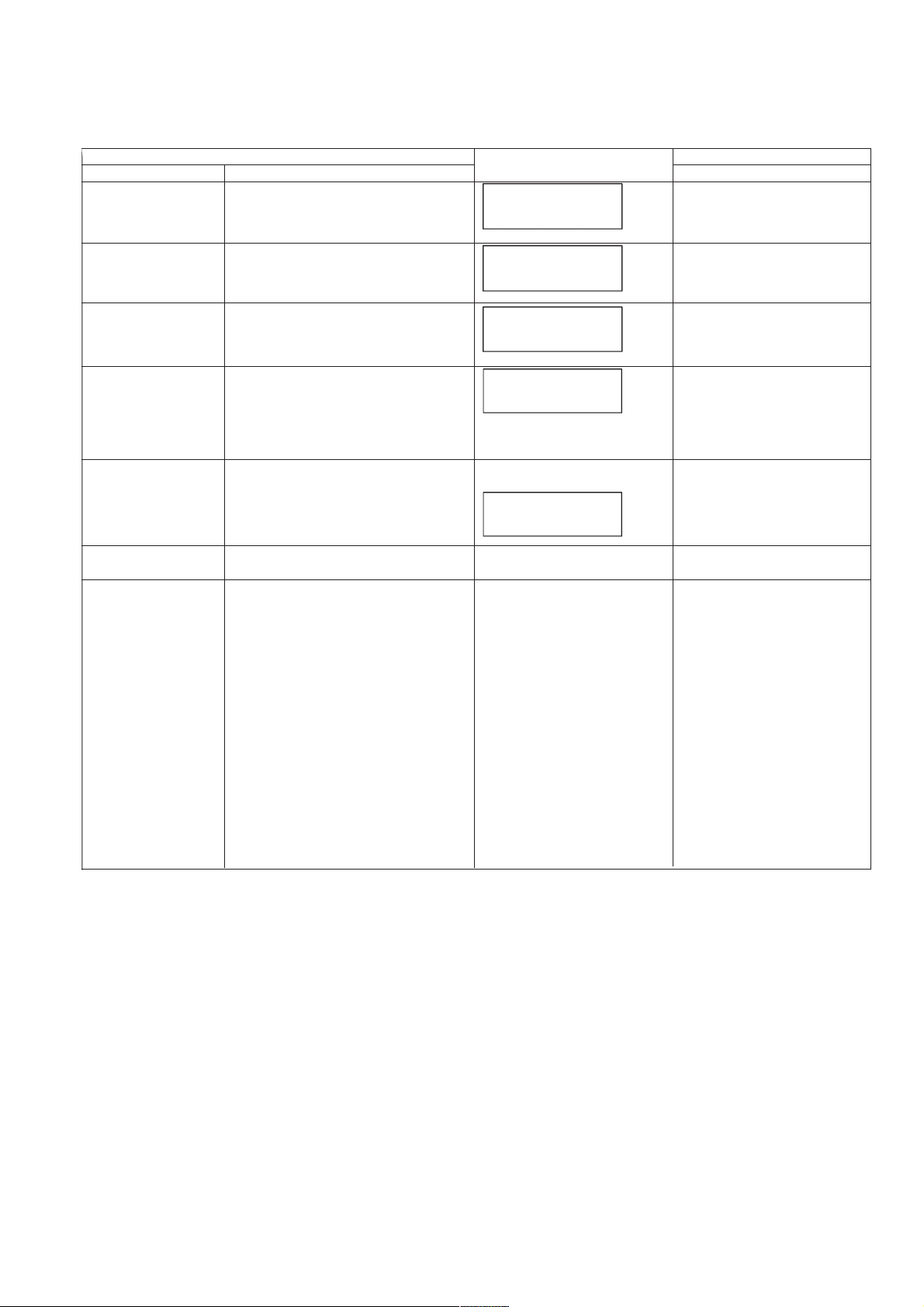

7.2. Special Mode Setting

7.2.1. Service Mode Table 1

Item FL display Key operation

Mode name Description Front Key

Initialize Mode *All the main unit’s parameters are initialized. Press [STOP], [SKIP FWD] and

INITIALIZE

Rating password The audiovisual level setting password is ini-

Service Mode Setting every kind of modes for servicing.

BD-ROM history cleaning < Persistent Storage> of BD-ROM standard is

Forced disc eject Removing a disc that cannot be ejected.

Forced power-off When the power button is not effective while

Aging Perform sequence of modes as * Aging

tialized to Level 8.

*Details are described in 7.3.1. Service Mode

at a glance.

cleaned.

Screen display: [The player’s history data has

been cleared] is displayed for five seconds.

The tray will open and unit will shift to P-off

mode.

While Demonstration Lock is being set, this

Forced disc eject function is not accepted.

power is ON, turn off the power forcibly.

Description shown below continually.

INITINIT

SERVICE

************

Same display as before ex

The display before execution

leaves.

ecution.

******

Display in P-off mode. Press [POWER] key over than 10

Display following the mode. When the power is ON, press

[OPEN/CLOSE] keys simultaneously for five seconds when

power is off.

Open the tray, and press [SKIP

REV] on remote control, follow by

[PLAY] simultaneously for 5

seconds.

When the power is off, press [SKIP

&

FWD] [SOUND]

and keys[PLAY] simultaneously for

5 seconds.

When disc is not in tray. press

[STOP] and [POWER] keys simultaneously for 5 seconds.

When power on press [STOP] on

main unit & [POWER] on remote

control.

When power is off, press [SKIP] &

[OPEN/CLOSE] keys simulta-

neously for 5 seconds or more.

seconds.

[SKIP FW], [PLAY] & [OPEN/

CLOSE] simultaneously for over

seconds and less than 10 seconds.

on remote control

NOTE1:

If Unit has not turned into Aging

mode by operations shown above,

execute TEST MODE once and re-

execute operation shown above.

(*All the main unit s parameters

include tuner are initialized by

mode.)

TEST

NOTE2:

If the unit has hung-up because of

pressing keys for over 10 seconds,

once turn off the power, and re-exe-

cute this command.

*When releasing Aging mode, press

[POWER] key over 10 seconds.

5

27

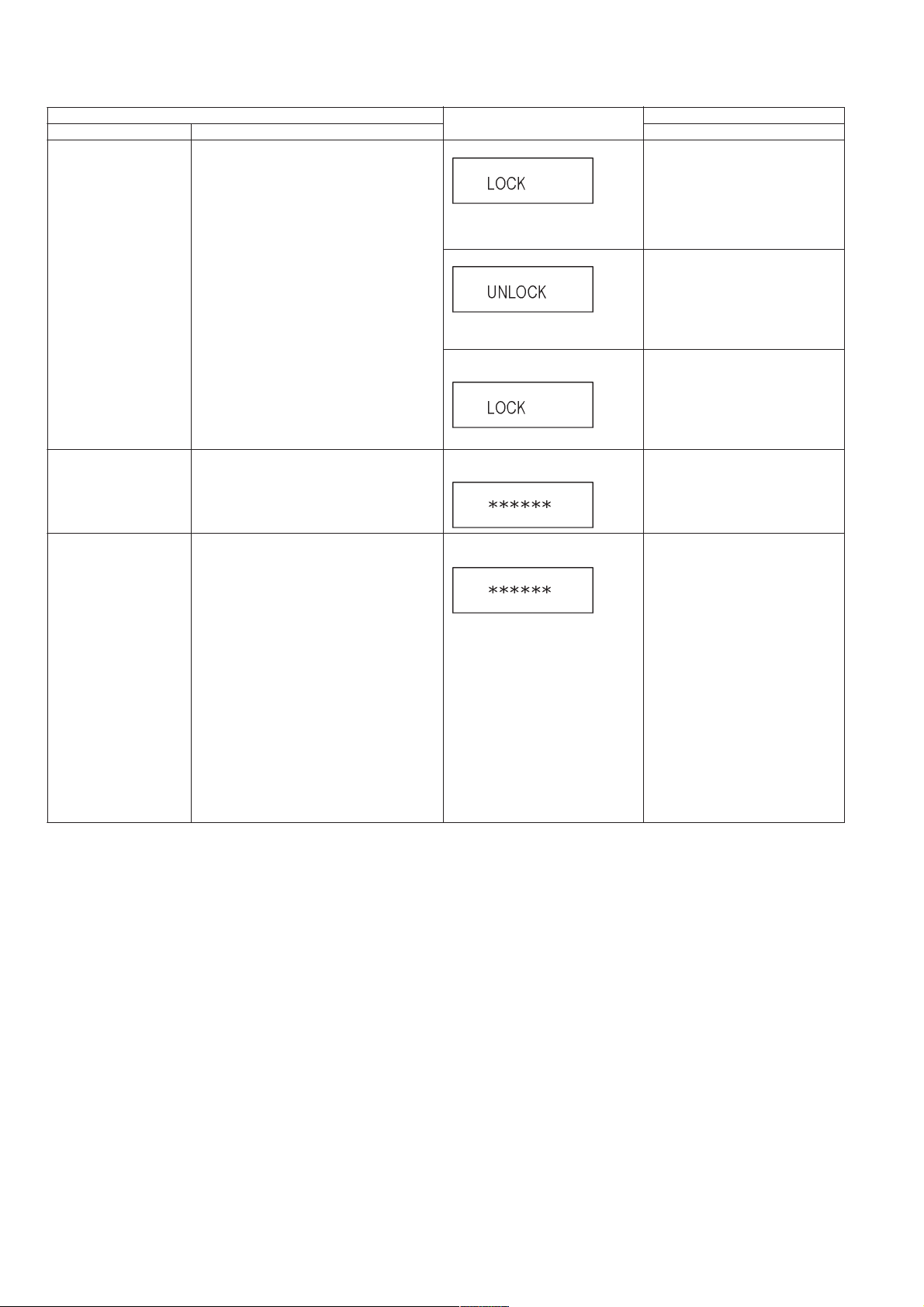

7.2.2. Service Mode Table 2

Item FL display Key operation

Mode name Description Front Key

Demonstration lock/

unlock

Progressive initialization The progressive setting is initialized to Inter-

Ejection of the disc is prohibited.

The lock setting is effective until unlocking the

tray and not released by Main unit

initialization of service mode.

lace.

*When lock the tray.

LOCK is displayed for 3 seconds.

*When unlock the tray.

UNLOCK is displayed for 3 sec-

onds.

*When press OPEN/CLOSE key

while the tray being locked.

Display LOCK for 3 seconds.

The display before execution

leaves.

When the power is on, press

[PLAY] and [OPEN/CLOSE] keys

simultaneously for 5 seconds.

Note:

When a disc is not in tray, this

setting is not effective.

When the power is on, press

[PLAY] and [OPEN/CLOSE] keys

simultaneously for 5 seconds.

Press [OPEN/CLOSE] key while the

tray is being locked.

When the power is on (SS mode),

press [STOP] and [PLAY] simultaneously for 5 seconds.

Micro-P version check

FL Display

M-XXXX

S-YYYY

ZZZZZZ

AA/BB/CC

POWER

M-> main version

S-> sub F/W

ZZZZZZ-> model no

AA/BB/CC-> Date

When the power is on, press &

hold [SKIP REV] follow by

[POWER].

28

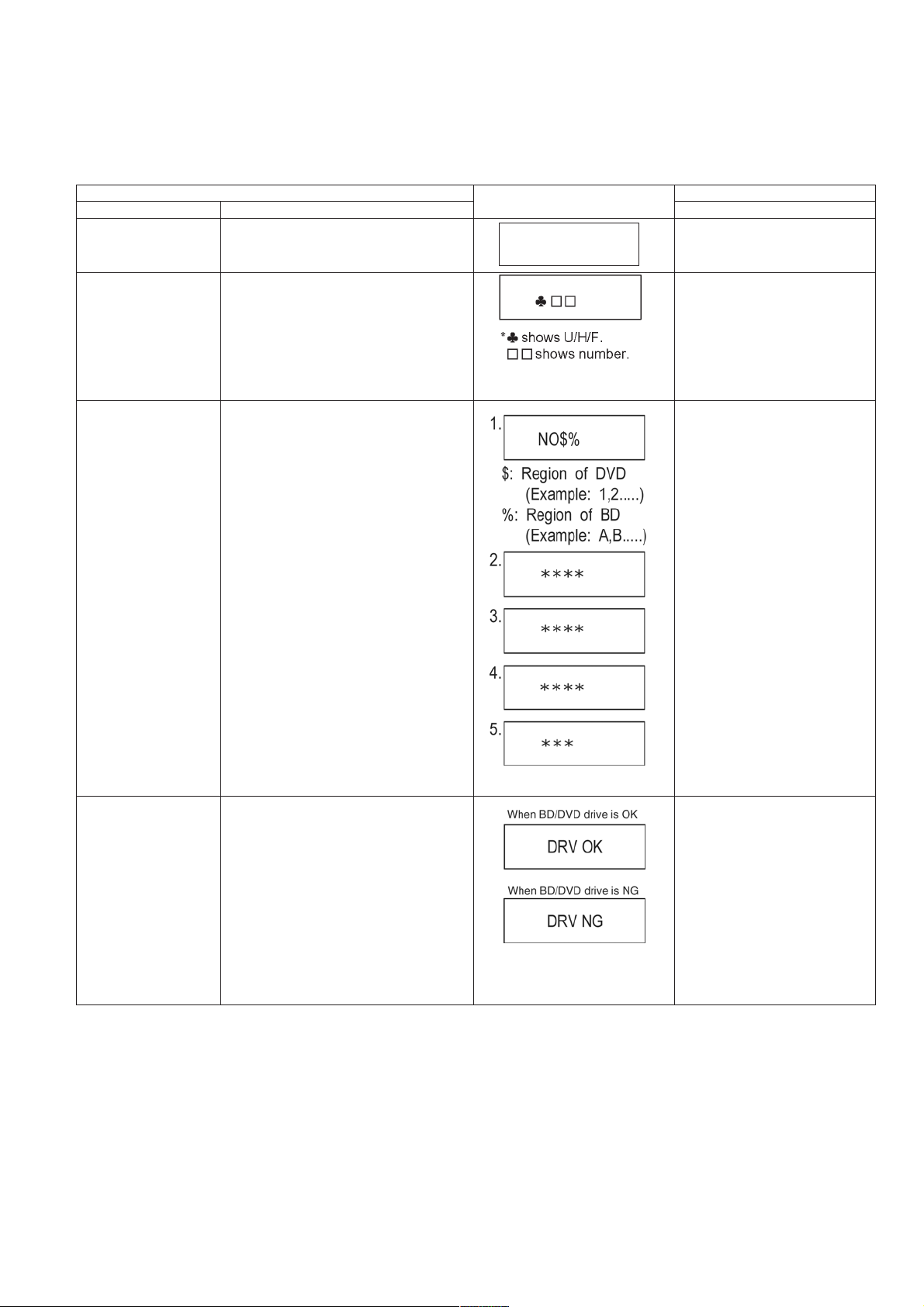

7.3. Service Mode at glance

Service mode setting: While the power is off, press [SKIP FWD] & [PLAY] on main unit follow by [SOUND] on remote control simultaneously for five second or more.

7.3.1. Service Mode Table 1

Item FL display Key operation

Mode name Description (Remote controller key)

Release Items Item of Service Mode executing is cancelled. Press [0] [0] or [Return] in service

SERVICE

mode.

Error Code Display Last Error Code of U/H/F held by Timer is dis-

played on FL.

*Details are described in 7.1.1. Self-Diagno-

sis Functions.

ROM Version Display 1. Region code (displayed for 5 sec.)

2. Main firm version (displayed for 5 sec.)

3. Timer firm version (displayed for 5 sec.)

4. Drive firm version (displayed for 5 sec.)

5. ROM correction version (left displayed)

Press [0] [1] in service mode

If any error history dose not exist,

[F00] is displayed.

Press [0] [2] in service mode

Drive check Simple quality of BD/DVD drive.

* are version displays.

Press [3] [8] in service mode.

*If the date of the present or the

trouble occurred time is incorrect, it

may be not able to judge correctly.

29

7.3.2. Service Mode Table 2

Item FL display Key operation

Mode name Description (Remote controller key)

Laser Used Time

Indication

Check laser used time (hours) of drive.

Press [4] [1] in service mode.

******

(******) is the used time display in

hour.

Laser used time of BD/DVD/CD

in Playback/Recording mode is

Counted.

1. Blu-ray Playback:

BP 0

2. Blu-ray Recording:

BR 0

3. DVD Playback:

DP9999

4. DVD Recording:

DR 0

5. CD:

CD 0

30

Loading...

Loading...