Panasonic SA-AK52 Schematic

ORDER NO. MD0101010C3

CD Stereo System

SA-AK52

Colour

(S)... Silver Type

Area

(GC)...Asia, Latin America, Africa and Middle Near East

TAPE SECTION :

AR2 MECHANISM SERIES

CD SECTION :

RAE0152Z-3 TRAVERSE DECK SERIES

Specifications

■ AMPLIFIER SECTION

PMPO 2300 W

RMS power output

THD 10%, both channels driven

80 Hz, both channel driven

(Low channel) 100 W per channel (6 Ω)

1 kHz, both channel driven

(High channel) 40 W per channel (6 Ω)

Total Bi-Amp power 140 W per channel

Input sensitivity

AUX 250 mV

MIC 0.7 mV

Input Impedance

AUX 13 kΩ

MIC 680 Ω

■ FM TUNER SECTION

Frequency range 87.5 - 108 MHz (50 kHz steps)

Sensitivity 2.5 µV (IHF)

S/N 26 dB 2.2 µV

Antenna terminal(s) 75 Ω (unbalanced)

■ AM TUNER SECTION

Frequency range

MW 522 - 1629 kHz (9 kHz steps)

520 - 1630 kHz (10 kHz steps)

SW 3.200 - 7.350 MHz (0.005 MHz

steps)

9.400 - 21.750 MHz (0.005 MHz

steps)

Sensitivity

MW

S/N 20 dB (at 999 kHz) 560 µV/m

SW

S/N 20 dB (at 5.3 MHz) 35.5 µV/m

■ CASSETTE DECK SECTION

Track system 4 track, 2 channel

Heads

Record/playback Solid permalloy head

Erasure Double gap ferrite head

Motor DC servo motor

Recording system AC bias 100 kHz

Erasing system AC erase 100 kHz

Tape speed 4.8 cm/s

Frequency response (+3 dB, -6 dB at DECK OUT)

NORMAL (TYPE I) 35 Hz - 14 kHz

HIGH (TYPE II) 35 Hz - 14 kHz

S/N 50 dB (A weighted)

Wow and flutter 0.18% (WRMS)

Fast forward and rewind time Approx. 120 seconds with

© 2001 Matsushita Electronics (S) Pte Ltd. All rights

reserved. Unauthorized copying and distribution is a

violation of law.

SA-AK52

C-60 cassette tape

■ CD SECTION

Sampling frequency 44.1 kHz

Decoding 16 bit linear

Beam source/wave length Semiconductor laser/780 nm

Number of channels Stereo

Frequency response 20 Hz - 20 kHz (+1, -2 dB)

Wow and flutter Below measurable limit

Digital filter 8fs

D/A converter MASH (1 bit DAC)

■ GENERAL

Power supply AC 110 V/127 V/220 V/230-240V,

Power consumption 180 W

50/60 Hz

Power consumption in standby mode

0.8 W

Dimensions (W x H x D) 250 x 332 x 316 mm

Mass 9.0 kg

■ SYSTEM

SC-AK52(GC) Music Center: SA-AK52(GC)

Speaker: SB-AK52(GC)

Notes:

1. Specifiacations are subject to change without notice. Weight and

dimensions are approximate.

2. Total harmonic distortion is measured by the digital spectrum

analyzer.

3. The labels “High” and “Low” on the rear of the speakers refer to

High frequency and Low frequency.

CONTENTS

Page Page

1 Before Use

2 Before Repair and Adjustment

3 Protection Circuitry

4 Accessories

5 Handling Precautions For Traverse Deck

6 Precaution of Laser Diode

7 Operation Procedures

8 Operation Checks and Main Component Replacement

Procedures

9 Self-Diagnostic Function

10 Descriptio n of Error Code

11 CD Test Mode Function

3

3

12 Measurem ents and Adjustments

3

13 Illustration of IC’s, Transistors and Diodes

14 Terminal Function of ICs

3

4

15 Block Diagram

5

16 Schematic Diagram

17 Printed Circuit Board

6

18 Wiring Connection Diagram

8

19 Troubleshooting Guide

18

20 Parts Location and Replacement Parts List

19

20

20

24

25

28

34

48

58

59

60

2

1 Before Use

Be sure to disconnect the mains cord before adjusting the voltage selector.

Use a minus(-) screwdriver to set the voltage selector (on the rear panel) to the voltage setting for the area in which the unit will

be used. (If the power supply in your area is 117V or 120V, set to the “127V” position.)

Note that this unit will be seriously damaged if this setting is not made correctly. (There is no voltage selector for some countries,

the correct voltage is already set.)

2 Before Repair and Adjustment

Disconnect AC power, discharge Power Supply Capacitors C531, C532, C533, C534, C579 through a 10Ω, 5W resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

Current consumption at AC 110 V, 60 Hz in NO SIGNAL mode should be ~650mA respectively.

3 Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

•

No sound is heard when the power is turned on.

•

Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

“shorted”, or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

SA-AK52

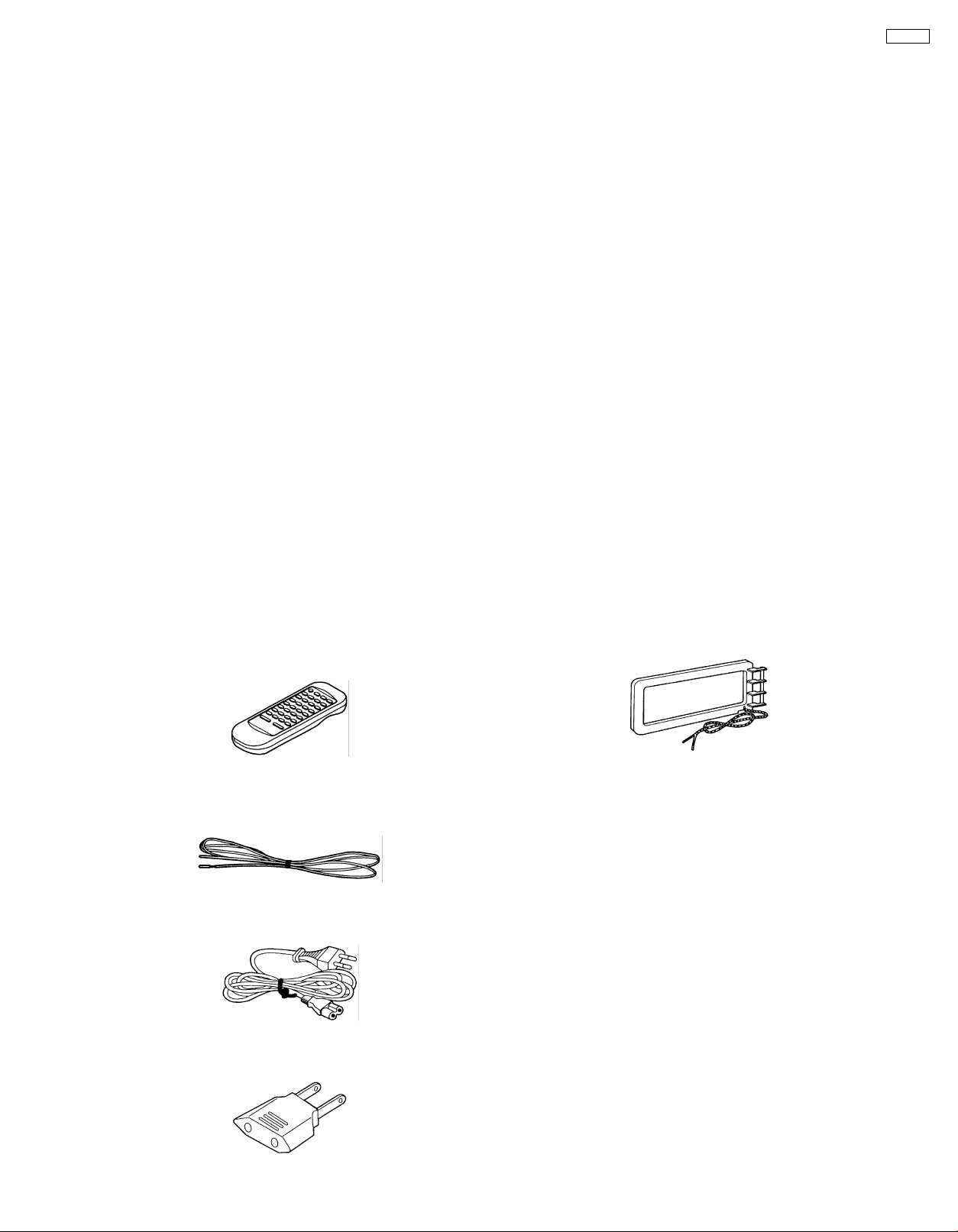

4 Accessories

Remote Control

Transmitter

FM indoor antenna

AC mains lead

AM Loop antenna

Power plug adapter

3

SA-AK52

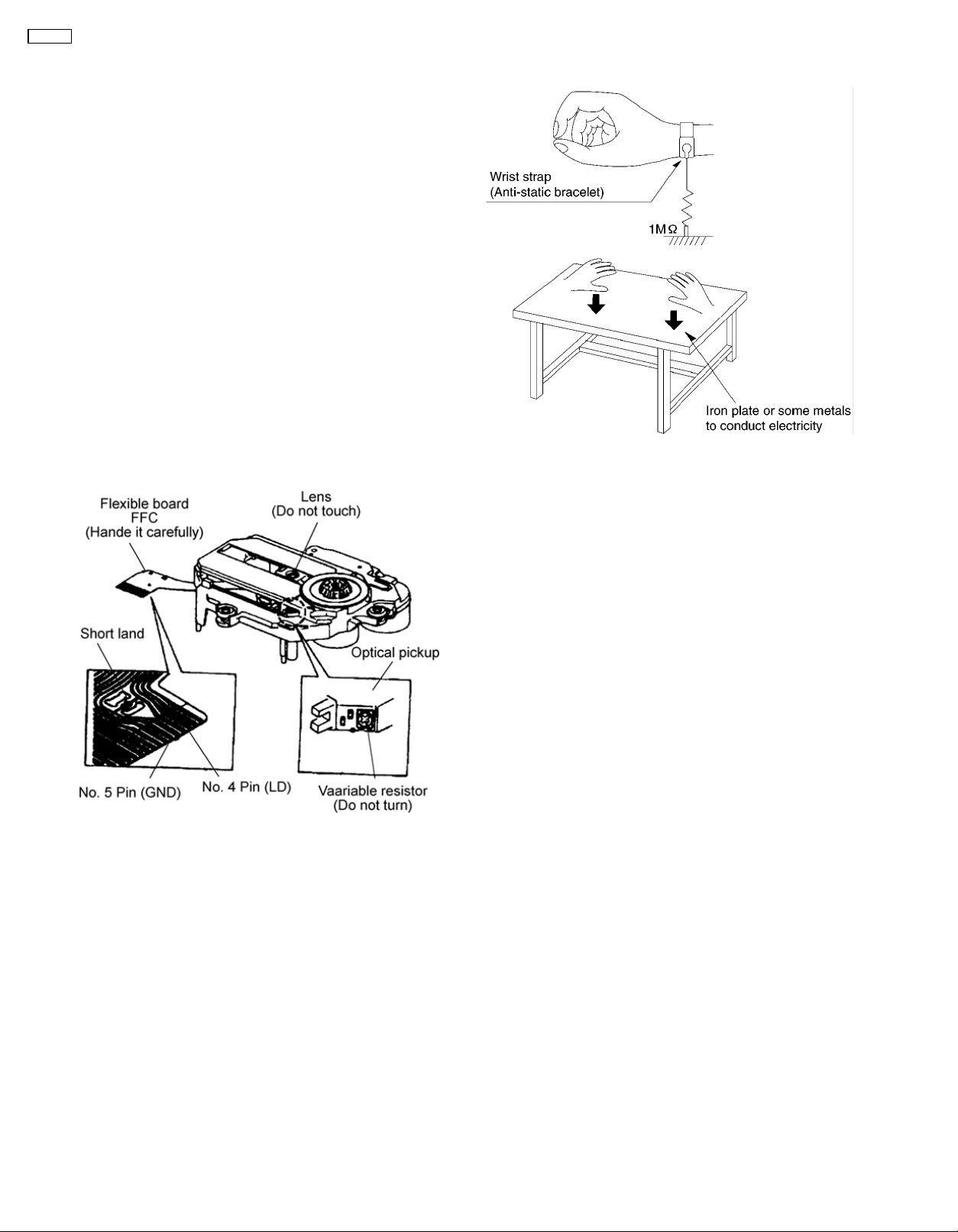

5 Handling Precautions For Traverse Deck

The laser diode in the traverse deck (optical pickup) may break

down due to potential difference caused by static electricity of

clothes or human body.

So, be careful of electrostatic breakdown during repair of the

traverse deck (optical pickup).

● Handling of traverse deck (optical pickup)

1. Do not subject the traverse deck (optical pickup) to

static electricity as it is extremely sensitive to electrical

shock.

2. The short land between the No.4 (LD) and No.5 (GND)

pins on the flexible board (FFC) is shorted with a solder

build-up to prevent damage to the laser diode.

To connect to the PC board, be sure to open by

removing the solder build-up, and finish the work

quickly.

3. Take care not to apply excessive stress to the flexible

board (FFC board).

4. Do not turn the variable resistor (laser power

adjustment). It has already been adjusted.

Caution when Replacing the Traverse Deck :

The traverse deck has a short point shorted with solder to

protect the laser diode against electrostatics breakdown. Be

sure to remove the solder from the short point before

making connections.

● Grounding for electrostatic breakdown prevention

1. Human body grounding

Use the anti-static wrist strap to discharge the static

electricity from your body.

2. Work table grounding

Put a conductive material (sheet) or steel sheet on the

area where the traverse deck (optical pickup) is placed,

and ground the sheet.

Caution :

The static electricity of your clothes will not be grounded

through the wrist strap. So, take care not to let your

clothes touch the traverse deck (optical pickup).

4

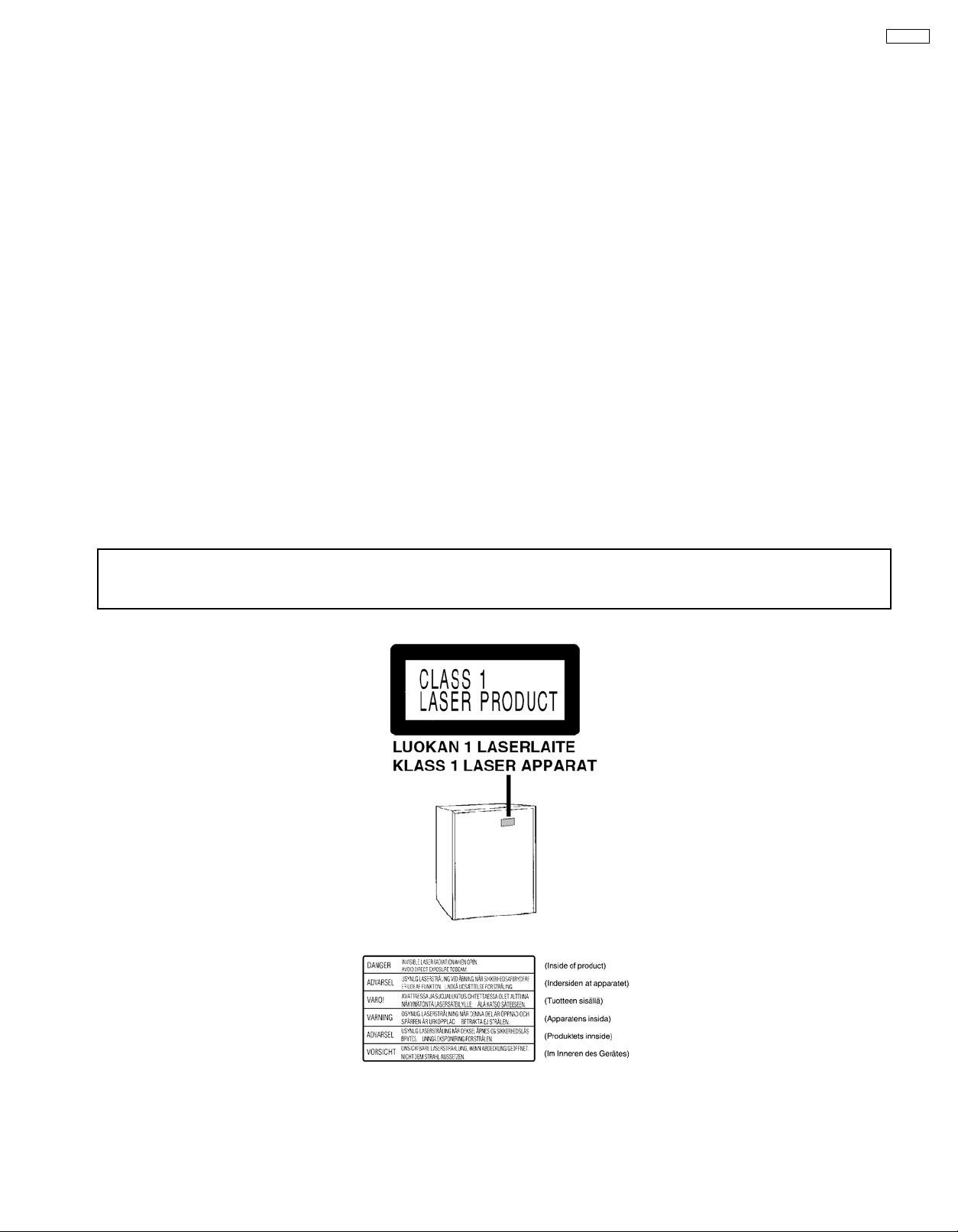

6 Precaution of Laser Diode

Caution :

This product utilizes a laser diode with the unit turned "ON", invisible laser radiation is emitted from the pick up lens.

Wavelength : 780 nm

Maximum output radiation power from pick up : 100 µW/VDE

Laser radiation from pick up unit is safety level, but be sure the followings:

1. Do not disassemble the optical pick up unit, since radiation from exposed laser diode is dangerous.

2. Do not adjust the variable resistor on the pick up unit. It was already adjusted.

3. Do not look at the focus lens using optical instruments.

4. Recommend not to look at pick up lens for a long time.

ACHTUNG :

Dieses Produkt enthält eine Laserdiode. Im eingeschalteten Zustand wird unsichtbare Laserstrahlung von der Lasereinheit

abgestrahlt.

Wellenlänge : 780nm

Maximale Strahlungsleistung der Lasereinheit :100W/VDE

Die Strahlung an der Lasereinheit ist ungefährlich, wenn folgende Punkte beachtet werden:

1. Die Lasereinheit nicht zerlegen, da die Strahlung an der freigelegten Laserdiode gefährlich ist.

2. Den werkseitig justierten Einstellregler der Lasereinhit nicht verstellen.

3. Nicht mit optischen Instrumenten in die Fokussierlinse blicken.

4. Nicht über längere Zeit in die Fokussierlinse blicken.

SA-AK52

ADVARSEL: I dette a apparat anvendes laser.

CAUTION!

THIS PRODUCT UTILIZES A LASER.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE SPECIFIED HEREIN MAY RESULT

IN HAZARDOUS RADIATION EXPOSURE.

Use of Caution Labels

■

5

SA-AK52

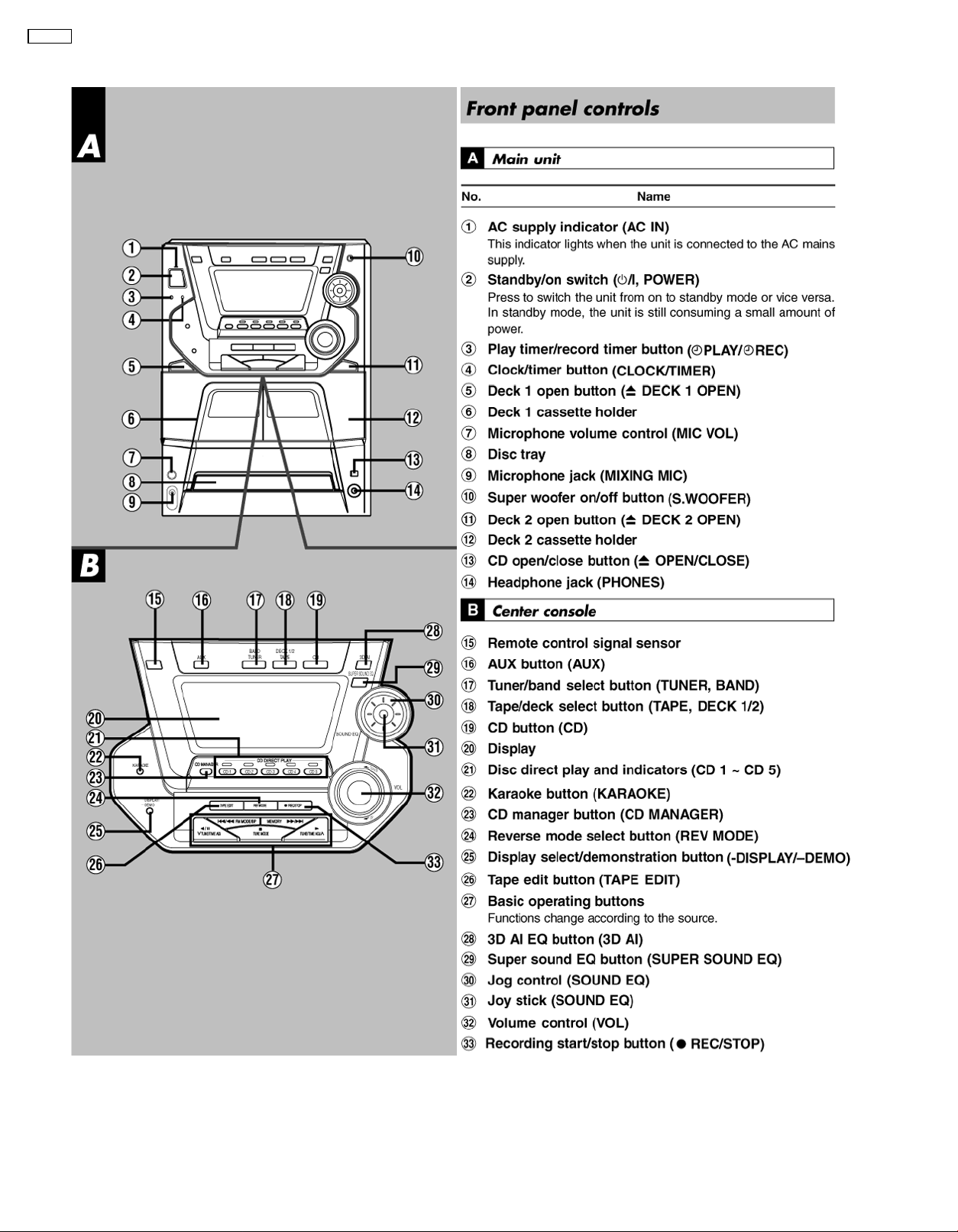

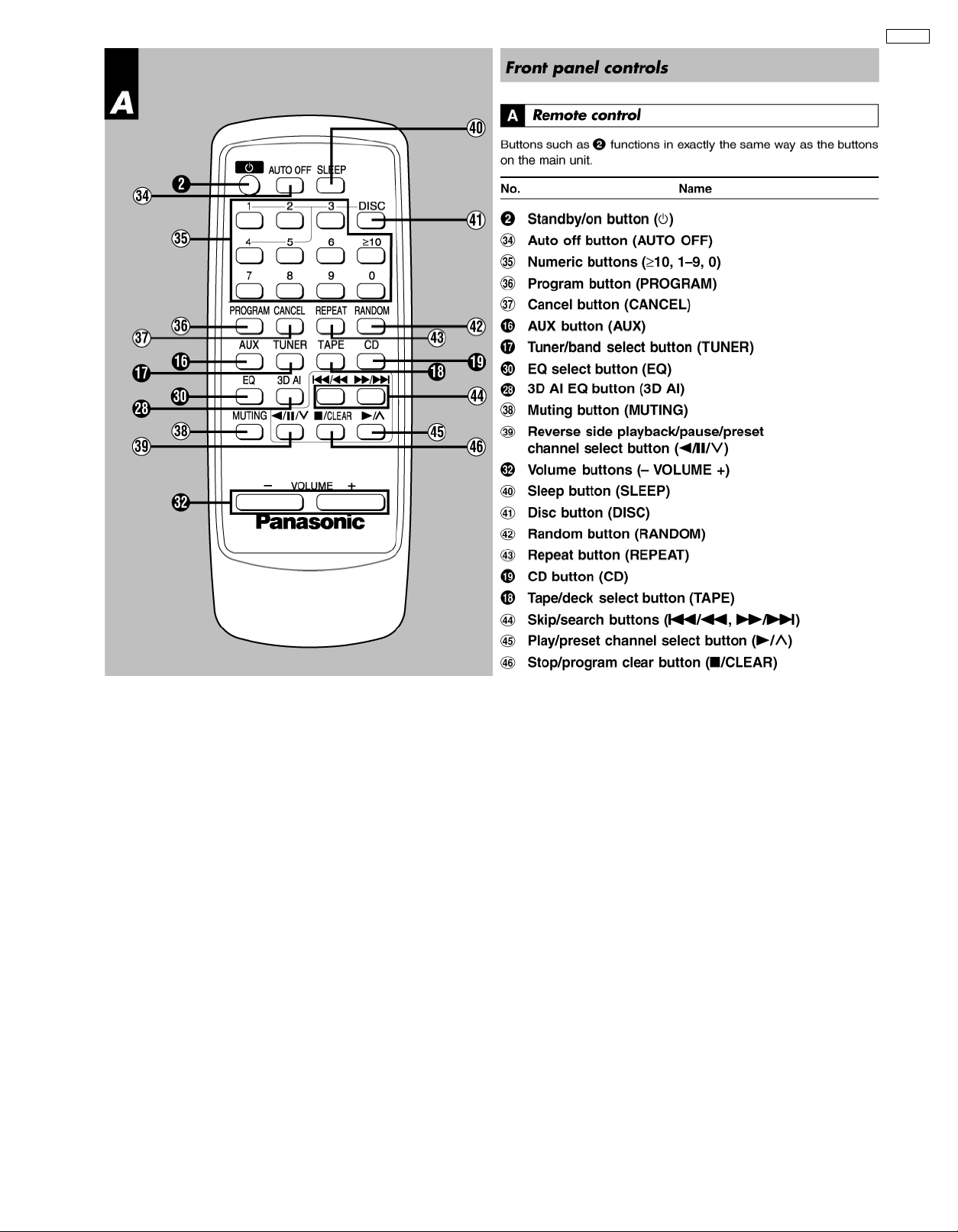

7 Operation Procedures

6

SA-AK52

7

SA-AK52

8 Operation Checks and Main Component Replacement

Procedures

“ATTENTION SERVICER”

Some chassis components may have sharp edges.

Be careful when disassembling and servicing.

This section describes procedures for checking the operation of the major printed circuit boards and replacing the

1.

main components.

For reassembly after operation checks or replacement, reverse the respective procedures.

2.

Special reassembly procedures are described only when required.

Select items from the following index when checks or replacement are required.

3.

Contents

Disassembly and assembly main unit

•

1. Checking of the Main, Panel, Deck and Power P.C.B.

Main Component Replacement Procedures

•

1. Replacement of the Traverse Deck.

2. Replacement of the Power Amplifier IC.

Disassembly and assembly of the Traverse Unit

•

Disassembly and assembly of the Disc Tray

•

Warning:

This product uses a laser diode. Refer to caution statement Precaution of Laser Diode.

ACHTUNG:

Die Lasereinheit nicht zerlegen.

Die Lasereinheit darf nur gegen eine vom Hertsteller spezifizierte Einheit ausgetauscht werden.

8

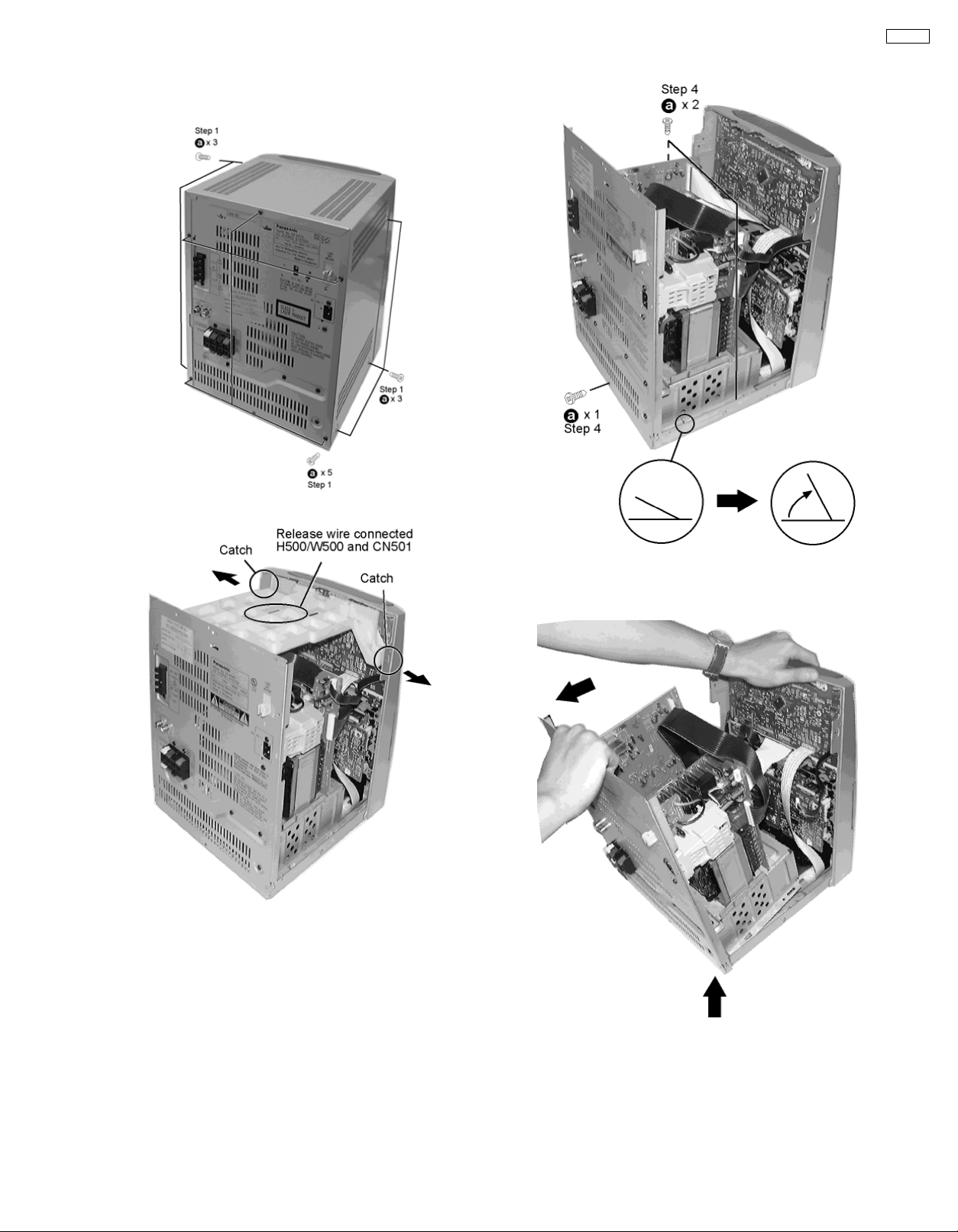

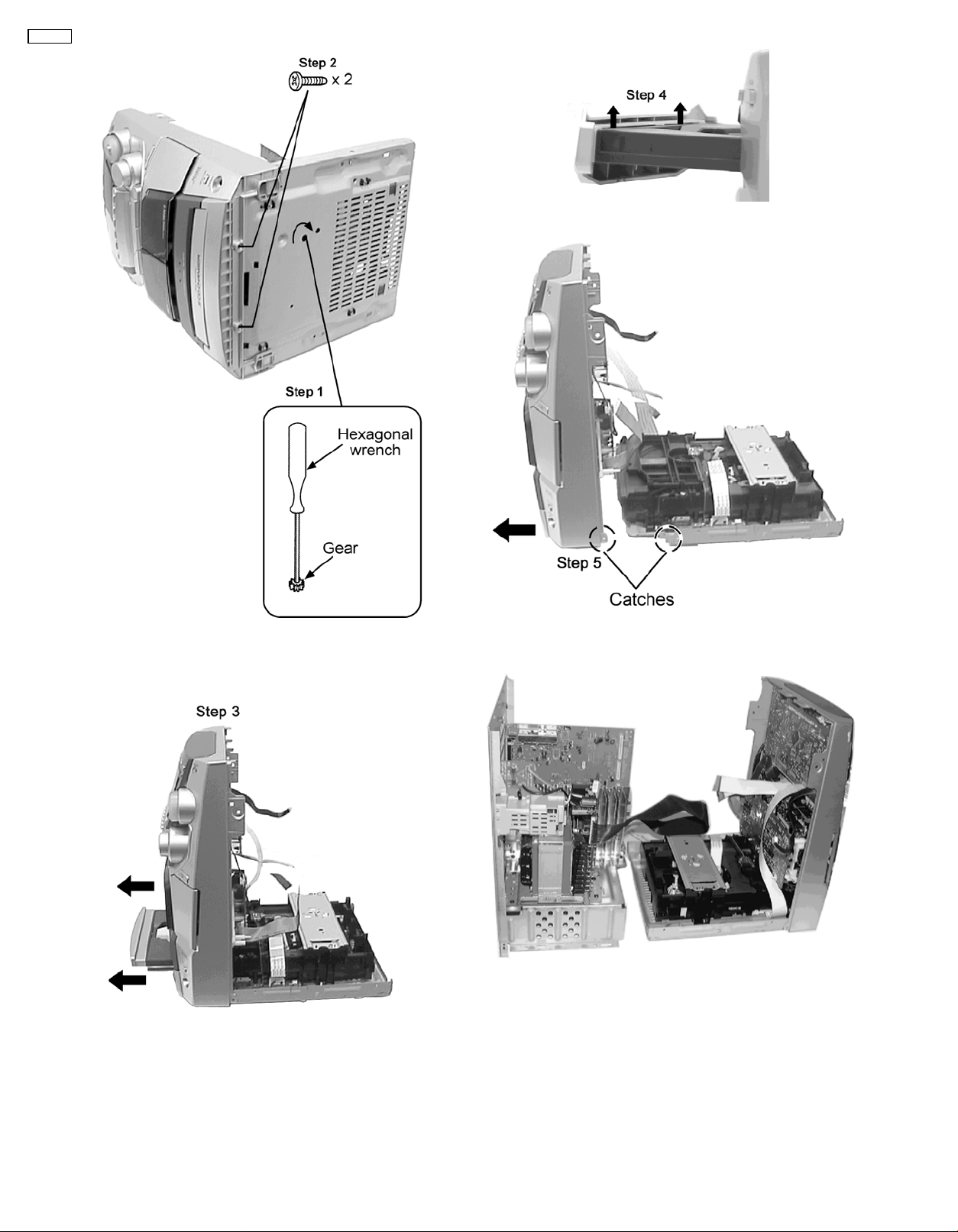

8.1. Disassembly and assembly main unit

Step 1 Remove 3 screws each side and 5 screws at rear panel.

Step 2 Remove the Top Cabinet

SA-AK52

Step 3 Remove T-bracket.

Step 4 Remove 2 screws each side of the inner chassis and a

screw at the rear panel. Turn locating pin 90°.

(Locating pin need not have to be bent back).

Step 5 Release the wires CN 300, 301, 302, 304 and 309.

Remove rear panel by pulling backward and lift rear panel assy

off.

Remove Front Panel

9

SA-AK52

Step 4 : Remove the CD lid in the direction of the arrow.

Step 1 : Use a hexagonal wrench and turn clockwise to release

the tray.

Step 2 : Remove the 2 screws.

Step 3 : Push the CD tray in the direction shown above.

Step 5 : Release the two catches shown above to remove the

front cabinet from the CD Traverse Unit.

Separated front and rear panel assy.

Removal of Inner bracket.

10

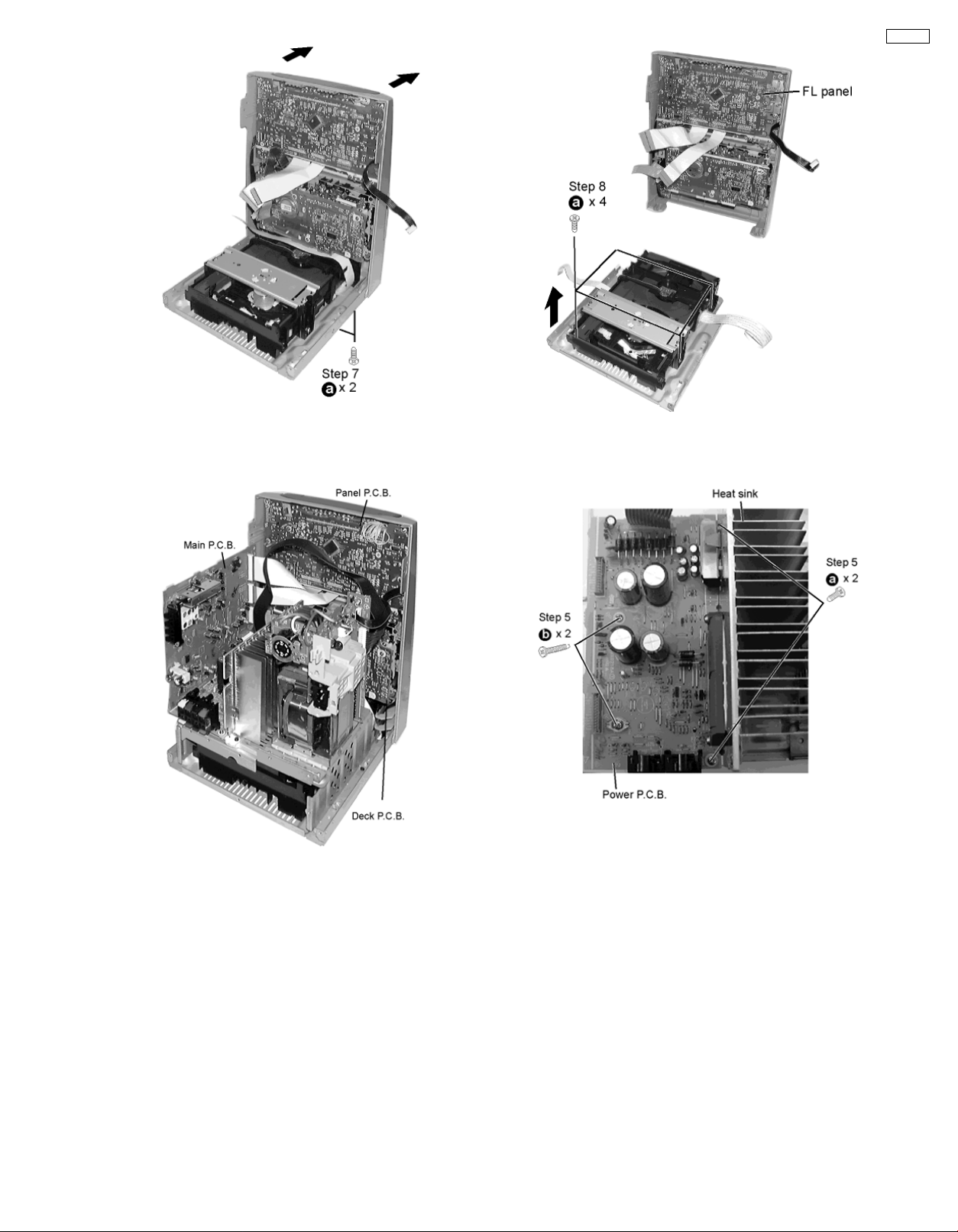

Step 7 Remove 2 screws from bottom and 2 screw beside

inner bracket to push forward to release the front panel.

Step 8 To release inner bracket, remove 4 screws.

8.1.1. Checking for Panel, Main and Deck P.C.B.

SA-AK52

Step 1 Remove 2 screws each side.

11

SA-AK52

8.1.2. Checking for Power P.C.B.

8.1.3. For Live Troubleshooting Procedure

Step 6 : Reconnect all connectors.

Step 7 : Use extension 14pin FFC wire for CN309.

Step 8 : Supply power for troubleshooting.

12

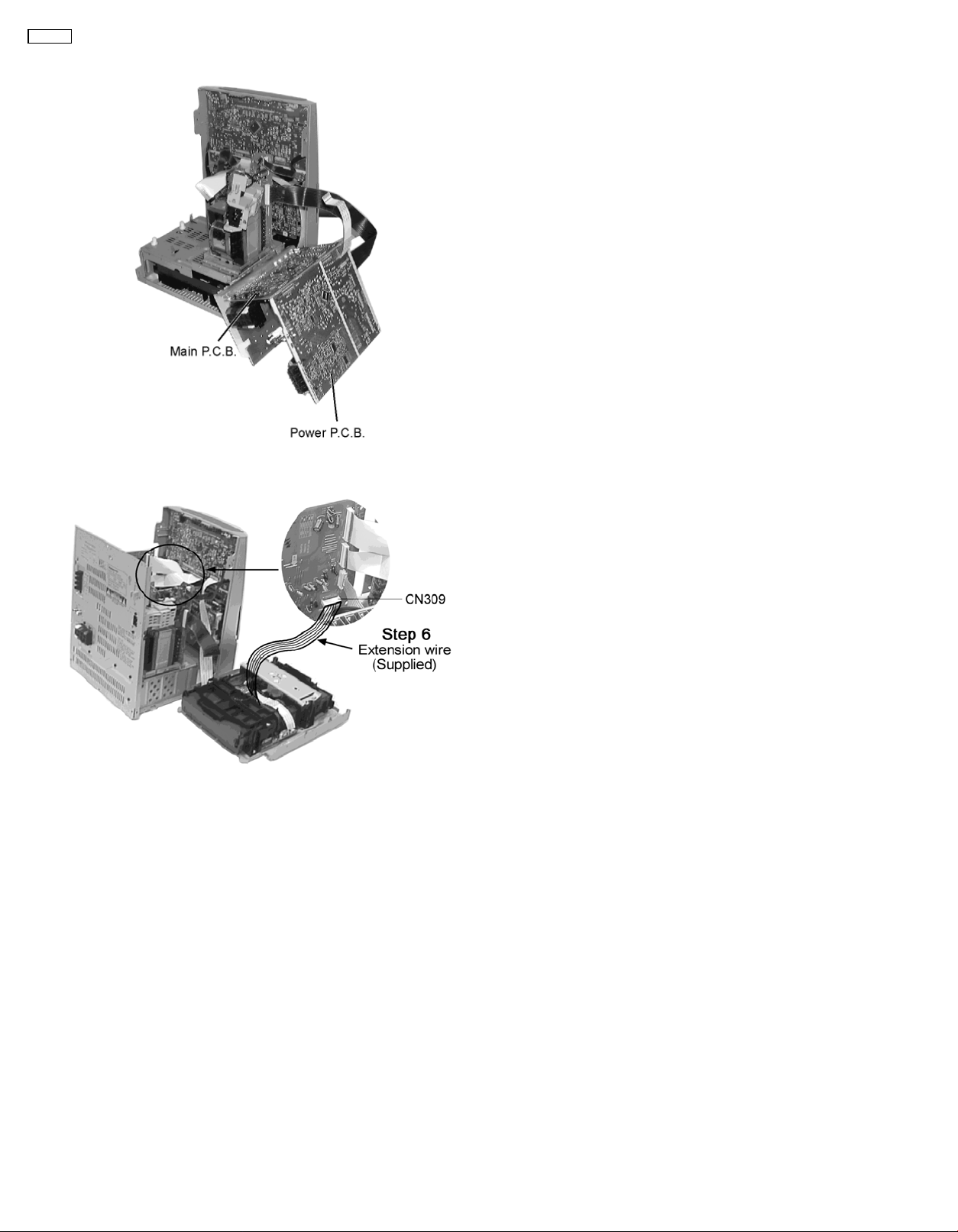

8.2. Main Component Replacement Procedures

8.2.1. Replacement of the Traverse Deck

SA-AK52

Step 1

Step 1 - Step 4

Unit’ (

Follow the procedures in ‘Disassembly of the Traverse

).

Step 3

Servo P.C.B.

Step 4

the 3 pins. Then remove the Traverse Deck.

Desolder the 4 legs of the 2 motors and pull out the

Widen the 3 bosses with a flat screwdriver and pull out

Step 5

• Removal of the flexible cable. Push the top of the connector

Note:

Insert a short pin into the flexible cable for traverse unit.

•

Step 1

Step 2

assembly.

Remove the flexible cable CN701.

in the direction of the arrow 1, and then pull out the flexible

cable in the direction of the arrow 2.

Installation of the CD servo P.C.B. after replacement

Connect the FFC board.

Install the CD servo P.C.B. in the traverse deck

13

SA-AK52

8.2.2. Replacement of the Power Amplifier IC

Step 1 Follow the procedures in ‘Checking Procedure for each

major P.C.B.’ ( Step 1 - Step 6 ).

Note:

Before installing the CD servo P.C.B., move the optical pickup

towards the outer edge from the marking (black triangle).

[Otherwise, the reset detect switch (S701) mounted on the CD

servo P.C.B. may be damaged.]

Step 4 Remove the wires at CN302, CN303 and CN304 and

pull out the Main PCB.

Step 5 Remove the 4 screws fixed to the Power Amplifier IC.

Step 6 Unsolder the terminals of Power Amp IC and replace

the respective component.

14

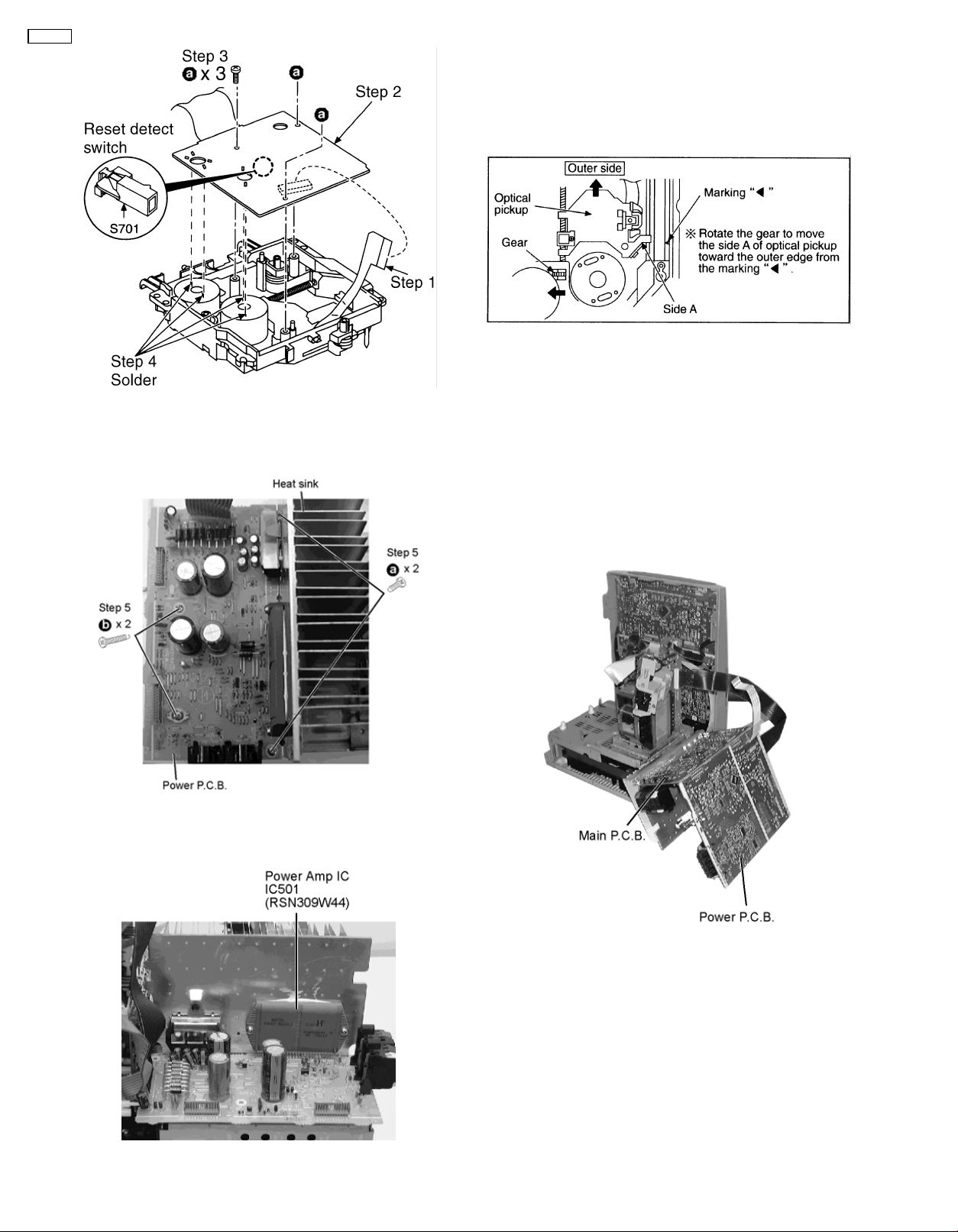

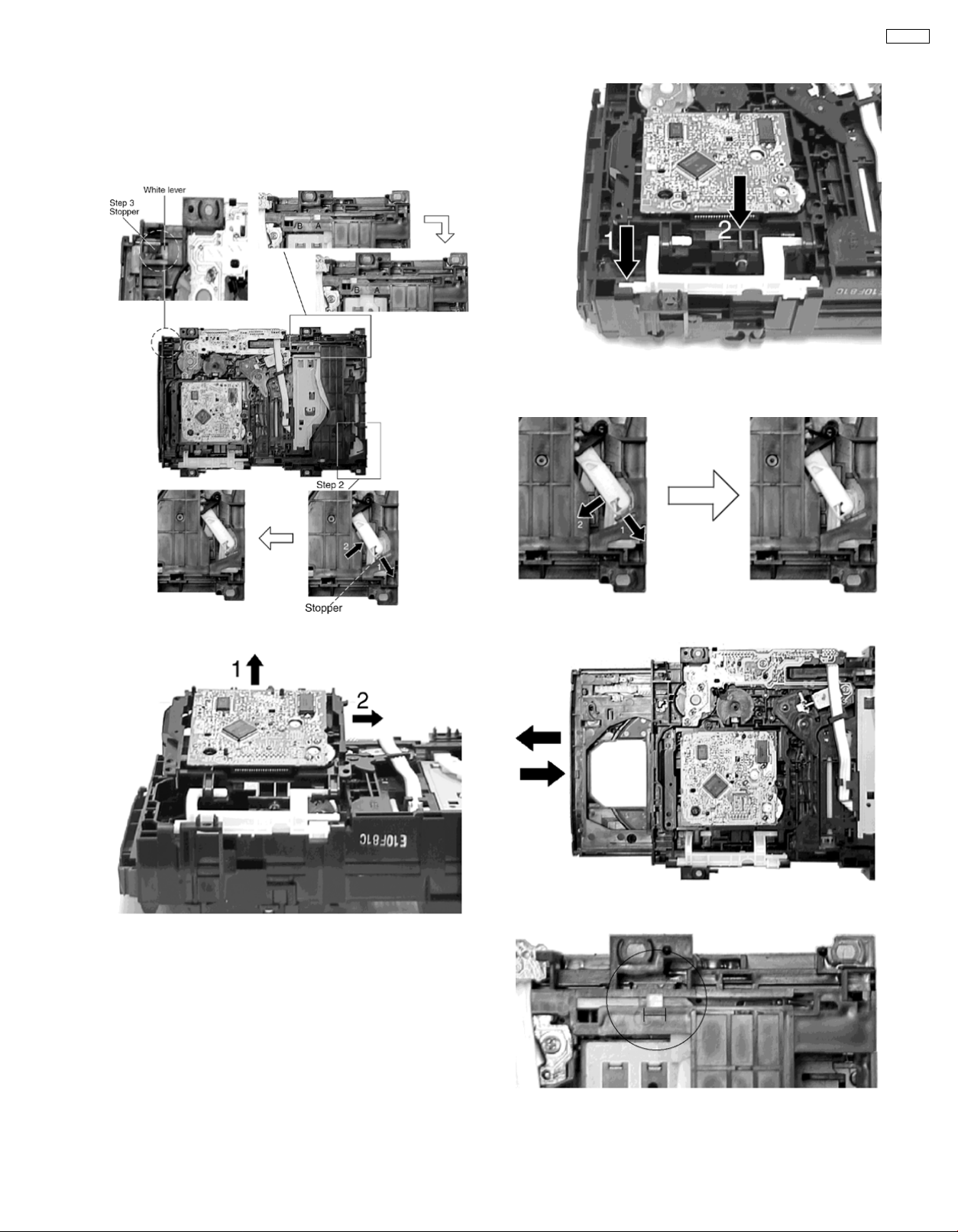

8.3. Disassembly and assembly of the Traverse Unit

Step 1 Push the lever from position A to B.

Step 2 Pull the stopper (black) in the direction of arrow 1 and

push the lever in the direction of arrow 2.

Step 3 Push the stopper (black) down until the white lever eject

out.

Step 3 Pull the stopper in the direction of arrow 1 and release

the lever in the direction of arrow 2 as shown.

SA-AK52

Step 4 Lift up the traverse unit and slide out the unit as shown.

• Replacement of Traverse Unit

Step 1 Place the traverse unit as shown.

Step 2 Press in the lever shaft in the direction of arrow 1 as

shown and push the traverse unit into the position in the

direction of arrow 2.

Step 4 Pull out the tray half way and push it back fully.

Step 5 Push the lever to the initial position indicated ‘|---|’.

15

SA-AK52

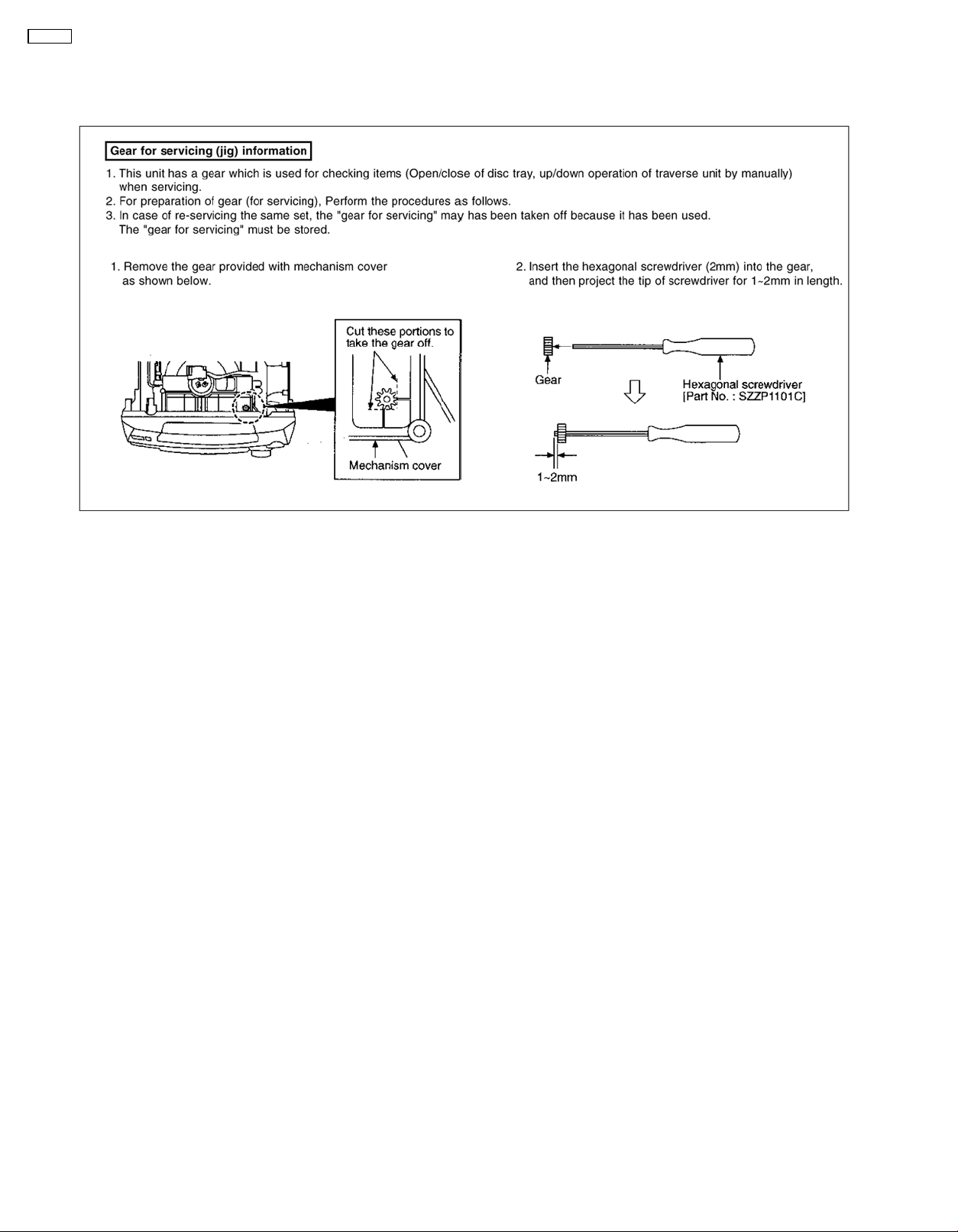

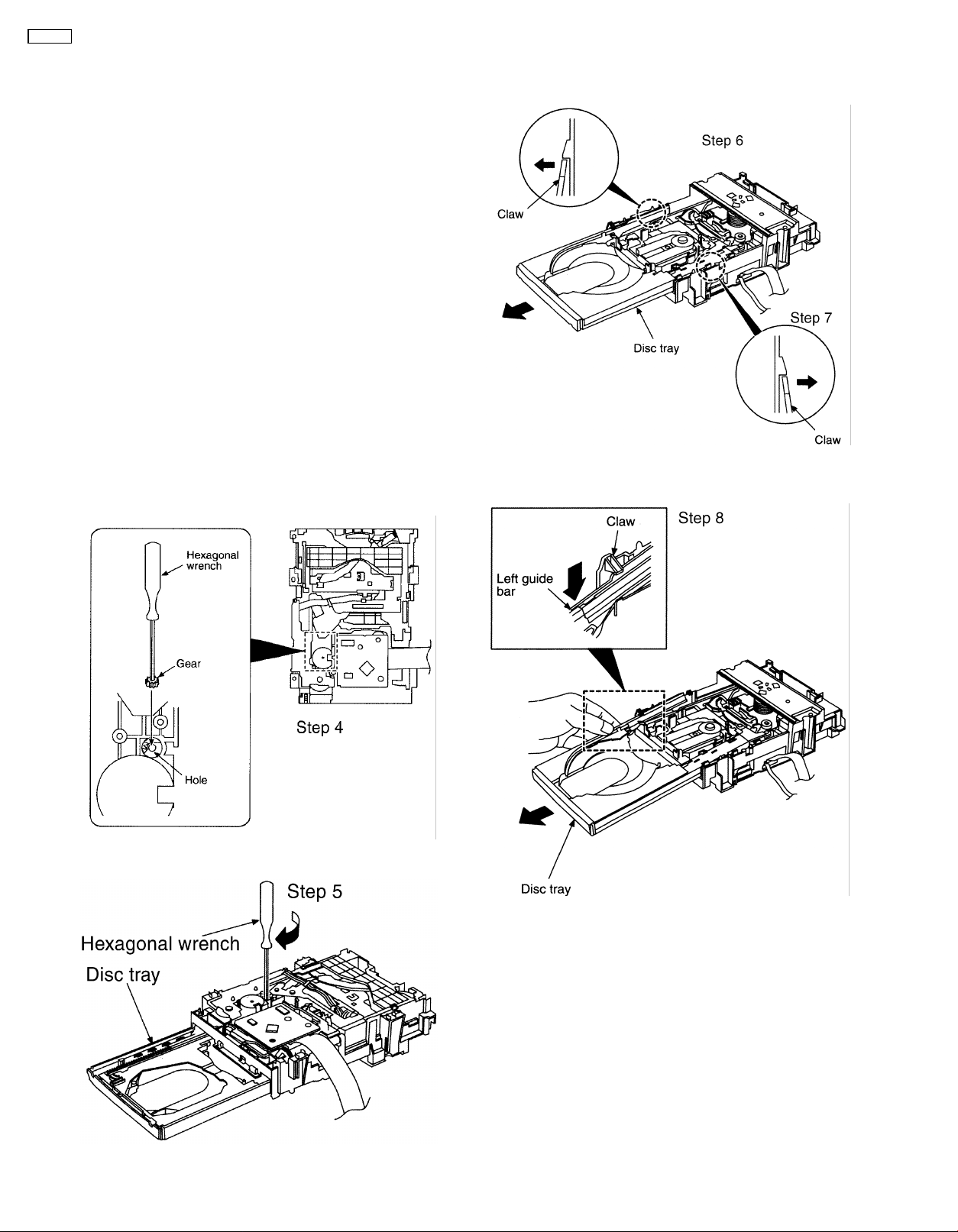

8.4. Disassembly and assembly of the Disc Tray

(clockwise), and then open the disc tray fully.

Step 2 With lifting the claw in the direction of arrow 1, draw the

clamp SW P.C.B. in the direction of arrow 2.

Step 3 Remove the mechanism cover.

Step 4 Insert the gear with hexagonal wrench into the hole.

Step 6 Upset the CD changer unit again.

Step 7 Release both the claws, and then draw the disc tray.

Step 5 Rotate the hexagonal wrench in the direction of arrow

Step 8 With forcing the left guide bar manually because the left

guide bar interferes with claw, draw the disc tray.

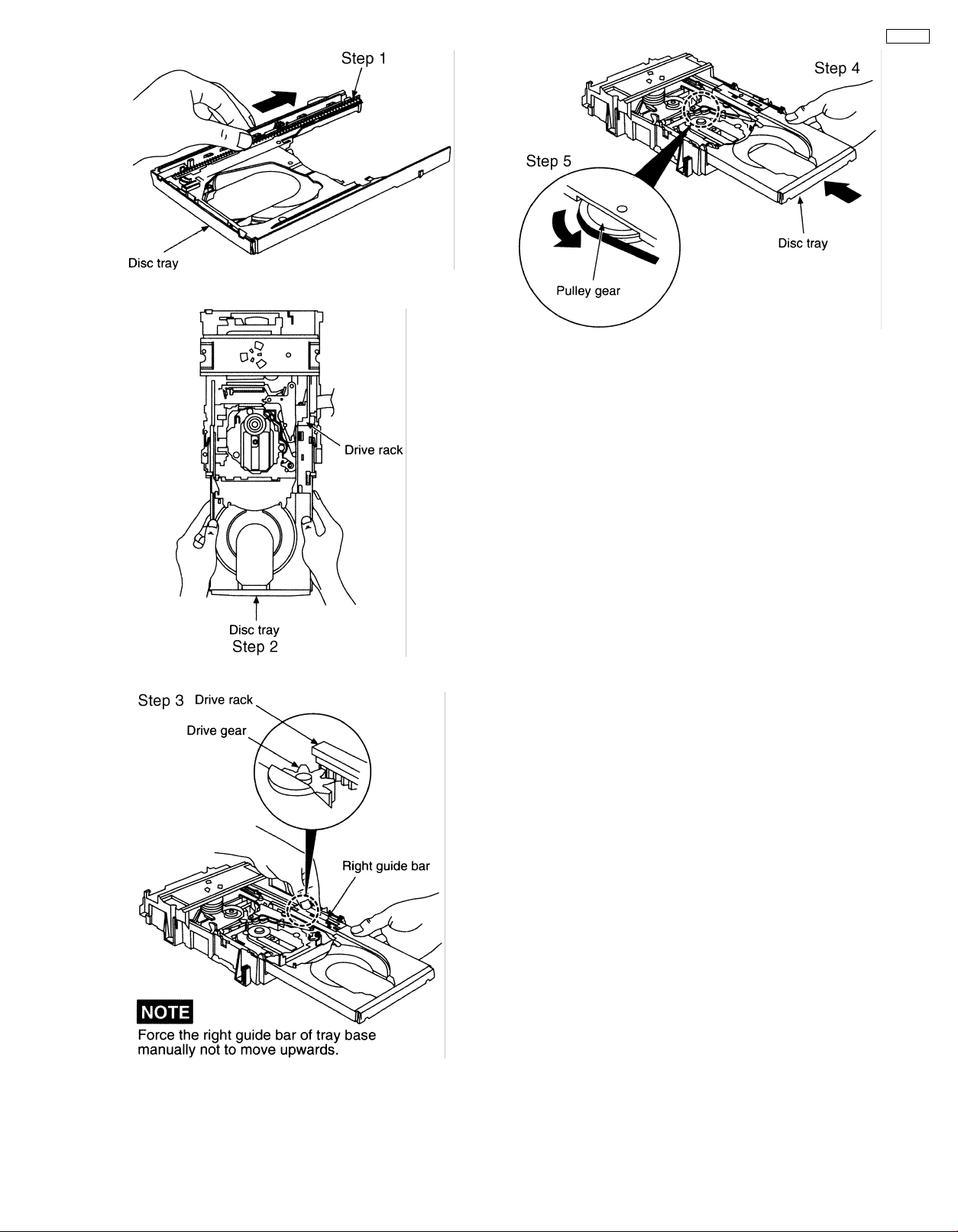

• Installation of the disc tray after replacement

16

Step 1 Slide the drive rack fully in the direction of the arrow.

SA-AK52

Step 4 Holding the disc tray manually, rotate the pulley gear in

the direction of arrow.

Step 5 Rotate the gear 5 or 6 times manually, and then push

the disc tray.

Step 2 Holding the drive rack, not to move, install the disc tray.

Step 3 Align the drive rack with the drive gear.

17

SA-AK52

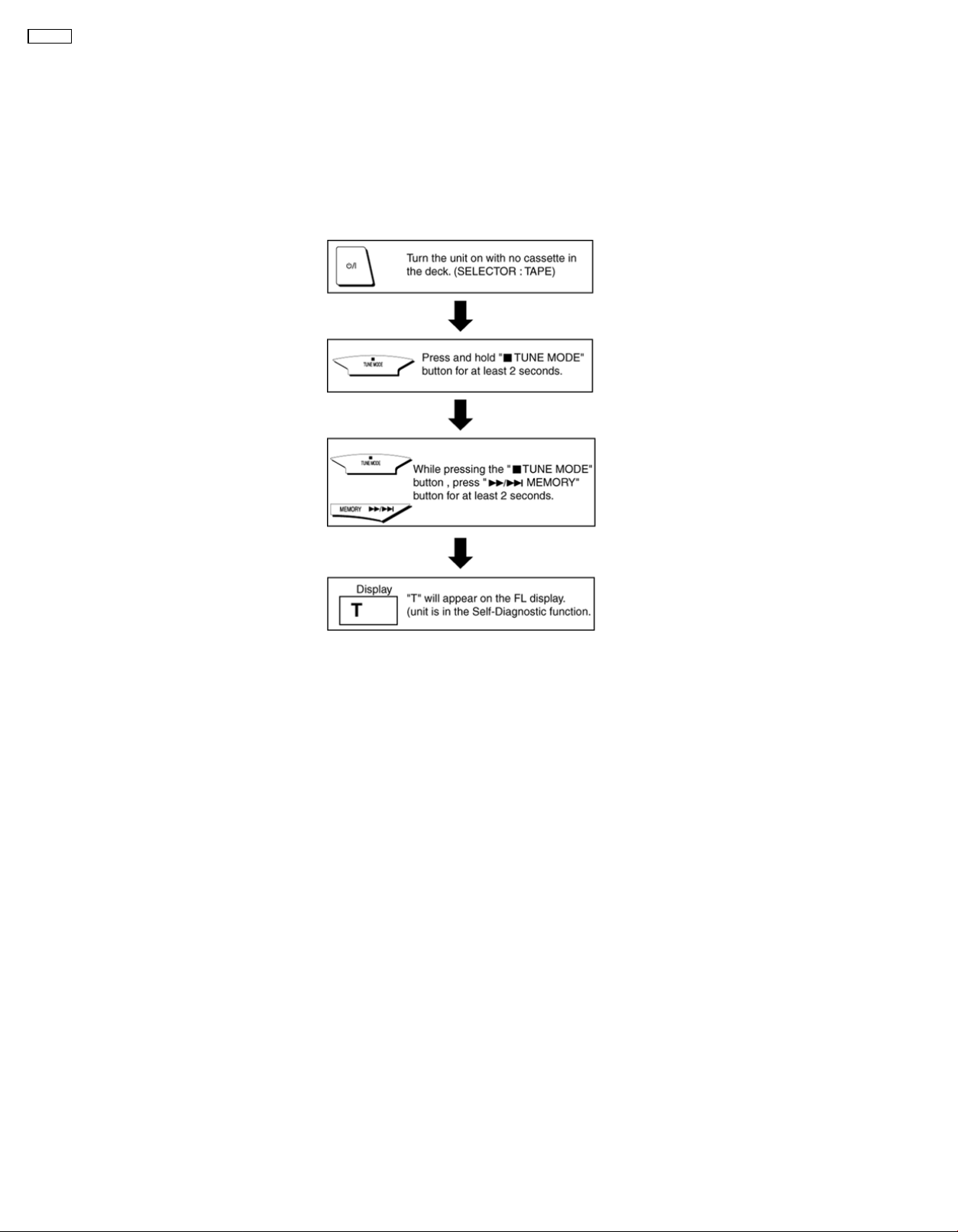

9 Self-Diagnostic Function

9.1. Self-diagnostic display

This unit is equipped with a self-diagnostic display function which, if a problem occurs, will display an error code corresponding to

the problem.

Use this function when performing maintenance on the unit.

9.2. How to enter the Self-Diagnostic Function

9.3. Cassette Mechanism Test (For error code H01, H02, H03, F01, F02)

1. Press “TAPE, DECK 1/2” to select Deck 2.

2. Load a cassette tape with the erasure prevention tab, remove from left side only and close the cassette holder.

3. Press “FAST FORWARD MEMORY” (Tape will be stop after 2 seconds)

4. Load a cassette tape with the erasure prevention tab, remove from right side only and close the cassette holder.

5. Press “REVERSE FM MODE/BP” (Tape will be stop after 2 seconds)

6. Load a pre-recorded tape with both side record tabs intact and close the cassette holder.

7. Press “PLAY/TUNE/TIME ADJ UP” (After TPS function, tape will stop automatically)

8. Press “REC/STOP” (Tape will not move)

9. Press “STOP/TUNE MODE” to indicate Error code.

• If several problem exist, error code will change each time when “■ /TUNE MODE” is pressed.

(e.g. H01 → H03 → F01 .....etc.)

10. Press “TAPE, DECK 1/2” to select Deck 1.

11. Repeat step 2 to 9 to test Deck 1. (Tape Deck 1 will not check H02 because of no recording function)

9.4. CD Mechanism Test (F15, F26, F16, F17, F27, F28, F29, H15, F75)

1. Press “CD”.

2. Press “OPEN/CLOSE (1)” and place a CD.

3. Press “OPEN/CLOSE (1)” to close the tray.

4. Press “OPEN/CLOSE (5)” and wait until the tray is open.

5. Press “OPEN/CLOSE (1)” and remove the CD.

6. Press “OPEN/CLOSE (1)” to close the tray.

18

7. Press “■/TUNE MODE” to indicate Error Code.

• If several problem exist, error code will change each time when “■/TUNE MODE” is pressed. (e.g. F15 → F26 → F16 ....etc).

9.5. To clear all Error code

1. Press “STOP/TUNE MODE” button for 5 seconds.

2. FL indicator shows “CLEAR” for 1 second and change to “T”.

9.6. How to get out from Self-Diagnostic function

1. Press “Power” button OFF.

9.7. Power Amplifier Failure (F61)

1. When power amplifier fail, F61 will indicate automatically.

10 Description of Error Code

10.1. Error detection for Cassette Mechanism block

SA-AK52

No. Error Error

1 MODE SW

detection error

2 REC INH SW

detection error

3 HALF SW

detection error

4 Reel Pulse

detection error

5 TPS abnormal F02 Cassette deck will not perform TPS function.

Display

H01 Faulty operation of cassette mechanism.

H02 Recording not possible.

H03 Playback cannot perform.

F01 The tape advances slightly and then stops.

Problem condition

Faulty contact or short-circuit of mechanism mode switch (S951, S971).

Faulty contact or short-circuit of REC INH switch (S974, S975).

Faulty contact or short-circuit of HALF siwtch (S952, S972).

Faulty reel pulse, faulty hole detect IC (IC951, IC971).

Faulty playback EQ/recording amplifier IC (IC101).

10.2. Error detection for CD/Changer block

No. Error Error

1 REST SW detection error F15 CD does not function.

2 CD tray opens automatically F16 CLAMP switch (S4) NG (Check & Replace)

3 Does not startup when [PLAY]

button is pressed

4 Transmission error between CD

servo LSI and micon

5 Startup fails even when you

insert CD or the selected disc tray

does not open

6 Cannot insert CD F28 Tray 1 detect switch NG (Check & Replace)

7 Cannot eject CD F29 Check if disc is stuck. Tray 2 detect switch NG (Confirm & Replace)

8 The CD tray closes H15 CD disc tray detect switch NG (S3) (Check & Replace)

Display

F17 BOTTOM switch (S5) NG (Check & Replace)

F26 CD does not function.

F27 Tray 1 detect switch or Tray 2 detect switch NG (Check & Replace)

Problem condition

This error occurs when the Optical Pick Up REST SW (S701) is not

detected within the specified time (about 8 seconds)

This error occurs when the POWER is ON for the CD block and an error

is detected after the transmission has started.

10.3. Power Supply related error detection

No. Error Error

1 POWER AMP

output abnormal

Display

F61 When POWER is switched on, power become off automatically.

Problem condition

During normal operation, if DC DET become L, PCNT shall become

L and the error display on the left shall be displayed. (IC501)

19

SA-AK52

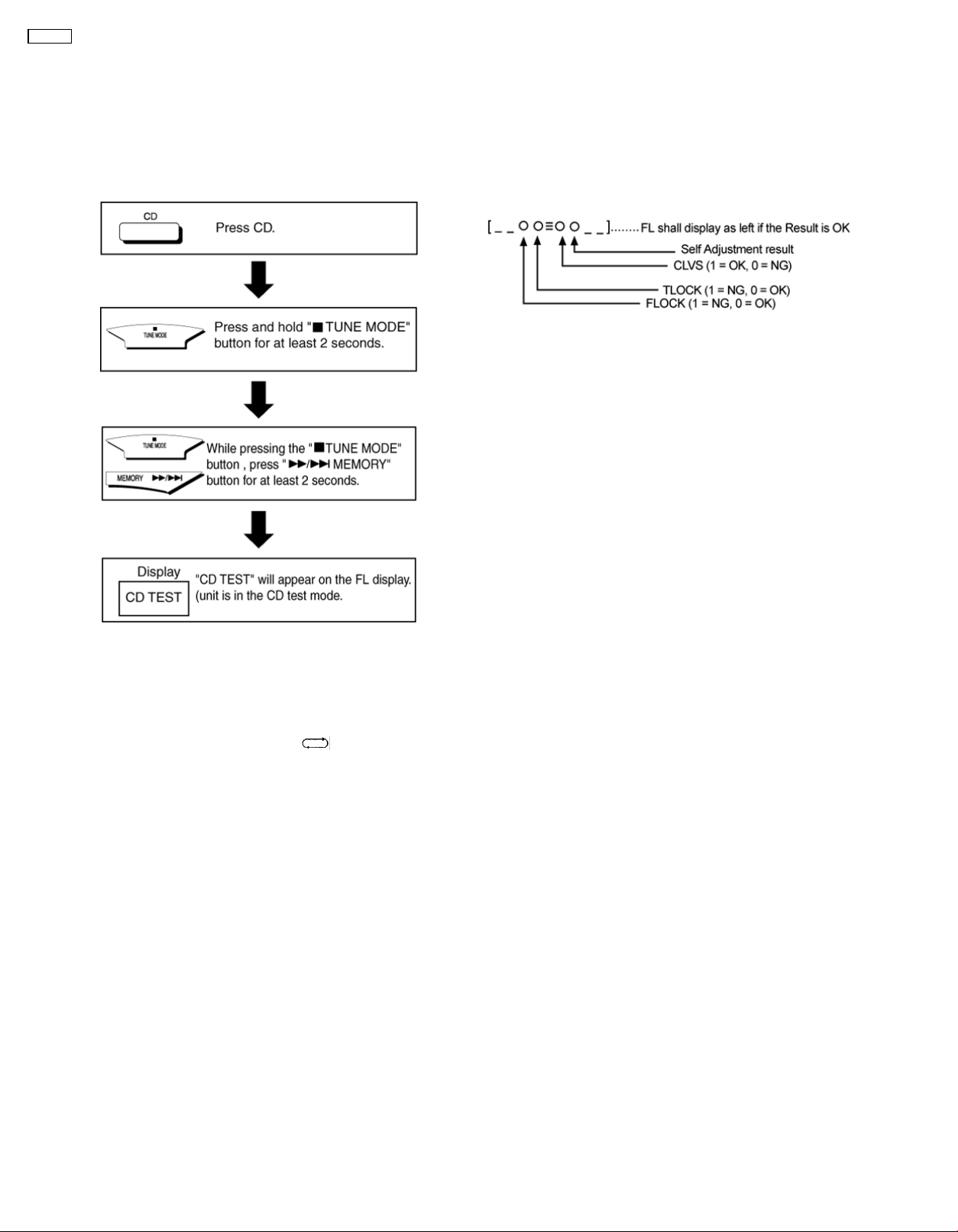

11 CD Test Mode Function

This CD test mode is provided to check CD unit without

connecting to changer loading mechanism. This mode shall

operate CD PLAY with CD unit being connected only and CD

Automatic Alignment result is shown on FL display.

11.1. How to set CD test mode

11.2. CD Automatically Adjustment

result indication

Under CD test mode, pressing the numeric key ‘0’ on the

remote controller will display the auto adjustment result.

FLOCK, TLOCK and CLVS status shall be shown as below:

During the above display, executing CD PLAY will display auto

adjustment result for CD PLAY mode.

12 Measurements and Adjustments

12.1. Cassette Deck Section

• Measurement Condition

− Reverse-mode selector switch:

− Tape edit: NORMAL

− Record timer: OFF

− Make sure head, capstan and press roller are clean.

− Judgeable room temperature 20 ± 5 °C (68 ± 9°F)

• Measuring instrument

− EVM (Electronic Volmeter)

− Digital quency counter

• Test Tape

− Head azimuth adjustment (8 kHz, -20 dB); QZZCFM

− Tape speed gain adjustment (3 kHz, -10 dB);

QZZCWAT

− Playback gain adjustment (315 Hz, 0 dB); QZZCFM

− CrO2 tape, QZZCRX

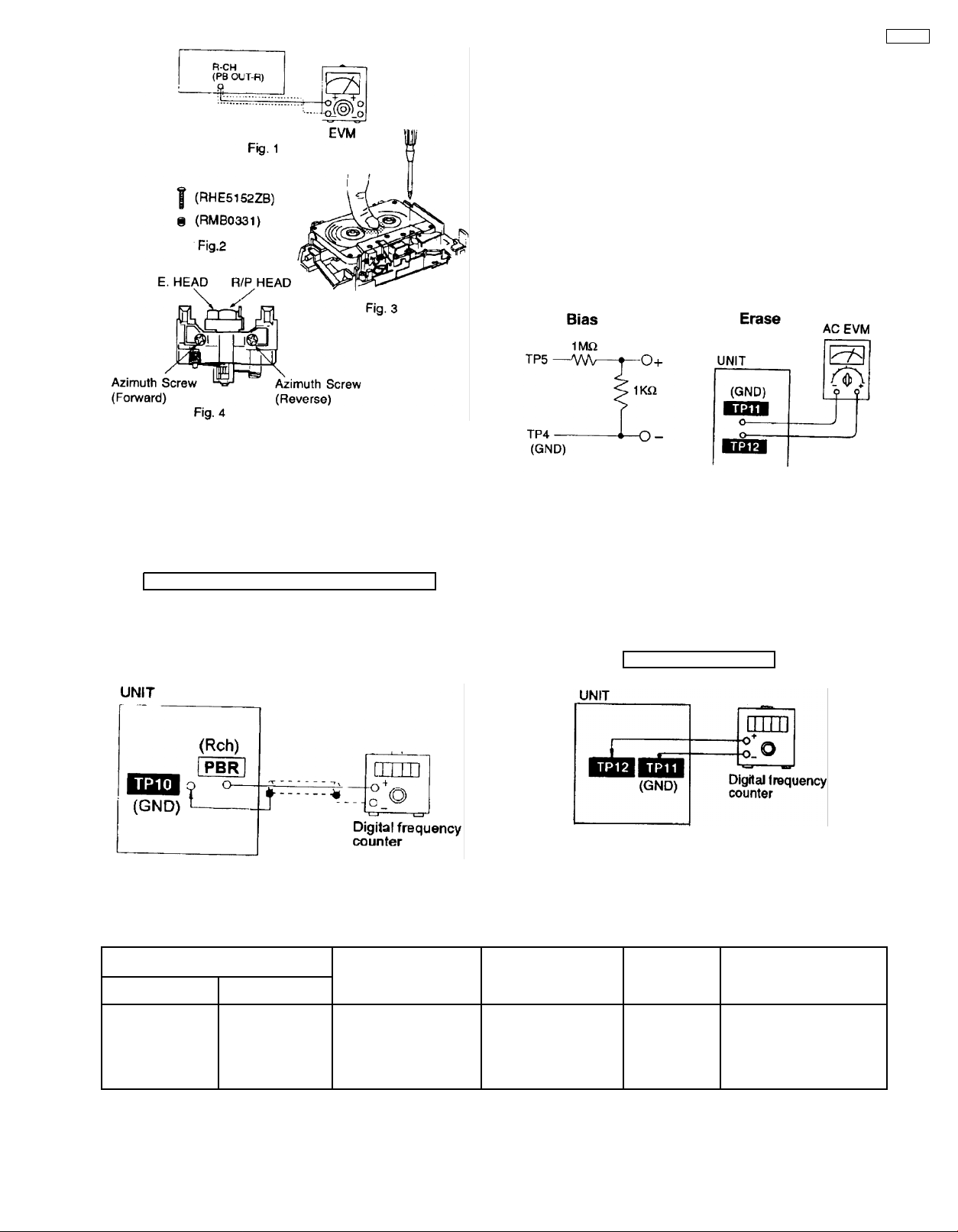

12.1.1. Head Azimuth Adjustment (Deck

1/2)

wish to readjust the head azimuth without replacing the

acrews and springs, a fine adjustment to the azimuth screw

and spring.

• Please remove the screw-locking bond left on the head

base when replacing the azimuth screw.

• If you wish to readjust the head azimuth, be sure to adjust

with adhering the cassette tape closely to the mechanism

by pushing the center of cassette tape with your finger.

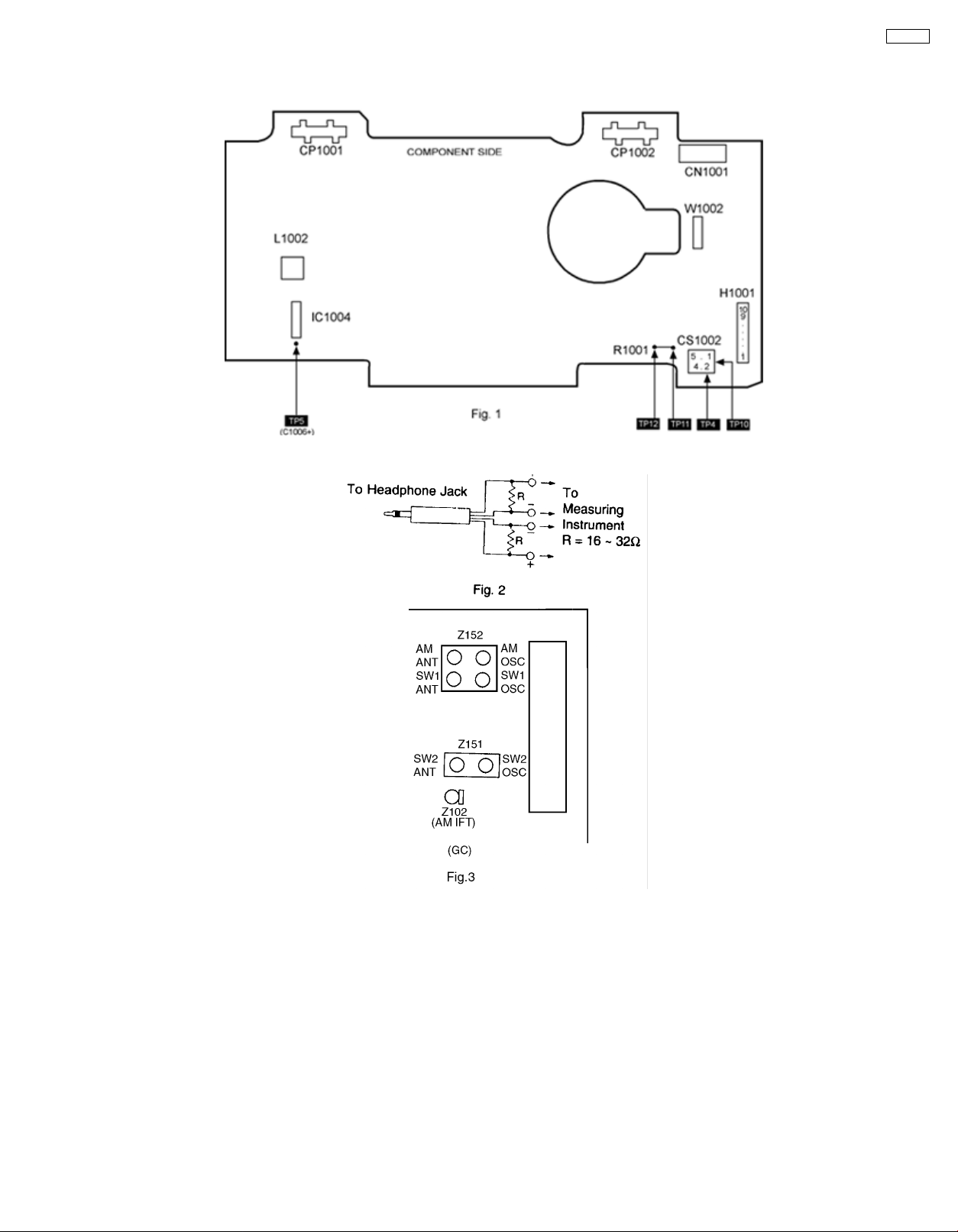

(shown in Fig. 3)

1. Playback the azimuth adjustment portion (8 kHz, -20dB) of

the test tape (QZZCFM) in the forward play mode. Vary the

azimuth adjustment screw until the output of the R-CH (PB

OUT-R) are maximized.

2. Perform the same adjustment in the reverse play mode.

3. After the adjustment, apply screwlock to the azimuth

adjusting screw.

Caution:

• Please replace both azimuth adjustment screw

(RHE5152ZB) and springs (RM0331) simultaneously when

readjusting the head azimuth. (shown in Fig. 2) Even if you

20

12.1.2. Tape Speed Adjustment (Deck 1/2)

1. Set the tape edit button to “NORMAL” position.

2. Insert the test tape (QZZCWAT) to DECK 2 and playback

(FWD side) the middle portion of it.

3. Adjust Motor VR (DECK 2) for the output value shown

below.

Adjustment target: 2940~3060 Hz (NORMALspeed)

4. After alignment, assure that the output frequency of the

DECK 2 REV and DECK 1 FWD are within ±45Hz and ±60

Hz respectively of the value of the output frequency of

DECK 2 FWD.

SA-AK52

12.1.3. Bias and Erase Voltage Check

1. Set the unit “AUX” position.

2. Insert the Normal blank tape (QZZCRA) into DECK 2 and

the unit to “REC” mode (use “● REC/STOP” key).

3. Measure and make sure that the output is within the

standard value.

4. Insert the CrO2 tape (QZZCRX).

5. Repeat step 2 and 3.

Bias voltage for Deck 2 14 ± 4mV (Normal)

Standard value) 17 ± 5mV (CrO2)

Erase voltage for Deck 2 more than 80mV (Normal)

more than 90mV (CrO2)

12.1.4. Bias Frequency Adjustment (Deck

1/2)

1. Set the unit to “AUX” position.

2. Insert the Normal blank tape (QZZCRA) into DECK 2 and

set the unit to “REC” mode (● use “REC/STOP” key).

3. Adjust L1002 so that the output frequency is within the

standard value.

Standard Value: 97 ±8 kHz

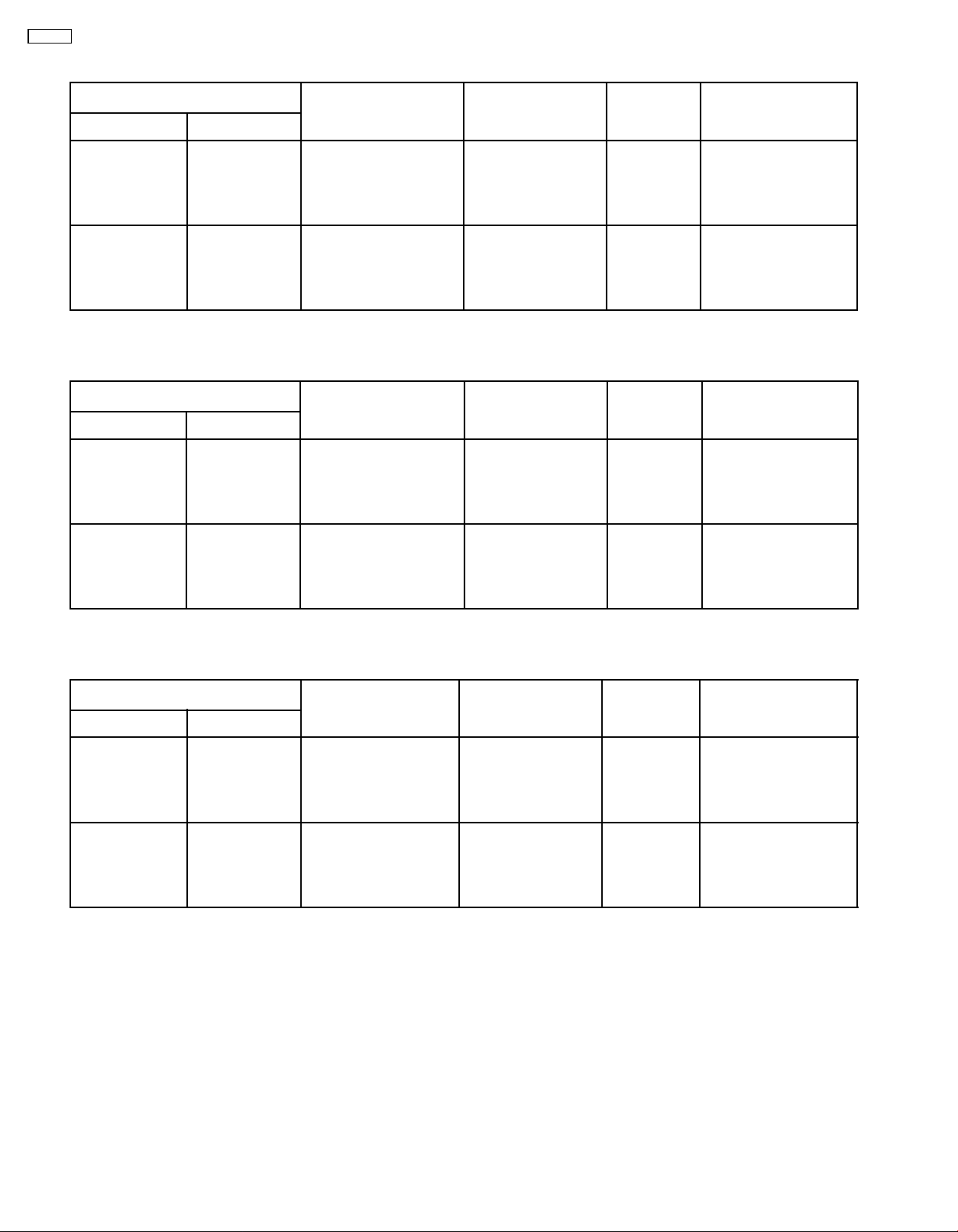

12.2. Tuner Section

12.2.1. AM-IF Alignment

SIGNAL GENERATOR OR SWEEP

CONNECTIONS FREQUENCY

Fashion a loop of

several turns of wire

and radiate a signal

into the loop ant. of

receiver.

GENERATOR

450 kHz 30% Mod.

at 400Hz.

RADIO DIAL SETTING INDICATOR

Point of non-interference

(on/about 600 kHz)

(ELECTRONIC

VOLTMETER

OSCILLOSCOPE)

Headphones Jack (32Ω)

Fabricate the plug as

shown in Fig. 2 and then

connect the lead wires of

the plug to the

measuring instrument.

21

ADJUSTMENT

(Shown in

Fig.3)

Z102 (AM IFT) Adjust for maximum output.

REMARKS

SA-AK52

12.2.2. AM-RF Alignment

SIGNAL GENERATOR OR SWEEP

CONNECTIONS FREQUENCY

Fashion a loop of

several turns of wire

and radiate a signal

into the loop ant. of

receiver.

Fashion a loop of

several turns of wire

and radiate a signal

into the loop ant. of

receiver.

GENERATOR

522 kHz Tuning capacitor fully closed Headphones Jack (32Ω)

603 kHz Tuning to signal Headphones Jack (32Ω)

RADIO DIAL SETTING INDICATOR

12.2.3. SW1-RF Alignment (GC)

SIGNAL GENERATOR OR SWEEP

CONNECTIONS FREQUENCY

Fashion a loop of

several turns of wire

and radiate a signal

into the loop ant. of

receiver.

Fashion a loop of

several turns of wire

and radiate a signal

into the loop ant. of

receiver.

GENERATOR

3.2 MHz Tuning capacitor fully closed Headphones Jack (32Ω)

3.2 MHz Tuning to signal Headphones Jack (32Ω)

RADIO DIAL SETTING INDICATOR

(ELECTRONIC

VOLTMETER

OSCILLOSCOPE)

Fabricate the plug as

shown in Fig. 2 and then

connect the lead wires of

the plug to the

measuring instrument.

Fabricate the plug as

shown in Fig. 2 and then

connect the lead wires of

the plug to the

measuring instrument.

(ELECTRONIC

VOLTMETER

OSCILLOSCOPE)

Fabricate the plug as

shown in Fig. 2 and then

connect the lead wires of

the plug to the

measuring instrument.

Fabricate the plug as

shown in Fig. 2 and then

connect the lead wires of

the plug to the

measuring instrument.

ADJUSTMENT

(Shown in

Fig.3)

Z152 (GC),

(AM OSC Coil)

Z152 (GC),

(AM ANT Coil)

ADJUSTMENT

(Shown in

Fig.3)

Z152

(SW1 OSC

Coil)

Z152

(SW1 ANT Coil)

REMARKS

Adjust for maximum output.

Adjust for maximum output.

REMARKS

Adjust for maximum output.

Adjust for maximum output.

12.2.4. SW2-RF Alignment (GC)

SIGNAL GENERATOR OR SWEEP

CONNECTIONS FREQUENCY

Fashion a loop of

several turns of wire

and radiate a signal

into the loop ant. of

receiver.

Fashion a loop of

several turns of wire

and radiate a signal

into the loop ant. of

receiver.

GENERATOR

9.4 MHz Tuning capacitor fully

9.4 MHz Tuning to signal Headphones Jack (32Ω)

RADIO DIAL SETTING INDICATOR

closed

(ELECTRONIC

VOLTMETER

OSCILLOSCOPE)

Headphones Jack (32Ω)

Fabricate the plug as

shown in Fig. 2 and then

connect the lead wires of

the plug to the

measuring instrument.

Fabricate the plug as

shown in Fig. 2 and then

connect the lead wires of

the plug to the

measuring instrument.

ADJUSTMENT

(Shown in

Fig.3)

Z151

(SW2 OSC Coil)

Z151

(SW2 ANT Coil)

REMARKS

Adjust for maximum output.

Adjust for maximum output.

22

12.3. Alignment Points

Cassette Deck section

Tuner section

SA-AK52

23

SA-AK52

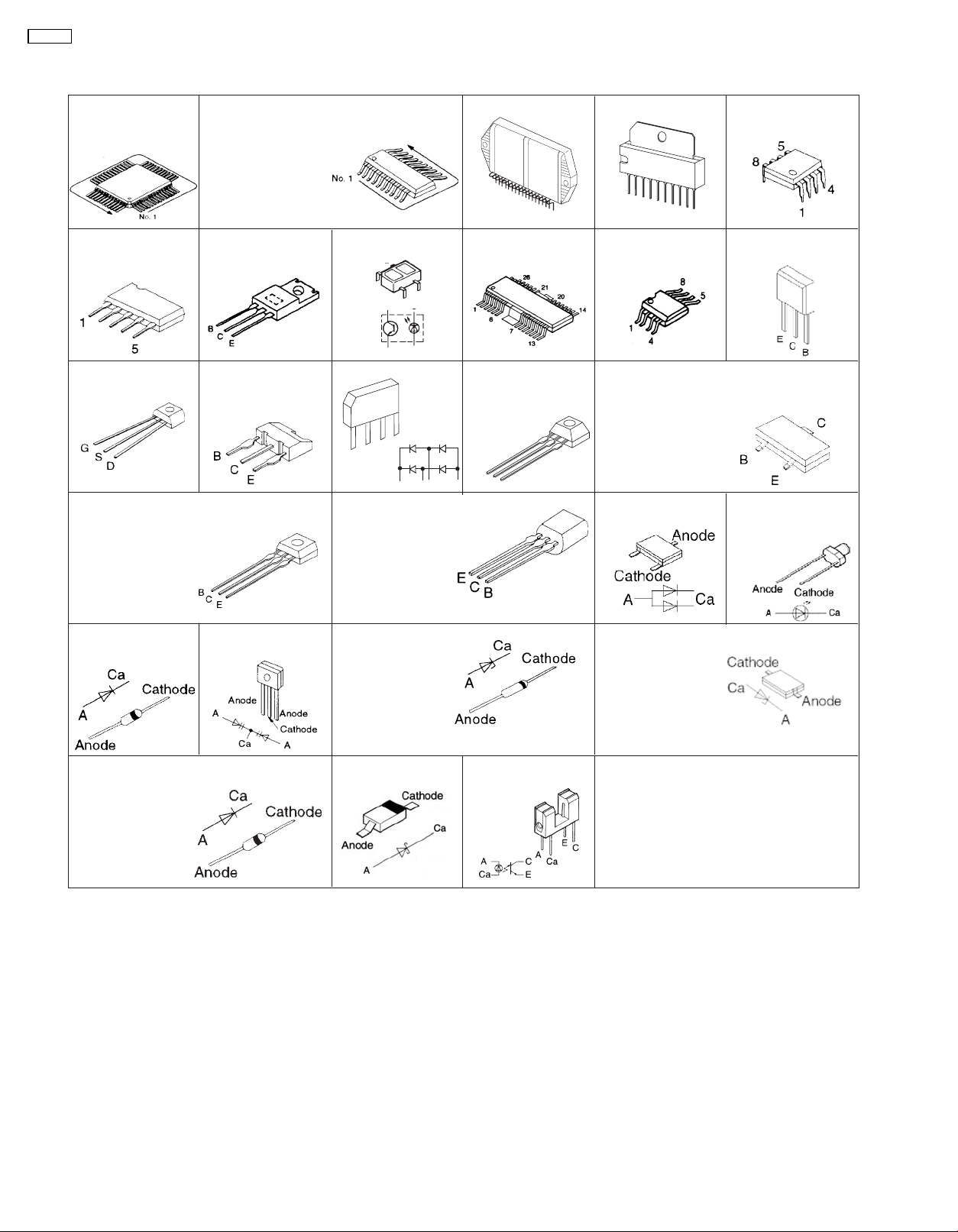

13 Illustration of IC’s, Transistors and Diodes

M38B79MFA053(100P)

BH3874AKS2 (64P)

MN662790RSC (80P)

BA7755A

2SK544F-AC

2SA933SSTA

2SC2787FL1TA

2SD2144STA

KTC3199GRTA

RVTDTC143EST

2SC2786MTA

BU2090AF-E2 (16P)

LA1833NMNTLM (24P)

LC72131MDTRM (20P)

AN7348STA-E1 (24P)

BA4558FE2 (8P)

AN8885SBE1 (28P)

TC4052BFNELM (16P)

KTC2026

KTA1046

2SD1859QRTV2

2SB1238QRTV2

0N2180RLC1

2

1

4

2

1

KBP152G4R5

4

3

2

1

123 4

KTA12710YTA

KTC3205YTA

2SB621ARSTA

KRC101MTA

KTA1504GRTA

KTD1146YTA

KTC32030YTA

RSN309W44B

TA7291P

M5218AP

93LC46B

1

26

AN8739SBE2

3

3

4

KRA102MTA

KRC103MTA

KRC102MTA

2SC1740SSTA

1

KIA4558FEL

2SA1037AKSTX

2SC2412KT96R

KRA102STA

KTC3875GRTA

10

2SC2058SPTA

2SA1309ARTA

DTA114EKA146

DTC143XKA146

KRC111STA

KTD1304TA

KRC102STA

B

C

E

KRA102STA

DAP202KT146

SLI325URCT31

SLR325MCT31W

SLR325DCT31

1N5402BM21

RL1N4003S-P

1T3T

RVD1SS133TA

1SS291TA

MA165TA

MA700ATA

MA723TA

SVC211SPA-AL

MA4020LTA

MTZJ7R5ATA

MTZJ4R7BTA

MTZJ20BTA

MTZJ240TA

MA728TX

1SS355TE17

UDZSTE175R1B

UDZTE173R6B

MA8300MTX

UDZSTE177R5B

GP1S94

24

Loading...

Loading...