Panasonic S12NKUW-1, S9NKUW-1 Installation Manual

PRINTED IN MALAYSIA

F615165

ENGLISH

Is there any gas leakage at fl are nut

connections?

Has the heat insulation been carried out at fl are

nut connection?

Is the connecting cable being fi xed to terminal

board fi rmly?

Is the connecting cable being clamped fi rmly?

Is the drainage ok?

(Refer to “Check the drainage” section)

Is the earth wire connection properly done?

CHECK ITEMS

Is the indoor unit properly hooked to the

installation plate?

Is the power supply voltage complied with rated

value?

Is there any abnormal sound?

Is the cooling operation normal?

Is the thermostat operation normal?

Is the remote control’s LCD operation normal?

Is the Air purifying fi lter installed?

1. To cut

When properly fl ared, the internal surface of the

fl are will evenly shine and be of even thickness.

Since the fl are part comes into contact with the

connections, carefully check the fl are fi nish.

Improper fl aring

Inclined

Surface

damaged

Cracked Uneven

thickness

3. To fl are

Bar

Red arrow mark

Handle

Core

Yok e

Clamp handle

Bar

0 –

1

/32"

Copper

pipe

Reamer

2. To remove burrs

Point down

Pipe

F615165

•

Read the following “SAFETY PRECAUTIONS” carefully before installation.

•

Electrical work must be installed by a licensed electrician. Be sure to use the correct rating of the power plug and main circuit for the model to be installed.

•

The caution items stated here must be followed because these important contents are related to safety. The meaning of each indication used is as below.

Incorrect installation due to ignoring of the instruction will cause harm or damage, and the seriousness is classifi ed by the following indications.

The items to be followed are classifi ed by the symbols:

•

Carry out test running to confi rm that no abnormality occurs after the installation. Then, explain to user the operation, care and maintenance as stated in

instructions. Please remind the customer to keep the operating instructions for future reference.

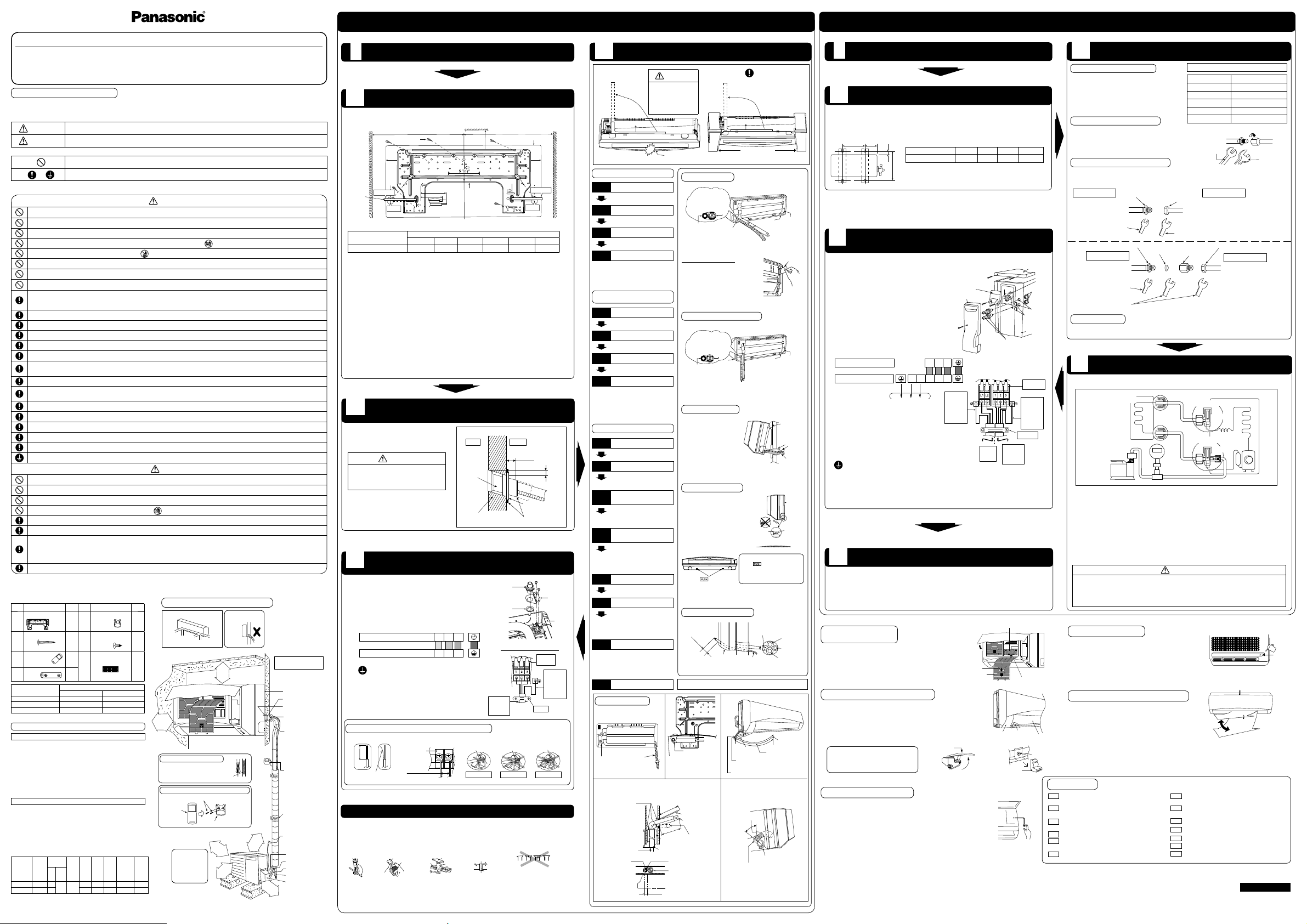

Required tools for Installation Works

INDOOR UNIT

1

2

HOW TO FIX INSTALLATION PLATE

The mounting wall shall be strong and solid enough to prevent it from the vibration.

SELECT THE BEST LOCATION

(Refer to “Select the best location” section)

The center of installation plate should be at more than 1 at right and left of the wall.

The distance from installation plate edge to ceiling should more than 2.

From installation plate left edge to unit’s left side is 3.

From installation plate right edge to unit’s right is 4.

b : For left side piping, piping connection for liquid should be about 5 from this line.

: For left side piping, piping connection for gas should be about 6 from this line.

1. Mount the installation plate on the wall with 5 screws or more (at least 5 screws).

(If mounting the unit on the concrete wall, consider using anchor bolts.)

Always mount the installation plate horizontally by aligning the marking-off line with the thread and

using a level gauge.

2. Drill the piping plate hole with ø2

3

/4" hole-core drill.

Line according to the left and right side of the installation plate. The meeting point of the extended line is

the center of the hole. Another method is by putting measuring tape at position as shown in the diagram

above. The hole center is obtained by measuring the distance namely 5

1

/16" for left and right hole

respectively.

Drill the piping hole at either the right or the left and the hole should be slightly slanting to the outdoor

side.

INDOOR UNIT INSTALLATION

4

OUTDOOR UNIT

1

SELECT THE BEST LOCATION

(Refer to “Select the best location” section)

After selecting the best location, star t installation to Indoor/Outdoor Unit Installation Diagram.

1. Fix the unit on concrete or rigid frame fi rmly and horizontally by bolt nut (ø

13

/32").

2. When installing at roof, please consider strong wind and earthquake.

Please fasten the installation stand fi rmly with bolt or nails.

2

INSTALL THE OUTDOOR UNIT

CUTTING AND FLARING THE PIPING

1. Please cut using pipe cutter and then remove the burrs.

2. Remove the burrs by using reamer. If burrs is not removed, gas leakage may be caused.

Turn the piping end down to avoid the metal powder entering the pipe.

3. Please make fl are after inserting the fl are nut onto the copper pipes.

TO DRILL A HOLE IN THE WALL AND

INSTALL A SLEEVE OF PIPING

1. Insert the piping sleeve to the hole.

2. Fix the bushing to the sleeve.

3. Cut the sleeve until it extrudes about

19

/32" from the wall.

4. Finish by sealing the sleeve with putty

or caulking compound at the fi nal stage.

CONNECT THE CABLE TO THE INDOOR

UNIT

5

1. The inside and outside connecting cable can be connected without

removing the front grille.

2. Unscrew the conduit cover and fi x the conduit connector to conduit

cover with lock nut, then secure it against chassis.

3. Connecting wire between indoor unit and outdoor unit should be

UL listed or CSA approved 4 conductor wires minimum AWG16

in accordance with local electric codes.

Ensure the colour of wires of outdoor unit and terminal number

are the same as the indoor's repectively.

This equipment must be properly earthed.

Earth lead wire shall be Yellow/Green (Y/G) in colour and

shall be longer than other lead wires as shown in the

fi gure for electrical safety in case of the slipping.

3

Terminals on the indoor unit 1 2 3

Colour of wires (connecting wire)

Terminals on the outdoor unit 1 2 3

HOW TO TAKE OUT FRONT GRILLE

Please follow the steps below to take out front grille if necessary such as when

servicing.

1. Set the vertical airfl ow direction louvers to the horizontal position.

2. Slide down the 2 caps on the front grille as shown in the illustration at right,

and then remove the 2 mounting screws.

3. Pull the lower section of the front grille towards you to remove the front grille.

AUTO SWITCH OPERATION

The below operations will be performed by pressing the “AUTO” switch.

1. AUTO OPERATION MODE

The Auto operation will be activated immediately once the Auto Switch is pressed

and release before 5 sec..

2. TEST RUN OPERATION (FOR PUMP DOWN/SERVICING PURPOSE)

The Test Run operation will be activated if the Auto Switch is pressed continuously

for more than 5 sec. A “pep” sound will occur at the fi fth sec., in order to identify

the starting of Test Run operation.

3. REMOTE CONTROLLER RECEIVING SOUND ON/OFF

The ON/OFF of Remote controller receiving sound can be change over by the following steps:

a) Press AUTO switch continuously until “pep pep pep pep” sound is heard (about 16 sec.).

b) Release the Auto switch button.

c) Press the remote controller “AC RESET” button once, “pep” sound will occur.

d) Press Auto switch again. Everytime Auto switch is pressed (within 60 sec. interval), remote

controller receiving sound status will be reversed between ON and OFF.

Long “peep” sound indicates that remote controller receiving sound is ON.

Short “pep” sound indicates that remote controller receiving sound is OFF.

1 Philips screw driver

2 Level gauge

3 Electric drill, hole core drill (ø2

3

/4")

4 Hexagonal wrench (

5

/32")

5 Spanner

6 Pipe cutter

7 Reamer

8 Knife

9 Gas leak detector

10 Measuring tape

11 Thermometer

12 Megameter

13 Multimeter

14 Torque wrench

13.3 Ibf.ft

31.0 Ibf.ft

40.6 Ibf.ft

47.9 Ibf.ft

73.8 Ibf.ft

15 Vacuum pump

16 Gauge manifold

Cover for

the bottom

piping

Tape it with piping in a

position as mentioned

in Fig. below.

Cover for

the right

piping

Piping

Drain hose

Cover for

the left

piping

Right and Right Bottom piping

6

1. Please carry out insulation at pipe connection portion as mentioned in Indoor/Outdoor Unit Installation

Diagram. Please wrap the insulated piping end to prevent water from going inside the piping.

2. If drain hose or connecting piping is in the room (where dew may form), please increase the insulation by

using POLY-E FOAM with thickness 1/4" or above.

PIPING INSULATION

Pressure test to system to 400 PSIG with dry nitrogen, in stages. Thoroughly leak check the system.

If the pressure holds, release the nitrogen and proceed to section 4.

Gas Leak Checking

1. Connect a charging hose with a push pin to the Low side of a charging set and the service port of the

3-way valve.

2. Connect the micron gauge between vacuum pump and service port of outdoor units.

3. Turn on the power switch of the vacuum pump and make sure that connect digital micron gauge

and to pull down to a value of 500 microns.

4. To make sure micron gauge a value 500 microns and close the low side valve of the charging set and

turn off the vacuum pump.

5. Disconnect the vacuum pump house from the service port of the 3-way valve.

6. Tighten the service port caps of the 3-way valve at a torque of 13.3 Ibf.ft with a torque wrench.

7. Remove the valve caps of both of the 2-way valve and 3-way valve. Position both of the valves to “Open”

using a hexagonal wrench (5/32").

8. Mount valve caps onto the 2-way valve and the 3-way valve.

•

Be sure to check for gas leakage.

Install the indoor unit

Hook the indoor unit onto the

upper portion of installation

plate. (Engage the indoor

unit with the upper edge of

the installation plate). Ensure

the hooks are properly seated

on the installation plate by

moving it in left and right.

Drain hose

Sleeve for

piping hole

Indoor unit

Hooks at

installation

plate

Piping

WHEN INSTALLING AN AIR CONDITIONER, BE SURE TO EVACUATE THE AIR INSIDE THE INDOOR

UNIT AND PIPES in the following procedure.

4

EVACUATION OF THE EQUIPMENT

3

CONNECT THE PIPING

Please make fl are after inserting fl are nut (locate at

joint portion of tube assembly) onto the copper pipe.

(In case of using long piping)

Connect the piping

•

Align the center of piping and suffi ciently tighten the

fl are nut with fi ngers.

•

Further tighten the fl are nut with torque wrench in

specifi ed torque as stated in the table.

Decide piping length and then cut by using pipe cutter.

Remove burrs from cut edge.

Make fl are after inserting the fl are nut (locate at valve) onto

the copper pipe.

Align center of piping to valve and then tighten with torque

wrench to the specifi ed torque as stated in the table.

CONNECT THE CABLE TO THE

OUTDOOR UNIT

5

1. Remove Top panel.

2. Remove Control Board Cover (Resin and Metal).

3. Remove Plugs.

4. Fix the conduit connectors to the knockout holes with

lock-nuts, then secure them against the side panel.

5. All wires pass through conduits.

6. Connecting wire between indoor unit and outdoor unit

should be UL listed or CSA approved 4 conductor

wires minimum AWG16 in accordance with local

electric codes.

7. Wire connection to the power supply (208/230V 60Hz)

through circuit breaker.

•

Connect the UL listed or CSA approved wires

minimum AWG14 to the terminal board, and

connect the other end of the wires to ELCB / GFCI.

8. Connect the power supply cord and connecting wire

between indoor unit and outdoor unit according to the

diagram below.

9. Secure the wire onto the control board with the

holder (clamper).

10. After completing wiring connections, reattach

the control board cover (Metal and Resin) and

the top panel to the original position with the

screws.

11. For wire stripping and connection requirement,

refer to instruction 5 of indoor unit.

This equipment must be properly earthed.

•

Earth lead wire shall be Yellow/Green (Y/G) in

colour and shall be longer than other lead wires

as shown in the fi gure for electrical safety in

case of the slipping.

Air purifying fi lter 7

Air fi lter

1

3

2

Example: For S9NKUW-1

If the unit is installed at 32.8 ft distance, the quantity of additional refrigerant

should be 1.64 oz .... (32.8 - 24.6) ft x 0.2 oz/ft = 1.64 oz.

Attached accessories

Rear Side of Indoor Unit

Decide piping length and then cut by using pipe cutter. Remove burrs from cut edge.

Make fl are after inserting the fl are nut (locate at valve) onto the copper pipe.

Align center of piping to valve and then tighten with torque wrench to the specifi ed torque as stated in the

table.

Holder

Power

supply

cord

Indoor &

outdoor

cable

connection

Terminal

Board

Earth wire

longer than

others

AC wires

for safety

reason

Earth wire

longer than

others

AC wires

for safety

reason

Control Board

Metal Cover

Top Panel

Power

Supply

Wires

Lock Nuts

Knockout

Holes

Plugs

Side Panel

Connectors

Control Board

Cover (Resin)

Terminals on the indoor unit

Colour of wires (connecting cable)

Terminals on the outdoor unit

(power supply cord)

1 2 3

L1 L2 1 2 3

POWER SUPPLY

Hall Union

Flare Nut

Pipe Size

Reducer

Packing

Torque Wrench for Flare

Nut and Pipe Size Reducer

Wrench

(Adjustable Wrench)

Applicable to

Gas side of

CS-S12NKUW-1

(Connection pipe)

(Auxiliary pipe)

Female side

Male side

Hall Union

Flare Nut

(Auxiliary pipe)

(Connection pipe)

Applicable to

Liquid and Gas side of

CS-S9NKUW-1

Liquid side of

CS-S12NKUW-1

Torque Wrench

for Flare Nut

Wrench

(Adjustable Wrench)

Male side Female side

• Pipe size reducer (CZ-MAIP) for outdoor Multi connection CS-S12NKUW-1

SAFETY PRECAUTIONS

WARNING

This indication shows the possibility of causing death or serious injury.

CAUTION

This indication shows the possibility of causing injury or damage to properties only.

Symbol with white background denotes item that is PROHIBITED.

Symbol with dark background denotes item that must be carried out.

No. Accessories par t Qty. No. Accessories par t Qty.

1

Installation plate

1

5

Remote control

holder

1

2

Installation plate fi xing

screw

5

6

Remote control

holder fi xing screw

2

3

Remote Control

1

7

Air purifying fi lter

1

4

Battery

2

Piping direction Attention not to bend

up drain hose

(Front side)

Right

Rear

Right bottom

Left

Rear

Left bottom

Left

Indoor/Outdoor Unit Installation Diagram

Applicable piping kit

Piping size

Gas Liquid

CZ-3F5, 7BP

3/8" (9.52 mm) 1/4" (6.35 mm)

CZ-4F5, 7, 10BP

1/2" (12.7 mm) 1/4" (6.35 mm)

CZ-52F5, 7, 10BP 5/8" (15.88 mm)

1/4" (6.35 mm)

Do not install the unit in excessive oil fume areas such as kitchen,

workshop and etc.

There should not be any heat source or steam near the unit.

There should not be any obstacles blocking the air circulation.

A place where air circulation in the room is good.

A place where drainage can be easily done.

A place where noise prevention is taken into consideration.

Do not install the unit near a door way.

Ensure the spaces indicated by arrows from the wall, ceiling, fence or

other obstacles.

Recommended installation height for indoor unit shall be at least 8.2 ft.

If an awning is built over the unit to prevent direct sunlight or rain,

be careful that heat radiation from the condenser is not obstructed.

There should not be any animal or plant which could be affected by

hot air discharged.

Keep the spaces indicated by arrows from wall, ceiling, fence or

other obstacles.

Do not place any obstacles which may cause a short circuit of the

discharged air.

If piping length is over the [piping length for additional gas], additional

refrigerant should be added as shown in the table.

INDOOR UNIT

OUTDOOR UNIT

SELECT THE BEST LOCATION

Model

Capacity

(Btu/h)

Piping size

Std.

Length

(ft)

Max.

Eleva-

tion

(ft)

Min.

Piping

Length

(ft)

Max.

Piping

Length

(ft)

Additional

Refrige-

rant (oz/ft)

Piping

Length

for add.

gas (ft)

Gas Liquid

S9NKUW-1

8500 3/8"

1/4"

24.6

16.4 9.8 49.2 0.2 24.6

S12NKUW-1

11900 1/2" 16.4 9.8 49.2 0.2 24.6

1

31

/32"

or more

2

9

/

16

"

or more

(Left and right are identical)

• Carry out insulation after

checking for gas leaks and

secure with vinyl tape.

Vinyl tape

• This illustration is for

explanation purposes only.

The indoor unit will actually face

a different way.

3

15

/

16

"

or more

39

3

/

8

"

or more

3

15

/

16

"

or more

11

13

/

16

"

or more

It is advisable to

avoid more than 2

blockage directions.

For better ventilation

& multiple-outdoor

installation, please

consult authorized

dealer/specialist.

Installation plate 1

Sleeve (

)

Bushing-Sleeve (

)

Bend the pipe as

closely on the wall as

possible, but be careful

that it doesn’t break.

Saddle (

)

Conduit

(Power supply cord (

))

Control Board cover

Remote control holder fi xing screws

6

Remote control holder

5

Remote

control

3

Additional drain hose

Gas side piping (

)

Conduit

(Connecting cable)

Putty (

)

(Gum Type Sealer)

Installation parts you

should purchase ()

Vinyl tape (wide) ()

• Apply after carrying

out a drainage test.

• To carry out the

drainage test,

remove the air fi lters

and pour water into

the heat exchanger.

Liquid side piping (

)

Insulation of piping connections

Attaching the remote control holder to the wall

Wall

Wall

Wall

Installation

plate 1

2 screw

More than 1

More than 1

Measuring

Tape

Indoor unit

9

17

/32"

5

1

/16"

9

1

/4"

5

1

/16"

More than

2

Model

Dimension

123456

S9NKUW-1, S12NKUW-1 19 3/32" 3 7/32" 6 1/2" 6 7/32" 1 11/16" 3 3/4"

Chassis

Conduit

Connector

Conduit

Cover

Lock Nut

Earth Wire

longer than

others

AC wires

for safety

reason

Terminal

Board

Holder

Indoor and

outdoor

cable

connection

Wire stripping

7

/32"

or more

(gap between

wires)

ACCEPT

PROHIBITED

Conductor

over inserted

No loose strand when inserted

Indoor/outdoor

connecting

terminal board

13/32" ± 1/16"

WIRE STRIPPING AND CONNECTING REQUIREMENT

Conductor

fully inserted

PROHIBITED

Conductor not

fully inserted

Use shock absorber

during pull out the

piping to protect the

intake grille from

damage

Piping

Intake grille

Shock absorber

Piping

CAUTION

Do not turn over the

unit without it’s shock

absorber during pull

out the piping. It may

cause intake grille

damage.

1. FOR THE RIGHT REAR PIPING

Step-1

Pull out the Indoor piping

Step-2

Install the Indoor Unit

Step-3

Secure the Indoor Unit

Step-4

Insert the connecting cable

CAUTION

When the wall is hollow, please be sure

to use the sleeve for tube assembly to

prevent dangers caused by mice biting the

connecting cable.

19

/32"

Putty or caulking compound

ø2

3

/4" through hole

Indoor

Outdoor

Sleeve for

tube

assembly

Approx. 7/32" - 9/32"

Bushing for tube

assembly

Wall

Cover for the

bottom piping

Cover for the

bottom piping

Tape it with

piping in a position as

mentioned in

Fig. below.

Piping

Drain

hose

Cover

for the

left

piping

Right Rear piping

Cover for piping

In case of the cover is cut, keep

the cover at the rear of chassis as

shown in the illustration for future

reinstallation.

(Left and 2 bottom covers for piping.)

How to keep the cover

marking

PUSH

PUSH

To take out the unit, push

the

marking at the

bottom unit, and pull it slightly

towards you to disengage the

hooks from the unit.

1. Press the lower left and right side

of the unit against the installation

plate until hooks engages with their

slot (sound click).

Installation

plate

Unit’s

hook

Secure the Indoor Unit

Guide

surface

Connecting cable

About

2

3

/

4

" - 3

5

/

32

"

Connecting cable

Gas side

piping

Liquid side

piping

Drain hose

Insert the connecting cable

2. FOR THE RIGHT BOTTOM

PIPING

Step-1

Pull out the Indoor piping

Step-2

Install the Indoor Unit

Step-3

Insert the connecting cable

Step-4

Secure the Indoor Unit

Step-1

Replace the drain hose

Step-2

Bend the embedded piping

• Use a spring bender or

equivalent to bend the piping so

that the piping is not crushed.

Step-3

Pull the connecting cable

into Indoor Unit

• The inside and outside

connecting cable can be

connected without removing the

front grille.

Step-4

Cut and fl are the

embedded piping

• When determining the

dimensions of the piping, slide

the unit all the way to the left on

the installation plate.

• Refer to the section “Cutting

and fl aring the piping”.

Step-5

Install the Indoor Unit

Step-6

Connect the piping

• Please refer to “Connecting

the piping” column in outdoor

unit section. (Below steps are

done after connecting the

outdoor piping and gas-leakage

confi rmation.)

Step-7

Insulate and fi nish the piping

• Please refer to “Piping and

fi nishing” column of outdoor

section and “Insulation of

piping connection” column as

mentioned in indoor/outdoor

unit installation.

Step-8

Secure the Indoor Unit

3. FOR THE EMBEDDED PIPING

(This can be used for left rear piping and bottom piping also.)

Rear view for left piping installation

Drain cap

Drain hose

Replace the drain hose

Adjust the piping slightly

downwards.

Drain hose

Connecting cable

Sleeve for piping hole

Drain hose

Piping

Connecting

cable

More than 45

9

/32"

•

How to pull the piping and drain hose out, in case of

the embedded piping

.

PVC tube

for drain

hose

Indoor unit

2

27

/32"

Piping

Cable

Apply putty or

caulking material

to seal the wall

opening.

Connecting cable

Piping

More than

18

1

/

2

"

More than

45

9

/

32

"

PVC tube (VP-65) for piping

and connecting cable

PVC tube for drain hose (VP-30)

PVC tube for

drain hose (VP-20)

More than 27

9

/16"

Drain hose

from main unit

•

In case of left piping how to insert

the connecting cable and drain hose.

Cable

45°

Drain

hose

Piping

(For the right piping, follow the same

procedure)

Model A B C D

S9NKU-1, S12NKU-1

22 7/16" 4 1/8" 23/32" 12 19/32"

AB

C

D

Connecting The Piping to Indoor

Do not overtighten, over tightening may cause gas leakage.

Piping size Torque

1/4" 13.3 Ibf.ft

3/8" 31.0 Ibf.ft

1/2" 40.6 Ibf.ft

5/8" 47.9 Ibf.ft

3/4" 73.8 Ibf.ft

Connecting The Piping to Outdoor

Torque

wrench

Spanner

or Wrench

Connecting The Piping to Outdoor Multi

Gas side

Liquid side

Outdoor unit

Three-way valve

Indoor unit

Vacuum

pump

Close

Close

CAUTION

•

If micron gauge value does not descend 500 microns, take the following measures:

- If the leak stops when the piping connections are tightened fur ther, continue working from step 3.

- If the leak does not stop when the connections are retightened, repair location of leak.

- Do not release refrigerant during piping work for installation and reinstallation.

- Be careful with the liquid refrigerant, it may cause frostbite.

1. Open the front panel.

2. Remove the air fi lters.

3. Put the air purifying fi lter into place as shown in illustration at right.

INSTALLATION OF AIR

PURIFYING FILTER

•

Open front panel and remove air fi lters.

(Drainage checking can be carried out without removing the

front grille.)

•

Pour a glass of water into the drain tray-styrofoam.

•

Ensure that water fl ows out from drain hose of the indoor unit.

Drain

traystyrofoam

CHECK THE DRAINAGE

•

Operate the unit at cooling operation mode for fi fteen

minutes or more.

•

Measure the temperature of the intake and discharge air.

•

Ensure the difference between the intake temperature and

the discharge is more than 46.4°F.

Discharge air

EVALUATION OF THE PERFORMANCE

Cap

Screw

(Move the vane

to upward)

Vane

When reinstalling the front grille, fi rst set

the vertical airfl ow direction louver to the

horizontal position and then carry out

above steps 2 - 3 in the reverse order.

Cap

Vane

Front grille

WARNING

Do not install outdoor unit near handrail of veranda. When installing air-conditioner unit on veranda of a high rise building, child may climb up to outdoor unit and

cross over the handrail causing an accident.

Do not use unspecifi ed cord, modifi ed cord, joint cord or extension cord for power supply cord. Do not share the single outlet with other electrical appliances. Poor

contact, poor insulation or over current will cause electrical shock or fi re.

Do not tie up the power supply cord into a bundle by band. Abnormal temperature rise on power supply cord may happen.

Do not insert your fi ngers or other objects into the unit, high speed rotating fan may cause injury.

Do not sit or step on the unit, you may fall down accidentally.

Keep plastic bag (packaging material) away from small children, it may cling to nose and mouth and prevent breathing.

When installing or relocating air conditioner, do not let any substance other than the specifi ed refrigerant, eg. air etc. mix into refrigeration cycle (piping).

Mixing of air etc will cause abnormal high pressure in refrigeration cycle and result in explosion, injury etc.

Do not add or replace refrigerant other than specifi ed type. It may cause product damage, burst and injury etc.

●

For R410A model, use piping, fl are nut and tools which is specifi ed for R410A refrigerant. Using of existing (R22) piping, fl are nut and tools may cause abnormally

high pressure in the refrigerant cycle (piping), and possibly result in explosion and injury.

●

Thickness or copper pipes used with R410A must be more than 1/32". Never use copper pipes thinner than 1/32".

●

It is desirable that the amount of residual oil is less than 0.0008 oz/ft..

Engage authorized dealer or specialist for installation. If installation done by the user is incorrect, it will cause water leakage, electrical shock or fi re.

Install according to this installation instructions strictly. If installation is defective, it will cause water leakage, electrical shock or fi re.

Use the attached accessories parts and specifi ed parts for installation. Otherwise, it will cause the set to fall, water leakage, fi re or electrical shock.

Install at a strong and fi rm location which is able to withstand the set’s weight. If the strength is not enough or installation is not properly done, the set will drop

and cause injury.

For installation work, follow all electrical, building, plumbing, local codes, regulations and these installation instructions. If electrical circuit capacity is not enough or a

defect is found in electrical work, it will cause electrical shock or fi re.

Do not use spliced wires for indoor / outdoor connection cable. Use the specifi ed indoor / outdoor connection cable, refer to instruction 5 INDOOR/OUTDOOR

UNIT ELECTRICAL WIRING and connect tightly for indoor/outdoor connection. Clamp the cable so that no external force will have impact on the terminal. If connection

or fi xing is not perfect, it will cause heat-up or fi re at the connection.

Wire routing must be properly arranged so that control board cover is fi xed properly. If control board cover is not fi xed perfectly, it will cause fi re or electrical shock.

This equipment must installed with an Earth Leakage Circuit Breaker (ELCB) or Ground Fault Current Interrupter (GFCI) or Appliance Leakage Current Interrupter

(ALCI) that has been certifi ed by an NRTL Certifi ed Testing Agency and that is suitable for the voltages and amperages involved. Otherwise, if may

cause electrical shock and fi re in case of equipment breakdown.

During installation, install the refrigerant piping properly before running the compressor. Operation of compressor without fi xing refrigeration piping and valves at opened

condition will cause suck-in of air, abnormal high pressure in refrigeration cycle and result in explosion, injury etc.

During pump down operation, stop the compressor before removing the refrigeration piping. Removal of refrigeration piping while compressor is operating and valves

are opened will cause suck-in of air, abnormal high pressure in refrigeration cycle and result in explosion, injury etc.

Tighten the fl are nut with torque wrench according to specifi ed method. If the fl are nut is over-tightened, after a long period, the fl are may break and cause refrigerant

gas leakage.

After completion of installation, confi rm there is no leakage of refrigerant gas. It may generate toxic gas when the refrigerant comes into contact with fi re.

Ventilate if there is refrigerant gas leakage during operation. It may cause toxic gas when the refrigerant comes into contact with fi re.

This equipment must be properly earthed. Earth line must not be connected to gas pipe, water pipe, earth of lightning rod and telephone. Otherwise, it may

cause electrical shock in case of equipment breakdown or insulation breakdown.

CAUTION

Do not install the unit at place where leakage of fl ammable gas may occur. In case gas leaks and accumulates at surrounding of the unit, it may cause fi re.

Do not release refrigerant during piping work for installation, re-installation and during repairing a refrigeration parts. Take care of the liquid refrigerant, it may

cause frostbite.

Do not install this appliance in a laundry room or other location where water may drip from the ceiling, etc.

Do not touch the sharp aluminium fi n, sharp parts may cause injury.

Carry out drainage piping as mentioned in installation instructions. If drainage is not perfect, water may enter the room and damage the furniture.

Select an installation location which is easy for maintenance.

Power supply connection to the room air conditioner.

Power supply cord shall be UL listed or CSA approved 3 conductor with minimum AWG14 wires.

Power supply point should be in an easily accessible place for power disconnection in case of emergency.

In some countries, permanent connection of this air conditioner to the power supply is prohibited.

Fix power supply connection to a circuit breaker for the permanent connection.

Use NRTL approved fuse or circuit breaker (rating refers to name plate) for the permanent connection.

Installation work.

It may take two people to carry out the installation work.

•

IMPORTANT (only for S9NKUW-1)

This product has been designed and manufactured to meet ENERGY STAR® criteria for energy effi ciency when matched with appropriate coil components. However,

proper refrigerant charge and proper air fl ow are critical to achive rated capacity and effi ciency. Installation of this product should follow the manufacturer’s

refrigerant charging and air fl ow instructions. Failure to confi rm proper charge and airfl ow may reduce energy effi ciency and shorten equipment life.

Two-way valve

3

b

5

c

6

a

4

Loading...

Loading...