Panasonic PV310 Installation Manual

Before Reading This Manual

Thank you for purchasing the MICRO-IMAGECHECKER PV310.

In this manual, information on the hardware (installation, wiring, etc.) and the software (functions, setting

procedures, etc.) is described. Read this User’s Manual carefully before use.

Safety Precautions

To ensure that you use this product correctly, read this User’s Manual thoroughly before use. Make sure

that you fully understand the product and information on safe.

Conventions used in the Safety Precautions

Symbols:

The following symbols used in Safety Precautions.

Symbol Explanation:

WARNING

This indicates the existence of a hazard that could result in death of or serious damage to the operator, if

the safety instruction is not observed.

CAUTION

This indicates the existence of a hazard that could result in serious bodily injury or property damage, if

the safety instruction is not observed.

WARNING

• Use the product within its specified ratings and environmental conditions. Failure to do so might

result in abnormal heat and smoke coming from the product.

• Do not use the product in the environment where combustible gas presents. This might cause

explosion.

• Do not throw the product into fire. This might cause the batteries and electronic parts in the product

to explode.

CAUTION

• To prevent abnormal heat and smoke coming from the product, do not make the product operate up

to the limits of guaranteed features and performance.

• Never attempt to disassemble or alter the product. Failure to do so might result in abnormal heat and

smoke coming from the product.

• Do not touch the terminals while the power is ON. This might result in an electric shock.

• Surely connect the wires and connectors. Failure to do so might result in abnormal heat and smoke

coming from the product.

• Do not allow liquid, combustible materials or metallic objects to come into the product. Failure to do

so might result in abnormal heat and smoke coming from the product. Be sure to ground the product.

Failure to do so might result in an electric shock.

• Do not install (connect or disconnect) the product while the power is ON. This might result in an

electric shock.

Table of Contents

Precautions before Use............................................................... xi

1. Names and Functions of Parts .............................................. 1

1.1 About the PV310 .......................................................................................... 2

1.2 Camera Peripherals...................................................................................... 4

1.2.1 Double Speed Random Camera: ANM831................................................ 4

1.2.2 Standard Camera: ANM832....................................................................... 5

1.2.3 Camera Cable/Camera Extension Cable................................................... 5

1.2.4 Camera Switching Unit: ANPV3700........................................................... 6

1.3 Keypad ......................................................................................................... 7

1.4 VGA Monitor ................................................................................................. 8

2. Installation and Wiring............................................................ 9

2.1 Connecting Peripherals .............................................................................. 10

2.2 Installation Environment and Mounting Space ........................................... 11

2.2.1 Installation Environment........................................................................... 11

2.2.2 Mounting the PV310................................................................................. 13

2.3 VGA Monitor Installation Environment........................................................ 14

2.3.1 Installation Environment........................................................................... 14

2.3.2 VGA Monitor Installation ..........................................................................15

2.3.3 VGA Monitor: Power Wiring ..................................................................... 16

2.4 Installing the Camera.................................................................................. 17

2.5 View Range - Lens Selection Table ........................................................... 18

2.5.1 Double Speed Random Camera: ANM831.............................................. 18

2.5.2 Standard Camera: ANM832..................................................................... 19

2.5.3 Notes on Mounting a Camera .................................................................. 21

3. Input and Output Interface Ports ......................................... 23

3.1 Parallel Ports .............................................................................................. 24

3.1.1 Wiring to the Terminal Blocks ..................................................................24

3.1.2 Pin Assignments....................................................................................... 25

3.1.3 Notes on Power Supply and Wiring .........................................................26

3.1.4 About Grounding ...................................................................................... 27

3.1.5 Arrangements of the Output Terminals and Output Circuit...................... 28

i

3.1.6 Arrangements of Input Terminals and Input Circuit .................................30

3.1.7 FLASH Output Synchronizing Signal ....................................................... 32

3.2 About RS-232C Port ...................................................................................34

3.2.1 Port Used for RS-232C Communication .................................................. 34

3.2.2 Pin Assignments of COM1 Port And Example of Connections to External

Device ......................................................................................................35

3.3 About Ethernet Port.....................................................................................39

3.3.1 Port Used for Ethernet Communication ...................................................39

3.3.2 Pin Assignments of TOOL Port and Example of Connection with PC .....40

3.3.3 Vision Support Tool AXTOOL Ver. 3........................................................ 41

4. Basic Operation .....................................................................43

4.1 About Screen Monitor .................................................................................44

4.2 RUN and SETUP Modes.............................................................................45

4.2.1 About SETUP and RUN Modes ...............................................................45

4.2.2 Switching between RUN Mode and SETUP Mode .................................. 45

4.3 How To Preprocess and Display Images ....................................................46

4.4 Basic Operation Using the Keypad .............................................................47

4.4.1 Selecting an Option from the Menu..........................................................47

4.4.2 Setting (Inputting) Values......................................................................... 47

4.4.3 Setting the Inspection Area ......................................................................48

4.5 Temporarily Switching the Display Camera Images....................................51

4.5.1 Display Images......................................................................................... 51

4.5.2 Selecting a Display Camera Image Using the Display Camera Image

Function.................................................................................................... 51

4.5.3 Selecting a Display Gray Value/Binary Using the Display Gray Value/Binary

Function.................................................................................................... 52

5. Procedure for Setting Inspection Conditions .....................53

5.1 Setting Inspection Conditions......................................................................54

5.2 Selecting a Camera Mode...........................................................................55

5.3 Setting a Shutter Speed ..............................................................................57

5.4 Selecting a Product Type ............................................................................58

5.4.1 Selecting a Product Type .........................................................................58

5.4.2 Copying an Existing Product Type ...........................................................59

5.4.3 Deleting a Product Type...........................................................................59

5.4.4 Deleting All Product Types ....................................................................... 60

ii

5.4.5 Entering a Product Type Title................................................................... 60

5.5 Importing Images into a Memory ................................................................ 61

5.6 Inspection Overview ................................................................................... 62

5.7 Storing Setting (Revised) Data in the PV310 ............................................. 63

5.8 Executing Inspection .................................................................................. 64

5.8.1 Procedure for Inspection Execution ......................................................... 64

5.8.2 Process Sequence for Executing Inspection ...........................................65

6. Setting Checkers................................................................... 67

6.1 What Is a Checker? .................................................................................... 68

6.1.1 Types and Overview of Checkers ............................................................ 68

6.1.2 Basic Settings of Checkers ......................................................................70

6.1.3 Basic Procedure for Setting Checkers ..................................................... 70

6.1.4 Selecting a Checker Number and a Checker Type..................................71

6.1.5 Selecting a Camera Image....................................................................... 73

6.1.6 Preprocessing Settings ............................................................................74

6.1.7 Setting a Slice Level................................................................................. 78

6.1.8 Setting a (Mask) Area ..............................................................................80

6.1.9 Area Size Adjustment Function................................................................ 83

6.2 Convenient Functions for Setting a Checker .............................................. 88

6.2.1 Changing the Menu Window to a Translucent Color ...............................88

6.2.2 Temporarily Hiding the Menu Window ..................................................... 89

6.3 Binary Window............................................................................................ 90

6.3.1 Menu Options........................................................................................... 90

6.3.2 What Is Binary Window? ..........................................................................90

6.3.3 Setting Procedure ....................................................................................91

6.4 Gray Window .............................................................................................. 92

6.4.1 Menu Options........................................................................................... 92

6.4.2 What Is Gray Window? ............................................................................92

6.4.3 Setting Procedure ....................................................................................93

6.5 Binary Edge ................................................................................................ 94

6.5.1 Menu Options........................................................................................... 94

6.5.2 What Is Binary Edge? ..............................................................................94

6.5.3 Setting Procedure ....................................................................................95

6.6 Gray Edge .................................................................................................. 98

6.6.1 Menu Options........................................................................................... 98

iii

6.6.2 What Is Gray Edge? .................................................................................99

6.6.3 Setting Procedure...................................................................................100

6.7 Feature Extraction.....................................................................................105

6.7.1 Menu Options .........................................................................................105

6.7.2 What Is Feature Extraction?................................................................... 106

6.7.3 Setting Procedure...................................................................................108

6.8 Smart Matching .........................................................................................112

6.8.1 Menu Options .........................................................................................112

6.8.2 What Is Smart Matching? ....................................................................... 113

6.8.3 Setting Procedure...................................................................................114

6.9 Contour Matching......................................................................................124

6.9.1 Menu Options .........................................................................................124

6.9.2 What Is Contour Matching?.................................................................... 124

6.9.3 Setting Procedure...................................................................................125

6.10 Flaw Detection ........................................................................................128

6.10.1 Menu Options.........................................................................................128

6.10.2 What Is Flaw Detection? ........................................................................129

6.10.3 Setting Procedure...................................................................................132

6.11 Position Adjustment ................................................................................139

6.11.1 Overview.................................................................................................139

6.11.2 Refering to Position Adjustment Amount Using Checkers.....................140

6.12 Position Adjustment (Binary Edge)..........................................................141

6.12.1 Setting Procedure...................................................................................141

6.12.2 Saving a Base Position ..........................................................................142

6.12.3 What To Do If You Faced a Trouble ......................................................142

6.13 Position Adjustment (Gray Edge)............................................................143

6.13.1 Setting Procedure...................................................................................143

6.13.2 Saving a Base Position ..........................................................................144

6.13.3 What To Do If You Faced a Trouble ......................................................145

6.14 Position Adjustment (Feature Extraction)................................................146

6.14.1 Setting Procedure...................................................................................146

6.14.2 Saving a Base Position ..........................................................................147

6.14.3 What To Do If You Faced a Trouble ......................................................147

6.15 Position Adjustment (Matching)...............................................................148

6.15.1 Setting Procedure...................................................................................148

6.15.2 Saving a Base Position ..........................................................................148

iv

6.15.3 What To Do If You Faced a Trouble ......................................................149

6.16 Rotation Adjustment ............................................................................... 150

6.16.1 Overview ................................................................................................ 150

6.16.2 How Checkers Refer to Adjustment Amount .........................................151

6.17 Rotation Adjustment (Binary Edge Horiz., Binary Edge Vert.)................ 152

6.17.1 Setting Procedure .................................................................................. 152

6.17.2 Saving a Base Position ..........................................................................153

6.17.3 What To Do If You Faced a Trouble ......................................................153

6.18 Rotation Adjustment (Gray Edge Horiz., Gray Edge Vert.)..................... 154

6.18.1 Setting Procedure .................................................................................. 154

6.18.2 Saving a Base Position ..........................................................................155

6.18.3 What To Do If You Faced a Trouble ......................................................155

6.19 Rotation Adjustment (Feature Extraction) .............................................. 156

6.19.1 Setting Procedure .................................................................................. 156

6.19.2 Saving a Base Position ..........................................................................157

6.19.3 What To Do If You Faced a Trouble ......................................................157

6.20 Rotation Adjustment (360 Degree Detection)......................................... 158

6.20.1 Setting Procedure .................................................................................. 158

6.20.2 Saving a Base Position ..........................................................................158

6.20.3 What To Do If You Faced a Trouble ......................................................159

6.21 Rotation Adjustment: Matching............................................................... 160

6.21.1 Setting Procedure .................................................................................. 160

6.21.2 Saving a Base Position ..........................................................................160

6.21.3 What To Do If You Faced a Trouble ......................................................161

6.22 Rotation Adjustment (Contour) ............................................................... 162

6.22.1 Setting Procedure .................................................................................. 162

6.22.2 Saving a Base Position ..........................................................................162

6.22.3 What To Do If You Faced a Trouble ......................................................163

7. Calculation, Analysis and Output of Inspection Results. 165

7.1 Overview................................................................................................... 166

7.1.1 Calculation, Analysis, and Display of the Inspection Result Data.......... 166

7.1.2 Outputting Data to the External Device.................................................. 166

7.2 Numeric Calculation (CA01 to CA99) ....................................................... 167

7.2.1 Main Functions....................................................................................... 167

7.2.2 Reference Data and Calculation Functions ...........................................167

v

7.2.3 Creating a Numeric Calaulation ............................................................. 171

7.2.4 Specifying the Judge. Max./Min. Values- Judging the Calculation Results

................................................................................................................173

7.2.5 Copying a Numeric Calculation.............................................................. 173

7.2.6 Deleting a Numeric Calculation.............................................................. 174

7.2.7 Projection Distance ................................................................................175

7.2.8 Conversion of Length L into Actual Size Value: Conversion Data.........176

7.2.9 Restrictions on Numeric Calculation Function .......................................179

7.2.10 Error Messages Displayed When You Set Numeric Calculation Formula

................................................................................................................181

7.3 Judgment (JD01 to JD96) .........................................................................182

7.3.1 Main Functions .......................................................................................182

7.3.2 Reference Data and Operators ..............................................................182

7.3.3 Creating a Judgment Formula................................................................ 184

7.3.4 Saving Total Judgments......................................................................... 185

7.3.5 Saving a Conditional Formula for Save Image.......................................186

7.3.6 Restrictions on Judgment.......................................................................188

7.3.7 Error Messages Displayed When You Set a Judgment Formula...........188

7.4 Statistics (QS01 to QS96) .........................................................................189

7.4.1 Main Functions .......................................................................................189

7.4.2 Reference Data ...................................................................................... 189

7.4.3 Statistics Items .......................................................................................190

7.4.4 Referring Statistic Object Data............................................................... 190

7.4.5 Deleting the Data Referred to Statistics .................................................191

7.4.6 Resetting the Counted Results ..............................................................192

7.5 Data Monitor..............................................................................................193

7.5.1 Main Functions .......................................................................................193

7.5.2 Data Can Be Displayed in the Data Monitor Table ................................ 194

7.5.3 Referring the Data to Data Monitor Table ..............................................194

7.5.4 Saving the Fixed Name (Title) to the Cell ..............................................196

7.5.5 Changing the Number of Rows and Columns in the Data Monitor Table196

7.5.6 Selecting the Alignment of the Data Monintor........................................ 198

7.5.7 Changing Max. / Min. Values in RUN Mode...........................................199

8. TOOL.....................................................................................201

8.1 TOOL ........................................................................................................202

8.2 Drawing an Image on the Monitor Screen: Marker Function.....................203

8.2.1 Creating a New Marker ..........................................................................203

vi

8.2.2 Copying an Existing Marker ................................................................... 204

8.2.3 Deleting a Marker................................................................................... 204

8.3 Reference Point........................................................................................ 205

8.4 Group Move.............................................................................................. 206

8.5 Displaying the Settings in RUN Mode ...................................................... 207

8.5.1 Selecting an Display Image.................................................................... 208

8.5.2 Displaying a Checker Shape, Marker and Reference Point and Data

Monitor ...................................................................................................210

8.6 Execution Modes ...................................................................................... 211

8.6.1 Overview ................................................................................................211

8.6.2 Setting to Execution Mode ..................................................................... 212

8.6.3 “Execute All” Execution Mode................................................................ 213

8.6.4 “Automatic Switch” Execution Mode ...................................................... 214

8.6.5 “User-Defined” Execution Mode............................................................. 216

9. Environment Settings ......................................................... 218

9.1 What Are Environment Settings? ............................................................. 219

9.2 Initial Settings ........................................................................................... 223

9.2.1 A list of Initialization Menu Options ........................................................ 223

9.2.2 Protecting the Setting Data Using a Password ...................................... 224

9.3 Saving Images.......................................................................................... 226

9.3.1 What Is Image Save?............................................................................. 226

9.3.2 Saving Images Using the Keypad.......................................................... 227

9.3.3 Saving an Image per Inspection.............................................................228

9.3.4 Saving the Images of Which the Conditional Formula Was Judged as NG

............................................................................................................... 228

9.3.5 Selecting Operation When the Number of Saved Images Reached 16 pairs

............................................................................................................... 229

9.3.6 Performing Inspection While Only Saved Image Is Displayd (Display a Save

Image) .................................................................................................... 230

9.3.7 Running a Test Using a Saved Image ................................................... 231

9.3.8 Outputting a Save Image to the External Device (Backing up to Memory

Card) ......................................................................................................232

9.3.9 Erasing All the Saved Image.................................................................. 232

9.4 Outputting Images .................................................................................... 233

9.4.1 What Is Image Outputting? ....................................................................233

9.4.2 Outputting the Images to a Compact Flash Card................................... 234

9.4.3 Outputting the Images to PC (support in the near future)...................... 236

vii

9.5 Re-Registering the Template ....................................................................237

9.5.1 Re-Registering Mode and Diplay Options..............................................237

9.5.2 Setting Procedure...................................................................................237

9.6 Initializing Environment Settings ...............................................................238

10. Parallel Communication ....................................................239

10.1 Communications via Parallel Port ...........................................................240

10.1.1 Input from the External Device............................................................... 240

10.1.2 The Data Output from the PV310........................................................... 240

10.1.3 Data Assignment for Hanshake .............................................................242

10.2 Input/Output Timing According to Start Settings .....................................243

10.2.1 Starting Inspection - Once......................................................................243

10.2.2 Starting Inspection - Repeat...................................................................244

10.3 Input/Output Timing According to Handshake Settings...........................245

10.3.1 When the Handshake Function Is Set To “None” ..................................245

10.3.2 When the Handshake Function Is Set Not To “Yes”..............................246

10.4 Data Switch Timing According to Data Reset Conditions .......................247

10.4.1 Reset Condition: Hold ............................................................................247

10.4.2 Reset Condition: Output Off after Image Capture.................................. 248

10.4.3 Reset Condition: Output Off before Image Capture............................... 248

10.5 Switching Data Using External Signals ...................................................249

10.5.1 Switching the Product Types..................................................................249

10.5.2 Switching the Display Camera Images .................................................. 251

10.5.3 Re-registering the Template...................................................................252

10.5.4 Restoring the Setting Data Stored in CF Card....................................... 255

11. RS-232C Communication ..................................................257

11.1 Overview .................................................................................................258

11.2 Serial (Per Start)/Serial (Async.) .............................................................259

11.2.1 Selecting and Setting the Output Data to the External Device ..............259

11.2.2 Formats of the Commands from the External Device ............................259

11.2.3 Setting COM Port ...................................................................................260

11.2.4 Output Data ............................................................................................260

11.2.5 A List of Commands...............................................................................262

11.2.6 Details of Commands.............................................................................263

11.3 Computer Link.........................................................................................283

11.3.1 Overview and Communication Specifications........................................283

viii

11.3.2 Setting a Computer Link Communication .............................................. 286

11.3.3 Setting Output Conditions ...................................................................... 287

11.3.4 Configuring the COM Port...................................................................... 288

12. Ethernet Communication.................................................. 289

12.1 Overview and Ethernet Outputs ............................................................. 290

12.1.1 Overview ................................................................................................ 290

12.1.2 Selecting an Output Procedure and Output Data .................................. 291

12.2 Communication Methods........................................................................ 292

12.2.1 Communicating between one PV310 and one Computer...................... 292

12.2.2 Communicating between a Computer and Multiple PV310s .................293

13. Using a Compact Flash Card............................................ 295

13.1 Storing Data in a Compact Flash Card................................................... 296

13.2 Inserting and Removing the Memory Card............................................. 297

13.2.1 Inserting the Memory Card.....................................................................297

13.2.2 Removing the Memory Card.................................................................. 297

13.3 Backing up and Restoring Setting Data and Images.............................. 298

13.3.1 Backing up and Restoring the Setting Data........................................... 298

13.3.2 Backing up and Restoring the Memory Images .....................................299

13.3.3 Backing up and Restoring the Saved Images........................................ 301

13.4 Copying the Screen Display ................................................................... 303

13.5 Outputting the Inspection Results to a CF Card ..................................... 304

13.6 Using a Folder Tree................................................................................ 305

14. Information on the PV310 and Help Function Settings.. 307

14.1 Information on the PV310....................................................................... 308

14.1.1 Options of the INFO. Menu .................................................................... 308

14.1.2 Checking Remaining Storage Capacity of Memory............................... 308

Setting Date and Time Using the Calendar Feature.......................................... 309

14.1.3 Setting IP Address .................................................................................310

14.1.4 Version Information................................................................................ 310

14.2 Setting Help ............................................................................................ 311

14.2.1 Making Light Adjutments........................................................................ 311

14.2.2 Making Focal and Aperture Adjustments ...............................................312

14.2.3 Displaying an Image Profile ...................................................................313

14.2.4 Checking Connections Using I/O Monitor.............................................. 314

ix

15. Troubleshooting.................................................................315

15.1 ERROR (Error) Signal Is Output .............................................................316

15.2 Error Code Number Is Displayed in SETUP Mode..................................317

16. Camera Switching Unit ......................................................319

16.1 Overview .................................................................................................320

16.2 Functions and Settings............................................................................321

16.3 Remote Switching Signal ........................................................................322

17. General Specifications ......................................................323

18. Product Numbers ...............................................................329

19. Dimensions.........................................................................335

20. Appendix.............................................................................341

20.1 Pin Assignment of a Double Speed Random Camera (ANM831)...........342

20.2 Pin Assignment of a Standard Camera (ANM832)..................................343

Record of Changes ...................................................................344

x

Precautions before Use

Installation Environment

Avoid installing the PV310 in the following locations:

• Locations with direct sunlight or environmental temperatures that exceed a range between 0°C and

50 °C (a range of 0 to 40 °C for VGA monitor).

• Locations with a relative humidity exceeding a range of 35%RH to 75%RH (a range of 20%RH to

85%RH for VGA monitor) or with a condensing due to a sharp temperature change.

• Locations with an atmosphere containing corrosive gases or flammable gases.

• Locations subject to the main unit to direct vibration or impact.

• Locations with a lot of fine particles, iron filings or salt.

• Locations where the product can become wet with water, oil or chemicals.

• Locations with an atmosphere likely to contain organic solvents (such as benzene, paint thinner, and

alcohol) or strongly alkaline materials (such as ammonia and caustic soda).

Static Electricity

• In dry environment, there is a risk of generation of static electricity of extremely high voltage, so when

there is a need to touch the product, you should always discharge the accumulated static electricity

through your body by touching a grounded metal surface.

Cleaning

• Never use thinners or similar solvents, as they may dissolve the board and cause colors to run.

Power Supply Unit and Power Sequence

• Use an insulated power supply unit with a built-in protection circuit. The PV310 power supply unit is a

non-insulated circuit. Therefore, applying an abnormal voltage might damage the internal circuit. If

you use a power supply unit without a protection circuit, supply power through a protective device

such as a fuse.

• Consider the power supply sequence so that the power supply unit for the PV310 can be turned off

before the one for the input/output is turned off.

• If you turn the input/output power off before turning the PV310 off, the PV310 will detect a change in

the input signal level and may malfunction.

Before Turning on the PV310

Pay attentions to the followings when turning on the PV310 for the first time;

• Confirm no wiring waste or especially any conductive substance is on the printed circuit board.

• Confirm that the power wiring, input/output wiring and power supply voltage are correct.

• Confirm that the fixing and terminal screws are securely tightened.

xi

General Cautions

• Use the monitor, monitor cable, keypad, camera and camera cables of serial numbers specified by

Matsushita Electric Works, Ltd. A breakdown, damage or destruction by using any other than the

specified will not be covered by our guarantee.

• Do not disassemble, remodel the PV310 or change its internal settings. A breakdown, damage or

destruction by disassembling, remodeling the PV310 or not following the instruction described in the

manuals will not be covered by our guarantee.

• Do not change or set items that should not be as described in the manuals or the specifications.

Breakdown, damage or destruction resulting from changing or setting them will not be covered by our

guarantee.

• When all PV310 settings are complete, disconnect the keypad and the computer used for backing up

or restoring data from the PV310 in order to prevent a malfunction or an operation mistake due to

noises.

• Do not perform the insulation resistance or withstand voltage test between the power source or

input/output signals and the metallic part of connectors or camera cases.

To USA Customer

Products sold by Seller are covered by the warranty and patent indemnification provisions in its Terms

and Conditions of Sale only.

xii

Chapter 1

Names and Functions of Parts

1

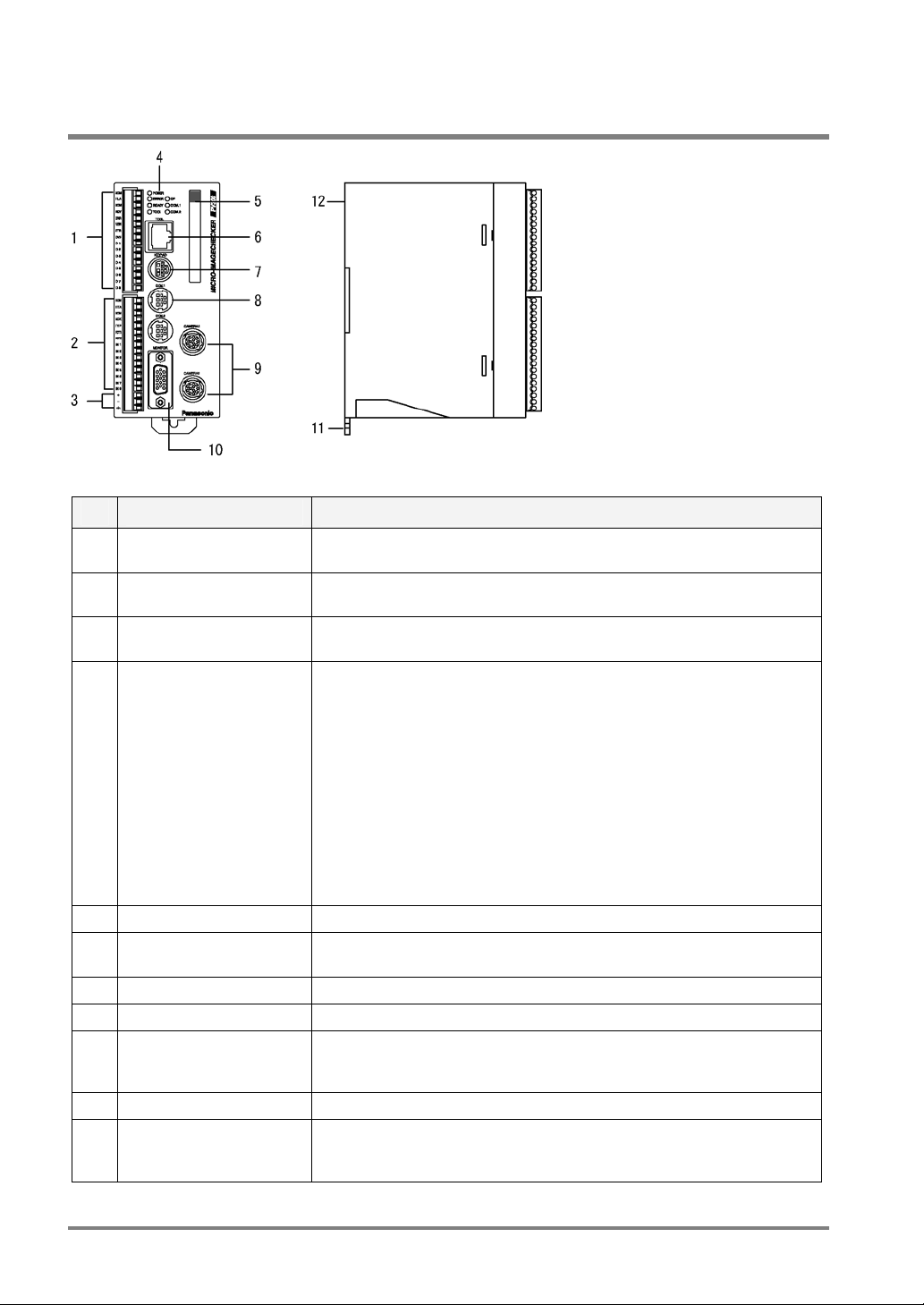

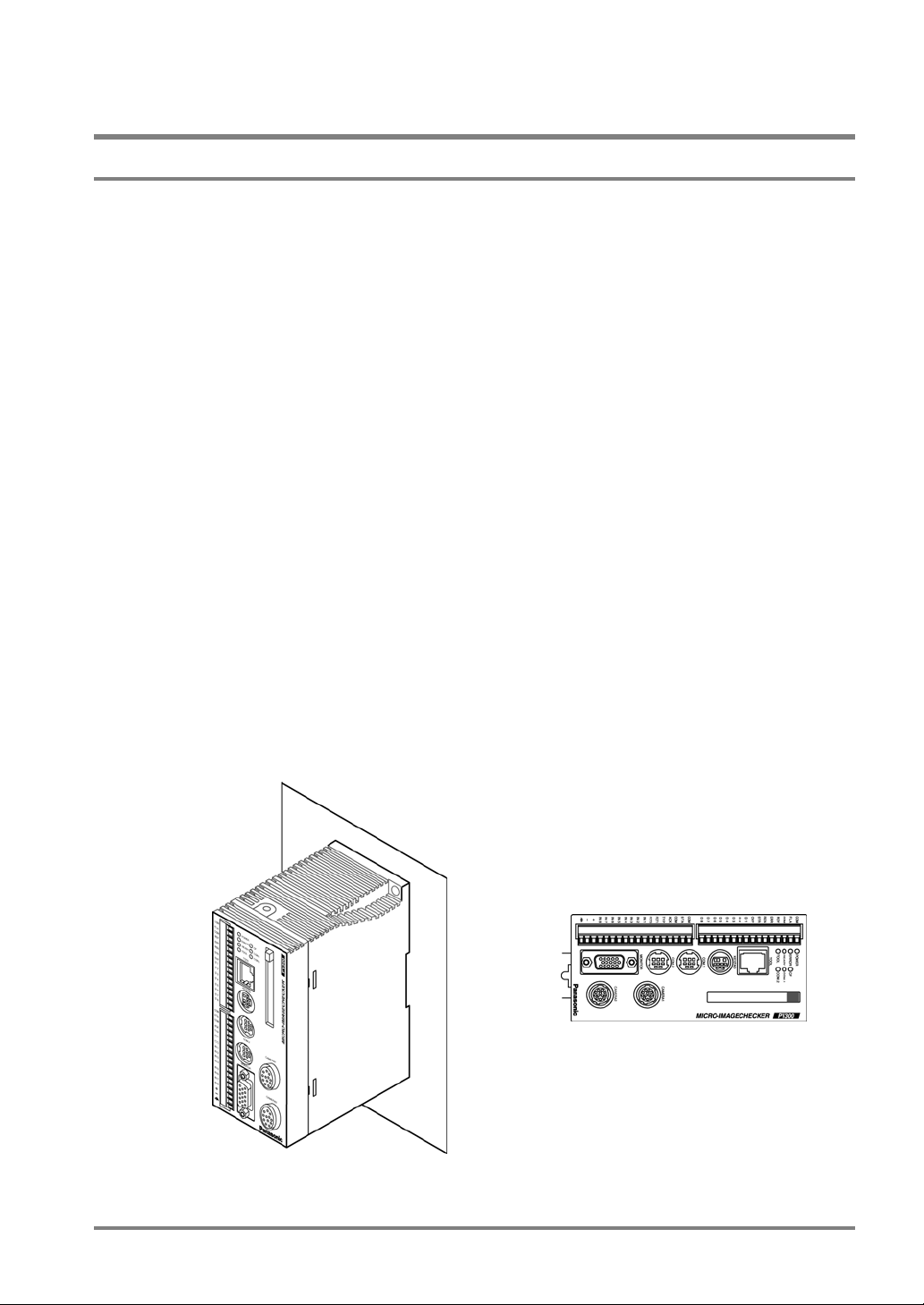

1.1 About the PV310

Designations and Descriptions of Each Part

No. Designation Description

1 External output terminal

(16 pins)

2 External input terminal (15

pins)

3 Power terminal Acceptable input voltage is 24V DC. The power terminal is located on the

4 Operating LEDs Indicate the operating status of the PV310.

5 Memory card slot Supports for a FAT16- formatted Compact Flash card (Max. 512MB )

6 TOOL port (Ethernet Port) Connects to the external device via Ethernet port. Use a cross cable

7 KEYPAD connector Connects to the operation keypad.

8 COM port (RS-232C port) Connects to the external device via the COM port. COM2 is not available.

9 Camera connectors Can connect to up to two cameras: CAMERA 1 and CAMERA 2. Using a

10 MONITOR Connects to the VGA monitor

11 DIN rail attachment lever

(for hooking with

one-touch operation)

An external output terminal block (by Phoenix), product #: 1840502.

An external input terminal. COMMON terminal is for +/-. An external

output terminal block (by Phoenix), product #: 1840528.

input terminal block.

• POWER (green):

The green POWER LED lights when the PV310 is being energized.

• ERROR (red):

The red ERROR LED lights when an error is detected.

• READY (green):

The green READY LED lights when the PV310 is ready to receive the

signals including start signal from the external device

• CF: The green CF LED lights when the PV310 is accessing the

memory card.

• COM1: The green COM1 LED lights when serial communication is

established.

when connecting between an external device and a PV310.

camera switching unit enables you to connect to maximum four standard

cameras.

Offers quick and easy mounting of the PV310 onto the DIN rail.

2

No. Designation Description

12 Backup battery This is a battery for retaining information about calendar in the PV310. If

the backup battery runs out, the screen monitor displays “Battery used

up!”. In such a case, replace with a new backup battery. Product number:

AFPG804 (Service life: About 10 years at 25°C)

Connect only the designated products to the PV310.

3

1.2 Camera Peripherals

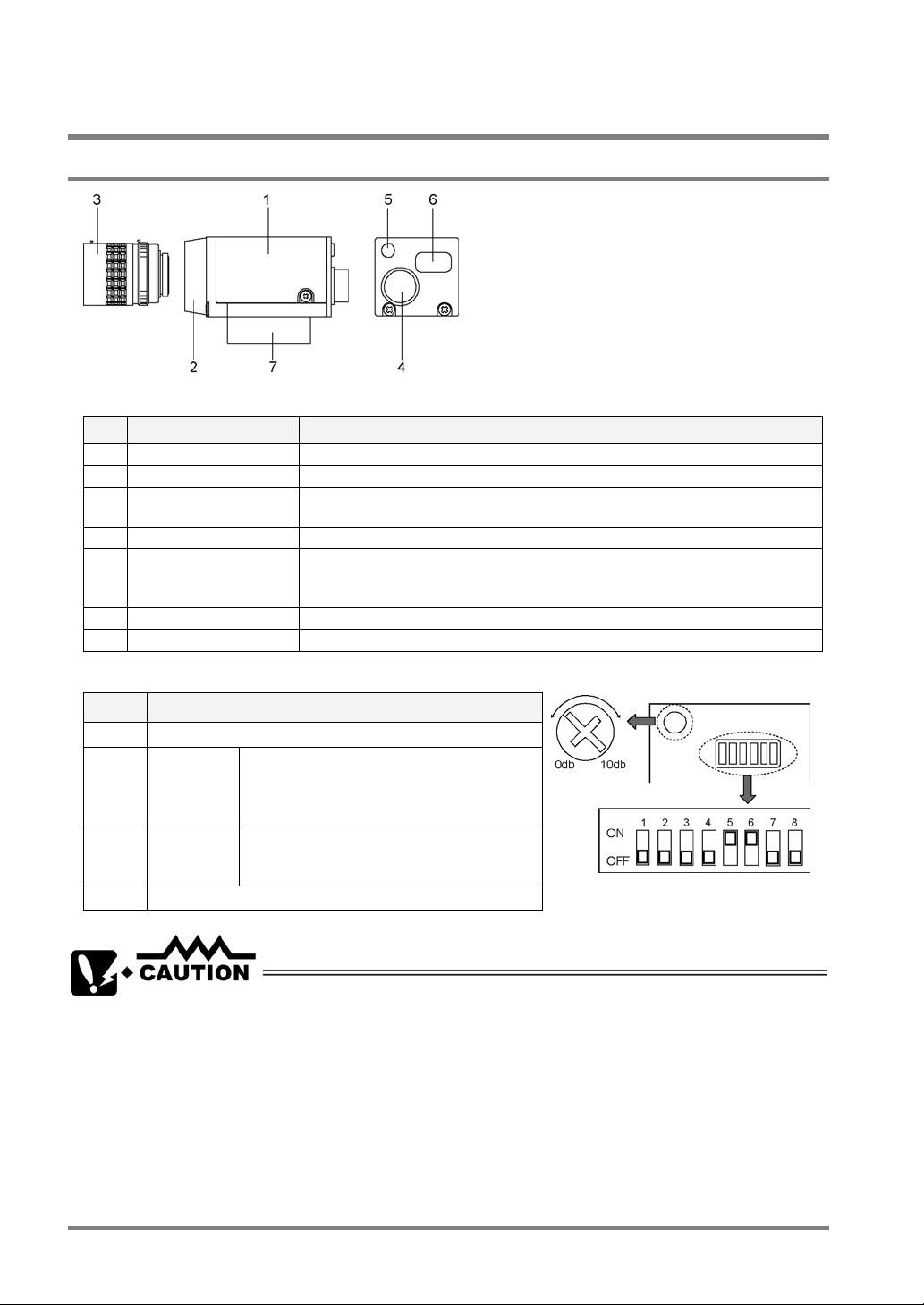

1.2.1 Double Speed Random Camera: ANM831

Names and the Description

No. Name Description

1 Camera Refers to the camera body.

2 Lens mount C-mount.

3 Lens Use the C-mount lens together with an adapter ring as necessary. Refer to

4 Cable connector Connects to the controller with a camera cable. (ANM84303**)

5 VOL knob for fine

adjustment of gain

6 DIP-SW Switches camera modes or adjusts camera gain

7 Holding fixture Mounts the camera

page 18 for selecting view range and lens.

Makes a fine adjustment for camera gain

If you turned this knob clockwise when the DIP SW 5 is in the ON position,

the image to be captured becomes brighter.

Positions of DIP Switches and VOL knob

No. Description

1-4

5 Gain fine

6 Camera

7-8 Always leave OFF.

*Default settings: DIP SW 5: ON, the rest of the dip switches: OFF, VOL knob: +10 dB

Always leave OFF

adjustment

mode

switching

ON: Allows you to make fine adjustment

within the range between 0 and +10dB

using the VOL knob

OFF: 0dB

ON: D.S. Random Frame mode

OFF: D.S. Random Field mode (default)

• Do not connect different types of cameras to the controller.

• Use the CAMERA 1 port when connecting just one camera to the controller.

• Use only the designated camera cable or camera extension cable.

• Use the specified camera (extension) cable.

• Do not connect multiple cables to extend the camera cable and camera extension cable.

• Do not touch the CCD element or the lens surface of the camera. Attach the lens cap to

keep off dust when not in use.

• Switch the dip switches in accordance with your camera mode.

• Leave the dip switches 1, 2, 3, 4, 7, and 8 OFF (default).

4

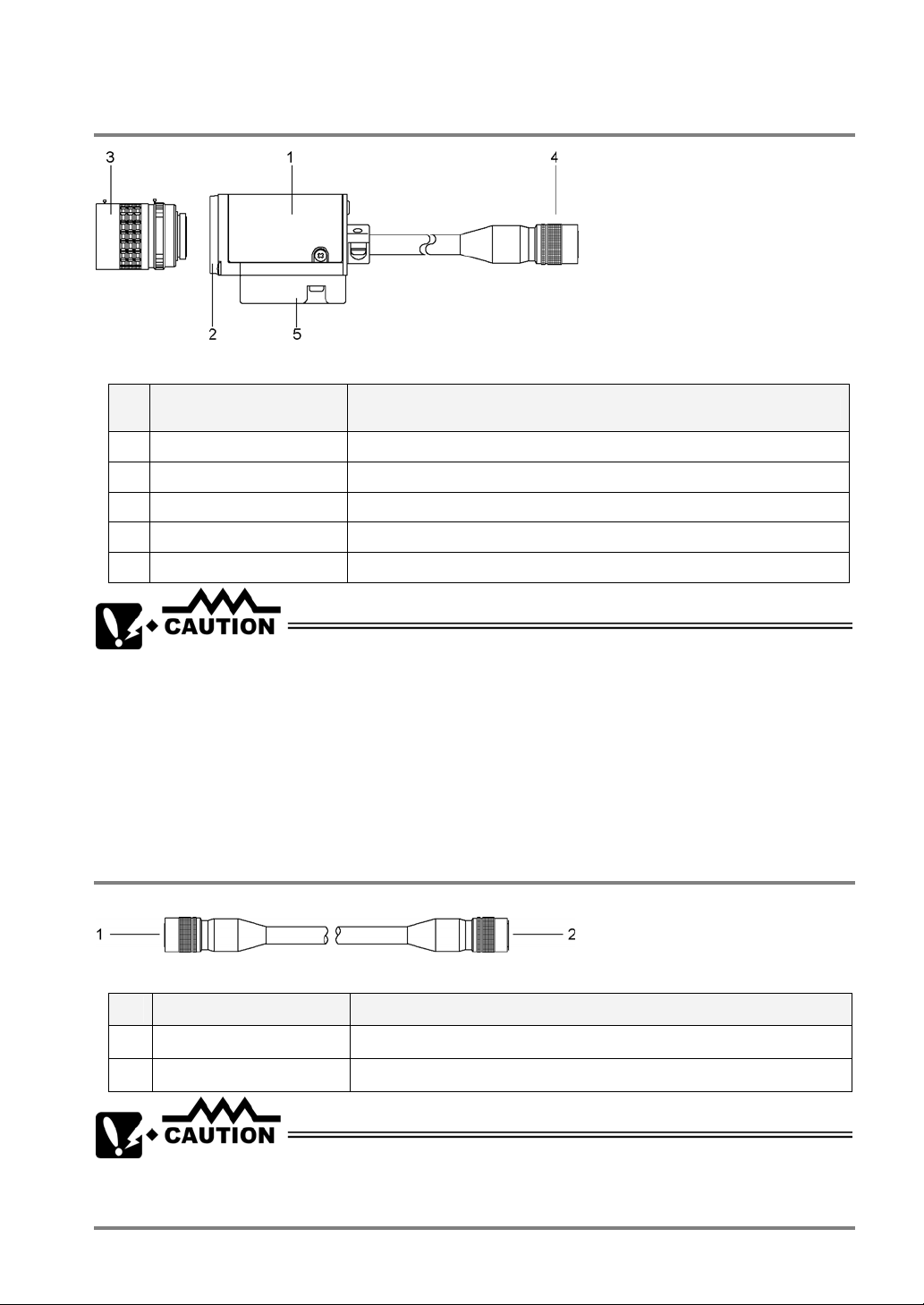

1.2.2 Standard Camera: ANM832

Part Names and the Descriptions

No

Part name Description

.

1 Camera The camera main unit.

2 Lens fixture CS-mount

3 Lens Use the C/CS-mount lens together with an adapter ring as necessary.

4 Connector Connects to the controller. Use a designated camera extension cable.

5 Holding fixture To mount the camera

• Do not connect different types of cameras to the controller.

• Use the CAMERA 1 port when connecting just one camera to the controller.

• Use only the designated camera cable or camera extension cable.

• Do not connect multiple cables to extend the camera cable and the camera extension cable.

• Do not touch the CCD element or the lens surface of the camera. Attach the lens cap to

keep off dust when not in use.

1.2.3 Camera Cable/Camera Extension Cable

Part Names and the Descriptions

No. Part name Description

1 Connector (round, male) Connects the male connector to the controller

2 Connector (round, female) Connects the female connector to the camera

• Use only the designated camera cable.

• Do not bend the camera cable forcibly or apply load to the connector joints.

5

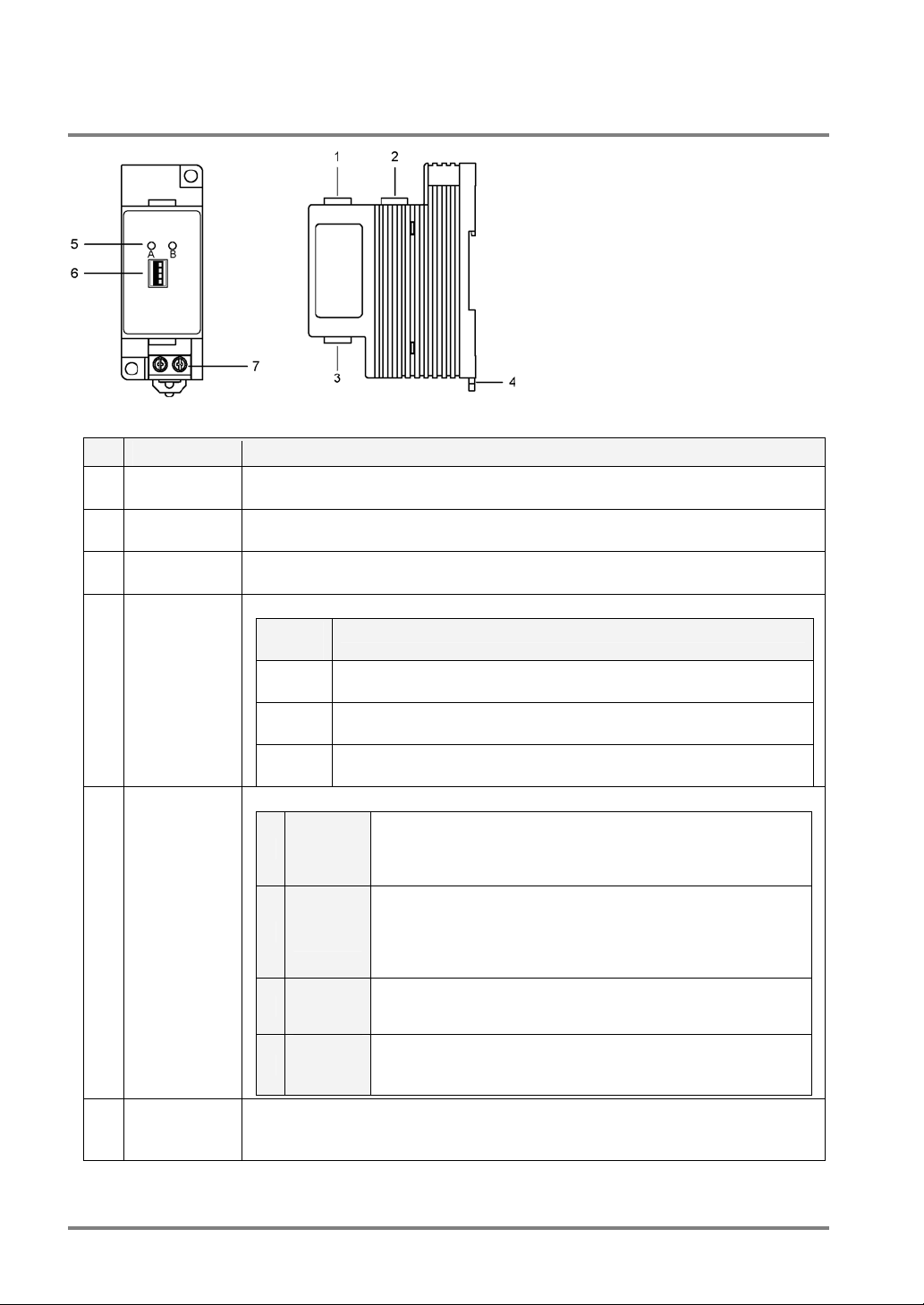

1.2.4 Camera Switching Unit: ANPV3700

Designations and Descriptions of Each Part

No Name Description

Input port for

1

Camera A

Input port for

2

Camera B

OUT (image

3

output) port

Camera

4

A/Camera B

indicators

Dip switches

5

(4)

6 Input terminal

for external

signal

*The division mode is available only in a standard camera ANM832 (ANM832CE). A double speed random

camera ANM831 is not available if it is in the division mode.

Connects a camera. Camera A is connected to this port.

Connects a camera. Camera B is connected to this port.

Outputs images to the PV310. Use the provided cable for switching cameras.

The indicators tell which camera is in use for capturing images.

Lighting

Lamp

A only The PV310 is in camera switching mode (the dip switch 2 is placed in

B only The PV310 is in camera switching mode (the dip switch 2 is placed in

A and B The PV310 is in DIV mode (the dip switch 2 is placed in the DIV

The four dip switches change the functions shown in the table below.

1

2

3 A / B

4

This is a terminal for switching cameras in DIV mode.

Status

the NORMAL position). The image captured by Camera A is output.

the NORMAL position.) The image captured by Camera B is output.

position).

If you want to switch between Camera A and Camera B using

LOCAL /

REMOTE

NORMAL

/ DIV*

Upper/

Lower

division

an external device when the PV310 is in camera switching

mode (the dip switch 2 is placed in the NORMAL position), set

to “REMOTE”.

If you want to switch between Camera A and Camera B (in

camera switching mode), set to “NORMAL”. If you want to

combine the upper and lower half parts of two images captured

by Camera A and Camera B in one image (in the DIV mode),

set to “DIV”.

This is a switch for changing the cameras to output the images

in camera switching mode (the dip switch 1 and 2 are placed in

LOCAL and NORMAL positions respectively).

In camera division mode (the dip switch 2 is placed in the DIV

position), select a part of the images captured by Camera A

and Camera B that you want, upper half or lower half.

6

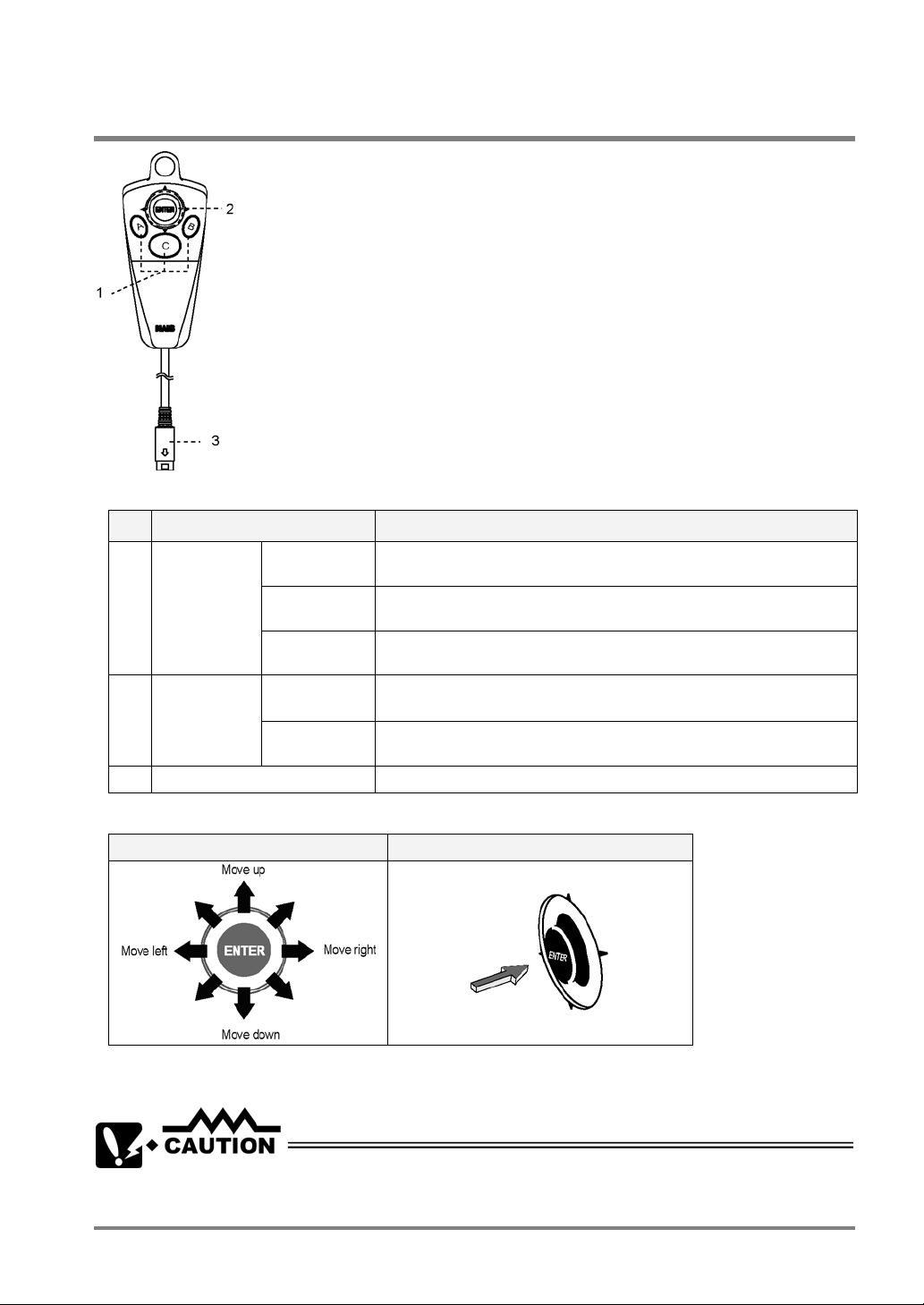

1.3 Keypad

Names and the Descriptions

No. Description Details

1 A, B, C keys

2 ENTER key

3 Connector Connects the keypad to the PV310.

A key Starts an inspection. Performs a test in SETUP mode. Executes

B key Displays a sub-menu for each menu. Press and hold down this key for

C key Switches between SETUP mode and RUN mode. Goes back to the

Cursor

Operation

Confirmation

Operation

inspection in RUN mode.

more than one second to save the screen copy on the memory card.

previous hierarchy or close the window.

Moves the cursor in the up to 8 directions.

Use this lever to select the menu and move the start and end points.

Executes (or Determines) the selected option.

Cursor Operation and Determination Operation with the Cursor Lever

Cursor operation Determination (ENTER) key operation

If you try to move the cursor while pressing and holding down the ENTER key, the highlighted option may be

determined. Release and move the ENETER key when you move the cursor.

Connect only the designated keypad (ANM852**) to the PV310.

7

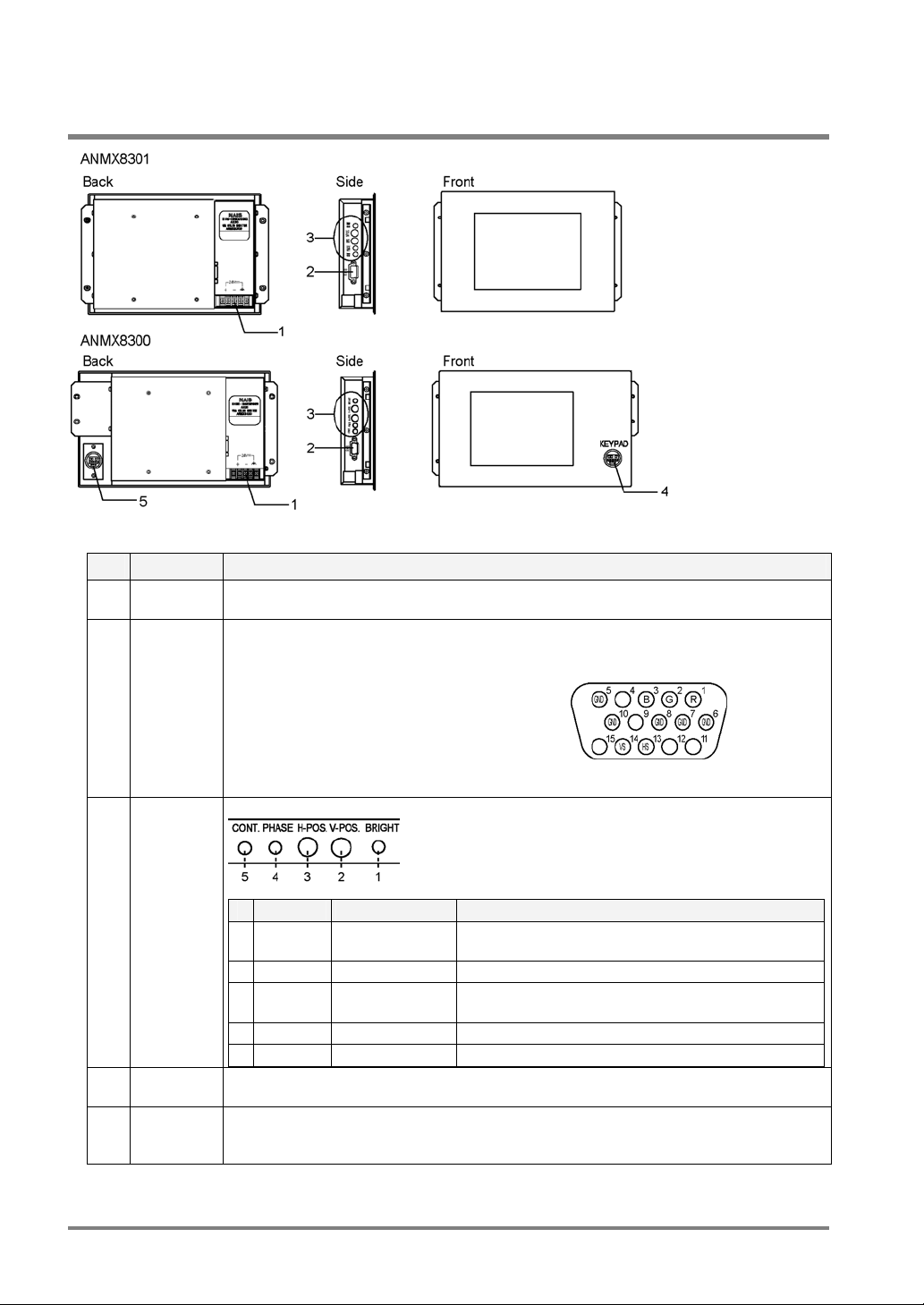

1.4 VGA Monitor

Part Names and the Descriptions

No. Part name Description

1 Power

connector

2 RGB input

connector

3 Adjustment

volume

Acceptable input voltage: 24V DC

A connector for RGB input. Connects to the monitor with the VGA monitor cable

-ANMX8331*. (Connector: Mini D-sub, 15 pins, female)

• 1 - R: Red image signal

• 2 - G: Green image signal

• 3 - B: Blue image signal

• 5, 6, 7, 8, and 10 - GND: Signal ground

• 13 - HS: Horizontal synchronizing signal

• 14 - VS: Vertical synchronizing signal.

The following adjustments are available

100%)

Adjusts the screen horizontal position (per 16 pixels).

4 Keypad

connector

5 Keypad

cable

connector

# Indication Name Function

1 BRIGHT Brightness Adjusts the brightness. (Brightness: approx. 20 to

2 V-POS. Vertical Position Adjusts the screen vertical position (per 16 lines).

3 H-POS. Horizontal

Position

4 PHASE Phase Adjusts the screen flickering.

5 CONT. Contrast Adjusts the contrast.

Connects the keypad (ANM852**). However, the keypad connector is available only if the

monitor is connected to the PV310 with the keypad cable.

Connects the keypad link cable (ANMX8333). (Connect one end of the cable to the

PV310). Use the connector in order to connect the keypad to the monitor front.

Caution: Check for proper connections before turning the PV310 on.

8

Chapter 2

Installation and Wiring

9

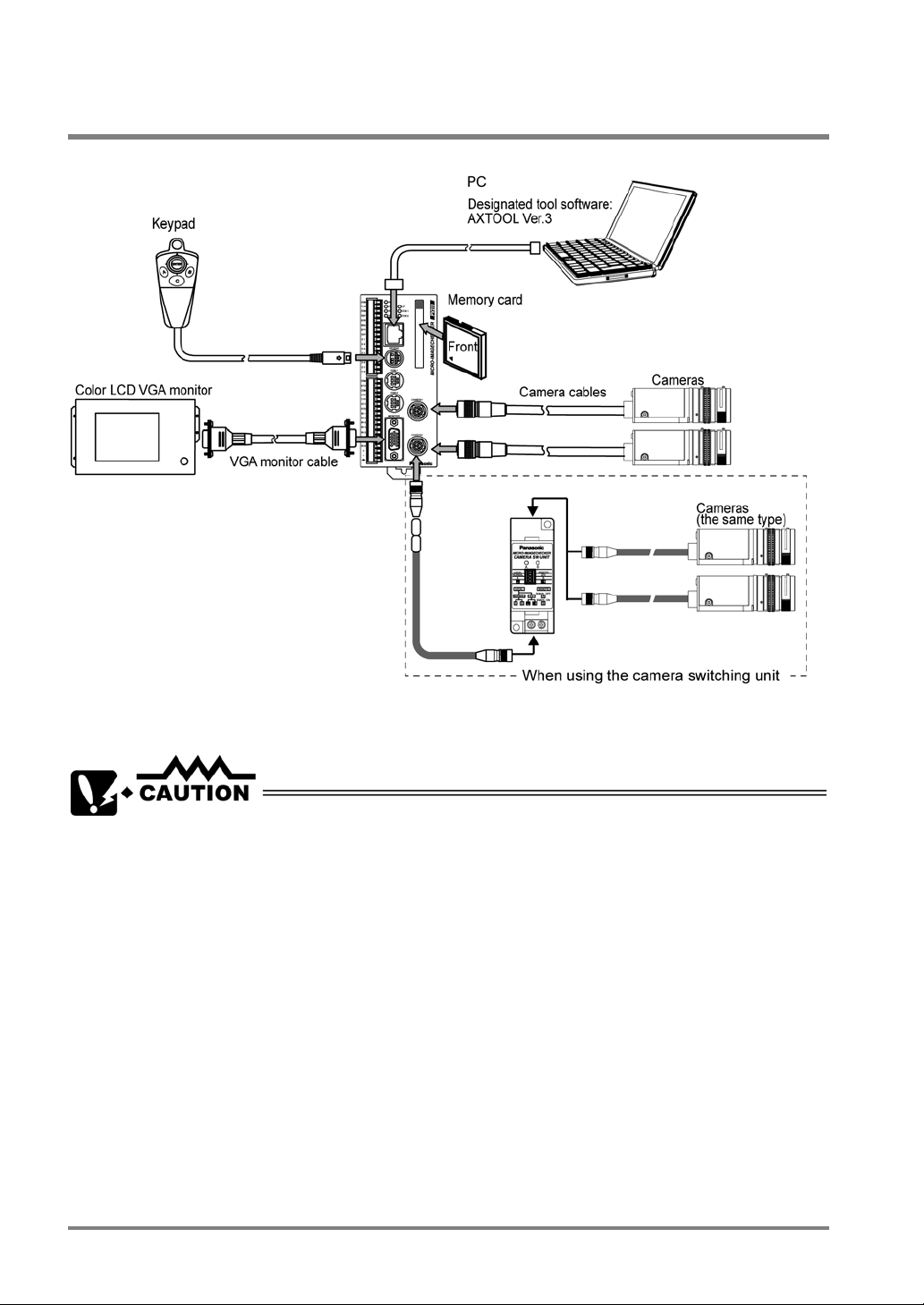

2.1 Connecting Peripherals

Be sure to turn the PV310 off before connecting the peripherals to the PV310.

• Connect only the designated products to the PV310.

• Be sure to remove power from the PV310 before connecting the peripherals to the PV310.

Failure to do so may damage to the device.

• Arrange the wiring not to apply load on the cable connector joints; otherwise, the

disconnection may be occurred.

• When unplugging the cable from the connector, be sure to hold it by its plug and avoid

exerting unnecessary force on the cable. Also, do not touch the terminals inside the

connectors. Take care not to allow water and dust to come into the connectors.

10

2.2 Installation Environment and Mounting Space

2.2.1 Installation Environment

Avoid Installing the Equipment in the Following Types of Locations:

• Locations with direct sunlight or environmental temperatures that exceed a range between 0ºC and

50ºC.

• Locations with a relative humidity exceeding a range of 35%RH to 75%RH

• Locations with a condensing due to a sharp temperature change

• Locations with an atmosphere containing corrosive gases or flammable gases

• Locations with a lot of fine particles, iron filings or salt

• Locations with an atmosphere likely to contain organic solvents (such as benzene, paint thinner),

and alcohol or strongly alkaline materials (such as ammonia and caustic soda)

• Locations subject to direct vibration or impact

• Locations subject to direct sunlight

• Locations where the product can become wet with water, oil or chemicals

• Locations where the product is applied with excessive load

Noise Countermeasure

• Keep the PV310 away from the devices that generate large switching surges, such as high-voltage

wires, high-voltage devices, power-driven lines and power-driven product as much as possible.

• Keep the PV310 as far away from the devices with a transmission system, such as radio equipment

as possible.

Countermeasure for Heat Radiation

• Install the PV310 in the correct direction for heat radiation (refer to the figures below).

• Do not mount the PV310 above the object with strong heat sources, such as a heater, transformer

and high-capacity resistor.

Correct Wrong

11

About Mounting Space

• Keep 50 mm or more space from other equipment to facilitate the unit exchange and cable wiring.

• When mounting a device in front of the PV310 (on the door of the control box, etc.) keep 100mm or

more space between them in order to prevent an impact from noise radiation or heating.

• Always keep 100mm or more space from upper surface of the PV310 to facilitate a keypad

connection or a wiring.

12

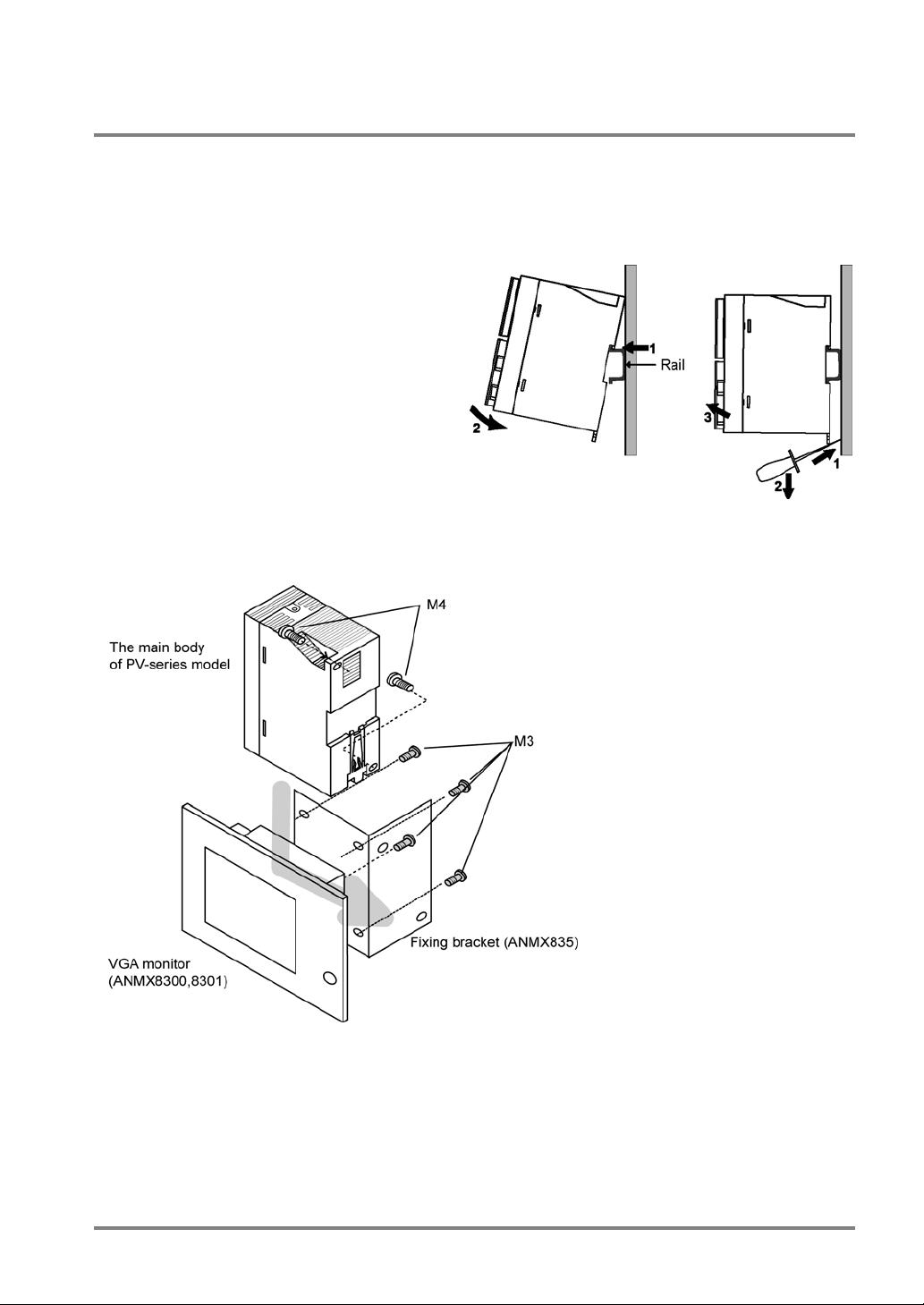

2.2.2 Mounting the PV310

There are the two ways to mount the PV310, by using screws or by hooking on the DIN rail.

Mounting the PV310 on the DIN rail

The PV310 can be mounted on or removed from a 35 mm wide DIN rail (DIN EN50022) with a single easy

operation.

To mount the PV310 on the DIN rail:

1. Hook the PV310 onto the DIN rail.

2. Press the lower part of the PV310 to fix it into

position.

To remove the PV310 from the DIN rail:

1. Insert the slot-head driver into the mounting

lever.

2. Press the mounting lever downward.

3. Lift and detach the PV310.

Mounting the PV310 to the VGA Monitor

If you want to mount the PV310 on the VGA monitor, use the fixture (ANMX835).

13

2.3 VGA Monitor Installation Environment

2.3.1 Installation Environment

Avoid installing the VGA Monitor in the Following Types of Locations:

• Locations with environmental temperatures that exceed a range of 0°C to 40°C

• Locations with a relative humidity exceeding a range of 20%RH to 85%RH

• Locations with a condensing due to a sharp temperature change

• Locations with an atmosphere containing corrosive gases or flammable gases

• Locations with a lot of dust, oily smoke and conductive dust

• Locations with a lot of fine particles, iron filings or salt

• Locations with an atmosphere likely to contain organic solvents (such as benzene, paint thinner,

and alcohol) or strongly alkaline materials (such as ammonia and caustic soda)

• Locations subject to direct vibration or impact

• Locations subject to direct sunlight

• Locations where the product can become wet with water, oil or chemicals

• Locations where the product is applied with excessive load

Noise Countermeasure

• Keep the PV310 as far away from the product that generates large switching surges, such as

high-voltage cable, high-voltage equipment, power cable and power equipment as possible.

• Keep as far away from the transmitting device (radio equipment, etc) as possible.

• Wire between the high-voltage line or power line and the DC power cable, VGA monitor cable or

keypad cable by using a duct or by keeping as much space between the lines and cables as

possible.

14

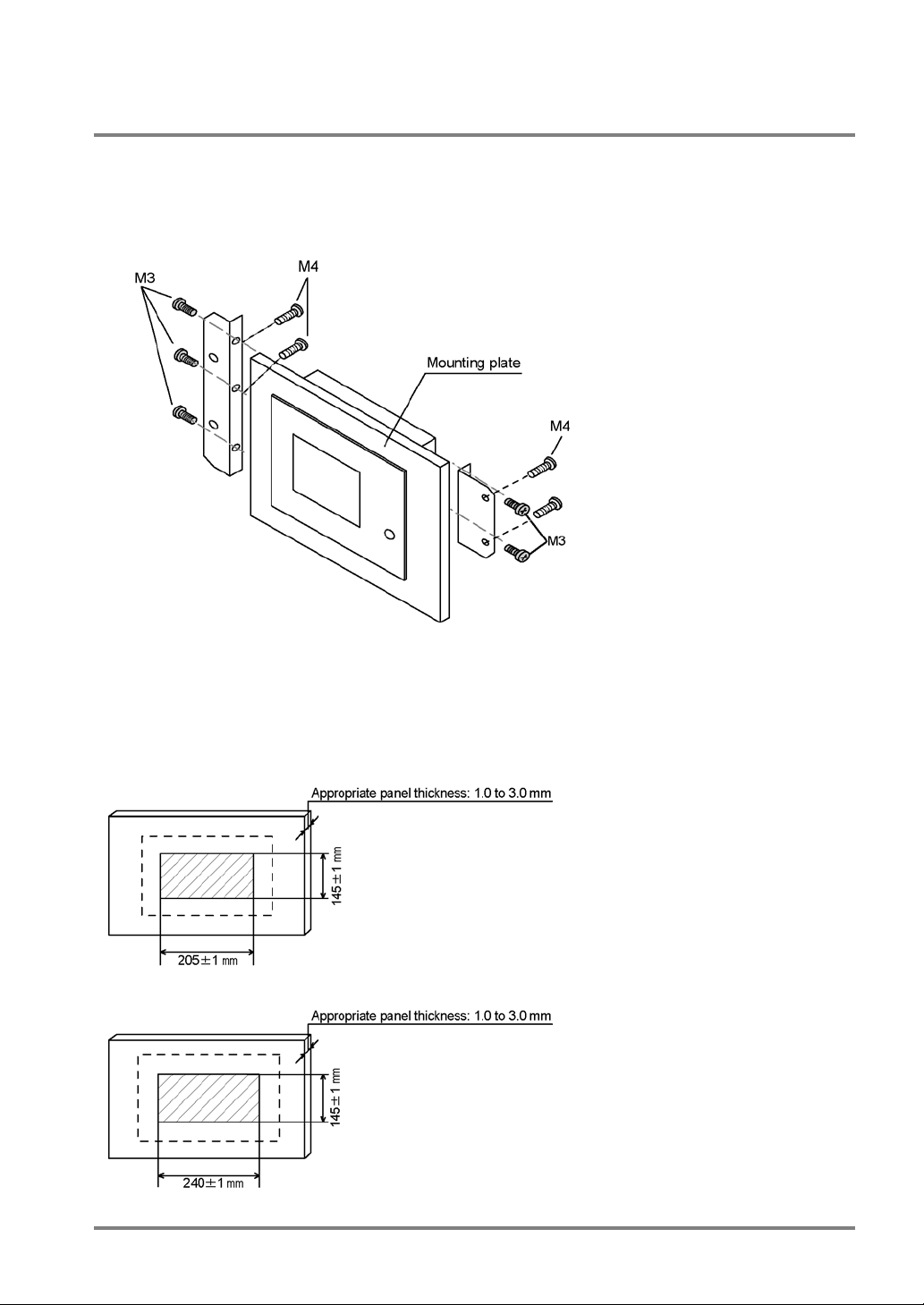

2.3.2 VGA Monitor Installation

To install the VGA monitor:

1. Insert the VGA monitor into the mounting plate.

2. Install the fixing fitting into the ditch of the VGA monitor using M3 screws and fix the VGA

monitor on the mounting plate using M4 screws.

Mounting Plate Cutting Dimensions

• When fixing the monitor or parts on the mounting plate or wiring the cables, it is recommended to

keep 30 mm to 50 mm spaces around the ANMX830* to prevent the cables from being damaged and

to increase work efficiency.

• Never block the ventilation slits.

ANMX8301

ANMX8300

15

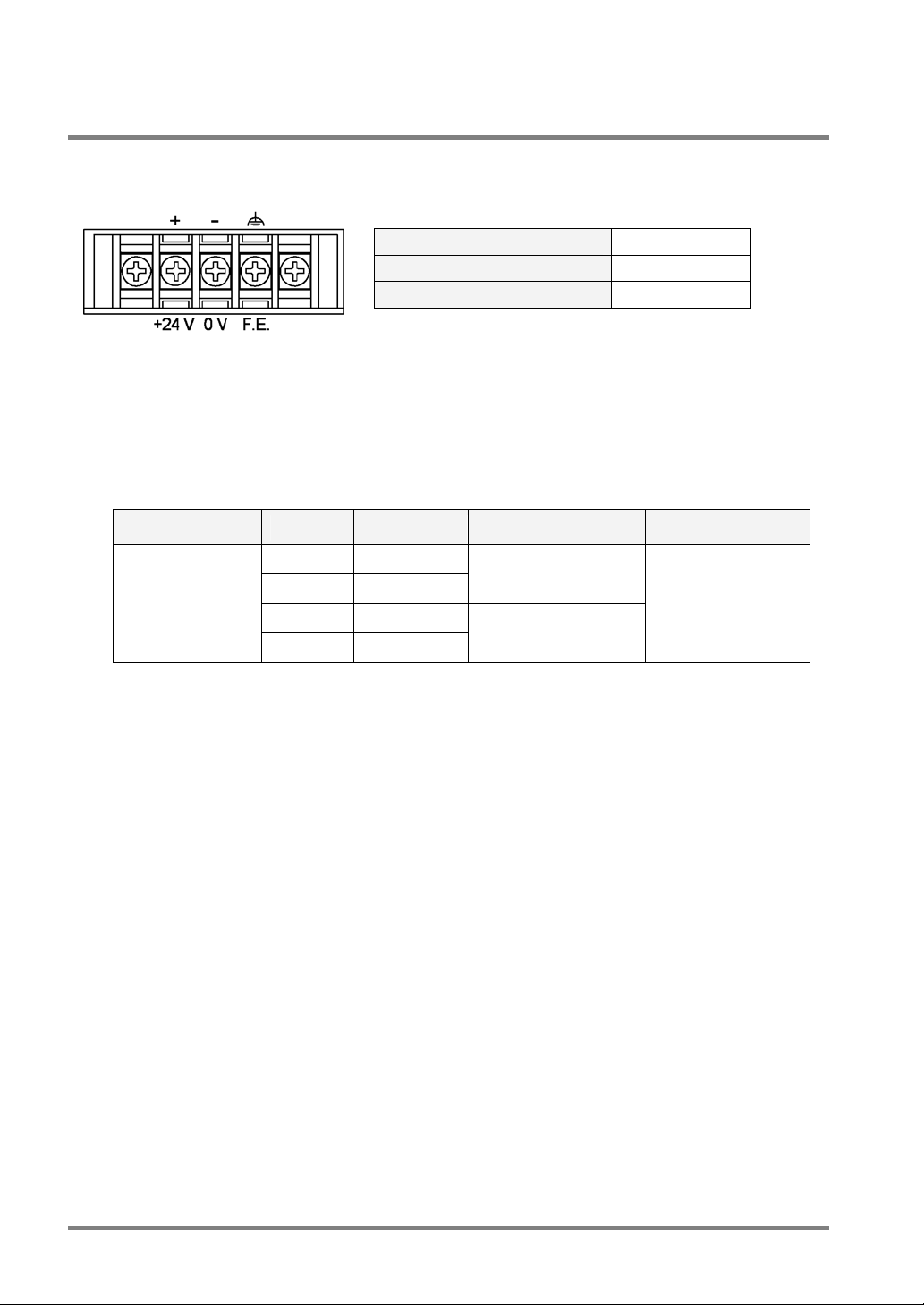

2.3.3 VGA Monitor: Power Wiring

Pin Assignments

Rated Voltage

Tolerance Voltage Range

Rated Consumption Current

Applicable Solderless Terminal

• Terminal screws are M3.

• It is suggested that solderless terminals are used to perform wiring. If you do not use a solderless

terminal, use the wires of which diameter is 0.5 mm

• Use up to 0.8 N•m of a tightening torque for fixing the terminal block. Failure to do so might damage

to the product.

Manufacturer Shape Model No. Applicable wire Tightening torque

JST Mfg. Co., Ltd.

R-type 1.25-MS3

A-type 1.25-B3A

R-type 2-MS3

A-type 2-N3A

2

to 1.25 mm2

0.25 mm

1.04mm

2

to 1.65 mm2

2

to 2.63 mm2

24 V DC

22.8 to 25.2 V DC

Less than 0.5 A

0.5N•m

16

Loading...

Loading...