Page 1

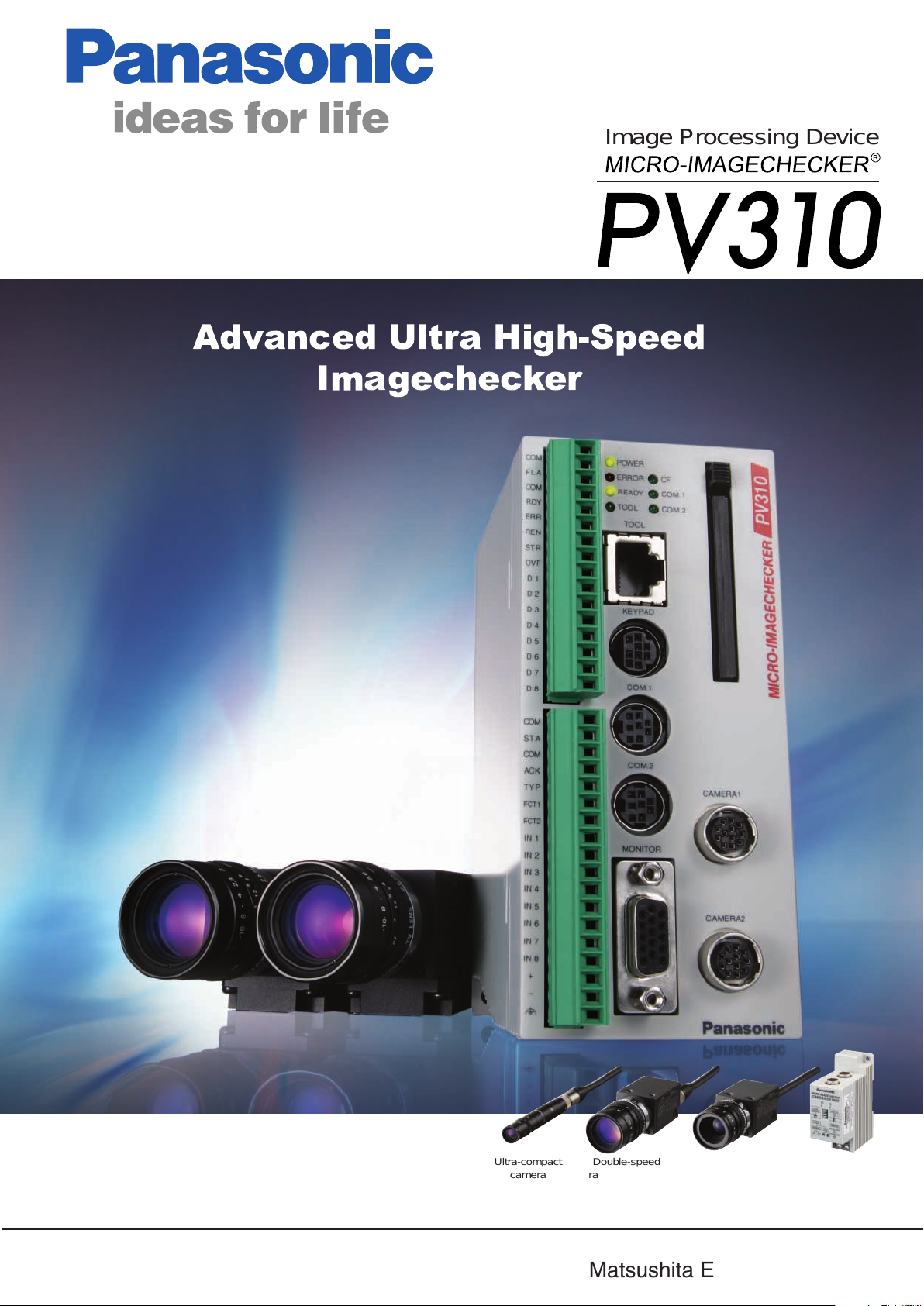

Image Processing Device

Advanced Ultra High-Speed

Imagechecker

http://www.mew.co.jp/ac/e

Ultra-compact

camera

Image Processing Device MICRO-IMAGECHECKER PV310

ARCT1B268E-2 '07 2

Double-speed

random camera

Standard camera Camera switching

Matsushita Electric Works, Ltd.

unit

Page 2

High

Performance

RISC-CPU

Image

Processor

Software

Optimization

The PV310 achieves ultra high-speed image processing by:

• utilizing two processors

(image processor + high-performance RISC CPU)

• optimizing its software

(unique, high-speed image processing algorithm)

Excellent Peripheral Functions of the PV310

Ultra-Compact Camera

(12 mm diameter)

Ultra-compact camera have been added to the conventional variety of

cameras already supported. This facilitates miniaturizing target

equipment and retrofitting cameras in narrower spaces.

New Function

Branch Execution/Designated Execution

Change inspection routines immediately! Tooling changes are a thing of

the past!

Branch

execu-

tion

Branches the instruction

stream to choose an

inspection to be executed

depending on the test results.

Start signal input

Execute Block 1

Test + Judgment

OK NG

Desig-

execution

Provides high-speed

execution without tooling

nated

changes, reducing time for

inspections.

Start signal input

(Designate the inspections to be executed)

Inspection 1 Inspection 2 Inspection 1 Inspection 2 Inspection 3

Block 1Execute Block 2 Execute Block 3 Block 2 Block 3

<Three different inspections>

New Function

Image Data Transfer and Storage When Running

Image data can be saved on a CF card even during inspection, which allows you to

examine the data in your office at your convenience or transfer configuration settings to

another Imagechecker.

You can also transfer image data via Ethernet. You can set the file name to be transferred,

image output method, etc. The software which allows you to receive data is available on

our website free of charge.

2 3

Page 3

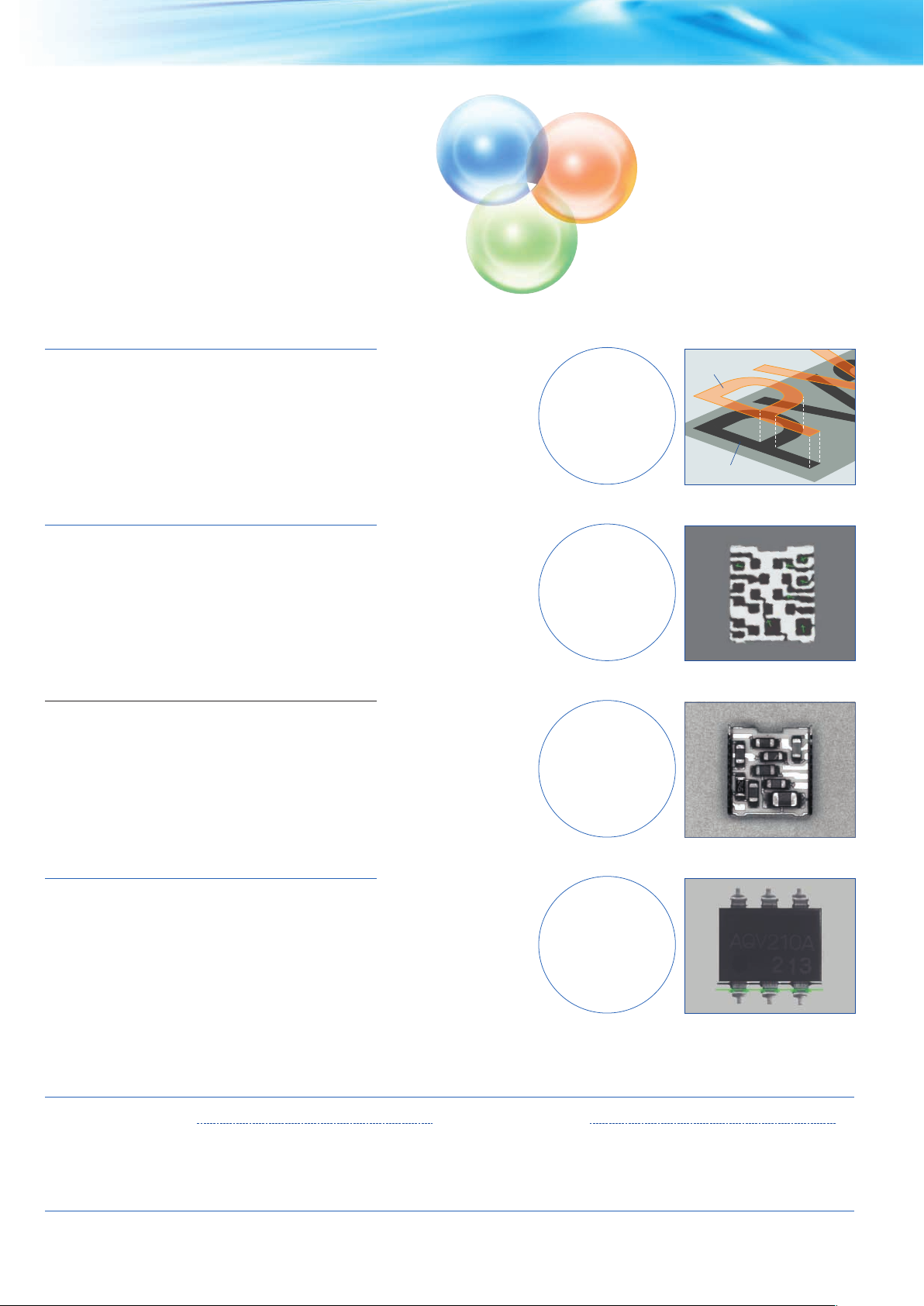

Enhanced Functionality, Improved Performance

Improved

Smart Matching From

0 to 360

The matching function has been improved to inspect

workpieces rotated from 0 to 360.

New Function

Auto Area

Adjustment

The inspection area can be

automatically adjusted to the workpiece

size to cover slight variations

(dimensional tolerance of workpieces).

New Function New Function

Flaw Detection

Scratches, stains, chipped edges, burrs

and other defects that could previously

only be detected by a more upscale

model can now be detected.

Filters Increase Reliability

13 filters are available to increase

the reliabilty and accuracy of

inspections. You may combine up

to 5 filters.

Auto

adjustment

New Function

Low Contrast

Matching

The workpiece can be detected even if

the contrast to the background is low or

if the workpiece itself is damaged.

Detects low-contrast

images.

Edge enhancement

Laplacian

Edge detection:

Y direction

Edge detection:

X direction

Sobel

Expansion

Workpiece

Prewitt

Detects partly chipped

images.

Contraction

Median

Smoothing

Expansion →

Contraction

Contraction →

Expansion

Background

cutting

Surface scratches

and stains

Chipping and burrs

Chipping and burrs

Filter useful for noise removal

•

Expansion → Contraction

(Black noise removal)

Filter useful for contour extraction

•

Sobel

(Edge detection)

Page 4

High-Speed Enhancements

[High Speed 1]

Smart Matching

Detects the presence (or absence) of a pattern (object) in

the search area that matches the template registered.

Detection of sub-pixel position possible with gray scale

matching. In addition, using the gray scale differential

processing function, shape inspection, e.g. to detect chips

or other flaws in an object, can also be carried out

simultaneously.

[High Speed 2]

Feature Extraction

Features, such as the number of objects, the area, central

coordinates, angle of the main axis, projection width or

perimeter length, can be extracted using a binary image.

High

Performance

RISC-CPU

Software

Optimization

[Processing Time]

Previous Model: 36.0 ms

3.8 ms

PV310:

Condition: Without orientation

correction

Template: 128 x 128

Search area: 512 x 480

[Processing Time]

Previous Model: 61.0 ms

3.9 ms

PV310:

Condition: With orientation

correction

Template: 486 x 452

Object color: Black

Image

Processor

Approx.

10

times faster than

previous model

Approx.

16

times faster than

previous model

Detects registered

template

Detection Image

[High Speed 3]

Gray Scale Window

An area can be created in a 256 gray scale image, with a

rectangular, circular or polygonal shape over the area

where object detection is to take place. An average value

for the brightness data (gray scale value) for all pixels in

that area can be calculated.

[High Speed 4]

Gray Scale Edge

The distance between lead pins or pitch size can be

measured for an inspection object. Parameters allow settings

to be made in great detail. Using the extreme accuracy of

sub-pixel processing, the edge in question can be reliably

extracted for a wide variety of object states.

[Processing Time]

Previous Model: 69.0 ms

1.7 ms

PV310:

Condition: With orientation

correction

Inspection area: 486 x 452

[Processing Time]

Previous Model: 28.0 ms

2.7 ms

PV310:

Condition: With orientation

correction

Inspection area: 200 x 160

Approx.

40

times faster than

previous model

Approx.

10

times faster than

previous model

Binary Window

Judges whether a certain amount of area for an object is present

using a binary image. High-speed processing is 23 times as fast

as previous models, even when multiple inspection areas are

specified.

4 5

[Processing Time] PV310: 2.1 ms Previous Model: 49.1 ms

Conditions: With orientation correction, inspection area: 486 x 452

Conditions: With orientation correction, inspection area: 486 x 452

Binary Edge

Determination of position and simple size measurement can be

carried out at approximately twice the speed of previous models. There

is no effect on inspection speed even if the inspection area is

increased for purposes of stability.

[Processing Time] PV310: 0.9 ms Previous Model: 1.8 ms

Conditions: With orientation correction, inspection area: 200 x 160

Page 5

User-Friendly Interface

An operation keypad makes configuration as easy as child's play.

The color display is easy to read and allows you to grasp information quickly.

Rich Information Display

The high performance VGA monitor displays inspected objects on the screen with high fidelity. Operations and settings can be

carried out easily via the pull-down menus and keypad.

Readability has been improved by displaying guidelines and character information in color and using a large character font.

In addition, parallel inspection output results can be monitored in color.

Status Display Area

Currently Selected Model Number,

Model Title and Shutter Speed

Currently Displayed Image Type

Message Area

Displays various messages, sub-windows for

checker settings and checker test results.

Overall Judgment Result

Displays OK (in green) when the output

judgment meets the judgment requirements

set in "Overall Judgment"

Signal Output Status

When the following signals are output, the

box below each signal is illuminated. (RUN

mode only)

R: READY signal

E: ERROR signal

1~8: D1 to D8 signals

Execution Time

Menu Bar

Displays menus for

setting inspection

conditions and the

inspection environment.

Screen Display Area

<RUN mode>

Displays images, checker

areas, inspection results,

etc. depending on the

settings in Settings Mode.

<Settings Mode>

Displays images, checker

areas, etc.

Settings windows called

from the menu bar are also

displayed in this area.

Menu Background Settings

A semi-transparent mode, allowing operations to be carried out while viewing captured images,

and a fill mode, which blocks out background colors, are both supported. You can select the menu

background color and set it as default.

Operation

keypad

Just position the cursor on a

menu item and press

<Enter>.

Semi-Translucent Mode

The PV310 can be used for a wide range of applications where high-speed processing is required, e.g.

Applications

inspecting:

Presence/absence of parts

Part size

Part orientation

Presence/absence of date or

serial no.

Product nameplate label

Remote control switch printing

Cap tightness

Fill Mode

Logo mark printing

Flat cable width

Label position

Debris/dirt on part

7-segment illumination

Substrate positioning

Metal part picking, etc.

Data Monitor

Up to 50 inspection results can be displayed in

a list on the monitor, allowing the operator to

check the results on the monitor. Threshold

adjustment (upper and lower limit values) can

also be changed on the data monitor without

having to enter them in the settings menu.

The size and display position can also be

changed.

Page 6

Full Selection of Interfaces

External interfaces are essential for image processing

devices of the future. The PV310 is equipped with a full

selection of interfaces that rival even large-scale devices.

Ethernet Connection

• The PV310 can be connected to a LAN using high-speed Ethernet

(100BASE-TX) to meet various application requirements.

• Captured images and measurement data can be transmitted to a PC at

high speed even during operation.

• The inspection status of multiple PV310 units can be monitored from a

single PC.

• With the high-speed connection to a PC, backing up image data is also

easy.

PC

Operation Keypad

The dedicated keypad with an

ergonomic structure provides

excellent operability.

External Memory (CF Card) Support

In RUN mode:

•

• Can save captured images.

[Storage capacity:

Approx. 2,000 images (512 MB)]

• Saves inspection results.

Facilitates trend tracking and data

analyses.

In the setting mode:

•

• Backs up setting data and image data

captured by the unit.

Note: Backup image data can be used as

regular bitmap files on a PC.

DIN Rail Installation

Connection of up to Two

Identical Cameras

Up to two identical cameras can be

connected. The following camera types

are available.

Standard camera

[ANM832 (CE)]

Double-speed random

camera [ANM831]

PLC Link Function

• The PV310 can communicate easily with external

devices, such as PLCs, using the RS232C port.

• The PV310 can be connected to other companies'

PLCs without requiring additional programming. Of

course it can be connected to our PLCs, too.

Supported Models:

• Matsushita Electric Works PLCs

• OMRON Corporation - C, CV and CS1 series

• Mitsubishi Electric Corporation - A, Q and FX series

• Rockwell Automation DF1 protocol

• Fuji Electric SX series

VGA Monitor

Judgment results and program

settings are displayed in color for

outstanding visibility.

(Captured images are in black

and white.)

Note: Commercially available VGA monitors may also be connected

(devices supporting horizontal synchronous frequency: 31.466KHz

and vertical synchronous frequency: 59.94KHz only.)

Operation cannot be guaranteed with devices from other manufacturers.

Ultra-compact camera

[ANPVCA1012]

PV310

Two cameras

Connection of up to Four Cameras

by a Camera Switching Unit

Up to four identical standard or double-speed random cameras can be

connected using a camera switching unit (option: ANPV3700).

* Excluding Ultra-compact camera

This connection is ideal for:

• Control of different inspections by a single controller unit

• Inspection of wide areas, and positioning of workpieces during the LCD

lamination process, etc.

PV310

Camera switching unit

(ANPV3700)

Cameras

Camera Switching Mode

•

Images taken by either of two cameras

connected to the camera switching unit

are output to the PV310.

* Available for ANM832 (CE) and

ANM831

Camera Image Split Mode

•

(top/bottom split and left/right split)

Half images taken by two cameras are

combined into one, which is then

output to the PV310.

* Available for ANM832 (CE) only

6 7

Page 7

Functions

Inspection programs for as many

as 64 product types can be set.

Upgraded

Improved

Smart Matching

Detection of sub-pixel position possible with gray

scale matching. In addition, using the gray scale

differential processing function, shape inspection,

etc. can also be carried out simultaneously. Memory

capacity has been increased 4 times over previous

models, allowing support for an even wider range of

applications.

Detects registered

template

Detection Image

Feature Extraction

Features, such as the number of objects, workpieces,

area, central coordinates, angle of the main axis,

projection width or perimeter length can be extracted.

Differential Function

Based on the position information obtained by the

matching function, the registered object and detected

object are overlapped and compared on a pixel-bypixel basis. Any pixels with a difference in brightness

over a certain level are detected. The area value of

such pixels can then be used to make pass/fail

judgments.

Template

Matching

detection

Difference detected =

NG

Gray Scale Window

An inspection area can be created in a 256 gray

scale image, with a rectangular, circular or polygonal

shape, over the area where object detection is to take

place. An average value for the brightness data (gray

scale value) for all pixels in that area can be

calculated.

Numerical Calculation/

Judgment Output

The numerical output function has been greatly

simplified so that even a novice can set it easily.

Operation has also become even easier as both

numerical calculations and judgment output can now

be set on the same screen (up to 96 formulas).

360° Contour Matching

Stable position detection is possible even for objects

that overlap because their contours can be extricated.

The range of settings has been doubled and support

has been added for 4 cameras.

Rotation/Position Adjustment

Highly accurate and reliable inspection is realized by automatically adjusting object orientation

and stop position deviation.

Complicated adjustments are also possible using the multiple adjustment function.

Multiple Adjustment

Position

adjustment 1

Detection Image

Position

adjustment 2

Search area Inspection object

Position Adjustment

Rotation Adjustment

Multiple Adjustment

Priority Adjustment

Previous

PV310

Mask

The shape of the inspection area can be set to

match particular targets. Mask area settings

can also be combined to allow efficient

inspections to be carried out only on the

necessary parts.

Inspection

area

Mask

Mask

Page 8

Settings

A full range of inspection modes to meet customers' needs. Support functions for optimal settings.

Setting Help

This function helps the user make settings that in the past relied heavily on human judgment, e.g. setting the focus, adjusting

the aperture, finding the optimal settings for the parallel monitor, lighting adjustment, density profile display, etc.

Density Profile Parallel Monitor

Collective Movement

Checkers that have been set can be moved

collectively all at once. This is useful for fine

adjustment when re-setting cameras. It is also

convenient when transferring product type data to a

different device.

Collective

Collective

Movement

Movement

Image Storage

Using a calendar function, the date a defect was

discovered and the number of inspections can be

added to saved color images. This is useful for later

verification (checking a defective product against a

saved image) and for analyzing defect tendencies.

Gray scale values for the image are displayed

in an easily understandable table.

Security

Passwords can be set in "environment" - "initial

settings". Vital setting data can be protected from

careless operating errors.

Global Support

(Multi-language Display & CE

Compliance)

Considering that the device may be shipped

overseas, the display can be switched between 6

different languages. The controller and dedicated

cameras are standardized items and CE compliant.

(Japanese)

The "Parallel Monitor" function is also useful during

actual operation for monitoring parallel input and

output signals to and from the PV310.

Inspection Mode

The PV300 is equipped with a variety of inspection

modes, such as position adjustment, rotation

adjustment, gray scale and binarization, to support a

wide range of inspection needs.

Position

Adjustment

Rotation

Adjustment

Binary Window

Gray Scale Window

Gray Scale Edge

Binary Edge

Feature Extraction

Binary Edge

Gray Scale

Edge

Feature

Extraction

Matching

Binary

Horizontal Edge

Binary Vertical

Edge

Gray Scale

Horizontal Edge

Gray Scale

Vertical Edge

Feature

Extraction

Matching

(Two checkers)

Contour

Matching

360 Matching

Smart Matching

Contour Matching

Flaw Detection

(English)

Selection is easy using

the Environment Settings Language menu.

8 9

Page 9

Support

Our popular menus and support software greatly improve workability during inspections.

Download from

CF Card

A program stored on a Compact Flash card

can be downloaded to the controller unit using

a parallel external signal.

CF Card

Statistical Support Print Screen

Statistical data such as the maximum, minimum and

average data values, number of failed results, etc.

can be displayed. Maximum, minimum and average

values in pass judgments can be checked, allowing

them to be used as a guide for subsequent upper and

lower limit settings.

Parallel Handshake Support

Parallel external output of 96 inspection and numerical calculation results is available.

Display and settings screens can be saved to

a memory card as bitmap files. This is

convenient for creating documents or for

checking previous images.

Full Peripheral Support with "AXTOOL" Vision Support Tool

The "AXTOOL" Vision Support Tool is full of enhanced functions and connects to PV310s

using a high-speed interface (100BASE-TX) to meet various application requirements.

PC

Ethernet

100BASE-TX

1. Backup/recovery of image and settings data

2. Copy/move/deletion of image and settings data

3. Check saved images on PC

4. Convert settings data to CSV format. Editing possible with Excel.

PV310

Product type

data backup

screen

Document

display screen

Image data

display screen

Download AXTOOL for free from:

http://www.mew.co.jp/ac/e/fasys/vision/

Note: The screen design may differ from that shown.

Page 10

Dimensions (Unit: mm)

Main Unit (Controller)

ANPV0310EDN

4.6

5

(10)

Operation Keypad

10059

130

(5) (Pullout dimensions)

ANM852**

ANM852**CE

54.4

ENTER

B

A

C

46

124.6

18

L

11.5

Double-Speed Random Camera: C Mount

ANM831

Without mounting bracket

29

2-M3

31

(

Depth

4mm)

54.5

(46.5)

8

24.5±0.6

19

13

4-M3

(

Depth

Ultra-Compact Camera

ANPVCA1012

(6.4)39.4±1

5.65

3.5

M10.5 P=0.5

12±0.1

2.42

9 (length toCCD)

(in air 7.4mm)

CCU

110±3

70

1

±

28

(3.1)

10

2.5mm)

0.6

±

26

156±3

Standard Camera: CS Mount

ANM832/ANM832CE/ANM83203

*1)

8

29

14

24.5±0.2

8

4mm)

Without mounting bracket

49.5

( 6.7)

4-M3 (

(19)

(31.3)

24.5

(3.25)

31

31

1/4-20UNC

±

0.6

(

Depth

9mm)

31

With mounting bracket

2.5

2-M3 (

Depth

0.2

±

26

Double-Speed Random Camera Cable

ANM84303

( 12.5)

9131

ANM84303CE

*2)

(43)

( 14.7)

Note *2) This is the length of cable in use.

Becomes slightly shorter with CE attached.

7.0

Camera Extension Cable

ANM840 A

ANM840 ACE

(43)

7.0

( 14.7)

(43)

L

The boxes correspond to the length of cable in use.

(43)

Depth

2.5mm)

Double-Speed Random Camera Cable

(Durable Type)

ANM84603

Camera Extension Cable (Durable Type)

ANM845

( 14)

( 11.9)

2-M3 (

( 14.7)

( 14.7)

( 14.7)

Depth

Note *1)

ANM832: 3000

ANM832CE: 2780

ANM83203: 300

7mm)

18.15

0.2

±

23

32.15

With mounting bracket

(52)

(52)

38

28±0.2

3000±50

7.9

7.9

1/4-20UNC

L

0.2

±

10.5

Depth

10mm

(52)

(52)

( 14)

( 11.9)

Lens

Mounting screws (lenses with lock only)

A

VGA Monitor

ANMX8301

C Mount Lens

ANB843L

ANB845NL

ANB846NL

ANB847L

ANM88161

ANM88251

ANM8850

B

B

A

55 55

ANM88501

Ultra-Compact Lens

ANPVL0401

ANPVL1201

ANPVL3001

258

255

f=8.5

f=16

f=25

f=50

f=16

f=25

f=50

f=50

f=4

f=12

f=30

AB

φ42

40

φ30

33

φ30

37.3

φ48

48

φ30.5

25

φ30.5

25.5

φ27.5

38.5

φ30.5

38.5

AB

φ12

14.8

φ12

14.4

φ12

25.3

45

2

43

3540

10

160

Camera Switching Unit

ANPV3700

ANMX8301

36

26.5±0.5

5.4

5

5

0.5

±

86.0

5.5

5.4

55 55

9.5 (Pullout dimensions)

223

220

74.6

51.4

59

29.5

25.4

7.2

96

35.4

48

DIN hook

45

2

43

90

160

Keypad hole

Without Keypad

Connector

31

Keypad Cable

(between VGA monitor and

controller)

ANMX8333*

With Keypad Connector

40

12

L

40

12

VGA Monitor Cable

ANMX8331*

57

31

18

L

10 11

Page 11

Part Nos. and Specifications

Part Nos.

Product Name

PV310 Controller

Double-Speed Random

Camera (C Mount)

Standard Camera

(CS Mount)

Double-Speed

Random Camera

Cable

Ultra-Compact Camera

Camera Extension

Cable

Camera Switching

Unit

VGA Monitor

Kit for

Installation

on Main Unit

Controller

Mounting

Brackets

Monitor

Cable

(With keypad

controller)

Keypad Cable

for Connection

to Main Unit

C Mount

Lens

UltraCompact

Camera Lens

Adapter Ring

Operation Keypad

COM Port

Cable

Specification Part No.

JPN/ENG

JPN/ENG

ENG/JPN

ENG/GER/FRN/ITA/SPN

progressive support

with 3 m cable

with 3 m cable

with 30 cm cable

3 m

3 m

Double-Speed Random

Camera Cable

(Durable Type) = 3 m

12-mm diameter

2 m extension: Total 5 m

7 m extension: Total 10 m

12 m extension: Total 15 m

17 m extension: Total 20 m

2 m extension: Total 5 m

7 m extension: Total 10 m

12 m extension: Total 15 m

17 m extension: Total 20 m

Durable extention 2 m: Total 5 m

Durable extention 7 m: Total 10 m

Durable extention 12 m: Total 15 m

Durable extention 17 m: Total 20 m

Supports standard camera

and double-speed random

camera

With keypad connector

Without keypad connector

With keypad connector.

Mounting brackets

(ANMX835)/Monitor cable:

0.5 m/Keypad cable: 0.5 m

Without keypad connector.

Mounting brackets

(ANMX835)/Monitor cable:

0.5 m

Brackets for mounting

VGA monitor on the

controller

Cable length: 0.5 m

(for single-unit mounting)

Cable length: 1 m

Cable length: 2 m

Cable length: 3 m

Cable length : 0.5 m

Cable length: 1 m

Cable length: 2 m

Cable length: 3 m

C mount lens with lock

f8.5

C mount lens with lock

f16

C mount compact lens with lock

f16

C mount compact lens

f25

C mount compact lens with lock

f25

C mount super-compact lens with lock

f50

C mount super-compact lens with lock

f50

C mount super-compact lens

f50

f4

Ultra-Compact Lens 12mm

f12

Ultra-Compact Lens 12mm

f30

Ultra-Compact Lens 12mm

5 mm

0.5/1/5/10/20/40 mm

with 2 m cable

with 3 m cable

with 5 m cable

with 10 m cable

with 2 m cable

with 3 m cable

with 5 m cable

with 10 m cable

for connection to PC

(D-SUB: 9 pins): 3 m

for connection to PLC

(discrete-wire cable): 3 m

CE

NPN

PNP

NPN

PNP

ANPV0310JDN

ANPV0310JDP

ANPV0310EDN

ANPV0310MDP

ANM831

ANM832

ANM832CE

ANM83203

ANM84303

ANM84303CE

ANM84603

ANPVCA1012

ANM84002A

ANM84007A

ANM84012A

ANM84017A

ANM84002ACE

ANM84007ACE

ANM84012ACE

ANM84017ACE

ANM84502

ANM84507

ANM84512

ANM84517

ANPV3700

ANMX8300

ANMX8301

ANMX8302

ANMX8303

ANMX835

ANMX83310

ANMX83311

ANMX83312

ANMX83313

ANMX83330

ANMX83331

ANMX83332

ANMX83333

ANB843L

ANB845NL

ANM88161

ANB846NL

ANM88251

ANB847L

ANM8850

ANM88501

ANPVL0401

ANPVL1201

ANPVL3001

ANB84805

ANB848

ANM85202

ANM85203

ANM85205

ANM85210

ANM85202CE

ANM85203CE

ANM85205CE

ANM85210CE

ANM81103

ANM81303

General Specifications

Controller: ANPV0310

Specification

Specification

Product Name

Product Name

Item

Rated Operating Voltage

Rated Operating Voltage

Rated Operating Voltage

Operating Voltage Range

Operating Voltage Range

Operating Voltage Range

Rated Current Consumption

Rated Current Consumption

Rated Current Consumption

Ambient Temperature (in use)

Ambient Temperature (in use)

Ambient Temperature (in use)

Storage Ambient Temperature

Storage Ambient Temperature

Storage Ambient Temperature

Ambient Humidity (in use and storage)

Ambient Humidity (in use and storage)

Ambient Humidity (in use and storage)

Noise Immunity

Noise Immunity

Noise Immunity

Vibration Resistance

Vibration Resistance

Vibration Resistance

Shock Resistance

Shock Resistance

Shock Resistance

Weight

Weight

Weight

Dimensions (mm)

24 V DC

24 V DC

24 V DC

21.6 to 26.4 V DC (including ripples)

21.6 to 26.4 V DC (including ripples)

21.6 to 26.4 V DC (including ripples)

0.7 A max. (1 camera) 0.9 A max. (2 cameras)

0.7 A max. (1 camera) 0.9 A max. (2 cameras)

0.7 A max. (1 camera) 0.9 A max. (2 cameras)

0 to 50∞C (no freezing or condensation)

0 to 50∞C (no freezing or condensation)

0 to 50°C (no freezing or condensation)

-20 to +60∞C (no freezing or condensation)

-20 to +60∞C (no freezing or condensation)

-20 to +60°C (no freezing or condensation)

35 to 75%

35 to 75%

35 to 75%

1000 V pulse width 50 ns/1 µs

1000 V pulse width 50 ns/1 µs

(using noise simulator method)

(using noise simulator method)

10 to 55 Hz, 1 cycle/1 min.

10 to 55 Hz, 1 cycle/1 min.

Double amplitude of 0.75 mm.

Double amplitude of 0.75 mm.

30 min. each in X, Y and Z directions

30 min. each in X, Y and Z directions

196 m/s2, 5 times each in X, Y and Z directions

196 m/s2, 5 times each in X, Y and Z directions

Approx. 450g

Approx. 450 g

W59 × H130 × D100 (with connector 110)

Specification

(at 25∞C with no freezing or condensation)

(at 25∞C with no freezing or condensation)

(at 25°C with no freezing or condensation)

Functional Specifications

Functional Specifications

Specification

Settings Data Storage Capacity

Frame Memory

Operation

Environment

Cameras

Monitor Output

Input/Output

Memory Card

Serial

Parallel

Keypad Input

Tools

Image Processing Functional Specifications

Item

Monitor Display

Number of Connected

Cameras

Processing Method

No. of Product Types

Inspection Functions

Numerical

Computation

Judgment Output

Statistics

Data Monitor

Approx. 4 MB

512 x 480 (pixels)

Menu selection by dedicated keypad

Key Emulation

Menu selection by serial command

2 Standard cameras, double-speed random

cameras, or ultra-compact cameras

(max. 4 cameras when using camera switching

unit, excluding ultra-compact camera)

Color VGA ouput

Compact Flash: 1 slot

RS-232C x 1 channel

Input: 13 points; output: 14 points;

removable screw-down terminal block

1 Connector for dedicated keypad (ANM8520*)

Ethernet: 1 channel

Specification

Full color VGA/gray scale image/

binary image

Two-screen compressed display: side-by-side

display (when gray scale image selected)

through/memory, data monitor, marker,

+ information display region (128x480)

Max. 2 cameras (Max. 4 cameras using camera

switching unit, excluding ultra compact camera)

Gray scale processing - Binary processing

Max. 64 types

(depends on settings data capacity)

Max. 99 checkers/product type

•Position adjustment, rotation adjustment,

binary window

•Gray scale window, binary edge, gray scale

edge

•Feature extraction, smart matching, contour

matching, scratch detection

Max. 96 functions/product type

Operators:

4-operation calculation, , arc tangent,

distance between 2 points,

parenthesis, sin, cos, absolute value of

difference

Max. 96 functions/product type

Operators:

NOT/AND/OR/XOR/parenthesis

Max. 96/product type

Calculation of no. of passes/no. of fails/pass

average/pass distribution/

pass max. value/pass min. value/pass range

(for judgment output no. of passes/no. of fails

only)

Max. 50/product type

Displayed on screen in table form during RUN

Title input and substitution of numerical

computation results, judgment output results,

statistical results and product numbers

possible

Camera Switching Unit: ANPV3700

Specification

Item

Product Name

Camera Switching 2-camera input - 1-camera output

Camera Image Split

ANM832 (CE) only

Functions

External Switching

Signal Input

DIP Switch Setting LOCAL/REMOTE, NORMAL/DIV, A/B,

Rated Voltage Range 12 V DC (supplied from the MICRO-

Weight

Included items: 1 connection cable (30 cm), 2 ferrite cores, and

The operation condition requirements are the same as those for the PV310

Controller.

(Switching by external signal input/Manual switching)

2-camera input - 1-camera output of top/bottom

split images/

2-camera input - 1-camera output of left/right

split images

1 input, photo-coupler bidirectional input

supported, 5 to 24 V DC

Top-Bottom/Left-Right

IMAGECHECKER unit)

Approx. 150 g (Main unit only)

1 installation manual

ItemItem

Operation Data

Marker

Serial

External Input/Output

Parallel

Ethernet

(1 channel)

CF Card

(1 slot)

Display

Functions

Other

Collective

Movement

Image Storage

Setting Help

Calendar

Password

Max. 4/environment

Substitution in numerical computation possible

Max. 8/product type

Graphic display on screen during RUN

RS-232C=1ch (max. speed 115200 bps)

• Input: start/product type switch/camera

display switch/template re-registration/

CompactFlash settings restore/reference to

and alteration of upper and lower values for

numerical computation/reference to and

alteration of binary level/reference to and

alteration of gray scale edge thresholds/data

storage/fixed length input for input commands

for statistics initialization (for PLC)

• Output: output (no. of inspections/judgment

output/numerical computations/statistics)

synchronous or asynchronous to inspection

start trigger

• Computer link support:

Supported models:

• Matsushita Electric Works PLC

• OMRON Corporation - C, CV and CS1 series

•

Mitsubishi Electric Corporation - A, Q and FX series

• Rockwell Automation DF1 protocol

• Fuji Electric SX series

Input: 13 points; output: 14 points

• Input: start/product type switch/camera

display switch/template re-registration/

data restore from Compact Flash

• Output: ready/error/flush/image

acquired/strobe/judgment output data/

synchronous output (no. of inspections/

judgment output/numerical computation/

statistics) possible by handshake output

• Output: no. of inspections/judgment

output/numerical computations/statistics/

settings data/image backup and

restore/conversion to documentation for

settings data (Vision AXTOOL)

• Output: no. of inspections/judgment

output/numerical computations/statistics/

settings data/image backup and restore/screen

dumps

Transparent menu/parallel output status

monitor/reference coordinate display/checkers

with fail results highlighted in different color

Collective movement of set checkers in units

of position/rotation adjustment groups

Max. 16 images/camera

Each time/storage possible according to

judgment result

Test runs available on stored images

Display of date and time saved

Function to maintain display of last image

saved

Focusing/aperture adjustment/parallel monitor/

lighting adjustment/gray scale profile display

Calendar information added to stored images

File time stamp

Password function for when moving between

settings modes

Specification

Specification

Page 12

PV310

ARCT1B268E-2

ARCT1B268E-2 200702-2YT

http://www.mew.co.jp/ac/e

Loading...

Loading...