Panasonic PT-EX600U, PT-EX600EL, PT-EW630U, PT-EW630UL, PT-EW630E Service Manual

...

ORDER NO. VED1205428CE

D10

LCD Projector

Model No. PT-EX600U

PT-EX600E

PT-EX600UL

PT-EX600EL

PT-EW630U

PT-EW630E

PT-EW630UL

PT-EW630EL

Lens is optional for the projectors that “L” follows in model number.

*

© Panasonic Corporation 2012.Unauthorized

copying and distribution is a violation of law.

-2-

Contents

Contents ....................................................................... 2

Safety Instructions ...................................................... 3

Safety precautions ...................................................... 4

Specifications .............................................................. 5

Circuit Protections ......................................................7

Fuse(F601) ................................................................. 7

Thermal fuse(SW902) ................................................ 7

Mechanical sensor switches ....................................... 8

Temperature sensors, wind sensors ........................... 9

Power failure and fan lock detection .........................10

Maintenance ............................................................... 11

Maintenance ............................................................. 11

Replacing the unit ..................................................... 13

Replacing the lamp unit ............................................ 15

How to check lamp runtime ...................................... 16

Warning message on the non-standard lamp used .. 16

Quick maintenance ................................................... 17

Removing and attaching the projection lens .............18

Using the lens antitheft screw ...................................19

Cleaning ................................................................... 20

Cleaning the projection lens ..................................... 20

Cleaning the projector cabinet .................................. 20

Security Function Notice .......................................... 21

Resetting procedure ................................................. 21

Standby Mode Notice ................................................ 22

Mechanical Disassembly .......................................... 23

Optical Parts Disassembly .......................................33

LCD panel type check .............................................. 33

Servicing Notice ........................................................39

Note on main board replacement ............................. 39

1.EEPROM data transfer .......................................... 39

2. Adjustment data setting ........................................ 40

Adjustments ............................................................... 41

Adjustments after parts replacement ........................ 41

Optical Adjustments .................................................. 42

1. Optical axis adjustment ........................................ 43

2. Contrast adjustment ............................................. 47

Electrical Adjustments .............................................. 48

Service adjustment menu operation ......................... 48

Circuit adjustments ................................................... 49

Test points and locations .......................................... 53

Service adjustment data .......................................... 54

Troubleshooting ........................................................ 80

Chassis overview ...................................................... 80

No power .................................................................. 81

No power (power supply) .......................................... 82

No power (power supply) .......................................... 83

No power (power supply) .......................................... 84

No power (fan control) .............................................. 85

No power (lamp control) ........................................... 86

Temperature abnormality .......................................... 87

No picture ................................................................. 88

No sound .................................................................. 89

Motor control problems ............................................. 90

Bus control ................................................................ 91

LED drive & RC control ........................................... 92

Indicators and projector condition ............................. 93

If an indicator turns on .............................................. 94

Power failure detection system ................................ 98

Diagnosis of power failure with RS-232C port ........ 103

Serial control interface ............................................ 104

Control Port Functions ...........................................107

IC Block Diagrams ................................................... 110

Exploded Views & Parts List .............................. SPL-1

Exploded Views ................................................... SPL-2

Mechanical Parts List ........................................ SPL-12

Electrical Parts List ........................................... SPL-14

Schematic Diagram & Circuit Boards Diagram . DIA-1

Pin description of diode, transistor and IC ...........DIA-2

Schematic Diagrams ............................................DIA-3

Printed Wiring Board Diagrams ........................DIA-13

-3-

Safety Instructions

The service technician is required to read and follow the “Safety Precautions” and “Important Safety Notice” in this service manual.

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It dose not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or repair the product or products dealt with in this service information by anyone else could result in serious injury or death.

WARNING : Use UV Radiation eye and skin protection during servicing

CAUTION

Precaution

If using of this projector at high altitudes, “Fan Control” to “ON1” for 1,000 to 2,000m or “ON2” for 2,000 to 2,700m.

(Refer to “PROJECTOR SETUP menu” in Operating Instructions.)

Failure to observe this may cause malfunctions. Never use this projector at an altitude of 2,700m or higher.

Using this projector at high altitude, consult your dealer or Authorized Service Center about preparations.

About lead free solder (PbF)

This projector is using the P.C.Board which applies lead free solder.

Use lead free solder in servicing from the standpoint of antipollution for the global environment.

Notes:

•Leadfreesolder:Sn-Ag-Cu(tin,silverandcopper)hasahighermeltingpoint(approx.217°C)thanstandardsolder.Typicallythemeltingpoint

•is30~40°Chigher.Whenservicing,useahightemperaturesolderingironwithtemperaturelimitationfunctionandsetitto370±10°C.

•Beprecautiousaboutleadfreesolder.Sn-Ag-Cu(tin,silverandcopper)willtendtosplashwhenheatedtoohigh(approx.600°Corhigher).

•UseleadfreesolderfortheP.C.Board(specifiedonitas“PbF”)whichusesleadfreesolder.(Whenyouunavoidablyuseleadsolder,uselead

•solderafterremovingleadfreesolder.Orbesuretoheattheleadfreesolderuntilitmeltscompletely,beforeapplyingleadsolder.)

•AftersoldertodoublelayeredP.CBoards,checkthecomponentsideforexceeesolderwhichmayflowontotheoppositeside.

About the identification of the lead free solder P.C.Board.

For the P.C.Board which applies lead free solder, the symbol as shown in the figure below is printed or stamped on the surface

or the back of P.C.Board.

For US

IMPORTANT SAFETY NOTICE

There are special parts used in Panasonic LCD Projectors which are important for safety. These parts are shaded on the schematic diagram. It is essential that these critical parts should be replaced with manufacturer’s specified parts to prevent shock,

fire, or other hazards. Do not modify the original design without permission of PANASONIC SOLUTIONS COMPANY.

WARNING:

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not

occur in a particular installation.

If this equipment dose cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, The user is encouraged to try to correct the interference by one or more of the following measures.

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

CAUTION : Any unauthorized changes or modifications to this equipment will void the user’s authority to operate this device.

-4-

Safety Instructions

<PT-FW430U/PT-FW430E/PT-FW430EA/PT-FX400U/PT-FX400E/PT-FX400EA>

1. Safety Precautions

1.1. General Guidelines

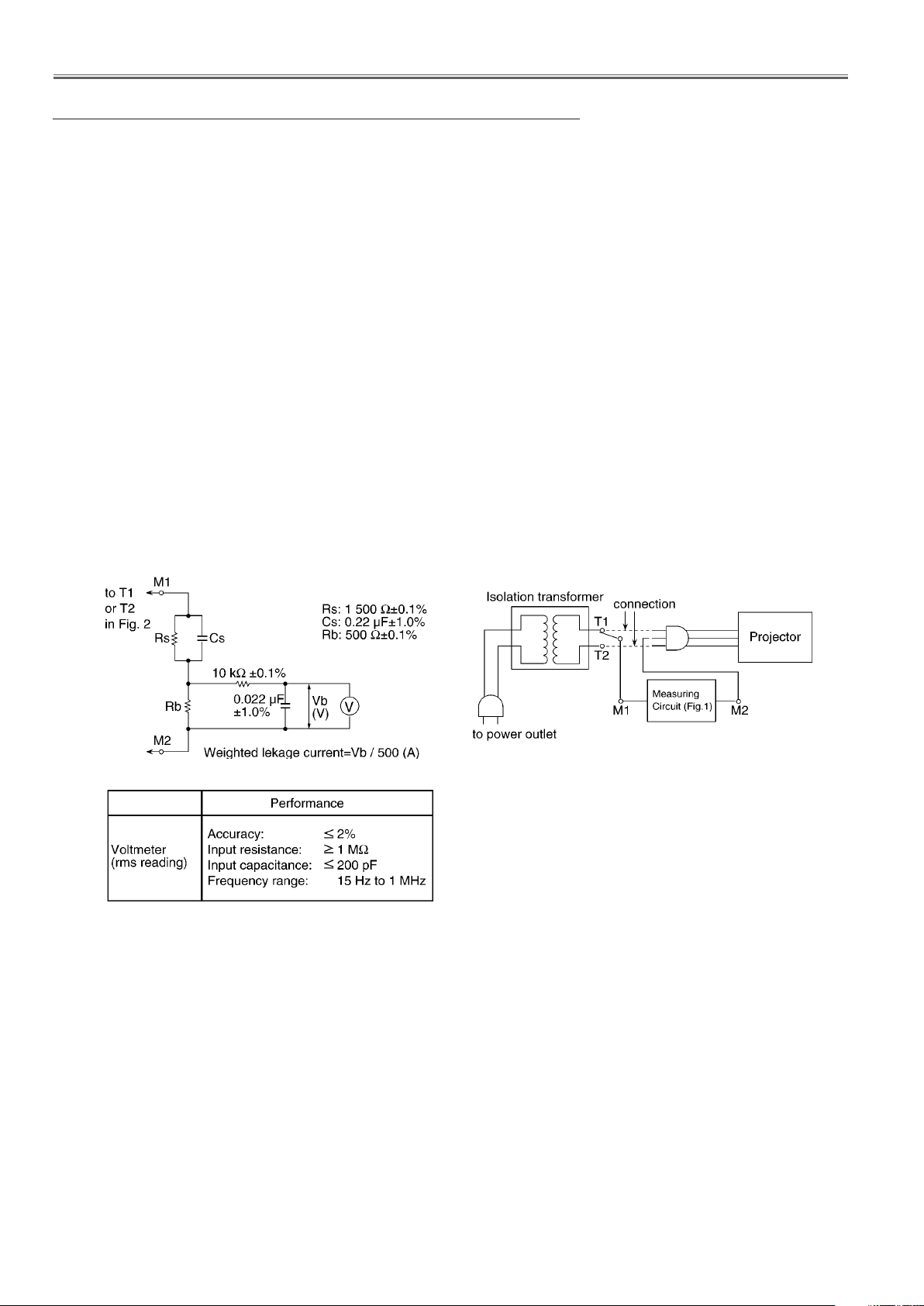

1.2. Leakage Current Check

1. Prepare the measuring circuit as shown in Fig.1.

Be sure to use a voltmeter having the performance described in Table 1.

2. Assemble the circuit as shown in Fig. 2. Plug the power cord in a power outlet.

3. Connect M1 to T1 according to Fig. 2 and measure the voltage.

4. Change the connection of M1 from T1 to T2 and measure the voltage again.

5. The voltmeter must read 0.375 V or lower in both of steps 3 and 4. This means that the current must be 0.75mA or less.

6. If the reading is out of the above standard, the projector must be repaired and rechecked before returning to the customer

because of a possibility of an electric shock.

- For continued safety, no modification of any circuit must be attempted.

- Unplug the power cord from the power outlet before disassembling this projector.

- Use correctly the supplied power cord and must ground it.

- It is advisable to use an isolation transformer in the AC power line before the service.

- Be careful not to touch the rotation part (cooling fan, etc.) of this projector when you service with the upper

case removed and the power supply turned ON.

- Observe the original lead dress during the service. If a short circuit is found, replace all the parts overheated

or damaged by the short circuit.

- After the service, all the protective devices such as insulation barriers, insulation papers, shields, and isolation

R-C combinations must be properly installed.

- After the service, check the leakage current to prevent the customer from getting an electric shock.

1.3. UV Precaution and UHM Lamp Precautions

- Be sure to unplug the power cord from the power outlet when replacing the lamp.

- Because the lamp reaches a very high temperature during its operation, wait until it cools completely when replacing

the Lamp Unit.

- The lamp emits small amounts of UV-radiation, avoid direct-eye contact with the light.

- The lamp unit has high internal pressure. If improperly handled, explosion might result.

- Because the high pressure lamp involves a risk of failure, never touch the lamp wire lead during the service.

Fig. 1

Fig. 2

Table. 2

Safety precautions

-5-

Specifications

Model No. PT-EX600U / E / UL / EL PT-EW630U / E / UL / EL

Power supply

Power consumption

Panel size

LCD panel

Lens*1

Luminous lamp

Light output *2

Applicable

scanning

frequency

*3

Display method

Drive method

Pixels

for RGB signal

for YPBPR signal

AC100 V - 240 V 50 Hz/60 Hz

100 V - 240 V 4.9 A-2.0 A 490 W

When [Standby mode] of [Setting] is set to [ECO]: 0.4 W

When [Standby mode] of [Setting] is set to [Network]: 11 W

When [Standby mode] of [Setting] is set to [Normal]: 15 W

1.93 cm(0.8")

(aspect ratio 4 : 3)

3 transparent LCD panels (RGB)

Active matrix method

786 432

(1 024 x 768) x 3 panels

Motorised zoom (1.6x) / Motorised focus

F 1.7 to 2.3, f 26.9 mm to 45.4 mm

330 W UHM lamp

6 000 lm 5 500 lm

Horizontal 15 kHz to 120 kHz, Vertical 48 Hz to 100 Hz

Dot clock frequency: up to 140 MHz

[525i(480i)] Horizontal 15.75 kHz, Vertical 60 Hz

[525p(480p)] Horizontal 31.5 kHz, Vertical 60 Hz

[750(720)/60p] Horizontal 45 kHz, Vertical 60 Hz

[1 125(1 080)/60i]Horizontal 33.75 kHz, Vertical 60 Hz

[625i(576i)] Horizontal 15.63 kHz, Vertical 50 Hz

[625p(576p)] Horizontal 31.25 kHz, Vertical 50 Hz

[750(720)/50p] Horizontal 37.5 kHz, Vertical 50 Hz

[1 125(1 080)50i] Horizontal 28.13 kHz, Vertical 50 Hz

•HD/SYNCandVterminalsarenotcompliantwith3valuecompositeSYNC

1.91 cm(0.75")

(aspect ratio 16 : 10)

1 024 000

(1 280 x 800) x 3 panels

for Video signal (including S-Video)

for HDMI signal

Color system

Projection size

Screen aspect ratio

Projection scheme

Speaker

Maximum usable volume output

Contrast ratio *1

*1: It is only for the model which with lens.

*2: Measurement, measuring conditions and method of notation all comply with ISO21118 international standards.

*3: For details of video signals that can be projected using this projector, refer to “List of compatible signals”.

Horizontal 15.75 kHz / 15.63 kHz, Vertical 50 Hz / 60 Hz

525p(480p), 625p(576p), 750(720)/60p, 750(720)/50p, 1 125(1080)/60p,

1 125(1 080)/50p, 1 125(1 080)/60i, 1 125(1 080)/50i

•Displayable resolution: VGA to WUXGA (non-interlace)

•Dot clock frequency: up to 162 MHz

7 (NTSC, NTSC4.43, PAL, PAL-N, PAL-M, SECAM, PAL60)

1.01 m-10.1 m(40"-400")

4 : 3 16 : 10

Front / Rear / Mount on Ceiling / Floor (Menu setting system)

1(3.7 cm round-type)

10W

5 000 : 1 (all white / all black)

-6-

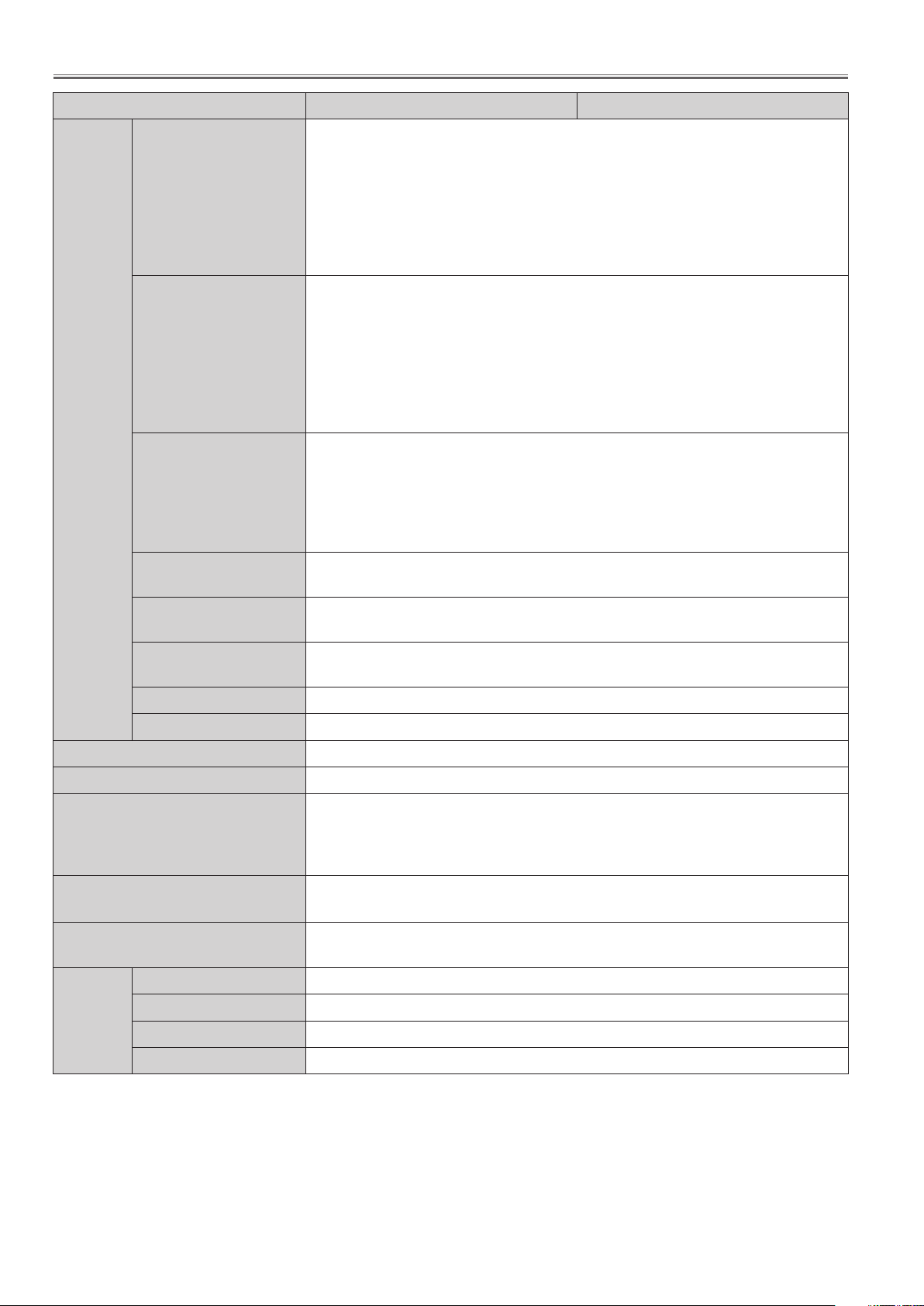

Specifications

Model No. PT-EX600U / E / UL / EL PT-EW630U / E / UL / EL

INPUT 1

<DVI_D>

<HDMI>

<RGB>

INPUT 2

<VIDEO>

<YPBPR>

<RGB,SYNC/HD,VD>

Terminals

INPUT 3

<VIDEO>

<YPBPR/YCBCR>

<S-VIDEO>

* Choose one item in the menu

DVI-D 24-pin (Single link), DVI 1.0 compatible, HDCP compatible)

HDMI 19-pin (HDCP and Deep color compatible)

D-sub HD 15-pin (female)

[RGBsignal] 0.7V[p-p]75Ω(WhenG-SYNCisset1.0[p-p]75Ω

HD/

SYNC TTL high impedance, automatic positive/negative polarity

compatible

VD TTL high impedance, automatic positive/

negative polarity compatible

* Choose one item in the menu

BNCx1[VIDEOsignal](1.0V[p-p]75Ω)

BNCx3[YPBPR signal] Y:1.0 V [p-p] including synchronization

signal,PBPR:0.7V[p-p]75Ω

BNCx5[RGBsignal]0.7V[p-p]75Ω(WhenG-SYNCisset1.0[p-p]75Ω

HD/SYNC TTL high impedance, automatic positive/negative polarity compatible

VD TTL high impedance, auto-

matic positive/ negative polarity compatible

* Choose one item in the menu

RCA x 1 [VIDEO signal] (1.0 V [p-p] 75 Ω)

RCA x 3 [YPBPR signal] Y:1.0 V [p-p] including synchronization

signal ,PBPR:0.7V[p-p]75ΩMiniDIN4pin

[S-VIDEOsignal]Y1.0V[p-p],C0.286V[p-p]75Ω,S1

signal compatible

<MONITOR OUT>

<AUDIO IN>

<VARIABLE AUDIO

OUT>

<SERIAL IN>

<LAN>

Power cable length

Cabinet

Dimensions

Weight

Operating environment

Power supply

Remote

control

Operating range

Weight

1 (D-sub HD 15 pin (female)

[RGBsignal] 0.7V[p-p]75Ω(WhenG-SYNCisset1.0[p-p]75Ω

2(M3stereominijack,0.5V[rms],inputimpedance22KΩandmore)

1(RCApinjackx2(L-R),0.5V[rms],inputimpedance22KΩandmore)

1 (M3 stereo mini jack, stereo monitor output compatible,

0V[rms]to2.0V[rms]valuable,outputimpedance2.2kΩandless)

1 (D-sub 9 pin, RS-232C compliant, for computer control use

1 (for RJ-45 network connection, PJLink compatible)

3.0 m(118.1")

Molded plastic

Width: 489.5 mm (19.27")

Height: 164 mm (6.46") (when front adjustable foot shortened)

Depth: 370.1 mm (14.57")*4 (including protractions)

433.8 mm (17.08")*5 (including protractions)

Approx. 9.6 kg(21.12 lbs.) *

Approx. 10.3 kg(22.71 lbs.) *

Operatingenvironmenttemperature:0°C(32°F)to40°C(104°F)*

6

7

8

Operating environment humidity: 20 % to 80 % (no condensation)

DC 3 V (battery (AAA/R03 or AAA/LR03 Type ) x 2)

Approx. 5 m (196.9") (when operated directly in front of receptor)

102 g (3.6 ozs.) (including batteries)

Dimensions

*4: The depth is for the projector that without the projection lens.

*5: The depth is for the projector that with the standard projection lens.

*6: This is an average value. It may differ depending on individual product. It is only for PT-EX600UL, PT-EX600EL,

PT_EW630UL and PT-EW630EL.

*7: This is an average value. It may differ depending on individual product. It is only for PT-EX600U,PT-EX600E, PT-EW630U

and PT-EW630E.

*8:Whenusingtheprojectorathighelevation1000mto2700msealevel,theoperatingenvironmenttemperaturewillbe0°C

to30°C.

•Thepartnumbersofaccessoriesandseparatelysoldcomponentsaresubjecttochangewithoutnotice.

Width : 48 mm (1.89"), Length : 145 mm (5.71"), Height : 27 mm (1.06")

-7-

Circuit Protections

This projector provides the following circuit protections to operate in safety. If the abnormality occurs inside the projector, it will automatically turn off by operating one of the following protection circuits.

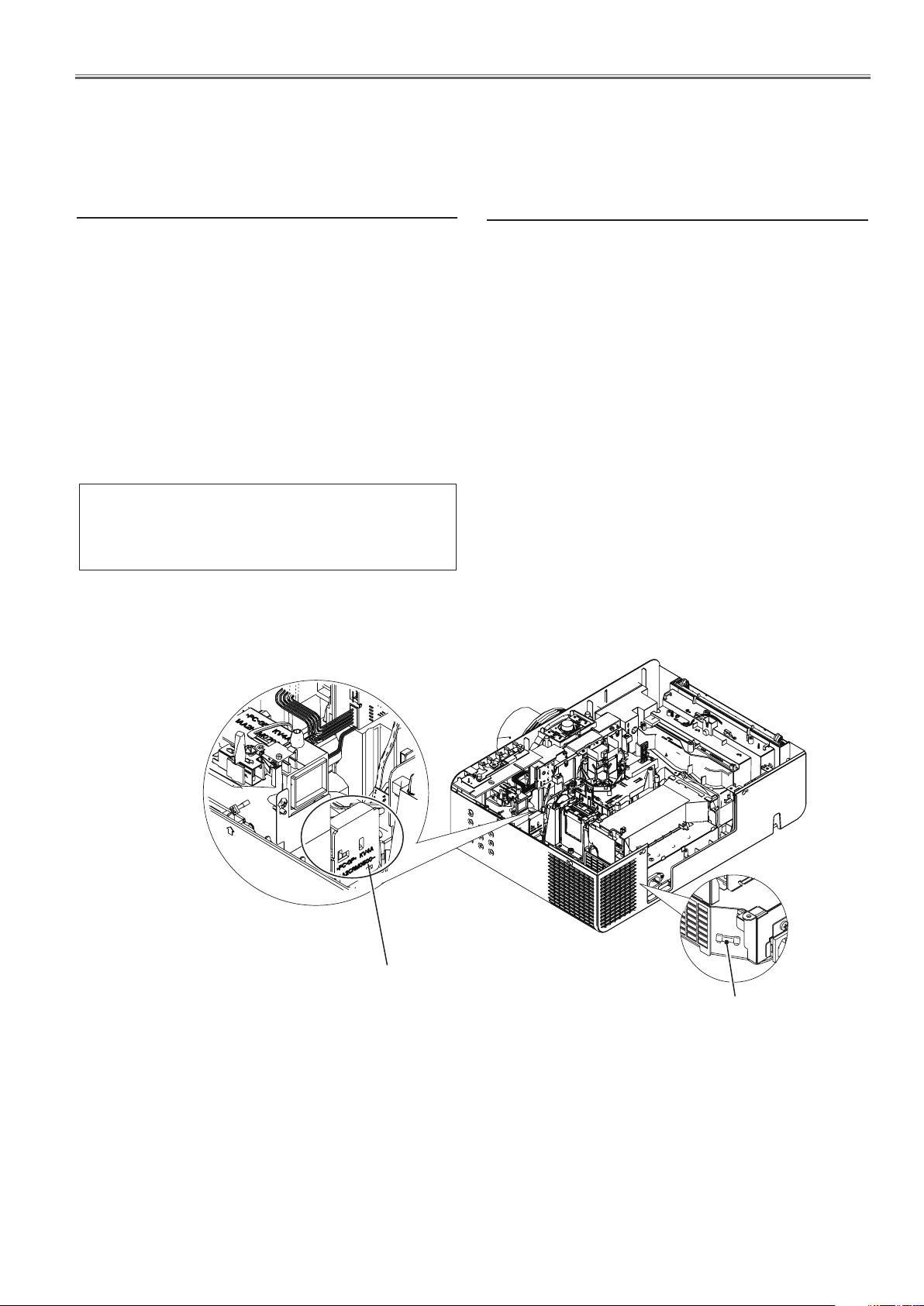

Fuse(F601)

A fuse is located inside of the projector. When the ON(G)/

STANDBY(R) indicator is not lighting, the fuse may be

opened. Check the fuse as following steps.

The fuse should be used with the type listed right;

How to replace the fuse

1. The fuse is placed on the power board under the main

board. Remove the cabinet top, main&AV board and

exhaust fan assy.

2. Take the fuse off, and replace the old one with the

specified type.

Fuse Part No: 423 035 4704

TYPE T10AH 250V FUSE

LITTEL FUSE INC. TYPE 0215010.MXEP

Thermal fuse(SW902)

There is the thermal fuse (SW902) inside of the projector to detect the internal temperature rising abnormally.

Whentheinternaltemperaturereachesnear113˚C,the

thermal fuse opens to cut off the power to the power

circuit.

If the thermal fuse opens, the projector cannot turn on.

Thermal fuse replacement is required.

Thermal fuse

(SW902)

Fuse

(F601)

-8-

Circuit Protections

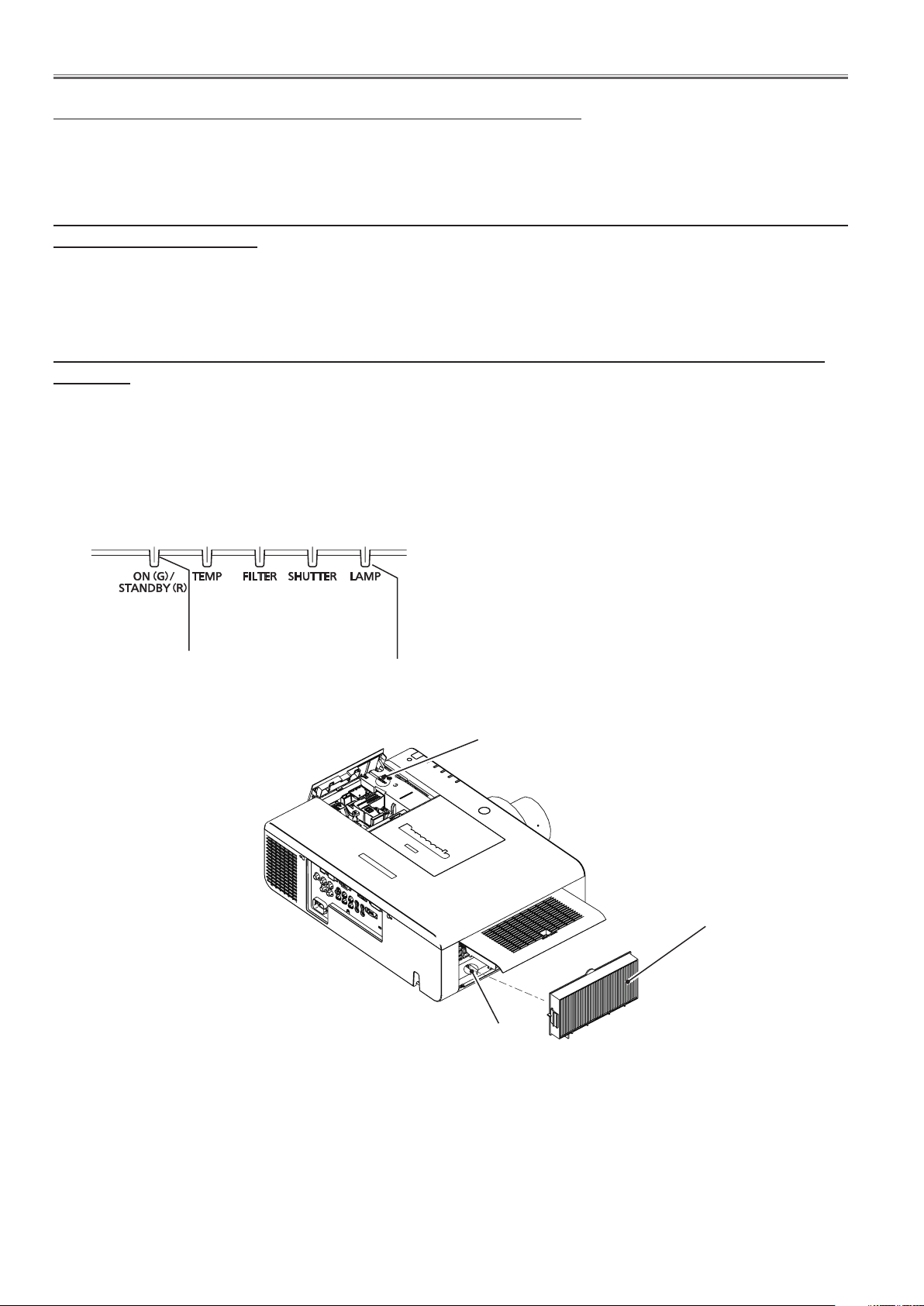

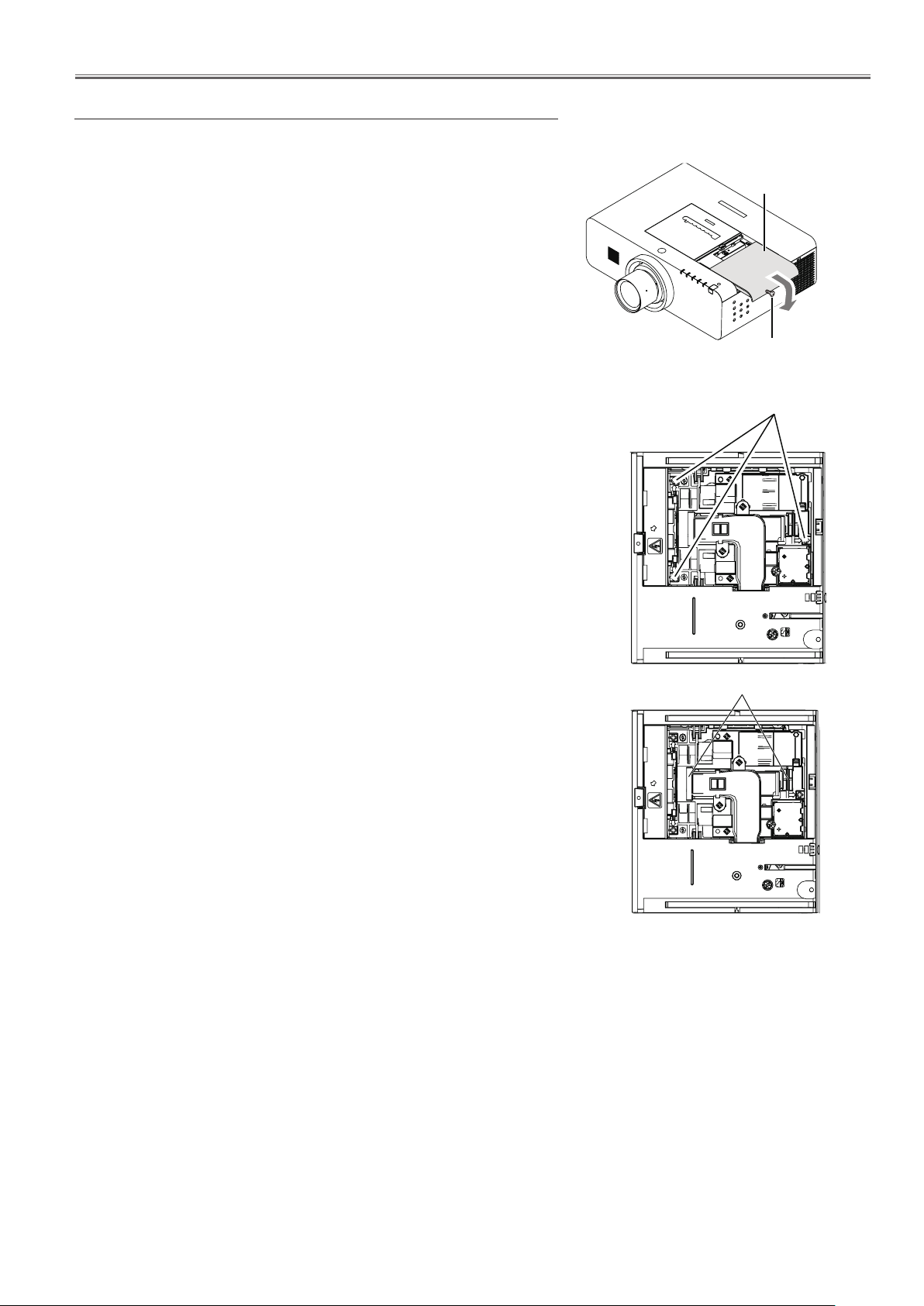

Mechanical sensor switches

This projector provides 2 mechanical sensor switches, the one is for air filter unit switch (SW1891) and the other one

is for lamp cover switch(SW901).

The projector is shut down and the < ON(G)/STANDBY(R)> indicator lights in red and other

indicators are blinking.

The air filter unit switch (SW1891) detects whether the air filter unit is installed correctly. If the air filter unit switch is

not installed correctly, the projector cannot turn on. In this case, the <ON(G)/STANDBY(R)> indicator lights in red and

other indicators are blinking.

- Check that the lamp cover is installed securely.

The projector is shut down and the < ON(G)/STANDBY(R)> and <LAMP> indicators are

blinking.

The lamp cover switch (SW901) detects whether the lamp cover is closed securely. If lamp cover is opened or not

closed completely, the drive signal to the lamp circuit is cut off. After opening the lamp cover for replacing the new

lamp assy, place the lamp cover correctly otherwise the projector cannot turn on.

- Check that the air filter unit is installed securely.

LED indicators

ON(G)/STANDBY(R)

indicator

LAMP indicator

Lamp cover switch(SW901)

Air filter unit

Air filter unit switch

(SW1891)

-9-

Circuit Protections

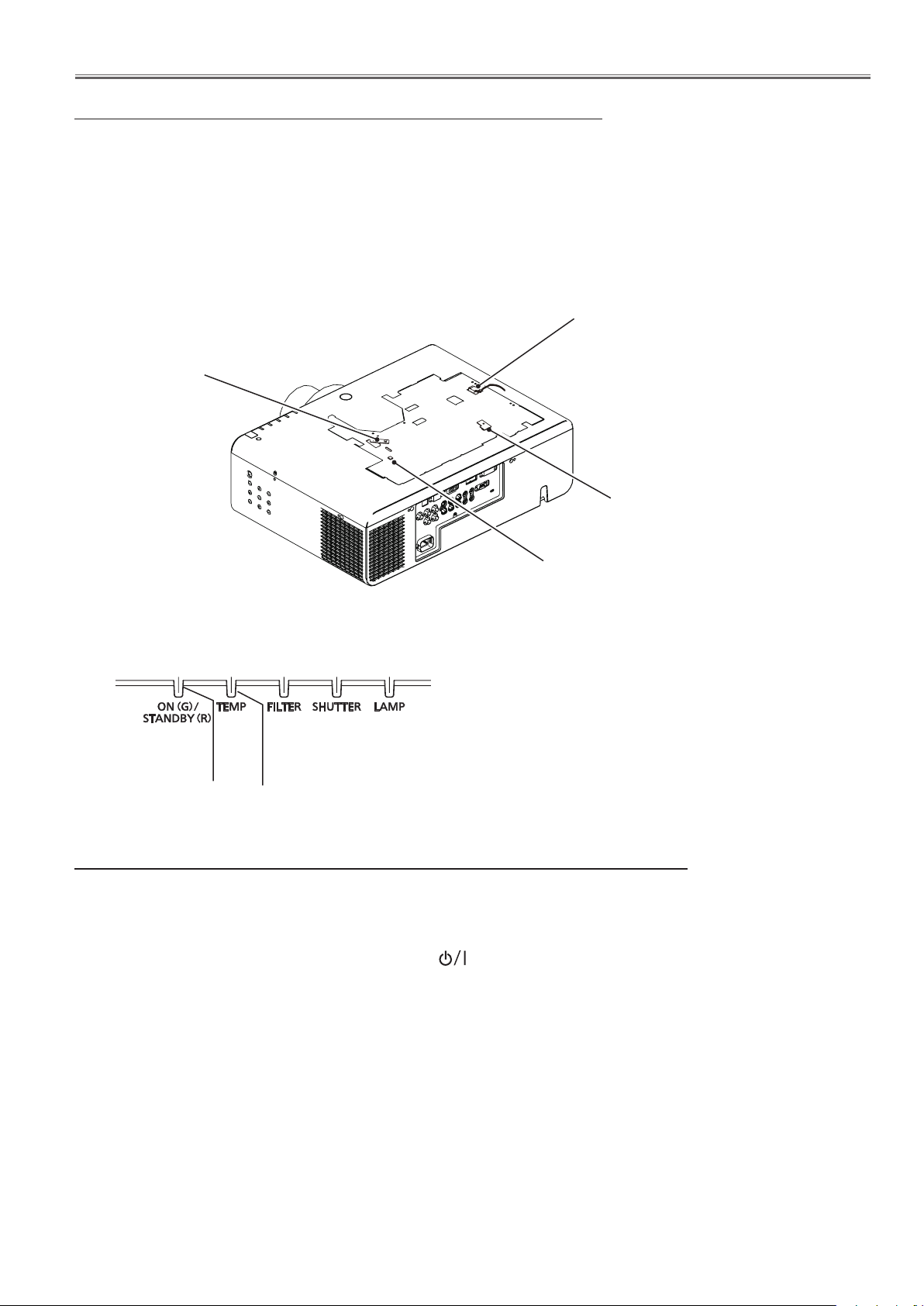

Temperature sensors, wind sensors

The projector provides 3 temperature sensor ICs and 1 wind sensor on the intake duct. These devices are monitoring

the surrounding temperature of the lamp, panel and intake duct, and the wind sensor is monitoring airflow passed

through the air filter in the intake duct.

- Internal temperature sensor A (IC1692) (around the Intake duct)

- Internal temperature sensor B (IC1816) (around the lamp house)

- Internal temperature sensor C (IC1814) (around the panel/prism)

- Wind sensor D (S901) (intake duct)

S901

Wind sensor

IC1814 on the

Sensor C board

IC1692 on the

Sensor A board

IC1816 on the main

board (behind)

Top view of the LED indicators

LED indicators

ON(G)/STANDBY(R)

TEMP. indicator

indicator

The projector is shut down and the < TEMP> indicator is blinking red.

When the temperature inside the projector reaches a certain level, the <TEMP> indicator starts blinking slowly. If the

temperature rises moreover, the projector will be automatically shut down to protect the inside of the projector, and

the <TEMP.> indicator is blinking fast and the <ON(G)/STANDBY(R)> indicator lights in orange. When the projector

has cooled down enough (to its normal operating temperature), the <ON(G)/STANDBY(R)> indicator lights in red and

the projector can be turned on again by pressing the button.

✔Note:

•The<TEMP>indicatorcontinuestoblinkevenafterthetemperatureinsidetheprojectorreturnstonormal.When

the projector is turned on again, the <TEMP> indicator stops blinking.

Check the items below

- Remove dust around the air filter.

- Ventilation slots of the projector are blocked. In such an event, reposition the projector so that ventilation slots are

not obstructed.

- Check if projector is used at higher temperature place (Normal; operating temperature is 0 to 40 ºC or 32 to 104

ºF).

-10-

Circuit Protections

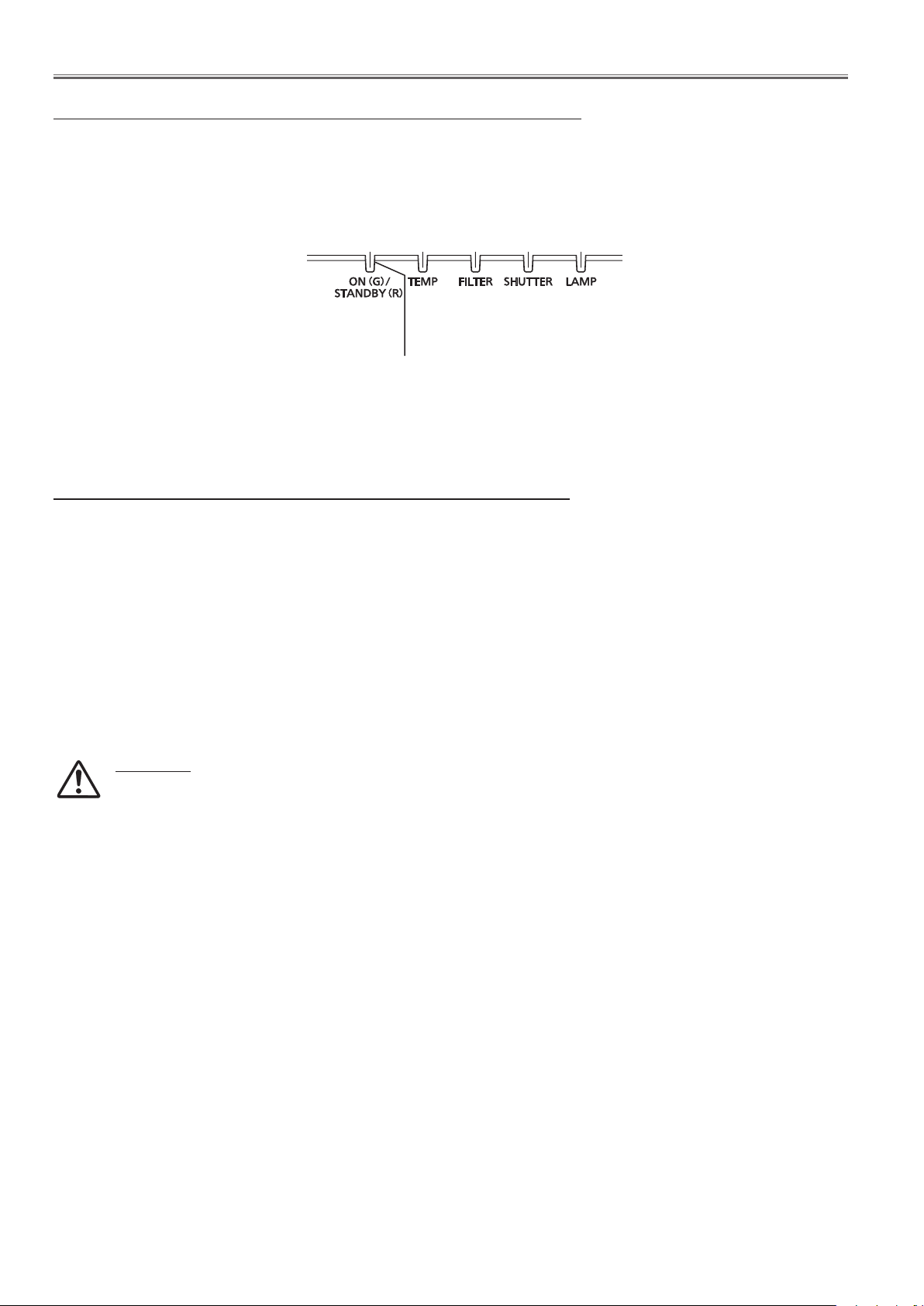

Power failure and fan lock detection

The projector provides the detection circuits of the power failure and the fan lock. When the detection circuit detects

an error at the power supply line or at the fan operation circuit, the projector will turn into the standby mode to protect

the other circuits defective.

Top view of the LED indicators

LED indicators

ON(G)/STANDBY(R)

indicator

The projector is shut down and all indicators are blinking.

When the projector detects an abnormal condition (Power supply lines failure , fans failure), it will be automatically

shut down to protect the inside of the projector and all of indicators blink. In this case, unplug the AC power cord and

plug it, and then turn on the projector once again to verify operation. If the projector cannot be turned on and these

indicators are still blinking, the projector may has an internal error. Unplug the AC power cord. See the troubleshooting chapter.

WARNING

DO NOT LEAVE THE PROJECTOR WITH THE AC POWER CORD CONNECTED UNDER AN

ABNORMAL CONDITION. IT MAY RESULT IN FIRE OR ELECTRIC SHOCK.

-11-

Maintenance

Before replacing the unit

When you perform maintenance or replacement of the parts, make sure to turn off the power and disconnect the

power plug from the wall outlet.

Maintenance

n Outer case

Wipe off dirt and dust using a soft dry cloth.

ò If the dirt is persistent, soak the cloth with water and wring it thoroughly before wiping. Dry off the projector with

a dry cloth.

ò Do not use benzene, thinner, or rubbing alcohol, other solvents, household cleaners. Using them may cause

deterioration of the outer case.

ò When using chemical treated dusters, follow its instruction.

n Front glass surface of the lens

Wipe off the dirt and dust off the front surface of the lens with soft clean cloth.

ò Do not use a cloth that has an abrasive surface or a cloth that is moist, oily, or covered with dust.

ò Do not use excessive force when wiping the lens as it is fragile.

Attention

The lens is made of glass. Impacts or excessive force when wiping may scratch its surface.

Please handle with care.

n Air filter unit

Clean the air filter unit in the following cases.

ò

When the replacement message is displayed and the filter

indicator <FILTER> lights up due to a blockage.

ò

The temperature inside the projector becomes high and

the temperature indicator <TEMP> lights, causing the

projector turn off, due to a blockage. (When the power

if turned off, temperature indicator <TEMP> flashes and

standby indicator <ON(G)/STABDBY(R)> lights in red.)

1) Turn off the projector, and unplug the AC power cord

from the AC outlet.

2) Clean up the dust on the projector and around the air

vents.

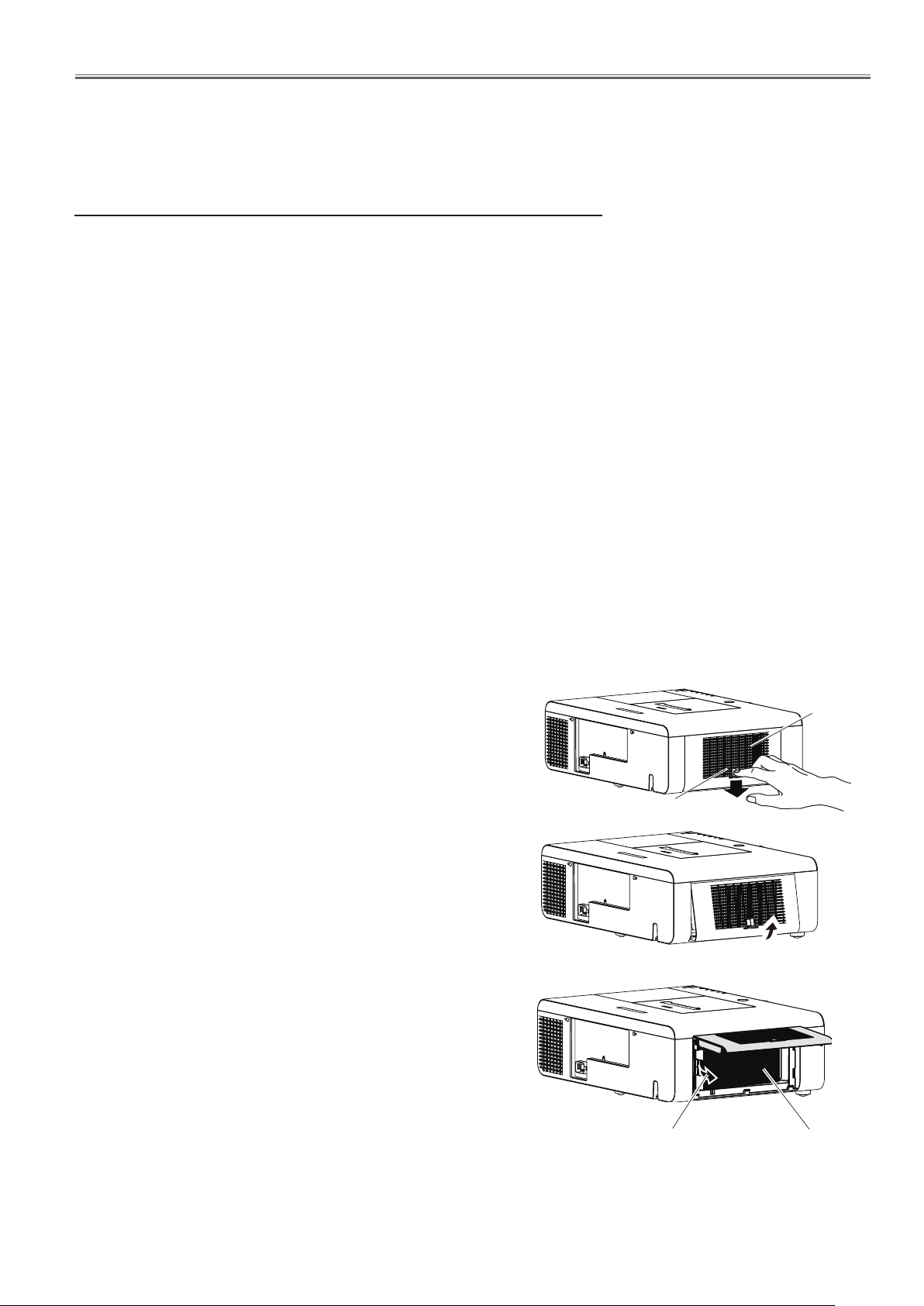

3) Press t downwards on the filter cover to release the

latch and open the filter cover.

4) Pull out the air filter unit.

ò Pick the tab and frame of the air filter unit, release the

lock with pressing the tab rightwards in the figure,

and then pull.

Filter cover

Latch

Ta b

Air filter unit

-12-

Maintenance

5) Clean the air filter unit.

ò Removing the dust from the air filter unit

(i) Remove the dust from the air filter unit using a vacuum or other cleaner.

•Ifthedustpersistsaftercleaningwithavacuum,washtheairfilterunitinwater.

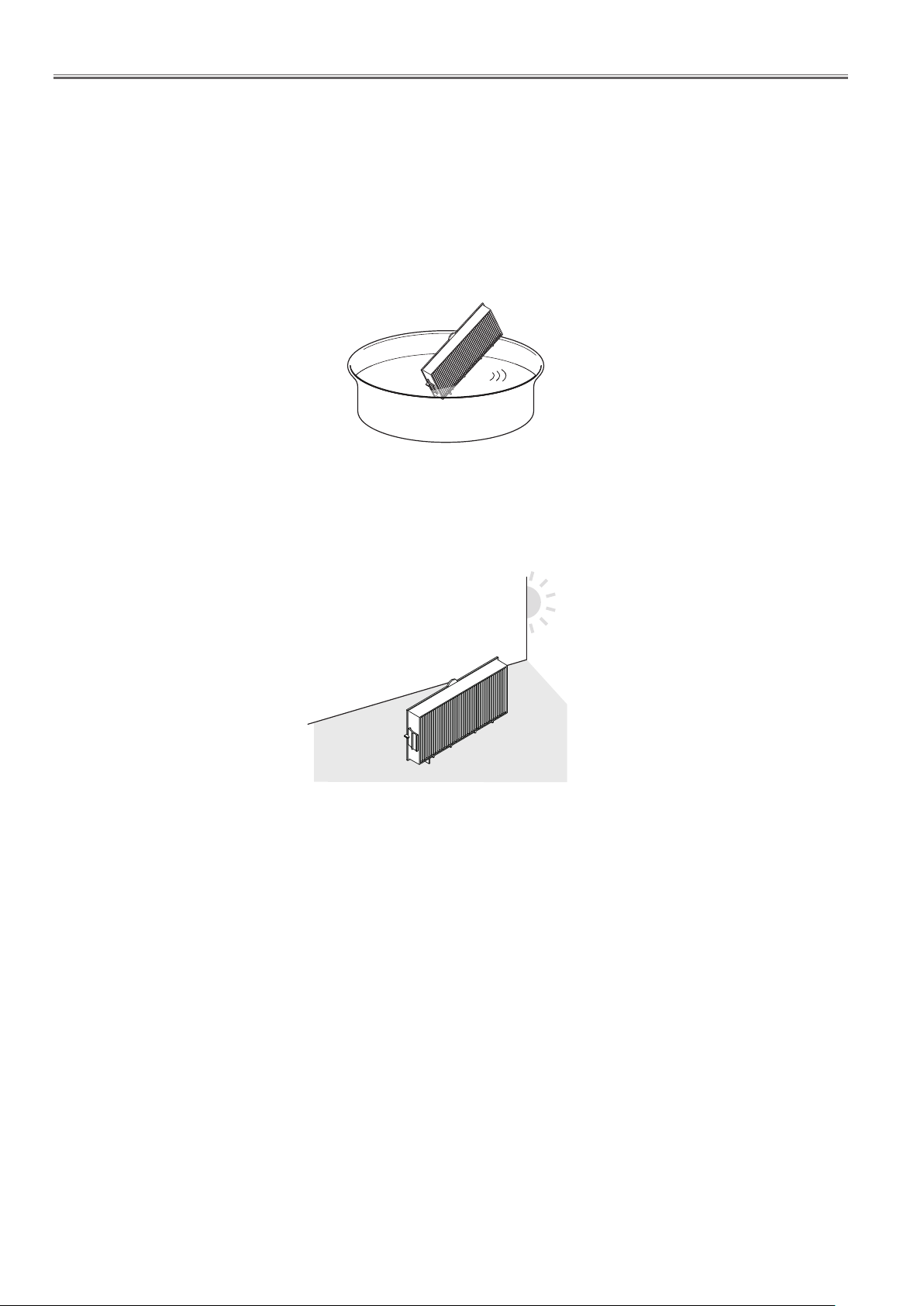

ò Washing the air filter unit

(i) Soak the air filter unit in water or warm water and rinse it lightly.

•Donotusematerialssuchasblushesordetergent.

•Whenyourinsetheairfilterunit,holdtheframeandavoidexcessiveforceonthefilterpart.

(ii) Change the water two or three times while you rinse the air filter unit.

•Rinseituntilthecloudofthewaterclears.Iftheairfilterunitisnotrinsedsufficiently,odormayresult.

ò Drying the air filter unit

Naturally dry the air filter unit in a well-ventilated place, avoiding dust and direct sunlight.

•Donotuseahairdrierorotherdrier.

6) Attach the air filter unit.

ò Hold the air filter unit that the tab is in left side in the figure. put the right side in the figure first, and press the

tab side until make a click sound.

7) Close and press up to lock the filter cover.

ò Make sure that the air filter cover is closed tightly.

8) Reset the filter counter.

ò Turn on the power and perform [Filter counter reset] in the [Setting] menu.

Attention

ò After washing the air filter unit, dry it thoroughly before attaching to the projector. Attaching wet air filter may

cause electric shock or malfunction.

Note

ò Be sure to attach the air filter unit properly. If you use the projector without attaching the air filter unit, the projec-

tor may be damaged due to the dirt or dust.

ò If the air filter unit has been damaged or dirt remains even after washing it, replace it with a a new filter.

ò It is recommended that the air filter unit is replaced after two times of cleaning and reusing.

ò After washing, the capability of the air filter unit may decrease.

ò After washing the air filter unit, reset the filter counter. Otherwise, the power of the projector may be turned off

for safety.

-13-

Maintenance

Replacing the unit

n Air filter unit

The replacement filter is optional. To purchase the product, consult your dealer.

Replacement air filter unit : ET-RFE200

Reset the filter counter.

•Turnonthepowerandperform[Filtercounterreset]inthe[Setting]menu.

Attention

•Turnoffthepowerbeforeyoureplacetheairfilterunit.

•Whenattachingtheairfilterunit,makesurethattheprojectorisstable,andworkinanenvironmentthatissafe,even

in the event of the air filter unit dropping.

•Donotoperatetheprojectorwiththeairfilterunitremoved.Dustmayaccumulateontheopticalelementsdegrading

picture quality.

•Afterreplacingtheairfilterunit,resetthefiltercounter.Otherwise,thepoweroftheprojectormaybeturnedofffor

safety.

-14-

Maintenance

n Lamp unit

The lamp unit is a consumable component. You can check the total usage time using lamp runtime in the information

menu.

It is recommended to ask an authorized engineer to replace the lamp unit. Contact your dealer.

Consult your dealer to purchase a replacement lamp unit.

CAUTION:

n Do not replace the lamp unit when it is hot. (Wait at least 1 hour after use.)

The inside of the cover can become very hot, take care to avoid burn injuries.

Replacement lamp unit : ET-LAE200

n Notes on the replacement of the lamp unit

•Theluminoussourceofthelampismadeofglassandmayburstifyou

hit it against a hard surface or drop it. Please handle with care.

•Aphillipsscrewdriverisrequiredforreplacementofthelampunit.

•Whenreplacingthelampunit,besuretoholditbythehandle.

•Whenreplacingthelampbecauseithasstoppedilluminating.Thereisa

possibility that the lamp may be broken. If replacing the lamp of a projector which has been installed on the ceiling. you should always assume

that the lamp is broken. And you should stand to the side of the lamp

cover, not underneath it. Remove the lamp cover gently .Small pieces of

glass may fall out when the lamp cover is opened. If pieces of glass get

into your eyes or mouth. Seek medical advice immediately.

•Thelampcontainsmercury.Consultyourlocalmunicipalityoryourdeal-

er about correct disposal of used lamp units.

Attention

•Donotuseotherthandesignatedlampunits.

•Thepart numbersofaccessoriesandseparatelysoldcomponentsaresubject

to change without notice

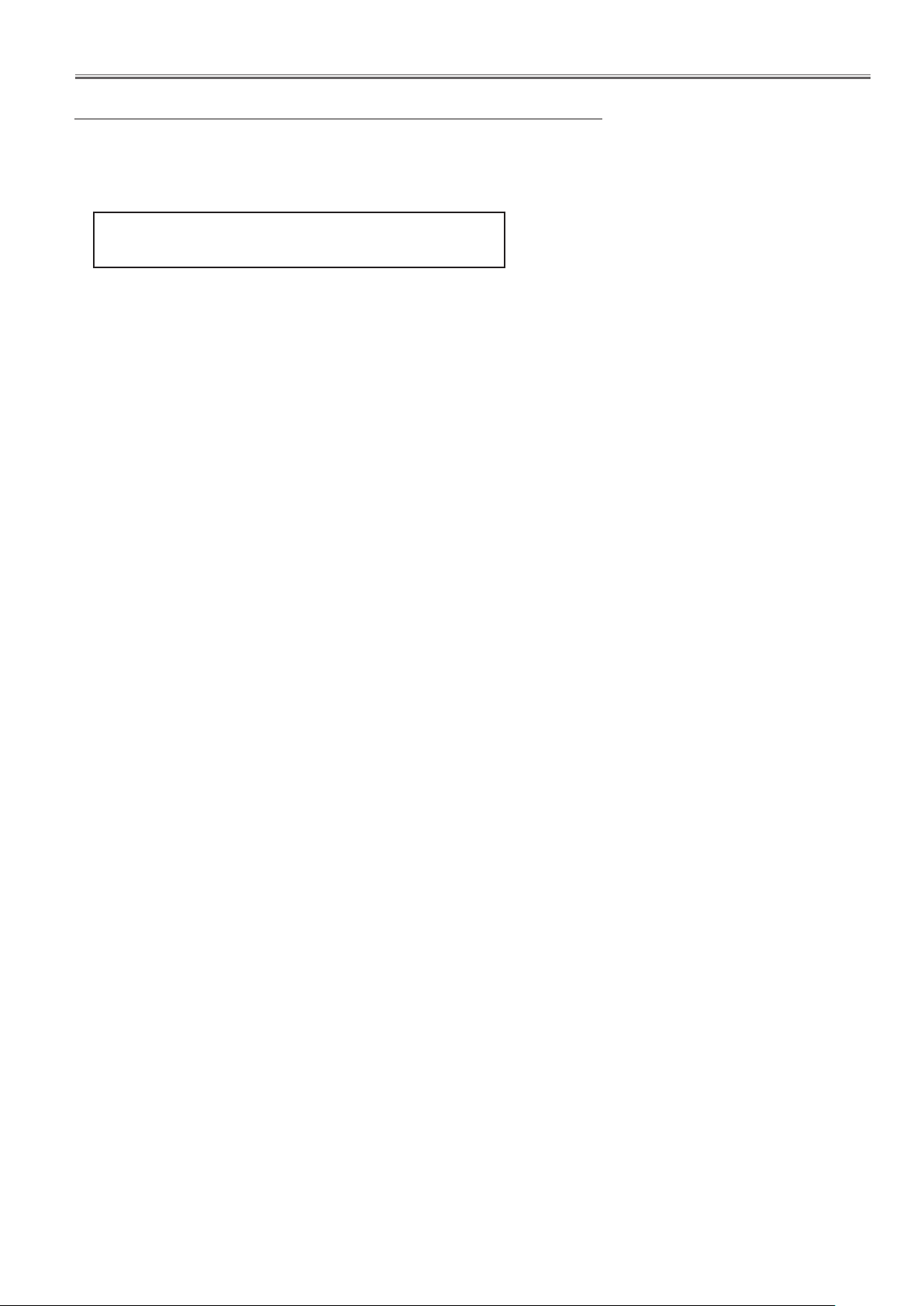

n When to replace the lamp unit

The lamp unit is a consumable component. Brightness decreases according to duration of usage, so periodical

replacement of the lamp unit is necessary. When the projection lamp of the projector reaches its end of life, the

lamp replacement icon appears on the screen and <LAMP> indicator lights yellow. Replace the lamp with a new

one promptly.

Lamp runtime

The message is displayed for 10 seconds. If

Over 3000 hours*

Over 3200 hours*

* 3200 hours of use is a rough guideline, but is not a guarantee. The lamp runtime differs depending on the setting of

"Lamp power" menu.

Note

•Thelampreplacementiconwillnotappearwhenthe[display]functionissetto[Off],orduring"Freeze".

you press any button within the 10 seconds,

the message disappears.

If the power is turned on without replacing

the lamp, the power automatically turns off

after approximately ten minutes to prevent the

malfunction of the projector.

On screen

Lamp replacement icon

Lights in yellow (even in stand-by

mode).

LAMP indicator

-15-

Maintenance

Replacing the lamp unit

CAUTION:

•When the projector is mounted on aceiling, do not

work with your face close to the projector.

•Attachthelampunitandthelampcoversecurely.

•Whenyouexperiencedifficultyininstallingthelamp,

remove it and try again. If you use force to install the

lamp, the connector may be damaged.

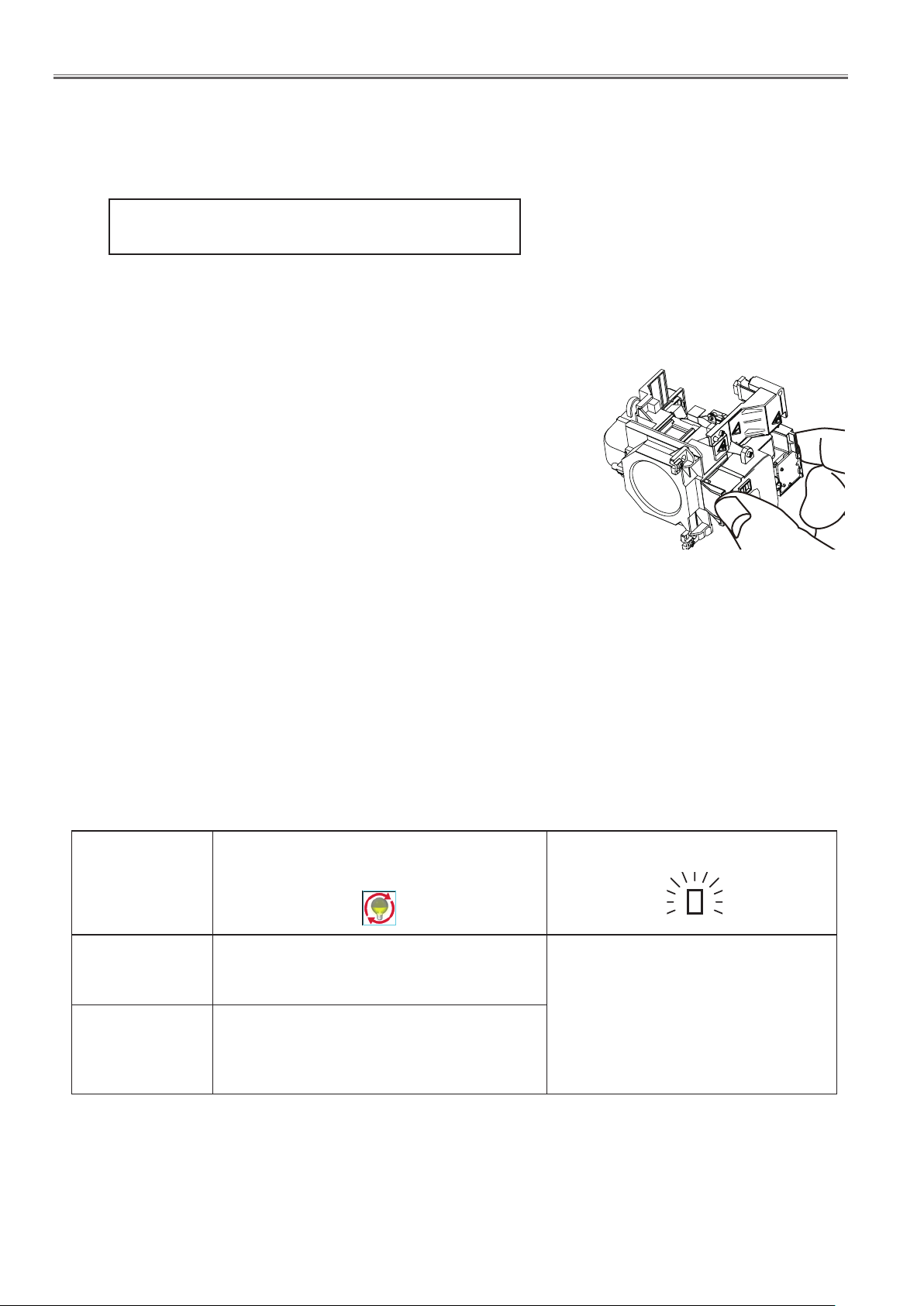

1) Turn off the projector. Unplug the AC power cord.

Wait at least 1 hour and make sure the lamp unit

and surroundings are cool.

2) Use a phillips screwdriver to loosen the lamp

cover fixing screw and remove the lamp cover.

•Removethe lampcoverbypullingitslowly toward

the direction of the arrow.

3) Use a phillips screwdriver to loosen the three

lamp unit fixing screws until the screws turn freely. hold the used lamp unit by its handles, and

pull it gently from the projector.

Lamp cover

Lamp cover

xingscrew

Lampunitxingscrews

4) Insert the new lamp unit in correct direction.

Tighten the three lamp unit fixing screws securely with a phillips screwdriver.

5) Attach the lamp cover, and tighten the lamp cover

fixing screw securely with a phillips screwdriver.

•Attach the lamp cover by pushing it slowly opposite

the direction of the arrow.

Attention

•When you replace the new lamp unit, the projector

resets the total usage time of the lamp unit automatically.

Handles

-16-

Maintenance

Counter

Projector 500H

Lamp

Normal 200H

Eco 300H

Corresponding value 425H

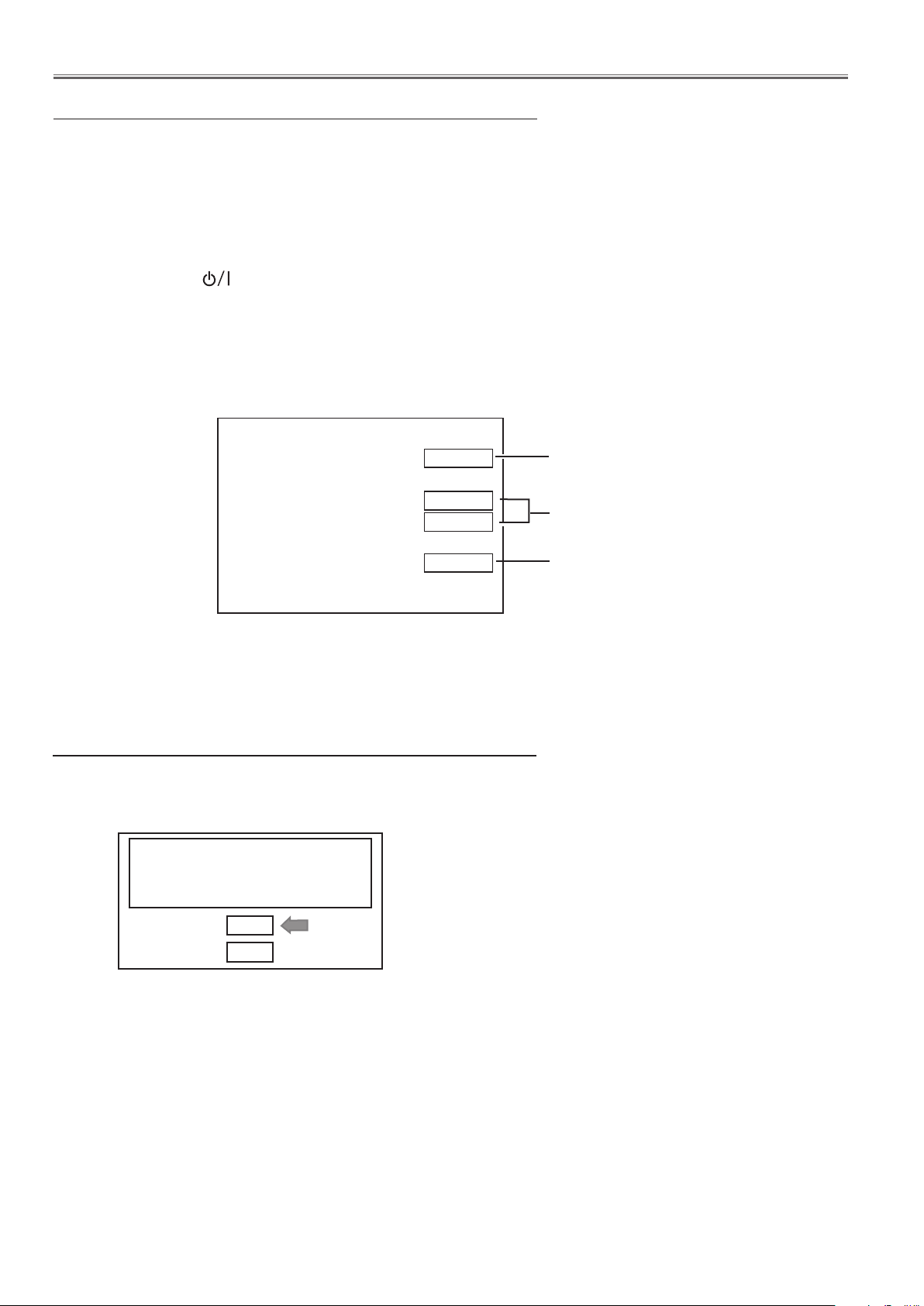

How to check lamp runtime

The LAMP indicator will light yellow when the lamp runtime (Corresponding value) reaches 3,000 hours. This is to

indicate that lamp replacement is required. The lamp runtime is calculated by using the below expression.

Lamp runtime (Corresponding value) = Tnormal + Teco x 0.75

Tnormal : used time in the Normal and Auto mode

Teco : used time in the Eco1 and Eco2 mode

You can check the lamp runtime following to the below procedure.

1 Press and hold the button on the projector or the POWER ON button on the remote control for more than 20

seconds.

2 The projector used time and lamp runtime will be displayed on the screen briefly as follows.

Projector used time

Cumulative lamp

operating time in

each mode.

lamp runtime

Warning message on the non-standard lamp used

If the non-standard lamp is used, the warning and confirmation messages will appear on the screen every startup.

Some of the functions are limited when the non-standard lamp is used in spite of the warning.

Since the lamp is not standard, projec-

tor failed to read lamp data.

Continue to use this lamp?

Yes

No

-17-

Maintenance

E

E

D

D

D

E

E

E

E

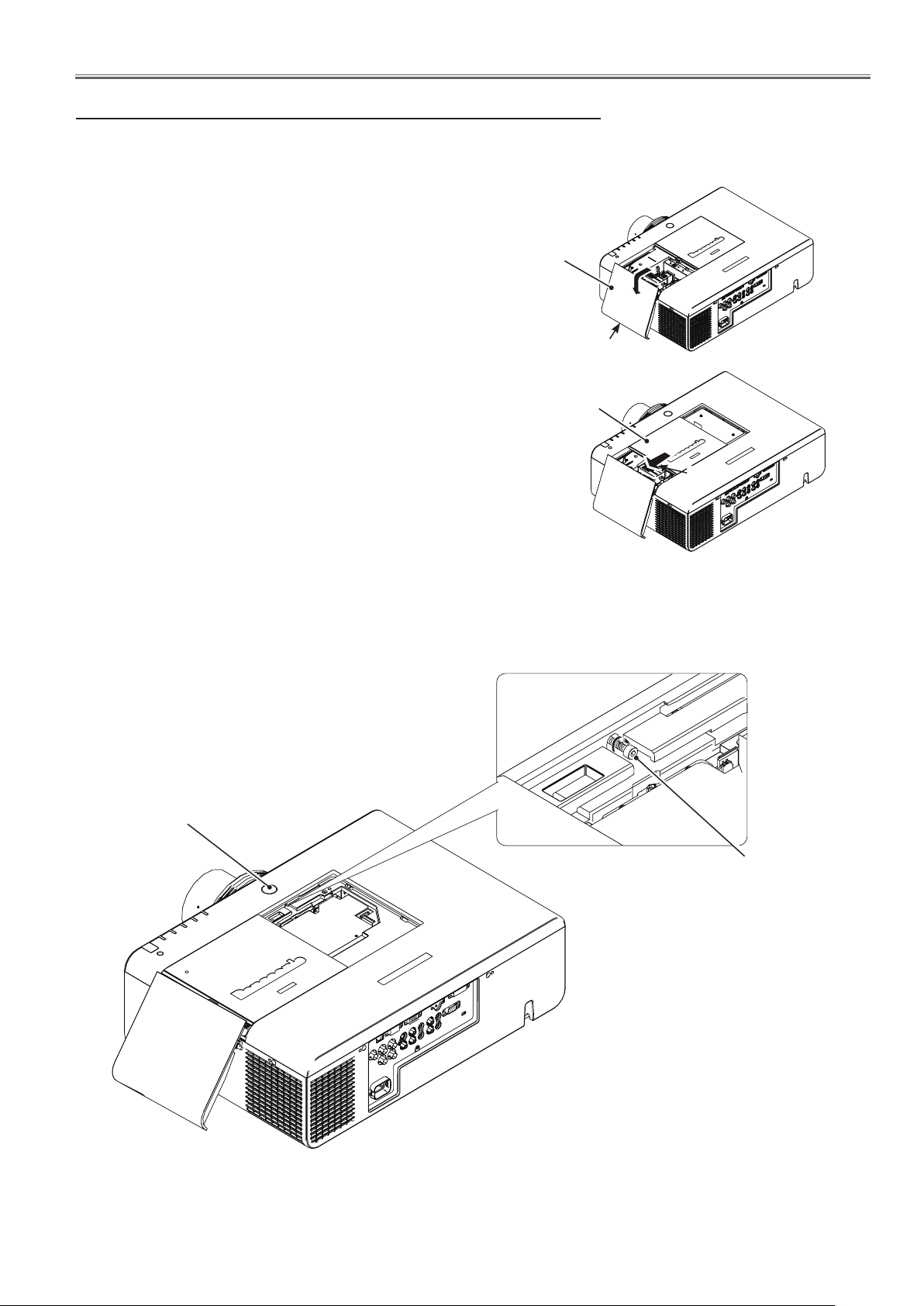

Quick maintenance

This projector provides a cabinet prism cover on the cabinet top to enhance the service maintenance. This enables

service personnel to align the optical adjustment or replace the optical parts without disassembly the cabinet top.

Loosen 1 screw-A on the lamp cover and slide it to

1

open (Fig. 1).

Lamp cover

Loosen 1 screw-B on the prism cover and slide it in the

2

arrow direction (Fig. 2).

Remove 2 screws-C(M3x6) and 1 screw-G(M3x10) to

3

take the prism cover shield (Fig.3) then Loosen 1 hex

screw-F and take the shutter assy off (Fig. 4).

Loosen 3 screws-D and take the LCD panel/prism assy

4

upward off (Fig. 5/Fig. 7).

Remove 2 screws-E on each stopper of the polarized

5

glass assy and take the polarized glass assy upward off

(Fig. 5/Fig. 7).

See chapter "Optical Parts Disassembly" for further information of the optical parts disassembly.

Fig. 7

Prism cover

Prism cover

shield

Fig. 1

A

B

Fig. 2

G

C

C

F

Shutter assy

Fig. 3

Setting the lamp cover switch to "Service"

When aligning the optical parts with the lamp cover open,

the projector cannot be turned on because the lamp cover

switch is off. Insert the flat screw driver into the opening on

the switch and set the lamp cover switch to "service" position

as shown in the figure below.

Lamp cover switch

"Service" position

After finishing the alignment, make sure that the lamp cover

switch is reset to its original position, and close the prism

cover and lamp cover securely.

Panel/prism

assy

Polarized glass assy

Fig. 4

Fig. 5

Fig. 6

-18-

Maintenance

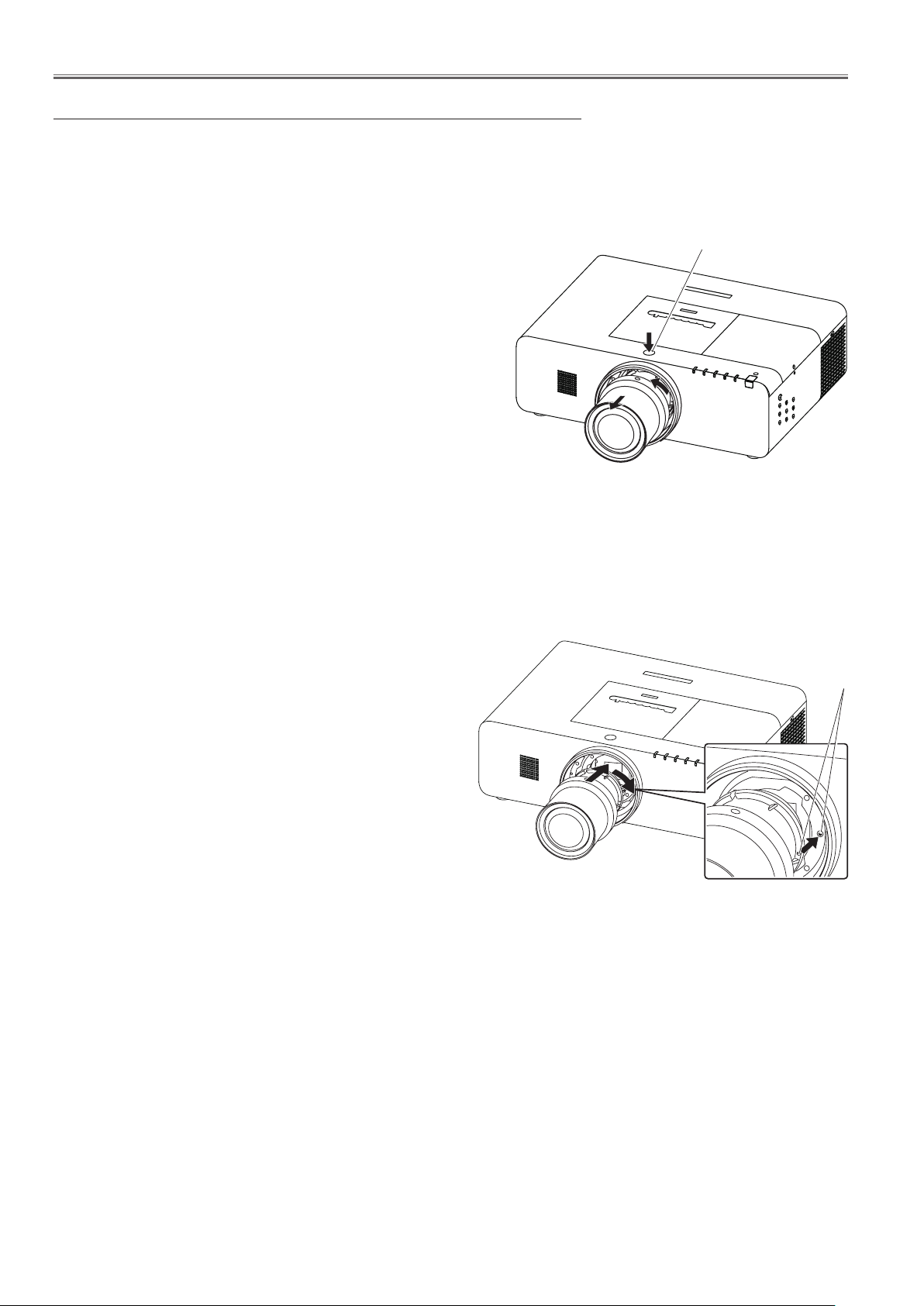

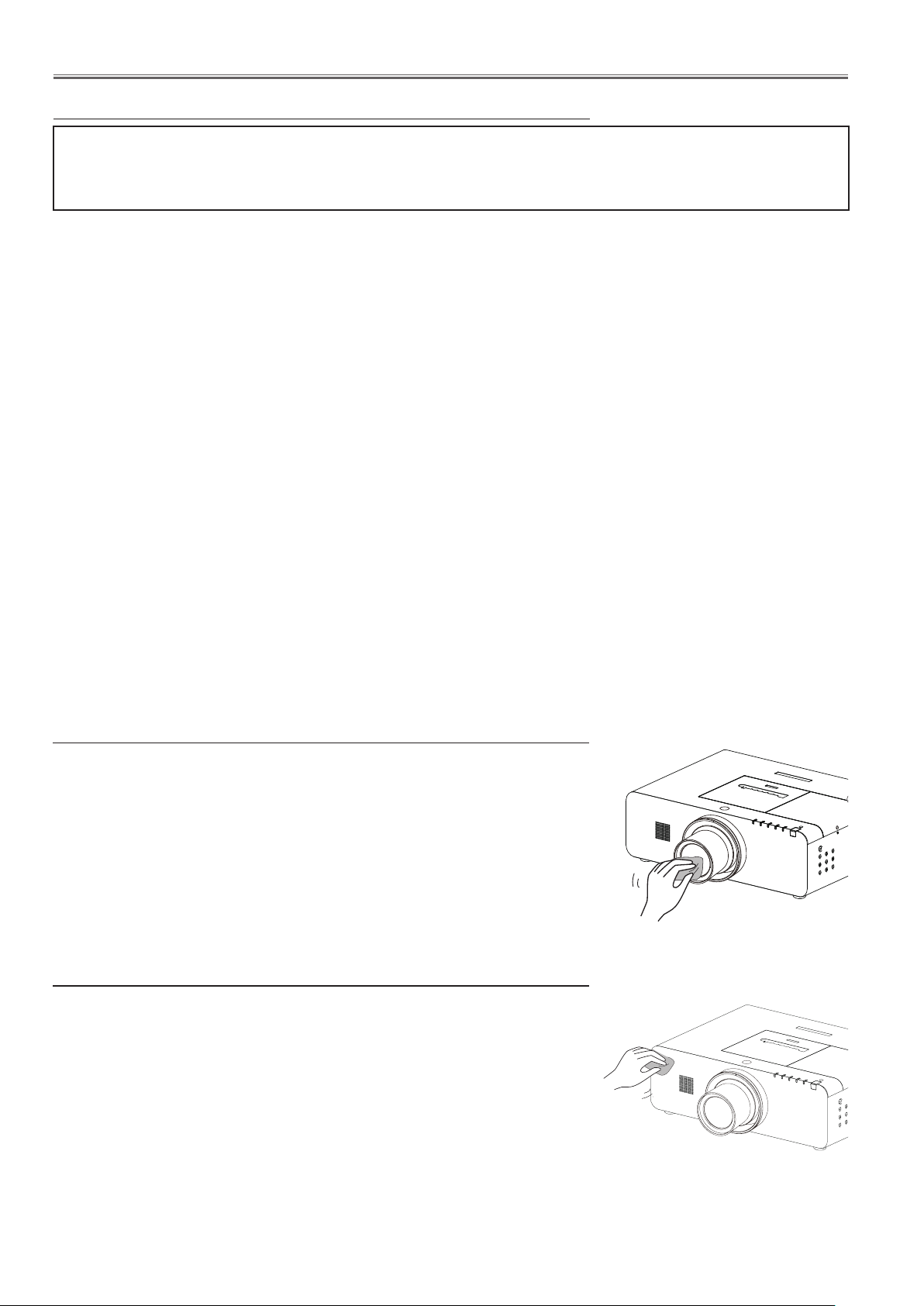

Removing and attaching the projection lens

When replacing the lens or using an optional lens, install the lens by following the instructions below. Ask the sales

dealerfordetailedinformationoftheoptionallensspecications.

Removing the lens

1. Press and hold the

button for more than 5 seconds to make the lens return

to the central position.

2. Turn off the projector and unplug the AC power cord.

3. While pressi ng th e len s rel ease button, ro tate the

pr ojection lens counterc lockwise , and remove the

projection lens.

Be careful when handling the lens. Do not drop.

ò

<LENS>

button or

<LENS SHIFT>

Lens release button

Attaching the lens to the projector

1. Remove the lens mount cove

2. Fit the lens to the projector by aligning the red dot on the

lens with the red dot of the projector.

3. Slowly turn the lens clockwise until it clicks. Make sure

that the lens is fully inserted to the projector.

Do not press the lens release button when attaching the lens.

ò

r.

Red dots

-19-

Maintenance

Using the lens antitheft screw

This projector provides a lens antitheft screw to protect the projection lens stolen from a suspicious person. Mount

the lens antitheft screw by following the instructions below.

Mounting the lens antitheft screw

Loosen a screw-A on the lamp cover and slide it to

1

open (Fig. 1).

Loosen a screw-B on the prism cover and slide it in

2

the arrow direction (Fig. 2).

Insert the lens antitheft screw onto the screw hole

3

on the cabinet top and turn it until the lens release

button is locked (Fig. 3).

Close the prism cover and tighten the screw-B, and

4

close the lamp cover and tighten the screw-A.

Check that the lens release button is locked to protect the projection lens removing.

Note: Be careful not to drop the lens antitheft screw into

the opening of the projector when mounting the

screw.

Lamp cover

Prism cover

A

B

Fig. 1

Fig. 2

Lens release button

Lens antitheft screw

Fig. 3

-20-

Maintenance

Cleaning

After long periods of use, dust and other particles will accumulate on the LCD panel, prism, mirror, polarized glass,

lens, etc., causing the picture to darken or color to blur. If this occurs, clean the inside of optical unit.

Remove dust and other particles using air spray. If dirt cannot be removed by air spray, disassemble and clean the

optical unit.

Cleaning with air spray

Remove the cabinet top following to “Mechanical Disassembly”. Clean up the LCD panel and polarizing plate by using

the air spray from the cabinet top opening.

Caution:

Use a commercial (inert gas) air spray designed for cleaning camera and computer equipment. Use a resin-based

nozzle only. Be very careful not to damage optical parts with the nozzle tip. Never use any kind of cleanser on the unit.

Also, never use abrasive materials on the unit as this may cause irreparable damage.

Disassembly cleaning

Disassembly cleaning method should only be performed when the unit is considerable dirty and cannot be sufficiently

cleaned by air spraying alone.

Be sure to readjust the optical system after performing disassembly cleaning.

1. Remove the cabinet top and main units following to “Mechanical Disassembly”.

2. Remove the optical base top following to “Optical Unit Disassembly”. If the LCD panel needs cleaning, remove

the LCD panel unit following to “LCD panel replacement”.

3. Clean the optical parts with a soft cloth. Clean extremely dirty areas using a cloth moistened with alcohol.

Caution:

The surface of the optical components consists of multiple dielectric layers with varying degrees of refraction. Never

use organic solvents (thinner, etc.) or any kind of cleanser on these components.

Since the LCD panel is equipped with an electronic circuit, never use any liquids (water, etc.) to clean the unit. Use of

liquid may cause the unit to malfunction.

Cleaning the projection lens

Unplug the AC power cord before cleaning.

Gently wipe the projection lens with a cleaning cloth that contains a small

amount of non-abrasive camera lens cleaner, or use a lens cleaning paper or

commercially available air blower to clean the lens.

Avoid using an excessive amount of cleaner. Abrasive cleaners, solvents, or

other harsh chemicals might scratch the surface of the lens.

Cleaning the projector cabinet

Unplug the AC power cord before cleaning.

Gently wipe the projector body with a soft dry cleaning cloth. When the cabinet

is heavily soiled, use a small amount of mild detergent and finish with a soft dry

cleaning cloth. Avoid using an excessive amount of cleaner. Abrasive cleaners,

solvents or other harsh chemicals might scratch the surface of the cabinet.

When the projector is not in use, put the projector in an appropriate carrying

case to protect it from dust and scratches.

-21-

Security Function Notice

This projector provides security functions such as "Key lock", "PIN code lock" and "Logo PIN code lock". When the

projector has set these security function on, you are required to enter correct PIN code to use the projector. If you

do not know the correct PIN code to the projector, the projector can no longer be operated or started. In this case,

you must reset those function first according to the resetting procedure described below and then check up on the

projector.

Function Description

Locks operation of the top control or the remote control.

Key lock

PIN code lock

Logo PIN code lock

If the Key lock is enabled with top control lock, the projector can no longer be started.

Initial setting: Key lock function is disabled

Prevents the projector from being operated by an unauthorized person.

Initial code: "1234"

Prevents an unauthorized person for changing the

start-up logo on the screen.

Initial code: "4321"

Resetting procedure

1. Disconnect the AC power cord from the AC outlet.

2. As pressing the ENTER button, connect the AC power cord into an AC outlet again.

3. Keep pressing the ENTER button and then press the button.

4. Release the button first and then release the ENTER button.

- The PIN code lock and Logo PIN code lock will be reset as the initial PIN code at the factory and

the key lock function is disabled.

Please refer to the owner's manual for further information of the security functions.

-22-

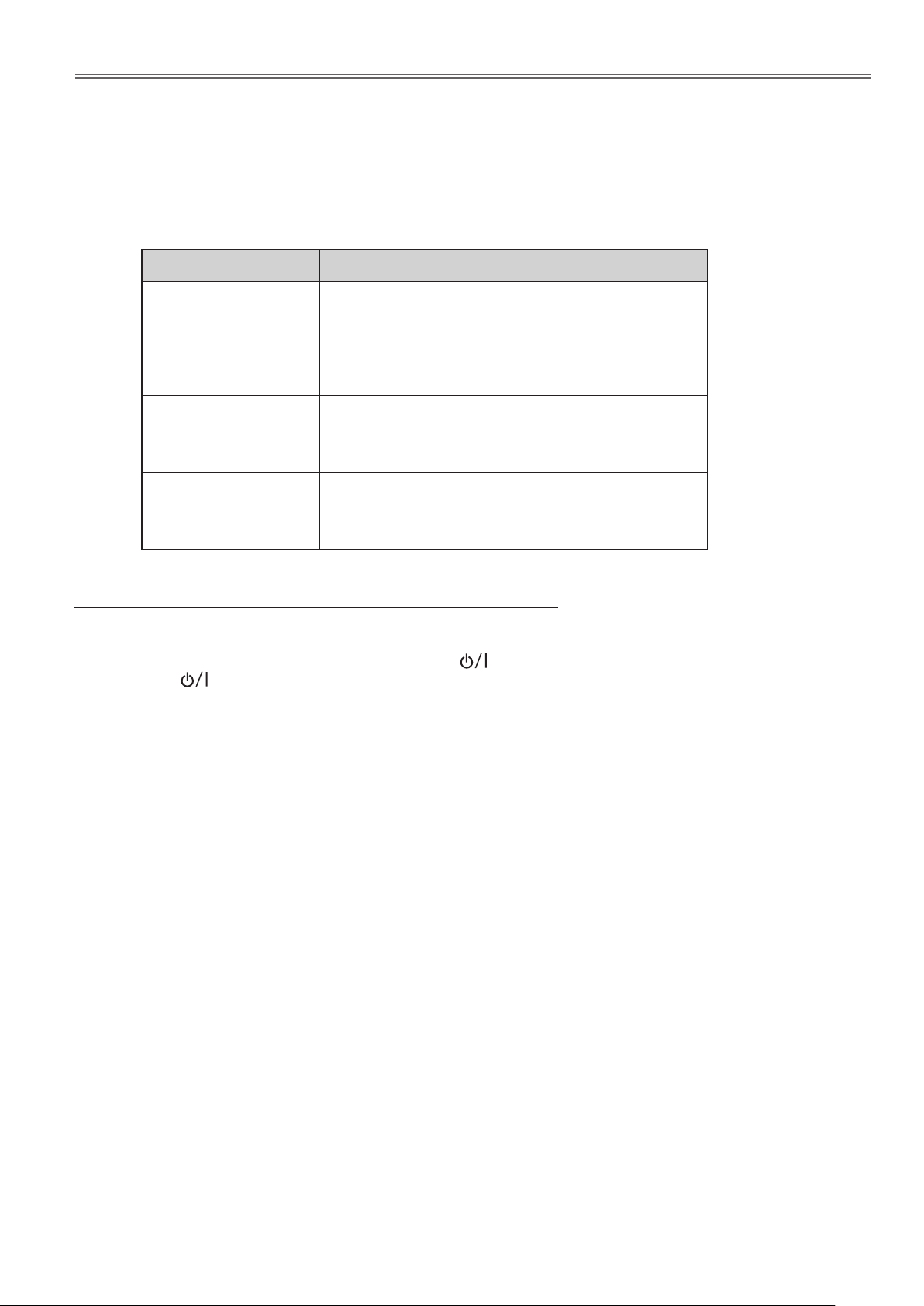

Standby Mode Notice

This projector provides 3 types of standby mode, Normal standby mode, Eco standby mode and Network standby

mode. According to the standby mode "Normal", "Eco" or "Network", several functions are restricted as shown in the

table below. To change the standby mode, use the projector's menu "Setting".

Normal ............ Normal standby mode.

Network .......... Supply the power to the network function even after turning off the projector. You can turn on /off

the projector via network, modify network environment, and receive an e-mail about projector status

while the projector is powered off.

Eco ................. Select "Eco" when you do not use the projector via network. The projector's network function will

stop when turning off the projector.

When "Eco" is selected, several functions will be restricted.

Restricted function in the standby mode

Function Normal Eco Network

Network

Serial command control

Monitor out

Audio out

RC sensor setting

*1 When "Eco" is selected, all of the infrared remote receivers, top, front or rear are activated in the eco

standby mode regardless of the RC sensor setting.

✔

✔

✔

✔

✔ ✔

--

--

✔

✔

-- --

-- --

*1

✔

-23-

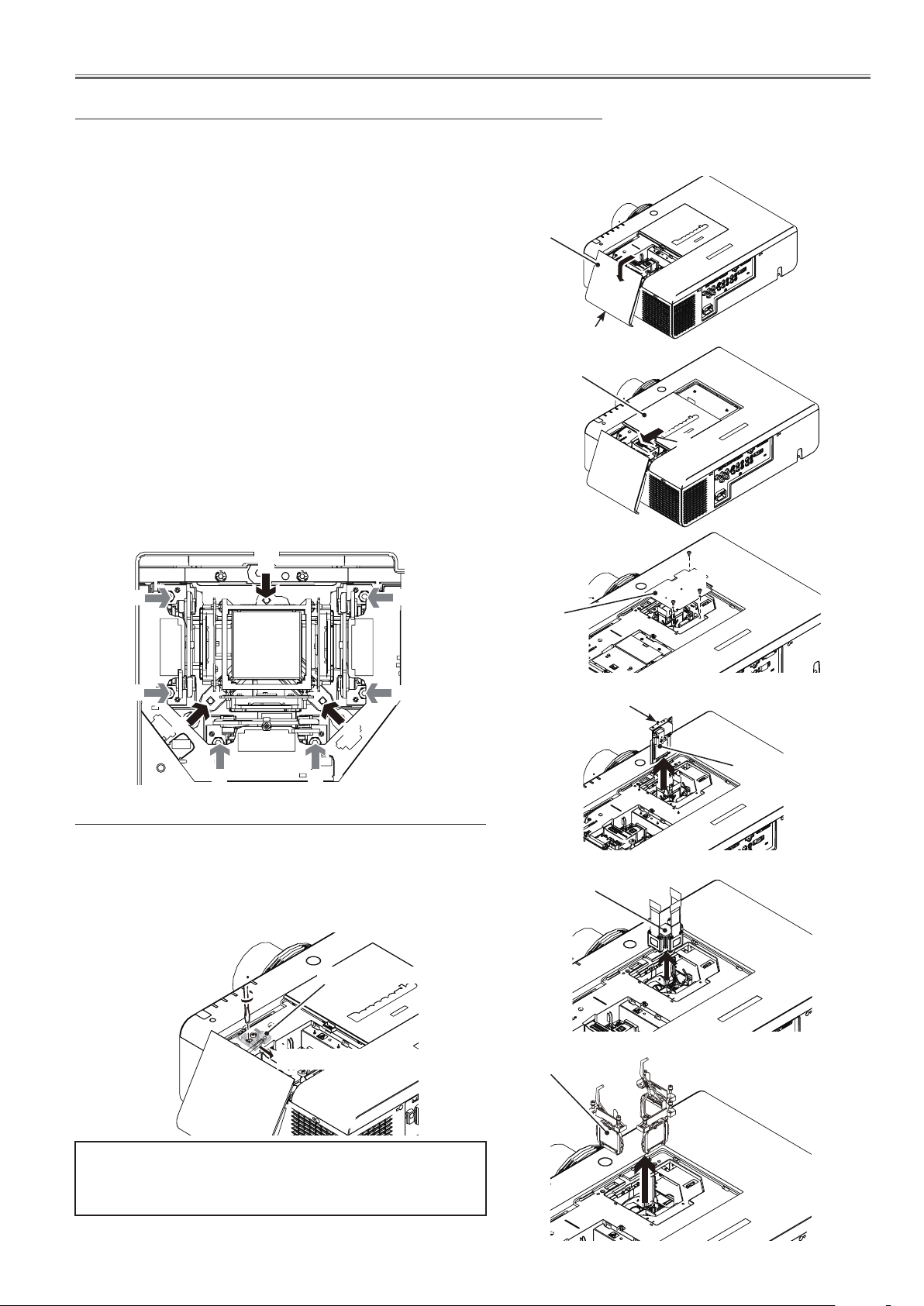

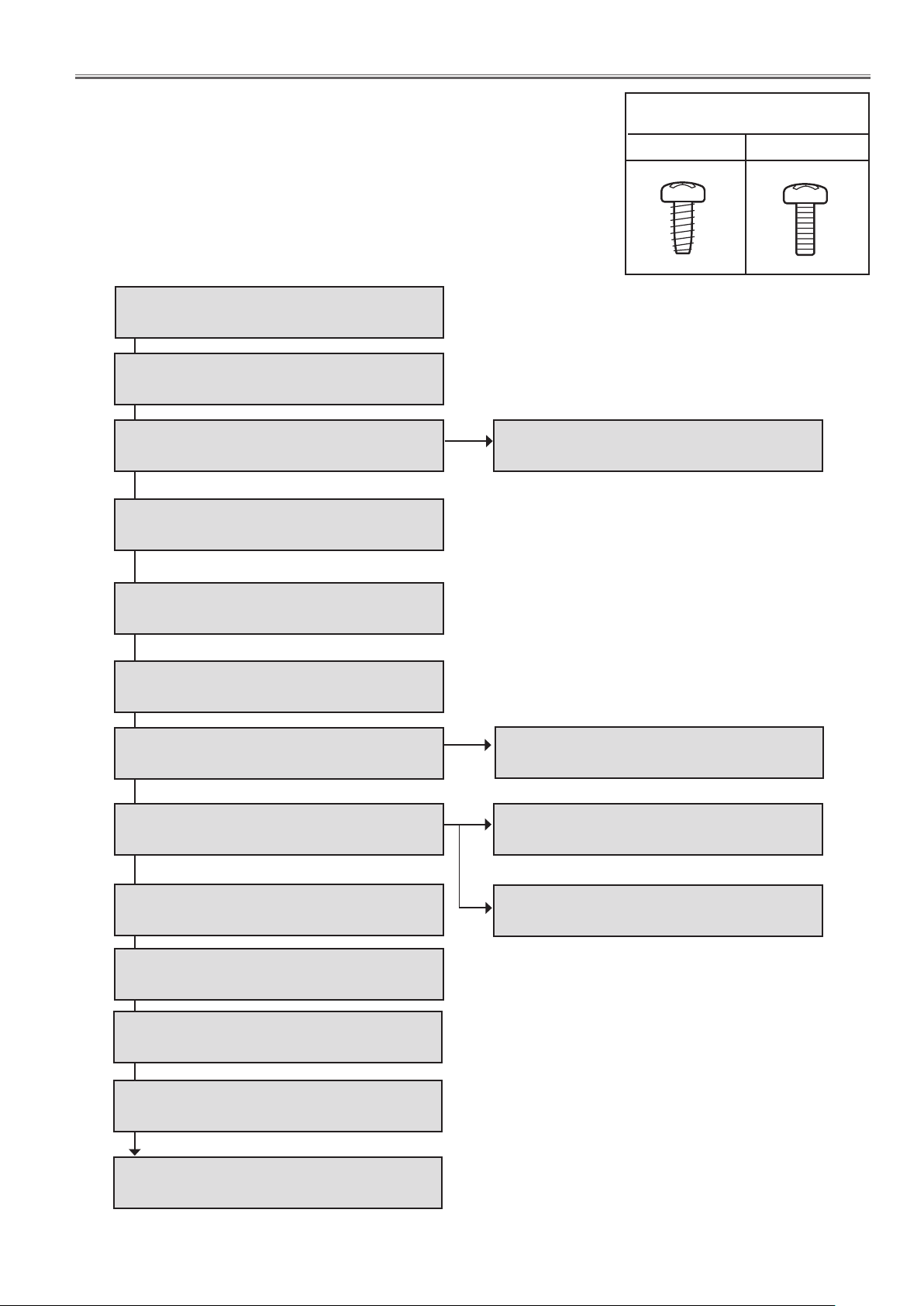

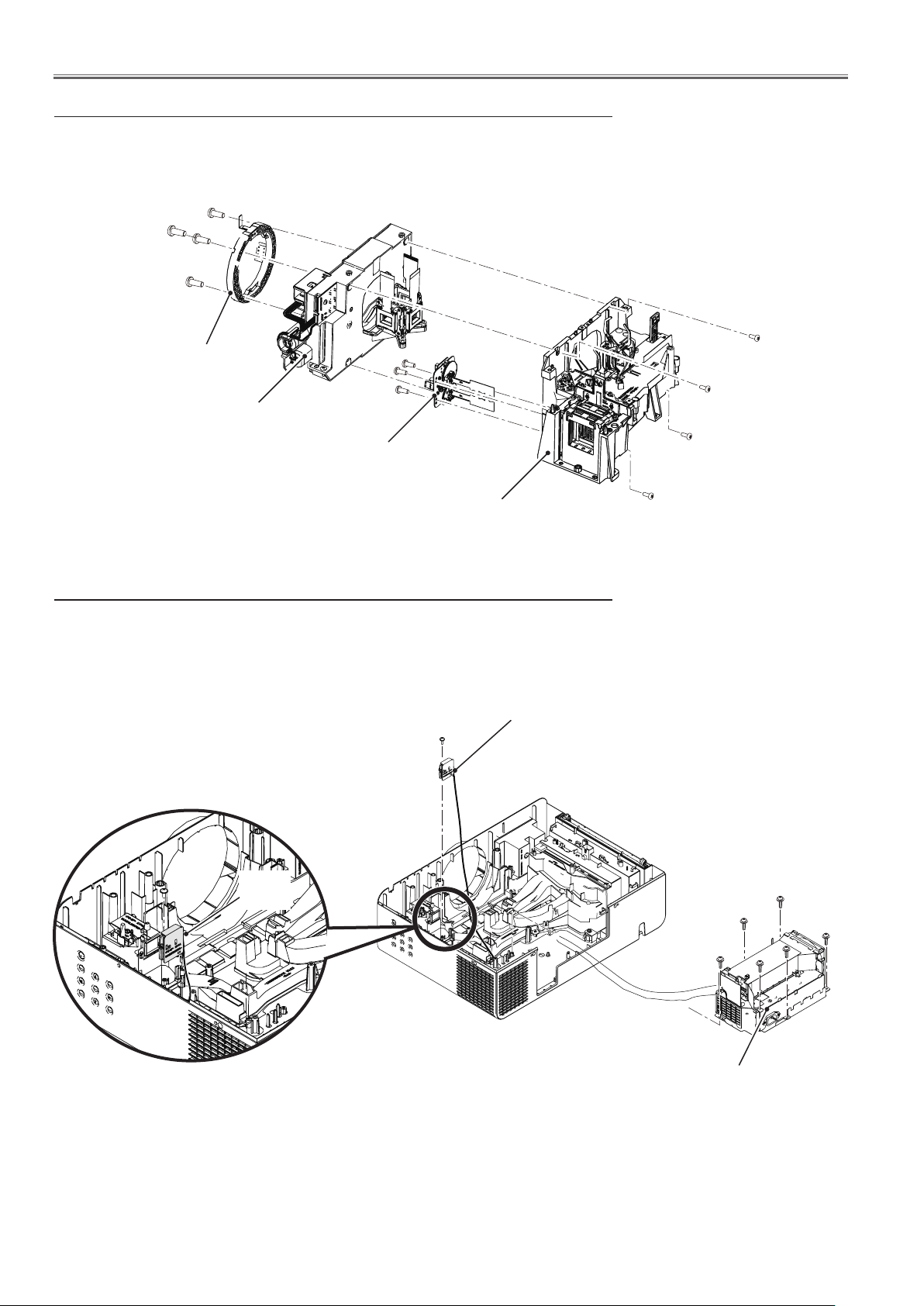

Mechanical Disassembly

Mechanical disassembly should be made following procedures in numerical order.

Following steps show the basic procedures, therefore unnecessary step may

be ignored.

Caution:

The parts and screws should be placed exactly the same position as the original

otherwise it may cause loss of performance and product safety.

1. Lamp cover and prism cover removal

2. Cabinet top removal

3. Fan (FN905) and main&AV board removal

4. Shutter and sensor C board removal

3-1. Main board and A/V board removal

Screws expression

(Type Diameter x Length) mm

T type M type

5. Lamp, lamp cover and ID connect board

removal

6. Projection lens removal

7. Optical unit removal

8. Power box and thermal SW (SW902)

removal

9. Control board and fans (FN902, FN903,

FN904) removal

10. Filter assy removal

11. Fans (FN908, FN909, FN910) removal

7-1. Lens shift assy and Iris assy removal

8-1. Thermal fuse replacing

8-2. Power box disassembly and fan

(FN901) removal

12. Fans (FN906, FN907, FN911) and

speaker removal

13. Cable reforming

-24-

Mechanical Disassembly

1. Lamp cover and prism cover removal

1. Loosen 1 screw-A and remove the lamp cover upward off.

2. Loosen 1 screw-B and remove the prism cover by sliding it in the arrow

direction.

Lamp cover

A

Prism cover

B

2. Cabinet top removal

1. Open the filter cover and remove the air filter unit.

2. Remove 12 screws-A (M3x8) to take the cabinet top assy upward off.

A

A

A

LED decoration

RC front

window

F/T RC+LED

board

T3x8

T3x8

T3x8

A

A

Cabinet top assy

Air filter unit

A

A

A

A

A

A

A

-25-

Mechanical Disassembly

3. Fan (FN905) and main&AV board removal

1. Remove 1 screw-A (M3x10) and 3 screws-B (T3x10) to take the fan (FN905)

upward off.

2. Remove 2 screws-C(M3x6) and 1 screw-J(M3x10) to take the prism cover

shield off.

3. Remove 12 sccrews-D(M3x10) , 1 screw-E(T3x10) and 3 sccrews-G(M3x6)

to take the main board shield top off.

4. Remove 1 screw-H(M3x10)and 1 screws-F(M3x8)

and then remove the main&AV board.

Main board

shield top

D

E

D

G

D

Prism cover

shield

D

D

D

D

D

G

G

D

J

C

C

D

D

D

Main&AV board

B

B

Fan (FN905)

A

B

3-1.Main board and A/V board removal

1. Release the 4 hooks to remove the AV panel .

2. Remove 6 hex-screws-B and 1 screw A (M3x8) to remove the AV board

from the main board.

H

F

Hooks

Main board

AV board

AV panel

B

B

A

B

B

B

B

-26-

Mechanical Disassembly

4. Shutter and sensor C board removal

1.

Remove 3 screws-A (M3x10)

shield bottom.

2. Loosen 1 hex screw-C and pull the shutter assy upward.

3. Remove 1 screw-D (T3x8) to take the sensor C board off.

4. Remove 1 screw-E (T3x8) to take the lamp cover switch off.

5. Remove 2 screws-F (T3x14) to take the wind sensor (S901) off.

6. Remove 1 screws-G (T3x10) to take the connect shield,

and remove 2 screw-H (T3x10) to pull the net shield

upward.

and 4 screw-B (T3x10)

to take the main board

B

B

Main board

B

A

B

shield bottom

A

A

Connect shield

Sensor C board

Lamp cover switch

E

5. Lamp, lamp cover and ID connect board removal

1. Loosen 3 screws-A and pull the lamp assy upward.

2. Remove 4 screws-B (T3x8) to take the lamp house holder upward off.

3. Remove 2 screws-C (T3x8) to take the ID connect board.

4. Remove 1 screw-D (T3x10) to remove the ballast socket.

G

D

F

Wind sensor (S901)

H

H

Net shield

C

Shutter assy

ID connect

board

Ballast

socket

Lamp assy

C

A

A

C

B

B

A

B B

D

-27-

Mechanical Disassembly

6. Projection lens removal

1. Press and hold the lens release button and turn the projection lens counterclockwise until it stops and put it out slowly.

Projection lens

Lens release button

7. Optical unit removal

1. Remove 2 screws-A (T3x8)and 7 screws-B (T4x10) and remove the optical

unit assy and lens shift assy.

2. Loose the lens cover top.

3. Remove the front ring cover by pressing it from back.

Lens cover top

Guides

Grooves

Front ring cover

B

B

B

B

A

B

B

B

A

Optical unit and

Lens shift assy

-28-

Mechanical Disassembly

7-1. Lens shift assy and Iris assy removel

1. Remove 4 screws-A (M3x8) to take the lens shift assy off.

2. Remove 4 screws-B (M3x14) to take the lens mount off.

3. Remove 3 screws-C (T3x8) to take the Iris assy.

B

B

B

B

Lens mount

C

C

C

Lens shift assy

Iris assy

Optical unit assy

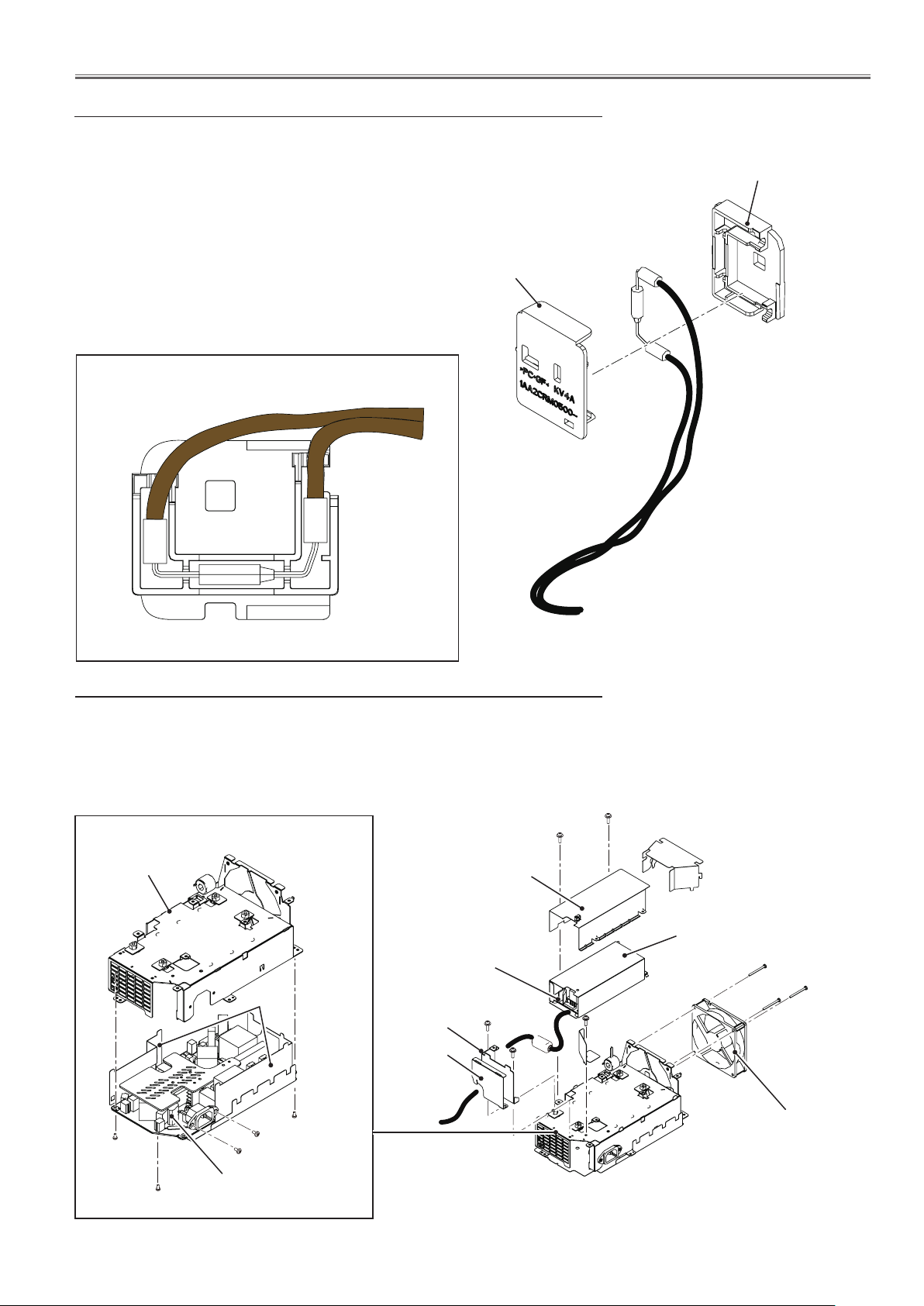

8. Power box and thermal fuse (SW902) removal

1. Remove 3 screws-A (M3x10) and 3 screws-B (T3x10) to remove the Power

Box assy.

2. Remove 1 screw-C (T3x8) and pull the SW902 upward off.

C

Thermal fuse(SW902)

A

A

A

A

SW902

B

A

A

Power box assy

B

A

B

-29-

Mechanical Disassembly

8-1. Thermal fuse replacing

1. Remove the thermal fuse spacer from the thermal fuse mounting.

2. Remove the thermal fuse(SW902).

3. Mount the thermal fuses as shown in the figure below.

Thermal fuse spacer

Top view of the fuse mounting

Thermal fuse mounting

8-2. Power box disassembly and fan (FN901) removal

1. Remove 2 screw-A (M3x10) to remove the ballast shield top.

2. Remove 2 screws-B (M3x10) to take the Holder. then remove 1 screw-D

(M3x10) to take the ballast board off.

3. Remove 3 screws-E (T3x28) to take the fan (FN901) off.

A

A

Power holder

M3x10

Spacer

M3x10

M3x6

Ballast shield top

Ballast board

Holder

Spacer

B

B

D

Spacer

E

E

FN901

E

M3x10

Power board

-30-

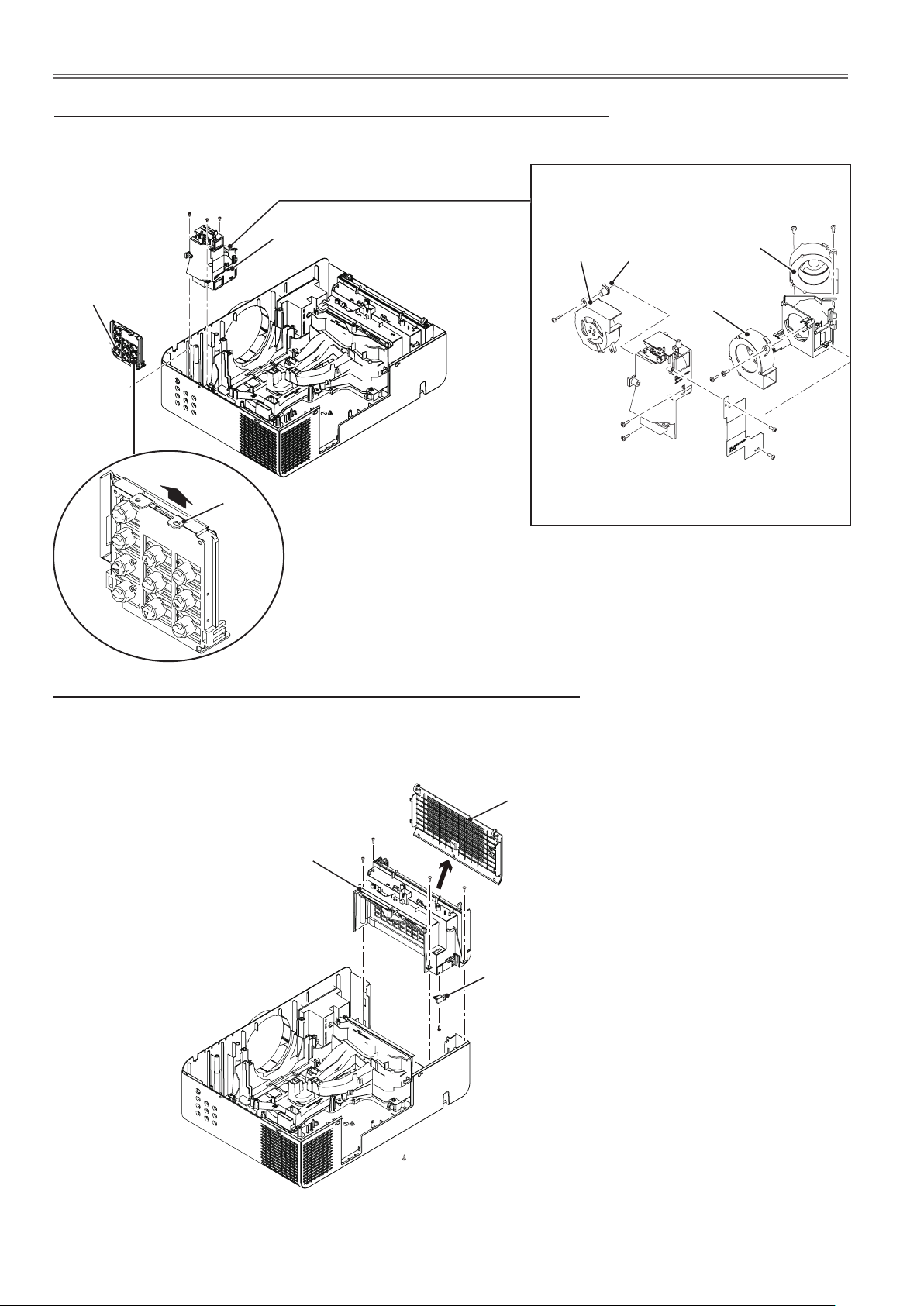

Mechanical Disassembly

9. Control board and fans (FN902,FN903,FN904) removal

1. Remove 3 screws-A (T3x8) to take the lamp fan assy off.

2. Pull the holder on the control board up to release the hook and remove the

Control board assy upward off.

A

A

A

T3x12

T3x12

Control board assy

Holder

10. Filter assy removal

Lamp fan assy

FN903

T3x22

T3x12

T3x12

Spacer

FN902

FN904

T3x12

T3x8

T3x8

1. Remove the filter cover by pulling it outside.

2. Remove 4 screws-A (T3x8) and 1 screw-B (M3x8) and pull the filter box

assy upward off.

3. Remove 1 screw-C (T3x6) to remove the filter switch(SW1891).

Filter cover

A

Filter box assy

A

A

A

Filter switch(1891)

C

B

Loading...

Loading...