Panasonic PT-D10000U, PT-DW10000U User Manual

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

INSTRUCTION MANUAL

HIGH-VOLTAGE

VACUUM CONTACTORS

CAPACITOR APPLICATION

6F9G0154

TYPE:CV-10HB 12(13.8)kV-400A-5kA

TYPE:CV-10HBL 12(13.8)kV-400A-5kA

TOSHIBA CORPORATION

© TOSHIBA Corporation 2001-2009

All Rights Reserved.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

CONTENTS

1.GENERAL DESCRIPTION・・・・・・・・・・・・・・・・・・・・ 2

2.PRECAUTIONS IN SPECIAL APPLICATION・・・・・ 3

3.RECEIVING AND UNPACKING・・・・・・・・・・・・・・・・ 4

4.STORAGE AND HANDLING・・・・・・・・・・・・・・・・・・・ 4

5.INSTALLATION・・・・・・・・・・・・・・・・・・・・・・・・・・・ 5

6.RATING・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 6

6F9G0154

7.OUTLINE DRAWING・・・・・・・・・・・・・・・・・・・・・・・・ 7

8.STRUCTURE・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 8

9.OPERATION・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 9

10.TRIAL OPERATION・・・・・・・・・・・・・・・・・・・・・・・・13

11.INSPECTION AND MAINTENANCE・・・・・・・・・・・・・14

12.CRITERIA FOR DURABILITY・・・・・・・・・・・・・・・・18

- 2 -

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Read this manual carefully to fully understand the operation.

And keep for maintenance.

WARNING : Never remodel or disassemble the equipment nor mount

nonstandard components.

This equipment shall only be used inside a metal enclosure (grounded)

in other establishments than domestic , or those that are connected to

the public power source system.

6F9G0154

1. GENERAL DESCRIPTION

(1) Ambient condition

The type CV vacuum contactor is manufactured in accordance with IEC 60470(2000).

The vacuum contactor should be used in the following conditions.

Table 1

Normal service condition

-Altitude : Less than 1000m

-Ambient temperature : -5℃ min. to +40℃ max.

Its average over a period of 24h

does not exceed +35℃

-Relative humidity : 45% min. to 85% max.

-Vibbration : 20Hz -9.8m/s

2

or less

CAUTION : Do not use in condition other than those specified

above , please consult .

(2) Locative condition

The location where the contactor is to be installed should be free from dust.

Corrosive gas and moisture.

When it is be used in a chemical plant or in outdoor panels,

take necessary precautions against corrosion,

water seepage and condensation.

See page 2.

- 3 -

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

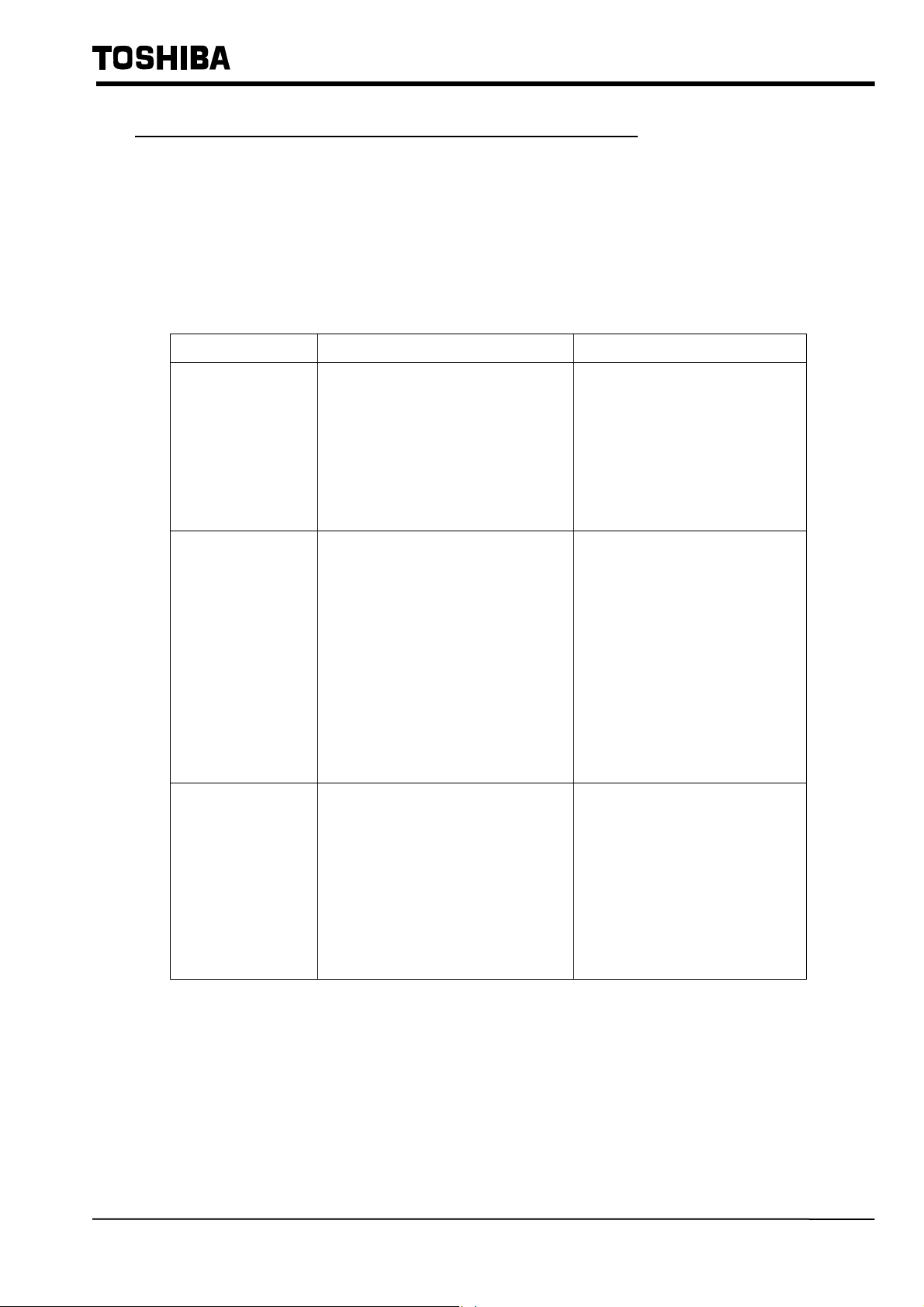

2. PRECAUTIONS IN SPECIAL APPLICATION (outdoor cubicle etc.)

In application, check the follow items, please carry out the maintenance

frequently. or perform the countermeasure.

(Visual inspection: once a month, regular inspection: once a year)

Table 2 Precaution in special application

Special condition Instance Caution items

6F9G0154

Contamination

Sea breeze

High humidity

Corrosion gas

Dust, iron-dust etc.

is very more place.

Place where suffer the

sea breeze.

Place where very more

snow and ice.

More humidity.

Place where near the

cooling tower.

Place where cause changing

the temperature suddenly.

Corrosion gas which come

Reduction of ventilation

Setting of ventilation for

sea breeze.

Frequent inspection.

Setting the space heater.

Setting the ventilation.

Prevention of flooding

into the cable pit.

Protection from corrosion

into the airport, chemical

Industry and water cleaning.

(EX.)

SO

, Cl2 ,NO2

2

gas .

Anti-gas treatment.

Examination of changing

of the insulation material.

- 4 -

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

3. RECEIVING AND UNPACKING

WARNING : If any parts are damaged or missing.

Do not install that has been damaged.

Make the following checks after unpacking :

(1) Check if there is any damage , foreign matter trapped , or water seepage

into the contactor.

(2) Check the nameplate to see if the specifications on the plate are correct.

6F9G0154

(3) Check the contact wear gauge and control cable.

(4) Check the tripping rod (Latched type).

4.STORAGE AND HANDLING

When the contactor is to be stored over a long period , the storage area

should be dry and dust free area.

If the contactor is left outdoors or in adverse conditions , corrosion

from gas , rust or insulation deterioration may result.

CAUTION : In handling , do not throw or drop contactor.

The contactor may break.

- 5 -

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

6F9G0154

5.INSTALLATION

When installing , protect from dust. Particularly when the contactor

is installed while the building is under construction , shield it from

cement dust and other foreign matter.

The following precautions should be taken.

(1) The mounting surface must be horizontal (level : less than ±1mm).

When the mounting surface is not horizontal , adjust with spacers.

(2) There are four mounting holes.

Use M10 bolts to securely mount the contactor.

(3) In wiring the main circuit terminals , ground terminals and control

circuit , wires should be given sufficient length to be flexible.

The ground wires should be more than 5.5mm

2

in cross section.

(4) Do not mount the contactor with its front inclined downward.

This may result in malfunction.

(5) Do not touch the vacuum interrupter surface with soiled hands.

(6) When it is applied to a capacitor load , be sure to used a space heater

to keep humidity low.

CAUTION : Do not install on energize contactor that has been bad condition.

- 6 -

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

6F9G0154

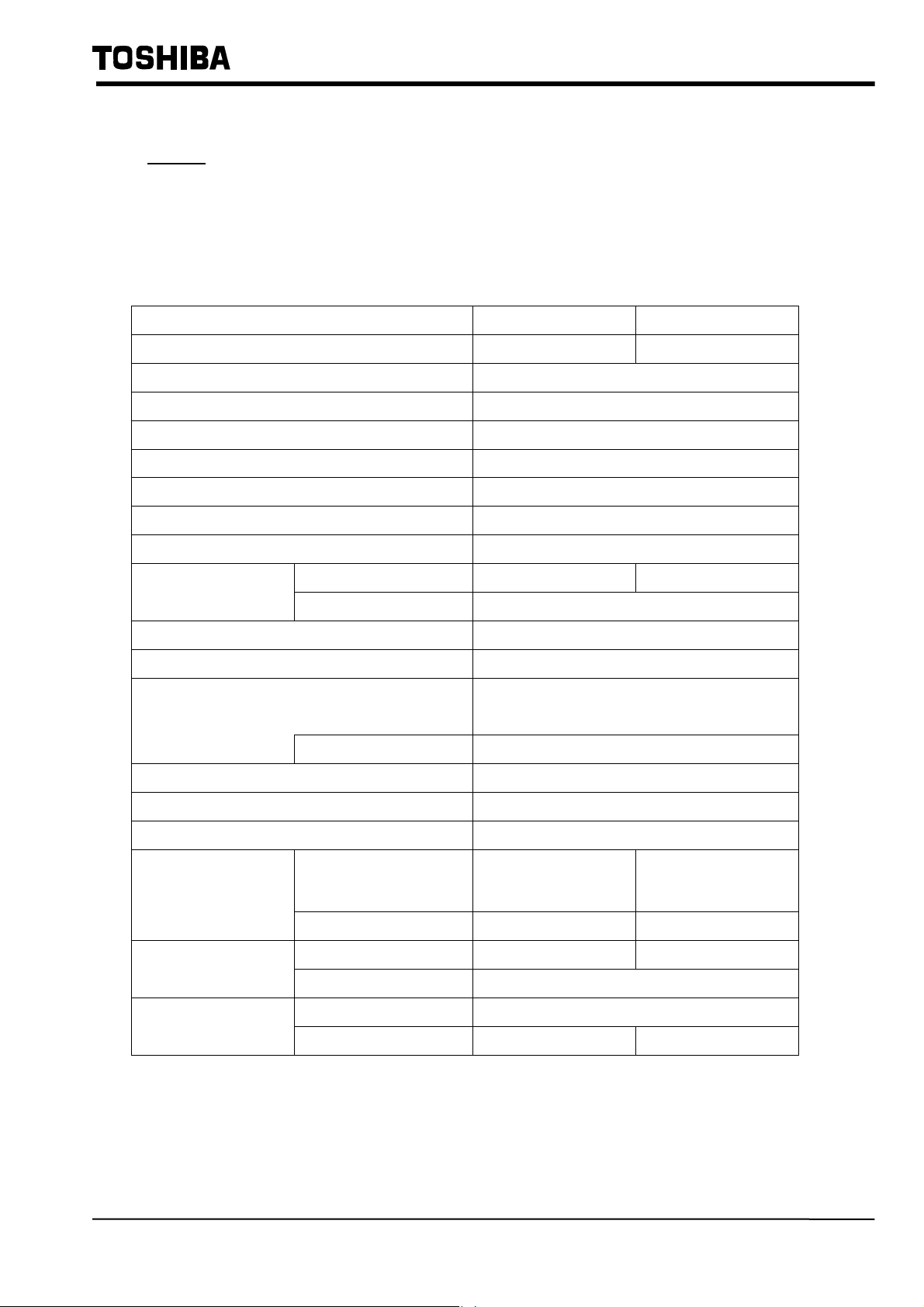

6.RATING

DANGER : Do not exceed the ratings specified on the contactor.

Table 3 Ratings

Type- form CV-10HB CV-10HBL

Operating mechanism Non-latched Latched

Rated operation voltage (kV)

Rated insulation level (kV) AC.28 , Imp.75

Rated operational current (A) 400

Thermal current (A) 450

Rated frequency (Hz) 50/60

Rated short-time withstand current (A-s)

Rated peak withstand current (A) 12500

12 (13.8)*

5000-1

Operations/hour 300 120 Rated duties

On load factor 40%

Rated making capacity (kA)

Rated breaking capacity (kA)

Short-circuit making and breaking current

(kA)

Duties

Withstand overload current (kA-s)

Mechanical operation (million) 0.25

Electrical operation (million) 0.1

Rated supply voltage

(Standard)

Auxiliary switches

Operating current (A)

(at 100V)

Closing voltage

Tripping voltage

Contact arrangement

Life (million) 0.1

Closing

Holding/Tripping

3.2(C-10s×100times)

2.56(CO-30s×25times)

5

O-3min-CO-3min-CO

8.0-1sec , 1.92-30sec

100-240VAC

100-220VDC

- 100-110VDC

4NO-2NC 2NO-1NC

6~7

0.6~0.7 3~4

100-240VAC

100-250VDC

* :13.8kV (maximum) for capacitor switching.

The rated making/breaking capacity has been confirmed at 12kV.

- 7 -

Loading...

Loading...