Panasonic PT-51G44A, PT-51G54A, PT-51G44CA, PT-61G54CA, PT-51G54CA Service Manual

...

ORDER NO. MTC9903012Cl

82

Service

Manual

7

Color Video Projection System

Main Manual

(P3)

Models

Chassis

PT-51 G44A AP815

PT-51 G44CA AP815

PT-51 G54A AP815

PT-51 G54CA AP815

PT-61 G54A BP815

PT-61 G54CA BP815

Note:

Refer to Technical Guide

(P3)

for

functional descriptions and Block

Diagrams.

(MTC9703689G1).

This Service manual is issued as a service guide for the models of the P3 family listed above. Included in this manual

are a set of schematic, block diagrams, functional descriptions, alignment procedures, disassembly procedures, and a

complete parts list.

"WARNING!

This Service Manual is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians.

Any attempt to

service or repair the product or products dealt with in this Service Manual by anyone else could result in serious injury or death."

Panasonic,

Copyright

1999

by Matsushita Electric Corporation of

America. All rights reserved. Unauthorized copying

and distribution is a violation of law.

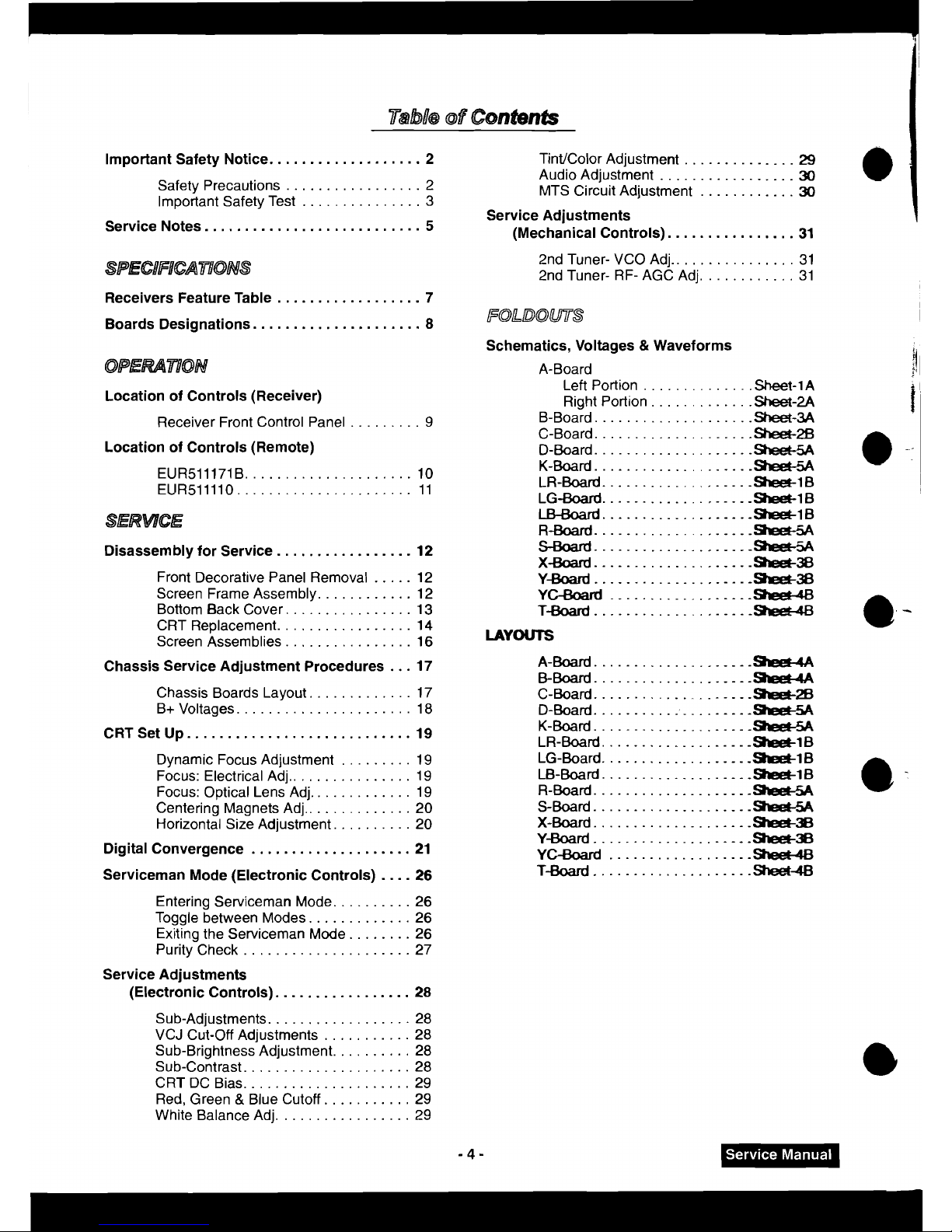

Important Safety Notice

...................

2

TintJColor Adjustment

..............

29

Audio Adjustment

.................

30

Safety Precautions

.................

2

MTS Circuit Adjustment

............

30

...............

Important Safety Test

3

Service Adjustments

Service Notes

...........................

5

(Mechanical Controls)

................

31

2nd Tuner- VCO Adj

.............

2nd Tuner- RF- AGC Adj

.........

Receivers Feature Table

..................

7

Boards Designations 8

FOLDOUTS

i

.....................

Location of Controls (Receiver)

.........

Receiver Front Control Panel 9

Location of Controls (Remote)

Disassembly for Service

.................

12

Front Decorative Panel Removal

.....

12

Screen Frame Assembly

............

12

Bottom Back Cover

................

13

CRT Replacement

.................

14

Screen Assemblies

................

16

Chassis Service Adjustment Procedures

...

17

Chassis Boards Layout

.............

17

B+ Voltages ...................... 18

CRT Set Up

............................

19

Dynamic Focus Adjustment

.........

19

Focus: Electrical Adj

................

19

Focus: Optical Lens Adj

.............

19

Centering Magnets Adj

..............

20

Horizontal Size Adjustment

..........

20

Digital Convergence

....................

21

....

Serviceman Mode (Electronic Controls) 26

Entering Serviceman Mode

..........

26

Toggle between Modes

.............

26

Exiting the Serviceman Mode

........

26

Purity Check

.....................

27

Service Adjustments

(Electronic Controls)

.................

28

Schematics. Voltages

&

Waveforms

a,

A-Board

j!

1

Left Portion

..............

Sheet-1

A

Right Portion

............

.Sheet

.2A

B-Board

....................

Sheet-3A

C-Board

Sheet-26

I!

....................

....................

D-Board

K-Board

ske+A

-:

....................

LR.Board

..................

B

LG-Board

..................

B

LBBoard

..................

.-

16

R-Board

....................

Se&+5A

SBoard

....................-

XBoard

....................

-38

Y-Board

....................

-38

YC-Board

.................

-9reelldS

TBoard

....................

LAYOUTS

e

-

A-Board

...................

.-

&Board

...................

--

C- Board

....................

Swa-28

D-Board

..........

:

........

-9PeC5A

K-Board

...................

zwx+5A

LR-Board

..................

-SreeclB

LG.Board

...................

SleeC1

B

LB-Board

...................

-16

R-Board

....................

SreetSA

S-Board

SreeCSA

e-

....................

X-

Board

....................

-38

yard

....................

-3B

YC-Board

..................

sheet46

T-Board

....................

Sheei4

Sub.Adjustments

..................

28

VCJ Cut-Off Adjustments

...........

28

Sub-Brightness Adjustment

..........

28

Sub.Contrast

.....................

28

CRT DC Bias

.....................

29

Red, Green

&

Blue Cutoff

...........

29

White Balance Adj

.................

29

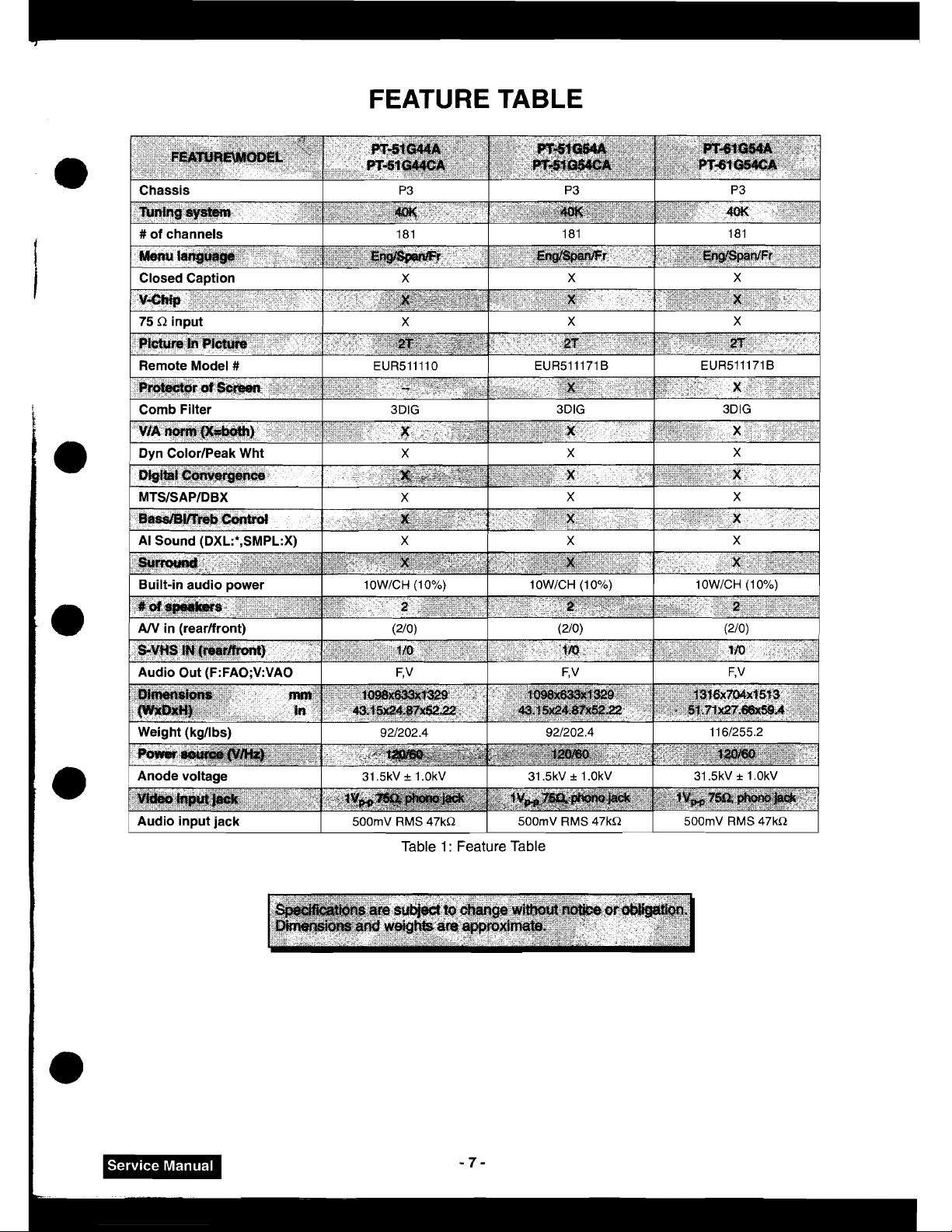

FEATURE

TABLE

Table 1 :

Feature Table

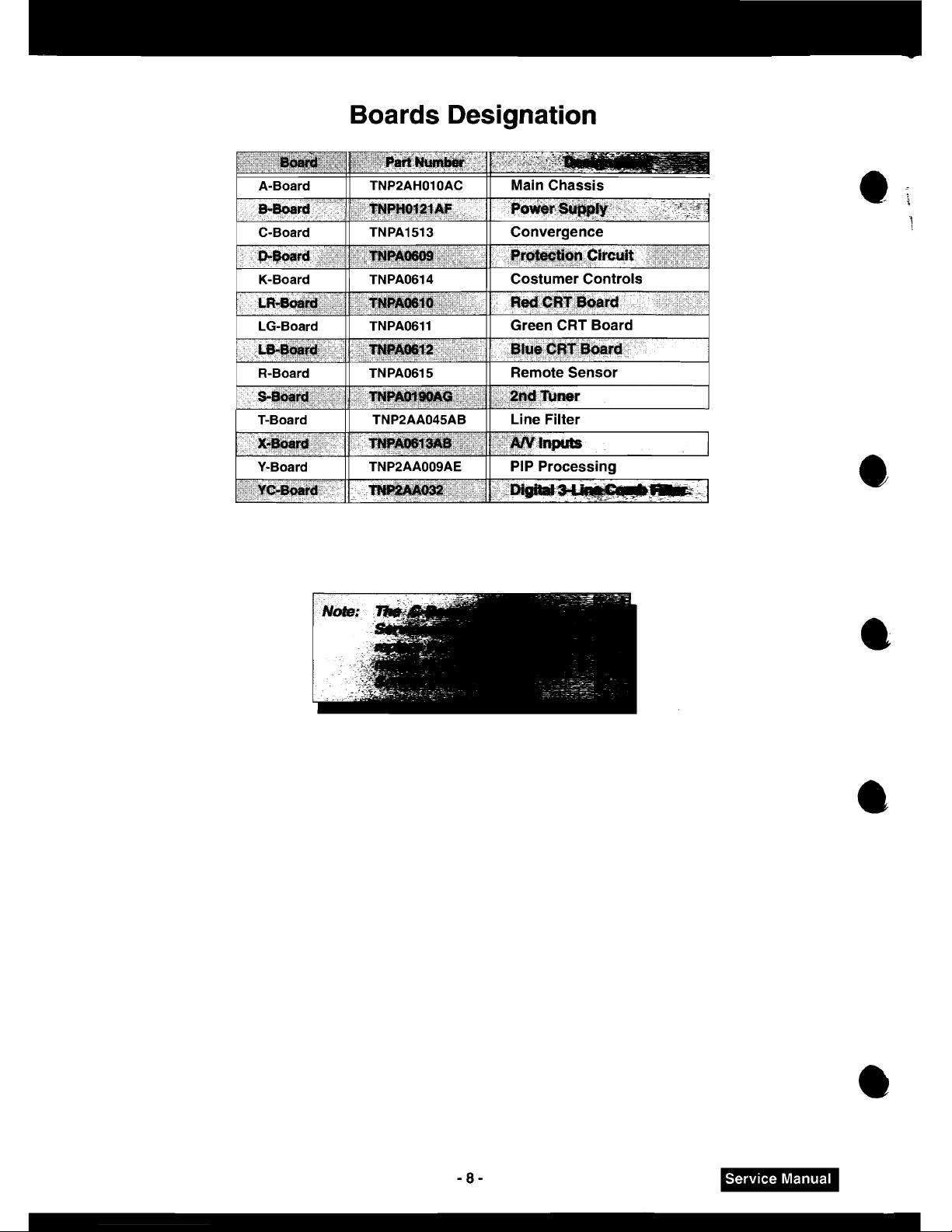

Boards Designation

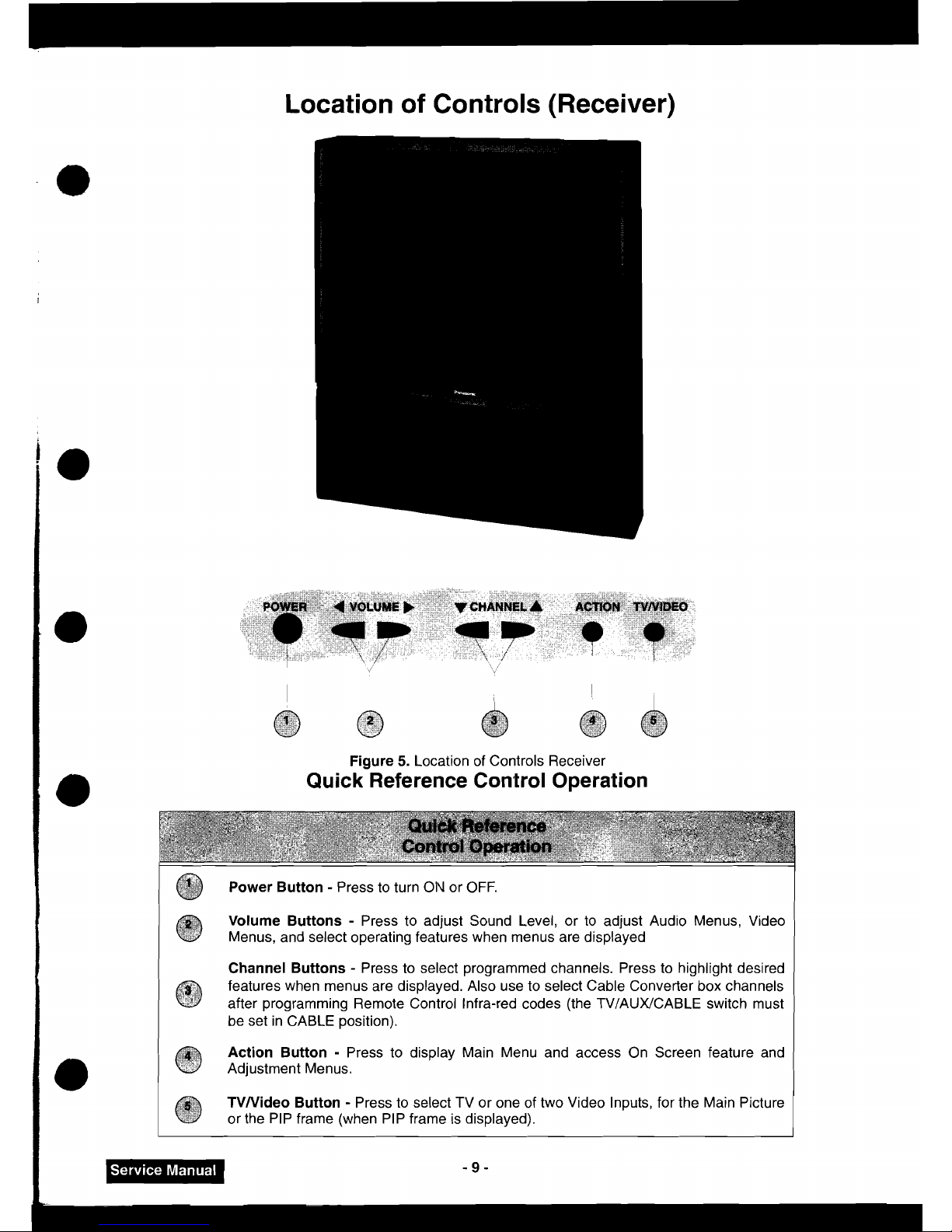

Location of Controls (Receiver)

POWER

(

VOLUME,

'l

CHANNEL

A

ACTtON

TVNlDEO

e

I

FC

.

I

I.

.

I

9-

.

..

.

,

,,

.

+

+

. .

I

Figure

5.

Location of Controls Receiver

Quick Reference Control Operation

Power Button - Press to turn OIV or OFF.

Volume Buttons - Press to adjust Sound Level, or to adjust Aud~o Menus, Video

Menus, and select operating features when menus are displayed

Channel Buttons - Press to select programmed channels. Press to highlight desired

features when menus are displayed. Also use to select Cable Converter box channels

@

after programming Remote Control infra-red codes (the TV/AUX/CABLE switch must

be set in CABLE position).

Action Button - Press to display Main Menu and access On Screen feature and

Adjustment Menus.

TVNideo Button - Press to select TV or one of two Video Inputs, for the Main Picture

or the PIP frame (when PIP frame is displayed).

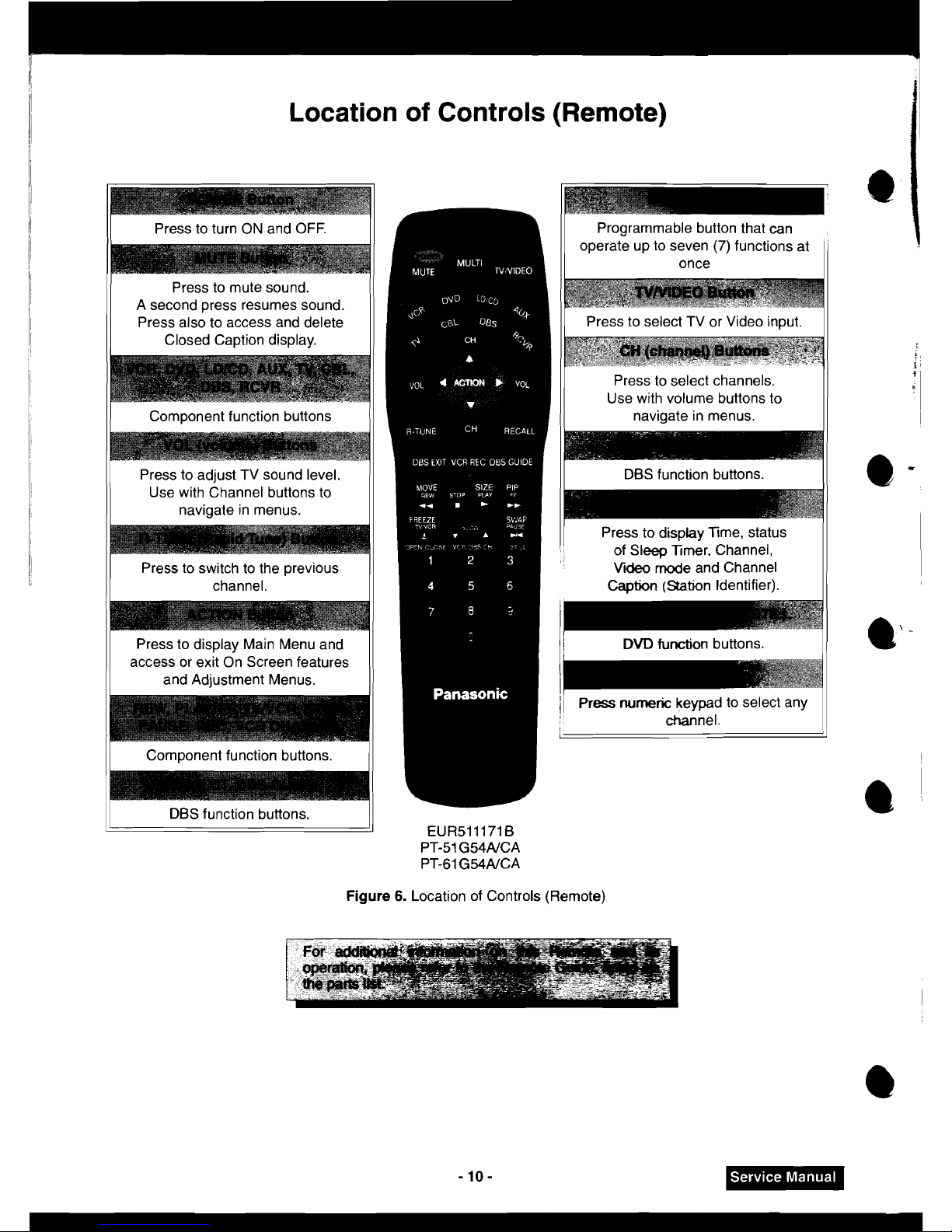

Location of Controls (Remote)

11

Press to turn ON and OFF.

11

A

second press resumes sound.

Press also to access and delete

Closed Caption display.

1)

Component function buttons

(1

Press to adjust TV sound level.

Use with Channel buttons to

navigate in menus.

Press to switch to the previous

1

I

Component function buttons.

/

1

DBS function buttons.

Programmable button that can

operate up to seven (7) functions at

once

11

Press to select TV or Video input.

I

Press to select channels.

Use with volume buttons to

navigate in menus.

I I

DBS function buttons.

I

I

11

Press to display Time, status

of Sleep Timer. Channel,

Mdeo

mode and Channel

Caption

(Stabn Identifier).

!I

DVD

function buttons.

1-

i

1

Press

numeric

keypad to select any

channel.

I

Figure

6.

Location of Controls (Remote)

I

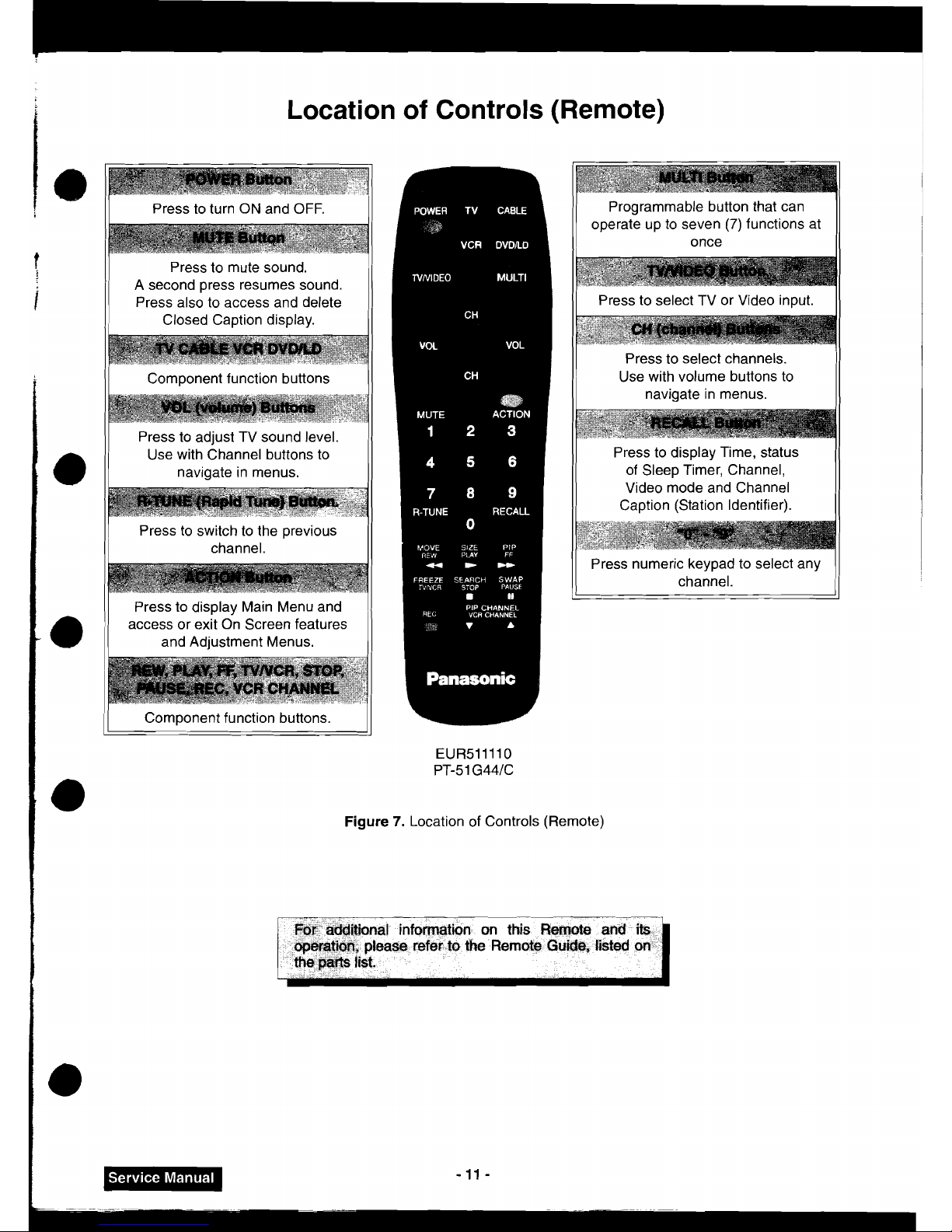

Location of Controls (Remote)

I

I

Press to turn ON and OFF.

I I

Press to mute sound.

A second press resumes sound.

Press also to access and delete

I

Closed Caption display.

11

Component function buttons

)I

Press to adjust TV sound level.

Use with Channel buttons to

navigate in menus.

II

ress to switch to the previous

channel.

11

Programmable button that can

operate up to seven

(7)

functions at

once

I(

Press to select TV or Video input.

11

Press to select channels.

I

Use with volume buttons to

navigate in menus.

Press to display Main Menu and

1

access or exit On Screen features

and Adjustment Menus.

I

Component function buttons.

U

Figu

Ire

!

7.

Location of Controls

(Re

--

Press to display Time, status

of Sleep Timer, Channel,

Video mode and Channel

Caption (Station Identifier).

--

-

-1

Press numeric keypad to select any

channel.

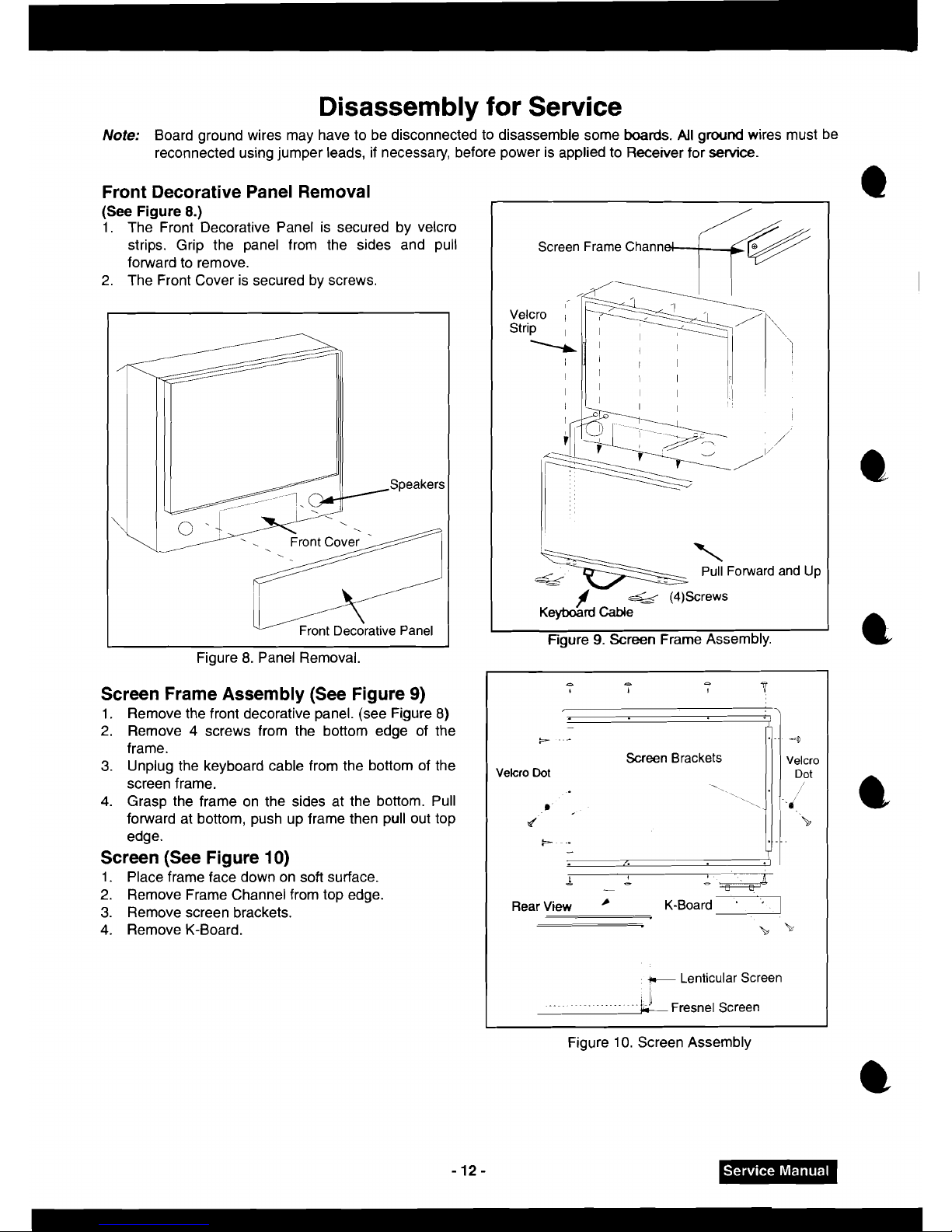

Disassembly

for

Service

Note:

Board ground wires may have to be disconnected to disassemble some

boards.

All

ground wires must be

reconnected using jumper leads, if necessary, before power is applied to Receiver for

service.

Front Decorative Panel Removal

(See

Figure

8.)

1.

The Front Decorative Panel is secured by velcro

strips. Grip the panel from the sides and pull

forward to remove.

2.

The Front Cover is secured by screws.

VJ

lecorative Panel

Figure 8. Panel Removal.

Screen Frame Assembly (See Figure

9)

1.

Remove the front decorative panel. (see Figure 8)

2.

Remove 4 screws from the bottom edge of the

frame.

3.

Unplug the keyboard cable from the bottom of the

screen frame.

4.

Grasp the frame on the sides at the bottom. Pull

forward at bottom, push up frame then pull out top

edge.

Screen (See Figure

10)

1.

Place frame face down on soft surface.

2.

Remove Frame Channel from top edge.

3.

Remove screen brackets.

4.

Remove K-Board.

Screen Frame Chann

#@

I

\

Pull Forward and

Up

4

f

e&

(4)Screws

Keyboard Cable

I

I

Figure

9.

Screen Frame Assembly.

a a

4

6

1

1

fS

-

k-

-.-

4

Screen Brackets

Velcro

Velcro

Dot

Dot

',

."

r

B

b

-

..

.

--.

-

L

I

I

!

-

-

-

I

,-

-

Rear

View

'

K-Board

'1

b

\<

-

Lenticular Screen

..-~

~~~-.~.......~-.

Fresnel Screen

Figure

10.

Screen Assembly

Disassembly for Service (Cont.)

Disassembly

of

Speaker Units Replacement

1. Remove the front decorative panel located under

control panel. (see Figure 8)

2. Each Left and Right speaker is secured to the

cabinet with (4) screws for each bracket.

3. Disconnect the

R & L speaker lead connectors

from the speaker units.

6

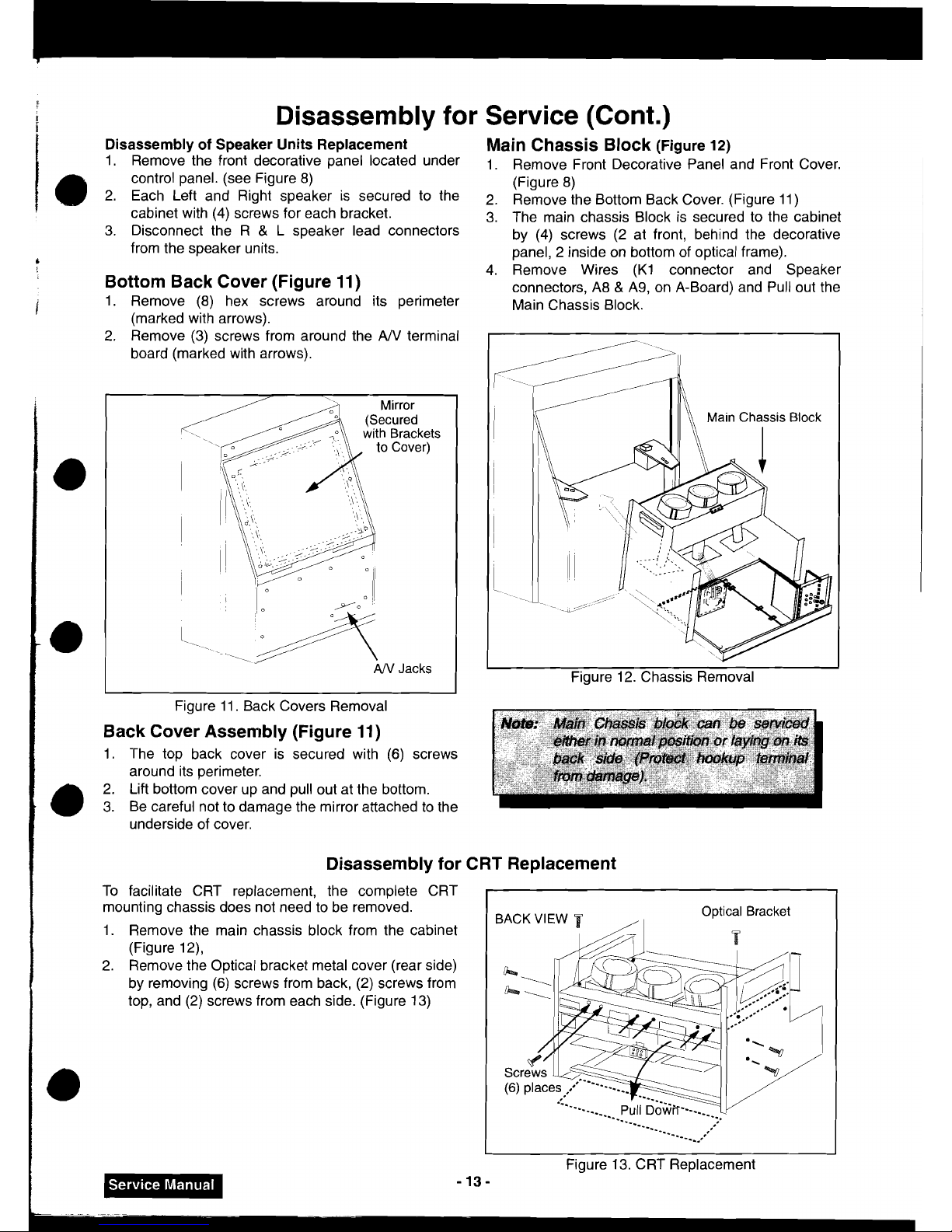

Bottom Back Cover (Figure

11)

\

1. Remove (8) hex screws around its perimeter

(marked with arrows).

2.

Remove (3) screws from around the

AN

terminal

board (marked with arrows).

AN

Jacks

Main Chassis Block

(Figure

12)

1. Remove Front Decorative Panel and Front Cover.

(Figure 8)

2. Remove the Bottom Back Cover. (Figure 11

)

3. The main chassis Block is secured to the cabinet

by (4) screws (2 at front, behind the decorative

panel, 2 inside on bottom of optical frame).

4. Remove Wires (K1 connector and Speaker

connectors, A8

&

A9, on A-Board) and Pull out the

Main Chassis Block.

I

Figure 12. Chassis Removal

Figure 11. Back Covers Removal

Back Cover Asserrrbly (Figure

11)

1. The top back cover is secured with (6) screws

around its perimeter.

2. Lift bottom cover up and pull out at the bottom.

/

3.

Be careful not to damage the mirror attached to the

I

underside of cover.

I

Disassembly for CRT Replacement

To facilitate CRT replacement, the complete CRT

mounting chassis does not need to be removed.

1. Remove the main chassis block from the cabinet

(Figure

12),

2. Remove the Optical bracket metal cover (rear side)

by removing (6) screws from back, (2) screws from

top, and (2) screws from each side. (Figure 13)

BACK VIEW

Optical Bracket

/I

Figure 13. CRT Replacement

-13-

Disassembly

for

Service

(Cont.)

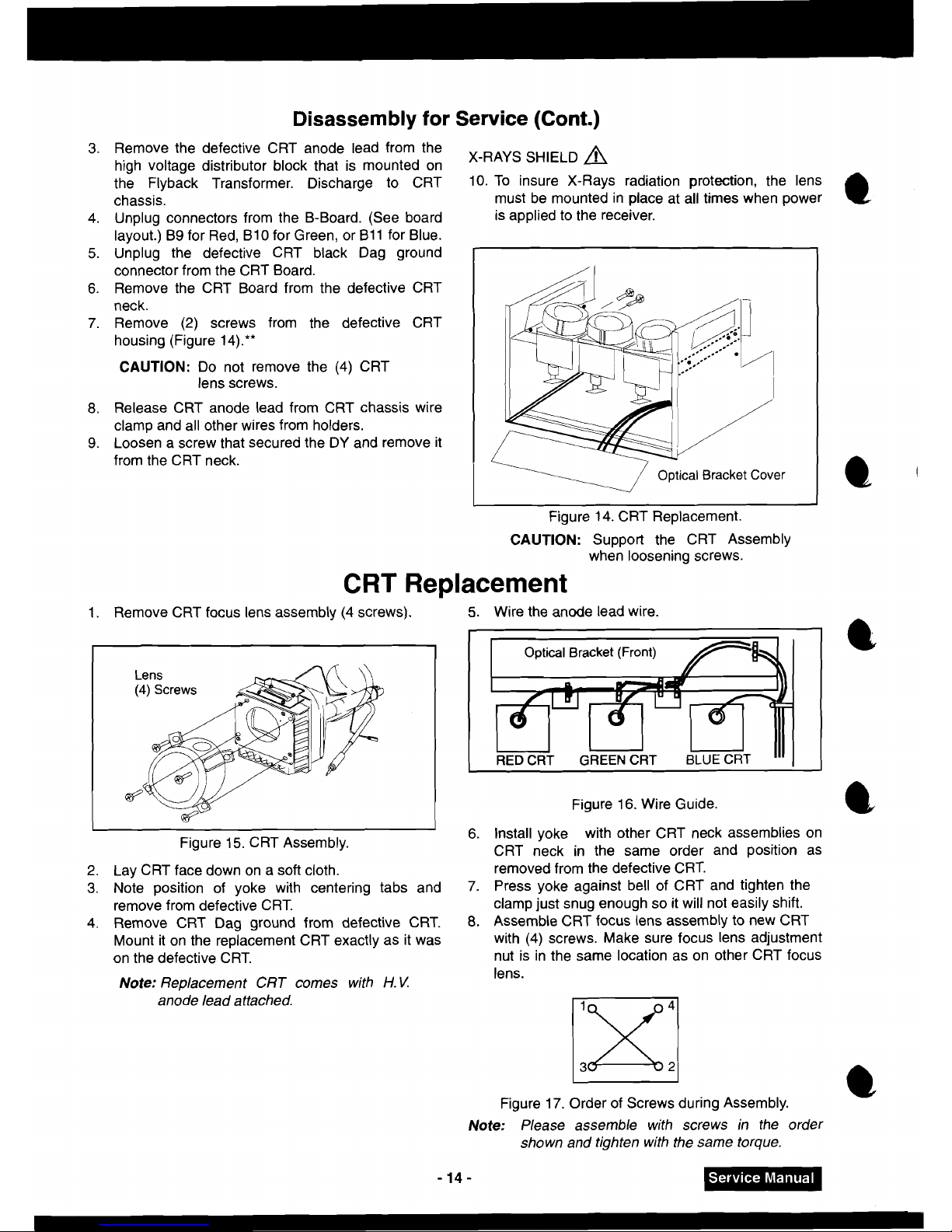

3.

Remove the defective CRT anode lead from the

high voltage distributor block that is mounted on

X-RAYS SHIELD

A

the Flyback Transformer. Discharge to CRT 10. TO insure X-Rays radiation protection, the lens

chassis.

must be mounted in place at all times when power

4. Unplug connectors from the B-Board. (See board

is applied to the receiver.

layout.)

B9 for Red, 810 for Green, or I311 for Blue.

5. Unplug the defective CRT black Dag ground

connector from the CRT Board.

6. Remove the CRT Board from the defective CRT

neck.

7. Remove (2) screws from the defective CRT

housing (Figure

14).**

CAUTION:

Do not remove the (4) CRT

lens screws.

8.

Release CRT anode lead from CRT chassis wire

clamp and all other wires from holders.

9. Loosen a screw that secured the DY and remove it

from the CRT neck.

Optical Bracket Cover

-

~i~ure 14. CRT Replacement.

CAUTION:

Support the CRT Assembly

when loosening screws.

CRT Replacement

1.

Remove CRT focus lens assembly (4 screws).

5.

Wire the anode lead wire.

Figure 16. Wire Guide.

6.

Install yoke with other CRT neck assemblies on

CRT neck in the same order and position as

removed from the defective CRT.

7.

Press yoke against bell of CRT and tighten the

clamp just snug enough so it will not easily shift.

8.

Assemble CRT focus lens assembly to new CRT

with (4) screws. Make sure focus lens adjustment

nut is in the same location as on other CRT focus

lens.

Figure 15. CRT Assembly.

2. Lay CRT face down on a soft cloth.

3.

Note position of yoke with centering tabs and

remove from defective CRT.

4. Remove CRT Dag ground from defective CRT.

Mount it on the replacement CRT exactly as it was

on the defective CRT.

Note:

Replacement CRT comes with

H.

V.

anode lead attached.

Figure 17. Order of Screws during Assembly.

C

Note:

Please assemble with screws in the order

shown and tighten with the same torque.

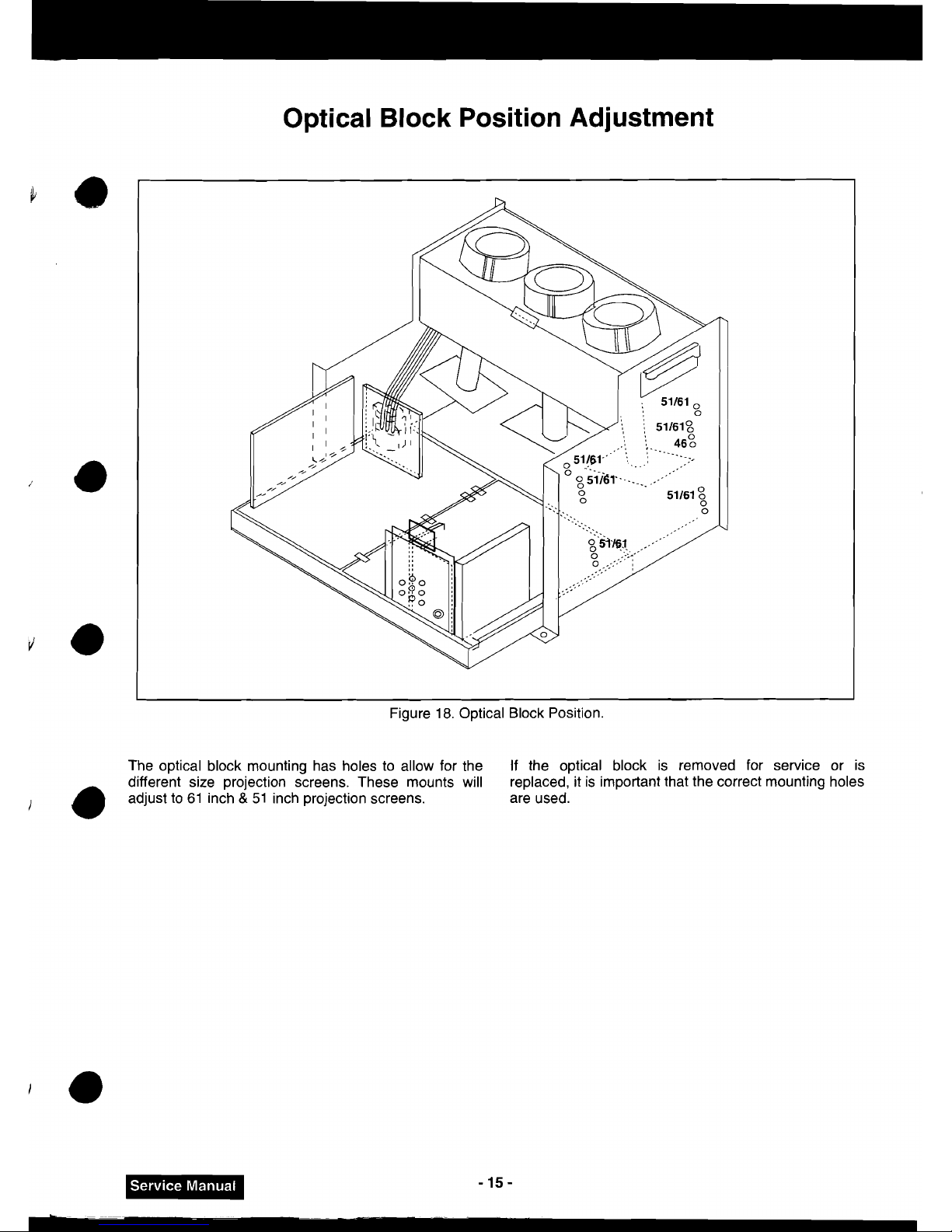

Optical Block Position Adjustment

Figure

18.

Optical Block Position.

The optical block mounting has holes to allow for the

If

the optical block is removed for service or is

different size projection screens. These mounts will replaced, it is important that the correct mounting holes

adjust to

61

inch

&

51

inch projection screens. are used.

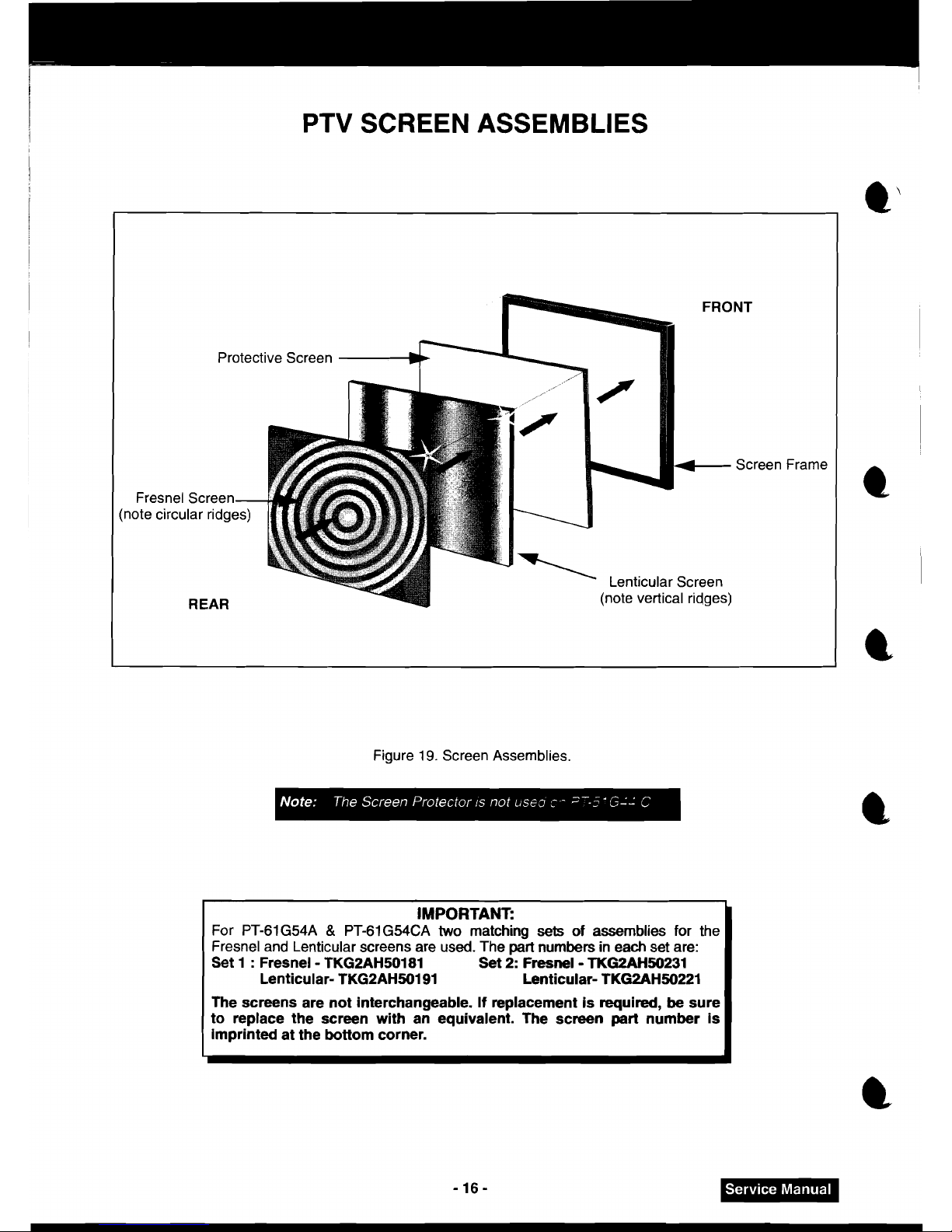

PTV

SCREEN ASSEMBLIES

Protective Screen

Screen Frame

Fresnel Screen

(note circular

r~dges)

Lentrcular Screen

REAR

(note vertical rldges)

Figure

19.

Screen Assemblies.

IMPORTANT:

For PT-61G54A & PT-61G54CA two matching

sets

of

assemblies for the

Fresnel and Lenticular screens are used. The

part

numbers

in each set are:

Set 1 : Fresnel - TKG2AH50181

Set

2: Fresnel - TKG2AH50231

Lenticular- TKG2AH50191 Lenticular- TKG2AH50221

The screens are not interchangeable. If replacement is required, be sure

to replace the screen with an equivalent. The screen

part

number is

imprinted at the bottom corner.

I

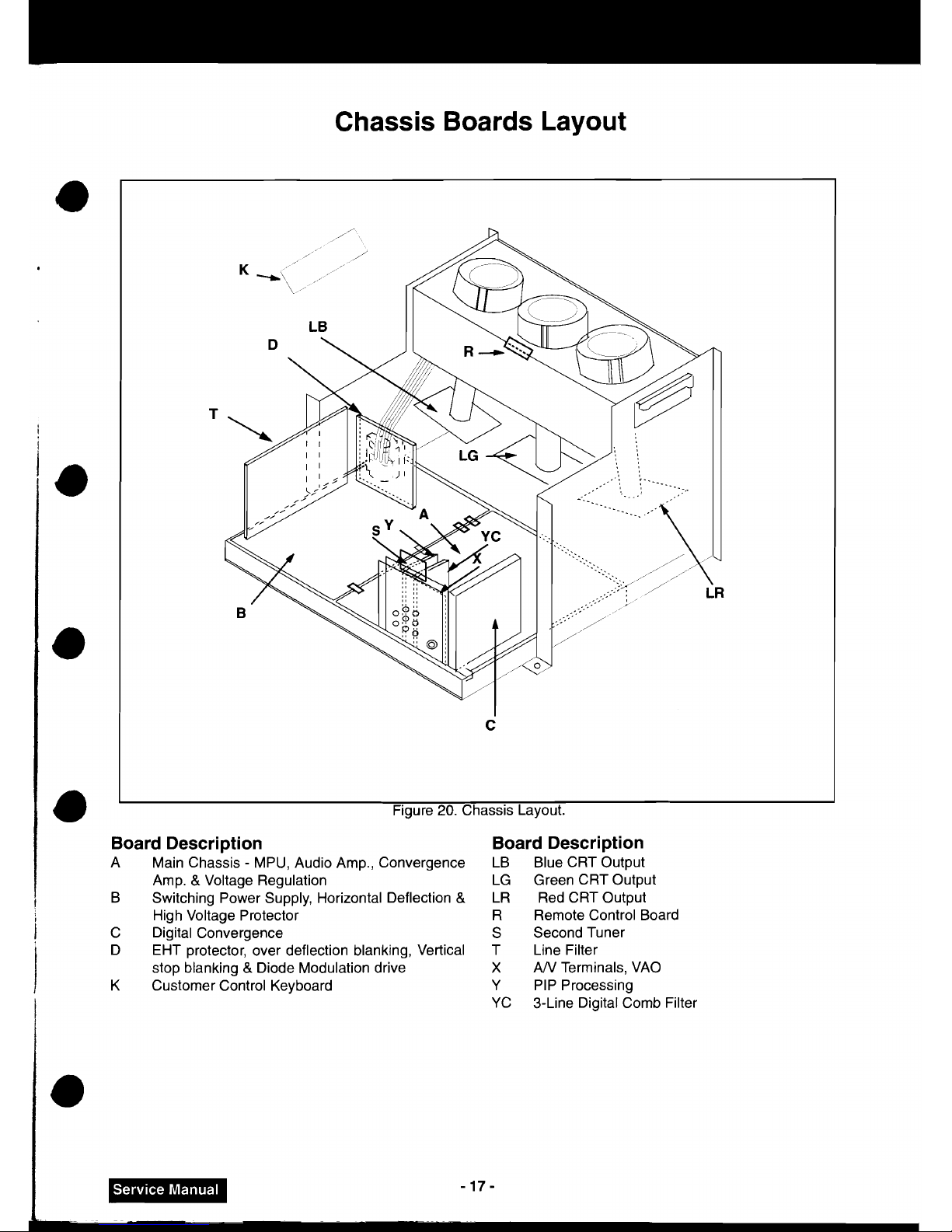

Chassis Boards Layout

i

1

..

T

I

C

Figure

20.

Chassis Layout.

!

Board Description Board Description

A Main Chassis - MPU, Audio Amp., Convergence LB Blue CRT Output

Amp.

&

Voltage Regulation LG Green CRT Output

B Switching Power Supply, Horizontal Deflection

&

LR Red CRT Output

High Voltage Protector

R Remote Control Board

I

C Digital Convergence

S Second Tuner

D EHT protector, over deflection blanking, Vertical T Line Filter

stop blanking

&

Diode Modulation drive

X

AN

Terminals, VAO

K Customer Control Keyboard Y PIP Processing

i

YC 3-Line Digital Comb Filter

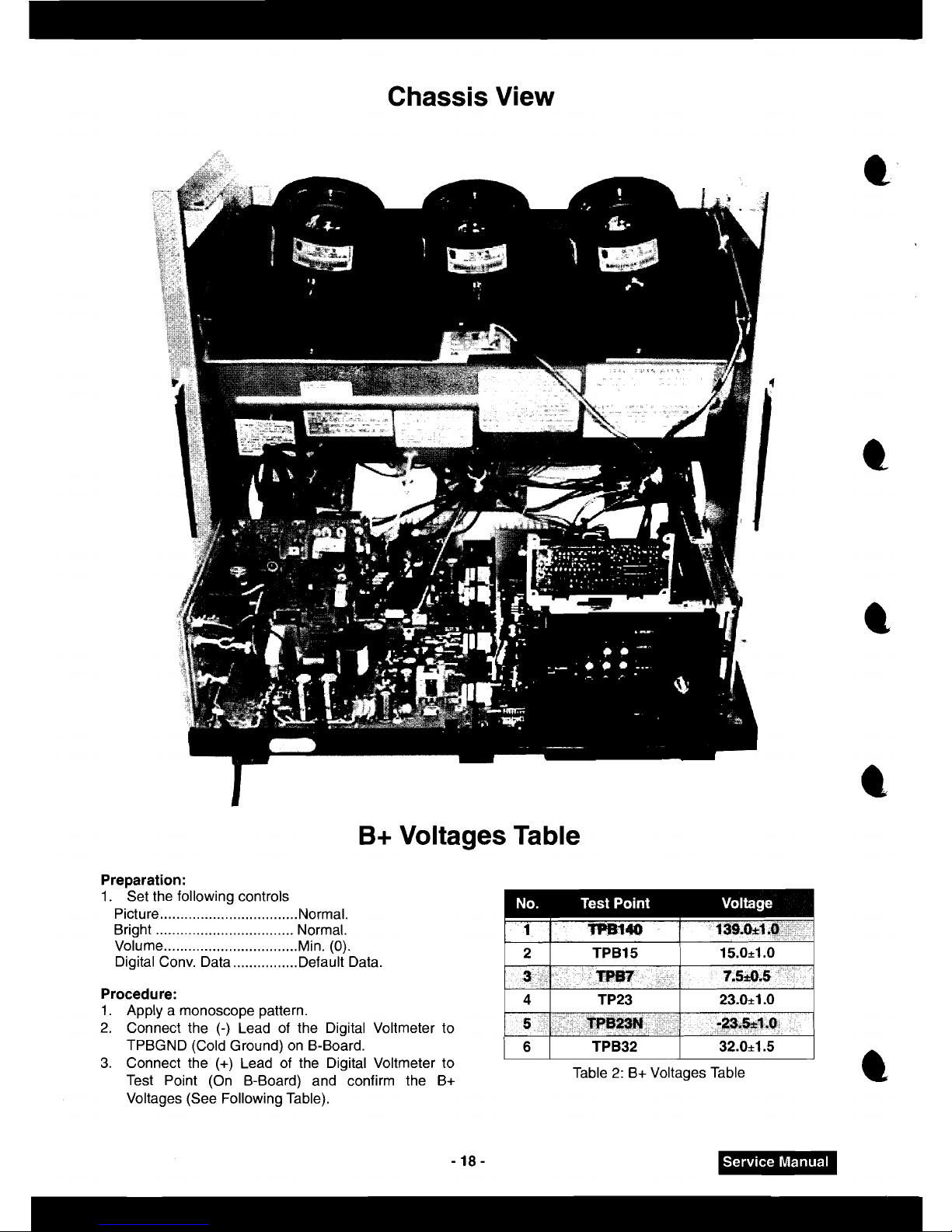

Chassis View

B+

Voltages Table

Preparation:

1.

Set the following controls

Picture

..................................

IYormaI.

Bright

..................................

Normal.

Volume

.................................

Mi.

(0).

Digital Conv. Data

................

Default Data.

Procedure:

1.

Apply a monoscope pattern.

2.

Connect the

(-)

Lead of the Digital Voltmeter to

TPBGND (Cold Ground) on

6-Board.

3.

Connect the

(+)

Lead of the Digital Voltmeter to

Test Point (On

6-Board) and confirm the B+

Voltages (See Following Table).

Table

2:

B+ Voltages Table

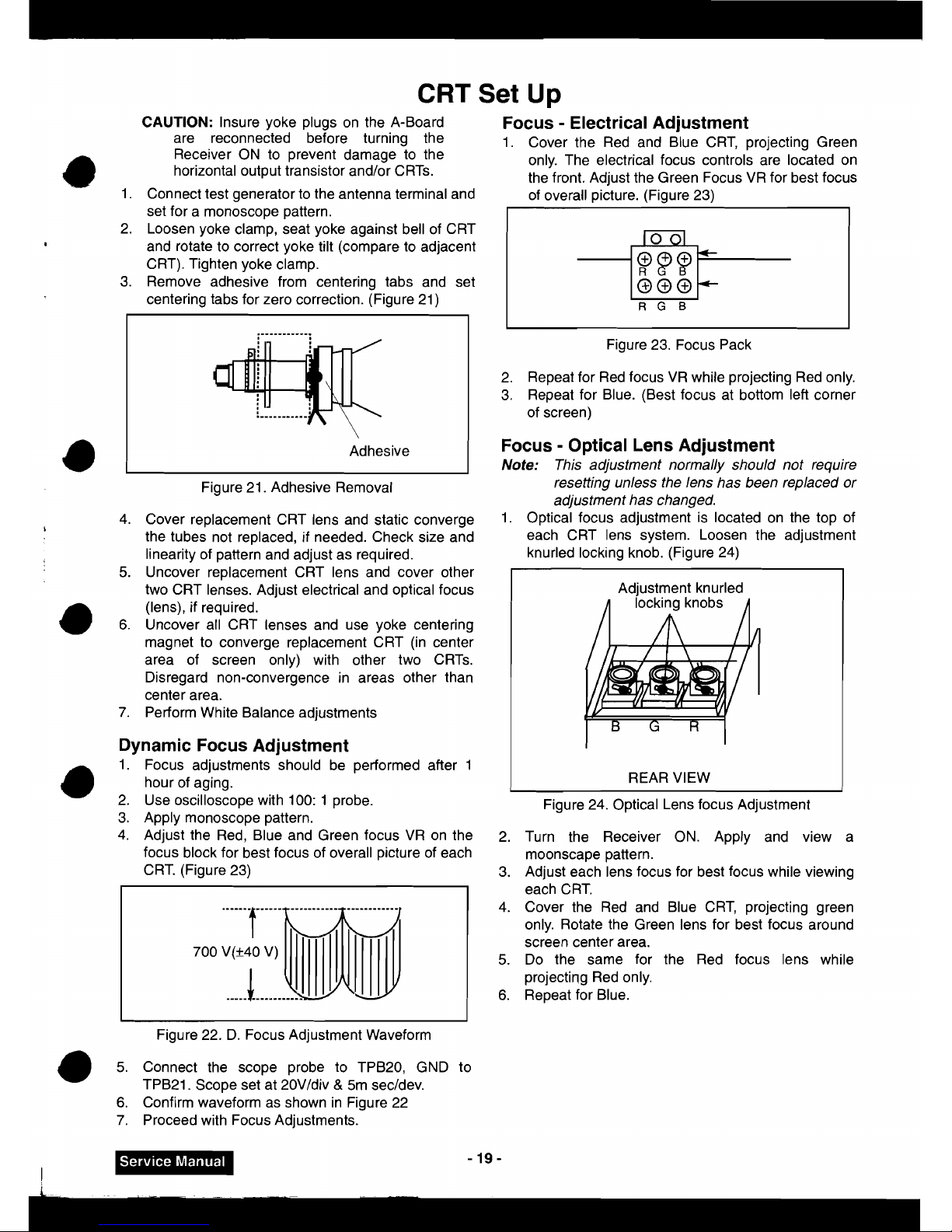

CRT

Set

Up

.-----------,

Adhesive

CAUTION:

Insure yoke plugs on the A-Board

Focus - Electrical Adjustment

are reconnected before turning the

1.

Cover the Red and Blue CRT, projecting Green

Receiver ON to prevent damage to the only. The electrical focus controls are located on

horizontal output transistor

and/or CRTs.

the front. Adjust the Green Focus VR for best focus

1.

Connect test generator to the antenna terminal and

of overall picture. (Figure 23)

Figure 21. Adhesive Removal

set for a monoscope pattern.

2. Loosen yoke clamp, seat yoke against bell of CRT

.

and rotate to correct yoke tilt (compare to adjacent

CRT). Tighten yoke clamp.

3. Remove adhesive from centering tabs and set

centering tabs for zero correction. (Figure 21)

4. Cover replacement CRT lens and static converge

L

the tubes not replaced, if needed. Check size and

linearity of pattern and adjust as required.

5.

Uncover replacement CRT lens and cover other

two CRT lenses. Adjust electrical and optical focus

(lens), if required.

6.

Uncover all CRT lenses and use yoke centering

magnet to converge replacement CRT (in center

area of screen only) with other two

CRTs.

Disregard non-convergence in areas other than

center area.

7.

Perform White Balance adjustments

-%-r

000

RGB

Dynamic Focus Adjustment

1.

Focus adjustments should be performed after 1

hour of aging.

2. Use oscilloscope with 100: 1 probe.

3. Apply monoscope pattern.

4. Adjust the Red, Blue and Green focus VR on the

focus block for best focus of overall picture of each

CRT. (Figure 23)

Figure 22. D. Focus Adjustment Waveform

Figure 23. Focus Pack

2. Repeat for Red focus VR while projecting Red only.

3. Repeat for Blue. (Best focus at bottom left corner

of screen)

Focus - Optical Lens Adjustment

Note:

This adjustment normally should not require

resetting unless the lens has been replaced or

adjustment has changed.

1.

Optical focus adjustment is located on the top of

each CRT lens system. Loosen the adjustment

knurled locking knob. (Figure 24)

Adjustment knurled

REAR

VIEW

Figure 24. Optical Lens focus Adjustment

2. Turn the Receiver ON. Apply and view a

moonscape pattern.

3. Adjust each lens focus for best focus while viewing

each CRT.

4. Cover the Red and Blue CRT, projecting green

only. Rotate the Green lens for best focus around

screen center area.

5.

Do the same for the Red focus lens while

projectiug Red only.

6.

Repeat for Blue.

5. Connect the scope probe to TPB20, GND to

TPB21. Scope set at 20VIdiv & 5m secldev.

6.

Confirm waveform as shown in Figure 22

7.

Proceed with Focus Adjustments.

Loading...

Loading...