Panasonic PT-47WX52F, PT-47WX52CF, PT-47WX42F, PT-47WX42CF Service Manual

ORDER NO. MTNC020409C1

B2

Service Manual

HDTV MONITOR

Main Manual

(P7W)

Panasonic

Models

Chassis

PT-47WX52F EP824

PT-47WX52CF EP824

PT-47WX42F EP824

PT-47WX42CF EP824

This service manual is issued as a service guide for the models of the P7W family listed above. Included in this

manual are a set of schematics, alignment procedures, disassembly procedures and a complete parts list.

“WARNING! This ServiceManualis designed for experiencedrepairtechniciansonly and is not designed for useby the generalpublic.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experiencedprofessional technicians. Any attempt to

service or repair the product or products dealt with in this Service Manual by anyone else could result in serious injury or death.”

The service technician is requiredtoreadand follow the “Safety Precautions”and“Important Safety Notice” in the Main Manual.

Copyright 2002by Matsushita Electric Corporation of

America. All rights reserved. Unauthorized copying

®

and distribution is a violation of law.

Important safety notice

Special components are used in this projection television which are important for safety. These components are

identified on the schematic diagram by the symbol and printed in BOLD TYPE on the replacement part list. It is

essential that these critical parts are replaced with the manufacturer’s specified replacement part to prevent x-ray

radiation, shock, fire or other hazards. Do not modify the original design without the manufacturer’s permission.

Safety precautions

General guidelines

An

isolation transformer

during the servicing of a PTV whose chassis is not

isolated from AC power line. Use a transformer of

adequate power rating as this protects the technician

from accidents resulting in personal injury from

electrical shocks. It will also protect the PTV from being

damaged by accidental shorting that may occur

during servicing.

When servicing, observe the original lead dress,

especially in the high voltage circuit. Replace all

damaged parts (also parts that show signs of

overheating.)

Always replace protective devices,suchas

fishpaper, isolation resistors and capacitors, and

shields after servicing the PTV. Use only

manufacturer’s recommended rating for fuses, circuits

breakers, etc.

High potentials, as high as 32.5kV, are present when

this PTV is operating. Operation of the PTV without the

rear cover introduces danger for electrical shock.

Servicing should not be performed by anyone who is

not thoroughly familiar with the necessary precautions

when servicing high-voltage equipment.

Extreme care should be practiced when handling the

picture tube

due to atmospheric pressure. (14.7 lbs. per sq. in.). Do

not nick or scratch the glass or subject it to any undue

pressure. When handling, use safety goggles and

heavy gloves for protection. Discharge the picture

tube by shorting the anode to chassis ground (not to

the cabinet or to other mounting hardware). When

discharging connect cold ground (i.e. DAG ground

lead) to the anode with a well insulated wire or use a

grounding probe.

. Rough handling may cause it to implode

X-ray precautions

The front area (between the projection tube and the

lens) is enclosed by a metal box t o ensure positive

safety during normal and abnormal conditions when

checking and repairing. To fully ensure safety, the

following precautions must be observed.

1. Do not remove the lens or metal box.

2. Make sure to turn the power OFF when the lens is

removed or when checking the cleanliness of the

lens.

3. Do not remove the lens or metal box to check the

projection tube for operation by watching it directly.

Use a mirror or paper to view the image.

Before returning a serviced PTV to the owner,the

service technician must thoroughly test the unit to

ensure that is completely safe to operate. Do not use a

line isolation transformer when testing.

Leakage current cold check

Unplug the AC cord and connect a jumper between the

two plug prongs. Press the POWER switch ON.

Measure the resistance between the jumpered AC plug

and expose metallic parts such as screw heads,

ServiceManual

should always be used

antenna terminals, control shafts, etc. If the exposed

metallic part has a return path to the chassis, the

reading should be between 240kΩ and 5.2MΩ. If the

exposed metallic part does not have a return path to

the chassis, the reading should be infinite.

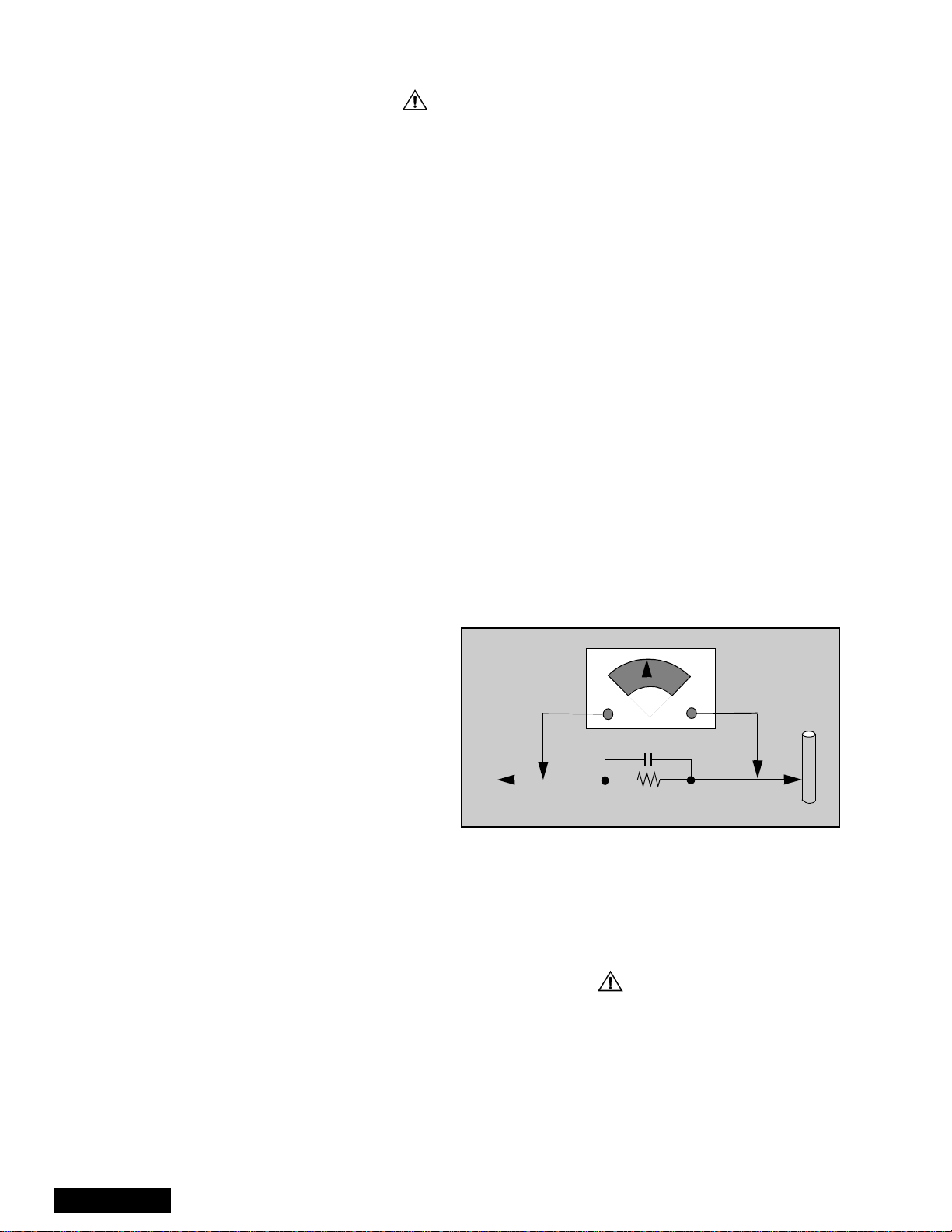

Leakage current hot check (see figure 1)

Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer during the check.

Connect a 1.5kΩ 10 watt resistor in parallel with a

0.15µF capacitor between and exposed metallic part

and ground. Use earth ground, for example a

water pipe.

Using a DVM with a 1000 ohms/volt sensitivity or

higher, measure the AC potential across the resistor.

Repeat the procedure and measure the voltage

present with all other expose metallic parts.

Verify any potential does not exceed 0.75 volt RMS. A

leakage current tester (such a Simpson model 229,

Sencore model PR57 or equivalent) may be used in

the above procedure, in which case any current

measure must not exceed 0.5 milliamp. If any

measurement is out of the specified limits, there is a

possibility of a shock hazard and the PTV must be

repaired and rechecked before it is returned to

the customer.

AC VOLTMETER

COLD

WATER

PIPE

(GROUND)

0.15µF

TO INSTRUMENT’S

EXPOSED METAL

PARTS

Figure 1. Hot check circuit

1500Ω,10W

Insulation test

Connect an insulation tester between an exposed

metallic part and AC line.

Apply 1080VAC/60Hz for 1 second. Confirm that the

current measurement is 0.5mA ~ 2.0mA. Repeat test

with other metallicexposed parts.

X-ray radiation

WARNING: The potential source of x-ray radiation in the

PTV is in the high voltage section and the picture tube.

Note: It is important to use calibrated equipment.

Apply all black video signals (1080i) and confirm high

voltage measures 31.5 ± 1.0kV. If the high voltage is

not within the range, change C514 to 1800pF, 2000pF,

2400pF or 2700pF until the desired value is obtained.

Apply NTSC white pattern and confirm the high voltage

measures 30.1 ± 1.5kV.

Apply HD 1080I white pattern and confirm the high

voltage measures 30.1 ± 1.5kV

-2-

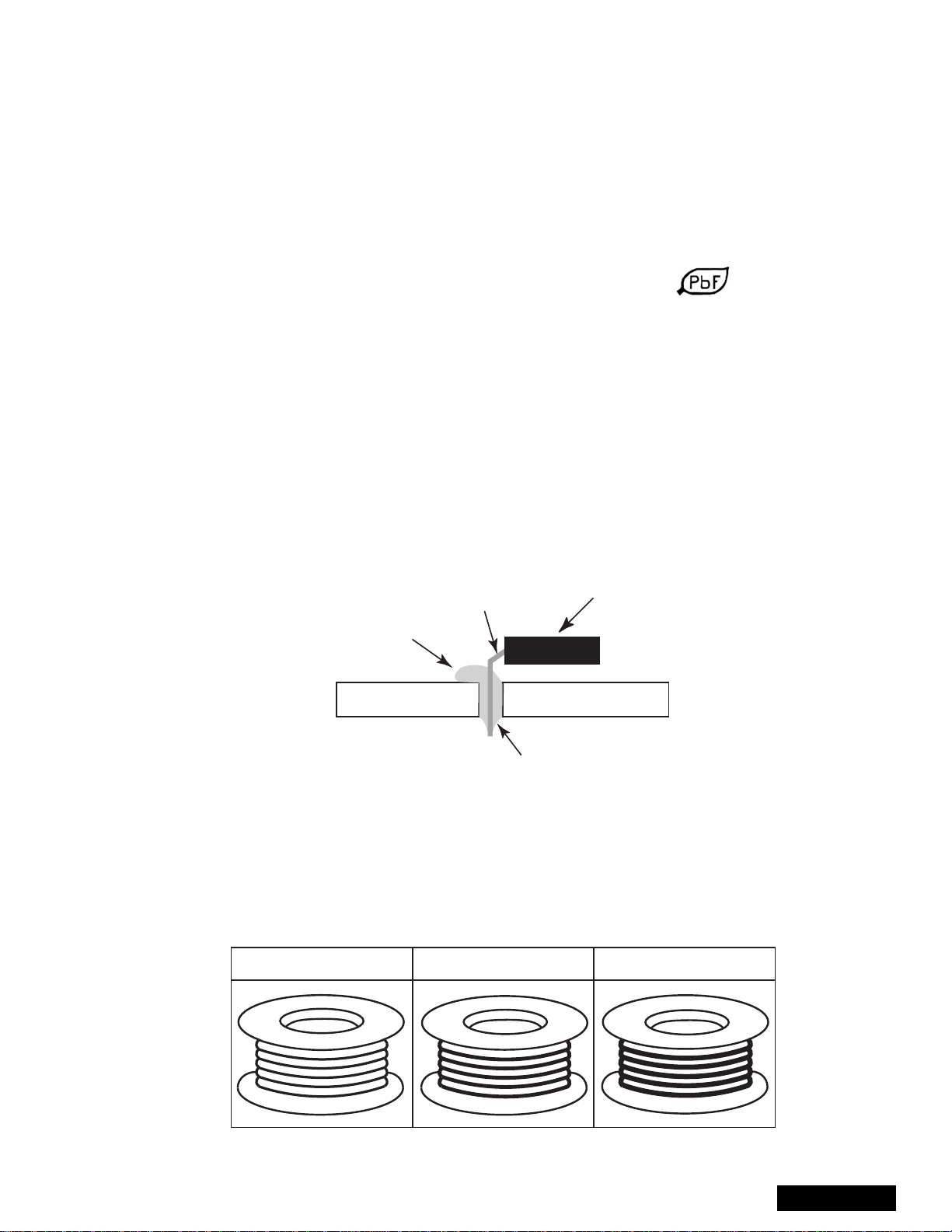

About lead free solder (PbF)

component

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For

service and repair work, we’d suggest the use of Pb free solder as well, although Pb solder may be

used.

PCBs manufactured using lead free solder will have the PbF within a leaf symbol stamped on the

back of PCB.

Caution

• Pb free solder has a higher melting point than standard solder. Typically the melting

point is 50 ~ 70 °F(30~40°C) higher. Please use a high temperature soldering iron

and set it to 700 ± 20 °F(370± 10 °C).

• Pb free solder will tend to splash when heated too high (about 1100 °For600°C).

If you must use Pb solder, please completely remove all of the Pb free solder on the

pins or solder area before applying Pb solder. If this is not practical, be sure to heat the

Pb free solder until it melts, before applying Pb solder.

• After applying PbF solder to double layered boards, please check the component side

for excess solder which may flow onto the opposite side. (see figure below)

component

remove all of the

excess solder

pin

slice view

solder

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu

(tin, silver, copper) solder. However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder

canalsobeused.

0.3mm X 100g

0.6mm X 100g 1.0mm X 100g

-3-

ServiceManual

Important safety tests

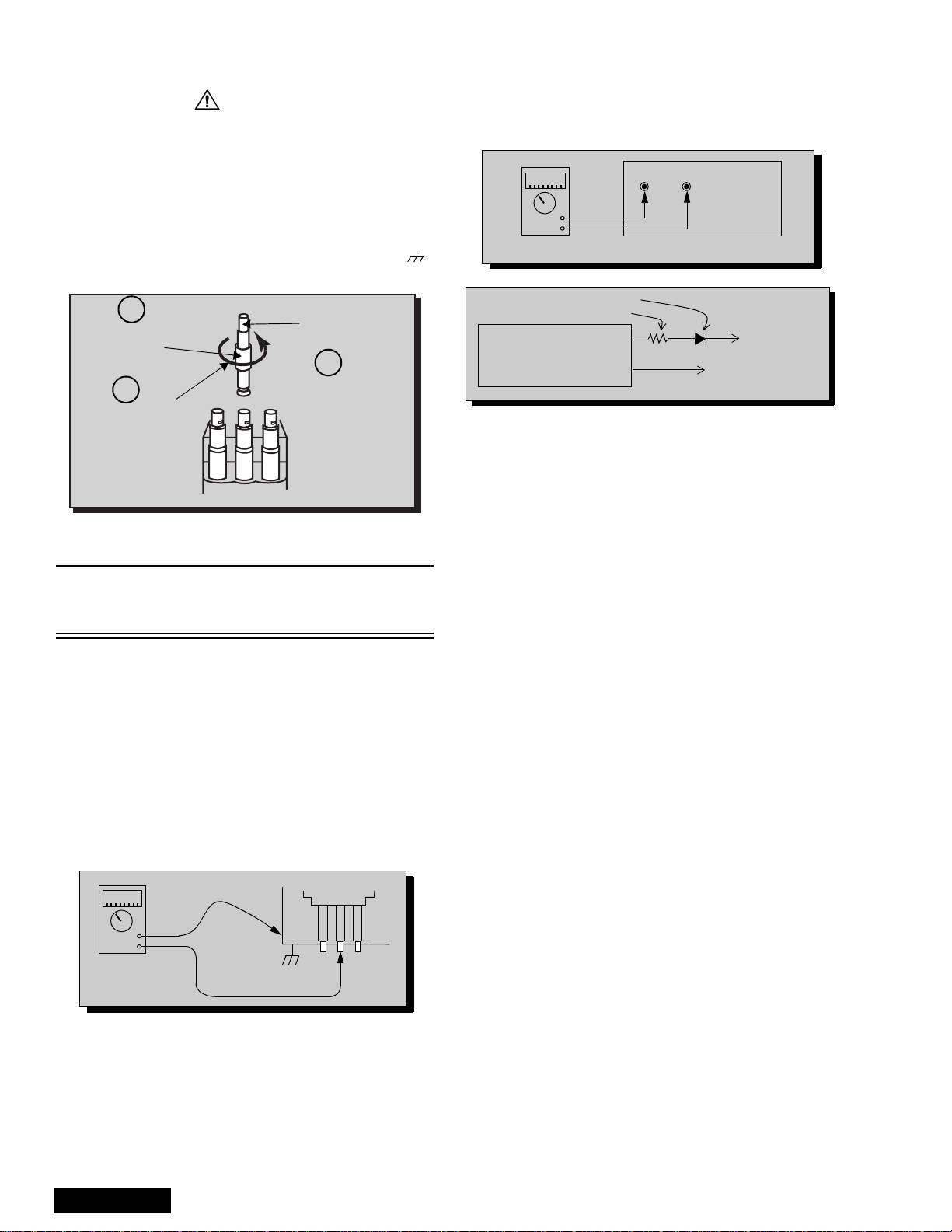

Measuring H.V.

The anode caps are cemented to the CRTs. To gain

access for high voltage measurement, remove the red

CRT’s anode lead from the flyback transformer

distributor. Grasp the anode lead protective cap at its

bottom and squeeze it against the locking cap body

inside, rotate 1/4 turn counter clockwise and pull the

anode lead sleeve out of the FBT distributor. Connect a

high voltage lead (+) from your H.V. meter to the FBT

distributor, and the common (-) to cold ground ( ).

(see figure 2).

1

Grasp protective

Anode lead

rubber cap

3

2

Push & rotate

Discharge to

CRT chassis

cap counterclockwise

to remove

FBT distributor

Figure 2. Removal of FBT leads

Note: Reinsert the anode lead into the FBT

distributor until it is tightly and fully seated.

Turn the locking cap clockwise to lock in place.

(EHT) Protector operation check

With the cabinet back removed, apply a nominal 120V

AC to the PTV.

Over voltage test

Preparation:

1. Turn PTV “OFF”

2. Connect a NTSC signal generator to the

antenna terminal.

3. Connect DVM (+) TPD50 and (-) TPD51 on

D Board (see figure 4)

4. Connect a H.V. meter (static type, class 0.1) with

high voltage leads to high voltage distributor

on FBT. (See figure 4)

TPD51 TPD50

-

+

D-Board

DVM

D-Board

IC802 PIN 2

OR TPD8

Variable

power

supply

MA150

100Ω 1/2 W

(+)

(15~25DC)

(-)

HEAT SINK OF Q551

Figure 4. DVM & power supply c onnection.

5. Connect the 15 ~25 VDC variable power supply to

(+) TPD8 or IC802 pin 2 (D-Board) and (-) heat

sink of Q551 (see figure 4).

Procedures:

1. Apply a NTSC white pattern.

2. Turn PTV ON.

3. Adjust the picture or brightness controls so that the

DVM reads 12.4 volts ±0.4 volts.

4. Increase the variable power supply until set turns

off. The set should turn off at 12.4 volts ± 0.4 volts

(DVM) and high voltage less than 36.4kV.

5. If the DVM reading is other than 12.4 volts (± 0.4

volts), readjust picture or brightness control and

repeat steps 3.

6. Turn off the variable supply and confirm that the set

will turn on with the remote control.

-

+

H.V. METER

ServiceManual

Cold ground

FBT Distributor

CRT

CHASSIS

Figure 3.Measuring H.V.

-4-

About format aspect switching(WX 16:9 or HX 4:3)

Widescreen 16:9 and non-widescreen 4:3 PTVs use the same

light box, for this reason is important to set it to the correct

version (16:9 or 4:3). To change the format please refer to

figure 62 on page 43.

Be sure to select the correct format for the serviced PTV.

-5-

ServiceManual

Importantsafetynotice...................2

Safetyprecautions........................2

Generalguidelines..................2

X-rayprecautions ..................2

Leakagecurrentcoldcheck...........2

Leakagecurrenthotcheck ...........2

Insulationtest .....................2

X-rayradiation.....................2

About lead free solder (PbF) . . . . . . . ........3

SuggestedPbfreesolder............3

Importantsafetytests....................4

MeasuringH.V.....................4

(EHT) Protector operation check. . . . . . . 4

About format aspect switching. . . . . ........5

Servicenotes ...........................7

Leadless chip component . . . . ........7

Componentremoval ................7

Chip component installation . . ........7

HowtoreplaceFlat-IC...............7

Featuretable............................9

Boardsdesignation.....................10

PTV-Locationofcontrols................11

Quick reference control operation . . . . . 11

Remote-Locationofcontrols.............12

Auto diagnosis feature. . . . . . . . . . . . .......14

A-Boardcheckpoints ...................15

A-Board check points waveforms. . . .......16

Chassis&boardslayout.................17

Boarddescription..................17

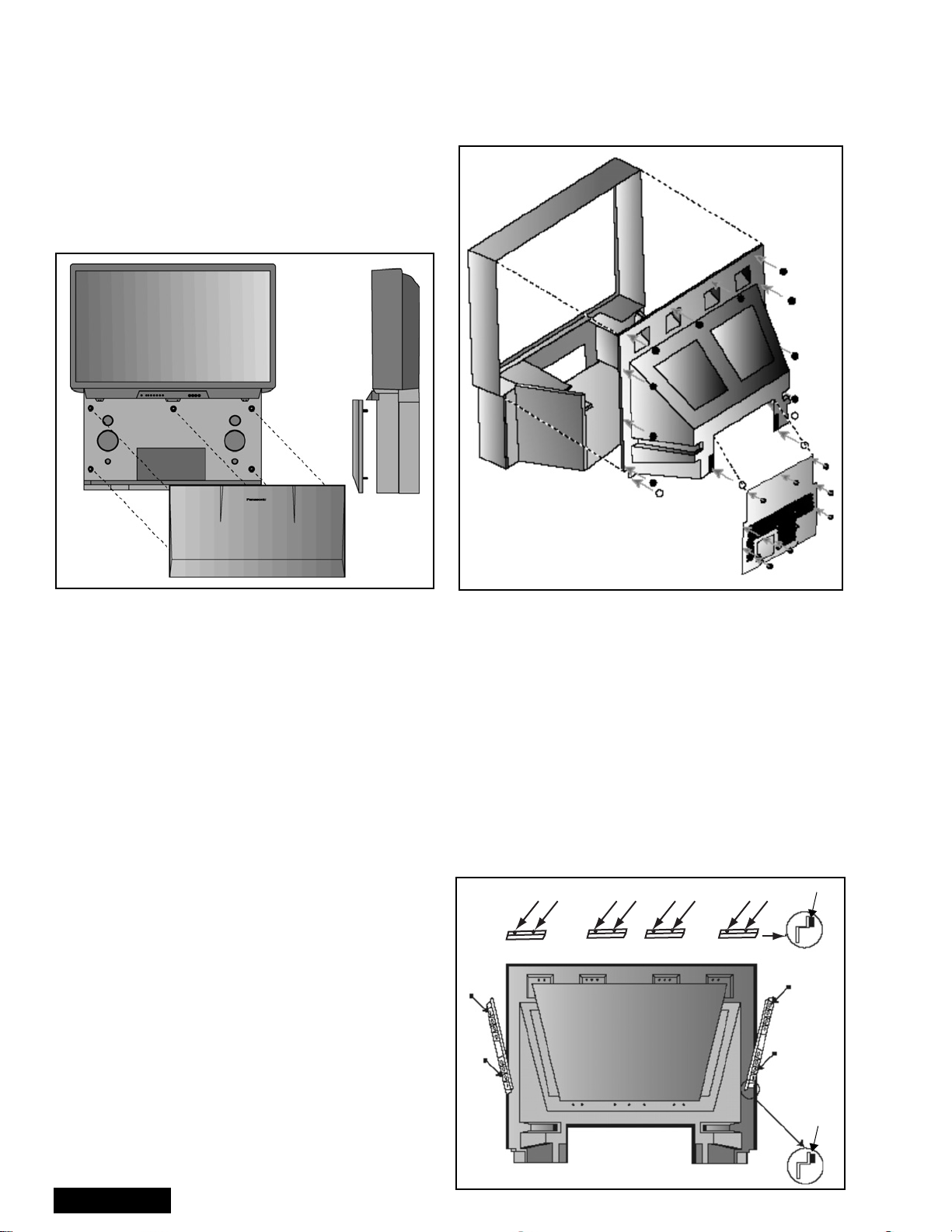

Disassemblyforservice .................18

Speakergrilleremoval..............18

Keyboardremoval.................18

Speakersreplacement..............18

Cabinet back lower cover removal . . .. 18

Cabinetbackcoverremoval.........18

Mirrorremoval....................18

Screenframeremoval..............19

Screenassembly..................19

Mainchassisblock ................19

Chassisassembly.................19

Disassembly for CRT replacement . . . . 20

CRTreplacement .................20

Optical block position adjustment . . . . . 21

PTVscreenassemblies.............22

B+voltagestable..................22

CRTsetup.............................23

Dynamicfocusadjustments..........23

Electricaladjustment...............23

Focus - Optical lens adjustment . . . . . .24

Opticaladjustments................24

NTSC Vertical size adjustment (VSIZE) 25

HD 1080i Vertical size

adjustment(VSIZE).............25

NTSC ZOOM Vertical size

adjustment(VSIZE).............26

NTSC Horizontal phase

adjustment(H-POS)............26

HD 1080i Horizontal phase adjustment

(H-POS) .....................26

Trapezoid adjustment (EWTRA) . . . . . . 26

NTSC Pincushion adjustment (PCC). . .26

HD 1080i Pincushion

adjustment(PCC)..............27

Centering magnets adjustment . . . . . . .27

NTSC Horizontal size

adjustment(HWID).............27

HD 1080i Horizontal size adjustment

(HWID)......................27

Convergenceadjustment............27

Coarse adjustmentmode (COARSE) . .29

Fine adjustment mode

(FINE)(convergence)...........30

Horizontal and vertical size check . . . . .33

Convergence alignment template . . . . . 33

Service mode (electronic controls). . . . . . . . . 34

Quickentrytoservicemode.........34

To toggle between aging

andservicemodes.............34

Exitingtheservicemode............34

Tocheckcolors...................34

Table of the service adjustments

items available for each format . . . . 35

480iServicemodeDACs ...........37

480pServicemodeDACs...........39

1080iServicemodeDACs ..........41

Instructional flow chart for format

aspect switching

(WX16:9orHX4:3)............43

Instructional flow chart for

servicemode..................44

NTSC Sub-Bright

adjustment(BRIGHT)...........46

1080i Sub-Bright

adjustment(BRIGHT)...........46

NTSC Color adjustment

(TINT,B-Y_G,R-Y_A) ..........46

1080i Color adjustment

(TINT,B-Y_G,R-Y_A) ..........46

Red, green & blue screen cutoff . . . . . .47

Whitebalanceadjustment...........47

Tintandcolorcheck ...............47

MTScircuitadjustments ............47

Inputleveladjustment(MTSIN).......47

Stereo separation adjustment

(SEPAL&SEPAH).............47

ClockAdjustment(CLOCK)..........48

Audiosignalpathblockdiagram ..........49

Video-chroma signal path block diagram . . . 50

IICconnection..........................51

Description of connectors. . . . ............52

Partslist ..............................53

Schematics........................66~103

ServiceManual

-6-

Service notes

Note: These components are affixed with glue. Be careful not to break or damage any foil under the

component or at the pins of the ICs when removing. Usually applying heat to the component for

a short time while twisting with tweezers will break the component loose.

Leadless chip component

(surface mount)

Chip components must be replaced with identical chips

due to critical foil track spacing. There are no holes in

the board to mount standard transistors or diodes.

Some chip capacitor or resistor board solder pads may

have holes through the board, however the hole

diameter limits standard resistor replacement to 1/8

watt. Standard capacitor may also be limited for the

same reason. It is recommended that identical

components be used.

Chip resistor have a three digi t numerical resistance

code - 1st and 2nd significant digits and a multiplier.

Example: 162 = 1600 or 1.6kΩ resistor, 0 = 0Ω (jumper).

Chip capacitors generally do not have the value

indicated on the capacitor. The color on the component

indicates the general range of the capacitance.

Chip transistors are identified by a two letter code. The

first letter indicated the type and the second letter , the

grade of transistor.

Chip diodes have a two letter identification code as per

the code chart and are a dual diode pack with either

common anode or common cathode. Check the parts

list for correct diode number.

Component removal

1. Use solder wick to remove solder from component

end caps or terminal.

2. Without pulling up, carefully twist the component

with tweezers to break the adhesive.

3. Do not reuse removed leadless or chip

components since they are subject to stress

fracture during removal.

Chip component installation

1. Put a small amount of solder on the board

soldering pads.

2. Hold the chip component against the soldering

pads with tweezers or with a miniature alligator clip

and apply heat to the pad area with a 30 watts iron

until solder flows. Do not apply heat for more than

3 seconds.

TYPE

Chip components

GRADE

c

c

SOLDER

CAPS

How to replace Flat-IC

- Required tools -

• Soldering iron • De-solder braids

• Sharp pliers (wire

cutters and long nose)

1. Cut the pins of the defective IC with the wire cutter

pliers, and remove it completely away from the

board. If the IC is glued to the board, apply hot air

to complete the removal. CAUTION- Do not pull or

twist the pliers, it may damage the soldering pads

in the board .

Flat-IC

2. Using the soldering Iron and the long nose pliers,

remove the IC pins that are still attached to the

board.

3. Using the de-solder braid and the soldering Iron,

remove the solder from the board soldering pads.

4. Position the new flat IC in place (apply the pins of

the flat IC to the soldering pads where the pins

need to be soldered). Properly determine the

positions of the soldering pads and pins by

correctly aligning the polarity symbol. Start aligning

and soldering Pin No.1, then align and solder the

pin in the apposite corner of the IC, this will help to

align the rest of the pins.

Polarity

symbol

• Magnifier

Soldering

Iron

De-Solder

Braid

Soldering

Iron

b

b

ANODES

MH DIODE

e

e

TRANSISTOR

COMMON

CATHODE

SOLDER

CAPS

CAPACITOR

1ST DIGIT

RESISTOR

2ND DIGIT

MULTIPLIER

=1600 = 1.6k

5. Solder all pins to the soldering pads using a fine

tipped soldering iron.

Solder

Soldering

Iron

6. Check with a magnifier for solder bridge between

the pins or for dry joint between pins and soldering

pads. To remove a solder bridge, use a de-solder

braid as shown in the figure below.

De-Solder

Braid

-7-

Solder

Bridge

Soldering

Iron

ServiceManual

Service notes (continued)

IMPORTANT: To protect against possible damage to

the solid state devices due to arcing or static discharge,

make certain that all ground wires and CRT DAG wire

are securely connected.

CAUTION: The power supply circuit is above earth

ground and the chassis cannot be polarized. Use an

isolation transformer when servicing the PTV to avoid

damage to the test equipment or to the chassis.

Connect the test equipment to the proper ground (( )

or ( )) when servicing, or incorrect voltages will

be measured.

WARNING: This PTV has been designed to meet or

exceed applicable safety and x-ray radiation protection

as specified by government agencies and independent

testing laboratories.

To maintain original product safety design standards

relative to X-ray radiation and shock and fire hazard,

parts indicated with the symbol on the schematic

must be replaced with identical parts. Order parts from

the manufacturer’s parts center using the parts

numbers listed in this service manual, or provide the

chassis number and the part reference number.

For optimum performance and readability, all other

parts should be replaced with components of

identical specification.

ServiceManual

-8-

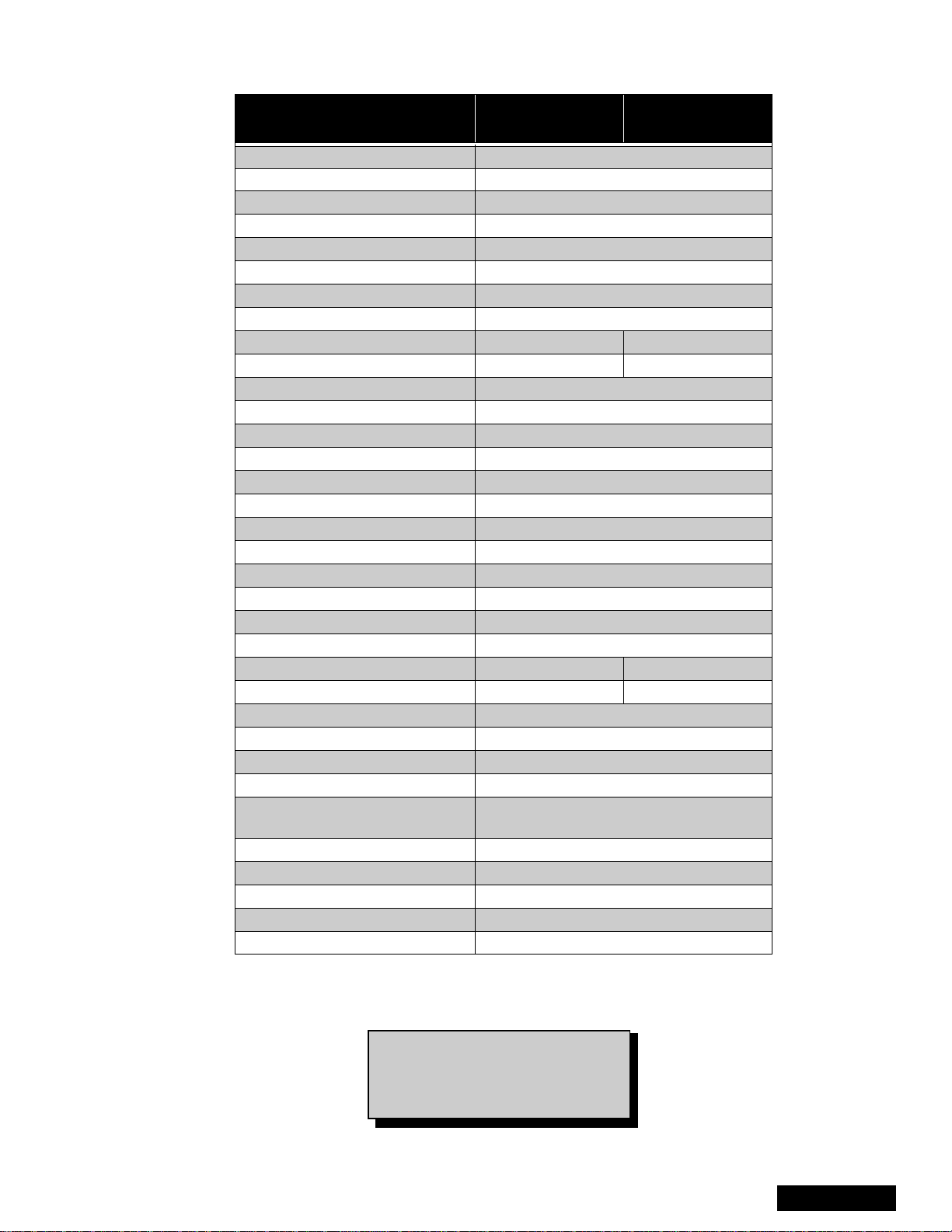

Feature table

FEATURE

Chassis P7W

Number of channels 181

Menu language Eng/Span/Fr

Closed caption (CC) X

V-Chip (USA/CANADA) X

Picture in Picture (PIP) 2T split

VIDEO INPUT MEMORY/SKIP SKIP

2RF X

Remote control number EUR7603Z30 EUR7603Z40

Screen protector W/PROT SCRN W/O PROT SCRN

Comb filter ADV 3D Y/C (NEW)

Color temp X

NEW YNR X

VM X (DIGITAL)

V/A norm X

DIGITAL SCAN RATE 1080i, 480p

NTSC LINE-DOUBLER 480p SMOOTH PROGRESSIVE

MTS/SAP/DBX X

Bass/Bl/Trebcontrol X

AI sound X

SURROUND X

Spatializer/BBE BBE

Built-in audio power 15WX2 (10%) 10WX2 (10%)

Number of speakers 4 2

A/V in (rear/front) 4 (3/1)

S-VHS in (rear/front) 2/1

Audio out Fixed & Variable

COMPONENT INPUT (Y, Pb, Pr) 2

Dimensions mm

WxDxH in

Weight (kg/lbs) 82/180.78

Power source (V/Hz) 120V 60Hz

Anode voltage 31.5kV ± 1.0kV

Video input jack 1Vp-p 75Ω,phono jack

Audio input jack 500mV RMS 47kΩ

PT-47WX52F

PT-47WX52CF

1111x1236x626

43.74x48.66x24.64

PT-47WX42F

PT-47WX42CF

Table 1: Feature Table

Specifications are subject to change

without notice or obligation.

Dimensions and weights are

approximate.

-9-

ServiceManual

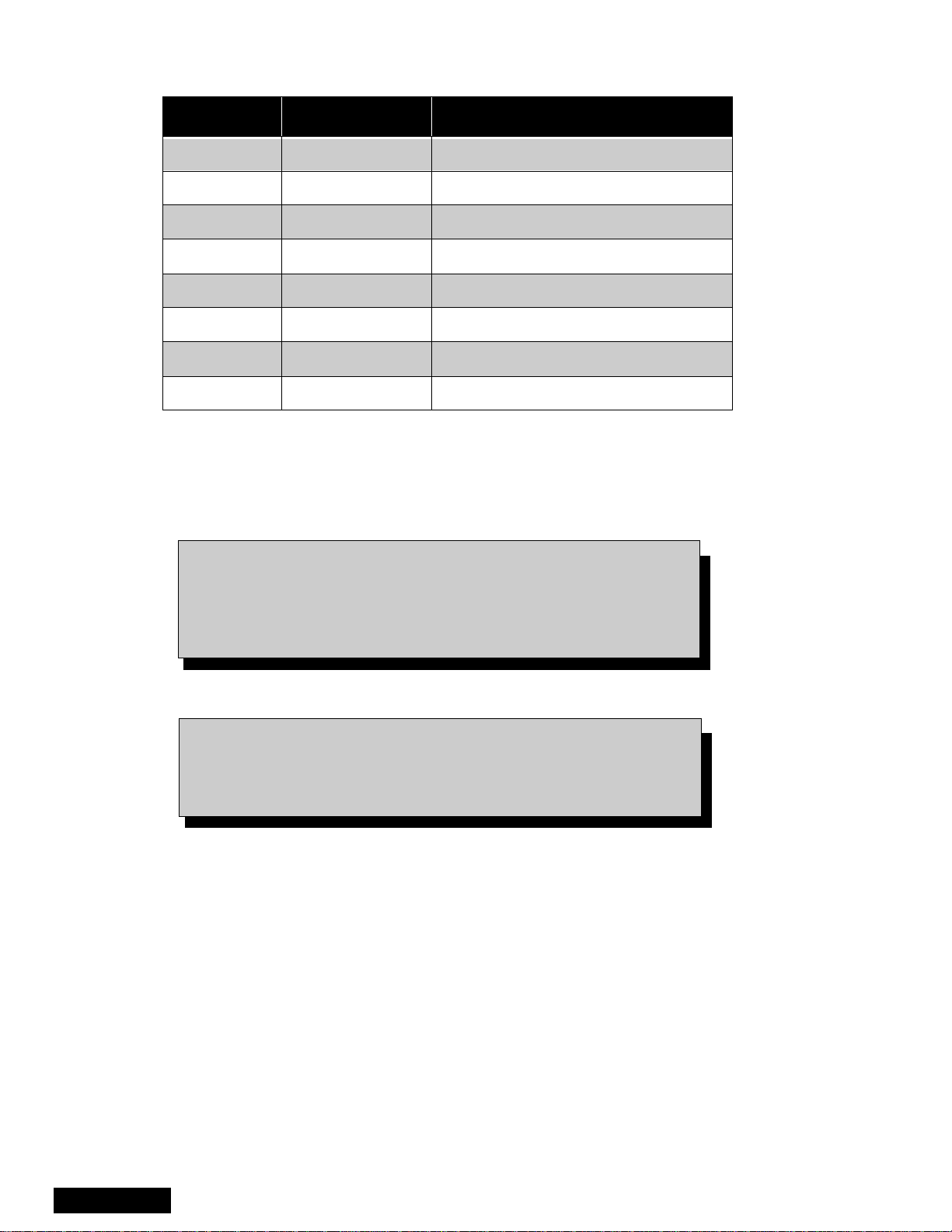

Boards designation

BOARD PART NUMBER BOARD DESCRIPTION

A-Board TNP2AH035 signal processing

D-Board TNPH0371 power and deflection

LB-Board TNP2AA110 blue driver

LG-Board TNP2AA111 green driver

LR-Board TNP2AA112 red driver

G-Board TNP2AA090 front A/V panel

K-Board TNP2AA089 front button panel

R-Board TNPA0615AB IR receiver

Table 2: Boards designation

Note: The A-Board (

A-Board both tuners, IC2302, IC7001, IC7002, IC871, IC872,

IC873. If any of these components or board is defective repleace

it with a new one and takeback the defective board tothe service

center.

Notice: When ordering any board, add and ” S” after the board

Example: If Order D-Board, should be ordered as:

TNP2AH035

suffix application.

) is non-serviceable.Exceptfor

TNPH0371

S.

ServiceManual

-10-

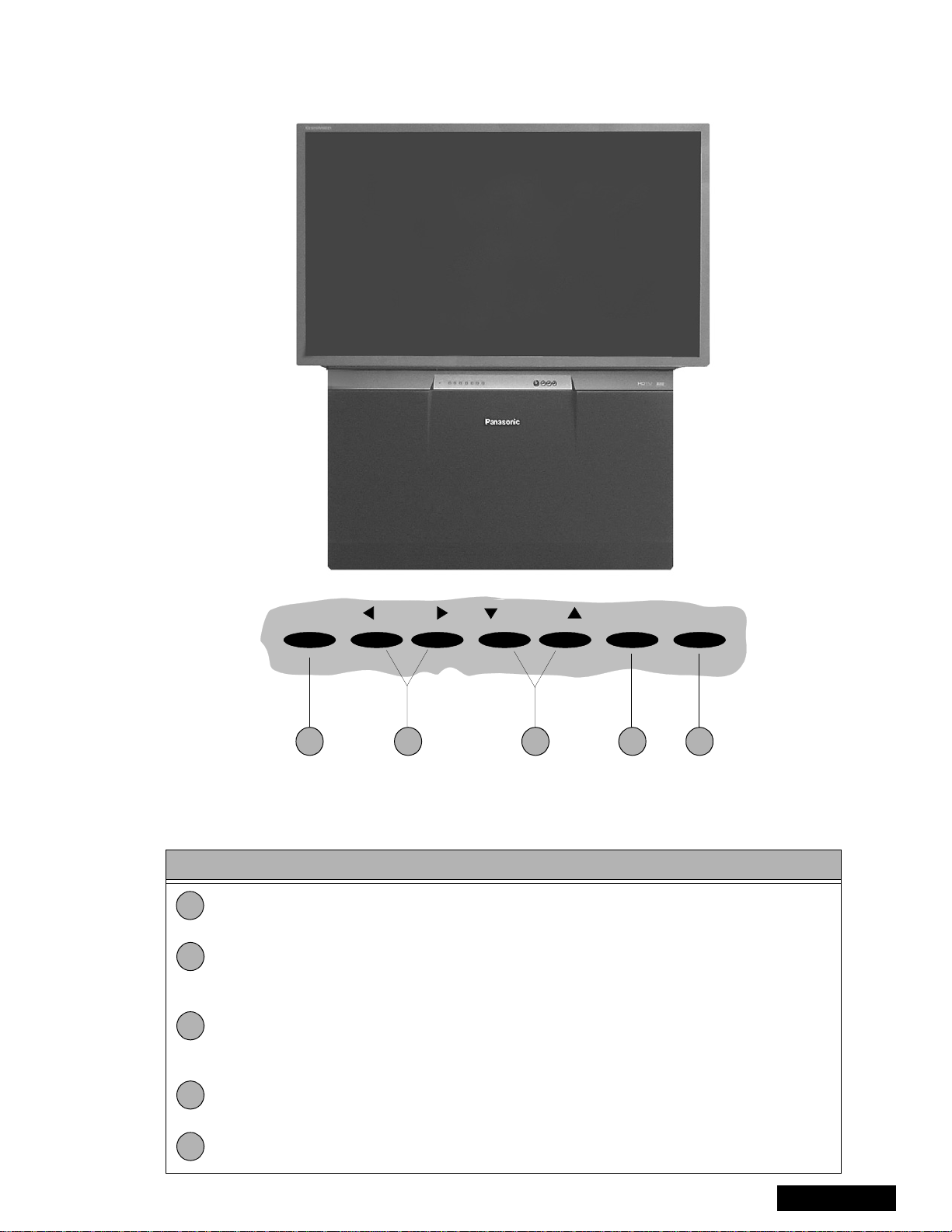

PTV - Location of controls

POWER VOLUME CHANNEL ACTION TV/VIDEO

1 2 4 53

Figure 5. Location of controls PTV

Quick reference control operation

Quick reference control operation

1

2

3

Power - Press to turn ON or OFF.

Volume - Press to adjust sound level, or to adjust audio menus, video menus, and

select operating features when menus are displayed

Channel - Press to select programmed channels. Press to highlight desired features

when menus are displayed. Also use to select cable converter box channels after

programming remote control infra-red codes (the TV/AUX/CABLE switch must be set

in CABLE position).

4

Action - Press to display main menu and access on screen feature and adjustment

menus.

5

TV/Video - Press to select TV or one of the video inputs, for the main picture or thePIP

frame (when PIP frame is displayed).

-11-

ServiceManual

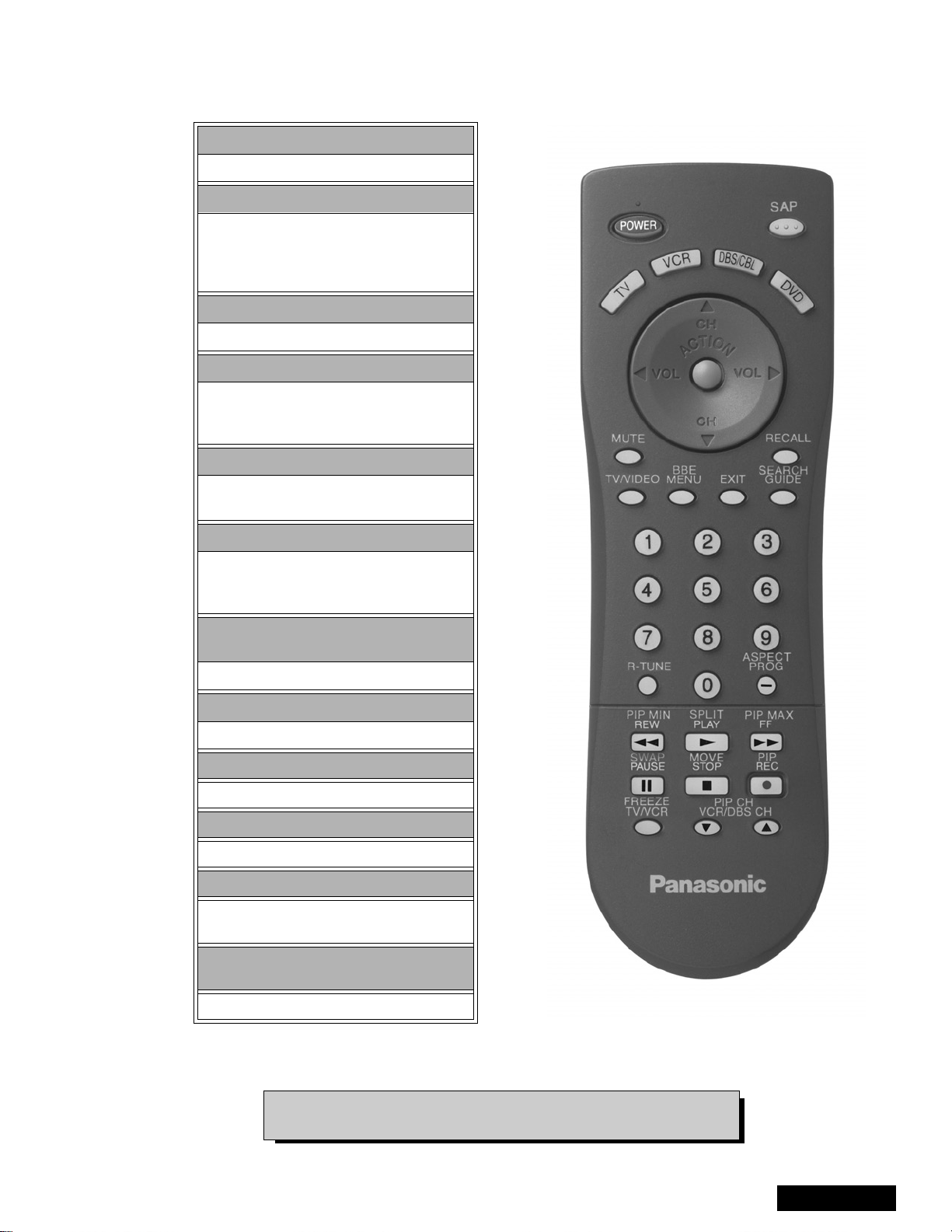

Remote - location of controls

POWER Button

Press to turn ON and OFF.

MUTE Button

Press to mute sound.

A second press resumes sound.

Press also to access and delete

Closed Caption display.

TV, VCR, DVD, CBS/CBL

Component function buttons

VOL (volume) Buttons

Press to adjust TV sound level.

Use with Channel buttons to

navigate in menus.

R-TUNE (Rapid Tune) Button.

Press to switch to theprevious

channel.

ACTION Button

Press to displaymain menu andaccess or

exit on screen features

and adjustment menus.

REW, PLAY, FF, TV/VCR, STOP, PAUSE,

REC & VCR CHANNEL Buttons

Component function buttons.

DBS EXIT& DBS GUIDE Buttons

DBS function buttons.

LIGHT Button

Press to light remote control buttons.

SAP

Access second audio program

ASPECT

Select picture size (ratio) to match

programming format

MOVE, PIP, SPLIT/SIZE, FREEZE, SWAP,

SEARCH, PIP CHANNEL

PIP function buttons

ServiceManual

Figure 6. Location of controls (EUR7603Z30 remote)

For additional information for this remote please refer to the

owner’s manual section remote operation, listed on the parts list.

-12-

Remote-locationofcontrols

POWER button

Press to turn ON and OFF.

MUTE button

Press to mute sound.

A second press resumes sound.

Press also to access and delete

Closed Caption display.

TV, VCR, DVD, CBS/CBL

Component function buttons

VOL (volume) buttons

Press to adjust TV sound level.

Use with channel buttons to

navigate in menus.

R-TUNE (rapid tune) button.

Press to switch to theprevious

channel.

ACTION button

Press to displayMain Menu andaccess or

exit On Screen features

and Adjustment Menus.

REW, PLAY, FF, TV/VCR, STOP, PAUSE,

REC & VCR CHANNEL buttons

Component function buttons.

DBS EXIT& DBS GUIDE buttons

DBS function buttons.

LIGHT button

Press to light remote control buttons.

SAP

Access second audio program

ASPECT

Select picture size (ratio) to match

programming format

MOVE, PIP, SPLIT/SIZE, FREEZE, SWAP,

SEARCH, PIP CHANNEL

PIP function buttons

Figure 7. Location of controls (EUR7613Z40 remote)

For additional information for this remote please refer to the

owner’s manual section remote operation, listed on the parts list.

-13-

ServiceManual

Auto diagnosis feature

This receiver incorporates a new auto-diagnosis

feature. With this new feature will be easier for the

technicial to detect the failures. There is a LED located

by the keyboard on the front panel, this LED will start

flashing when a failure is detected by the circuits

located in specific areas, depending on how many

times the LED is flashing, this will tell you what circuit

should be checked.

Make a count of flashing and see Table 3.

Please use this feature effectively especially for

intermittent problems.

NUMBER OF

FLASHES

1 +140

2LOWDC

3 CONVEREGENCE

4 HHS

5 IC4011

6IC4018

Table 3: SOS of front LED

After the count:

Proceed to check that area, verify what board is the

problem located, this way the area to check will be

reduced until the failure is found.

POSSIBLE CIRCUIT

ServiceManual

-14-

A-Board check points

-0.26V

-0.14V

0.00V

GV

-0.47V

RV

-0.53V

STB 3.3V

3.27V

BH

GH

RH

BV

-0.46V

CONV -18

-0.26V

CONV +18

-0.46V

9V

8.96V

2.5V

2.58V

VM

9.47V

G

3.6V

R

3.58V

B

3.45V

B

3.11V

R

3.17V

G

3.19V

Vp

0.00V

Hp

0.24V

STB 7V

6.96V

NTSC VIDEO

3.52V

SUB TUNER

VIDEO OUTPUT

2.13V

MAIN TUNER

VIDEO OUTPUT

2.25V

DTV1-Y

5.24V

MAIN-Y

3.77V

S-L

4.46V

SUB-Y

3.83V

S-R

4.46V

S+18

20.97V

S-18

-23.77V

S-R

0.00V

Figure 8. A-Board check points

Note: All the measurments are in DC with a digital multimeter, color bar

pattern, picture settings normalized and sound set to minimum.

-15-

ServiceManual

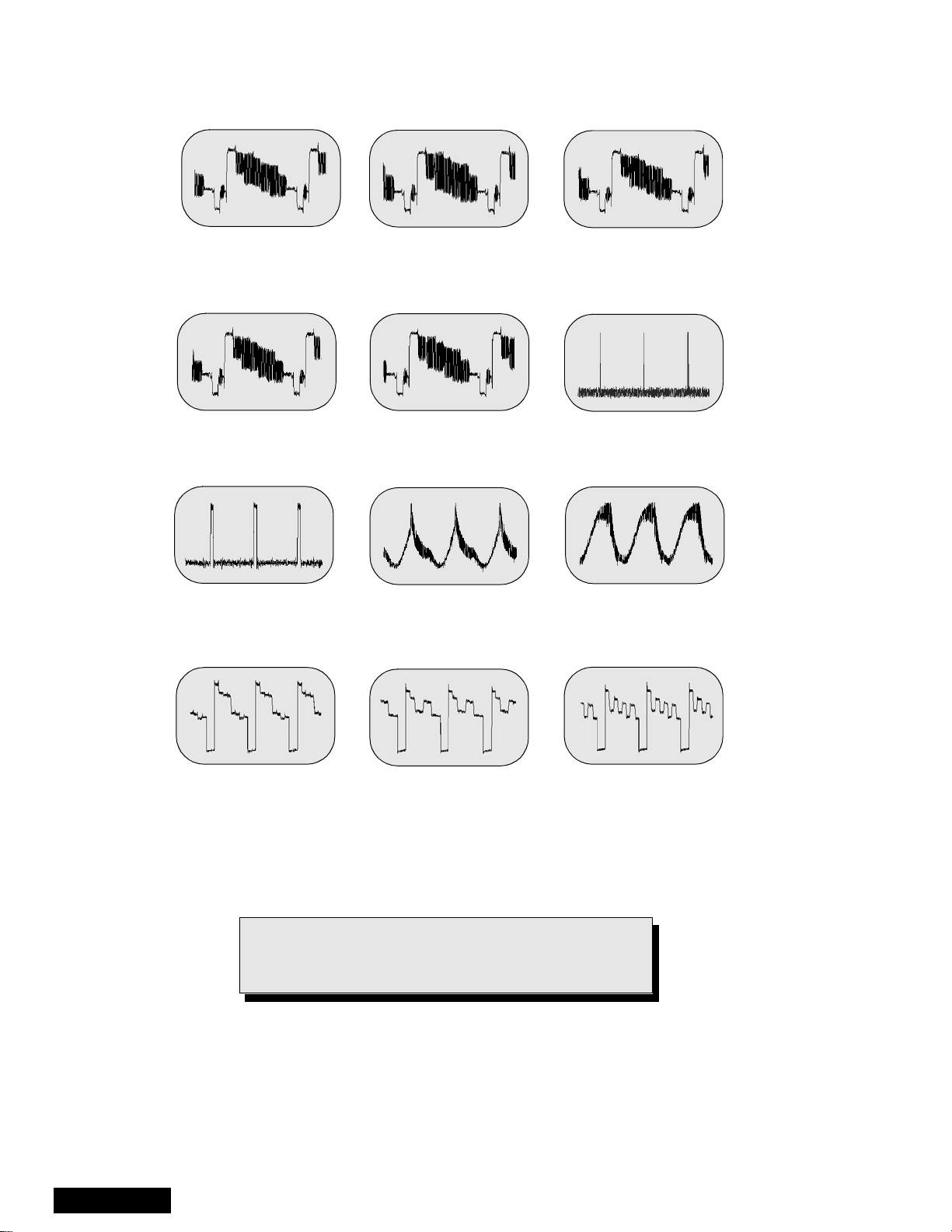

A-Board check points waveforms

Main tuner video output

15.72 kHz, 1 Vpp,

10µssec/div

Sub Y

15.72kHz, 1.92Vpp,

10µssec/div

HP

31.65kHz, 3.32Vpp,

10µssec/div

Sub tuner video output

15.72kHz, 1.00Vpp,

10µssec/div

NTSC video

15.72kHz, 2.02Vpp,

10µssec/div

Conv -18

60.24Hz, 0.75Vpp,

5µssec/div

Main Y

15.72kHz, 1.00Vpp

10µssec/div

VP

60Hz, 3.36Vpp,

5µssec/div

Conv +18

60.24Hz, 0.24Vpp,

5µssec/div

ServiceManual

G

31.65kHz, 4.72Vpp,

10µssec/div

Figure 9. A-Board check points waveforms.

Note: Waveforms were obtained with colorbar pattern,

picture settings normalized and sound set to

minimum.

R

31.65kHz, 4.44Vpp,

10µssec/div

-16-

B

31.65kHz, 4.40Vpp,

10µssec/div

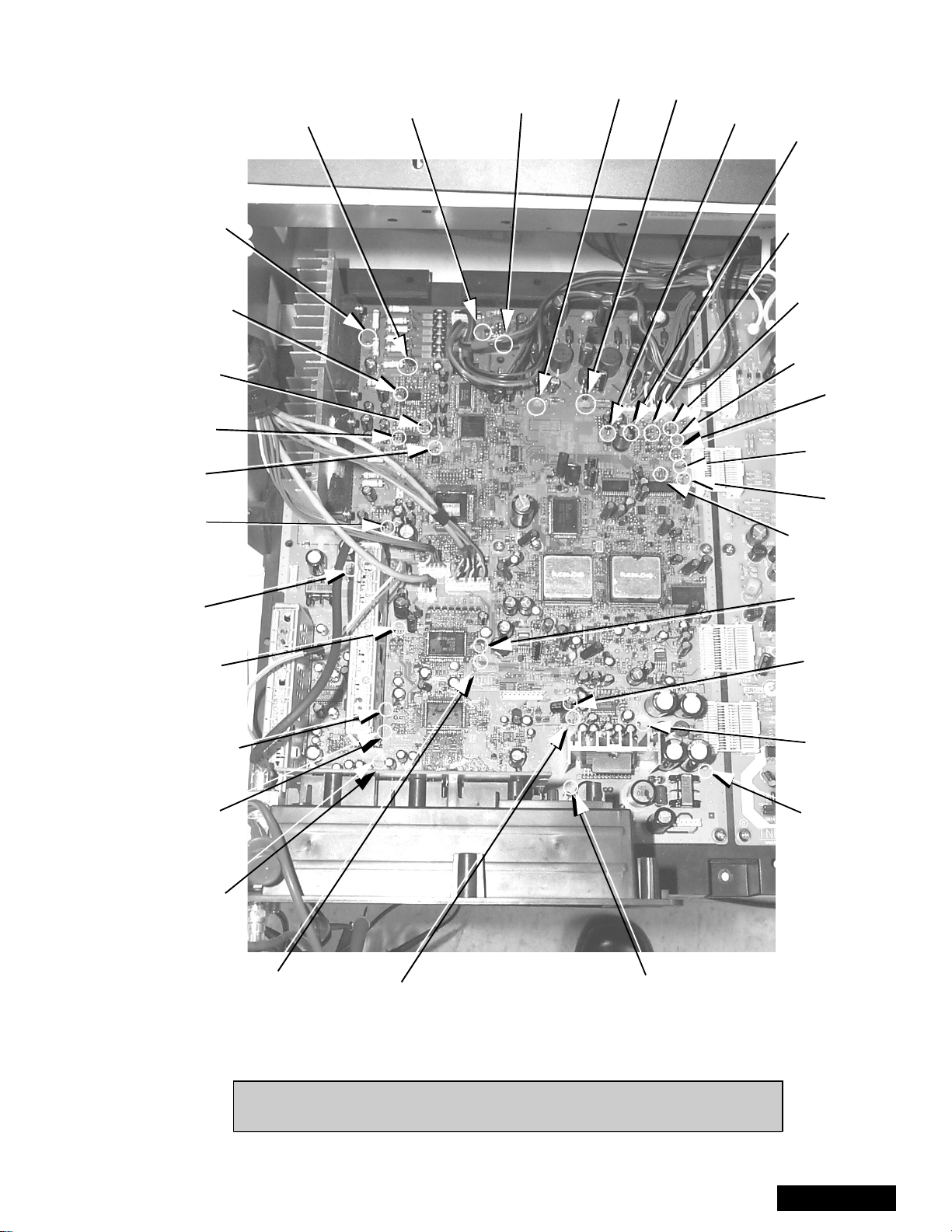

Chassis & boards layout

A

D

LR

Top view

LG

R

LB

Back view

Figure 10. Chassis & boards layout.

Board description

A Main chassis, video processing, convergence,

audio processing

D Power supply, vertical out, horizontal out

LB Blue CRT output

LG Green CRT output

LR Red CRT output

RIRsensor

-17-

ServiceManual

Disassembly for service

Note:

Speaker grille removal (figure 11)

The speaker grille is secured to the cabinet of the PTV.

grip panel from the sides and middle upper part, gently

pull forward to remove. When reassembling, make

certain to firmly press on the panel where the insertion

points (5) are located, one at each corner and one at

the middle top edge.

Board ground wires may have to be disconnected to disassemble some boards. All ground wires must be

reconnected using jumper leads, if necessary, before power is applied to PTV for service.

Figure 11. Speaker grille removal.

Keyboard removal

1. Remove the speaker grille. See figure 11.

2. Unplug the connectors from the Keyboard and

front A/V inputs assemblies. Remove the screws

affixing the keyboard to the frame assembly. Tilt

the keyboard assembly upward and release it from

the screen frame assembly.

Speakers replacement

1. Remove the speaker grille. See figure 11.

2. Each speaker is secured to the cabinet with (4)

screws.

3. Disconnect the R & L speaker lead connectors

from the speaker units.

Cabinet back lower cover removal (figure 12)

1. Remove (7) hex screws around the perimeter,

marked with arrows. See figure 12 for screws

location.

2. Remove (3) screws from around the A/V terminal

board (marked with arrows).

Screw count:

14 fasten the top back cover;

10 fasten the lower back cover

Figure 12. Lower cabinet back removal

Cabinet back cover removal (figure 12)

1. Remove the cabinet back lower cover. (Detailed

previously).

2. The top back cover (plastic shell) is secured with

(14) screws around its perimeter. See figure 12 for

screws location.

3. Be careful not to damage the mirror secured to the

underside of the back cover.

Mirror removal (figure 13)

The mirror is attached inside the cabinet cover.

Carefully remove the cabinet cover to access its

interior surface and remove the screws securing the

brackets that hold the mirror at the top and sides to the

mirror. See figure 13.

Screws (12 places)

Brackets (4 places)

Felt

ServiceManual

-18-

Bracket

(2 places)

Mirror

Felt

cabinet cover

(Inside view)

Figure 13. Mirror removal

Disassembly for service (continued)

Screen frame removal

1. Remove the speaker grille. Disconnect the cables

leading to the keyboard and the AV panels and

remove the keyboard and AV panel assembly. The

assembly is secured by three (3) screws.

2. At this point the front cover is held only by four

screws, be careful not to push the cabinet forward.

3. Remove screws and tilt the assembly forwardwhile

lifting it out of place.

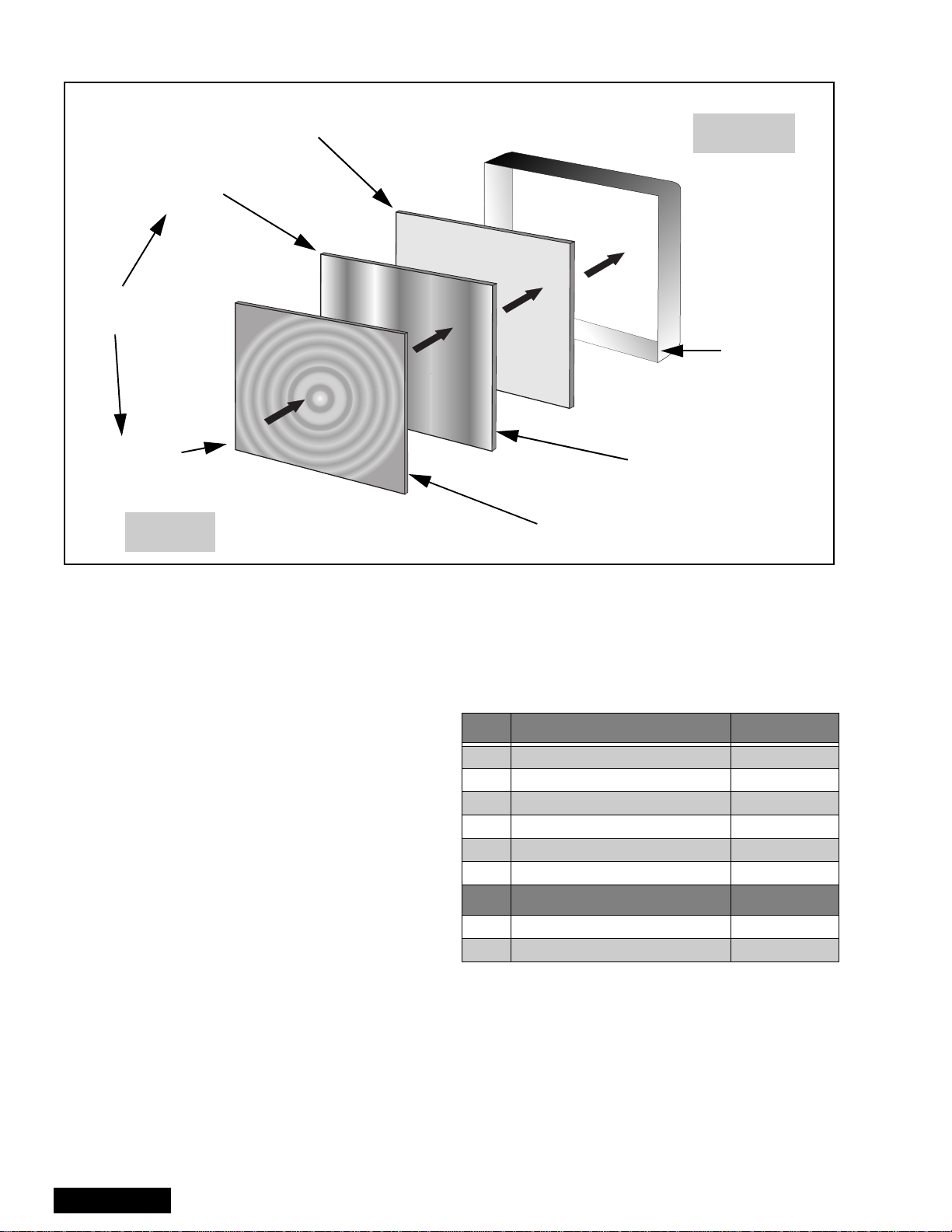

Screen assembly (figure 14)

1. Remove the screen frame. See screen frame

removal procedure above.

2. Place screen frame face down on a soft surface.

3. Remove all screen brackets and corner brackets

Note: The brackets are painted black (permanent

marker) on the edge to prevent reflection on

image.

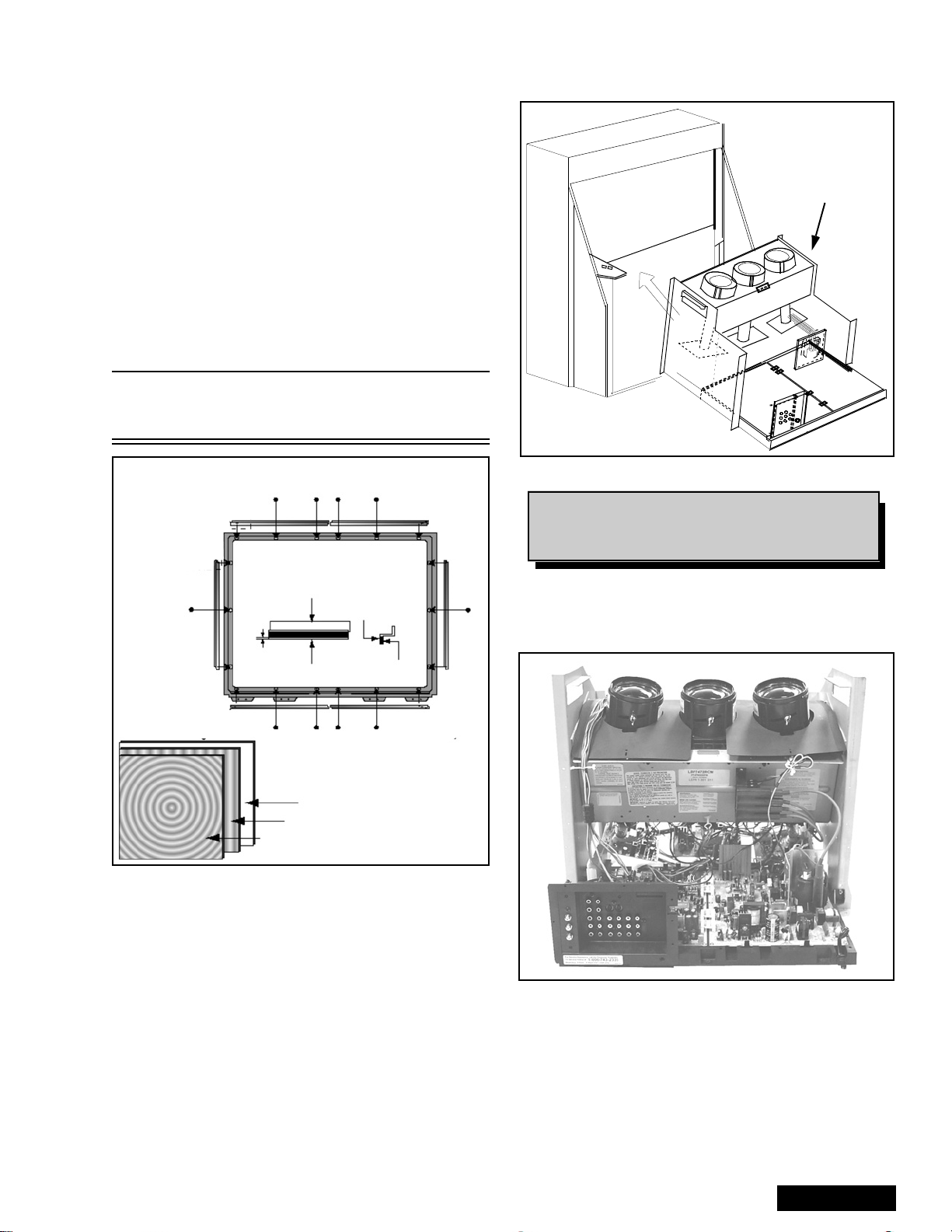

Main Chassis Block

Figure 15. Chassis removal

Note: Main chassis block can be serviced either

in normal position or layi ng on its b ack

(protect hookup terminal from damage).

Bracket

0 ± 0.5mm

Felt

Screws (18 places)

Lenticular screen

Fresnel screen

Fresnel

screen

Double

adhesive tape

Protective screen

Figure 14. Screen assembly

4. Note exact orientation and order of each screen.

The orientation and order of the screens is critical

for displaying pictures properly. Detailed screen

assembly can be seen in figure 14.

Main chassis block (figure 15)

1. Remove the speaker grille. See figure 11.

2. Remove the cabinet back lower cover. See

figure 12.

3. The main chassis block is secured to the cabinet

by screws at front, behind the Speaker Grill and

inside on the bottom of the optical frame).

4. Remove the horizontal barrier panel at the back of

the cabinet.

5. Unplug connectors (K1, G1 and speaker

connectors) and pull out the main chassis block.

Chassis assembly

The chassis assembly shown in figure 18 includes all

the electrical and optical (light box) components.

Figure 16. Chassis rear view

-19-

ServiceManual

Disassembly for service (continued)

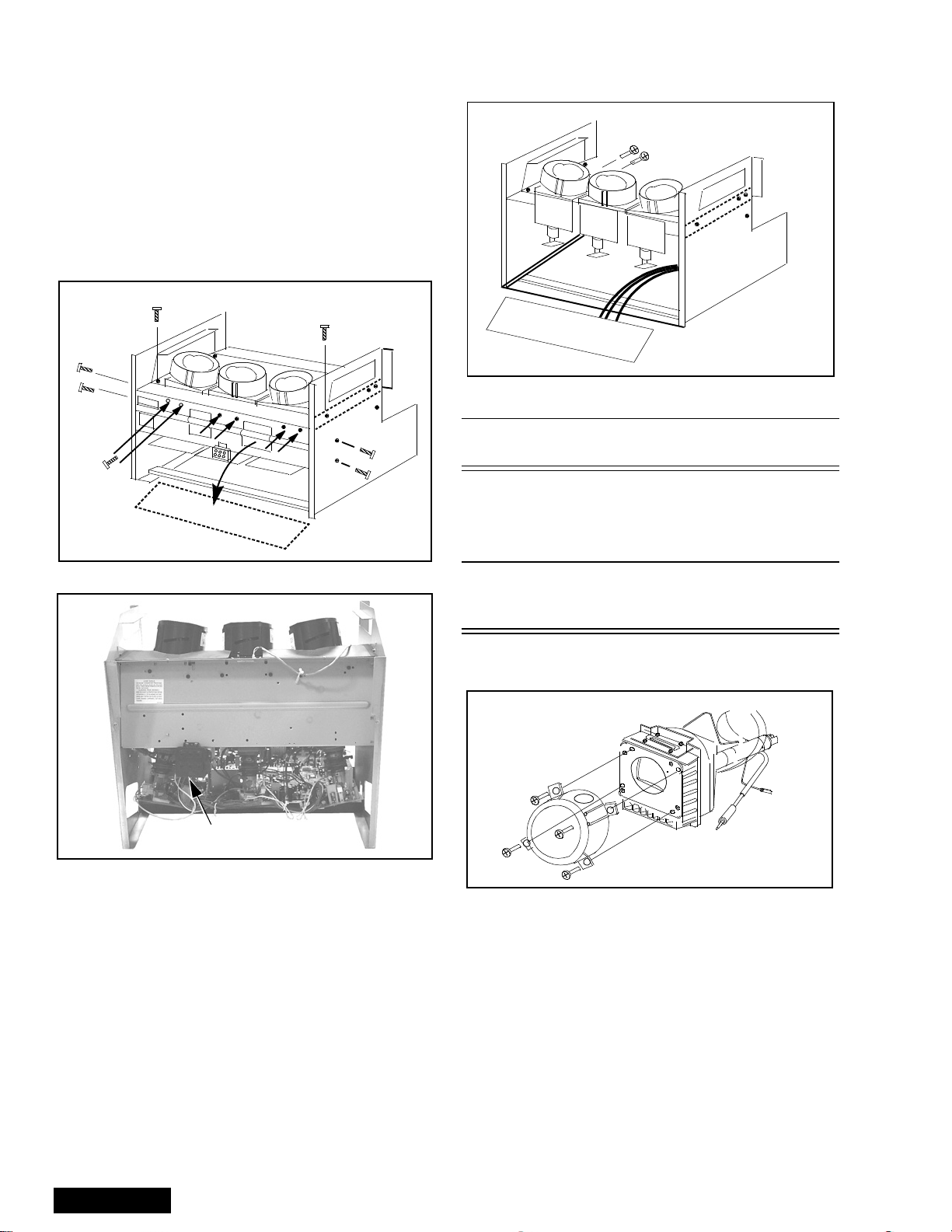

Disassembly for CRT replacement

To facilitate CRT replacement, the complete CRT

mounting chassis does not need to be removed.

1. Remove the main chassis block from the cabinet.

See figure 15.

2. Remove the optical bracket metal cover (rear side)

by removing (6) screws from back, (2) screws from

top, and (2) screws from each side. See figure 17

& figure 18.

REAR VIEW

Screws

(6) places

Optical bracket

Pull down

Figure 17. CRT replacement

Optical bracket cover

Figure 19. CRT replacement.

** CAUTION: Support the CRT assembly

when loosening screws.

8. Release CRT anode lead from CRT chassis wire

clamp and all other wires from holders.

9. Loosen a screw that secures the DY and remove it

from the CRT neck.

Caution: To insure x-ray radiation protection, the lens

must be mounted in place at all times when

power is applied to the PTV.

CRT replacement

1. Remove CRT focus lens assembly (4 screws).

Lens

(4) Screws

Focus pack

Figure 18. Light box front view

3. Remove the defective CRT anode lead from the

high voltage distributor block that is mounted on

the flyback transformer. Discharge to CRT chassis.

4. Unplug connectors from the B-Board. See board

layout. B9 for red, B10 for green, or B11 for blue.

5. Unplug the defective CRT black DAG ground

connector from the CRT Board.

6. Remove the CRT Board from the defective CRT

neck.

7. Remove (2) screws from the defective CRT

housing. See figure 19.**

CAUTION: Do not remove the (4) CRT

lens screws.

ServiceManual

Figure 20. CRT assembly.

2. Lay CRT face down on a soft cloth.

3. Note position of yoke with centering tabs and

remove from defective CRT.

4. Remove CRT DAG ground from defective CRT.

Mount it on the replacement CRT exactly as it was

on the defective CRT.

Note: Replacement CRT is supplied with H.V. anode

lead attached.

5. Wire the anode lead wire.

-20-

6. Wire the anode lead wire.

Optical bracket (front)

8. Press yoke against bell of CRT and tighten the

clamp just snug enough so it will not easily shift.

9. Assemble CRT focus lens assembly to new CRT

with (4) screws. Make sure focus lens adjustment

nut is in the same location as on other CRT focus

lens.

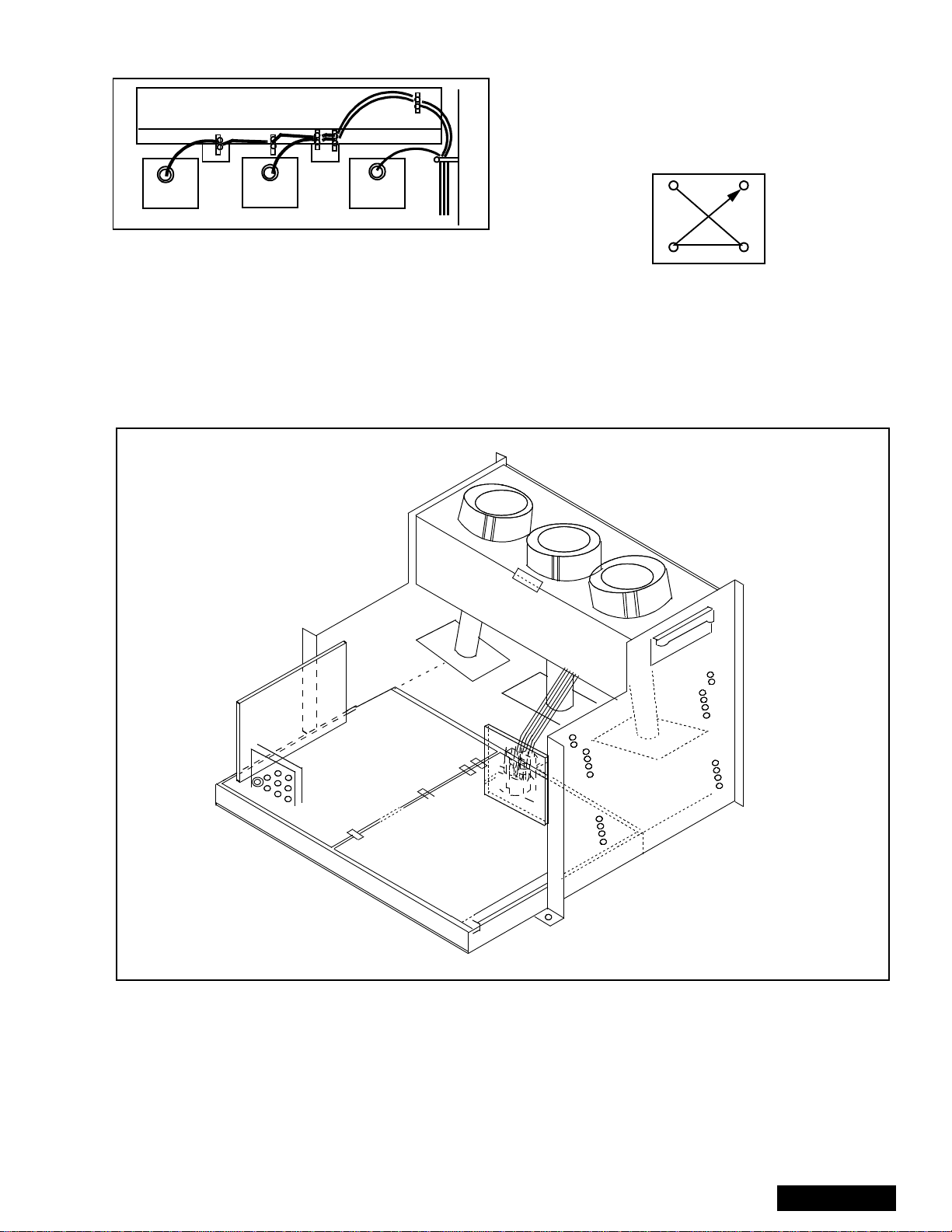

RED CRT GREEN CRT BLUE CRT

Figure 21. Wire guide.

7. Install yoke with other CRT neck assemblies on

CRT neck in the same order and position as

removed from the defective CRT.

Optical block position adjustment

1

4

23

Figure 22. CRT screw tightening order .

Note: Please assemble with screws in the order

shown and tighten with the same torque.

Figure 23. Optical block position.

The optical block mounting has holes to allow for the

different size projection screens. These mounts will

adjust to projection screens.

51/61

46

51/61

46

51/61

46

51/61

46

51/61

46

51/61

46

If the optical block is removed for service or is

replaced, it is important that the correct mounting holes

are used.

-21-

ServiceManual

PTV screen assemblies

Label on

lower left corner

(front side)

Labels on

opposite sides

Label on

lower left corner

(rear side)

REAR

Protective screen

FRONT

Front cabinet

Lenticular screen

(note vertical ridges)

Fresnel screen

(note circular ridges)

Figure 24. Screen assemblies.

B+ voltages table

Preparation:

Set the following controls

Picture..........................Normal.

Bright ...........................Normal.

Volume......................... Min. (0).

Procedure:

1. Apply a white NTSC pattern.

2. Connect the (-) lead of the digital voltmeter to

TPGND1 (cold ground).

3. Connect the (+) lead of the digital voltmeter to each

test point and confirm the B+ voltages (see

Table 4).

No. Test point (D-Board) Voltage

1 TPD14 138.6±1.0

2 TPD13 19.0

3 TPD12 19.0±1.5

4TPD11 -19.0

5 TPD10 22.0±1.5

6 C845 (-) -22.5

No. Test point (A-Board) Voltage

1TPA031 9.0±0.5

2 TPA030 5.0±0.5

Table 4: B+ voltages table

±1.5

±1.5

±1.5

ServiceManual

-22-

CRT set up

CAUTION: Insure yoke plugs on the A-Board

are reconnected before turning the PTV

ON to prevent damage to the horizontal

output transistor and/or CRTs.

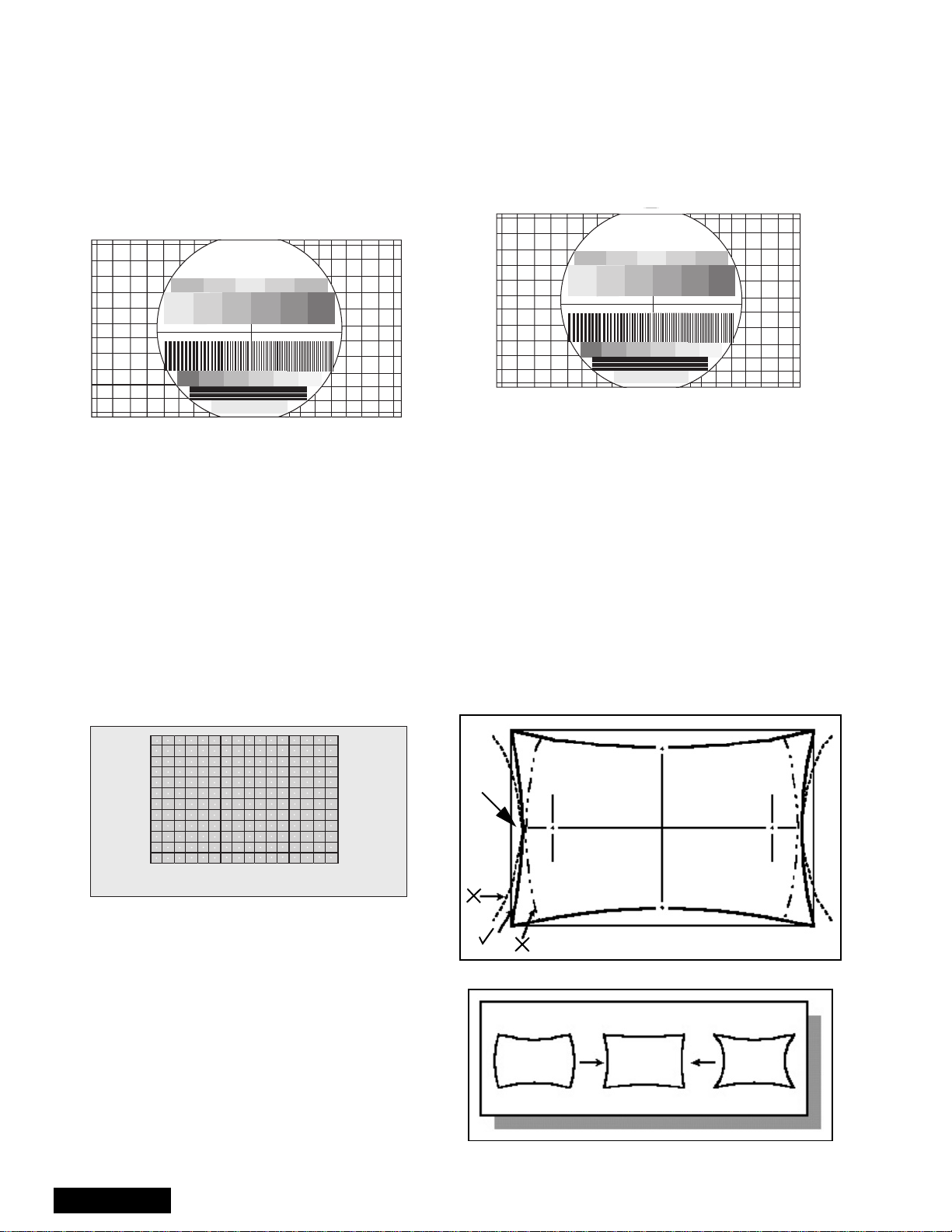

1. Connect test generator to the antenna terminal and

set for a monoscope pattern.

2. Loosen yoke clamp, seat yoke against bell of CRT

and rotate to correct yoke tilt (compare to adjacent

CRT). Tighten yoke clamp.

3. Remove adhesive from centering tabs and set

centering t abs for zero correction. (figure 25)

Centering magnets

Figure 25. Adhesive removal

4. Cover replacement CRT lens and static converge

the tubes not replaced, if needed. Check size and

linearity of pattern and adjust as required.

5. Uncover replacement CRT lens and cover other

two CRT lenses. Adjust electrical and optical focus

(lens), if required.

6. Uncover all CRT lenses and use yoke centering

magnet to converge replacement CRT (in center

area of screen only) with other two CRTs.

Disregard non-convergence in areas other than

center area.

7. Perform white balance adjustments.

Dynamic focus adjustments

1. Focus adjustments should be performed after 1

hour of aging.

2. Use oscilloscope with 100 : 1 probe.

3. Apply a NTSC crosshatch pattern to adjust focus.

4. Adjust the red, blue and green focus VR on the

focus block for best focus of overall picture of each

CRT. (figure 28)

Adhesive

16.7ms (V Rate)

Procedure:

Note: 1080i, 480p, 480i pattern can be obtained from

Panasonic’s TU-DST51 set-top box DTV

decoder.

1. Enter to service mode and set the following default

DATA:

NTSC NTSC ZOOM 1125i

H-PARA +317 +263 +317

V-SAW -23 -35 -23

V-PARA +69 +117 +69

Note: The signal (NTSC, 1125i) (NTSC ZOOM

option), should be displayed to enter values for

specific format adjustment.

2. For 1125i (1080i) set the default values.

3. For NTSC and NTSC ZOOM apply a white pattern

and perform the following steps.

4. Connect the scope probe to TPD30, GND to

TPD31.

5. Confirm that level of A is 600_V ± 100_V, adjust

H-PAR DAC to set to specification level.

6. Confirm that level of B is 280_V ± 50_V, adjust

V-PAR DAC to set to specification level.

7. Confirm that level of C is more tha 20 V, adjust

H-PAR DAC to set to specification level.

Focus - Electrical & optical adjustments

(use for minor adjustment or for final adjustment,

for complete adjustment see following section.)

Electrical adjustment

Note: 1080i, 480p, 480i pattern can be obtained from

Panasonic’s TU-DST51 set-top box DTV

decoder.

1. Apply a NTSC crosshatch with dots pattern.

Panasonic

FORMAT

A

B

280_V ± 100_V

B

>20_V

C

A

600_V ± 100_V

GND

Figure 26. D. Focus adjustment waveform

5. To change DAF DA TA, enter to service mode, then

press POWER on remote to display DACs menu,

then select DAC by pressing CH (RIGHT/LEFT)

and VOL (UP/DOWN), then press ACTION to enter

to DAC, then adjust by pressing VOL (RIGHT/

LEFT); press ACTION, to save press ACTION

again or OTHER to exit without saving.

-23-

Adjust electric focus VR

and lens focus on this circle

Figure 27. Lens focus adjustment

Table 5: Focus points

RED GREEN BLUE

Electric focus B A/B A

Optical Focus B A/B A

ServiceManual

2. Set VIDEO C_OFF DAC from 00 to 02, and project

only red. Adjust red focus VR so that focus is best..

screen

+

+

+

GB

R

+

R

++

GB

focus

Figure 28. Focus pack

3. Adjust red lens focus (mechanical) until focus is

best.

4. Adjust red focus VR again.

5. Set VIDEO C_OFF DAC from 00 to 01, and project

only green.

6. Repeat steps for green only.

7. Set VIDEO C_OFF DAC from 00 to 03, and project

only blue.

8. Repeat steps for blue only.

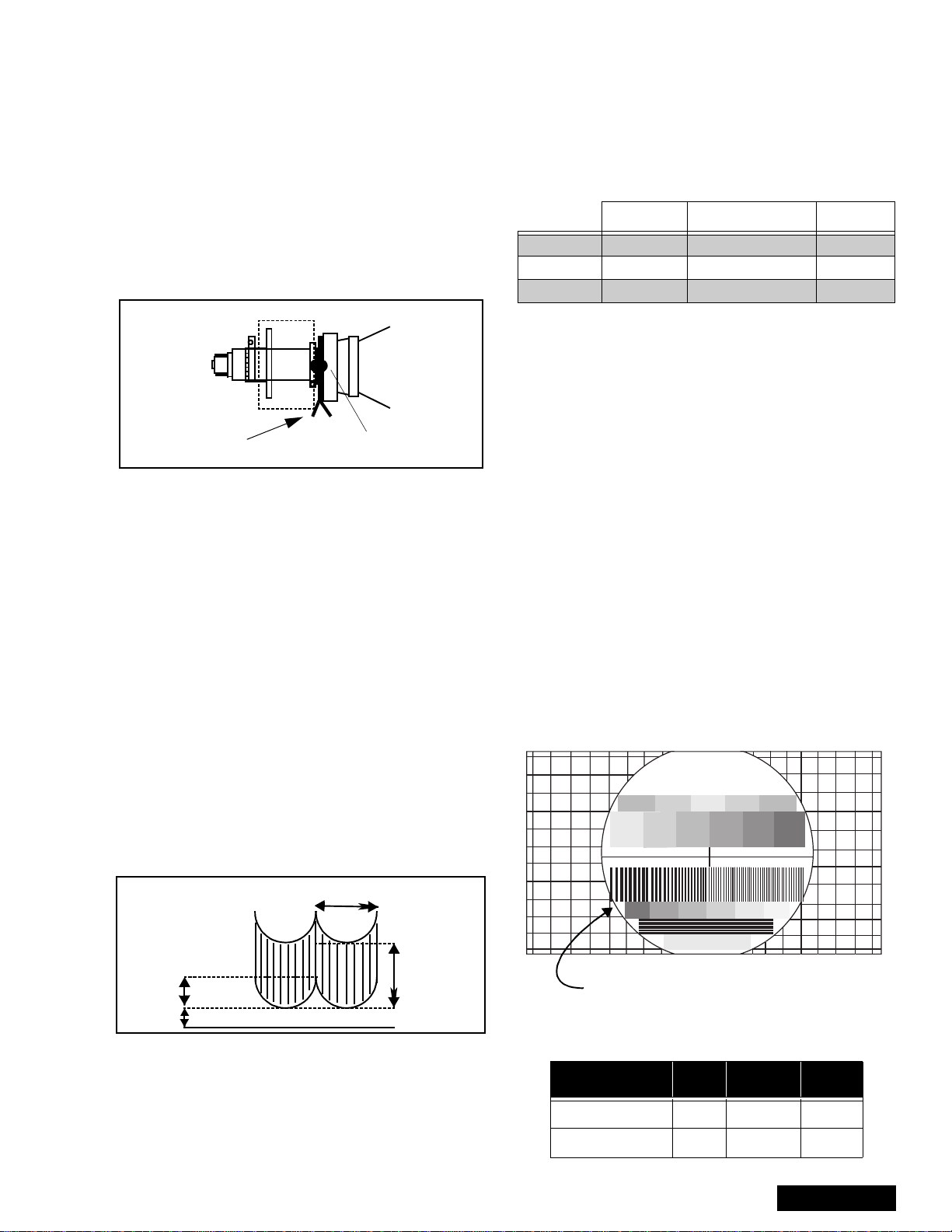

Focus - Optical lens adjustment

Optical adjustments

Note: This adjustment normally should not require

resetting unless the lens has been replaced or

adjustment has changed.

Electric & VM focus adjustment, complete

adjustment

(Perform this adjustment when a CRT is replaced

or when major adjustment is required)

Preparation:

1. Apply a NTSC crosshatch pattern with dots.

2. Set CONV “MUTE” DAC from 0 to 1 (disabling

digital convergence.)

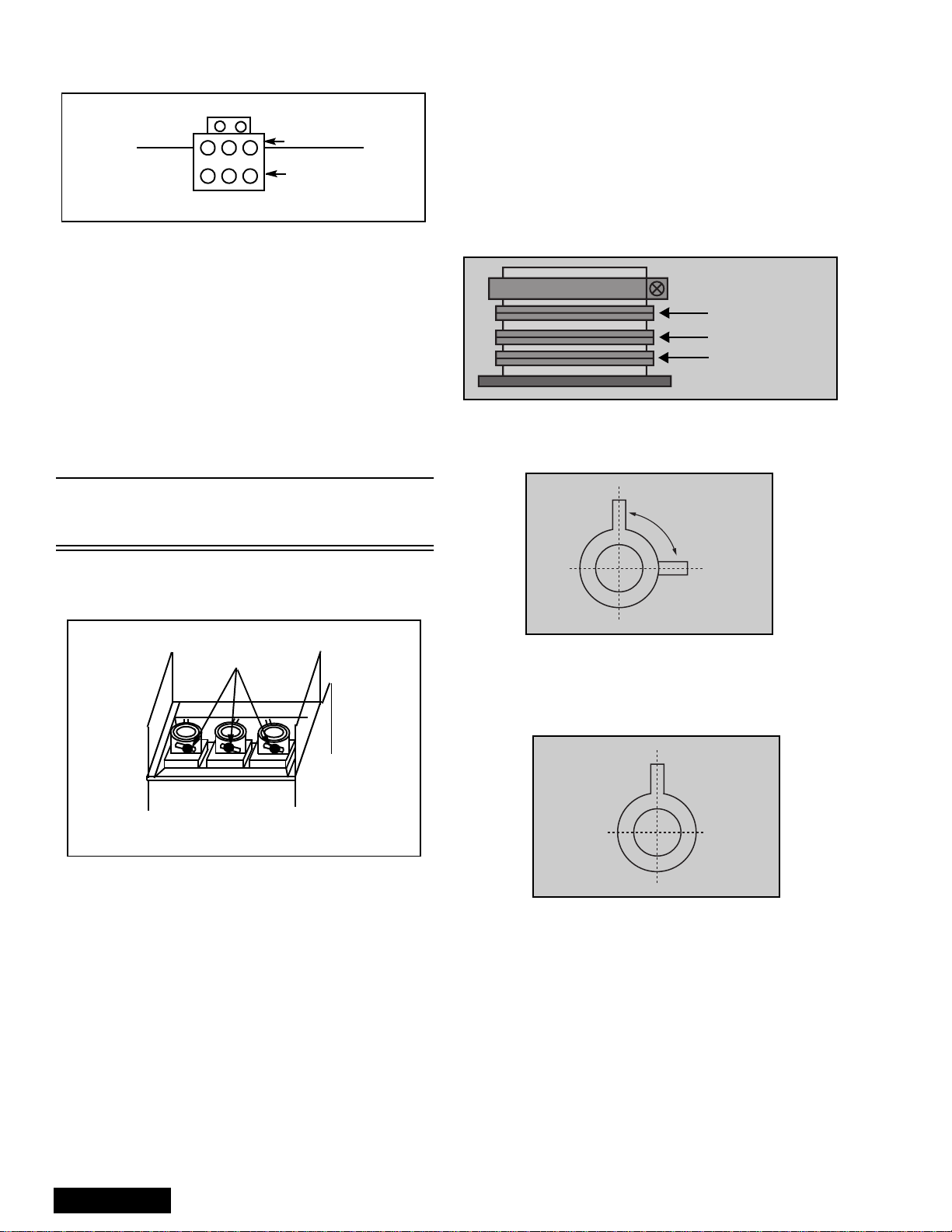

3. Position the longer tab of the four-pole magnet to

90 degrees (uncorrected position). (see figure 31).

6-pole magnet

(Dummy ring)

4-pole magnet

Alignment magnet

Figure 30. VM coil with focus

correction magnet

Set 90 deg rees

1. Optical focus adjustment is located on the top of

each CRT lens system. Loosen the adjustment

knurled locking knob. (figure 29)

Adjustment knurled

locking knobs

BGR

REAR VIEW

Figure 29. Optical lens focus adjustment

2. Turn the PTV ON. Apply and view a crosshatch

with dots pattern.

3. Adjust each lens focus for best focus while viewing

each CRT .

4. Cover the red and blue CRT, projecting green only.

Rotate the green lens for best focus around screen

center area.

5. Do the same for the red focus lens while projecting

red only.

6. Repeat for blue.

Figure 31. 4-pole magnet

4. Position the long tab of all alignment magnets and

of the dummy ring together in an uncorrected

position. (See figure 32).

Figure 32. Alignment magnet

(or dummy ring)

Procedure:

1. Apply an NTSC cross hatch pattern with dots.

2. Assure that digital convergence is disabled (DAC

MUTE from 0 to 1).

3. Set VIDEO “C_OFF” DAC from 00 to 02, to project

red only.

4. Turn the red electrical focus adjustment VR (on

focus pack) fully counterclockwise and note the

position of the dots at the center of the picture.

5. Turn the red electrical focus adjustment VR

fully clockwise.

ServiceManual

-24-

6. If the position of the dotsat the center of the screen

moves from the position noted in step 4., adjust the

alignment magnets until the dots are in the same

position as noted in step 4.

7. Turn the red electrical focus adjustment VR (on

focus pack) fully counterclockwise and confirm that

the position of the dots at the center of the screen

did not move from their position noted in step 4.

8. If the position of the dots at the center of screen

moved, repeat from step 4.

9. If the position of the dots moved after repeated

adjustments, adjust until the movement of the dots

is minimized.

10. Turn the red focus VR fully clockwise.

11. Adjust t he 4-pole magnets until the shape of the

dots at the center of the screen is circular .

12. Adjust red focus VR until optimum focus is

achieved.

13. Apply NTSC crosshatch with dots or any other

available pattern applicable to the following.

14. Confirm that the picture is correctly aligned in the

center of the screen, shown in figure 33, adjust the

centering magnets. Repeat the alignment magnet

adjustments and four pole magnet adjustments

(step 1. ~ step 12.).

NTSC Vertical size adjustment (VSIZE)

Note: 1080i, 480p, 480i pattern can be obtained from

Panasonic’s TU-DST51 set-top box DTV

decoder.

1. Apply a NTSC pattern (see avobe note) .

2. Set VIDEO “C_OFF” DAC from 00 to 01

(to project only green).

3. Adjust centering magnets so that the center of the

pattern get aligned with screen frame center.

4. Adjust VDEF “VSIZE” DAC until vertical size is

proportional on top and bottom. (See figure 34)

5. Set VIDEO “C_OFF” DAC from 01 to 00

Panasonic

FORMAT

Figure 34. Vertical size adjustment

HD 1080i Vertical size adjustment (VSIZE)

Note: 1080i, 480p, 480i pattern can be obtained from

Panasonic’s TU-DST51 set-top box DTV

decoder.

1. Apply a HD 1080i pattern (see avobe note).

2. Repeat vertical size adjustment from step 2

Figure 33. Centering magnet

15. Apply an NTSC cross hatch pattern with dots.

16. Set VIDEO “C_OFF” DAC from 00 to 01, to project

green only .

17. Repeat above procedures for the green.

18. Set VIDEO “C_OFF” DAC from 00 to 02, to project

red only.

19. Repeat above procedures for the blue.

20. Enable digital convergence by changing DAC

MUTE from 01 to 00.

21. Following adjustments, paint position of DY

centering magnets and fix the centering magnets of

DY, dummy rings of VM coil, four pole magnets of

VM coil and the alignment magnets of VM coil to

prevent them from moving.

Note: Please See “Service mode (electronic

controls)” on page 34 for entering and exiting

service mode.

Panasonic

FORMAT

Figure 35. Vertical size adjustment

-25-

ServiceManual

NTSC ZOOM Vertical size adjustment

(VSIZE)

Note: 1080i, 480p, 480i pattern can be obtained from

Panasonic’s TU-DST51 set-top box DTV

decoder.

1. Apply a NTSC pattern (see avobe note) .

2. Change aspect to ZOOM mode.

3. Repeat vertical size adjustment from step 2

4. Try making circle seem rounded (in proportion)

Panasonic

FORMAT

HD 1080i Horizontal phase adjustment

(H-POS)

Note: 1080i, 480p, 480i pattern can be obtained from

Panasonic’s TU-DST51 set-top box DTV

decoder.

1. Apply a HD 1080i pattern.

2. Repeat NTSC horizontal phase adjustment from

step 2.

Panasonic

FORMAT

Figure 38. H Phase adjustment

Figure 36. Vertical size adjustment

NTSC Horizontal phase adjustment

(H-POS)

Note: 1080i, 480p, 480i pattern can be obtained from

Panasonic’s TU-DST51 set-top box DTV

decoder.

1. Apply a NTSC crosshatch pattern with dots.

2. Set CONV “MUTE” DAC from 00 to 01 (disabling

digital convergence).

3. Set VIDEO “C_OFF” DAC from 00 to 01 to project

only green.

4. Turn green deflection yoke until line is perfectly

horizontal.

5. Adjust H-POS DAC data so that pattern is in the

center of screen.

Figure 37. H phase adjustment

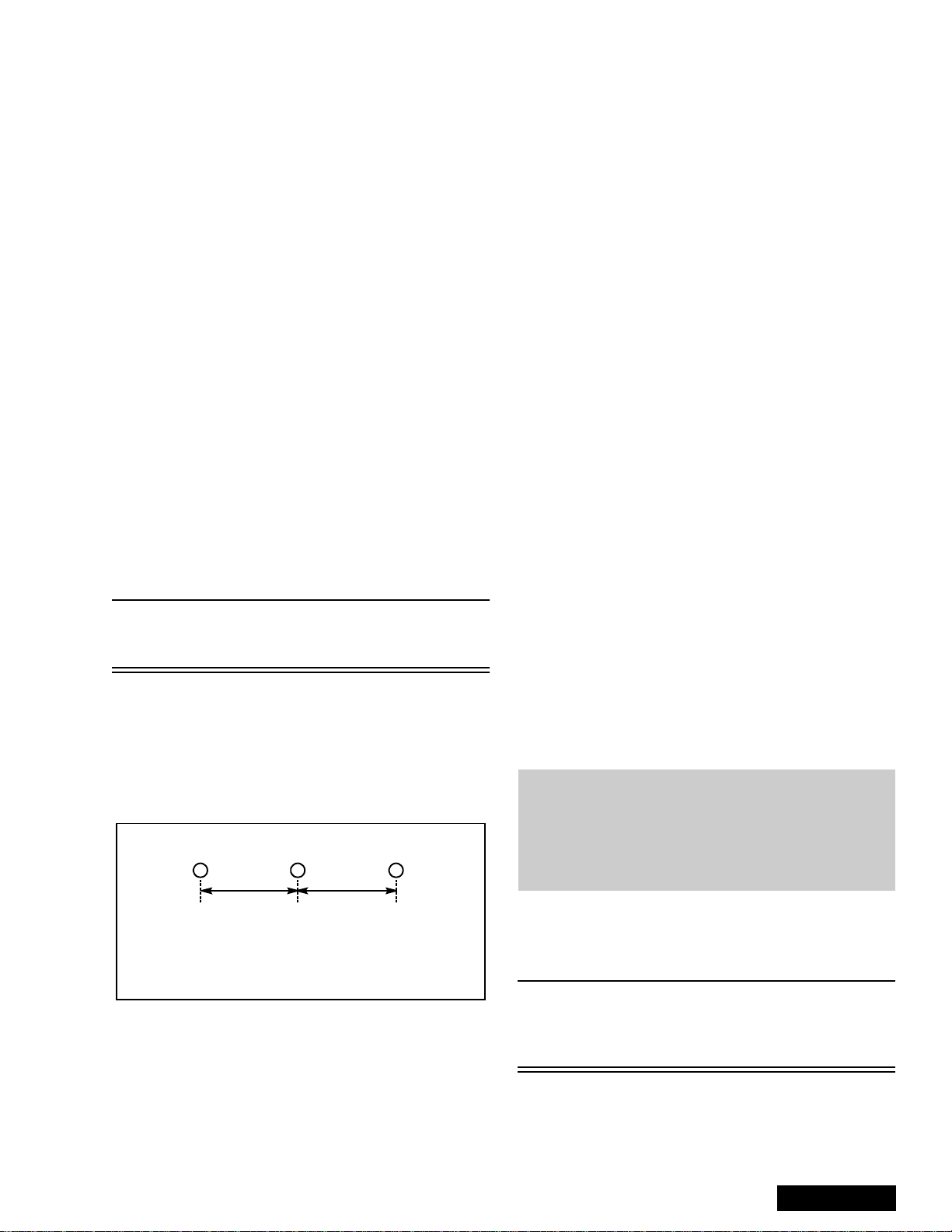

Trapezoid adjustment (EWTRA)

1. Set default value

NTSC Pincushion adjustment (PCC)

Note: 1080i, 480p, 480i pattern can be obtained from

Panasonic’s TU-DST51 set-top box DTV

decoder.

Procedure:

1. Apply a NTSC crosshatch pattern with dots.

2. Set VIDEO “C_OFF” DAC from 00 to 01 to project

only green.

3. Set DAC MUTE from 00 to 01 (disabling digital

convergence).

4. If the distance at “A” is not 10 ± 5mm, enter “H

DEF” “H WID” mode and adjust by VOLUME UP/

DOWN until it is 10 ± 5mm. See figure 39.

A

A=10±5mm

Line with dot

6. Enable digital convergence by changing DAC

MUTE from 01 to 00.

7. Set VIDEO “C_OFF” DAC from 01 to 00.

ServiceManual

Figure 39. Pincushion adjustment

NOT GOOD GOOD NOT GOOD

5. If not all corners of cross hatch appear in screen,

enter V DEF “V SIZE” mode and adjust until they

-26-

appear.

6. Confirm that measurement of “A” has not changed.

7. Enable digital convergence by changing DAC

MUTE from 01 to 00.

8. Set VIDEO “C_OFF” DAC from 01 to 00.

HD 1080i Pincushion adjustment (PCC)

Note: 1080i, 480p, 480i pattern can be obtained from

Panasonic’s TU-DST51 set-top box DTV

decoder.

Procedure:

1. Apply a HD 1080i pattern.

2. Repeat NTSC pincushion adjustment from step 2

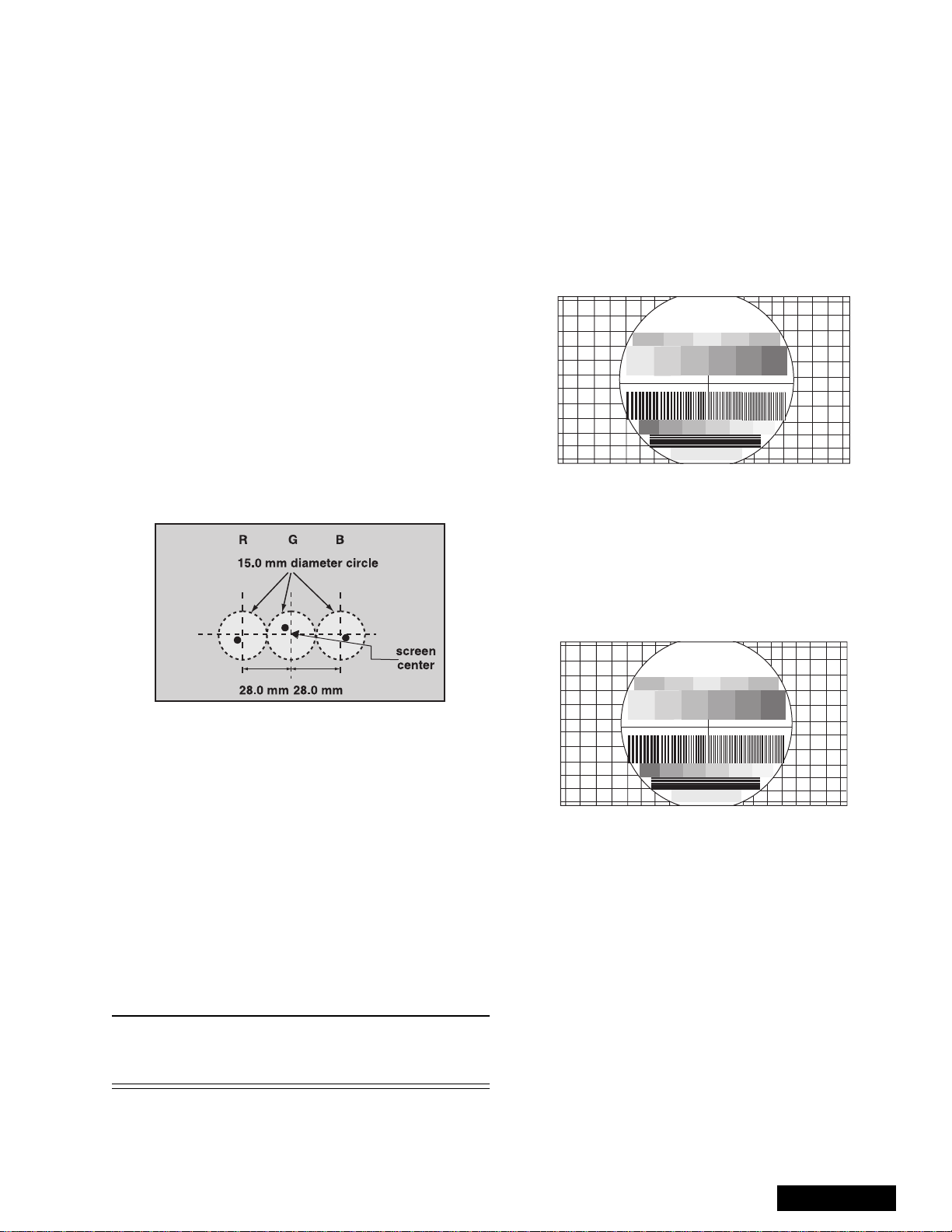

Centering magnets adjustment

Note: 1080i, 480p, 480i pattern can be obtained from

Panasonic’s TU-DST51 set-top box DTV

decoder.

Procedures:

1. Apply a NTSC crosshatch pattern with dots.

2. Set VIDEO “C_OFF” DAC from 00 to 01 to project

only green.

3. Set DAC MUTE from 00 to 01 (disabling digital

convergence).

4. Loosen the deflection coil screw on the green CRT.

5. Adjust green deflection coil until the horizontal

center line is horizontal.

6. Adjust centering magnets until the green pattern is

equal on left and right. Adjust also for horizontal

and vertical tilt.

Note: Push deflection coil to top of CRT neck,

then tighten deflection screw after adjusting

each CRT centering and tilt.

7. Set VIDEO “C_OFF” DAC from 01 to 03 to project

only blue. Adjust deflection coil until the horizontal

center line matches the pattern of the grid and is

leveled.

8. Adjust blue centering magnets until the pattern

center is at the appropriate distance as indicated

on figure 40.

RG

dd

B

12. Enable digital convergence by changing DAC

MUTE from 01 to 00.

13. Set VIDEO “C_OFF” DAC from 02 to 00. Following

the adjustment, make sure that all deflection coils

are pushed completely toward the CRT cones and

that all screws are tightened.

NTSC Horizontal size adjustment (H WID)

Note: 1080i, 480p, 480i pattern can be obtained from

Panasonic’s TU-DST51 set-top box DTV

decoder.

This adjustment is intended to adjust horizontal size of

the picture.

1. Apply a NTSC pattern.

2. Set VIDEO “C_OFF” DAC from 00 to 01 to project

only green.

3. Set DAC MUTE from 00 to 01 (disabling digital

convergence).

4. In service mode, adjust H-WID DAC until the

picture horizontal size is balanced at left and right

side of screen.

5. Set DAC MUTE from 01 to 00 (disabling digital

convergence).

6. Set VIDEO “C_OFF” DAC from 01 to 00.

HD 1080i Horizontal size adjustment

(H WID)

Note: 1080i, 480p, 480i pattern can be obtained from

Panasonic’s TU-DST51 set-top box DTV

decoder.

This adjustment is intended to adjust horizontal size of

the picture.

1. Apply a HD 1080i pattern.

2. Repeat NTSC horizontal size adjustment from

step 2.

Convergence adjustment

Note: 1080i, 480p, 480i pattern can be obtained from

Panasonic’s TU-DST51 set-top box DTV

decoder.

Note: It is strongly recommended to first read and

understand the following section prior to

make any adjustment.

Convergence adjustment must be perform

for 480i-p (same for interlace & progressive),

1080i and ZOOM 480i.

dmeasuredinmm

28 mm

Figure 40. Centering magnets adjustment.

9. Set VIDEO “C_OFF” DAC from 01 to 02 to project

only red.

10. Adjust red deflection coil until the horizontal center

line matches the pattern of the grid and is leveled.

11. Adjust red centering magnets until the pattern

center is at the appropriate distance as indicated

on figure 40.

TurnPTVonandallowittowarmupfor30

minutes prior to making adjustments

(WHITE PATTERN).

Note:

Preparation:

Place the convergence alignment template (see

“Convergence alignment template” on page 33) over

the PTV screen. Align the center lines of the template

with the mechanical center markerson the PTV screen

-27-

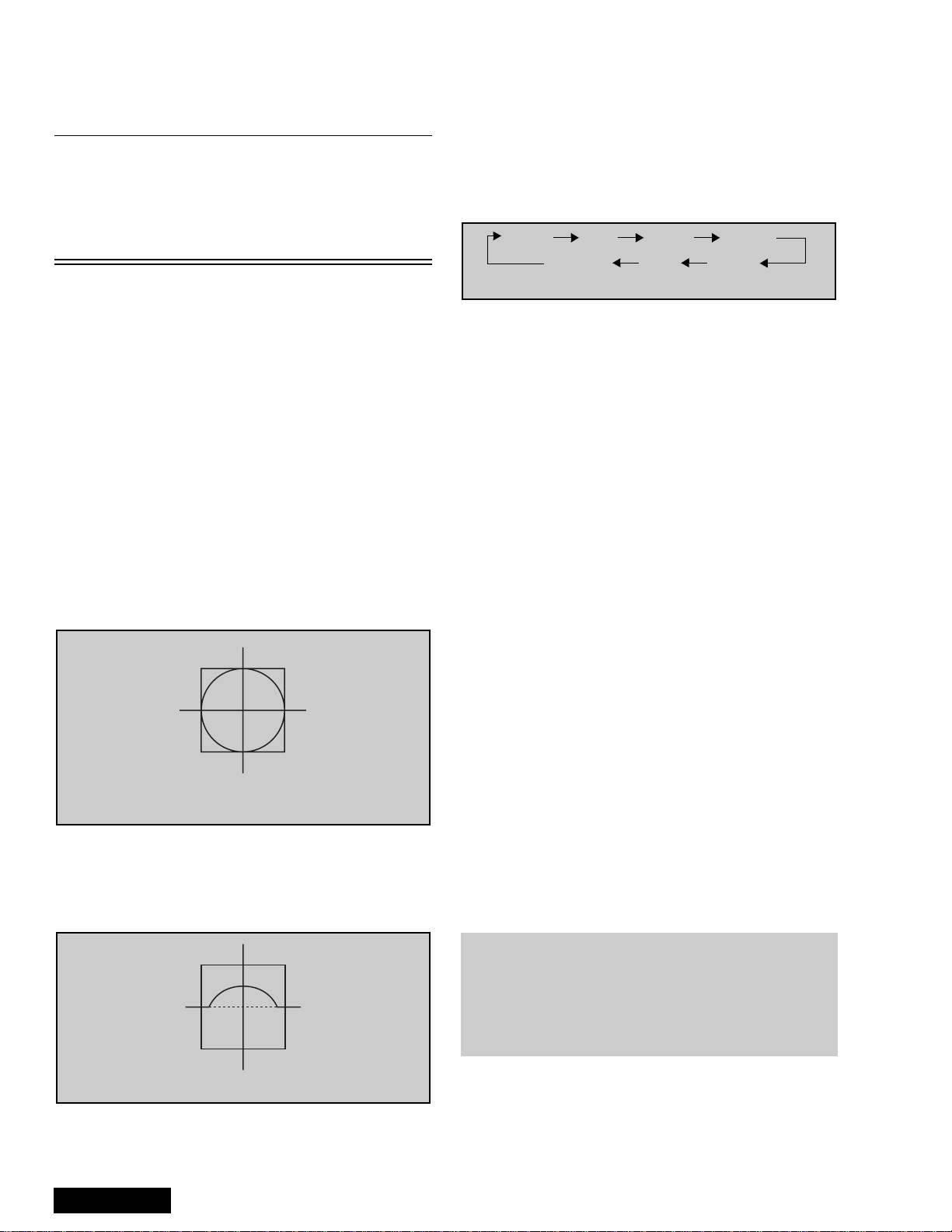

This PTV uses the scheme described below to

correct for misconvergence of the three CRT

projection tubes. There are various modes to

this operation.

ServiceManual

frame. If the template is not available, create one using

the dimensions provided in “Convergence alignment

template” on page 33.

Remote control must be used during the procedure.

Note: Apply the convergence alignment template to

the PTV screen frame to converge the green

raster only. Remove the convergence

alignment template following this alignment.

The red and blue rasters can then be aligned

to the green raster.

Raster Setup:

1. Enter to service mode (red CHK).

2. In SET-UP (roller guide menu) CONVERGENCE 1

set all values to 0.

3. Cover red & blue lens with caps.

4. Apply a pattern to adjust specific format:

• NTSC signal to adjust 480i-p (same for

interlace and progressive)

• 1080i signal to adjust 1080i

• 480i signal with PTV in ZOOM aspect to

adjust Z480i

5. Select DAC COARSE, then press ACTION to enter

to “CONVERGENCE ADJ” mode.

6. Press “0” key on remote.

7. Press ACTION key on remote to enter to

“TEST_POS” mode.

8. Move pattern by pressing VOL right - left and CH

up - down so that the cursor center overlap

monoscope pattern center.

30

Figure 41. Aligning cross-hair

cursor with center of pattern

9. Press “5” key on remote to exit superimpose mode

(monoscope pattern disappear).

10. Press “TV/VIDEO” key to enter “DATA_POS” mode

11. Adjust by pressing VOL right - left so that peak of

curve is the same position as center of cursor.

13. Press “5” key on remote so that monoscope

pattern appears (superimpose mode)

14. Move cursor by pressing VOL right - left and CH

up - down so that cursor center overlap

monoscope pattern center

15. Press “0” key to go back to “CONVERGENCE

ADJ” mode.

16. Press “TV/VIDEO” key to cycle through “COARSE

ADJ. MODE” options.

Static Size Skew Linear

KeyPinCorner

Figure 43. Coarse modes cycle

17.Tochangeto“FINEADJUSTMENTMODE”

options (DAC FINE), press “TV/VIDEO” key on

remote for at least 3 seconds, to go back to

“COARSE ADJ MODE” options press “TV/VIDEO”

on remote again for 3 seconds.

18. In “FINE ADJUSTMENT MODE” options, press

“MUTE” key on remote to switch between “cursor”

mode and “data” mode.

• Cursor mode: Allows cursor movement by

pressing VOL right - left and CH up - down.

• Data mode: Allows making adjustment by

pressing VOL right - left and CH up - down.

19. Either “COARSE ADJUSTMENT MODE” options

or “FINE ADJUSTMENT MODE” options, press “RTUNE” repeatedly key on remote to cycle through

different color adjustments (R, G , B, White)

20. To store adjustments press “7”, then “ACTION” key

on remote, otherwise press “POWER” then

“ACTION” to exit adjustments without saving.

21. Remote functions:

• 1,3.......... changecolorviewadj

• 2..................changepattern

• 7.......................savedata

• 5.........................overlap

• POWER....................toexit

• RECALL ............displayvalues

• R-TUNE...............cycle colors

• TV/VIDEO ............changemode

3secs.......changeoptions

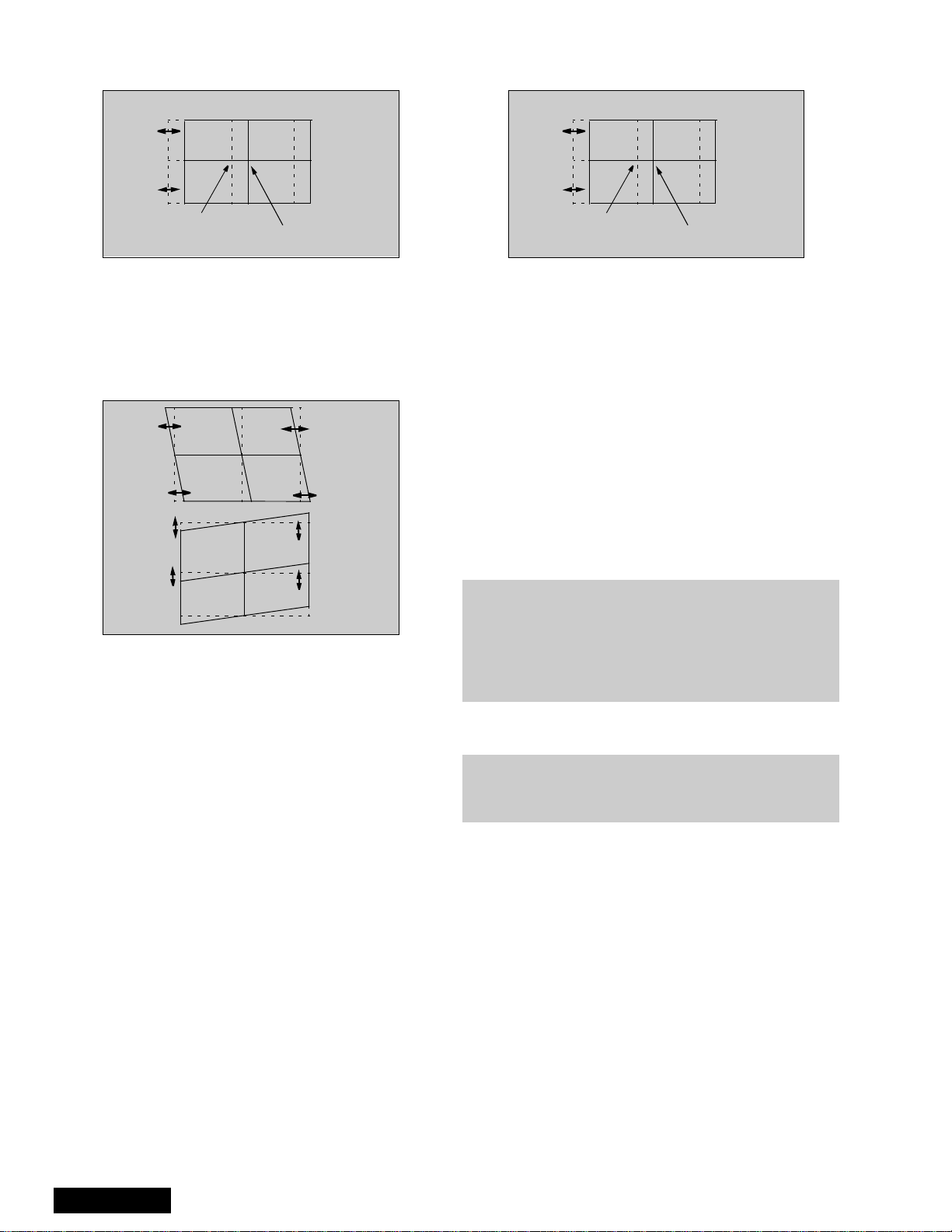

Coarse adjustment mode (COARSE)

Note: 1080i, 480p, 480i pattern can be obtained from

Panasonic’s TU-DST51 set-top box DTV

decoder.

Figure 42. Symmetrical shape

12. Press “TV/VIDEO” key on remote to enter

“OSD_POS” mode.

ServiceManual

Note: It is strongly recommended to first read and

understand the following section prior to

make any adjustment.

Convergence adjustment must be perform

for 480i-p (same for interlace & progressive),

1080i and ZOOM 480i.

Procedure:

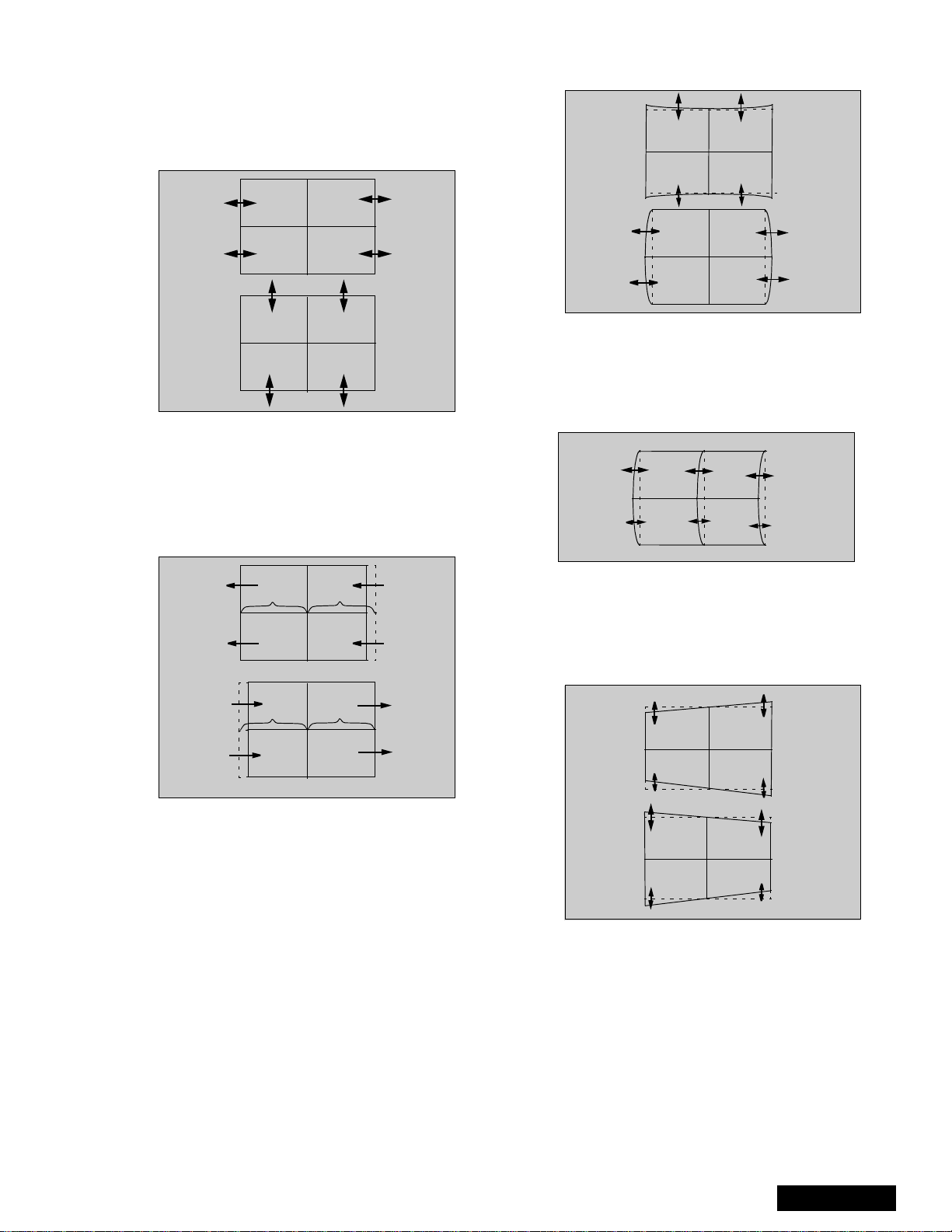

1. Enter to “G-SIZE” mode:

• DAC COARSE

• Press ACTION on remote

• TV/VIDEO (repeatedly)

• R-TUNE (repeatedly)

-28-

2. Press “2” repeatedly and apply the pattern of

border and cross.

3. Press RECALL to display values

4. Adjust size so that the line of the border closes to

the screen frame at top, bottom, left and right by

pressing CH up-down and VOL right-left.

Figure 44. H&Vsizeadjustment

5. Press “7” then “ACTION” key on remote to save

changes.

6. Enter to linearity “G-LINEAR” mode by pressing

“TV/VIDEO”.

7. Adjust linearity by pressing VOL right-left until A=B

(see figure 45)

12. Press “7” then “ACTION” key on remote to save

changes.

Figure 46. H&VPINadjustment

13. Enter to CORNER “G-CORNER” mode by pressing

TV/VIDEO.

14. Adjust by pressing VOL right-left (see figure 47).

15. Press “7” then “ACTION” key on remote to save

changes.

AB

AB

Figure 45. Linear mode adjustment

8. Press “7” then “ACTION” key on remote to save

changes.

9. Enter to PIN “G-PIN” mode by pressing “TV/

VIDEO”.

10. Adjust V_PIN by pressing CH up-down (see

figure 46).

11. Adjust H_PIN by pressing VOL right-left.

Figure 47. Corner adjustment

16.EntertoKEY“G-KEY”modebypressingTV/

VIDEO.

17. Adjust by pressing CH up-down (see figure 48)

18. Press “7” then “ACTION” key on remote to save

changes

Figure 48. KEY mode adjustment

Note: Confirm that pattern looks like a square and

almost overlaps the screen frame, check that

vertical and horizontal line center match with

the marks on screen frame, if linearity is not

good enough, repeat adjustments.

19. Enter to “STATIC” mode by pressing TV/VIDEO.

20. Press “1” or “3” repeatedly until green and red only

are shown.

-29-

ServiceManual

21. Adjust “R-STATIC” so that the center of red

overlaps with the center of green.

38. Adjust B-STATIC so that the center of blue

overlaps with the center of green (see figure 51).

red

Figure 49. STATIC mode adjustment

22. Enter to SKEW “R-SKEW” mode by pressing TV/

VIDEO

23. Adjust “R-SKEW” so that the vertical and horizontal

line of center overlaps with green (see figure 50)

24. Press “7” then “ACTION” key on remote to save

changes.

Figure 50. SKEW adjustment

green

Note: Remember always save data following each

adjustment by pressing “7” key on remote, then

ACTION.

25. Enter to LINEARITY “R-LINEAR” mode by

pressing TV/VIDEO.

26. Adjust Horizontal linearity (see figure 45)

27. Enter to SIZE “R-SIZE” mode by pressing TV/

VIDEO

28. Adjust so that the line on the border closes to the

screen frame at top, bottom, left and right (see

figure 44)

29. Enter to PIN “R-PIN” mode by pressing TV/VIDEO

30. Adjust horizontally and vertically (see figure 46)

31. Enter to CORNER “R-CORNER” mode by pressing

TV/VIDEO.

32. Adjust corners (see figure 47)

33. Enter to KEY “R-KEY” mode by pressing TV/

VIDEO

34. Adjust KEY (see figure 48)

35. Display pattern of border and cross, then check

that red overlaps green pattern, if it is not

satisfactory, repeat from step 19.

36. Enter to STATIC “B-STATIC” mode.

37. Press “1 or 3” key repeatedly on remote until only

green and blue pattern are displayed

blue

Figure 51. B-STATIC adjustment

39. Perform all adjustments for blue (B-SKEW, BLINEAR, B-SIZE, B-PIN, B-CORNER, B-KEY)

40. Display border and cross pattern and confirm that

blue overlaps with green pattern, if it is not

satisfactory, repeat for blue.

41. Press “1 or 3” key repeatedly on remote until

green, red and blue (white), confirm that red and

blue overlaps with green pattern.

42. Press “7” key on remote, then ACTION to save

changes.

43. Press POWER then ACTION to exit adjustments or

press TV/VIDEO for at least 3 seconds to change

to Fine Adjustment Mode.

green

Fine adjustment mode (FINE)

(convergence)

Note: It is strongly recommended to first read and

understand the following section prior to

make any adjustment.

Convergence adjustment must be perform

for 480i-p (same for interlace & progressive),

1080i and ZOOM 480i.

Helpful hint:

The easiest way to adjust convergence is to begin

from the center of the screen, to the border in all the

convergence adjustments.

Remote functions:

• 1,3............changecolorviewadj

• 2................... changepattern

• 7........................savedata

• 5......................... overlap

• POWER.....................toexit

• RECALL..............displayvalues

• R-TUNE................cyclecolors

• TV/VIDEO............ changemode

3 secs . . . . . . . . change options

• MUTE (“fine”). . . . . .cursor & data mode

About pattern:

• NTSC to adjust 480ip (same for interlace and

progressive)

• 1080i to adjust 1080i

• 480i with ptv in zoom aspect to adjust

Z480i

ServiceManual

-30-

Loading...

Loading...