Panasonic PT44LCX65, PT52LCX65, PT61LCX65 Schematic

Multi Media Display

PT-44LCX65

PT-52LCX65

PT-61LCX65

ORDER NO. MKE0505850C1

B2

© 2005 Panasonic Shikoku Electronics Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

PT-44LCX65 / PT-52LCX65 / PT-61LCX65

CONTENTS

Page Page

1 SAFETY PRECAUSIONS 3

1.1. GENERAL GUIDELINES

1.2. LEAKAGE CURRENT COLD CHECK

1.3. LEAKAGE CURRENT HOT CHECK

1.4. UV-PRECAUTION

2 PREVENTION OF ELECTROSTATIC DISCHARGE (ESD) TO

ELECTROSTATICALLY SENSITIVE (ES) DEVICES

3 ABOUT LEAD FREE SOLDER (PbF)

4 SERVICE NOTES

5 DISASSEMBLY / ASSEMBLY PROCEDURES

5.1. CABINET SECTION

6 ADJUSTMENT PROCEDURES 1

7 TROUBLESHOOTING HINTS FOR BLOCK LEVEL REPAIR

8 BLOCK DIAGRAMS

9 SCHEMATIC DIAGRAMS

9.1. SCHEMATIC DIAGRAM AND CIRCUIT BOARD LAYOUT

NOTES

9.2. INTERCONNECTION SCHEMATIC DIAGRAM

9.3. FRONT JACK SCHEMATIC DIAGRAM

9.4. OPERATION / THERMISTOR 1 / THERMISTOR 2 /

COVER SWITCH SCHEMATIC DIAGRAMS

20

20

41

44

51

59

59

60

61

62

3

3

3

3

4

5

6

9.5. VOLTAGE CHART

10 CIRCUIT BOARD LAYOUT

10.1. FRONT JACK C.B.A.

10.2. OPERATION C.B.A. / THERMISTOR 1 C.B.A. /

THERMISTOR 2 C.B.A. / COVER SWITCH C.B.A.

11 EXPLODED VIEWS

11.1. MAIN PARTS SECTION

11.2. FRONT AND BASE SECTION

11.3. DISPLAY SECTION

11.4. SCREEN SECTION

11.5. PROJECTION SECTION

11.6. TV UNIT SECTION

11.7. PACKING PARTS AND ACCESSORIES SECTION

12 REPLACEMENT PARTS LIST

12.1. REPLACEMENT NOTES

12.2. MECHANICAL REPLACEMENT PARTS LIST

12.3. OPTIONAL ACCESSORY REPLACEMENT PARTS LIST

12.4. ELECTRICAL REPLACEMENT PARTS LIST

63

65

65

66

67

67

69

70

72

74

75

76

77

77

78

80

80

2

1 SAFETY PRECAUSIONS

1.1. GENERAL GUIDELINES

1. For continued safety, no modification of any circuit should

be attempted.

2. Disconnect AC Plug before disassembling this unit.

3. It is advisable to use an isolation transformer in the AC

supply before servicing.

4. When servicing, observe the original lead dress. If a short

circuit is found, replace all parts which have been

overheated or damaged by the short circuit.

5. After servicing, see to it that all the protective devices such

as insulation barriers, insulation papers, shield, and

isolation R-C combinations etc. are properly installed.

6. After servicing, be sure to restore the wires, leads,

insulation barriers, shields, etc.

7. After servicing, make the leakage current checks to prevent

the customer from being exposed to shock hazards.

Caution:

Use a separate Isolation Transformer for this unit when

servicing.

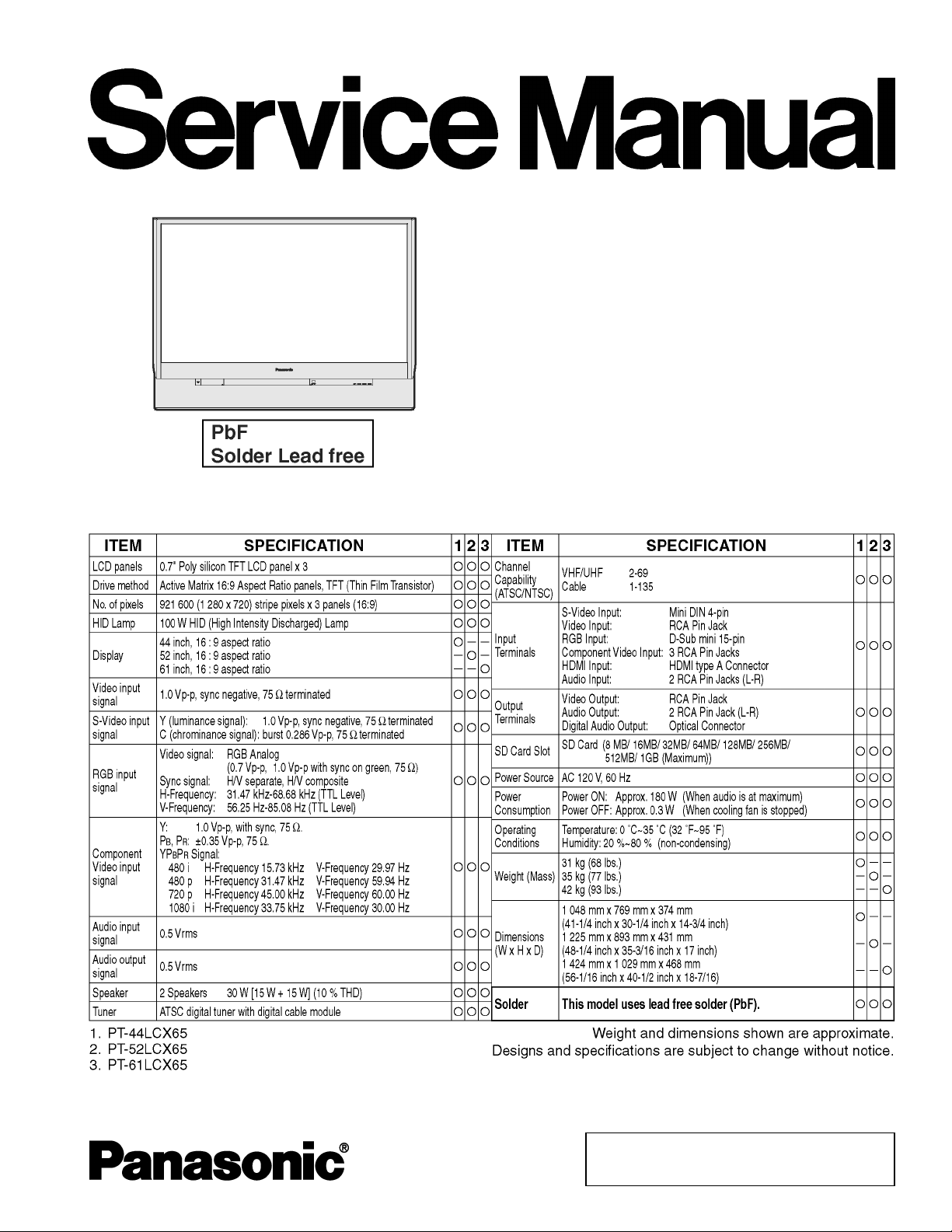

1.2. LEAKAGE CURRENT COLD

CHECK

PT-44LCX65 / PT-52LCX65 / PT-61LCX65

the limits specified, there is a possibility of shock hazard,

and the receiver should be repaired and rechecked before

it is returned to the customer.

Figure 1

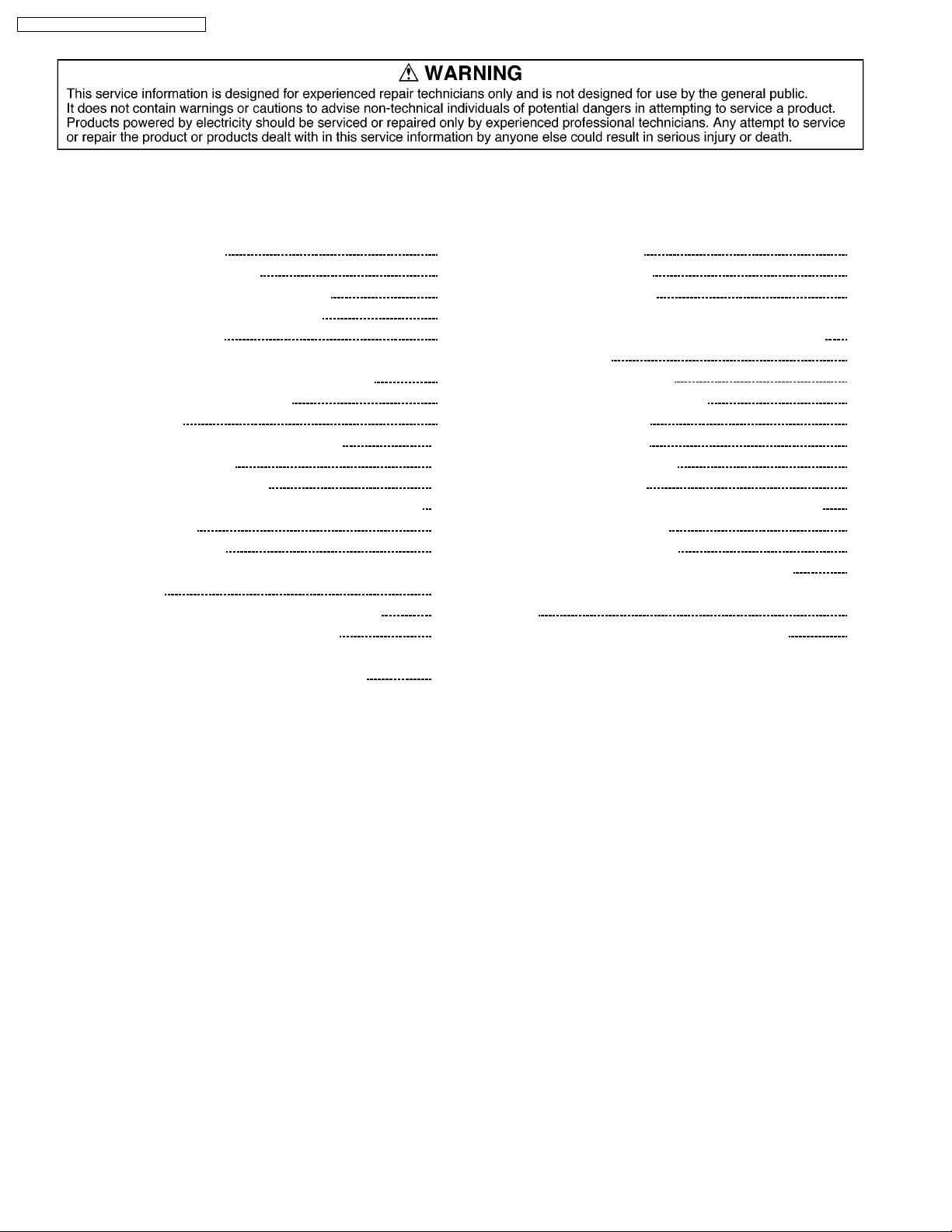

1.4. UV-PRECAUTION

1. Be sure to disconnect the AC Plug when replacing the

lamp.

2. Since the lamp reaches a very high temperature during its

operation, wait until it has completely cooled off when

replacing the Lamp Unit.

3. The lamp emits small amounts of UV-Radiation.

Avoid direct-eye contact by covering the Lamp and wearing

the UV protective glasses.

4. The high pressure lamp involves a risk of explosion.

1. Unplug the AC cord and connect a jumper between the two

prongs on the plug.

2. For physically operated power switches, turn power on.

Otherwise skip step 2.

3. Measure the resistance value, with an ohmmeter, between

the jumpered AC plug and each exposed metallic cabinet

part on the receiver, such as screwheads, connectors, etc.

When the exposed metallic part has a return path to the

chassis, the reading should be between 1 MΩ and 12 MΩ.

When the exposed metal does not have a return path to the

chassis, the reading must be infinity.

1.3. LEAKAGE CURRENT HOT

CHECK

1. Plug the AC cord directly into the AC outlet.

Do not use an isolation transformer for this check.

2. Connect "A" to exposed metallic part on the set. And

connect "B" to a good earth ground, as shown in Figure 1.

3. Use an AC voltmeter, with 1 kΩ/V or more sensitivity, to

measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverse the AC plug in theAC outlet and repeat each of the

above measurements.

6. The potential at any point should not exceed 0.25 V RMS.

A leakage current tester (Simpson Model 228 equivalent)

may be used to make the hot checks. Leakage current must

not exceed 1/2 mA. In case a measurement is outside of

Figure 2

3

PT-44LCX65 / PT-52LCX65 / PT-61LCX65

2 PREVENTION OF

ELECTROSTATIC

DISCHARGE (ESD) TO

ELECTROSTATICALLY

SENSITIVE (ES) DEVICES

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some field-effect

transistorsandsemiconductor "chip" components. The following

techniques should be used to help reduce the incidence of

component damage caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor

component or semiconductor-equipped assembly, drain off

any ESD on your body by touching a known earth ground.

Alternatively, obtain and wear a commercially available

discharging ESD wrist strap,whichshould be removed for

potential shock reasons prior to applying power to the unit

under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4. Use only an antistatic solder removal device. Some solder

removal devices not classified as "antistatic (ESD

protected)" can generate electrical charge sufficient to

damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum

foil or comparableconductivematerial).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

CAUTION :

Be sure no power is applied to the chassis or circuit, and

observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static

electricity (ESD)sufficientto damage an ES device).

4

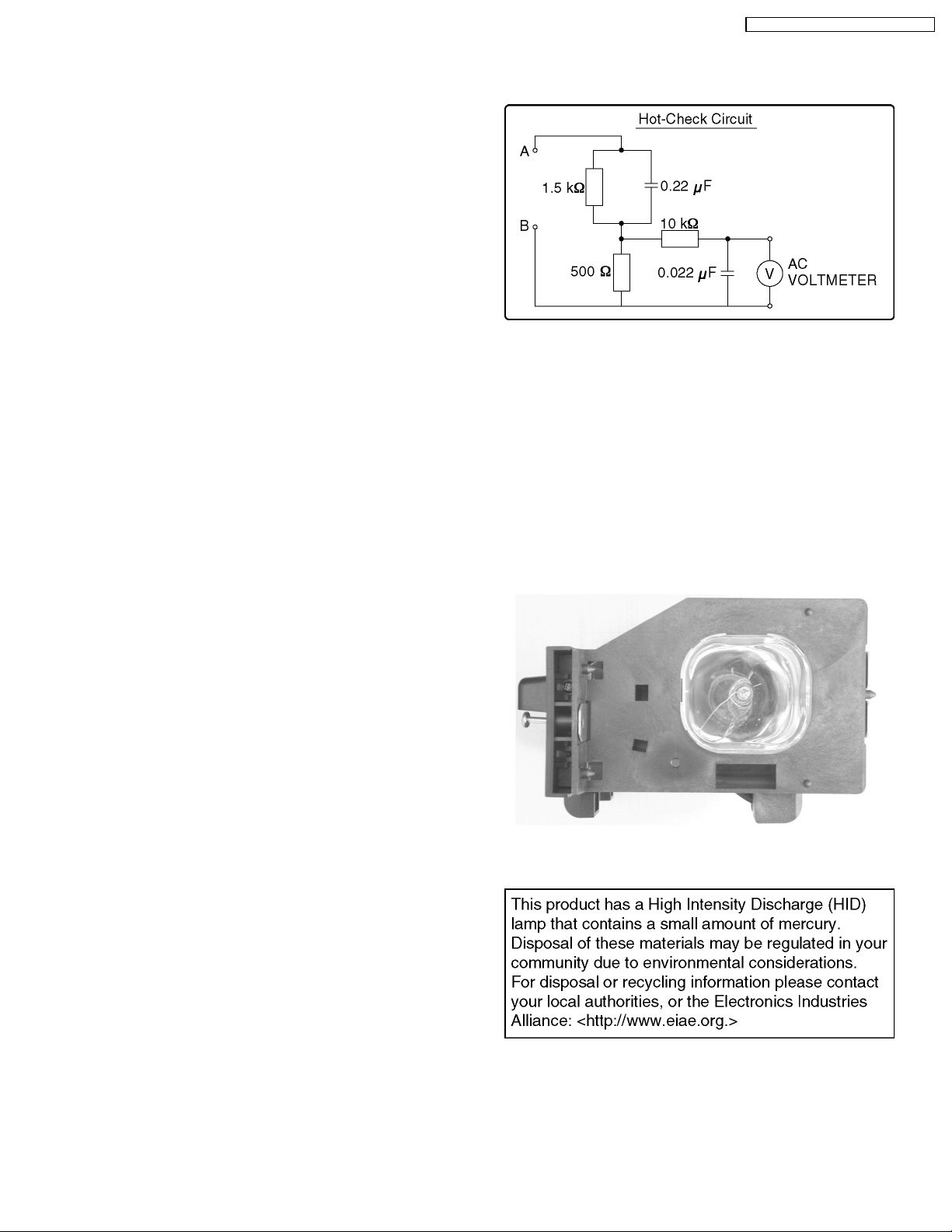

3 ABOUT LEAD FREE SOLDER (PbF)

PT-44LCX65 / PT-52LCX65 / PT-61LCX65

5

PT-44LCX65 / PT-52LCX65 / PT-61LCX65

4 SERVICE NOTES

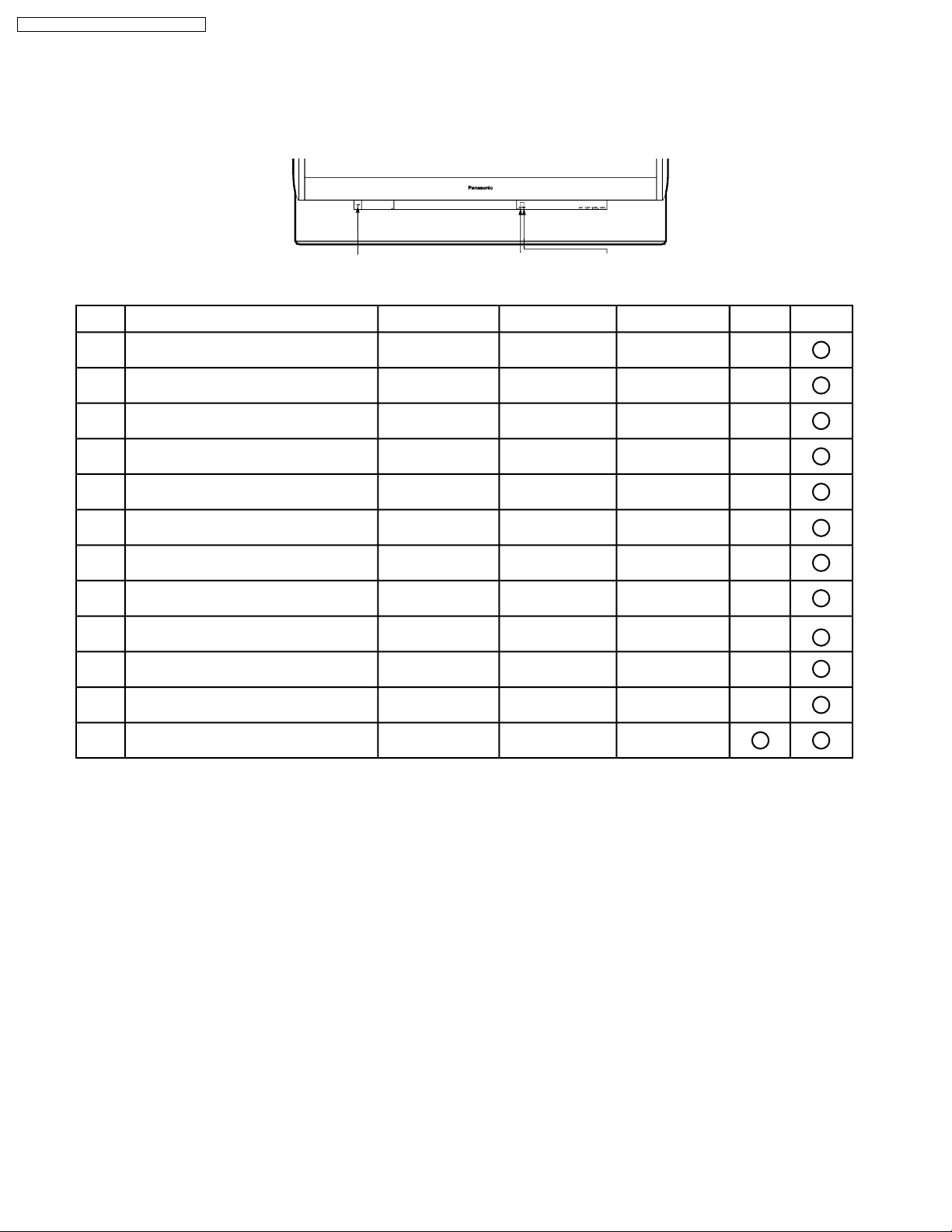

LED INDICATIONS FOR ERROR CONDITION

Each LED indication facilitates finding the cause of the error.

When an error is detected, the Lamp comes off and the LED on the front will flash.

POWER LED

TEMP LED

LAMP LED

(Note 2) (Note 3)

Error InformationError No. LAMP OFFLAMP LED OSD

Fan1, Fan2 or Fan3 stopped

1)

Lamp Cover open

2)

Temperature Sensor shorted or open

3)

(Thermistor 1 C.B.A.)

Abnormal Temperature

4)

(Thermistor 1 C.B.A.)

Ballast Error (abnormal Lamp or Ballast)

5)

Ballast Error (abnormal Lamp voltage)

6)

Ballast Error (abnormal temperature)

7)

Ballast Error (other causes)

8)

Abnormal Voltage (+17V, +9V, +5V line) for LCD

9)

Drive C.B.A.

Temperature Sensor shorted or open

10)

(Thermistor 2 C.B.A.)

11)

Abnormal Temperature

(Thermistor 2 C.B.A.)

Clogged air filter

12)

flashes orange once

every 5 seconds

flashes orange twice

every 5 seconds

-

--

-

-

-

flashes orange 7 times

every 5 seconds

-

-

-

TEMP LEDPOWER LED

--

-

flashes once

every 5 seconds

flashes twice

every 5 seconds

--

-

-

-

flashes 3 times

every 5 seconds

flashes 3 times

every 5 seconds

flashes 4 times

every 5 seconds

flashes 5 times

every 5 seconds

-

-

flashes once

every 5 seconds

flashes twice

every 5 seconds

flashes 3 times

every 5 seconds

flashes 4 times

every 5 seconds

flashes 3 times

every 5 seconds

-

-

-

Note:

1.When two or more errors have occurred at the same time, the LED will alternate flash patterns as shown above every 5 seconds.

2.Warning OSD appears when the air filter is clogged.

3.LAMP OFF: The LED will flash immediately after the Lamp comes off.

6

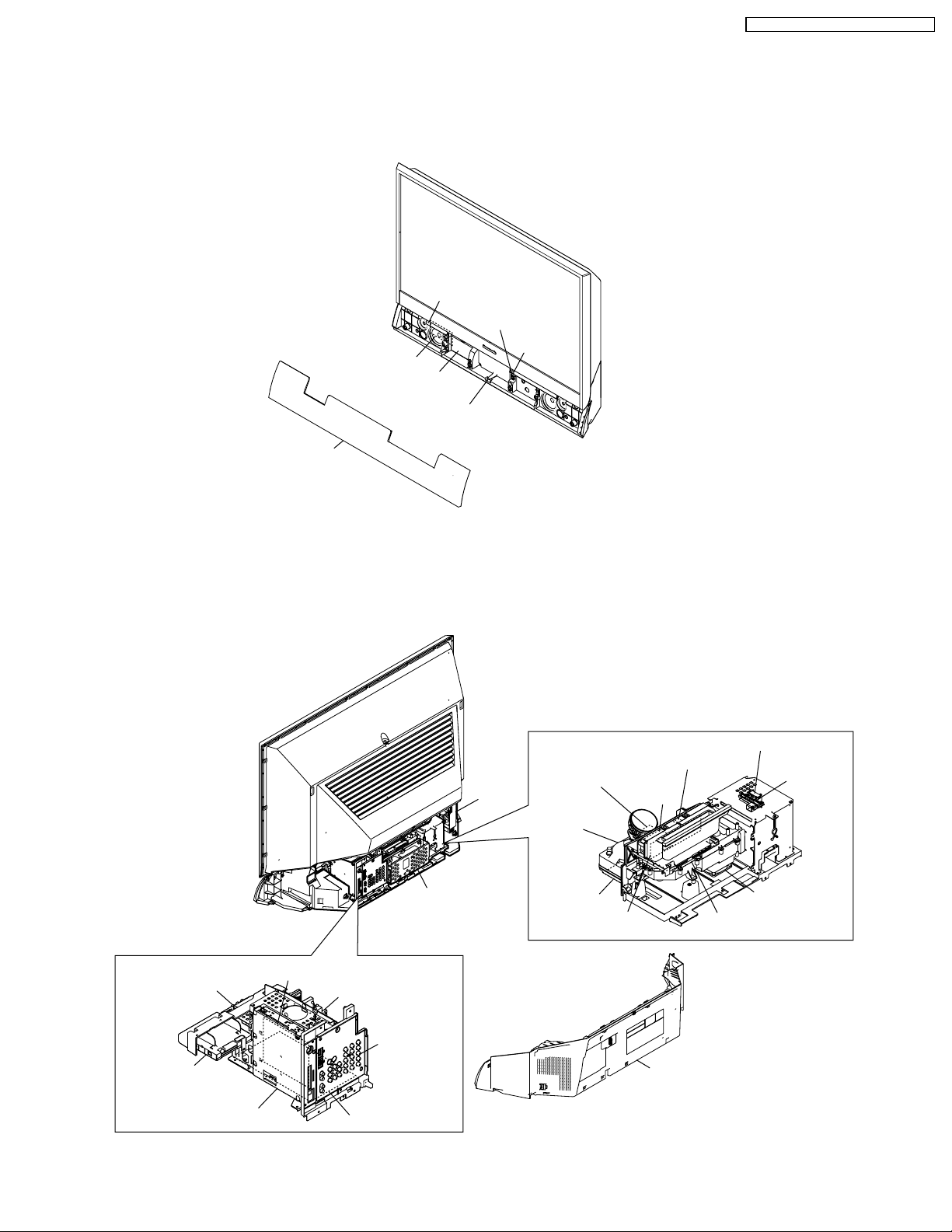

MAIN PARTS LOCATION

Front Cover Unit

PT-44LCX65 / PT-52LCX65 / PT-61LCX65

<Front View>

POWER LED

TEMP LED

LAMP LED

Operation C.B.A.

Lamp Cover

Optical Cover

Front Jack C.B.A.

Card C.B.A.

Main C.B.A.

<Rear View>

Power C.B.A.

Rear Jack

C.B.A.

Fan 3

Ballast C.B.A.

Projection Unit & Top Duct 3

Cover Switch C.B.A.

Thermistor 1 C.B.A.

Air Filter

Fan Case Unit

(Fan 1)

Air Filter

Air Filter

Thermistor 2 C.B.A.

Thermal

Fuse Unit

Fan 2

LCD Drive C.B.A.

Rear Cover

Digital T uner C.B.A.

TV Unit & Digital Tuner C.B.A.

Base C.B.A.

7

PT-44LCX65 / PT-52LCX65 / PT-61LCX65

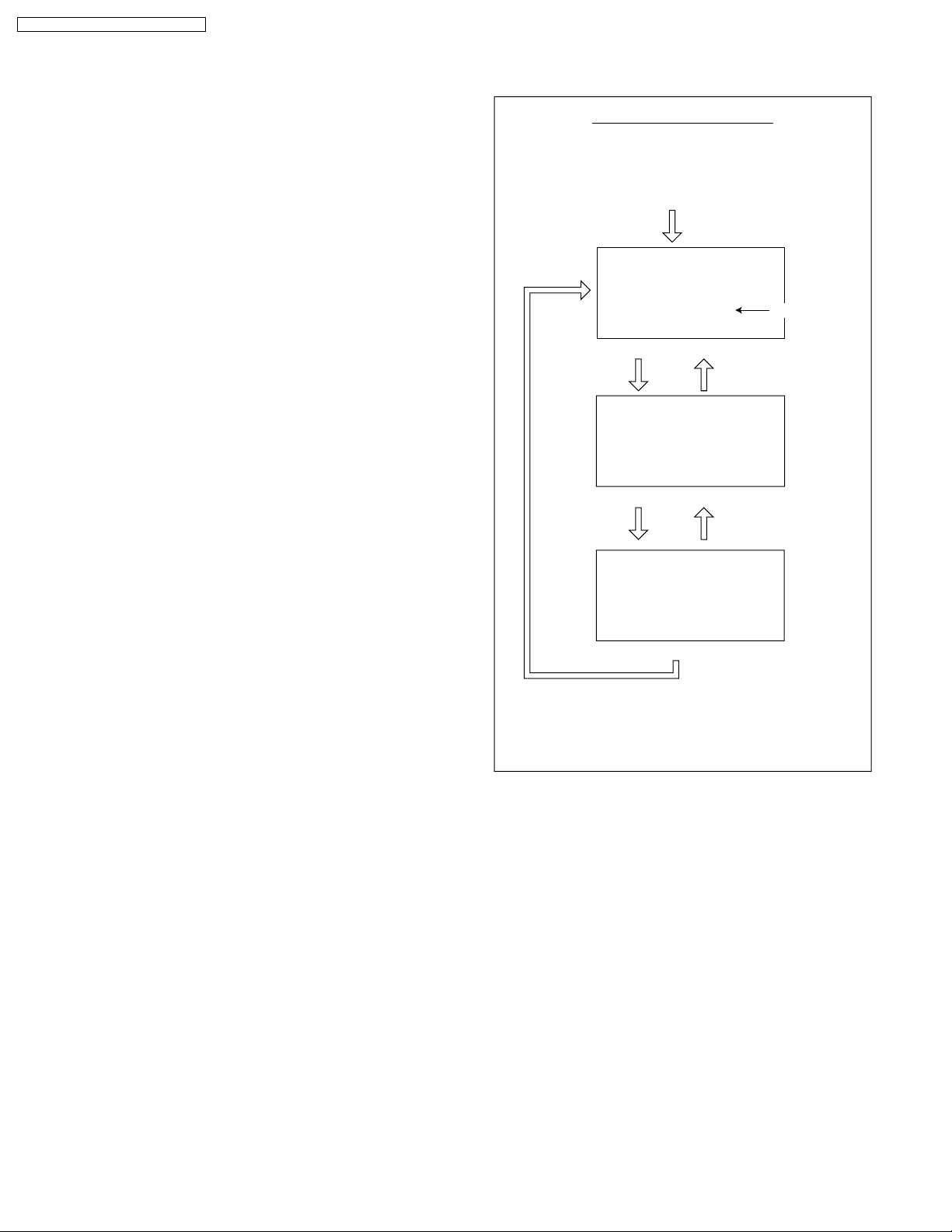

SERVICE MODE

In this mode, the following information can be confirmed on the

screen:

Service Mode (1/3)

- Current Lamp elapsed time

- The number of Lamp ON (For reference only)

- BKSV number read-out

Service Mode (2/3)

- Key detection check

- Communication check for IIC bus on the Main C.B.A.

- Total Lamp elapsed time

- Communication check for IIC bus on the Main C.B.A.

- EEPROM IC6007 version and build version

- IC6003 software version and build version

Service Mode (3/3)

- IC6003 Port information

Note:

IC6003: Main Microcontroller on the Main C.B.A.

(For reference only)

(For reference only)

Service Mode Map

Enter :

VOLUME DOWN button + TV/VIDEO key

(on the front) (on the remote)

(for more than 5 seconds in power off condition)

Power ON

SERVICE Mode 1/3

LAMP OPERATION TIME

CURRENT LAMP: 2000h

OSD DISP : ON

LON COUNT : 153

BKSV: B0 3A 59 CD 66

< Service Mode (1/3) >

CH DOWN key CH UP key

SERVICE Mode 2/3

IR:1 UNIT:1

IC3001:1 4201:1 5004:1

5103:1 5301:1 5501:1

5805:1 SAP:1

TOTAL : 12345h

IC6005:1 6007:1 MTNR:1

E:050405B1

F:0000000

IC6003 V:0100000

< Service Mode (2/3) >

CH DOWN key

SERVICE Mode 3/3

IC6003 PORT

P0:10101010 P8:---10110

P1:-1111100 P9:--111111

P2:00000000 PA:00000000

P3:00000000 PB:11111110

P4:--111110 PC:11111100

P5:10110101 PD:-----111

P6:01011001 PE:11000000

P7:10101001 PF:----0011

< Service Mode (3/3) >

CH UP key

BKSV number

Exit:

CH DOWN key

Power OFF.

(When turning the power on again after once turning

off, wait for approx. 10 seconds. Or, the unit can not be

released from Service Mode.)

Fig. 1-1

8

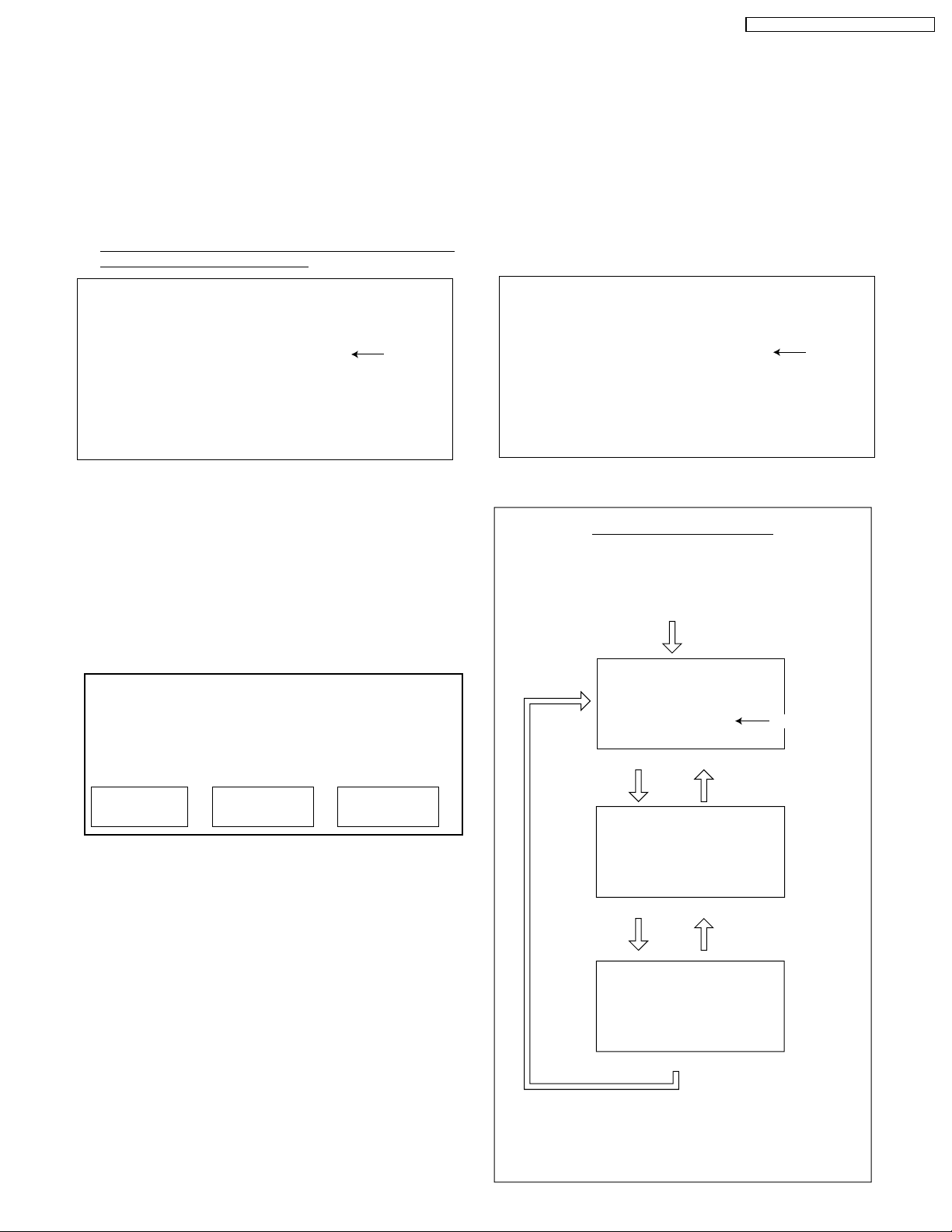

PT-44LCX65 / PT-52LCX65 / PT-61LCX65

BEFORE REMOVING THE MAIN C.B.A. OR

THE TV UNIT FROM THE UNIT AT THE

USE’S LOCATION

Note:

The TV Unit includes the Main C.B.A.

CAUTION:

Be sure to make a note of the CURRENT LAMP value

1.

(value A) in Service Mode (1/3):

SERVICE Mode 1/3

LAMP OPERATION TIME

CURRENT LAMP: 2000h

OSD DISP : ON

LON COUNT : 153

BKSV: 4B 7E 3D CA FB

<Service Mode (1/3)>

Fig. 2

LAMP OPERATION TIME is stored in EEPROM on the

Main C.B.A. Therefore, before removing the Main C.B.A. or

the TV Unit at the user’s location, make a note of the

CURRENT LAMP value (value A) in Service Mode (1/3).

Then, after installing the new Main C.B.A. or the TV Unit at

the user’s location, set the CURRENT LAMP value to the

original value (value A) in Service Mode.

Otherwise, OSD and LED Lamp replacement indications

will be displayed at the wrong time.

Note:

In case it is impossible to make a note of the CURRENT

LAMP value because of a defective Main C.B.A., ask the

customer their daily average use and the approximate age

of the current Lamp. Then, calculate the CURRENT LAMP

value as follows and make a note.

Daily average use

(hours) (days) (hours)

Approx. age CURRENT LAMP

X=

Note:

The TOTAL value can be set to the original value in Service

Mode (2/3) by similar method:

Before removing the Main C.B.A. at the user’s location,

make a note of the TOTAL value in Service Mode (2/3).

Then, after installing the new Main C.B.A. at the user’s

location, set the TOTAL value to the original value in

Service Mode.

Value A

(Changeable)

WHEN REINSTALLING THE MAIN C.B.A.

OR THE TV UNIT INTO THE UNIT AT THE

USER’S LOCATION

CAUTION:

1. Set CURRENT LAMP value to original value as follows.

1) Select CURRENT LAMP in Service Mode (1/3).

2) Press the VOLUME UP/DOWN key on the remote to

change to the original value (value A) that was noted

before removing the Main C.B.A. or the TV Unit at the

user’s location.

SERVICE Mode 1/3

LAMP OPERATION TIME

CURRENT LAMP: 2000h

OSD DISP : ON

Value A

(Changeable)

LON COUNT : 153

BKSV: 48 BF 9D 72 B5

<Service Mode (1/3)>

Fig. 3

Service Mode Map

Enter :

VOLUME DOWN button + TV/VIDEO key

(on the front) (on the remote)

(for more than 5 seconds in power off condition)

Power ON

SERVICE Mode 1/3

LAMP OPERATION TIME

CURRENT LAMP: 2000h

OSD DISP : ON

LON COUNT : 153

BKSV: B0 3A 59 CD 66

< Service Mode (1/3) >

CH DOWN key CH UP key

SERVICE Mode 2/3

IR:1 UNIT:1

IC3001:1 4201:1 5004:1

5103:1 5301:1 5501:1

5805:1 SAP:1

TOTAL : 12345h

IC6005:1 6007:1 MTNR:1

E:050405B1

F:0000000

IC6003 V:0100000

< Service Mode (2/3) >

CH DOWN key

SERVICE Mode 3/3

IC6003 PORT

P0:10101010 P8:---10110

P1:-1111100 P9:--111111

P2:00000000 PA:00000000

P3:00000000 PB:11111110

P4:--111110 PC:11111100

P5:10110101 PD:-----111

P6:01011001 PE:11000000

P7:10101001 PF:----0011

< Service Mode (3/3) >

CH UP key

BKSV number

Exit:

CH DOWN key

Power OFF.

(When turning the power on again after once turning

off, wait for approx. 10 seconds. Or, the unit can not be

released from Service Mode.)

9

PT-44LCX65 / PT-52LCX65 / PT-61LCX65

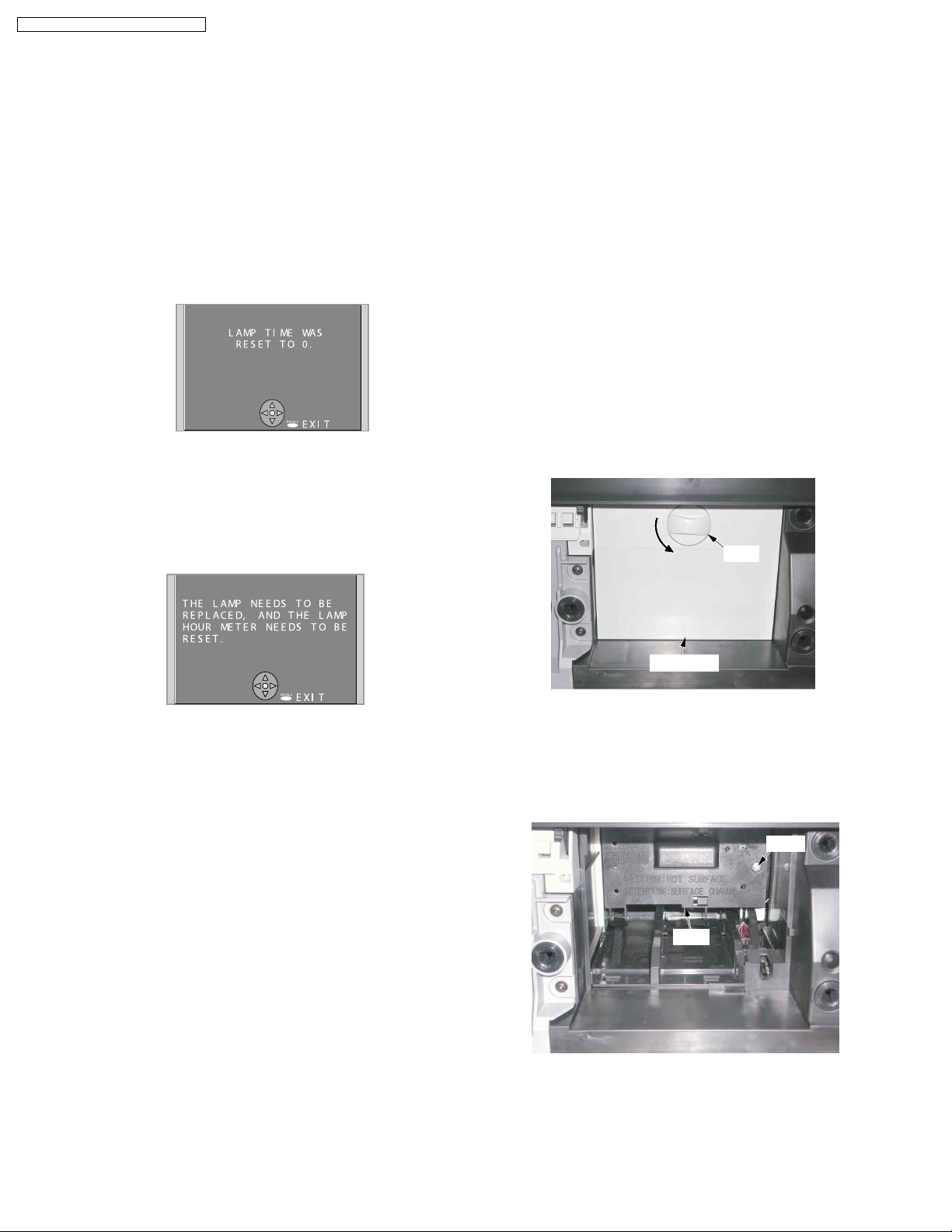

REPLACEMENT OF LAMP

Lamp Time Reset Procedure:

Be sure to reset the Lamp time to "0" after replacing the new

Lamp.

1. Plug in the AC Cord, and turn on the power by pressing the

POWER button.

2. Press and hold the VOLUME DOWN button on the unit and

the SPLIT key on the remote together for over 5 seconds

in power on condition.

When the reset is finished, the display as shown in Fig. 51 appears and the LAMP LED goes out.

Fig. 5-1

Note:

1. The unit will detect when the Lamp’s end of life is

approaching and the following message will be

displayed. And the LAMP indicator light will be lit when

the Lamp’s end of life is approaching.

Lamp Replacement Procedure:

1. Press the POWER button to turn off the power.

2. Wait for about 1 minute until the cooling fan stops.

Note:

The lamp cooling fan will continue to operate for about 1

minute after the power is turned off. Do not unplug the AC

Cord from the outlet until the fan has stopped. Avoid

interrupting the power by using circuit breakers or switchable

power strips.

3. After the cooling fan has stopped, unplug the AC Cord from

the outlet.

Note:

Please wait more than one hour before replacing the lamp.

[ Forced cooling function ]

If you need to replace the lamp more urgently:

- The Projection display has a forced cooling feature.

After the POWER button is turned OFF, and during the

first minute of the normal cooling fan operation, press

the VOLUME UP button on the unit and CH UP key on

the remote at the same time for more than 5 seconds.

The cooling fan operates for about 10 minutes. (LAMP

LED will flash 5 times every 5 second and POWER LED

will flash red for 10 minutes.)

4. Remove the Front Cover Unit from the latches.

5. Turn the Knob to the left.

Knob

Fig. 5-2

2. Influences of frequent lighting, continuous light use for

over 24 hours, the number of times lit, the length of time

between lightings, etc. may shorten lamp life. (Because

of this, we recommend having a replacement lamp on

hand.)

WARNING:

- The lamp could rupture if dropped and lamp fragments

could cause injury.

- Because the lamp unit is hot immediately after its use,

touching it may cause burns.

Please allow the lamp to cool before handling or replacing

the lamp unit.

- If replacement of the lamp unit becomes necessary during

the operation of the Projection Display, follow the procedure

to turn off the power and wait until the lamp unit cools

completely.

Cautions for Lamp Unit Replacement:

- Do not disassemble the Lamp.

- The lamp may be hot. Be careful when handling. Wear

gloves.

- Under no circumstance should you touch the actual bulb.

At this high operating temperature the natural oil on your

finger can cause the glass to weaken where touched and

the bulb can crack or explode.

Lamp Cover

Fig. 5-3

6. Pull the Lamp Cover out.

7. Loosen the Screw on the Lamp. Then, pull the Lamp.

Note:

Because the Lamp may still be hot, use caution when

handling.

Screw

Lamp

Fig. 5-4

8. Install the new Lamp, and tighten the Screw.

9. Install the Lamp Cover, and turn the Knob to the right.

10.Install the Front Cover Unit.

Note:

After replacing the Lamp, use caution to reset the Lamp time.

10

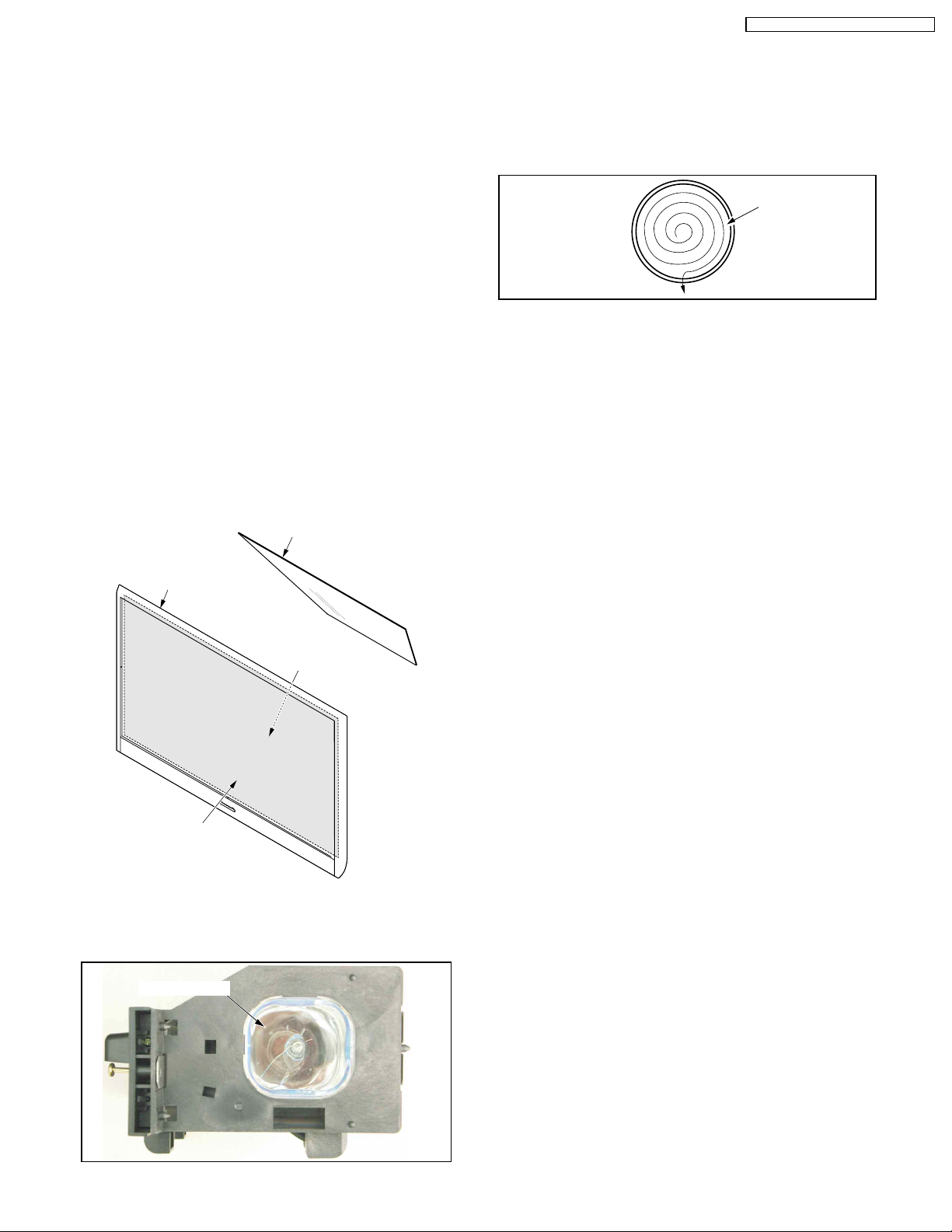

PT-44LCX65 / PT-52LCX65 / PT-61LCX65

CLEANING METHOD

THE SCREEN UNIT AND THE MIRROR

- THE SCREEN UNIT (Lenticular Screen, Fresnel Lens)

It is strongly recommended that the Lenticular Screen surface

(outside) and the Fresnel Lens surface (inside) should be

wiped gently with a clean, soft, dry cloth to remove the dirt.

Note:

1. If the dirt cannot be removed by wiping with a clean, soft, dry

cloth, use a clean, soft, dry cloth moistened with diluted

neutral pH liquid cleanser or a lens cleaner (usually

containing a small amount of ethyl alcohol) and wipe lightly.

Take care not to leave any streaks.

Do not use cleaning materials containing methyl alcohol,

acetone, or dichloromethane.

2. Use an air blower to clean the inner surface of the Lenticular

Screen and the outer surface of the Fresnel Lens (the

surfaces that one another). These surfaces must not be

wiped with a cloth.

- THE MIRROR

Remove any dirt with an air blower or wipe with a clean, soft,

dry cloth. If wiped too forcefully, the surface of the Mirror can

be damaged. If wiping with a clean, dry cloth does not remove

the dirt, the Mirror must be replaced.

Mirror

THE PROJECTION LENS

Use lens cleaning paper and cleaner available at your local

camera shop, etc. Dampen the cleaning paper with cleaner

and gently wipe the surface of the lens from the center outward

to remove dust.

Lens

Screen Unit

Fresnel Lens surface

(inside)

Lenticular Screen surface

(outside)

Fig. 6-1

THE LAMP

Gently wipe the surface of the glass of the Lamp with cleaning

paper or soft cloth.

Surface of glass

Fig. 6-2

11

PT-44LCX65 / PT-52LCX65 / PT-61LCX65

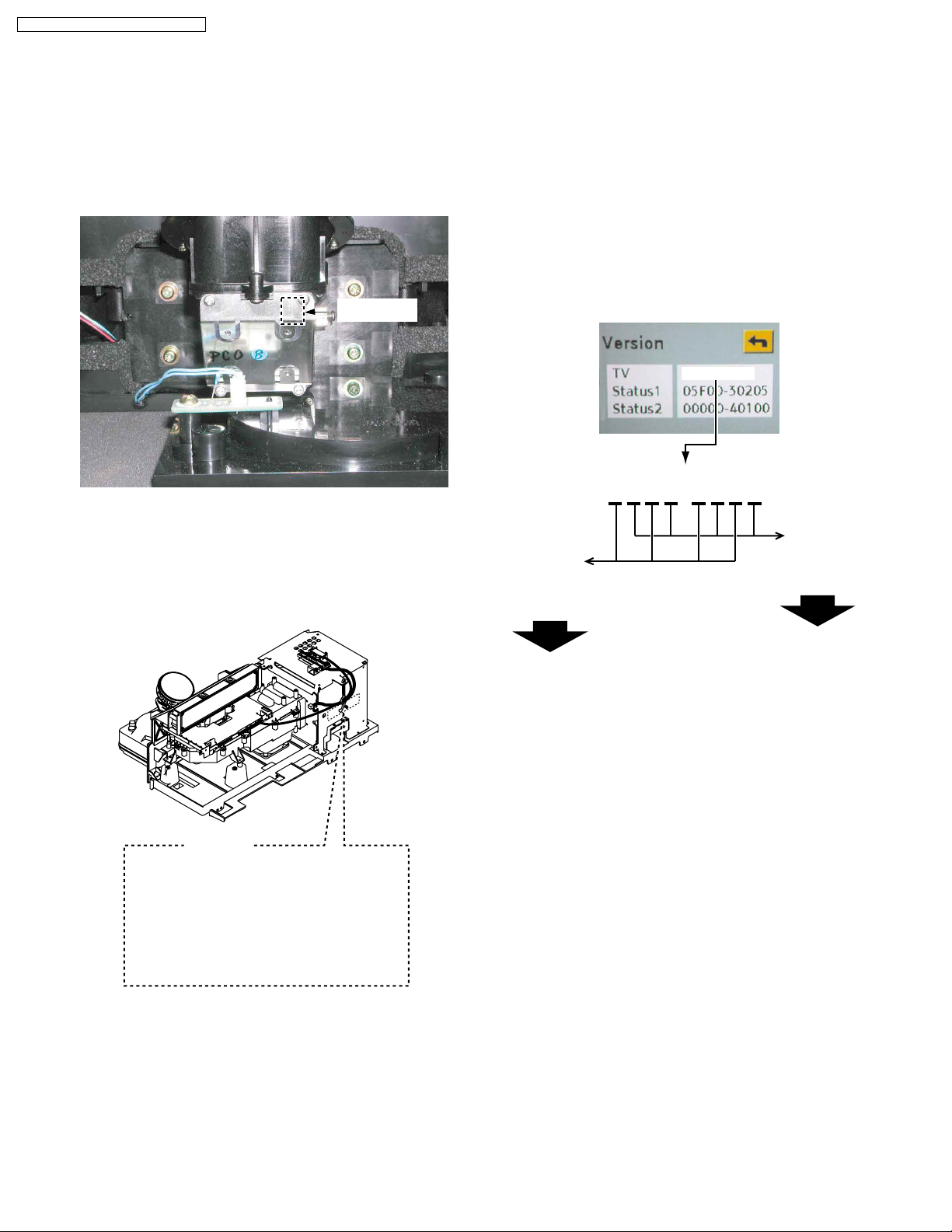

TO DISTINGUISH THE PROJECTION

LENS UNIT OR THE PROJECTION UNIT

The only difference between the 44 inch model, the 52 inch

model and the 61 inch model of the Projection Unit is the

Projection Lens. To distinguish, see marking (E, F or J) on the

Projection Lens.

X X X F

<Front View>

E with red: for 44 inch model

F with black: for 52 inch model

J with blue: for 61 inch model

And also, see the stamp on the Lamp Wall of the Projection

Unit.

E, F or J

TO READ THE DIGITAL TUNER (PEAKS)

SOFTWARE VERSION AND TV

MICROCONTROLLER SOFTWARE

VERSION

1. Press MENU key with the power on.

2. Press CH UP/DOWN key and select "Setup."

Then press OK key.

3. Press CH UP/DOWN key and select "About."

Then press OK key.

4. Select "Version" and press OK key.

Version menu will appear as shown below.

Starting with the second digit from the right or from the left.

0121-4610

0121-4610

Read every

Read every

other number

from the right:

1420

other number

from the left:

1160

Stamp

44"LSXA0625

52"LSXA0626

61"LSXA0699

TV Microcontroller software Ver. : 1.160

Digital Tuner (Peaks) software Ver. : 1.420

: for 44 inch model

: for 52 inch model

: for 61 inch model

12

MODEL

PT-44LCX65

PT-52LCX65

PT-61LCX65

NOT USED

MARK

A

B

C

PT

Note:

Refer to Item 3 of Schematic Diagram Notes of

Schematic Diagram and Circuit Board Layout Notes,

for mark "PT."

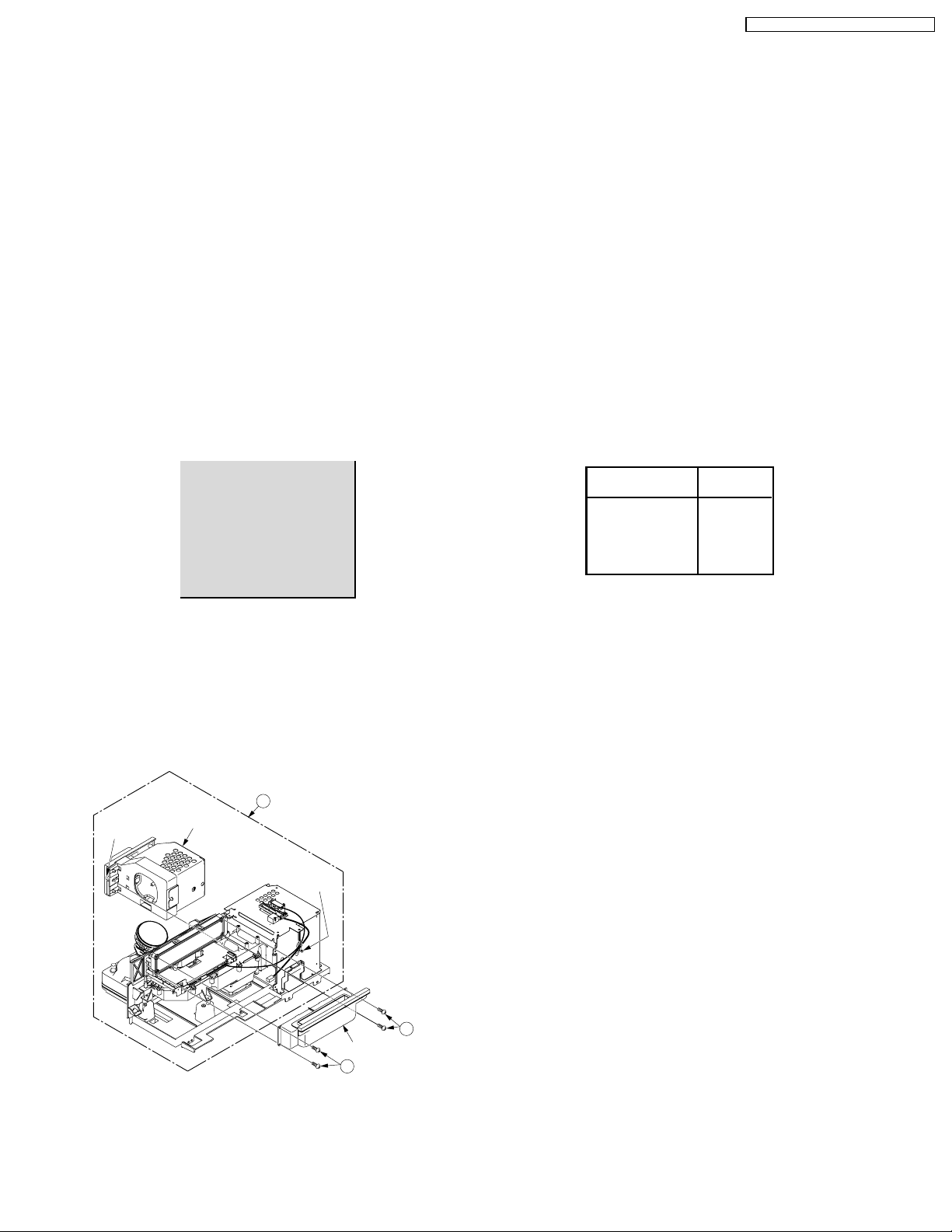

PT-44LCX65 / PT-52LCX65 / PT-61LCX65

RESET USER’S MEMORY FUNCTIONS

Be sure to reset the user’s memory:

- After replacing the Digital Tuner C.B.A.

- If the secret code of V-chip is forgotten.

- When moving the unit to a new location.

1. Turn on the power.

2. Press and hold the VOLUME DOWN button on the unit and

the OK key on the remote for more than 3 seconds. When

reset is finished, power shuts off automatically (the user’s

memory is reset).

CLOGGED AIR FILTER DETECTION

When a dirty or clogged air filter is detected, the OSD display

appears for 1 minute. And then the Lamp is turned OFF.

When this OSD display appears, remove the Projection Unit

from rear, and clean the air filters gently on the Projection Unit.

AIR FILTER CLEANING

IS RECOMMANDED AT THIS

TIME. FIRST TURN THE

UNIT OFF.

PLEASE CALL FOR

SERVICE.

UNIT WILL BE TURNED

OFF AFTER 1 MINUTE.

DO NOT UNPLUG AC CORD DURING

COOLING OPERATION

The lamp cooling fan will continue to operate for approximately

1 minute after the power is turned off.

At the same time, the POWER LED will flash red.

Do not disconnect the AC Cord from the power outlet and do

not open any circuit breakers while the cooling fan is still

operating.

HOT CIRCUIT

Primary circuit exists on the Ballast C.B.A. and the Power

C.B.A.

This circuit is identified as "HOT" on the C.B.A. and in the

Service Manual. Use extreme care to prevent accidental shock

when servicing.

MODEL NO. IDENTIFICATION MARK

Use Marks shown in the chart below to distinguish the different

models included in this Service Manual.

BEFORE REMOVING THE PROJECTION

UNIT FROM THE UNIT AT THE USER’S

LOCATION

When removing the Projection Unit, remove the Lamp and the

Top Duct 3 Unit from the Projection Unit and keep them. Then,

reinstall this Lamp and the Top Duct 3 Unit into the new

Projection Unit.

21

Projection Unit

Screw

for lamp

Lamp

Clamper

421

Top Duct 3 Unit

421

13

PT-44LCX65 / PT-52LCX65 / PT-61LCX65

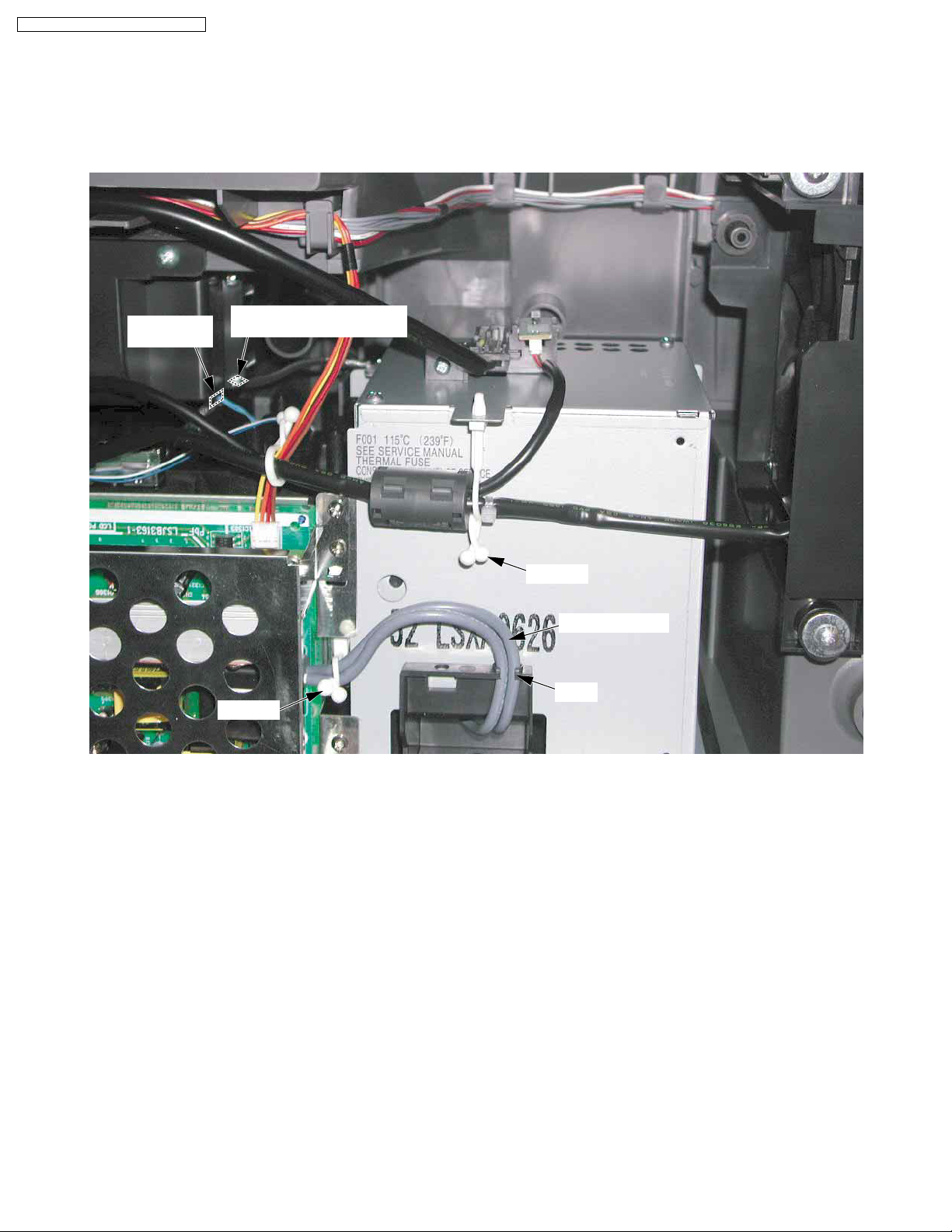

WIRE AND LEAD POSITION DIAGRAM OF THE UNIT

After servicing, make sure that all wires, leads, and clampers are placed in their original position. It is important for the best

operation of the unit.

Note: Use extreme care especially for the following.

AC Cord

Fig. 9-1

Thermal Fuse Unit

Fan 3

14

PT-44LCX65 / PT-52LCX65 / PT-61LCX65

After servicing, make sure that all wires, leads, and clampers are placed in their original position. It is important for the best

operation of the unit.

Note: Use extreme care especially for the following.

Speaker Connectors

P6005 (From Operation C.B.A.)

Fig. 9-2

15

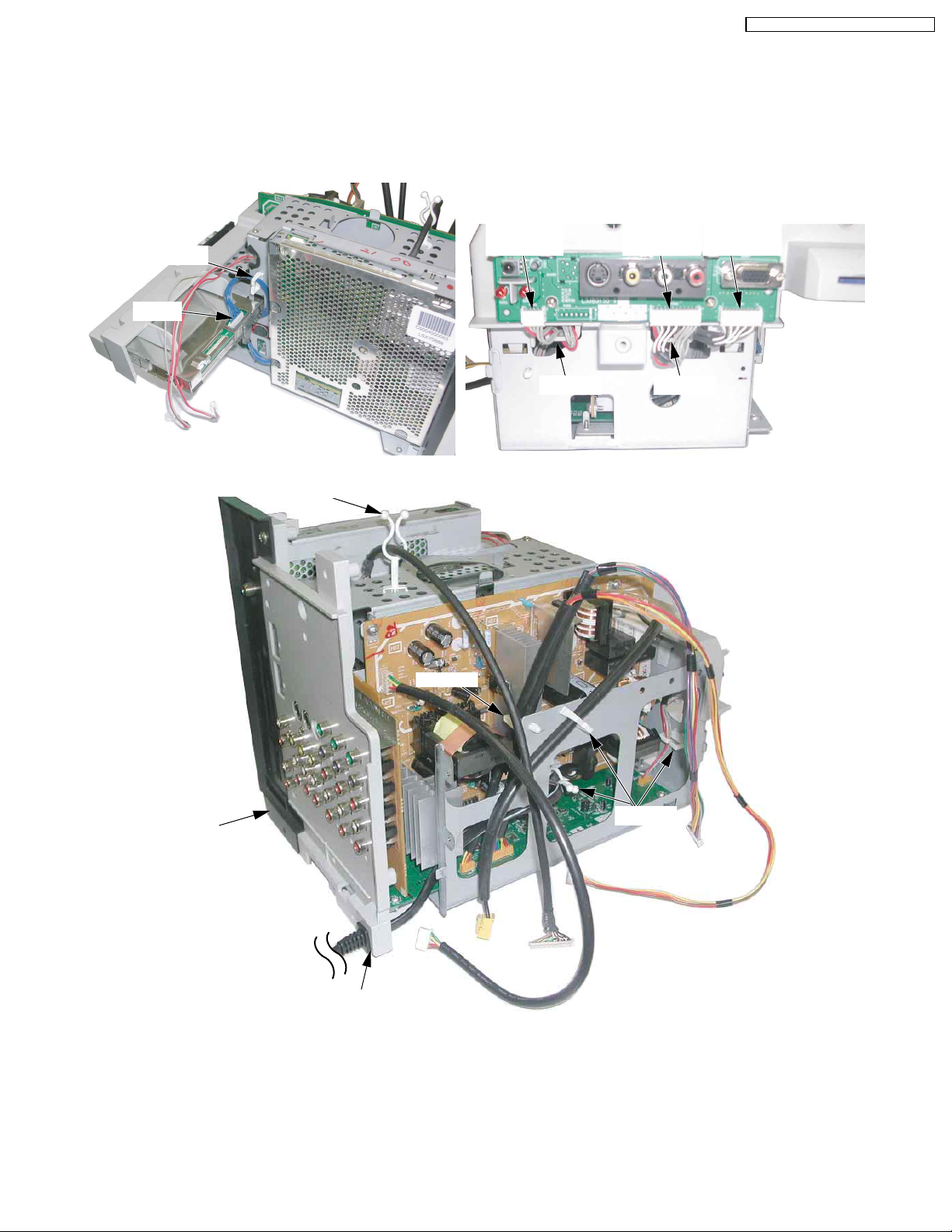

PT-44LCX65 / PT-52LCX65 / PT-61LCX65

After servicing, make sure that all wires, leads, and clampers are placed in their original position. It is important for the best

operation of the unit.

Note: Use extreme care especially for the following.

Clamper

20-pin Cable

Clamper

GND Wire

of 20-pin Cable

Fig. 9-3

16

PT-44LCX65 / PT-52LCX65 / PT-61LCX65

After servicing, make sure that all wires, leads, and clampers are placed in their original position. It is important for the best

operation of the unit.

Note: Use extreme care especially for the following.

Clamper

GND Wire

P1302

(From Power

C.B.A.)

P2501

(From

Main

C.B.A.)

P2901

(From

Base

C.B.A.)

P1306

(From Thermal Fuse Unit)

P2903

(From

Fan2)

P1301

(From Power

C.B.A.)

Fig. 9-4

P2904

(From

Fan3

C.B.A.)

P2303

(From

Thermistor

2 C.B.A.)

P2502

(From Cover Switch

C.B.A.)

Clamper

P1305

(From Base

C.B.A.)

17

PT-44LCX65 / PT-52LCX65 / PT-61LCX65

After servicing, make sure that all wires, leads, and clampers are placed in their original position. It is important for the best

operation of the unit.

Note: Use extreme care especially for the following.

P2902

(From Fan1)

P2302

(From Thermistor 1 C.B.A.)

Clamper

Lamp Connector

Hook

Clamper

Fig. 9-5

18

PT-44LCX65 / PT-52LCX65 / PT-61LCX65

After servicing, make sure that all wires, leads, and clampers are placed in their original position. It is important for the best

operation of the unit.

Note: Use extreme care especially for the following.

Clamper

P9003

Clamper

P3903

(From Base

C.B.A.)

Clamper Clamper

P3902

(From Base

C.B.A.)

P3901

(From Base

C.B.A.)

TV Unit

Clamper

Clampers

Hook

Fig. 9-6

19

PT-44LCX65 / PT-52LCX65 / PT-61LCX65

5 DISASSEMBLY / ASSEMBLY PROCEDURES

5.1. CABINET SECTION

CABINET SECTION

DISASSEMBLY METHOD OF CABINET SECTION

Cabinet section contains following removal procedures:

REMOVAL OF THE BALLAST C.B.A. AND THE PROJECTION UNIT FROM THE CABINET

REMOVAL OF THE TV UNIT AND THE DIGITAL TUNER C.B.A. FROM THE CABINET

REMOVAL OF THE BASE BODY UNIT

REMOVAL OF THE FRONT JACK C.B.A., THE CARD C.B.A., THE REAR JACK C.B.A., THE POWER C.B.A., THE MAIN

C.B.A. AND THE BASE C.B.A. FROM THE TV UNIT

REMOVAL OF THE SCREEN UNIT FROM THE DISPLAY

REMOVAL OF THE MIRROR FROM THE BACK COVER

REMOVAL OF THE OPERATION C.B.A. FROM THE CABINET

DISASSEMBLY FLOWCHART

This flow chart indicates the disassembly steps of the cabinet parts and the P.C.Boards in order to gain access to item (s) to be

serviced. When reassembling, perform the step (s) in the reverse order. Bend, route and dress the wires as they were originally.

FRONT COVER UNIT

SIDE COVER L/R UNIT

(DISPLAY)

SCREEN UNIT

MIRROR

BACK COVER

Note :

a. Place a cloth or some other soft material under the P.C. Boards or Unit to prevent damage.

b. When reinstalling, ensure that the connectors are connected firmly and electrical components have not been damaged.

c. Do not supply power to the unit during disassembly and reassembly.

REAR COVER

BASE BODY UNIT

BALLAST C.B.A.

PROJECTION UNIT

OPERATION

C.B.A.

DIGIT AL TUNER C.B.A.

TV UNIT

FRONT JACK C.B.A.

CARD C.B.A.

REAR JACK C.B.A.

POWER C.B.A.

MAIN C.B.A.

BASE C.B.A.

20

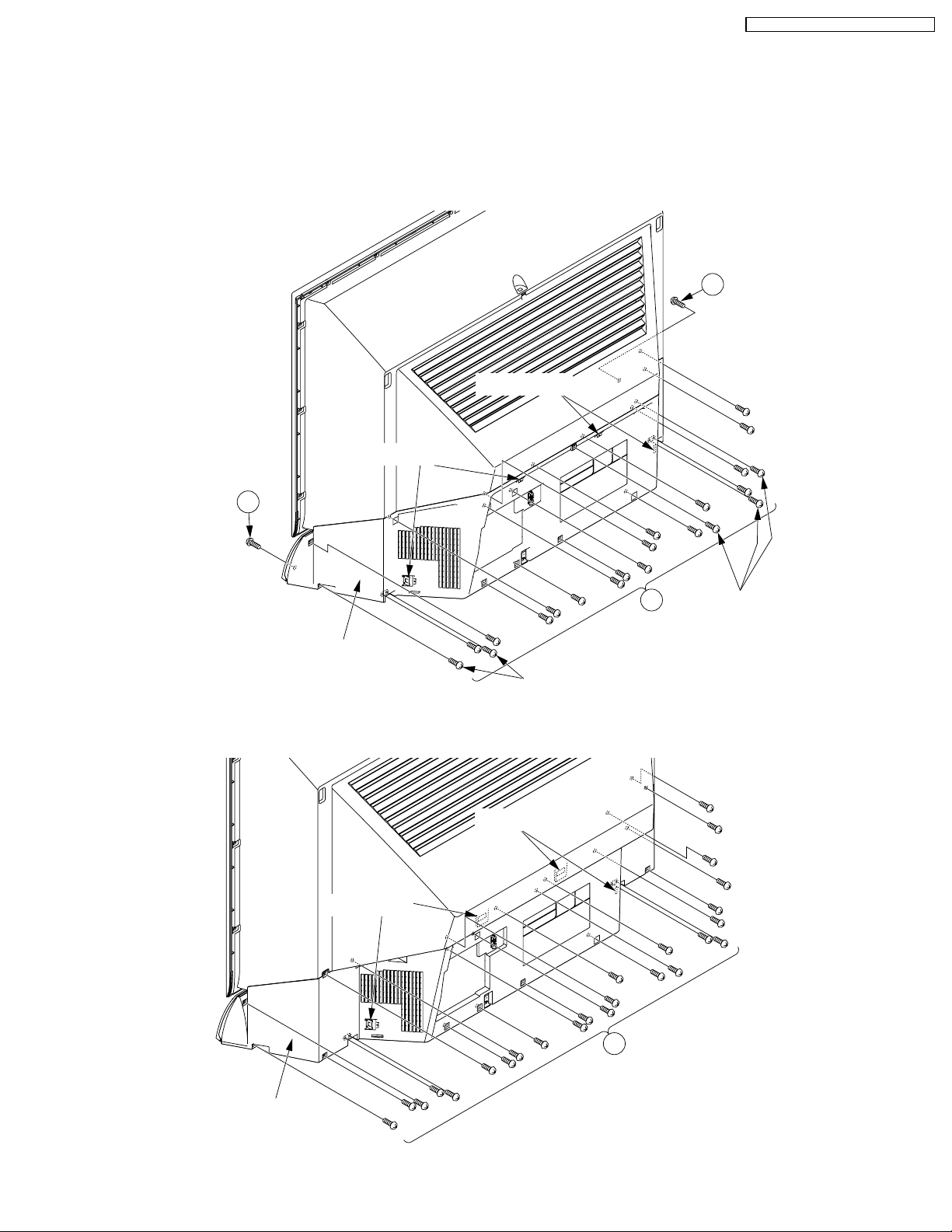

PT-44LCX65 / PT-52LCX65 / PT-61LCX65

REMOVAL OF THE BALLAST C.B.A. AND THE PROJECTION UNIT FROM THE CABINET

1. (PT-44LCX65/PT-52LCX65)

Remove the Rear Cover by removing the 18 (or 21: PT-52LCX65) Screws (401, 454) then pinching the 4 latch tabs.

(PT-44LCX65)

Note:

Remove the Front Cover

Unit and remove the 2

Screws from front side.

454

latch tabs

(PT-44LCX65)

Note:

Remove the Front Cover

Unit and remove the 2

Screws from front side.

454

latch tabs

Rear Cover

(PT-52LCX65)

Fig. D1-1-1

(PT-61LCX65)

Remove the Rear Cover by removing the 25 Screws (401) then pinching the 4 latch tabs.

latch tabs

latch tabs

401

401

(PT-52LCX65)

Rear Cover

Fig. D1-1-2

21

PT-44LCX65 / PT-52LCX65 / PT-61LCX65

2. 1) Disconnect Connectors P1301, P1302, P1305, P2501 (20-pin Cable), P2901, P2904.

Note: Take extreme care not to damage the 20-pin Cable when disconnecting.

2) Remove the 5 Screws (401) and the 3 Screws (402).

3) Slide and lift up the Projection Unit with the Ballast C.B.A. by releasing the 4 Guide Tabs.

*

402

*

402

<Bottom View of Projection Unit>

Projection Unit

with Ballast C.B.A.

Guide Tabs (X4)

401

GND Wire of

20-pin Cable

Slide and

Lift up

401

*: The 2 Screws *(401) and the 5 Screws *(402) are for removing the Ballast C.B.A.

401

Clamper

P2501

(From

Main

C.B.A.)

P2901

(From

Base

C.B.A.)

P2904

(From

Fan3

C.B.A.)

401

402

Clamper

*

402

*

402

P1302

(From Power

C.B.A.)

**

401 401 401

P1301

(From Power

C.B.A.)

P1305

(From Base

C.B.A.)

23

Reassembly Note: When installing, tighten the 3 Screws (401) in order.

Fig. D1-2

22

1 2 3

*

402

1

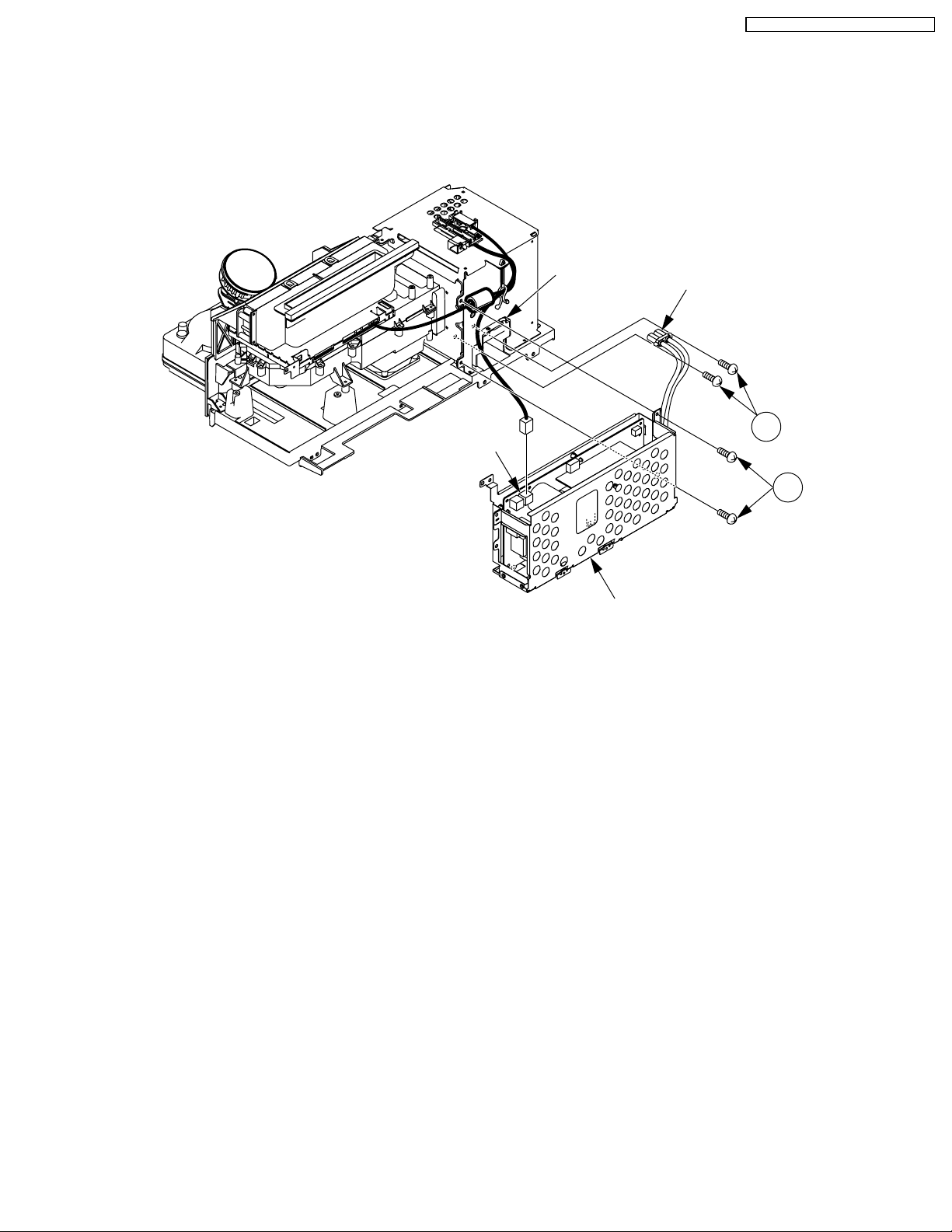

3. 1) Disconnect the Connector P1306.

2) Remove the 2 Screws (451) and disconnect the Lamp Connector while releasing the hook.

3) Remove the Ballast C.B.A. by releasing the 2 Screws (402).

Hook

PT-44LCX65 / PT-52LCX65 / PT-61LCX65

Lamp

Connector

P1306

Fig. D1-3

451

402

Ballast C.B.A.

23

PT-44LCX65 / PT-52LCX65 / PT-61LCX65

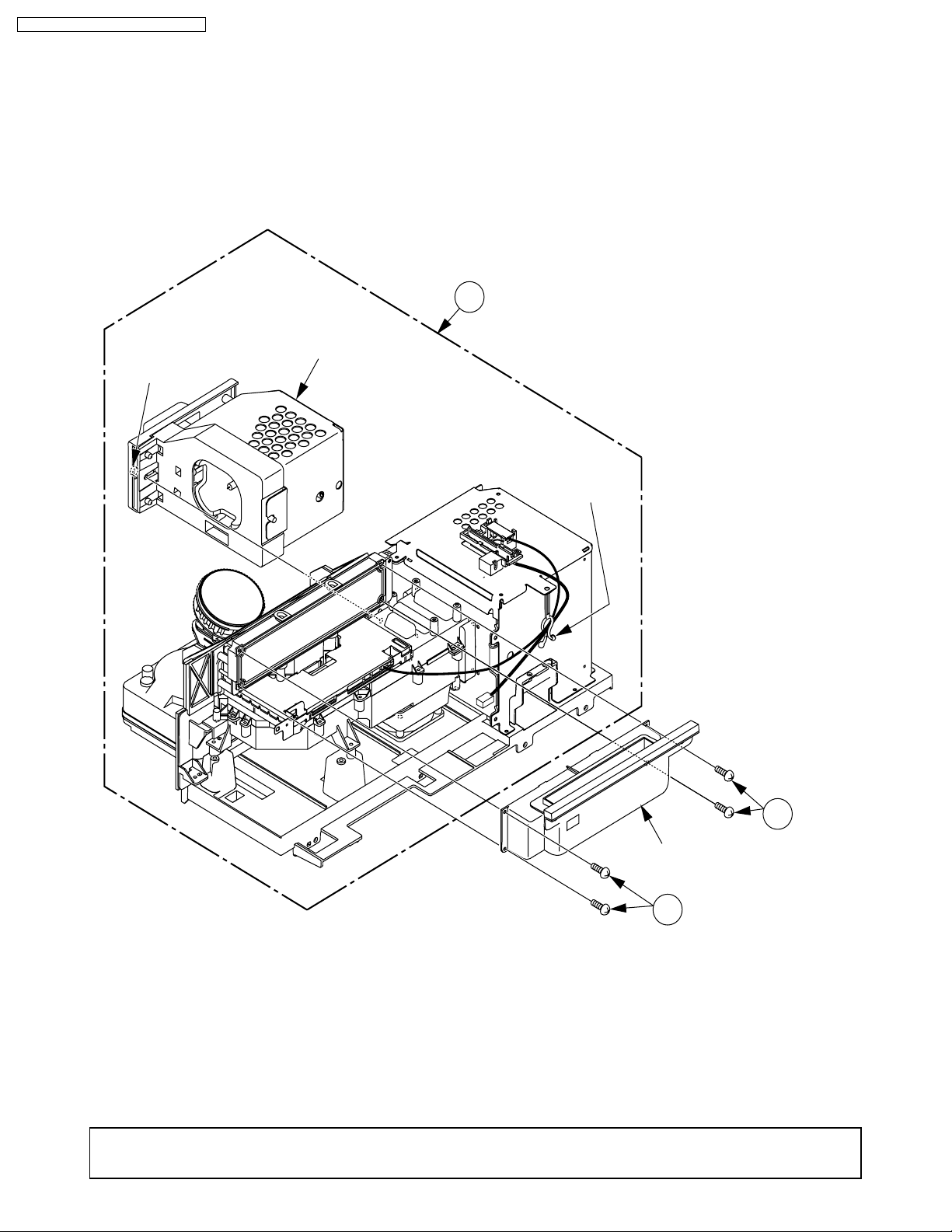

4. 1) Remove the Top Duct 3 Unit by removing the 4 Screws (421).

CAUTION:

When removing the Screws (421) on the Top Duct 3 Unit, plastic dust may be produced. Therefore, confirm that there is no dust

on the Top Duct 3 Unit. If there is dust, clean the Top Duct 3 Unit with a brush, etc. Otherwise, dust may adhere to the inside of

the screen.

2) Remove the Lamp from the Projection Unit by loosening the Screw.

21

Projection Unit

Screw

for lamp

Lamp

Clamper

421

Top Duct 3 Unit

421

Fig. D1-4

Note:

After replacing the Projection Unit, be sure to perform "ADJUSTMENT of Projection Unit." Refer to "WHEN REINSTALLING THE

PROJECTION UNIT OR THE BASE BODY UNIT INTO THE UNIT AT THE USER’S LOCATION:."

Replacement Note of Projection Unit:

These parts will be necessary when replacing. Set aside, and keep and re-use.

- Top Duct 3 Unit

24

PT-44LCX65 / PT-52LCX65 / PT-61LCX65

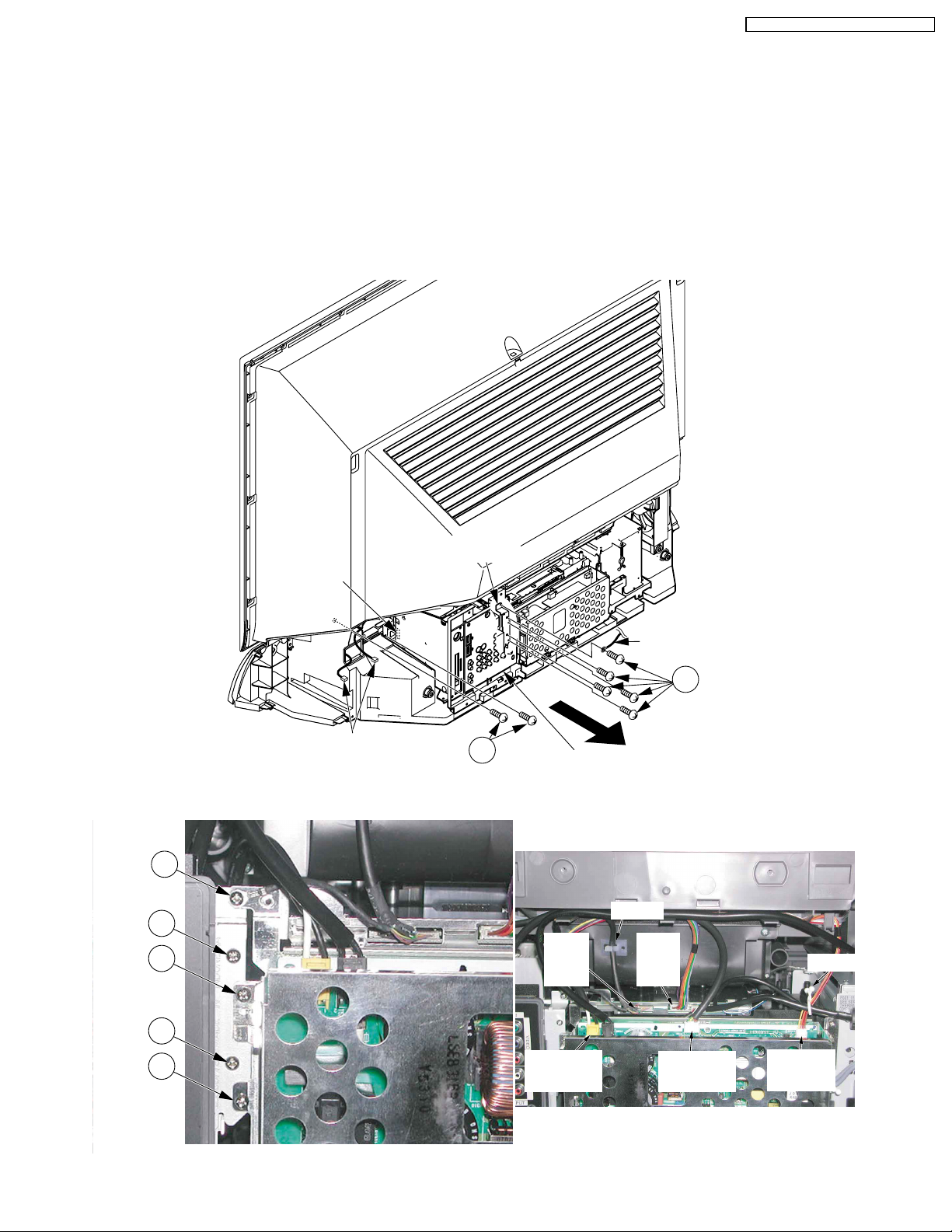

REMOVAL OF THE TV UNIT AND THE DIGITAL TUNER C.B.A. FROM THE CABINET

1. Remove the Rear Cover. Refer to Step 1 in "REMOVAL OF THE BALLAST C.B.A. AND THE PROJECTION UNIT FROM THE

CABINET."

2. 1) Remove the 2 Screws (401) and the 5 Screws (402) on the Earth Plate A. Then, remove the Earth Plate A.

2) Disconnect Connector P1301, P1302, P1305, P2501 (20-pin Cable), P2901 and the 2 Speaker Connectors.

Note: Take extreme care not to damage the 20-pin Cable when disconnecting.

3) Slide the TV Unit with the Digital Tuner C.B.A. slightly, and disconnect Connector P6005.

4) Remove the TV Unit with the Digital Tuner C.B.A.

Earth Plate A

P6005

Speaker

Connectors

The 5 Screws (402) are for removing the Earth Plate A

402

402

402

GND Wire of

20-pin Cable

402

401

Slide

TV Unit

with Digital Tuner C.B.A.

Clamper

P2501

(From

Main

C.B.A.)

P2901

(From

Base

C.B.A.)

Clamper

402

402

Fig. D2-1

25

P1302

(From Power

C.B.A.)

P1301

(From Power

C.B.A.)

P1305

(From Base

C.B.A.)

Loading...

Loading...