Panasonic PAC service manual

Technical Tips

RAC/PAC

1

Table of contents

Page 3 Check list before you call

Page 4 Inverter technology

Page 5 26 thru 42k Btu units dual wiring diagram

Page 6 9 thru 24k Btu units wiring diagram

Page 7 Flexi Multi wiring diagram

Page 8 Trouble shooting for 9-24k Btu units

Page 9 Fault code retrieval procedure

Page 10-14 Indoor/Outdoor board trouble shooting procedure

Page 15 Trouble shooting for 26-42k Btu units

Page 16 EPROM replacement procedure

2

Check the items below before calling Tech Support+

Description of Problem and date:

1) Verify there is a matching set. On PAC make sure it was not changed from a C to a CH.

_____________________________________

2) Mod# & Serial#______________________________________________

3) New Install? ___ If not how long did it run? ______________________

4) Wrong unit installed in a low ambient application? ________________

5) Verify wiring is correct. Was shielded control wire used (PAC)? _____

6) What are the code/codes? _____________________________________

7) What is the voltage with load and no load? ______________________

8) What is VDC between 2&3 (RAC)? ____________________________

9) Are the service valves open? __________________________________

10) When power is first applied, does the expansion valve Tick? _______

11) Are the power lights on boards lit? ____________________________

12) How long does the unit run before locking out? __________________

13) What are the pressures & super heat while the unit is running? ________________

14) Does the indoor unit beep when a command is sent by the remote? Is it in the correct mode?

_________________________________________

15) Is the powers relay energized (RAC) in condenser? _______________

16) Is the transformer on the indoor unit good (PAC)? ______________

17) Is there a condensation pump and is it wired correctly? Is the safety used and how is it wired?

_______________________________________

18) Have you put the unit into diagnostic mode (RAC)? If so what is the code?

________________________________________________________

19) Is there a red power light on the outdoor board (RAC)? __________

20) What lights are on and are they flashing? ______________________

*RAC is any 9-24,000 BTU model or any Flexi Multi model.

*PAC is any 26-42,000 BTU model.

How was the problem resolved?

3

Caution for Installation

Higher Pressure (R410A is 1.6 times higher than R22.)

Compressor oil is different.

R410A uses Polyol Esther Oil (Synthetic fluid)

Different Gauge-manifold, Charge hose, etc., must be used for R410A.

Near-Azeotrope Type Refrigerant

Only charge the refrigerant in liquid form.

For Technical Information or Parts: call 1-800-851-1235 or visit our website: www.sanyohvac.com

INVERTER TECHNOLOGY

• The DC motor uses powerful Neodymium magnets, which are approximately 15-20 times stronger than the ferrite magnets used in

conventional AC compressors. This, combined with precise digital control gives the SANYO DC compressor an operation rate of 15-20%

higher than that of a conventional AC compressor.

• The SPW outdoor units utilize the latest SANYO twin rotary compressor in which perfectly balanced dual rotors revolve smoothly and

efficiently to provide powerful, quiet and vibration free performance.

• Can operate down as low as 23% of total outdoor unit capacity.

• An Inverter compressor is designed to vary its speed as the demands in the room change. Inverter compressors are designed to Soft Start

therefore causing no dips in power supply.

• Single phase AC power is supplied to the outdoor unit where it is rectified and converted into DC power to drive the compressor the

input frequency is then modified to allow the compressor to run at a variety of speeds.

• As the compressor speed decreases, the amount of refrigerant entering the indoor unit also decreases. This results in a more comfortable

environment as the unit only produces the appropriate amount of cooling or heating required at that time - no more temperature swings.

• Inverter compressors have been shown to reduce power consumption by as much as 60% when compared to conventional fixed speed

equivalents.

• Taking inverter technology to a new level of comfort

4

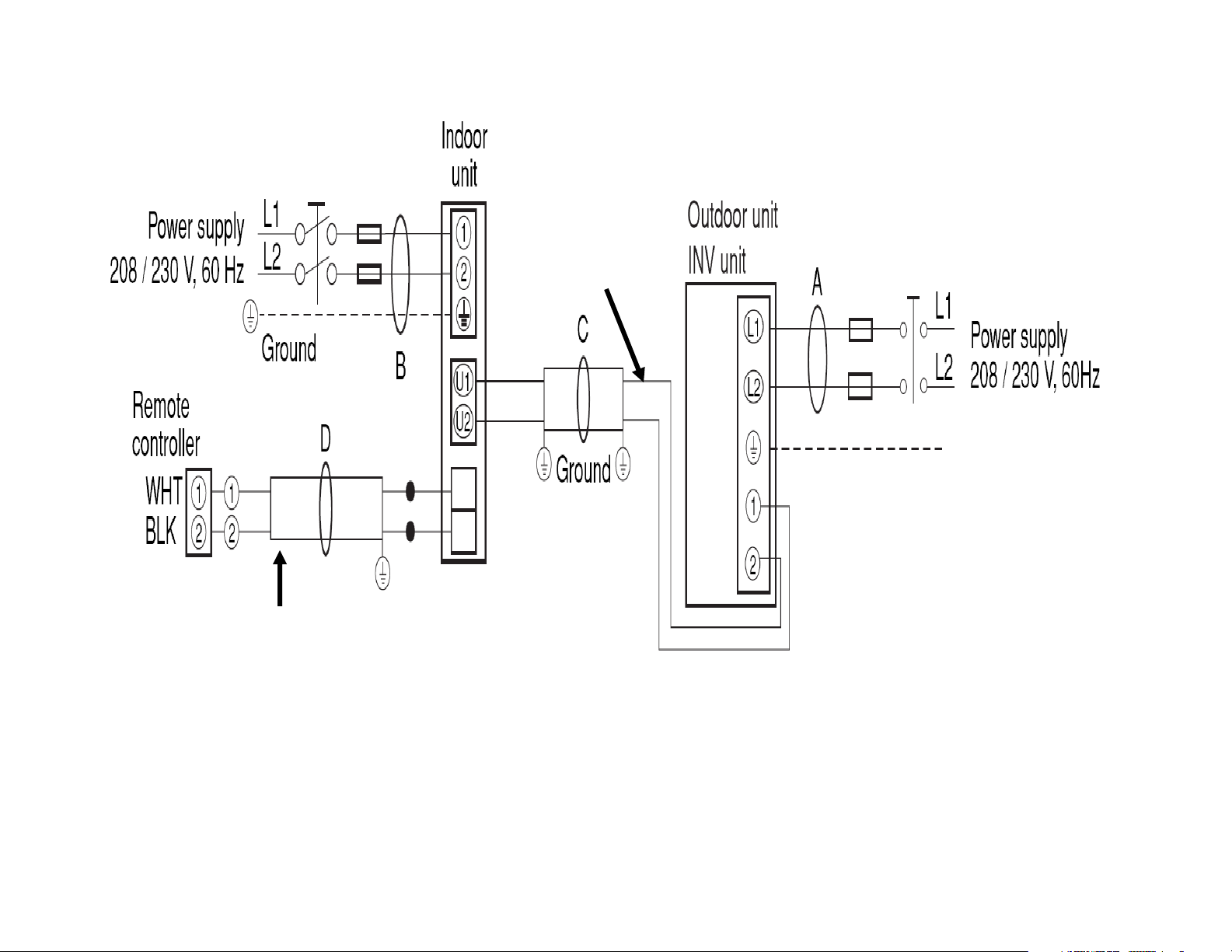

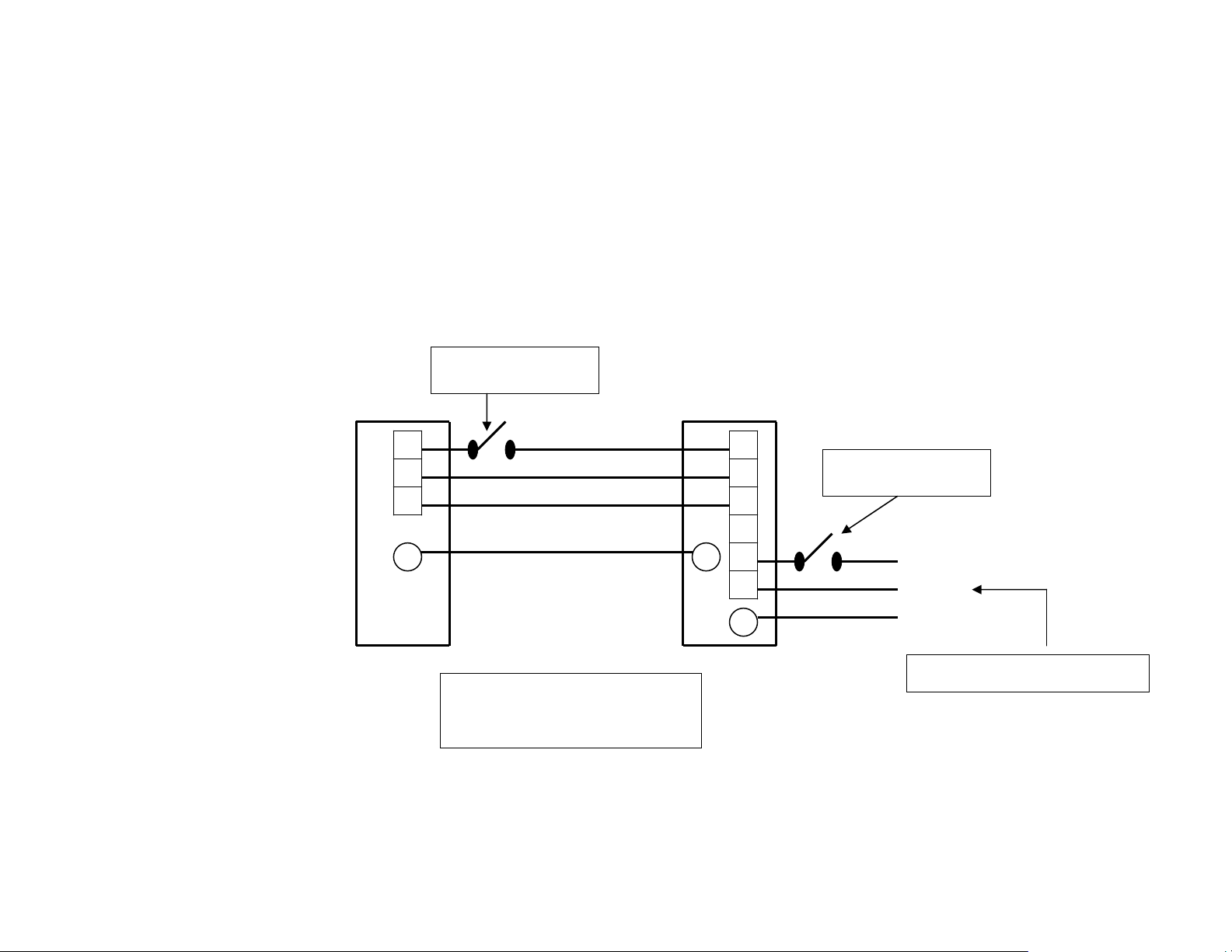

DUAL – CIRCUIT WIRING (26 - 42,000 BTU’s Models)

18-2

Shielded Wire

5 VDC

12 – 15 VDC

18-2 Shielded Wire

5

RAC Single Split System (A/C & HP)

¾

Installation wiring for 115 volt single split systems

¾ Note: The 9,000 & 12,000 BTU models in a single split

Combination requires a 115 volt power supply.

Disconnect Switch

(Field Supplied)

1

2

3

G G

Indoor Unit

Typical Installation Wiring

C-CL0971 & CH0971

For

C-CL1271 & CH1271

:

Hot

Neutral

12-15 VDC Signal

1

2

3

4

5

6

G

Outdoor Unit

Disconnect Switch

(Field Supplied)

Hot

Neutral

Ground

115 VAC (Power Supply)

6

Loading...

Loading...