Page 1

查询KFG2816D1M-DEB供应商

OneNAND128 FLASH MEMORY

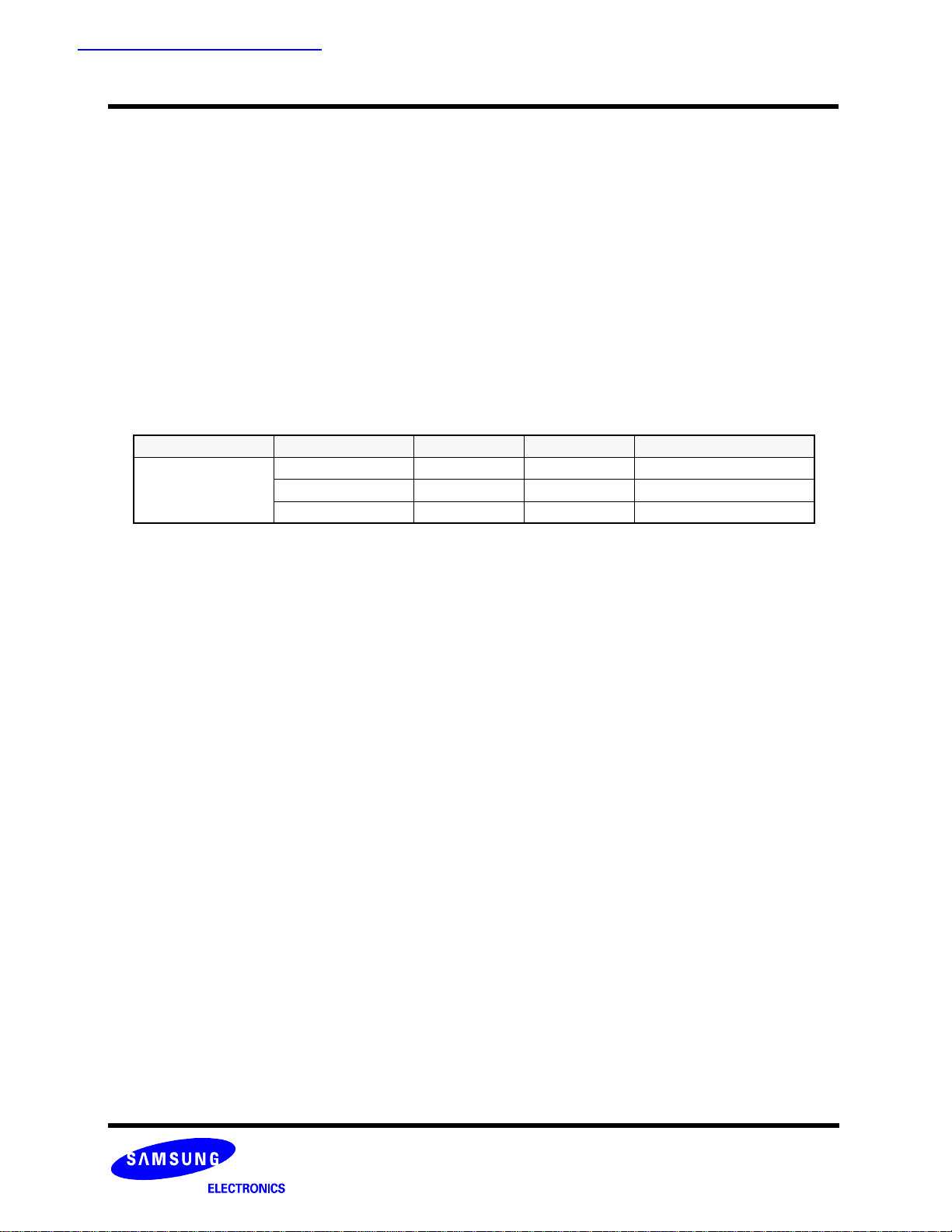

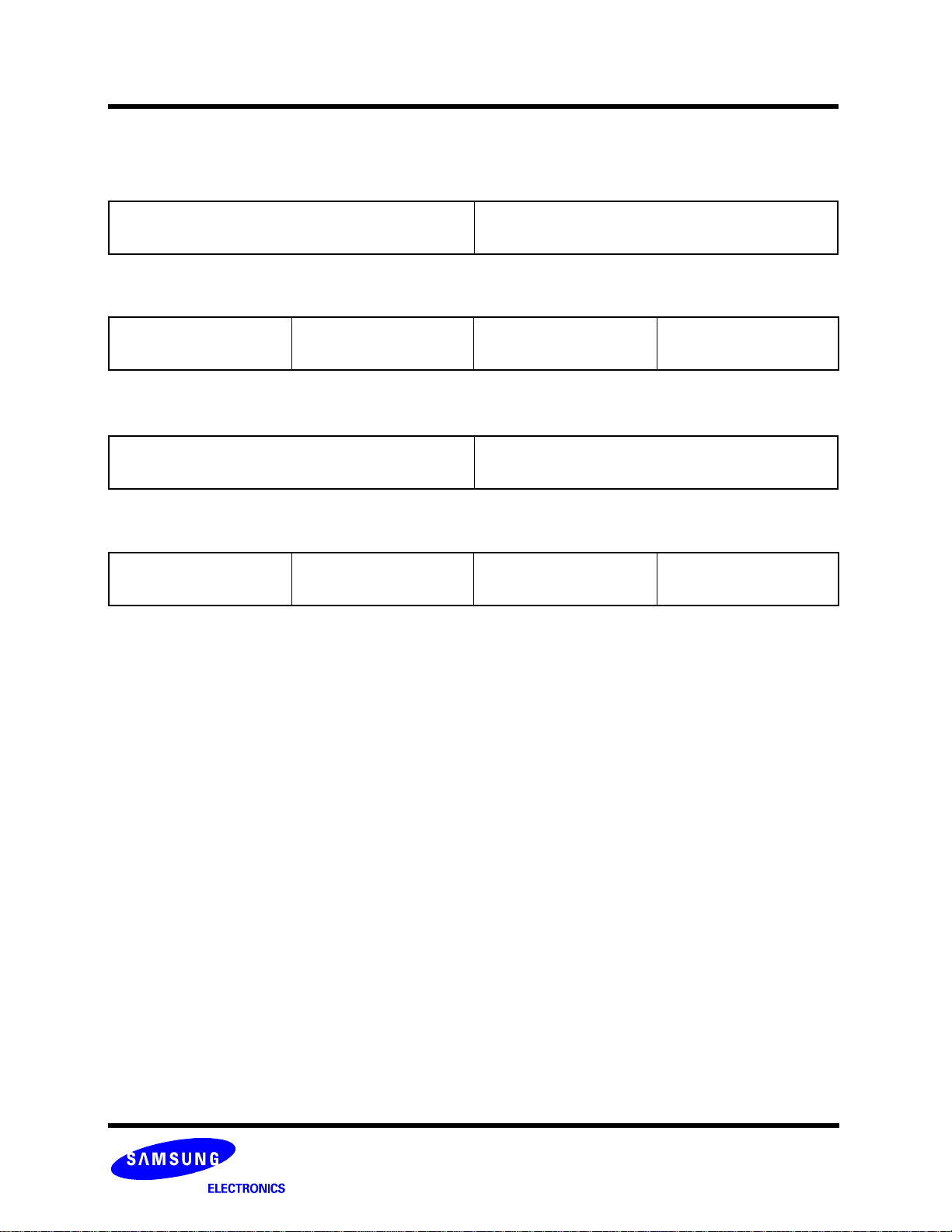

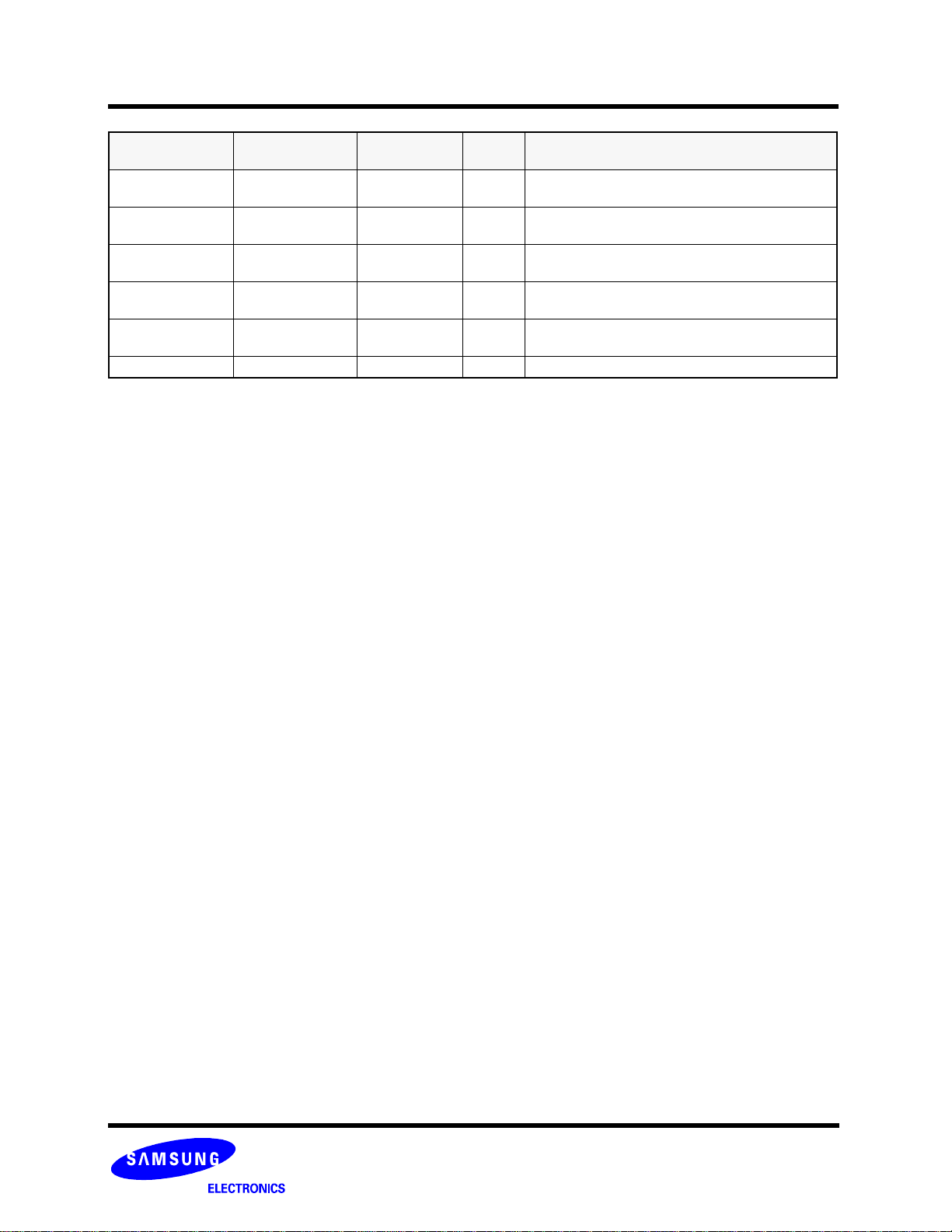

OneNAND SPECIFICATION

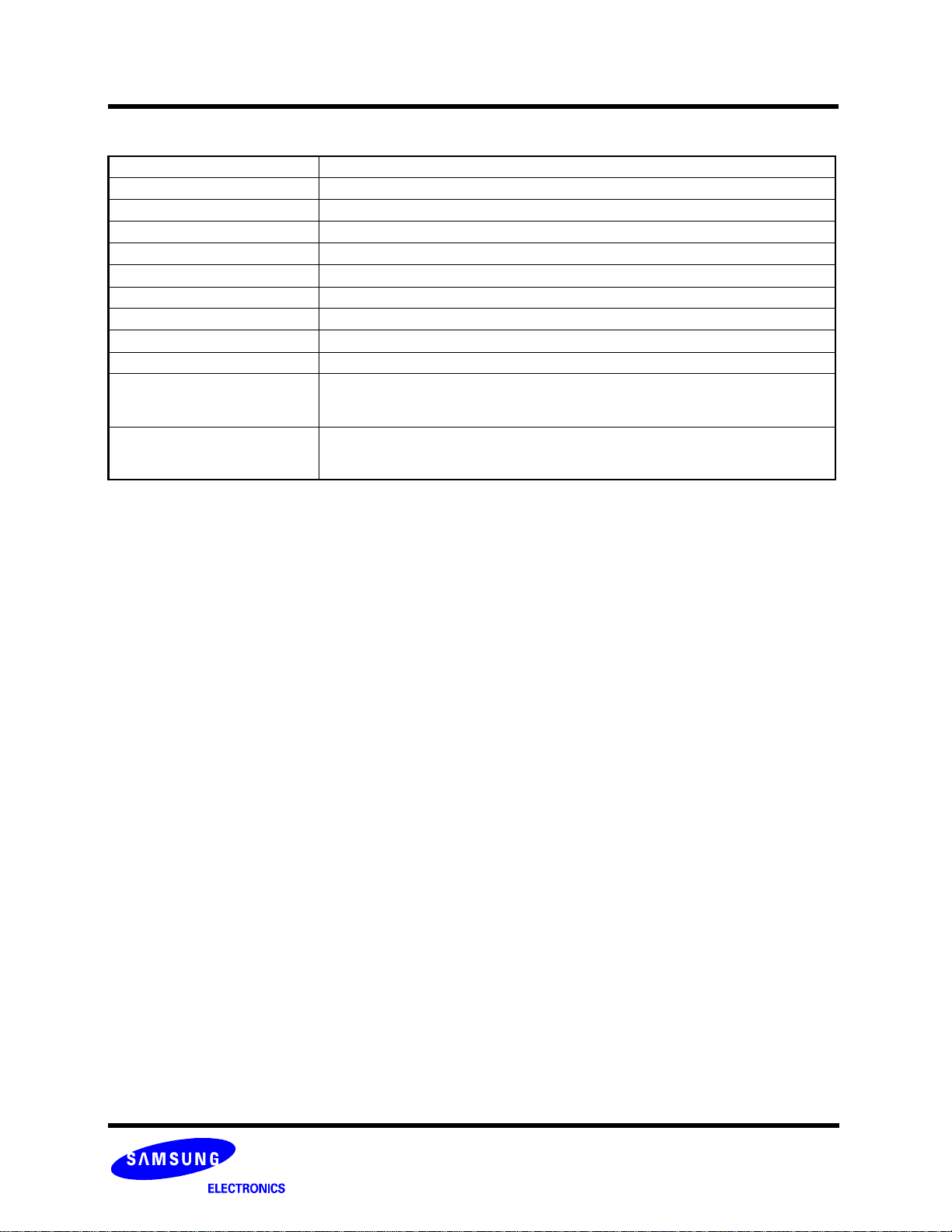

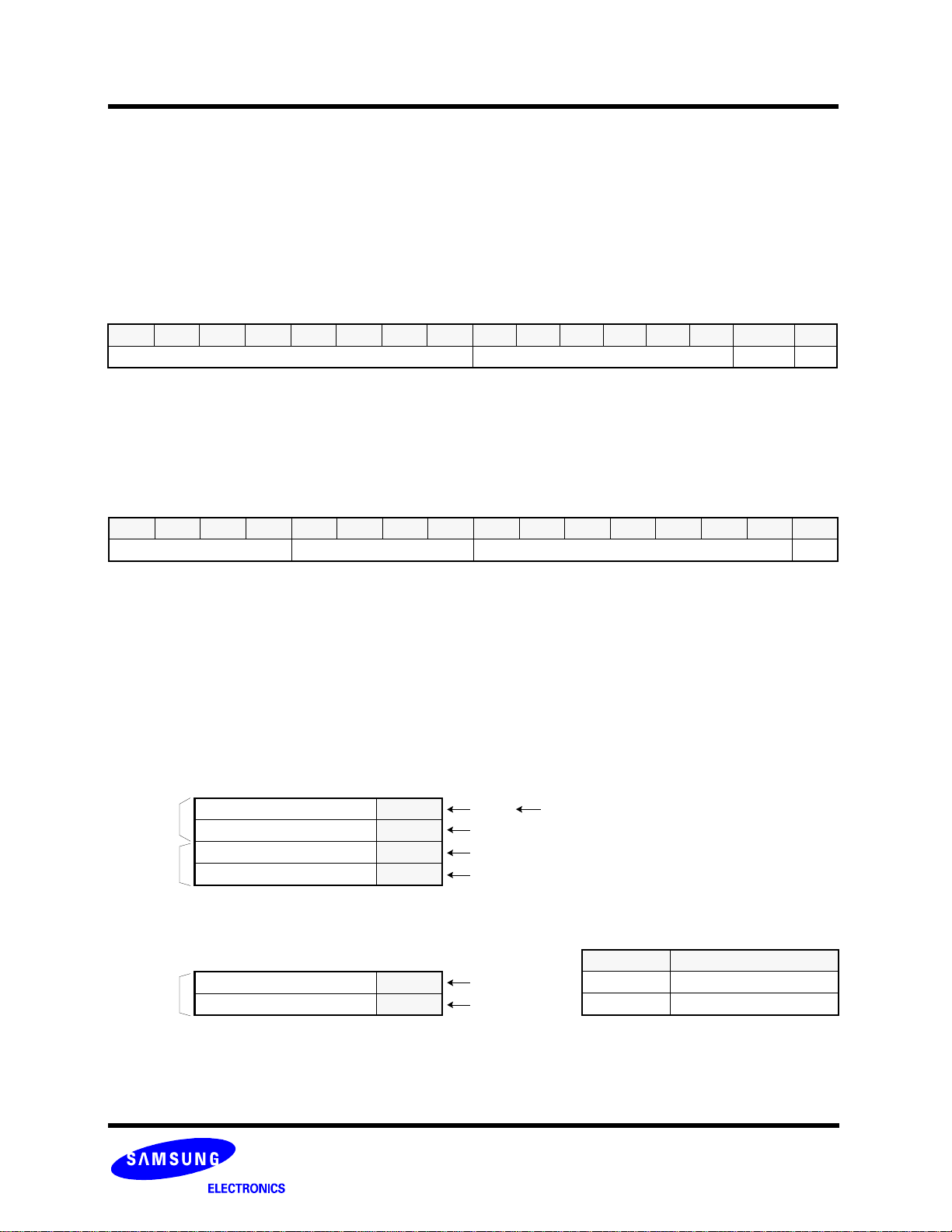

Product Part No. VCC(core & IO) Temperature PKG

KFG2816Q1M-DEB 1.8V(1.7V~1.95V) Extended 67FBGA(LF)/48TSOP1

OneNAND128

KFG2816D1M-DEB 2.65V(2.4V~2.9V) Extended

KFG2816U1M-DIB 3.3V(2.7V~3.6V) Industrial 67FBGA(LF)/48TSOP1

67FBGA(LF)/48TSOP1

Version: Ver. 1.0

Date: June 15th, 2005

1

Page 2

OneNAND128 FLASH MEMORY

INFORMATION IN THIS DOCUMENT IS PROVIDED IN RELATION TO SAMSUNG PRODUCTS,

AND IS SUBJECT TO CHANGE WITHOUT NOTICE.

NOTHING IN THIS DOCUMENT SHALL BE CONSTRUED AS GRANTING ANY LICENSE,

EXPRESS OR IMPLIED, BY ESTOPPEL OR OTHERWISE,

TO ANY INTELLECTUAL PROPERTY RIGHTS IN SAMSUNG PRODUCTS OR TECHNOLOGY. ALL

INFORMATION IN THIS DOCUMENT IS PROVIDED

ON AS "AS IS" BASIS WITHOUT GUARANTEE OR WARRANTY OF ANY KIND.

1. For updates or additional information about Samsung products, contact your nearest Samsung office.

2. Samsung products are not intended for use in life support, critical care, medical, safety equipment, or similar

applications where Product failure could result in loss of life or personal or physical harm, or any military or

defense application, or any governmental procurement to which special terms or provisions may apply.

OneNAND

rightful owners.

Copyright

™‚ is a trademark of Samsung Electronics Company, Ltd. Other names and brands may be claimed as the property of their

© 2005, Samsung Electronics Company, Ltd

2

Page 3

OneNAND128 FLASH MEMORY

Document Title

OneNAND

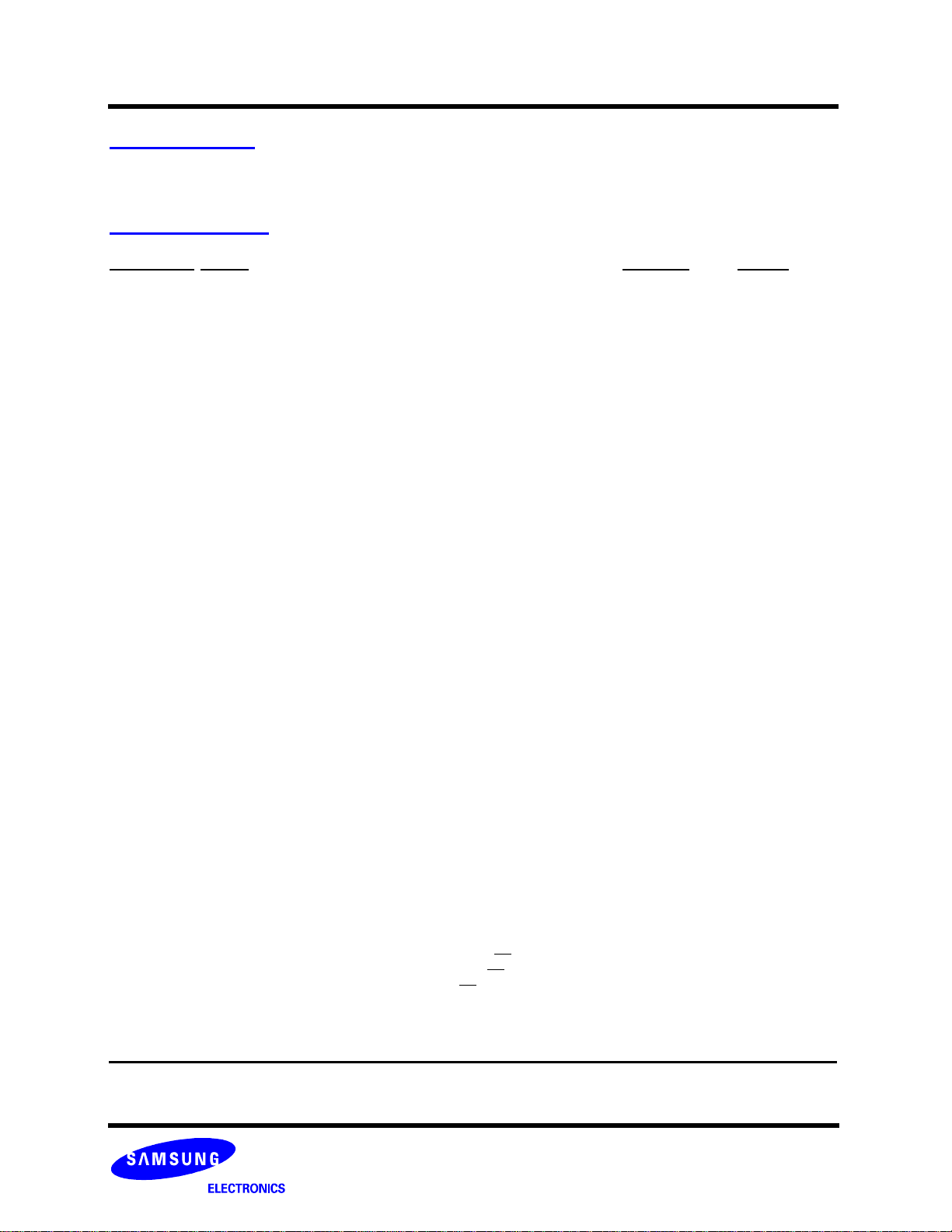

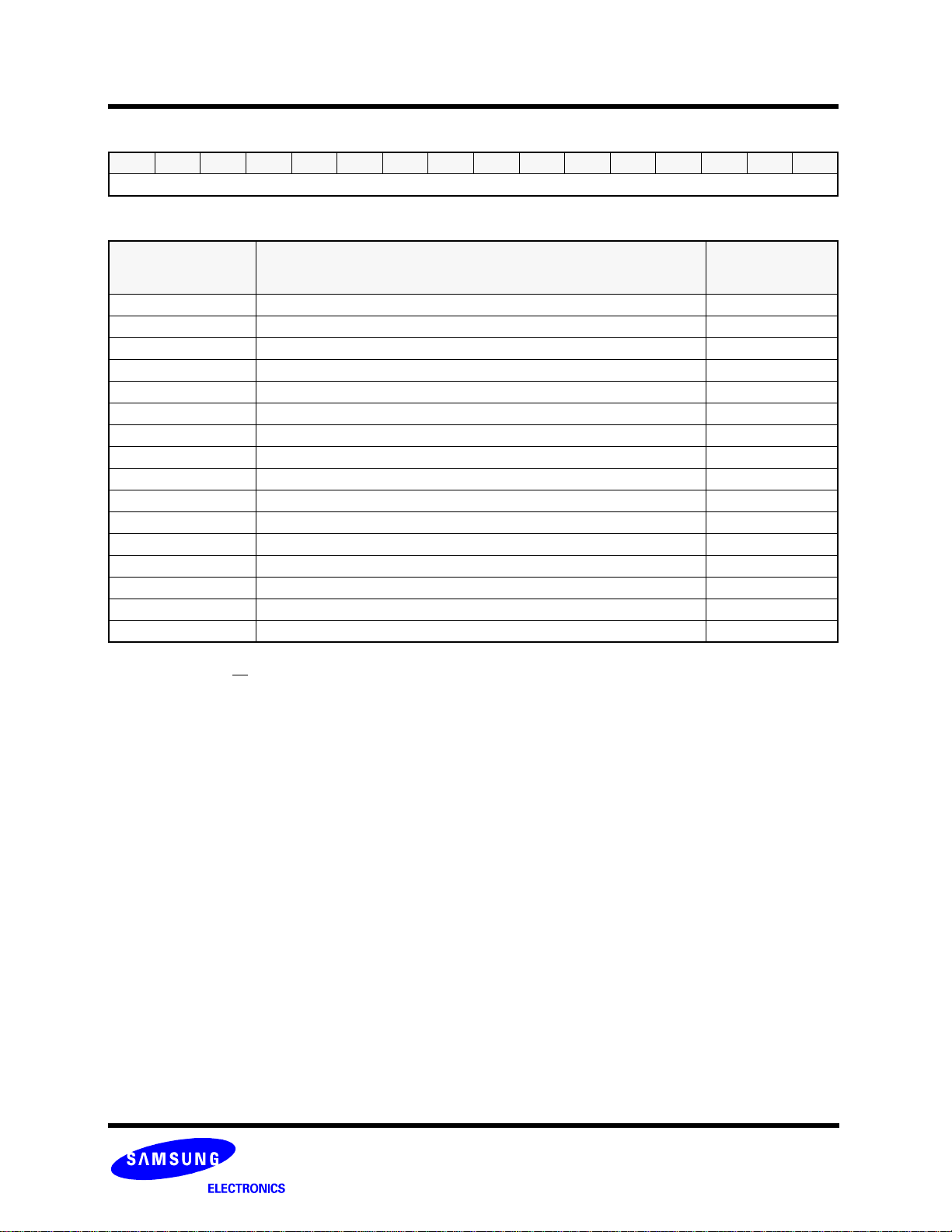

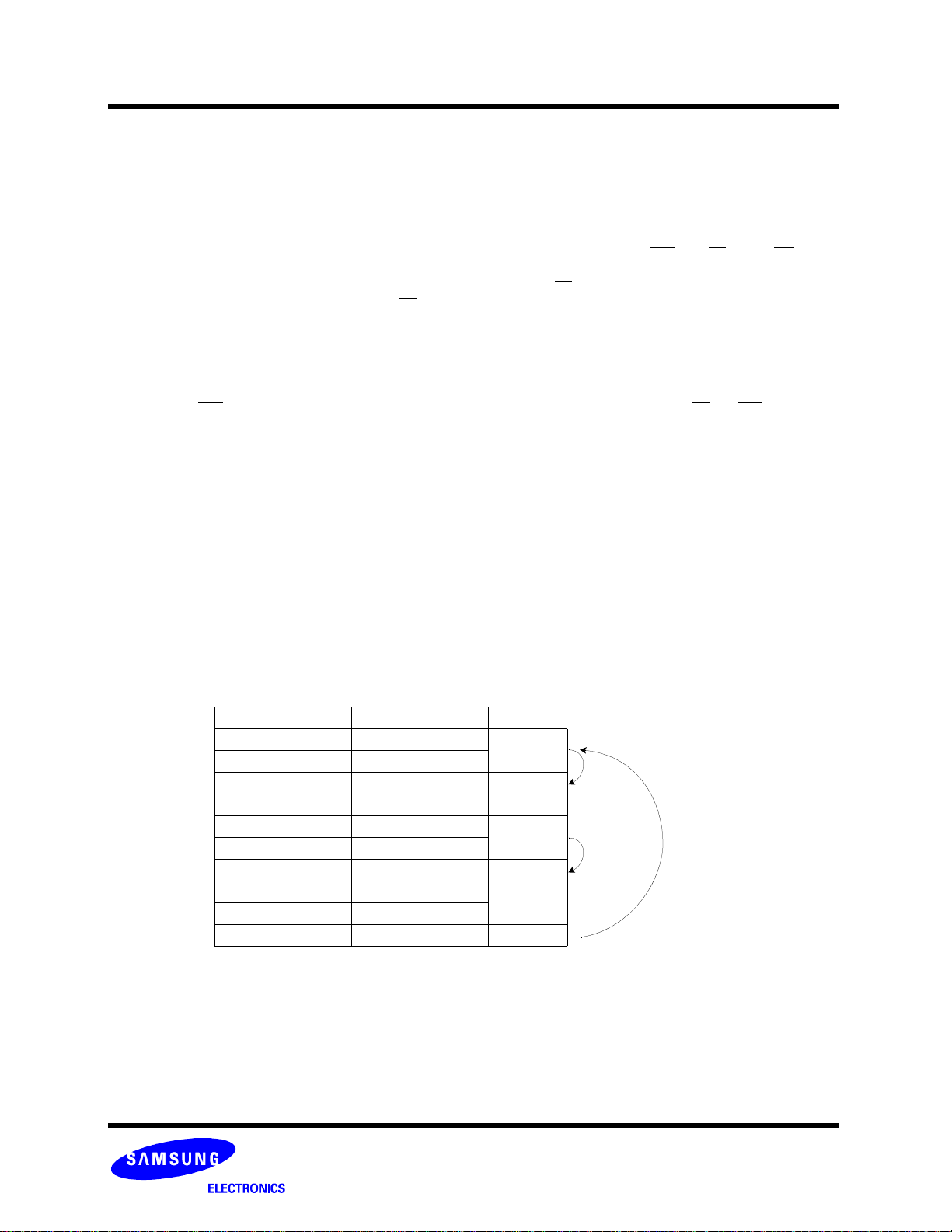

Revision History

Revision No.

0.0

0.1

1.0

History

1. Initial Issue.

1. Corrected the errata

2. Revised Cold Reset

3. Added TSOP1 Package Information

4. Revised FBGA package type

5. Added 67FBGA Package Information

6. Revised typical tOTP, tLOCK from 300us to 600us

7. Revised max tOTP, tLOCK from 600us to 1000us

8. Deleted Lock All Block, Lock-Tight All Block Operation

9. Added Endurance and Data Retention

10. Revised Load Data into Buffer Operation Sequence

11. Revised Warm Reset

12. Revised Programmable Burst Read Latency Timing Diagram

13. Revised Multi Block Erase Flow Chart

14. Revised Extended Operating Temperature

1. Added Copyright Notice in the beginning

2. Corrected Errata

3. Updated Icc2, Icc4, Icc5, Icc6 and I

4. Revised INT pin description

5. Added OTP erase case NOTE

6. Revised case definitions of Interrupt Status Register

7. Added a NOTE to Command register

8. Added ECClogSector Information table

9. Removed ’data unit based data handling’ from description of Device

Operation

10. Revised description on Warm/Hot/NAND Flash Core Reset

11. Revised Warm Reset Timing

12. Revised description for 4-, 8-, 16-, 32-Word Linear Burst Mode

13. Revised OTP operation description

14. Added note for OTP

15. Removed all block lock default case after cold or warm reset

16. Added explanation for each prohibited case in protect mode

17. Revised the case of writing other commands during Multi Block Erase

routine

18. Added note for Erase Suspend/Resume

19. Added supplemental explanation for ECC Operation

20. Removed classification of ECC error from ECC Operation

21. Removed redundant sentance from ECC Bypass Operation

22. Added technical note for Boot Sequence

23. Added technical note for INT pin connection guide

24. Excluded tOEH from Asynchronous Read Table

25. Revised Asycnchronous Read timing diagram for CE

26. Revised Asynchronous Write timing diagram for CE

27. Revised Load operation timing diagram for CE

in Internal Register Reset

L

SB

don’t care mode

don’t care mode

don’t care mode

Draft Date

Sep. 9, 2004

Oct. 28, 2004

Jun. 15, 2005

Remark

Advance

Advance

The attached datasheets are prepared and approved by SAMSUNG Electronics. SAMSUNG Electronics CO., LTD. reserve the right

to change the specifications. SAMSUNG Electronics will evaluate and reply to your requests and questions about device. If you have

any questions, please contact the SAMSUNG branch office near you.

3

Page 4

OneNAND128 FLASH MEMORY

1. FEATURES

♦ Architecture

• Design Technology: 0.12µm

• Voltage Supply

- 1.8V device(KFG2816Q1M) : 1.7V~1.95V

- 2.65V device(KFG2816D1M) : 2.4V~2.9V

- 3.3V device(KFG2816U1M) : 2.7V~3.6V

• Organization

- Host Interface:16bit

• Internal BufferRAM(3K Bytes)

- 1KB for BootRAM, 2KB for DataRAM

• NAND Array

- Page Size : (1K+32)bytes

- Block Size : (64K+2K)bytes

♦ Performance

• Host Interface type

- Synchronous Burst Read

: Clock Frequency: up to 54MHz

: Linear Burst - 4 , 8 , 16 , 32 words with wrap-around

: Continuous Sequential Burst(512 words)

- Asynchronous Random Read

: Access time of 76ns

- Asynchronous Random Write

• Programmable Read latency

• Multiple Sector Read

- Read multiple sectors by Sector Count Register(up to 2 sectors)

• Multiple Reset

- Cold Reset / Warm Reset / Hot Reset / NAND Flash Reset

• Power dissipation (typical values, C

- Standby current : 10uA@1.8V device, 15uA@2.65V/3.3V device

- Synchronous Burst Read current(54MHz) : 12mA@1.8V device, 20mA@2.65V/3.3V device

- Load current : 20mA@1.8V device, 20mA@2.65V/3.3V device

- Program current: 20mA@1.8V device, 20mA@2.65V/3.3V device

- Erase current: 15mA@1.8V device, 18mA@2.65V/3.3V device

• Reliable CMOS Floating-Gate Technology

- Endurance : 100K Program/Erase Cycles

- Data Retention : 10 Years

L=30pF)

♦ Hardware Features

• Voltage detector generating internal reset signal from Vcc

• Hardware reset input (RP

• Data Protection

- Write Protection mode for BootRAM

- Write Protection mode for NAND Flash Array

- Write protection during power-up

- Write protection during power-down

• User-controlled One Time Programmable(OTP) area

• Internal 2bit EDC / 1bit ECC

• Internal Bootloader supports Booting Solution in system

)

♦ Software Features

• Handshaking Feature

- INT pin: Indicates Ready / Busy of OneNAND

- Polling method: Provides a software method of detecting the Ready / Busy status of OneNAND

• Detailed chip information by ID register

♦ Packaging

• Package

- 67ball, 7mm x 9mm x max 1.0mmt , 0.8mm ball pitch FBGA

- 48 TSOP 1, 12mm x 20mm, 0.5mm pitch

4

Page 5

OneNAND128 FLASH MEMORY

2. GENERAL DESCRIPTION

OneNAND is a single-die chip with standard NOR Flash interface using NAND Flash Array. This device is comprised of logic and

NAND Flash Array and 3KB internal BufferRAM. 1KB BootRAM is used for reserving bootcode, and 2KB DataRAM is used for buffering data. The operating clock frequency is up to 54MHz. This device is X16 interface with Host, and has the speed of ~76ns random

access time. Actually, it is accessible with minimum 4clock latency(host-driven clock for synchronous read), but this device adopts the

appropriate wait cycles by programmable read latency. OneNAND provides the multiple sector read operation by assigning the number of sectors to be read in the sector counter register. The device includes one block sized OTP(One Time Programmable), which

can be used to increase system security or to provide identification capabilities.

5

Page 6

OneNAND128 FLASH MEMORY

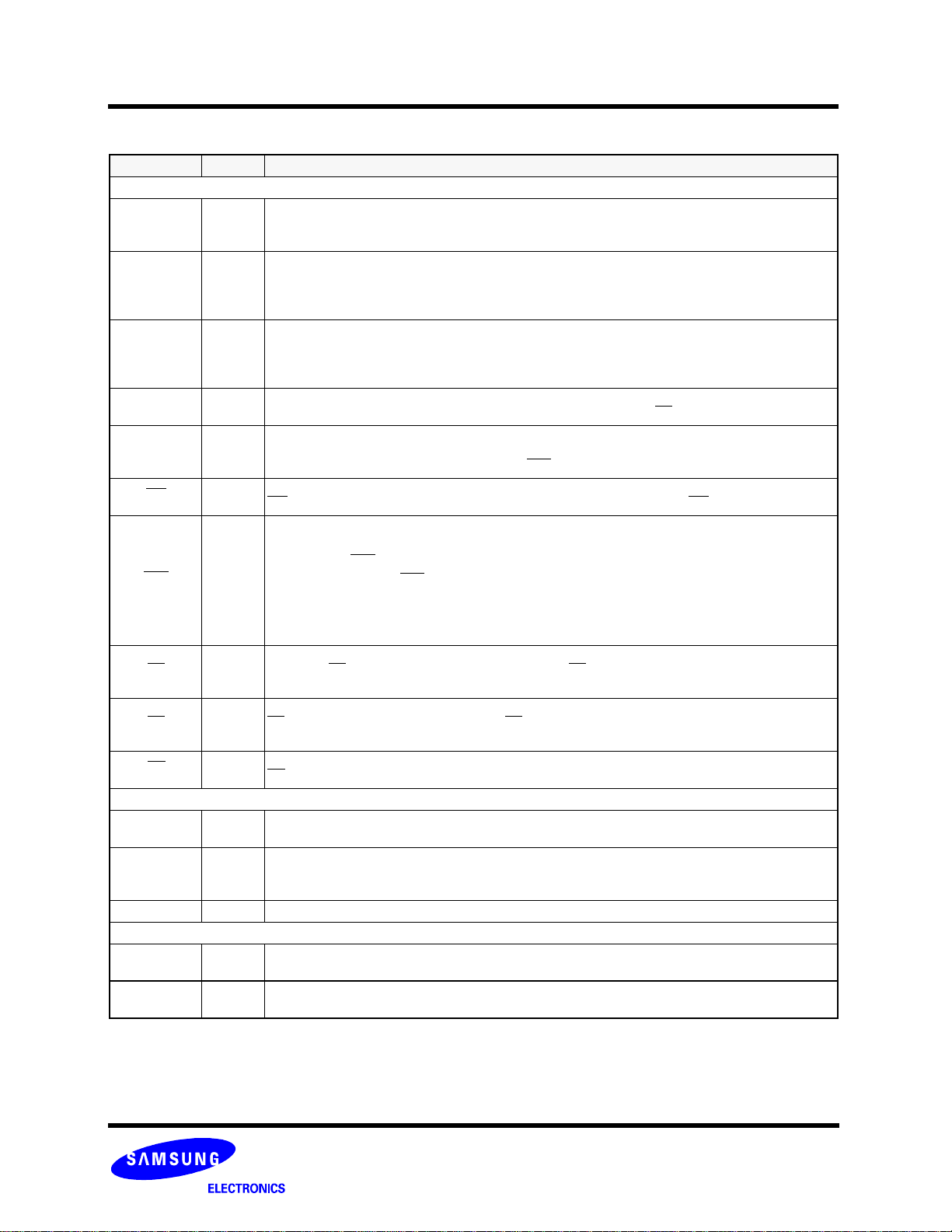

3. PIN DESCRIPTION

Pin Name Ty pe Nameand Description

Host Interface

Address Inputs

A15~A0 I

DQ15~DQ0 I/O

INT O

RDY O

CLK I

WE

AVD I

RP

CE

OE

Power Supply

CC-Core/Vcc

V

V

CC-IO/Vccq

V

SS Ground for OneNAND

etc.

DNU

NC

- Inputs for addresses during operation, which are for addressing

BufferRAM & Register.

Data Inputs/Outputs

- Inputs data during program and commands during all operations, outputs data during memory array/

register read cycles.

Data pins float to high-impedance when the chip is deselected or outputs are disabled.

Interrupt

Notifying Host when a command has completed. It is open drain output with internal resistor(~50kohms).

After power-up, it is at hi-z condition. Once IOBE is set to 1, it does not float to hi-z condition even when

the chip is deselected or when outputs are disabled.

Ready

Indicates data valid in synchronous read modes and is activated while CE

Clock

CLK synchronizes the device to the system bus frequency in synchronous read mode.

The first rising edge of CLK in conjunction with AVD

Write Enable

I

WE

controls writes to the bufferRAM and registers. Datas are latched on the WE pulse’s rising edge

Address Valid Detect

Indicates valid address presence on address inputs. During asynchronous read operation, all addresses

are latched on AVD

CLK’s rising edge while AVD

> Low : for asynchronous mode, indicates valid address ;for burst mode,

causes starting address to be latched on rising edge on CLK

> High : device ignores address inputs

Reset Pin

I

When low, RP resets internal operation of OneNAND. RP status is don’t care during power-up

and bootloading.

Chip Enable

I

CE-low activates internal control logic, and CE-high deselects the device, places it in standby state,

and places ADD and DQ in Hi-Z

Output Enable

I

OE

-low enables the device’s output data buffers during a read cycle.

Power for OneNAND Core

This is the power supply for OneNAND Core.

Power for OneNAND I/O

This is the power supply for OneNAND I/O

Vcc-IO is internally connected to Vcc-Core, thus should be connected to the same power supply.

Do Not Use

Leave it disconnected. These pins are used for testing.

No Connection

Lead is not internally connected.

’s rising edge, and during synchronous read operation, all addresses are latched on

is held low for one clock cycle.

low latches address input.

is low

NOTE:

Do not leave power supply(V

CC, VSS) disconnected.

6

Page 7

OneNAND128 FLASH MEMORY

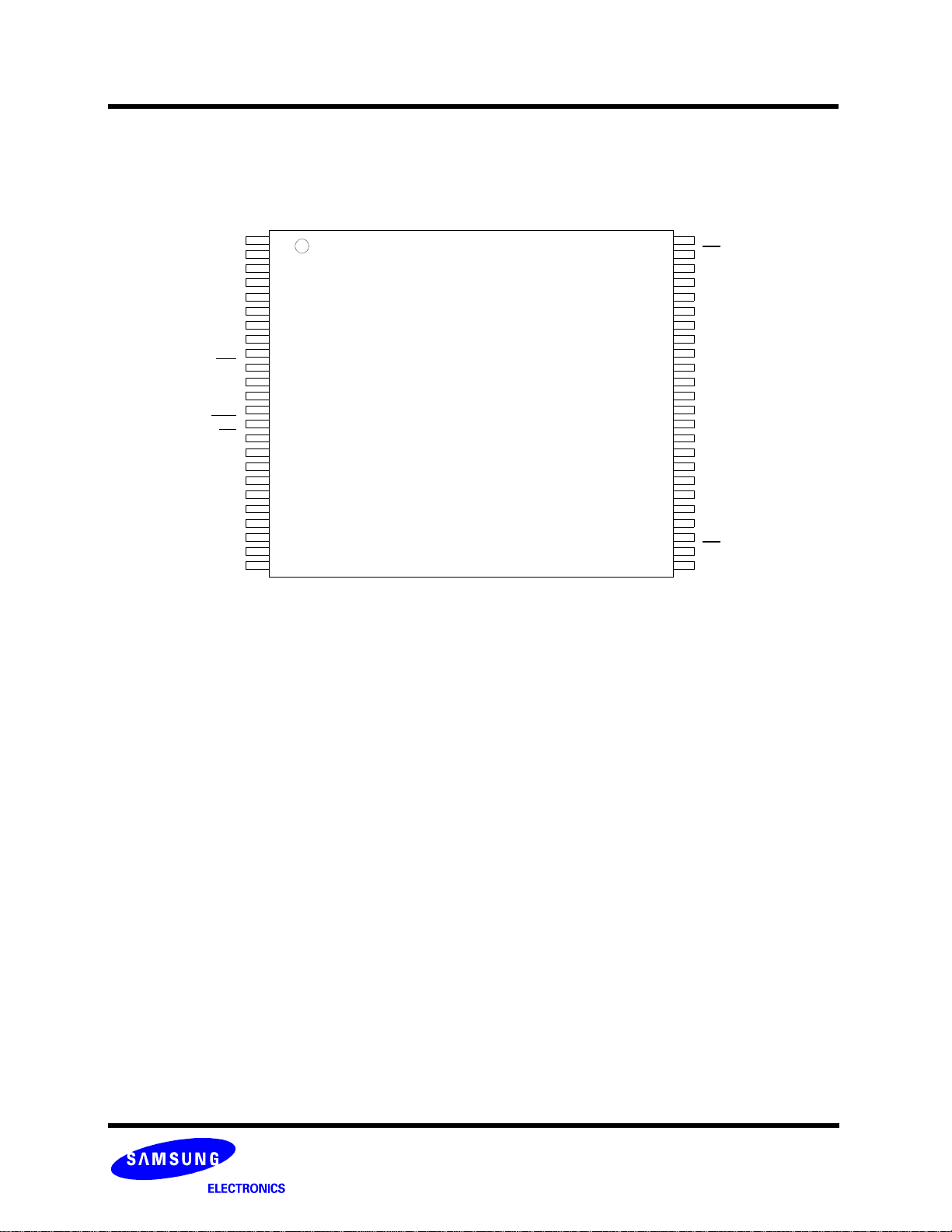

4. PIN CONFIGURATION

4.1 TSOP1

N.C

A15

A14

A13

A12

A11

A10

A9

A8

WE

V

SS

V

CC

INT

AVD

RP

A7

A6

A5

A4

A3

A2

A1

A0

N.C

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

48-pin TSOP1

Standard Type

12mm x 20mm

0.5mm pitch

(TOP VIEW, Facing Down)

TSOP1 OneNAND Chip

48pin, 12mm x 20mm, 0.5mm pitch TSOP1

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

V

SS

OE

DQ15

DQ7

DQ14

DQ6

V

CC

DQ13

DQ5

DQ12

DQ4

DQ11

DQ3

DQ10

DQ2

V

SS

DQ9

DQ1

DQ8

DQ0

RDY

CLK

CE

V

CC

Q

7

Page 8

OneNAND128 FLASH MEMORY

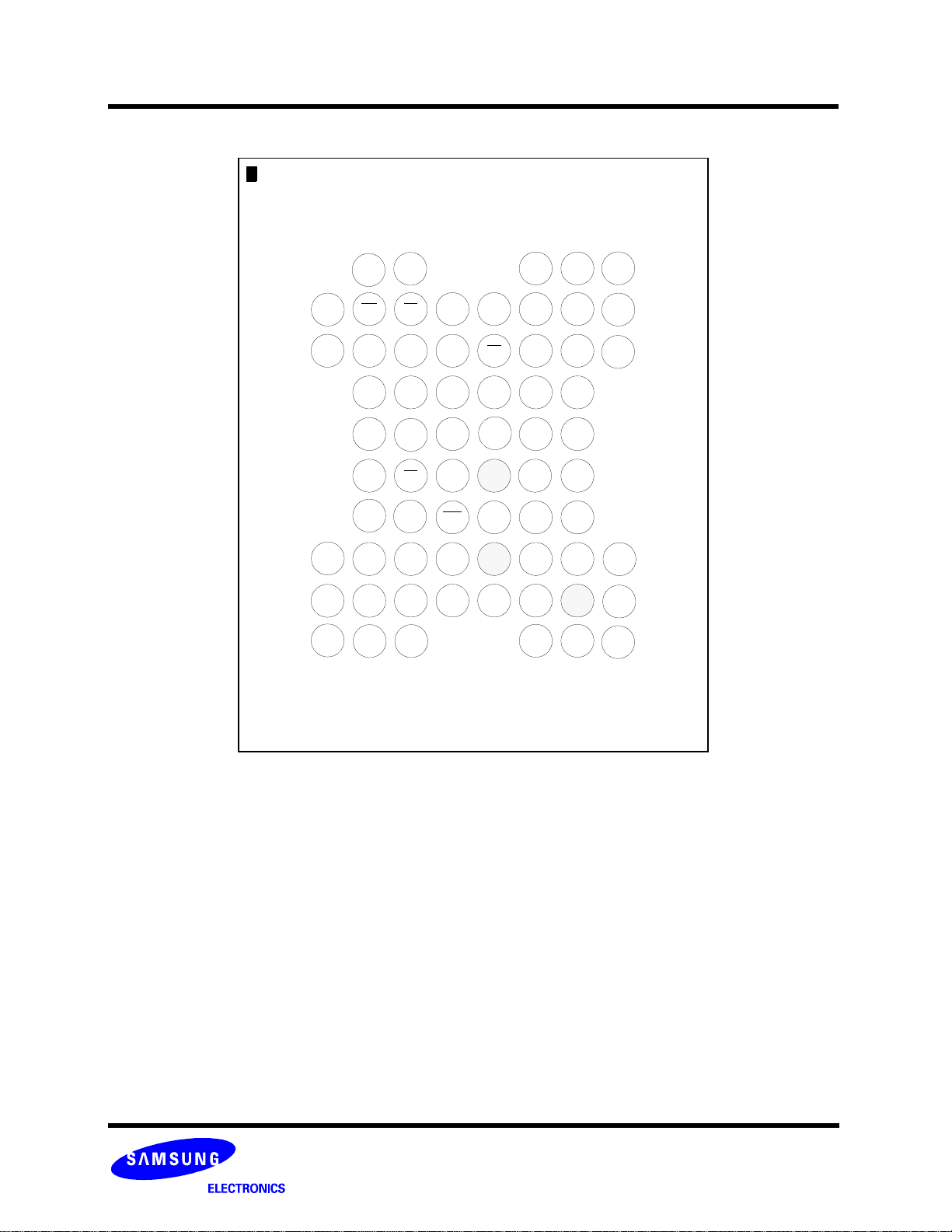

4.2 67FBGA

NC

NC

WE RP DQ14

NC

DQ12 DQ8 DQ1 OE DQ9

NC

DQ7 DQ4 DQ11 DQ10 DQ3

DQ15 A12 DQ0 DQ5 DQ6

CLK

CE DQ2 NC NC A9

A14

A13

NC

INT A0 A1 NC A10 A6

NC

NC

A4 A5 A2 A3 NC

RDY

NC NC

VSS VSS

A15

AVD A7 A11 A8

NC NC

DQ13

VCC

Core

VCC

NC NC

NC

NC

NC

IO

NC

NC

NC

(TOP VIEW, Balls Facing Down)

67ball FBGA OneNAND Chip

67ball, 7.0mm x 9.0mm x max 1.0mmt , 0.8mm ball pitch FBGA

8

Page 9

OneNAND128 FLASH MEMORY

TERMS, ABBREVIATIONS AND DEFINITIONS

B (capital letter) Byte, 8bits

W (capital letter) Word, 16bits

b (lower-case letter) Bit

ECC Error Correction Code

Calculated ECC ECC which has been calculated during load or program access

Written ECC ECC which has been stored as data in the NAND Flash Array or in the BufferRAM

BufferRAM On-chip Internal Buffer consisting of BootRAM and DataRAM

BootRAM A 1KB portion of the BufferRAM reserved for Bootcode buffering

DataRAM A 2KB portion of the BufferRAM reserved for Data buffering

Memory NAND Flash array which is embedded on OneNAND

Partial unit of page, of which size is 512B for main area and 16B for spare area data.

Sector

Data unit

It is the minimum Load/Program/Copy-Back program unit while one~two sector operation is

available

Possible data unit to be read from memory to BufferRAM or to be programmed to memory.

- 528B of which 512B is in main area and 16B in spare area

- 1056B of which 1024B is in main area and 32B in spare area

9

Page 10

OneNAND128 FLASH MEMORY

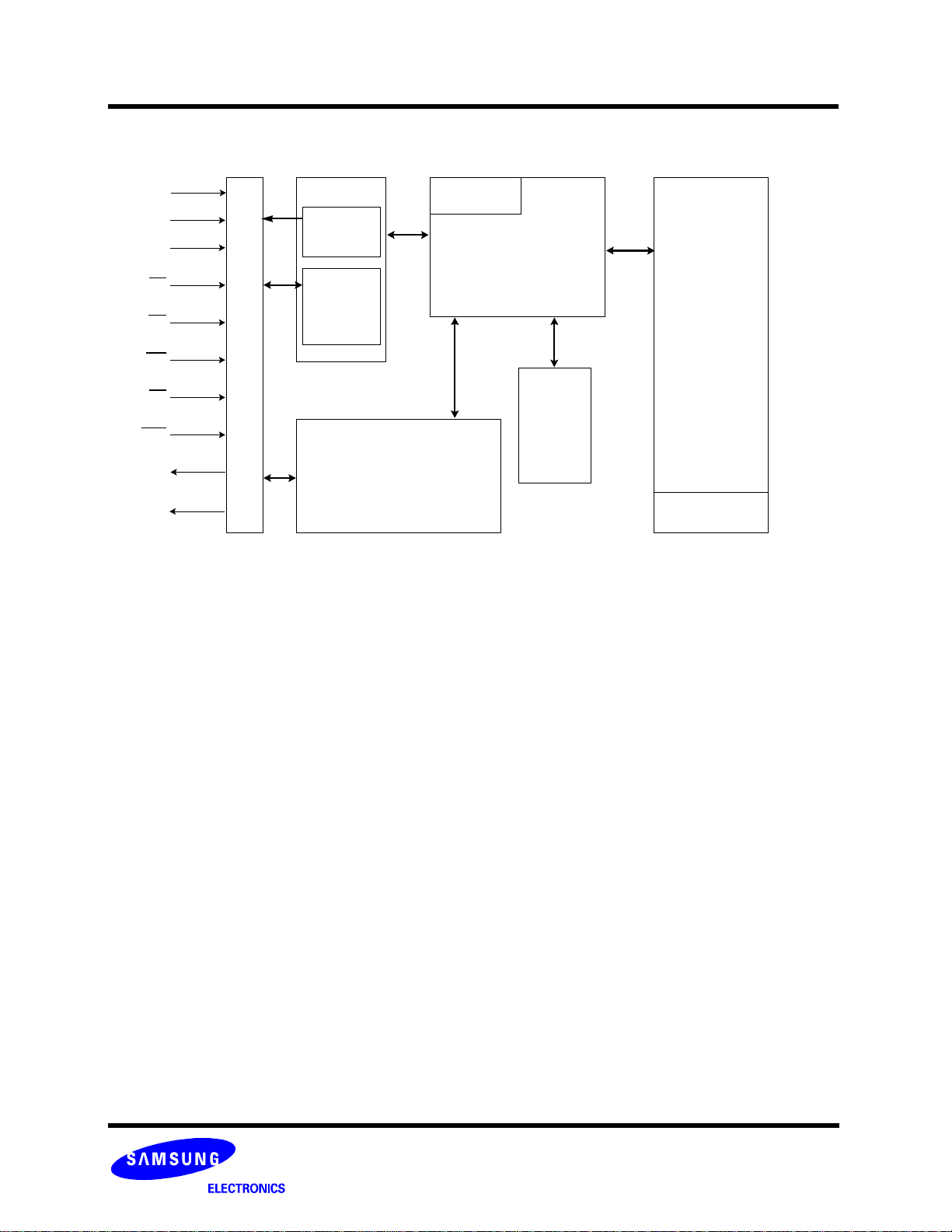

5. BLOCK DIAGRAM

DQ15~DQ0

A15~A0

CLK

CE

Host Interface

OE

WE

RP

AVD

INT

RDY

- Host Interface

- BufferRAM(BootRAM, DataRAM)

- Command and status registers

- State Machine (Bootloader is included)

- Error Correction Logic

- Memory(NAND Flash Array, OTP)

BufferRAM

BootRAM

DataRAM

Internal Registers

(Address/Command/Configuration

/Status Registers)

Bootloader

StateMachine

NAND Flash

Array

Error

Correction

Logic

OTP

(One Block)

NOTE:

1) At cold reset, bootloader copies boot code(1K byte size) from NAND Flash Array to BootRAM.

Figure 1. Internal Block Diagram

10

Page 11

OneNAND128 FLASH MEMORY

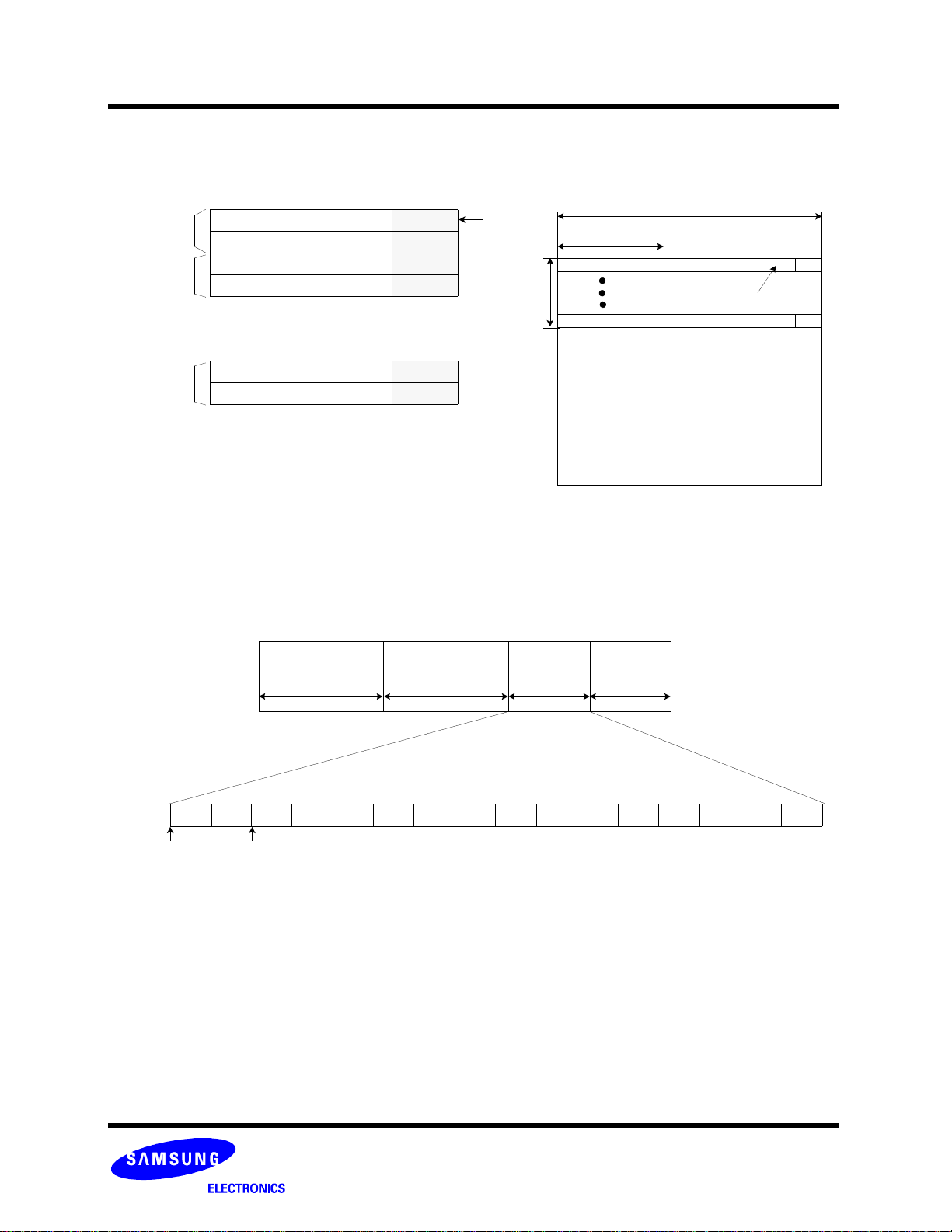

BootRAM

DataRAM 0

DataRAM 1

Main area data

(512B)

{

BootRAM 0

BootRAM 1

DataRAM 0_0

DataRAM 0_1

Main area data

(512B)

{

DataRAM 1_0

DataRAM 1_1

(BufferRAM)

Figure 2. BufferRAM and NAND array structure

Spare area data

(16B)

{

Spare area data

(16B)

{

Sector

Block:

64pages

64KB+2KB

Page:1KB+32B

Sector(main area):512B

Sector(spare area):16B

(NAND array)

Spare

Main area

256W

Note1 Note1 Note2 Note2 Note2 Note3 Note3 Note3 Note4 Note4

LSB MSB

LSB MSB

1st W

NOTE:

1) The 1st word of spare area in 1st and 2nd page of every invalid block is reserved for the invalid block information by manufacturer.

Please refer to page 59 about the details.

2) These words are managed by internal ECC logic. So it is recommended that the important data like LSN(Logical Sector Number)

are written.

3) These words are reserved for the future purpose by manufacturer. These words will be dedicated to internal logic.

4) These words are for free usage.

5) The 5th, 6th and 7th words are dedicated to internal ECC logic. So these words are only readable. The other words are program-

mable by command.

6) ECCm 1st, ECCm 2nd, ECCm 3rd: ECC code for Main area data

7) ECCs 1st, ECCs 2nd: ECC code for 2nd and 3rd word of spare area.

LSB MSB

{

nd

2

Figure 3. Spare area of NAND array assignment

W

LSB MSB

{

rd

3

W

Main area

LSB MSB

{

256W

th

4

W

{

area

8W

ECCm

ECCm

1st

2nd

LSB MSB

th

5

W

{

Spare

area

8W

ECCm

ECCs

3rd

1st

LSB MSB

th

6

W

ECCs

2nd

LSB MSB

{

(Note3)

th

7

W

FFh

{

LSB MSB

{

th

8

W

11

Page 12

OneNAND128 FLASH MEMORY

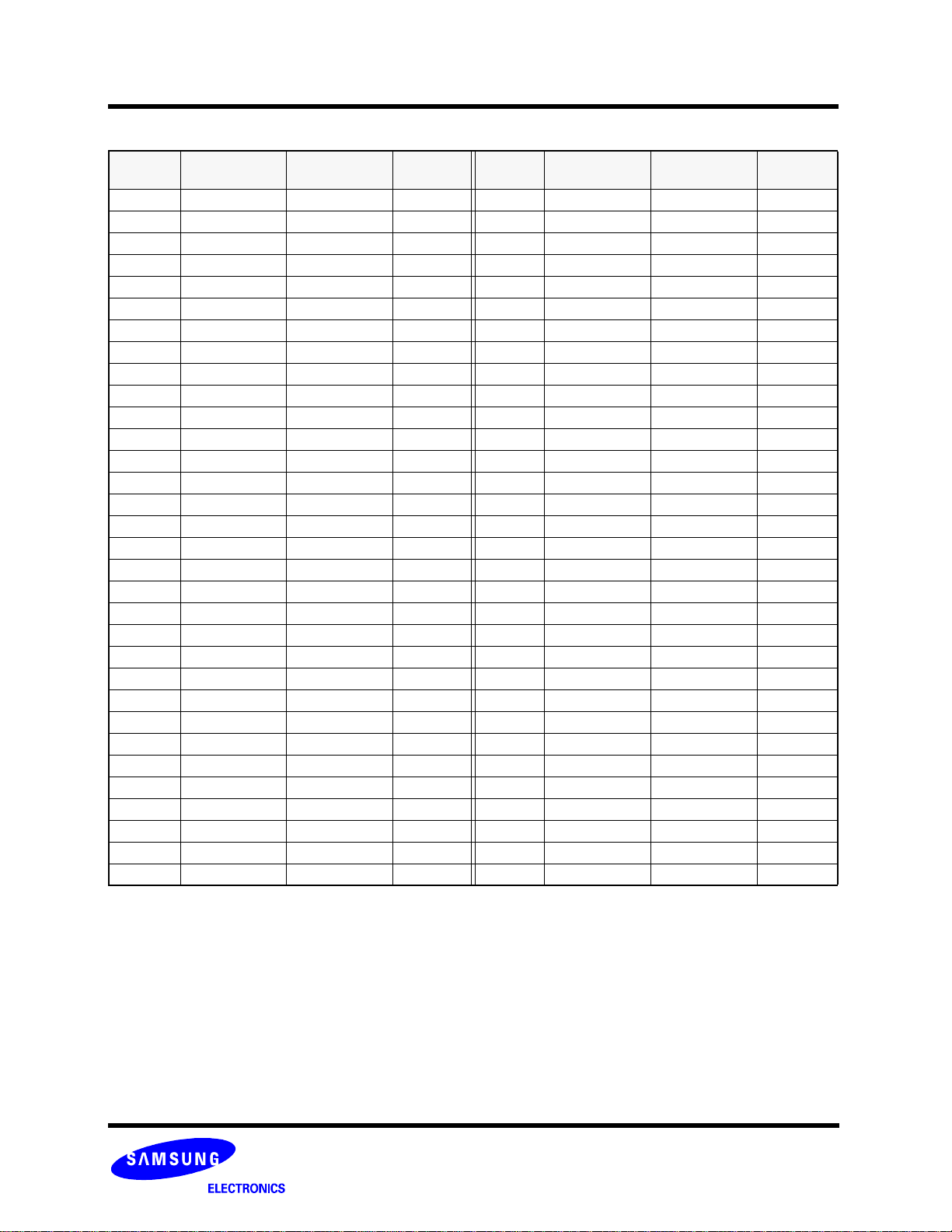

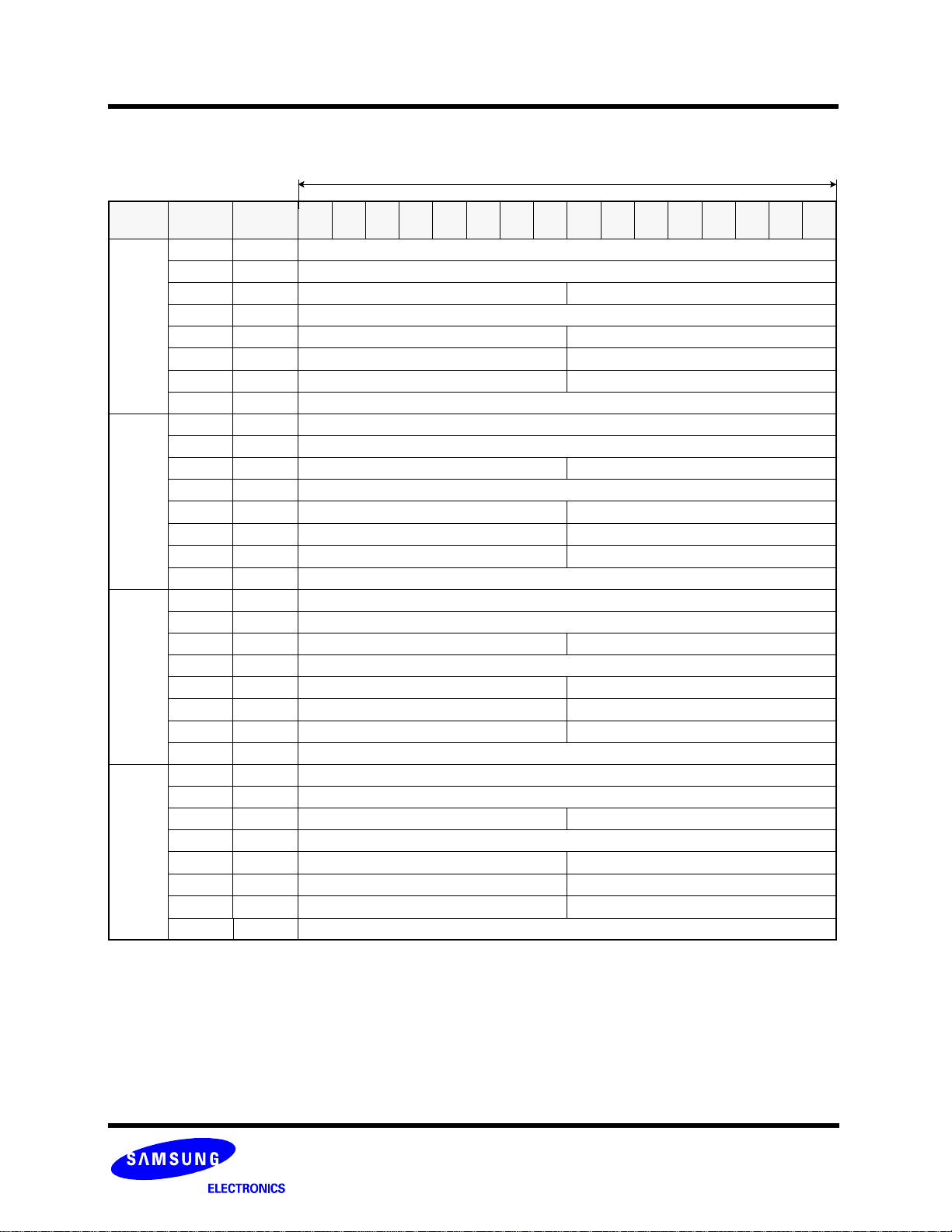

6. ADDRESS MAP For OneNAND NAND Array (word order)

Block Block Address

Block0 0000h 0000h~00FDh 64KB Block32 0020h 0000h~00FDh 64KB

Block1 0001h 0000h~00FDh 64KB Block33 0021h 0000h~00FDh 64KB

Block2 0002h 0000h~00FDh 64KB Block34 0022h 0000h~00FDh 64KB

Block3 0003h 0000h~00FDh 64KB Block35 0023h 0000h~00FDh 64KB

Block4 0004h 0000h~00FDh 64KB Block36 0024h 0000h~00FDh 64KB

Block5 0005h 0000h~00FDh 64KB Block37 0025h 0000h~00FDh 64KB

Block6 0006h 0000h~00FDh 64KB Block38 0026h 0000h~00FDh 64KB

Block7 0007h 0000h~00FDh 64KB Block39 0027h 0000h~00FDh 64KB

Block8 0008h 0000h~00FDh 64KB Block40 0028h 0000h~00FDh 64KB

Block9 0009h 0000h~00FDh 64KB Block41 0029h 0000h~00FDh 64KB

Block10 000Ah 0000h~00FDh 64KB Block42 002Ah 0000h~00FDh 64KB

Block11 000Bh 0000h~00FDh 64KB Block43 002Bh 0000h~00FDh 64KB

Block12 000Ch 0000h~00FDh 64KB Block44 002Ch 0000h~00FDh 64KB

Block13 000Dh 0000h~00FDh 64KB Block45 002Dh 0000h~00FDh 64KB

Block14 000Eh 0000h~00FDh 64KB Block46 002Eh 0000h~00FDh 64KB

Block15 000Fh 0000h~00FDh 64KB Block47 002Fh 0000h~00FDh 64KB

Block16 0010h 0000h~00FDh 64KB Block48 0030h 0000h~00FDh 64KB

Block17 0011h 0000h~00FDh 64KB Block49 0031h 0000h~00FDh 64KB

Block18 0012h 0000h~00FDh 64KB Block50 0032h 0000h~00FDh 64KB

Block19 0013h 0000h~00FDh 64KB Block51 0033h 0000h~00FDh 64KB

Block20 0014h 0000h~00FDh 64KB Block52 0034h 0000h~00FDh 64KB

Block21 0015h 0000h~00FDh 64KB Block53 0035h 0000h~00FDh 64KB

Block22 0016h 0000h~00FDh 64KB Block54 0036h 0000h~00FDh 64KB

Block23 0017h 0000h~00FDh 64KB Block55 0037h 0000h~00FDh 64KB

Block24 0018h 0000h~00FDh 64KB Block56 0038h 0000h~00FDh 64KB

Block25 0019h 0000h~00FDh 64KB Block57 0039h 0000h~00FDh 64KB

Block26 001Ah 0000h~00FDh 64KB Block58 003Ah 0000h~00FDh 64KB

Block27 001Bh 0000h~00FDh 64KB Block59 003Bh 0000h~00FDh 64KB

Block28 001Ch 0000h~00FDh 64KB Block60 003Ch 0000h~00FDh 64KB

Block29 001Dh 0000h~00FDh 64KB Block61 003Dh 0000h~00FDh 64KB

Block30 001Eh 0000h~00FDh 64KB Block62 003Eh 0000h~00FDh 64KB

Block31 001Fh 0000h~00FDh 64KB Block63 003Fh 0000h~00FDh 64KB

NOTE 1) The 2nd bit of Page and Sector address register is Don’t care. So the address range is bigger than the real range.

Even though 2nd bit is set to "1", this bit is always considered "0". Please refer to Start Address 8 register.

Page and Sector

Address

(1)

Size Block Block Address

Page and Sector

Address

(1)

Size

12

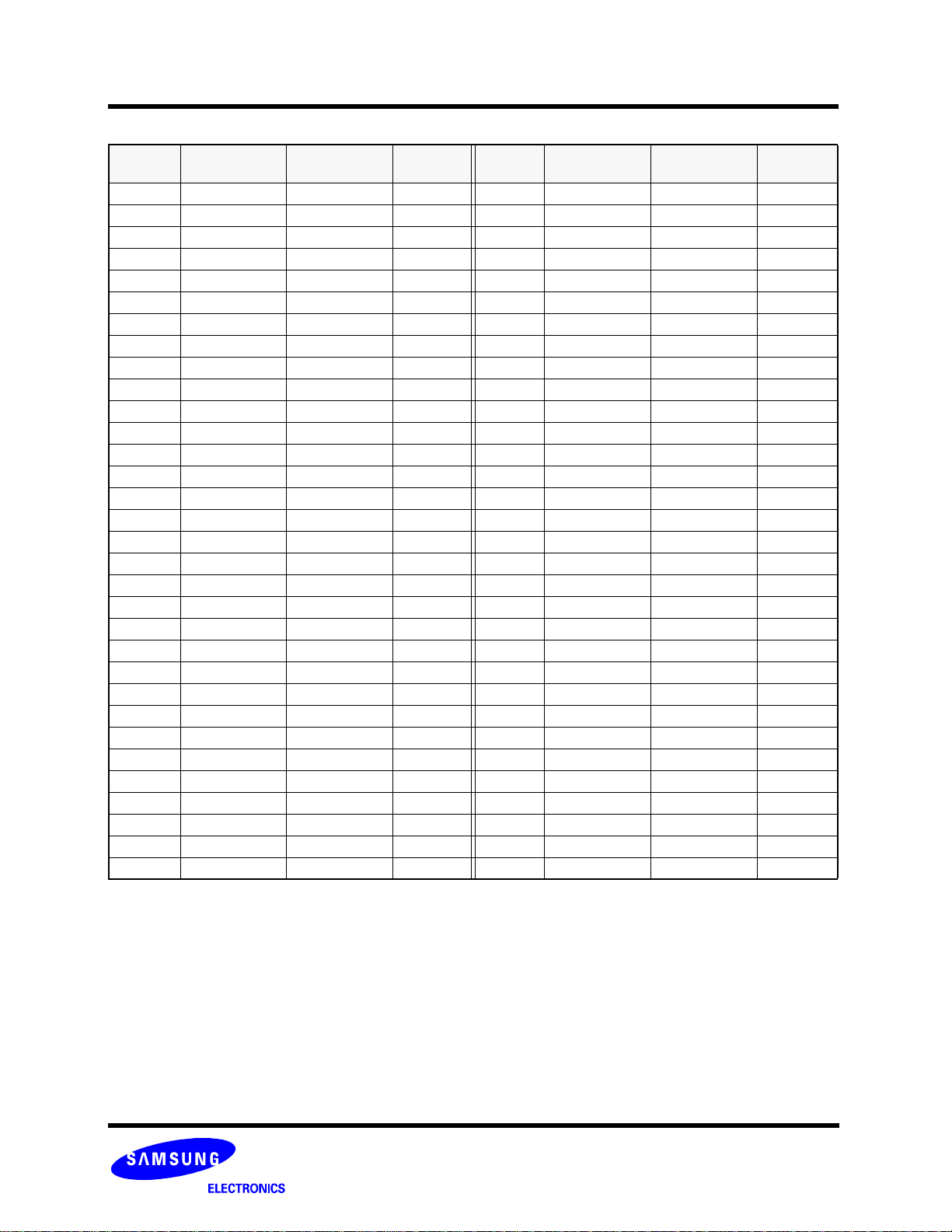

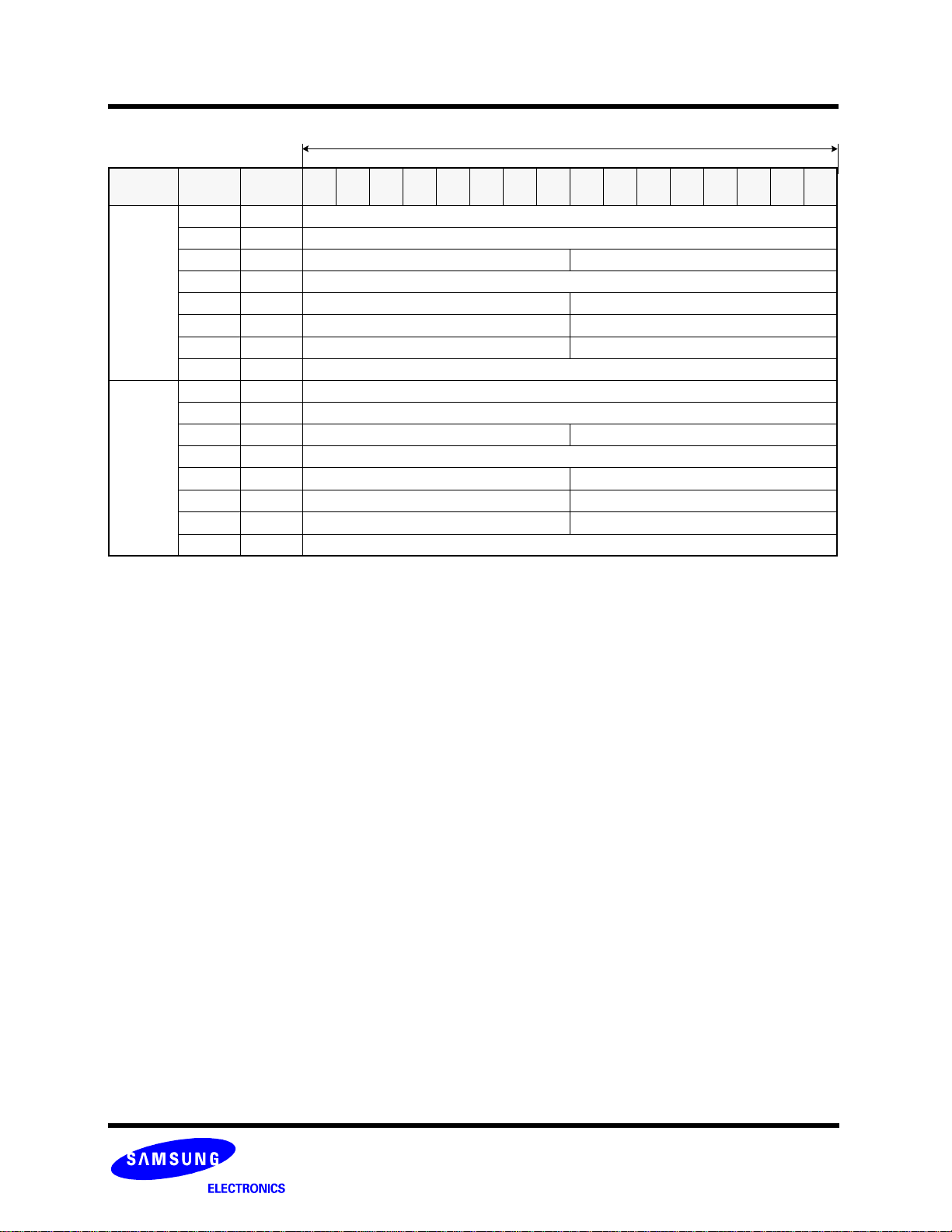

Page 13

OneNAND128 FLASH MEMORY

Block Block Address

Page and Sector

Address

(1)

Size Block Block Address

Page and Sector

Address

(1)

Block64 0040h 0000h~00FDh 64KB Block96 0060h 0000h~00FDh 64KB

Block65 0041h 0000h~00FDh 64KB Block97 0061h 0000h~00FDh 64KB

Block66 0042h 0000h~00FDh 64KB Block98 0062h 0000h~00FDh 64KB

Block67 0043h 0000h~00FDh 64KB Block99 0063h 0000h~00FDh 64KB

Block68 0044h 0000h~00FDh 64KB Block100 0064h 0000h~00FDh 64KB

Block69 0045h 0000h~00FDh 64KB Block101 0065h 0000h~00FDh 64KB

Block70 0046h 0000h~00FDh 64KB Block102 0066h 0000h~00FDh 64KB

Block71 0047h 0000h~00FDh 64KB Block103 0067h 0000h~00FDh 64KB

Block72 0048h 0000h~00FDh 64KB Block104 0068h 0000h~00FDh 64KB

Block73 0049h 0000h~00FDh 64KB Block105 0069h 0000h~00FDh 64KB

Block74 004Ah 0000h~00FDh 64KB Block106 006Ah 0000h~00FDh 64KB

Block75 004Bh 0000h~00FDh 64KB Block107 006Bh 0000h~00FDh 64KB

Block76 004Ch 0000h~00FDh 64KB Block108 006Ch 0000h~00FDh 64KB

Block77 004Dh 0000h~00FDh 64KB Block109 006Dh 0000h~00FDh 64KB

Block78 004Eh 0000h~00FDh 64KB Block110 006Eh 0000h~00FDh 64KB

Block79 004Fh 0000h~00FDh 64KB Block111 006Fh 0000h~00FDh 64KB

Block80 0050h 0000h~00FDh 64KB Block112 0070h 0000h~00FDh 64KB

Block81 0051h 0000h~00FDh 64KB Block113 0071h 0000h~00FDh 64KB

Block82 0052h 0000h~00FDh 64KB Block114 0072h 0000h~00FDh 64KB

Block83 0053h 0000h~00FDh 64KB Block115 0073h 0000h~00FDh 64KB

Block84 0054h 0000h~00FDh 64KB Block116 0074h 0000h~00FDh 64KB

Block85 0055h 0000h~00FDh 64KB Block117 0075h 0000h~00FDh 64KB

Block86 0056h 0000h~00FDh 64KB Block118 0076h 0000h~00FDh 64KB

Block87 0057h 0000h~00FDh 64KB Block119 0077h 0000h~00FDh 64KB

Block88 0058h 0000h~00FDh 64KB Block120 0078h 0000h~00FDh 64KB

Block89 0059h 0000h~00FDh 64KB Block121 0079h 0000h~00FDh 64KB

Block90 005Ah 0000h~00FDh 64KB Block122 007Ah 0000h~00FDh 64KB

Block91 005Bh 0000h~00FDh 64KB Block123 007Bh 0000h~00FDh 64KB

Block92 005Ch 0000h~00FDh 64KB Block124 007Ch 0000h~00FDh 64KB

Block93 005Dh 0000h~00FDh 64KB Block125 007Dh 0000h~00FDh 64KB

Block94 005Eh 0000h~00FDh 64KB Block126 007Eh 0000h~00FDh 64KB

Block95 005Fh 0000h~00FDh 64KB Block127 007Fh 0000h~00FDh 64KB

NOTE 1) 2nd bit of Page and Sector address is Don’t care. So the address range is bigger than the real range.

Even though 2nd bit is set to "1", this bit is always considered "0". Please refer to Start Address 8 register.

Size

13

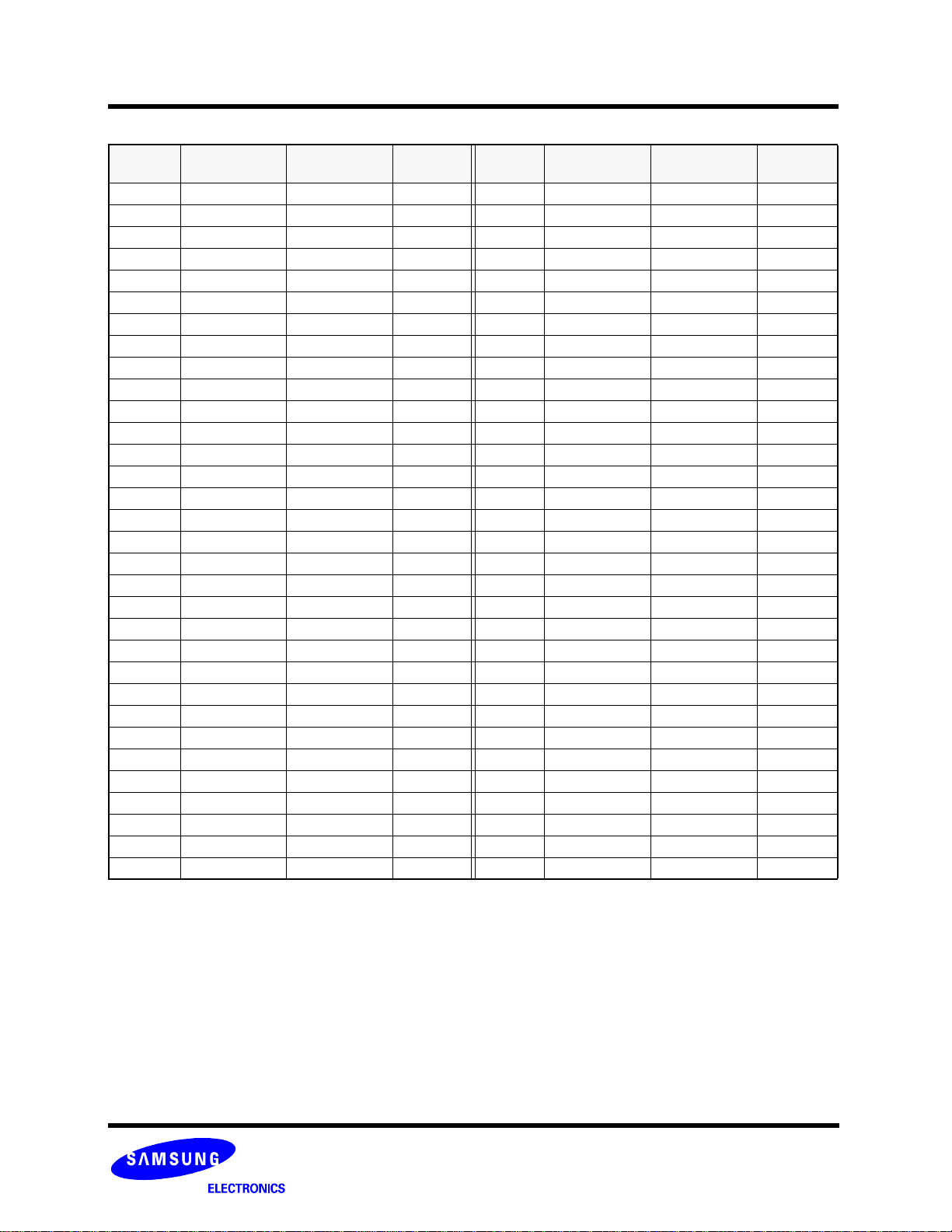

Page 14

OneNAND128 FLASH MEMORY

Block Block Address

Page and Sector

Address

(1)

Size Block Block Address

Page and Sector

Address

(1)

Block128 0080h 0000h~00FDh 64KB Block160 00A0h 0000h~00FDh 64KB

Block129 0081h 0000h~00FDh 64KB Block161 00A1h 0000h~00FDh 64KB

Block130 0082h 0000h~00FDh 64KB Block162 00A2h 0000h~00FDh 64KB

Block131 0083h 0000h~00FDh 64KB Block163 00A3h 0000h~00FDh 64KB

Block132 0084h 0000h~00FDh 64KB Block164 00A4h 0000h~00FDh 64KB

Block133 0085h 0000h~00FDh 64KB Block165 00A5h 0000h~00FDh 64KB

Block134 0086h 0000h~00FDh 64KB Block166 00A6h 0000h~00FDh 64KB

Block135 0087h 0000h~00FDh 64KB Block167 00A7h 0000h~00FDh 64KB

Block136 0088h 0000h~00FDh 64KB Block168 00A8h 0000h~00FDh 64KB

Block137 0089h 0000h~00FDh 64KB Block169 00A9h 0000h~00FDh 64KB

Block138 008Ah 0000h~00FDh 64KB Block170 00AAh 0000h~00FDh 64KB

Block139 008Bh 0000h~00FDh 64KB Block171 00ABh 0000h~00FDh 64KB

Block140 008Ch 0000h~00FDh 64KB Block172 00ACh 0000h~00FDh 64KB

Block141 008Dh 0000h~00FDh 64KB Block173 00ADh 0000h~00FDh 64KB

Block142 008Eh 0000h~00FDh 64KB Block174 00AEh 0000h~00FDh 64KB

Block143 008Fh 0000h~00FDh 64KB Block175 00AFh 0000h~00FDh 64KB

Block144 0090h 0000h~00FDh 64KB Block176 00B0h 0000h~00FDh 64KB

Block145 0091h 0000h~00FDh 64KB Block177 00B1h 0000h~00FDh 64KB

Block146 0092h 0000h~00FDh 64KB Block178 00B2h 0000h~00FDh 64KB

Block147 0093h 0000h~00FDh 64KB Block179 00B3h 0000h~00FDh 64KB

Block148 0094h 0000h~00FDh 64KB Block180 00B4h 0000h~00FDh 64KB

Block149 0095h 0000h~00FDh 64KB Block181 00B5h 0000h~00FDh 64KB

Block150 0096h 0000h~00FDh 64KB Block182 00B6h 0000h~00FDh 64KB

Block151 0097h 0000h~00FDh 64KB Block183 00B7h 0000h~00FDh 64KB

Block152 0098h 0000h~00FDh 64KB Block184 00B8h 0000h~00FDh 64KB

Block153 0099h 0000h~00FDh 64KB Block185 00B9h 0000h~00FDh 64KB

Block154 009Ah 0000h~00FDh 64KB Block186 00BAh 0000h~00FDh 64KB

Block155 009Bh 0000h~00FDh 64KB Block187 00BBh 0000h~00FDh 64KB

Block156 009Ch 0000h~00FDh 64KB Block188 00BCh 0000h~00FDh 64KB

Block157 009Dh 0000h~00FDh 64KB Block189 00BDh 0000h~00FDh 64KB

Block158 009Eh 0000h~00FDh 64KB Block190 00BEh 0000h~00FDh 64KB

Block159 009Fh 0000h~00FDh 64KB Block191 00BFh 0000h~00FDh 64KB

NOTE 1) 2nd bit of Page and Sector address is Don’t care. So the address range is bigger than the real range.

Even though 2nd bit is set to "1", this bit is always considered "0". Please refer to Start Address 8 register.

Size

14

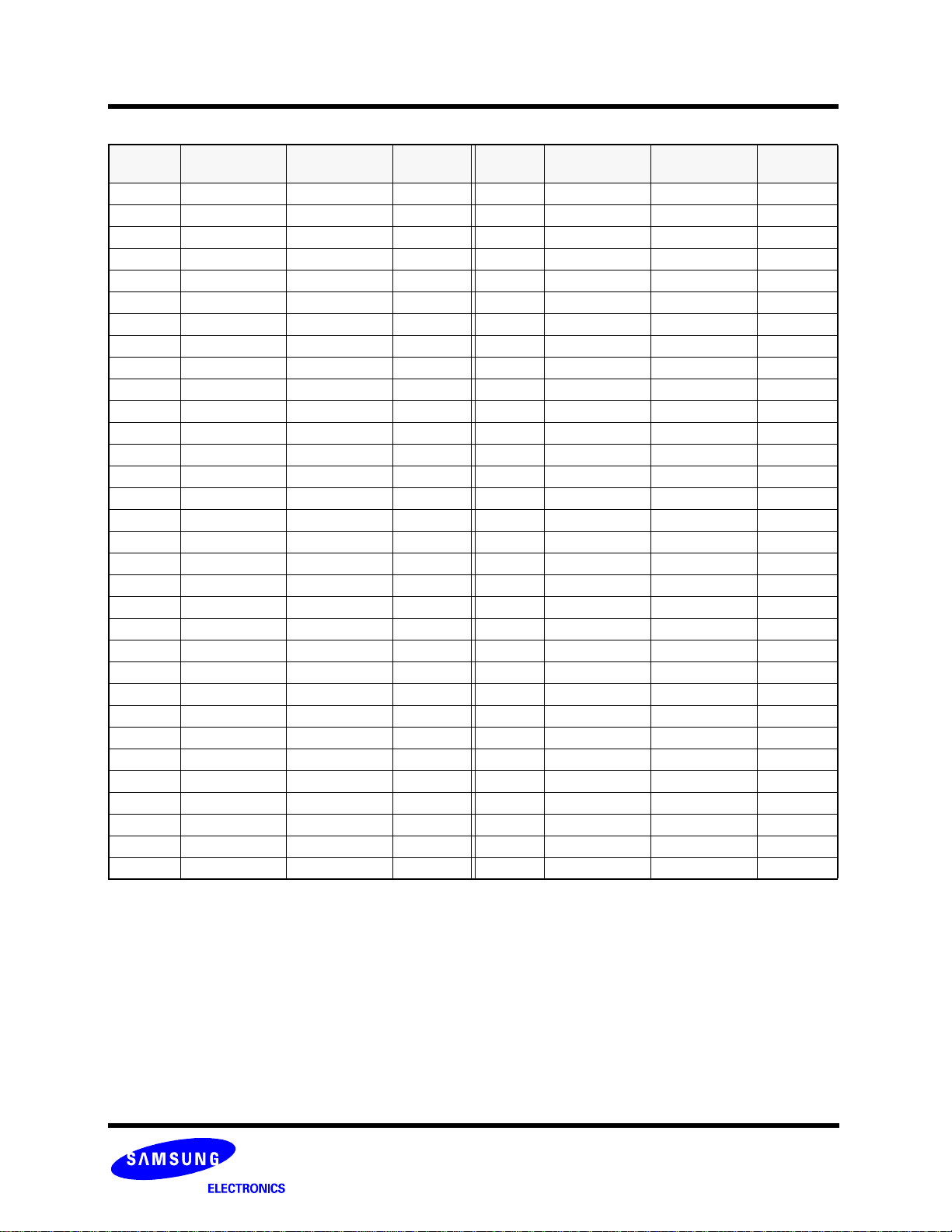

Page 15

OneNAND128 FLASH MEMORY

Block Block Address

Page and Sector

Address

(1)

Size Block Block Address

Page and Sector

Address

(1)

Block192 00C0h 0000h~00FDh 64KB Block224 00E0h 0000h~00FDh 64KB

Block193 00C1h 0000h~00FDh 64KB Block225 00E1h 0000h~00FDh 64KB

Block194 00C2h 0000h~00FDh 64KB Block226 00E2h 0000h~00FDh 64KB

Block195 00C3h 0000h~00FDh 64KB Block227 00E3h 0000h~00FDh 64KB

Block196 00C4h 0000h~00FDh 64KB Block228 00E4h 0000h~00FDh 64KB

Block197 00C5h 0000h~00FDh 64KB Block229 00E5h 0000h~00FDh 64KB

Block198 00C6h 0000h~00FDh 64KB Block230 00E6h 0000h~00FDh 64KB

Block199 00C7h 0000h~00FDh 64KB Block231 00E7h 0000h~00FDh 64KB

Block200 00C8h 0000h~00FDh 64KB Block232 00E8h 0000h~00FDh 64KB

Block201 00C9h 0000h~00FDh 64KB Block233 00E9h 0000h~00FDh 64KB

Block202 00CAh 0000h~00FDh 64KB Block234 00EAh 0000h~00FDh 64KB

Block203 00CBh 0000h~00FDh 64KB Block235 00EBh 0000h~00FDh 64KB

Block204 00CCh 0000h~00FDh 64KB Block236 00ECh 0000h~00FDh 64KB

Block205 00CDh 0000h~00FDh 64KB Block237 00EDh 0000h~00FDh 64KB

Block206 00CEh 0000h~00FDh 64KB Block238 00EEh 0000h~00FDh 64KB

Block207 00CFh 0000h~00FDh 64KB Block239 00EFh 0000h~00FDh 64KB

Block208 00D0h 0000h~00FDh 64KB Block240 00F0h 0000h~00FDh 64KB

Block209 00D1h 0000h~00FDh 64KB Block241 00F1h 0000h~00FDh 64KB

Block210 00D2h 0000h~00FDh 64KB Block242 00F2h 0000h~00FDh 64KB

Block211 00D3h 0000h~00FDh 64KB Block243 00F3h 0000h~00FDh 64KB

Block212 00D4h 0000h~00FDh 64KB Block244 00F4h 0000h~00FDh 64KB

Block213 00D5h 0000h~00FDh 64KB Block245 00F5h 0000h~00FDh 64KB

Block214 00D6h 0000h~00FDh 64KB Block246 00F6h 0000h~00FDh 64KB

Block215 00D7h 0000h~00FDh 64KB Block247 00F7h 0000h~00FDh 64KB

Block216 00D8h 0000h~00FDh 64KB Block248 00F8h 0000h~00FDh 64KB

Block217 00D9h 0000h~00FDh 64KB Block249 00F9h 0000h~00FDh 64KB

Block218 00DAh 0000h~00FDh 64KB Block250 00FAh 0000h~00FDh 64KB

Block219 00DBh 0000h~00FDh 64KB Block251 00FBh 0000h~00FDh 64KB

Block220 00DCh 0000h~00FDh 64KB Block252 00FCh 0000h~00FDh 64KB

Block221 00DDh 0000h~00FDh 64KB Block253 00FDh 0000h~00FDh 64KB

Block222 00DEh 0000h~00FDh 64KB Block254 00FEh 0000h~00FDh 64KB

Block223 00DFh 0000h~00FDh 64KB Block255 00FFh 0000h~00FDh 64KB

NOTE 1) 2nd bit of Page and Sector address is Don’t care. So the address range is bigger than the real range.

Even though 2nd bit is set to "1", this bit is always considered "0". Please refer to Start Address 8 register.

Size

15

Page 16

OneNAND128 FLASH MEMORY

Detailed information of Address Map (word order)

• BootRAM(Main area)

-0000h~01FFh: 2(sector) x 512byte(NAND main area) = 1KB

0000h~00FFh(512B)

BootM 0

(sector 0 of page 0)

• DataRAM(Main area)

-0200h~05FFh: 4(sector) x 512byte(NAND main area) = 2KB

0200h~02FFh(512B)

DataM 0_0

(sector 0 of page 0)

• BootRAM(Spare area)

-8000h~800Fh: 2(sector) x 16byte(NAND spare area) = 32B

8000h~8007h(16B)

BootS 0

(sector 0 of page 0)

• DataRAM(Spare area)

-8010h~802Fh: 4(sector) x 16byte(NAND spare area) = 64B

8010h~8017h(16B)

DataS 0_0

(sector 0 of page 0)

0300h~03FFh(512B)

DataM 0_1

(sector 1 of page 0)

8018h~801Fh(16B)

DataS 0_1

(sector 1 of page 0)

0400h~04FFh(512B)

DataM 1_0

(sector 0 of page 1)

8020h~8027h(16B)

DataS 1_0

(sector 0 of page 1)

0100h~01FFh(512B)

BootM 1

(sector 1 of page 0)

0500h~05FFh(512B)

DataM 1_1

(sector 1 of page 1)

8008h~800Fh(16B)

BootS 1

(sector 1 of page 0)

8028h~802Fh(16B)

DataS 1_1

(sector 1 of page 1)

*NAND Flash array consists of 1KB page size and 64KB block size.

16

Page 17

OneNAND128 FLASH MEMORY

Spare area assignment

Equivalent to 1word of NAND Flash

Buf.

Word

Address

Byte

Address

F E D C B A 9 8 7 6 5 4 3 2 1 0

BootS 0 8000h 10000h BI

8001h 10002h Managed by Internal ECC logic

8002h 10004h Reserved for the future use Managed by Internal ECC logic

8003h 10006h Reserved for the current and future use

8004h 10008h

8005h 1000Ah

ECC Code for Main area data (2

ECC Code for Spare area data (1

nd

) ECC Code for Main area data (1st)

st

) ECC Code for Main area data (3rd)

8006h 1000Ch FFh(Reserved for the future use)

8007h 1000Eh Free Usage

BootS 1 8008h 10010h BI

8009h 10012h Managed by Internal ECC logic

800Ah 10014h Reserved for the future use Managed by Internal ECC logic

800Bh 10016h Reserved for the current and future use

800Ch 10018h

800Dh 1001Ah

ECC Code for Main area data (2

ECC Code for Spare area data (1

nd

) ECC Code for Main area data (1st)

st

) ECC Code for Main area data (3rd)

800Eh 1001Ch FFh(Reserved for the future use)

800Fh 1001Eh Free Usage

DataS

0_0

8010h 10020h BI

8011h 10022h Managed by Internal ECC logic

8012h 10024h Reserved for the future use Managed by Internal ECC logic

8013h 10026h Reserved for the current and future use

8014h 10028h

8015h 1002Ah

ECC Code for Main area data (2

ECC Code for Spare area data (1

nd

) ECC Code for Main area data (1st)

st

) ECC Code for Main area data (3rd)

8016h 1002Ch FFh(Reserved for the future use)

8017h 1002Eh Free Usage

DataS

0_1

8018h 10030h BI

8019h 10032h Managed by Internal ECC logic

801Ah 10034h Reserved for the future use Managed by Internal ECC logic

801Bh 10036h Reserved for the current and future use

801Ch 10038h

801Dh 1003Ah

ECC Code for Main area data (2

ECC Code for Spare area data (1

nd

) ECC Code for Main area data (1st)

st

) ECC Code for Main area data (3rd)

801Eh 1003Ch FFh(Reserved for the future use)

801Fh 1003Eh Free Usage

ECC Code for Spare area data (2

ECC Code for Spare area data (2

ECC Code for Spare area data (2

ECC Code for Spare area data (2

nd

)

nd

)

nd

)

nd

)

17

Page 18

OneNAND128 FLASH MEMORY

Equivalent to 1word of NAND Flash

Buf.

Word

Address

Byte

Address

F E D C B A 9 8 7 6 5 4 3 2 1 0

DataS 1_0 8020h 10040h BI

8021h 10042h Managed by Internal ECC logic

8022h 10044h Reserved for the future use Managed by Internal ECC logic

8023h 10046h Reserved for the current and future use

8024h 10048h

8025h 1004Ah

ECC Code for Main area data (2

ECC Code for Spare area data (1

nd

) ECC Code for Main area data (1st)

st

) ECC Code for Main area data (3rd)

8026h 1004Ch FFh(Reserved for the future use)

8027h 1004Eh Free Usage

DataS 1_1 8028h 10050h BI

8029h 10052h Managed by Internal ECC logic

802Ah 10054h Reserved for the future use Managed by Internal ECC logic

802Bh 10056h Reserved for the current and future use

802Ch 10058h

802Dh 1005Ah

ECC Code for Main area data (2

ECC Code for Spare area data (1

nd

) ECC Code for Main area data (1st)

st

) ECC Code for Main area data (3rd)

802Eh 1005Ch FFh(Reserved for the future use)

802Fh 1005Eh Free Usage

NOTE:

- BI: Invalid block Information

ECC Code for Spare area data (2

ECC Code for Spare area data (2

nd

)

nd

)

>Host can use complete spare area except BI and ECC code area. For example,

Host can write data to Spare area buffer except for the area controlled by ECC logic at program operation.

>OneNAND automatically generates ECC code for both main and spare data of memory during program operation in case of ’with ECC’ mode ,

but does not update ECC code to spare bufferRAM.

>When loading/programming spare area, spare area BufferRAM address(BSA) and BufferRAM sector count(BSC) is chosen via Start buffer register

as it is.

18

Page 19

OneNAND128 FLASH MEMORY

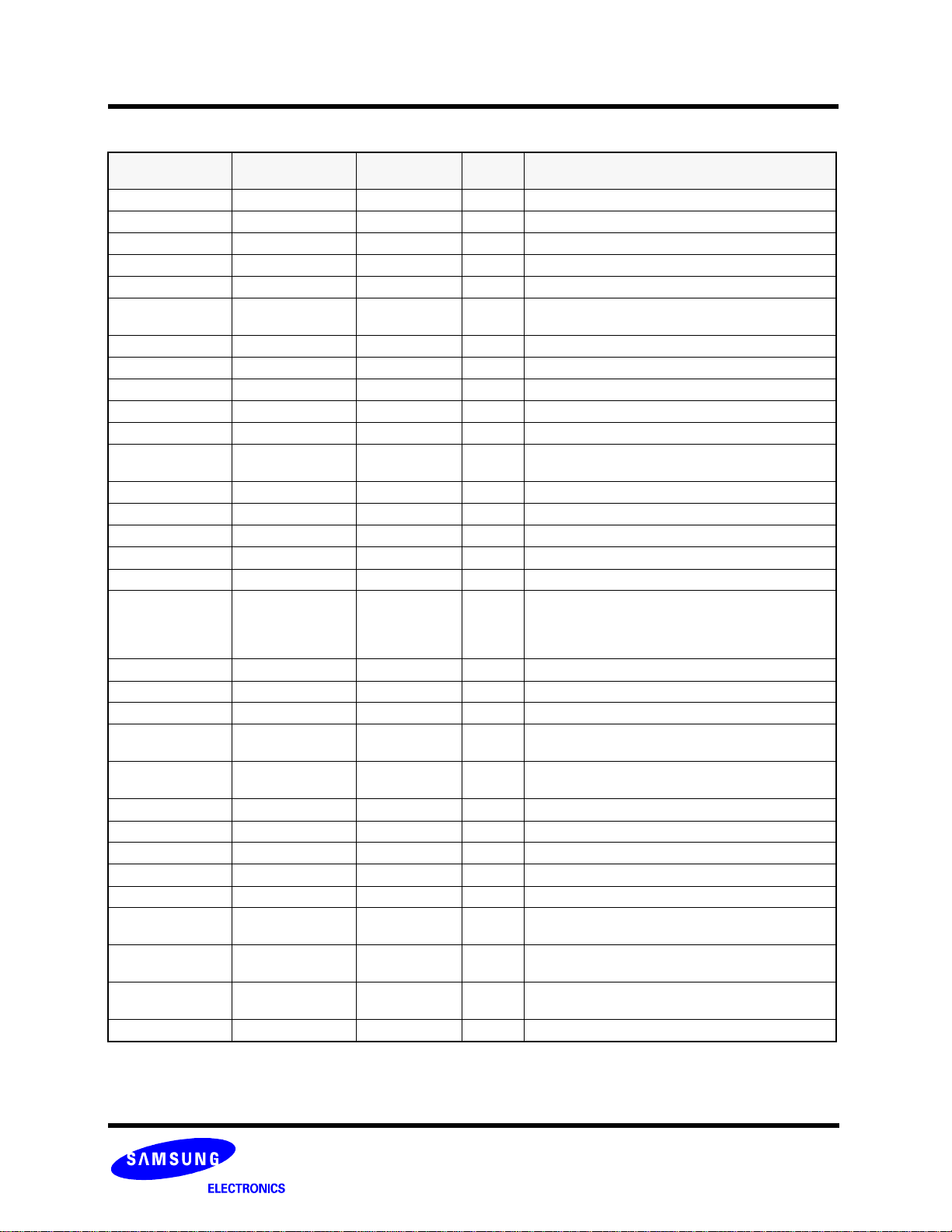

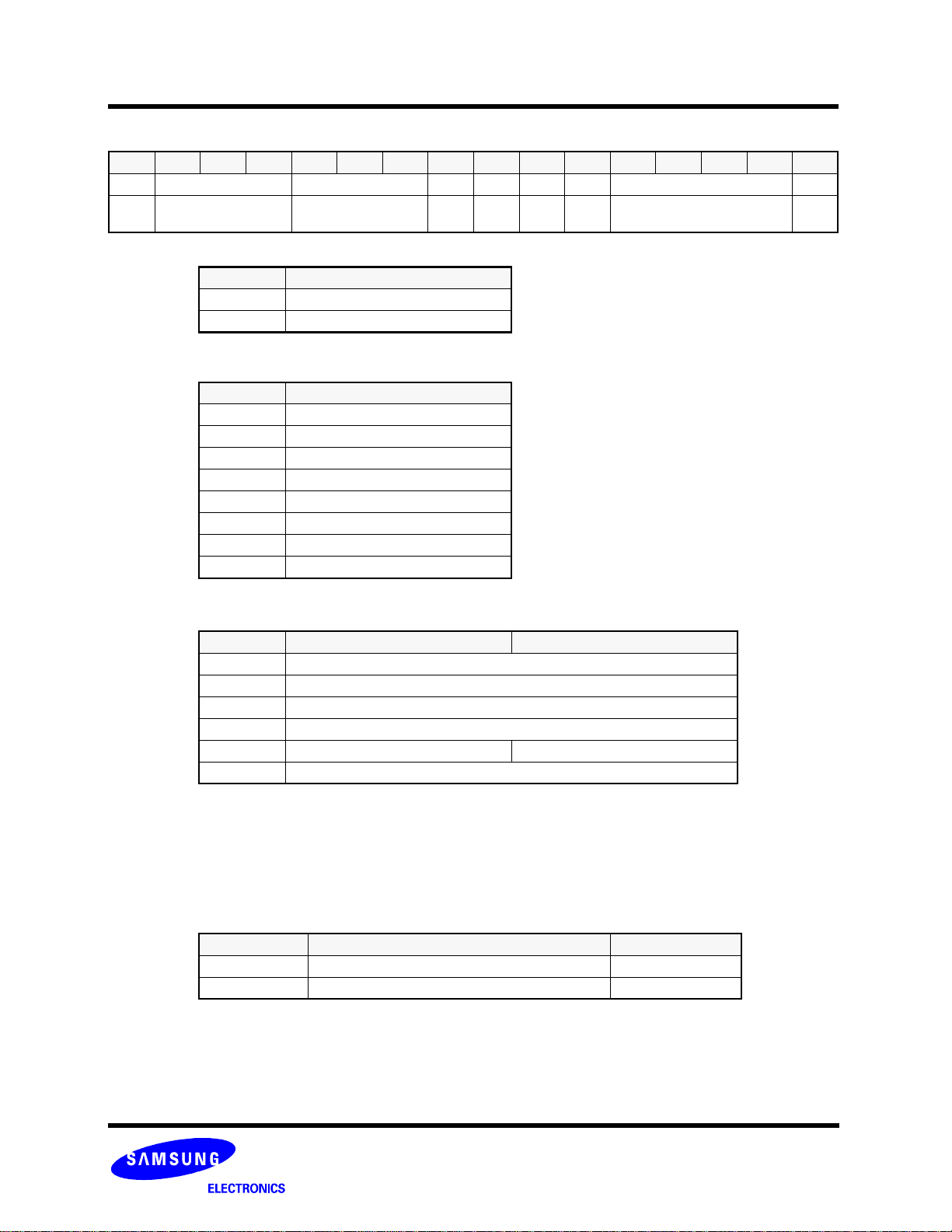

7. Detailed address map for registers

Address

(word order)

F000h 1E000h Manufacturer ID R Manufacturer identification

F001h 1E002h Device ID R Device identification

F002h 1E004h Version ID R Version identification

F003h 1E006h Data Buffer size R Data buffer size

F004h 1E008h Boot Buffer size R Boot buffer size

F005h 1E00Ah

F006h 1E00Ch Technology R Info about technology

F007h~F0FFh 1E00Eh~1E1FEh Reserved - Reserved for User

F100h 1E200h Start address 1 R/W NAND Flash Block address

F101h 1E202h Start address 2 R/W Reserved

F102h 1E204h Start address 3 R/W Destination Block address for Copy back program

F103h 1E206h Start address 4 R/W

F104h 1E208h Start address 5 - N/A

F105h 1E20Ah Start address 6 - N/A

F106h 1E20Ch Start address 7 - N/A

F107h 1E20Eh Start address 8 R/W NAND Flash Page & Sector address

F108h~F1FFh 1E210h~1E3FEh Reserved - Reserved for User

F200h 1E400h Start Buffer R/W

F201h~F207h 1E402h~1E40Eh Reserved - Reserved for User

F208h~F21Fh 1E410h~1E43Eh Reserved - Reserved for vendor specific purposes

F220h 1E440h Command R/W Host control and memory operation commands

F221h 1E442h

F222h 1E444h

F223h~F22Fh 1E446h~1E45Eh Reserved - Reserved for User

F230h~F23Fh 1E460h~1E47Eh Reserved - Reserved for vendor specific purposes

F240h 1E480h Controller Status R Controller Status and result of memory operation

F241h 1E482h Interrupt R/W Memory Command Completion Interrupt Status

F242h~F24Bh 1E484h~1E496h Reserved - Reserved for User

F24Ch 1E498h

F24Dh 1E49Ah

F24Eh 1E49Ch

F24Fh~FEFFh 1E49Eh~1FDFEh Reserved - Reserved for User

Address

(byte order)

Name

Amount of

buffers

System

Configuration 1

System

Configuration 2

Unlock Start

Block Address

Unlock End

Block Address

Write Protection

Status

Host

Access

R Amount of data/boot buffers

Destination Page & Sector address for Copy

back program

Number Buffer of for the page data transfer to/from the

memory and the start Buffer Address

The meaning is with which buffer to start and how many

buffers to use for the data transfer

R, R/W Memory and Host Interface Configuration

-N/A

Start memory block address to unlock in Write

R/W

Protection mode

End memory block address to unlock in Write

R/W

Protection mode

Current memory Write Protection status

R

(unlocked/locked/tight-locked)

Description

19

Page 20

OneNAND128 FLASH MEMORY

Address

(word order)

FF00h 1FE00h

FF01h 1FE02h

FF02h 1FE04h

FF03h 1FE06h

FF04h 1FE08h

FF05h~FFFFh 1FE12h~1FF0Ah Reserved - Reserved for vendor specific purposes

Address

(byte order)

Name

ECC Status

Register

ECC Result of

main area data

ECC Result of

spare area data

ECC Result of

main area data

ECC Result of

spare area data

Host

Access

R ECC status of sector

ECC error position of Main area data error for first

R

selected Sector

ECC error position of Spare area data error for first

R

selected Sector

ECC error position of Main area data error for second

R

selected Sector

ECC error position of Spare area data error for second

R

selected Sector

Description

20

Page 21

OneNAND128 FLASH MEMORY

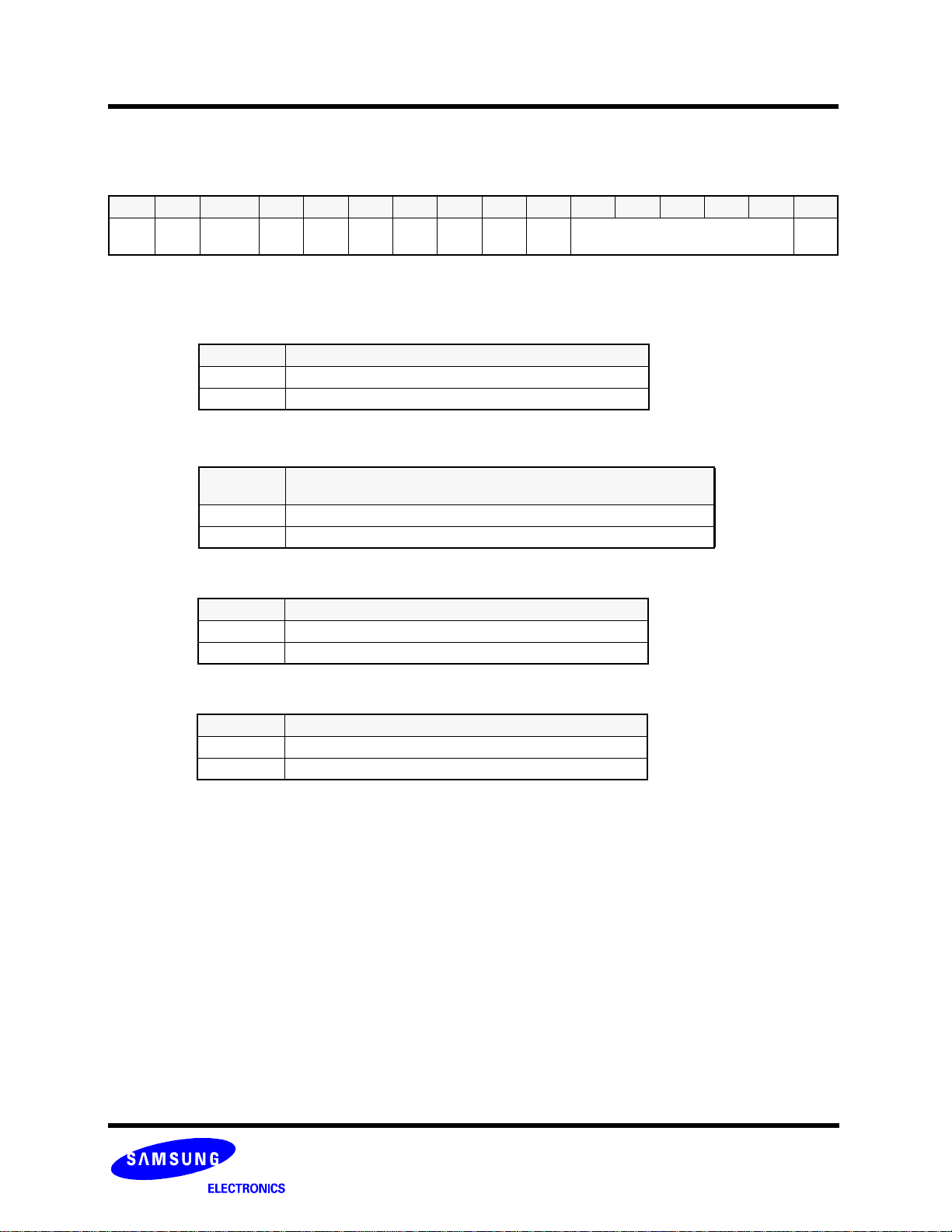

7. Address Register (word order)

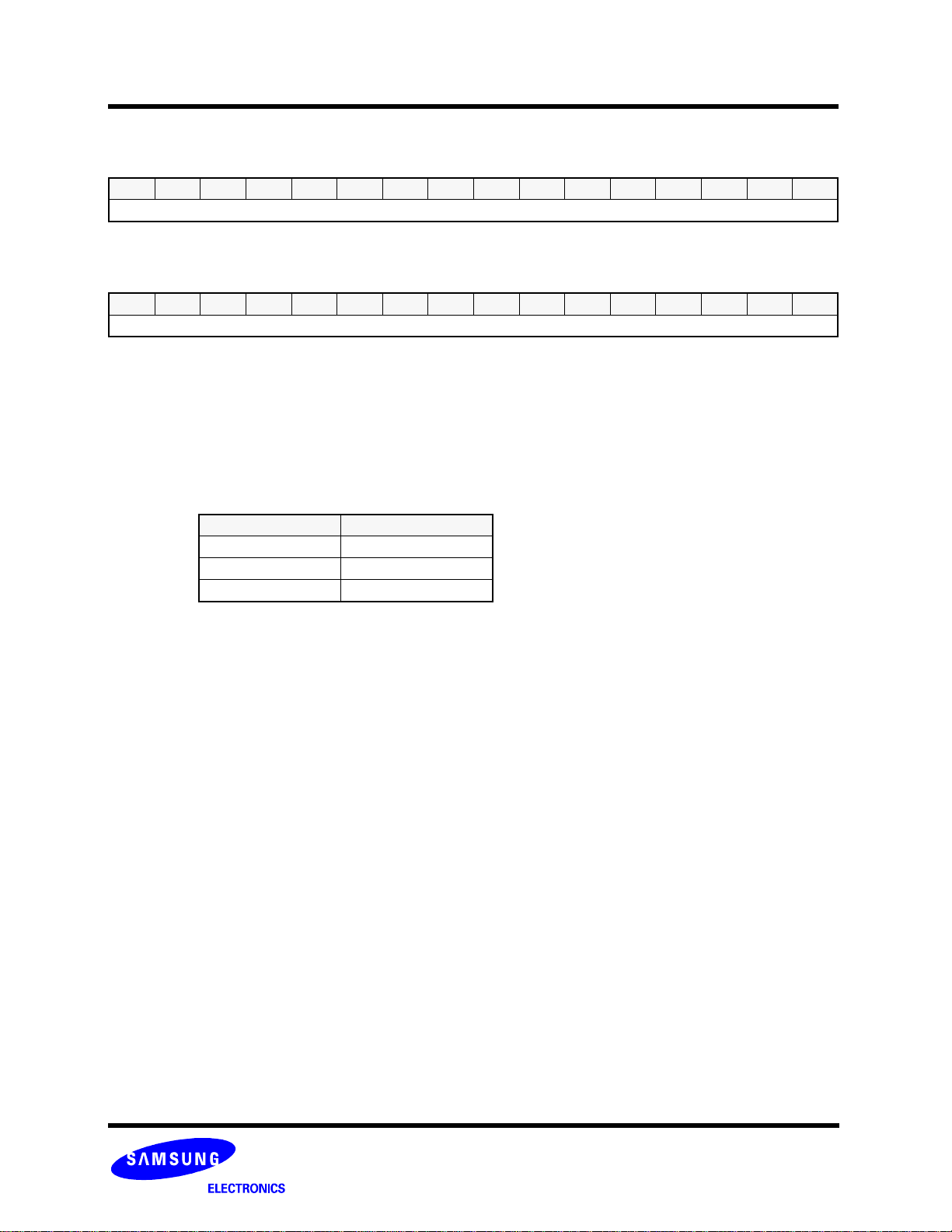

7.1 Manufacturer ID Register (R): F000h, default=00ECh

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

ManufID

ManufID (Manufacturer ID): manufacturer identification, 00ECh for Samsung Electronics Corp.

7.2 Device ID Register (R): F001h, default=refer to Table1

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

DeviceID

DeviceID (Device ID): Device Identification,

Table 1.

Device DeviceID[15:0]

KFG2816Q1M 0004h

KFG2816D1M 0005h

KFG2816U1M 0005h

7.3 Version ID Register (R): F002h

: N/A

21

Page 22

OneNAND128 FLASH MEMORY

7.4 Data Buffer size Register(R): F003h, default=0400h

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

DataBufSize

DataBufSize: total data buffer size in words in the memory interface used for shrinks

Equals two buffers of 512 words each(2x512=2

7.5 Boot Buffer size Register (R): F004h, default=0200h

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

BootBufSize: total boot buffer size in words in the memory interface

(512 words=2

9

, N=9)

7.6 Amount of Buffers Register (R): F005h, default=0201h

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

DataBufAmount BootBufAmount

DataBufAmount: the amount of data buffer=2(2N, N=1)

BootBufAmount: the amount of boot buffer=1(2

7.7 Technology Register (R): F006h, default=0000h

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Tech: technology information, what technology is used for the memory

N

N

, N=0)

, N=10)

BootBufSize

Te ch

Tech Technology

0000h NAND SLC

0001h NAND MLC

0002h-FFFFh Reserved

22

Page 23

OneNAND128 FLASH MEMORY

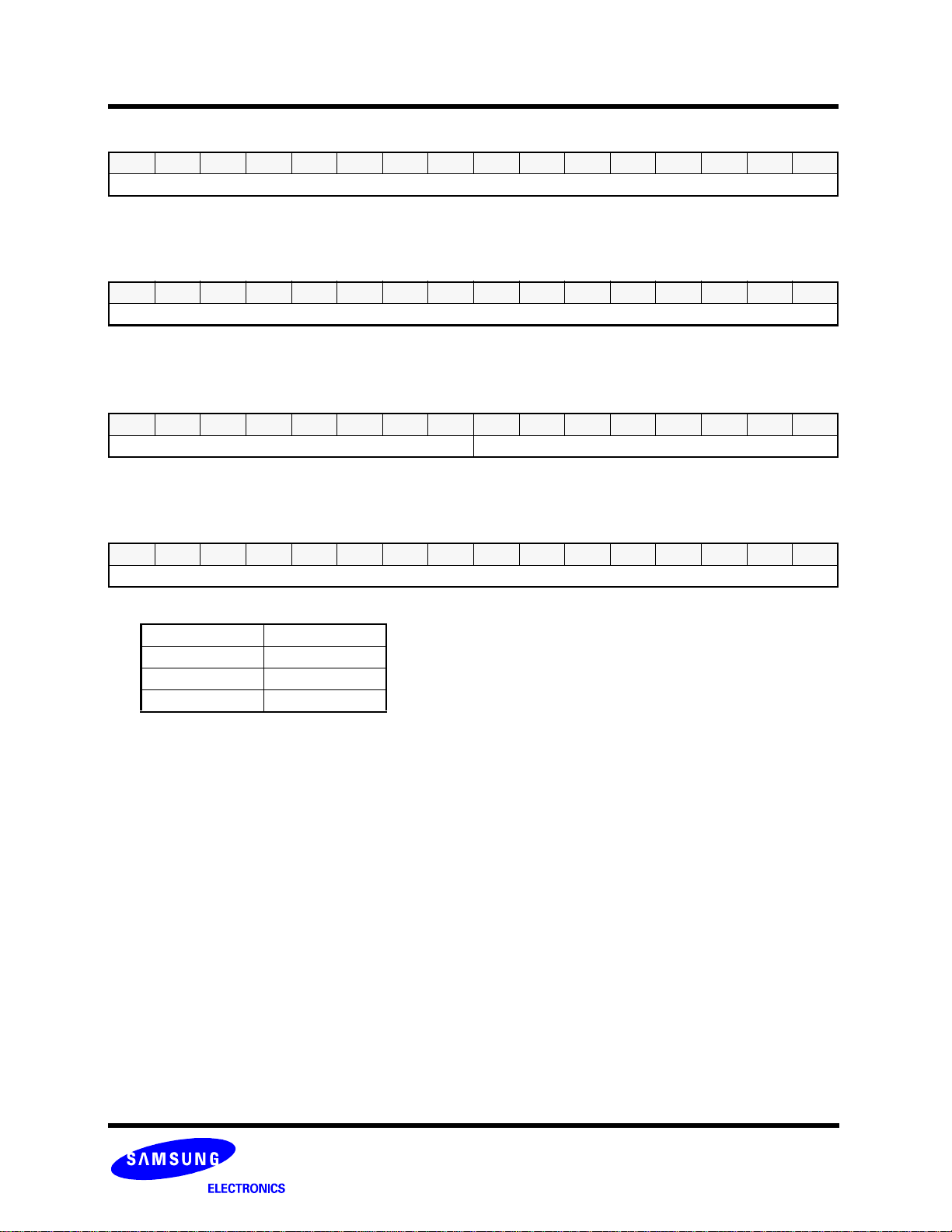

7.8 Start Address1 Register (R/W): F100h, default=0000h

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Reserved(00000000) FBA

FBA (NAND Flash Block Address): NAND Flash block address which will be read or programmed or erased.

Device Number of Block FBA

128Mb 256 FBA[7:0]

7.9 Start Address2 Register (R/W): F101h, default=0000h

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Reserved(0000000000000000)

7.10 Start Address3 Register (R/W): F102h, default=0000h

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Reserved(00000000) FCBA

FCBA (NAND Flash Copy Back Block Address): NAND Flash destination block address which will be copy back programmed.

Device Number of Block FBA

128Mb 256 FBA[7:0]

7.11 Start Address4 Register (R/W): F103h, default=0000h

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Reserved(00000000) FCPA Reserved FCSA

FCPA (NAND Flash Copy Back Page Address): NAND Flash destination page address in a block for copy back program operation.

FCPA(default value) = 000000

FCPA range : 000000~111111, 6bits for 64 pages

FCSA (NAND Flash Copy Back Sector Address): NAND Flash destination sector address in a page for copy back program operation.

FCSA(default value) = 0

FCSA range : 0~1, 1bits for 2 sectors

23

Page 24

OneNAND128 FLASH MEMORY

7.12 Start Address5 Register: F104h

: N/A

7.13 Start Address6 Register: F105h

: N/A

7.14 Start Address7 Register: F106h

: N/A

7.15 Start Address8 Register (R/W): F107h, default=0000h

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Reserved (00000000) FPA Reserved FSA

FPA (NAND Flash Page Address): NAND Flash start page address in a block for page read or copy back program or program operation.

FPA(default value)=000000

FPA range: 000000~111111 , 6bits for 64 pages

FSA (Flash Sector Address): NAND Flash start sector address in a page for read or copy back program or program operation.

FSA(default value) = 0

FSA range : 0~1, 1bits for 2 sectors

7.16 Start Buffer Register (R/W): F200h, default=0000h

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Reserved(0000) BSA Reserved(0000000) BSC

BSC (BufferRAM Sector Count): this field specifies the number of sectors to be read or programmed or copy back programmed.

Its maximum count is 2 sectors at 0(default value)value.

For a single sector access, it should be programmed as value 1 and it should be programmed as value 0 for two sectors.

However internal RAM buffer reached to 1 value(max. value), it counts up to 0 value to satisfy BSC value.

for example) if BSA=1101, BSC=0, then selected BufferRAM are ’1101->1100’.

BSA (BufferRAM Sector Address): It is the place where data is placed and specifies the sector 0~1 in the internal BootRAM and DataRAM.

BSA[3] is the selection bit between BootRAM and DataRAM.

BSA[2] is the selection bit between DataRAM0 and DataRAM1.

BSA[0] is the selection bit between Sector0 and Sector1 in the internal BootRAM and DataRAM.

While one of BootRAM or DataRAM0 interfaces with memory, the other RAM is inaccessible.

BootRAM

DataRAM0

DataRAM1

Main area data

{

BootRAM 0

BootRAM 1

DataRAM 0_0

DataRAM 0_1

DataRAM 1_0

DataRAM 1_1

Spare area data

{

BSA

0000

0001

1000

1001

1100

1101

24

Sector: (512 + 16)byte

BSC Number of Sectors

1 1 sector

0 2 sectors

Page 25

OneNAND128 FLASH MEMORY

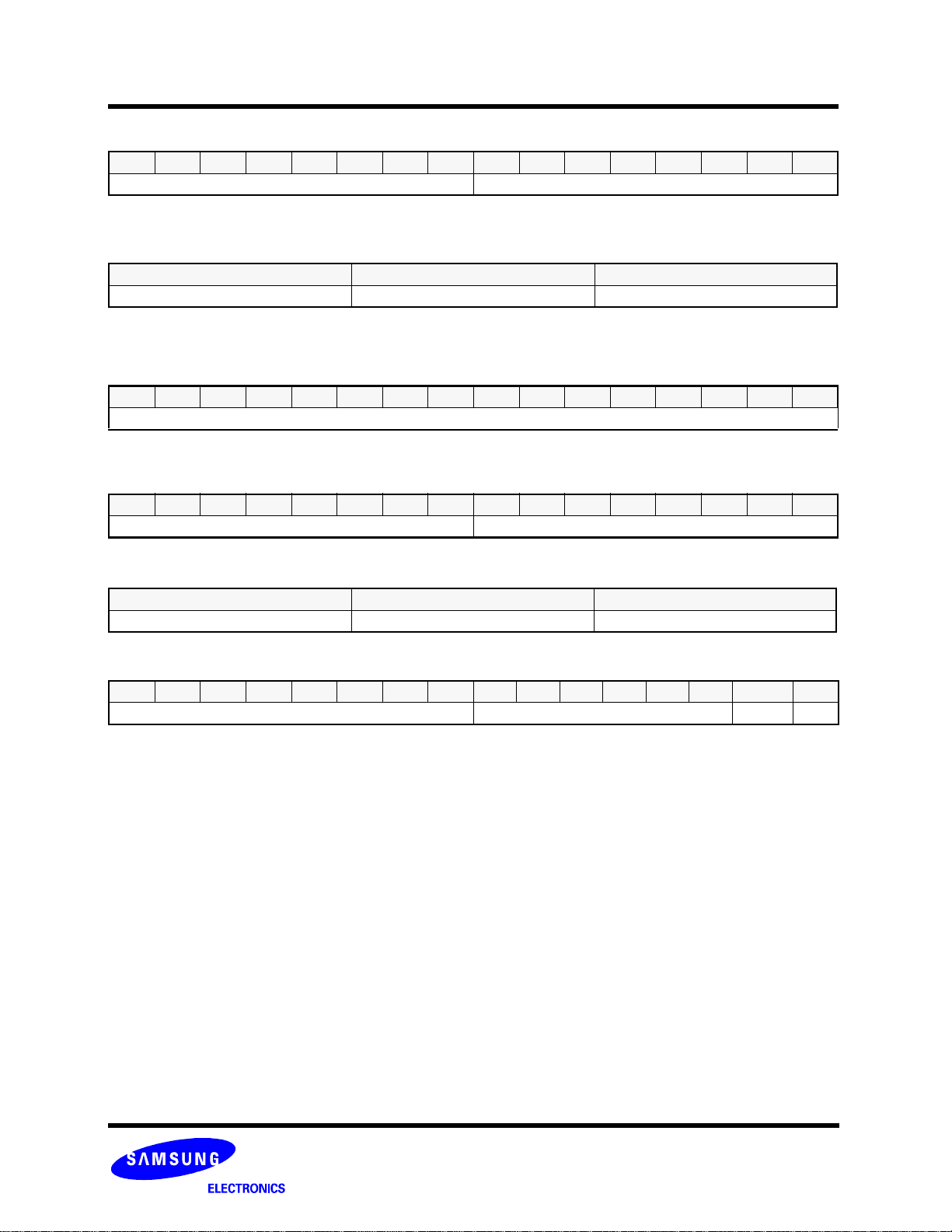

7.17 Command Register (R/W): F220h, default=0000h

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Command

Command: operation of the memory interface

Acceptable

CMD Operation

0000h Load single/multiple sector data unit into buffer 00F0h, 00F3h

0013h Load single/multiple spare sector into buffer 00F0h, 00F3h

0080h Program single/multiple sector data unit from buffer 00F0h, 00F3h

001Ah Program single/multiple spare area sector from buffer 00F0h, 00F3h

001Bh Copy back program 00F0h, 00F3h

0023h Unlock NAND array block(s) from start block address to end block address -

002Ah Lock NAND array block(s) from start block address to end block address -

002Ch Lock-tight NAND array block(s) from start block address to end block address -

0071h Erase Verify Read 00F0h, 00F3h

0094h Block Erase 00F0h, 00F3h

0095h Multi-Block Erase 00F0h, 00F3h

00B0h Erase Suspend 00F3h

0030h Erase Resume 00F0h, 00F3h

00F0h Reset NAND Flash Core -

00F3h Reset OneNAND 1) -

0065h OTP Access 00F0h, 00F3h

NOTE:

1)’Reset OneNAND’(=Hot reset) command makes the registers(except RDYpol, INTpol, IOBE, and OTP

the warm reset(=reset by RP

pin).

L bits) and NAND Flash core into default state as

command

during busy

This R/W register describes the operation of the OneNAND interface.

Note that all commands should be issued right after INT is turned from ready state to busy state. (i.e. right after 0 is written to INT register.) After any

command is issued and the corresponding operation is completed, INT goes back to ready state. (00F0h and 00F3h may be accepted during busy state

of some operations. Refer to the rightmost column of the command register table above.)

25

Page 26

OneNAND128 FLASH MEMORY

7.18 System Configuration 1 Register (R, R/W): F221h, default=40C0h

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

R/W R/W R/W R/W R/W R/W R/W R R

RM BRL BL ECC

RM (Read Mode): this field specifies the selection between asynchronous read mode and synchronous read mode

RDY

pol

INT

pol

IOB

E

RM Read Mode

0 Asynchronous read(default)

1 Synchronous read

BRL (Burst Read Latency): this field specifies the initial access latency in the burst read transfer.

BRL Latency Cycles

000 8(N/A)

001 9(N/A)

010 10(N/A)

011 3(up to 40MHz)

100 4(default, min.)

101 5

110 6

111 7

Reserved(0000)

BW

PS

BL (Burst Length): this field specifies the size of burst length during Sync. burst read. Wrap around and linear burst.

BL Burst Length(Main) Burst Length(Spare)

000 Continuous(default)

001 4 words

010 8 words

011 16 words

100 32 words N/A

101~111 Reserved

ECC: Error Correction Operation,

0=with correction(default), 1=without correction(by-passed)

RDYpol: RDY signal polarity

0=low for ready, 1=high for ready((default)

INTpol: INT Pin polarity

0=low for Interrupt pending , 1=high for Interrupt pending (default)

INTpol INT bit of Interrupt Status Register INT Pin output

00 1

10 0

IOBE: I/O buffer enable for INT and RDY signals, INT and RDY outputs are HighZ at power-up, bit 7 and 6 become valid after IOBE is set to1. IOBE can

be reset only by Cold reset or by writing 0 to bit 5 of System Configuration 1 register.

0=disable(default), 1=enable

BWPS: boot buffer write protect status,

0=locked(fixed)

26

Page 27

OneNAND128 FLASH MEMORY

7.19 System Configuration 2 Register : F222h

: N/A

7.22 Controller Status Register (R): F240h, default=0000h

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

OnGo Lock Load Prog Erase Error Sus PRp RSTB OTP

OnGo: this bit shows the overall internal status of OneNAND

0=ready, 1=busy

Lock: this bit shows whether host loads data from NAND Flash array into locked BootRAM or programs/erases locked block of NAND Flash array.

L Reserved(000000)

Lock Locked/Unlocked Check Result

0 Unlocked

1 Locked

Error (Current Sector/Page Write Result): this bit shows current sector/page Load/Program/Copy Back Program/Erase result of flash memory or whether

host puts invalid command into the device.

TO

(0)

Error

Current Sector/Page Load/Program/CopyBack. Program/Erase Result

and Invalid Command Input

0Pass

1Fail

Sus (Erase Suspend/Resume):this bit shows the Erase Suspend Status.

Sus Erase Suspend Status

0 Erase Resume(Default)

1 Erase Suspend

OTPL (OTP Lock Status):this bit shows OTP block is locked or unlocked. OTPL bit is automatically updated at power-on.

OTPL OTP Locked/Unlocked Status

0 OTP Block Unlock Status(Default)

1 OTP Block Lock Status(Disable OTP Program/Erase)

TO (Time Out): time out for read/program/copy back program/erase

0=no time out(fixed)

Load : this bit shows the Load operation status

0=ready(default), 1=busy or error case, refer to the table 3

Prog (Program Busy) : this bit shows the Program operation status

0=ready(default), 1=busy or error case, refer to the table 3

Erase (Erase Busy) : this bit shows the Erase operation status

0=ready(default), 1=busy or error case, refer to the table 3

RSTB (Reset Busy) : this bit shows the Reset operation status

0=ready(default), 1=busy or error case, refer to the table 3

27

Page 28

OneNAND128 FLASH MEMORY

Table 3. Controller Status Register output for modes.

Mode

OnGo Lock Load Prog Erase Error Sus Reserved(0) RSTB OTPL Reserved(0) TO

Load Ongoing 1 0 1 0 0 0 0 0 0 0/1 00000 0

Program Ongoing 1 0 0 1 0 0 0 0 0 0/1 00000 0

Erase Ongoing 1 0 0 0 1 0 0 0 0 0/1 00000 0

Reset Ongoing 1 0 0 0 0 0 0 0 1 0/1 00000 0

Multi-Block Erase

Ongoing

Erase Verify Read

Ongoing

1 0 0 0 1 0 0 0 0 0/1 00000 0

1 0 0 0 0 0 0 0 0 0/1 00000 0

Load OK 0 0 0 0 0 0 0 0 0 0/1 00000 0

Program OK 0 0 0 0 0 0 0 0 0 0/1 00000 0

Erase OK 0 0 0 0 0 0 0 0 0 0/1 00000 0

Erase Verify Read

3)

OK

Load Fail

1)

0 0 0 0 0 0 0 0 0 0/1 00000 0

0 0 1 0 0 1 0 0 0 0/1 00000 0

Program Fail 0 0 0 1 0 1 0 0 0 0/1 00000 0

Erase Fail 0 0 0 0 1 1 0 0 0 0/1 00000 0

Erase Verify Read

3)

Fail

Load Reset

2)

0 0 0 0 1 1 0 0 0 0/1 00000 0

0 0 1 0 0 1 0 0 1 0/1 00000 0

Program Reset 0 0 0 1 0 1 0 0 1 0/1 00000 0

Erase Reset 0 0 0 0 1 1 0 0 1 0/1 00000 0

Erase Suspend 0 0 0 0 1 0 1 0 0 0/1 00000 0

Program Lock 0 1 0 1 0 1 0 0 0 0/1 00000 0

Erase Lock 0 1 0 0 1 1 0 0 0 0/1 00000 0

Load Lock(Buffer Lock) 0 1 1 0 0 1 0 0 0 0/1 00000 0

OTP Program

Fail(Lock)

0 1 0 1 0 1 0 0 0 1 00000 0

OTP Program Fail 0 0 0 1 0 1 0 0 0 0 00000 0

OTP Erase Fail 0 1 0 0 1 1 0 0 0 0/1 00000 0

Program Ongo-

ing(Susp.)

1 0 0 1 1 0 1 0 0 0/1 00000 0

Load Ongoing(Susp.) 1 0 1 0 1 0 1 0 0 0/1 00000 0

Program Fail(Susp.) 0 0 0 1 1 1 1 0 0 0/1 00000 0

Load Fail(Susp.) 0 0 1 0 1 1 1 0 0 0/1 00000 0

Invalid Command 0 0 0 0 0 1 0 0 0 0/1 00000 0

Invalid Command(Susp.)

NOTE:

1. ERm and/or ERs bits in ECC status register at Load Fail case is 10. (2bits error - uncorrectable)

2. ERm and ERs bits in ECC status register at Load Reset case are 00. (No error)

3. Multi Block Erase status should be checked by Erase Verify Read operation.

4. OTP Erase does not update the register and the previous value is kept.

0 0 0 0 1 1 1 0 0 0/1 00000 0

Controller Status Register [15:0]

28

Page 29

OneNAND128 FLASH MEMORY

7.23 Interrupt Status Register (R/W): F241h, default=8080h(after Cold reset),8010h(after Warm/Hot reset)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

INT Reserved(0000000) RI WI EI RSTI Reserved(0000)

Bit

Address

15 INT(interrupt): the master interrupt bit 1 1 0 Interrupt Off

- Set to ’1’ of itself when one or more of RI, WI, EI and

RSTI is set to ’1’, or Unlock(0023h), Lock(002Ah), Lock tight(002Ch), or Erase Verify Read(0071h), or OTP

access(0065h) operation, or "Load Data into Buffer" is

completed.

- Cleared to ’0’ when by writing ’0’ to this bit or by

reset(Cold/Warm/Hot reset).

’0’ in this bit means that INT pin is low status.

(This INT bit is directly wired to the INT pin on the chip.

INT pin goes low upon writing ’0’ to this bit when

INTpol is high and goes high upon writing ’0’ to this

bit when INTpol is low. )

7 RI(Read Interrupt): 1 0 0 Interrupt Off

- Set to ’1’ of itself at the completion of Load Operation

(0000h, 0013h, or boot is done.)

- Cleared to ’0’ when by writing ’0’ to this bit or by reset

(Cold/Warm/Hot reset).

6 WI(Write Interrupt): 0 0 0 Interrupt Off

- Set to ’1’ of itself at the completion of Program Operation

(0080h, 001Ah, or 001Bh)

- Cleared to ’0’ when by writing ’0’ to this bit or by reset

(Cold/Warm/Hot reset).

5 EI(Erase Interrupt): 0 0 0 Interrupt Off

- Set to ’1’ of itself at the completion of Erase Operation

(0094h, 0095h, or 0030h)

- Cleared to ’0’ when by writing ’0’ to this bit or by reset

(Cold/Warm/Hot reset).

4 RSTI(Reset Interrupt): 0 1 0 Interrupt Off

- Set to ’1’ of itself at the completion of Reset Operation

(00B0h, 00F0h, 00F3h, or warm reset is released.)

- Cleared to ’0’ when by writing ’0’ to this bit.

Bit Name Default State Valid

Cold Warm/Hot

States

0->1 Interrupt Pending

0->1 Interrupt Pending

0->1 Interrupt Pending

0->1 Interrupt Pending

0->1 Interrupt Pending

Function

7.24 Start Block Address (R/W): F24Ch, default=0000h

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Reserved(00000000) SBA

SBA (Lock/Unlock/Lock-tight Start Block Address): Start NAND Flash block address in Write Protection mode, which follows ’Lock block command’ or

’Unlock block command’ or ’Lock-tight command’.

7.25 End Block Address (R/W): F24Dh, default=0000h

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Reserved(00000000) EBA

EBA (Lock/Unlock/Lock-tight End Block Address): End NAND Flash block address in Write Protection mode, which follows ’Lock block command’ or

’Unlock block command’ or ’Lock-tight command’. EBA should be equal to or larger than SBA.

Device Number of Block SBA/EBA

128Mb 256 [7:0]

29

Page 30

OneNAND128 FLASH MEMORY

7.26 NAND Flash Write Protection Status (R): F24Eh, default=0002h

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Reserved(0000000000000) US LS LTS

US (Unlocked Status): ’1’ value of this bit specifies that the current block in NAND Flash is unlocked.

LS (Locked Status): ’1’ value of this bit specifies that the current block in NAND Flash is in locked status.

LTS (Lock-tighten Status): ’1’ value of this bit specifies that current block in NAND Flash is lock-tighten.

7.27 ECC Status Register(R): FF00h, default=0000h

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Reserved(00000000) ERm1 ERs1 ERm0 ERs0

ERm (ECC Error for Main area data) & ERs (ECC Error for Spare area data)

: ERm0/1 is for first/second selected sector in main of BufferRAM, ERs0/1 is for first/second selected sector in spare of

BufferRAM.

ERm and ERs show the number of error nits in a sector as a result of ECC check at the load operation.

ERm, ERs ECC Status

00 No Error

01 1-bit error(correctable)

10

11 R eserve d

NOTE:

1. 3bits or more error detection is not supported.

2-bit error(uncorrectable)

7.28 ECC Result of first selected Sector Main area data Register (R): FF01h, default=0000h

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Reserved(0000) ECCposWord0 ECCposIO0

1)

7.29 ECC Result of first selected Sector Spare area data Register (R): FF02h, default=0000h

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Reserved(0000000000) ECClogSector0 ECCposIO0

7.30 ECC Result of second selected Sector Main area data Register (R): FF03h, default=0000h

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Reserved(0000) ECCposWord1 ECCposIO1

7.31 ECC Result of second selected Sector Spare area data Register (R): FF04h, default=0000h

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Reserved(0000000000) ECClogSector1 ECCposIO1

NOTE:

1. ECCposWord: ECC error position address that selects one of Main area data(256words)

2. ECCposIO: ECC error position address which selects one of sixteen DQs (DQ 0~DQ 15).

3. ECClogSector: ECC error position address that selects one of the 2nd word and LSB of the 3rd word of spare area. Refer to the below table.

ECClogSector Information [5:4]

ECClogSector Error Position

00 2nd word

01 3rd word

10, 11 Reserved

4. ECCposWord, ECCposIO and ECClogSector are updated in boot loading operation, too.

30

Page 31

OneNAND128 FLASH MEMORY

8. Device Operation

The device supports both a limited command based and a register based interface for performing operations on the device, reading

device ID, writing data to buffer etc. The command based interface is active in the boot partition, i.e. commands can only be written

with a boot area address. Boot area data is only returned if no command has been issued prior to the read.

8.1 Command based operation

The entire address range, except for the boot area, can be used for the data buffer. All commands are written to the boot partition. Writes outside the

boot partition are treated as normal writes to the buffers or registers. The command consists of one or more cycles depending on the command. After

completion of the command the device starts its execution. Writing incorrect information which include address and data or writing an improper command

will terminate the previous command sequence and make the device go to the ready status. The defined valid command sequences are stated in Table4.

Table 4. Command Sequences

Command Definition Cycles 1st cycle 2nd cycle

Read Data from Buffer

Write Data to Buffer

Reset OneNAND

Load Data into Buffer

Read Identification Data

NOTE:

1) DP(Data Partition) : DataRAM Area

2) BP(Boot Partition) : BootRAM Area [0000h ~ 01FFh, 8000h ~ 800Fh].

3) Load Data into Buffer operation is available within a block(64KB)

4) Load 1KB unit into DataRAM0. Current Start address(FPA) is automatically incremented by 1KB unit after the load.

5) 0000h -> Data is Manufacturer ID

0001h -> Data is Device ID

0002h -> Current Block Write Protection Status

toggling can terminate ’Read Identification Data’ operation.

6) WE

3)

6)

Add

Data Data

Add

Data Data

Add

Data 00F0h

Add

Data 00E0h

Add

Data 0090h Data

1

1

1

2

2

1)

DP

DP

2)

BP

BP BP

0000h

BP

XXXXh

4)

5)

8.1.1 Read Data from Buffer

Buffer can be read by addressing a read to a wanted buffer area

8.1.2 Write Data to Buffer

Buffer can be written by addressing a write to a wanted buffer area

8.1.3 Reset OneNAND

Reset command is given by writing 00F0h to the boot partition address. Reset will return all default values into the device.

8.1.4 Load Data into Buffer

Load Data into Buffer command is a two-cycle command. Two sequential designated command activates this operation. Sequentially writing 00E0h

and 0000h to the boot partition [0000h~01FFh, 8000h~800Fh] will load one page to DataRAM0. This operation refers to FBA and FPA. FSA, BSA, and

BSC are not considered.

At the end of this operation, FPA will be automatically increased by 1. So continuous issue of this command will sequentially load data in next page to

DataRAM0. This page address increment is restricted within a block.

The default value of FBA and FPA is 0. Therefore, initial issue of this command after power on will load the first page of memory, which is usually boot

code.

8.1.5 Read Identification Data

Read Identification Data command consists of two cycles. It gives out the devices identification data according to the given address. The first cycle is

0090h to the boot partition address and second cycle is read from the addresses specified in Table5.

31

Page 32

OneNAND128 FLASH MEMORY

Table 5. Identification data description

Address Data Out

0000h Manufacturer ID 00ECh

0001h Device ID refer to table 1

0002h Current Block Write Protection Status

8.2 Device Bus Operations

Operation CE OE WE ADD0~15 DQ0~15 RP CLK AV D

Standby H X X X High-Z H X X

Warm Reset XXXXHigh-ZL XX

Asynchronous Write L H L Add. In Data In H L

Asynchronous Read L L H Add. In Data Out H L

Load Initial Burst Address L H H Add. In X H

refer to NAND Flash Write Protection Status Register

Burst Read L L H X

Terminate Burst Read

Cycle

Terminate Burst Read

Cycle via RP

Terminate Current Burst

Read Cycle and Start

New Burst Read Cycle

Note : L=VIL (Low), H=VIH (High), X=Don’t Care.

HXHXHigh-ZHXX

XXXXHigh-ZLXX

Burst Data

Out

H H Add In High-Z H

H

X

32

Page 33

OneNAND128 FLASH MEMORY

8.3 Reset Mode

Cold Reset

At system power-up, the voltage detector in the device detects the rising edge of Vcc and releases internal power-up reset signal

which triggers bootcode loading. Bootcode loading means that the boot loader in the device copies designated sized data(1KB) from

the beginning of memory to the BootRAM.

POR triggering level

System Power

OneNAND

Operation

1)

Sleep Bootcode copy Idle

Bootcode - copy done

2)

RP

INT

INT bit

IOBE bit

INTpol bit

Note: 1) Bootcode copy operation starts 400us later than POR activation.

The system power should reach 1.7V after POR triggering level(typ. 1.5V) within 400us for valid boot code data.

2) 1K bytes Bootcode copy takes 70us(estimated) from sector0 and sector1/page0/block0 of NAND Flash array to BootRAM.

Host can read Bootcode in BootRAM(1K bytes) after Bootcode copy completion.

3) INT register goes ‘Low’ to ‘High’ on the condition of ‘Bootcode-copy done’ and RP

If RP

goes ‘Low’ to ‘High’ before ‘Bootcode-copy done’, INT register goes to ‘Low’ to ‘High’ as soon as ‘Bootcode-copy done’

High-Z

0 (default)

0 (default)

1 (default)

rising edge.

3)

1

1

Figure 5. Cold Reset Timings

33

Page 34

OneNAND128 FLASH MEMORY

Warm Reset

Warm reset means that the host resets the device by RP pin, and then the device stops all logic current operation and executes internal reset operation(Note 1) synchronized with the falling edge of RP

the rising edge of RP

reset operation in case RP

contents of memory cells being altered are no longer valid as the data will be partially programmed or erased. Warm reset has no

effect on contents of BootRAM and DataRAM.

CE, OE

. The device logic will not be reset in case RP pulses shorter than 200ns, but the device guarantees the logic

pulse is longer than 200ns. NAND Flash core reset will abort current NAND Flash Core operation. The

RP

and resets current NAND Flash core operation synchronized with

MuxOneNAND

Operation

INT

RDY

initiated by RP

Operation or Idle

High-Z High-Z High-Z

internal reset operation

low

NAND Flash core reset

initiated by RP

high

Idle

Operation

Figure 6. Warm Reset Timings

Operation or Idle

34

Page 35

OneNAND128 FLASH MEMORY

Hot Reset

Hot reset means that the host resets the device by reset command(Note 2), and then the device logic stops all current operation and

executes internal reset operation(Note 1) , and resets current NAND Flash core operation. Hot reset has no effect on contents of

BootRAM and DataRAM.

AVD

A0~A15

DQ0~DQ15

BP(Note 3)

or F220h

00F0h

or 00F3h

CE

WE

INT

RDY

OneNAND

Operation

High-Z

Operation or Idle OneNAND reset

Idle

Figure 7. Hot Reset Timings

NOTE:

1. Internal reset operation means that the device initializes internal registers and makes output signals go to default status and bufferRAM data are kept

unchanged after Warm/Hot reset operations.

2. Reset command : Command based reset or Register based reset

3. BP(Boot Partition) : BootRAM area[0000h~01FFh, 8000h~800Fh]

35

Page 36

OneNAND128 FLASH MEMORY

NAND Flash Core Reset

Host can reset NAND Flash Core operation by NAND Flash Core reset command. NAND Flash Core Reset will abort the current

NAND Flash core operation. During a NAND Flash Core Reset, the content of memory cellls being altered is no longer valid as the

data will be partially programmed or erased. NAND Flash Core Reset has an effect on neither contents of BootRAM and DataRAM

nor register values.

AVD

A0~A15

DQ0~DQ15

CE

WE

INT

RDY

OneNAND

Operation

F220h

00F0h

High-Z

Operation or Idle NAND Flash Core reset

Figure 8. NAND Flash Core Reset Timings

Idle

36

Page 37

OneNAND128 FLASH MEMORY

Table 6. Internal Register reset

Hot

Reset

(00F3h)

Internal Registers Default Cold Reset

Warm Reset

(RP

)

F000h Manufacturer ID Register (R) 00ECh N/A N/A N/A N/A

F001h Device ID Register (R) Note3 N/A N/A N/A N/A

F002h Version ID Register (rR) - N/A N/A N/A N/A

F003h Data Buffer size Register (R) 0400h N/A N/A N/A N/A

F004h Boot Buffer size Register (R) 0200h N/A N/A N/A N/A

F005h Amount of Buffers Register (R) 0201h N/A N/A N/A N/A

F006h Technology Register (R) 0000h N/A N/A N/A N/A

F100h Start Address1 Register (R/W): FBA 0000h 0000h 0000h 0000h N/A

F101h Start Address2 Register (R/W): Reserved 0000h 0000h 0000h 0000h N/A

F102h Start Address3 Register (R/W): FCBA 0000h 0000h 0000h 0000h N/A

F103h Start Address4 Register (R/W): FCPA, FCSA 0000h 0000h 0000h 0000h N/A

F107h Start Address8 Register (R/W): FPA, FSA 0000h 0000h 0000h 0000h N/A

F200h Start Buffer Register (R/W): BSA, BSC 0000h 0000h 0000h 0000h N/A

F220h Command Register (R/W) 0000h 0000h 0000h 0000h N/A

F221h System Configuration 1 Register (R/W) 40C0h 40C0h O

(Note1) O (Note1) N/A

F240h Controller Status Register (R) 0000h 0000h 0000h 0000h N/A

F241h Interrupt Status Register (R/W) - 8080h 8010h 8010h N/A

F24Ch Lock/Unlock Start Block Address (R/W) 0000h 0000h 0000h N/A N/A

F24Dh Lock/Unlock End Block Address (R/W) 0000h 0000h 0000h N/A N/A

F24Eh NAND Flash Write Protection Status (R) 0002h 0002h 0002h N/A N/A

FF00h ECC Status Register (R) (Note2) 0000h 0000h 0000h 0000h N/A

FF01h

FF02h

FF03h

FF04h

ECC Result of Sector 0 Main area data Register(R)

ECC Result of Sector 0 Spare area data Register (R)

ECC Result of Sector 1 Main area data Register(R)

ECC Result of Sector 1 Spare area data Register (R)

0000h 0000h 0000h 0000h N/A

0000h 0000h 0000h 0000h N/A

0000h 0000h 0000h 0000h N/A

0000h 0000h 0000h 0000h N/A

Hot

Reset

(BP-F0)

NAND Flash

Reset(00F0h)

NOTE: 1) RDYpol, INTpol, and IOBE are reset by Cold reset. The other bits are reset by Cold/Warm/Hot reset.

OTP

2) ECC Status Register & ECC Result Registers are reset when any command is issued.

3) Refer to table 1

L is not reset but updated by Cold reset.

37

Page 38

OneNAND128 FLASH MEMORY

Write Protection

Write Protection for BootRAM

At system power-up, the voltage detector in the device detects the rising edge of Vcc and releases the internal power-up reset signal

which triggers bootcode loading. And the designated size data(1KB) is copied from the beginning of the memory to the BootRAM.

After the bootcode loading is completed, the BootRAM is always locked to protect the significant boot code from accidental write.

Write Protection for NAND Flash array

Write Protection Modes

The device offers both hardware and software write protection features for NAND Flash array. The software write protection feature is

used by writing Lock command or Lock-tight command to command register; The 002Ah or 002Ch command is written into F220h

register. The partial write protection feature is also permitted by writing Partial Lock(002Ah) and Partial Lock-Tight(002Ch) command

with the start address and the end address to F24Ch and F24Dh registers. The hardware write protection feature is used by executing

cold or warm reset. The default state is locked, and all NAND Flash array goes to locked state after cold or warm reset.

Write Protection Commands

Individual or consecutive instant secured block protects code and data by allowing any block to be locked or lock-tighten. The write

protection scheme offers two levels of protection. The first allows software-only control of write protection(useful for frequently

changed data blocks), while the second requires hardware interaction before locking can be changed(protects infrequently changed

code blocks).

The following summarize the locking functionality.

> All blocks power-up in a locked state. Unlock command can unlock these blocks with the start and end block address.

> Partial Lock-Tight command makes the part of locked block(s) to be lock-tightened by writing the start and end block address. And

lock-tightened state can be returned to lock state only when cold or warm reset is asserted.

> Only one individual area can be lock-tightened by Partial Lock-tight command; i.e lock-tightening multi area is not available.

> Lock-tightened blocks offer the user an additional level of write protection beyond that of a regular locked block. Lock-tightened

block can’t have it’s state changed by software, it can be changed by warm reset or cold reset.

> Unlock start or end block address is reflected immediately to the device only when Unlock command is issued, and NAND Flash

write protection status register is also updated at that time.

> Unlocked blocks can be programmed or erased.

> Only one area can be released from lock state to unlock state with Unlock command and addresses. This unlocked area can be

changed with new Unlock command; when new Unlock command is issued, last unlocked area is locked again and new area is

unlocked.

> Partial Lock command makes the part of unlocked block(s) to be locked with the start and end block address.

> Only one area can be locked with Partial Lock command and address. This locked area can be changed with new Partial Lock command; when new Partial Lock command is issued, last unlocked area is locked again and new area is unlocked.

Write Protection Status

The block current Write Protection status can be read in NAND Flash Write Protection Status Register(F24Eh). There are three bits US, LS, LTS -, which are not cleared by hot reset. These Write Protection status registers are updated when Write Protection command is entered.

The followings summarize locking status.

example)

In default, [2:0] values are 010.

-> If host executes unlock block operation, then [2:0] values turn to 100.

-> If host executes lock-tight block operation, then [2:0] values turn to 001.

38

Page 39

OneNAND128 FLASH MEMORY

Locked

> Command Sequence :

Start block address+End block address+Lock block command

(002Ah)

> All blocks default to be locked after Cold reset or Warm reset

> Unlocked blocks can be locked by using the Lock block

command and a lock block’s status can be changed to

unlock or lock-tight using the appropriate software commands

Unlocked

> Command Sequence :

Start block address+End block address+Unlock block command

(0023h)

> Unlocked block can be programmed or erased

> An unlocked block’s status can be changed to the locked or

lock-tighten state using the appropriate software command

> Only one sequential area can be released to unlock state from

lock state ; Unlocking multi individual area is not available

Lock-tighten

> Command Sequence :

Start block address+End block address+Lock-tight block command

(002Ch)

> Lock-tighten blocks offer the user an additional level of write

:

protection beyond that of a regular lock block. A block that

is lock-tighten cannot have its state change by software,

only by Cold or Warm reset.

> Only locked blocks can be lock-tighten by Lock-tight command.

> Lock-tighten blocks revert to the locked state at Cold or Warm

reset

> Lock-tighten area does not change with any command;

when new unlock command is issued including the lock-tighten

area, new unlocked command is ignored.

Figure 9. Operations of NAND Flash Write Protection

39

Page 40

OneNAND128 FLASH MEMORY

Lock

SBA, EBA

+Partial Lock

Command

+Partial Lock-tight

Unlock

Lock

SBA, EBA

Command

Lock

Unlock

Lock

SBA, EBA

+Unlock

Command

SBA, EBA

+Unlock

Command

Lock

Lock-tight

Lock

SBA, EBA

+Partial Lock-tight

Command

Lock-tight

Lock

SBA, EBA

+Partial Lock-tight

Command

Sustained

with last

SBA, EBA

Note ; The below cases are prohibited in write protection modes.

Even though these cases happen, Error bit of Controller Status Register(F240h)is not updated.

Lock

Unlock

Changed

with new

SBA, EBA

SBA, EBA

+Partial Lock

Command

Power On

Lock-tight

Lock

Unlock

Lock

Unlock

Changed

with new

SBA, EBA

Case1. Unlock

Lock-tight

Lock

SBA

EBA

Case2. Lock

Lock-tight

Unlock

SBA

EBA

Case3. Lock-tight

Lock

Unlock

SBA

EBA

If this case happens, the command is ignored and last status is sustained.

If this case happens, the command is ignored and last status is sustained.

If this case happens, the selected area changes to be lock-tight.

Figure 10. State diagram of NAND Flash Write Protection

40

Page 41

OneNAND128 FLASH MEMORY

Load Operation

The load operation is initiated by setting up the start address from which the data is to be loaded. The load command is issued in

order to initiate the load. The device transfers the data from NAND Flash array into the BufferRAM. The ECC is checked and any

detected and corrected error is reported in the status response as well as any unrecoverable error. When the BufferRAM has been

filled an interrupt is issued to the host in order to read the contents of the BufferRAM. The read from the BufferRAM consist of asynchronous read mode or synchronous read mode. The status information related to the BufferRAM fill operation can be checked by

the host if required.

The device provides dual data buffer memory architecture. The device is capable of data-read operation from one data buffer and

data-load operation to the other data buffer simultaneously. Refer to the information for more details in "Read while Load operation".

Start

Write ’FBA’ of Flash

Add: F100h DQ=FBA

Write ’FPA, FSA’ of Flash

Add: F107h DQ=FPA, FSA

Write ’BSA, BSC’ of DataRAM

Add: F200h DQ=BSA, BSC

Write 0 to interrupt register

Add: F241h DQ=0000h

Write ’Load’ Command

Add: F220h

DQ=0000h or 0013h

Wait for INT register

low to high transition

Add: F241h DQ[15]=INT

Read Controller

Status Register

Add: F240h DQ[10]=Error

DQ[10]=0?

YES

Host reads data from

DataRAM

Read completed

NO

Map Out

Figure 11. Load operation flow-chart

41

Page 42

OneNAND128 FLASH MEMORY

Read Operation

The device has two read configurations ; Asynchronous read and Synchronous burst read.

The initial state machine makes the device to be automatically entered into asynchronous read mode to prevent the memory content

from spurious altering upon device power up or after a hardware reset. No commands are required to retrieve data in asynchronous

mode. The synchronous mode will be enabled by setting RM bit of System configuration1 register to Synchronous read mode.

Asynchronous Read Mode (RM = 0)

For the asynchronous read mode a valid address should be asserted on A0-A15, while driving AVD and CE to VIL. WE should

remain at V

put data. The chip enable access time(t

access time(t

Synchronous (Burst) Read Mode (RM = 1)

The device is capable of continuous linear burst operation and linear burst operation of a preset length. For the burst mode, the initial

word(t

of System configuration 1 register for the subsequent words of each burst access. The registers also can be read during burst read

mode by using AVD

needed after the host has completed status reads or the device has completed the program or erase operation.

Continuous Linear Burst Read

The initial word(tIAA) is output asynchronously regardless of BRL bit in System Configuration 1 register. Subsequent words are output

t

BA after the rising edge of each successive clock cycle, which automatically increments the internal address counter. The RDY output

indicates this condition to the system by pulsing low. The device will continue to output sequential burst data, wrapping around after it

reaches the designated location(See Figure 12 for address map information) until the system asserts CE

conjunction with a new address. The cold/warm/hot reset or asserting CE

IH . The data will appear on DQ15-DQ0. Address access time (tAA) is equal to the delay from valid addresses to valid out-

CE) is the delay from the falling edge of CE to valid data at the outputs. The output enable

OE) is the delay from the falling edge of OE to valid data at the output.

IAA) is output asynchronously regardless of BRL bit in System Configuration 1 register. But the host should determine BRL bit

signal with a address. To initiate the synchronous read again, a new address during CE and AVD low toggle is

high, RP low or AVD low in

high or WE low pulse terminate the burst read operation.

If the device is accessed synchronously while it is set to asynchronous read mode, it is possible to read out the first data without problems.

Division Add.map(word order)

BootM(0.5Kw) 0000h~01FFh

BufM 0(0.5Kw) 0200h~03FFh

BufM 1(0.5Kw) 0400h~05FFh Buffer1

Reserved Main 0600h~7FFFh N/A Reg.

BootS(16w) 8000h~800Fh

BufS 0(16w) 8010h~801Fh

BufS 1(16w) 8020h~802Fh Buffer1

Reserved Spare 8030h~8FFFh