Page 1

Order No. PAPTH160301CE

Service Manual

Fully Automatic Washing Machine

NA-F100A2

Product Colour

White (W)

Destination

Thailand

WARNING

The service information is designed for experienced repair technicians only and is not designed for use by the general

public. It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting

to service a product. Products powered by electricity should be serviced or repaired only by experienced professional

technicians. Any attempt to service or repair the product or products dealt within this service information by anyone

else could result in serious injury or death.

IMPORTANT SAFETY NOTICE

There are special components used in this equipment which are important for safety. These parts are marked by

in the Schematic Diagrams, Circuit Board Diagrams, Exploded Views and Replacement Parts List. It is essential that

these critical parts should be replaced with manufacturer’s specifi ed parts to prevent shock, fi re or other hazards. Do

not modify the original design without permission of manufacturer.

© Panasonic Appliances (Thailand) Co., Ltd. 2016.

All rights reserved. Unauthorized copying and

distribution is a violation of law.

Service NA-F100A2.indd 1Service NA-F100A2.indd 1 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 2

CONTENT

1. Attention in the Repair Work Security 3

2. Parts Identifi cation 4

3. Specifi cations 5

4. Technical Information

4.1 Standard Wash Capacity 6

4.2 Standard Water Supply 6

5. Installation

5.1 Check the Location 7

5.2 Attach the bottom cover 7

5.3 Attach the external drain water hose 7

5.4 Connect the water tap adaptor and water supply hose 8

5.5 Connect the power plug and grounding wire 8

5.6 Check the Washing Machine does not wobble 8

5.7 Perform a trial operation 8

6. Operations Panel 9

7. Washing 10

8. Washing Options 11-12

9. Maintenance 13

10. Test Mode 14 - 15

11. Troubleshooting 16

12. Table of Errors

12.1 U-Error indication 17

12.2 H-Error indication 18

13. Wiring Diagram

NA-F100A2 19

14. Disassembly

14.1 Controller Unit 20

14.2 Panel Face B 20

15. Parts exploded view and replacement Parts List

15.1 Parts exploded view : Part A 21

15.2 Replacement Parts List : Part A 22

15.3 Parts exploded view : Part B 23

15.4 Replacement Parts List : Part B 24

15.5 Parts exploded view : Part C 25

15.6 Replacement Parts List : Part C 26

15.7 Parts exploded view : Packing 27

15.8 Replacement Parts List : Packing 28

- 2 -

Service NA-F100A2.indd 2Service NA-F100A2.indd 2 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 3

1. ATTENTION IN THE REPAIR WORK SECURITY

In order to prevent any accident during repair work and ensure security of the product after repair work,

somethings surely followed are explained below.

The level of the arised damages or dangers, when indicated contents are ignored, are classified by

following indications and explained.

WARNING

The content in the column of this indication is

´%HDVVXPHGWKDWSRVVLEO\GLHRUJHWVHULRXVO\LQMXUHGµ

ATTENTION

Types of the contents being followed are classified by following figured symbols and explained.

(The following is an example of expression in pictures)

This figured symbol means caution “ ATTENTION µ

This figured symbol means must not do “ PROHIBITION µ

This figured symbol means surely execute “ INSTRUCTIONS µ

The content in the column of this indication is

´%HDVVXPHGWKDWSRVVLEO\JHWGDPDJHVRUSRVVLEO\RQO\GDPDJHREMHFWRFFXUHGµ

WARNING

Connection of cables should be done according to regular work.

&RQQHFWLRQRIFDEOHVVKRXOGEHWLJKWHQHGUHOLDEO\ZLWKVWUHQJWKXVLQJVROGHUOHVVWHUPLQDO

(specified parts always using regular bonding plier)

,QVWDOODILUHSURWHFWLRQFRYHUILUHSURRIFRYHULQJFRQQHFWLQDUHDFRPSOHWHO\DQGFORVHRSHQLQJ

areas by tape. (Please reuse the fire protection cover which came with the products).

:KHQGUDZLQJFDEOHVDURXQGIL[LQJWKRVHFDEOHVZLWKFDEOHVXSSUHVVLRQSDUW'RQRWWRXFK

rotating part, high temperature part and surface of metal.

%HVXUHWRUHSODFHZLWKFDEOHXQLWZKHQDQ\FDEOHZDVVQDSSHG:KHQDSDUWRIWKHFDEOHXQLW

was cut, you must not do the connection repair. It may be the cause of smoke, ignition or

receiving an electric shock.

Be careful about receiving an electric shock.

:KHQGRLQJHOHFWULFFRQQHFWLRQVHUYLFH

such as voltage measurement, please be

careful enough about receiving an electric

shock at electric charging parts and cable

terminal parts.

Be sure to use specified parts.

Always use specified parts for the parts

with mark in the electric circuit

diagrams and parts list. It may be the

cause of smoke, ignition or damage.

Pull out electric plug when doing repair work.

'LVDVVHPEOLQJDVVHPEOLQJDQGUHSODFLQJ

parts should be done after pulling out

electric plug. Receiving an electric shock

or getting an injury may occur.

Do not touch any rotating object with hand

unless it stops completely.

Slow rotation may also roll in your hands

and cause injury.

Rebuilding is prohibited.

'RQRWUHEXLOGPDFKLQHSDUWVDQG

components when repairing service.

It may be the cause of damage or ignition.

Straightly pull out or insert in huasuton terminal.

'RQRWWZLVWLW,WPD\EHWKHFDXVHRI

damage or ignition.

ATTENTION

Please wear gloves when disassembling, replacing and assembling.

Always wear gloves to prevent an injury by the metal end face or an electric shock at the time of

the electricity service

Please be careful to the edges of the metal end face.

:HDUWKHZRUNLQJFORWKHVRIORQJVOHHYHVWRSUHYHQWDQLQMXU\E\WKHPHWDOHQGIDFHRUSOHDVH

work after covering the end face with tape or towel.

- 3 -

Service NA-F100A2.indd 3Service NA-F100A2.indd 3 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 4

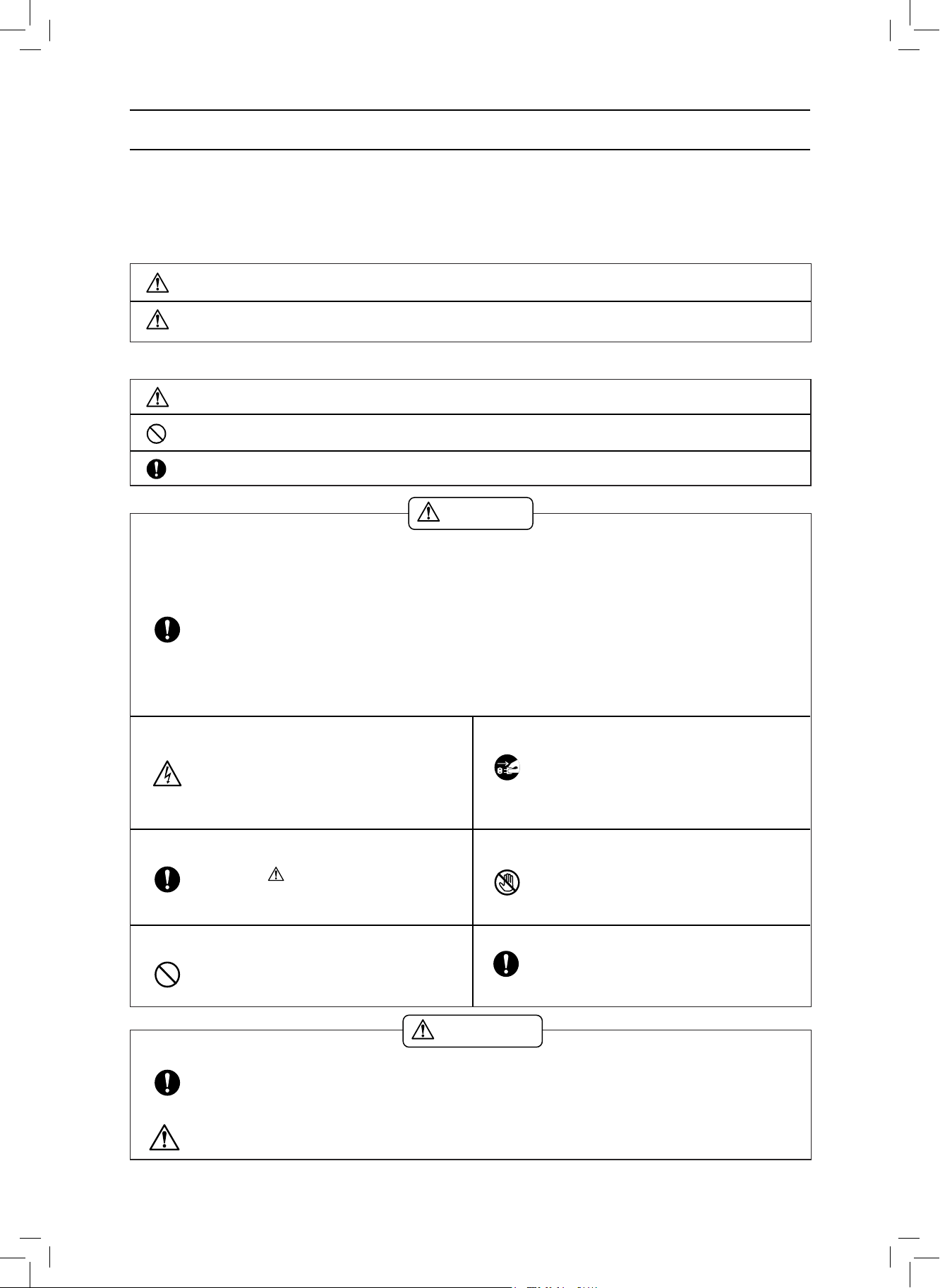

2. PARTS IDENTIFICATION

Lint fi lter

Operation PanelDetergent inlet

Lid

Tub

Pulsator

Adjustable leg

Power cord and plug

Softener

inlet

External drain water hose

Water supply valve

(P. 13)

Accessories

●Water supply hose ●Water tap adaptor ●External drain water

hose

●Bottom cover ●Screw

For the bottom cover

- 4 -

Service NA-F100A2.indd 4Service NA-F100A2.indd 4 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 5

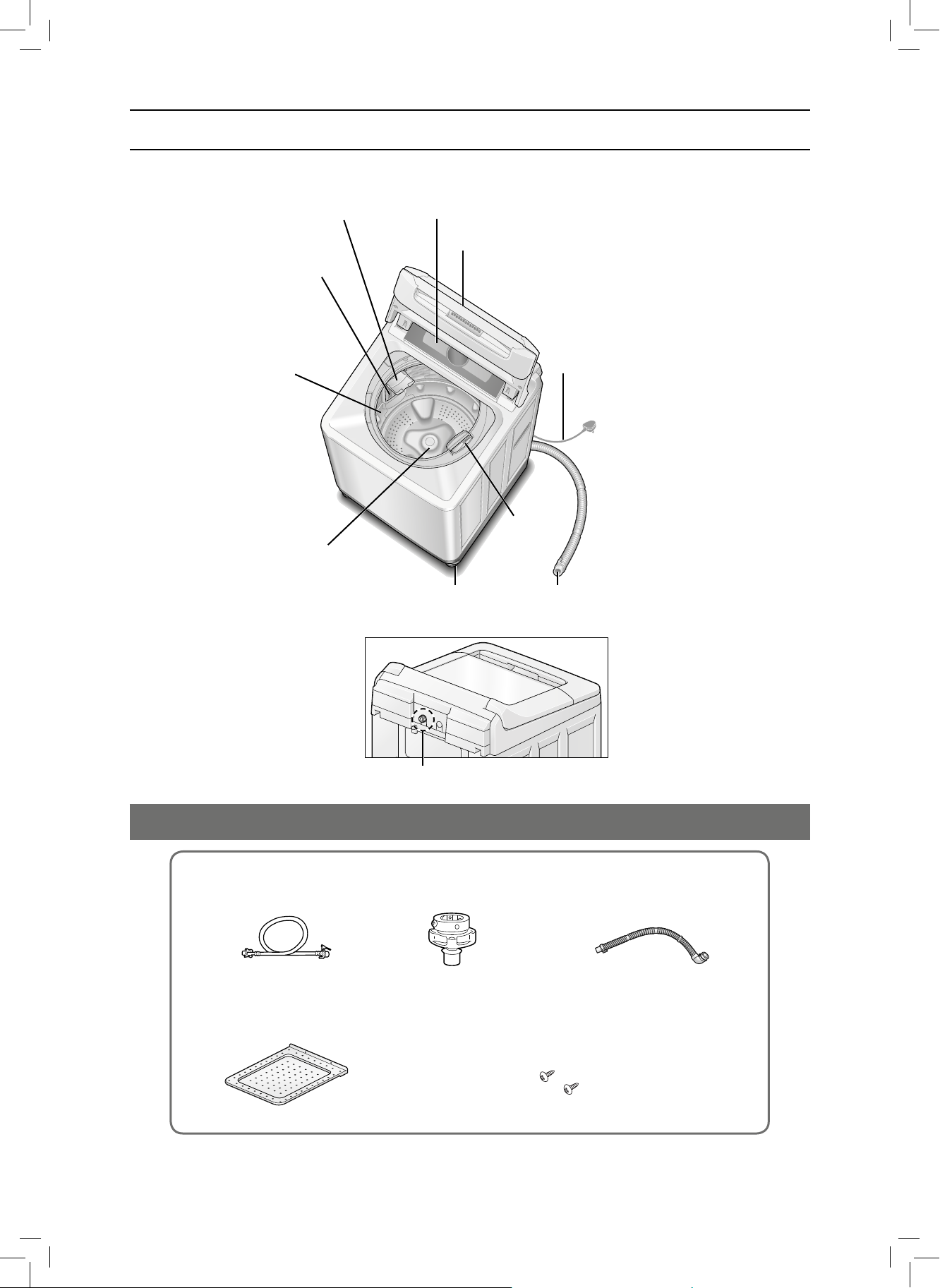

3. SPECIFICATIONS

Model NA-F100A2

Country Thailand

Model Code W9CP

Rate voltage and Frequency 220V / 50Hz

Power Cord Unit C3

Body Colour White

Rate Power Consumption

(Wash / Spin)

Power Consumption 220V/50Hz 120Wh

Standard Capacity Wash 10.0 Kg

Standard Consumption Water 160 Liter

Product Weight Accessories 38 Kg

Outer Dimension (mm.) Body 600 X 652 X 1034

Pulsator with rated load (rpm.) 95 rpm / min

Spin Tub with rated load (rpm.) 700 rpm / min

Water Supply Pressure 0.01 to 1 MPa (0.1 to 10 Kgf / cm

Motor Thermo protector of the single-phase induction motor 135°C

Safety Switch Checking Unbalance

Buzzer Rings when finishing washing or unusual

Detergent Case Dispenser Usable

Fabric Softener Dispenser Usable

Filter Unit Usable

Child Safety Usable

Auto Restart Usable

Auto Power Off Usable

220V/50Hz 400W / 220W

Spin 10.0 Kg

Packing 44 Kg

Package 660 X 720 X 1144

2

) / 1 ~ 18 liter / min.

- 5 -

Service NA-F100A2.indd 5Service NA-F100A2.indd 5 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 6

4. TECHNICAL INFORMATION

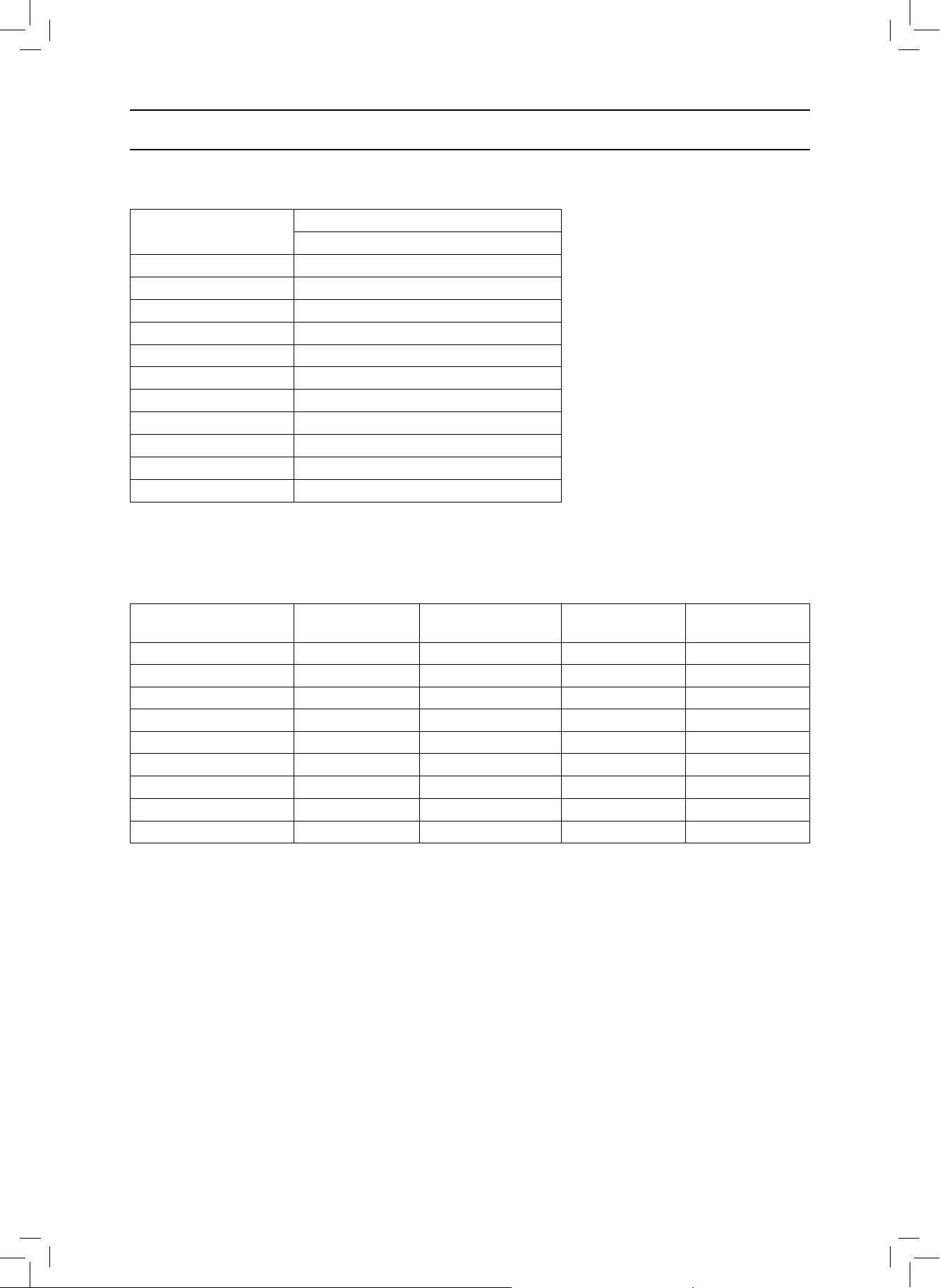

4.1 Standard Wash Capacity

PROGRAM

POWER WASH + SOAK 10.0 kg

STANDARD WASHING 10.0 kg

STANDARD SPIN 10.0 kg

ENERGY SAVE(SPEEDY)

DELICATE 4.2 kg

BABY-CARE 10.0 kg

FRAGRANCE 10.0 kg

BLANKET 4.2 kg

EXTREME WASH 10.0 kg

AIR DRY 2.0 kg

TUB HYGIENE -

Note : - Normal course and Water Save course are recommended for a normally soiled load at the rated

capacity of this washing machine.

MAXIMUM CAPACITY

NA-F100A2

10.0 kg

4.2 Standard Water Supply

PROGRAM

NORMAL 55 min 12 min Refill twice

ENERGY SAVE(SPEEDY)

DELICATE 40 min 9 min Twice

BABY-CARE 65 min 12 min Refill twice

FRAGRANCE 75 min 12 min Twice

BLANKET 65 min 12 min Refill twice

POWER WASH + SOAK 115 min (Soak 60min)+12 min Refill twice

EXTREME WASH 64 min 12 min Refill twice

TUB HYGIENE 145 min (Soak 60min)+12 min Refill twice 7 min

Note : -Total time is approximate (When the standard water supply rate is 15 L / min).

-Total time may increase depending on low water pressure, bad draining conditions, and the amount

and type of clothes.

TOTAL TIME

(APPROX.)

40 min 9 min Refill twice

WASH RINSE SPIN

5 min

5 min

1 min

7 min

5 min

3 min

5 min

5 min

- 6 -

Service NA-F100A2.indd 6Service NA-F100A2.indd 6 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 7

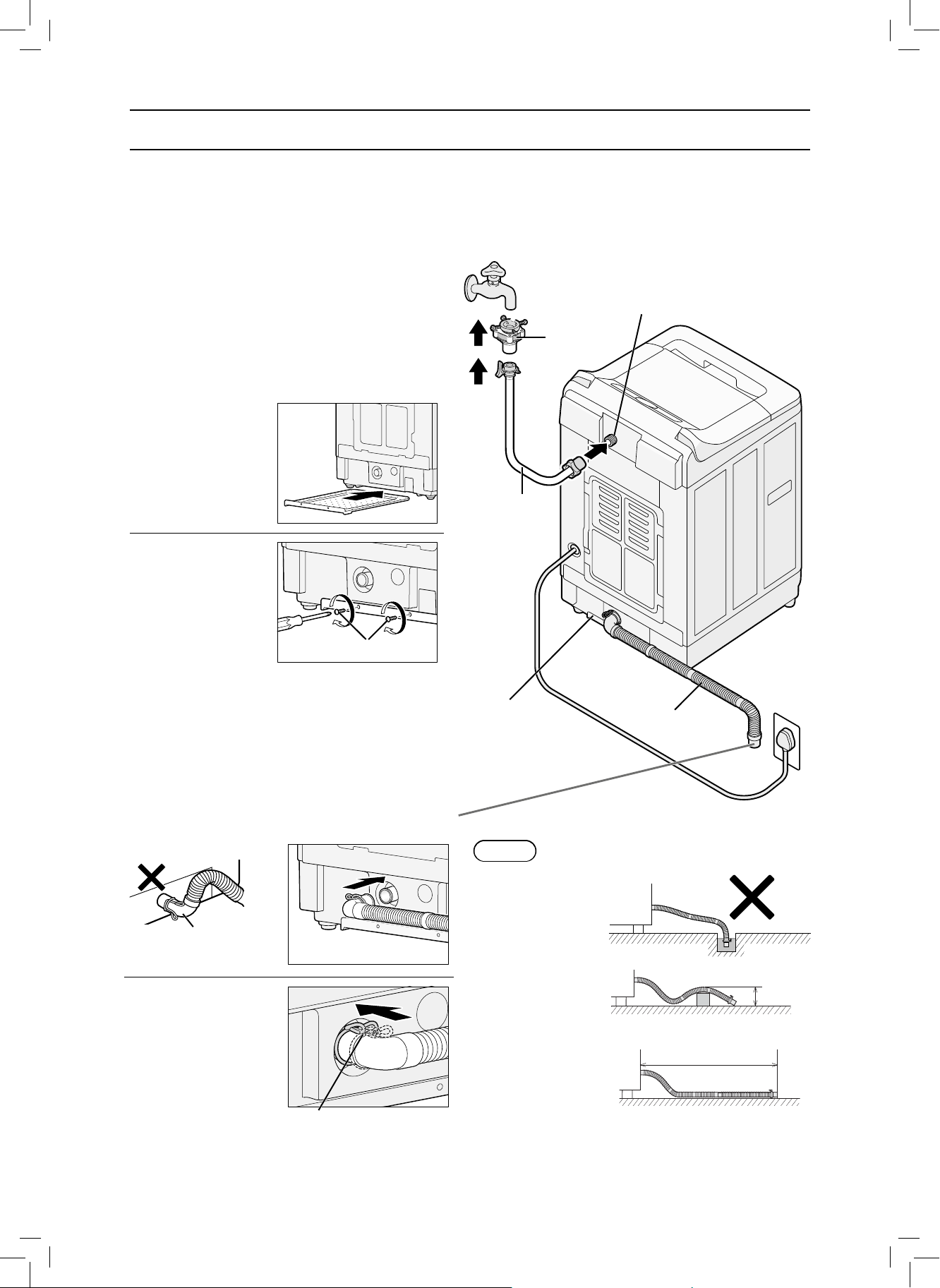

5. INSTALLATION

5.1 Check the location.

■

Avoid the following locations for installation.

Locations with a possibility of freezing

•

Damp locations or locations where it may be

•

exposed to rain, etc.

(To prevent electric shock or fi re)

Locations exposed to direct sunlight

•

(To prevent malfunction or deformation)

Uneven or unstable locations (on blocks,

•

timbers, a table with wheels, etc.)

5.2 Attach the bottom cover.

Insert the bottom

cover along the

guides.

Water supply

valve screw

Water tap

adaptor

Water supply

hose

Fix with 2 screws.

Screw

5.3 Attach the external drain water hose.

Connect.

Elbow

Do not direct the

elbow upward.

Slide the hose band in

the arrow direction.

●Slide all the way until

it stops.

Insert all the way.

Bottom cover

NOTE

●Do not put the

hose tip under

water.

●Do not raise the

hose higher than

10 cm above the

fl oor.

●Do not extend the

overall length to

more than 3 m.

External drain

water hose

10 cm or

less

3 m or less

Hose band

- 7 -

Service NA-F100A2.indd 7Service NA-F100A2.indd 7 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 8

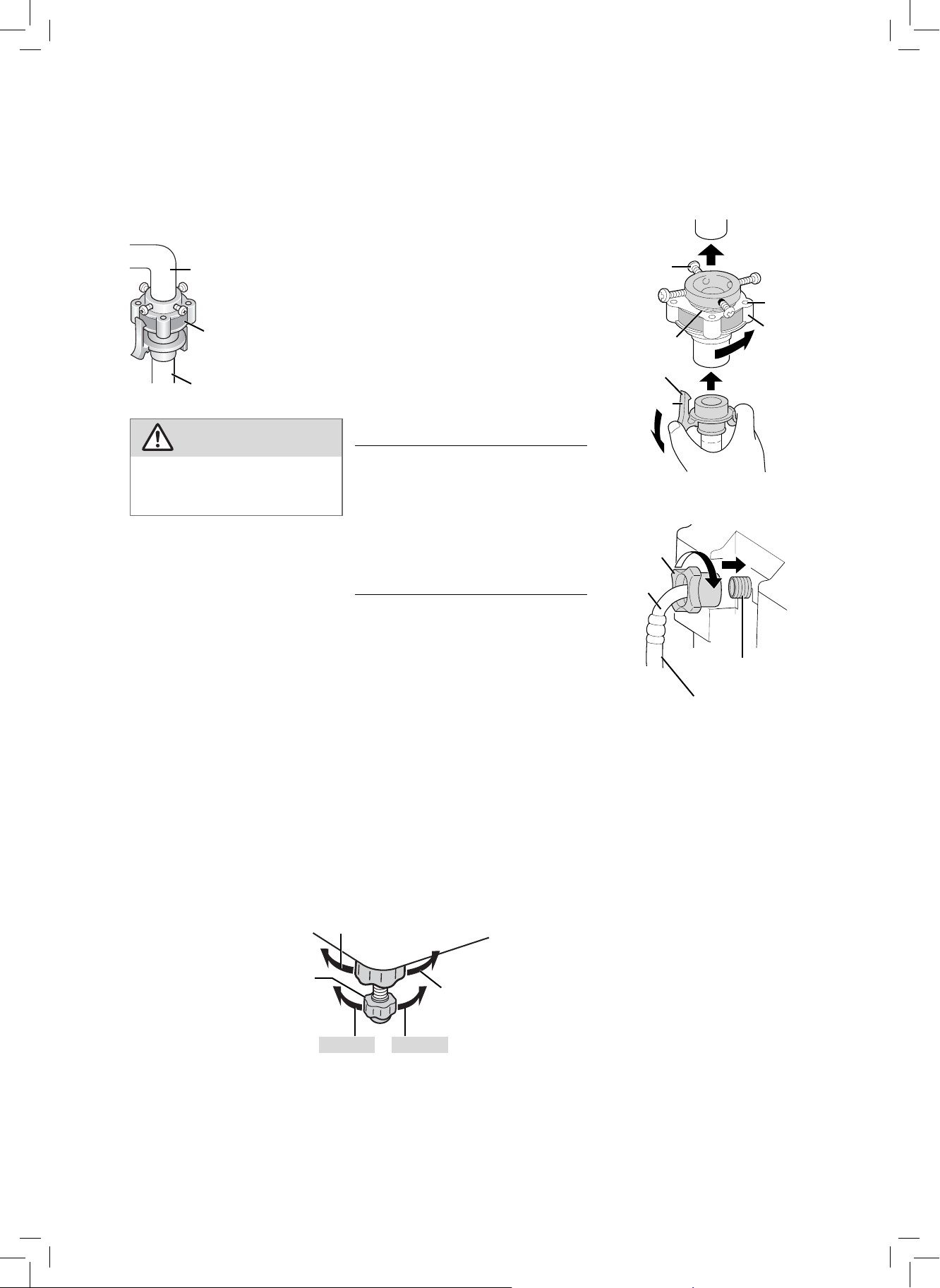

■

Make sure to ask a service person for installation. Do not install by yourself.

■

If the installation, test run and inspection of the washing machine are not carried out following this

installation method, Panasonic will not be liable for any accident or damage caused.

5.4 Connect the water tap adaptor and water supply hose.

Connect the water tap adaptor to

Water faucet

Water tap adaptor

Water supply hose

the water faucet.

Turn part A to the left until approx.

1

4 mm of the thread becomes

visible.

Loosen the 4 screws.

2

Connect to the faucet and tighten

3

the screws.

Turn part A to the right and tighten

4

securely. (To prevent water

leakage)

Screw

Thread

Claw

Lever

CAUTION

●Tighten the nut fi rmly.

●Do not twist, squash, modify

or cut the hose.

Connect the water supply hose to

the water tap adaptor.

Insert the hose into the adaptor while

pushing down the lever, and hook

the claw of the lever on the fl ange of

the adaptor.

Nut

Part A

Flange

Connect the water supply hose to

the water supply valve screw.

Hold the elbow and tighten the nut.

1

Check that the elbow is not loose.

2

5.5 Connect the power plug and grounding wire.

●Ask a service person to do the grounding work.

●In case of a 2-pin power cord, establish a ground.

5.6 Check the washing machine does not wobble.

■

If the washing machine wobbles

Turn the adjustable leg knob to

1

the left to loosen.

Turn the adjustable

2

leg to eliminate

wobble.

Turn to the right to

3

tighten.

Elbow

Water supply

valve screw

Water supply hose

To lowerTo raise

5.7 Perform a trial operation.

●Check that there is no water leakage, abnormal sounds or error display.

- 8 -

Service NA-F100A2.indd 8Service NA-F100A2.indd 8 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 9

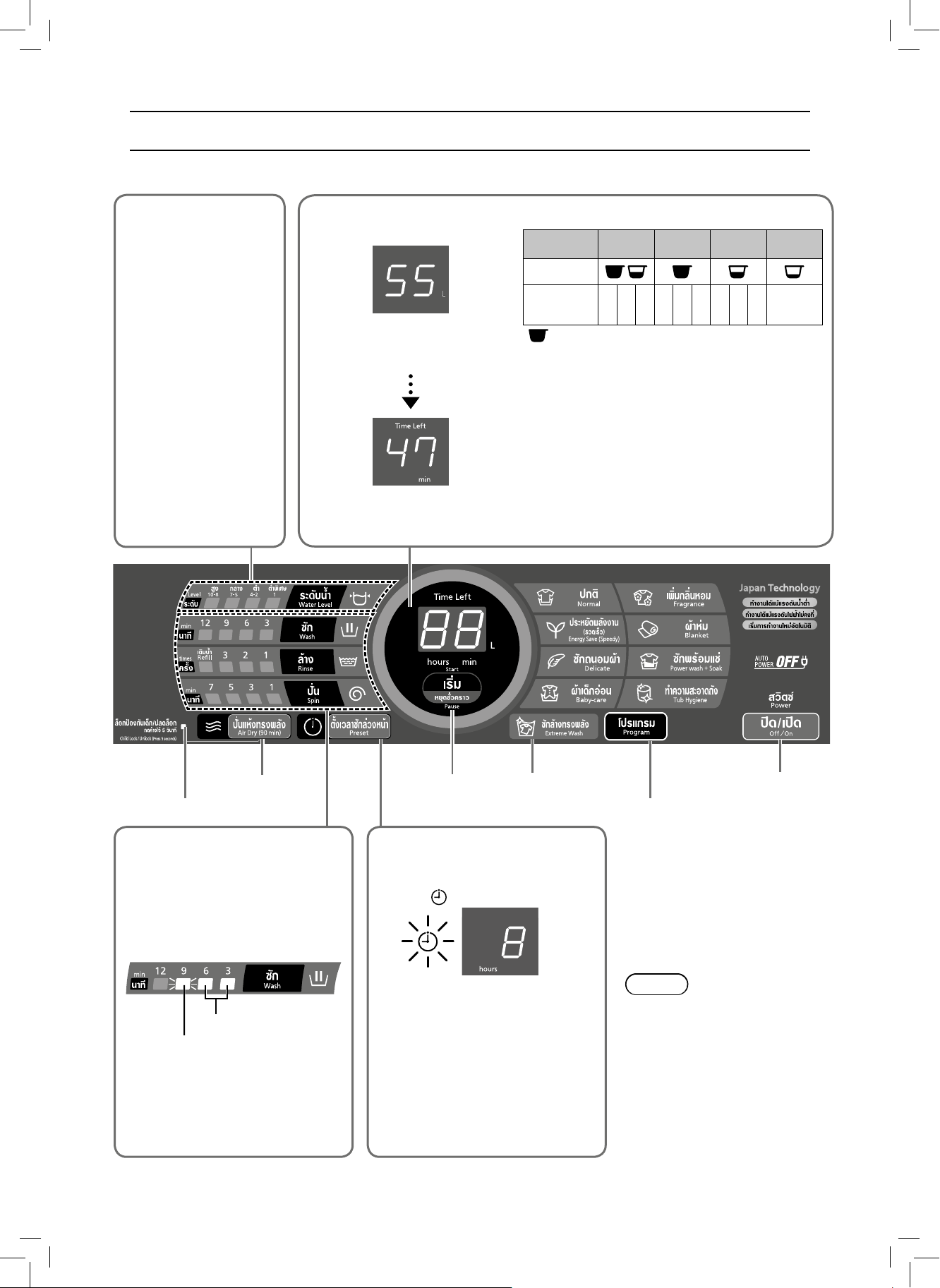

6. OPERATION PANEL

NA-F100A2

Change water

amount

During the wash

process, press “Water

Level” to change the

water amount.

●Some water amounts

cannot be selected

depending on the

program.

●When the remaining

time is displayed,

press “Water Level”

to check the water

amount.

Water amount/

remaining time

After starting operation, indicates

the water amount according to

the amount of laundry.

After approx. 5 seconds, indicates

the approximate remaining time

(min).

Water level/water amounts

Level

Detergent*

Water amount

(L)

* : 1 scoop of detergent

●Each water level, except “Extra Low”, has

three water amount options that can be

switched while the level is lit by pressing

“Water Level”.

High

10-8

72 59 55 51 47 43 38 33 27 14

Mid

7-5

Low

4-2

Extra Low

1

Air Dry (P.12)

Child Lock lamp (P.13)

Change process

settings

Change the combination of wash,

rinse and spin processes, and the

time length or number of times for

individual processes. (P.12)

Lighted

Flashing (in progress)

●After starting operation, you

can change settings only during

wash process by pressing

“Start/Pause”.

Start/Pause

Extreme Wash (P.11)

Preset

Set the time to finish washing (in

hours). (

●Setting range: 2 - 24 hours later,

in one-hour increments. (3 - 24

hours later for the Power wash

+ Soak program)

●Not available for the following

programs:

Delicate, Fragrance, Blanket,

Tub Hygiene, Air Dry

lights.)

e.g.) 8 hours later

- 9 -

Power Off/On

Program selection

NOTE

●In case of a power failure

during operation, operation will

resume from the point where it

was stopped when the power

is recovered (Auto Restart).

●The power turns off

automatically if you do not

press “Start/Pause” within

10 minutes after power-on.

Service NA-F100A2.indd 9Service NA-F100A2.indd 9 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 10

7. WASHING

Preparation:

●Check if the washing machine is properly installed.

●Turn on the water faucet.

1

2

3

4

Timer preset

3

After loading laundry

Turn the power on.

●The Normal program is selected when the

power is turned on.

Select a program.

Press the button repeatedly until

the desired program lights up.

■

Timer preset

Start.

The pulsator moves without

water and measures the amount

of laundry (approx. 5 seconds).

Water amount indication

(approx. 5 seconds)

Remaining time indication

●To check the water amount

Press “Water Level”.

→

After pressing "Start"

■

You can change the water level until the

●

end of the wash process.

You can change each of the "Wash",

●

"Rinse" and "Spin" operation contents until

the end of the wash process. Press "Pause"

beforehand.

You cannot change the program.

●

According to the water amount indication

Put in detergent.

●Approx. 20 seconds after the water amount

is displayed, water supply begins.

2

Set how many hours later to fi nish

operation. (P. 9)

●2 minutes after start-up, all indications except

turn off.

●To confi rm after the timer has been set, press

.

●To cancel or change, press .

●The hours that can be set differ depending on

the program.

1

Fragrance

Use this program to add a particularly large

amount of fabric softener for nice scent and

softness.

When the Fragrance program is

selected

●The buzzer sounds before the final rinse and

operation is paused.

●Put the desired amount of fabric softener which

has been diluted with water directly into the tub.

●Operation will resume if the lid is left closed for

more than 1 hour.

●The Fragrance program cannot be selected when

Child Lock (P. 13) is set.

¥p¥~

}pììm®p

®Ô¡Ó

Close the lid.

5

Operation ends with beeps.

Service NA-F100A2.indd 10Service NA-F100A2.indd 10 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

- 10 -

Page 11

8. WASHING OPTIONS

Air Dry Select “Delicate”/“Blanket”/“Extreme Wash”

Delicate

Use this program to gently wash delicate

clothes and stylish garments.

Load laundry evenly.

●Load items that easily fl oat fi rst,

and press them from above.

●Use laundry nets for delicate

underwear only.

●Amount that can be washed at

one time:

Water Level Capacity

55 L 4.2 k

51 L 3.0 k

47 L 1.0 k

g

g

g

NOTE

●Do not use bleach.

●Use liquid delicate detergent.

●After operation ends, take out clothes immediately.

(To prevent wrinkles and colour staining)

Blanket

■

Washable blankets

Material: 100% synthetic fi bre or 100% cotton

•

Weight: 4.2 kg or less

•

Blankets with a machine-washable tag

•

attached

●Put a blanket in the net and load it in the tub.

Roll

●The zipper part

should face up.

(To prevent

damage to the

net)

Extreme Wash

Use this program to clean clothes thoroughly by

plenty of water in wash and rinse process.

■

Recommended type of clothes

Heavy dirt clothes

•

Thick clothes e.g. Jeans

•

Dark colour

•

Towel

•

Duvet

•

Ring Shower

Good to know

The amount of water in the wash will be used

•

more than normal program 2-3 levels.

The water flow from ring shower lets water

•

penetrate into fabric texture and the clothes stay

under water, resulting in higher dirt removing

effi ciency.

Rinsing twice with the maximum water level is

•

added to thoroughly clean clothes.

For higher rinsing effi ciency

NOTE

●Use liquid detergent.

●The water amount indication shows the maximum

and cannot be changed.

Service NA-F100A2.indd 11Service NA-F100A2.indd 11 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

- 11 -

Page 12

WASHING OPTIONS

Air Dry

Water is removed from clothes by the air blown

from the tub rotation.

■

Clothes that can be dried

Material: Synthetic fi bre

•

Weight: 2.0 kg or less

•

After loading clothes and closing the lid

Turn the power on.

1

Press.

2

Start.

3

After 90 minutes, drying

ends with beeps.

NOTE

●Clothes may not be suffi ciently dried depending on

the amount and type of clothes, the temperature,

and the installation condition of the washing

machine.

●Since no heater is used for this function, you may

feel that clothes are cold and half dry.

Wash / Rinse / Spin

Preparation: Turn on the water faucet.

After loading laundry

Turn the power on.

1

According to your purpose

Change process

2

After closing the lid

settings.

●Change the water amount

as necessary.

Start.

3

Operation ends with

beeps.

Contents of Programs

Program

Normal 55 min 12 min Refi ll twice 5 min

Energy Save (Speedy) 50 min 9 min Refi ll twice 5 min

Delicate 40 min 9 min Twice 1 min

Baby-care 65 min 12 min Refi ll twice 7 min

Extreme Wash 65 min 12 min Twice 5 min

Fragrance 75 min 12 min Twice 5 min

Blanket 65 min 12 min Refi ll twice 3 min

Power wash + Soak 115 min

Tub Hygiene

NOTE

●

Total time is approximate.

(When the standard water supply rate is

15 L / min)

●Total time may increase depending on low water

pressure, bad draining conditions, and the amount

and type of clothes.

Total time

(approx.)

145 min

Wash Rinse

2)

2)

(Soak 60 min) +

(Soak 60 min) +

1) Refi ll:

It fills the tub with water, and rinses

laundry while supplying water.

2) Remaining time of 90 minutes or less

will be displayed.

3) Although the time indication is “12 min”, soaking is

done before that.

- 12 -

12 min

12 min

3)

Refi ll twice 5 min

3)

Refi ll twice 7 min

1)

Spin

Service NA-F100A2.indd 12Service NA-F100A2.indd 12 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 13

9. MAINTENANCE

Cancelling end buzzer

Pressing down,

press.

Then hold on for

3 seconds.

●To reset, do the same procedure.

2 short

beeps

4 short

beeps

Setting Child Lock

To prevent children from falling into the tub and

drowning, if the lid is opened while the washing

machine is operating, this function sounds a buzzer

until it is closed. Not closing it within 10 seconds

fl ushes the water out.

●This function does not lock the lid and button

operations.

●When water is drained forcibly, “U 99” is displayed.

(P.17)

After closing the lid

Turn the power on.

Lint fi lter

After each operation

Lint fi lter

Remove the

fi lter.

Open the fi lter

and remove

lint.

●If lint is diffi cult to

remove, soak and

wash the fi lter in

water.

Press and hold for

5 seconds.

●To cancel, do the same procedure.

2 short

beeps

4 short

beeps

Turning the tub by hand

If it is diffi cult to reach the detergent or softener inlet.

Turn the power on.

When a clicking sound is heard

Turn the tub.

(Clockwise only)

NOTE

●If there is water in the tub or “Start” is pressed, the

tub cannot be turned.

Attach the fi lter in its original

position.

1 2

3 4

NOTE

●Do not wash laundry without the fi lter.

(To prevent damage to clothes)

●Turn the tub by hand if it is diffi cult to remove the

fi lter.

●If the fi lter is broken, purchase a new one at your

local dealer.

Click

- 13 -

Service NA-F100A2.indd 13Service NA-F100A2.indd 13 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 14

10. TEST MODE

Fig-1

Fig-2

-Set the power switch to "off" as Fig-1.

-Press and hold both the "Water level" and "Wash" buttons with one hand.

-Press the power swith to "on".

-Release your fingers from the buttons and power switch which you pressed same as Fig-2.

-Within three seconds press the "Water level" button to set the desire check procedure.

(Check Contents as press button step by step : A,B,C,E M,G and H)

Number of timers

The “Water Level”

button is pressed

0A

1B

2C

Check

Procedure

Check

Contents

●Cycle end buzzer ●When the end buzzer sound

●Timer indicator

●Auto power off

●Washing operation

●Spinning operation

●Lid / SF switch

Lamp illumination

condition

Operation condition

three times, the lamps will fl ash

on and off the remaining time

display and the power will be

switched off immediately after

operation is fi nished.

●If there is no water in the

tub, the operation still wash.

●If the PCB fault occurred,

an error indication “H05” will

display.

●The spinning operation,

Check lid & SF switch

operation.

●“Light up” lid switch working.

●Adjust the water

amount against

amount detection

3E

●Press the “Wash” button to

adjust L0 (initial mode)

L1 (1-rank higher water level).

●Press “Start/Pause” button

to confi rm.

- 14 -

Service NA-F100A2.indd 14Service NA-F100A2.indd 14 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 15

Set to initial mode

for tension of belt

4M

In case to change PCB or

move V-belt. Set the V-belt

tension to initial mode for using

below procedure.

The initial display will be

indicated “b0”, after that press

“Start/Pause” button once, it

shall be listened click sound six

times to set properly.

Indicate the error

message of the last

time

5G

Indicate the

operation times

6H

“Digit lights” shall be indicate

“E” initially, press “Wash” button

to show the last error and press

the wash button again to return

to initial mode.

If any error message occurred

in the past, “H” or “U” some

number shall be indicated

alternately.

If no error message occurred,

the light indicates “00”.

“Digit lights” shall be indicate

“C” initially, press “Wash”

button to change indication

Digit of operation times.

Press once : Digit “Thousand.

Hundred”.

Press twice : Digit “Ten.One”.

- 15 -

Service NA-F100A2.indd 15Service NA-F100A2.indd 15 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 16

11. TROUBLESHOOTING

Symptoms Points to be checked

Time indication increases or

does not decrease

Time

Operation time is longer than

the time indication.

Operation does not stop even

after the preset time.

Main unit

No operation

Cannot change process settings

(after start-up).

No water supply

Water is supplied in the middle

of wash process.

Wash

●Time indication is approximate. Remaining time is corrected

during operation and displayed.

●The operation time may be longer if laundry is concentrated

on one side or the water supply or drainage is not good.

(Error Display "U11", "U14")

●Power failure?

●Is the lid closed completely?

●Has the power fuse blown or the breaker tripped?

●Is the power plug inserted completely?

●Is the water faucet turned on?

●Did you press “Start”?

●Is the timer preset?

●Process settings can be changed during wash process by

pressing “Pause”. To change the program or settings after the

end of wash process, turn the power off and on again.

●Is the water faucet turned on?

●Water outage?

●Is the water supply fi lter clogged with dirt?

●If the water level drops, water is added automatically.

●With a large amount of laundry, water is added several times

automatically.

The water level is too high for

the amount of laundry.

The water level is too low for the

amount of laundry.

Operation started with rinse, but

water is not supplied.

Rinse/Spin

Operation suddenly changes to

rinse process in the middle of

spin.

Only spin is desired, but

operation starts with rinse.

Irregular rotation during spin

Power failure/

The breaker has tripped.

Others

Water outage

Cannot select the Fragrance

program.

●If laundry is wet or there is water in the tub before operation,

the water level may be higher.

●With light clothes (of synthetic fi bre, etc.), the water level may

be lower.

●If there is no water in the tub, water is supplied after spin.

●If there is water in the tub, water is supplied after water

discharge.

●If clothes are concentrated on one side of the tub, the

washing machine automatically corrects unevenness by

starting rinse process.

(Place clothes as evenly as possible.)

●The tub rotation speed is adjusted to reduce foaming during

spin.

●Operation will resume from the point where it was stopped

when the power is recovered (Auto Restart).

●When water supply is recovered, remove the water supply

hose, release turbid water from the faucet, and then start the

washing machine.

●If Child Lock is set, the Fragrance program cannot be

selected.

- 16 -

Service NA-F100A2.indd 16Service NA-F100A2.indd 16 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 17

12. TABLE OF ERRORS

12.1 U-Error indication

● If there is an operation error or if there is a problem with the washing machine, such as faulty draining,

spining etc; operation will stop, the warning buzzer will sound, and an error indication will be displayed.

- All the switchs cannot be operated.

- An error indication will be displayed.

Indication Content Check Point Method to clear

U11

U12

U13

U14

U99

Water can not drain Check at drain water hose, clogged or not?

Check at hose tip under water flow.

Check at drain hose raised higher than 10 cm.

above the floor.

Check total length longer than 3 m.

(including the extension hose).

The lid is open Did you try to run the washing machine with

the lid open?

Spin or Air Dry is

not possible

Water can not be

supplied

Water has been

forcibly drained

Are clothes concentrated on one side of tub?

Is the washing machine installed on an

unstable or inclined surface?

Is the water faucet turned on?

Water outage?

Is the water supply filter clogged with dirt?

Water has been forcibly drained because the

lid was open for 10 seconds or more with Child

lock set.

Resume operation by

opening and closing

the lid

Clear and clean drain

hose

Close the lid

Distribute the clothes

evenly and close the lid

Resume operation by

opening and closing

the lid

Resume operation by

opening and closing

the lid

Disconnect the power

plug--->plug in (after 5

sec.)

- 17 -

Service NA-F100A2.indd 17Service NA-F100A2.indd 17 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 18

12.2 H-Error indication

● If there is an operation error or if there is a problem with the washing machine,

- All the switchs cannot be operated.

- An error indication will be displayed.

Indication

H01

H02

H04

H05

H12

H17

H21

Content Check Point Method to clear

Water level sensor

error

Motor triac error

Load relay short

error

The memory circuit

of IC error

Safety switch

connection error

Thermistor error

(for X series)

Overflow error

Check at condition of the connector

Replace the Pressure sensor switch

Replace PCB board

In water drain action check both side of

capacitor that voltage not equal to “0” V.

Replace PCB board

After turn on the Motor for 2 seconds,

capacitor voltage is not “0”

Replace PCB board

Replace Safety switch

Replace PCB board

Check Feed valve and PCB

Replace Feed valve

Disconnect the power

plug--->plug in

Disconnect the power

plug--->plug in

Change Capacitor

Disconnect the power

plug--->plug in

Disconnect the power

plug--->plug in

Disconnect the power

plug--->plug in

Disconnect the power

plug--->plug in

- 18 -

Service NA-F100A2.indd 18Service NA-F100A2.indd 18 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 19

13. WIRING DIAGRAM

NA-F100A2

FEED

VALVE1

YELLOW

WIRING DIAGRAM

ELECTRONIC CONTROLLER

RED

GRAY

BLUE

PURPLE

WHITE

YELLOW

BLACK

YELLOW WHITE

RED YELLOW

BROWN WHITE

GRAY BLACK

BLUE

LIGHT BLUE

ORANGE WHITE

BLUE

YELLOW

YELLOW

GEARED MOTOR

RED

CAPACITOR

BLUE

YELLOW

RED

BLUE

MOTOR

DIFFERENT COLOR CONNECTION CAUTION

MR.SENSOR

BROWN

GREEN/YELLOW

BLUE

SAFETY SW.

PRESSURE SENSOR

- 19 -

Service NA-F100A2.indd 19Service NA-F100A2.indd 19 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 20

14. DISASSEMBLY

14.1 Controller Unit

Fig.1 Fig.2 Fig.3 Fig.4

- Use Screwdriver (+) take off screws at Panel A as Fig.1

- Pull off Insulatiron Spacer A loose from lock of Controller Unit as Fig.2

- Use Screwdriver (+) take off screws at Controller Unit with Panel Face B as Fig.3

- Change new part of Controller Unit as Fig.4

14.2 Panel Face B

Fig.5 Fig.6 Fig.7

- Use Screwdriver (-) push lock loose from Panel Face C as Fig.5

- Use Screwdriver (-) push insert between Panel Face B and Panel Face C as Fig.6

- Take off all parts of Panel Face B for change new part as Fig.7

- 20 -

Service NA-F100A2.indd 20Service NA-F100A2.indd 20 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 21

15.

PARTS EXPLODED VIEW AND REPLACEMENT PARTS LIST

15.1 Parts Exploded View : Part A

A19

A20

A2

A3

A5

A4

A10

A8

A9

A7

A6

A13

A14

A10

A15

A21

A1

A11

- 21 -

A18

A17

A16

A12

Service NA-F100A2.indd 21Service NA-F100A2.indd 21 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 22

15.2 Replacement Parts List

Parts List - Part A

Ref.

No. TH

A1 BODY B AXW01029CP00 1

A2 PANEL FACE B AXW01469CP00 1 ENGLISH/THAI

A3 PANEL FACE D AXW01488XT00 1

A4 PANEL FACE E AXW01498XT00 1

A5 PANEL FACE C AXW01479CP00 1

A6 CONTROLLER UNIT AXW024C9CP06 S 1

A7 INSULATION SPACER A AXW04868XT00 1

A8 PANEL A AXW01309CP00 1 WHITE

A9 LOCATING INSTRUCTION D AXW99628XT00 1 THAI

A10 LID HINGE SPRING AXW11168XT00 1 RIGHT SIDE

A11 ANTIFREEZE INSTRUCTION B AXW99599CP00 1

A12 PANEL A BACK COVER AXW01389CP00 1

A13 PRESSURE SENSOR UNIT AXW024T04200 S 1

A14 SUB DRAIN HOSE UNIT AXW002Q9CP00 1

A15 SAFETY SWITCH A AXW166125000 S 1

A16 FEEDING VALVE AXW292126616 S 1

A17 SOAP CASE PACKING AXW21647EC00 1

A18 CONNECTOR LEAD WIRE UNIT AXW014A9CP00 S 1

A19 LID UNIT AXW001G9CP00 S 1 WHITE

A20 LID HINGE SHAFT AXW01937JS00 2

A21 SENSOR UNIT AXW024N09400 S 1

Part Name Part No. Safety

AXW01469ME00 ENGLISH/WATER SAVE

AXW01469CP10 ENGLISH/ENERGY SAVE

AXW024C9ME06 S

AXW99628XV00 ENGLISH

AXW99629CP00 INDONESIAN

AXW11168XT50 1 LEFT SIDE

F100A2

Remark

Screws

Ref.

No. TH

SPECIAL TAPPING SCREW XTWAXW469J 4

BINDING TAPPING SCREW XTB4+12CFJ 4

Part Name Part No. Safety

XTB4+15CFJ 6

XTB4+15CFJ 2

XTB4+15CFJ 4

XTB4+15CFJ 6

XTB4+15CFJ 2

F100A2

Remark

BODY B~BODY AU

LID UNIT

CONTROLLER HOLDER~PANEL A

PANEL A BACK COVER~SAFETY SW.

PANEL A~BODY B

PANEL A BACK COVER~BODY B

PANEL A BACK COVER~FEEDING VALVE

- 22 -

Service NA-F100A2.indd 22Service NA-F100A2.indd 22 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 23

15.3 Parts Exploded View : Part B

B2

B20

B1

B16

B18

B21

B16

B17

B14

B15

B9

B2

B19

B10

B11

B12

B4

B3

Accessories

B13

B4

B4

B6

B12

B7

B8

- 23 -

Service NA-F100A2.indd 23Service NA-F100A2.indd 23 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 24

15.4 Replacement Parts List

Parts List - Part B

Ref.

No. TH

B1 BODY A UNIT AXW001A9CP00 1

B2 GRIP AXW01106UP0W 2

B3 BASE A AXW03019CP00 1 BLACK

B4 LEG COVERING AXW03397JS00 3 BLACK

B6 ADJUSTABLE LEG UNIT AXW003D7EC00 1

B7 SERVICE PRESSURE HOSE UNIT AXW012D8AR00 1

B8 BOTTOM COVER AXW21586ZR00 1

B9 BACK PANEL AXW01566ZV10 1

B10 POWER CORD UNIT -S3 AXW004A772D4 S

POWER CORD UNIT -C3 AXW004A72974 S 1

POWER CORD UNIT -A2 AXW004A83440 S

POWER CORD UNIT -C2-E AXW004A73719 S

B11 CHEMICAL COVER AXW04487EC10 1

B12 HOSE B UNIT AXW002E8XT00 1

B13 HOSE BAND AXW02458AR00 1

B14 CAPACITOR AXW04037P967 S 1 12.5μF, COIL0.5

B15 NAME PLATE AXW01539CP00 S 1 THAI

B16 BODY A PROTECTION AXW90468AR30 2 t20x50x50/FRONT SIDE

B17 BODY A PROTECTION AXW90468AR10 1 t30x50x50/REAR SIDE

B18 BODY A PROTECTION AXW90467JP50 1 t1x70x240/LEFT SIDE

B19 BODY A PROTECTION AXW90466AA6M 1 t1x70x120/RIGHT SIDE

B20 SPINNER LID LABEL AXW11178XT1W 1 THAI

B21 EARTH WIRE UNIT AXW030C8XT00 S EXTERNAL EARTH

Part Name Part No. Safety

AXW001A9CP50 FOR EXTERNAL EARTH

AXW01539CP10 S ENGLISH

AXW01539CP20 S ENGLISH

AXW01539CP30 S ENGLISH

AXW01539CP40 S ENGLISH

AXW11178XV0W ENGLISH

AXW11179CP0W INDONESIAN

F100A2

Remark

Screws

Ref.

No. TH

SPECIAL TAPPING SCREW XTTAXW444J 10 BASE A

PAN HEAD TAPPING SCREW XTN4+8HFJ 1 EARTH U~BODY A

Part Name Part No. Safety

XTTAXW444J 4 BACK PANEL

XTTAXW444J 2 BOTTOM COVER

XSN4+W10FJ 1 CAPACITOR

F100A2

Remark

- 24 -

Service NA-F100A2.indd 24Service NA-F100A2.indd 24 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 25

15.5 Parts Exploded View : Part C

C1

GREY

C15

NATURAL

C13

C2

C3

C4

C5

C6

C7

(For A1)

C11

C14

C12

GREY

C15

C9

C8

C10

C30-1

C30-2

C30-3

C30-4

C30-5

C30-6

C30-7

C15

C17

C16

C18

C19

C20

C21

C22

C23

C25

C24

C26

C27

NATURAL

C15

C28

C30

C31

C32

C29

- 25 -

Service NA-F100A2.indd 25Service NA-F100A2.indd 25 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 26

15.6 Replacement Parts List

Parts List - Part C

Ref.

No. TH

C1 OUTER TUB COVER

C2 SCREW CAP

C3 O-RING

C4 PULSATOR

C5 SHAFT BUSHING

C6 SPINNER SHAFT FLANGE NUT

C7 SPINNER FLANGE WASHER B

C8 BALANCER UNIT

C9 SOFTENER CASE LID

C10 TUB B UNIT

C11 SLOT

C12 FILTER UNIT

C13 TUB E UNIT

C14 TUB UNIT

C15 SUSPENSION UNIT

C16 OUTER TUB A

C17 OUTER TUB B

C18 MOTOR WASHER A

C19 MOTOR

C20 MOTOR WASHER B

C21 MOTOR PULLEY UNIT

C22 V-BELT

C23 SPINNER PLATE B

C24 OVER FLOW HOSE B

C25 EARTH WIRE UNIT

C26 HOSE BAND

C27 HOSE A

C28 HOSE BAND

C29 MACHA-CASE UNIT

C30 VALVE UNIT

C30-1 VALVE ROD A

C30-2 VALVE WASHER

C30-3 VALVE LID

C30-4 VALVE SPRING B

C30-5 VALVE ROD B

C30-6 VALVE PACKING

C30-7 VALVE FRAME A

C31 GEARED MOTOR

C32 LEAD WIRE UNIT

Part Name Part No. Safety

AXW32248AR0W

AXW21118XW00

AXW02577BK00

AXW05019CP00

AXW05046ZR00

AXW15176RU10

AXW151980200

AXW035A8AR0W

AXW21778AR1B

AXW012T9CP00

AXW11989CP00

AXW022A8AR1W

AXW012V9CP00

AXW002A9CP00

AXW034U9CP00

AXW034U9CP50

AXW12018AR00

AXW12028AR00

AXW04207JS10

AXW040159626

AXW04217BK10

AXW004G8AR20

AXW004G8AR10

AXW041219860

AXW04127BL60

AXW32328AR00

AXW02348AR10

AXW003F9CP00

AXW02458AR00

AXW02479CP00

AXW02457EC00

AXW020A8AH20

AXW009D8AR00

AXW09328AR00

AXW09728AR00

AXW09038AR00

AXW09718AR00

AXW09818AR00

AXW090956N2A

AXW09018AR00

AXW348204506

AXW014B9CP00

S1

S 1 INTERNAL

S1

S1

F100A2

1

1

1

1

1

1

1

1

1 BLUE

1

1

1 WHITE

1

1

2

2 REAR/RIGHT+LEFT/GREY

1

1

2

2

1

1 M-19.8", 50Hz

1

1

1 HOSE A - BASE A

1

1 HOSE A - VALVE UNIT

1

1

1

1

1

1

1

1

1

FRONT/RIGHT+LEFT/NATURAL

M-19.5", 60Hz

GEARED MOTOR - SENSOR UNIT

Remark

Screws

Ref.

No. TH

SPECIAL TAPPING SCREW

PAN HEAD TAPPING SCREW

SPECIAL SMALL SCREW

SPECIAL BOLT

SPECIAL TAPPING SCREW

Part Name

Part No.

XTWAXW523

XTN4+8HFJ

XSSAXW682

XVGAXW705

XVGAXW839J

XVGAXW840J

XTWAXW6517J

XTWAXW6517J

XTWAXW6518J

XTWAXW530

Safety

F100A2

8 TUB A~TUB D

1 EARTH U~OUTER TUB B

1 PULSATOR UNIT

1 MOTOR PULLEY

2 MOTOR

4 MECHA CASE~OUTER TUB B

7 OUTER TUB A~B

4 SPINNER PLATE B

3 GEARED MOTOR (CLUTCH)

8 BALANCER U~TUB A

Remark

- 26 -

Service NA-F100A2.indd 26Service NA-F100A2.indd 26 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 27

15.7 Parts Exploded View : Packing

Accessories

7

6

9

8

10

1

4

3

THIS PART USE FOR PACKING,

NOT PART OF PRODUCT.

2

Fully Automatic

Washing Machine

Fully Automatic

Washing Machine

5

- 27 -

Service NA-F100A2.indd 27Service NA-F100A2.indd 27 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Page 28

15.8 Replacement Parts List

Parts List - Packing

Ref.

No. TH

1 PROTECTION CASE A AXW90019CP00 1 THAI

2 CASE PLATE A AXW91189CP00 2

3 CORNER CUSHION -F AXW90159CP00 1 FRONT SIDE

CORNER CUSHION -B AXW90159CP50 1 BACK SIDE

4 CORNER PAD AXW90168XT00 2 FRONT SIDE

5 PROTECTION CASE B UNIT AXW090B9CP00 1

6 LID SHEET AXW90698XT00 1 TOP LID UNIT

7 OPERATING INSTRUCTION AXW99019CP00 1 ENGLISH/THAI

8 ACCESORY BAG AXW90576UP30 1

9 SPIN TUB SUPPORT AXW90859CP00 1

10 SIDE CUSHION AXW90049CP00 1

Part Name Part No. Safety

AXW90019CP50 ENGLISH

AXW90698XT50 1 UNDER LID UNIT

AXW99019ME00 ENGLISH (WATER SAVE)

AXW99019CP10 ENGLISH (ENERGY SAVE)

AXW99019CP20 ENGLISH/INDONESIAN

F100A2

Remark

- 28 -

Service NA-F100A2.indd 28Service NA-F100A2.indd 28 4/26/2559 BE 11:50 AM4/26/2559 BE 11:50 AM

Loading...

Loading...